Graphene/conductive polymer composite material and preparation method thereof

A conductive polymer and composite material technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of limited material application, agglomeration rate characteristics, poor uniformity of composite products, etc., to avoid agglomeration and improve rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of graphene / conductive polymer composite material, comprises the following steps:

[0028] A) Spray drying the graphene solution or the modified graphene solution to obtain graphene microspheres;

[0029] B) mixing and infiltrating the graphene microspheres obtained in the step A) with the liquid conductive polymer monomer to obtain a reaction precursor;

[0030] C) mixing the reaction precursor obtained in step B) with an acid solution containing an oxidizing agent, and performing a polymerization reaction to obtain an intermediate product;

[0031] D) reducing the intermediate product obtained in step C) to obtain a graphene / conductive polymer composite material.

[0032] In the present invention, firstly, the graphene solution or the modified graphene solution is spray-dried to obtain graphene microspheres, and then the obtained graphene microspheres are mixed with a liquid conductive polymer monomer, infiltrated, ...

Embodiment 1

[0050] Spray-dry the graphene oxide aqueous solution with a concentration of 0.01wt% at 100°C to obtain graphene oxide microspheres, then mix 0.1g of the obtained graphene oxide microspheres with 1g of aniline monomer, and fully infiltrate to obtain the mixture , add this mixture with 2g of ammonium persulfate and 0.1g of sodium dodecylbenzenesulfonate to 100ml of hydrochloric acid solution with a concentration of 0.1mol / L, react for 5h under stirring conditions to obtain a reaction product, and hydrate the reaction product Hydrazine reduction yields spherical graphene / polyaniline composites.

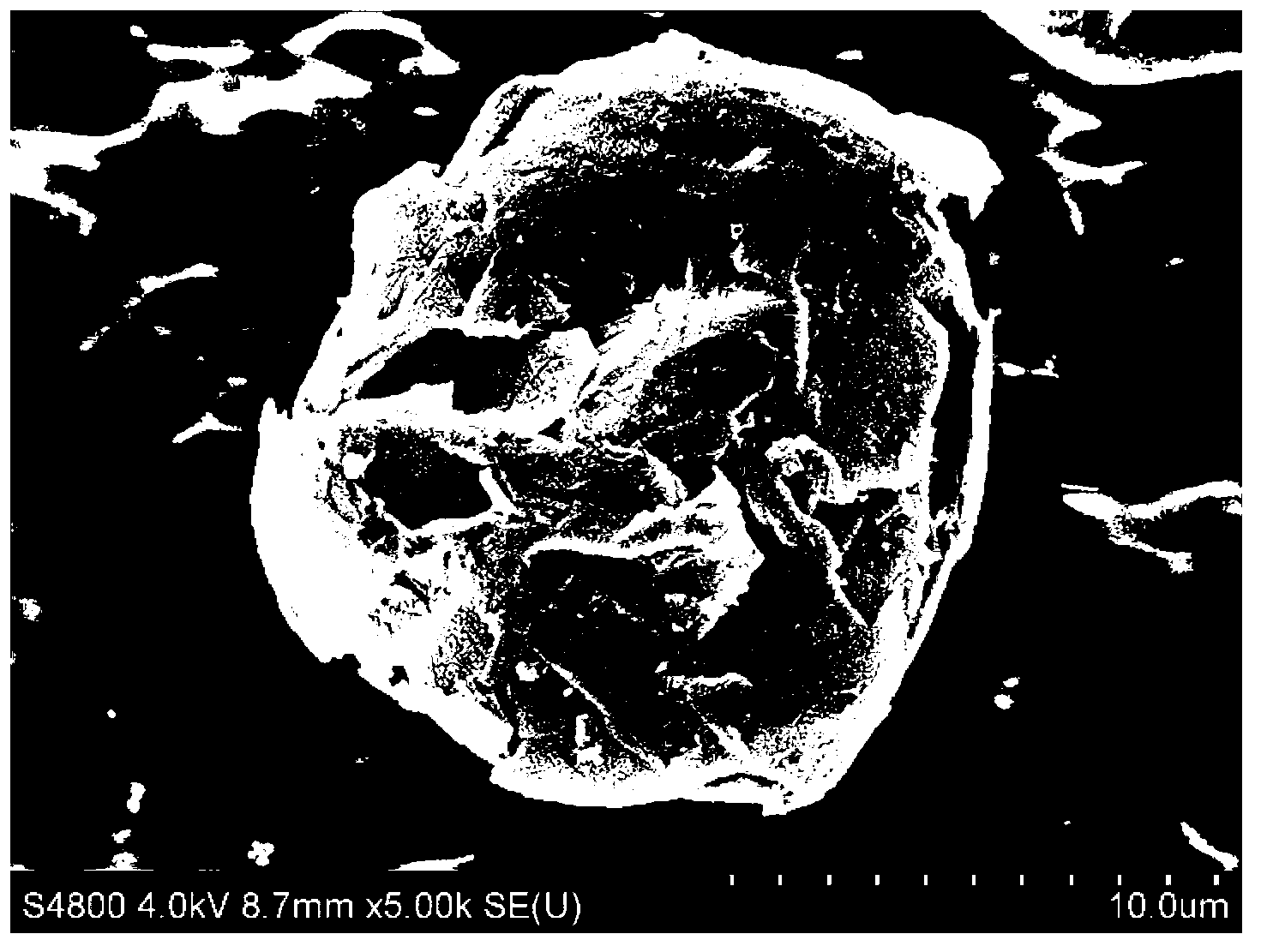

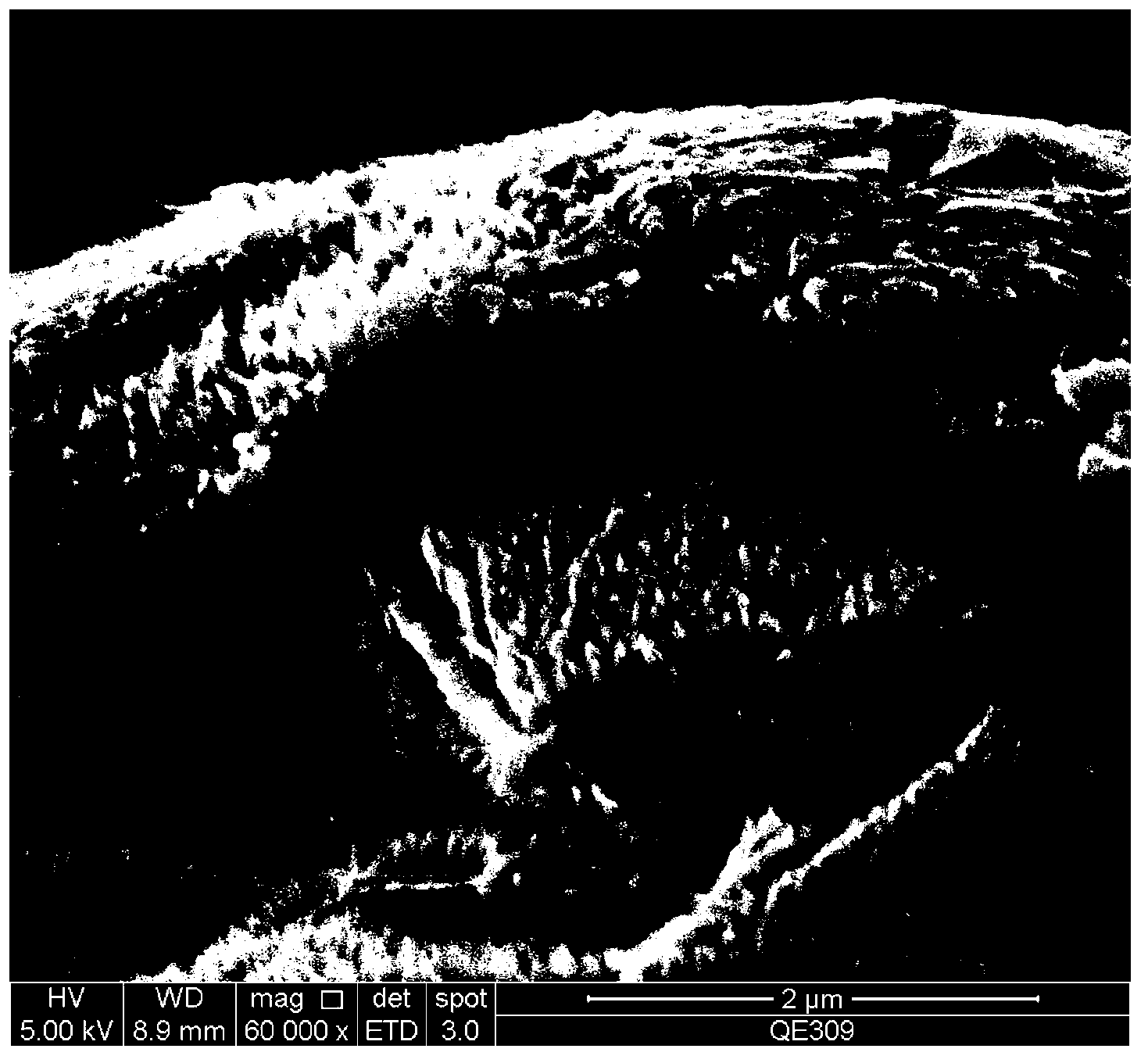

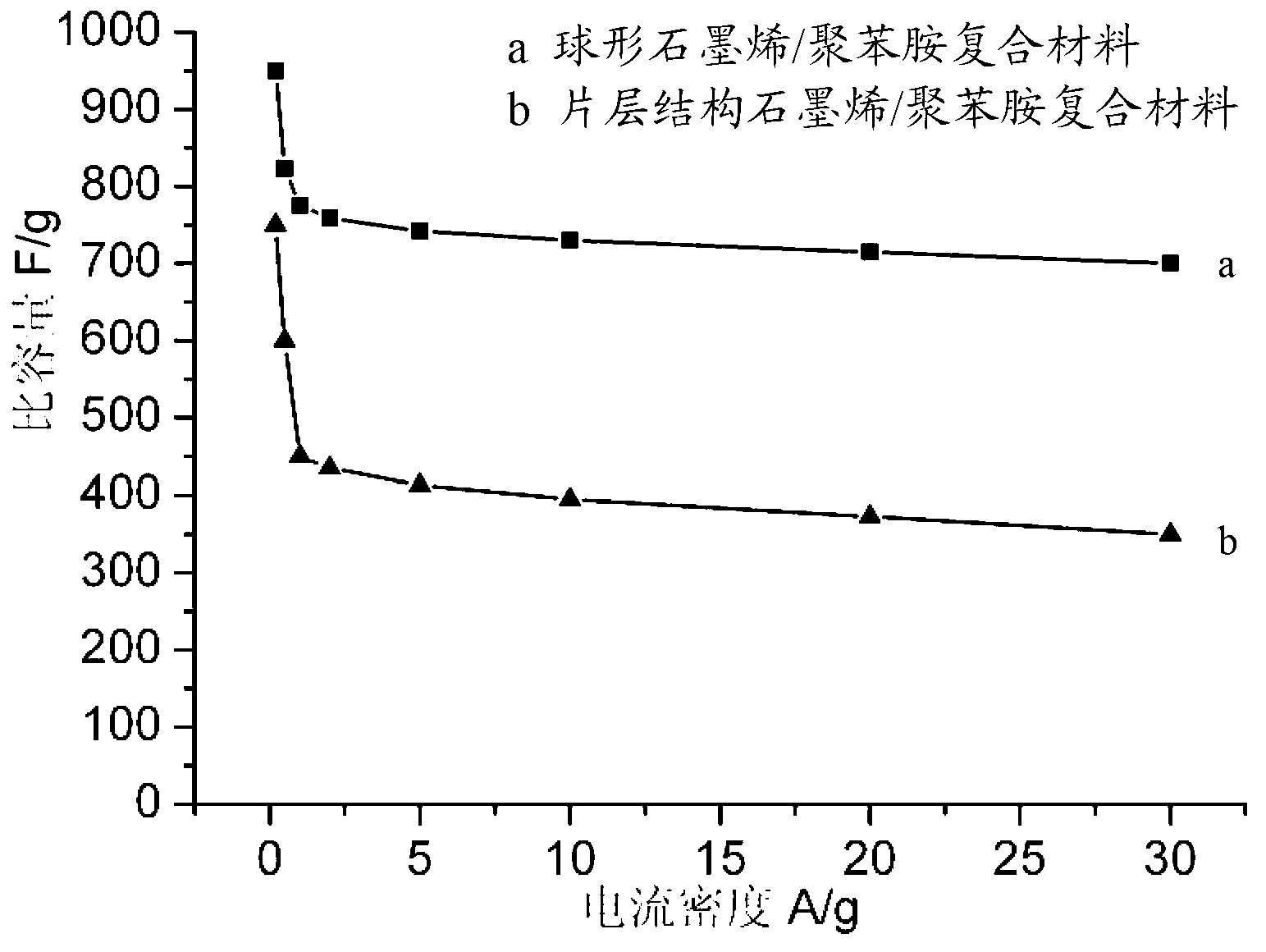

[0051] Its morphology was detected by scanning electron microscopy, and the results were shown in figure 1 and figure 2 ,in, figure 1 The scanning electron micrograph of the spherical graphene / polyaniline composite material prepared for Example 1 of the present invention, figure 2 A partially enlarged scanning electron microscope image of the spherical graphene / polyaniline composit...

Embodiment 2

[0059] A graphene aqueous solution with a concentration of 1wt% was spray-dried at 500°C to obtain graphene microspheres, and then 10 g of the obtained graphene microspheres were mixed with 1 g of pyrrole monomer and fully infiltrated to obtain a mixture. The mixture was mixed with Add 0.2g of ammonium persulfate and 0.5g of sodium dodecyl sulfate into 200ml of sulfuric acid solution with a concentration of 5mol / L, and react for 10h under stirring conditions to obtain a reaction product, which is annealed at 100°C to obtain a spherical shape Graphene / polypyrrole composites.

[0060] The electrochemical test of the obtained spherical graphene / polypyrrole composite material shows that the initial specific capacity of the composite material is as high as 950F / g at a current density of 10A / g, and the capacity can still maintain about 95% after 10,000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com