Patents

Literature

519 results about "Mean diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mean diameter. noun. The average of two measurements of the diameter taken at right angles to each other.

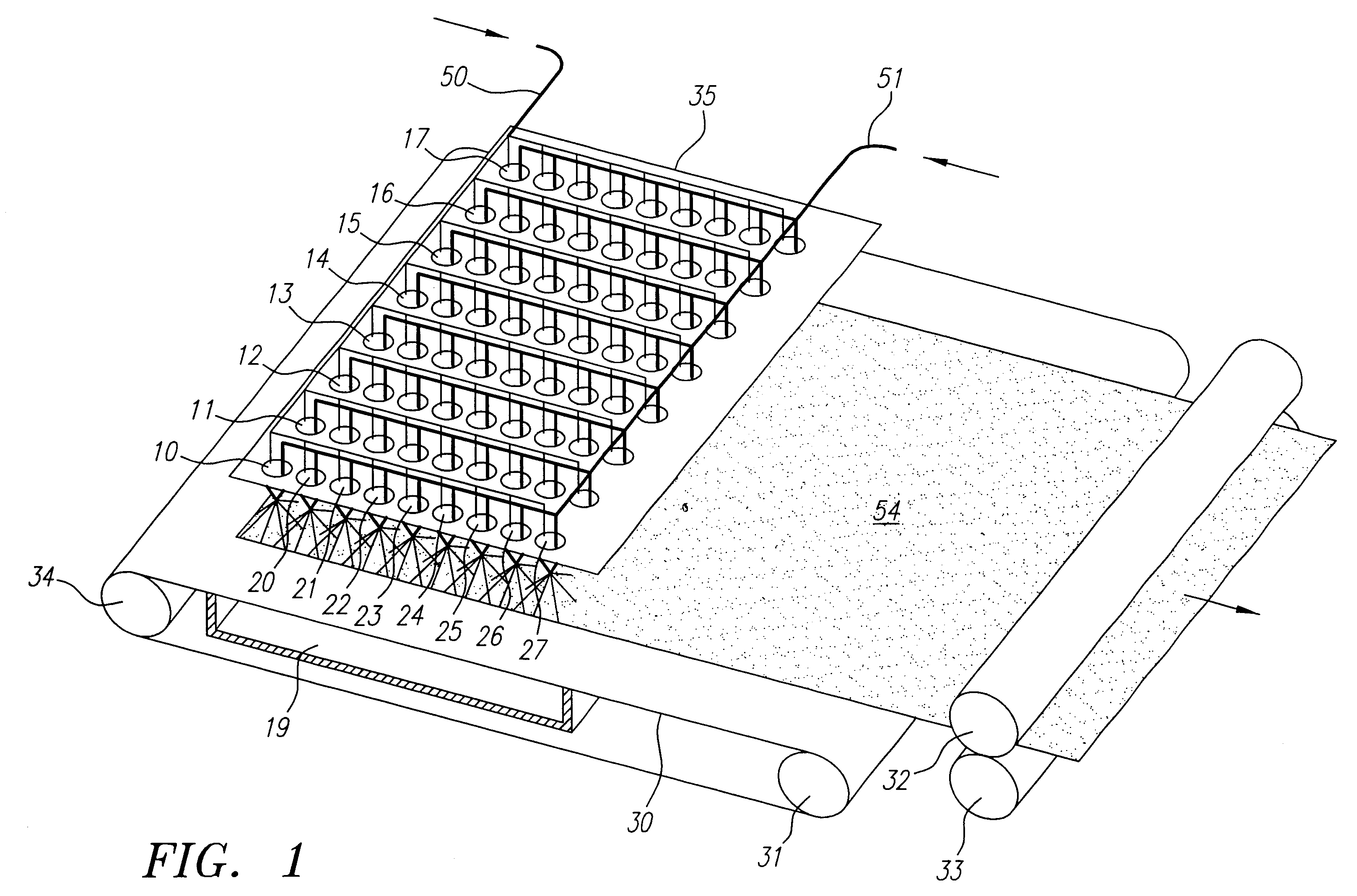

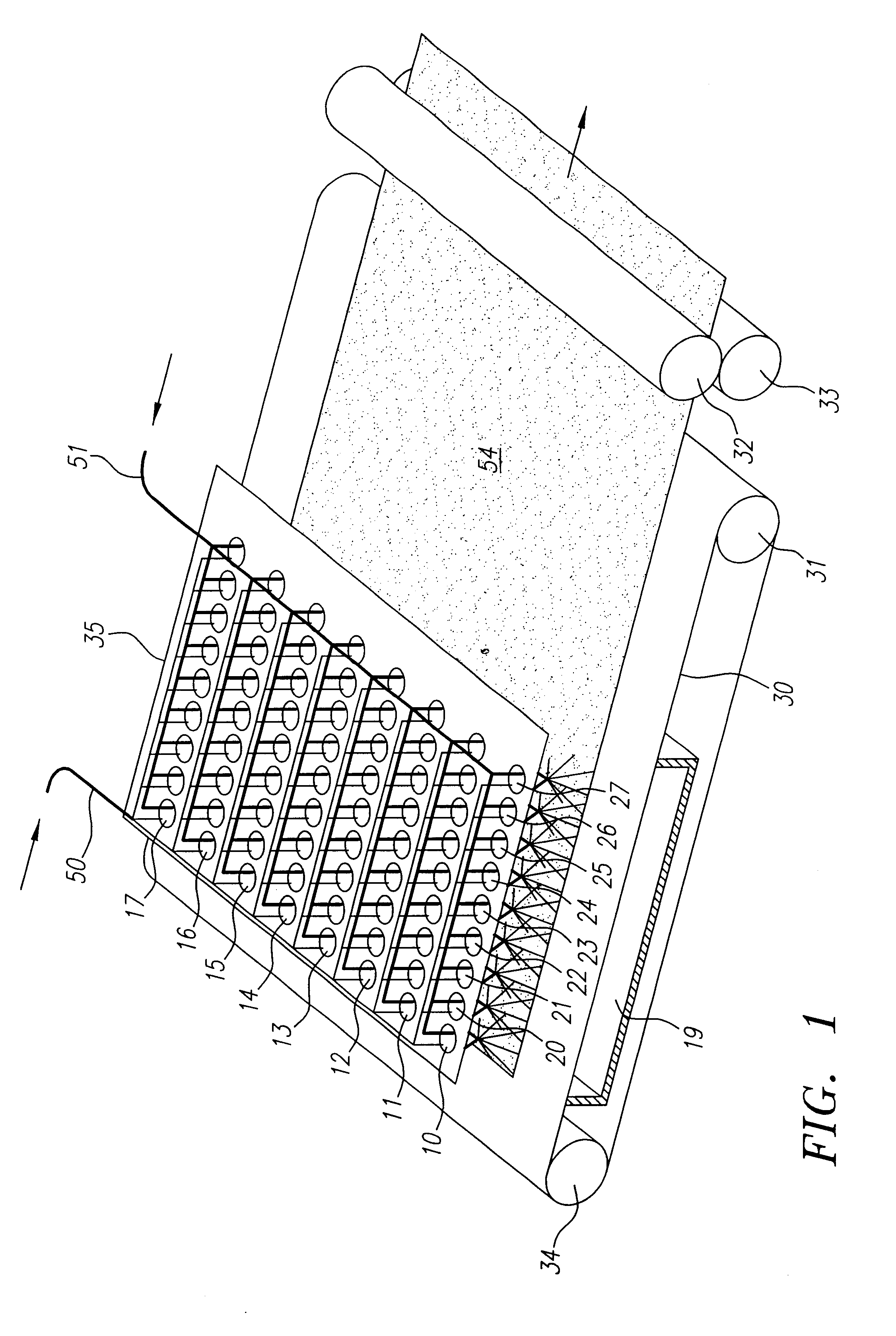

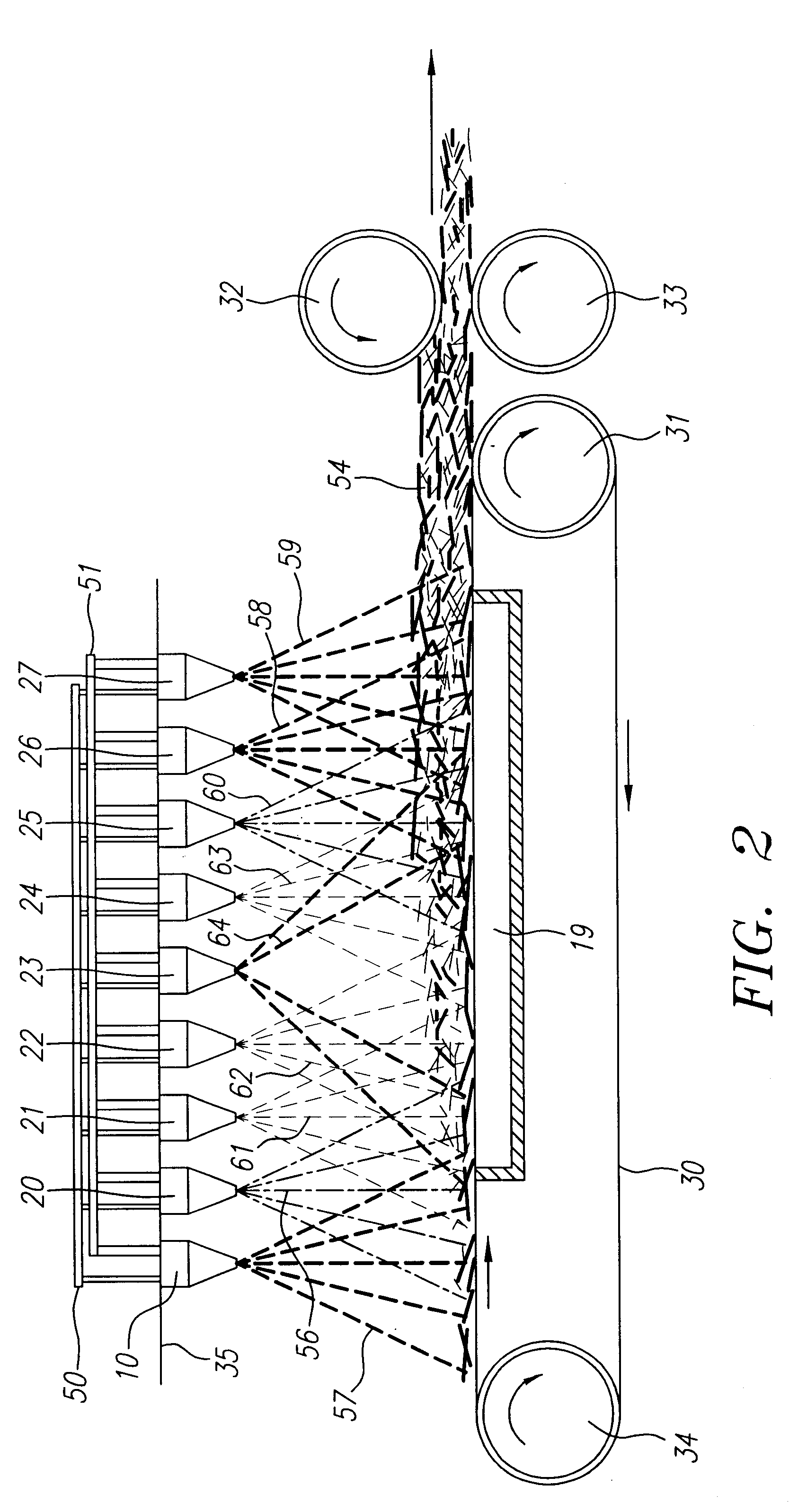

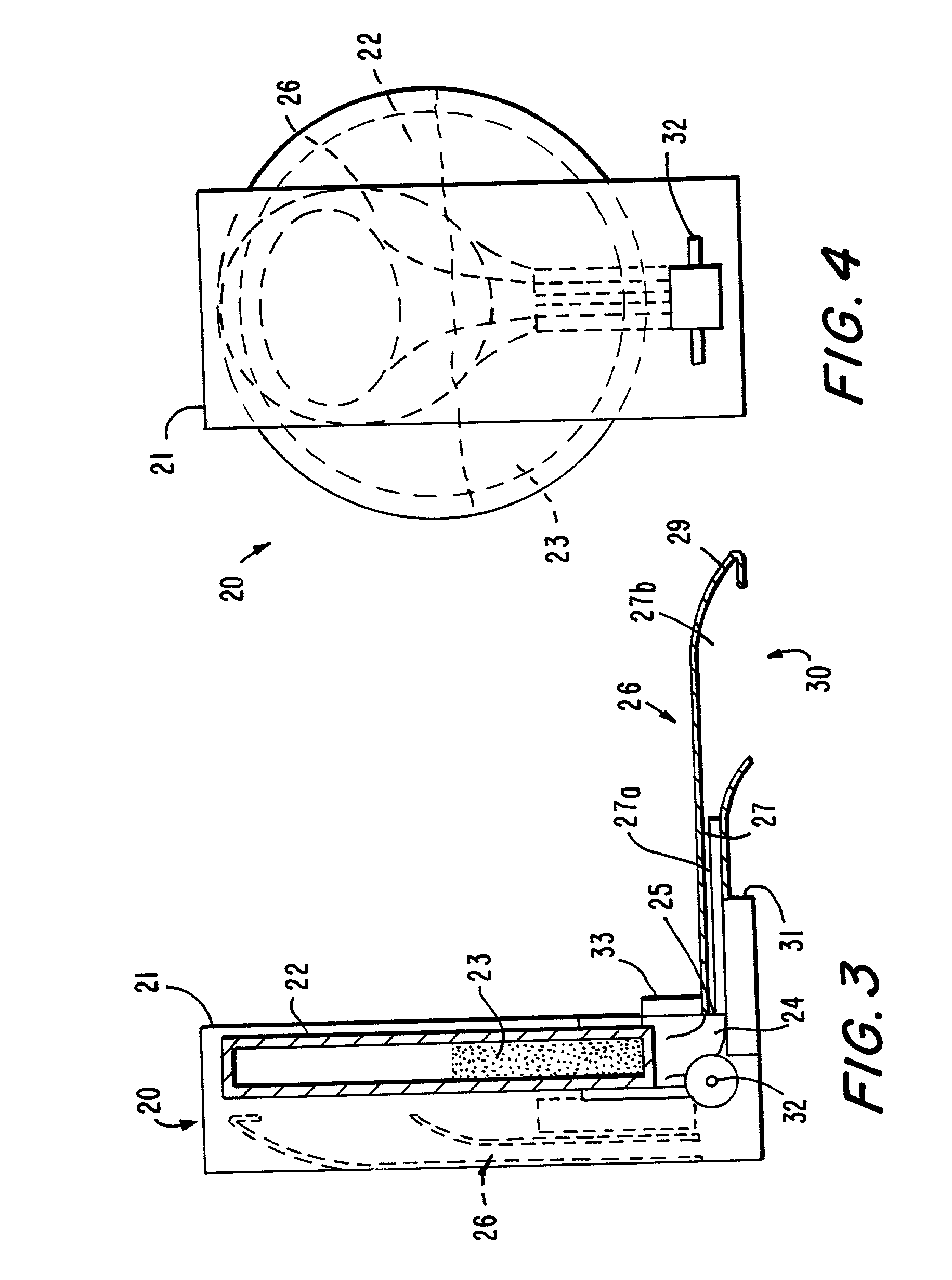

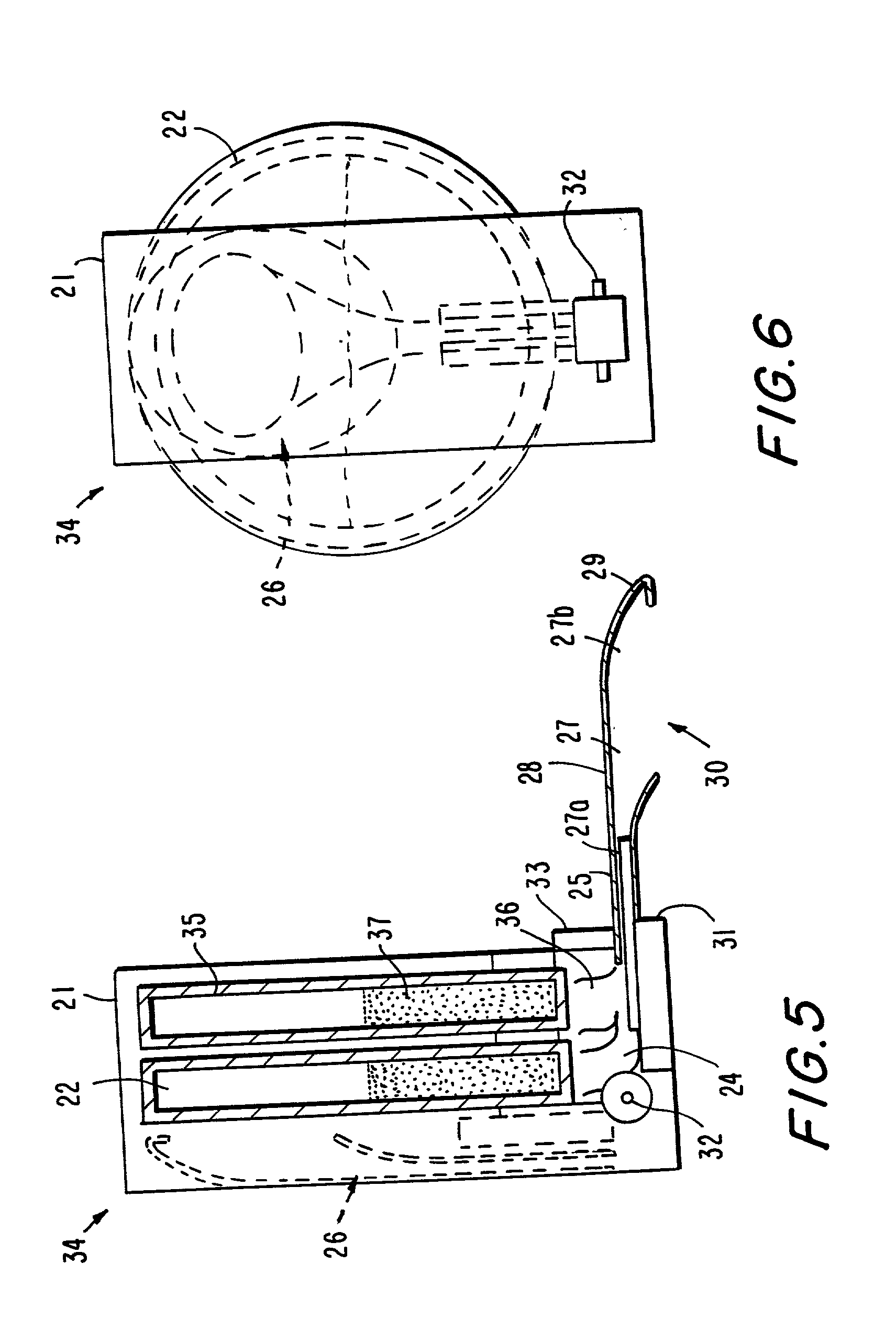

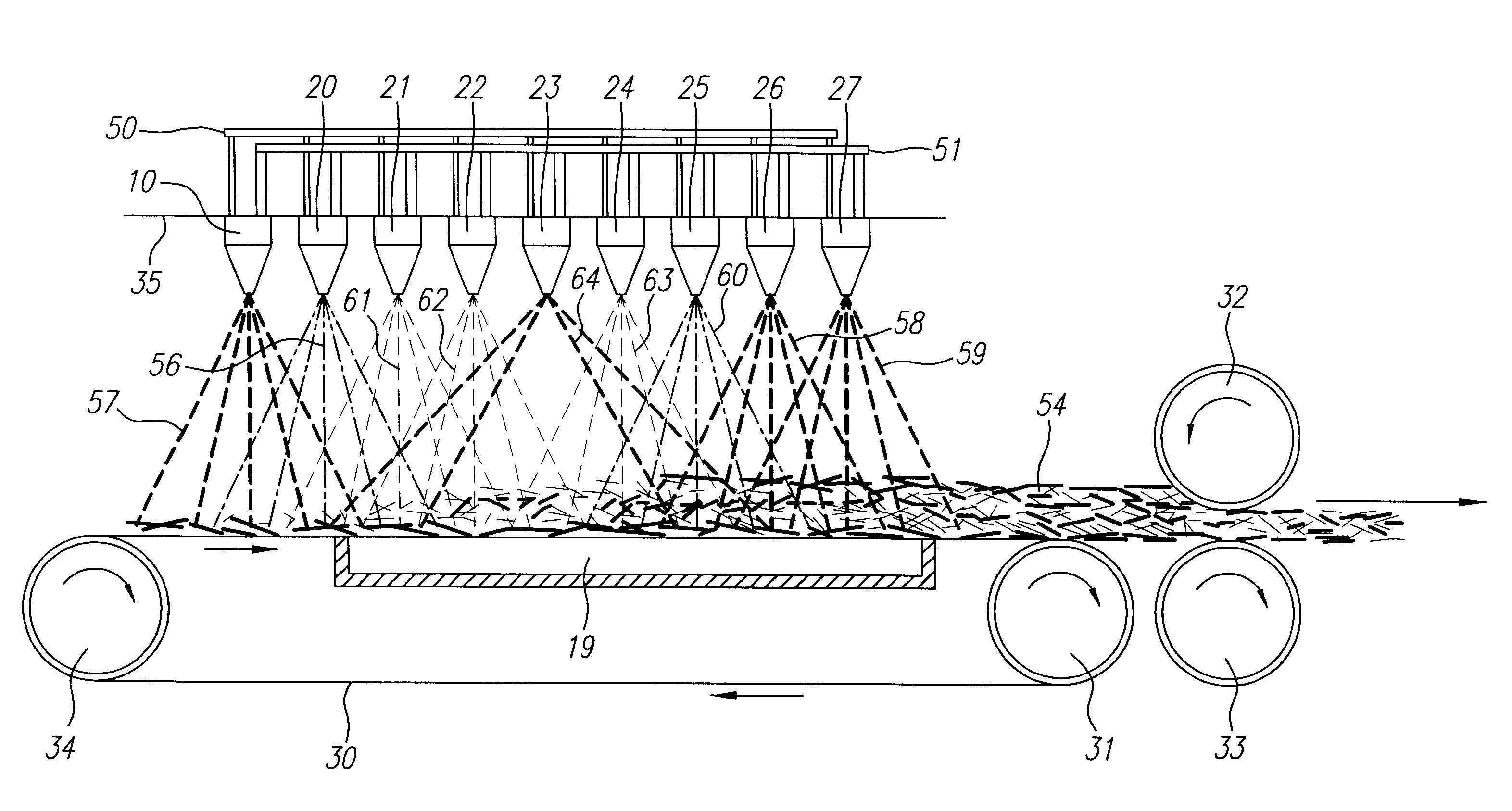

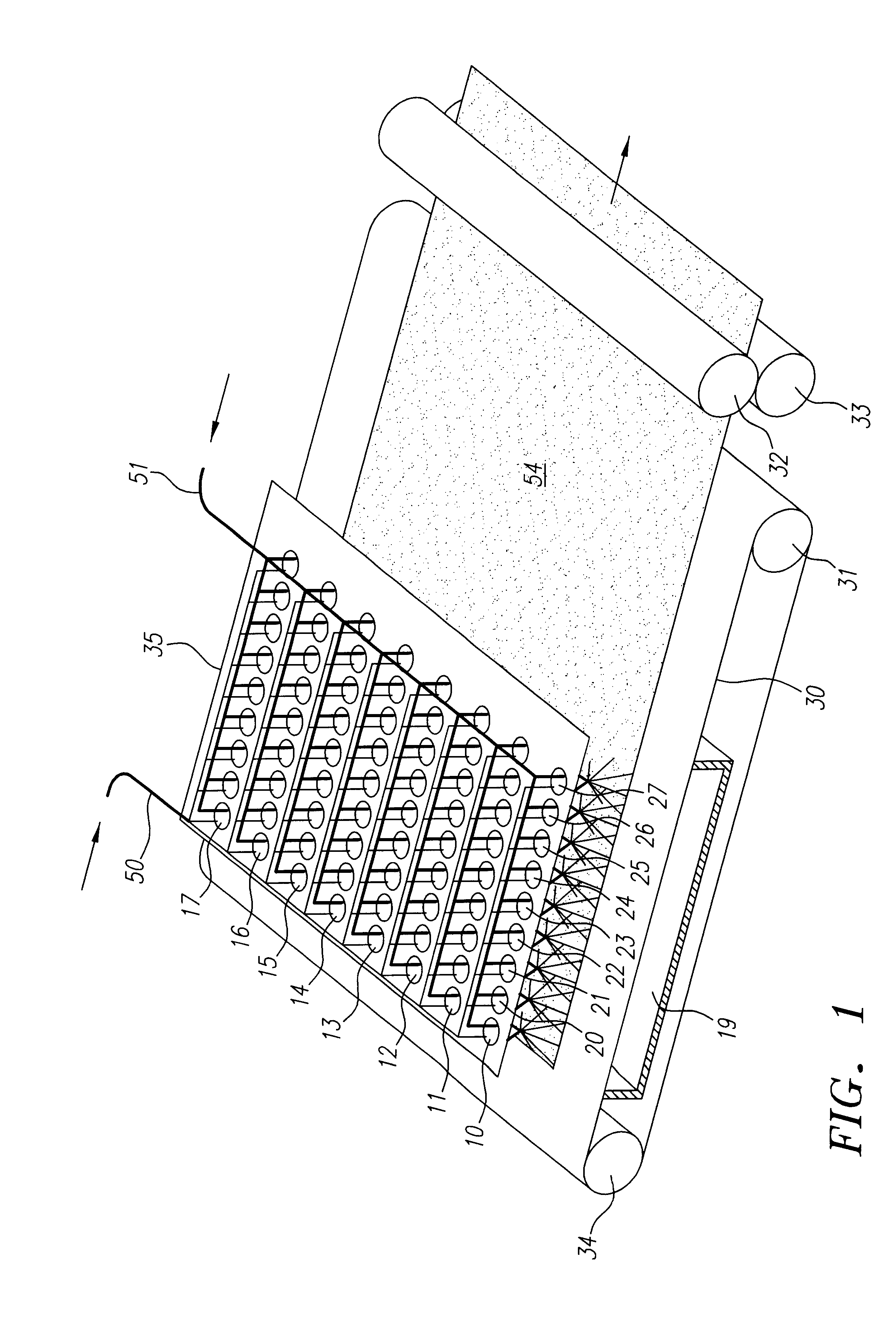

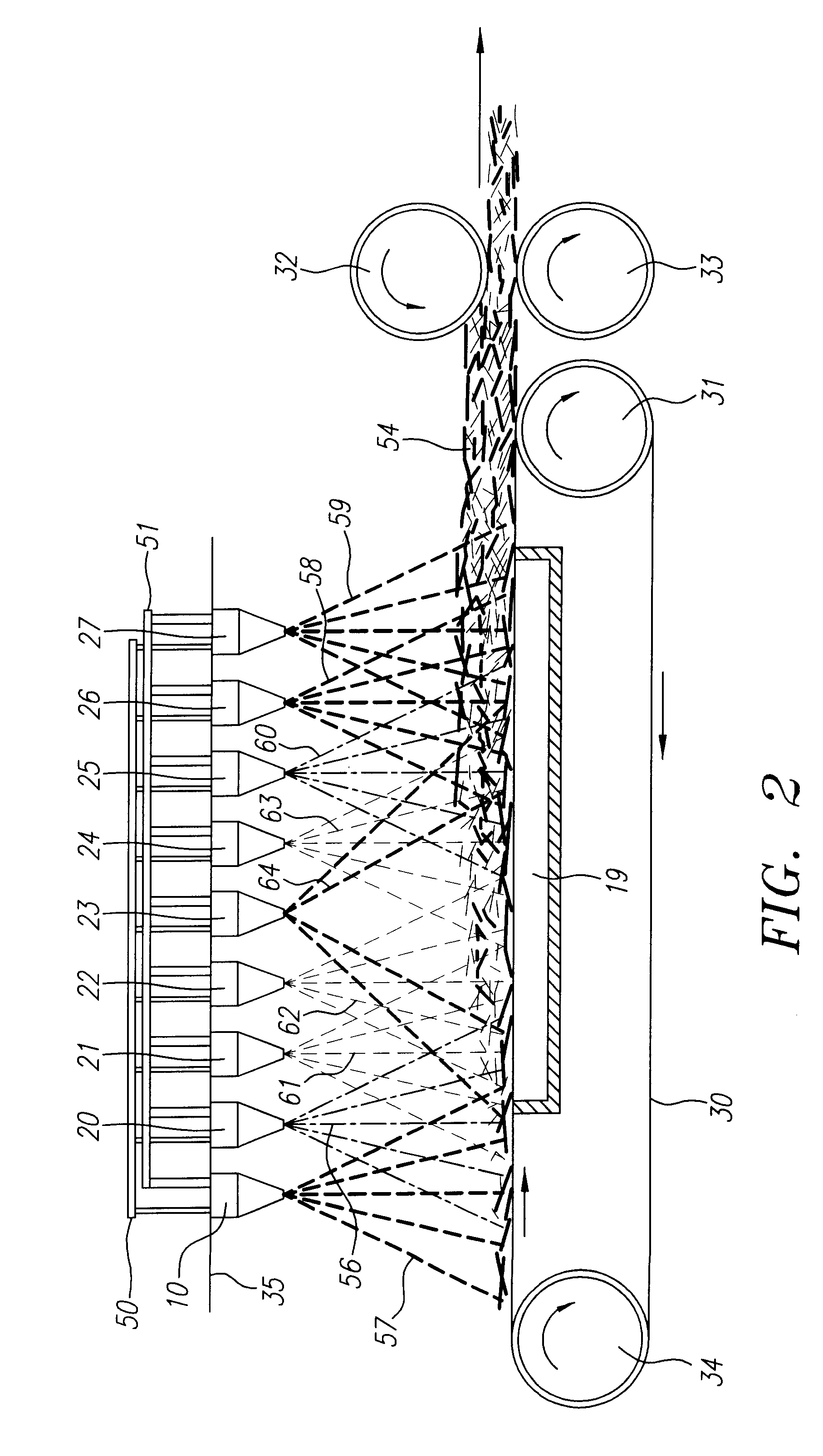

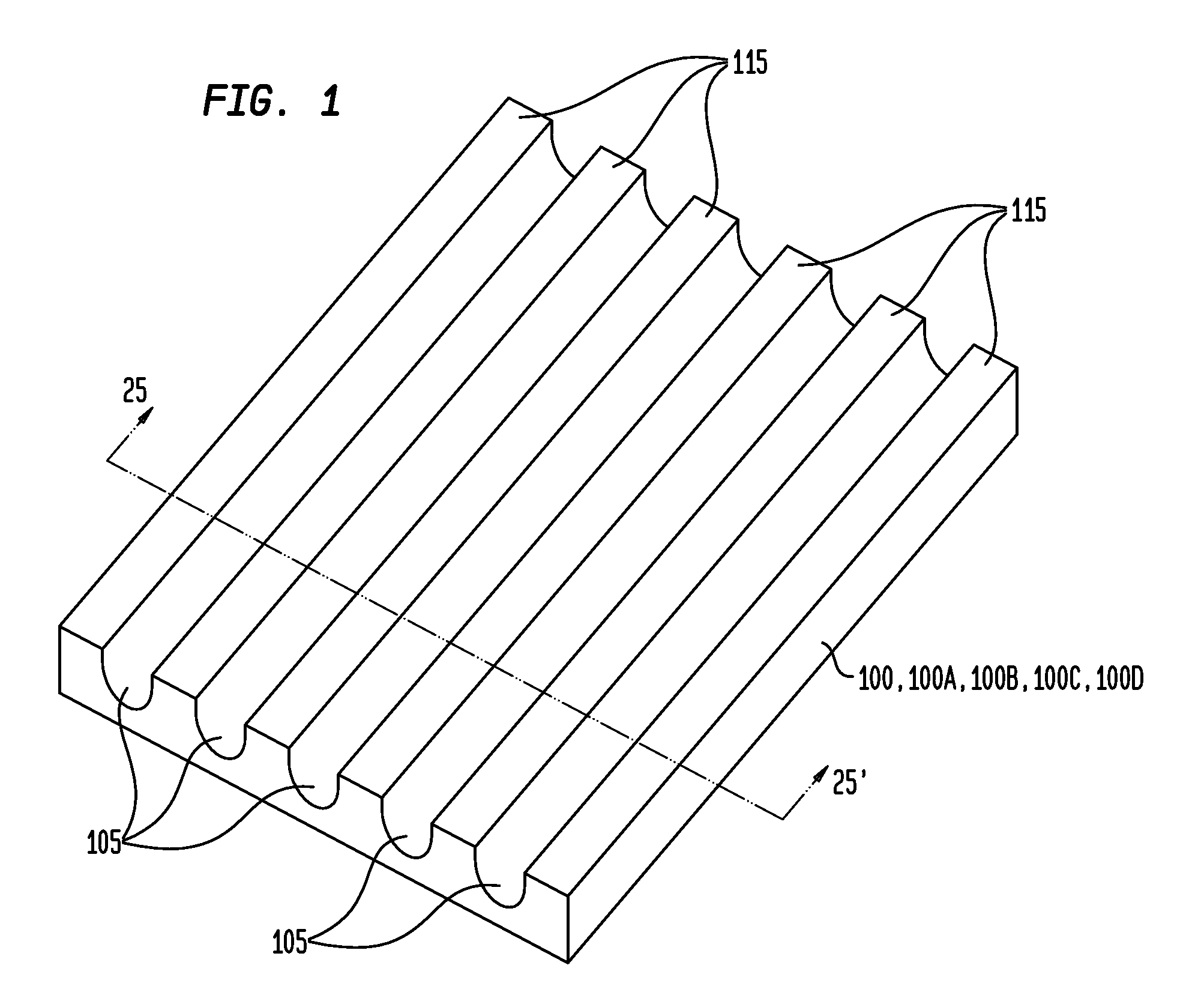

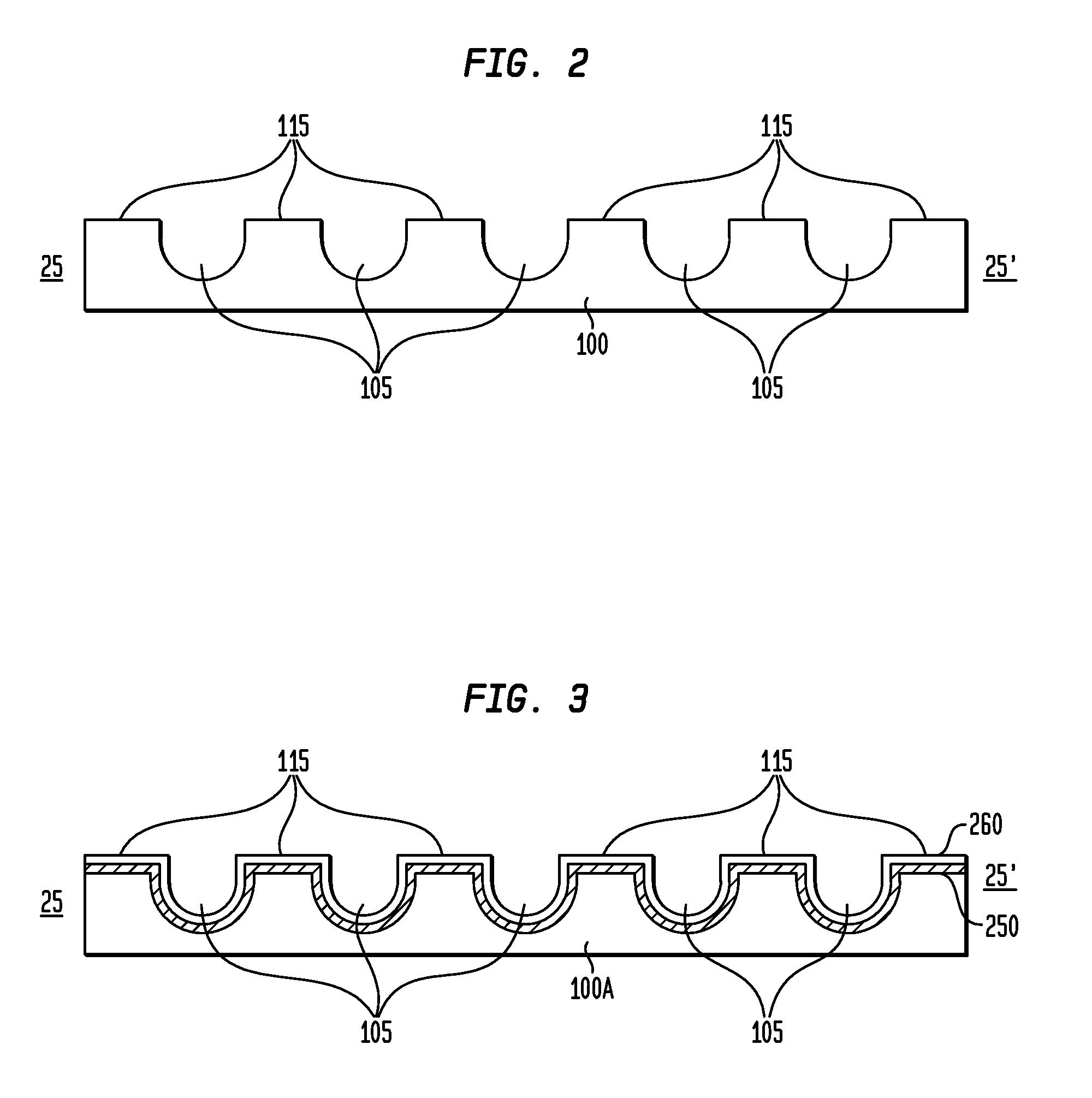

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

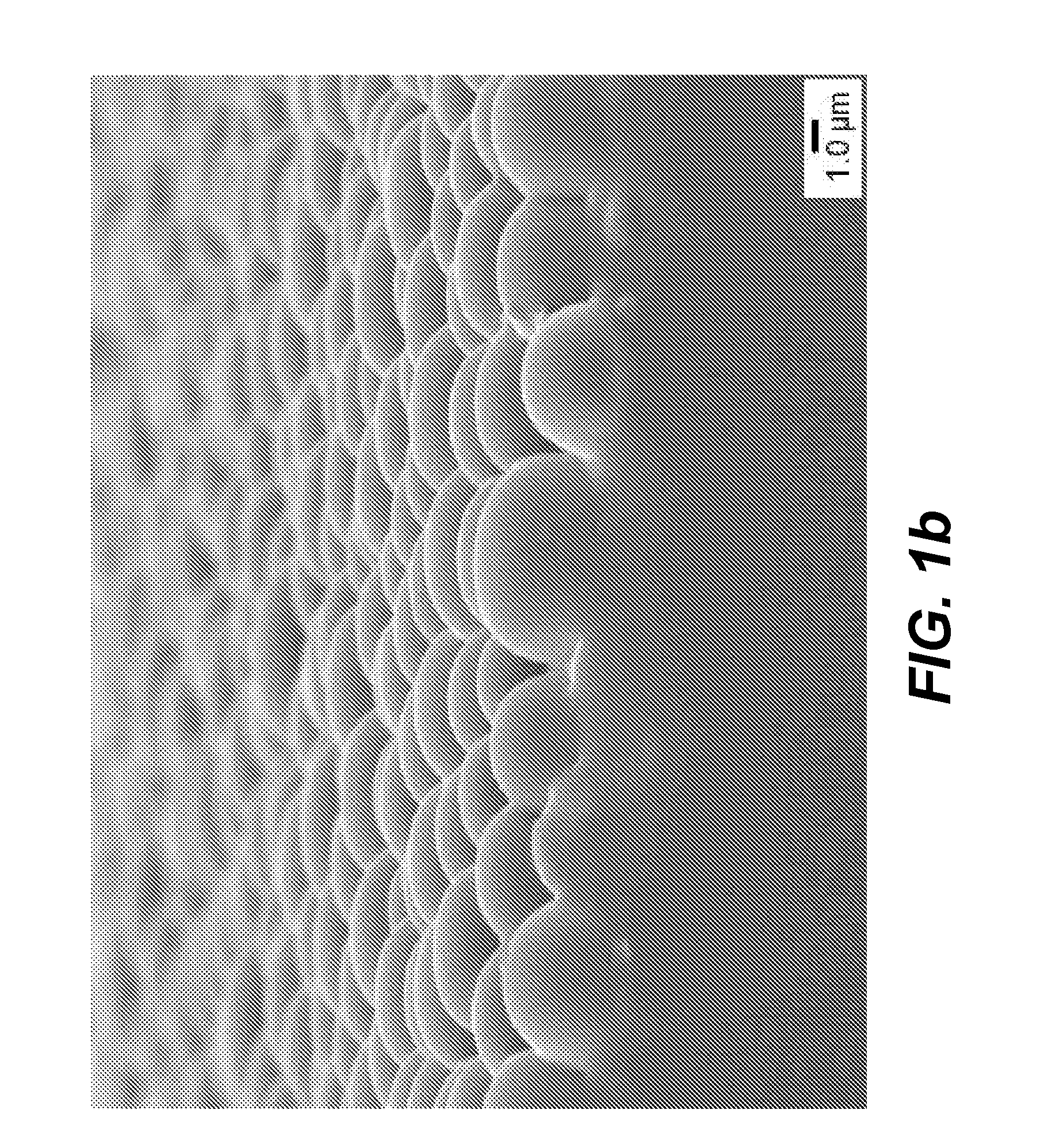

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

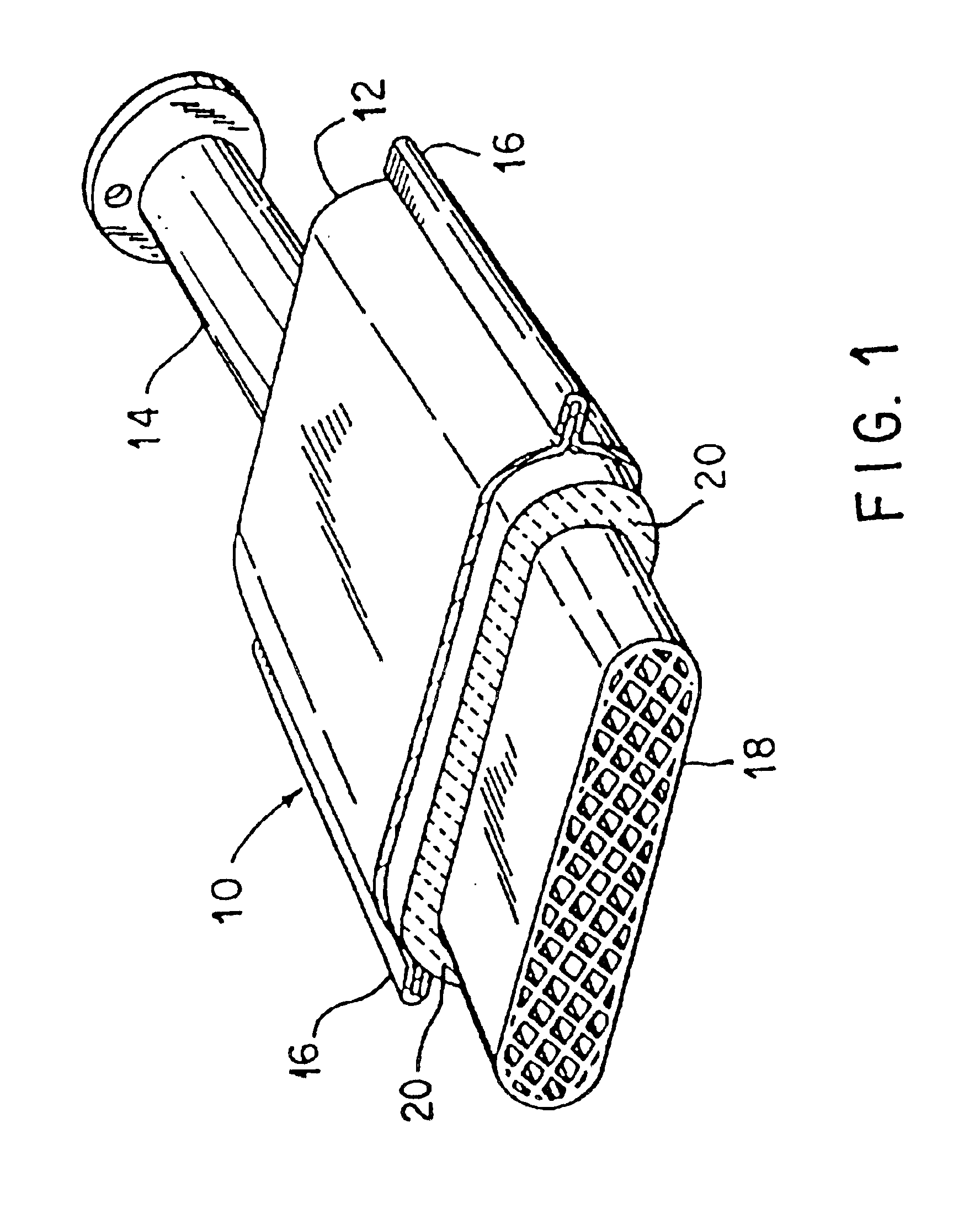

Delivery of oral drugs

InactiveUS20010020147A1Comfortable and convenient motionComfortable and convenient feelPowder deliveryLiquid surface applicatorsMean diameterHuman patient

Disclosed is a system for delivery of a drug comprising a multiple unit dosing device comprising a housing and an actuator, said device containing multiple doses of multiparticulates comprising drug particles, said device upon actuation delivering a unit dose of said multiparticulates, said drug particles having a mean diameter of greater than 10 mum to about 1 mm such that an effective dose of said drug cannot be delivered into the lower lung of a human patient. Also disclosed are novel methods, devices and dosage forms for delivering a drug.

Owner:PHARMAKODEX LTD

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

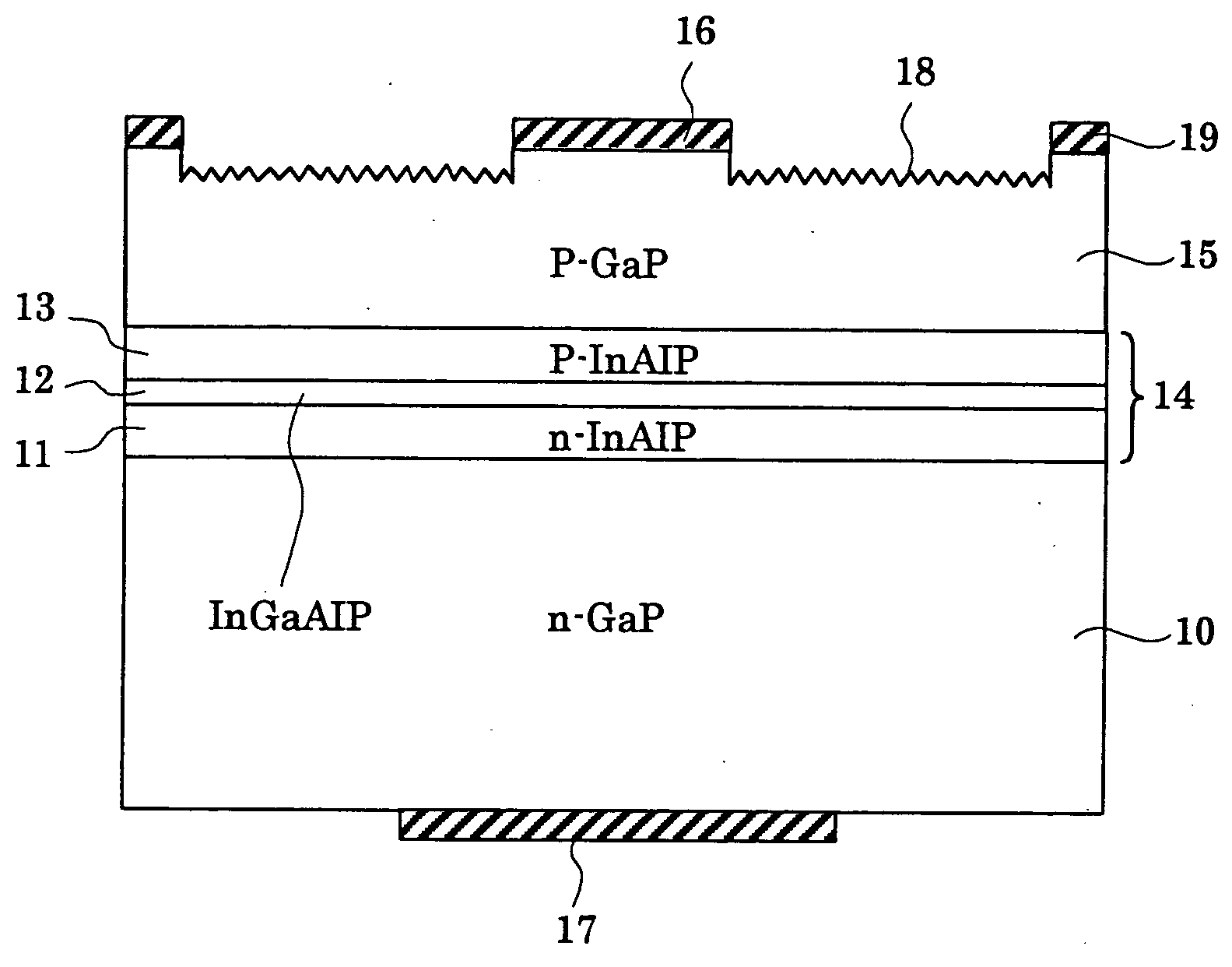

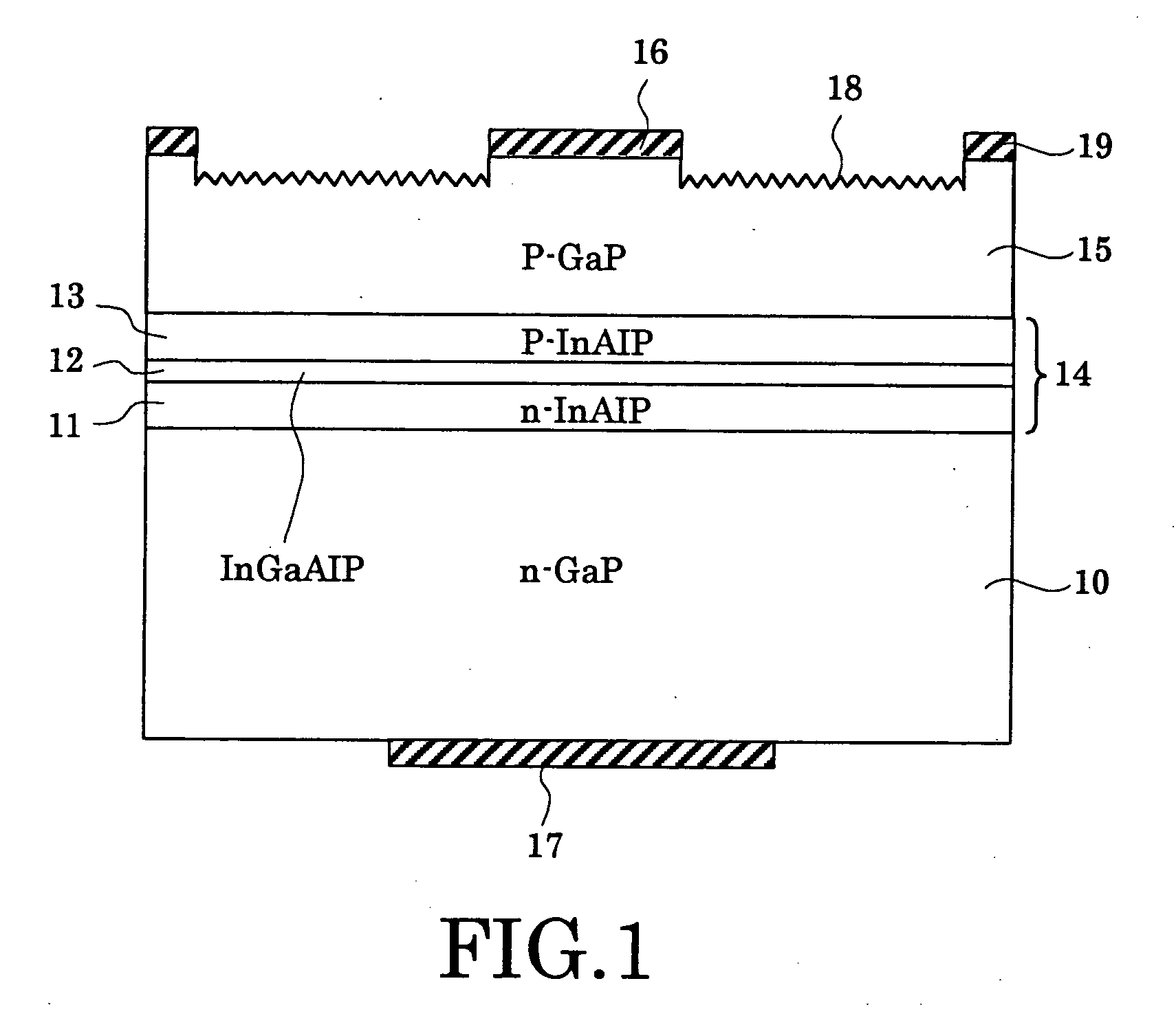

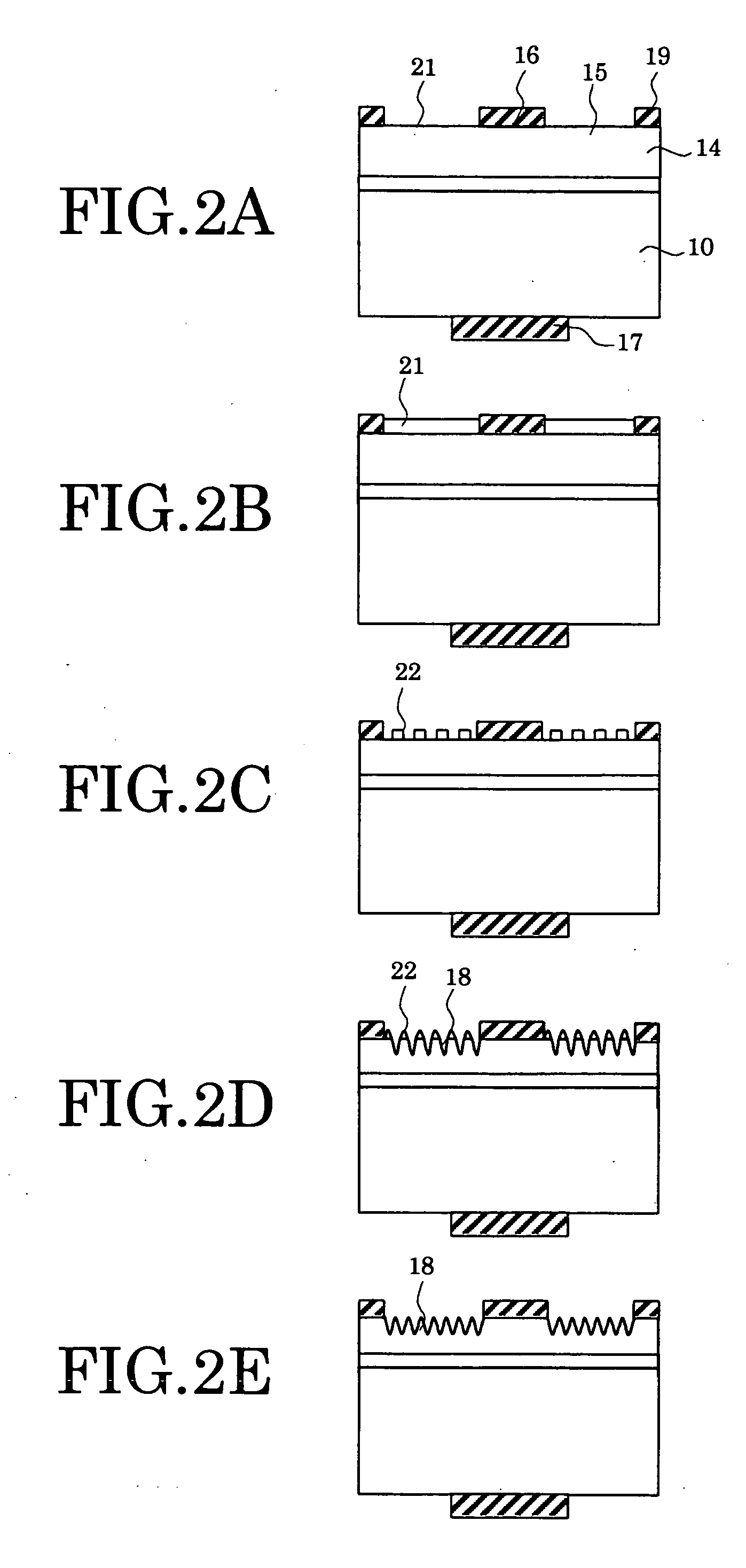

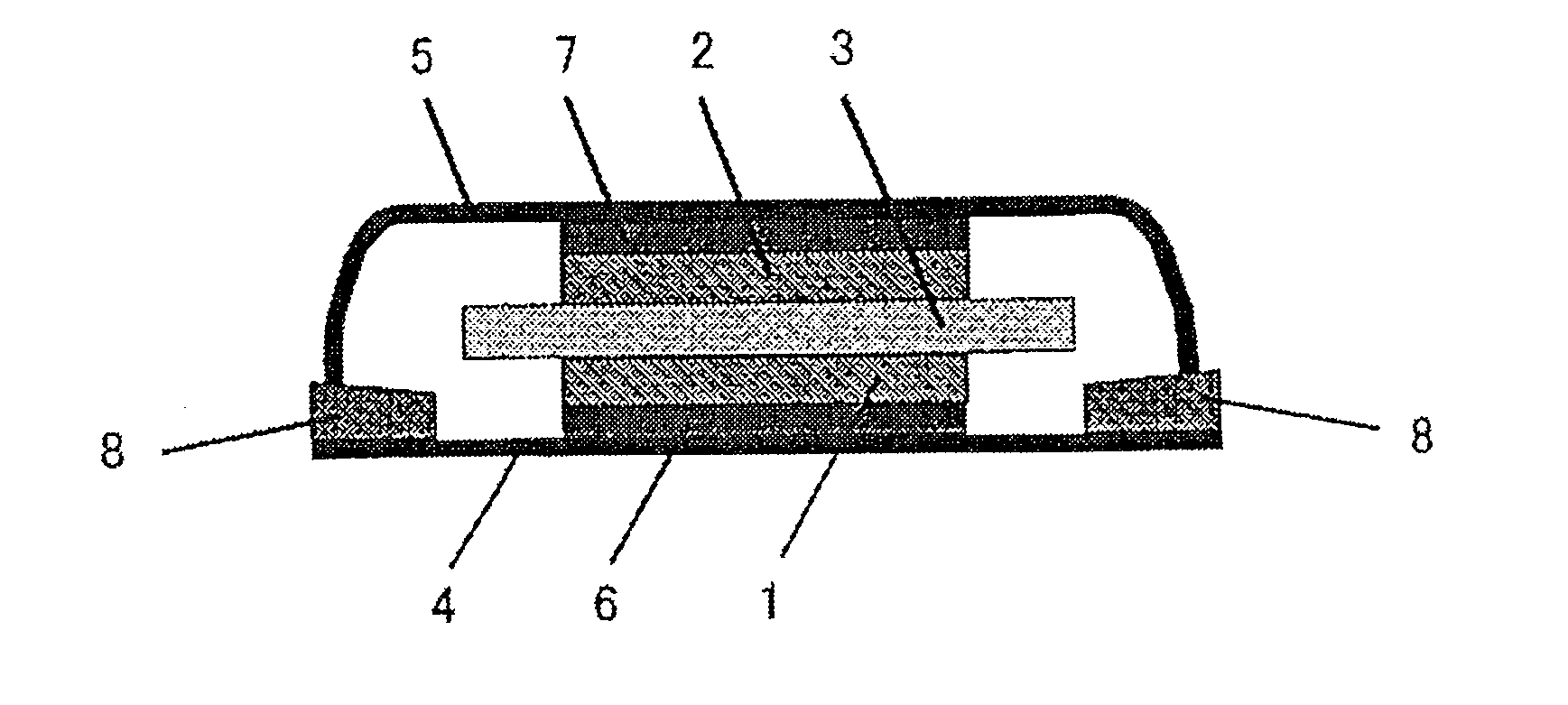

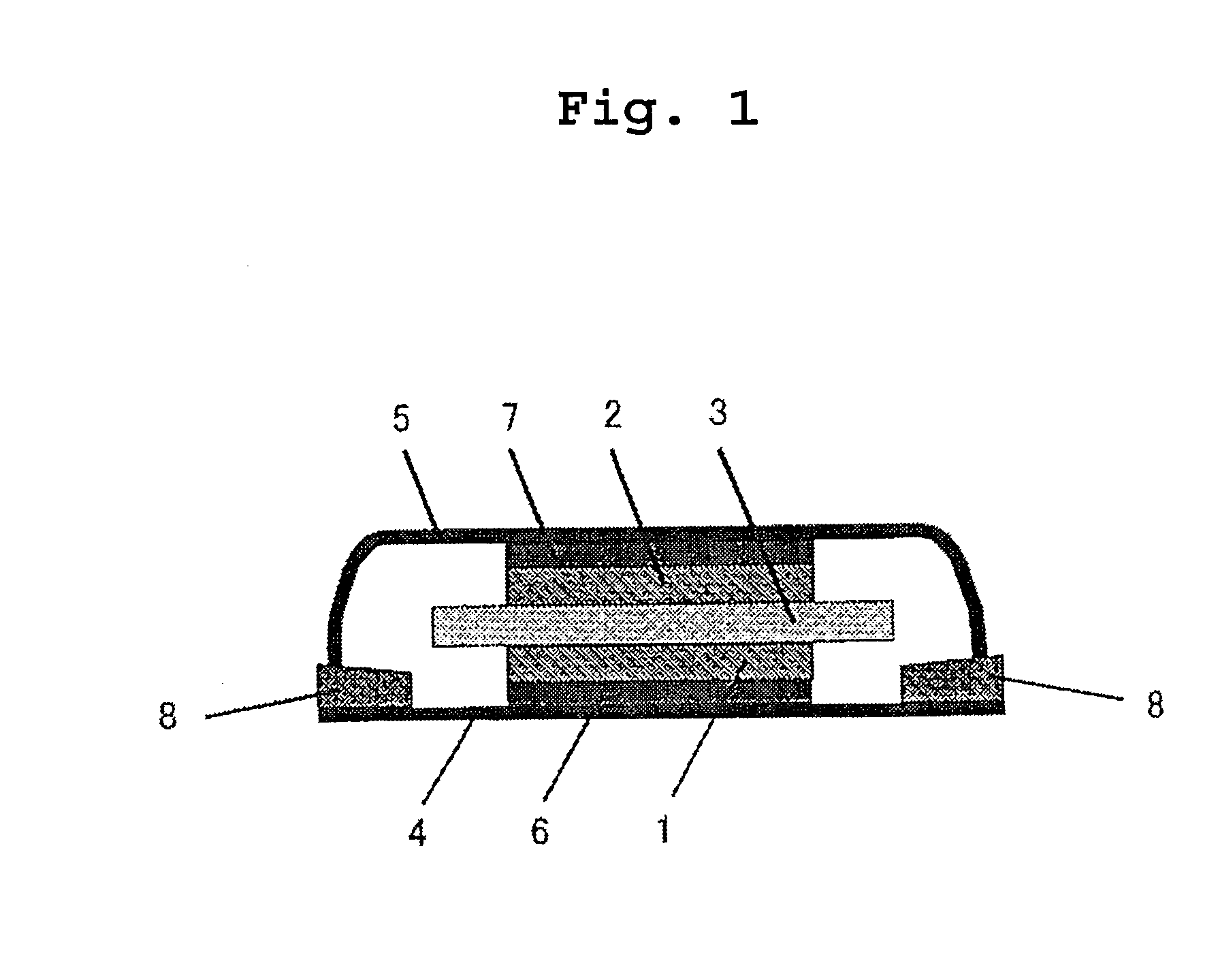

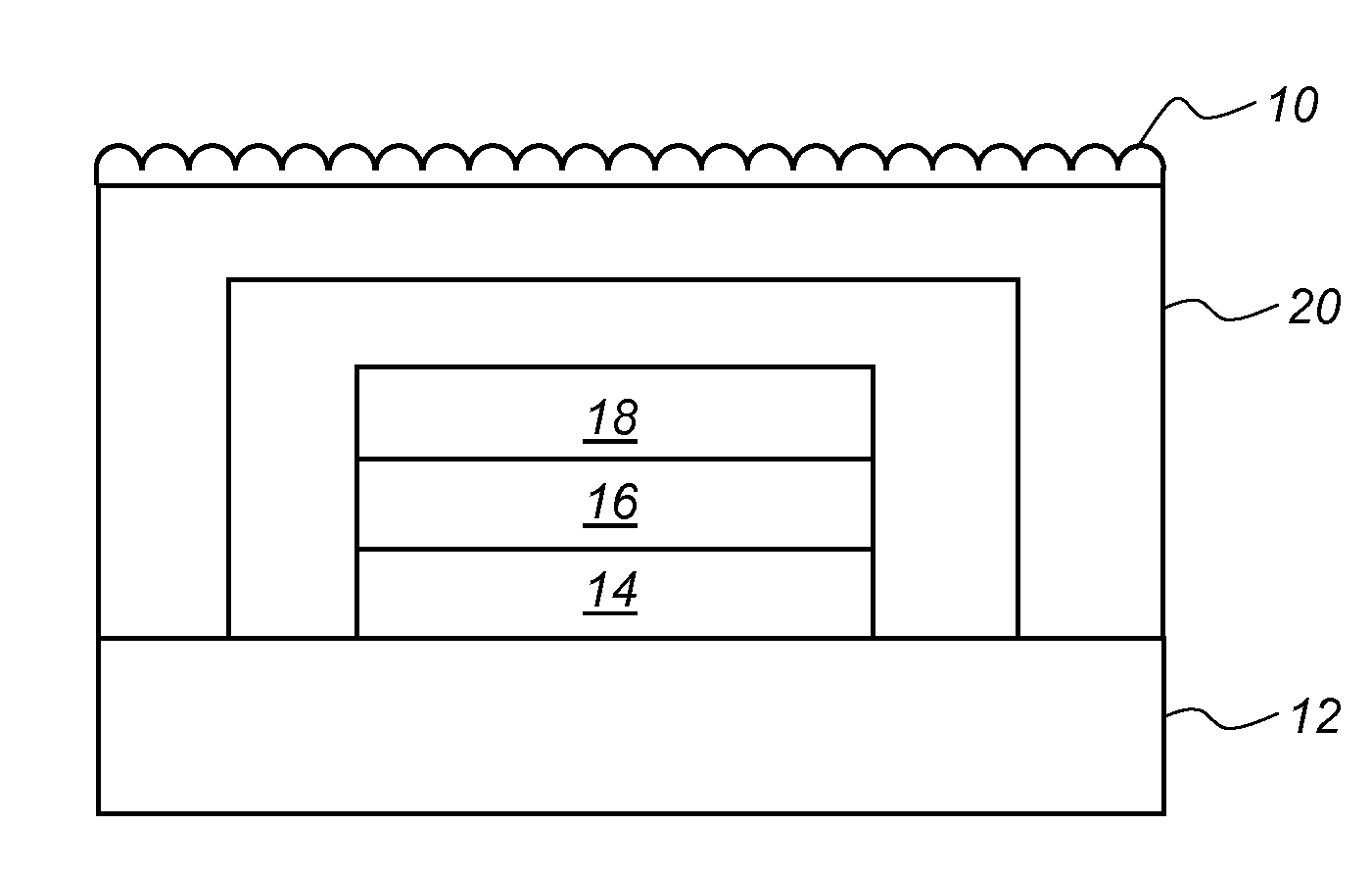

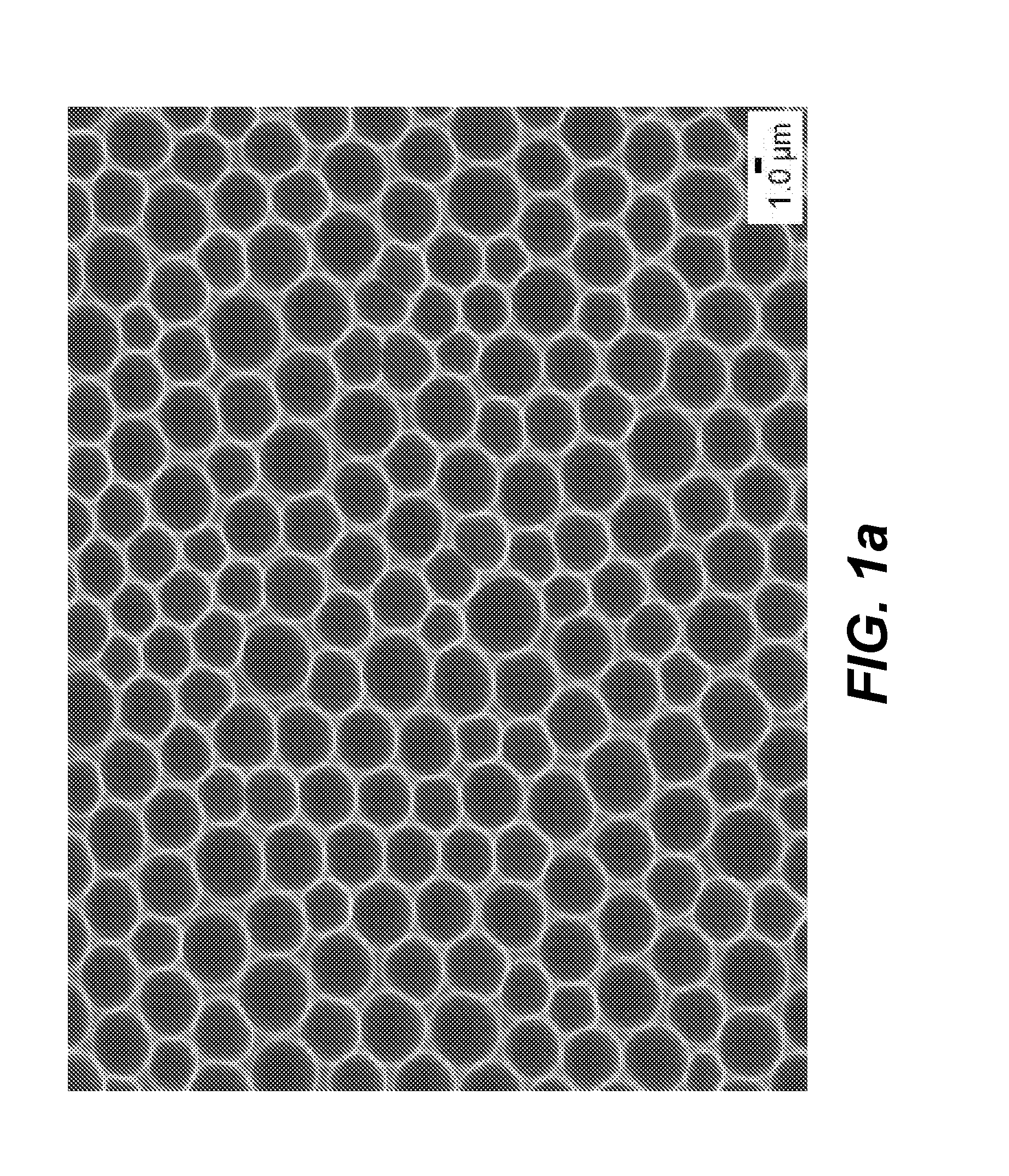

Light-emitting device and method for manufacturing the same

InactiveUS20050112886A1Small sizeGood effectLayered productsSemiconductor/solid-state device manufacturingRough surfaceMean diameter

A nanometer size roughened structure is formed on a surface of a light-emitting element, and luminous efficiency is improved. The roughened structure on the surface of the light-emitting element of the invention is formed into the following shape such that the refractive index smoothly changes: (1) the mean diameter of projections on the roughened surface is smaller than the light wavelength; (2) a pitch of the roughened surface is irregular; and (3) positions of the top and bottom of the roughened surface are distributed from their mean values within the light wavelength in order to give a smooth gradient of the refractive index. The surface of such light-emitting element is obtained by forming a thin film on the surface of the light-emitting element using a resin composition which contains a block copolymer or graft copolymer and forms a micophase-separated structure in a self-organization manner; selectively removing at least one phase of the microphase-separated structure of the thin film formed on the surface; and etching the surface of the light-emitting element using the remaining phase as an etching mask.

Owner:AGILENT TECH INC

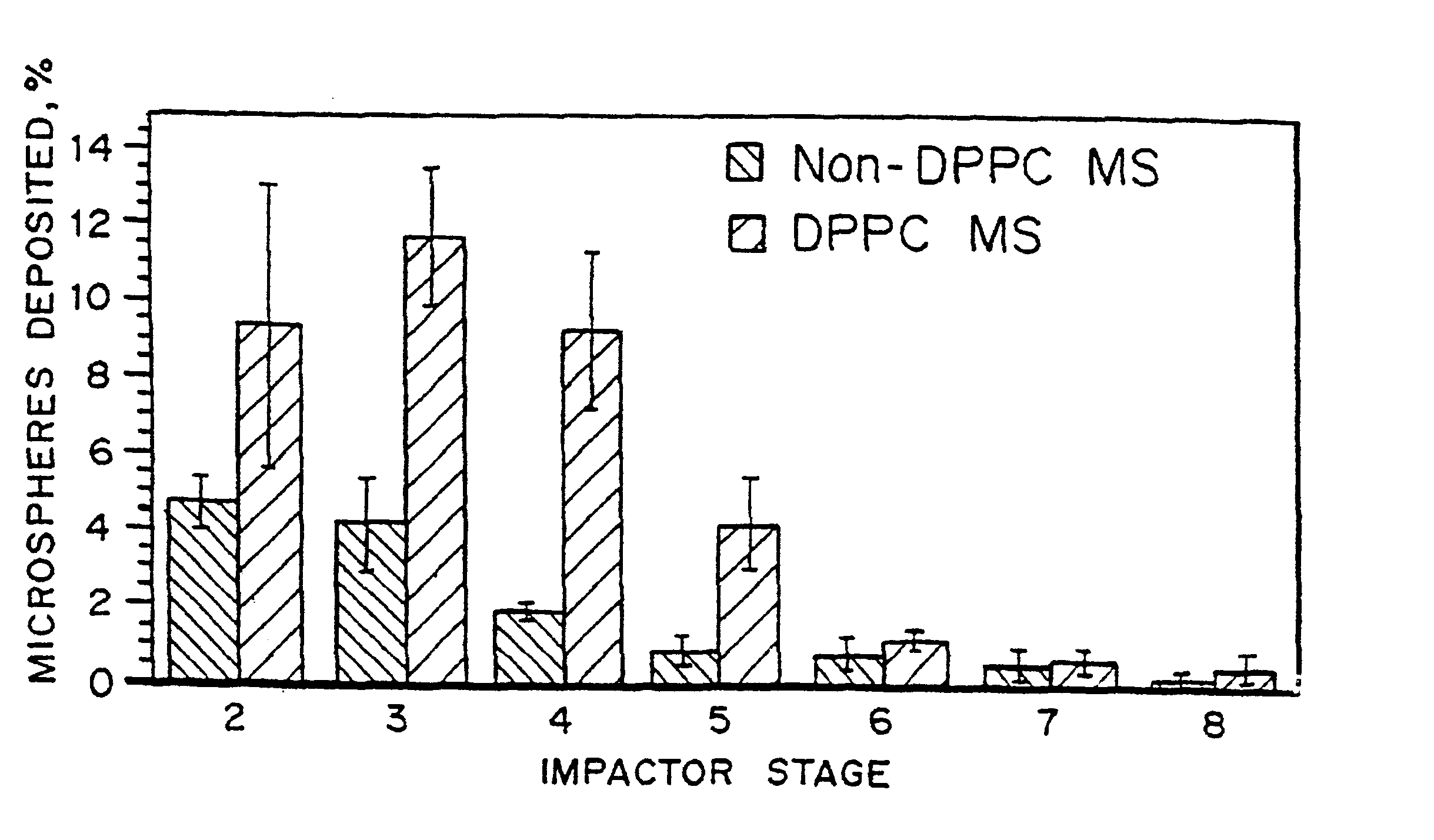

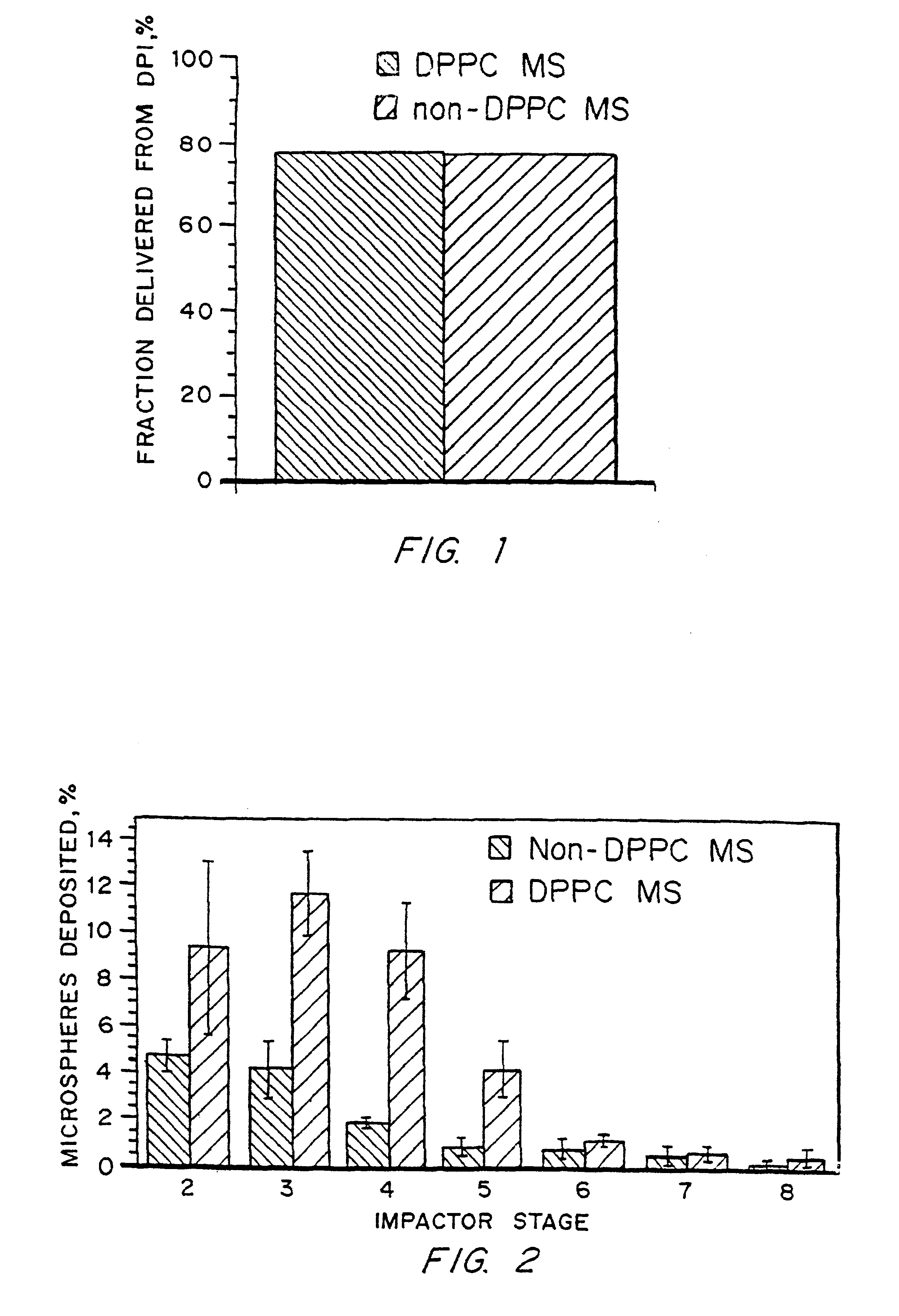

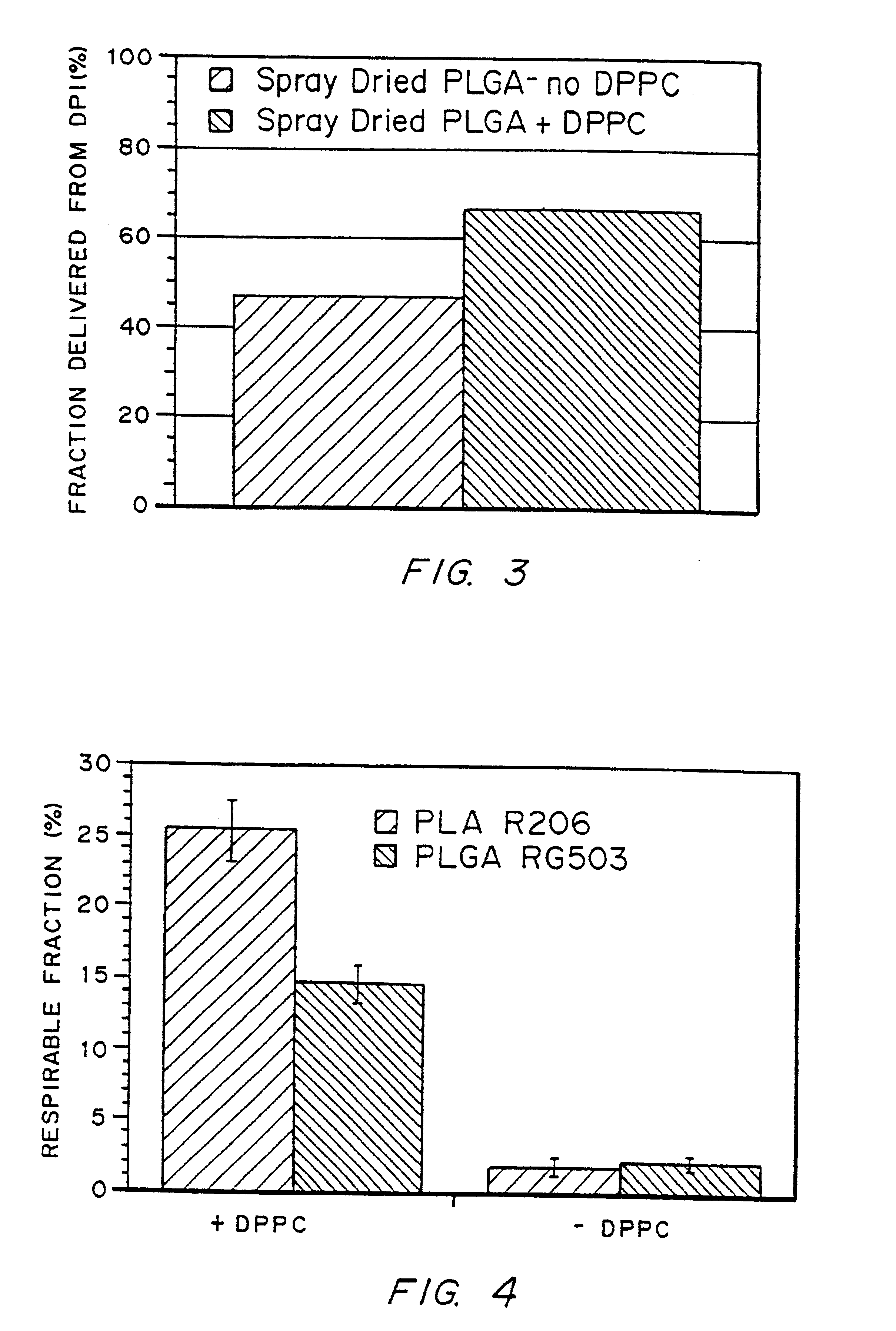

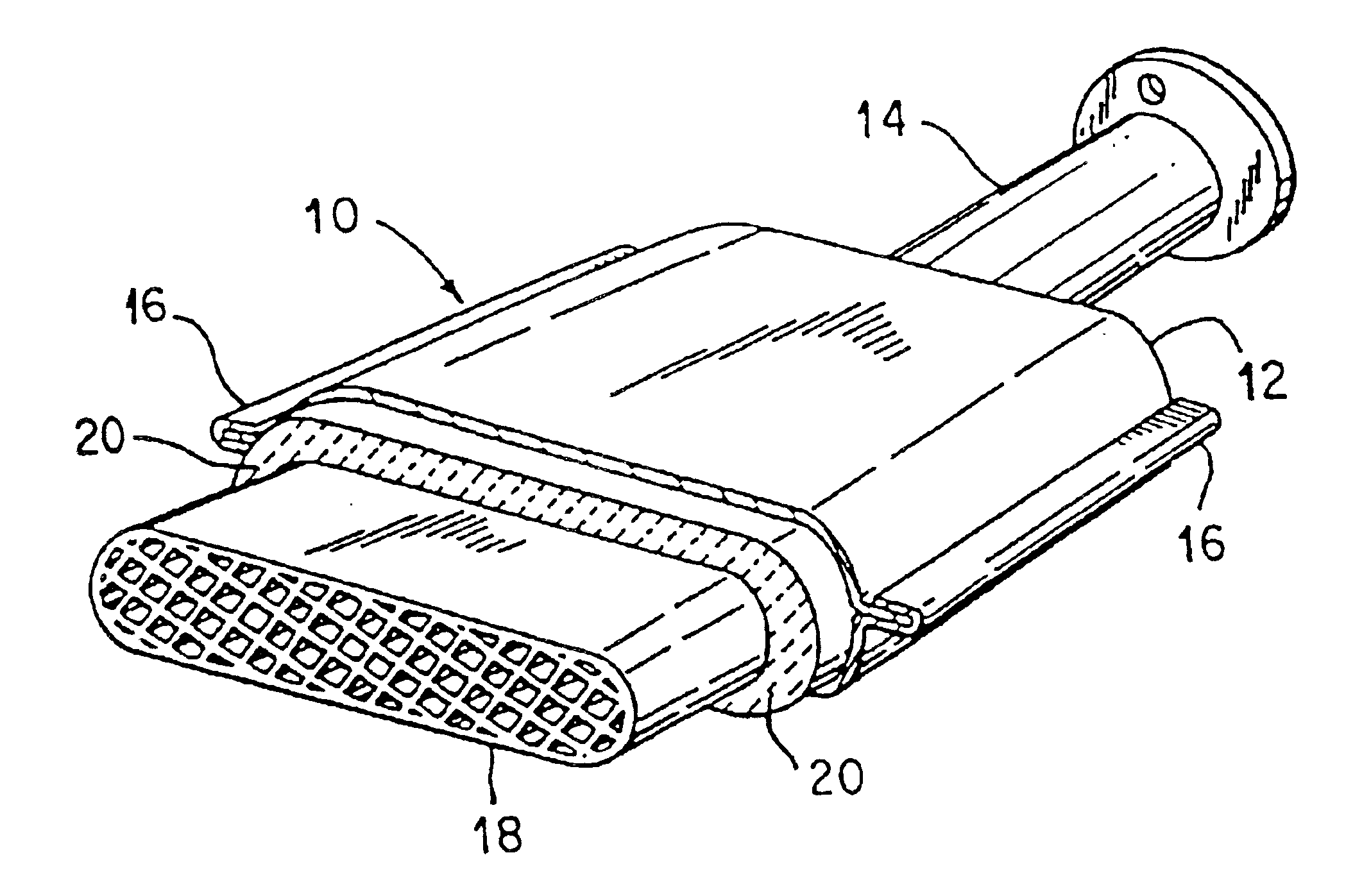

Particles incorporating surfactants for pulmonary drug delivery

Improved aerodynamically light particles for drug delivery to the pulmonary system, and methods for their synthesis and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of a biodegradable material and have a tap density less than 0.4 g / cm3 and a mass mean diameter between 5 mum and 30 mum. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear alpha-hydroxy-acid polyester backbone having at least one amino acid group incorporated therein and at least one poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 mum, can be used for enhanced delivery of a therapeutic agent to the alveolar region of the lung. The aerodynamically light particles incorporating a therapeutic agent may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of wide variety of therapeutic agents.

Owner:MASSACHUSETTS INST OF TECH

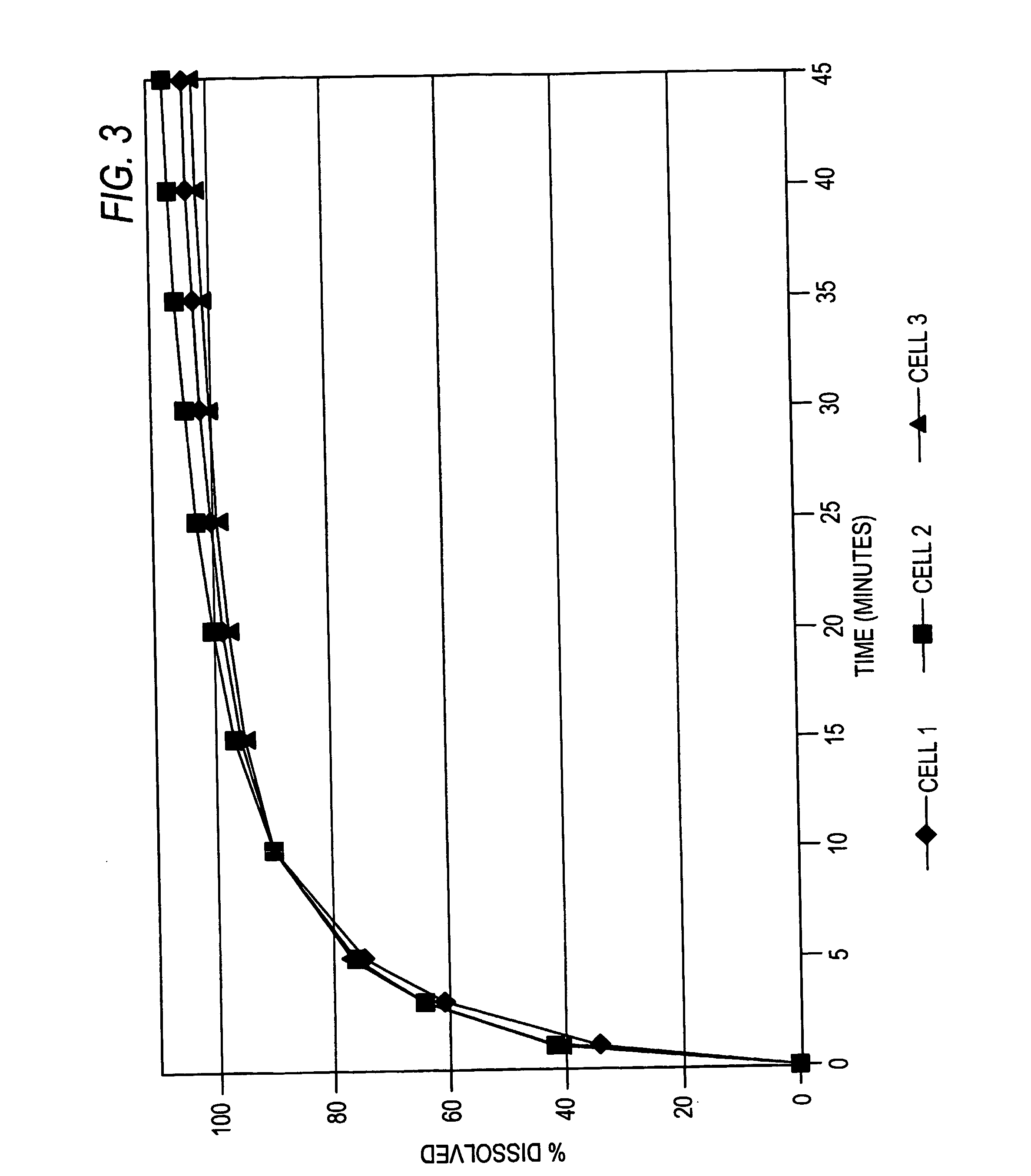

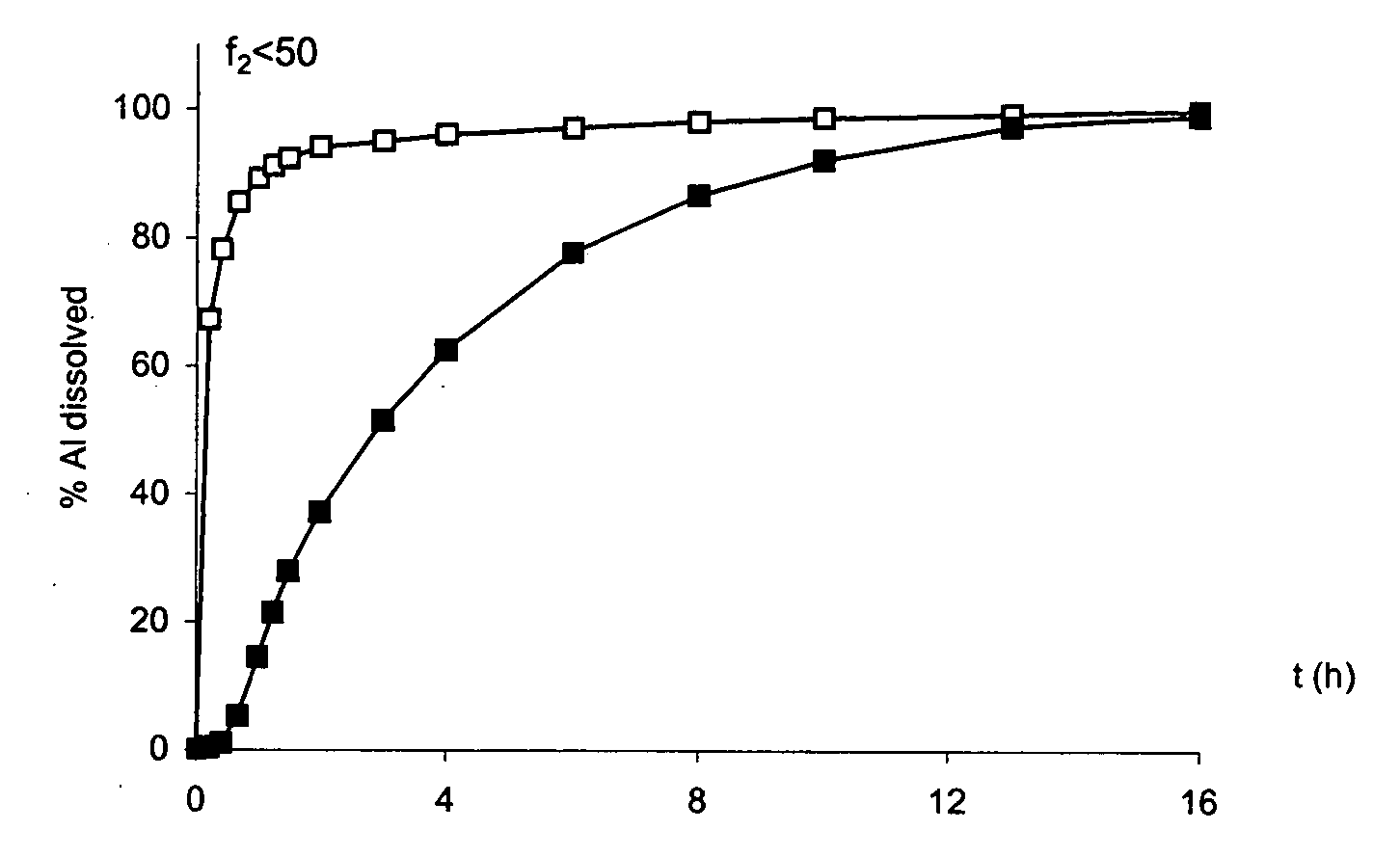

Stable probiotic microsphere compositions and their methods of preparation

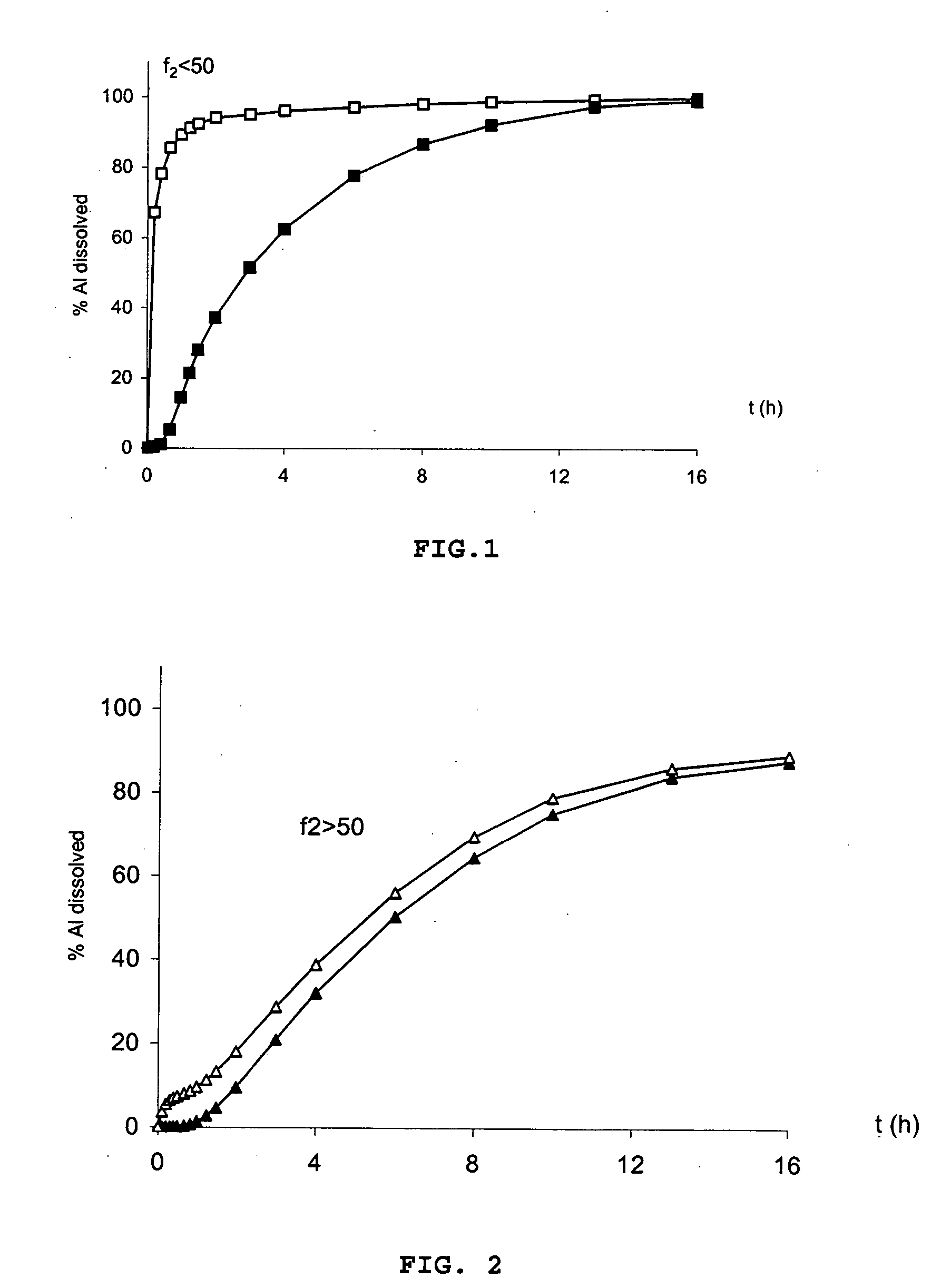

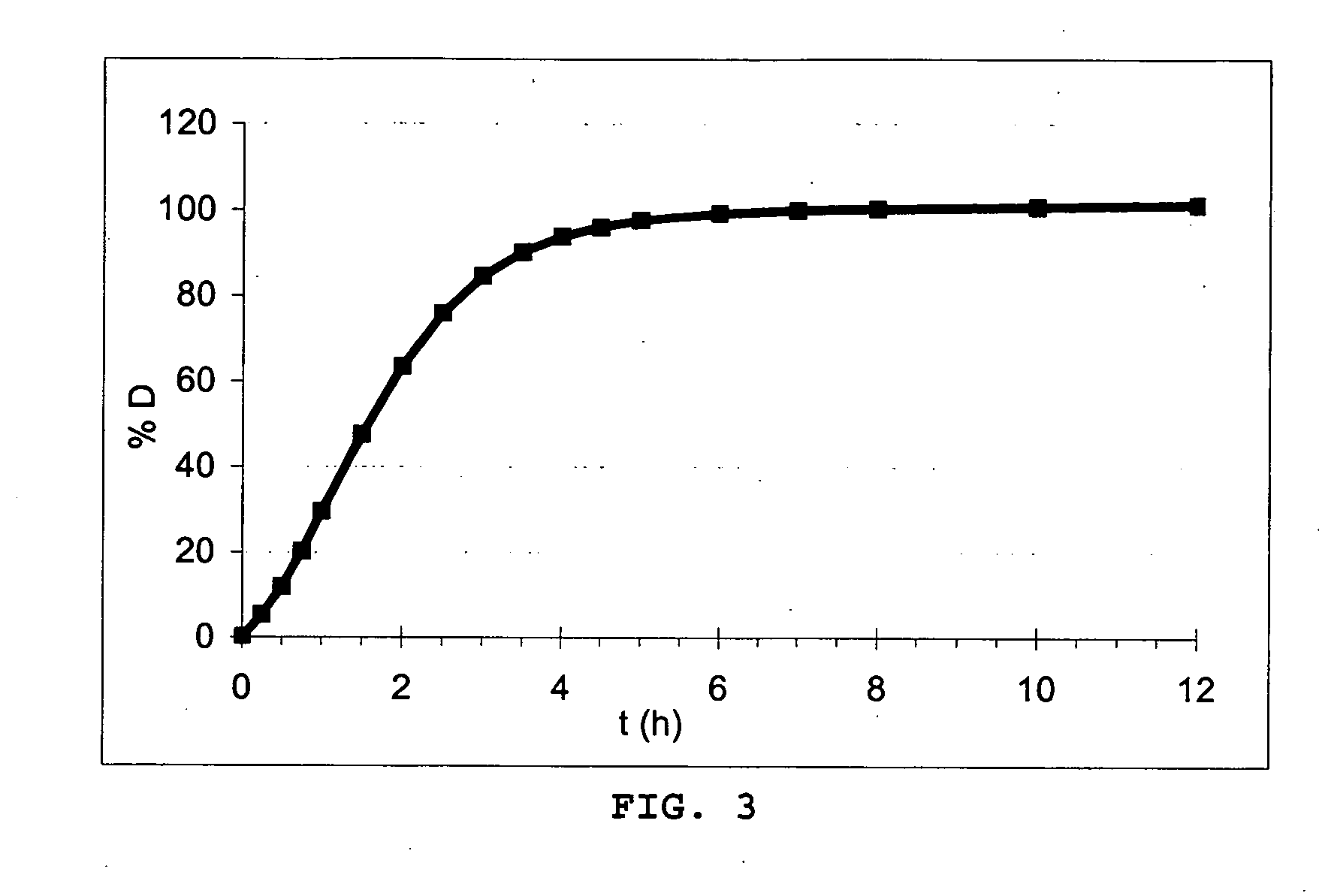

The invention relates to viable and stable probiotic formulations for intestinal targeting made of microspheres comprising each a core of one or more probiotic bacteria, microcrystallline cellulose with a degree of polymerization from 165-365 and mean diameter from 45 to 180 μm, a disintegrant and a stabilizer, the core being coated with a non-enteric coating and further coated with an enteric coating. Each probiotic microsphere has a residual moisture level of less than 5% and a water activity (aw) between 0.1 and 0.5. Such a probiotic microsphere shows no reduction in viable bacteria after one hour in simulated gastric fluid. The present invention also relates to the process of preparing such formulation.

Owner:CANACURE CORP

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

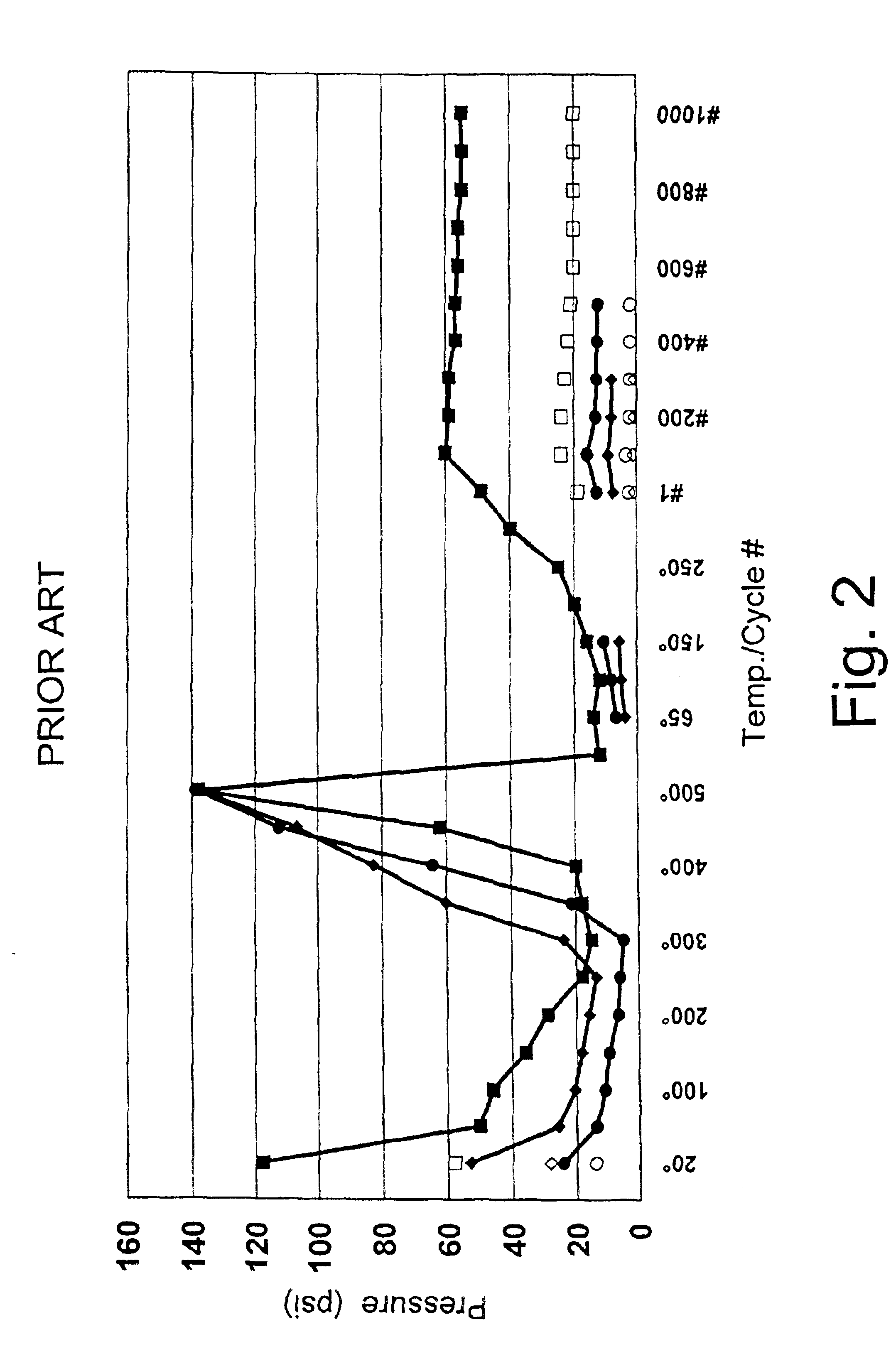

Amorphous non-intumescent inorganic fiber mat for low temperature exhaust gas treatment device

A non-intumescent mat for providing a support structure for low temperature fragile structures in exhaust gas treatment devices, such as catalytic converters, diesel particulate traps, and like, comprising amorphous inorganic fibers. The fibers have Young's Modulus of less than about 20×106 psi and a geometric mean diameter less than about 5 μm. The mat is adapted to provide a holding force of at least 15 psi throughout an average mat temperature range from ambient temperature up to at least about 350° C. The amorphous inorganic fibers are preferably melt formed fibers comprising the fiberization product of a melt comprising alumina / silica.

Owner:UNIFRAX I LLC

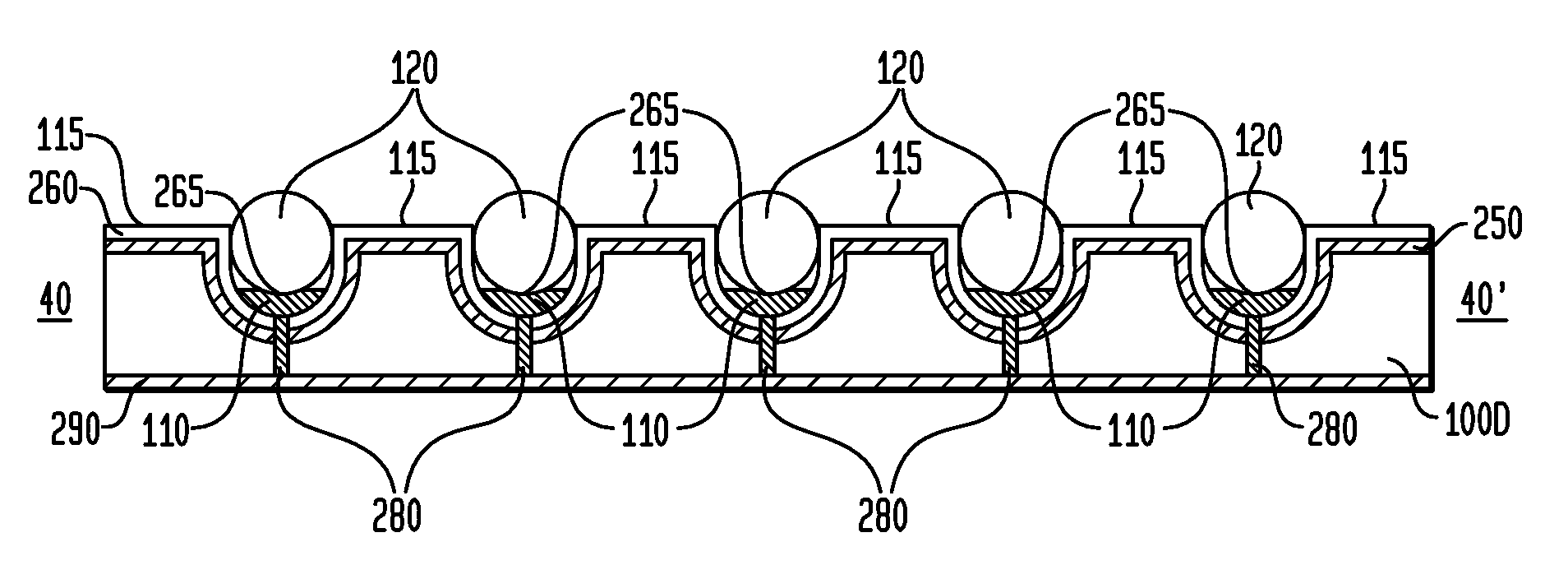

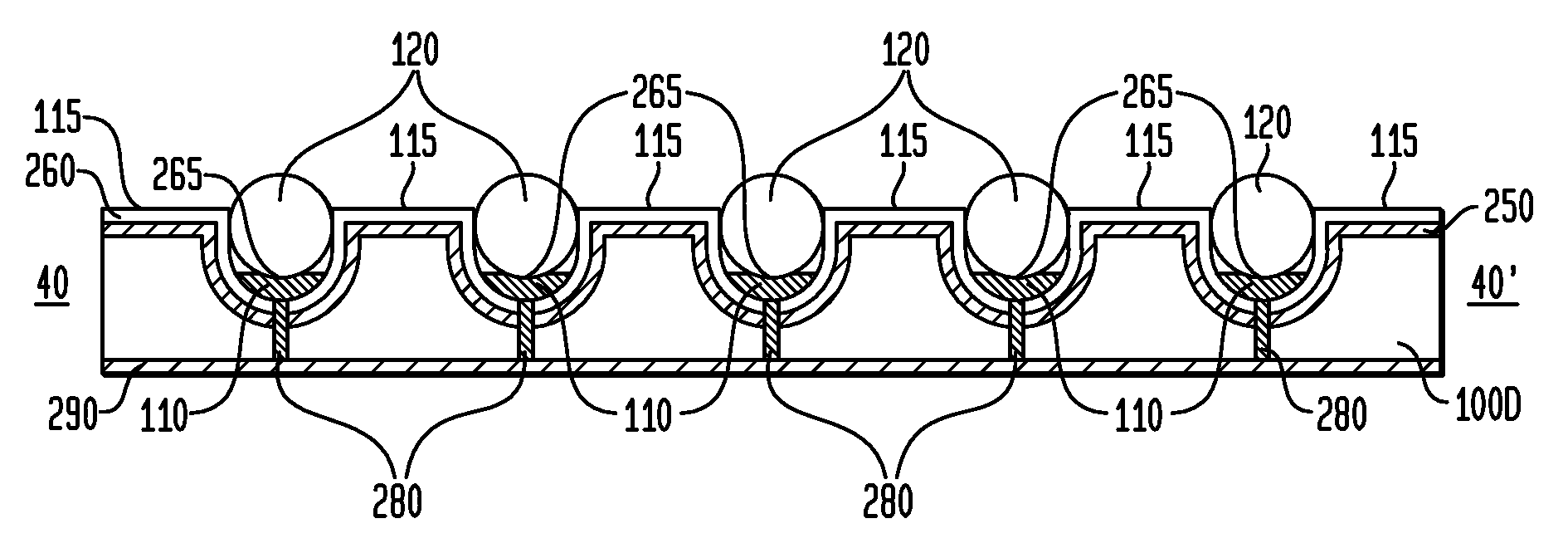

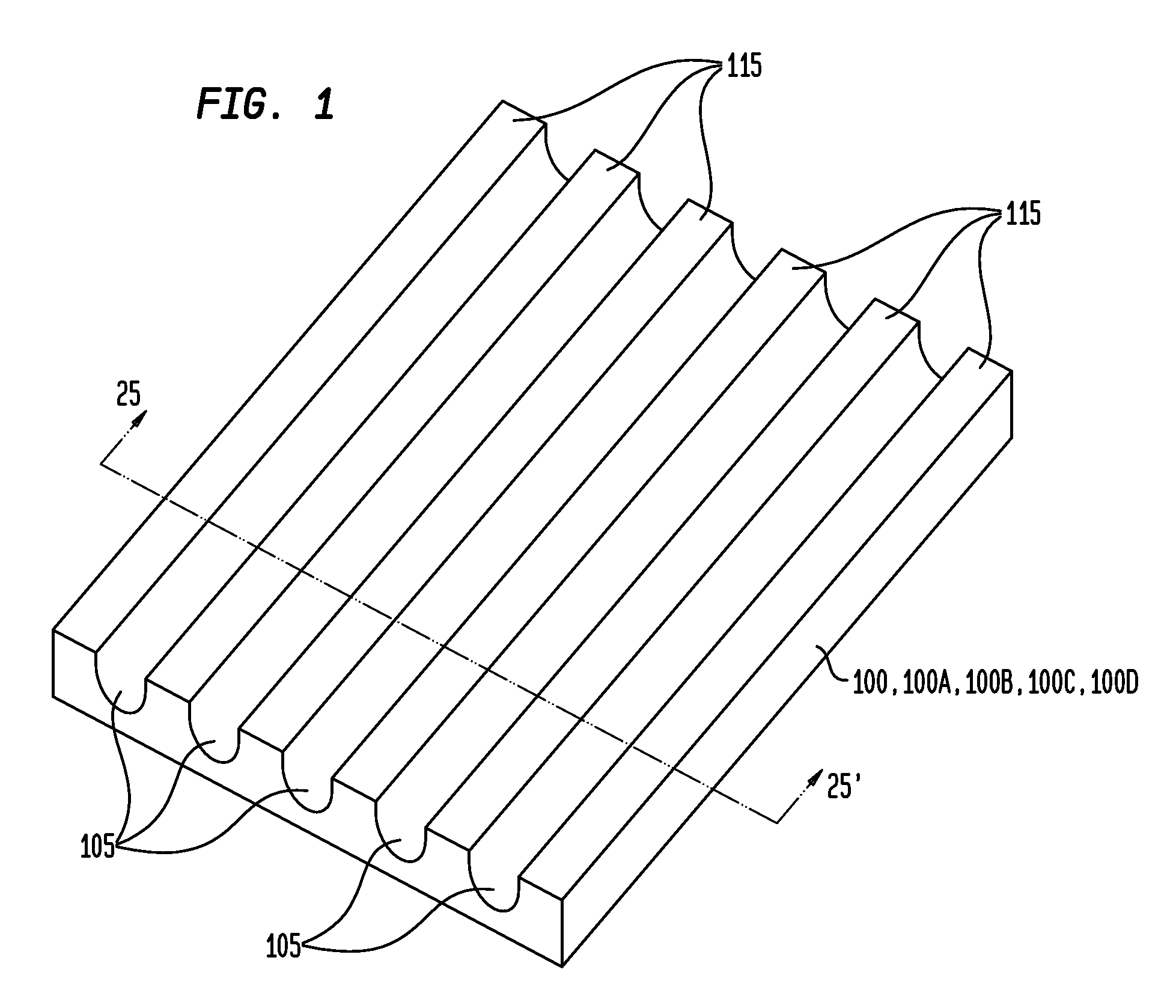

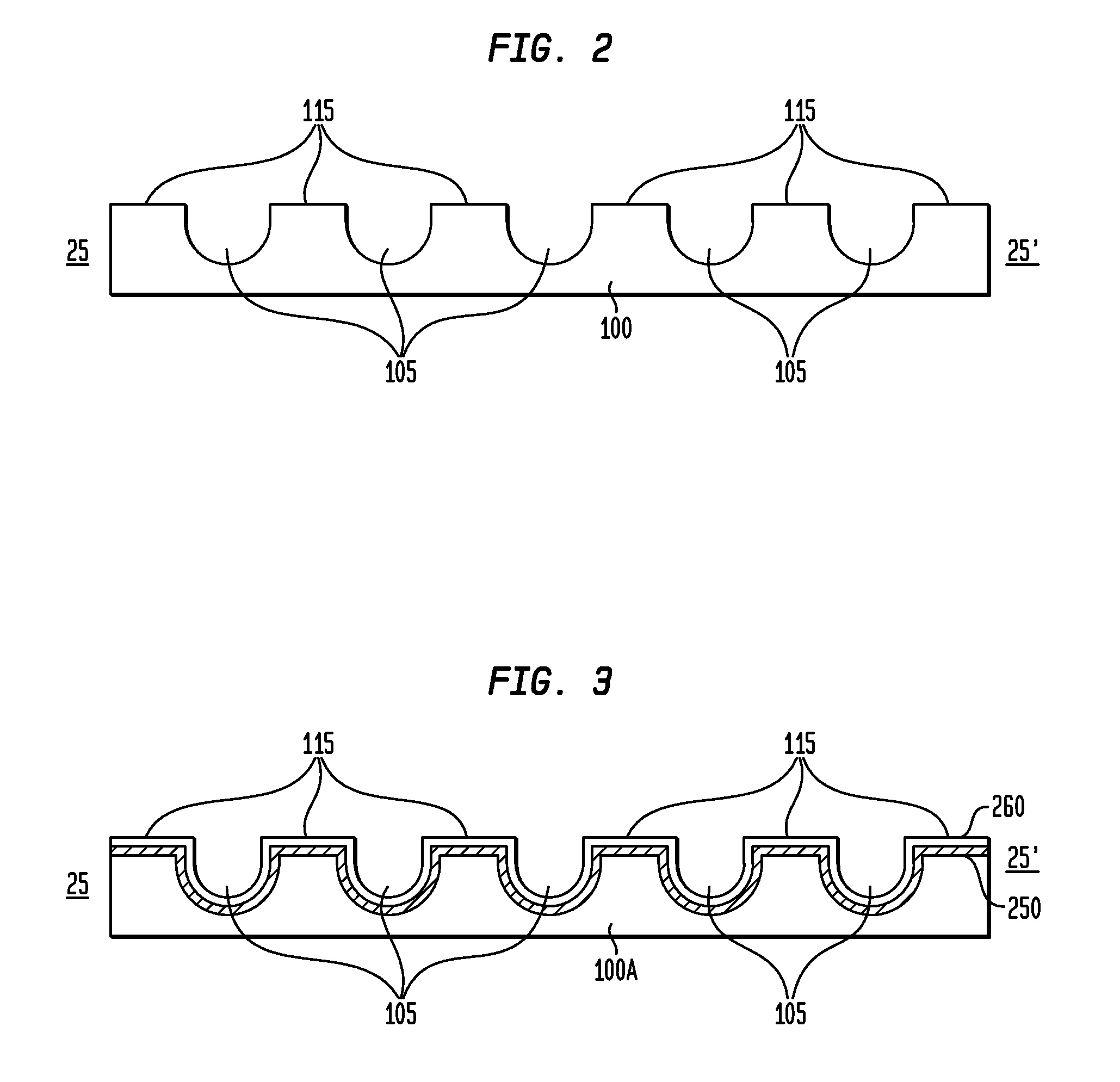

Light Emitting, Photovoltaic Or Other Electronic Apparatus and System

ActiveUS20100065862A1Low finished product costIncrease useMaterial nanotechnologyFinal product manufactureMean diameterElectrical conductor

The present invention provides an electronic apparatus, such as a lighting device comprised of light emitting diodes (LEDs) or a power generating apparatus comprising photovoltaic diodes, which may be created through a printing process, using a semiconductor or other substrate particle ink or suspension and using a lens particle ink or suspension. An exemplary apparatus comprises a base; at least one first conductor; a plurality of substantially spherical or optically resonant diodes coupled to the at least one first conductor; at least one second conductor coupled to the plurality of diodes; and a plurality of substantially spherical lenses suspended in a polymer attached or deposited over the diodes. The lenses and the suspending polymer have different indices of refraction. In some embodiments, the lenses and diodes have a ratio of mean diameters or lengths between about 10:1 and 2:1. The diodes may be LEDs or photovoltaic diodes, and in some embodiments, have a junction formed at least partially as a hemispherical shell or cap.

Owner:UNITED STATES GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE NAT AERONAUTICS & SPACE ADMINSTRATION +1

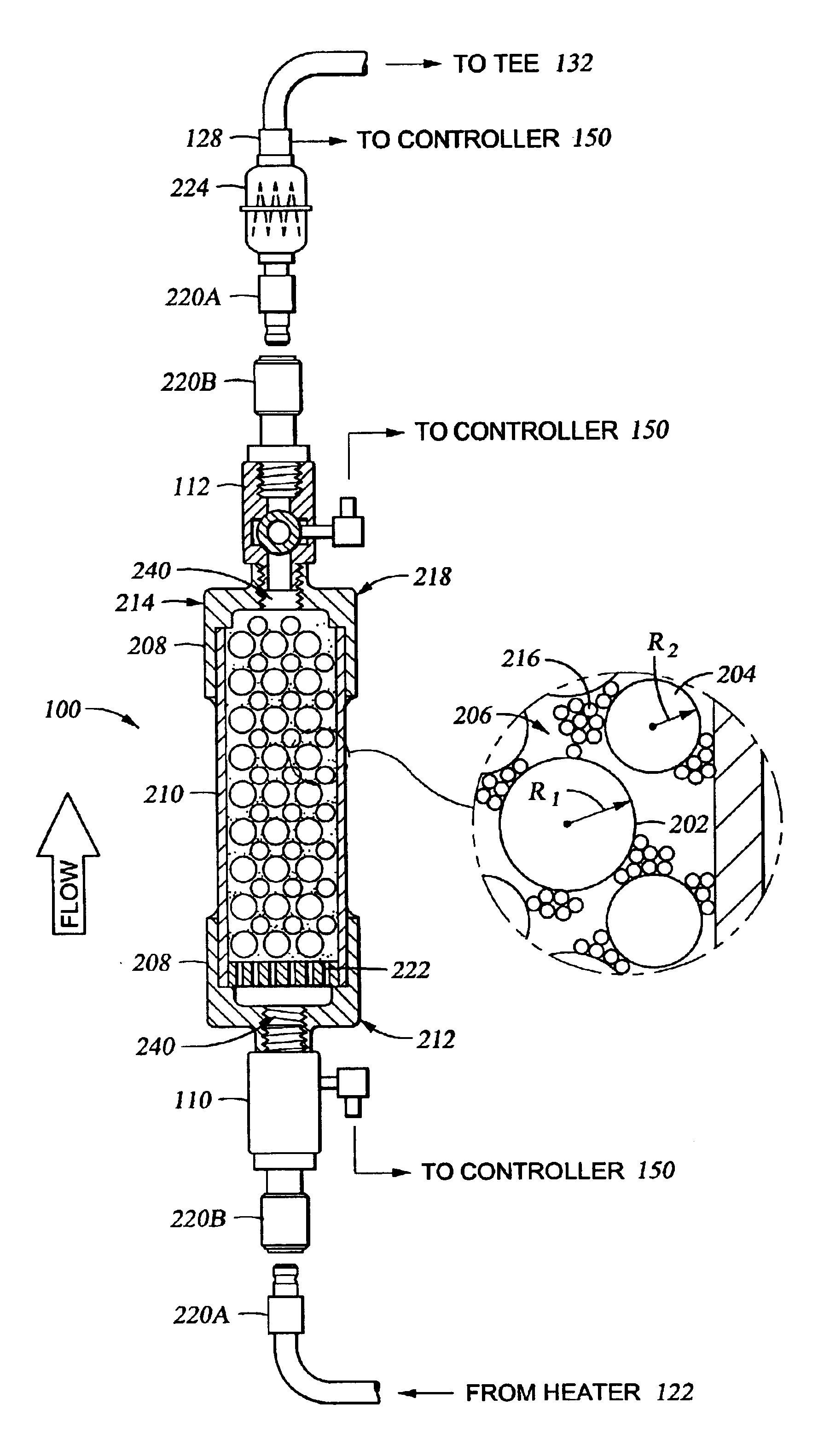

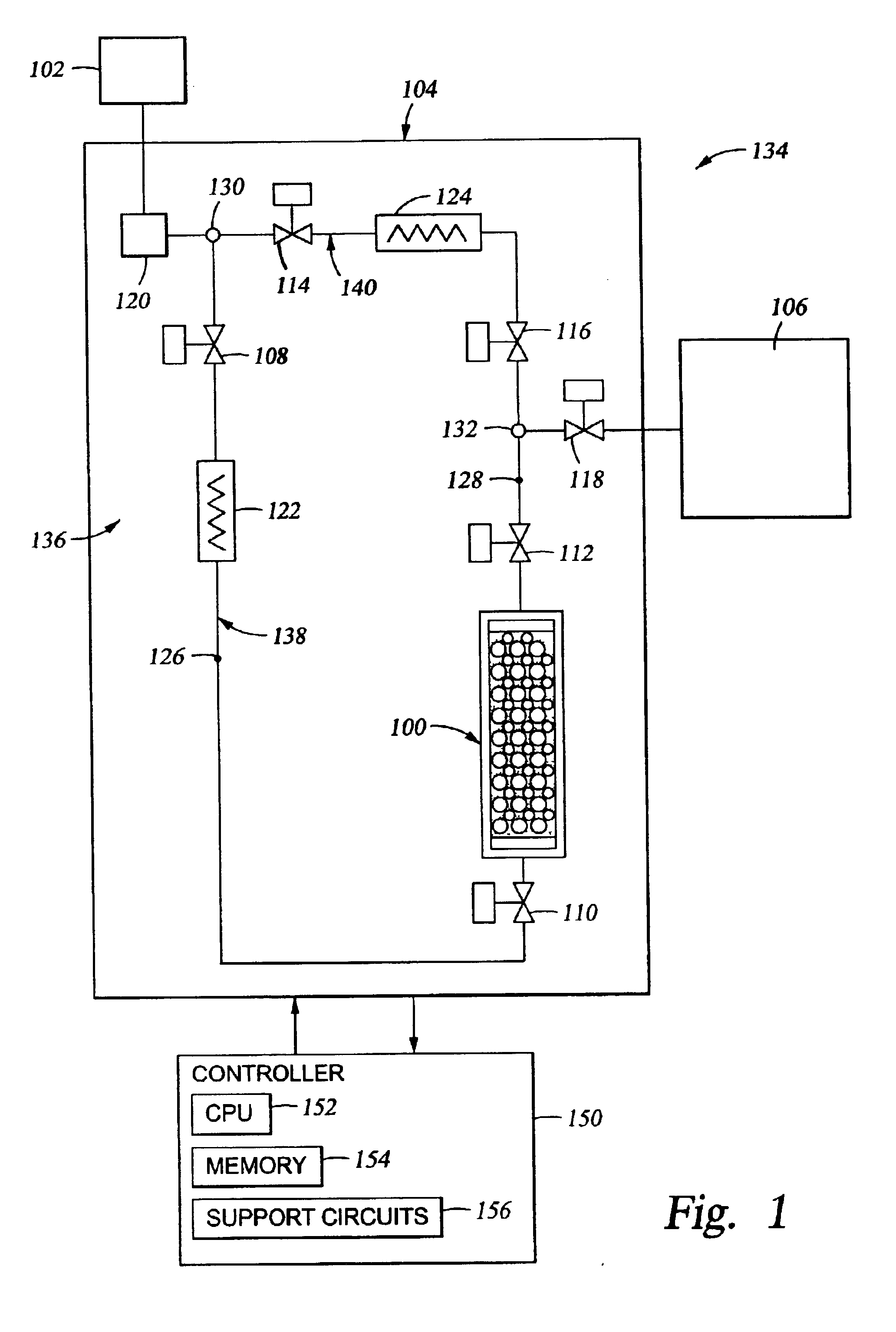

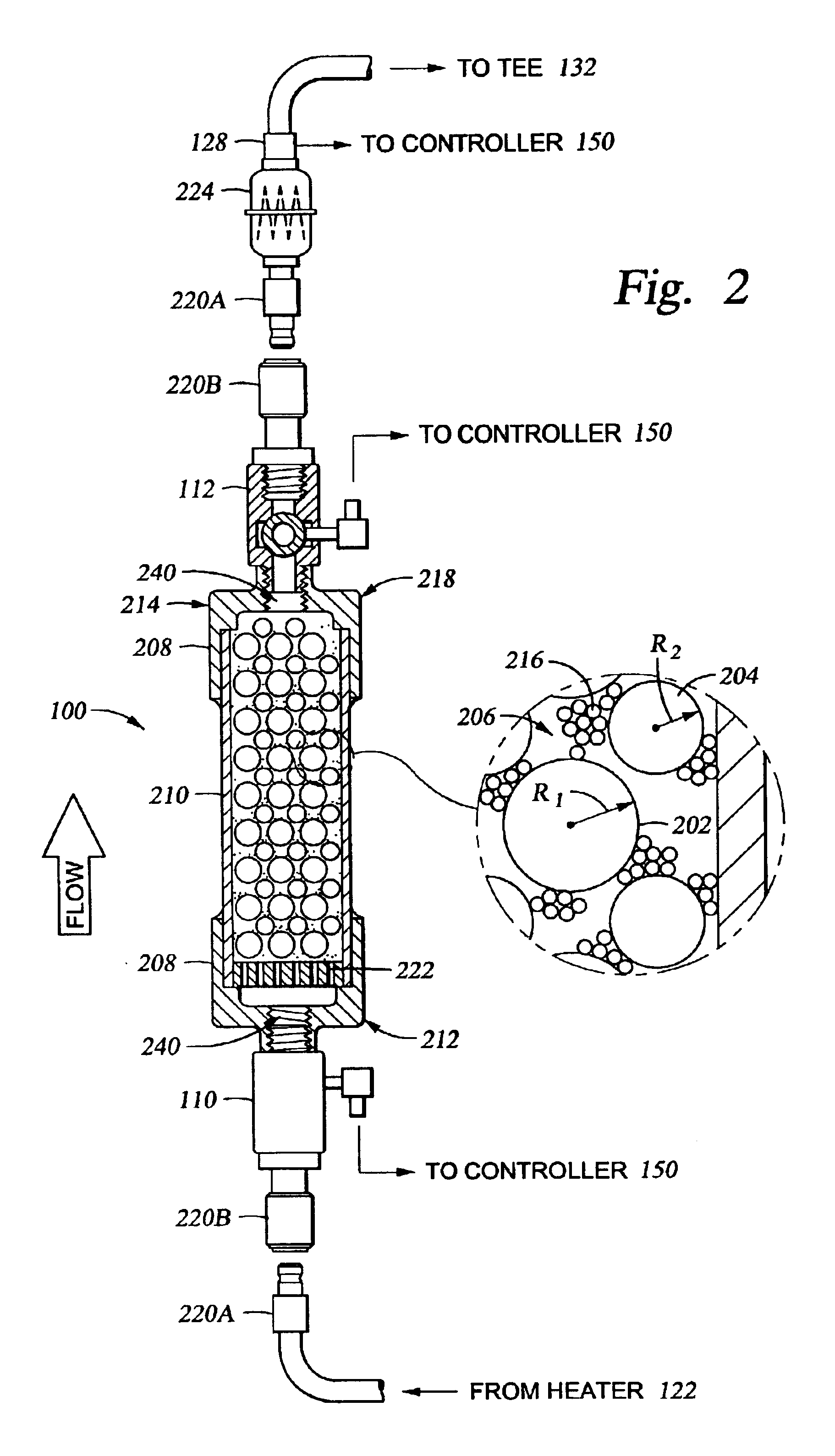

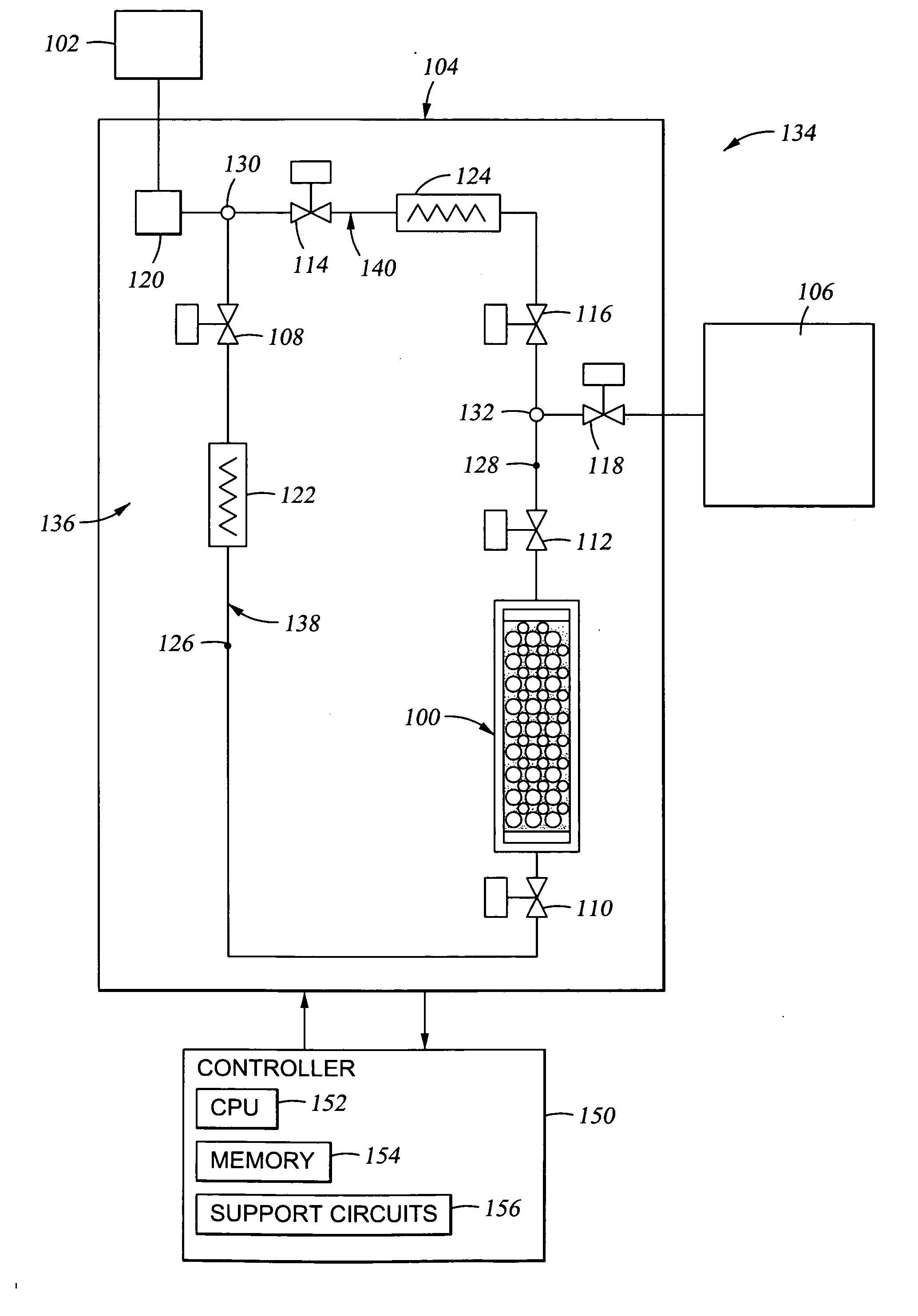

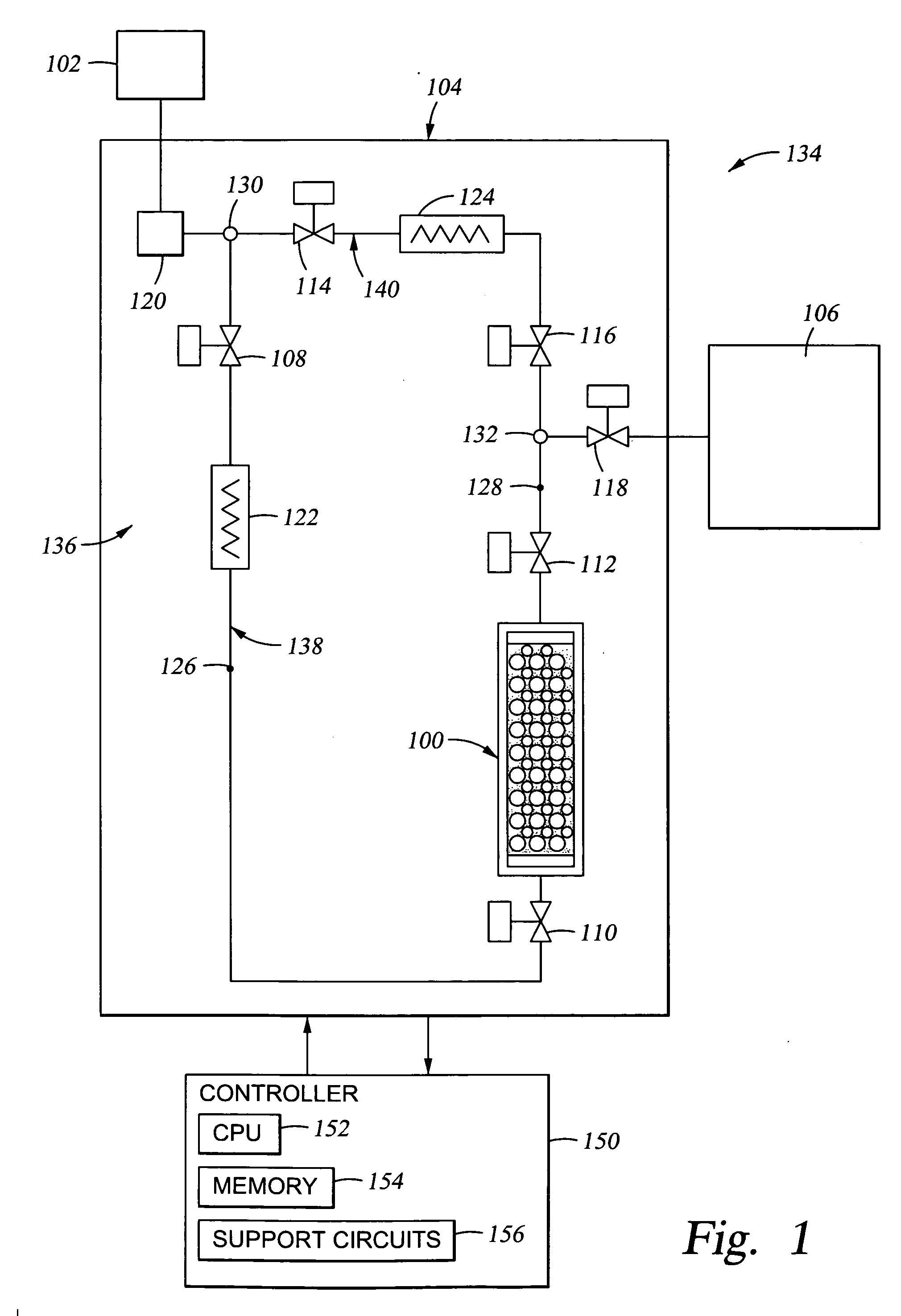

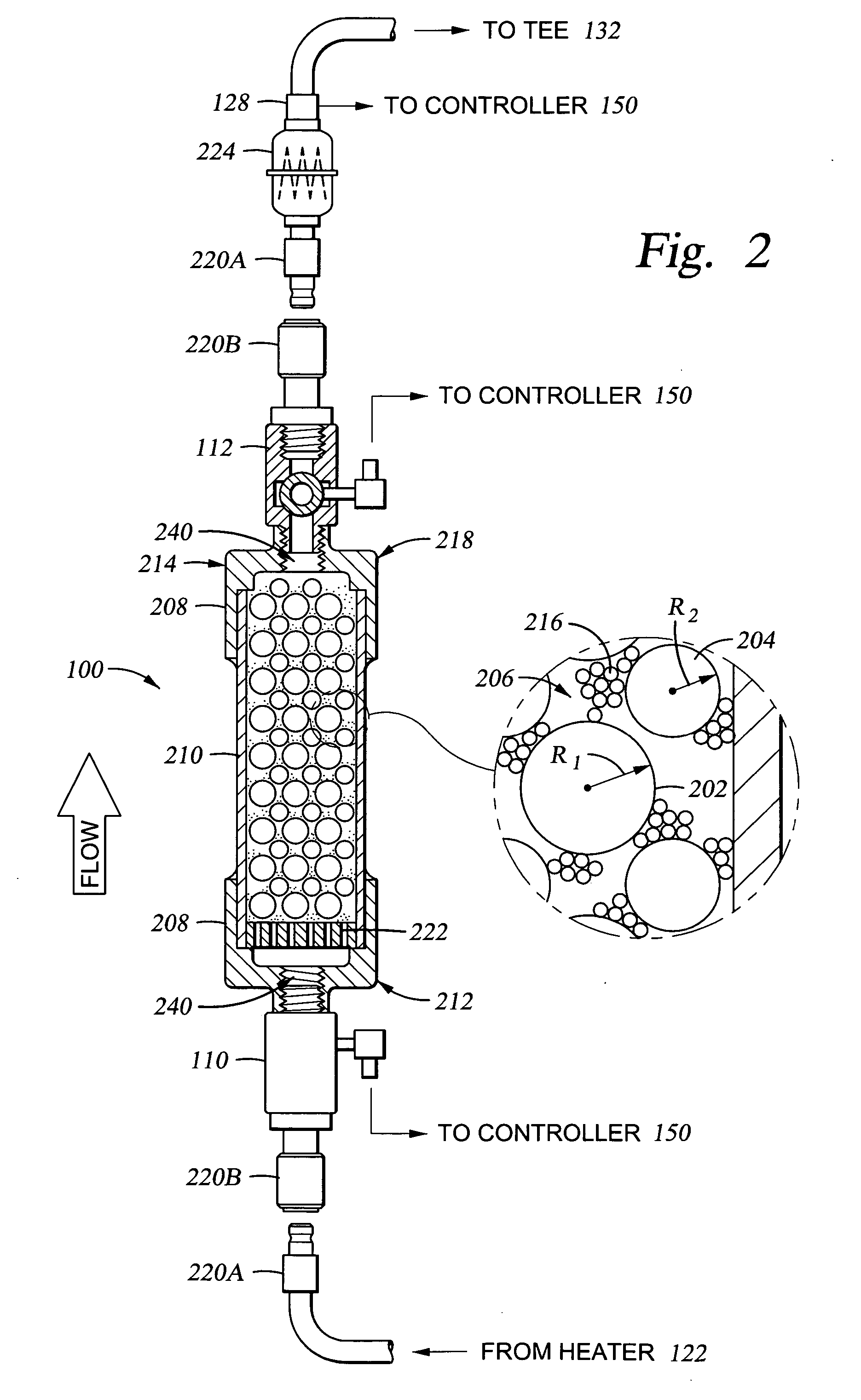

Method and apparatus for generating gas to a processing chamber

A method and apparatus for generating gas for a processing system is provided. In one embodiment, an apparatus for generating gas for a processing system includes an unitary, isolatable, transportable canister having a plurality of first spacing elements, a plurality of second spacing elements and a solid material disposed within the canister. The spacing elements have different mean diameters. The solid material is adapted to produce a gas vapor when exposed to a temperature above a predetermined level at a predetermined pressure. In another embodiment, an apparatus for generating gas includes a gas source coupled to a processing chamber by a first gas line. A canister is coupled in-line with the first gas line and contains a solid material that produces a process gas when heated. A heater is disposed between the gas source and the canister to heat gas flowing into the canister.

Owner:APPLIED MATERIALS INC

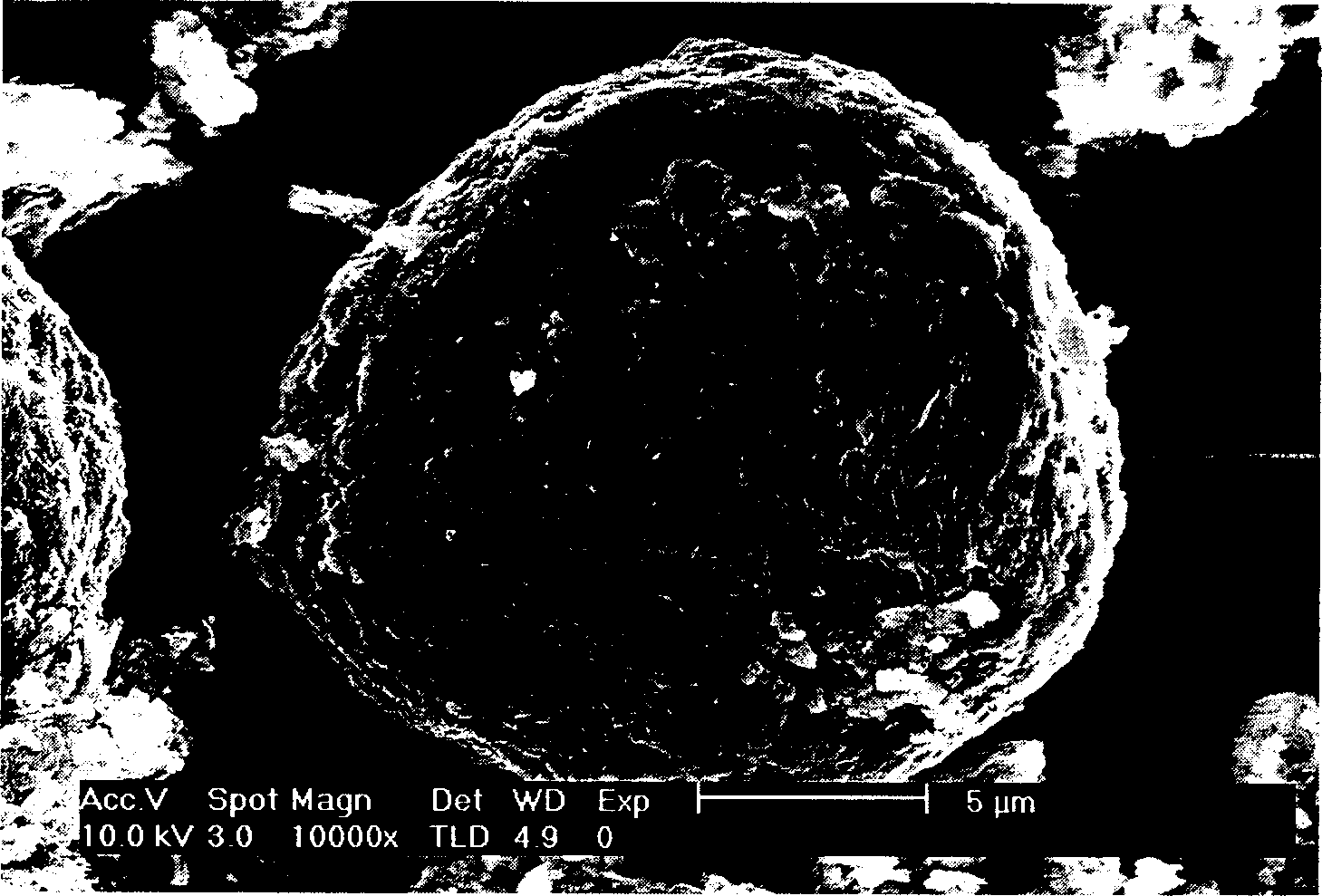

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Method of exfoliating skin

InactiveUS6294179B1Avoid excessive abrasion of and damageInorganic/elemental detergent compounding agentsCosmetic preparationsMean diameterViscous liquid

A viscous, liquid, skin washing composition comprising water, at least one surface active agent, abrasive particles and a viscosifier, CHARACTERISED IN THAT the viscosity of the composition is typically that of a shower gel, i.e. in the range 4000-8000 mPas measured at a shear rate of 10 s-1, the particles, preferably calcite, have a mean diameter of 40-400 micrometres and a bulk density of 1-4.

Owner:LEVER BROTHERS

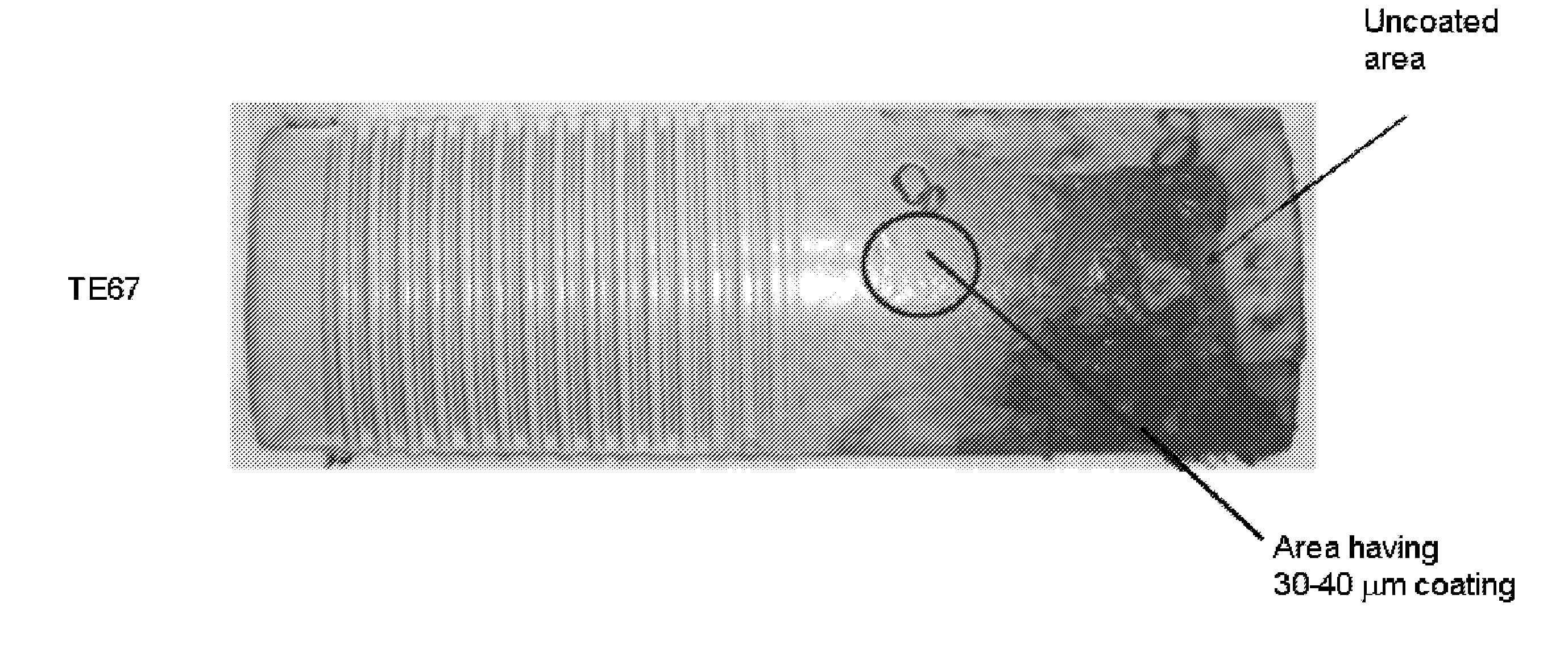

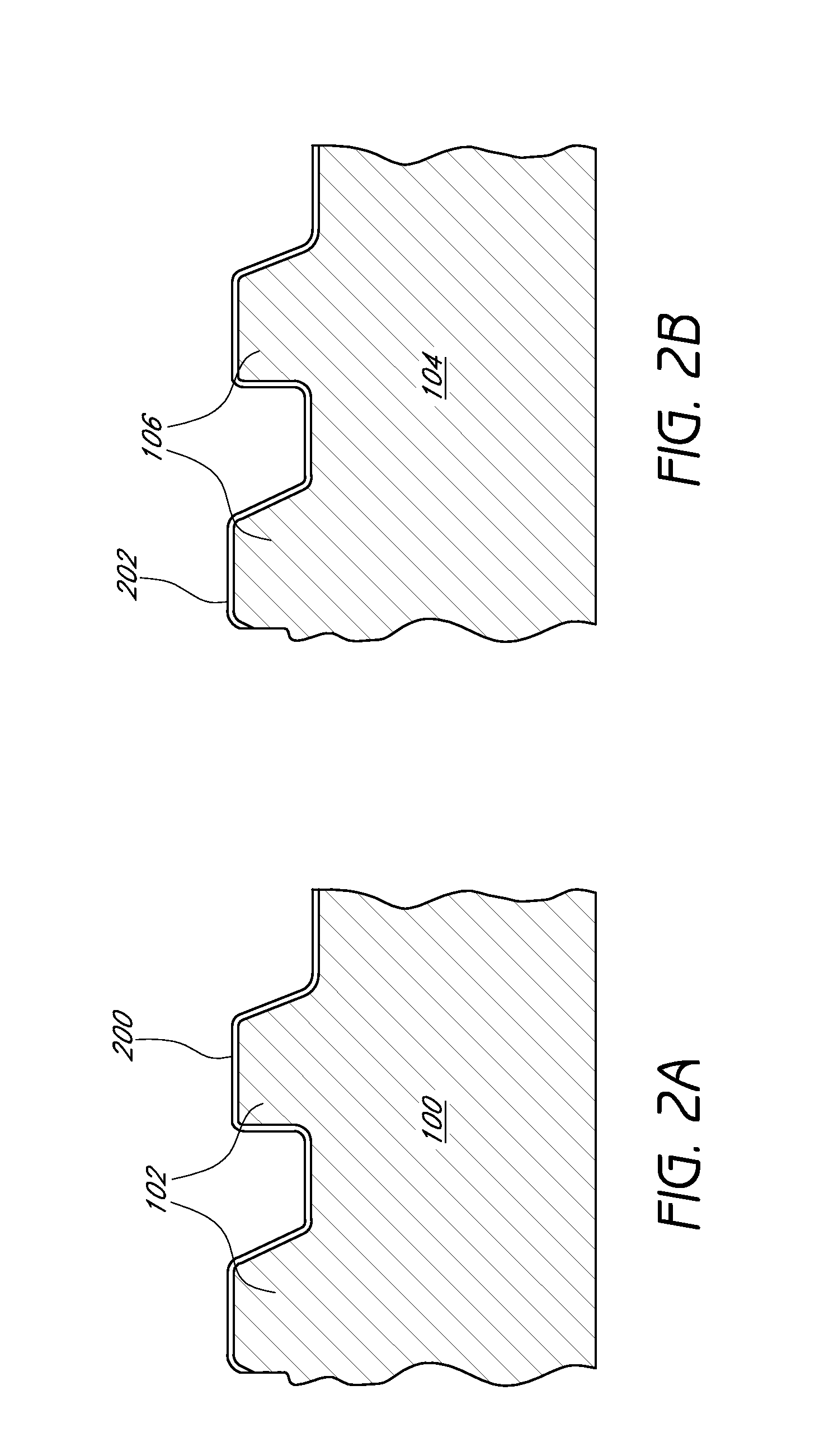

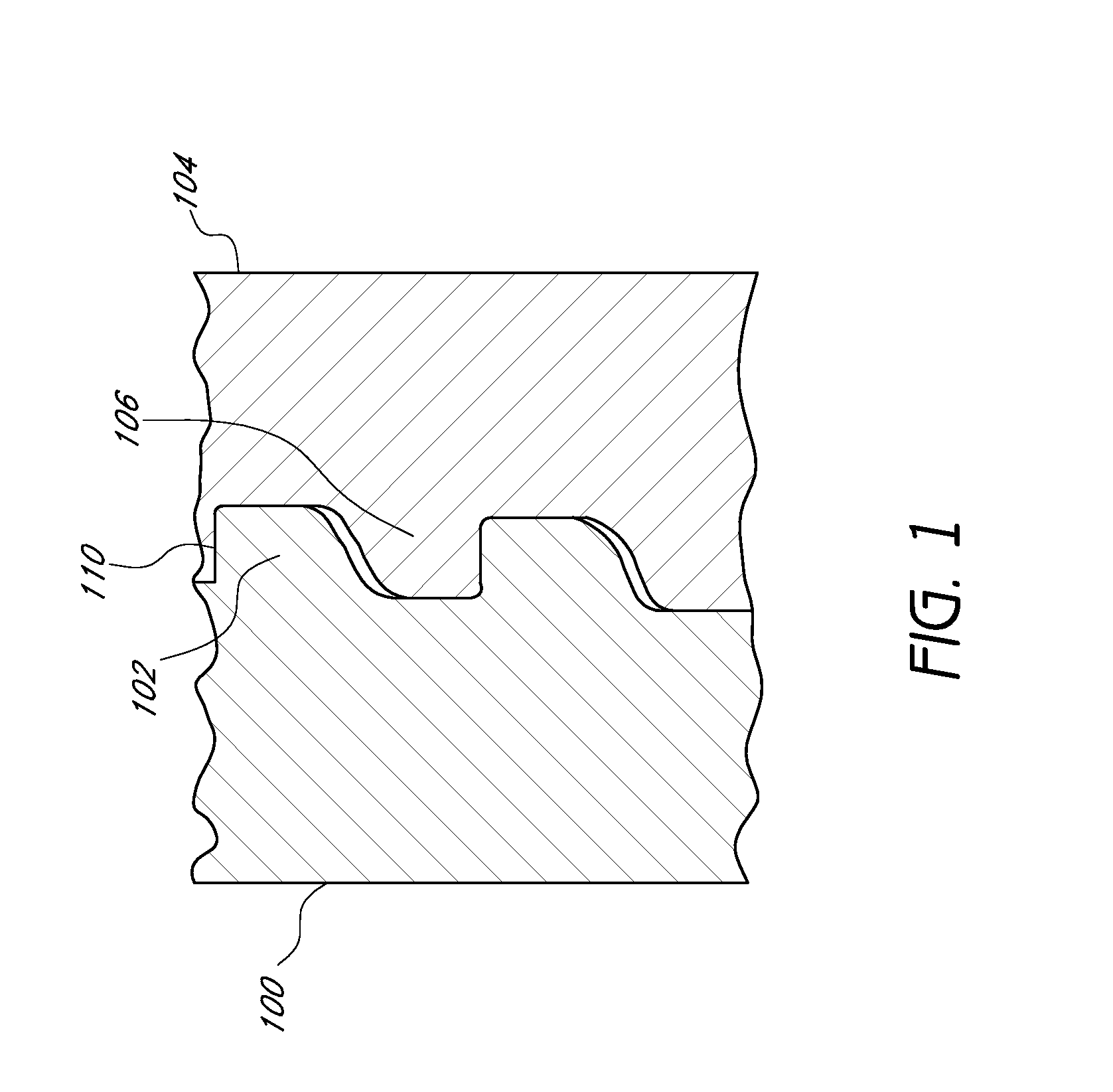

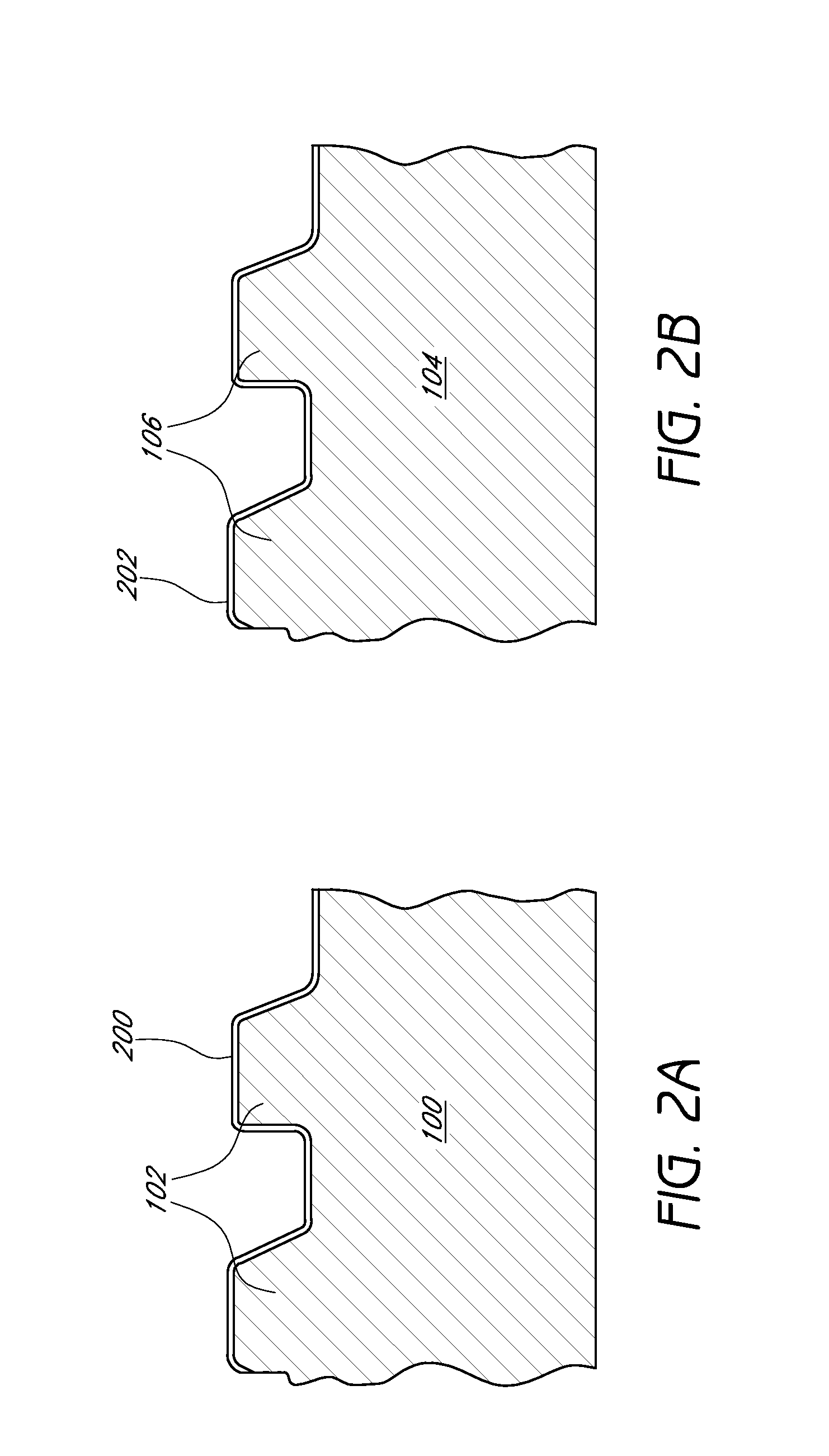

Nanocomposite coatings for threaded connections

Coating systems which provide corrosion resistance and, optionally, lubrication, for threaded connections are disclosed. The compositions comprise a first coating composition comprising polymer matrices of polyimides or epoxies which are modified with small amounts of a fluorine containing polymer. Also present in the coating compositions are corrosion inhibiting agents and inorganic particles having a mean diameter of between approximately 10 nm and 10 μm. Solid lubricants, which may include at least one of PTFE, HDPE, Graphite, and MoS2, are optionally added to provide the first coating with a low coefficient of friction. The coating systems may further comprise a second coating composition, comprising a solid lubricant dispersed within an epoxy resin and a solvent. The first and second coating compositions are deposited on at least a portion of at least one of the pin and box members of the threaded connections.

Owner:TENARIS CONNECTIONS

Method of Manufacturing a Light Emitting, Photovoltaic or Other Electronic Apparatus and System

ActiveUS20100068838A1Low finished product costIncrease useMaterial nanotechnologyStatic indicating devicesMean diameterElectrical conductor

The present invention provides a method of manufacturing an electronic apparatus, such as a lighting device having light emitting diodes (LEDs) or a power generating device having photovoltaic diodes. The exemplary method includes forming at least one first conductor coupled to a base; coupling a plurality of substantially spherical substrate particles to the at least one first conductor; converting the substrate particles into a plurality of substantially spherical diodes; forming at least one second conductor coupled to the substantially spherical diodes; and depositing or attaching a plurality of substantially spherical lenses suspended in a first polymer. The lenses and the suspending polymer have different indices of refraction. In some embodiments, the lenses and diodes have a ratio of mean diameters or lengths between about 10:1 and 2:1. In various embodiments, the forming, coupling and converting steps are performed by or through a printing process.

Owner:NTHDEGREE TECH WORLDWIDE +1

Method and apparatus for providing gas to a processing chamber

InactiveUS20050257735A1Polycrystalline material growthFrom chemically reactive gasesMean diameterProcess engineering

A method and apparatus for generating gas for a processing system is provided. In one embodiment, an apparatus for generating gas for a processing system includes a unitary, isolatable, transportable canister having a plurality of first spacing elements, a plurality of second spacing elements and a solid material disposed within the canister. The spacing elements have different mean diameters. The solid material is adapted to produce a gas vapor when exposed to a temperature above a predetermined level at a predetermined pressure. In another embodiment, an apparatus for generating gas includes a gas source coupled to a processing chamber by a first gas line. A canister is coupled in-line with the first gas line and contains a solid material that produces a process gas when heated. A heater is disposed between the gas source and the canister to heat gas flowing into the canister.

Owner:APPLIED MATERIALS INC

Functional powders for oral delivery

InactiveUS20050013862A1Great tasteMinimize pulmonary aspirationPowder deliveryOrganic active ingredientsMean diameterPharmaceutical formulation

In certain embodiments the invention is directed to a drug formulation for gastrointestinal deposition comprising a non-compressed free flowing plurality of particles comprising a core comprising a drug and a pharmaceutically acceptable excipient, said core overcoated with a functional coating, said drug particles having a mean diameter of greater than 10 μm to about 1 mm.

Owner:PHARMAKODEX LTD

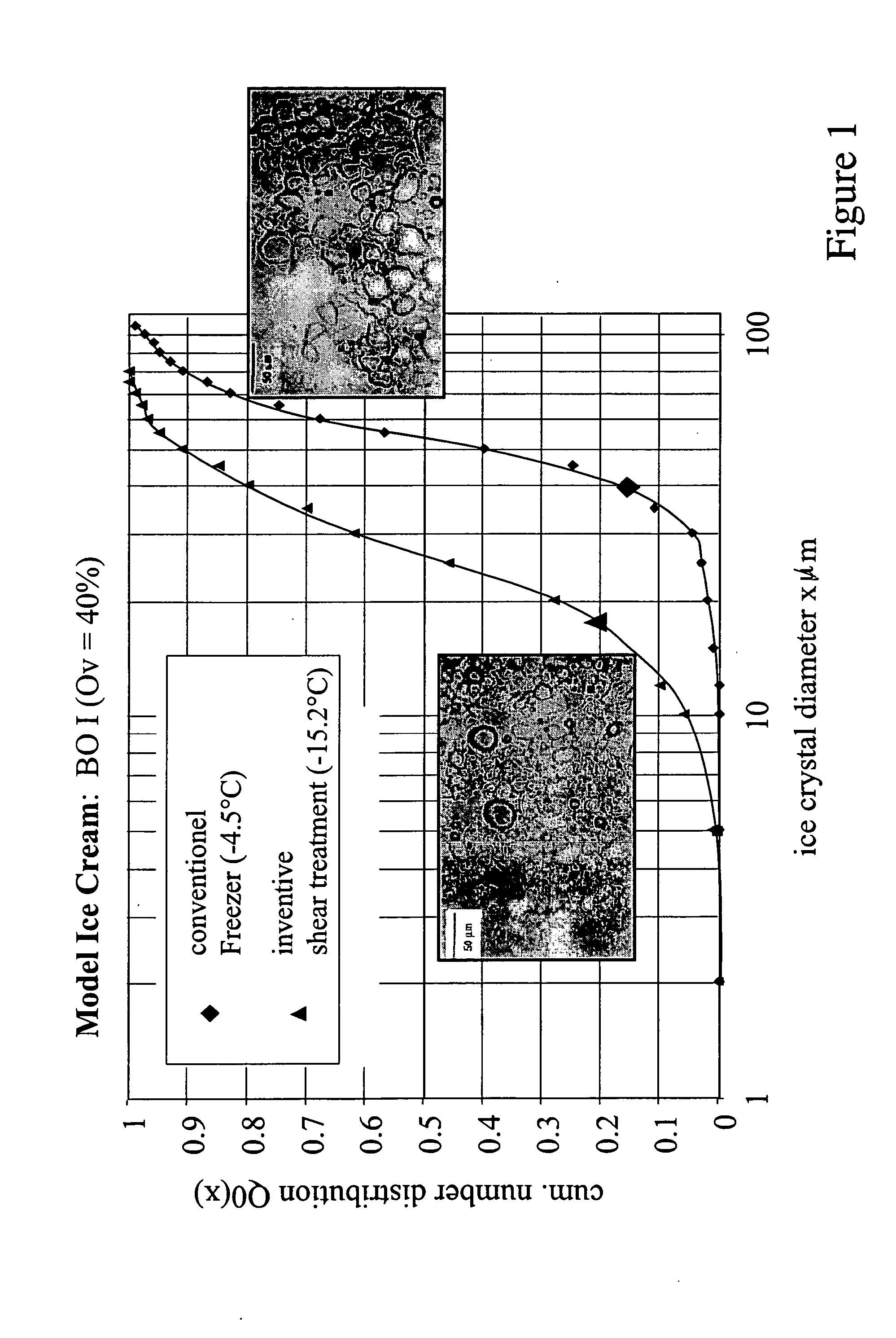

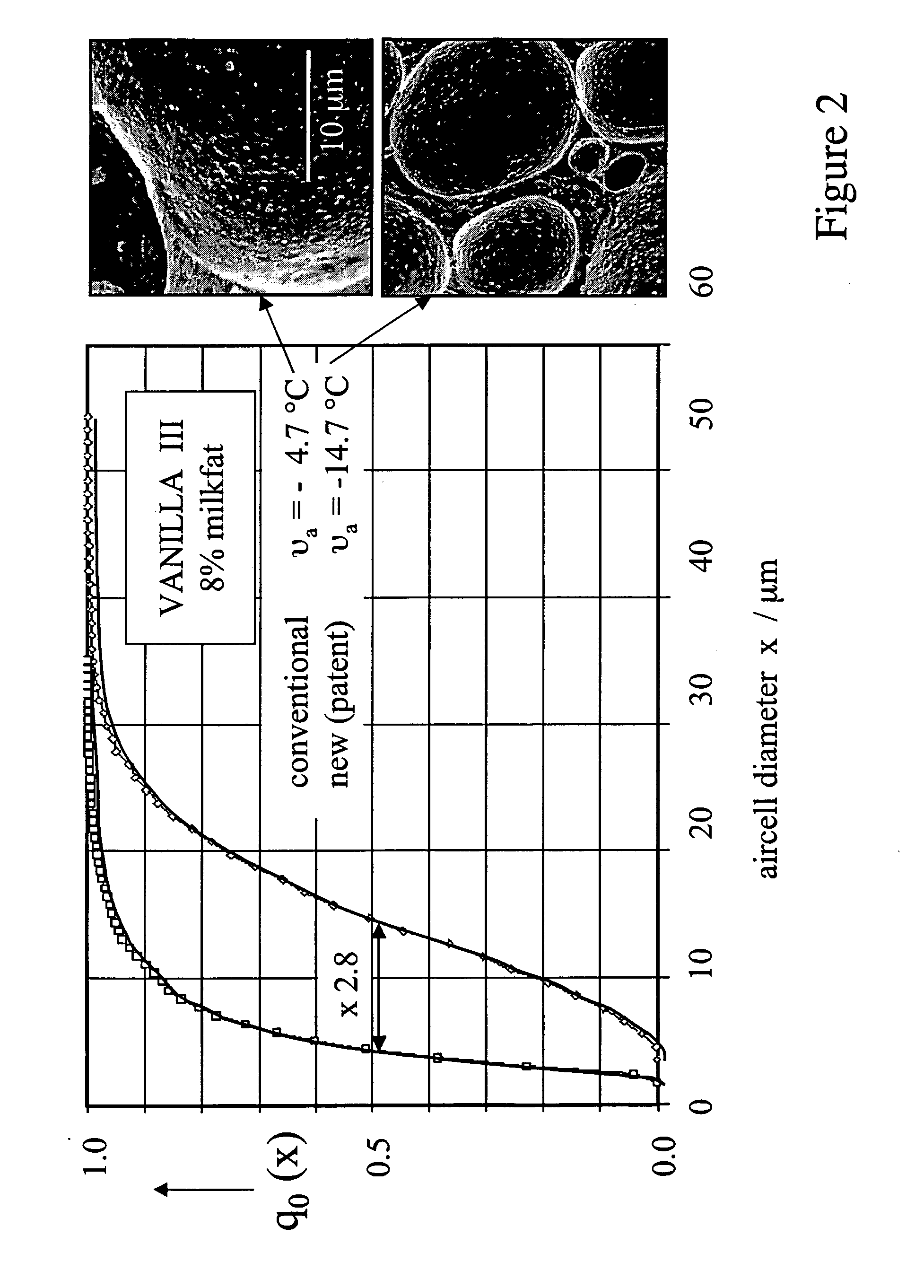

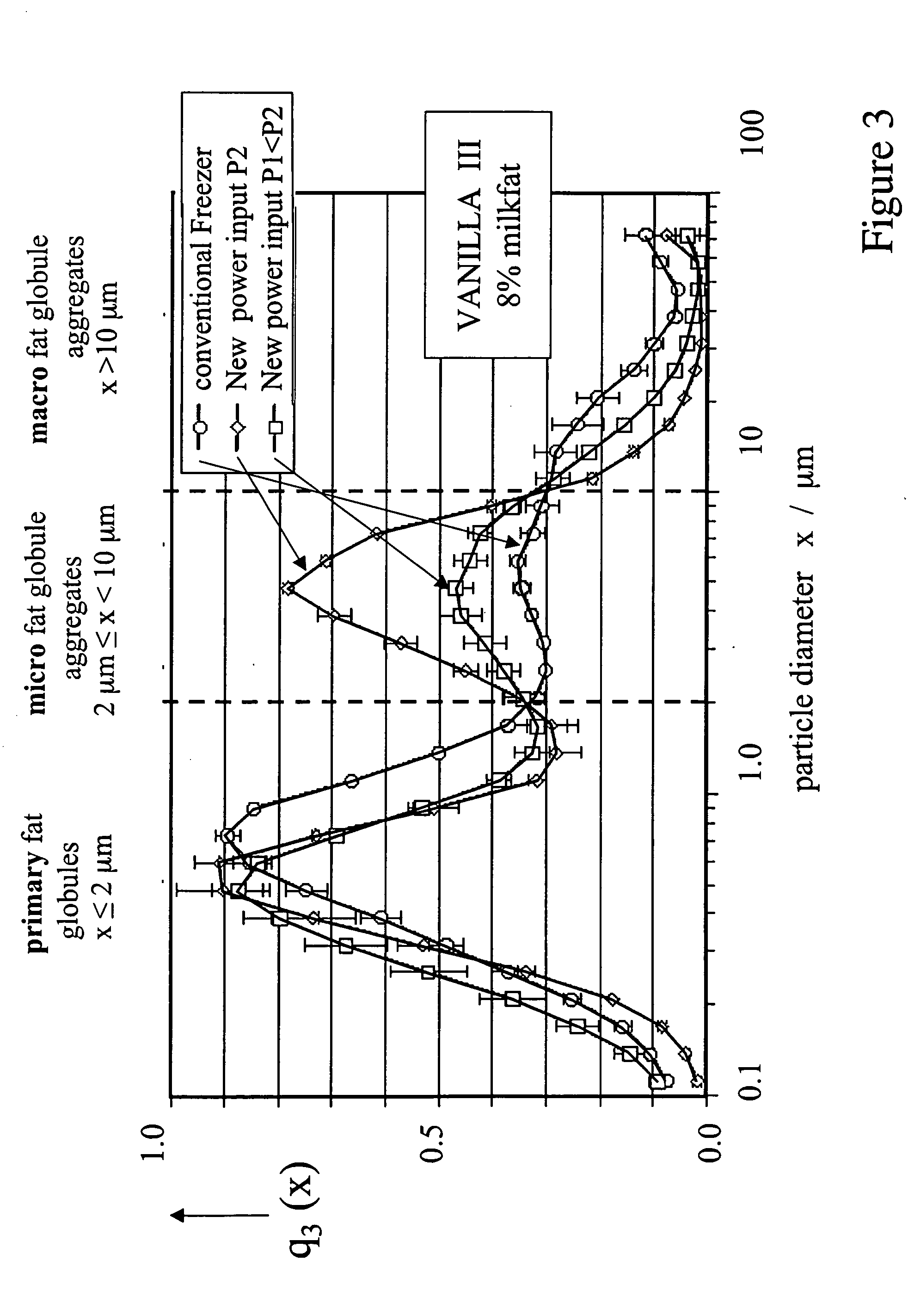

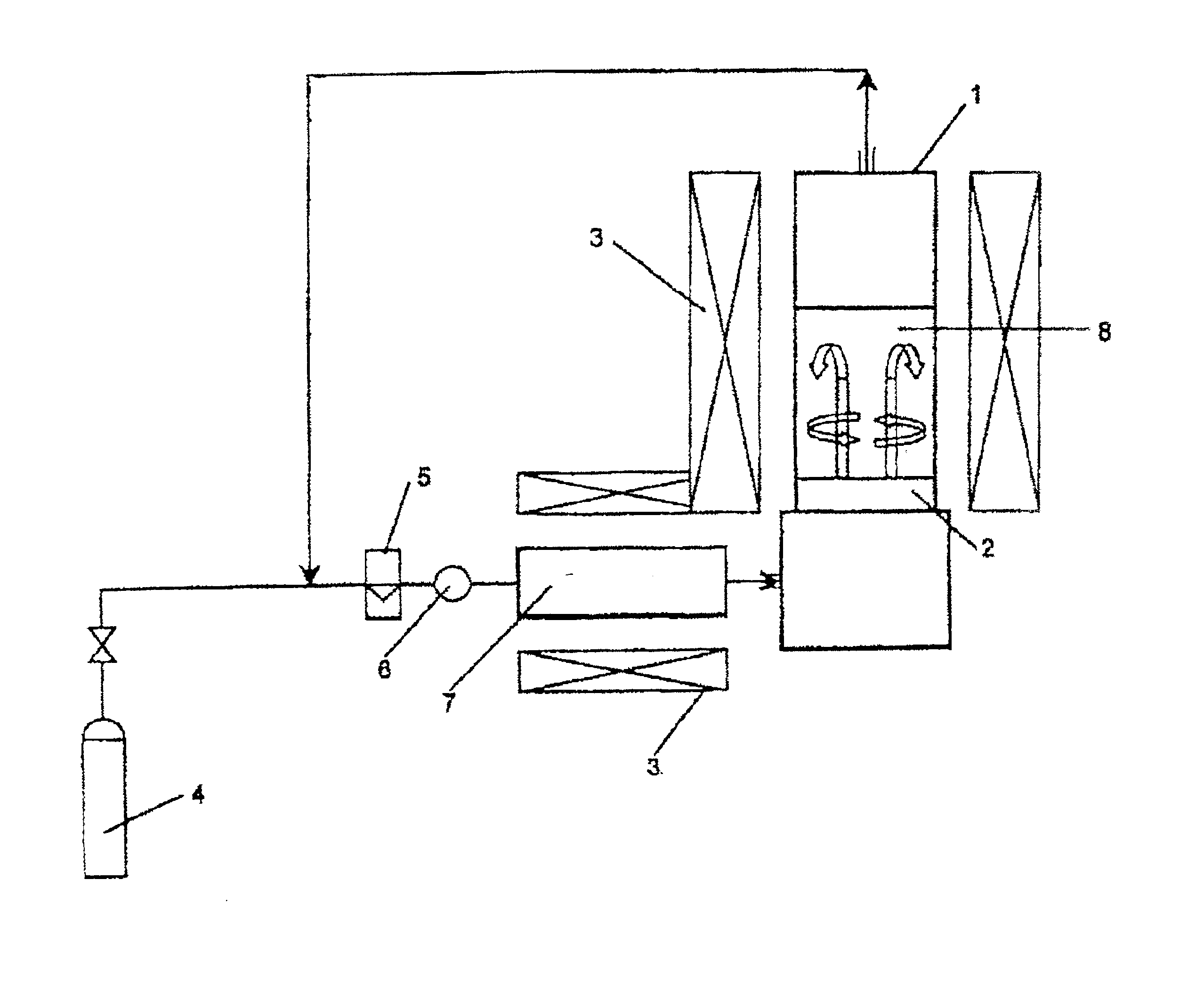

Aerated frozen suspensions with adjusted creaminess and scoop ability based on stress-controlled generation of superfine microstructures

Products that are aerated multiphase systems containing an aqueous continuous fluid phase which may include solutes thus forming an aqueous syrup and disperse phases like gas / air cells, water ice crystals and solid / semi-solid fat globules or aggregates thereof, whereas the disperse phases are that finely structured that their mean diameters are below phase specific critical maximum values and thereby generate a most preferred by consumers, full rich silky-creamy mouth feel at much lower fat content than usual in conventional related products like premium and super premium ice creams.

Owner:SOC DES PROD NESTLE SA

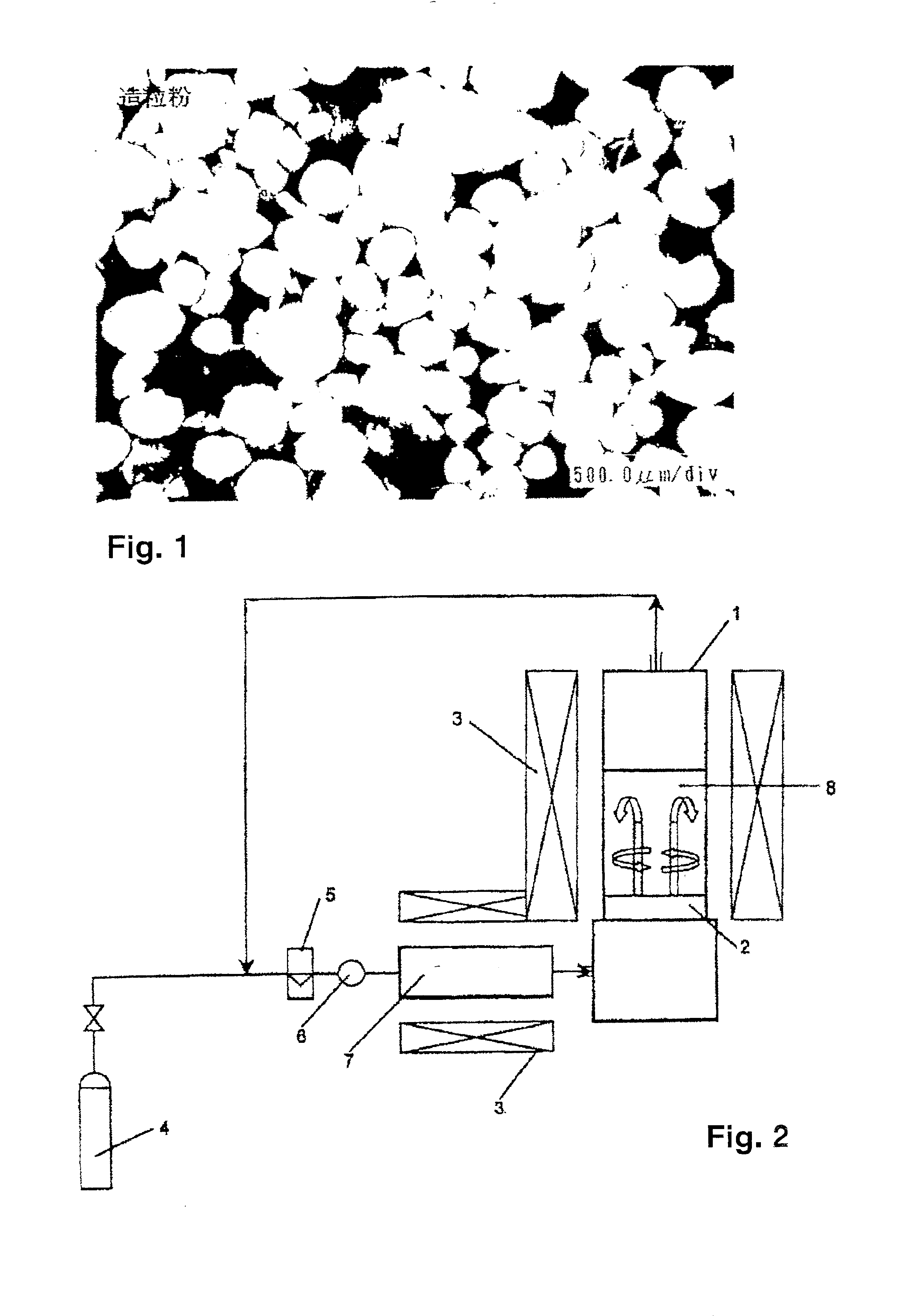

Porous silica granule, method for producing the same, and method for producing synthetic quartz glass powder using the porous silica granule

InactiveUS6849242B1Minimizes pore diameterHigh bulk densitySilicaGlass blowing apparatusMean diameterSlurry

The granule consists of individual granules approximately spherical in shape, having a pore volume of 0.5 cm3, a mean diameter of pores of 50 nm or less, a specific surface area of 100 m2 / g or less, and a bulk density of 0.7 g / cm3 or higher. It is produced by dispersing a fumed silica obtained by hydrolysis of a silicon compound into pure water to obtain a slurry, and drying the slurry. The granule is used for producing high purity synthetic quartz glass powder. The method further comprises: a first heat treatment under an oxygen-containing atmosphere, a second heat treatment in a temperature range of from 600 to 1100° C., and a third heat treatment in a temperature range of from 1100 to 1300° C. under an atmosphere containing hydrogen chloride; and a step of densification comprising calcining the product at a temperature not higher than 1500° C. under vacuum or in an atmosphere of gaseous hydrogen or gaseous helium. To calcine the powder without causing fusion adhesion of the particles, bubbling fluidization of said porous silica granule is conducted by supplying gaseous helium and calcining thereof in a temperature range of from 1000 to 1600° C.

Owner:HERAEUS QUARZGLAS +1

Emulsion containing organosilicon-based portions of hollow spheres

The present invention relates to a composition in the form of an emulsion containing portions of hollow spheres of organosilicon-based material, the portions of hollow spheres having a mean diameter ranging from 0.05 to 10 μm. The invention also relates to physiologically acceptable emulsion compositions comprising hollow spheres, and to a process for fading out skin surface defects, in particular to reduce the sheen of the skin and / or to fade out pores, shadows under the eyes, marks, wrinkles and / or fine lines, comprising the topical application to the skin of the above-mentioned compositions.

Owner:LOREAL SA

Black ink for ink-jet recording having dispersed particles with specific volume mean diameter, ink set and ink-jet recording method using the same

InactiveUS6849111B2Material nanotechnologyMeasurement apparatus componentsMean diameterOrganic solvent

The present invention provides an ink-jet recording black ink containing at least water, a water-soluble organic solvent and a self-dispersible carbon black, and an ink-jet recording ink set and an ink-jet recording method using the ink-jet recording black ink. A volume mean diameter of dispersed particles contained in the black ink is in a range of 85 to 115 nm, and a volume of dispersed particles having a particle diameter of 0.5 to 1.0 μm contained in the black ink is in a range of 0.001 to 0.03% relative to a volume of the ink.

Owner:FUJIFILM BUSINESS INNOVATION CORP

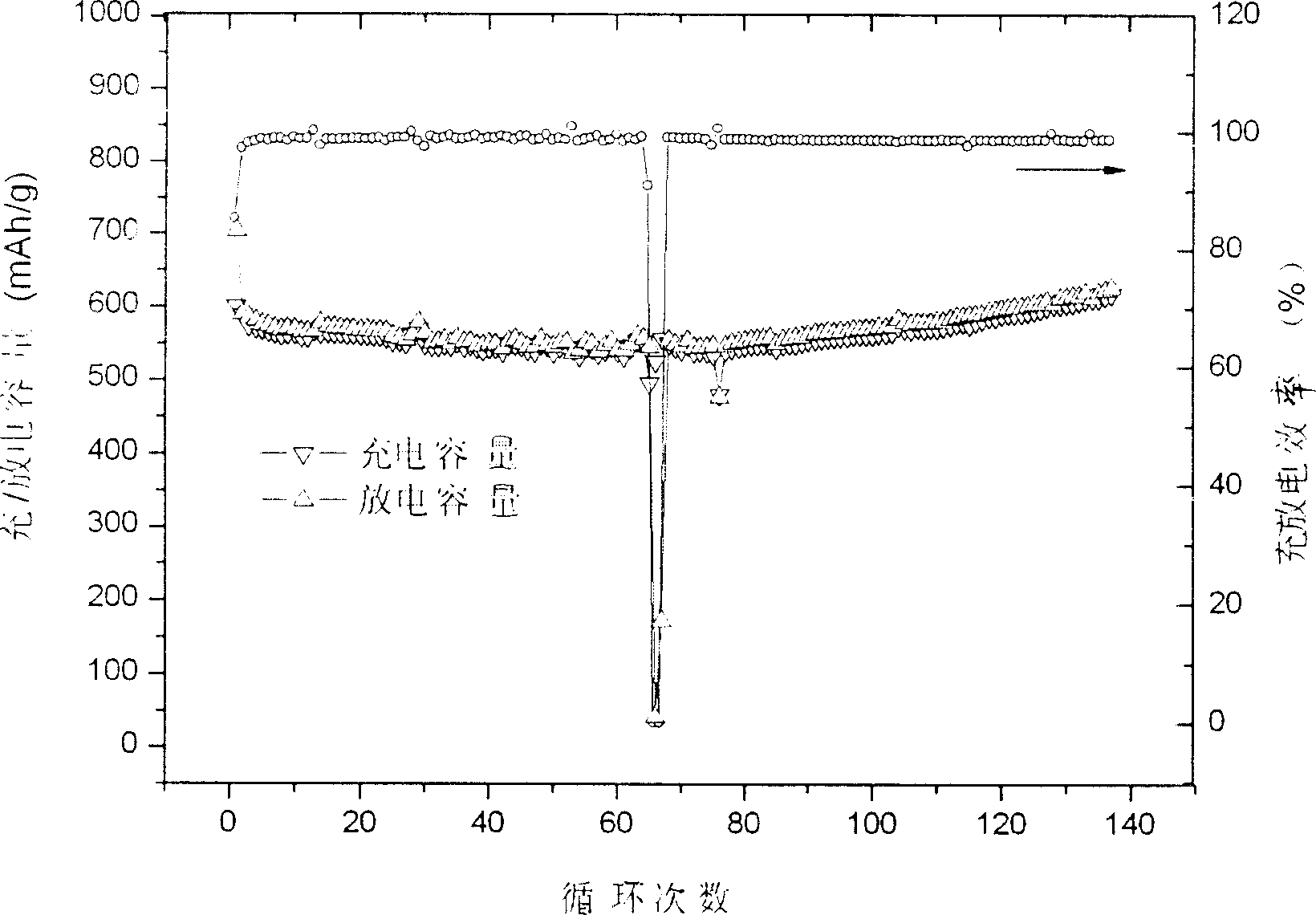

Negative electrode for lithium secondary battery and lithium secondary battery

ActiveUS20030235762A1Inhibit deteriorationImprove discharge characteristicsElectrode thermal treatmentElectrode carriers/collectorsMean diameterLithium

A negative electrode for a lithium secondary battery obtained by providing an active material layer containing particles of an active material and a binder on a surface of a current collector which is an electrically conductive metal foil, and sintering the layer under a non-oxidizing atmosphere; wherein the mean diameter of the particles of the active material is not smaller than 1 mum and not greater than 10 mum, and the particle size distribution of the particles is such that at least 60 volume % of the particles are in a range of not smaller than 1 mum and not greater than 10 mum.

Owner:PANASONIC ENERGY CO LTD

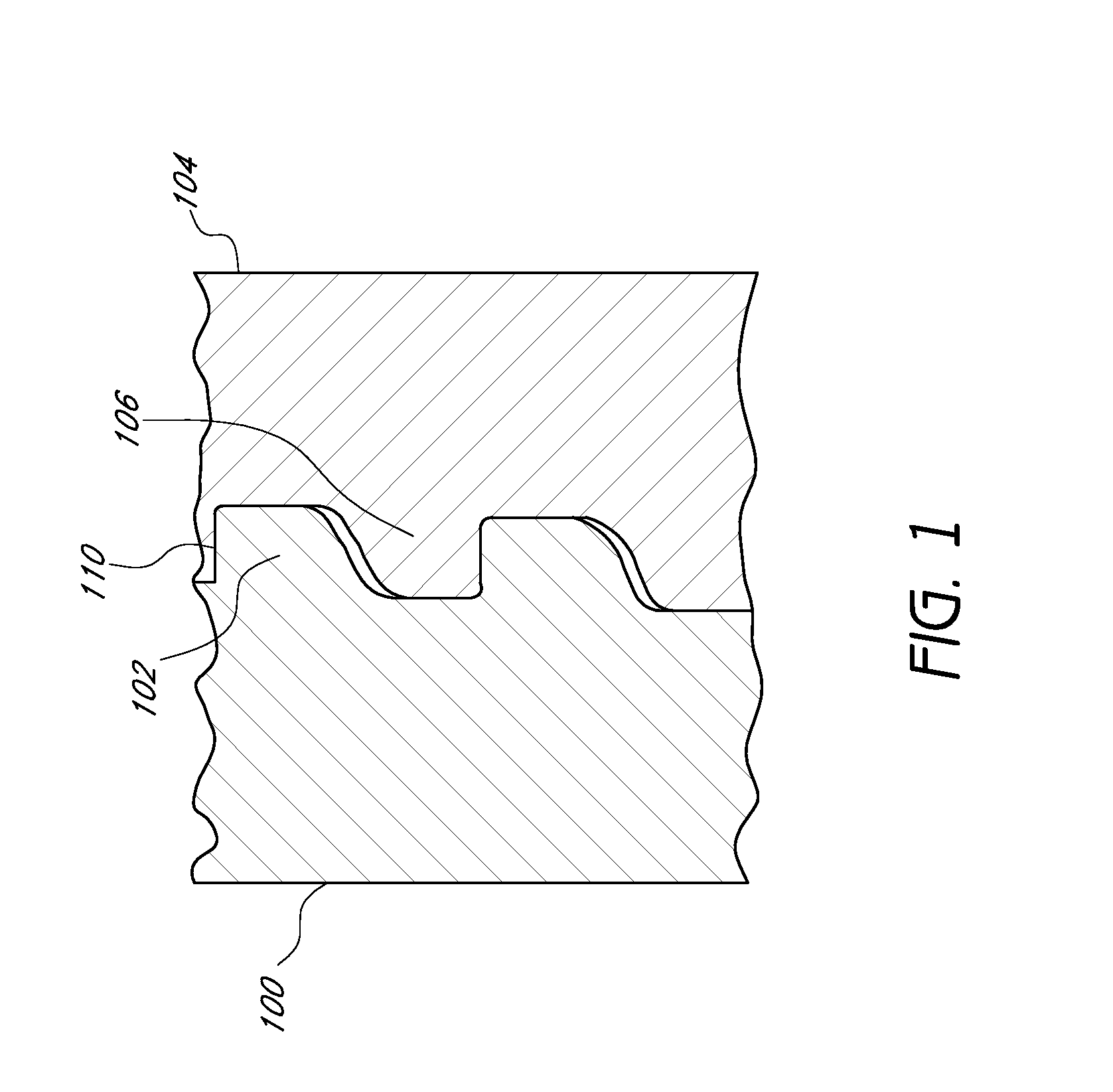

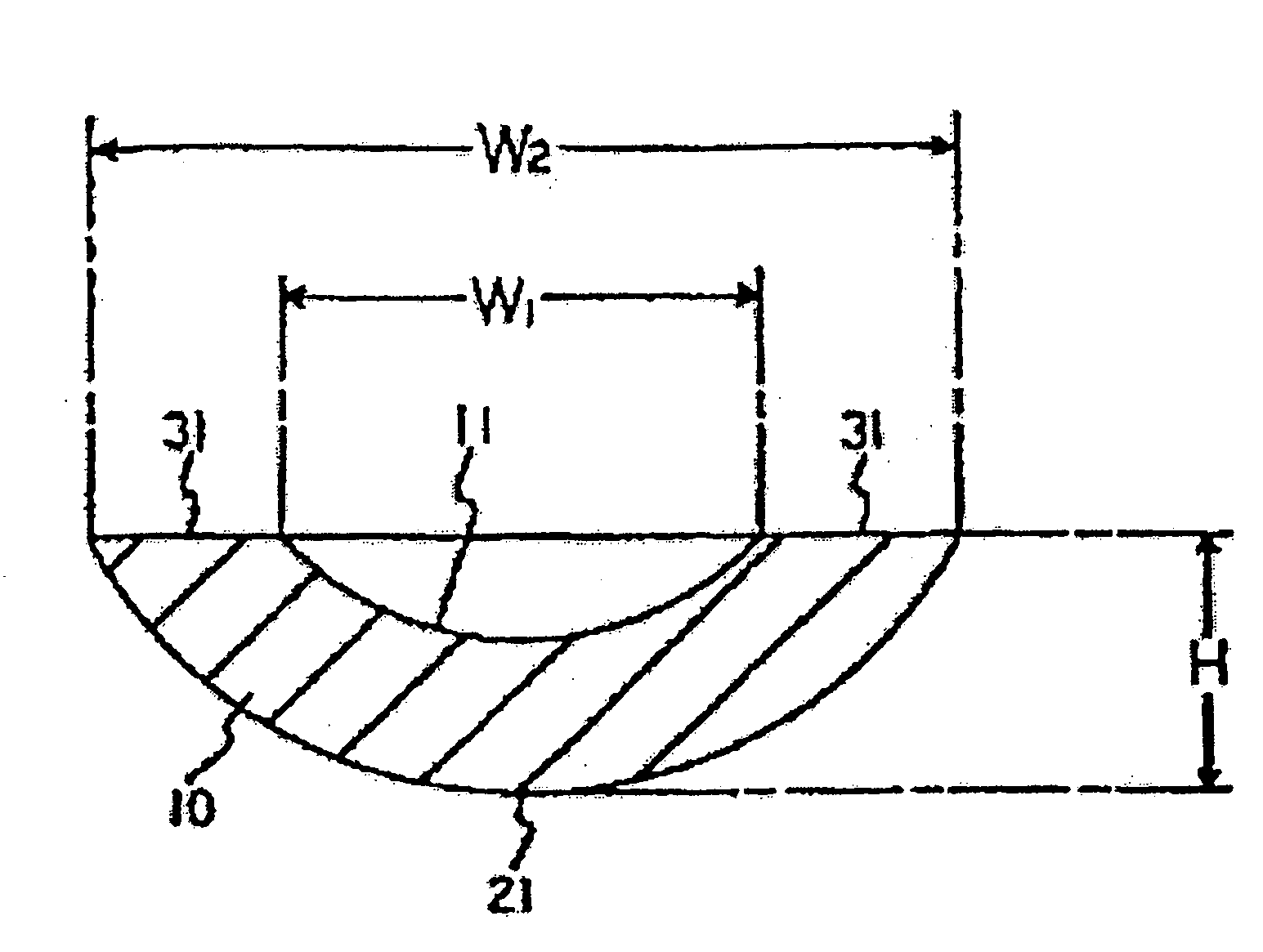

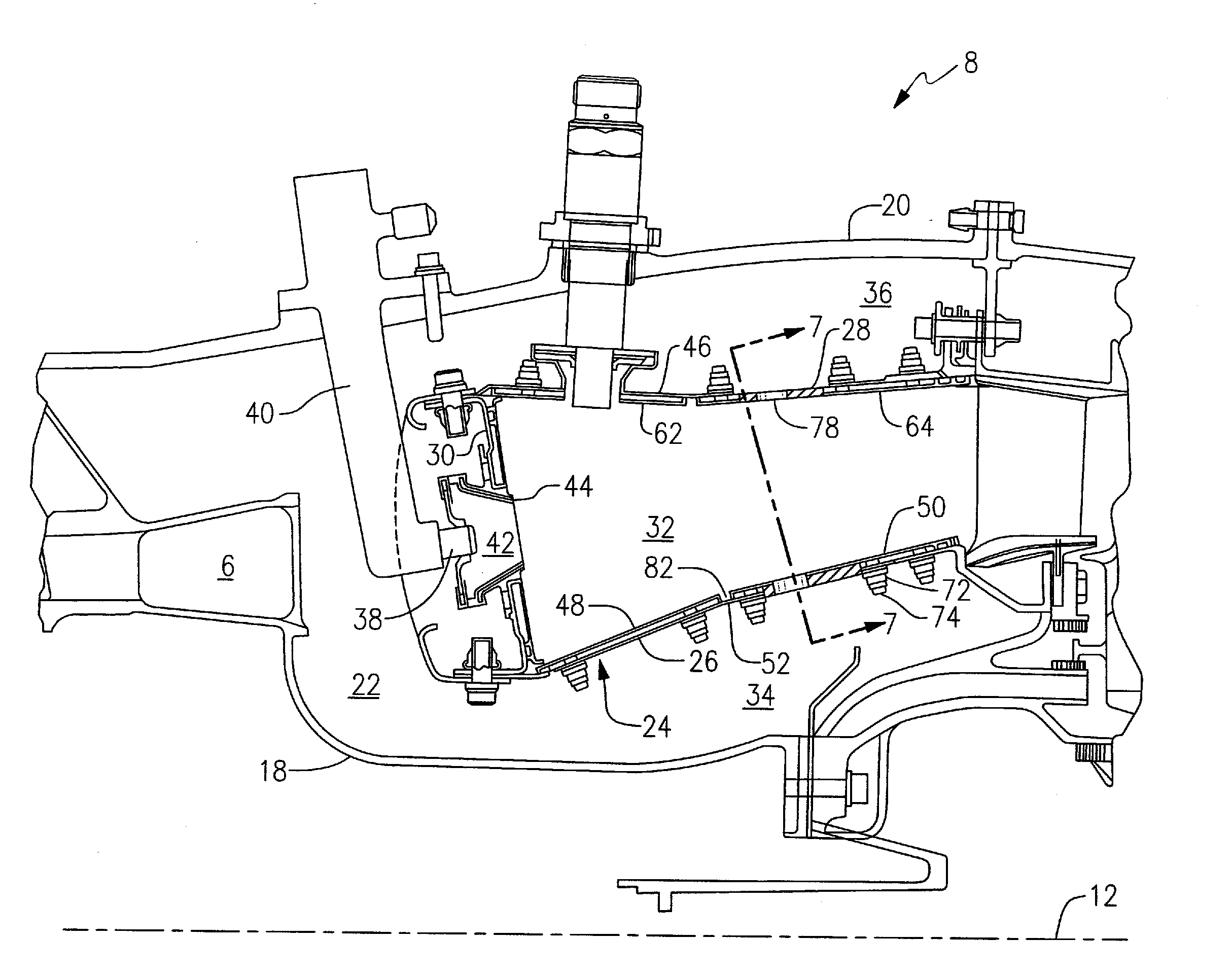

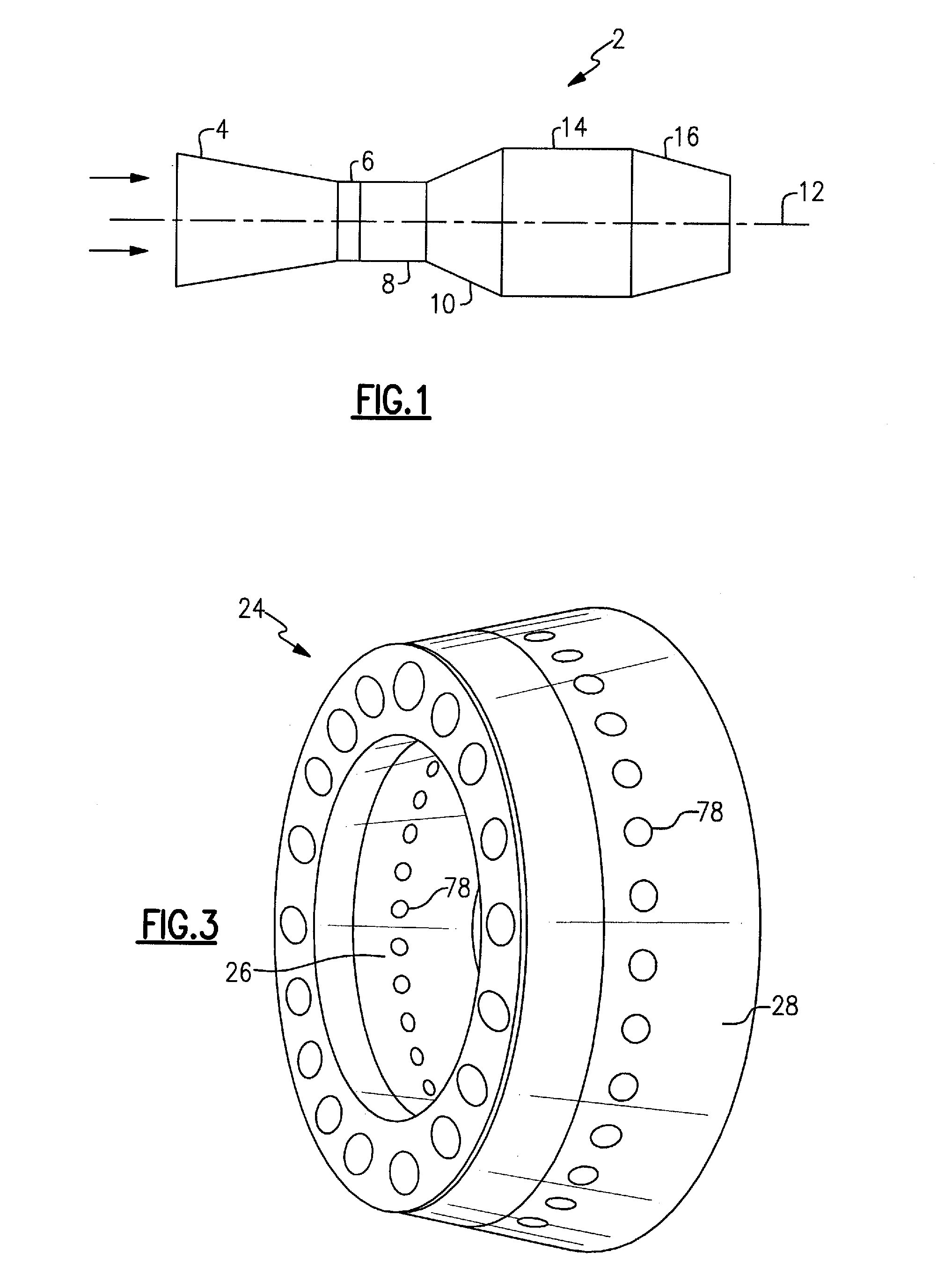

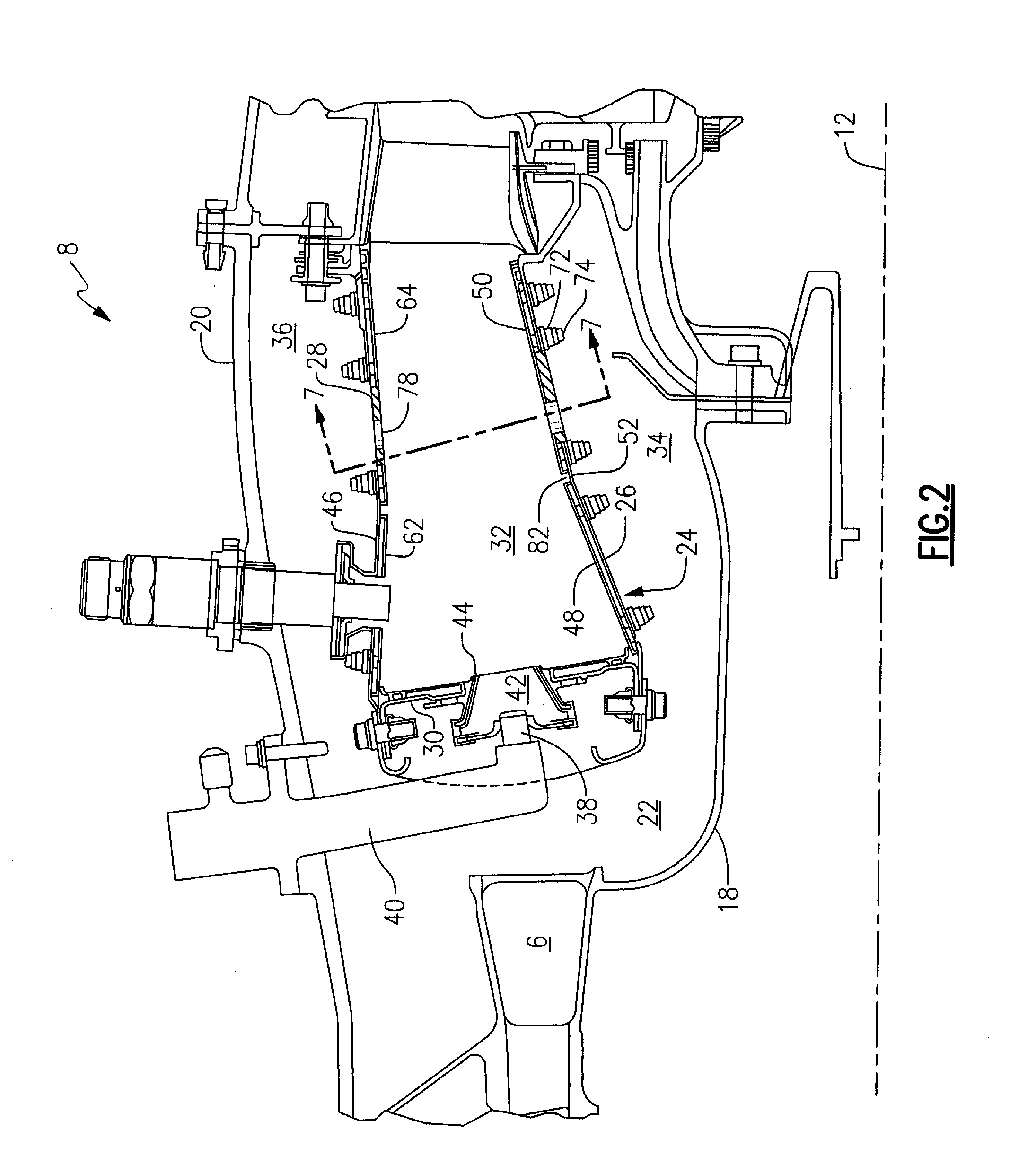

Combustor panel arrangement

ActiveUS20110126543A1Reduce the impactReduce impactTurbine/propulsion fuel supply systemsContinuous combustion chamberMean diameterCombustor

A combustor module for a gas turbine engine is provided that includes a first annular liner assembly extending along a longitudinal axis of the engine. The first annular liner assembly includes a first annular support shell and a plurality of first heat shield panels coupled to the first annular support shell. The first heat shield panels form a segmented ring defining a plurality of first axial seams therebetween. The combustor module further includes a bulkhead coupled to the first annular liner assembly. The bulkhead provides a plurality of fuel nozzles for passing a first mass flow comprising fuel and air. The combustor module further includes a second annular liner assembly coupled to the bulkhead. The second annular liner assembly is in spaced-apart generally coaxial relationship from the first annular liner assembly by a channel height H. The second annular liner assembly includes an air admittance hole having a mean diameter D extending along a hole axis. The hole axis is offset from the first axial seam defined by the first heat shield panels.

Owner:RTX CORP

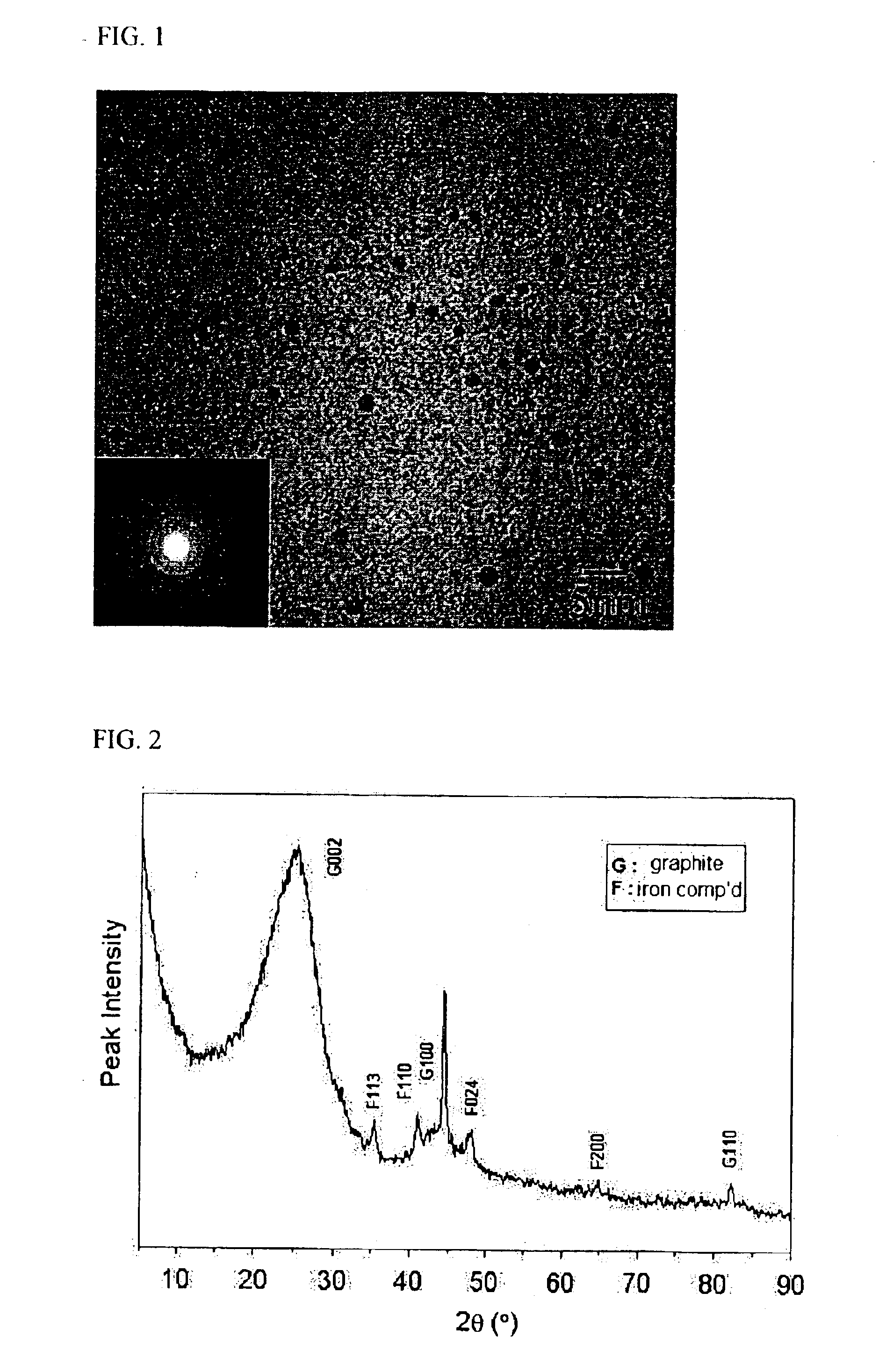

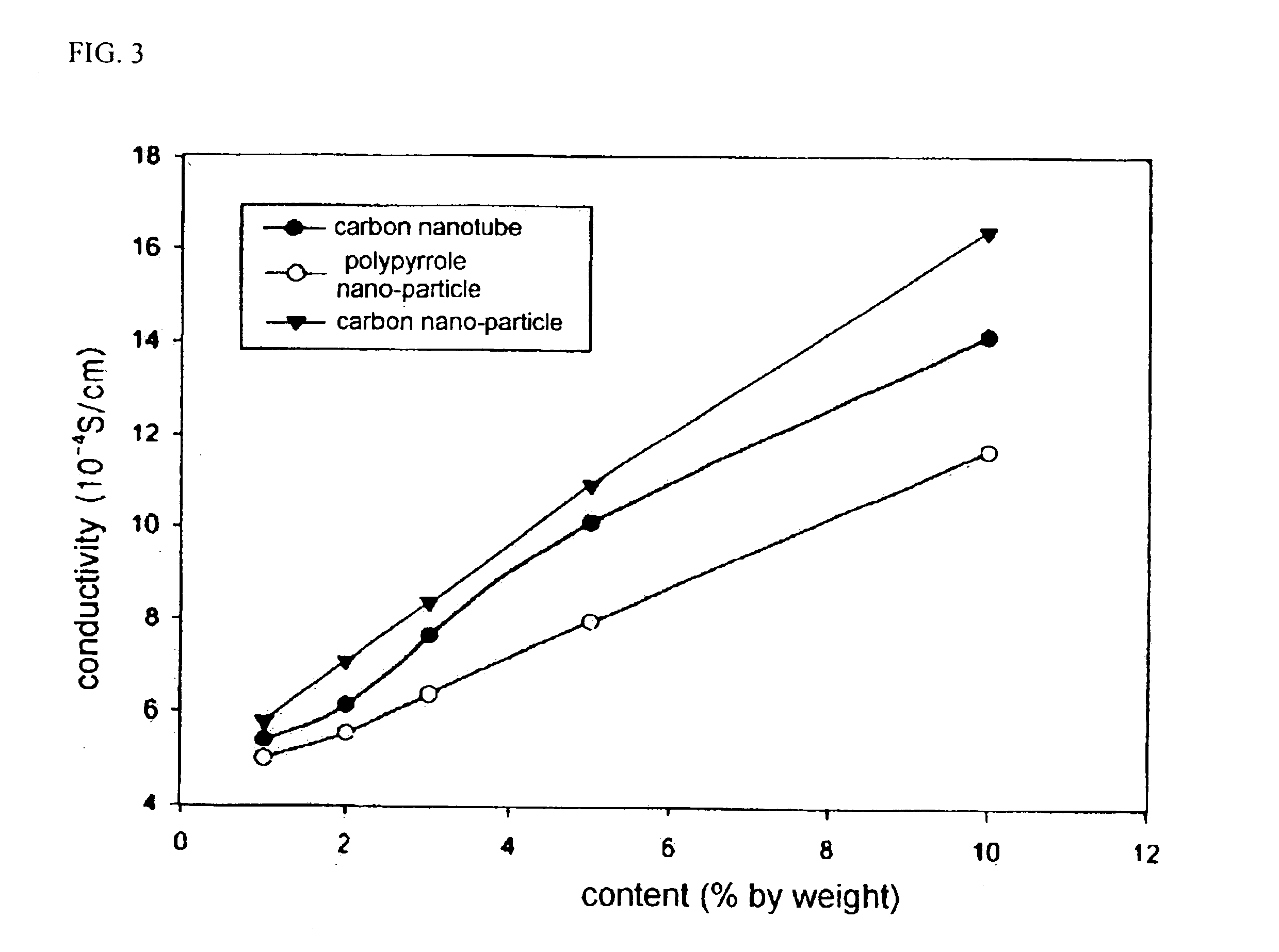

Carbon nano-particle and method of preparing the same and transparent conductive polymer composite containing the same

ActiveUS6919063B2Low costNovel methodMaterial nanotechnologyNanoinformaticsMean diameterConductive polymer composite

The present invention relates to a novel carbon nano-particle and a novel method of preparing the same and a transparent, conductive polymer composite containing the same. The carbon nano-particle has the mean diameter of 1 through 50 nm and the shape of sphere, rod or others, which is a novel material not known in the relevant art. Because of a particle size less than ½ of the shortest wavelength of a visible ray, a transparent resin containing the carbon nano-particle can maintain the transparency. Furthermore, the carbon nano-particle has the excellent electric conductivity and the ferromagnetic property, and can be made by a novel, low cost method entirely different from those of fullerene and carbon nanotube.

Owner:DONG WOON INT

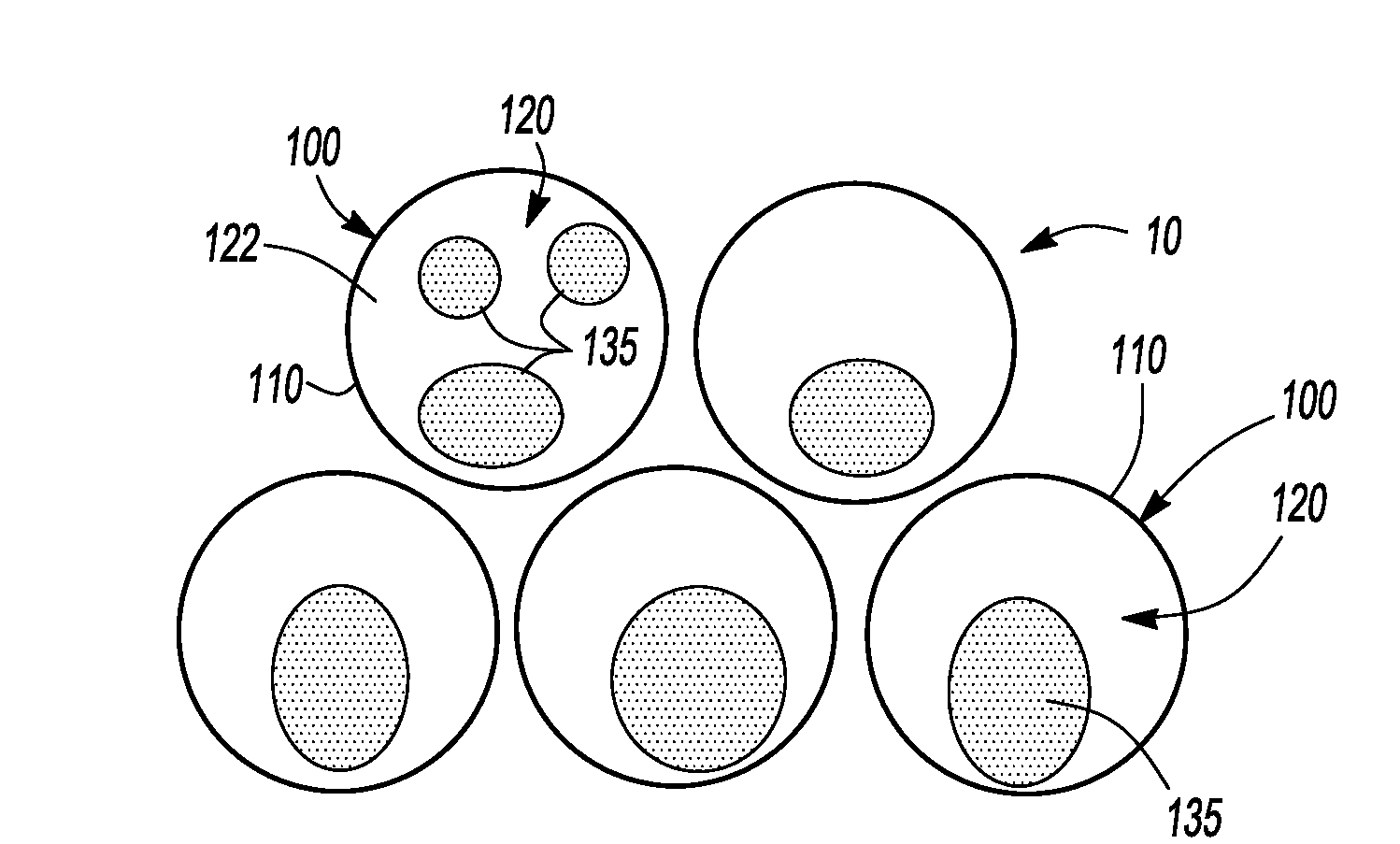

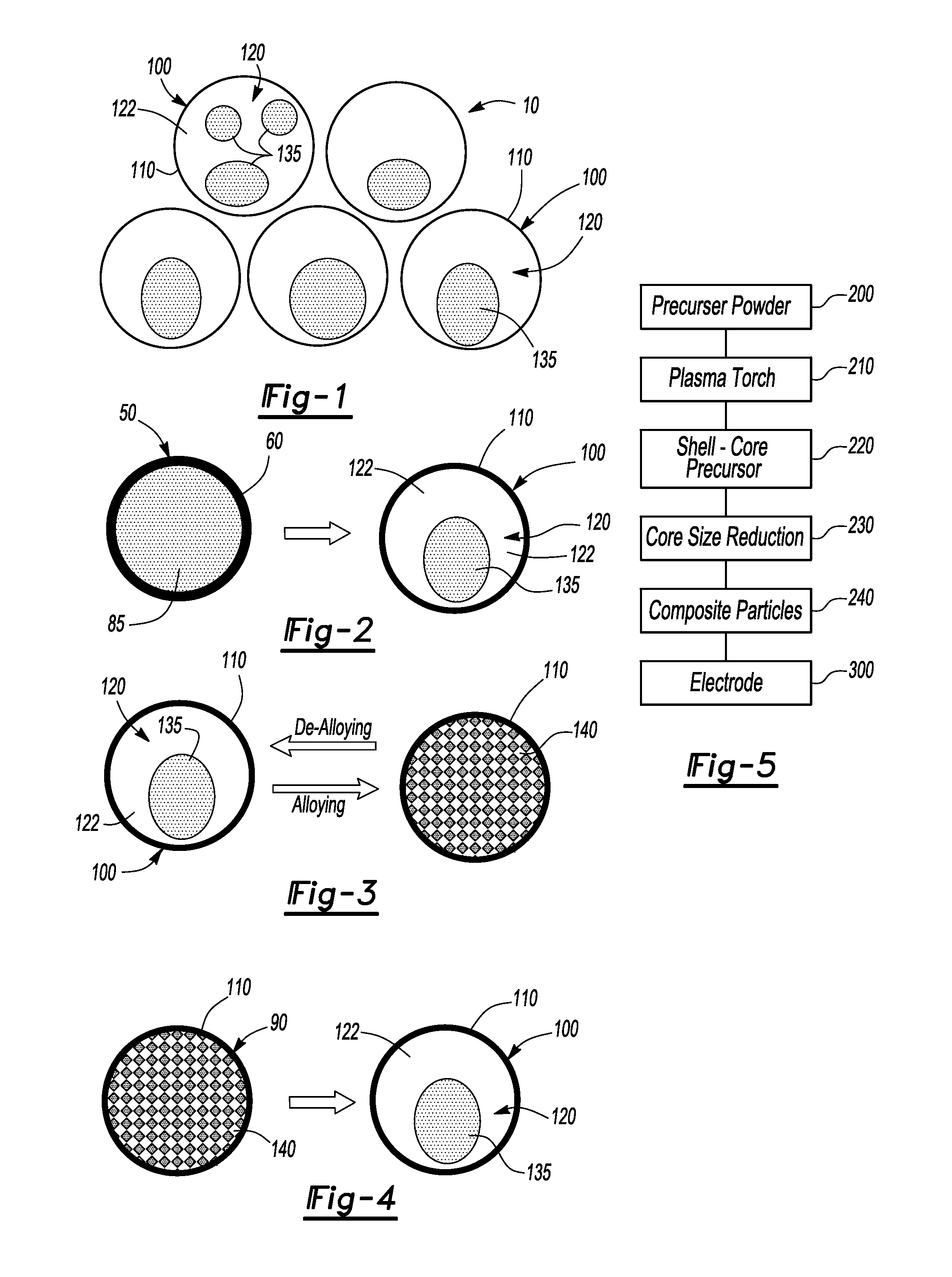

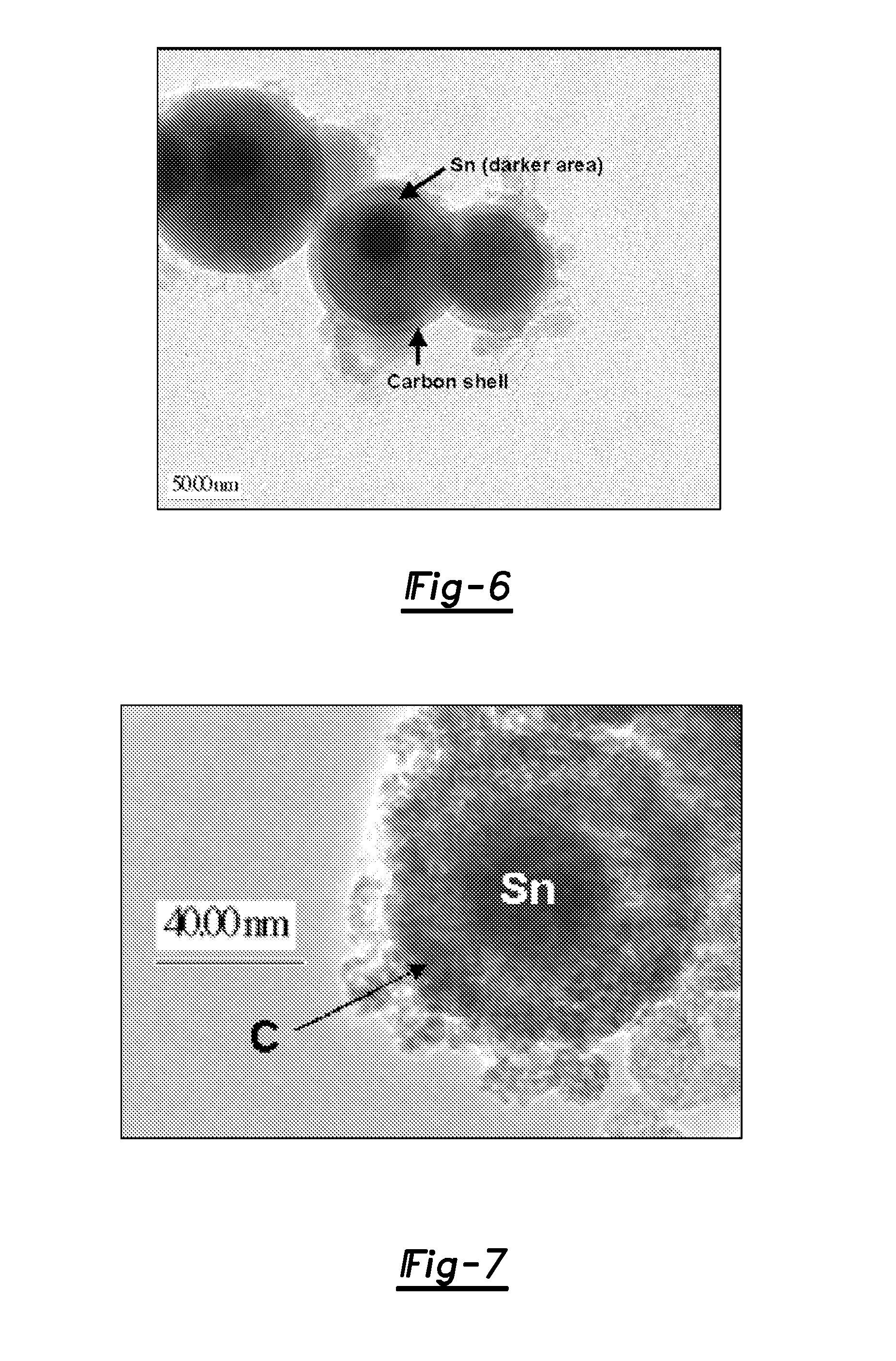

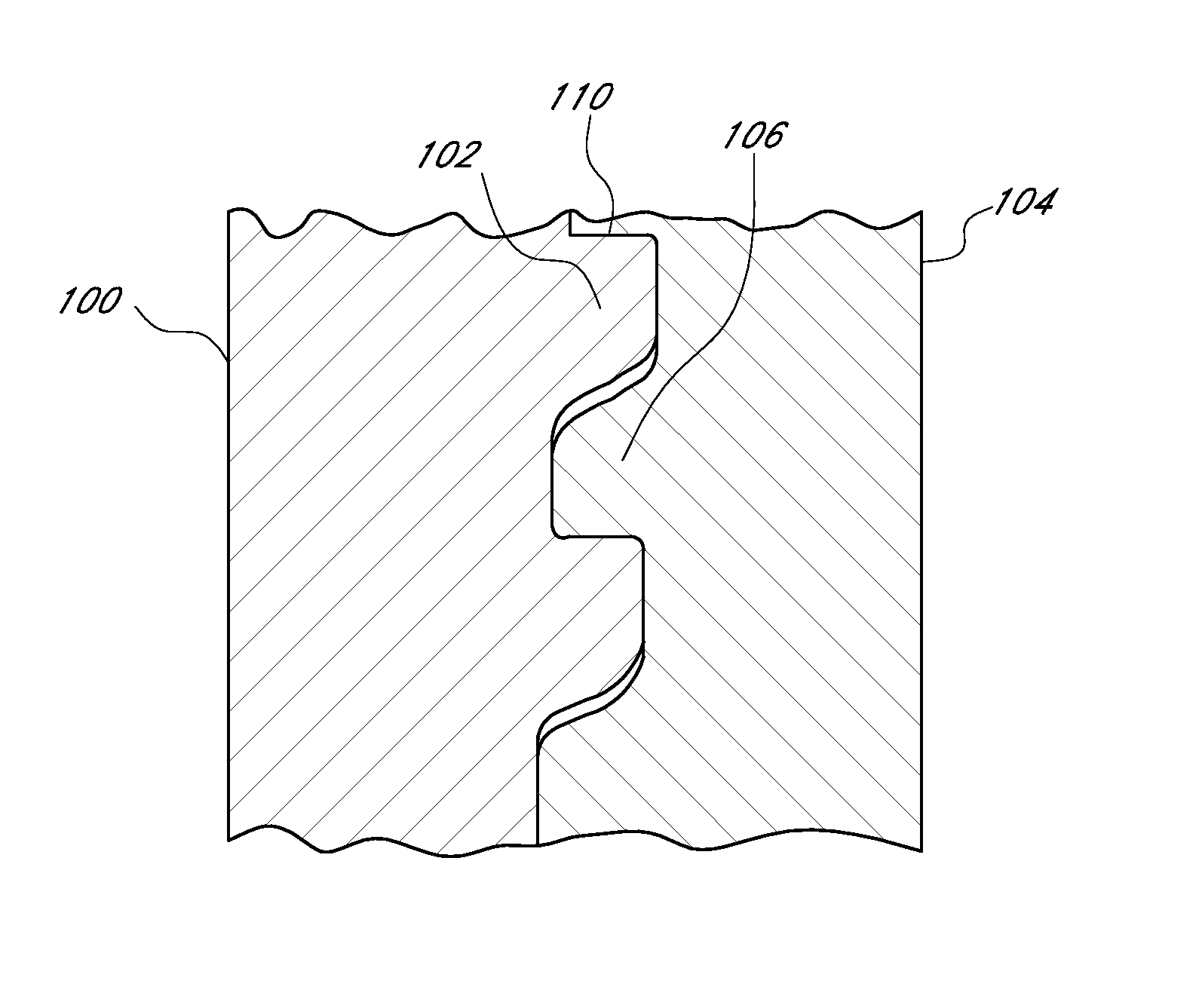

Material With Core-Shell Structure

Disclosed is a material having a composite particle, the composite particle including an outer shell and a core. The core is made from a lithium alloying material and the outer shell has an inner volume that is greater in size than the core of the lithium alloying material. In some instances, the outer mean diameter of the outer shell is less than 500 nanometers and the core occupies between 5 and 99% of the inner volume. In addition, the outer shell can have an average wall thickness of less than 100 nanometers.

Owner:TRIAD NAT SECURITY LLC +2

Nanocomposite coatings for threaded connections

Coating systems which provide corrosion resistance and, optionally, lubrication, for threaded connections are disclosed. The compositions comprise a first coating composition comprising polymer matrices of polyimides or epoxies which are modified with small amounts of a fluorine containing polymer. Also present in the coating compositions are corrosion inhibiting agents and inorganic particles having a mean diameter of between approximately 10 nm and 10 μm. Solid lubricants, which may include at least one of PTFE, HDPE, Graphite, and MoS2, are optionally added to provide the first coating with a low coefficient of friction. The coating systems may further comprise a second coating composition, comprising a solid lubricant dispersed within an epoxy resin and a solvent. The first and second coating compositions are deposited on at least a portion of at least one of the pin and box members of the threaded connections.

Owner:TENARIS CONNECTIONS

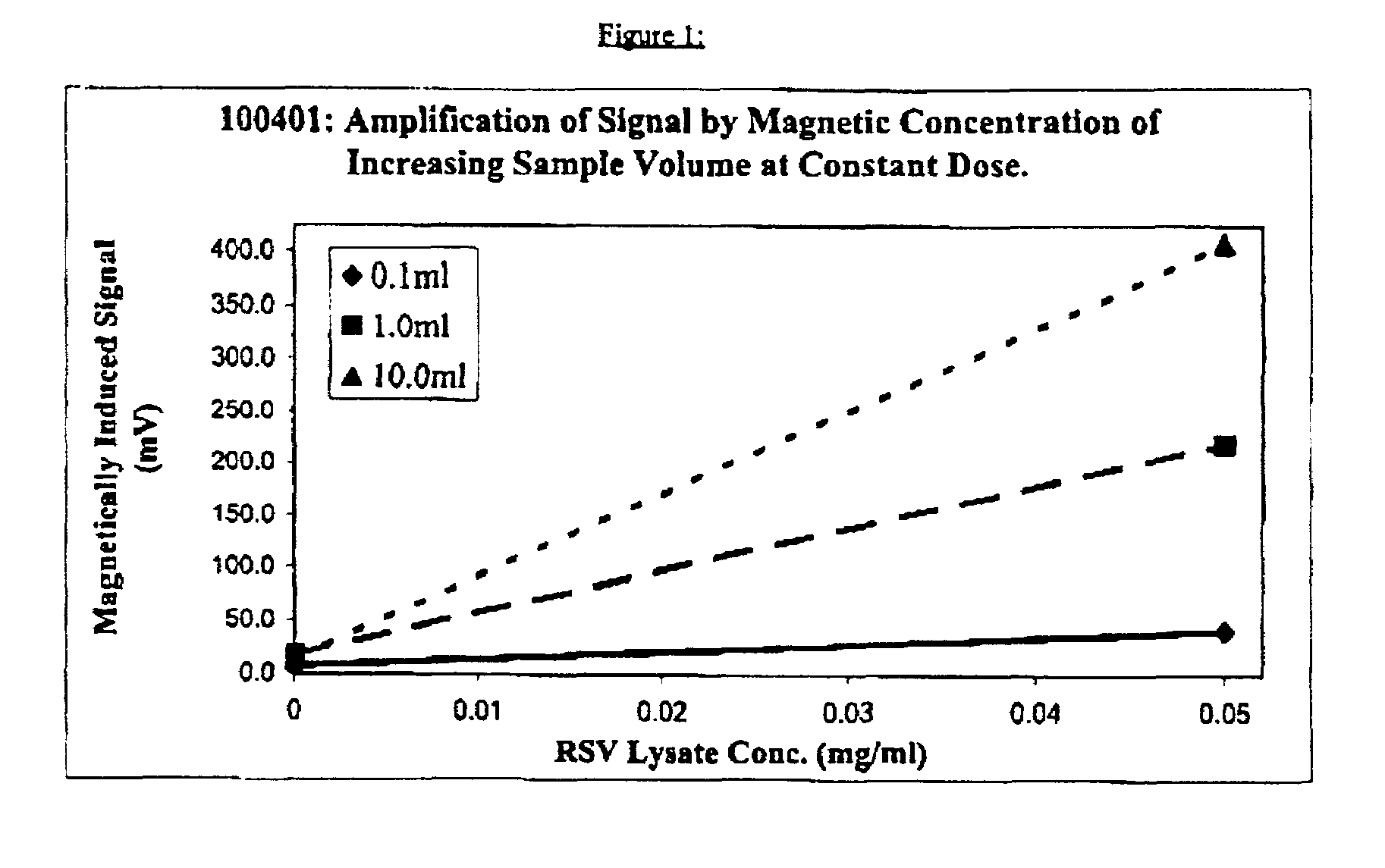

Process for (A) separating biological/ligands from dilute solutions and (B) conducting an immunochromatographic assay thereof employing superparamagnetic particles throughtout

InactiveUS7018849B2Highly effectiveBioreactor/fermenter combinationsBiological substance pretreatmentsMean diameterSuperparamagnetism

Superparamagnetic (“SPM”) subunits of 1–30 nm average mean diameter (e.g. ferro fluid) subparticles are treated with a magnetically noninterfering substance capable of coating and covering them (e.g, BSA) and they spontaneously form agglomerates of about 100 nm to about 450 nm or higher average mean diameter and are then used to form complexes with target biological ligands such as viruses, contained in large volumes of liquid. The complexes are subjected to the gradient intensity of a strong magnetic field, and excess liquid is removed, where upon an immunochromatographic assay is conducted to determine the identity and / or amount of target ligand present, in which operation SPM particles that bonded to the ligand function as tags for ligand detection.

Owner:ABBOTT DIAGNOSTICS SCARBOROUGH INC

Anti-misuse oral microparticle medicinal formulation

InactiveUS20070264326A1Avoid fraudulent abuseReduce riskPowder deliveryDispersion deliveryOral medicineMean diameter

The field of the present invention is that of solid microparticulate analgesic oral medicines. The invention is that of providing novel analgesic medicines which allow at the same time the prevention of misuse and of addiction to certain analgesics, and / or the control of variability in the plasma concentration and / or the facilitation of oral administration; and / or the combination of analgesics with one another and / or with one or more active ingredients in the same oral form. The medicine according to the invention comprises (i) anti-misuse means and a plurality of microcapsules with modified release of analgesic(s), having a mean diameter of between 50 and 600 μm, (ii) at least 1000 microcapsules per dose; it being possible for this medicine to be administered once or twice a day for analgesic purposes.

Owner:FLAMEL TECHNOLOGIES

Hydrocracking catalyst having a unique silica-alumina substrate

A hydrocarbon conversion catalyst contains at least one silica-alumina having the following characteristics: A content by weight of silica SiO2 of between 10 and 60% by weight; an Na content less than 300 ppm by weight; a total pore volume of between 0.5 and 1.2 m / g measured by mercury porosimetry; a porosity of said silica-alumina wherein: the volume of mesopores whose diameter is between 40 Å and 150 Å, and whose mean diameter varies between 80 and 120 Å represents between 30 and 80% of the total pore volume, and (ii) the volume of macropores, whose diameter is greater than 500 Å and preferably between 1000 Å and 10,000 Å represents between 20 and 80% of the total pore volume; a specific surface area greater than 200 m<2> / g, and at least one hydro-dehydrogenating element selected metals of group VIB and group VIII, and optionally phosphorus, boron, silicon, or elements of group VIIA, VIIB or VB.

Owner:INST FR DU PETROLE

Light emitting device with microlens array

A light-emitting device, comprising: a light emitting element on a first side of a transparent substrate or cover through which light is emitted; and a microlens array on a second side, opposite to the first side, of the transparent substrate or cover though which light is emitted; wherein the microlens array comprises individual hemispherical shaped microlenses having a mean diameter of less than 20 micrometers and a mean microlens height to diameter ratio of greater than 0.30, and has a microlens area fill factor greater than 0.8.

Owner:GLOBAL OLED TECH

Anti bacteria natural silk composite nano-fiber material and its preparation method

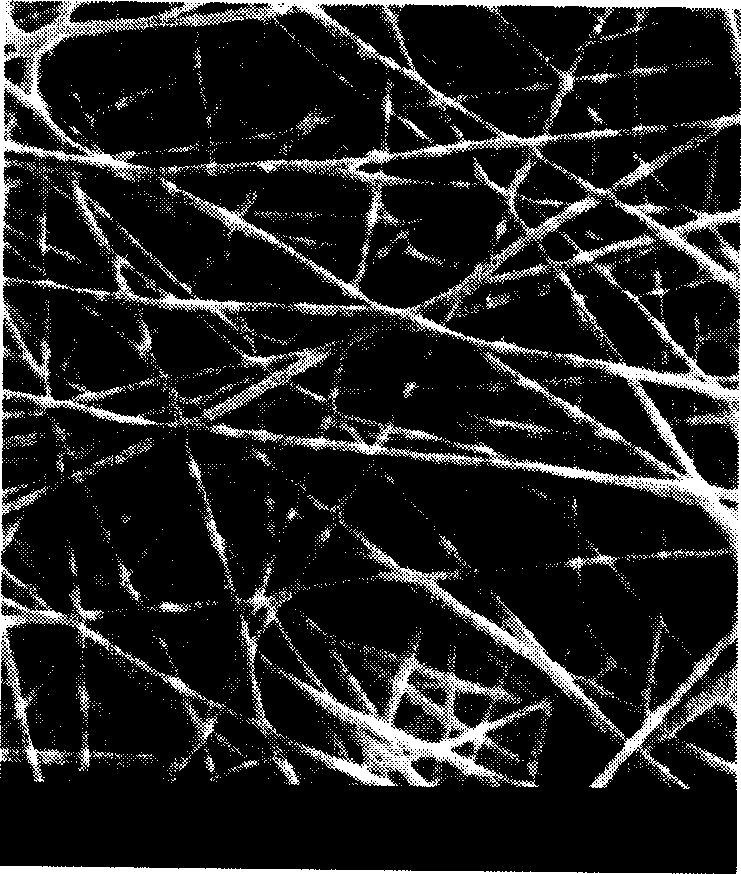

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com