Defoaming device and method for coal-mine foam drilling

A defoaming device and foam technology, which are used in earth-moving drilling, flushing wells, wellbore/well components, etc., can solve the problem that there is no underground foam drilling process in coal mines, it is difficult to meet fast and reliable defoaming, and space conditions are limited. and other problems to achieve the effect of overcoming the influence of repeated foaming, light weight and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

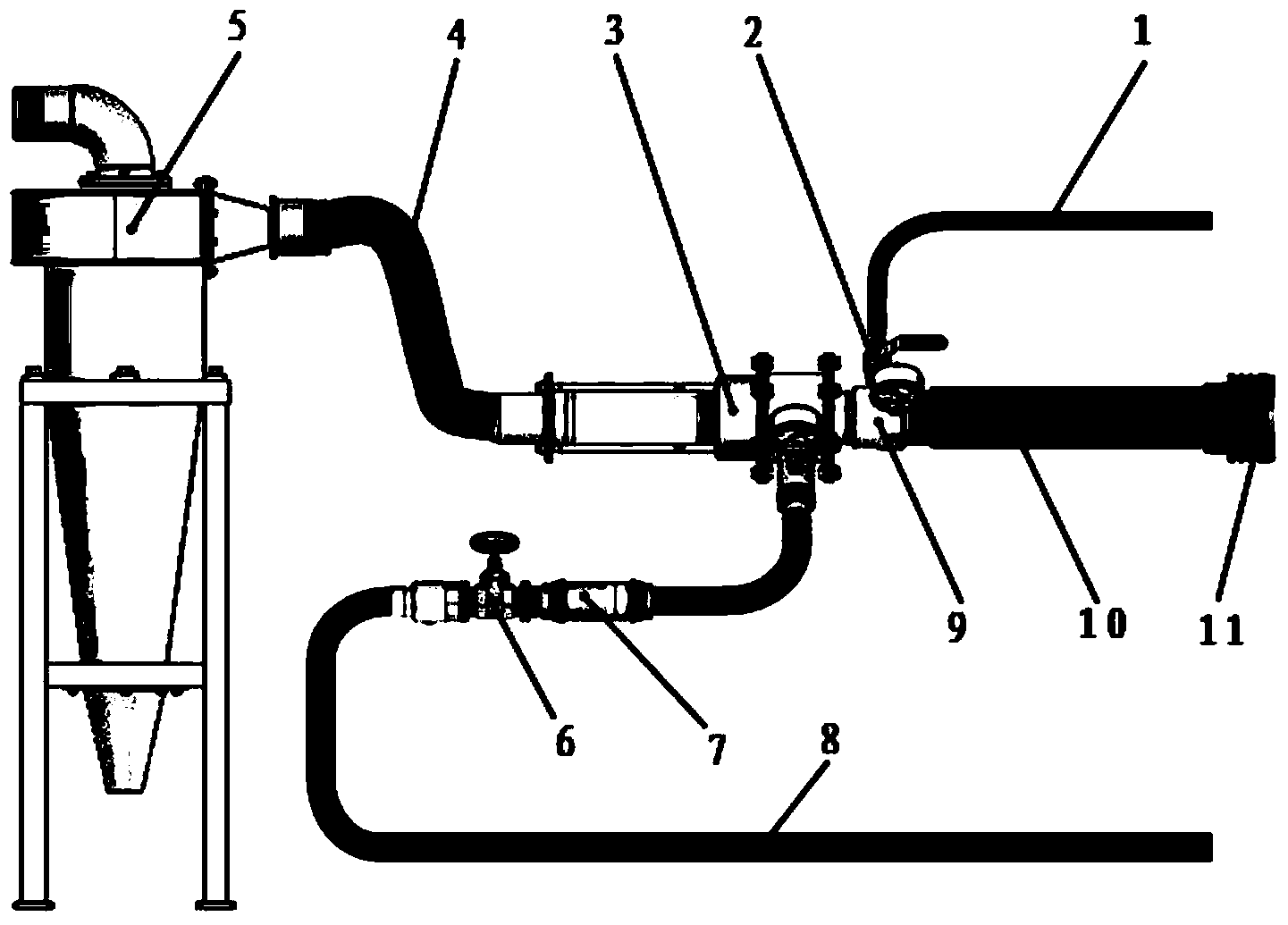

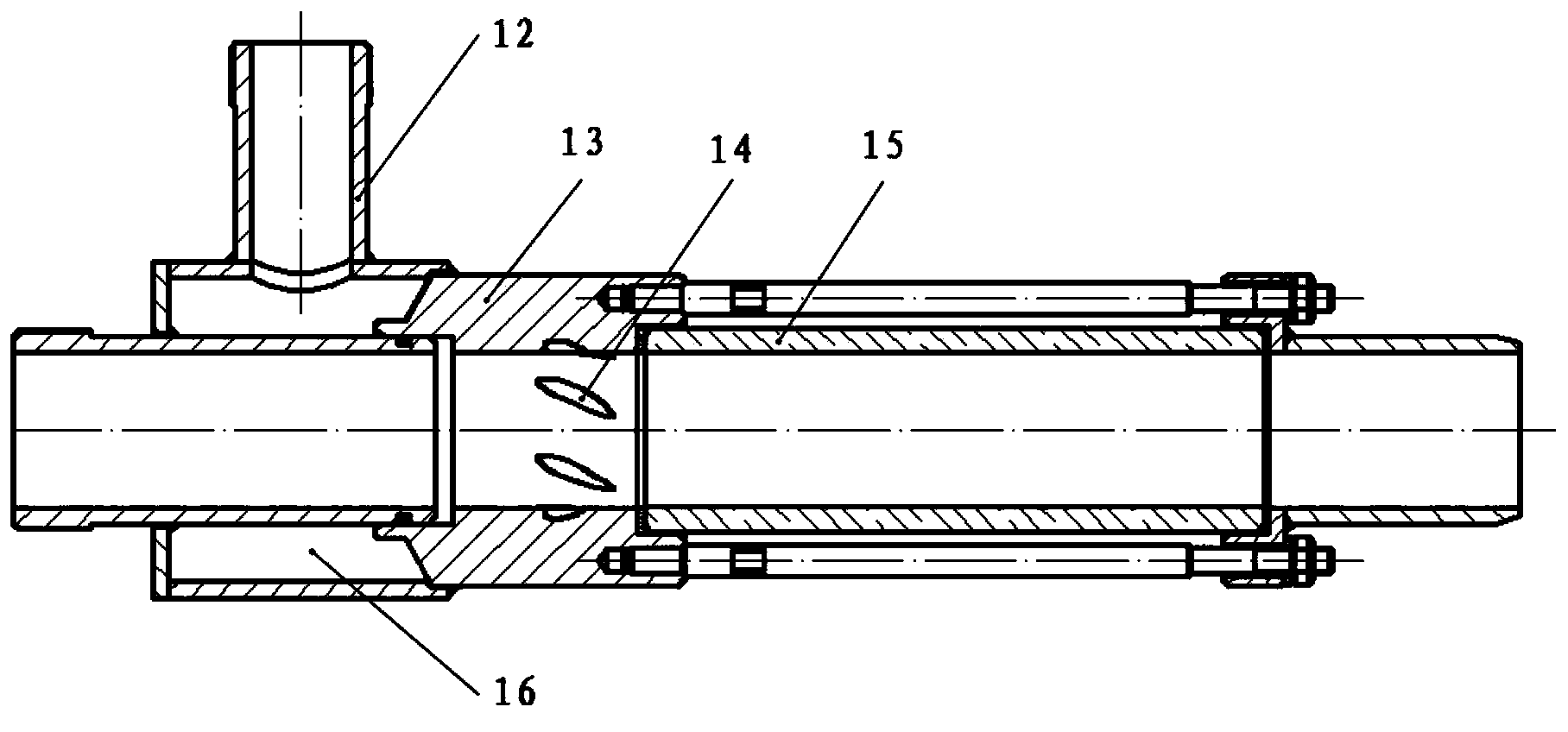

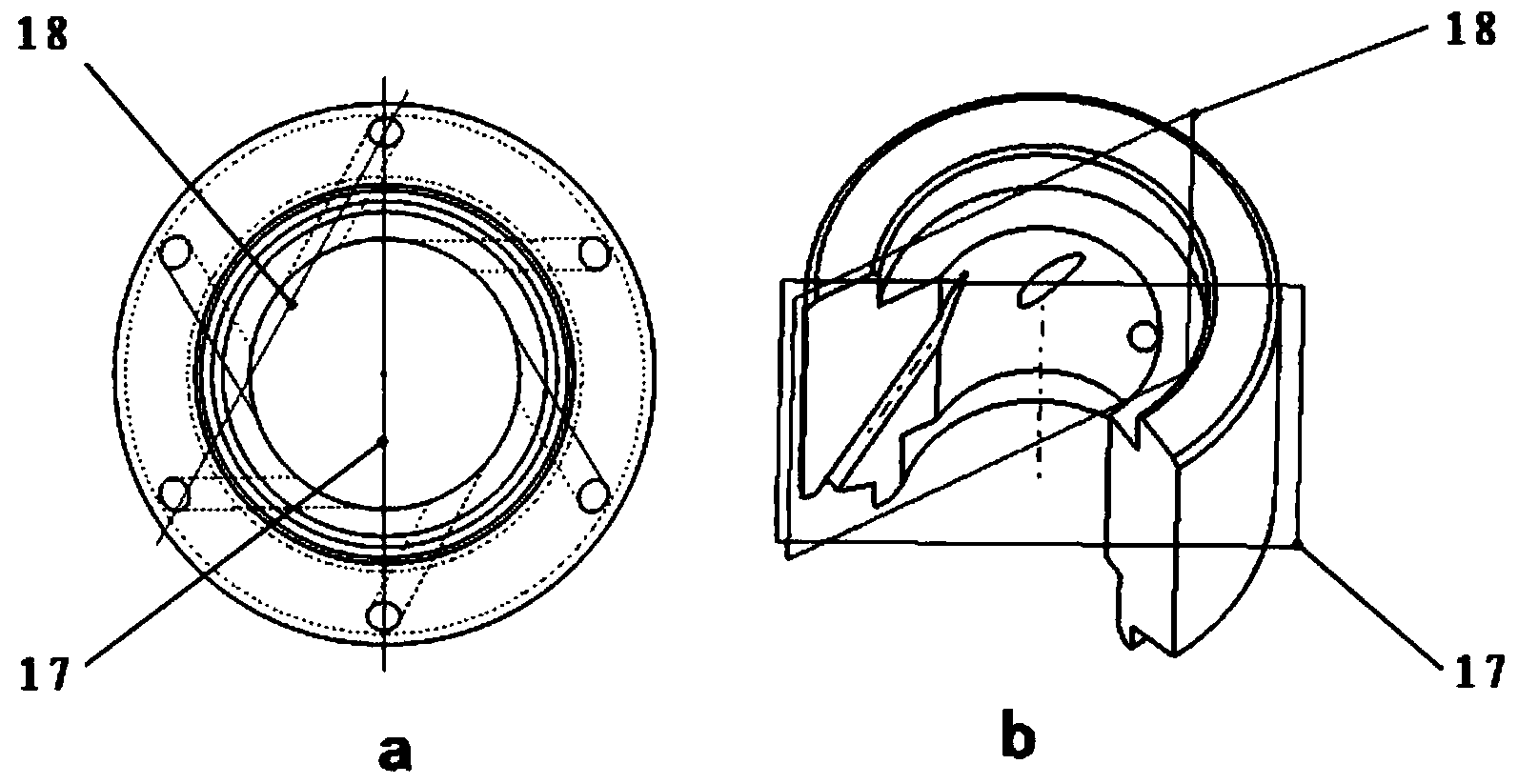

[0028] see figure 1 , a defoaming device for underground foam drilling in coal mines includes three key components: a rotary jet defoamer 3, a defoamer solution injector 9 and a centrifugal defoamer 5, wherein the core component is the rotary jet defoamer 3 and the defoamer The agent solution injector 9 is directly connected by thread, and is connected with the centrifugal defoaming device 5 by a rubber hose.

[0029] The defoaming method of the present invention is realized through the following steps:

[0030] a. Connect the intake high-pressure rubber hose 8 with the gas source, slowly open the compressed air control valve 6, and indicate the gas volume by the gas flow m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com