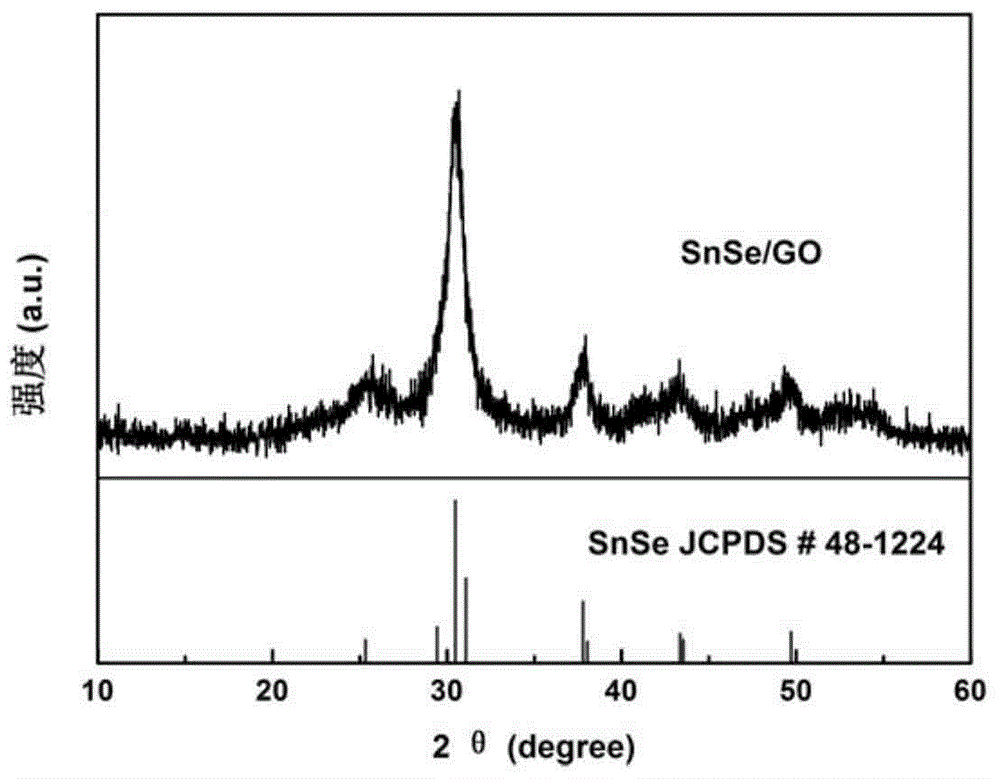

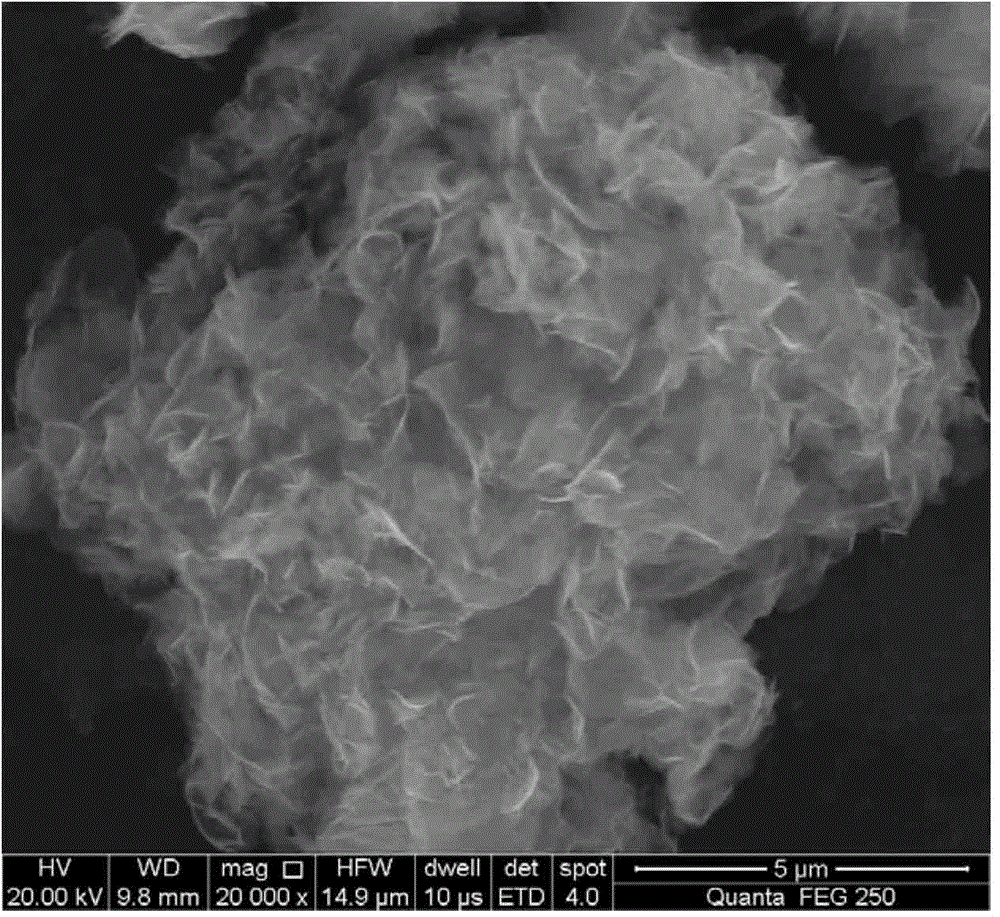

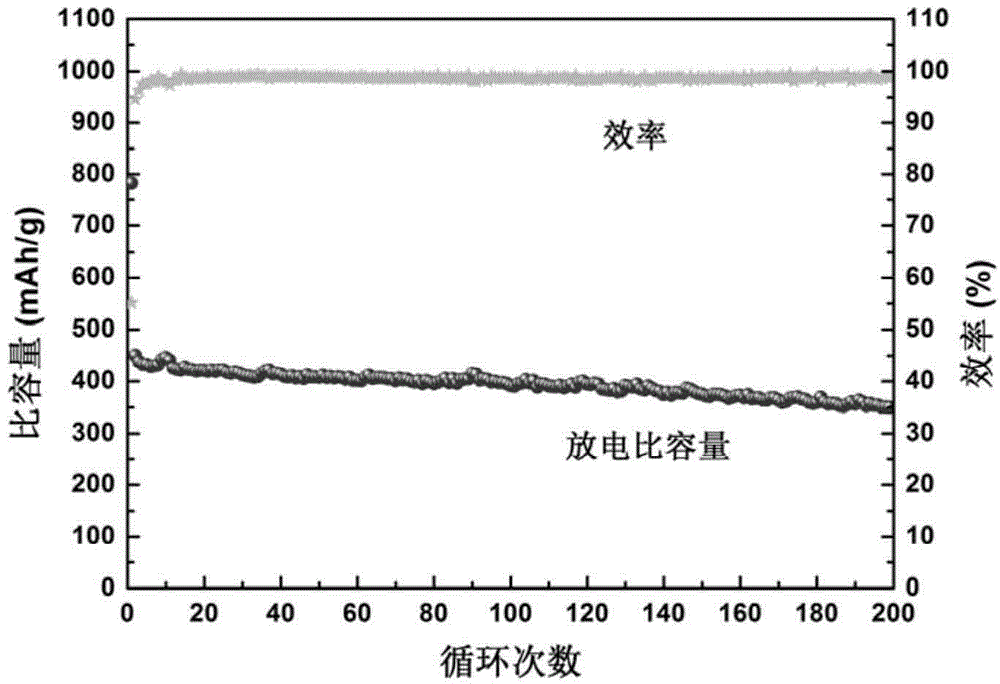

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

A graphene negative electrode, sodium ion battery technology, applied in nanotechnology for materials and surface science, electrode manufacturing, battery electrodes, etc., can solve the problem of no composite material sodium battery negative electrode material, graphene oxide and SnSe composite preparation composite Material technology and other issues to achieve the effect of avoiding excessive capacity decay, improving cycle stability, and high discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Take by weighing 5g of flaky graphite with a purity of 99.5%, add it into a mixed solution containing 350mL mass fraction of 98% concentrated sulfuric acid and 50mL mass fraction of 85% phosphoric acid, add 30g potassium permanganate in batches for oxidation, the The mixed solution was kept at 0° C., stirred for 2 h, then stirred in a water bath at room temperature for 12 h, and further stirred at 80° C. for 0.5 h to obtain a mixture. 350 mL of deionized water was slowly added to the mixture under ice bath conditions. After 15 minutes, add 15g of hydrogen peroxide to remove potassium permanganate, then the color of the mixture turns bright yellow, filter with suction, wash with dilute hydrochloric acid with a concentration of 10% for 3 times, filter with suction, and dry in vacuum at 60°C for 48 hours to obtain graphite oxide ene (GO).

[0043] Weigh 0.3g GO, add 20mL deionized water and 40mL ethylene glycol to ultrasonically disperse for 3h to form a dispersion liquid,...

Embodiment 2

[0051] Take by weighing 3g of flaky graphite with a purity of 99.5%, add it to a mixed solution containing 350mL mass fraction of 98% concentrated sulfuric acid and 50mL mass fraction of 85% phosphoric acid, and add 18g potassium permanganate in batches for oxidation. The mixed solution was kept at 0° C., stirred for 2 h, then stirred in a water bath at room temperature for 12 h, and further stirred at 80° C. for 0.5 h to obtain a mixture. 350 mL of deionized water was slowly added to the mixture under ice bath conditions. After 15 minutes, add 9g of hydrogen peroxide to remove potassium permanganate, then the color of the mixture turns bright yellow, filter with suction, wash with dilute hydrochloric acid with a concentration of 10% for 3 times, filter with suction, and dry in vacuum at 60°C for 48 hours to obtain graphite oxide ene (GO).

[0052] Weigh 0.3g GO, add 40mL deionized water and 80mL ethylene glycol to ultrasonically disperse for 3h to form a dispersion liquid, t...

Embodiment 3

[0056] Take by weighing 5g of flaky graphite with a purity of 99.5%, add it into a mixed solution containing 300mL mass fraction of 98% concentrated sulfuric acid and 50mL mass fraction of 85% phosphoric acid, add 30g potassium permanganate in batches for oxidation, and The mixed solution was kept at 0° C., stirred for 2 h, then stirred in a water bath at room temperature for 12 h, and further stirred at 80° C. for 0.5 h to obtain a mixture. 350 mL of deionized water was slowly added to the mixture under ice bath conditions. After 15 minutes, add 15g of hydrogen peroxide to remove potassium permanganate, then the color of the mixture turns bright yellow, filter with suction, wash with dilute hydrochloric acid with a concentration of 10% for 3 times, filter with suction, and dry in vacuum at 60°C for 48 hours to obtain graphite oxide ene (GO).

[0057] Weigh 0.1g GO, add 30mL deionized water and 60mL ethylene glycol to ultrasonically disperse for 3h to form a suspension, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com