Perforating movable line bundle airtight technology

A kind of airtight and technological technology, applied in the direction of electrical components, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of small space, air leakage, and thick colloid at the potting place, and achieve good airtightness and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

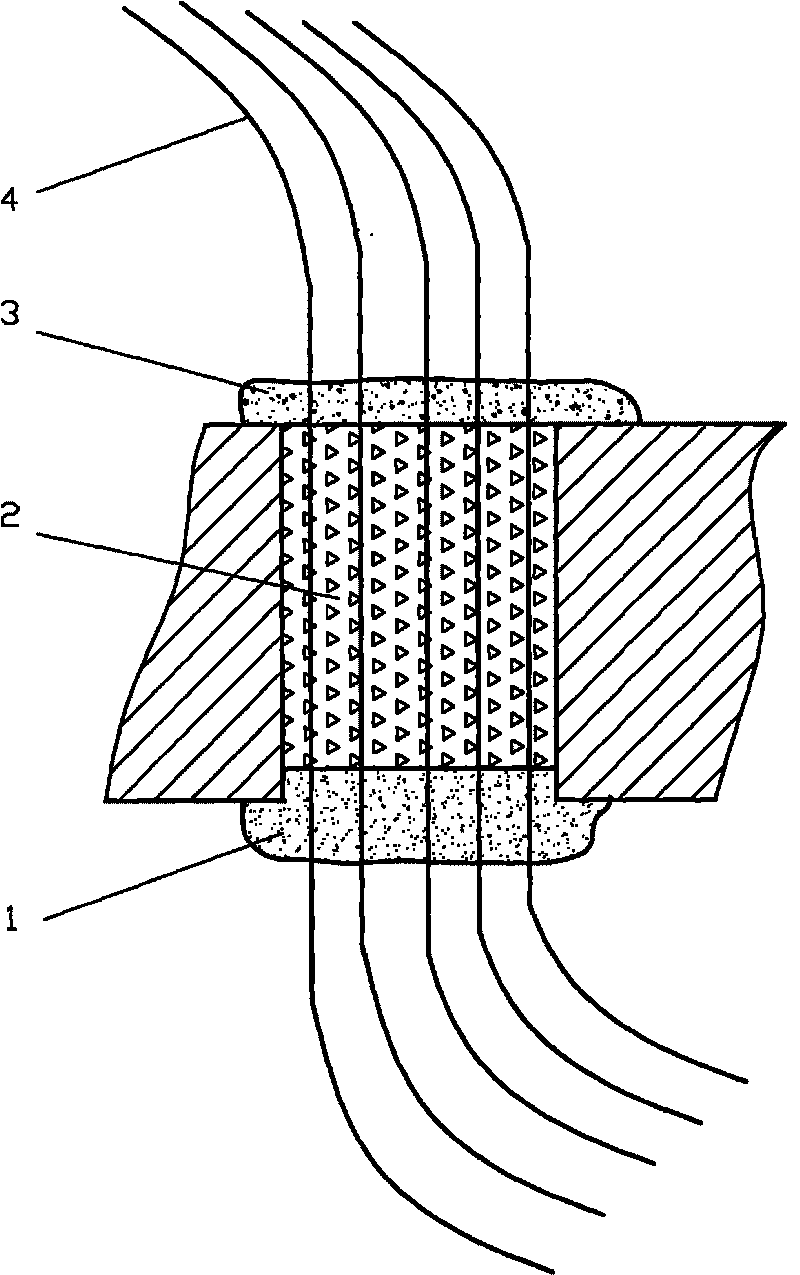

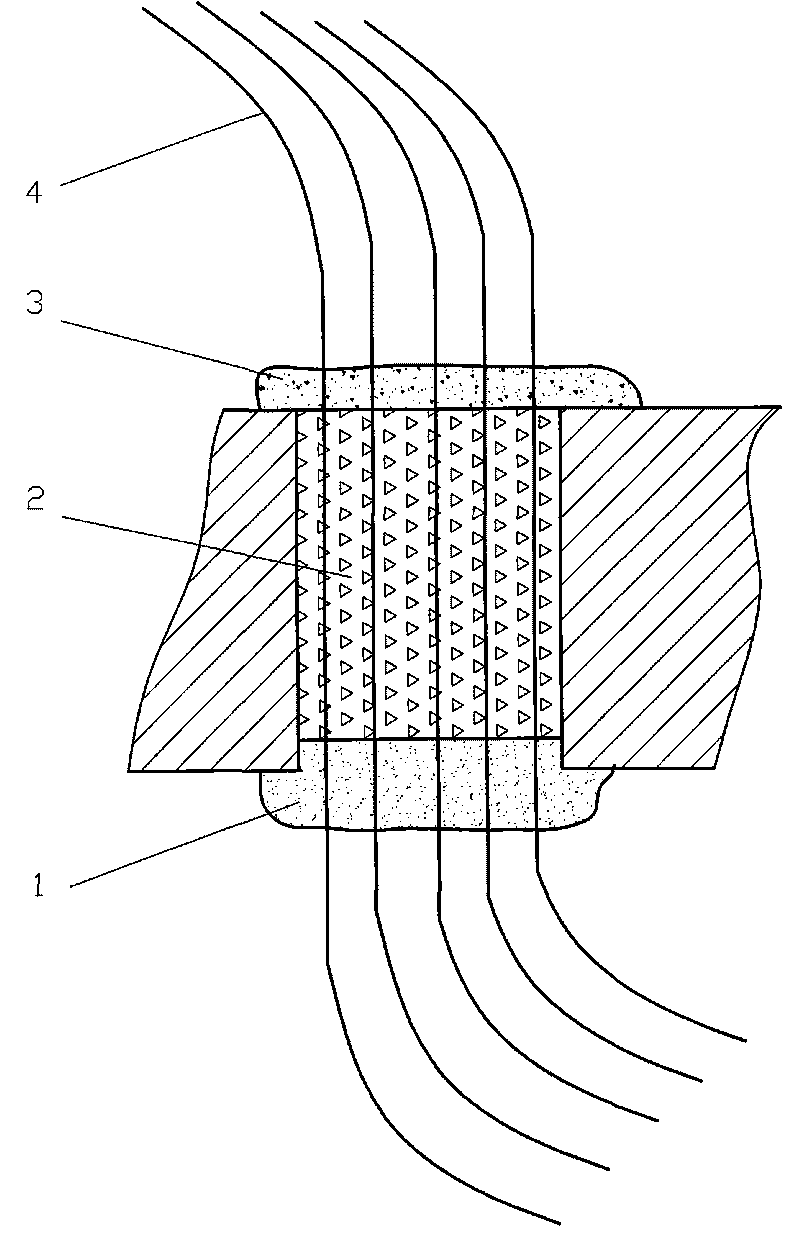

[0011] The present invention comprises the following steps:

[0012] 1. Use GD414 silicone rubber with high bonding strength and certain fluidity to lay the bottom layer 1 on the opposite side of the cable perforation (the bottom end in the figure). The rubber hose and pouring head are primed and sealed, as shown in the attached figure. It is required to cover the entire bottom surface evenly, and the thickness should not exceed 3mm. The 4 spaces between each wire should be potted with glue; ② After potting, in order to prevent the wire harness from moving, fix the wire harness on both sides to the side wall of the housing with paper tape ③Cure at room temperature for 24 hours, and check that the position of the hose on the wiring harness is correct. The wires 4 include shielded wires and coaxial video wires. Since the outermost layer of the shielded wires is a metal mesh sleeve, there are gaps along the entire length. In order to achieve airtightness, the shielding layer sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com