Vacuum setting machine for shoemaking

A setting machine and vacuum technology, applied in footwear, applications, household appliances, etc., can solve the problems of difficult sealing and poor sealing effect, and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

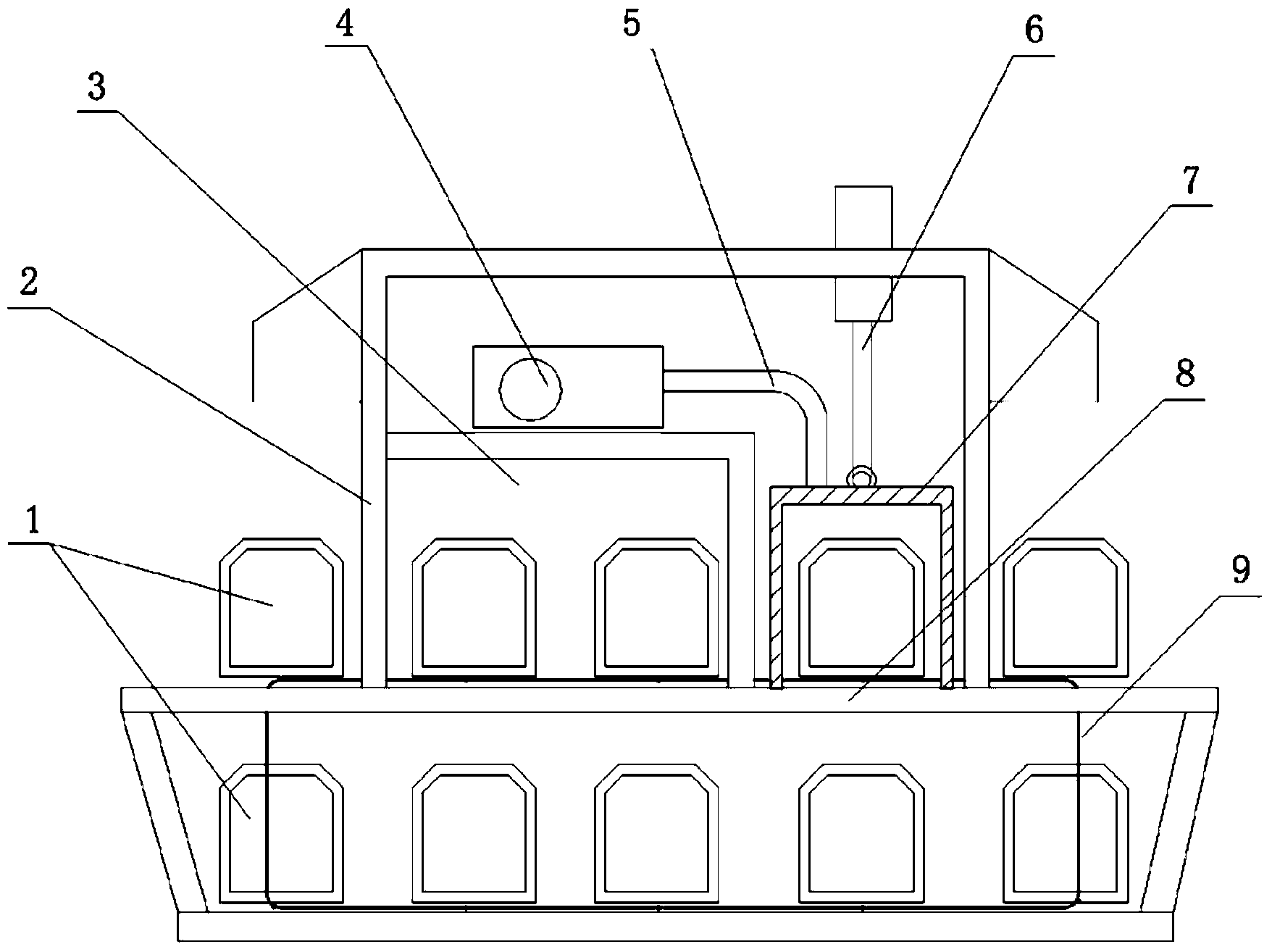

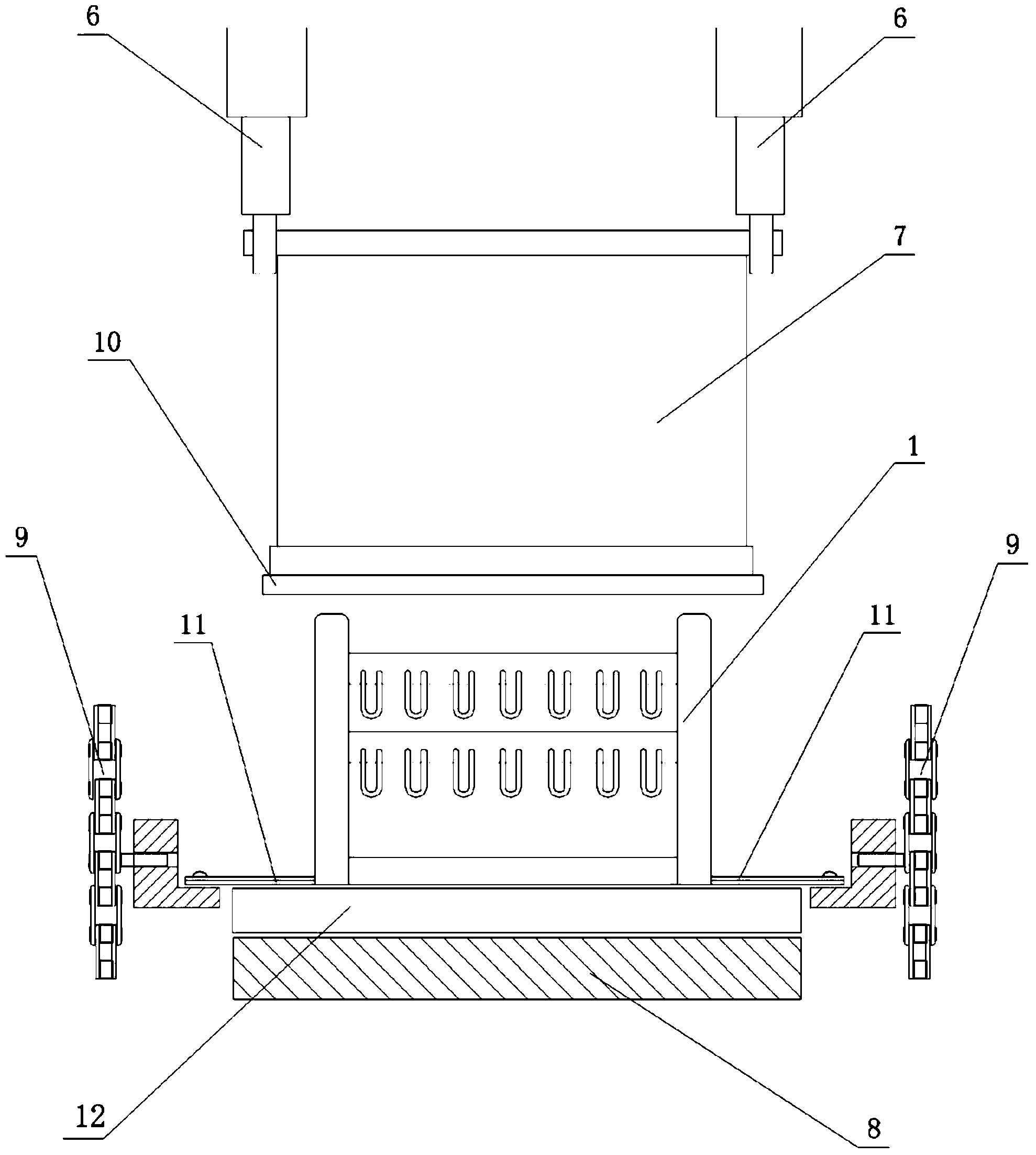

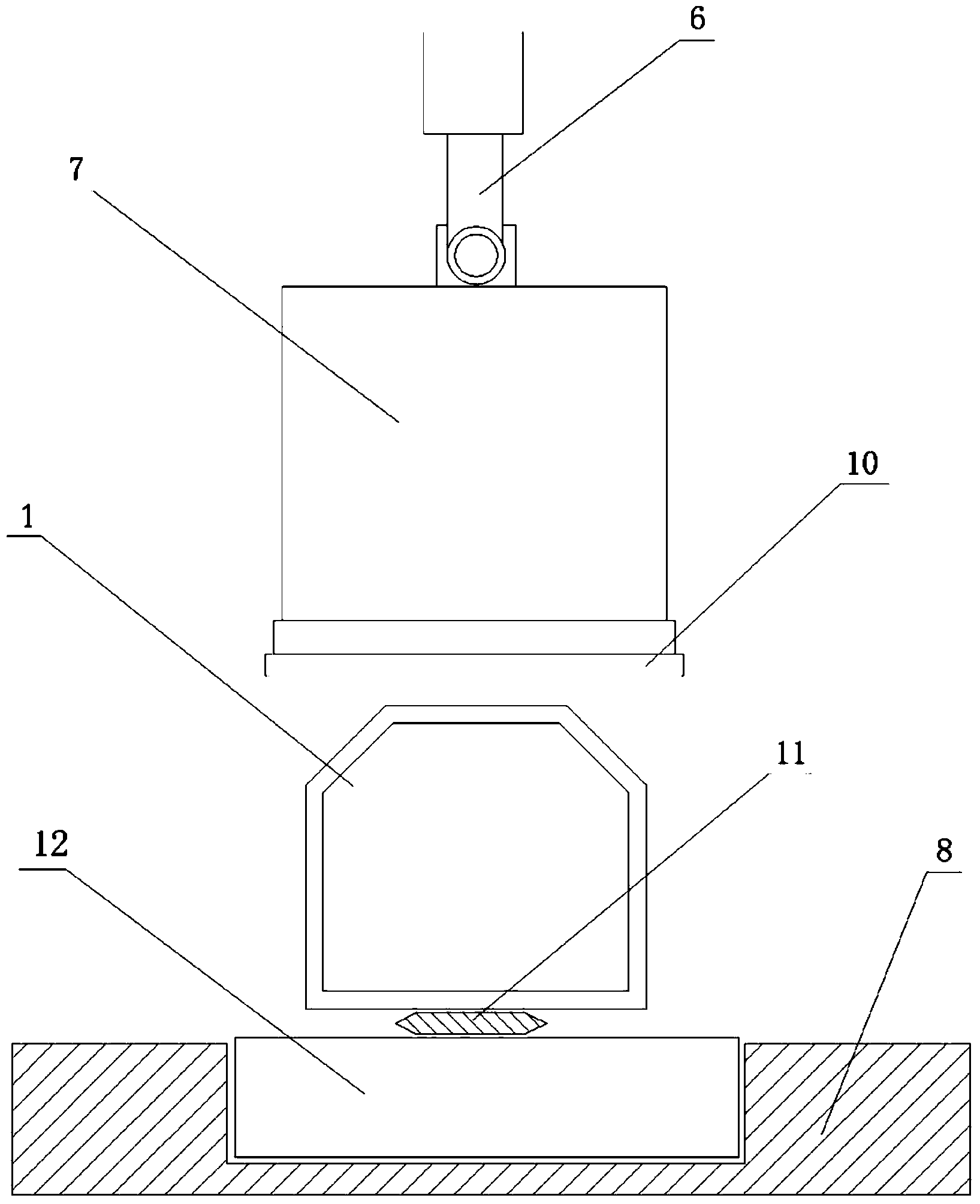

[0028] like figure 1 , figure 2 and image 3 As shown, a vacuum setting machine for shoemaking includes a frame 2, a shoe basket 1, a processing box 3, a vacuum cover 7, a conveying device 9, a power device and a control device. Both ends of the shoe basket 1 are respectively connected to the conveying device 9, and the conveying device 9 accurately conveys the shoe basket 1 to the processing box 3 in time sequence under the action of the power device and the control device Neutralize below the vacuum cover 7; the vacuum cover 7 is connected with a lifting device 6, and the lifting device 6 can put down the vacuum cover 7 to cover the shoe basket 1, and the vacuum cover 7 is fastened on the A closed cavity is formed on the bottom plate 8; the lifting device 6 can also lift the vacuum cover 7 and remove the shoe basket 1 through the conveying device 9 . The cavity formed between the vacuum cover 7 and the base plate 8 is connected to the vacuum pump 4 through the pipeline 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com