Patents

Literature

183results about How to "Good spherical shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

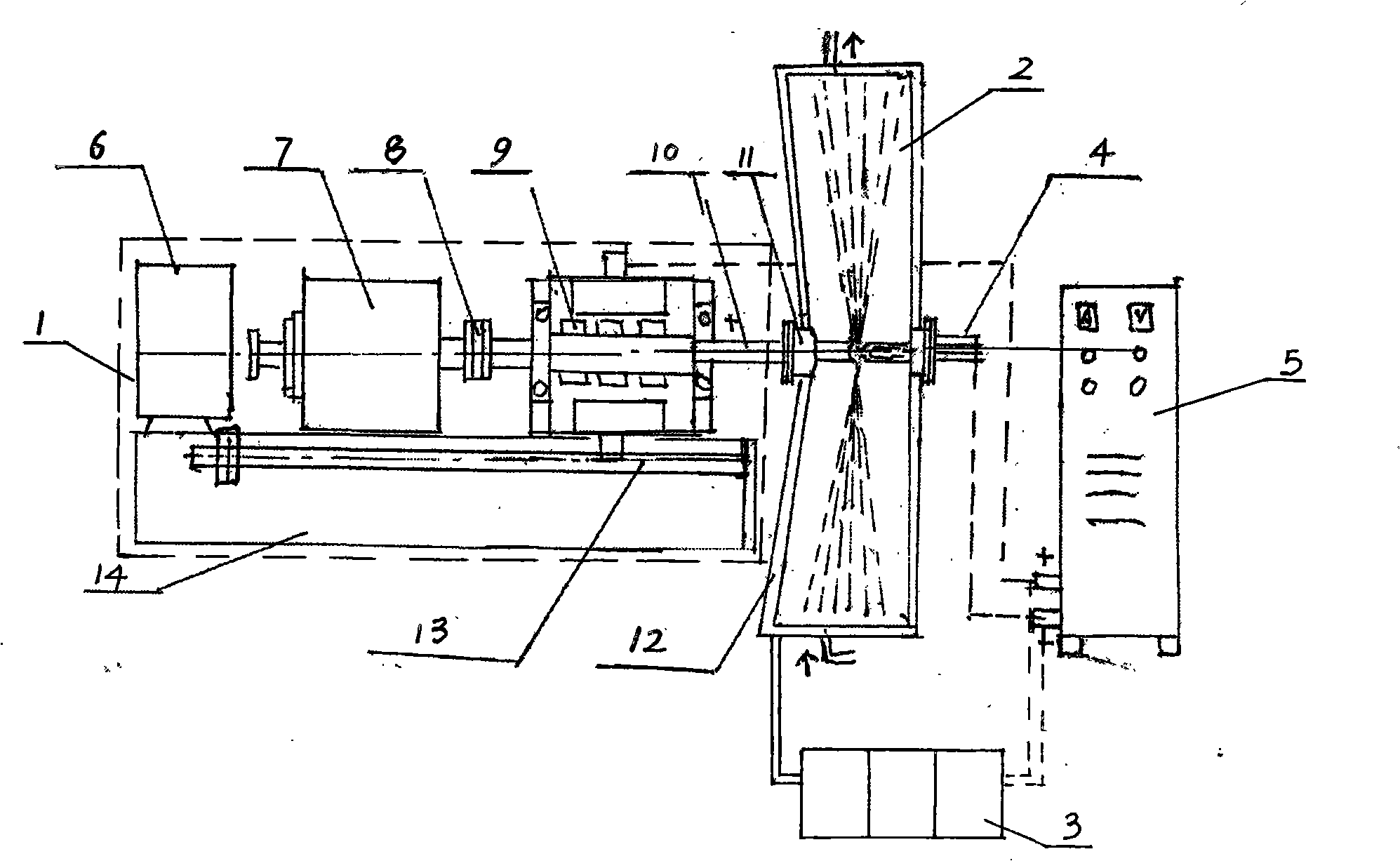

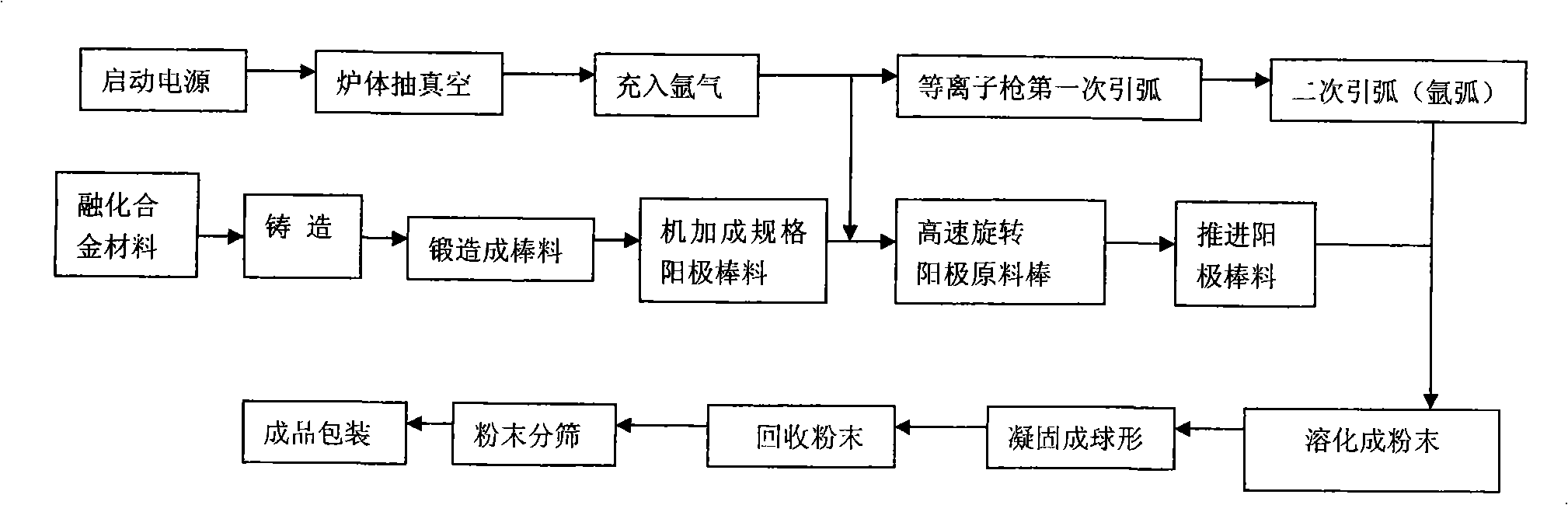

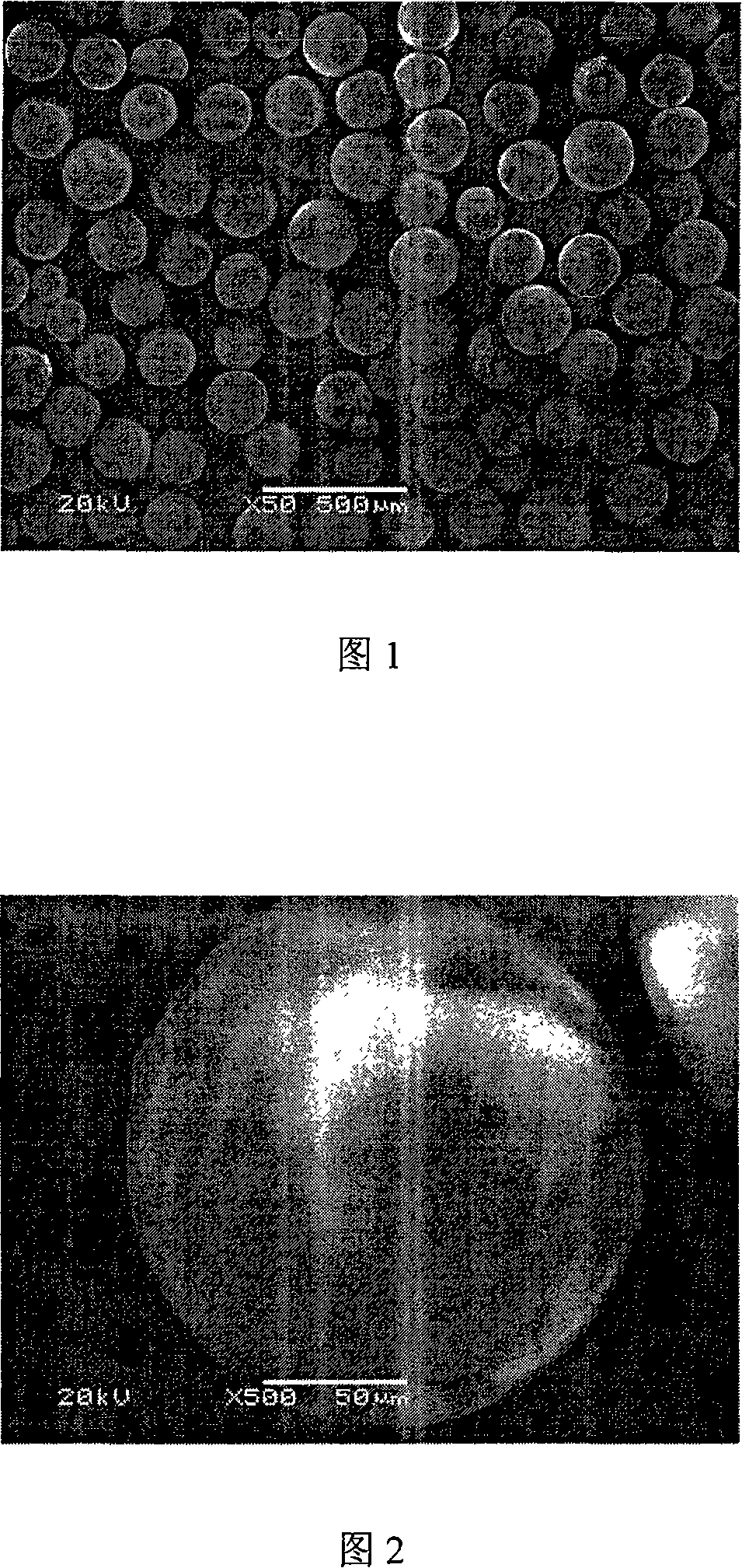

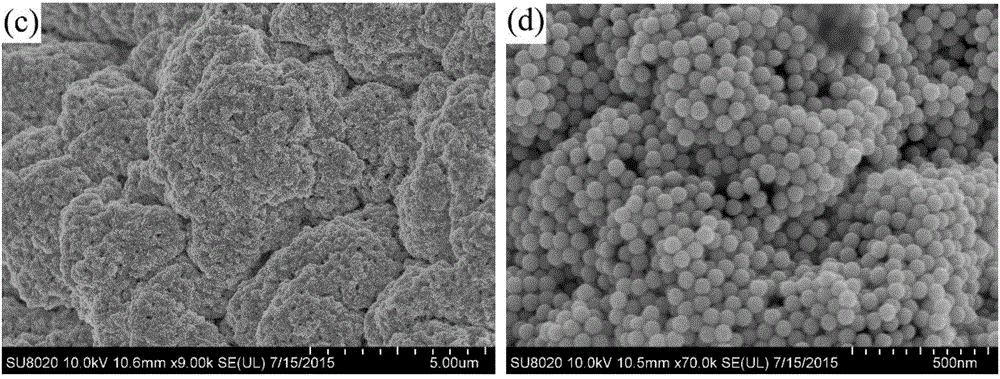

Plasma rotating electrode milling machine group and technique

The invention relates to a plasma rotary electrode powder milling set and a process thereof, relating to the technical field of powder metallurgy. The milling set comprises a rotating feeding mechanism, a vacuum furnace, a vacuum unit, a plasma gun device and an electrical source. The rotating feeding mechanism is arranged at the exterior of one side of the vacuum furnace; the plasma gun device is arranged at the interior of the other side of the vacuum furnace; the vacuum unit is communicated with the vacuum furnace through a ventilation pipe, wherein, the vacuum furnace body has a double-decker sandwich structure, and cooling circulating water is injected into the sandwich structure; a receiving mechanism is arranged at the bottom part of the vacuum furnace, wherein, the receiving mechanism comprises two cut-off valves connected in series. The process includes the following steps: metal is processed into electrode bars; low-voltage heavy current is applied to the electrode bars to melt the electrode bars in a highly vacuumized melting chamber through the high temperature produced by the cathode arc of the plasma gun, and to eject the molten metal instantly by the strong centrifugal force produced through the high-speed rotation of the electrode bars to produce fine metal powders. The invention is characterized in that the yield of perfect spherical metal powders is up to 97 percent, and the powders are free from the contamination of any microelement.

Owner:张建利

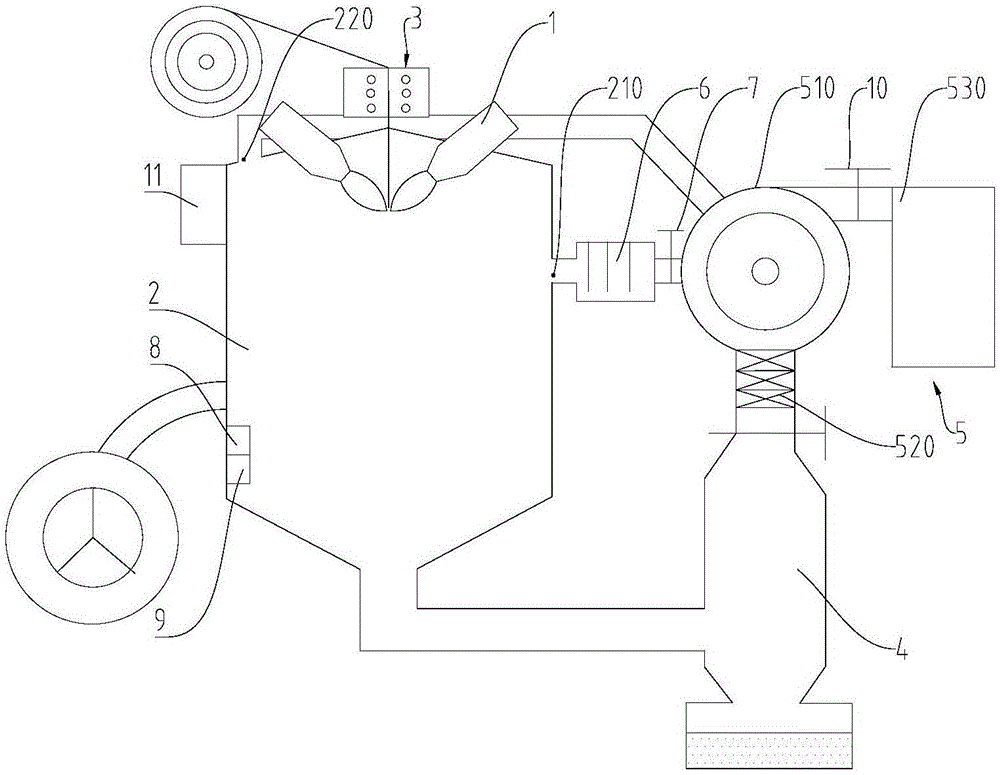

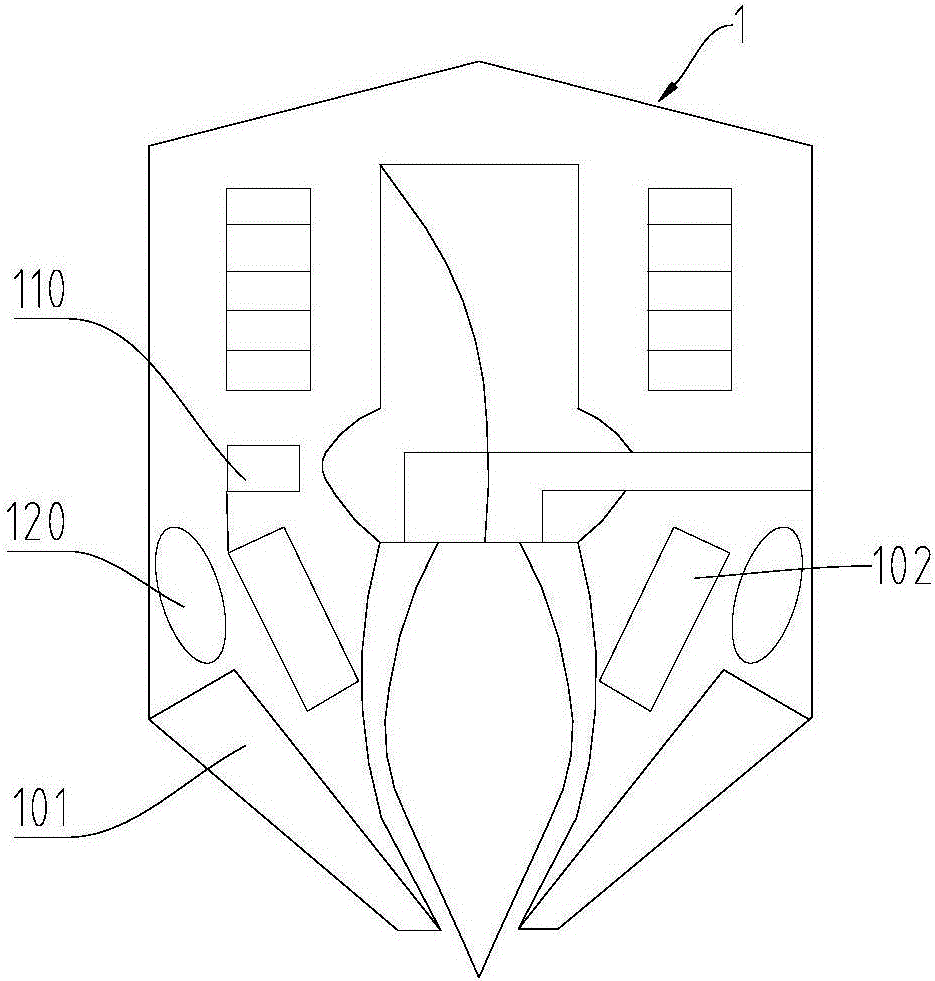

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

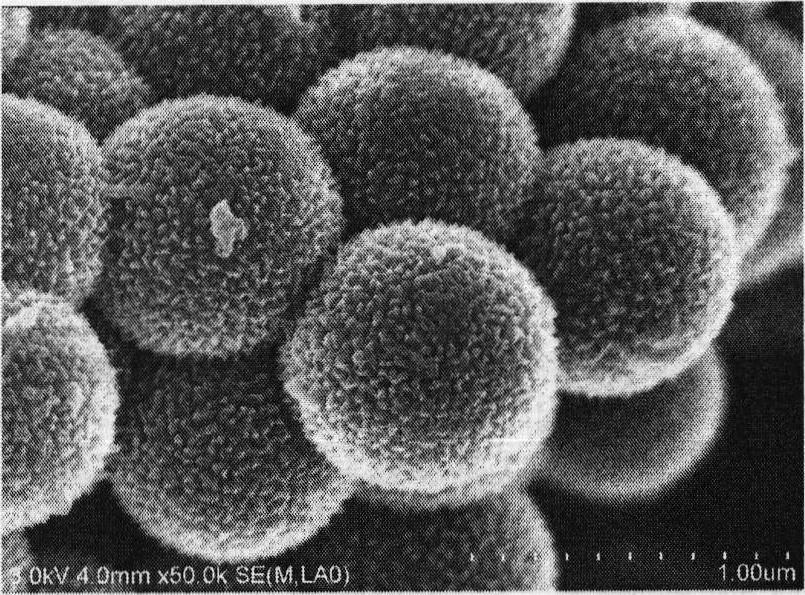

Method for preparing poly-organic silsesquioxane microsphere

ActiveCN101676023AGood spherical shapeSimple processMicroballoon preparationMicrocapsule preparationAlcoholHydrogen

The invention discloses a method for preparing poly-organic silsesquioxane microsphere, comprising the following steps: 1) adding mixture of one or arbitrary several kinds selected from compound in structure general formula R1Si(OR2)3 into the mixture solution of water and alcohol, uniformly stirring the mixture, wherein R1 is hydrogen, methyl or vinyl, R2 is C1-C4 alkyl; 2) adding aqueous solution of alkali metal hydroxide or ammonia water into the reaction system and obtaining products after reaction. The method uses one-step method and the reaction is performed at normal temperature withoutcatalyst containing inorganic ion. The technology is simple and the production period is short and the obtained poly-organic silsesquioxane microsphere has good shape and the particle size is in narrow distribution at micro order.

Owner:ETERNAL CHINA INVESTMENT

Microencapsulation method for preparing hydrotropic substance serving as core material by using complex coacervation method

InactiveCN102580638AEnsure safetyImprove permeabilityMicroballoon preparationMicrocapsule preparationMass ratioFreeze-drying

The invention relates to a microencapsulation method for preparing a hydrotropic substance serving as a core material by using a complex coacervation method. The method is simple in process and low in cost, and the product has high encapsulation rate. The method comprises the following steps of: (1) weighing specific protein and polysaccharide in a certain ratio, stirring and dissolving in hot water to form a wall material solution; (2) weighing a certain mass of hydrotropic core material substance, adding an oil phase substance and an emulsifier in a certain mass ratio, and performing high-speed dispersion to form water / oil (W / O) emulsion; (3) directly pouring the emulsion into the wall material solution, stirring at the constant temperature of 45 DEG C, regulating pH by using 10 percent acid, and reacting for 15 minutes; (4) cooling to the temperature of below 15 DEG C, regulating the pH to 6.0, and adding glutamine transaminase for solidifying; and (5) filtering to obtain a wet capsule product. A dry microcapsule product can be obtained by freeze drying or spray drying.

Owner:山东省万兴食品有限公司 +1

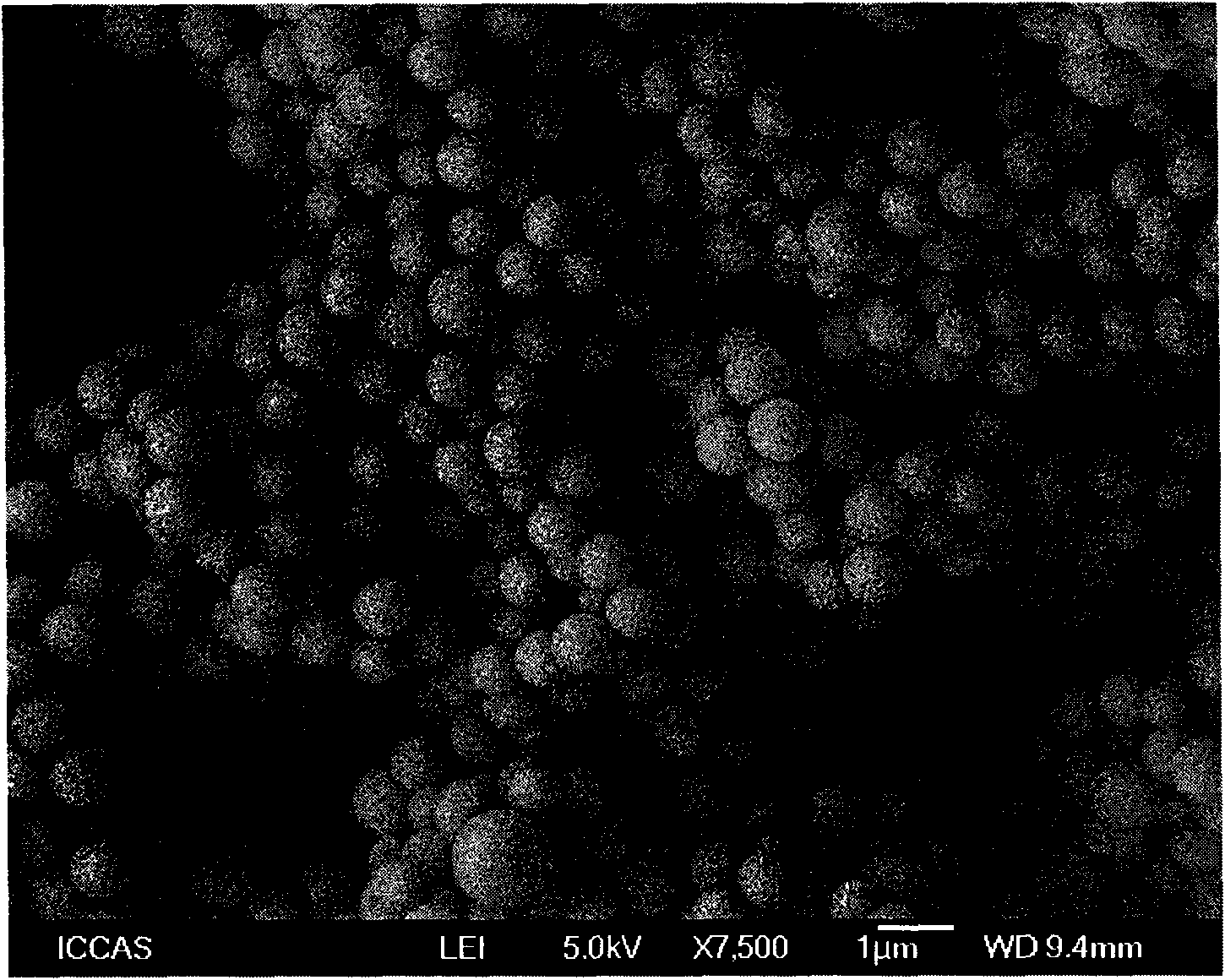

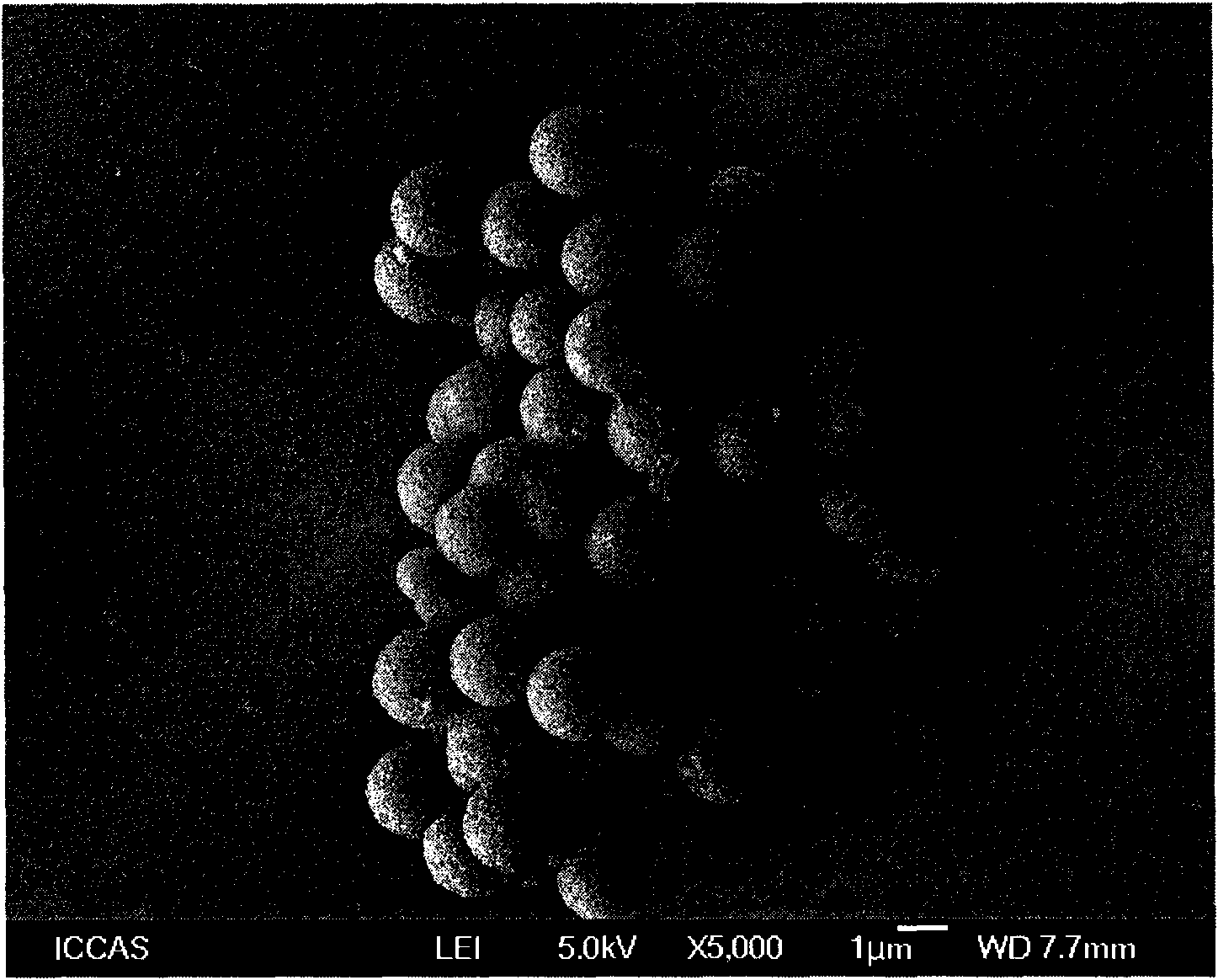

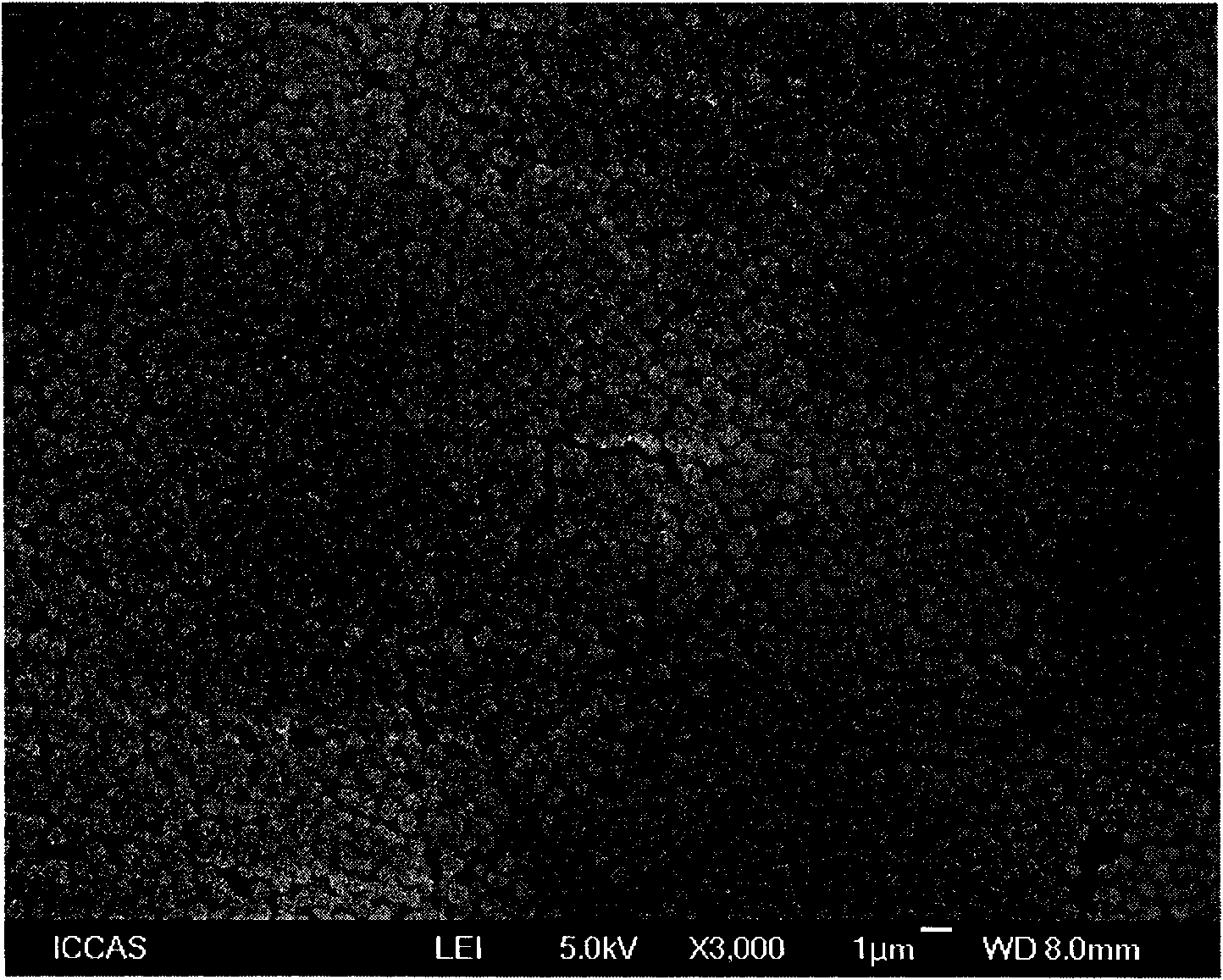

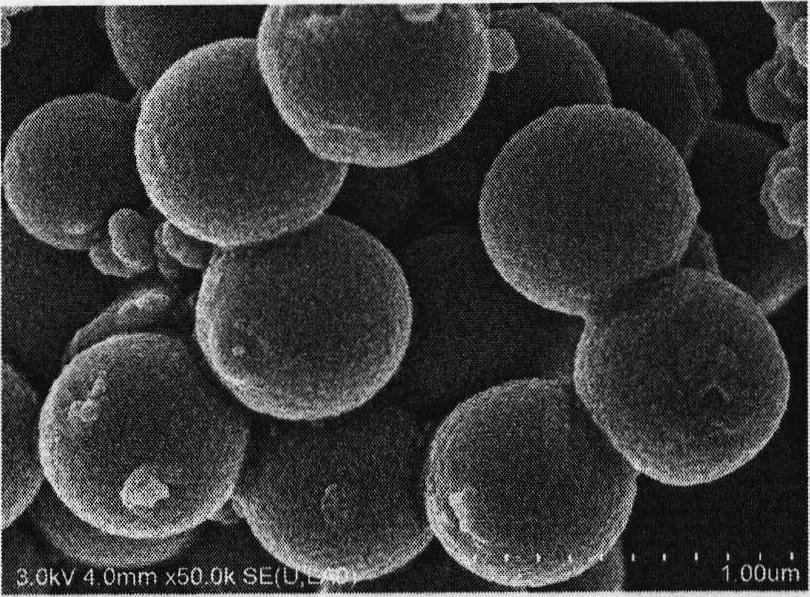

Method for preparing polystyrene/conductive polymer composite hollow microspheres

The invention discloses a method for preparing polystyrene / conductive polymer composite hollow microspheres, which comprises the following steps of: adding aniline or pyrrole and acid or mixture thereof into polystyrene emulsion under the protection of inert gas, stirring the obtained mixture for at least 10 minutes, and then adding an initiator into the mixture to perform polymerization, whereinthe molar ratio of the aniline or the pyrrole to the acid is 0.2 to 0.8, the weight ratio of the aniline or the pyrrole to the polystyrene is 0.1 to 1.0, and the initiator is ammonium persulfate, potassium persulfate, iron trichloride or ferrous sulfate heptahydrate / hydrogen peroxide. Different from the traditional method for preparing the hollow polymer microspheres, the method does not need high-temperature calcination or solvent denucleation treatment and can prepare the polymer composite hollow microspheres by one step, and the microspheres have good appearance and monodispersity. The method is simple, has a few operation steps, and is easy for subsequent treatment; and because the used solvent is a green solvent, the method is safe and reliable, and has low cost.

Owner:BEIJING NORMAL UNIVERSITY

Golf ball manufacturing method

InactiveUS20060273485A1Good spherical shapeEasy to reboundAuxillary shaping apparatusDomestic articlesThin layerEngineering

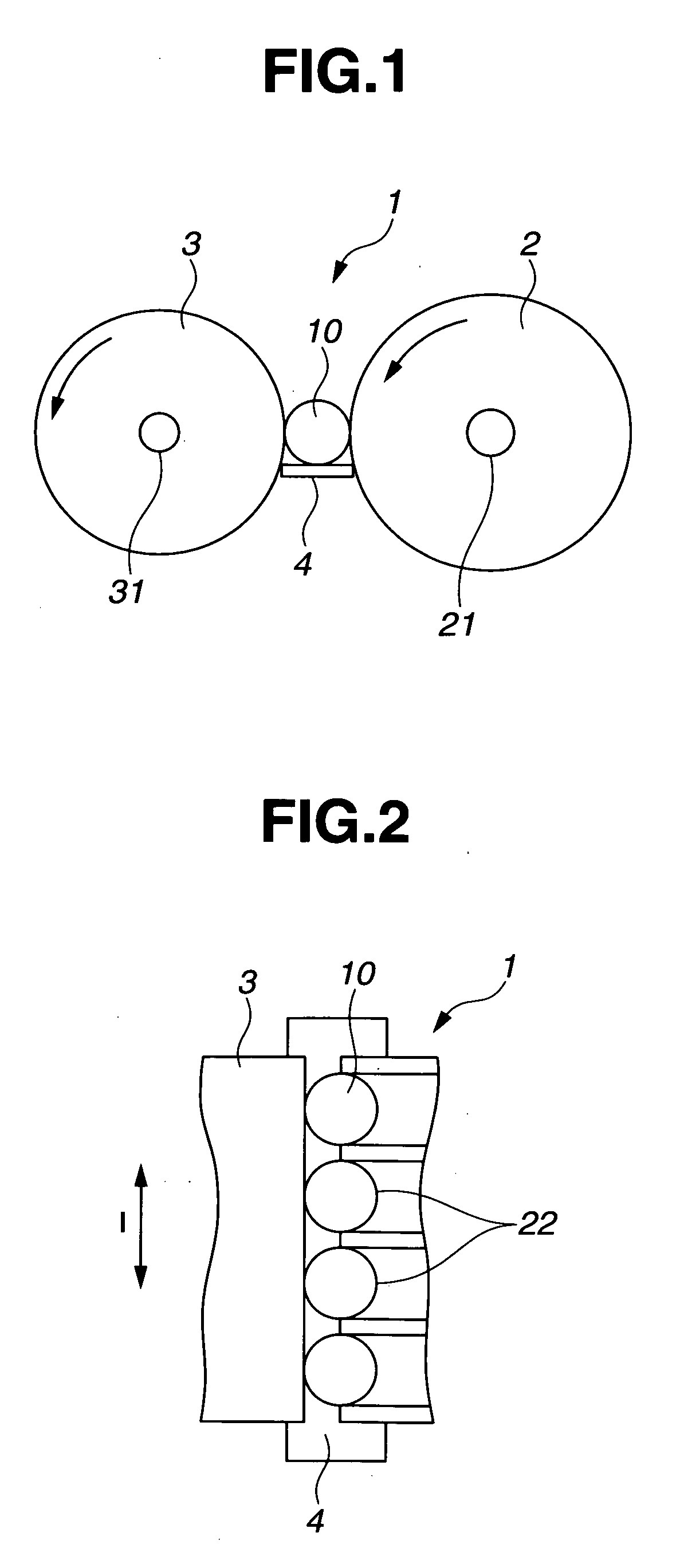

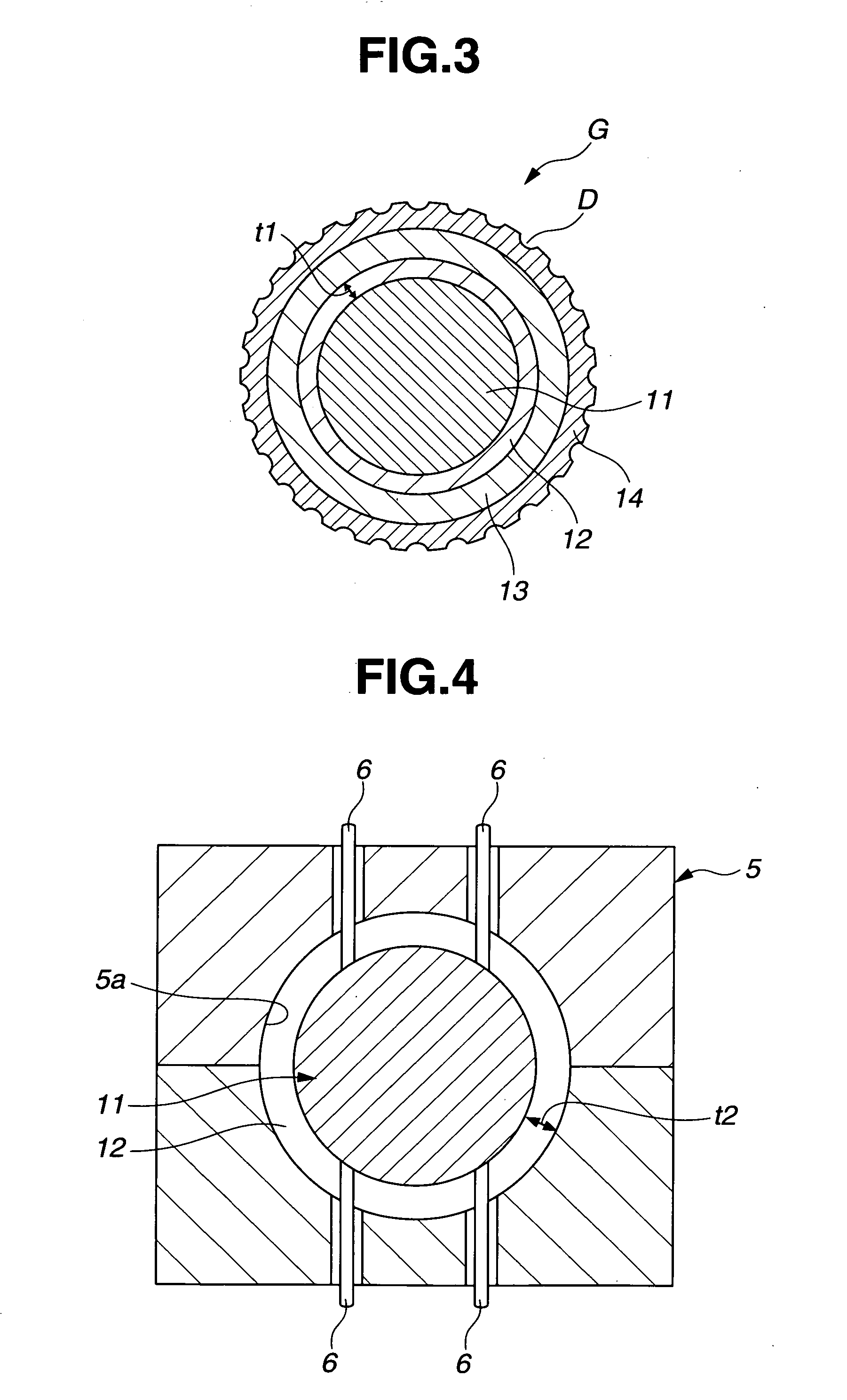

The invention provides a method of manufacturing golf balls composed of a core and one or more cover layer which encloses the core, at least one cover layer being a thin layer having a thickness of 1.0 mm or less. The thin layer is formed to a desired thickness on a surface of a core or spherical body by holding within a mold cavity the core or a spherical body composed of the core enclosed by a cover layer and injecting a synthetic resin material into a space defined by a surface of the core or spherical body and an inner face of the mold cavity so as to form a cover layer on the surface of the core or spherical body, then grinding the resulting cover layer to a thickness of at least 0.1 mm with a specific type of grinder. Golf balls obtained in this way can be provided with a good sphericity even when the cover is formed to a very small thickness.

Owner:BRIDGESTONE SPORTS

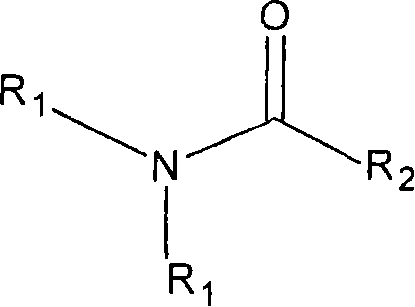

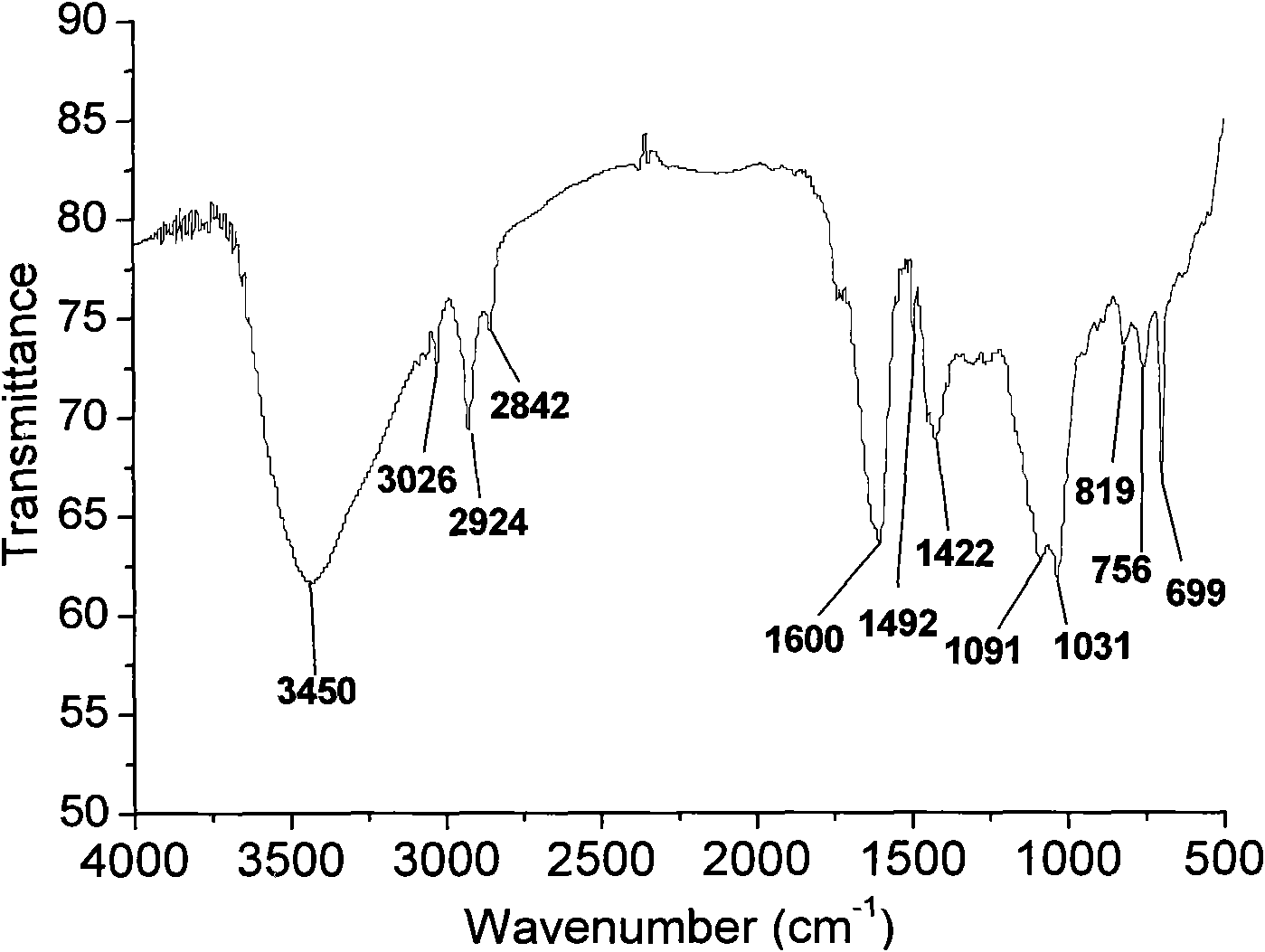

Elution-extracting resin using amide compound as extracting agent and preparation method thereof

InactiveCN101139418AHigh selectivityImprove extraction abilitySolid sorbent liquid separationLiquid wasteGram

The present invention discloses the solvent impregnated resin which uses amide compound as the extraction agent. The extraction agent is embedded in the polymer. The prevent invention is characterized in that the polymer is the styrene - divinylbenzene copolymer resin, and the extraction agent is the amide compound with the content of 20 percent to 60 percent. The solvent impregnated resin is ivory ball particle in appearance, with a particle diameter of 60 to 200 items a heap density of 0.53 to 0.94 gram per milliliter, and a specific surface area of 128 to 260 millimeters 2 / gram. The present invention also discloses the preparation method for the solvent impregnated resin. The solvent impregnated resin provided by the present invention has the advantages of low cost, less wastage of extraction agent, high column load, good mass transfer performance, easiness to be regenerated, long service life, ease use, good repeatability, and high reproducibility and so on. The solvent impregnated resin is of the characteristics of both particle and liquid in terms of extraction and cleaning. The present invention can be widely used in the separation and analysis of 90Sr in the plant and the animal samples, in the removal and callback of 90Sr during the treatment of nuclear fuel high-level radioactive liquid waste, as well as in the separation, purifying and callback of radioactive medical isotopes 90Sr.

Owner:SICHUAN UNIV

Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

InactiveCN101857698AAchieve adsorptionSynthetic conditions are mildPharmaceutical non-active ingredientsOn/in organic carrierUltrasonic emulsificationFiltration

The invention provides a polystyrene / calcium alginate composite gel microsphere in a nuclear shell structure and a preparation method thereof, relating to biopolymer materials. The polystyrene / calcium alginate composite gel microsphere in the nuclear shell structure takes a polystyrene microsphere as a core and calcium alginate gel as a shell, wherein the grain size of the core is 1-100 microns, and the thickness of the shell layer is 50-800 nm. The preparation method comprises the following steps of: mixing polystyrene microsphere with aqueous solution containing a surface active agent I, and carrying out ultrasonic emulsification to obtain mixed solution A; adding sodium alga acid solution in the mixed solution A, and stirring to obtain mixed solution B; adding organic solution containing a surface active agent II into the mixed solution B, and stirring to obtain mixed solution C; adding calcium chloride solution which has the same volume with the sodium alga acid solution into the mixed solution C under stirring to react, and carrying out vacuum filtration, washing the solution until no calcium ion residue exists on the surface and drying to obtain a product D; and dispersing the product D into water, centrifuging the mixture, pouring out supernate and taking out precipitate to obtain the product.

Owner:XIAMEN UNIV

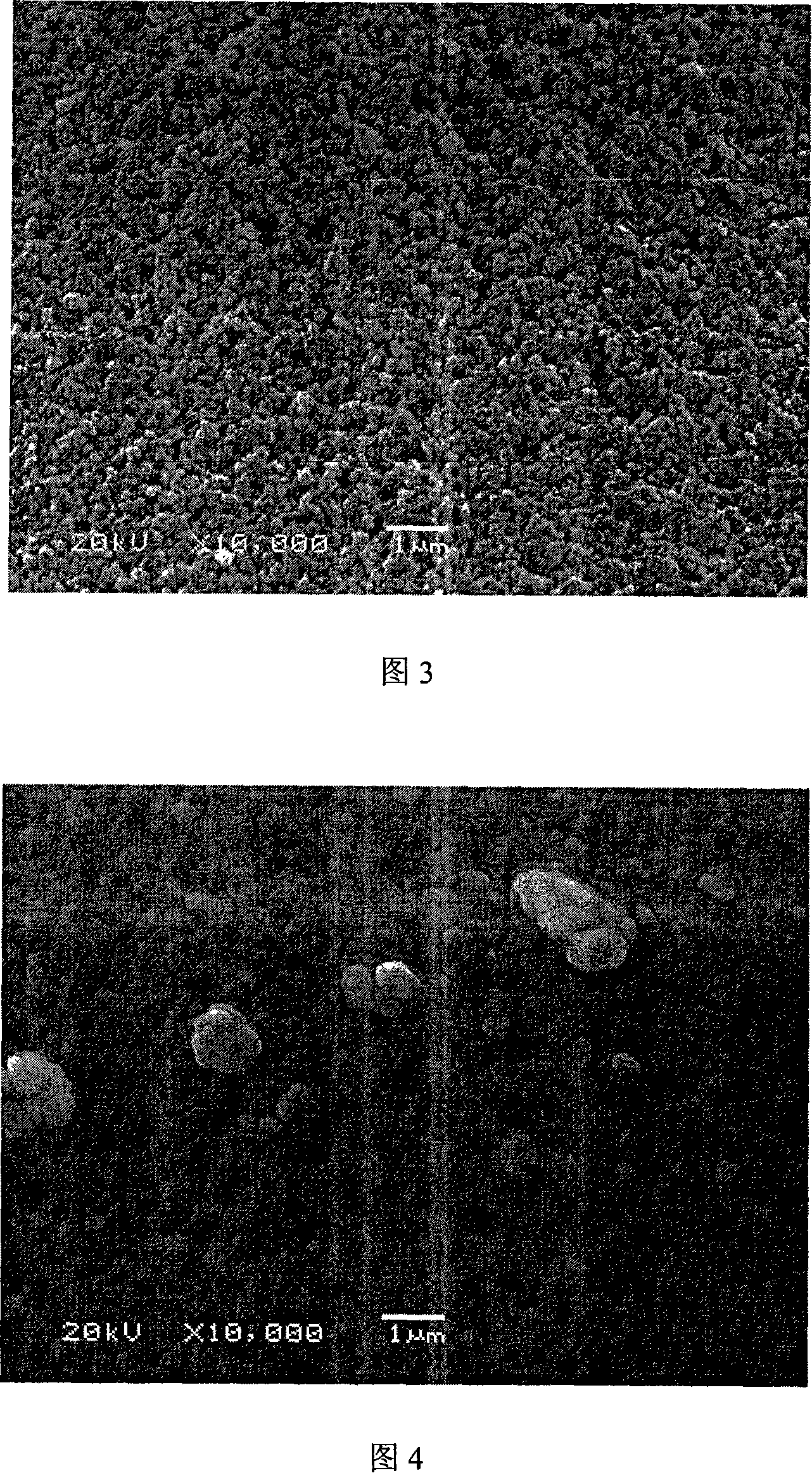

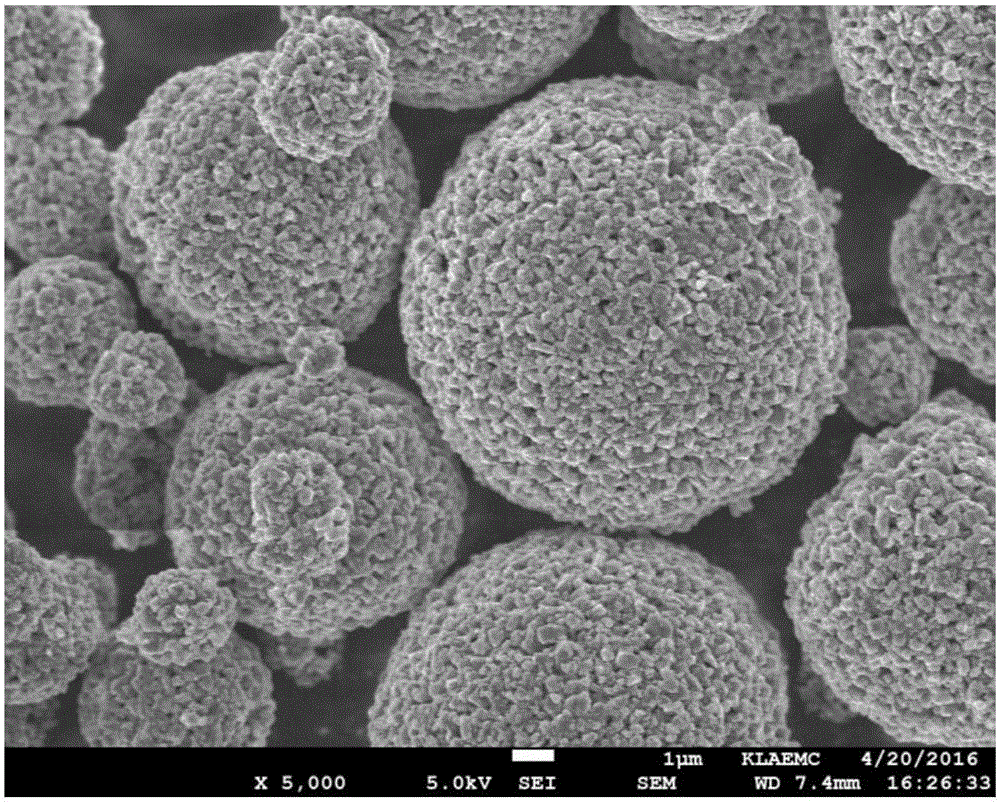

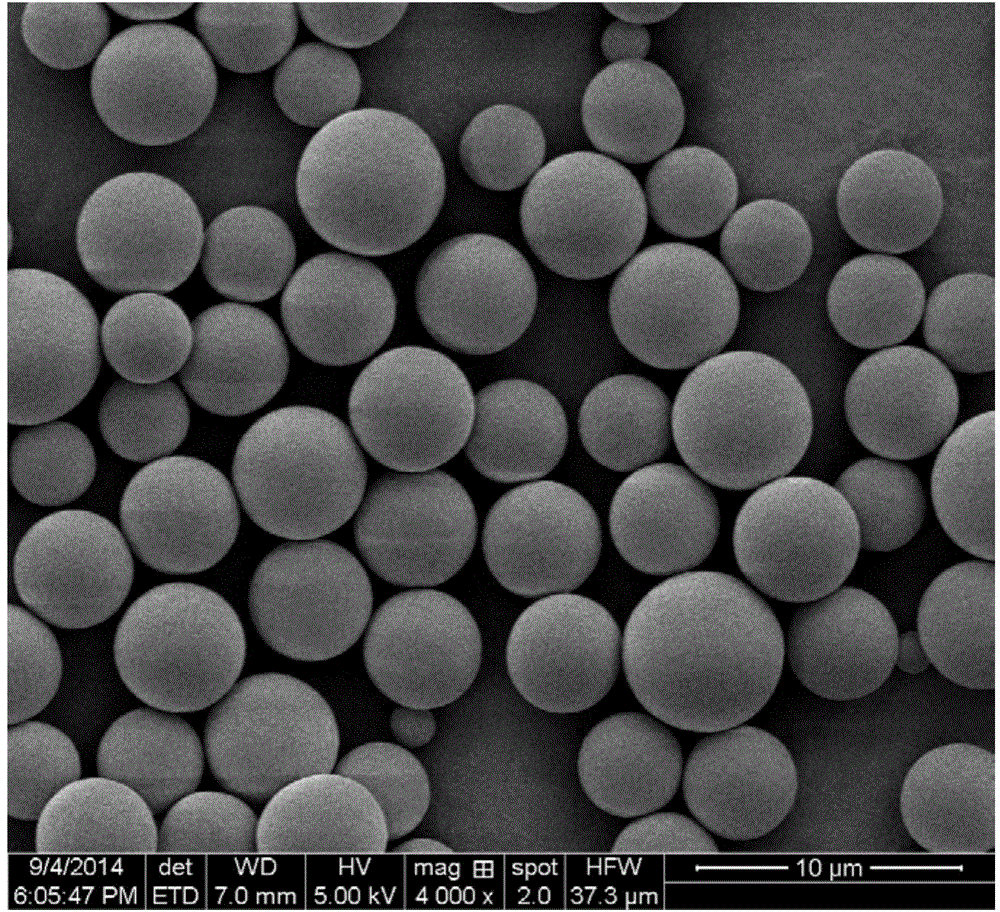

Preparation method of porous carbon microsphere

InactiveCN103569995APreparation raw materials are cheapRaw materials are readily availableCarbon preparation/purificationRough surfaceMicron scale

The invention discloses a preparation method of a porous carbon microsphere. The preparation method comprises the following steps: subjecting o-dihydroxybenzene and formaldehyde to carry out polymerization reactions in a silica sol solution under the catalytic action of acid so as to obtain compound microspheres of o-dihydroxybenzene-formaldehyde resin-oxidized nano particles, and then subjecting the compound microspheres to the processes of carbonization and silicon oxide removing so as to obtain porous carbon microspheres with a even particle size. The size of the porous carbon microsphere is in a micron scale range; the porous carbon microsphere has a good spherical shape and a rough surface, is rich in medium holes with a size of 10 to 40 nanometers, integrally has two hole structures, namely the medium hole and the micro hole, and has a large specific surface area. The porous carbon microsphere has a high purity, and the carbon content can reach 95% or more.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

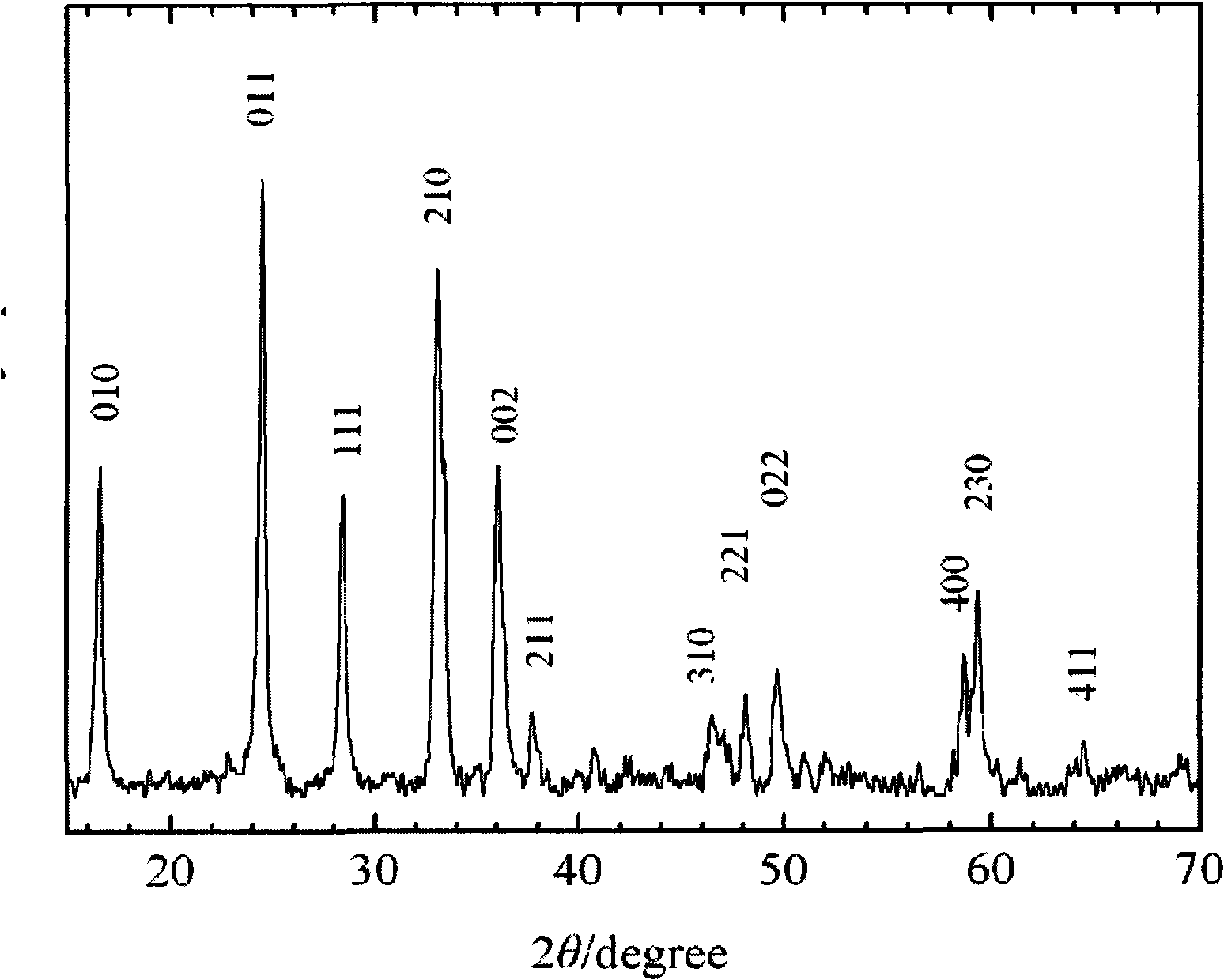

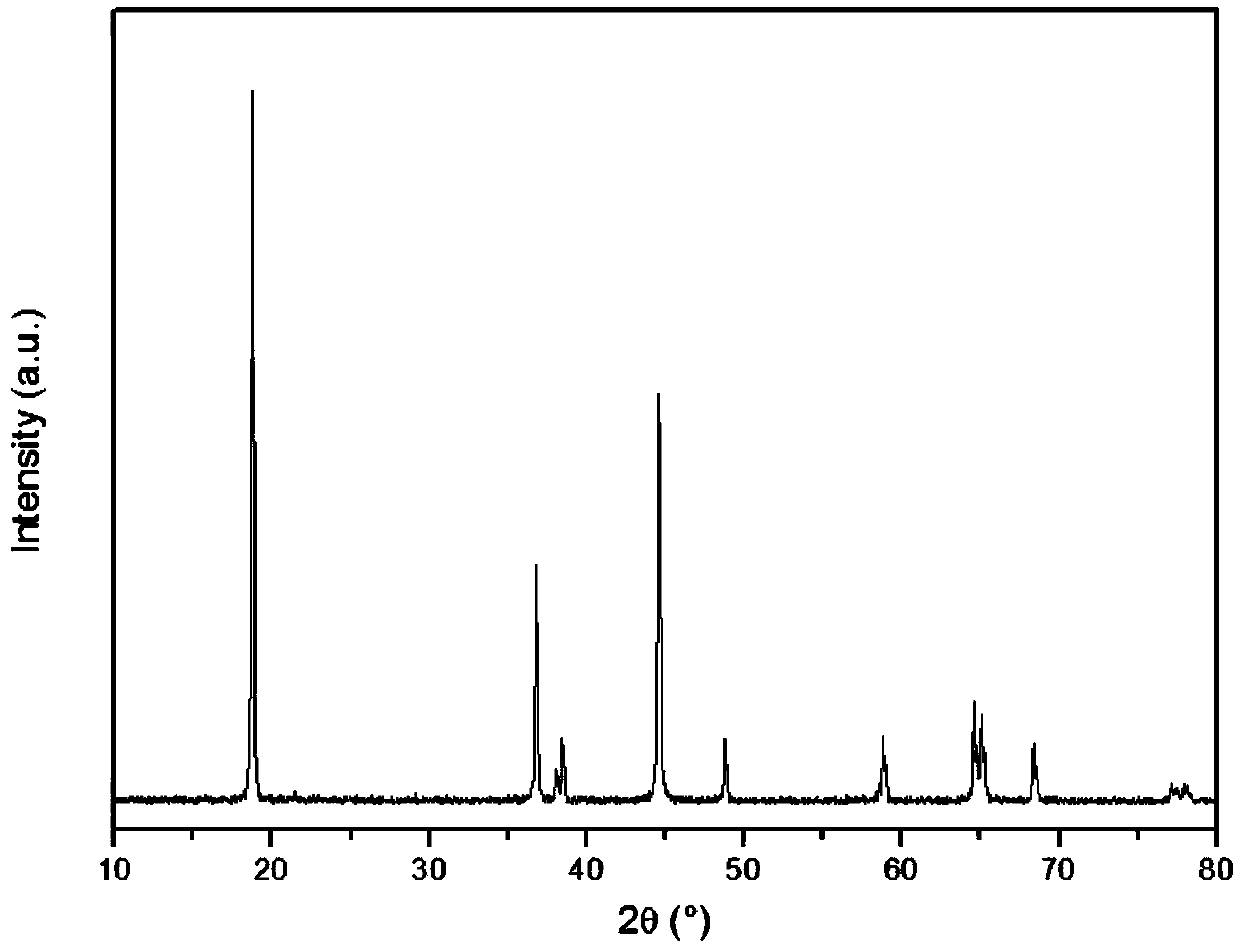

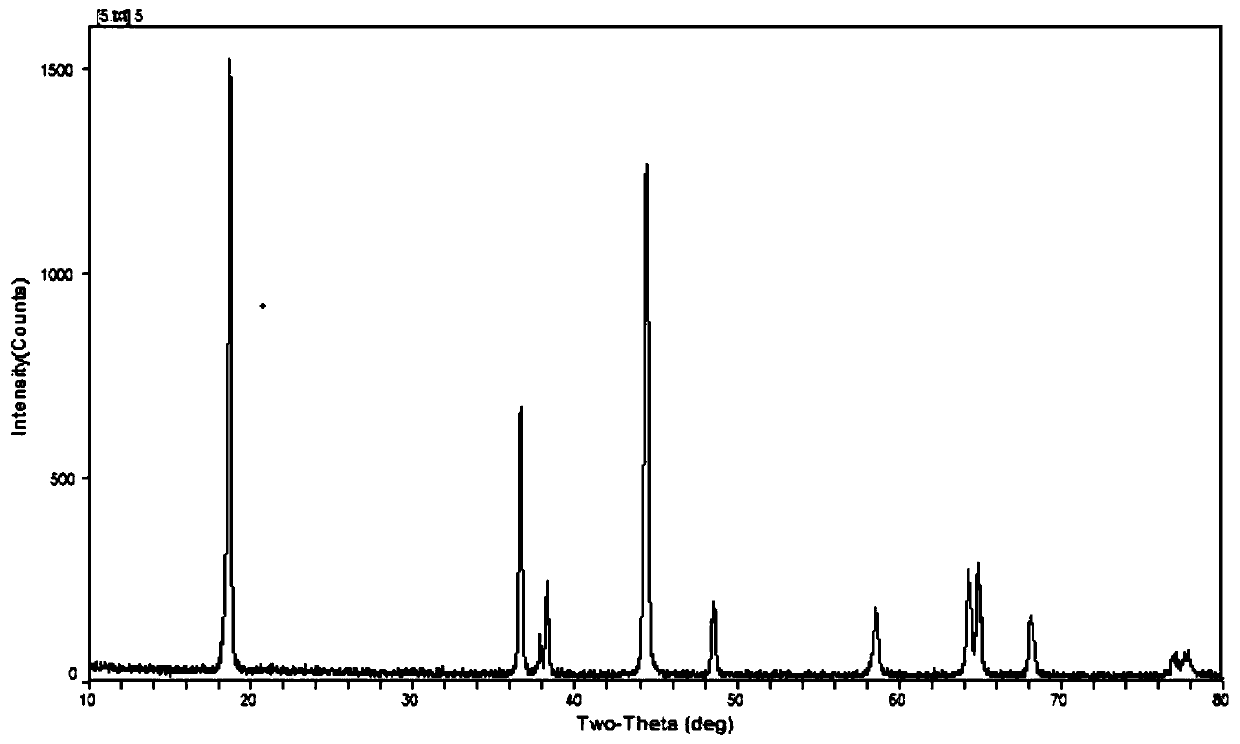

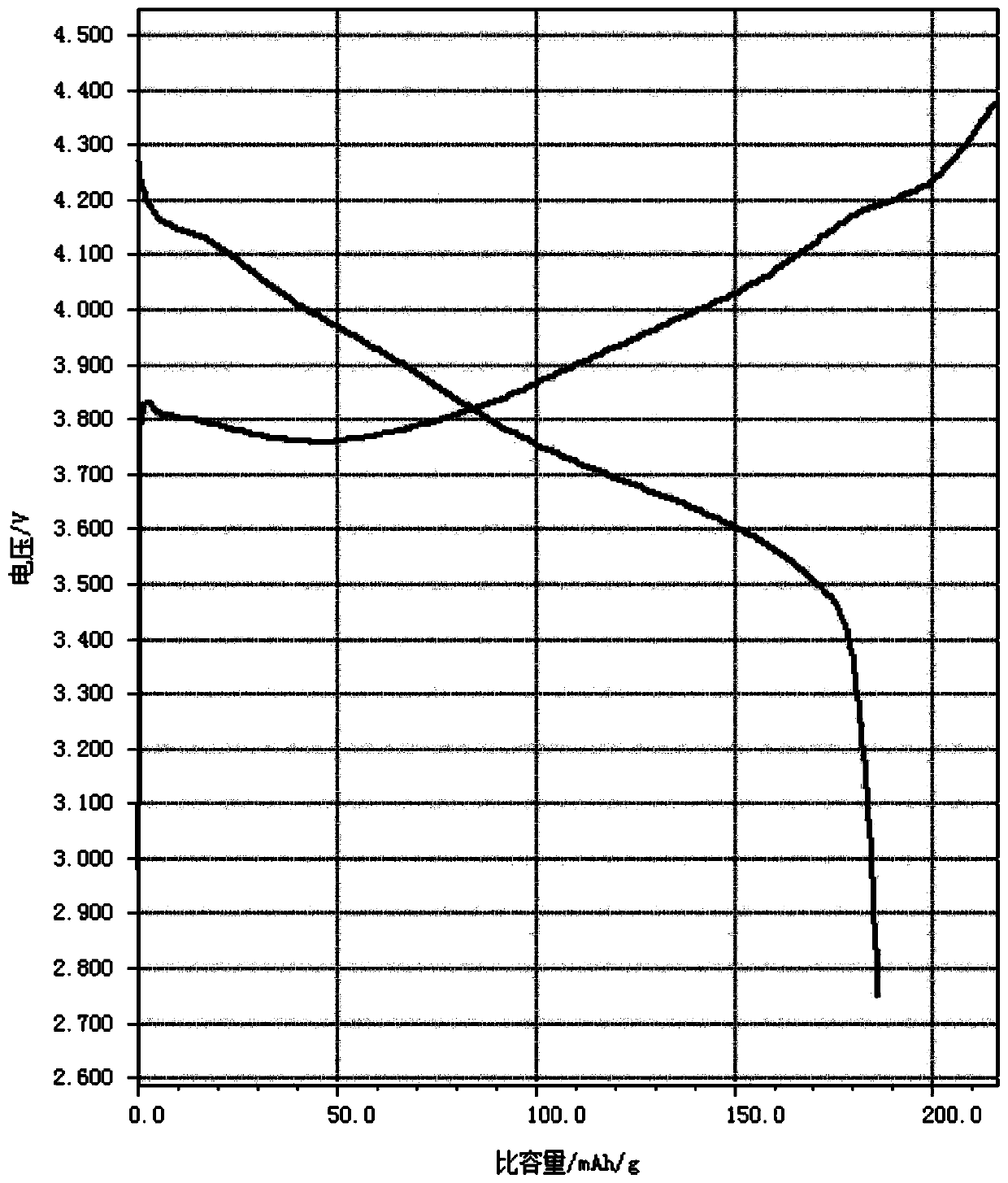

Method for preparing lithium-manganese silicate of cathode material of lithium-ion battery

InactiveCN101540392AWide variety of sourcesNo pollution in the processElectrode manufacturing processesSilicon compoundsPolyolBoiling point

The invention discloses a liquid-phase method for preparing lithium-manganese silicate of a cathode material of a novel lithium-ion battery. Lithium salts, manganese salts and ester orthosilicate of certain proportion are mixed in polyalcohol, the mixture is heated to the temperature of the boiling point of the polyalcohol, kept at a temperature for a certain period of time and cooled slowly; after the mixture is dried, a mixed precursor is obtained; and then after being mixed and carried out ball milling with an addition agent, the mixed precursor is calcined under inert atmosphere so as to obtain the lithium-manganese silicate ion battery cathode material. The lithium-manganese silicate material is easily and safely prepared with low cost. The lithium-manganese silicate material prepared by the method has the advantages of low cost, good electrochemical performance, environmental protection, and the like and has wide application prospect in the field of the lithium-ion battery.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of thorium-uranium mixed oxide ceramic microspheres

ActiveCN103165206ANo stringent requirementsFlat surfaceNuclear energy generationReactors manufactureOxide ceramicMixed oxide

The invention belongs to a preparation method of nuclear fuel, and concretely relates to a preparation method of thorium-uranium mixed oxide ceramic microspheres. The method uses an internal gelation method, and comprises using an acid-lacking uranyl nitrate solution and thorium nitrate as raw materials, preparing sol, dispersing gelling, washing, drying, calcining and reduction sintering to prepare ThO2-UO2 microspheres with a diameter of 0.05-0.20 mm. The ThO2-UO2 microspheres has outstanding advantages of smooth surface, good sphericity, compact inside, uniformly distributed thorium, and a density being greater than 96.8% TD; and the method is simple, and can prepare the thorium-uranium mixed oxide ceramic microspheres with different thorium contents.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

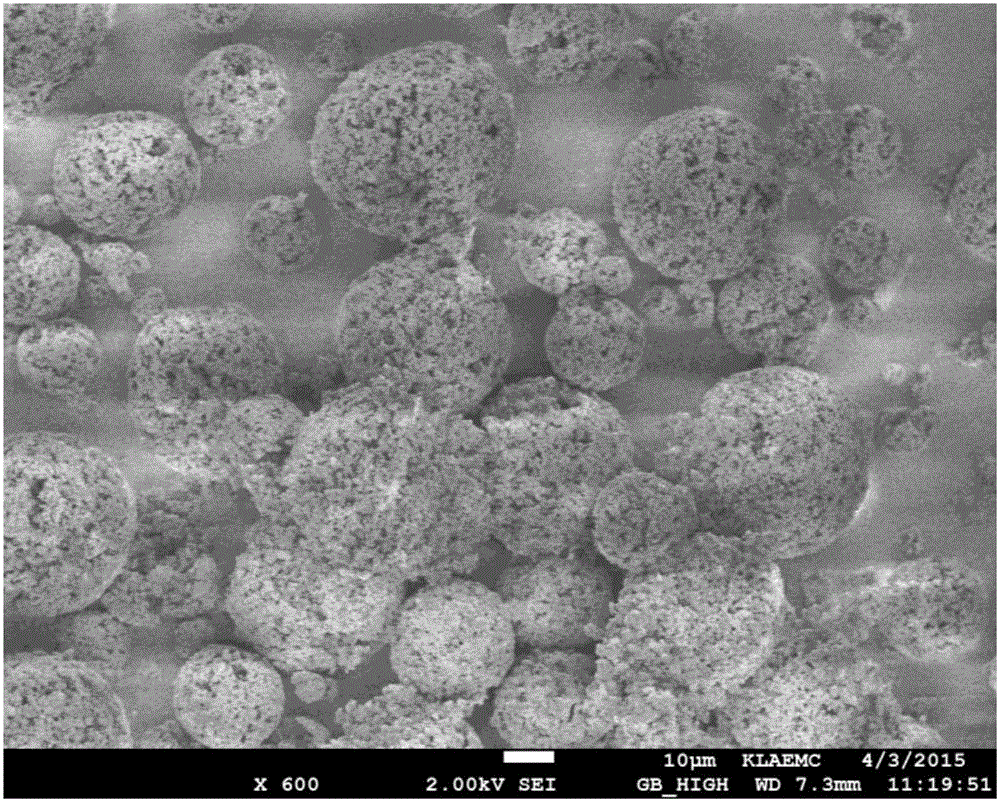

Method for preparing precursor of positive material of nickel manganese cobalt multi-element lithium ion battery

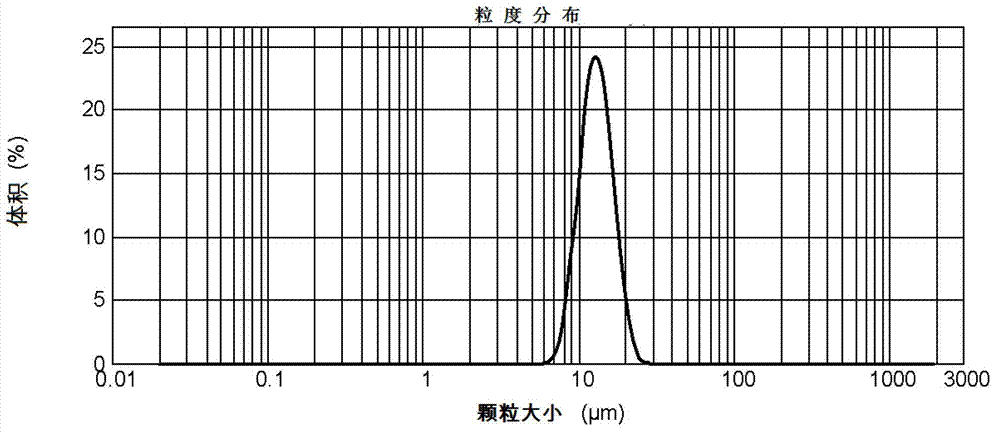

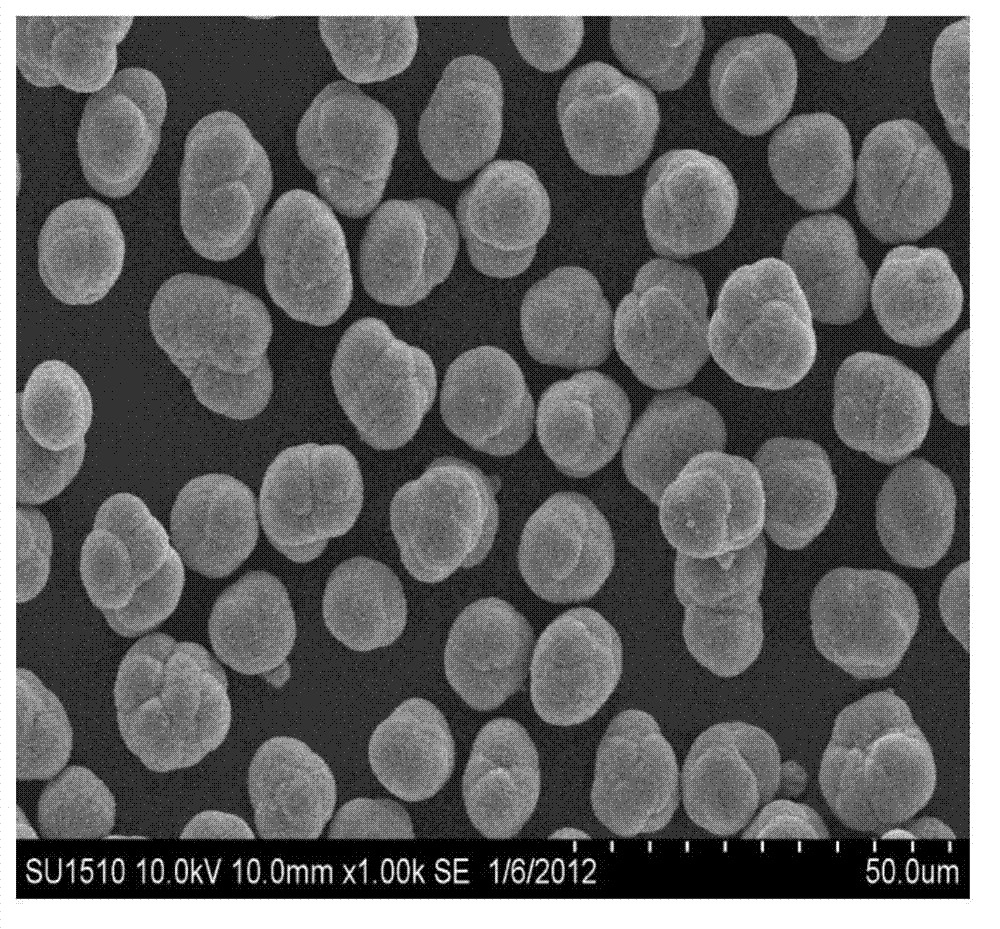

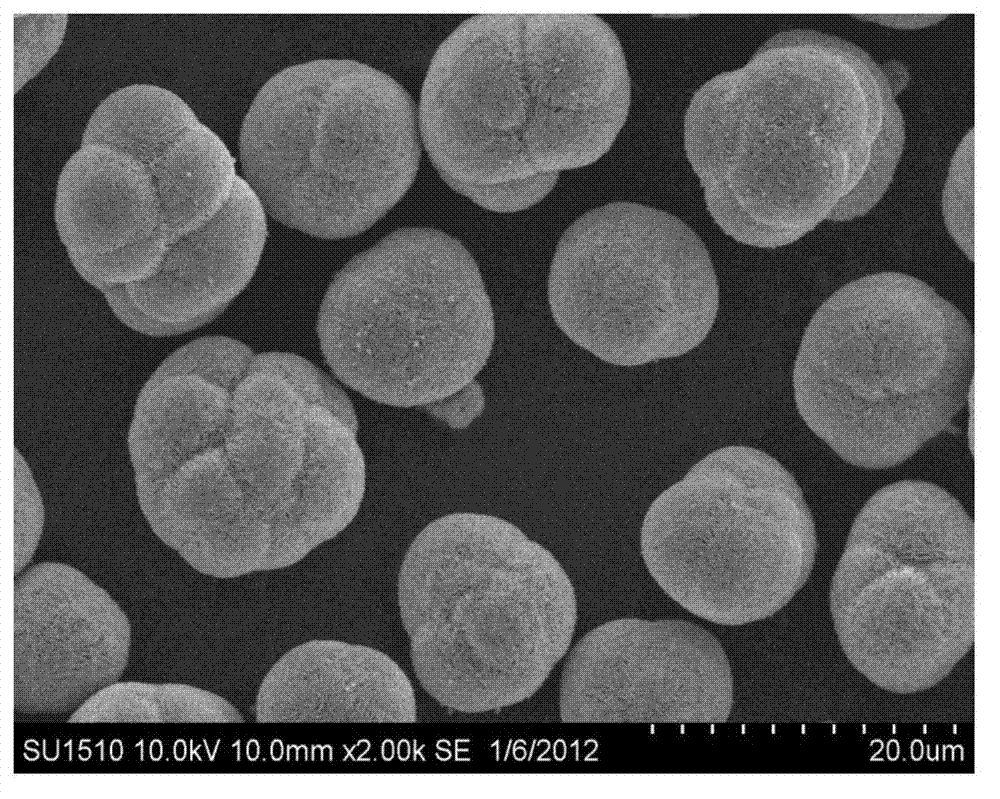

The invention discloses a method for preparing a precursor of a positive material of a nickel manganese cobalt multi-element lithium ion battery. The method comprises the following steps of: firstly, dissolving nickel, cobalt and manganese with deionized water, and preparing a multi-element metal salt solution with the total metal ionic molar concentration between 0.8 and 2.5mol / L, wherein the molar ratio of nickel to cobalt to manganese elements in the multi-element metal salt solution is (0-1):(0-1):(0-1); secondly, preparing alkali solution with concentration between 2 and 4mol / L; thirdly, reacting the salt solution with the alkali solution, wherein the temperature is controlled to be between 40 and 70 DEG C and the stirring speed is controlled to be between 100 and 600 revolutions / min, and the adding speed of salt and alkali solutions is controlled, so that the pH value of the reaction system is controlled to be between 8 and 11; and continuously stirring for 30 minutes to 2 hours after the reaction is completed, standing for 2 to 4 hours, filtering to obtain solid matters, and washing with deionized water until the content of Na<+> is lower than 0.03 percent, and drying to obtain the required precursor of the positive material of the nickel manganese cobalt multi-element lithium ion battery. According to the invention, an ammonia complexing agent is not used, and the method has the advantages of no ammonia or nitrogen pollution risk, good product sphericity, uniform granules, narrow granularity distribution and the like.

Owner:深圳市天骄科技开发有限公司

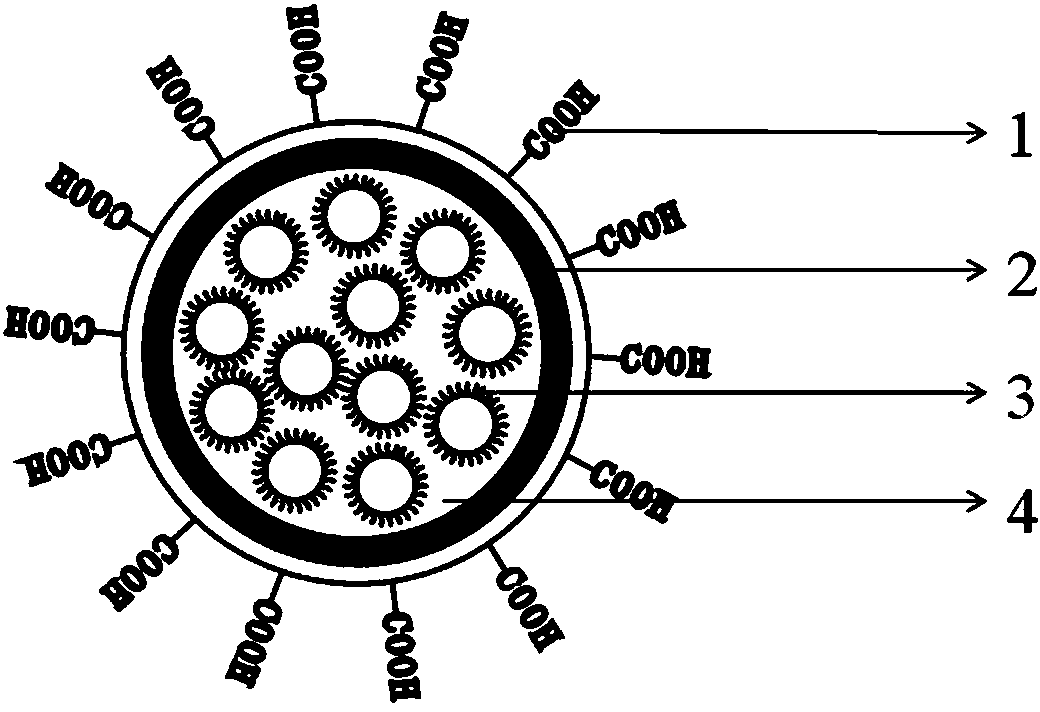

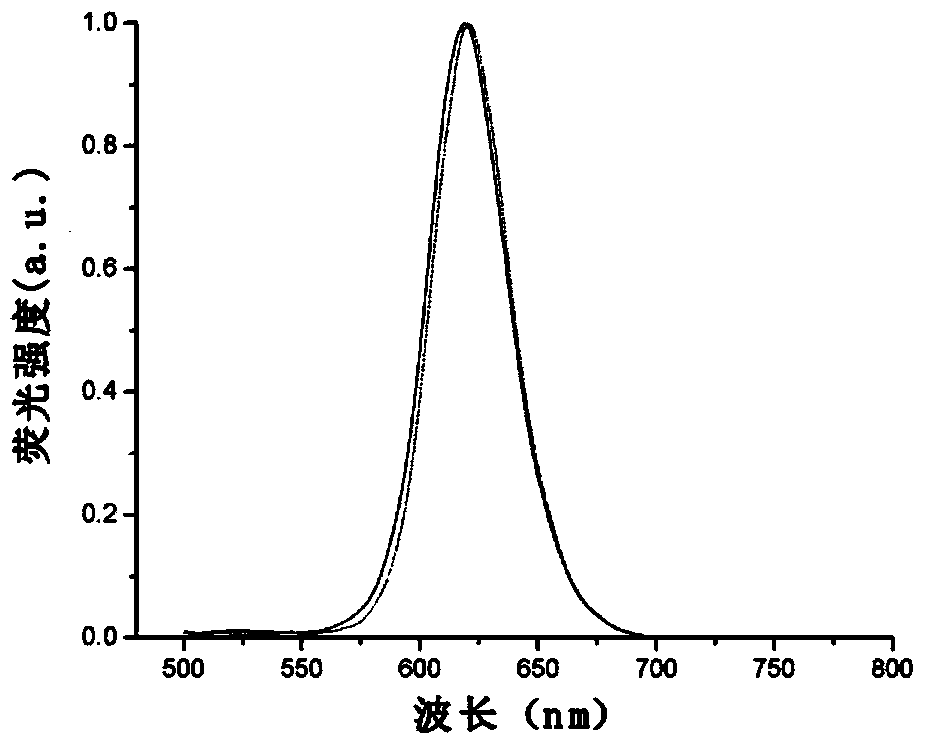

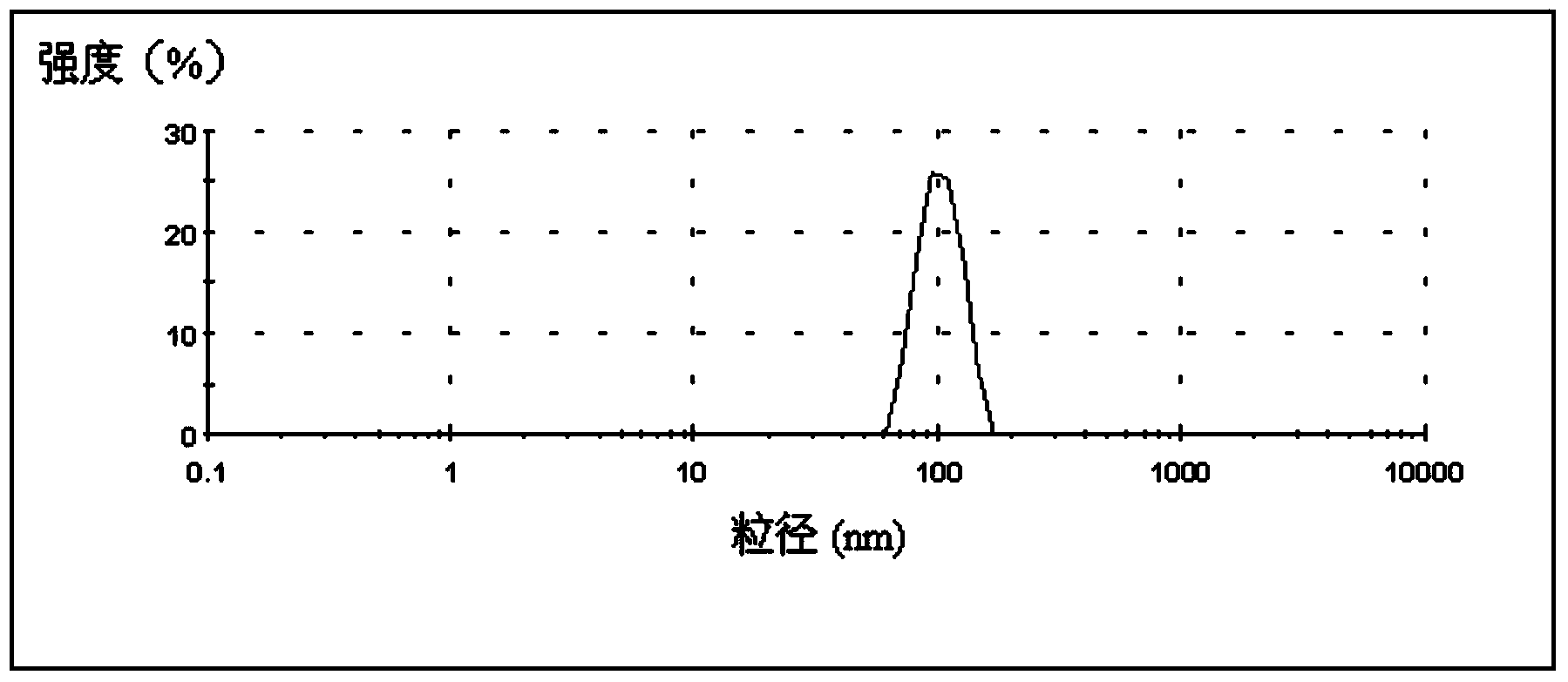

Water-soluble quantum dot fluorescent nanosphere and preparation method thereof

InactiveCN103361067AGood spherical shapeEasy to functionalizeLuminescent compositionsMaterial analysisFluorescenceSide chain

The invention relates to a water-soluble quantum dot fluorescent nanosphere and a preparation method thereof. The preparation method comprises the following steps of: grafting alkylamine on a side chain of a hydrophilic polymer of polyacrylic acids to prepare an amphipathic polymer; and coating the amphipathic polymer on the surface of a quantum dot by using a reaction system of water / an emulsifying agent / the amphipathic polymer / oil through a phase transfer method to obtain a fluorescent nanosphere with the quantum dot coating quantity of 10-80, the uniform grain size of 30-300nm and favorable dispersibility. The water-soluble quantum dot fluorescent nanosphere is good in fluorescence and colloid stability, capable of being stored for a long term, rich in carboxyl on the surface, capable of being coupled with an antibody and other amino-contained biomolecules such as antibodies, nucleic acids, enzymes, amino acids and even amino-contained inorganic molecules, easy in operation of coupling reaction of carboxyl and amino, high in connection efficiency, simple in preparation process and suitable for large-scale production.

Owner:TIANJIN UNIV

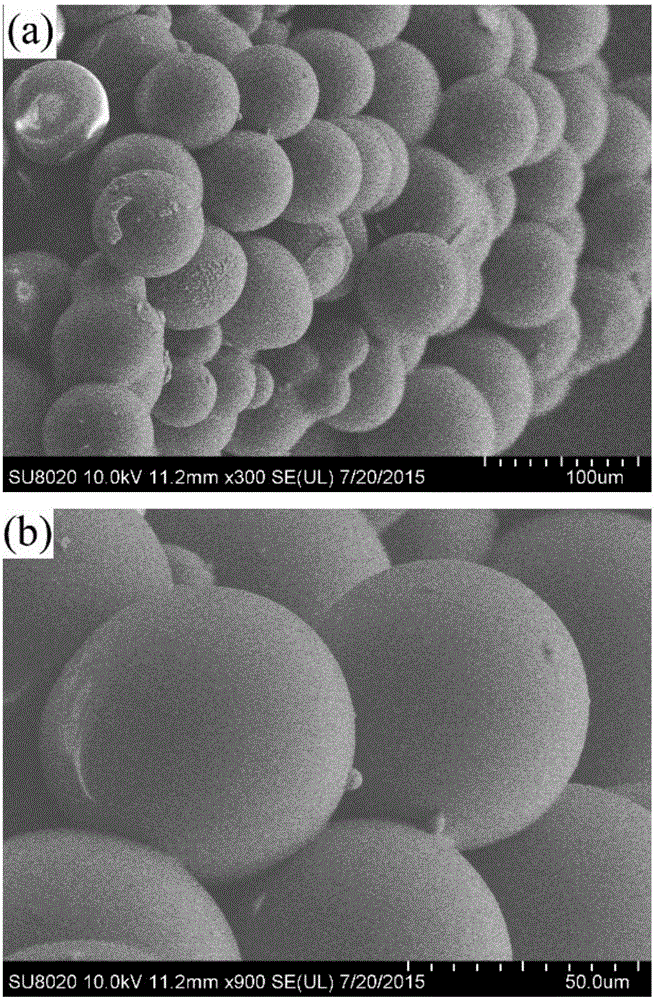

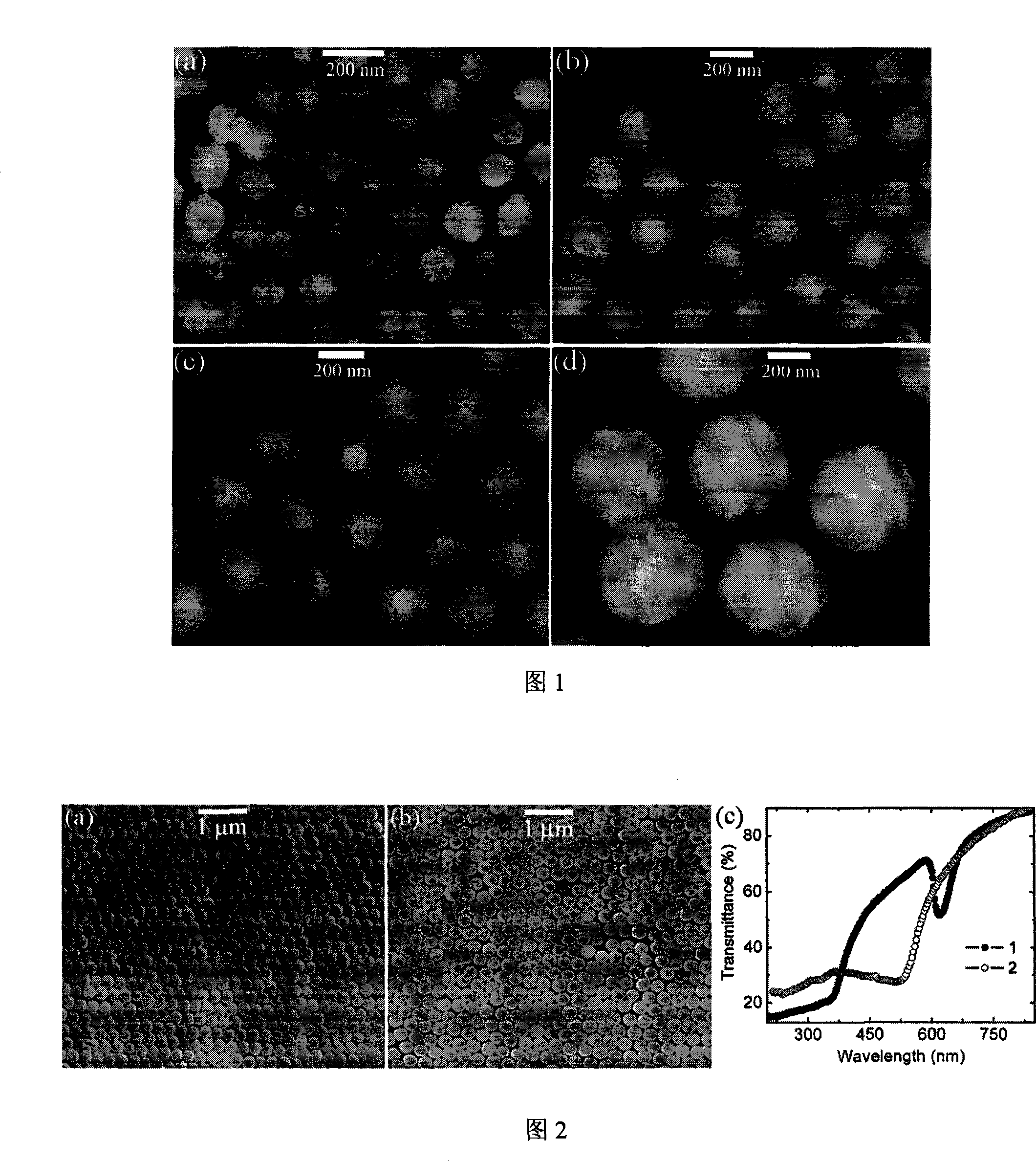

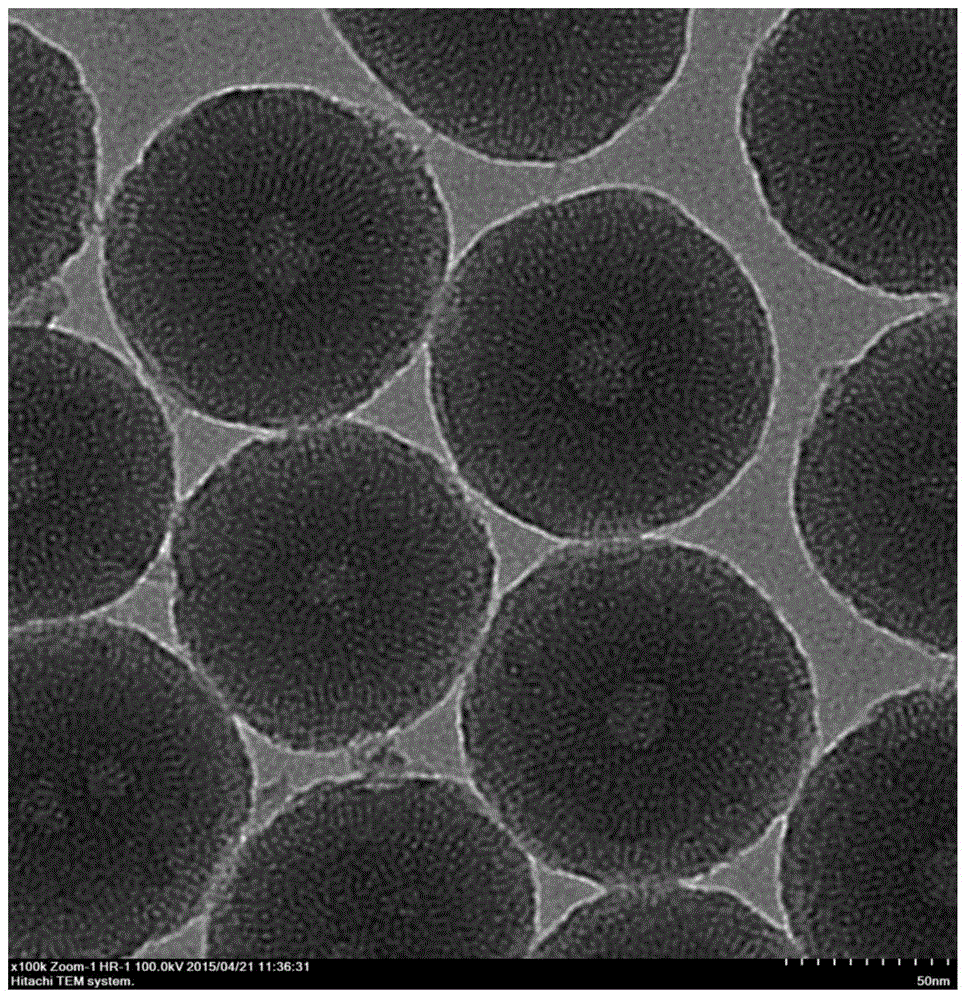

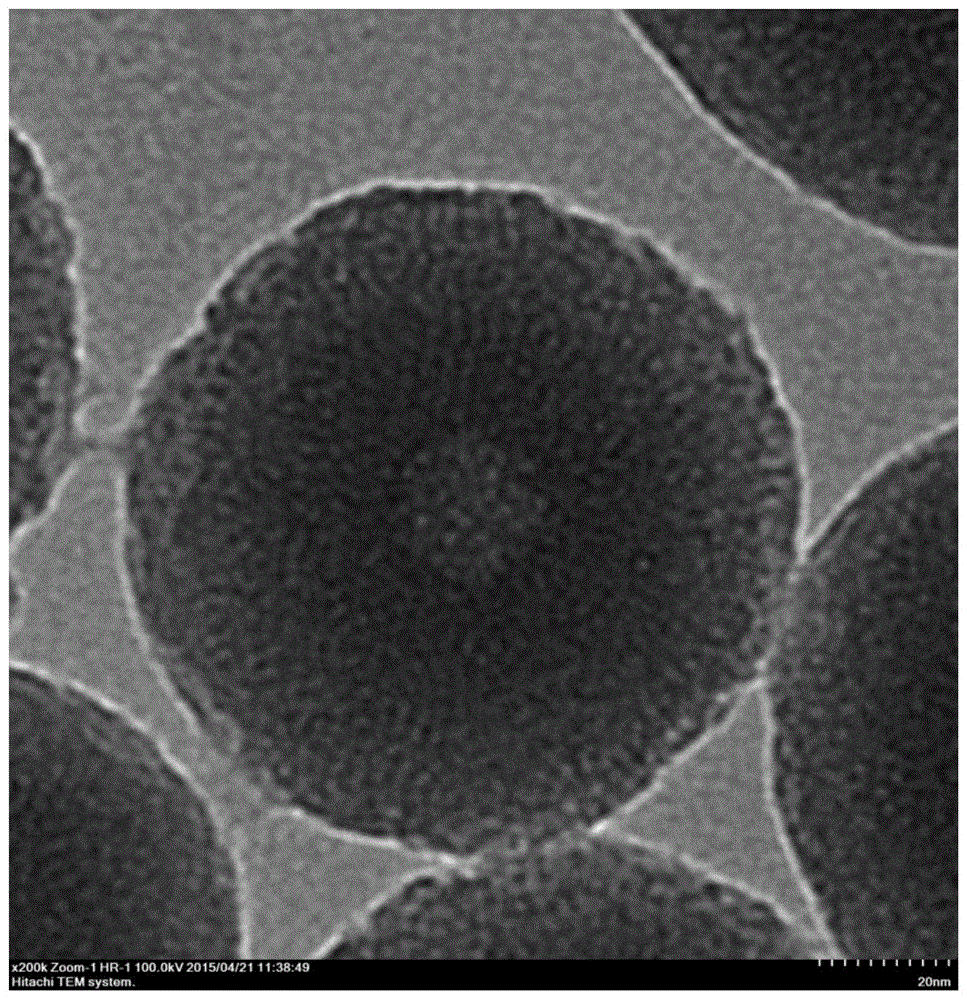

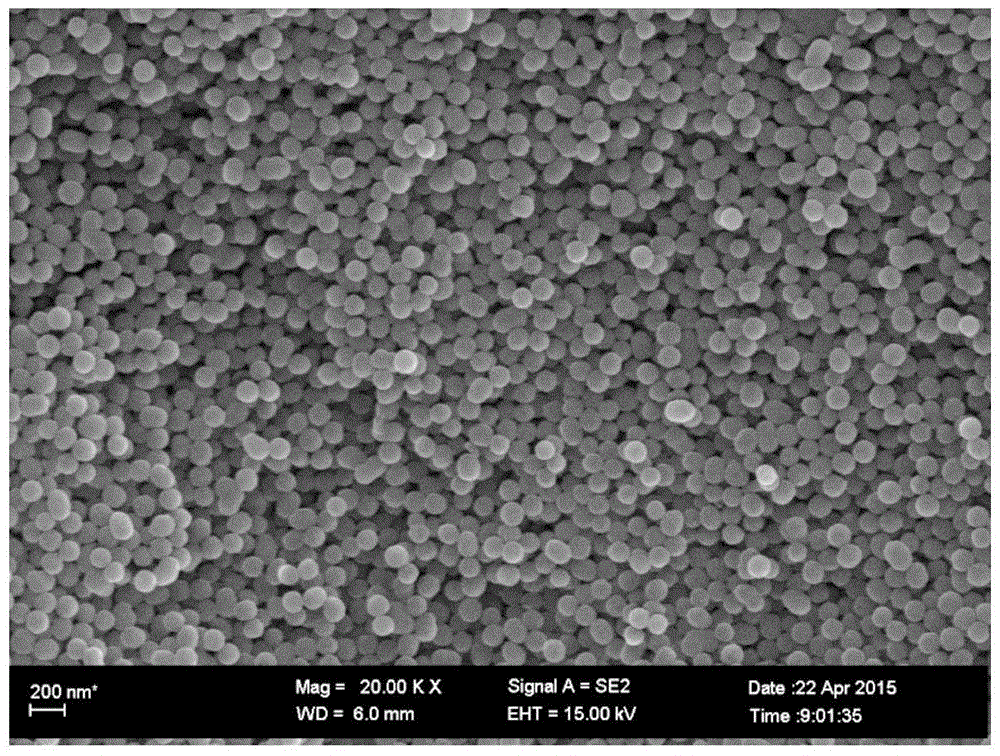

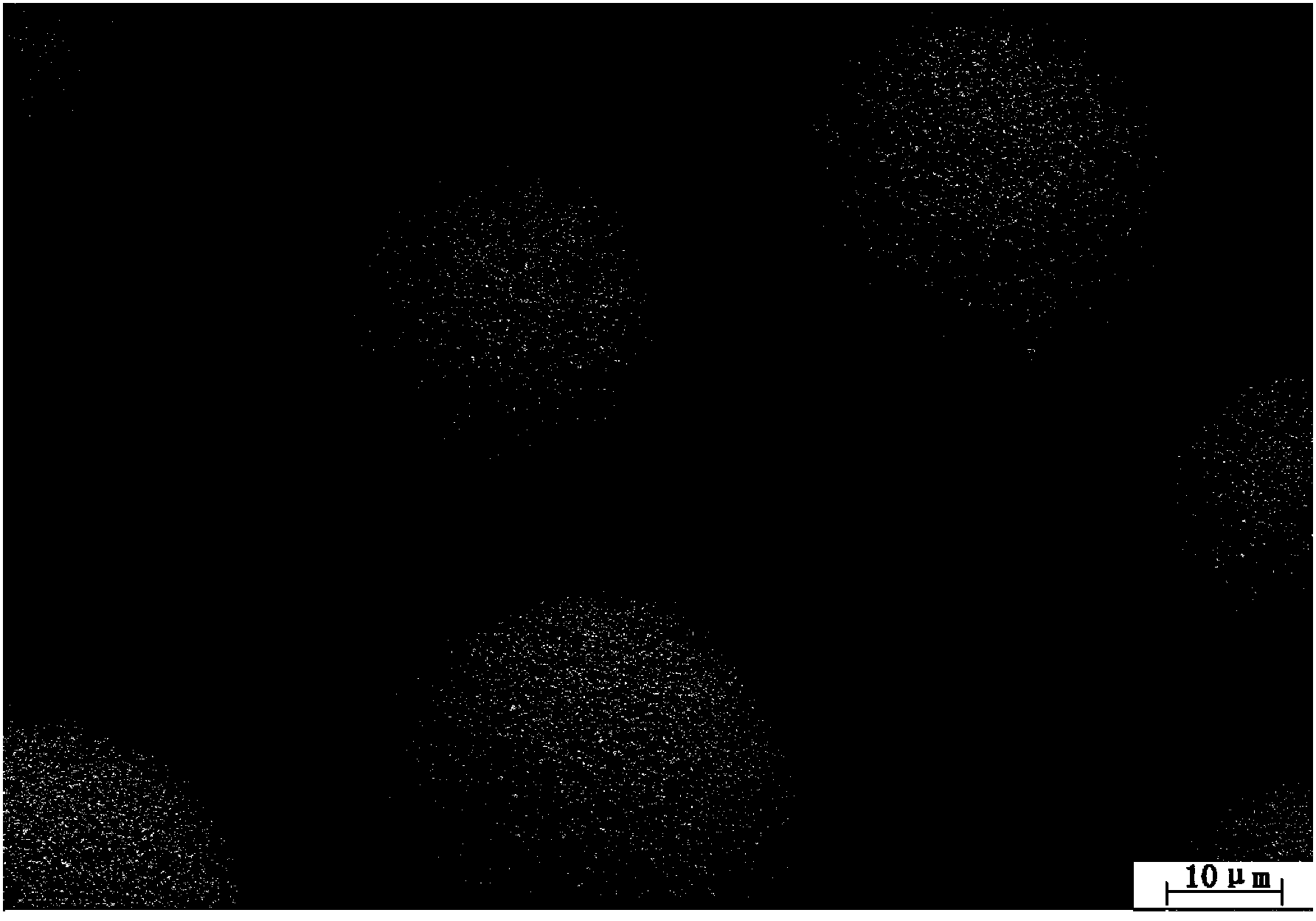

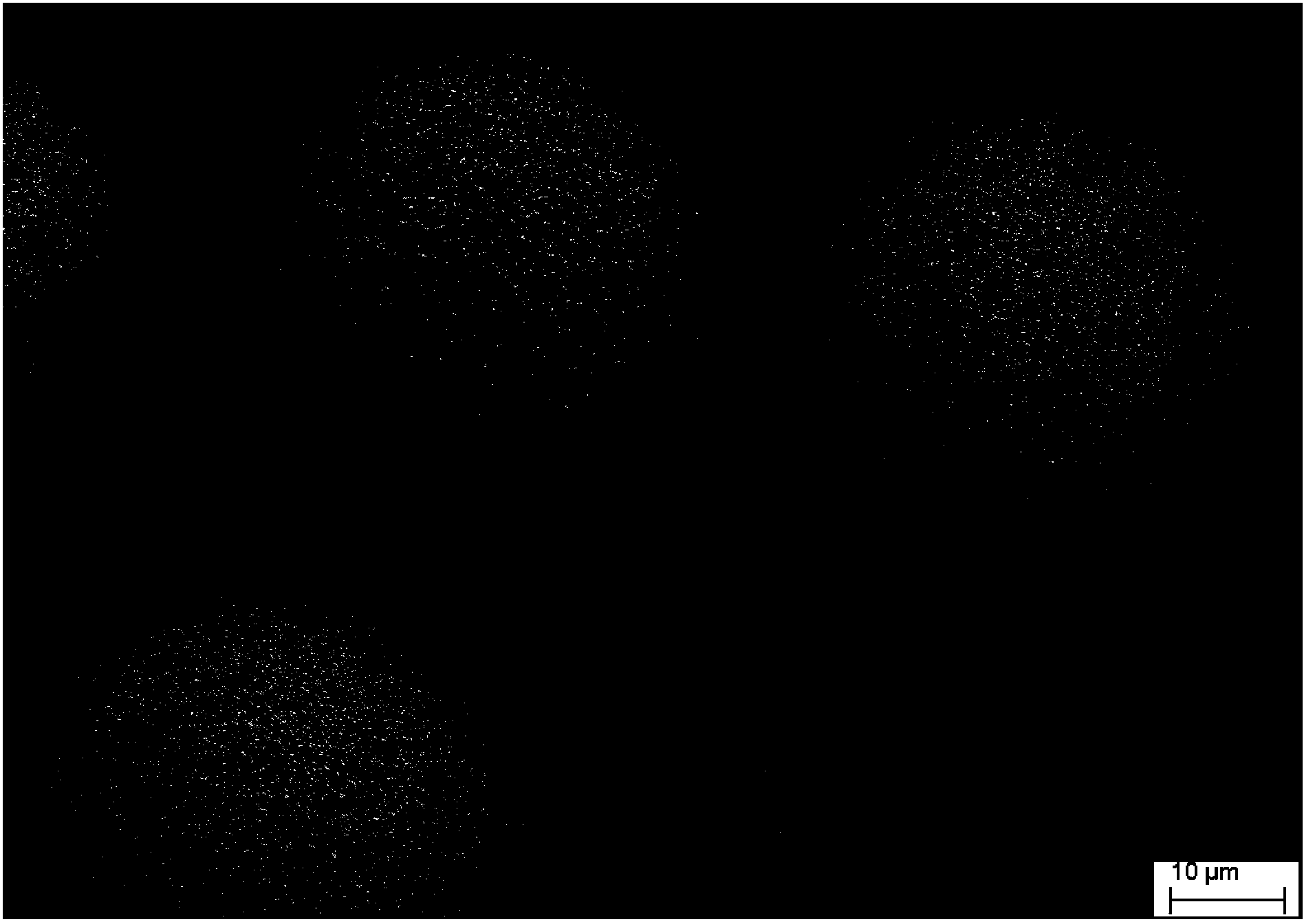

Hydrogel@gold nanocomposite and preparation method and application thereof

ActiveCN106018376AImprove mutual couplingHigh sensitivityMaterial nanotechnologyRaman scatteringMicrofluidic chipMicrometer

The invention discloses a hydrogel@gold nanocomposite and a preparation method and application thereof. The hydrogel@gold nanocomposite is composed of one or more core-shell structure units, and each core-shell structure unit is of a core-shell structure with hydrogel microspheres serving as the core and a gold nanosphere layer serving as the shell. The diameter of each gold nanosphere is 30-60 nm, and the diameter of each hydrogel microsphere is 5-200 micrometers. The preparation method includes the steps that the microfluidic chip technology is adopted to prepare the P(AAm-co-AAc) hydrogel microspheres; chloroauric acid is reduced in ethanediol to prepare the gold nanospheres; the gold nanospheres are transferred into water and mixed with the P(AAm-co-AAc) hydrogel microspheres, the mixture is subjected to standing for 12-48 h, and the hydrogel@gold nanocomposite is obtained. According to the hydrogel@gold nanocomposite and the preparation method and application thereof, the properties of a gold nanomaterial and hydrogel can be effectively exerted, the SERS effect can be substantially enhanced, and the sensitivity of SERS detection can be improved, and the detection capability on low-concentration molecules can be improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing gelatin microballoon embolization agent

InactiveCN103006573AGood biocompatibilityPromote degradationGranular deliveryMacromolecular non-active ingredientsCross-linkSide effect

The invention relates to a method for preparing a gelatin microballoon embolization agent, which comprises the following steps of dissolving gelatin or mixture of gelatin and medicine at 30-70 DEG C, filtering to obtain gelatin solution with 15%-60% of solid content, adding gelatin solution into oil phase liquid paraffin with mass ratio of 1%-2% of stabilizer Span 80, wherein the volume ratio of water and oil is 1 / 1-1 / 10, stirring for 15 minutes by 200-800r / min, adding cross-linking agent aldehyde compound with mass percent of 2%-50% at low temperature of 0-10 DEG C, solidifying for 1-2 hours, washing or drying the cross-linking agent to obtain the microballoon embolization agent after freeze drying or dehydration. The method has the beneficial effects that the gelatin microballoon embolization agent has certain elasticity and expansibility, the surface is smooth, the sphere is obvious, the size and the shape of the sphere is uniform, the grain size is controllable, clinical embolization effect can be improved, and side effect can be lowered, the clinical controllability is strong, antitumor drug can be added into the microballoon in manufacture process, so that double therapeutical effect of medicine treatment and embolization can be realized. The gelatin has good biocompatibility and biodegradablity, and clinical safety can be guaranteed.

Owner:杭州艾力康医药科技有限公司

Method for preparing sodium alginate/ chitosan sustained-release microcapsule by external gelation

InactiveCN101239052AEasy to prepareGood spherical shapePharmaceutical delivery mechanismPharmaceutical non-active ingredientsCalcium EDTADispersed media

The invention discloses a method for emulsionizing outer gelation and preparing sodium alginate / chitosan slow release micro-capsule in one step. The current preparation method of calcium alginate gel by internal gelation has defects that small parts of the calcium salt granules cannot be richly reacted with glacial acetic acid and remained in the sodium alginate calcium beads, the encapsulization materials are easily lost and the wrapping rate is low due to the calcium salt is difficult to evenly disperse. The invention uses the sodium alginate liquor as the disperse phase, the edible plant oil as the disperse medium and the sorbitan monooleate as the surfactant to emulsionize small liquid drops wrapped with oil; calcium chloride chitosan liquor is used for initiating the gelation reaction of the sodium alginate so as to generate sodium alginate / chitosan slow release micro-capsule; the oil remained on the surface is eliminated by a oil removing device with precipitation self-drifting method. The invention elevates the micro-capsule medicine contents and the wrapping rate.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

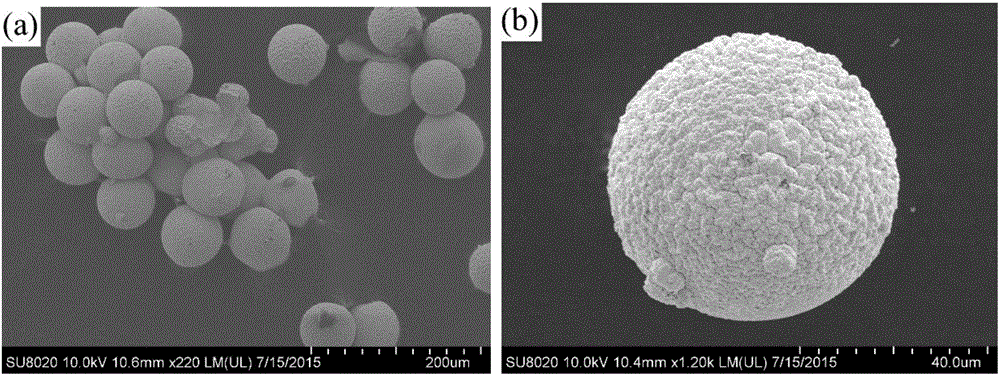

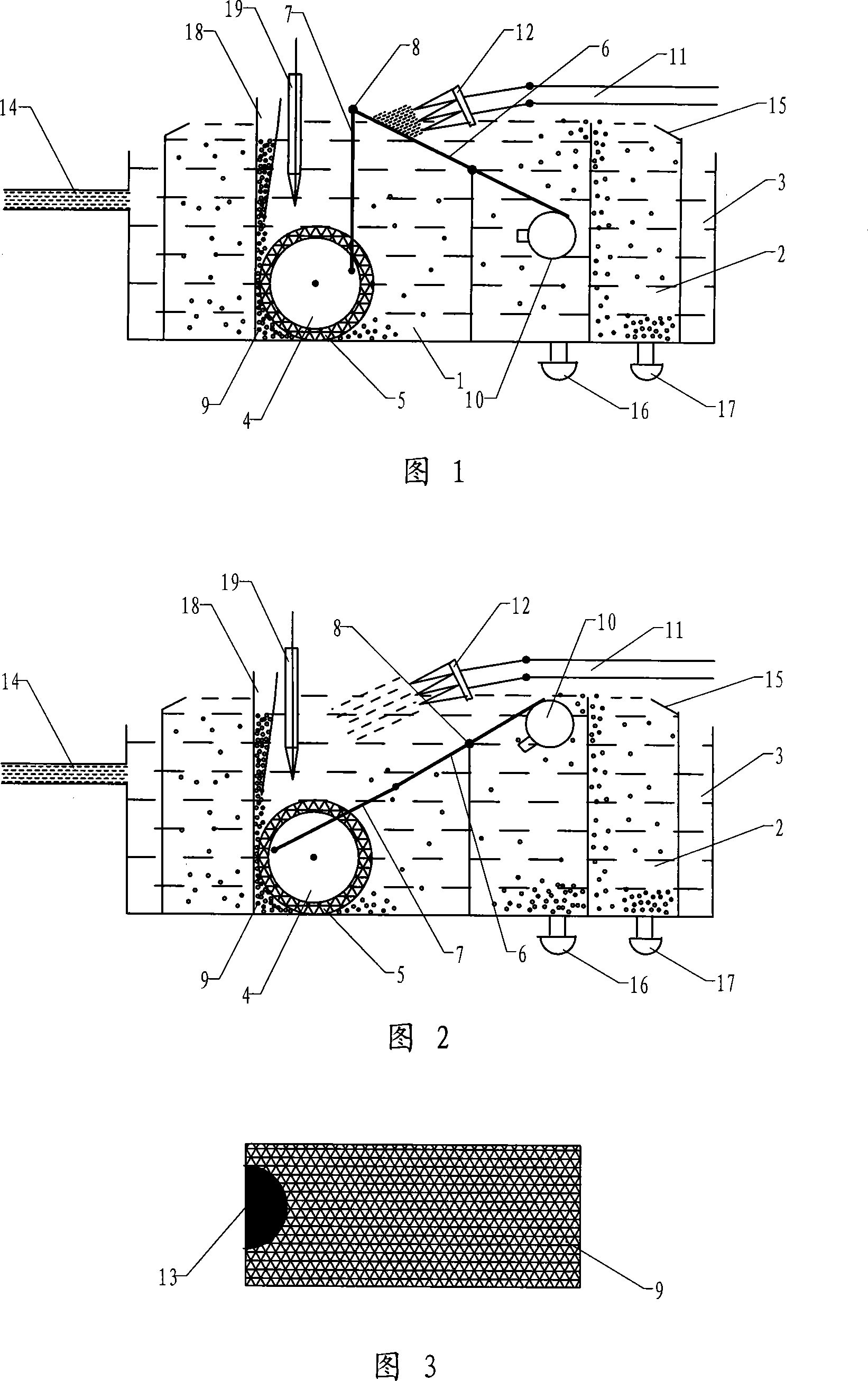

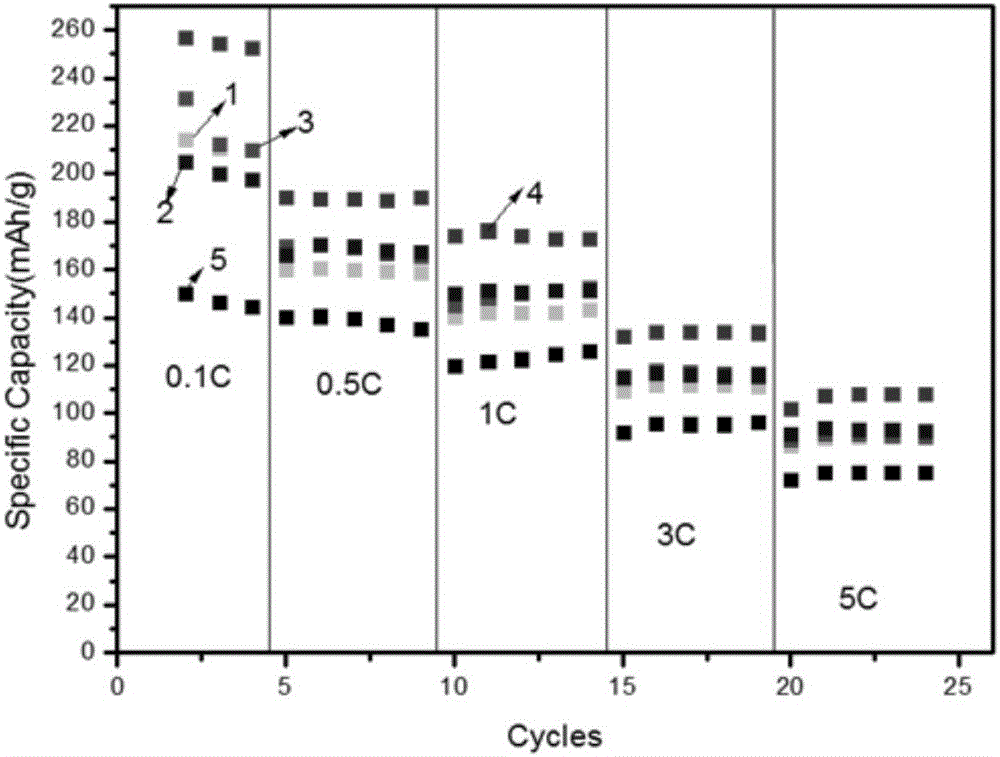

Positive electrode material of high-capacity lithium ion battery and preparation method of positive electrode material

InactiveCN105514373AHigh discharge specific capacityExcellent cycle stabilityCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention discloses a positive electrode material of a high-capacity lithium ion battery and a preparation method of the positive electrode material. The preparation method comprises the following steps: dissolving raw materials into de-ionized water to prepare a mixed solution A and a mixed solution B, which have the same volume and different concentrations; adding a sodium hydroxide solution and an ammonia water solution into a container C in a parallel flow manner to be subjected to co-precipitation, so as to prepare a co-precipitate Ni1-x-yCoxAly(OH)2+y precursor; after ageing, filtering, washing and drying the prepared co-precipitate precursor, uniformly mixing the co-precipitate precursor with a lithium source; pressing and molding mixed materials, putting the mixture into a pipe furnace for presintering, and sintering the mixture in an oxygen / oxygen-enriching air airflow to obtain a target product. The positive electrode material of the lithium ion battery, provided by the invention, has no impure phases and has high crystallization quality; the product has a uniformly-distributed grain diameter and a regular spherical shape, and has a very high specific discharge capacity and relatively excellent circulating stability; the positive electrode material can meet high-energy density and high-power charging and discharging requirements, a process is simple and a manufacturing cost is relatively low.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

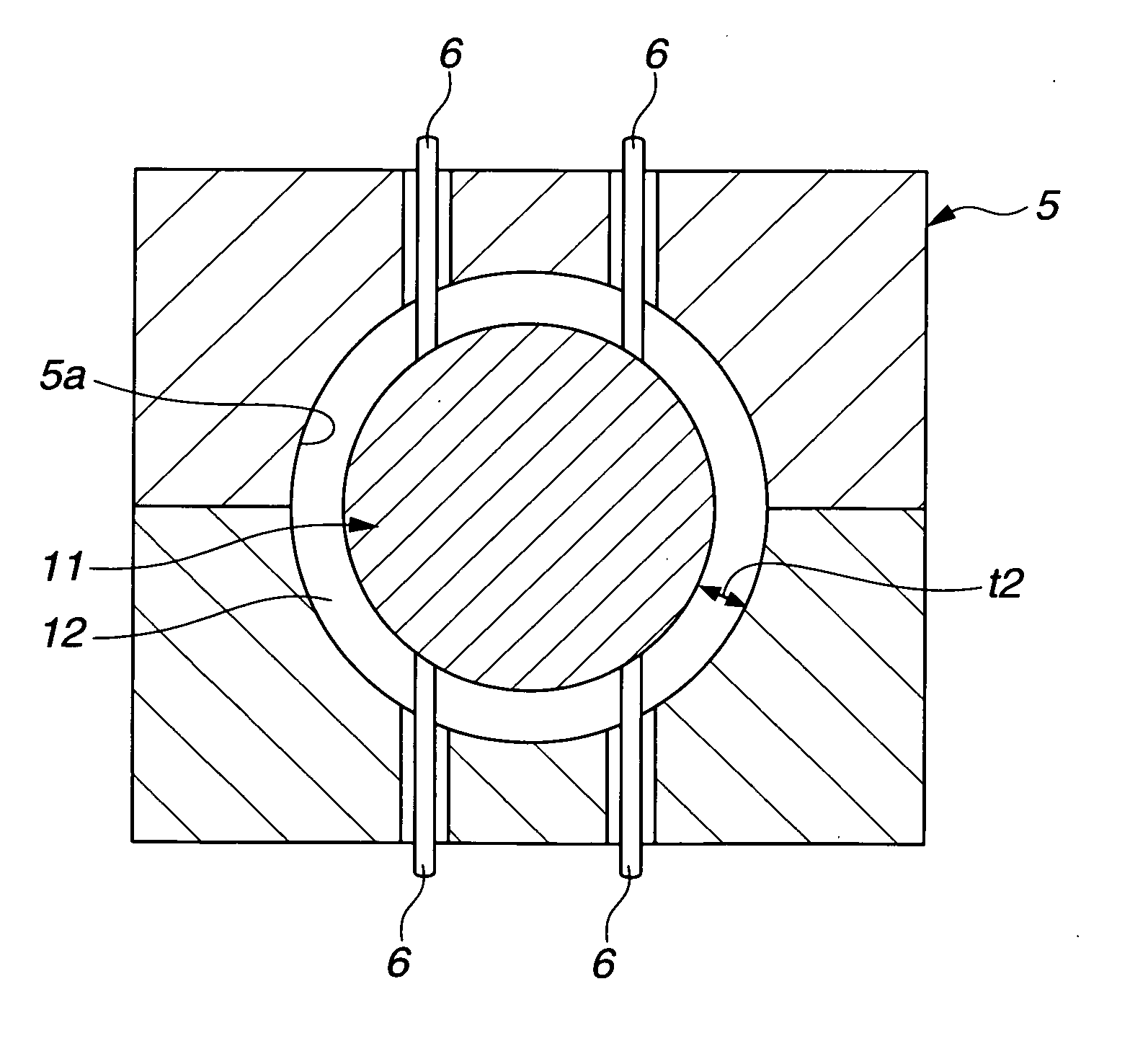

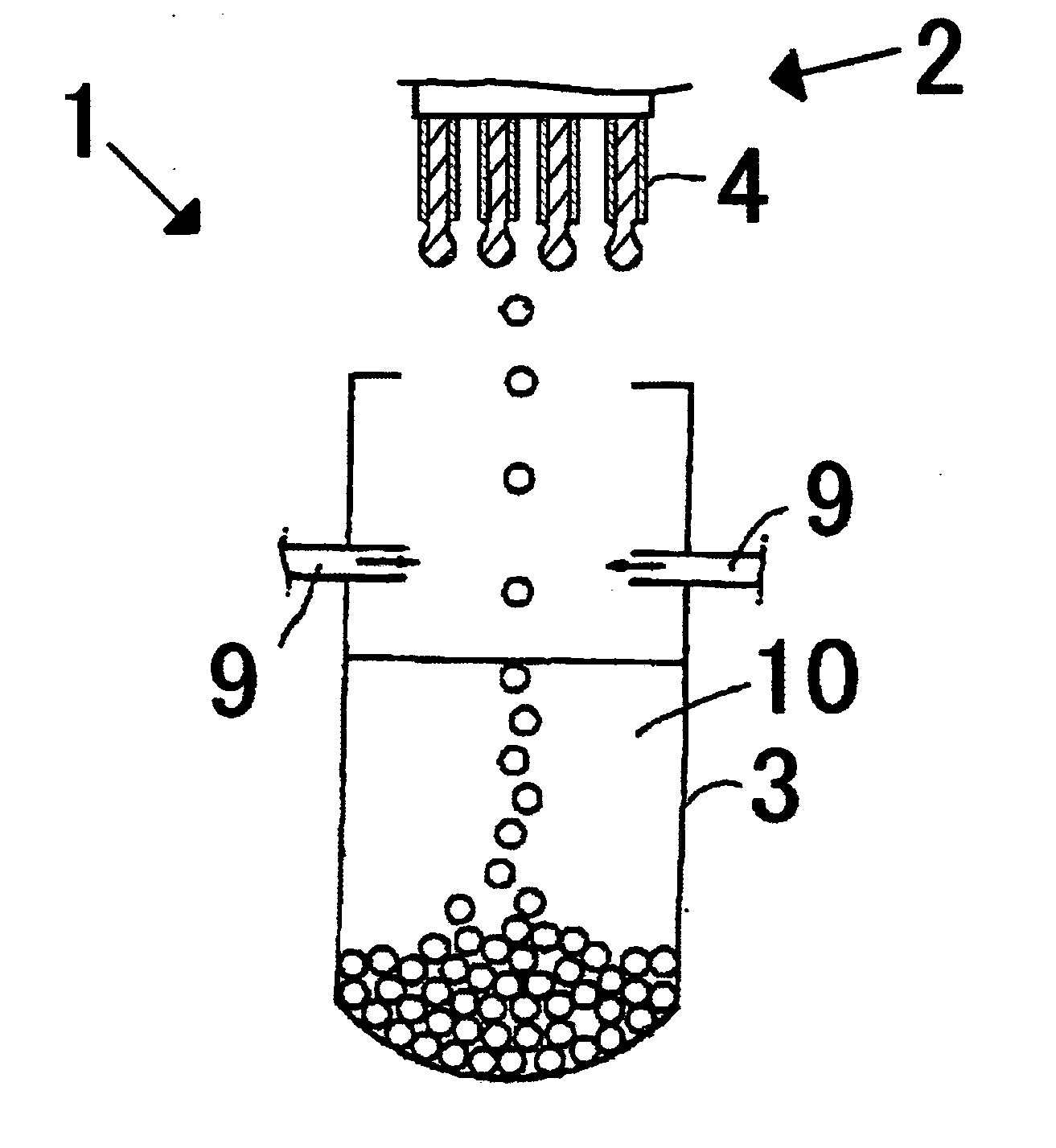

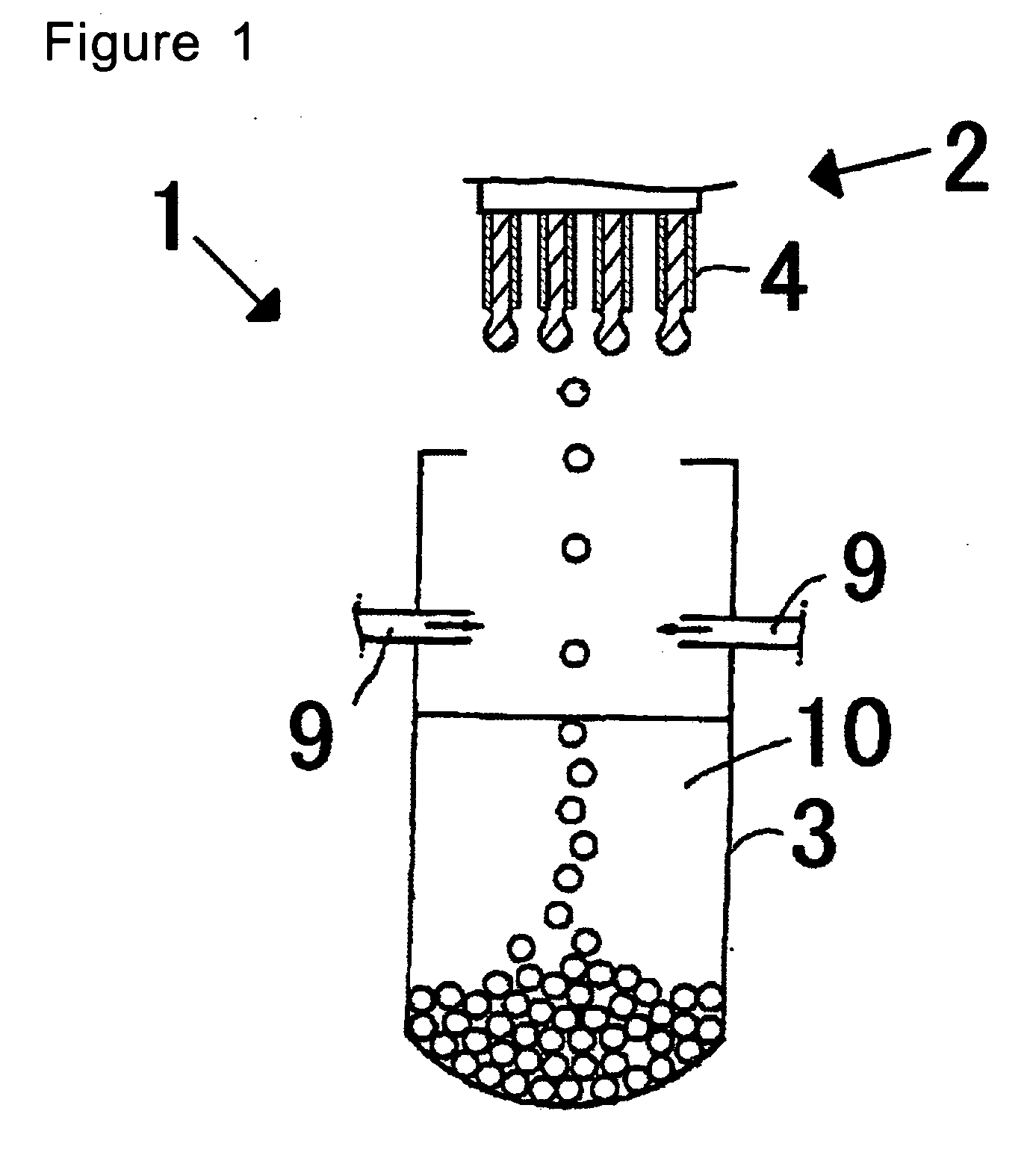

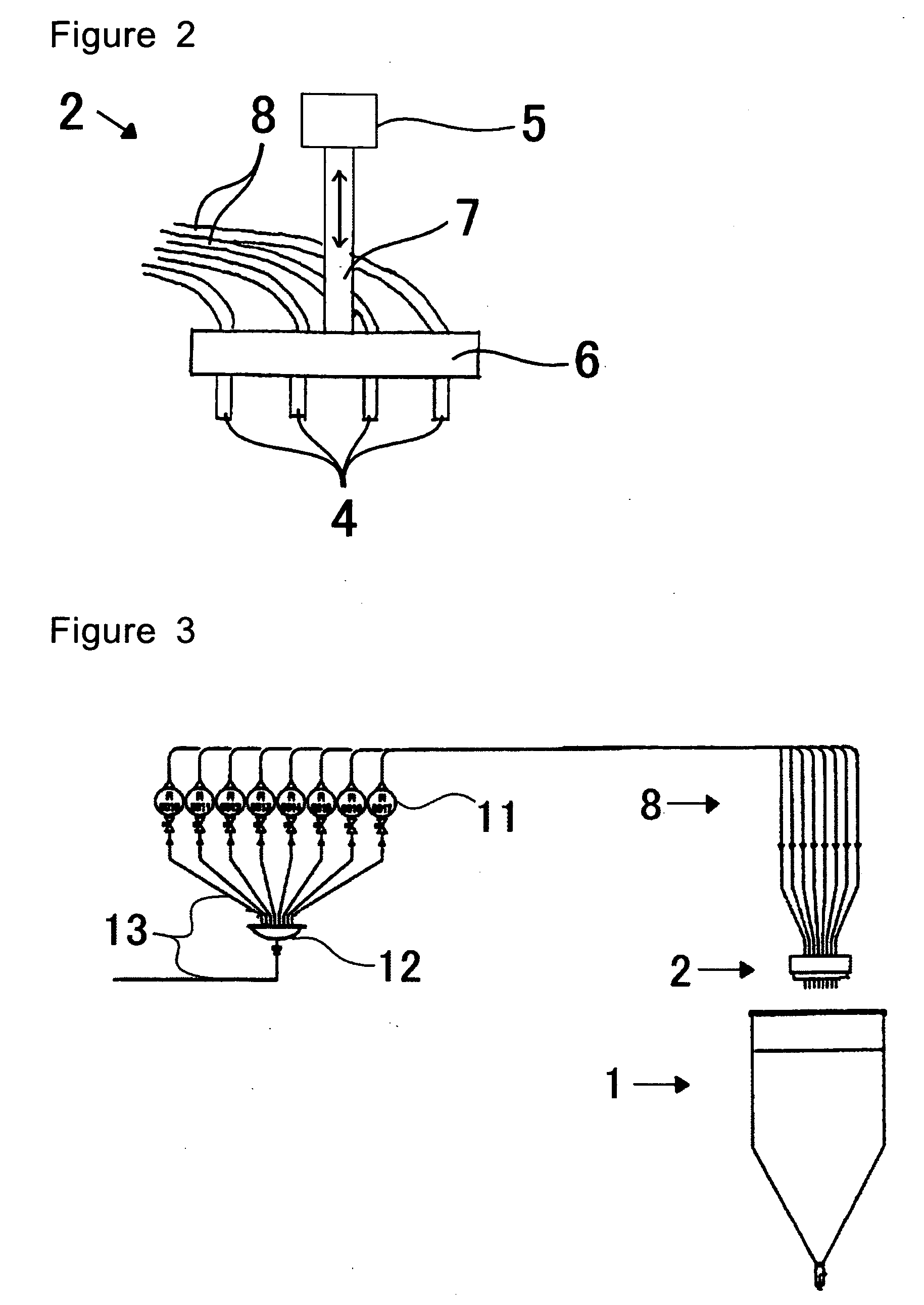

Dripping nozzle device, device for recovering feedstock liquid, device for supplying a feedstock liquid, device for solidifying the surfaces of drops, device for circulation aqueous ammonia solution, and apparatus for droducing ammonium diuranate particles

InactiveUS20070056637A1Particle diameters of the drops can be controlled easilyEliminate resonanceShaking/oscillating/vibrating mixersGranulation by liquid drop formationAmmonium hydroxideAmmonium diuranate

This invention provides a dripping nozzle device to produce ADU particles with good sphericity, a device for recovering a feedstock liquid to prepare a uniform feedstock liquid, a device for supplying a feedstock liquid to form drops with a uniform volume, a device for solidifying the surfaces of drops so that the drops will not deform easily when they fall onto and hit the surface of an aqueous ammonia solution, a device for circulating an aqueous ammonia solution so that the uranyl nitrate in the drops can be changed to ammonium diuranate completely, to such an extent that uranyl nitrate in the center of each drop is changed to ammonium diuranate, and an apparatus for producing ammonium diuranate particles with good sphericity. The dripping nozzle device is provided with a single vibrator to vibrate nozzles simultaneously. The device for recovering a feedstock liquid recovers the feedstock liquid remaining in the nozzles and mixes it with a fresh feedstock liquid. The device for supplying a feedstock liquid is provided with a light irradiator for irradiating falling drops with light. The device for solidifying the surfaces of drops sprays ammonia gas over each of the paths along which the drops dripping from the nozzles fall. The device for circulating an aqueous ammonia solution enables drops to flow upward in the aqueous ammonia solution in the aqueous ammonia solution reservoir. The apparatus for producing ammonium diuranate utilizes these devices.

Owner:NUCLEAR FUEL INDS

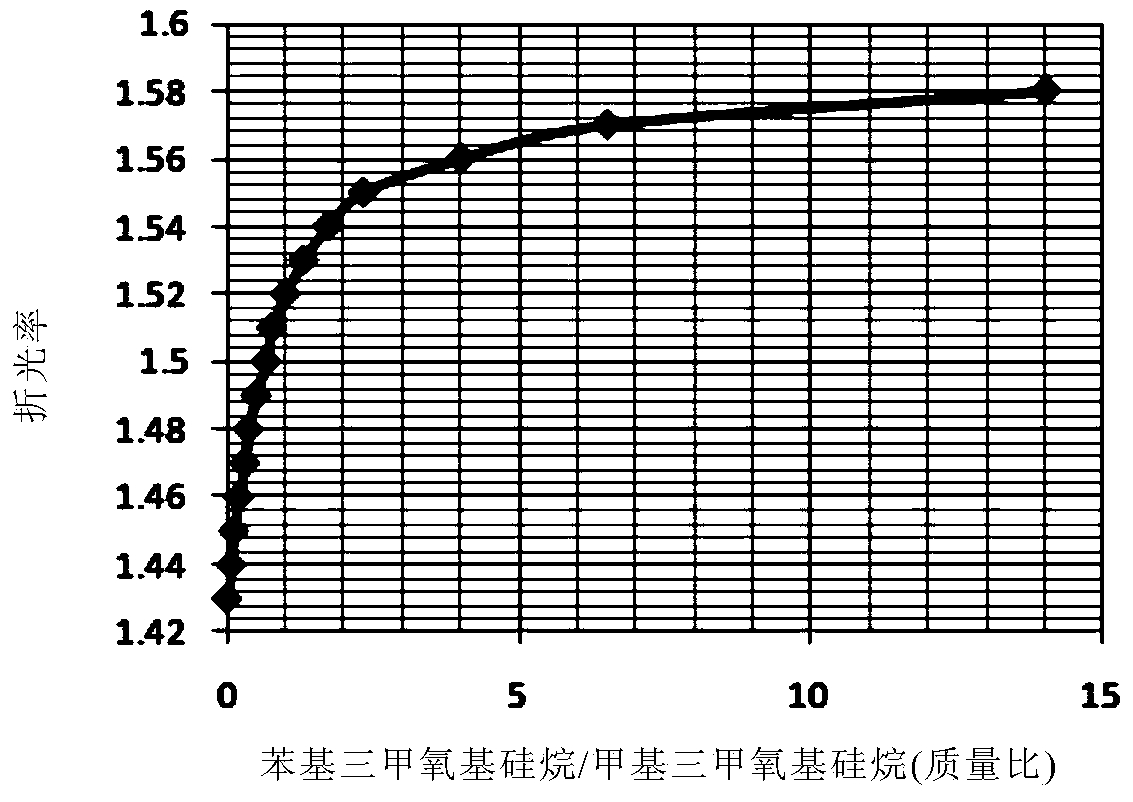

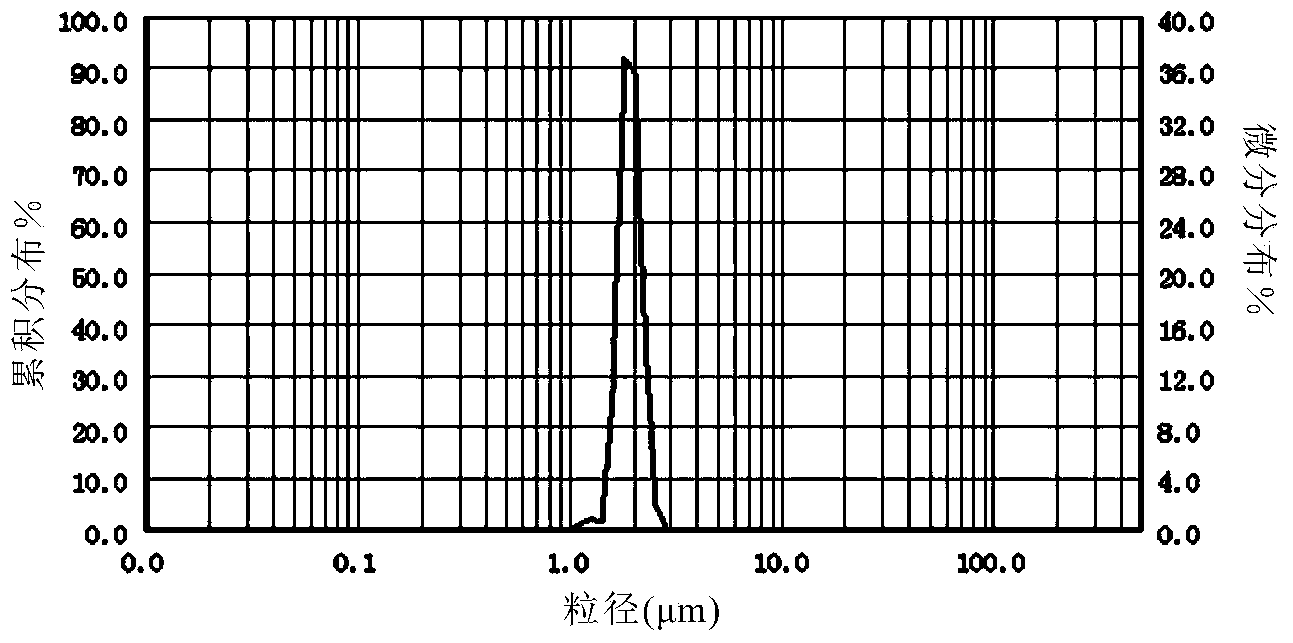

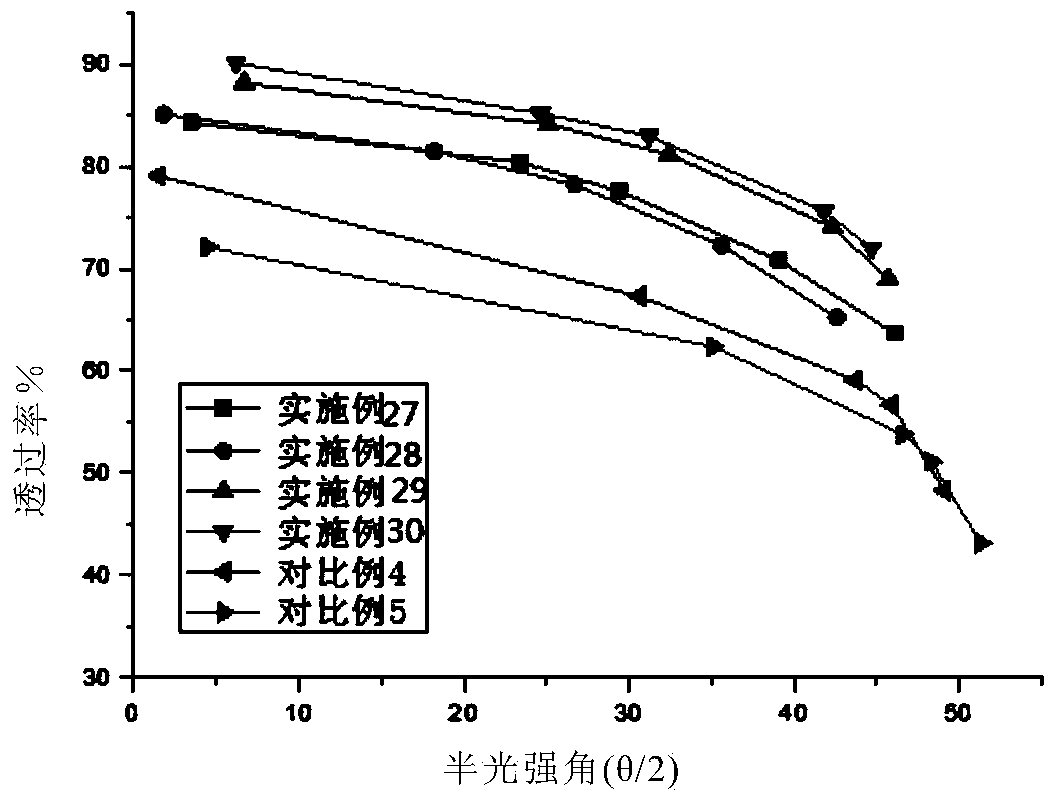

Polysiloxane microsphere with core-shell structure and preparation method thereof

ActiveCN103897189AGood spherical shapeNarrow distributionDiffusing elementsMicrosphereRefractive index

The invention relates to a polysiloxane microsphere with a core-shell structure and a preparation method thereof. The polysiloxane microsphere comprises a core, and a shell which wraps the core; the absolute value of the refractive index difference value between the core and the shell is 0.01 to 0.012; and the particle size of the microsphere is 0.1 to 50 microns and accounts for 20 to 70% of the particle size of the polysiloxane microsphere. The polysiloxane microsphere disclosed by the invention can be used as a light diffusant to be applied to LED lighting and LCD backlight and other diffusion materials; and the polysiloxane microsphere is high in light transmittance and also remains good diffusion effect.

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

Method for preparing lithium titanate material

The invention provides a method for preparing a lithium titanate material. A certain quantity of lithium-containing compound, titanium-containing compound and additive are weighed, and a certain amount of deionized water and dispersion agent are added for primary dispersion; moisture is removed after drying to obtain solid 1; then the obtained solid 1 is roasted in air to obtain a primary battery material; a certain quantity of carbon-containing wrapping material and additive are weighed and dispersed in water, the primary battery material is added for secondary sufficient mixing, moisture is moved after drying, and solid 2 is obtained, finally the obtained solid 2 is roasted in the inert or reduction atmosphere, and the graphene-wrapped battery material containing a certain amount of additive is obtained. Due to two times of dispersion and roasting, it is guaranteed that the carbon-containing wrapping layer covers the surface of lithium titanate in a sufficiently uniform and compact mode and is not prone to being damaged or falling off, and accordingly the defect of insufficient wrapping is overcome. Due to use of the additive, conductivity of a lithium titanate body is improved, rate capability of the lithium titanate material is improved, conductivity is high, and gas generation is prevented.

Owner:天津普兰能源科技有限公司

Double-layer sustained and controlled release nanoparticle and preparation method thereof and application

ActiveCN103381146AImprove hydrophilic abilityImprove flexibilityPowder deliveryOrganic active ingredientsControlled releaseMedicine

The invention discloses a double-layer sustained and controlled release nanoparticle and a preparation method thereof and application in preparation of antitumor medicines. The double-layer sustained and controlled release nanoparticle is formed by a lactic acid-glycolic acid copolymer nanoparticle inner core and a polyethylene glycol questin grafting chitosan casing covering an outer layer of the lactic acid-glycolic acid copolymer nanoparticle inner core and can simultaneously load hydrophilic and lipophilic medicines. The drug entrapment rate is high, time-ordered release of inner layer medicines and outer layer medicines can be achieved, the double-layer sustained and controlled release nanoparticle has the effects of sustained release and controlled release, and in addition, the double-layer sustained and controlled release nanoparticle further has the advantages of being controllable in grain size, uniform in particle size distribution, smooth and round in forma and good in stability and dispersibility and the like.

Owner:XINXIANG MEDICAL UNIV

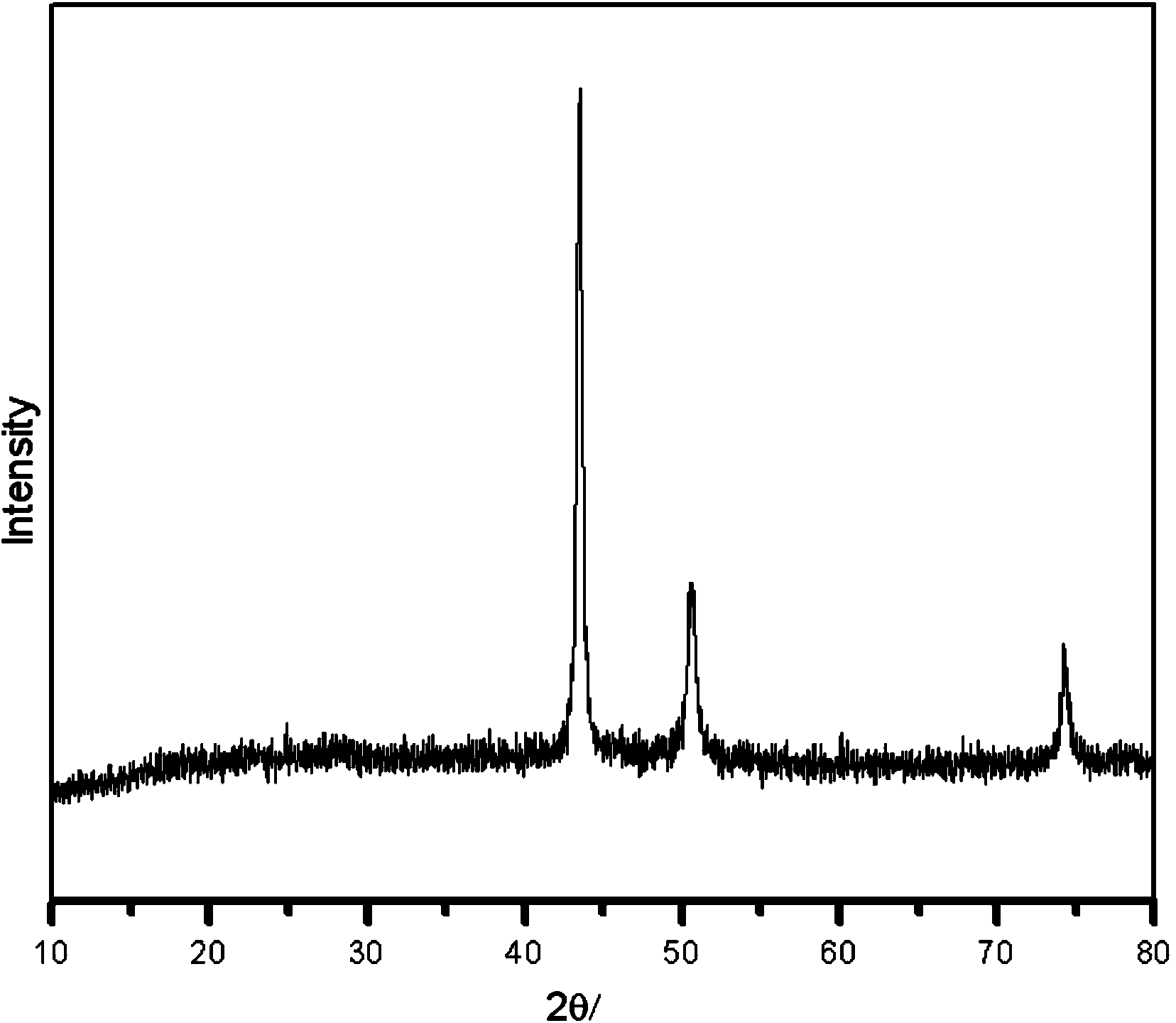

Powdered catalyst for synthesizing octahedral diamond

ActiveCN101829587AReduce oxygen contentImprove the activation effectPhysical/chemical process catalystsUltra-high pressure processesOctahedronChemical composition

The invention discloses a powdered catalyst for synthesizing octahedral diamond. The powdered catalyst comprises the following alloy components by weight percentage: 3 to 7% of Nb, 3 to 5% of Mn, 2 to 2.5% of Co, 0.1 to 1% of Si, 0.5 to 1% of B4C, 0.02% of V and the balance of Fe. The preparation method of the powdered catalyst comprises the following steps of: firstly, preparing the alloy components according to the weight percentage, melting the materials and preparing the prefabricate alloy ingots in the protection of inert gases; secondly, re-melting the prefabricate alloy ingots; and finally, grinding and atomizing the metal fluid into the metal powder at the high pressure gas of 3 to 4.5 MPa, granulating the powder into spherical particles and sieving the prepared powder catalyst. Compared with the prior art, the catalyst for synthesizing the octahedral diamond improves the yielding by about 40 percent and improves the crystal form regularity of the diamond by about 35%. The content of the synthesized octahedron reaches 80 to 87%. The powdered catalyst of the invention has the oxygen content of not more than 100 PPm with uniform chemical ingredients; the particle has good spherical degree and the granularity is negative 200 / positive 500; and the percentage of the granularity scale is 75 to 95%.

Owner:山东昌润钻石股份有限公司

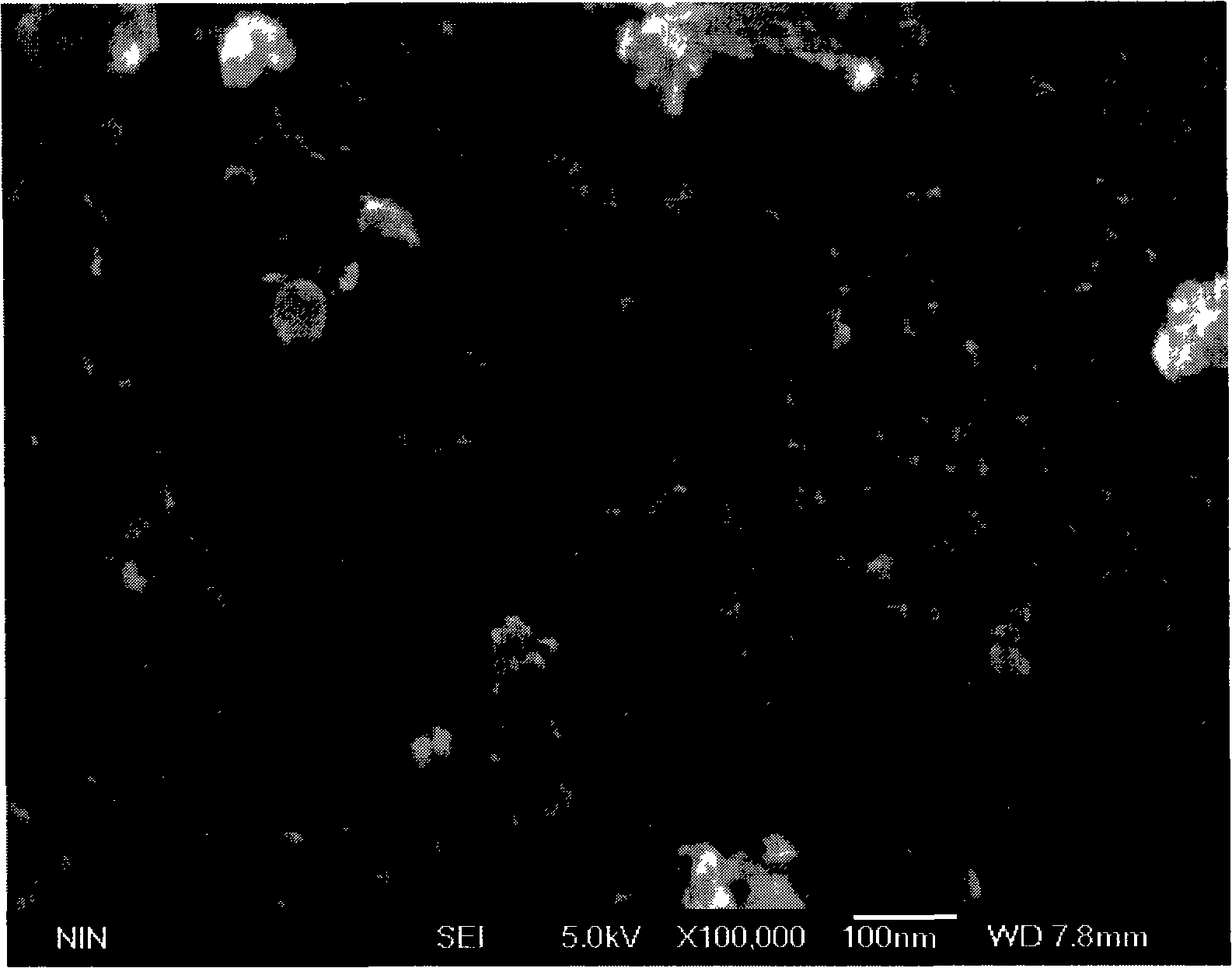

Method for enwrapping ferric oxide by silicon dioxide

InactiveCN101186762AEvenly wrappedGood dispersionInorganic pigment treatmentAlcoholPhysical chemistry

The invention discloses a process for coating ferric oxide with silicon dioxide, which comprises the procedures that ferric oxide particles are homogeneously dispersed into mixed solution of ethanol and ammonia, then the mixture is added into n-pentanol solution of polyvinylpyrrolidone in the condition of stirring, the mixture is continuously stirred for 6-24hours, after the reaction liquid is centrifugated, the fluid portion is removed, thereby ferric oxide particles coated by silicon dioxide are achieved. The invention employs restriction of polyvinylpyrrolidone to water and perfect adsorption effect of polyvinylpyrrolidone to ferric oxide, successfully locates hydrolysis reaction of ethyl orthosilicate on the surface of the ferric oxide, thereby the ferric oxide is coated homogeneously. Thickness of layer of the silicon dioxide can be constantly increased by simply increasing mass ratio of ethyl orthosilicate and ferric oxide particles. The invention has the advantages of low costs and simple operation, which needs no complex equipment and is capable of rapid volume-production, and the like.

Owner:NANJING UNIV

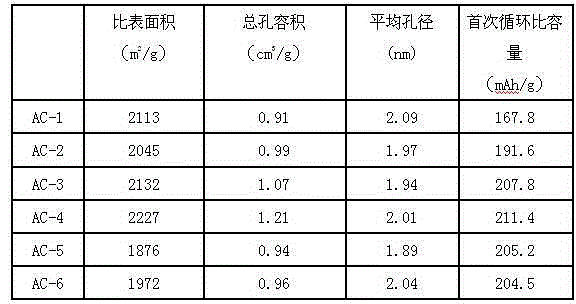

Supercapacitor spherical active carbon preparation method

The present invention discloses a supercapacitor spherical activated carbon preparation method, which comprises: mixing starch and a catalyst in water to prepare a starch aqueous solution, and carrying out spray-drying to obtain a dried starch mixture; carrying out heating and stabilization treatment on the dried starch mixture in an inert atmosphere to obtain starch-based carbon microspheres; and uniformly mixing the starch-based carbon microspheres and an activator, drying the water, heating under an inert atmosphere, activating, cooling, taking out, and washing the activated product to achieve a neutral state to obtain the starch-based active carbon microspheres. According to the present invention, the supercapacitor spherical activated carbon maintain the good starch sphere, and the prepared supercapacitor adopting the supercapacitor spherical activated carbon as the supercapacitor electrode has excellent electrochemical performance, and has high electrical capacitance and good cycle stability under high current conditions.

Owner:中国东方电气集团有限公司

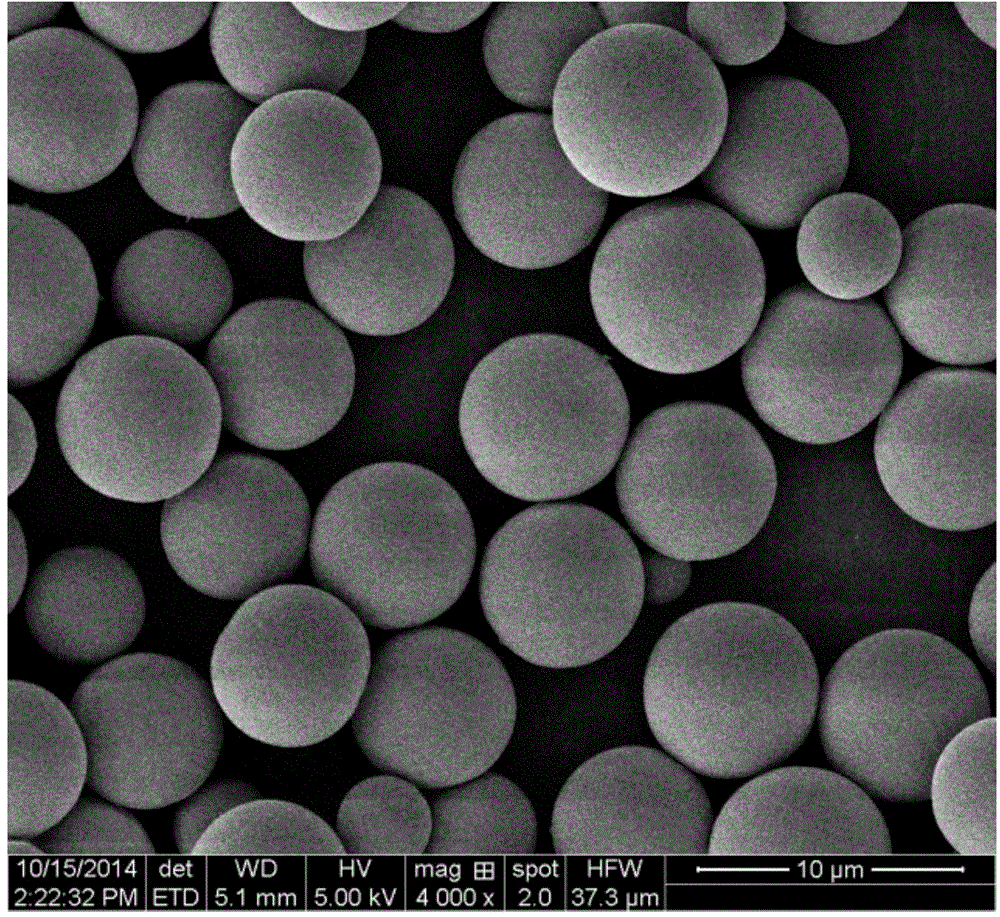

Highly cross-linked monodisperse epoxy-group-containing polymeric microsphere and preparation method thereof

InactiveCN104788609AGood dispersionGood spherical shapeMicroballoon preparationMicrocapsule preparationEpoxyCross-link

The invention relates to a highly cross-linked monodisperse epoxy-group-containing polymer microsphere and a preparation method thereof. The microsphere contains an epoxy group, methacrylic acid glycidyl ester is used as a monomer, divinyl benzene (DVB) is used as a cross-linking agent, and the microsphere is obtained through polymerization; the particle size of the microsphere is 2 to 10 [mu]m, and the polydispersity index is 1.04 to 1.07. The preparation method comprises the following steps: (1), methacrylic acid glycidyl ester, the DVB and an initiating agent are together added into a solvent for uniform mixing, after nitrogen is introduced, sealing is performed, the reaction temperature is controlled to be 82 to 90 DEG C, and the reaction time lasts for 3 to 5 hours; (2), a reaction product obtained in the step (1) is washed and dried, so that the polymer microsphere is obtained. The polymer microsphere prepared by the invention contains the epoxy group, the epoxy group is an active group, derivative reaction is facilitated, and the problems of high hydrophobicity, high probability of non-specific adsorption can be solved.

Owner:UNIV OF JINAN

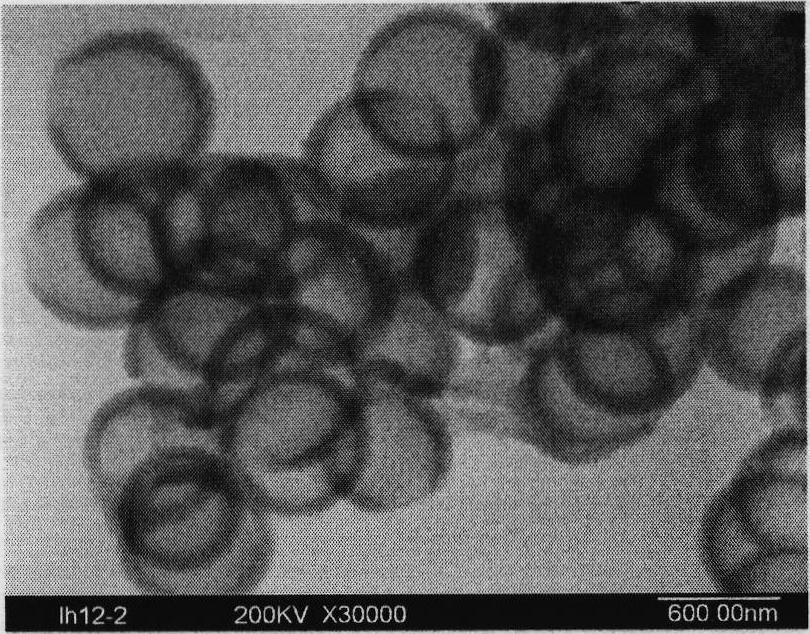

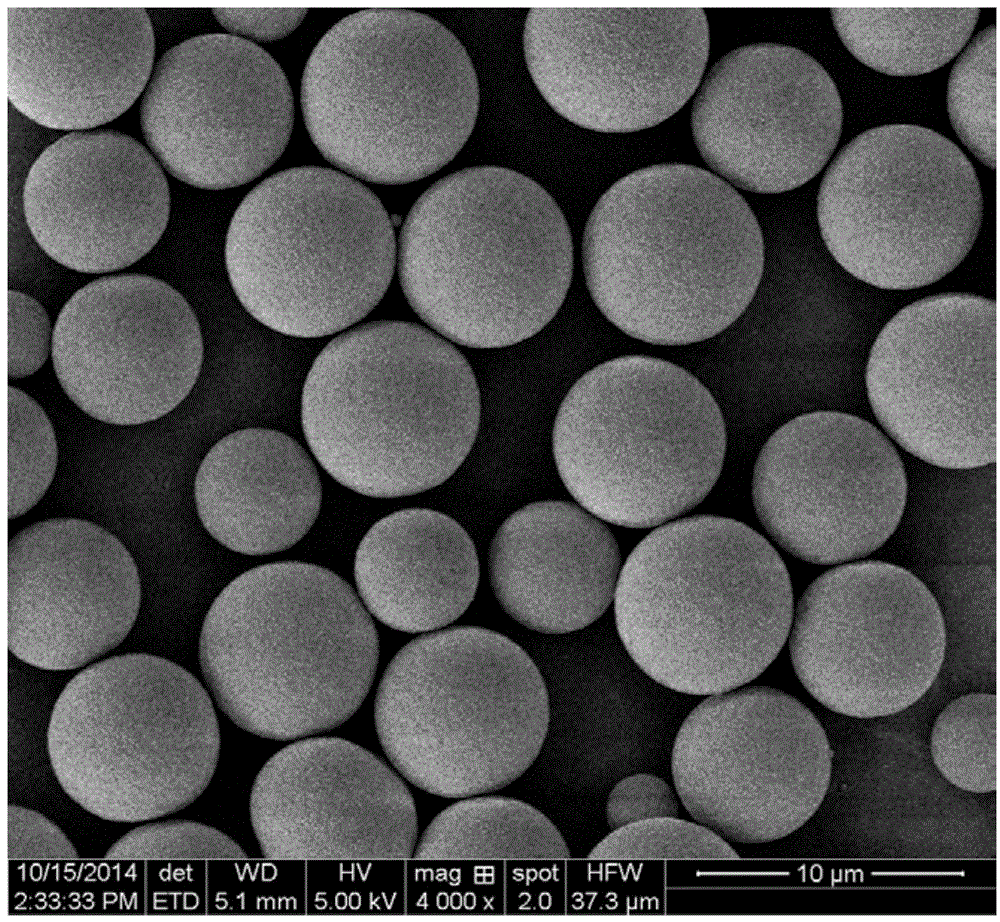

Ordered mesoporous organic silicon oxide hollow ball prepared through one-step method and preparation method of ordered mesoporous organic silicon oxide hollow ball

ActiveCN105036145AFast preparationSimple manufacturing processSilicaSpherical morphologySilicon oxide

The invention relates to an ordered mesoporous organic silicon oxide hollow ball prepared through a one-step method and a preparation method of the ordered mesoporous organic silicon oxide hollow ball. The prepared ordered mesoporous organic silicon oxide hollow ball has good spherical morphology. The ball grain size ranges from 50 nm to 100 nm. The ball grain size distribution is uniform. The ordered mesoporous organic silicon oxide hollow ball is high in monodispersity, strength and dispersibility. A spherical shell comprises ordered radial mesoporous ducts. The preparation method is simple and easy to implement and can be easily conducted in an industrial mode. The ordered mesoporous organic silicon oxide hollow ball can be prepared through one step without sacrificial template or postprocessing. The fastest preparation process lasts for only 0.25 h. By means of the structure, reaction molecules or medicine molecules can conveniently enter and leave the ordered mesoporous organic silicon oxide hollow ball, and the ordered mesoporous organic silicon oxide hollow ball has good application prospects in the fields of medicine slow release, release control, medical imaging, catalysis and the like.

Owner:TSINGHUA UNIV +1

Shell-core alpha-totaxin microcapsule and preparation method thereof

InactiveCN107875139AGood spherical shapeCosmetic preparationsOrganic active ingredientsMicrofluidicsSpherical shaped

The invention discloses a shell-core alpha-totaxin microcapsule and a preparation method thereof. An O / W / O liquid drop template is prepared by adopting a microfluidics splitter through taking alpha-totaxin as a core material and adding a dilutent and taking sodium alginate as a wall material. The number of core materials wrapped by the microcapsules can be controlled by regulating the internal andexternal phase flow rate, and the spherical shape of a shell layer can be kept well by adopting curing means of combining internal and external gelatinization. The Finner and Fmiddle flow rate are constant, the Fouter flow rate is regulated so as to control the number of the core materials wrapped in the shell-core microcapsules, the alpha-totaxin microcapsule with uniform grain size and a shell-core structure, and the cured liquid drop can keep good sphere through combining the internal and external gelatinization.

Owner:SUN YAT SEN UNIV

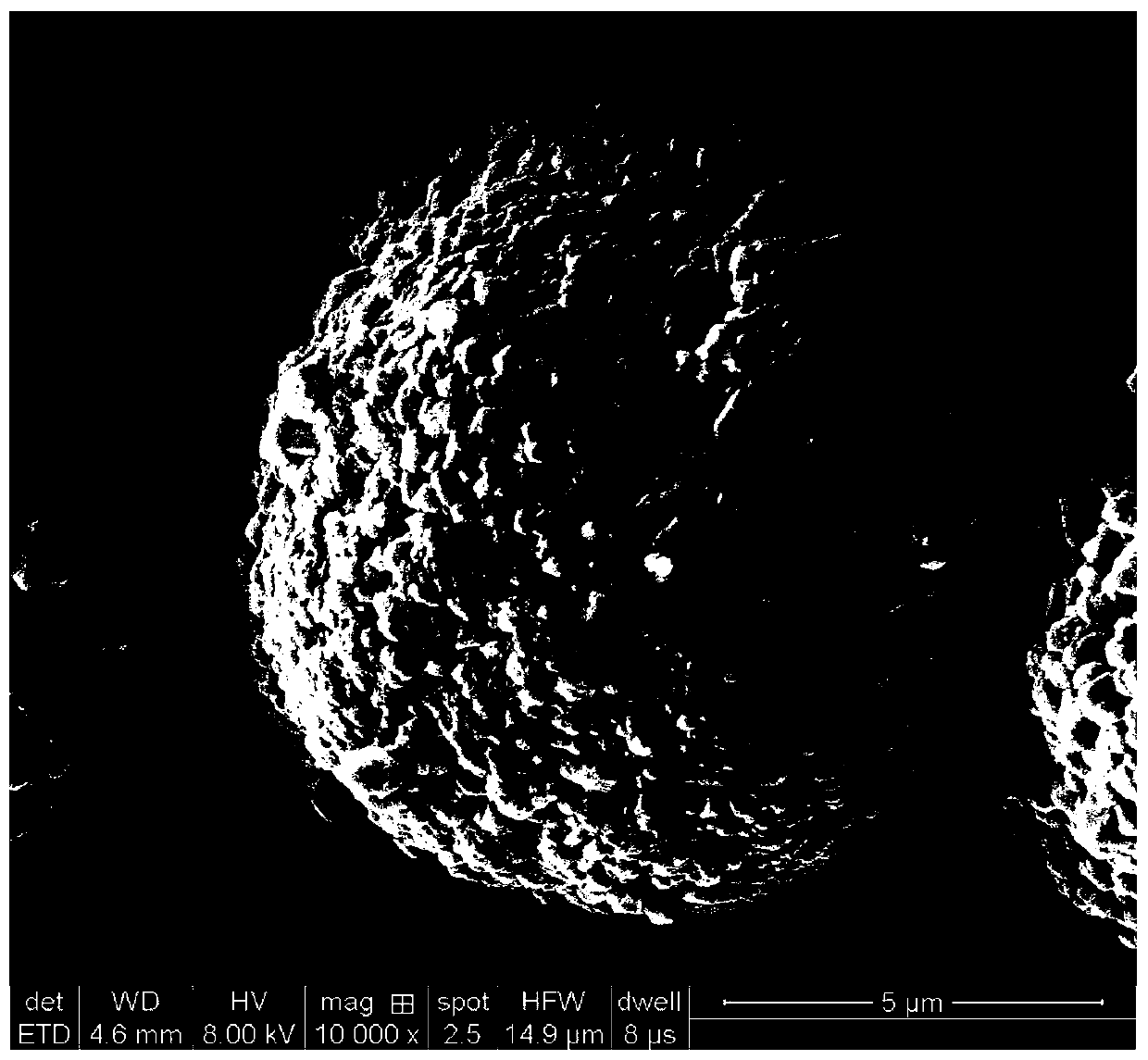

Plasma-etching-resistant granulated yttrium oxide for hot spraying and preparation method thereof

The invention belongs to the technical field of hot spraying, and particularly relates to plasma-etching-resistant granulated yttrium oxide for hot spraying and a preparation method thereof. The preparation method of the plasma-etching-resistant granulated yttrium oxide for hot spraying comprises the following steps: preparing nano or ultrafine yttrium oxide powder and deionized water or an organic solution into a paste, performing depolymerization and reduction, adding surface activity activator into the paste for preparation, and performing hot expansion balling and high-temperature densification treatment to obtain the granulated yttrium oxide for hot spraying. According to the invention, the surface activity activator is added into the paste before hot expansion balling, so that the prepared granulated yttrium oxide for hot spraying is favorable in spherical degree, and the high-spherical-degree favorable-flowability high-density granulated yttrium oxide for hot spraying can be obtained without later spheroidization, thereby achieving favorable flowability during hot spraying, ensuring that the supply of the granulated yttrium oxide for hot spraying is more stable, and providing a guarantee for obtaining a hot spray coating having a uniform thickness.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

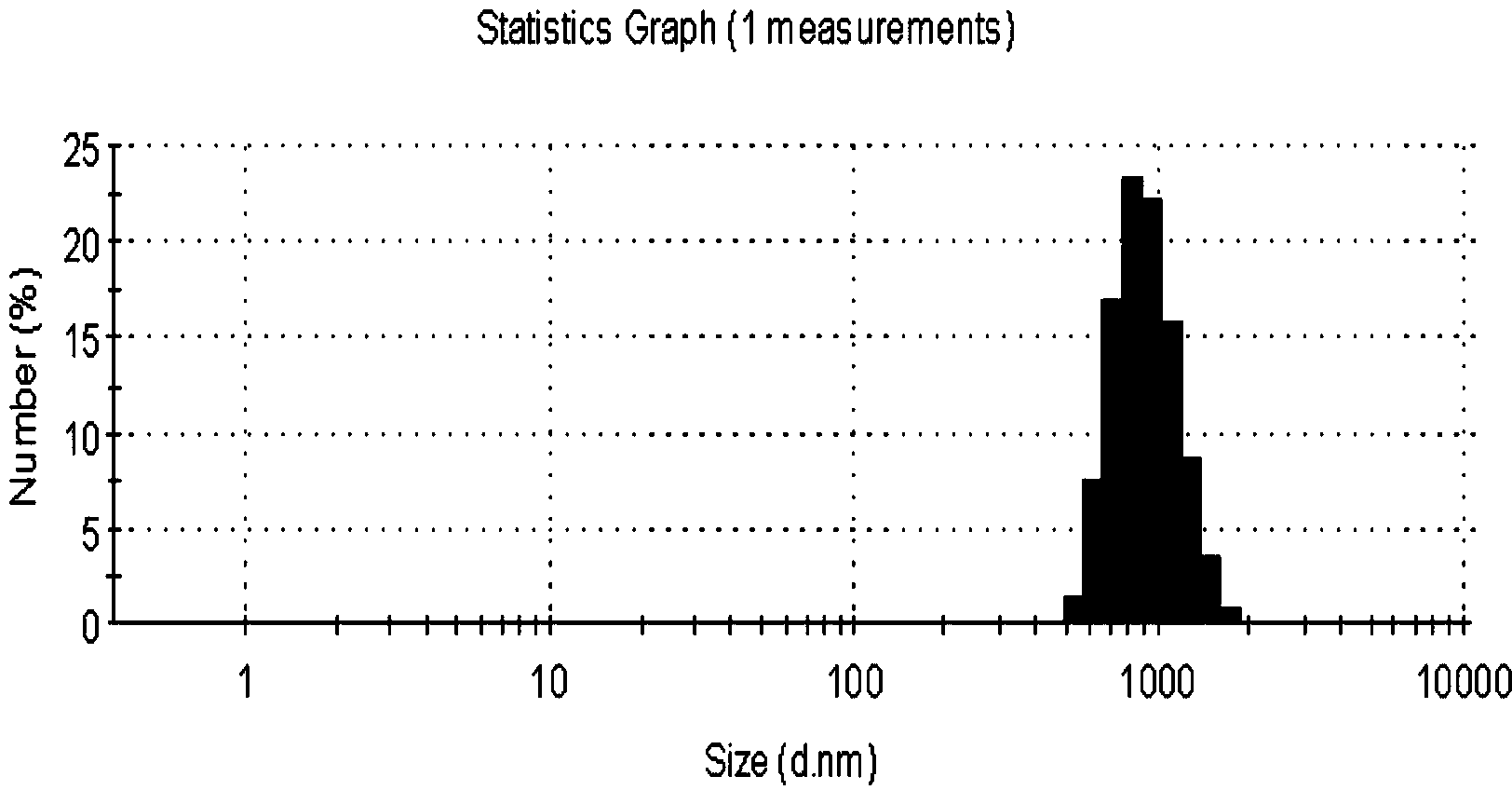

Method for recycling ultrafine copper powder from waste liquid containing complexing copper

ActiveCN103506632AImprove thermal conductivityImprove self-healing abilityRecovery methodLiquid waste

The invention discloses a method for recycling ultrafine copper powder from waste liquid containing complexing copper, and belongs to the technical field of chemical engineering recycling. According to the technical scheme, the method for recycling the ultrafine copper powder from waste liquid containing the complexing copper comprises the steps of adding a pvp dispersing agent in the waste liquid containing the copper, then adding glucose and NaOH, conducting heating and stirring to conduct a prereduction reaction, after the reaction, adding thiourea dioxide, conducting heating and stirring to conduct a reduction reaction, after the reaction is finished, conducting filtering, conducting washing for two times, conducting ethyl alcohol washing for two times, conducting vacuum drying, and obtaining the ultrafine copper powder. According to the method for recycling the ultrafine copper powder, the copper removal rate is 99%, the granularity of the recycled and obtained ultrafine copper powder can be 700nm-1500nm, the purity of the produced copper powder can be more than 99.95%, and the prepared ultrafine copper powder is applied to a plurality of fields of conducting resin, conductive coatings, conductive composite material raw materials, high-performance catalysts, lubricant additives, nanocrystalline copper, medicines and the like.

Owner:JINAN UNIVERSITY

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com