Highly cross-linked monodisperse epoxy-group-containing polymeric microsphere and preparation method thereof

An epoxy group, monodisperse technology, applied in the field of highly cross-linked monodisperse polymer microspheres and their preparation, can solve the problems of microspheres lack of active groups, unsuitable for chromatographic media, difficult to derivatize, etc., and achieve safe reaction conditions Reliable, cheap and easy to obtain raw materials, quick response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of highly cross-linked monodisperse polymer microspheres containing epoxy groups, comprising steps as follows:

[0037] (1) Add 2.18ml of divinylbenzene monomer, 0.51ml of glycidyl methacrylate and 0.20g of azobisisobutyronitrile into 32.31ml of acetonitrile. After mixing, add them to the polytetrafluoroethylene in the stainless steel reactor In the lining, nitrogen gas was introduced for 15 minutes, and after removing oxygen, it was sealed; then placed in an oil bath, the temperature of the oil bath was set at 85°C, and the reaction time was 4 hours;

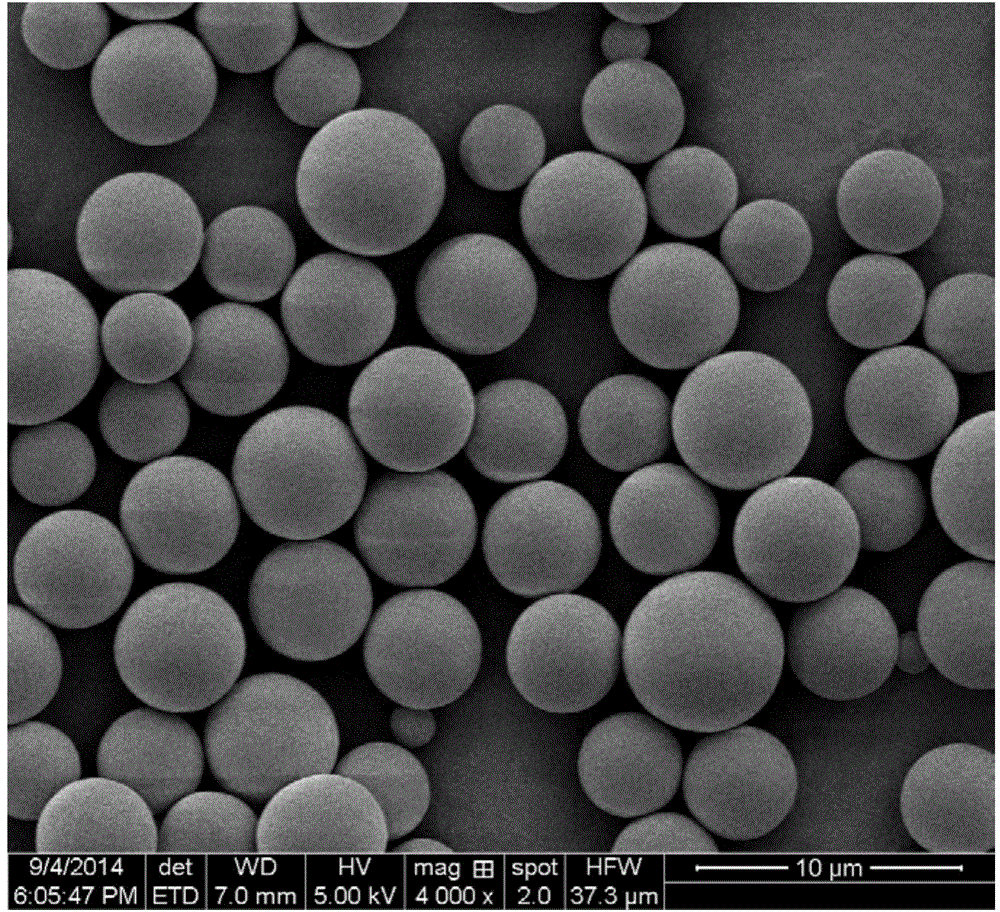

[0038] (2) Stop heating, wash with 50ml of methanol, and dry at 50°C to constant weight to obtain polymer microspheres. Recording its average particle diameter is 4.41 μ m, polydispersity coefficient is 1.07, and productive rate is 83.1%, and the scanning electron micrograph of product polymer microsphere is as follows figure 1 shown.

Embodiment 2

[0040] A preparation method of highly cross-linked monodisperse polymer microspheres containing epoxy groups, comprising steps as follows:

[0041] (1) 4.19ml of divinylbenzene monomer, 0.44ml of glycidyl methacrylate and 0.35g of azobisisobutyronitrile were added to 30.37ml of acetonitrile, and after being miscible, they were added to the polytetrafluoroethylene of the stainless steel reactor In the lining, nitrogen gas was introduced for 15 minutes, and after removing oxygen, it was sealed; then placed in an oil bath, the temperature of the oil bath was set at 85°C, and the reaction time was 4 hours;

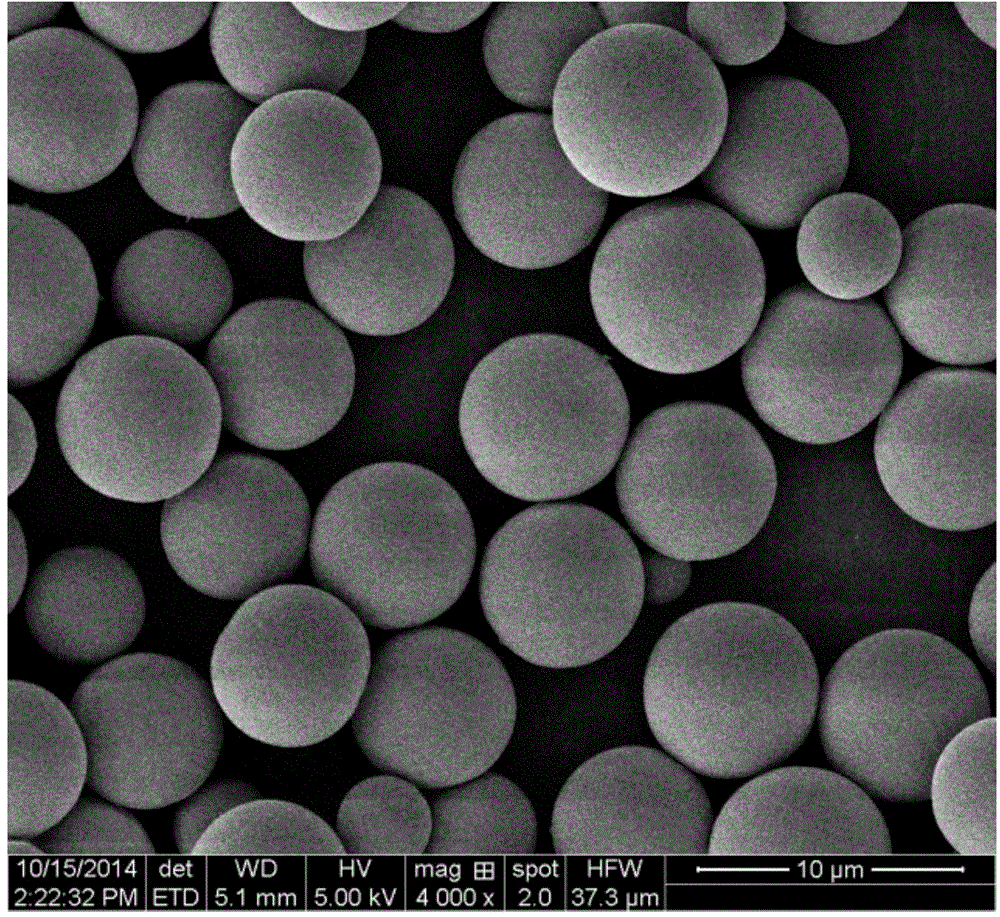

[0042] (2) Stop heating, wash with 50ml of methanol, and dry at 50°C to constant weight to obtain polymer microspheres. Recording its average particle diameter is 5.70 μ m, polydispersity coefficient is 1.04, and productive rate is 90.9%; The scanning electron micrograph of product polymer microsphere is as figure 2 shown.

Embodiment 3

[0044]A preparation method of highly cross-linked monodisperse polymer microspheres containing epoxy groups, comprising steps as follows:

[0045] (1) Add 3.21ml of divinylbenzene monomer, 1.29ml of glycidyl methacrylate and 0.35g of azobisisobutyronitrile into 30.5ml of acetonitrile. After mixing, add them to the polytetrafluoroethylene in the stainless steel reactor In the lining, nitrogen gas was introduced for 15 minutes, and after removing oxygen, it was sealed; then placed in an oil bath, the temperature of the oil bath was set at 85°C, and the reaction time was 4 hours;

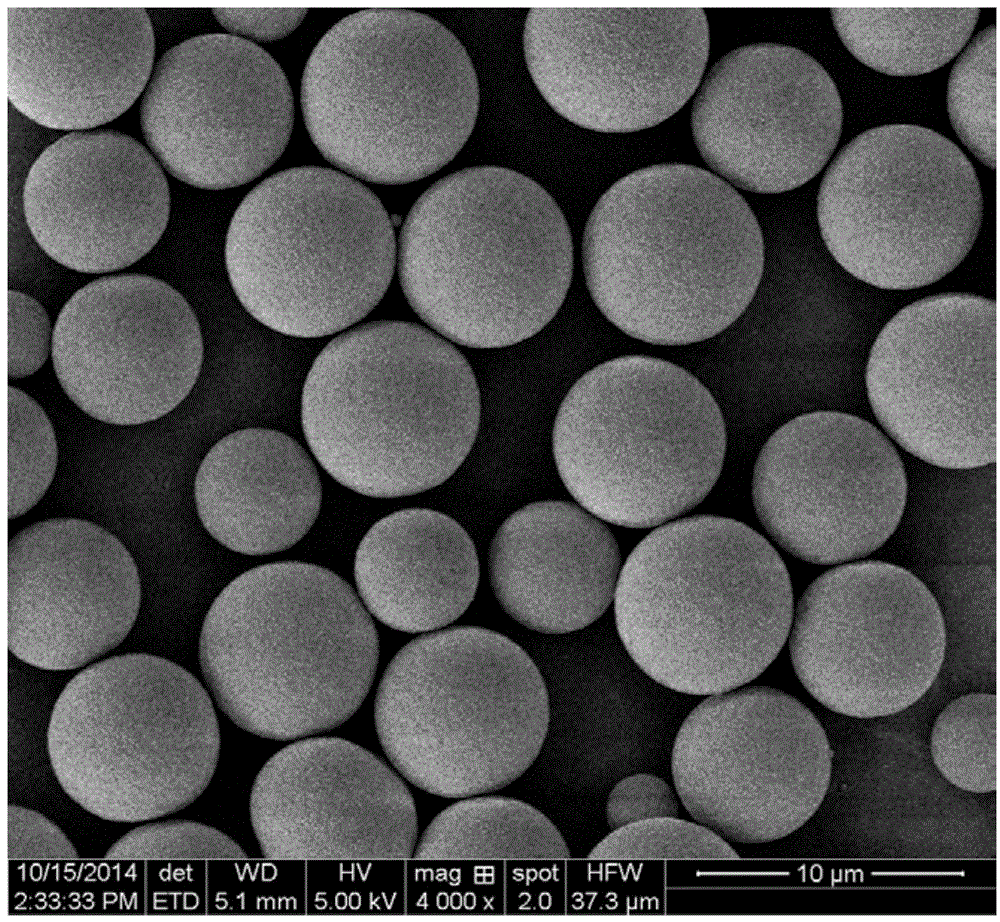

[0046] (2) Stop heating, wash with 50ml of methanol, and dry at 50°C to constant weight to obtain polymer microspheres. Recording its average particle diameter is 5.82 μ m, polydispersity coefficient is 1.06, and productive rate is 92.5%; The scanning electron micrograph of product polymer microsphere is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com