Patents

Literature

254 results about "Aluminum thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

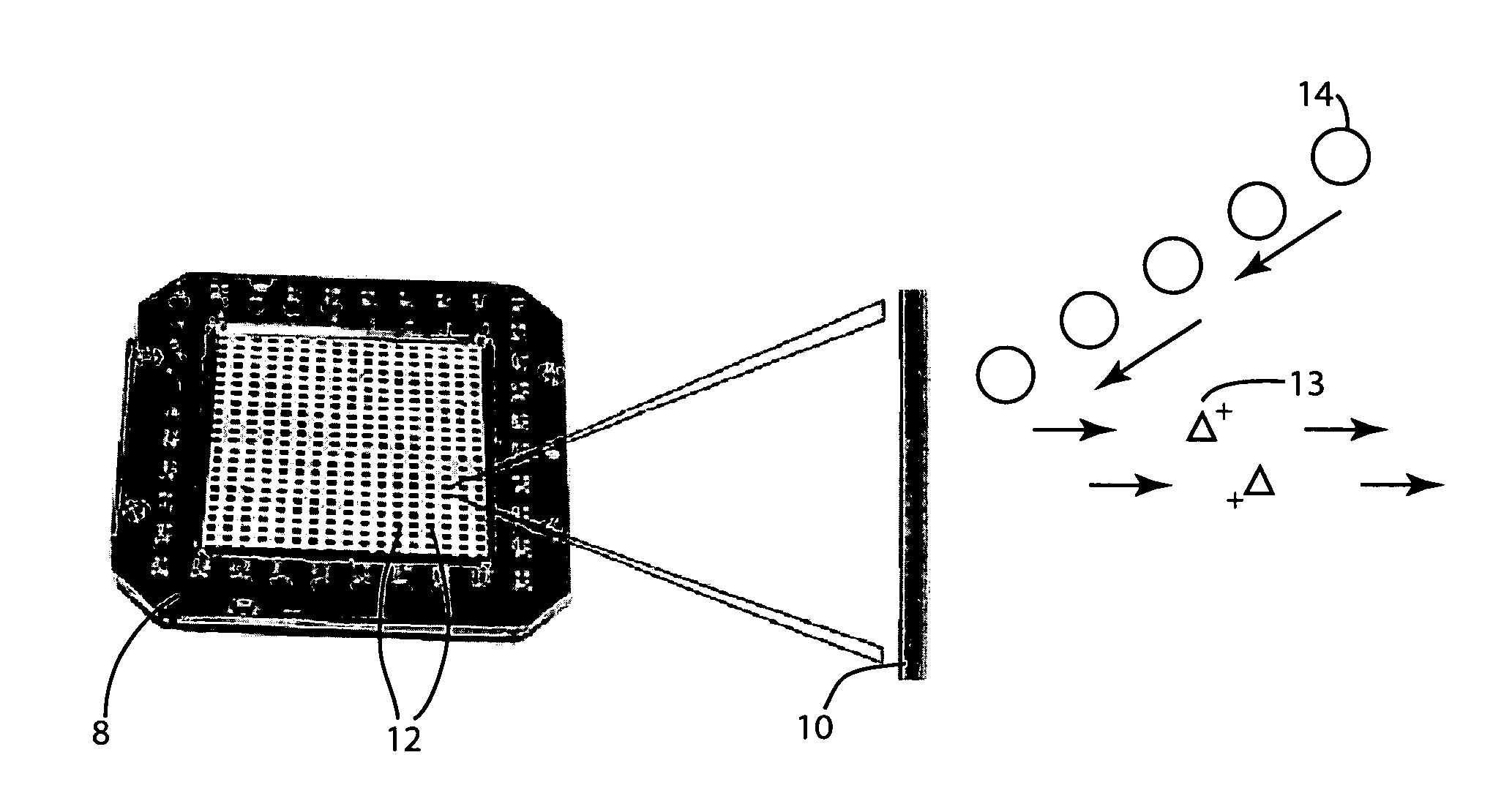

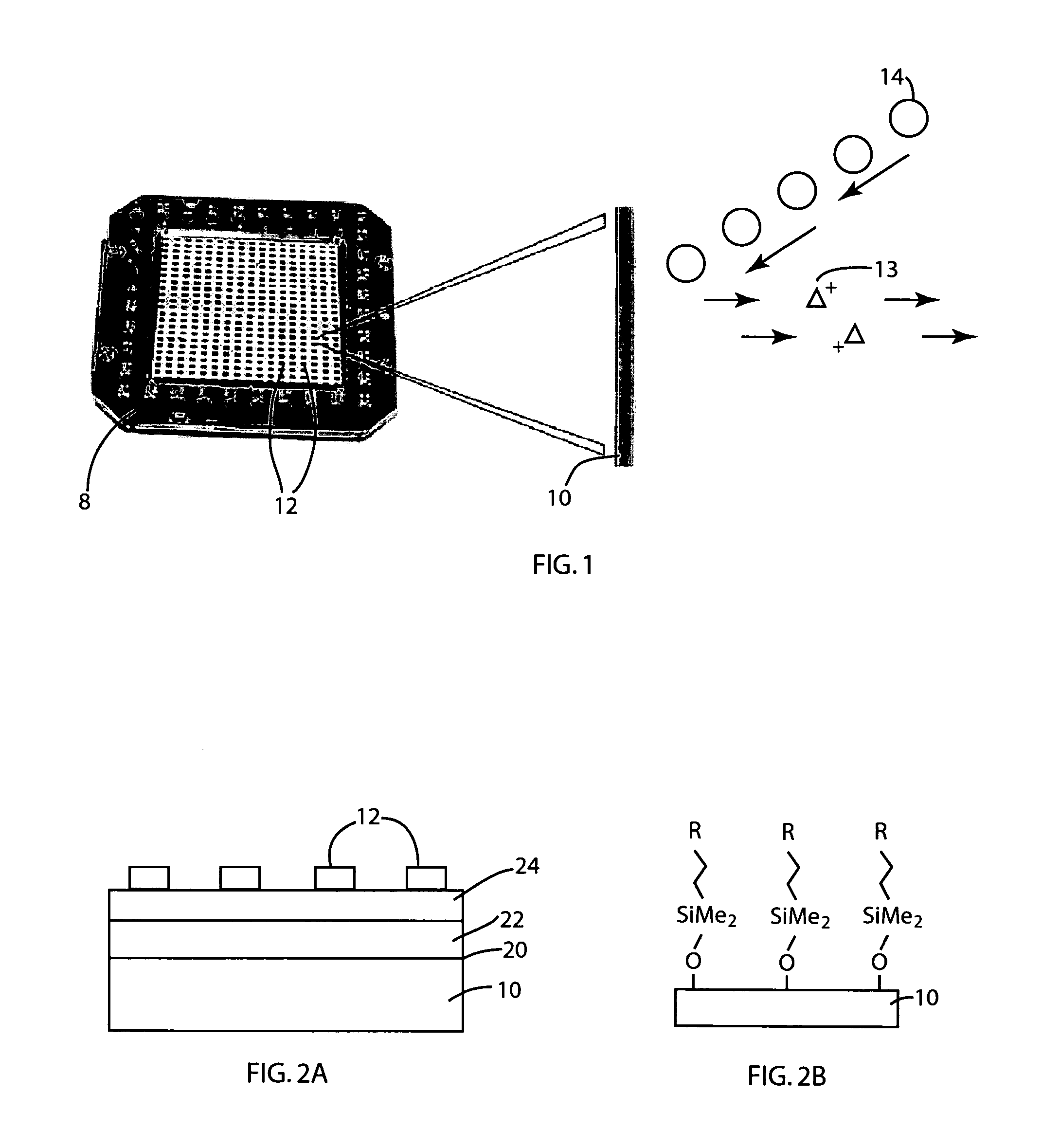

Nanostructured thin films and their uses

InactiveUS20080073505A1Improve uniformityStrong adhesionNanotechSamples introduction/extractionNano structuringThin membrane

The present invention generally discloses the use of a nanostructured non-silicon thin film (such as an alumina or aluminum thin film) on a supporting substrate which is subsequently coated with an active layer of a material such as silicon or tungsten. The base, underlying non-silicon material generates enhanced surface area while the active layer assists in incorporating and transferring energy to one or more analytes adsorbed on the active layer when irradiated with a laser during laser desorption of the analyte(s). The present invention provides substrate surfaces that can be produced by relatively straightforward and inexpensive manufacturing processes and which can be used for a variety of applications such as mass spectrometry, hydrophobic or hydrophilic coatings, medical device applications, electronics, catalysis, protection, data storage, optics, and sensors.

Owner:NANOSYS INC

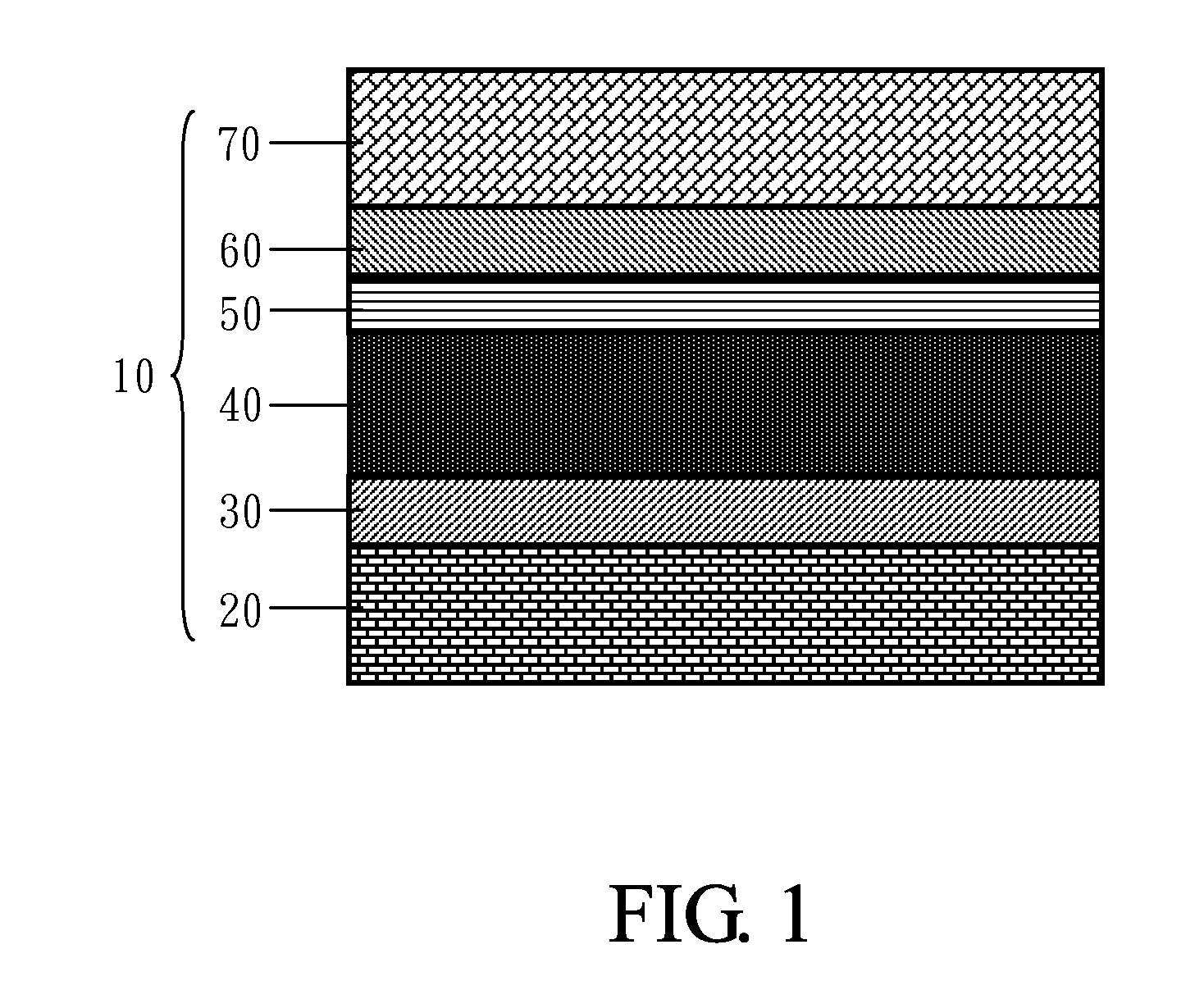

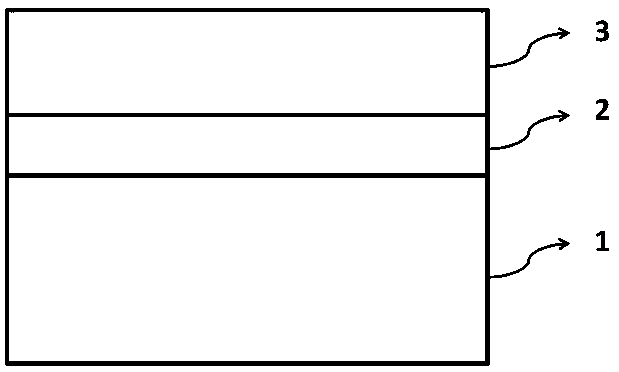

Aluminum film packaging materials used for lithium batteries

ActiveUS20150104698A1Maintain good propertiesEffectively extended service lifeJackets/cases materialsLi-accumulatorsConductive coatingTemperature resistance

A method for lithium aluminum film packaging materials, with water, high temperature and corrosion resistance, the substrate layer, and then layer, aluminum foil layer, anti-corrosion layer, adhesive layer and the inner layer together constitute from the outermost to innermost layer laminate structure in which one side of the aluminum foil layer, or both side surface of the conductive coating material to said coating and curing anticorrosive layer, and the use of fluorine-containing polyurethane resin constituting the laminated rubber layer and the inner layer of corrosion between the adhesive layer, used lithium batteries as plastic film packaging applications, it can promote lithium battery with Merit water resistance, high temperature resistance and corrosion resistance, and enhance the use of lithium batteries in years.

Owner:NANYA PLASTICS CORP

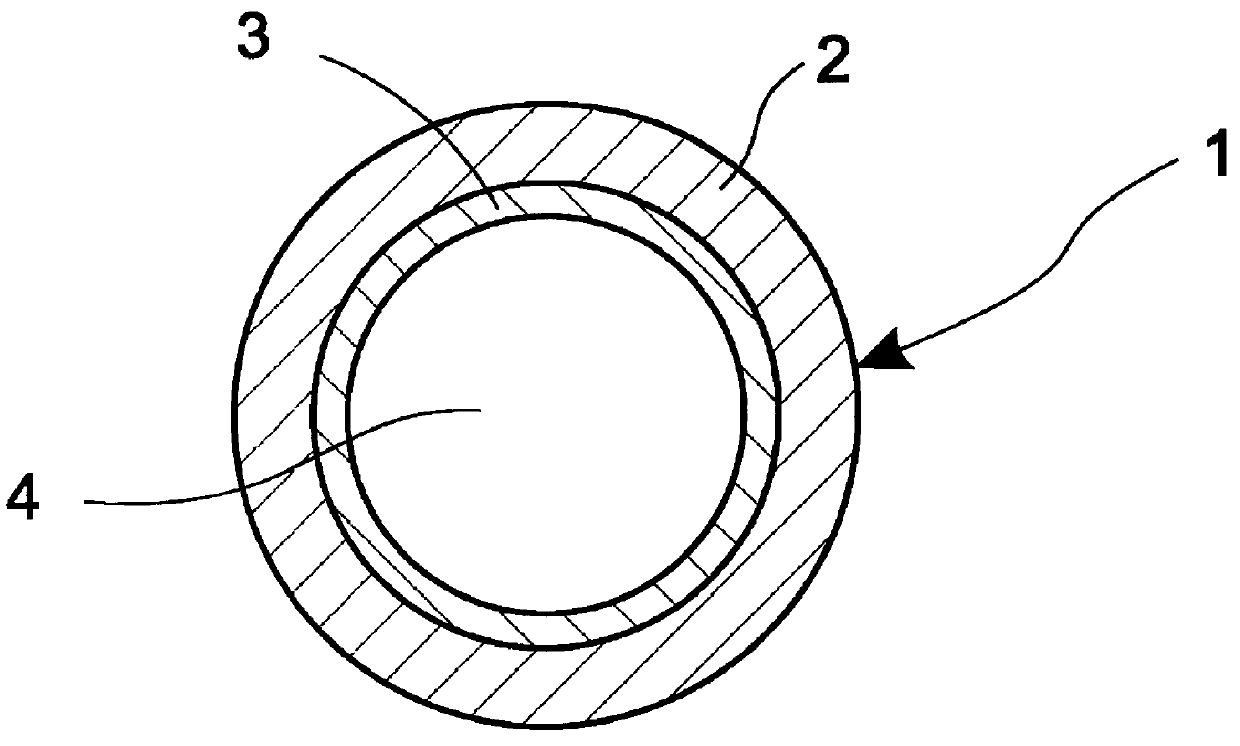

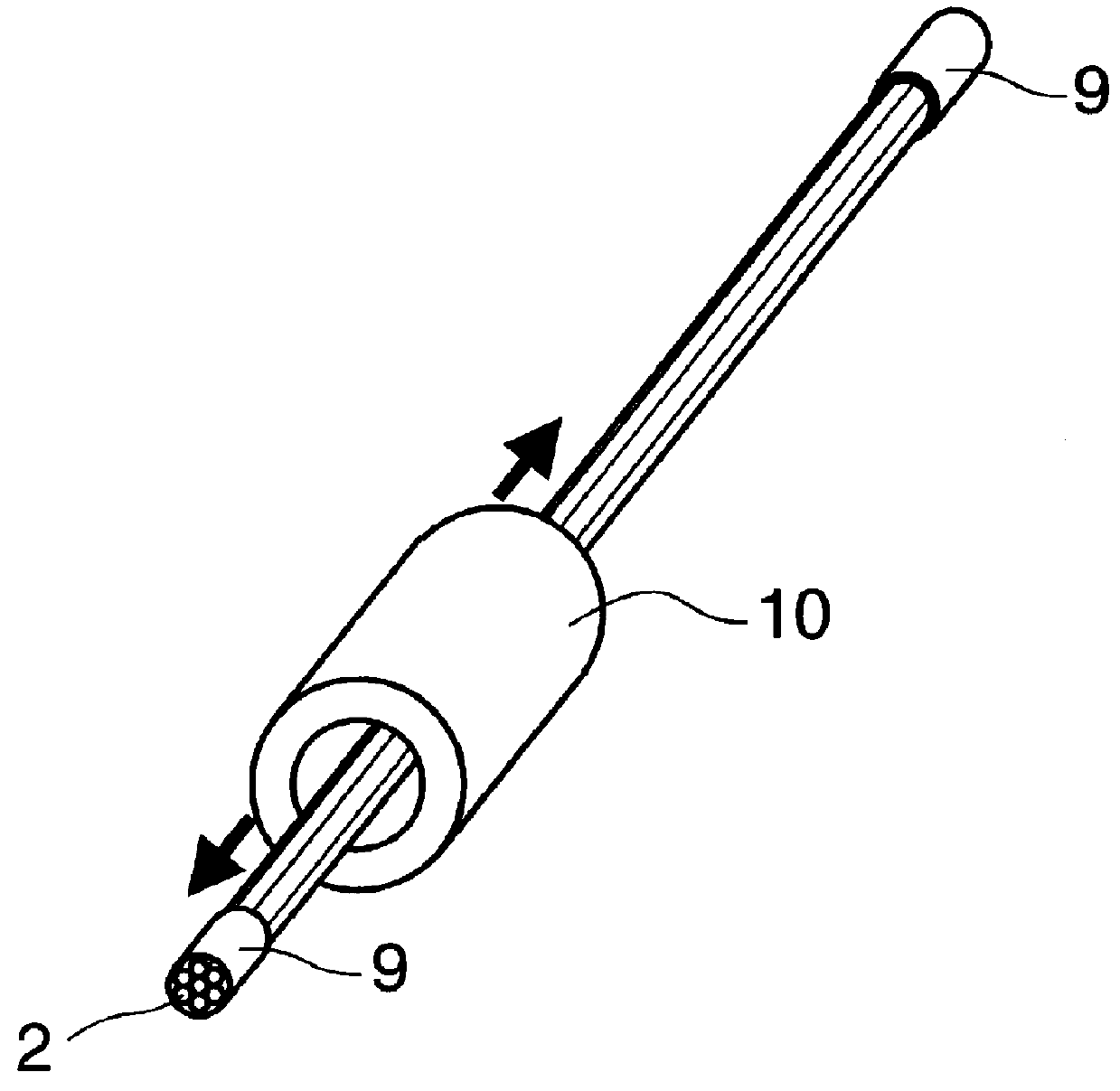

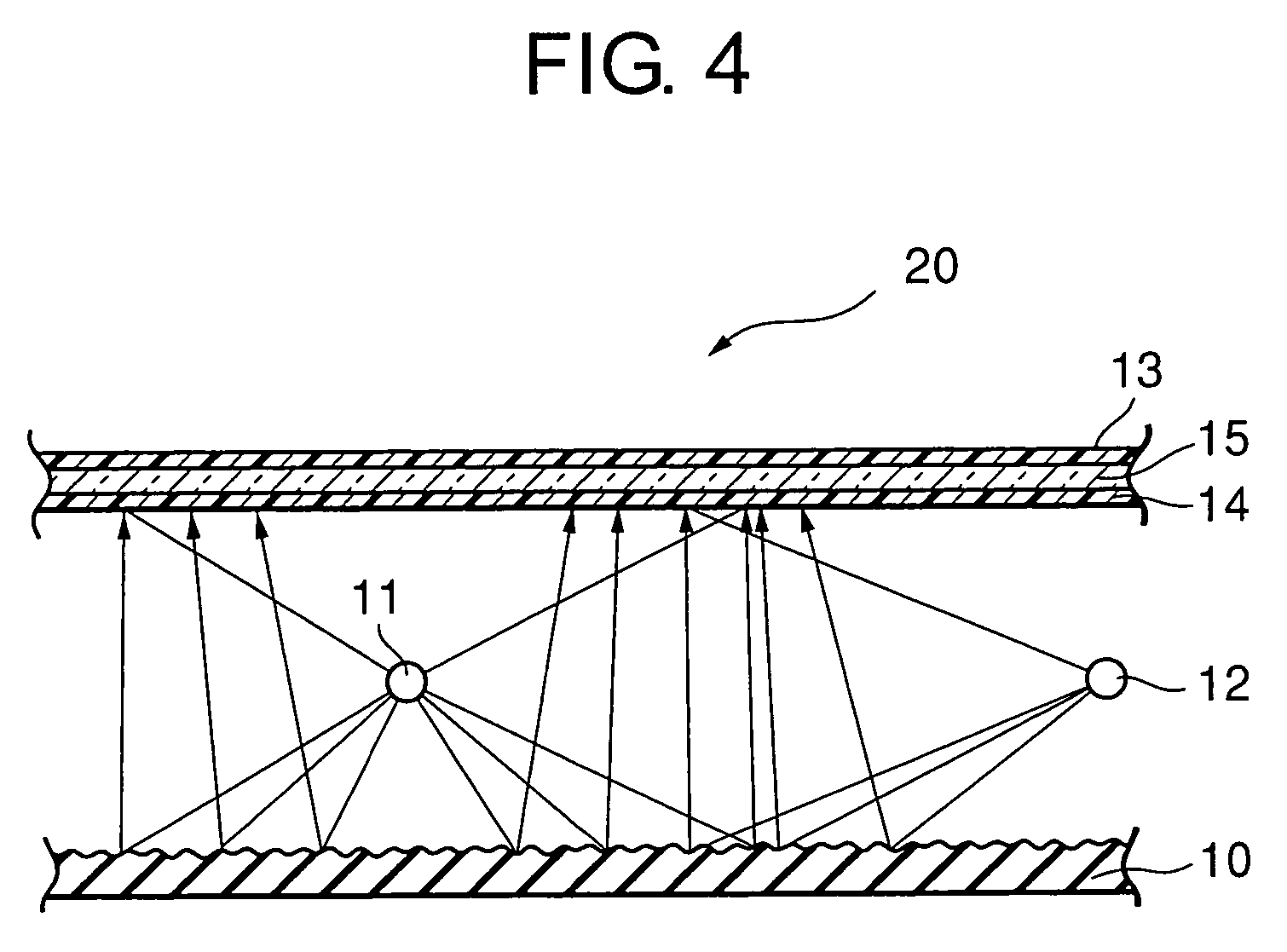

Hollow waveguide for ultraviolet light and making the same

InactiveUS6141476ACladded optical fibreOptical waveguide light guideUltrasound attenuationUltraviolet lights

A hollow waveguide that transmits ultraviolet light with low attenuation. The present invention comprises a small-diameter, thin-wall, glass tube and a thin aluminum film on the inner surface of the glass tube. The aluminum film is deposited by a chemical vapor deposition method using an organometallic of aluminum as a precursor. The deposition process produces high smoothness of the film surface.

Owner:MATSUURA YUJI +1

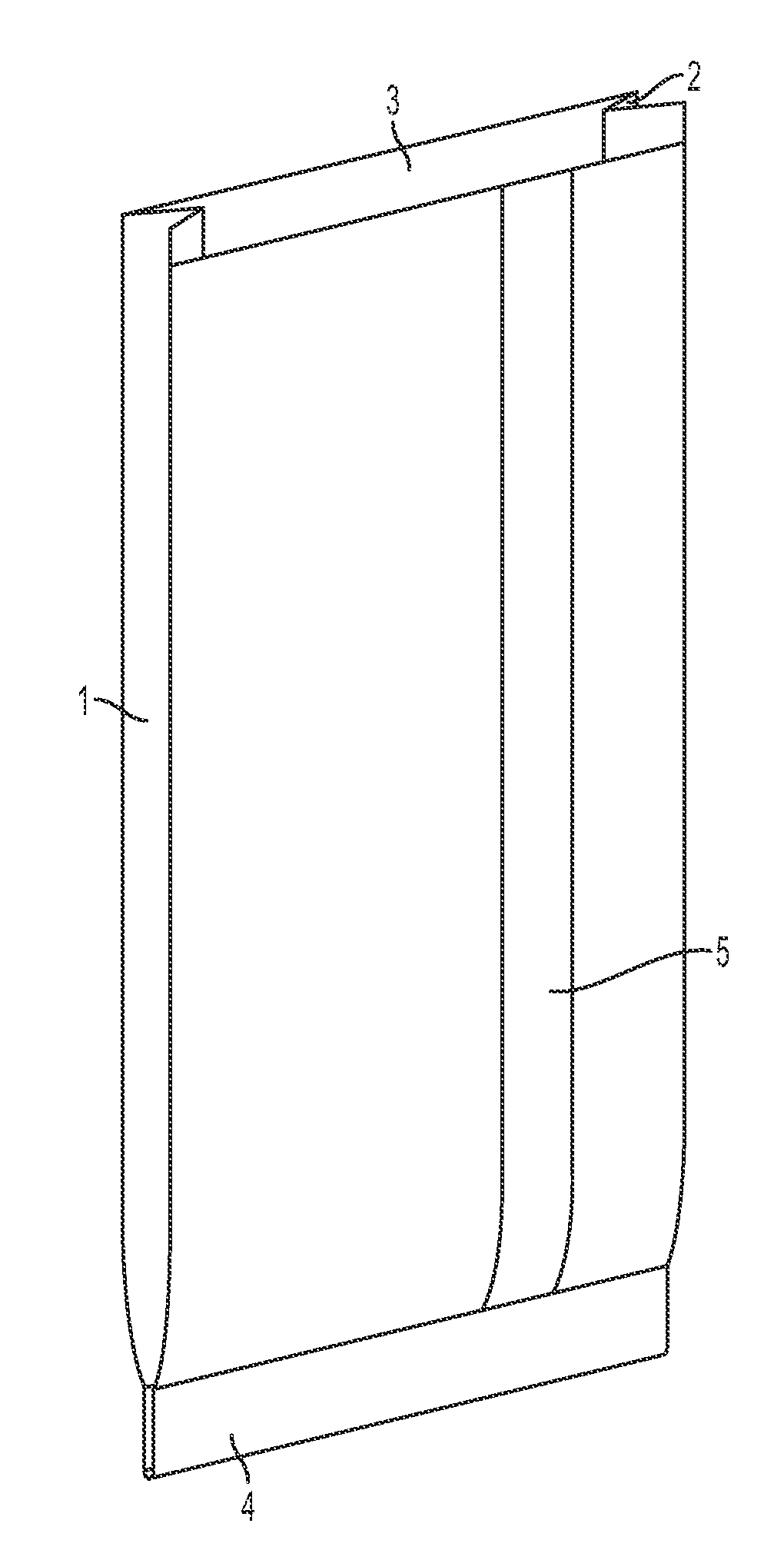

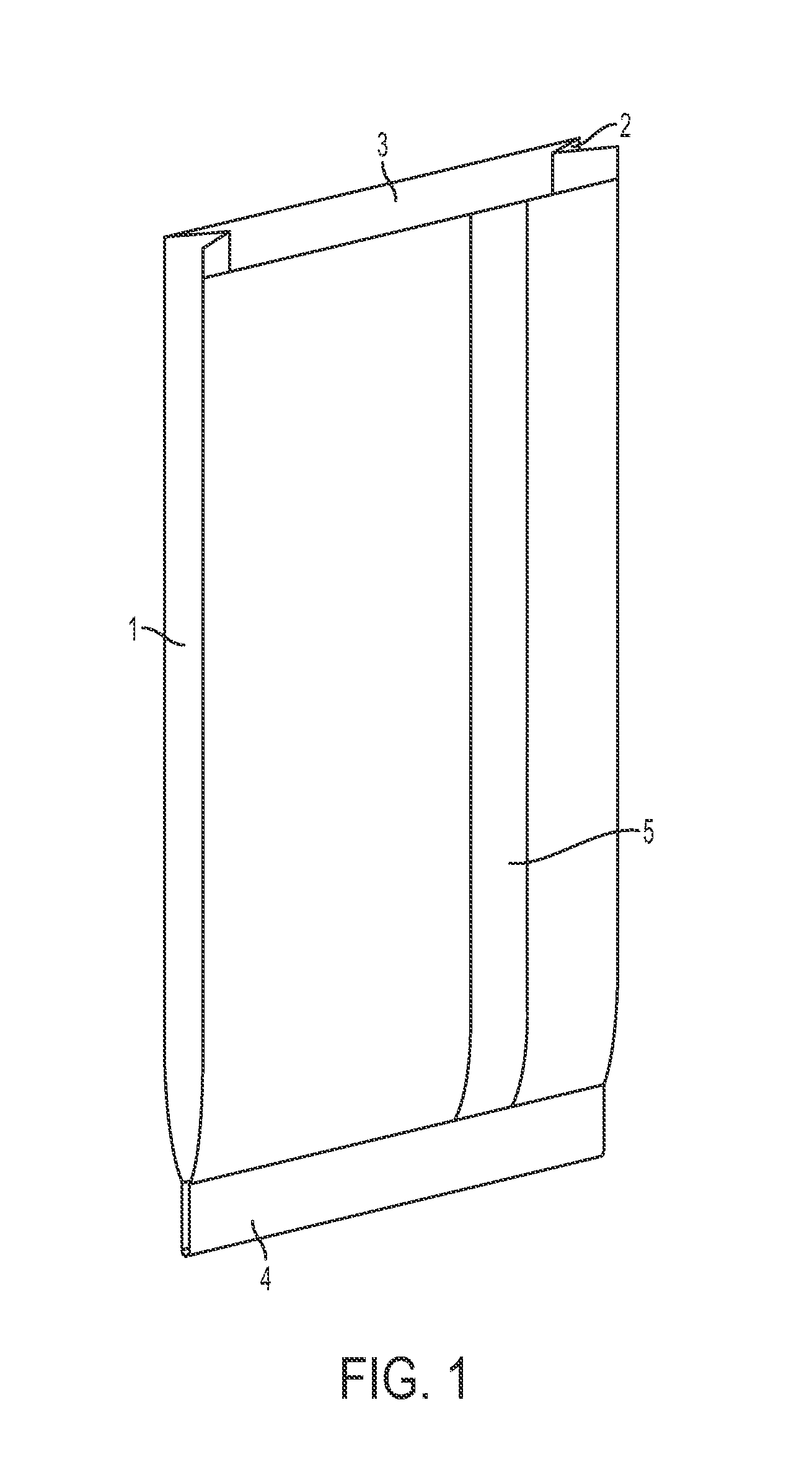

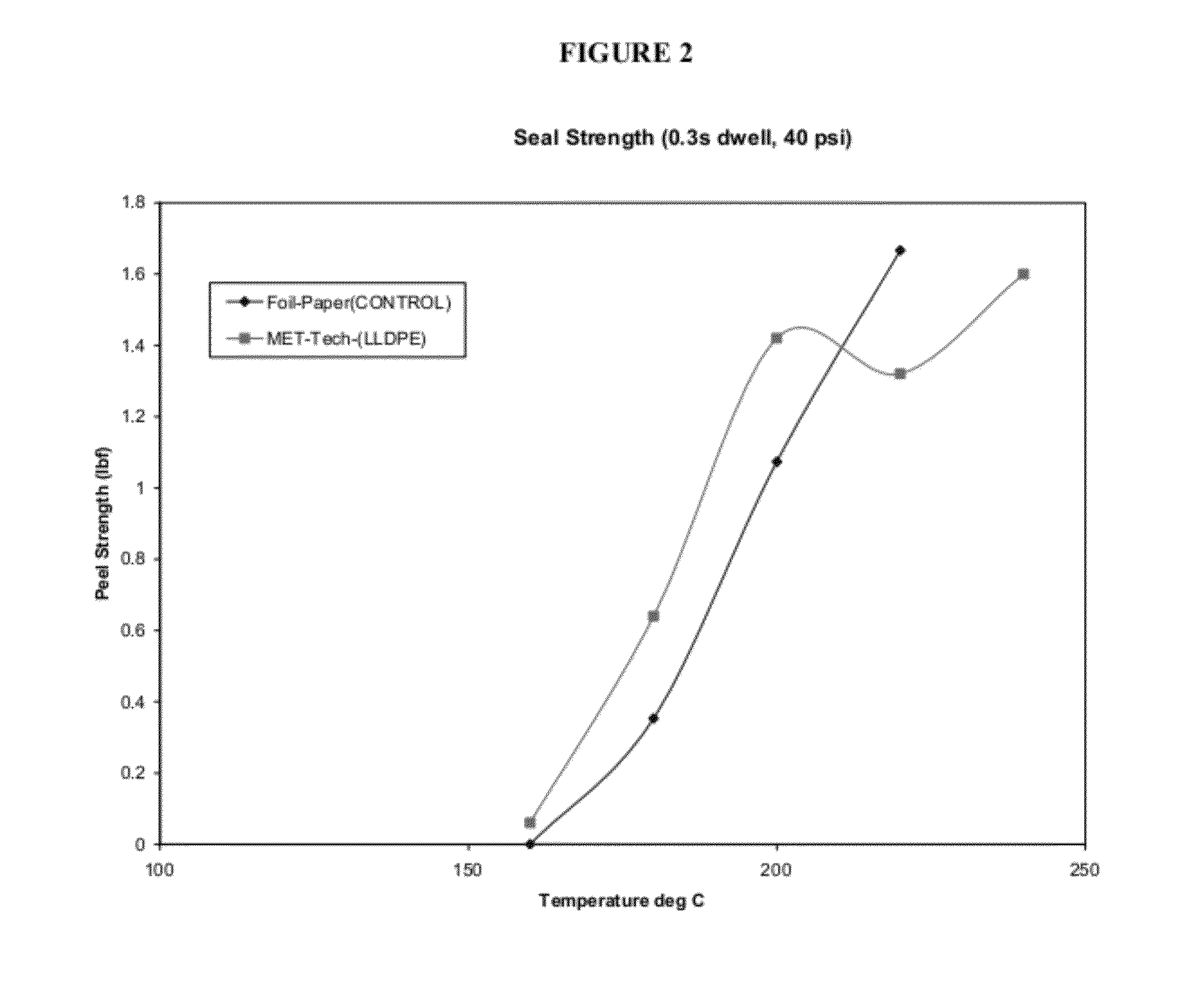

Laminate for packaging hygroscopic materials, pouches made therefrom, and method for manufacturing same

InactiveUS20120207954A1Good heat sealing performanceReduce water permeabilityBag making operationsFlexible containers manufacturePuncture resistancePolymer

The present invention provides a novel packaging laminate designed particularly for packaging highly hygroscopic, pelleted, flowable materials. It is a multilayer structure which incorporates a layer of heat-sealable polymeric material which has had a thin film of aluminum deposited onto it by vapour coating. This layer combined with a further effective barrier layer provides the low WVTR in the range required by such highly hygroscopic materials. This laminate can be used with additional structural layers of paper or plastic, to form bags that have the features of very low WVTR, excellent puncture resistance, and excellent heat sealability.

Owner:HOOD PACKAGING

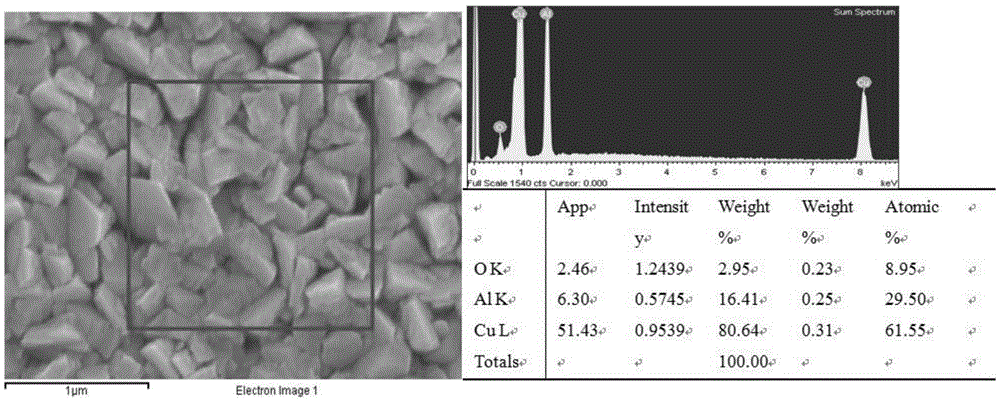

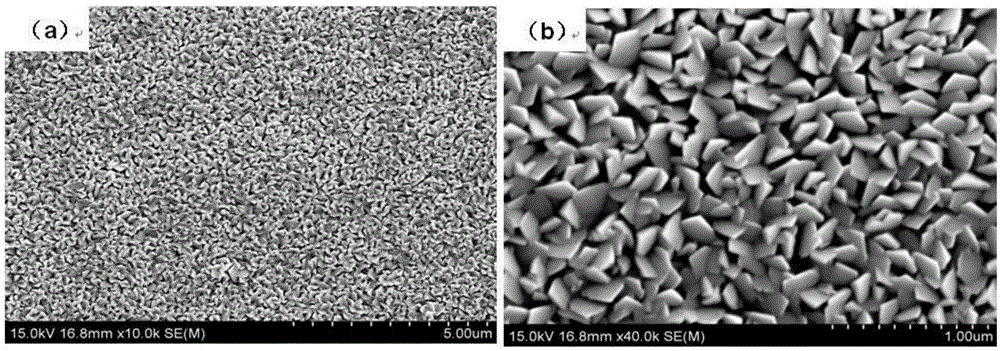

Method for preparing nano porous copper thin film material by magnetron sputtering

ActiveCN105543796AStructural continuityMeet the areaVacuum evaporation coatingSputtering coatingAlloyCopper foil

The invention relates to a method for preparing a nano porous copper thin film material by magnetron sputtering. The method takes a commercial copper foil as a base body material and takes high-purity copper target and aluminum target as sputtering materials; magnetron sputtering equipment is a preparation tool; a nano porous copper thin film is obtained by sputtering a copper-aluminum thin film through a glow discharge principle, and dealloying and corroding to remove an active component aluminum after annealing and alloying. The method provided by the invention is a two-step reaction method, the problems in the prior art that steps for carrying out smelting, ball milling and melt spinning on alloy auxiliary materials are complicated and consumed time is long are solved, and steps of a preparation process are simplified; a nano porous structure of nano porous copper is obtained and the size of the thin film is controllable; the obtained structure is better than a nano porous copper powder sample obtained by a traditional method; furthermore, an application range of the nano porous copper is enlarged and the nano porous copper has a commercial prospect.

Owner:SHANDONG UNIV

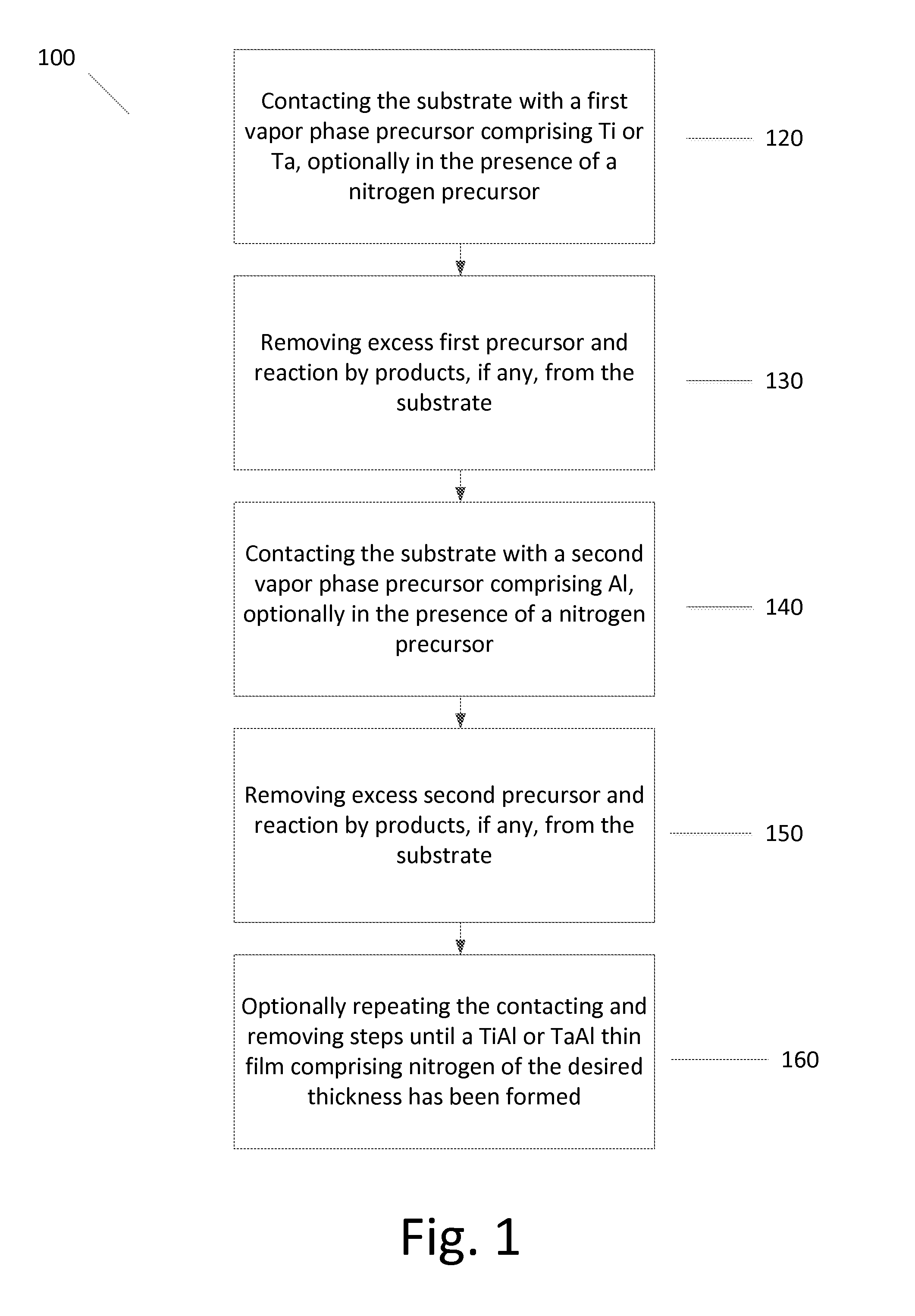

Titanium aluminum and tantalum aluminum thin films

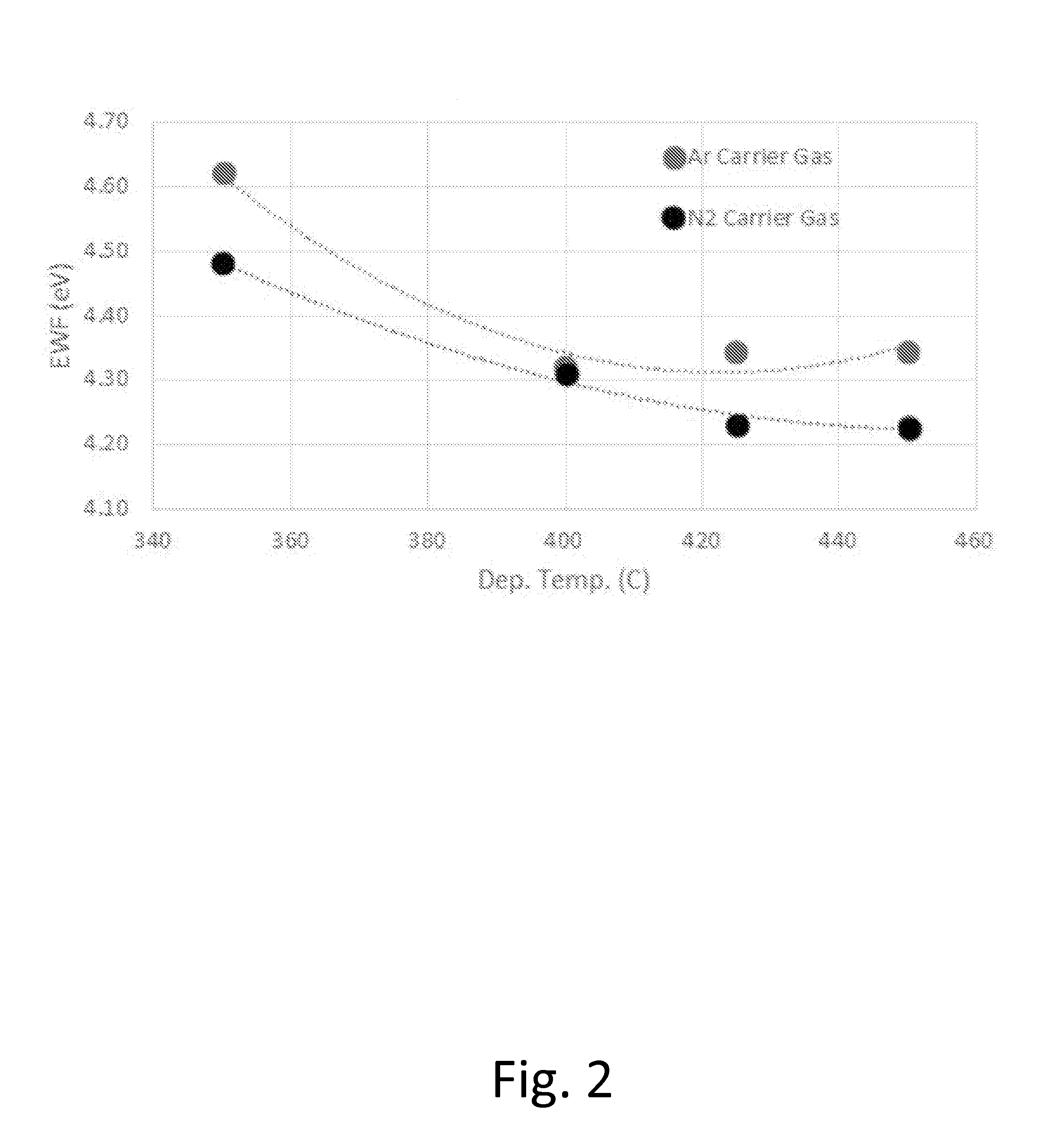

ActiveUS20160118261A1Aid removalSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseNitrogen

A process for depositing titanium aluminum or tantalum aluminum thin films comprising nitrogen on a substrate in a reaction space can include at least one deposition cycle. The deposition cycle can include alternately and sequentially contacting the substrate with a vapor phase Ti or Ta precursor and a vapor phase Al precursor. At least one of the vapor phase Ti or Ta precursor and the vapor phase Al precursor may contact the substrate in the presence of a vapor phase nitrogen precursor.

Owner:ASM IP HLDG BV

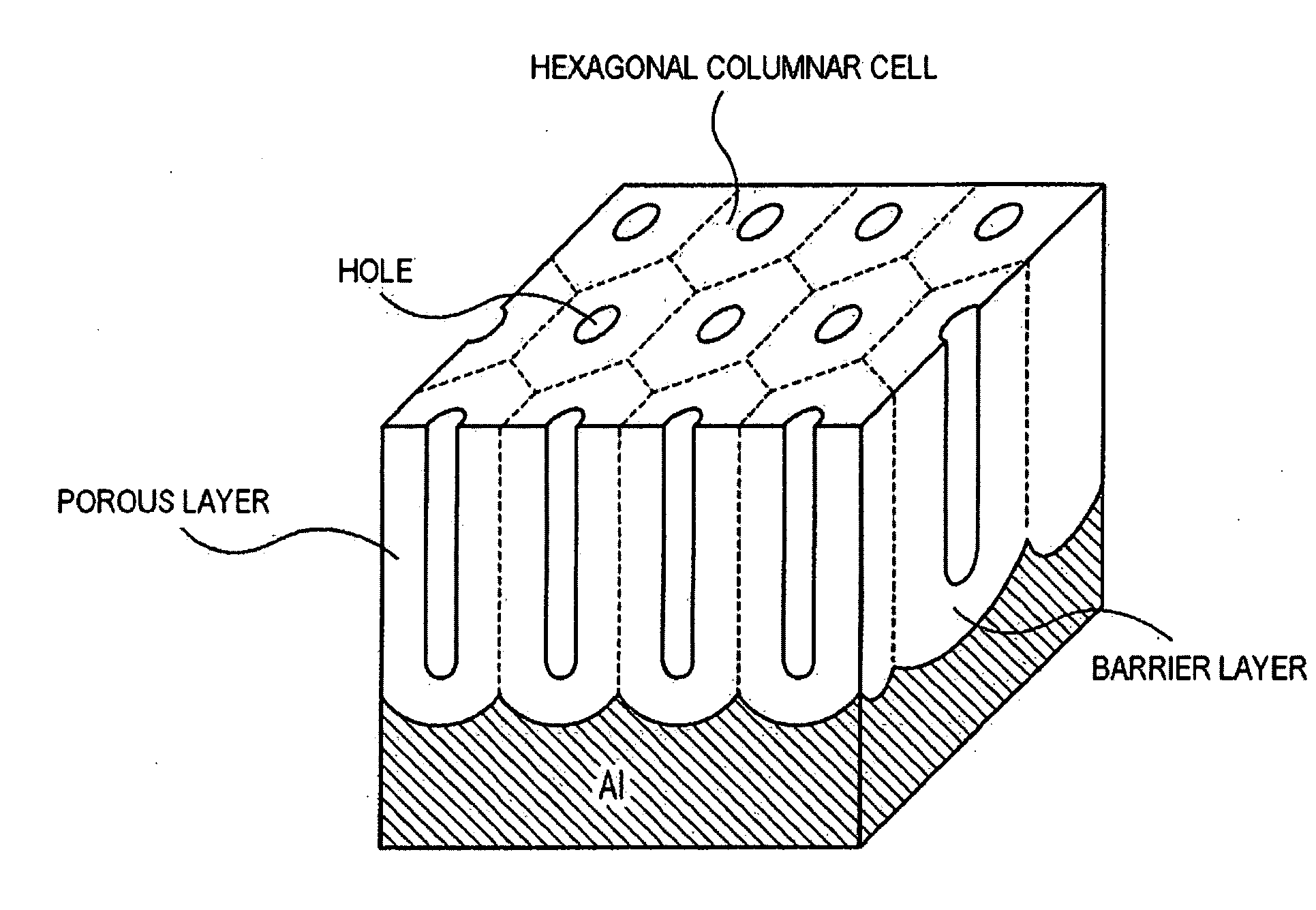

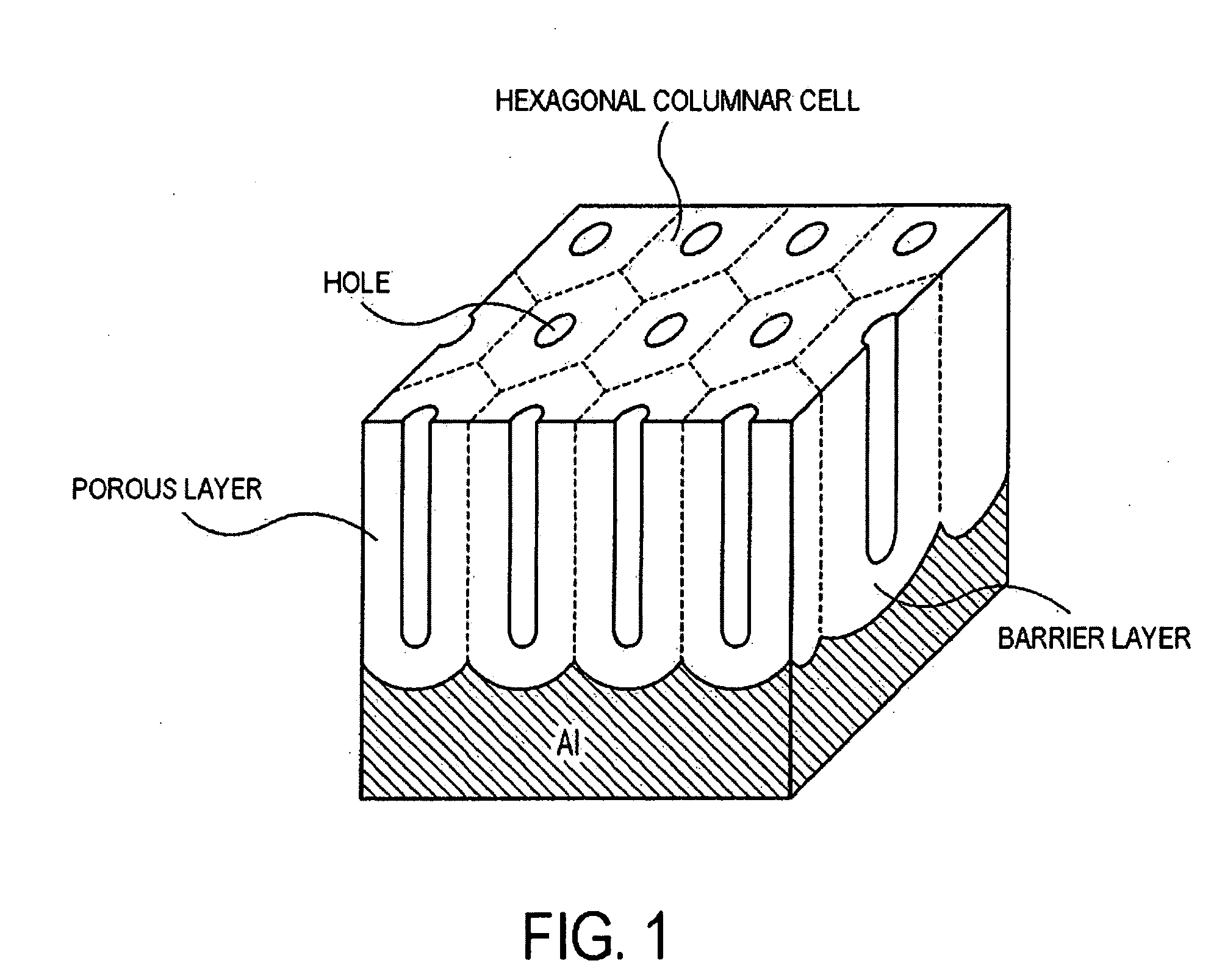

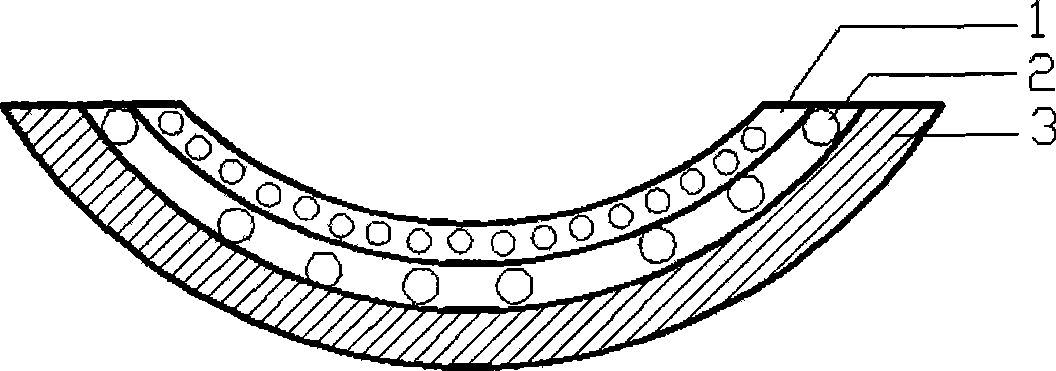

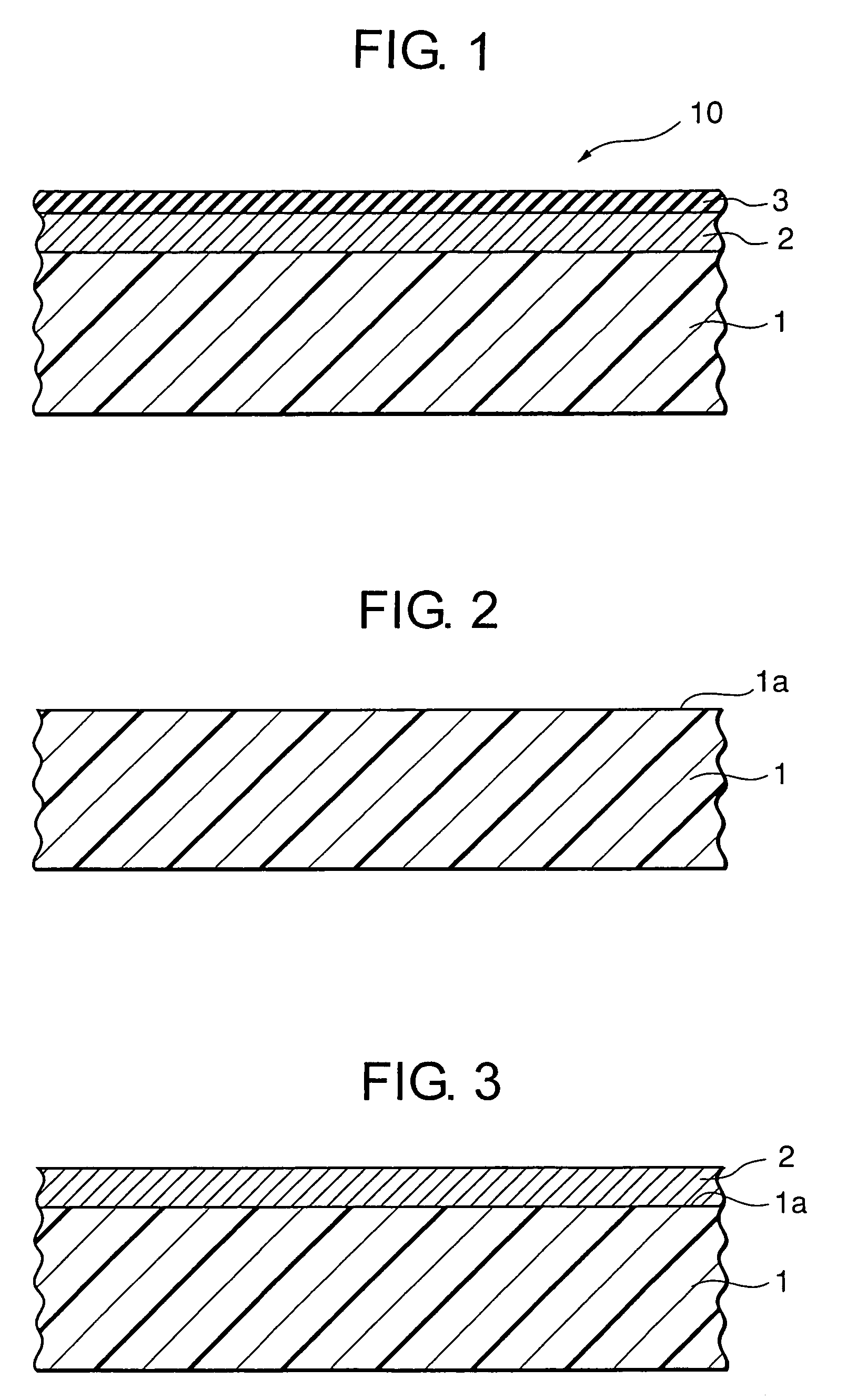

Method of fabricating an alumina nanohole array, and method of manufacturing a magnetic recording medium

InactiveUS20090145769A1Improve surface smoothnessReduce usageMagnetic layer production by platingPatterned record carriersGrain growthPatterned media

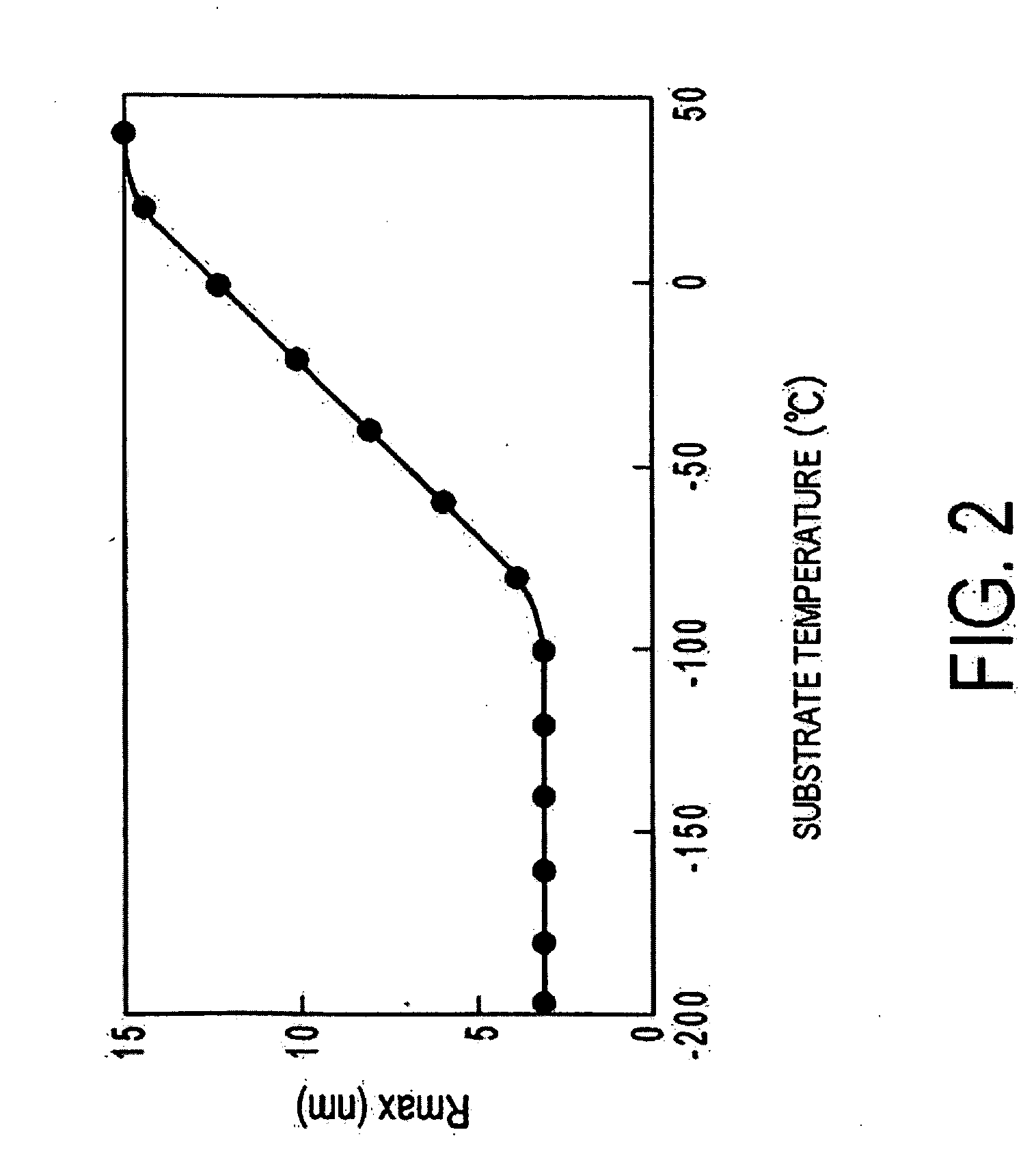

An alumina nanohole array and a method of fabricating the same includes the steps of forming an aluminum thin-film on a substrate at a substrate temperature of −80° C. or below so that crystal grain growth is suppressed, even when a high-purity aluminum material is used, thus providing improved surface smoothness; and anodizing the aluminum thin-film. Preferably, the method additionally includes texturing by pressing a mold having an orderly array of projections against the aluminum thin-film to form pits on the aluminum thin-film which enables a larger array area to be formed. When the mold and the aluminum thin-film are held at a temperature of 150 to 200° C., the pressure used for pit formation is reduced. A magnetic recording medium manufactured by a method therefore includes forming a magnetic layer within the nanoholes so that the medium is suitable as a bit patterned media for a perpendicular recording system.

Owner:FUJI ELECTRIC CO LTD

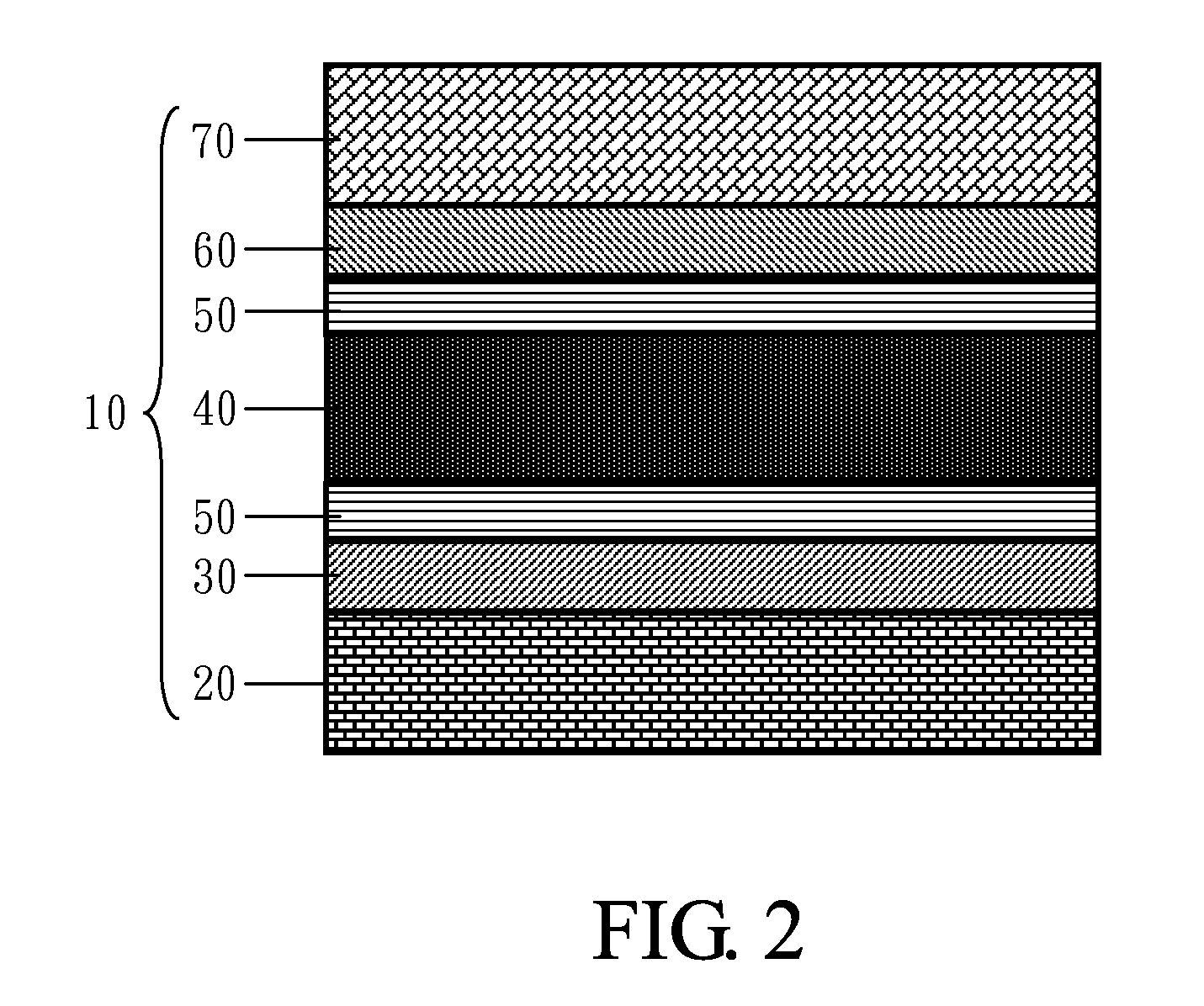

Silicon-based heterojunction solar cell and preparation method thereof

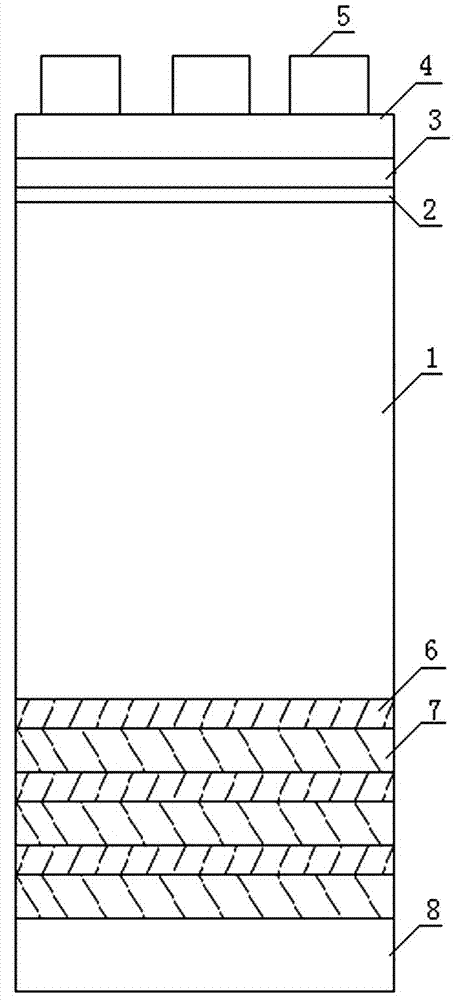

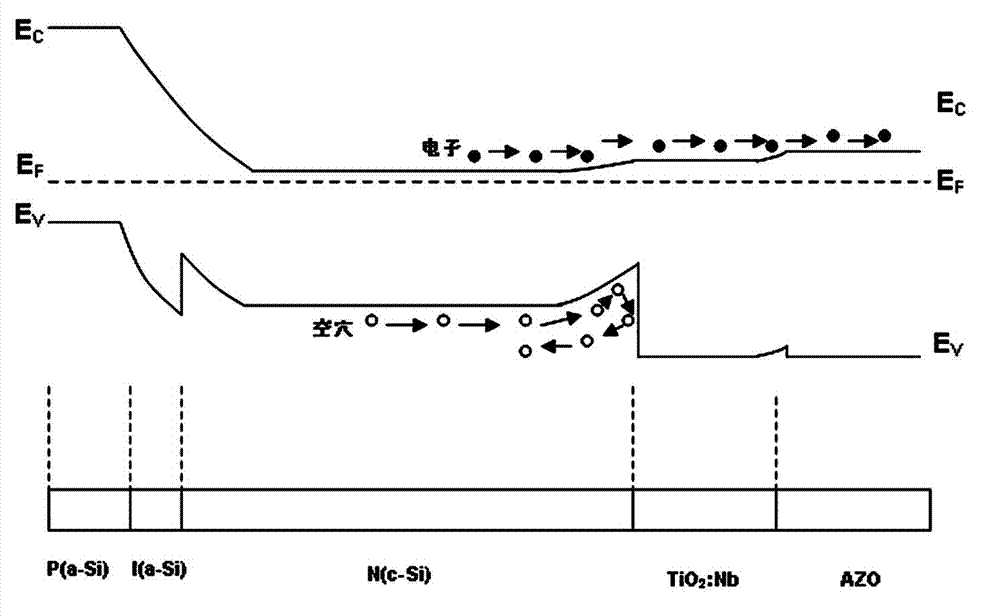

ActiveCN102931267ACombination of good conductivityImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationHeterojunctionNiobium

The invention discloses a silicon-based heterojunction solar cell which comprises grid electrodes, a transparent conductive film, a boron-doped amorphous silicon, an intrinsic amorphous silicon, an N-type monocrystalline and a back electrode in sequence, wherein the back electrode is formed by a distributed Bragg reflector and an aluminum thin film, the distributed Bragg reflector is formed by arranging niobium-doped titanium dioxide thin films and aluminum-doped zinc oxide thin films at intervals, and the aluminum thin film is arranged on the surface layer of the aluminum-doped zinc oxide thin film on the outermost layer of the distributed Bragg reflector. The distributed Bragg reflector used as the back electrode consists of two transparent conductive films with different refraction indexes, so that the resistance of the cell device connected in series is reduced, the collection of current carriers is facilitated, and the photoelectric conversion efficiency of the cell is high; and by adopting the back-reflecting electrode formed by combining the distributed Bragg reflector and the aluminum anode, the long wave band of the near infrared part with characteristic wavelength can be reflected to the inside of the crystalline silicon wafer to be reabsorbed through the two layers of conductive films with different refractive indexes, so that both the current and the photoelectric conversion efficiency of the cell are improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

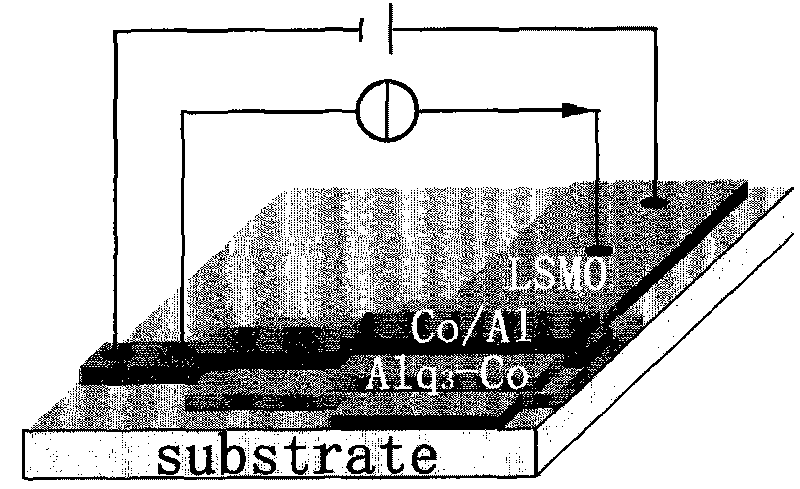

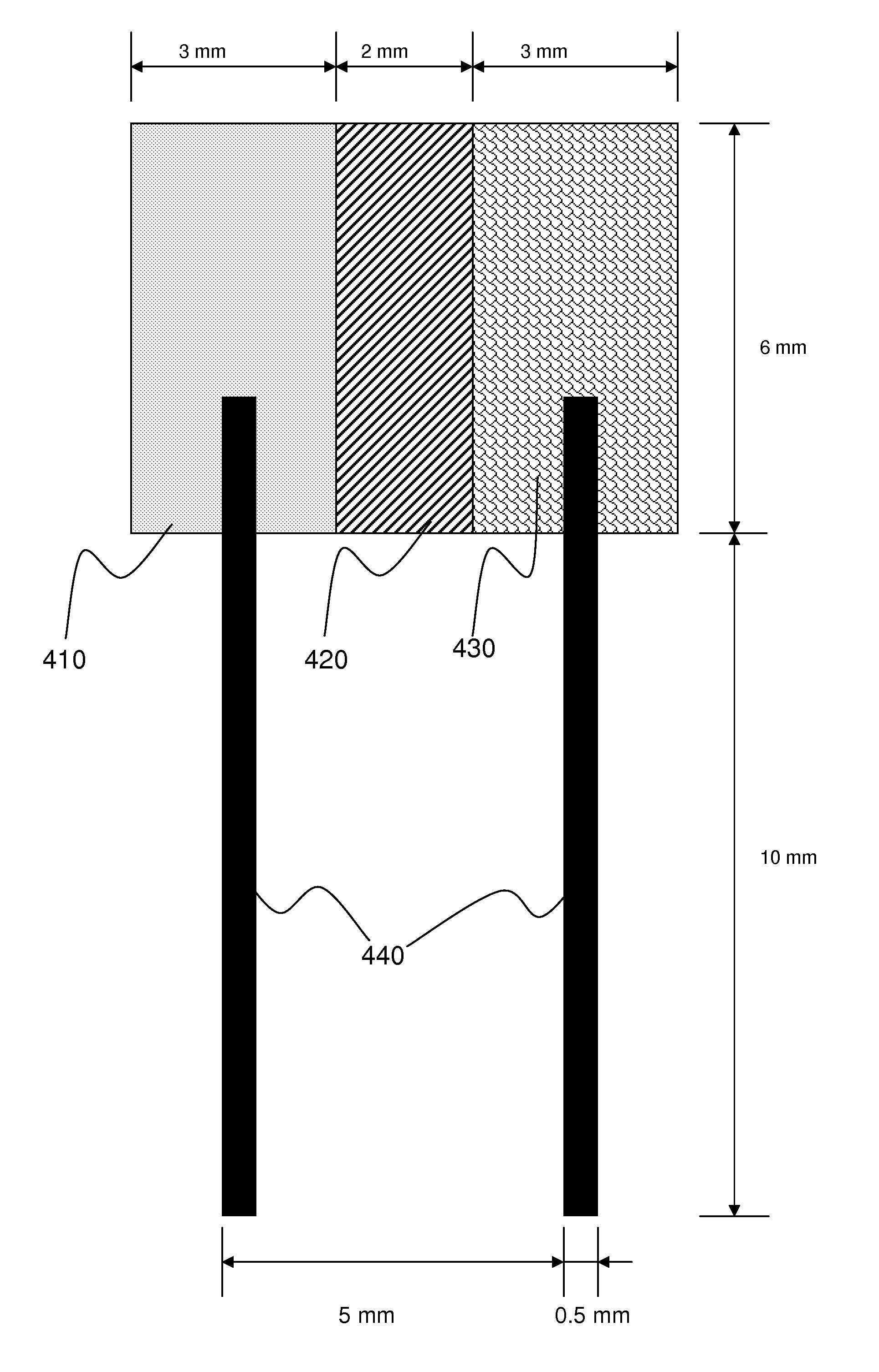

Nano-composite organic spin valve

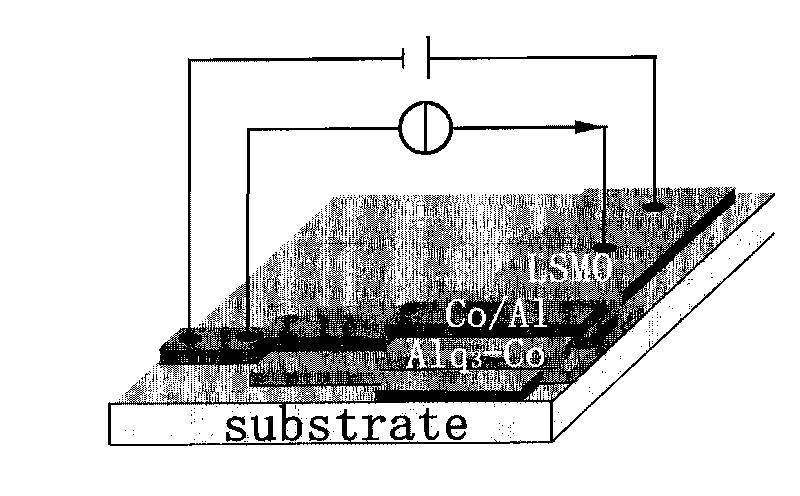

InactiveCN101710528ALarge magnetoresistance characteristicsAchieve transformationMagnetic film to substrate applicationSubstrate/intermediate layersEvaporationOptoelectronics

The invention discloses a nano-composite organic spin valve, belonging to technical field of spintronics. The spin valve comprises a sandwich structure; a top electrode is a transitional metallic cobalt thin film which is provided with an aluminum thin film as a protective layer; a bottom electrode is a La-Sr-Mn-O thin film; a middle transport layer is a nano-composite of the transitional metallic cobalt and organic micro-molecular 8-hydroxyquinoline aluminum. The preparation method of the spin valve comprises the following steps of: preparing a La-Sr-Mn-O thin film bottom electrode of the spin valve on a strontium titanate substrate by using a laser pulse deposition method; preparing the middle transport layer of the transitional metallic cobalt and 8-hydroxyquinoline aluminum by thermal evaporation; preparing the transitional metallic cobalt thin film as the top electrode on the middle transport layer of the nano-composite; and heating for evaporating the aluminum thin film as the protective layer on the top electrode of the transitional metallic cobalt thin film.

Owner:SHANDONG UNIV

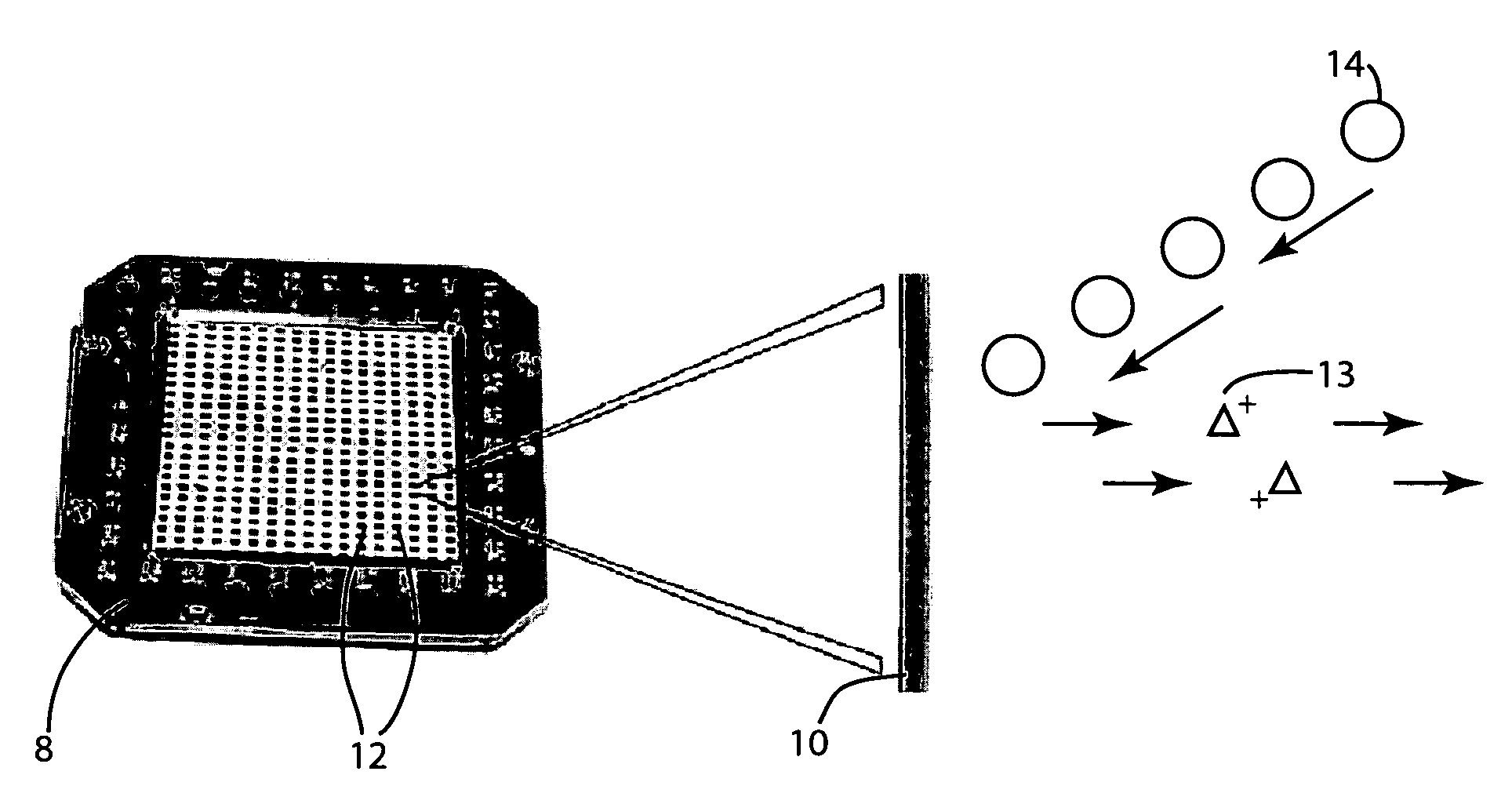

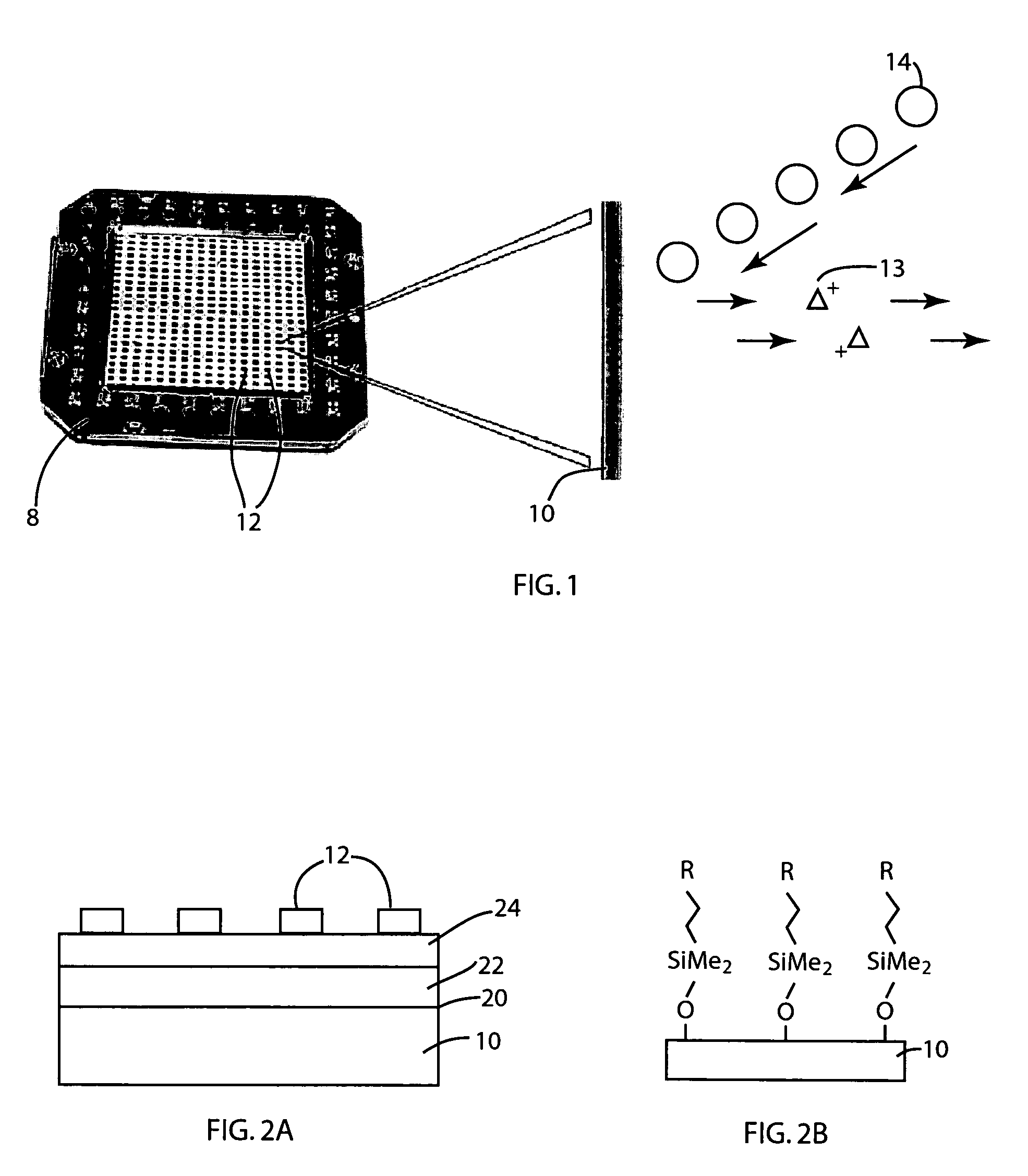

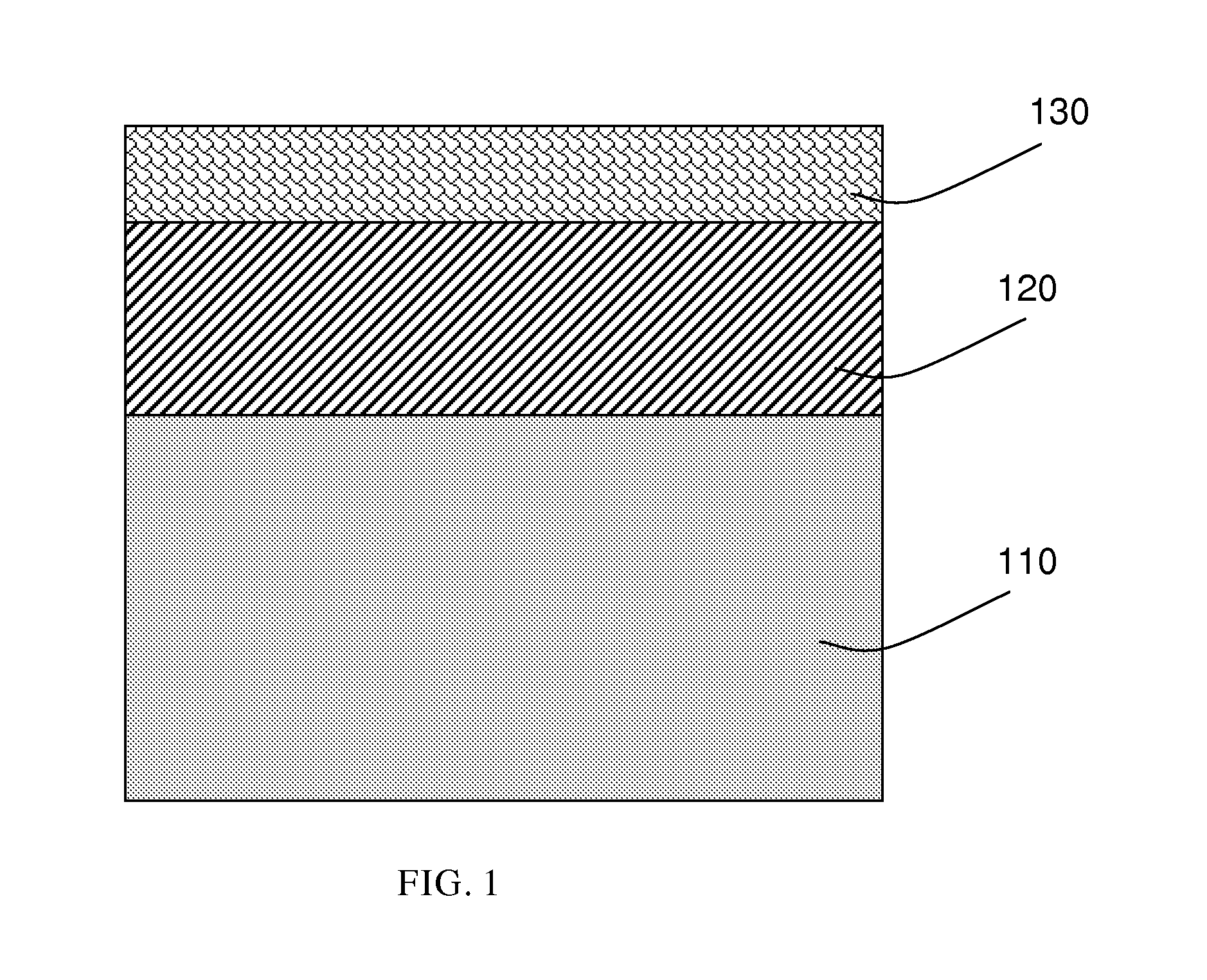

Nanostructured thin films and their uses

InactiveUS7391018B2Improve uniformityStrong adhesionNanotechSamples introduction/extractionDesorptionSilicon thin film

The present invention generally discloses the use of a nanostructured non-silicon thin film (such as an alumina or aluminum thin film) on a supporting substrate which is subsequently coated with an active layer of a material such as silicon or tungsten. The base, underlying non-silicon material generates enhanced surface area while the active layer assists in incorporating and transferring energy to one or more analytes adsorbed on the active layer when irradiated with a laser during laser desorption of the analyte(s). The present invention provides substrate surfaces that can be produced by relatively straightforward and inexpensive manufacturing processes and which can be used for a variety of applications such as mass spectrometry, hydrophobic or hydrophilic coatings, medical device applications, electronics, catalysis, protection, data storage, optics, and sensors.

Owner:NANOSYS INC

N-type single crystal silicon substrate PN junction inversion layer battery and manufacturing method thereof

InactiveCN102044574AImprove stabilityIncrease short circuit current densityFinal product manufactureSemiconductor devicesSesquioxideMetal electrodes

The invention discloses an N-type single crystal silicon substrate PN junction inversion layer battery, which comprises an N-type single crystal silicon substrate, a front electrode, a rear electrode, a front surface aluminum sesquioxide film and a silicon nitride film, wherein the front electrode comprises a local boron diffusion area, a Ti / Pb film and a front surface metal electrode; and the rear electrode comprises a rear surface metal electrode and a rear surface aluminum sesquioxide film. The invention also discloses a manufacturing method for the N-type single crystal silicon substrate PN junction inversion layer battery. The Al2O3 carries fixed negative charges, a P-type inversion layer is induced on the front surface of the N-type single crystal silicon substrate, and a front electric field is provided; and in the absence of the influence of boron doping, the stability of the battery is improved, meanwhile, the absorption on short wave is reduced, blue light response is improved, the short circuit current density of the battery is improved, and the efficiency of the battery is promoted.

Owner:ALTUSVIA ENERGY TAICANG

Collecting electrode used in super capacitor and its surface treating method

InactiveCN101174509AEfficient removalEvenly distributedElectrode manufacturing processesElectrode carriers/collectorsChemical treatmentInternal resistance

The invention discloses a collector of super capacitor and the surface processing method, which is characterized in that a collector body film can be an aluminum film, a copper foil, a foam nickel film, a stainless steel film or punching nickel film; the purity of aluminum is over 99.9%; the thickness of the corrosion aluminum foil is 15 to 50 Mum; the roughness is 1.5 to 3.0 Mum; the collector body is spongy under 20000X electronic microscope; the average diameter of the corrosion hole is 0.05 to 0.2 Mum; 5 to 10 billion holes are arranged in the area of 1 cm2; the tensile strength is 1.0 to3.0 kg / cm. The invention has the advantages that chromic acid mixture is adopted for chemical treatment for the surface of the current collector; dust on the surface of aluminum foil of the current collector during storage and transportation can be removed; anti-septic oil and anti-sticking agent on the aluminum foil during machining process are also effectively removed; active functional groups are added, enabling even and consistent distribution of coated electrode material; the adhesion strength of the electrode film is improved; internal resistance of the electrode is reduced, the specificsurface area is increased; the collector is applicable to large scale production.

Owner:NINGBO FUDA ELECTRIC APPLIANCE

Laser electrolytic aluminum film regeneration coating and preparation method thereof

InactiveCN102585648AImprove poor temperature resistanceHigh surface brightnessCoatingsThermographyButyl acetateFoaming agent

The invention relates to a holographic anti-counterfeiting printing industrial material, in particular to a laser electrolytic aluminum film regeneration coating and a preparation method thereof, and provides a method for overcoming product defects and improving the die pressing property of a half-finished die belt, a laser electrolytic aluminum film regeneration coating for reusing a half-finished product which is difficult for die pressing, and a preparation method thereof. A regeneration zone of which the temperature resistance range is 200-225 DEG C is coated between an imaging layer and an aluminum-plated layer; and the coating consists of the following components in parts by weight: 100 parts of acrylic resin, 0.1-1 part of nano silica, 0.3 parts of anti-foaming agent, 0.2 parts of flatting agent, 0.5 parts of pH value adjusting agent, and a solvent consisting of 37-118 parts of ethyl acetate and 37-118 parts of butyl acetate in the mixture ratio of 1:1. According to different components of a coating composition, the defects of poor temperature resistance and high rejection rate of a film coating are overcome, the problems of peeling and plate adhering are solved, the operation is easy, the production yield is increased, and the die pressing fie belt has high surface brightness and excellent representation.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

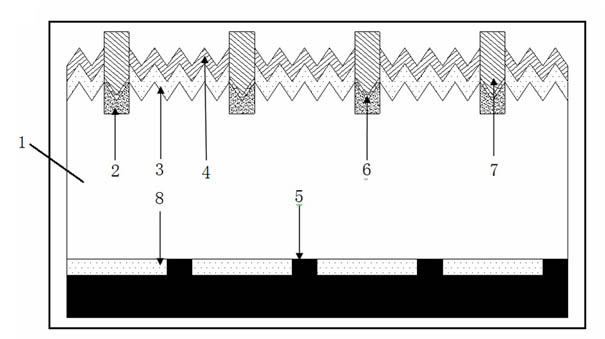

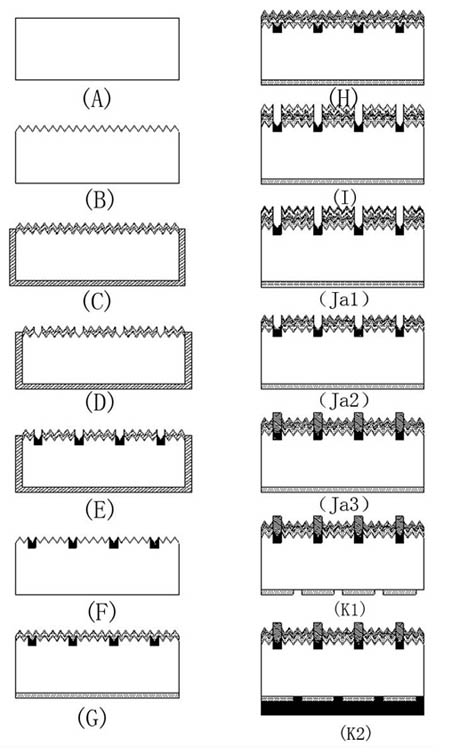

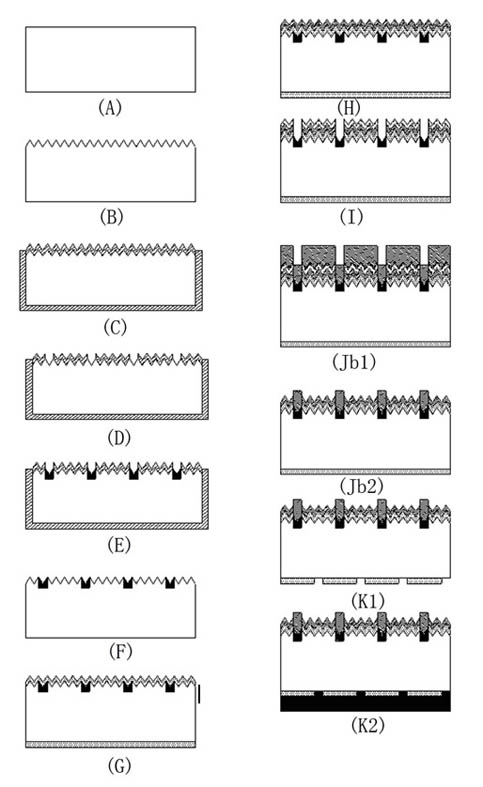

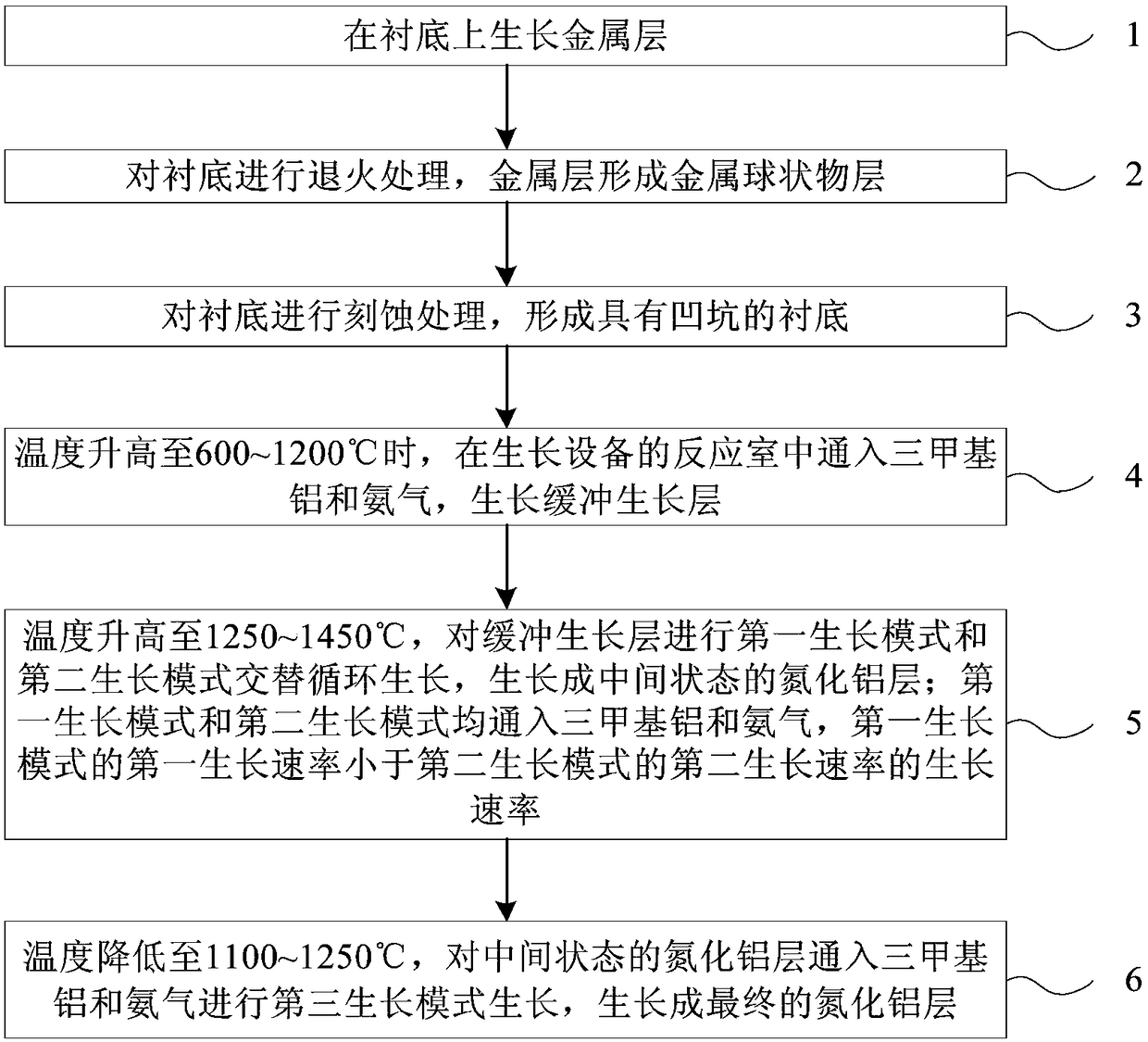

Epitaxial structure of ultraviolet LED with aluminum nitride film and growth method of aluminum nitride film

ActiveCN108257853APromote growthEasy to implementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltravioletAmmonia gas

The present invention provides an epitaxial structure of an ultraviolet LED with an aluminum nitride film and a growth method of the aluminum nitride film. The growth method of the aluminum nitride film includes the following steps that: 1) a metal layer is grown on a substrate; 2) annealing treatment is performed on the substrate, so that the metal layer can form a metal ball-shaped object layer;3) etching treatment is performed on the substrate, so that a pitted substrate can be formed; 4) when temperature rises to 600 to 1200 DEG C, trimethylaluminum and ammonia gas are introduced into a reaction chamber, so that a buffer growth layer can be to grown; 5) when temperature rises to 1250 to 1450 DEG C, first growth mode / second growth mode alternate cyclic growth is carried out, so that anintermediate-state aluminum nitride layer can be formed; and 6) when temperature drops to 1100 to 1250 DEG C, the trimethylaluminum and ammonia are introduced into the aluminum nitride layer, so thatthird growth mode growth can be performed. The aluminum nitride film obtained by using the method has good crystal quality; and the surface cracks of the aluminum nitride film can be reduced.

Owner:MAANSHAN JASON SEMICON CO LTD

Human and mirror interaction method and system based on facial expression recognition and color emotion feedback

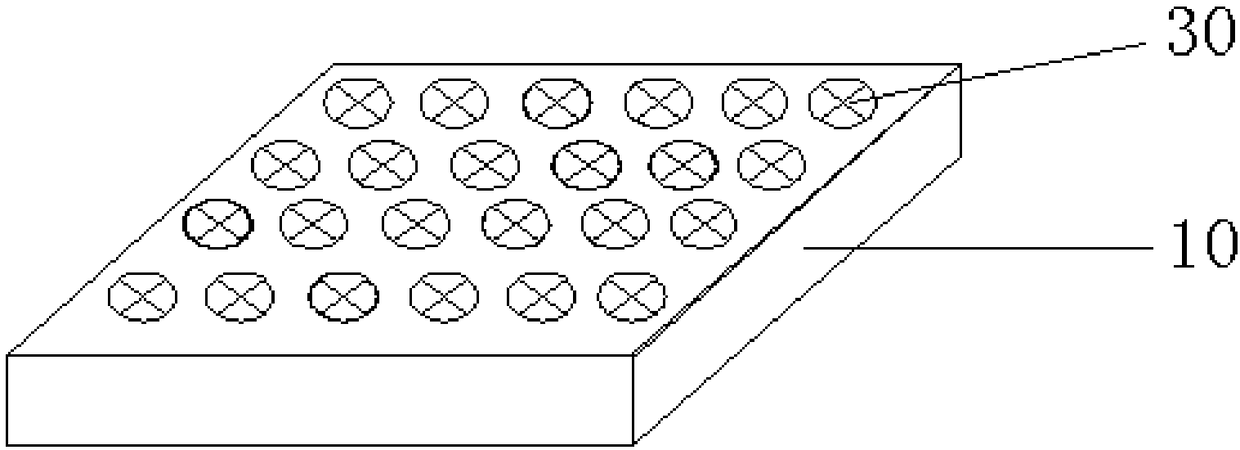

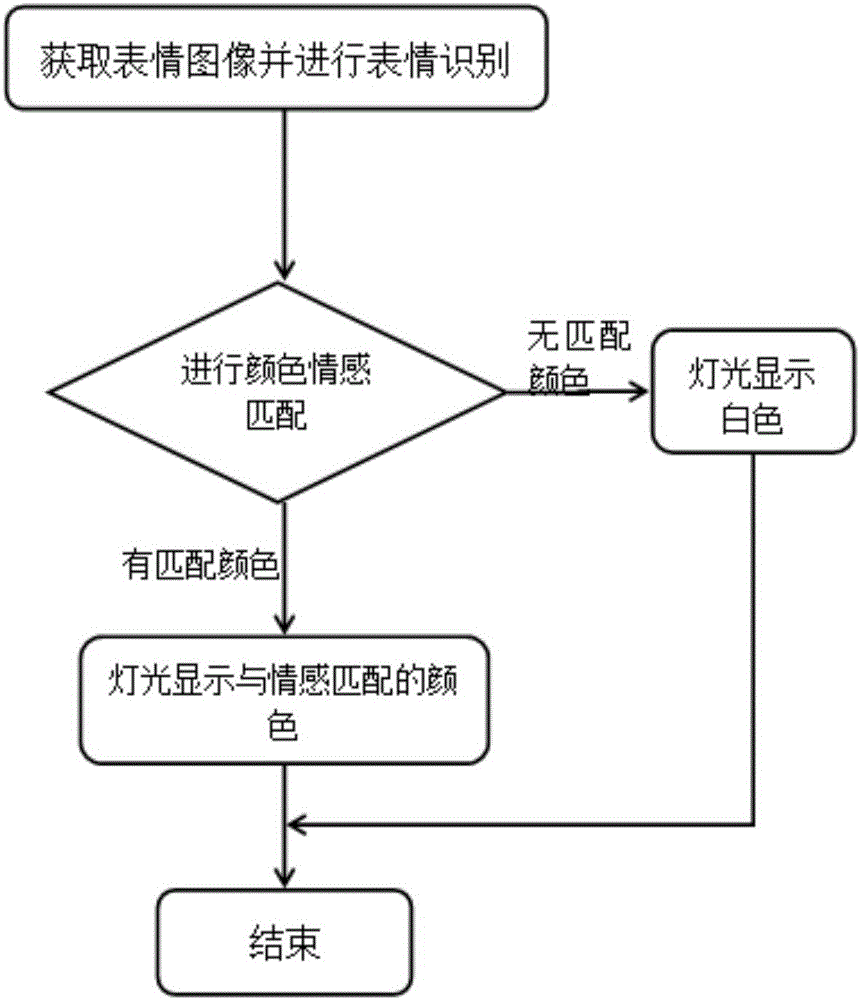

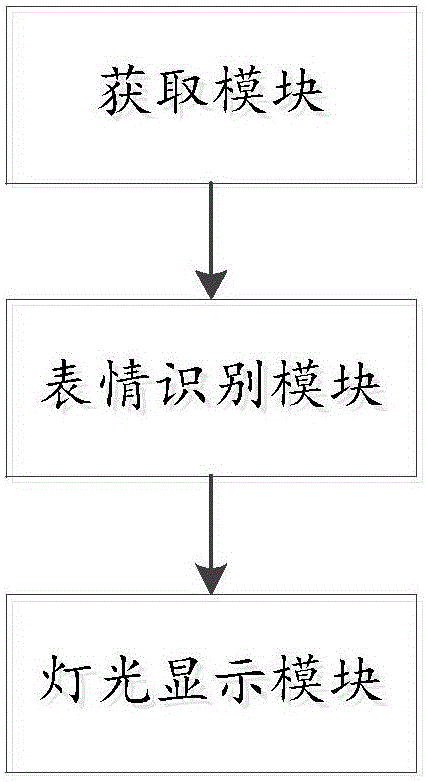

InactiveCN106125929AHigh resolutionSimple structureInput/output for user-computer interactionGraph readingPattern recognitionHuman body

The invention relates to a human and mirror interaction method based on facial expression recognition and color emotion feedback. The human and mirror interaction method comprises the following steps that firstly, when approaching of the human body is detected, a facial expression image is obtained; secondly, the facial expression image is processed and subjected to expression recognition, and a recognized expression is obtained; thirdly, according to preset expression and color matching rules, a display color corresponding to the recognized expression is determined, and corresponding light display is carried out. The structure is simple, the making material of an intelligent mirror is similar to that of a common mirror, and it is only needed to plate an aluminum thin film on common glass so as to ensure that the resolution of the intelligent mirror is high enough; the facial expression recognition function is achieved, and the intelligent mirror can be used for recognizing the facial expression with the assistance of the existing expression recognition technology; the LED color light feedback function is achieved, and the recognized expression and the emotion corresponding to the recognized expression can be fed back through different light emitting conditions of external LED lamps.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

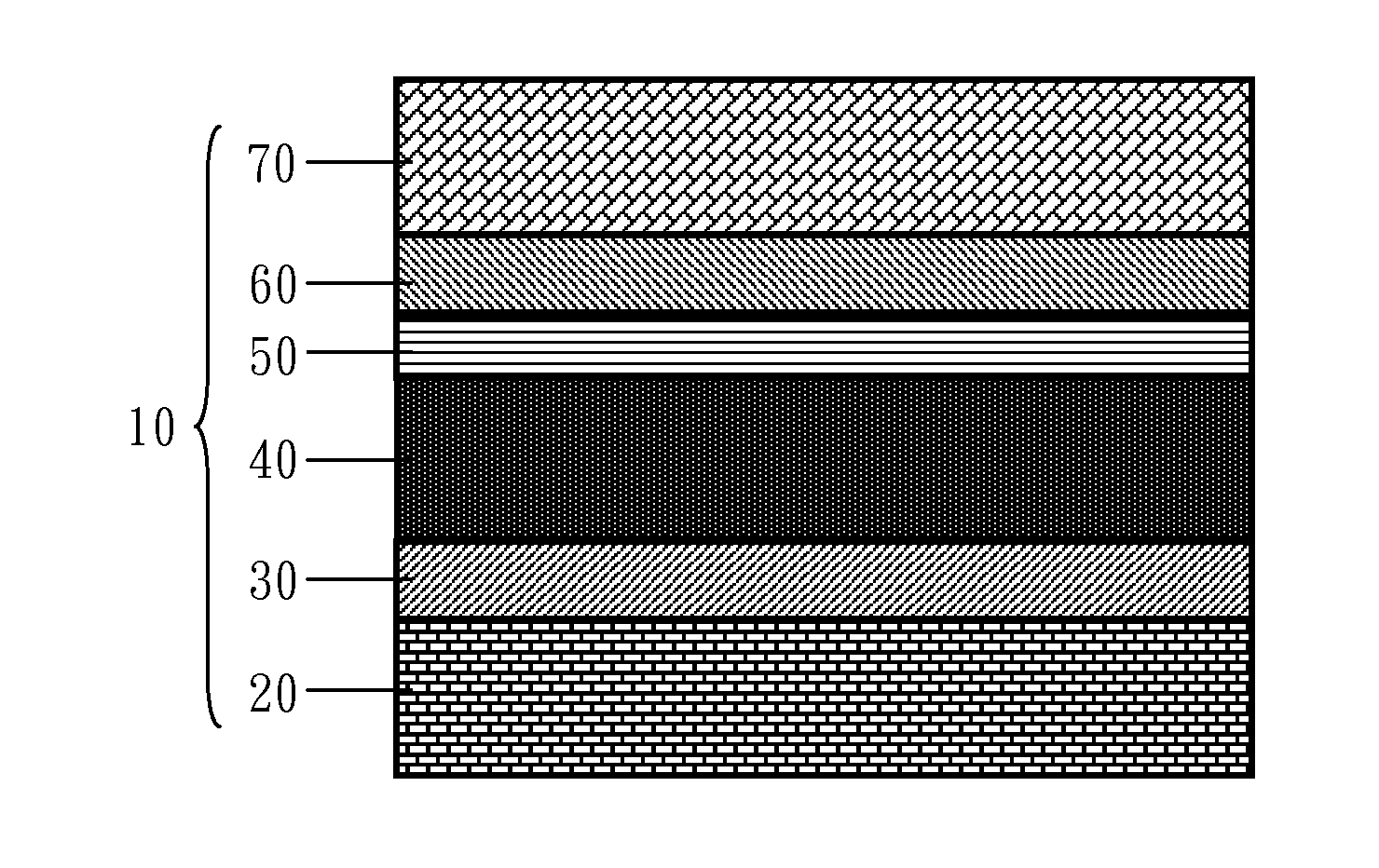

Aluminum-induced crystallization polycrystalline silicon thin-film solar cell and preparation method thereof

ActiveCN103137765AReduce the thickness of the absorbing layerPromote absorptionFinal product manufacturePhotovoltaic energy generationMetallic aluminumBack surface field

The invention discloses an aluminum-induced crystallization polycrystalline silicon thin-film solar cell and a preparation method of the aluminum-induced crystallization polycrystalline silicon thin-film solar cell and belongs to the field of silicon thin-film solar cells. A structure of the aluminum-induced crystallization polycrystalline silicon thin-film solar cell comprises a glass substrate, a metallic aluminum back reflecting layer, a P+ type back surface field layer, a P type absorption layer and a N+ type transmission layer. Metal electrodes are arranged on the P+ type back surface field layer and the N+ type transmission layer. The preparation method includes the following steps of sequentially depositing an amorphous silicon thin film and an aluminum film through an aluminum-induced crystallization technology, wherein the thickness range is between 100 nm-150nm and 100nm-120nm, conducting annealing process for 1-5 hours at a temperature of 450DEG C-500DEG C, wherein positions of a silicon layer and an aluminum layer can exchange and amorphous silicon is changed into polycrystalline silicon with a grain size of 5mu-10mu, and preparing the P type absorption layer, the N+ type transmission layer and the metal electrodes. The aluminum-induced crystallization polycrystalline silicon thin-film solar cell and the preparation method of the aluminum-induced crystallization polycrystalline silicon thin-film solar cell can theoretically reduce the thickness of an original cell by 50% and greatly save cost of raw materials.

Owner:JIANGSU LONGBAO ELECTRONICS SCI & TECH CO LTD

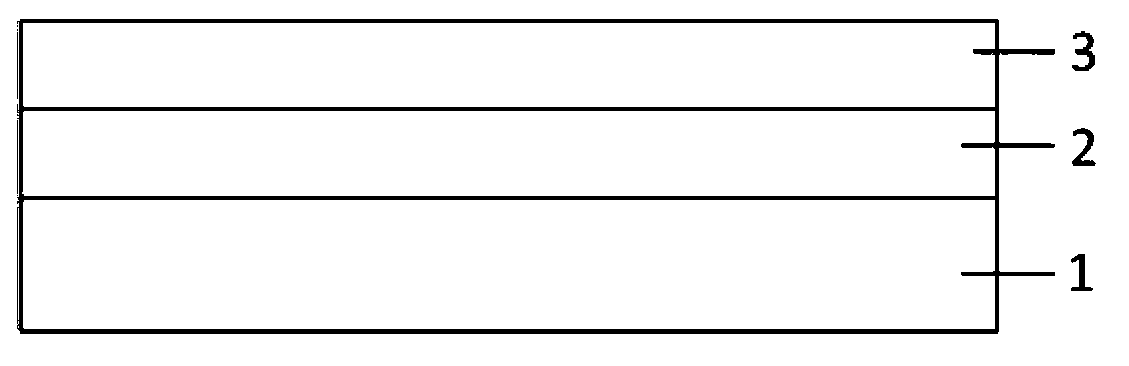

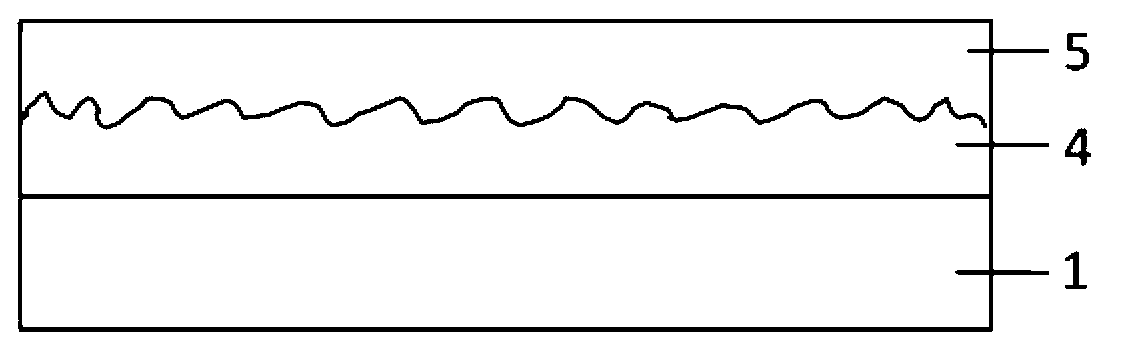

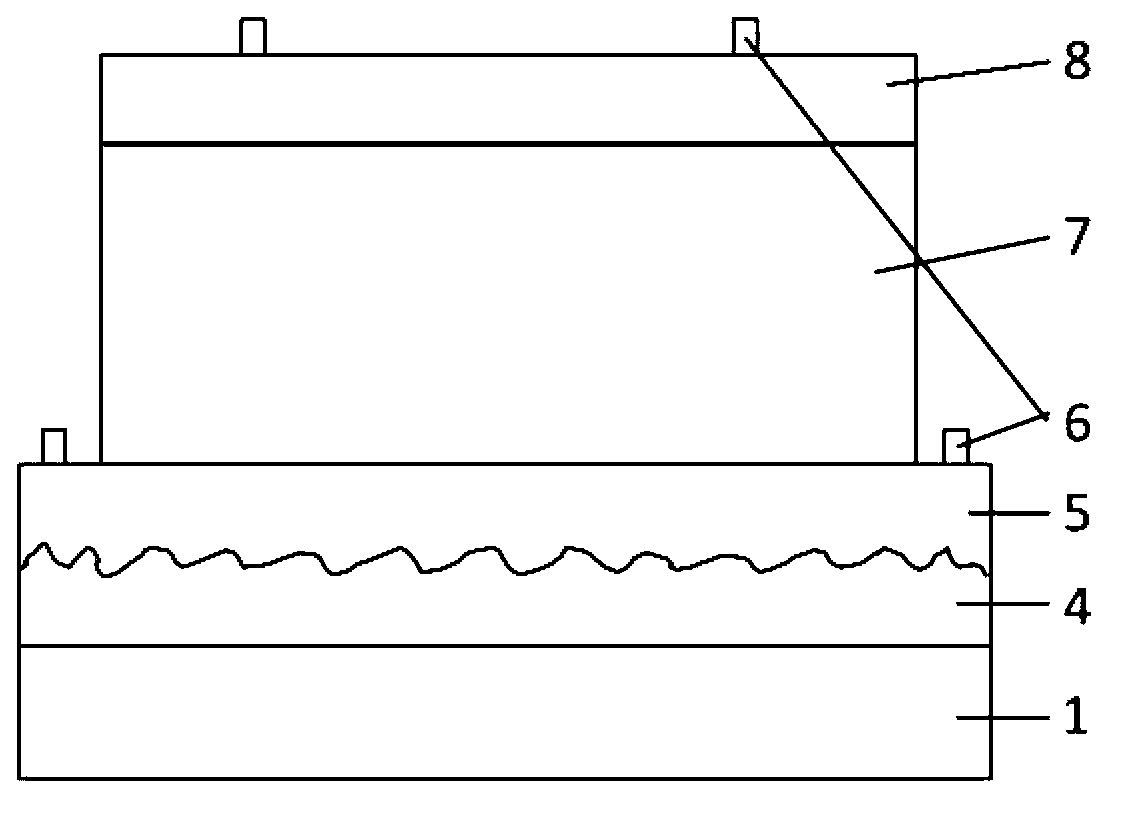

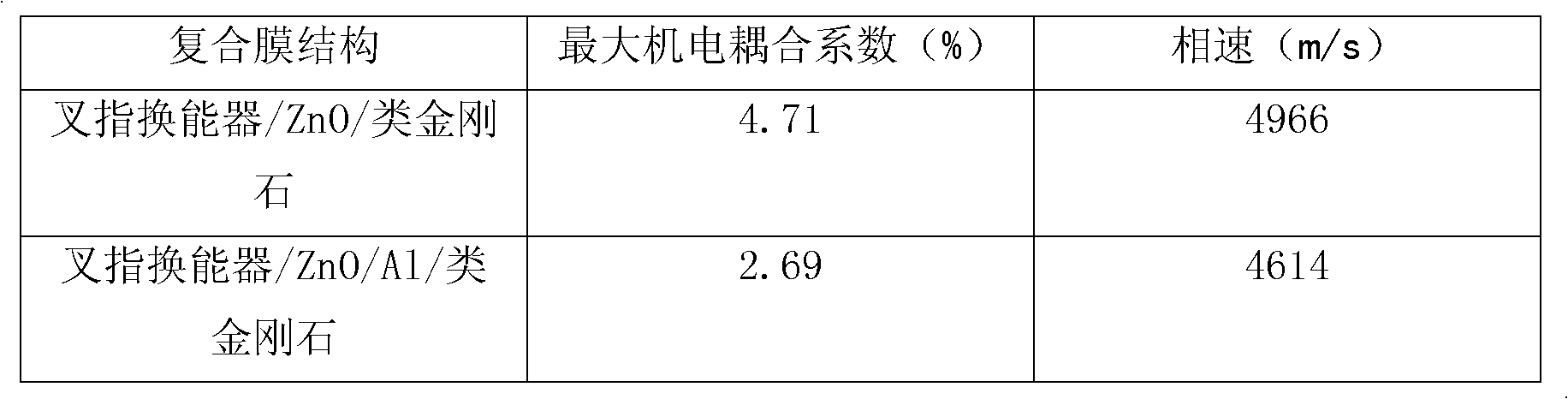

Zinc oxide piezoelectric film for SAW (Surface Acoustic Wave) device and manufacturing method thereof

InactiveCN102611405AReduce lossHigh crystallinityImpedence networksComposite filmElectromechanical coupling coefficient

The invention relates to a zinc oxide piezoelectric film for an SAW (Surface Acoustic Wave) device, which is of a zinc oxide / aluminum / diamond-like composite film structure. A manufacturing method comprises the following steps of: placing single crystal silicon wafer with the cleaned surface into a vacuum growth cavity of a pulse laser system, depositing the diamond-like / aluminum thin film with graphite and aluminum as a target material; and depositing a zinc oxide film on the surface of the Al film with the zinc oxide as the target material through a radio-frequency magnetron sputtering process. The invention has the advantages that: the manufacturing method is simple and feasible and has low cost; the prepared diamond-like film surface is smooth and flat so as to be capable of largely reducing sound wave loss in a transmission process, the deposited Al film largely improves the electromechanical coupling coefficients of the zinc oxide film, the crystallization degree of the zinc oxide film is high, c-axis orientation is high, and the zinc oxide / aluminum / diamond-like composite film structure can be used for manufacturing high-performance, high-frequency and high power devices.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

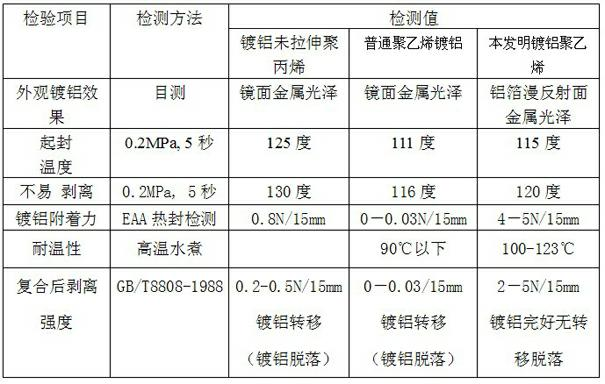

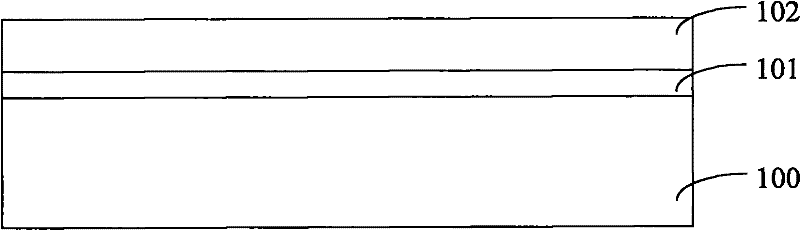

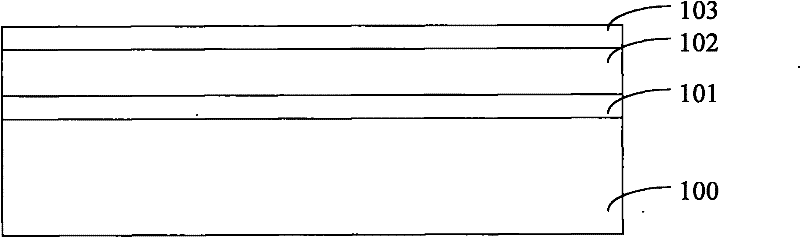

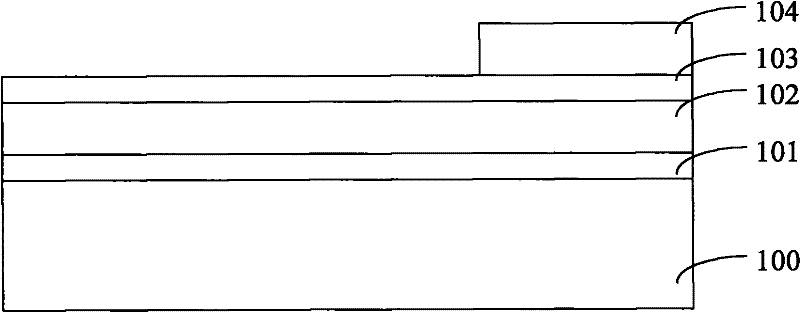

Polyethylene aluminum-plated film with metal luster of aluminum foil diffuse surface

InactiveCN102152543AIncrease polarityImprove bindingMetal layered productsPolymer scienceAluminum foil

The invention discloses a polyethylene aluminum-plated film with metal luster of an aluminum foil diffuse surface. An aluminum-plated functional layer comprises 50 to 80 parts of polyethylene and 20 to 50 parts of ethylene acrylic acid copolymer or ethylene methyl acrylate copolymer or ethylene vinyl acetate copolymer. The ethylene acrylic acid copolymer or ethylene methyl acrylate copolymer or ethylene vinyl acetate copolymer is added into the polyethylene, the polarity of the material and the binding force of the material with an aluminum material are improved, and after the film is processed through a film blowing or casting process, the surface haze is improved; meanwhile, the aluminum foil diffuse surface is formed, and the polyethylene aluminum-plated film with metal luster of the aluminum foil diffuse surface is formed through vacuum aluminum plating. The appearance of the product has the metal luster of the aluminum foil diffuse surface, and the product has ideal processability, excellent aluminum adhesive force, excellent gas barrier property, excellent moisture barrier property, good heat sealing performance and low-temperature mechanical property, and is suitable for mass production and low in industrial production cost.

Owner:郑勇 +1

Method for forming aluminum thin film

InactiveCN102237299ASmall grainQuality improvementSemiconductor/solid-state device manufacturingAluminum metalAluminum thin film

The invention discloses a method for forming an aluminum thin film. The method comprises the following steps of: providing a substrate; and gradually forming the aluminum thin film on the substrate by using at least two sub-steps of forming an aluminum metal layer, wherein the thickness of the aluminum metal layer which is formed in each sub-step is less than or equal to 0.45 mu m. By the method, the size of grains in the aluminum thin film is reduced, and the surface quality of the aluminum thin film is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

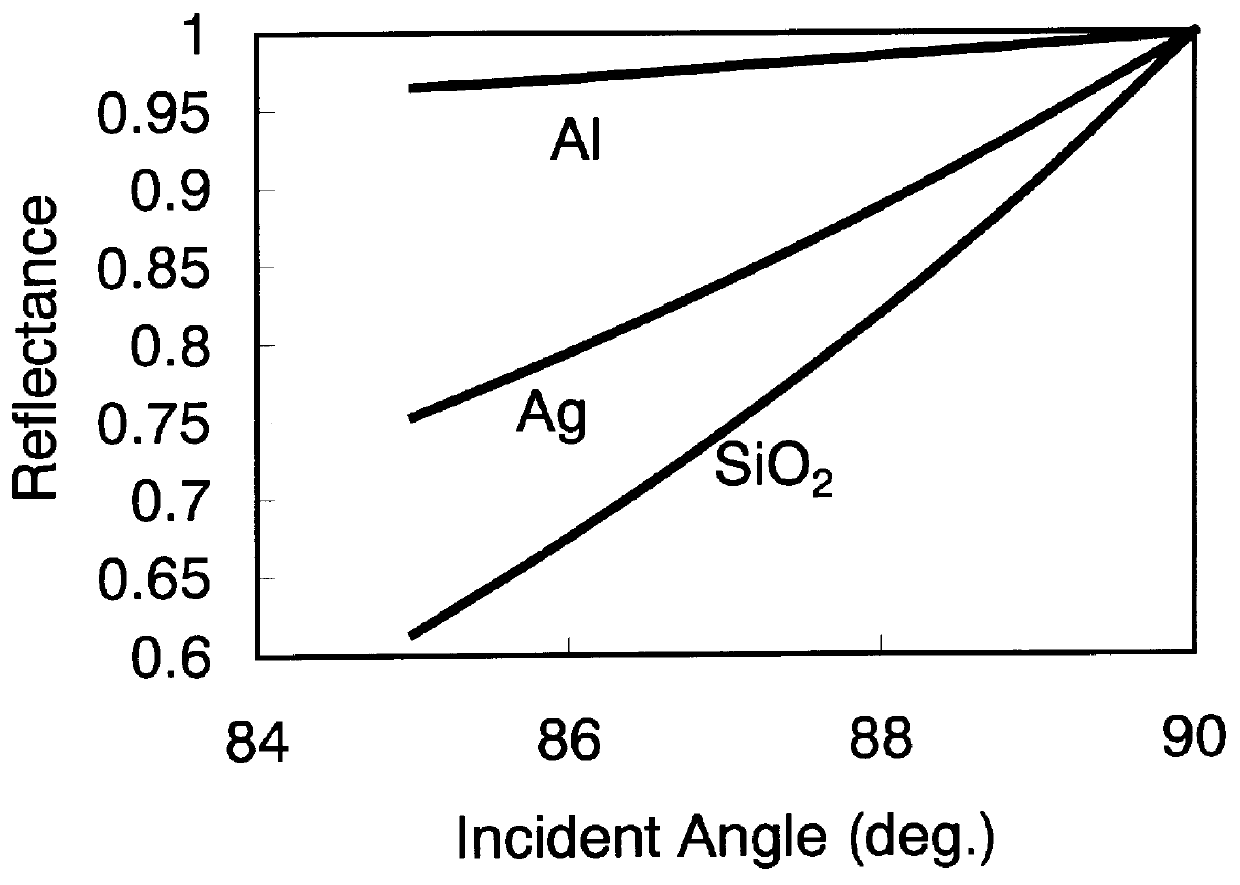

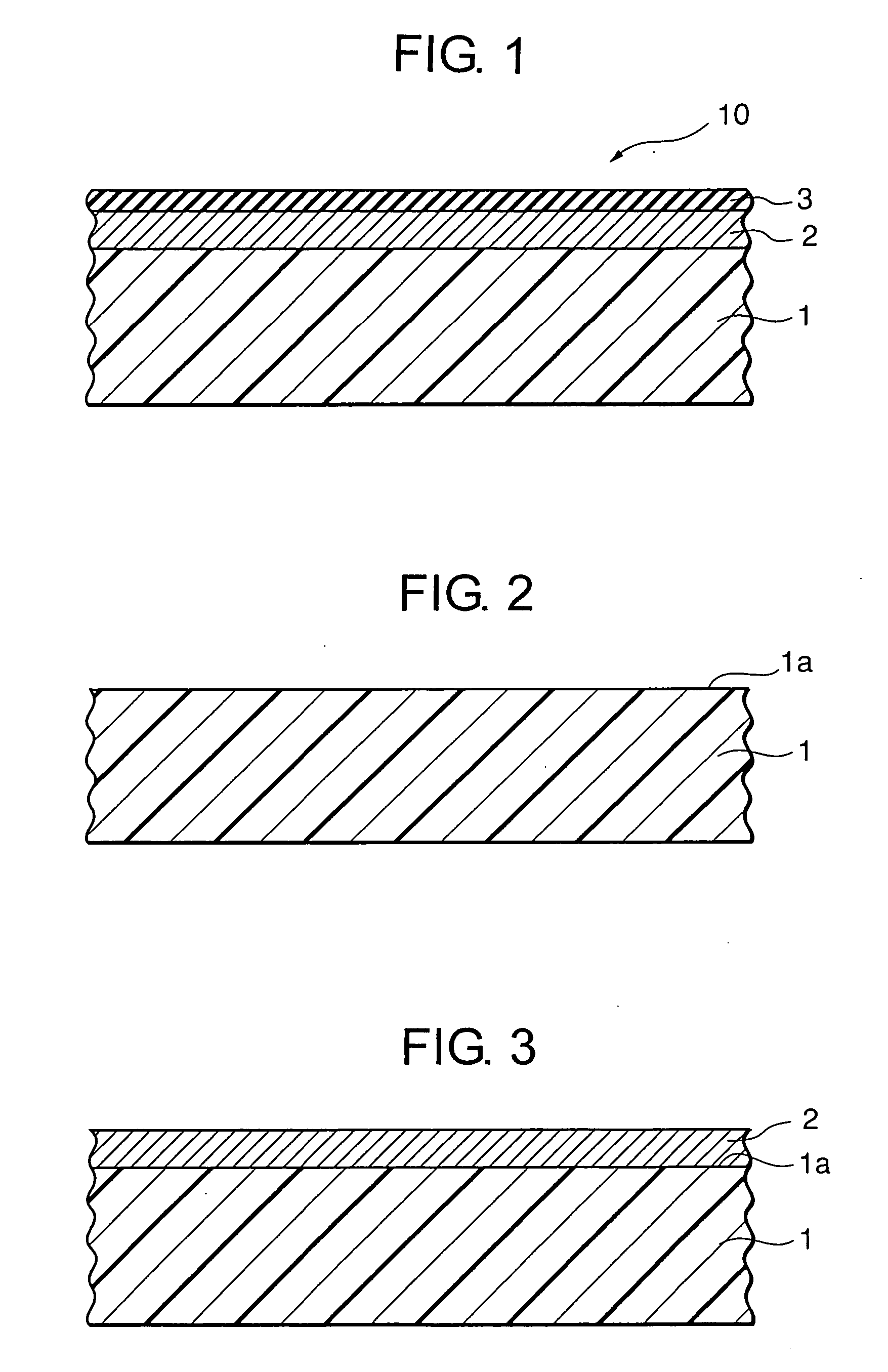

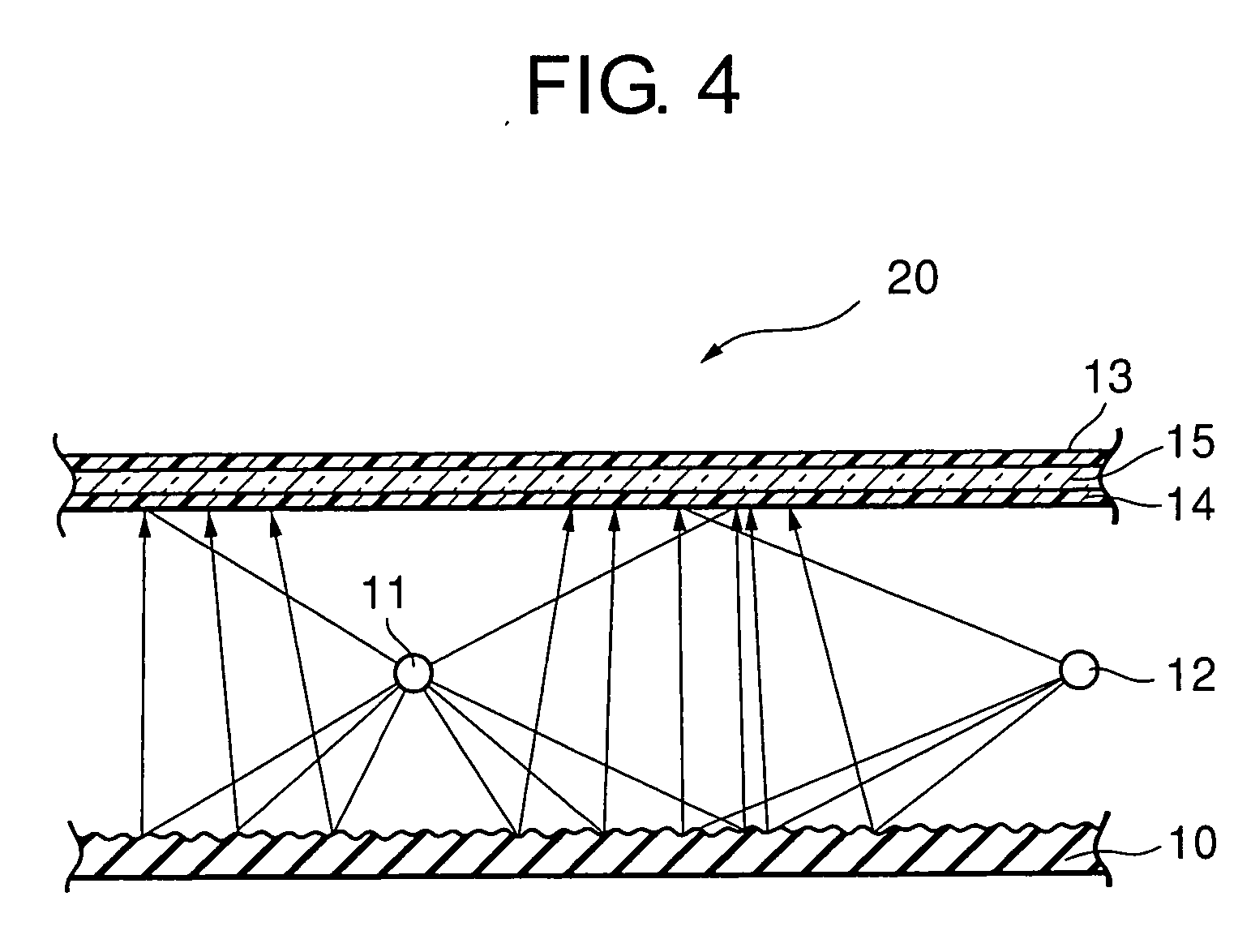

Visible light-reflecting member

InactiveUS20060215409A1Uniform film formationImprove corrosion resistanceMirrorsElongate light sourcesX-rayPeak intensity

A visible light-reflecting member is disclosed which uses a plate or a film for reflecting visible lights, whose reflective surface is provided with an aluminum thin film having an aluminum purity of not less than 99 mass % and an X-ray diffraction pattern wherein, among peak intensities ascribed to aluminum, the peak intensity ascribed to the (111) plane is higher than the total of the other peak intensities.

Owner:FOUND FOR ADVANCEMENT OF INT SCI

Membrane stress control method

InactiveCN101457347AQuality is not affectedAdaptableVacuum evaporation coatingSputtering coatingMembrane stressPolymer thin films

The invention relates to a method for controlling stress of films, belonging to the thermal control field of spacecrafts. The method employs a magnetic-control sputtering film deposition technique to deposit a tin film and an aluminium film on a polymer film, subsequently pumps vacuum and heats so that Sn-Al alloy is formed between the tin film and the aluminium film and expansion distortion of the crystal lattice is generated to introduce reverse stress to counterbalance the existing intrinsic compressive stress, thus presenting a smooth film in microscopic view. The method can be applied to the stress control technique of micro-mechanical shutter films and flexible thermal-control films used for satellite thermal-control, has strong adaptability and wide applicability, does not affect quality of films, and has unique advantages on the stress control and wide application prospect.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

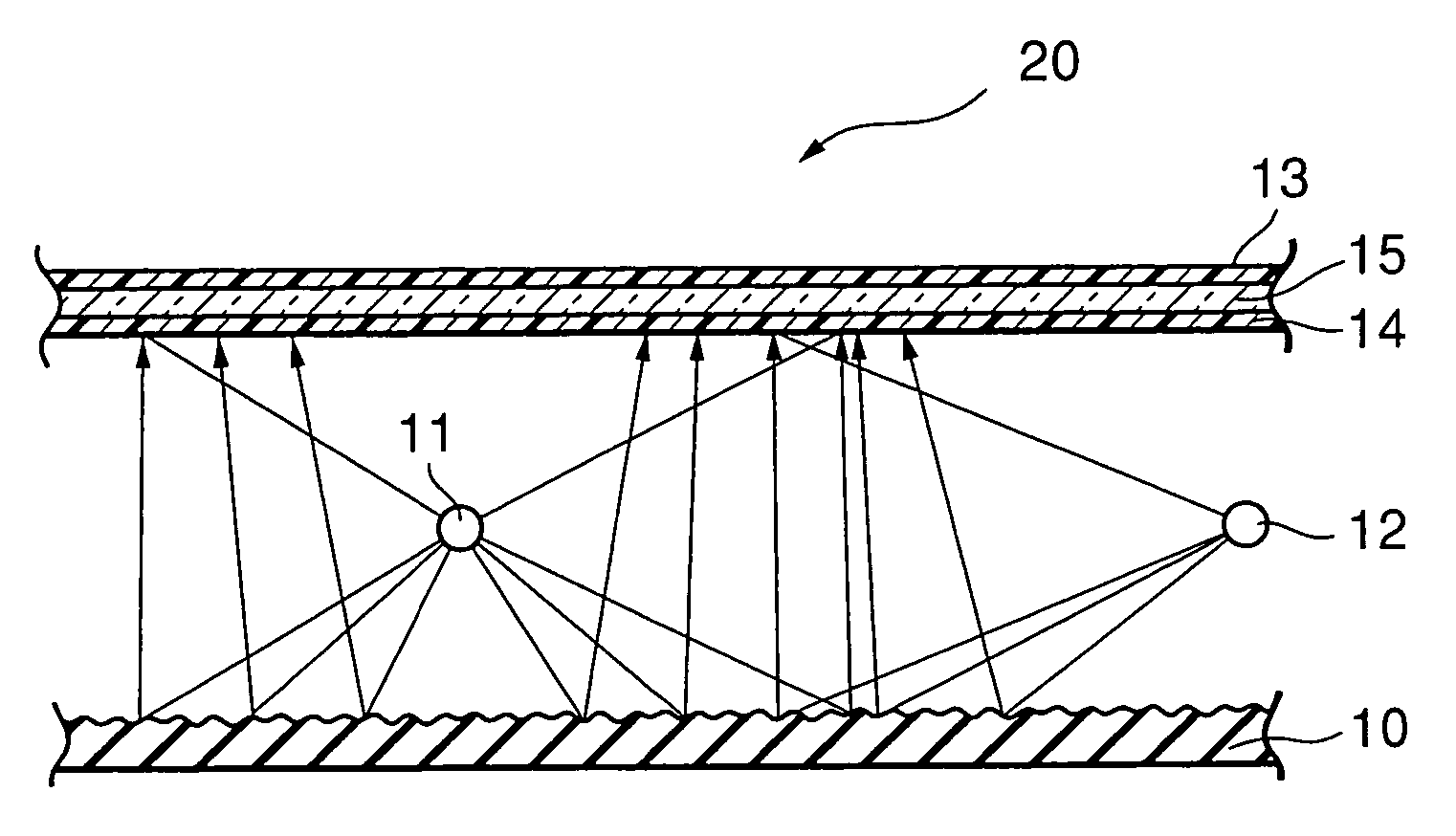

Temperature-measuring member, temperature-measuring device, and method for measuring temperature

InactiveCN101344438ASimple and high-precision measurementThermometers using physical/chemical changesCcd cameraAluminum thin film

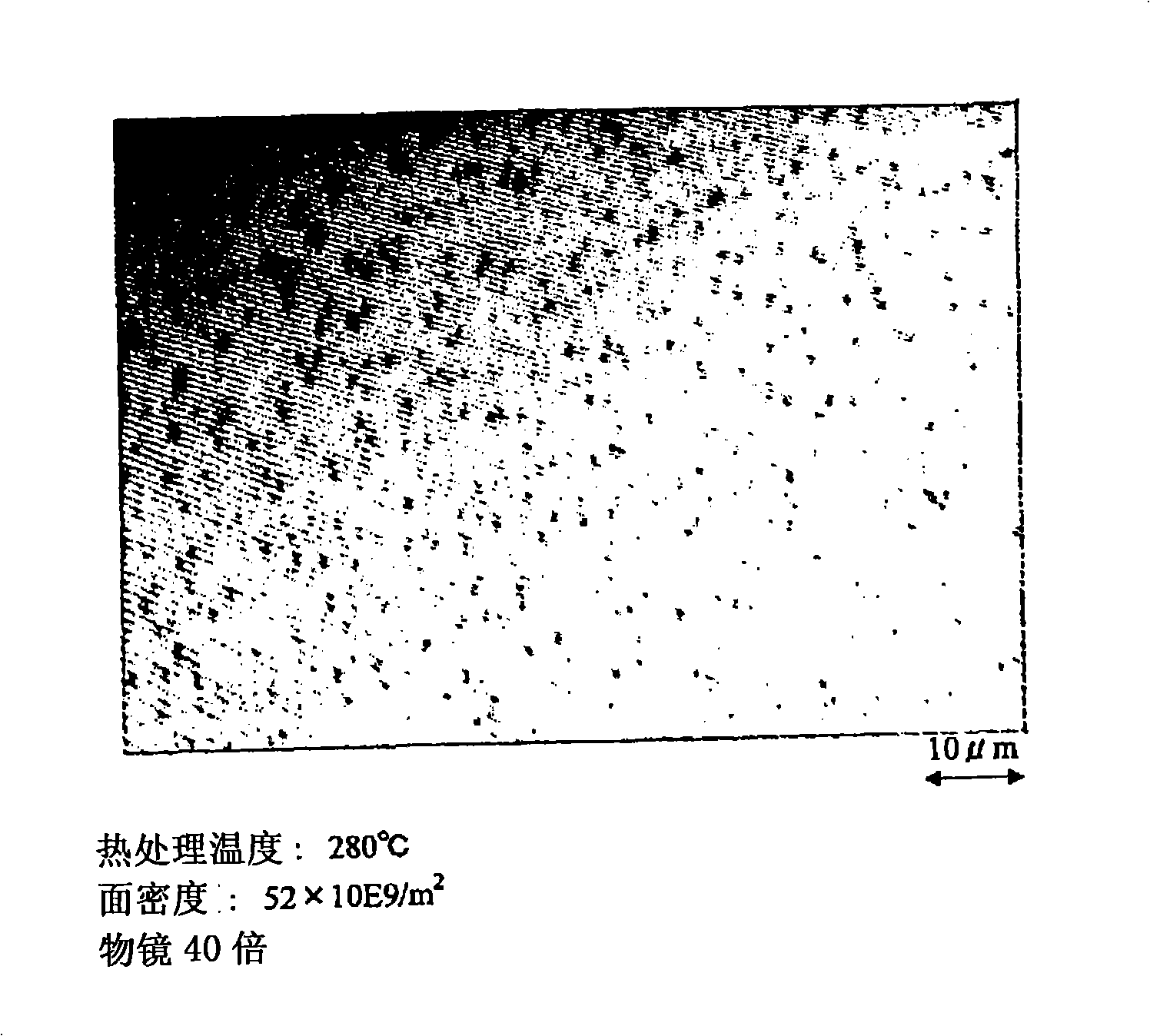

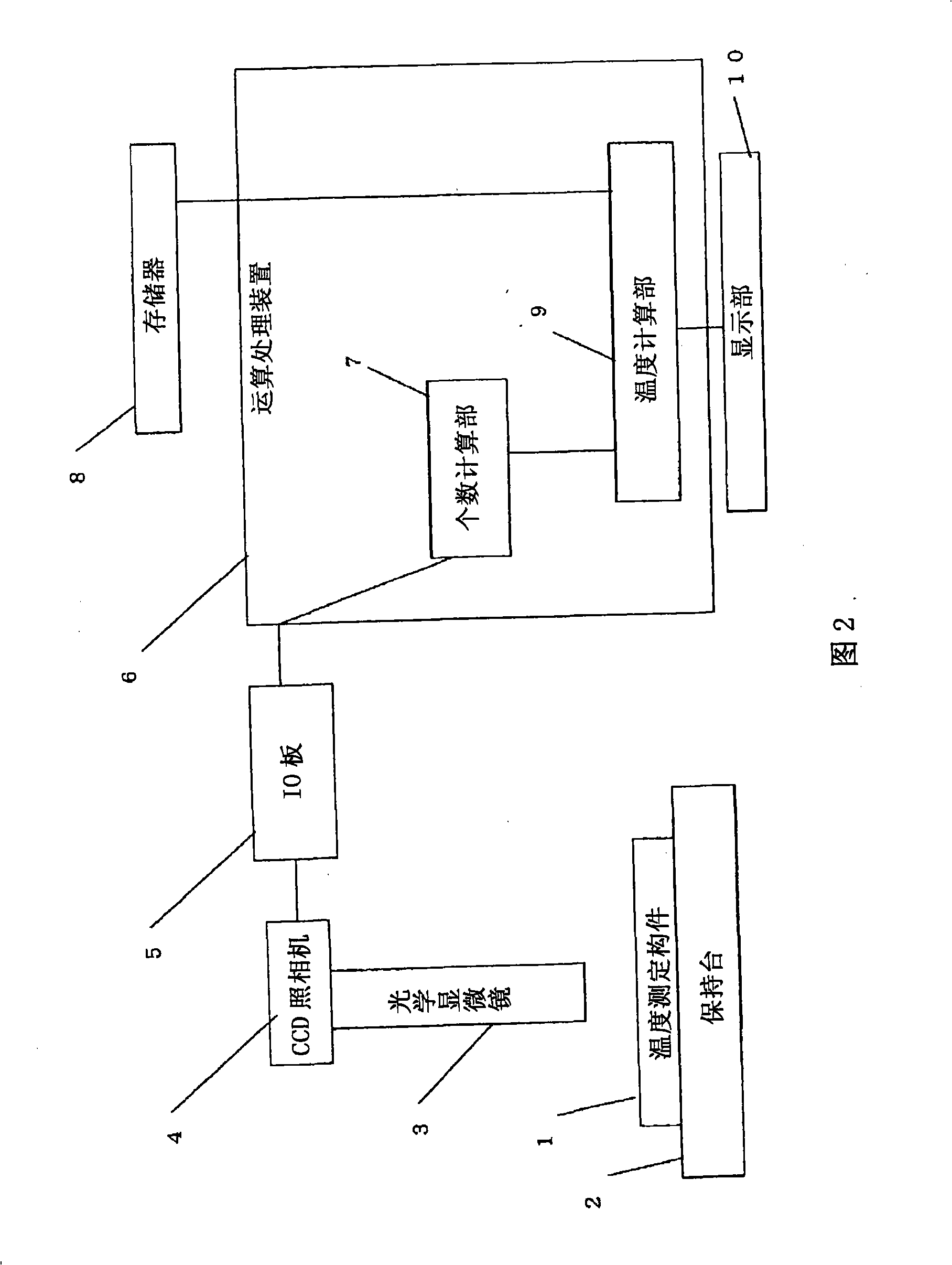

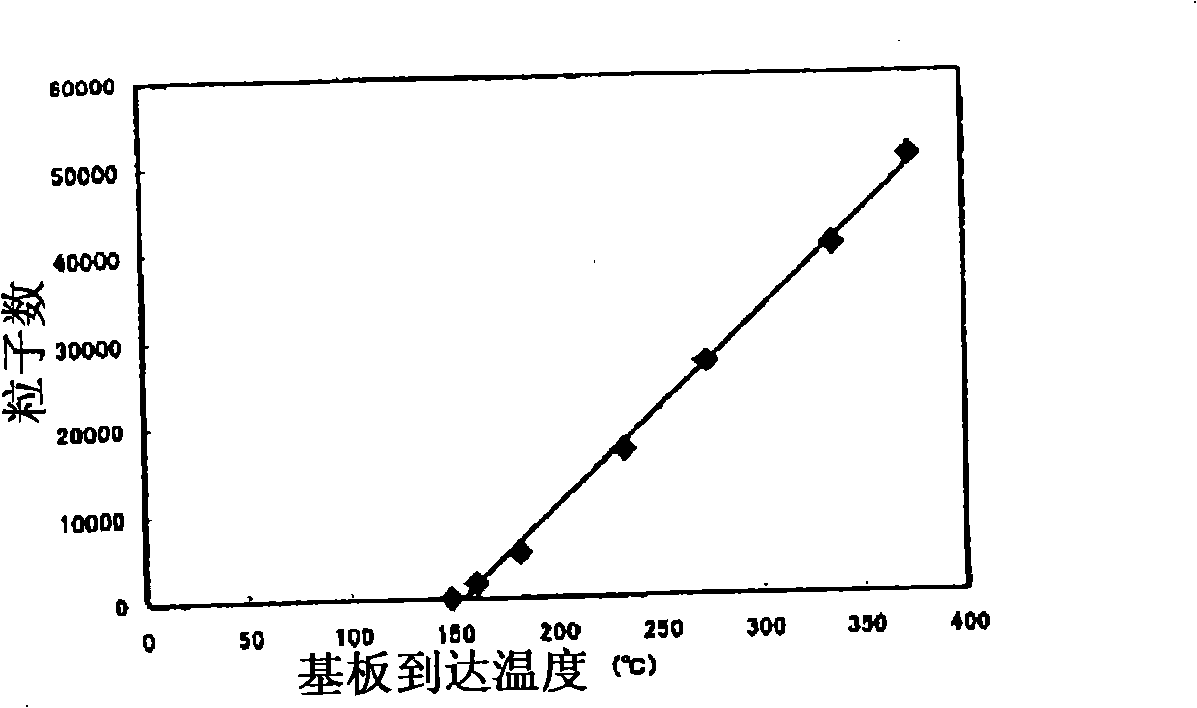

The invention provides a temperature-measuring member, a temperature-measuring device, and a method for measuring temperature, wherein maximum temperature can be reached in a wide temperature range from low temperature to high temperature without external wirings, and impurities dust are not provided. The surface density of projections formed on a thin metal film of a temperature-measuring member having the metal film having been subjected to a temperature profile is calculated with a number-calculating section 7 according to image data fed into an arithmetic processing unit through a CCD camera 4, and an I / O board 5. The maximum temperature of the object is determined with the temperature-calculating unit according to the surface density and data on the maximum temperature and surface density previously stored in a memory 8. Furthermore, a temperature-measuring member 9 constituted by a thin aluminum film arranged on a substrate is used. A reduction in the reflectivity of the film due to projections formed on the film surface according to a temperature profile to which the member has been subjected is measured. The maximum temperature in the temperature profile is estimated according to the reduction in reflectivity.

Owner:KOBE STEEL LTD

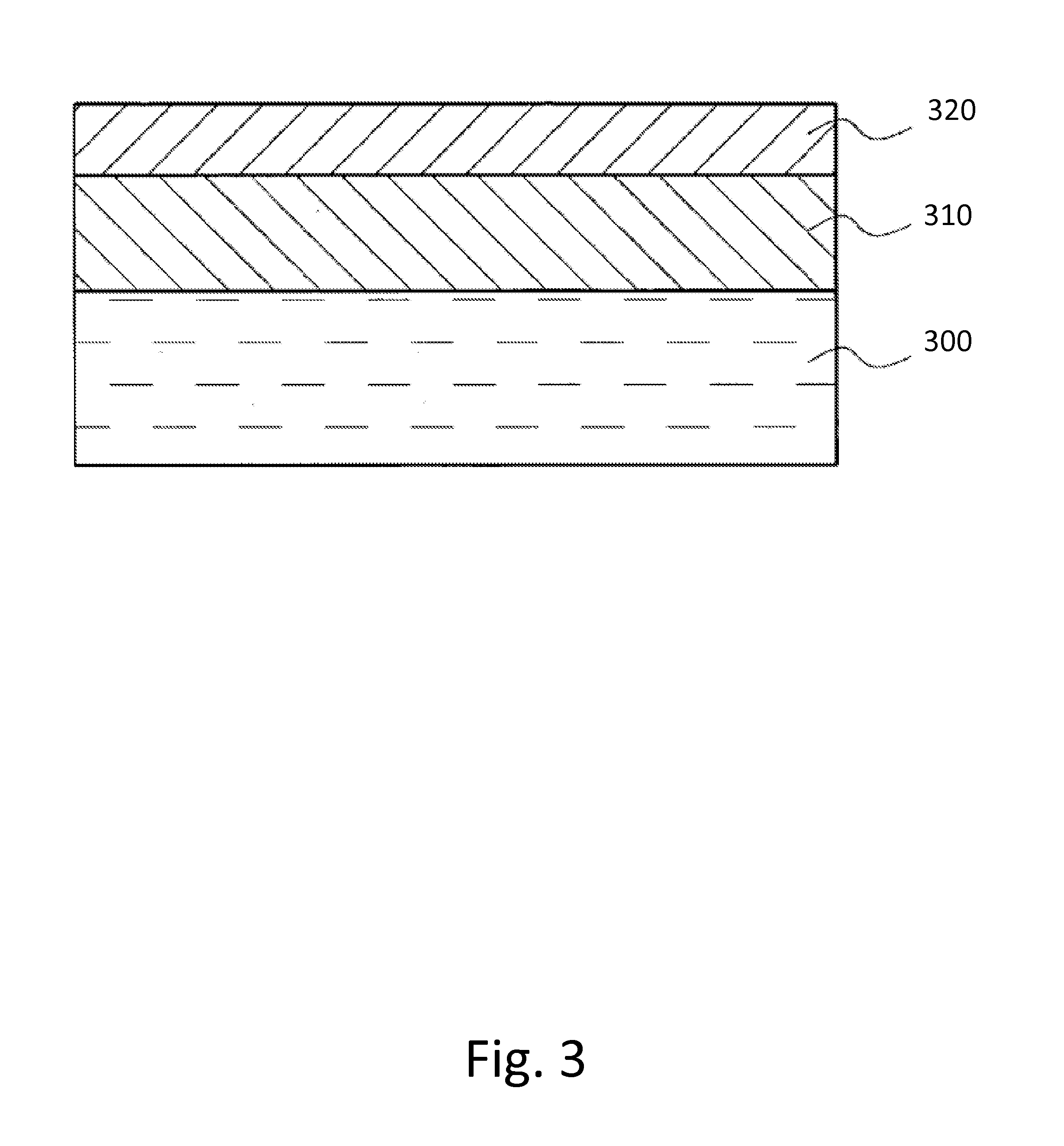

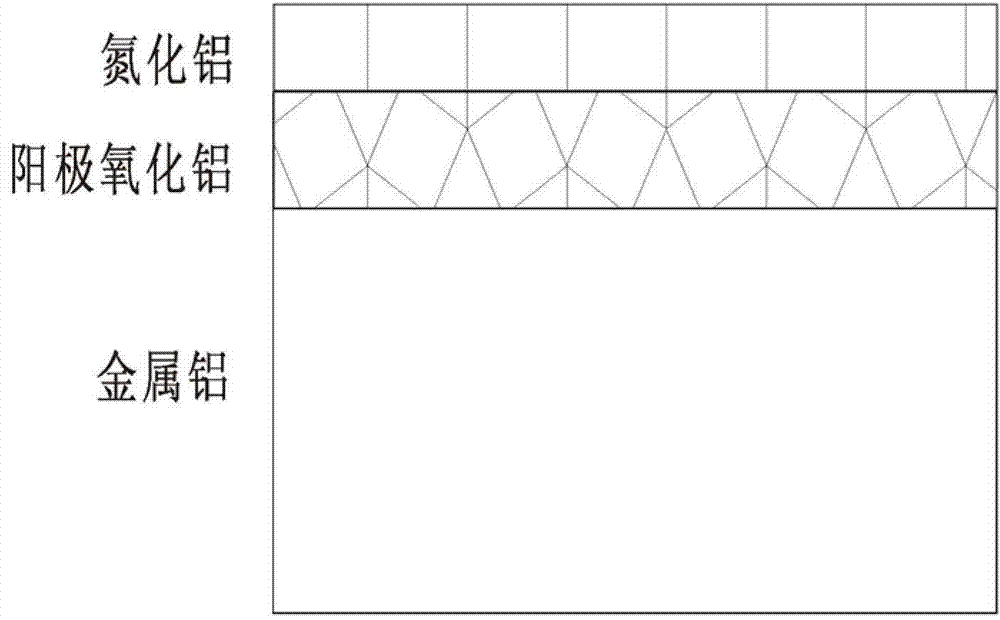

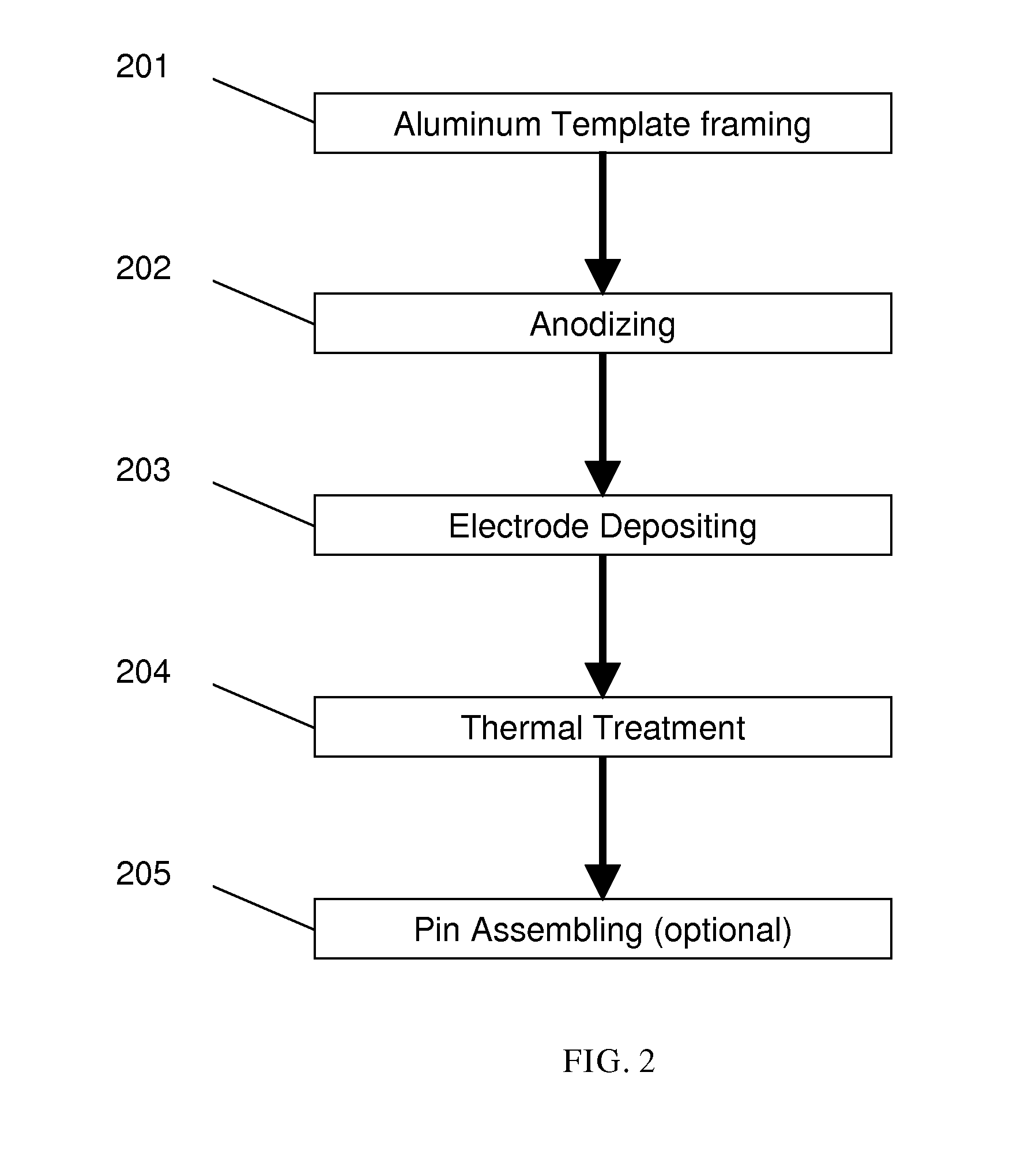

Metal aluminum base aluminum nitride package substrate and preparation method thereof

InactiveCN103035585AImprove thermal shock resistanceNo crackingAnodisationSemiconductor/solid-state device detailsThermal dilatationMetallic aluminum

The invention discloses a metal aluminum base aluminum nitride package substrate and a preparation method thereof, and belongs to the field of microelectronic materials. The package substrate comprises a metal aluminum base, a porous anodic alumina film formed on the surface of the metal aluminum base, and an aluminum nitride film formed on the surface of the anodic alumina film, wherein the porosity of the anodic alumina film is reduced gradually along the direction from the metal aluminum base to the aluminum nitride film. According to the preparation method of the package substrate, metal aluminum is used as the base, anodic oxidation is carried out on one surface of aluminum to generate a layer of the porous anodic alumina film, and then the aluminum nitride film is deposited on the anodic alumina film in a vacuum mode. According to the metal aluminum base aluminum nitride package substrate, the anodic oxidation is carried out on the metal aluminum base, an anodic alumina thermal stress buffer layer with a coefficient of thermal expansion gradually varied is formed between the aluminum base and the aluminum nitride film, thermal shock resistance is improved obviously, cracking does not occur under 300 DEG C thermal shock, and therefore the metal aluminum base aluminum nitride package substrate can be applied in a subsequent process of semiconductor chip package well.

Owner:WUHAN BOOYEN TECH

Visible light-reflecting member

InactiveUS7331695B2Improve corrosion resistanceInhibit coloringMirrorsElongate light sourcesX-rayPeak intensity

A visible light-reflecting member is disclosed which uses a plate or a film for reflecting visible lights, whose reflective surface is provided with an aluminum thin film having an aluminum purity of not less than 99 mass % and an X-ray diffraction pattern wherein, among peak intensities ascribed to aluminum, the peak intensity ascribed to the (111) plane is higher than the total of the other peak intensities.

Owner:FOUND FOR ADVANCEMENT OF INT SCI

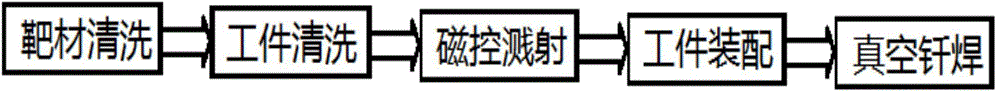

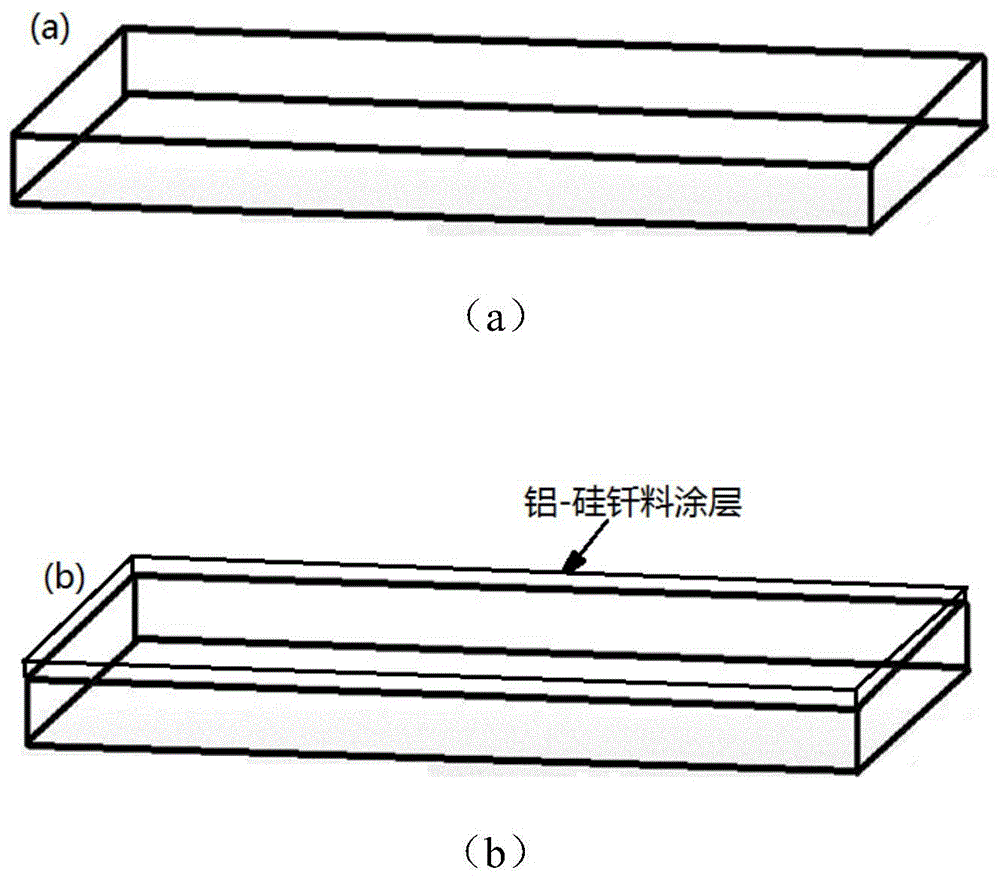

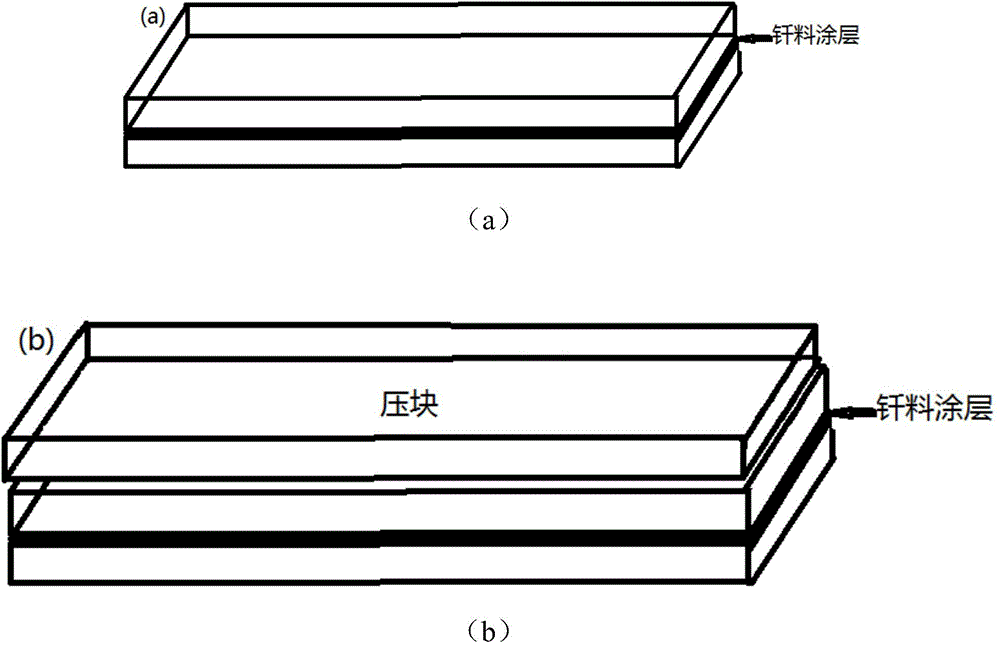

Vacuum brazing method for aluminum alloy solderless piece

InactiveCN104400169ASuccessful implementation of vacuum brazingAvoid designSoldering apparatusRoom temperatureSilicon thin film

The invention provides a vacuum brazing method for an aluminum alloy solderless piece. The method comprises the following steps that (1) a high-purity pure aluminum target material and a pure silicon target material are selected; (2) acetone and ethyl alcohol are sequentially adopted to wipe the target materials and a to-be-soldered part so as to remove oil contamination; (3) a magnetron sputtering method is utilized for depositing a pure aluminum thin film and a pure silicon thin film on the surface of the to-be-soldered part; (4) the to-be-soldered part with the thin films deposited on the surface is taken out of a vacuum chamber; (5) the to-be-soldered part is assembled; (6) the assembled the to-be-soldered part is conveyed to a vacuum brazing furnace to be heated and soldered; and (7) the to-be-soldered part is cooled to the room temperature and is taken out. The vacuum brazing method has the advantages that a solder piece is not adopted; the requirement that according to an existing vacuum brazing technology, a soldering face of a to-be-soldered workpiece must be a plane is avoided; vacuum brazing of structures of a slope, a curved surface and the like is smoothly achieved; and processes of solder piece design, solder piece cutting, solder piece cleaning and the like are avoided.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

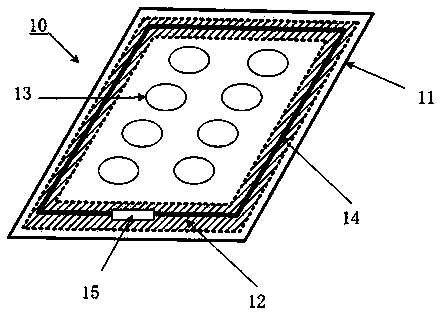

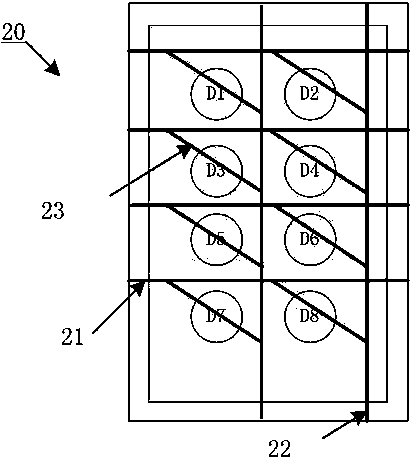

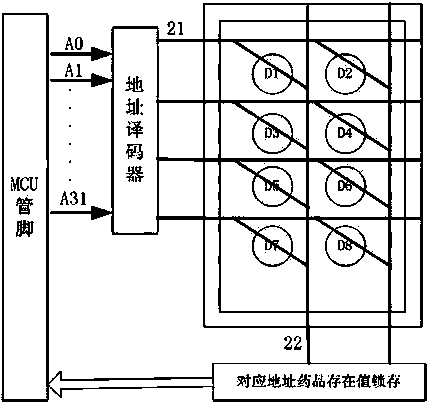

Intelligent RFID medicine plate system suitable for medicine plate management

ActiveCN103413206ALow costOvercoming Difficulty Reading SituationsSensing record carriersResourcesRelevant informationThe Internet

The invention relates to an intelligent RFID medicine plate system suitable for medicine plate management. The intelligent RFID medicine plate system for medicine plate management comprises a medicine existence detection thin film, a medicine plate and an intelligent medicine box. An RFID chip and an aluminum film antenna form a built-in RFID label on the medicine plate, and therefore the problems produced when an existing RFID label is adhered to the medicine plate aluminum thin film are solved. Relevant information such as authentication security information, production logistics information and use method information of medicine are written on the chip through a matched RFID card reader, the intelligent medicine box can read information in the medicine plate RFID chip and conduct information verification by being connected with a server through the internet, and the intelligent medicine box can further read data of the medicine existence detection thin film arranged on the medicine plate, record the dosage and the time each time a patient takes medicine and upload the dosage and the time to the server so that the patient or other guardians can conveniently look up the dosage and the time through a personal mobile terminal.

Owner:SHANGHAI AISINOCHIP ELECTRONICS TECH

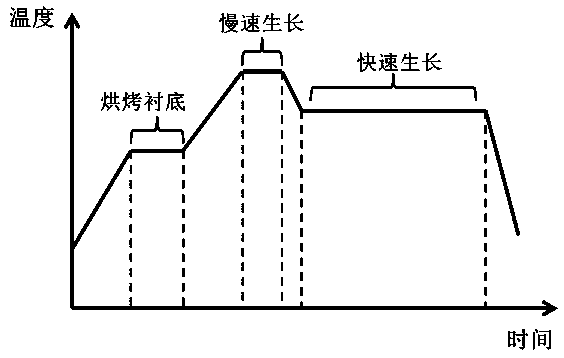

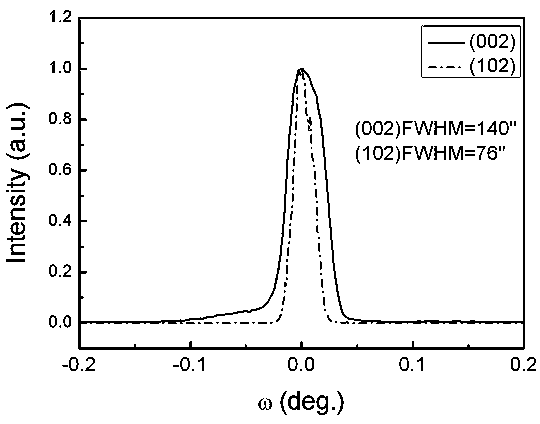

Homogeneous epitaxial growth method of high-quality aluminum nitride film

InactiveCN111188090AImprove performanceQuality improvementPolycrystalline material growthFrom chemically reactive gasesFilm baseThin membrane

The invention relates to a homogeneous epitaxial growth method of a high-quality aluminum nitride film. The homogeneous epitaxial growth method of the high-quality aluminum nitride film based on an aluminum nitride substrate is carried out in MOCVD equipment, and comprises the following steps: selecting an aluminum nitride substrate; putting the substrate into an MOCVD reaction cavity, and heatingto bake the substrate; introducing ammonia gas (NH3) to protect the substrate, further increasing the growth temperature, introducing trimethylaluminum (TMAl) and ammonia gas (NH3) at the same time,and growing a first aluminum nitride (AlN) optimization layer at a low growth rate; and then reducing the growth temperature, and increasing the growth rate to grow a second high-quality AlN epitaxialfilm. The method has the advantages that the method is simple and feasible, the growth period is short, the material performance is good, and the method is an effective solution for realizing high-quality and low-cost growth of the AlN epitaxial film.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

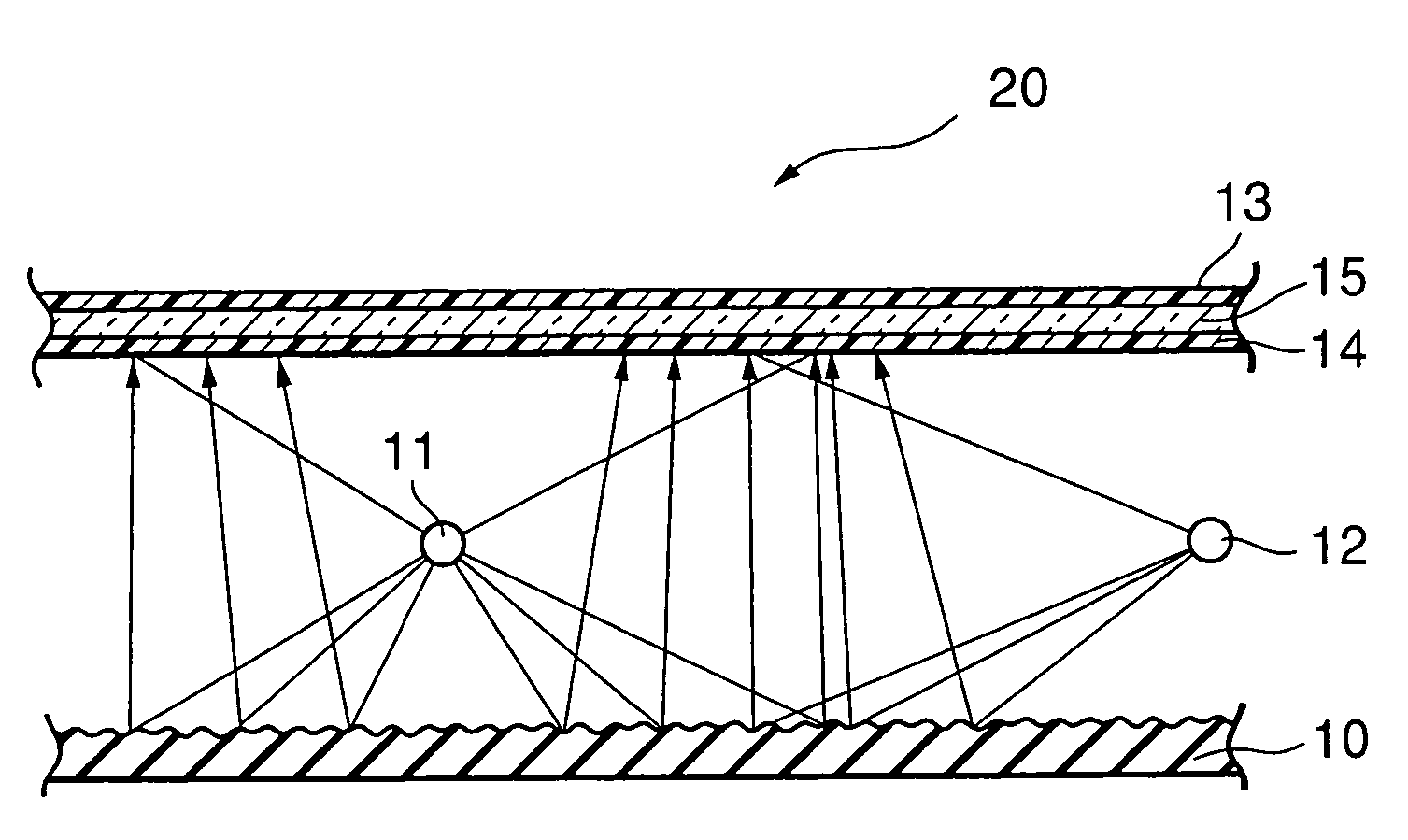

Rapid response relative humidity sensor using anodic aluminum oxide film

InactiveUS8783101B2Simple and cost-effectiveStable responseSurface reaction electrolytic coatingUsing mechanical meansCapacitanceHysteresis

Owner:NANO & ADVANCED MATERIALS INST

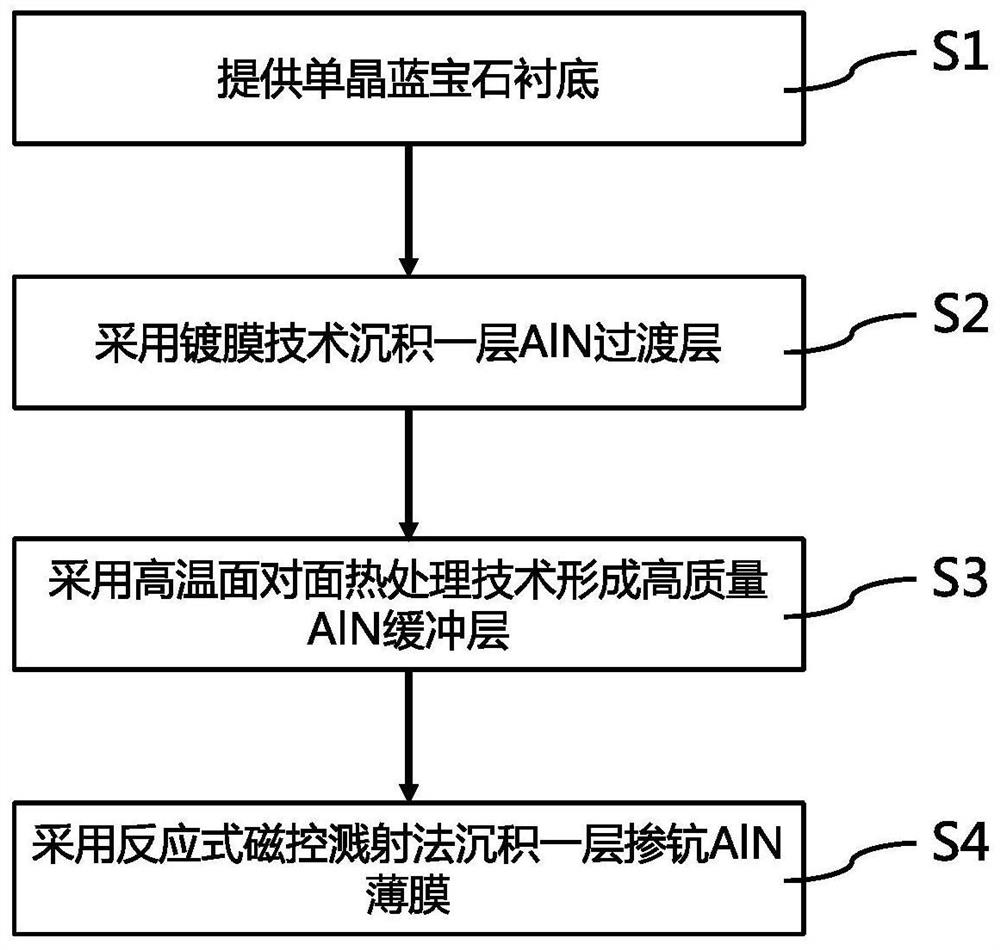

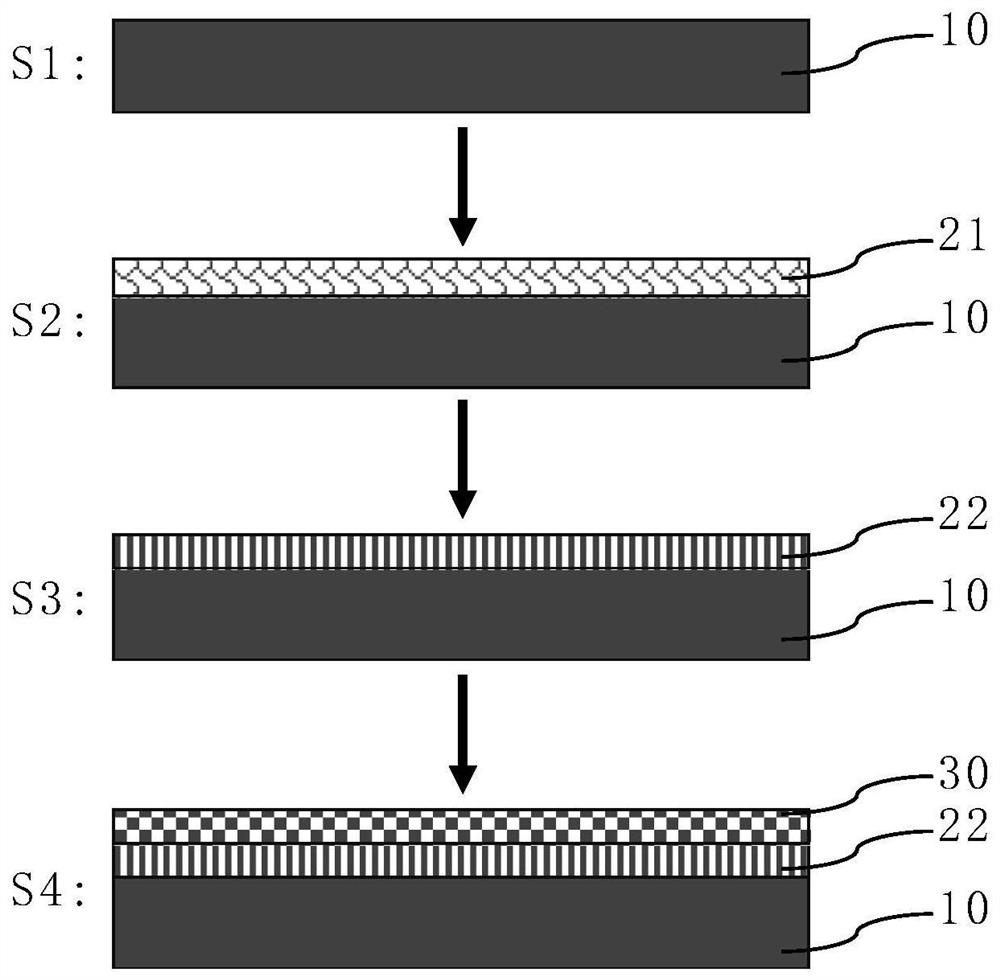

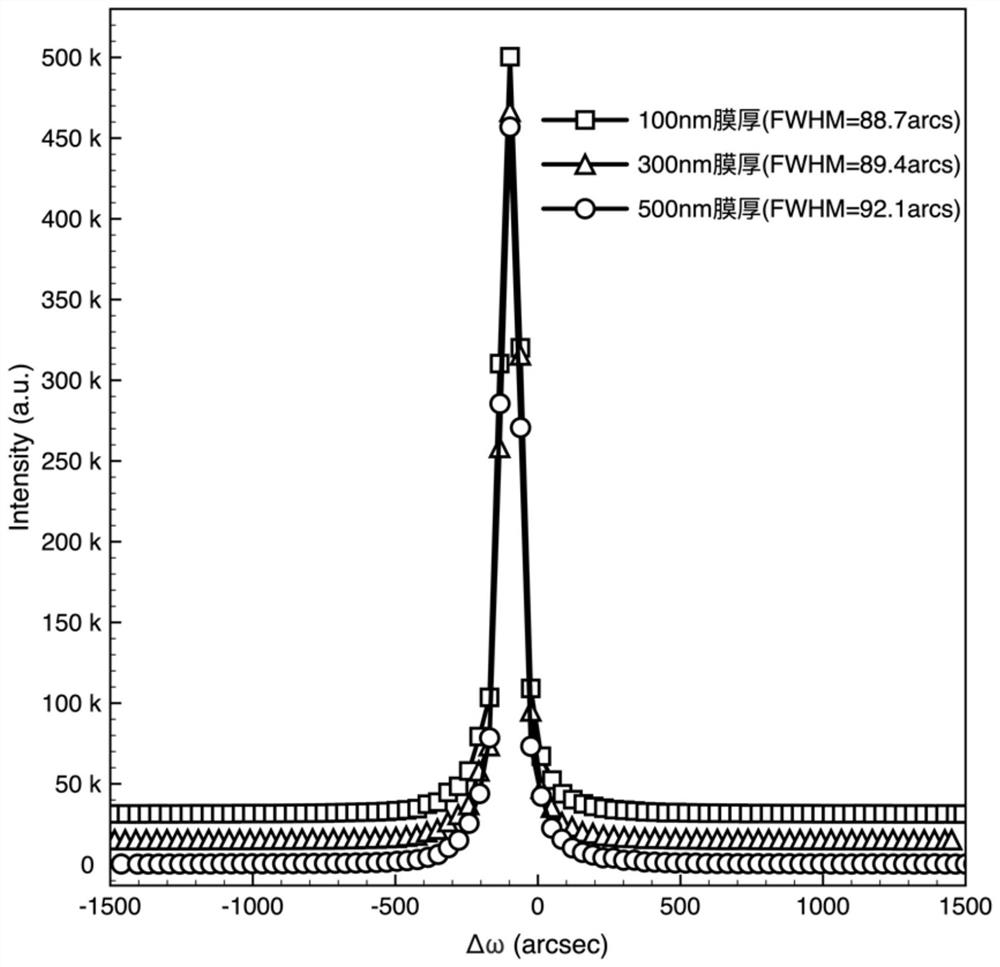

Preparation method of high-quality scandium-doped aluminum nitride film template

PendingCN113174574AImprove crystal qualitySolve the important problem of poor crystal qualityVacuum evaporation coatingSputtering coatingHigh concentrationElectromechanical coupling coefficient

The invention provides a preparation method of a high-quality scandium-doped aluminum nitride film template. The preparation method includes the following steps of: S1, preparing a substrate; S2, depositing a film transition layer on the substrate by adopting a coating technology; S3, thermally treating the film transition layer at a high temperature in a pure nitrogen atmosphere by adopting a high-temperature face-to-face heat treatment technology to form a high-quality buffer layer; and S4, depositing a scandium-doped aluminum nitride film on the buffer layer by adopting a reactive magnetron sputtering deposition method. The preparation method provided by the invention can be used for preparing a scandium-doped aluminum nitride thin film with a high crystallization property, solves the problem that the orientation of the aluminum nitride thin film is seriously deteriorated due to doping of a high Sc concentration, and achieve results of far exceeding the level of the prior art under different film thicknesses, and lays a solid foundation for application of SAW / BAW devices with a higher frequency, enhanced piezoelectric response, a higher electromechanical coupling coefficient and a higher Q value.

Owner:ULTRATREND TECH INC

Method for producing solenoid micro-inductance device based on amorphous FeCuNbCrSiB magnetic film

InactiveCN1812020ASolve for uniformityImprove high frequency performanceDecorative surface effectsVacuum evaporation coatingSputteringElectrical conductor

The invention is a kind of producing method of solenoid micro-inductance device based on non-crystal FeCuNbCrSiB magnetic thin film in microelectronic technology field. The method is as follows: making double-side alignment symbol; sputtering substrate; spinning photoresist, exposing, developing; electroplating ground loop and connecting conductor; removing photoresist and substrate; sputtering aluminium oxide thin film and polishing aluminium oxide thin film; sputtering FeCuNbCrSiB magnetic thin film and etching FeCuNbCrSiB magnetic thin film; sputtering substrate; spinning photoresist, exposing, developing; electroplating connecting conductor; removing photoresist and substrate; sputtering aluminium oxide thin film and polishing aluminium oxide thin film; sputtering substrate; spinning photoresist, exposing, developing; electroplating topping coil and pin; removing photoresist and substrate; sputtering aluminium oxide thin film and polishing aluminium oxide thin film; magnetic field annealing.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com