Method for preparing polystyrene/conductive polymer composite hollow microspheres

A technology of conductive polymer and polystyrene, applied in the field of preparation of polymer composite hollow microspheres, achieves the effects of simple method, good monodispersity and controllable monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

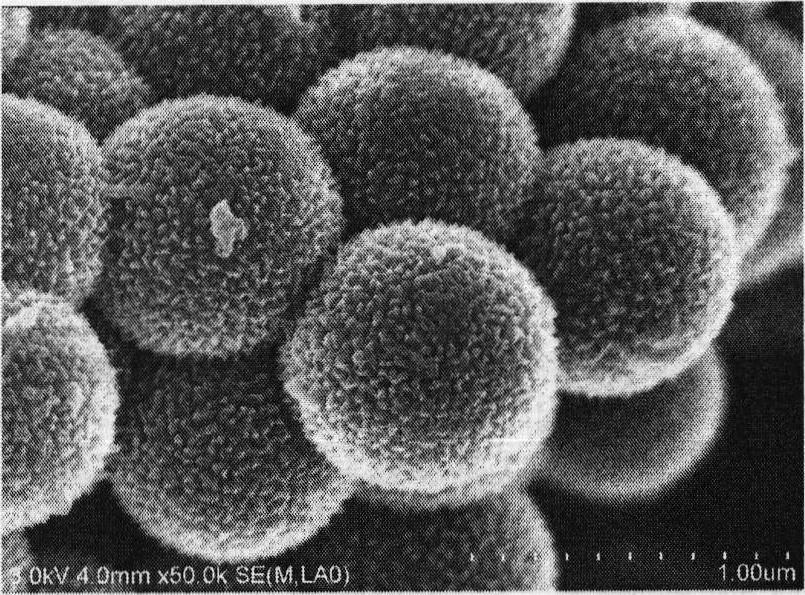

[0037] Embodiment 1: be the PSt microsphere of 720nm with particle diameter as template coating PANI

[0038] The PSt emulsion (solid content is 9.63wt%) and 34mL deionized water that the particle diameter prepared by 6.37g reference example 1 is 720nm is added in the single-necked round bottom flask, ultrasonic vibration 30min, make dispersion uniform (solid content is 1.52wt%) %). Then pass N under magnetic stirring 2 After reaching 20min, cool with an ice-water bath, mix 0.4mL aniline (ANI) (0.4g, 4mmol) with 2mL 2.5mol / L hydrochloric acid (5mmol) aqueous solution first and then add it, the pH of the whole mixture obtained is about 1, magnetically stir After 30 min, 10 mL of aqueous solution containing 1 g of APS (4 mmol) was added (the molar ratio of APS to ANI was 1:1) to initiate polymerization. After reacting in an ice-water bath for 8 h, the reaction was continued at room temperature for 16 h under magnetic stirring to obtain an average PSt / PANI composite hollow micr...

Embodiment 2

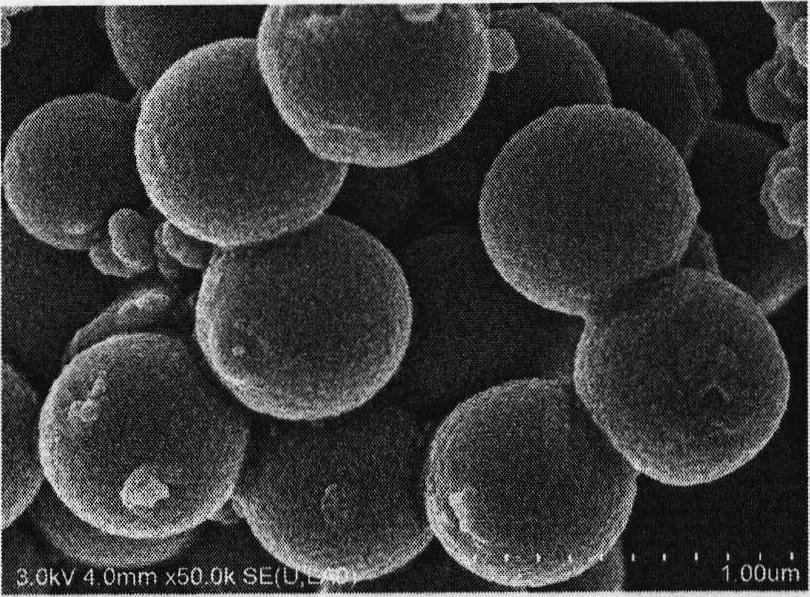

[0040] Embodiment 2: Be that the PSt microsphere of 260nm is template-coated PANI with particle diameter

[0041] Repeat Example 1, the difference is: the PSt emulsion in Example 1 is changed to 6.75g (solid content is 9.10wt%) PSt emulsion with a particle diameter of 260nm prepared in Reference Example 3, and 34mL deionized The water was changed to 33 mL deionized water. As a result, PSt / PANI composite hollow microspheres with an average particle size of 380nm and a shell thickness of about 60nm were obtained.

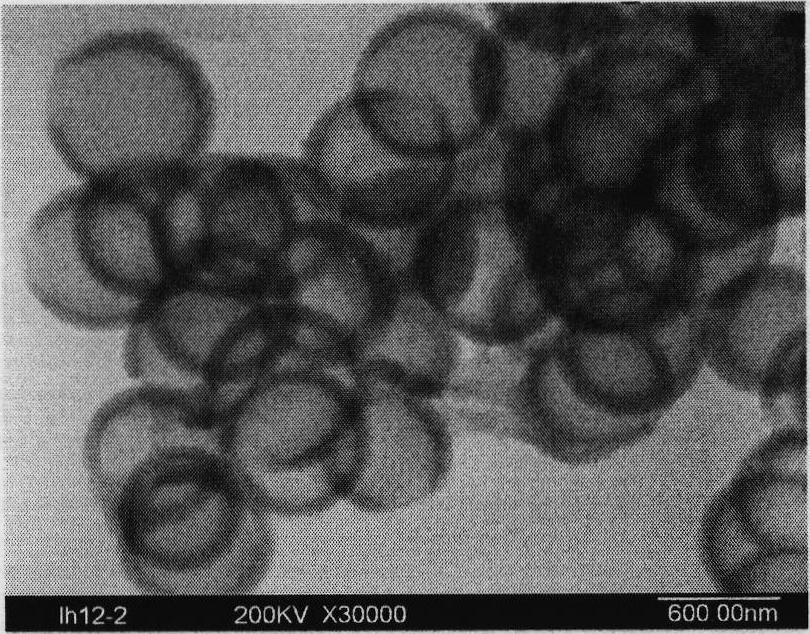

[0042] The scanning electron micrograph of the PSt / PANI composite hollow microsphere shows that polyaniline is coated with a certain thickness on the surface of the PSt microsphere; the transmission electron micrograph of the PSt / PANI composite hollow microsphere shows that the composite microsphere is hollow.

Embodiment 3

[0043] Example 3: Using PSt microspheres with a particle size of 650nm as a template and APS as an oxidant to coat PPy

[0044] The PSt emulsion (solid content is 10.30wt%) and 34mL deionized water that 6.5g reference example 2 prepares is 650nm PSt emulsion (solid content is 1.65wt%) joins in the single-necked round-bottomed flask, ultrasonic vibration 30min, makes dispersion uniform (solid content is 1.65wt%) %). Then pass N under magnetic stirring 2 After 20 min, cool in an ice-water bath, mix 0.3 mL of pyrrole (py) (0.29 g, 4 mmol) with 2 mL of 2.5 mol / L hydrochloric acid (5 mmol) aqueous solution and add to it, the pH of the whole mixture obtained is about 1, and stir magnetically for 30 min , then add 10mL aqueous solution containing 0.98g APS (4mmol) (the molar ratio of APS to pyrrole is 1:1) to initiate polymerization, react in an ice-water bath for 8h, continue to react at room temperature under magnetic stirring for 16h, and obtain the average particle size PSt / PPy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com