Patents

Literature

221results about How to "Improve defoaming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Defoaming composition of polyether modified siloxane

ActiveCN101780384ARaw materials are easy to getSimple preparation processTransportation and packagingMixingSilica particleSolvent

The invention discloses a defoaming composition of polyether modified siloxane, which comprises the following components in percentage by weight: 60-80% of the polyether modified siloxane, 10-20% of silica particles, 2.5-4.0% of anionic surfactant, 7.5-15% of solvent and 0-1.0% of additive. The product of the invention is prepared by premixing the polyether modified siloxane and the silica particles evenly, then adding the surfactant, the solvent and the additive in proportion, and stirring for 30min at ordinary temperature. The invention not only has high defoaming efficiency and lasting antifoaming effect, but also can not affect the microbial fermentation process.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

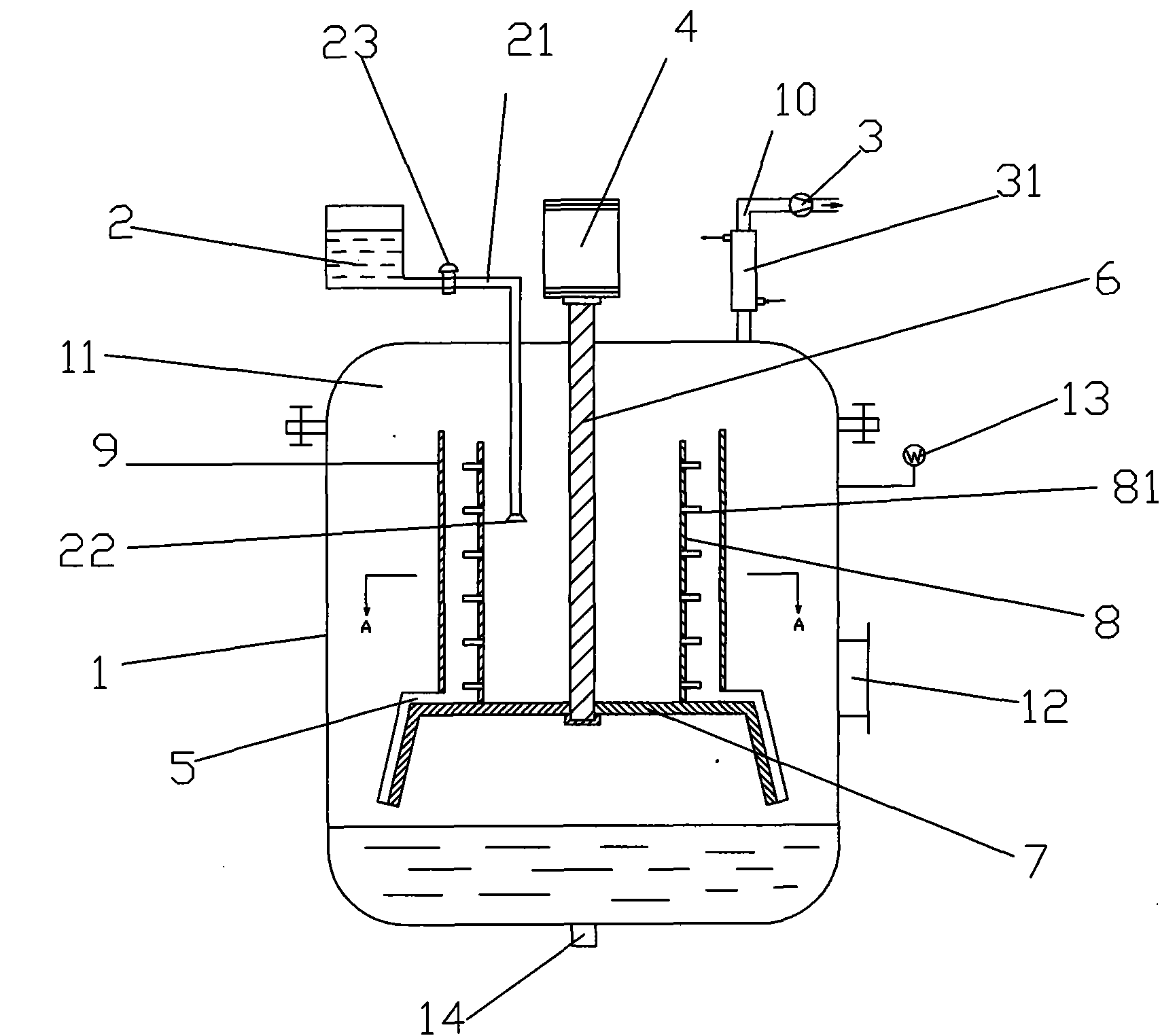

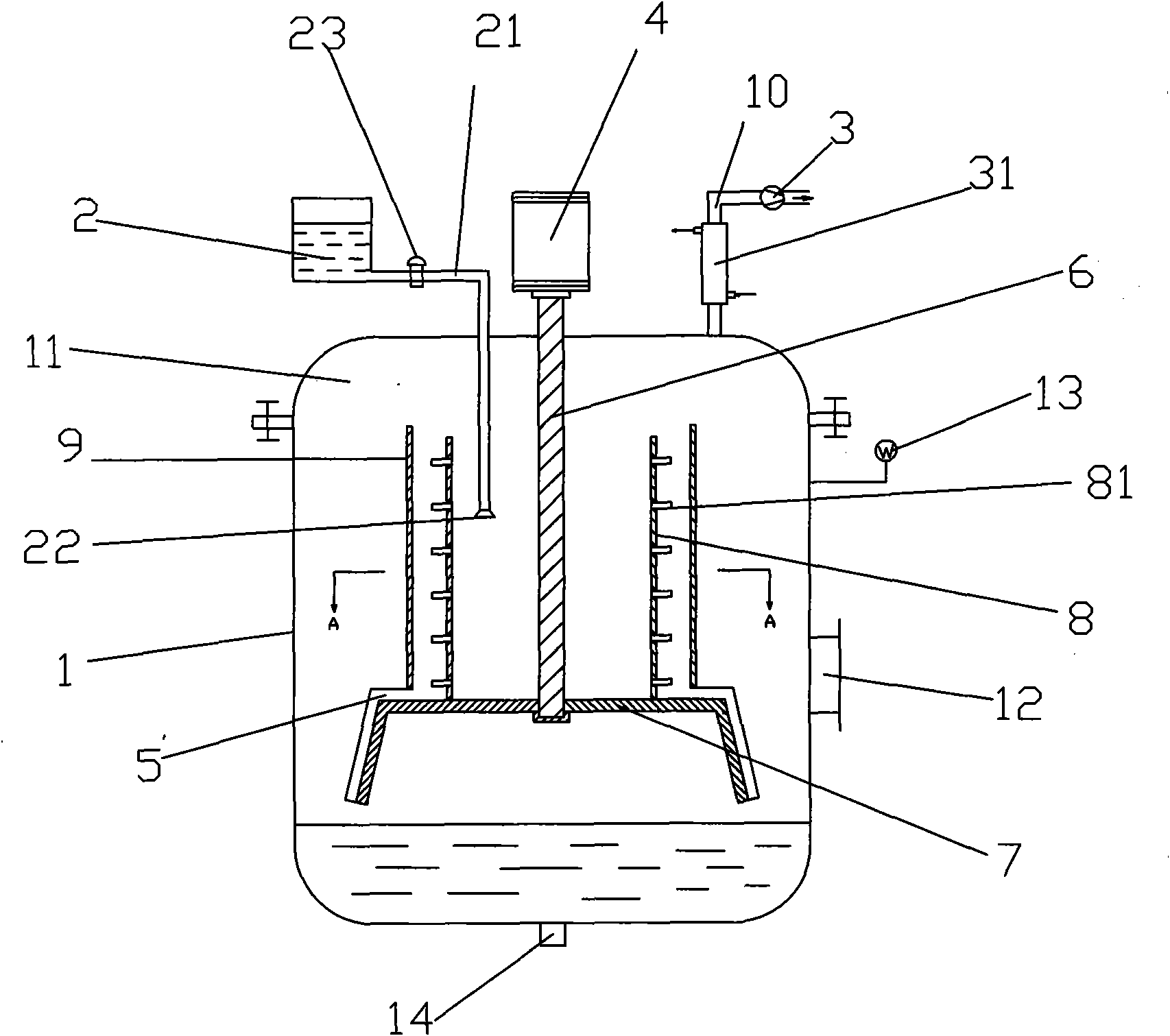

Defoaming device for high viscosity liquid product

ActiveCN101972560AImprove defoaming efficiencySimple structureFoam dispersion/preventionLiquid productLow voltage

The invention discloses a defoaming device for a high viscosity liquid product, which comprises a vacuum stirred tank, a storage tank, a vacuum pump and a motor, wherein a sealable cavity of the vacuum stirred tank is respectively conducted with the storage tank and the vacuum pump and is provided with a stirred shaft; the lower end of the stirred shaft is fixedly connected with a horizontal metal baseboard the edge of the periphery of which is declivous; the metal baseboard is provided with a barrel filter and a barrel clapboard surrounding the stirred shaft at intervals; under the condition of low voltage and rotating centrifuge, the high viscosity liquid enters the inside of the filter by the spraying of the storage tank, enters a draft duct between the clapboard and the metal baseboard along a metal pipe on the clapboard after the impact and centrifugation defoaming, and then flows to the bottom of the vacuum stirred tank after the impact and centrifugation defoaming again, and finally a high viscosity liquid product is obtained after the defoaming. The invention has simple structure, is easy to operate, has high defoaming efficiency and the like, and overcomes the defects that the existing device has sole defoaming mode and low defoaming efficiency.

Owner:SUZHOU SUNMUN TECH CO LTD

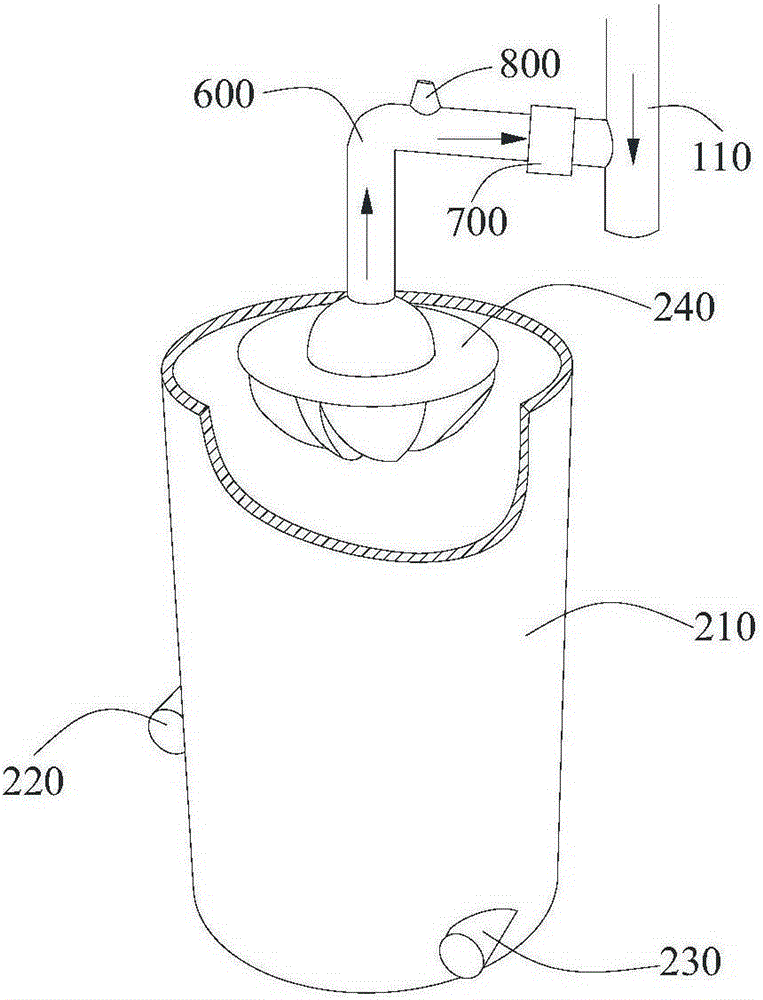

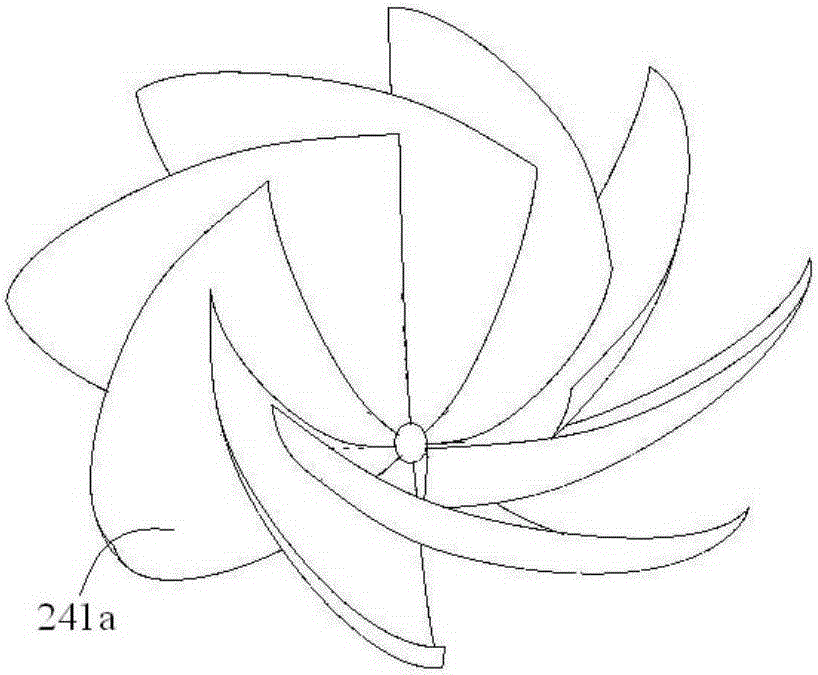

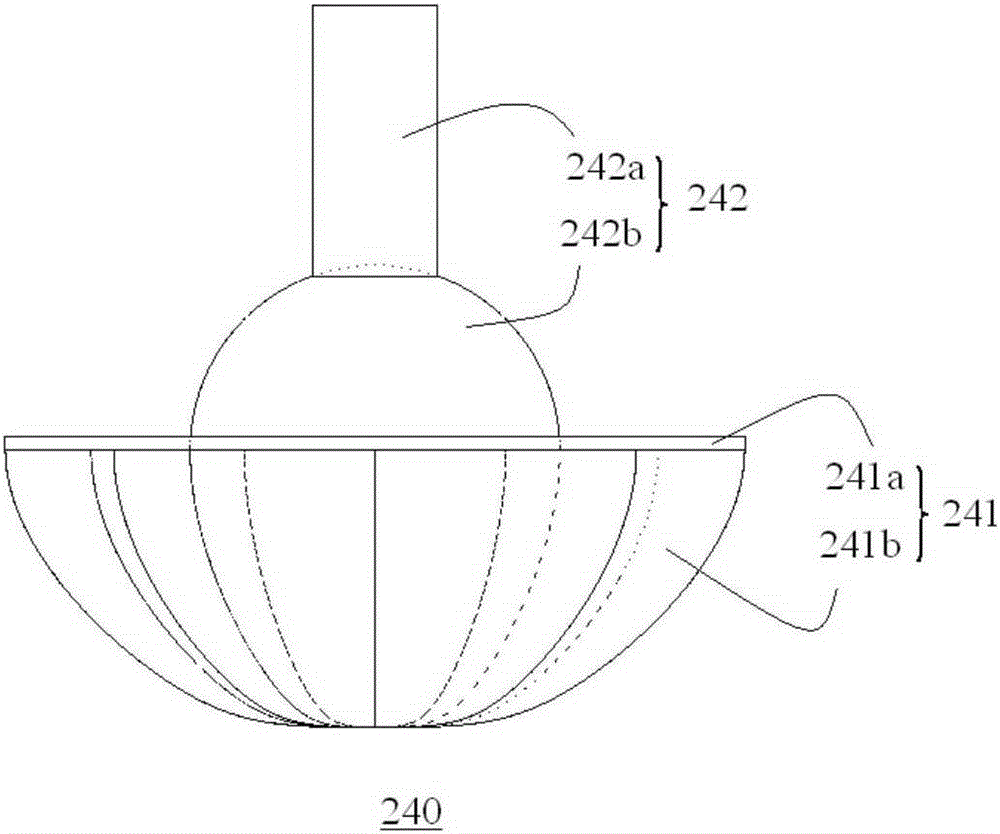

Food processor with high-efficiency defoaming device

The invention relates to a food processor with a high-efficiency defoaming device. A food processor main body comprises a grinding cutter, a motor, a grinding cutter shaft and a barrel body, and the high-efficiency defoaming device is arranged on the food processor; the high-efficiency defoaming device comprises a defoamer main body; the defoamer main body is provided with a foam inlet, an air outlet and a liquid outlet; and at least one of the top of the foam inlet of the defoamer main body, the top of the air outlet, the top of the liquid outlet and the top of the defoamer main body is positioned at 5mm-800mm above the liquid level of foodstuff. According to the food processor, under the situations of heating at any temperature and any heating power and intensely grinding, foams generated when the foodstuff is ground, heated and cooked are rapidly and actively broken, so that grinding or heating cooking operation is continuously and rapidly carried out without intermittent stop, therefore the grinding or cooking time is greatly shortened, and the working efficiency is improved.

Owner:王晓东

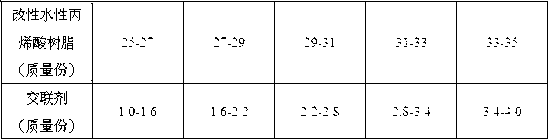

Water-based release agent and preparation method thereof

InactiveCN103254706AEasy to peelImprove the level ofPolyurea/polyurethane coatingsWater basedOrganic solvent

The invention discloses a water-based release agent and a preparation method thereof. The formula of the water-based release agent comprises the following components in parts by weight: 25 to 35 parts of modified water-based acrylic resin, 50 to 70 parts of deionized water, 1 to 4 parts of a crosslinking agent, 0.1 to 0.5 part of a defoaming agent, 1 to 5 parts of glycol. 0.1 to 0.5 part of improved polyurethane and 0.1 to 0.6 part of ammonia water at the mass concentration of 15 percent, wherein the weight ratio of the modified water-based acrylic resin to the crosslinking agent comprises five groups. The preparation method of the water-based release agent comprises the following steps of: (1) mixing and stirring the modified water-based acrylic resin and the deionized water to prepare emulsion dispersed uniformly; and (2) adding the crosslinking agent, the defoaming agent, the glycol and the improved polyurethane into the emulsion, stirring to prepare coating, and adjusting the pH value of the coating to be 6.2 to 8.2 by using the ammonia water. The water-based release agent is not externally crosslinked with a protected object during use and is easy to remove after film formation; and an organic solvent is not adopted, so the water-based release agent is environment-friendly, pollution-free and low in cost.

Owner:广东鑫皇冠新材料有限公司

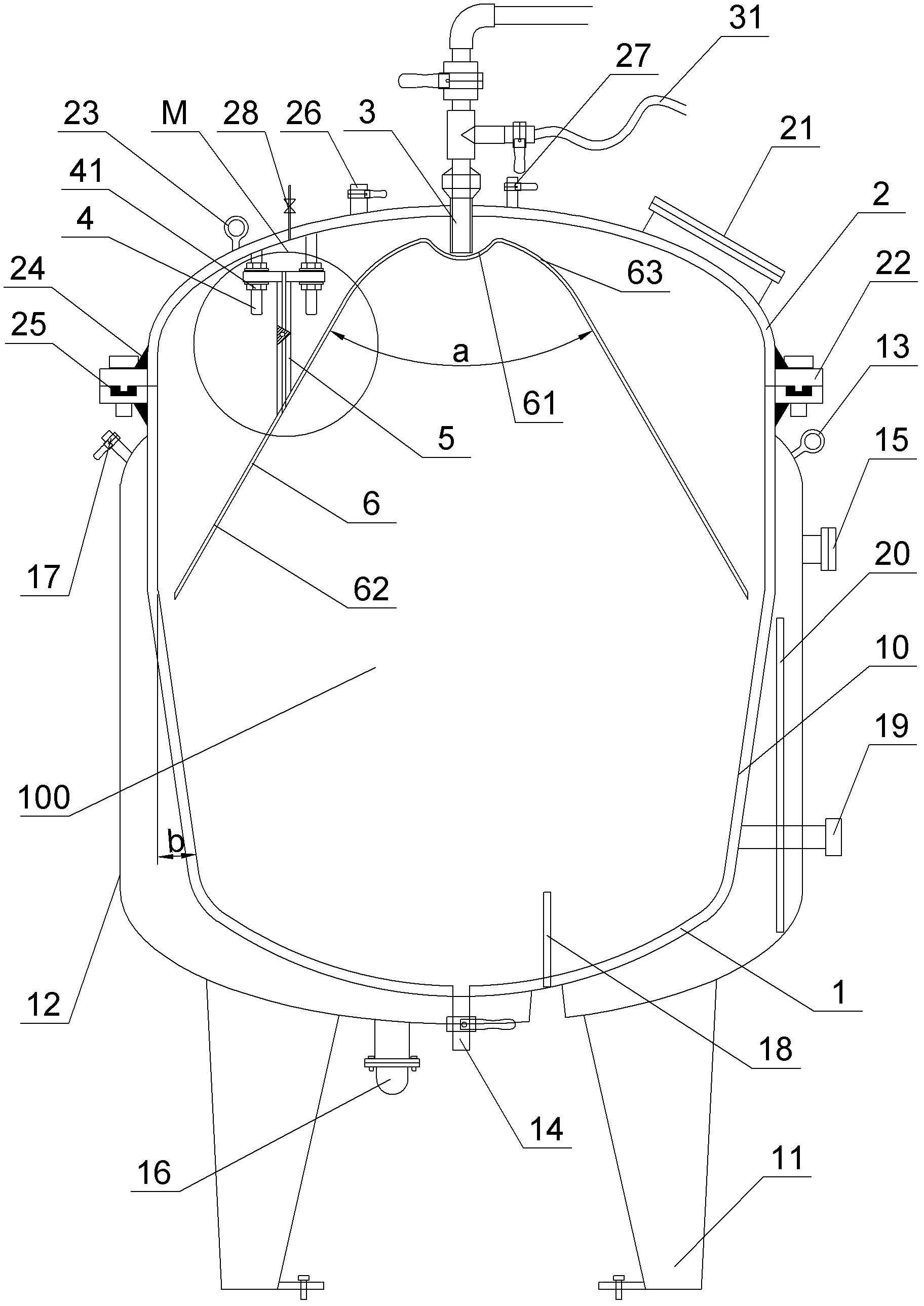

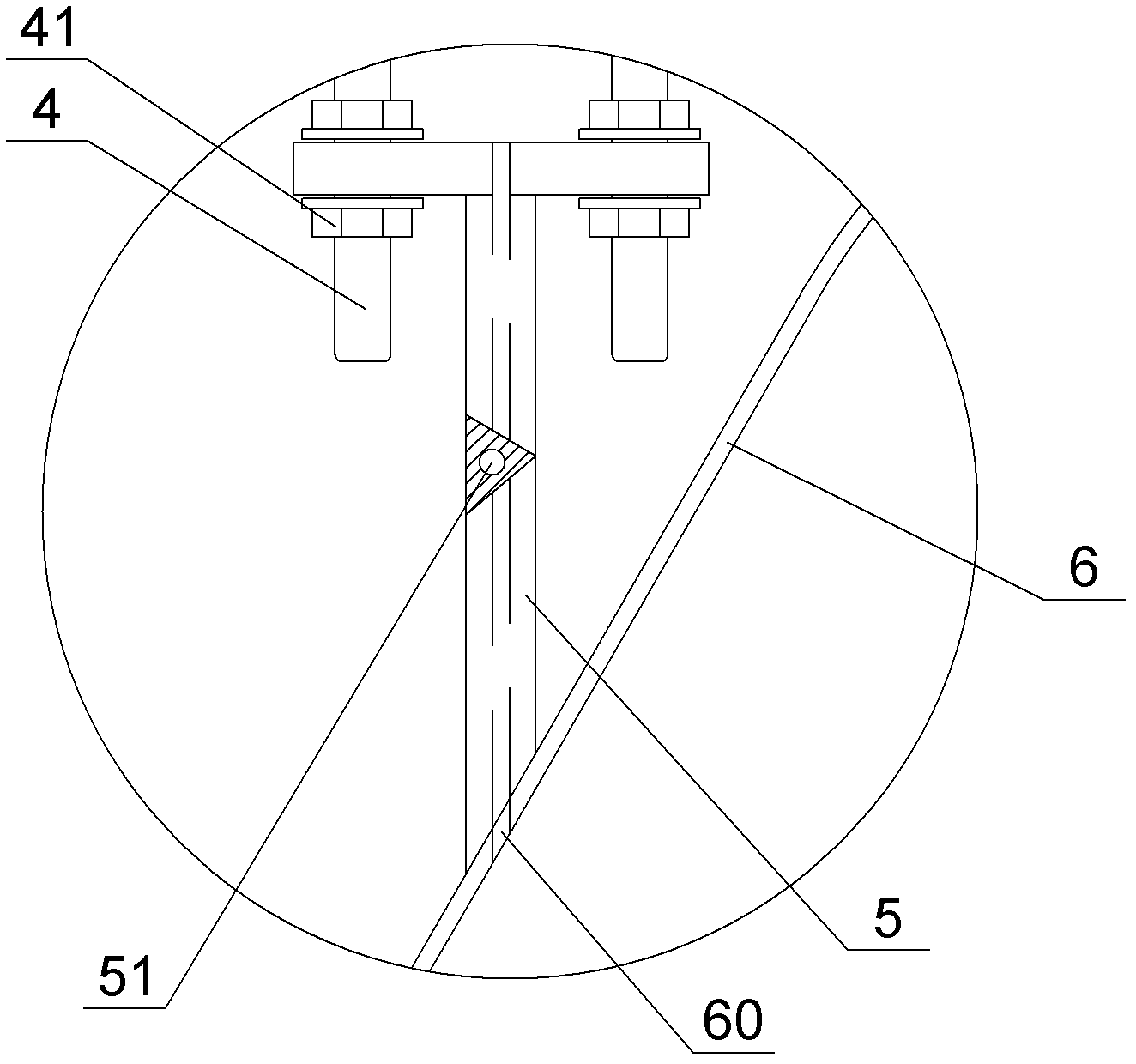

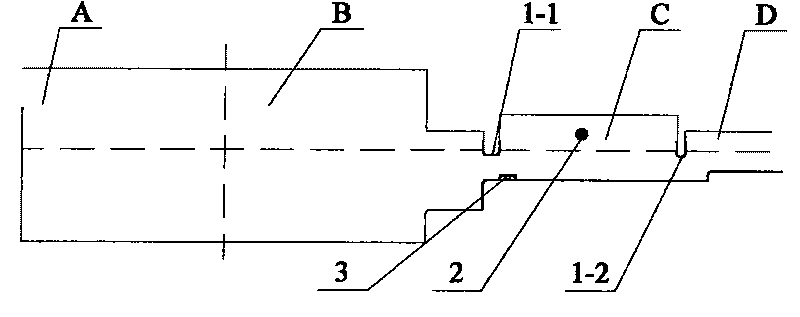

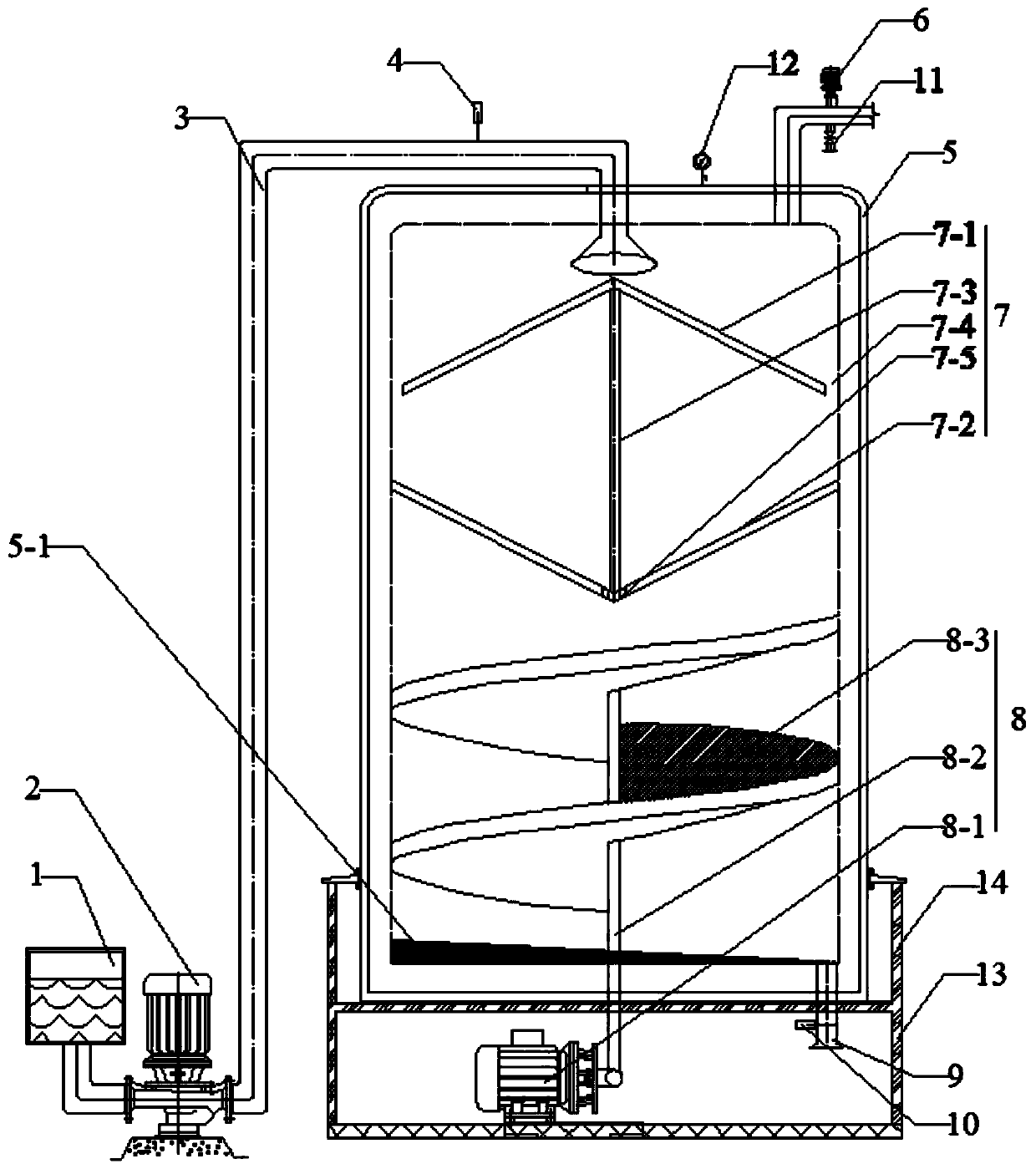

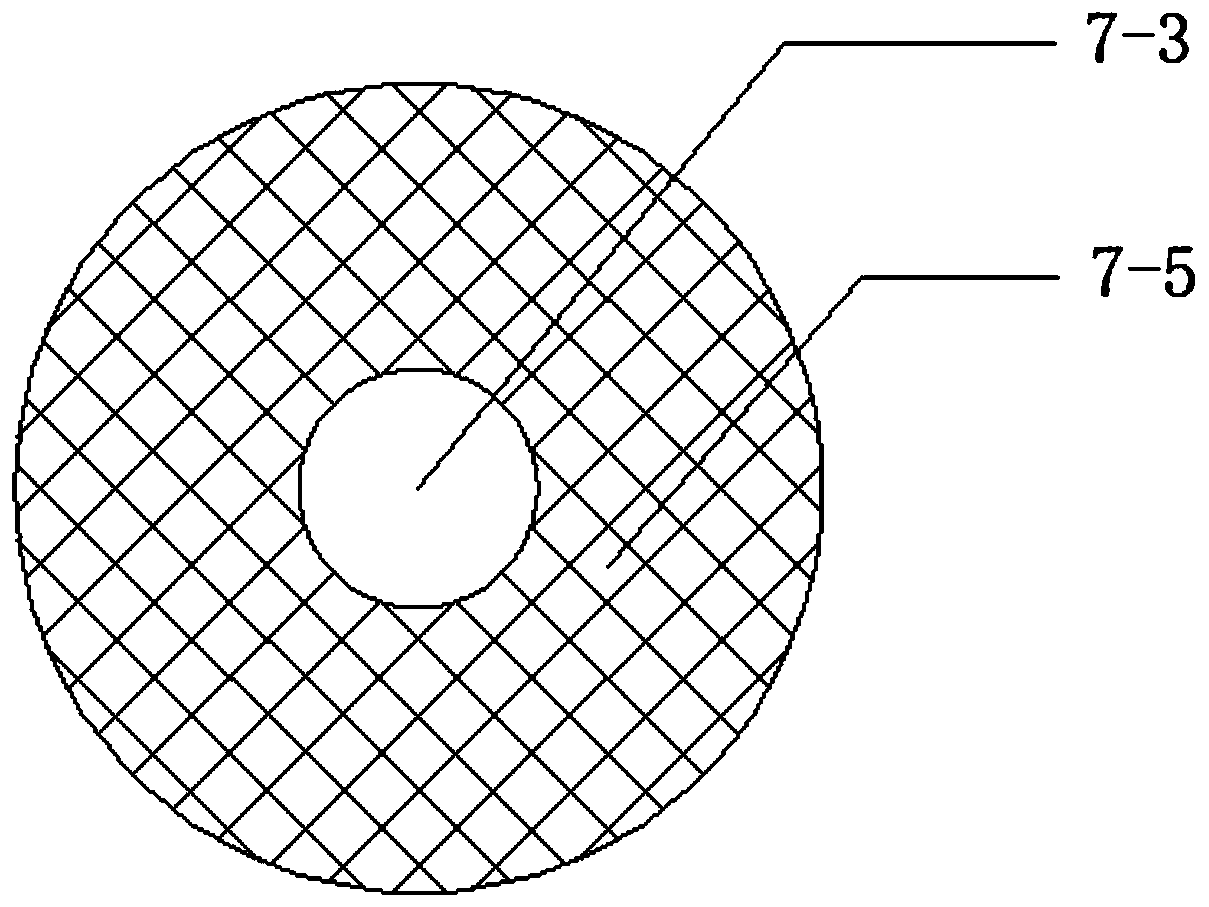

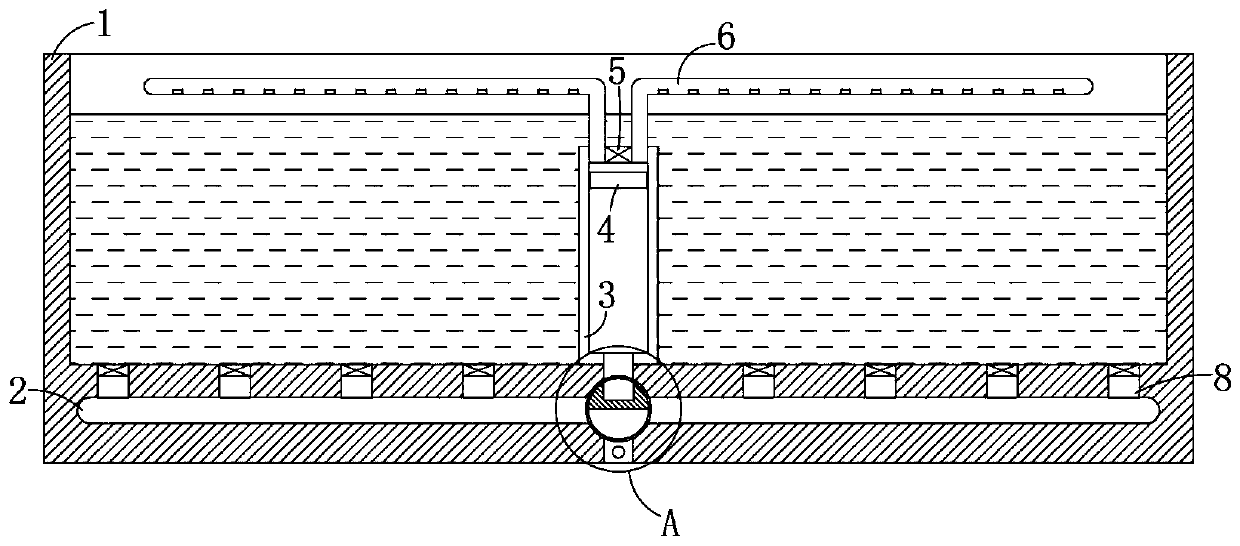

Ultrafiltration membrane deaerating unit

ActiveCN102657958ASolve the accuracy problemGood filtration accuracyLiquid degasificationUltrafiltrationUltrafiltrationDeaerator

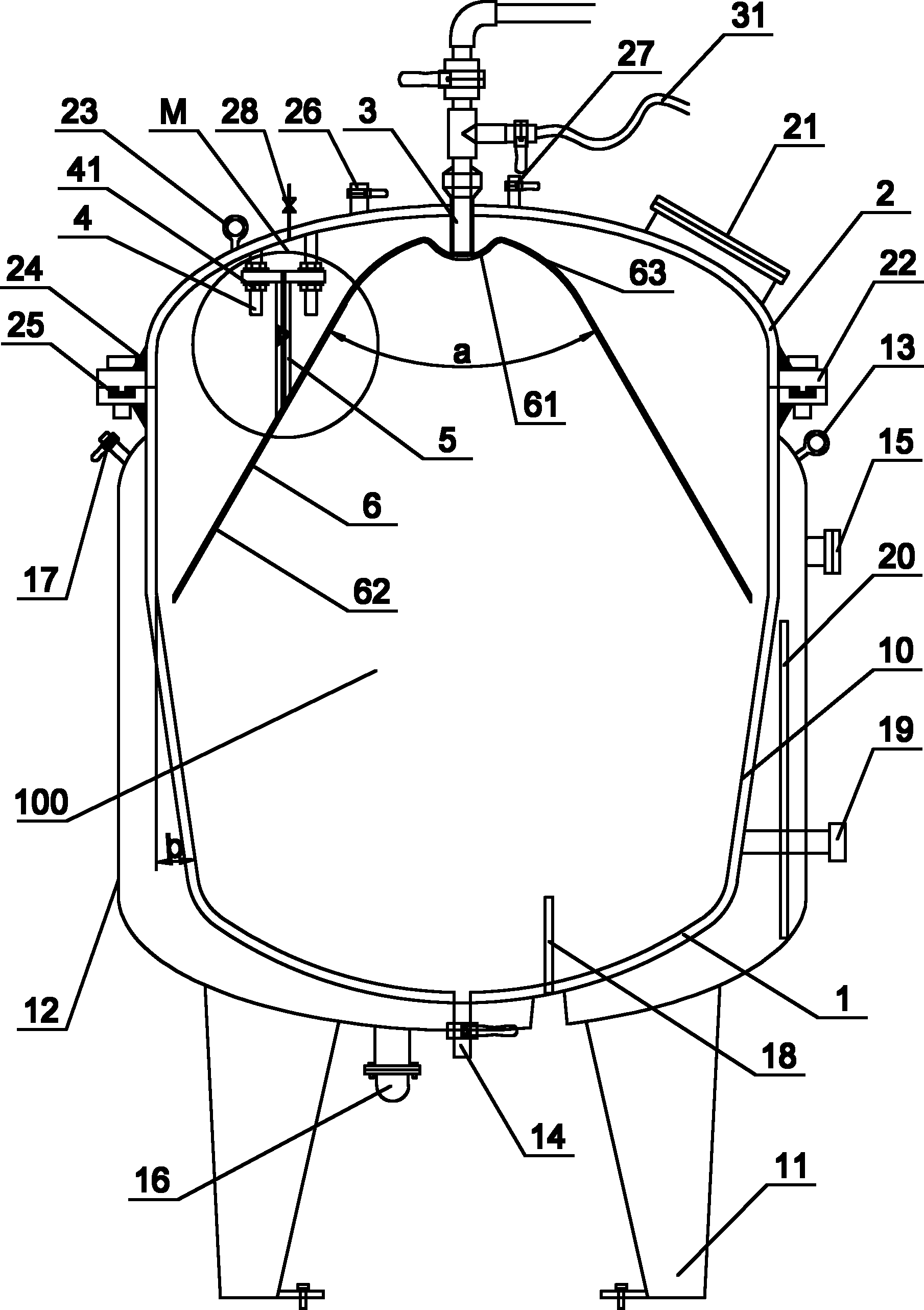

The invention discloses an ultrafiltration membrane deaerating unit which is high in deaerating efficiency and effective in deaerating and enables ultrafiltration membrane filtrating precision to be improved and blow holes in spinning to be avoided. The ultrafiltration membrane deaerating unit is capable of removing bubbles once and is widely applicable to feed liquid in wide viscosity range. The ultrafiltration membrane deaerating unit comprises a tank (1) and an upper cover (2). The tank (1) and the upper cover (2) are connected to form a closed space (100). A feed pipe component (3) is connected to the center of the top of the upper cover (2). A liquid outlet (14) is reserved at the center of the bottom of the tank (1). An umbrella-shaped deaerator (6) is arranged on the inner upper portion of the closed space (100) and comprises an overflow groove (61) at the center of the top and a deaeration leveling umbrella-shaped face (62) around the overflow groove (61), and the overflow groove (61) corresponds to a feed inlet of the feed pipe component (3). A slanting deaeration membrane-drawing slope is reserved on the lower middle of the inner wall of the tank (1). The ultrafiltration membrane deaerating unit is widely applicable to the field of ultrafiltration membrane preparation.

Owner:怀集汇清环保设备工程有限公司

Diesel fuel and lubricating oil antifoams and methods of use

InactiveUS20020129542A1Good defoaming effectMaintain performance characteristicDewatering/demulsification with chemical meansLiquid carbonaceous fuelsDemulsifierOrganic group

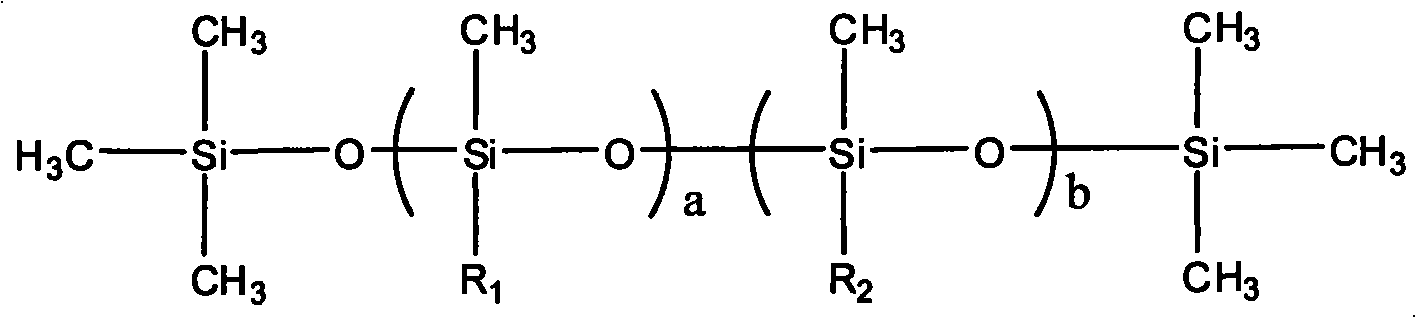

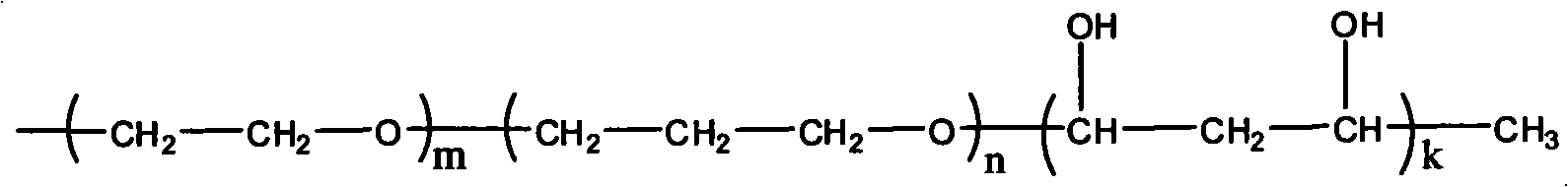

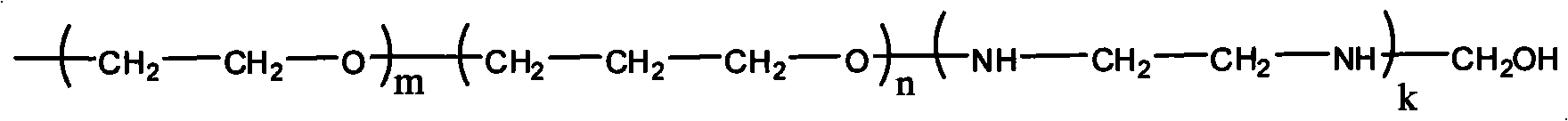

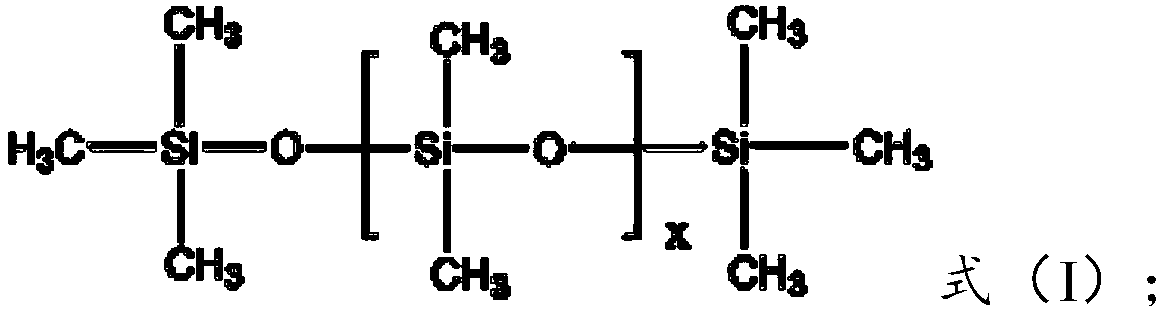

The present invention relates to diesel fuel and lubrication oil defoaming agents, and crude oil demulsifiers, as well as methods for using same. In particular, the defoaming agents and demulsifiers are comprised of copolymers which have structures constituting a backbone of polysiloxane onto which is grafted an organic group. These structures comprise a polymer of the formula MD.sub.xD'.sub.yD".sub.zM, where M is O.sub.0.5Si(CH.sub.3).sub.3, D is a OSi(CH.sub.3).sub.2, D' is OSi(CH.sub.3)R, D" is OSi(CH.sub.3)R', R is a polyhydric C.sub.6-C.sub.28 organic group, R' is a phenol derivative or a long chain aliphatic group or polyethers, z is between 0 and 80, x+y+z is between 10-200, x / z is .gtoreq.1, and x / (y+z) is between about 1 and about 5, or formula M'D.sub.aM' where M' is O.sub.0.5Si(CH.sub.3).sub.2R, a is between 4-10, and R and D are the same as defined above.

Owner:GRABOWSKI WOJCIECH +1

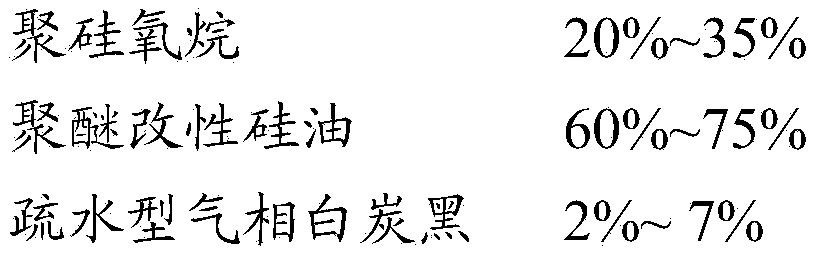

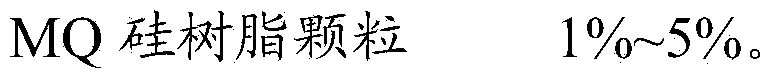

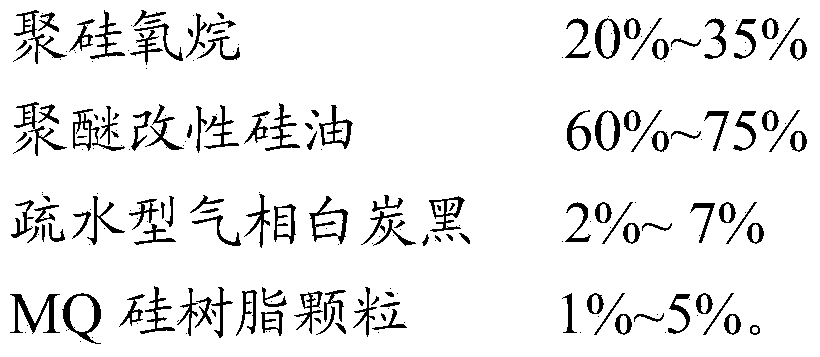

Organic silicon defoamer for paper making industry and preparation method thereof

ActiveCN103669108AIncreased diffusion rateImprove defoaming efficiencyDefoamers additionPaper/cardboardStructural formulaFumed silica

The invention discloses an organic silicon defoamer for a paper making industry and a preparation method thereof. The organic silicon defoamer is obtained by emulsifying an organic silicon defoaming composition comprising an active composition, an emulsifier and an additive, the active composition comprises polysiloxane, polyether modified silicone, hydrophobic fumed silica and MQ silicon resin particles, polysiloxane is methylsilicone oil or hydroxyl silicone oil with the viscosity of 10,000-50,000 mPA.s at 25 DEG C, the structural formula of polyether modified silicone is R(PO)b(EO)a(PO)-(Me2SiO)mSiMe2-(PO)(EO)a(PO)bR and / or R(PO)b(EO)a(PO)-(Me2SiO)mSiMe3, the particle sizes of the MQ silicon resin particles are 5-20 micron, and the specific surface area of hydrophobic fumed silica is 100-300 m<2> / g. The invention further provides the preparation method of the defoamer. The defoamer is prepared from organic silicon, hydrophobic fumed silica and the MQ silicon resin particles through a special process, has excellent defoaming efficiency and dedoaming activity durability, and is good in storage stability and dilution stability.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

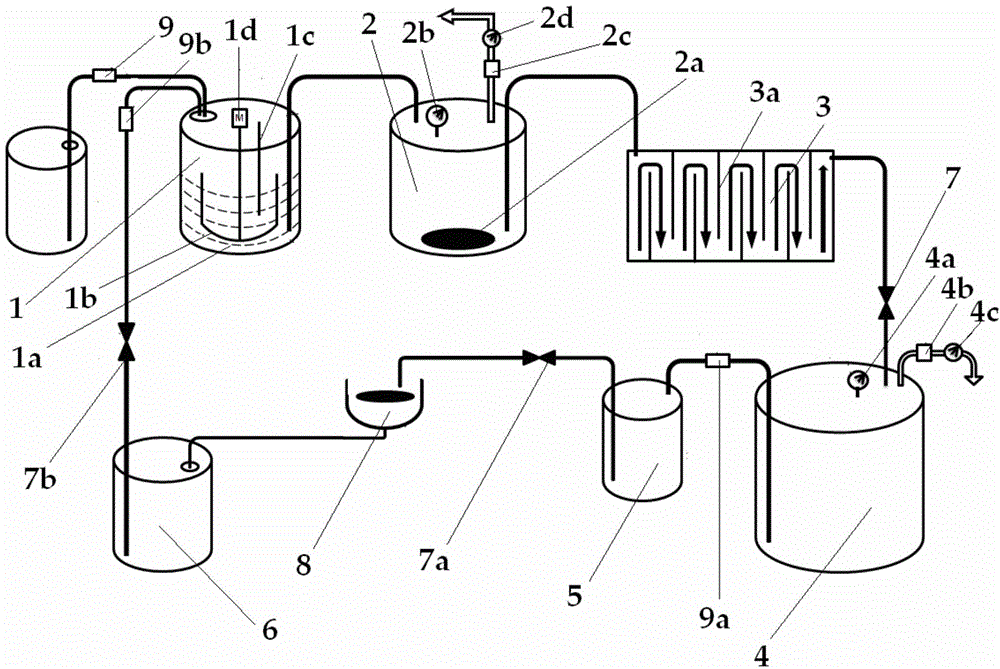

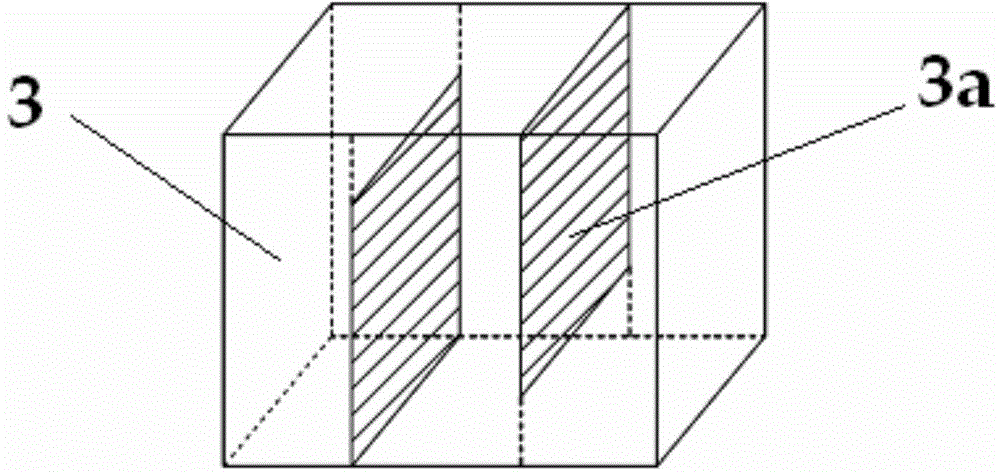

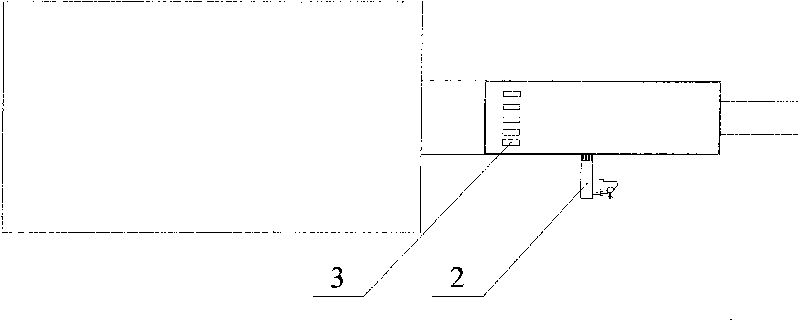

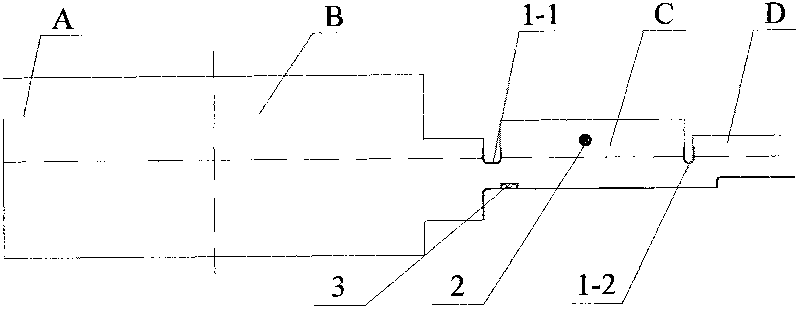

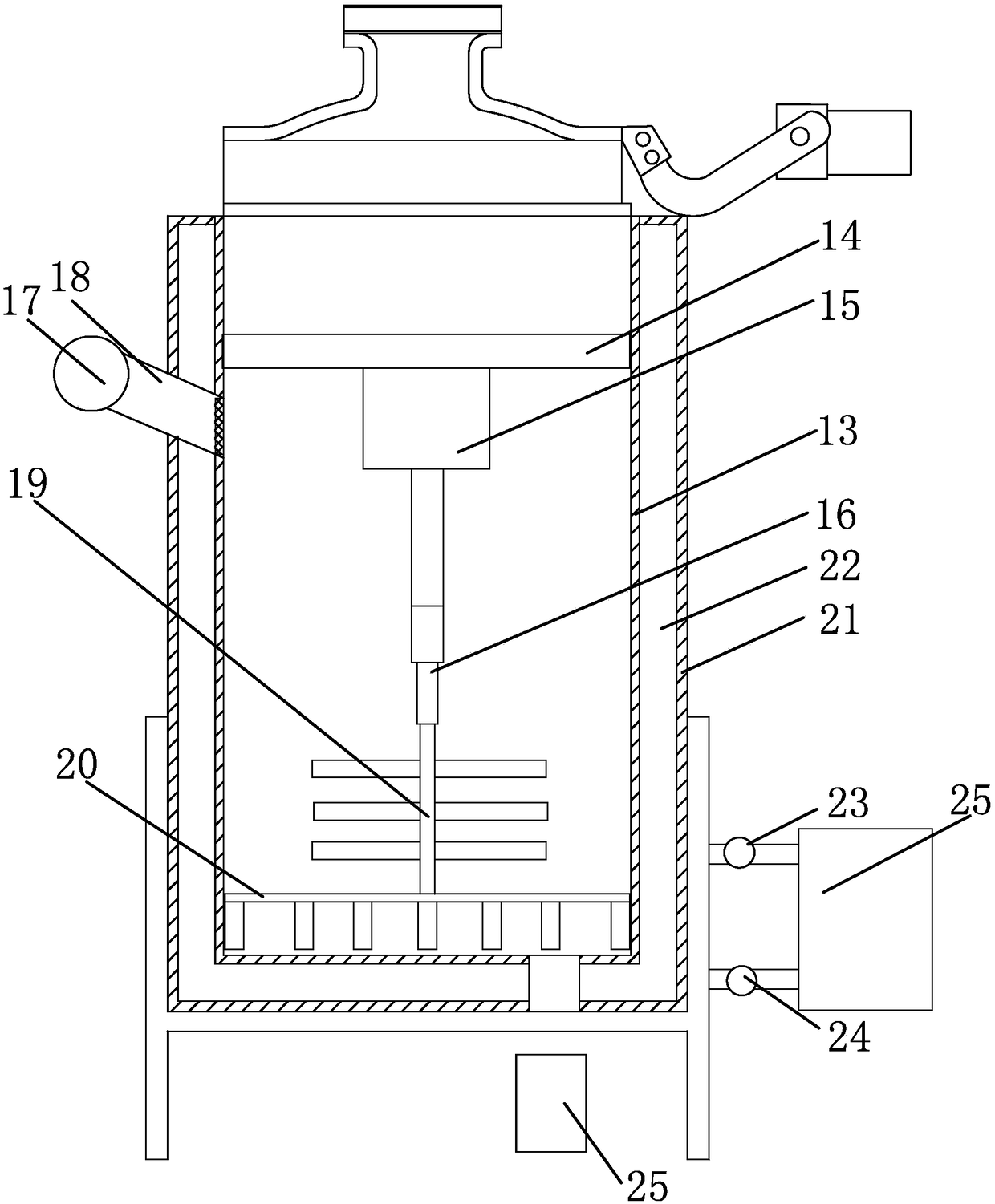

De-foaming and recycling system and process

ActiveCN103949092ADegassing achievedAffect supplyFiltration circuitsFoam dispersion/preventionSuction forceContinuous use

The invention belongs to the technical field of charge-discharge control devices and methods for de-foaming mechanisms, and discloses a de-foaming and recycling system and process. A new liquid material enters a stirring tank under the action of a vacuum pump and a suction pipe and is stirred at constant speed and constant temperature; the stirred liquid material is fed into a first vacuum de-foaming tank through a metal pipeline under the action of vacuum suction force and is de-foamed primarily; the liquid material which is de-foamed primarily is fed into a second cascade type de-foaming tank through a metal pipeline under the action of the vacuum suction force and is de-foamed secondarily; the liquid material which is de-foamed secondarily is fed into a third vacuum de-foaming tank through a metal pipeline under the action of the vacuum suction force and is de-foamed for the third time; the liquid material which is de-foamed for the third time; enters a storage tank under the action of the vacuum suction force and is directly subjected to optical disk spin-coating operation; after the optical disk spin-coating operation is performed, the remaining liquid material flows into a recycling tank, flows into the stirring tank under the action of the vacuum suction force, and is mixed with a new liquid material for continuous use so as to be recycled. The system and the process are low in cost, easy to operate and high in de-foaming efficiency, and cannot affect the physical and chemical performances of the de-foamed liquid material; the liquid material can be continuously fed, de-foamed, used and recycled.

Owner:TDK DALIAN

Production of fluorophosphate optical glass, and production of optical element

InactiveUS20120111061A1Good visible light transmittancePromote absorptionGlass furnace apparatusGlass drawing apparatusTransmittanceLength wave

In a method for producing a fluorophosphate optical glass comprising melting a glass raw material to give a molten glass, and refining, homogenizing and then quickly quenching the molten glass to produce the fluorophosphate optical glass, even if the glass is flown from a refining tank that is set to a high temperature to an operation tank that is set to a low temperature, bubbles are not generated in the glass.The content of Fe in terms of Fe2O3 and the content of Cu in terms of CuO is controlled so thatthe total of the contents of Fe and Cu is 20 ppm or more, and the obtained fluorophosphate optical glass has such transmittance property that the internal transmittance in terms of a thickness of 10 mm becomes 98% or more at a wavelength region of at least from 400 to 500 nm.

Owner:HOYA CORP

Method for improving clarifying effect of molten glass in floating production and kiln device

InactiveCN101717178ASpeed up dischargeExtend the life cycleGlass furnace apparatusGeneration rateKiln

The invention relates to a method for improving a clarifying effect of molten glass in floating production and a kiln device, which solve the technical problems of improving the clarifying effect of molten glass in floating production and further reducing the generation rate of bubbles so as to produce a high-quality glass base plate. The method is realized in a molten glass clarifying kiln; after a glass material is melted in the clarifying kiln and processed by a clarifying area and a cooling adjustment area, the molten glass is output; a clarification forcing area is additionally arranged between the clarifying area and the cooling adjustment area of the clarifying kiln, and the length and the detention time of a clarifying process of the molten glass are increased to match for carrying out clarification forcing processing on the molten glass; the kiln device is provided with two U-shaped walls, and the two U-shaped walls form a sealed clarification forcing area by a top wall, a bottom wall and a side wall of a kiln body. The invention obviously improves the clarifying effect and the qualified rate of products and can efficiently carry out defoaming clarification on the molten glass and obviously reduce the influence of the clarifying bubbles on the quality of the glass base plate.

Owner:TUNGHSU GRP

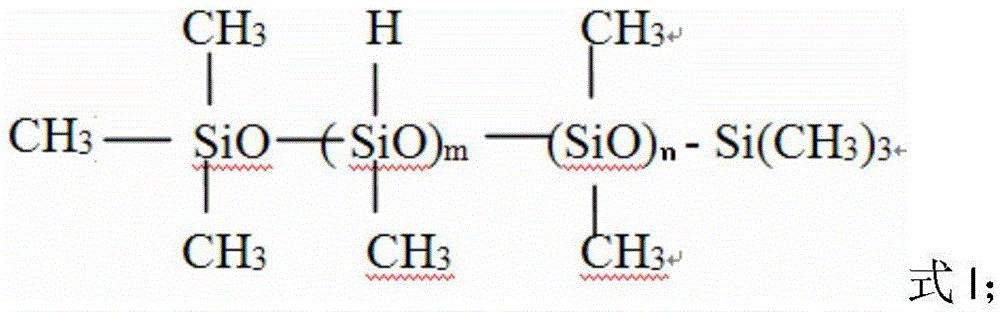

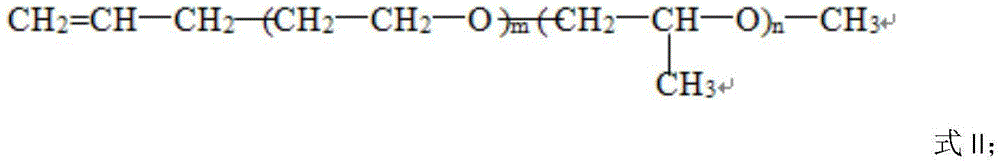

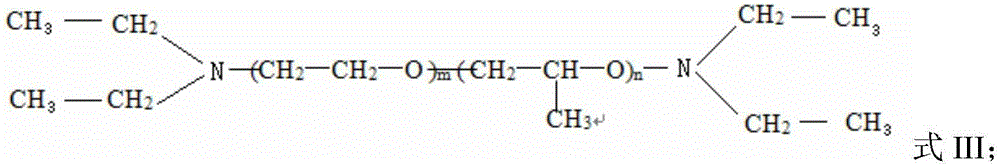

Emulsion breaking type de-foaming agent for oil field and preparation method thereof

ActiveCN107523279AImprove defoaming efficiencyReduce dosageDrilling compositionFoam dispersion/preventionPolyethylene polyamineHydrocarbon solvents

The invention relates to an emulsion breaking type de-foaming agent for an oil field and a preparation method thereof. The emulsion breaking type de-foaming agent for the oil field is prepared by taking polyether modified silicone oil as a main body and polyethylene polyamine polyether as an auxiliary agent and adding a synergist and a solvent. The polyether modified silicone oil is prepared by taking terminated allyl methyl-terminated polyether and low-hydrogen-containing silicone oil as raw materials and reacting at pre-set temperature under the action of a platinum catalyst. The emulsion breaking type de-foaming agent for the oil field is prepared by uniformly mixing and stirring the following components in percentage by mass: 7 percent to 10 percent of the polyether modified silicone oil, 2 percent to 5 percent of the polyethylene polyamine polyether, 1 percent to 5 percent of the synergist and the balance of the solvent. The emulsion breaking type de-foaming agent for the oil field, provided by the invention, not only has the characteristics of small dosage and high de-foaming efficiency, but also has a certain emulsion breaking capability; the aim of reducing the dosage of an emulsion breaking agent of the oil field and the de-foaming agent can be realized. The emulsion breaking type de-foaming agent can be directly added into a foaming solution and can also be added after being diluted to 5 to 20 times by utilizing a hydrocarbon solvent. The emulsion breaking type de-foaming agent for the oil field is very suitable for treating crude oil of the oil field, especially an offshore oil field.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Emulsified type hyperbranched polyether modified organic siliconde foamer and preparation method thereof

InactiveCN106390531AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionAluminum silicateUltra fine

The invention discloses an emulsified type hyperbranched polyether modified organic siliconde foamer, which is prepared from the following raw materials in parts by weight: 25 to 40 parts of polysiloxane, 15 to 23 parts of hyperbranched polyether, 18 to 27 parts of allyl glycidyl ether, 40 to 60 parts of epoxypropane, 0.3 to 0.6 part of double metal cyanide complex, 50 to 70 parts of isopropanol, 0.2 to 0.7 part of chloroplatinic acid catalyst, 3 to 7 parts of ultra-fine aluminum silicate, 1 to 2 parts of sorbitol, 0.8 to 2 parts of tween-60, 2 to 4 parts of sodium carboxymethyl cellulose, appropriate amount of deionized water, and 1 to 3 parts of compound emulsifier. The invention also relates to a preparation method, which comprises the following steps of adopting the hyperbranched polyether containing a large number of hydroxyl at the tail end as a raw material for preparing end-allyl grouphyperbranched polyether, utilizing a double bond structure of a modified hyperbranched polyetherend group and polysiloxane for hydrosilylation reaction, synthetizing hyperbranched polyether modified polysiloxane, and preparing the defoamer which has an excellent anti-shearing performance.

Owner:合肥新万成环保科技有限公司

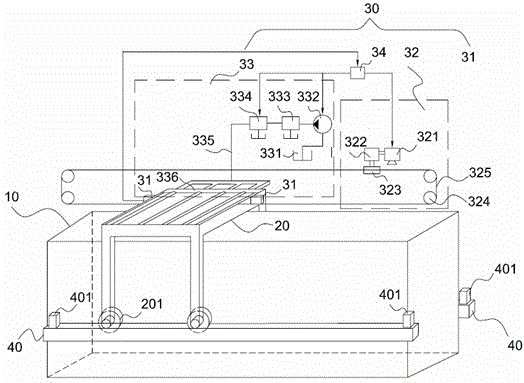

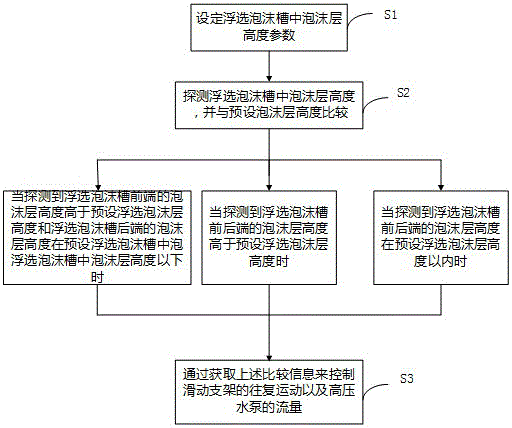

Self-adaptive flotation foam de-foaming device and de-foaming method

ActiveCN104147813ADone successfullyReduce liquidityFoam dispersion/preventionMineral SourcesReciprocating motion

The invention relates to the field of mineral processing flotation equipment, and specifically discloses a self-adaptive flotation foam de-foaming device and a de-foaming method. The device comprises a flotation foam tank, a sliding support arranged on the flotation foam tank, and a self-adaptive control de-foaming system used for controlling the reciprocating movement of the sliding support on the flotation foam tank. According to the invention, the de-foaming method is an advanced, high-efficiency, pollution-free and continuous novel flotation foam removing method. With the device and the method, a foam control difficulty caused by large foam amount, viscous foam, and low foam fluidity when a collecting agent such as amine is used in mineral flotation is solved. With the method, flotation process work can be completed smoothly, sorting index can be improved, and high-efficiency processing and comprehensive utilization of the type of mineral resource can be realized.

Owner:KUNMING UNIV OF SCI & TECH

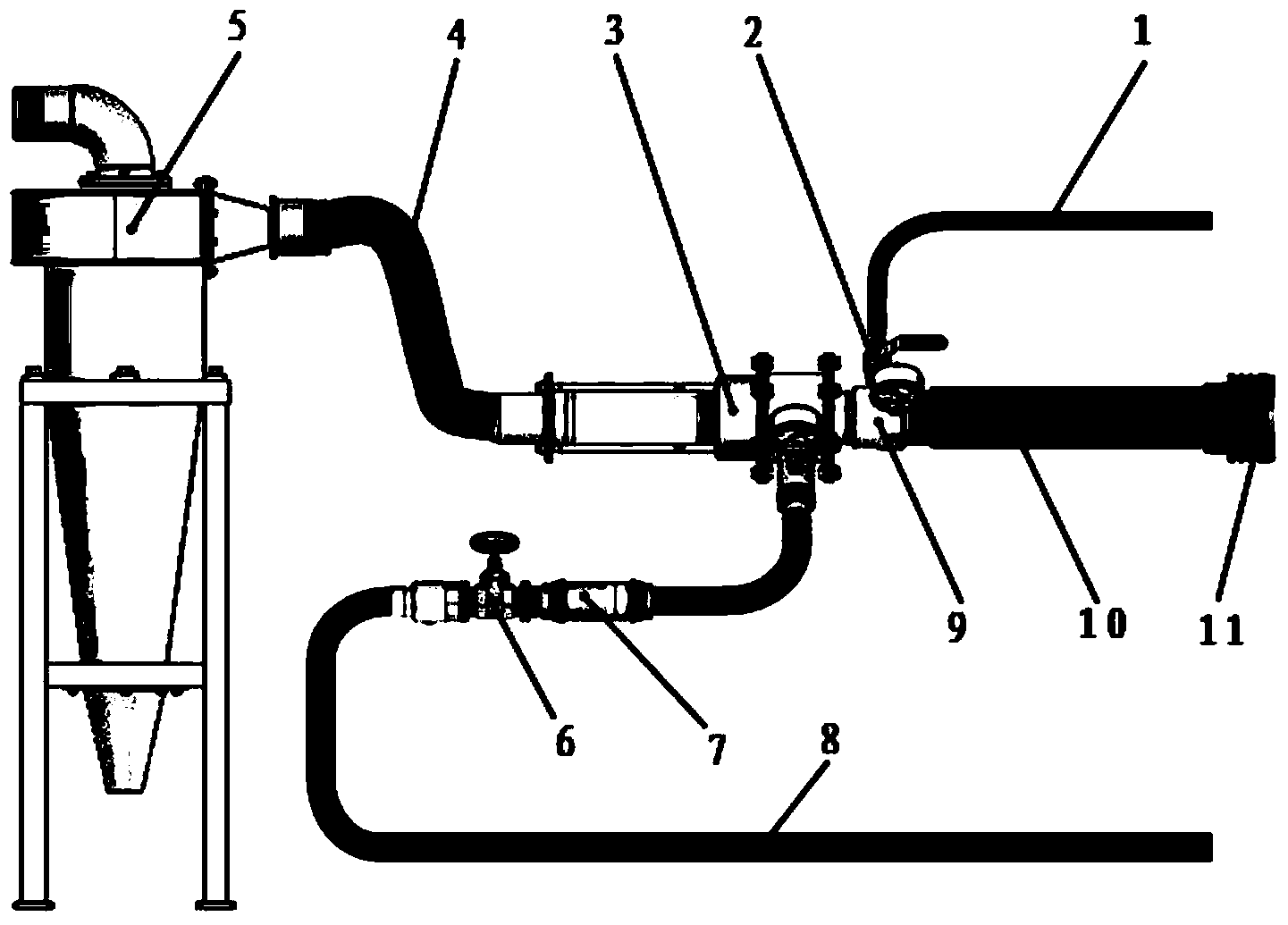

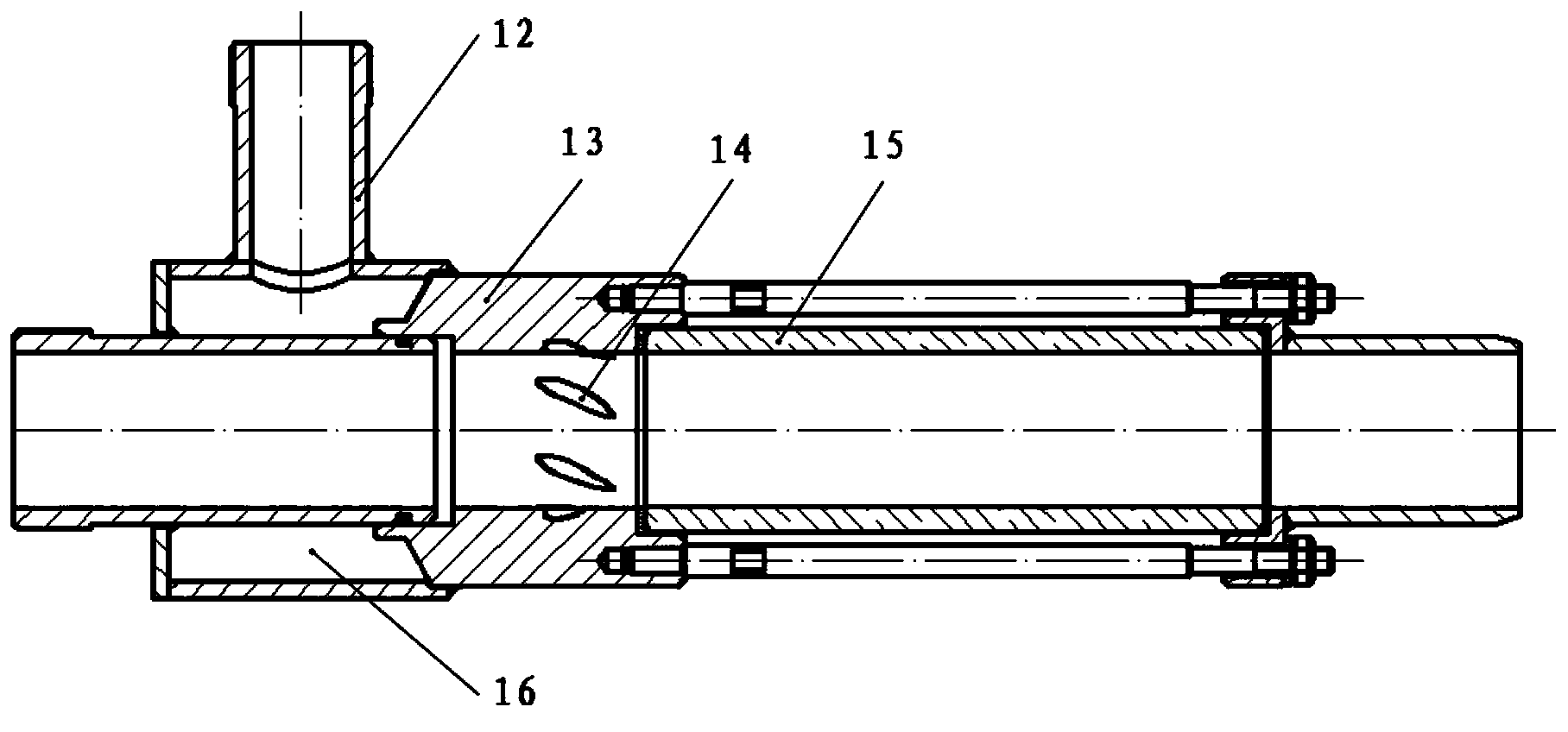

Defoaming device and method for coal-mine foam drilling

The invention discloses a defoaming device and method for coal-mine foam drilling. When a foam drilling process is utilized to perform construction of bedding gas drainage long boreholes among soft coal seams in the coal mine, the problems that waste foam accumulates in the drilling field for a long time and normal drilling construct operations are affected exist. According to the defoaming method, compressed air is adopted as a motive medium, wall-adherent jet is adopted as one single motive source, three technical manners of chemical defoaming, air flow jet defoaming and centrifugal defoaming are integrated, and the defoaming method has the advantages of reliable and rapid defoaming; the matching device is free of movable parts and electrical components, the requirements on explosion-proof performance of equipment in coal-mine construction operating environment can be met, and the defoaming device has the advantages of small size, lightweight performance and low requirements on place conditions.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Hyperbranched polyether modified organosilicon defoaming agent with lasting foam inhibiting effect and preparation method thereof

InactiveCN106310727AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionCelluloseEpoxy

The invention discloses a hyperbranched polyether modified organosilicon defoaming agent with a lasting foam inhibiting effect, composed of the following raw materials in parts by weight: 28-45 partsof polysiloxane, 16-26partsof hyperbranched polyether, 20-28 partsof allyl glycidyl ether, 45-60 partsof epoxy propane, 0.3-0.7 partof bimetal cyanide complex, 50-70 partsof isopropanol, 0.3-0.7 partof chloro-platinic acid catalyst, 3-7 partsof superfine aluminum silicate, 1-2partsof sorbitol, 1-2 partsof tween 60, 2-4 partsof sodium cellulose glycolate, an appropriate amount of de-ionized water, 4-10 partsof white carbon black, 1-2 partsof methyl triethoxy silane, 0.5-1partof ammonium carbonate and 0.6-2 partsof potassium hydroxide. The hyperbranched polyether modified organosilicon defoaming agent takes the hyperbranched polyether containing a large quantity of hydroxyl groups at the terminals as a raw material to prepare allyl-terminated hyperbranched polyether, and a polyether terminal modified double bond structure is used to generate silicon hydrogen addition reaction with the polysiloxane to synthesize hyperbranched polyether modified polysiloxane, and the defoaming agent has excellent shear resistant performance.

Owner:合肥新万成环保科技有限公司

A preparing method of an ethylene oxide-epoxypropane composite antifoaming agent

ActiveCN105498300AShorten the lengthGuaranteed stabilityFoam dispersion/preventionEthylene DibromidePolydimethylsiloxane

A preparing method of an ethylene oxide-epoxypropane composite antifoaming agent is disclosed. The method includes condensing ethylene oxide and epoxypropane which are adopted as raw materials, adding an alkali for neutralization, blending with polydimethylsiloxane, adding water and emulsifying. According to the method, a novel polymer is formed through condensation of the ethylene oxide and the epoxypropane so as to reduce the length of branch chains and ensure product stability. In addition, a small amount of the polydimethylsiloxane is blended, thus eliminating foams produced due to various reasons, saving the production cost and increasing the defoaming efficiency.

Owner:YIXING FENGYE CHEM CO LTD

Hyperbranched polyether modified polysiloxane defoamer containing nanosilicon dioxide and preparation method thereof

InactiveCN106474775AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionEnd-groupAluminum silicate

The invention discloses a hyperbranched polyether modified polysiloxane defoamer containing nanosilicon dioxide. The hyperbranched polyether modified polysiloxane defoamer is prepared from, by weight, 25-40 parts of polysiloxane, 13-23 parts of hyperbranched polyether, 16-26 parts of allyl glycidyl ether, 38-58 parts of epoxypropane, 0.3-0.5 part of double metal cyanide, 50-70 parts of isopropanol, 0.2-0.5 part of a chloroplatinic acid catalyst, 2-6 parts of ultra-fine aluminum silicate, 1-2 parts of sorbitol, 1-2 parts of tween-60, 2-4 parts of sodium carboxymethylcellulose, an appropriate amount of deionized water, 4-11 parts of nanosilicon dioxide powder and 45-60 parts of dodecyl alcohol. The hyperbranched polyether containing a large number of hydroxyls at the tail end is adopted as a raw material, end-allyl hyperbranched polyether is prepared, a modified polyether end group double-bond structure and polysiloxane are adopted for performing a hydrosilylation reaction, the hyperbranched polyether modified polysiloxane is synthesized, and the defoamer prepared through the hyperbranched polyether modified polysiloxane has the excellent anti-shearing performance.

Owner:合肥新万成环保科技有限公司

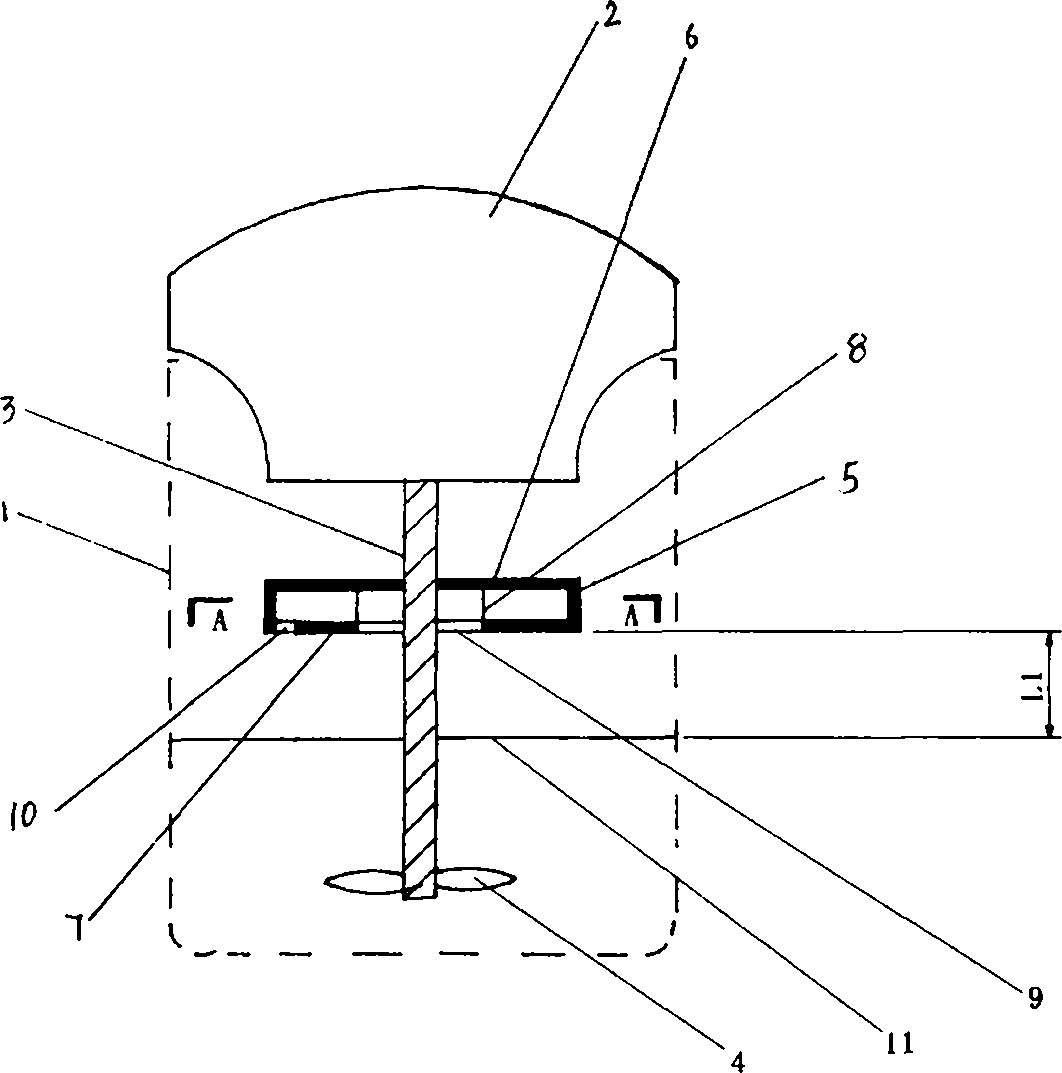

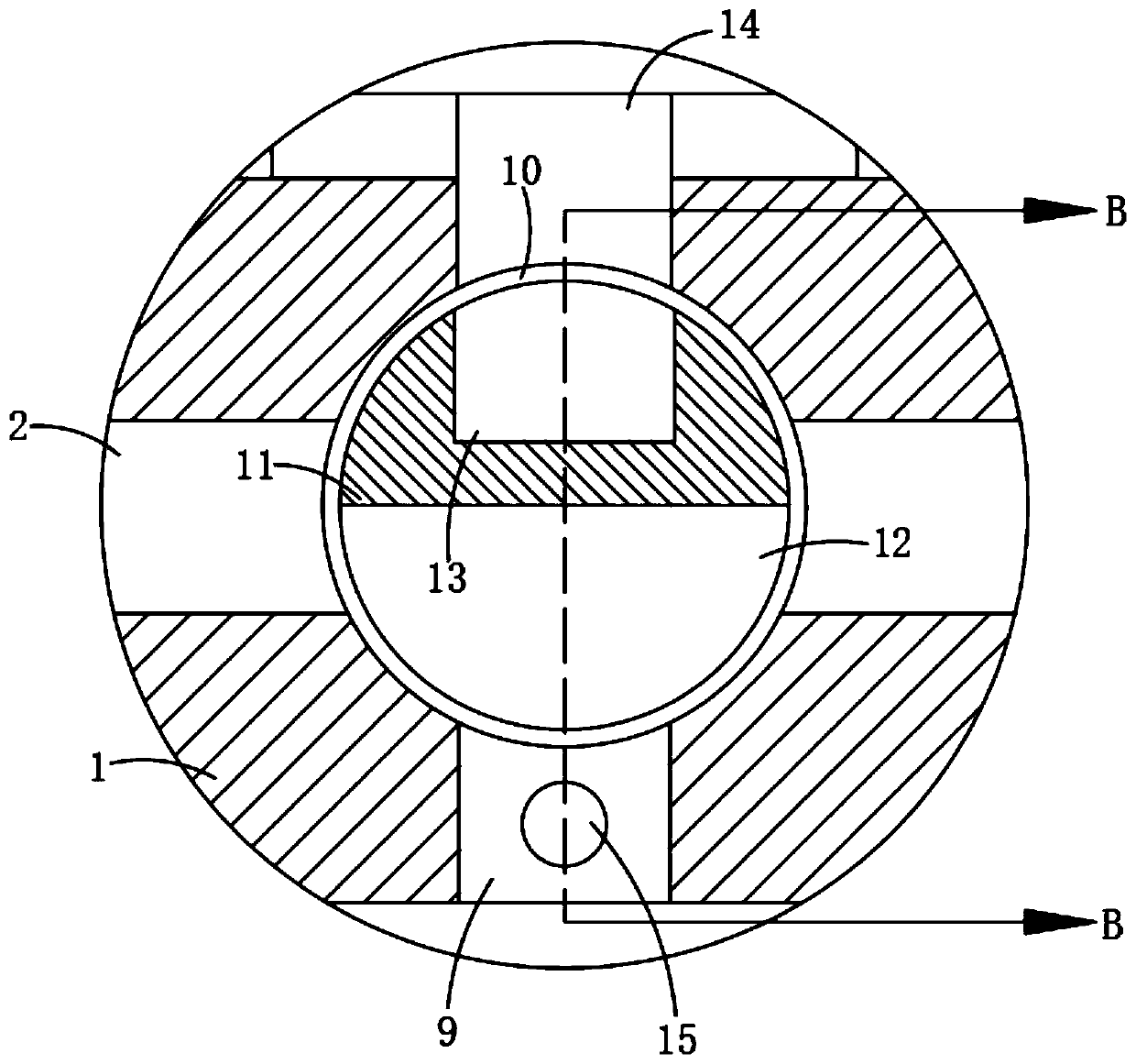

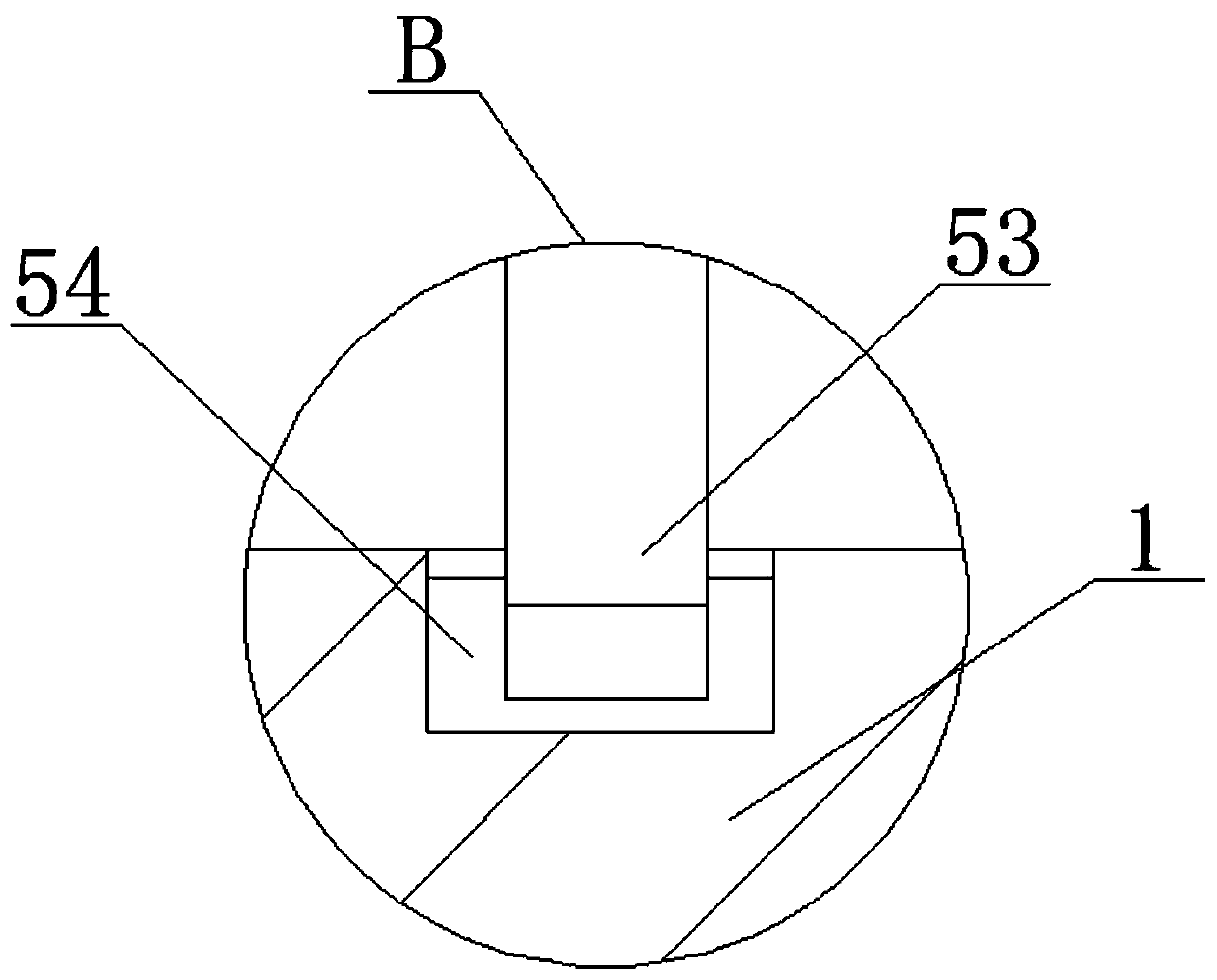

Bubble removing system

ActiveCN105251241ABig spaceSimple structureWater/sewage treatment with mechanical oscillationsLiquid degasification by filtrationEngineeringCavity wall

The invention provides a bubble removing system. The bubble removing system comprises a main bubble removing apparatus; the main bubble removing apparatus comprises a first enclosed container, a main gelatin inlet pipe, a main gelatin outlet pipe and a bubble colleting member; the cross section of the inner cavity of the first enclosed container is circular, and the first enclosed container is used for accommodating gelatinoids; the main gelatin inlet pipe penetrates the sidewall of the first enclosed container and is tangent to the inner cavity wall of the first enclosed container and arranged on the upper part of the first enclosed container; the main gelatin outlet pipe penetrates the sidewall of the first enclosed container and is arranged on the lower part of the first enclosed container; and the bubble colleting member comprises a hollow bubble collecting part and a communicating part, the bubble collecting part is arranged at the central part of the top of the inner cavity of the first enclosed container to collect gelatinoids located at the top of the first enclosed container and rich in bubbles, and the communicating part is arranged out of the first enclosed container and communicated with a hollow part of the bubble collecting part. The bubble removing system can highly efficiently remove bubbles in the gelatinoids.

Owner:BOE TECH GRP CO LTD +1

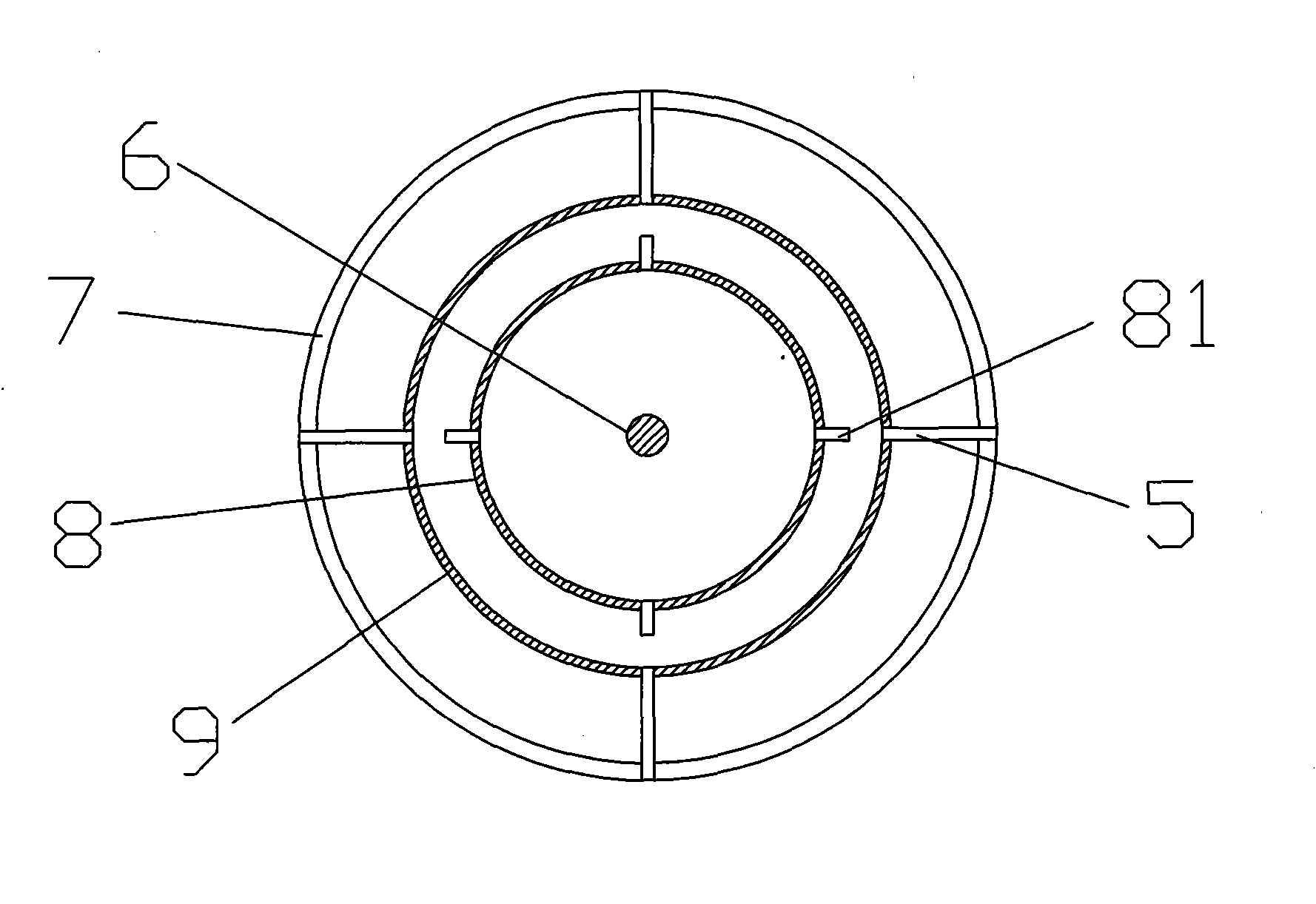

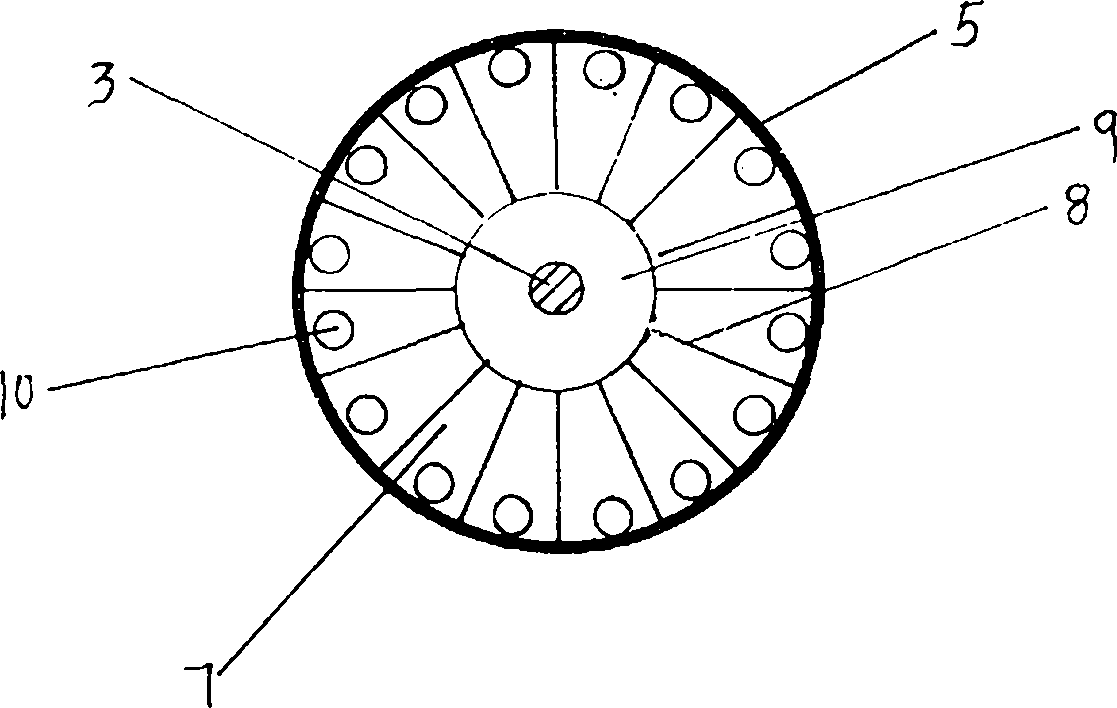

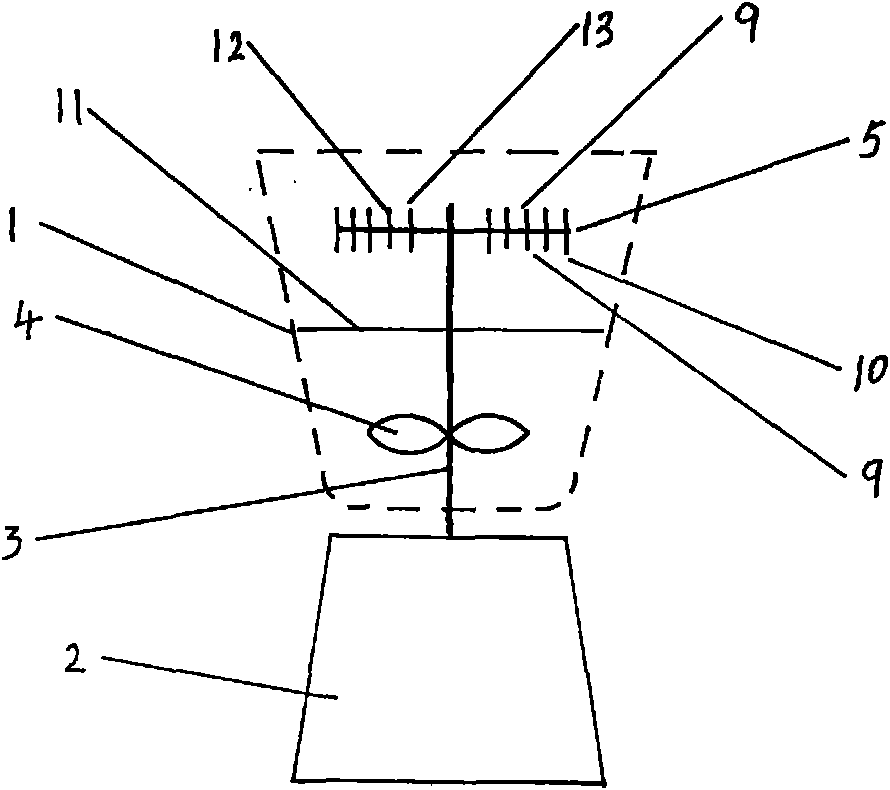

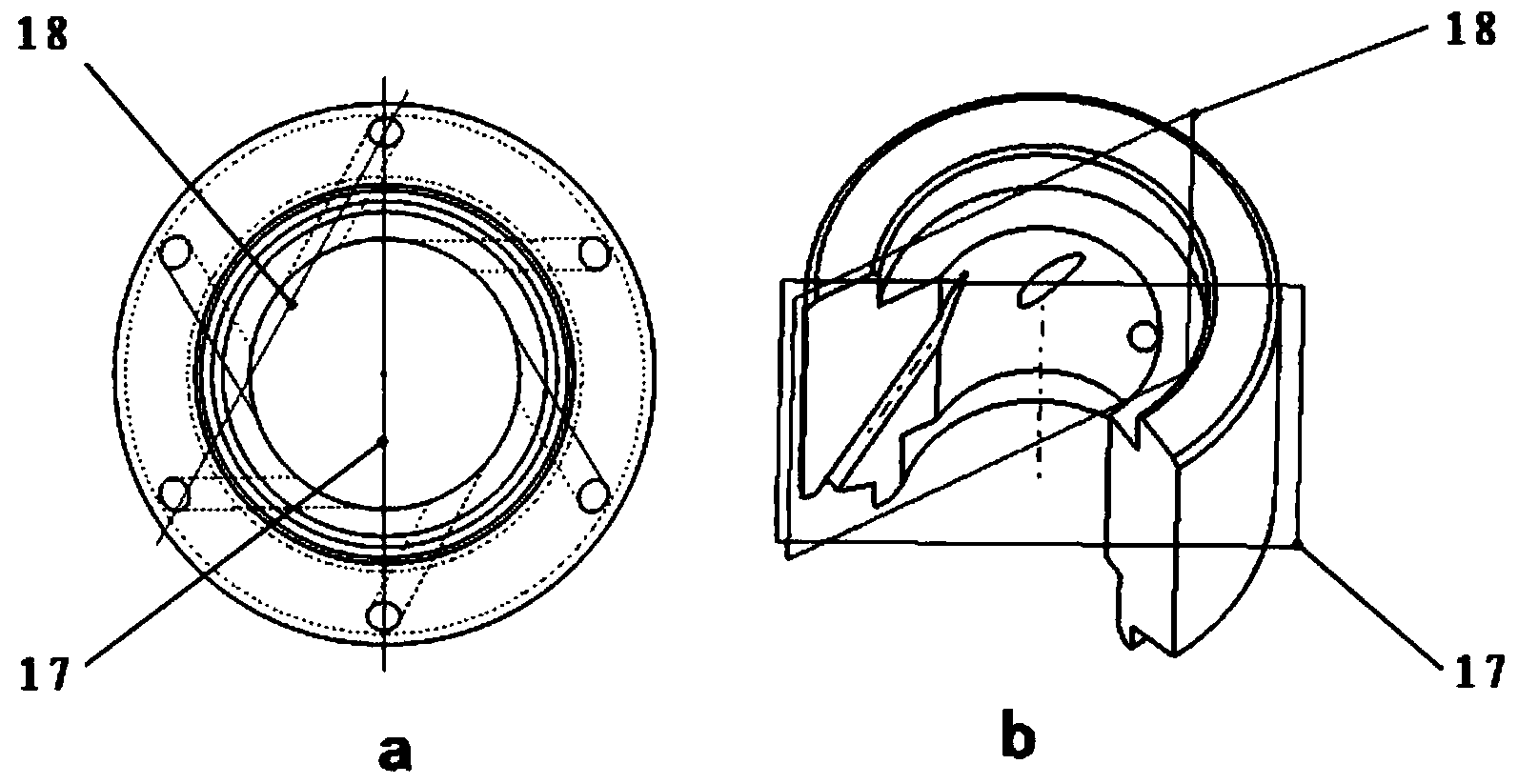

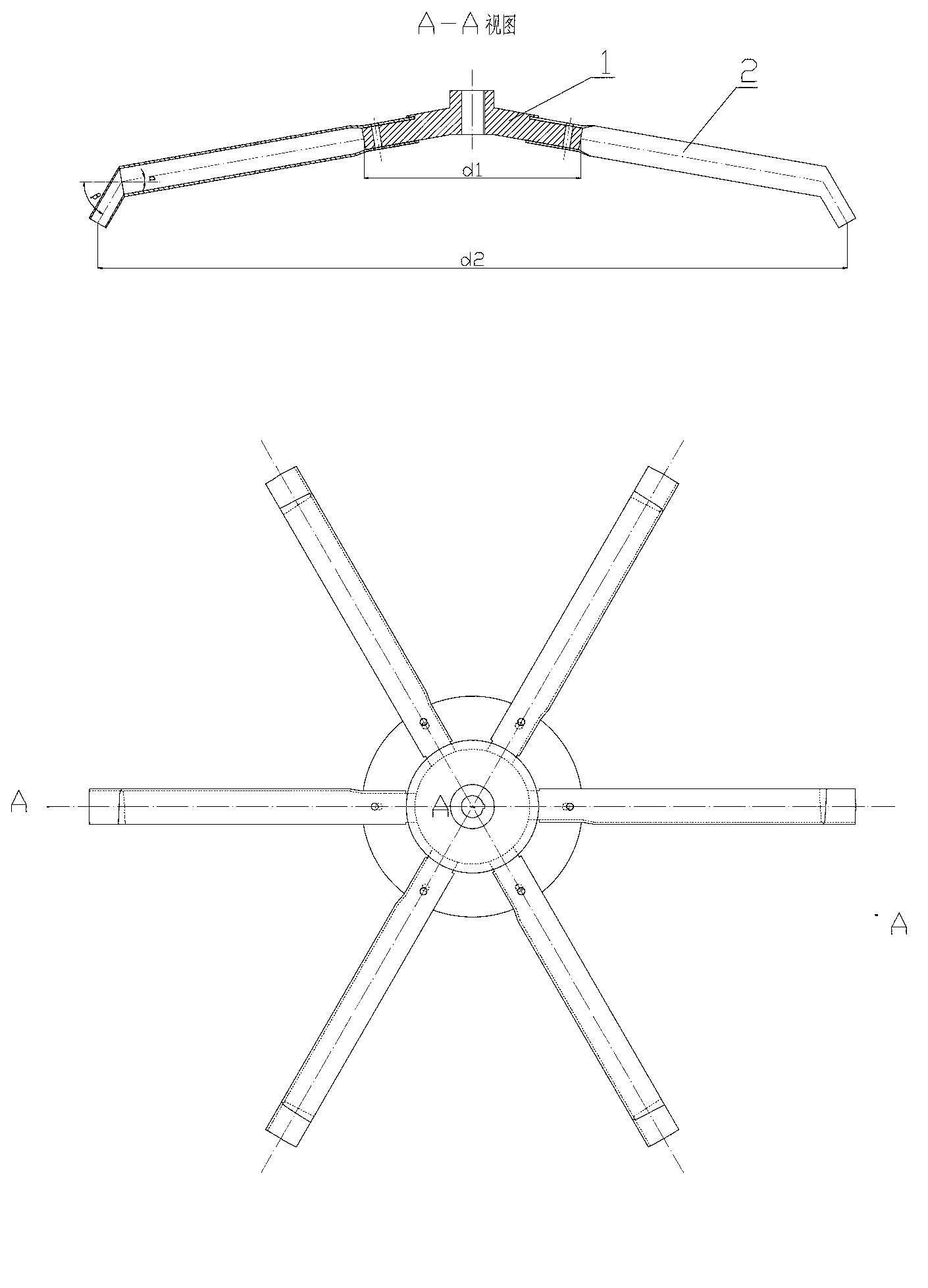

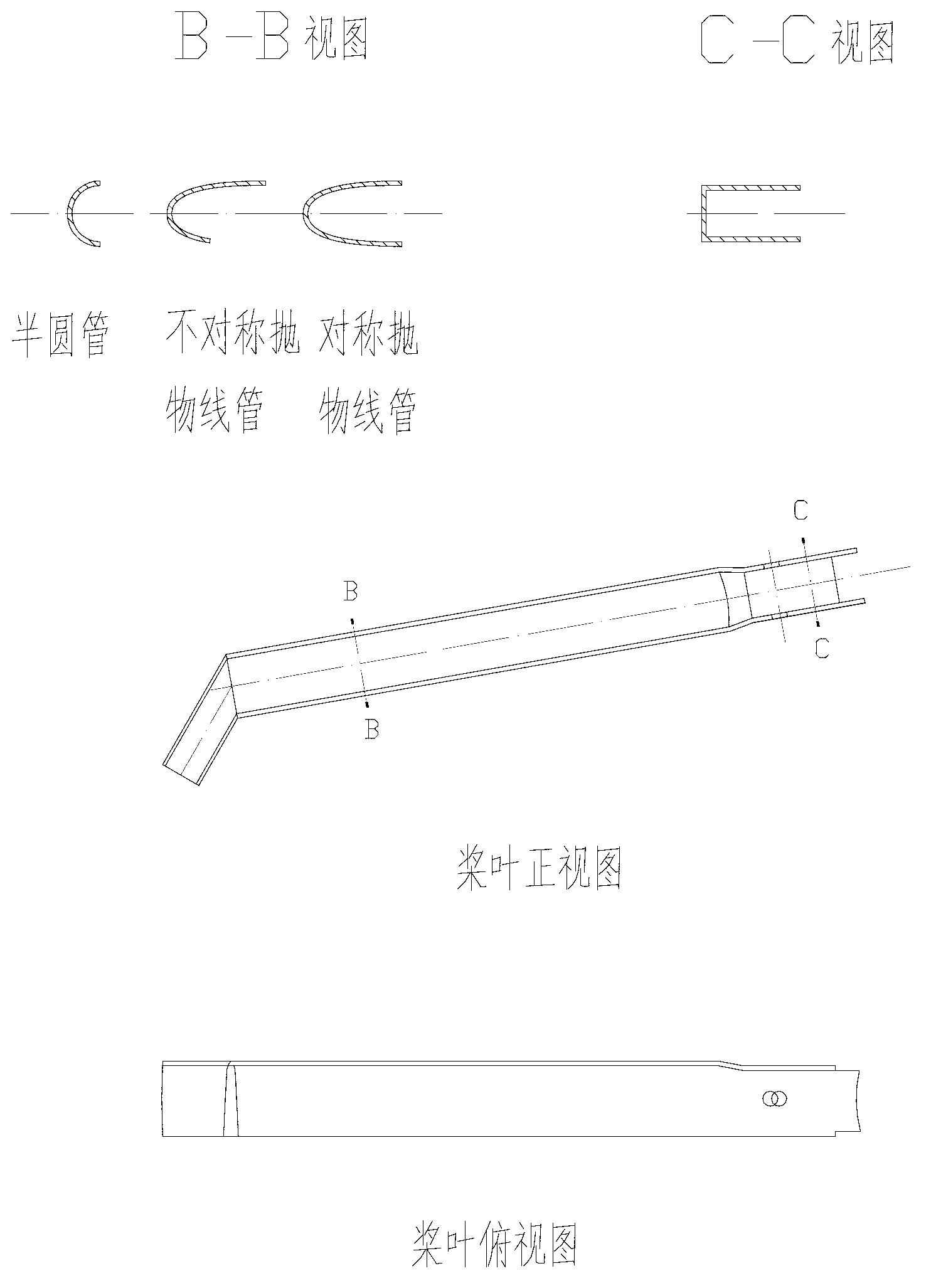

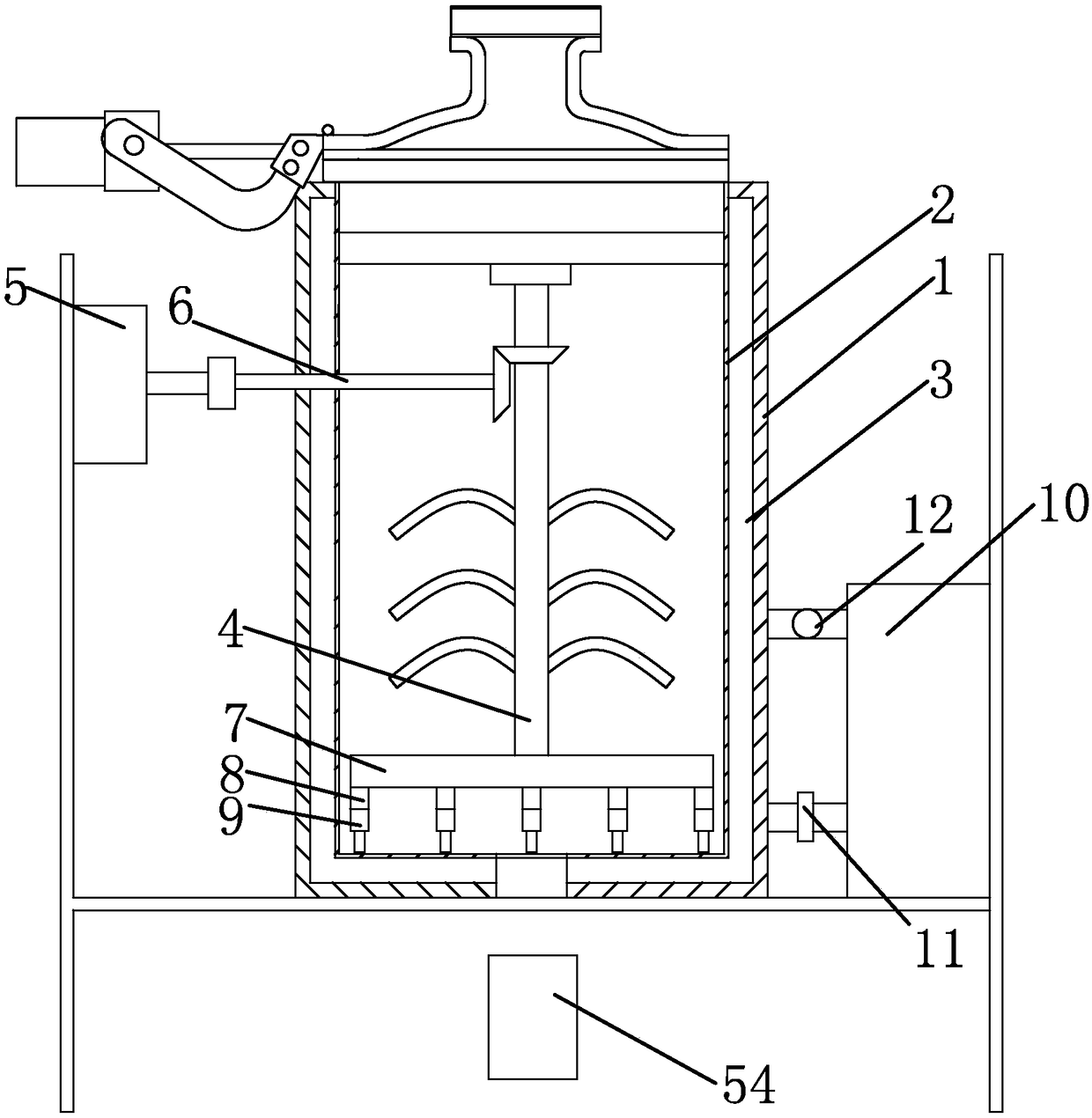

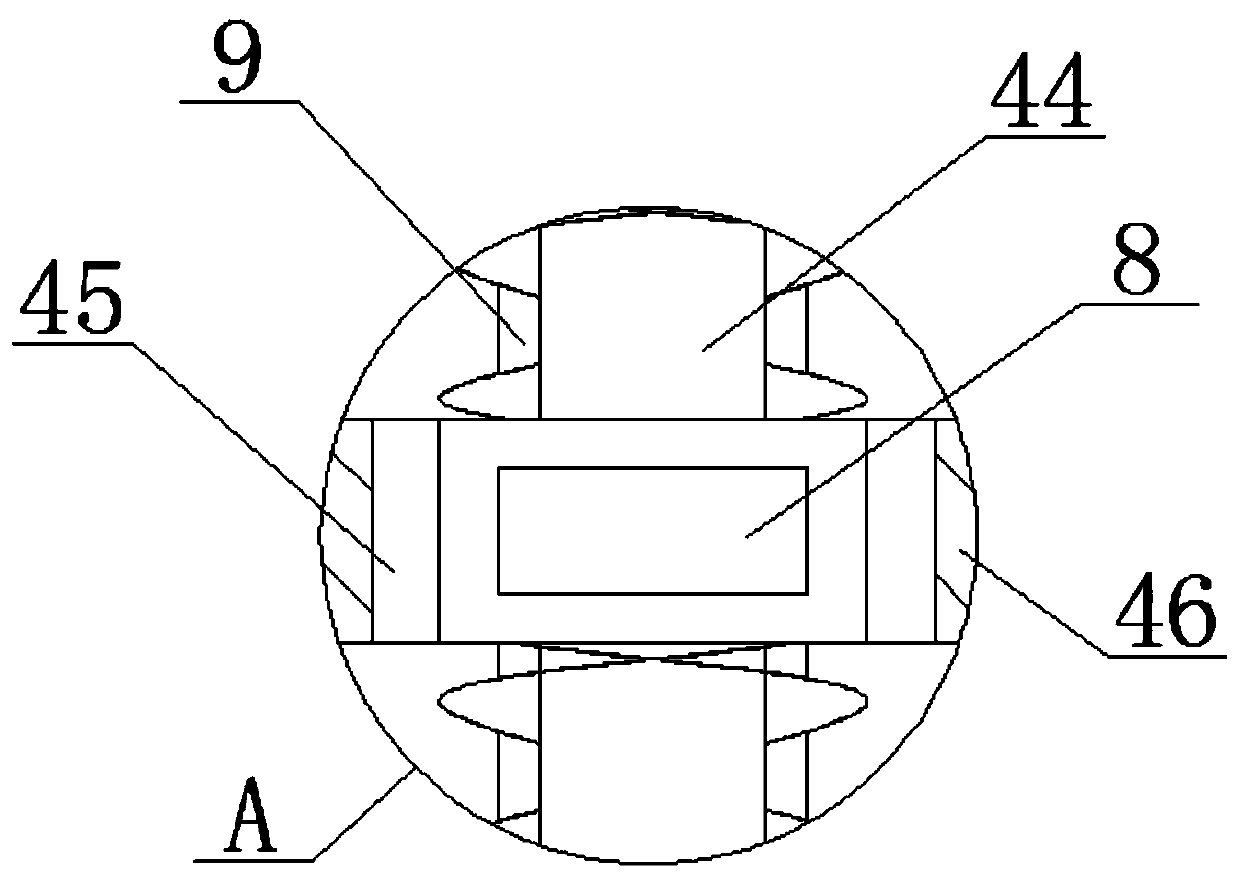

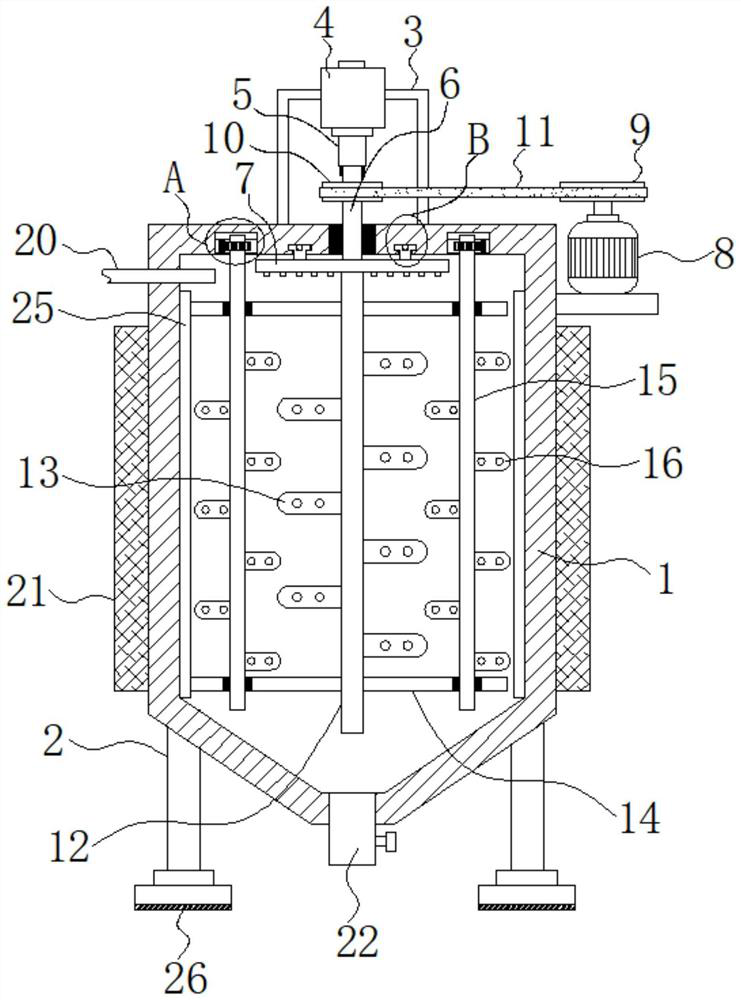

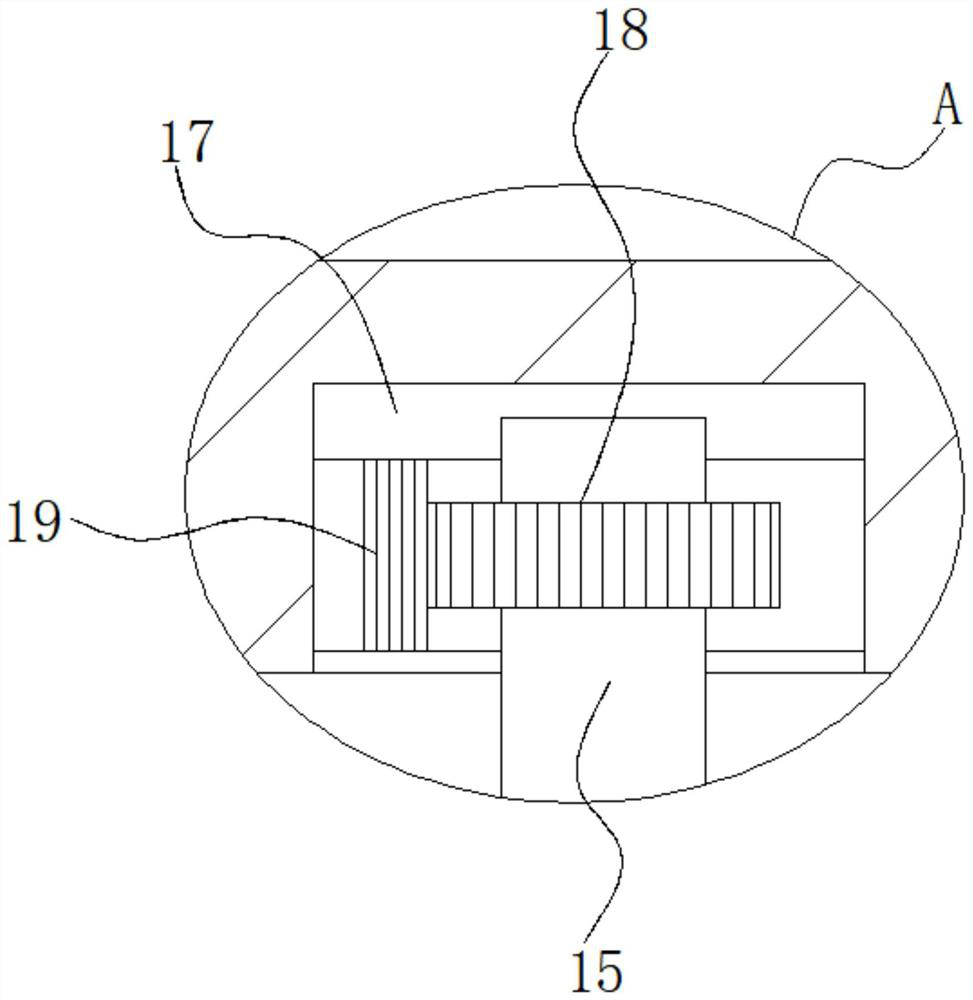

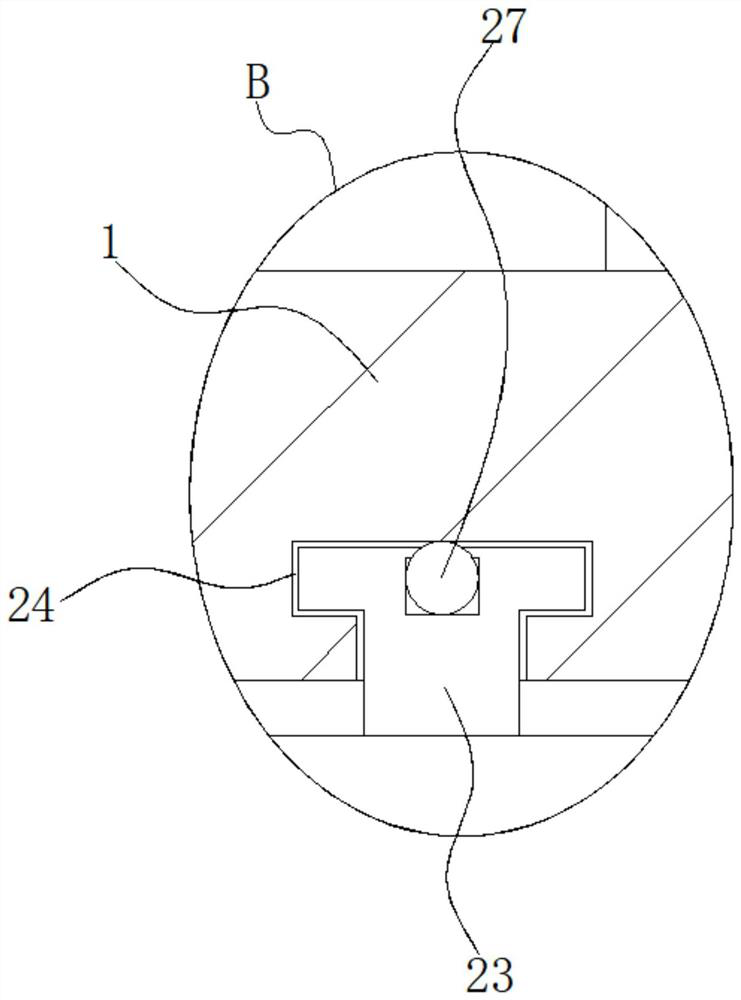

Mechanical defoaming device applied to stirred tank reactor

InactiveCN103055551AAvoid stickingEasy to cleanChemical/physical/physico-chemical stationary reactorsFoam dispersion/preventionEngineeringCentrifugal force

The invention discloses a mechanical defoaming device applied to a stirred tank reactor and belongs to the technical field of chemical machinery. The mechanical defoaming device comprises a hub and a paddle, wherein the center of the hub is a hollow cylinder; the periphery of the hub is provided with a cone frustum and has an included angle downwards; the section of the blade is a semicircular tube type groove, a symmetric parabolic groove or an asymmetric parabolic groove; 4-16 paddles are symmetrically arranged on the hub; the tail end of the paddle is provided with a downwards inclined liquid guide rail, so that the defoamed liquid is injected into the liquid level; the defoaming device is arranged on a stirring shaft in the tank and rotates along with the stirring shaft together; and the raising foam in the reaction kettle is captured by the paddle groove of the defoaming device and is pushed to the tail end of the paddle under the action of the centrifugal force. Because the hub and the paddle are downwards inclined, the foam facilitates the liquid film to discharge liquid in the motion process, and the film is compressed, sheared and crushed. A super-hydrophobic material is coated on the surface of the paddle, and the defoaming effect is improved. The paddle structure is simple, can be pressed and formed by the plates, can be manufactured into different specifications and sizes according to the requirements and is low in manufacturing cost.

Owner:JIANGNAN UNIV

Vacuum defoaming device and defoaming method for high-viscosity liquid

PendingCN110141889ASpeed up film formationSpeed up the flowLiquid degasificationEngineeringThin film flow

The invention discloses a vacuum defoaming device and a defoaming method for high-viscosity liquid. The vacuum defoaming device is provided with two opposite defoaming baffles and a large-area spiralplate; so high-viscosity liquid is always in the state of a thin-film flow layer, which allows the surface area and the surface tension of the high-viscosity liquid to be greatly increased and bubblesto be effectively eliminated; and the low-speed rotation of the spiral plate accelerates the film formation speed and the flowing speed of the high-viscosity liquid, and the rotational shear force generated by the spiral plate can also eliminate bubbles. The defoaming method of the invention adopts multiple defoaming manners, and performs efficient and stable defoaming through a combination of acertain degree of vacuum, the rotating speed of the spiral plate and the flow control of feed and discharge flow valves. According to a technical scheme described in the invention, the vacuum defoaming device has the advantages of simple structure, simple operation, low energy consumption, low cost, high defoaming efficiency and the like, is suitable for defoaming of high-viscosity liquid, and canprotect high-viscosity liquid from the adverse impact of high temperature, defoaming agent and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

High-temperature-resistant and alkali-resistant hyperbranched polyether modified organic silicon defoamer and preparation method thereof

InactiveCN106390532AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionAluminum silicateDouble bond

The invention discloses a high-temperature-resistant and alkali-resistant hyperbranched polyether modified organic silicon defoamer. The defoamer is prepared from raw materials in parts by weight as follows: 25-40 parts of polysiloxane, 16-24 parts of hyperbranched polyether, 17-25 parts of allyl glycidyl ether, 42-57 parts of propylene oxide, 0.3-0.5 parts of a bimetal cyanided complex, 50-70 parts of isopropyl alcohol, 0.2-0.6 parts of a chloroplatinic acid catalyst, 3-6 parts of superfine aluminum silicate, 1-2 parts of sorbitol, 1-2 parts of Tween 60, 2-4 parts of sodium carboxymethyl cellulose, a proper amount of deionized water, 1-3 parts of wollastonite, 2-3 parts of nano silicon oxide and 3-5 parts of sodium p-styrene sulfonate. Hyperbranched polyether containing a lot of hydroxyl groups at tail ends is used as the raw material, allyl-terminated hyperbranched polyether is prepared, a modified hyperbranched polyether-terminated double bond structure and polysiloxane are subjected to a hydrosilylation reaction, hyperbranched polyether modified polysiloxane is synthesized, and the defoamer prepared from the hyperbranched polyether modified polysiloxane has excellent shear resistance.

Owner:合肥新万成环保科技有限公司

Self-defoaming microbial sewage treatment tank

ActiveCN110615522AGood defoaming effectWide range of defoamingTreatment using aerobic processesSustainable biological treatmentHigh pressureHigh frequency vibration

The invention discloses a self-defoaming type microbial sewage treatment tank. The tank comprises a tank body, wherein an aeration pipe is embedded into the inner bottom of the tank body; a pluralityof air outlet holes communicated with the aeration pipe are formed in the side wall of the tank body; a first one-way valve is installed in a gas outlet hole; a stainless steel pipe is rotatably connected to the inner bottom of the tank body; a sliding block is slidably connected to the inner wall of the stainless steel pipe in a sealed mode; a water inlet is formed in the upper end of the stainless steel pipe; and a second one-way valve is installed in the water inlet. According to the treatment tank, high-speed high-pressure gas is introduced into the gas inlet hole to push the sliding blockto move upwards, then water flowing into the stainless steel pipe from the water inlet can be sprayed out through the spraying pipe and sprayed on the water surface, so that water spraying defoamingcan be carried out, complex equipment does not need to be laid, meanwhile, the sliding block is pushed by gas to move upwards in the stainless steel pipe to spray water, high-frequency vibration generated when the water pump works cannot be generated, a large amount of foam cannot be generated, and the defoaming effect is good.

Owner:BEIJING HUAMING GUANGYUAN ENVIRONMENT TECH

Cyclodextrin-modified polyether-grafted polysiloxane defoamer and preparation method thereof

InactiveCN106422428AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionAluminum silicateDouble bond

The invention discloses a cyclodextrin-modified polyether-grafted polysiloxane defoamer and a preparation method thereof. The cyclodextrin-modified polyether-grafted polysiloxane defoamer comprises the following raw materials in parts by weight: 25-40 parts of polysiloxane, 14-21 parts of hyperbranched polyether, 16-25 parts of allyl glycidyl ether, 42-58 parts of propylene oxide, 0.3-0.6 part of a bimetallic cyanide complex, 50-70 parts of isopropanol, 0.2-0.7 part of a chloroplatinic acid catalyst, 3-7 parts of superfine aluminum silicate, 1-2 parts of sorbitol, 0.8-2 parts of tween 60, 2-4 parts of sodium carboxymethyl cellulose, a proper amount of deionized water and 6-10 parts of alpha-cyclodextrin. The hyperbranched polyether containing a large number of hydroxyl groups at terminals is used as a raw material for preparing terminated allyl hyperbranched polyether, and a hydrosilylation reaction is performed on double-bond structures of terminal groups of the modified hyperbranched polyether and the polysiloxane to synthesize hyperbranched polyether-modified polysiloxane; the prepared defoamer has excellent shear resistance.

Owner:合肥新万成环保科技有限公司

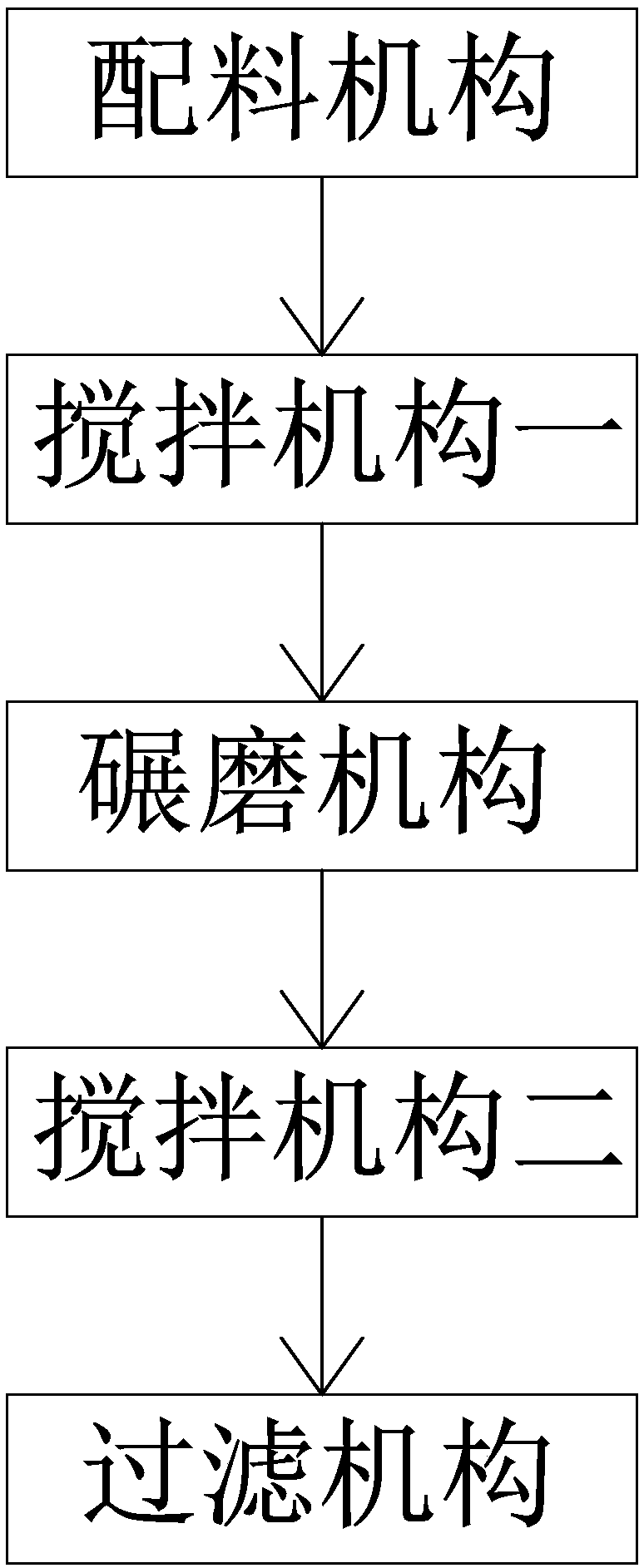

Production line for silver paste

PendingCN108079884AImprove production efficiencyReduce the number of replacementsTransportation and packagingRotary stirring mixersSilver pasteManufacturing line

The invention provides a production line for silver paste, and belongs to the technical field of silver paste preparation. The production line solves a problem of low productivity in the prior art. The production line for the silver paste comprises a frame, the frame is provided with a feeding end and a discharging end, and a proportioning mechanism capable of preparing the silver paste, a stirring mechanism1 capable of stirring the silver paste, a grinding mechanism capable of grinding the silver paste, the stirring mechanism 2 capable of stirring the silver paste, and a filtering mechanism capable of filtering the silver paste are arranged from the feeding end to the discharging end sequentially. The production line for the silver paste has the advantages of high production efficiency.

Owner:ZHEJIANG KAIYING NEW MATERIAL

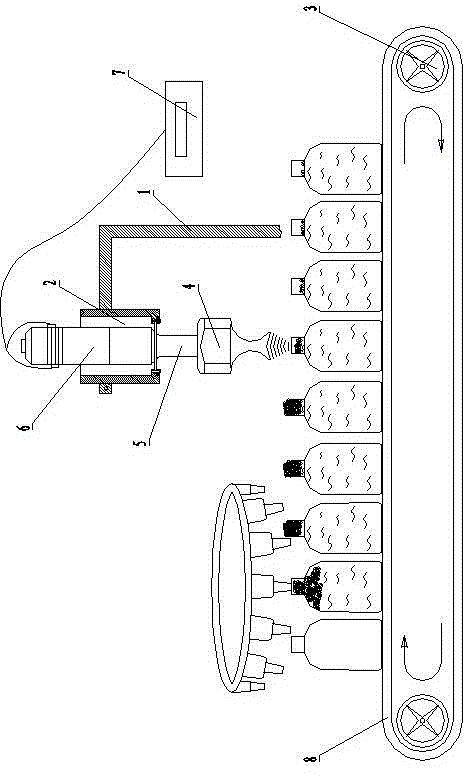

Filling production line for defoaming by using ultrasonic wave

InactiveCN104609350AReduce pollutionWarranty against materialEnergy based chemical/physical/physico-chemical processesLiquid bottlingEngineeringConveyor belt

The invention relates to a filling production line for defoaming by using ultrasonic wave. The filling production line comprises an ultrasonic generation device and a conveyor belt device, wherein the ultrasonic generation device comprises a tool head which is sequentially connected with an amplitude-change pole, an ultrasonic transducer and an ultrasonic drive power supply; the conveyor belt device comprises a conveyor belt; the conveyor belt is positioned below the ultrasonic generation device; a central axis of the tool head is vertical to the central axis of the conveyor belt; the lower end face of the tool head is parallel to the surface of the conveyor belt; a pot mouth liquid level of a pot body on the conveyor belt is not contacted with the lower end face of the tool head. The invention provides a convenient and efficient defoaming technology specially used for the filling production line. In the entire defoaming process, a defoamer is not used, a manner of in-container vacuumizing limited by container is not adopted, and the automation technology of defoaming the pot mouth liquid level by the filling production line is realized through pushing effect of the automated conveyor belt and the wave focusing effect of the tool head.

Owner:HANGZHOU SUCCESS ULTRASONIC EQUIP

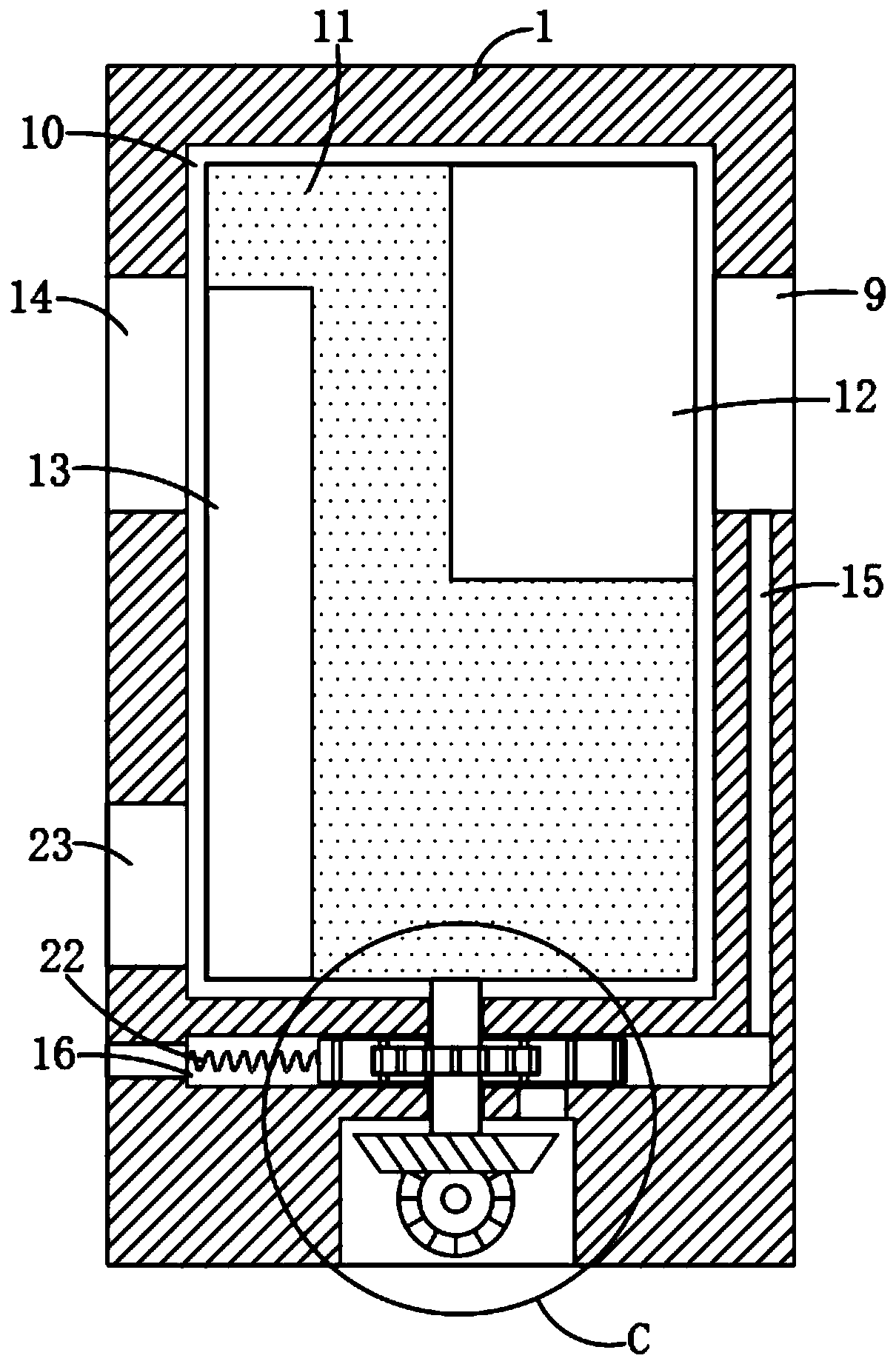

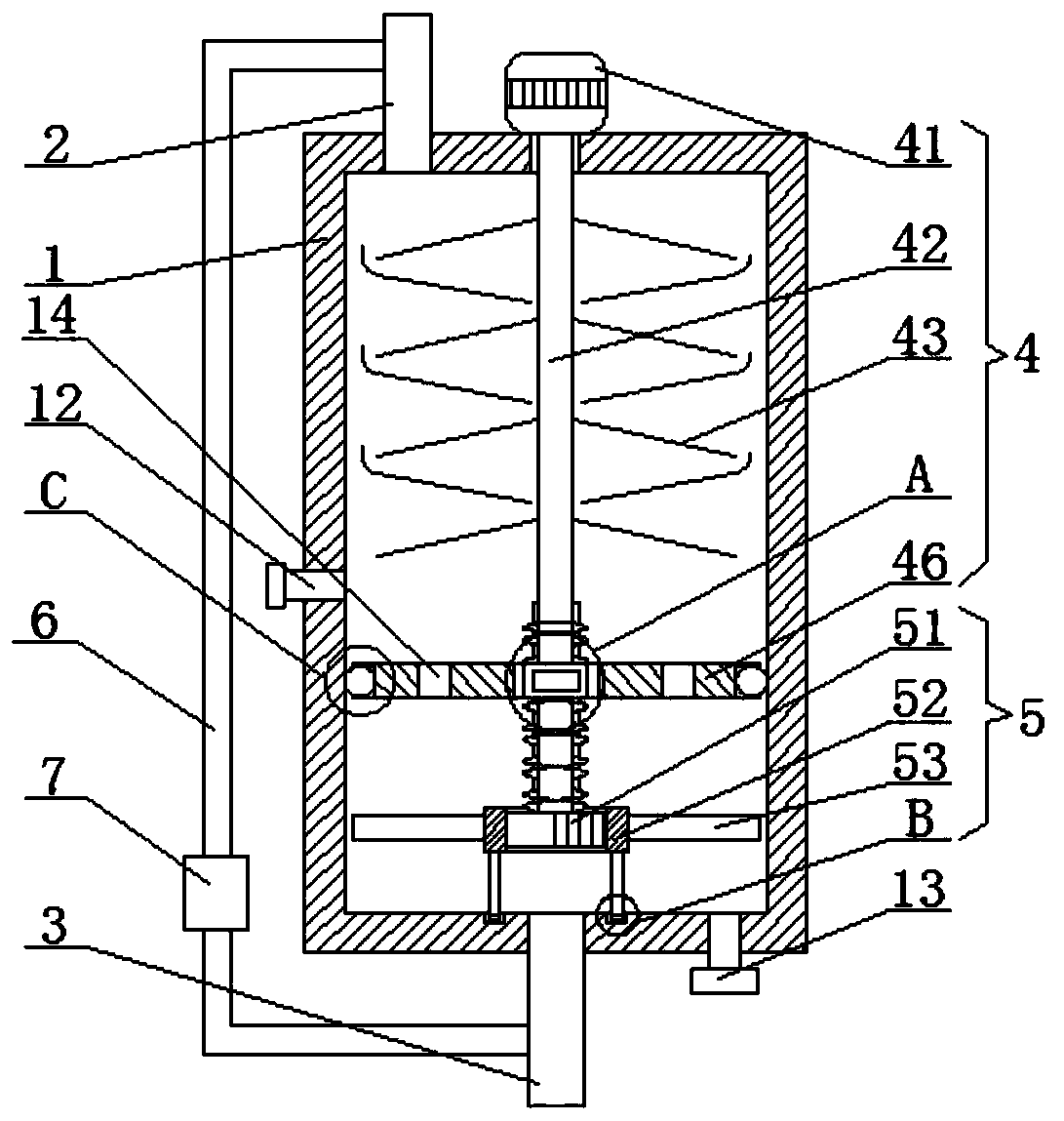

Vacuum defoamation device used for producing high-polymer material

InactiveCN110124358AWell mixedImprove defoaming efficiencyShaking/oscillating/vibrating mixersTransportation and packagingCouplingEngineering

The invention relates to the technical field of vacuum defoamation, and discloses a vacuum defoamation device used for producing a high-polymer material. The vacuum defoamation device used for producing the high-polymer material comprises a tank, wherein a material inlet is formed in the top of the tank, a material outlet is formed in the bottom of the tank, the material inlet and the material outlet are connected through a circulation mechanism, and a defoamation and mixing mechanism is fixedly connected with the tank; and the defoamation and mixing mechanism comprises a driving motor, a rotating shaft, inclined defoamation layers, a reciprocating screw, a ball nut and a mixing board, the driving motor is fixedly connected with the center of the upper end of the tank, a rotating hole is formed in the center of the upper end of the tank, one end of the rotating shaft is connected with an output end of the driving motor through a coupler, the end, away from the driving motor, of the rotating shaft penetrates through the rotating hole, and extends into the tank, the inclined defoamation layers are installed on the rotating shaft, and one end of the reciprocating screw is connected with the end, away from the driving motor, of the rotating shaft. By means of the vacuum defoamation device used for producing the high-polymer material, the high-polymer material in the tank is fully mixed and stirred, so that the defoamation efficiency is improved.

Owner:马鞍山久特新材料科技有限公司

Liquid crystal panel defoaming equipment

InactiveCN104407458AImprove defoaming efficiencyNo air tightness requirementNon-linear opticsLiquid-crystal displayEngineering

The invention relates to liquid crystal panel defoaming equipment which comprises an adsorption unit for adsorbing a panel, and a pressurizing unit for providing compressed air which acts on the surface of the panel to realize defoaming. The liquid crystal panel defoaming equipment has the beneficial effects of opened type high-pressure defoaming, no airtight requirement and high defoaming efficiency.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Paint defoaming device

The invention relates to the technical field of paint production equipment, and discloses a paint defoaming device. The paint defoaming device comprises a barrel, wherein the bottom of the barrel is of a conical structure; a plurality of supporting legs are fixedly connected to the bottom of the barrel; the top of the barrel is fixedly connected with a vacuum pump through a bracket; the input endof the vacuum pump is fixedly connected with an exhaust pipe; the bottom end of the exhaust pipe is rotationally connected with a rotating pipe through a first sealing bearing; the other end of the rotating pipe penetrates through the center of the top of the barrel and extends downwards to fixedly communicate with a transverse pipe; the lower surface of the transverse pipe communicates with a plurality of evenly-distributed extraction openings; the rotating pipe is rotationally connected with the top of the barrel through a second sealing bearing; a supporting plate is fixedly connected to the outer side wall, close to the top, of the barrel; a driving motor is fixedly installed on the supporting plate; and an output shaft of the driving motor is fixedly connected with a driving chain wheel. According to the paint defoaming device, paint can be conveniently, comprehensively and fully stirred, so the defoaming effect of paint is effectively guaranteed.

Owner:马鞍山采石矶涂料有限公司

Method for preparing foam killer

ActiveCN101376089BEasy to prepareLong hydrophilic linkTransportation and packagingMixingEpoxyGlycerol

The invention discloses a preparation method of a deformer. The method comprises the following steps: polymerizing glycerin into polyglycerol with the average polymerization degree of 2 to 15 under the effect of a catalyst; carrying out ring opening polymerizing reaction among polyglycerol, propylene oxide and epoxy ethane to get polyglycerol polyalkoxy ether; and conducting esterification reaction between polyglycerol polyalkoxy ether and C12 to C22 fatty acid to get the deformer. The preparation method is easy to operate and has low cost; and the deformer produced by using the method has excellent deforming effect and can be widely applied into use.

Owner:威尔(福建)生物有限公司 +1

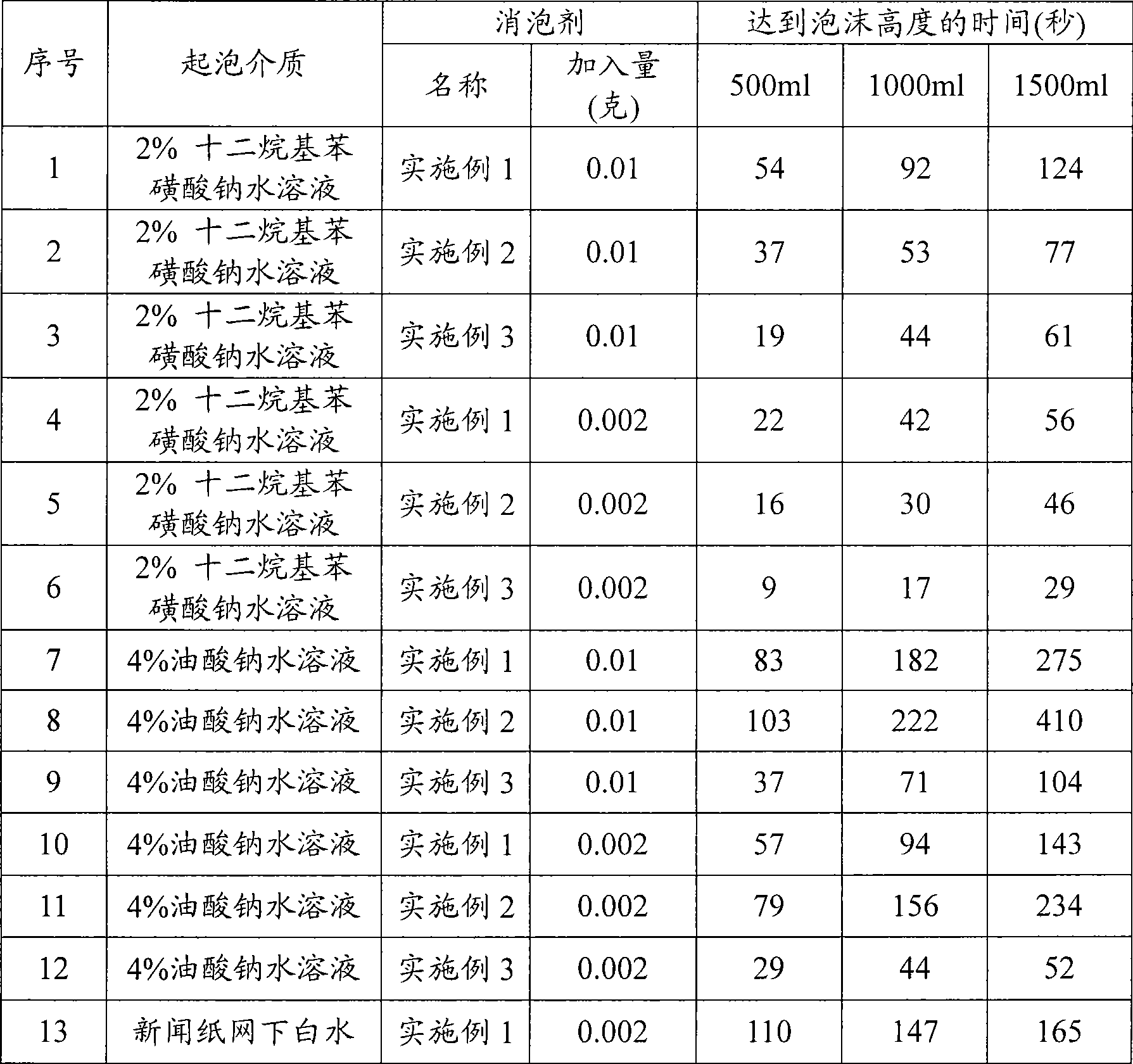

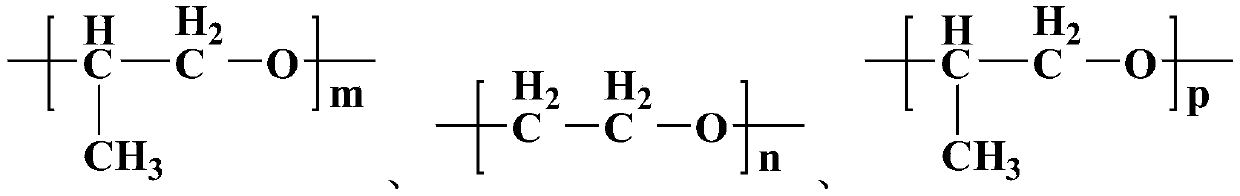

Preparation method of high-molecular-weight block polyether, silyl ether mixed defoaming agent and preparation method thereof

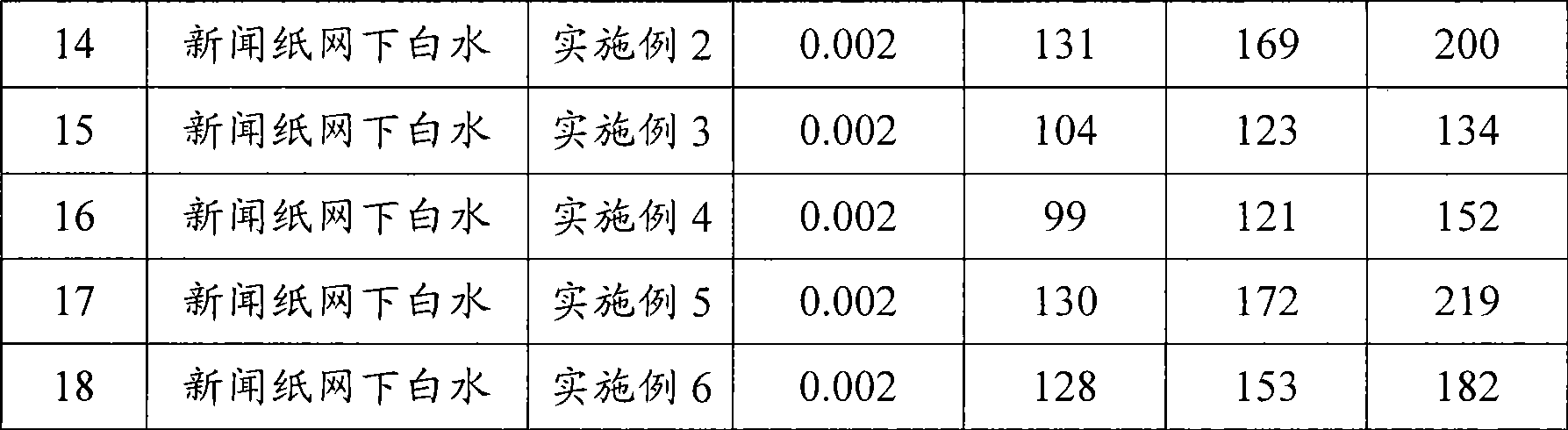

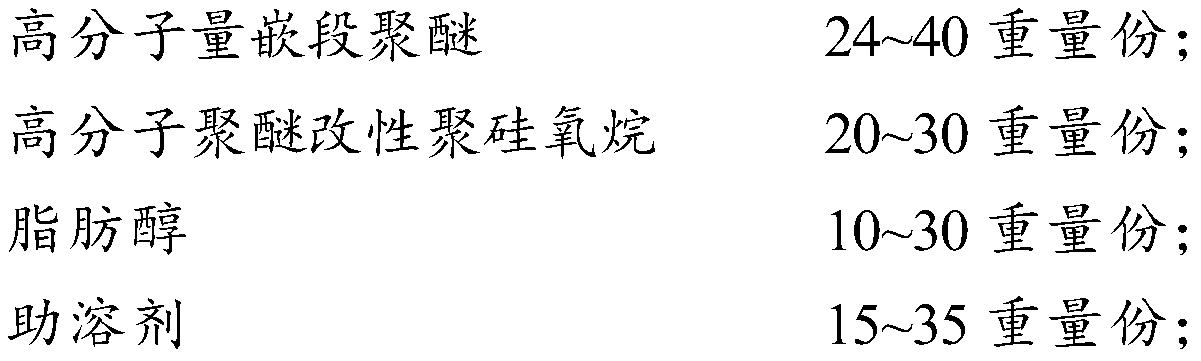

PendingCN111019116ANot easy to decomposeLong foam suppression timeFoam dispersion/preventionAlkanePolymer science

The invention provides a silyl ether mixed defoaming agent. The silyl ether mixed defoaming agent comprises the following components in parts by weight: 24-40 parts of high molecular weight block polyether; 20-30 parts of polymer polyether modified polysiloxane; 10-30 parts of fatty alcohol; and 15-35 parts by weight of a cosolvent; wherein the high-molecular-weight block polyether is obtained bypolymerizing polyol and alkylene oxide; wherein the high-molecular silyl ether modified polysiloxane is prepared from high-molecular-weight block polyether modified polysiloxane. Compared with the prior art, the polyether chain segment with hydrophilicity is grafted to the polysiloxane chain segment with hydrophobicity, so that the formed silyl-ether copolymer has the advantages of two defoaming agents, namely silicon and ether; the high molecular polyether modified polysiloxane and the high molecular weight block polyether are compounded for use, so that the good defoaming effect of the highmolecular polyether modified polysiloxane and the good foam inhibition effect of the high molecular weight block polyether have a synergistic effect, the reduction of the foam amount is effectively ensured, and meanwhile, the fatty alcohol with high surface activity is matched, so that the improvement of the defoaming efficiency is promoted.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com