Patents

Literature

58results about How to "Increase the reaction interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

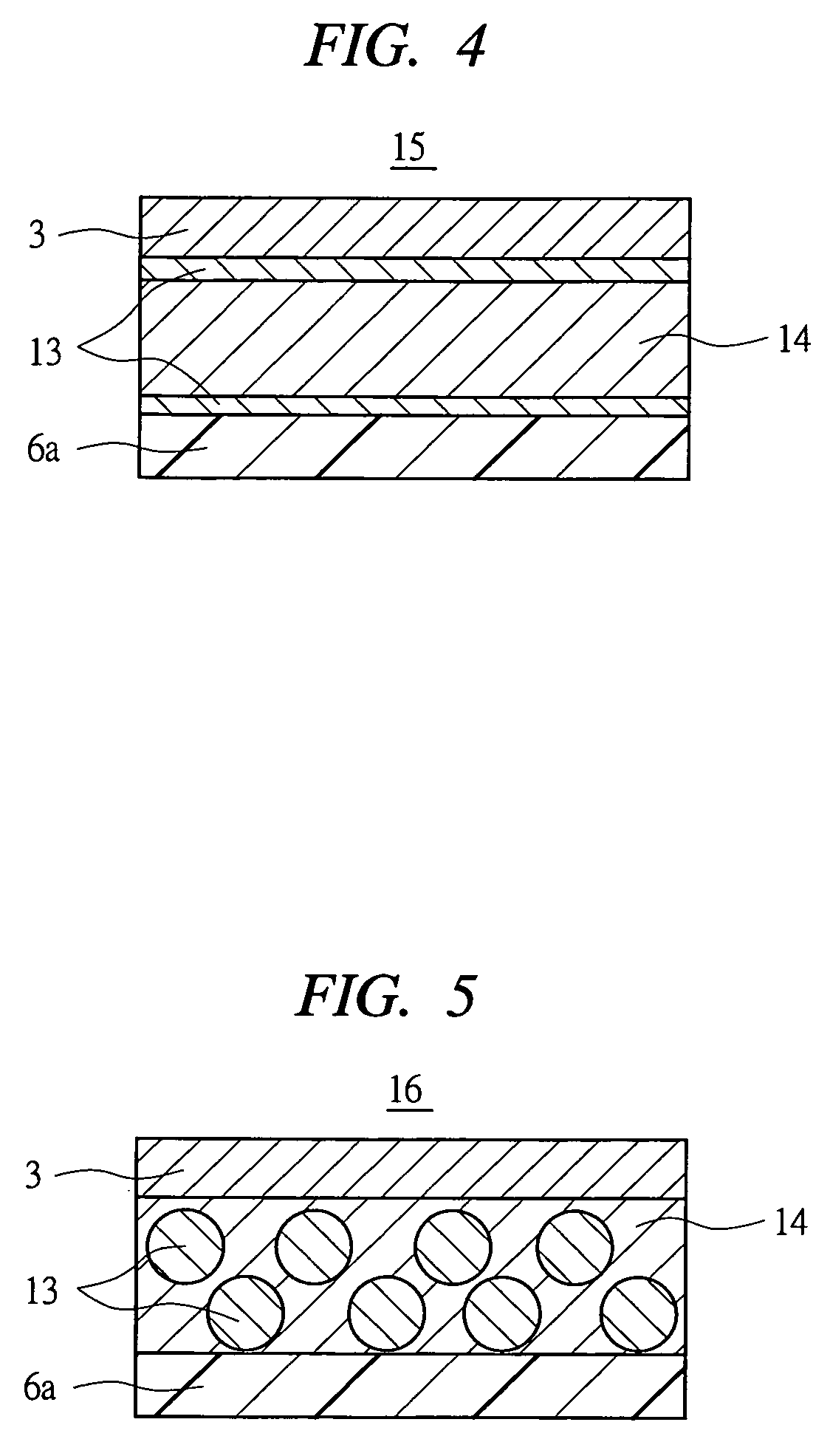

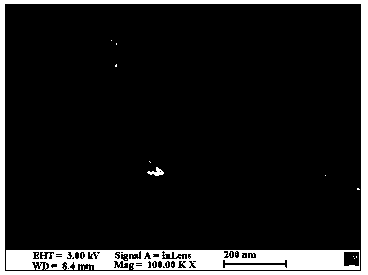

Structure of gas element ensuring high catalytic activity and conductivity and production method thereof

InactiveUS20070095662A1Increase interfaceLow temperatureMaterial electrochemical variablesElectrolyteOxygen ions

Owner:DENSO CORP

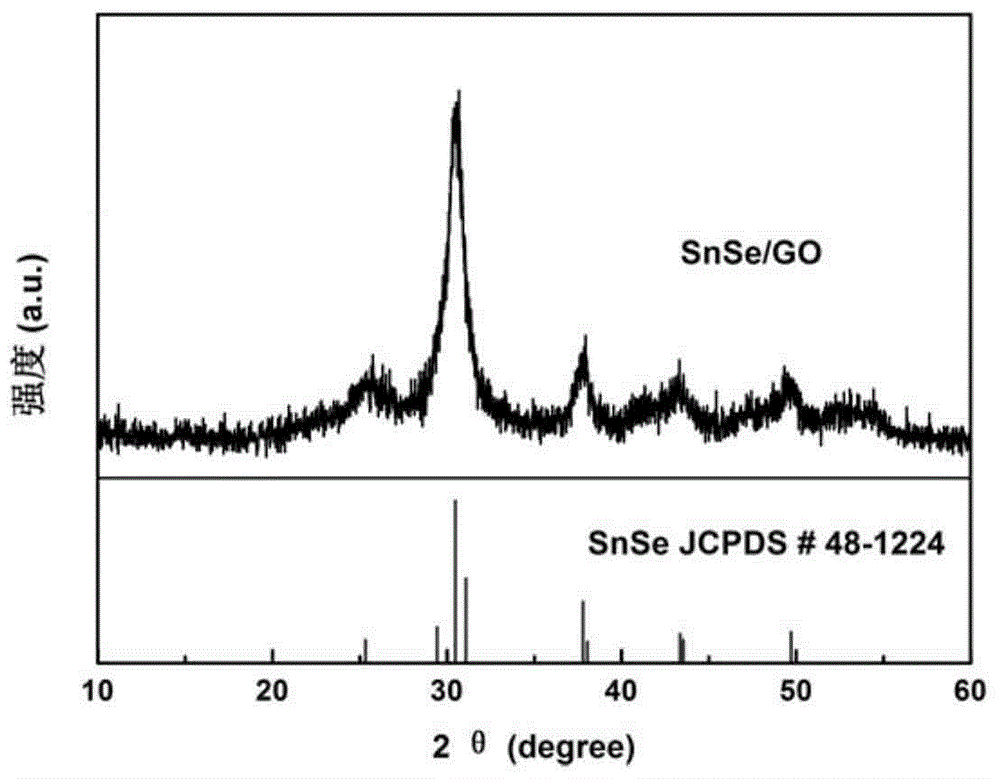

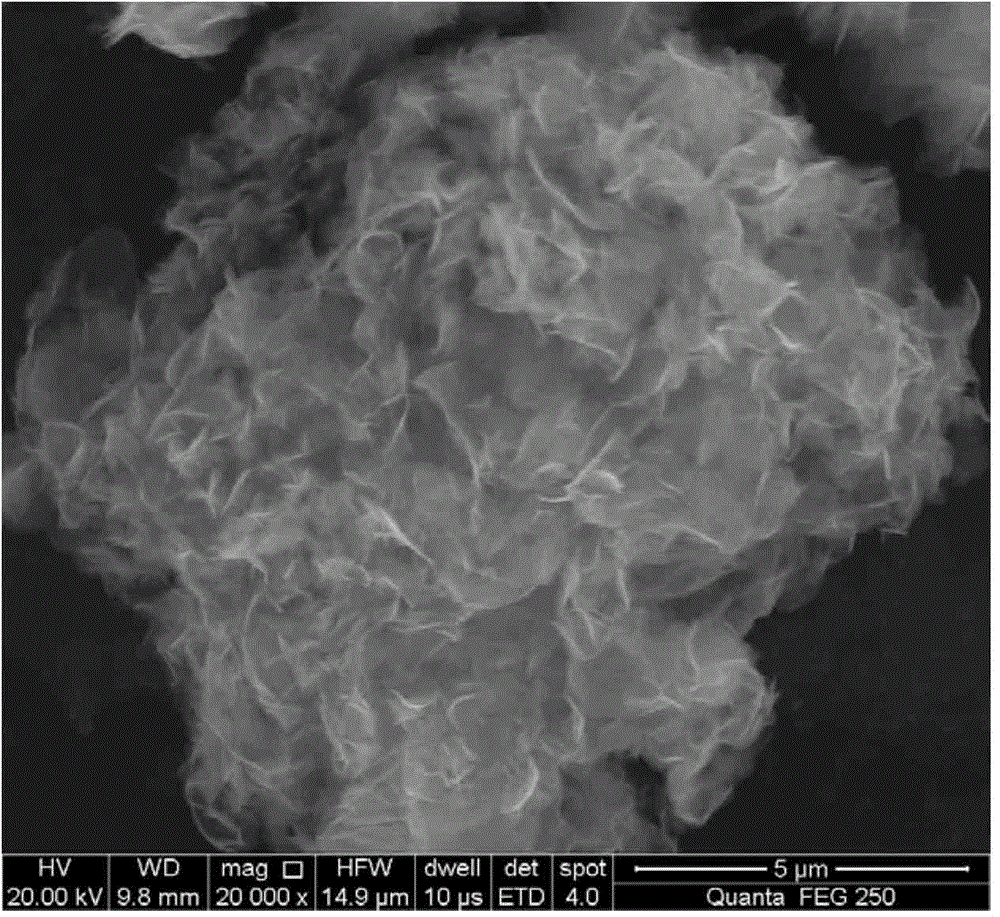

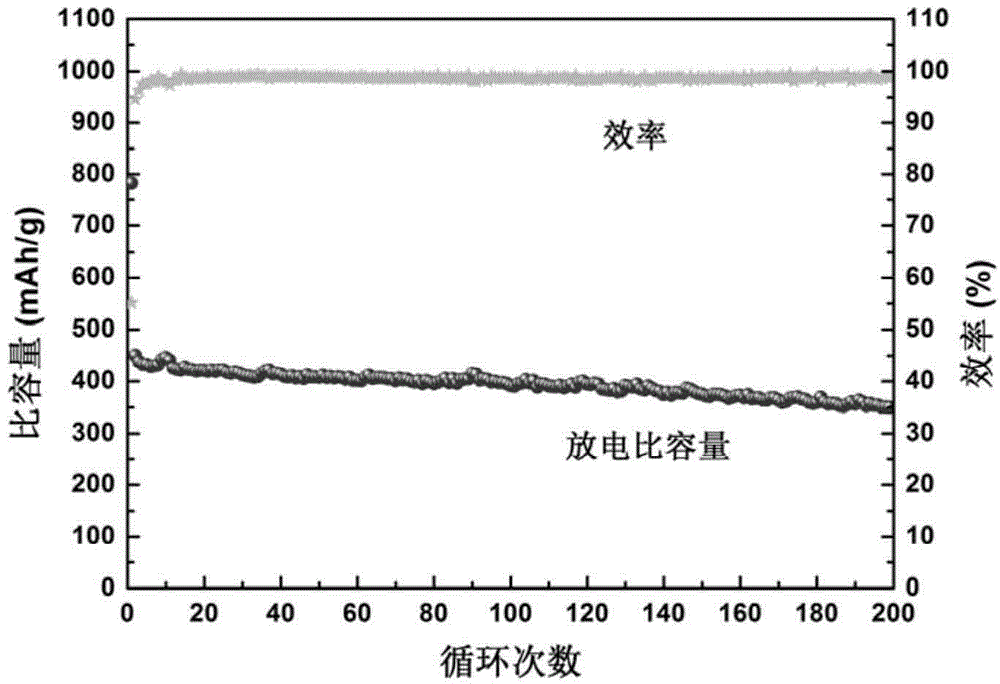

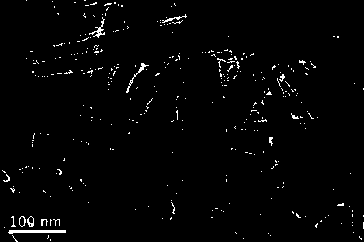

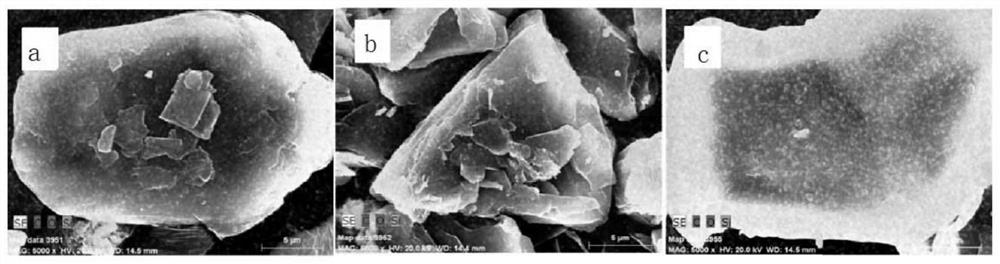

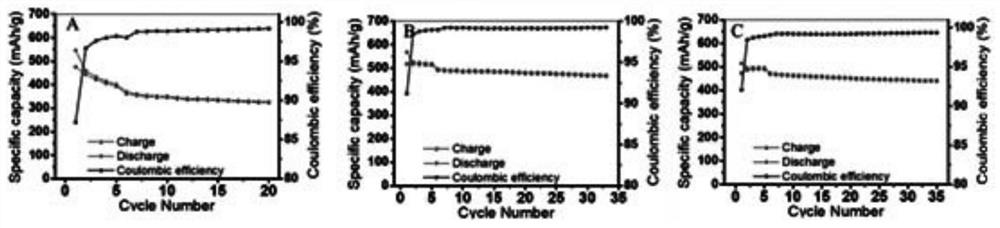

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

ActiveCN104617271AEasy to prepareGood repeatabilityMaterial nanotechnologyElectrode manufacturing processesOperabilitySodium-ion battery

The invention discloses a stannic selenide / graphene oxide negative pole composite material for a sodium ion battery and a preparation method thereof. The negative pole composite material is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The preparation method comprises the following steps of: ultrasonically dispersing graphene oxide powder into a mixed solution of water and ethylene glycol to obtain a dispersion solution; adding tin salt and selenite to the dispersion solution, then carrying out hydrothermal reaction, and placing a hydrothermal reaction product into an inert gas protective tube furnace for heat treatment so as to obtain a negative pole composite material which has nanometer sheet-like morphology and is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The composite material disclosed by the invention can be used for preparing the sodium ion battery which has the characteristics of high discharging specific capacity, excellent magnification property, long cycle life and the like. The preparation method disclosed by the invention has the advantages of simplicity, reliability, good process repeatability, high operability, low cost and suitability for industrialized production.

Owner:CENT SOUTH UNIV

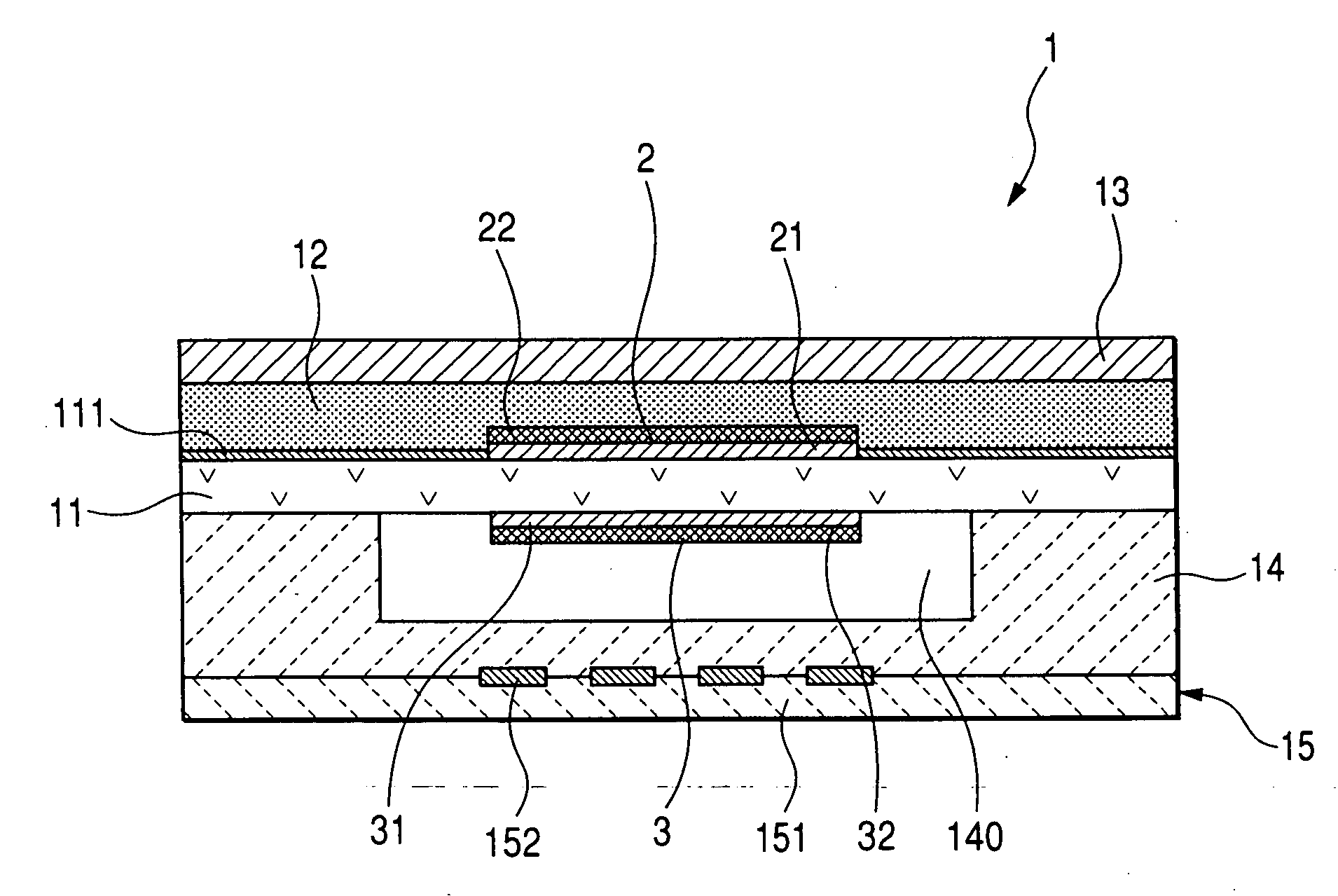

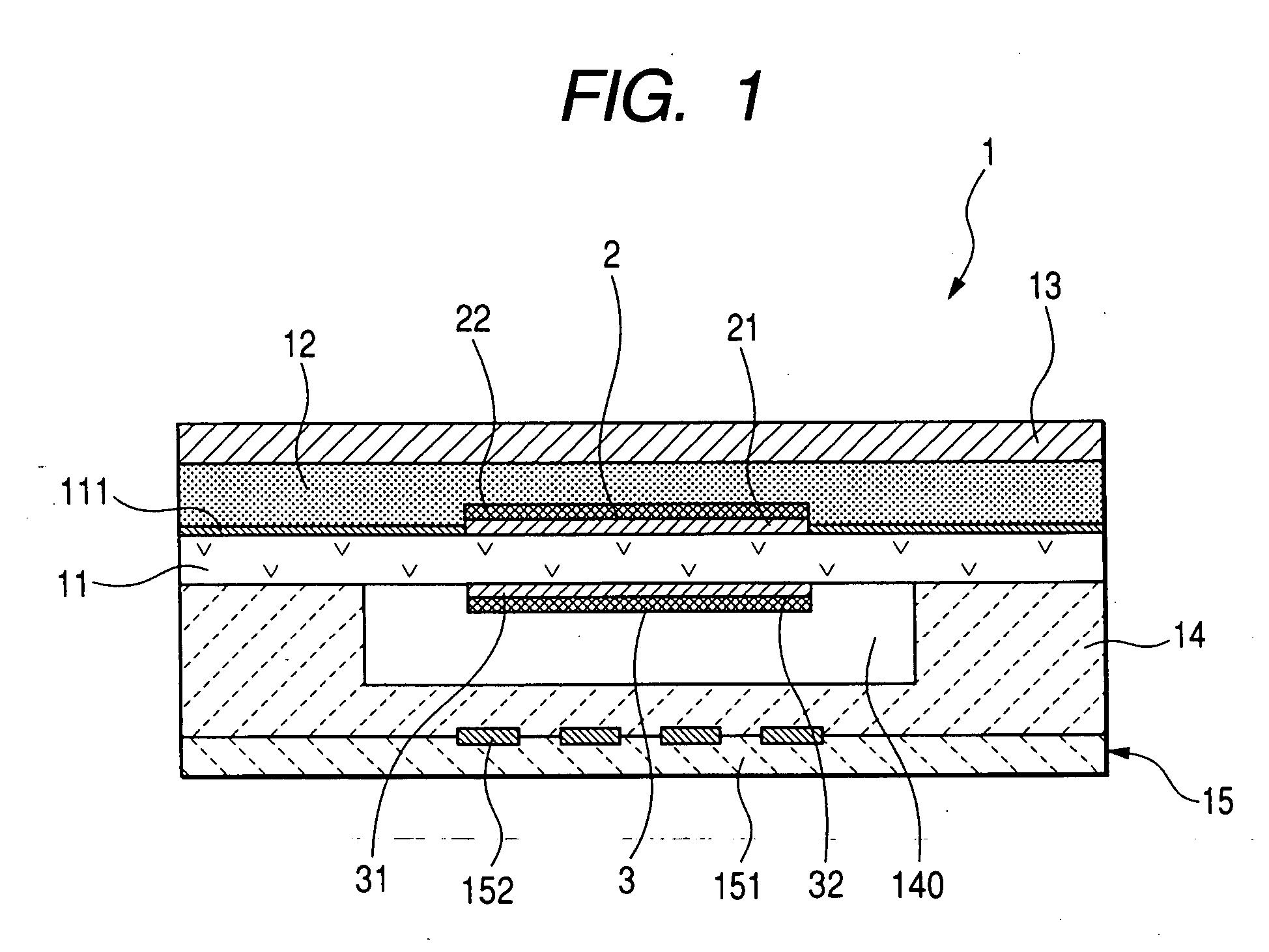

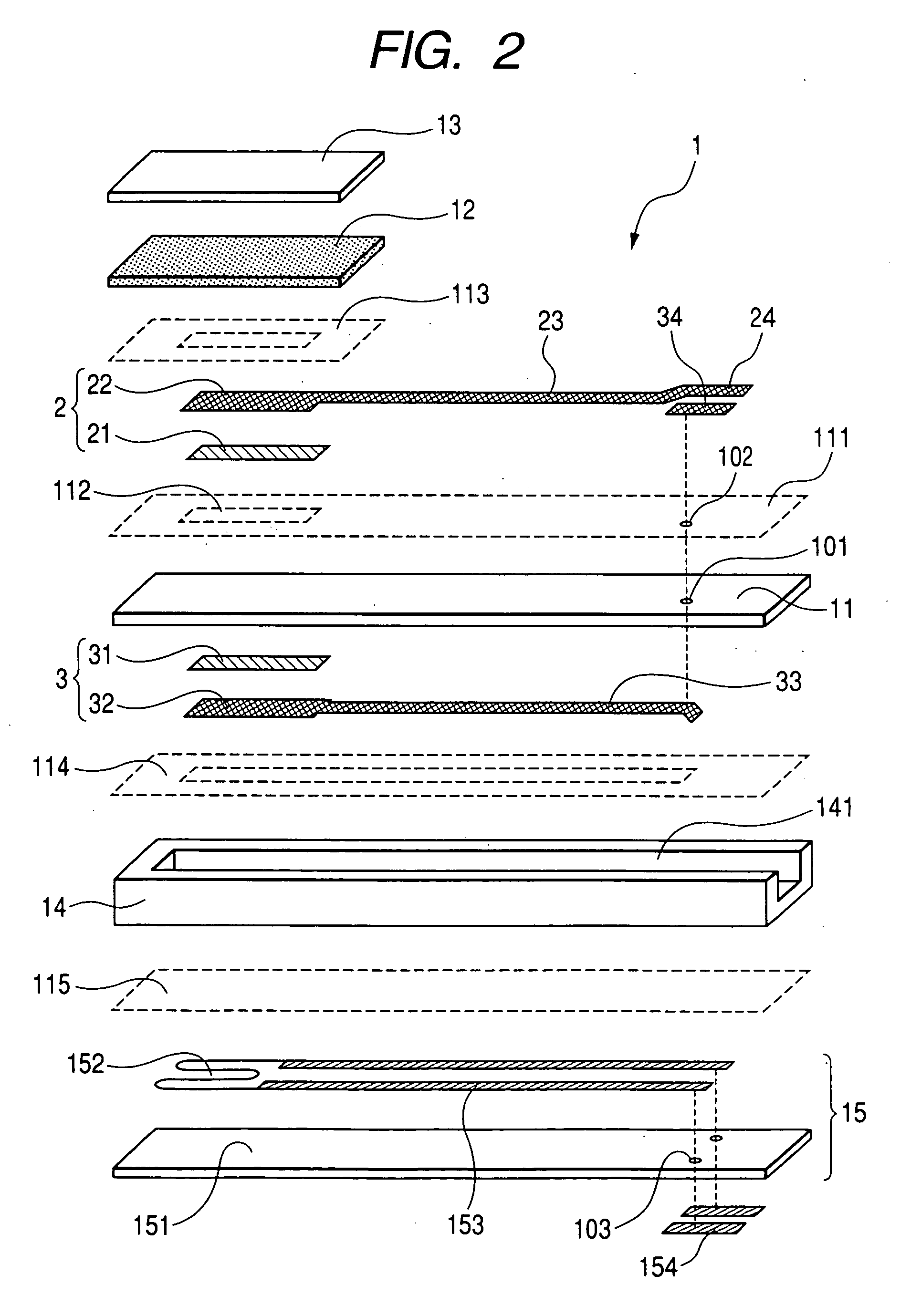

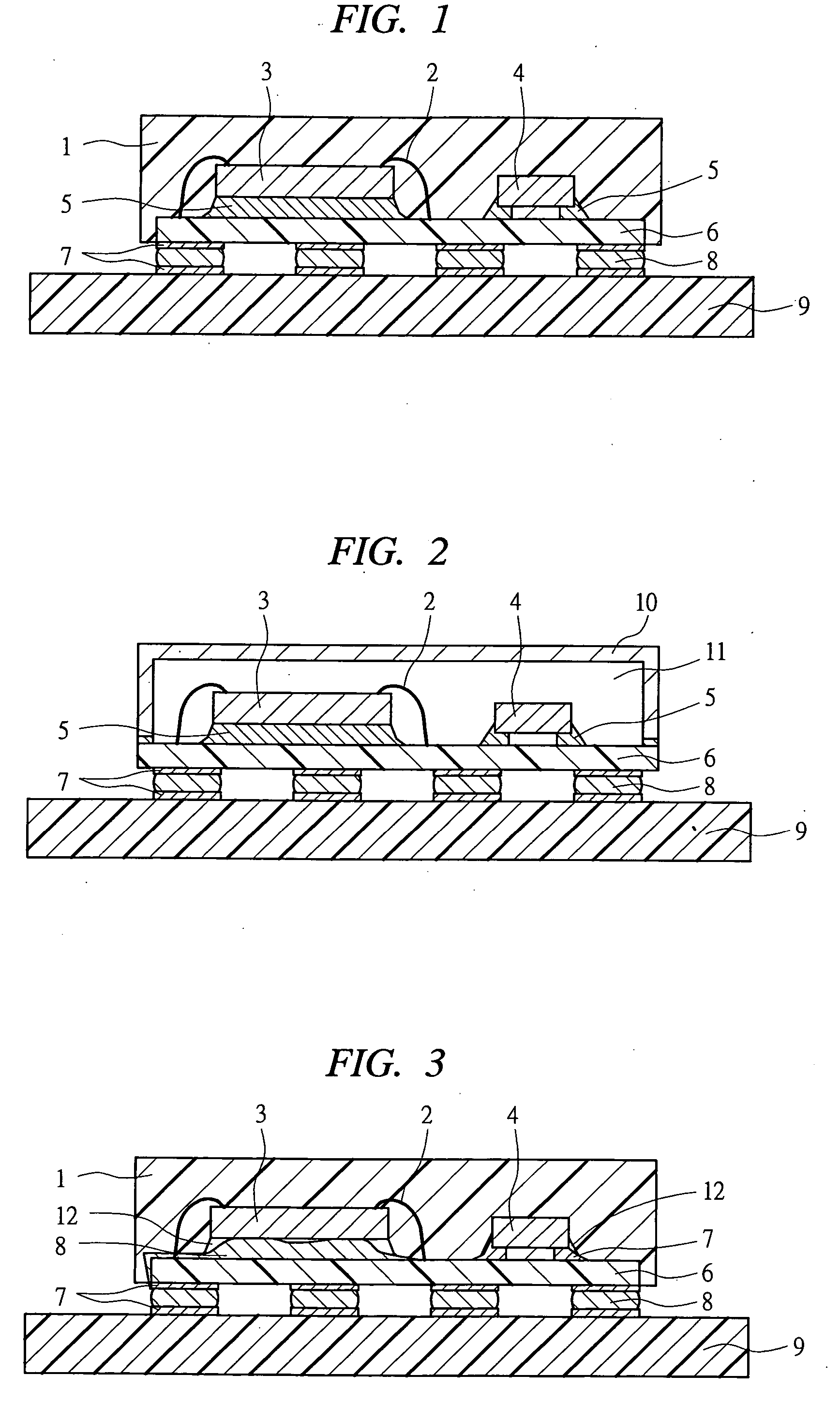

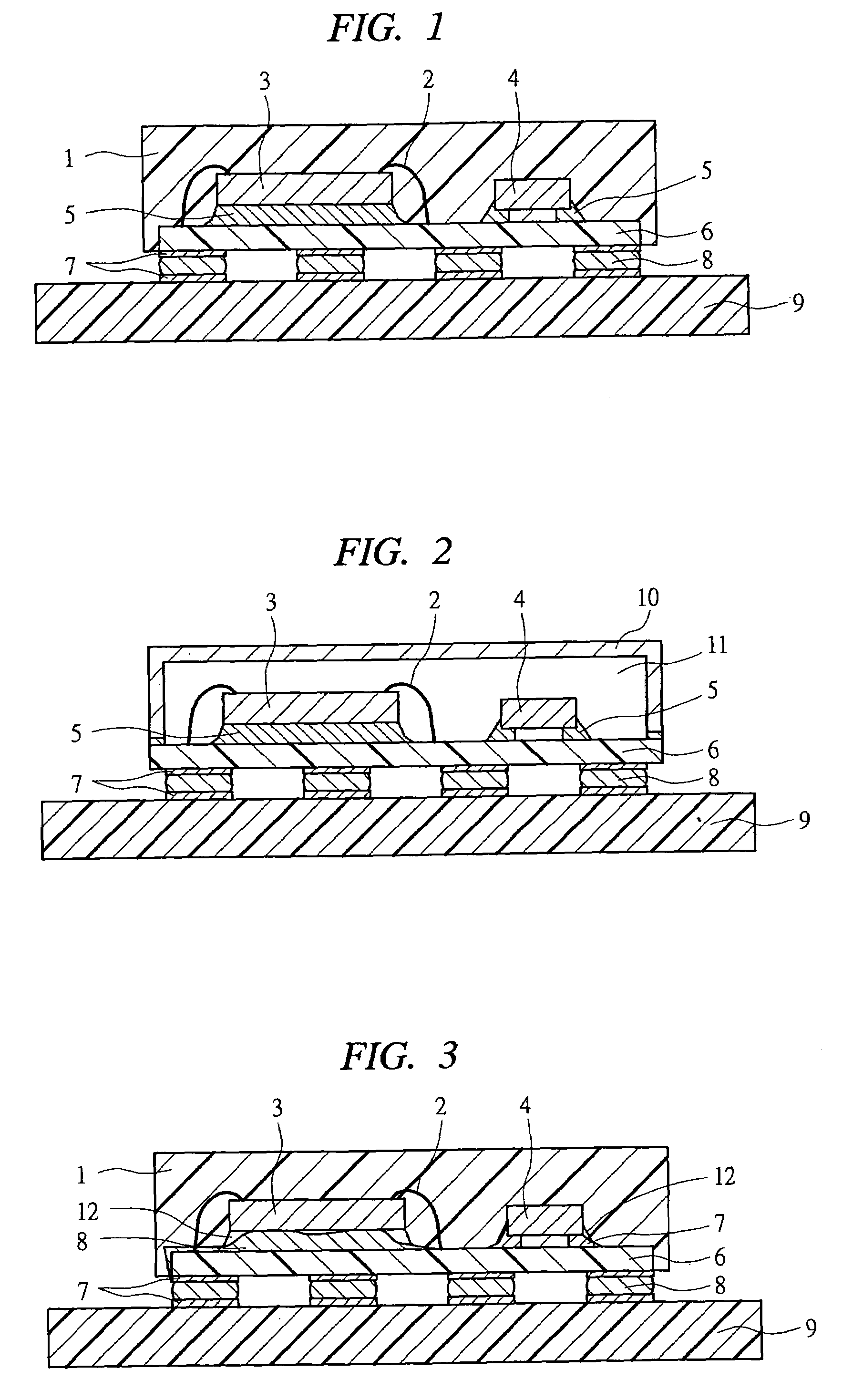

Semiconductor device and manufacturing method thereof

InactiveUS20060186550A1Increasing reactive surfaceReduce harmSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceMetal

In a semiconductor module connecting a semiconductor element and a passive element to a printed board, each of connection portions between the semiconductor element and the printed board and between the passive element and the printed board includes a metal with a melting point of 260° C. or higher and an intermetallic compound with a melting point of 260° C. or higher. Specifically, by connecting them using Pb-free solder with a melting point of 260° C. or lower, the printed board capable of lowering in cost, lightening, and reducing back height can be applied to a module board.

Owner:RENESAS ELECTRONICS CORP

Concrete sealing curing agent

The invention provides a concrete sealing curing agent. The concrete sealing curing agent is prepared from a component A and a component B, which are packaged independently, wherein the component A is prepared from the following components in percentage by weight: 20 weight percent to 25 weight percent of sodium silicate, 5 weight percent to 15 weight percent of poly-lithium silicate, 5 weight percent to 15 weight percent of silica sol, 3 weight percent to 7 weight percent of a photocatalyst, 0.5 weight percent to 1 weight percent of a penetrating agent, 0.5 weight percent to 1 weight percent of a surfactant, 0.4 weight percent to 0.6 weight percent of a surface modifier, 0.4 weight percent to 0.6 weight percent of a de-foaming agent and the balance of de-ionized water; the component B is prepared from the following components in percentage by weight: 0.2 weight percent to 0.6 weight percent of graphene, 25 weight percent to 45 weight percent of organic silicon modified water-based epoxy resin, 5 weight percent to 15 weight percent of silica sol, 0.1 weight percent to 2 weight percent of a catalyst, 0.1 weight percent to 3 weight percent of a stabilizer and the balance of de-ionized water. The concrete sealing curing agent provided by the invention has the advantages of reasonable design, high rigidity, high permeability, good wearing resistance and good waterproof performance, and also has a protection effect on concrete.

Owner:湖北省路桥集团有限公司

Silicon/graphene oxide anode material for lithium battery and preparation method thereof

InactiveCN104916823AEasy to prepareGood repeatabilityFinal product manufactureCell electrodesNano siliconOperability

The present invention discloses a silicon / graphene oxide anode composite material for a lithium battery and a preparation method thereof. The anode composite material is formed by uniformly adsorbing nano silicon to the surface of graphene oxide. According to the preparation method, graphene oxide powder is ultrasonically dispersed in mixed solution of water and ethylene glycol to obtain dispersion liquid; the nano silicon and a dispersing agent are added into the dispersion liquid; ball milling is carried out until the nano silicon is completely dispersed; and drying is carried out to obtain the anode composite material with the sheet-like morphology, of which the nano silicon is uniformly adsorbed to the surface of the graphene oxide. The composite material can be used for preparing the lithium ion battery with the characteristics of high specific discharge capacity, excellent rate capability, long cycle life and the like; and the preparation method is simple and reliable, is good in process repeatability, has high operability, is low in cost and is suitable for industrial production.

Owner:田东

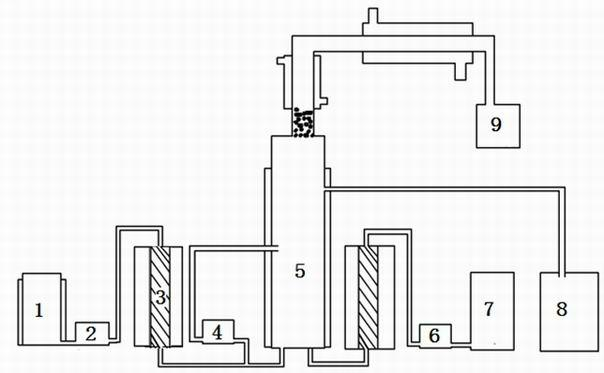

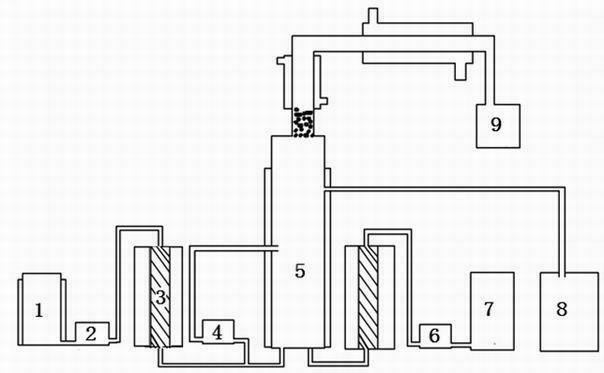

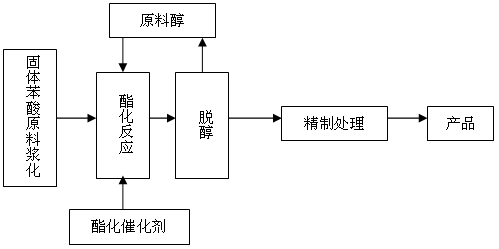

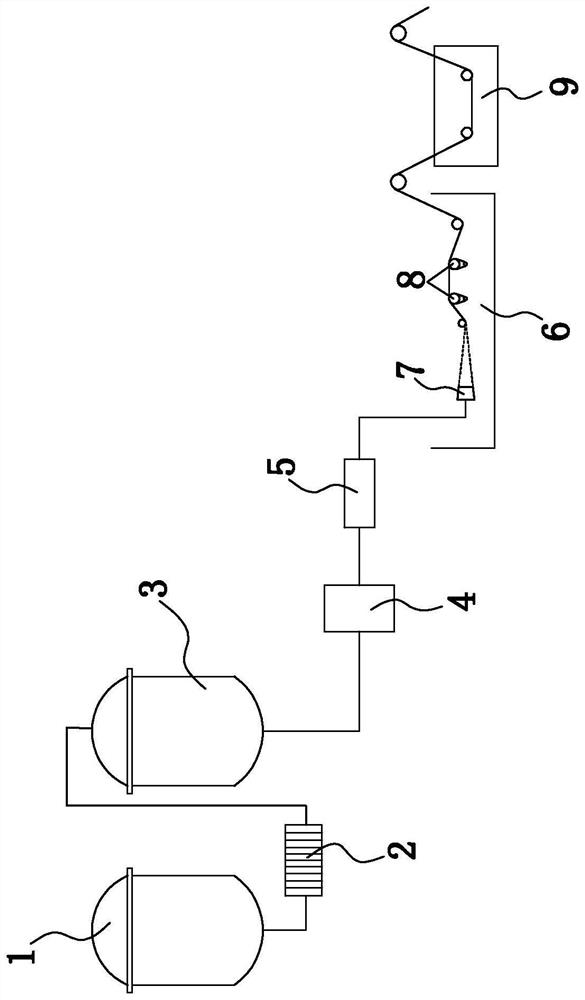

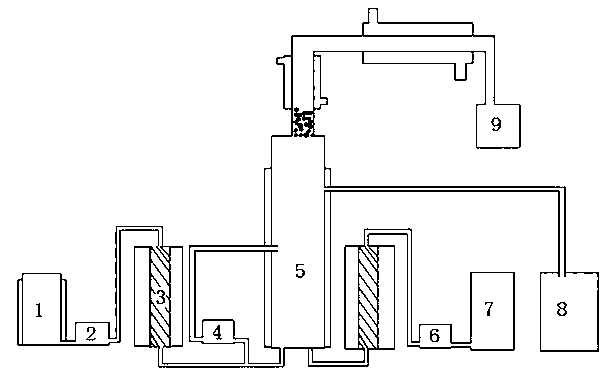

Method for continuously preparing polyester polyol and device used in method

The invention discloses a method for continuously synthesizing polyester polyol and a device used in the method. A solid raw material, namely acid or acid anhydride, and liquid polyol are used for synthesizing the polyester polyol in the presence of a catalyst. The method comprises the following steps of: preheating to melt the solid raw material for synthesizing the polyester polyol or slurryingin an alcoholic solution to obtain slurry, adding the catalyst, injecting the slurry into a slurry tank, metering by using a first metering pump, adding into a reaction kettle into which part of polyol is put in advance, starting a circulating pump to ensure that reaction liquid in the reaction kettle is circulated and fully reacted, and reacting according to the conventional steps under the conventional reaction conditions; and when an acid value is less than 1mgKOH / g, starting a second metering pump, continuously adding the polyol for reaction into the reaction kettle, continuously adding the slurry in the slurry tank into the reaction kettle, opening a discharge port at the upper end, and continuously discharging. The raw material is fluidized in advance, so that a high specific surface area and pipeline liquidity are achieved, and continuous feeding is facilitated.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

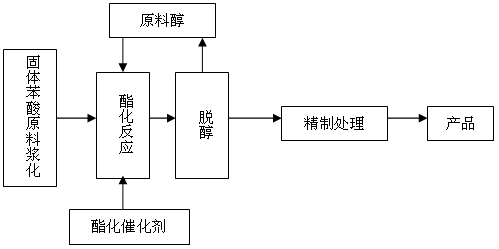

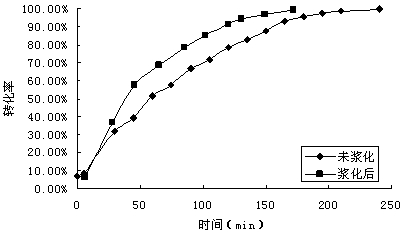

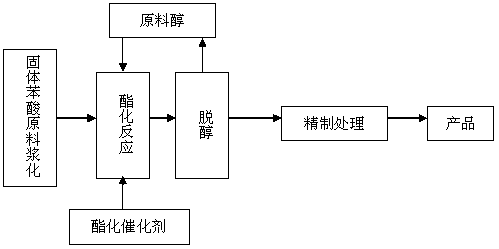

Process for preparing benzoic ether plasticizer by using slurry method

InactiveCN102153467AReduce consumptionIncrease the reaction interfaceOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPtru catalyst

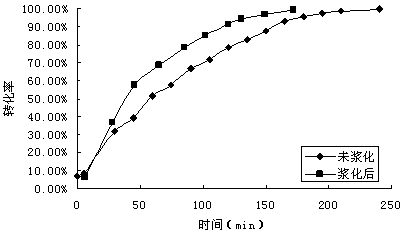

The invention relates to a process for preparing a benzoic ether plasticizer by using a slurry method. In the process, benzoic acid and alcohol react in the presence of a catalyst to produce a benzoic ether plasticizer. The process is characterized by comprising the following steps of: slurrying solid granular, powdery or blocky raw material benzoic acid in alcohol; after the slurrying is finished, adjusting the mole ratio of the alcohol to the benzoic acid to be (1-4):1; then mixing with a conventional catalyst which accounts for 0.1-0.2% of the mass of the raw material benzoic acid, raisingthe temperature to 210-240 DEG C gradually while stirring in a reactor with an oil-water separator, reacting for 1-4h under heat insulation and ending the reaction till the acid value is lower than 1; and then performing conventional dealcoholization and purification treatment to obtain the benzoic ether plasticizer. The invention has the advantages that the original solid benzoic acid raw material is slurried under the condition that original equipment is not necessary to change completely, therefore, the reaction contact area of two phases is increased, the reaction speed is increased greatly, the efficiency is increased and the energy is saved.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

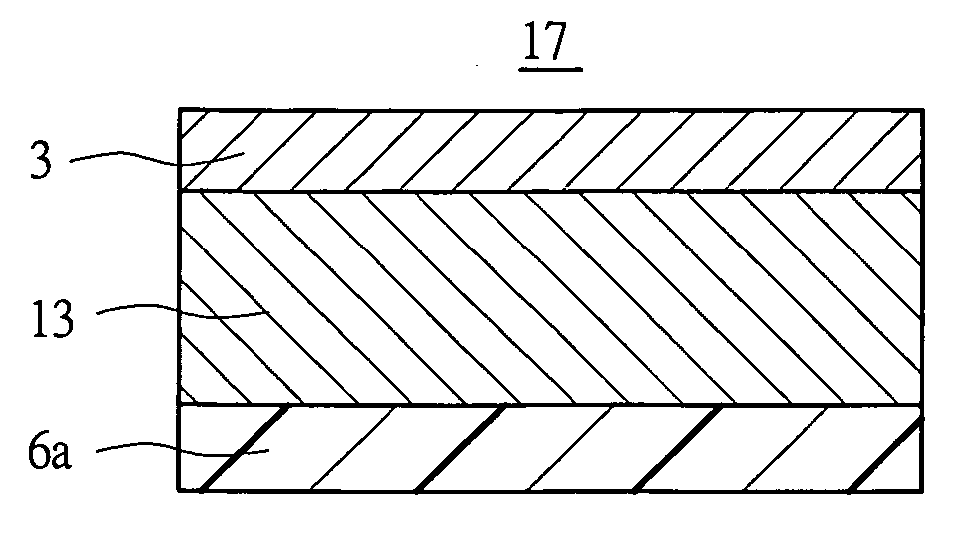

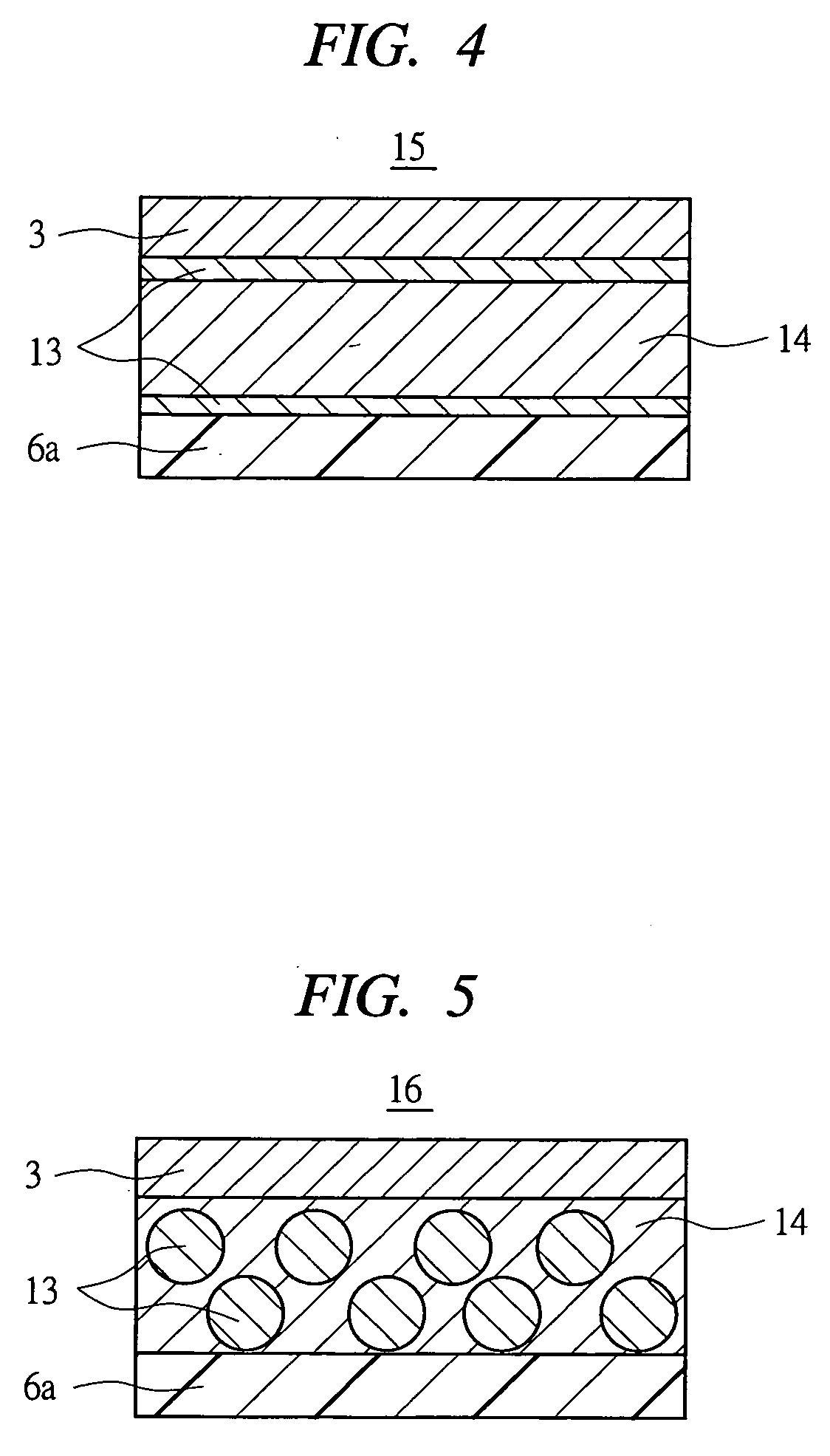

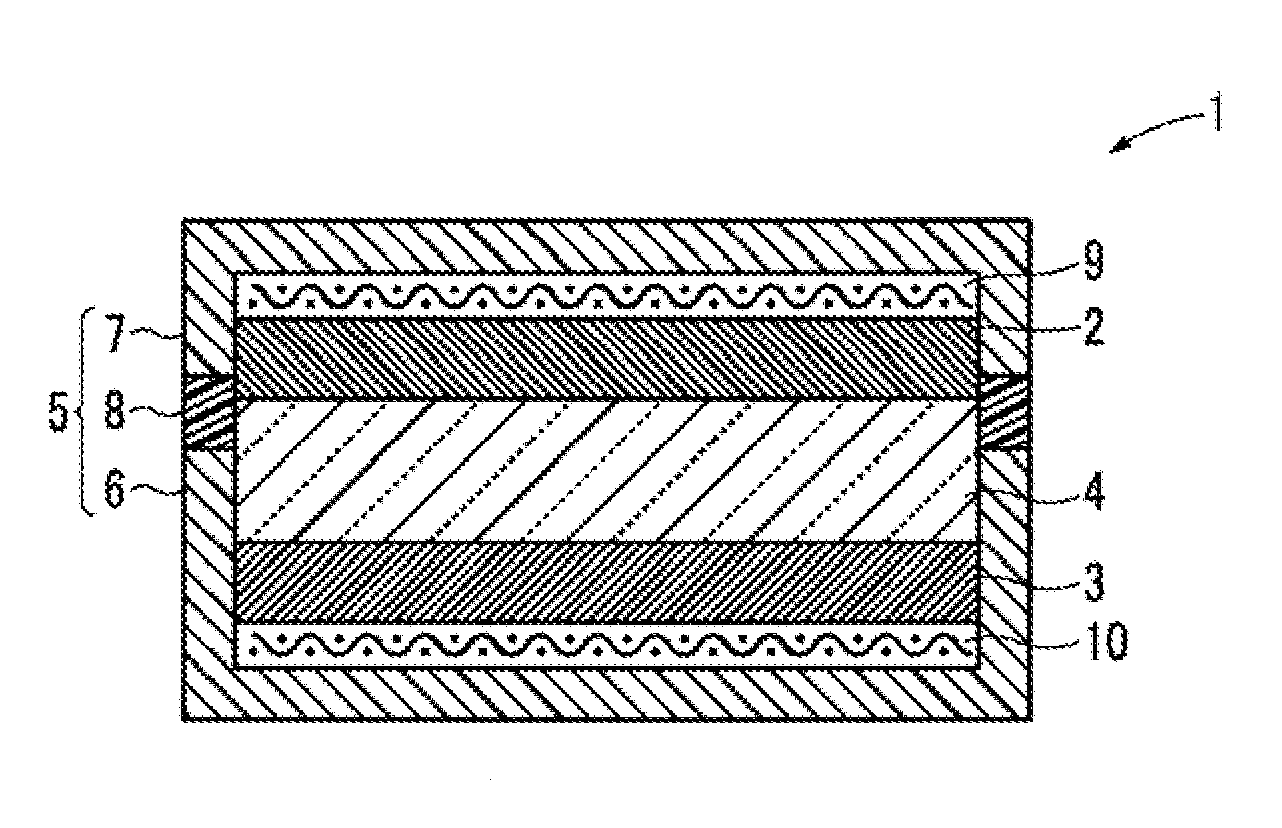

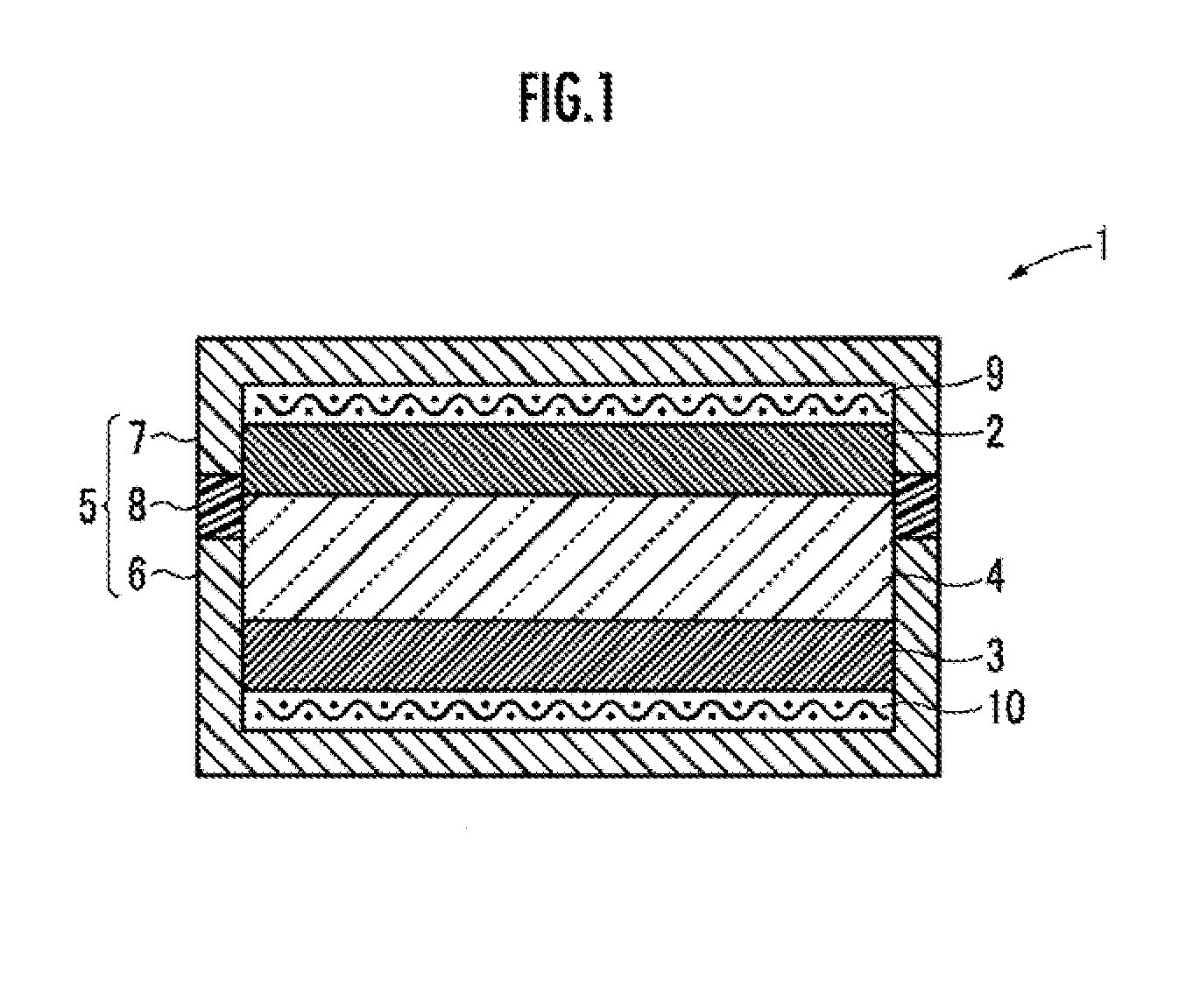

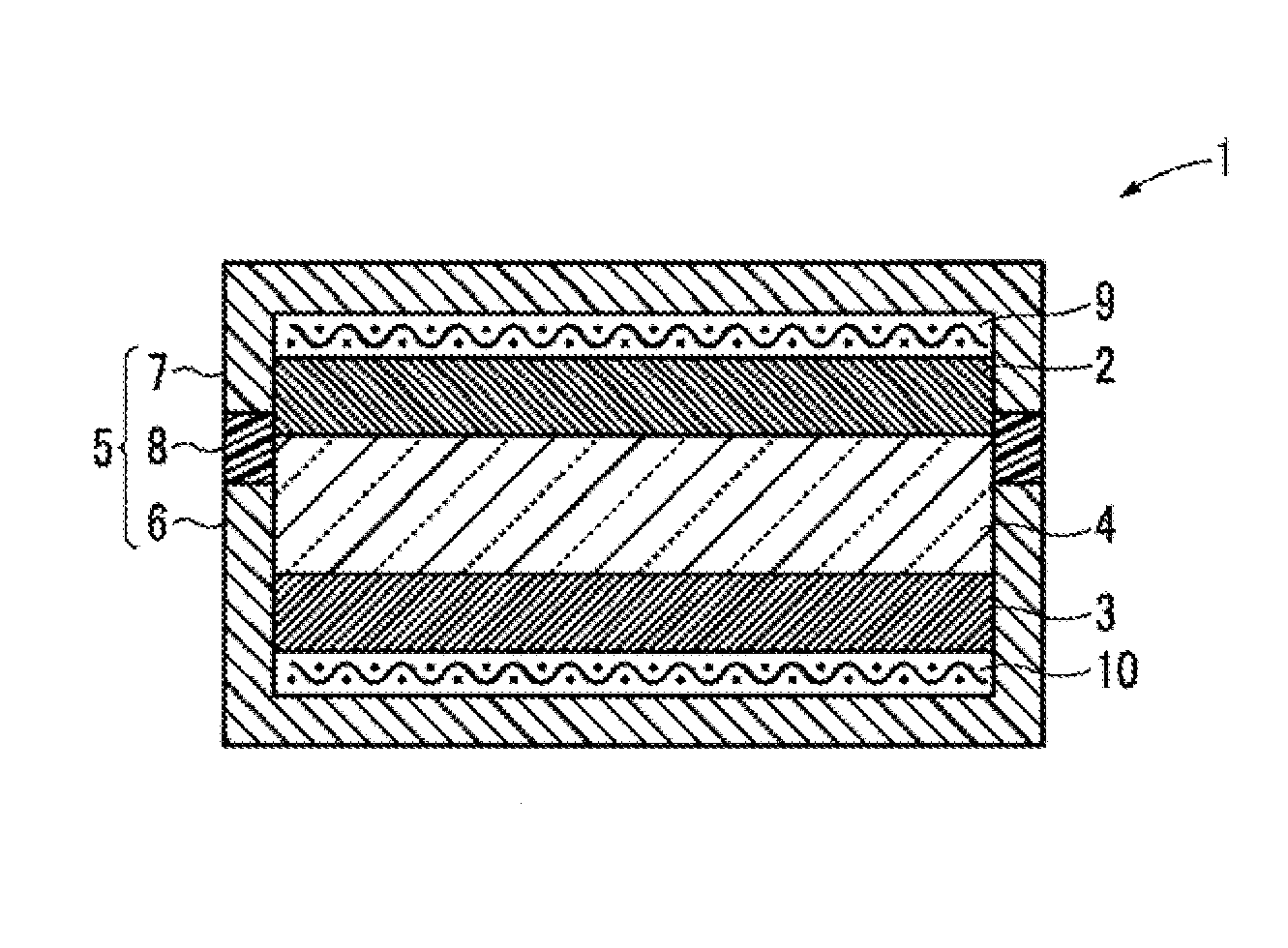

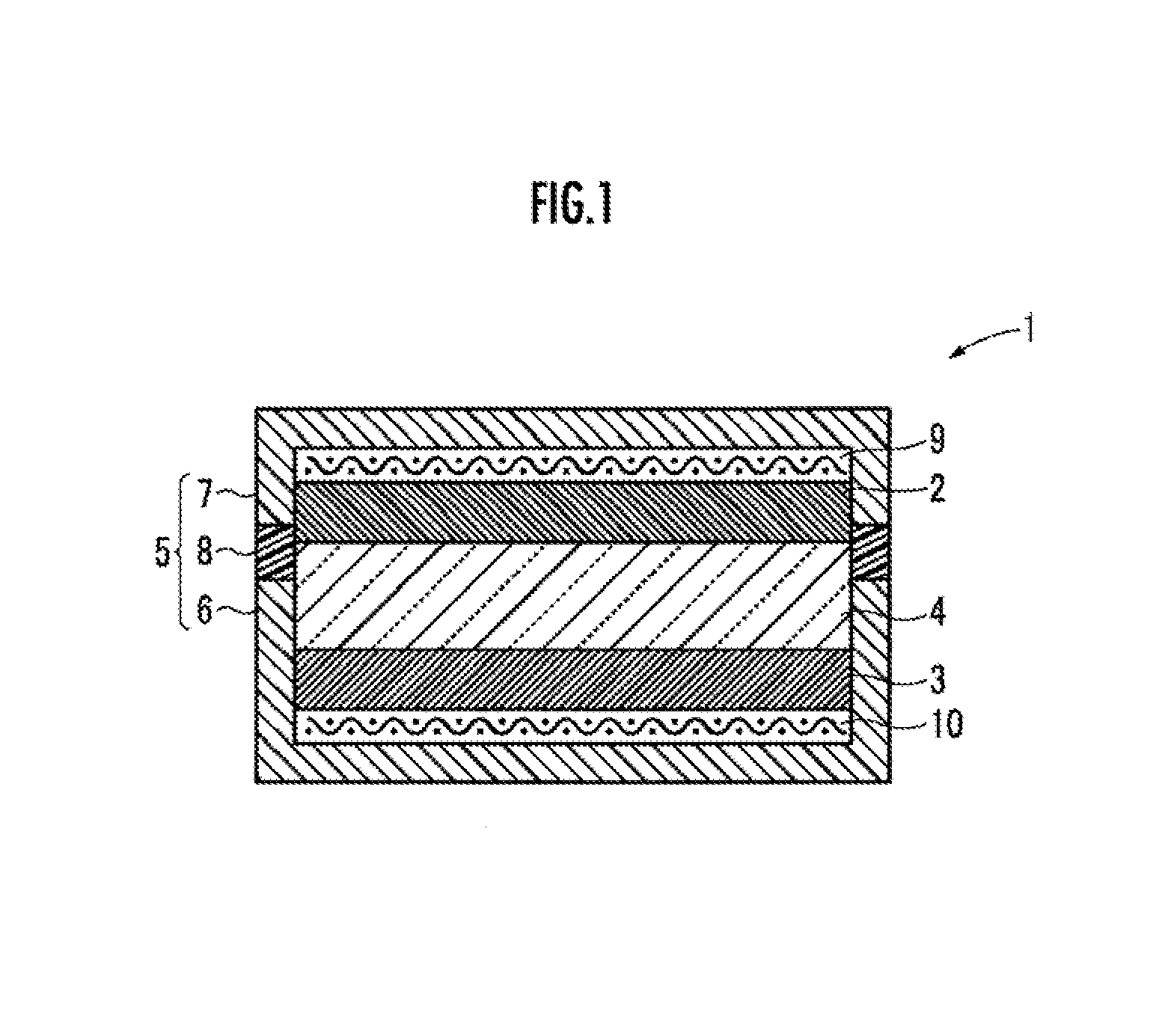

Metal oxygen battery

InactiveUS20130164616A1Easy dischargeIncrease the reaction interfaceFuel and secondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumOrganic acid

There is provided a metal oxygen battery which uses an oxygen-storing material containing YMnO3 as a positive electrode material, and can reduce the discharge overpotential. The metal oxygen battery 1 has a positive electrode 2 to which oxygen is applied as an active substance, a negative electrode 3 to which metallic lithium is applied as an active substance, and an electrolyte layer 4 interposed between the positive electrode 2 and the negative electrode 3. The positive electrode 2 contains, as an oxygen-storing material, a composite metal oxide obtained by crushing and mixing a yttrium salt, a manganese salt and an organic acid, primarily calcining the mixture, and thereafter, adding a zirconium salt to the obtained primarily calcined material, and secondarily calcining the mixture, the composite metal oxide containing YMnO3 and ZrO2.

Owner:HONDA MOTOR CO LTD

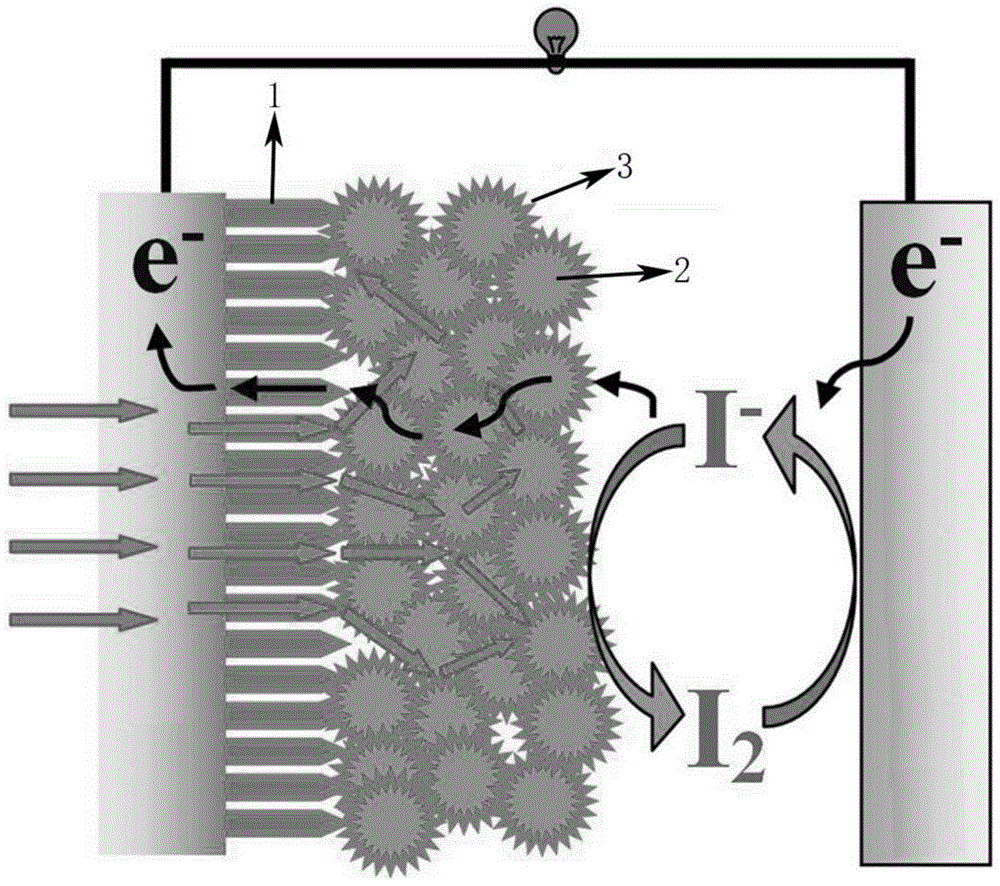

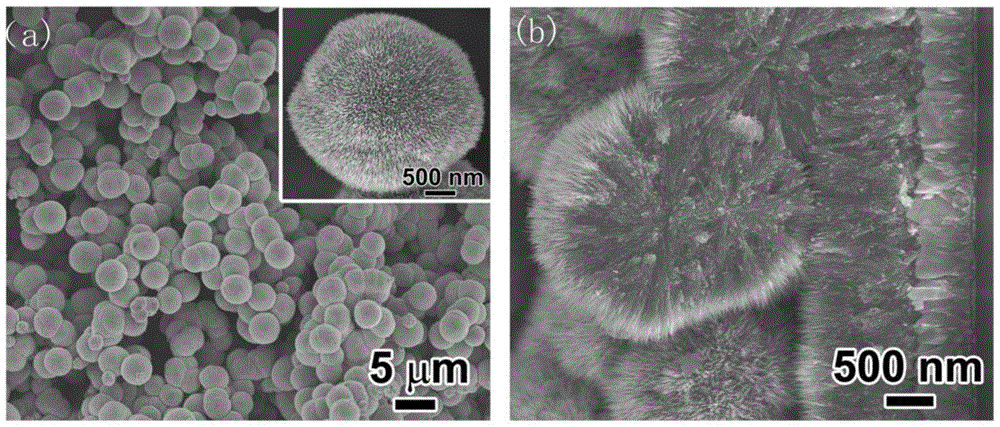

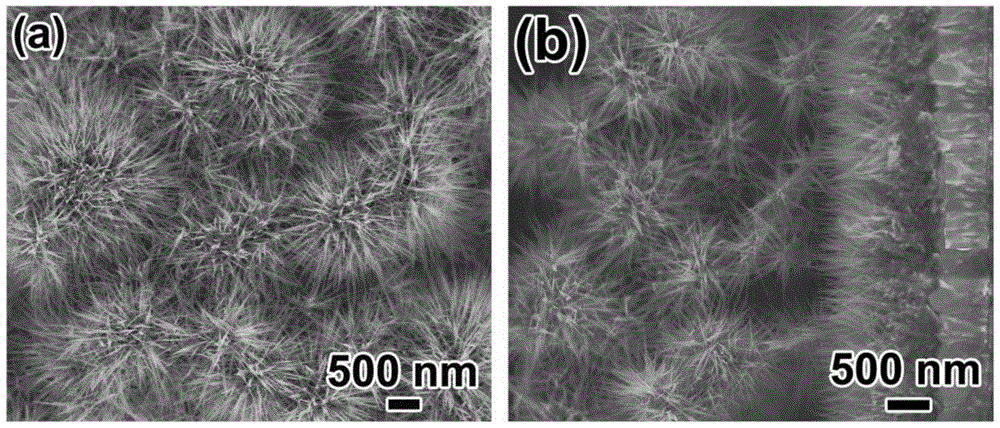

Solar cell electrode, preparation method therefor, and solar cell

InactiveCN105702472ASolve a series of contradictions that cannot be balancedRealize a series of contradictions that cannot be balancedLight-sensitive devicesPhotovoltaic energy generationMicro nanoElectronic transmission

The invention relates to the technical field of solar energy capturing and conversion, and discloses a solar cell electrode, a preparation method therefor, and a solar cell comprising the electrode. The solar cell electrode has a double-layer titanium oxide micro-nano structure, wherein the lower layer is a one-dimensional nanowire array which vertically grows on a transparent conductive glass substrate, and the upper layer is a three-dimensional dendritic micro-nano ball structure stacked on the one-dimensional nanowire array. The design of the novel electrode successfully avoids a series of contradiction which cannot be considered by a conventional electrode. Compared with a conventional photoelectrode, the electrode has a large electronic transmission free path, is high in visible light absorption efficiency, has a large photoelectric conversion reaction interface, can achieve one-step integration, has an electron flow and high-reaction interface for the preparation of the solar cell with the high photoelectric conversion ratio, meets the requirements for strong scattering and absorption of visible light, greatly improves the overall performance of the solar cell, and speeds up the industrial transformation of this type of new energy devices and the final large-scale industrialized application.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

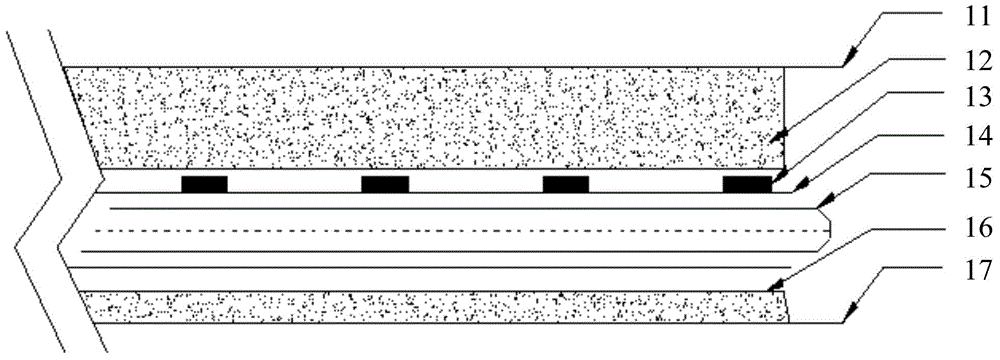

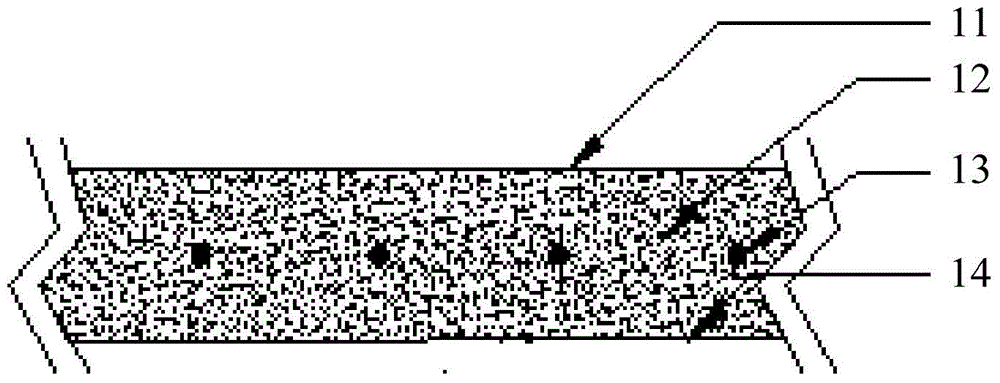

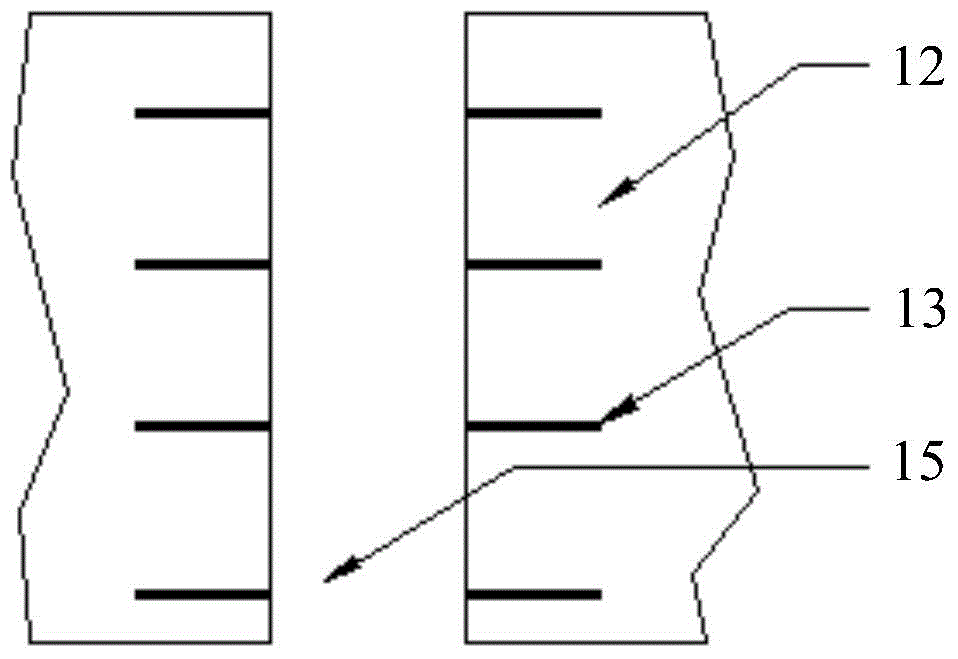

Coal bed underground gasifying method

ActiveCN104314549AEasy to controlIncrease spawn rate effectConstructionsCoal gasificationProcess engineeringEngineering

The invention relates to a coal bed underground gasifying method. The coal bed underground gasifying method comprises the following steps of establishing a gasifying tunnel in a to-be-gasified coal bed; arranging a plurality of blasting devices in the to-be-gasified coal bed, wherein the blasting devices are arranged corresponding to a plurality of coal bed sections of the to-be-gasified coal bed; igniting or striking a fire in the gasifying tunnel to start the gasifying process; utilizing a flame movement heating method to gradually blast the blasting devices, so as to loosen the coal bed sections before the corresponding coal bed section is gasified. The coal bed underground gasifying method has the advantages that the blasting devices are pre-arranged in the to-be-gasified coal bed, so while cracks in the coal bed are increased by blasting, and the gasifying is also performed; before the gasifying of each coal bed section, the looseness of the corresponding coal bed section is completed, and the gasifying efficiency is improved.

Owner:ENN SCI & TECH DEV

Fuel oil preparation technique utilizing waste plastics

InactiveCN104479721AEvenly heatedReduce high temperature wall sticking and cokingLiquid hydrocarbon mixture productionHydrocarbon oils treatmentTemperature controlLiquid fuel

The invention discloses a fuel oil preparation technique utilizing waste plastics. The preparation technique comprises the following steps: the waste plastics are chopped, the chopped waste plastics are added into a cracking kettle, a catalyst and quartz sand are added, and the materials are heated at a heating rate of 5 to 10 DEG C per minute after uniform stirring and mixing; the materials are heated within different temperature ranges through temperature control to achieve a slow reaction, and condensates within the different temperature ranges are respectively collected; after the mixed cracking reaction is completed, the collected liquid fuel oils are respectively sent to a rectifying tower for rectification, and fraction products within the different temperature ranges are respectively collected; the fractions captured from the rectifying tower respectively undergo extraction separation through a complexation extraction solvent. The technique provided by the invention has the advantages that the quartz sand is added into the reaction kettle, so as to achieve uniform heating of the reaction materials, enlarge the reaction contact surface, and reduce the phenomena of wall sticking and coking of the materials under a high temperature; the fuel oil yield is high, and the fuel oil quality is stable; the technique is simple to operate, so as to facilitate scale production.

Owner:云浮市力道新能源科技有限公司

Semiconductor device and manufacturing method thereof

InactiveUS7274103B2Reduce harmIncrease the reaction interfaceSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceMetal

In a semiconductor module connecting a semiconductor element and a passive element to a printed board, each of connection portions between the semiconductor element and the printed board and between the passive element and the printed board includes a metal with a melting point of 260° C. or higher and an intermetallic compound with a melting point of 260° C. or higher. Specifically, by connecting them using Pb-free solder with a melting point of 260° C. or lower, the printed board capable of lowering in cost, lightening, and reducing back height can be applied to a module board.

Owner:RENESAS ELECTRONICS CORP

Preparation method of lithium-ion battery

InactiveCN109786855AIncrease in sizeSizeElectrode manufacturing processesFinal product manufactureFlocculationTetrafluoroethylene

The invention discloses a preparation method of a lithium-ion battery. The method comprises a preparation process of positive paste and negative paste, wherein the positive paste and the negative paste are prepared through the process of mixing, soaking, dispersion and flocculation of a positive raw material and a negative raw material; the positive paste contains, by weight, 80-90 parts of a nickel-cobalt-manganese ternary material, 1-5 parts of a binder and 5-20 parts of a conductive agent; and the negative paste contains polytetrafluoroethylene which is added according to the proportion of60% of negative raw material paste, wherein the 60% of polytetrafluoroethylene contains 2 parts of carboxymethylcellulose. According to the method, the nickel-cobalt-manganese ternary material is adopted as the positive raw material of the lithium-ion battery first, the positive raw material is made into appropriate paste through pretreatment of the positive material and the paste making process of mixing, soaking and flocculation, and the positive paste is spread on an aluminum thin film to form the intact lithium-ion battery in cooperation with the functions of the negative material, an electrolytic solution and a membrane. The battery has the advantages that discharge voltage is high, safety is good, and repeated discharge can be performed multiple times cyclically.

Owner:泰顺永庆电力技术有限公司

Pennisetum sinese porous carbon-based solid catalyst and preparation method thereof

ActiveCN109603905ARich sourcesLow priceOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePorous carbon

The invention provides a pennisetum sinese porous carbon-based solid catalyst and a preparation method thereof, and belongs to the technical field of solid catalyst preparation. The preparation methodof the pennisetum sinese porous carbon-based solid catalyst comprises the following steps: pyrolyzing pennisetum sinese under normal pressure to obtain a pre-carbonized product, activating the pre-carbonized product by using 5-sulfosalicylic acid to obtain an activated precursor, preparing a pennisetum sinese porous carbon carrier through an anaerobic pyrolysis process, and finally, preparing thepennisetum sinese porous carbon-based solid catalyst by adopting 1,4-phenylenediamine-2,5-disulfonic acid diazonium salt as a sulfonating agent. The prepared catalyst can be used for a hydrolysis reaction of cellulose, and the yield of reducing sugar is high. The preparation method disclosed by the invention is simple and feasible and has high catalytic activity and good heat stability, and the main raw materials are reproducible, are low in cost and are environmentally friendly. The method provides a new way for solid catalyst preparation.

Owner:FUZHOU UNIV

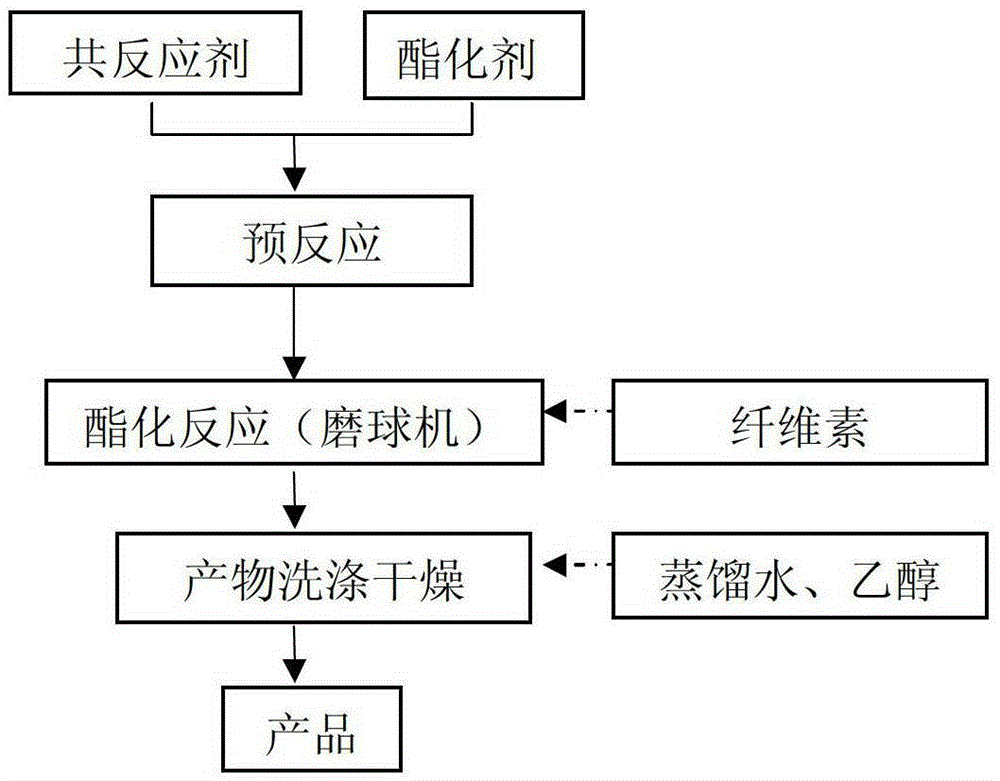

A kind of cellulose fatty acid ester and preparation method thereof

The invention belongs to the field of cellulose modification, and more specifically relates to a cellulose higher fatty acid ester and a preparation method thereof. The weight ratio of cellulose, an esterifying agent and a coreactant, which are the principle raw materials of the cellulose higher fatty acid ester, is 100g:50g-300g:100g-600g. The preparation method comprises steps of pre-reaction and esterification reaction, wherein the esterifying agent and the coreactant are mixed uniformly firstly; the mixture is subjected to pre-reaction for 10 to 30min at a temperature of 50 to 90 DEG C; cellulose is mixed with the mixture uniformly after the pre-reaction, and the mixture is delivered into a ball grinder and is subjected to esterification reaction for 20 to 90min at the temperature of 40 to 90 DEGC with a stirring speed of 100 to 500rmp; and then obtained reaction product is washed and dried so as to obtain the cellulose higher fatty acid ester. Mechanical activation technology is employed so as to increase esterification efficiency of cellulose, shorten reaction time and simplify the processing steps.

Owner:福建鸿燕化工有限公司

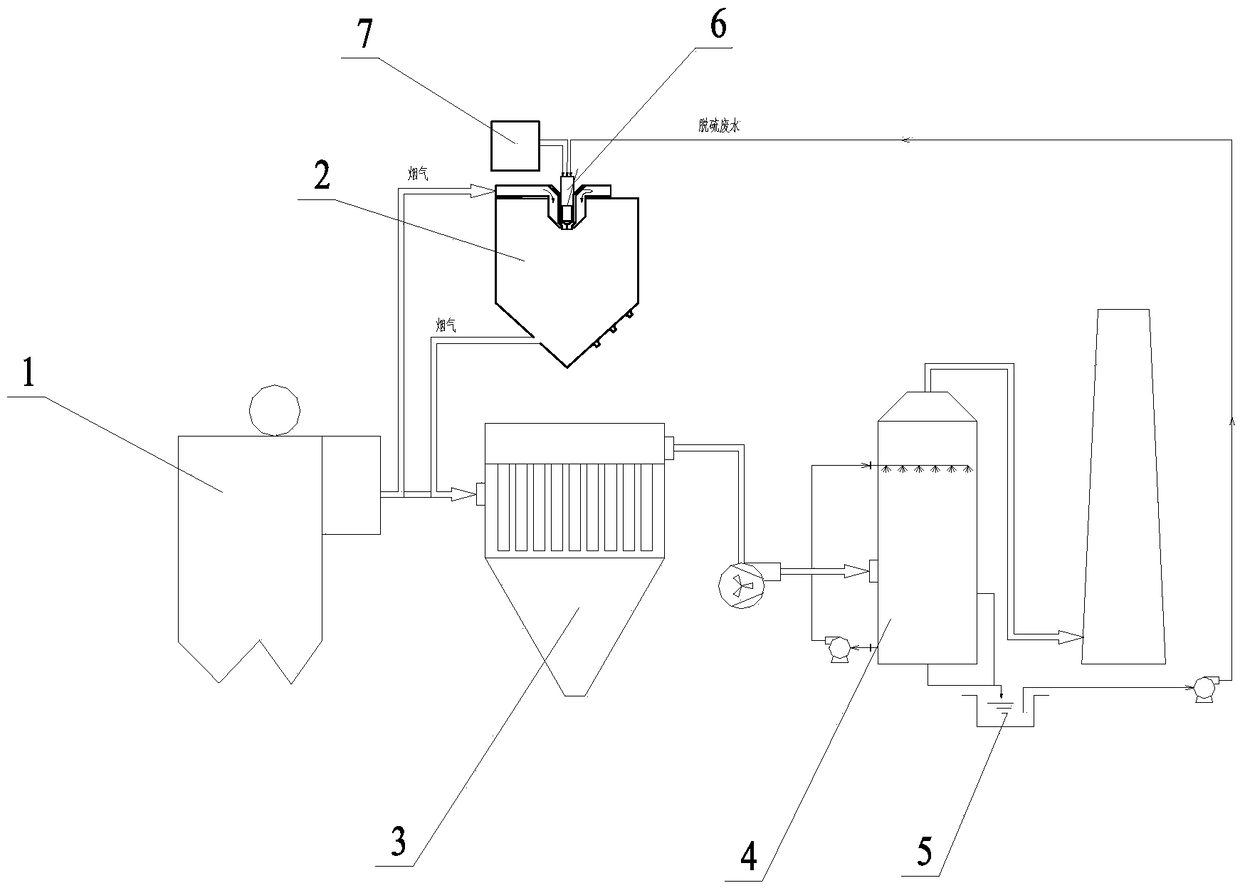

Zero-discharge system for desulfurization wastewater

PendingCN109133234AShort processLess process equipmentWater contaminantsWaste water treatment from gaseous effluentsSludgeProcess engineering

The invention discloses a zero-discharge system for desulfurization wastewater. The zero-discharge system comprises a boiler, a dust remover and a desulfurization tower, which are arranged in sequence; a drying tower is arranged between the boiler and the dust remover; and a rotary atomizer is arranged on the tower top of the drying tower. The rotary atomizer rotates at a high speed and wastewatergenerated by the desulfurization tower is sprayed into the drying tower by the rotary atomizer; and an air flow diversion device is arranged in the drying tower, exhaust gas generated by the boiler enters the drying tower through an exhaust gas inlet and forms a downwards rotating air flow under the diversion of the air flow diversion device, and the rotating direction of the air flow is oppositeto the rotating direction of the rotary atomizer. The zero-discharge system for the desulfurization wastewater provided by the invention is used for wastewater treatment, in which the desulfurizationwastewater is directly atomized by the rotary atomizer and instantaneously evaporated by the hot exhaust gas in the drying tower, therefore no sludge is produced and no heating is needed in the process, so that the construction cost and the running cost of the zero-discharge system for the desulfurization wastewater are greatly reduced.

Owner:江苏海澜正和环境科技有限公司

Method for treating papermaking black liquid

InactiveCN103669071ADoes not consume energyNo polluting emissionsRegeneration of alkali lyeCalcium silicateBlack liquor

The invention discloses a method for treating papermaking black liquid, which is characterized in that: the method comprises: placing 2-4m2 of nanometer titanium dioxide-supported catalytic sheet into per cubic meter of the papermaking black liquid to be treated, then adding 100-200L / m3 of calcium silicate hydrate emulsion, fully stirring, and finally carrying out settlement and separation. The method treats papermaking black liquid by nanometer titanium dioxide-supported catalytic sheet and calcium silicate hydrate emulsion, and not only has advantages of simple process and low treatment cost, but also can effectively remove papermaking black liquid.

Owner:乐山市洁宇纳米应用技术研究所

Metal oxygen battery

InactiveUS8835061B2Easy dischargeIncrease the reaction interfaceFuel and secondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumOrganic acid

There is provided a metal oxygen battery which uses an oxygen-storing material containing YMnO3 as a positive electrode material, and can reduce the discharge overpotential. The metal oxygen battery 1 has a positive electrode 2 to which oxygen is applied as an active substance, a negative electrode 3 to which metallic lithium is applied as an active substance, and an electrolyte layer 4 interposed between the positive electrode 2 and the negative electrode 3. The positive electrode 2 contains, as an oxygen-storing material, a composite metal oxide obtained by crushing and mixing a yttrium salt, a manganese salt and an organic acid, primarily calcining the mixture, and thereafter, adding a zirconium salt to the obtained primarily calcined material, and secondarily calcining the mixture, the composite metal oxide containing YMnO3 and ZrO2.

Owner:HONDA MOTOR CO LTD

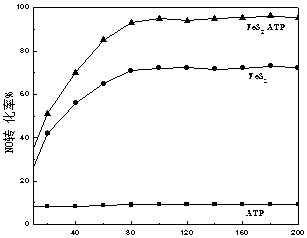

Preparation method of ferrous sulfide/attapulgite composite

InactiveCN108043425AAvoid uneven loadGood dispersionDispersed particle separationCatalyst activation/preparationDispersityAlcohol

The invention relates to a preparation method of a ferrous sulfide / attapulgite composite and belongs to the field of utilization of nonmetal mineral materials. The preparation method comprises the steps as follows: a certain amount of ferric nitrate, thioacetamide and attapulgite are weighed and added to deionized water for ultrasonic treatment and stirring, a mixed liquid is transferred to a reaction kettle to react at the temperature of 160-220 DEG C, water washing and alcohol washing are performed after the reaction, drying is performed, and the ferrous sulfide / attapulgite composite can beobtained. The prepared ferrous sulfide / attapulgite composite is uniform in loading and good in dispersity, experimental raw materials are easy to obtain, no complicated equipment is required, and theferrous sulfide / attapulgite composite has a good low-temperature conversion effect on nitrogen oxide under the assistance of light.

Owner:盱眙县中材凹凸棒石粘土有限公司

Process for preparing benzoic ether plasticizer by using slurry method

InactiveCN102153467BReduce consumptionIncrease the reaction interfaceOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPtru catalyst

The invention relates to a process for preparing a benzoic ether plasticizer by using a slurry method. In the process, benzoic acid and alcohol react in the presence of a catalyst to produce a benzoic ether plasticizer. The process is characterized by comprising the following steps of: slurrying solid granular, powdery or blocky raw material benzoic acid in alcohol; after the slurrying is finished, adjusting the mole ratio of the alcohol to the benzoic acid to be (1-4):1; then mixing with a conventional catalyst which accounts for 0.1-0.2% of the mass of the raw material benzoic acid, raisingthe temperature to 210-240 DEG C gradually while stirring in a reactor with an oil-water separator, reacting for 1-4h under heat insulation and ending the reaction till the acid value is lower than 1; and then performing conventional dealcoholization and purification treatment to obtain the benzoic ether plasticizer. The invention has the advantages that the original solid benzoic acid raw material is slurried under the condition that original equipment is not necessary to change completely, therefore, the reaction contact area of two phases is increased, the reaction speed is increased greatly, the efficiency is increased and the energy is saved.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

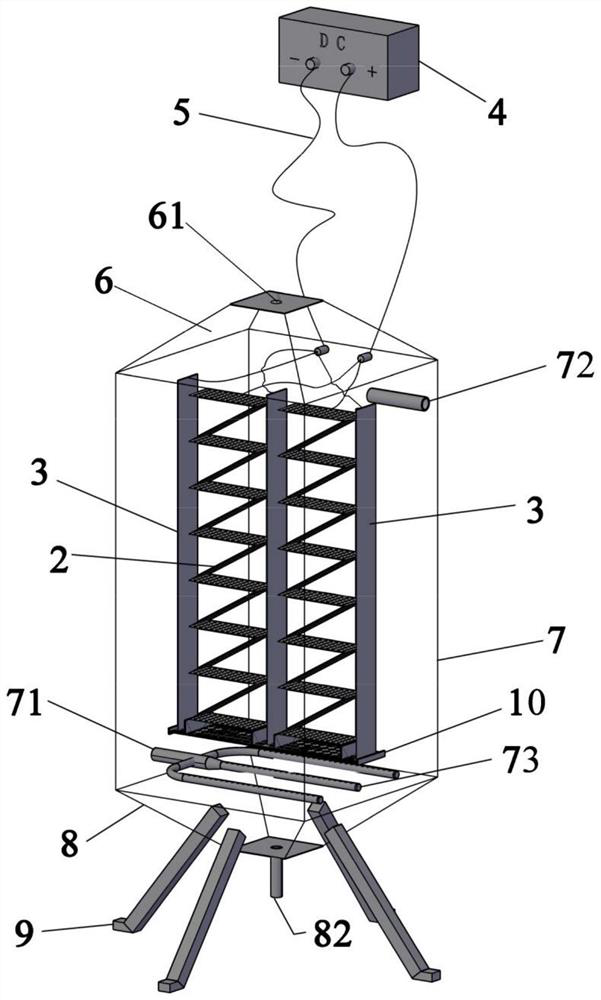

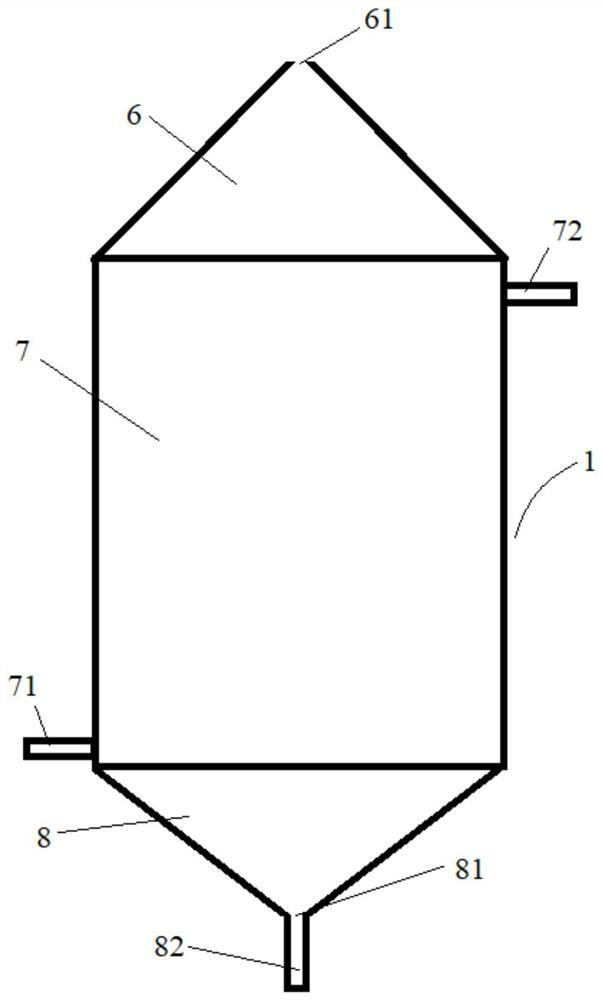

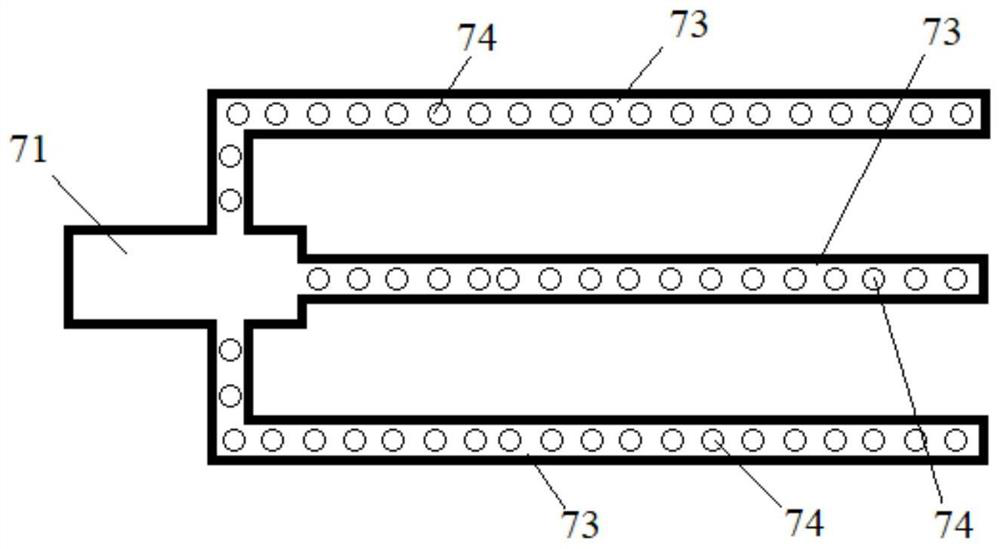

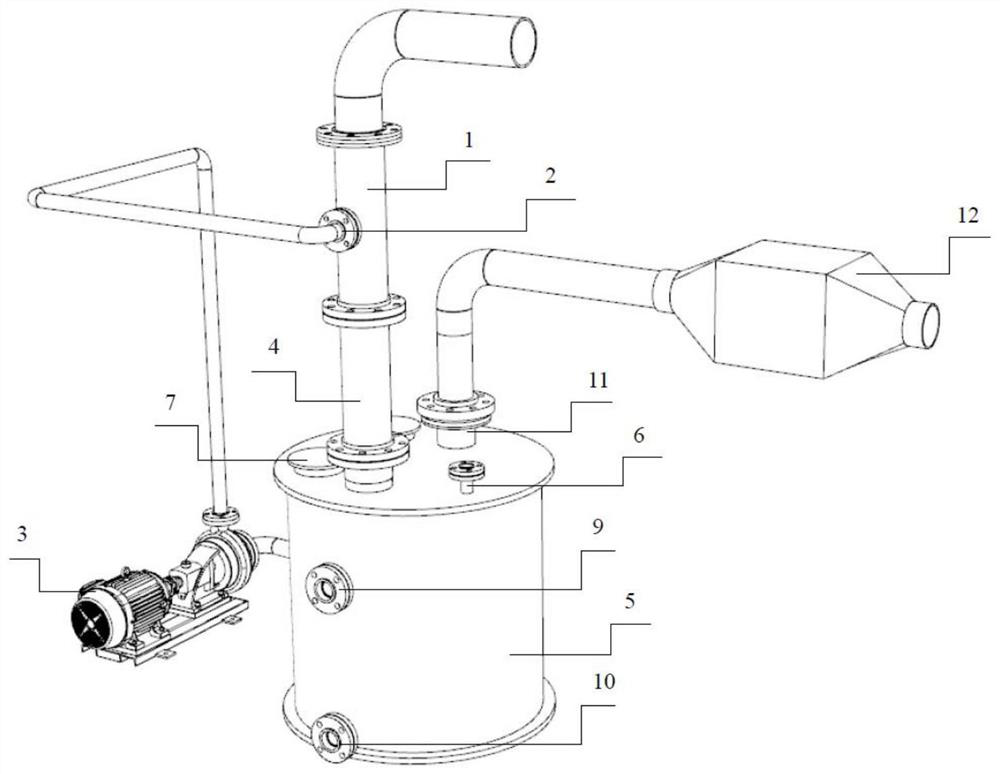

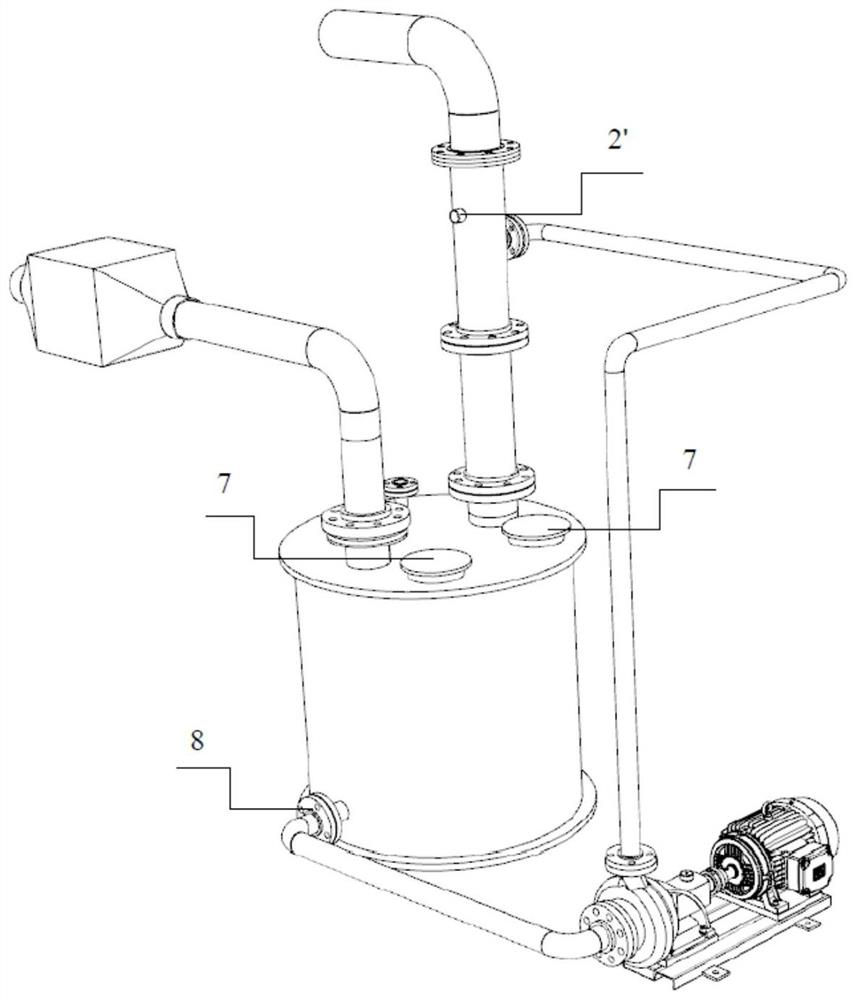

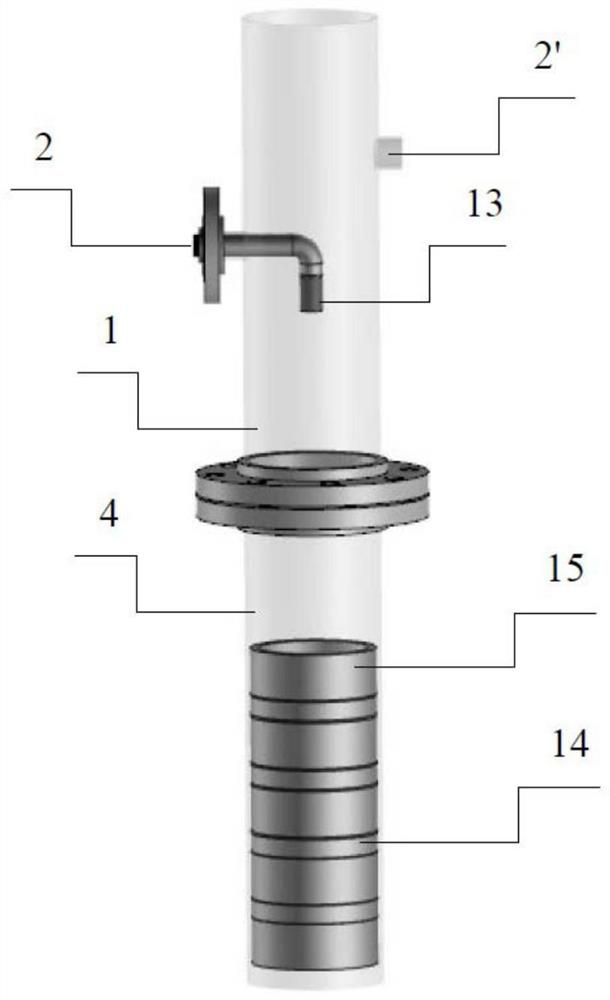

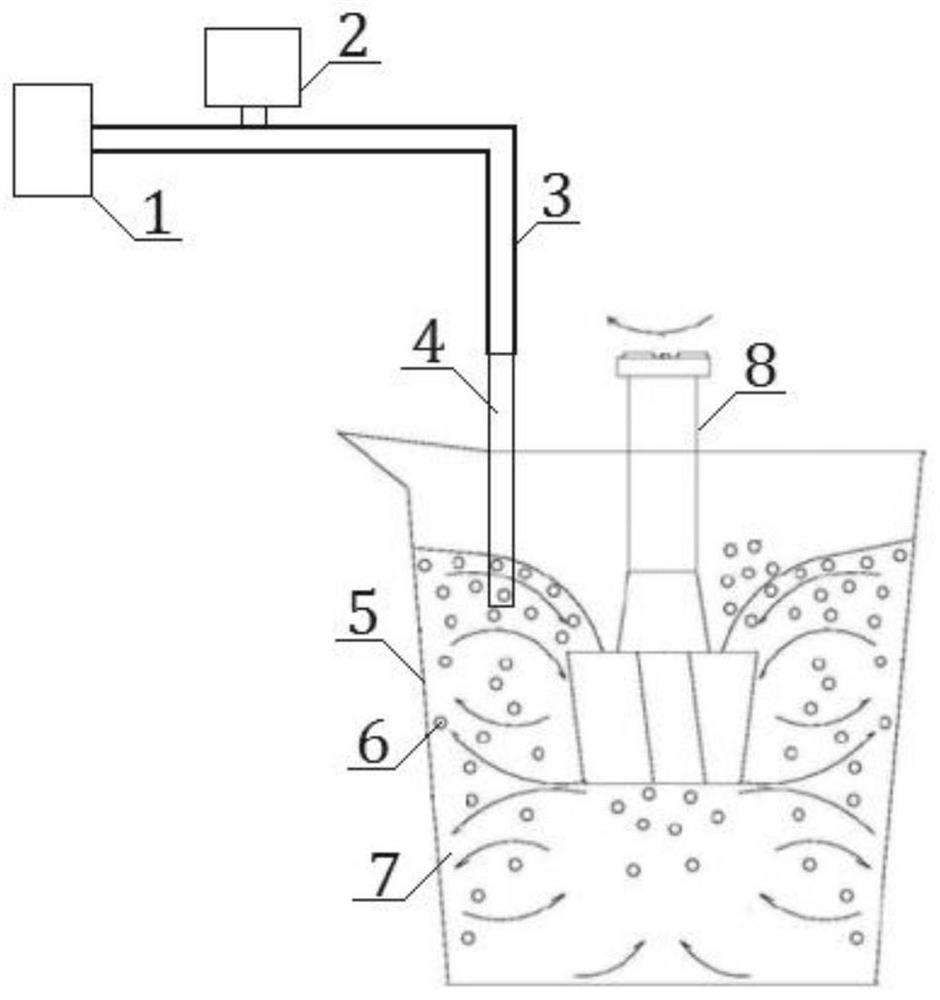

Nanometer electrochemical reaction device

ActiveCN111847595AGood electrical conductivityImprove response performanceWater/sewage treatmentElectrochemical responseCorrosion resistant

The invention discloses a nanometer electrochemical reaction device. The device comprises a shell, a power supply, an anode assembly and a cathode assembly, wherein the anode assembly and the cathodeassembly are arranged in the shell; the anode assembly and the cathode assembly are respectively connected with a positive electrode and a negative electrode of the power supply arranged outside the shell through wires; the anode assembly is composed of one or more Fe-Ti-ZnO composite nanometer polar plates made of Fe, Ti and ZnO. The anode plate is good in conductivity, corrosion resistance and catalytic performance; and the folded anode assembly composed of the water passing holes and the multiple anode plates is more beneficial to forming turbulent flow in the reaction device by water liquid, the reaction efficiency is improved, oils, acidic substances and refractory organic pollutants in water are efficiently removed, and the important practical value is achieved.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Efficient chemical deodorization device and method

PendingCN113996168ALarge amount of processingSmall pressure dropDispersed particle separationAtomized substancesThermodynamicsLiquid storage tank

The invention discloses an efficient chemical deodorization device and method. The device comprises: an absorption liquid storage tank, wherein a reaction pipe is connected to a gas inlet of the absorption liquid storage tank, and a demister connected to a gas outlet of the absorption liquid storage tank; a liquid spraying pipe, wherein the lower end of the liquid spraying pipe is connected with the reaction pipe, and an external fan connected with the upper end of the liquid spraying pipe; and a circulation mechanism, wherein the extraction end of the circulation mechanism is connected with the liquid outlet of the absorption liquid storage tank, and the discharge end of the circulating mechanism is connected with the liquid spraying pipe. According to the efficient chemical deodorization device, a gas-liquid co-flow chemical technology is adopted; and the device is large in treatment capacity, small in pressure drop, free of a flooding phenomenon, and capable of remarkably reducing a tower diameter and a tower height and decreasing the investment cost of the device.

Owner:BEIJING DRAINAGE EQUIP

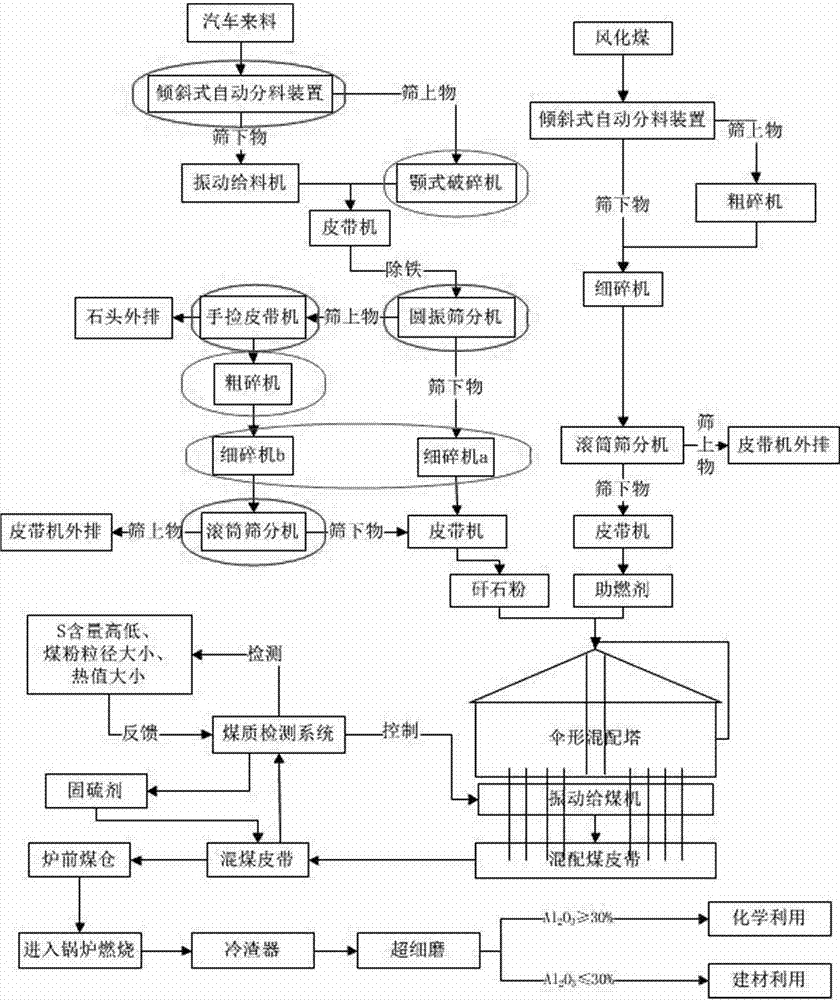

Method for sulfur fixation temperature control burning of coal gangue and efficient coupling and utilizing of lime ash

ActiveCN104848212AReduce energy consumptionEliminate coal blocking faultsFluidized bed combustionGrain treatmentsResource utilizationCoal blending

The invention discloses a method for sulfur fixation temperature control burning of coal gangue and efficient coupling and utilizing of lime ash, belongs to the technical field of resource utilization of solid wastes and provides the method for the sulfur fixation temperature control burning of the coal gangue and efficient coupling and utilizing of the lime ash. By using the technology, a circulating fluidized bedboiler can operate safely, stably and reliably, and efficient, automatic and accurate coal blending is realized under the condition of storing coal on a large scale; meanwhile, fly ash is utilized on a large scale. The method comprises the following steps of a, screening and crushing low-grade fuel; b, screening crushed fuel for mixing; c, intelligently controlling the mixed fuel to burn; d, after burning, performing temperature control cooling on the burnt lime ash; e, performing superfine grinding on cooled fly ash. The method disclosed by the invention is mainly applied to temperature control burning of the circulating fluidized bedboiler and efficient utilization of the lime ash.

Owner:SHANXI UNIV +1

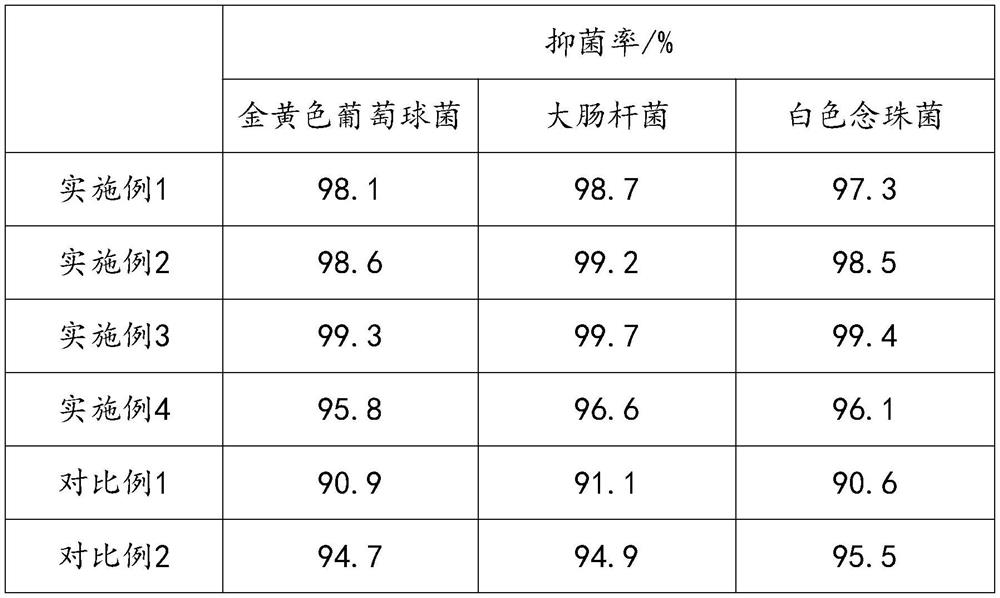

Preparation method of chitosan fiber non-woven fabric applied to surface layer of paper diaper

ActiveCN114318669ABiodegradableImprove antibacterial propertiesArtificial filament washing/dryingWet spinning methodsWoven fabricPolymer chemistry

The invention relates to the field of disposable hygienic products, and provides a preparation method of a chitosan fiber non-woven fabric applied to the surface layer of a paper diaper, and the preparation method comprises the following steps: 1) preparing N-carboxyethyl chitosan; (2) preparing modified chitosan; (3) preparing modified chitosan fibers; and (4) preparing the chitosan fiber non-woven fabric. The prepared chitosan fiber non-woven fabric can effectively prevent diaper rash and better protect baby skin.

Owner:FUJIAN HENGAN HLDG CO LTD +2

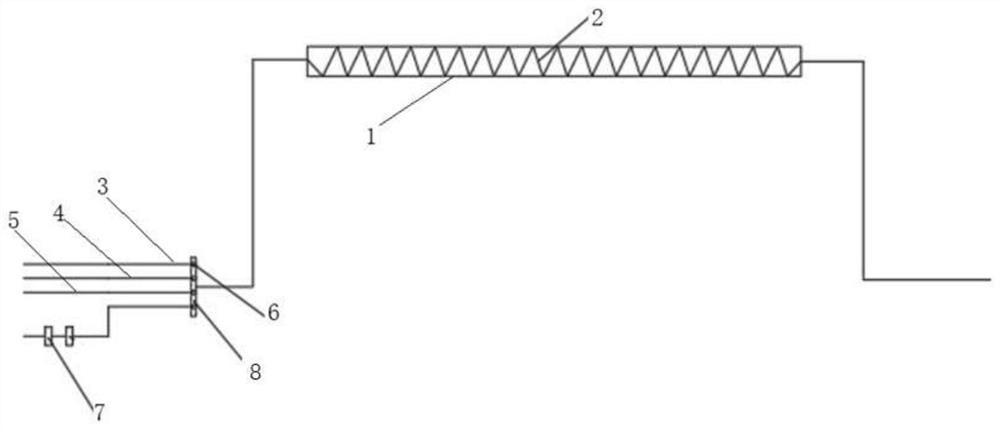

Molten iron desulfurization device and method

PendingCN113699316ASmall granularityHigh specific surface areaProcess engineeringManufacturing engineering

The invention belongs to the technical field of molten iron desulfurization, and discloses a molten iron desulfurization device and method. The molten iron desulfurization device comprises a blowing gas source, a stock bin, a conveying pipe, a desulfurization spray gun, a molten iron tank and a stirring paddle, the blowing air source is connected with the conveying pipe, and the stock bin is connected with the conveying pipe; the desulfurization spray gun is connected with the conveying pipe; the desulfurization spray gun is movably arranged in the molten iron tank; and the stirring paddle is arranged in the molten iron tank. The molten iron desulfurization device and method provided by the invention can greatly improve the dispersion degree and utilization rate of a desulfurizer.

Owner:BEIJING SHOUGANG CO LTD

Silicon-carbon negative electrode material and preparation method thereof

The invention provides a silicon-carbon negative electrode material and a preparation method thereof, belonging to the technical field of material preparation. The method specifically comprises the following steps: step 1, putting a nanoscale graphite substrate into a chamber of a settling device, and conducting sufficient heating to remove moisture under the protection of nitrogen gas; step 2, introducing a gas mixture of inert gas containing a silicon source and hydrogen at a high temperature, and uniformly settling nanoscale elemental silicon generated by a reaction in the graphite base mentioned in the step 1 under high-temperature catalysis; and step 3, introducing a gas carbon source into a silicon-carbon composite negative electrode material prepared in the step 2 under the protection of inert gas, and performing sintering treatment with a temperature controlled to be 400-600 DEG C, thereby finally obtaining the carbon-coated silicon-carbon negative electrode material. The novelpreparation method provided by the invention is simple, and the whole preparation process is completed in one step; and a prepared sample does not need to be transferred and prepared multiple times,and the whole preparation process is short in time and can be completed within 24 hours.

Owner:南京同宁新材料研究院有限公司

Cement sealing curing agent and preparation method thereof

The invention discloses a cement sealing curing agent and a preparation method thereof. The curing agent is prepared by mixing component A and component B at a ratio of 6:1, and the raw material formula of component A includes sodium polysilicate, polysilicic acid Lithium, hydroxyethyl cellulose, zeolite, metakaolin, sodium dihydrogen phosphate, wetting agent, penetrant, defoamer, surface modifier, stabilizer, deionized water, the raw material formula of component B includes aliphatic Urethane Acrylate, Trimethylolpropane Triacrylate, Nano Graphene Oxide, Nano Iron, Aluminum Hydroxide, Aluminum Sulfate, Sodium Hydroxide, Deionized Water. The permeability of the present invention is stronger, which greatly improves the strength and wear resistance of the surface layer of the concrete structure, and prolongs the service life of the ground. Component A of the curing agent can be used alone, but under the action of component B, it will be greatly To shorten the curing time and increase its strength to a certain extent, component B plays a synergistic effect on component A.

Owner:力特克新材料(广东)有限公司

Low-concentration flue gas desulfurization method for hydroelectric silicon smelting

ActiveCN109482048AReduce emission concentrationReduce generationDispersed particle separationParticulatesSorbent

The invention discloses a low-concentration flue gas desulfurization method for hydroelectric silicon smelting. The method comprises the following steps: 1) preparing absorption slurry, namely fully uniformly mixing a desulfurization adsorbent ground to the granularity of 325-400 meshes and water so as to obtain the absorption slurry; 2) absorbing acid gas, namely enabling the absorption slurry and flue gas to be fully contacted in a desulfurizing tower when flue gas during hydroelectric silicon smelting enters a desulfurization system, so that acid gas and particles in the flue gas are absorbed by the absorption slurry; and 3) discharging the flue gas, namely detecting the emission concentration of SO2 at the outlet, discharging the SO2 while meeting requirements, if not, returning to thedesulfurization system to treat, filtering the absorption slurry after absorption, and returning the filtrate to the step (2) to serve as absorption liquid, and taking the filter residues as by-products for sales, thereby obtaining the product. According to the method disclosed by the invention, limestone and other desulfurization adsorbents are mixed with water to prepare the absorption slurry,the flue gas enters the desulfurization system to be fully contacted with the slurry, and the acid gas and particles are removed, so that the emission concentration of sulfur dioxide in the flue gas is reduced to 80mg / Nm3, and green and environmental-friendly production is effectively realized.

Owner:云南永昌硅业股份有限公司

Method for continuously preparing polyester polyol and device used in method

The invention discloses a method for continuously synthesizing polyester polyol and a device used in the method. A solid raw material, namely acid or acid anhydride, and liquid polyol are used for synthesizing the polyester polyol in the presence of a catalyst. The method comprises the following steps of: preheating to melt the solid raw material for synthesizing the polyester polyol or slurrying in an alcoholic solution to obtain slurry, adding the catalyst, injecting the slurry into a slurry tank, metering by using a first metering pump, adding into a reaction kettle into which part of polyol is put in advance, starting a circulating pump to ensure that reaction liquid in the reaction kettle is circulated and fully reacted, and reacting according to the conventional steps under the conventional reaction conditions; and when an acid value is less than 1mgKOH / g, starting a second metering pump, continuously adding the polyol for reaction into the reaction kettle, continuously adding the slurry in the slurry tank into the reaction kettle, opening a discharge port at the upper end, and continuously discharging. The raw material is fluidized in advance, so that a high specific surface area and pipeline liquidity are achieved, and continuous feeding is facilitated.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

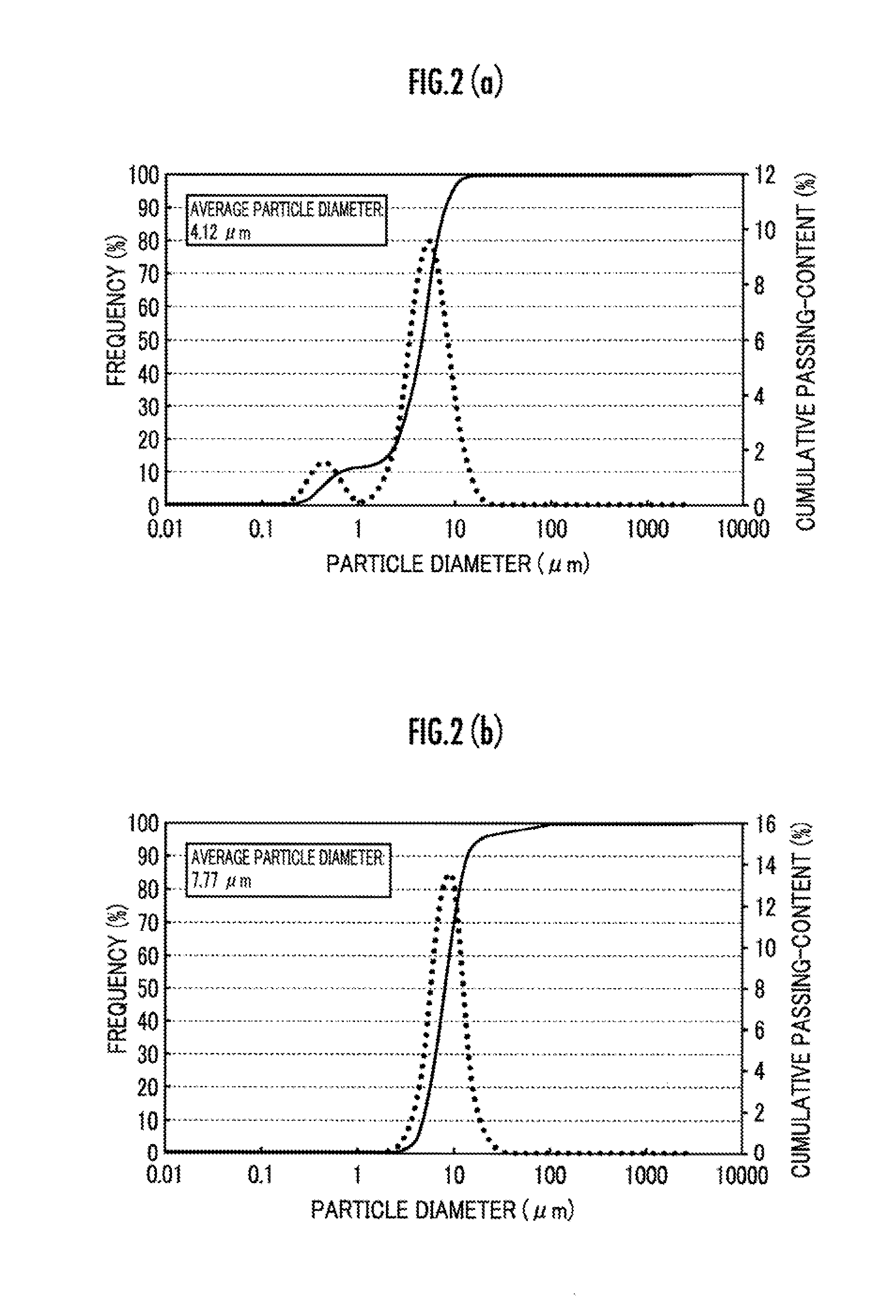

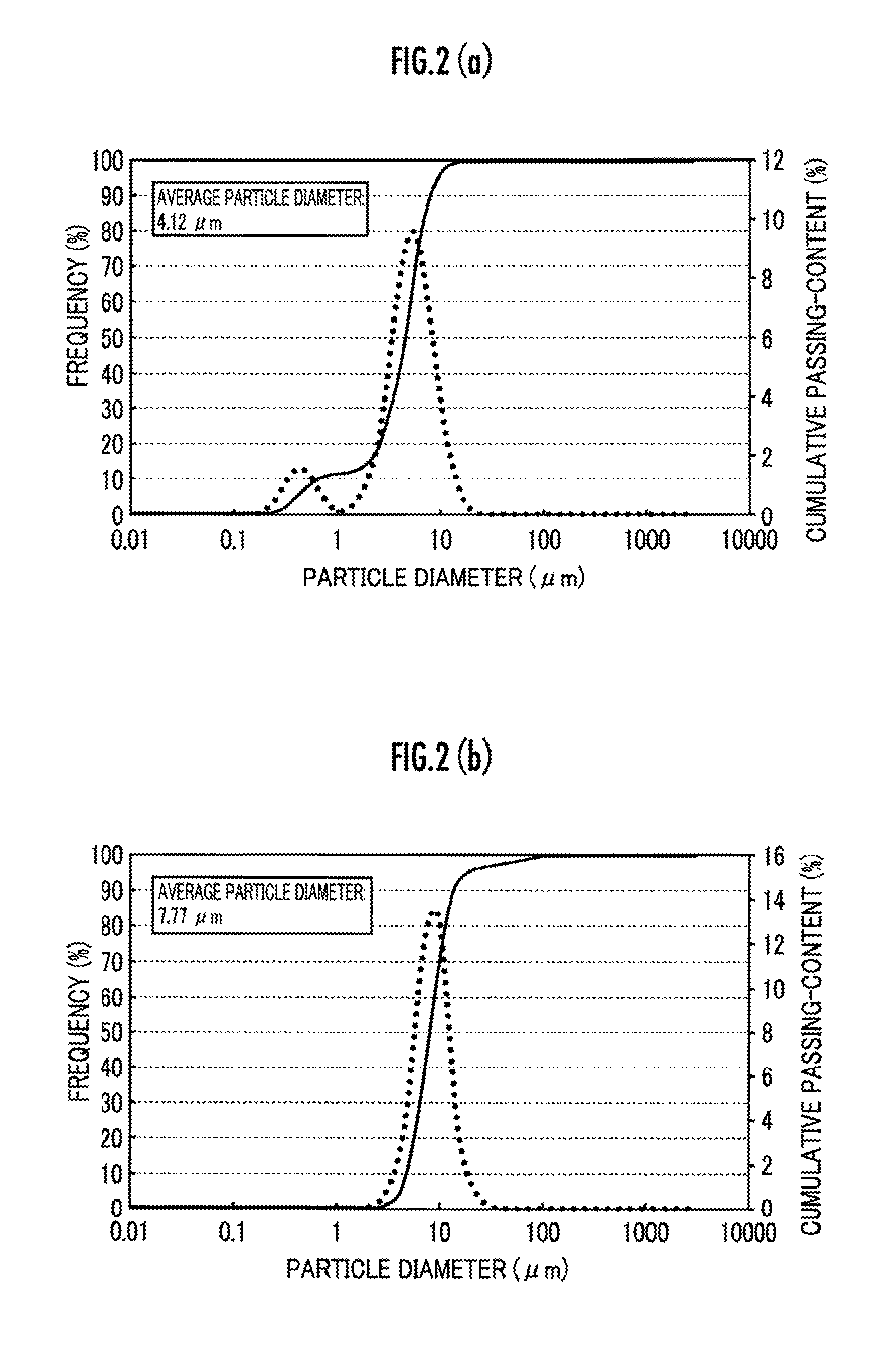

Sodium bicarbonate anti-hardening agent and application method thereof

PendingCN113233479ARaw materials are easy to obtainLow priceAlkali metal carbonates moisture absorption preventionSodium bicarbonateSilicon oxide

The invention particularly relates to a baking soda anti-hardening agent and an application method thereof.The baking soda anti-hardening agent is prepared from, by mass, 2-12 parts of silicon dioxide, 2-12 parts of talcum powder, 2-12 parts of magnesium hydroxide, 2-12 parts of magnesium oxide and 2-12 parts of calcium oxide, the particle size range of silicon dioxide is 4.5-5 micrometers, the particle size range of talcum powder is 6-6.5 micrometers, the particle size range of magnesium hydroxide is 6-6.5 [mu]m, the particle size range of magnesium oxide is 6-6.5 [mu]m, and the particle size range of calcium oxide is 6-6.5 [mu]m. The baking soda anti-hardening agent and baking soda are uniformly mixed according to a ratio of 1:4 and then are stored. The anti-hardening agent for the baking soda can effectively prevent the baking soda from hardening, the influence on the desulfurization effect of the baking soda is very small, the desulfurization efficiency can reach 98% or above, and the use method is simple.

Owner:安徽京科环境发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com