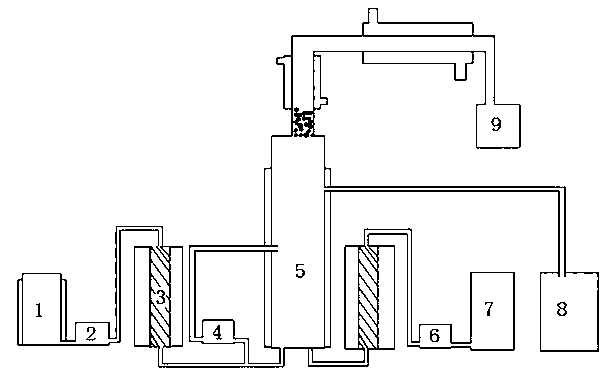

Method for continuously preparing polyester polyol and device used in method

A technology for polyester polyol and polyol, applied in the field of polyester polyol, can solve the problems of high energy consumption and long time-consuming synthesis process, and achieve the advantages of increasing the reaction contact surface, facilitating continuous feeding, and increasing the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw materials: terephthalic acid, diethylene glycol, glycerin, catalyst;

[0026] Diethylene glycol, glycerin and terephthalic acid with a molar ratio of 1:0.2:1 are refined and injected into the raw material tank, and the heat preservation and stirring are started to prevent sedimentation. The reactor is filled with a feed pump and 0.03% of the catalyst is added. Raise the temperature and turn on the circulating pump to make the material circulate and react. When the water comes out from the top of the kettle, turn on the condensed water to keep the top temperature at 100-102°C; gradually raise the temperature to 260°C, and vacuumize from the water tank to gradually <0.09MPa; When the acid value of the material in the kettle drops to 1mgKOH / g, the feed pump and outlet can be turned on to realize continuous reaction.

Embodiment 2

[0028] Raw materials: terephthalic acid, diethylene glycol, neopentyl glycol, catalyst;

[0029] Refining diethylene glycol, neopentyl glycol and terephthalic acid with a molar ratio of 1:0.3:1 are poured into the raw material tank and turned on for heat preservation and stirring to prevent sedimentation. Fill the reactor with a feed pump and add 0.05% of Catalyst, heat up and turn on the circulating pump to make the material circulate and react, turn on the condensed water when the water comes out from the top of the kettle, keep the top temperature at 100-102°C; gradually increase the temperature to 260°C, vacuumize from the water tank, gradually <0.09MPa ; When the acid value of the material in the kettle drops to 1mgKOH / g, the feed pump and outlet can be opened to realize continuous reaction.

Embodiment 3

[0031] Raw materials: terephthalic acid, diethylene glycol, neopentyl glycol, catalyst;

[0032] Refining diethylene glycol, neopentyl glycol and terephthalic acid with a molar ratio of 1:0.3:1 are poured into the raw material tank and turned on for heat preservation and stirring to prevent sedimentation. Fill the reactor with a feed pump and add 0.05% of Catalyst, heat up and turn on the circulating pump to make the material circulate and react, turn on the condensed water when the water comes out from the top of the kettle, keep the top temperature at 100-102°C; gradually increase the temperature to 260°C, vacuumize from the water tank, gradually <0.09MPa ; When the acid value of the material in the kettle drops to 1mgKOH / g, the feed pump and outlet can be opened to realize continuous reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com