Patents

Literature

476results about How to "Uniform film formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

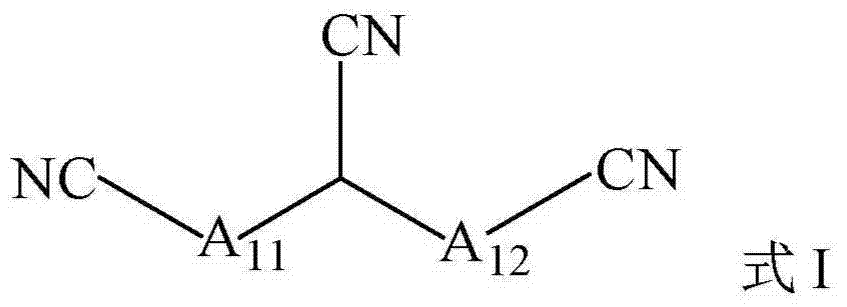

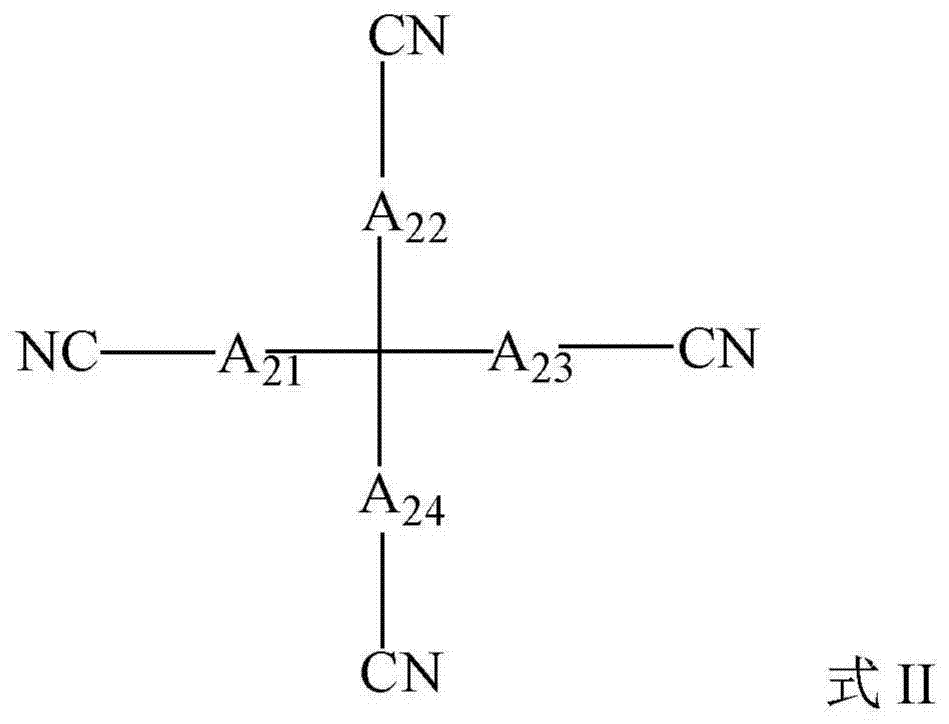

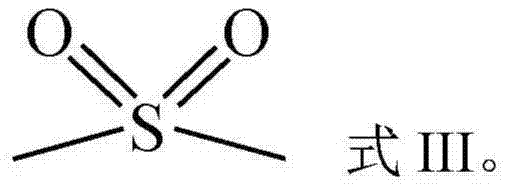

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

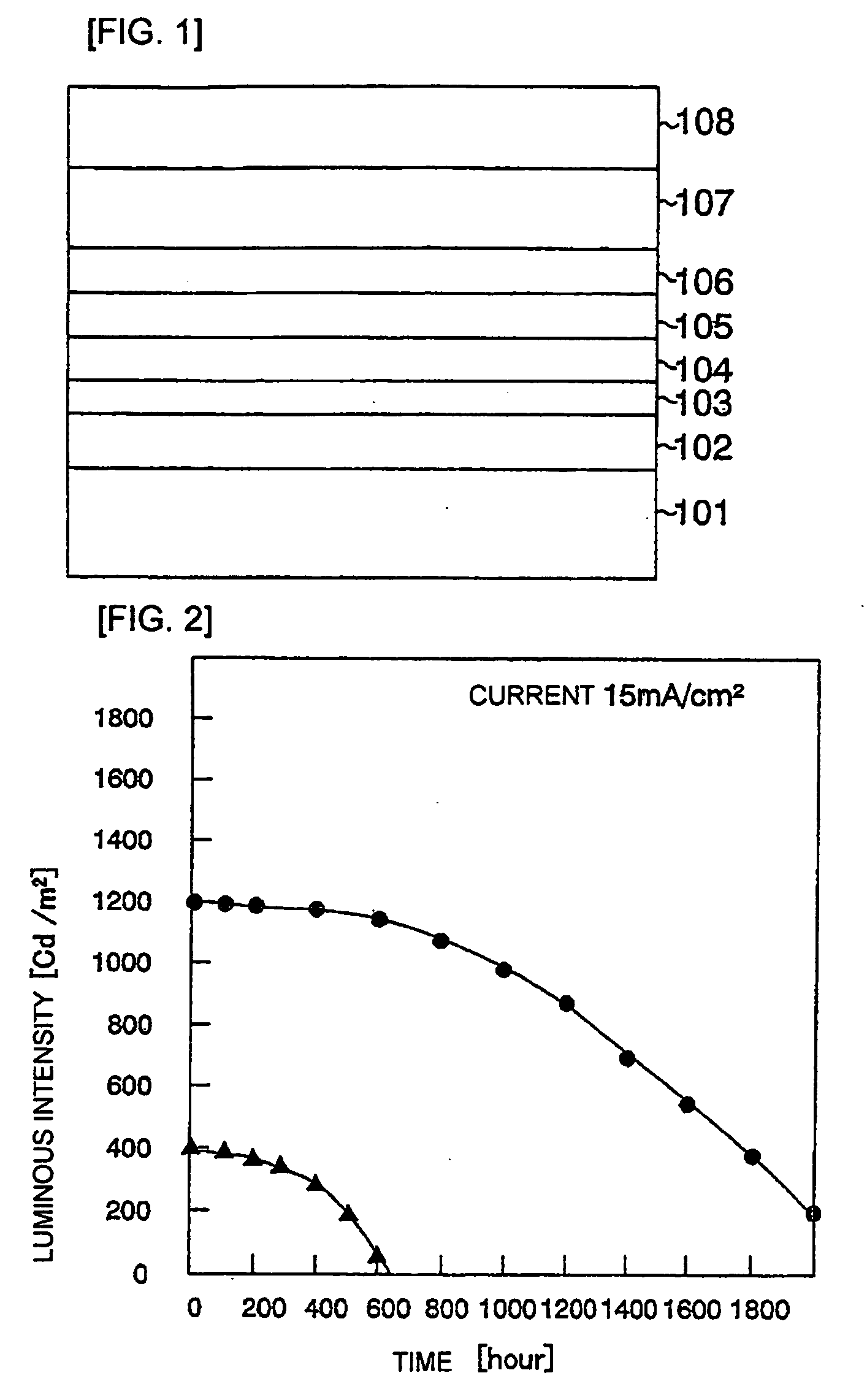

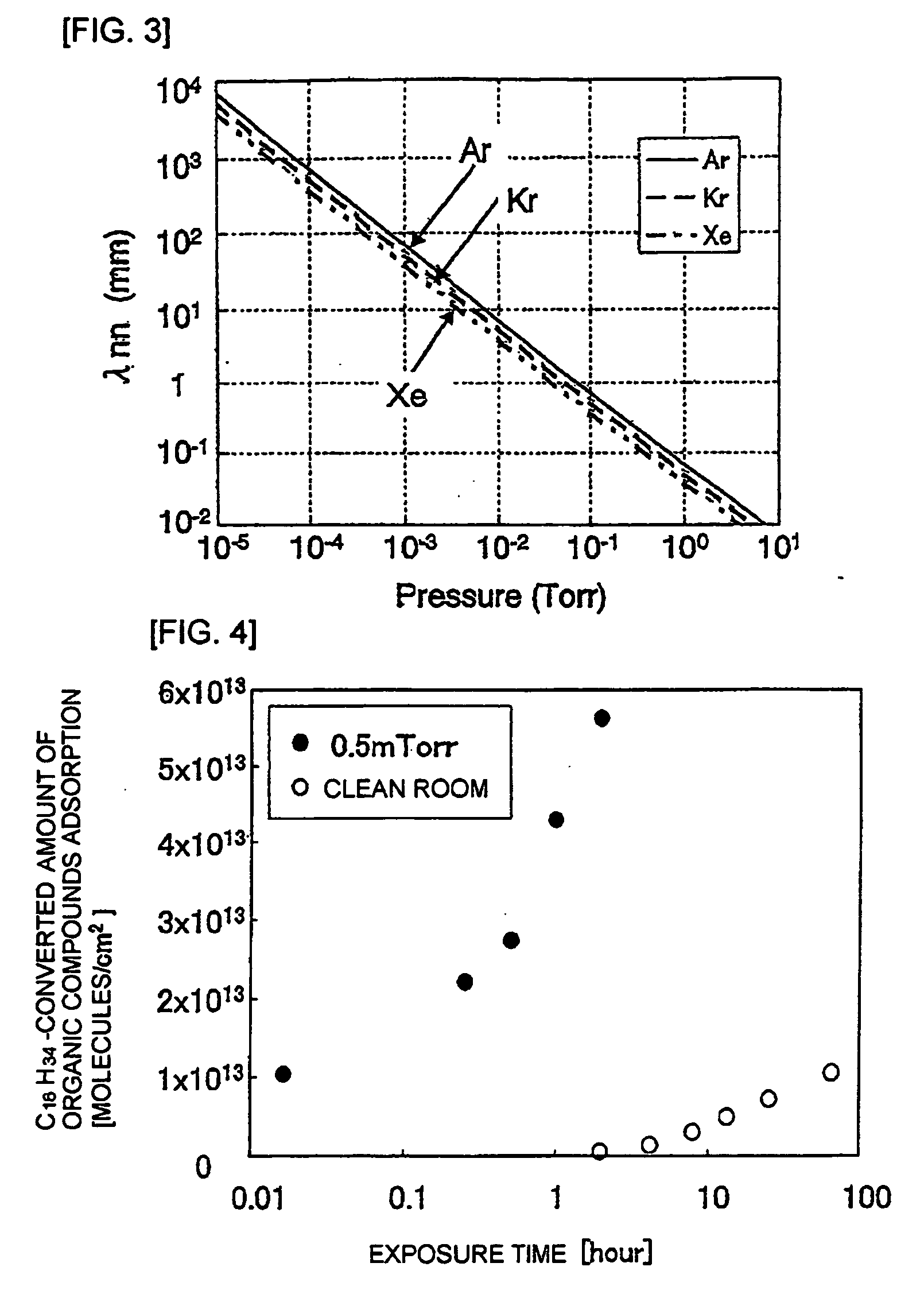

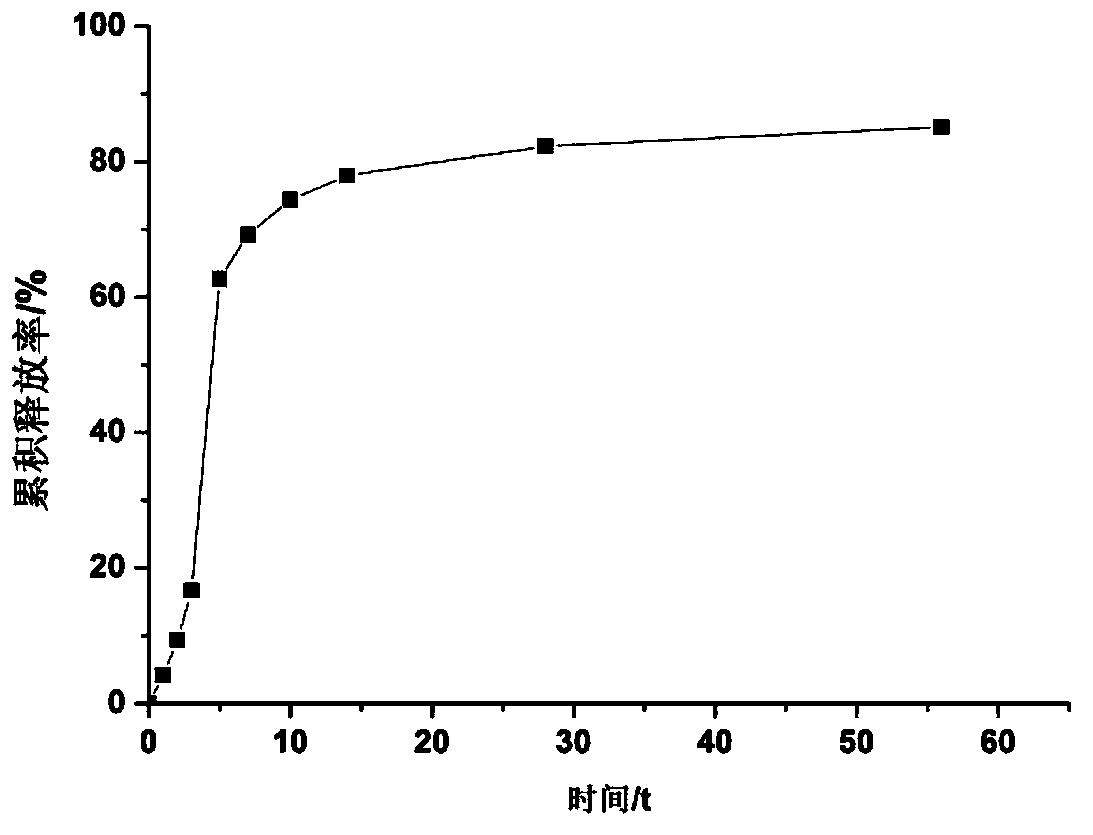

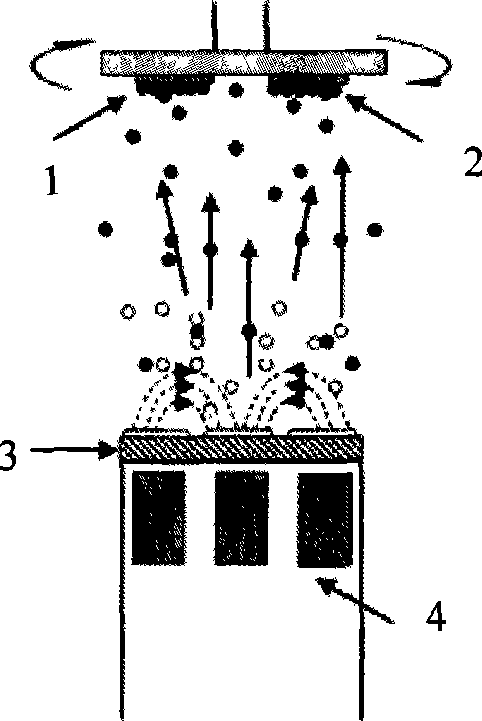

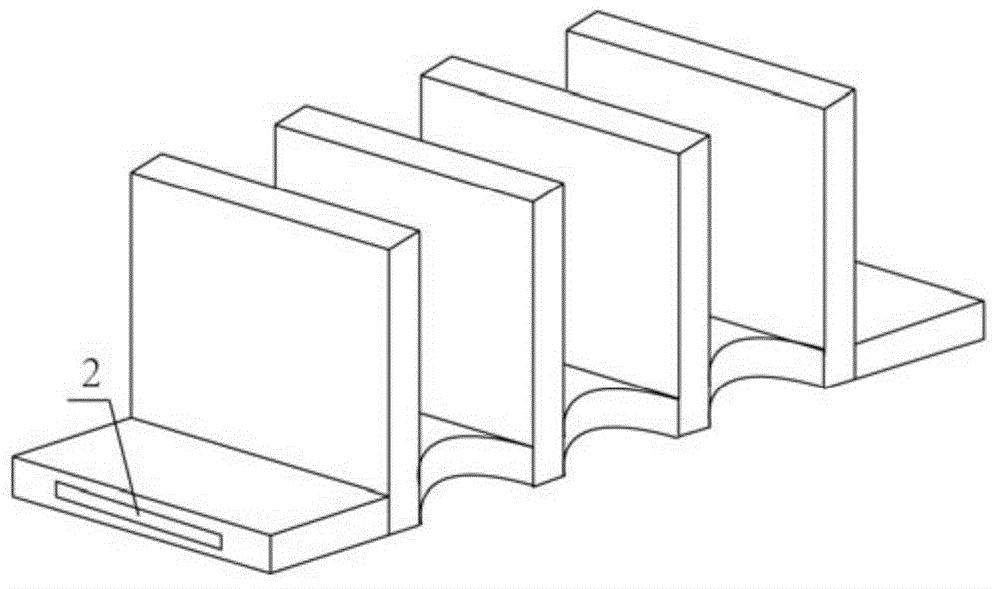

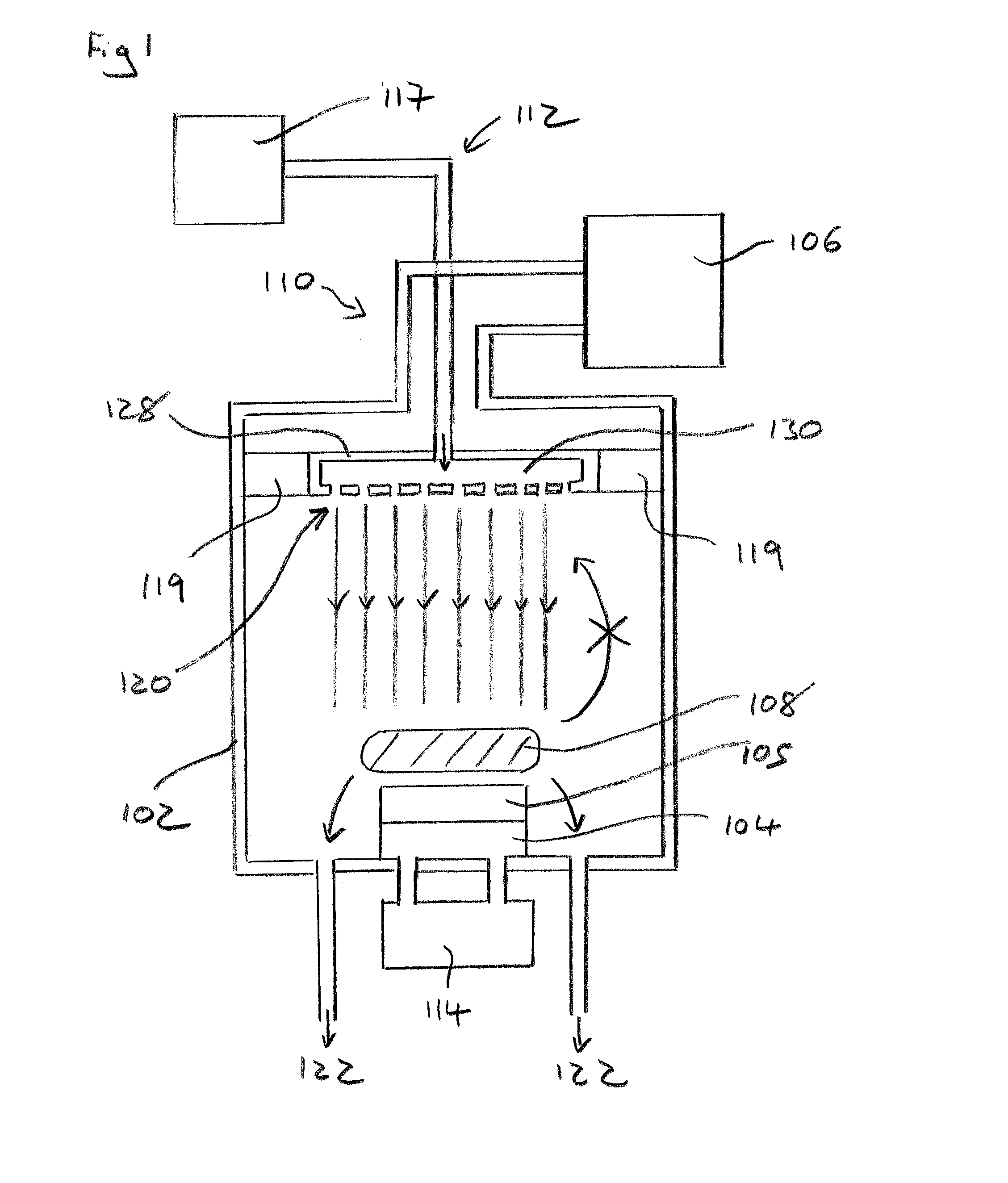

Film-Forming Apparatus And Film-Forming Method

InactiveUS20080241587A1High film forming rateUniform film formationDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringRaw material

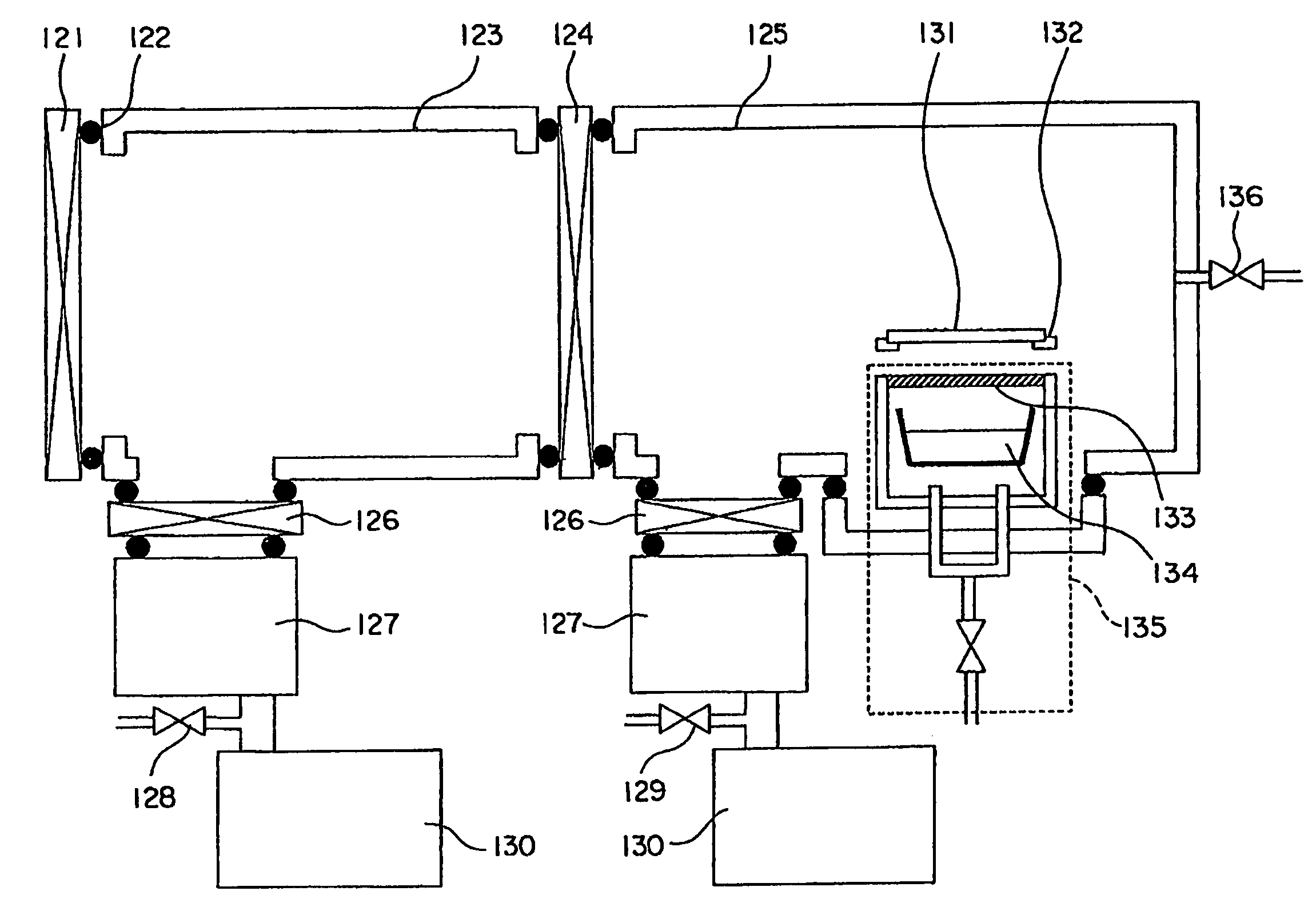

For increasing the film-forming rate and enabling uniform film formation and waste elimination of raw material, a film-forming method and a film-forming apparatus can reach an evaporated film-forming material to a surface of a substrate by the flow of a transport gas so as to control the film-forming conditions by the flow of the gas. Thereby a uniform thin film can be deposited on the large-area substrate. That is, by directing the evaporated raw material toward the substrate, it is possible to increase the film-forming rate and achieve uniform film formation.

Owner:OHMI +1

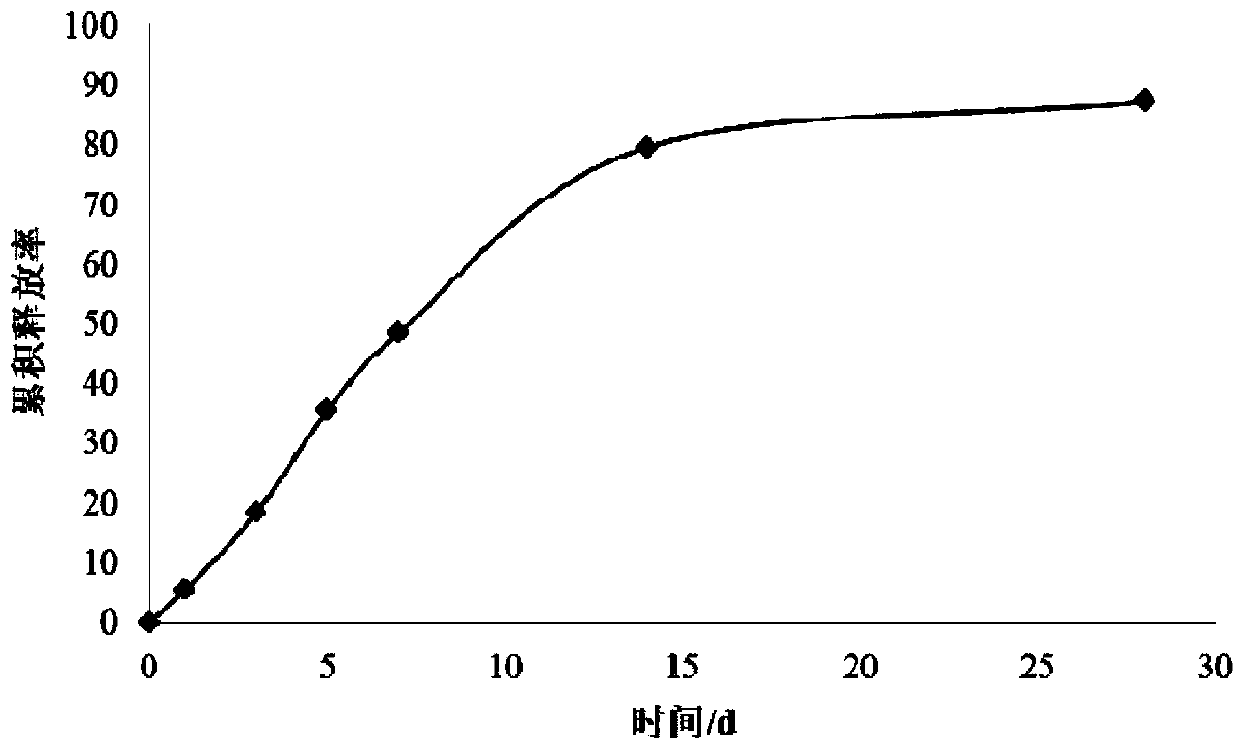

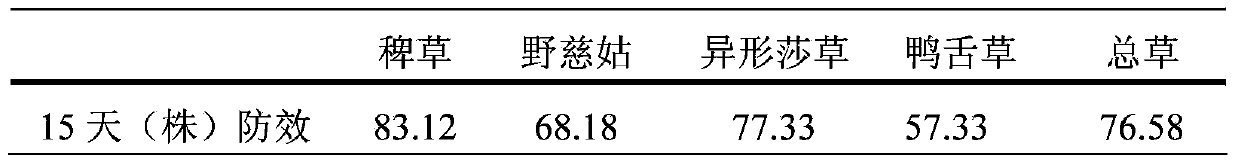

Polymer-coated controlled release pesticide granule and preparation method thereof

ActiveCN103387456AImprove water resistanceImprove targetingFertilizer mixturesWater basedPolyurethane membrane

The invention discloses a polymer-coated controlled release pesticide granule and a preparation method thereof. The polymer-coated controlled release pesticide granule comprises a pesticide granule and a polymer layer, wherein the pesticide granule is coated by the polymer layer; the pesticide granule contains one or more effective pesticide components; the polymer layer is a hydrophobic membrane layer and comprises a water-based polyacrylate membrane material or a polyurethane membrane material; the mass of the polymer layer accounts for 3%-15% of the weight of the polymer-coated controlled release pesticide granule. The effective pesticide components are acted on the peripheries of crop roots after the polymer-coated controlled release pesticide granule disclosed by the invention is applied along with a base fertilizer. The polymer-coated controlled release pesticide granule has good prevention and control effects on farmland weeds, soil insects and soil-borne diseases, and the coating material synthesis and preparation process is advanced and the polymer-coated controlled release pesticide granule has good controlled release property. The polymer-coated controlled release pesticide granule provided by the invention has the advantages of pesticide utilization ratio improvement, environment pollution reduction, sustainable development and wide application prospect.

Owner:BEIJING BOYICHENG SCI & TECH

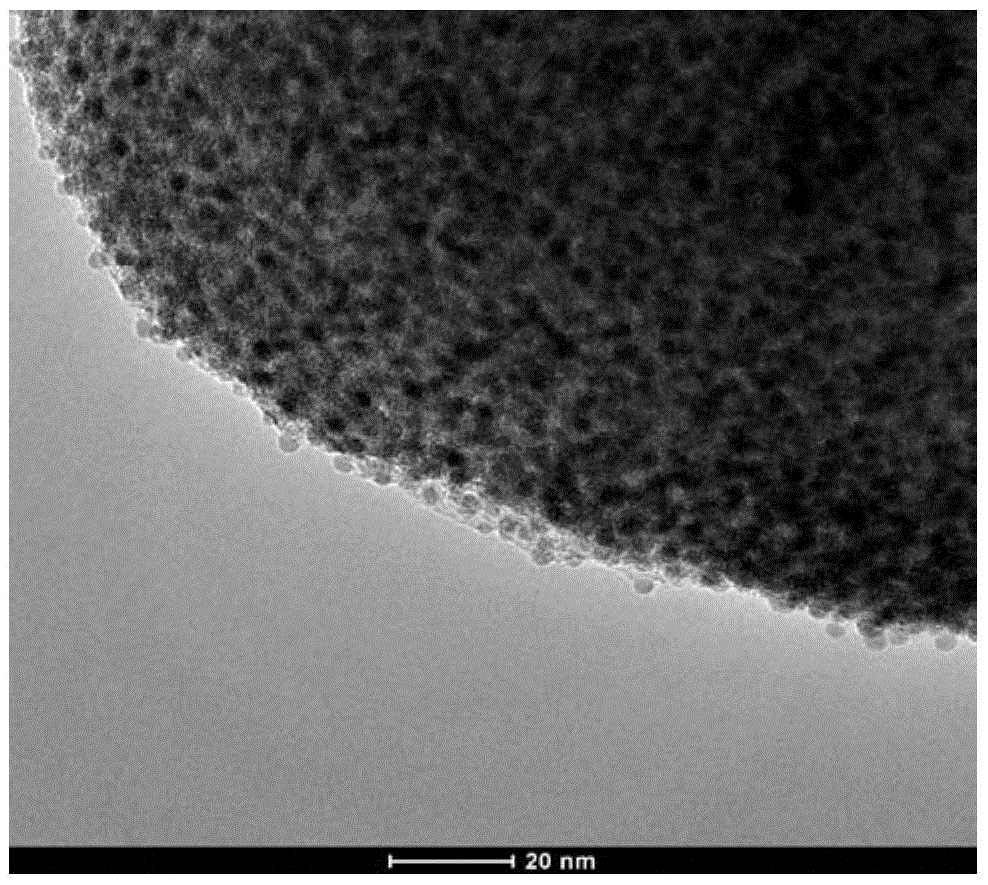

Zinc oxide-based nanoparticle ink and electroluminescent device

InactiveCN107099190AVolatileEvenly dispersedMaterial nanotechnologySolid-state devicesAlcoholNanoparticle

The invention provides zinc oxide-based nanoparticle ink. The zinc oxide-based nanoparticle ink comprises a solvent and zinc oxide-based nanoparticles uniformly dispersed in the solvent. The zinc oxide-based nanoparticle ink comprises, by mass, 0.01 to 20.00% of the zinc oxide-based nanoparticles and 80.00 to 99.99% of the solvent. The zinc oxide-based nanoparticle ink is characterized in that the solvent comprises at least one alcohol ether ester compound. The zinc oxide-based nanoparticle ink can solve the problem that the existing zinc oxide-based nanoparticle ink is not suitable for ink-jet printing and has poor film-forming quality. The invention provides an electroluminescent device. An electron transport layer of the device is prepared from the zinc oxide-based nanoparticle ink through ink-jet printing.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

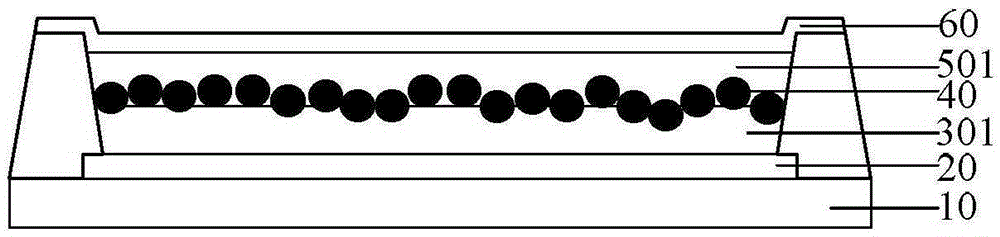

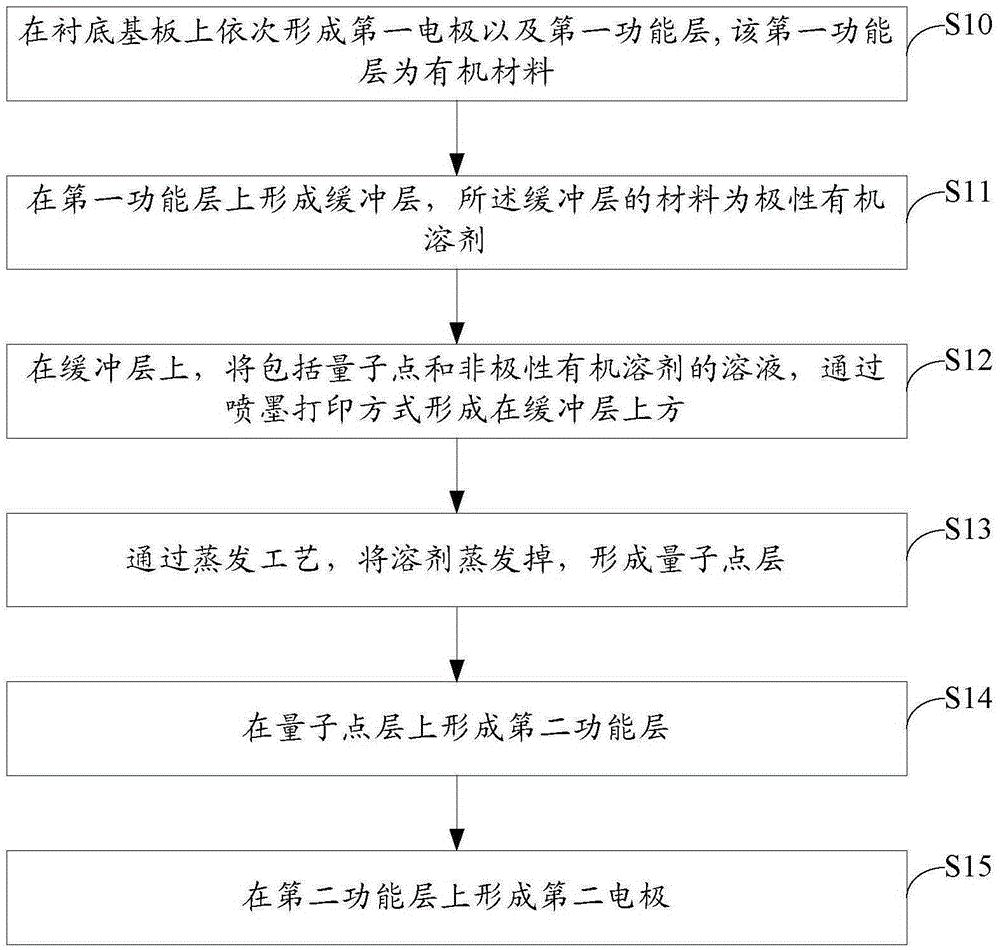

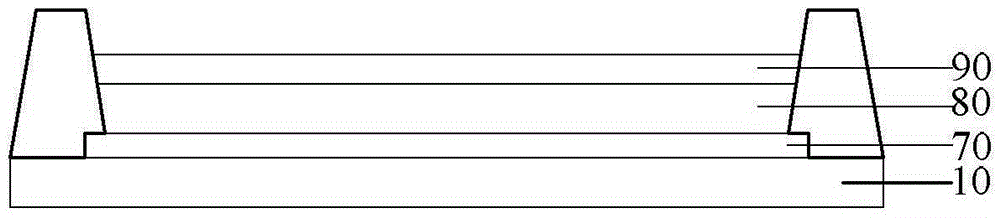

QLED and preparing method thereof, and display device and preparing method thereof

InactiveCN105428546AImprove performanceAvoid corrosionSolid-state devicesSemiconductor/solid-state device manufacturingSolventQuantum dot

An embodiment of the invention provides a QLED and a preparing method thereof, and a display device and a preparing method thereof, which relate to the technical field of display, and can avoid a functional layer of an organic material positioned below a quantum dot layer from being corroded and enable the quantum dot layer to be uniform in film forming. The preparing method of the QLED comprises: forming a first electrode, a first functional layer, the quantum dot layer, a second functional layer and a second electrode on a base substrate in sequence; after the first functional layer is formed from the organic material and before the quantum dot layer is formed, the preparing method further comprises: forming a buffer layer made from a polar organic solvent; on the basis, forming the quantum dot layer which includes: forming a solution containing quantum dots and a nonpolar organic solvent above the buffer layer by adopting an ink-jet printing manner; evaporating the solvent by an evaporation process to form the quantum dot layer. The preparing method is used for the QLED.

Owner:BOE TECH GRP CO LTD

Micro-nano blocking lubricant for drilling fluid and preparation method thereof

ActiveCN108239522AHigh fat contentImprove temperature resistanceDrilling compositionMicro nanoSolid particle

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

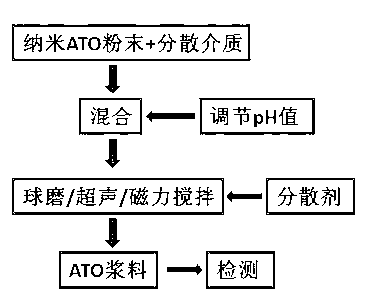

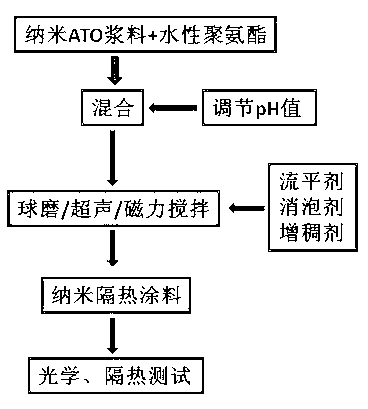

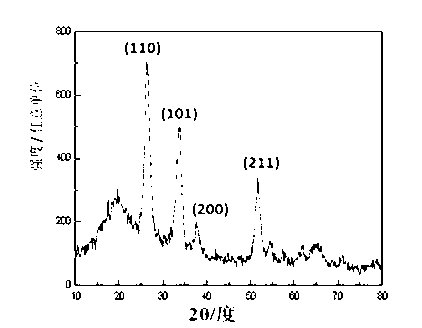

Preparation method of nano antimony tin oxide transparent insulation film

InactiveCN103102083AHigh visible light transmittanceImprove barrier propertiesPolyurea/polyurethane coatingsCzochralski methodThermal insulation

The invention discloses a preparation method of a nano antimony tin oxide (ATO) transparent insulation film. The method comprises following steps: 1) preparation of a nano ATO slurry: mixing an ATO nanopowder and a dispersant according to proportion and stirring thoroughly, and regulating a pH value to prepare the nano ATO slurry; 2) preparation of a nano ATO thermal insulation coating: mixing the nano ATO slurry and aqueous polyurethane, adjusting a pH value, adding a leveling agent, a defoaming agent and a thickener for dispersion, so as to prepare a nano thermal insulation coating; and 3) preparation of a transparent insulation film: immersing a clean glass substrate in the prepared nano thermal insulation coating liquid, and preparing a transparent film on the glass substrate by using a spin coating method / Czochralski method / bar coating method. The nano ATO transparent thermal insulation film prepared by the method provided by the invention has high visible light transmittance and infrared barrier property, and is suitable for building thermal insulation glass. The film preparation process is simple, environment-friendly, low-cost, and can form a uniform film with large area.

Owner:HANGZHOU DIANZI UNIV

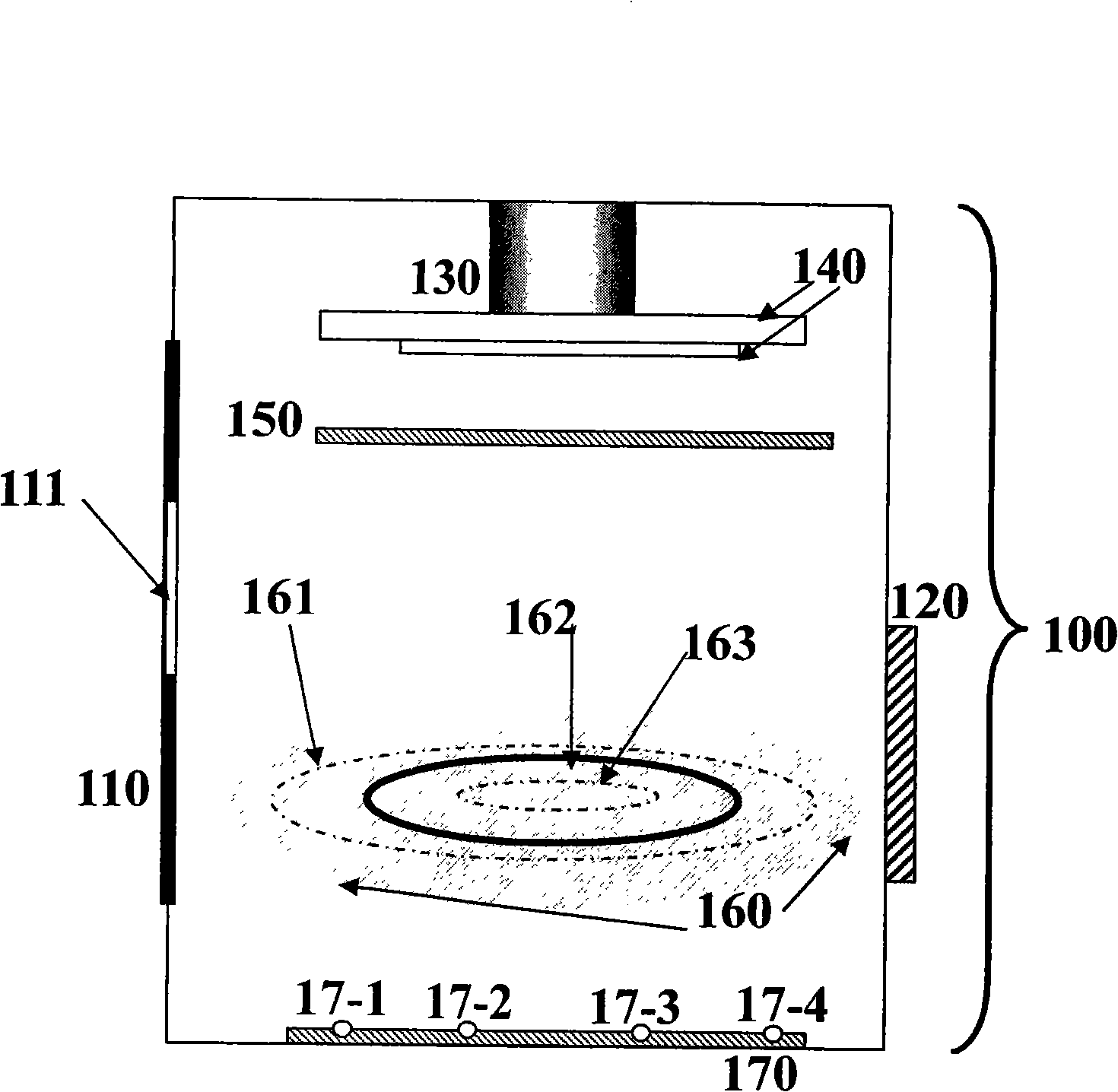

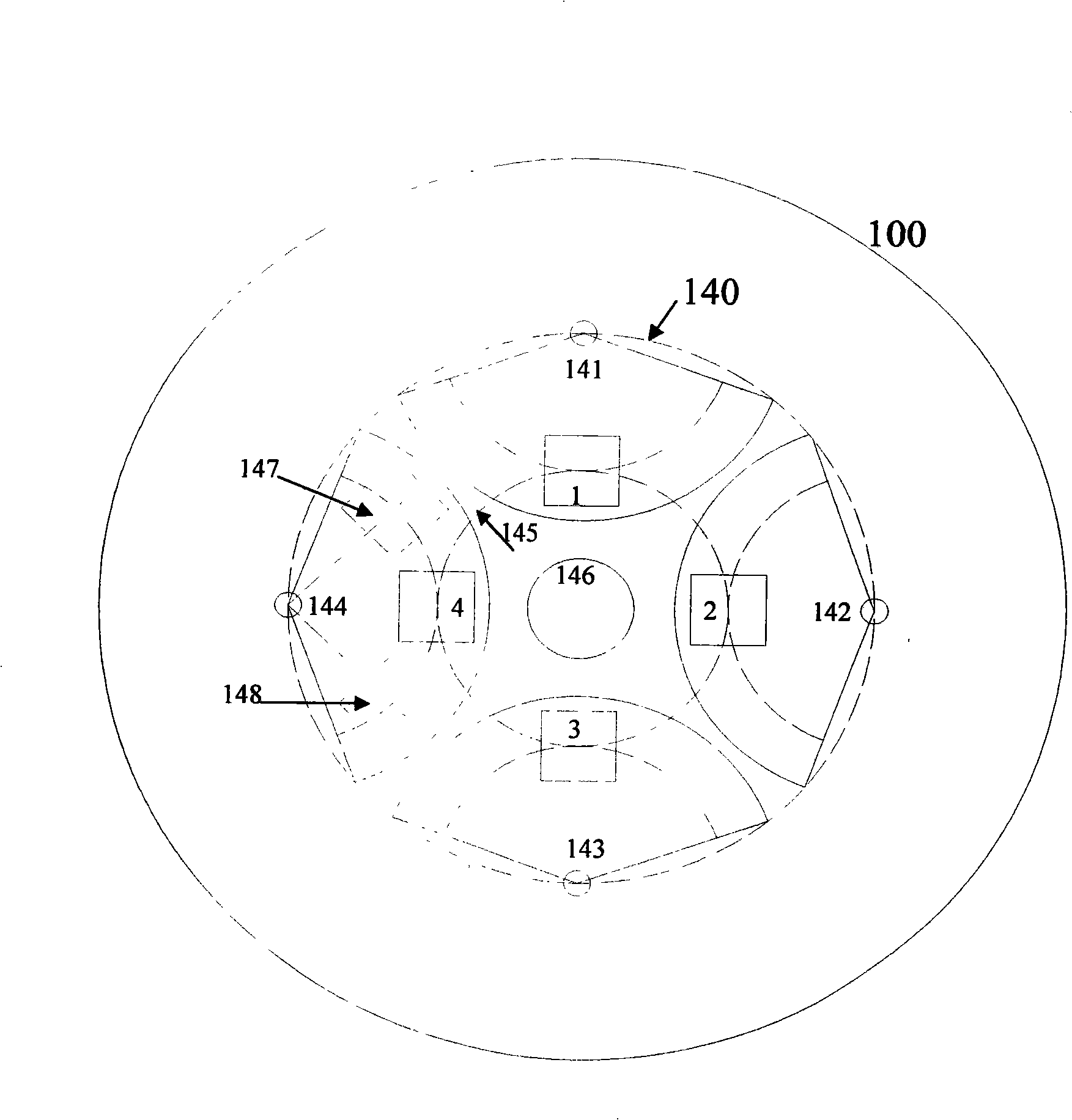

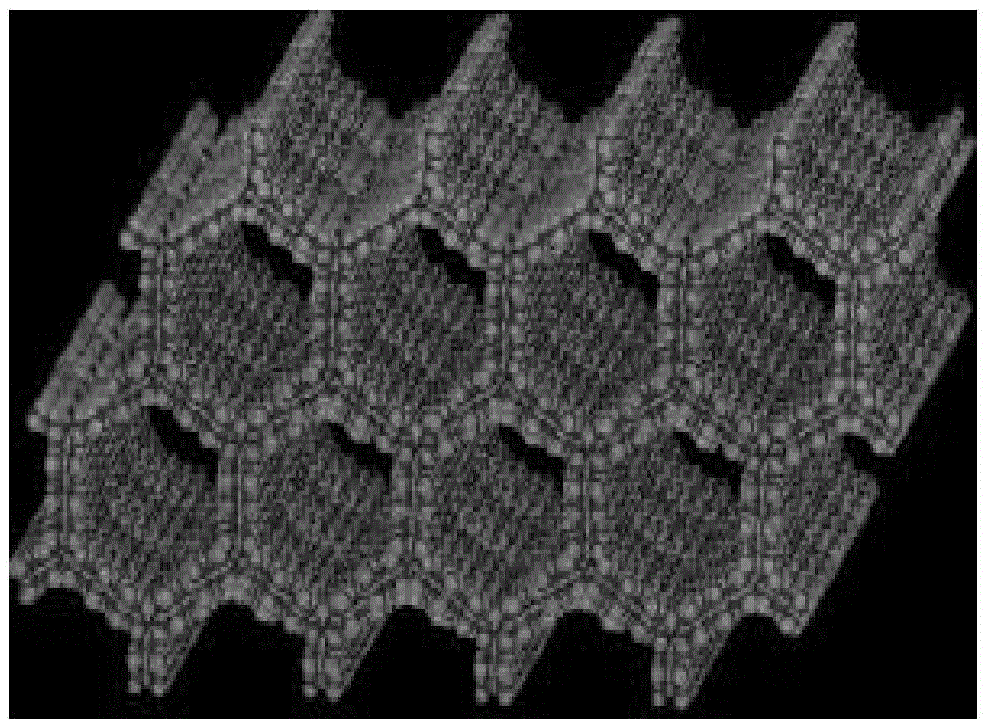

Multi-source vacuum evaporation device having multi-layer radial type evaporation source distribution structure

InactiveCN101280418AShorten the timeSave spaceVacuum evaporation coatingSputtering coatingDistributed sourceDistribution method

The invention relates to a multiple-source vacuum coating device of a multiple-layer radiating type evaporator source distribution structure, and an operating mode of a substrate during the filming process. The system takes a medial axle of a filming vacuum chamber as a center, and effectively arranges more evaporator sources by adopting a two-layer or multiple-layer outward radiating evaporator source distribution method on the identical horizontal plane, to satisfy the requirements of the multiple-source in the multiple-layer part structure; simultaneously, the metal evaporator source is positioned at the position approximately vertical to a coating specimen stage, to remove the shadow effect generated during the metal costing process; the rotation of the substrate during the evaporating process, and the use of an independent small baffle plate and an masking plate of each sample in the sample base frame are matched, the uniform film manufacture of the larger-sized substrate not only can be realized, the preparation of a plurality of samples and a plurality of structures in the identical vacuum process but also can be realized, and the efficiency and the comparability of the result is improved; further, the multiple-layer distributing source structure can effectively utilize the space, the volume of the volume chamber body is greatly reduced under the condition of identical evaporating amount.

Owner:NANJING FANGYUAN GLOBAL DISPLAY TECH

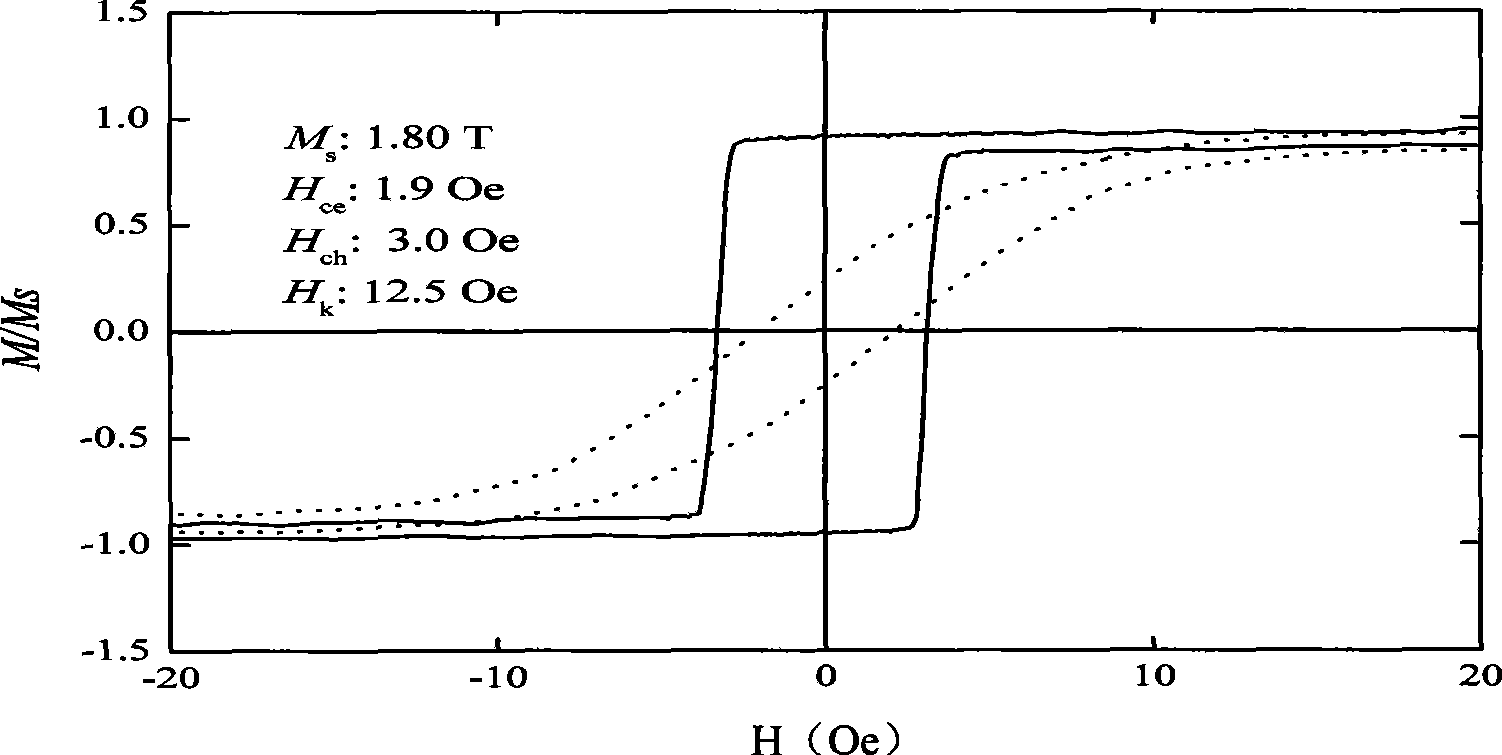

Production method for film generating in-plane uniaxial magnetic anisotropy in non-inducement magnetic field

InactiveCN101429646AExcellent soft magnetic propertiesUniform film formationVacuum evaporation coatingSputtering coatingSputter depositionMagnetic anisotropy

The invention provides a preparation method for an in-plane uniaxial magnetic anisotropic film generated in a non-induction magnetic field, and relates to a soft-magnetic film material. The invention provides the preparation method for the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field. The soft-magnetic film material comprises the following components according to the atomic percentage: 92 to 98 percent of magnetic alloy or magnetic metal and 2 to 8 percent of non-magnetic metal. The preparation method comprises the following steps: assembling a substrate into a sputtering chamber, and installing an iron target and a non-magnetic metal target, or a ferrocobalt target and a non-magnetic metal target; starting a vacuum system for air extraction till the background vacuity of the sputtering chamber is above 5x10<-4>Pa; heating up the substrate to reach a preset temperature of the substrate; and introducing reaction gas into the sputtering chamber to make the target surface build up luminance, carrying out presputtering firstly, then starting a substrate rotating button when the luminance is stable, opening a substrate baffle, and finally carrying out sputtering deposition to obtain the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field.

Owner:XIAMEN UNIV

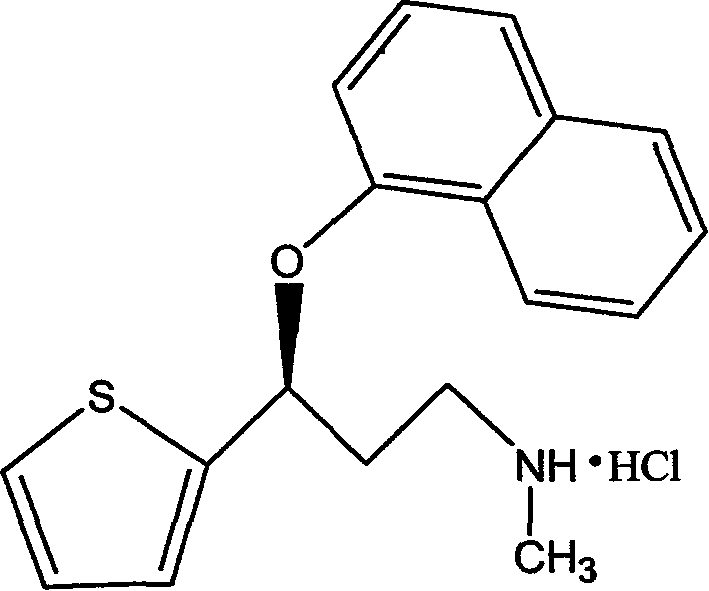

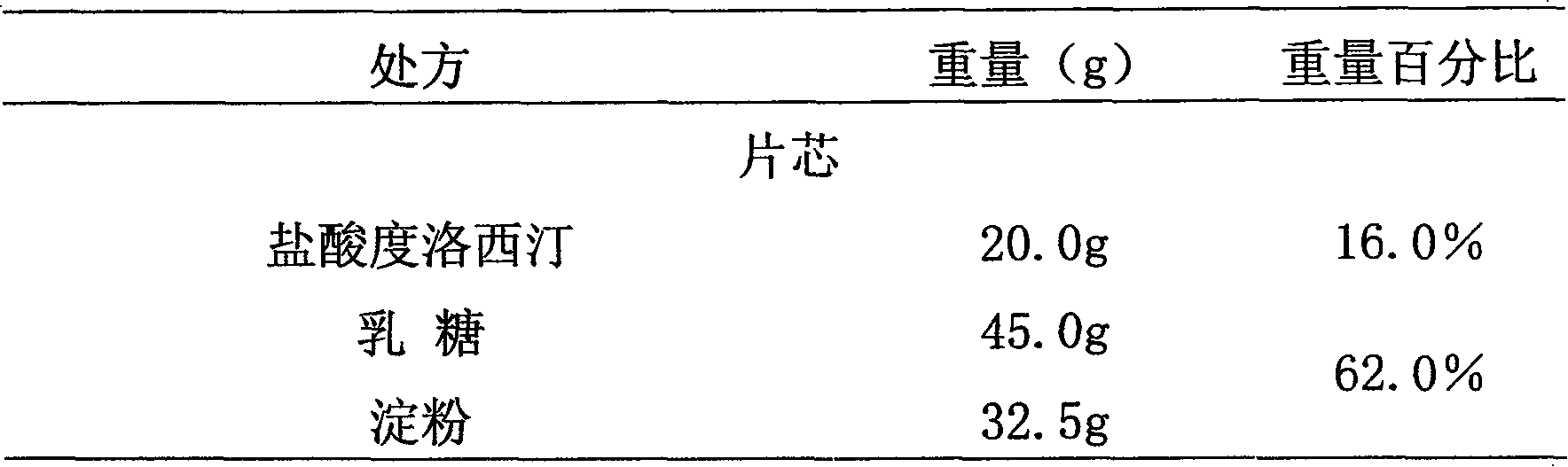

Medicinal preparations containing duloxetine hydrochloride and preparation method thereof

ActiveCN101190208AImpact releaseImprove toleranceOrganic active ingredientsNervous disorderIsolation layerPharmaceutical formulation

The invention relates to an enteric-coated tablet containing duloxetine hydrochloride and a preparation method thereof. The enteric-coated tablet of duloxetine hydrochloride consists of three parts: a tablet core, a gastric-coated isolation layer and an enteric-coated layer. The technical proposal of the invention can effectively avoid the cross reaction between the medicine and enteric coating material occurring during the releasing process of the medicine and affecting the release of the medicine; therefore, the stability of the medicine can be effectively improved. The preparation method is simple and is easy to be operated, which is suitable for industrialized production.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

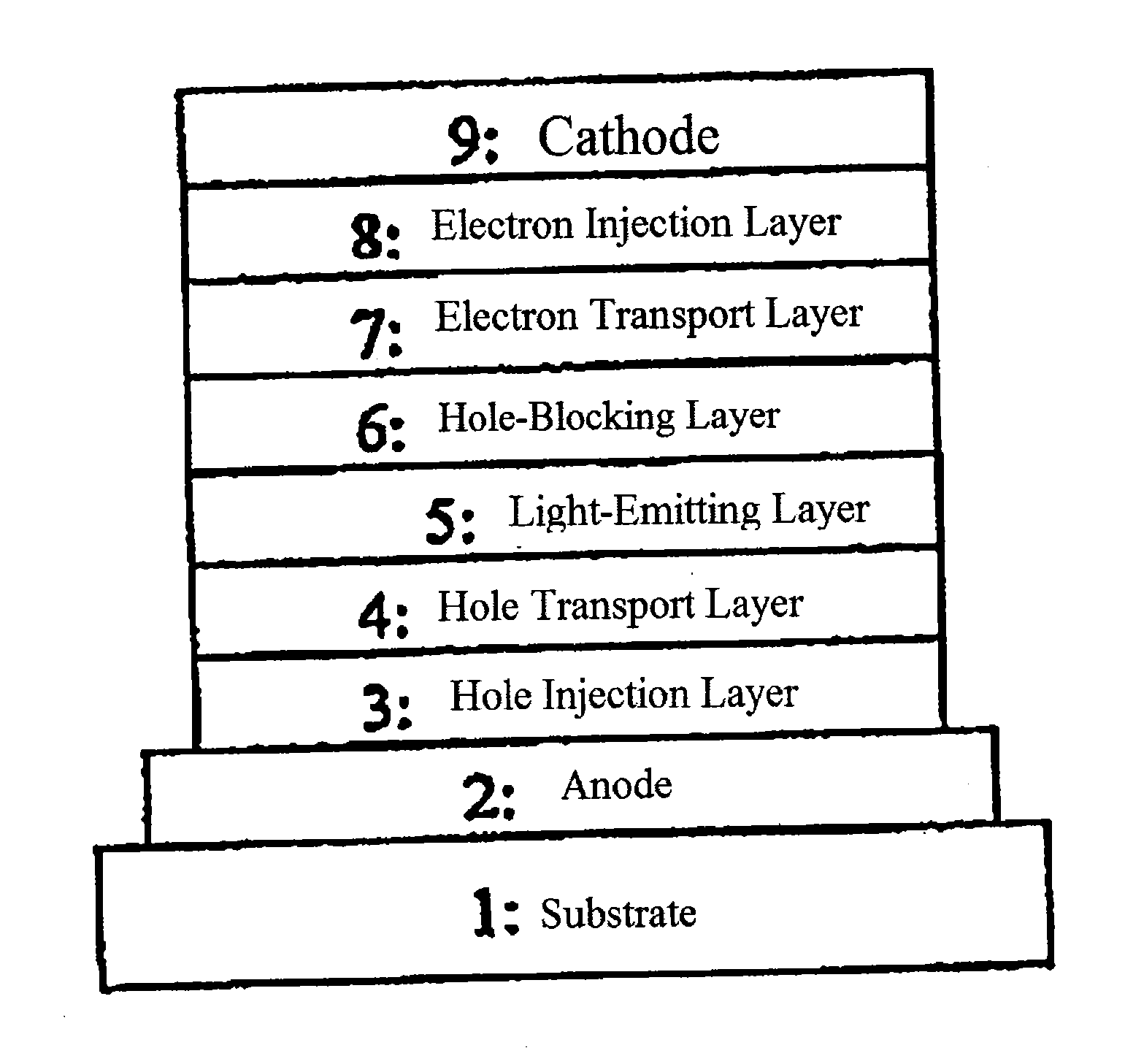

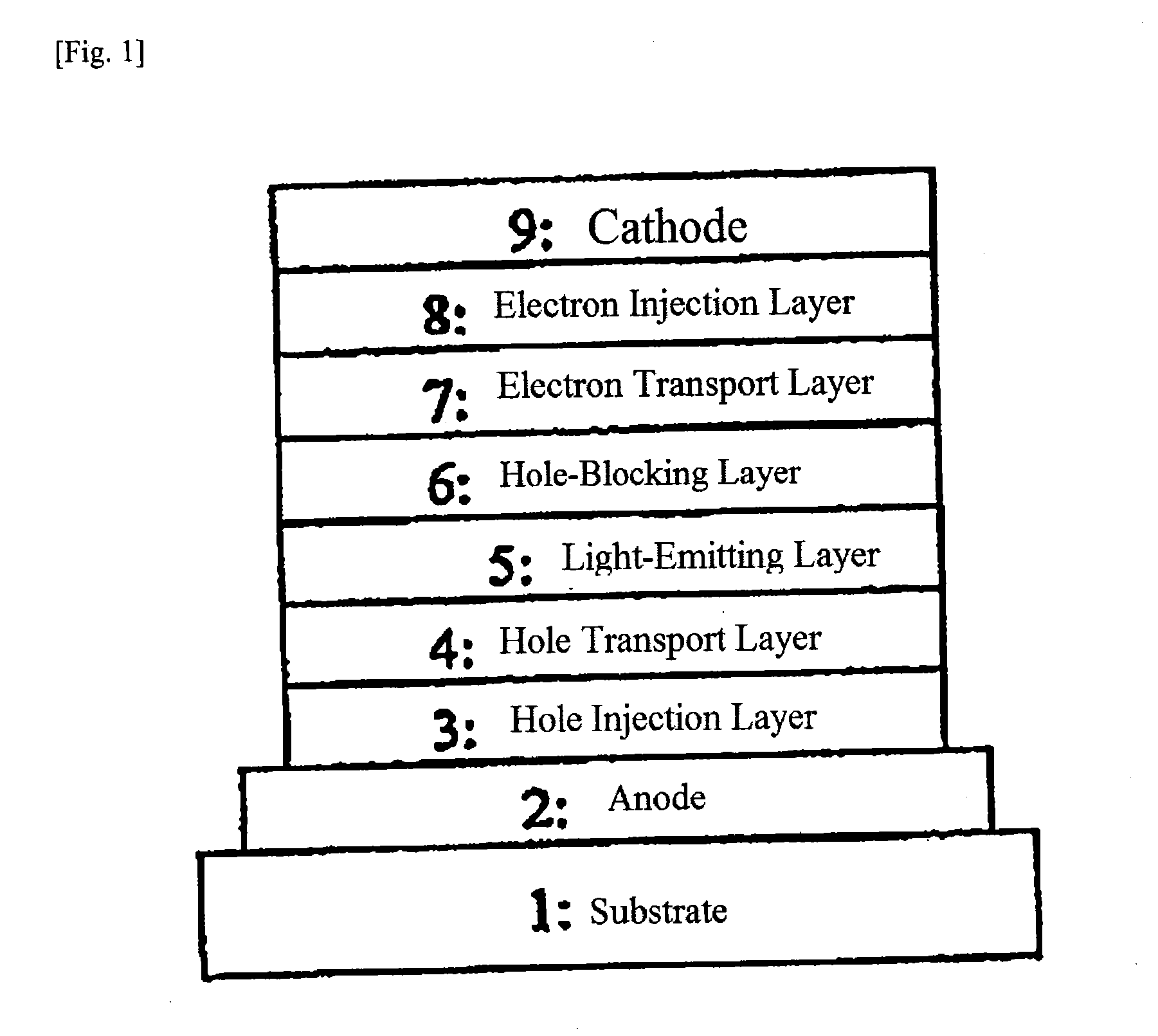

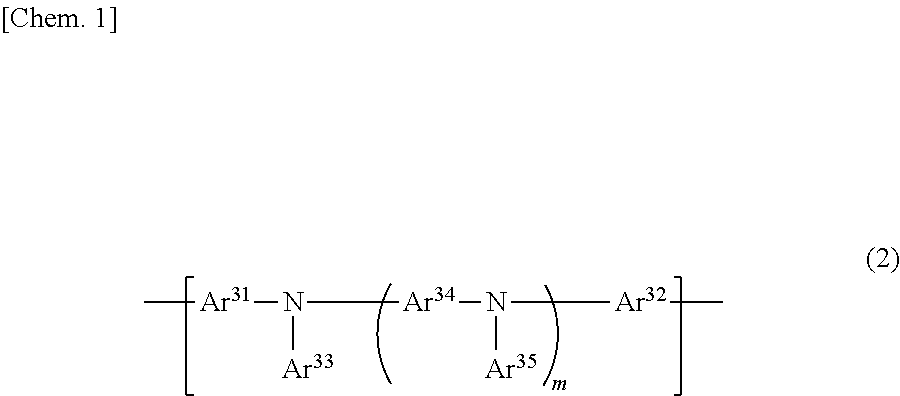

Composition for organic electroluminescent elements and organic electroluminescent element

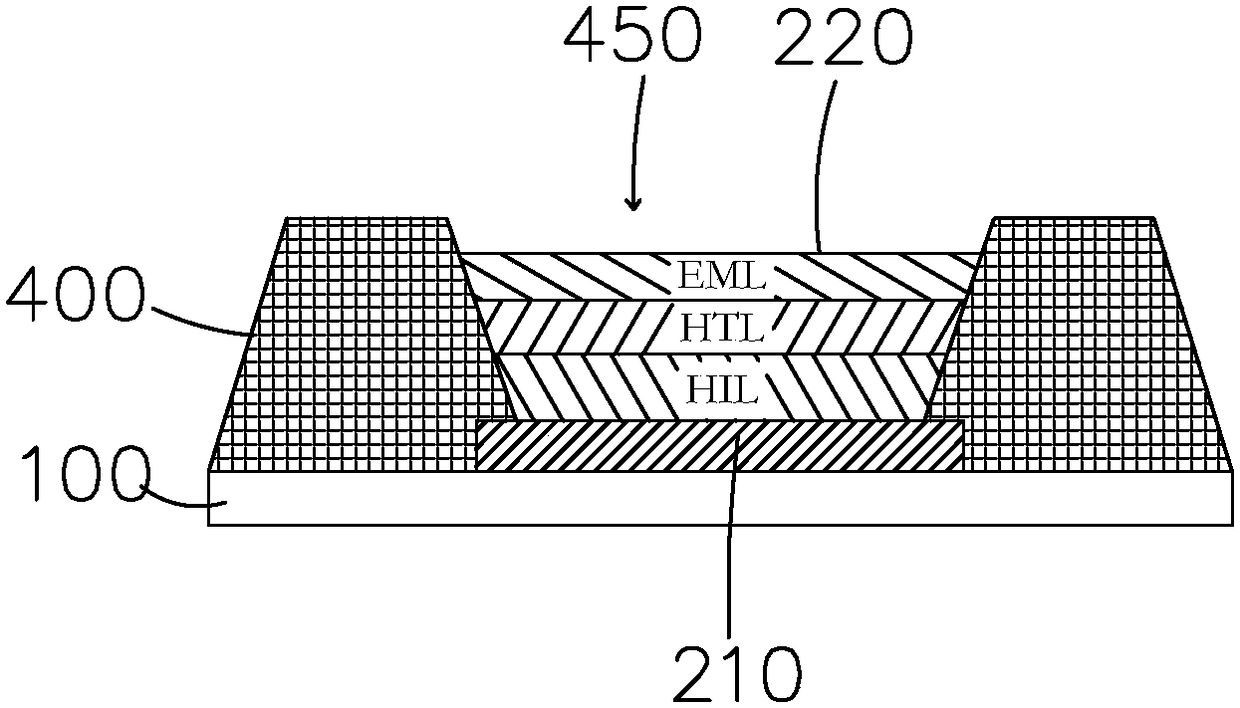

InactiveUS20150021587A1Long drive lifeUniform film formationLayered productsConductive materialHole injection layerSolvent

The objection of invention is to provide a composition for organic electroluminescent element having a smaller amount of foreign substance. The invention is a composition for organic electroluminescent element, which is for forming at least one layer selected from the group consisting of a light emitting layer, a hole injection layer and a hole transportation layer, wherein the composition comprises an aromatic amine polymer having a weight average molecular weight of 3,000 to 1,000,000 and a solvent, and a Zn concentration in the composition is less than 0.5 ppm.

Owner:MITSUBISHI CHEM CORP

Multifunctional degradable liquid mulch film, production method and uses thereof

InactiveCN101402794ADispersed particle size is smallEvenly dispersedOrganic fertilisersPlant protective coveringsPolyvinyl alcoholMulch

The invention provides a multi-functional degradable liquid mulching film which comprises the materials with the following weight percentage: a polymer of polyether glycol-polyvinyl alcohol-polyaspartate: 15.0 percent to 40.0 percent, an emulsifier: 1.0 percent to 5.0 percent, a disperse speader: 0.5 percent to 5.0 percent, a pH value regulator: 0.1 percent to 5.0 percent, an antifreeze: 1.0 percent to 5.0 percent, and water as the rest; after the mulching film being watered and sprayed on soil surface, the macromolecules thereof are combined with soil particles and a layer of black curing film can be formed on the soil surface rapidly which can restrain the soil water from vaporizing and prompt the soil to absorb more solar energy, thereby improving the earth temperature. The liquid mulching film completely degrades into a humic acid organic fertilizer, water and carbon dioxide which can be absorbed by crops; the degradation products effectively accelerate the formation of soil grain clusters; and the number of grain clusters with water stability is increased by 10 percent to 15 percent and the volume weight of soil can be decreased by 5 percent to 10 percent. If sprayed on the surface of sandy soil, the liquid mulching film can effectively slow down the infiltration of the water to reserve water, thereby saving the water consumption of irrigation. The liquid mulching film can replace plastic mulching films in a certain range and has a certain social meaning and market prospect.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

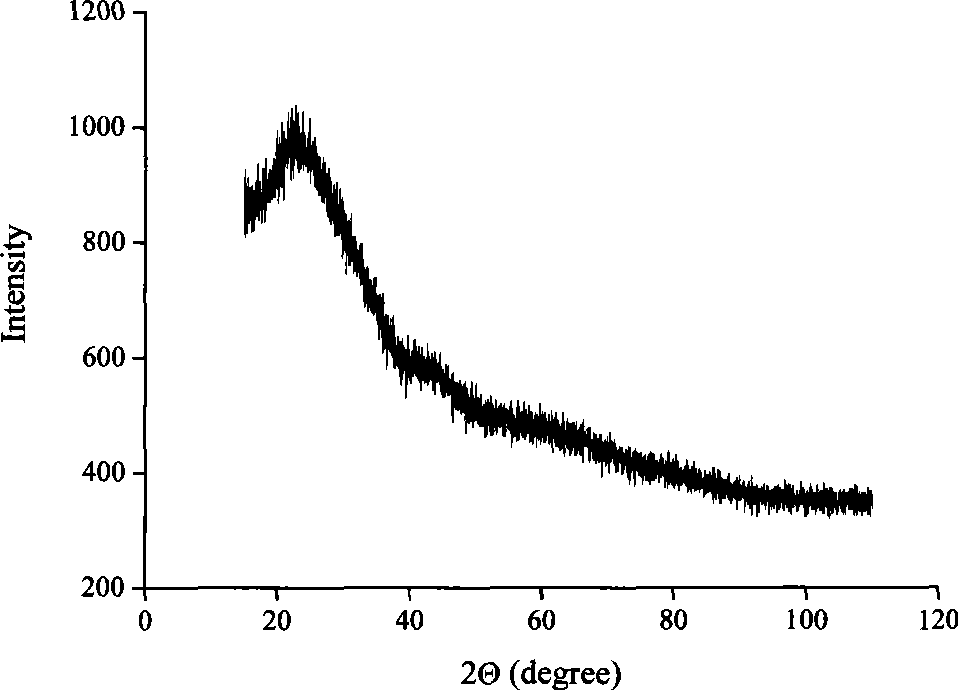

Titanium dioxide thin film and preparation thereof

The invention discloses a titanium dioxide film and a preparation method thereof. The titanium dioxide film comprises the following compositions of titanium dioxide, a dispersant, an emulsifier, a pore-making agent, water and pure nitric acid; the titanium dioxide, the dispersant, the pore-making agent, part of the water and the nitric acid are mixed and slowly ground; the mixture is added with the residual water slowly, ground for 40 to 60 minutes, added with the emulsifier and continuously ground to produce a titanium dioxide sizing agent; and a film is prepared on conductive glass by a scraping knife method and dried for 12 to 48 hours at room temperature; the dried film is put into a muffle furnace for sintering, thereby producing the titanium dioxide film. The titanium dioxide film provided by the invention has the advantages of good electricity conducting performance, good film forming effect, suitable thickness, simple preparation method, low cost and uneasy cracking and can be used for a dye-sensitized solar cell.

Owner:BYD CO LTD

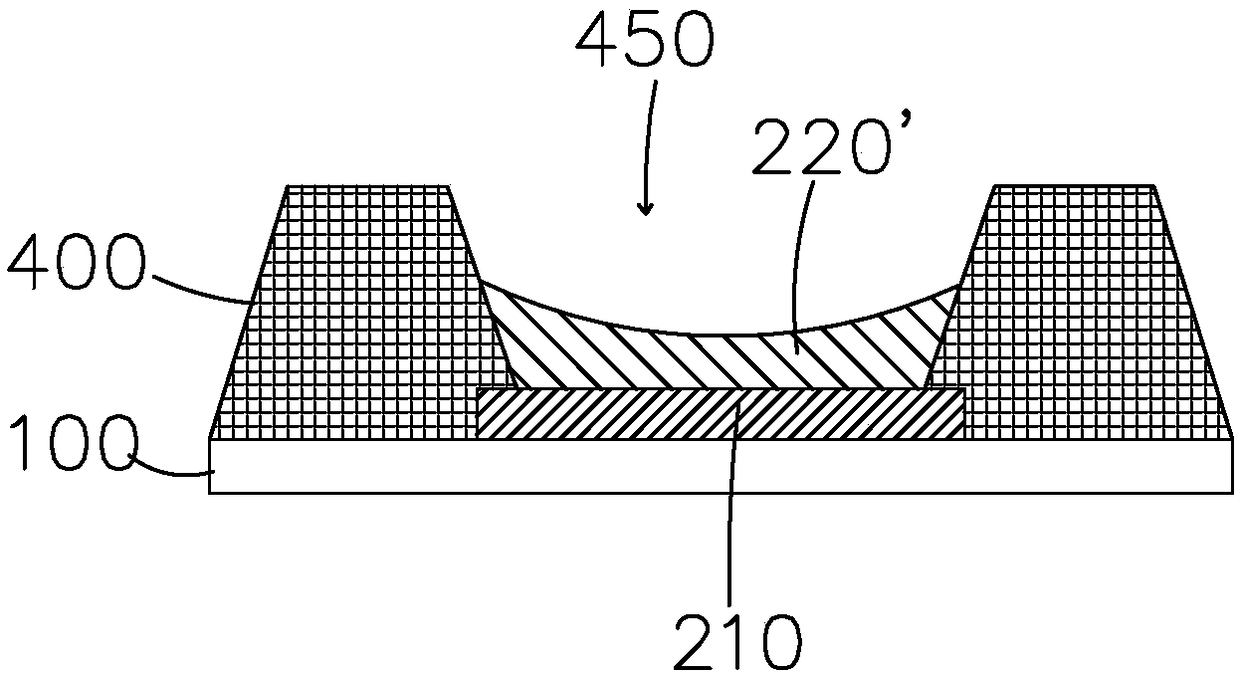

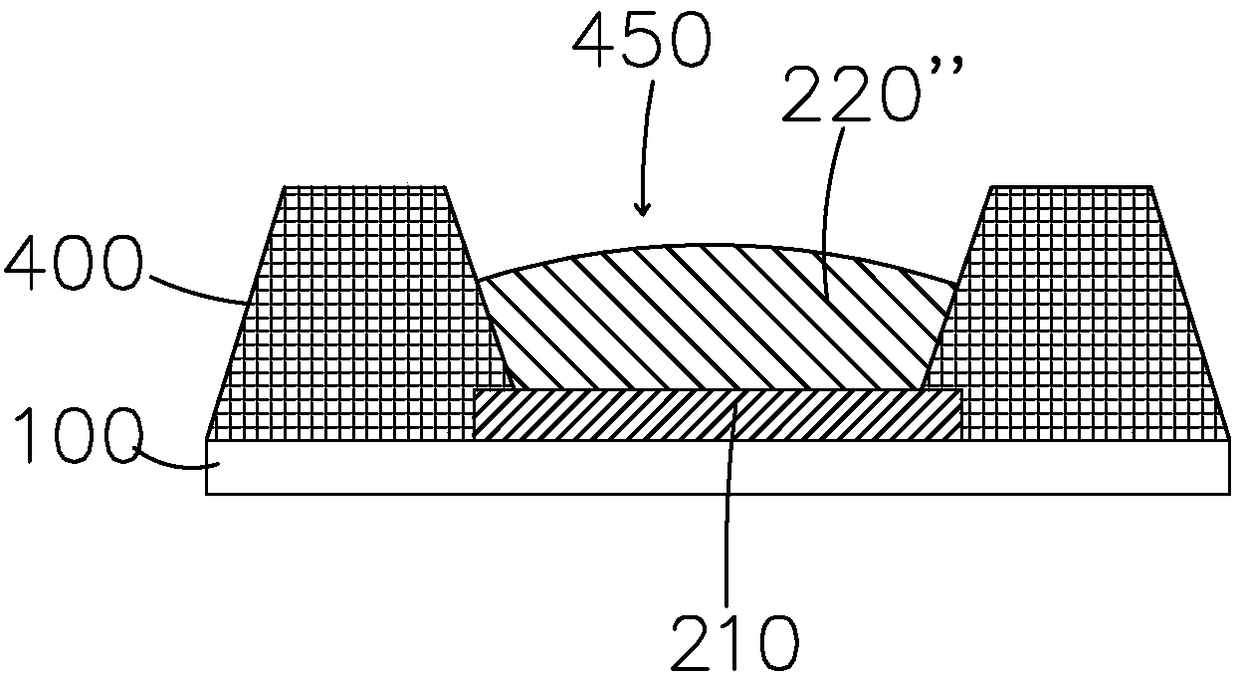

OLED device

ActiveCN108598110AImprove uniformity of light emissionUniform film formationSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsAnode

The invention provides an OLED device, comprising a substrate, an anode layer, a pixel definition layer and an organic functional layer, wherein the pixel definition layer consists of a hydrophobic dam layer and a hydrophilic dam layer; a plurality of ladder-like step platforms are arranged on the hydrophobic dam layer; the hydrophobic dam layer defines a pixel opening area of which the upper partis wide and the lower part is narrow above the anode layer through the plurality of step platforms; and the hydrophilic dam layer is arranged on the upper surface of each step platform. Thereby, whenmanufacturing the organic functional layer by using an ink-jet printing technology, the film surface of an ink material that forms the organic functional layer can be leveled in the pixel opening area, and thus the uniform film formation of the organic functional layer in the pixel opening area can be achieved, the uniformity of luminance of the OLED device can be effectively improved, and the microcavity effect of top-emitting OLED devices can also be accurately controlled.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

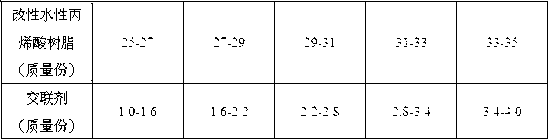

Water-based release agent and preparation method thereof

InactiveCN103254706AEasy to peelImprove the level ofPolyurea/polyurethane coatingsWater basedOrganic solvent

The invention discloses a water-based release agent and a preparation method thereof. The formula of the water-based release agent comprises the following components in parts by weight: 25 to 35 parts of modified water-based acrylic resin, 50 to 70 parts of deionized water, 1 to 4 parts of a crosslinking agent, 0.1 to 0.5 part of a defoaming agent, 1 to 5 parts of glycol. 0.1 to 0.5 part of improved polyurethane and 0.1 to 0.6 part of ammonia water at the mass concentration of 15 percent, wherein the weight ratio of the modified water-based acrylic resin to the crosslinking agent comprises five groups. The preparation method of the water-based release agent comprises the following steps of: (1) mixing and stirring the modified water-based acrylic resin and the deionized water to prepare emulsion dispersed uniformly; and (2) adding the crosslinking agent, the defoaming agent, the glycol and the improved polyurethane into the emulsion, stirring to prepare coating, and adjusting the pH value of the coating to be 6.2 to 8.2 by using the ammonia water. The water-based release agent is not externally crosslinked with a protected object during use and is easy to remove after film formation; and an organic solvent is not adopted, so the water-based release agent is environment-friendly, pollution-free and low in cost.

Owner:广东鑫皇冠新材料有限公司

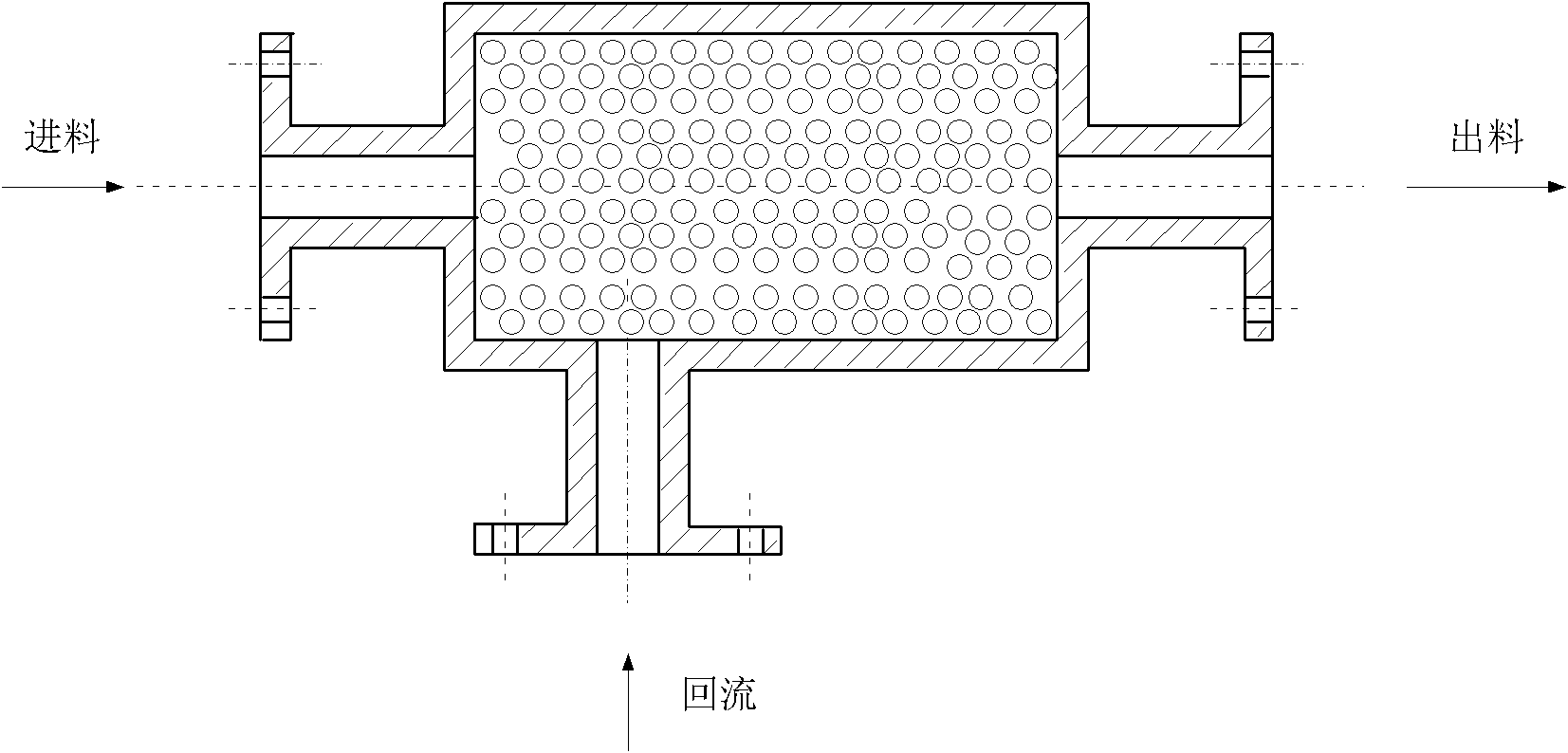

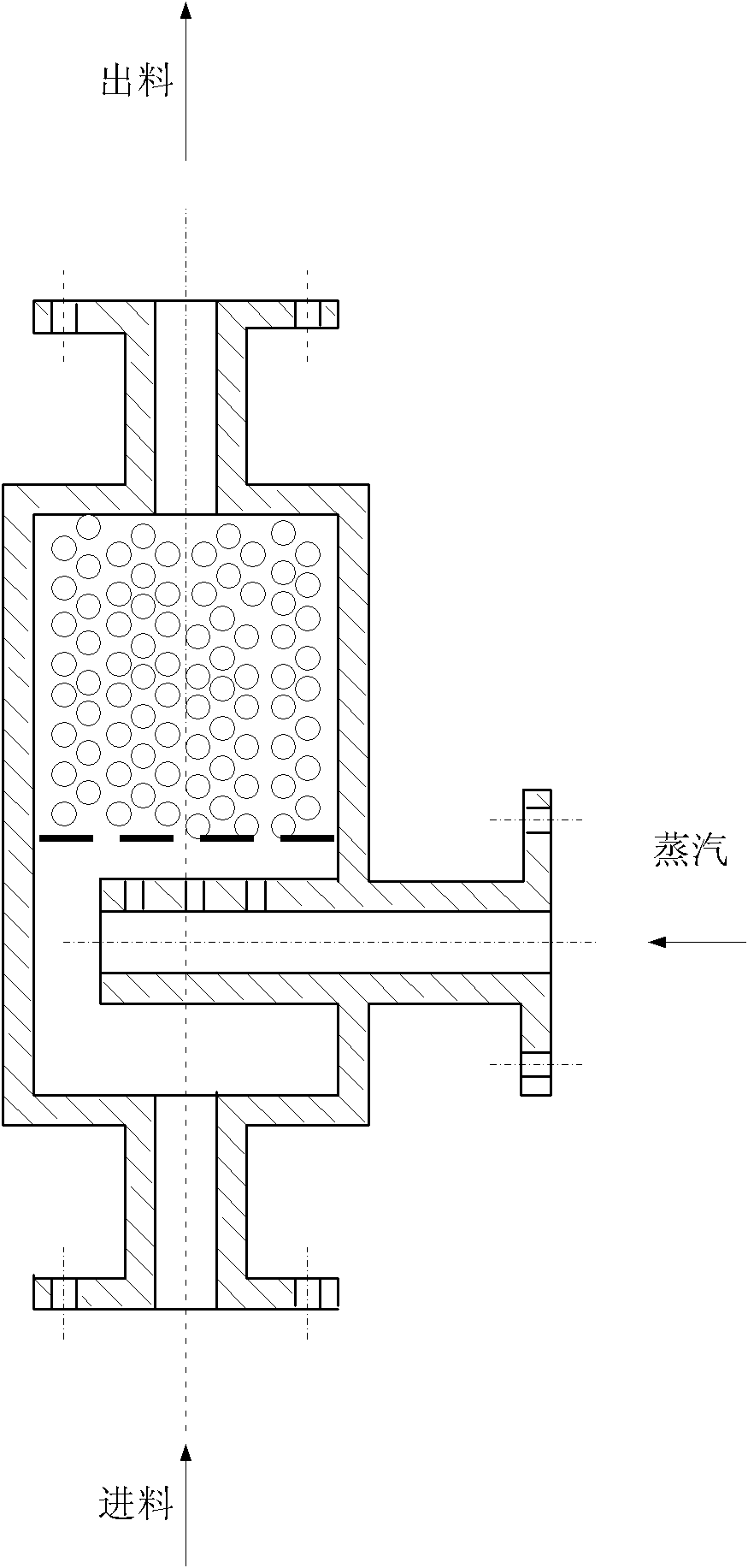

Method and device for reducing volatile matters of o-cresol-formaldehyde epoxy resin

ActiveCN102464792AUniform film formationGuaranteed removal rateMultiple-effect evaporationEpoxyVapor–liquid separator

The invention discloses a method and device for reducing volatile matters of an o-cresol-formaldehyde epoxy resin. The method comprises the following step of: performing a two-stage desolventizing step, including a coarse desolventizing step and a fine desolventizing step to remove a solvent and a high-boiling residue component from an o-cresol-formaldehyde epoxy resin. The device comprises a feed pump, a first pipeline mixer, a falling film evaporator, a gas-liquid separator, a primary removal extraction pump, a second pipeline mixer, a thin-film evaporator, a packing tower and a secondary removal extraction pump which are connected in sequence, wherein a part of an o-cresol-formaldehyde epoxy resin solution output by the gas-liquid separator returns to the first pipeline mixer through areflux pump; a steam inlet / outlet is formed in the second pipeline mixer; and both the gas-liquid separator and a film evaporator are provided with a volatile matter gas-phase outlet. According to the method and the device for reducing the volatile matters of the o-cresol-formaldehyde epoxy resin, volatile matters of a product can be reduced to be below 0.05 percent, and the performance of the product applied to an electronic molding compound can be improved remarkably.

Owner:CHINA PETROCHEMICAL CORP

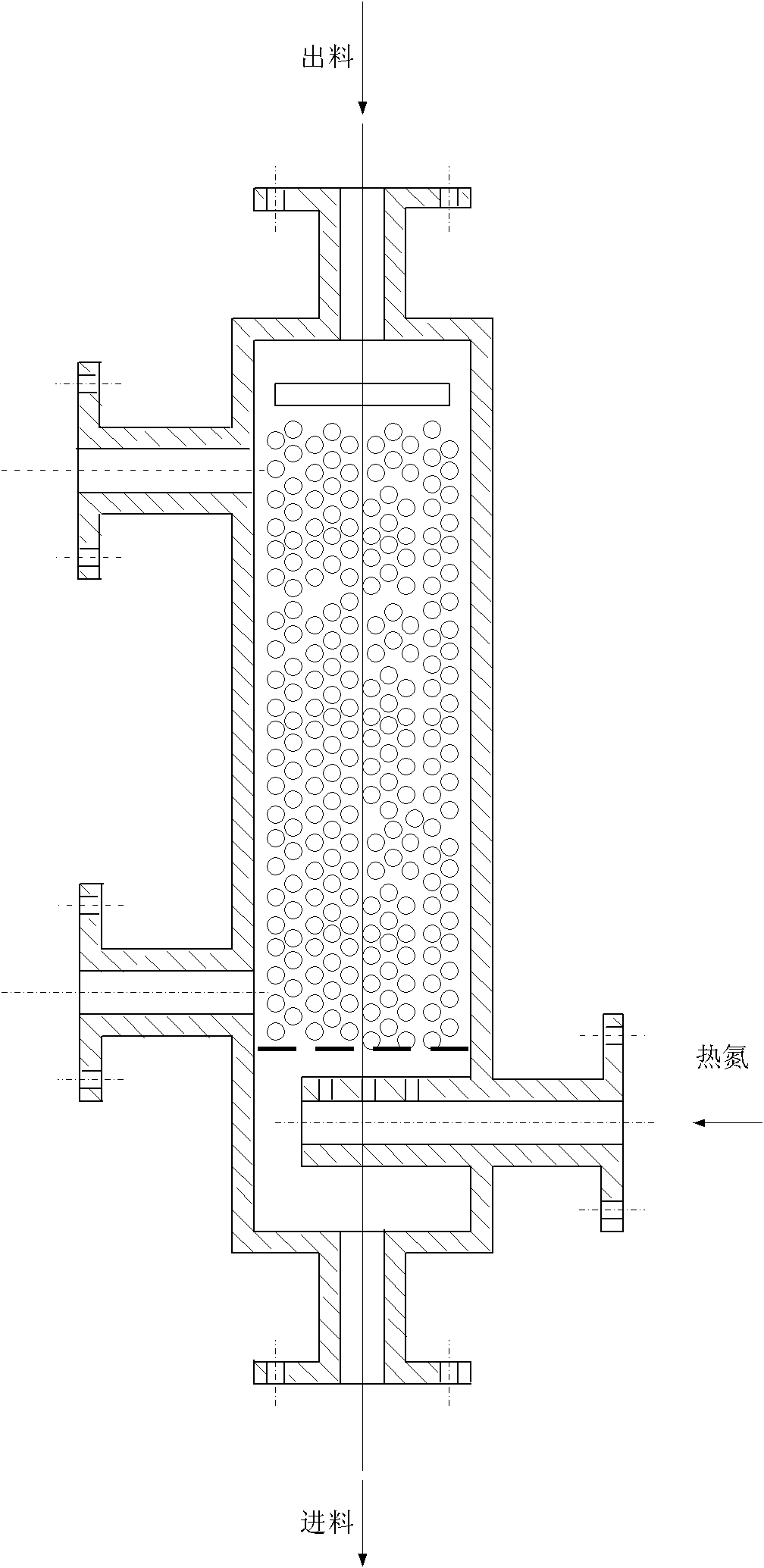

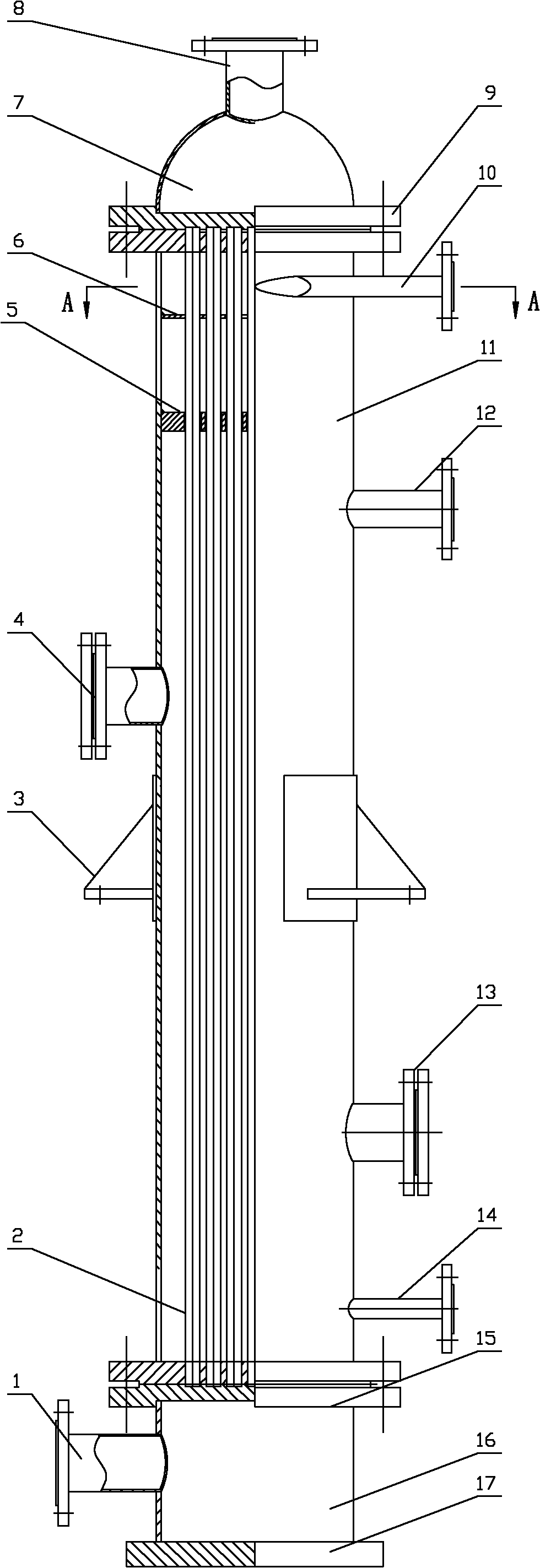

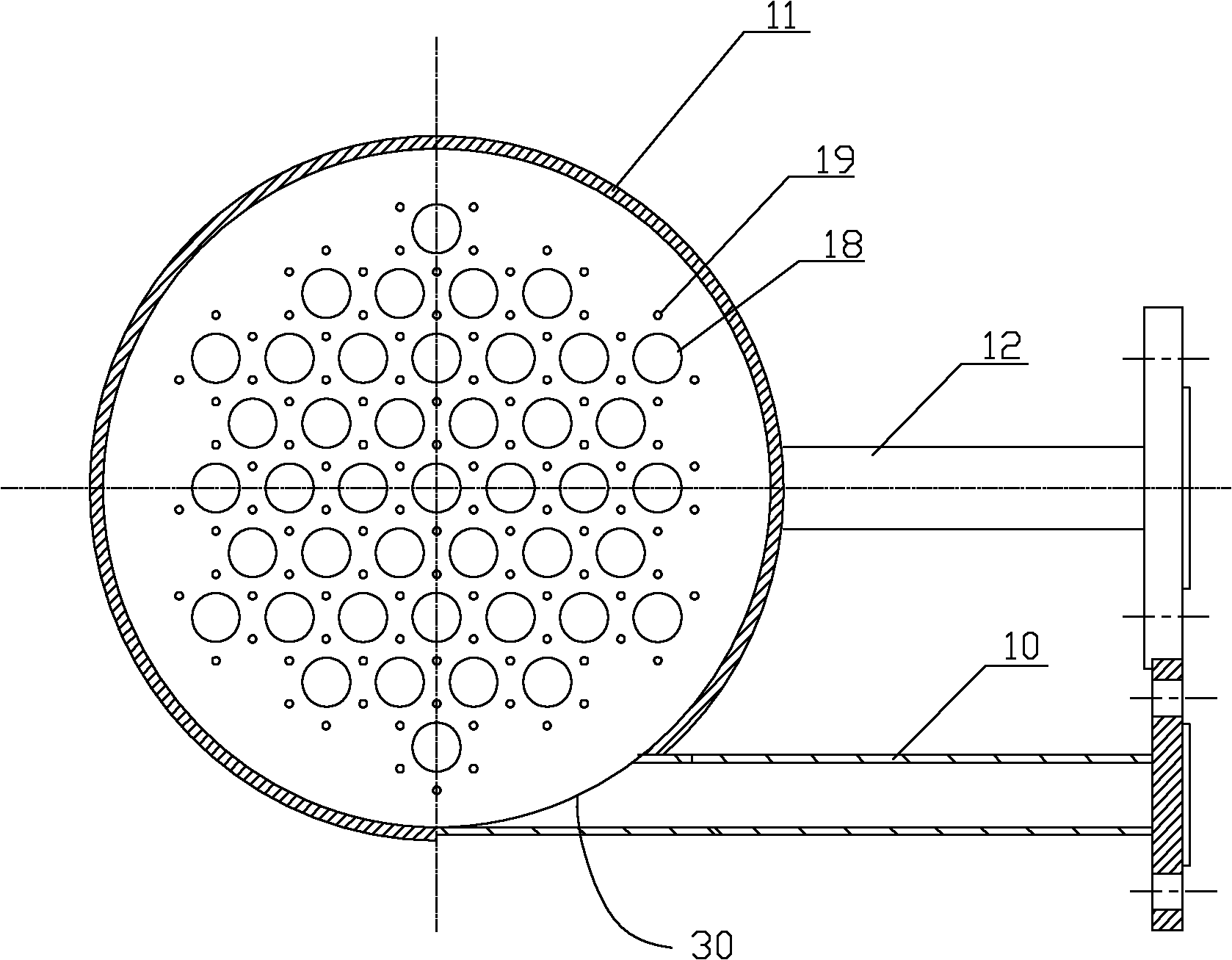

Vertical falling-film heat exchanger outside pipe

ActiveCN102155854AUniform liquid filmIncrease the heat exchange areaStationary conduit assembliesTrickle coolersChemical industryEngineering

The invention discloses a vertical falling-film heat exchanger outside a pipe, which comprises a heat exchanger shell, a reinforced heatexchange tube bundle, a film distributing device, a tube pass accommodating chamber, sight glasses, a fluid inlet and outlet pipeline and the like. The double-layer film distributing device is arranged at the top of a heat exchanger; and a fluid flows down uniformly along the outer wall of a pipe in a film shape through the film distributing device to take away heat of another fluid in a heat exchange tube or transfer the heat to another fluid in the heat exchange tube so as to realize heat exchange of two different fluids. Because a tangential-flow liquid introducing manner and the unique double-layer film distributing device are adopted for the heat exchanger, the problems of nonuniform film distribution, low effective heat exchange area and the like of the traditional falling-film heat exchanger are solved. By adopting the device, the mass transfer resistance of the fluid can be effectively reduced, the heat transfer and mass transfer capacities of the heat exchanger are remarkably improved, and the device can be widely applied to the industries, such as chemical industry, thermotechnical industry, light industry, food, pharmacy, metallurgy, sea water desalination and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for preparing acetylene selective hydrogenation catalyst

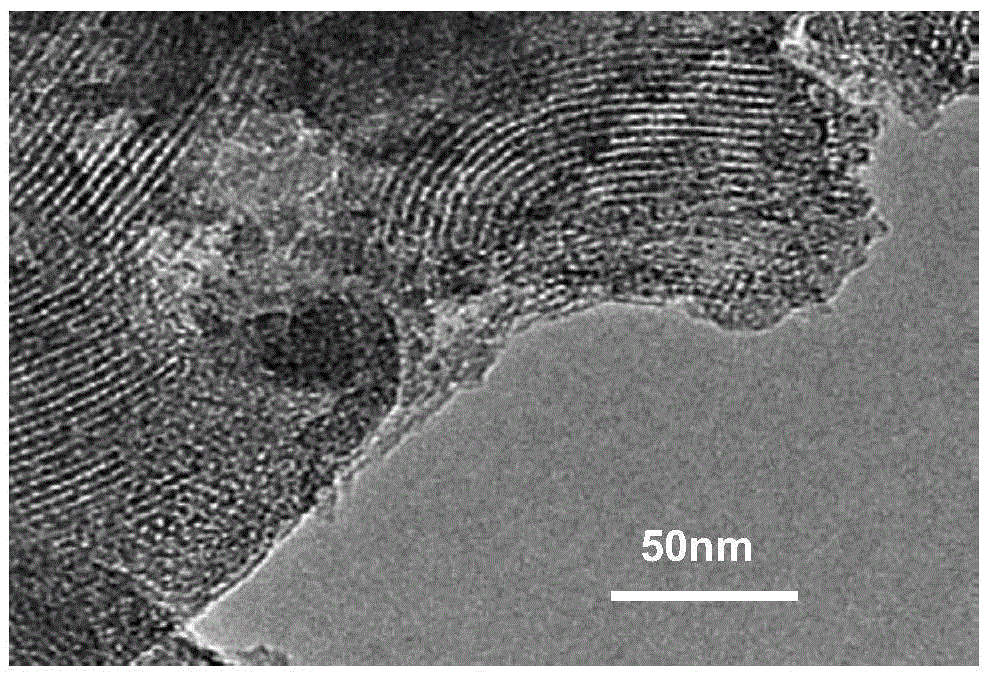

ActiveCN105536851ASimple structureUniform film formationMolecular sieve catalystsCatalyst activation/preparationDispersityNano structuring

The invention discloses a method for preparing an acetylene selective hydrogenation catalyst. The method mainly overcomes the defects that in the prior art, Pd particle size distribution is wide, distribution uniformity is poor, and a metallic oxide serving as a substrate lacks a controllable nano structure. Firstly, a three-dimensional nano structure is provided through a mesoporous material, a metallic oxide is deposited on the structure, and a metallic oxide substrate with the three-dimensional nano structure same as the mesoporous material is obtained; then, by means of the atomic layer deposition, nano Pd metal particles are loaded and deposited on the surface of the metallic oxide substrate, and the loading amount of Pd and the metallic oxide can be adjusted according to different deposition period numbers. The catalyst prepared through the method is of the three-dimensional nano structure and large in specific surface area, the Pd metallic particles are high in dispersity, uniform in distribution, uniform in size and good in activity, selectivity and stability in the acetylene selective hydrogenation catalysis reaction. The method avoids the characteristics that metallic particle size distribution is wide and distribution is not uniform in the preparation process of an impregnation method and a chemical plating method.

Owner:XIAN MODERN CHEM RES INST

Quantum dot ink and quantum dot color filter

ActiveCN109535836ASuppresses the phenomenon of prone to edge depositionImprove stabilityInksDispersion stabilityQuantum dot

The invention discloses a quantum dot ink and a quantum dot color filter. Specifically, the quantum dot ink includes quantum dots, photodiffusion particles and an ester solvent with a ring structure.The quantum dots account for 10wt%-45wt% of the quantum dot ink. The quantum dot ink provided by the invention adopts ring structure esters as the solvent, and improves the dispersion stability of quantum dots and photodiffusion particles in ink. When the ink is used for inkjet printing, the process is smooth and nozzles are not blocked, the obtained quantum dot color filter has the characteristics of good flatness, uniform film and high emergent light brightness.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

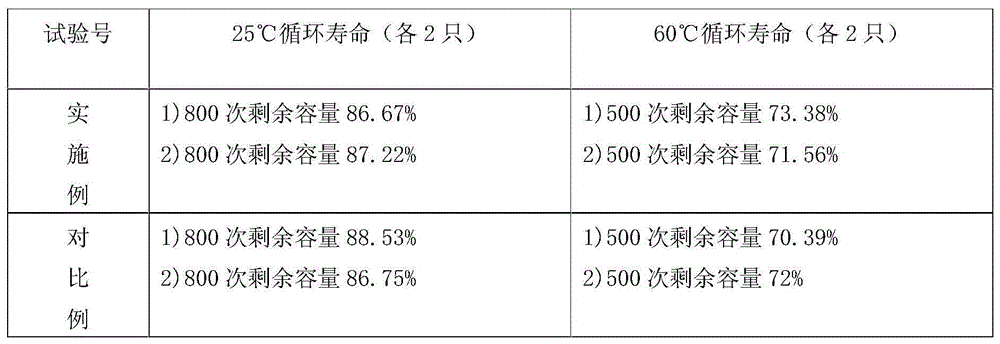

Quick forming method of power type soft packaging polymer battery

InactiveCN104600385AImprove conductivityHigh activitySecondary cells charging/dischargingElectrolyte accumulators manufactureRoom temperatureEngineering

The invention discloses a quick forming method of a power type soft packaging polymer battery. The quick forming method comprises the following steps of (1), flatly putting the battery in a fixture, and exposing positive and negative lugs; (2), adjusting a pressure plate on the fixture, so that the battery can be pressed by the pressure plate, pressing the surface of the battery, and fixing well by adjusting a limiting screw; (3), respectively connecting positive and negative joints of a forming cabinet to the positive and negative lugs of the battery; (4), putting the battery and the fixture in a high-temperature oven, setting the temperature at 60 DEG C, and charging after carrying out heat preservation for 1h; and (5), taking out the fixture and the battery after charging, adjusting the fixture to further pressurize, pressing the surface of a battery cell, fixing well by adjusting the limiting screw, putting the fixture and the battery in the oven with the temperature of 85 DEG C, taking out the fixture and the battery after keeping for 2-4h, and standing at normal temperature for 24-48h; and completing the forming process after standing. According to the invention, medium and small ratio current formation of the battery is carried out; and the problem that an SEI film is poorly formed due to gas production, uneven contact and the like of a pole piece in the forming process is solved.

Owner:HONGDE NEW ENERGY TECH

Emulsion paraffin water repellent for fiber board

ActiveCN101597482ALow wax consumptionImprove water resistanceOther chemical processesParaffin waxFiber

The invention provides an emulsion paraffin water repellent for a medium density fiber board, which is prepared by taking solid paraffin and water as main materials, lauryl sodium sulfate, SPAN-60 and monoglyceride as emulsifiers, peregal 0 and tween-80 as catalysts and polyvinylalcohol as a colloid protecting agent. The water repellent comprises the following components in portion by weight: 40 to 45 portions of paraffin, 45 to 50 portions of water, 1.0 to 1.5 portions of lauryl sodium sulfate, 1.5 to 2.5 portions of SPAN-60, 0.5 to 1.0 portion of monoglyceride, 0.5 to 1.0 portion of peregal 0, 1.0 to 1.5 portions of tween-80, and 0.1 to 0.5 portion of polyvinylalcohol. The water repellent is unnecessarily melted or dissolved by a solvent when used; in addition, the water repellent also has the advantages of even film forming, small granularity, good dispersibility, good storing stability, easy combination with water solutions or emulsions of other materials for use, safety, high efficiency, economy and convenience, and can meet the requirements of the water repellent on low paraffin consumption and good water resisting property in the fiber board industry.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

Preparation method of printed display device

ActiveCN107403824AImprove performanceReduce surface tensionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRoom temperature

The invention relates to a preparation method of a printed display device. The preparation method comprises the following steps of S1, depositing a first electrode layer on a substrate; S2, preparing a pixel definition layer on the first electrode layer and forming pixel pits; S3, performing ink-jet printing of functional layer ink in the pixel pints, and then putting into a saturated vapor atmosphere of a second solvent to perform vapor treatment, wherein the functional layer ink comprises a functional layer material and a first solvent; putting the device after vapor treatment into a room temperature condition, and naturally drying in air or nitrogen environment; and next, performing heat treatment to form a functional layer; and S4, depositing an electron transfer layer and a second electrode layer on the functional layer, and performing packaging to obtain the printed display device. By virtue of the preparation method of the printed display device, the wettability of ink and pixel Bank can be improved, so that the ink can be subjected to uniform film forming in the whole pixel region, and generation of electric leakage can be suppressed effectively.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

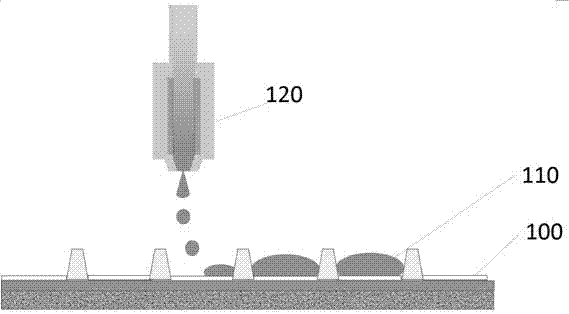

Evaporation source, film-forming facility and film-forming method thereof

ActiveCN104328377AUniform film formationEvaporation process time is shortVacuum evaporation coatingSputtering coatingSteam pressureEvaporation

The invention relates to the technical field of organic device preparation, and discloses an evaporation source, a film-forming facility and a film-forming method thereof. Through setting an evaporation surface of the evaporation source to be matched with the size of a substrate to be evaporated, the evaporation surface can not move in the process of evaporation, and the evaporation of a film on the substrate is completed in a time, so that a situation that in the process of evaporation, because steam evaporated on the whole substrate is in a same steam pressure, a formed film is uniform is ensured. Meanwhile, the technical scheme of the invention also has the advantages of short evaporation process time and high production efficiency.

Owner:BOE TECH GRP CO LTD +1

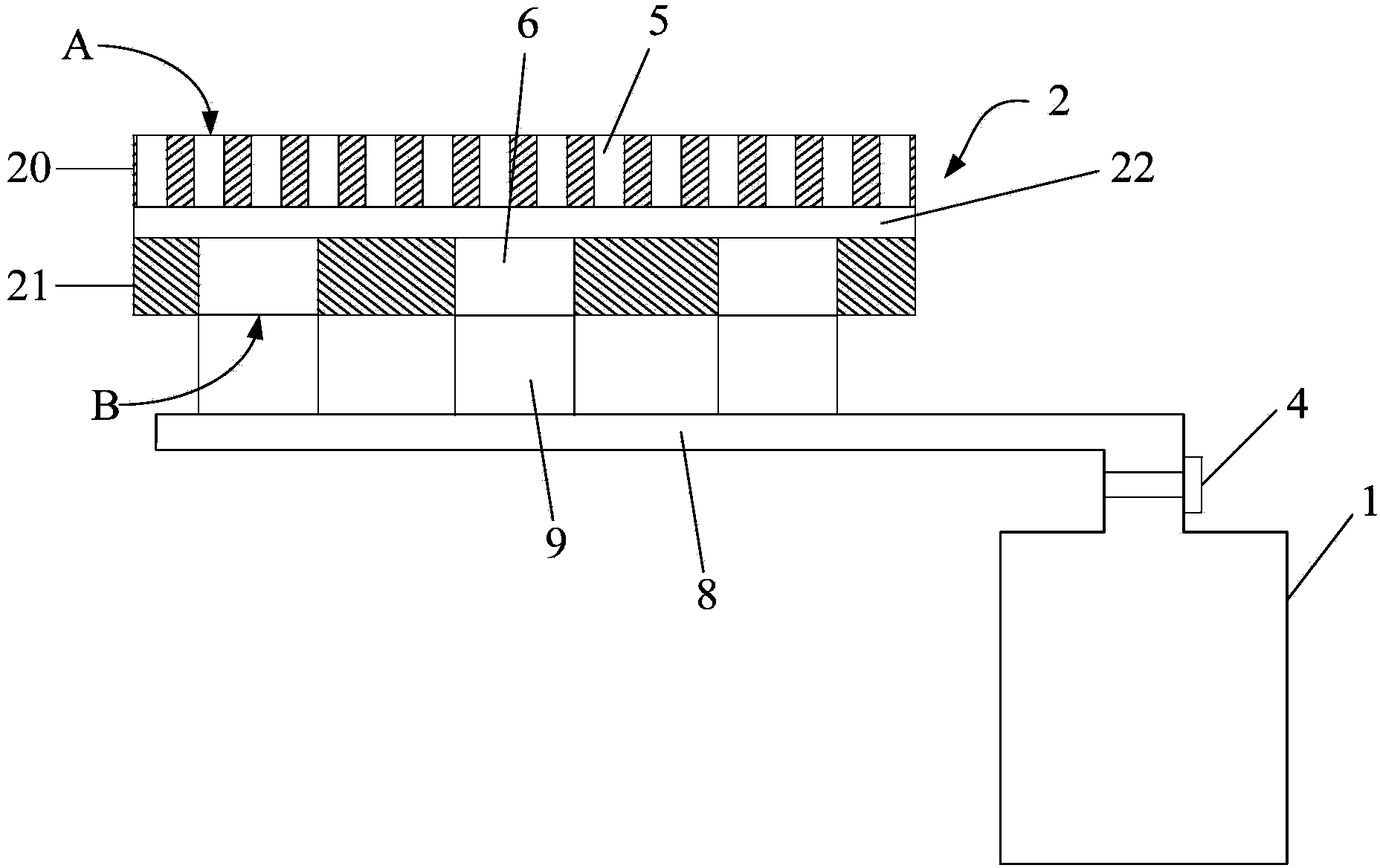

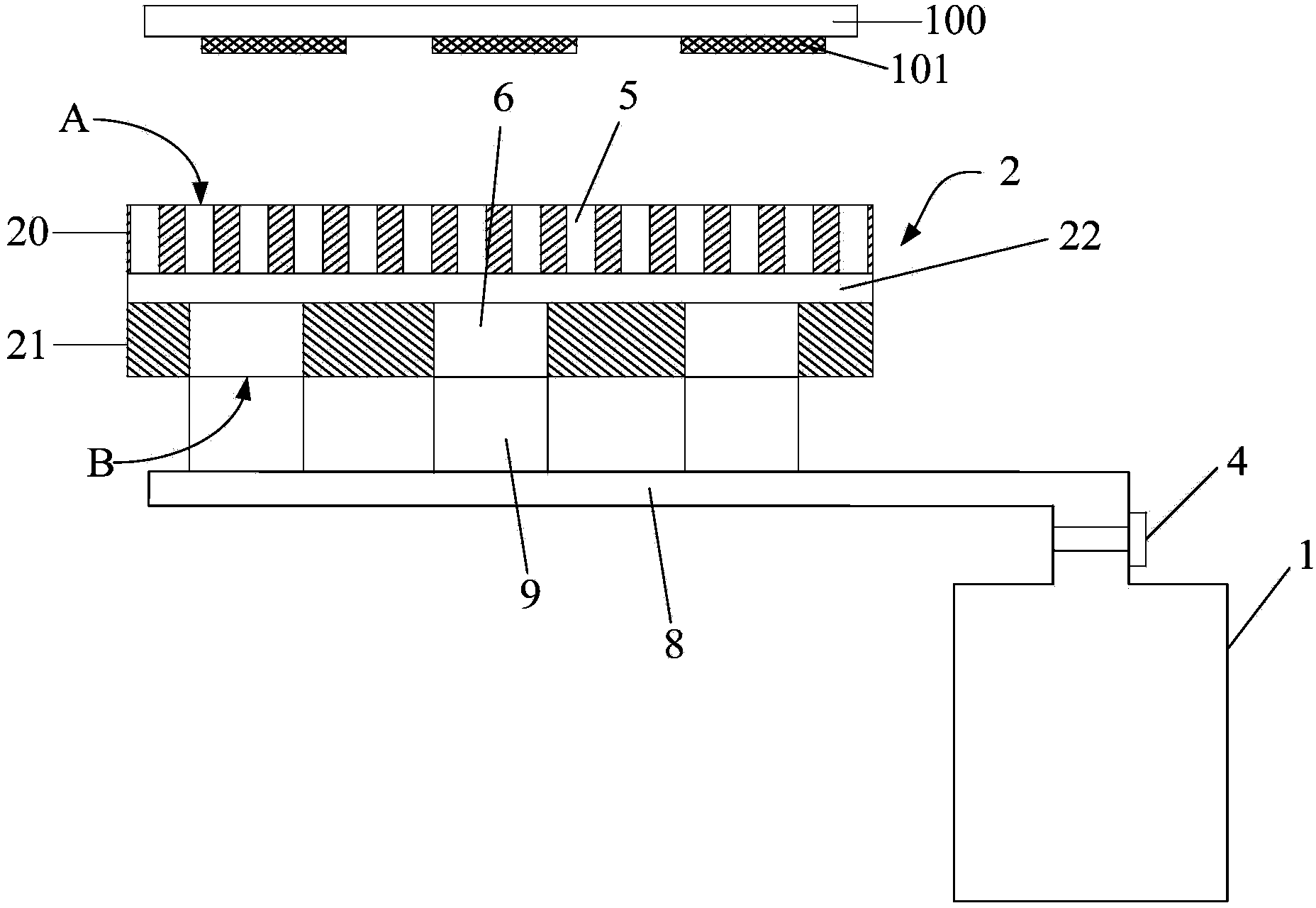

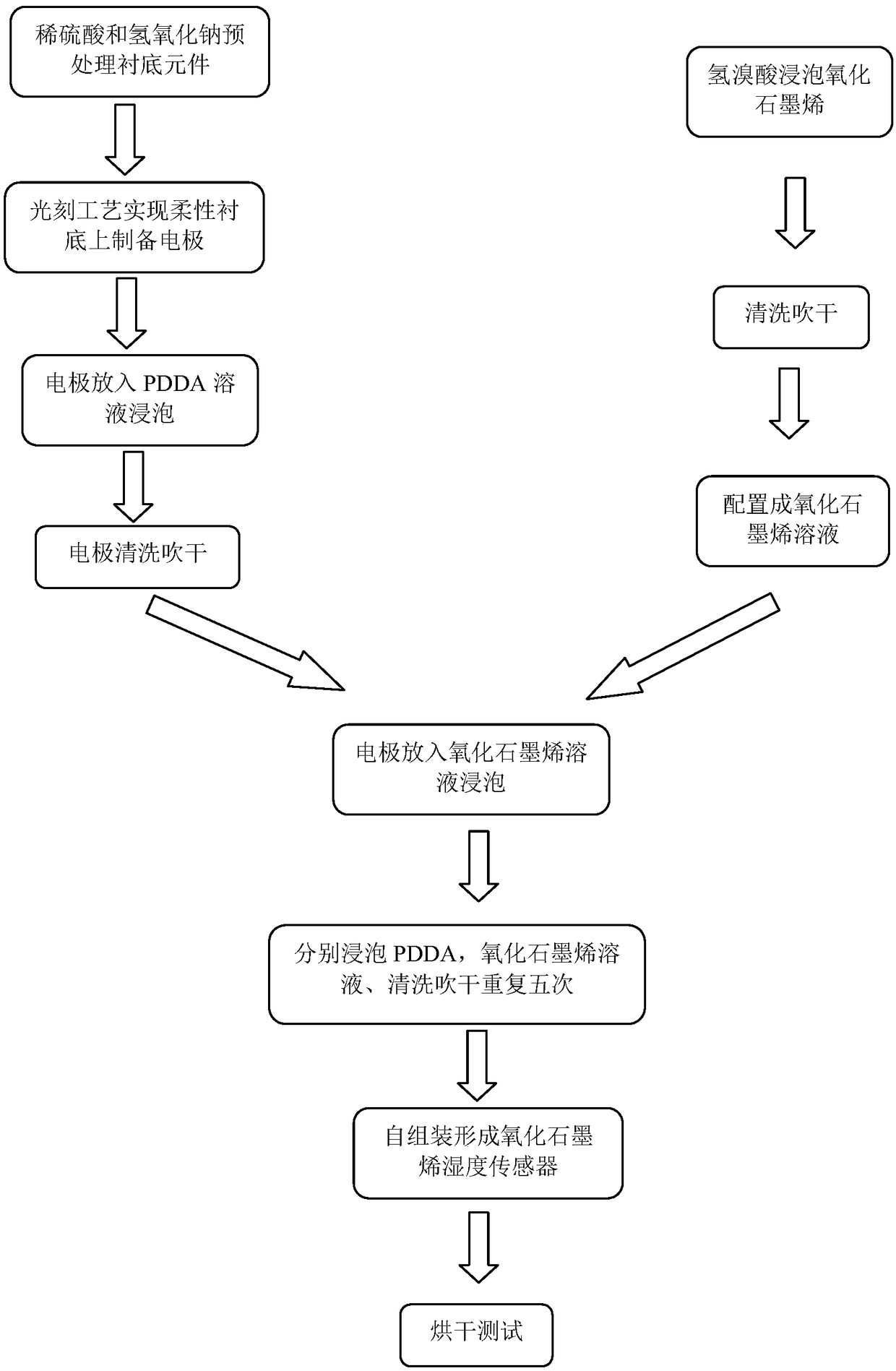

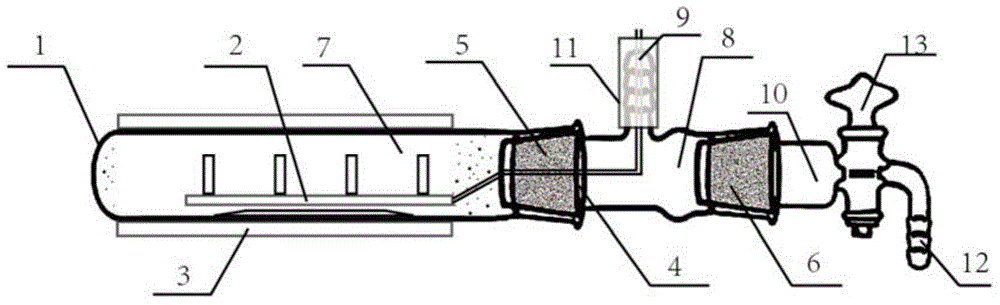

Humidity sensor and improvement and preparation of humidity sensor based on graphene oxide

InactiveCN108414583AImprove conductivityIncreased sensitivityMaterial resistanceCvd grapheneHydrobromic acid

The invention discloses a humidity sensor and improvement and preparation of the humidity sensor based on graphene oxide. The humidity sensor is provided with a humidity sensitivity component based ona reduced graphene oxide material, a graphene oxide material is treated by hydrobromic acid solution to obtain the reduced graphene oxide material in the humidity sensitivity component, the humiditysensitivity component can respond to environment humidity, and the environment humidity is sensed. According to the humidity sensor, a treatment process of the key graphene material humidity sensitivity component in the humidity sensor and a micro-composition, a structure and the like of the correspondingly acquired reduced graphene oxide material are improved, the graphene oxide material is treated by the hydrobromic acid solution to obtain the reduced graphene oxide material or the graphene oxide material and a polycationic polymer alternately deposit to form a graphene oxide composite filmby an electrostatic inducement layer by layer self-assembly method, and the acquired humidity sensor can keep good stability, humidity sensitivity and humidity stickiness in high-humidity environments.

Owner:HUAZHONG UNIV OF SCI & TECH +1

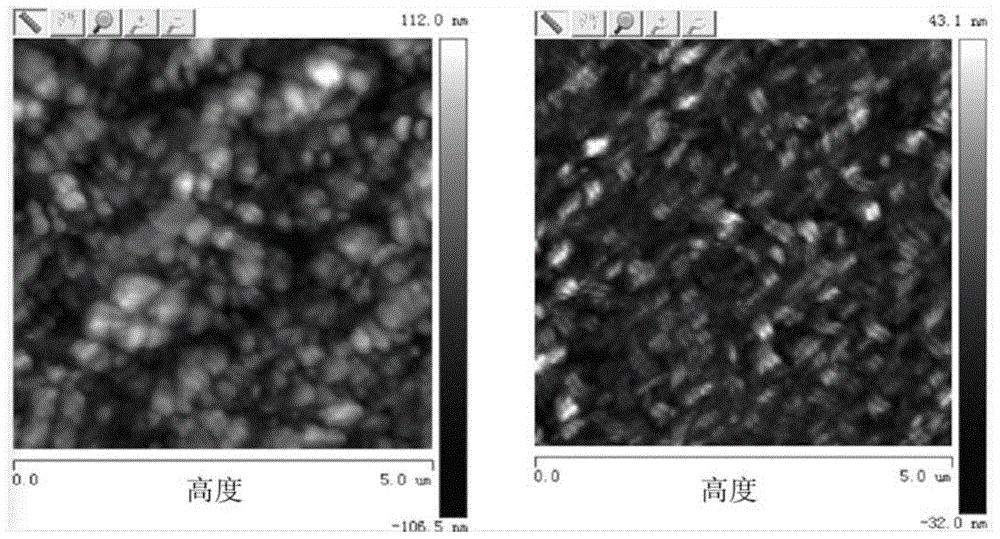

Method for preparing organic ammonium metal halide film

InactiveCN104404478AImprove diffractionStrenuous exerciseChemical vapor deposition coatingChemical reactionCharge carrier mobility

The invention discloses a method for preparing an organic ammonium metal halide film. A half-closed type carrier gas free hot wall type low-pressure chemical vapor deposition method process is adopted to prepare the organic ammonium metal halide film. The method comprises the following steps: firstly, preparing a metal halide (MX2) film on a quartz substrate by using a dry method or a wet method, and transferring the metal halide (MX2) film into a glass tube for annealing, wherein one end of the glass tube is sealed and the other end is grounded; secondly, transferring the energy to organic ammonium (AX) powder inside the glass tube through a hot wall, forming steam blocks through self-diffusion of AX steam in low vacuum, performing chemical reaction on MX2 with a hot substrate to generate the film which is uniform in thickness, good in appearance, high in light absorption rate and smooth in surface, and performing in-situ annealing so as to generate the AMX3 film which is dense in structure and high in crystallinity degree. The method has the advantages that in-situ annealing can be performed in the film formation process, continuous vacuuming is not needed, the preparation time is shortened, the energy consumption is reduced, the filming efficiency is high, the charge capture trap in the film is reduced, and the carrier mobility is increased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

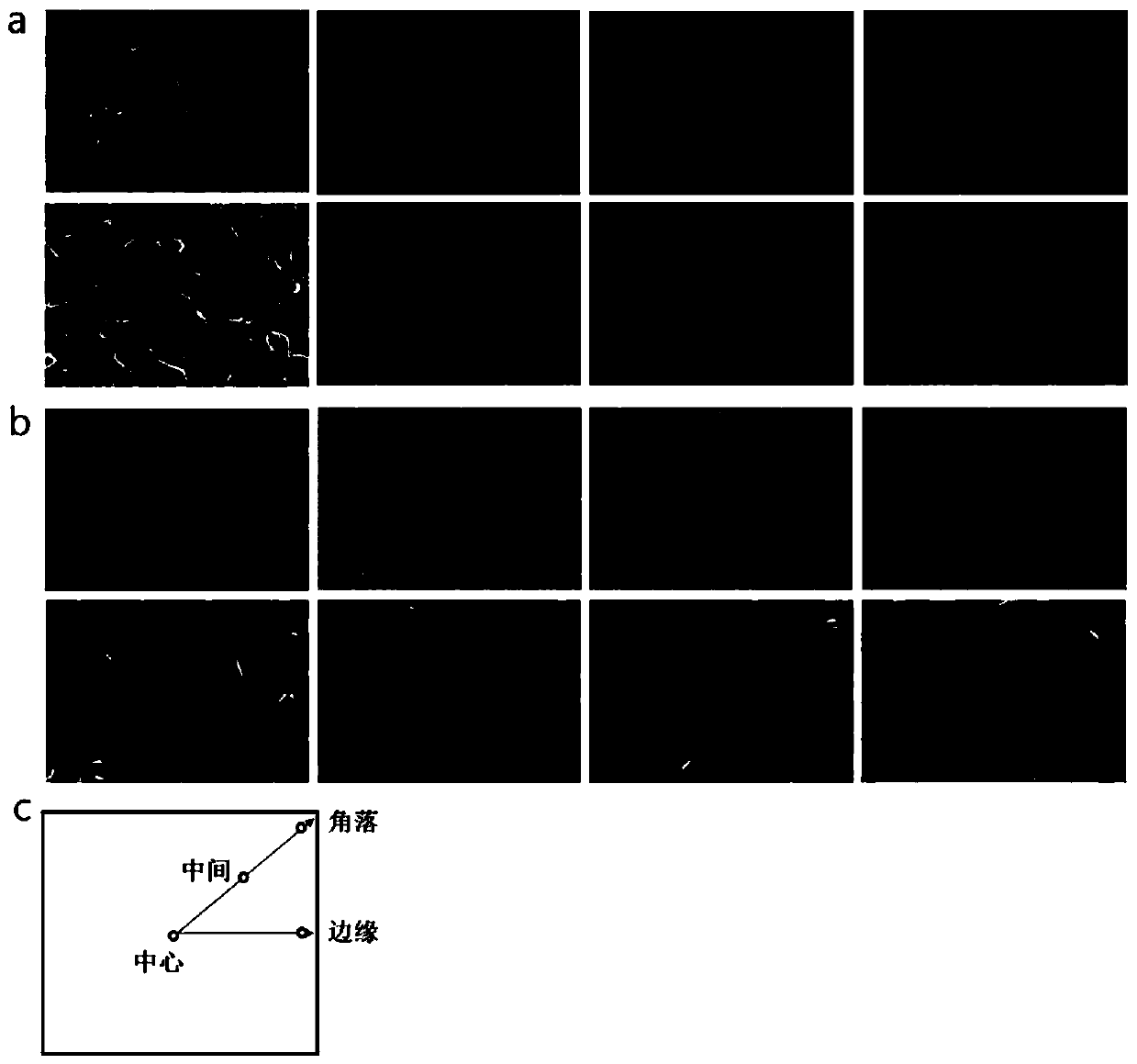

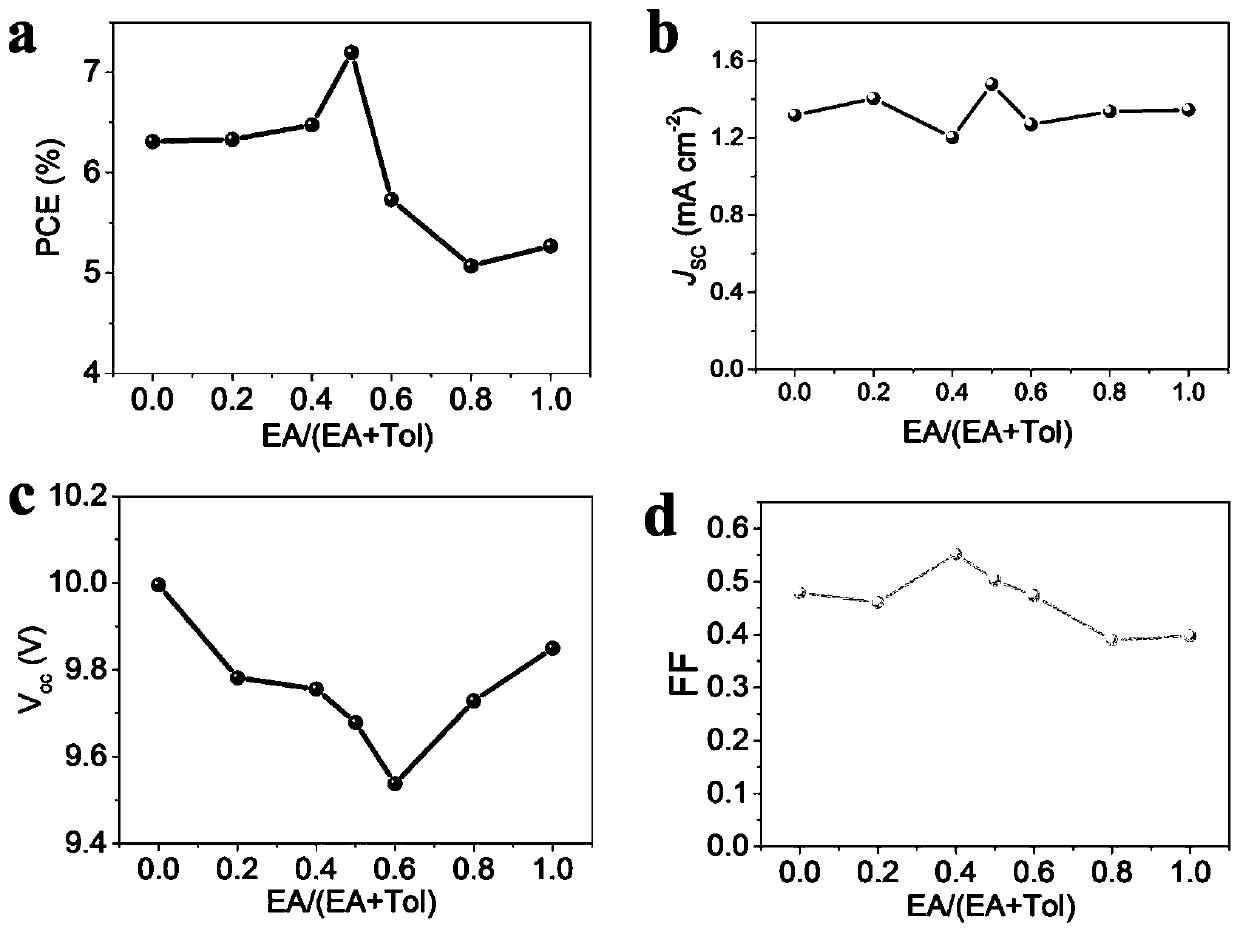

Method for preparing large-area perovskite layer and perovskite solar cell

PendingCN110718632ARefine the grain sizeReduce supersaturationSolid-state devicesSemiconductor/solid-state device manufacturingChlorobenzenePerovskite solar cell

The invention discloses a method for preparing a large-area perovskite layer and a perovskite solar cell. The method comprises the following steps of coating a perovskite precursor solution on a substrate to form a perovskite precursor layer; adding a mixed anti-solvent, and carrying out annealing treatment to obtain the perovskite layer, wherein the mixed anti-solvent is a mixed solvent formed bymixing a solvent A and a solvent B; the solvent A is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and diethyl ether, the solvent B is selected from any one of methylbenzene, chlorobenzene, dichloromethane, ethyl acetate, anisole and monohydric alcohol with 3-6 carbon atoms, the solvent A and the solvent B are different, and a volume ratio of the solvent A to the mixed anti-solvent is 10%-90%. In the invention, a supersaturation degree of the perovskite precursor solution in a crystallization process is reduced by using the mixed anti-solvent so that crystallization nucleation sites are uniformly generated, the perovskite thin film with uniform film formation and a large grain size is finally obtained, and a good application prospect is possessed in the field of preparation of large-area perovskite devices.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Environment-friendly strippable water-based paint and preparation method thereof

ActiveCN102031042ANo pollution in the processUniform film formationCellulose coatingsPolyamide coatingsEnvironmental resistanceDaily living

The invention relates to the field of package paint in daily living, in particular to an environment-friendly strippable water-based paint and a preparation method thereof. The strippable paint comprises the following components in parts by weight: 8 to 16 parts of cellulose resin, 1 to 4 parts of polyamide resin, 20 to 40 parts of cosolvent, 40 to 70 parts of deionized water, and 0 to 2 parts of PH regulator, and the paint is prepared by a reverse filling method. The strippable paint prepared by the method is an environment-friendly and strippable water-based paint which has the advantages of good leveling property, fast film forming and uniform film forming; the film forming thickness is between 65 and 85 microns, the paint is easy to strip, is green and environment-friendly and has no pollution, has no or little residues of the solvent and reacting monomer; and the filmed paint resists aging, is easy to strip, has the advantages of good weather resistance, safety, high efficiency and lower cost, is economical and convenient, and has good market popularization prospect.

Owner:哈尔滨大东方新材料科技股份有限公司

Quantum dot ink based on ink-jet printing

The invention specifically relates to quantum dot ink based on ink-jet printing, belonging to the technical field of electro-optic display devices. The quantum dot ink comprises quantum dots and an organic solvent, wherein the organic solvent is a single solvent or a mixed solvent which is a low-polarity or non-polar solvent, and the mass content of the solvent accounts for 40-99.9 wt% of the quantum dot ink. The ink provided by the invention has good dispersibility and stability and proper boiling point, surface tension and viscosity, can meet the requirements of quantum dot ink-jet printing, achieves uniform film-forming, and is beneficial for industrialization of quantum dot pixelated displays.

Owner:FUZHOU UNIV

Perovskite quantum dot ink and luminescent film

ActiveCN109651887ADoes not destroy luminosityIncrease concentrationInksDispersion stabilityQuantum dot

The present application discloses a perovskite quantum dot ink. The perovskite quantum dot ink comprises 0.1-20 wt% of perovskite quantum dots, 70-90 wt% of a solvent and 0-5-10 wt% of a cationic dispersant. The addition of the cationic dispersant increases the dispersion concentration and dispersion stability of the perovskite quantum dots in the ink. The perovskite quantum dot ink achieves a smooth process when applied to inkjet printing, and makes an obtained luminescent film have excellent properties.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

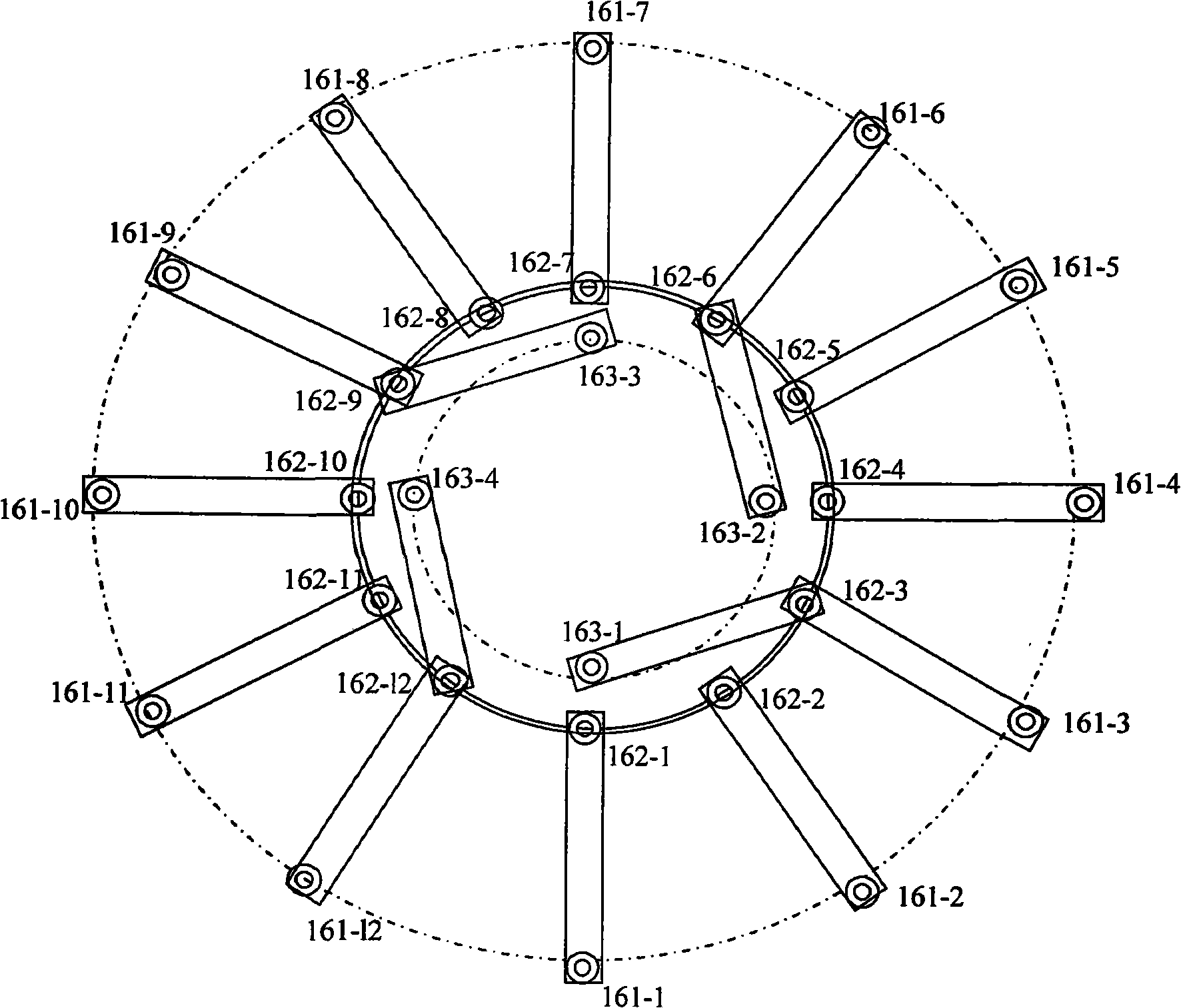

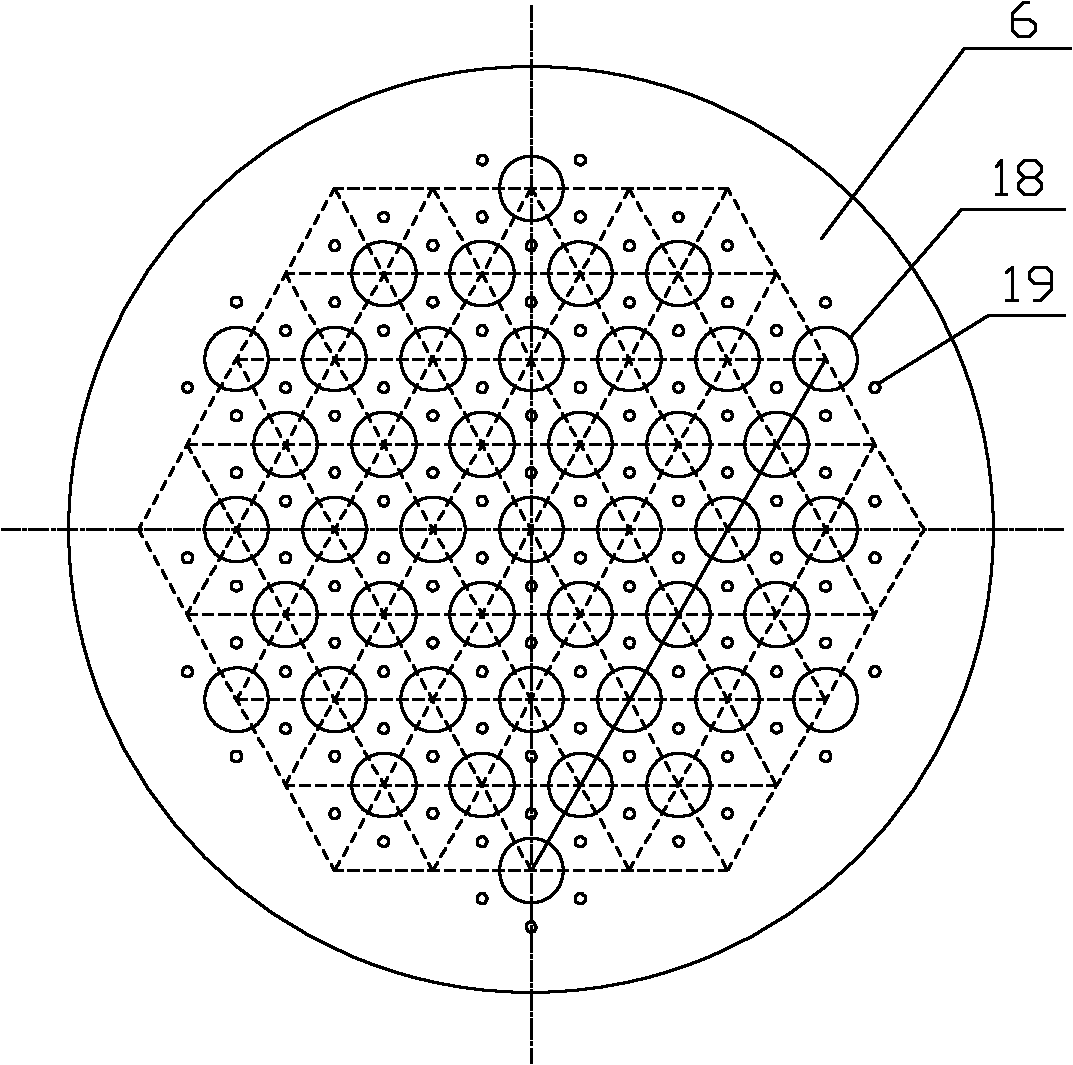

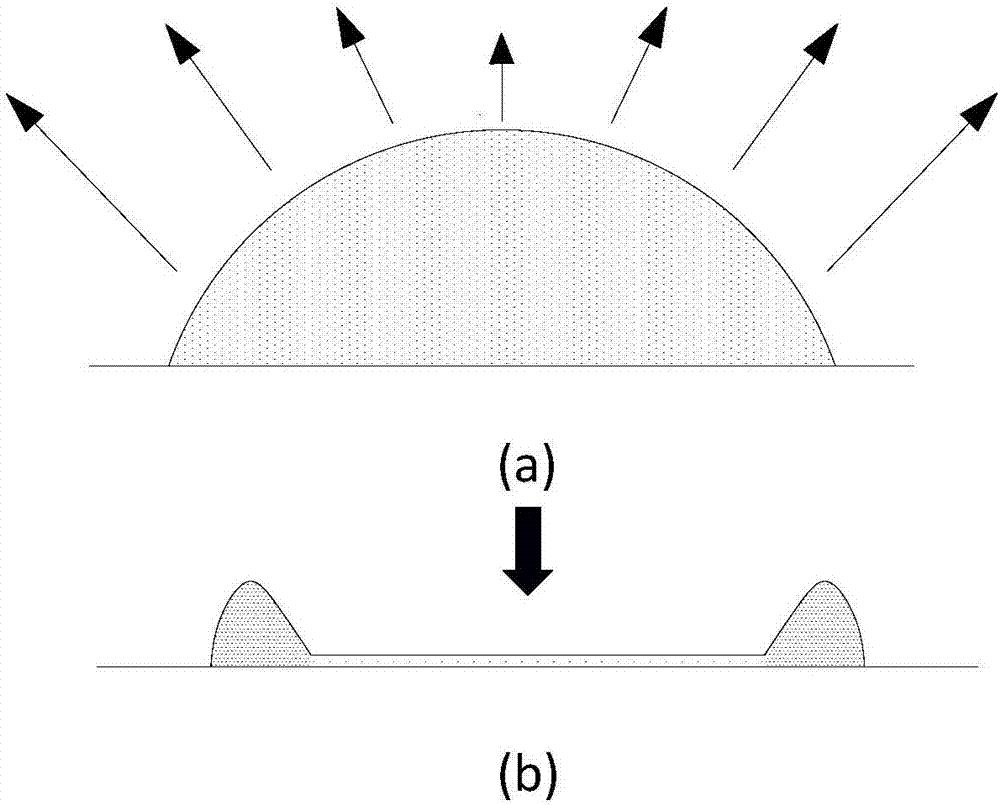

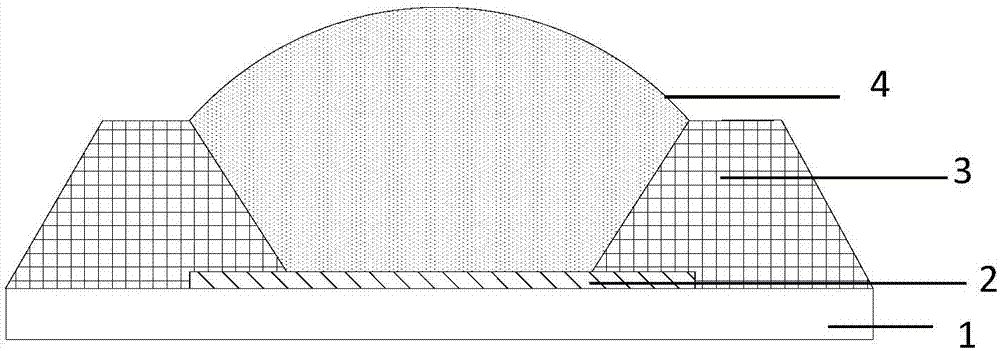

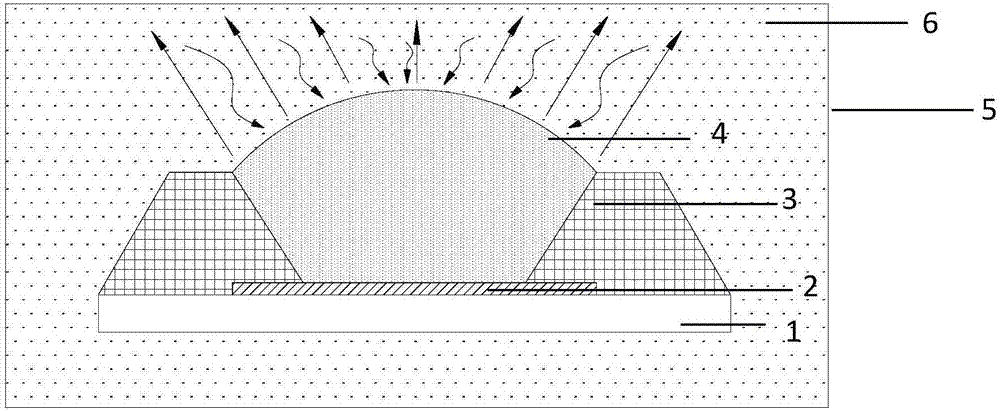

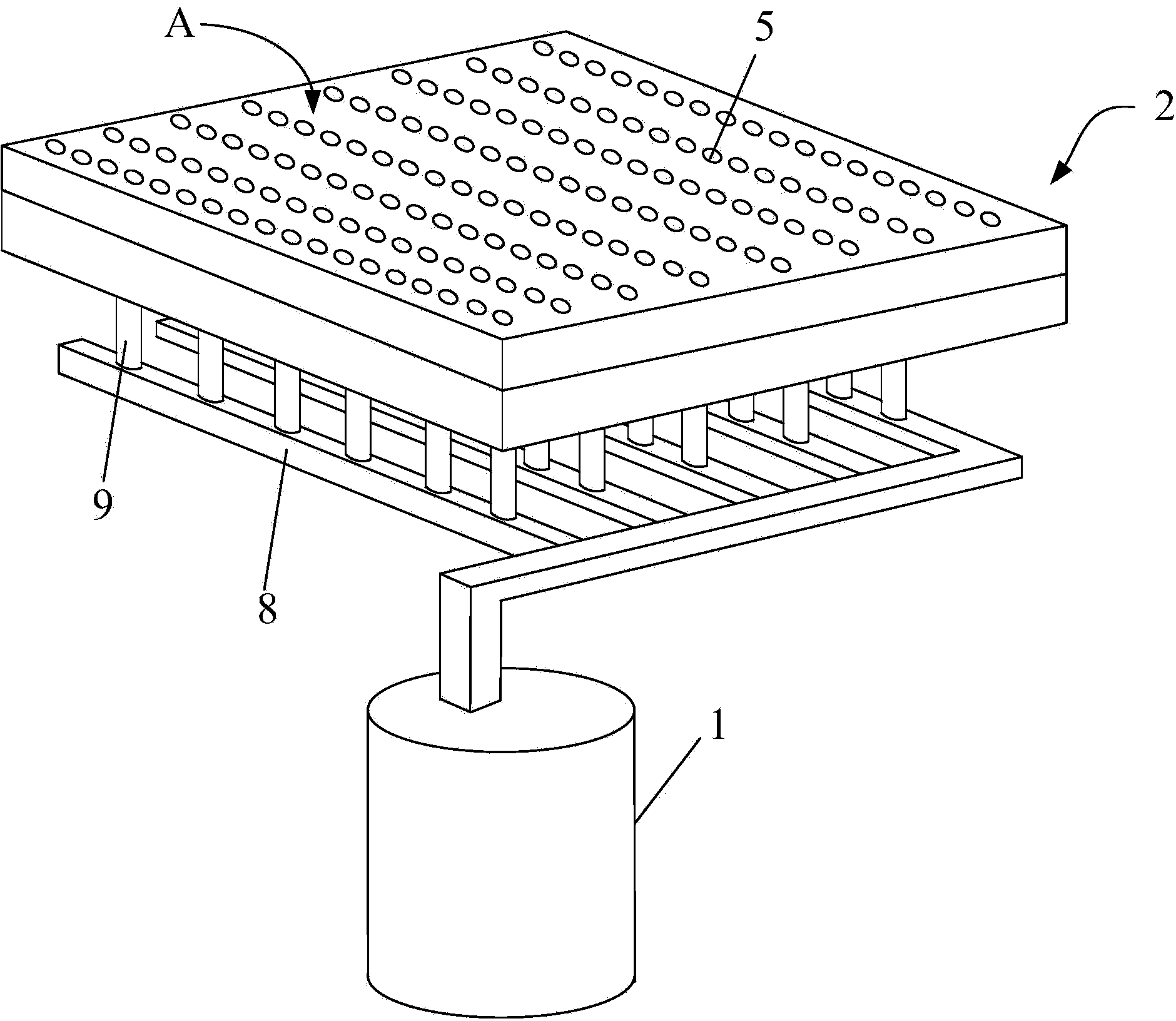

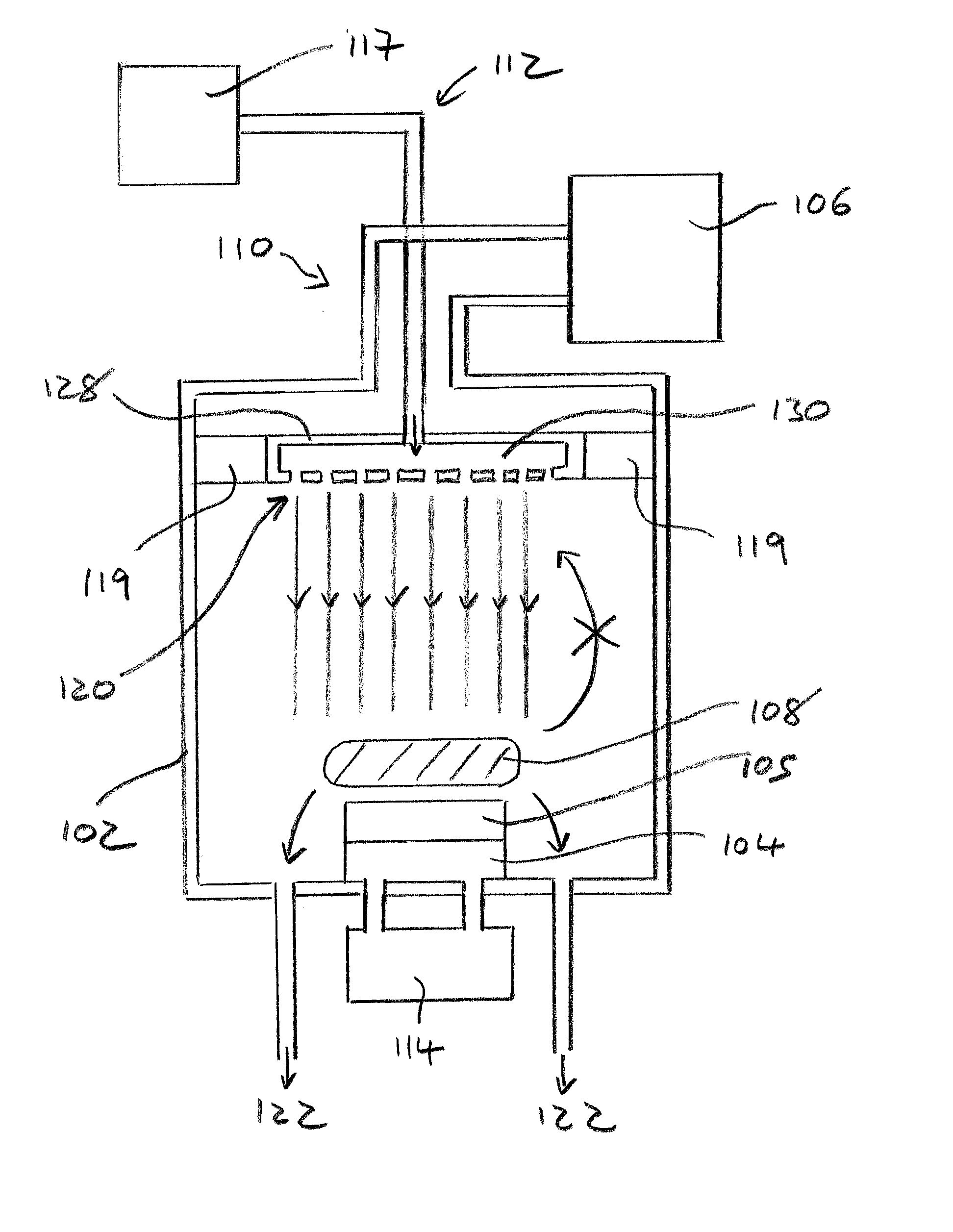

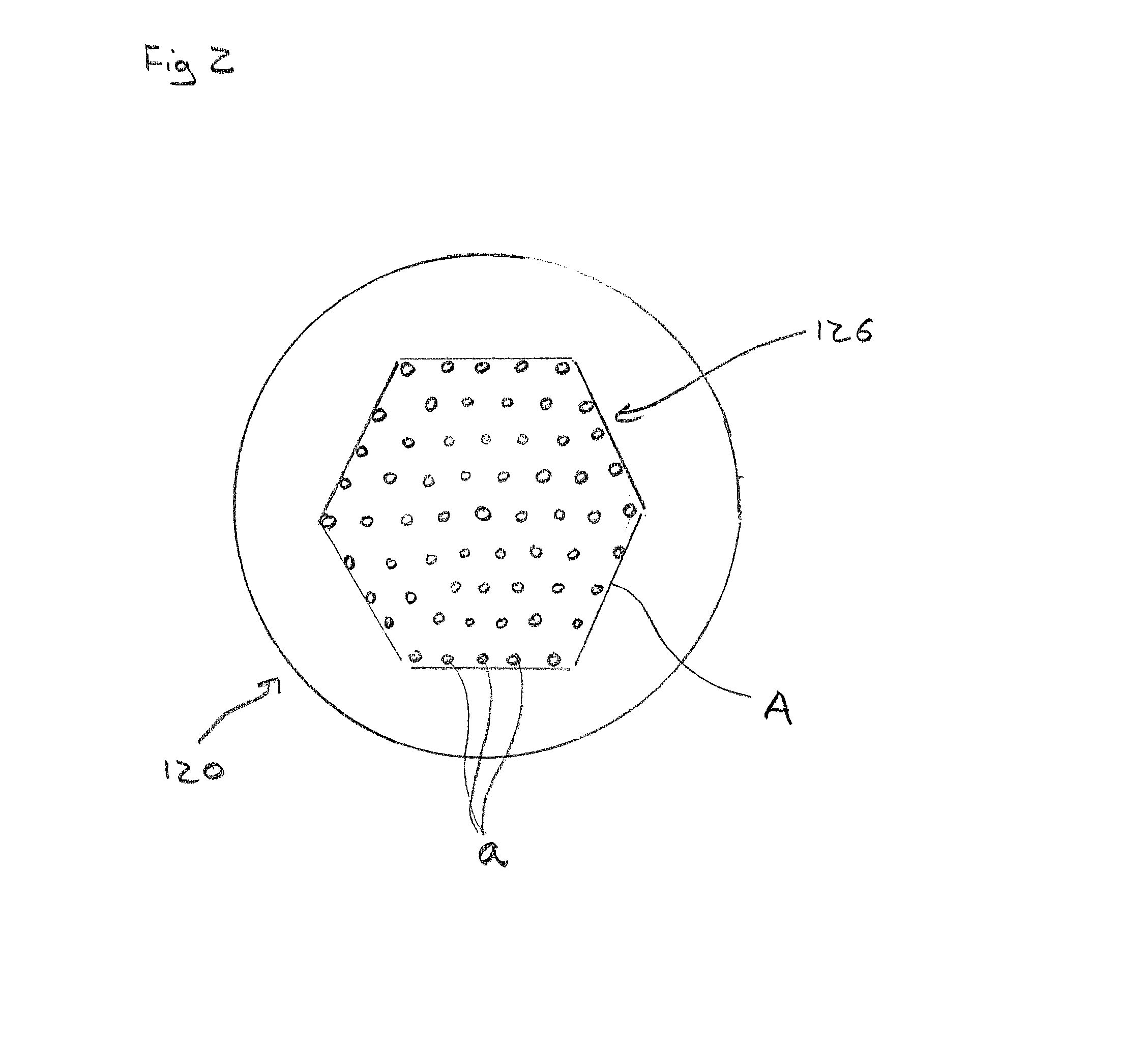

Microwave plasma reactor for manufacturing synthetic diamond material

ActiveUS20150030786A1Increase speedReduce decreasePolycrystalline material growthElectric discharge tubesSynthetic diamondPlasma reactor

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapour deposition, the microwave plasma reactor comprising: a plasma chamber; a substrate holder disposed in the plasma chamber for supporting a substrate on which the synthetic diamond material is to be deposited in use; a microwave coupling configuration for feeding microwaves from a microwave generator into the plasma chamber; and a gas flow system for feeding process gases into the plasma chamber and removing them therefrom; wherein the gas flow system comprises a gas inlet nozzle array comprising a plurality of gas inlet nozzles disposed opposite the substrate holder for directing process gases towards the substrate holder, the gas inlet nozzle array comprising: at least six gas inlet nozzles disposed in a substantially parallel or divergent orientation relative to a central axis of the plasma chamber; a gas inlet nozzle number density equal to or greater than 0.1 nozzles / cm2, wherein the gas inlet nozzle number density is measured by projecting the nozzles onto a plane whose normal lies parallel to the central axis of the plasma chamber and measuring the gas inlet number density on said plane; and a nozzle area ratio of equal to or greater than 10, wherein the nozzle area ratio is measured by projecting the nozzles onto a plane whose normal lies parallel to the central axis of the plasma chamber, measuring the total area of the gas inlet nozzle area on said plane, dividing by the total number of nozzles to give an area associated with each nozzle, and dividing the area associated with each nozzle by an actual area of each nozzle.

Owner:ELEMENT SIX TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com