Water-based release agent and preparation method thereof

A water-based release type, water-based acrylic technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as failure to meet inspection standards, large residues, and low volatility of organic solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

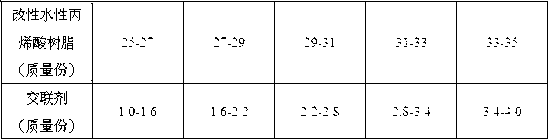

[0028] The formula component of this water-based release agent is calculated in an amount by mass:

[0029] 25 parts of modified water-based acrylic resin;

[0030] 50 parts of deionized water;

[0031] 1.0 parts of polycarbodiimide crosslinking agent;

[0032] 0.1 part of modified silicone defoamer;

[0033] 1 part of ethylene glycol antifreeze;

[0034] 0.1 part of modified polyurethane thickener;

[0035] The mass concentration is 0.1-0.6 part of ammonia water of 15%.

[0036] The preparation method step of the aqueous release agent of above-mentioned formula is:

[0037] (1) Put 25 parts by mass of modified water-based acrylic resin and 50 parts by mass of deionized water into the reactor, and use a high-speed disperser to stir at a medium-low speed at a temperature of 20-30°C. 300-400 rpm, stirring for 3-6 minutes to obtain a uniformly dispersed emulsion;

[0038] (2) Add 1.0 part by mass of polycarbodiimide crosslinking agent, 0.1 part by mass of modified silicone...

Embodiment 2

[0043] The formula component of this water-based release agent is calculated in an amount by mass:

[0044] 28 parts of modified water-based acrylic resin;

[0045] 56 parts of deionized water;

[0046] 2.0 parts of trifunctional aziridine crosslinking agent;

[0047] 0.2 parts of polyether silicone oil defoamer;

[0048] 2 parts of ethylene glycol;

[0049] 0.2 part of modified polyurethane;

[0050] The mass concentration is 0.1-0.6 part of ammonia water of 15%.

[0051] The preparation method step of the aqueous release agent of above-mentioned formula is:

[0052] (1) Put 28 parts by mass of modified water-based acrylic resin and 56 parts by mass of deionized water into the reactor, and use a high-speed disperser to stir at a medium-low speed at a temperature of 20-30°C. 300-400 rpm, stirring for 3-6 minutes to obtain a uniformly dispersed emulsion;

[0053] (2) Add 2.0 parts by mass of a trifunctional aziridine crosslinking agent, 0.2 parts by mass of polyether sil...

Embodiment 3

[0058]The formula component of this water-based release agent is calculated in an amount by mass:

[0059] 30 parts of modified water-based acrylic resin;

[0060] 60 parts of deionized water;

[0061] 2.5 parts of polycarbodiimide crosslinking agent;

[0062] 0.3 parts of modified silicone defoamer;

[0063] 3 parts of ethylene glycol;

[0064] 0.3 part of modified polyurethane;

[0065] The mass concentration is 0.1-0.6 part of ammonia water of 15%.

[0066] The preparation method step of the aqueous release agent of above-mentioned formula is:

[0067] (1) Put 30 parts by mass of modified water-based acrylic resin and 60 parts by mass of deionized water into the reaction kettle, and use a high-speed disperser for medium-low speed stirring at a temperature of 20-30°C. 300-400 rpm, stirring for 3-6 minutes to obtain a uniformly dispersed emulsion;

[0068] (2) Add 2.5 parts by mass of polycarbodiimide crosslinking agent, 0.3 parts by mass of modified silicone defoamer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com