Zero-discharge system for desulfurization wastewater

A desulfurization wastewater and zero-discharge technology, which is applied in the direction of gaseous effluent wastewater treatment, water pollutants, water/sewage treatment, etc., can solve the problems of high construction costs and treatment costs, large and complex systems, and high operating costs, and reduce construction costs. The effect of cost and operating cost, less process equipment and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

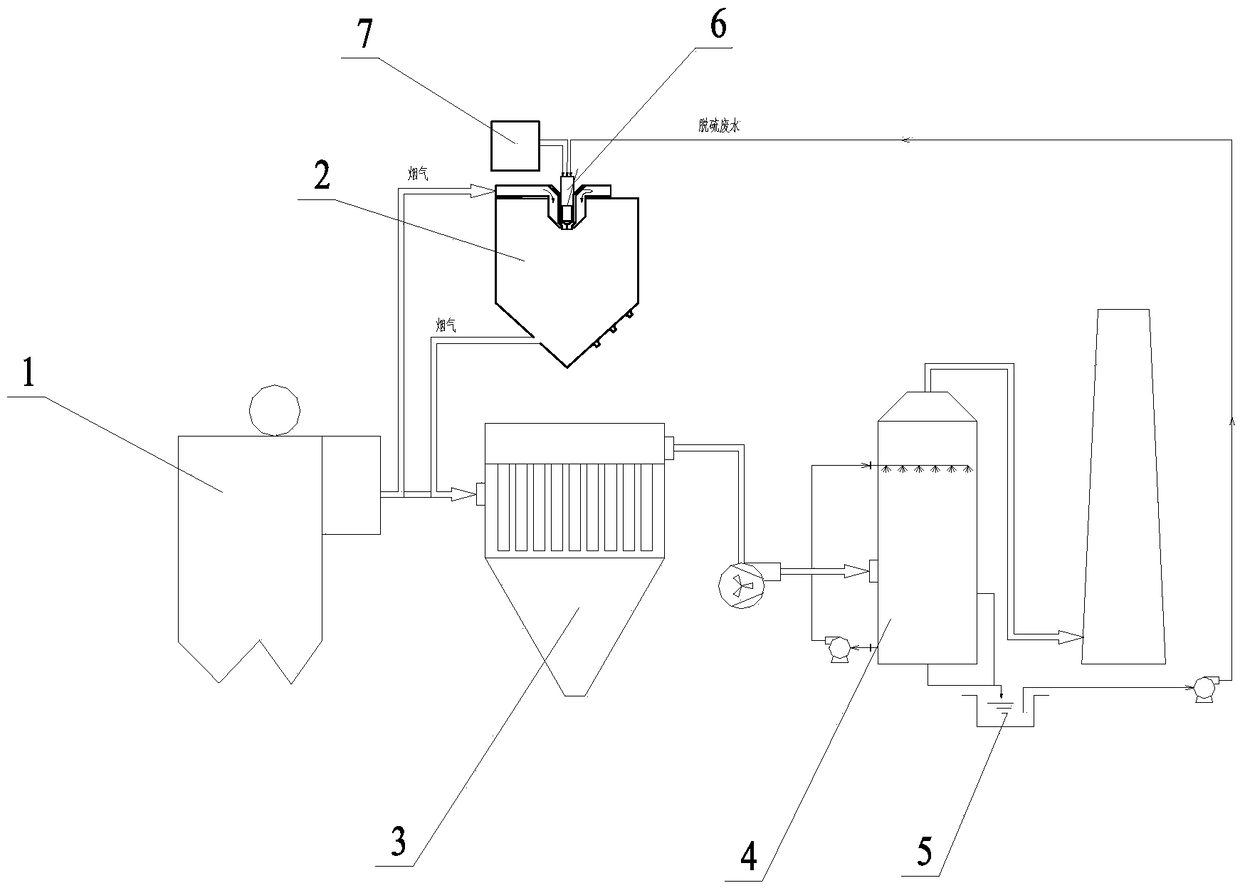

[0024] Embodiment: A zero discharge system for desulfurization wastewater, comprising a boiler 1, a drying tower 2, a dust collector 3 and a desulfurization tower 4, the top of the drying tower 2 is provided with a flue gas inlet, the bottom of the drying tower 2 is provided with a flue gas inlet, and the drying The flue gas inlet of tower 2 is connected with the outlet of boiler 1, the flue gas outlet of drying tower 2 is connected with the inlet of dust collector 3, the outlet of dust collector 3 is connected with the inlet of desulfurization tower 4 through the fan, and the outlet of desulfurization tower 4 is connected with waste water Pool 5 is connected, and waste water is discharged into waste water pool 5.

[0025] The upper part of the drying tower 2 is a cylindrical structure, the lower part is an inverted pyramid structure, and the horizontal angle of the lower vertebral body is greater than 60°. The bottom of the drying tower 2 is also provided with a heat tracing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com