Anti bacteria natural silk composite nano-fiber material and its preparation method

A technology of composite nanofibers and antibacterial silkworms, which is applied in the fields of rayon manufacturing, fiber chemical characteristics, cellulose/protein conjugated artificial filaments, etc. Wound healing and other issues, to achieve excellent bactericidal effect, excellent bactericidal, and maintain the effect of persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

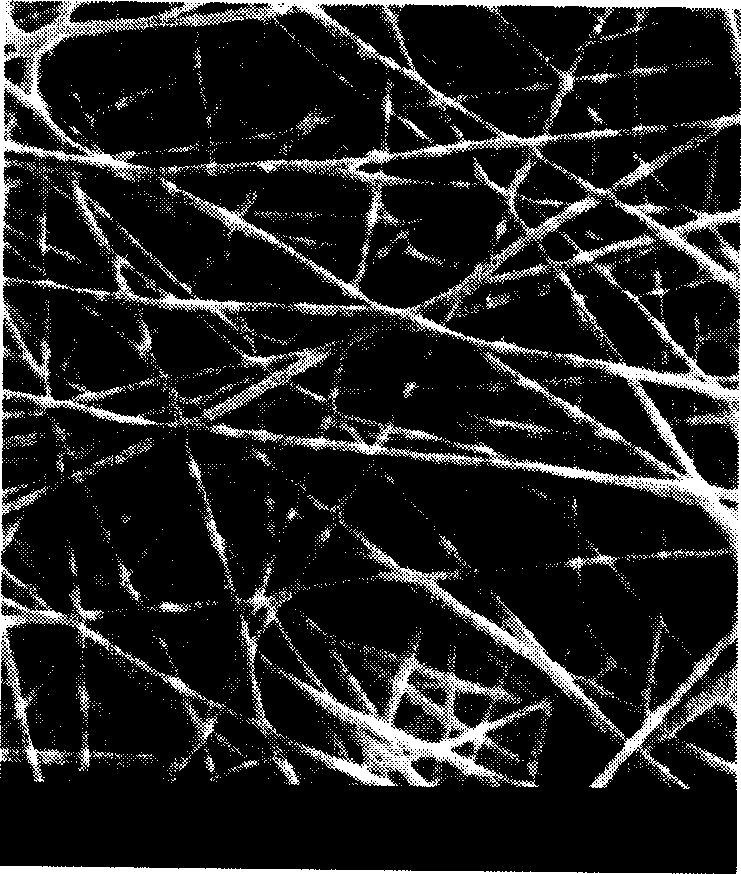

Image

Examples

Embodiment 1

[0022] 1. Put 0.1 kg of leftover silk into 3 liters of 0.05% sodium carbonate aqueous solution by mass fraction, boil for 0.5 hour, repeat the treatment three times, remove all the sericin around the silk, and obtain silk fibroin;

[0023] 2. After drying the obtained silk fibroin, use 0.6 liter of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 to heat and dissolve at 78±2°C to form a silk protein solution;

[0024] 3. Pour the above-mentioned silk protein solution into the cellulose semi-permeable membrane, dialyze with tap water first, and then dialyze with deionized water to remove ethanol and calcium chloride small molecules in the solution, and then filter with multi-layer degreasing gauze to prepare Obtain pure silk fibroin solution;

[0025] 4. Take 100ml of pure silk fibroin solution and pour it into an area of 20×20cm 2 In a polystyrene (ABS) tray, dry film under 25 ℃, RH65% constant temperature and humidity conditions, take off the regene...

Embodiment 2

[0034] 1. Put 0.2 kg of waste mulberry silk into 6 liters of aqueous sodium carbonate solution with a mass fraction of 0.05%, boil for 0.5 hour, repeat the treatment three times, remove all the sericin around the silk, obtain silk fibroin, and dry at room temperature;

[0035] 2. Dissolve the dried silk fibroin with 1.2 liters of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 at 78±2°C to form a silk protein solution;

[0036] 3. Pour the fibroin solution prepared in step 2 into a cellulose dialysis bag, first dialyze with tap water, then dialyze with deionized water to remove ethanol and calcium chloride in the solution, and then filter with degreasing gauze to obtain Pure silk fibroin solution;

[0037] 4. Pour 100ml of pure silk fibroin protein solution into a stainless steel plate, freeze at -25°C for 12 hours, and then vacuum-dry it in a freeze dryer for 24 hours to obtain a spongy silk fibroin film, which is bagged for use;

[0038] 5. 6.7 gram...

Embodiment 3

[0046] 1. Put 0.2 kg of waste mulberry silk into 6 liters of aqueous sodium carbonate solution with a mass fraction of 0.05%, boil for 0.5 hour, repeat the treatment three times, remove all the sericin around the silk, obtain silk fibroin, and dry at room temperature;

[0047] 2. Dissolve the dried silk fibroin with 1.2 liters of calcium chloride, water and ethanol solution with a molar ratio of 1:8:2 at 78±2°C to form a silk protein solution;

[0048] 3. Pour the fibroin solution prepared in step 2 into a cellulose dialysis bag, first dialyze with tap water, then dialyze with deionized water to remove ethanol and calcium chloride in the solution, and then filter with degreasing gauze to obtain Pure silk fibroin solution;

[0049] 4. Pour 100ml of pure silk fibroin solution into a stainless steel plate, freeze at -18°C for 8 hours, and then vacuum-dry it in a freeze dryer for 18 hours to obtain silk fibroin powder, which is bagged for use;

[0050] 5. Join 16.2 grams of silk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com