Patents

Literature

718 results about "Soft Coals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

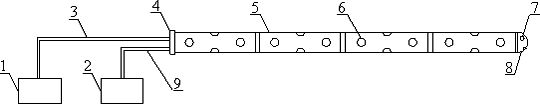

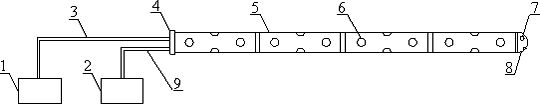

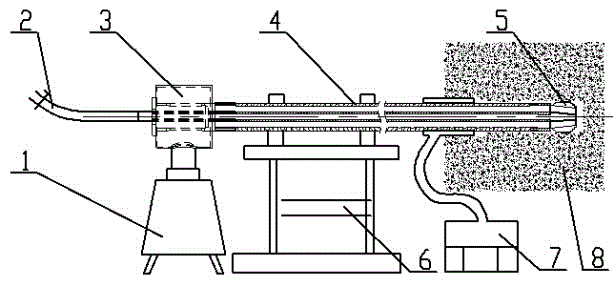

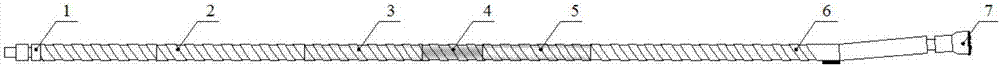

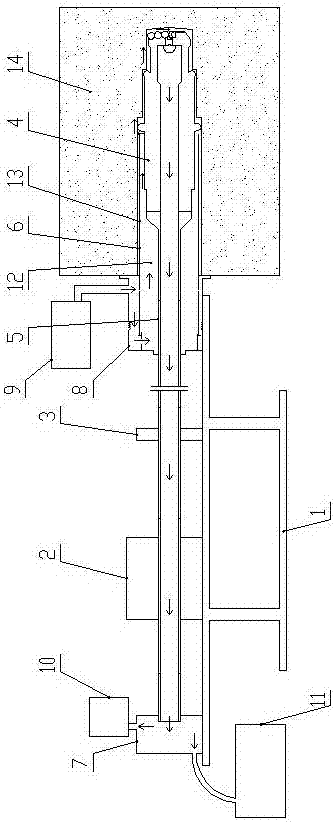

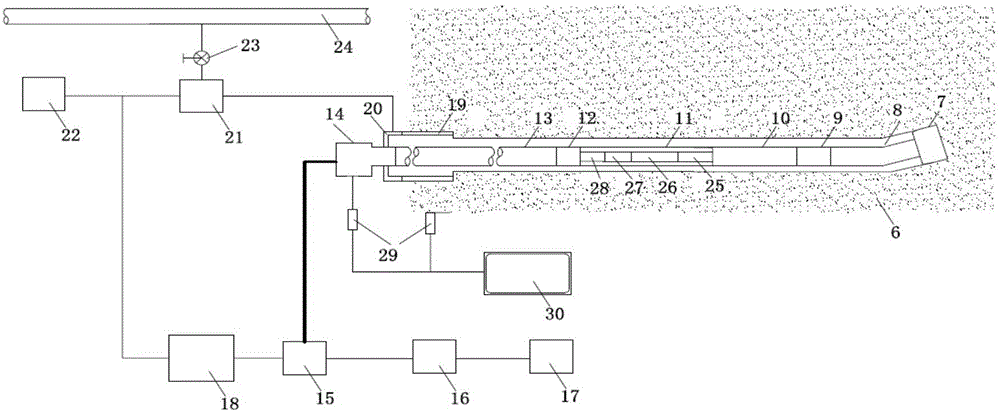

Gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process

ActiveCN102587828AOvercome the problem of frictional resistanceReduce displacementDrilling rodsGas removalHydraulic pumpAir compressor

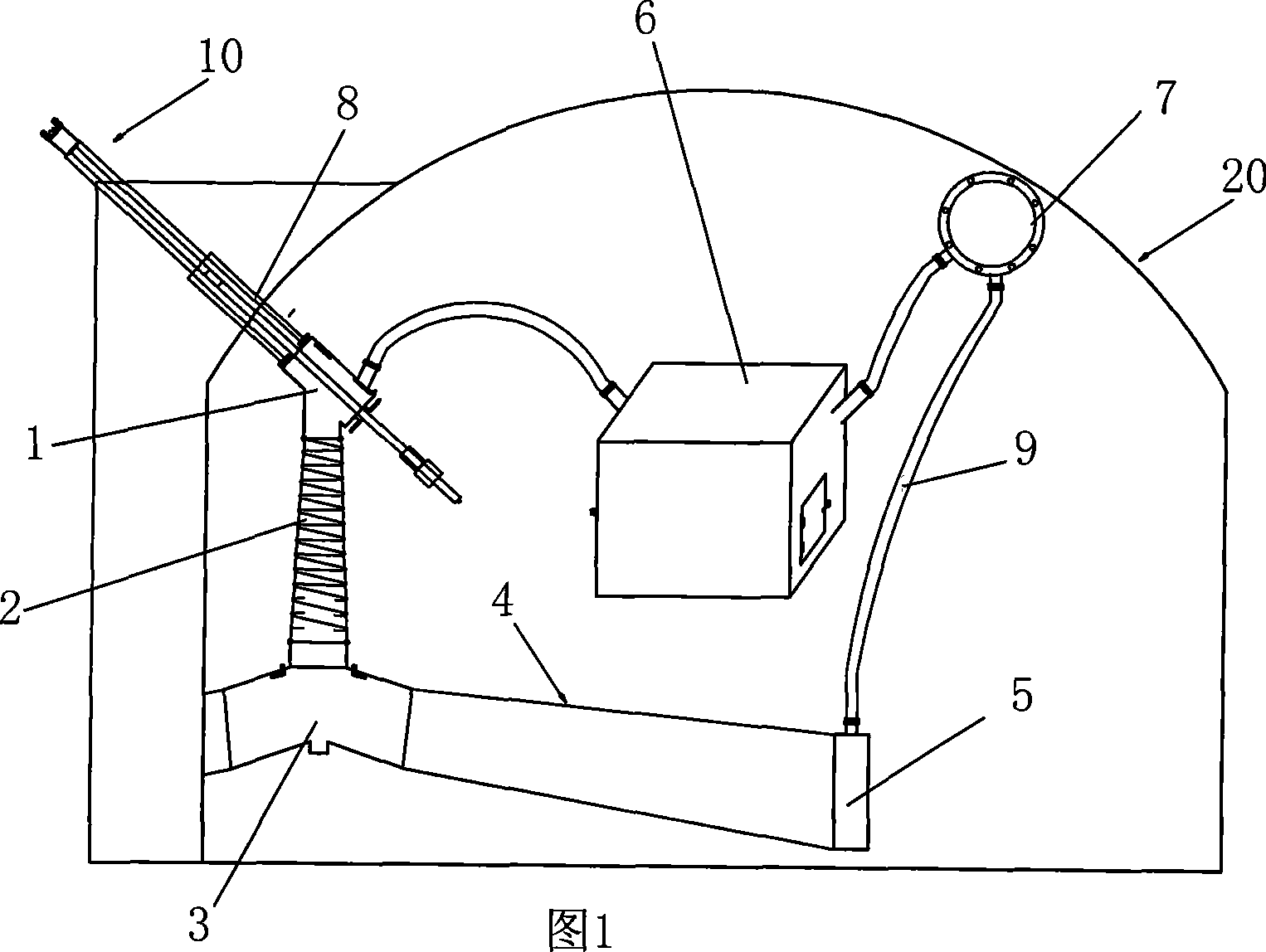

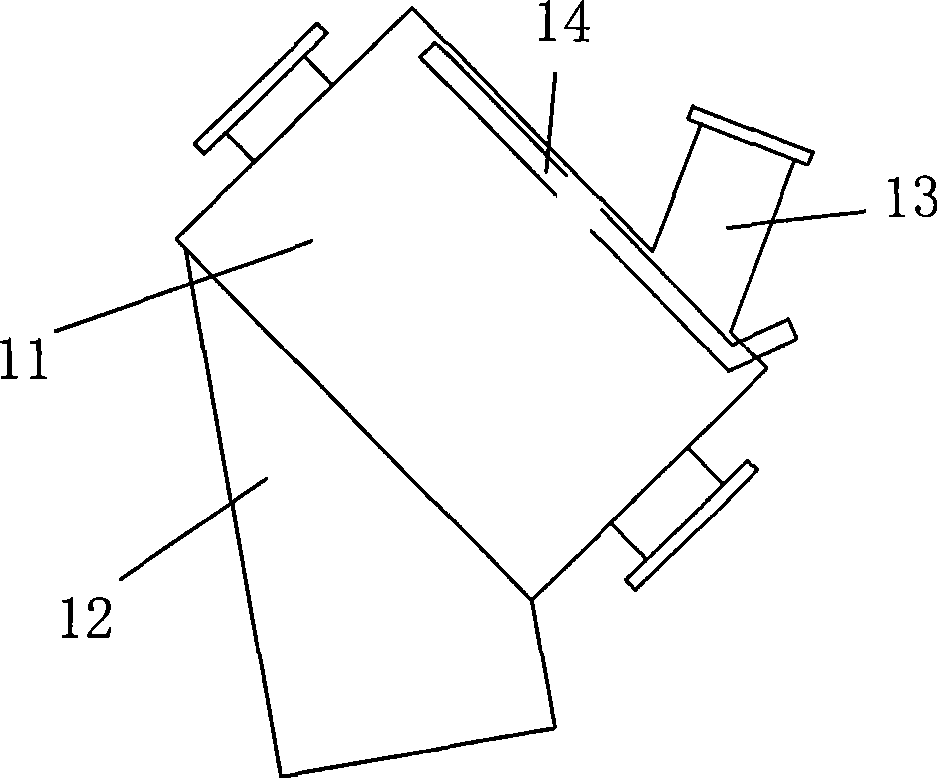

A gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process belong to soft coal seam cooperative drilling and protecting systems and process. The gas extraction and drilling cooperative drilling and protecting integrated system mainly consists of a control table, a hydraulic pump station, an air compressor, a feeding device, a drill stem, a hole protecting tube, a drill bit and the like. The hole protecting tube is located in the drill stem, and the hole protecting tube and the drill stem are synchronously connected and drill cooperatively. The depth of a drilled hole is equal to the length of the hole protecting tube. Finally, the hole protecting tube penetrates through the drill bit, and the drill stem is withdrawn while the hole protecting tube is remained in the hole to realize functions of supporting a hole wall and extracting gas. The system and the process are convenient in operation, the hole protecting tube and the drill stem realize cooperative drilling and protecting, the hole protecting tube is easy to be remained in the drilled hole, problems that the hole collapses and the hole protecting tube is difficult to be fed to the drilled hole can be resolved, the hole protecting depth is high, the hole wall can be supported more effectively, deformation and collapse are prevented, accordingly high gas extraction concentration and flow of the soft coal seams are guaranteed, and the gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and the process are particularly applicable to quite soft coal seams with the value of the firmness factor f smaller than 0,3.

Owner:CHINA UNIV OF MINING & TECH

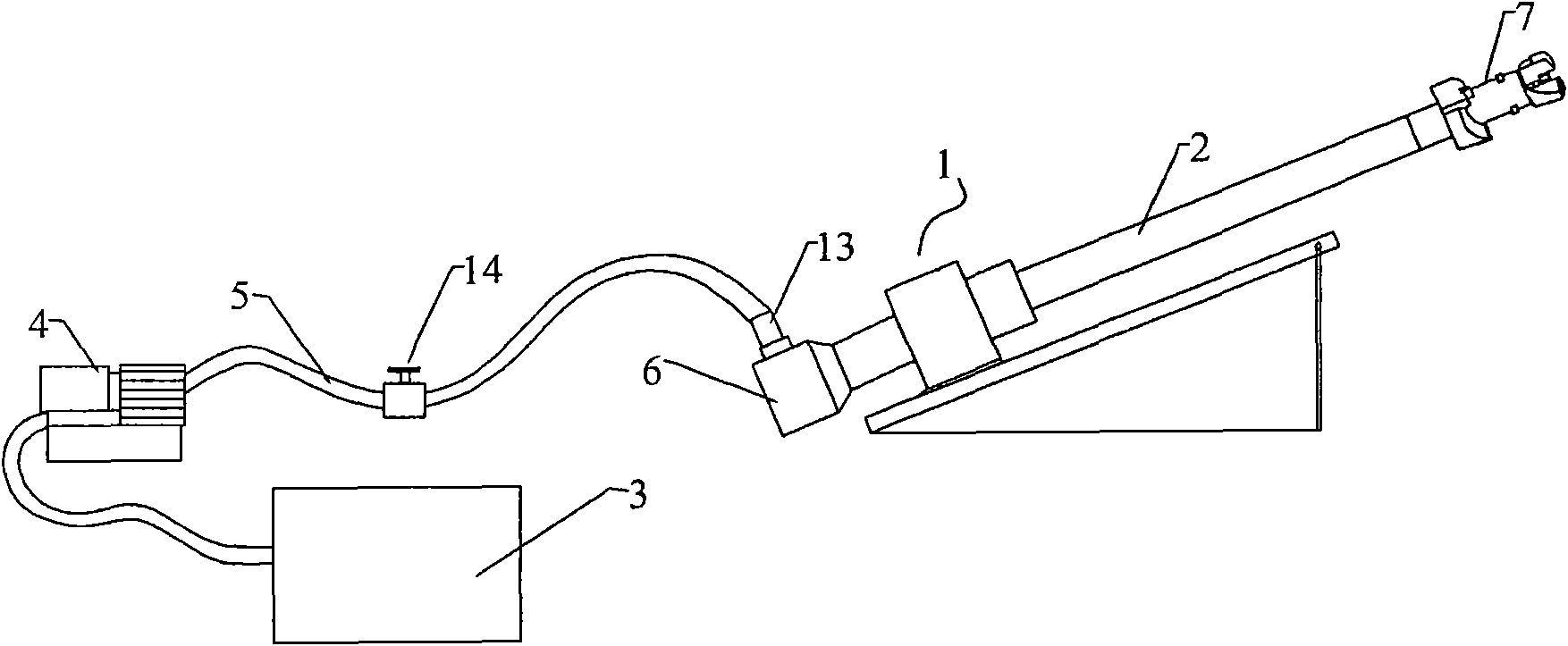

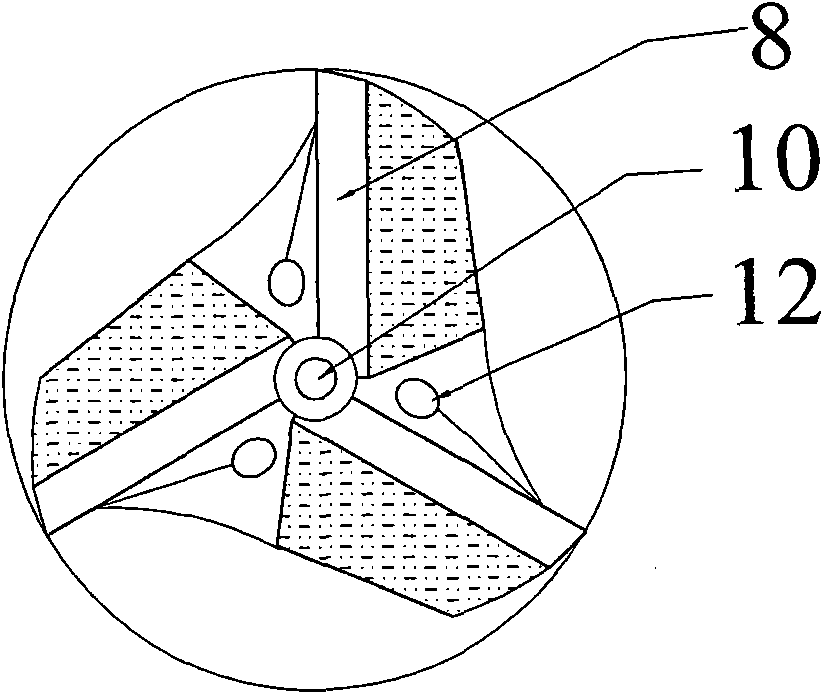

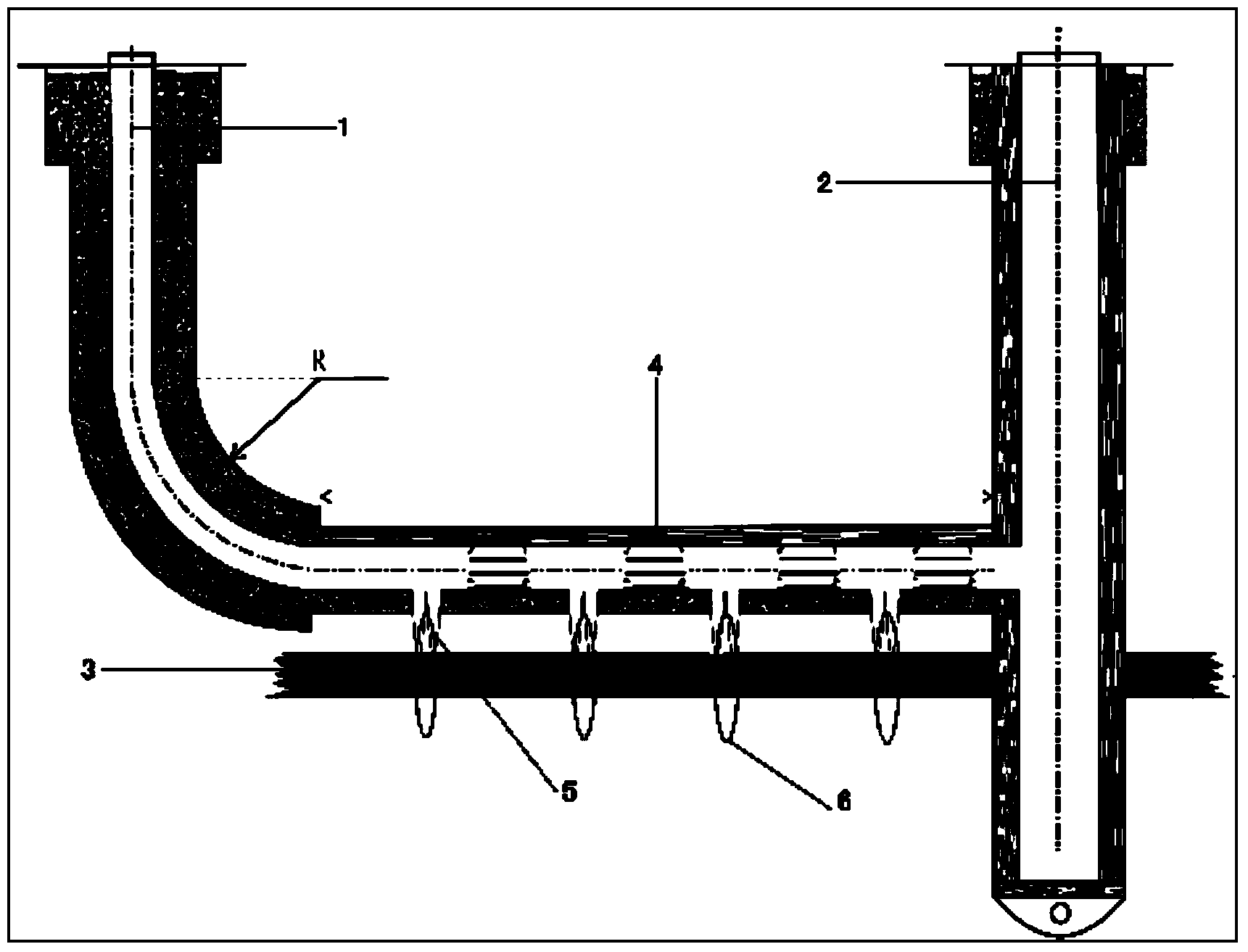

High-pressure water jet system and method for drilling and enlarging holes on coal bed

ActiveCN101586441ASolve the problem of difficult drilling and reaming constructionLow running costDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

The invention discloses a high-pressure water jet system for drilling and enlarging holes on coal bed, comprises a high-prerssure water jet system, a drilling machine, a drilling rod and tool system. The high-pressure water jet system includes a water tank, a high-pressure pump, a high-pressure hose connected in sequence, the drilling machine includes a control panel and a machine body, the drilling rod and tool system includes a high-pressure rotation sealing device, a high-pressure sealing drilling rod, a tower-like drill combined of jet mechnical blades with a high-pressure water jet nozzle. According to the invention, drilling and enlarging holes on coal bed is implemented by combination function of rotation cutting of high-pressure water jet to coal of hole bottom and wall, and function of grinding of mechnical blades, which can avoid phenomenon of drilling block and drilling clip during process of drilling holes on coal bed, long drilling holes are formed on soft coal bed with high ground stress, air-conductivity and pressure relief range of coal around drilling holes are enlarged, gas drainage effect and outburst control effect of drilling hoels on coal bed are improved. Additionaly, the invention also discloses a high-pressure water jet method for drilling and enlarging holes on coal bed.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

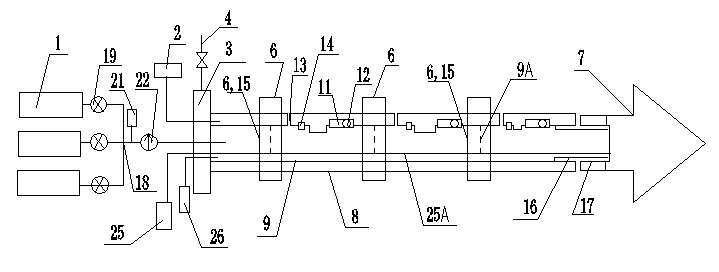

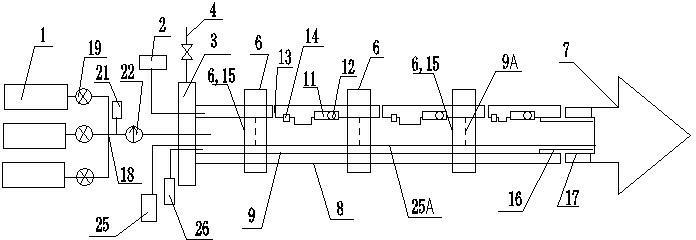

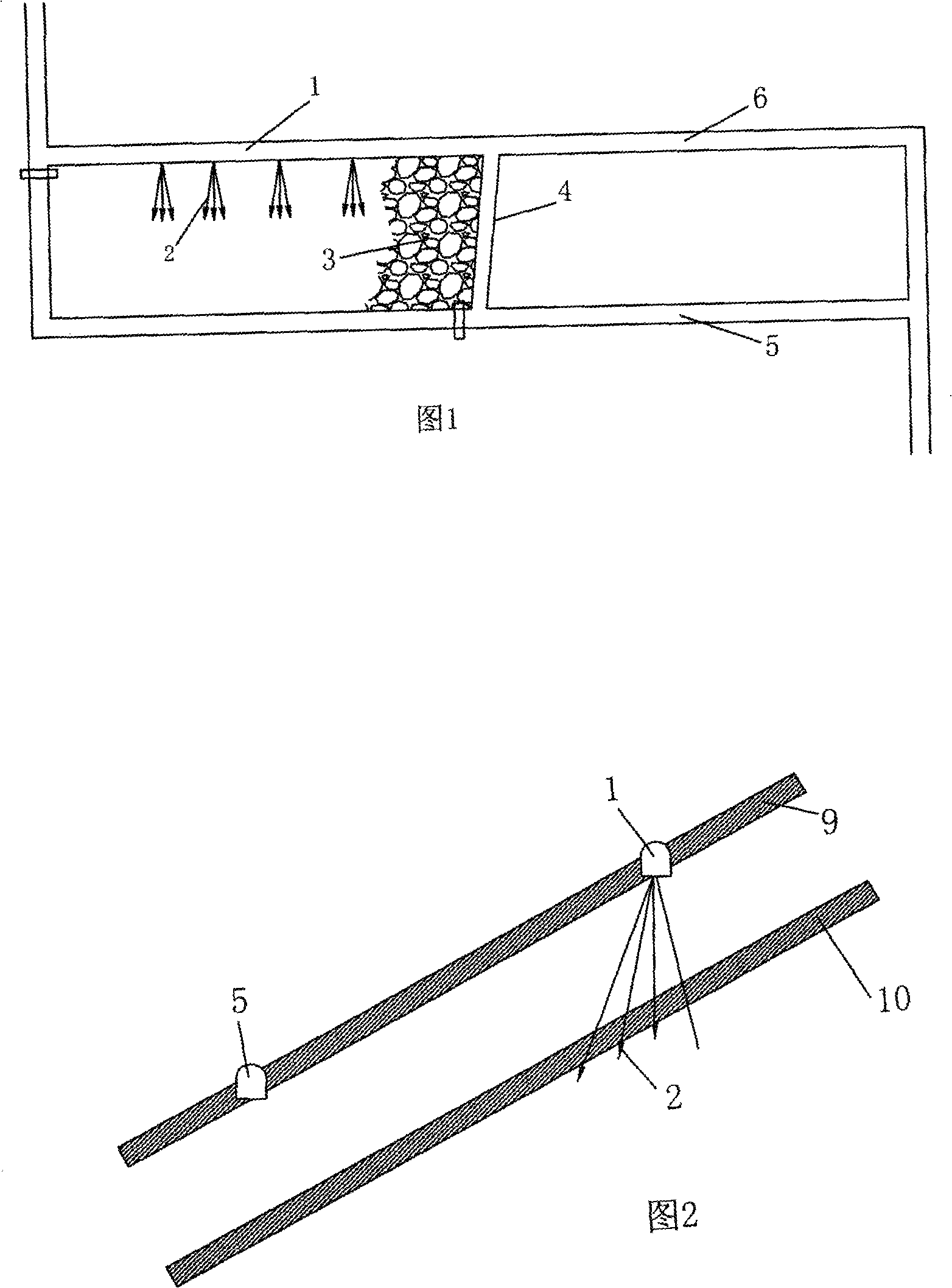

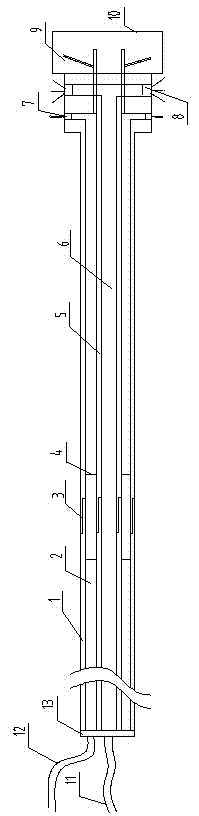

Gas drainage system and method for hyposmosis soft coal seams

InactiveCN102116168AMake up for the inconvenience of reconstruction of collapsed holesSimple structureDrilling rodsFluid removalEngineeringAir compressor

The invention discloses a gas drainage system for hyposmosis soft coal seams, which comprises a power device mechanism, a drilling-pressing-pumping integrated mechanism, and a metering mechanism. The power device mechanism comprises an air compressor and an air drilling machine; the drilling-pressing-pumping integrated mechanism comprises a rotary blowout preventer, a boosting pipeline, a drill pipe, a multiple-completion packer, an inner drill pipe connector, a power motor, an electromotor, and an auto-reducing and reaming triple-wing drill bit. The air compressor is sealed and communicated with the inner drill pipe through a high pressure hose; moreover, a control valve, a flowmeter and a pressure meter are arranged on the high pressure hose. The invention also discloses a method using the system to pump gas. The system not only can be used for drilling to make up the difficulty of inconvenient transformation of the gravitation of the soft coal seams, but also can timely implement pressing and cave forming on coal bodies to pump gas after drilling. The method integrates drilling with pressing and cave forming, and improves the ventilation property of the coal seams through cave forming. Integration of drilling, pressing and pumping effectively prevents the problem that transformation of a reservoir can not be continued due to collapse of coal holes to a certain extent.

Owner:HENAN POLYTECHNIC UNIV

Yolk coal rock formation downward hole pumping and mining pressure relief mash gas construction method

The invention relates to a method for drainaging pressure relief gas construction by a downward borehole in soft coal seam and strata, characterized in that a downward cross-seam borehole is arranged on the roadway segment retained for next sublevel on the mining face of a protecting layer, and the lower covered protecting coal seam is gas pre-drainaged through the downward cross-seam borehole. The construction of the downward cross-seam borehole comprises the following steps: a borehole enlarging segment is formed downwards from the bottom plate of the coal seam of the roadway segment retained for next sublevel, the borehole protection is finished in the inner sleeve in the middle lower part of the borehole enlarging segment, slurry is injected between the outer wall of the inner sleeve and a rock to from a borehole sealing segment, and the further construction of the downward cross-seam borehole is carried out in the inner sleeve. According to the invention, the pressure relief gas of the protecting layer namely the lower covered coal seam is maximally drainaged when the protecting layer is mined, the mining effect of the protecting layer is improved, and the safe stoping of the mining face is ensured.

Owner:HUAINAN MINING IND GRP

Continuous sedimentation process for production of needle coke

InactiveCN101531909AGood for long-term operationEasy to operateWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionTarQuinoline

The invention relates to a continuous sedimentation process for production of needle coke. Under the continuous condition of in-out materials, the process carries out settling separation on an insoluble substance of quinoline to obtain a qualified light phase of the insoluble substance of the quinoline. The mixed ratio of an aliphatic solvent to an aromatic solvent is (0.6-1.2) to 1; the mixed ratio of a mixed solvent to soft coal-tar asphalt is (0.6-1.2) to 1; the mixed oil is pumped into settling separation equipment by a pump for the settling separation; light liquid slowly rises; and after the insoluble substance of the quinoline reaches the requirement, the light liquid is continuously discharged from the upper part and distilled to obtain refined asphalt. The continuous sedimentation process has the advantages that the prior intermittent sedimentation process is improved into the continuous sedimentation process, namely the in-out materials are processed under the continuous operating condition. The continuous operation can simplify operation, reduce equipment, the floor space and the blocking of the equipment, and is favorable for long-period operation of the process.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Water purification active carbon prepared from vegetal castoff and preparation method thereof

ActiveCN101121514ASuitable for removalStrong decolorization abilityOther chemical processesWater/sewage treatment by sorptionAdditive ingredientChemistry

A purified water activated carbon produced from the plant castoff includes the material ingredients of following weight percentage: The percentage of highly processed plant waste residue is between 80 percent and 84 percent. The percentage of non highly processed plant waste residue or a soft coal is between 15 percent and 19 percent. The percentage of a chemical additive is between 1 percent and 5 percent. The present invention makes the best of a lignin, a fibrin and a rudimental sugar in the plant waste residue and takes the ingredients as a backbone. A little chemical substance is used to adjust the hole distribution and the surface functional groups. The produced purified water activated carbon has the following advantages. (1). Strong decoloration capability. The present invention is applicable to the color substance with giant molecule group. (2). Strong deodorization capability. The present invention is especially applicable to the alga and alga poison. (3). Strong capability of removing the harmful and organic residuum (MCA / DCA / THC / MTBE and others). The present invention has also a low cost and a good effect.

Owner:邹炎

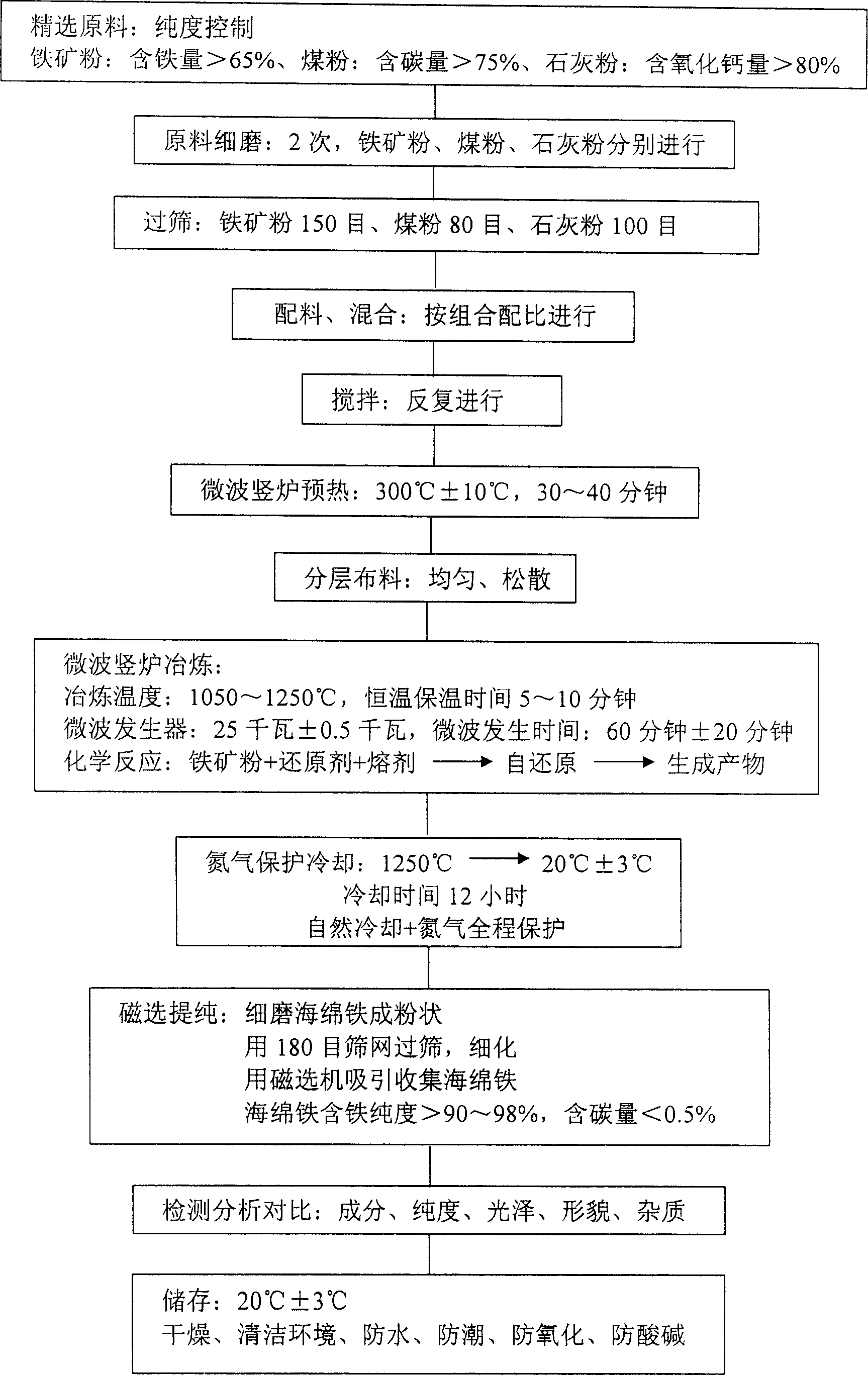

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

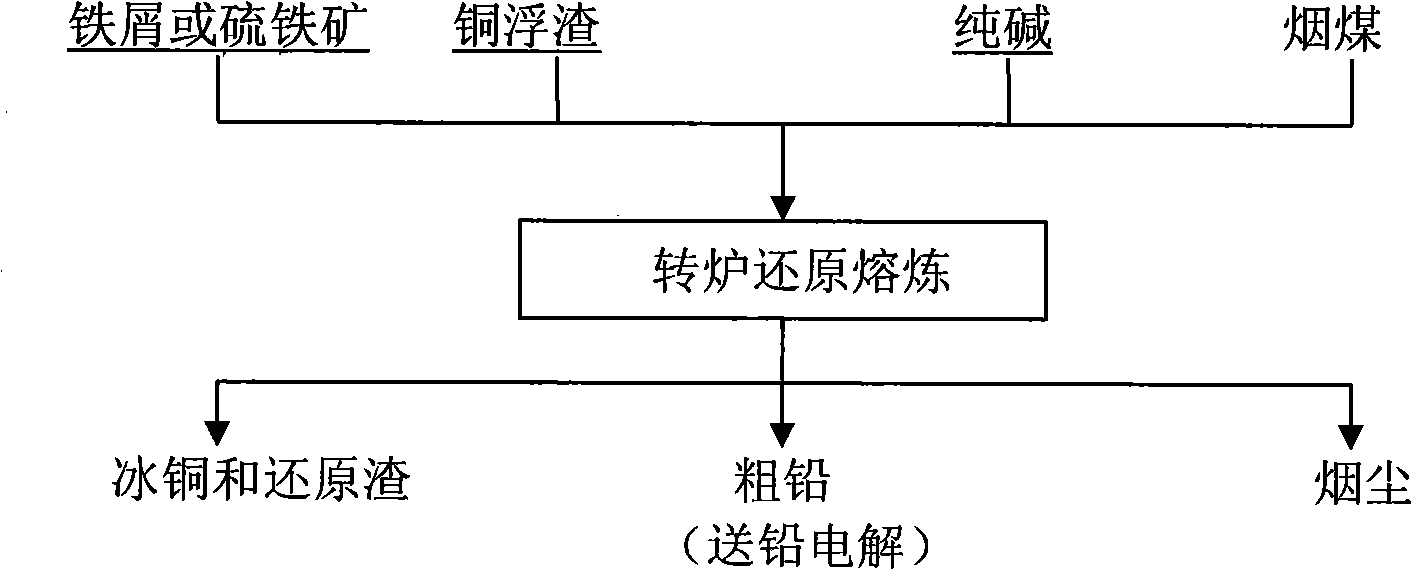

Method for treating copper scum using converter

The invention relates to a method for processing copper dross slag by using a converter, which belongs to the technical field of thermometallurgy. Copper dross slag, calcined soda, scrap iron or sulfurous iron ore and soft coal are proportioned in proportion and then are added into a converter for retailoring. The temperature is controlled within the range of from 700 DEG C to 800 DEG C, the smelting lasts for 1.5 hours to 2 hours, so that lead in the metal form in the copper dross slag is separated from copper; then the temperature is increased to the slag overtemperature of 1100 DEG C to 1250 DEG C, the smelting lasts for 2.5 hours to 3 hours, so that lead compound is deoxygenated to produce metal lead, and the copper becomes copper matte to realize the separation of copper and the lead. The dross slag on the copper matte and the wet lead are fished out to obtain the copper matte and the wet lead. Because the operation process of the invention is carried out in the converter, the separation of copper and lead is more complete. The method can solve the problems of high energy consumption, heavy environmental pollution, low metal recovery ratio, high production cost and the like in the prior copper dross slag processing.

Owner:KUNMING UNIV OF SCI & TECH +1

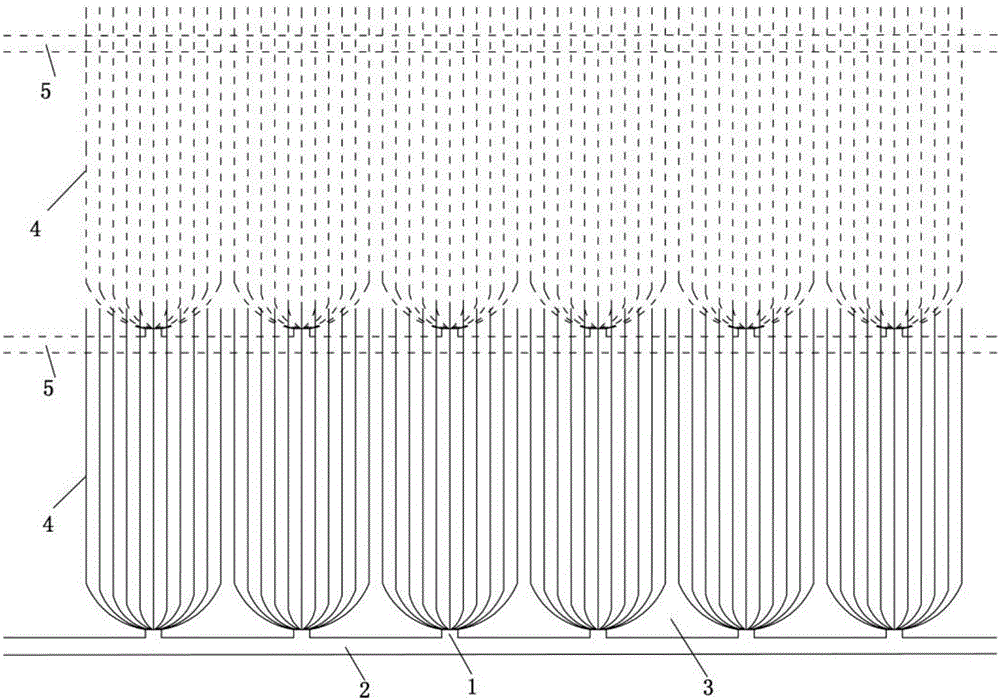

Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

ActiveCN103967472AFor precise controlSolving the Difficulties of Directional DrillingFluid removalSoil scienceDrill

The invention relates to a horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing. In order to solve the problems that hole forming performance of horizontal drilling in a coal bed is poor and buried drill accidents can happen easily and to achieve the forced gas drainage effect on tectonic soft coal, the well track of a horizontal well is controlled in mudstone or sand stone with a certain range above a coal bed top boundary, and the horizontal well is docked with a drainage vertical well at a far end. An ultra deep penetration perforating technology is used, according to the requirement for certain hole density and orientation, orientated perforating is conducted downwards on the horizontal well section in a segmented mode, a steel sleeve, a well cementation cement ring and a mudstone top plate are penetrated, and the horizontal well is communicated with a target coal layer below. Then, a clear water sand carrying fracturing technology is used, staged fracturing is conducted on the target coal bed according to the requirements for large discharge capacity, large liquid amount, high prepad fluid ratio, large sand amount and middle sand ratio, and the purpose of increasing production is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Three-soft-coal-layer reciprocating-type coal-pillar-free fully-mechanized mining method

InactiveCN103410515AReduce retentionLow costUnderground chambersUnderground miningResource recoveryEngineering

The invention relates to a three-soft-coal-layer reciprocating-type coal-pillar-free fully-mechanized mining method which comprises steps as follows: a plurality of parallel adjacent working surfaces are arranged and exploited sequentially, wherein every two adjacent working surfaces are alternately exploited by a forward coal mining process and a backward coal mining process; in the drifting process, the roadway is combinedly supported by anchor rods, anchor cables, metal meshes and W-shaped steel tapes; and in the stoping process, the haulage roadway adopts gob-side entry retaining. The invention implements supporting in a combined support mode, and the anchor cables, anchor rods, metal meshes and W-shaped steel tapes constitute the support body; as the working surface exploitation lower gangway adopts gob-side entry retaining, the three soft coal layers have favorable support effect and entry retaining effect; and compared with the subsequent retreat-type coal mining, the invention can reduce the stoping roadway by 25-40% for one mining area, and enhance the resource recovery rate by 10-15%.

Owner:SHANDONG UNIV OF SCI & TECH

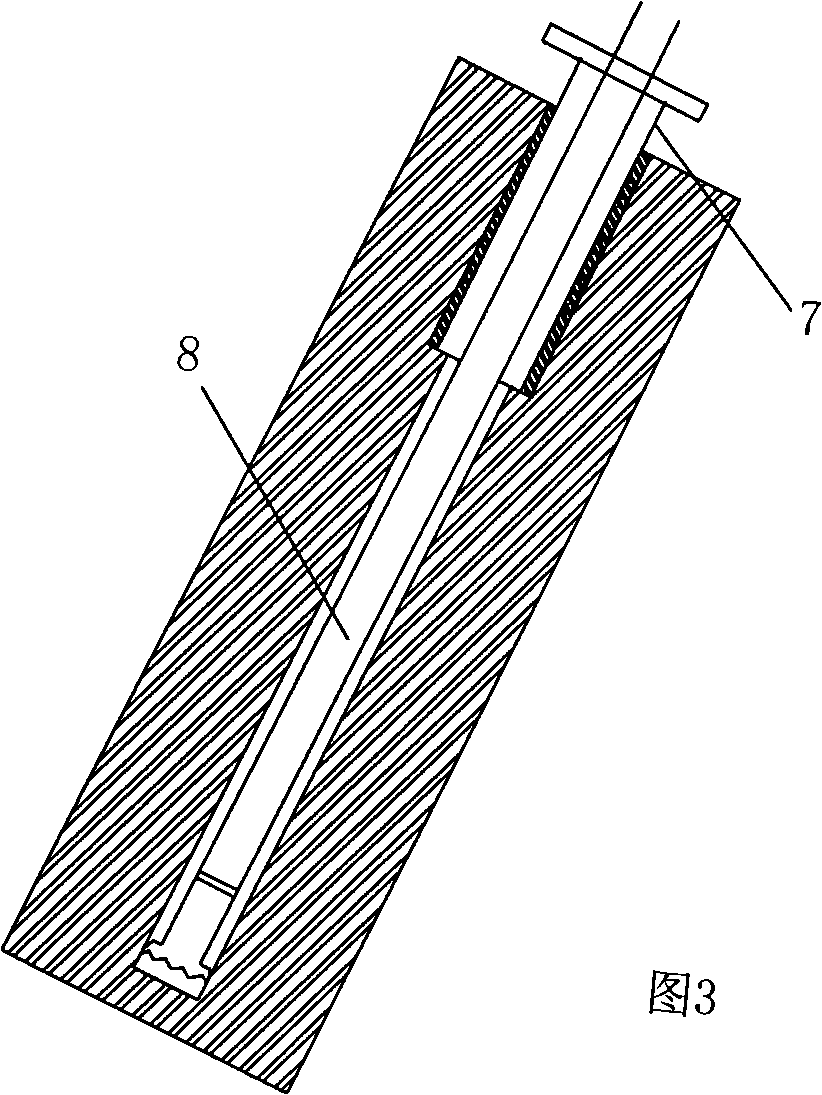

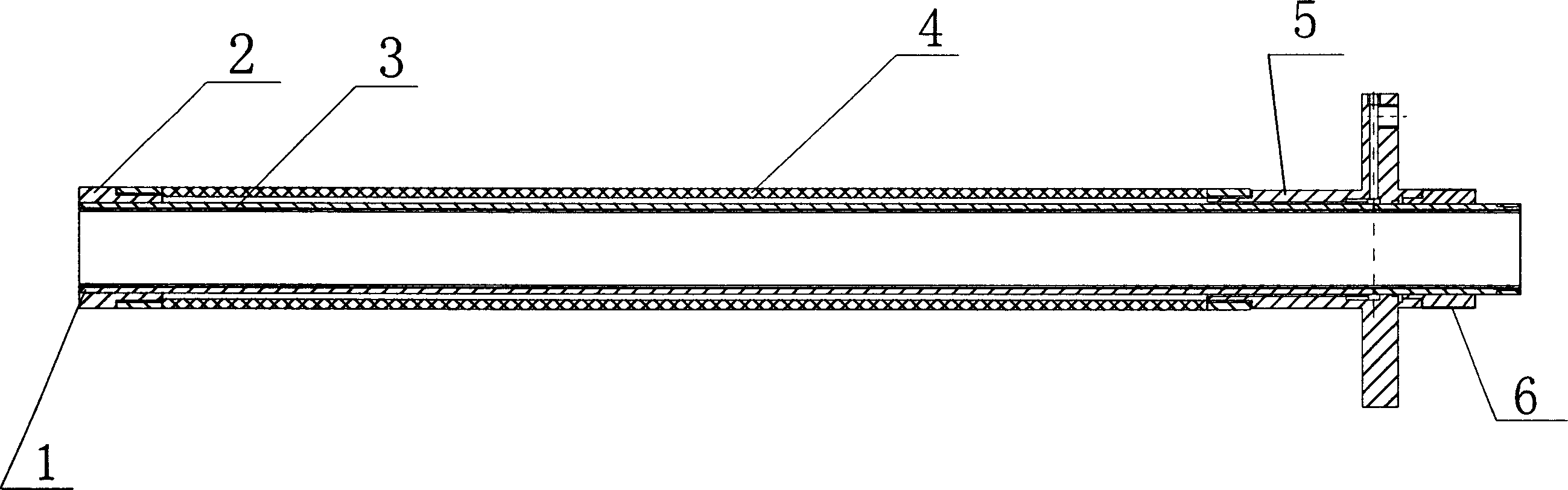

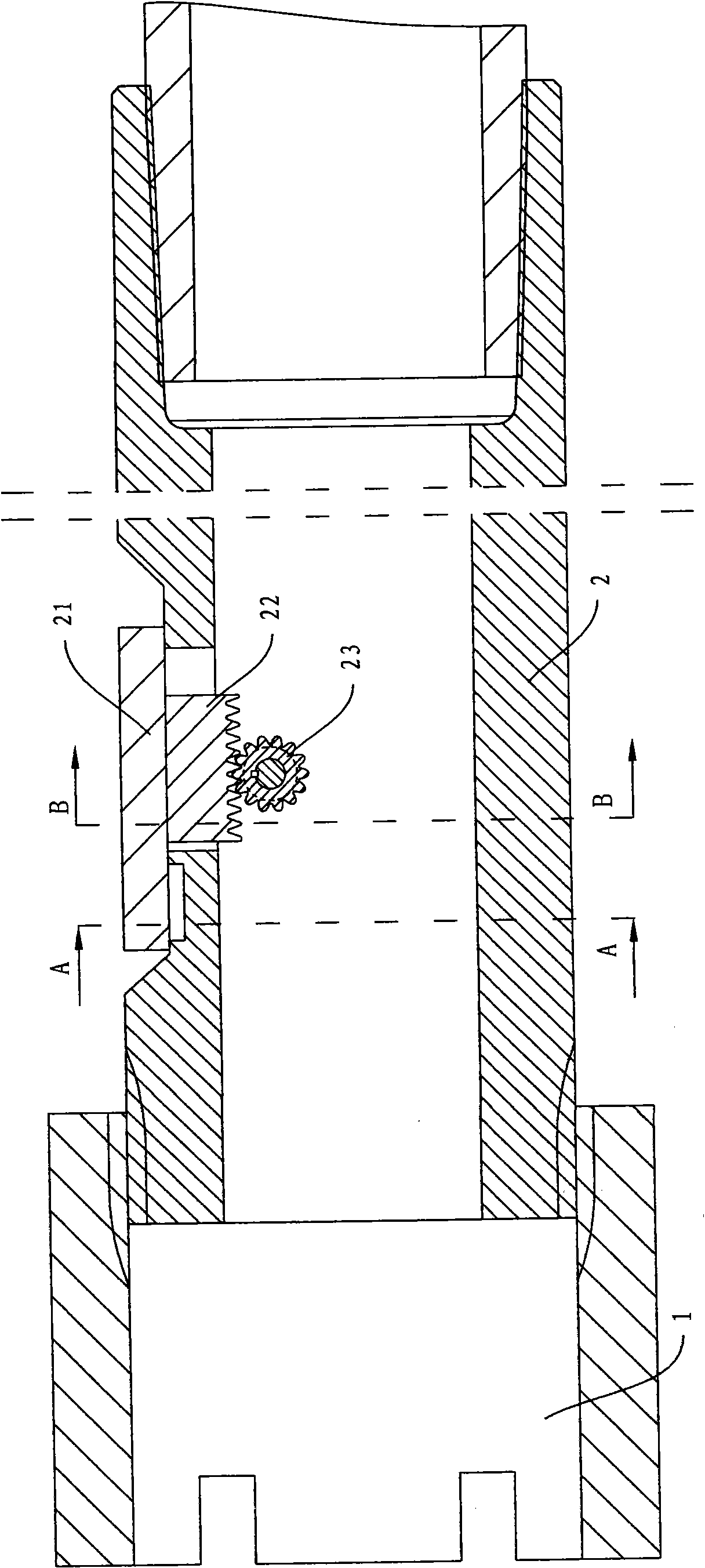

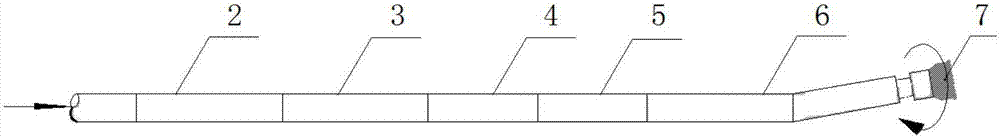

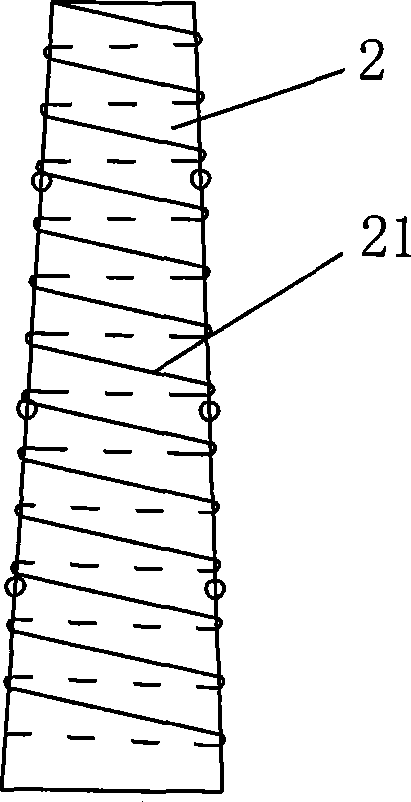

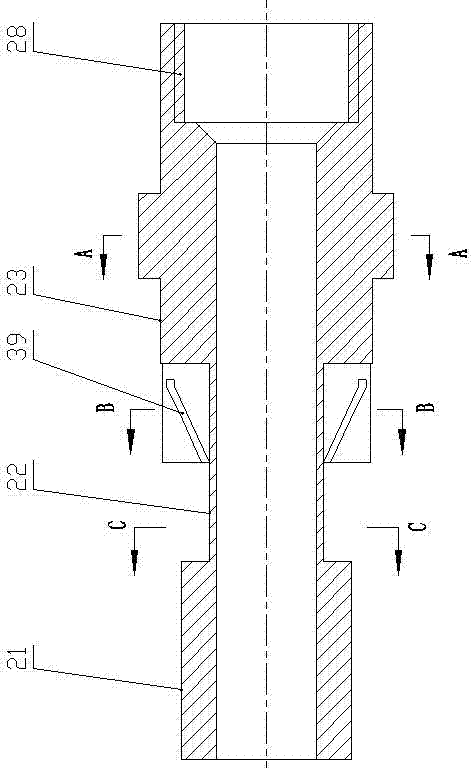

Feeding method and device for hole protecting pipe for soft coal seam gas extraction hole

The invention relates to a feeding method for a hole protecting pipe for a soft coal seam gas extraction hole. The feeding method is characterized in that an epoxy resin adhesive is used for filling sieve pores of the hole protecting pipe before the hole protecting pipe is fed into a drill hole, air with a certain pressure is pressed into the hole protecting pipe in the process of feeding the hole protecting pipe into the drill hole, the air flows into the drill hole through a vent hole arranged at the top end of the hole protecting pipe, and high-speed air currents discharge coal dusts from an orifice along the hole protecting pipe and a gap of the wall of the drill hole. After the hole protecting pipe is fed into the bottom of the hole, an epoxy resin adhesive dissolving agent is injected into inner holes of the hole protecting pipe for dissolving the expoxy resin adhesive in the sieve pores so as to extract the gas. The feeding method is convenient in operation, can overcome the problem that the hole protecting pipe is difficult to feed into the drill hole due to the residual coal dusts in the gas extraction hole and local hole collapse, and has the advantages of long feeding distance of the hole protecting pipe, thereby ensuring the higher concentration and high flow of the soft coal seam gas extraction. The feeding method is particularly suitable for soft coals and very soft coal seams in which hole collapse easily occurs.

Owner:CHINA UNIV OF MINING & TECH

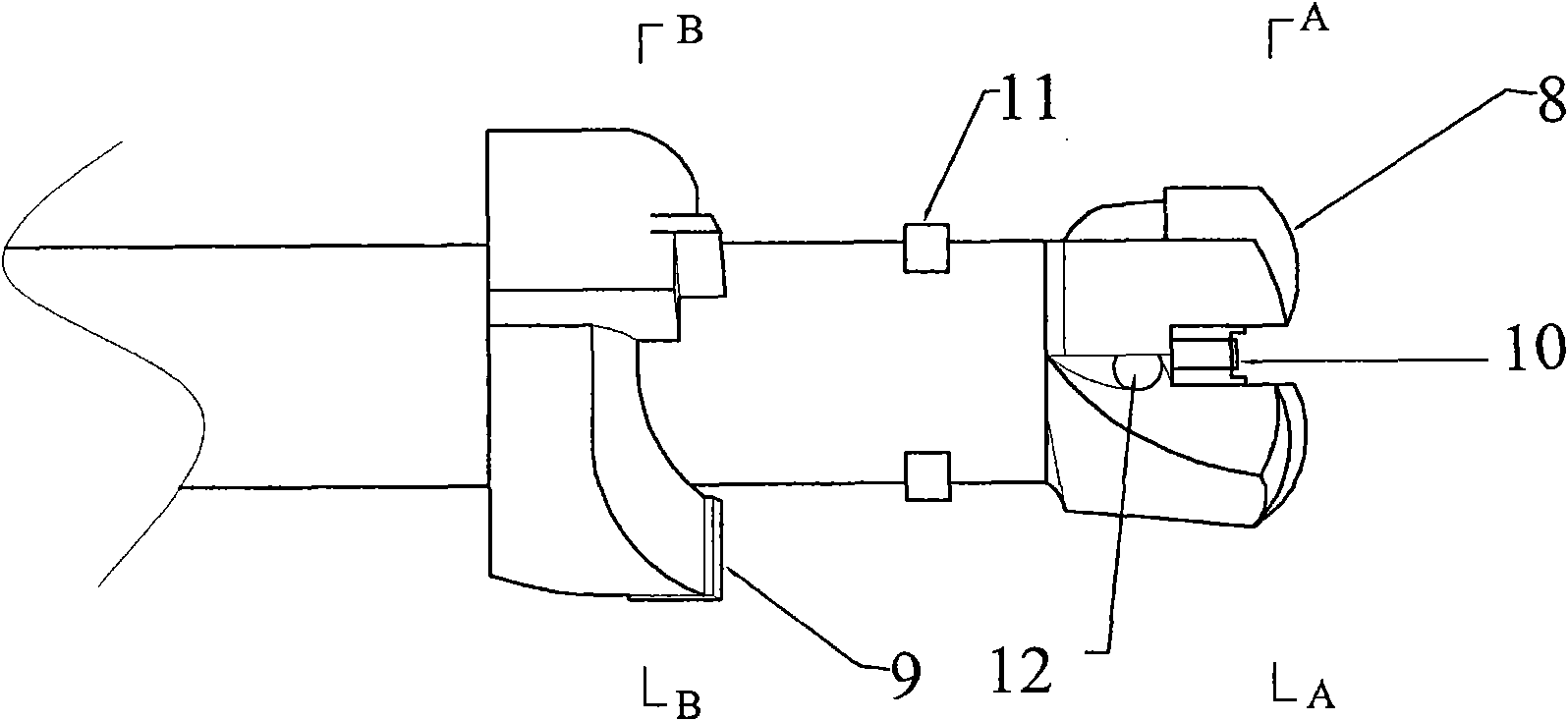

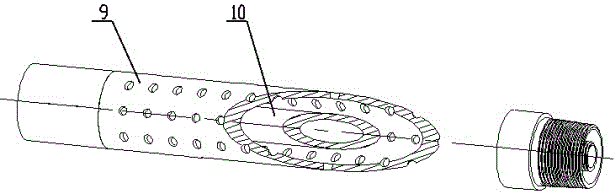

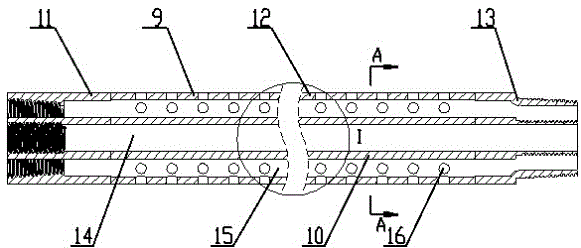

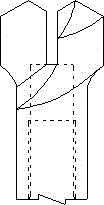

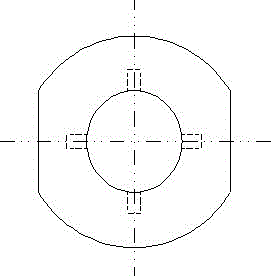

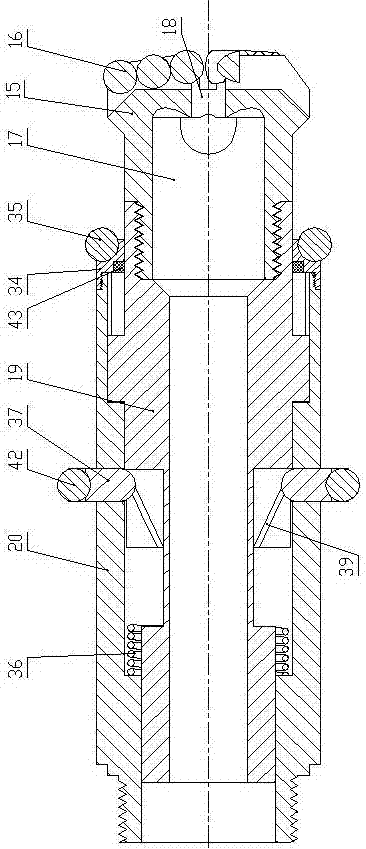

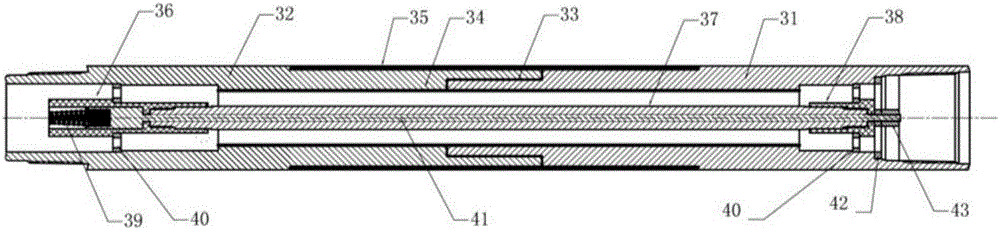

Dual-channel porous turbulence pressure relief drilling tool for soft coal rock drilling, and construction method of drilling tool

The invention discloses a dual-channel porous turbulence pressure relief drilling tool for soft coal rock drilling, and a construction method of the drilling tool. The drilling tool comprises a drilling tail rotating slag tapping device, a dual-channel porous turbulence pressure relief drilling rod and a dual-channel drilling bit, wherein the drilling tail rotating slag tapping device is connected with the dual-channel porous turbulence pressure relief drilling rod on a drilling machine, and the dual-channel drilling bit is mounted at the front end of the dual-channel porous turbulence pressure relief drilling rod. The drilling tool is mainly used for easy-to-shrink and broken soft coal rock drilling. The construction method of the drilling tool comprises the steps that the drilling machine and an air supply system are started; an air flow enters an inner channel of the dual-channel porous turbulence pressure relief drilling rod and reaches the bottom of a drilling hole; and the air flow carries drilling cuttings to reverse out along an outer channel of the dual-channel porous turbulence pressure relief drilling rod to enter a dust collector connected with the drilling tail rotating slag tapping device. The drilling tool is novel in design; deslagging is accomplished in an annular space in the drilling rod, so that influences of drilling hole shrinkage and drilling hole damage on a drilling hole deslagging space can be avoided effectively; and due to the porous characteristic of the surface of the drilling rod, stress between a rod body in a drilling hole blocking area and coal slag can be released effectively, the stacked drilling cuttings can be evacuated, and heat gathering on the surface of the drilling rod can be prevented.

Owner:HENAN POLYTECHNIC UNIV

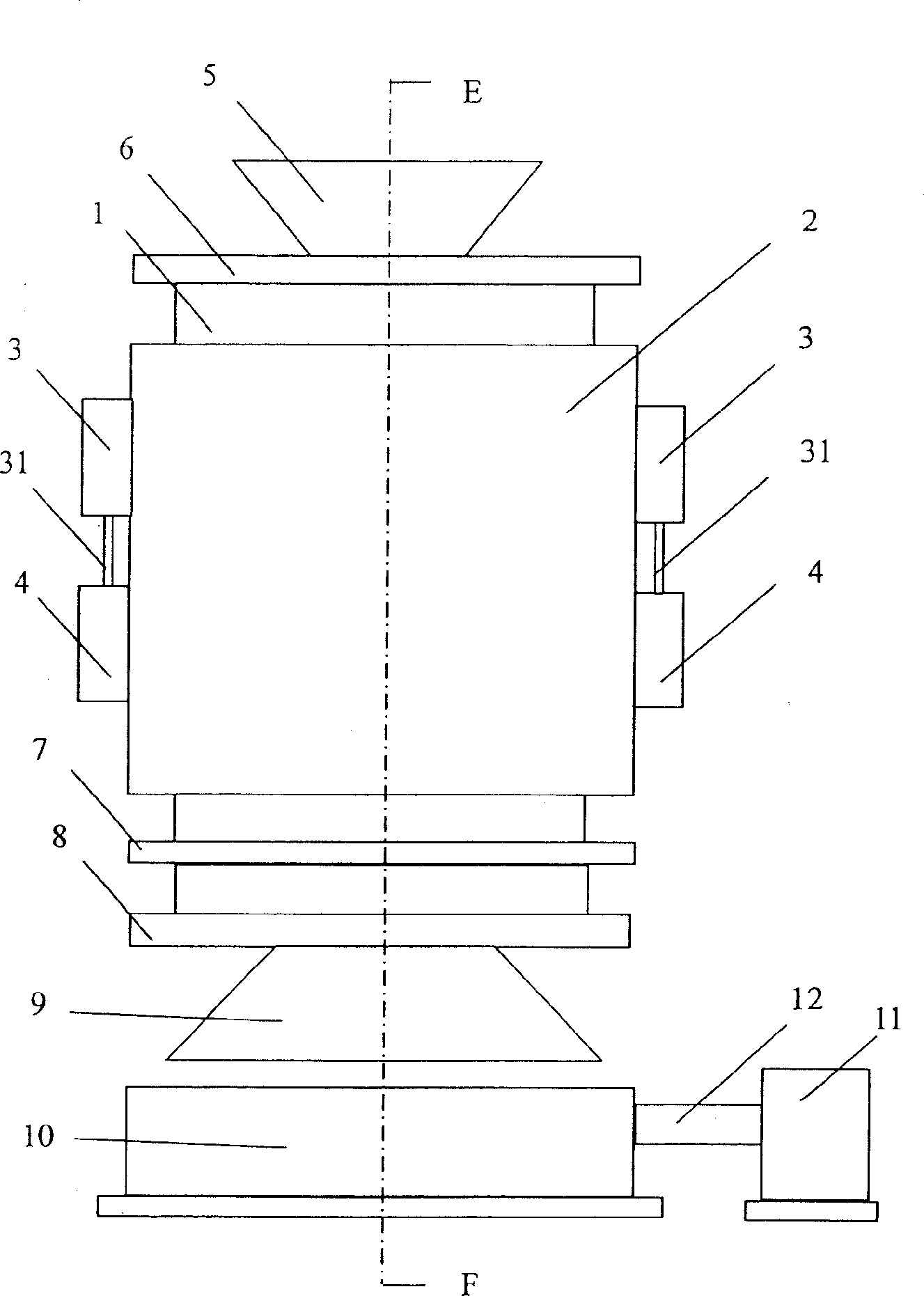

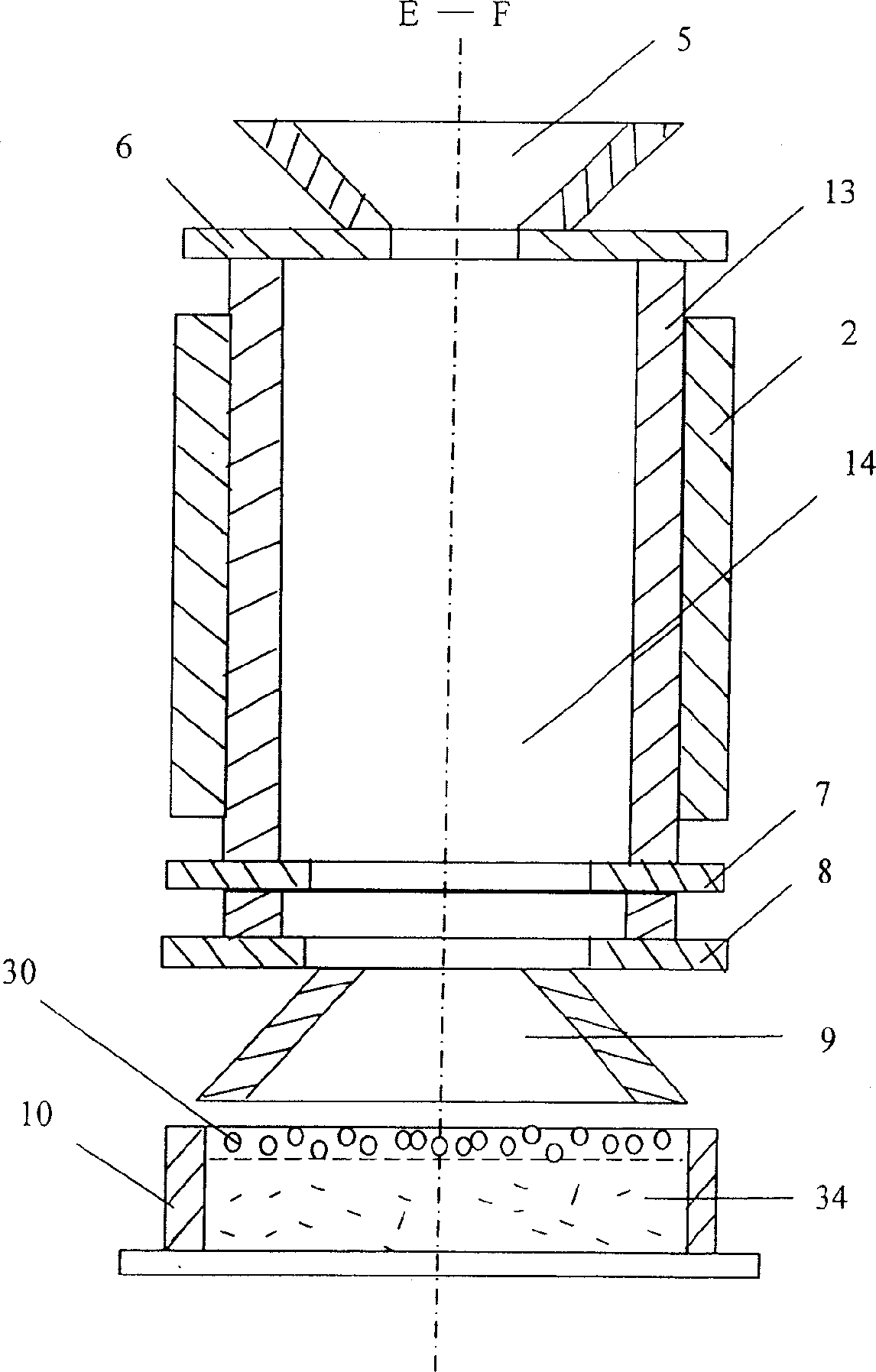

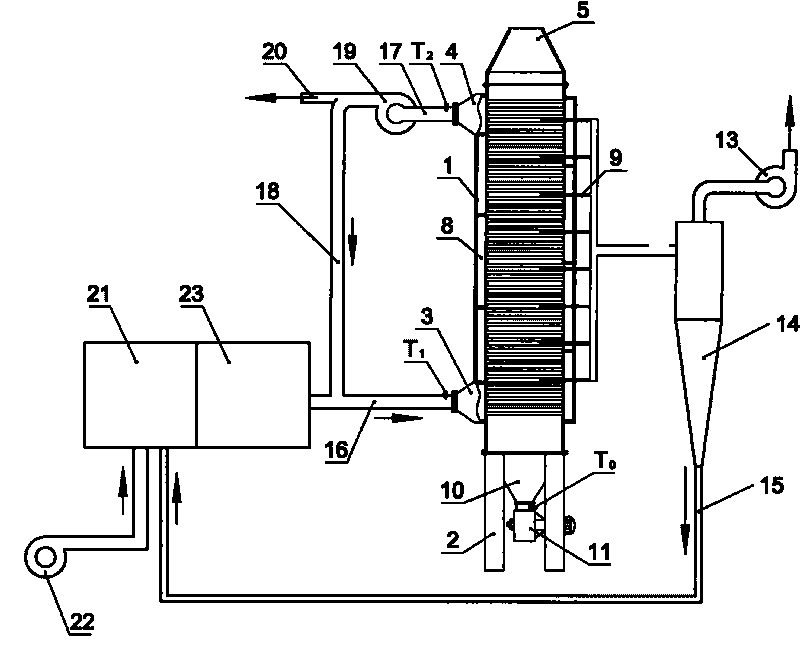

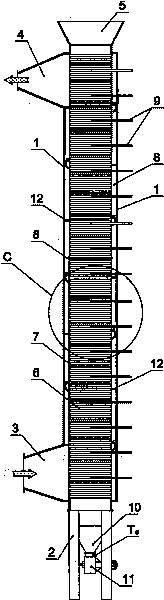

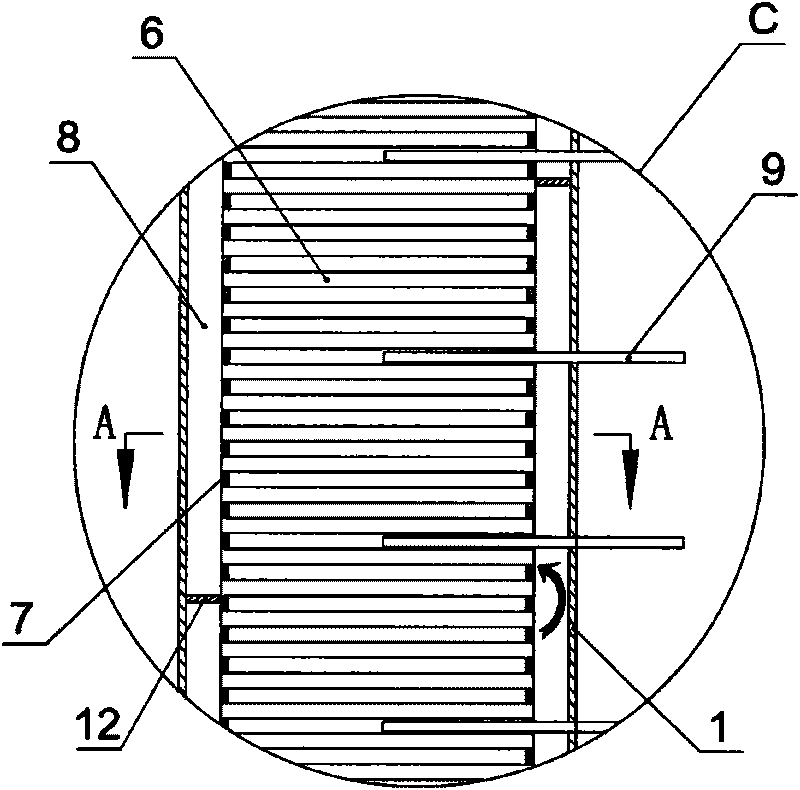

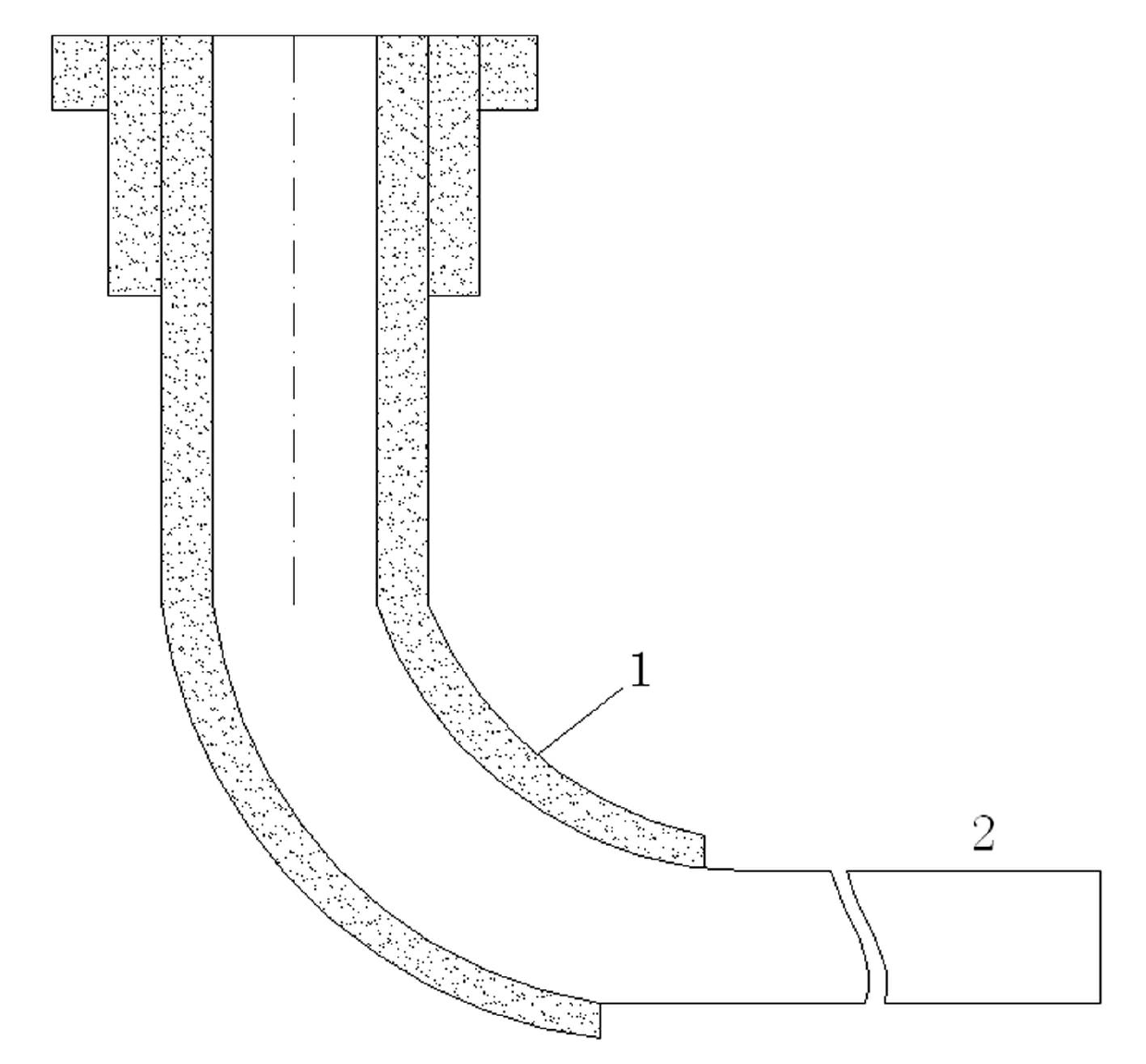

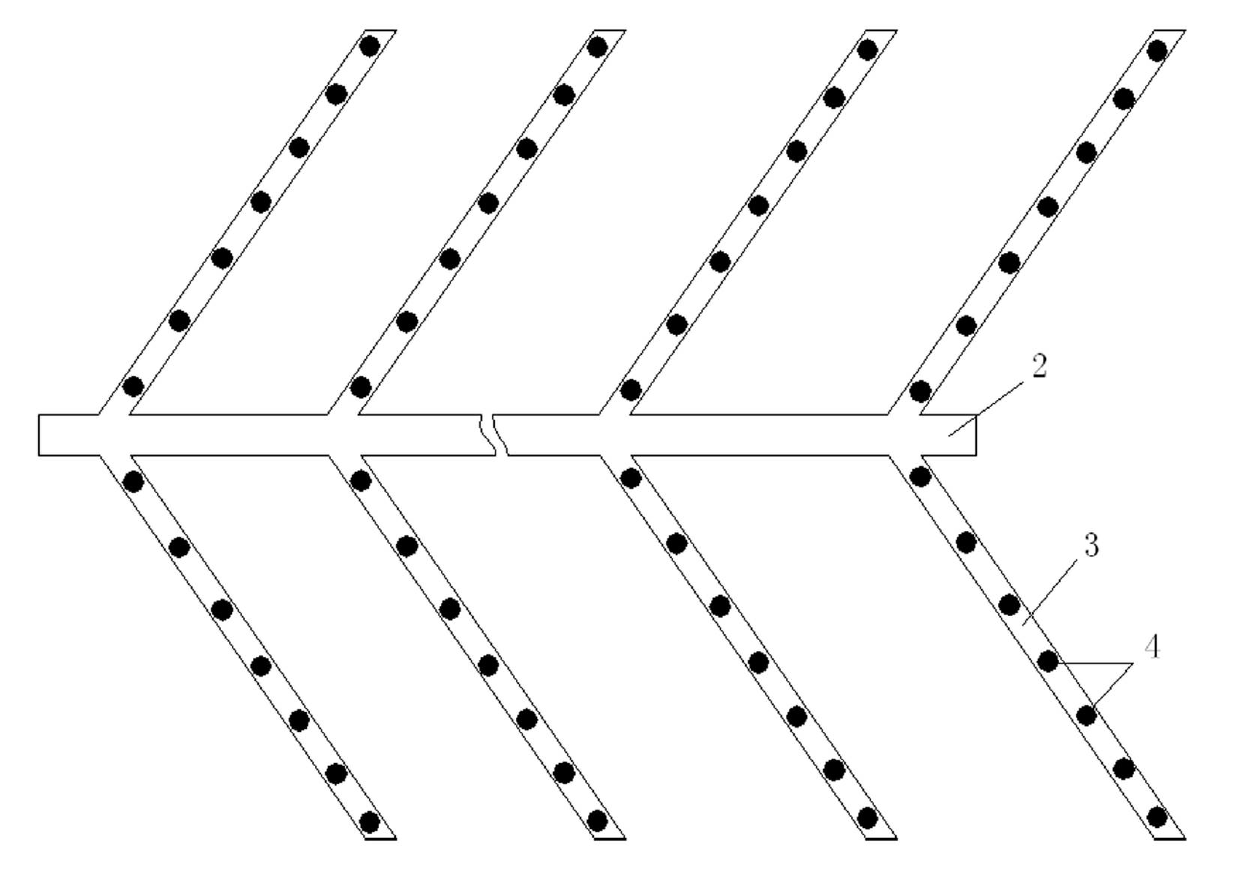

Oxygen-free drying and upgrading system of lignite and lignite drying process

InactiveCN101706196ALong-distance transportSolve fire problemsDrying solid materials with heatSolid fuelsFreeze-dryingFlue gas

The invention relates to an oxygen-free drying and upgrading system of lignite and a lignite drying process. The drying and upgrading system comprises a drying device and a heating system, wherein the drying device comprises a vertical drying cylinder as well as a lignite inlet, a lignite outlet, a gas inlet pipe and a gas outlet pipe which are arranged at the upper and the lower ends of the vertical drying cylinder. The outer sides of two side walls of the drying cylinder are respectively provided with hot gas cavities, and a certain amount of discharge pipes or discharge plates are communicated between the two hot gas cavities so that the lignite in the drying cylinder is completely isolated from hot gas in the hot gas cavities and the discharge pipe or the discharge plate. A thermometer T1 and a thermometer T2 are respectively installed at the nozzle of the gas inlet pipe and the nozzle of the gas outlet pipe, and a thermometer T0 is arranged at a discharge hole. The drying cylinder is also internally provided with a steam pipe which is led out of the drying device. Drying is carried out at normal pressure, and the flue gas input temperature T1, the flue gas output temperature T2 and the final heating temperature T0 of the lignite are controlled, thereby part of combined water in the lignite can be removed, the lignite is transformed from soft coal to hard coal and from hydrophily to hydrophobicity, the lignite can be transported, stored and used as soft coal, and the lignite drying process is very beneficial to popularization and implementation.

Owner:郑州拉姆顿清洁能源工程技术有限公司

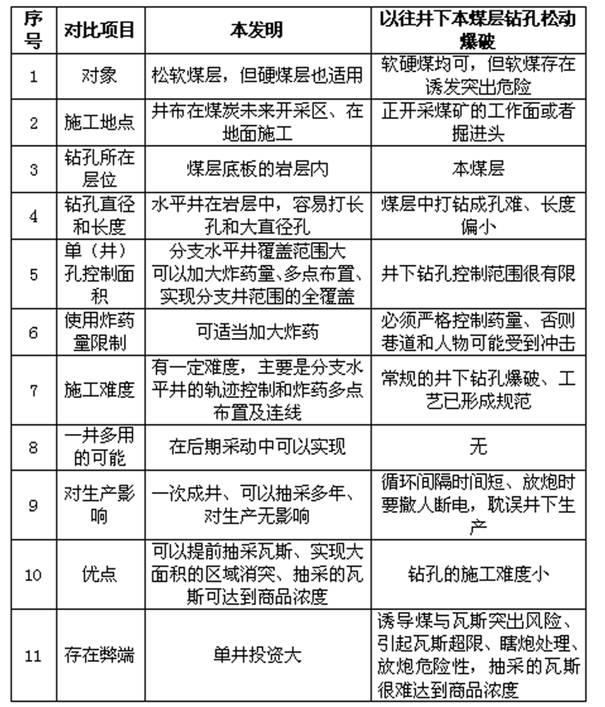

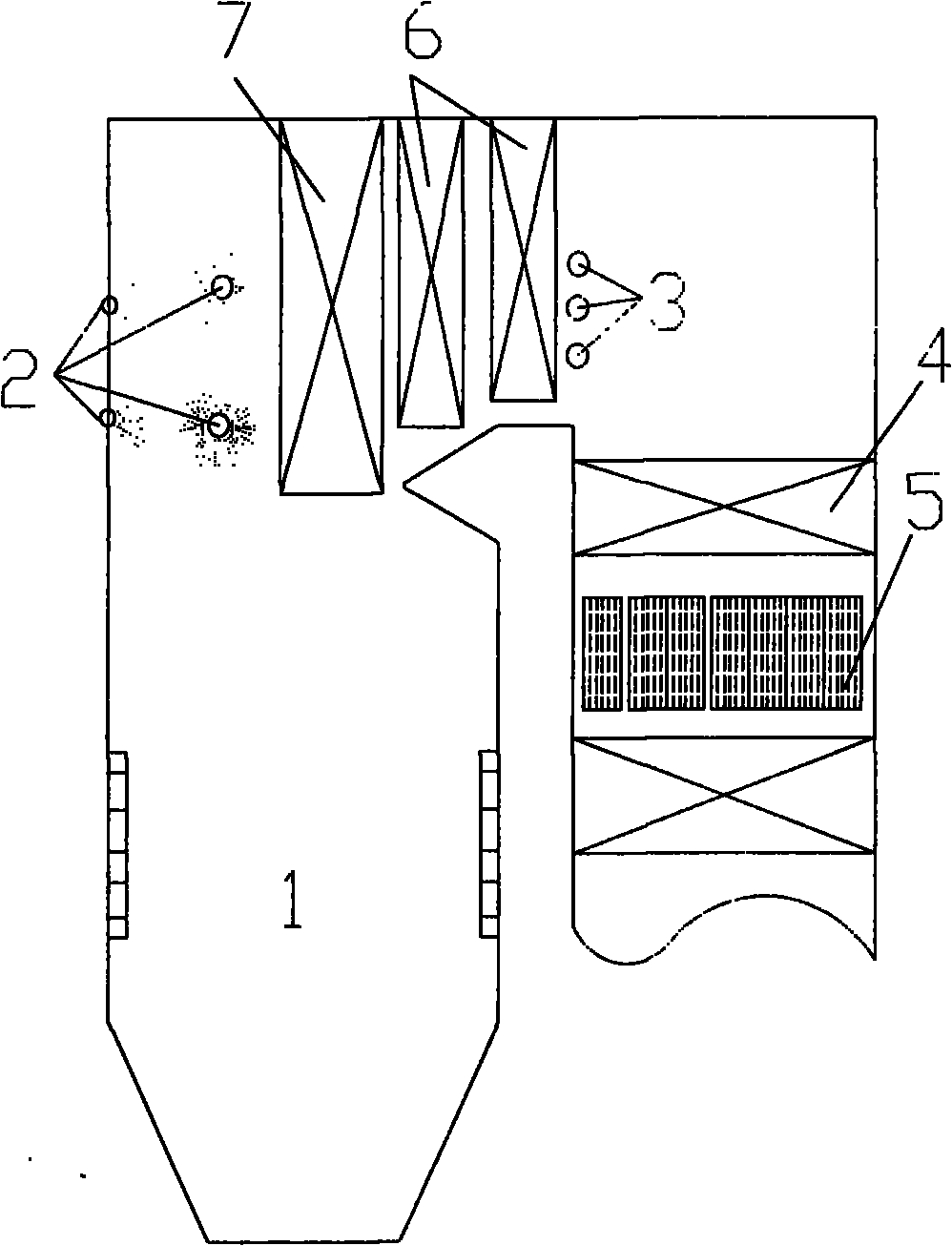

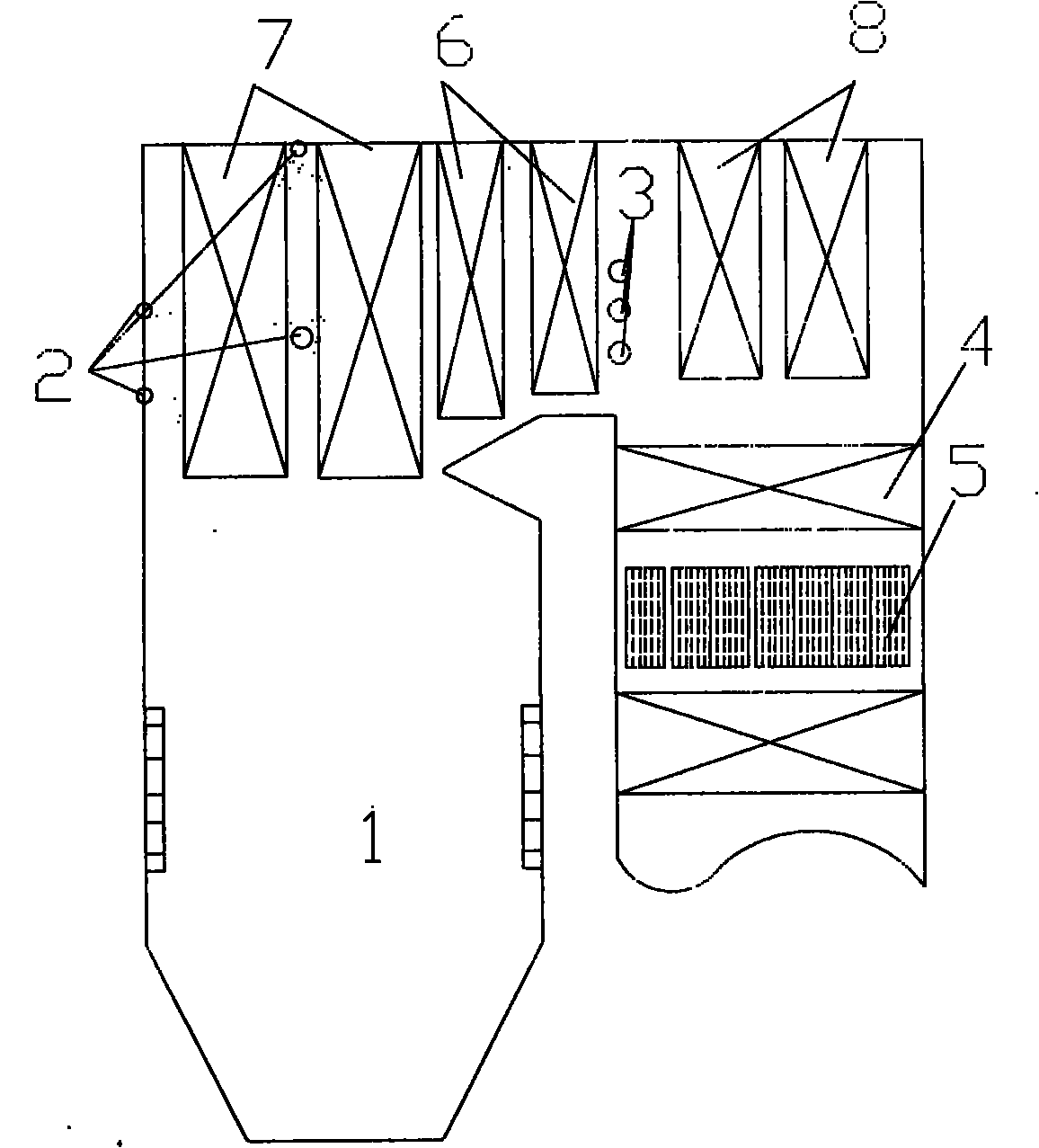

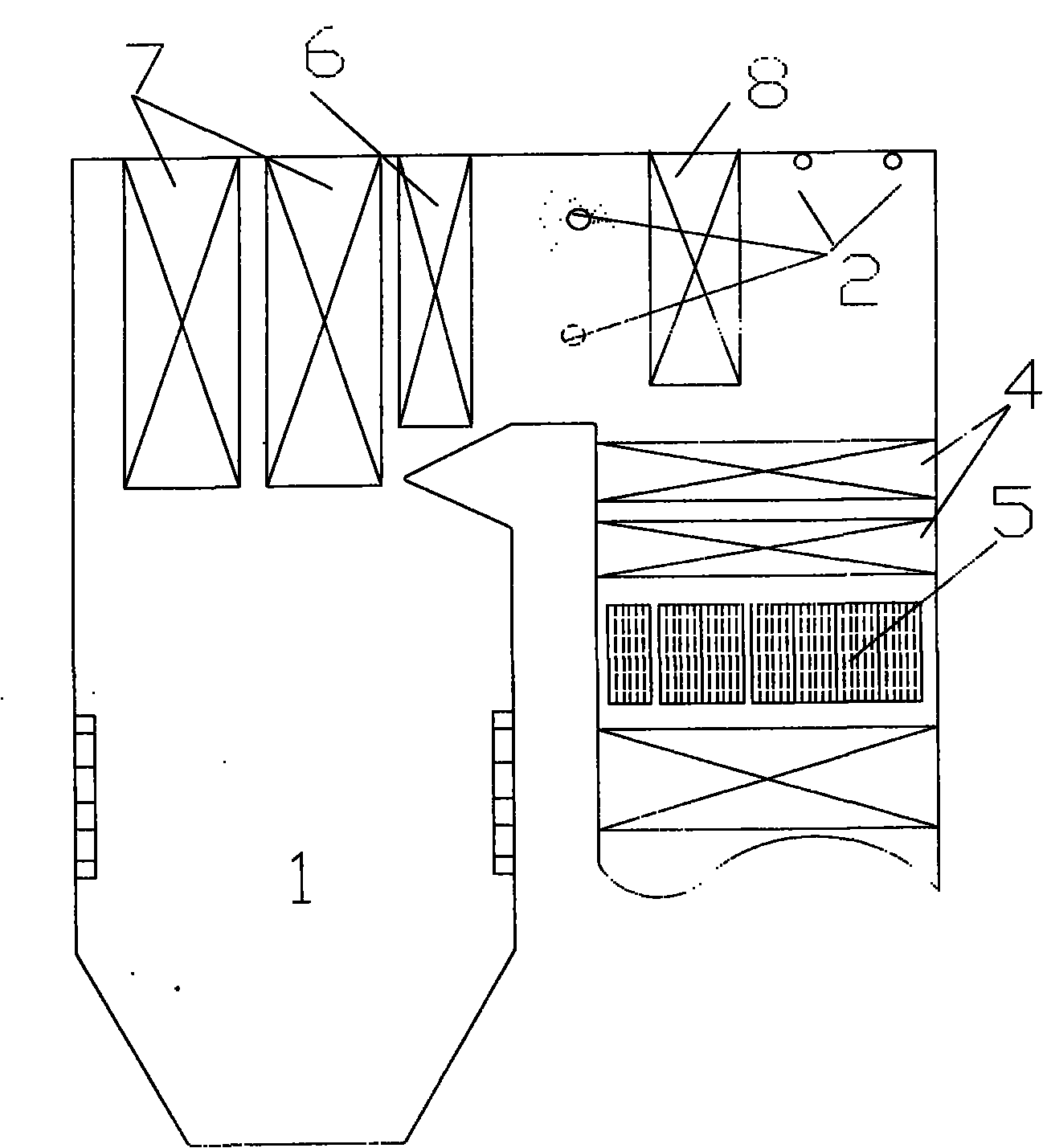

Loose blasting gas extraction technology of horizontal branch well of coal seam floor

InactiveCN102168575ARealize regional conflict eliminationRealize resource developmentFluid removalDirectional drillingStructure of the EarthHorizontal branch

The invention provides a loose blasting gas extraction method of a horizontal branch well of a coal seam floor. The method sequentially comprises the following steps of selecting a coal reservoir with a gas content of more than 8m3 / t and a solid coefficient f of less than 0.5; selecting 1-2 m coal seam floor as a layer of a main horizontal well and a branch horizontal well; determining positions of a ground well mouth and a deflection point according to the layer of the main horizontal well section; using a trisected structure as a well body structure and using open hole wells as the main horizontal well and the branch horizontal well; constructing the main horizontal well and the branch horizontal well in a selected floor rock layer; placing explosive points on the branch horizontal well section, wherein the explosive points are connected with each other by lines; and detonating all explosives through the ground; and mounting gas extraction equipment to extract the gas on the ground, wherein the gas can also be extracted at a negative pressure in a coal mining stage so that the well has multiple purposes. By using the method, the gas can be extracted on a soft coal ground to eliminate outburst and furthest reduce gas outburst disasters, and the gas (coal bed gas) resources can also be developed.

Owner:HENAN POLYTECHNIC UNIV

Method for realizing SNCR and SCR combined denitration by using coal-fired boiler

The invention discloses a technique for controlling pollutant discharge of coal-fired boilers, and aims to provide a method for realizing SNCR and SCR combined denitration by using a coal-fired boiler. The method comprises the following steps of: arranging a reducing agent spray gun on a flue gas channel of the coal-fired boiler at the flue gas temperature of between 600 and 950 DEG C, and arranging an SCR reactor loaded with an SCR catalyst in a tail gas flue of the boiler; and atomizing a reducing agent by the reducing agent spray gun, then spraying the reducing agent into a gas flue of a furnace chamber, and performing a selective catalytic reduction reaction on the surface of a catalyst when an exhaust gas mixed with NH3 and HNCO flows through the SCR reactor, wherein NO in the flue gas is reduced into N2. The method saves an SCR reducing agent spraying system, improves the utilization ratio of the catalyst in the process of an SNCR reaction, is convenient and easy to implement on a denitration improvement project by the existing furnace, has the denitration efficiency of over 90 percent, is suitable for furnaces burning soft coals and brown coals, is suitable for both medium-sized and large-sized boilers and has extensive application prospects.

Owner:ZHEJIANG UNIV +1

Method for preparing active semicoking H2S desulphurizer

InactiveCN1621498AWide variety of sourcesLow pricePhysical/chemical process catalystsOther chemical processesSorbentCoking plant

The present invention discloses the preparation process of active semi-coke H2S desulfurizer. The active semi-coke H2S desulfurizer is prepared with lignite semi-coke, anthracite or soft coal semi-coke and other carbon containing material and through first pressurized hydrothermal chemical modification, subsequent soaking with cuprammonia, CuSO4 solution or K2CO3 solution, drying and high temperature calcining. The present invention has the features of wide material source, low cost, repeated use of the adsorbent product, final use in waste water treatment and as fuel and no secondary pollution. The present invention may be used widely in purifying gas in various plants and environment protecting industry.

Owner:OCEAN UNIV OF CHINA

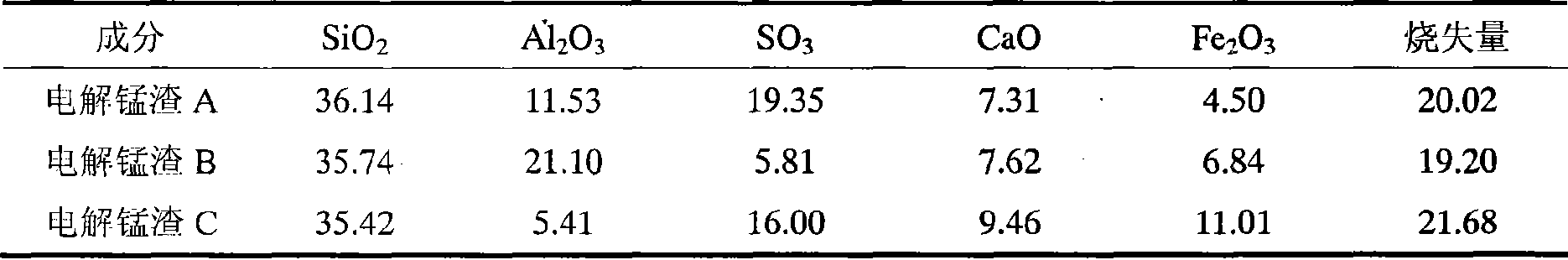

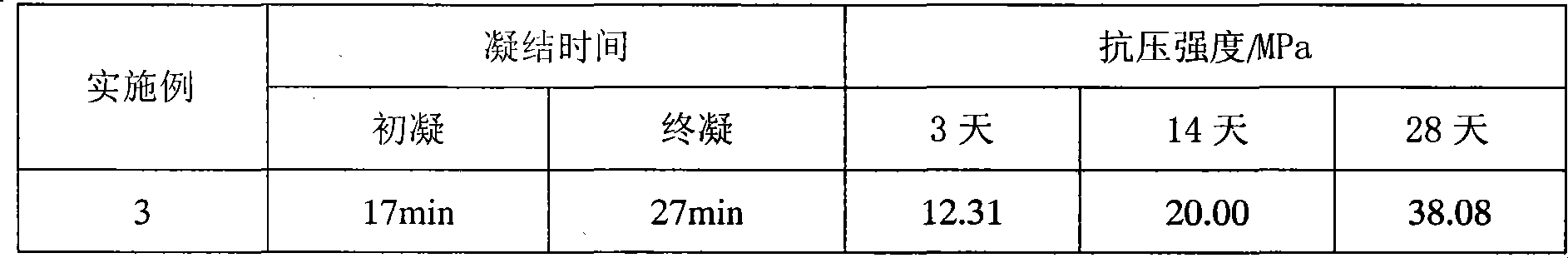

Manufacture of sulphur aluminate cements with electrolytic manganesium residue and method of manufacturing the same

A sulphate-aluminium-like cement produced by using electrolytic manganese slag and the preparation method of the cement relate to the production of the sulphate-aluminium-like by using industrial wastes and the preparation method of the cement. The raw materials of the cement clinker of the invention contain limestone, electrolytic manganese slag, kaolin and soft coal, and dihydrate gypsum is added to the fired cement clinker; the preparation method comprises the following steps: using the limestone, electrolytic Manganese slag, kaolin and soft coal as the raw materials of the clinker; first, levigating and homogenizing the raw materials, and calcining the raw materials into the clinker at a relatively low temperature; then adding the dihydrate gypsum to the clinker according to the requirement and then levigating the mixture to be the finished product. The cement is characterized in that the firing temperature ranges from 150 DEG C to 200 DEG C which is lower than that of the common Portland cement, and the energy-saving advantage is obvious; the mixture proportion range of the components is wide; the mixing amount of the manganese slag is great; and the fired cement has wide application, and so on. The preparation method can be widely used for producing the sulphate-aluminium-like cement by using electrolytic the manganese slag, and is in particular applicable to the production of early strength cement, rapid-hardening high-strength cement, expansive cement and low-alkali cement, and the like.

Owner:CHONGQING UNIV

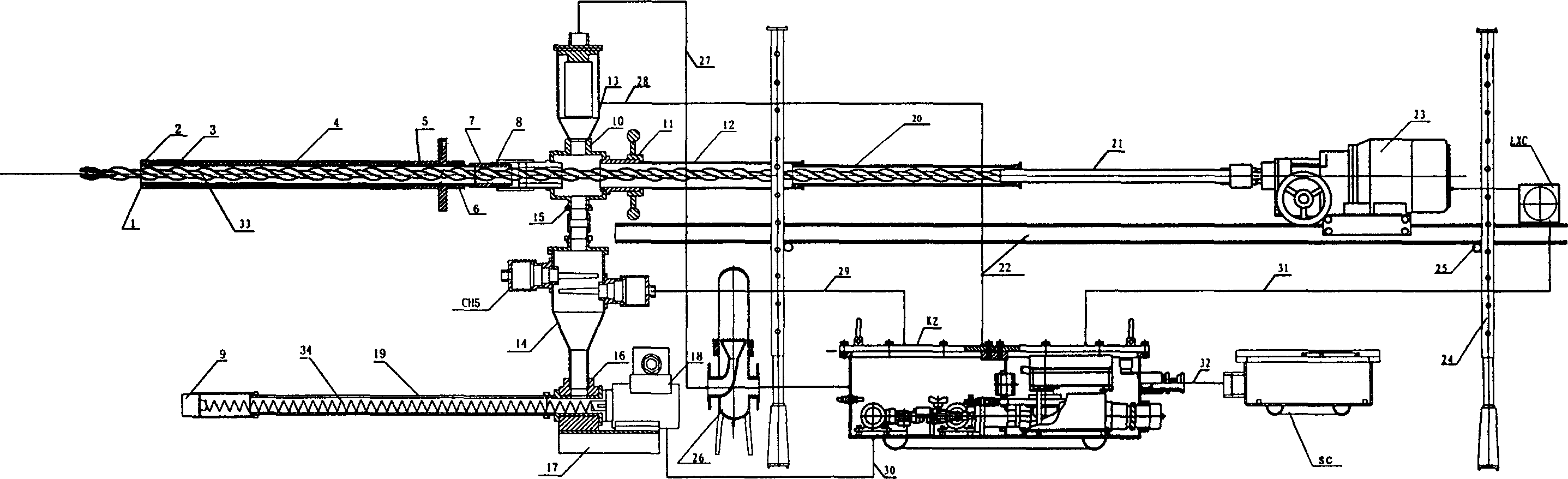

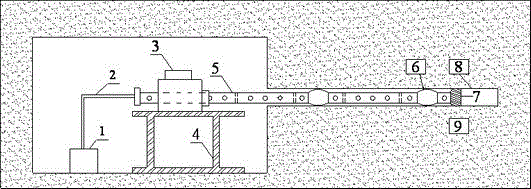

Continuous drilling flowrate process capable of predicting coal draft outburst and its apparatus

InactiveCN1847620APerceived heightControl startMining devicesDust removalData acquisitionEngineering

The present invention is continuous drilling flow rate capable of predicting coal draft outburst and its apparatus. By means of the method of drilling holes in the coal bed drilling direction for data acquisition and the apparatus comprising hole sealing capsule unit, solid-gas separator, filter, coal bit controller, electric rock drill with connected displacement sensor LXC, controller unit KZ with explosion resistant enclosure and connected computer data acquisitor SC, the present invention can determine the gas distribution in the drilling direction, obtain the gas flow rate distribution curve along the drilling depth during coal bed drilling process, so as to determine the distance of soft coal containing high pressure gas to the ground, judge the distance to the place with maybe outburst. The present invention has compact reasonable structure, high accuracy and stable and reliable measurement result, and may be used widely.

Owner:CHINA UNIV OF MINING & TECH

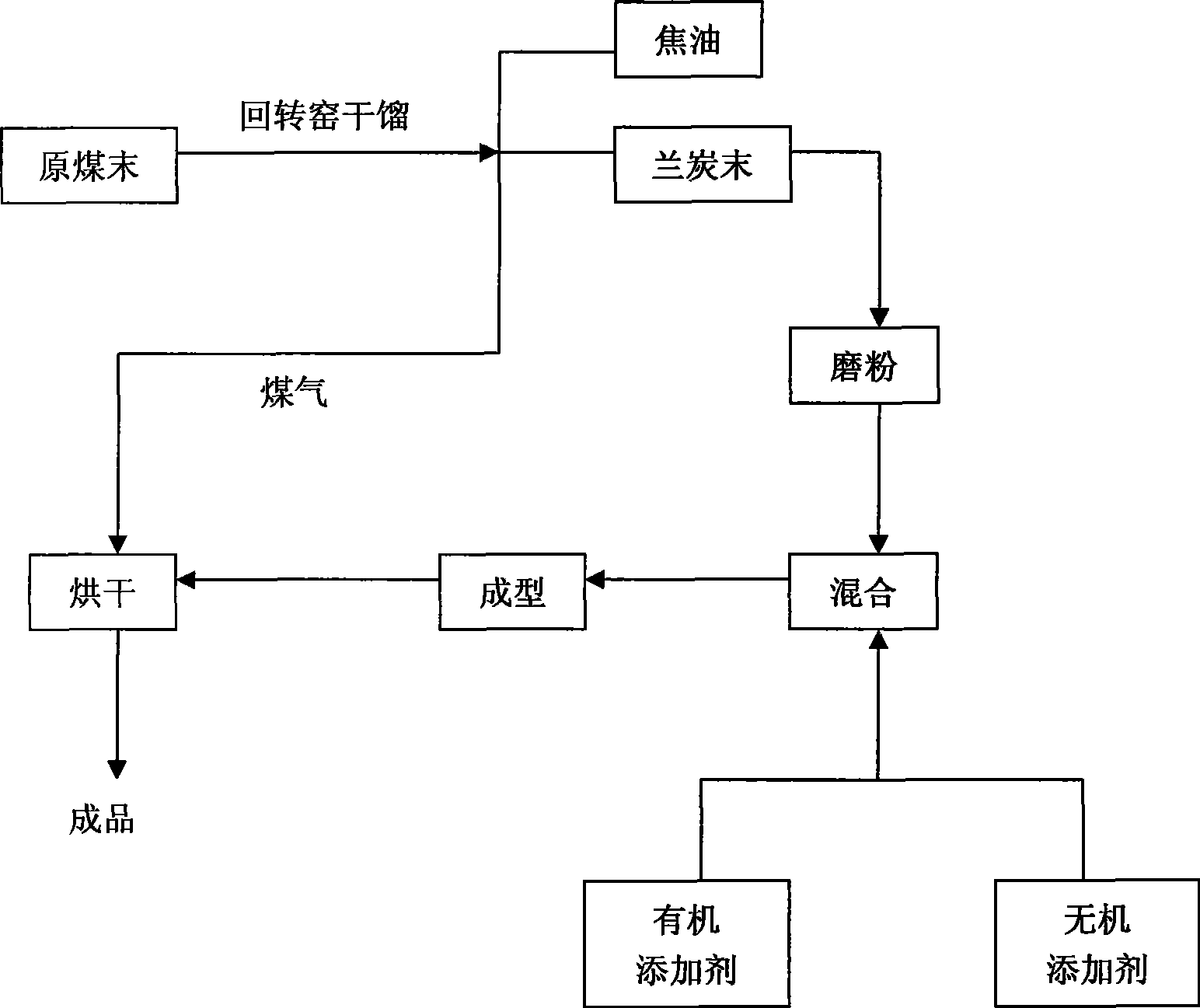

Method for producing moulded coal by oil-rich coal with low-ash low-sulfur low-phosphor and high-heat productivity

InactiveCN101445756AIncrease added valueLow ash low sulfurSolid fuelsChemical industrySodium Bentonite

The invention relates to a method for producing environmental protective smokeless moulded coal by oil-rich coal with low-ash low-sulfur low-phosphor and high-heat productivity. Soft coal powder is used as a raw material to produce tar, coal gas and semi coke powder by low-temperature carbonization. The semi coke powder is powdered and added with caking agent and additive to be mixed, extruded to be formed and then dried, and the environmental protective clean smoke less molded coal is produced, wherein, the caking agent is compound caking agent, including organic caking agent, inorganic caking agent; the organic caking agent is polyvinyl alcohol and starch; the polyvinyl alcohol and the starch are made into 5 percent to 10 percent of latex; every ton of moulded coal is added with 1-2kg of the polyvinyl alcohol and 6-15kg of the starch; the inorganic caking agent is bentonite; and every ton of the moulded coal is added with 20-40kg of the bentonite. The production method can relieve the status that smokeless coal has insufficient resource and is in short supply and increases a novel raw material supply variety for the coal used for Chinese chemical industry and synthetic ammonia gas-making industry, and at the same time the technical processing can improve the added value of Shenfu raw coal powder and the semi coke powder and changes waste into valuable.

Owner:杨兴平

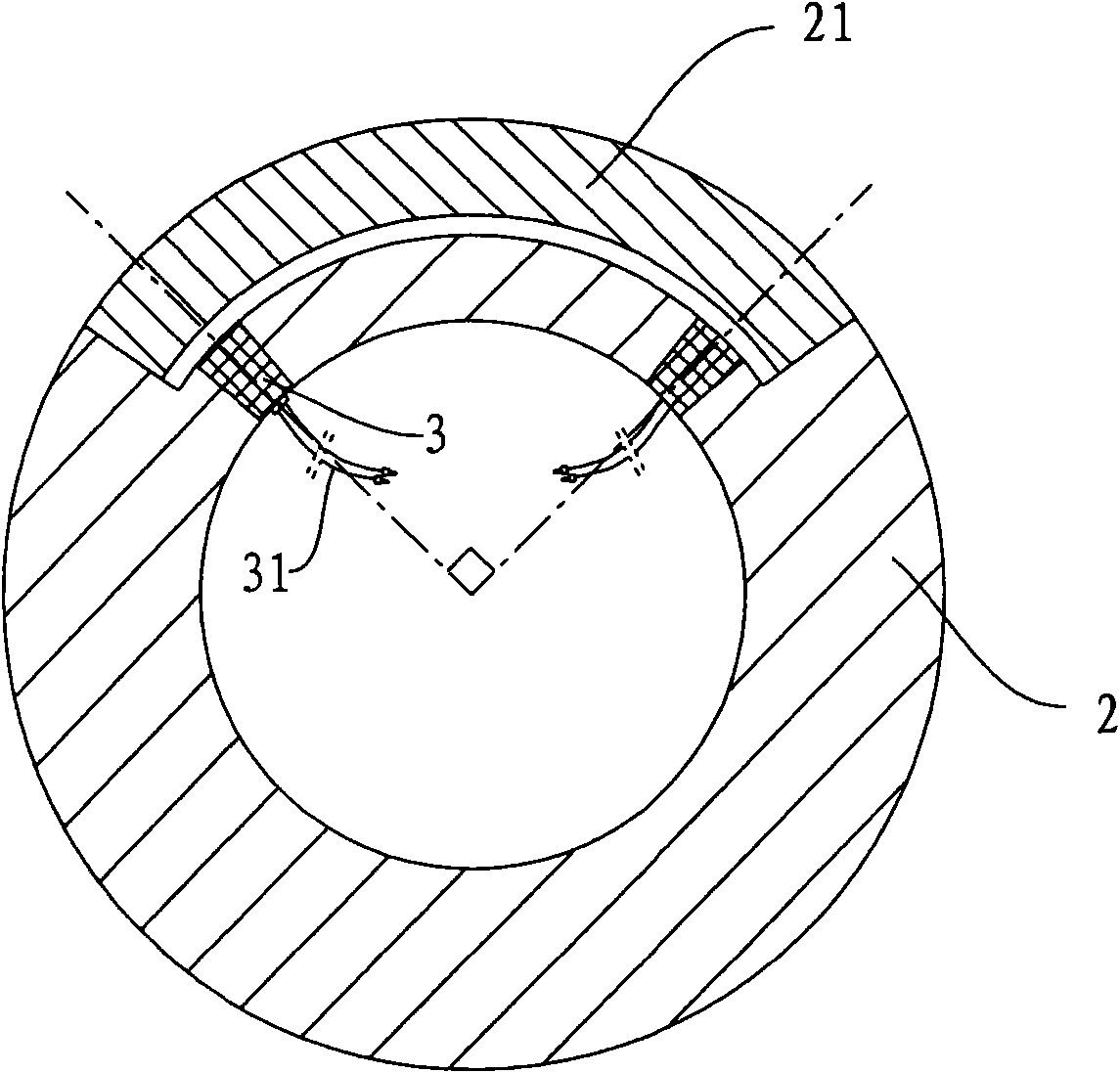

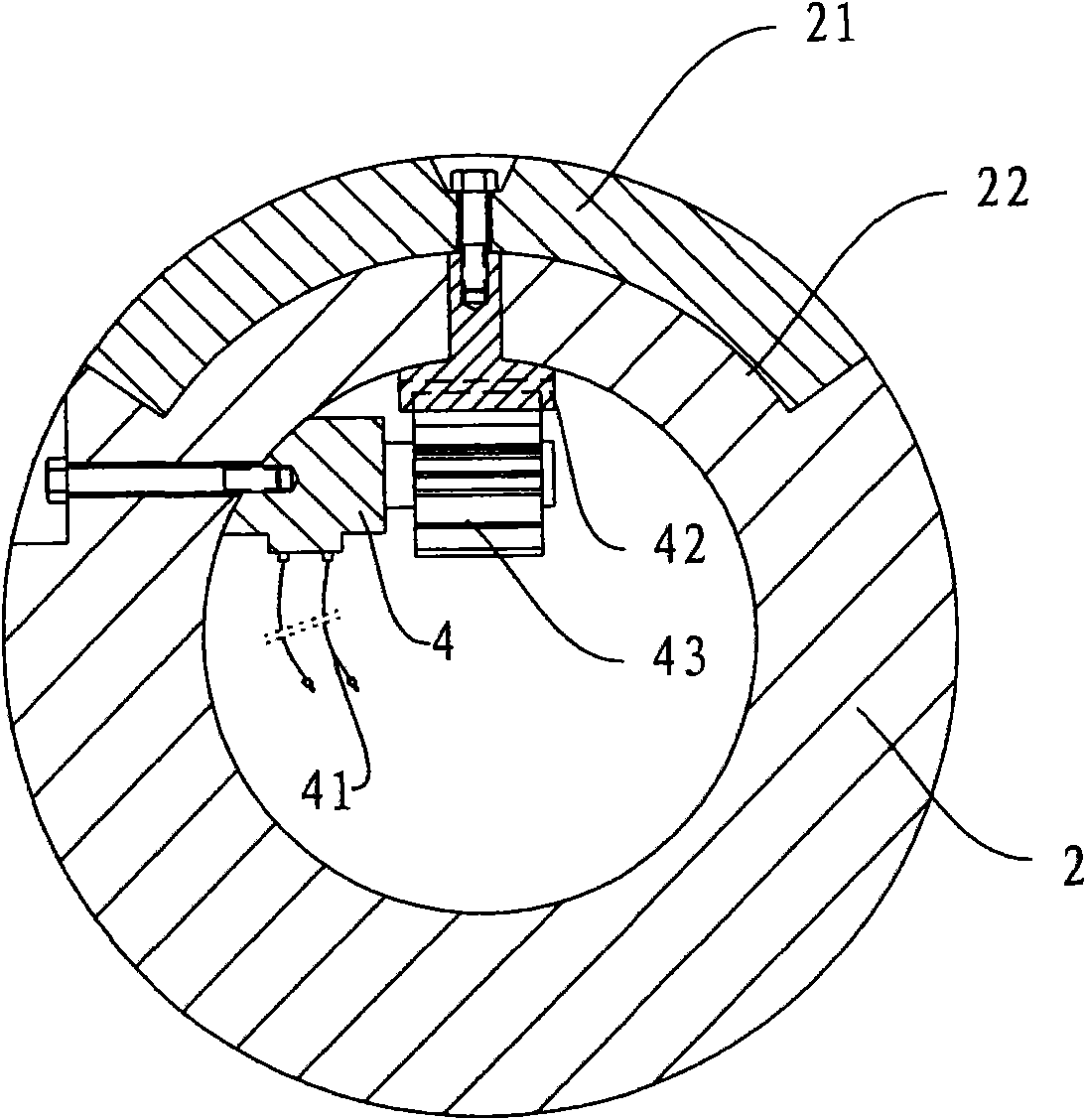

Device and method for measurement while drilling of ground stress

InactiveCN101581219AEasy to useContinuous measurementSurveyConstructionsSignal processingPressure sensor

The invention discloses a device for the measurement while drilling of ground stress, which comprises a drill, a drill rod and a drill head, wherein the side wall, close to the drill head, of the drill rod connected with the drill head is provided with a pressure sensor; and the drill rod is also provided with a sliding cover protecting the pressure sensor; and the sliding cover slides open and closes through a driving device. The invention also discloses a method for the measurement while drilling of ground stress, which comprises the following steps: selecting a position to be measured and performing drilling construction by using the device for the measurement while drilling of ground stress; stopping a machine after drilling, separating the drill rod from the drill, directly connecting the pressure sensor with a signal processing unit, and sliding the sliding cover open to expose the pressure sensor by using the sliding cover driving device; and measuring the ground stress of a coal bed by using the pressure sensor. The device and the method can measure the ground stress while drilling, be used underground conveniently, allow for continuous, accurate and quick measurement in a measurement hole and measure the ground stress of soft coal beds.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

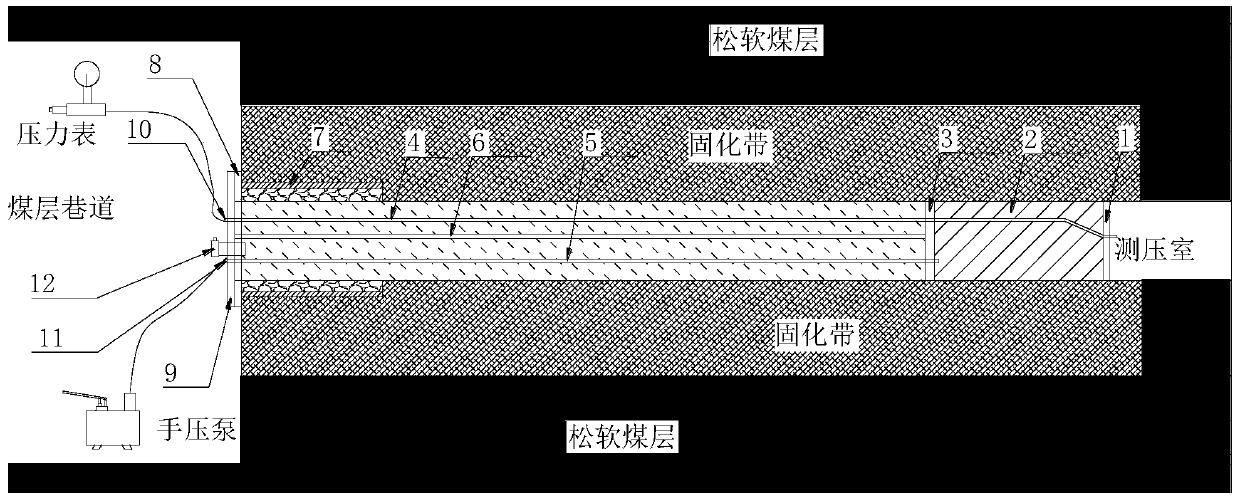

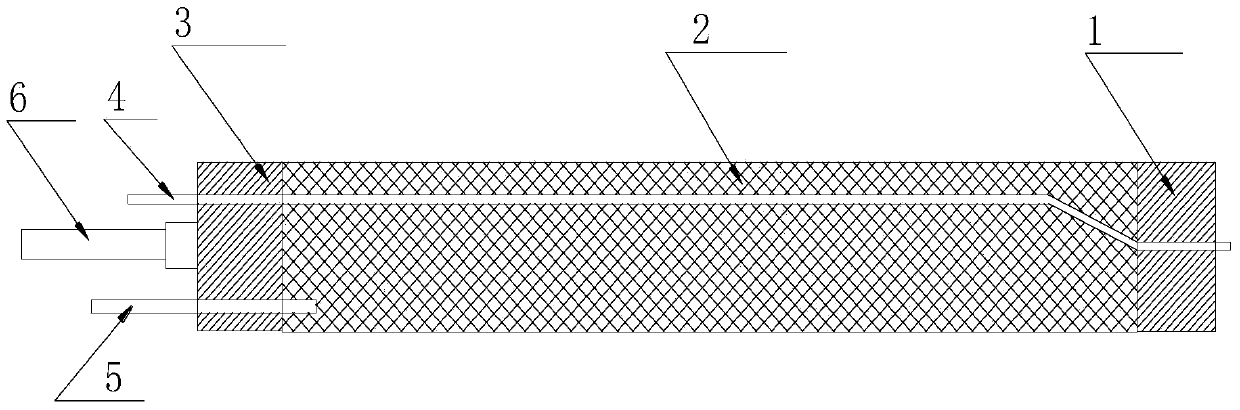

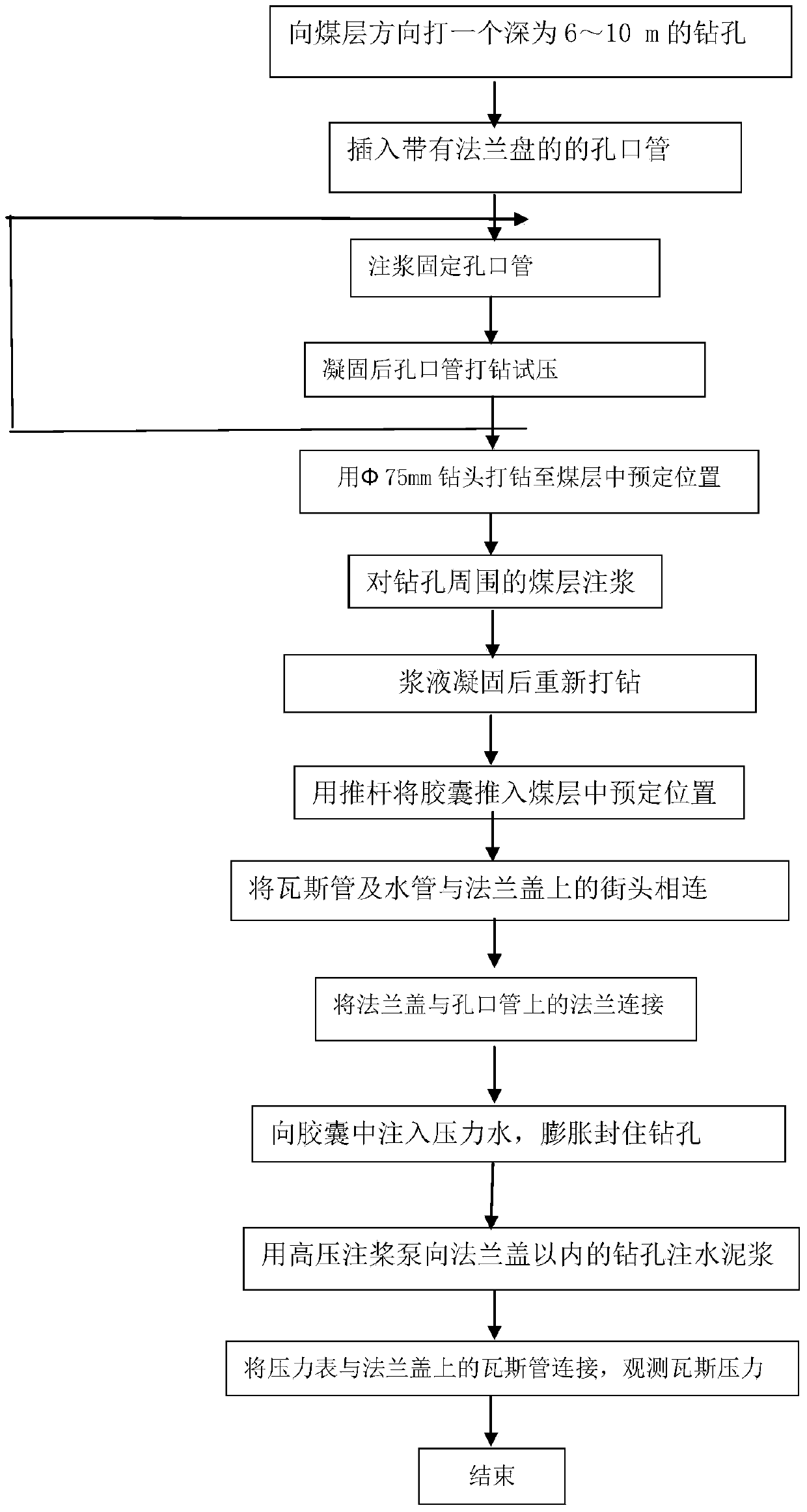

Method for drilling holes on soft coal seam to measure coal seam gas pressure

InactiveCN103742129AWill not leakAvoid the impact of pressure measurement resultsSurveySealing/packingMeasurement deviceCement slurry

A method for drilling holes on a soft coal seam to measure coal seam gas pressure comprises the steps of drilling a shallow hole on the coal seam, placing an orifice pipe in the hole, utilizing cement slurry to fix the orifice pipe in the coal seam; performing drilling through the orifice pipe to the deep part of the coal seam, quitting a drill rod, injecting mixed slurry A and B to solidify coal around the drilled hole, performing drilling again along the originally drilled hole to exceed grouting depth by 3-5m; quitting the drill rod, inserting a capsule hole sealing device with a gas pipe and a water pipe in the drilled hole, sequentially connecting a push rod to push the capsule hole sealing device to be near the drilled hole grouting depth; on an orifice, respectively connecting the gas pipe and the water pipe with a connector on a flange cover, fixing the flange cover on the orifice pipe, utilizing a manual pump to inject water into the capsule hole sealing device in the drilled hole through a water pipe connector, and expanding the capsule hole sealing device to seal the drilled hole; injecting high-pressure cement slurry through a grouting valve on the flange cover, and connecting a gas pipe connector with a pressure meter, so that the gas pressure of the soft coal seam can be measured. The method is simple and convenient to operate, and a measurement device is simple.

Owner:CHINA UNIV OF MINING & TECH

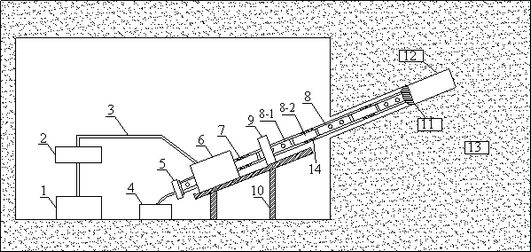

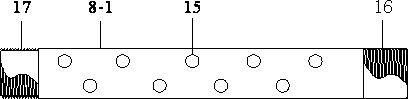

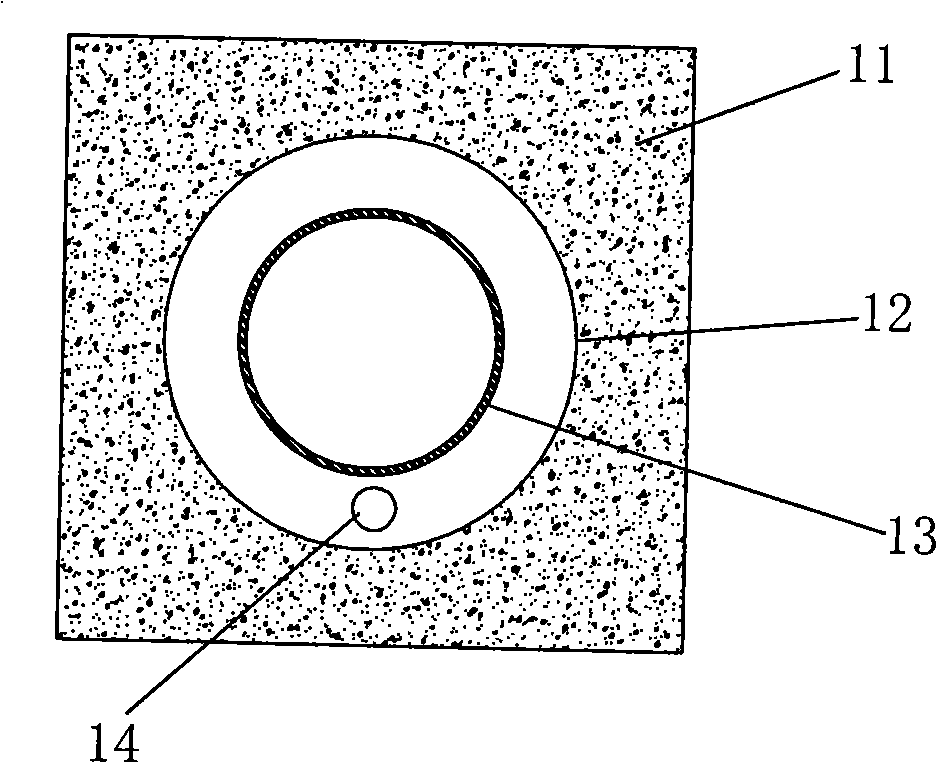

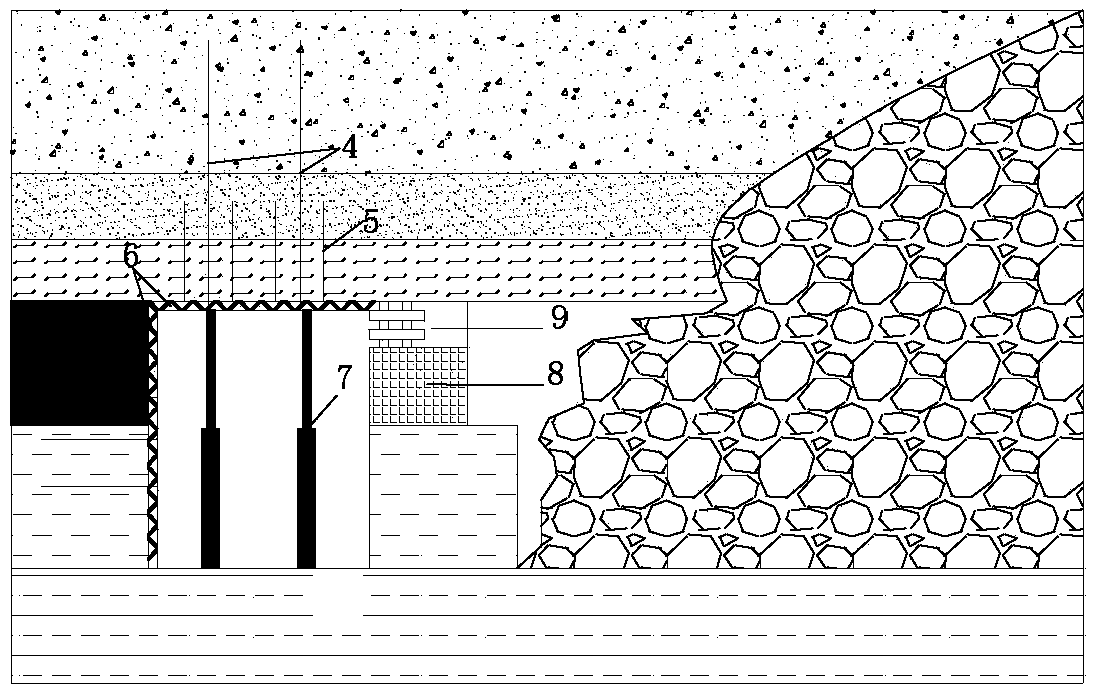

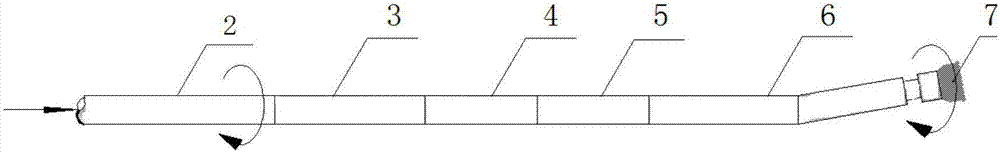

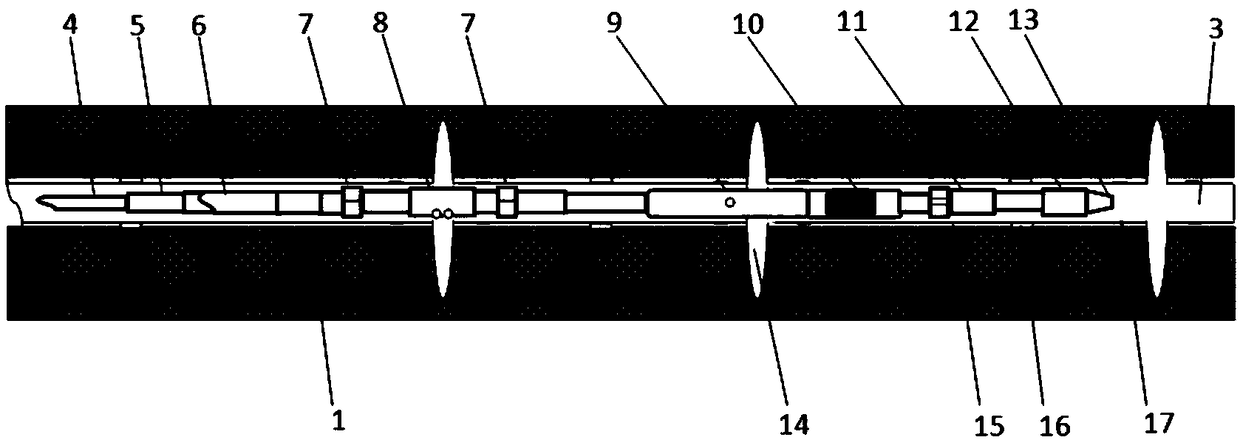

Multiple step type drilling and protecting integrated system and process for soft coal seam

ActiveCN102747953AEffective supportLarge diameterDrill bitsDirectional drillingWhole bodyAir compressor

The invention discloses a multiple step type drilling and protecting integrated system and a process for a soft coal seam. The system mainly comprises an air compressor, a high-pressure rubber hose, a hole protecting drilling machine, a rack, a hole protecting drilling rod, a guider and a simple drill. The process comprises the steps of firstly drilling a hole by using a common drilling rod and a common drill and pulling the common drilling rod and the common drill out of the hole after the hole is formed; then performing second drilling of the formed drill hole by using the hole protecting drilling rod and the simple drill in a matching mode, and simultaneously performing wind-power auxiliary slagging, when an end hole point is drilled, the hole protecting drilling rod is not withdrawn, the whole body is left inside the hole, and hole wall supporting and gas extraction functions are achieved; and finally pulling out and recycling the hole protecting drilling rod through the hole protecting driller after the gas extraction is completed. According to the system and the process, the process is unique, a hole protecting pipe can transmit high-pressure air and can extract gas, the coal dust discharging performance is strong, the hole protecting pipe moves forwards along the drill hole easily, the hole protecting pipe diameter is large, the hole protecting length is long, the problems that the soft coal seam is small in hole protecting pipe diameter and short in feeding distance are solved, and the system and the process are particularly suitable for soft high gas coal seams with a value of a sturdiness coefficient f, which ranges between 0.3 and 0.8.

Owner:CHINA UNIV OF MINING & TECH

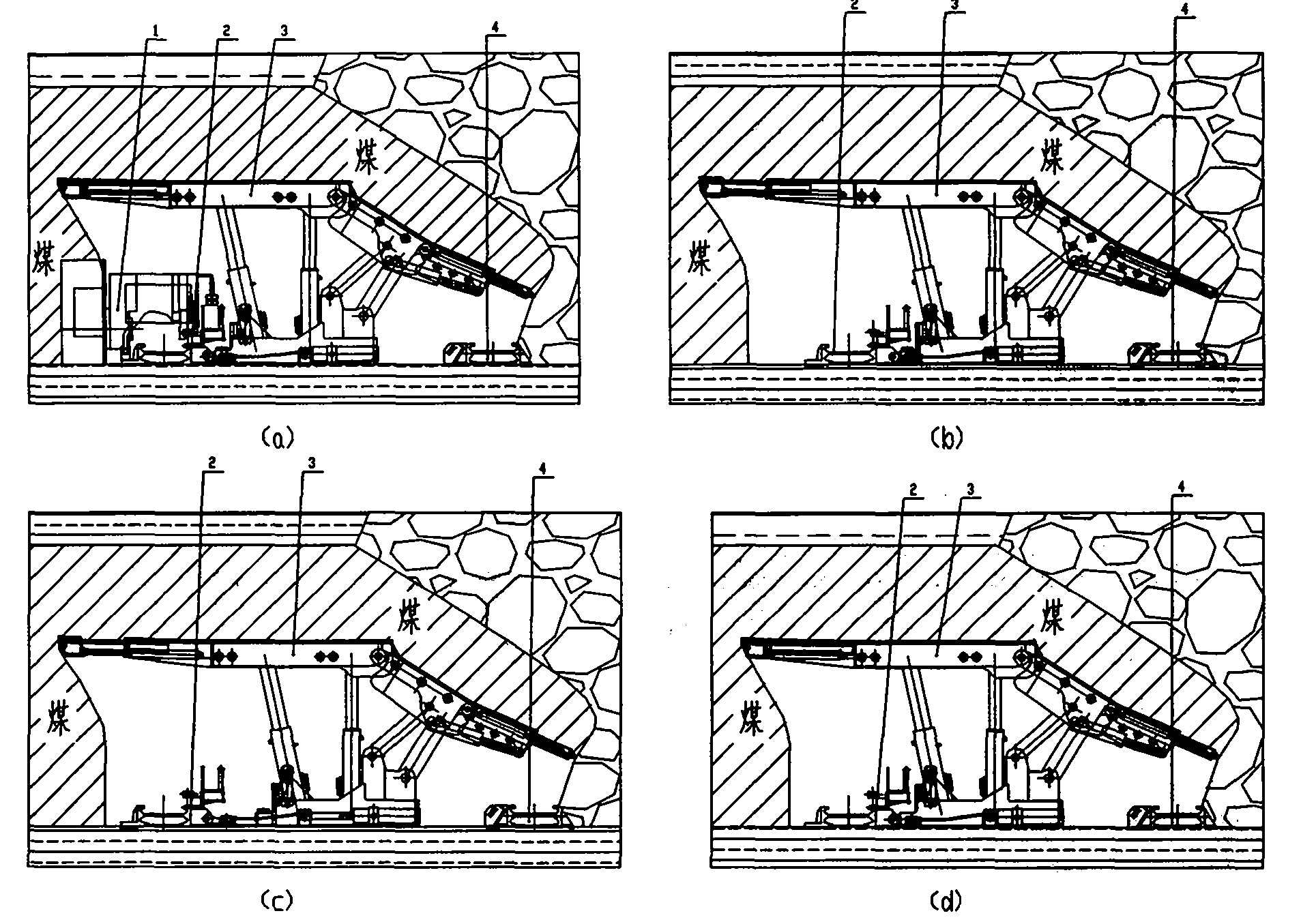

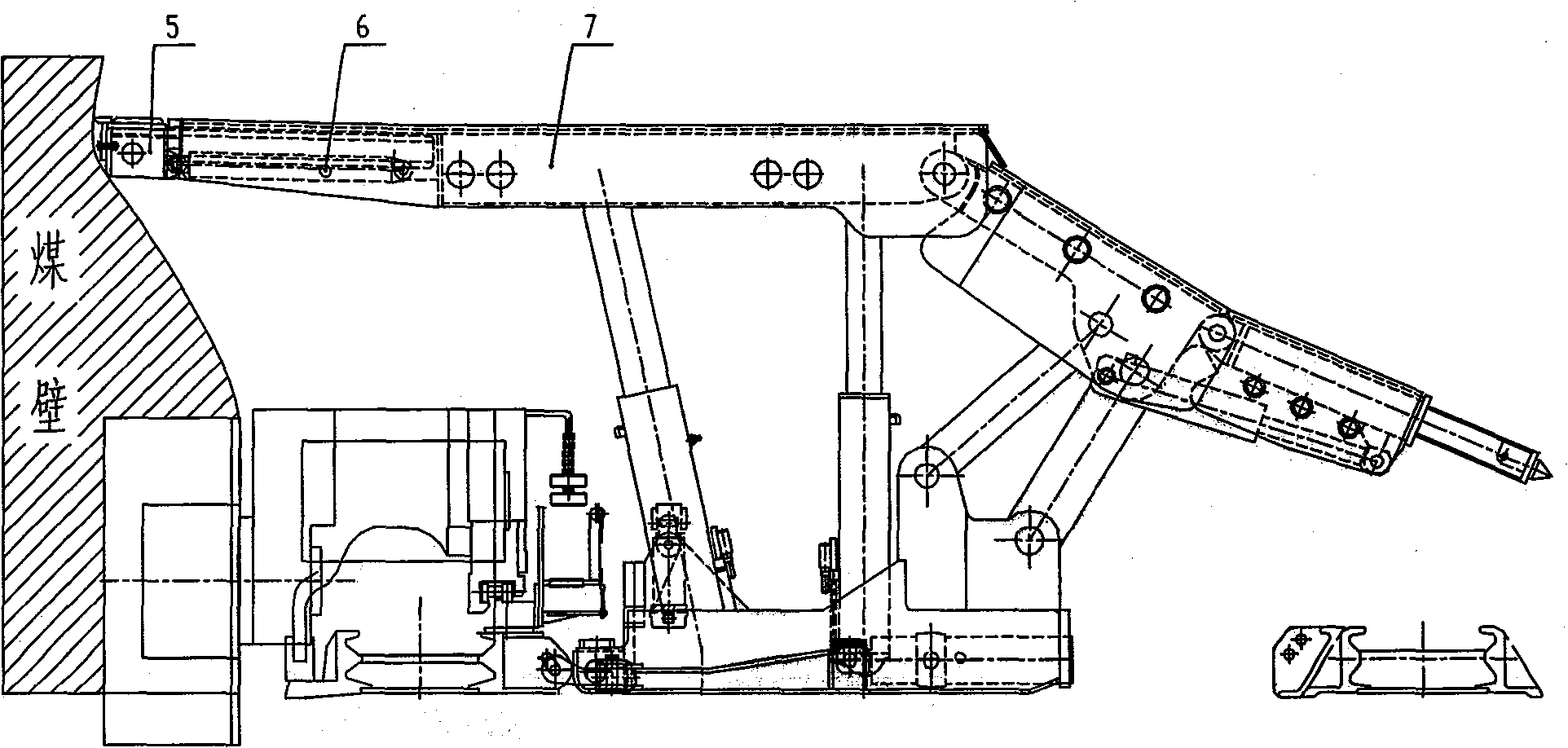

Very soft thick coal seam forepoling hold top coal caving mining method and hydraulic support structure

InactiveCN101936164ARealize fully enclosed miningImprove the support effectUnderground miningSurface miningEngineeringFall accident

The invention discloses a very soft thick coal seam hold and full-mechanized top coal caving mining method and a top coal caving hydraulic support structure which is applicable to the process requirements of very soft coal seam hold and full-mechanized top coal caving, and the method can form the hold mining process features by using a roller of a coal mining machine to cut and load coal under a top beam of the support, realize the full-closed mining of a working face, and lead the beam end distance of the top beam (the distance between the front end of the top beam and the coal wall when using the coal mining machine to cut and mine) to be close to zero or be a negative value, and a coal shoveling plate is arranged at the front end of a shovel type telescopic beam, thereby being capable of shoveling off top coal under the situation that the coal wall spalling is insufficient, protecting an exposed top plate under the situation that the coal wall is sufficiently spalled and further avoiding the large-area roof-fall accidents, wherein the telescopic stroke of a jack of the telescopic beam is larger than a web of the coal mining machine. The method can realize the full-mechanized mining of a very soft coal seam and has the advantages of low cost, simple process, safety, high efficiency and the like.

Owner:TIANDI SCI & TECH CO LTD

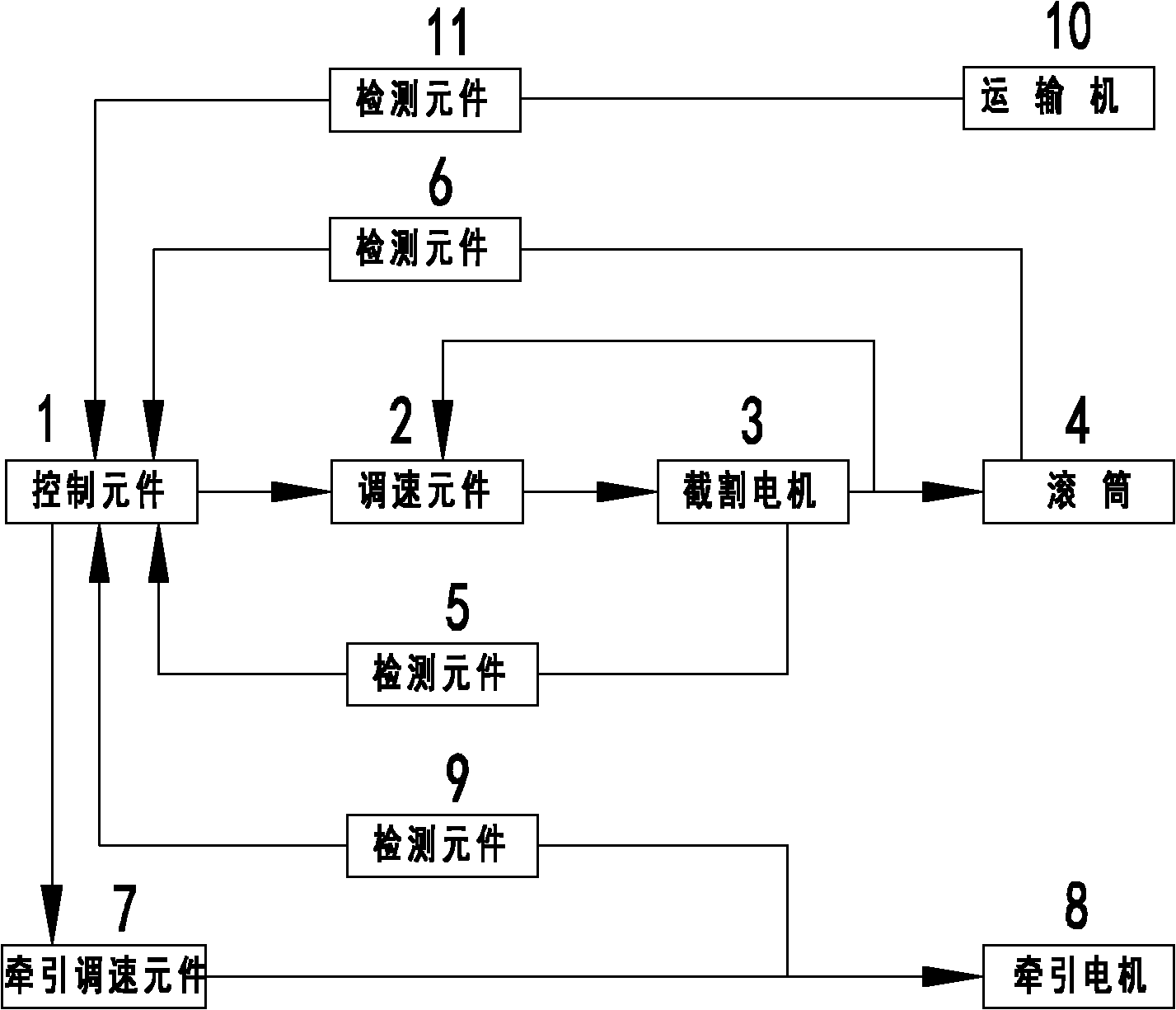

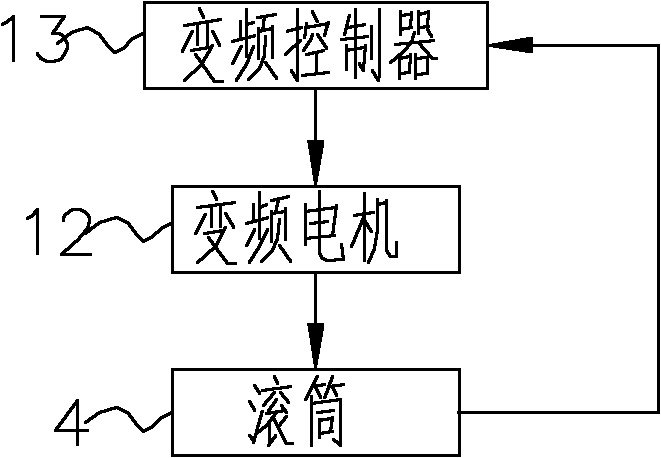

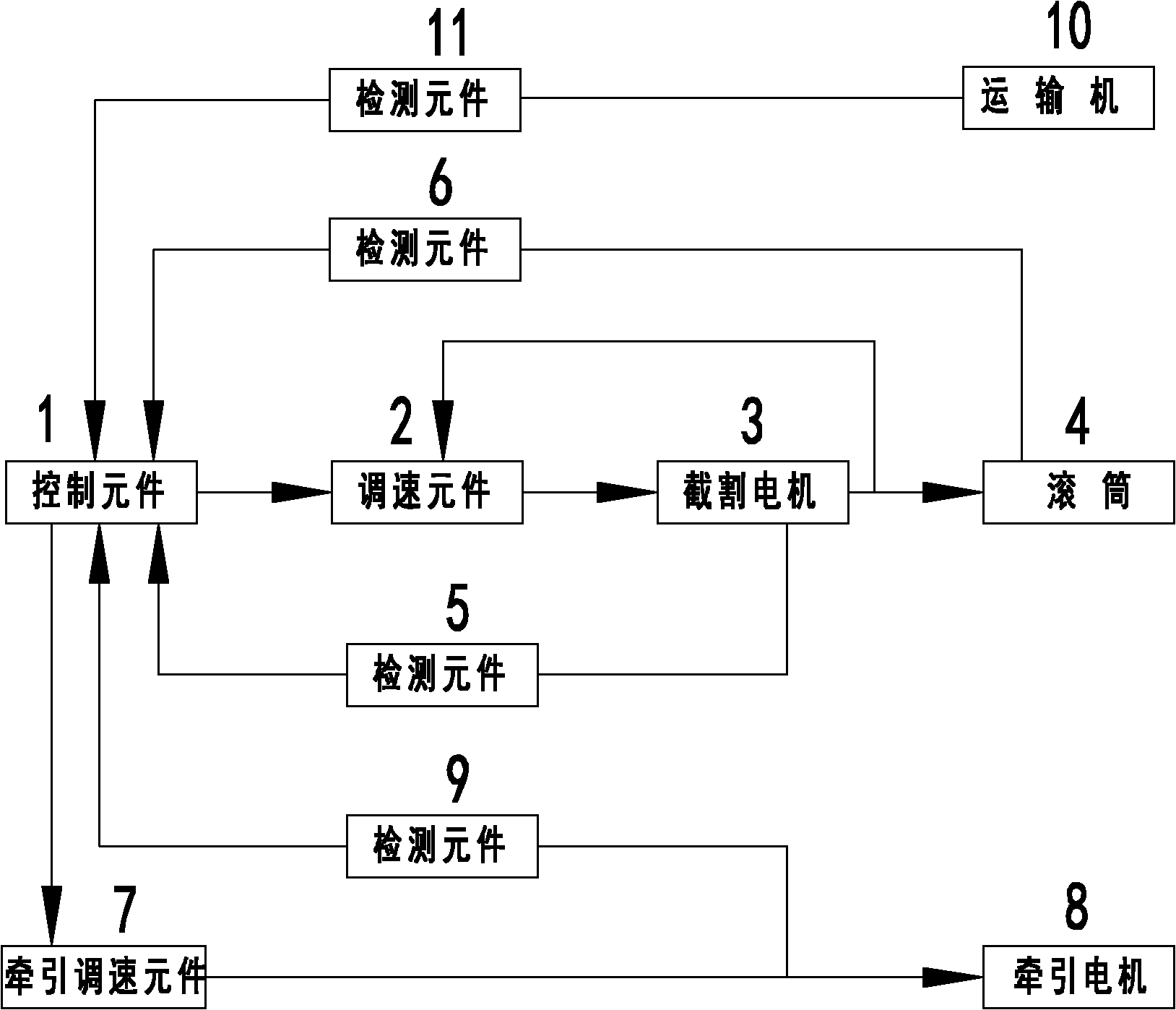

Coal mining equipment and roller electrical speed regulating system

ActiveCN102108862AEnsure coal mining efficiencyIncrease speedEnergy industryDriving meansStress conditionsEngineering

The invention discloses a roller electrical speed regulating system for coal mining equipment, which comprises a first detection element, a control element and a speed regulating element. In the system, the rotation speed of the roller can adapt to randomly changing condition of a coal cutting coal bed, so as to prevent the roller from being damage by an encountered hard coal bed and prolong the service life of the roller; meanwhile, under a normal use condition, for example the coal mining equipment works on a soft coal bed, the roller can rotate at a high speed to ensure the coal mining efficiency of the coal mining equipment. The control element also can regulate a traction speed by the traction speed regulating element, so that the traction speed of a coal mining machine and a cutting speed are consistent enough to realize high-efficiency cutting. The control element also can detect the coal loading effect of the roller and receive the stress condition of a conveyor through the detection element so as to control the cutting and traction speeds of the coal mining machine and ensure the high yield and efficiency of the fully mechanized coal mining equipment. The invention also discloses the coal mining equipment having the roller electrical speed regulating system.

Owner:益阳市科技成果转化服务中心 +1

Drilling tool assembly used for directional hole-forming underground coal mine and provided with air screw motor and construction method

InactiveCN106869791AIncrease the encounter rateIncreased drilling depthDrilling rodsConstructionsMotor driveNon magnetic

Disclosed is a drilling tool assembly used for directional hole-forming underground a coal mine and provided with an air screw motor and construction method. The drilling tool assembly comprises a directional drill bit, the air screw motor, a lower non-magnetic drill rod, a wireless electromagnetic wave measurement while drilling short section, an upper non-magnetic drill rod, a middle drill rod and a blower which are connected in sequence. The drilling tool assembly can carry out composite drilling and sliding directional drilling for construction: when composite drilling is conducted, the air screw motor drives the directional drill bit to crush rocks in rotatably, meanwhile, the middle drill rod rotates to drive the air screw motor to rotate, boring mud at the bottom of a hole is discharged from the bottom of the hole by compressed air along an annular gap, and the middle drill rod can be used for auxiliary slagging; and when sliding directional drilling is conducted, the middle drill rod does not rotate, the directional drill bit is driven by the air screw motor driven by the compressed air to rotate to crush rocks, and the track of the hole is controlled by changing the elbow orientation of the air screw motor. Thus, according to the drilling tool assembly used for directional hole-forming underground the coal mine and provided with the air screw motor and construction method, the drilling depth of a soft coal seam and the coal seam drilling-encounter rate can be improved greatly, and the drilling gas extraction effect is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Anti-collapsing drilling method for grout spraying of soft coal seam

ActiveCN104747075ALittle impact on air permeabilityImprove pumping efficiencyFlushingSealing/packingMining engineeringSpray nozzle

An anti-collapsing drilling method for grout spraying of a soft coal seam includes the following steps that first, an anti-collapsing drilling device for grout spraying of the soft coal seam is machined and tested; second, technological parameters of the anti-collapsing drilling device for grout spraying are designed; third, hole reinforcing grout is prepared, and the solidification property of the grout is tested; fourth, the anti-collapsing drilling device for grout spraying of the soft coal seam is installed; fifth, anti-collapsing drilling for grout spraying is performed; sixth, drilling stops till the designed depth is achieved, clean water is used for cleaning a grout spraying pipeline and a spray nozzle, and a drill stem and a drill bit are withdrawn. Due to the adoption of the method, the efficiency for drilling bedding holes in the soft coal seam is substantially improved, the hole forming rate for drilling holes in 100 meters is substantially increased, and time for drilling the bedding holes in the soft coal seam is shortened; the gas drainage efficiency of the bedding holes in the soft coal seam is substantially improved, and time for gas pre-drainage of the soft coal seam is greatly shortened; the probability that gas exceeds the limit is greatly reduced in the tunneling and stoping period, and valuable time and a safety guarantee are provided for safe and efficient stoping and tunneling of a coal mine.

Owner:河南理工大学科技园有限责任公司

Drill hole spray safety protection system

Owner:HUAINAN MINING IND GRP

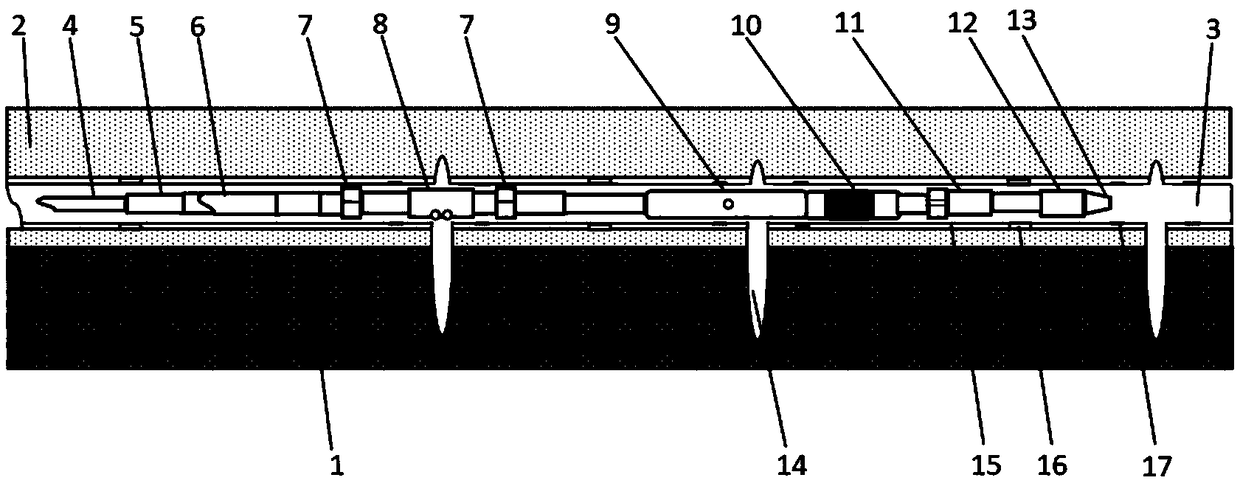

Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

ActiveCN109339855AAvoid prone to collapse holesAvoid problems such as drill stickingFluid removalGas removalSand blastingCoiled tubing

The invention relates to a coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method. The method includes the steps that first, a gas extraction long drilled hole is constructed in a mudstone or sandstone roof with a certain distance to the top boundary of a broken soft coal seam or a hard layer of the broken soft coal seam or a hard coal seam with a good coal body structure; second, a guiding shoe and a rigid casing are lowered; third, cement paste blocking is carried out on annular space between the gas extraction long drilled hole and the rigid casing so as to solidify the hole; fourth, packing staging is carried out through a mode of dragging a packer by coiled tubing, an ejector carries out sand blasting perforation, and fracturing is carried out on the annulus between the coiled tubing and the casing; fifth, a fracturing tool is lifted out, and uniform blowout of fracturing fluid is carried out. The method can solve the problems that in existing gas extraction hole-drilling, hole forming is difficult, the crack initiation position of fracturing cracks is not determined, the fracturing cracks extend short, the fracturing modification effect is poor, the extraction affecting range is small and nonuniform, and extraction duration is short, and realizes gas extraction long drilled hole forming and multi-level precise staged fracturing.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Hole drilling and protecting method of drilling tool for soft coal seam gas extraction hole drilling and protecting

A hole drilling and protecting method of a drilling tool for soft coal seam gas extraction hole drilling and protecting comprises the following steps that the drilling tool for soft coal seam gas extraction hole drilling and protecting is installed in a drilling position of a coal seam roadway; the front portion of a drill bit is stressed so that a compression spring in the drill bit is compressed, a telescopic column is made to slide outwards, after the preset stroke is reached, the drilling diameter of a hollow internal slag discharging variable-diameter drill bit is increased and kept at as a definite value finally, and a PVC hole protecting pipe follows up gradually. Water flow reaches the bottom of a drill hole through a gap between the PVC hole protecting pipe and a hollow unthreaded drill rod, or high-pressure air penetrates through the hollow unthreaded drill rod and reaches the bottom of the drill hole. When the stress at the front end of the drill bit disappears, the telescopic column resets to the initial position, the hollow internal slag discharging variable-diameter drill bit and the hollow unthreaded drill rod can be drawn out at the moment, the PVC hole protecting hole is reserved in the hole, and gas is exhausted smoothly. By the adoption of the hole drilling and protecting method, the speed of gas extraction hole construction is improved, construction safety is guaranteed, and innovation of the drilling tool for soft coal seam gas extraction hole drilling and protecting is achieved.

Owner:HENAN POLYTECHNIC UNIV

Underground progressive gas pre-extraction and directional hole drilling system and method for broken and soft coal seam

ActiveCN105971517AImprove hole depthHigh hole forming precisionSurveyDrilling rodsRock cuttingEngineering

The invention relates to an underground progressive gas pre-extraction and directional hole drilling system and method for a broken and soft coal seam. An orifice bubble filling system is utilized to provide a continuous bubble flow for a drill hole to drive hole bottom grooving air screw motor to perform rapid drilling, and scouring to the hole wall of the broken and soft coal seam is reduced. A triquetrum auger stem is used for strengthening residue discharge. An orifice bubble-eliminating extraction system is utilized to eliminate bubbles, remove rock cuttings and perform gas extraction, and construction safety is guaranteed. A dual-drive compound directional drilling technology is combined to regulate and control a drilling trajectory and ensure that the drill hole extends along the designed trajectory and penetrates through and covers an unmined working face and a roadway to be excavated. The hole forming depth, the hole forming precision, hole forming efficiency and hole forming rate of the broken and soft coal seam with the Platts hardness coefficient f greater than or equal to 0.5 but smaller than or equal to 0.8 are wholly improved, the formed hole is used for progressive gas pre-extraction in a broken and soft coal seam zone, and a standard-reaching period of the working face of the broken and soft coal seam and coal roadway driving gas extraction is shortened.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com