Patents

Literature

223results about How to "Will not leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital authentication control method for access control system and access control system using the same

InactiveCN101246607AWill not leakImprove convenienceUser identity/authority verificationIndividual entry/exit registersElectricityCiphertext

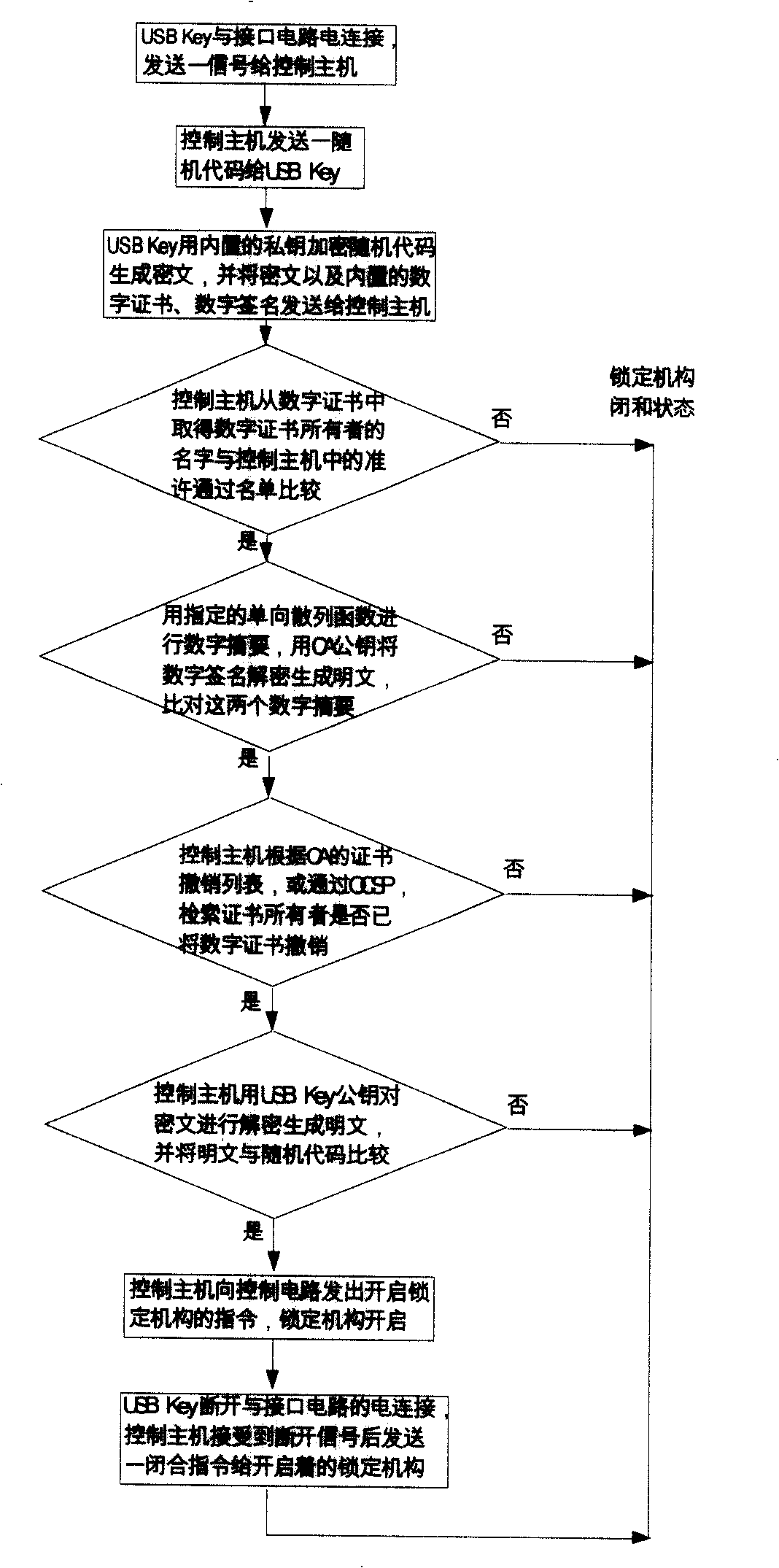

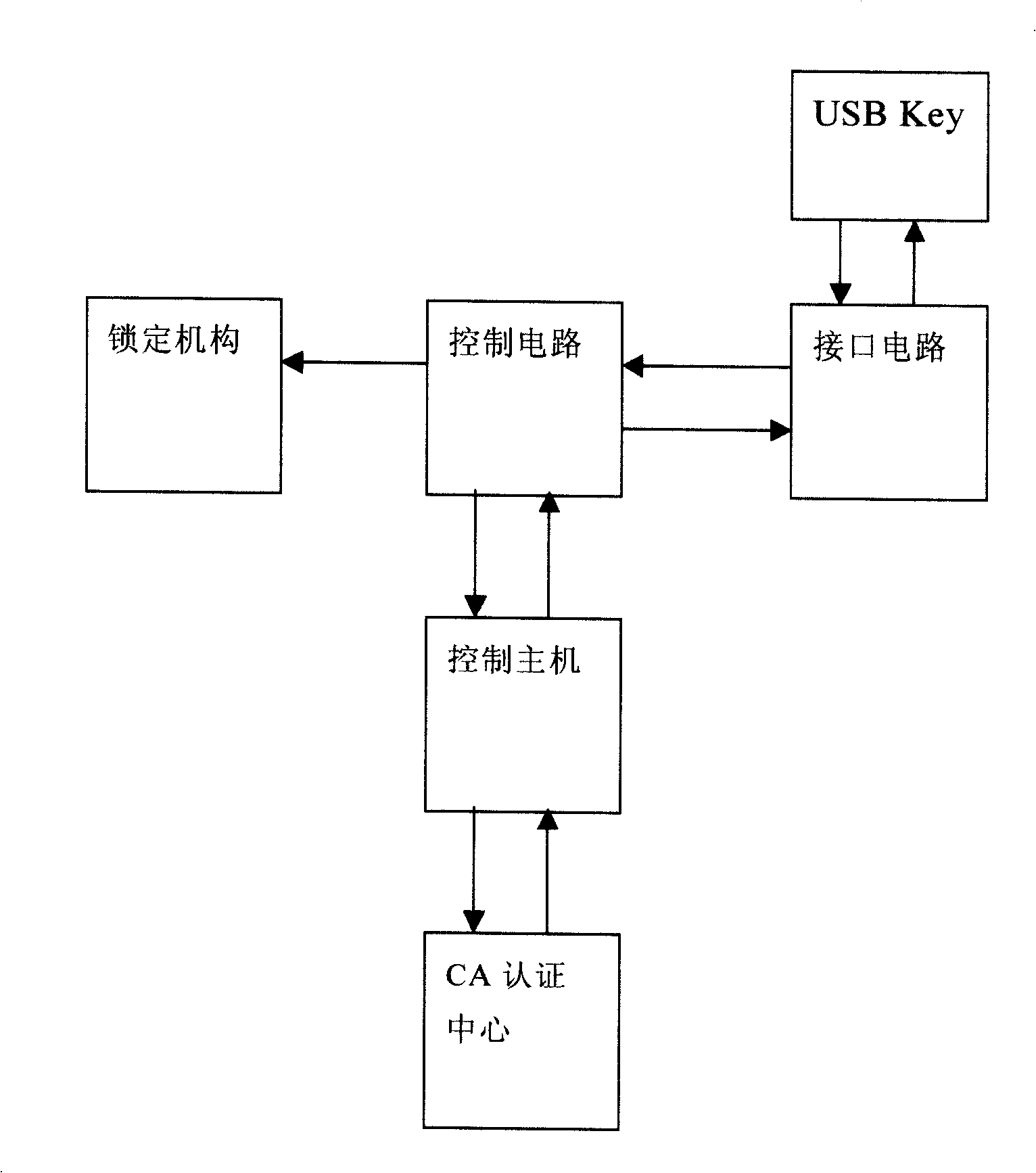

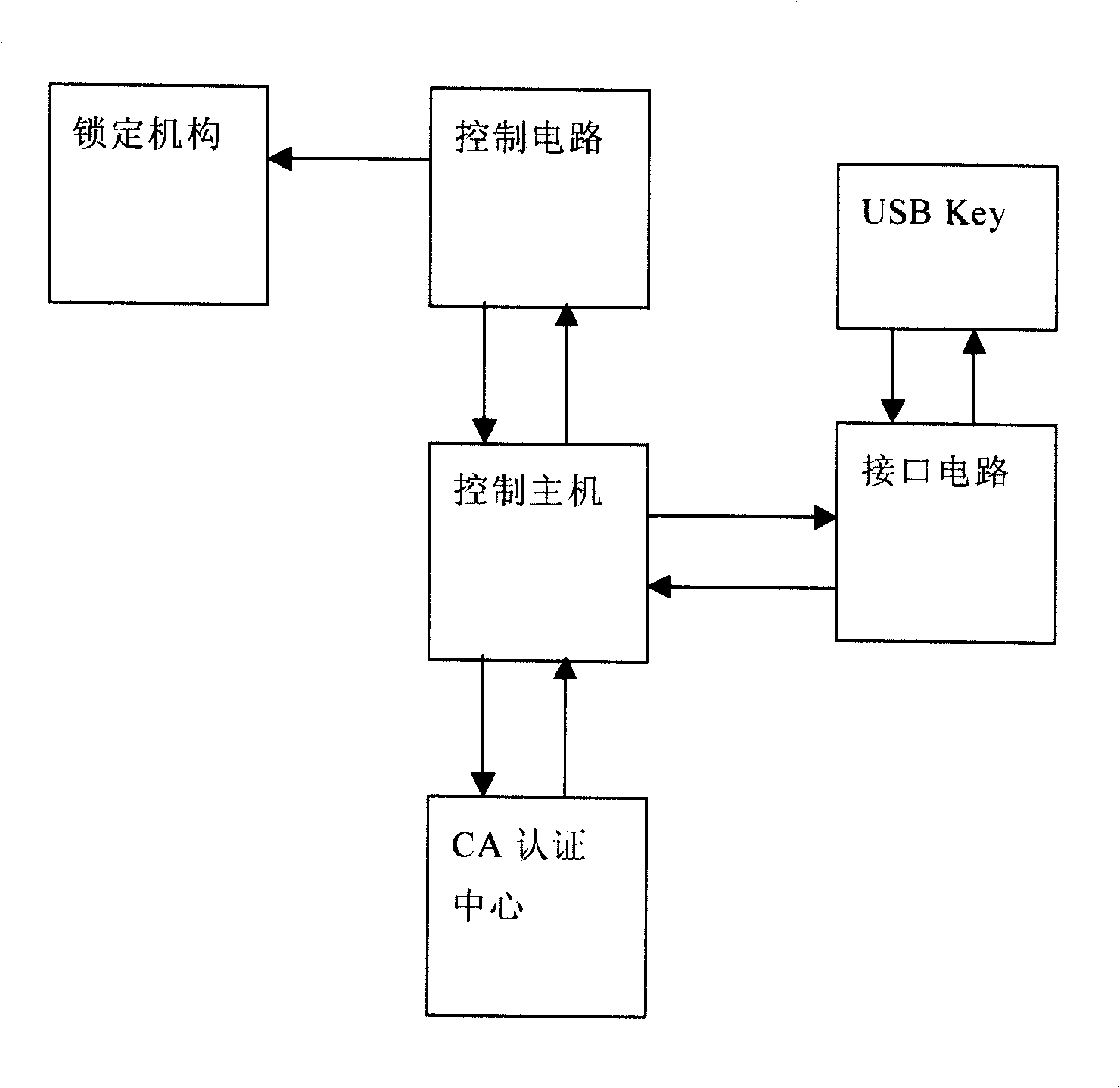

The present invention provides a digital certificate control method of access control system, the control master transmits a random code to USB Key when the USB Key is connected to the interface circuit, the USB Key uses inner key encryption to generate cryptograph and transmits to the control master, the control master USB Key of the digital certificate and decoding the received cryptograph to cleartext, the control master compares the cleartext with the random code, when the comparing result is identical, the indentity of USB Key holder is determined; the control master transmits opening command to open lock mechanism after determining legal identity and access permision of the holder, when USB Key breaks the connection with the interface circuit, the control master transmits closing command, the locking mechanism is closed. The invention also provides an access control system applying the above method, including an access control system, an inner key, a digital certificate and a USB Key of digital signature and a locking mechanism. The access control method and system of the invention has convenience, high security and high credibility.

Owner:陈年

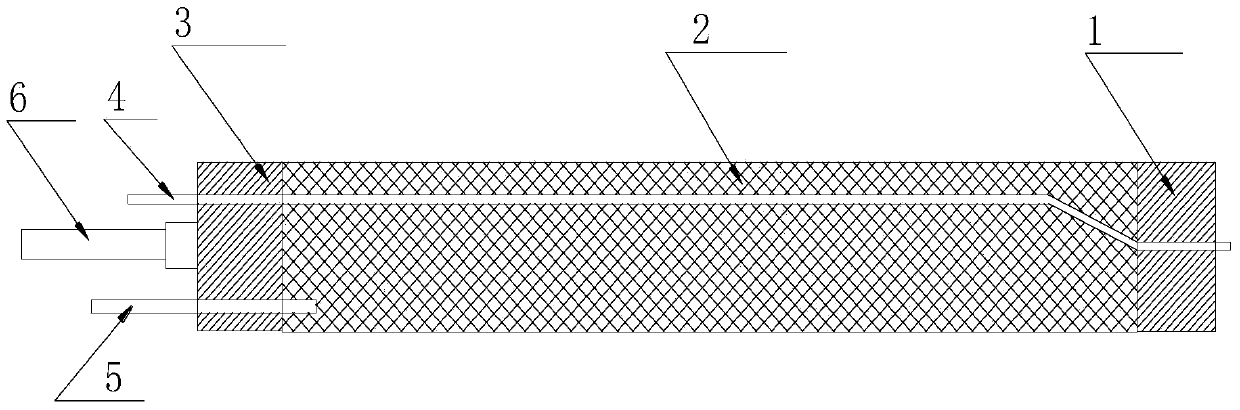

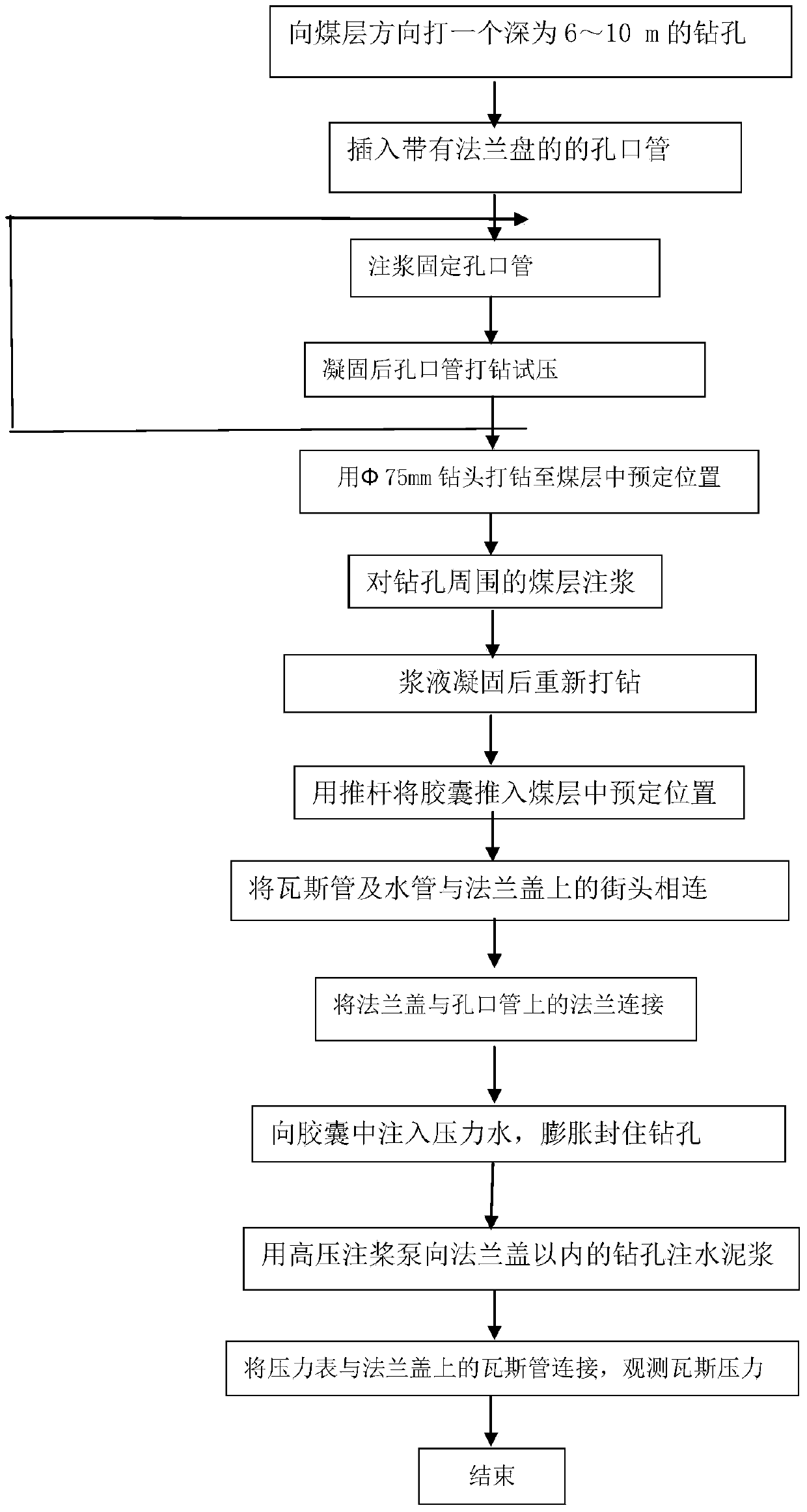

Method for drilling holes on soft coal seam to measure coal seam gas pressure

InactiveCN103742129AWill not leakAvoid the impact of pressure measurement resultsSurveySealing/packingMeasurement deviceCement slurry

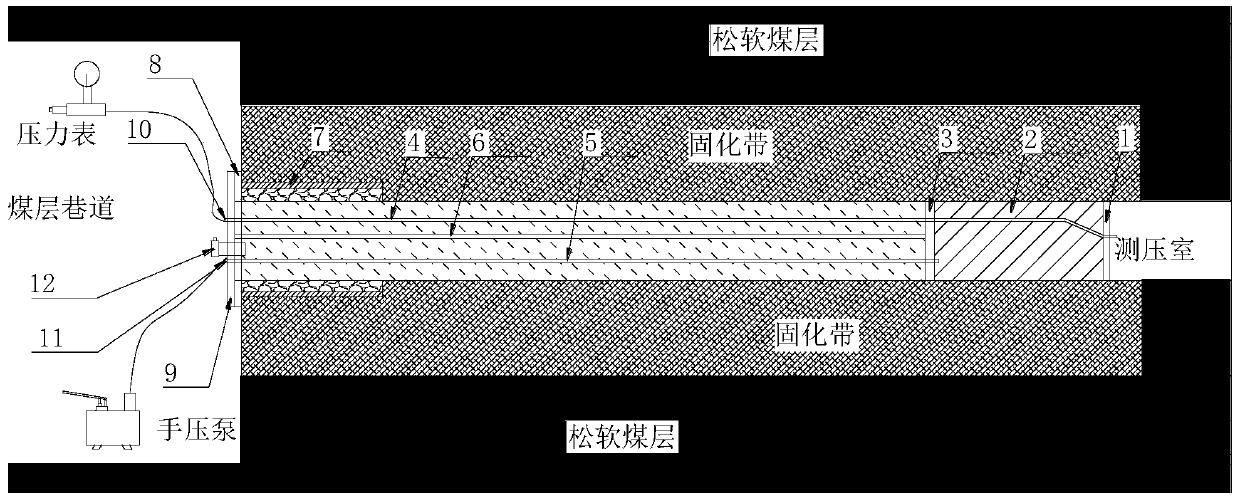

A method for drilling holes on a soft coal seam to measure coal seam gas pressure comprises the steps of drilling a shallow hole on the coal seam, placing an orifice pipe in the hole, utilizing cement slurry to fix the orifice pipe in the coal seam; performing drilling through the orifice pipe to the deep part of the coal seam, quitting a drill rod, injecting mixed slurry A and B to solidify coal around the drilled hole, performing drilling again along the originally drilled hole to exceed grouting depth by 3-5m; quitting the drill rod, inserting a capsule hole sealing device with a gas pipe and a water pipe in the drilled hole, sequentially connecting a push rod to push the capsule hole sealing device to be near the drilled hole grouting depth; on an orifice, respectively connecting the gas pipe and the water pipe with a connector on a flange cover, fixing the flange cover on the orifice pipe, utilizing a manual pump to inject water into the capsule hole sealing device in the drilled hole through a water pipe connector, and expanding the capsule hole sealing device to seal the drilled hole; injecting high-pressure cement slurry through a grouting valve on the flange cover, and connecting a gas pipe connector with a pressure meter, so that the gas pressure of the soft coal seam can be measured. The method is simple and convenient to operate, and a measurement device is simple.

Owner:CHINA UNIV OF MINING & TECH

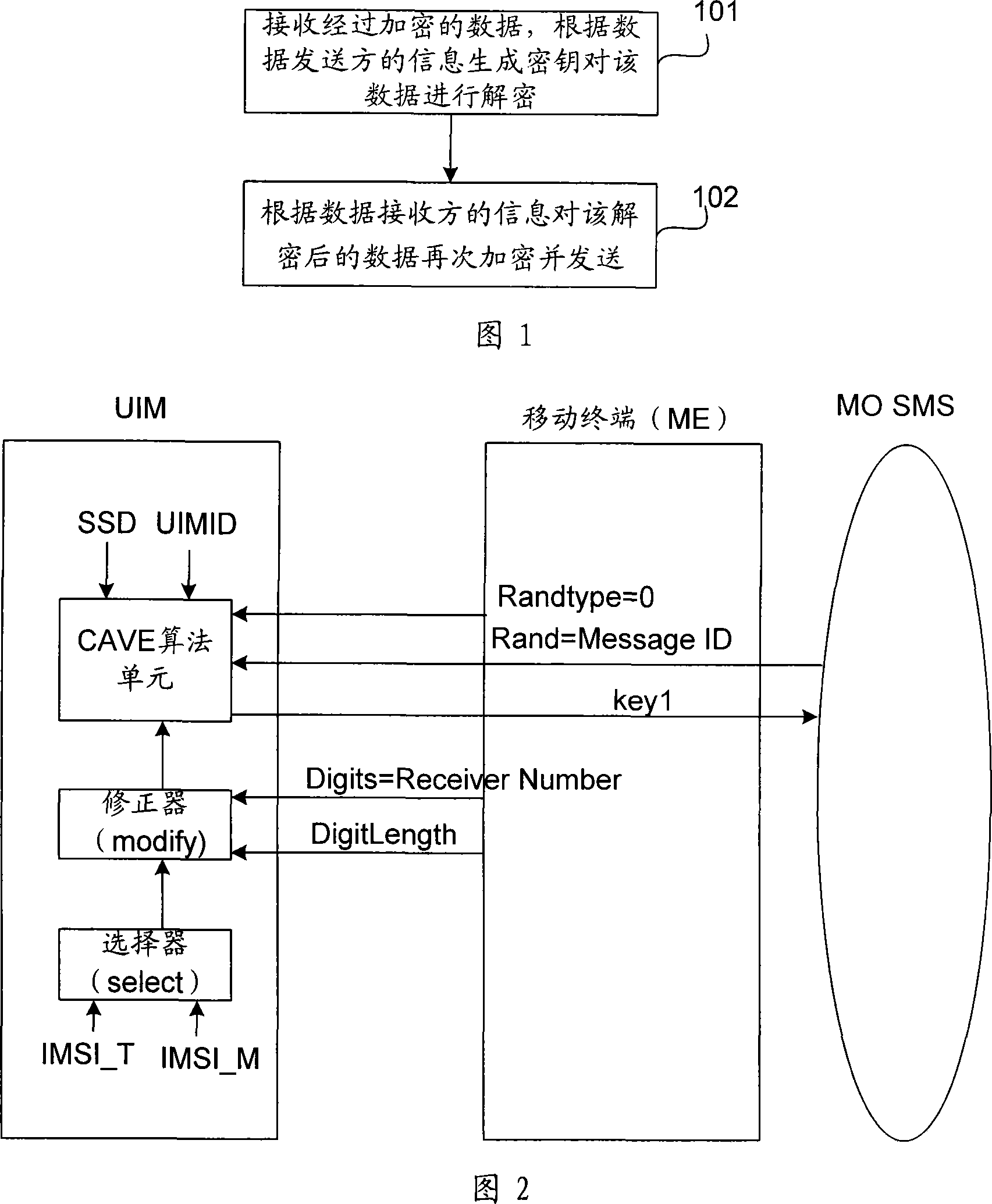

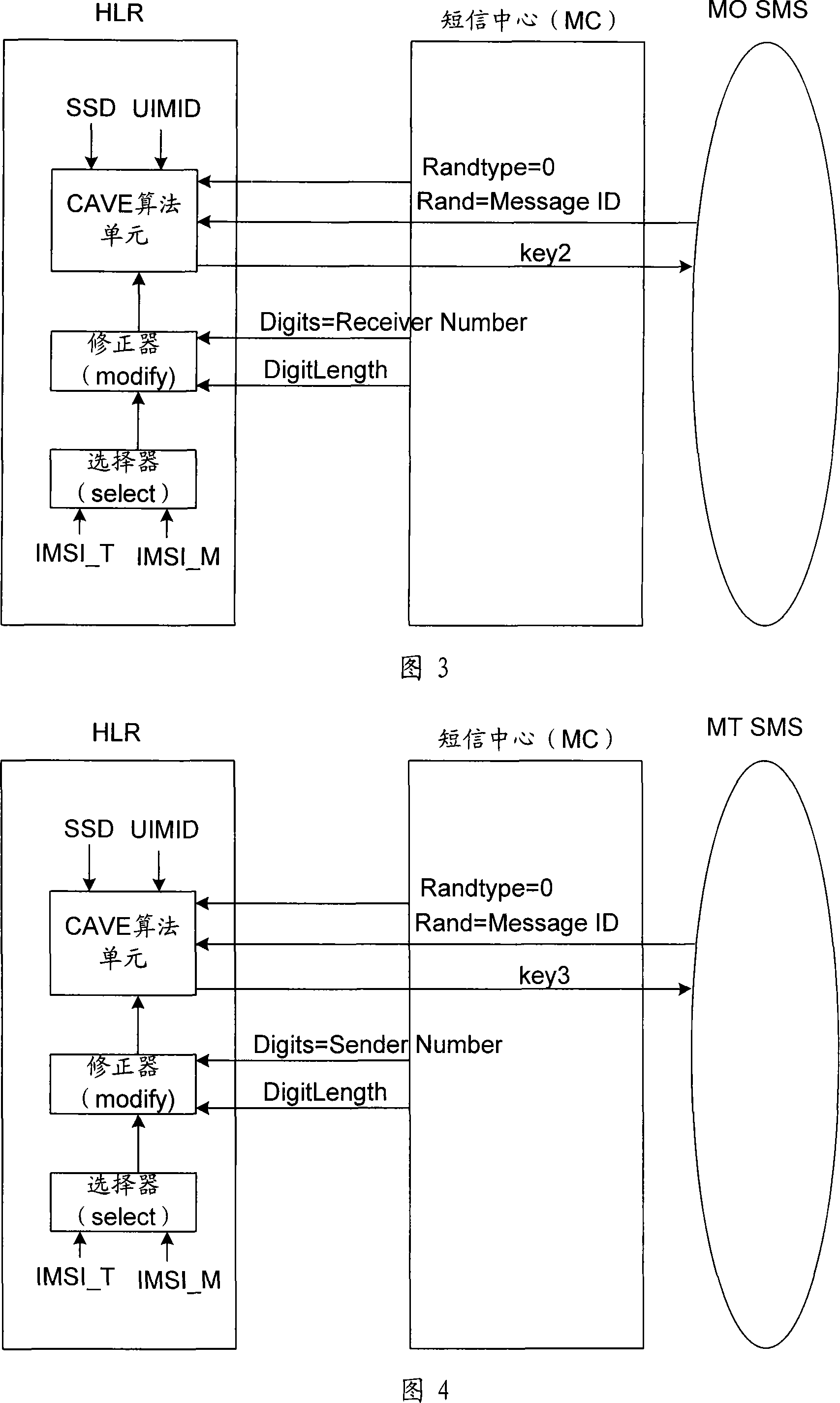

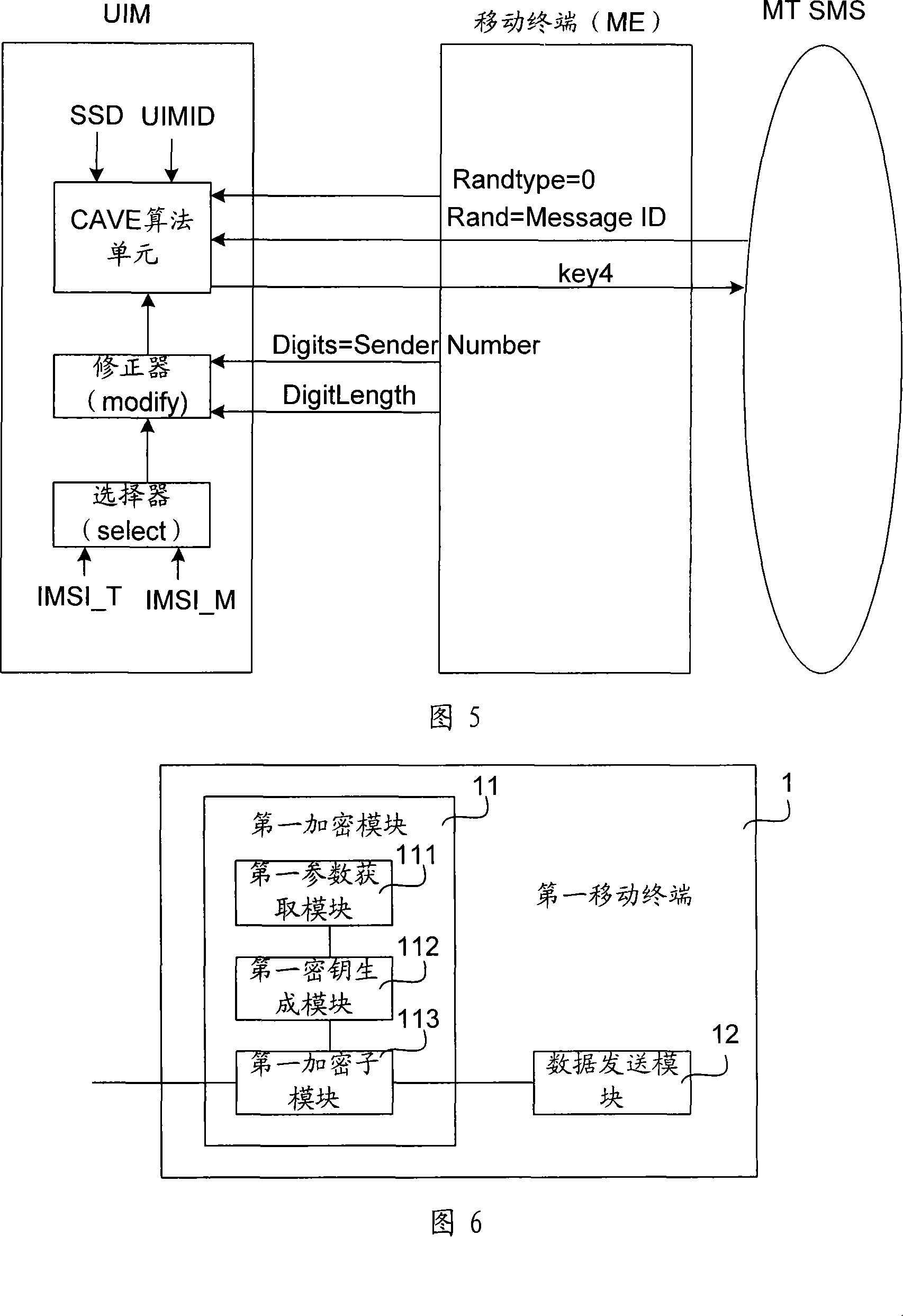

Data transmission method, device and system and mobile terminal

InactiveCN101242264AWill not leakImprove securityKey distribution for secure communicationRadio/inductive link selection arrangementsComputer hardwareData transmission

An embodiment of the invention relates to a data transmitting method, a device, a system and a mobile terminal, wherein the data transmitting method comprises: receiving a encrypted data, and decrypting the data by creating a key based on the information of the data sender; and re-encrypting and sending the data after decrypted based on an information of the data receiver. The data transmitting method and the system provided by the embodiment of the invention encrypt the data by the mobile terminal of the receiver, the data transmitting device decrypts and re-encrypts the data, and the mobile terminal of the receiver re-decrypts the date after receiving the data to obtain the data. The invention avoids singly sending a once key, the method is simple and the security is high.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

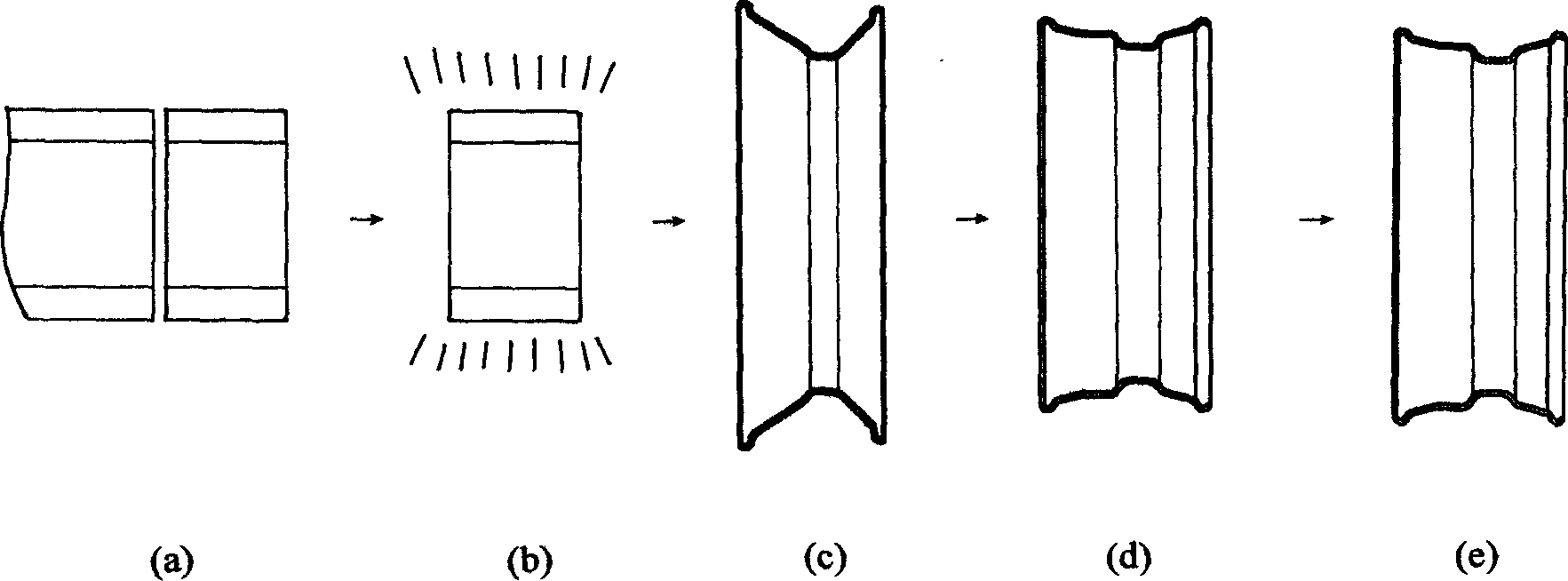

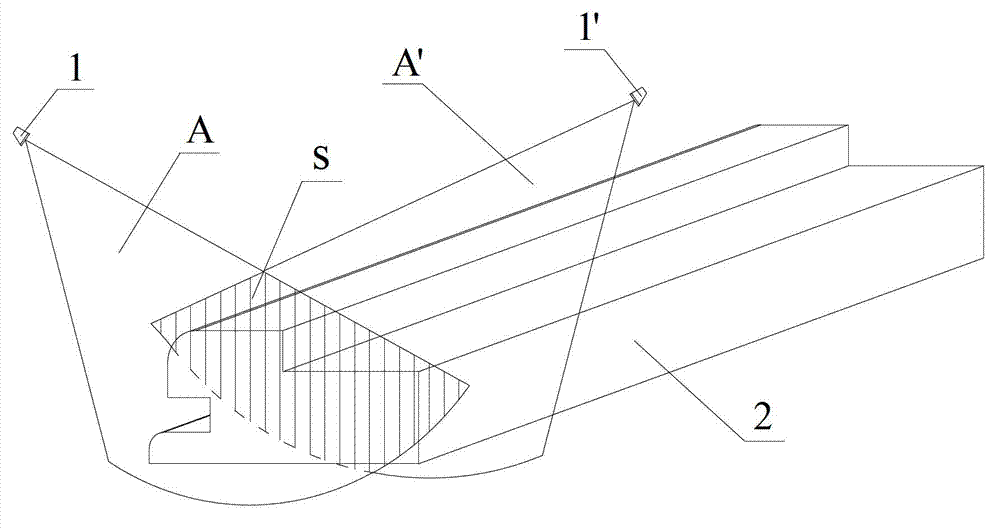

No-seam steel felly making process

The no-seam steel felly making process includes the following steps: cutting cast steel pipe blank, heating, rolling expansion to form the intermediate blank, rotation pressurizing and finishing. Using cast steel pipe blank, rather than great caliber thin wall seam-less steel pipe, has low cost, and the felly product has high machining precision, raised material strength and no air leakage. The no-seam steel felly may be used in no-inner tube wheel and has the advantages of high safety, high reliability, low oil consumption, etc.

Owner:JIAXING STONE WHEEL

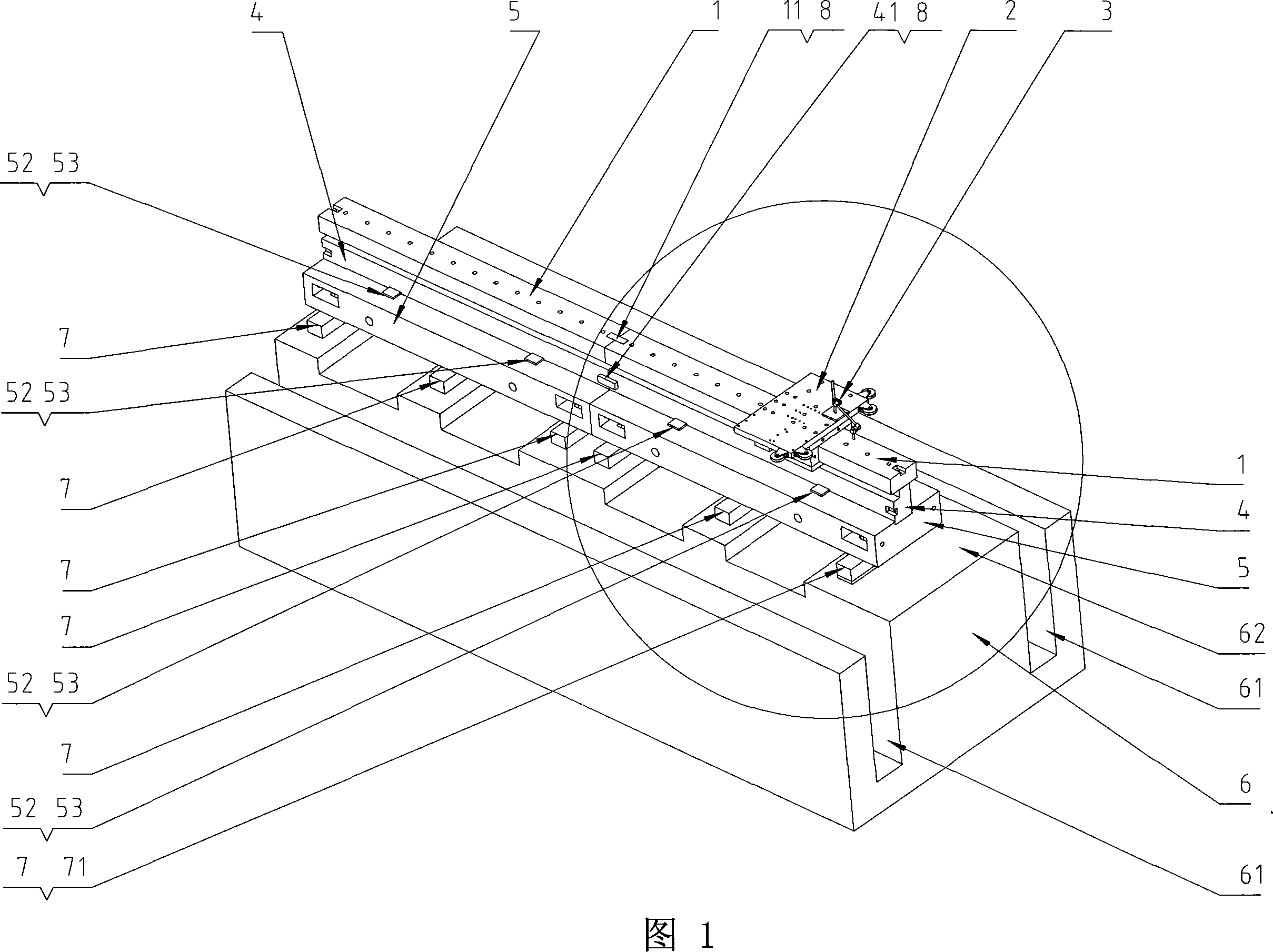

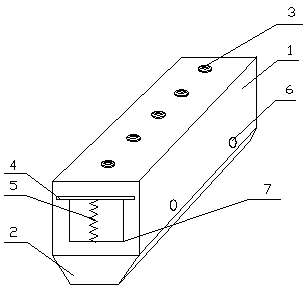

Method and device for mounting ultralong air-float guide rail

InactiveCN101067974AWill not leakReduce the impactMachine supportsInstrumental componentsMeasurement deviceTest platform

This invention discloses an installation method and a device for supper long gas-floated guideways, which localizes a first section part and installs a mobile test platform on it sliding along the guiedway and installs a measurement device, connects the first section with another section and moves the platform to the joint of the two guideways to test the joint accuracy and correct it according to the requirement of installation accuracy, then connects a next section in terms of the said method till to the finish. The device includes groundsill, an adjustable pad iron, two or more than two guideways connected end to end, supporting beams and bases supported on the groundsill by the adjustable pad iron, the supporting beams are set in the installation slots on the base and the guideways are fixed on the supporting beams by fasteners.

Owner:NAT UNIV OF DEFENSE TECH

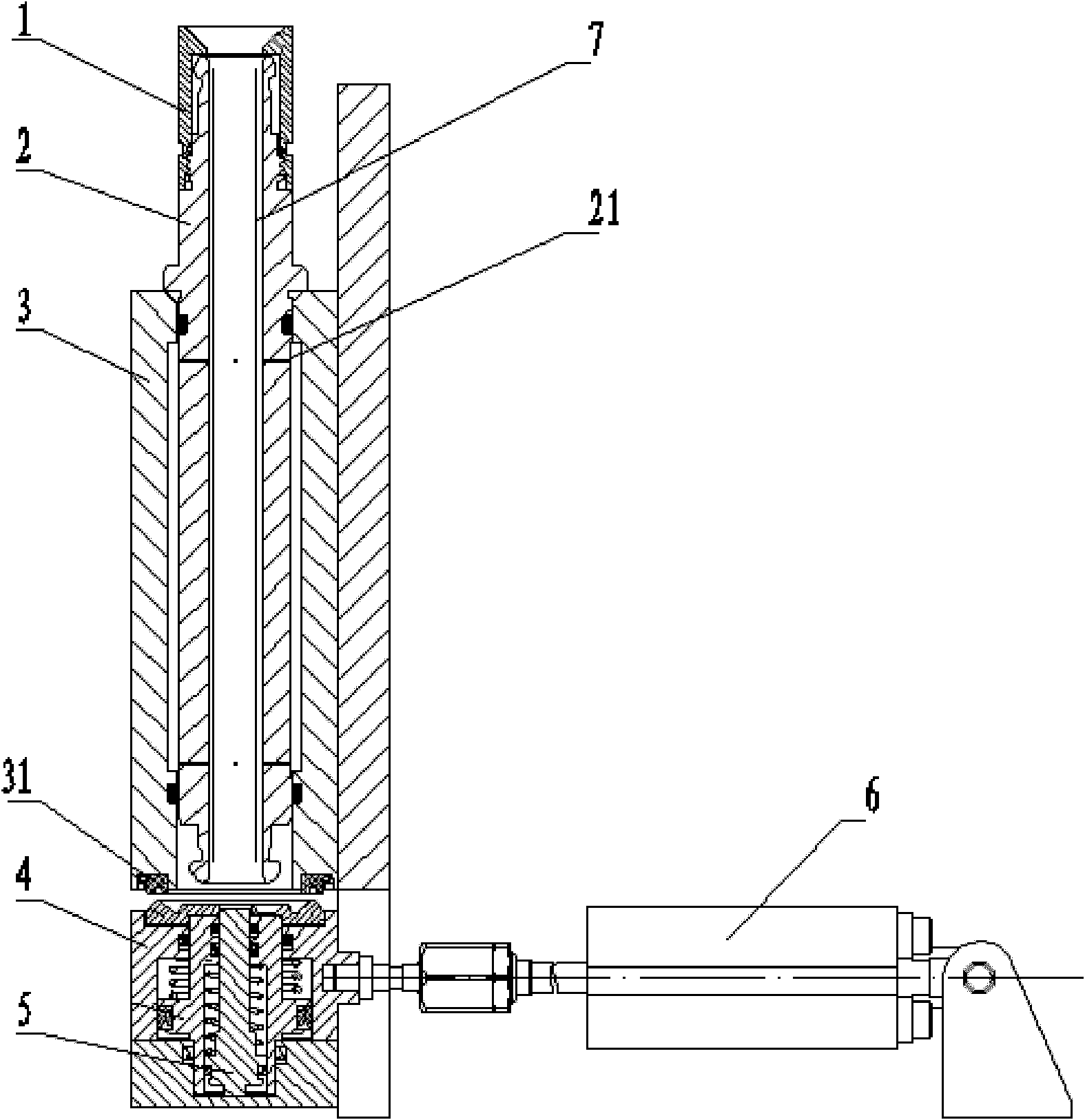

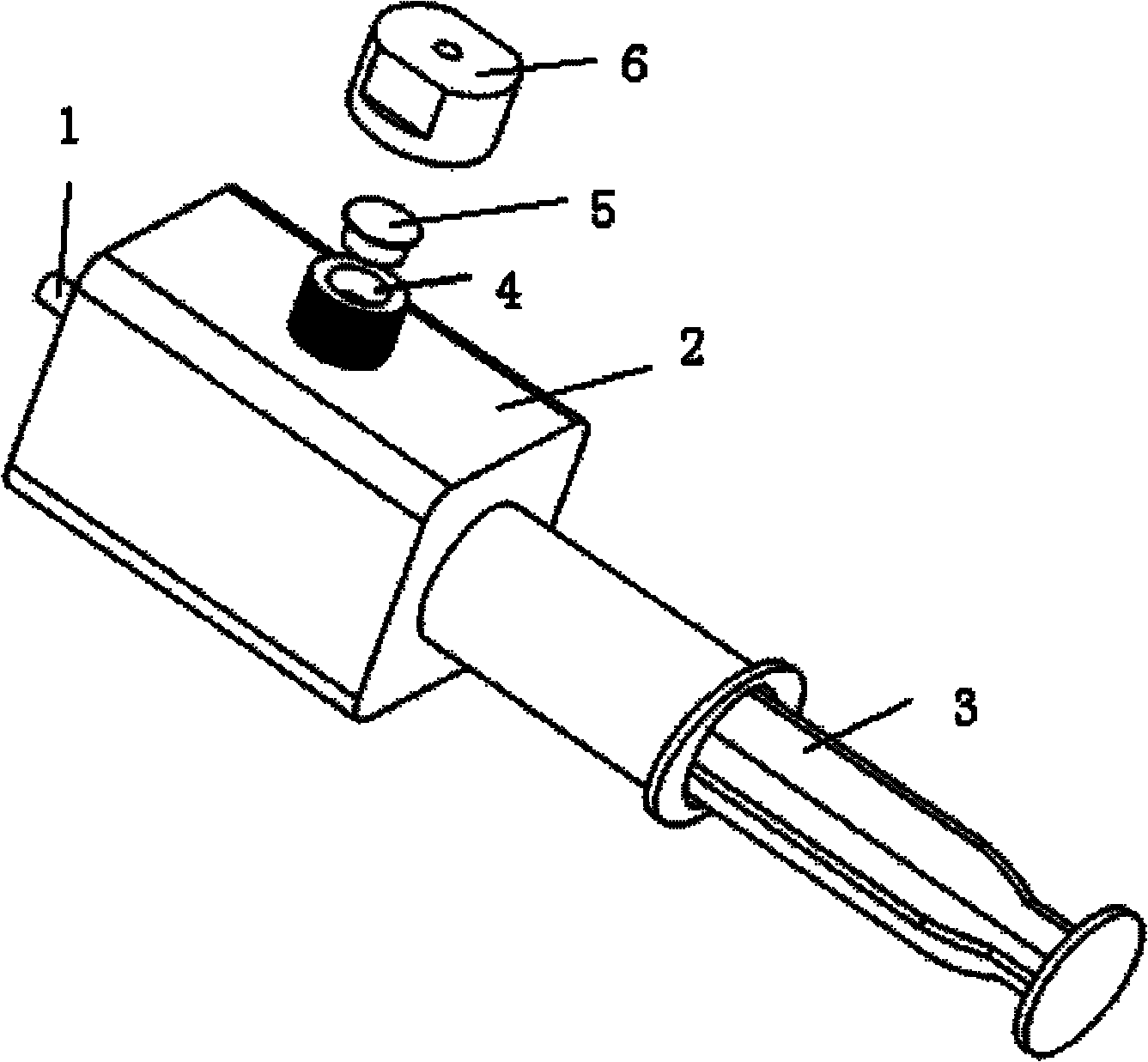

Air leakage detection device for infusion tube

ActiveCN103063379AReduce pollutionCompact operationMeasurement of fluid loss/gain rateEngineeringControl circuit

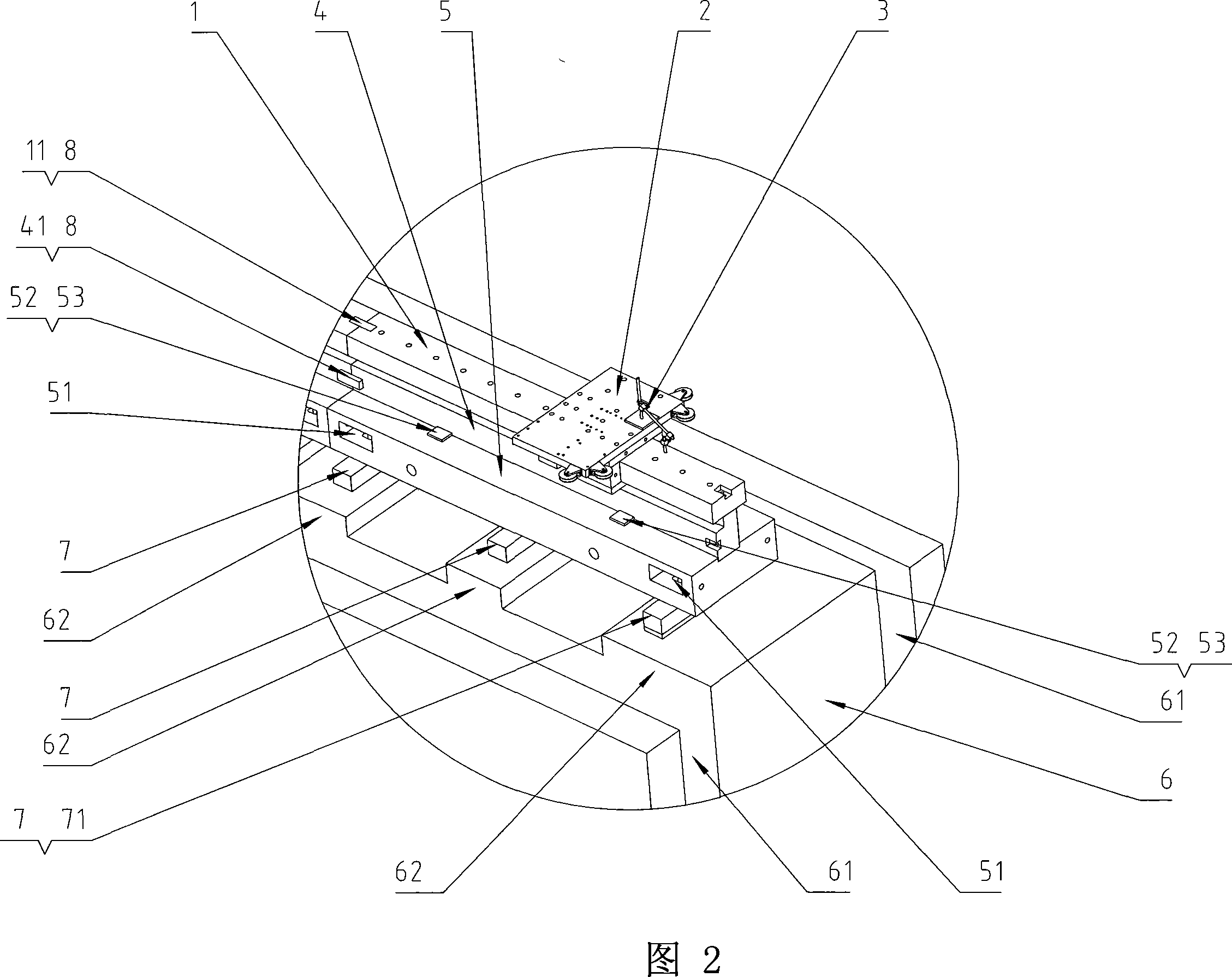

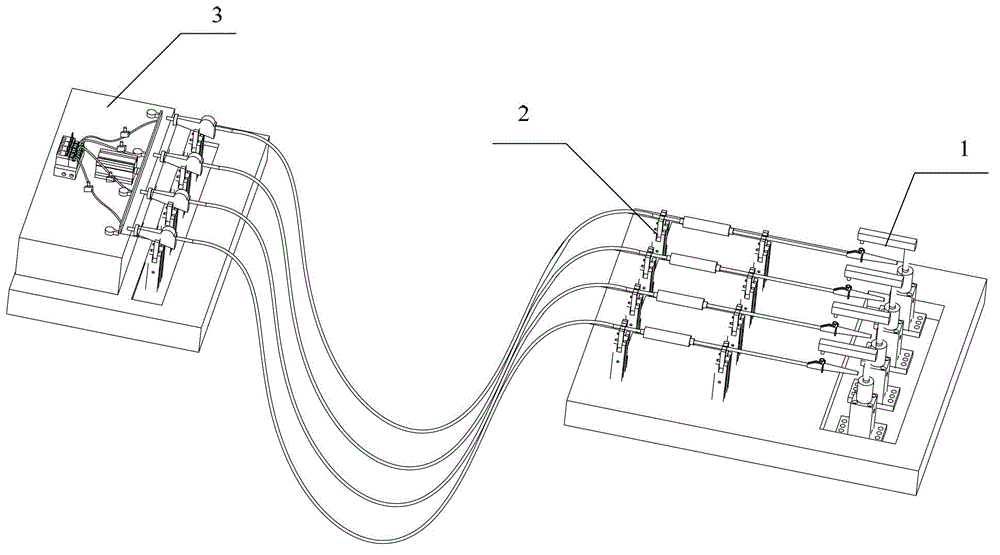

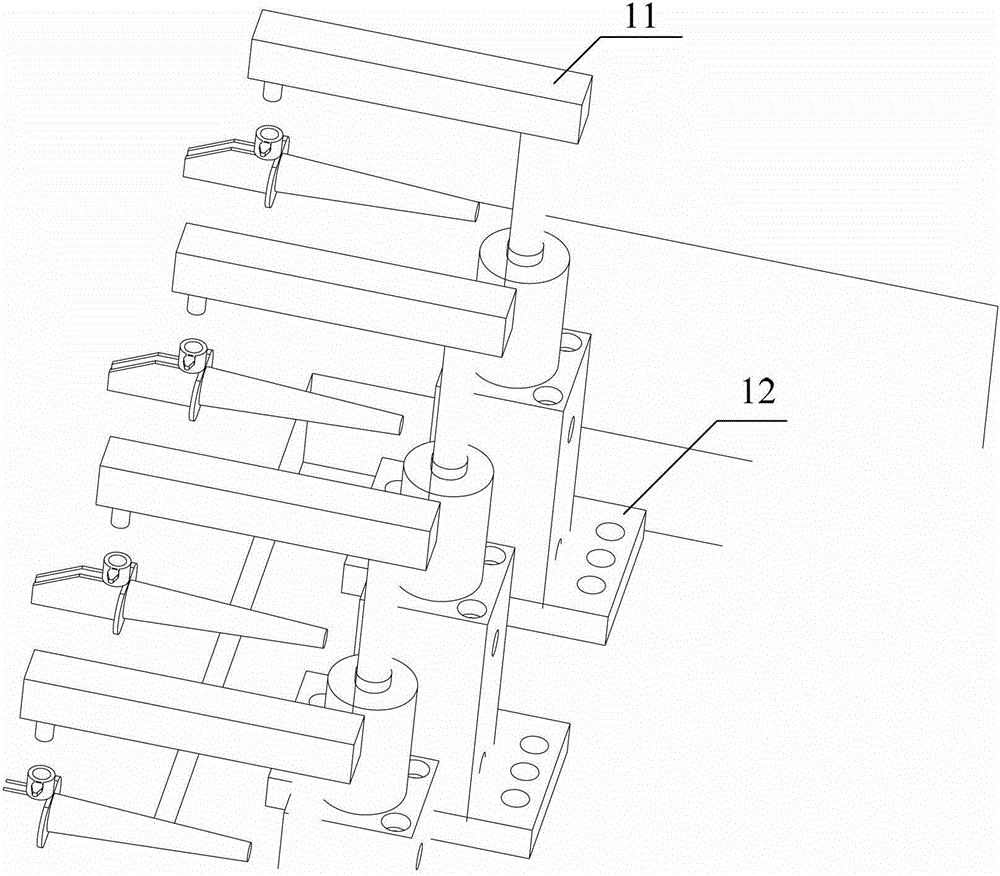

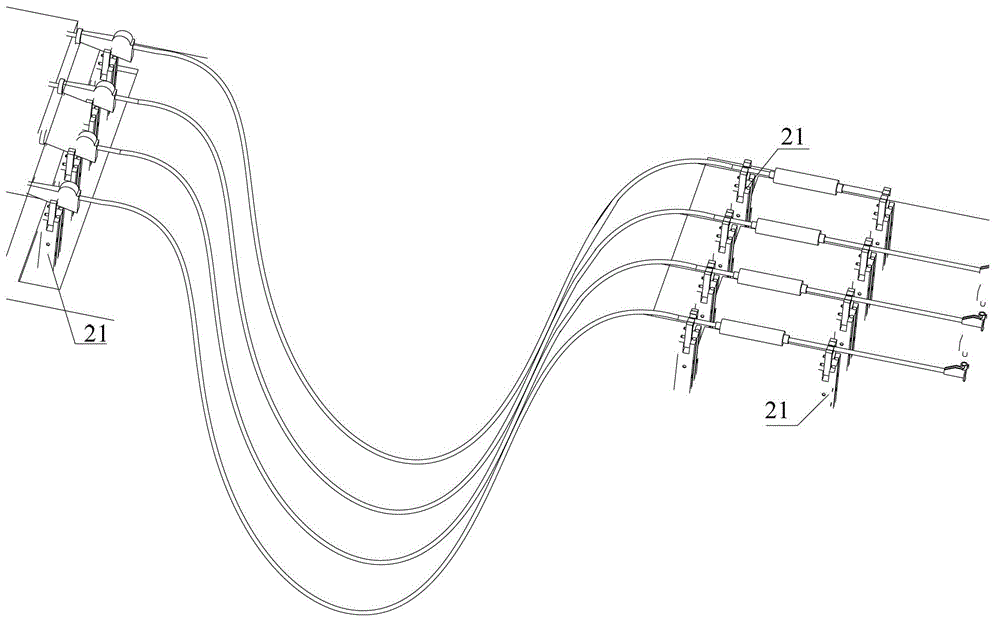

The invention discloses an air leakage detection device. The air leakage detection device is arranged on a working table, is used for achieving air leakage detection to an infusion tube and is characterized by comprising a sealed part (1), a clamping part (2) and a gas transmission part (3), wherein the sealed part (1) is arranged at one end of the working table and is used for sealing of an aeration end of a needle head of the infusion tube; the clamping part (2) is arranged in the middle of the working table and is used for clamping and fixing the infusion tube to be detected and enabling the position of the infusion tube to be fixed in the process of detection; the gas transmission part (3) is arranged at the other end of the working table and is used for transmitting gas to and pressurize the other end, relative to a pillow, of the infusion tube. After aeration and pressure maintaining for a period of time, the detection whether the infusion tube leaks the gas can be achieved through a pressure change inside a measuring tube. The air leakage detection device is compact in operation, higher in efficiency than manual operation and small in pollution to the infusion tube than the manual operation. A pneumatic control circuit is adopted to pressurize the infusion tube and test the magnitude of pressure, and therefore the possibility of manual misjudgment is reduced, and the operation precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

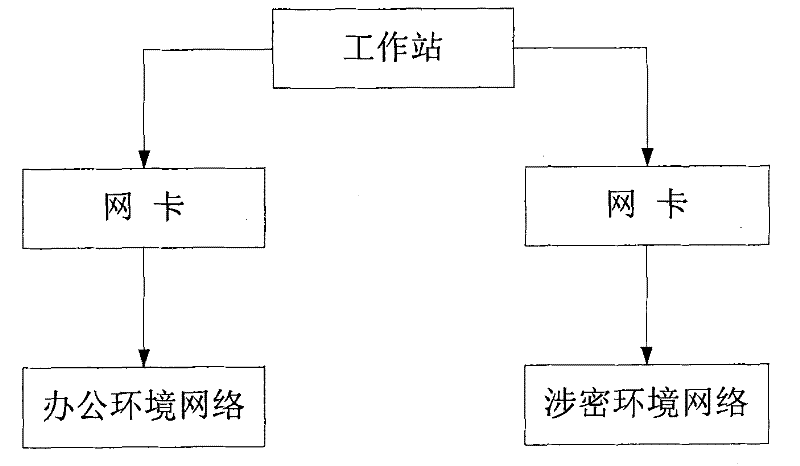

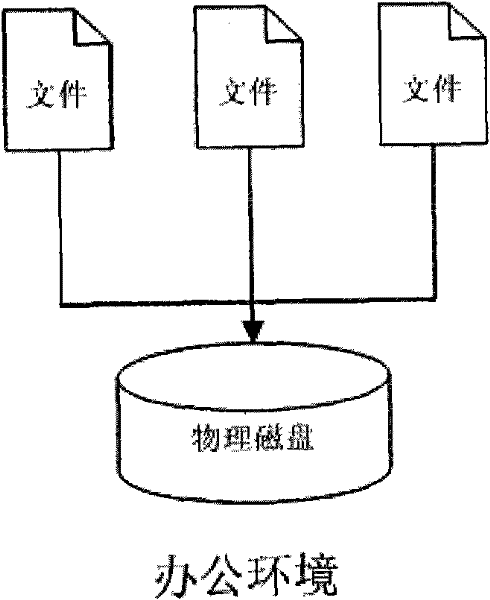

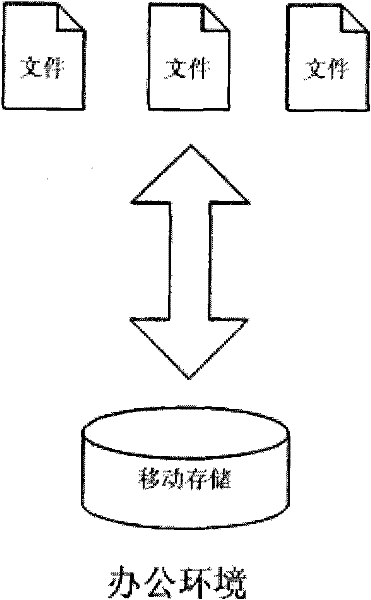

Computer network environment isolation system implemented by using software

ActiveCN102346818AAchieve isolationWill not leakInternal/peripheral component protectionOperational systemNetwork connection

The invention relates to a computer network environment isolation system. The system comprises at least one computer, wherein the computer is connected to at least one non-confidential network and at least one confidential network; the computer comprises at least one first operating system connected with the non-confidential network and at least one second operating system connected with the confidential network; the computer also comprises an environment switching module, and the environment switching module is used for switching between the first operating system and the second operating system; and the first operating system cannot access the data in the second operating system. A virtual disk in a virtual operating system is used as the working disk under the confidential network environment, and a user can switch the two different operating systems in the non-confidential network and the confidential network, so data file and data transmission in different network environments can be controlled and isolated; and the system also has the characteristics of low cost and good compatibility.

Owner:NANJING UNARY INFORMATION TECH

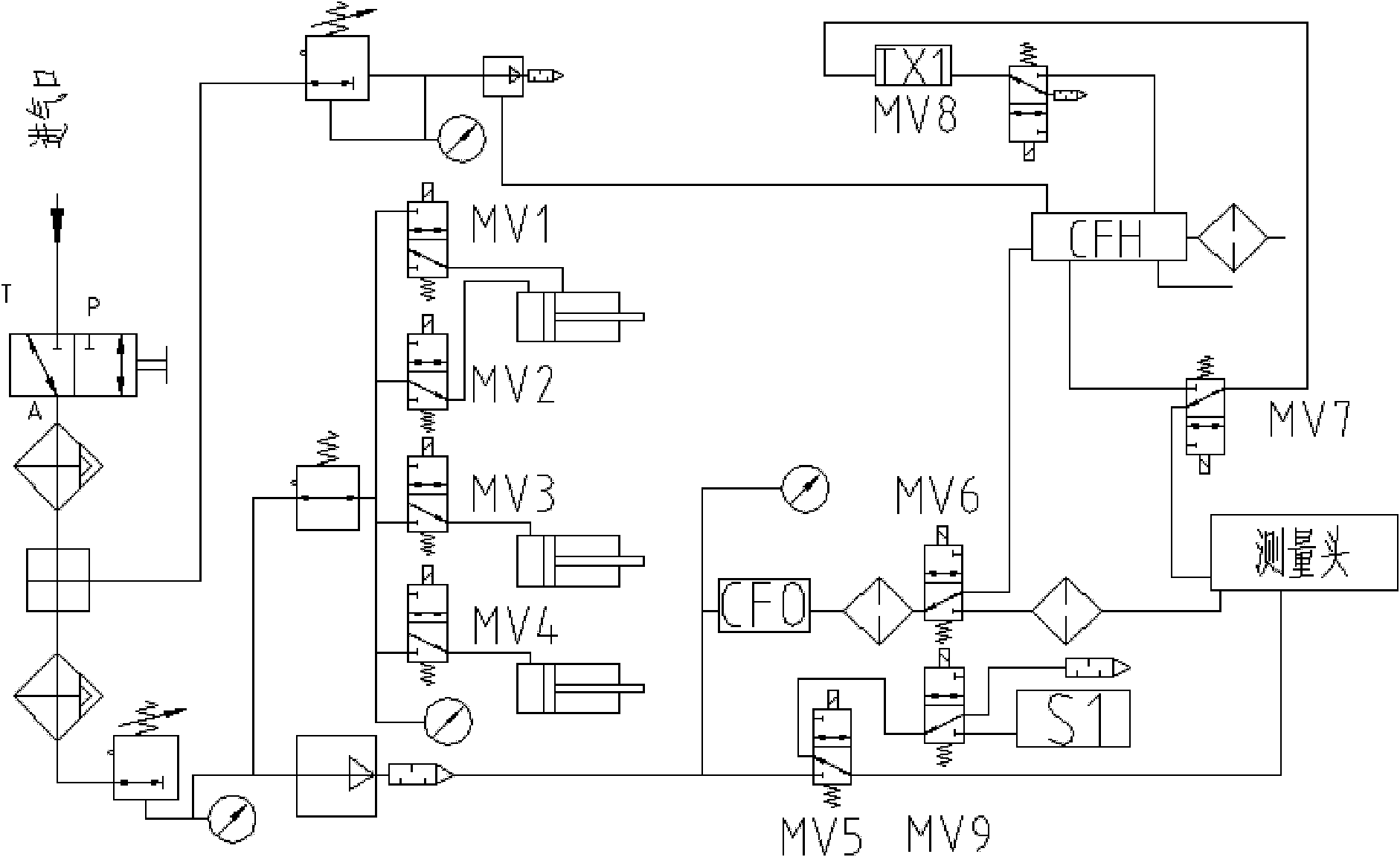

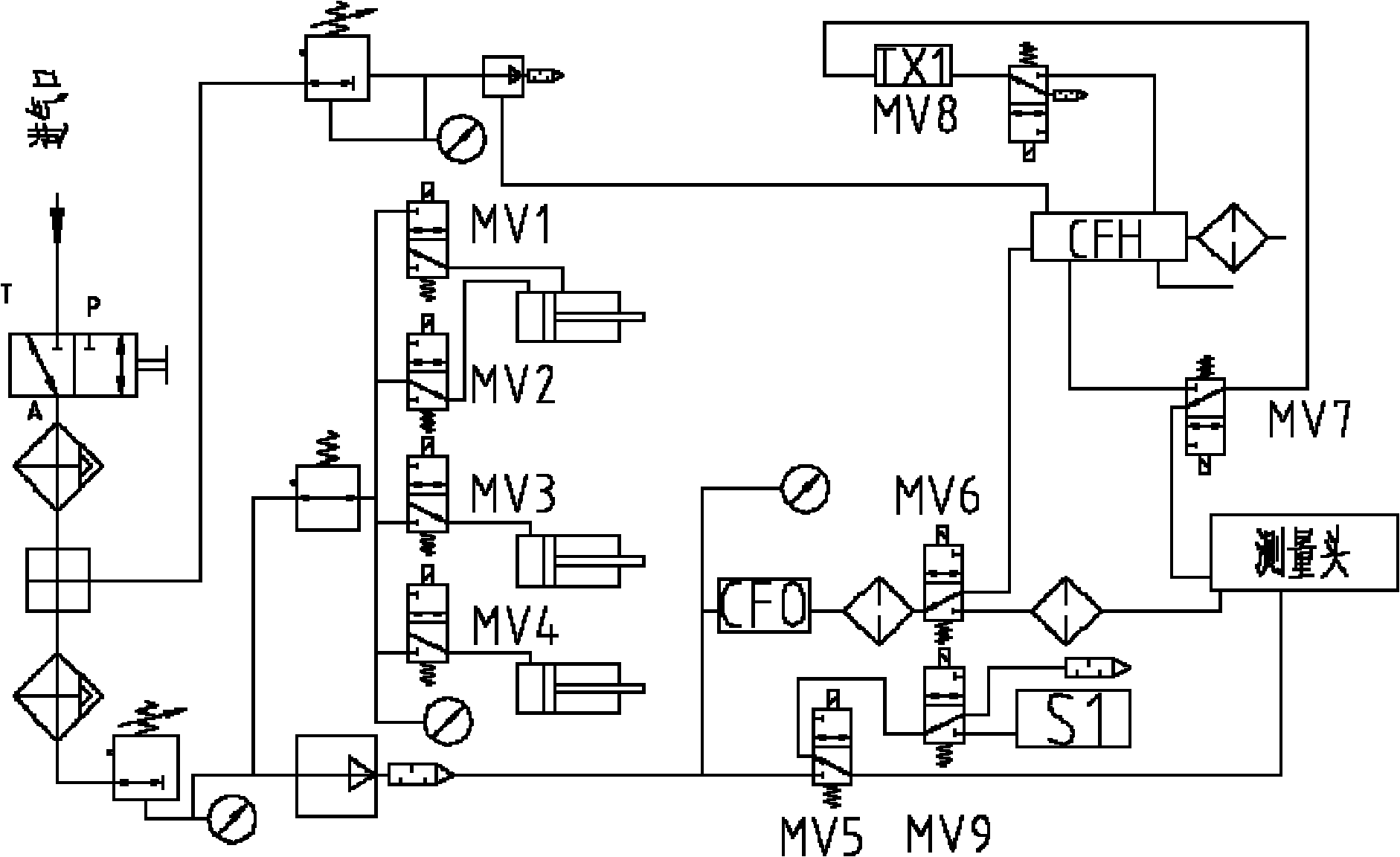

Device and method for measuring suction resistance of filter stick or cigarette

The invention discloses a device and a method for measuring suction resistance of a filter stick or cigarette. The device comprises a control system, an air circuit system, a first pressure difference converter, a vacuum flow sucker and a suction resistance meter, wherein the control system further comprises a digital output module and an analog input module; the air circuit system further comprises a first solenoid valve, a second solenoid valve, a third solenoid valve, a fourth solenoid valve, a fifth solenoid valve and a sixth solenoid valve; the suction resistance meter further comprises a metering head, an auxiliary cylinder and a linear cylinder; the metering head further comprises a metering base, a metering tube and a latex sleeve; and the auxiliary cylinder comprises a first cylinder and a second cylinder. By using the technical scheme in the invention, the suction resistance of the filter stick or cigarette can be detected, analyzed and controlled at real time, the positioning accuracy is high and the measured data is accurate.

Owner:ZHENGZHOU HAIYI TECH

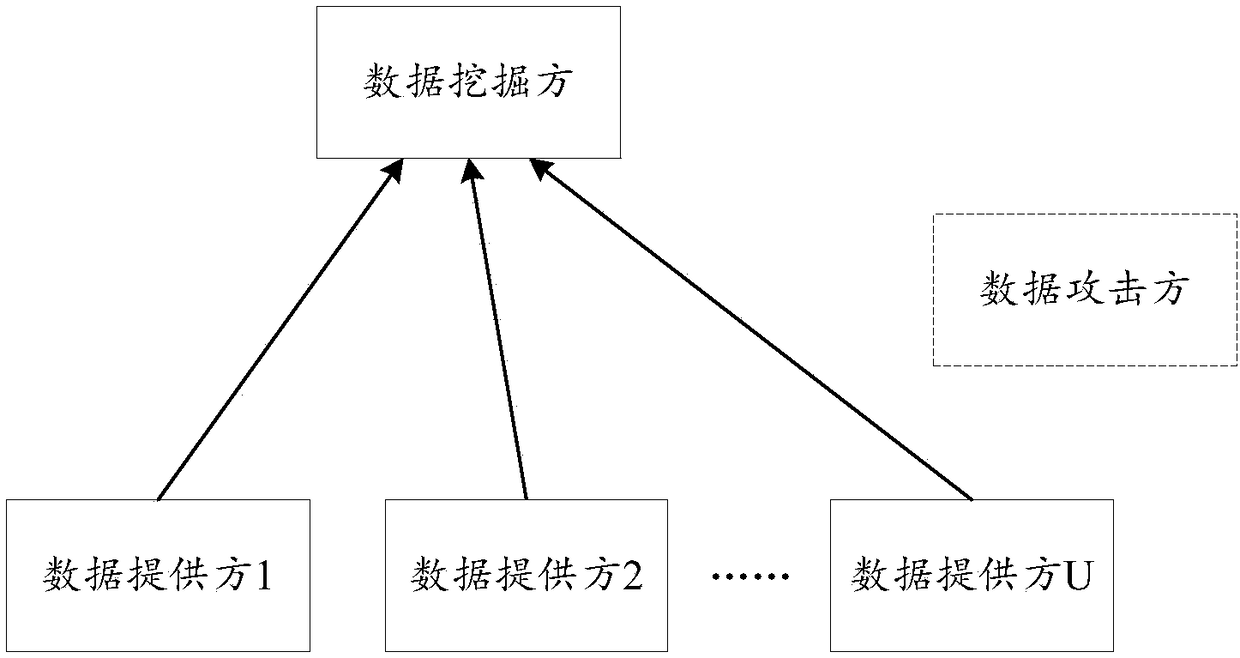

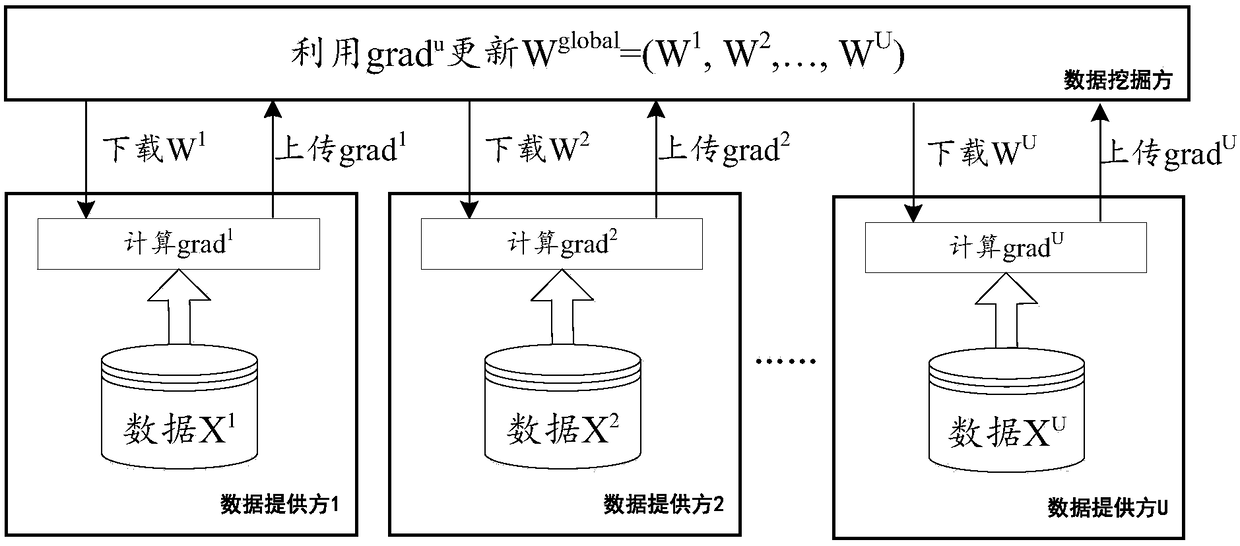

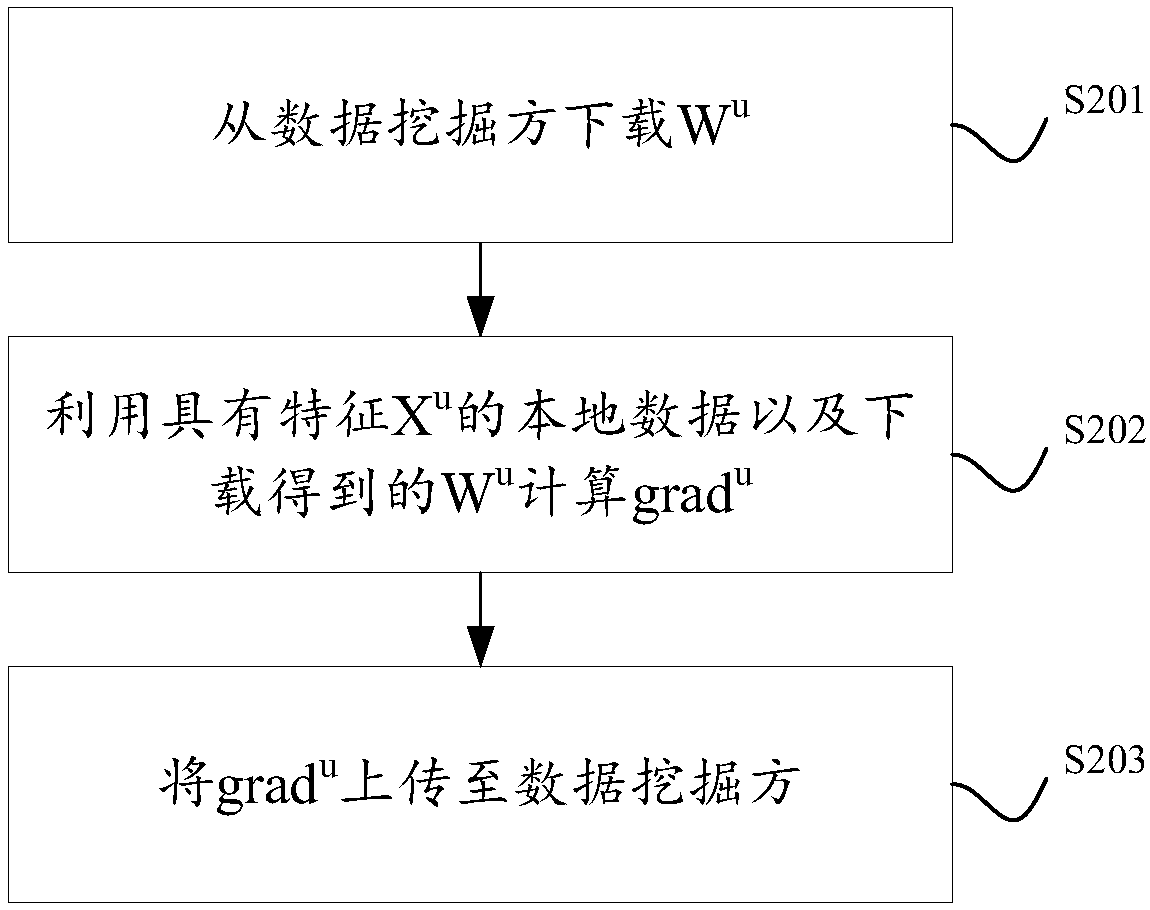

Model training method and apparatus based on shared data

ActiveCN109388662AWill not leakNo lossData miningSpecial data processing applicationsData sharingComputer science

A model training method and apparatus based on shared data are disclosed. The scheme is used to train the data model according to the mass data sample, wherein the data samples are from multiple dataproviders, different data providers can provide data sample characteristics from different dimensions, the data samples with richer feature dimensions can be formed after the data shared by differentdata providers are integrated, so that a better data model can be trained and the security of data sharing can be ensured at the same time.

Owner:ADVANCED NEW TECH CO LTD

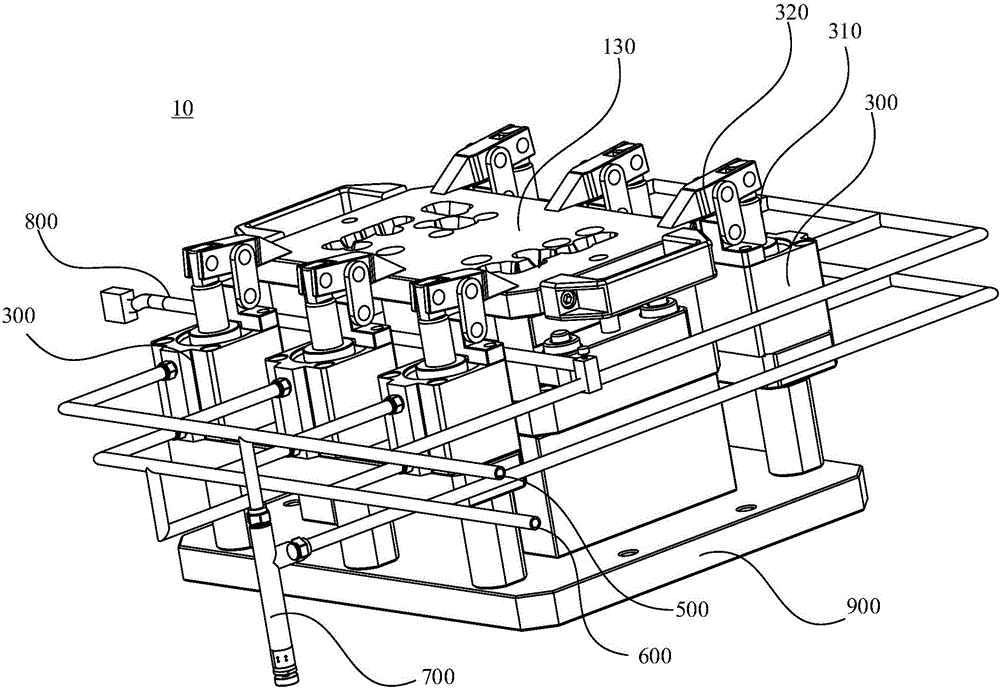

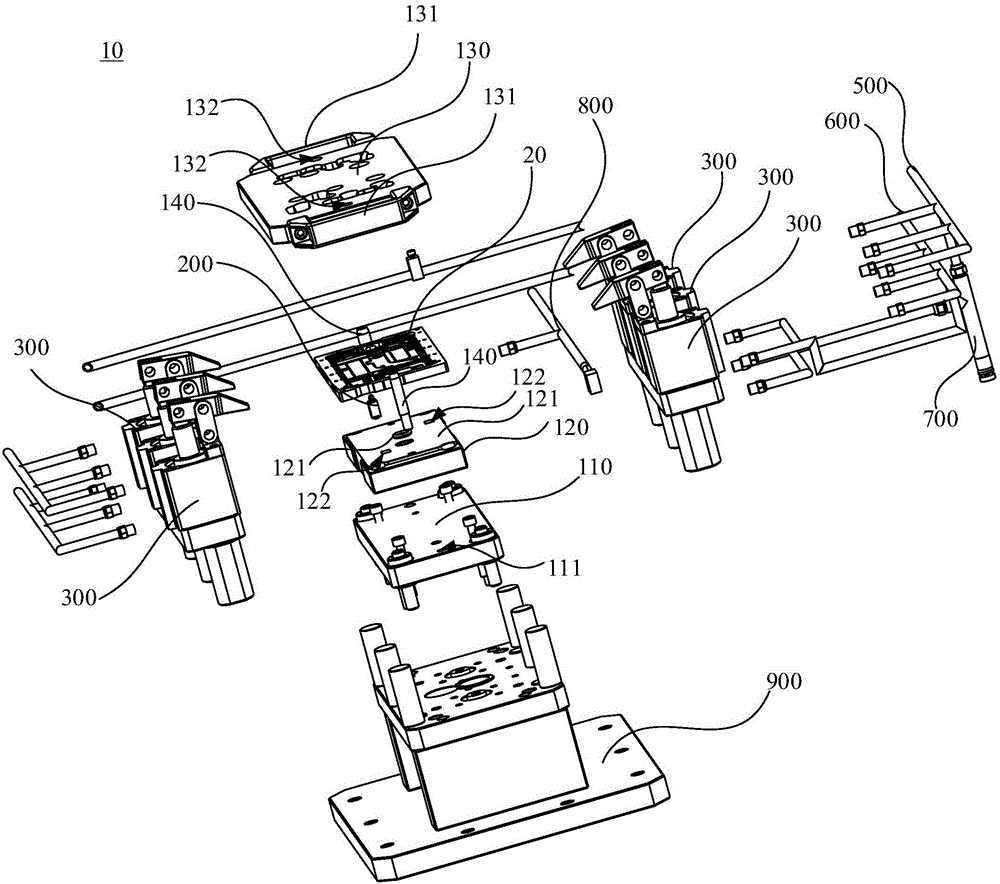

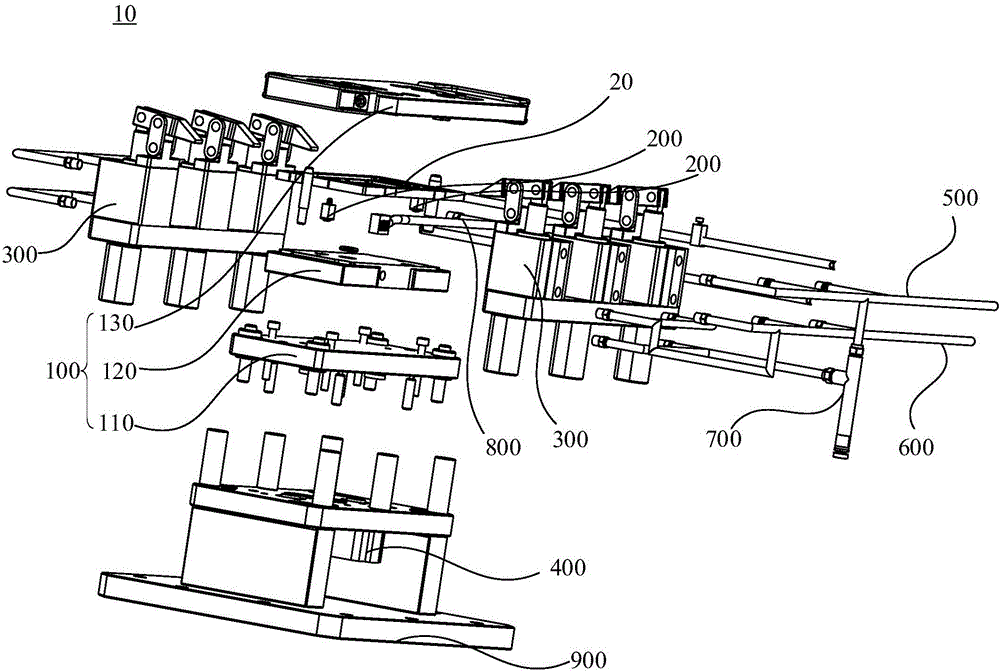

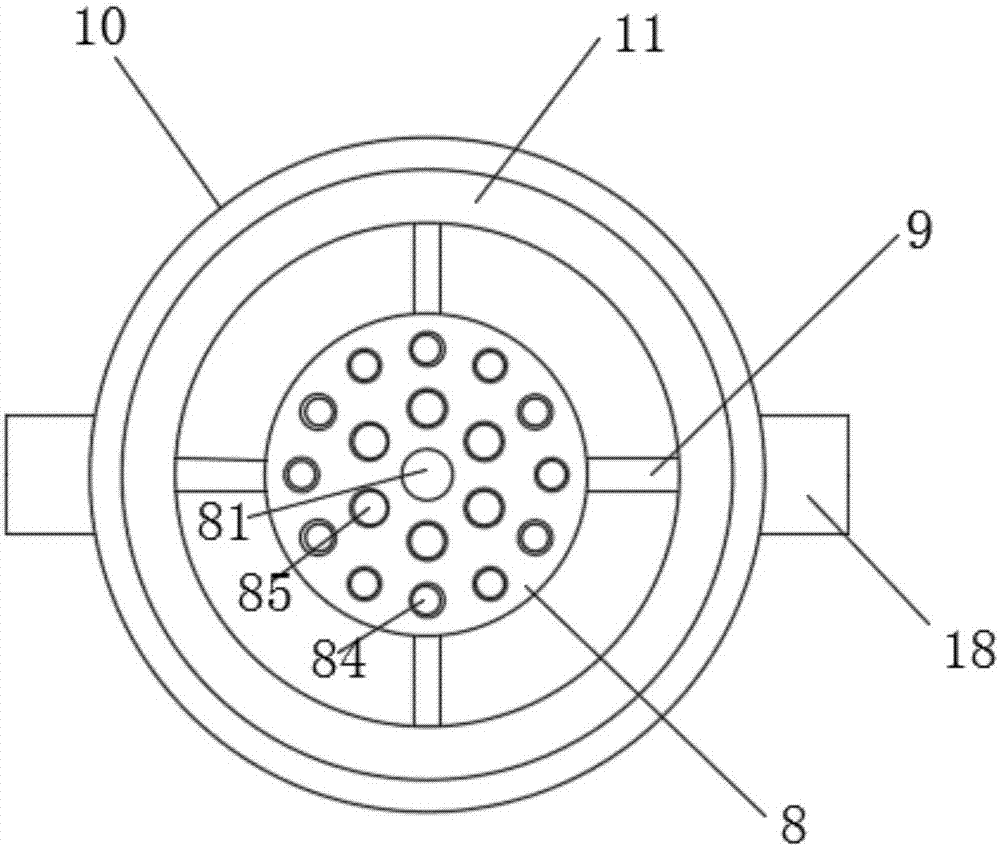

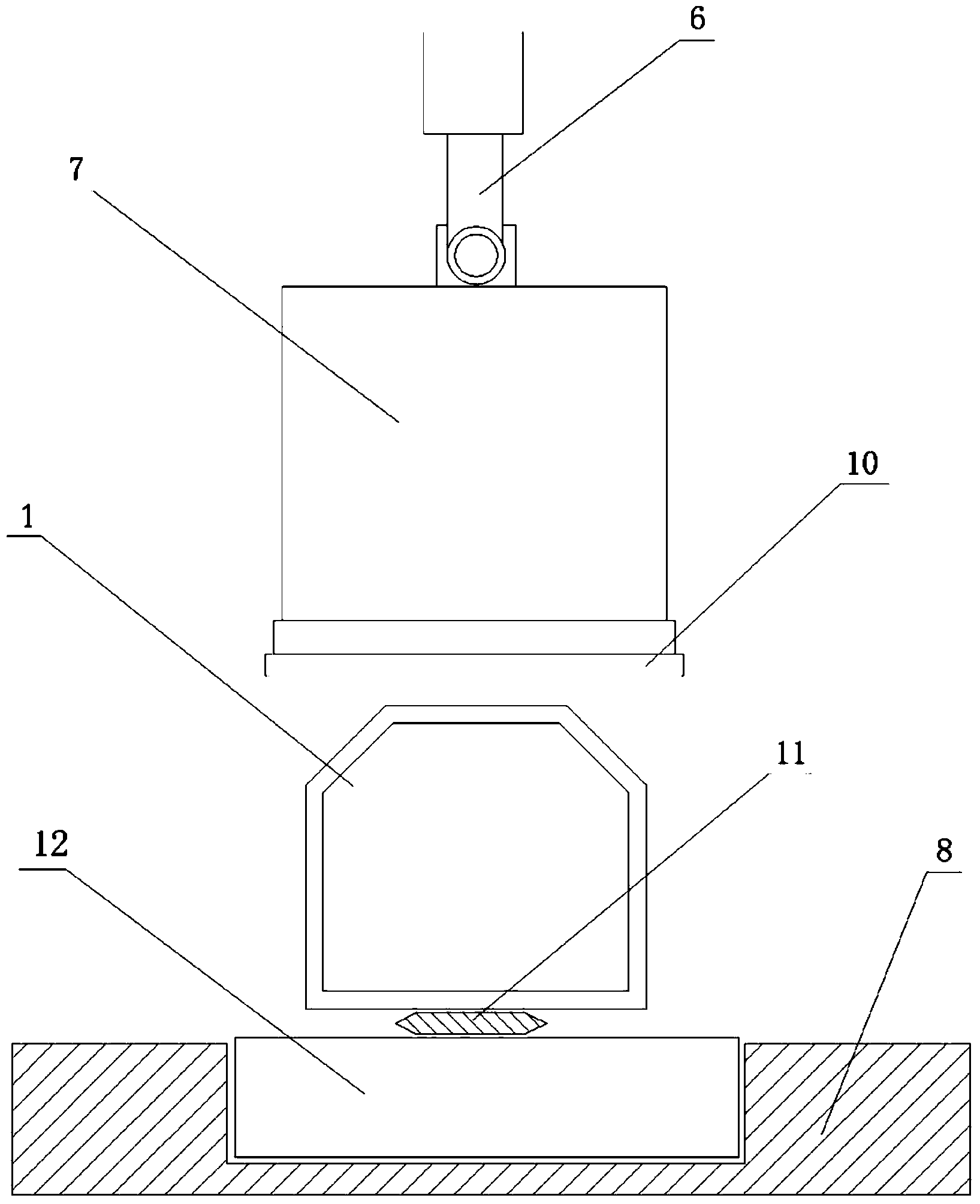

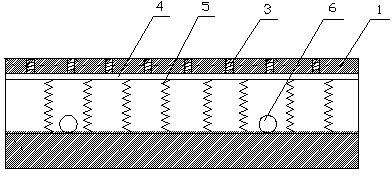

Fixture and air pressure detection mechanism thereof

ActiveCN105922037AImprove sealingWill not leakMeasurement devicesPositioning apparatusNumerical controlSolenoid valve

The invention relates to a fixture and an air pressure detection mechanism thereof. The fixture further comprises a base, first air cylinders, second air cylinders, an air inlet pipe and an air outlet pipe; the air pressure detection mechanism comprises a pressure solenoid valve, a three-way pipe and a seal ring, and the three-way pipe comprises a first opening, a second opening and a third opening which communicate with one another; when a workpiece is arranged on the positioning surface of a positioning plate, high-pressure air of the air inlet pipe is introduced into a positioning air hole via the second opening and the third opening; if the workpiece is clamped in place and the positioning surface of the positioning plate is clean, the surface of the workpiece and the sealing performance of the seal ring are better, the positioning air hole cannot leak air at the moment, the pressure solenoid valve detects the preset air pressure value, and an intelligent numerically-controlled machine tool is started normally; if the workpiece is not clamped in place and / or the positioning surface of the positioning plate is not clean, the positioning air hole in the positioning plate leaks air, the air pressure value detected by the pressure solenoid valve is reduced, and the intelligent numerically-controlled machine tool cannot be started at the moment.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD +1

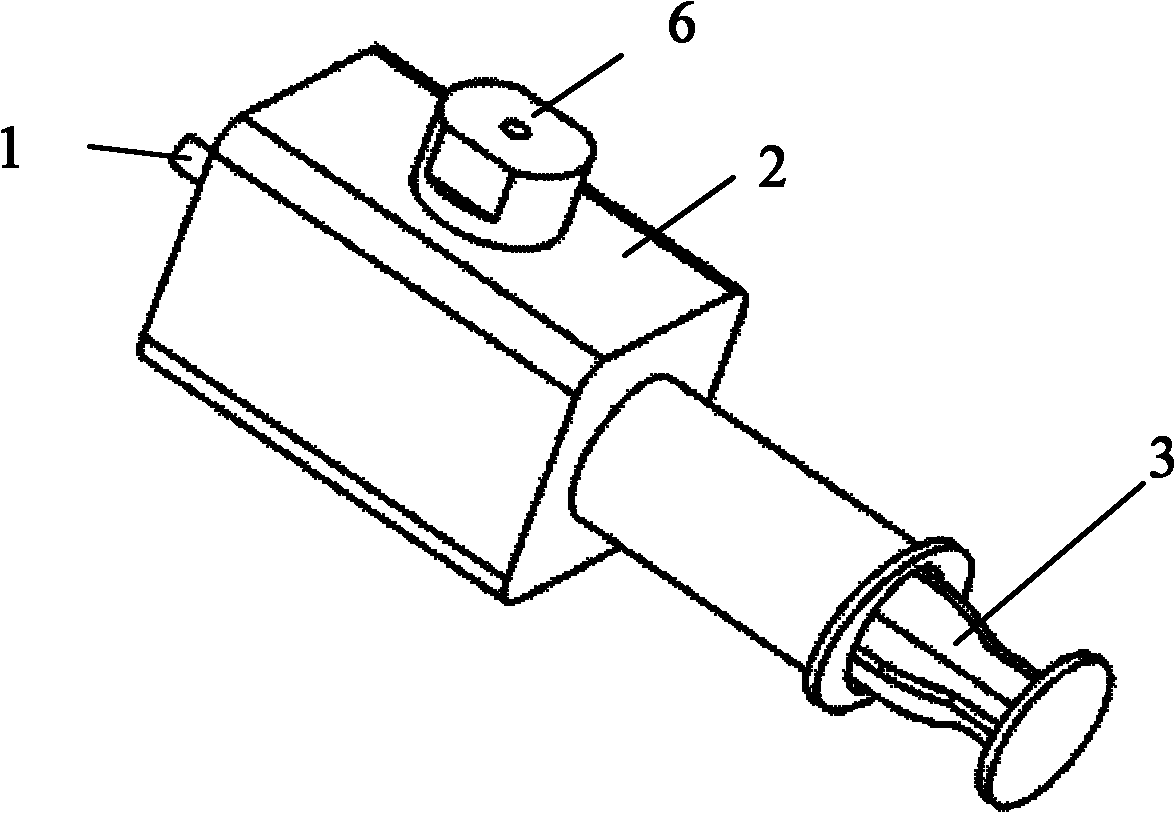

Gas sampling method and device

ActiveCN101846597AAvoid interferenceSolve the difficulty of samplingWithdrawing sample devicesPreparing sample for investigationEngineeringProduct gas

The invention relates to a method for sampling gas in a battery, which comprises the following steps of: A, sampling the gas in the battery for the first time into a gas sampler; B, pre-mixing the gas sampled for the first time; and C, sampling the pre-mixed gas for the second time to a detection device. The invention also relates to a gas sampler, which comprises a sampling needle and a gas collecting cylinder, wherein the gas collecting cylinder comprises a sampling port on one end part of the body of the gas collecting cylinder, a gas suction / exhaust push rod of which one end is inserted into the body of the gas collecting cylinder, and a secondary sampling port on the wall of the gas collecting cylinder; the secondary sampling port is sealed by a sealing device; and the sampling needle is arranged at the sampling port. The gas sampling method and the gas sampler can overcome the defects of difficult sampling, high equipment loss, and difficult acquisition of uniform gas samples in the prior art.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

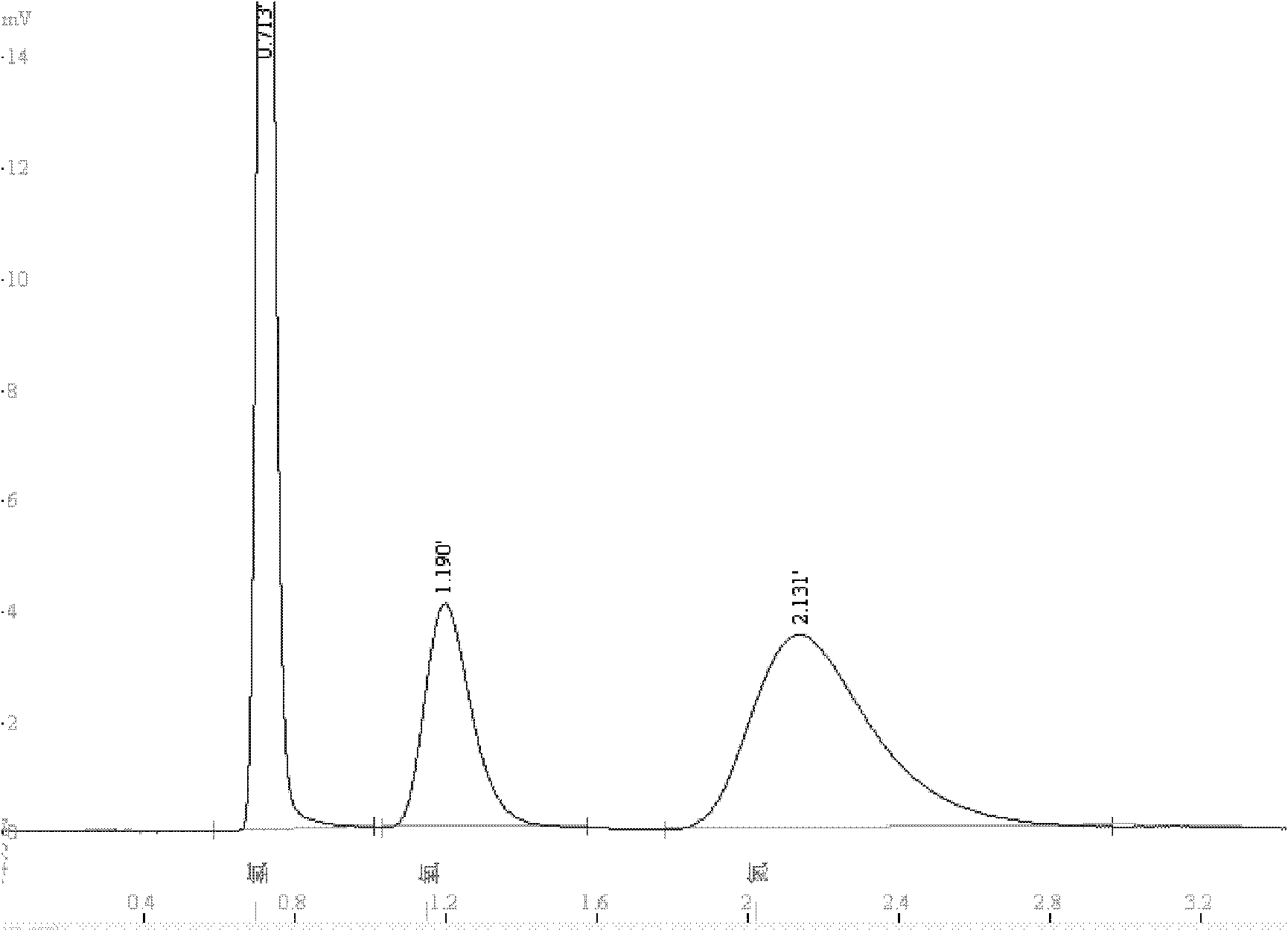

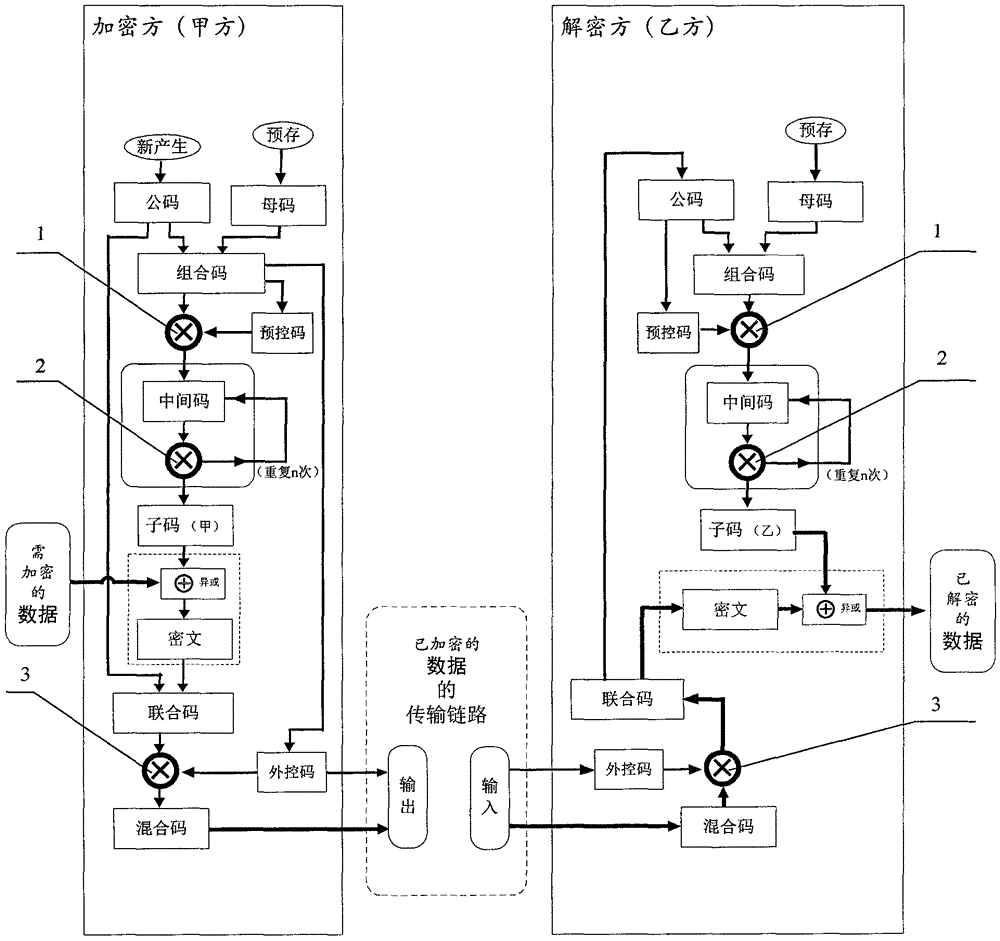

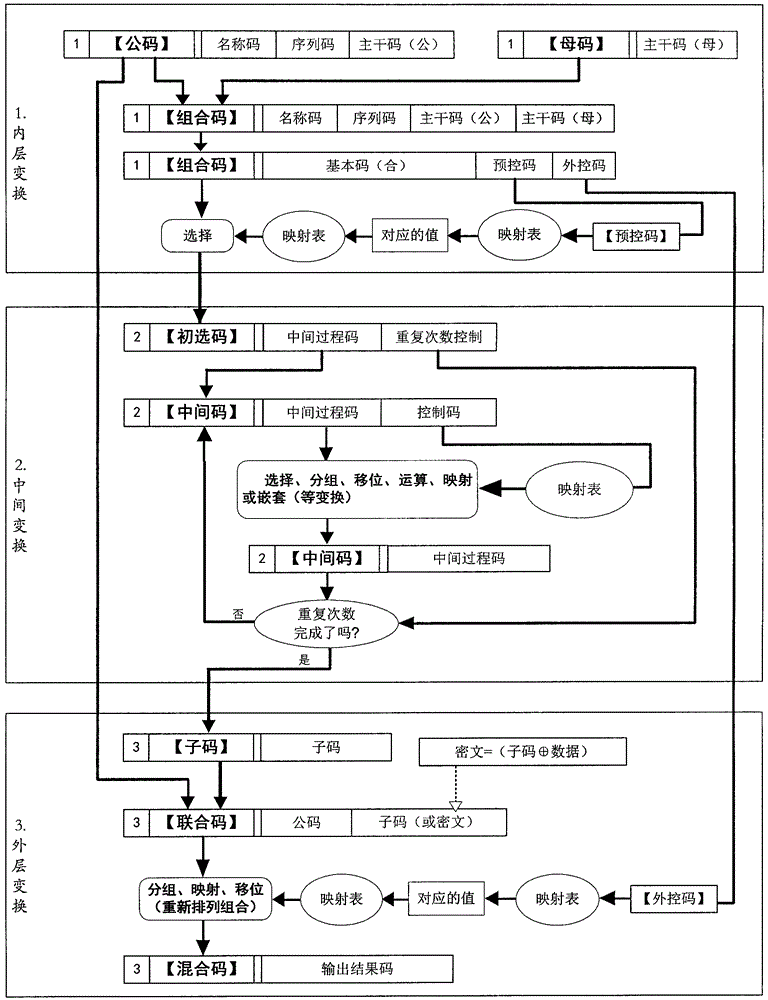

Coding convention control transformation type information authentication method, and coding convention control transformation type information encryption/decryption method

ActiveCN104868995AEasy to operateEasy to implementUser identity/authority verificationComputer hardwareCoding conventions

The present invention relates to an information technology and an electronic technology, and mainly provides a coding convention control transformation type information authentication method, and a coding convention control transformation type information encryption / decryption method. According to the present invention, the coding convention control transformation is a technology core, defines a series of different transformation modes in a coding format and according to the artificial convention, and divides the to-be-transformed data into the control codes and the basic codes. The control codes transform the basic codes according to a coding defined control mode to generate a new data result, so that the information authentication or the information encryption / decryption is carried out according to the coding convention control transformation and the generated result. The coding convention control transformation type information authentication method, and the coding convention control transformation type information encryption / decryption method of the present invention are simple, easy, safe and reliable, are low in cost, are very suitable for the software program processing, and can be widely used in the fields, such as the daily life, the economy, the military, etc.

Owner:陈麟华

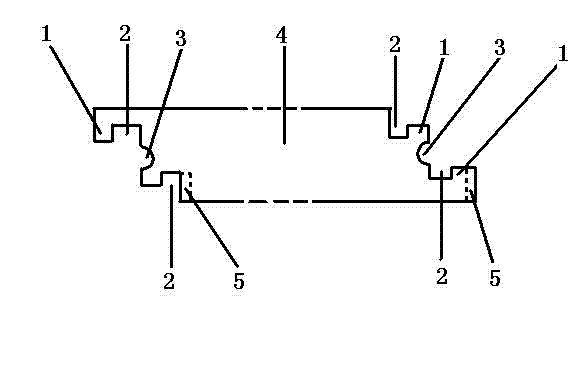

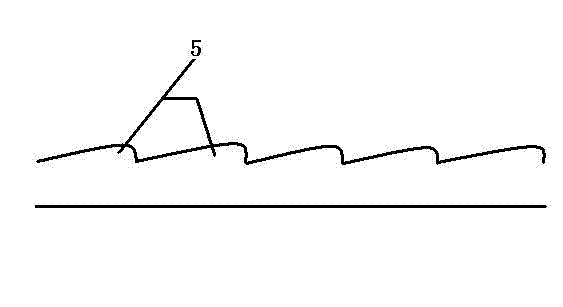

Heated floor locks

The invention relates to heated floor locks. The heated floor locks comprise oblique tenons, pores, lock heads and lock grooves, wherein the heated floor locks include male and female heated floor locks; the male lock comprises a first lock groove, a first lock head, a pore, a second lock groove, a second lock head and an oblique tenon from the side near a plate body to one tail end of the plate body in sequence; the female lock has a similar structure; the oblique tenons are put at the ends of the plate body, are wavy and have the same size; and the length and width of the floors are respectively integral multiples, within 100 times, of the length of the oblique tenons. The heated floor locks have the following advantages: through optimal design, the male and female lock heads are fit with the male and female lock grooves, so that the two floors can not move back and forth; hot air can pass through the pores, so that the floors become heated floors; the male and female oblique tenons are locked and the elastic oblique tenons can exist, so that the two floors are combined more closely, can not move left and right, are integrally combined firmly and can not undergo air leakage; and the modes of pressing and horizontal moving are used during installation, the integral structure is simple and the aim of locking is achieved.

Owner:宣建民

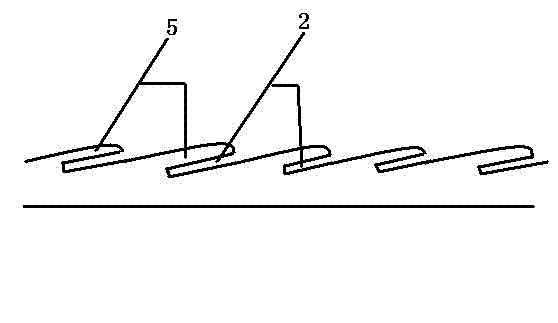

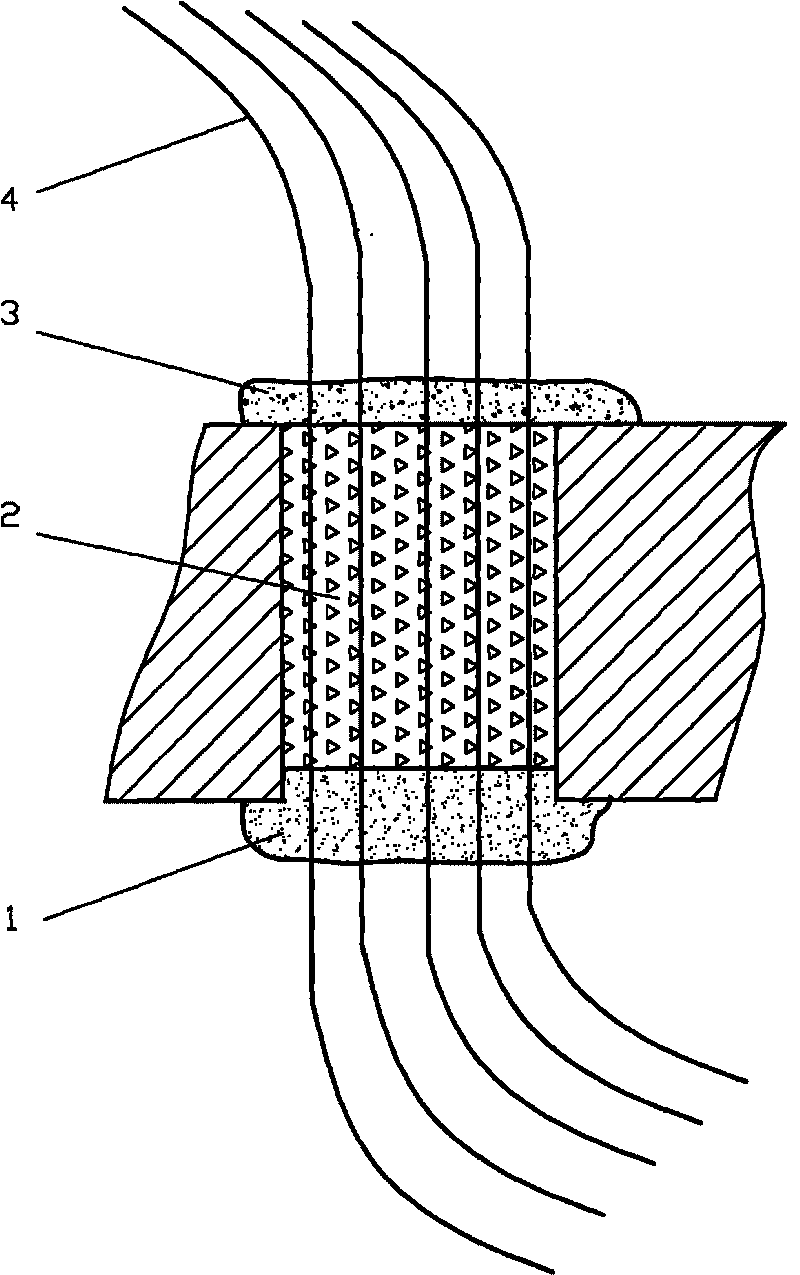

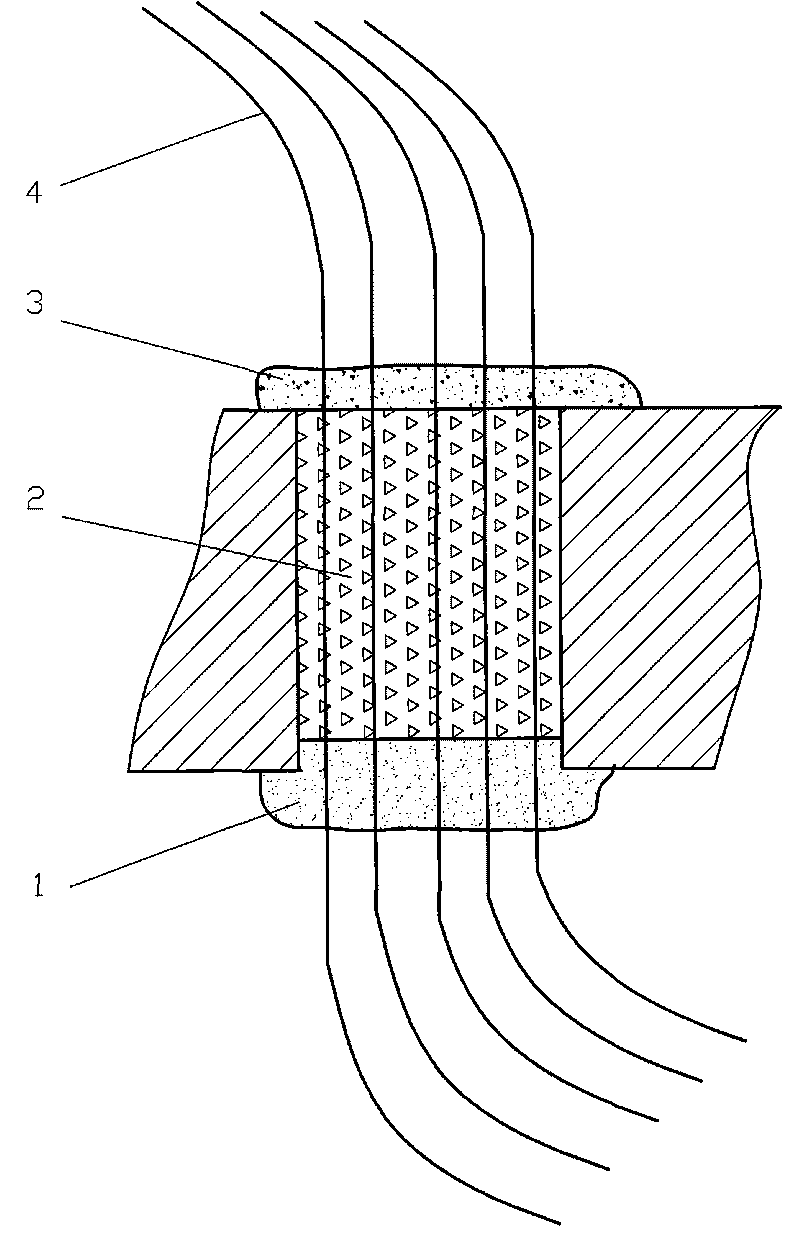

Perforating movable line bundle airtight technology

The invention relates to a perforating movable line bundle airtight technology which comprises the following steps: 1. punching a bottom layer 1: (1) adding a casting head at the bottom end of cable aperture which is perforated with leads by using a silicon rubber GD414 rubber tube for bottoming and encapsulating; (2) fixing line bundles at two sides on a side wall of a shell by using paper self-adhesive tapes; and (3) curing at normal temperature for 24h; 2. encapsulating a middle layer 2: (1) uniformly stirring equivalently proper amount of A type adhesive HJ101 and B type adhesive HJ101 in a container; (2) stopping encapsulating in the position having 1-2mm distance to an orifice, and using a heat blower to blow the liquid adhesive; (3) adding proper liquid adhesive to enable an adhesive surface to be flushed with an upper end surface of the perforating hole; (4) after the liquid adhesive does not flow, finishing and clearing; (5) standing and curing at normal temperature for 24h; and (6) clearing adhesive residues and dirt on an external surface in a part encapsulating position; and 3. encapsulating a top layer 3: uniformly covering a layer of 703 silicon rubber on the surface of HJ101 epoxy resin adhesive, and curing at normal temperature. The invention has simple technology and good air tightness, and can not leak air under the condition of high temperature or low temperature.

Owner:HEBEI HANGUANG HEAVY IND

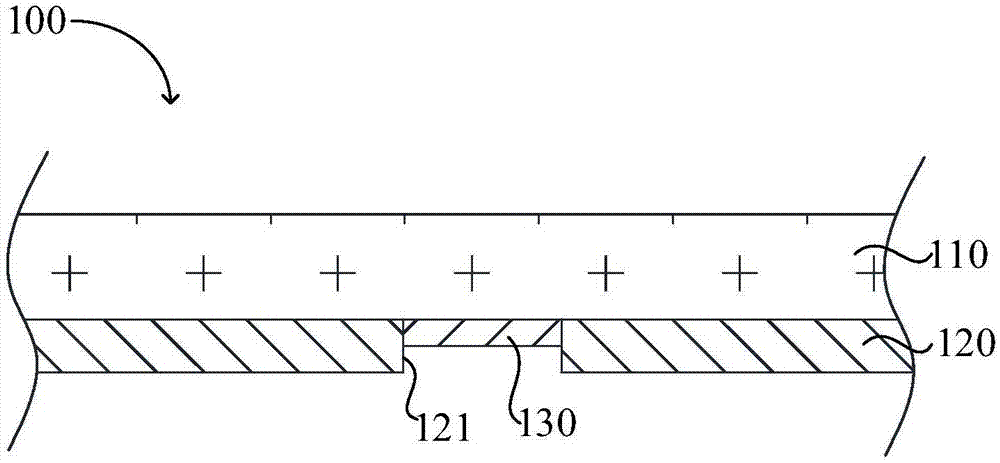

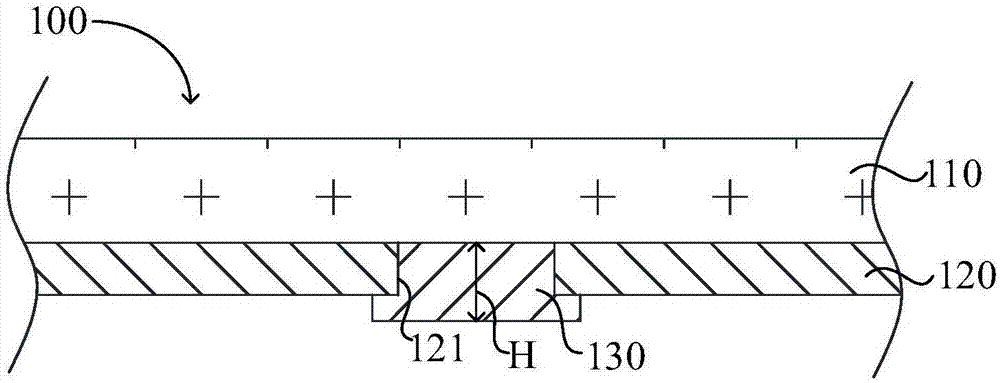

Cover plate assembly and mobile terminal comprising same

InactiveCN107390793ALow costWith light guide functionDetails for portable computersTelephone set constructionsLight guidePulp and paper industry

The invention discloses a cover plate assembly and a mobile terminal comprising the same. The cover plate assembly comprises a cover plate and an appearance ink layer which are arranged sequentially, a light-emitting hole is formed in the appearance ink layer, and a light guide ink layer is arranged in the position of the light-emitting hole. The mobile terminal comprises the cover plate assembly. According to the cover plate assembly and the mobile terminal comprising the same, a light guide membrane is replaced with the light guide ink layer, the light guide ink layer is directly arranged on the cover plate by printing, spraying or a similar technology, the cover plate assembly has the light guide function as well, and the light guide membrane, gum and the like are not required so that the material cost is saved; the light guide membrane is not required to be pasted at the assembly stage so that manpower is saved; short assembly due to human causes can be avoided, and the rework rate is reduced.

Owner:HUAQIN TECH CO LTD

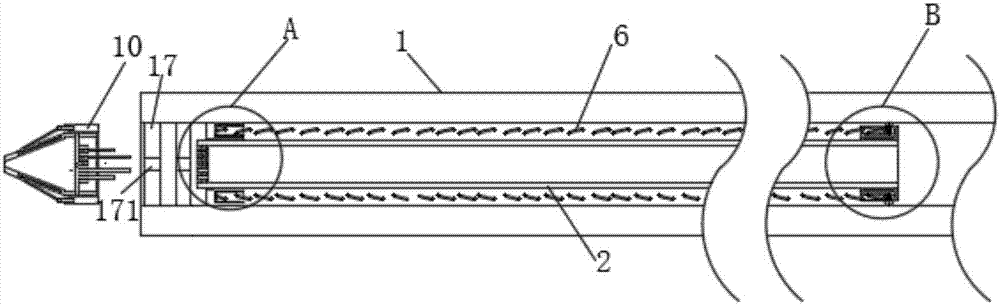

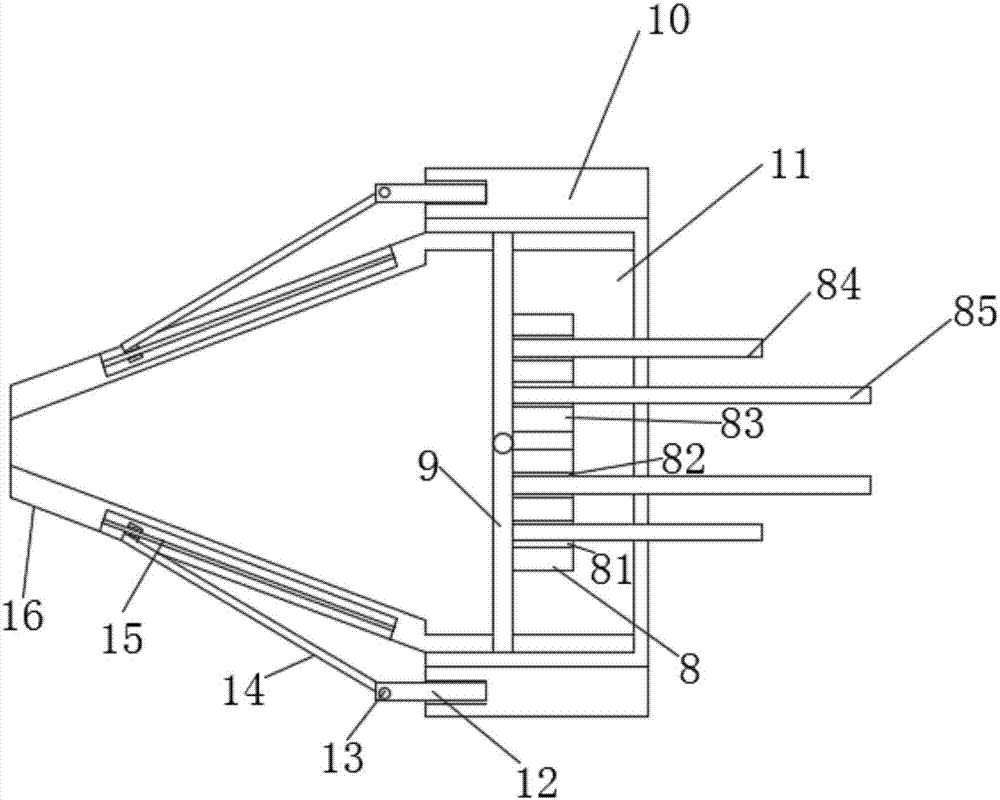

Telescopic sprayer for mortar spraying machine and capable of controlling flow

InactiveCN107442307AImprove the use effectImprove work efficiencyUnderground chambersSpray nozzlesEngineeringSprayer

The invention discloses a telescopic sprinkler head for a spraying machine with controllable flow rate, which comprises an outer conduit, an inner conduit and a sprinkler head, the outer conduit is provided with an inner conduit, and a first ferrule is fixedly sleeved on the inner conduit , the inner end of the inner catheter is provided with a catheter chuck, and the catheter chuck and one side of the first ferrule are engaged with each other, the two sides of the first ferrule are provided with spring grooves, and the inner walls of the two spring grooves are respectively fixed The first spring is connected, and the end of the inner conduit away from the first ferrule is slidably sleeved with the second ferrule. In the present invention, an inner conduit is arranged in the outer conduit, and a filter plate is arranged on the inner conduit, and three filter ports are arranged on the filter plate, and a disc seat is provided on the spray head device detachably threaded with the inner conduit, and three filter ports are arranged on the disc seat. There are two slots, and two plugs are plugged into the disc seat, and the flow rate through the filter port is controlled by moving the nozzle device to control the flow rate of the nozzle, so as to meet the spraying requirements of different walls and improve the use of the spraying machine. Effect.

Owner:赵杭森

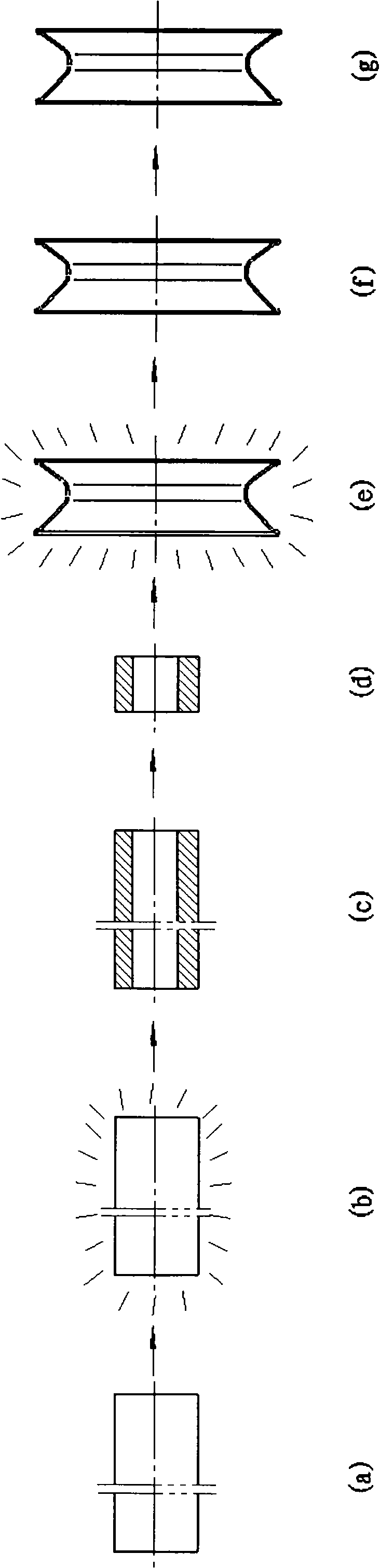

Process for forming spare billet of wheel rim without inner tube with constant strength variable cross-section

The invention relates to a process for forming a spare billet of a wheel rim without an inner tube with a constant strength variable cross-section, which comprises the following step that a casting billet steel bar is processed into a spare billet through the working procedures of heating, punching, baiting, thermal ring rolling, sizing and spreading and scale removing. Because the process adopts the casting billet steel bar as a raw material, the cost is reduced. In the process of the thermal ring rolling, the cast structure of the casting billet steel is changed into a forge structure. The processing of sizing and spreading carried out afterwards not only can improve the spare billet precision of the wheel rim, but also can improve the strength of the wheel rim by 20 percent through cold machining. The wheel rim manufactured by the process has no welding lines, and a manufactured wheel does not have air leakage in the process of use, can be used as a wheel without an inner tube of a high-speed heavy-load transport vehicle and has the advantages of safety, reliability, low oil consumption, and the like. Used heating equipment, punching equipment, ring rolling equipment and sizing and spreading equipment can all be selected from home equipment. The process for forming a spare billet of a wheel rim without an inner tube with a constant strength variable cross-section has less investment and low production cost.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH +1

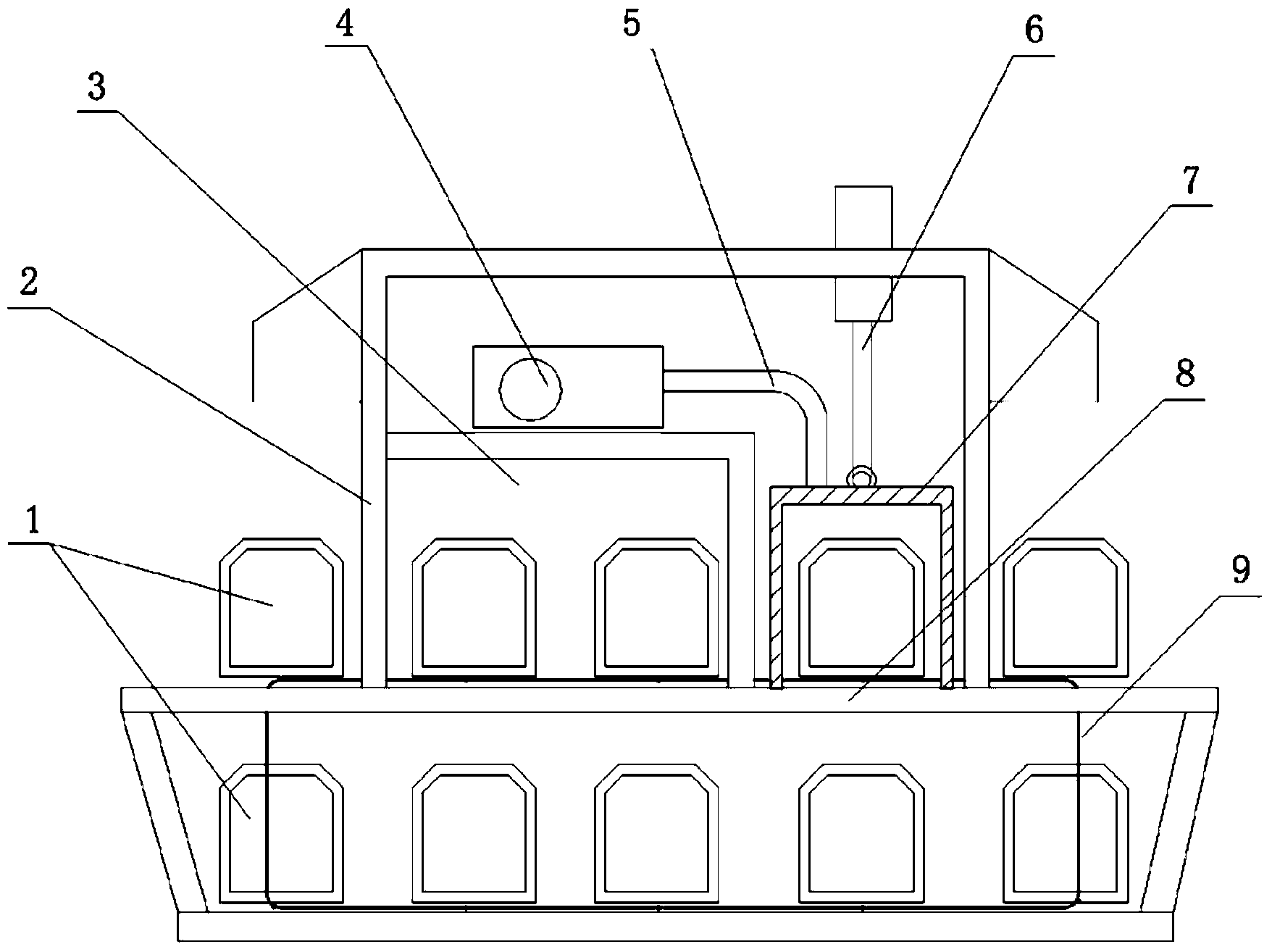

Vacuum setting machine for shoemaking

The invention discloses a vacuum setting machine for shoemaking. The vacuum setting machine comprises a frame, a shoe basket, a treatment box, a vacuum hood, a conveying device, a power device and a control device. Two ends of the shoe basket are respectively connected onto the conveying device; the conveying device accurately conveys the shoe basket into the treatment box and below the vacuum hood in time sequence under the action of the power device and the control device; a lifting device is connected onto the vacuum hood; a cavity formed between the vacuum hood and a bottom plate is connected with a vacuum pump through a pipeline; supporting plates are respectively mounted at the two bottom ends of the shoe basket; the two sides of the supporting plates are in the shape of knife edges; an upper sealing gasket is arranged at the opening of the vacuum hood; a lower sealing gasket is arranged on the bottom plate. As the upper sealing gasket is arranged at the opening of the vacuum hood, the lower sealing gasket is arranged on the bottom plate, and the supporting plates at the two ends of the shoe basket are in the shape of knife edges, the supporting plates are buckled between the upper sealing gasket and the lower sealing gasket during vacuum pumping, the sealing effect is good, and air leakage can not occur.

Owner:赵宽学

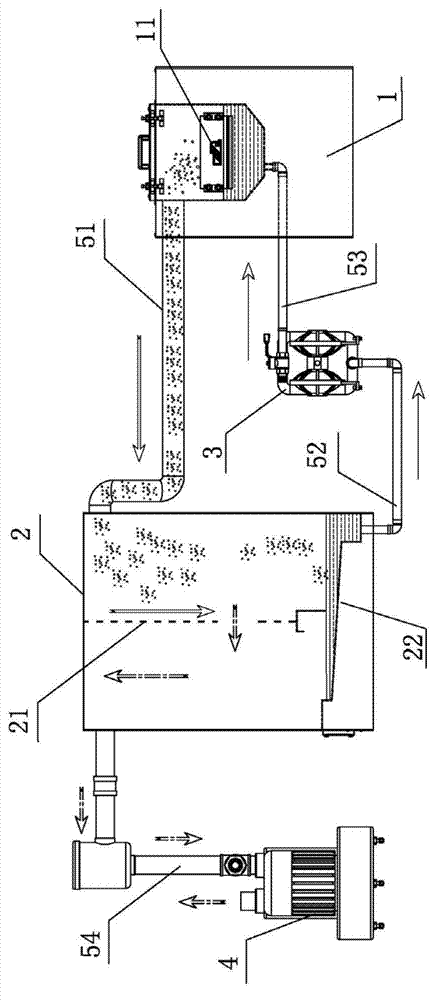

Device and method for spraying coating

InactiveCN102728510AFull spraySpray evenlyLiquid surface applicatorsSpraying apparatusSpray coatingAir blower

The invention relates to a device and a method for spraying a coating. The device for spraying the coating comprises a spraying box (1), a coating recycling box (2), a coating pump (3) and an air blower, wherein the upper end of the spraying box (1) and the upper end of the coating recycling box (2) are communicated through a first connecting pipe (5) and are closed; the middle of the spraying box (1) is provided with a feed inlet (11) through which the spraying box (1) is communicated with external atmosphere; the coating is accommodated in the part of the spraying box (1), which is below the feed inlet (11); an inlet of the coating pump (3) is connected with the coating recycling box (2); an outlet of the coating pump (3) is connected with the spraying box (1), so that the recycled coating in the coating recycling box (2) is conveyed to the part below the spraying box; and an air blower (4) is connected with the upper part of the coating recycling box (2) and exhausts air. By the device and the method, the coating can be uniformly distributed on the surface of a workpiece, and the coating can be effectively prevented from being diffused in the air outside the device, so that the air is prevented from being polluted, health of spraying personnel is guaranteed, and the coating is fully utilized simultaneously.

Owner:大连渴望科技发展有限公司

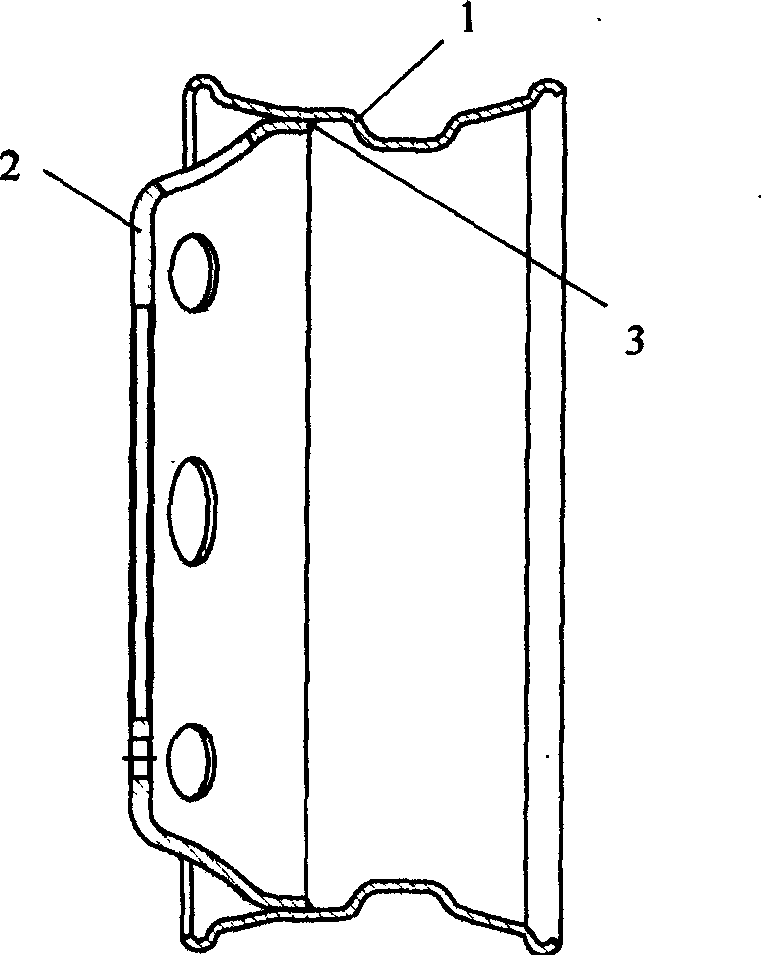

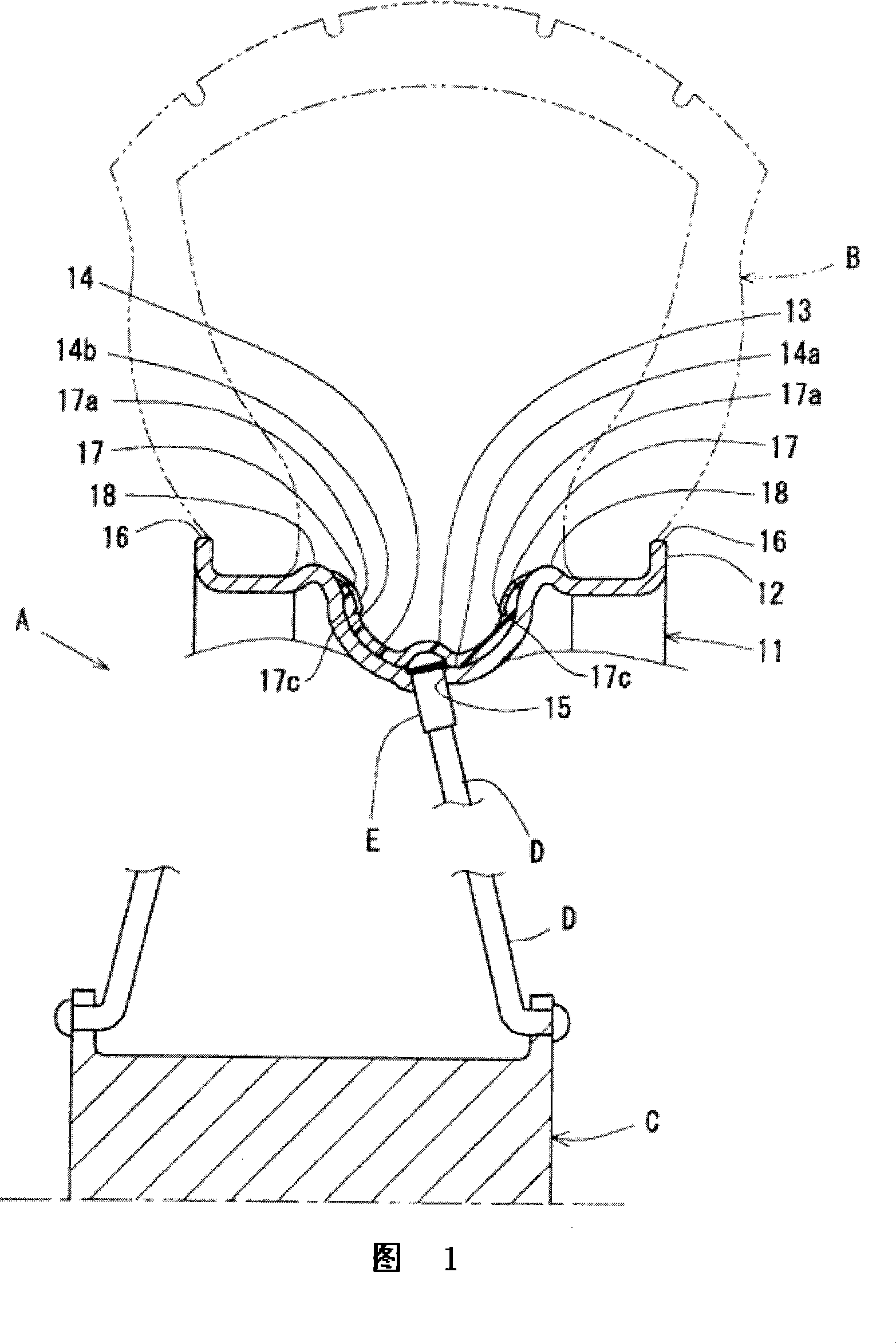

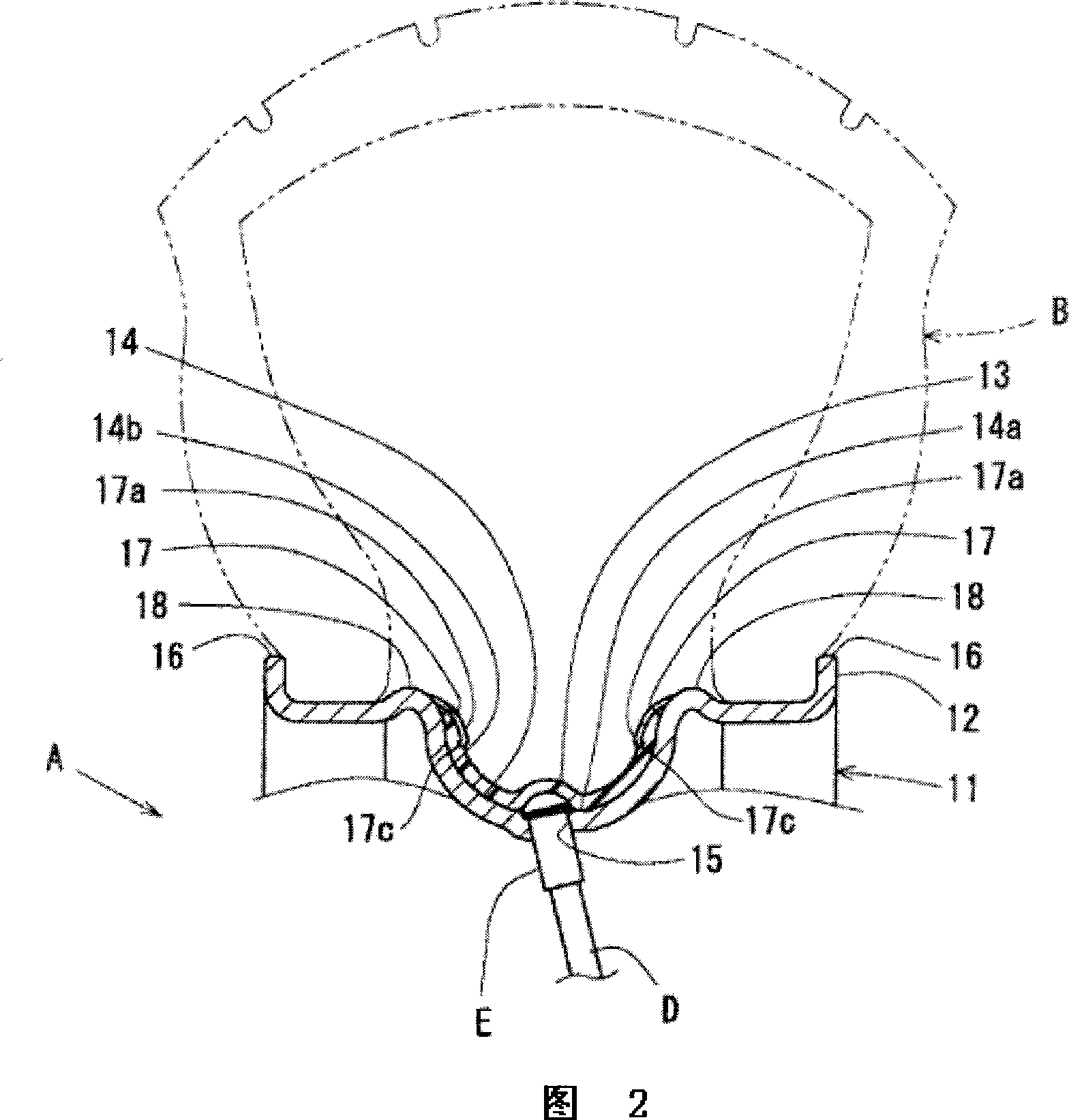

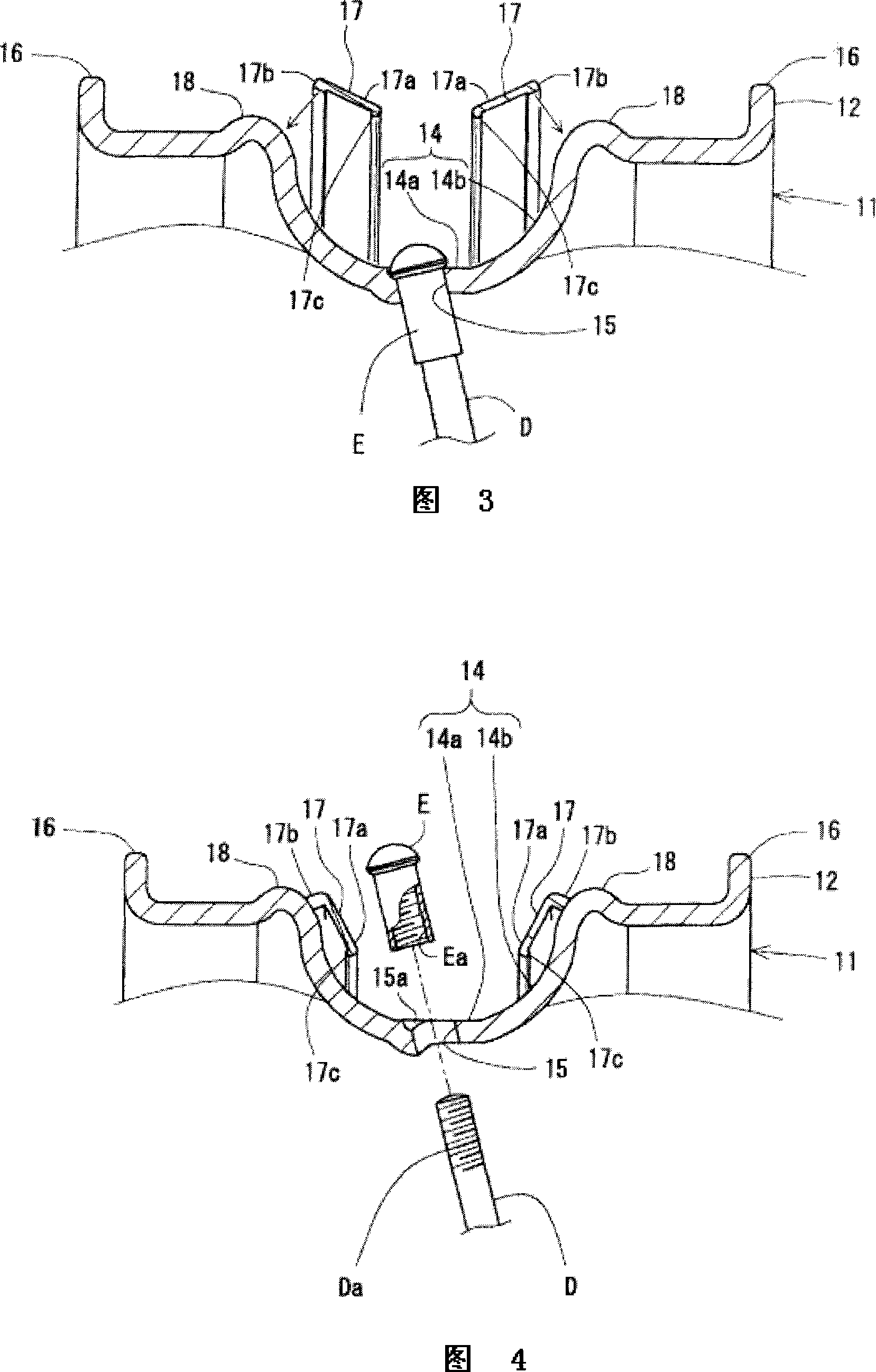

Rim without inner tyre and manufacturing method thereof

InactiveCN101125520ADisassemble at willWill not leakWithout separate inflatable insertsTubeless tireEngineering

The invention relates to a tubeless rim and manufacturing method thereof. The steel ring is overall sealed to form rim for assembing tubeless tire by setting a groove on a steel ring body, setting steel wire mounting hole on the bottom of the groove, welding a limited location snapping plate on the left and right side walls of the groove and filling and mounting with sealant material in the whole ring annular space between the left and right side walls and limited location snapping plate. Because of the action of limiting location and attaching, the sealant material is reliably lacated in the groove and the sealing is ensured, without coming off. The sealant material is set in manner of active assembling to allow disassembly as required. The invention has features of reasonable and simple structure and simple mountation and safe work, simple maintenace and low cost and provids convenience for installing the tubeless tire on the steel rim.

Owner:藤井博实

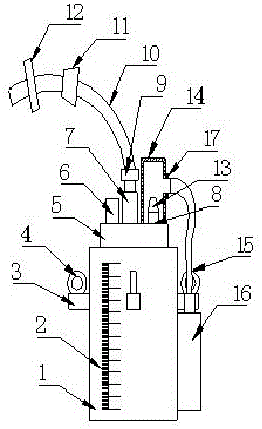

Negative-pressure indicating drainage bottle

InactiveCN105107031AGuaranteed negative pressureWill not flow backIntravenous devicesSuction pumpsReflux valveEngineering

The invention relates to a negative-pressure indicating drainage bottle which comprises a bottle body, wherein measurement scale lines are formed on the front surface of the bottle body, mounting bases are respectively arranged in the middle parts of the front surface, the back surface, the left side and the right side of the bottle body, hanging rings are arranged on the upper sides of the mounting bases, a bottle cap is arranged on the upper side surface of the bottle body, a vacuum indicator, a drainage opening and an extraction opening are arranged on and formed in the bottle cap in sequence from left to right, the drainage opening is connected with a drainage tube through a Ruhr connector, a reflux valve is arranged in the middle of the drainage tube, a tube clamp is arranged on the end of the drainage tube, a check valve is arranged on the upper end of the extraction opening, an extraction chamber is arranged outside the extraction opening, a connecting tube is connected to the right end of the extraction chamber, and a minipump is connected to the other end of the connecting tube. The negative-pressure indicating drainage bottle has the advantages of simple structure, safety, accuracy, good use effect and strong practicability.

Owner:HENAN YADU IND

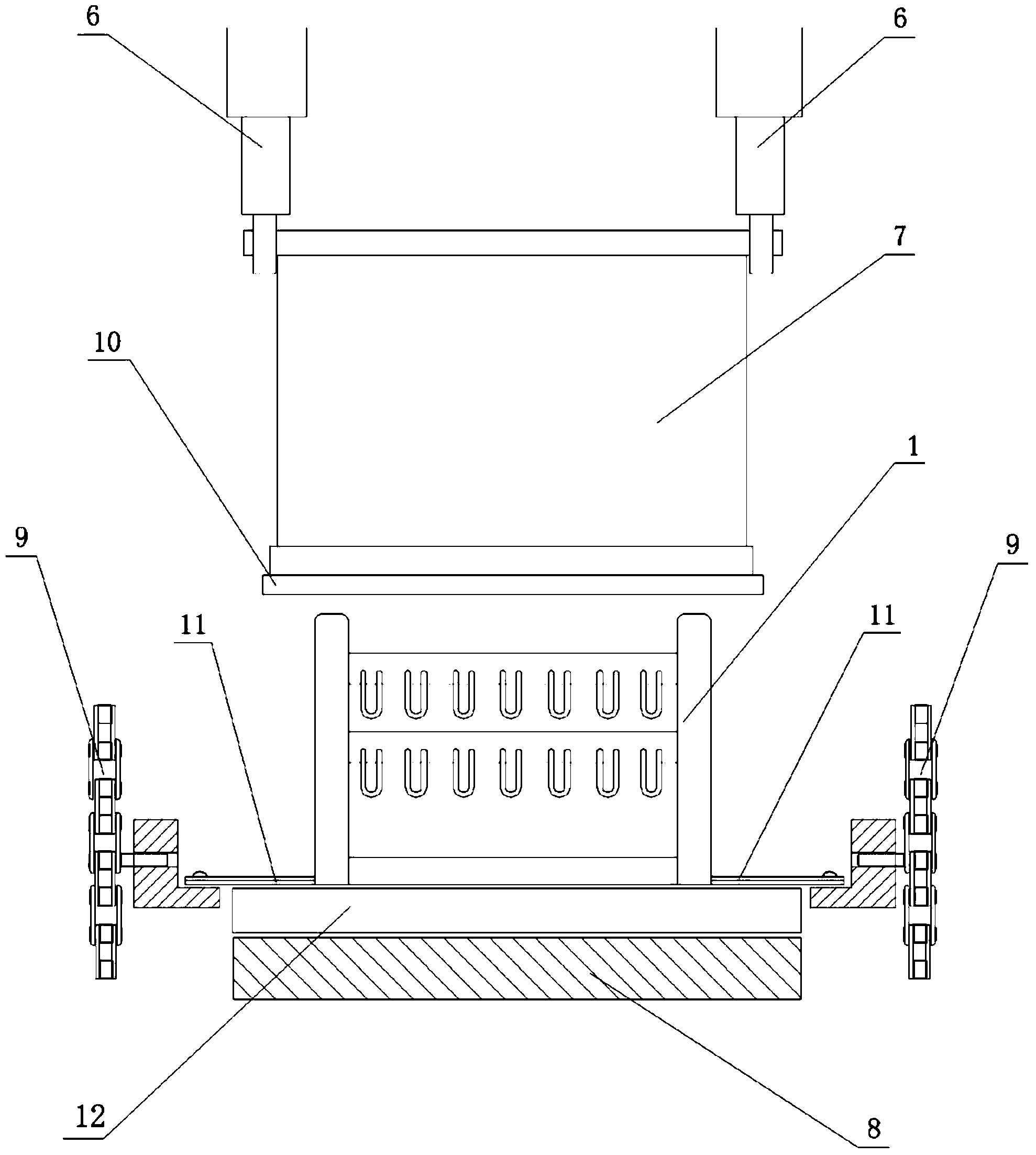

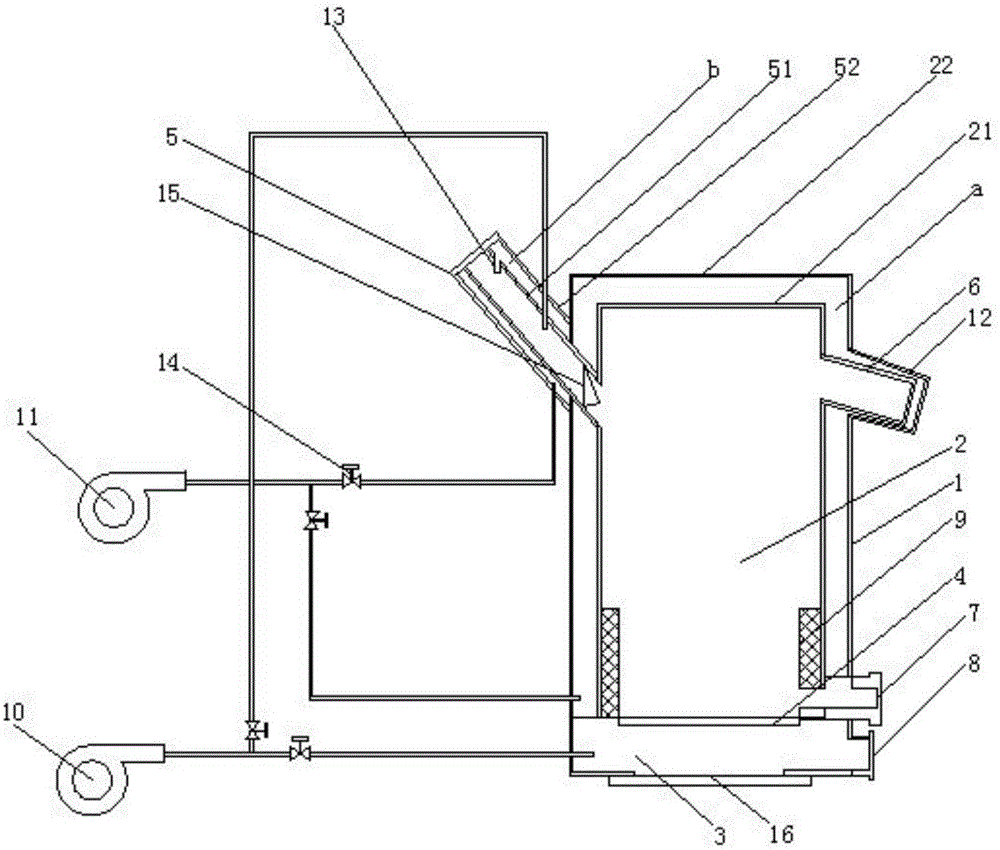

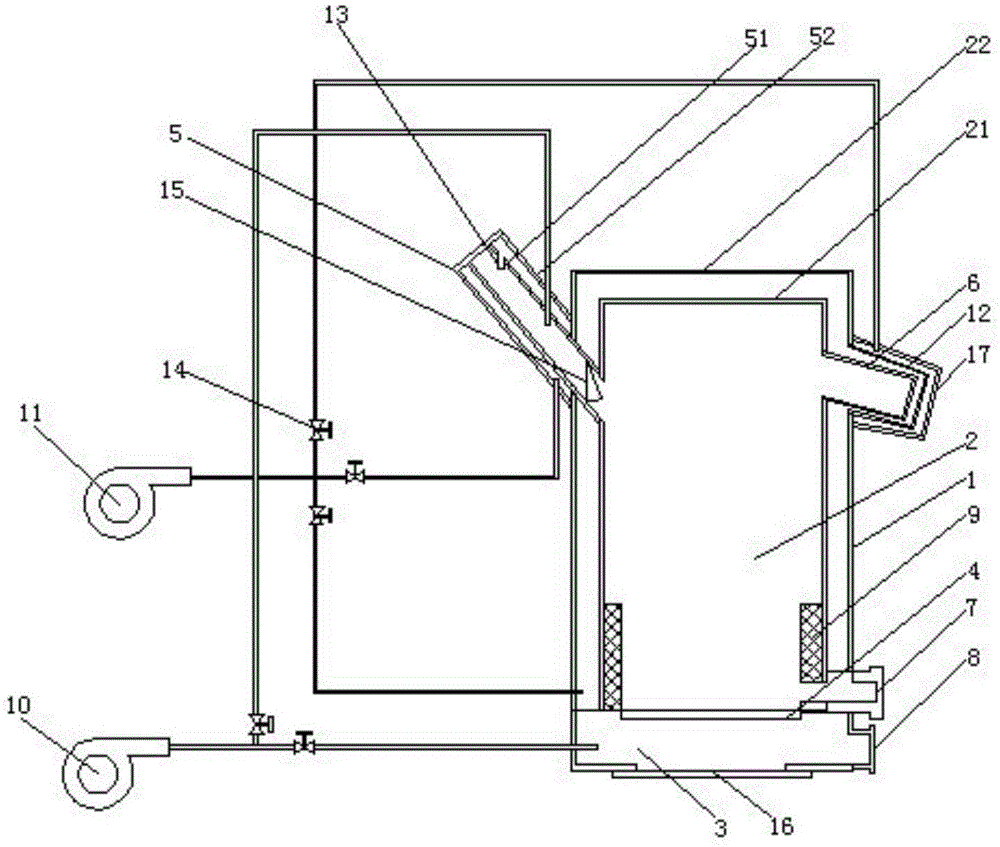

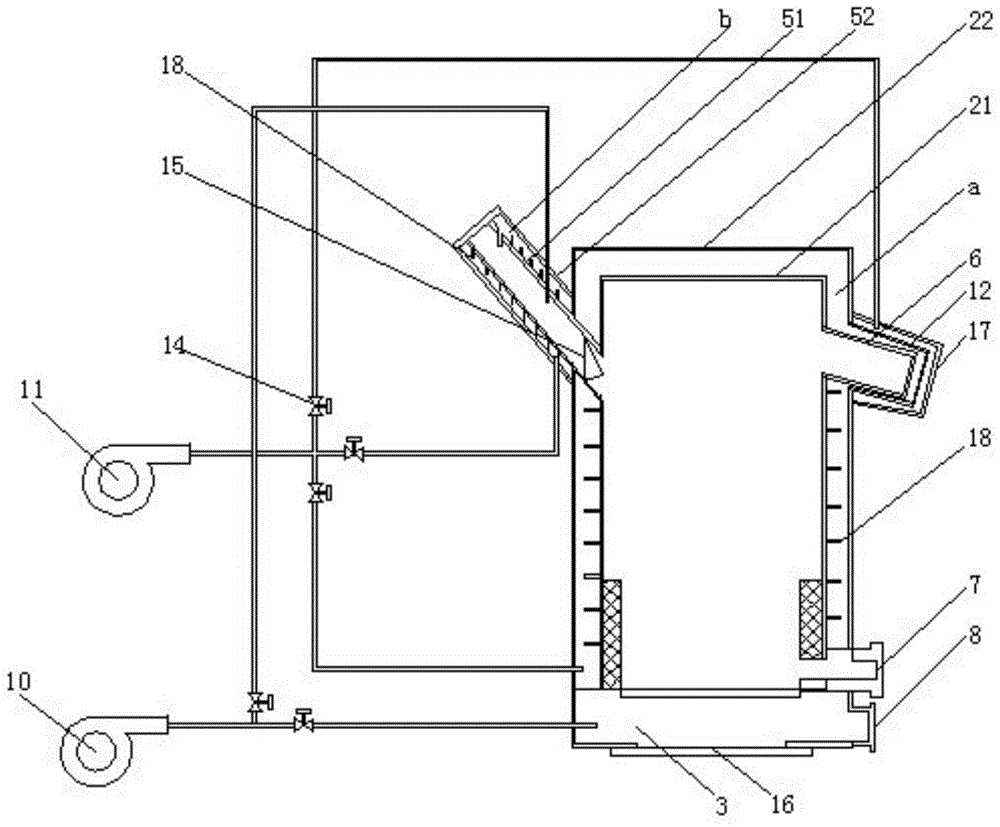

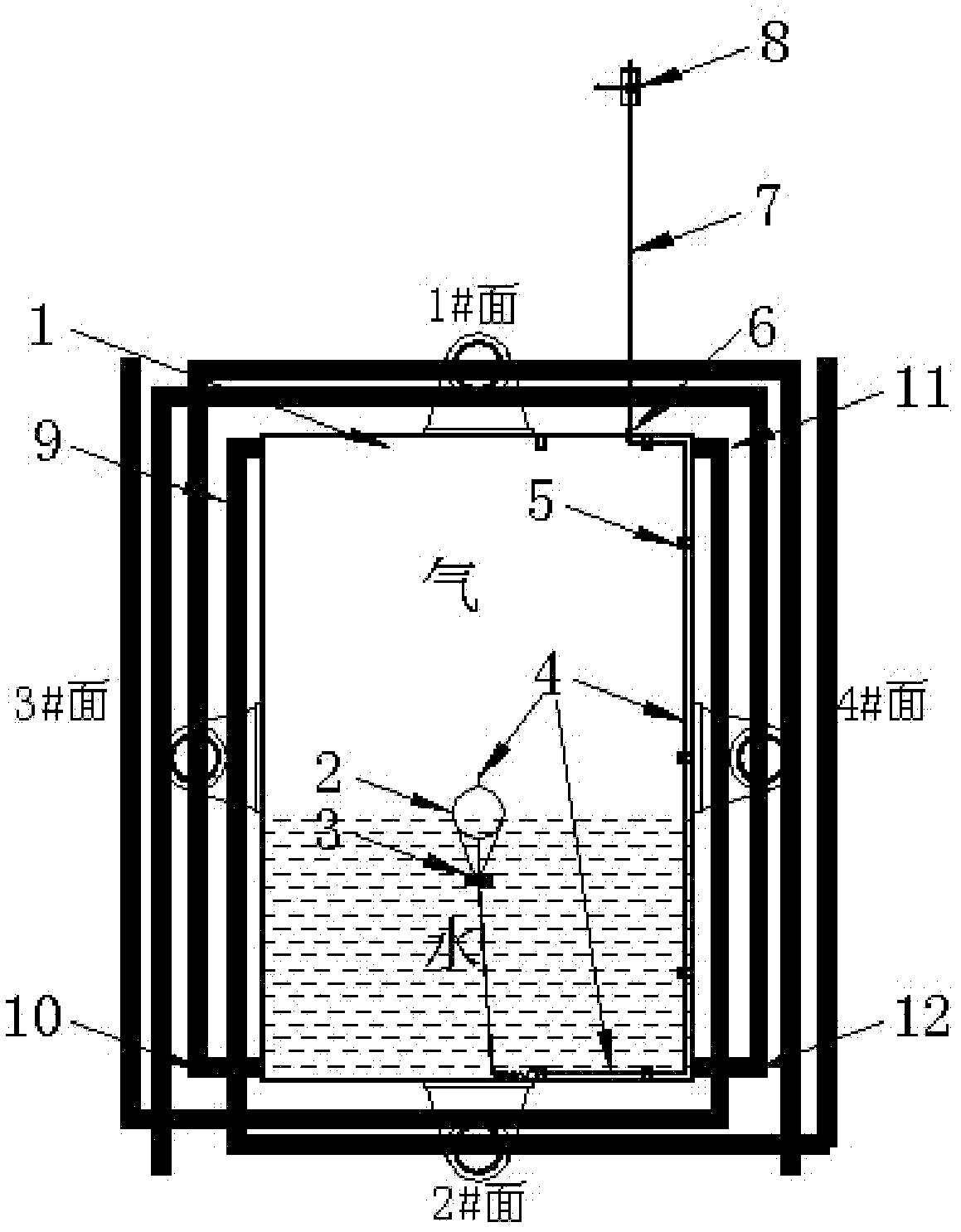

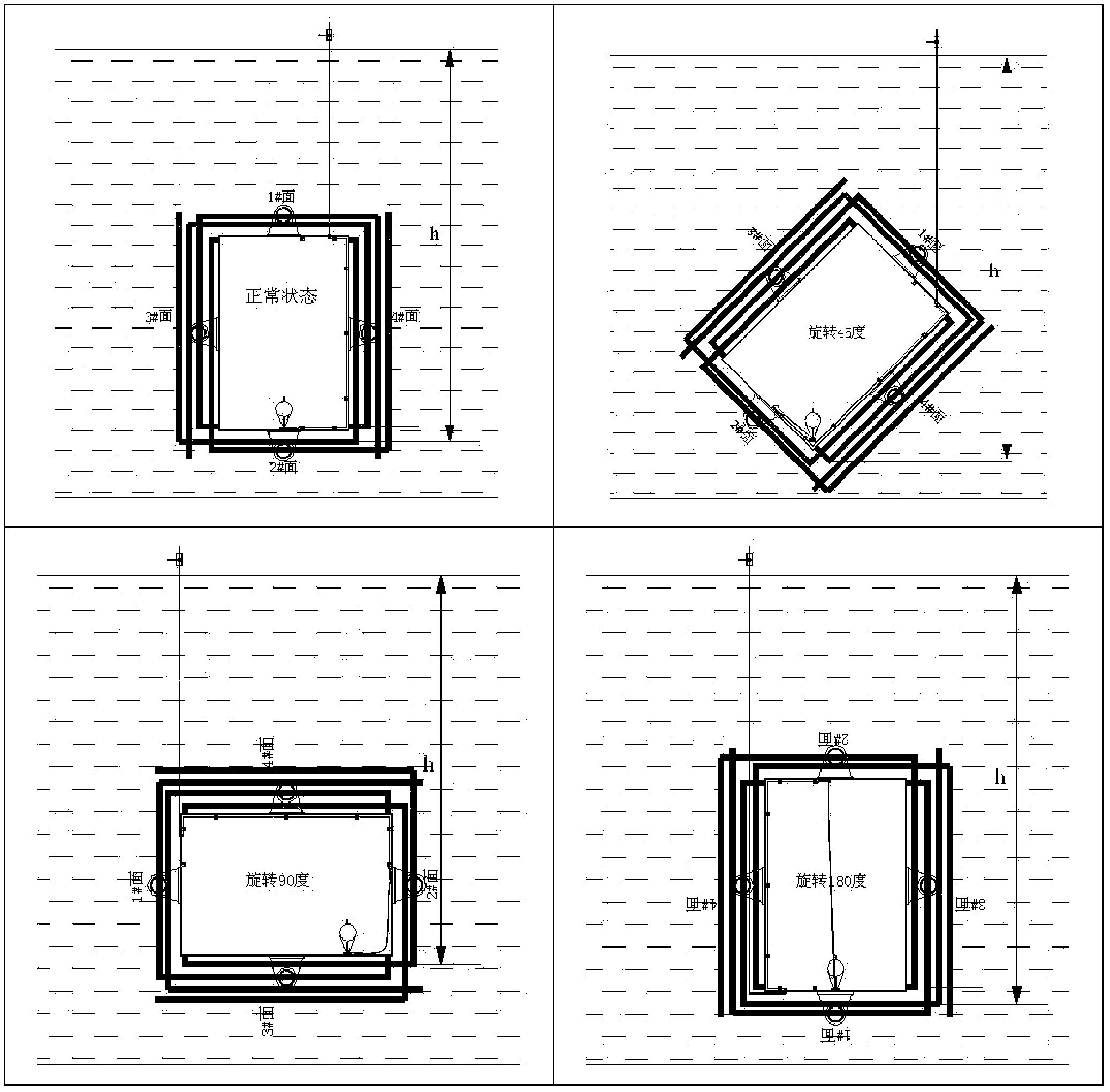

Biomass gasification burner

InactiveCN104566339AEfficient use ofExtended service lifeSolid fuel combustionChamber doorsCombustionEngineering

The invention discloses a biomass gasification burner. The biomass gasification burner comprises a furnace; a movable grate in the furnace divides the furnace into a furnace chamber and an ash chamber; the upper side of the furnace is provided with a feeding device and burner ports; the furnace chamber comprises an inner liner and an outer liner; a gap a is reserved between the inner liner and the outer liner; the burner port is communicated with the inner liner; the outer liner is welded with two layers of burner ports with similar structures in clearance fit; the feeding device has an inner layer structure and an outer layer structure; a gap b is reserved between the inner layer structure and the outer layer structure; the gap b is communicated with a feeding device passage through a guide hole; the inner layer structure is communicated with the inner liner; the outer layer structure is fixedly welded to the outer wall of the outer liner; the gap b is not communicated with the gap a; the biomass gasification burner also comprises a primary fan and a secondary fan; the primary fan is communicated with the feeding device passage and the ash chamber through a pipeline; and the secondary fan is communicated with the gap a and the gap b through a pipeline. The biomass gasification burner is reasonable in structure, large in power, sufficient in combustion, high in heat efficiency, low in emission, convenient to installat, small in occupied space and low in operation cost.

Owner:王海峰

Thin-wall deep diving pontoon capable of automatically realizing internal and external pressure balance

The invention relates to a thin-wall deep diving pontoon capable of automatically realizing internal and external pressure balance. The pontoon comprises a pontoon main body, lifting lugs, external water pipes, a floating ball, a weight, an internal gas pipe, pipe clamps, a gas pipe joint, an external gas pipe and a ball valve, wherein the external water pipes are arranged on the outer walls of the four sides of the pontoon main body, are continuously arranged along the side lines of the outer walls of the pontoon and pass through all corners; the lifting lugs are arranged on the outer walls of the four sides of the pontoon main body; the weight is fixedly connected below the floating ball and arranged in the pontoon; the internal gas pipe is fixed between the upper end of the floating ball and the weight; the port of the gas pipe on the floating ball is open; the internal gas pipe with enough length is arranged in the pontoon, so that the floating ball and the weight can arrive in any place in the pontoon; the internal gas pipe extends to the inner port of the gas pipe joint along the inner wall of one side of the pontoon main body through the pipe clamps; the gas pipe joint crosses one side wall of the pontoon main body, and a junction is sealed by welding; one end of each external water pipe is connected to the outer port of the gas pipe joint; and the ball valve is arranged at the other end of each external gas pipe.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Novel sealing strip

Owner:JIANGSU SHUANGYING TEXTILE TECH

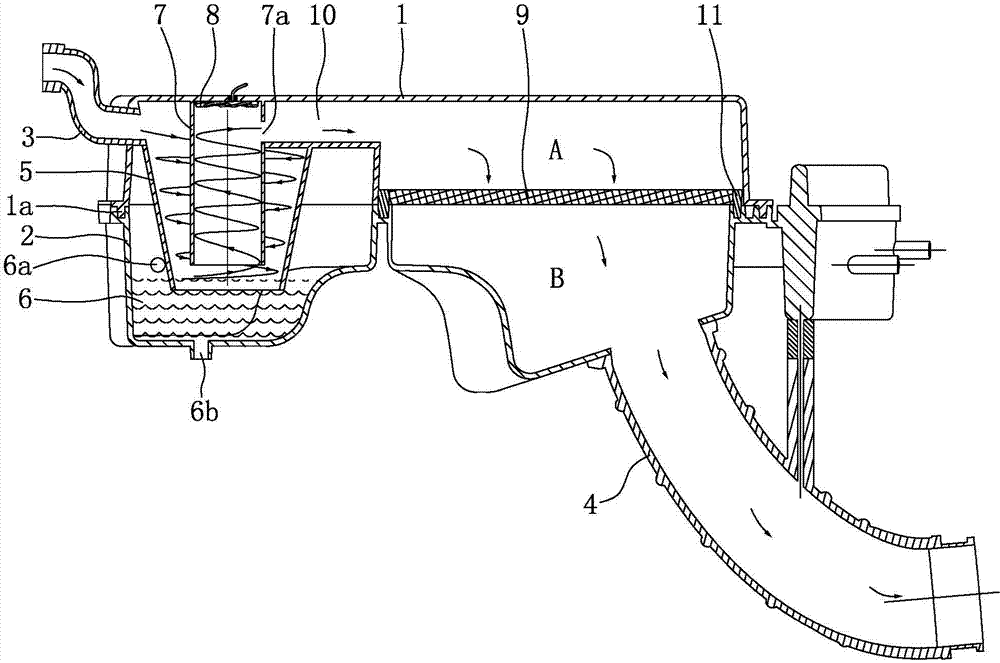

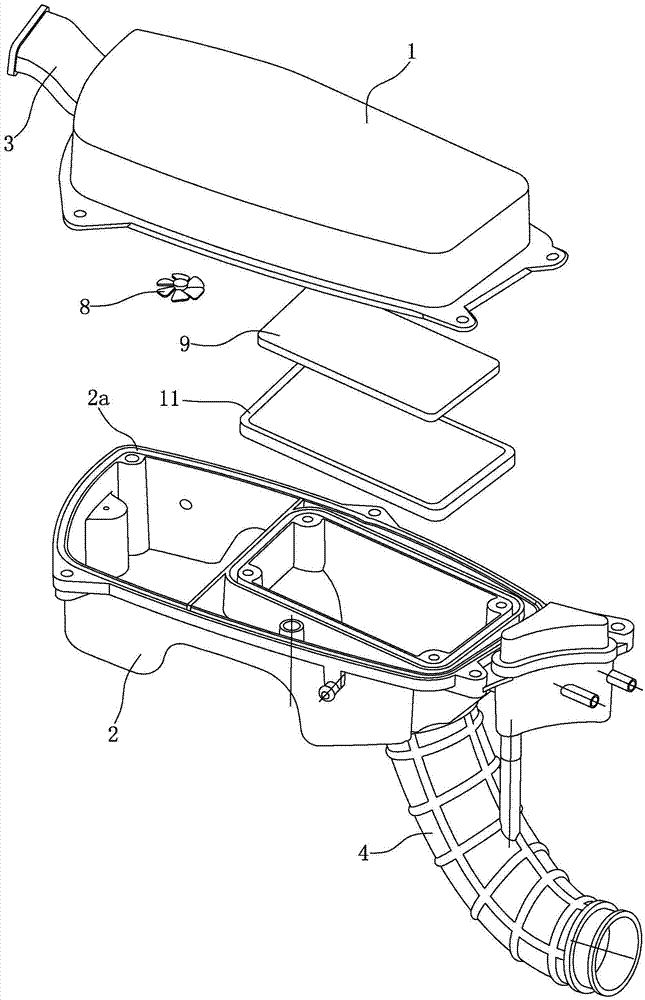

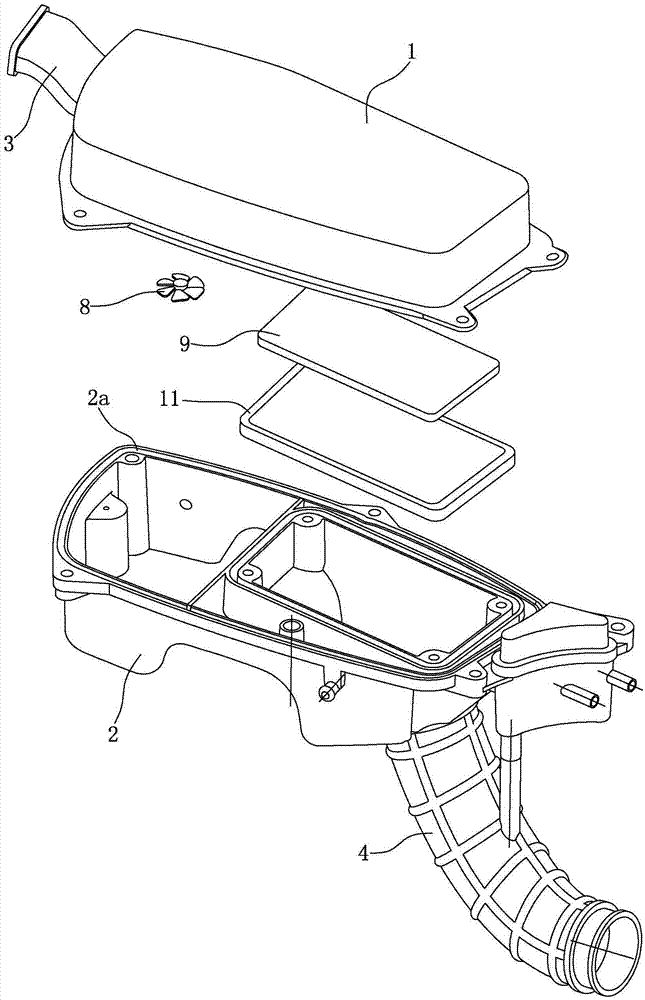

Triple purification type motorcycle air cleaner

InactiveCN104500289AExtended service lifeSmall dust particle sizeMachines/enginesAir cleaners for fuelAir cleanersAerospace engineering

The invention discloses a triple purification type motorcycle air cleaner. The inner part of a shell is divided into a front cavity and a rear cavity through a partition, and a separating cylinder (5) is arranged in the front cavity of the shell. An air inlet is formed in the front wall at the upper end of the separating cylinder (5) and communicated with the rear end of an air inlet pipe (3). An air guide cylinder (7) is arranged in the separating cylinder (5), and a spiral-flow type exhaust fan (8) is mounted at the inner top of the air guide cylinder (7). The rear cavity of the shell is divided into an upper expansion chamber (A) and a lower air outlet chamber (B) through a filter element (9), and the front end at the upper part of the expansion chamber (A) is communicated with an air outlet (7a) formed in the rear wall of the upper end of the air guide cylinder (7) through a drainage channel (10). The triple purification type motorcycle air cleaner can effectively remove dust and particles in air through three times of purification including adsorption, cyclone separation and filtration, can ensure smoothness of air inflow, has the characteristics of being skillful in design, simple in structure and low in cost, and is suitable for various motorcycles.

Owner:力帆科技(集团)股份有限公司

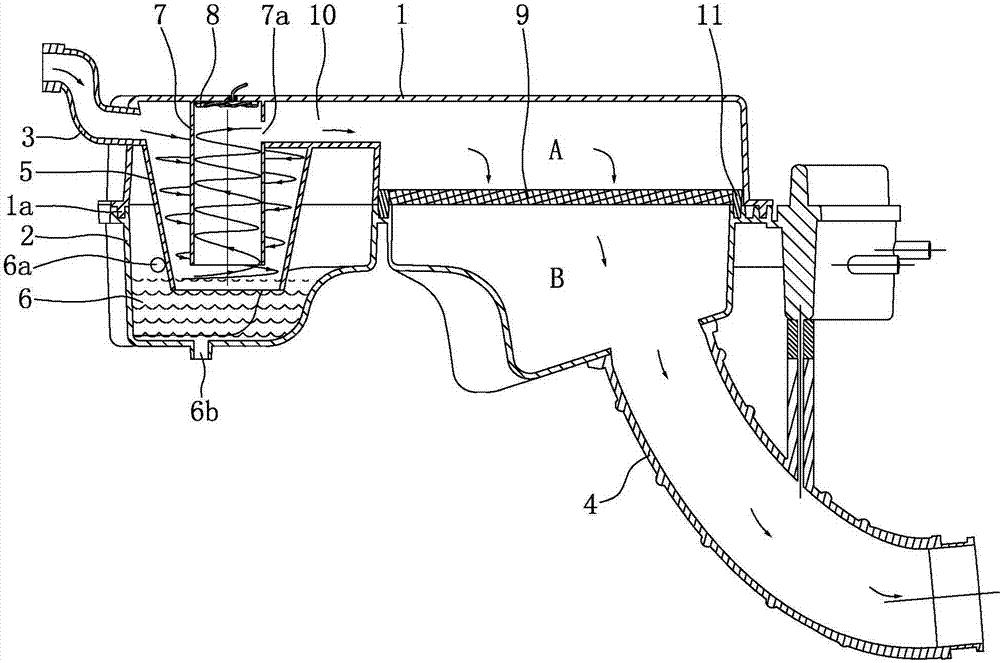

Oil-bath type dust removal structure of motorcycle air cleaner

InactiveCN104500290AExtended service lifeGuaranteed patencyMachines/enginesAir cleaners for fuelCyclonic separationFiltration

The utility model discloses an oil-bath type dust removal structure of a motorcycle air cleaner. An upper end cover (1) and a lower end cover (2) are interlocked to form a shell of the air cleaner, and a front cavity and a rear cavity are formed in the shell. A separating cylinder (5) is arranged in the front cavity of the shell, and a liquid storage chamber (6) used for storing engine oil is formed in the bottom of the front cavity of the shell. The separating cylinder (5) is in a cone shape with the large top and the small bottom, and an air inlet is formed in the front wall at the upper end of the separating cylinder (5). An air guide cylinder (7) is arranged in the separating cylinder (5), and a spiral-flow type exhaust fan (8) is mounted at the inner top of the air guide cylinder (7). An air outlet (7a) communicated with the rear cavity of the shell is formed in the rear wall at the upper end of the air guide cylinder (7). The oil-bath type dust removal structure can effectively remove dust and particles in air through three times of purification including adsorption, cyclone separation and filtration, so that the air flowing to an engine is clean, the service life of the engine is greatly prolonged, and the smoothness of air inflow can be ensured.

Owner:力帆科技(集团)股份有限公司

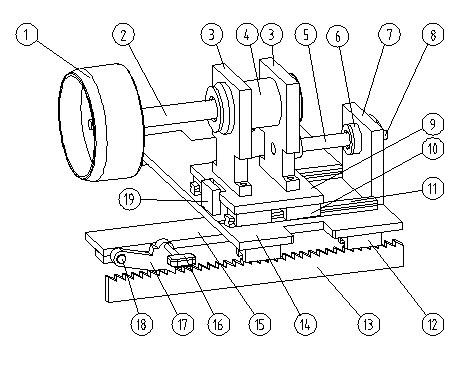

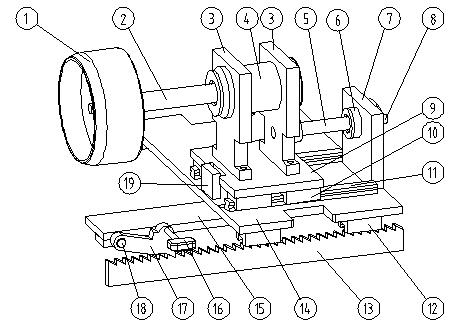

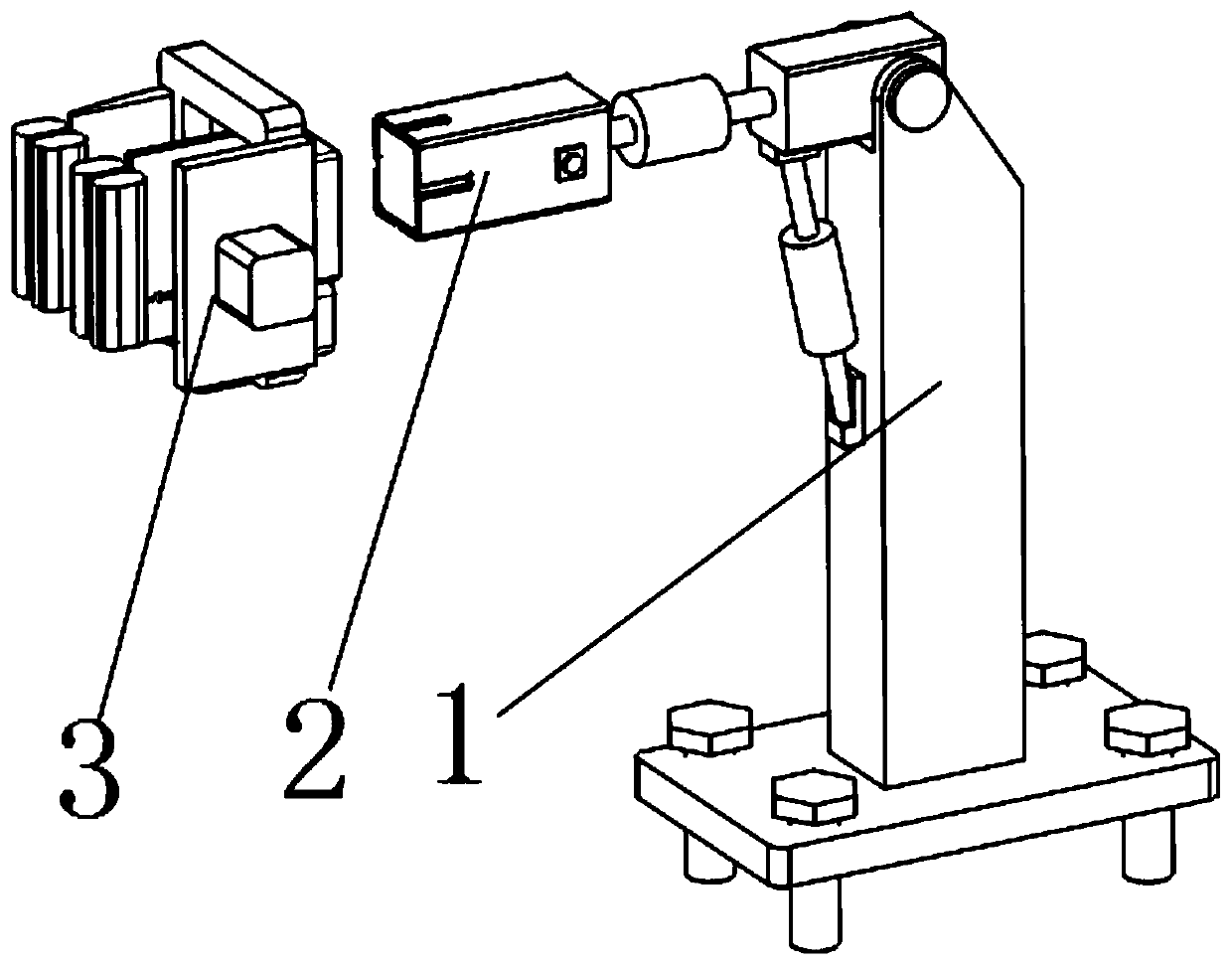

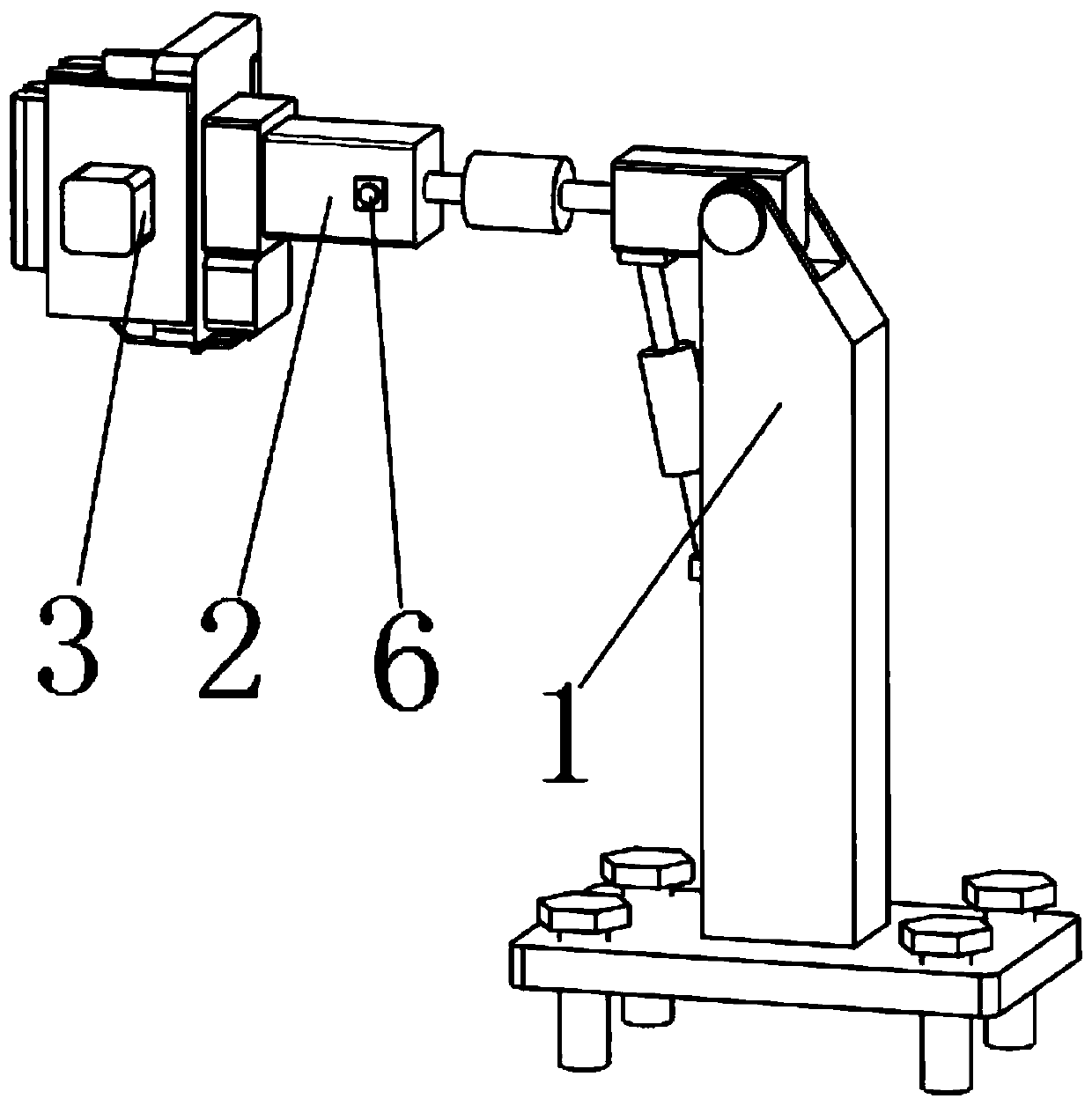

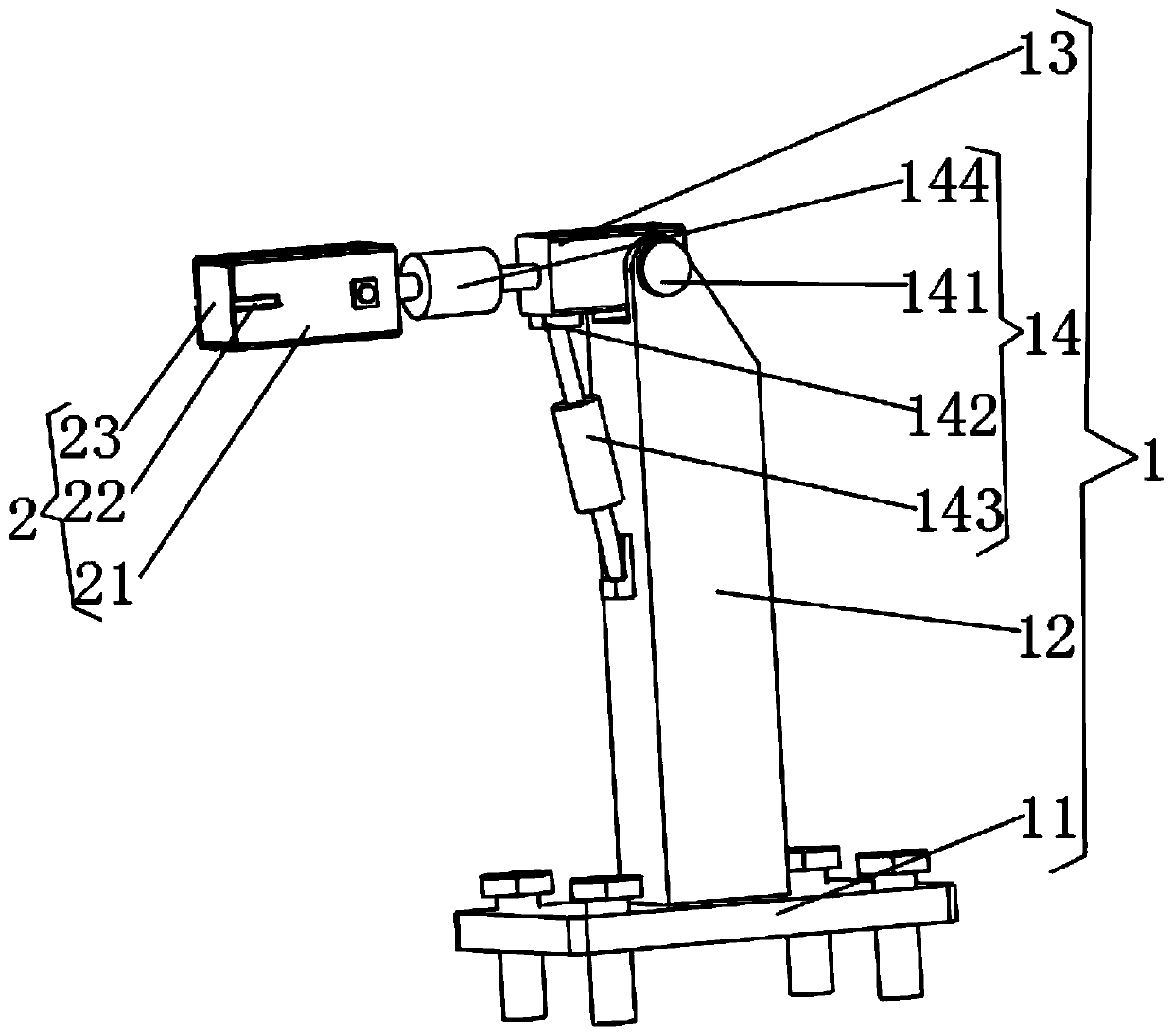

Tailstock locking device

The invention relates to a tailstock locking device, comprising an end cap and a stand, wherein the stand is provided with a big carriage which moves and is positioned along the stand; the big carriage is provided with a small carriage which moves in parallel to the moving direction of the big carriage; the small carriage is provided with a support 1 which is horizontally provided with a rotation shaft in the direction consistent to the moving direction of the big carriage and the small carriage, and the end cap is arranged on one end of the rotation shaft; and a control device for controlling the movement amount of the small carriage is arranged between the big carriage and the small carriage. The tailstock locking device is suitable for circular screens with different lengths and ensures that slippage cannot generate under the action of the axial force of compressed air, therefore, the compressed air in the circular screen cannot be leaked.

Owner:杭州东城图像技术有限公司

Multi-specification clamping manipulator for automobile maintenance

InactiveCN111168703AAvoid collisionWon't wear outGripping headsMachines/enginesControl engineeringAirbag

The invention discloses a multi-specification clamping manipulator for automobile maintenance and belongs to the technical field of mechanical automation. The multi-specification clamping manipulatorcomprises a mechanical arm. The mechanical arm comprises a base connected with a manipulation machine tool through a bolt. A fixed arm is welded to the surface of the base. A rotary device is arrangedat the top end of the fixed arm. A movable arm is arranged in the rotary device. A connection device is fixed to the end, away from the fixed arm, of the rotary device. A first mechanical head is arranged at the end, away from the rotary device, of the connection device. An abrasion prevention device is fixed to the bottom end of the first mechanical head. A control switch is fixed to the surfaceof the connection device. A second mechanical head is arranged at the end, away from the rotary device, of the connection device and is slidably connected with the connection device. A mode that a hard clamp is coated with an airbag to conduct clamping is adopted, hard materials of the tail end of the clamp are coated softly, when engines of high-end car series are clamped, lifted, moved and cleaned through the clamp, and abrasion to shells of the car series due to the hard clamp and collision to precise parts in the engines are avoided.

Owner:葛润生

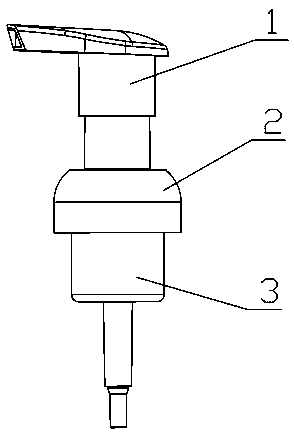

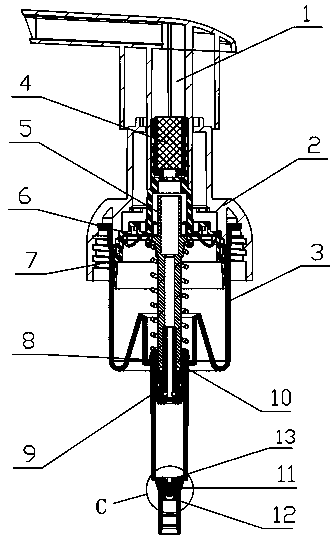

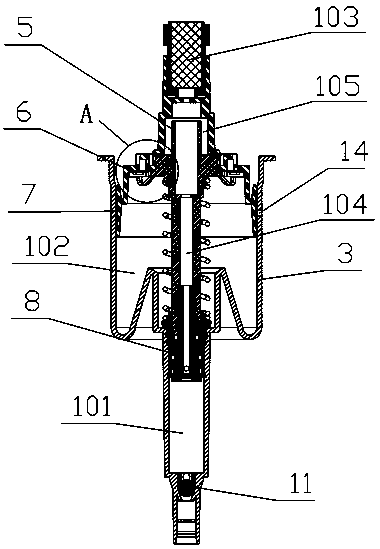

Foam pump with breathing sheet

PendingCN110329653ASmooth inhalationHigh exhalation pressureClosuresSingle-unit apparatusInternal pressureEngineering

The invention discloses a foam pump with a breathing sheet. The foam pump with the breathing sheet consists of a nozzle pressing head, a coil cover and a pump body, wherein the pump body comprises a pump body shell, a liquid inlet one-way valve, a large piston, a main valve rod, a valve needle, a rod bottom piston, a spring and a fixed clamping ring. The foam pump uniquely designs a breathing sheet structure, the breathing sheet, the main valve rod and the large piston are matched, so that air inlet is smoother, the pressure of an air inlet cavity is larger, larger internal pressure can be generated, gas liquid is mixed uniformly, and foam is rich.

Owner:沈利庆

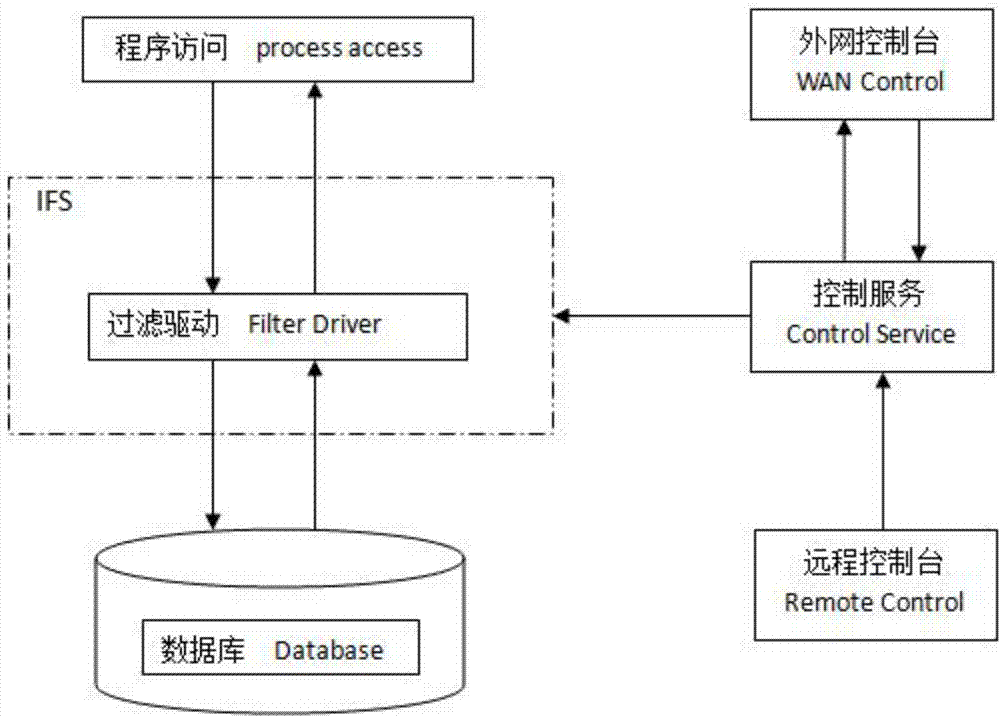

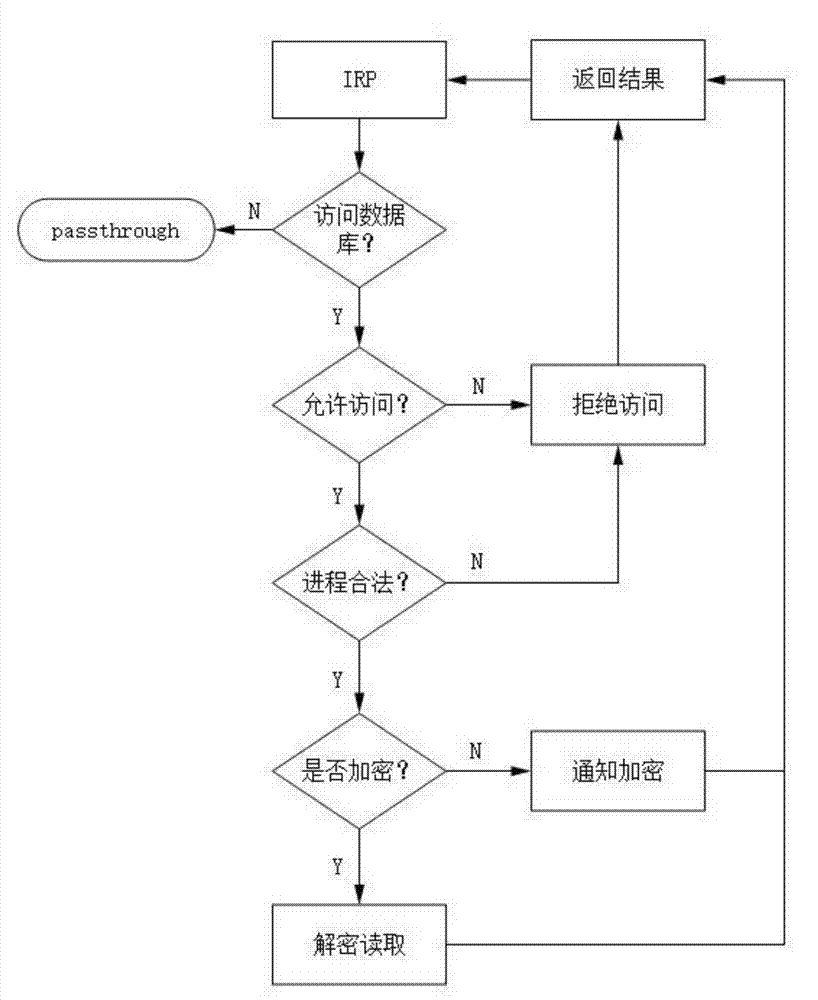

Control method for preventing database information from being leaked internally

The invention provides a control method for preventing database information from being leaked internally. In the method, a control service, a filter driver, a remote console and a WAN console are adopted. Database files are encrypted automatically in a remote control mode by means of the filter driver, thereby being prevented from being copied and leaked by operation and maintenance staff; illegal export of database information is controlled through the filter driver, so the content of a database is prevented from being embezzled illegally by the operation staff; the WAN console is used for remote control, so the risk that database hardware is stolen is further reduced, and the security of the database information is improved.

Owner:WUHAN FORWORLD SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com