Patents

Literature

2986results about "Wet spinning methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

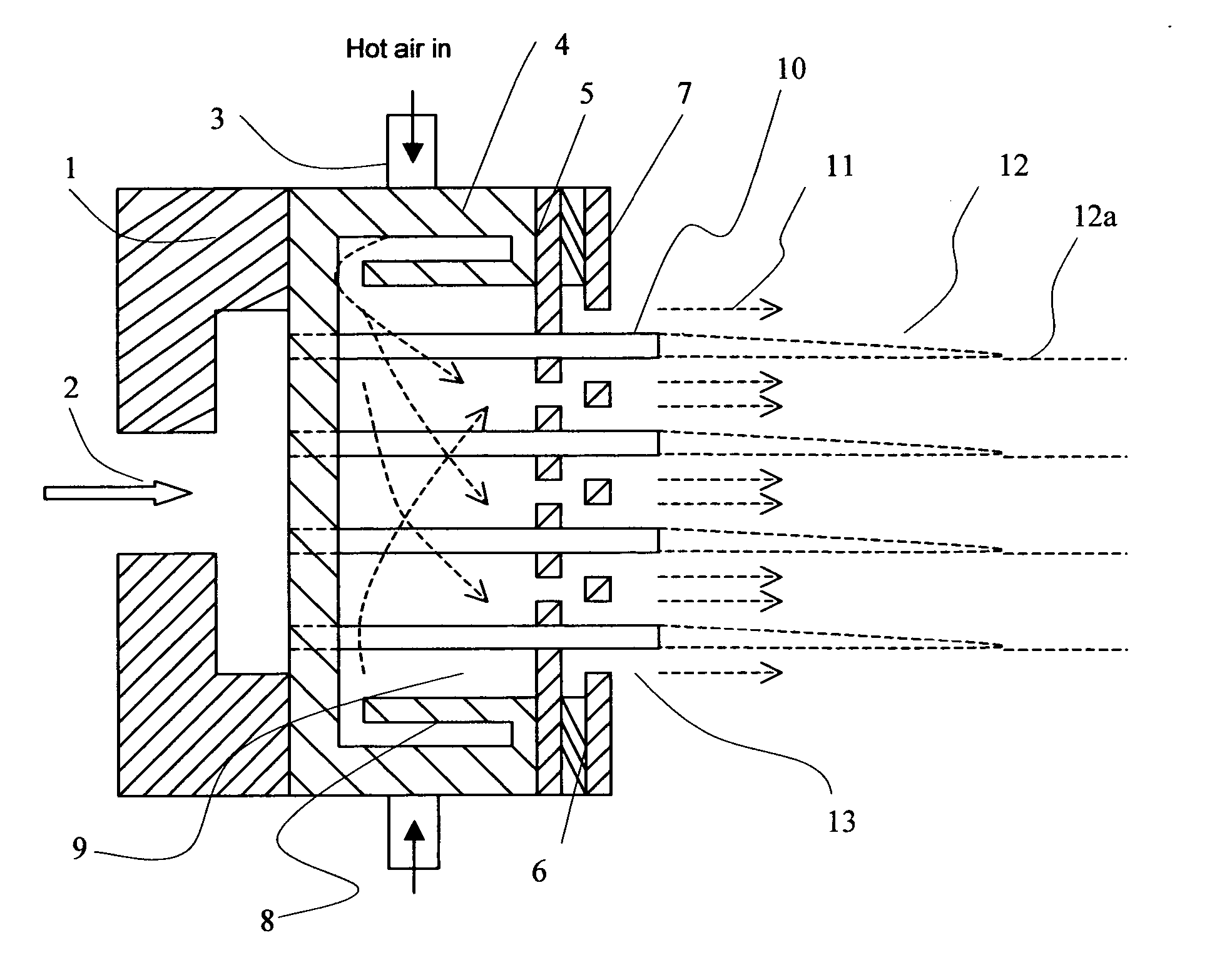

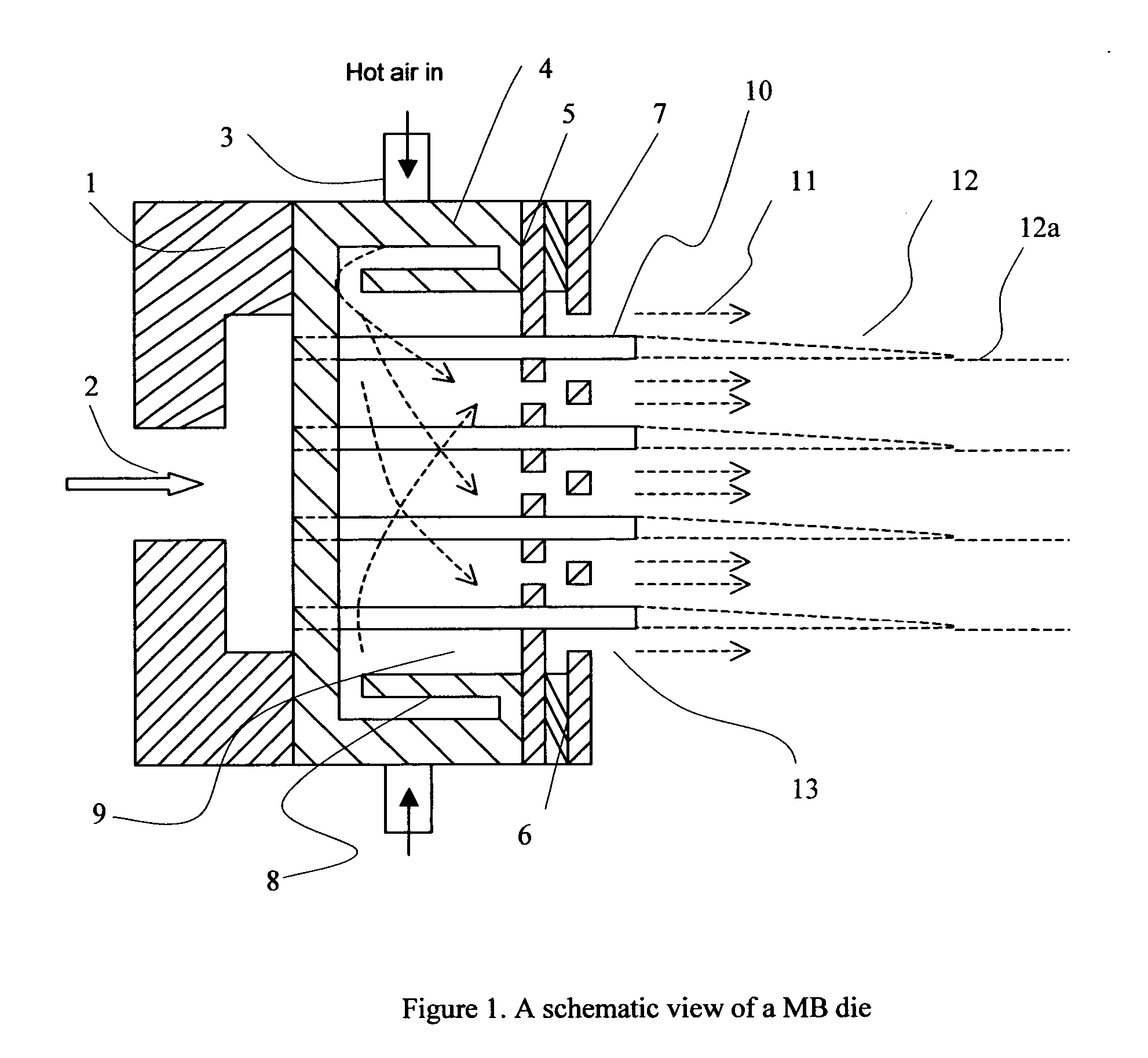

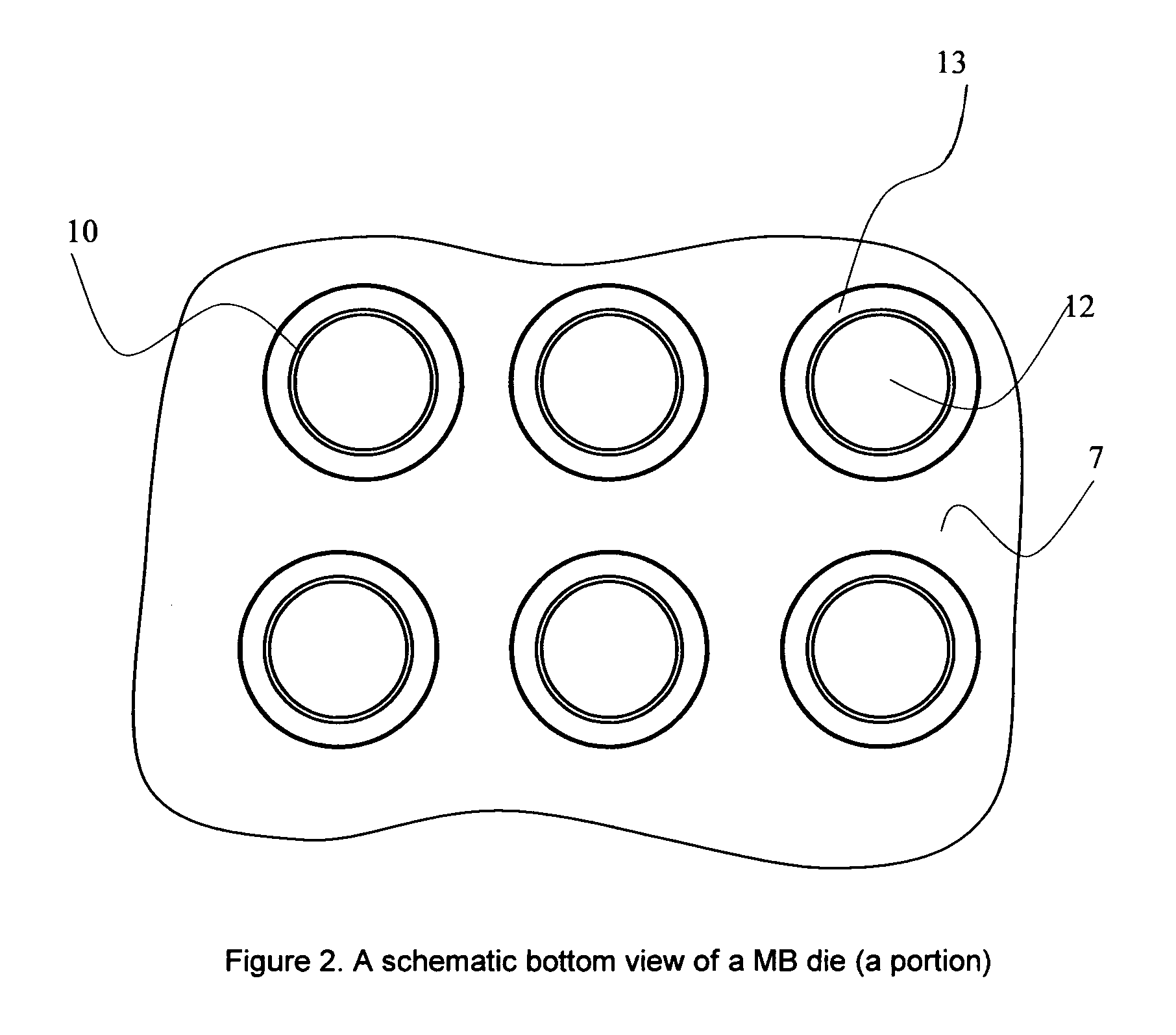

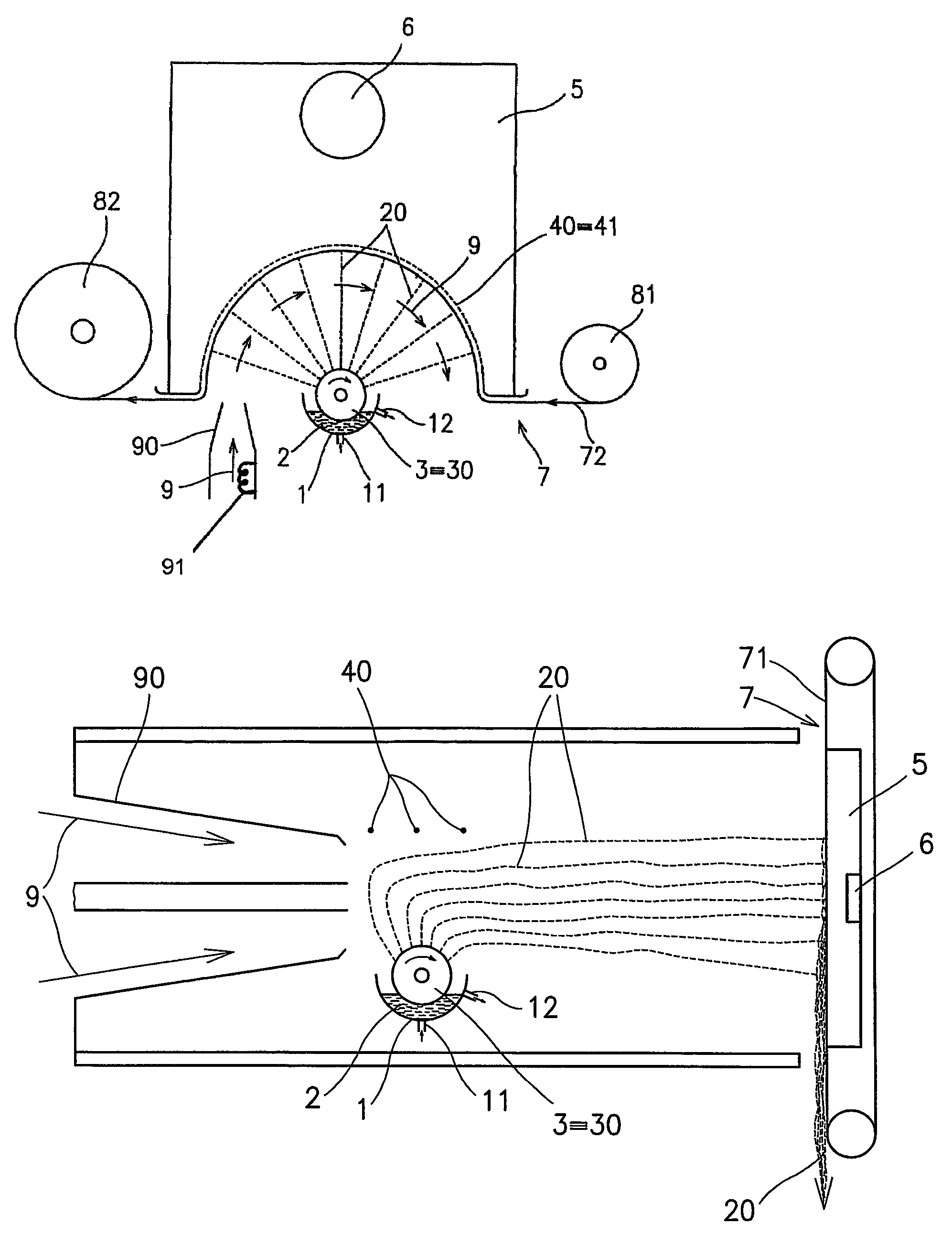

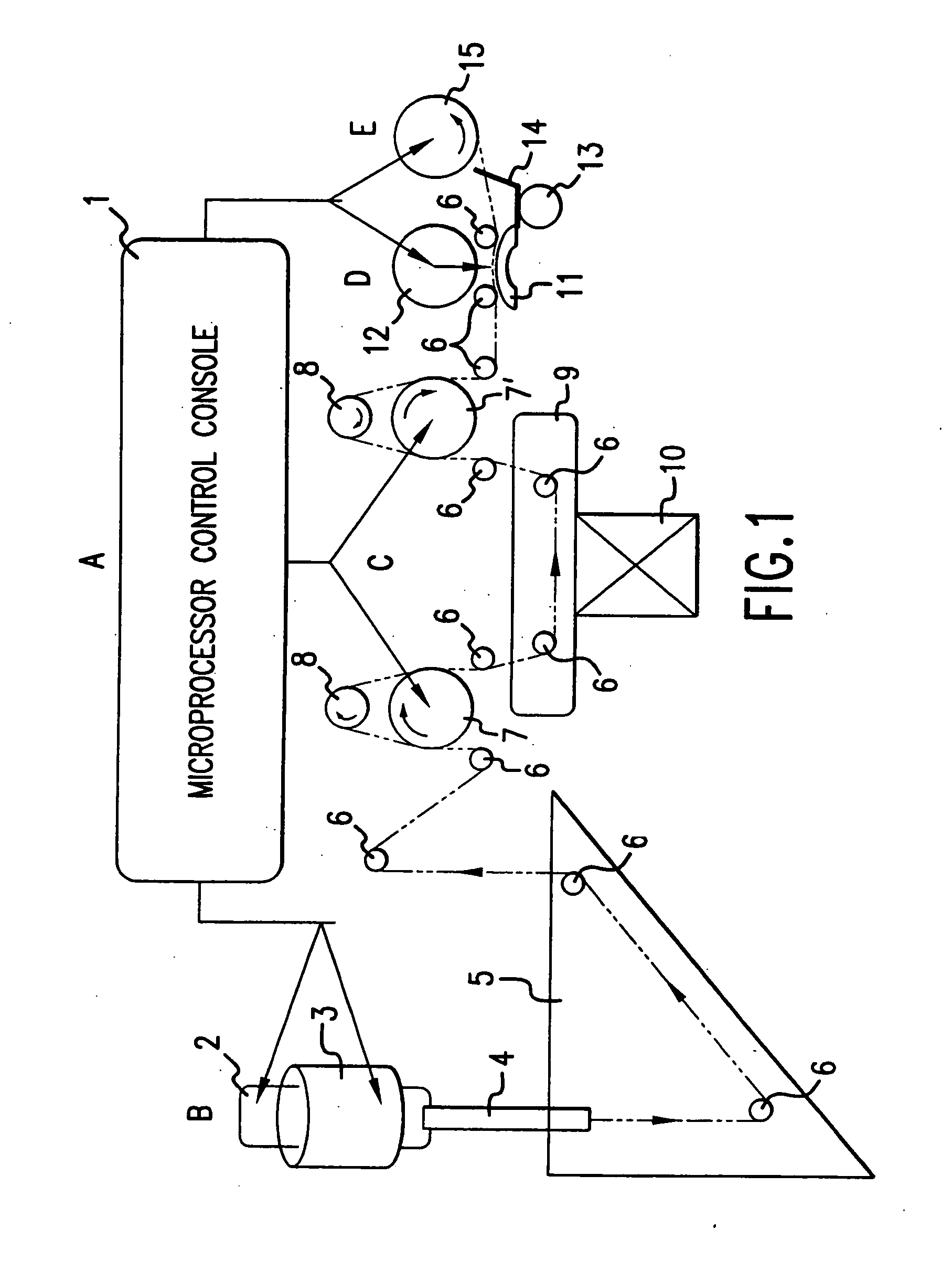

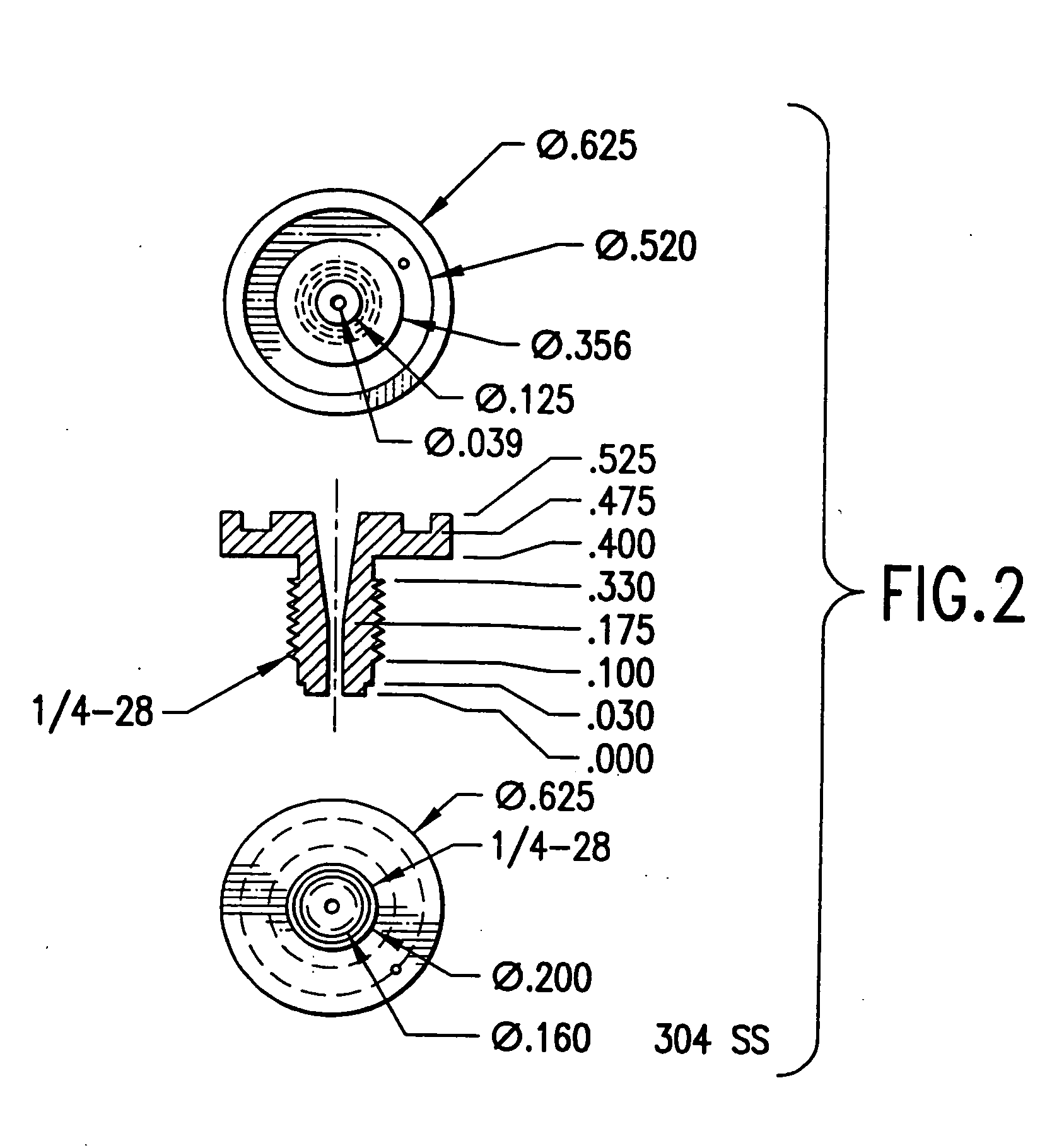

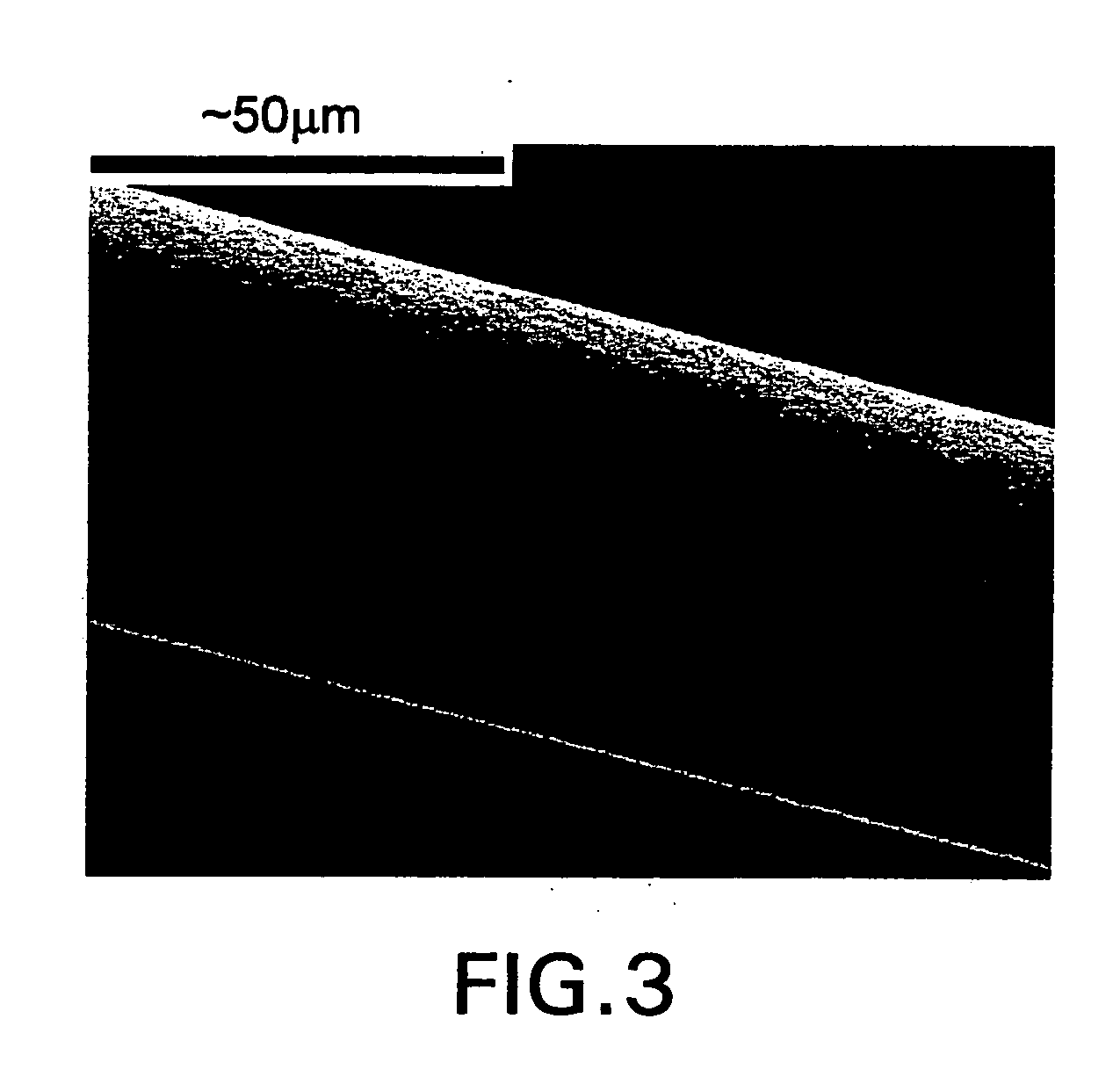

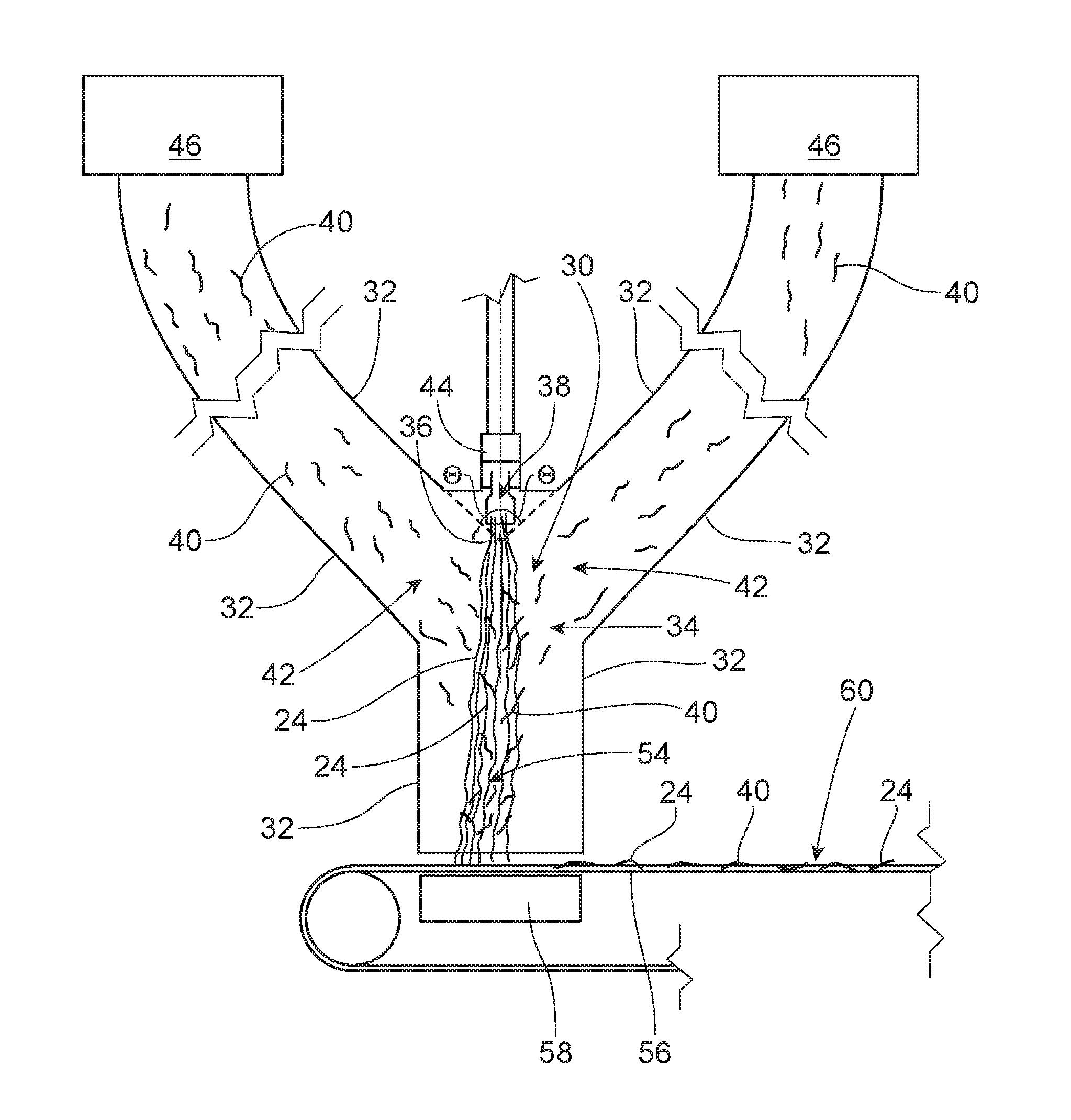

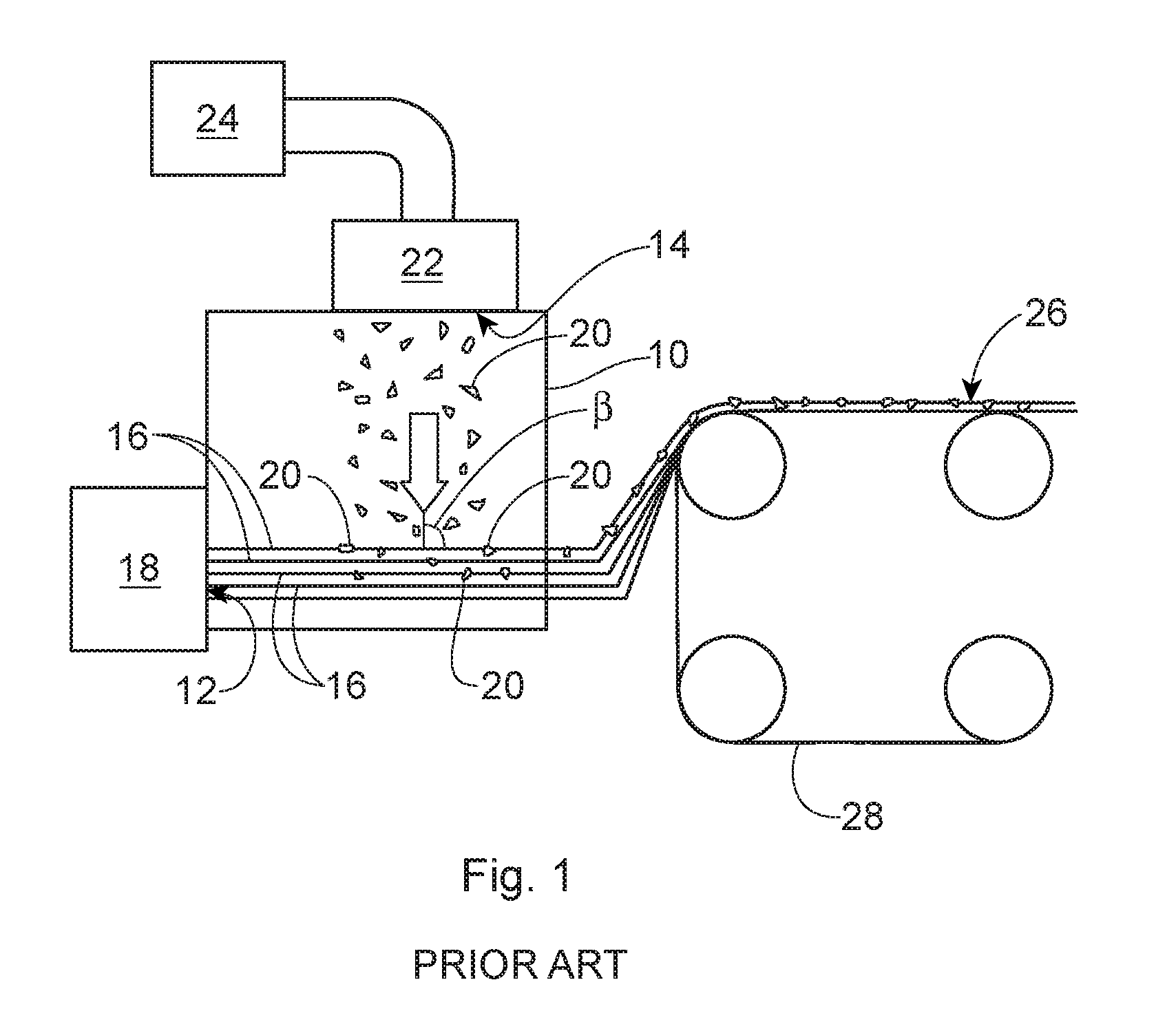

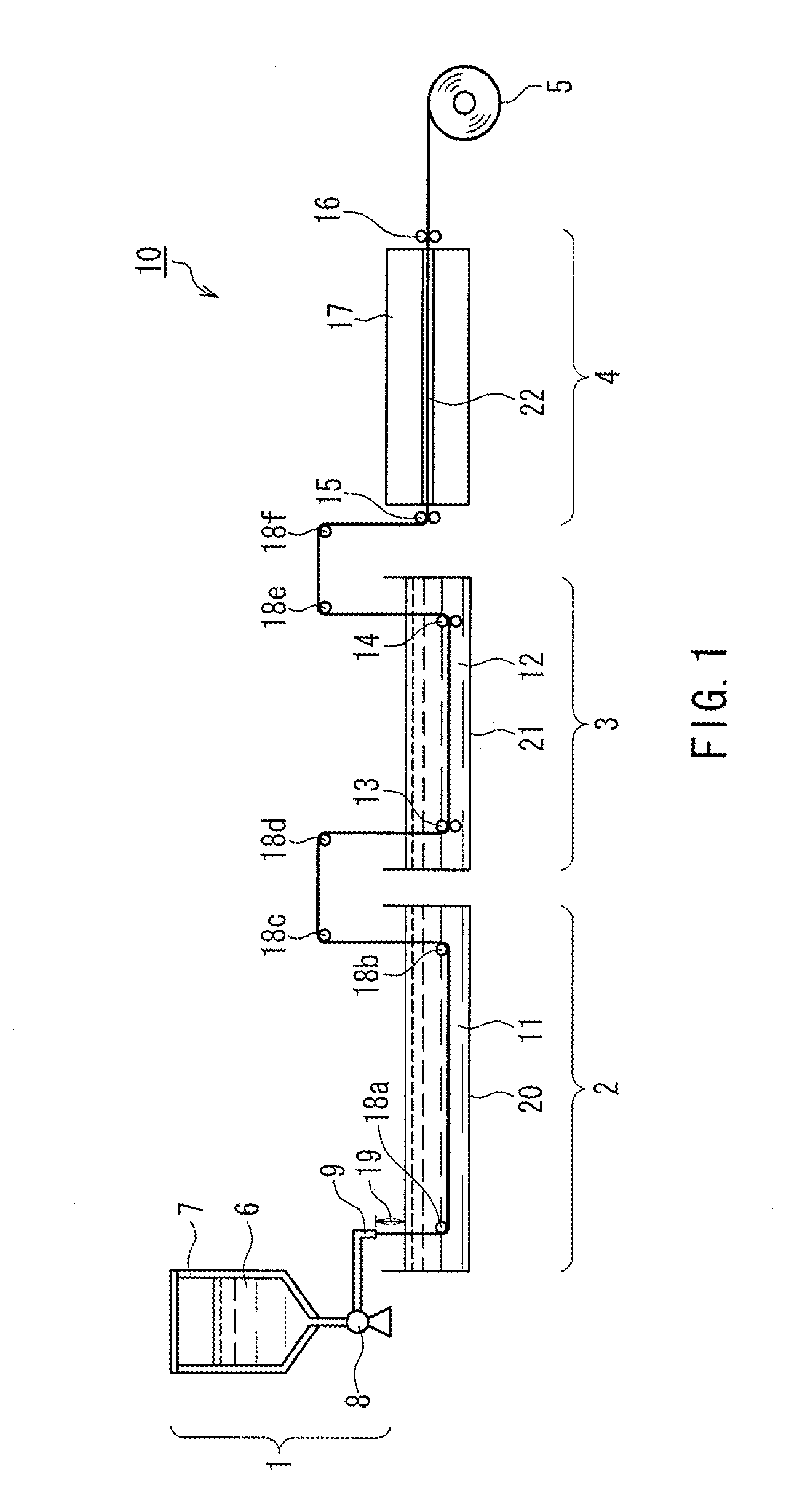

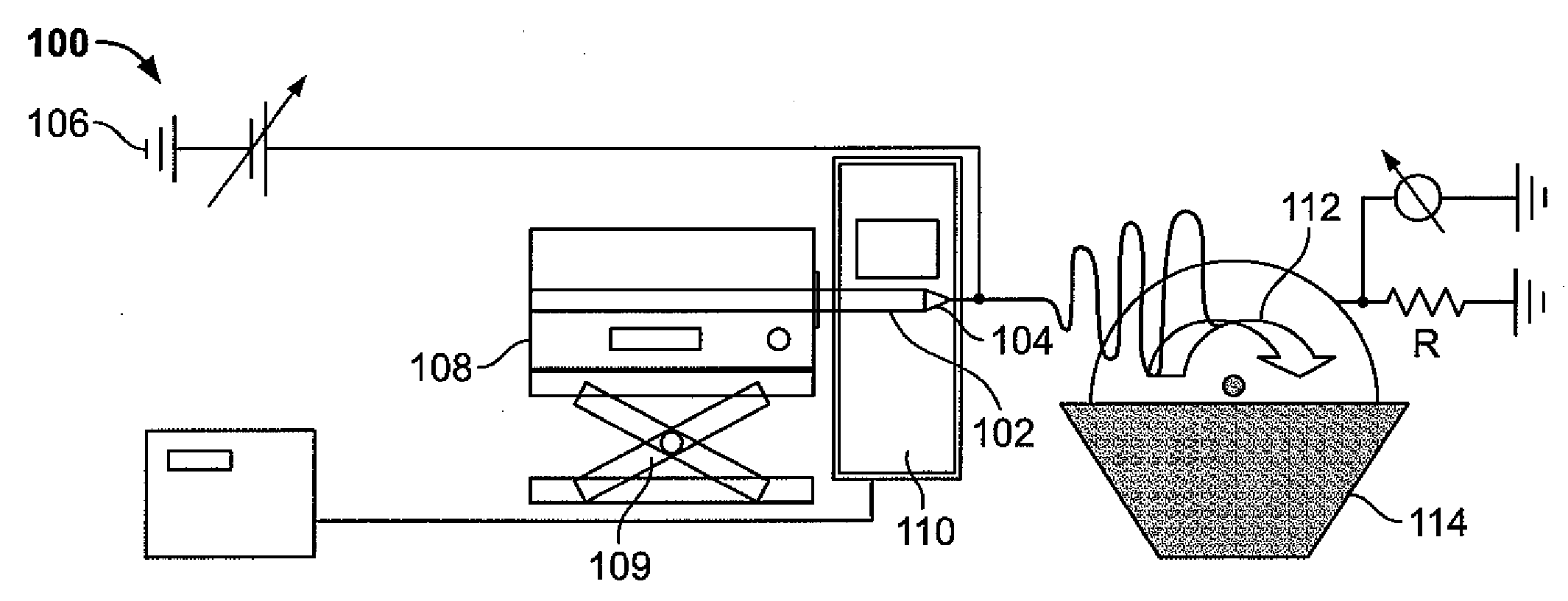

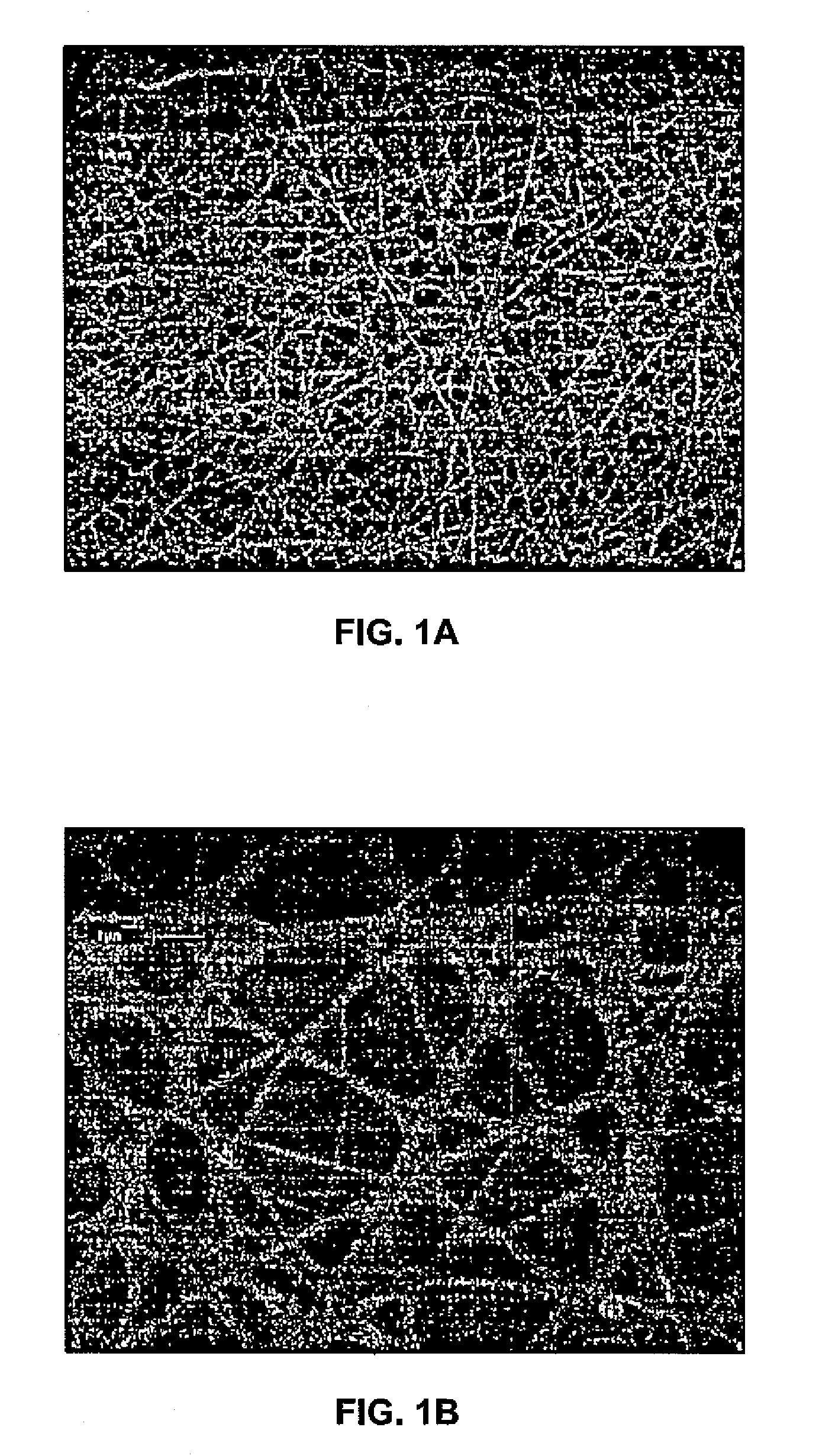

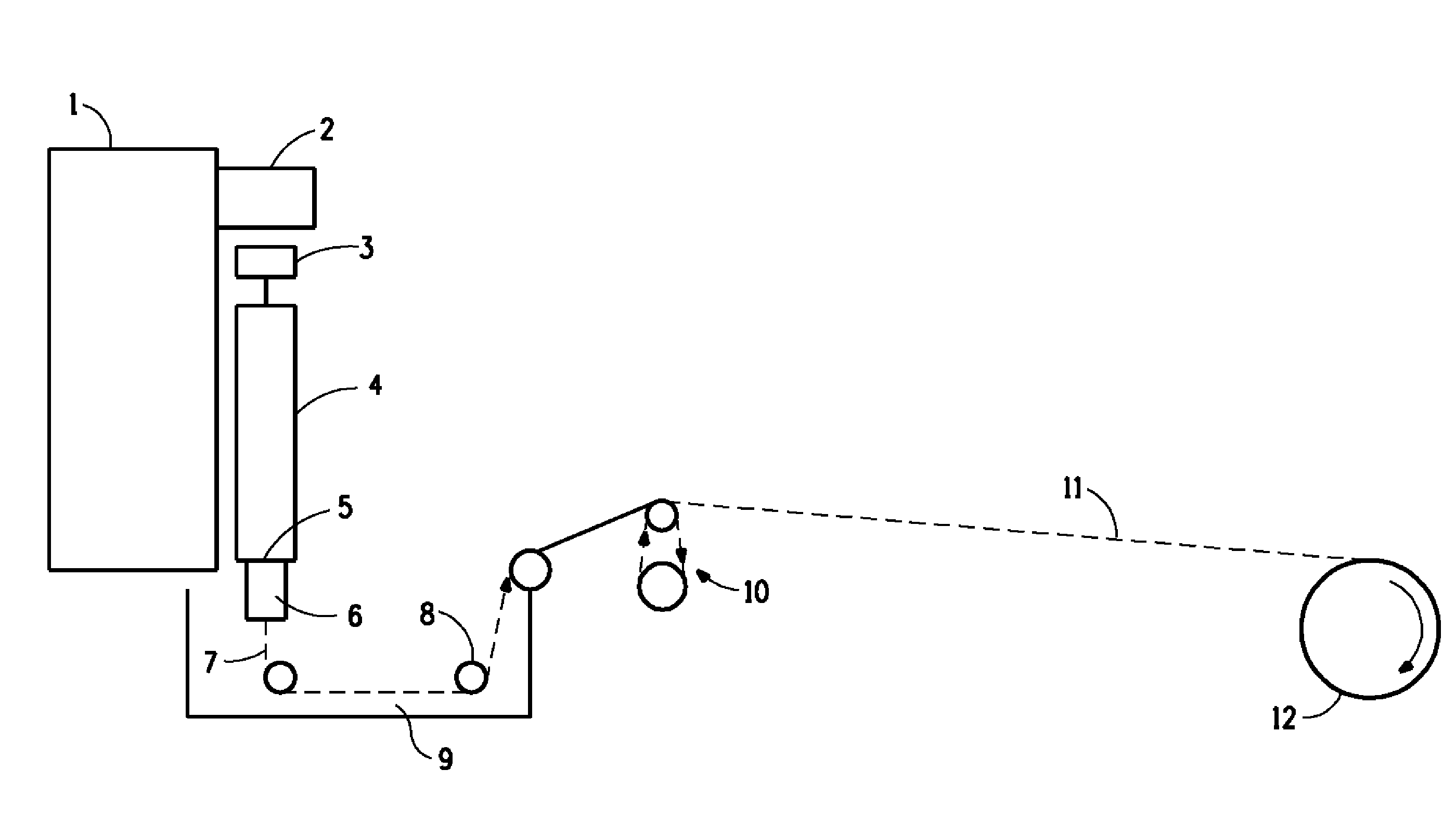

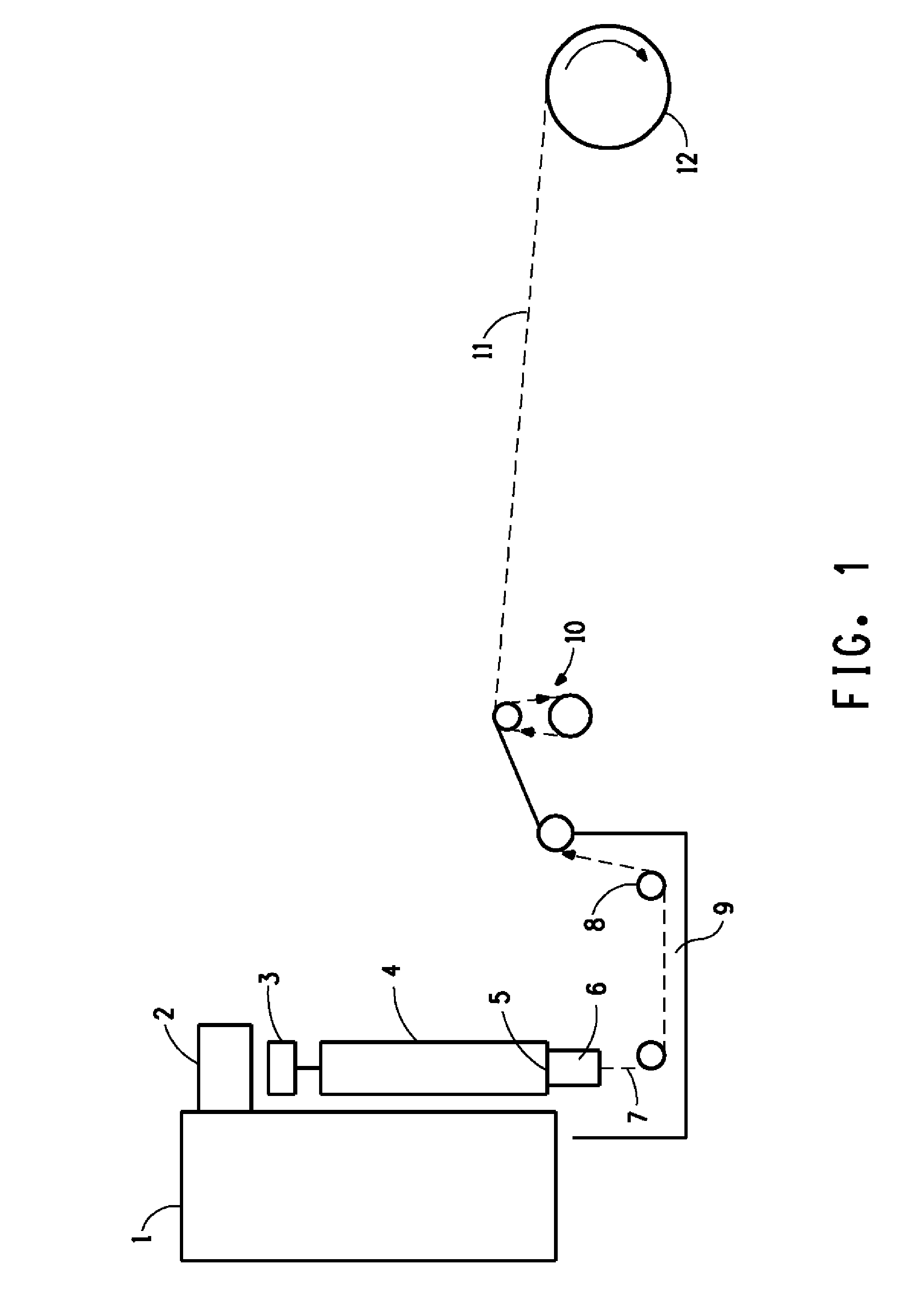

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

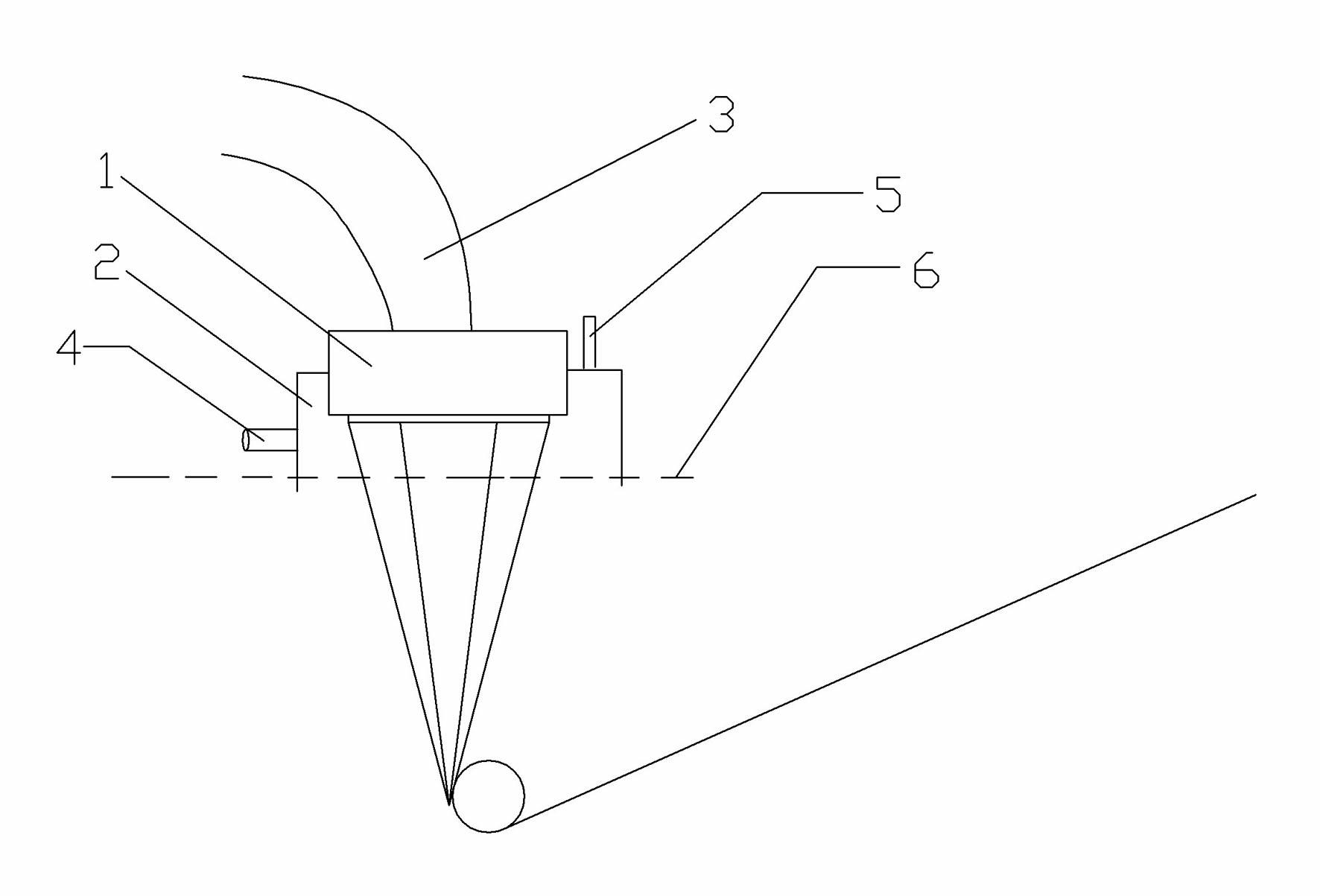

Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

ActiveUS7585437B2High quality and uniformity of layerSpinnerette packsNanotechnologyPotential differenceElectrospinning

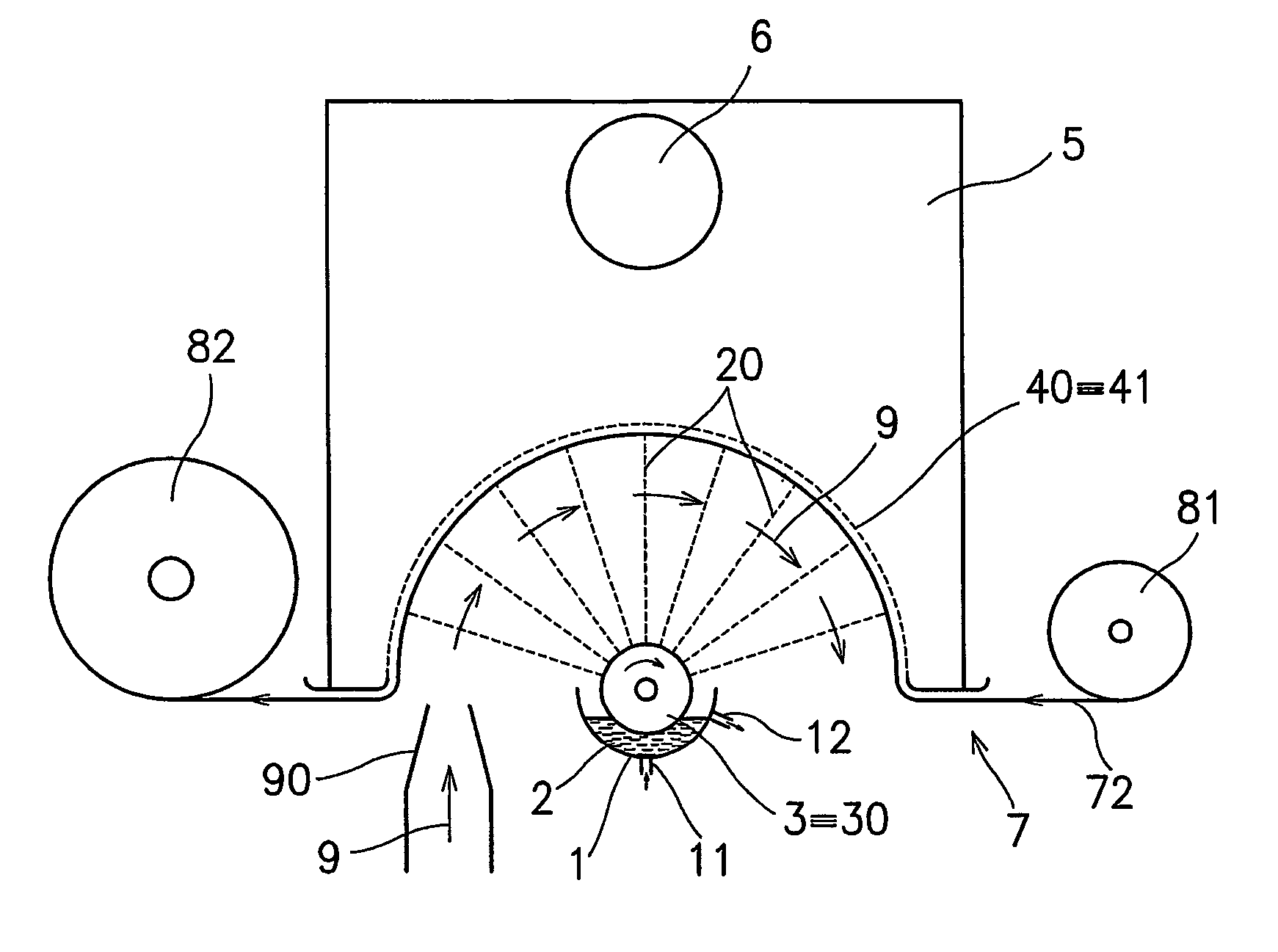

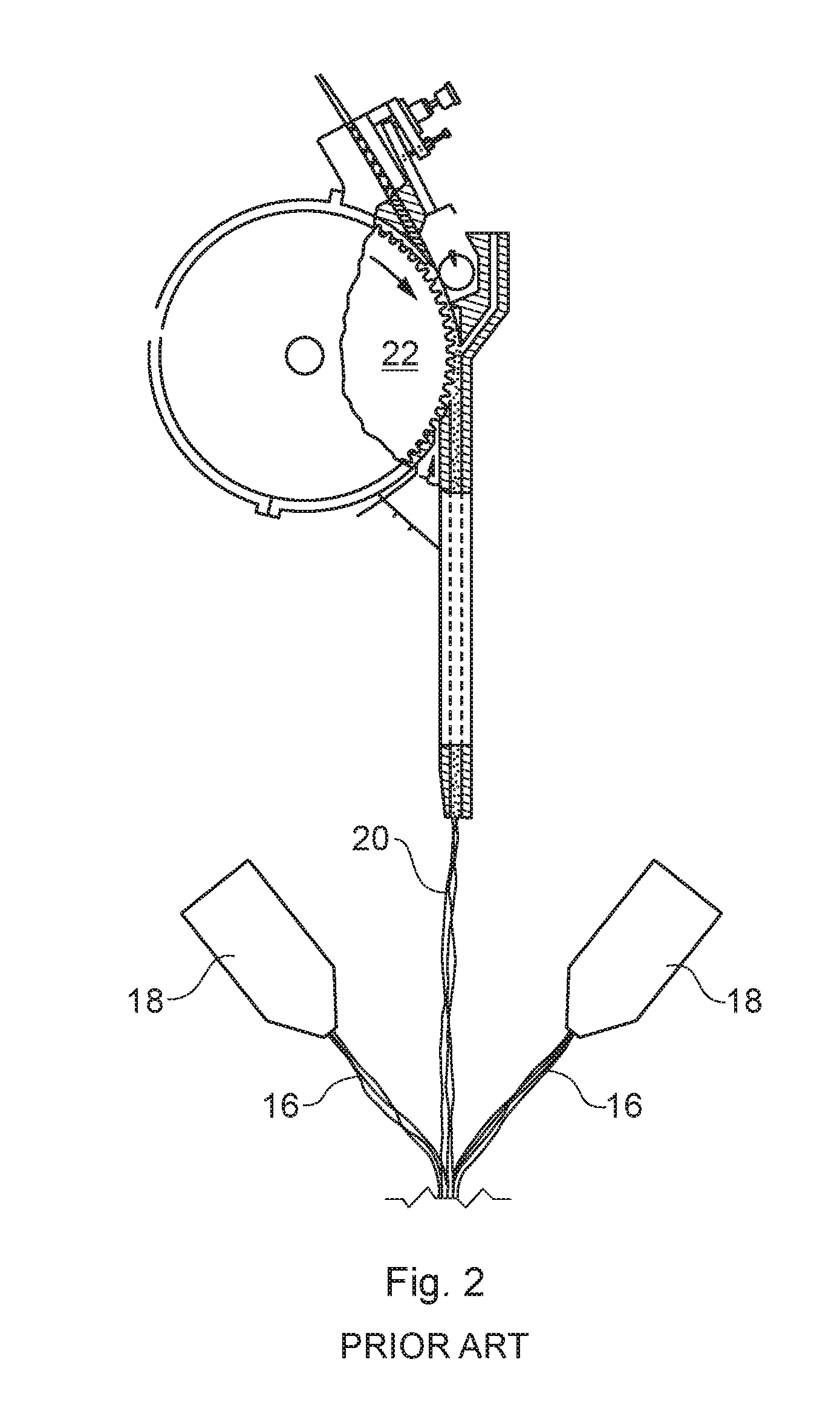

A method of nanofibers production from a polymer solution uses electrostatic spinning in an electric field created by a potential difference between a charged electrode and a counter electrode. The polymer solution for spinning is supplied into the electric field using the surface of a rotating charged electrode. On a part of the circumference of the charged electrode near to the counter electrode, a spinning surface is created for attaining a high spinning capacity. In a device for carrying out the method, the charged electrode is pivoted and part of its circumference is immersed in the polymer solution. The free part of the circumference of the charged electrode is positioned opposite the counter electrode.

Owner:TECHNICKA UNIVEZITA V LIBERCI

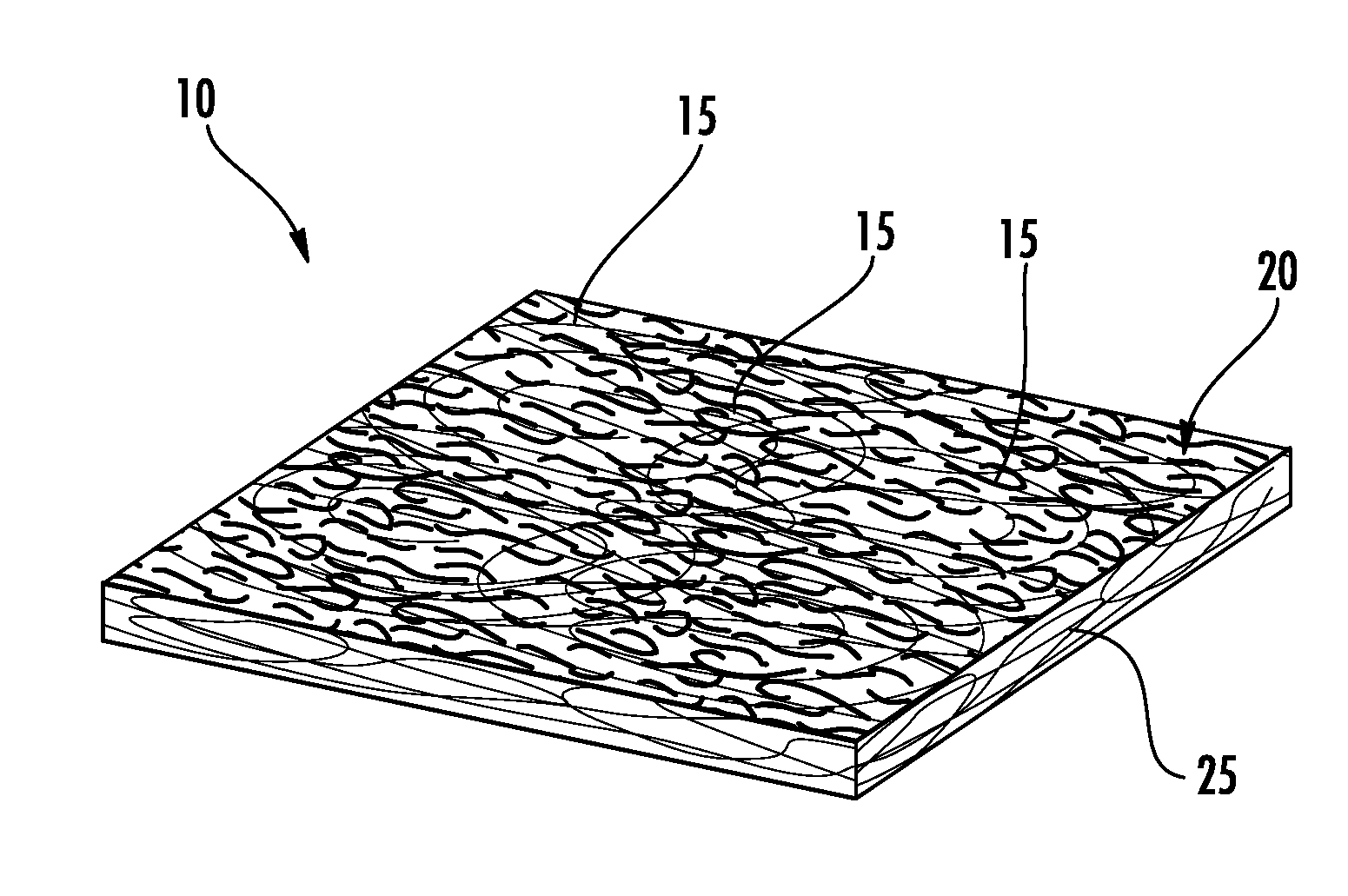

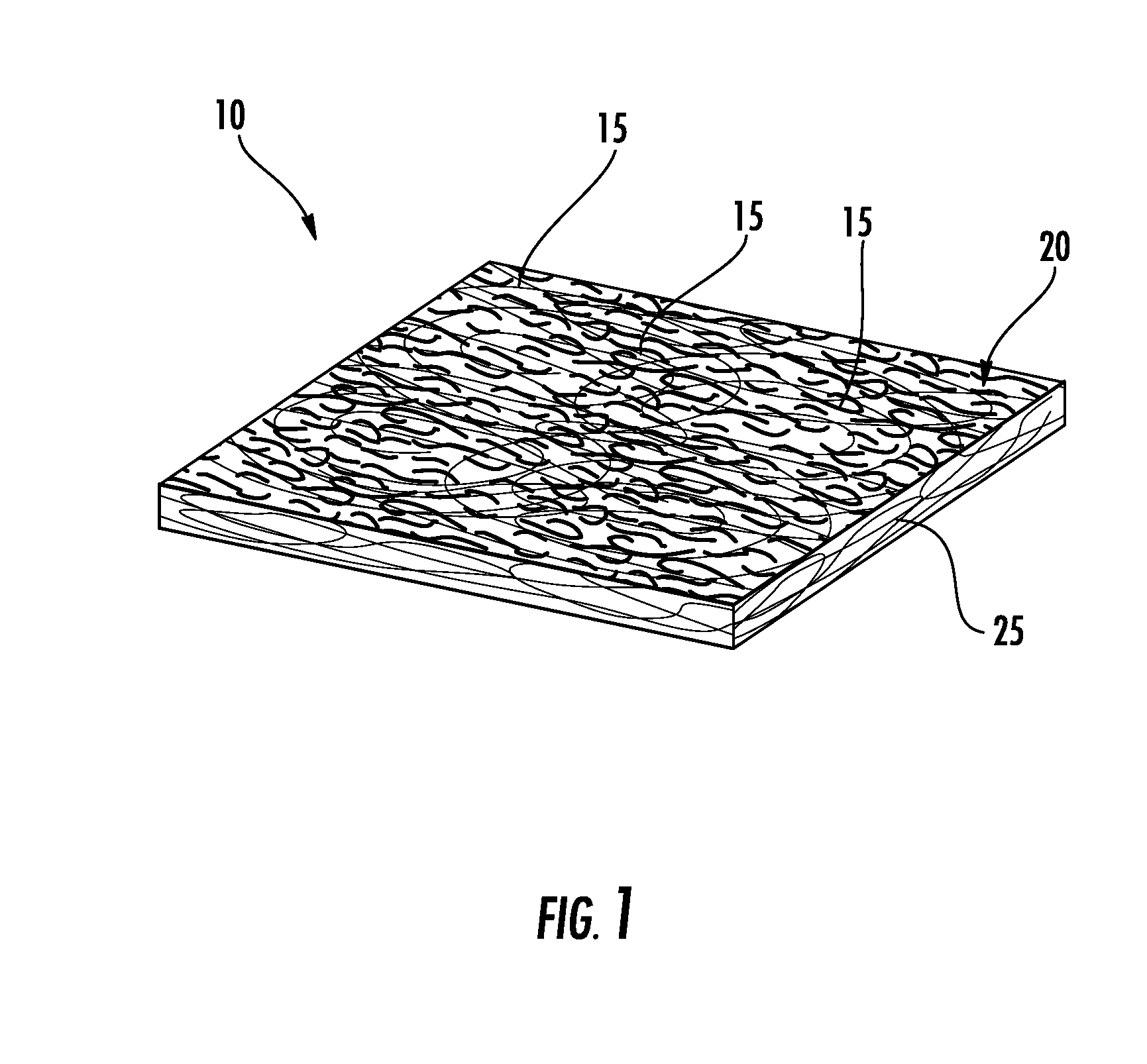

Methods of Applying Skin Wellness Agents to a Nonwoven Web Through Electrospinning Nanofibers

Generally, the present invention is directed to, in one embodiment, a method for forming a composite nonwoven web configured to deliver skin wellness agents to the skin of a user. According to the method, an aqueous system of a hydrophilic polymer and a skin wellness agent is formed. The aqueous system is then electrospun onto a surface of a nonwoven web containing synthetic fibers. The resulting nanofibers have an average diameter of from about 50 nanometers to about 5000 nanometers, such as from about 200 nanometers to about 700 nanometers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

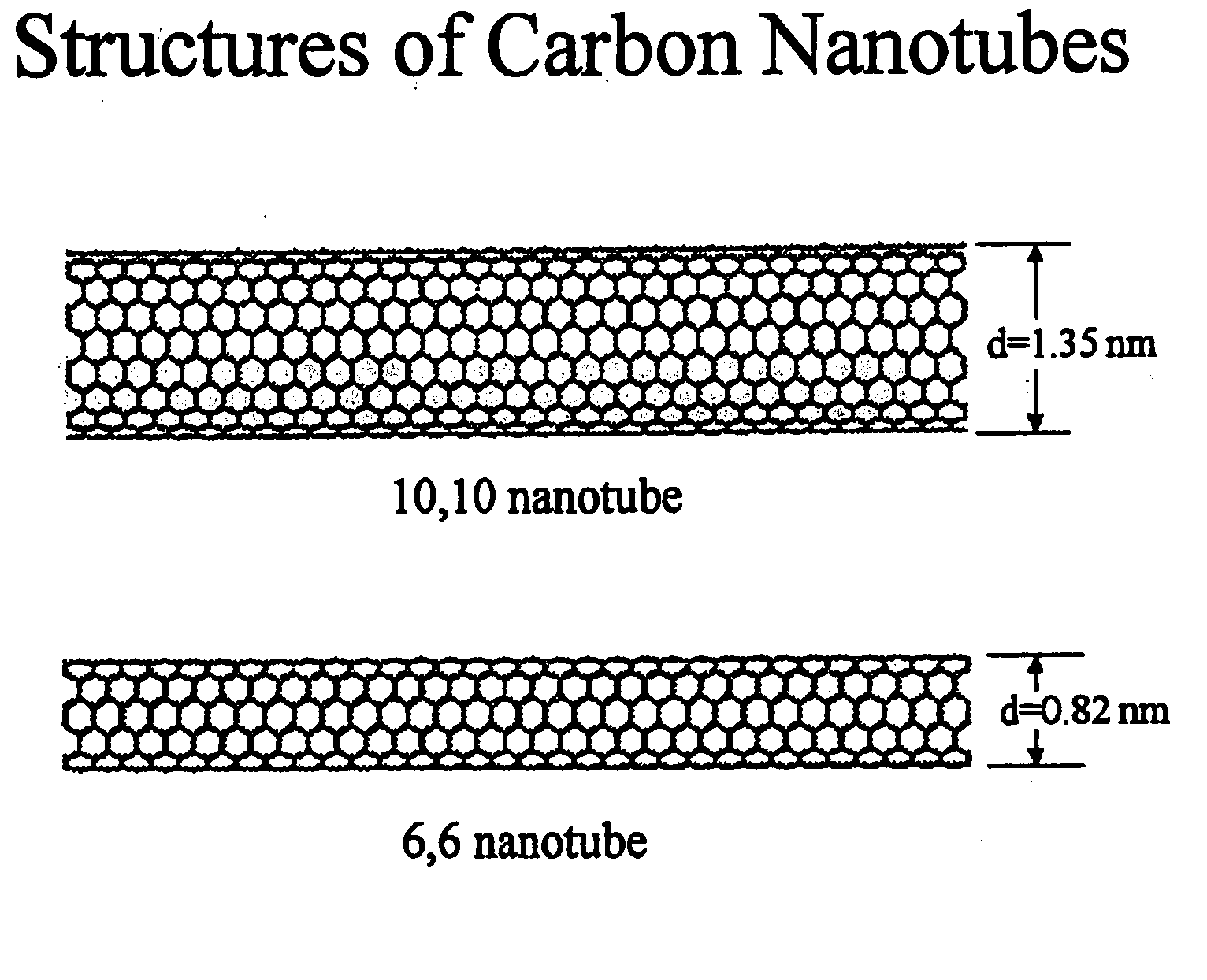

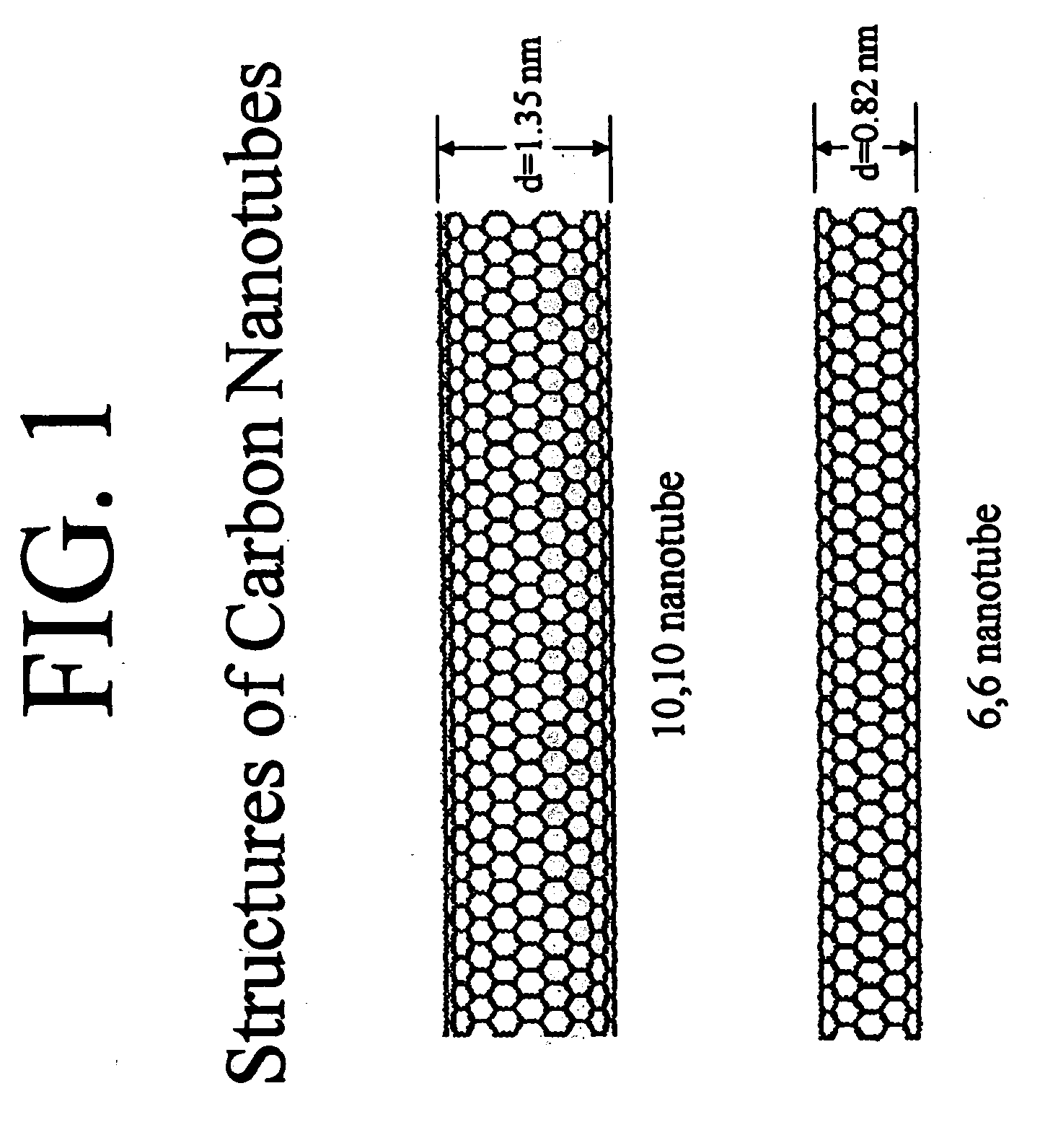

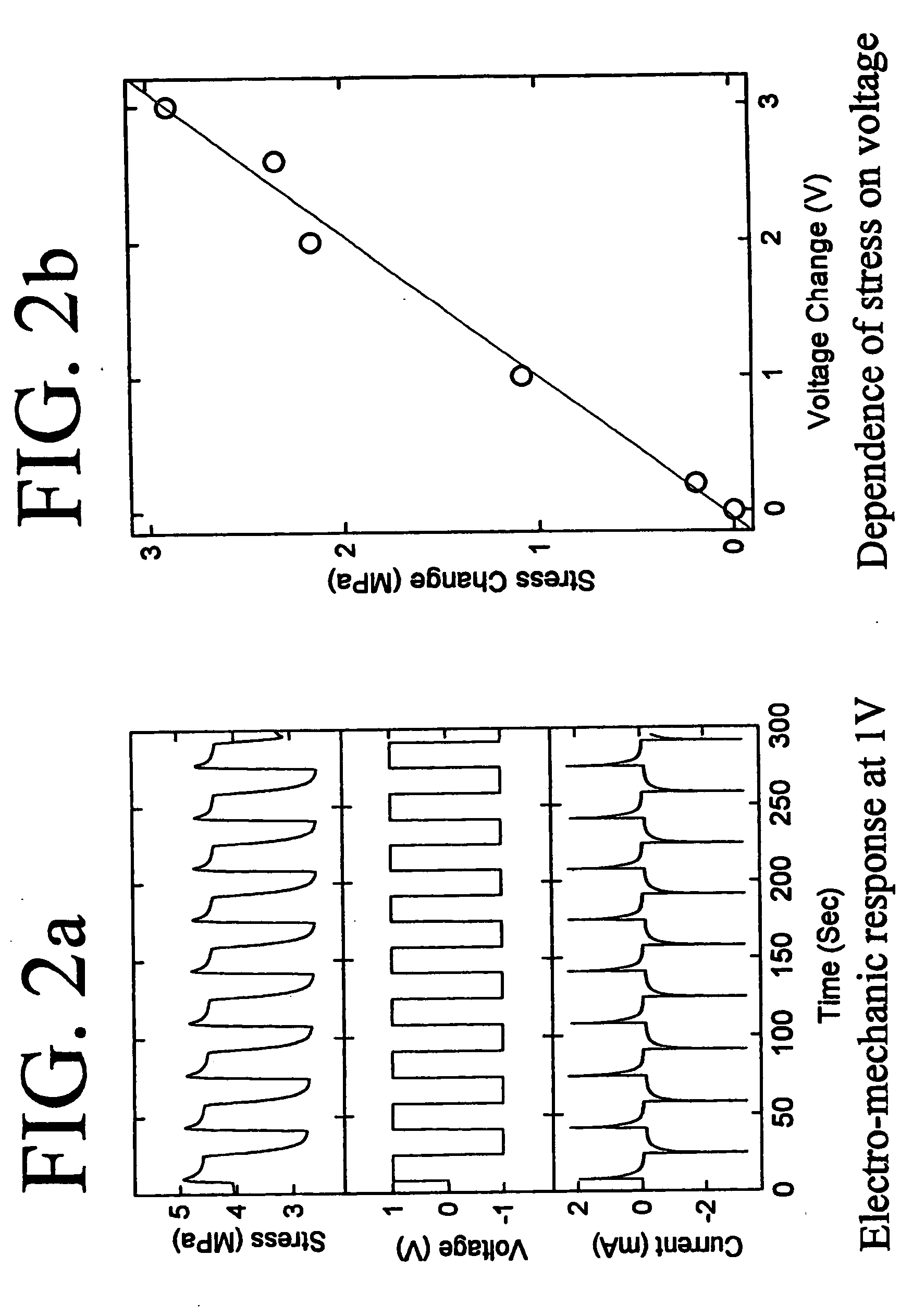

Spinning, processing, and applications of carbon nanotube filaments, ribbons, and yarns

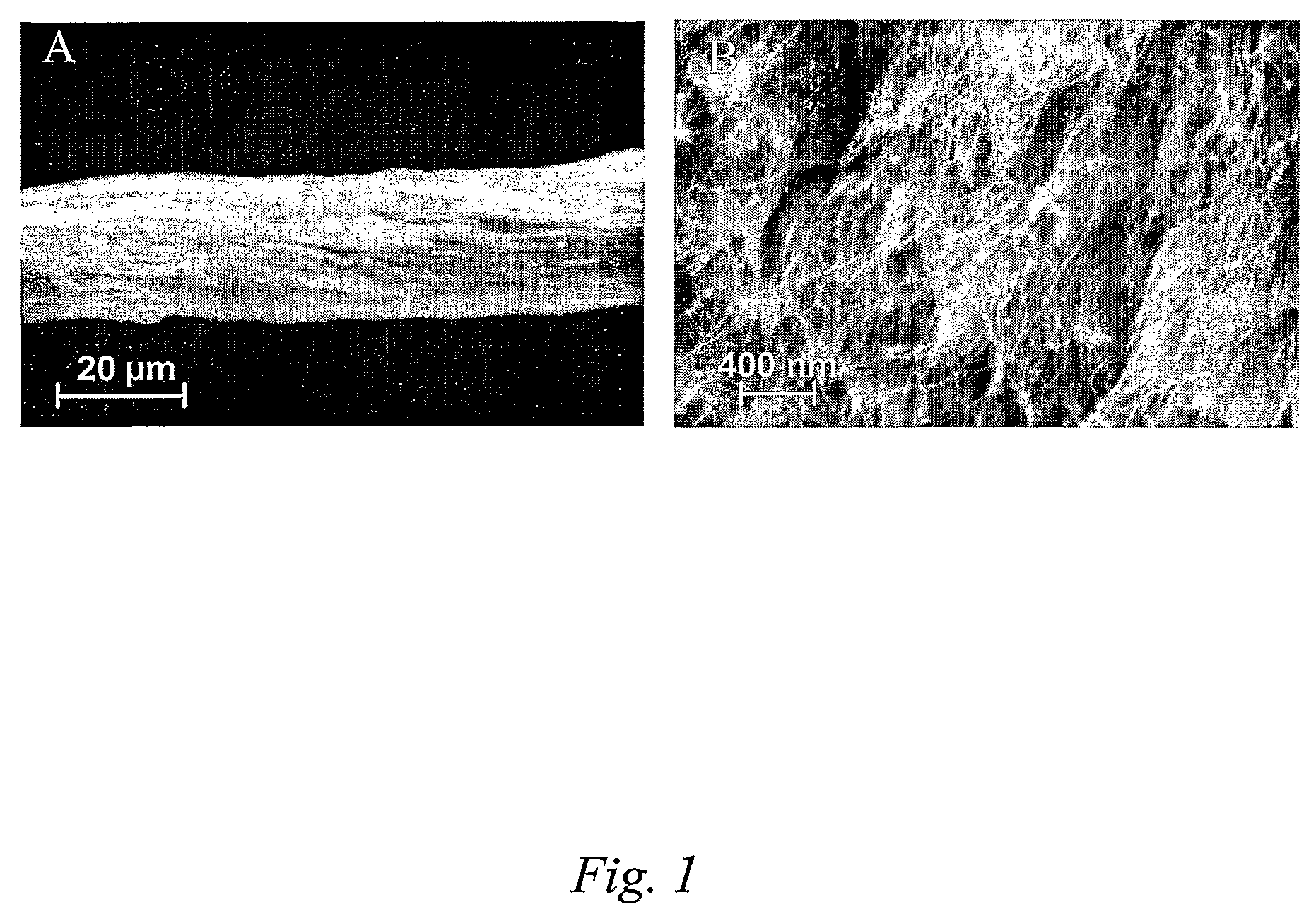

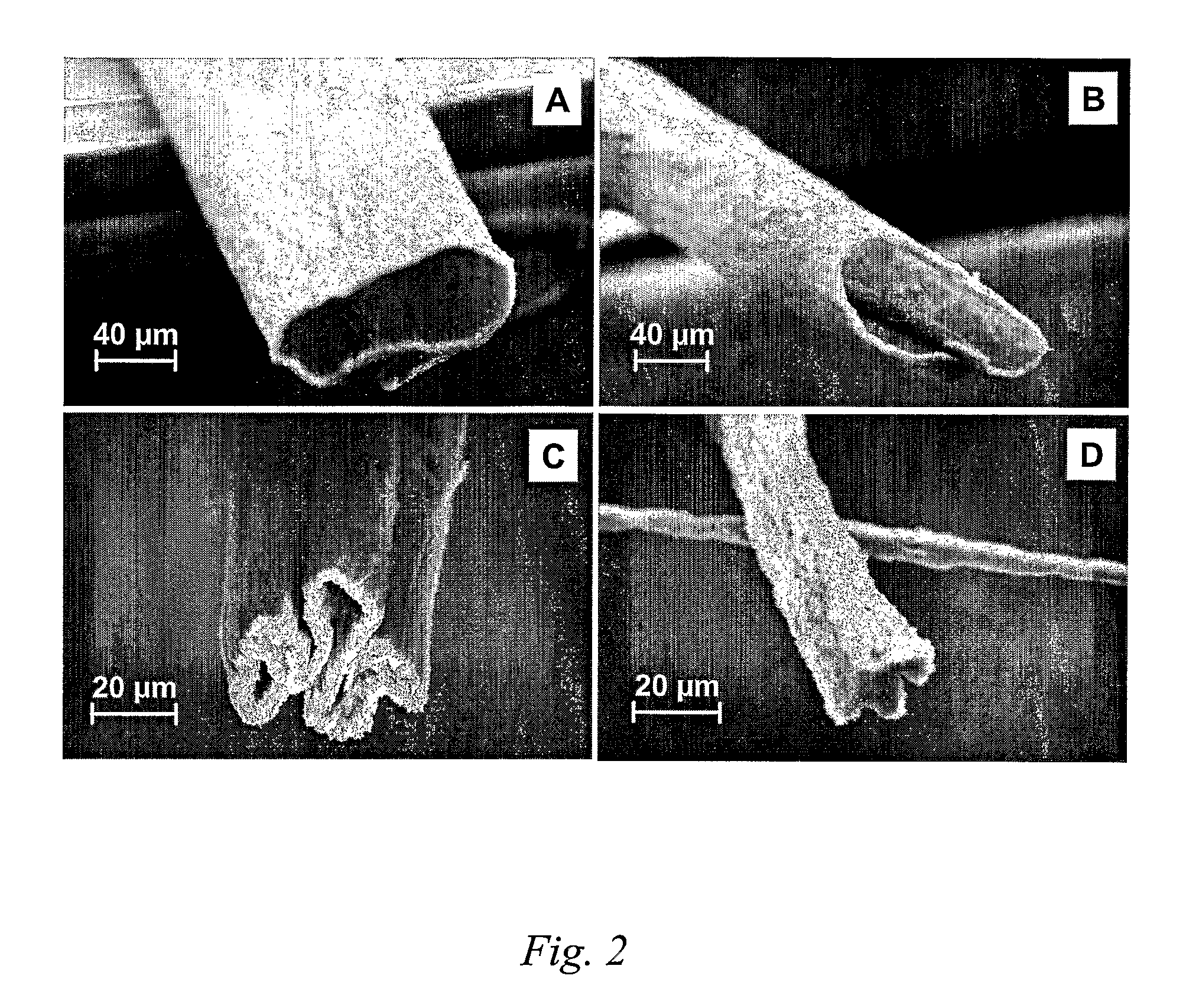

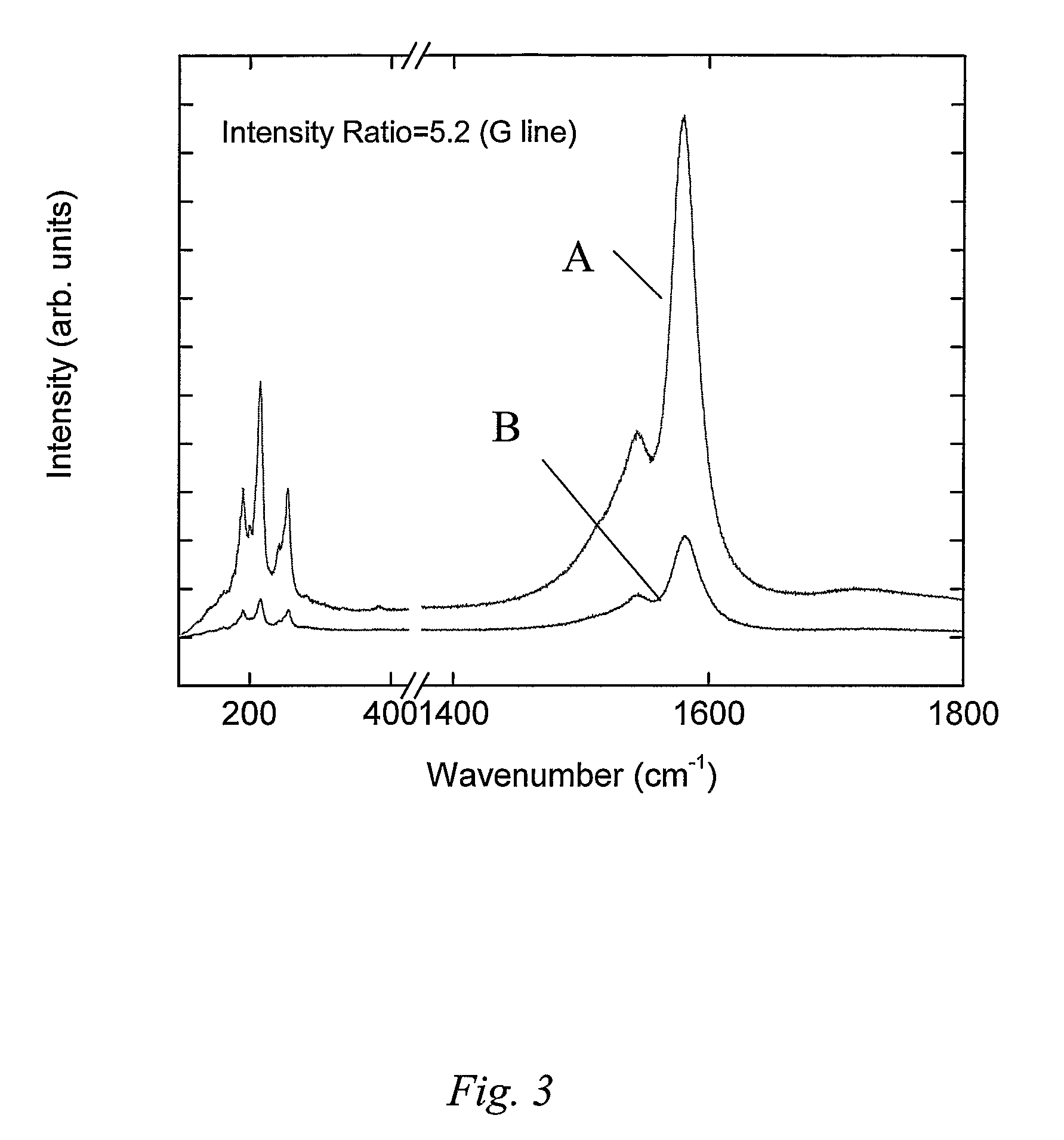

InactiveUS20040096389A1Improve mechanical propertiesRaise the ratioMaterial nanotechnologyWet spinning methodsYarnFiber

Coagulation spinning produces structures such as fibers, ribbons, and yarns of carbon nanotubes. Stabilization, orientation, and shaping of spun materials are achieved by post-spinning processes. Advantages include the elimination of core-sheath effects due to carbonaceous contaminants, increasing mechanical properties, and eliminating dimensional instabilities in liquid electrolytes that previously prohibited the application of these spun materials in electrochemical devices. These advances enable the application of coagulation-spun carbon nanotube fibers, ribbons, and yarns in actuators, supercapacitors, and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

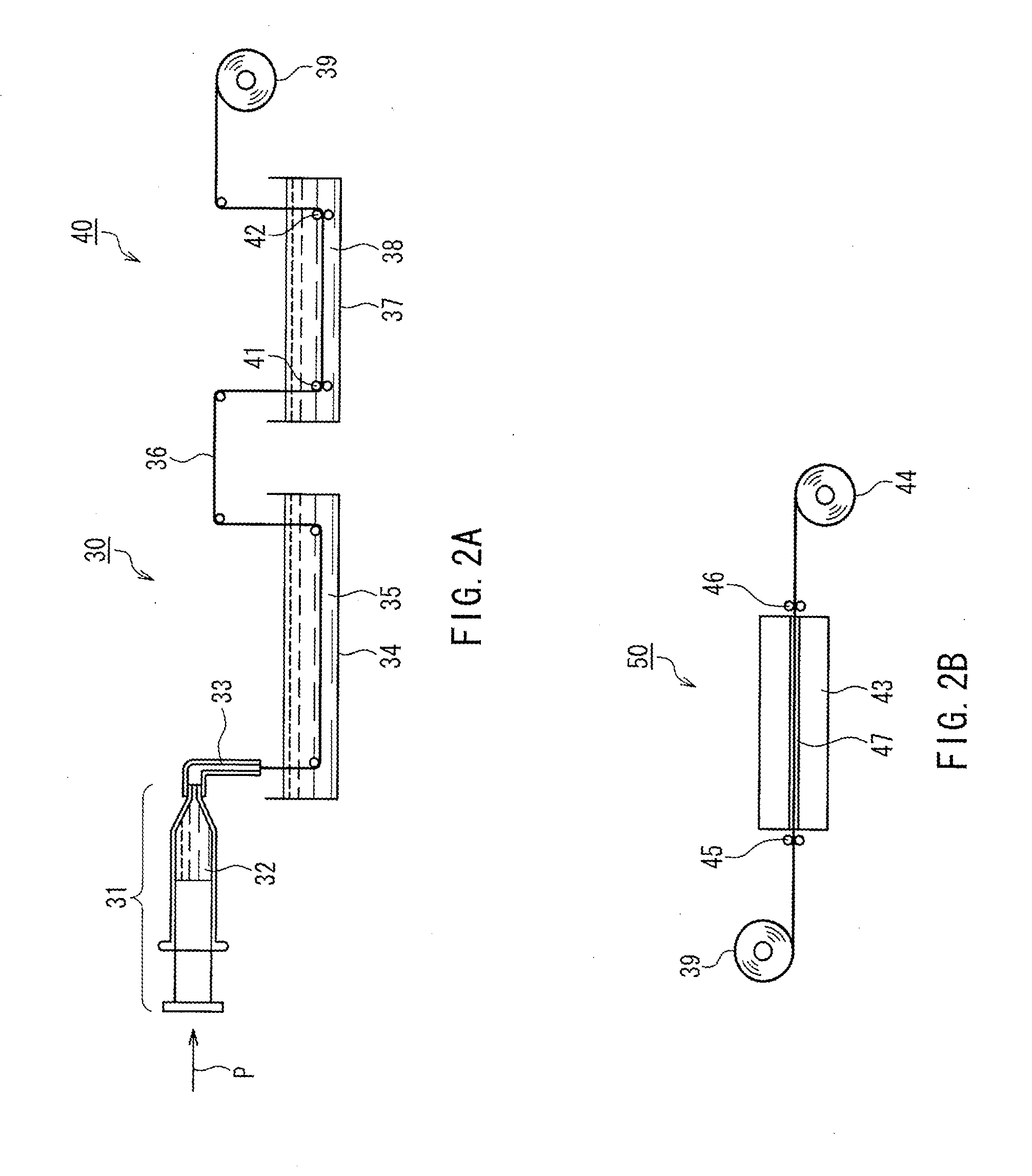

Methods and apparatus for spinning spider silk protein

InactiveUS20050054830A1Peptide/protein ingredientsMonocomponent fibroin artificial filamentBiotechnologySpider Proteins

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:NEXIA BIOTECH

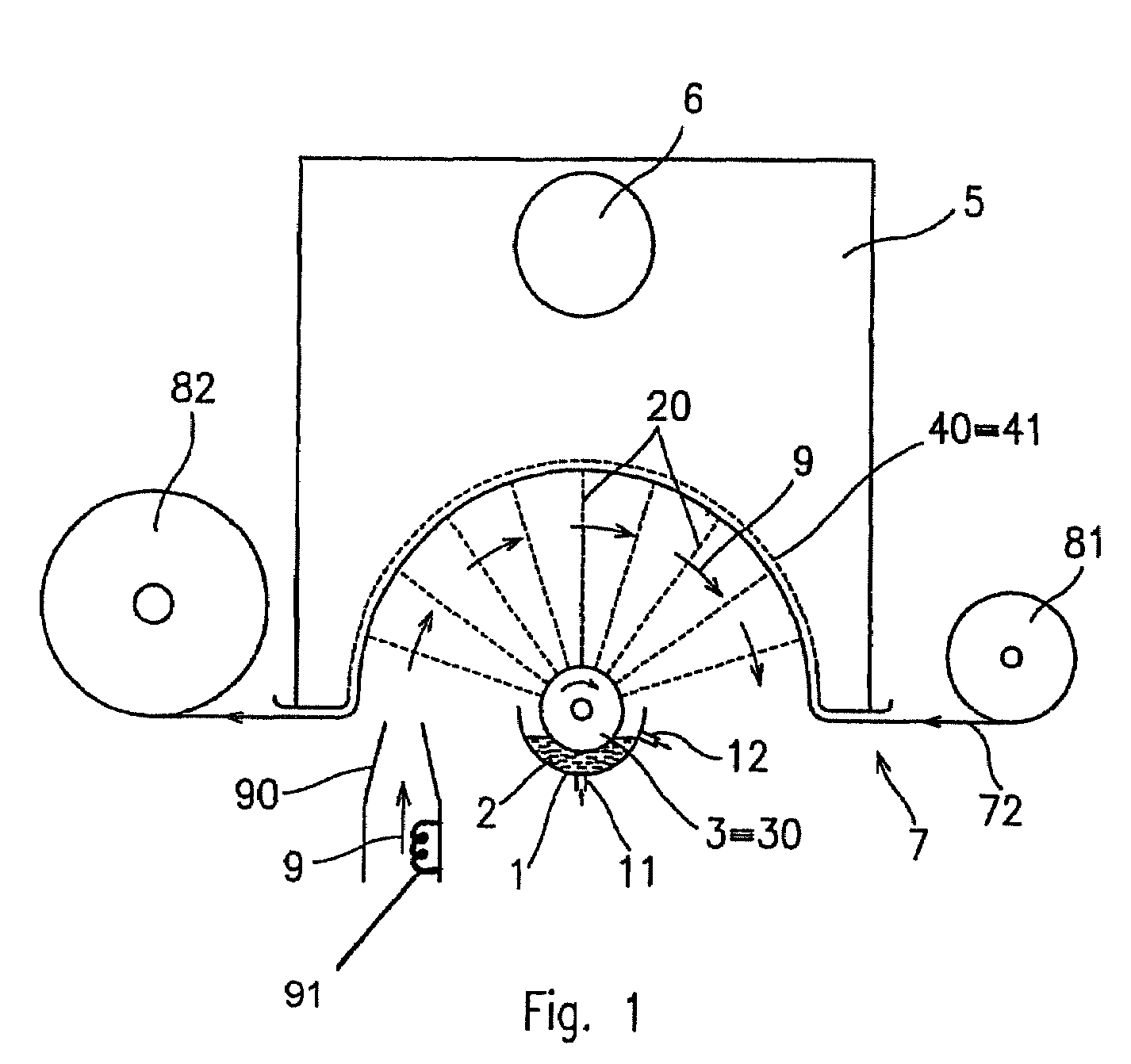

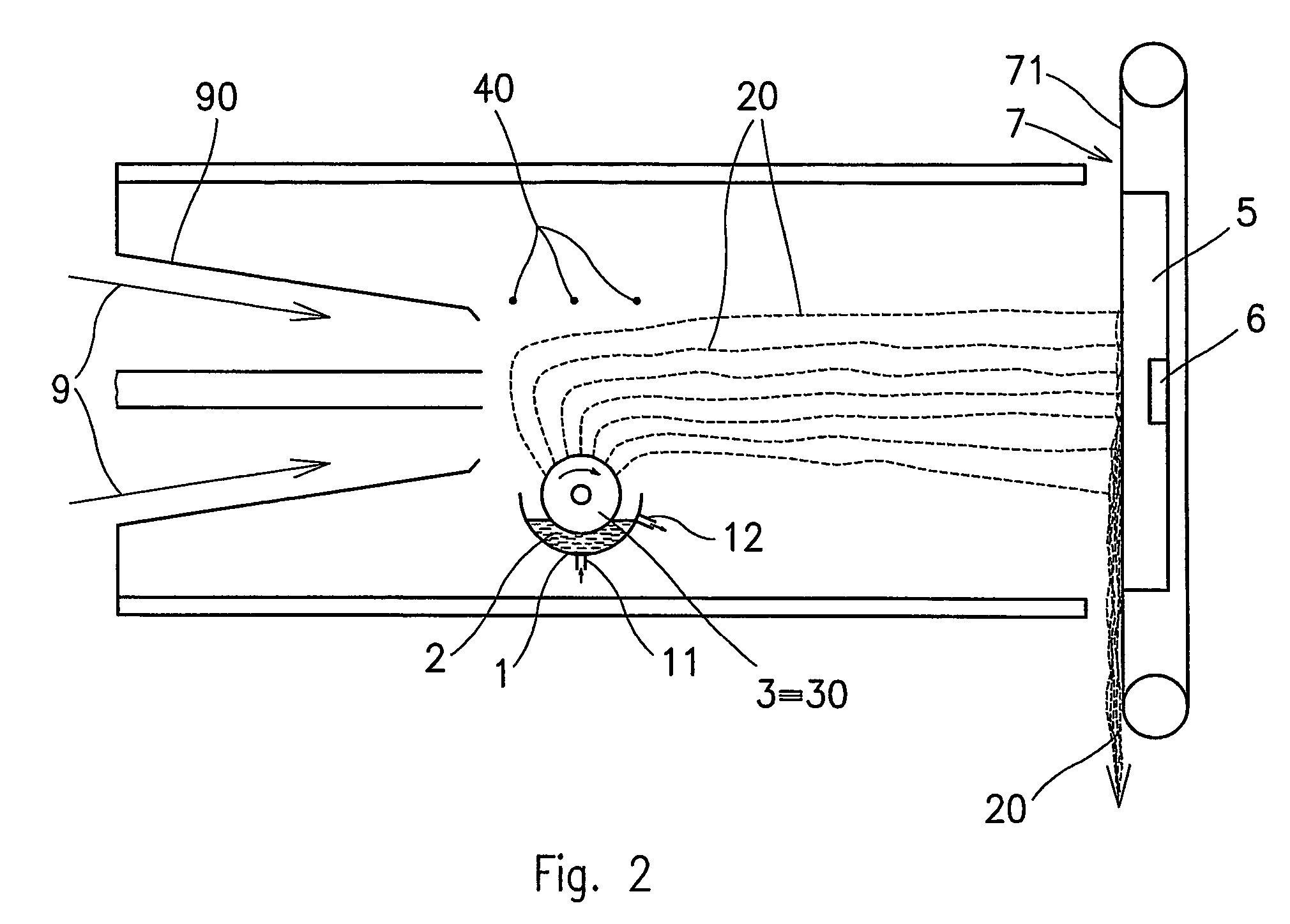

Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

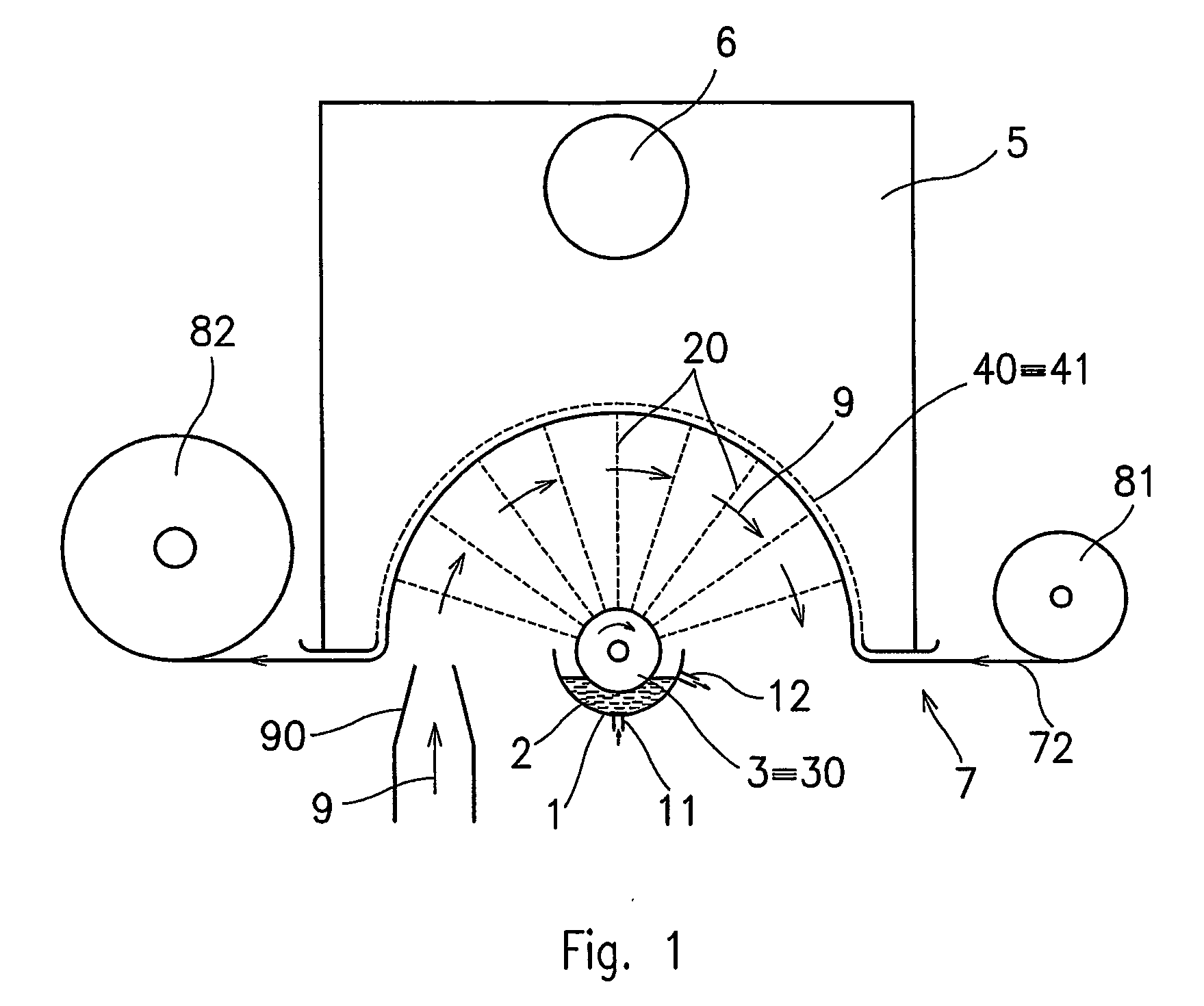

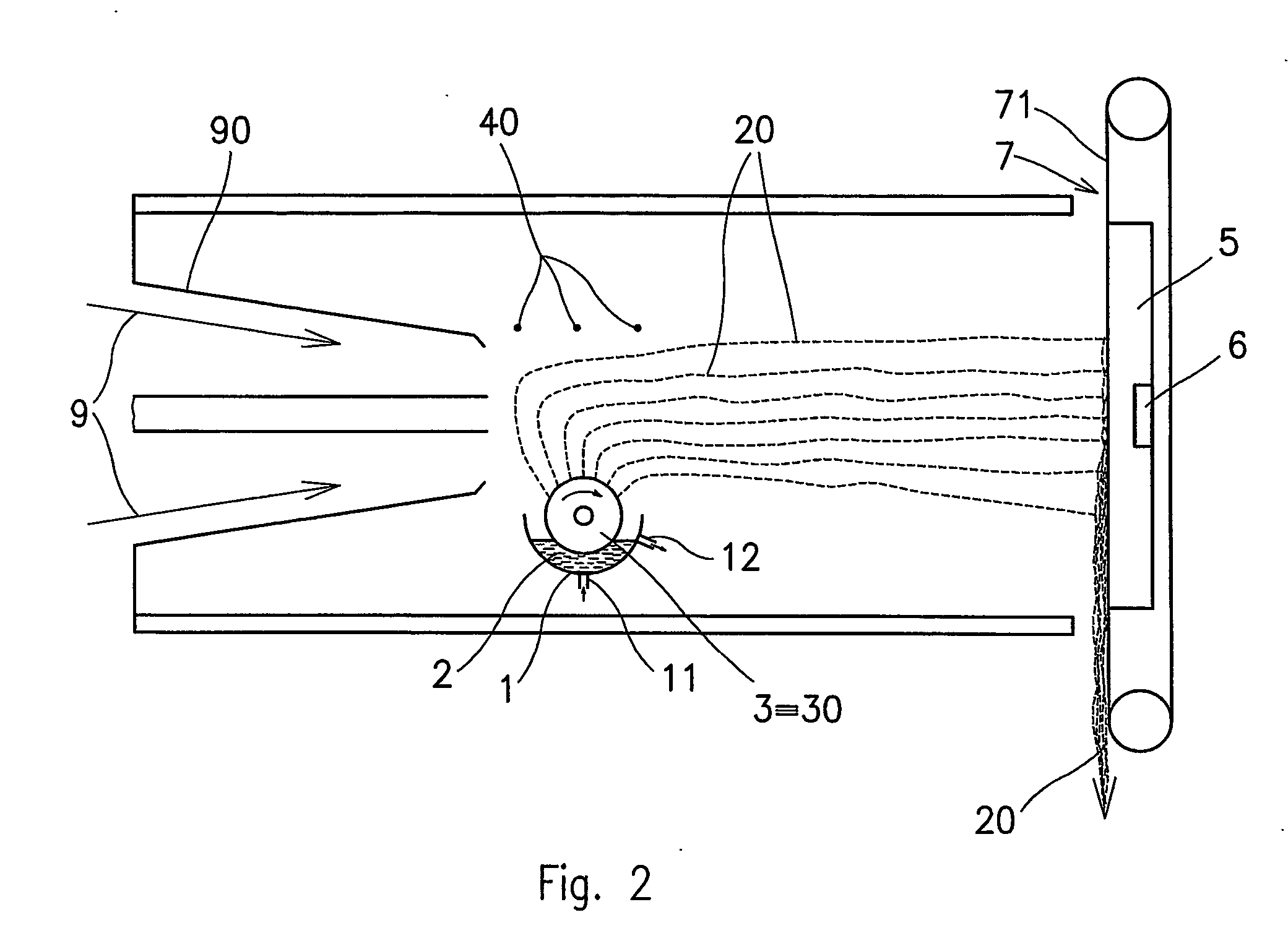

ActiveUS20060290031A1Quality improvementImprove uniformityElectric discharge heatingSpinnerette packsElectrospinningPotential difference

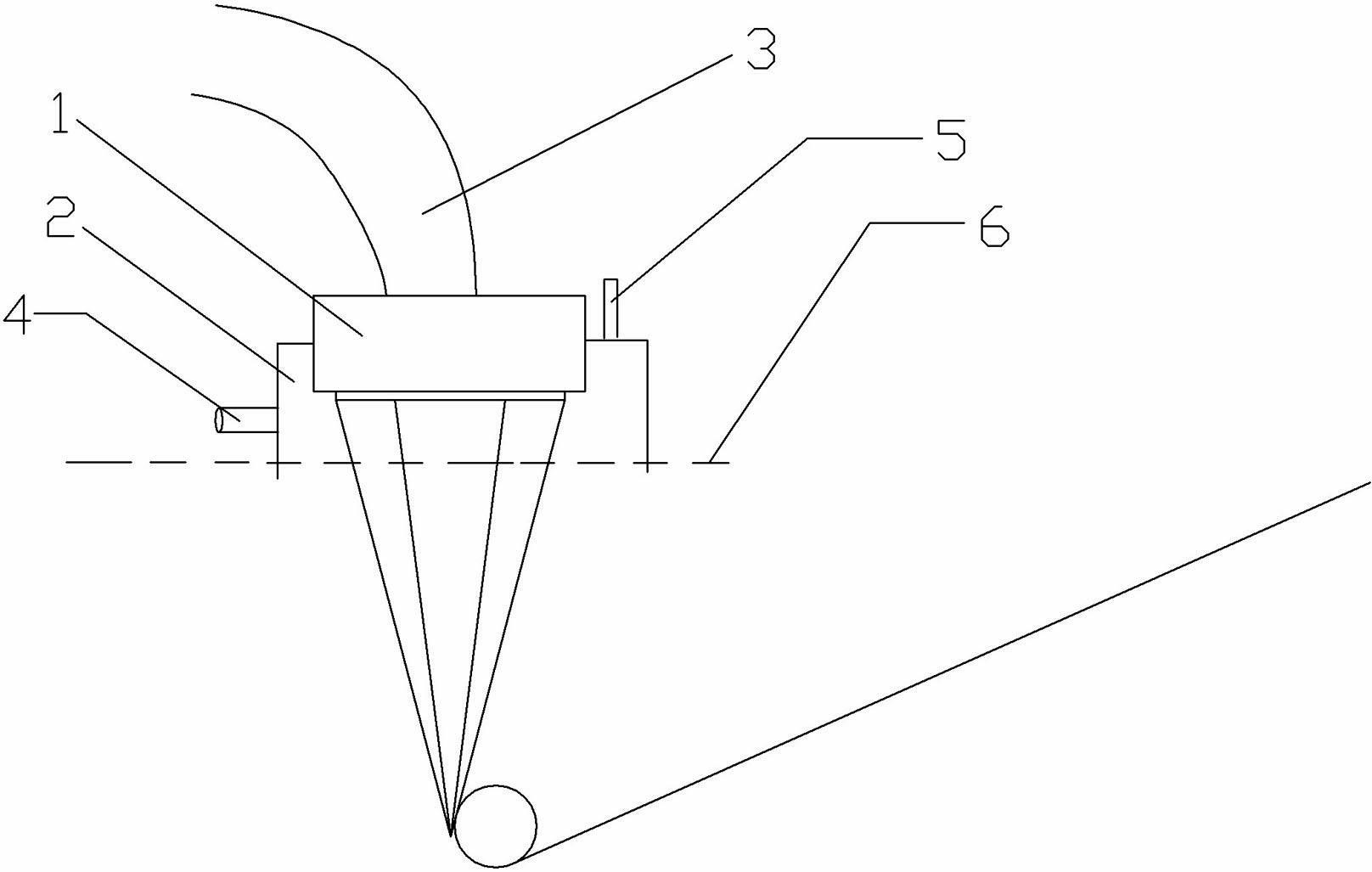

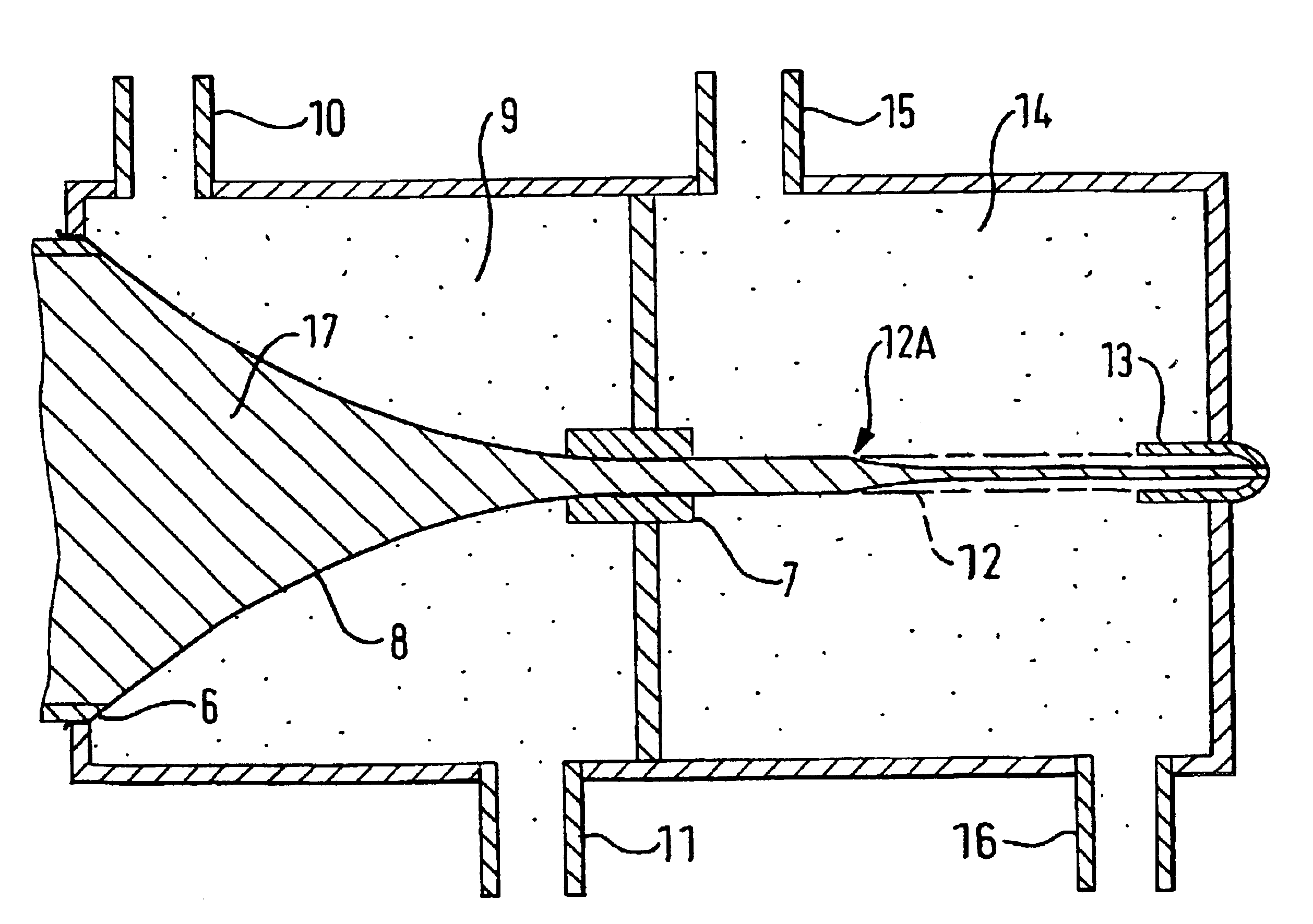

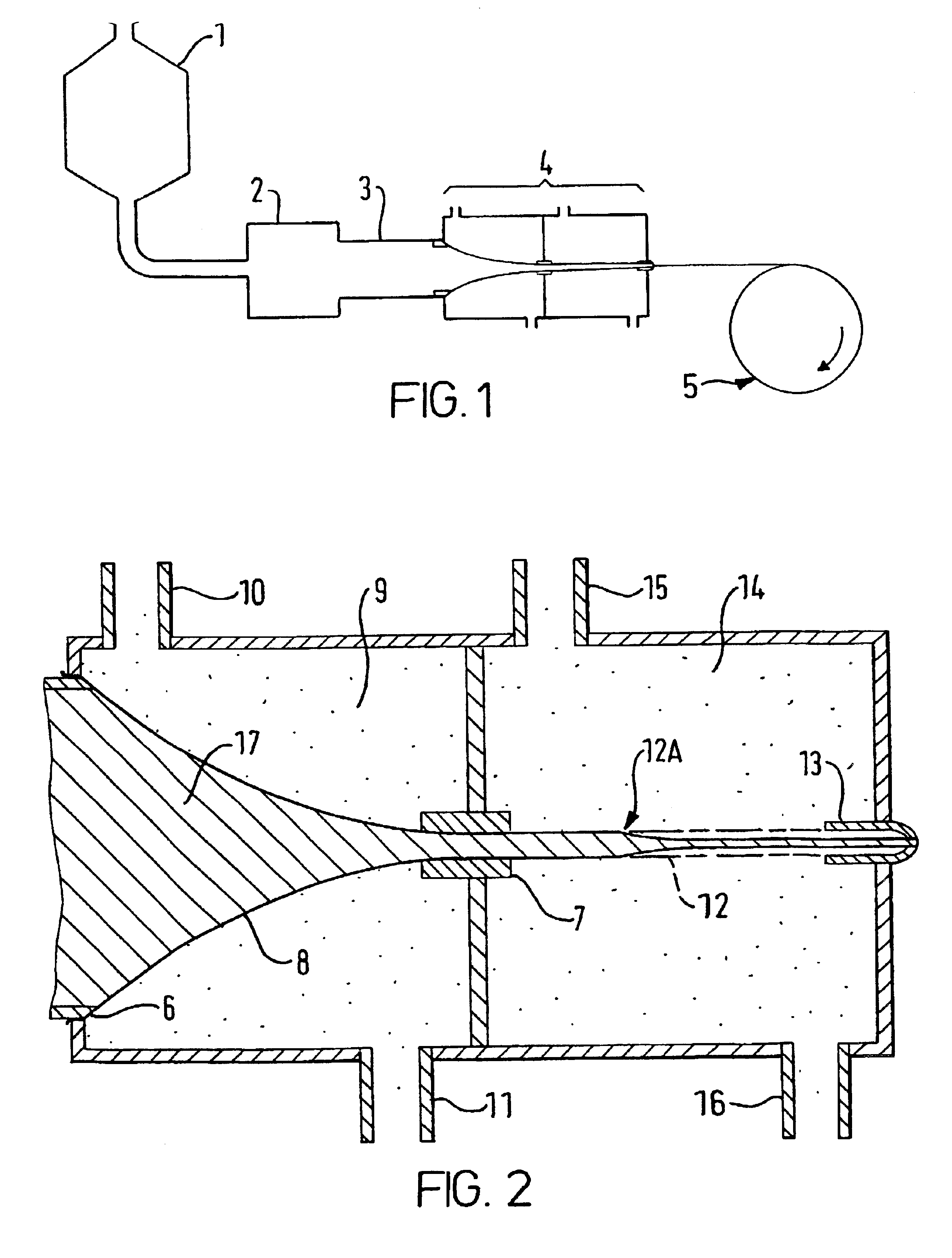

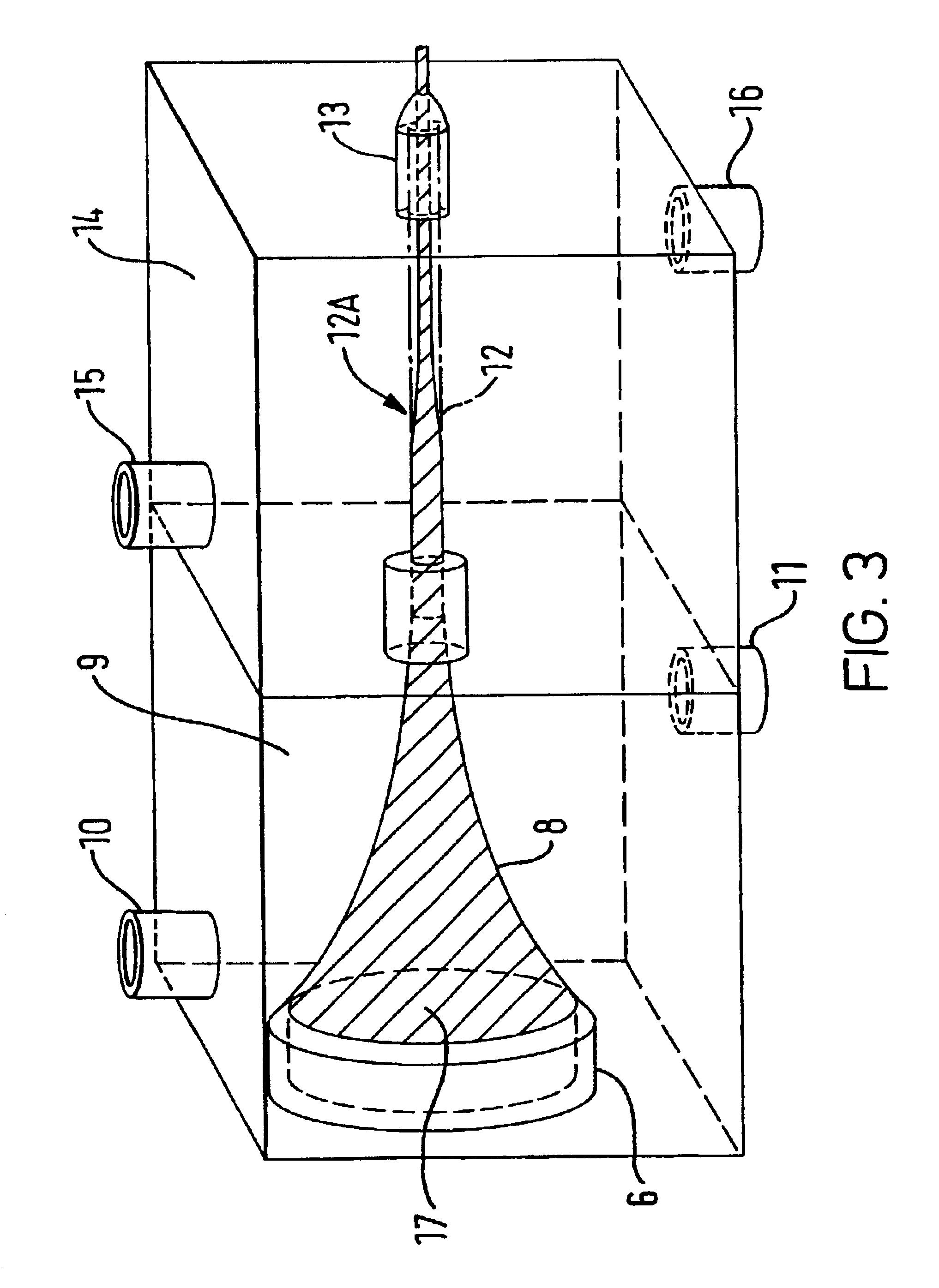

The invention relates to a method of nanofibres production from a polymer solution using electrostatic spinning in an electric field created by a potential difference between a charged electrode and a counter electrode. The polymer solution (2) is for spinning supplied into the electric field using the surface of the rotating charged electrode (30), while on a part of the circumference of the charged electrode (30) near to the counter electrode (40) is a spinning surface created, by which is a high spinning capacity reached. Further the invention relates to a device for carrying out the method, where the charged electrode (30) is pivoted and by its (bottom) part of its circumference it is immersed in the polymer solution (2), while against the free part of the circumference of the charged electrode (30) is positioned the counter electrode (40).

Owner:TECHNICKA UNIVEZITA V LIBERCI

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

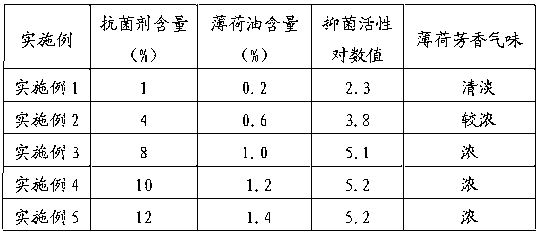

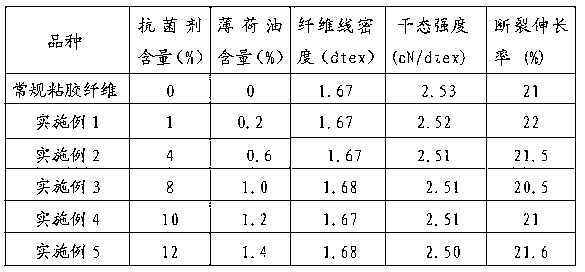

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Polymer-free carbon nanotube assemblies (fibers, ropes, ribbons, films)

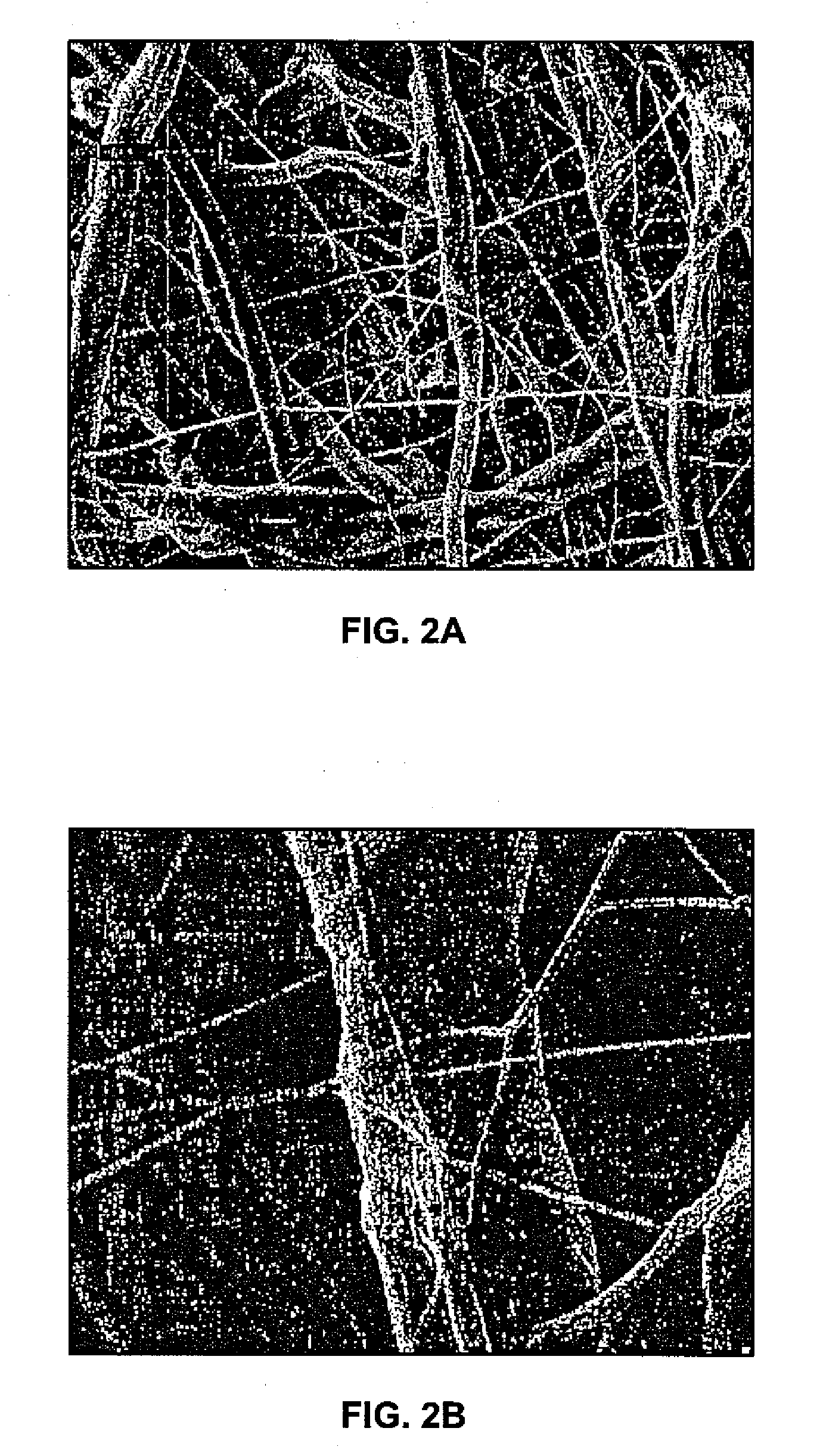

InactiveUS7938996B2Improve mechanical propertiesHigh mechanical strengthPigmenting treatmentRotating receptacle mixersFiberFlocculation

Process, apparatus, compositions and application modes are provided that relate to nanofiber spinning without the use of superacids in the spinning solution. The methods employ either acids or bases for a flocculation solution. The advances disclosed therein enable the use of nanofibers, including carbon nanotubes, for a variety of applications including, but not limited to, electromechanical actuators, supercapacitors, electronic textiles, and in devices for electrical energy harvesting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Coforming Processes and Forming Boxes Used Therein

ActiveUS20160355950A1Improve stabilityImproved sheet formationWet spinning methodsNon-woven fabricsFiberPolymer chemistry

Coforming processes for commingling two or more separate materials, for example solid additives, for example fibers and / or particulates, and filaments, and equipment; namely, forming boxes, useful in such coforming processes and more particularly to coforming processes for commingling filaments with one or more fibers, such as pulp fibers, and forming boxes useful therein are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Hollow fiber, dope composition for forming hollow fiber, and method of making hollow fiber using the same

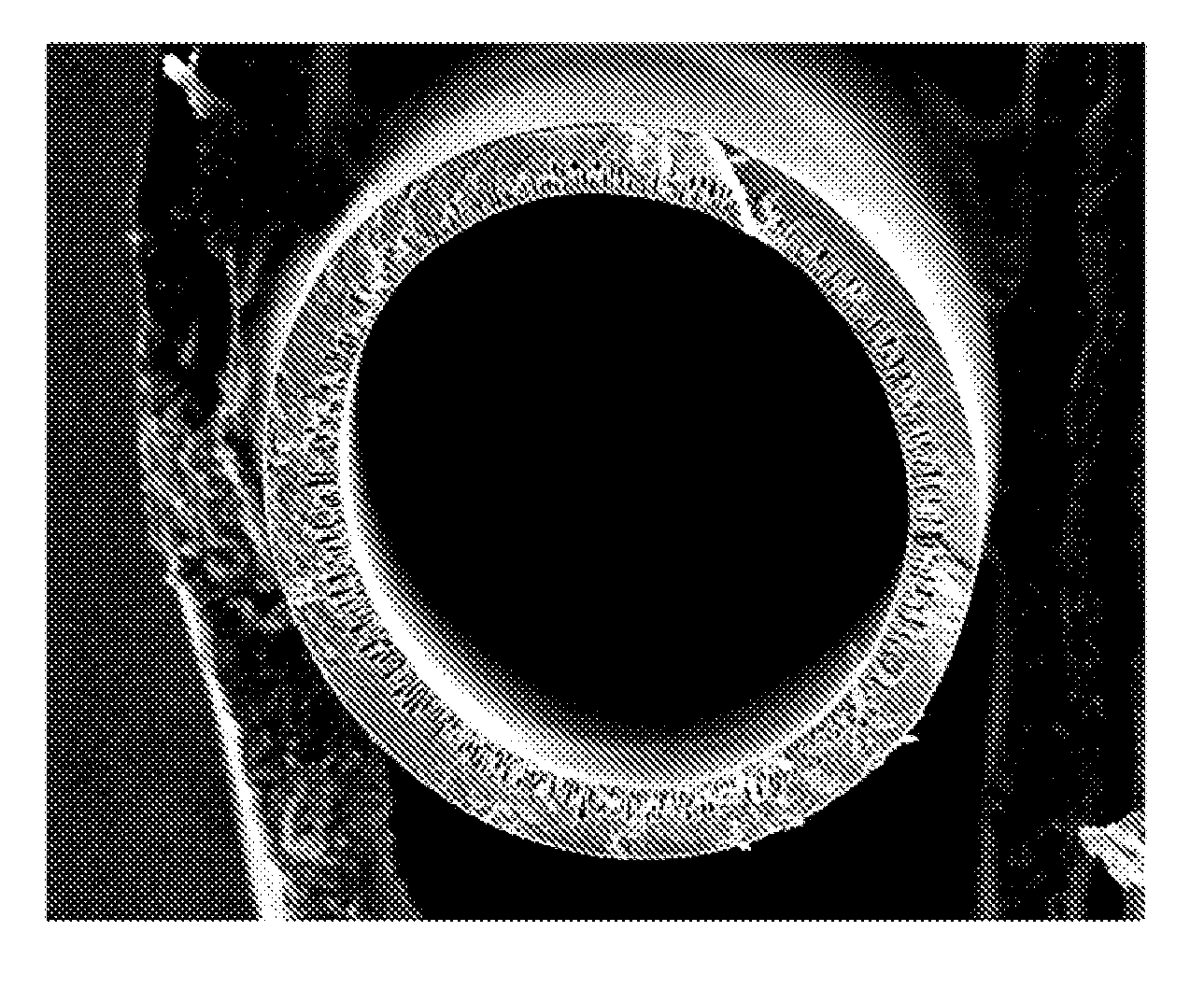

InactiveUS20090297850A1Improve permeabilityHigh selectivitySuture equipmentsCosmetic preparationsHollow fibreFiber

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

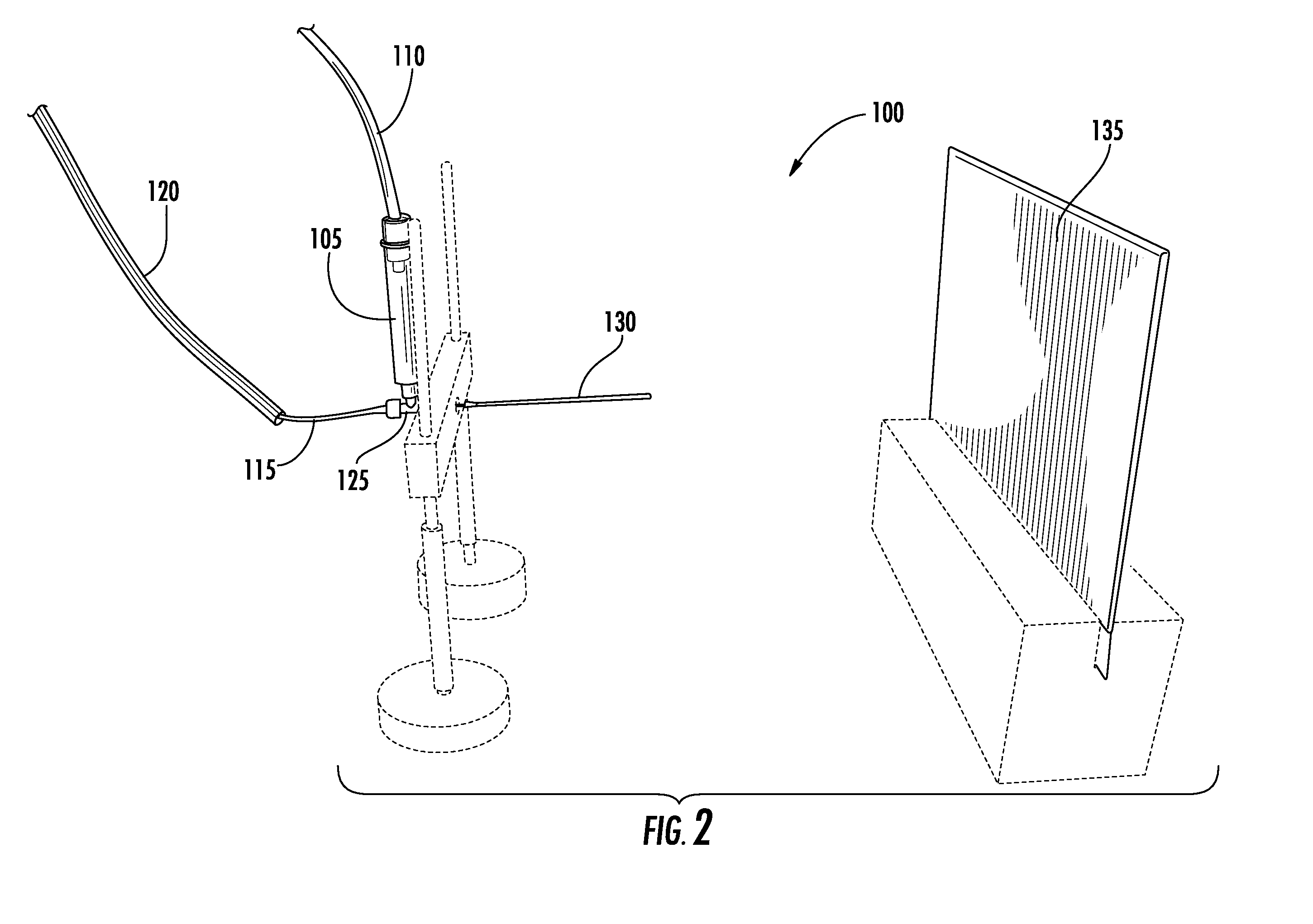

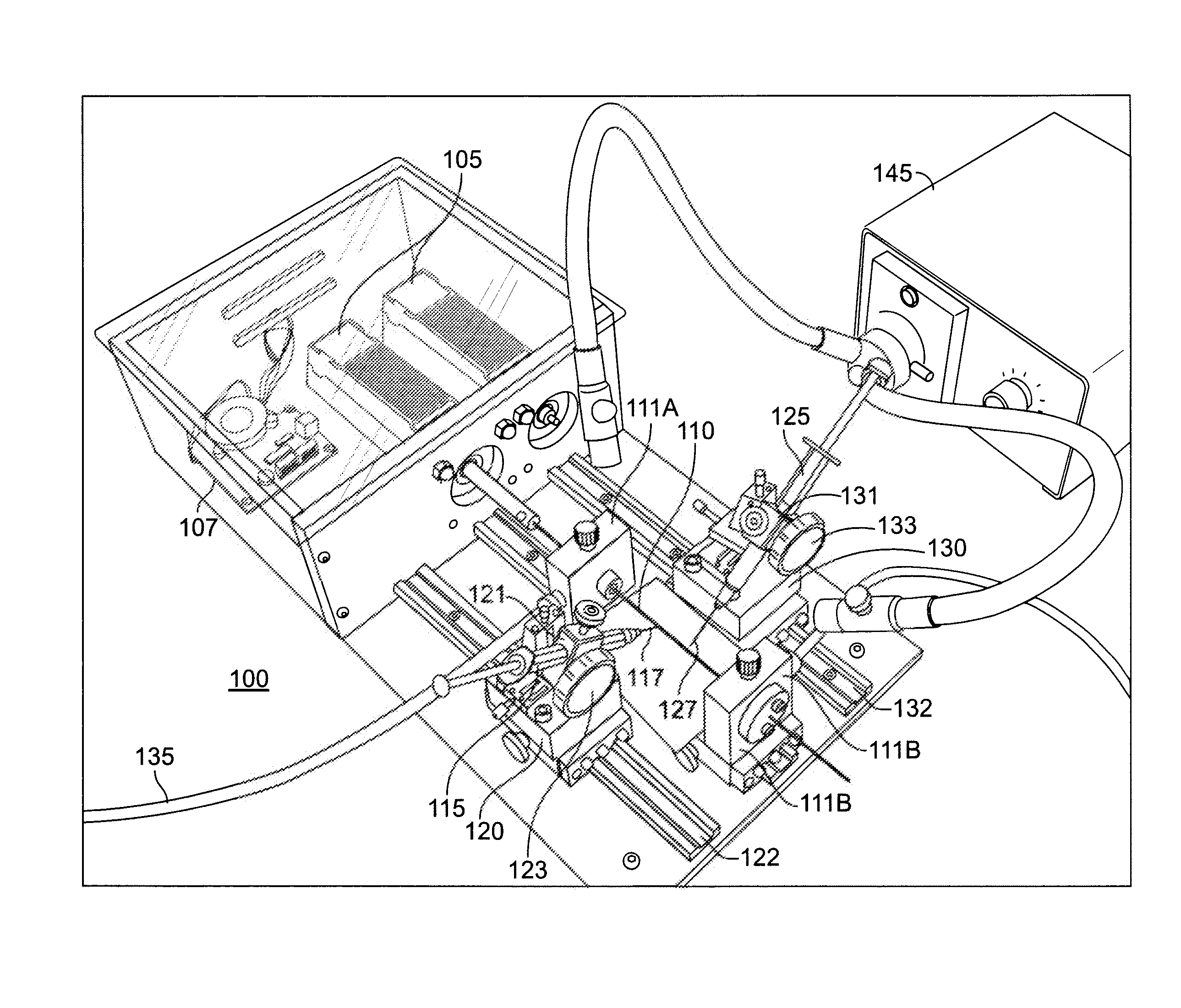

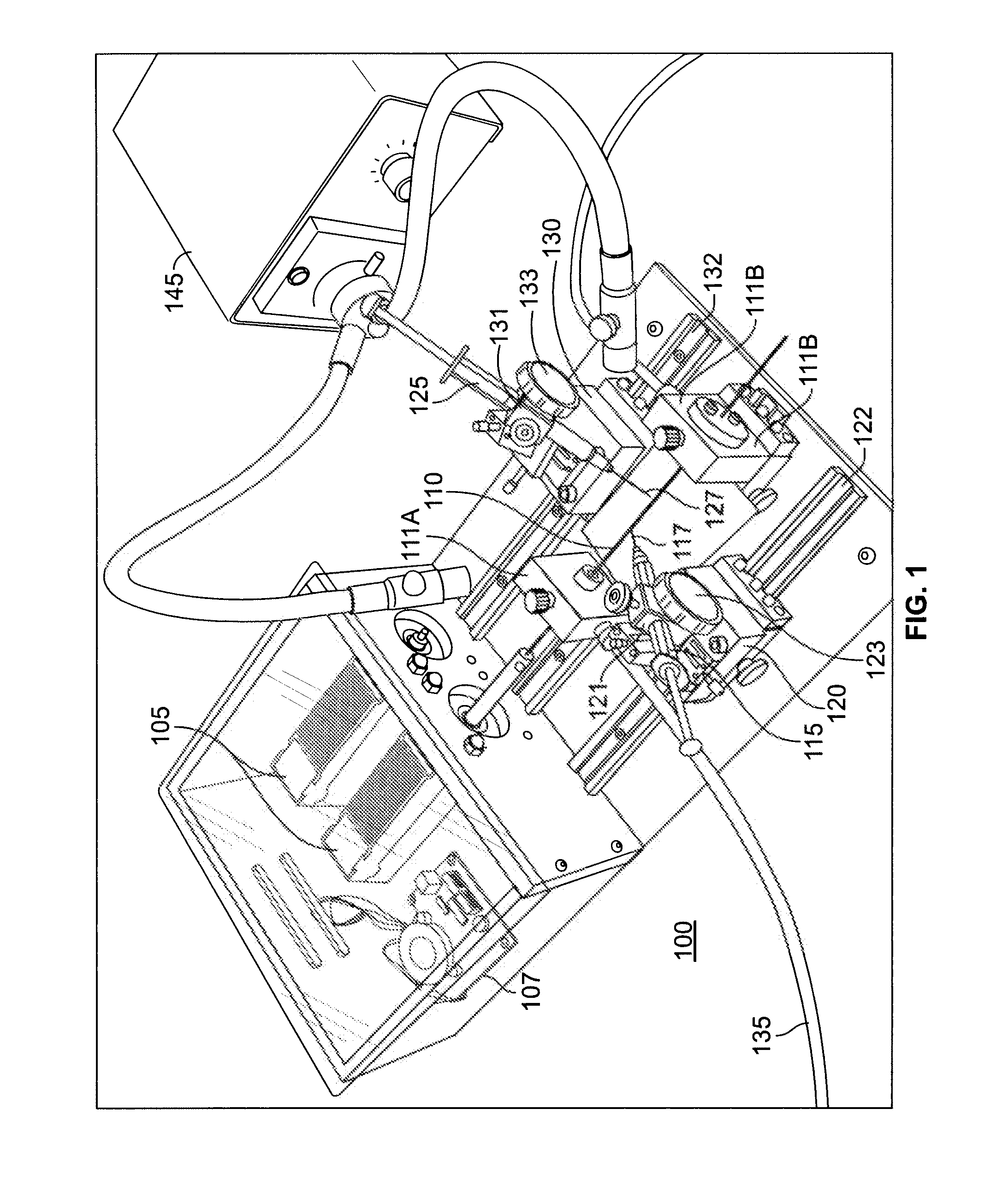

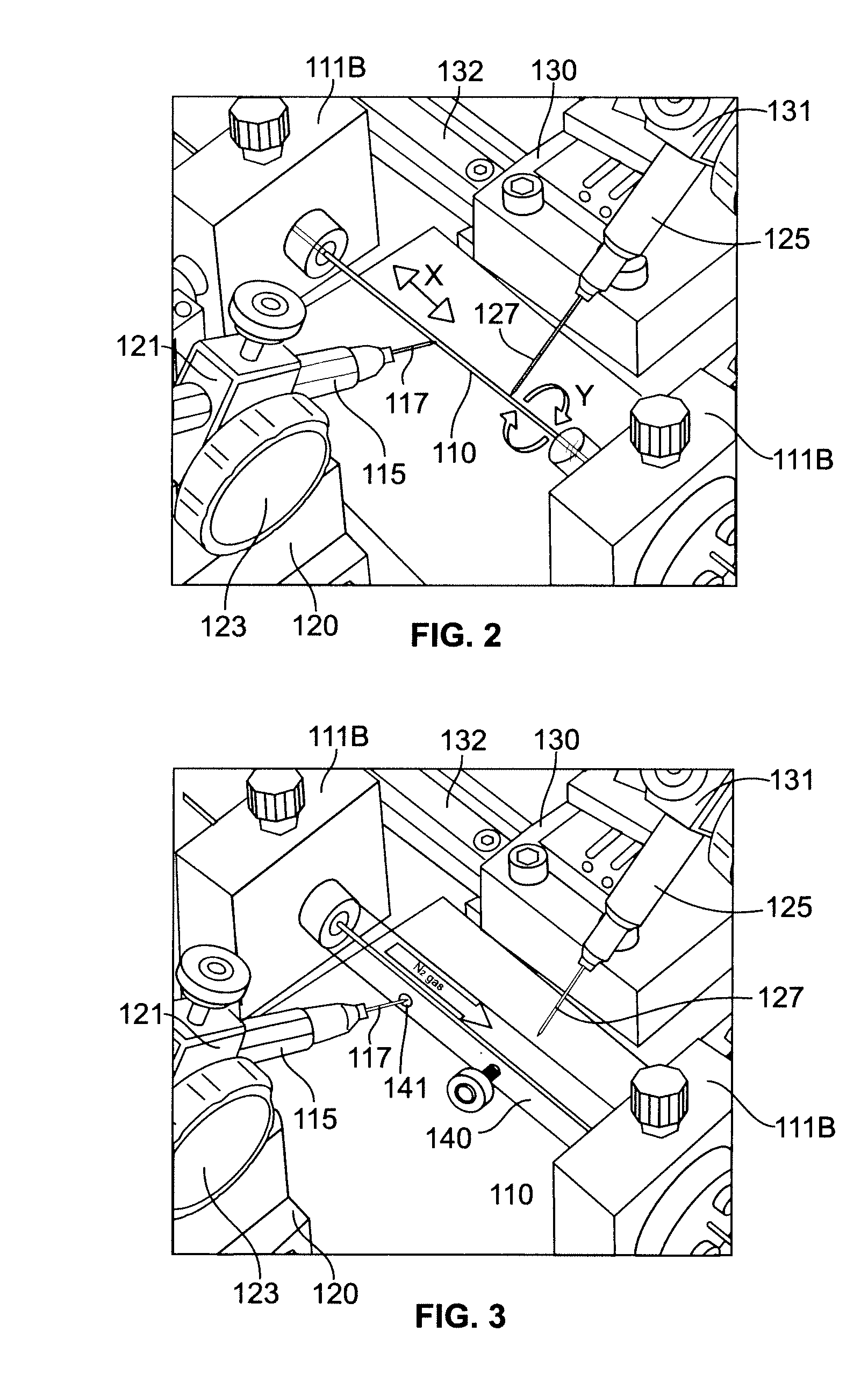

System and method for making biomaterial structures

ActiveUS20110076384A1Unique and robust mechanical propertyProperty is limitedNew-spun product collectionMonocomponent fibroin artificial filamentFiberMaterials processing

A system and method for making a biomaterial device includes a support structure providing a shape for a biomaterial device. At least one applicator has a supply of biomaterial solution and is positioned along the support structure. The at least one applicator forms a biomaterial fiber by applying shear force to the biomaterial solution and delivering the biomaterial fiber to the support structure. A controller causes relative movement between the support structure and the at least one applicator, and the biomaterial fiber is arranged on the support structure according to the relative movement to form the biomaterial device. The biomaterial may be silk fibroin which may be wound onto a reciprocating and rotating mandrel. Control over the properties of the biomaterial device is achieved through appropriate selection of material processing, winding strategy, and post-winding processing.

Owner:TRUSTEES OF TUFTS COLLEGE +1

Bamboo-charcoal viscose fiber and method for making same

InactiveCN1607271AStrong ability to absorb odorMonocomponent cellulose artificial filamentWet spinning methodsEmulsionEngineering

Said invention discloses a bamboo charcoal viscose fiber and producing method. The bamboo charcoal is finely selected, coarse cracked, dust removed, trash extracted, and pulverized to less than 0.5 micrometer, the bamboo charcoal micropowder and dispersant are put in water to made into aqueous emulsion slurry, filtered four times by two-layer of poplin filter fabric, respectively spinning in filament spinning machine and shorts spinning machine to obtain said bamboo charcoal viscose fiber which has bacteriostasis and antibiotic effect.

Owner:XINXIANG CHEM FIBER

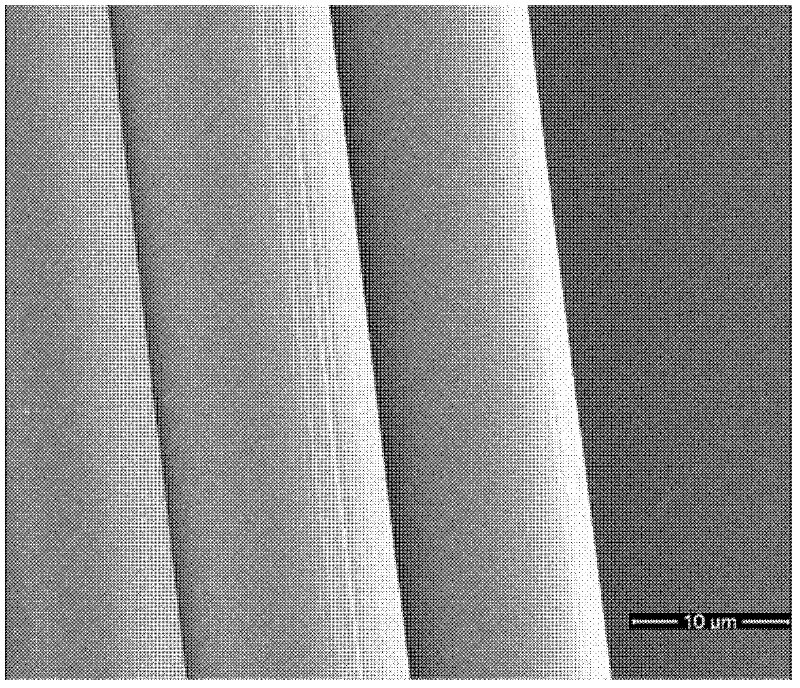

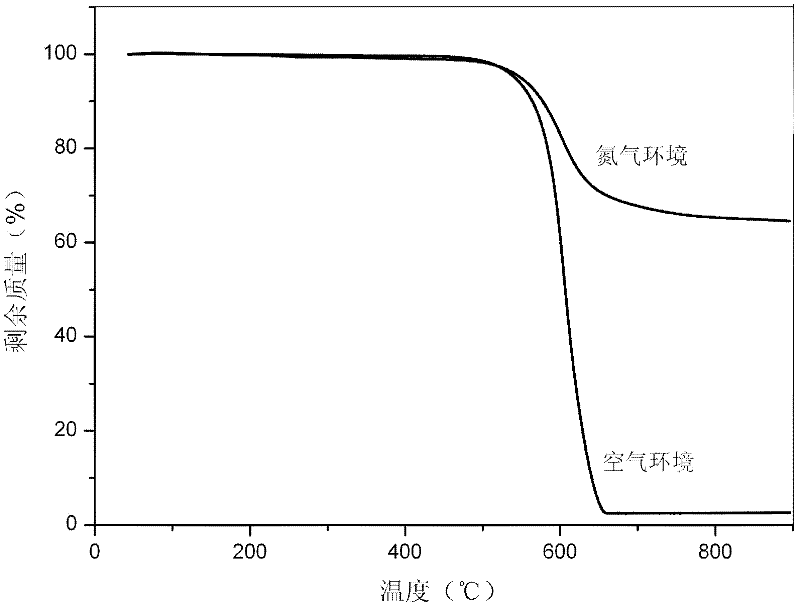

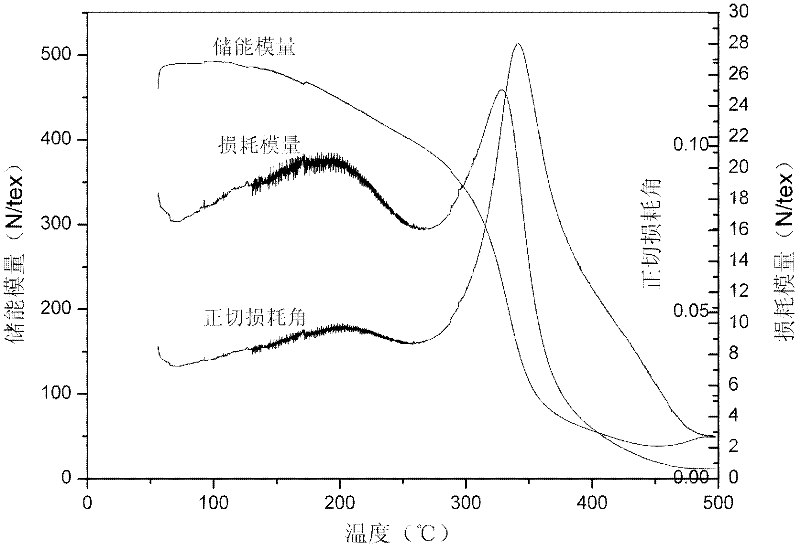

Preparation method of ultra-high molecular weight polyethylene fiber

InactiveCN101575742AImprove mechanical propertiesReduce internal stressArtificial filament washing/dryingWet spinning methodsFiberPolymer science

The invention relates to a preparation method of ultra-high molecular weight polyethylene fiber, which comprises the following steps: firstly, mixing ultra-high molecular weight polyethylene powder with solvent for swelling to obtain suspending liquid, and then extruding and dissolving the suspending liquid through a double screw extruder to obtain 4-25 percent of spinning solution, wherein the solvent is liquid hydrocarbon under room temperature; secondly, spraying and cooling the spinning solution to obtain gel filament; thirdly, applying 1-10 times of pretensioning to the gel filament, settling the pretensioned gel filament for 12-48h, extracting and drying the gel filament; fourthly, applying 4-130 times of heat drawing to the dried gel filament 70-160 DEG C to obtain the ultra-high molecular weight polyethylene fiber. After the gel filament is formed and pretentioned to a certain degree, the primary filament can be more uniform and has higher tension property , and the ultra-high molecular weight polyethylene fiber with excellent property can be prepared.

Owner:杨珍芬

Multifunctional viscose and preparation method thereof

ActiveCN104831389AGood far infraredImproves UV resistanceGrapheneArtificial filaments from viscoseViscoseAntibacterial activity

The invention provides multifunctional viscose. The multifunctional viscose comprises viscose, graphene and nano-silver, wherein nano-silver is loaded to a graphene slice layer in situ. The invention further provides a preparation method of the multifunctional viscose. The preparation method is characterized by comprising the following steps: (a) dispersing graphene in a water solution, so as to obtain a graphene dispersion liquid; (b) dissolving silver salt into the graphene dispersion liquid, adding a reducing agent, and carrying out reduction reaction, so as to obtain nano-silver-loaded graphene dispersion liquid; and (c) uniformly mixing the nano-silver-loaded graphene dispersion liquid with viscose liquid, and carrying out spinning, so as to obtain the multifunctional viscose. An experimental result shows that compared with viscose which is not added with nano-silver-loaded graphene, the multifunctional viscose has the advantages that the far infrared temperature increase performance is increased by not less than 100%, the ultraviolet protecting coefficient is increased by not less than 70%, and the antibacterial activity reaches 99.9% and is increased by not less than 100%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Method for preparing polyacrylonitrile-based carbon fiber protofilament

ActiveCN101165237AEfficient removalGood removal effectArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

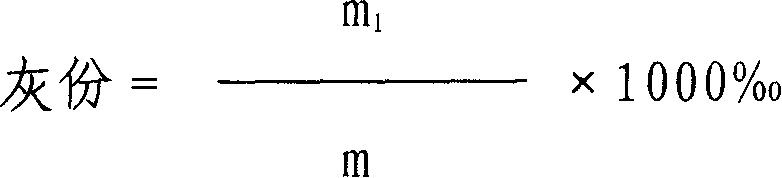

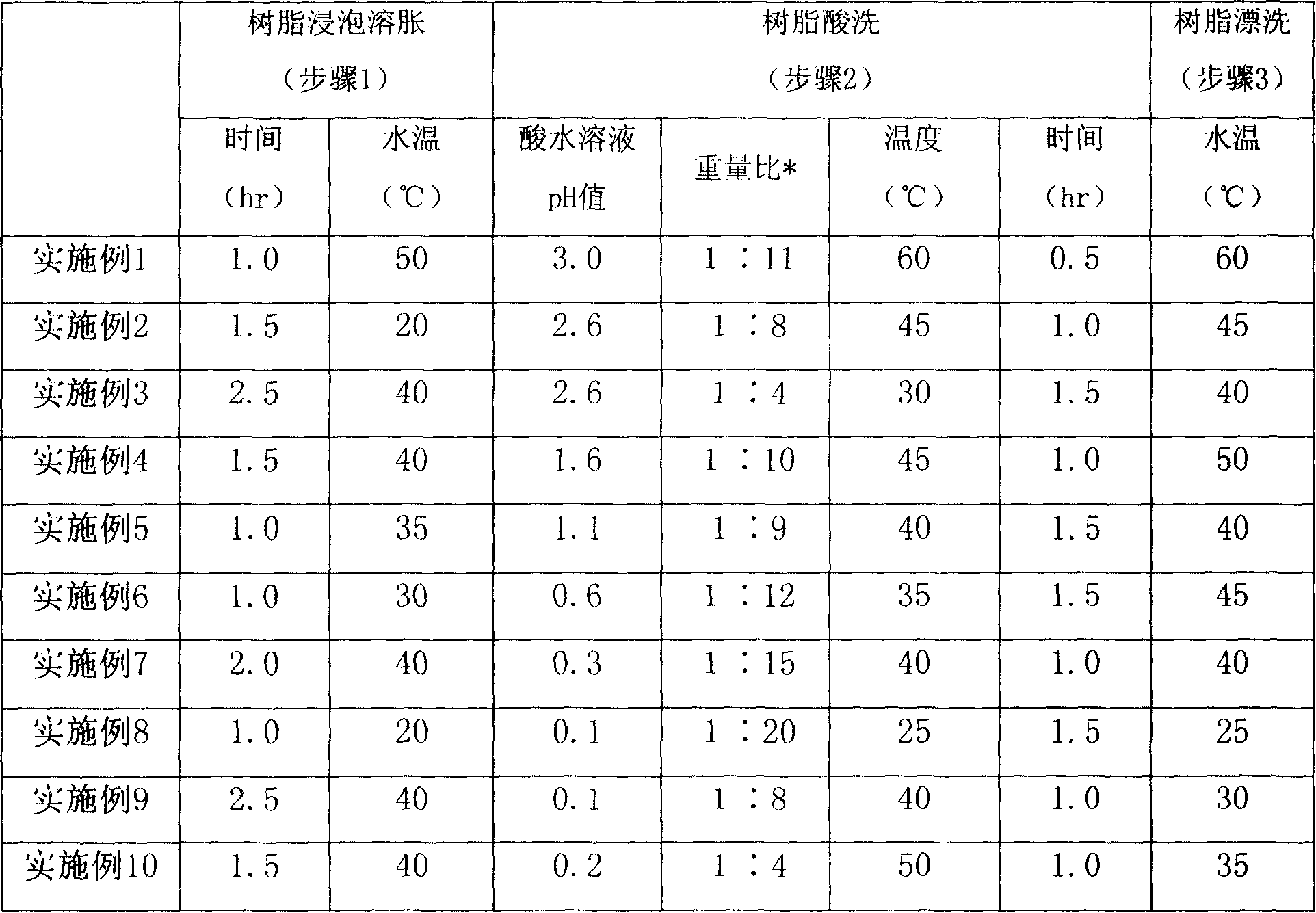

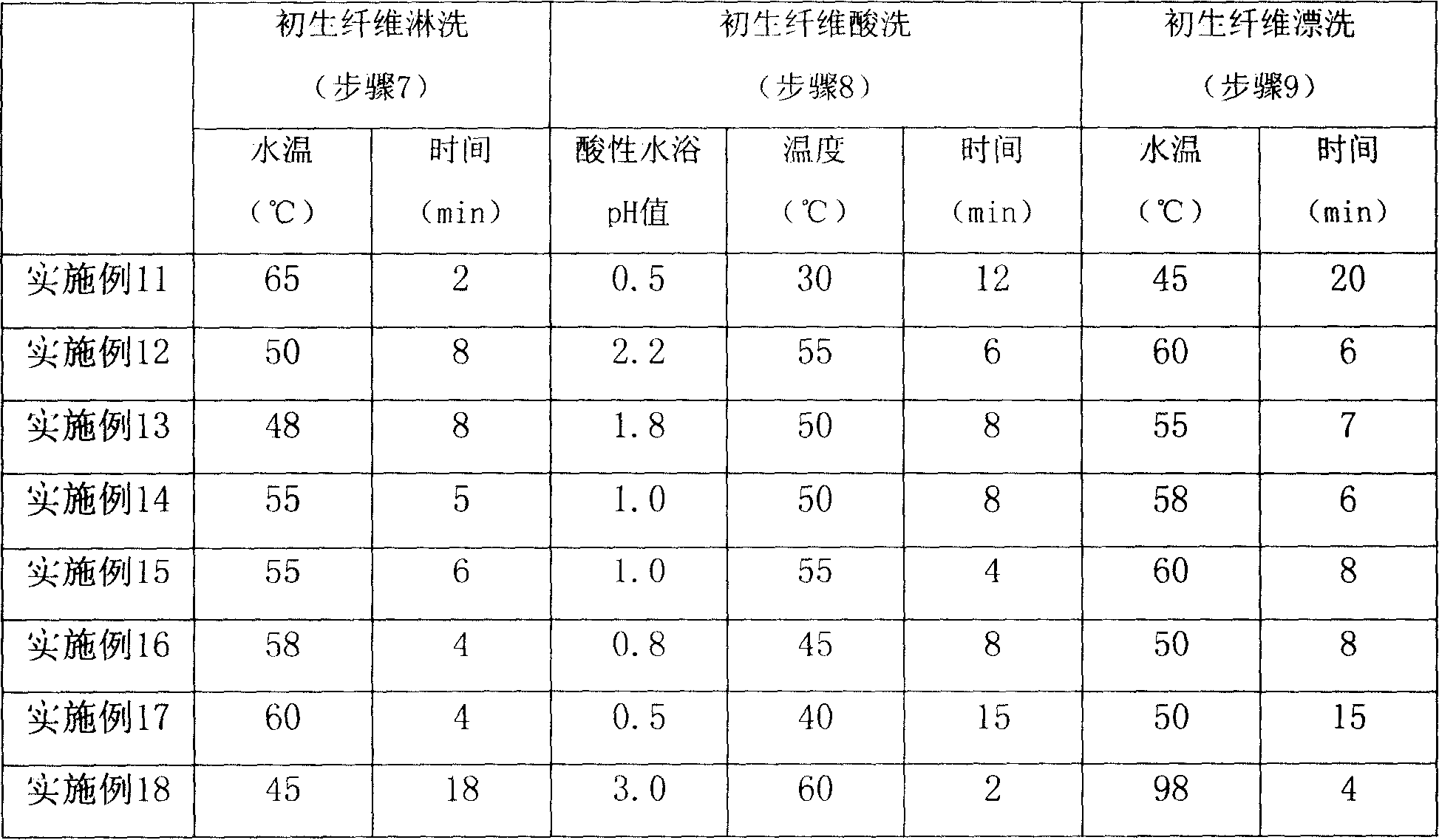

The process of preparing polyacrylonitrile fiber for carbon fiber includes the following steps: soaking resin in deionized water at 20-50 deg.c to swell for 1-2.5 hr; pickling in water solution of nitric acid or hydrochloric acid in pH 0.1-3.0 at 25-60 deg.c for 0.5-1.5 hr; rinsing with deionized water to neutral; dewatering and drying to water content lower than 3 %; dissolving in 35-58 wt% concentration NaSCN aqua to form spinning fluid in resin content of 8-16 wt%; debubbling and spinning to form initial fiber; washing with deionized water, acid aqua and hot water successively; drafting, oiling, drying, densifying, etc to produce polyacrylonitrile fiber for carbon fiber. The polyacrylonitrile fiber product has ash content not higher than 0.01% and alkali metal ion content not higher than 0.005%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Artificial polypeptide fiber and method for producing the same

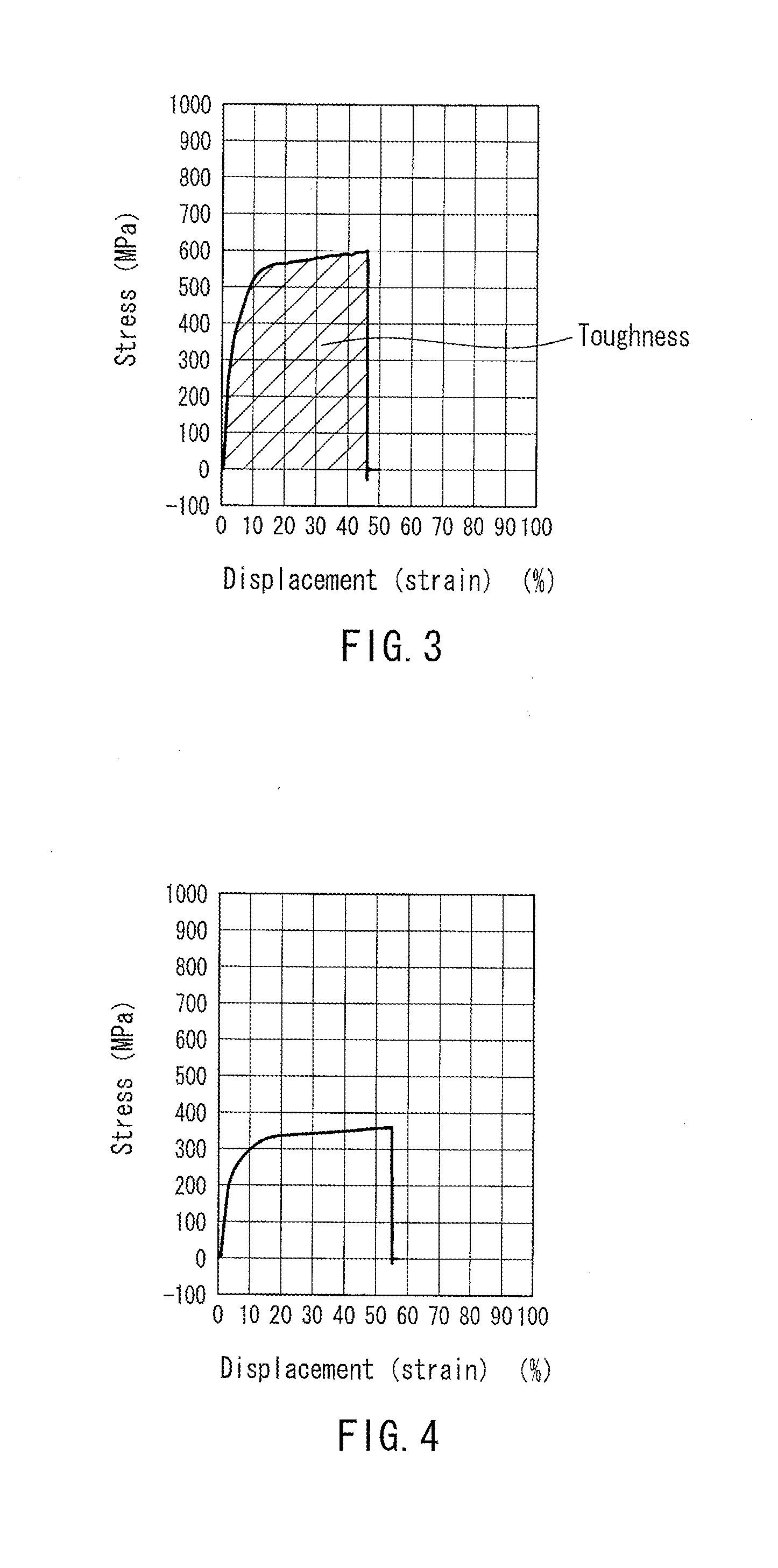

ActiveUS20140058066A1High stressImprove toughnessPeptide/protein ingredientsMonocomponent polypeptides artificial filamentFiberSpider Proteins

An artificial polypeptide fiber of the present invention is an artificial fiber containing a polypeptide as a main component, and has a stress of 350 MPa or more and a toughness of 138 MJ / m3 or more. A method for producing an artificial polypeptide fiber of the present invention is a method for producing the artificial polypeptide fiber obtained by spinning a spinning solution (6) containing a polypeptide derived from natural spider silk proteins and performing drawing of at least two stages. The drawing of at least two stages includes a first-stage drawing (3) in wet heat and a second-stage drawing (4) in dry heat. Thereby, the present invention provides high-toughness artificial polypeptide fibers having favorable stress and rupture elongation, and a method for producing the same.

Owner:SPIBER INC

Anti bacteria natural silk composite nano-fiber material and its preparation method

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

Apparatus and Method for Producing Electrospun Fibers

InactiveUS20080296808A1Artificial filaments from cellulose solutionsElectric discharge heatingFiberBiomedical engineering

An apparatus for making electrspun fibers comprises a collector that may be submerged in a coagulation bath. The collector may be automatically movable between a first position and a second position, wherein at least a portion of the collected fibers are submerged in a coagulation bath in the first position and spaced apart from the coagulation bath in the second position. The collector may be a rotating collector. A process for making electrospun fibers comprises electrospinning a dispersion and collecting a plurality of electrospun fibers, followed by submerging the collected fibers in a coagulation bath.

Owner:CORNELL RES FOUNDATION INC

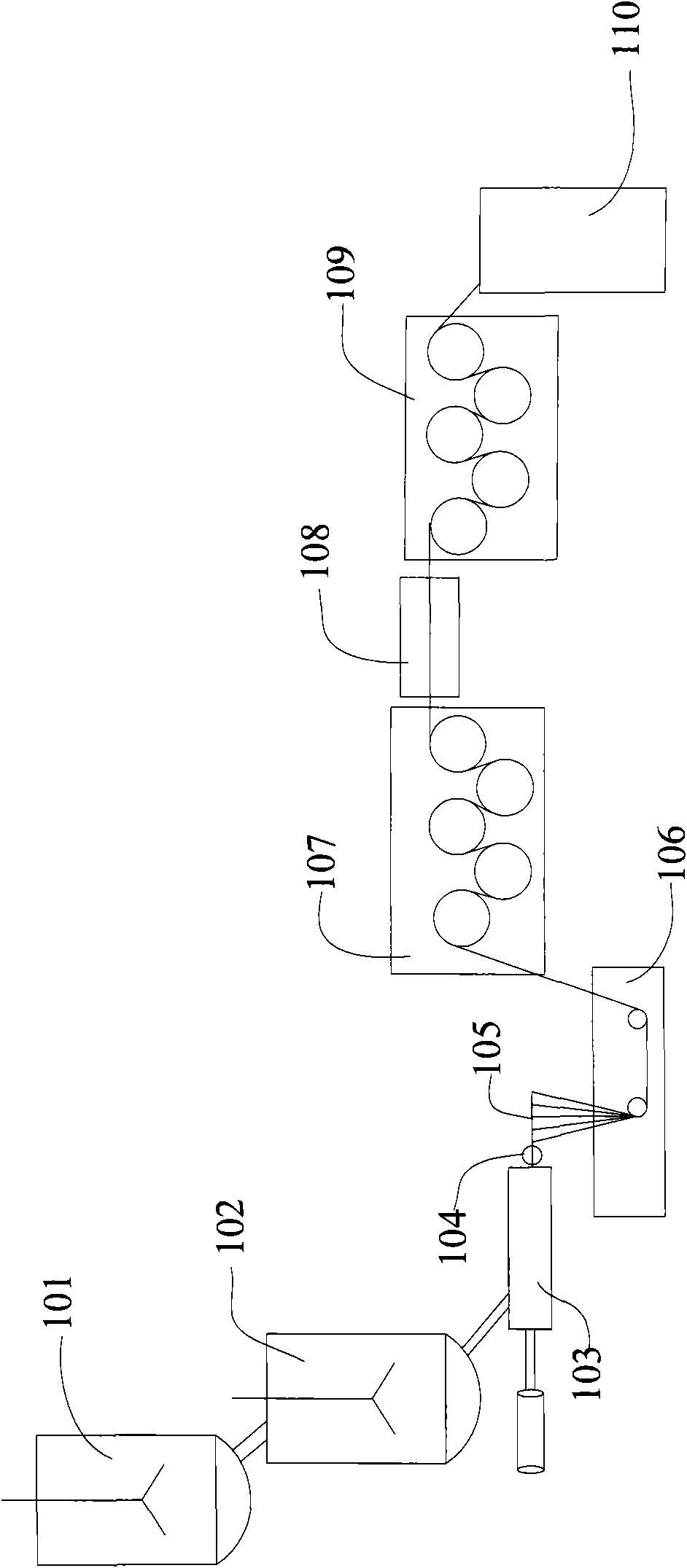

A method for preparing polyacrylonitrile carbon fiber precursors by dry jet wet spinning

ActiveCN102277629AFull and even contactInhibition formationArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentYarnGas liquid reaction

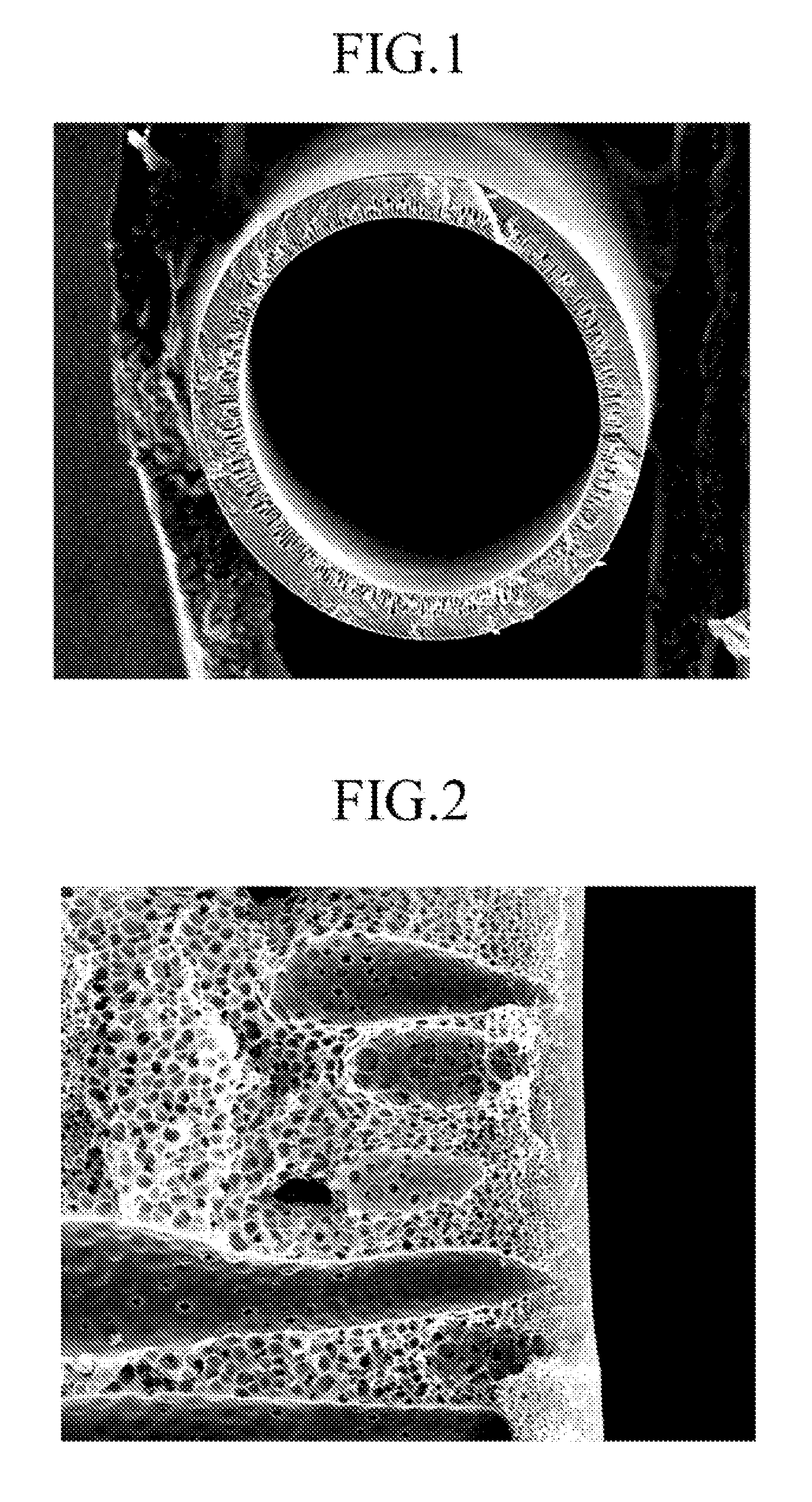

The invention relates to a method for preparing a polyacrylonitrile carbon fiber precursor. The method comprises the following steps of: copolymerizing acrylonitrile and copolymerization components in multicomponent solution so as to form polymer spinning stock solution which has a relatively uniform and controllable molecular structure, performing demonomerization on the spinning stock solution,defoaming, filtering, and preparing the polyacrylonitrile carbon fiber precursor by a dry-jet wet-spinning process. The key technology of the method is that: a gas storage box is arranged on a dry wet spinning pack, the gas storage box and the liquid level of coagulating bath fluid form a dry-jet wet-spinning air layer into a confined space, and ammonia is persistently aerated into the space to carry out gas-liquid reaction with spinning solution trickle in the air layer. The polyacrylonitrile precursor prepared by the method has regular sections and few defects, the density is not less than 1.187g / cm<3>, the density after carbonization is not less than 1.79g / cm<3>, the strength is not less than 5.1GPa, and the modulus of elasticity is 280 to 300GPa.

Owner:KINGFA SCI & TECH CO LTD +1

Apparatus and method for forming materials

InactiveUS6858168B1Improves molecular orientationReduce pressure requirementsSpinnerette packsConfectioneryHydrogenSolid mass

An apparatus and method for forming liquid spinning solution into a solid formed product whereby the solution is passed through at least one tubular passage (17) having walls formed at least partly of semipermeable and / or porous material. The semipermeable and / or porous material allows parameters, such as the concentration of hydrogen ions, water, salts and low molecular weight, of the liquid spinning solution to be altered as the spinning solution passes through the tubular passage(s).

Owner:SPINOX LTD

Novel Composition for Preparing Polysaccharide Fibers

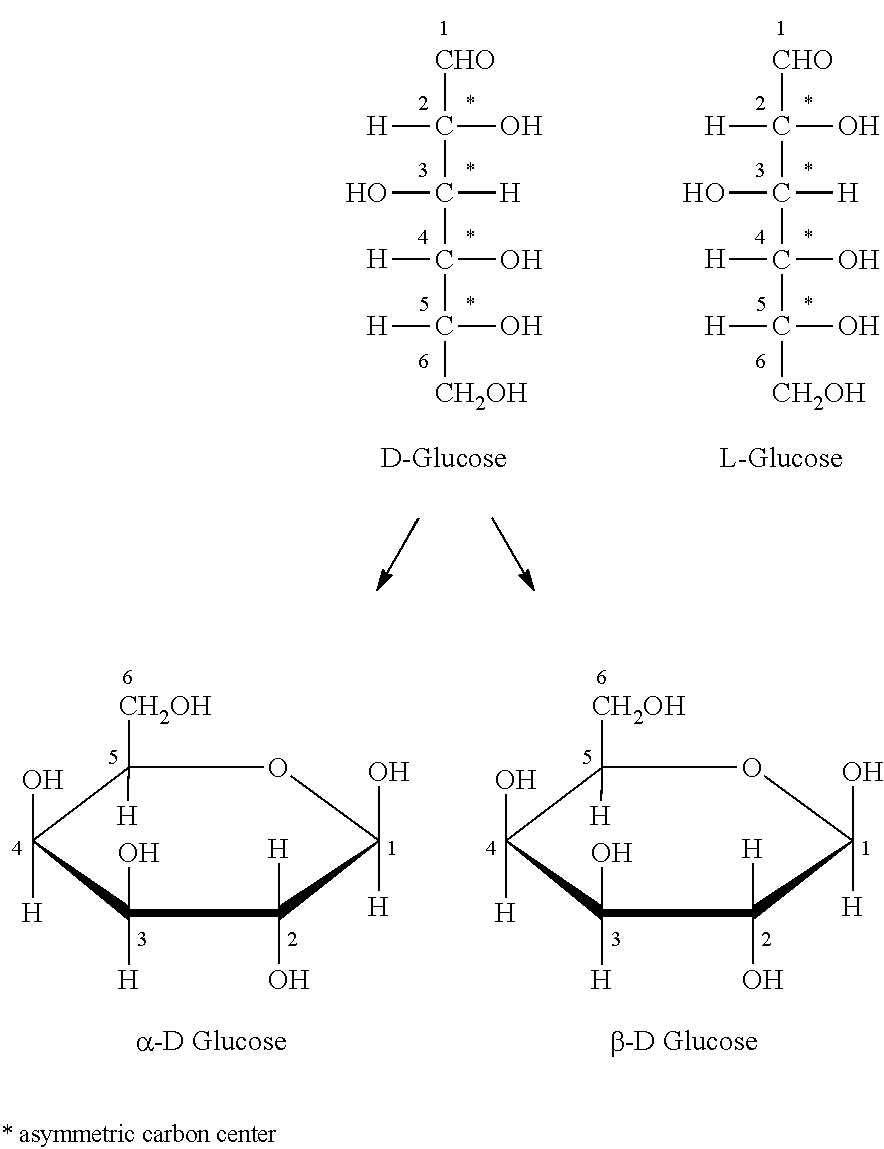

This invention pertains to a novel process for preparing fibers from poly(α(1→3) glucan). The fibers prepared according to the invention, have“cotton-like” properties, are useful in textile applications, and can be produced as continuous filaments on a year-round basis. The process comprises solution spinning from a novel solution of poly(α(1→3) glucan) in a mixture of water and N-methylmorpholine-N-oxide followed by coagulation in a liquid coagulant that comprises a liquid that is not water.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

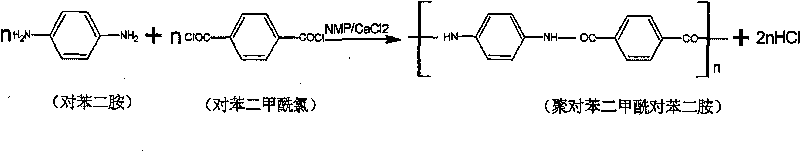

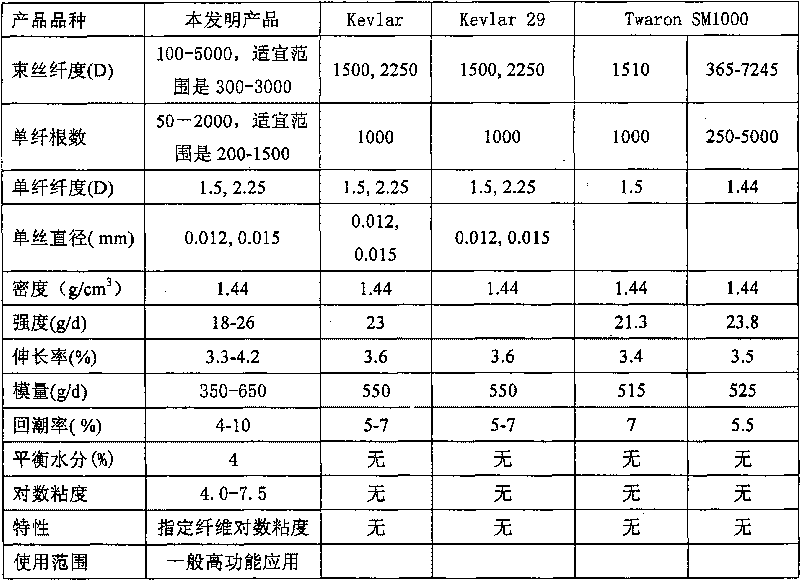

Polyphenylene terephthalamide fibre and preparation method thereof

ActiveCN101724935AHigh overall process efficiencyLow efficiencyWet spinning methodsMonocomponent polyamides artificial filamentPolymer scienceAramid

The invention discloses a polyphenylene terephthalamide fibre and a preparation method thereof. For the polyphenylene terephthalamide fibre (PPTA) which has with high performance and is prepared by the dry-jet wet spinning method, a polyphenylene terephthalamide fibre (PPTA) polymer which has the inherent viscosity of 4.5-8.0dL / g and is obtained by adopting the low-temperature solution polycondensation method is used as the start point, and the polyphenylene terephthalamide fibre is adaptive to the industrial large-scale production. The inherent viscosity of the fibre is reduced by 0.5dL / g than the inherent viscosity of the polymer. The polyphenylene terephthalamide fibre (PPTA) with high performance comprises the specific indexes as follows: a synnema titer is 300-3000 denier, an intensity is 18-26g / denier, an elongation rate is 3.2-3.8percent, a modulus is 350-650 g / denier, a water ratio is 3-10 percent and an inherent viscosity is 4-7.5dL / g. The physical property of the fibre is superior to the traditional aramid fibre II fibre. The invention discloses the inherent viscosity with the purpose of specifically showing the material of polyphenylene terephthalamide with higher molecular weight.

Owner:中蓝晨光化工有限公司

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

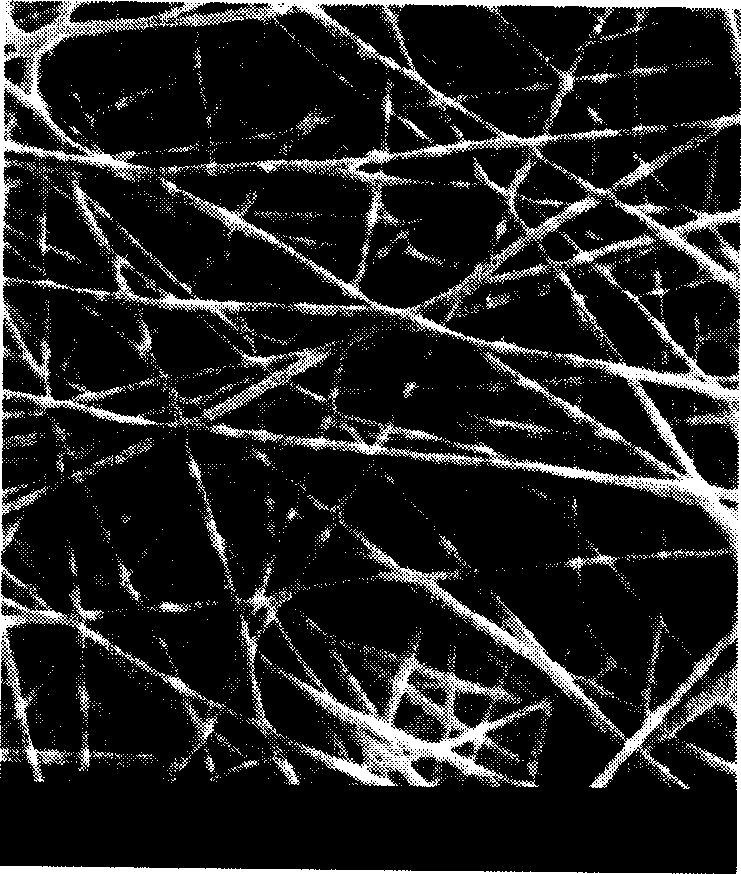

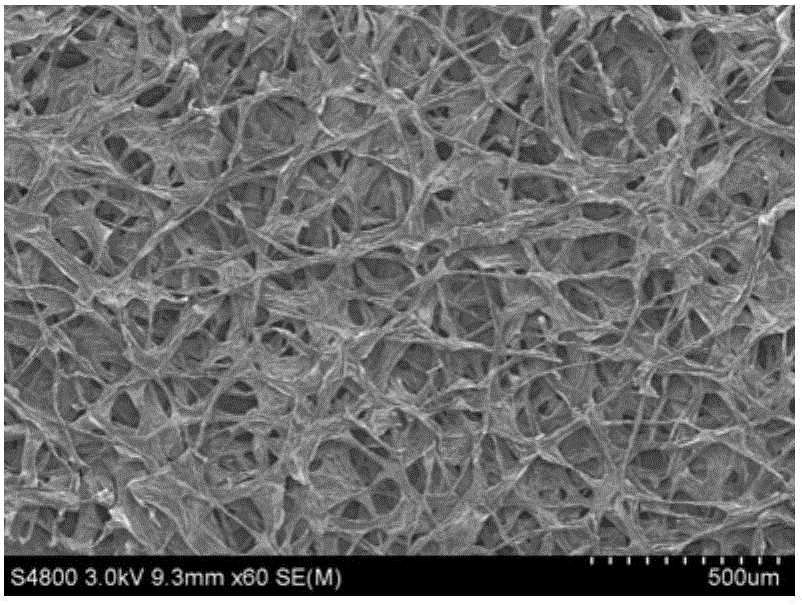

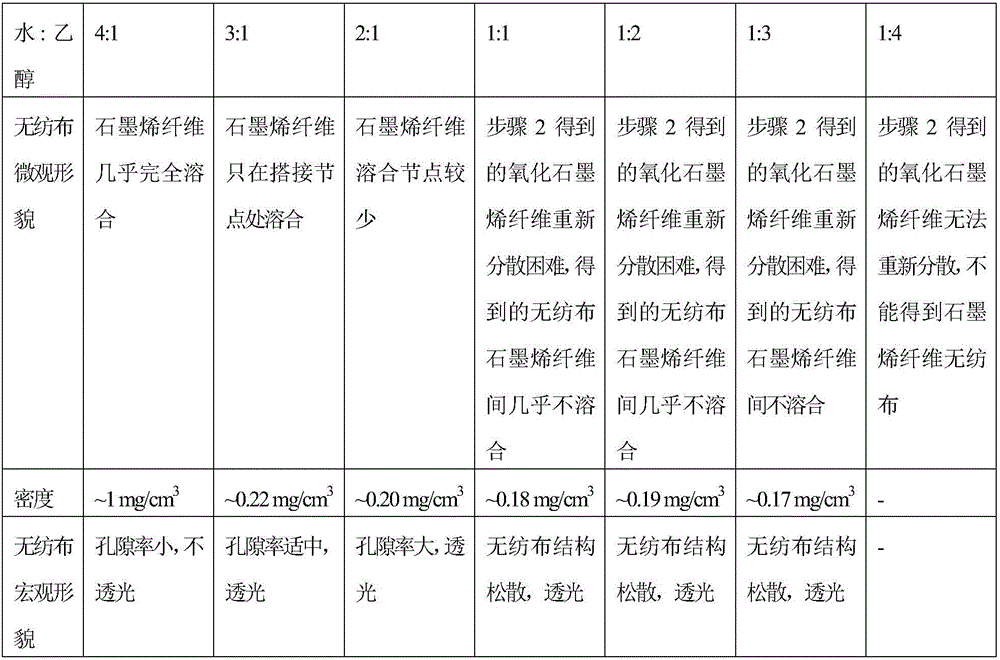

Graphene fiber non-woven fabric and preparation method thereof

ActiveCN106192201AGood electrical and thermal conductivitySimple methodNew-spun product collectionGrapheneElectricityPolymer science

The invention discloses a graphene fiber non-woven fabric and a preparation method thereof. The non-woven fabric is obtained by filtering and depositing a graphene short-fiber dispersion solution through a filter net and performing drying and reduction, so that the structural unit of the non-woven fabric is disorderly-stacked and bonded graphene short fiber, and fiber is overlapped to form a large number of holes through which liquid of gas can pass. The graphene fiber non-woven fabric has the good mechanical strength and tenacity, is completely composed of graphene fiber, does not contain high polymer materials as a skeleton or adhesives, the electricity and heat conducting performance of the reduced network structure overlapped by the graphene fiber is excellent, and the non-woven fabric can be used as a multifunctional high-performance fabric.

Owner:杭州德烯科技集团有限公司

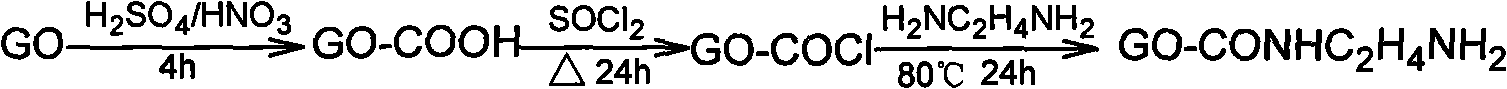

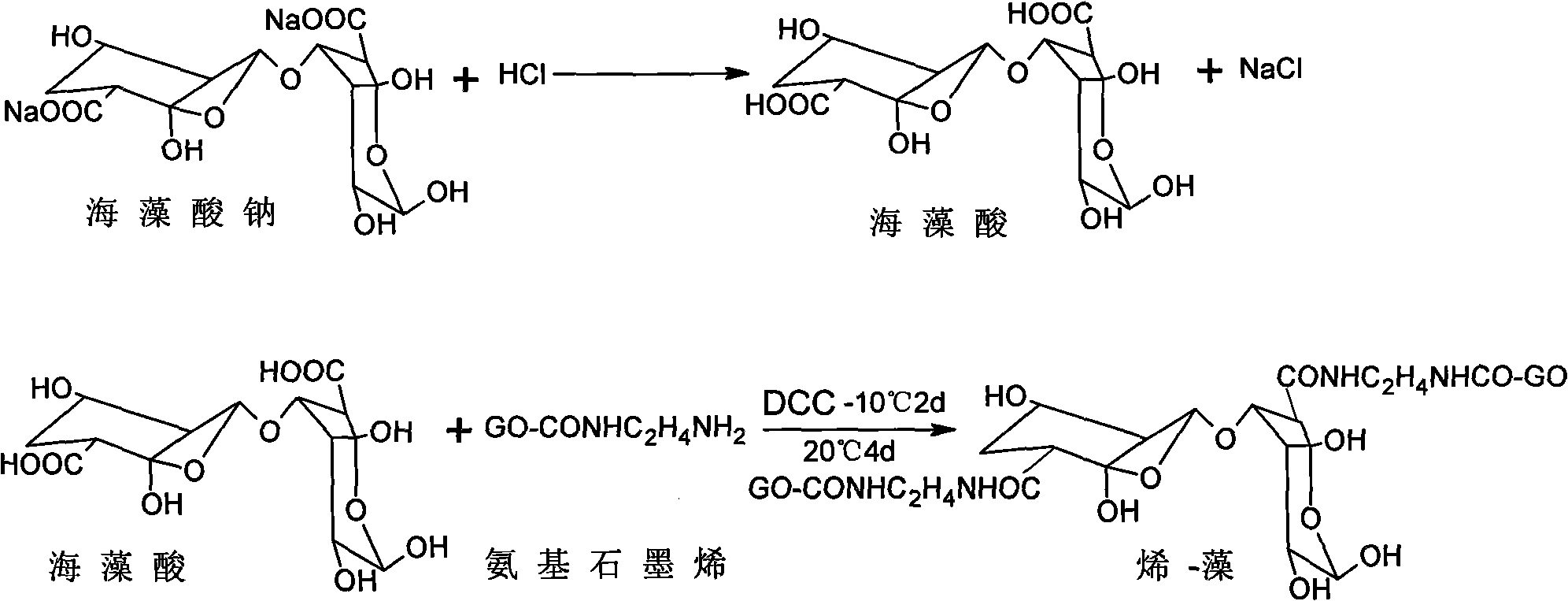

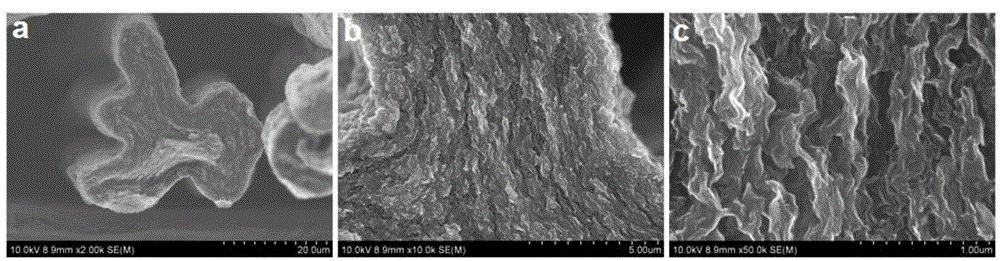

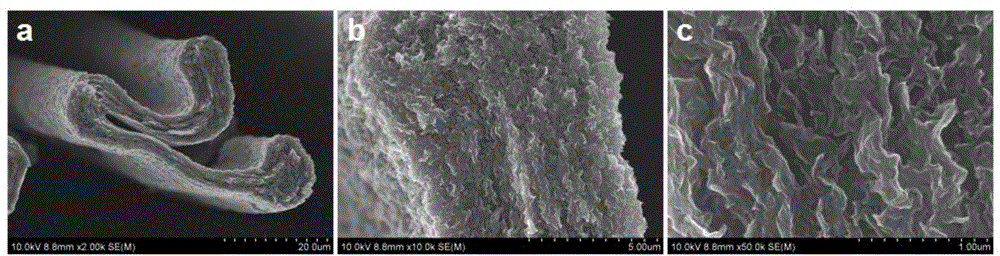

Method for preparing graphene functionalized alginate fibers

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

High-wetness modulus adhesive colloid fiber and preparing method

InactiveCN101024907AHigh strengthResistant to multiple deformationsArtificial filaments from viscoseBleaching apparatusFiberPolymer science

The invention discloses a high-humidity modulus viscose fiber with dry strength of 3.5-6.0cN / dtex, wet elastic modulus of 0.35-0.60cN / dtex and wet strength of 2.0-4.5cN / dtex, and prepared of cellulose pulp with degree of polymerization of 500-1200 and alpha-cellulose content >=95% by the steps of dip-basifying, squeezing, ageing, yellowing, dissolving, wet spinning moulding, drafting, etc. And it has features of higher intensity and wet modulus, better loop strength performance, and lower brittleness; and the fabrics made by it has features of high intensity, multiple deformation resistance, alkali resistance, etc.

Owner:CHTC HELON

Hemp-material viscose fiber and preparing method thereof

InactiveCN101130885AQuality improvementHigh whitenessWet spinning methodsVegetable materialAfter treatmentHemp plant

The present invention discloses a method for preparing hemp viscose fiber by using hemp plant and hemp visose fiber prepared by adopting said method. Said method includes the following steps: preparing raw material, digesting, washing material, pulping, removing sand, bleaching, water-washing, fiber-making, impregnating, pressing, pulverizing, aging, xanthating, dissolving, mixing, filtering, defoaming, spinning, drawing, cutting and making after-treatment.

Owner:CHTC HELON

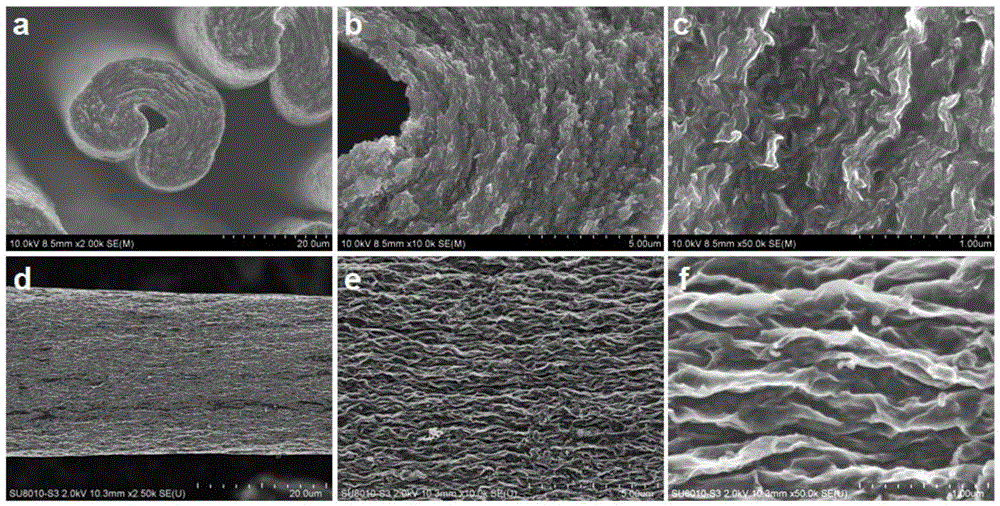

Water-soluble polymer/graphene composite fiber as well as preparation method and application thereof

ActiveCN104451925AHigh strengthImprove toughnessElectroconductive/antistatic filament manufactureElectrode carriers/collectorsFiberMicro structure

The invention relates to water-soluble polymer / graphene composite fiber as well as a preparation method and application thereof. The cross section of the fiber is special-shaped, the surface of the fiber is of an orientated micro-fiber-shaped structure, the strength of the fiber is greater than 100 MPa, the elongation at break is greater than 2%, and the conductivity of the fiber is greater than 0.1 S / cm. The preparation method comprises the following steps: preparing a composite spinning liquid, extruding into a coagulating bath for curing, drafting, leading out of the coagulating bath, drying, and coiling, thereby obtaining the water-soluble polymer / graphene composite fiber; and finally reducing by using a chemical or physical method, thereby obtaining the water-soluble polymer / graphene composite fiber. The cross section of the composite fiber provided by the invention is of a special-shaped structure, the surface of the fiber is of a rich groove micro structure, the strength and the toughness of the fiber are greatly improved when being compared with those of pure graphene fiber, and good conductivity is still maintained, so that the water-soluble polymer / graphene composite fiber has a wide application prospect in the fields such as anti-electrostatic and conductive fabrics, electromagnetic wave absorption and shielding fabrics, energy storage devices, sensors and water treatment.

Owner:DONGHUA UNIV

High-strength high modulus polyimide fiber and preparation method thereof

ActiveCN102345177AImprove performanceReasonable molecular structureArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to high-strength high modulus polyimide fiber and a preparation method thereof, which belongs to the high performance organic fiber technical field. The fiber comprises the polyimide fiber which is prepared by biphenyltetracarboxylic dianhydride (BPDA), para-phenylene diamine (pPDA) and 2-(4-aminophenyl)-5-aminobenzimidazoles (BIA), wherein the mol ratio of pPDA to BIA is 1:10-3:1, other di-amine and di-anhydride monomers are added in the synthesis process, a gradient temperature reaction method and a one step continuous preparation method are used in the preparation process, so that the difficulties for synthesizing and processing due to the content increase of 2-(4-aminophenyl)-5-aminobenzimidazoles are solved, the problems of poor homogeneity and stability of thefiber performance can be solved, and the high-strength high modulus polyimide fiber can be obtained, the strength can reach 4.5GPa, the modulus can reach 201GPa, and the raw material source is wide, the spinning process can be continuously performed, the method has low cost and high efficiency which is capable of realizing the industrial production.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com