Patents

Literature

420 results about "Conductive polymer composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

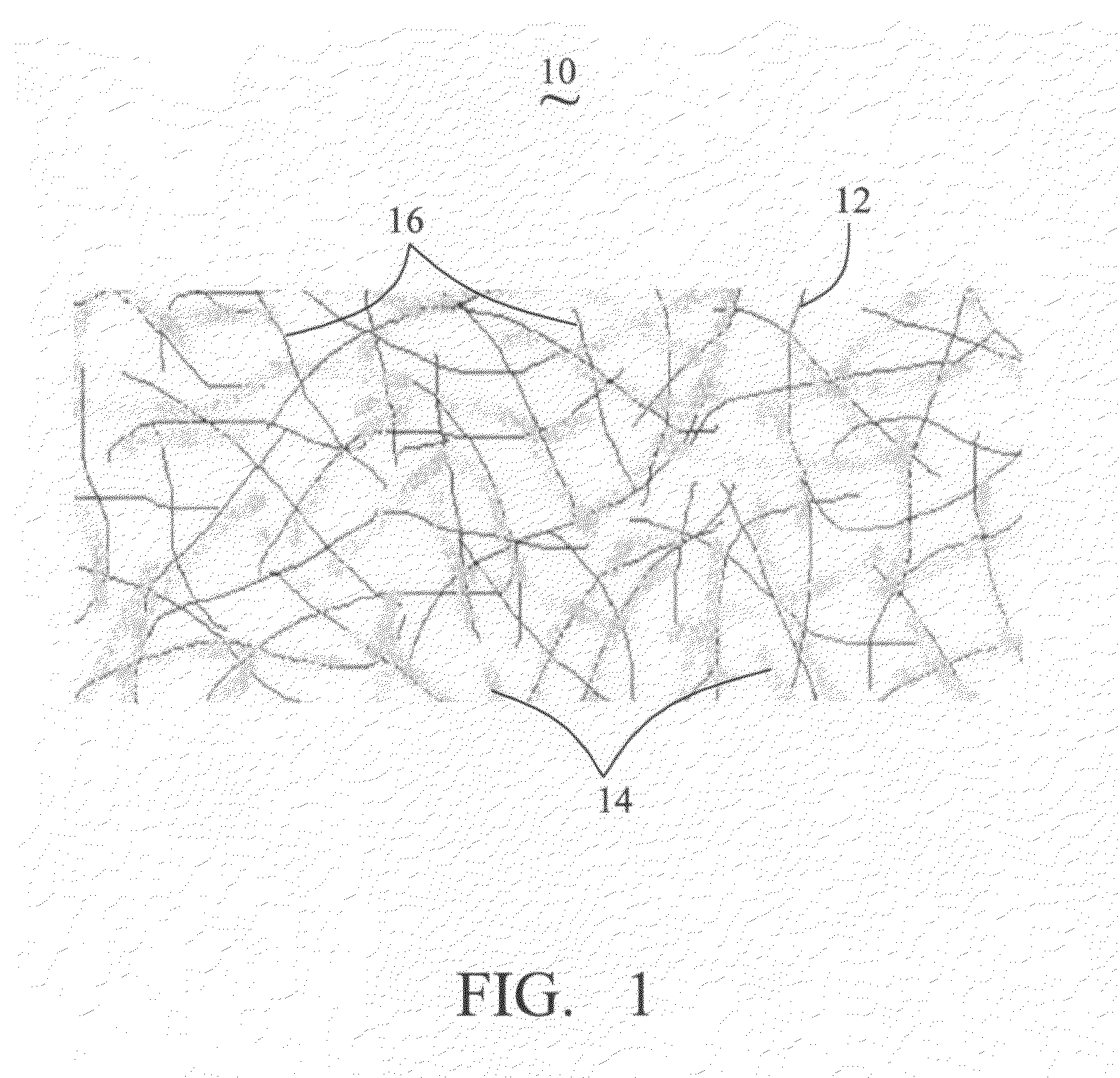

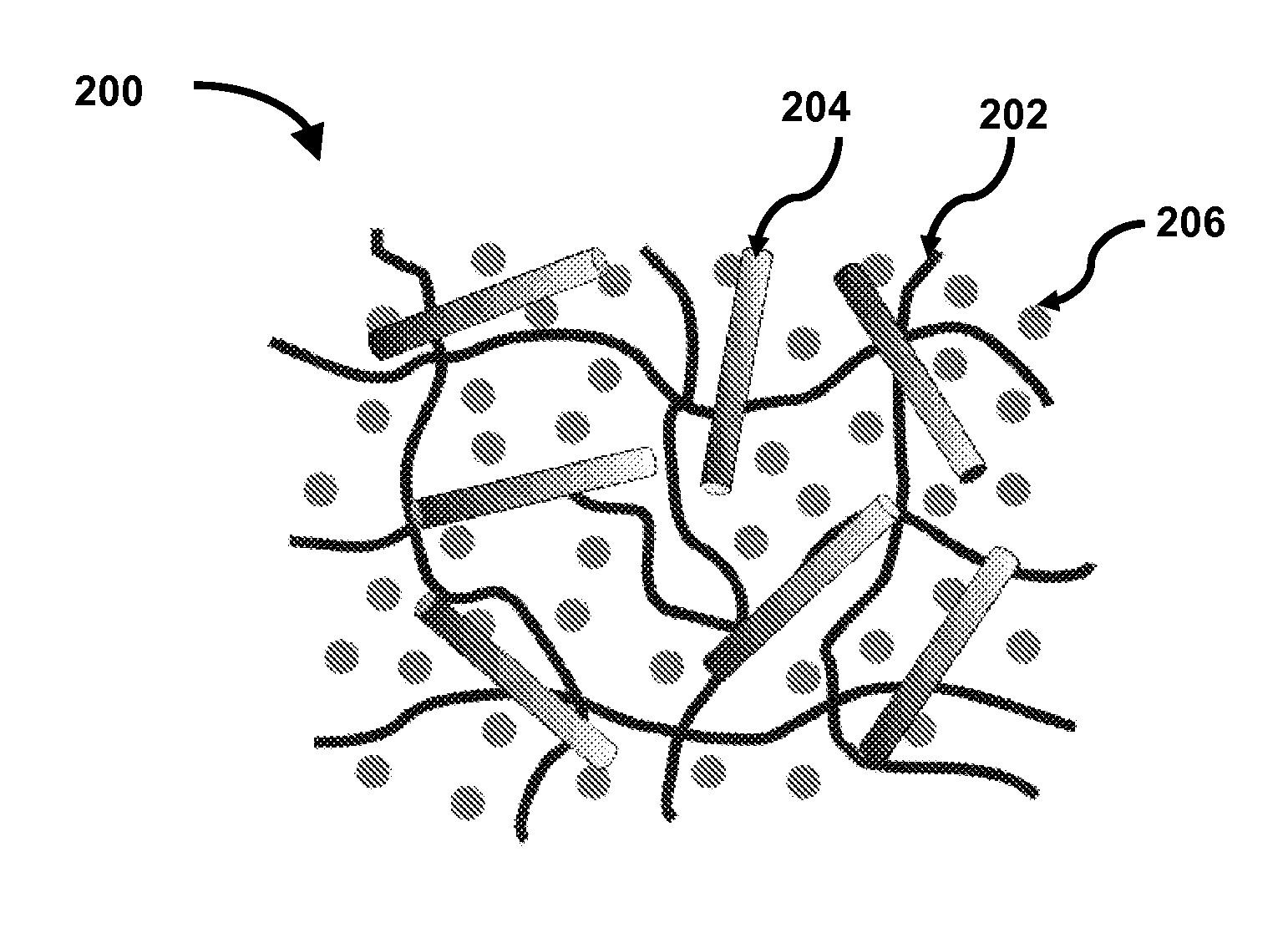

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

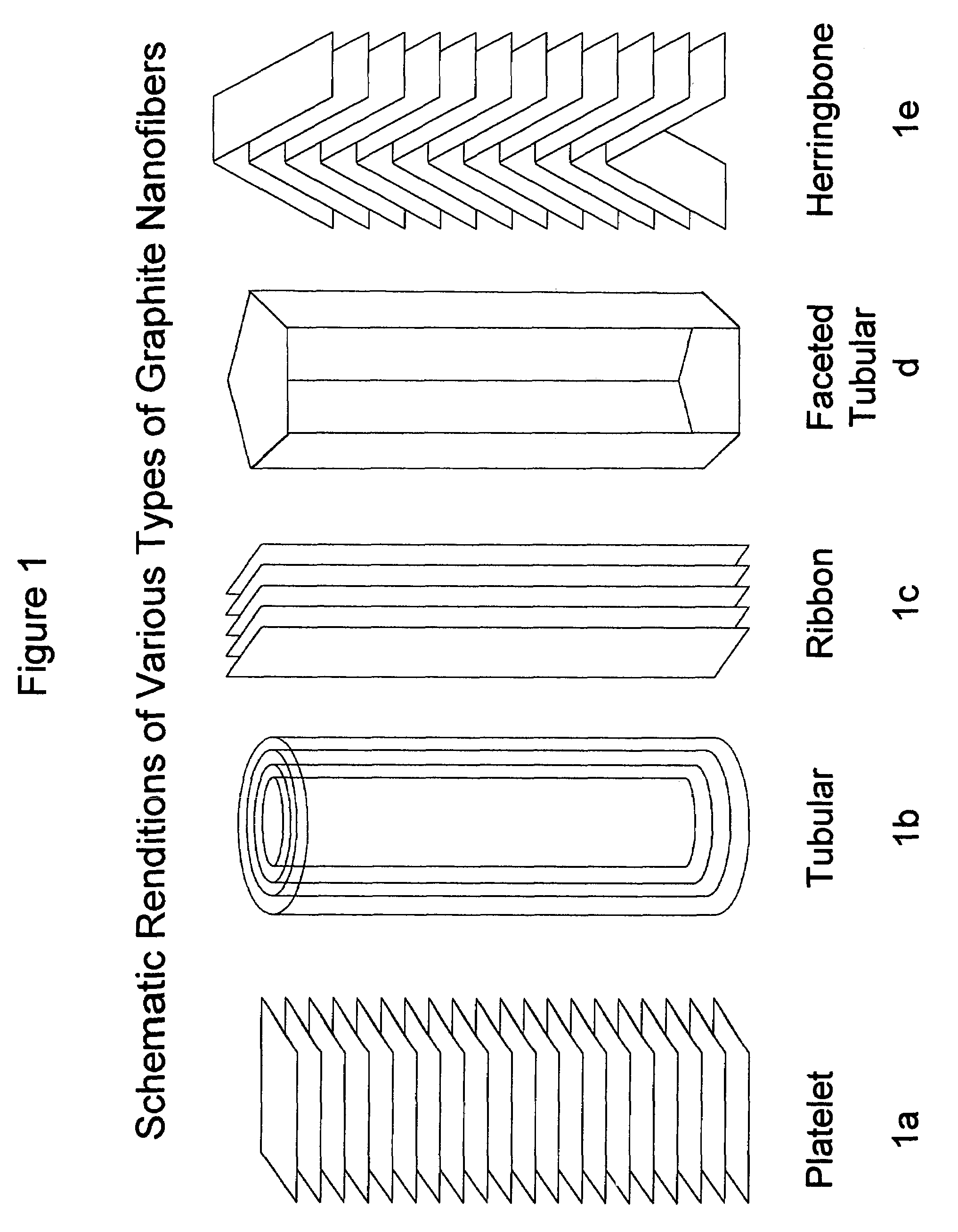

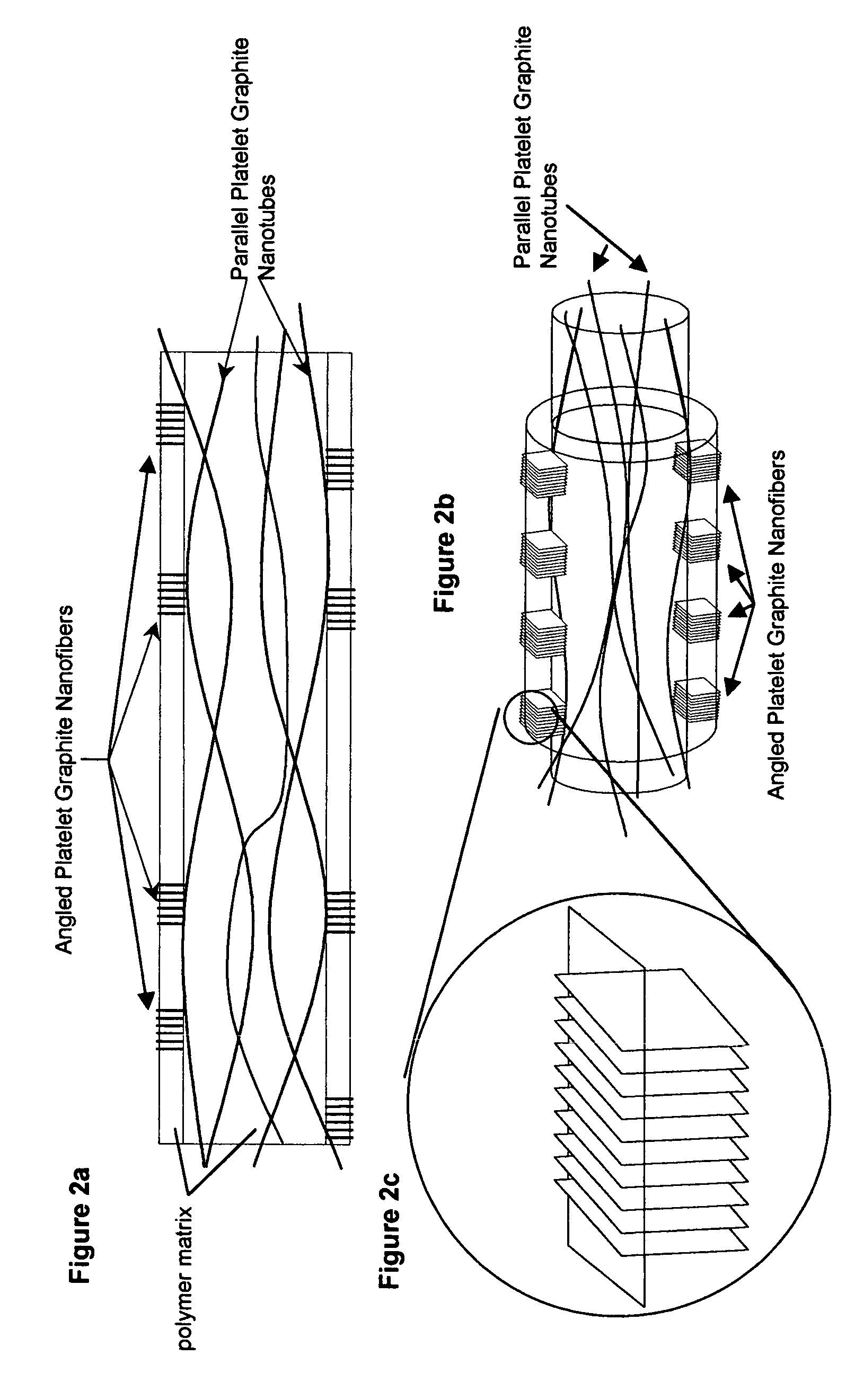

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

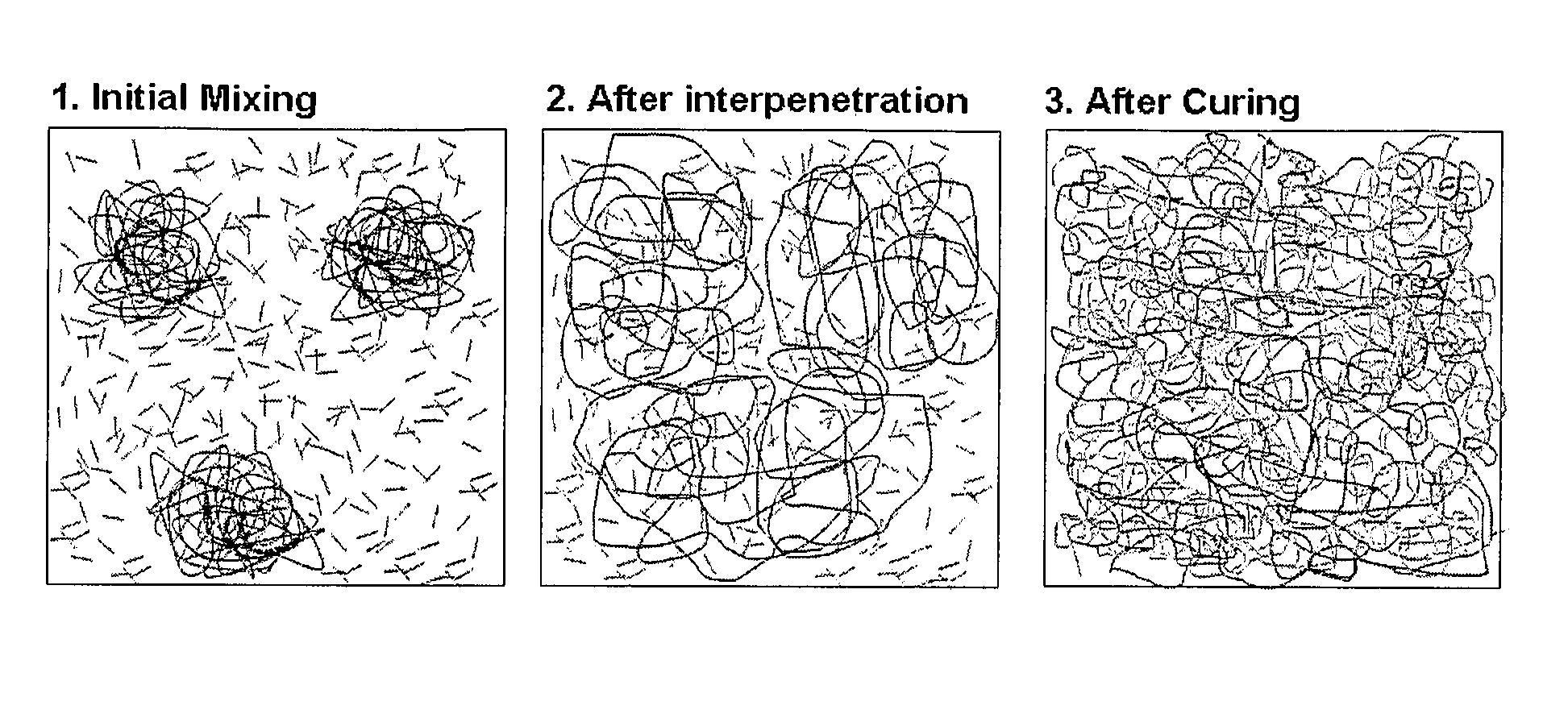

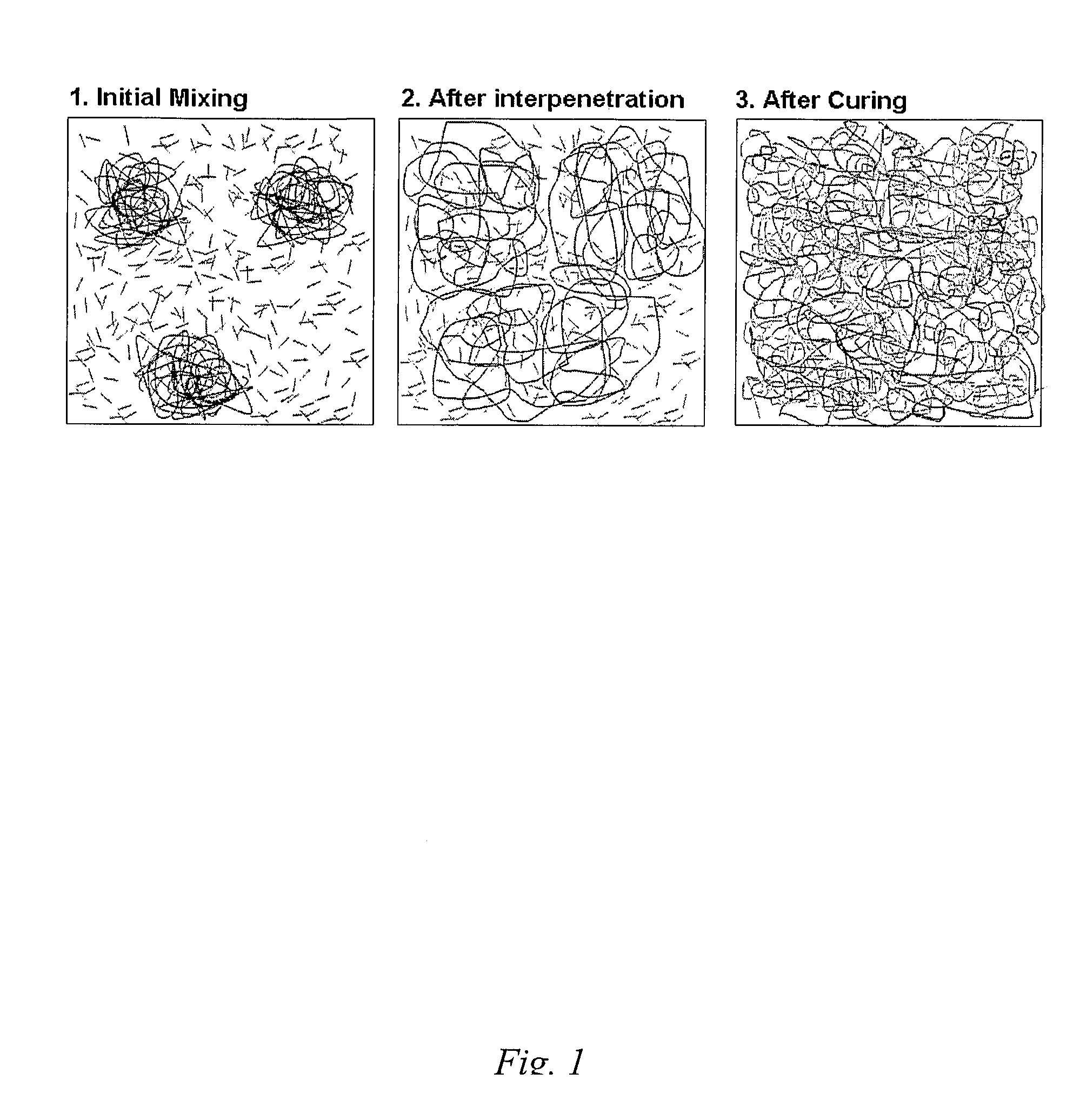

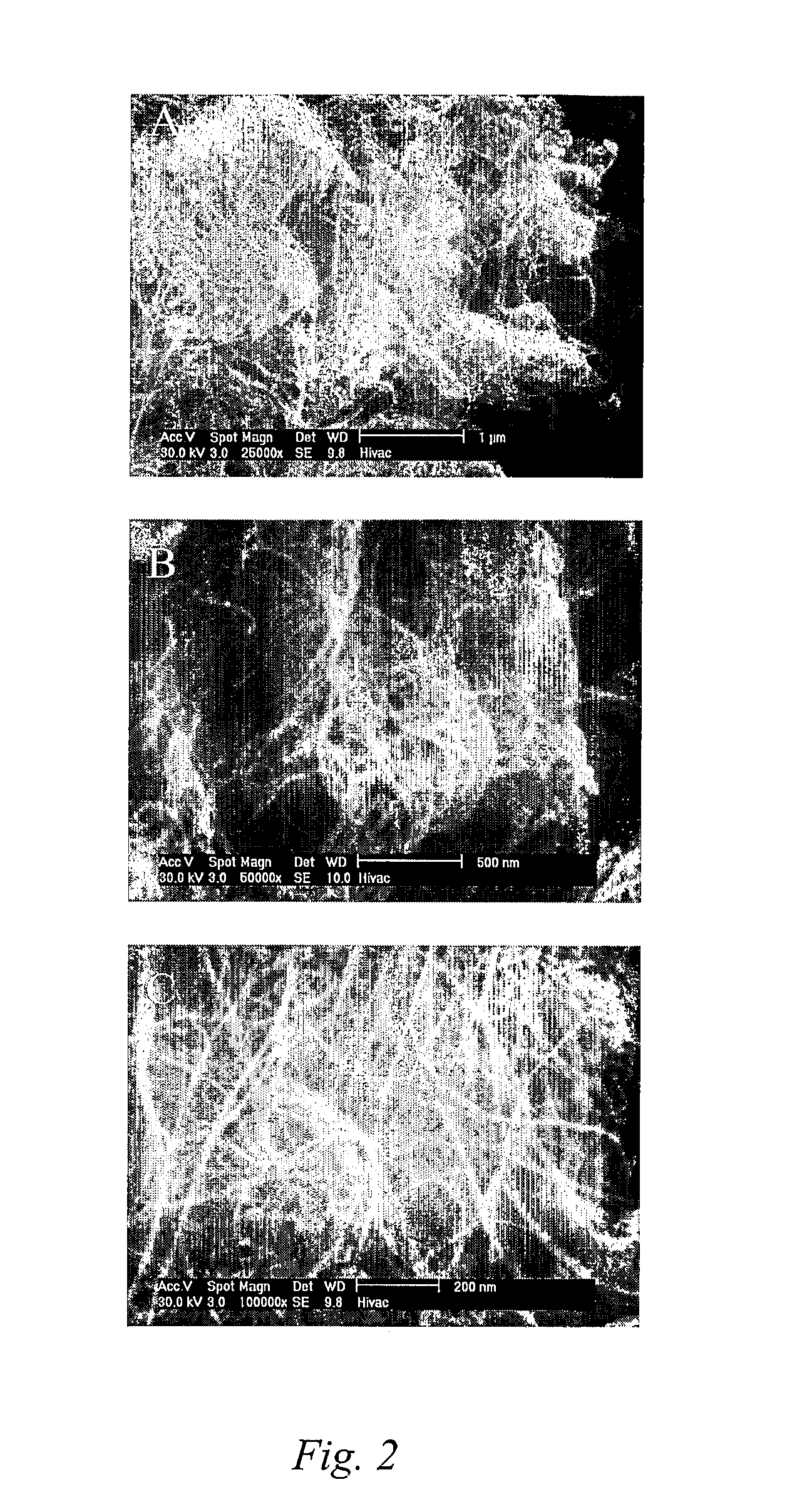

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

Multi-component conductive polymer structures and a method for producing same

InactiveUS7238415B2Material nanotechnologyElectroconductive/antistatic filament manufacturePolymer scienceConductive polymer composite

Owner:CATALYTIC MATERIALS

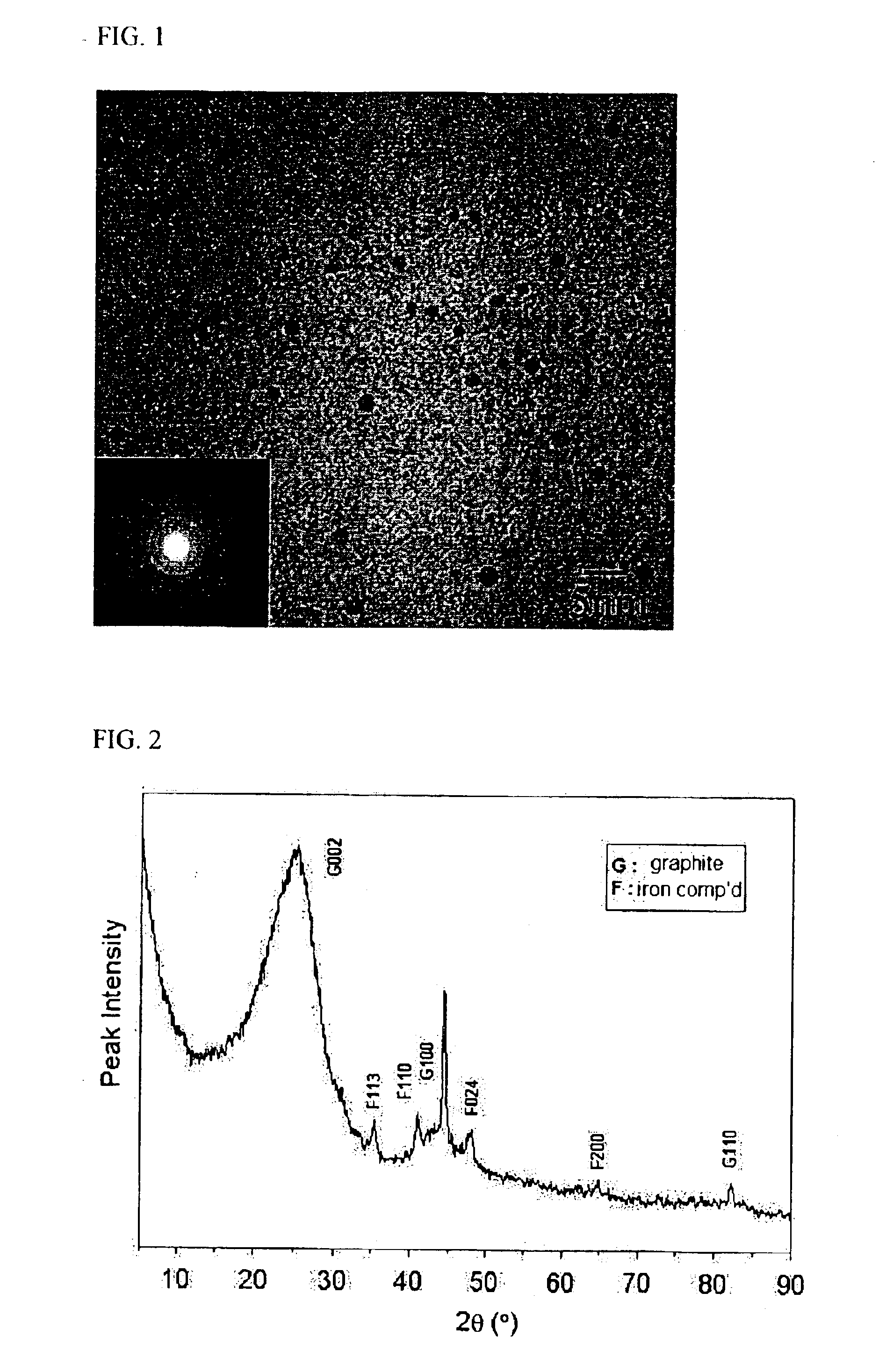

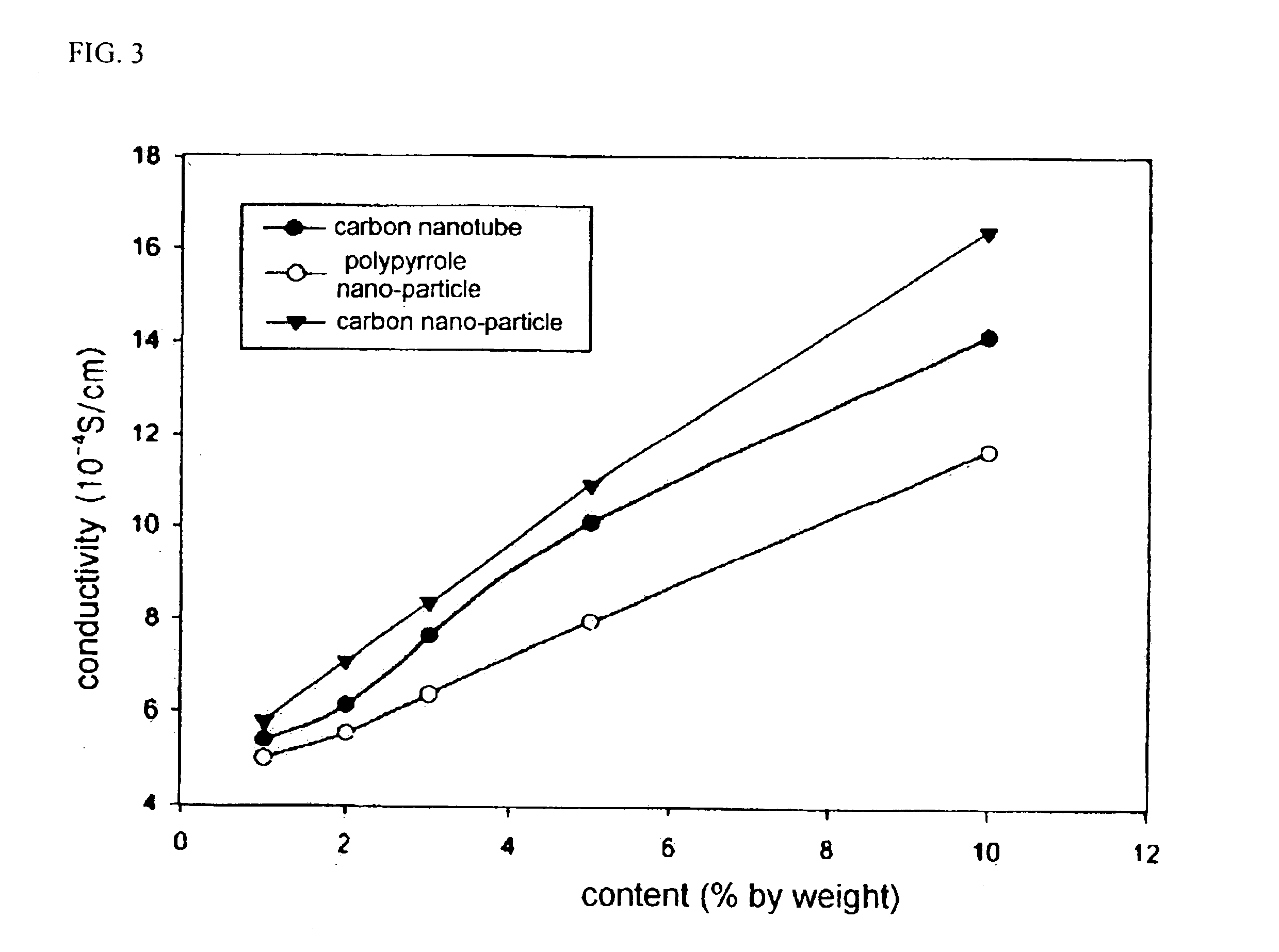

Carbon nano-particle and method of preparing the same and transparent conductive polymer composite containing the same

ActiveUS6919063B2Low costNovel methodMaterial nanotechnologyNanoinformaticsMean diameterConductive polymer composite

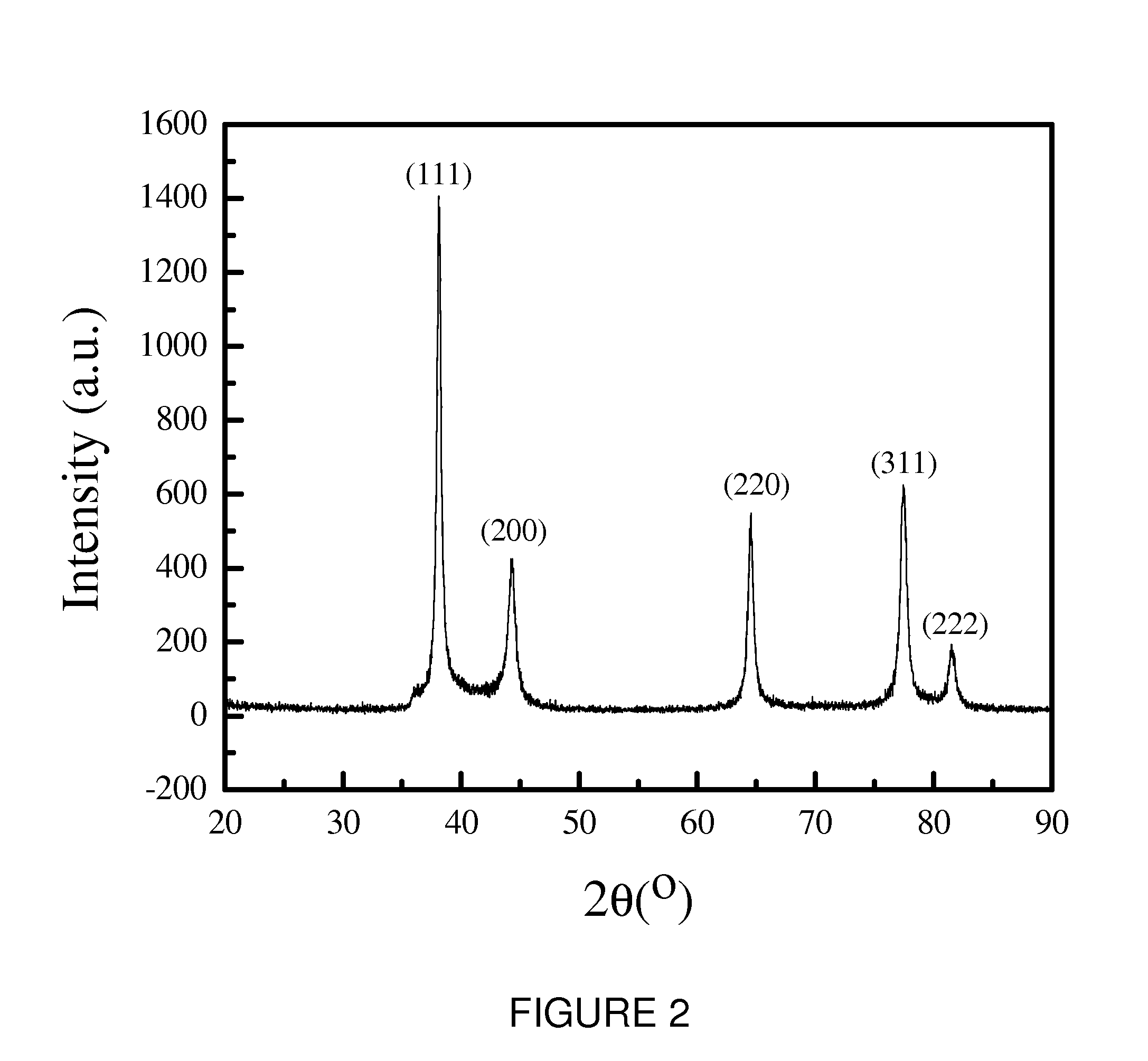

The present invention relates to a novel carbon nano-particle and a novel method of preparing the same and a transparent, conductive polymer composite containing the same. The carbon nano-particle has the mean diameter of 1 through 50 nm and the shape of sphere, rod or others, which is a novel material not known in the relevant art. Because of a particle size less than ½ of the shortest wavelength of a visible ray, a transparent resin containing the carbon nano-particle can maintain the transparency. Furthermore, the carbon nano-particle has the excellent electric conductivity and the ferromagnetic property, and can be made by a novel, low cost method entirely different from those of fullerene and carbon nanotube.

Owner:DONG WOON INT

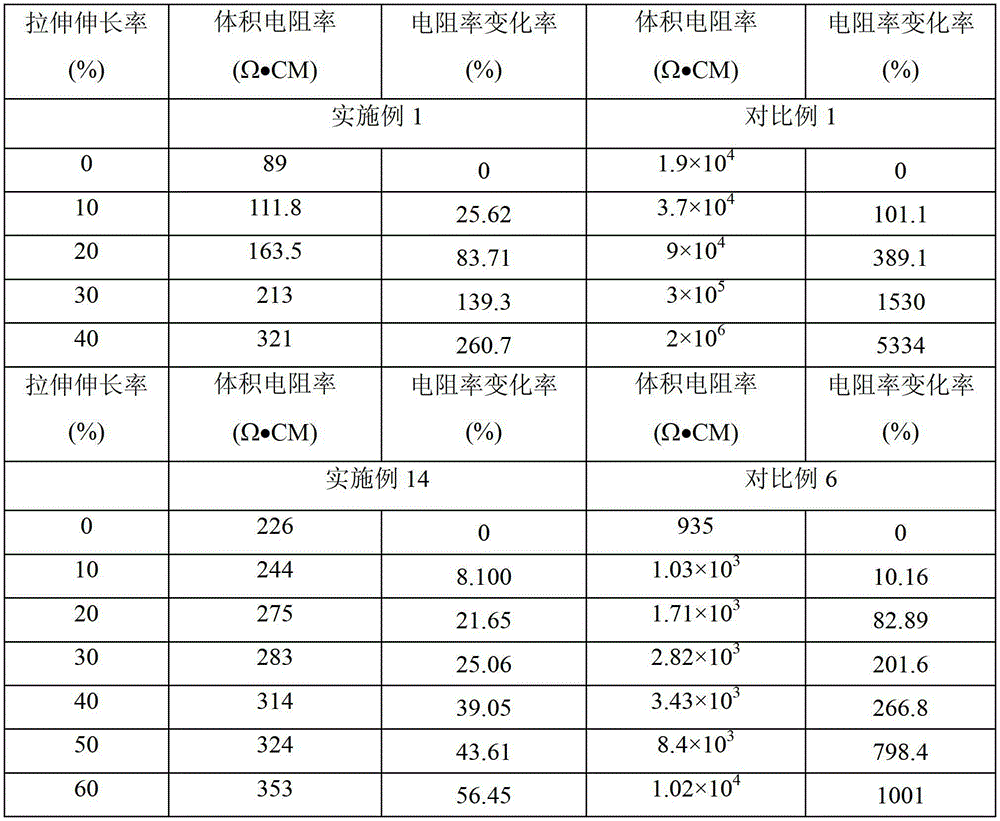

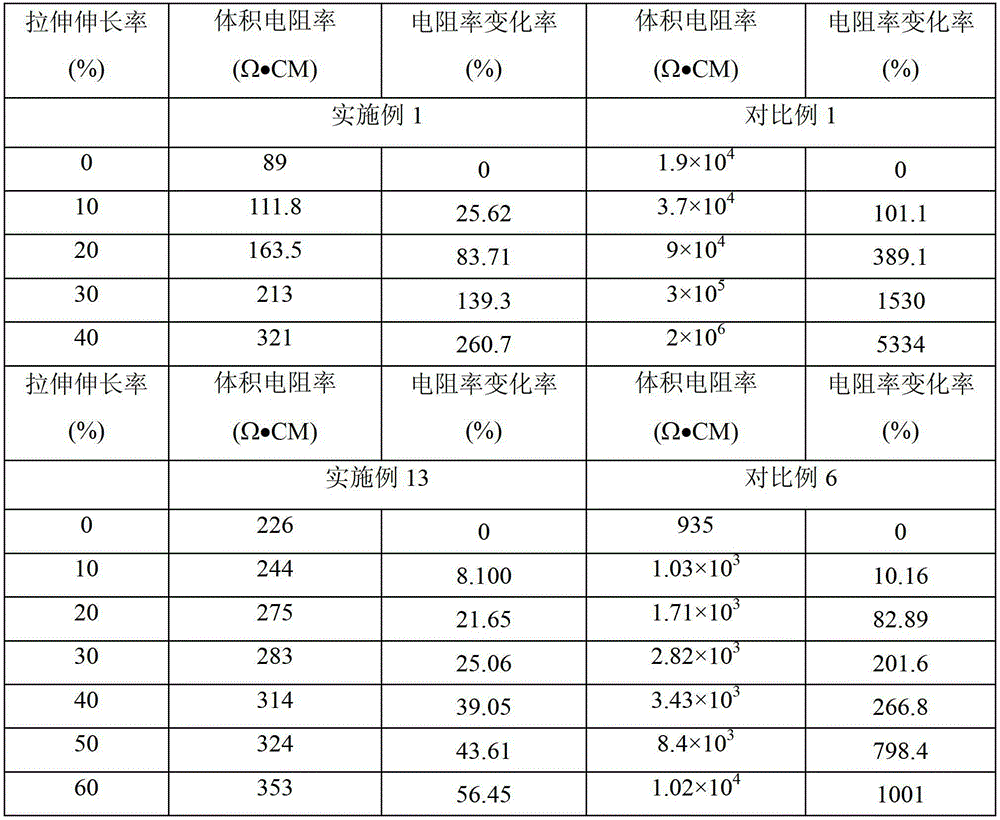

Conductive polymer composite material and preparation method thereof

The invention provides a conductive polymer composite material and a preparation method thereof. The composite material includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is more excellent in conductive performance, can be prepared through a conventional melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

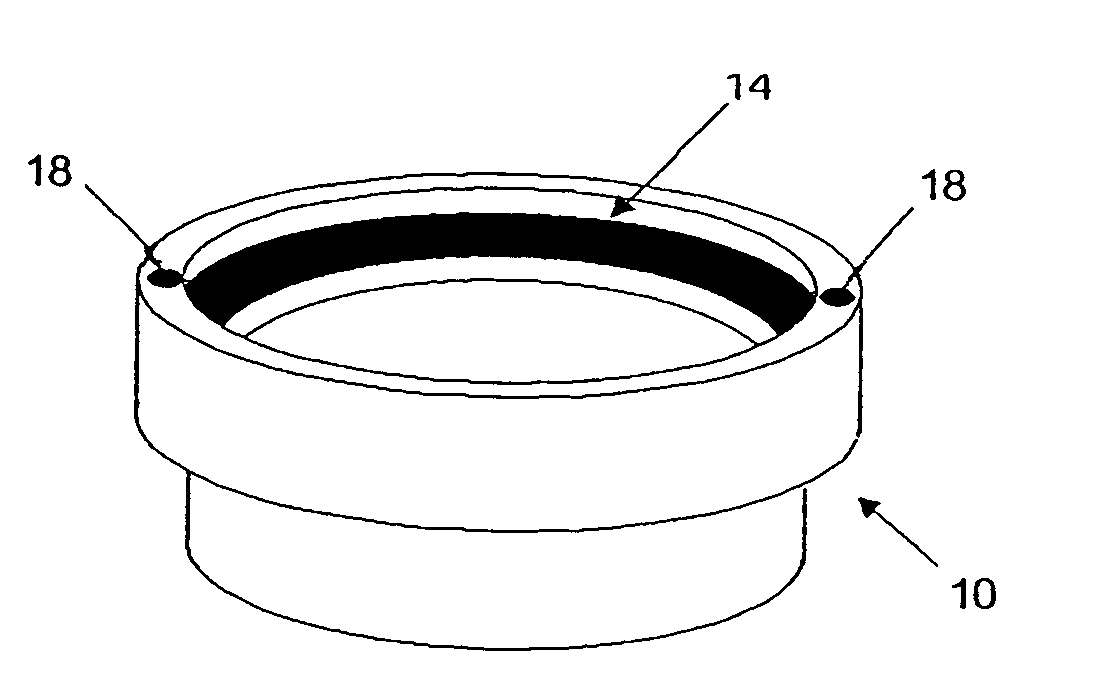

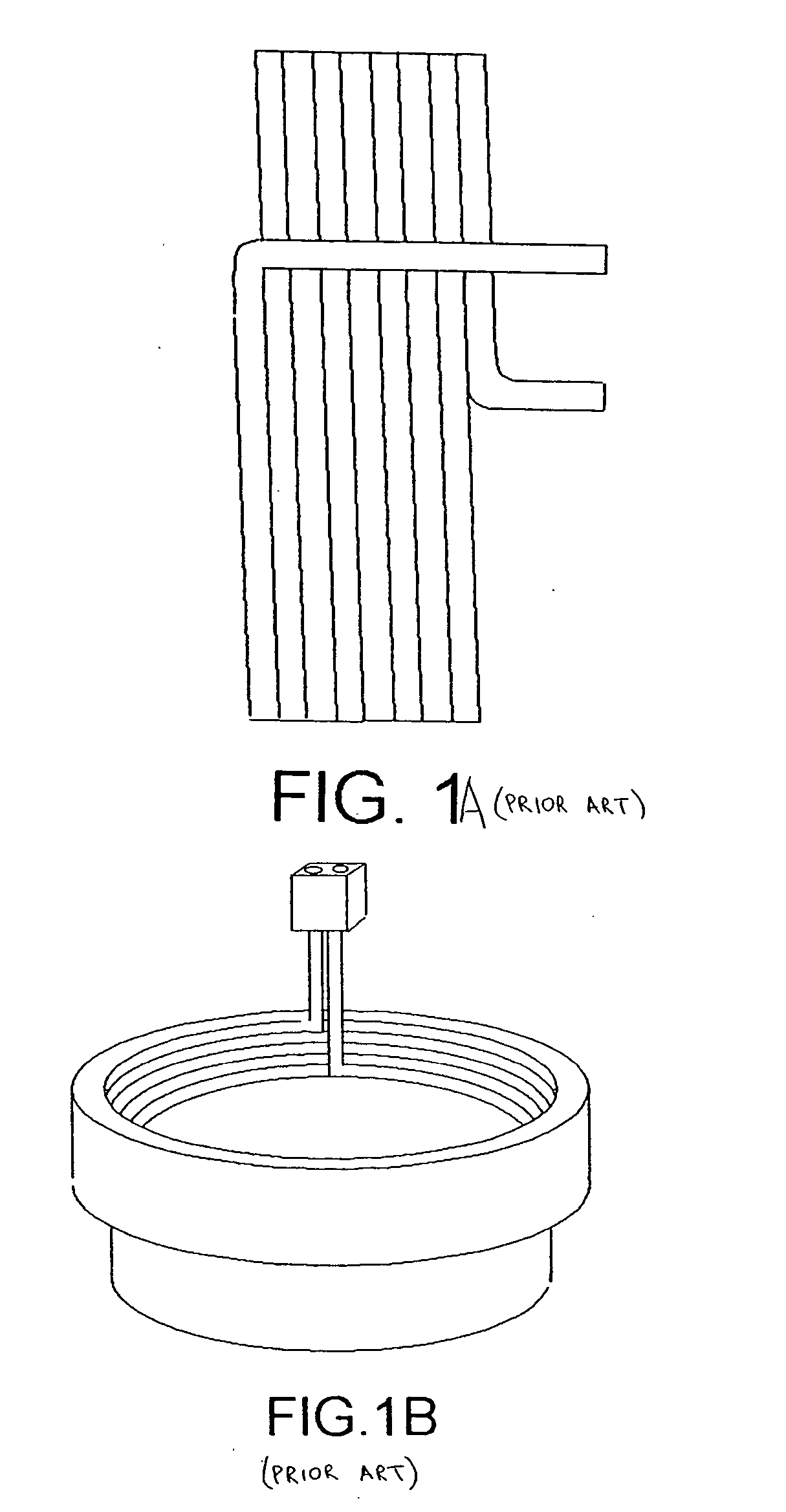

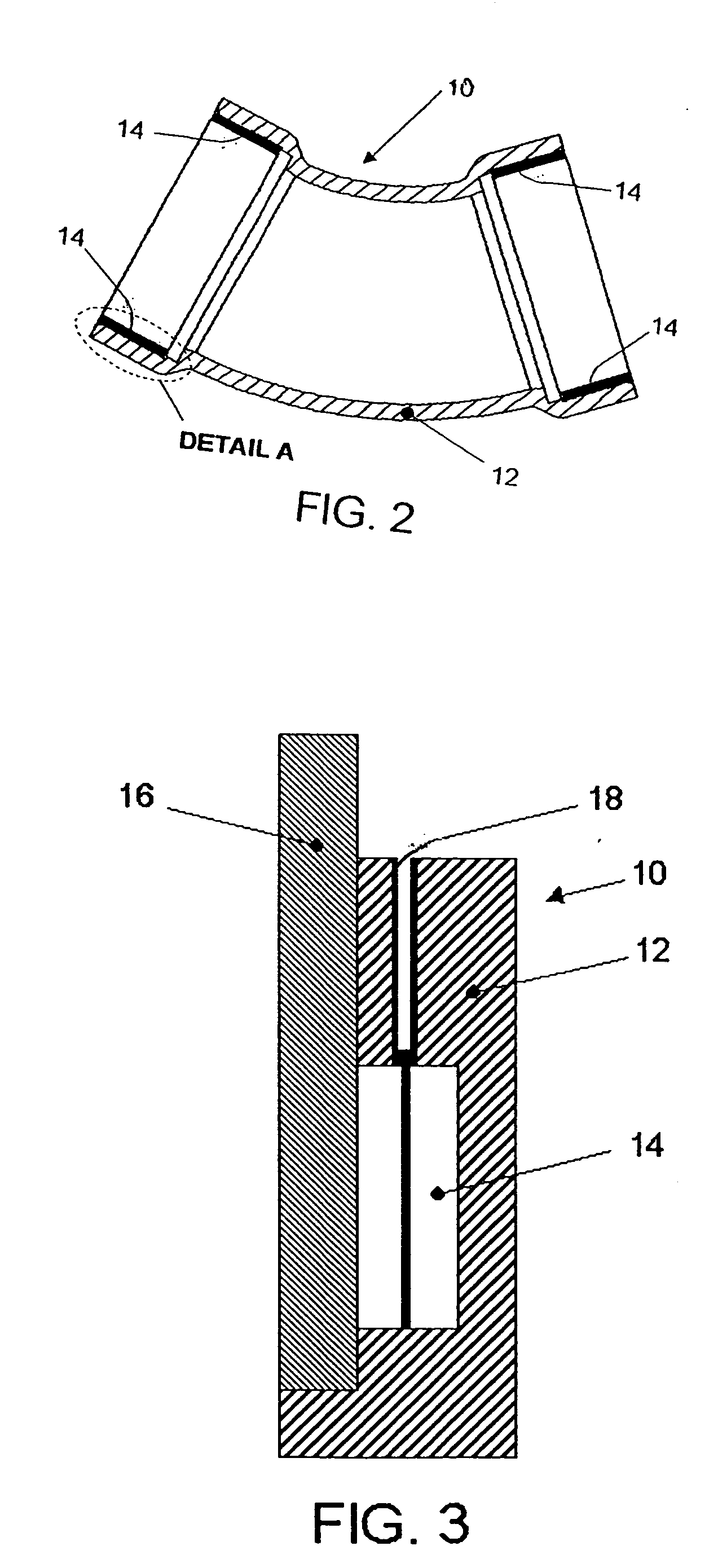

Electrofusion pipe-fitting joining system and method utilizing conductive polymeric resin

InactiveUS20060016552A1Material nanotechnologyMechanical working/deformationConductive polymer compositePipe fitting

A joining device for electrofusion of at least one end of a pipe to a fitting is provided which includes a fitting of a polymeric material and a collar adapted to receive the end of the pipe. The collar is fabricated from a conductive polymer composite material and positioned within the fitting. A connector for connecting the collar to a source of current may be provided which may be integral to the fitting. Likewise, the collar may be integral to the fitting. All three of the connector, collar and fitting are preferably an integral unit. A method of making the joining device and a method of using the joining device are also provided.

Owner:GEORGE FISCHER SLOANE

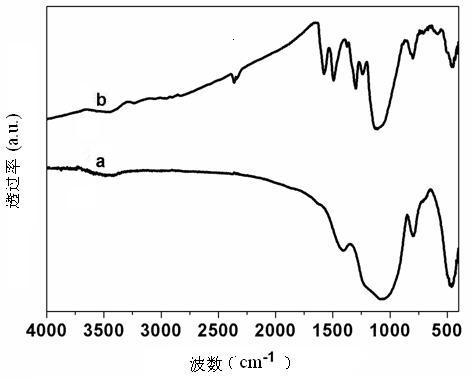

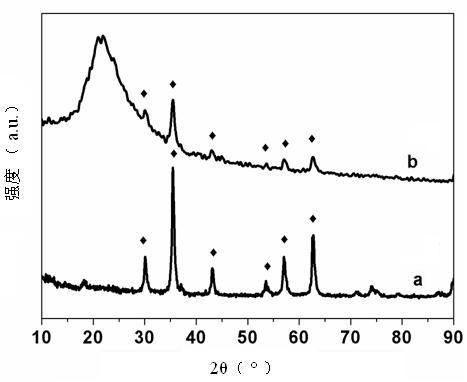

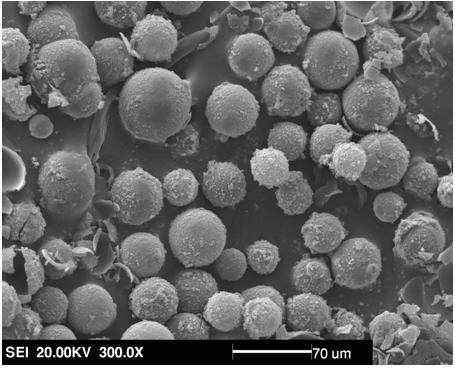

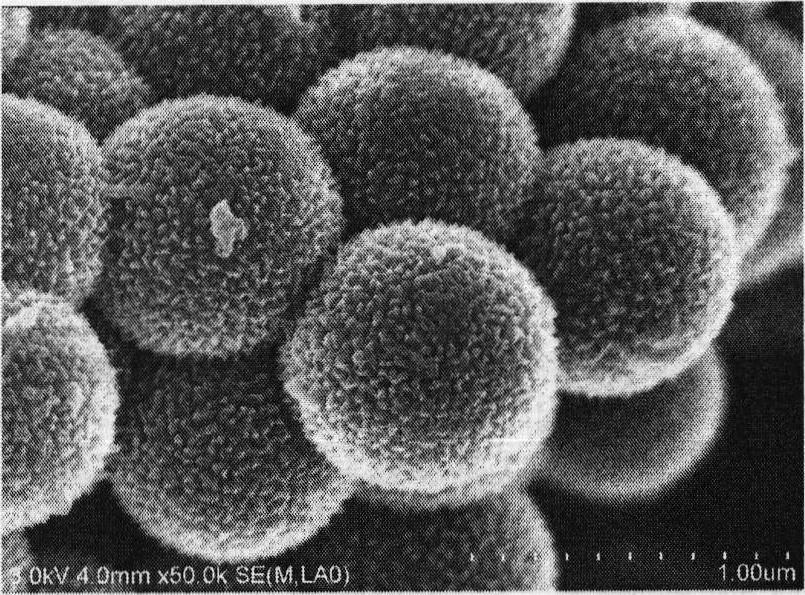

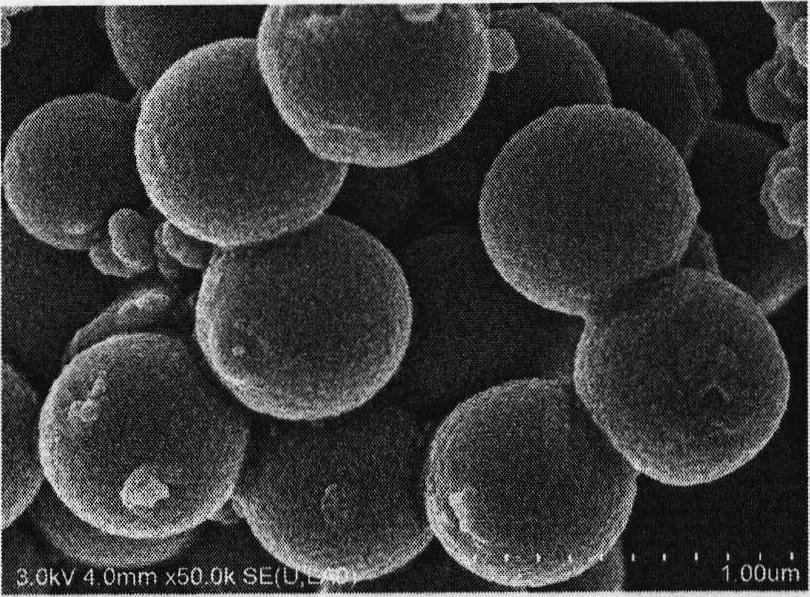

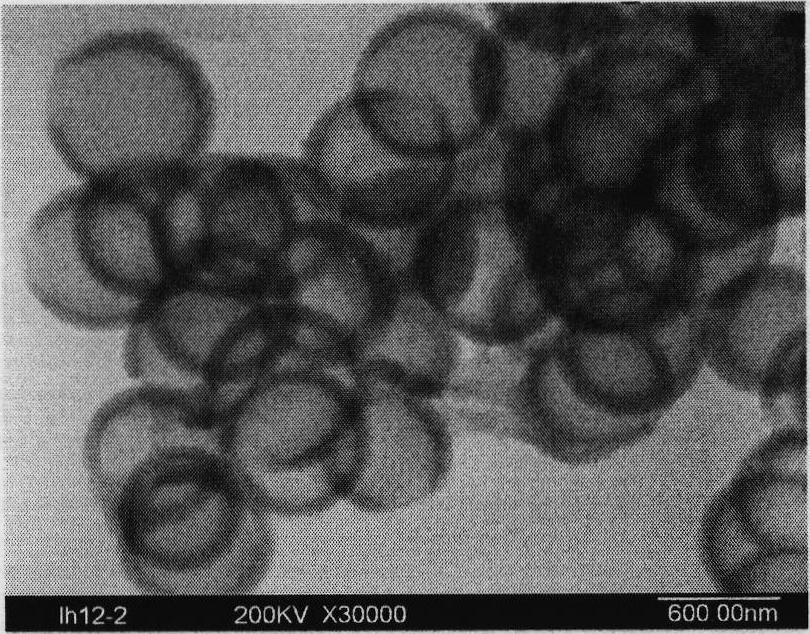

Method for preparing magnetic ferroferric oxide/conductive polyaniline light-weight composite hollow microspheres

InactiveCN101885915AGood dispersionNot easy to reuniteMicroballoon preparationMicrocapsule preparationConductive polymer compositeMicrosphere

The invention provides a method for preparing magnetic ferroferric oxide / conductive polyaniline light-weight composite hollow microspheres, which relates to a method for preparing a magnetic ferroferric oxide / conductive polyaniline composite material. The invention solves the problems of high density and easy agglomeration of the traditional magnetic nanometer particle / conductive polymer composite material. The method comprises the following steps of: regulating ferrous chloride and ferric chloride solutions to be alkaline, adding sodium dodecyl benzene sulfonate and reacting to obtain ferroferric oxide; and modifying hollow glass microspheres by using poly(diallyldimethylammonium chloride) solutions after alkaline cleaning, then reacting the hollow glass microspheres with the ferroferric oxide, sequentially immersing obtained solid particles by using the poly(diallyldimethylammonium chloride) solutions and polystyrene sulfonic acid solutions, then adding the solid particles to aniline solutions, initiating polymerization by using ammonium persulfate, and washing and drying the solid particles to obtain the composite hollow microspheres. The composite hollow microspheres have both conductivity and magnetism, the density is 0.78-0.8g / cm<3>, and the composite hollow microspheres are not easy to agglomerate and are used for fields of military equipment stealth technology and civil anti-electromagnetic radiation.

Owner:HARBIN INST OF TECH

Conductive thermoplastic elastomer and preparation method thereof

ActiveCN104098795AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialThermoplasticConductive polymer composite

The invention provides a conductive thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. A weight ratio of the component b to the component a is more than 30:70 and is lower than 75:25. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is excellent in conductive performance, can be prepared through a melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

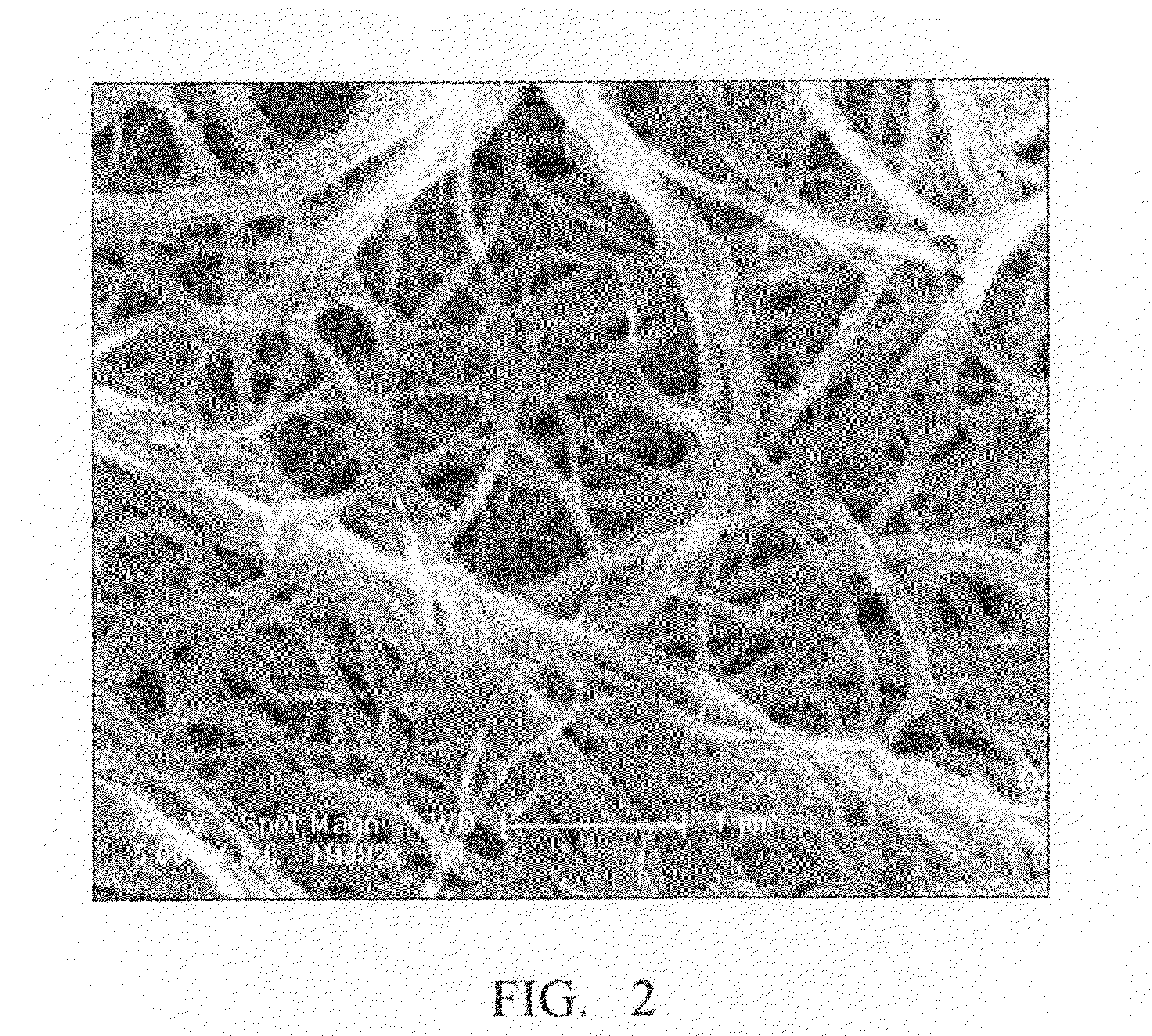

Carbon nanotube-conductive polymer composite

ActiveUS20100019209A1Reduce contractionReduce expansionMaterial nanotechnologyHybrid capacitor electrodesFiberPolymer science

A carbon nanotube-conductive polymer composite includes a plurality of CNTs and conductive polymer fibers. The CNTs are connected with each other to form a network. The conductive polymer fibers adhere to surfaces of the CNTs and / or tube walls of the CNTs.

Owner:TSINGHUA UNIV +1

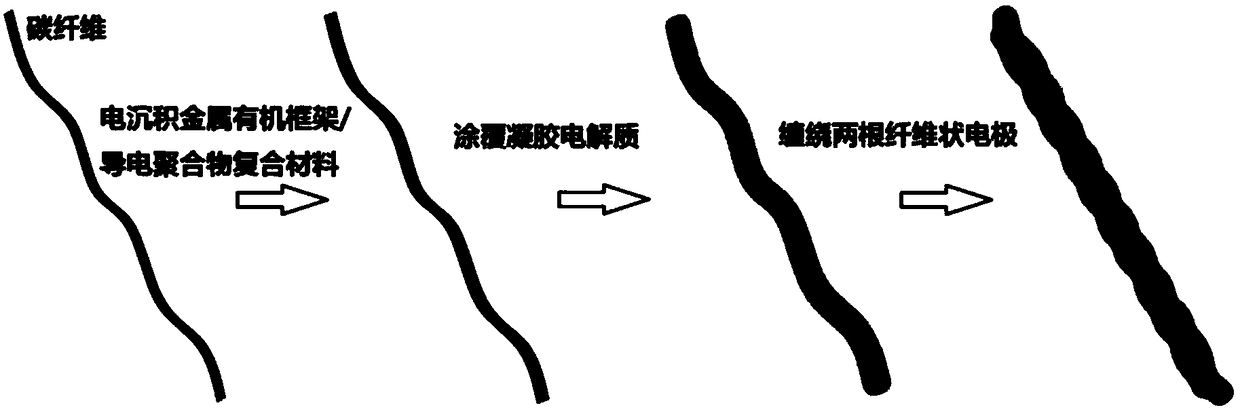

Metal organic frame/conductive polymer composite material and preparation and application thereof

ActiveCN108335919AIncrease capacityIncrease capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceConductive polymer composite

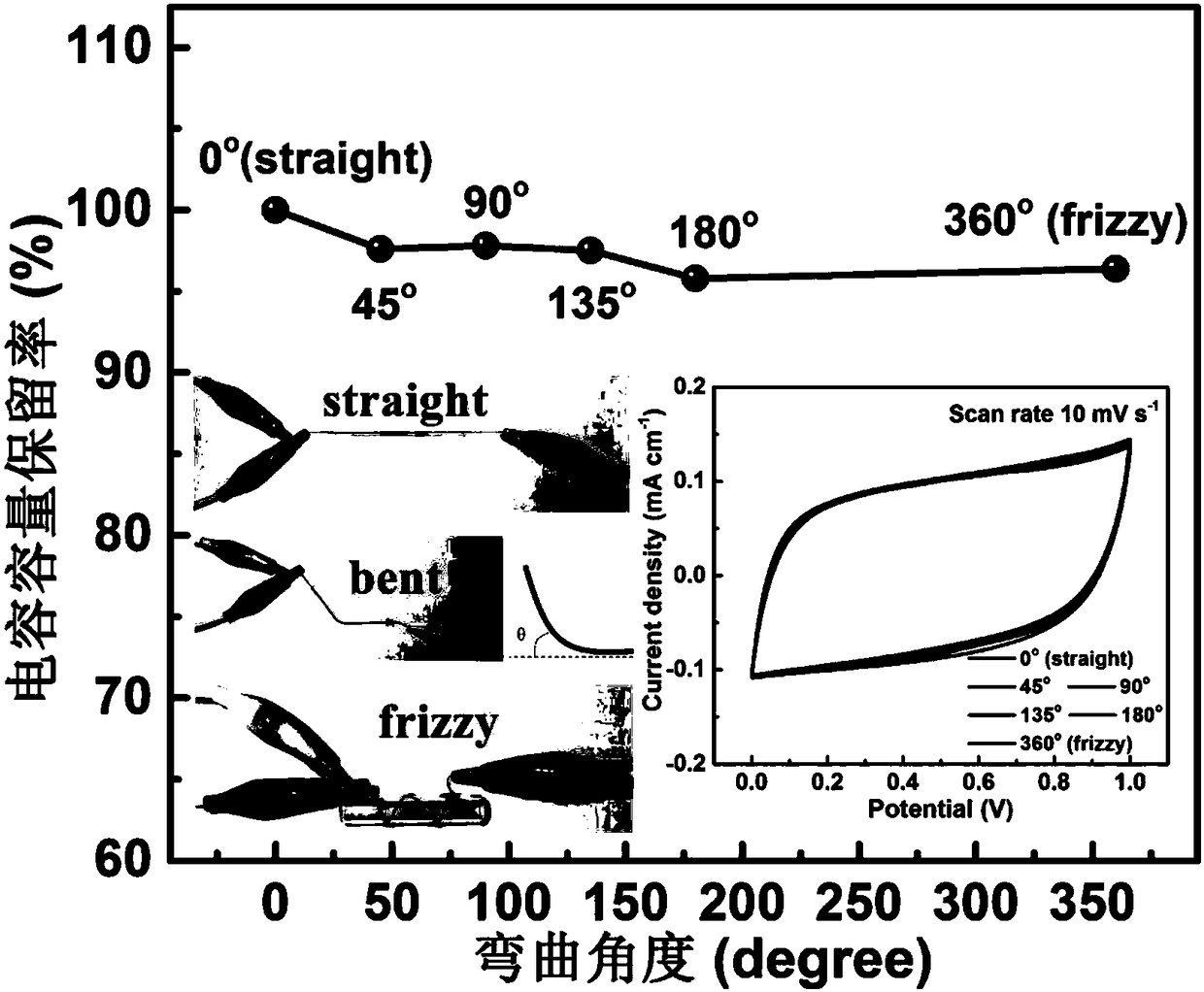

The invention belongs to the technical field of flexible energy storage devices, and particularly relates to a metal organic frame / conductive polymer composite material, a preparation method thereof and application in knittable, flexible and fibroid supercapacitors. Carbon fiber bundles are adopted as an electrode substrate, the electro-deposition metal organic frame / conductive polymer composite material is adopted as an electrode active material, polyvinyl alcohol-electrolyte gel is adopted as solid electrolyte and a membrane, and the prepared fibroid supercapacitor has the excellent capacitive performance, good mechanical flexibility, wide working temperature range and stable long-term service life, capable of being directly knitted and integrated into textile easily, and capable of providing an efficient energy storage system for wearable mobile equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

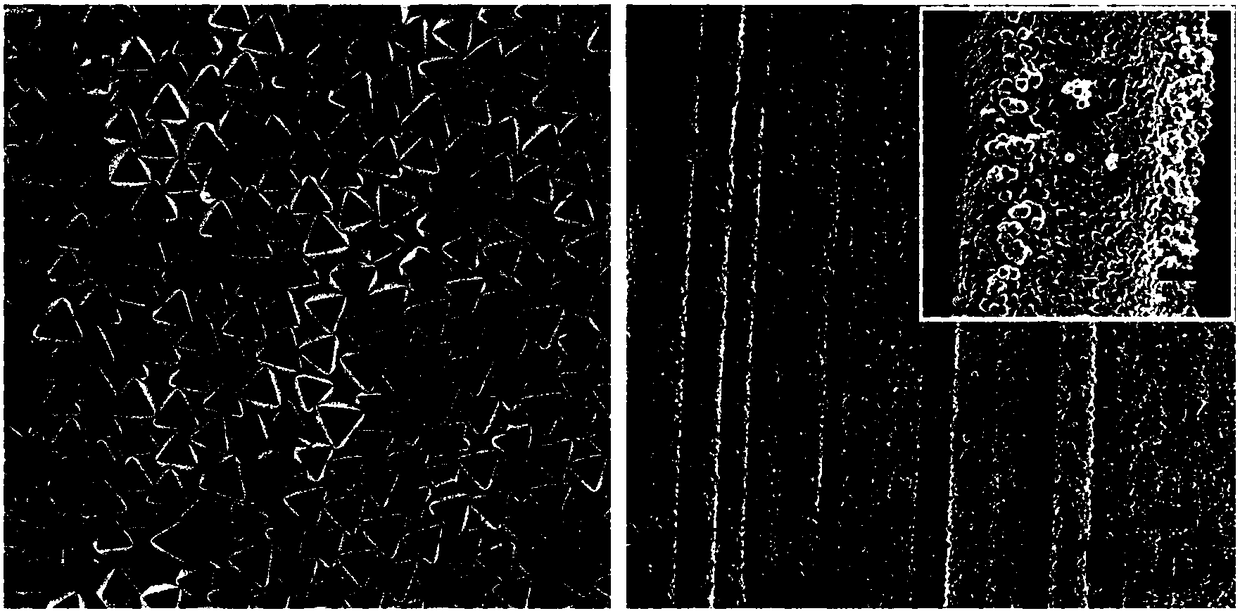

Graphene/conductive polymer composite film and preparation method thereof

ActiveCN101798462AImprove conductivityImprove antistatic performanceOrganic conductorsCarbon-silicon compound conductorsConductive polymer compositeComposite film

The invention relates to a graphene / conductive polymer composite film and a preparation method thereof. The graphene / conductive polymer composite film comprises products prepared by the following reaction: 1) preparing graphite oxide from graphite by a chemical oxidation method; 2) adding an oxidant ammonium persulfate into monomer containing acid solution to prepare conductive polymer; 3) performing ultrasonic dispersion on the graphite oxide and the conductive polymer in N-methylpyrrolidone, adding a reducing agent, and stirring; 4) coating solution prepared by step 3) on the surface of a substrate to form a film, washing and drying; and 5) repeating the step 4) until the film has the required thickness. The graphene / conductive polymer composite film and the preparation method have the advantages that: 1) the formed graphene / conductive polymer composite film has good electric conduction and antistatic property, and has the conductivity between 1*10<-3> and 1*10<2>S / cm; 2) the conjugated structure of the grapheme and the conductive polymer ensures that the grapheme and the conductive polymer have high compatibility; 3) the composite film has controllable thickness; and 4) the preparation method has simple conditions and easy operation.

Owner:武汉工大科技园发展有限公司

Conductive polymer composites

InactiveUS20080272344A1Printed circuit aspectsConductive materialConductive polymer compositeFlip chip interconnect

The present invention relates generally to conductive polymer composites, electrically conductive adhesives, and methods of producing the same. The conductive polymer composites and electrically conductive adhesives may be used for electronic component interconnects, flip chip interconnections, electrical connections to circuit boards, jumper connections, or similar uses. The method of forming a conductive polymer composite includes mixing conductive metal flakes, functionalized conductive metal nanoparticles, and a polymer precursor and curing the polymer precursor to form a composite. In one embodiment, the conductive polymer composites may be composed of microparticles of silver flake and sintered silver nanoparticles between the silver flakes. The polymer composites have an electrical conductivity of less than 10−5 Ω·cm.

Owner:GEORGIA TECH RES CORP

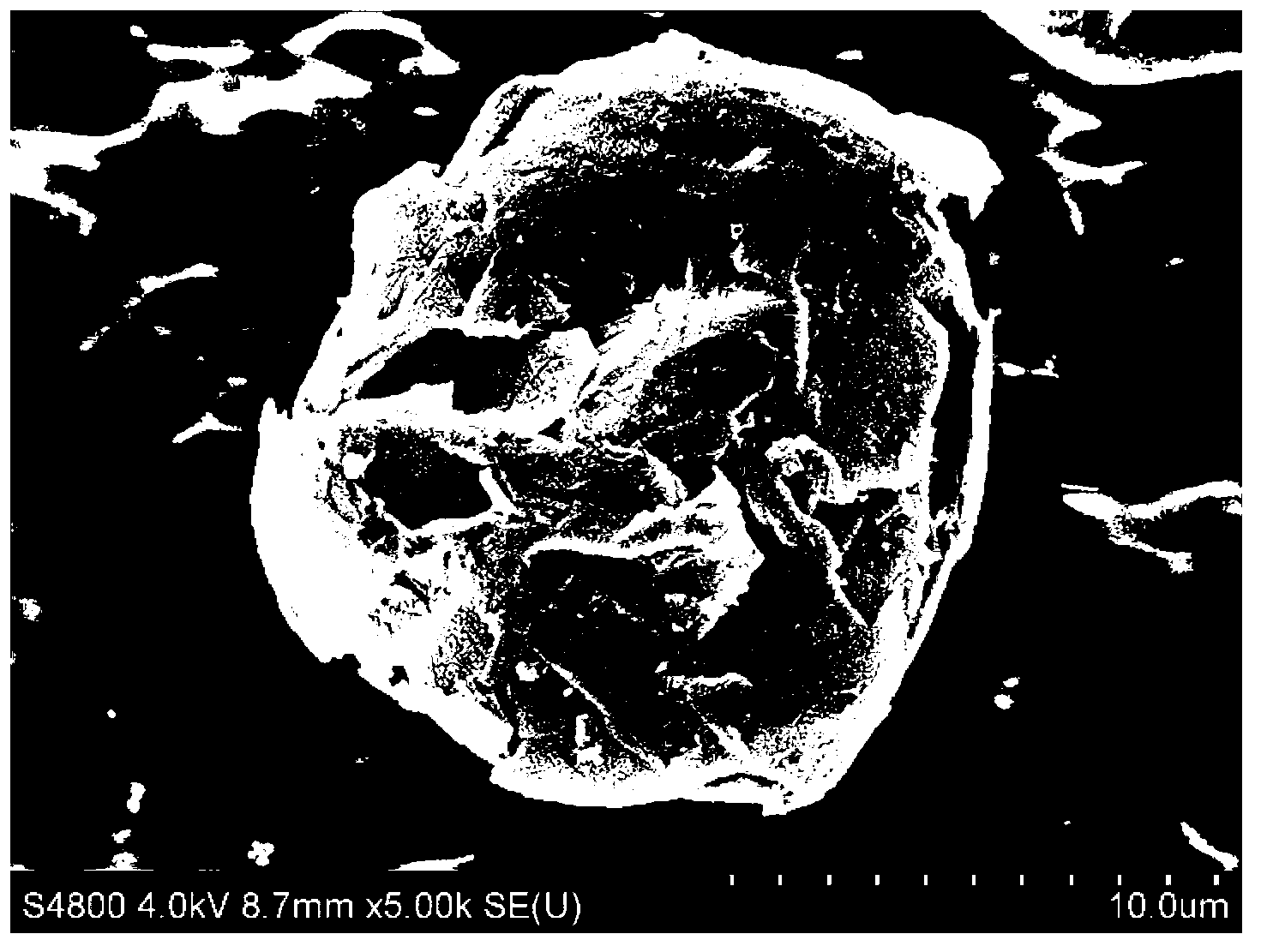

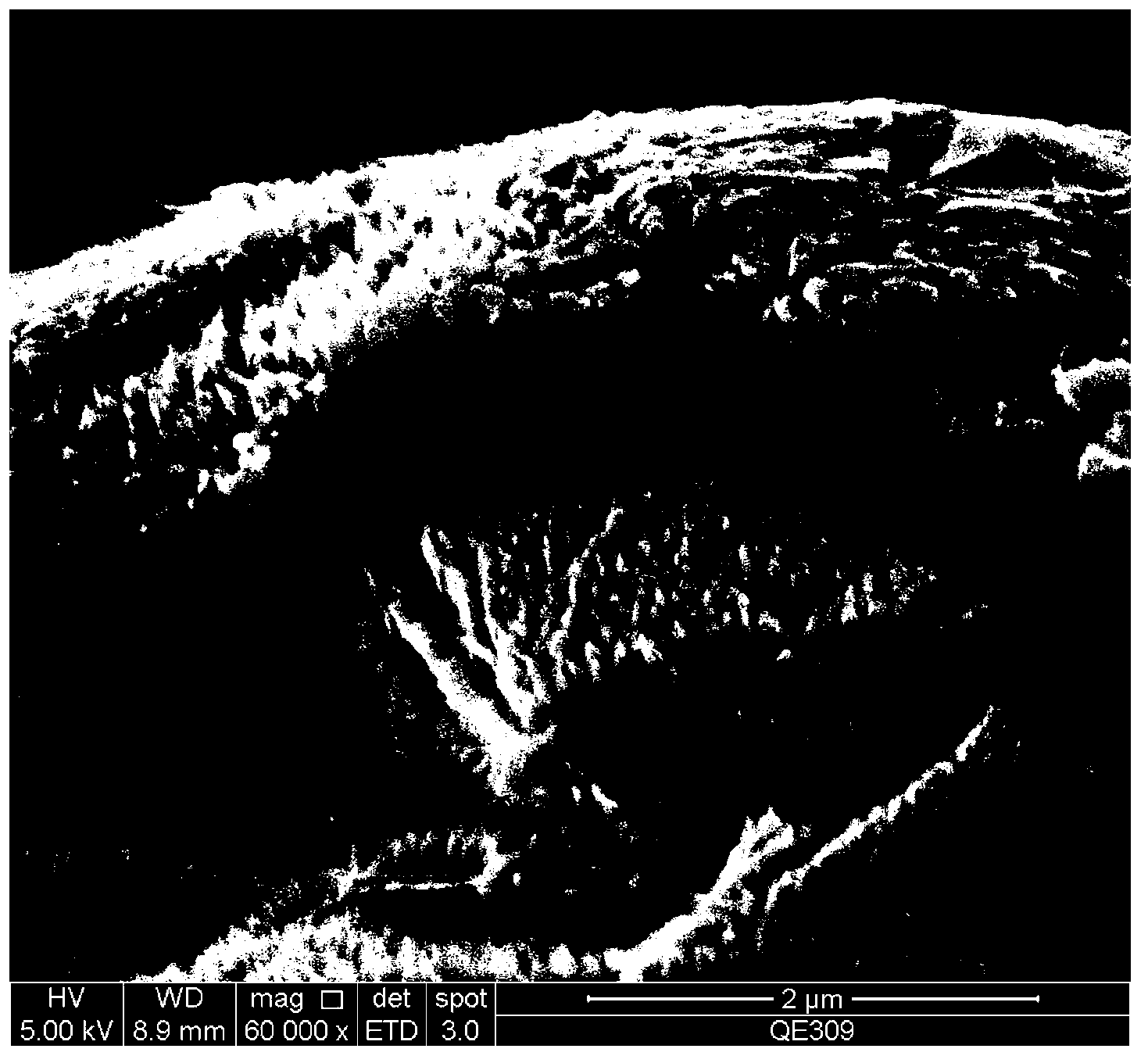

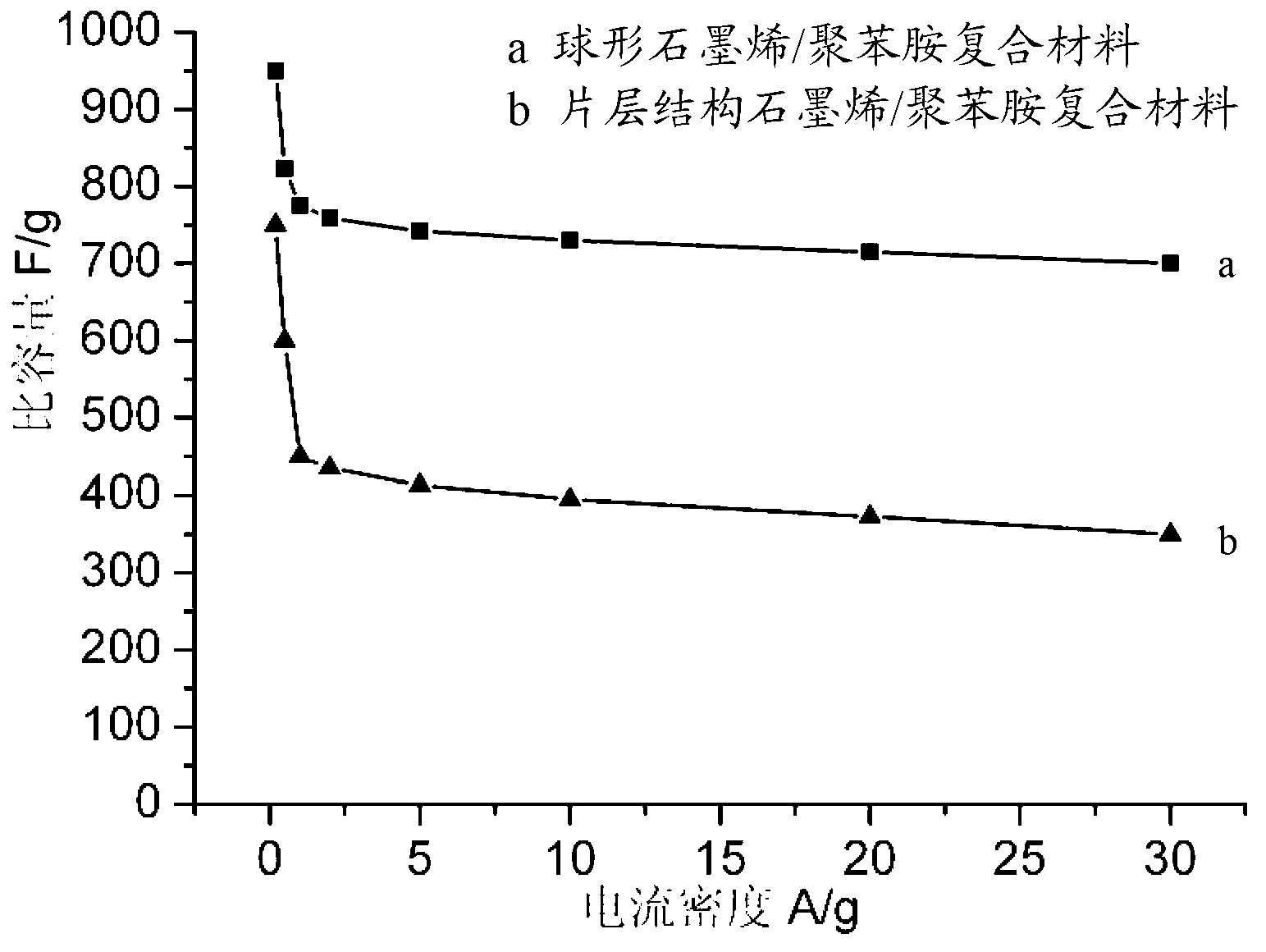

Graphene/conductive polymer composite material and preparation method thereof

ActiveCN102850543AAvoid reunionImproved magnification performanceHybrid capacitor electrodesConductive polymer compositeReduction treatment

The invention provides a preparation method of a graphene / conductive polymer composite material. The method includes that firstly a graphene solution or a modified graphene solution is subjected to spray drying to obtain a graphene microsphere, then the obtained graphene microsphere is mixed with a liquid conductive polymer monomer to be soaked, then the graphene microsphere is mixed with an acid solution containing an oxidant to be subjected to a polymerization reaction, and the reduction treatment is performed to obtain the graphene / conductive polymer composite material. The composite material is formed by coating a nanoscale conductive polymer on the surface of the graphene microsphere, so that agglomeration of the graphene during large current charge-discharge is avoided, and the rate capability of the composite material during the large current charge-discharge is improved. An experimental result shows that according to the composite material, when the electric current density is 1A / g, the first time discharge capacity reaches to 1000F / g, when the electric current density is 10A / g, the first time discharge capacity is still high and is in a range from 750F / g to 1000F / g, and the specific capacity maintains 90% after 10000 times of circulations.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

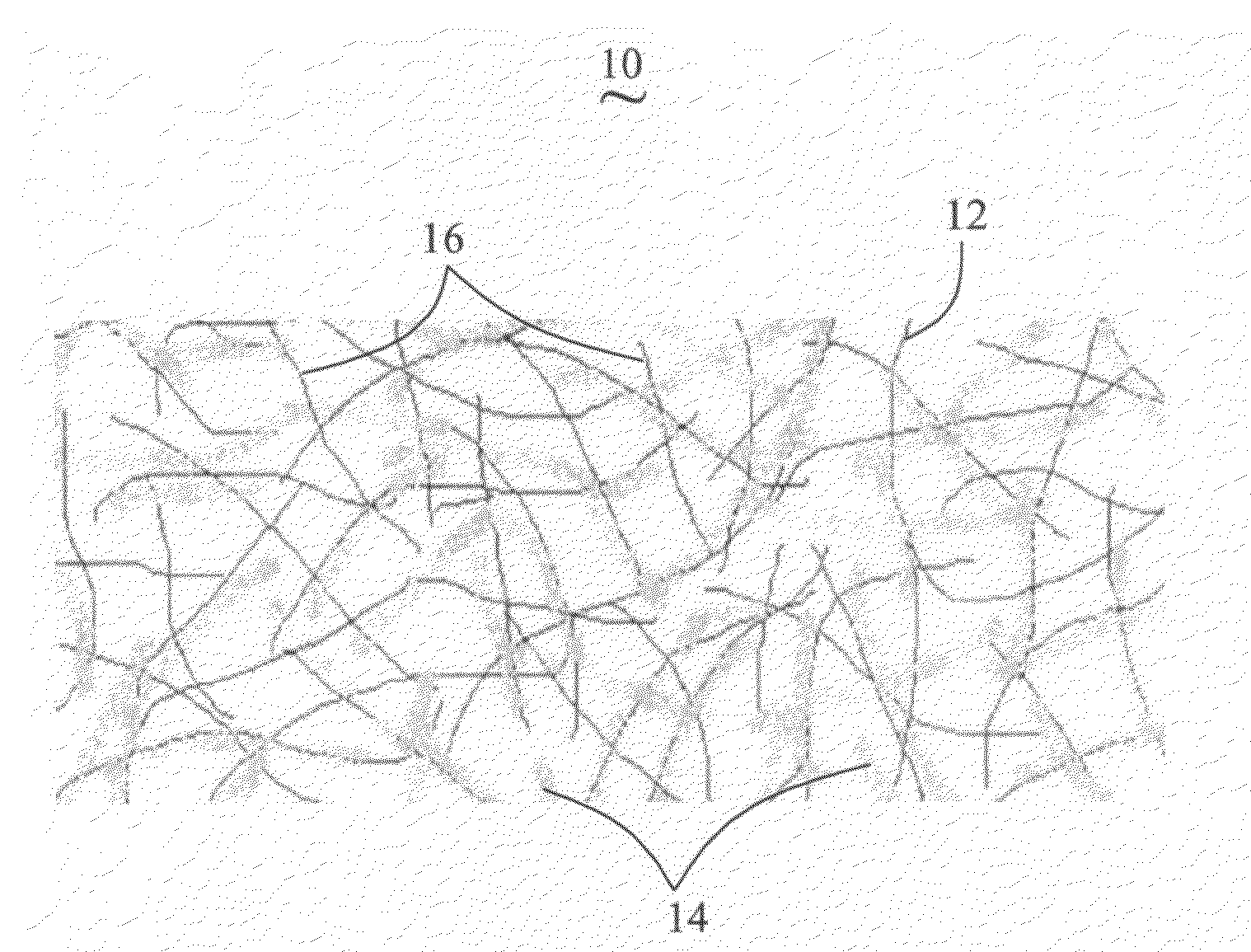

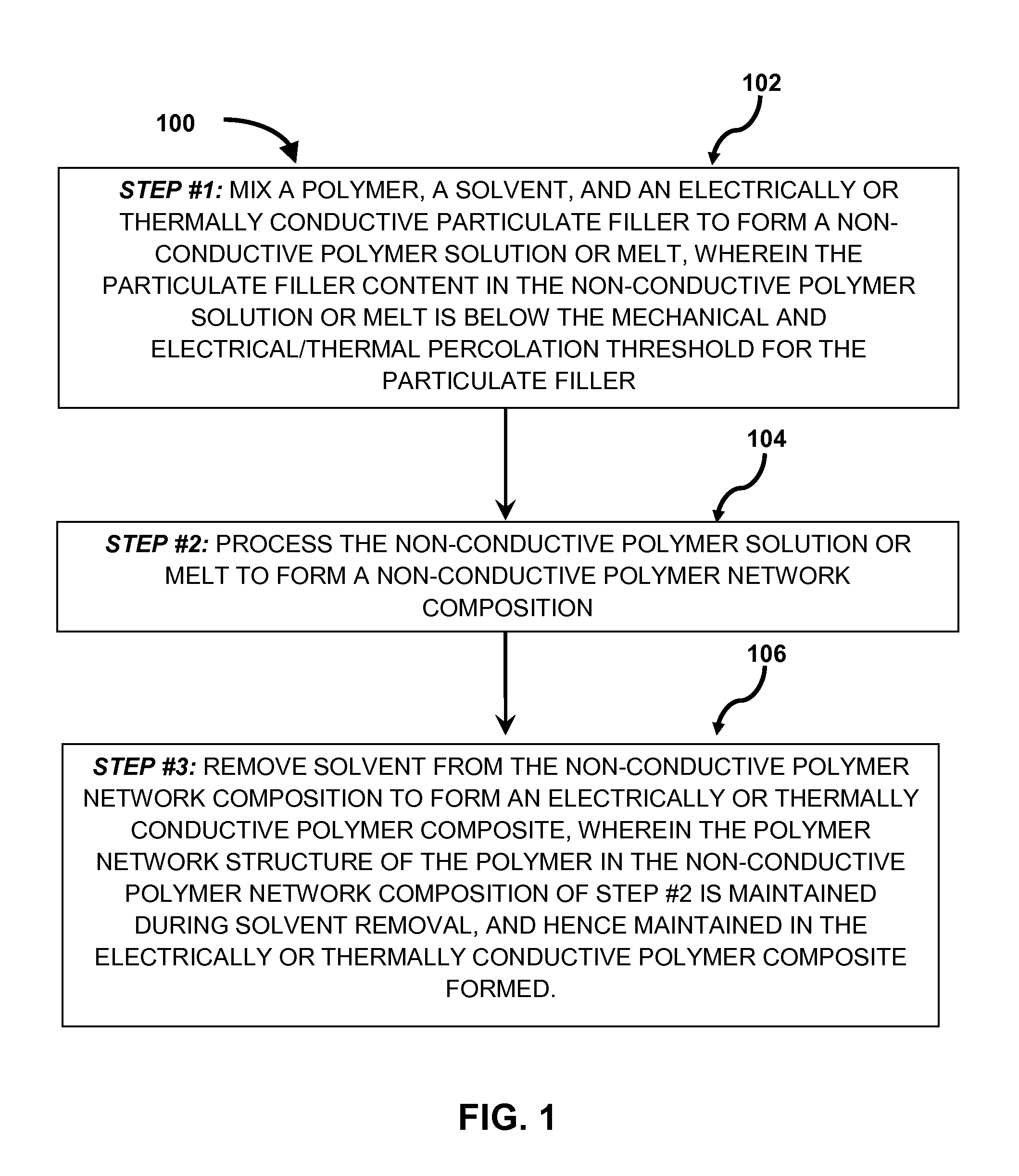

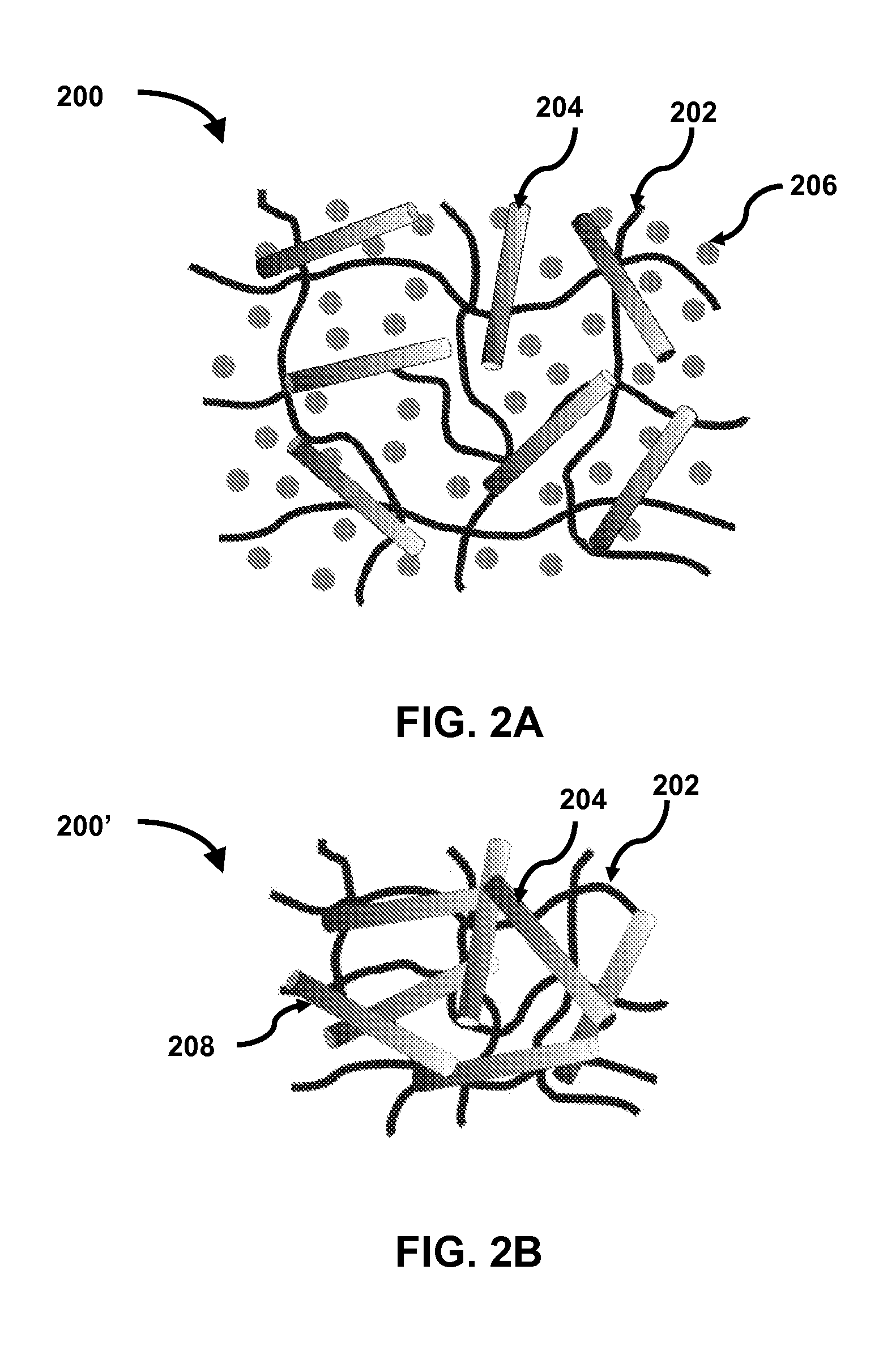

Solvent assisted processing to control the mechanical properties of electrically and/or thermally conductive polymer composites

ActiveUS20150083961A1Conductive materialNon-conductive material with dispersed conductive materialParticulatesElectricity

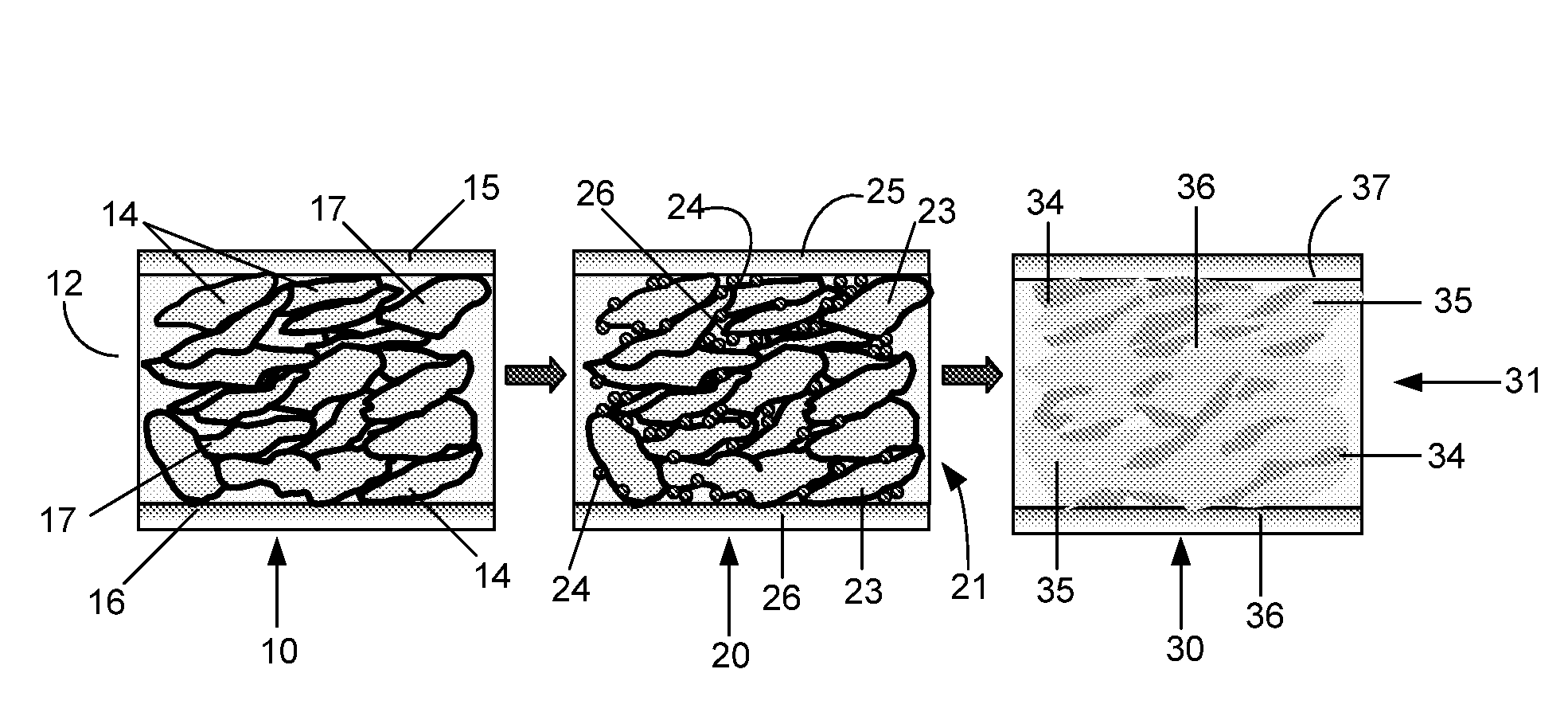

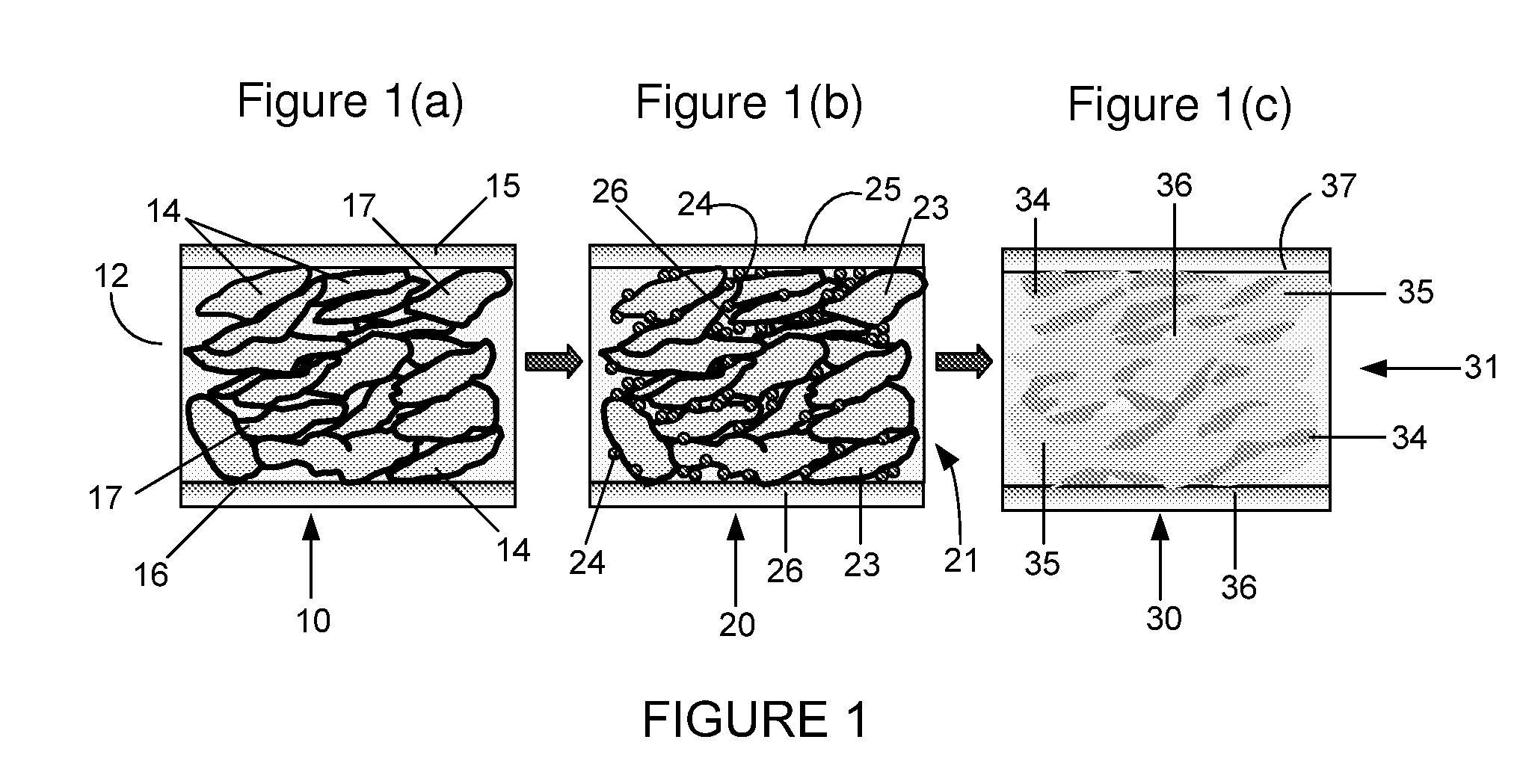

Electrically and / or thermally conductive polymer composites and methods of preparing same are provided. In some embodiments, a method for preparing an electrically and / or thermally conductive polymer composite may include (1) mixing a polymer, a conductive particulate filler, and a solvent compatible with the polymer to form a non-conductive polymer solution or melt; (2) processing, the non-conductive polymer solution or melt to form a non-conductive polymer network composition; wherein the presence of solvent during three-dimensional network formation manipulates the polymer network structure; and (3) removing the solvent from the non-conductive polymer network composition to form an electrically and / or thermally conductive polymer composite. The altered polymer chain structure present in the non-conductive polymer network composition is maintained in the composite, and offsets the impact of particulate filler addition including increased modulus, decreased elasticity, and decreased elongation at break. This method enables development of composite materials with electrical / thermal and mechanical performance that can be tailored independently.

Owner:US SEC THE ARMY THE

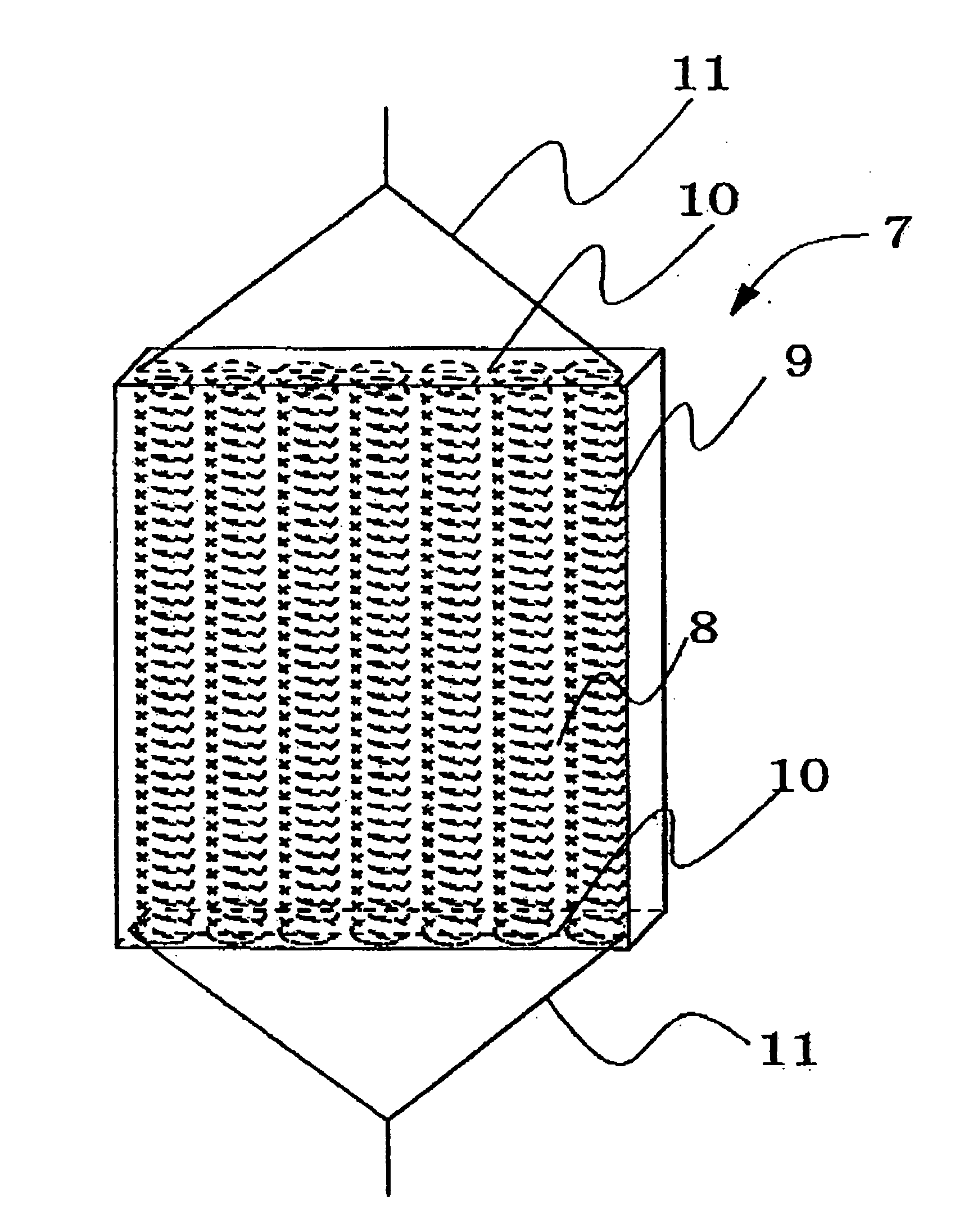

Conductive polymer composite structure

InactiveUS20060124470A1Good deformabilityEasy to getElectrolytic capacitorsSynthetic resin layered productsFiberConductive polymer composite

In order to obtain actuator elements capable of being displaced such as expansion and contract or bending for practical use even when used as actuator elements with larger size, stacked layers or bundles in which conductive polymer-containing layers or fiber-like tubes are provided with conductive polymer composite structures which include conductive substrates and conductive polymers, said conductive substrates have deformation property, and conductivity of said conductive substrates is not less than 1.0×103 S / cm are used.

Owner:EAMEX

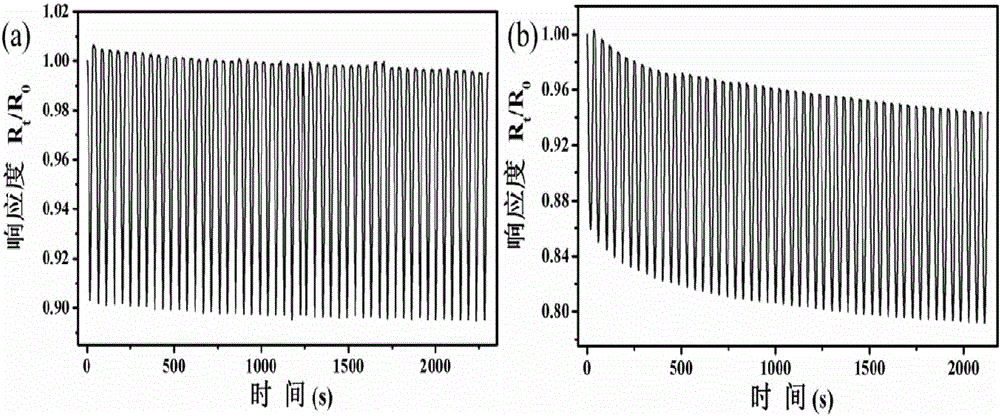

Preparation method of porous conductive polymer material with pressure-sensitive property and application thereof

ActiveCN106009029AImproved and stable electrical performanceLow percolation valueForce measurement using piezo-resistive materialsMaterial strength using repeated/pulsating forcesConductive polymer compositePolymer science

The invention belongs to the field of conductive polymer composites pressure-sensitive materials and particularly relates to a preparation method of a porous conductive polymer material with pressure-sensitive property and an application thereof. The preparation method of the porous conductive polymer material with pressure-sensitive property comprises the following steps: a) suspension preparation; b) unidirectional freezing; and c) low-temperature low-pressure drying. The porous conductive polymer composite with pressure-sensitive property prepared in the invention has excellent stability and resilience and can be used for preparing a light polymer-based strain sensor; and by combining the obtained conductive polymer composite with the circuit board and semiconductor technology, various pressure-sensitive sensors with good stability and long service life can be made.

Owner:ZHENGZHOU UNIV

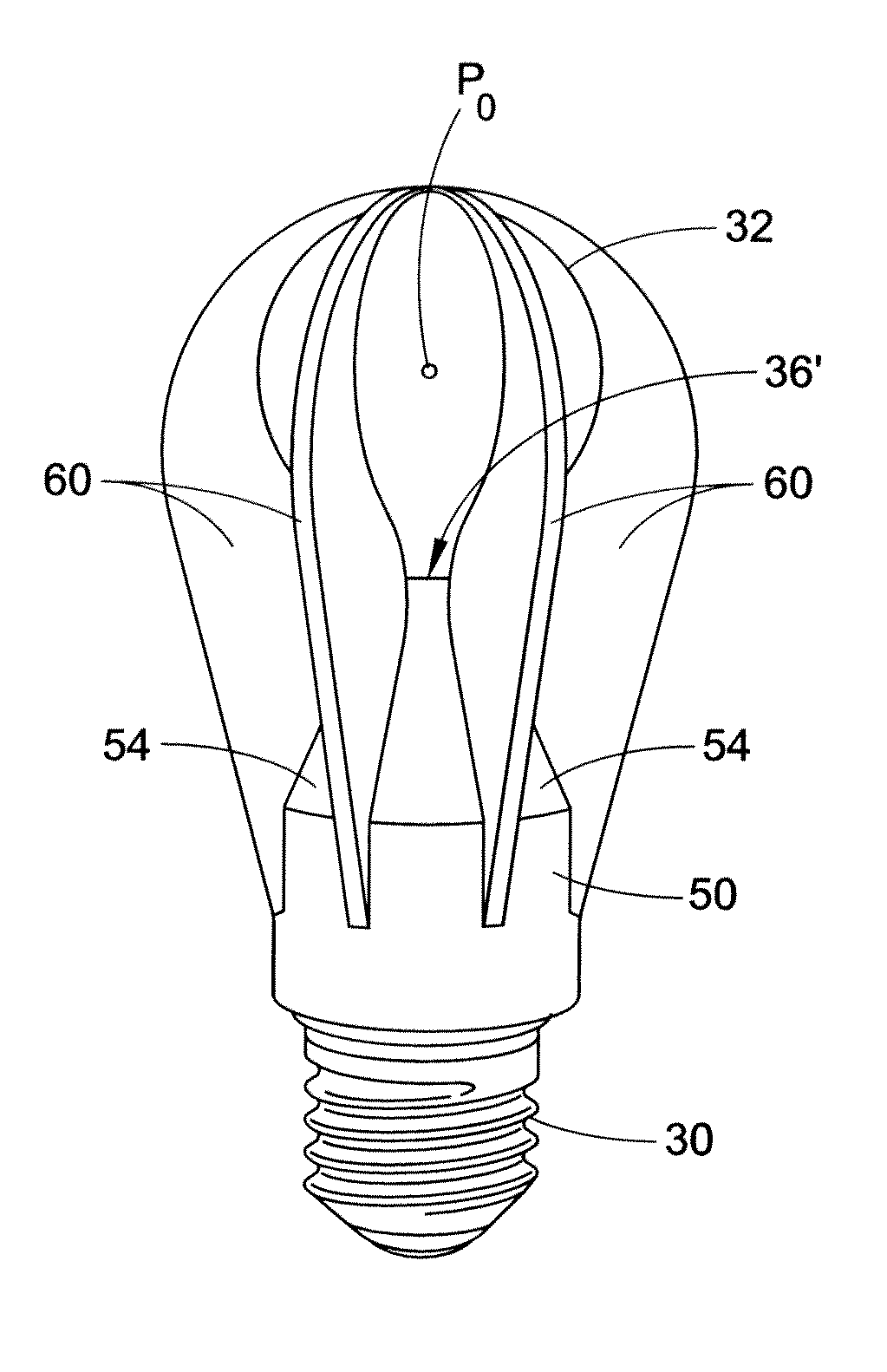

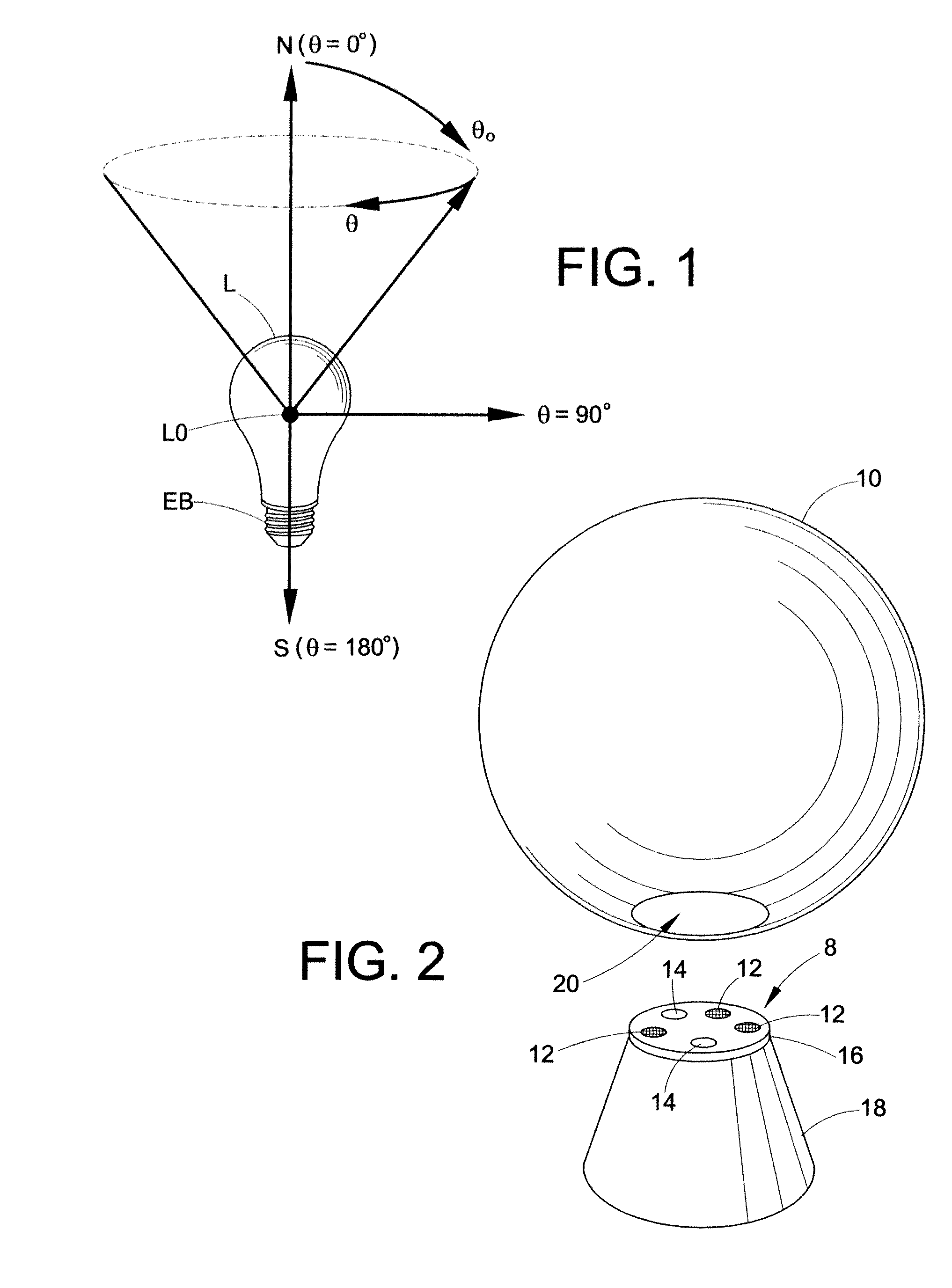

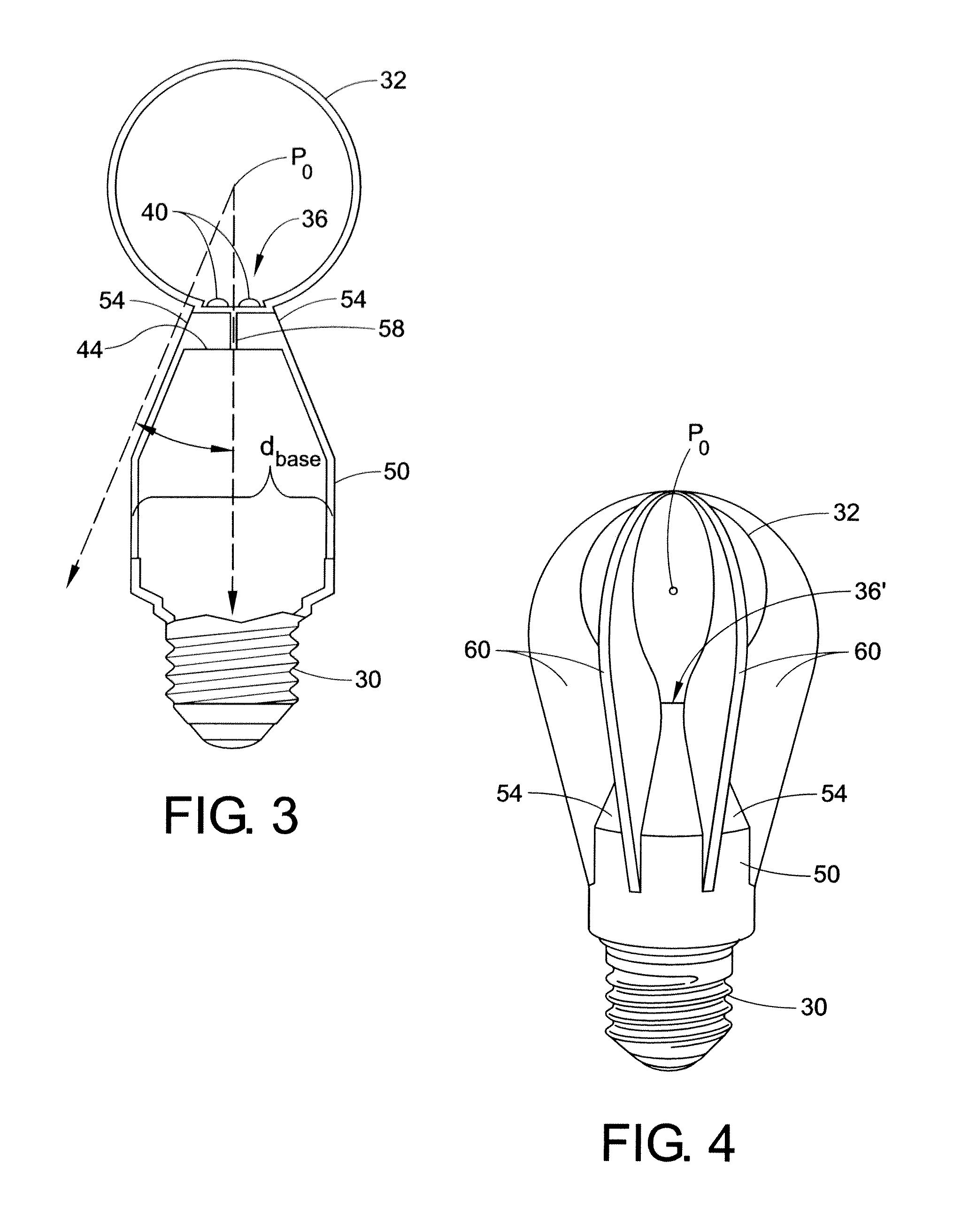

Transparent thermally conductive polymer composites for light source thermal management

ActiveUS20110169394A1Discharge tube luminescnet screensPoint-like light sourceConductive polymer compositeCarbon nanotube

A light emitting apparatus is provided. The light emitting apparatus includes a light transmissive envelope, a light source being in thermal communication with a heat sink, and a plurality of heat fins in thermal communication with the heat sink and extending in a direction such that the heat tins are adjacent the light transmissive envelope. The plurality of heat fins comprises a carbon nanotube filled polymer composite.

Owner:CONSUMER LIGHTING (U S) LLC

Method for preparing polystyrene/conductive polymer composite hollow microspheres

The invention discloses a method for preparing polystyrene / conductive polymer composite hollow microspheres, which comprises the following steps of: adding aniline or pyrrole and acid or mixture thereof into polystyrene emulsion under the protection of inert gas, stirring the obtained mixture for at least 10 minutes, and then adding an initiator into the mixture to perform polymerization, whereinthe molar ratio of the aniline or the pyrrole to the acid is 0.2 to 0.8, the weight ratio of the aniline or the pyrrole to the polystyrene is 0.1 to 1.0, and the initiator is ammonium persulfate, potassium persulfate, iron trichloride or ferrous sulfate heptahydrate / hydrogen peroxide. Different from the traditional method for preparing the hollow polymer microspheres, the method does not need high-temperature calcination or solvent denucleation treatment and can prepare the polymer composite hollow microspheres by one step, and the microspheres have good appearance and monodispersity. The method is simple, has a few operation steps, and is easy for subsequent treatment; and because the used solvent is a green solvent, the method is safe and reliable, and has low cost.

Owner:BEIJING NORMAL UNIVERSITY

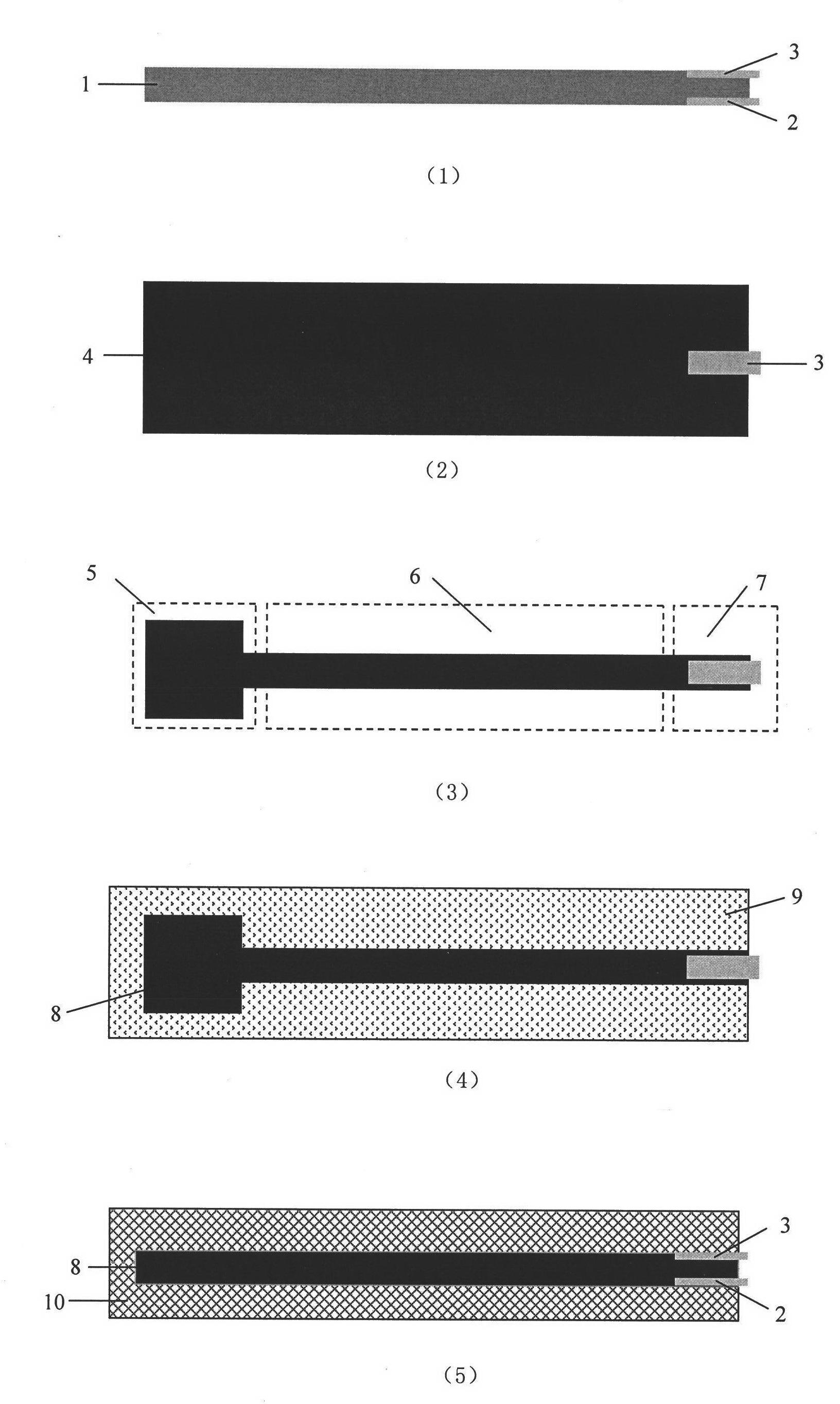

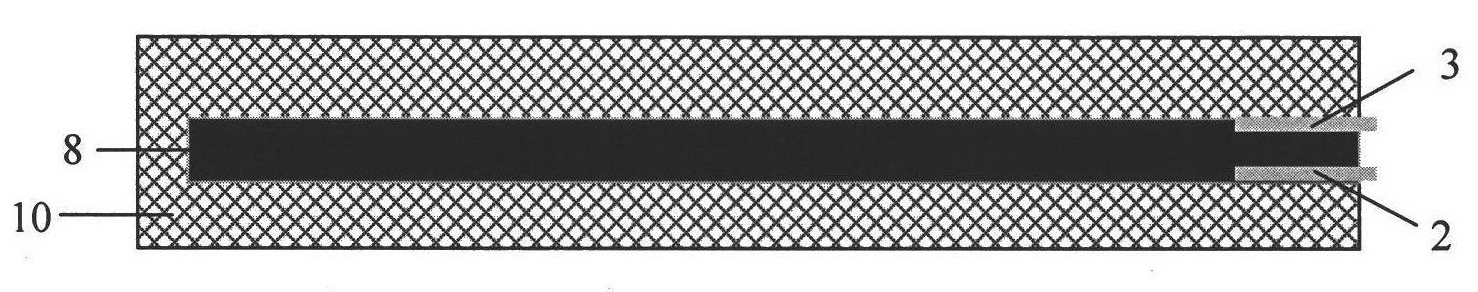

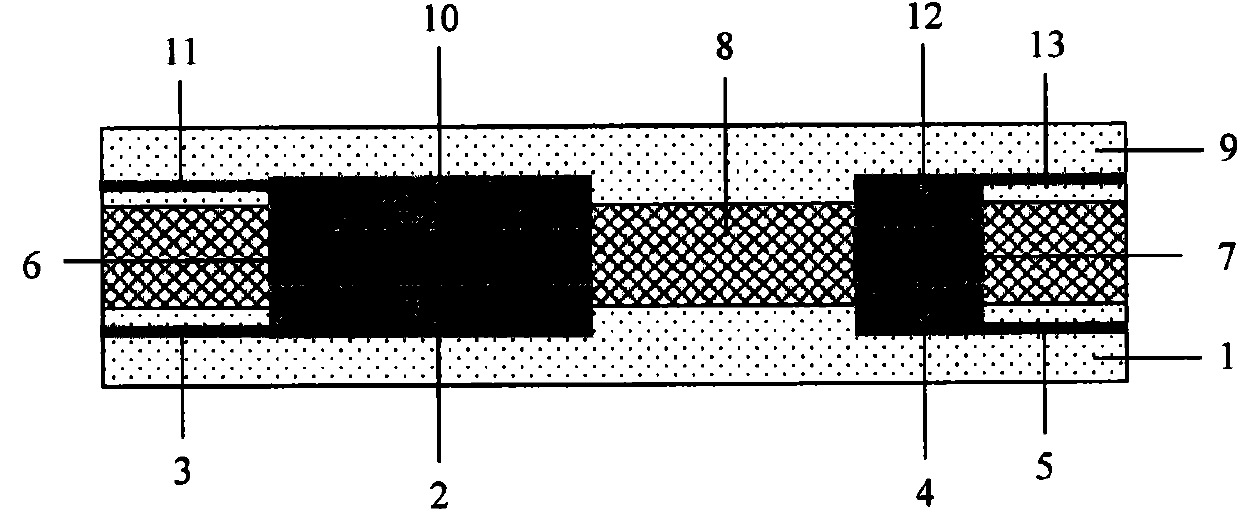

Method for developing flexible pressure sensitive probe with side electrode

InactiveCN102141451AReduce thicknessReduce complexityForce measurement using piezo-electric devicesConductive polymer compositeSurface layer

The invention relates to a method for developing a flexible pressure sensitive probe with a side electrode and belongs to the technical field of sensors. The probe consists of a sensitive area, a conductive area and an interface area, wherein the sensitive area and the conductive area both have a three-layer flexible structure of which the middle layer is made of a conductive polymer composite material and of which the outmost two layers are insulated packaging thin films; and the interface area has a five-layer structure of which the middle layer is made of the conductive polymer composite material, of which the two sub outer layers are connected with a subsequent circuit, and of which the two outmost layers are insulated packaging thin films. The conductive polymer composite material is prepared by dispersing nano conductive powder into a polymer substrate by using a solution mixing process. The insulated packaging thin film is prepared by vulcanization forming of a liquid polymer material in the presence of a catalyst and a crosslinking agent. The pressure sensitive probe developed by the method provided by the invention has no rigid electrodes in the sensitive area and the conductive area, has the advantages of high flexibility, small thickness, simple structure, simple process, low cost and the like, and is particularly suitable for measuring pressure and displacement between curved surface layers.

Owner:NORTHEASTERN UNIV

Silicon rubber/conductive ethylene propylene terpolymer and its preparing method

InactiveCN1470559AGood effectImprove mechanical propertiesNon-conductive material with dispersed conductive materialConductive polymer compositePolymer science

The present invention relates to a silicone rubber / EPT conductive rubber and its preparation method. Its raw material composition includes EPT rubber raw rubber, silicone rubber raw rubber, silane coupling agent, organic peroxide, carbon black and white carbon black, and its preparation method includes the following steps: adopting open double roller mixing machine, successively mixing them uniformly, sheeting, rolling and others. Said invention conductive rubber has good mechanical property, and its preparation method is simple, its cost is low and its product quality is good.

Owner:SHANDONG UNIV

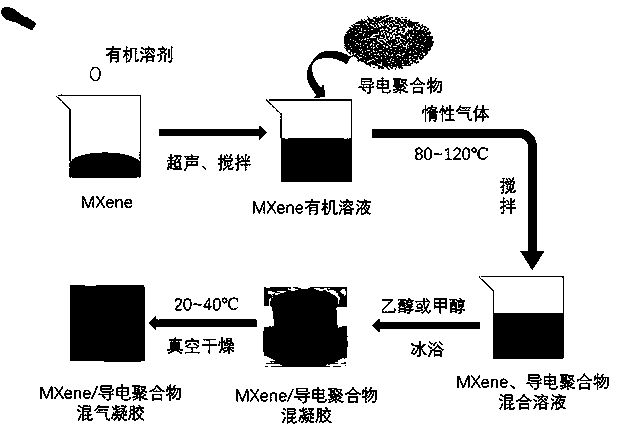

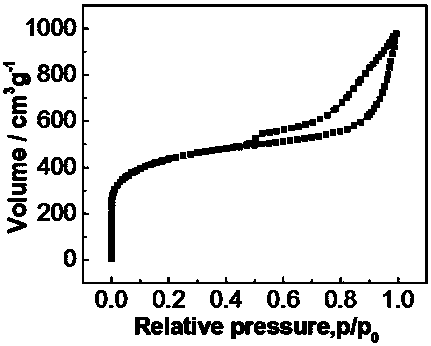

MXene/conductive polymer composite aerogel and preparation method thereof

ActiveCN108530889AImprove surface utilizationReduce collapseConductive polymer compositePolymer science

The invention discloses an MXene / conductive polymer composite aerogel. The MXene / conductive polymer composite aerogel is of an integrated three-dimensional grid structure which is formed by insertinglaminated MXene into a conductive polymer aerogel, wherein the conductive polymer comprises one or more of polyaniline, polypyrrole and polythiophene. The invention further discloses a preparation method of the MXene / conductive polymer composite aerogel. The method is characterized in that the MXene and the conductive polymer are mixed with organic solution and then are rapidly cooled and separated under heat inducing and solvent inducing effects under the inert gas protection; then the vacuum drying is carried out to obtain the MXene / conductive polymer composite aerogel.

Owner:BEIJING UNIV OF CHEM TECH

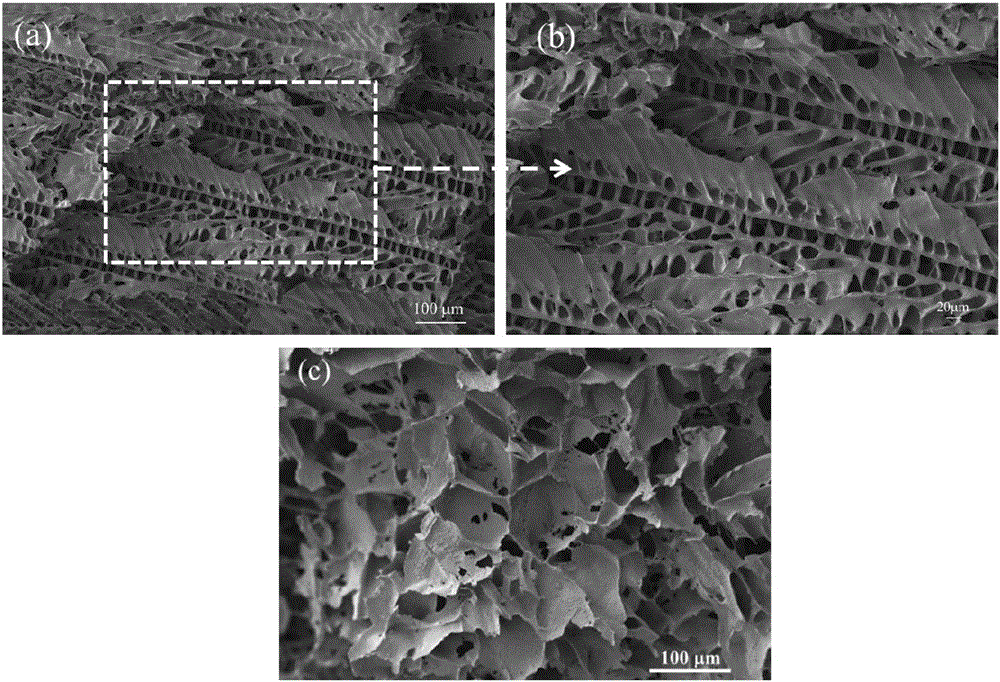

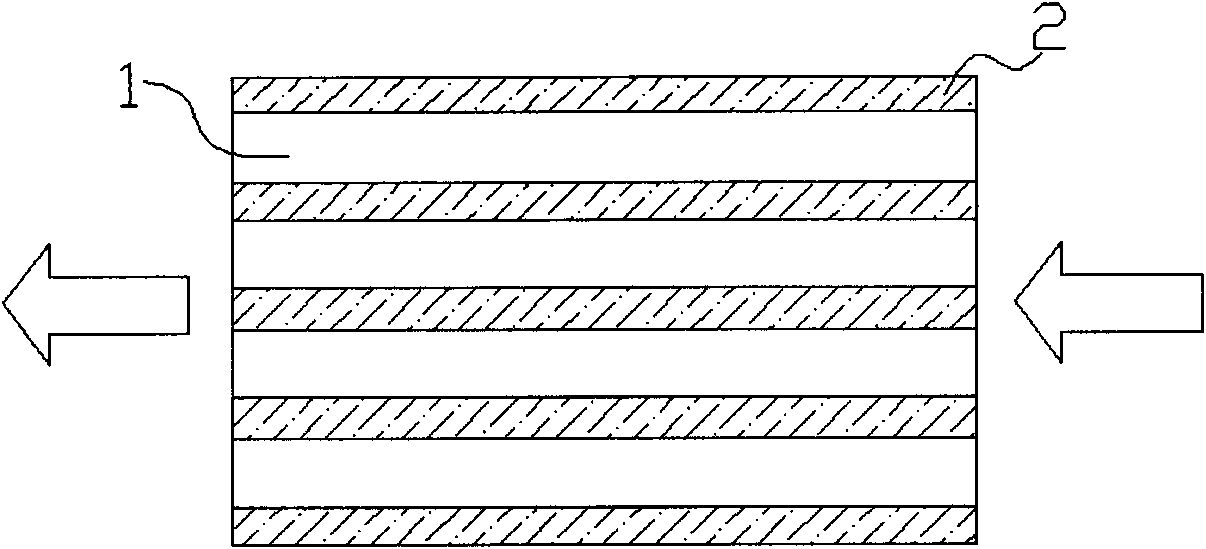

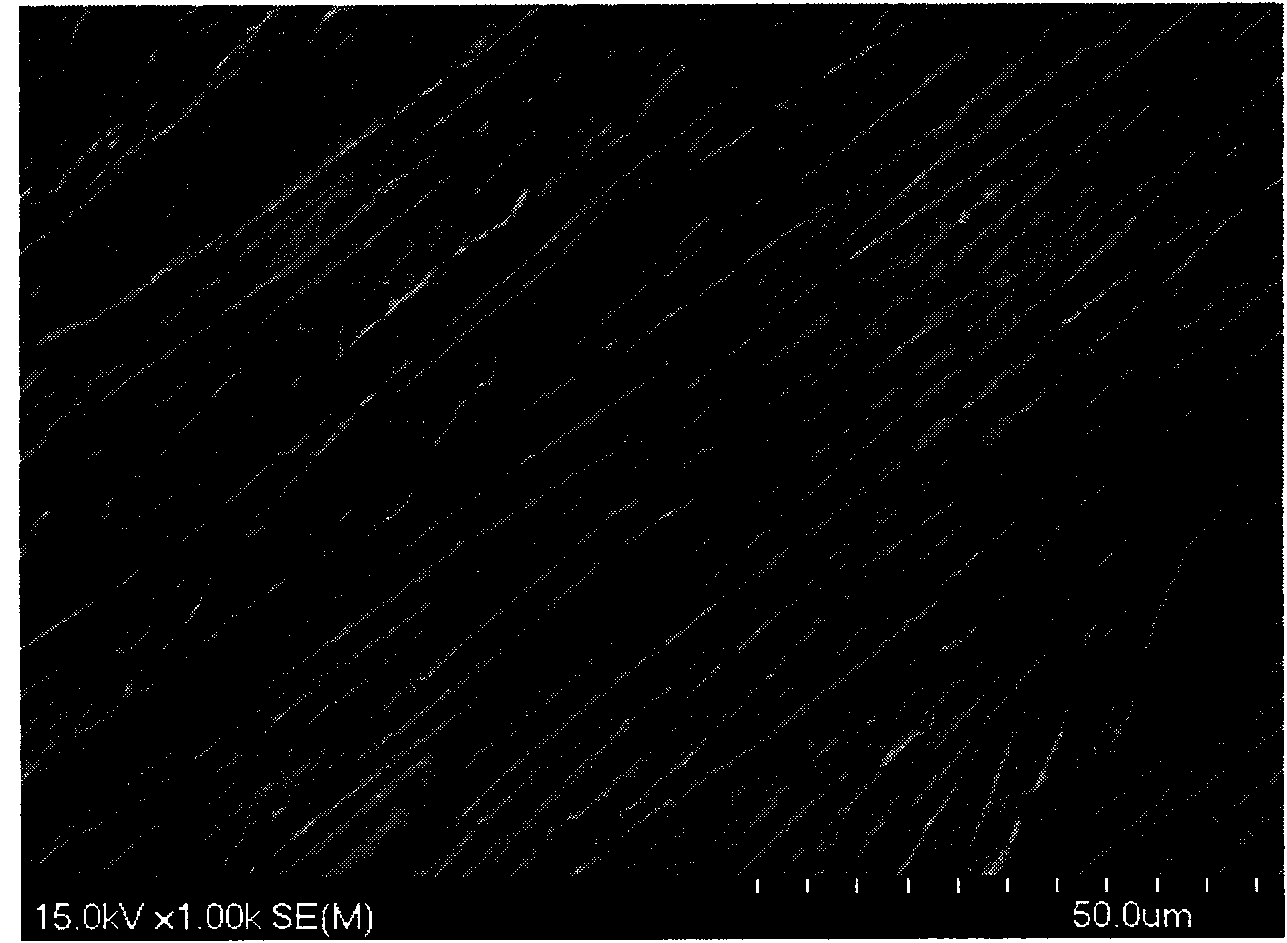

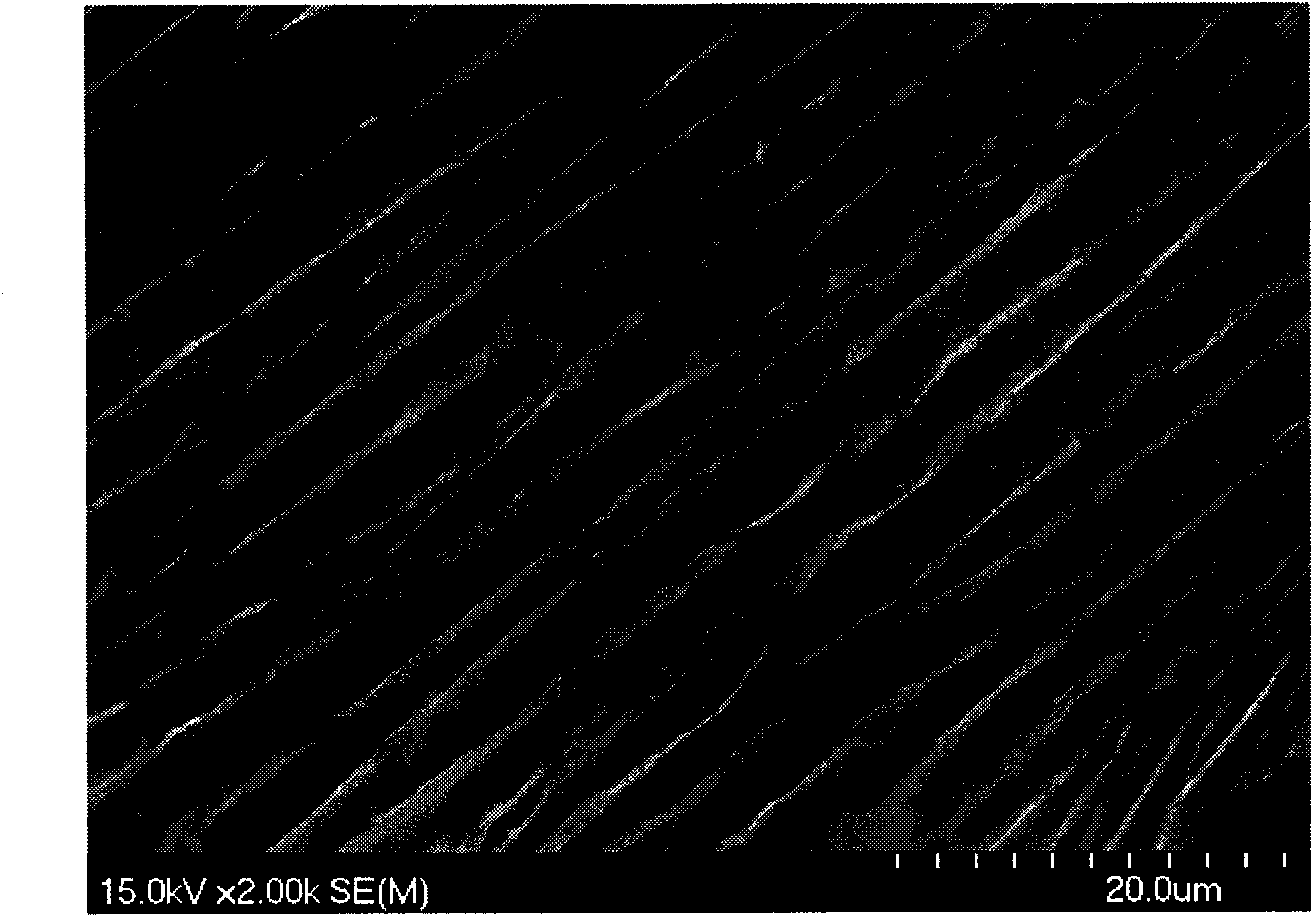

Method for preparing conductive polymer composite with one-dimensional oriented porous structure

ActiveCN101993546AIncrease productivitySimple processMaterial resistanceChemical reactionConductive polymer composite

The invention discloses a method for preparing a conductive polymer composite with a one-dimensional oriented porous structure. The preparation method mainly relates to physical phase change and does not relate to a chemical reaction, and compared with the conventional methods such as a micromachining method, a photoetching method, soft photoetching technology and the like, the preparation method has the characteristics of simplicity of process, high controllability, low requirements on equipment, high production efficiency and investment saving. The conductive polymer composite with the one-dimensional oriented porous structure prepared by the method has the application potential in aspects of flow gas sensors and the like.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST +1

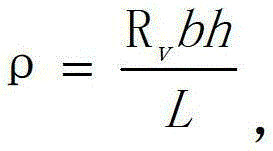

Composite type flexible pressure and displacement sensitive element and preparation method thereof

InactiveCN103743438AIncreasing the thicknessImprove flexibilityMeasurement devicesConductive polymer compositeCopper foil

The invention relates to a composite type flexible pressure and displacement sensitive element and a preparation method thereof, and belongs to the technical field of measurement. The composite type flexible pressure and displacement sensitive element comprises a displacement sensitive layer, a pressure sensitive layer and an insulated encapsulation layer, wherein the displacement sensitive layer is formed by a copper foil coil covering a polyimide film; the pressure sensitive layer is formed by a conductive polymer composite material which is embedded in Polydimethyl Siloxane; the insulated encapsulation layer is formed by a flexible polymer material which is vulcanized at the outer parts of the displacement sensitive layer and the pressure sensitive layer; information of pressure and displacement can be obtained through detecting the impedance change of the copper foil coil. The composite type flexible pressure and displacement sensitive element prepared by the invention has dual functions of pressure measurement and non-contact displacement measurement and can be applied to the fields of multi-sensitive electronic skin preparation or pressure measurement and non-contact displacement measurement between small narrow curved layers of a whole machine and complete equipment in an intelligent manufacturing complete process.

Owner:NORTHEASTERN UNIV

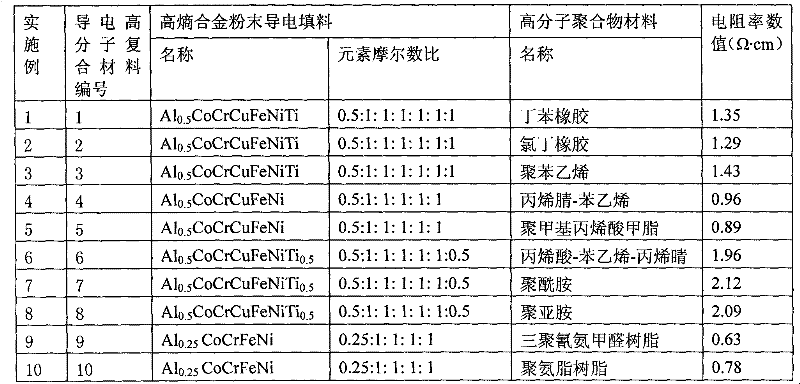

High-entropy alloy powder conductive polymer composite material and manufacturing method thereof

InactiveCN102220026AIncrease moistureLow costNon-conductive material with dispersed conductive materialConductive polymer compositeHigh entropy alloys

The invention relates to a high-entropy alloy powder conductive polymer composite material and a manufacturing method thereof. The high-entropy alloy powder conductive polymer composite material is characterized by being prepared from a multi-component high-entropy alloy powder conductive filling material and a polymer material; the conductive filling material contains five to ten kinds of primary metallic elements and each one of the primary metallic elements accounts for 5 to 30 atomic percentage of the conductive filling material; and the polymer material is a natural rubber or a synthetic polymer material. The high-entropy alloy powder conductive polymer composite material has the advantages of stabilization, oxidation resistance and low cost.

Owner:黄元盛

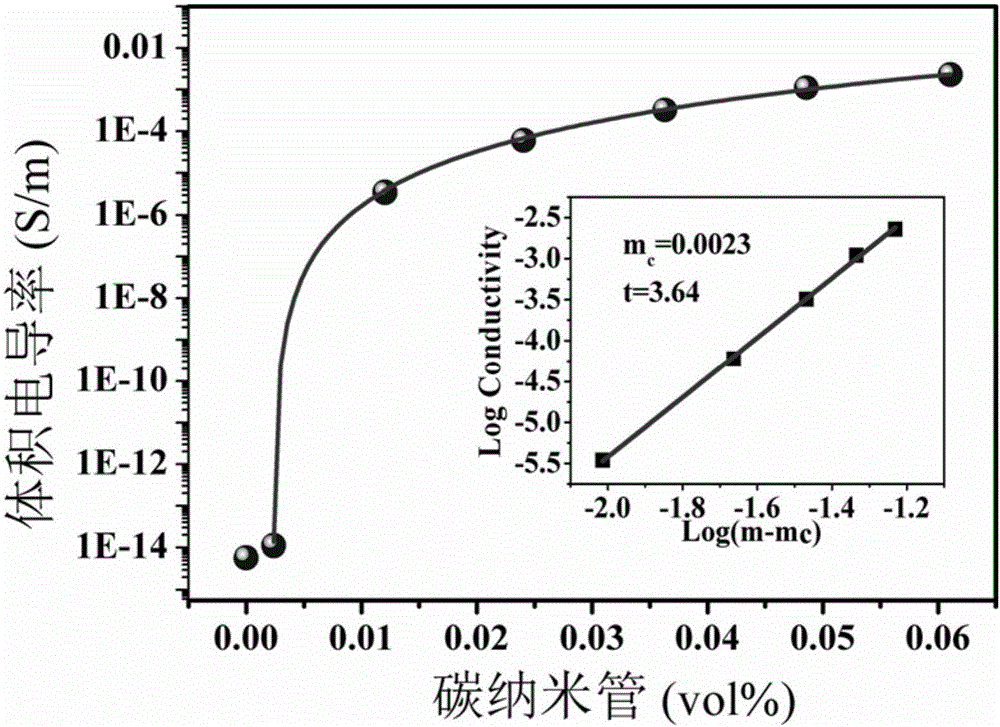

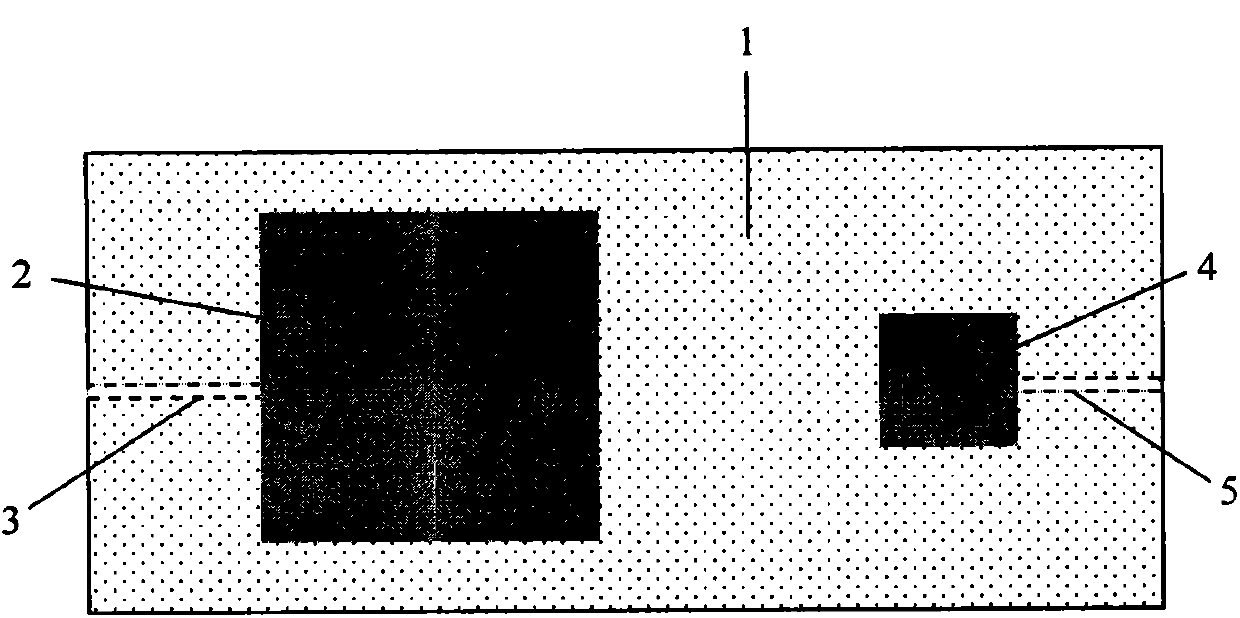

Differential type flexible piezoresistive device based on conductive polymer composite

InactiveCN103808437AThe content of conductive phase increasesLow content of conductive phaseForce measurement using piezo-resistive materialsConductive polymer compositeIndustrial equipment

The invention relates to a differential type flexible piezoresistive device based on a conductive polymer composite, which belongs to the technical field of measurement. The piezoresistive device comprises two piezoresistive units based on the conductive polymer composite, an increasing type piezoresistive unit and a decreasing type piezoresistive unit; the conductive polymer composite is prepared by a solution mixing method; the conductive phase content of the increasing type piezoresistive unit is higher than the critical content of the composite, and the resistance thereof is increased with the increasing of a pressure; the conductive phase content of the decreasing type piezoresistive unit is lower than the critical content of the composite, and the resistance thereof is reduced with the increasing of a pressure; the absolute values of the resistance changes of the increasing type piezoresistive unit and the decreasing type piezoresistive unit are equal under the same pressure by designing the electrode areas thereof, so as to form a differential structure. The piezoresistive device developed by the method disclosed by the invention has the advantages of being high in sensitivity, high in flexibly, low in cost and the like, as well as is especially suitable for a narrow curved-surface interlayer small-pressure measurement for industrial equipment.

Owner:NORTHEASTERN UNIV

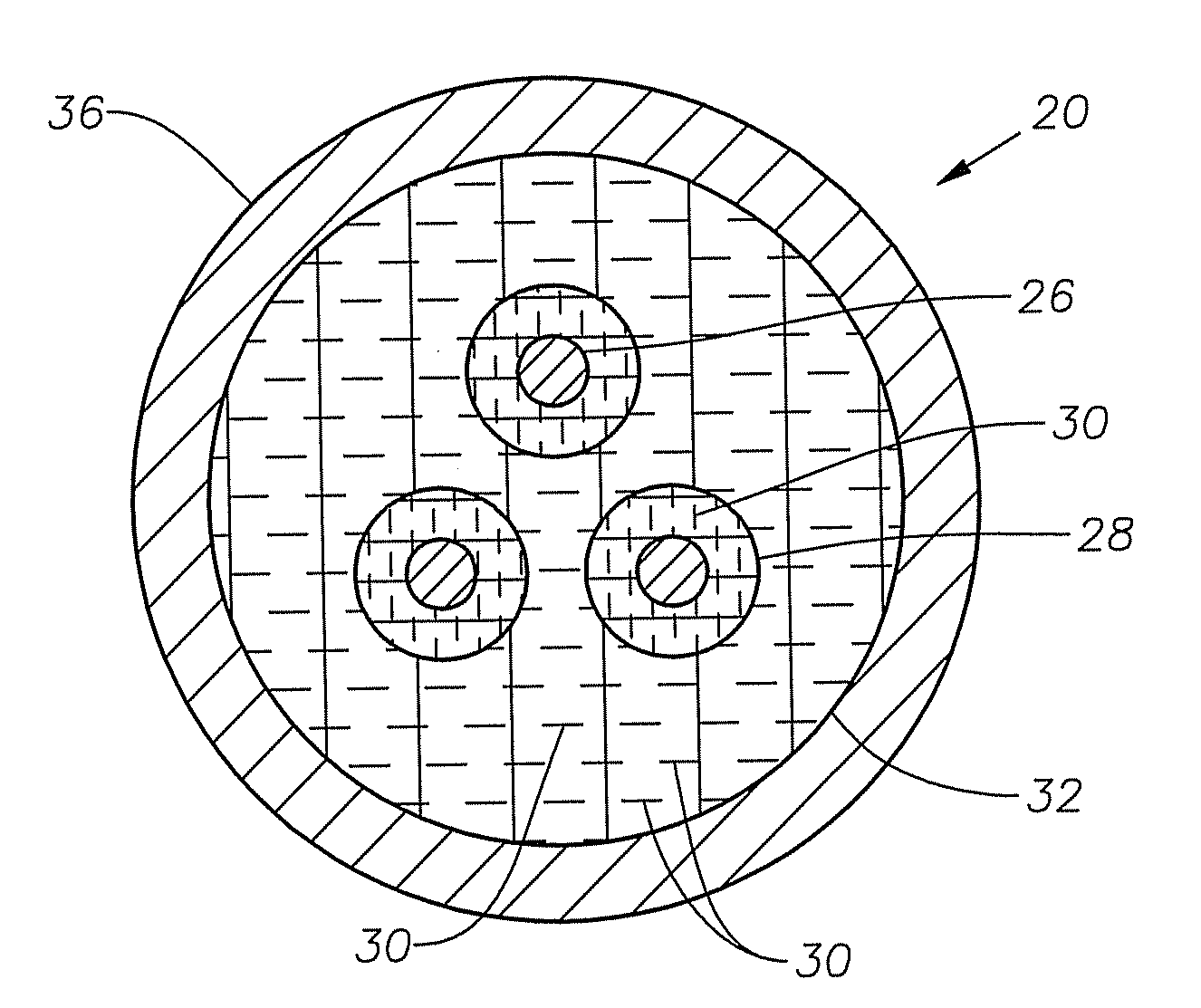

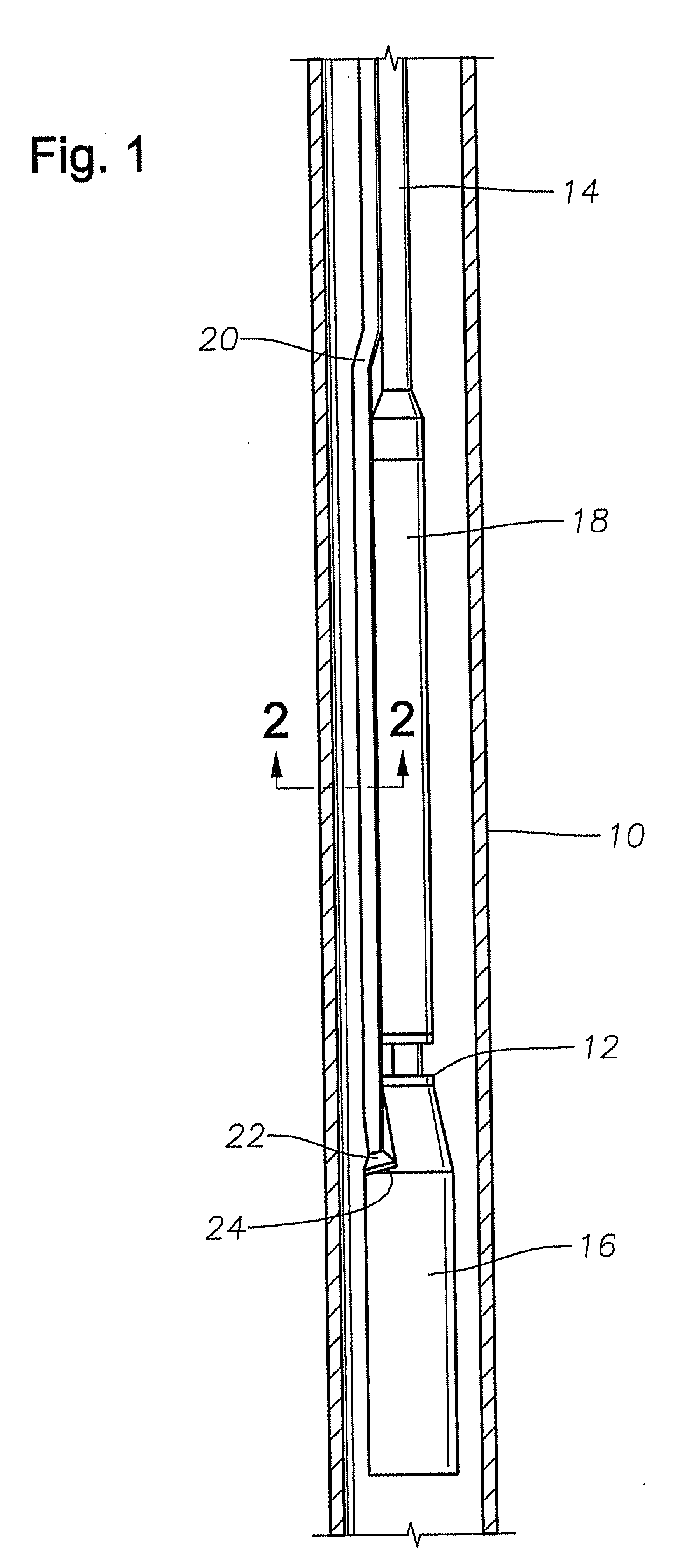

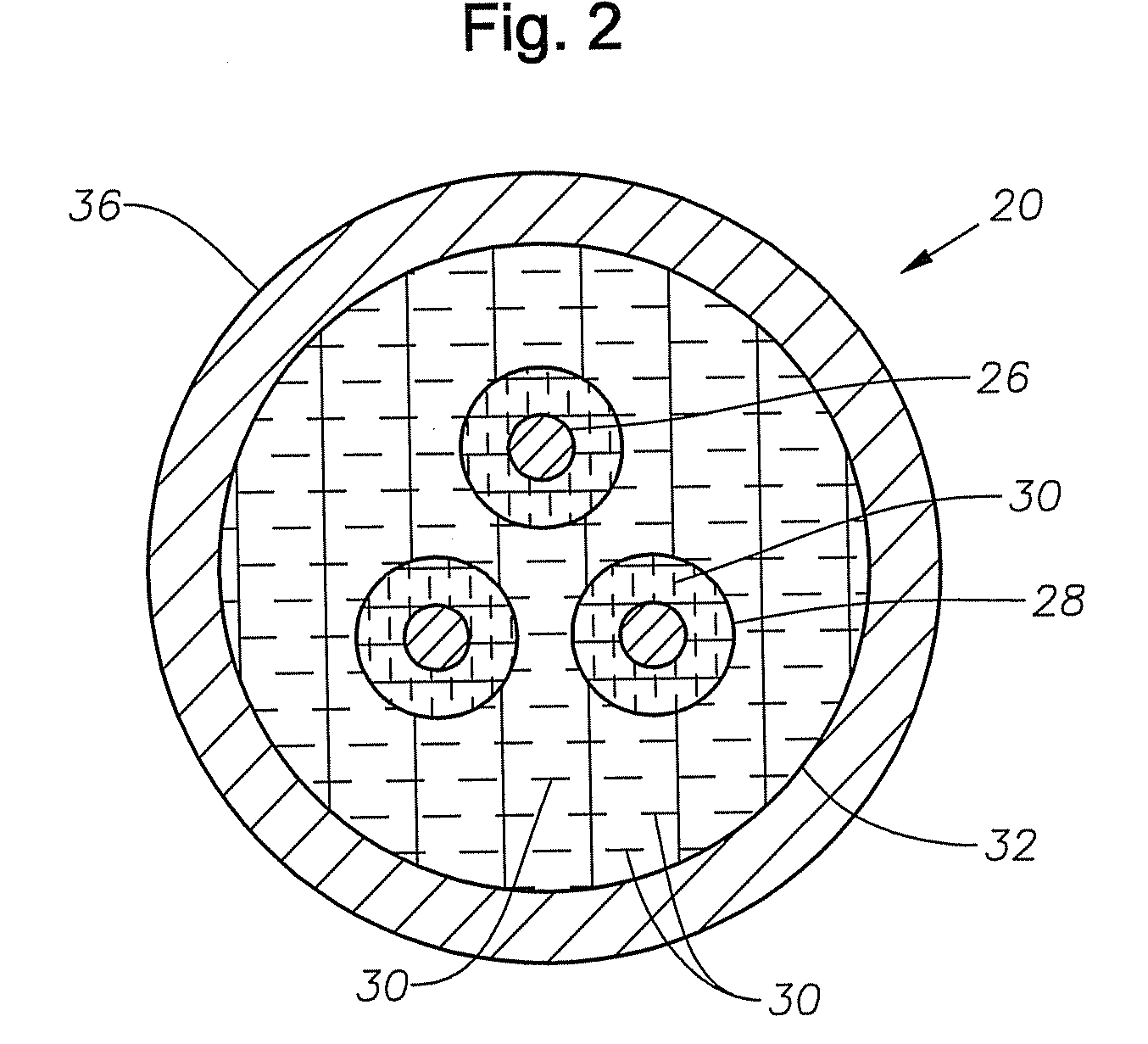

Downhole Cable With Thermally Conductive Polymer Composites

ActiveUS20100096161A1Improve insulation performanceEfficiently and quickly dissipate heatRubber insulatorsPlastic/resin/waxes insulatorsElectricityConductive polymer composite

A cable for transmitting electricity for use with an electric submersible pump has a plurality of conductors for conducting electricity along the length of the cable. A first layer of insulation surrounds each of the conductors. A jacket, or second layer of insulation, surrounds all of the conductors and the first layer of insulation. Both the first layer of insulation and the jacket insulation are comprised of an polymeric compound. At least one of the insulation layers has filler material dispersed therein, the filler material having a higher level of thermal conductivity than the insulation layer it is contained in.

Owner:BAKER HUGHES INC

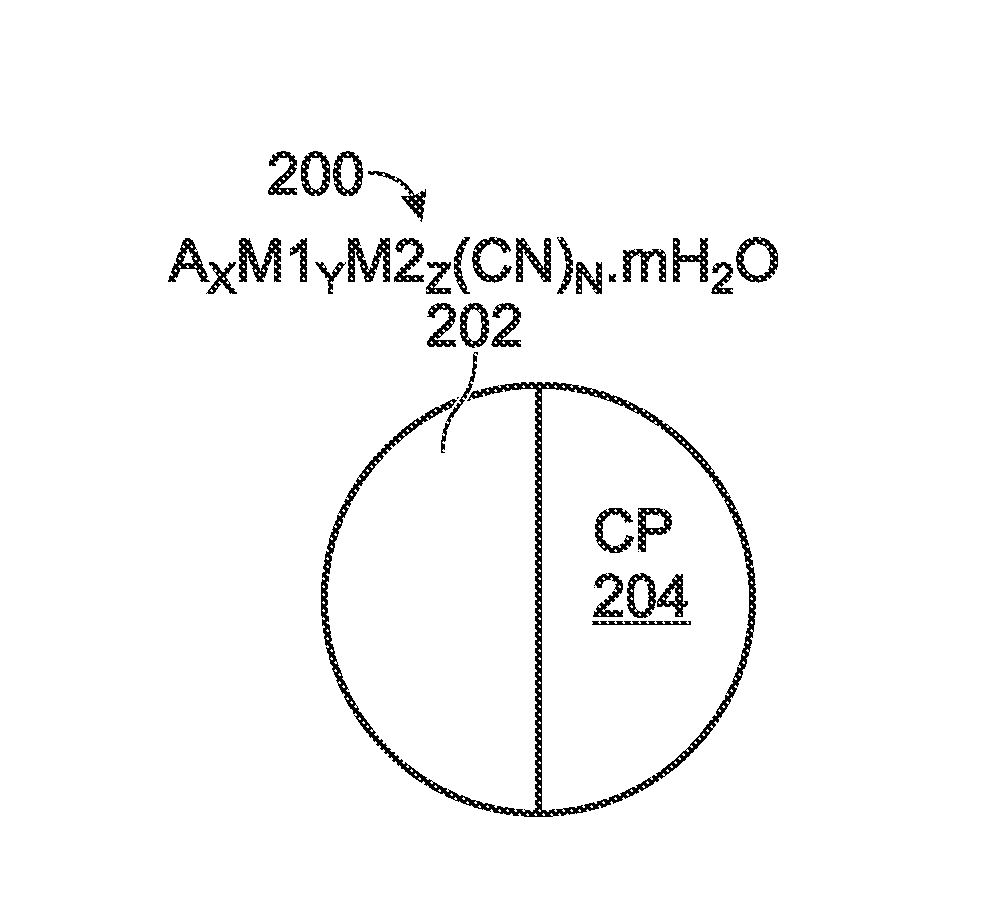

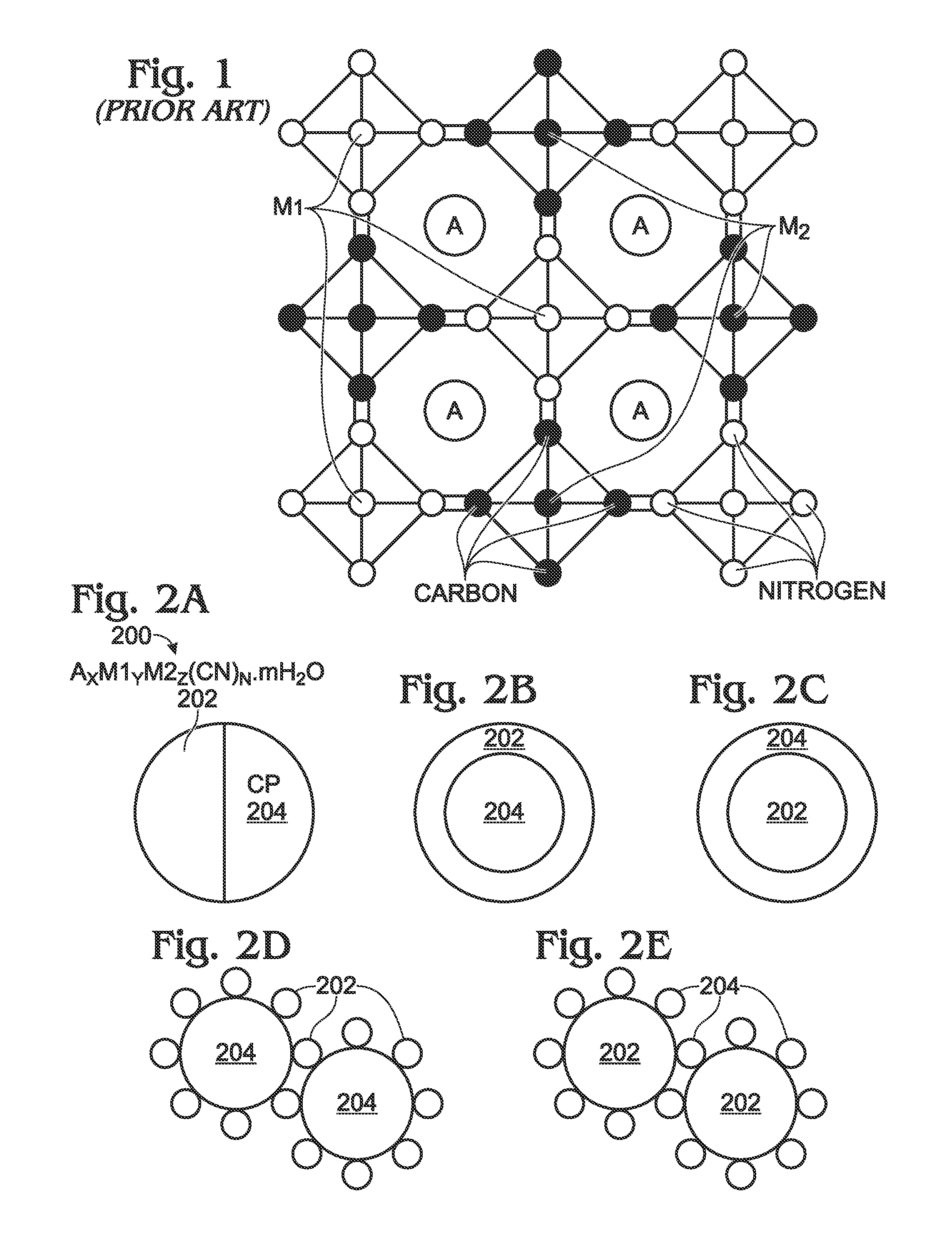

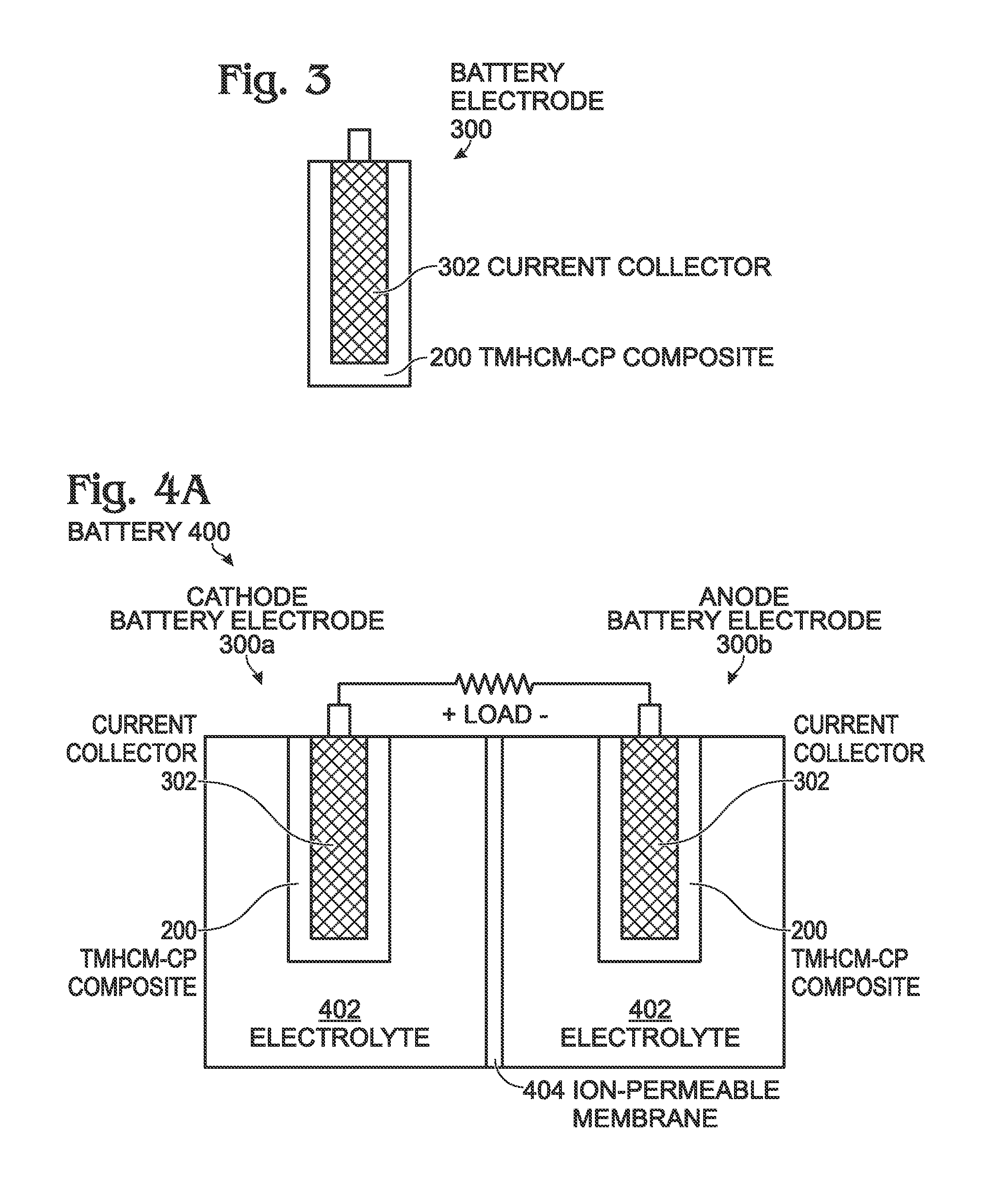

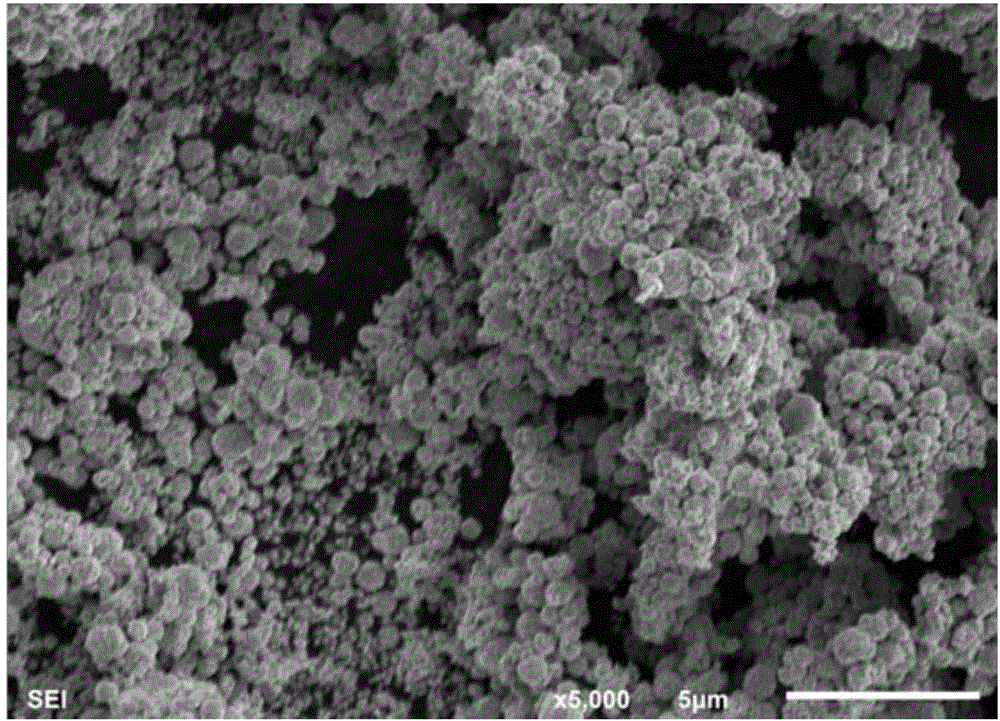

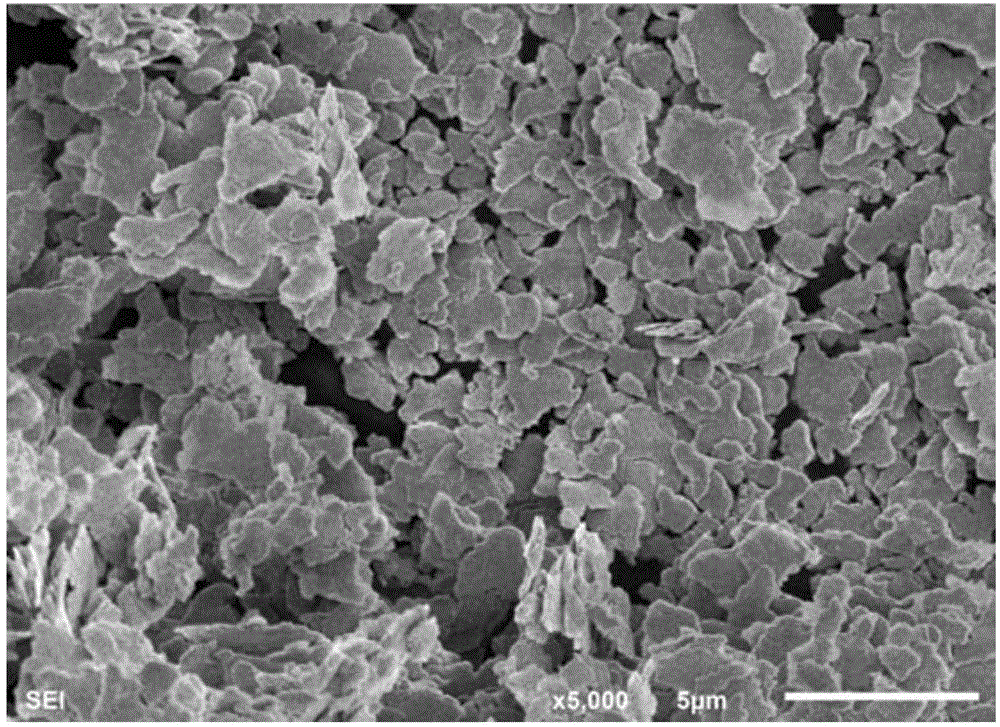

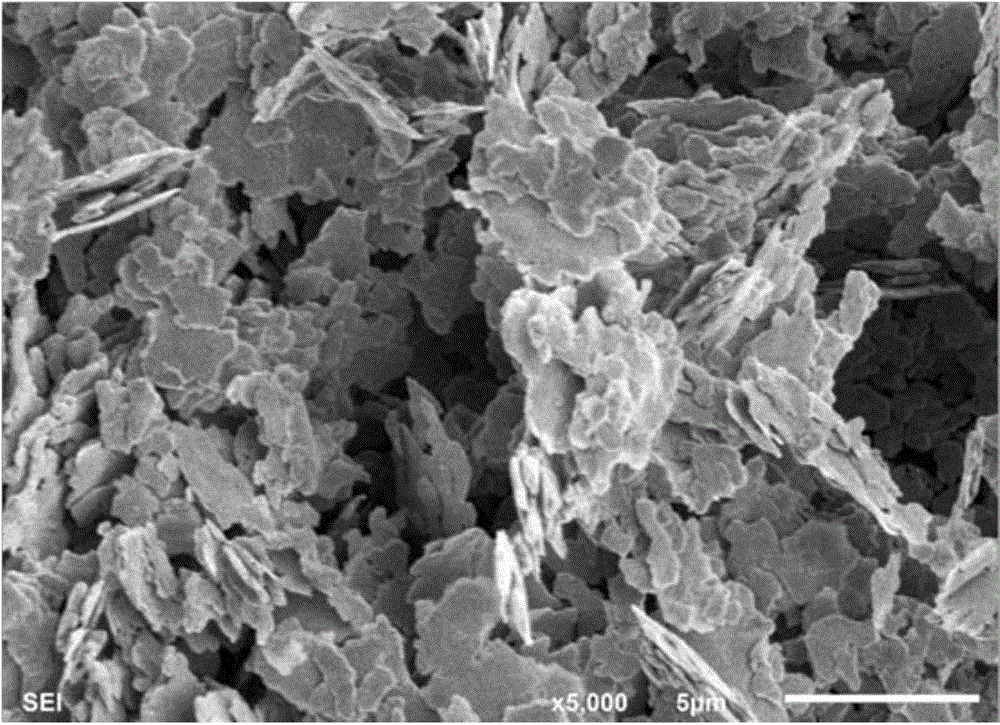

Transition Metal Hexacyanometallate-Conductive Polymer Composite

ActiveUS20140038044A1Conductive materialActive material electrodesAlkaline earth metalConductive polymer composite

A transition metal hexacyanometallate (TMHCM)-conductive polymer (CP) composite electrode is provided. The battery electrode is made up of a current collector and a transition metal hexacyanometallate-conductive polymer composite overlying the current collector. The transition metal hexacyanometallate-conductive polymer includes a AXM1YM2Z(CN)N.MH2O material, where A may be alkali metal ions, alkaline earth metal ions, ammonium ions, or combinations thereof, and M1 and M2 are transition metal ions. The transition metal hexacyanometallate-conductive polymer composite also includes a conductive polymer material. In one aspect, the conductive polymer material is polyaniline (PANI) or polypyrrole (Ppy). Also presented herein are methods for the fabrication of a TMHCM-CP composite.

Owner:SHARP KK

Micro-nano silver/conductive polymer composite, preparation method thereof and application

InactiveCN104599737AGood particle size controllabilitySimple manufacturing methodNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyesterMicro nano

The invention belongs to the technical field of composites, and discloses a micro-nano silver / conductive polymer composite, a preparation method thereof and an application. The preparation method of the composite includes the steps: (1) preparing silver-ammonia solution, adding surface-active agents into the silver-ammonia solution, uniformly mixing the silver-ammonia solution and the surface-active agents to obtain emulsion, dripping reducing agent solution under the condition of stirring, performing reaction for 30-60min after dripping, washing the solution and separating deposits to obtain micro-nano silver powder; (2) weighing polyester or acrylic acid resin and dissolving the resin by solvents to obtain polymer solution, dispersing the micro-nano silver powder in the solvents to obtain silver dispersion liquid, adding the silver dispersion liquid into the polymer solution, uniformly mixing the silver dispersion liquid and the polymer solution, and dispersing the solution for 5-30min by a three-roller machine to obtain the micro-nano silver / conductive polymer composite. The composite has the advantage of fine conductivity and can be applied to the field of conductive electrodes, touch screen electrodes, thin-film conductive switches and the like.

Owner:SOUTH CHINA UNIV OF TECH

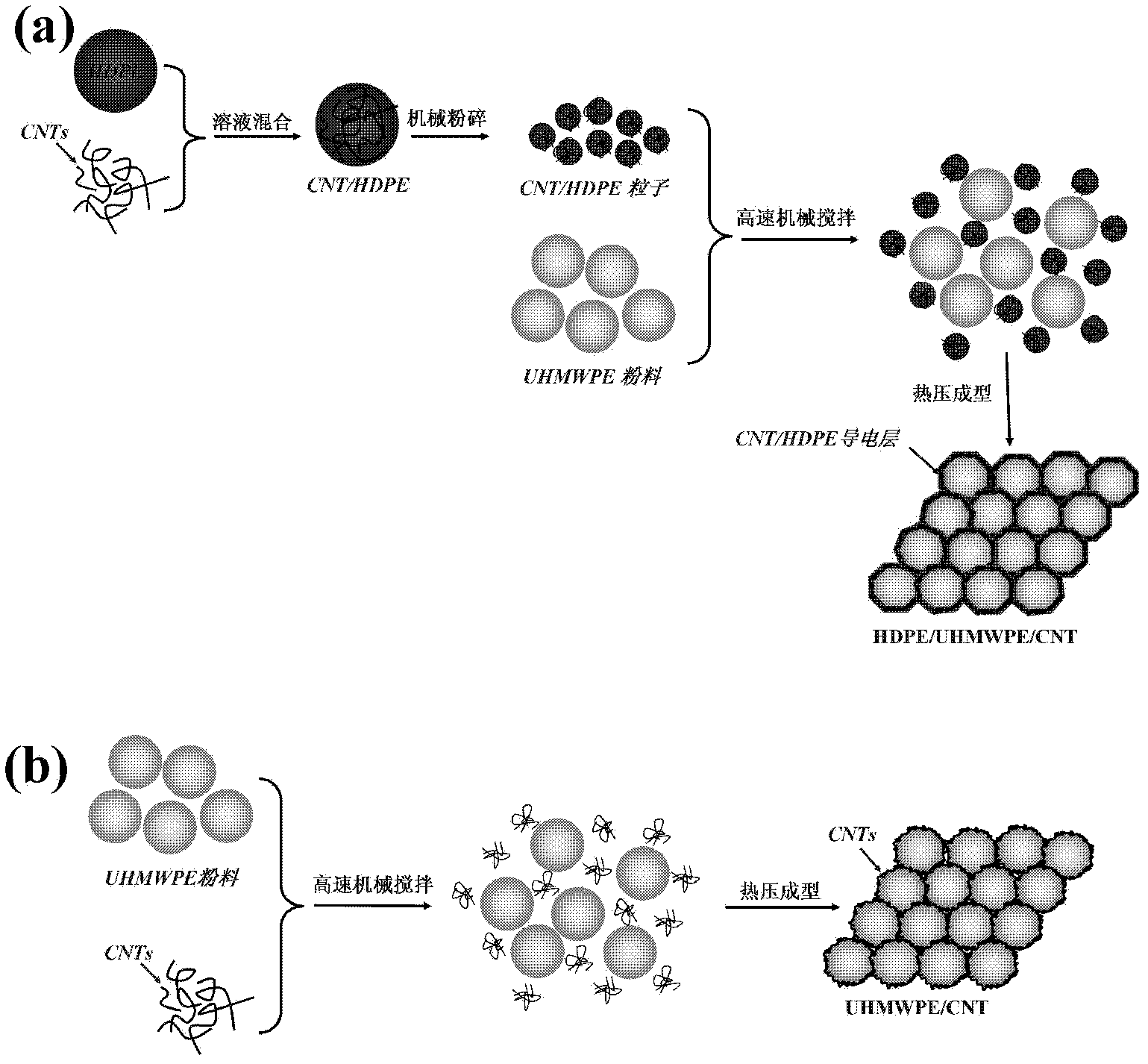

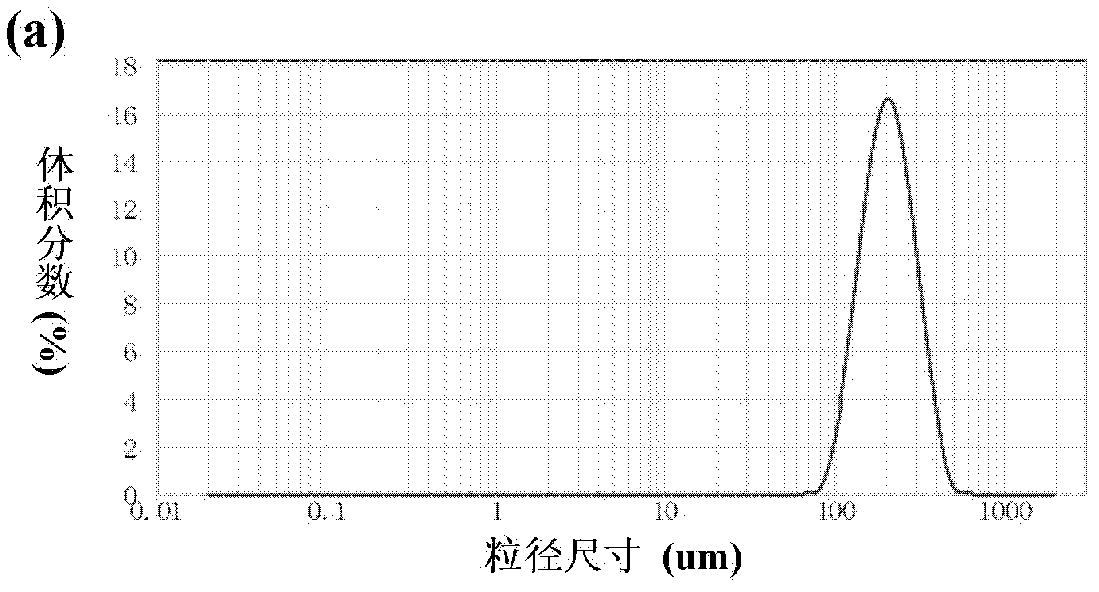

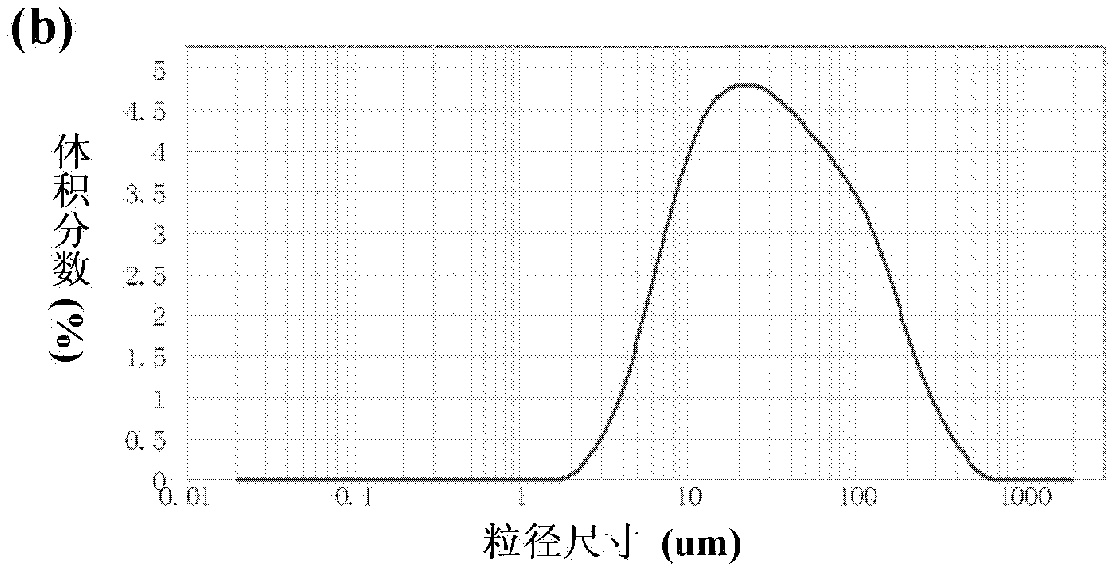

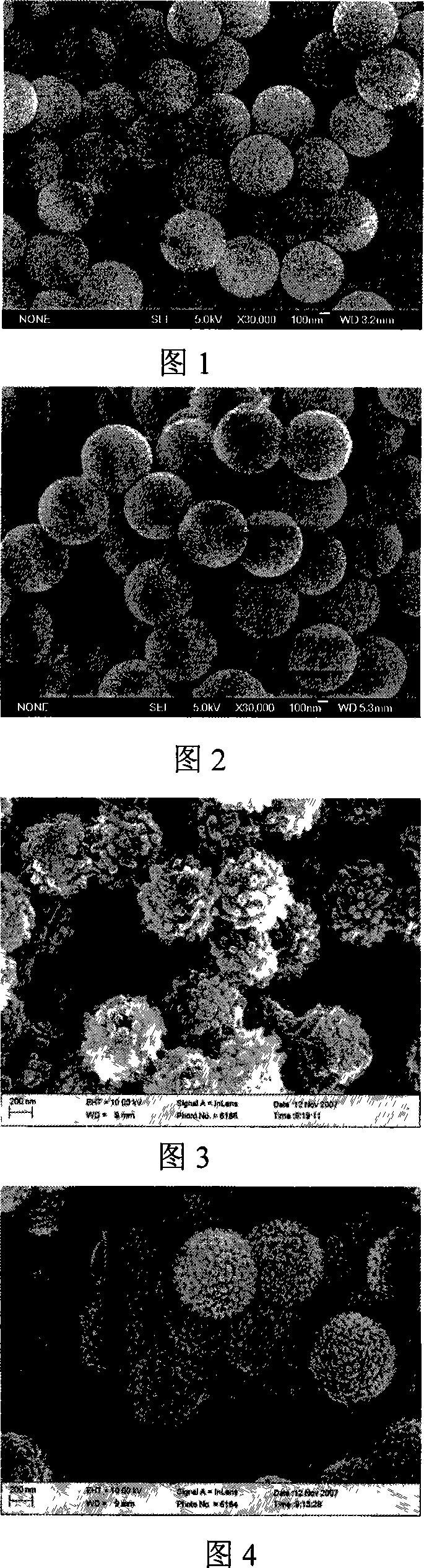

Method for preparing high-ductility conductive polymer composite material

ActiveCN102617918ANon-conductive material with dispersed conductive materialPolymer scienceConductive polymer composite

The invention relates to a method for preparing a high-ductility conductive polymer composite material. Main raw materials of the composite material include, by weight, 80-99% of UHMWPE (ultrahigh molecular weight polyethylene), 0.9-18% of HDPE (high-density polyethylene) and 0.1-2% of CNT (carbon nano tube). The method includes the steps: (1) drying the raw materials; (2) preparing conductive parent stock of the CNT or HDPE; (3) crushing and granulating; (4) compositing and mixing; and (5) pressing to obtain a target product. Compared with a traditional conductive material of an isolation structure, the composite material prepared by the method has the advantages that the composite material has excellent impact property, the impact strength of the composite material is higher than 58.1KJ / m2, the fracture elongation of the composite material is 478%, the preparation process is simple, the technology is easy to control, production cost is low, and mass production is easily realized.

Owner:安徽瑞琦塑胶科技有限公司

Method for preparing morphology-controlled polyphenylethene/polyaniline conductive polymeric composite microspheres

The invention relates to a preparation method of polystyrene / polyaniline conductive polymer composite microspheres with controllable shape and appearance, belonging to the polymer composite technical field, which is characterized in that: firstly, a plurality of PS microspheres with a certain diameter are prepared by the emulsifier-free emulsion polymerization, the PS microspheres are taken as the hard template and added into deionized water in which a plurality of aniline monomers are dispersed, the mixture is stirred by magnetic force to form homogenous emulsion at the ambient temperature; secondly, oxidant solution is added into the former mixture one-time, the PS microspheres are taken as the hard template and the micelle formed by the aniline monomers are taken as the ''soft template''; at last, the polystyrene / polyaniline conductive polymer composite microspheres are obtained by conventional post-processing. The preparation method of polystyrene / polyaniline conductive polymer composite microspheres with controllable shape and appearance has the advantages that: the shape and appearance of the polystyrene / polyaniline conductive polymer composite microspheres can be controlled just by regulating the redox ability of the oxidant; meanwhile, the wall thickness of the core-shell structure and the diameter and the length of the nanometer fiber can be controlled by regulating the addition of the aniline monomers and the redox ability and the addition of the oxidant.

Owner:UNIV OF SCI & TECH BEIJING

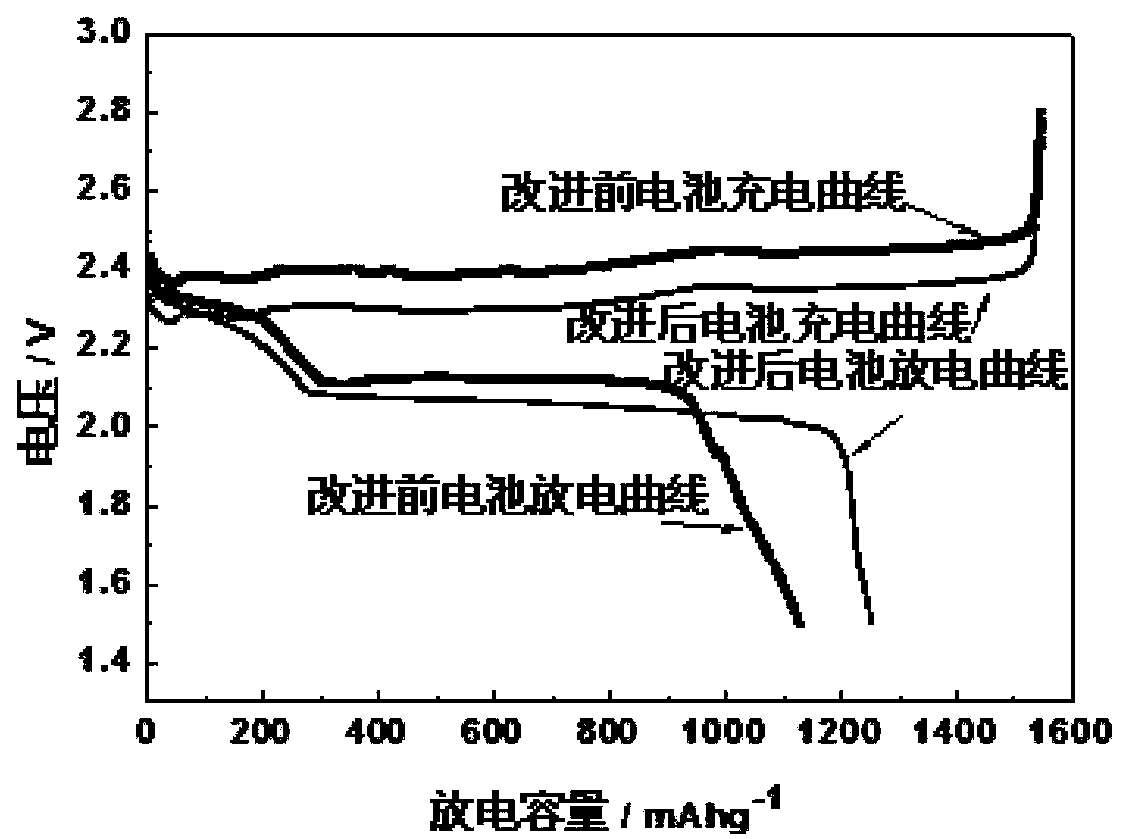

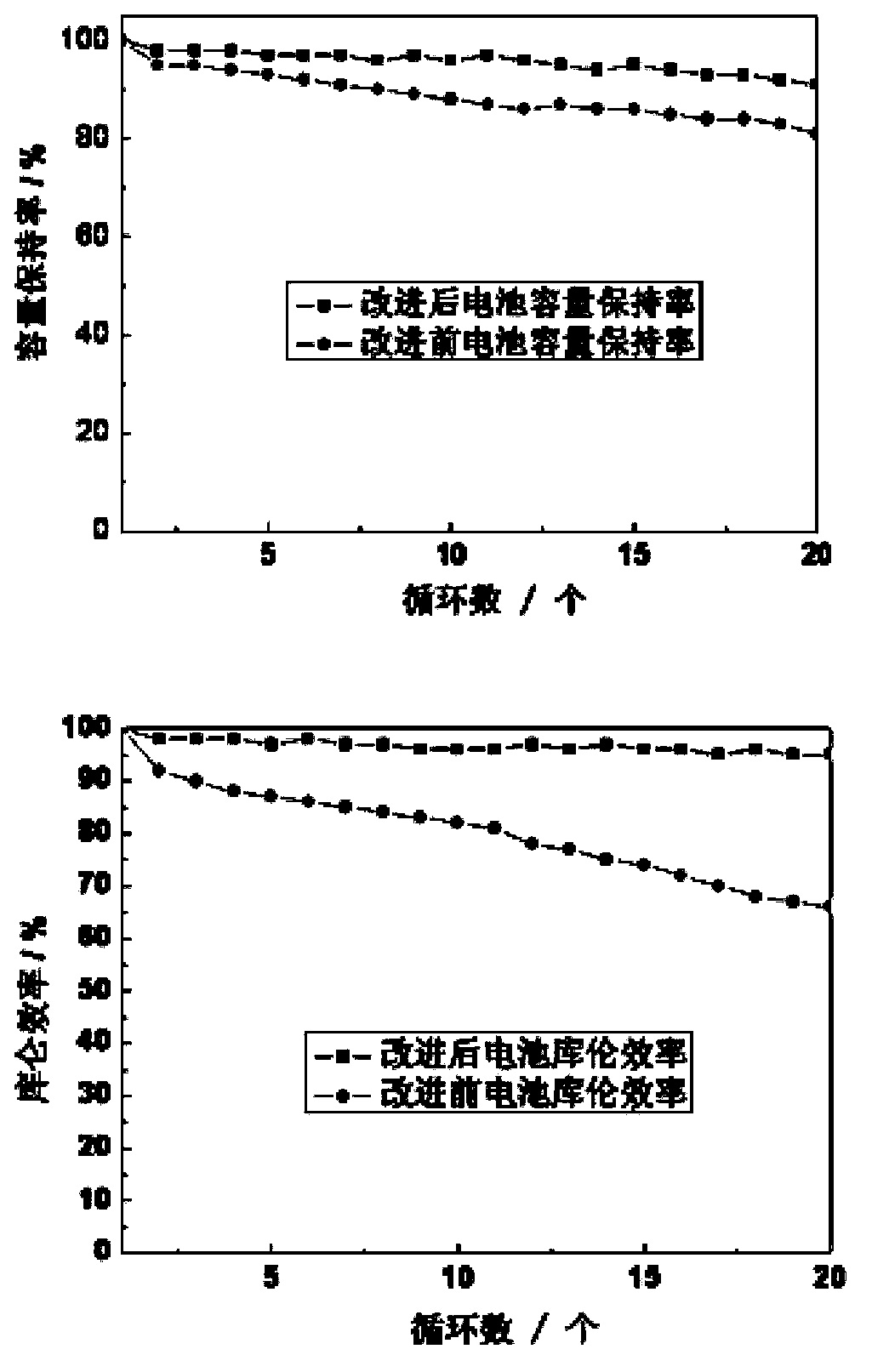

Positive electrode for lithium sulfur battery

ActiveCN104300112AImprove cycle stabilityLow costNon-aqueous electrolyte accumulator electrodesConductive polymer compositeOxide composite

The invention relates to a positive electrode for a lithium sulfur battery. The material of the positive electrode is a one or two or above two of a carbon-sulfur composite material, a sulfur-conductive polymer composite material and a sulfur-metal oxide composite material, and the content of sulfur in the positive electrode material is 10-95%; the positive electrode material also contains nano-gold or / and nano-silver particles; and a ratio of the total addition of the nano-gold or / and silver to the mass of the positive electrode material is 1:(0.01-1). The electronic orbital effect of the nano-gold or / and silver is used to complex polysulfide in order to make products in the discharge process maximally fixed in a positive electrode region, so the self discharge phenomenon caused by the dissolution of the polysulfide is effectively inhibited, thereby the coulomb efficiency and the cycle stability of the lithium sulfur battery are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com