Patents

Literature

888results about How to "High discharge specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

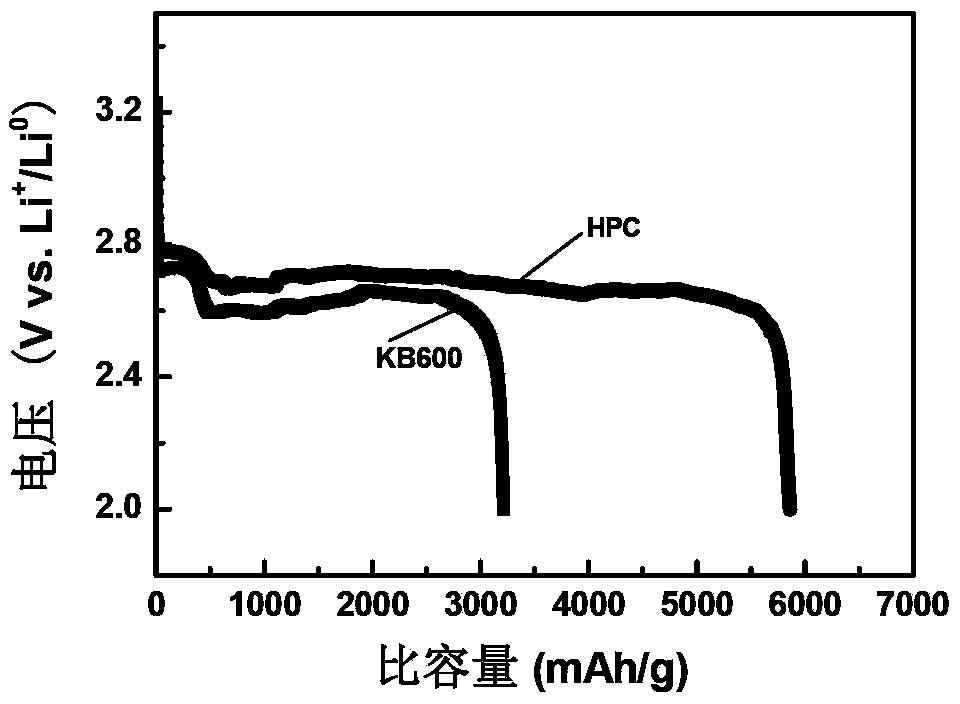

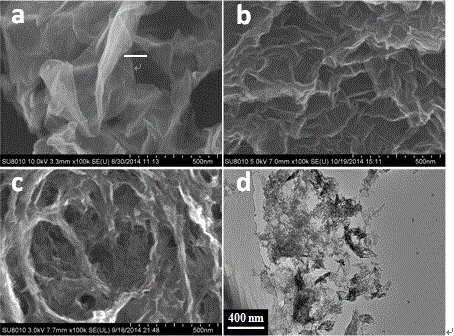

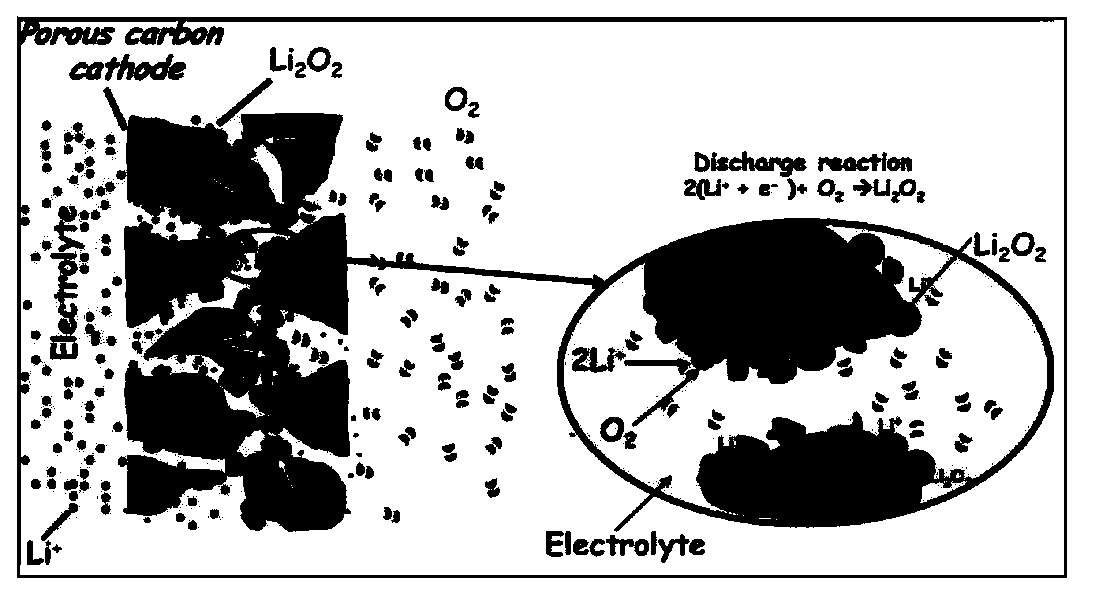

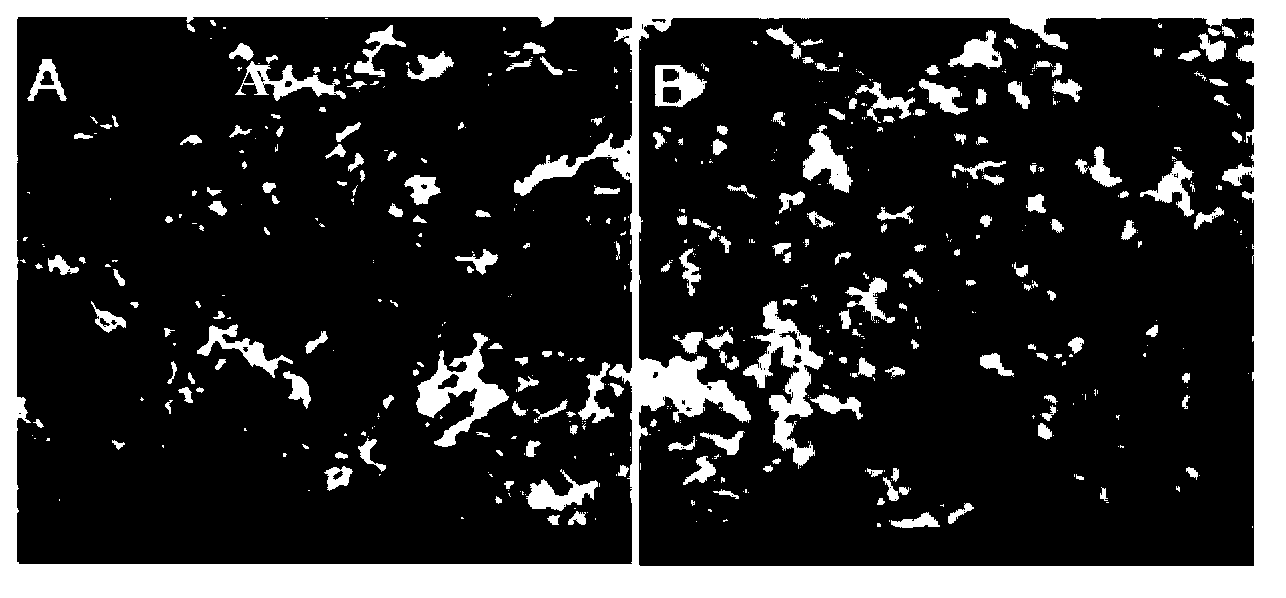

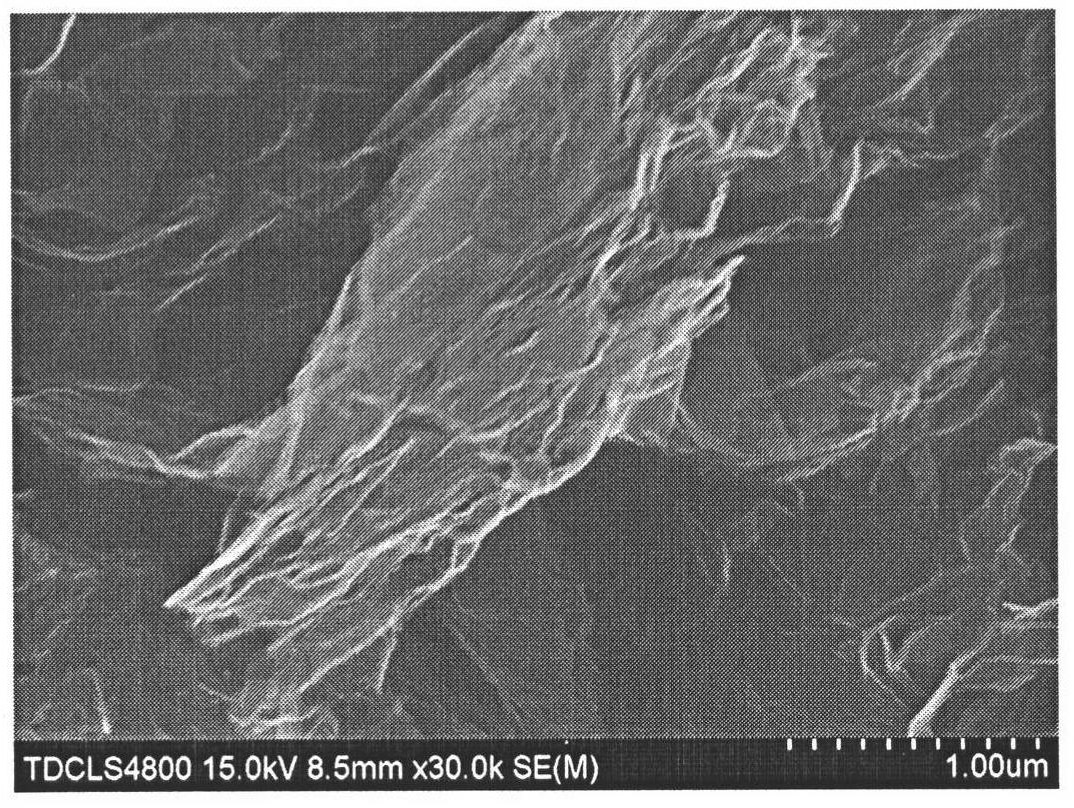

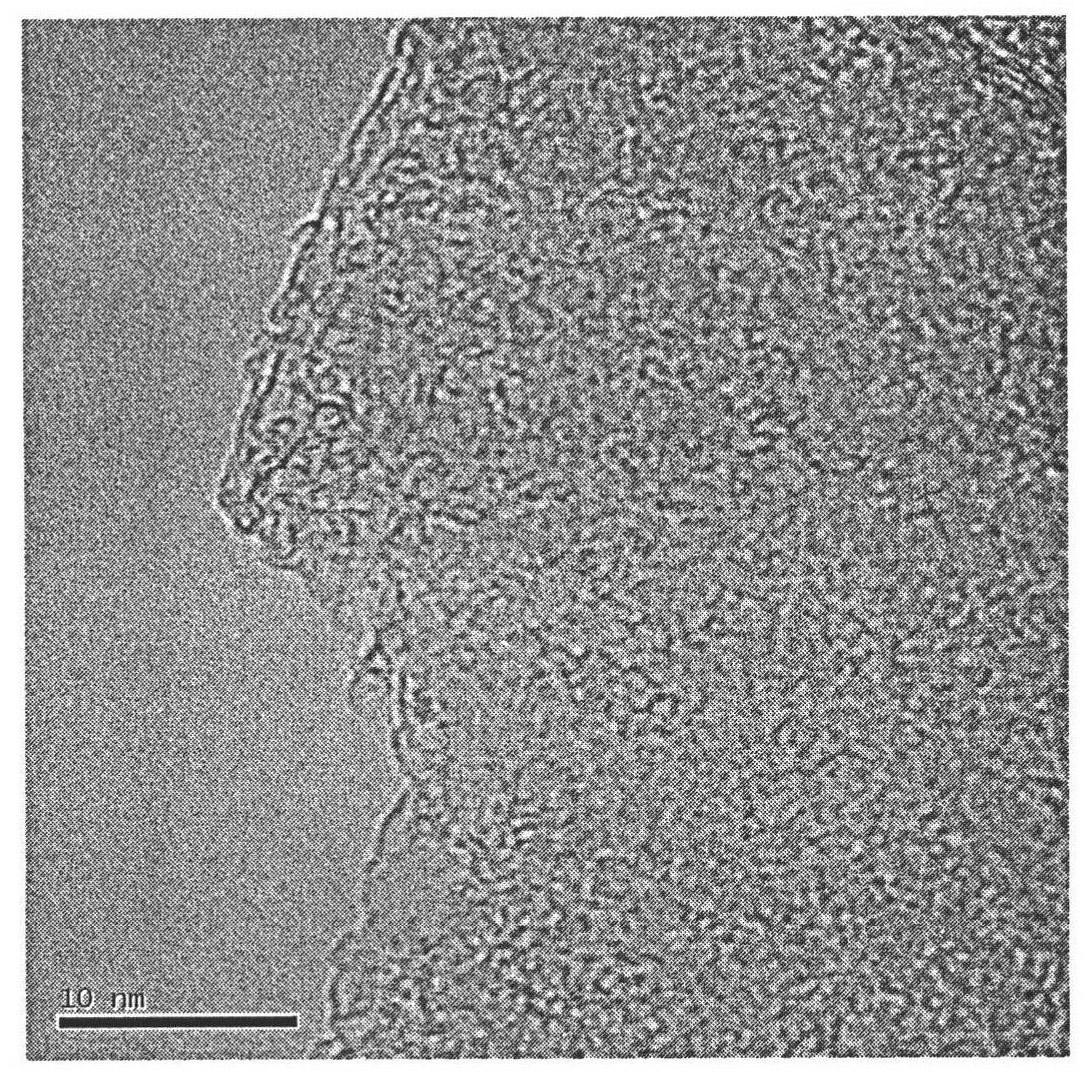

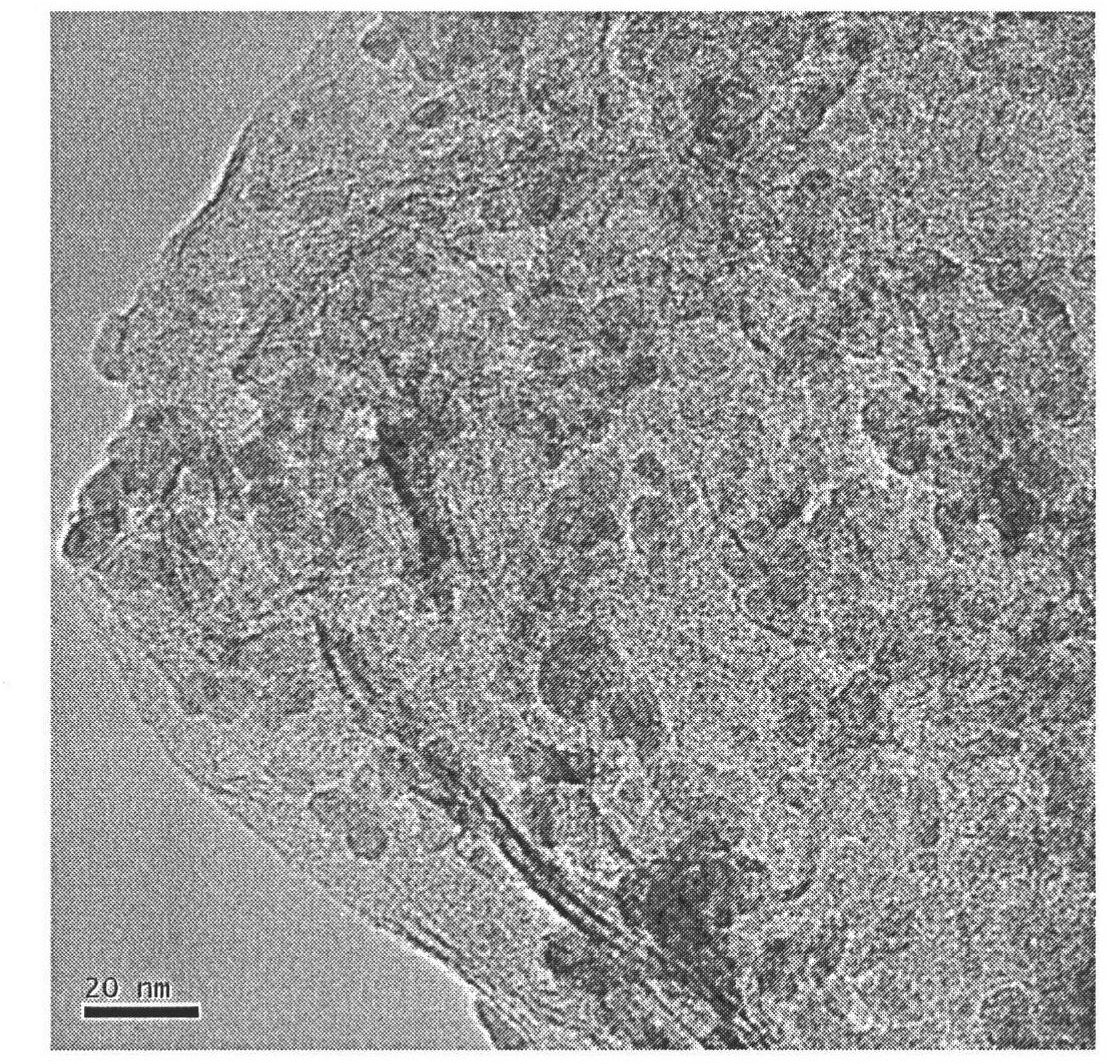

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

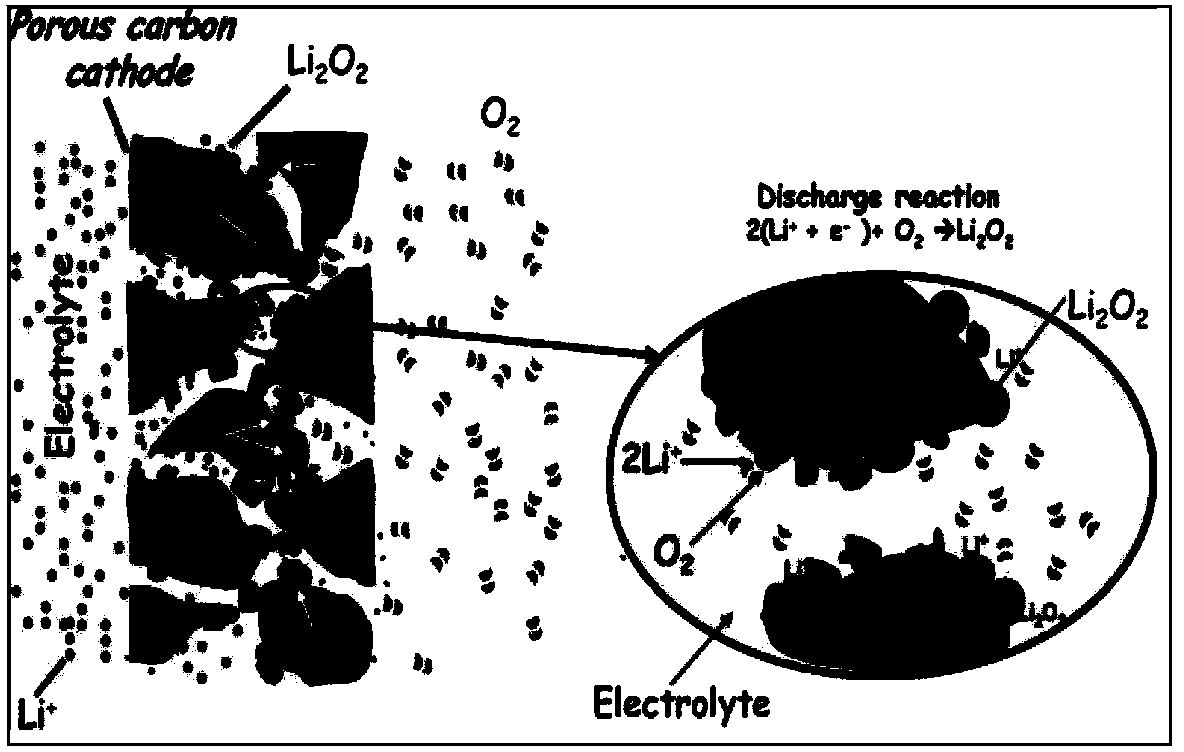

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

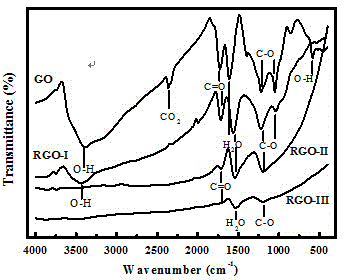

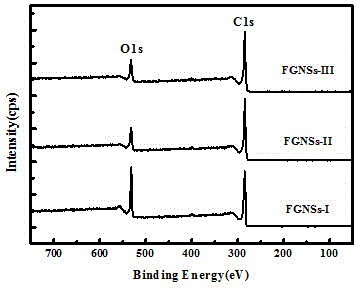

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

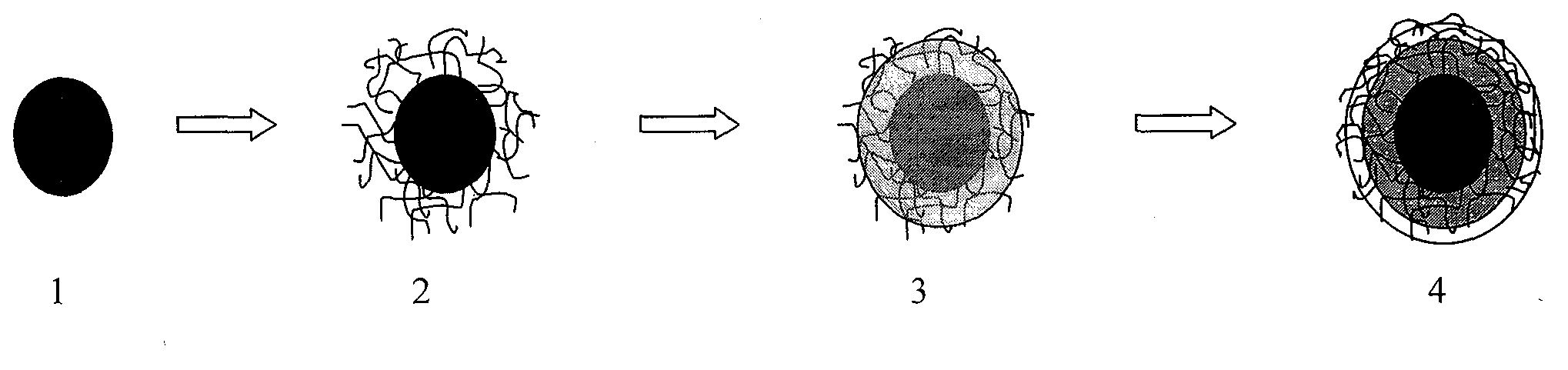

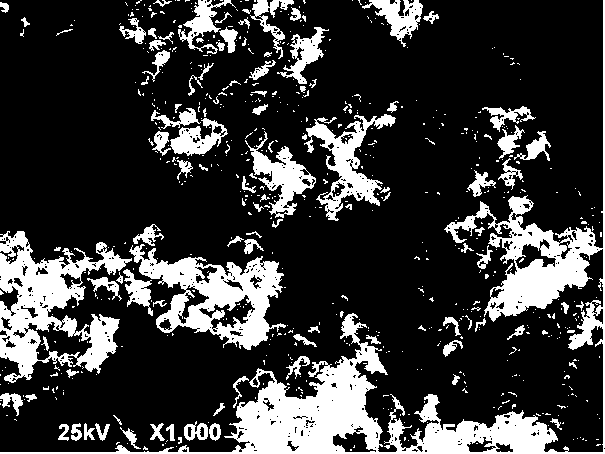

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

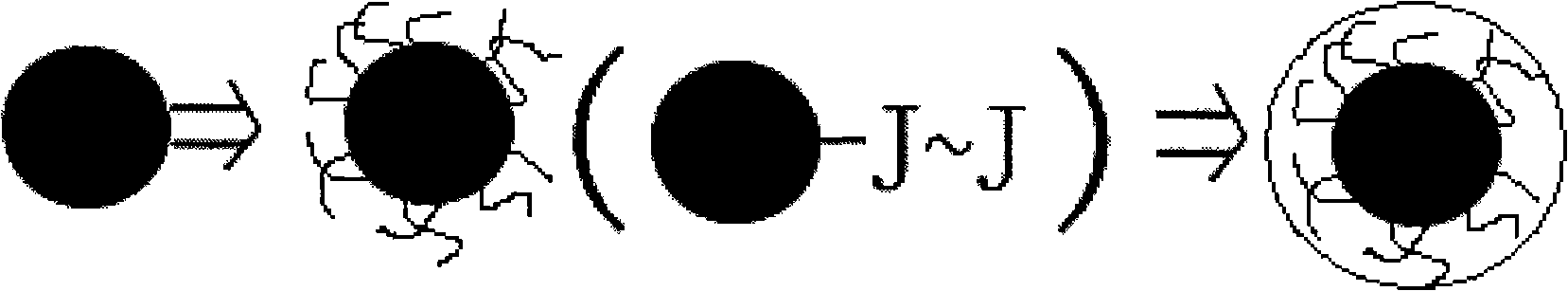

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

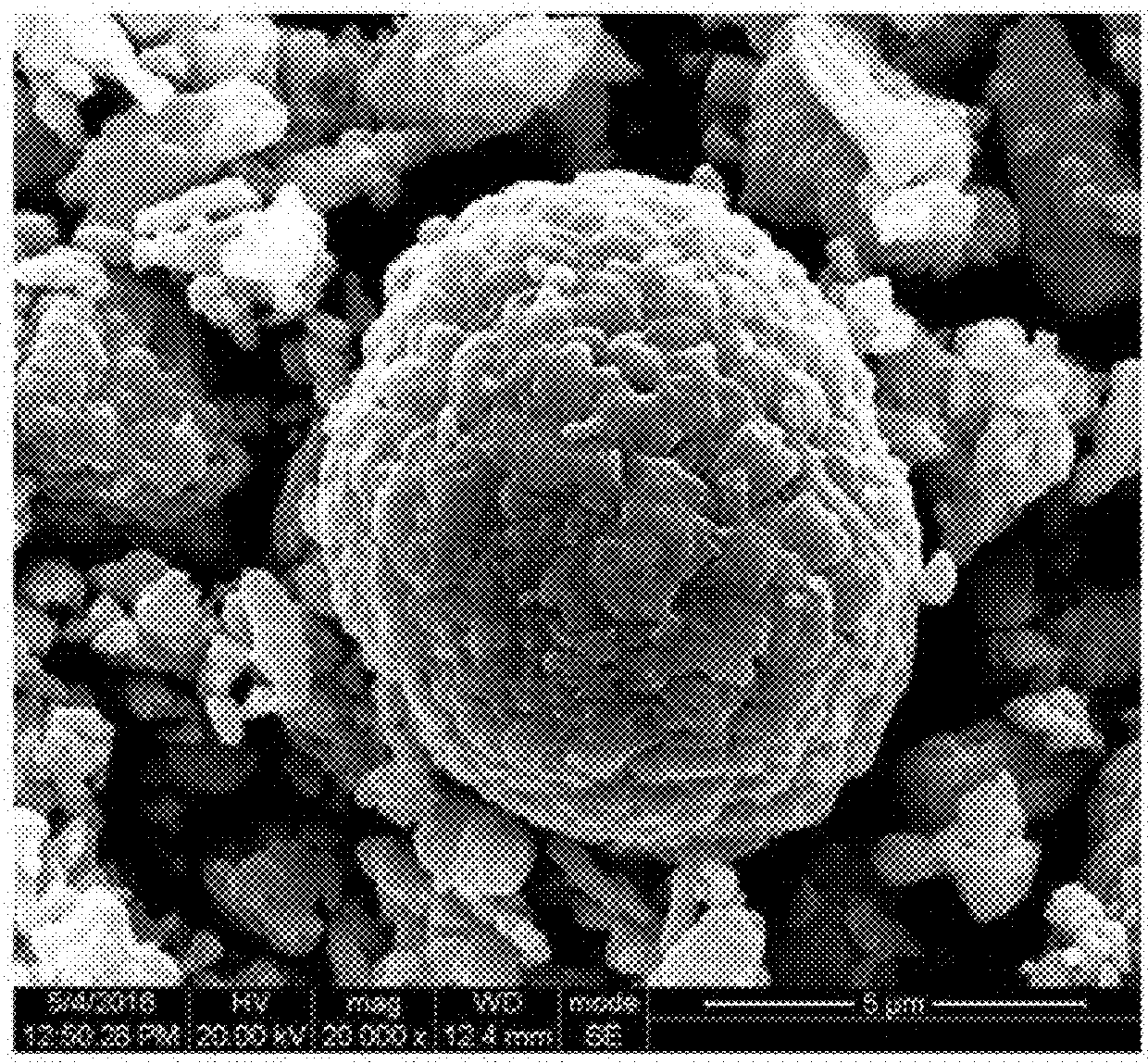

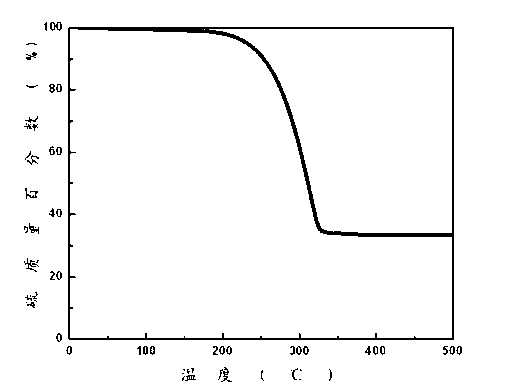

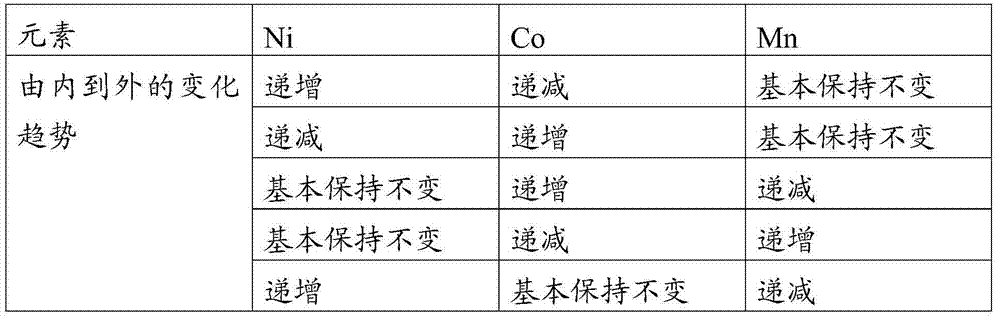

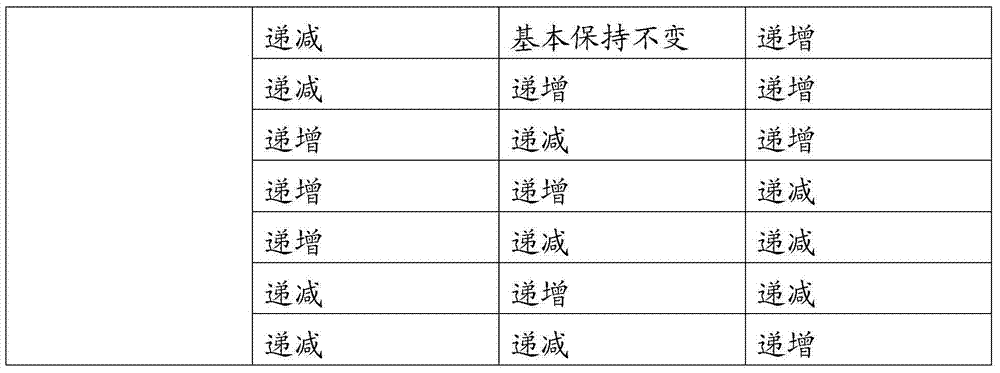

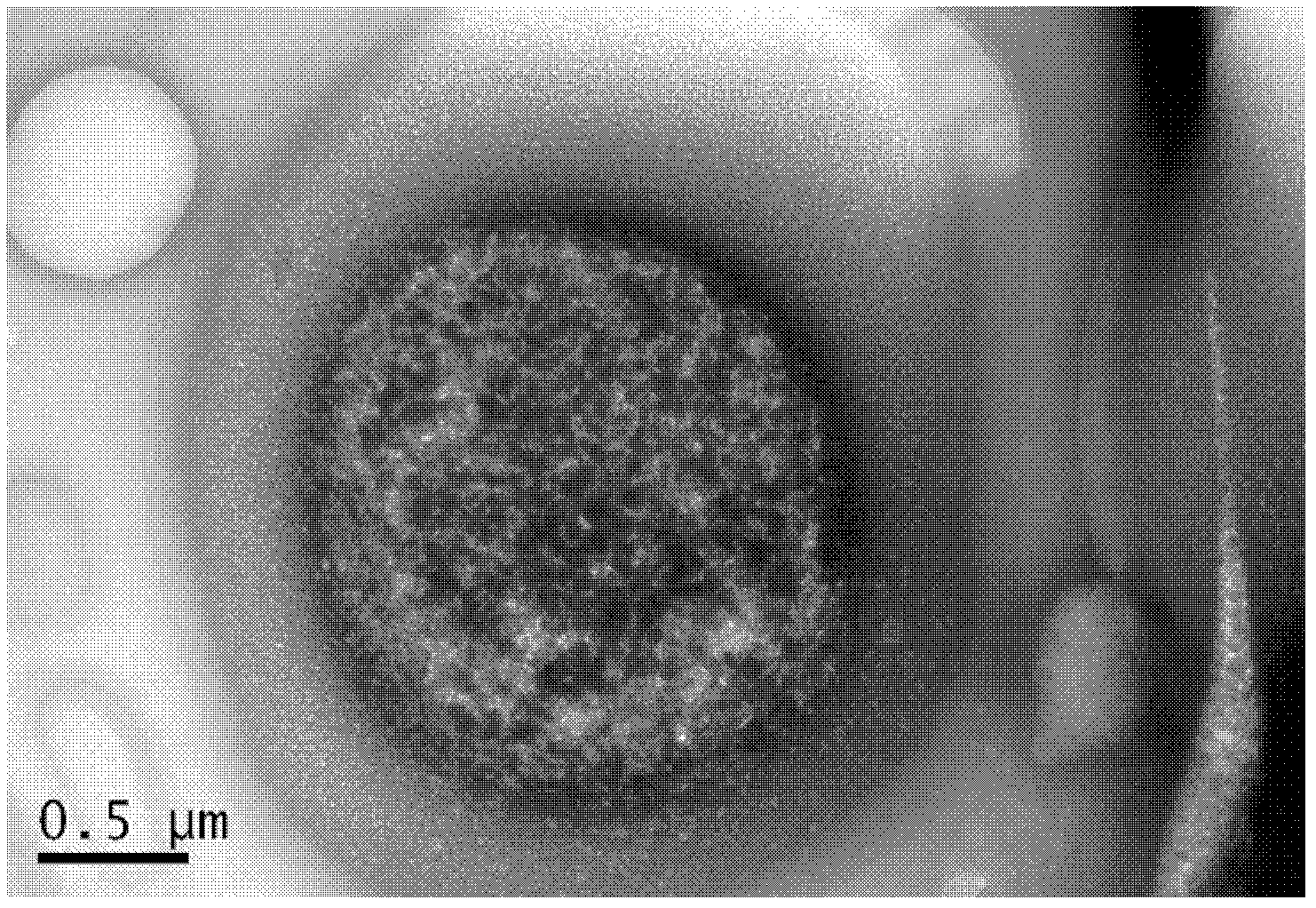

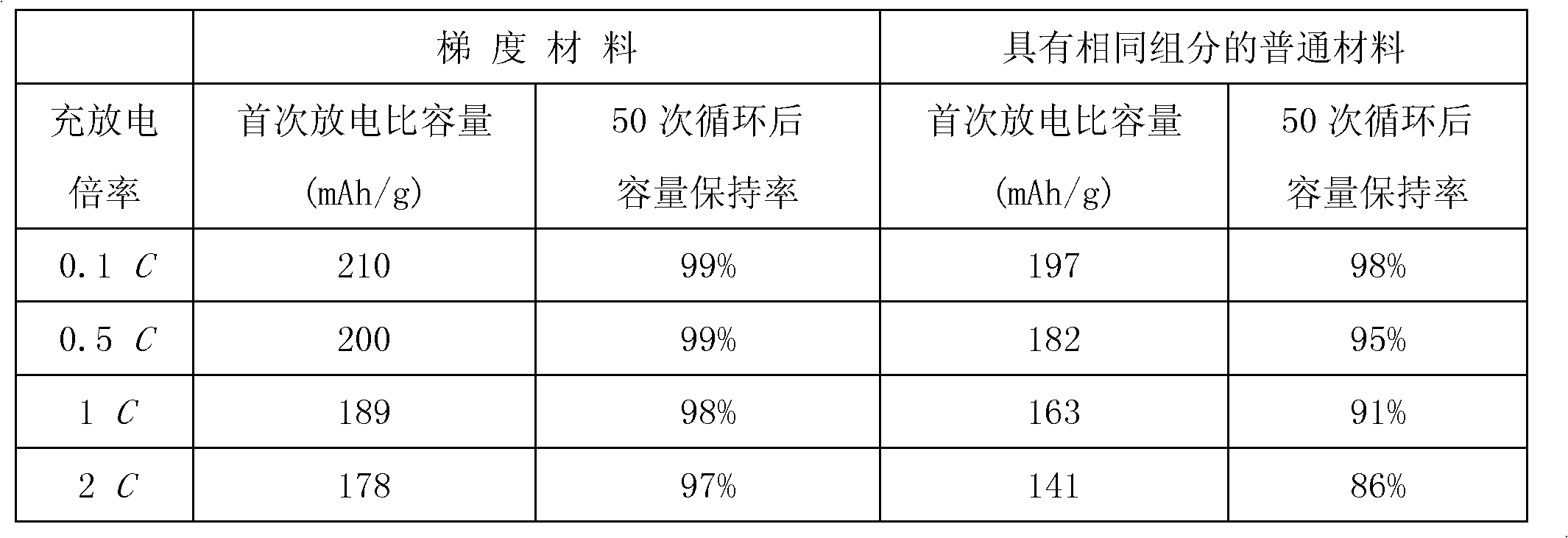

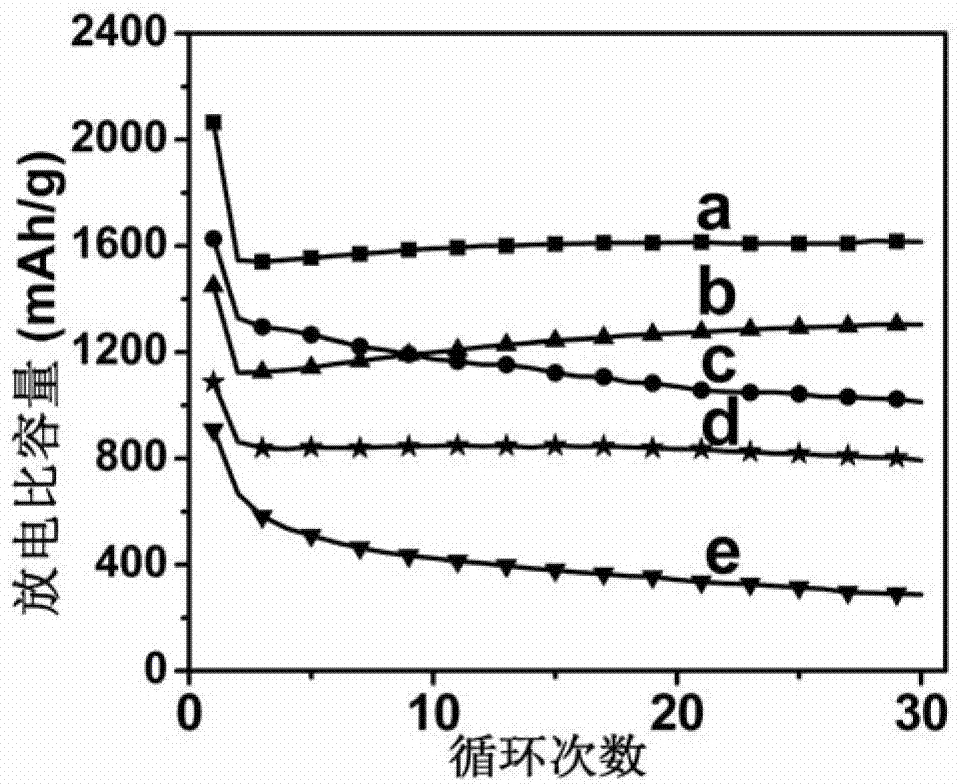

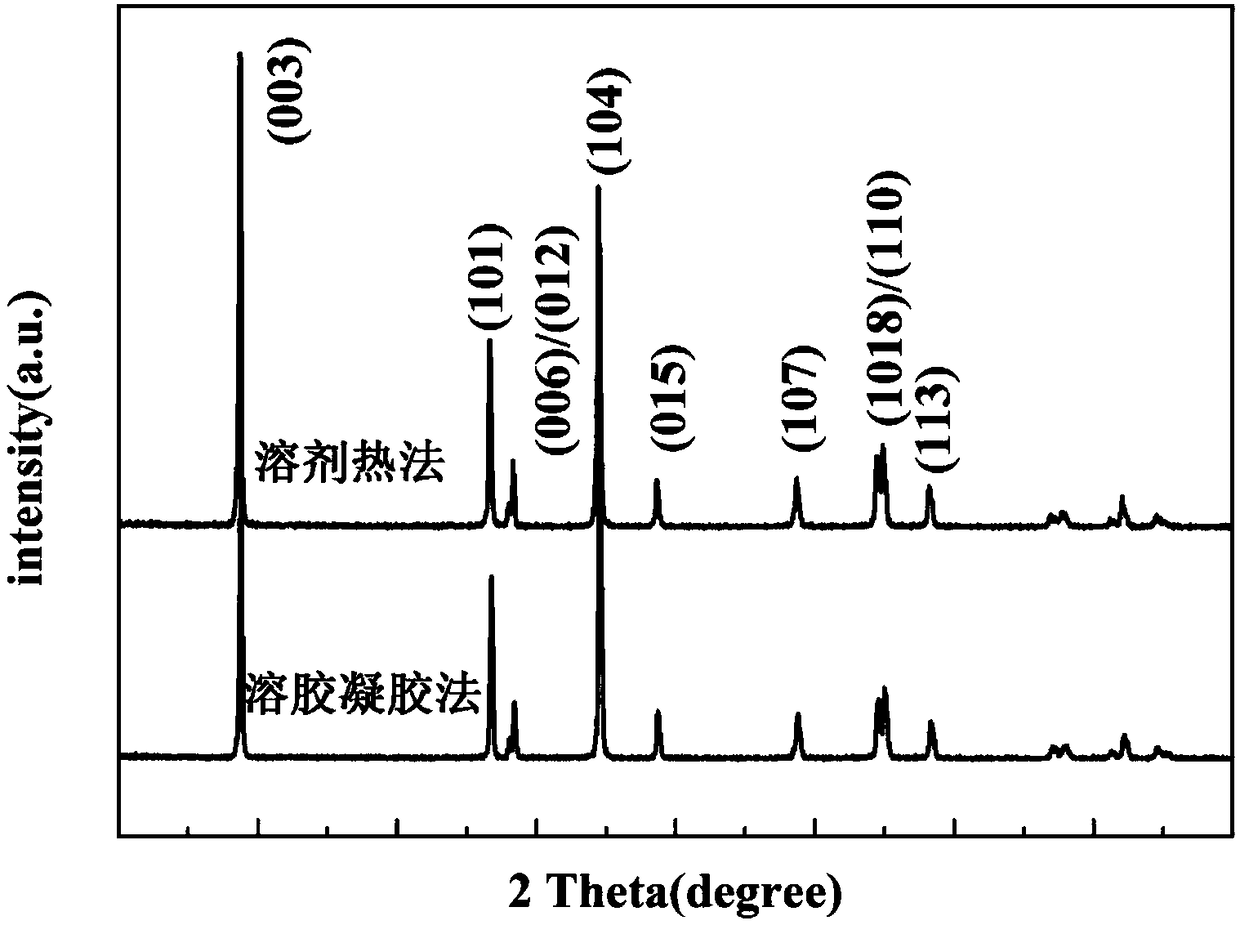

Gradient distribution multivariate composite material precursor as well as preparation method and application thereof

ActiveCN103367704AImproved thermal stability and safety performanceHigh discharge specific capacityCell electrodesIonTemperature cycling

The invention relates to a gradient distribution multivariate composite material precursor as well as a preparation method of the gradient distribution multivariate composite material precursor and an application in preparation of a lithium ion battery anode material. The precursor is prepared from the following molecular formula: NixCoyMnzM1-x-y-z(OH)2, wherein x is more than 0.2 and less than 0.8, y is more than 0.1 and less than 0.5, z is more than 0 and less than 0.6, and M is a doped metal ion and comprises one or more of Mg, Ca, Zn, Al, Cr, Zr and Ti; the precursor comprises a core part and an outer layer shell part in which multiple layers are sequentially covered in the core; a molecular formula composition of the core part is NikConMnmM1-k-n-m(OH)2, wherein k is more than 0.5 and less than 1, n is more than 0.05 and less than 0.5, and m is more than 0 and less than 0.6; and the outer layer shell part is used for controlling the proportion of the raw material components and a preparation process to ensure that the material composition of the outer layer shell part is distributed in a gradient mode. Compared with a ternary material with a uniform internal structure, the lithium ion battery anode material has the advantages that the high specific discharge capacity is developed; and meanwhile, the cycling stability, the high-temperature cycling stability and the rate capability of the materials also can be greatly improved.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

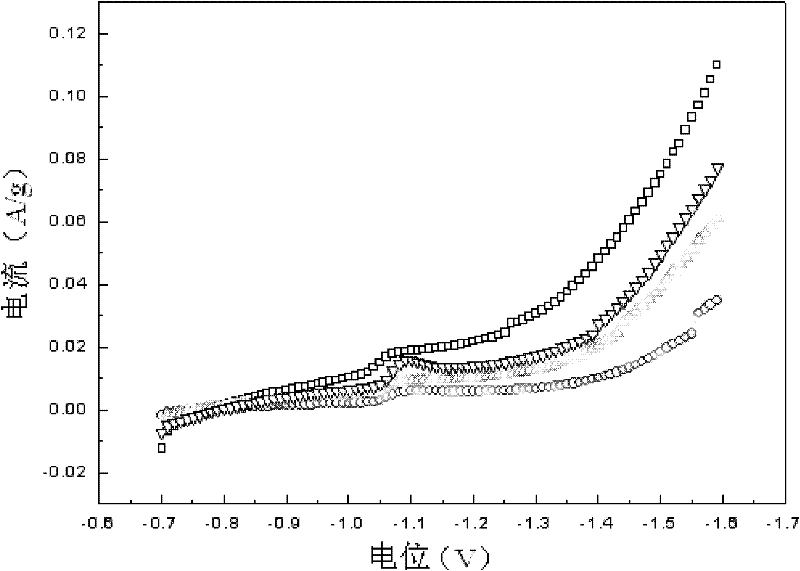

Modified activated carbon with high hydrogen evolution potential and preparation method thereof as well as lead-acid battery negative lead paste containing modified activated carbon

InactiveCN102306784AHigh discharge specific capacityImprove cycle performanceCell electrodesActivated carbonElectrode potential

The invention relates to a modified activated carbon with high hydrogen evolution potential and a preparation method thereof as well as a lead-acid battery negative lead paste containing the modified activated carbon and relates to a modified activated carbon and a preparation method thereof as well as a lead-acid battery negative lead paste containing the modified activated carbon. According to the invention, the problem of the poor cycle life of the lead-acid battery caused by the unmatching between the added activated carbon and the lead electrode potential, the large hydrogen-evolution speed and the serious hydrogen evolution in the existing lead-acid battery negative electrode is solved. In the modified activated carbon provided by the invention, a hydrogen evolution inhibitor is loaded on the activated carbon, wherein the hydrogen evolution inhibitor is one or a mixture of more than one selected from In2O3, Ga2O3 and Bi2O3, or the hydrogen evolution inhibitor is In(OH)3, Ga(OH)3 or Bi(OH)3. The modified activated carbon is prepared by a ball-milling method or a solvent precipitation method. The hydrogen evolution overpotential of the modified activated carbon is improved obviously, the hydrogen evolution speed of the modified activated carbon is reduced and the hydrogen evolution potential of the modified activated carbon is matched with a Pb electrode potential; and meanwhile, the discharge specific capacity in a cyclic process can be obviously improved, the cycle performance can be obviously improved, and the specific capacity can still reach 90mAh.g<-1> after being cycled for 500 times.

Owner:HARBIN INST OF TECH

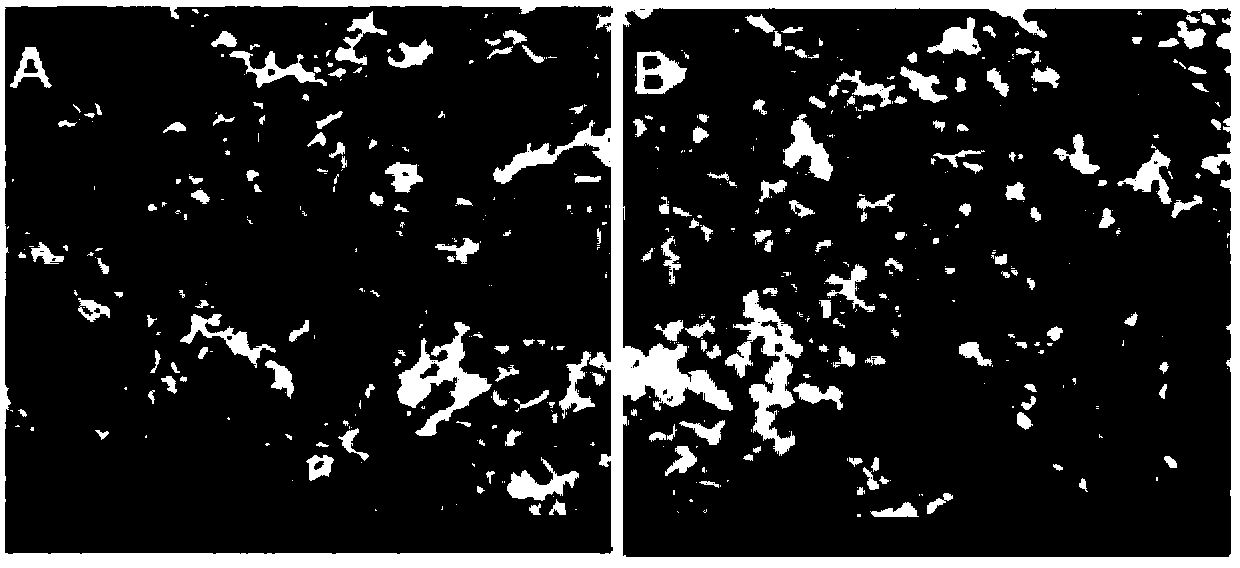

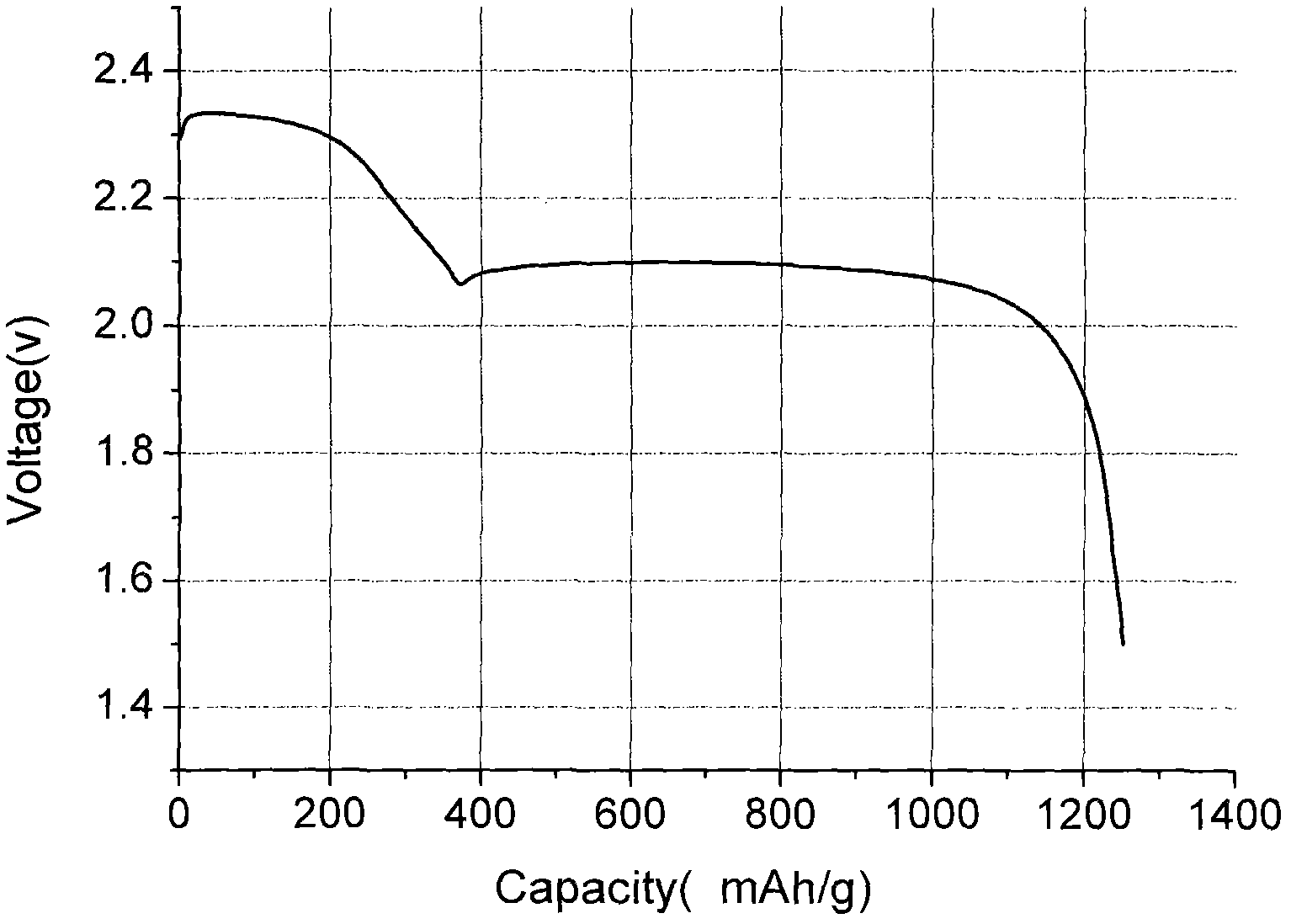

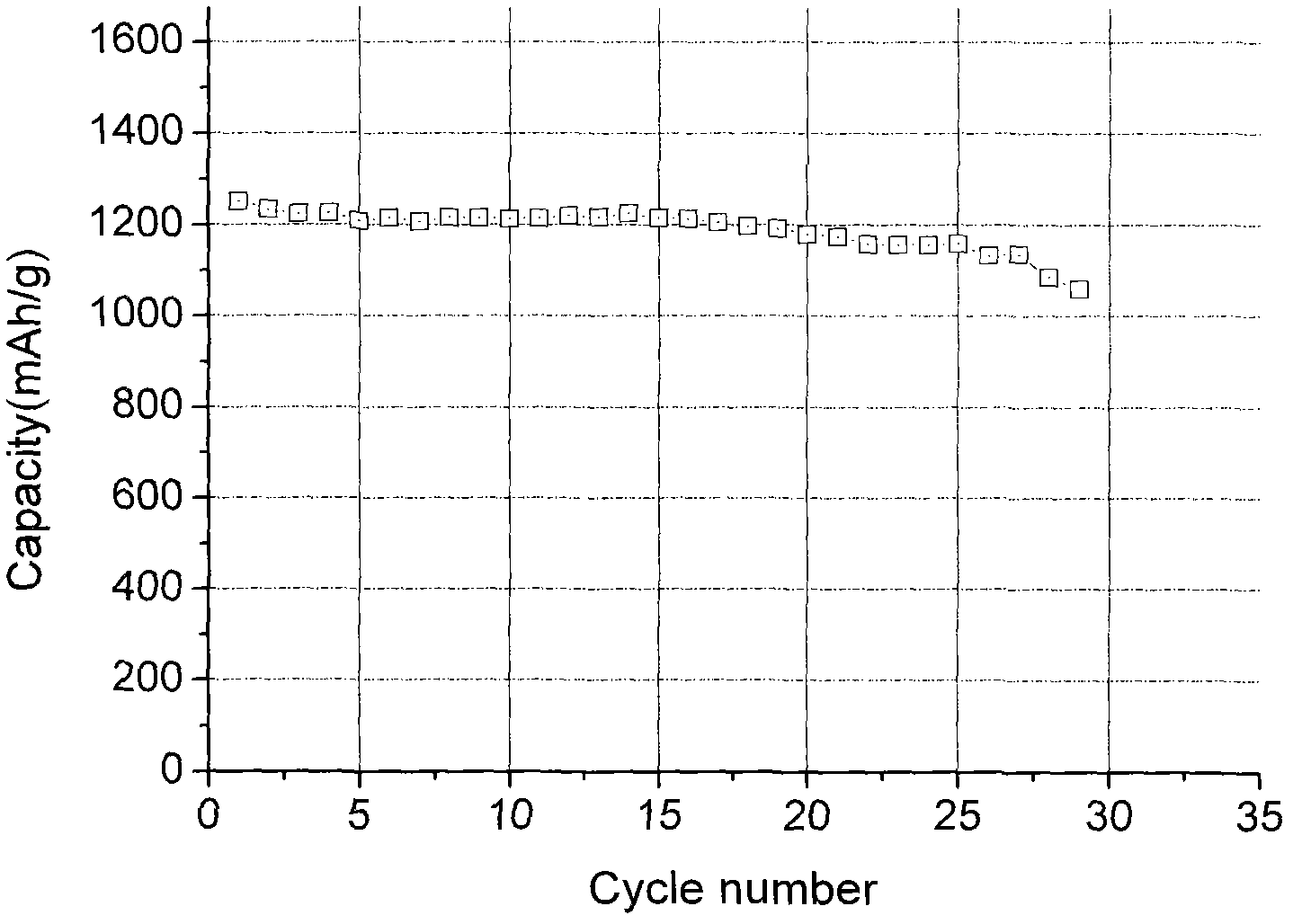

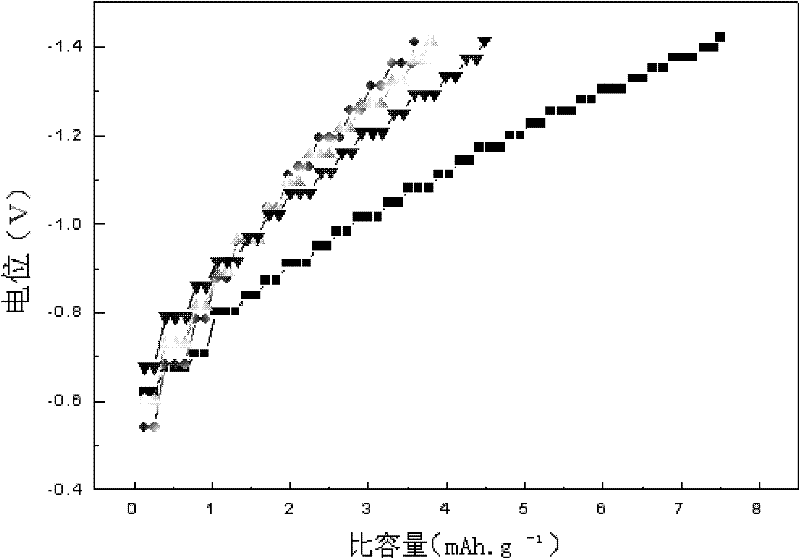

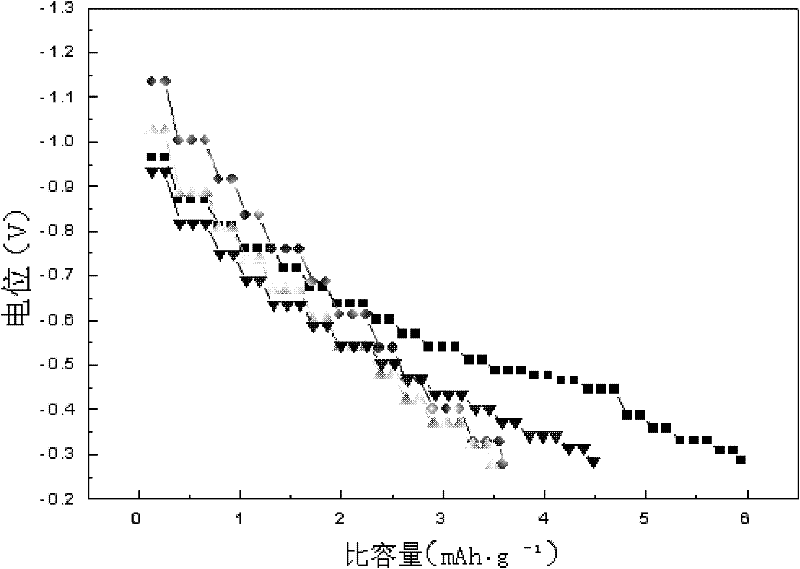

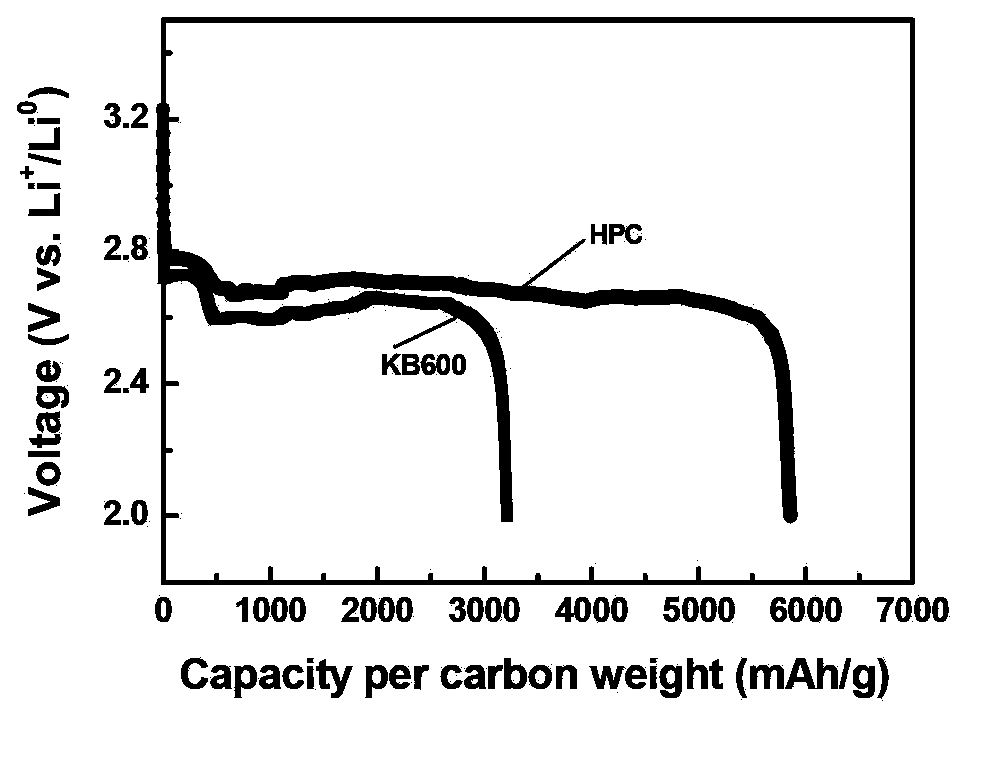

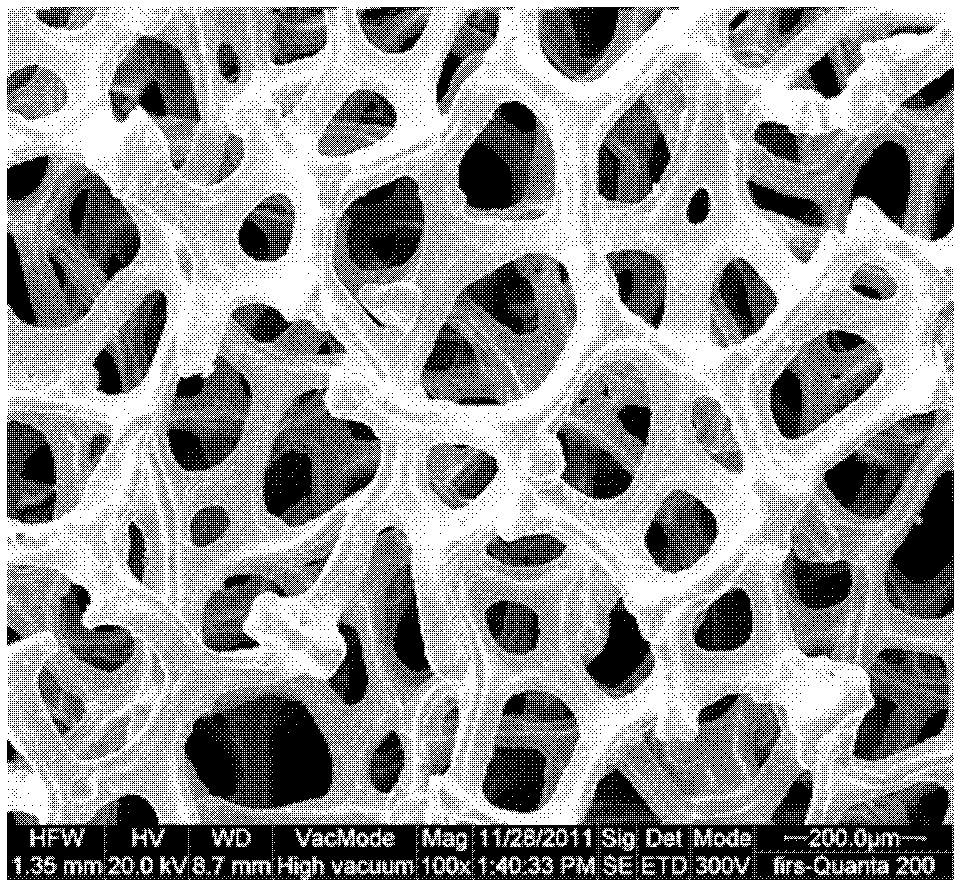

Porous carbon material used for lithium-air cell anode

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

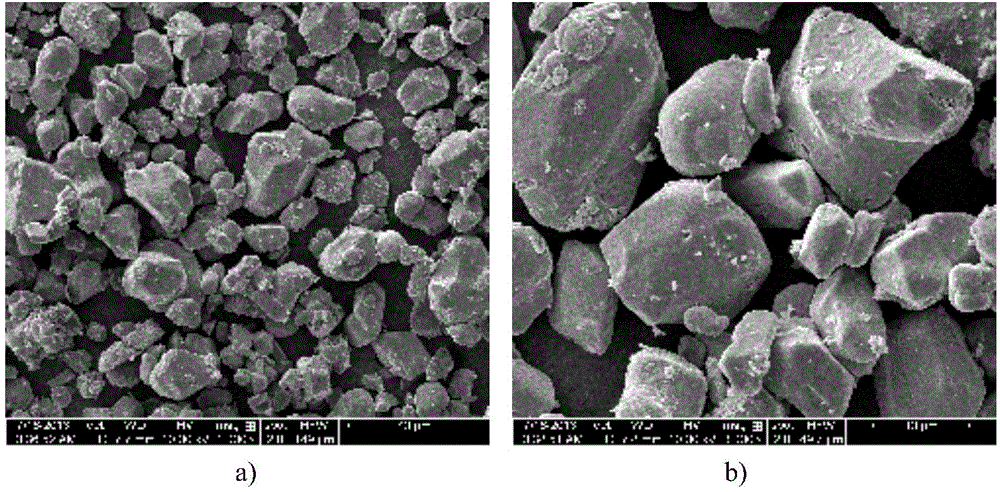

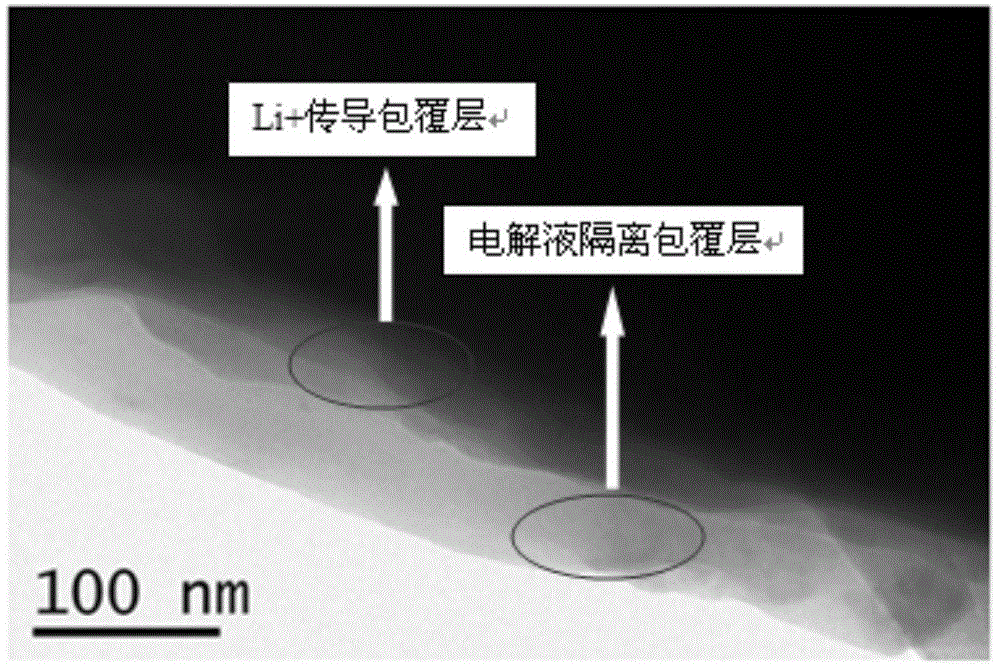

Surface-modified lithium cobaltate material and preparation method thereof

ActiveCN103606674AHigh discharge specific capacityLess side effectsCell electrodesLithiumDouble coating

The invention discloses a surface-modified lithium cobaltate material and a preparation method thereof. The lithium cobaltate material comprises a core particle and a surface-modified layer coating the core particle, wherein the core particle is a lithium cobaltate-based positive material with a structural formula as follows: LixCo(1-y)MyO2, wherein x is greater than 1 and not greater than 1.2, y is not less than 0 and not greater than 0.1, M is a doping element; the surface-modified layer comprises a Li<+1> conducting layer and an electrolyte isolating layer; the core particle is coated by the Li<+1> conducting layer and the electrolyte isolating layer in sequence. According to the invention, by sufficiently utilizing dynamic characteristic that different substances react with residual Li salt on the surface of the lithium cobaltate, and characteristic of final reaction product performance, the lithium cobaltate material with double coating layers is prepared. The material is high in comprehensive performances, has high discharge capacity, high cycling stability and the like. The preparation method disclosed by the invention is simple in process and easily realizes industrial production.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

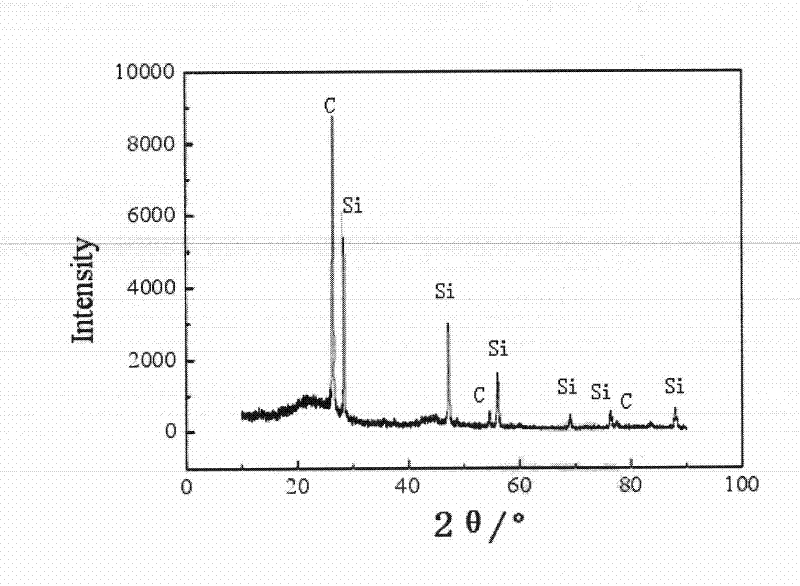

High-capacity silicon-carbon composited anode material, preparation method and application thereof

InactiveCN102637872AOvercoming the low capacity of lithium deintercalationPromote circulationCell electrodesSecondary cellsCarbon compositesPyrolytic carbon

The invention relates to a high-capacity silicon-carbon composited anode material, a preparation method and application thereof, wherein the silicon-carbon composited anode material comprises the following compositions in parts by weight: 1-30 parts of silicon materials, 30-120 parts of carbon materials, and 10-80 parts of pyrolytic carbon. The silicon materials in the silicon-carbon composited anode material disclosed by the invention are uniformly adhered to the surfaces of carbon material particles, and then the outer layers of the carbon material particles are wrapped with the pyrolytic carbon, therefore, the silicon-carbon composited anode material disclosed by the invention has the advantages of lower first irreversible specific capacity, higher specific capacity, excellent cycle performance, low preparation cost and the like; and the first discharge capacity of the silicon-carbon composited anode material is greater than 450 mAh.g<-1> under a 0.2 C discharge ratio, and the retention rate of capacity after 50 cycles is more than 80%.

Owner:天津市贝特瑞新能源材料有限责任公司

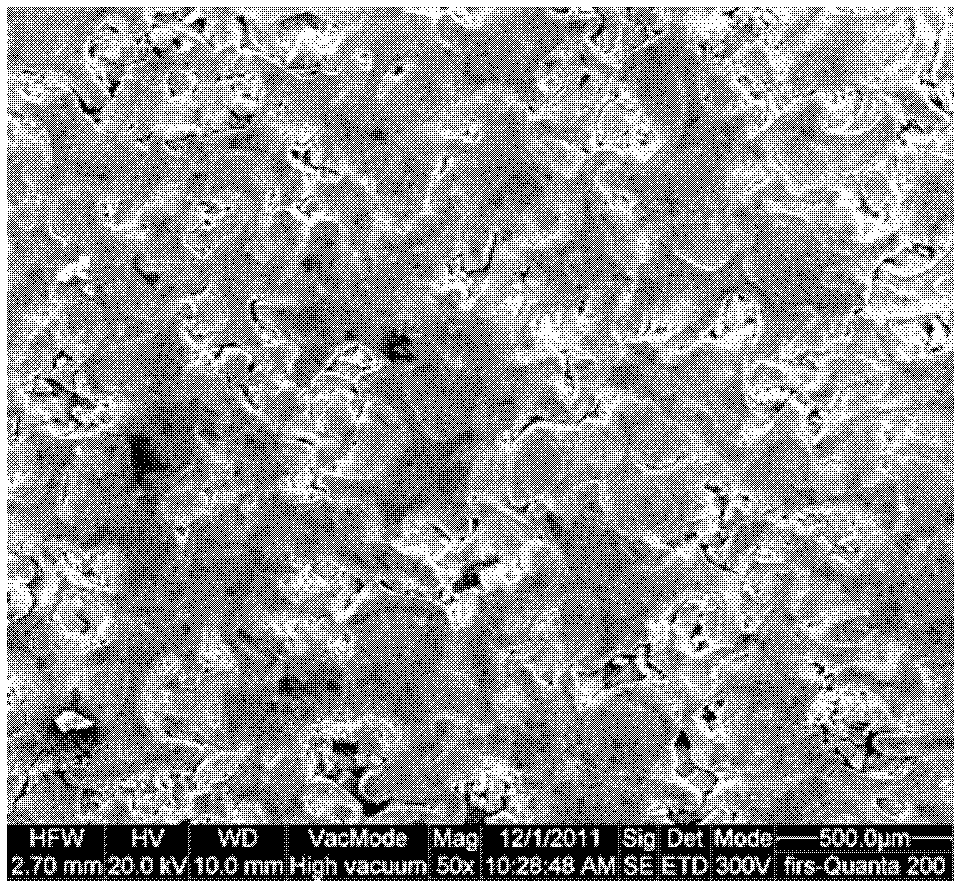

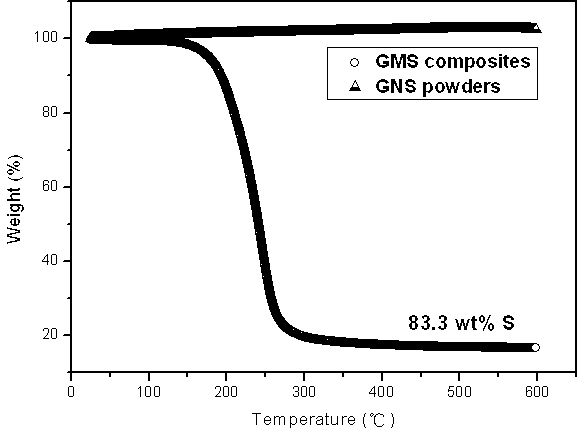

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

Method for preparing silicon-based anode material of lithium-ion battery

The invention relates to a method for preparing a silicon-based anode material of a lithium-ion battery, belonging to the field of lithium-ion battery. Silicon oxide and Mg powder are weighed and matched, the adding amount of the magnesium powder and the silicon oxide is calculated according to the Mg / O atomic ratio of 0.1:1-1.3:1, the magnesium powder and the silicon oxide are evenly mixed and placed in flowing nitrogen or argon and other inert atmospheres, the needed temperature of 500-1000 DEG C is achieved by the temperature increase rate of 1-30 DEG C / min, and the temperature is kept for 0.5-6 hours. Then, the mixture is cooled to room temperature by program in a temperature-controlling manner or by power-off in a natural manner. Or the silicon oxide, the Mg and balls are weighed and matched, the mixture is arranged in a ball mill, the high energy ball milling is carried out under the inert atmosphere, the ratio of the balls to materials is 1:1-50:1, the rotational speed is 100-3000 turns, and the ball milling time is 0.5-100 hours. The method has the advantages of low material cost, simple process, less time consumption, high yield and good capacity and circulating performance of products.

Owner:UNIV OF SCI & TECH BEIJING

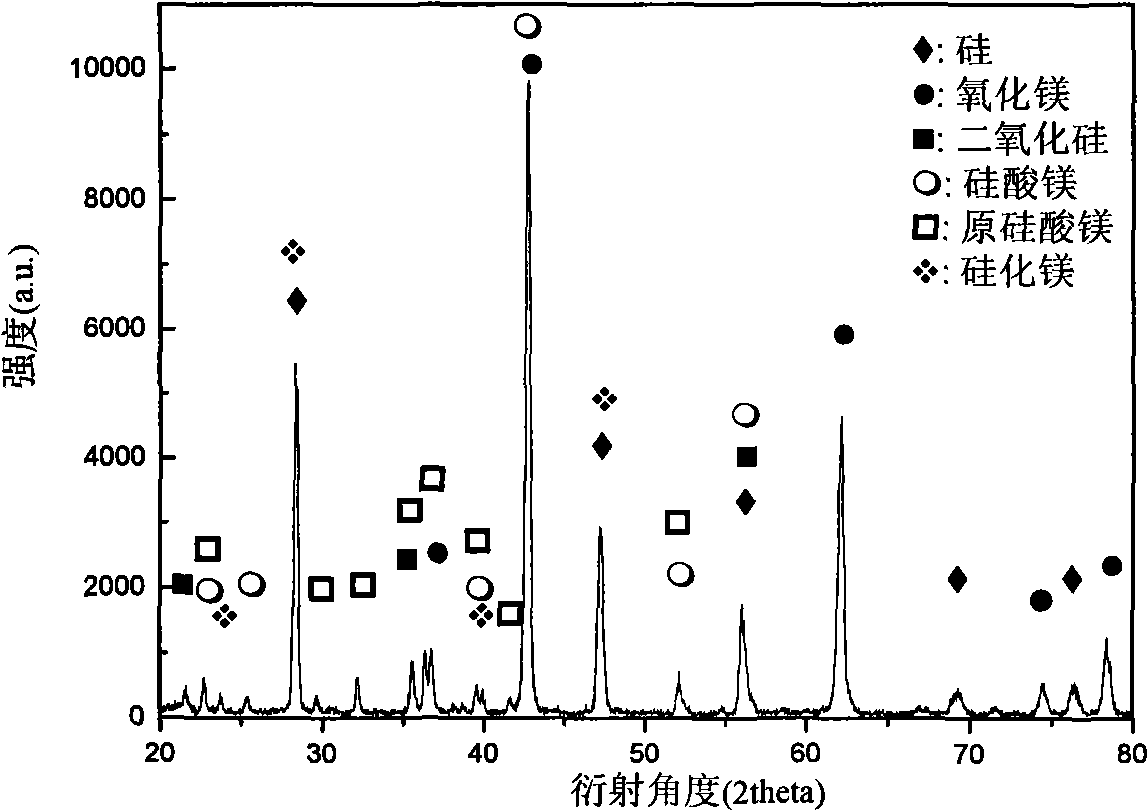

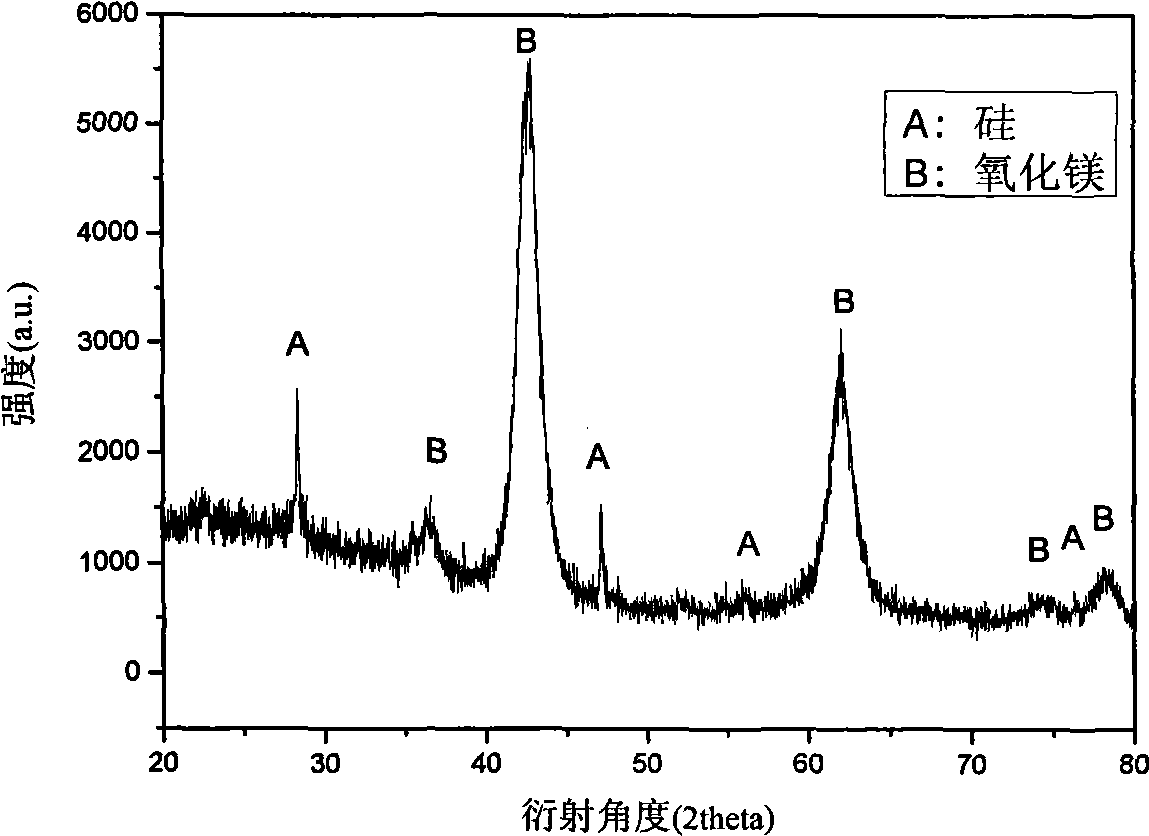

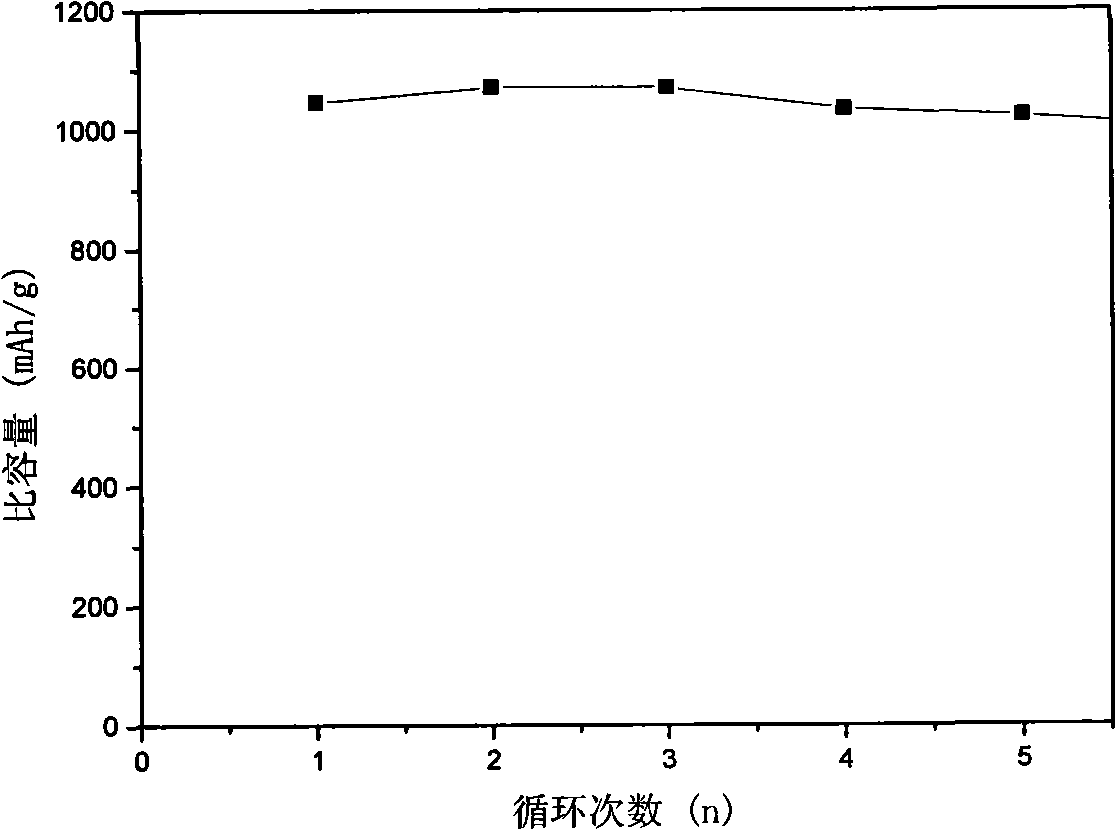

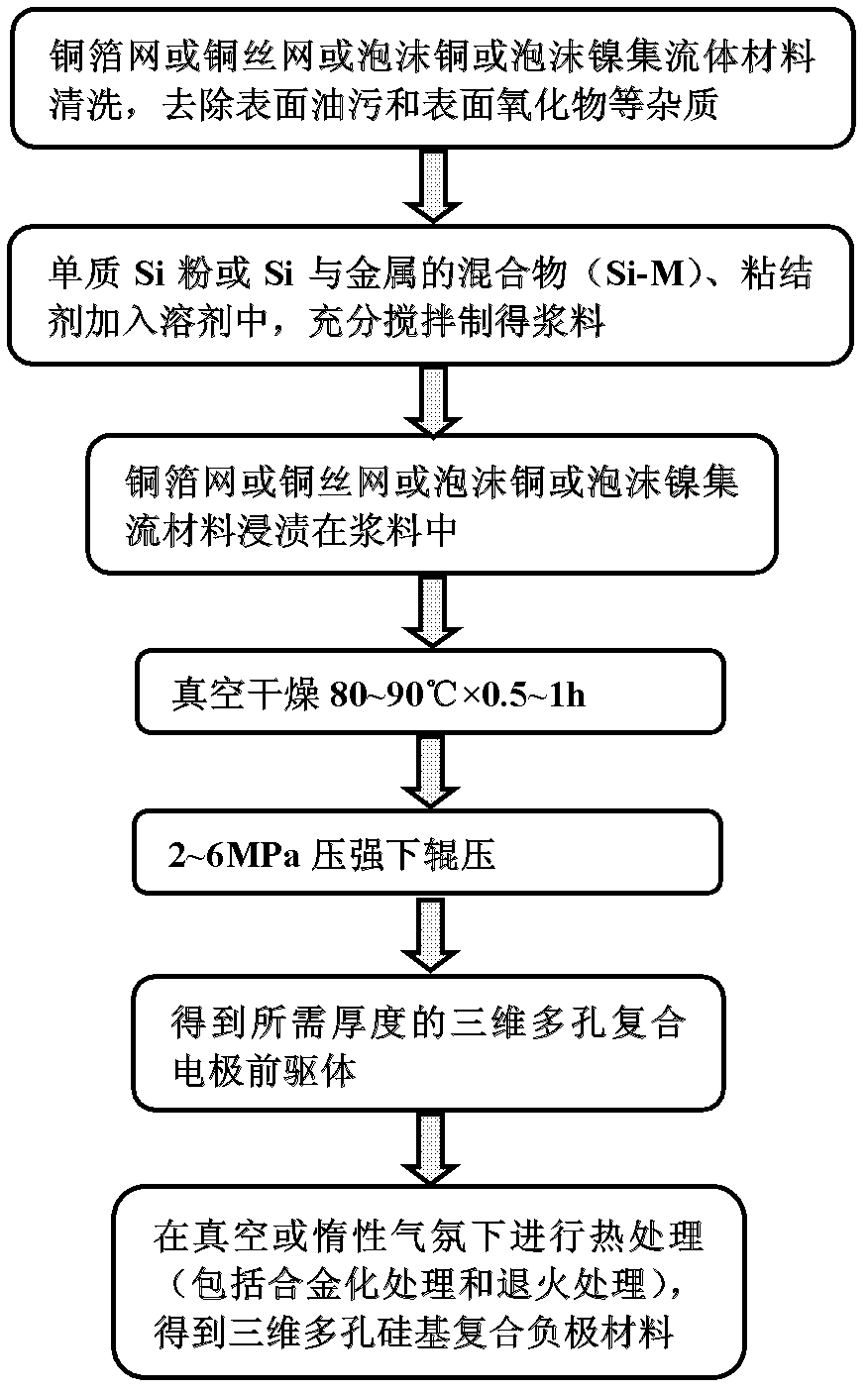

Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

ActiveCN102683655AEasy to operateReduce processing costsElectrode carriers/collectorsSecondary cellsCopper wireCopper foil

The invention discloses a three-dimensional porous silicon-based composite negative electrode material of a lithium ion cell and a preparation method thereof. A collection body material, such as a copper foil net or a copper wire net or foam copper or foam nickel, which has a three-dimensional net structure, enables electrode active substances to be uniformly dispersed in the material and the surface of the material, and has high temperature resistant characteristic and excellent conductivity, is adopted; and a sizing material containing simple substance silicon or a mixture of simple substance silicon and metal M is combined with the copper foil net or copper wire net or foam copper or foam nickel by a dipping method, and then the three-dimensional porous silicon-based composite negative electrode material is formed by a heat treatment (alloying and annealing treatment) manner. According to the invention, based on the three-dimensional porous structure, the forming of silicon metal alloy as well as excellent binding force between the negative electrode material and the three-dimensional porous collection body material, the cell prepared from the porous silicon-based composite negative electrode material has higher discharge specific capacity and first charge-discharge efficiency and excellent cycle performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

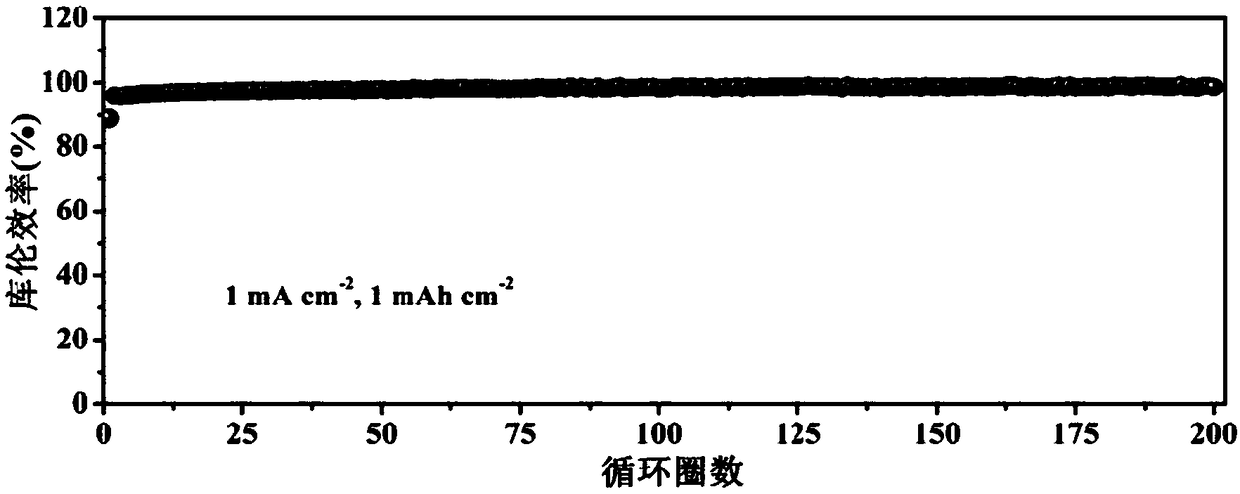

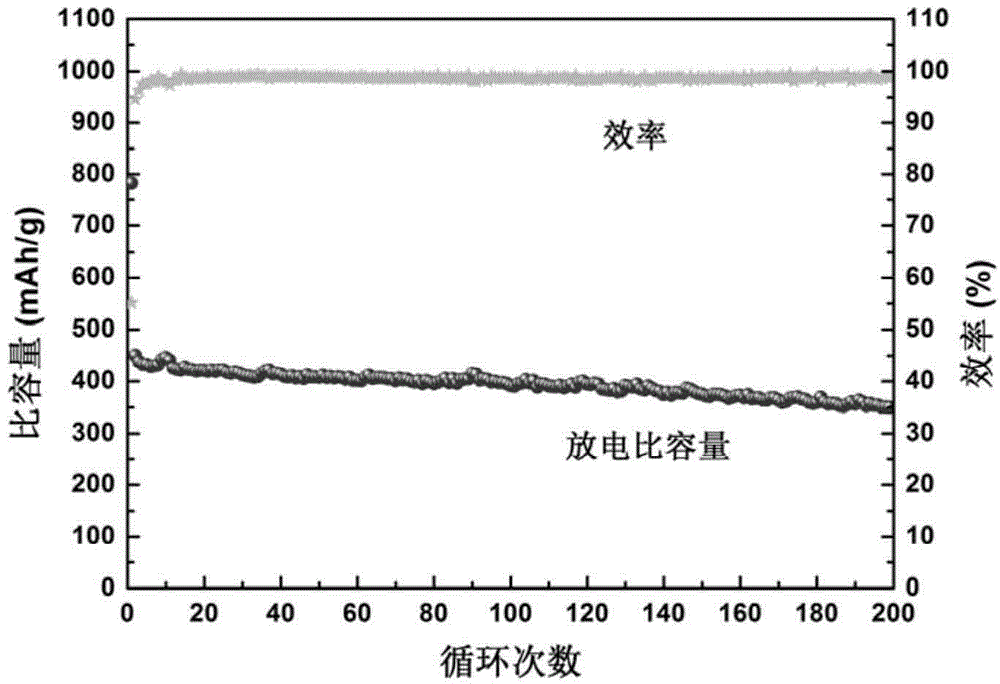

Lithium metal battery lithium negative electrode surface modification method, and lithium metal battery

ActiveCN108448058ASimple processEasy to operateElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersHigh energyShielding gas

The invention discloses a lithium metal battery lithium negative electrode surface modification method, and a lithium metal battery. The modification method comprises the following steps: a lithium metal negative electrode is impregnated in or coated with a fluorine-containing ionic liquid in a dry protection gas atmosphere, is fluorinated, and is taken out to make a protection layer rich in lithium fluoride formed on the surface of the metal lithium negative electrode in order to obtain a lithium fluoride coated metal lithium negative electrode. The lithium fluoride protection layer obtainedby surface fluorination is very uniform and dense, and can reduce the consumption of lithium metal and an electrolyte and inhibit the formation of lithium dendrites in order to make the metal lithiumnegative electrode have a high specific discharge capacity, a long cycle life and a good safety, so the stability and the high efficiency of the lithium metal battery in a long cycle process are achieved, use requirements of a high-energy and high-power power battery are met, the industrialization process of the lithium metal battery is facilitated, and lithium metal battery has a wide applicationprospect.

Owner:SOUTH CHINA UNIV OF TECH

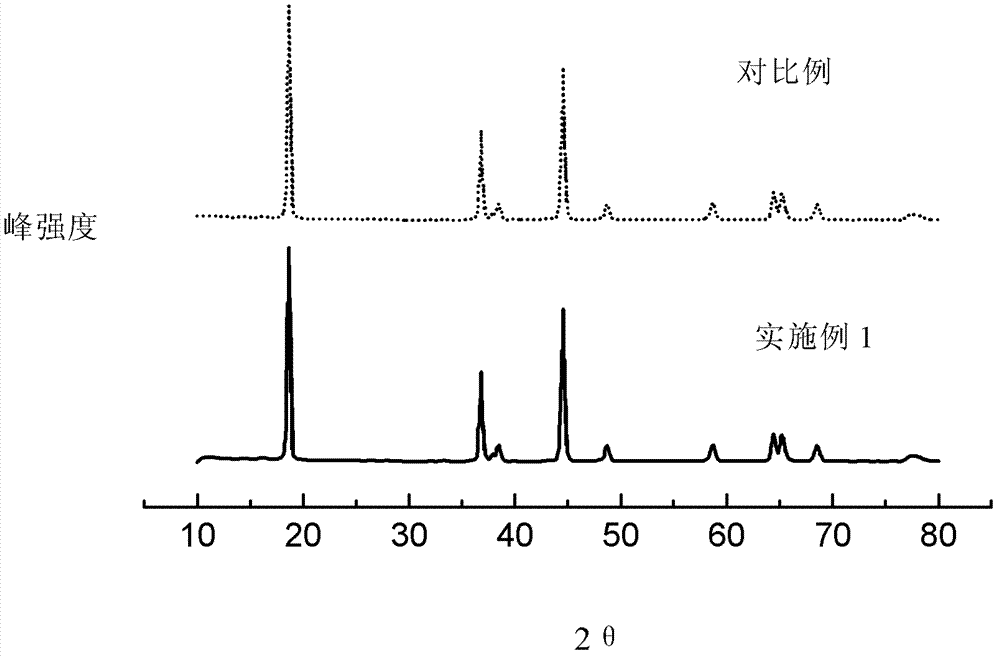

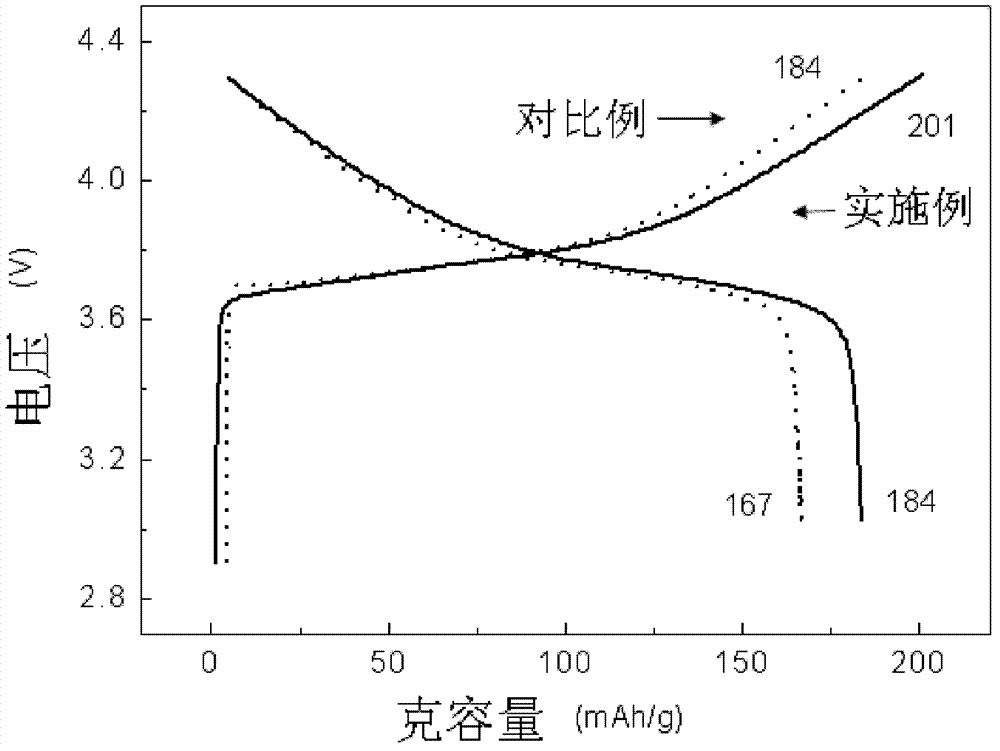

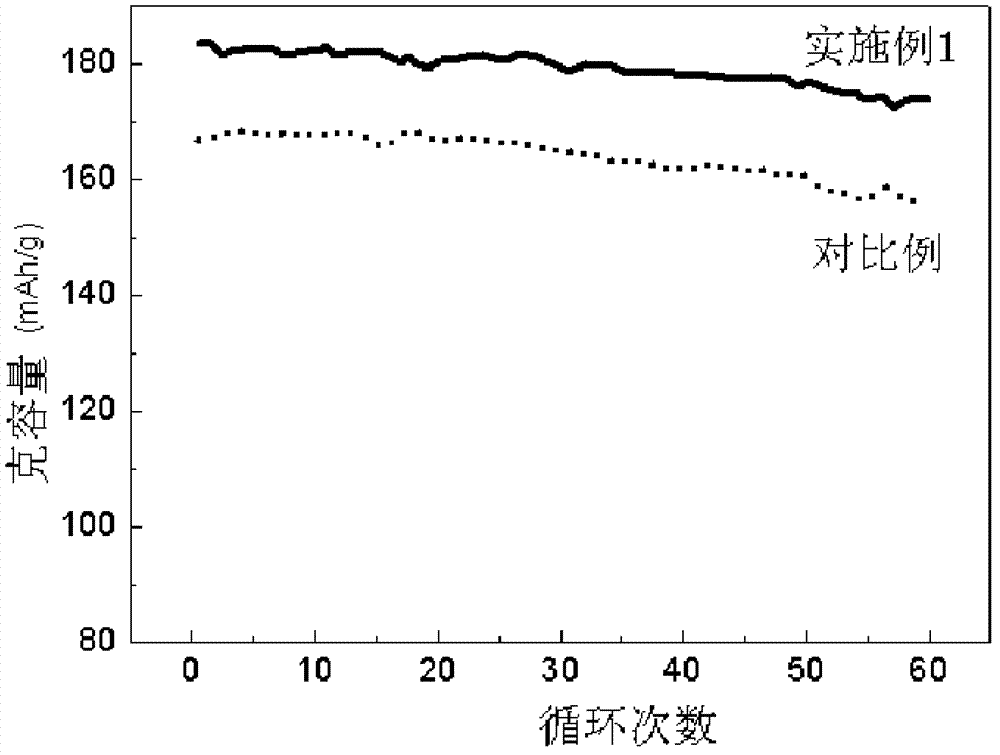

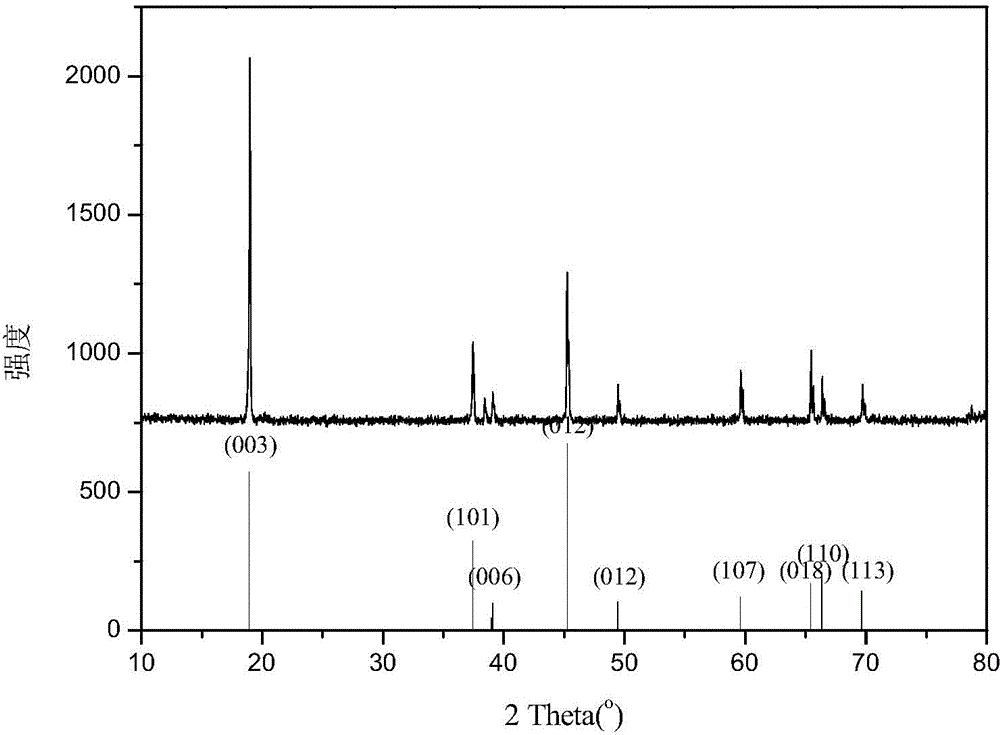

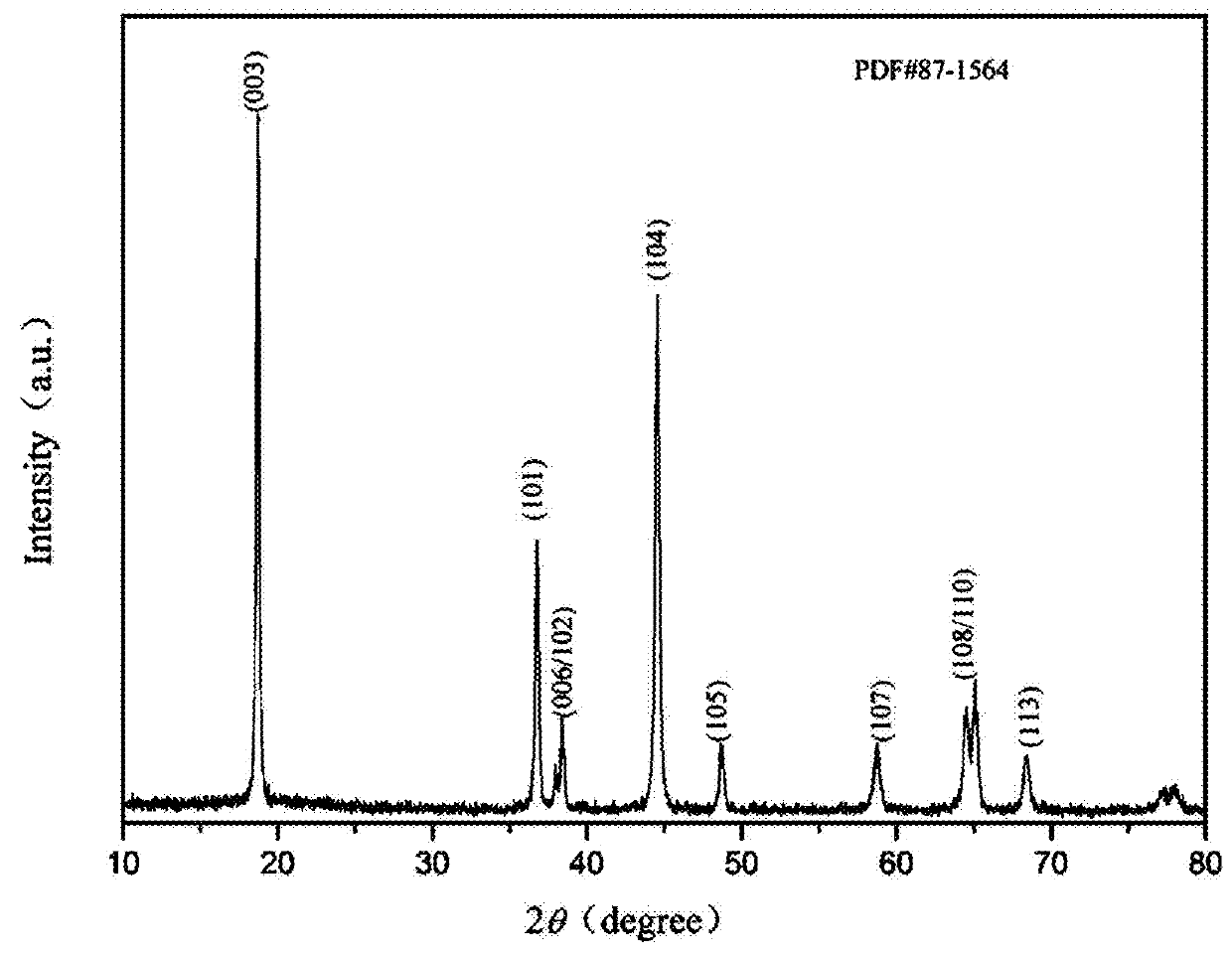

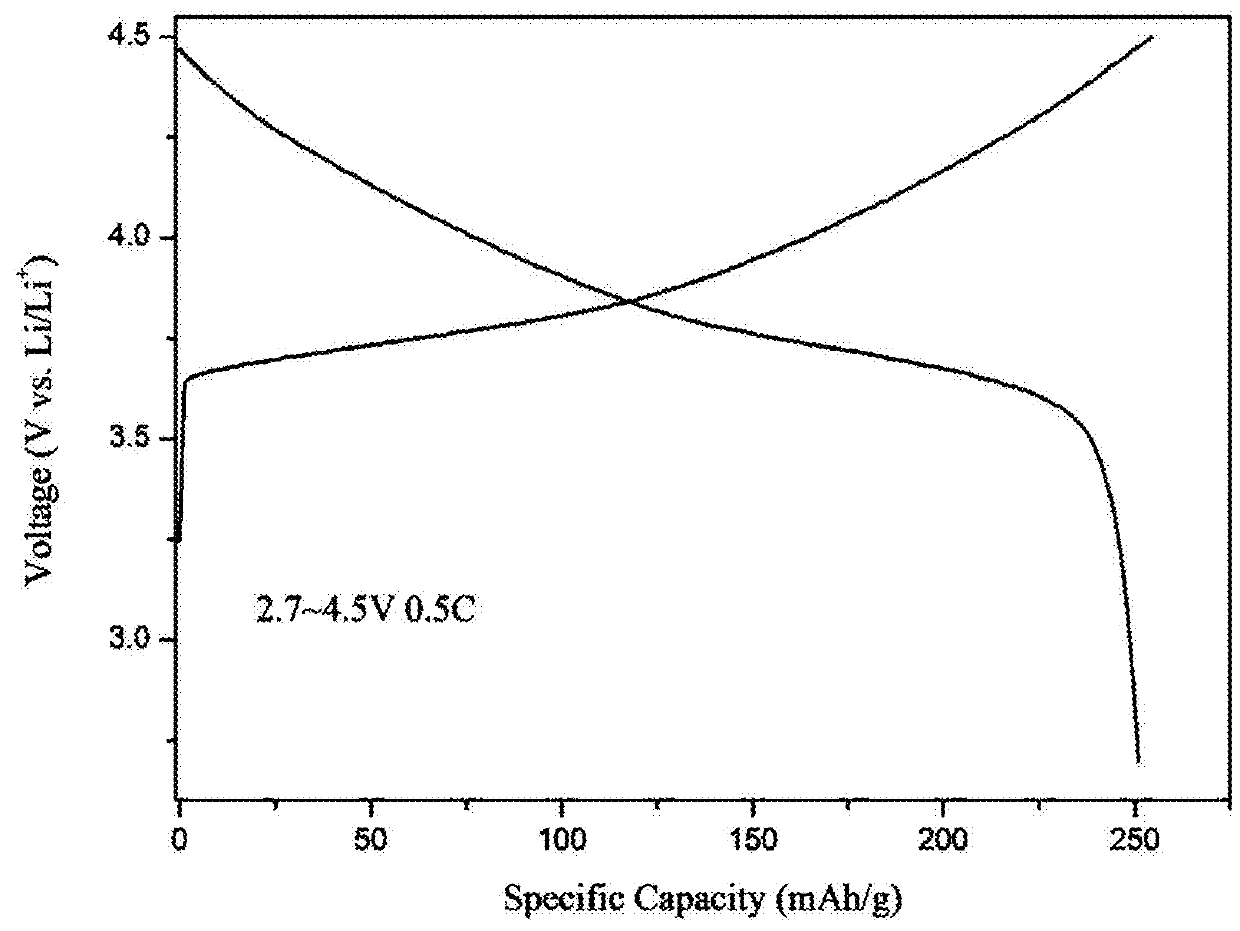

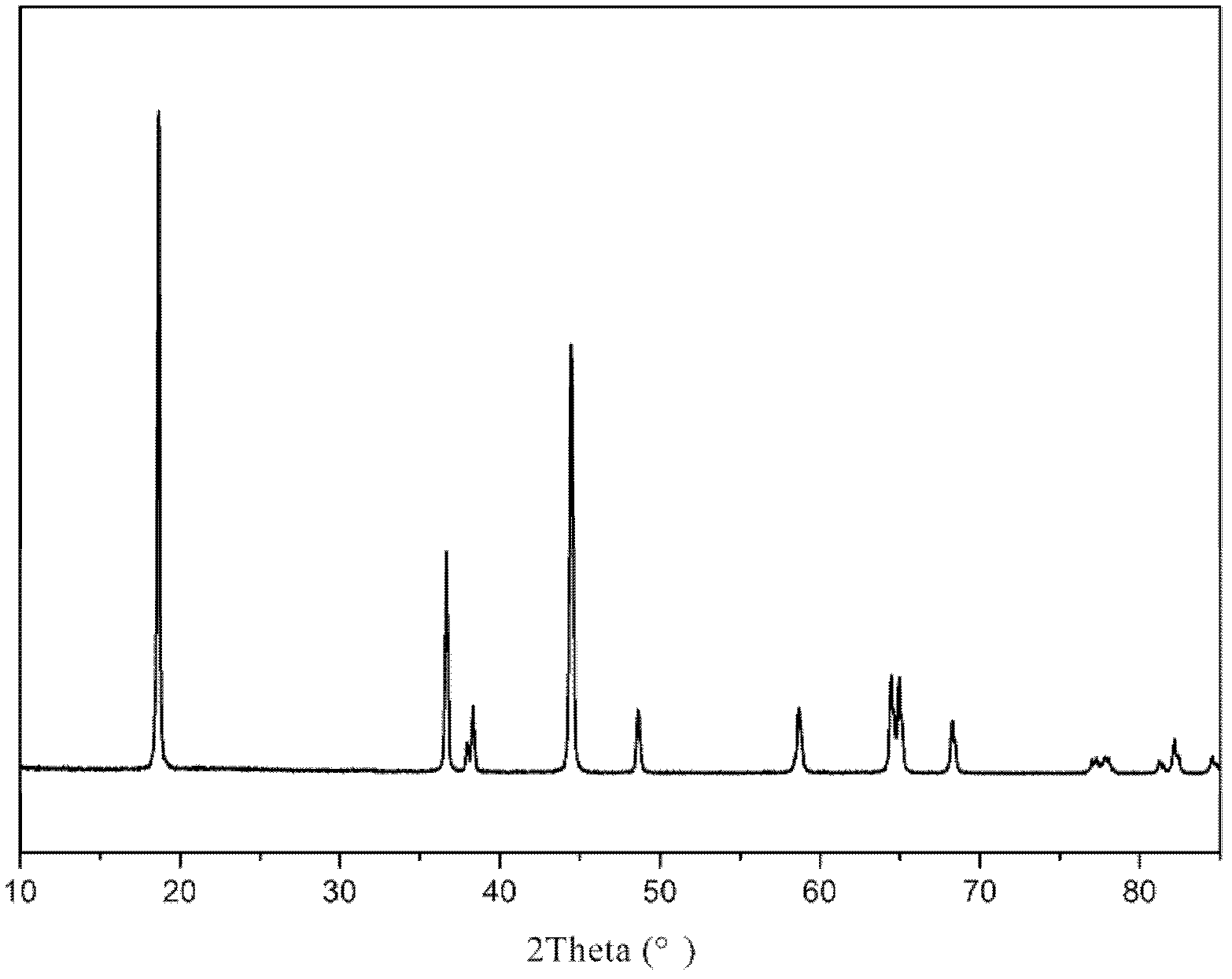

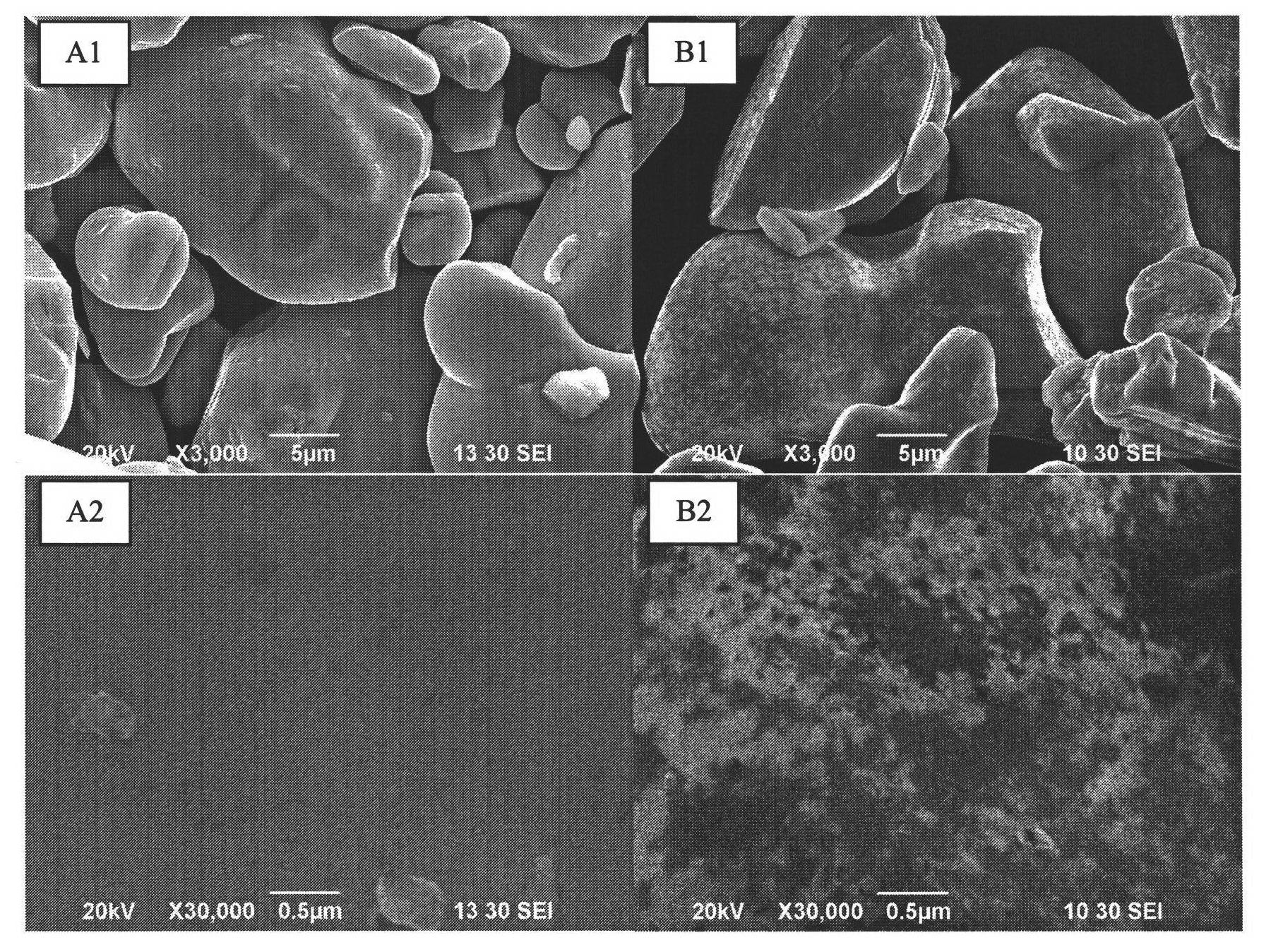

High-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof

ActiveUS20180183045A1Improve cycle stabilityGood chemical uniformityCell electrodesSecondary cellsAir atmosphereHigh energy

The present invention discloses a high-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof. The chemical formula of the material is LiNi0.6-xMgxCo0.2-yAlyMn0.2-zTizO2-dFd, wherein 0<x,y,z,d≤0.05. The precursor of the positive electrode material is synthesized by gradient co-precipitation method and the positive electrode material is prepared by solid phase method. The content of nickel in the synthesized precursor particles has a gradient distribution from the inside to the outside. The obtained precursor is mixed and grinded evenly with the lithium source and the fluorine source at a certain ratio and put into the tube furnace. The obtained precursor is then pre-sintered in the oxygen-enriched air atmosphere and then heated up to be sintered, to obtain the target product. The positive electrode material for lithium-ion battery prepared by the method is free from impurity phase and has a good crystallinity, which is a high energy density positive electrode material.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

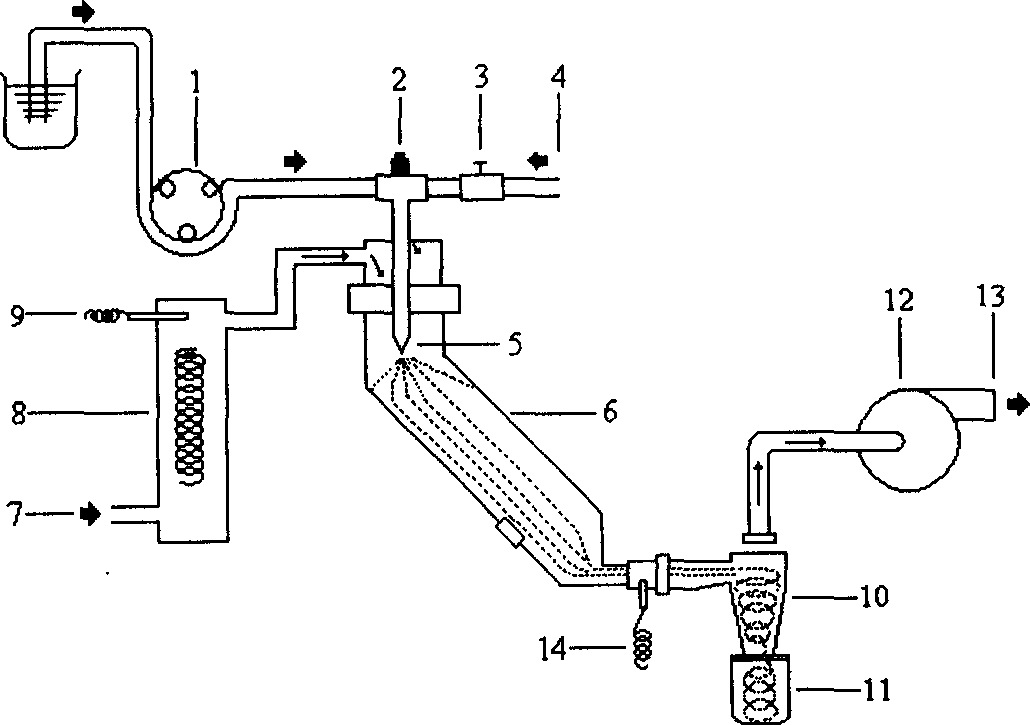

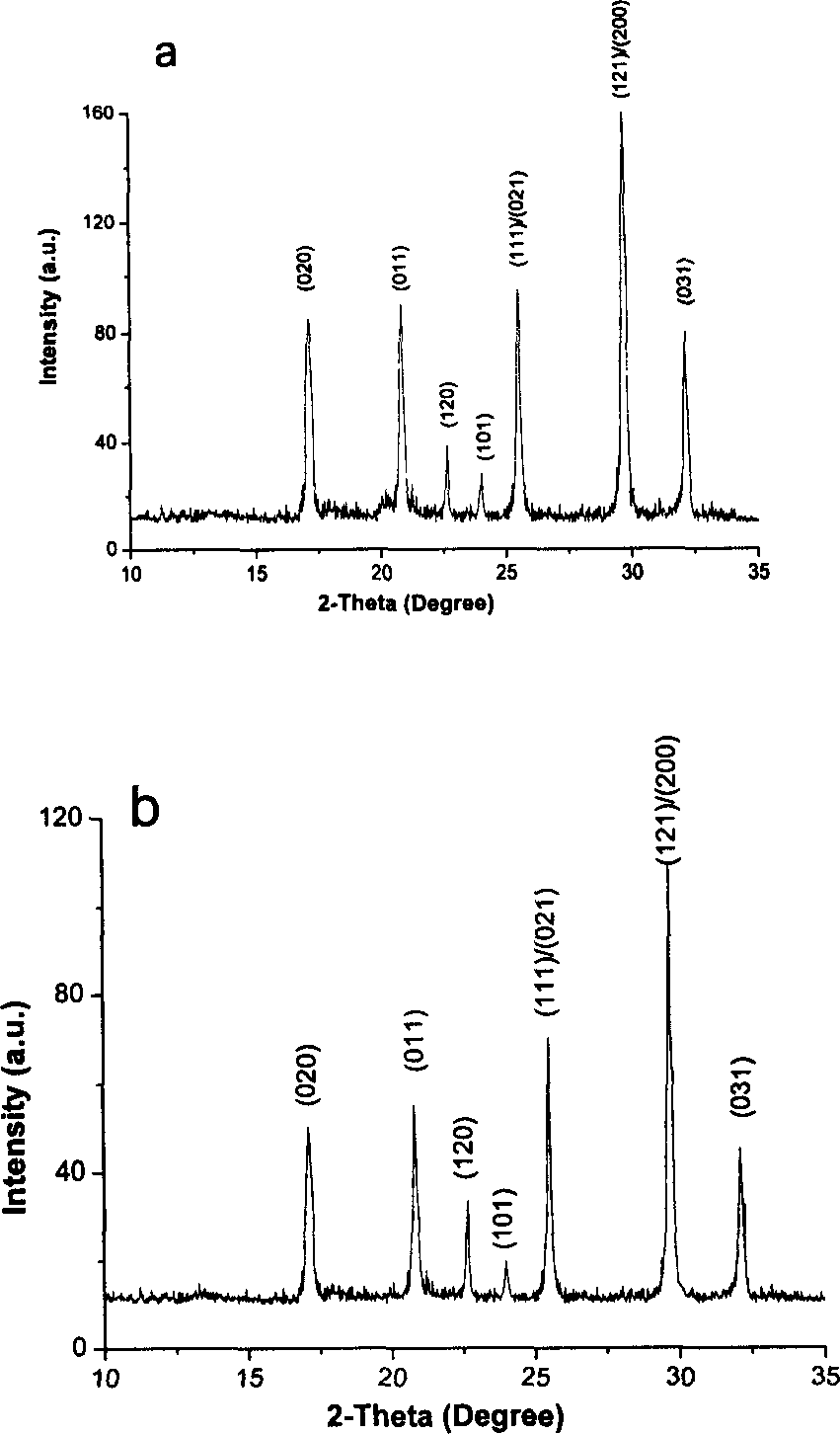

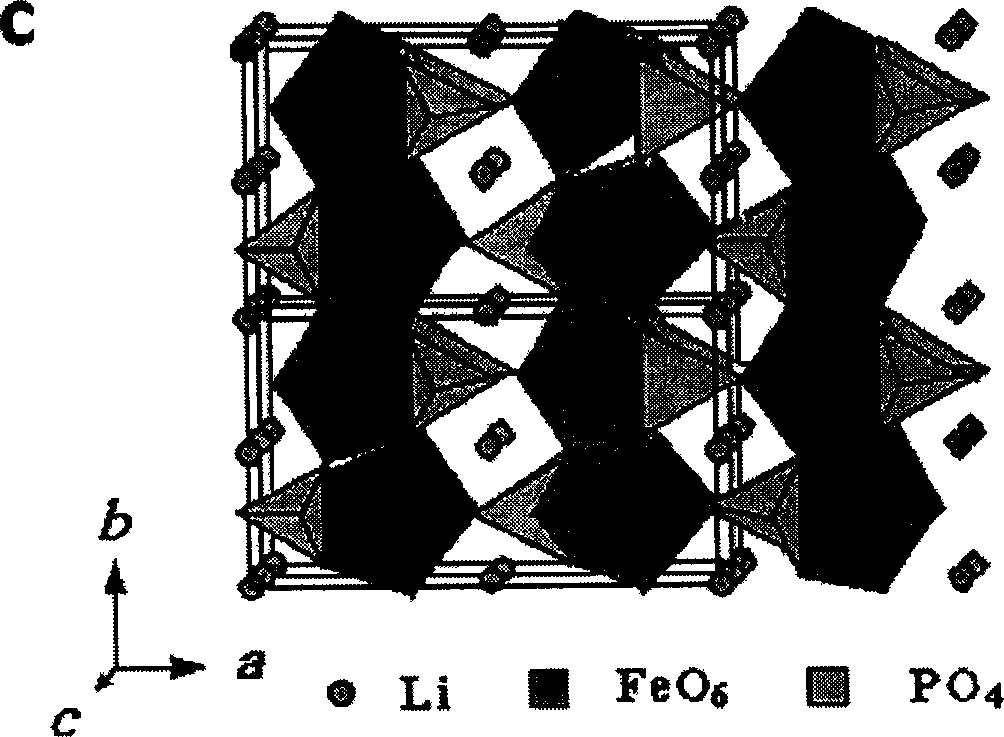

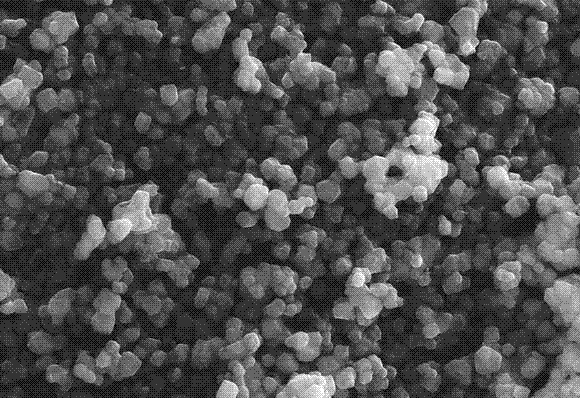

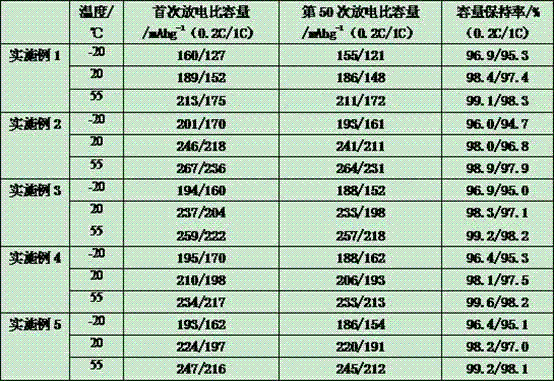

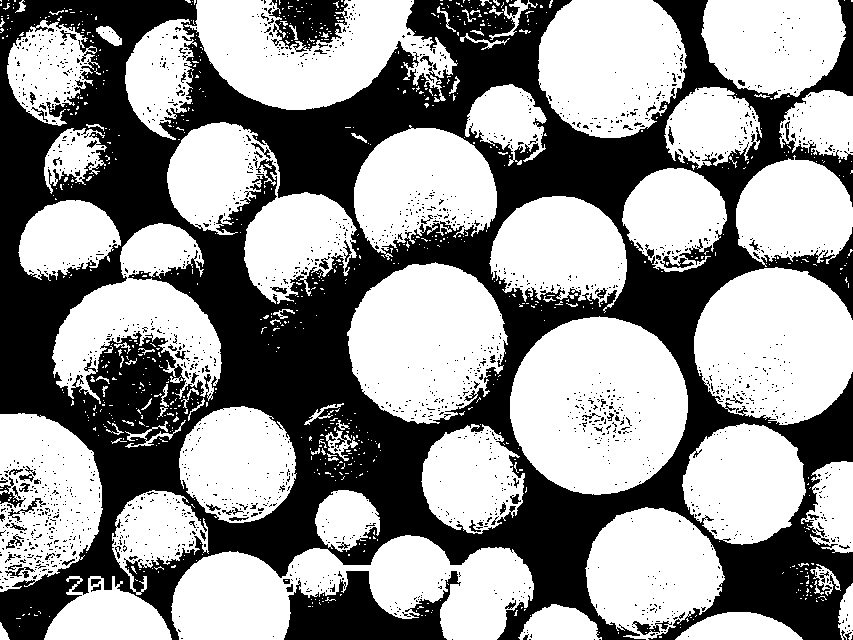

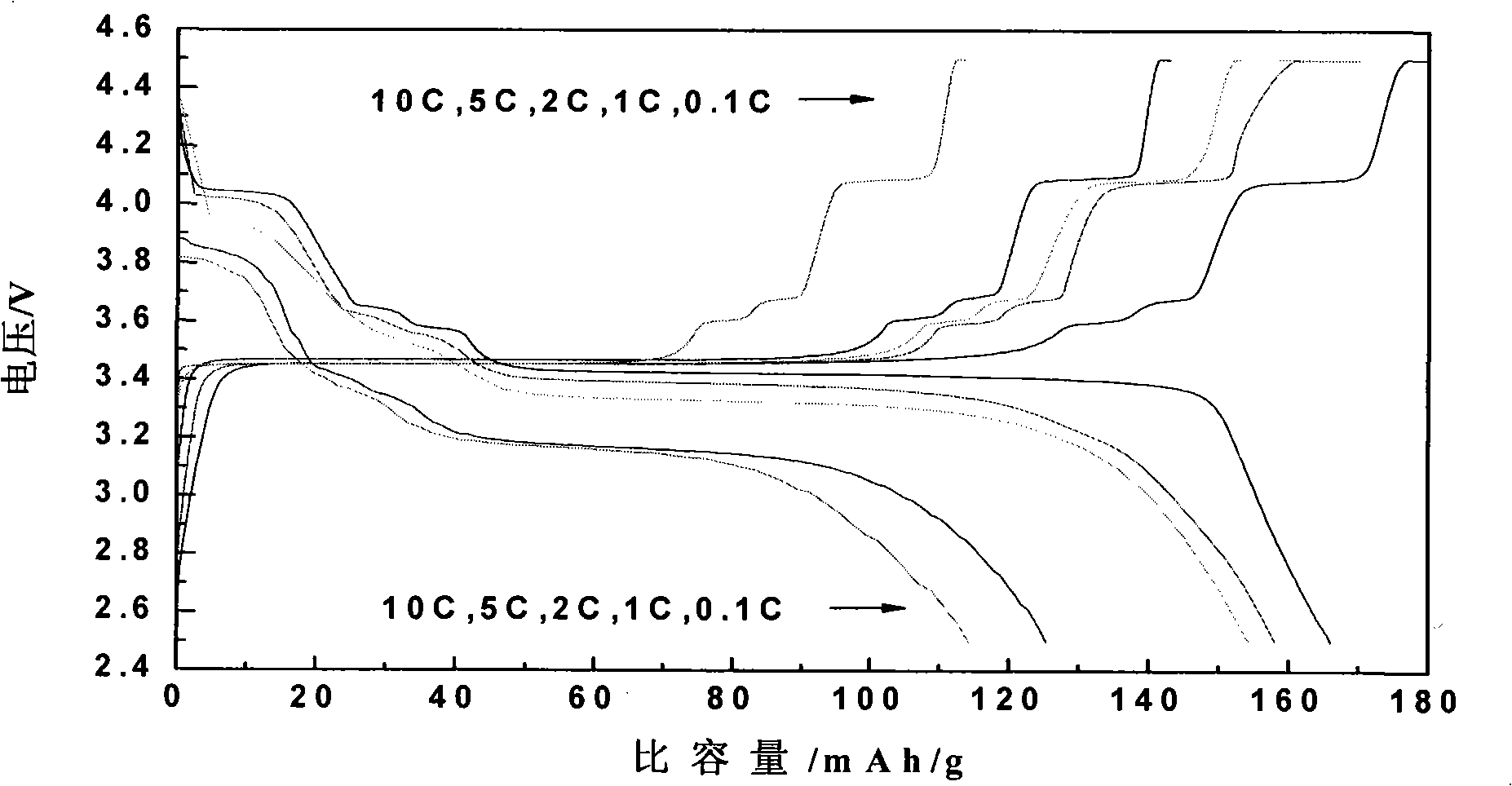

Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

InactiveCN1773754AProlong the fall timePromote growthCell electrodesPhosphorus compoundsLithium iron phosphateHigh density

An electrode material of Fe¿CLi phosphate and its composite metal phosphate is electrode material of LiFePO4 and LiFePO4 / MxP in high density spherical shape with diameter of 2micro m. The electrode material of LiFePO4 and LiFePO4 / MxP can be prepared by low ¿C temperature controllable one ¿C stage atomizing process in short flow.

Owner:NANKAI UNIV

Cathode material for fast lithium ion conductor phase-modified lithium ion battery and preparation method thereof

InactiveCN102760884AImprove transmission characteristicsImprove surface propertiesCell electrodesRare-earth elementElectrical conductor

The invention discloses a cathode material for a fast lithium ion conductor phase-modified lithium ion battery and a preparation method thereof. The key points of the technical scheme are as follows: the cathode material for the fast lithium ion conductor phase-modified lithium ion battery is a composite material consisting of a rare-earth element doped composite layered lithium ion battery cathode material xLi2MO3 (1-x) LiN(1-y)RyO2 (M is Mn, Ti or Sn, N is Mn, Ni, Co, Fe, Cr, V or Mo, R is one or more than one of Sc, Y, Pr, Nd, La, Ce, Sm, Yb, Eu and Gd, x is larger than 0 and smaller than 1, and y is larger than 0 and smaller than 0.2) and a fast lithium ion conductor, wherein the molar ratio of the fast lithium ion conductor to the rare-earth element doped composite layered lithium ion battery cathode material is n:1, and n is larger than 0 and smaller than or equal to 0.15. The invention also discloses a preparation method of the cathode material for the fast lithium ion conductor phase-modified lithium ion battery. The cathode material for a fast lithium ion conductor phase-modified lithium ion battery has the advantages of high specific capacity, good rate capacity, stability in recycling and strong temperature adaptation.

Owner:HENAN NORMAL UNIV

Preparation method for nitrogen-doped porous carbon sphere-sulfur composite positive material

The invention discloses a preparation method for a nitrogen-doped porous carbon sphere-sulfur composite positive material. The preparation method comprises the following steps of: performing spray pyrolysis on a nitrogen-containing carbon source, silica sol and de-ionized water to obtain a spherical nitrogen-doped pyrolytic carbon-silicon dioxide composite, adding the composite into excessive hydrofluoric acid for reaction, and washing and drying the reactants to obtain nitrogen-doped porous carbon spheres; and adding a sulfosalt solution into the nitrogen-doped porous carbon spheres under a vacuum condition, adding glycerin, which is taken as a dispersing agent, into the carbon spheres, adding an acid solution to the carbon spheres under magnetic stirring, and filtering and washing the mixture, and performing vacuum drying on the washed mixture to obtain the nitrogen-doped porous carbon sphere-sulfur composite positive material. The sulfur content of the prepared composite material is 50 to 90 percent, sulfur particles are more uniformly distributed in porous structures of the porous carbon spheres, and carbon and sulfur particles are more closely bound. The material is high in mechanical stability, specific discharge capacity and cycle performance. The method is simple in process, easy to operate, pollution-free and suitable for industrial implementation and batch production.

Owner:SHENZHEN RES INST CENT SOUTH UNIV

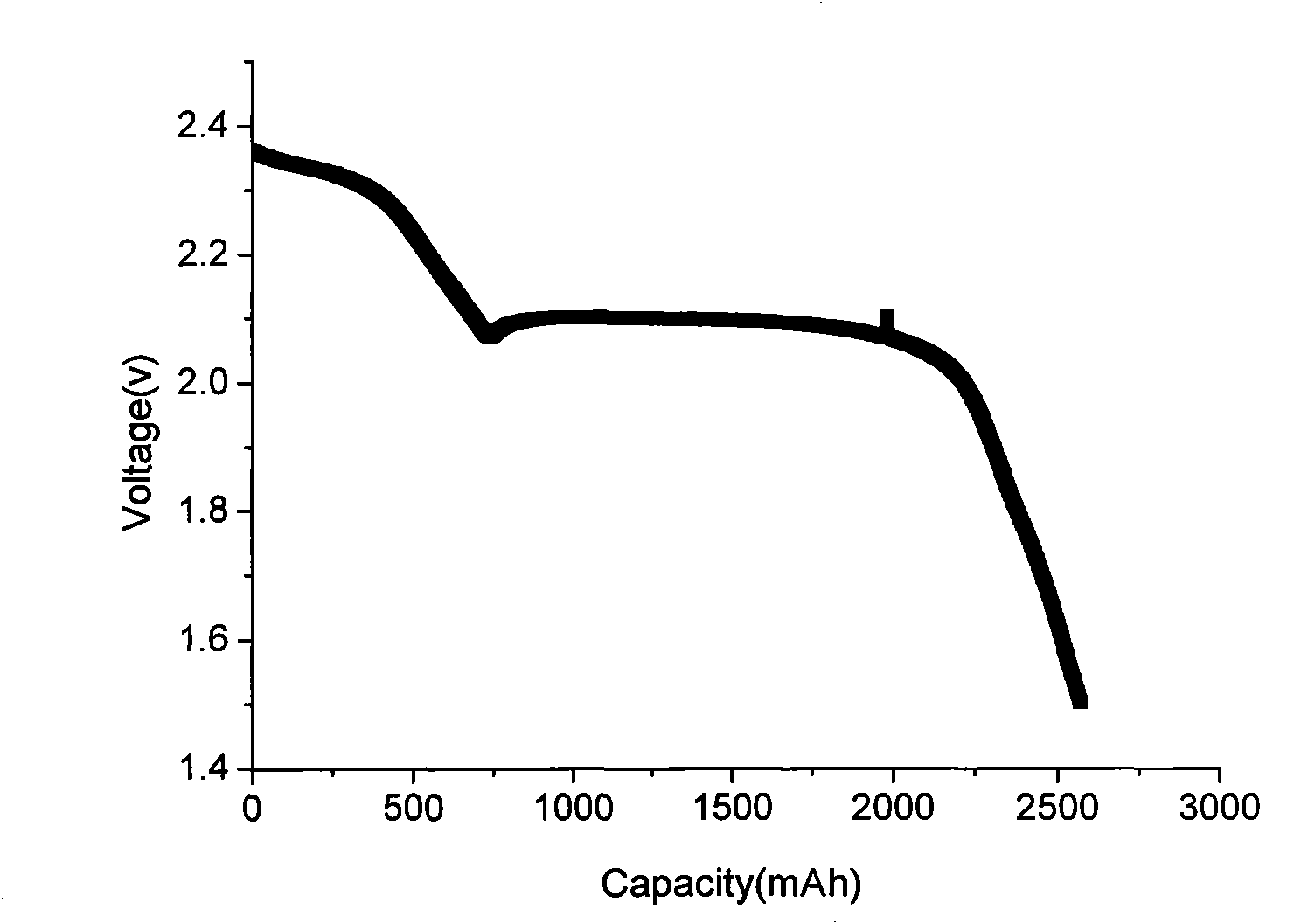

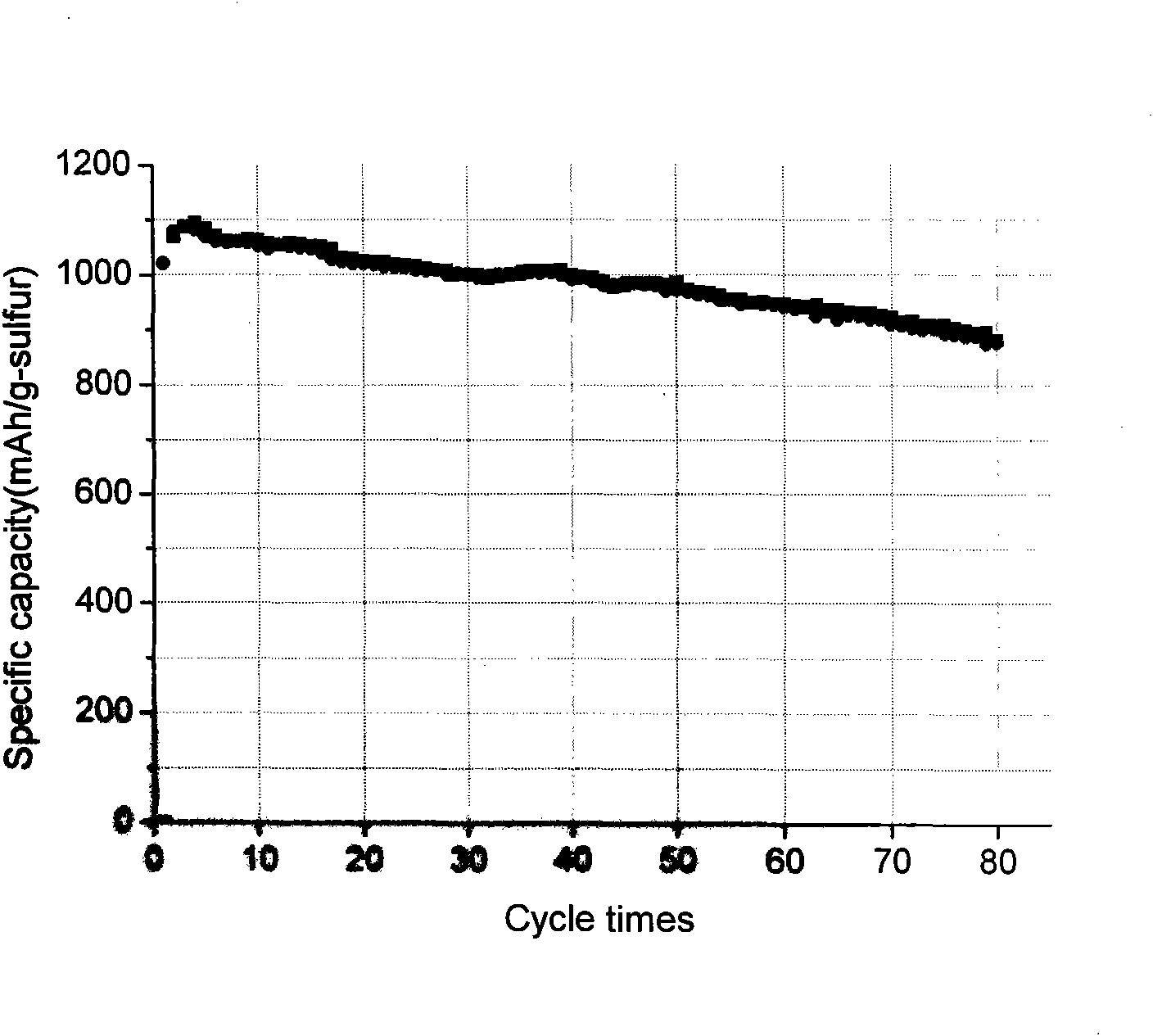

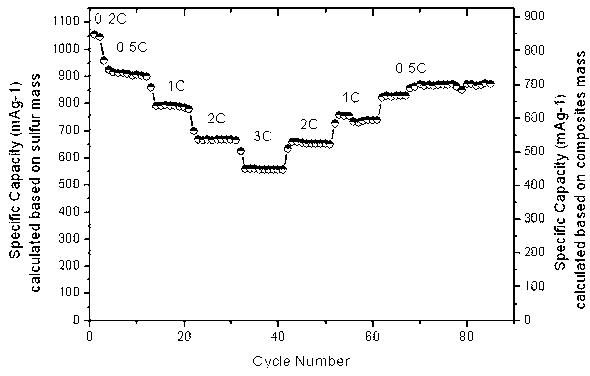

Preparation method of novel porous skeleton MIL-101(Cr)@S/graphene composite material for cathode of lithium sulfur battery

InactiveCN102751494AImprove adhesionImprove cycle performanceCell electrodesElectrical batteryLithium–sulfur battery

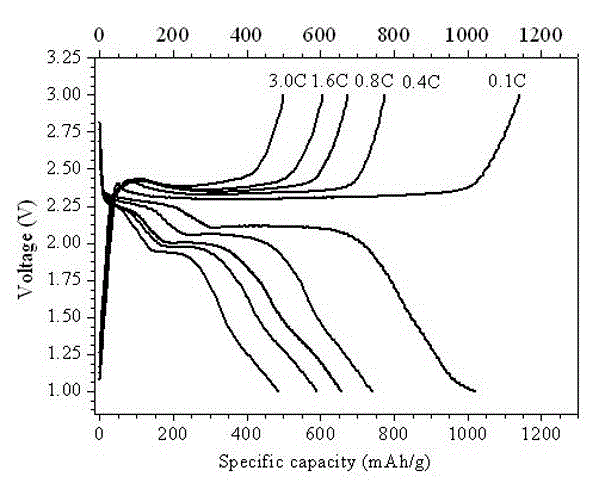

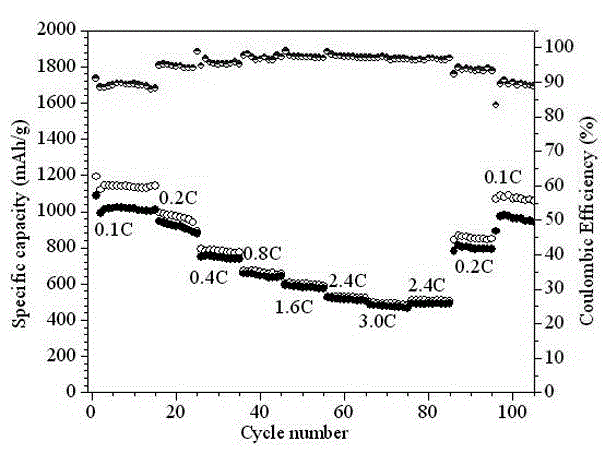

The invention discloses a preparation method of a metal organic skeleton MIL-101(Cr)@S / graphene composite material as the cathode material of a lithium sulfur battery. The preparation method comprises the following steps of: evenly loading sulfur into a three-dimensional pore channel of MIL-101(Cr) by a melting diffusing method, and mixing with graphene, so that the MIL-101(Cr)@S / graphene composite material can be prepared. The metal organic skeleton crystal material in the composite material is has superhigh specific surface area and pore volume and has a skeleton structure which has medium-mirco double pores, so that the dual effects of dispersing and fixing the sulfur grains can be played, and the whole electrical conductivity of the composite material can be improved due to graphene, so that the polarization of the material can be weakened, the discharge multiplying power performance can be improved, the coulomb efficiency can be improved and the like. The electrochemical performance test shows that the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method can reach 1087mAh / g under the condition that the multiplying power is less than 0.1C, and the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method is respectively kept at 807 and 387mAh / g under the condition that the multiplying power is 0.8C and 2.4C when the circulation times is 116 and 150. The preparation method has the advantages that the preparation method has the characteristics of being simple in process, convenient to operate, good in material performance and the like, and is suitable for large-scale industrial production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

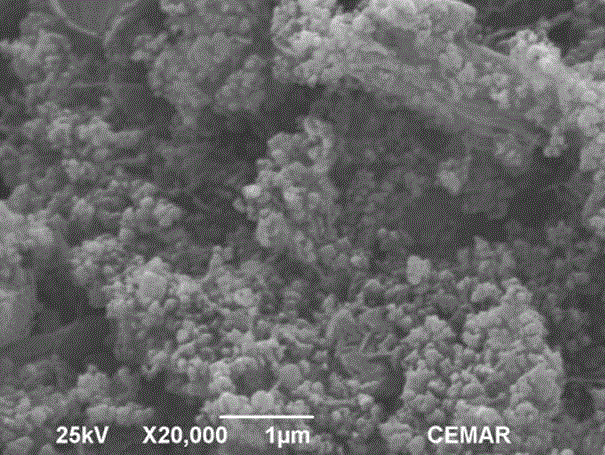

Lithium-ion-battery gradient cathode-material precursor and preparation method thereof

The invention relates to a preparation method for a lithium-ion-battery gradient cathode-material precursor, and belongs to the technical field of preparation of lithium ion batteries cathode materials. The concrete steps of the method comprise; preparing a solution A and a solution B with different molar ratios from a nickel salt, a cobalt salt and a manganese salt, and controlling the volume of the solution A and the solution B to be same; employing a metering pump to gradually adding the solution A into the solution B, then adding the uniformly-mixed solution into a reaction kettle, and also adding an alkali solution and a complexing agent solution into the reaction kettle, and stabilizing synthesis technology parameters during reaction, stopping reaction once the solution A and the solution B are completely consumed, finally centrifuging, washing and drying, so as to prepare the spherical cathode material precursor with different-concentration gradient-distributed elements. The disclosed preparation method helps to improve the processing performance and the tap density of the cathode material, and overcome the disadvantages about capacity and stability of the material, and by controlling the morphology and the particle size of the cathode material, the physicochemical performances of the cathode material are controlled and the material stability is improved.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

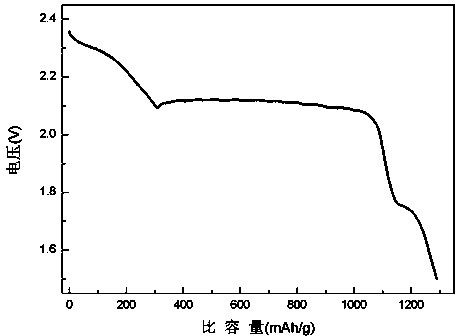

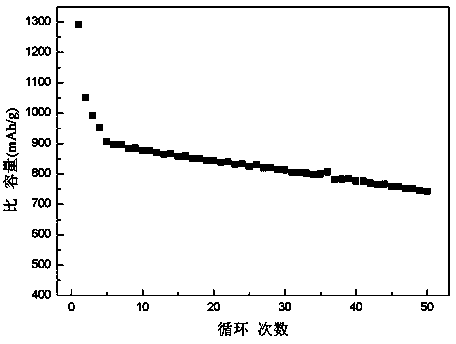

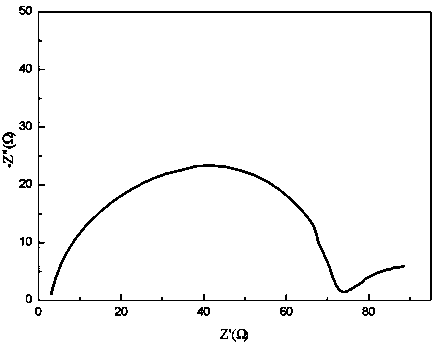

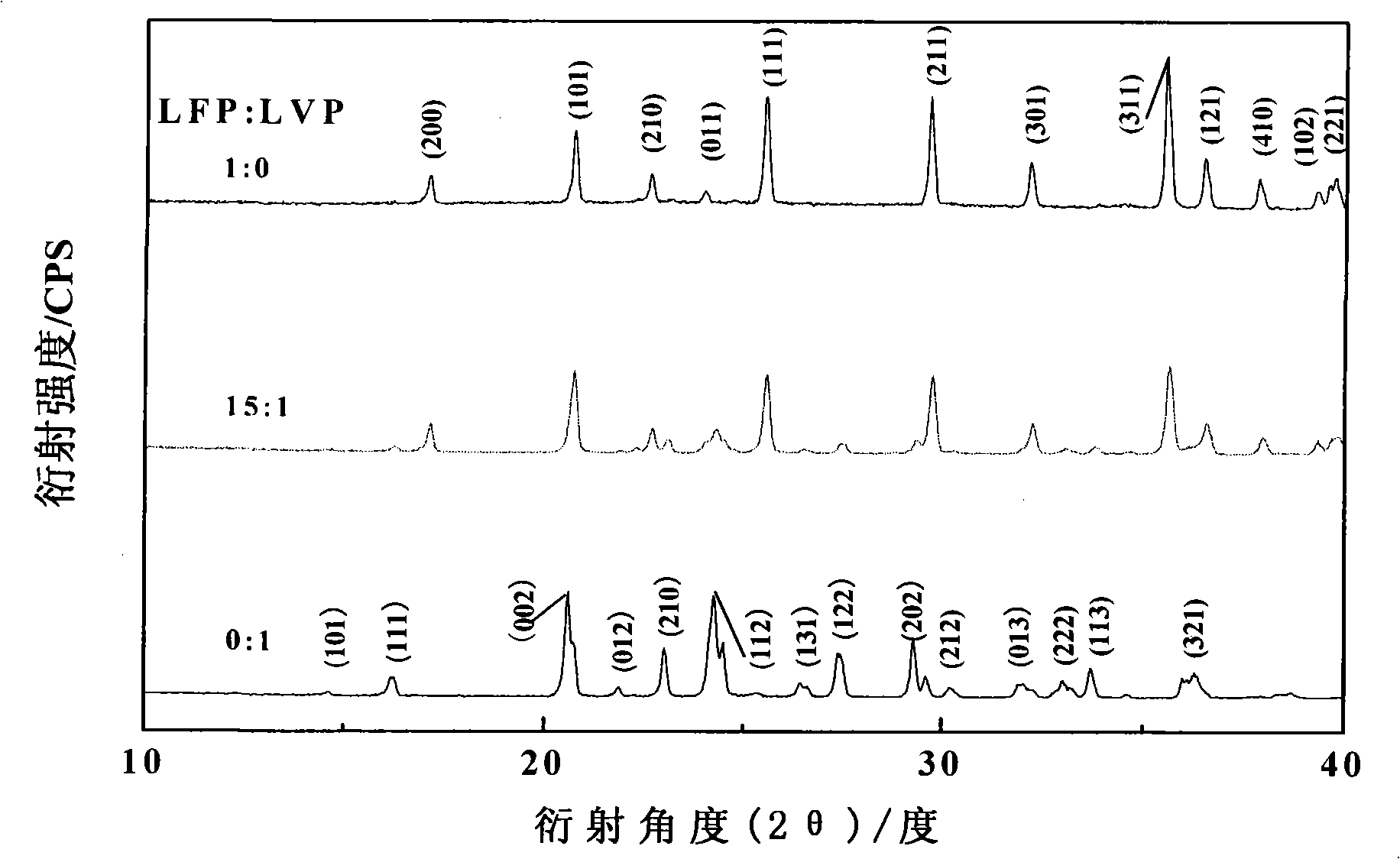

An anode material for compound lithium ion battery

InactiveCN101262058AOvercoming the problem of low conductivityImprove high rate discharge performanceCell electrodesPhysical chemistrySolid solution

The invention discloses a positive electrode material for a compound lithium ion battery. LiFePO4 is adopted as matrix, and Li3V2 (PO4)3 or LiVPO4F is adopted to wrap the surface of LiFePO4 particles or to exist among LiFePO4 particles or to directly form a solid solution with LiFePO4, and the molar ratio of LiFePO4 and Li3V2 (PO4)3 or LiVPO4F is (1-100):(100-1). The compound lithium ion battery of the invention has excellent performances of charge / discharge and magnification, and the positive electrode material of the compound lithium ion battery is suitable for producing power cells.

Owner:CENT SOUTH UNIV

Preparation method of graphene loaded with anatase type nano titanium dioxide and application thereof

InactiveCN102324505ASmall sizeEvenly dispersedAlkaline accumulator electrodesNanotechnologyFlake graphiteSODIUM DODECYL BENZENE SULFONATE

The invention discloses a preparation method of graphene loaded with anatase type nano titanium dioxide and an application thereof. The preparation method comprises the following steps: preparing graphite oxide from crystalline flake graphite; carrying out reduction reaction on the graphite oxide to obtain graphene by taking hydrazine hydrate as a reducing agent and sodium dodecyl benzene sulfonate as a dispersing agent; preparing titanium hydroxide colloidal solution by taking tetrabutyl titanate as a titanium source; mixing the ethanol solution of graphene and the titanium hydroxide colloidal solution, stirring and calcining to prepare the graphene loaded with anatase type nano titanium dioxide. The graphene loaded with anatase type nano titanium dioxide prepared by the method can be mixed with copper powder to prepare the negative electrode of a nickel-hydride secondary battery. The method provided by the invention has the advantages of simple preparation process and low cost and is easy to operate. When the prepared graphene loaded with anatase type nano titanium dioxide is used as the active material of the cathode of the secondary battery, the effects of high discharge specific capacity and good circulation stability are achieved.

Owner:TIANJIN UNIV

Method for preparing lithium ion battery anode material with concentration gradient

ActiveCN102637866AImprove stabilityImprove electrochemical performanceCell electrodesCapacitanceManganese

The invention discloses a method for preparing a lithium ion battery anode material with a concentration gradient. The method comprises the following steps of: diffusing a spherical high-nickel material in a solution containing lithium, nickel, cobalt and manganese by using a proper dispersing agent; then preparing a precursor in a nuclear shell structure by using a spray drying method; and finally, combining a proper roasting system so as to enable a nickel element of a precursor nuclear layer to be diffused to a shell layer to form a concentration gradient layer. The anode material has stable properties, high charge-discharge capacitance, good circulating property, good heat stability, security and high stability, and can be suitable for being used in low-temperature and high-temperature working environments.

Owner:CENT SOUTH UNIV

Preparation method of cathode material of lithium ion battery coated with metal oxides on surface

InactiveCN101950803AHigh discharge specific capacityImprove cycle performanceCell electrodesSecondary cellsSolventAmount of substance

The invention discloses a preparation method of a cathode material of a lithium ion battery coated with metal oxides on the surface, which comprises the following steps of: 1, dissolving an easily soluble metal salt into a solvent to form a solution under the heating condition; 2, adjusting the pH value of the solution in the step 1 with an alkali solution under the stirring condition to ensure that the solution forms a sol matter; 3, putting a lithium-containing cathode material into the sol matter under the stirring condition, reacting for a period of time to ensure that hydrolysate evenly deposits and absorbs on the surface of the lithium-containing cathode material; 4, drying the lithium-containing cathode material absorbed with the hydrolysate on the surface; and 5, roasting the dried lithium-containing cathode material to form the lithium-containing cathode material coated with the metal oxides on the surface. The preparation method is easy and reliable; and the lithium-containing cathode material coated with the metal oxides on the surface can remarkably improve the energy density, the safety and the charge and discharge circulating stability of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

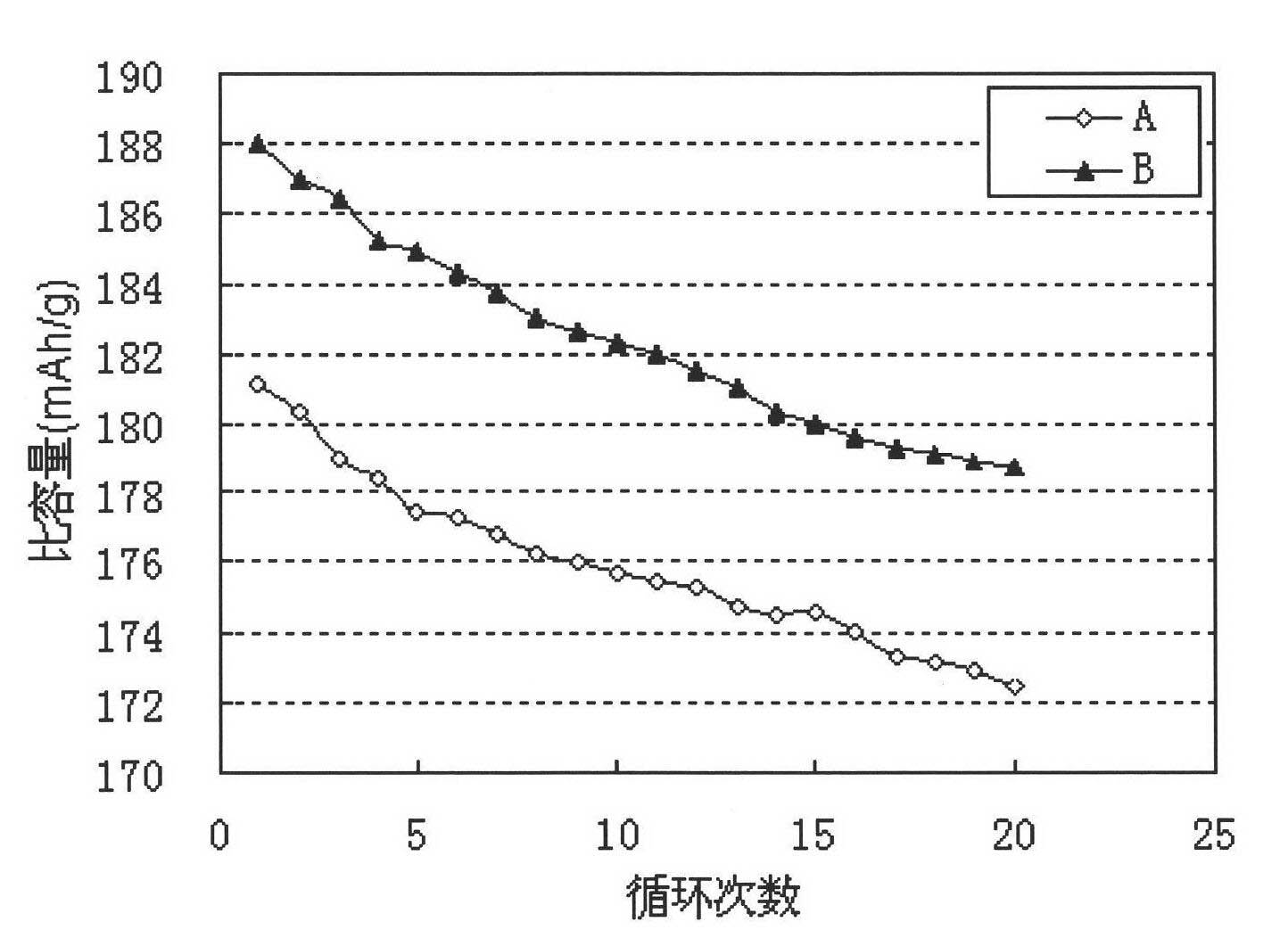

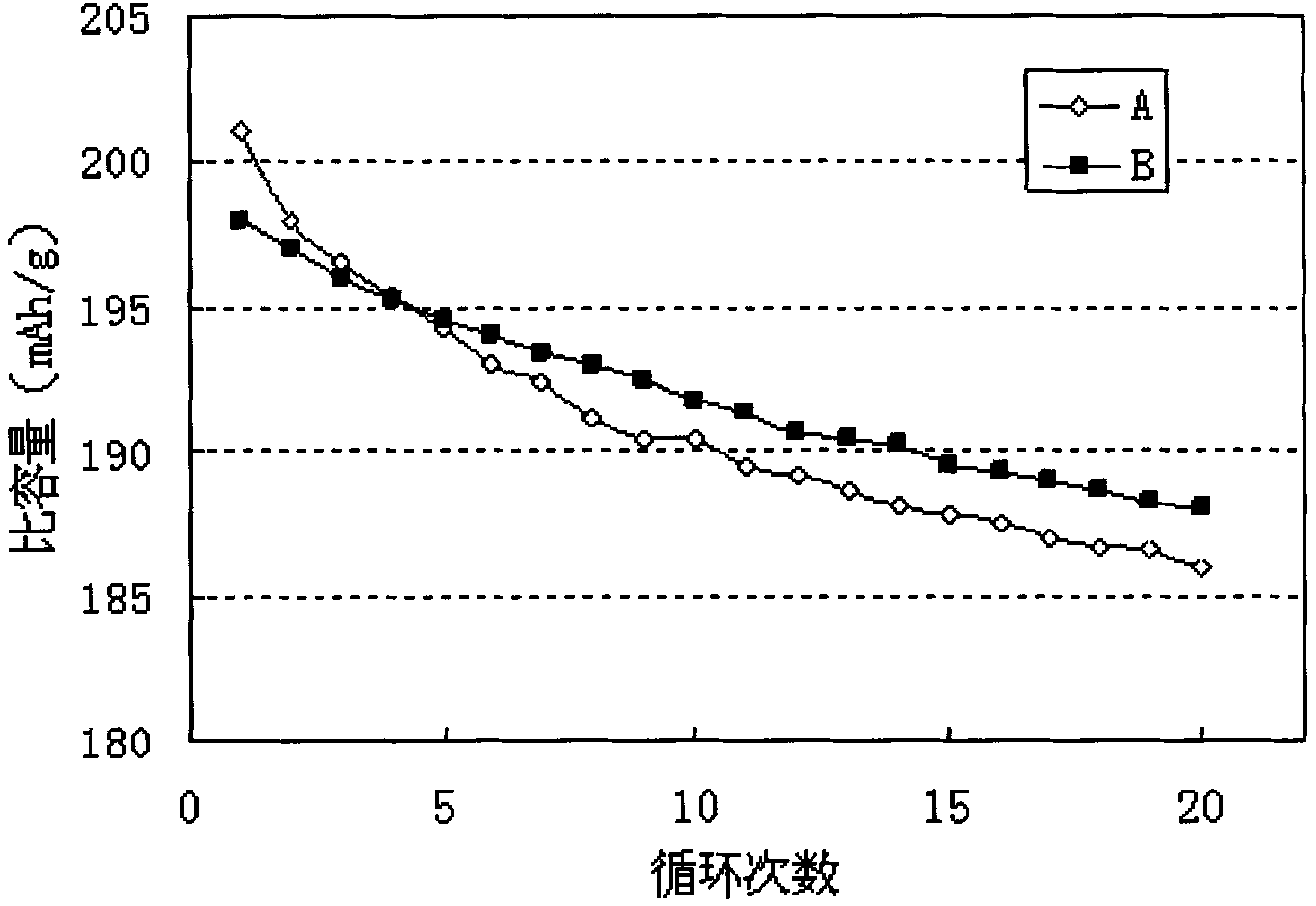

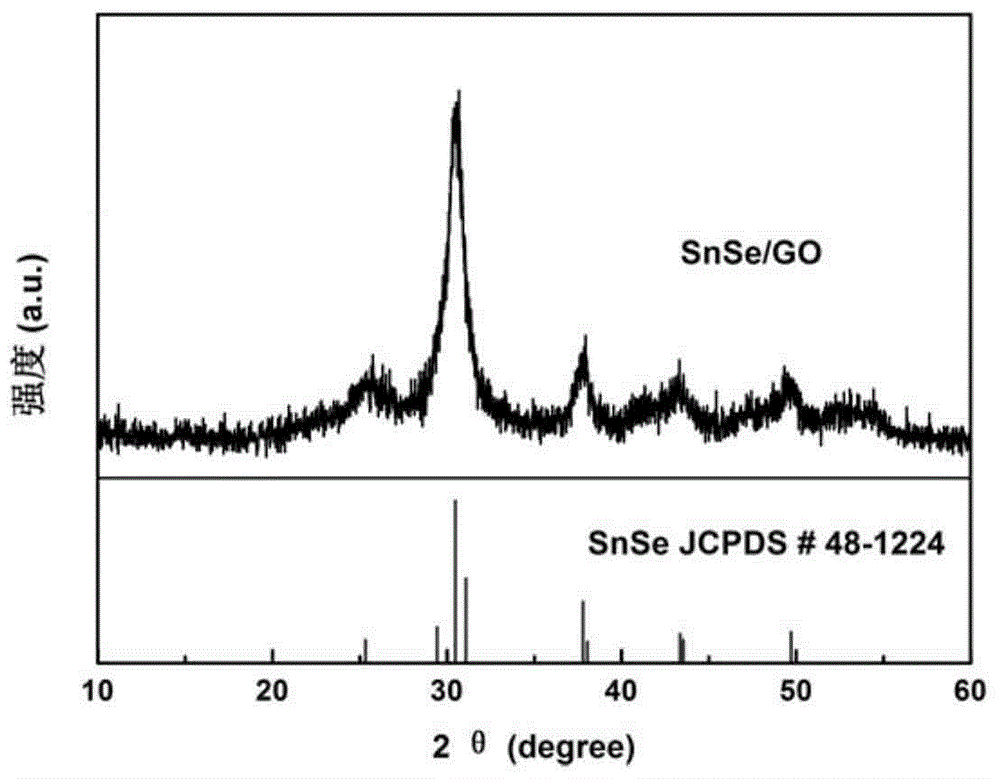

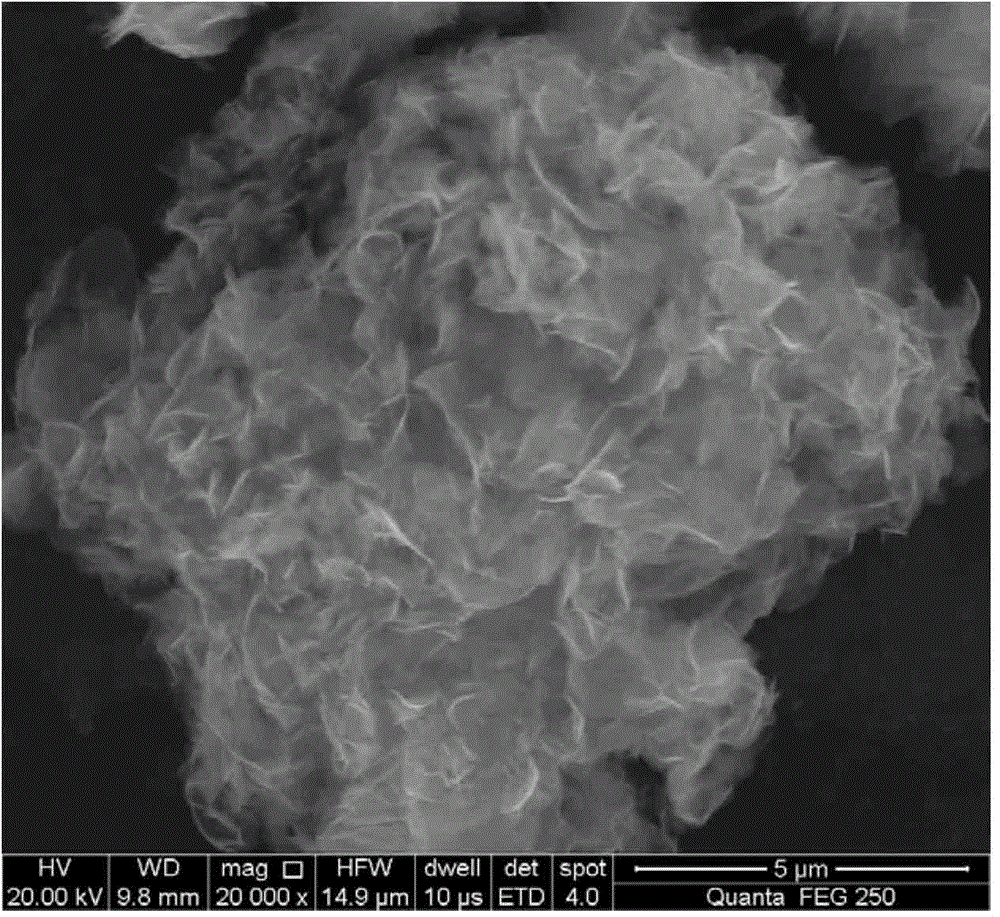

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

ActiveCN104617271AEasy to prepareGood repeatabilityMaterial nanotechnologyElectrode manufacturing processesOperabilitySodium-ion battery

The invention discloses a stannic selenide / graphene oxide negative pole composite material for a sodium ion battery and a preparation method thereof. The negative pole composite material is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The preparation method comprises the following steps of: ultrasonically dispersing graphene oxide powder into a mixed solution of water and ethylene glycol to obtain a dispersion solution; adding tin salt and selenite to the dispersion solution, then carrying out hydrothermal reaction, and placing a hydrothermal reaction product into an inert gas protective tube furnace for heat treatment so as to obtain a negative pole composite material which has nanometer sheet-like morphology and is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The composite material disclosed by the invention can be used for preparing the sodium ion battery which has the characteristics of high discharging specific capacity, excellent magnification property, long cycle life and the like. The preparation method disclosed by the invention has the advantages of simplicity, reliability, good process repeatability, high operability, low cost and suitability for industrialized production.

Owner:CENT SOUTH UNIV

Quinone compound anode material for aqueous lithium ion battery and aqueous lithium ion battery

ActiveCN105047932APolymer designabilityHigh discharge specific capacityCell electrodesFinal product manufactureElectrode potentialCarbon nanotube

The invention relates to a quinone compound anode material for an aqueous lithium ion battery. The quinone compound anode material is quinone polymers directly connected through C-C bonds or connected through N atoms or S atoms, or is a quinone compound formed by in-situ composition of a quinone compound monomer with a high-conductivity carbon material during the polymerization process, and the high-conductivity carbon material is selected from one or more of graphite oxide, carbon black, carbon nano tube and expanded graphite. The material has the advantages of high molecule designability, high discharging specific capacity (the maximum can reach 200mAh g<-1>, appropriate electrode potential (2-2.8V to Li / Li<+>), high rate capability and cycle performance and the like, and the aqueous lithium ion battery prepared from the material has the advantages of long cycle life, high efficiency, safety, low cost, environmental friendliness and the like.

Owner:中国人民解放军军事科学院防化研究院

Lithium ion secondary battery and preparation method thereof

ActiveCN102903930AHigh charge and discharge capacityImprove securityCell electrodesFinal product manufactureCobaltTin

The invention relates to a lithium ion secondary battery which consists of a shell, a positive electrode plate, a diaphragm, a negative electrode plate and electrolyte. The positive electrode plate consists of a positive electrode current collector and a negative electrode active material bonded on the positive electrode current collector; the negative electrode plate consists of a negative electrode current collector and a negative electrode active material bonded on the negative electrode current collector; the positive electrode active material is an iron phosphate ferrovanadium lithium composite material of a nano oxide doped with an M element; the negative electrode active material is a lithium titanate composite material; the M element is selected from any one or the combination of at least two of aluminum, lithium, boron, silver, copper, chromium, zinc, titanium, gallium, germanium, zirconium, tin, silicon, iron, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium, tungsten, molybdenum, niobium, yttrium, lanthanum, selenium and cadmium; the lithium oil secondary battery has the obvious characteristics of excellent electrical chemical performance, high safe performance, long cycle service life, low cost, environment friendliness and the like, is beneficial to widening the application range of the lithium ion battery, and has important practical significance and wide market prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

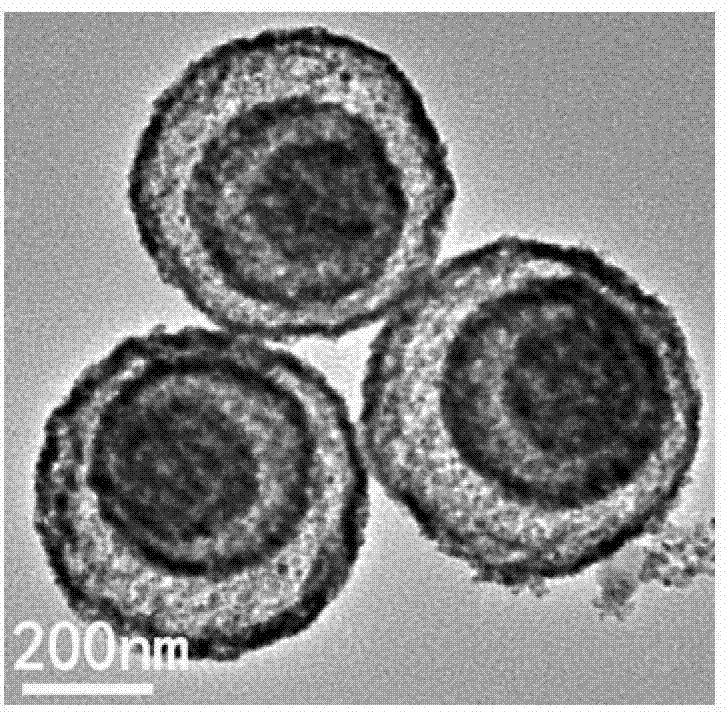

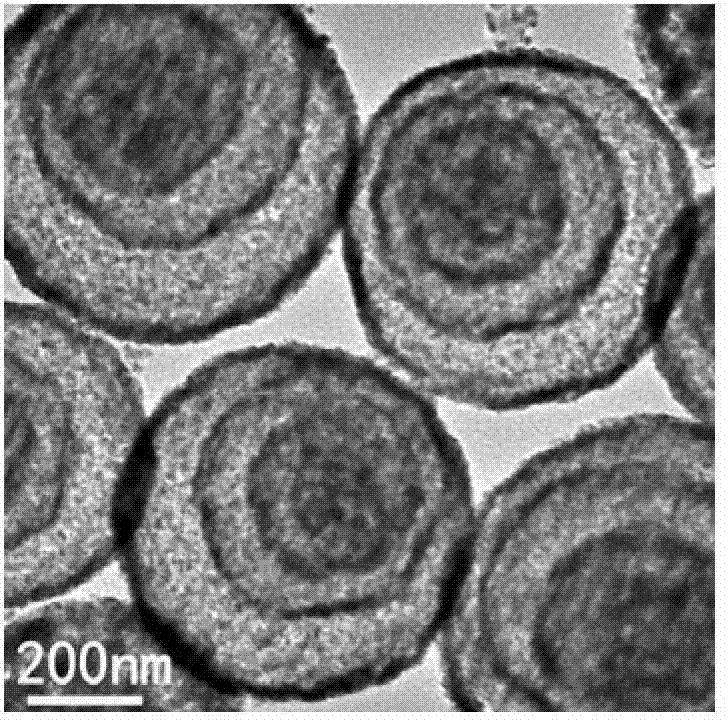

Cobaltosic oxide multi-shell hollow sphere cathode material for lithium ion battery and preparation method thereof

ActiveCN103247777AHigh specific surface areaImprove cycle performanceCell electrodesCell component detailsCapacitanceSodium-ion battery

The invention provides a cobaltosic oxide multi-shell hollow sphere cathode material for a lithium ion battery and a preparation method thereof. The method comprises the steps of: taking a carbon sphere prepared by a hydrothermal method as a template; controlling the quantity of cobalt ions in the carbon sphere and the entering depth thereof by controlling the ratio of water to ethanol in a cobalt salt solution, the temperature of the solution and the adsorption capacity of the carbon sphere; and preparing single-shell, dual-shell, tri-shell and four-shell cobaltosic oxide hollow spheres. The lithium ion battery of taking the cobaltosic oxide multi-shell hollow sphere as a cathode has large specific surface area and a plurality of lithium ion storage sites; the specific capacitance is improved; meanwhile, the appropriate multi-shell cavity structure not only can adjust the electrode structure and volume change, but also can effectively reduce the transmission distance between the lithium ion and electrons. Thus, the cycling performance and rapid charge and discharge capacity are obviously improved. The method disclosed by the invention is convenient and concise to operate, and high in controllability, and has a wide application prospect; and the performance of the lithium ion battery can be obviously improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of lithium sulphur battery anode material with high power and high specific capacity

InactiveCN102709533APromote circulationHigh discharge specific capacityCell electrodesElectrical batteryActive agent

The invention discloses a preparation method of a lithium sulphur battery anode material with high power and high specific capacity, belonging to the field of material chemistry. According to the invention, an active agent is taken as a medium, and a graphene-coated sulphur particle compound is prepared with a simple chemical method. The preparation comprises the following steps of: (1) preparation of graphene oxide; and (2) synthesis of the graphene-coated sulphur particle compound. The preparation method disclosed by the invention has the characteristics of simple process, convenience for operation, excellent material performance and the like, and is suitable for large-scale industrialized production. The graphene-coated sulphur particle compound prepared according to the invention has the advantages of high sulphur contant, large discharge specific capacity, high power density, good cyclic performance and the like, and has a wide application prospect in relevant fields such as portable electronic devices, electric vehicles and energy storage.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

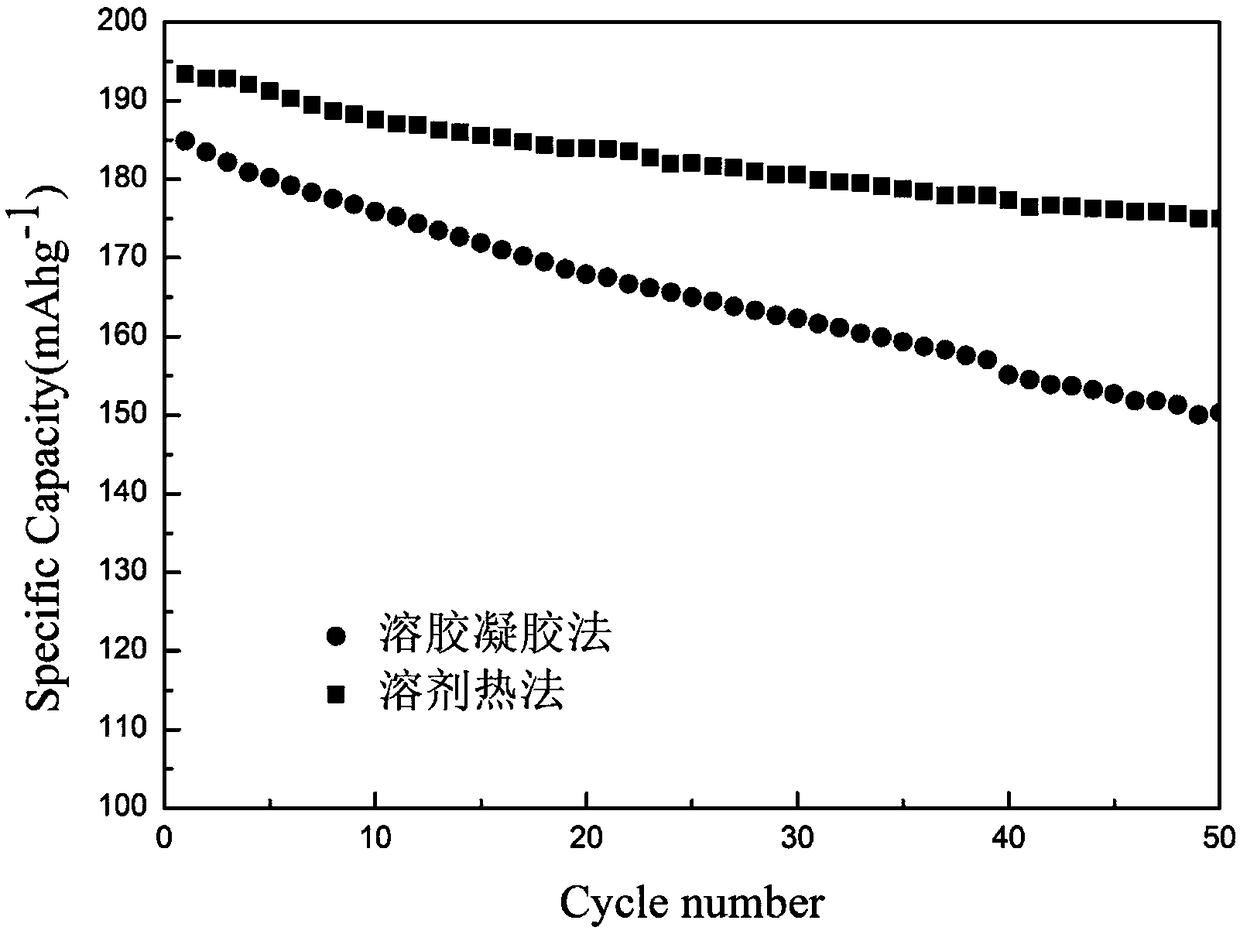

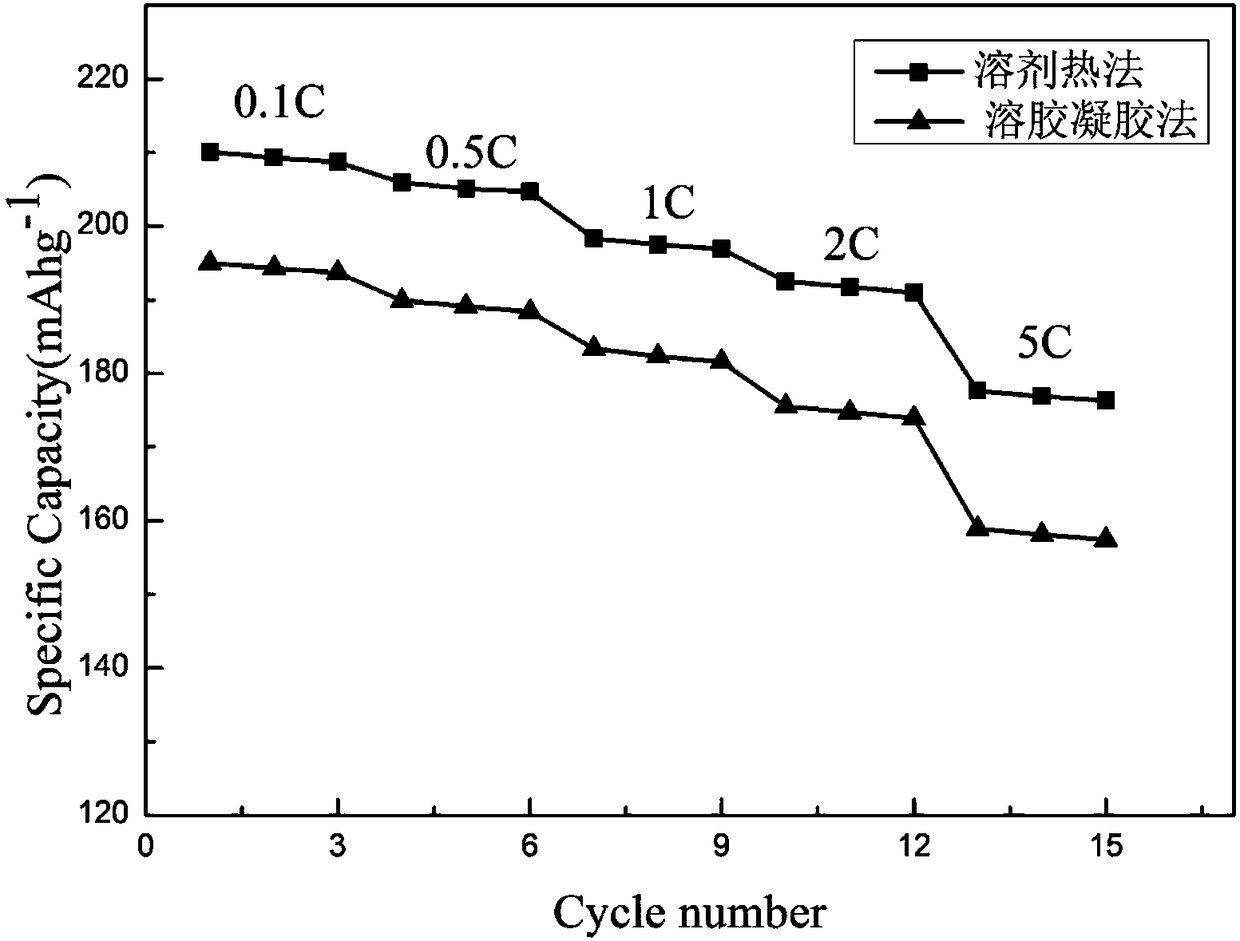

Coating method for improving electrochemical property of high-nickel ternary nickel cobalt manganese anode material

ActiveCN108321366AImprove electrochemical performanceAvoid direct contactCell electrodesSecondary cellsManganeseElectrochemistry

The invention discloses a coating method for improving electrochemical properties of a high-nickel ternary nickel cobalt manganese anode material. The coating method comprises the following steps: dissolving a titanium source into a solvent so as to obtain a solution, dissolving a lithium source, and further adding citric acid so as to obtain a mixed solution; uniformly dispersing a high-nickel ternary nickel cobalt manganese anode material into a solvent, adding the mixed solution, uniformly mixing, and performing a hydrothermal reaction or a solvent thermal reaction so as to obtain a reaction solution; evaporating the reaction solution to a gel state, and drying so as to obtain an anode material mixture; calcining the anode material mixture, thereby obtaining the high-nickel ternary nickel cobalt manganese anode material with a lithium titanate coating layer. The coating method for improving the electrochemical properties of the high-nickel ternary nickel cobalt manganese anode material, which is disclosed by the invention, is simple in process, low in cost and good in repeatability, the obtained coating layer is high in crystallization degree, small in particle size and good inuniformity, and the charge and discharge specific capacity, the circulation property and the multiplying power of the high-nickel ternary nickel cobalt manganese anode material can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com