Patents

Literature

5689results about How to "Spray evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

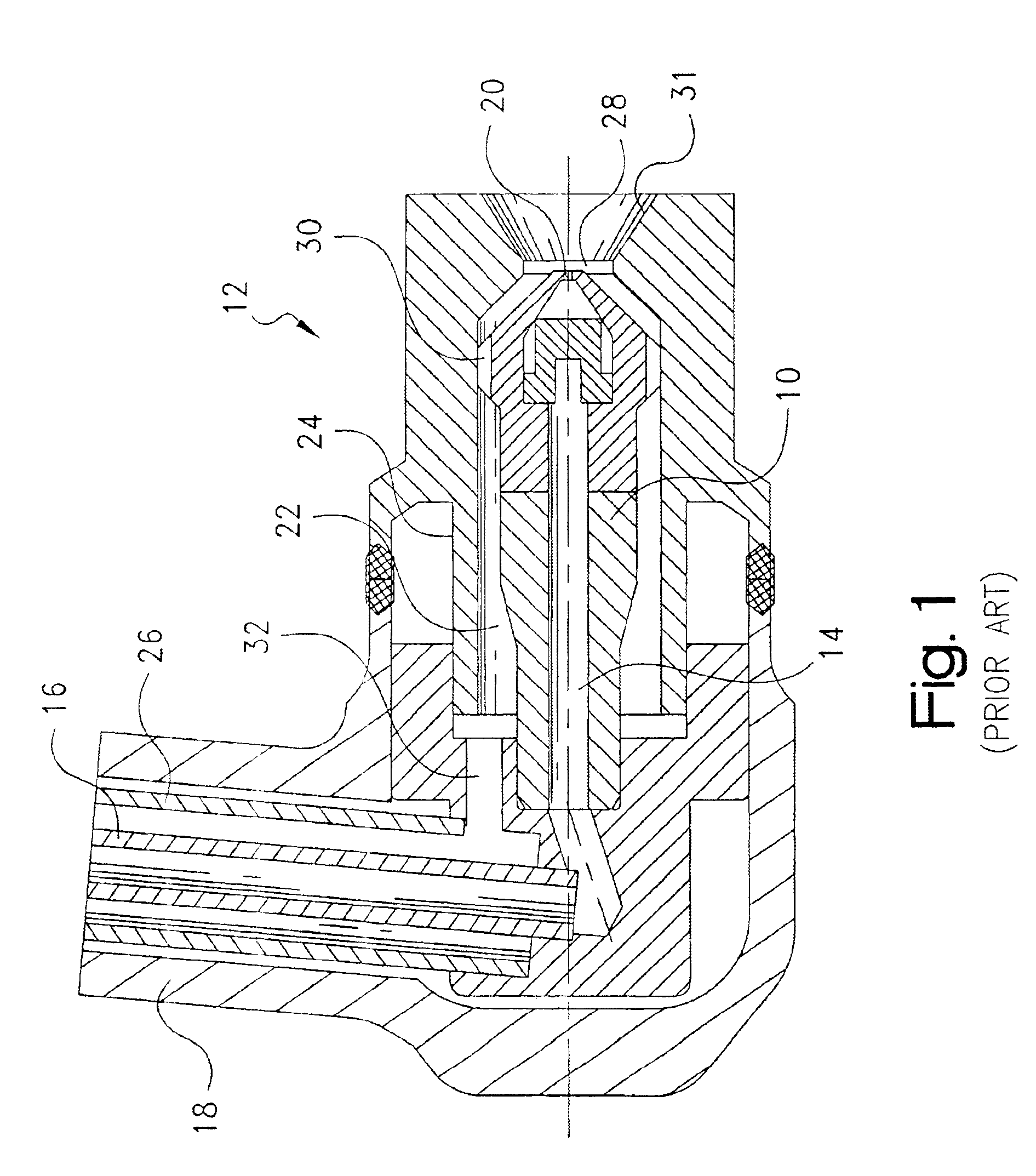

Chemical vapor deposition method

InactiveCN1847450ASpray evenlyElectric discharge tubesSemiconductor/solid-state device manufacturingElectric power systemGas phase

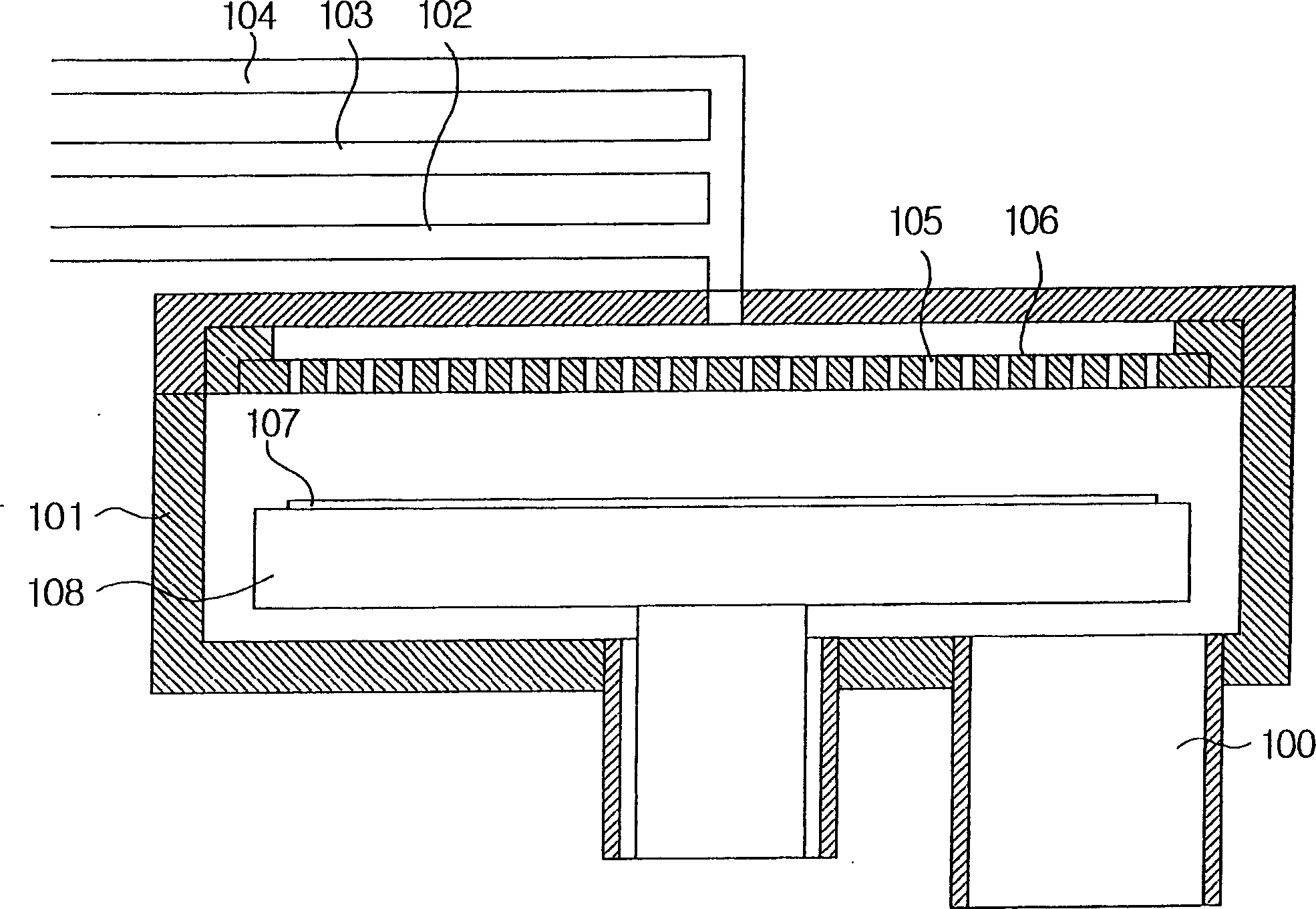

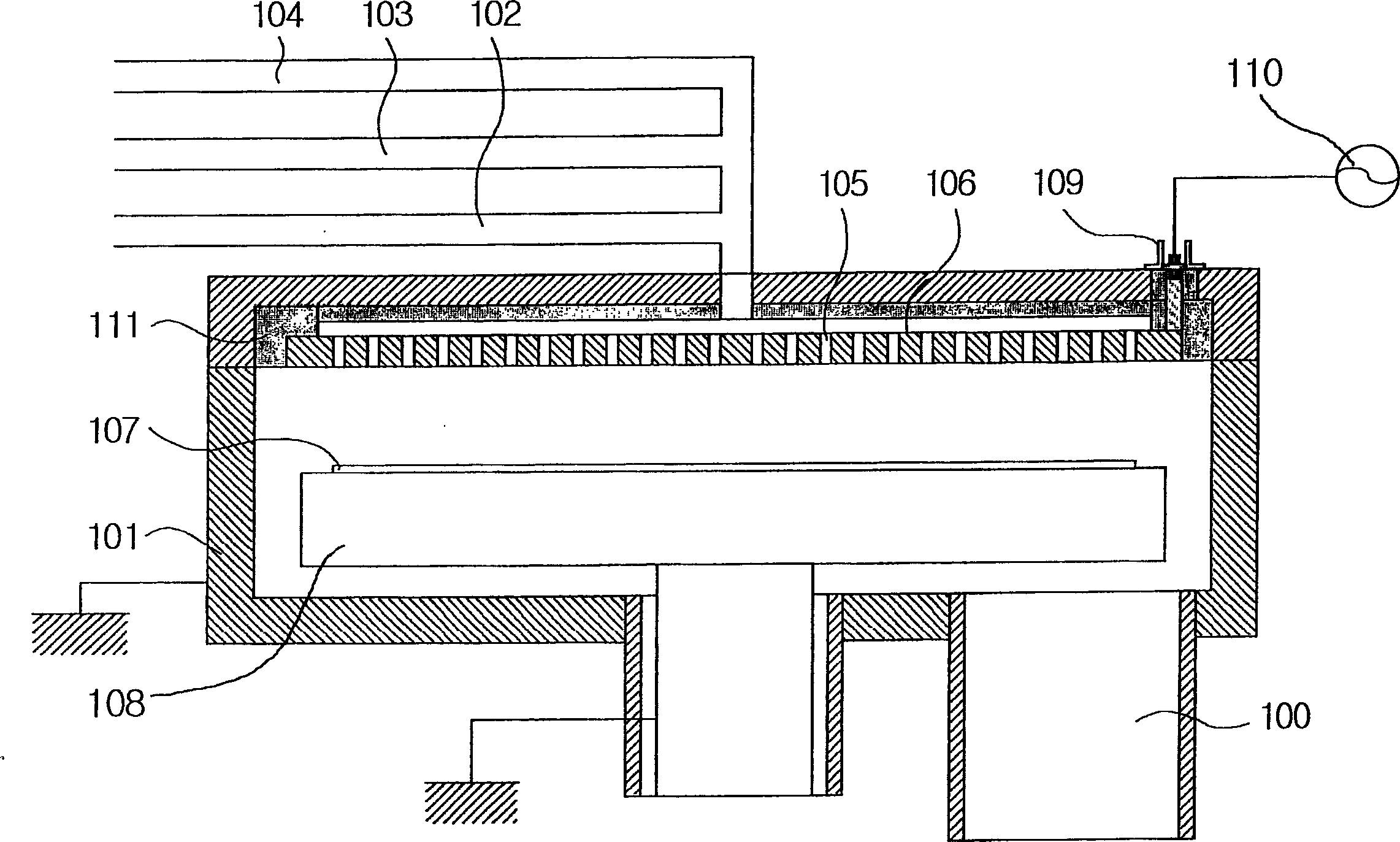

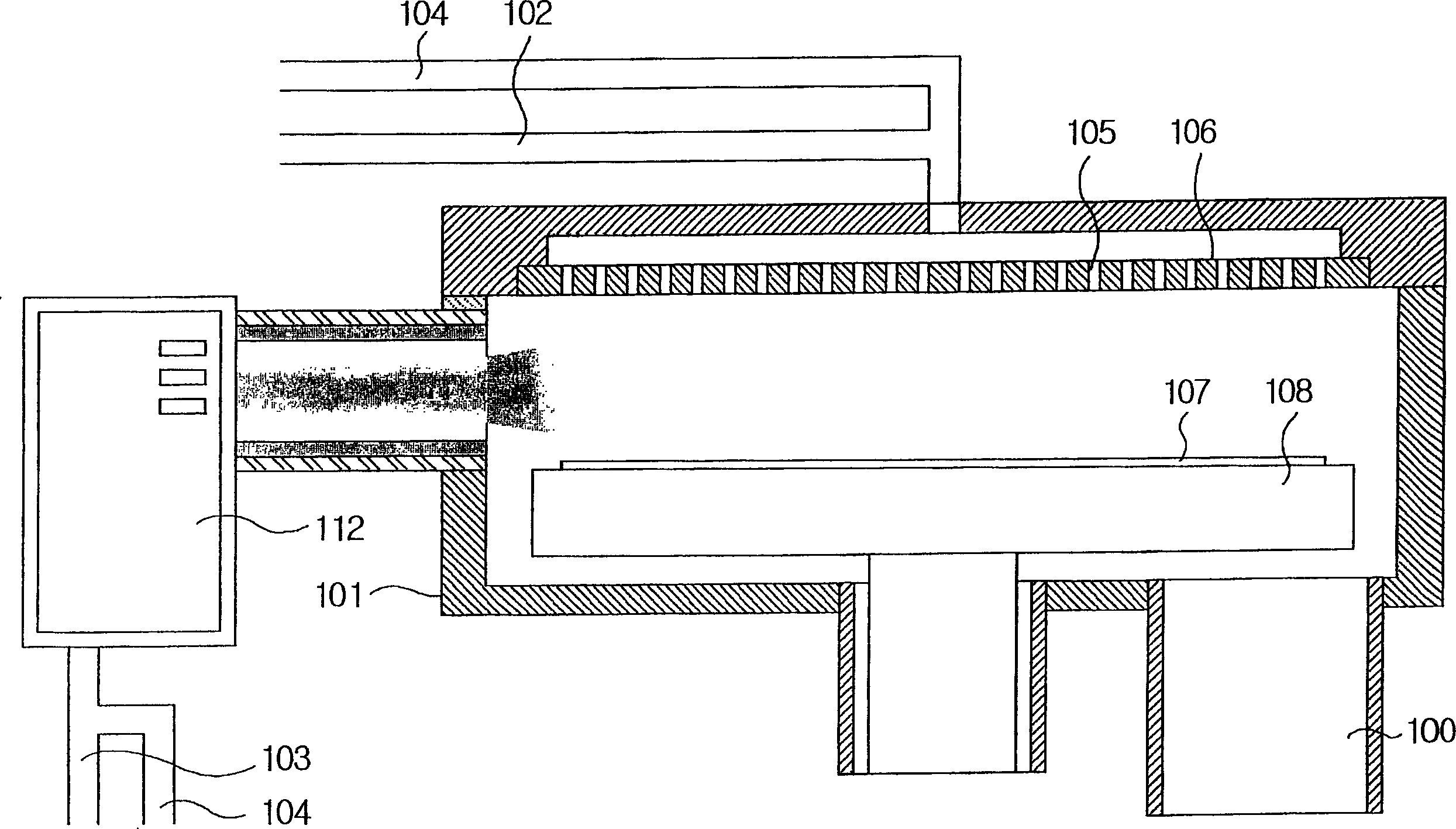

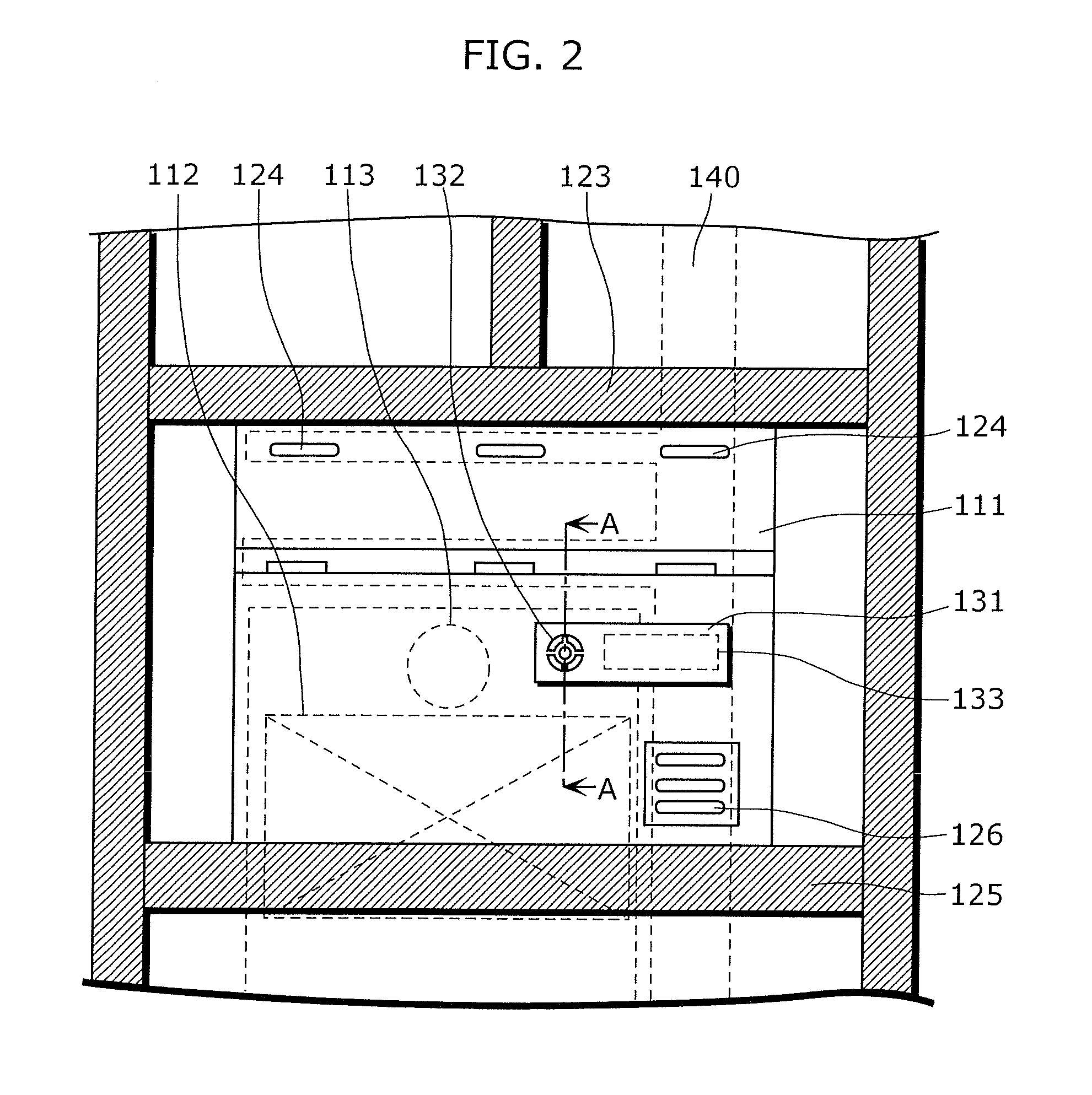

The present invention relates to chemical vapor deposition apparatus. In the chemical vapor deposition apparatus, an RF power source connection portionconnected to an external RF power source is installed on an upper side of a chamber; an RF electrode plate is installed within the chamber to be spaced with a predetermined gap from an inner upper surface of the chamber and to be spaced with a predetermined gap from a showerhead disposed below the RF electrode plate; plasma is generated in a first buffer portion, which is defined by a gap between the RF electrode plate and an upper surface of the showerhead, by means of the electric power applied from the external RF power source to the RF electrode plate; the showerhead is divided into two sections in a vertical direction and a second buffer portion is defined by a space between the two sections; reactant gases are supplied to the first buffer portion in which the plasma is generated; and source gases are supplied to the second buffer portion.

Owner:WONIK IPS CO LTD

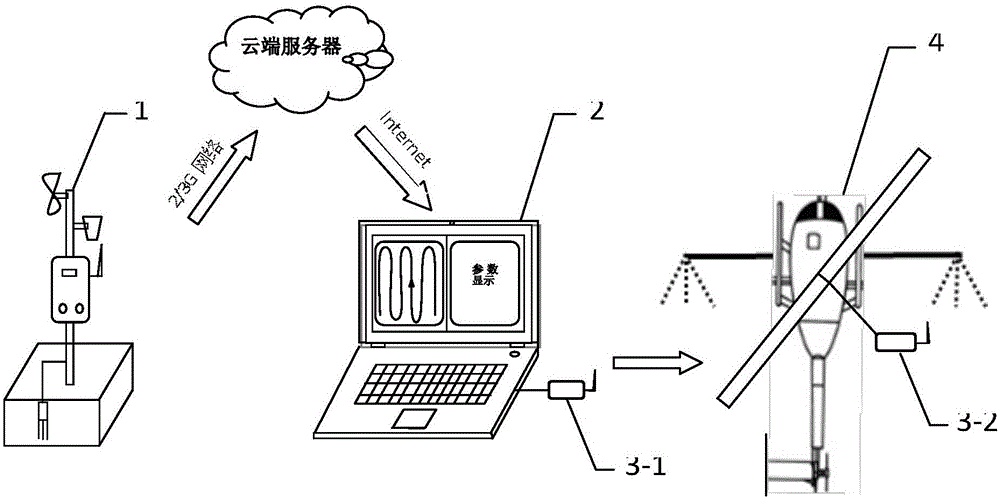

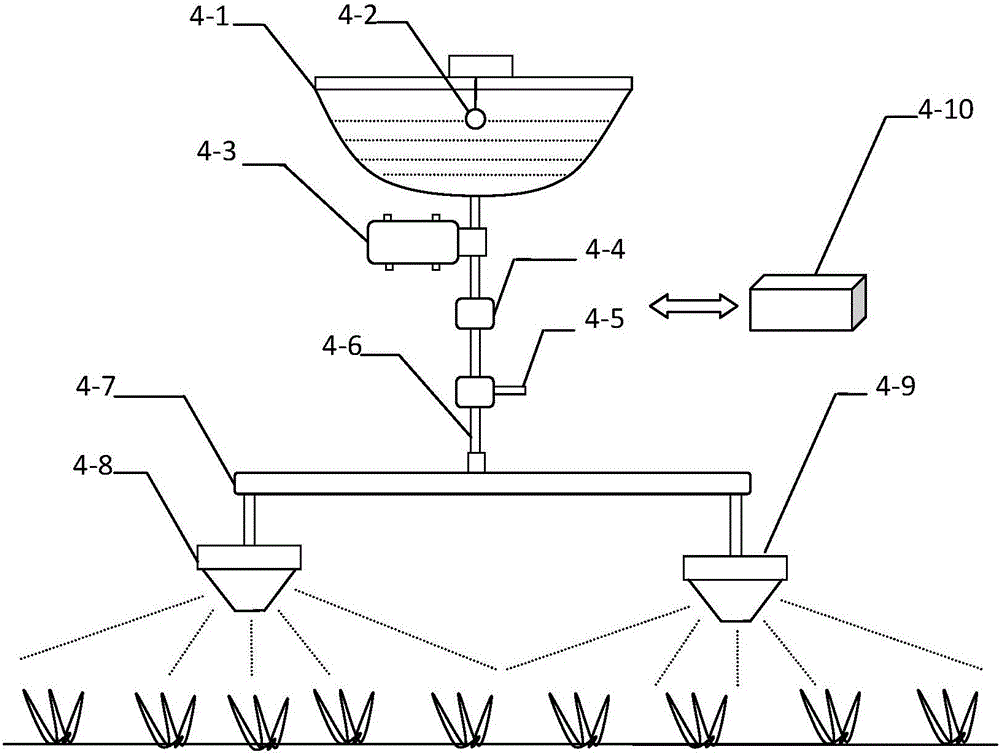

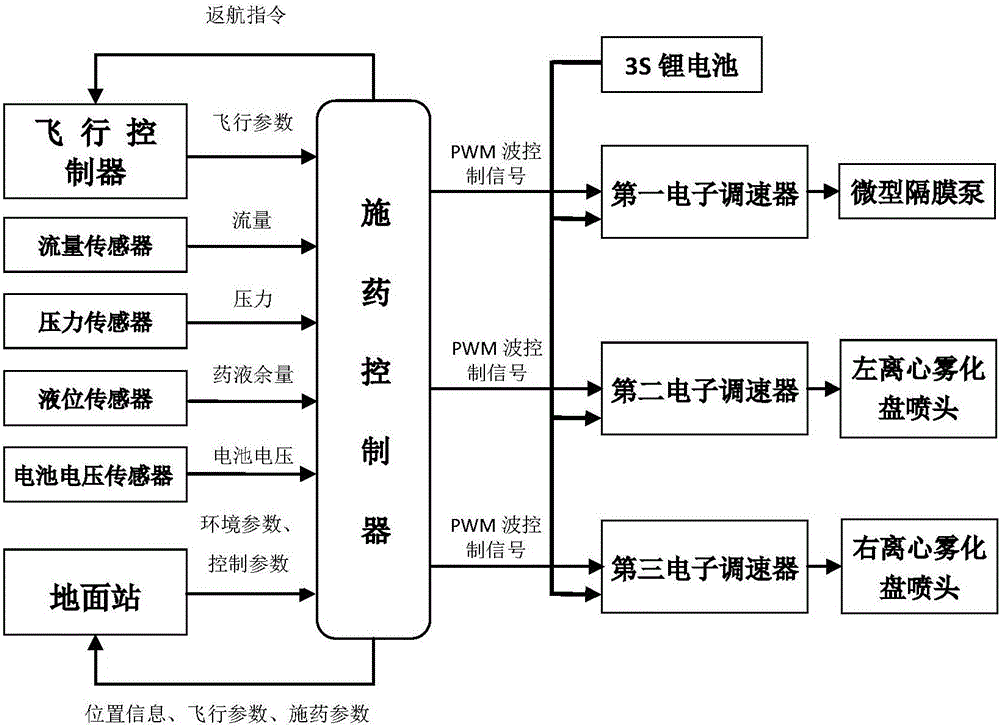

Intelligent pesticide applying system and control method of plant protection unmanned aerial vehicle

InactiveCN105905302ARealize remote controlRealize visual monitoringAircraft componentsLaunching weaponsTraffic capacityDiaphragm pump

The invention relates to an intelligent pesticide applying system and a control method of a plant protection unmanned aerial vehicle. The system is provided with a meteorological station used for measuring environment parameters and sending collected data to a ground station. The ground station sends the environment parameters, pesticide applying control parameters and control commands to an onboard pesticide applying controller on the plant protection unmanned aerial vehicle through a wireless data transmission module. Meanwhile, a flight controller measures real-time geographic information parameters and flight parameters of the plant protection unmanned aerial vehicle and sends collected data to the onboard pesticide applying controller in real time. The onboard pesticide applying controller conducts autonomous programmed decisions by combining the flight parameters, the environment parameters, the pesticide applying control parameters and the control commands, a miniature diaphragm pump and two centrifugal atomization disc sprayers are independently controlled, and therefore the pesticide liquid flow, the mist drop diameters and spraying width parameters of the plant protection unmanned aerial vehicle are intelligently controlled. By means of the intelligent pesticide applying system and the control method, it is guaranteed that pesticide in an operation area is quantitative and evenly sprayed in a fully covering mode, the phenomena of repeated spraying and miss-spraying of the pesticide are avoided, the pesticide applying quality is improved, and effective prevention and treatment of farmland pest and disease damage are guaranteed.

Owner:CHINA AGRI UNIV

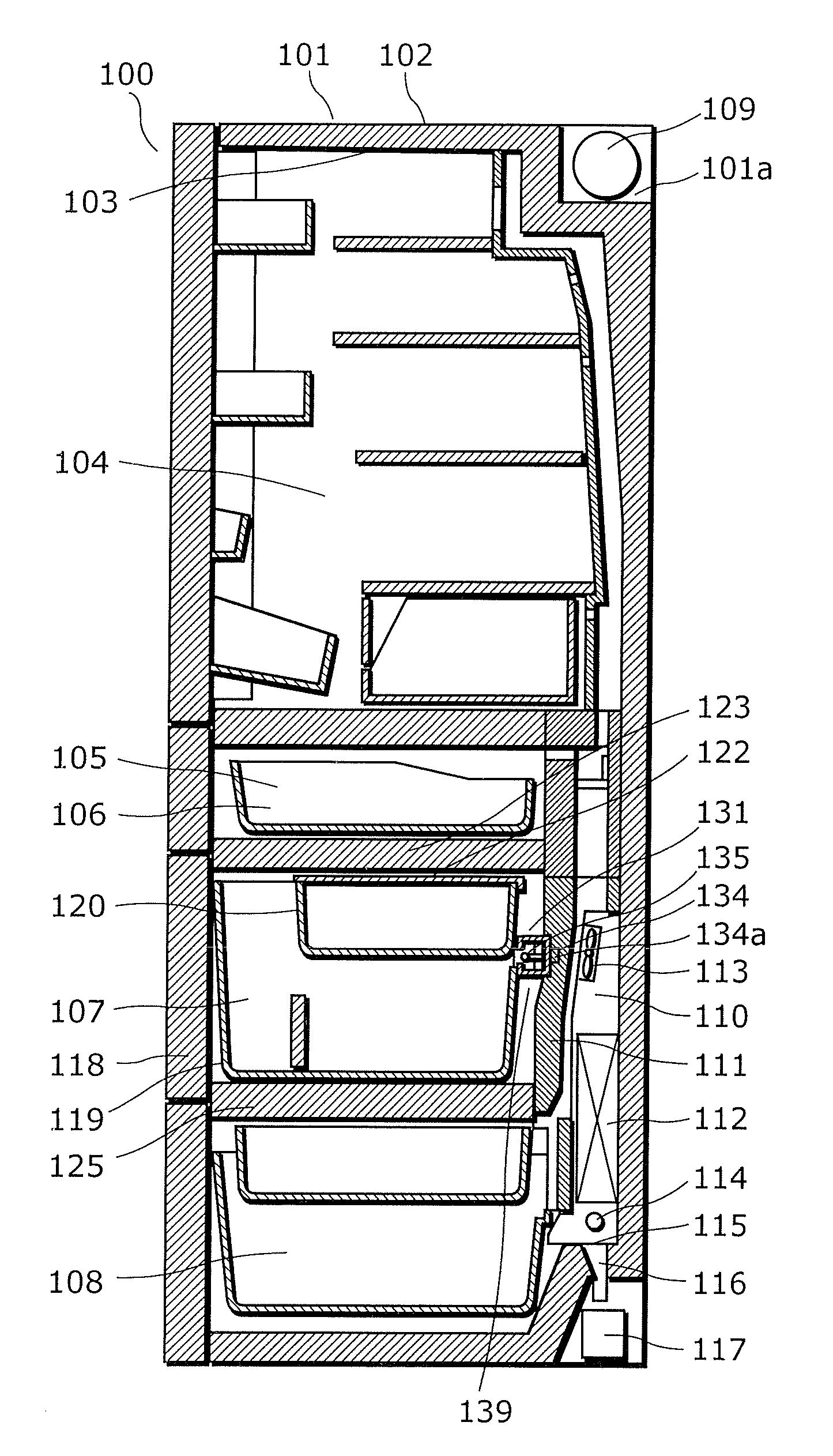

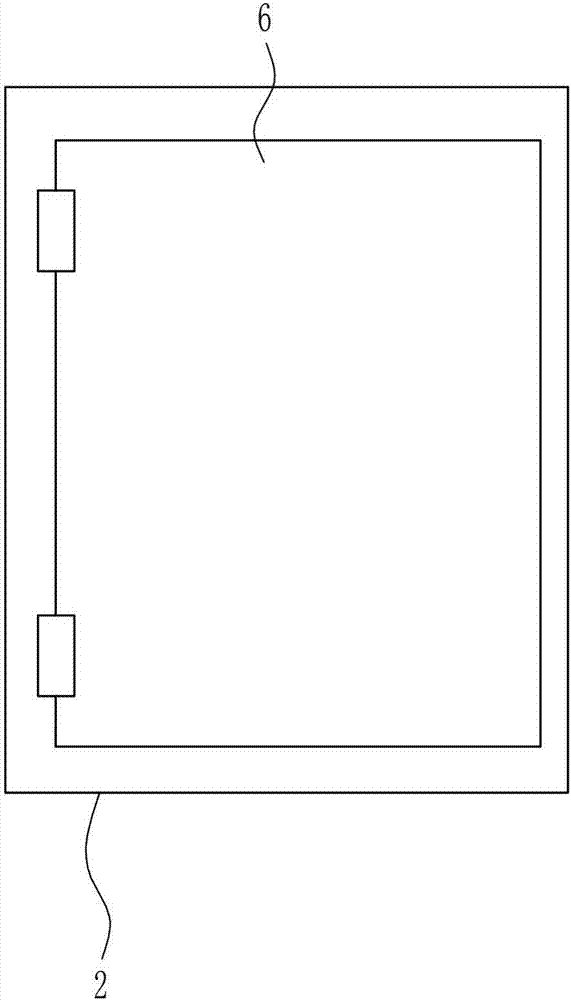

Refrigerator

InactiveUS20100223944A1Reduce adhesionEliminate growthBurnersFruit and vegetables preservationNano sizeEngineering

To provide a refrigerator including: a heat-insulating main body; a storage compartment defined in the heat-insulating main body; and a mist spray apparatus that sprays a fine mist into the storage compartment. The fine mist generated by the mist spray apparatus has a nano-size particle diameter and reduces microorganisms adhering to the inside of the storage compartment and to vegetable surfaces, the microorganisms including molds, bacteria, yeasts, and viruses.

Owner:PANASONIC CORP

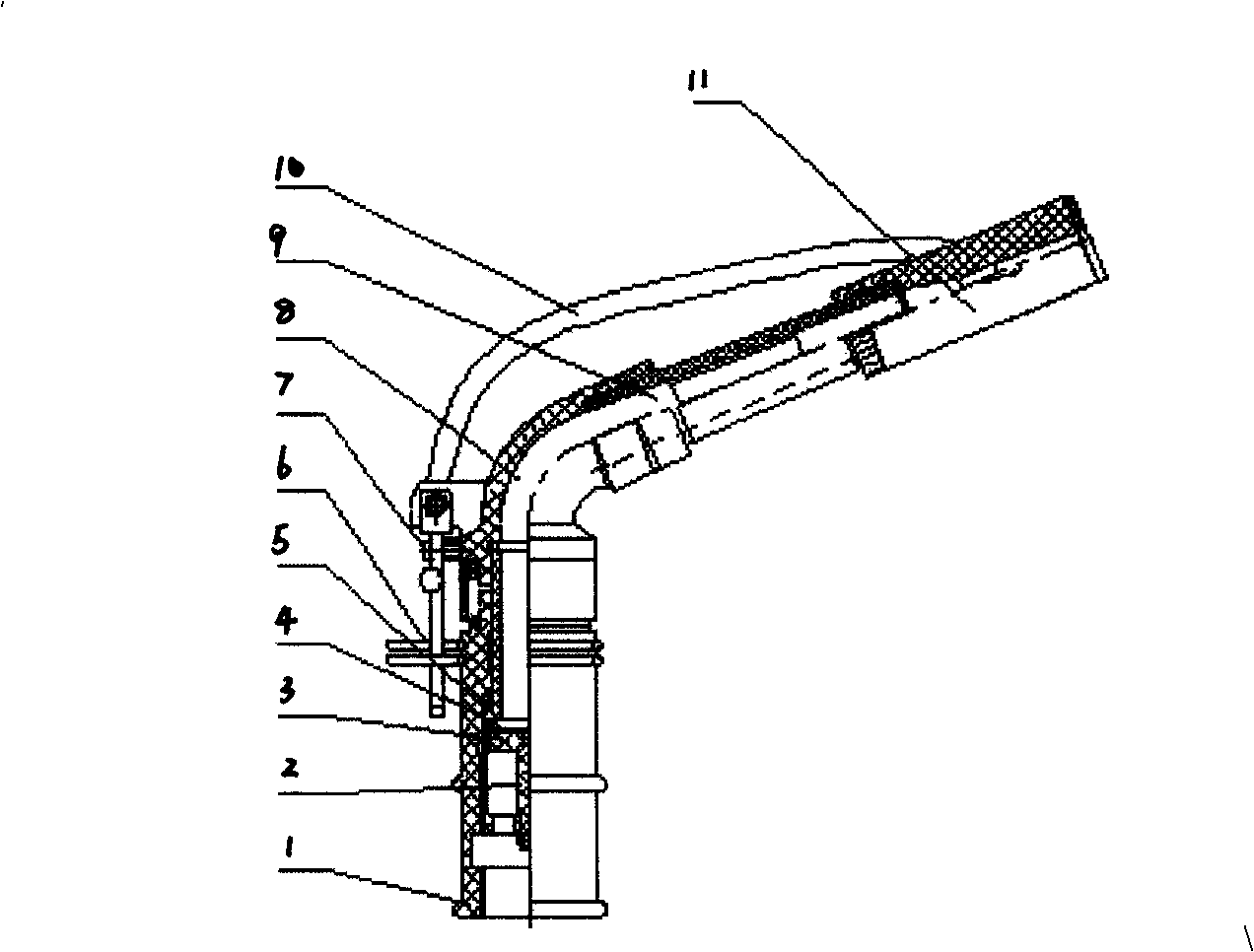

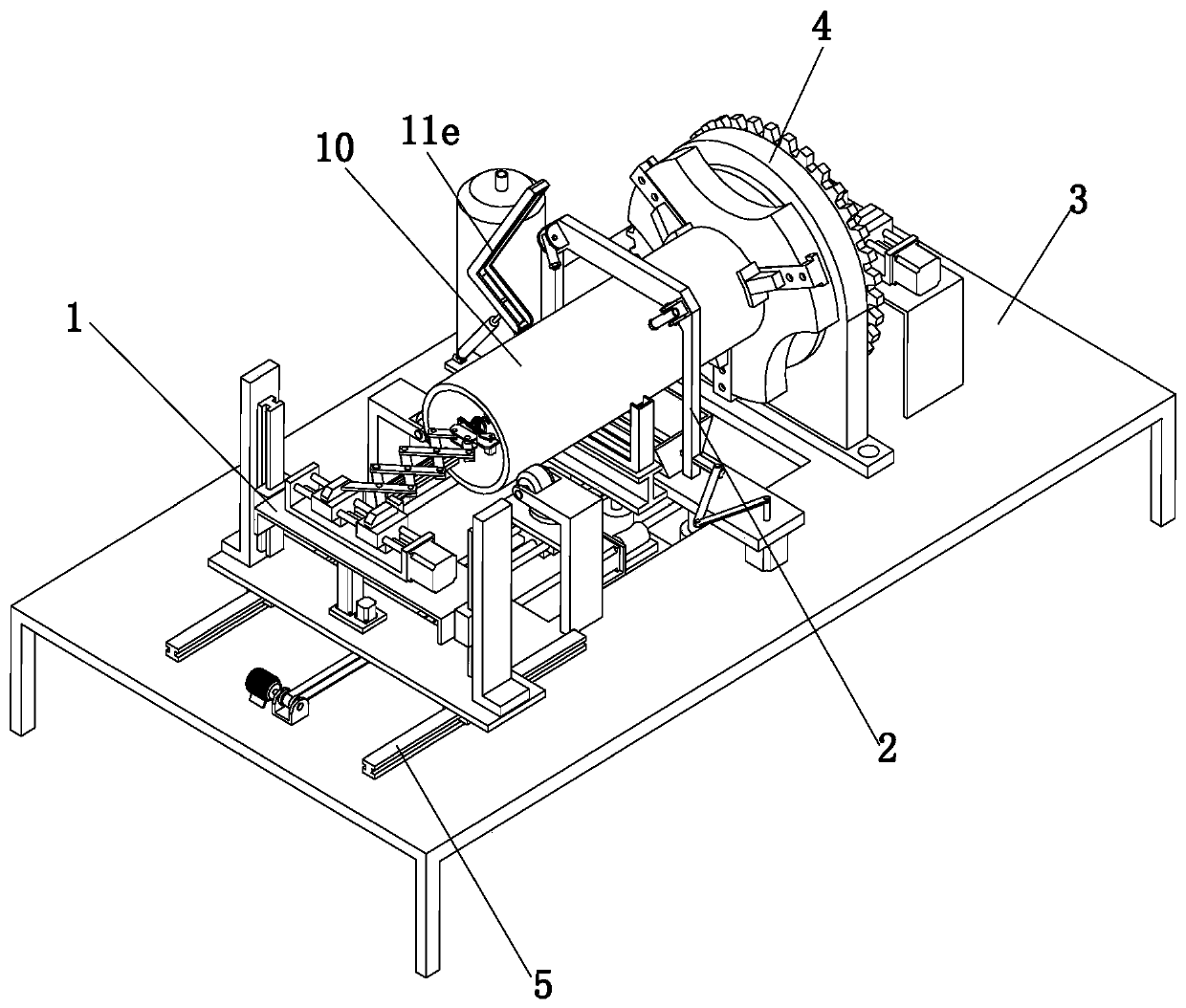

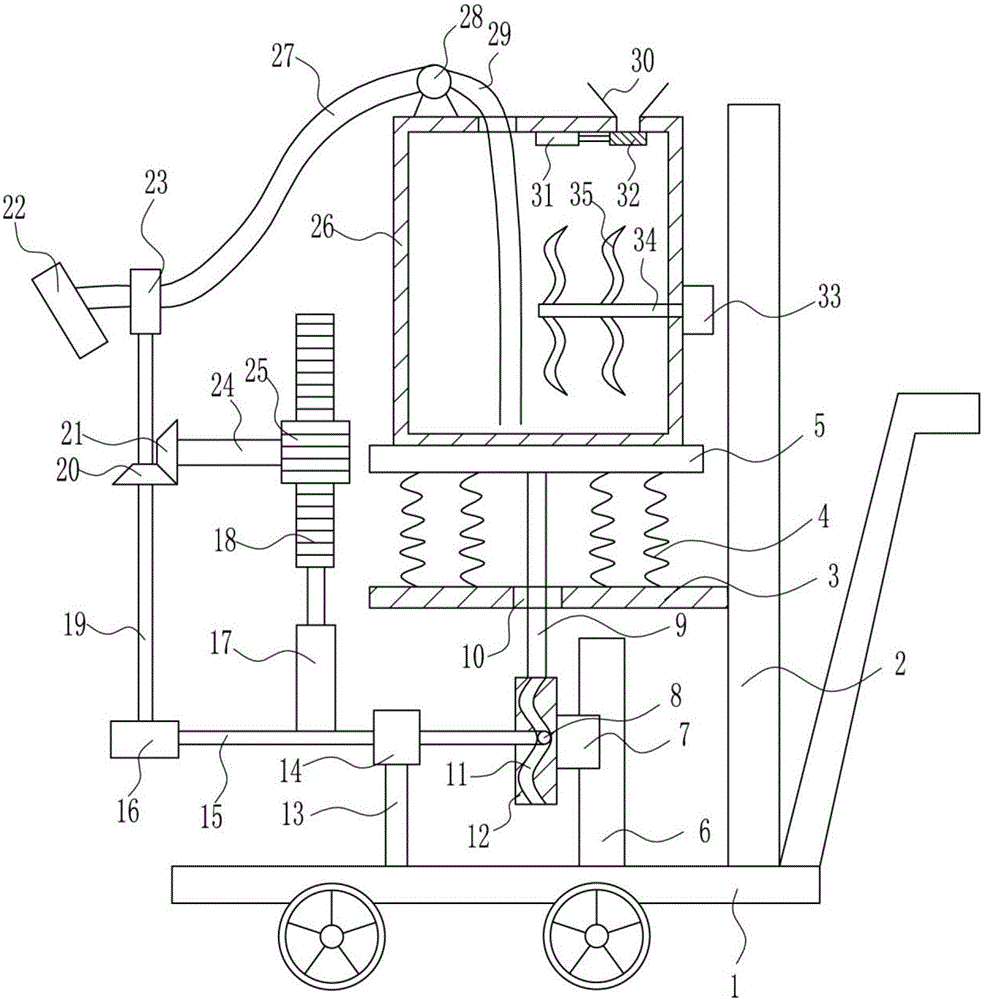

Engineering oil pipe surface paint spraying device

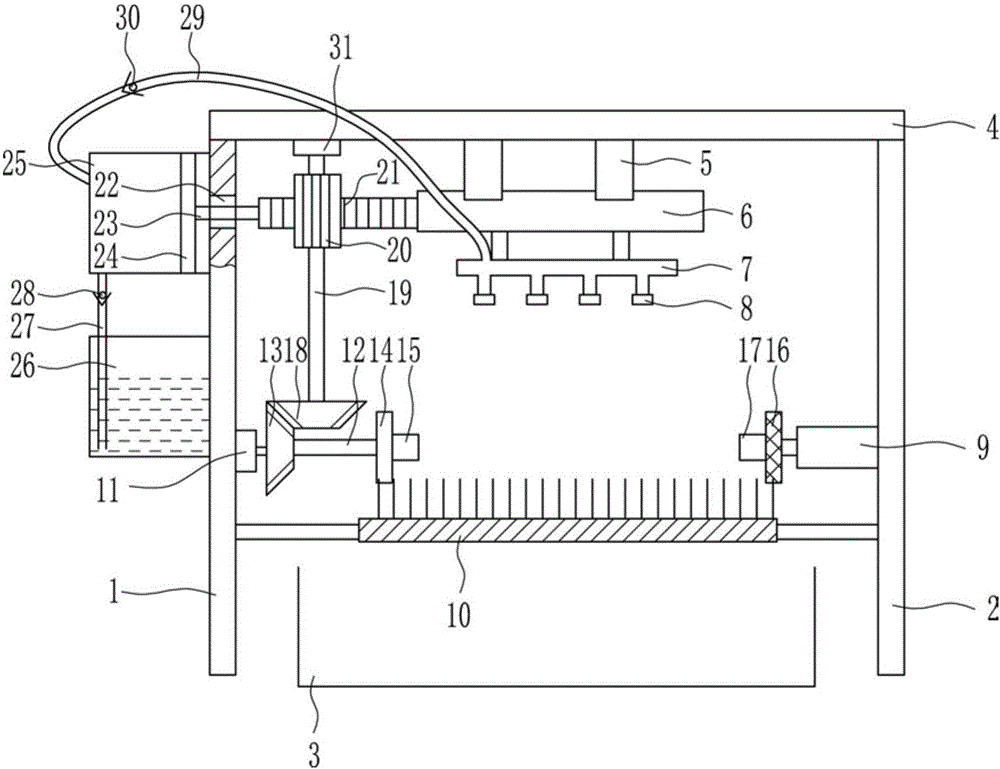

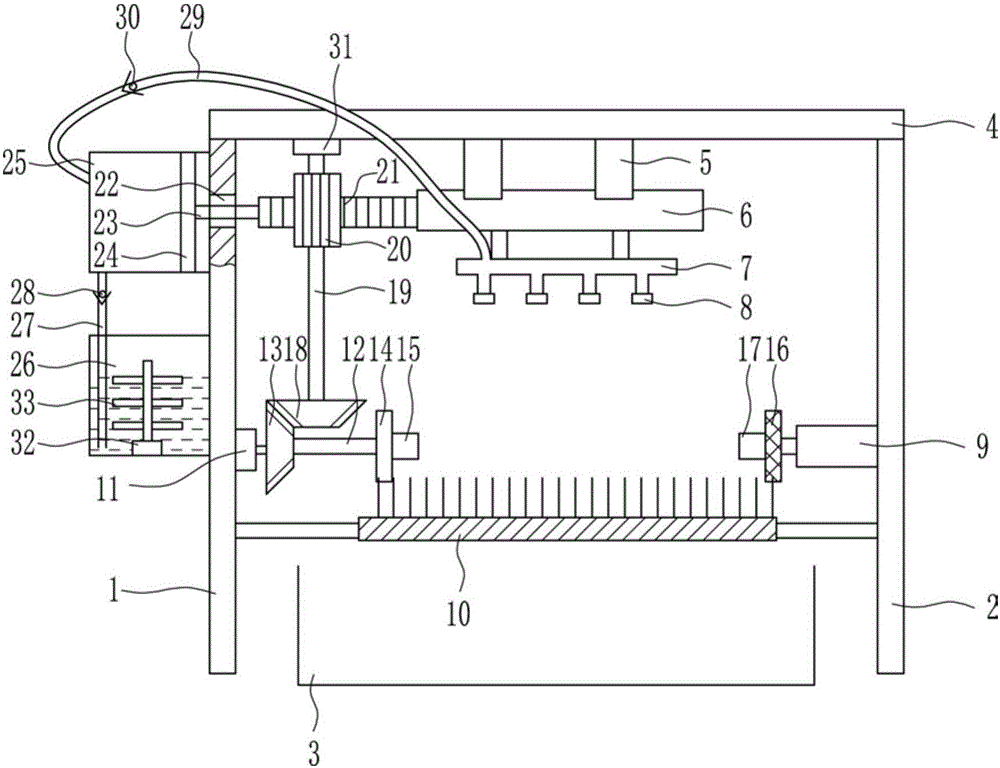

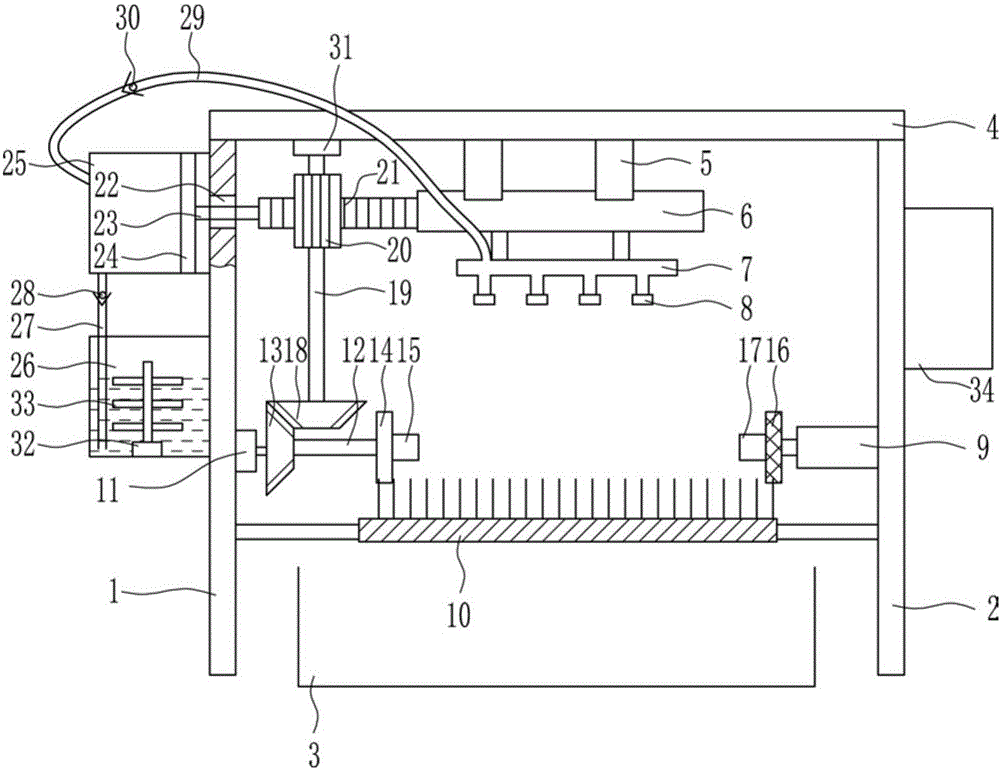

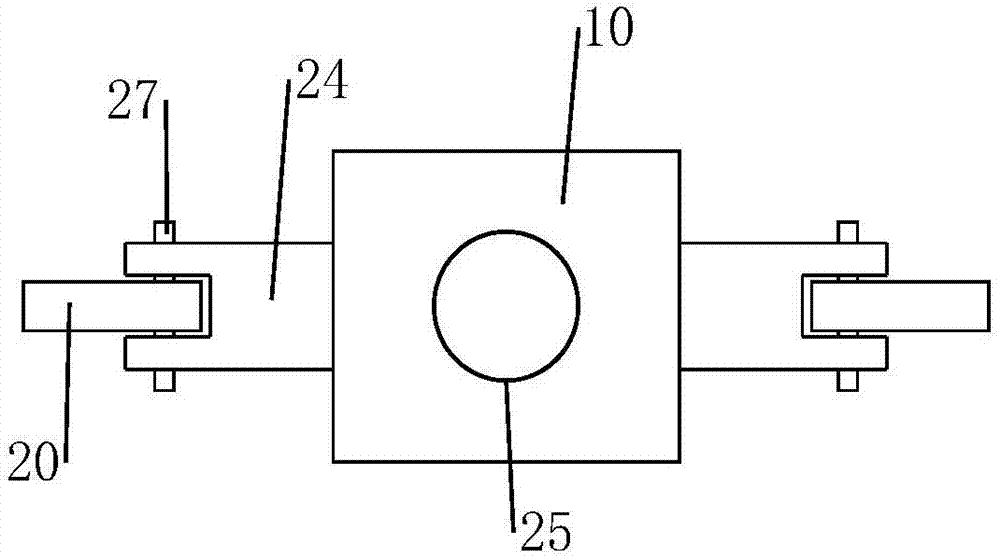

The invention relates to an engineering oil pipe paint spraying device, in particular to an engineering oil pipe surface paint spraying device. According to the technical problem to be solved, the engineering oil pipe surface paint spraying device does not need assistance of manual labor, and is good in automatic performance, high in maneuverability, high in working efficiency, convenient to operate and capable of uniformly spraying paint to the surface of an engineering oil pipe. To solve the technical problem, the engineering oil pipe surface paint spraying device comprises a left support, a right support, a material collecting frame, a top plate, a sliding block, a sliding rail, a hollow pipe, a spraying head, an air cylinder, a hairbrush, a first motor, a first rotating shaft, a first bevel gear and the like. The left support and the right support are vertically arranged in a bilateral symmetry manner. The material collecting frame is arranged below the position between the left support and the right support. According to the engineering oil pipe surface paint spraying device, in the process of spraying the paint to the surface of the engineering oil pipe, while the engineering oil pipe rotates, the spraying head sprays the paint.

Owner:平湖市穗丰五金有限公司

Atomizing agent containing medicinal plant oil

The present invention provides a spray containing medicinal vegetable oil. The liquid medicine of said spray contains one or more than one medicinal vegetable oil with therapeutic action and effective dose and oleaginous liquid medicine carrier. The described oleaginous liquid medicine carrier is formed from one or more than one synthetic or natural fatty oil.

Owner:晏四平

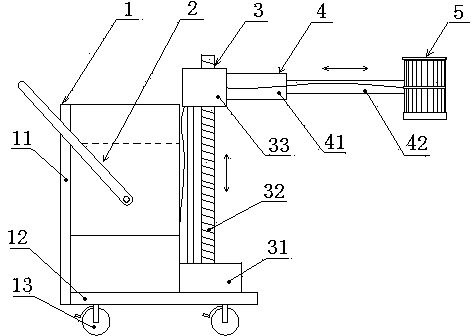

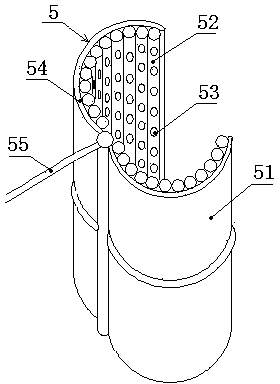

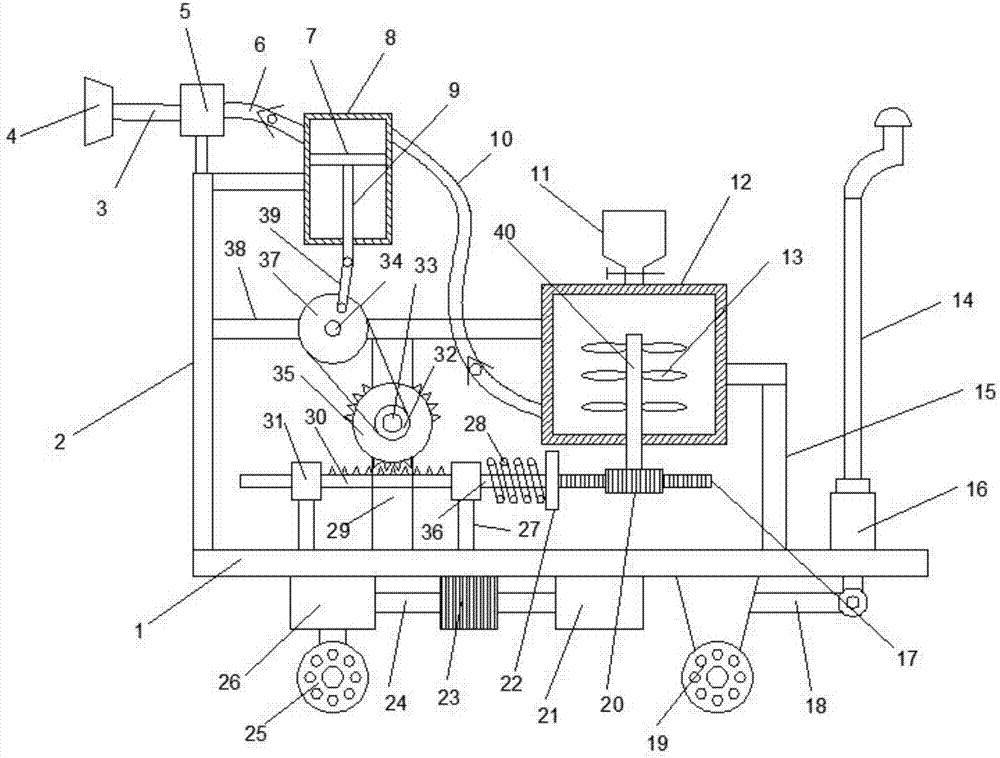

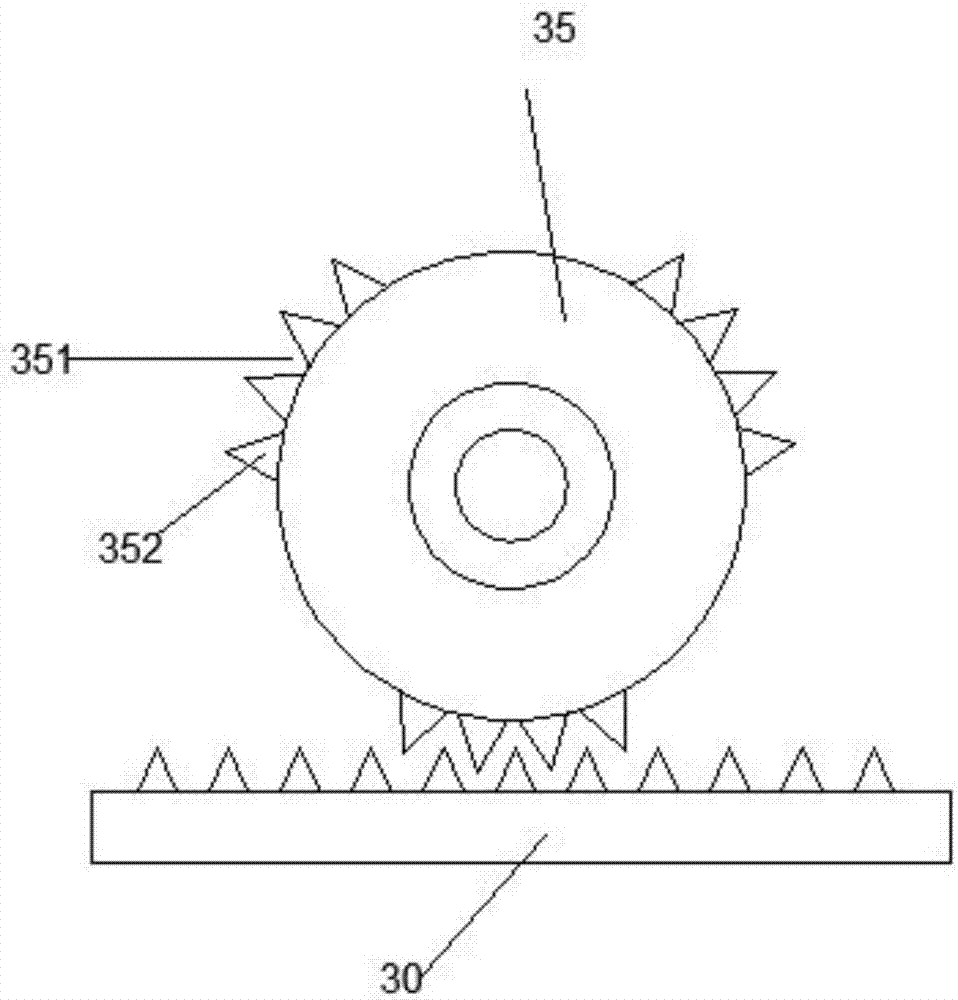

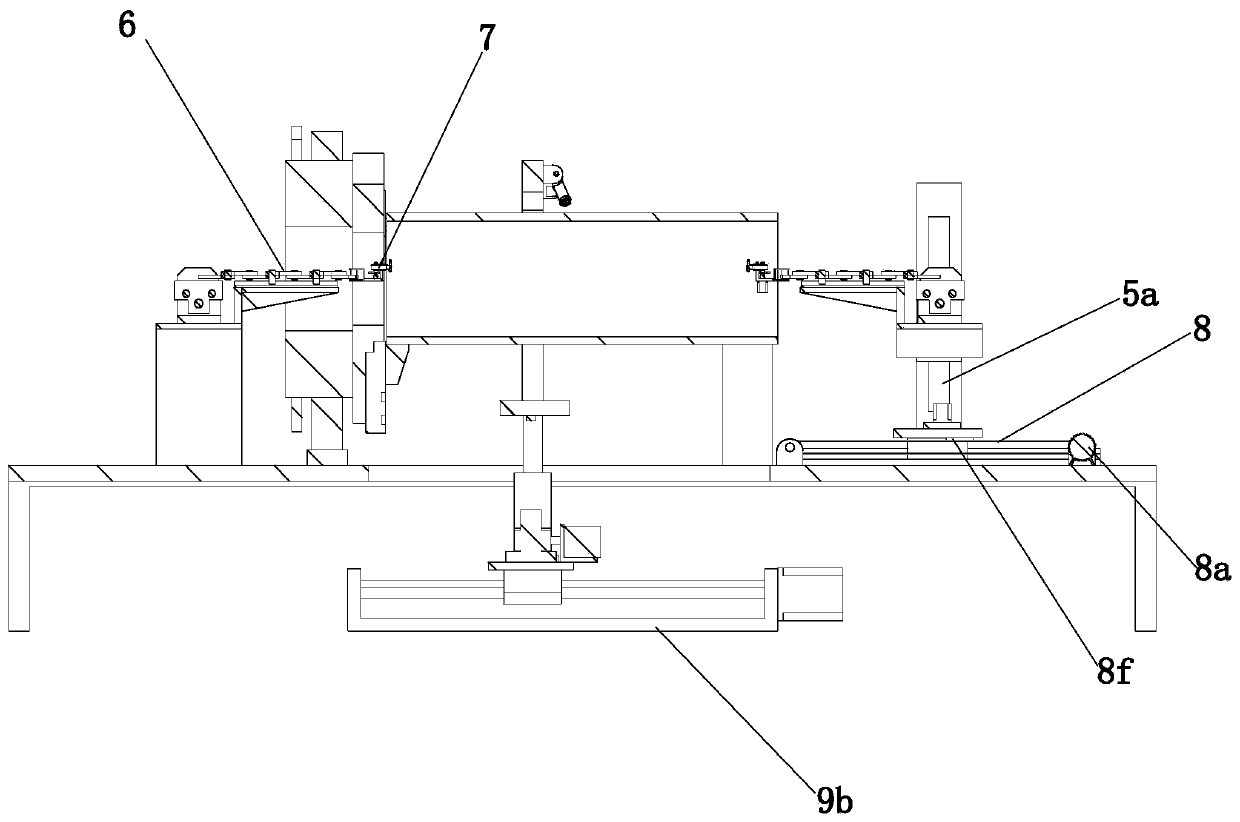

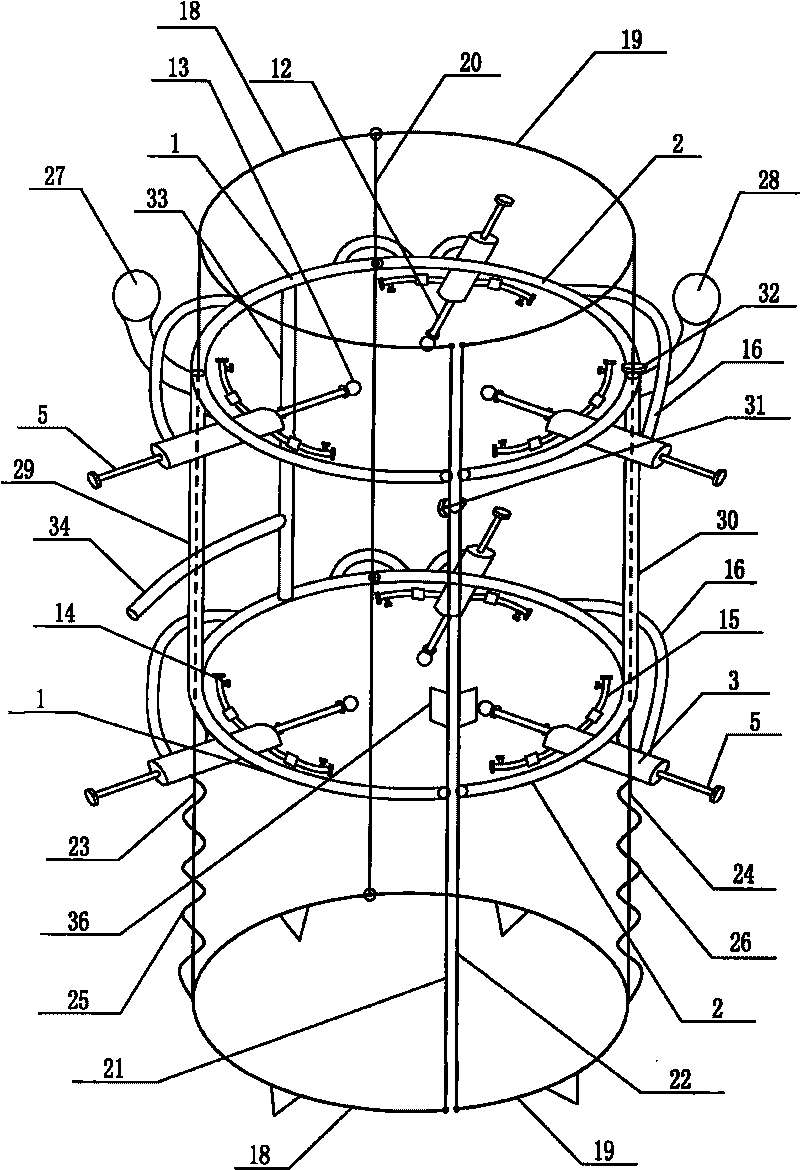

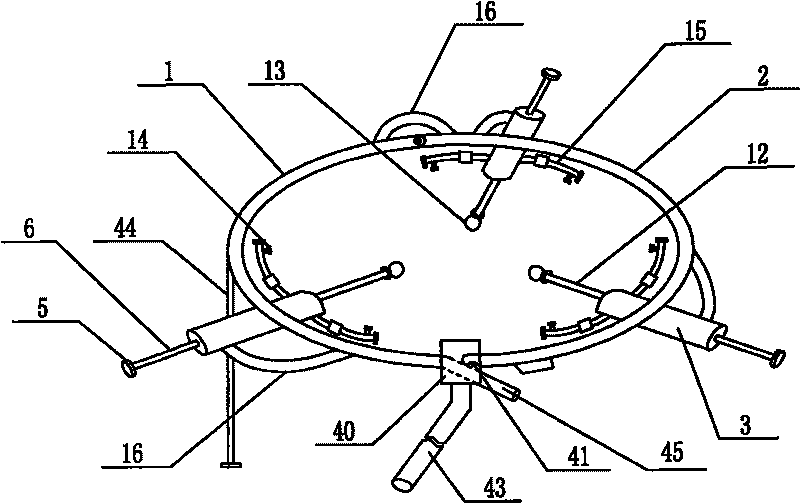

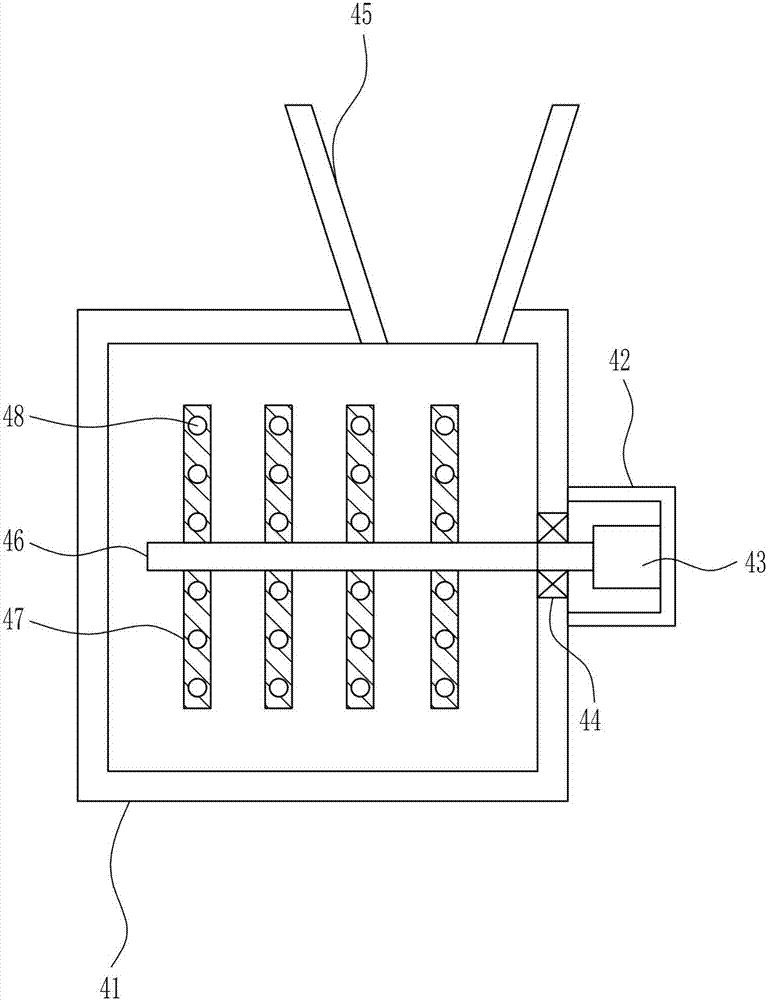

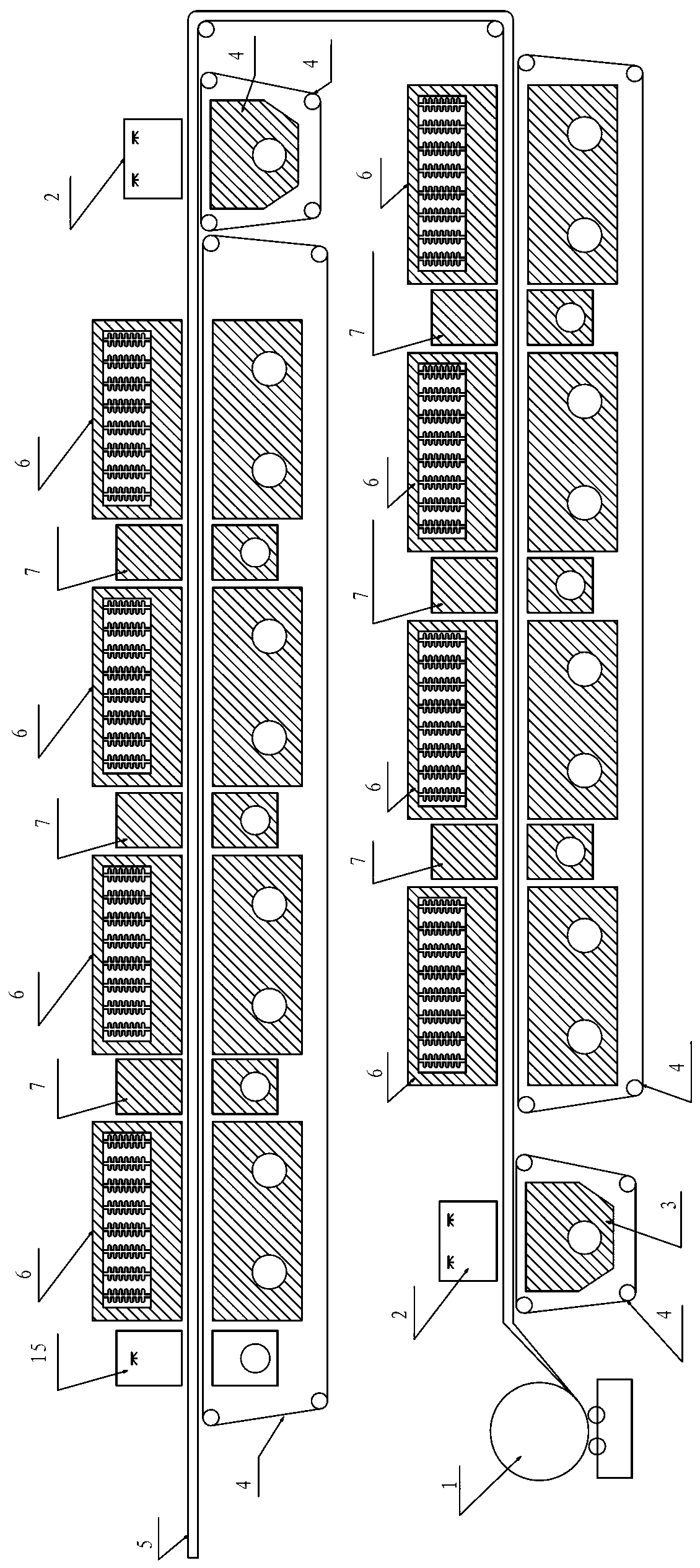

Intelligent tree brushing machine and method

InactiveCN103535224ASpray evenlyImprove the efficiency of brushing treesSpraying apparatusPlant protectionEngineeringMechanical engineering

The invention provides an intelligent tree brushing machine and method. The tree brushing machine comprises a vehicle body, a paint box, a lifting device, a horizontal expansion device and a tubular spraying device, wherein the lifting device comprises a transmission device and a lengthways screw; the lengthways screw is capable of rotating positively and negatively under the driving of a transmission device; the lengthways screw is provided with a lifting block; the horizontal expansion device fixed on the lifting block comprises a cylinder and a horizontal expansion support lever; the tubular spraying device is arranged at the terminal end of the horizontal expansion support lever; the tubular spraying device comprises two semi-cylindrical sleeves which can be opened and closed and 24 vertical spraying pipes; the vertical spraying pipes are uniformly provided with spray head beams; the vertical spraying pipes are vertically arranged at the inner sides of the semi-cylindrical sleeves; the upper parts of the vertical spraying pipes are communicated with guide pipes arranged at the upper parts of the semi-cylindrical sleeves. According to the invention, automatic placement is realized, a tree can be brushed easily once the tubular spraying device is sleeved on the tree, the tree brushing efficiency is improved, and labor force is reduced.

Owner:董廷秀

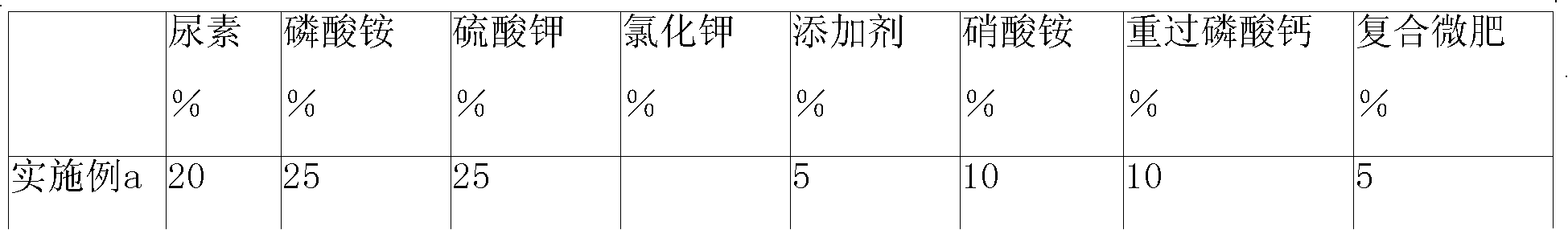

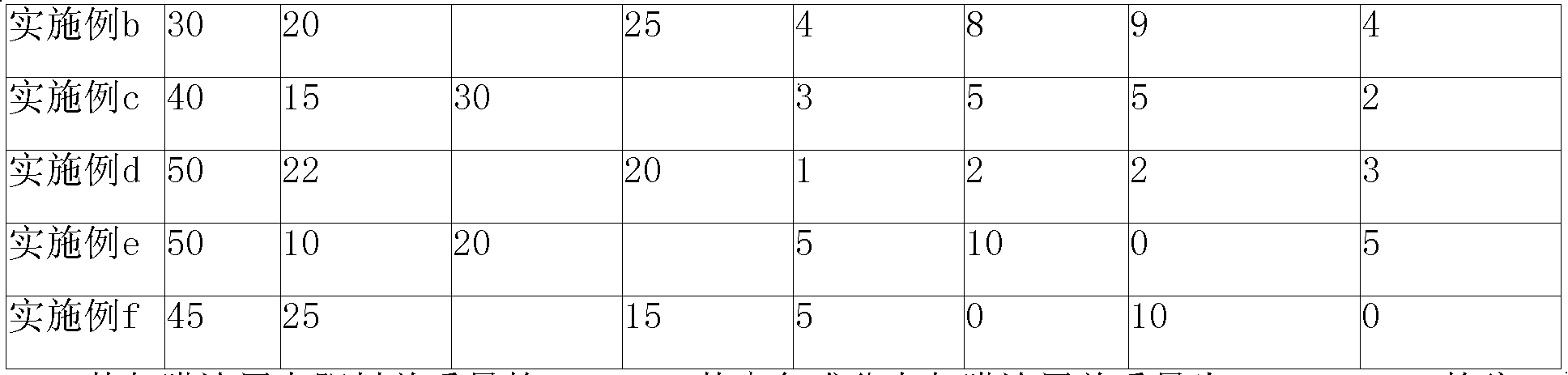

Long-acting special controlled release fertilizer for corn and preparation method thereof

InactiveCN101177365ALess hygroscopic expansion and contractionSimple preparation processFertilizer mixturesPotassiumNutrient

A special controlled-release fertilizer for long-acting corn and its preparation method. The fertilizer core accounts for 80-92% of the total weight of the fertilizer, wherein the weight sum of nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer calculated by pure nitrogen, phosphorus pentoxide and potassium chloride is the fertilizer 25%-50% of the total weight, the weight ratio is: 2-4:1-2:1-3; the coating coating accounts for 8-20% of the total weight of the fertilizer, including: 69.5-93% sulfur, 530 % polyethylene wax, 0.5-2% leveling agent. Melt sulfur, add montmorillonite and stir evenly, then add leveling agent, stir evenly to form molten sulfur. The molten sulfur and polyethylene wax are simultaneously sprayed on the surface of the fertilizer core to form a slow-release coating layer. The process occupies less land, requires less investment in equipment, and consumes less energy. It has the characteristics that one fertilization can meet the nutrient needs of corn throughout the growth period. The fertilizer effect is long and safe, and fertilization is simple.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Variable-spray whole-torrential flow showerhead

InactiveCN101352702ASimple structureGuaranteed uptimeWatering devicesMovable spraying apparatusJet flowDifferential pressure

The invention pertains to a key device for water-saving irrigation, which is a wall-attached fluidic nozzle that realizes variable spraying; the nozzle comprises a static plate, a moving plate, a spraying body, a spraying tube, a rotating seal mechanism, a knighthead, a spacing ring, a reversing mechanism and a fluidic element body and is characterized in that the static plate and the moving plate are added to a nozzle spin; the moving plate is pressed to match a hollow shaft, and rotates along with the nozzle. The fluidic element body comprises a reverse air supply nozzle, a signal water receiving nozzle, an outlet cover plate, a signal water intake nozzle and a honeycomb duct; signal water in a signal water receiving nozzle leads one side of main jet-flow to form a low-pressure spiral area at intervals; by opening and closing an air supply receiving nozzle, the other side of the main jet-flow is led to switch between high pressure and low pressure so as to form a differential pressure between the right and the left ends of the main jet-flow, thus realizing the wall attachment of water flow and finishing direct spraying, stepping and reverse running of the nozzle. The static plate and the moving plate at the position of the nozzle spin move relatively to change the area of stopflow at an inlet and regulate the flow and the pressure of the inlet so as to change the spraying range of nozzle and realize variable spraying.

Owner:JIANGSU UNIV

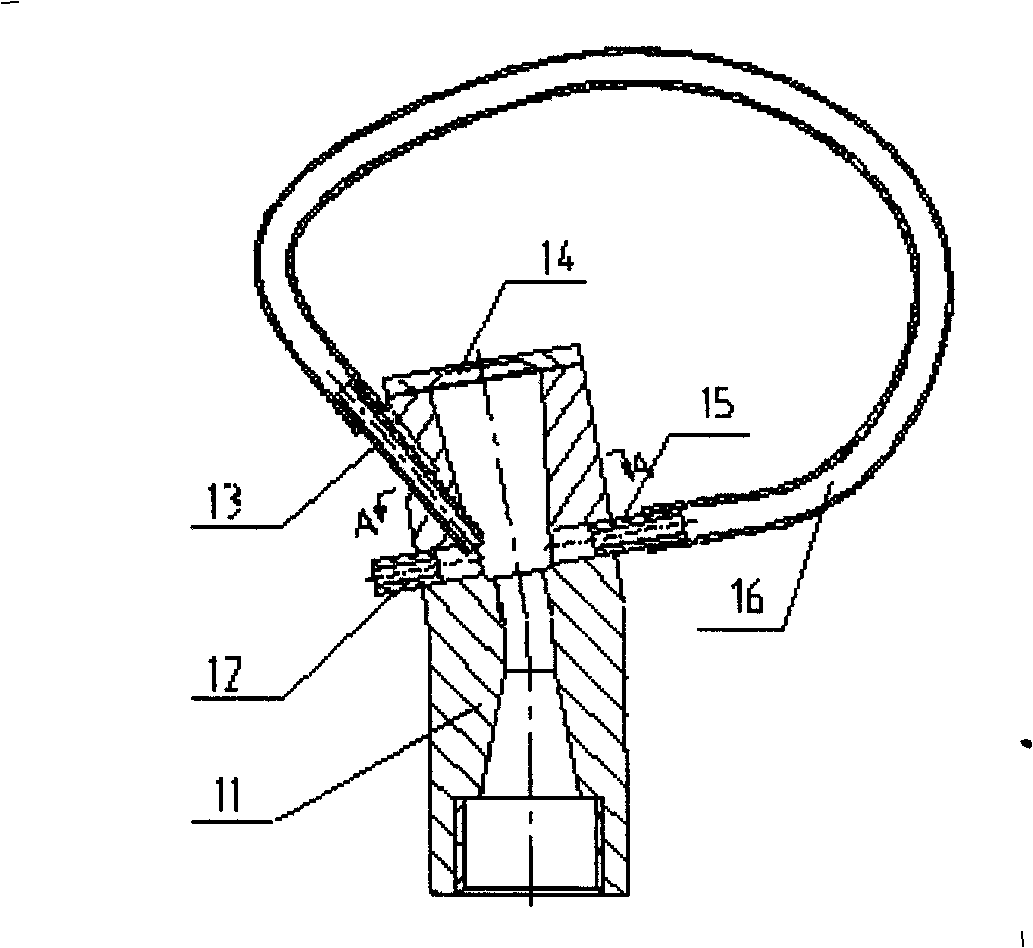

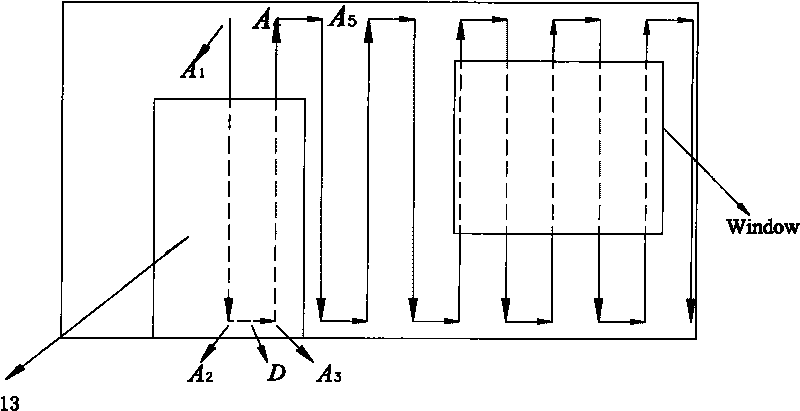

Method for indoor spray-finishing by using robot spraying system

InactiveCN101716568ASpray evenlyAvoid white spaceLiquid surface applicatorsSpraying apparatusMaster controllerControl theory

The invention discloses a method for indoor spray-finishing by using a robot spraying system, which is characterized in that: house data is read into a main controller of the robot spraying system through a data interface; the main controller fixes the original position point of a robot according to the read house data; the robot spraying system sprays walls; the robot spraying system sprays wall corners; the main controller receives signals sent by a distance measurement sensor which is arranged on a robot basal body and judges whether the robot basal body reaches the original position point, when the robot basal body reaches the original position point, the main controller controls a robot traveling device to stop moving; and the robot spraying system sprays the ceiling. By adopting the method, any house with flat walls can be sprayed, the walls and the ceiling can be uniformly sprayed, and the blank parts of doors and windows can be effectively avoided to uniformly spray the wall corners. In addition, the spraying process is intelligent and fully automatic.

Owner:CHONGQING UNIV

Agricultural spraying and irrigating device with good mixing effects

InactiveCN107318602AReasonable structureInnovative designTransportation and packagingRotary stirring mixersDrive shaftAgricultural engineering

The invention discloses an agricultural spraying and irrigating device with good mixing effects. The agricultural spraying and irrigating device comprises a support seat. A first support frame is connected with the middle of the upper end of the support seat, a driving shaft is connected with the middle of the first support frame, a driving gear is connected with the middle of the front end of the driving shaft, gear tooth groups are uniformly connected with the outer side of the driving gear, a driving belt pulley is connected with the middle of the driving shaft and is positioned at the front end of the driving gear, a first rack meshes with the lower end of the driving gear, limiting stoppers are connected with the middles of two ends of the first rack, a fixing shaft is connected with the right end of the first rack, a fixing barrier is connected with the right end of the fixing shaft, a second rack is connected with the right end of the fixing barrier, a stirring gear is connected with the front end of the middle of the second rack, a third support frame is connected with the right side of the upper end of the support seat, a stirring tank is connected with the upper end of the third support frame, a driven shaft is connected with the middle of a fourth support frame, and a driven belt pulley is connected with the front end of the middle of the driven shaft. The agricultural spraying and irrigating device has the advantages that the agricultural spraying and irrigating device not only has spraying functions, but also has irrigating functions, and the good mixing effects can be realized by the agricultural spraying and irrigating device.

Owner:侯添有

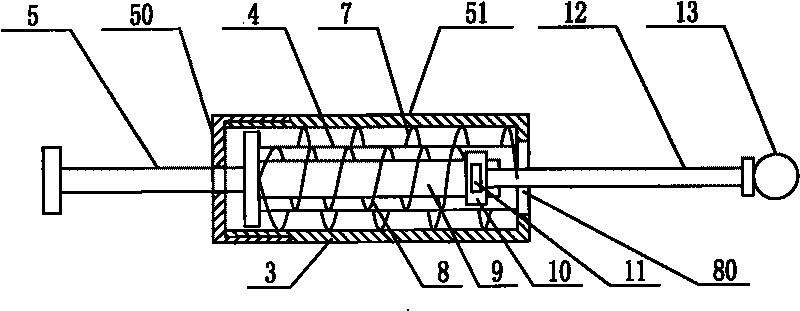

Rapid mechanical component antirust oil spraying device

InactiveCN106733345AFlexible swingExtended service lifeLiquid surface applicatorsLiquid spraying apparatusMechanical componentsSprayer

The invention relates to an antirust oil spraying device, and in particular relates to a rapid mechanical component antirust oil spraying device. The technical problem to be solved by the invention is to provide the rapid mechanical component antirust oil spraying device which is uniform in spraying, saving in material, and convenient to operate. In order to solve the technical problem, the invention provides the rapid mechanical component antirust oil spraying device comprising a base plate, a left rack, a box, a water pipe, a first check valve, a cylinder, a piston, a flexible pipe, a processing frame, a right rack, a screen plate, a sprayer, a second check valve and a top plate, wherein the left rack is welded with the left side of the top of the base plate, a first fixing rod is welded with the upper part of the right side of the left rack, and a motor is connected with the first fixing rod via a bolt. According to the device provided by the invention, the effects of being uniform in spraying, saving in material, and convenient to operate are achieved, and the device is low in manufacturing cost, reasonable in structure, prone to maintain and repair, convenient to use, reduced in investment of manpower and material resources and improved in work efficiency.

Owner:孝感市伊莱迦电子科技有限公司

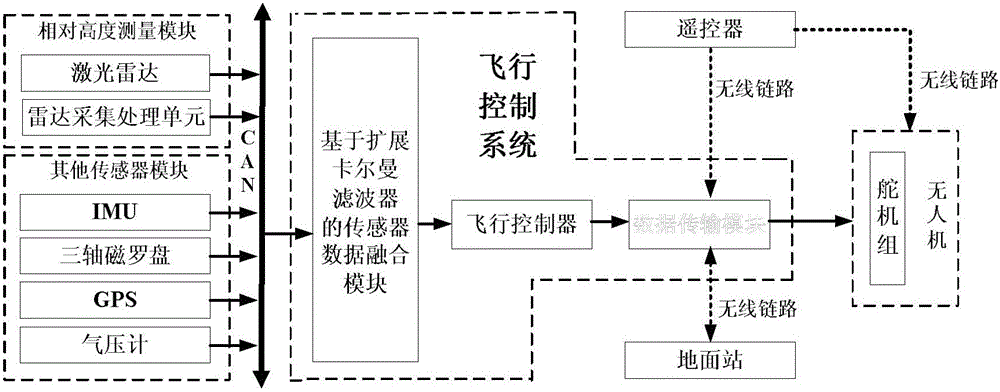

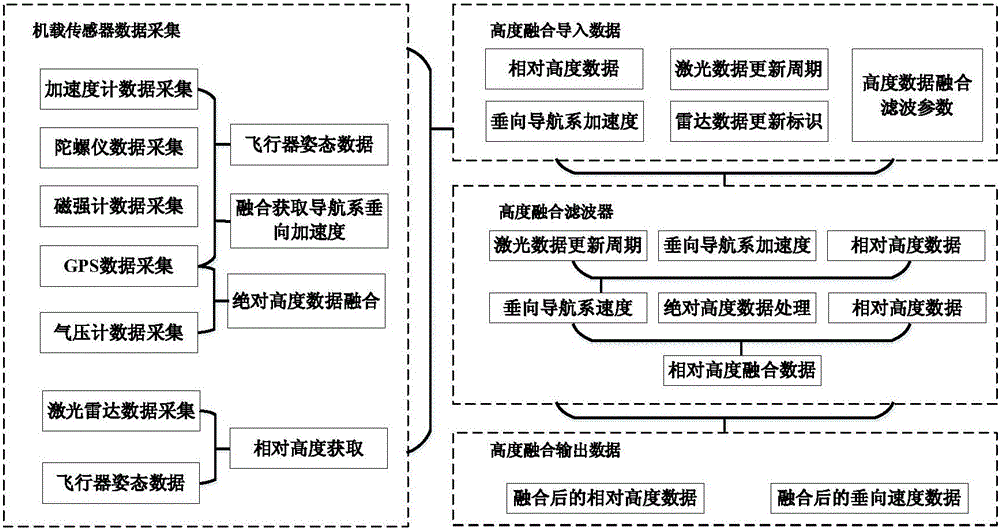

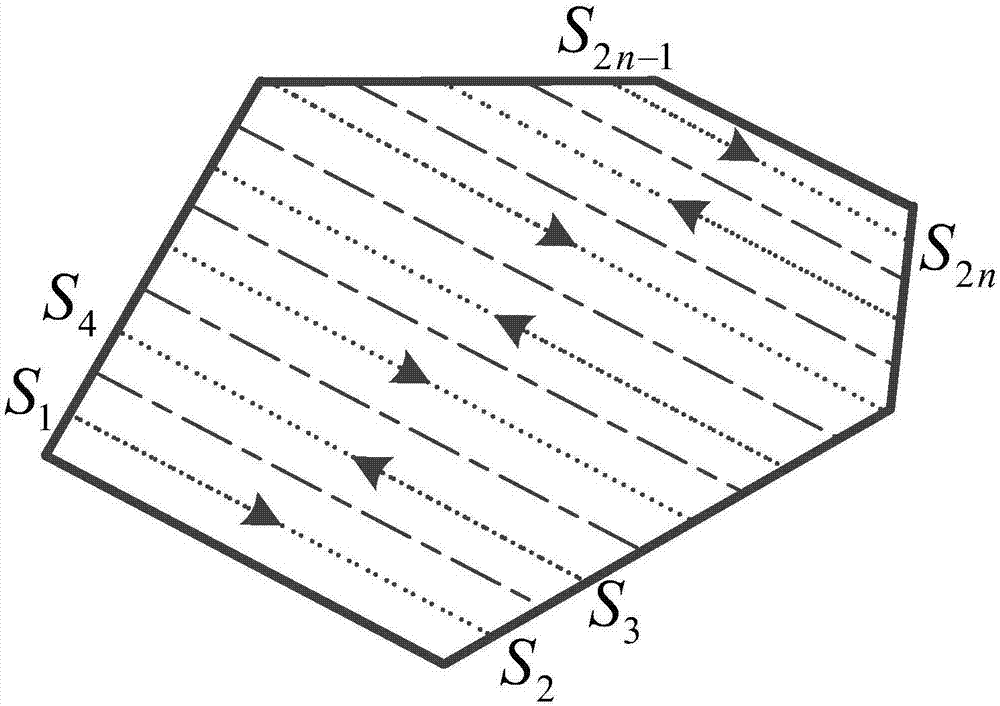

Unmanned plane terrain following system and method based on laser radar

InactiveCN105824322ATroubleshoot flight control issuesSpray evenlyPosition/course control in three dimensionsRadarUncrewed vehicle

The invention relates to an unmanned plane terrain following system and method based on a laser radar. The unmanned plane terrain following system comprises a relative altitude measuring module, other sensor modules, and a flight control system. The unmanned plane terrain following method comprises the following steps: 1) the laser radar acquires the relative altitude information of the flight environment and a radar acquisition processing unit performs acquisition and preprocessing calculation on the radar data and outputs the processed result to the flight control system; 2) a sensor data integration module based on an extended kalman filter receives the relative altitude information from the relative altitude measuring module and the flight state information from the other sensor modules; the relative altitude information and the flight state information are fused and processed through the sensor data integration module based on the extended kalman filter, so that a flight command is generated; and 3) the flight command is controlled through flight, and is transmitted to an unmanned plane steering engine group through a data transmission module. The unmanned plane terrain following system and method based on a laser radar solve the problem of measurement of relative altitude of an unmanned plane, height keeping flight of an unmanned plane and automatic taking off and landing of an unmanned plane.

Owner:一飞智控(天津)科技有限公司

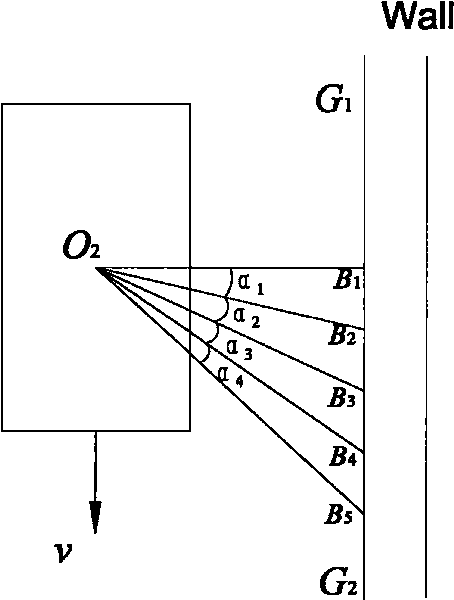

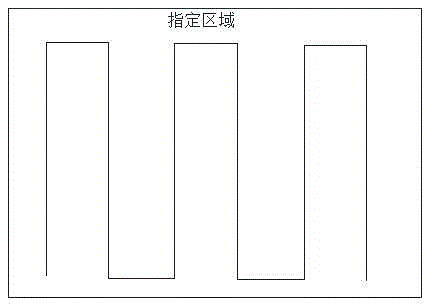

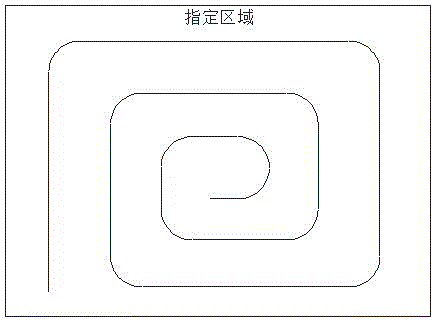

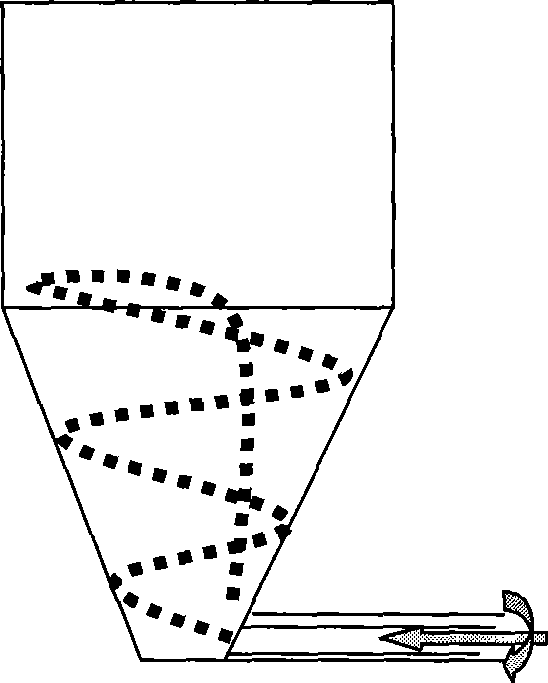

Spraying method for plant protection unmanned aerial vehicle (UAV)

InactiveCN104881037AMove forward at a constant speedHigh speedPosition/course control in three dimensionsRADIUSAirplane

The invention discloses a spraying method for a plant protection unmanned aerial vehicle (UAV). The spraying method includes a method in which an aircraft body carries a spray unit, flies to a designated area and spraying a soup downward, and also comprises executing steps of a flight route of the aircraft body which are an S1 step of dividing the designated area into at least one rectangular area; an S2 step of performing spiral rotation flight along the surrounding of one rectangular area, with an interval of adjacent flight paths as the spraying radius; and an S3 step of stopping spraying the soup after the aircraft body flies to the central portion of the rectangular area, or flying straightly toward a closest side of the rectangular area to another rectangular area. The invention is capable of reducing the turning of the aircraft body and reducing the loss.

Owner:SHENZHEN XIANGNONG INNOVATION TECH CO LTD

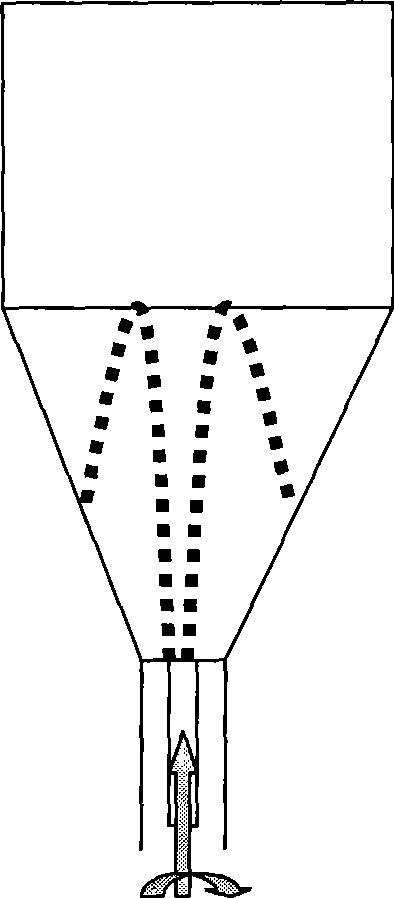

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

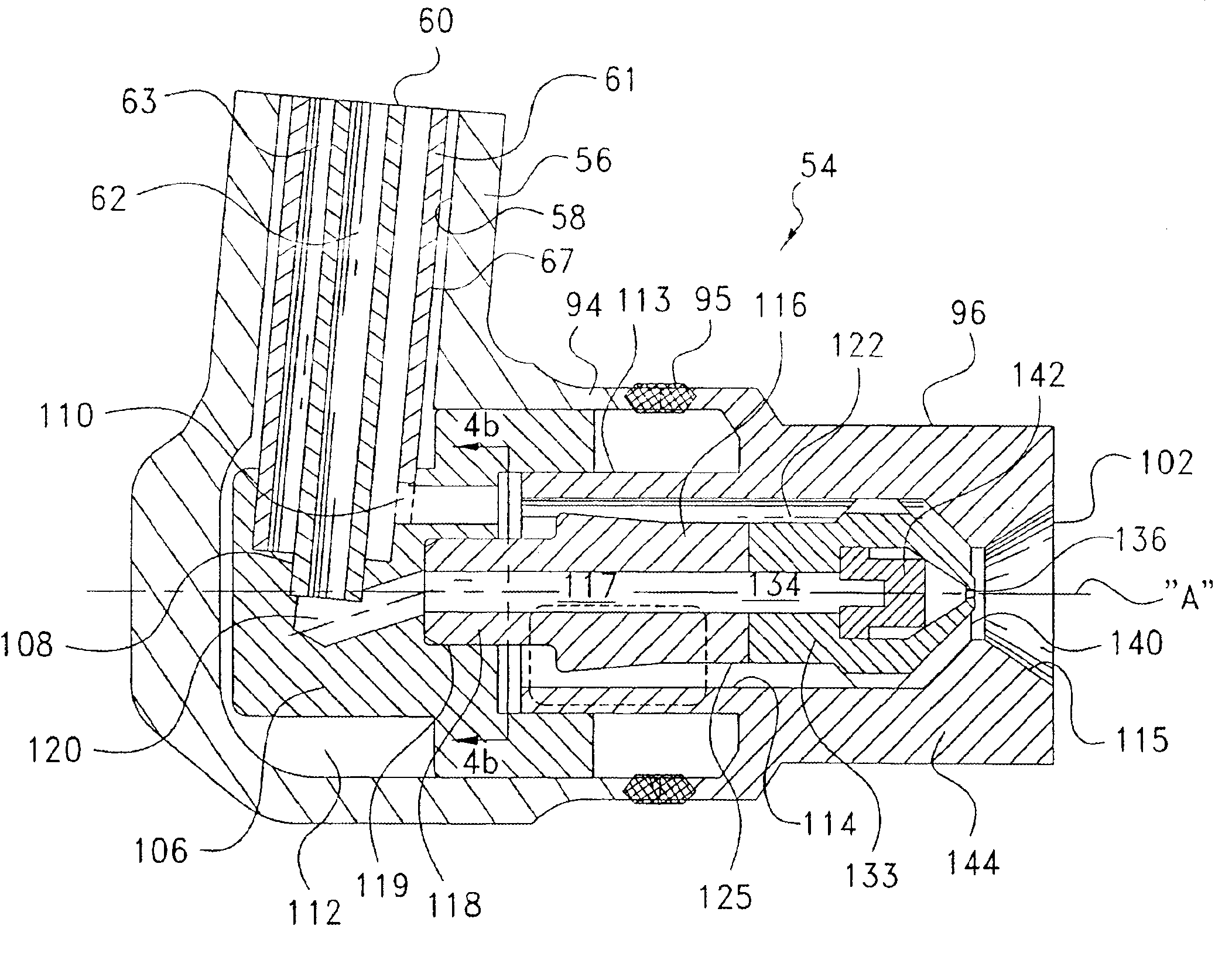

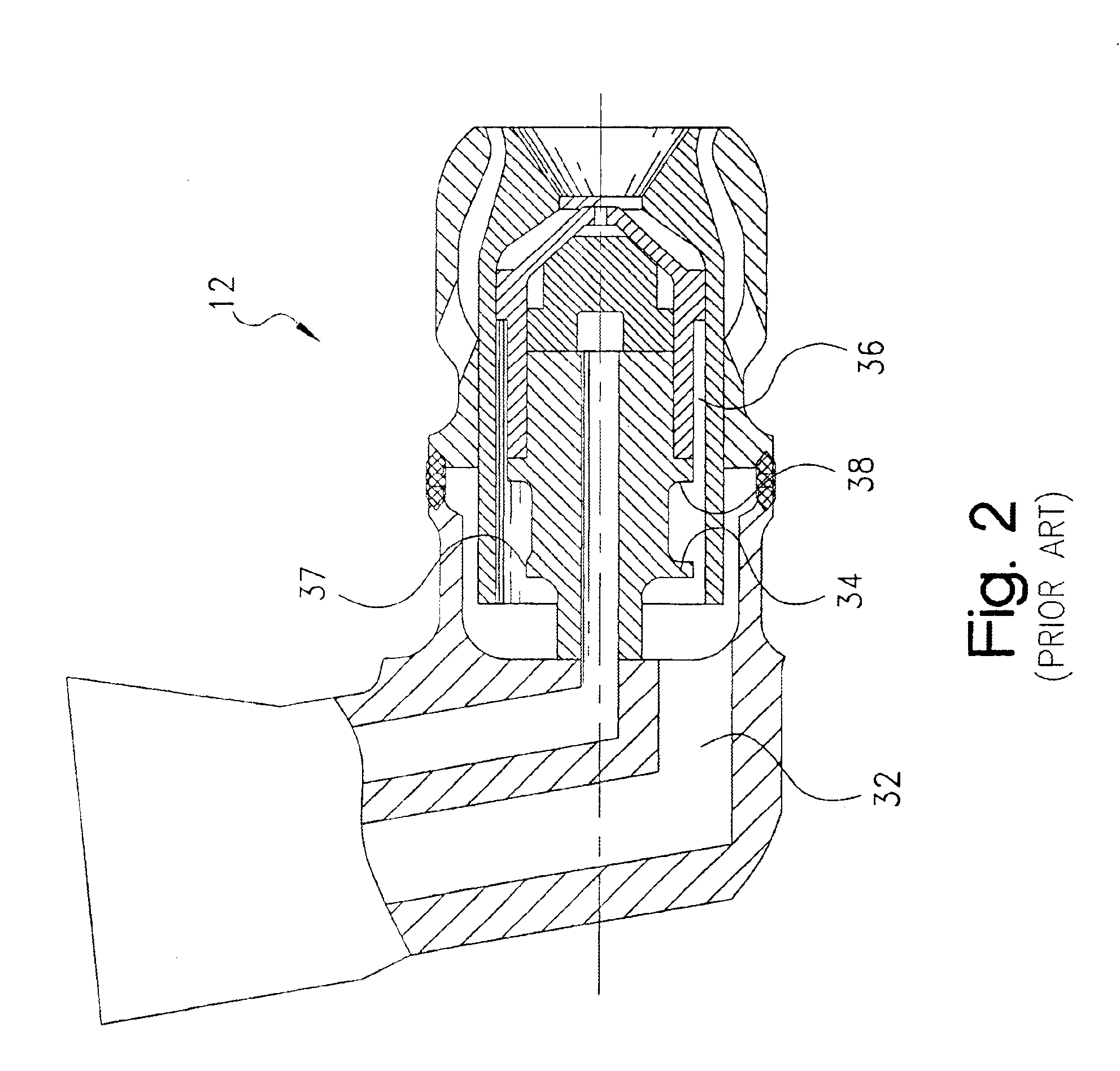

Nozzle with flow equalizer

InactiveUS6895755B2Reduce complexityLow costBurnersTurbine/propulsion fuel supply systemsEngineeringGuide tube

A fuel injector for a gas turbine engine has an inlet fitting, a fuel nozzle, and a housing stem with a pair of fuel conduits fluidly interconnecting the nozzle and fitting. The fuel nozzle includes an annular secondary fuel passageway directing fuel from one fuel conduit to an annular discharge orifice at a discharge end of the nozzle. The secondary fuel passageway is defined between an outer, annular fuel conduit portion and a primary adapter. The primary adapter has an outer surface with a distinct, radially-outwardly-projecting annular shoulder to restrict flow through the secondary passageway and provide substantially uniform distribution of flow through the passageway downstream of the shoulder, for improved combustion and flame stability.

Owner:PARKER INTANGIBLES LLC

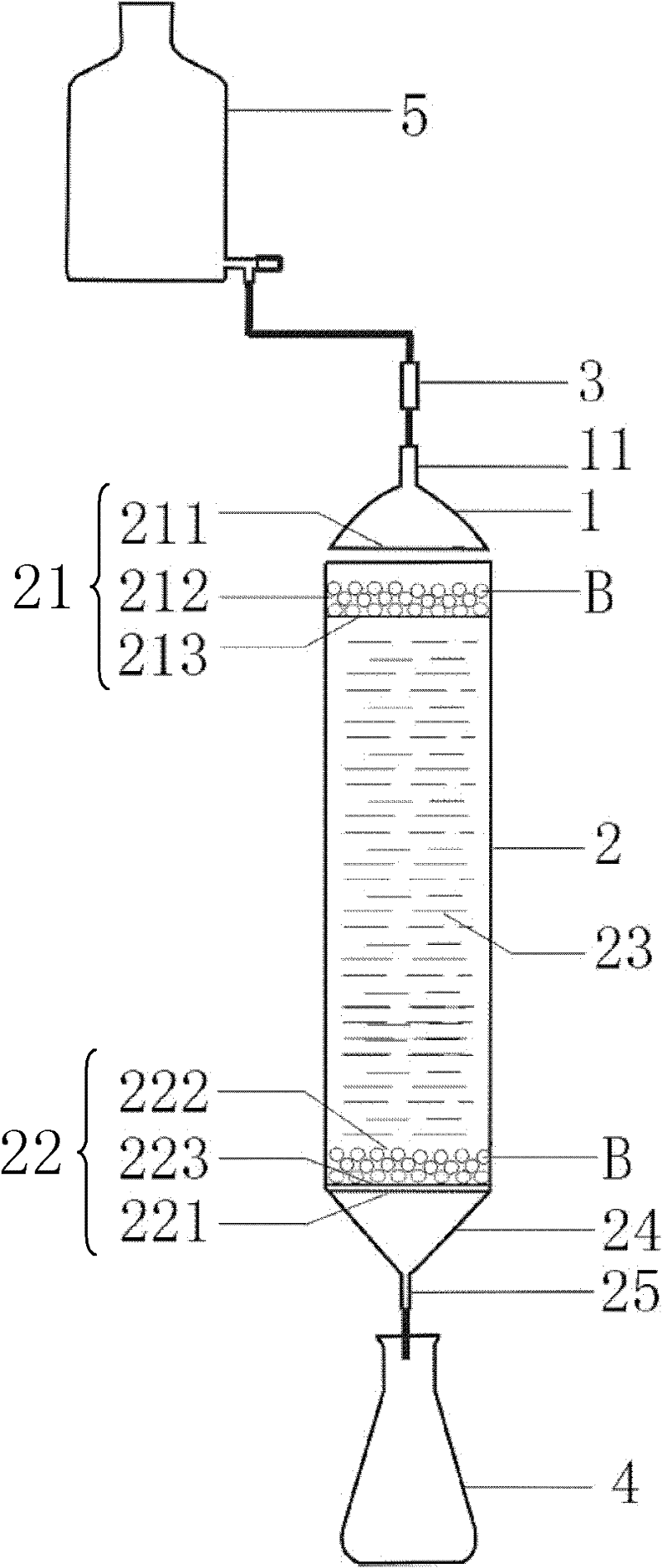

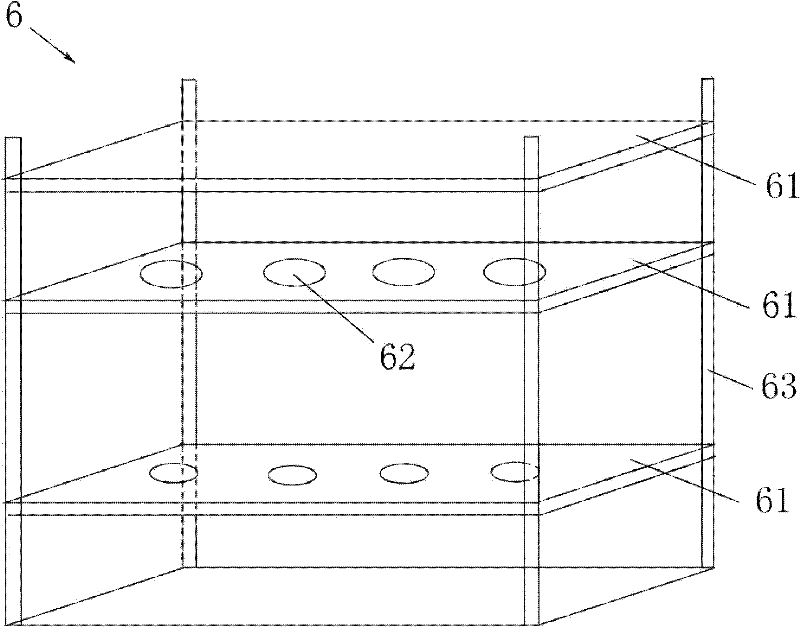

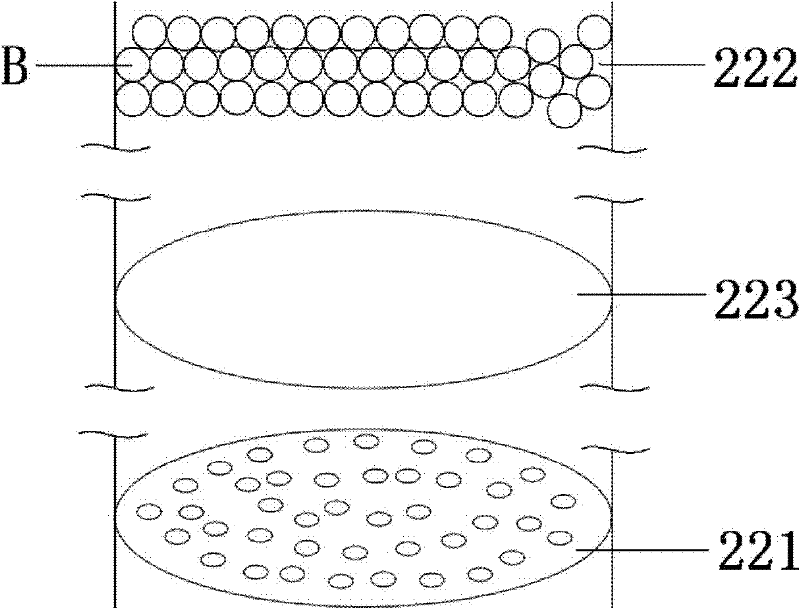

Leaching device used in vertical transfer of pollutants in soil

InactiveCN102411043AReduce the impact of horizontal migrationPrecise control of flow rateEarth material testingSpray nozzleWater flow

The invention relates to a leaching device used in vertical transfer of pollutants in soil. The leaching device comprises a spray nozzle, a water flow meter, a leaching column for holding an experimental earth pillar and a percolate accommodating container, wherein, the leaching column is internally provided with at least two filter layers capable of filtering leaching liquid, a filter layer structure is respectively arranged on the upper and lower ends of the experimental earth pillar, and each filter layer is provided with a filter screen layer, a filter bulb layer and a filter paper layer; and in addition, the height of the leaching column body is 90cm-150cm, and the inner diameter of the cross section of the column body is 5cm-15cm. The leaching device has the advantages that on the basis of the large axial size of the leaching column, vertical transfer of the pollutants in the profile of the deeper soil can be simulated; by setting the water flow meter, the flow velocity and flow rate of injection water can be accurately controlled; by setting the upper filter layer, the injection water can be uniformly sprayed; and by setting the lower filter layer, the filter effect can be ensured and percolate can be timely and effectively discharged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

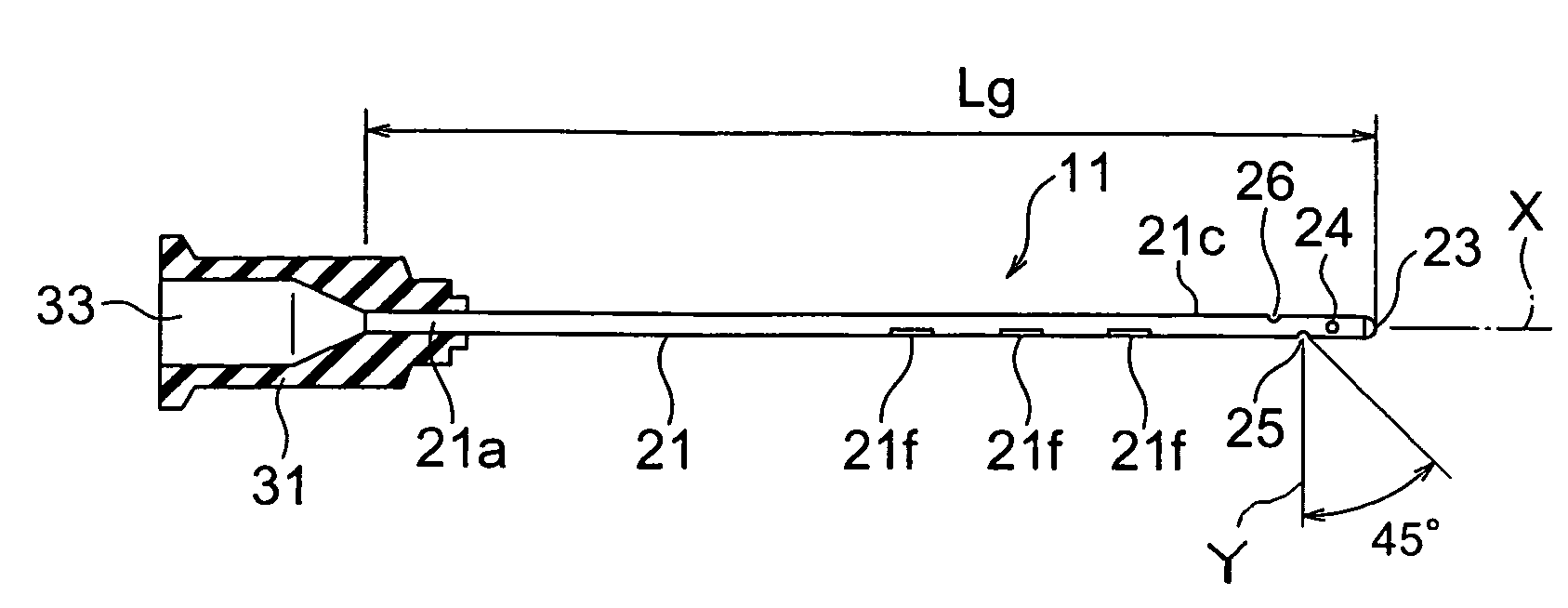

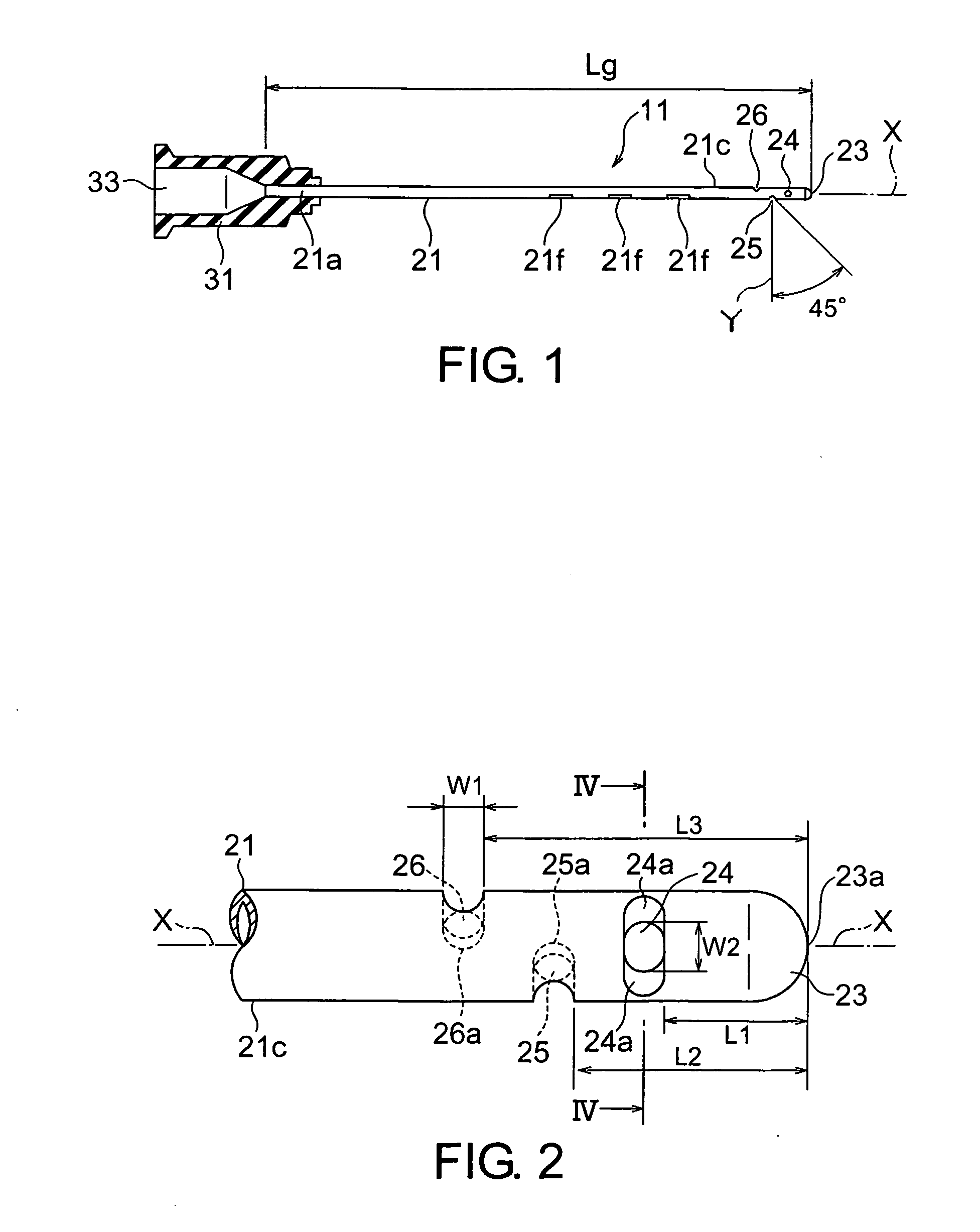

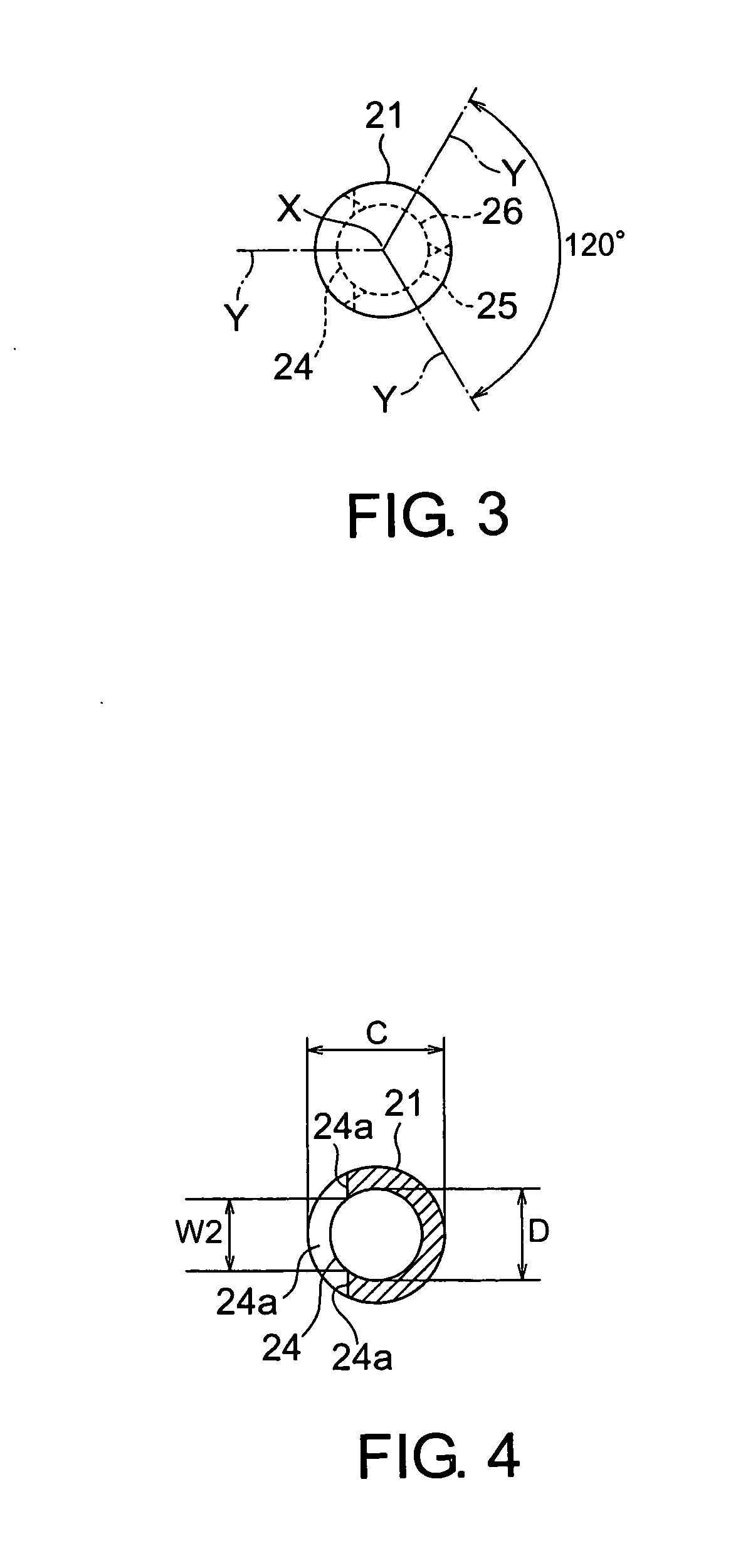

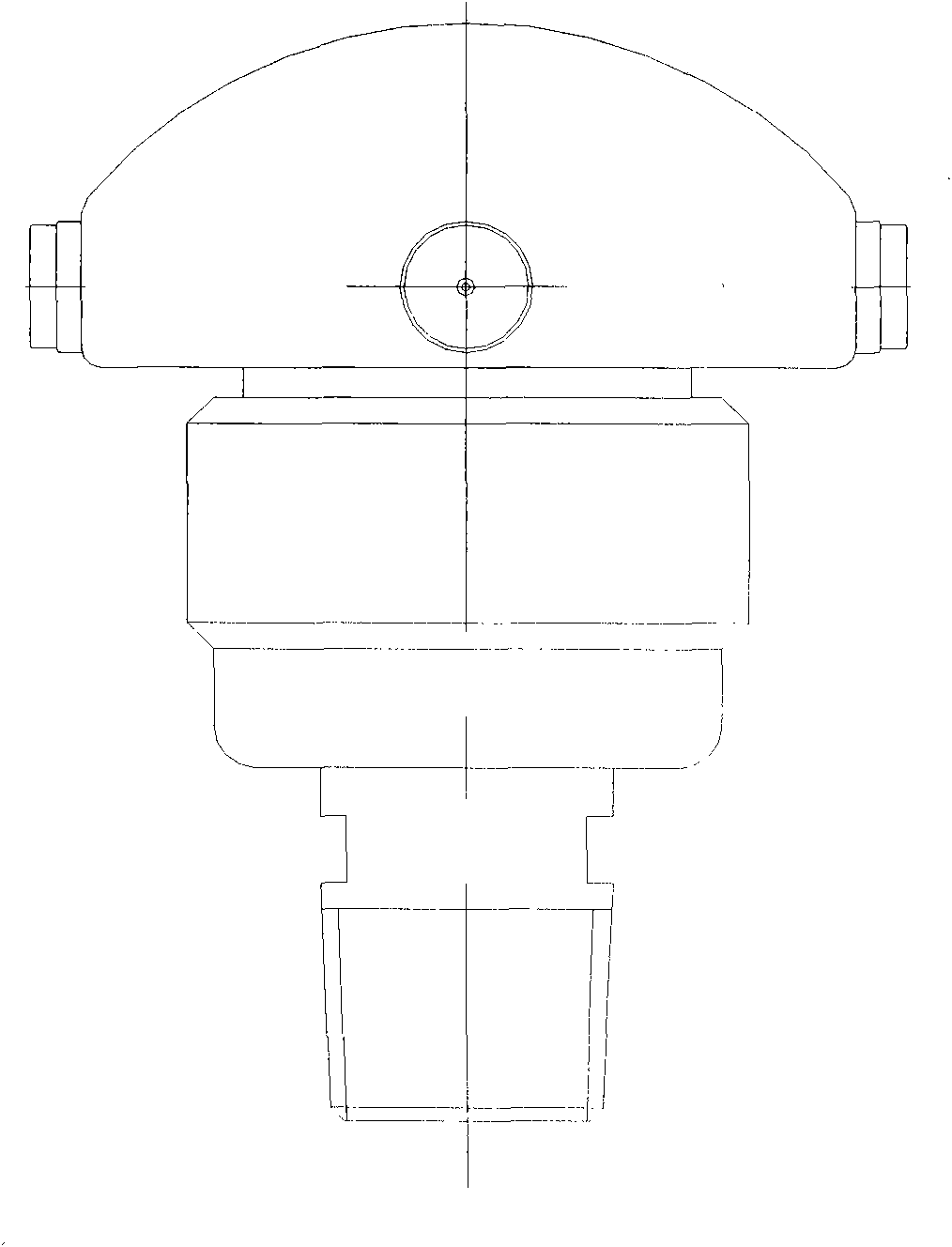

Liquid injection needle element capable of jetting a liquid in a predetermined angle range and method of producing the same

InactiveUS20060223026A1Accurately and efficiently jettingAvoid drippingLiquid surface applicatorsWheelchairs/patient conveyanceSpray nozzleMechanical engineering

A cannula has a front part in a direction of a center axis X with its forward end portion closed. The front part has a plurality of nozzle orifices each of which has an orifice axis Y intersecting the center axis X. Each of the nozzle orifices has a first diameter in a first direction parallel to the center axis X and a second diameter in a second direction perpendicular to the first direction. The first diameter ranges between 0.1 mm and 0.5 mm while the second diameter ranges between 0.1 mm and 0.3 mm so that a liquid in the cannula is jetted from the nozzle orifices in an angle range of 45 degrees towards the forward end portion with respect to the orifice axis.

Owner:MATSUMOTO DENTAL UNIVERSITY

Rotary water mist sprayer

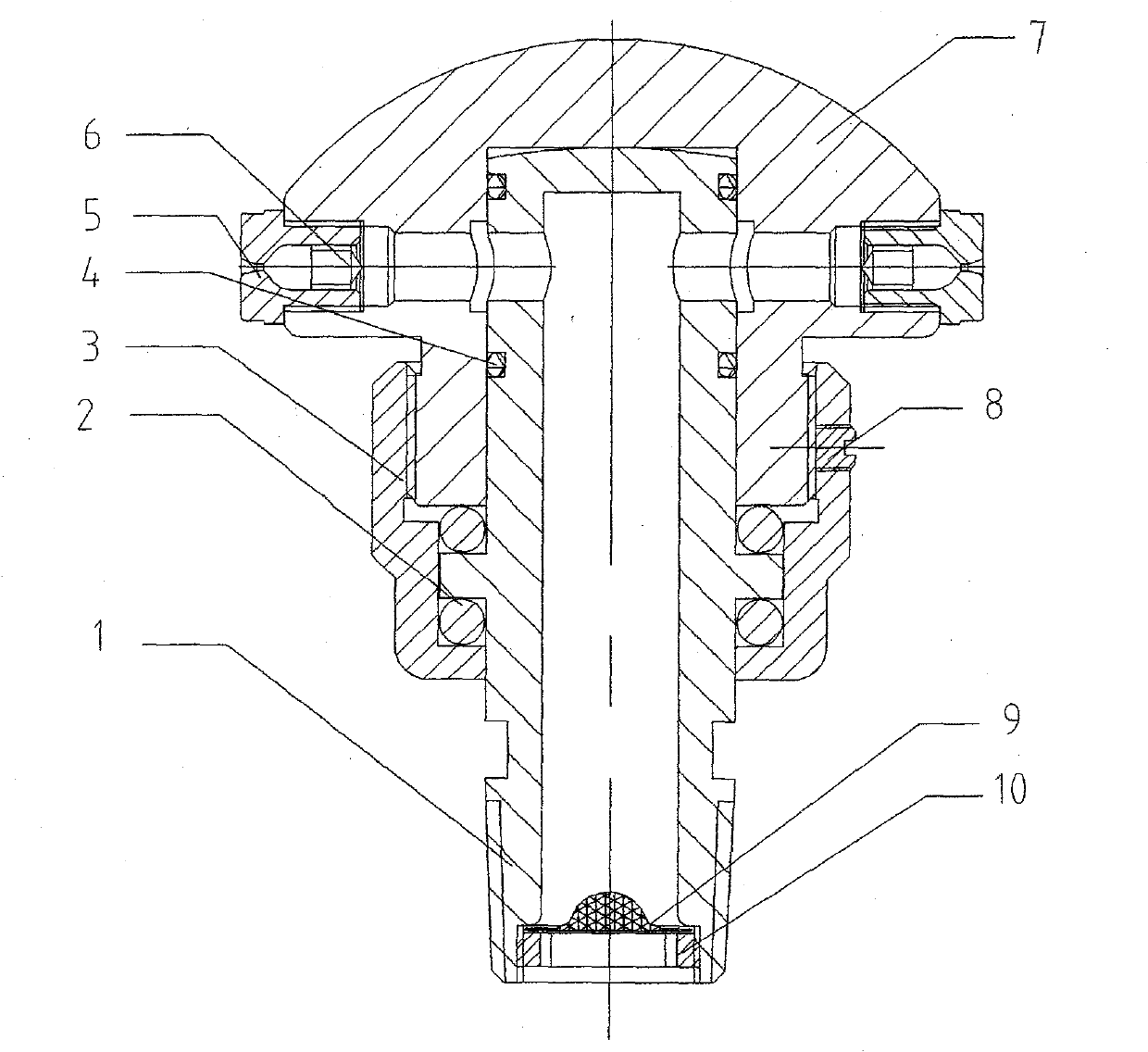

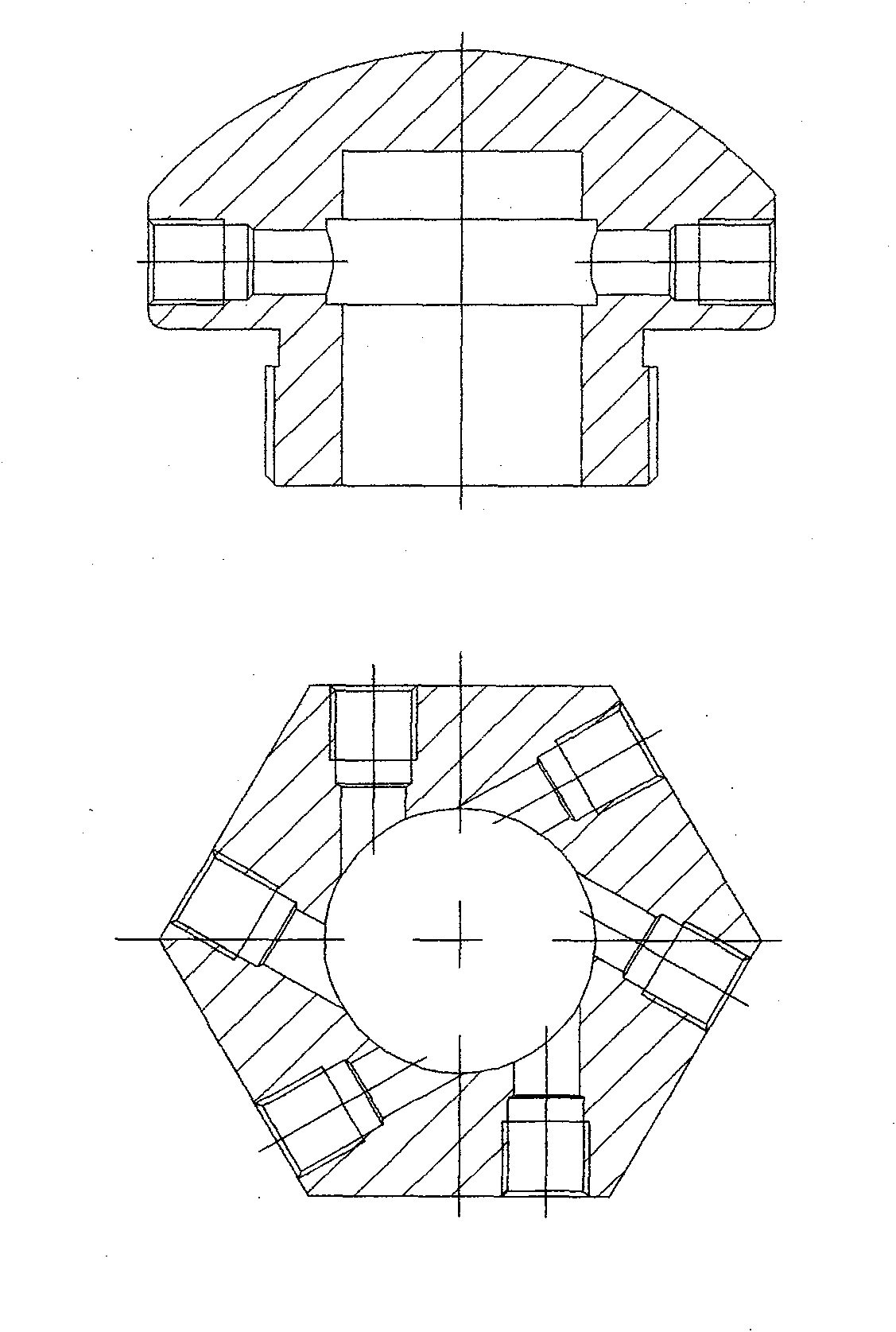

The invention relates to a rotary water mist sprayer which is usually installed outside protected facilities, at safety evacuation exits, air wells and the like. The rotary water mist sprayer adopts a structure of dual-way rolling balls and dual-way O-shaped rings and is shaped as a mushroom. When the rotary water mist sprayer works, a high-pressure water source enters a mandrel through a filter screen and arrives at each spray core and spray nozzle of the sprayer body, the water flow is atomized into fine water drops less than 120 mu m to be sprayed, and the eccentric reacting force generated by each spray nozzle enables the sprayer body to rotate around the mandrel, and the water mist is sprayed in complete 360 DEG C. The invention belongs to the fields of fire control isolation, protection cooling and elimination of infrared radiation and radar signature of protected facilities. The rotary water mist sprayer is provided with a lock plunger, a filter screen, the mandrel, the rolling balls, screws, the spray cores, the spray nozzles, the spray body and the O-shaped rings and is widely applied to military industry, electric power, chemical industry, aerospace, ships, metallurgy, undergrounds and tunnels.

Owner:上海南晓消防工程设备有限公司

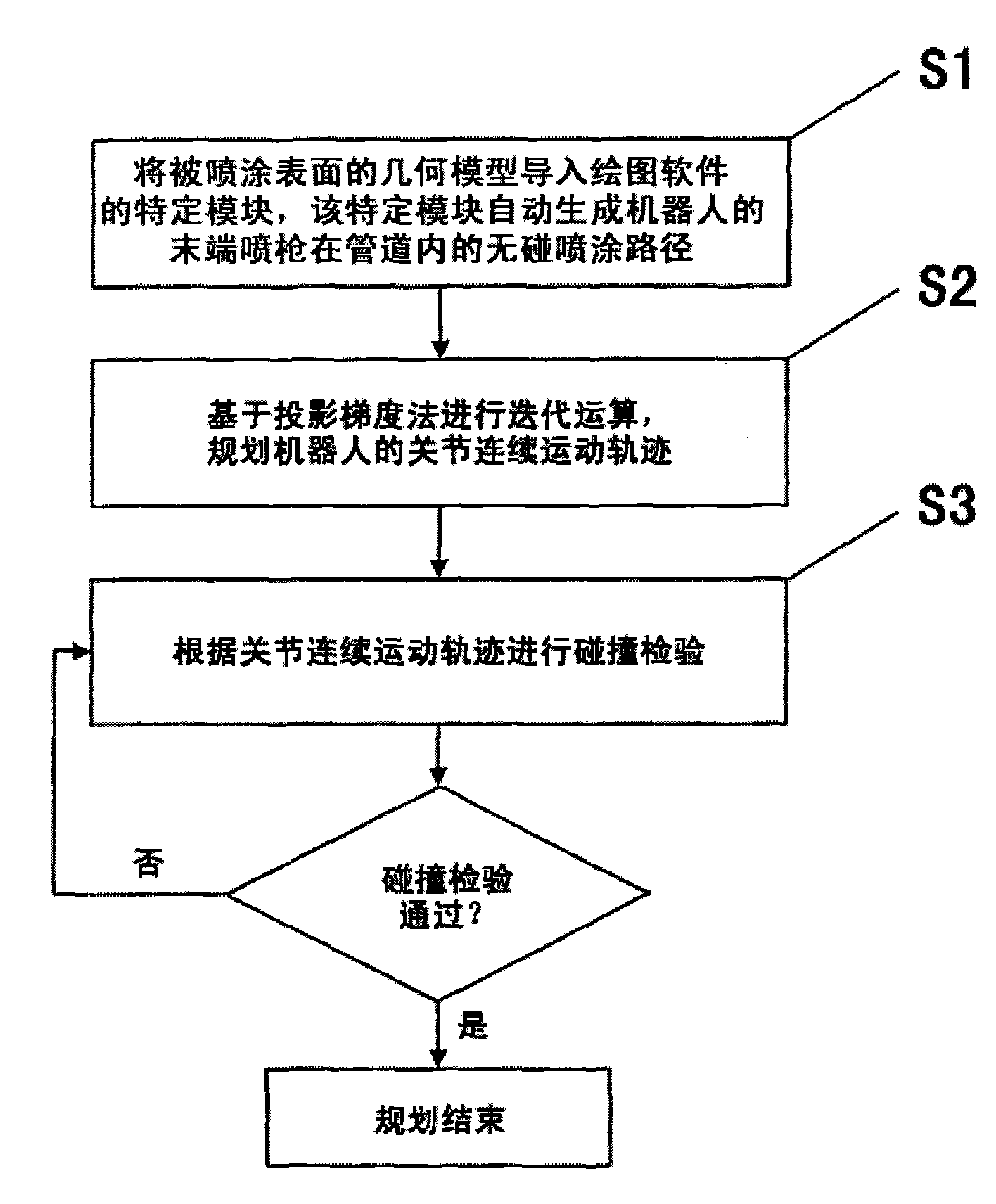

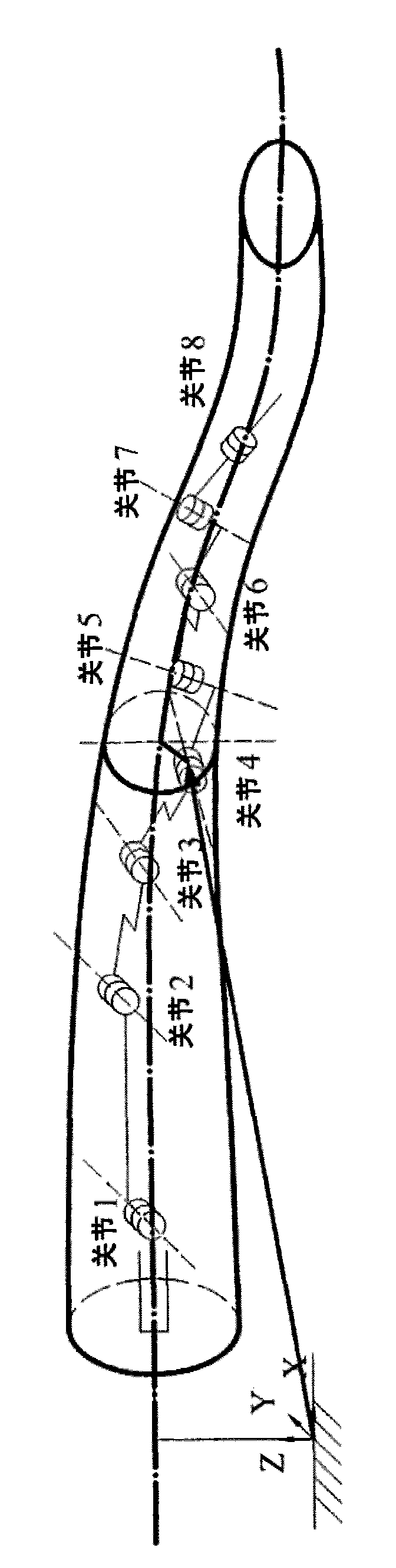

Pipeline spraying robot and operation track planning method thereof

InactiveCN101612734ASmall amount of calculationImprove spray qualityProgramme-controlled manipulatorSpraying apparatusAbnormal shapedEngineering

The invention discloses a pipeline spraying robot with multiple-redundant degree of freedom and an operation track planning method thereof. The method comprises the following steps: S1, a geometric mode of a sprayed surface is led into a specified module of a drawing software, the specified module automatically generates a no-touching spraying path of the spraying workpiece of the robot in the pipeline; S2, iterative operation is carried out based on a projection gradient method, and the continuous movement track of the joints of the robot is planned; S3, collision detection is carried out according to the continuous movement track of the joints, if colliding, the weighting coefficient of an optimization function is revised, and S2 is restarted to re-plan the continuous movement track of the joint; otherwise, planning ends. The method of the invention has small calculation amount, can ensure no wall collision occurs when the method is used for spraying the inner wall of a special-shaped long path after planning tracks, and has high spraying quality.

Owner:TSINGHUA UNIV +1

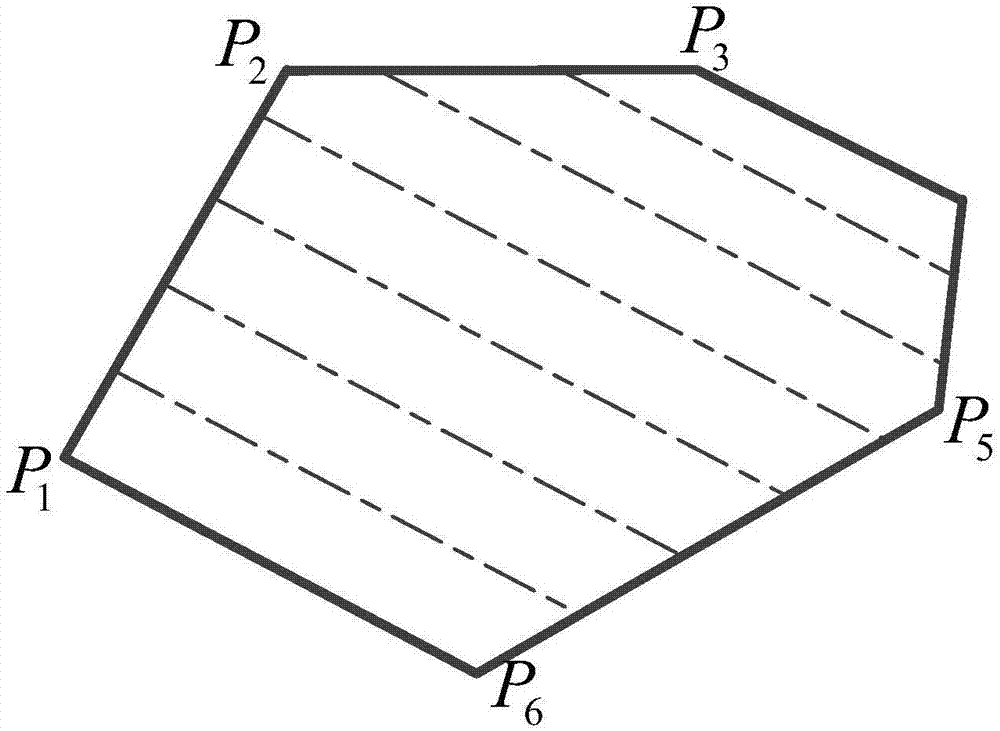

Autonomous path planning method for plant protection unmanned aerial vehicle

InactiveCN107992078AImprove the effect of prevention and controlSave human effortPosition/course control in three dimensionsUncrewed vehiclePlanning approach

The invention discloses an autonomous path planning method for a plant protection unmanned aerial vehicle. A spraying area of the unmanned aerial vehicle is given. After the unmanned aerial vehicle receives a spraying task, a to-be-sprayed area is divided into strip-shaped areas, a spraying path is planned, the unmanned aerial vehicle tracks the spraying path to carry out a spraying mission, complex earlier-stage preparatory work is not required before the unmanned aerial vehicle works, spraying work is performed according to the pre-planned path, overspray and missing spray and the like are avoided, pesticides are saved, the pest control effect is improved, and manpower is saved.

Owner:XIAN TANVEN INTELLIGENT TECH CO LTD

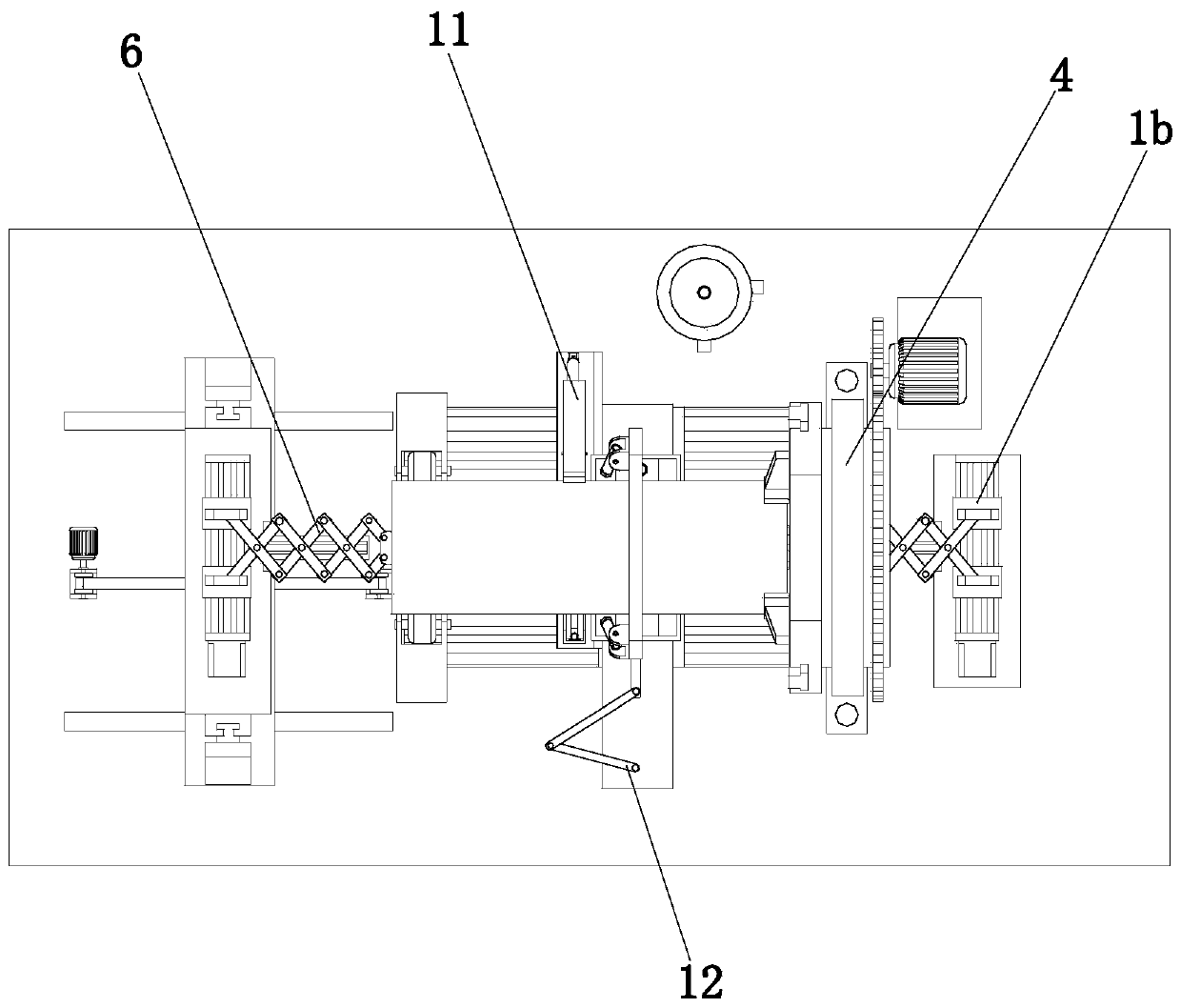

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

Liquid medicine sprayer with adjustable spraying angle for landscape garden maintenance

InactiveCN107361045ASpray evenlyReduce labor intensityTransportation and packagingRotary stirring mixersSprayerEngineering

The invention discloses a liquid medicine sprayer with an adjustable spraying angle for landscape garden maintenance, comprising a base, a liquid medicine box, a support platform, a support box body, a screw, a lifting sleeve, a fixed sleeve, a swing rod and a nozzle; the screw is rotationally arranged in the support box body the lifting sleeve sleeves the screw in threaded connection manner, first fixed connecting rods are fixedly and symmetrically welded to two ends of the lifting sleeve, the fixed sleeve is fixedly mounted on the lower surface of the middle of a top plate of the support box body, second fixed connecting rods are fixedly and symmetrically welded to two ends of the fixed sleeve, the top end of the swing rod is hinged to the first fixed connecting rods through via holes, the nozzle is arranged at the bottom end of the swing rod, and the middle of the swing rod is connected to the second fixed connecting rods through movable connecting rods. The liquid medicine sprayer is simple in structure and convenient to move, allows liquid medicine to be mixed well, enables the spraying angle of liquid medicine to be conveniently adjusted, has an adjustable spraying range and good spraying uniformity, and is suitable for popularization and use.

Owner:广西东创智能科技有限公司

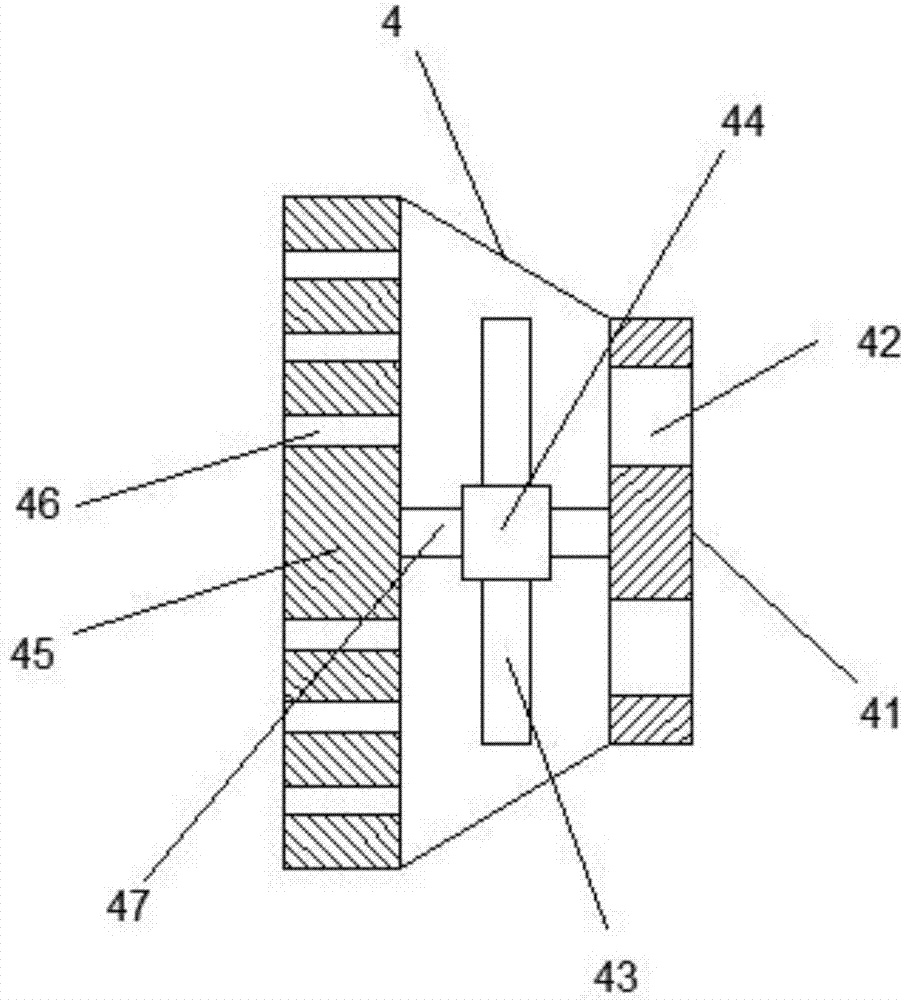

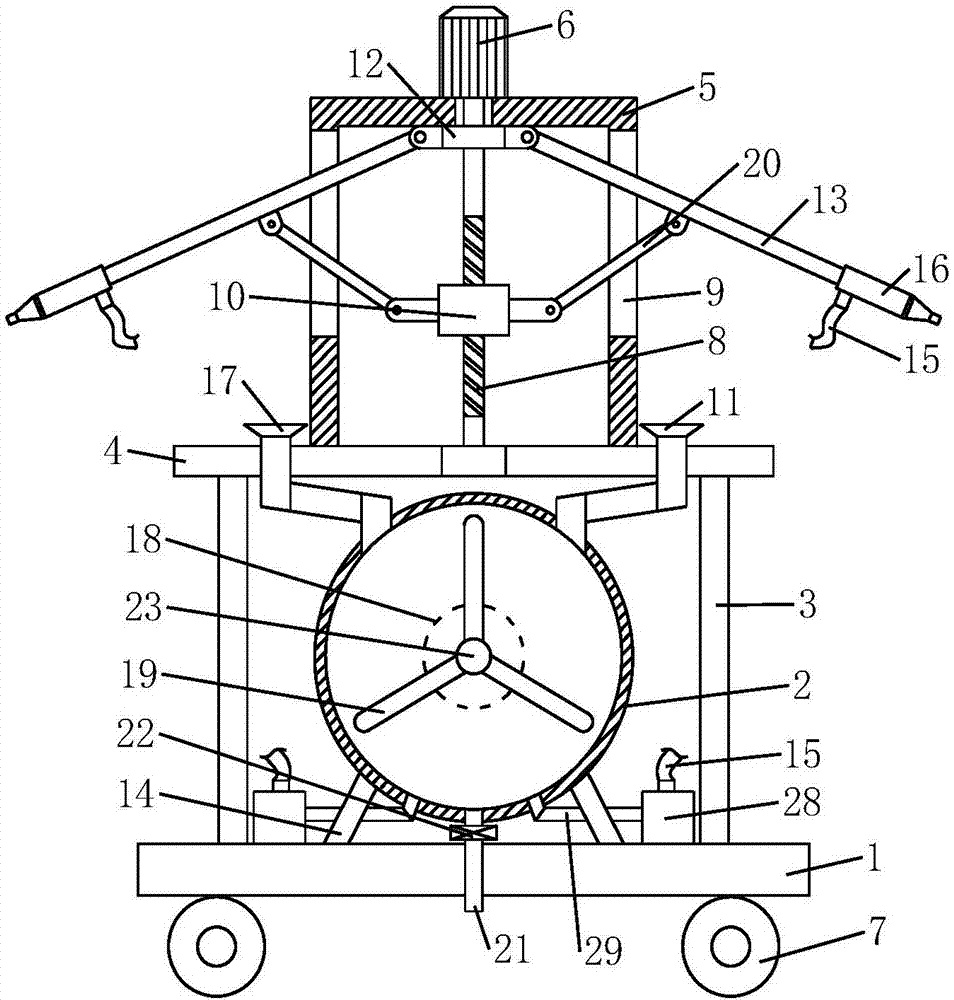

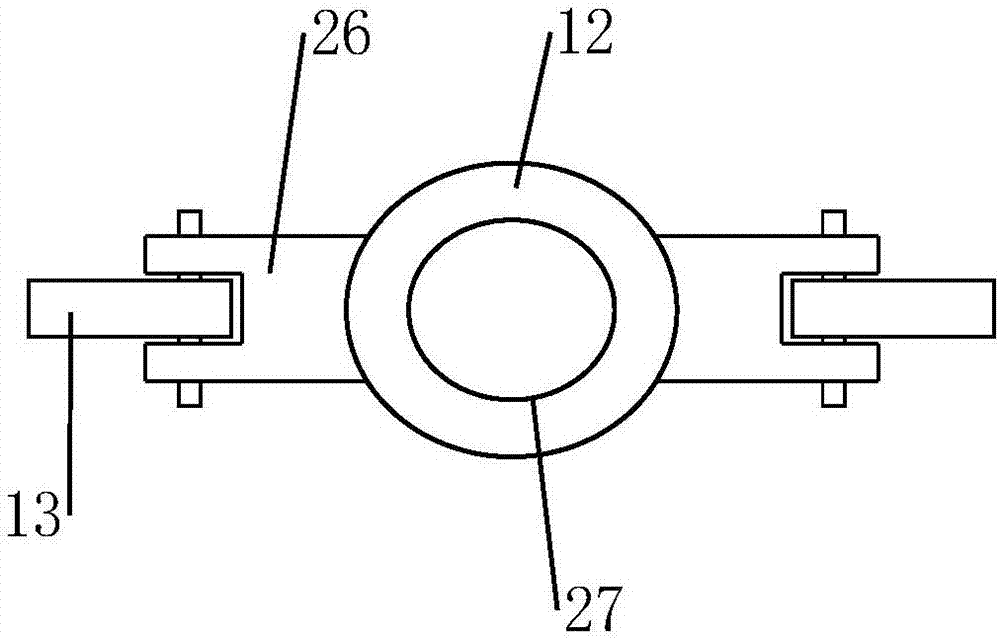

Garden whitewashing machine

InactiveCN101722130ALittle effect on healthSpray evenlyLiquid surface applicatorsSpraying apparatusSEMI-CIRCLEAgricultural engineering

The invention discloses a garden whitewashing machine, comprising a coating device, a regulating device and an annular mounting bracket; wherein the coating device is arranged on the regulating device, the regulating device is arranged on the annular mounting bracket, the annular mounting bracket is composed of two semi-circle annular mounting brackets, and corresponding ends of the two semi-circle annular mounting brackets are hinged. The invention has simple operation, convenient use, uniform coating, high efficiency and low labour intensity, saves soup and has less influence on health of operator, thus being applicable to trees in different tree diameters and different soup spraying heights; the invention is easy to dismount and mount, also can be applied to coating on the surface of telegraph pole and other columnar objects, has good market prospect and is easy to popularize and use.

Owner:SHENZHEN LEIXIN LANDSCAPE & CONSTR CO LTD

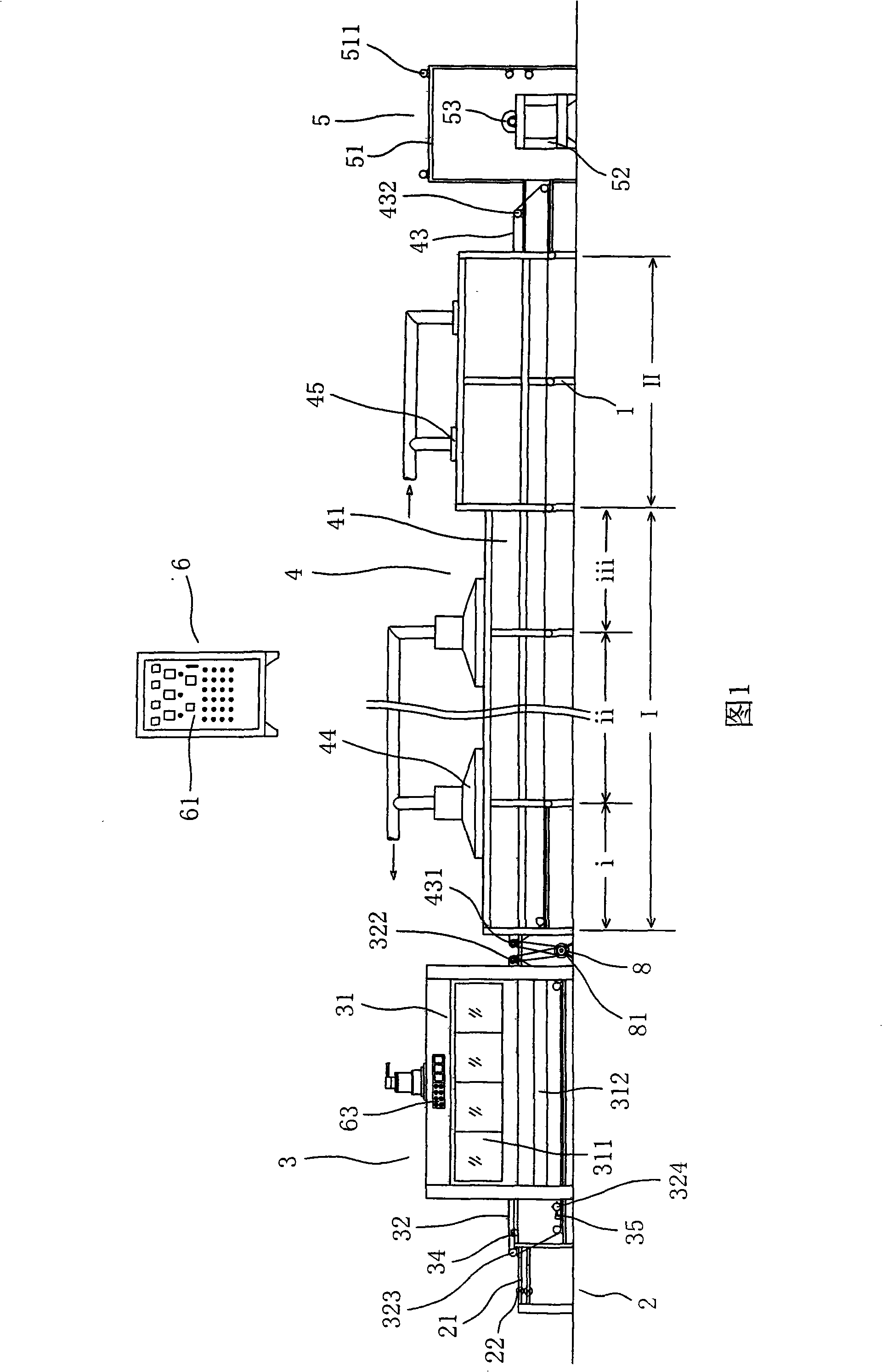

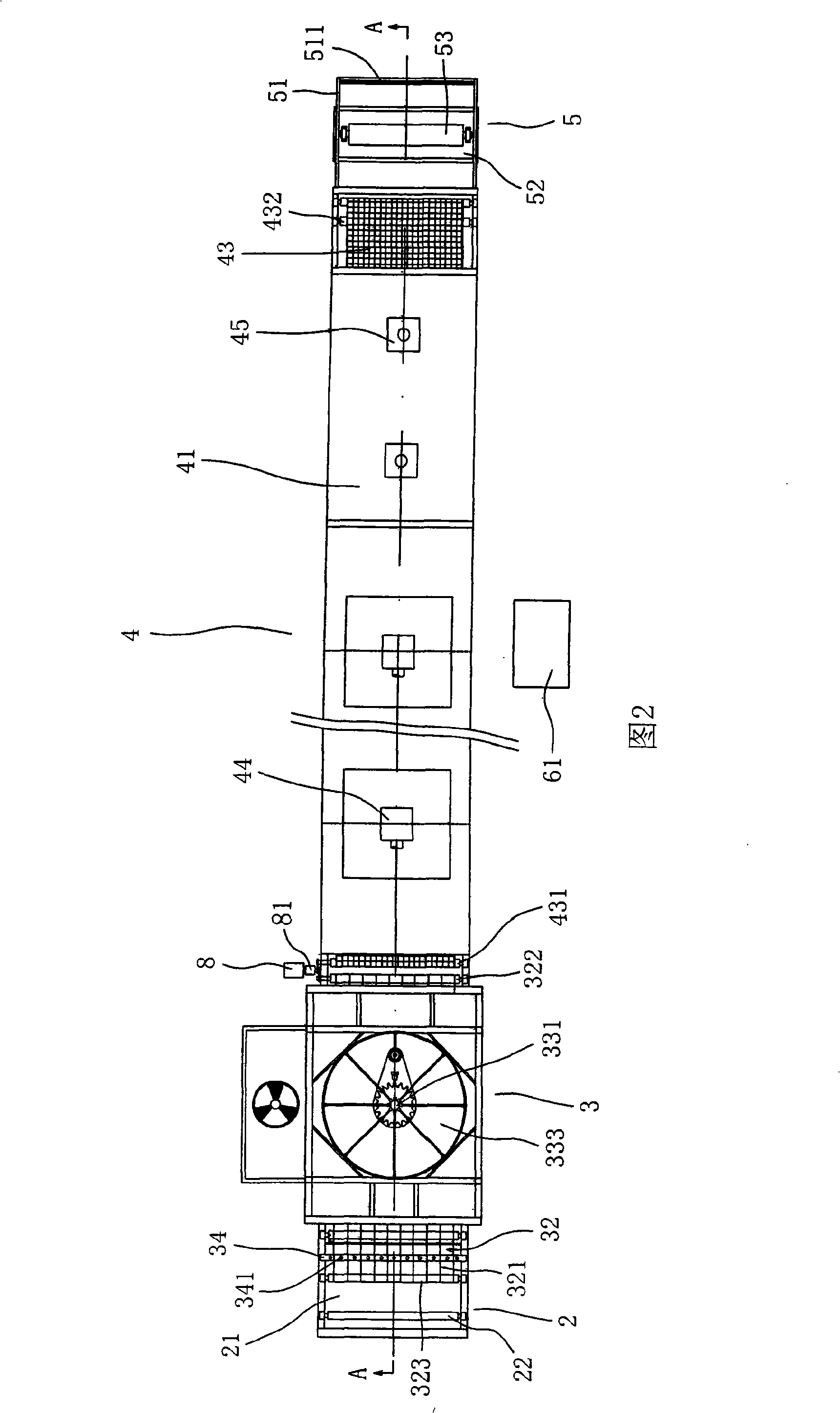

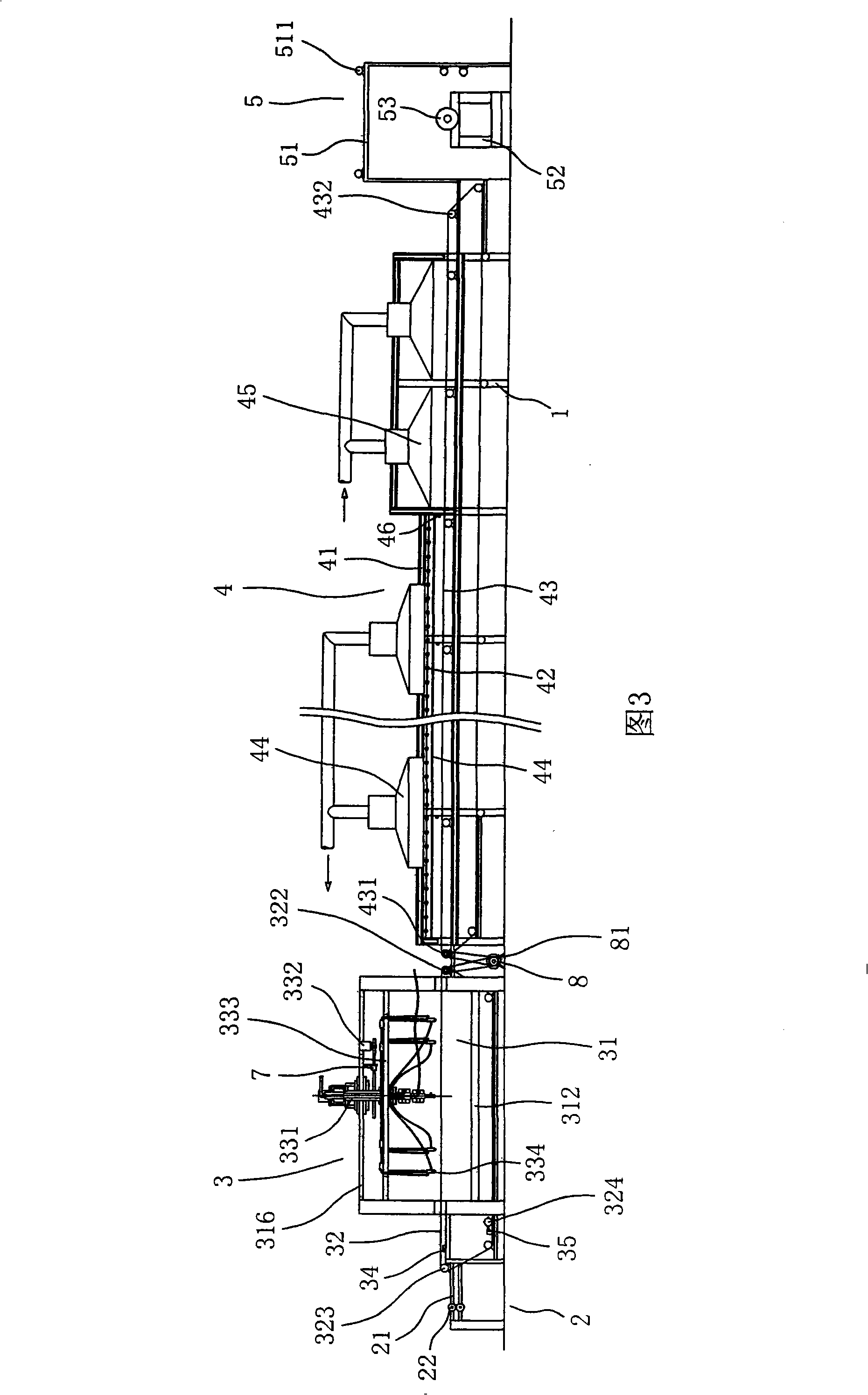

Swinging automatically spraying and drying machine

ActiveCN101406867ASpray evenlySpeed up dryingLiquid surface applicatorsDrying solid materials with heatEngineeringData processing

The invention provides a rotary type automatic spraying drier, which comprises a frame, as well as a feeding mechanism, a spraying system, a drying system, a receiving mechanism and a microcomputer control system which are arranged on the frame in sequence, wherein a spraying conveying belt of the spraying system accurately and evenly sprays a sprayed object through an automatic spraying pistol which rotates along the central rotating shaft; and a drying conveying belt continuously conveys the sprayed object to pass through a drying case which is provided with a drying area and a cooling area in time with even spraying, quick drying and low discharging temperature. Each drive mechanism is intensively controlled by a microcomputer data processing center CPU of the control system, so the rotary type automatic spraying drier has the advantages of high automation degree, great improvement of work efficiency, accurate spraying, paint conservation and cost reduction.

Owner:XTEPCHINA

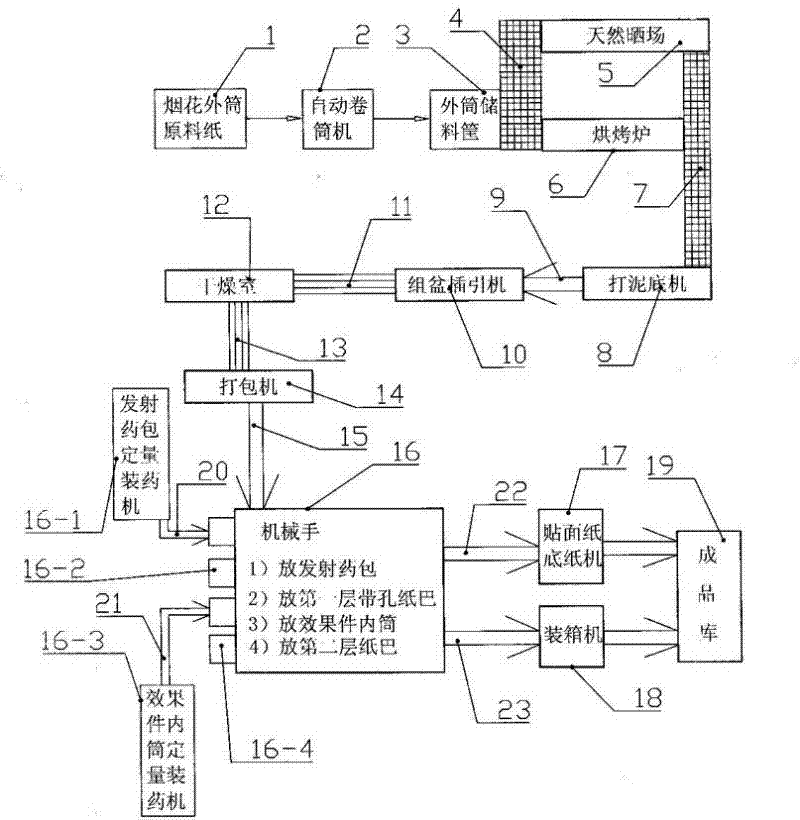

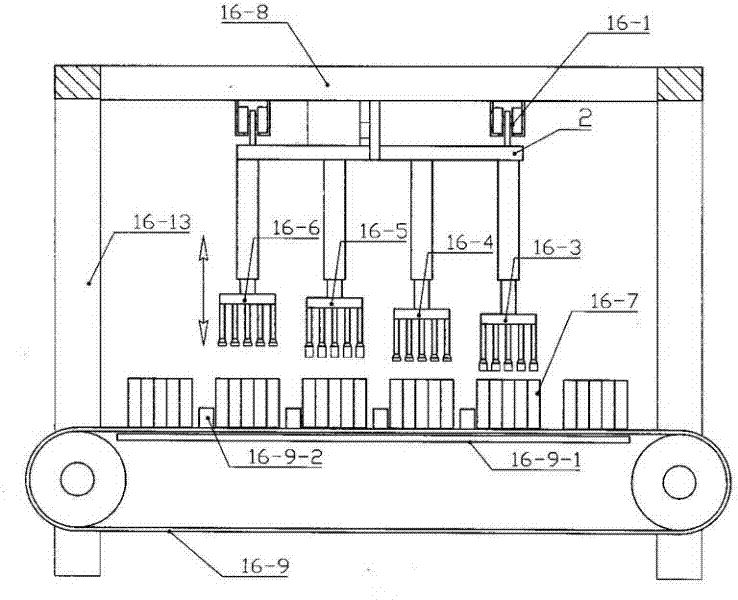

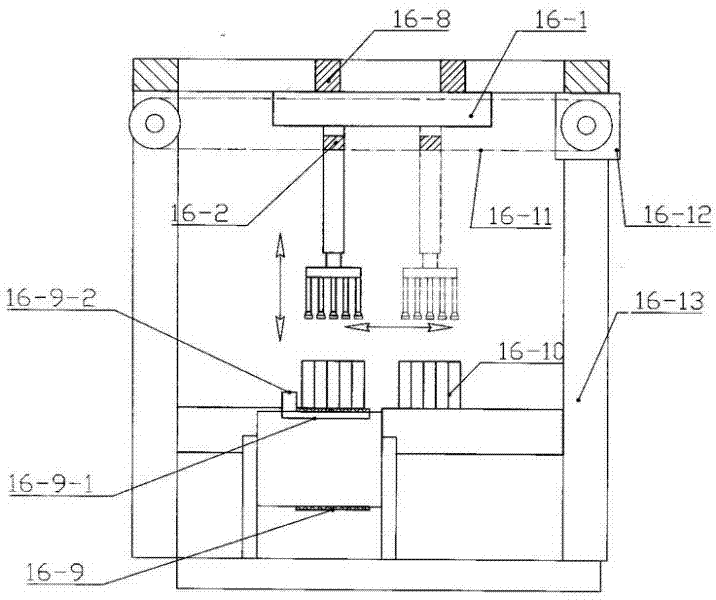

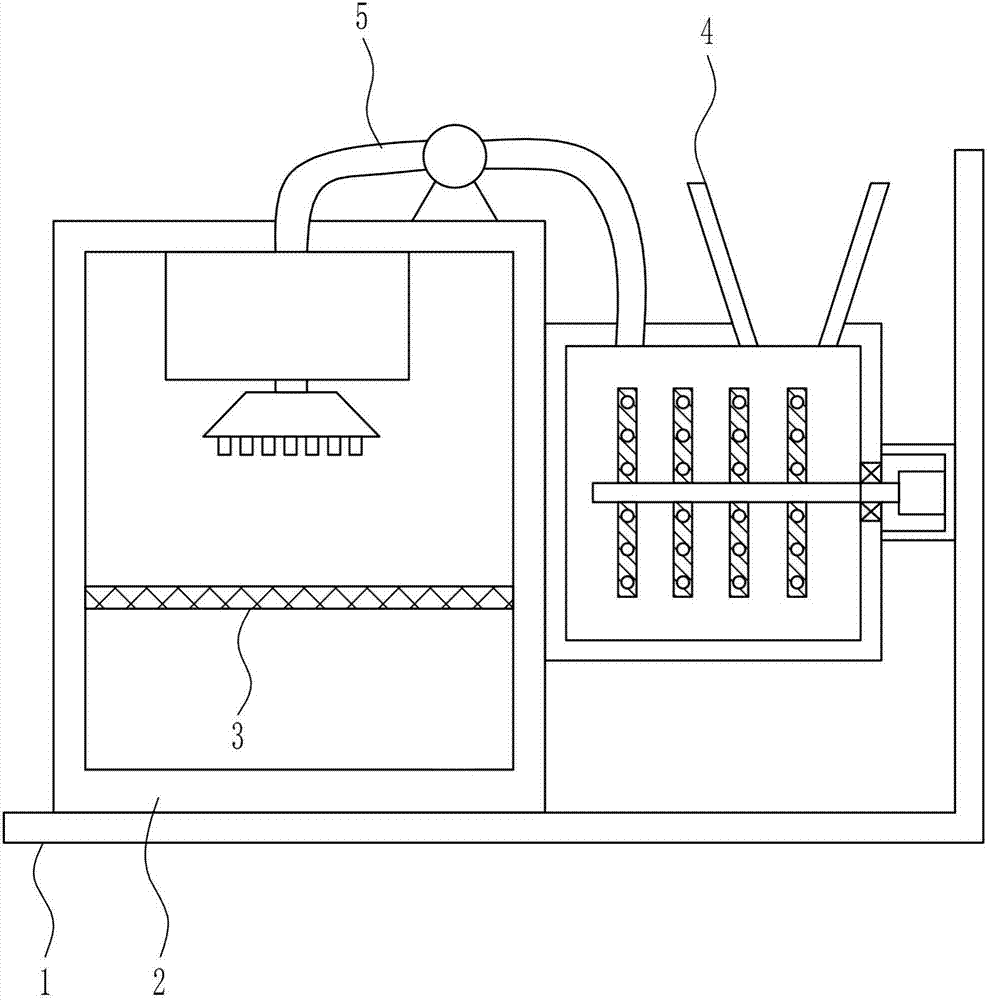

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

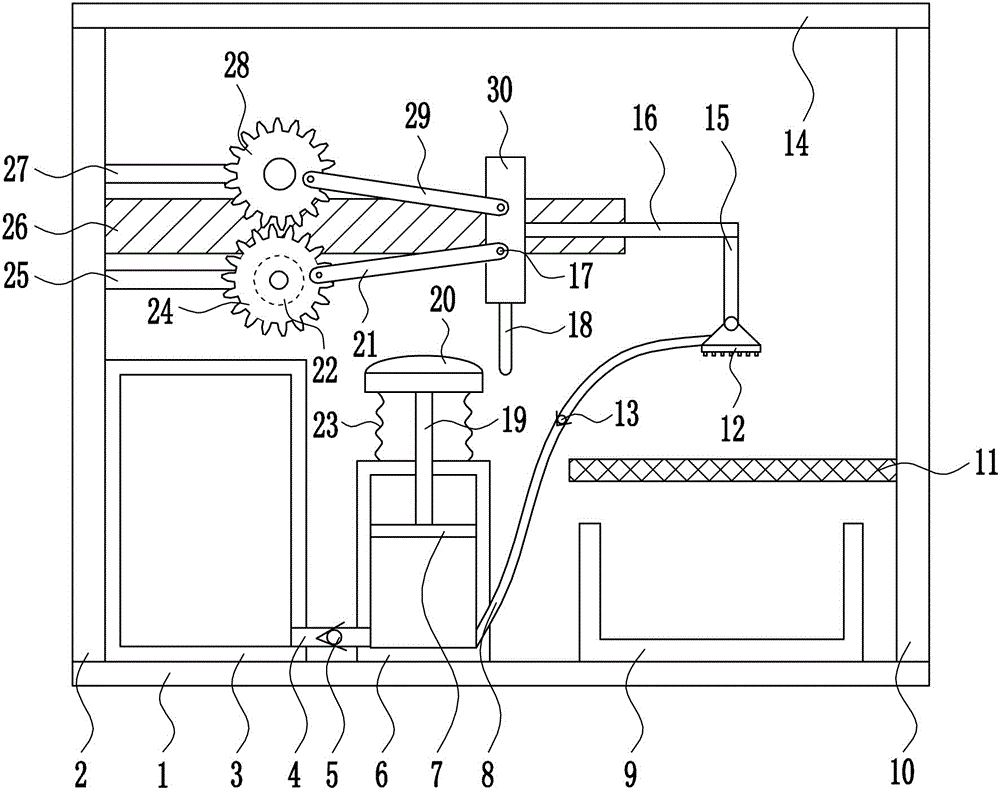

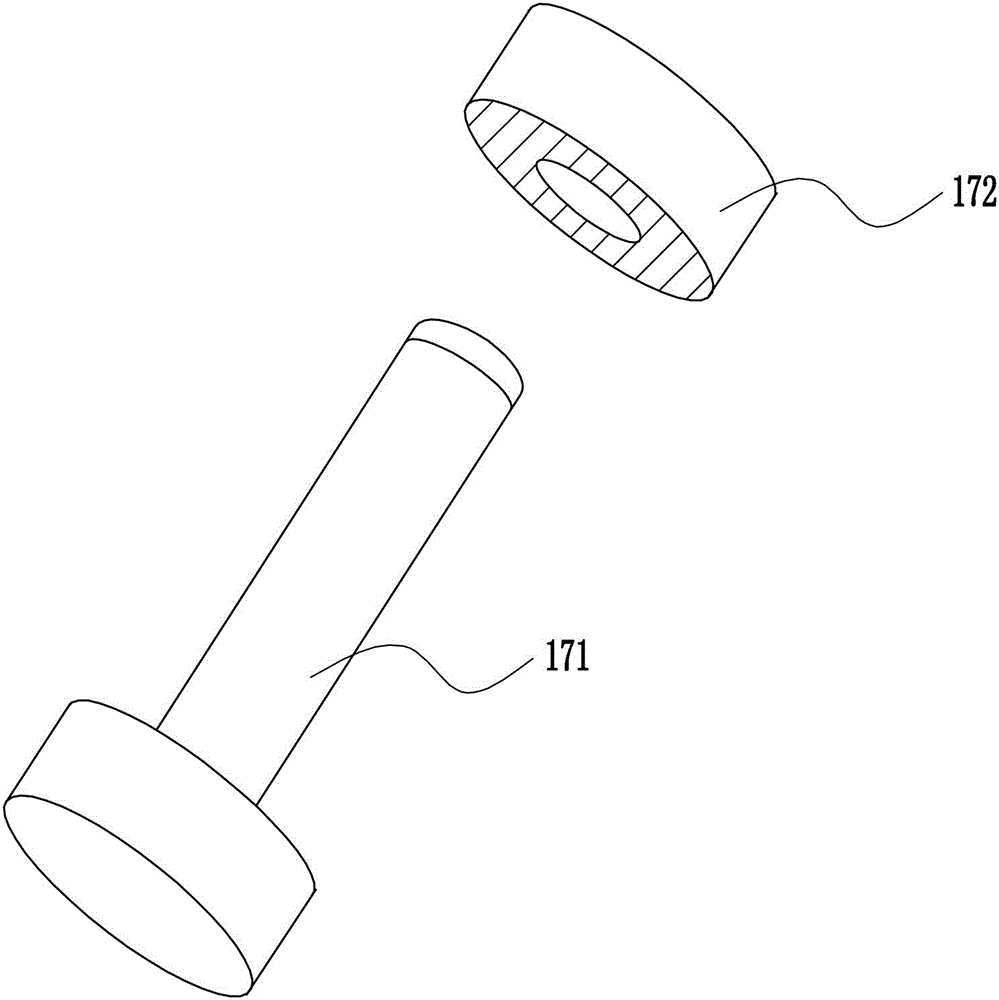

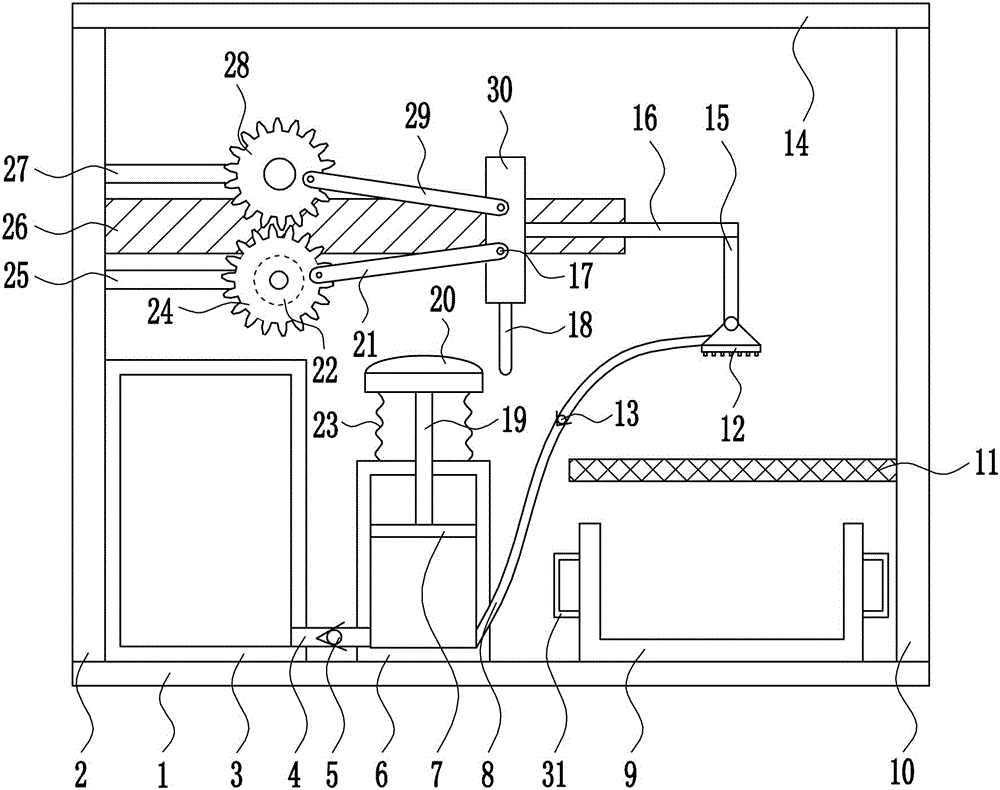

Coating spraying device for parts of agricultural machinery

InactiveCN107225065AStir wellImprove spraying effectLiquid surface applicatorsLiquid spraying apparatusAgricultural engineeringAgricultural machinery

The invention relates to a spraying device, in particular to a paint spraying device for parts and components of agricultural machinery. The technical problem to be solved by the present invention is to provide a paint spraying device for parts of agricultural machinery with high efficiency and good spraying effect. In order to solve the above-mentioned technical problems, the present invention provides such a paint spraying device for parts and components of agricultural machinery, including a bracket, etc.; The middle part of the side is connected with a stirring mechanism, the right side of the stirring mechanism is connected with the left wall of the bracket, the upper part of the spraying box is provided with a spraying mechanism, and the left side of the front part of the spraying box is connected with a box door through a hinge connection. The invention designs a paint spraying device for parts of agricultural machinery, which is provided with a stirring mechanism, which can stir the paint more fully, so that the spraying effect of the parts is better, and is provided with a spraying mechanism.

Owner:刘万忠

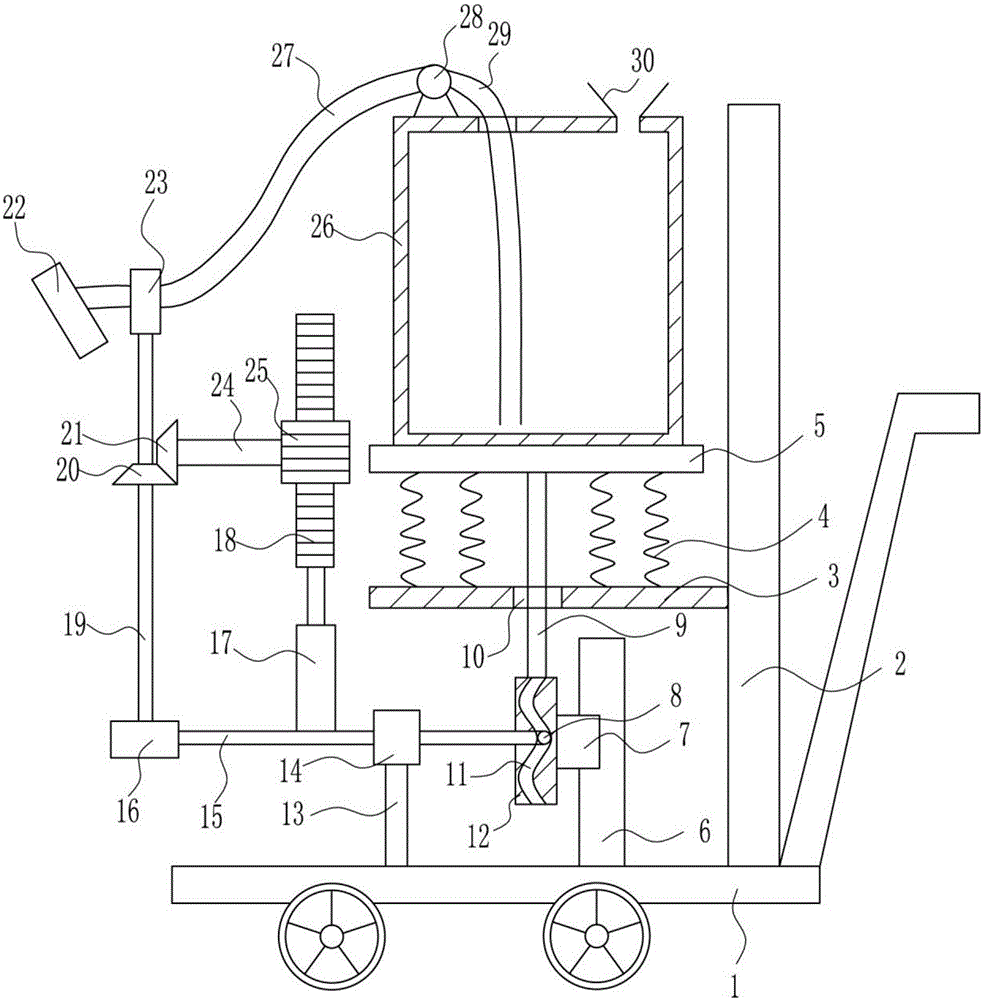

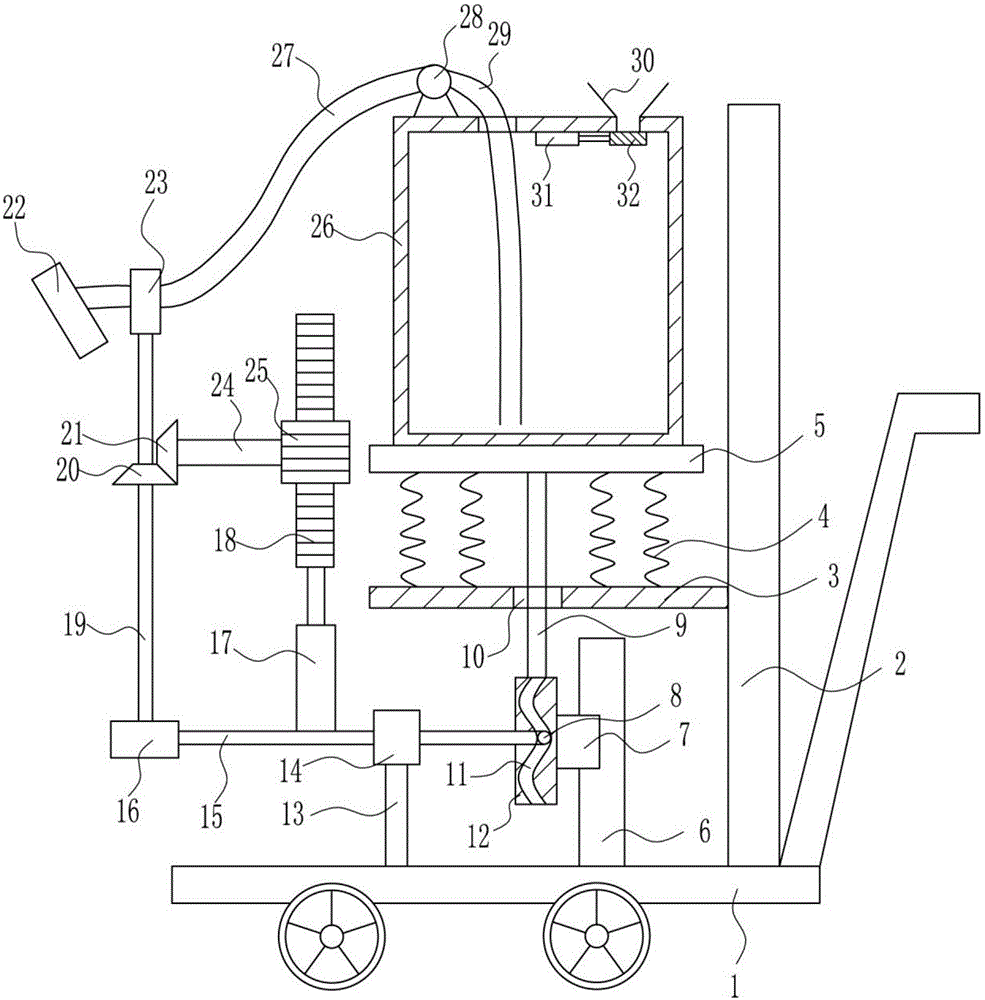

Efficient pesticide spraying device for pineapple planting

The invention relates to a pesticide spraying device, in particular to an efficient pesticide spraying device for pineapple planting, aiming at providing an efficient pesticide spraying device, which is high in spraying efficiency, uniform in spraying, large in spray range and good in damping effect, for pineapple planting. In order to solve the technical problems, the invention provides the efficient pesticide spraying device for pineapple planting. The efficient pesticide spraying device comprises a trolley, a right side plate, a guide plate, a spring, a placement plate, a sliding rail, a sliding block, a rolling shaft, a lifting rod, a movable block, a support rod, a guide sleeve, a guide rod, a bearing seat, and the like, wherein the support rod, the sliding rail and the right side plate are sequentially arranged on the trolley from left to right; the guide plate is arranged in the middle of the left side of the right side plate, and a guide hole is formed in the guide plate. The efficient pesticide spraying device fully utilizes the energy of the up and down vibration, caused by the unevenness of the ground in a process of pushing the trolley on a farmland, of an iron pesticide box; due to the buffer action of the spring, a damping effect is achieved.

Owner:西双版纳昇辉农业科技有限公司

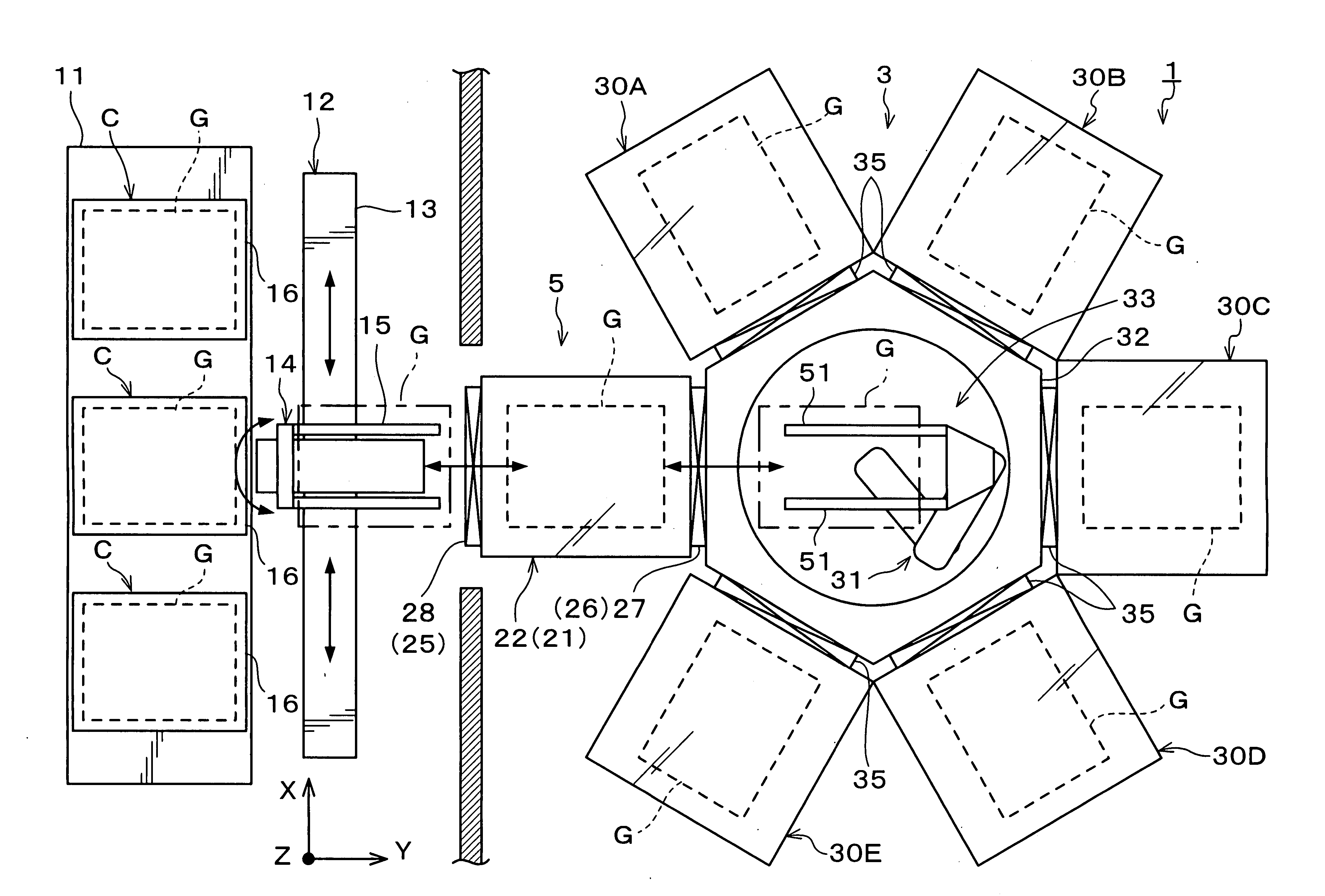

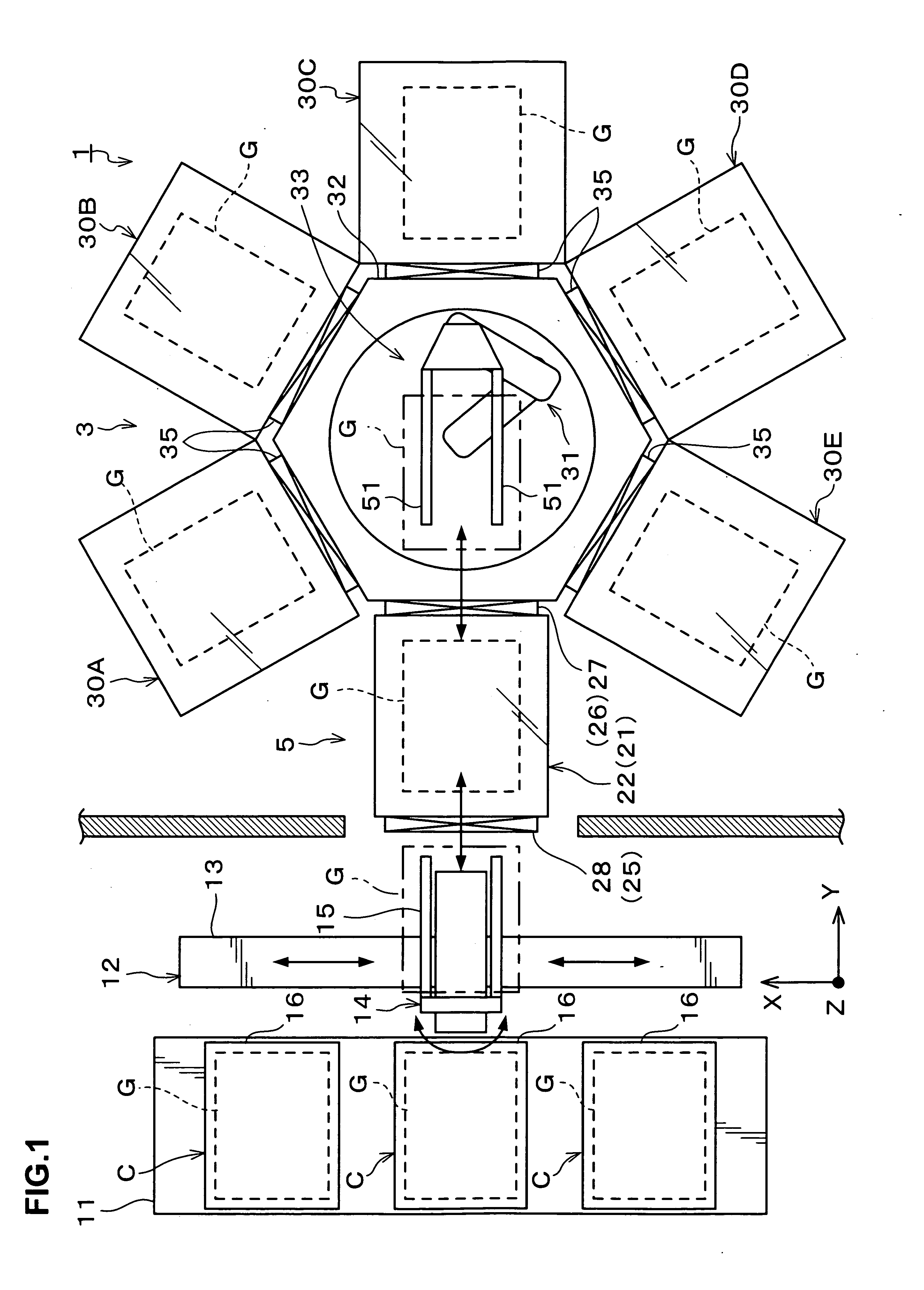

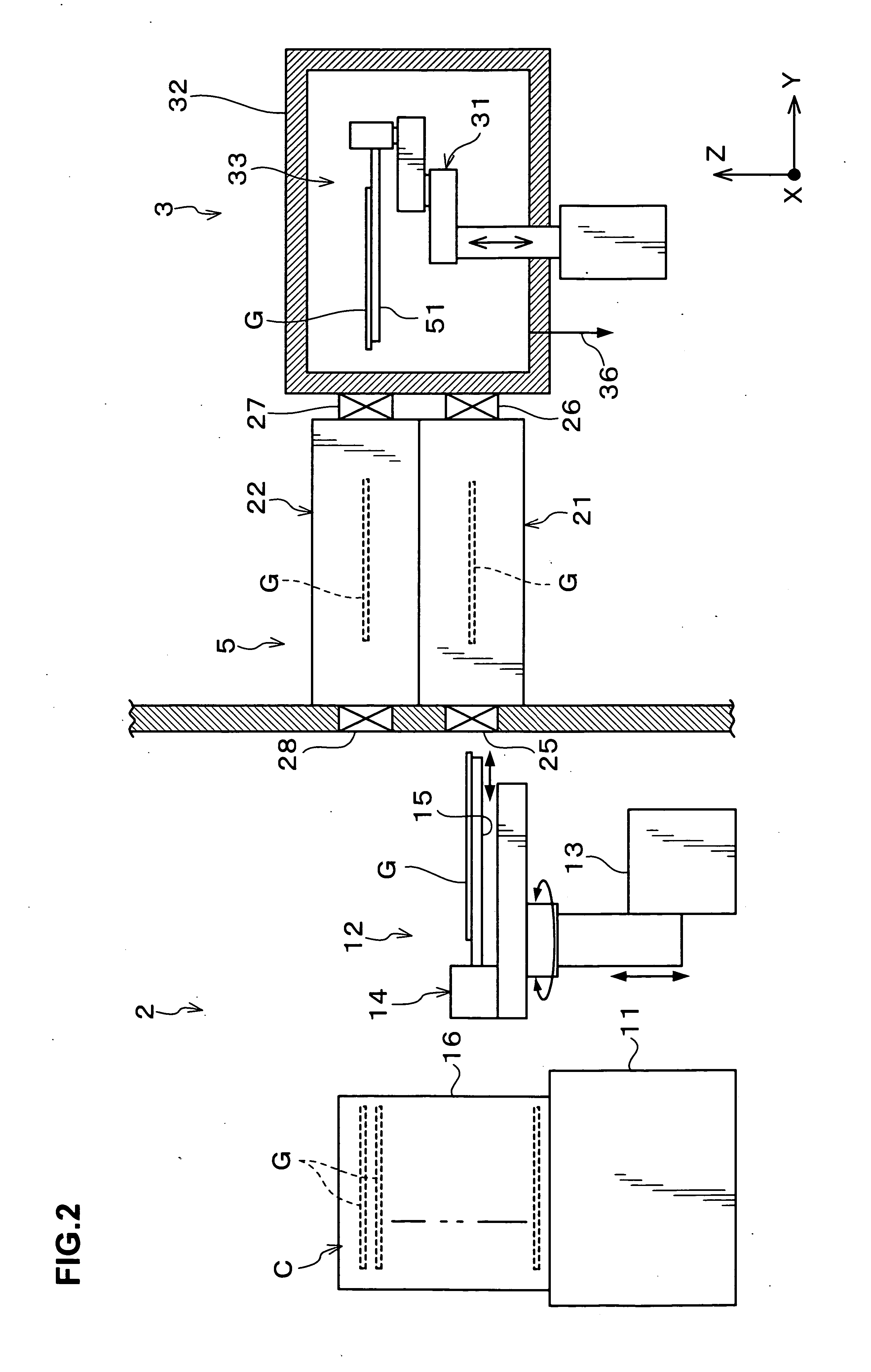

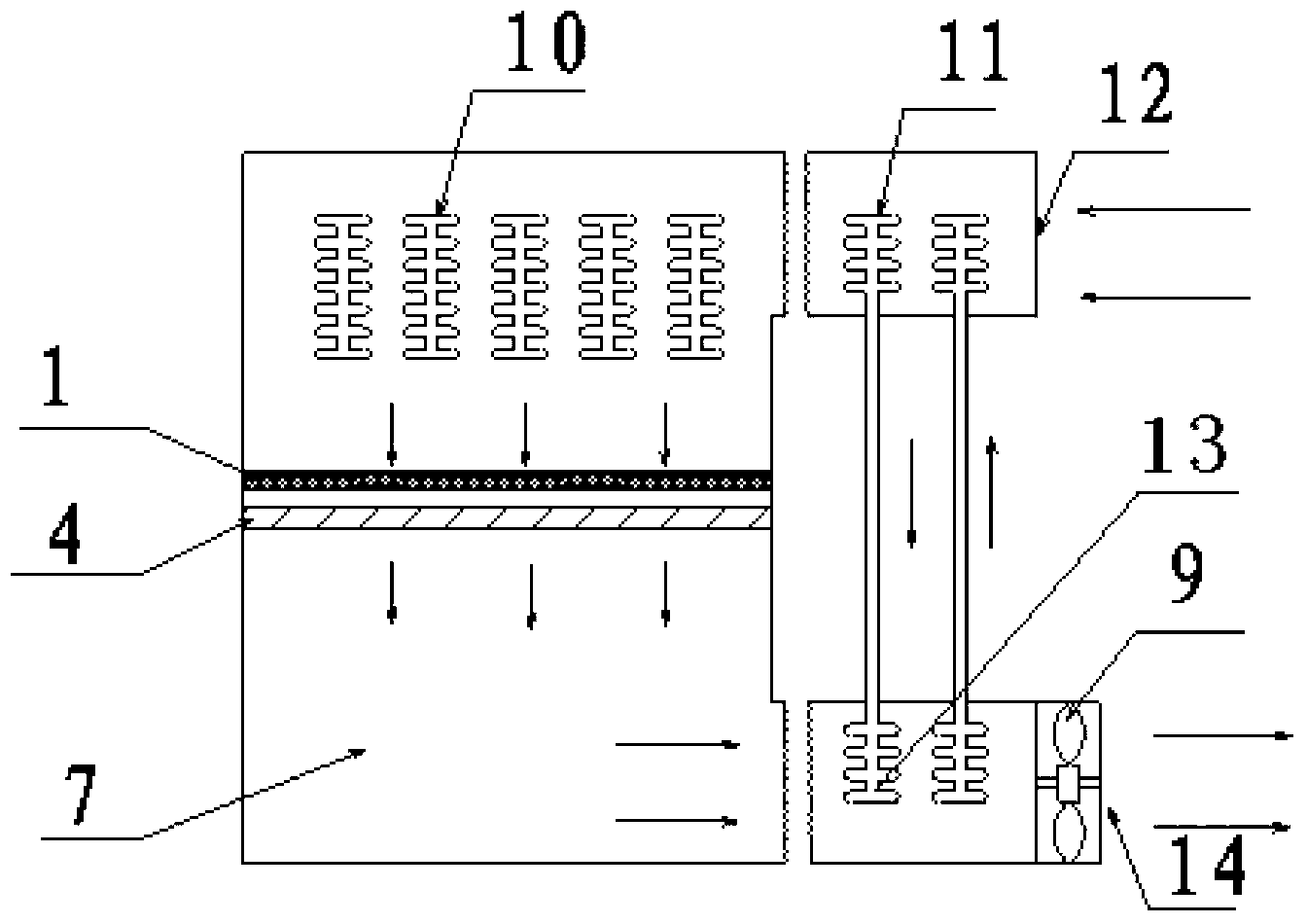

Load lock apparatus, processing system and substrate processing method

InactiveUS20060231027A1Improve thermal conductivityEffective temperature controlLiquid fillingSemiconductor/solid-state device manufacturingTemperature controlEngineering

A load lock apparatus including a carry port provided on a side of a carry-in / out section for carrying a substrate in / out from / to the outside, and a carry port provided on a side of a processing section for processing the substrate, includes: a temperature controlling plate for controlling a temperature of the substrate, the temperature controlling plate configured including a plate body made of a porous material and a temperature controlling gas supply path for supplying a temperature controlling gas controlled in temperature to the plate body. The temperature controlling gas passes through the plate body, blows out from a surface of the plate body, and is supplied to the substrate.

Owner:TOKYO ELECTRON LTD

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

Extruded hard pellet feed for lactating sows and preparation method thereof

ActiveCN102524582AFully gelatinizedImprove digestibilityFeeding-stuffAnimal feeding stuffAnimal scienceRapeseed

The invention discloses an extruded hard pellet feed for lactating sows, which is prepared by the following raw materials in parts by weight: 50-55 parts of corn, 3-4.5 parts of imported super steam fish meal, 3-5 parts of fermented soya bean meal, 8-10 parts of flour, 10-15 parts of wheat, 13.5-15.1 parts of non-transgenic soya bean, 2-4 parts of rapeseed meal, 5-10 parts of extruded-soybean, 1-2 parts of mineral substance premix, 0.2-0.3 parts of vitamins premix, 1.0-2.0 parts of calcium hydrogen phosphate, 2.5-4 parts of soybean oil, 1-2 parts of calcium propionate and 0.1-0.2 parts of oligosaccharide. The extruded hard pellet feed is prepared by tempering the raw materials in the formula by using a double-shaft squeezing well-done extruder under a certain condition and then curing under a certain curing condition. The crude protein of the extruded hard pellet feed is greater than 16.2%, the curing degree is above 80%, the extruded hard pellet feed has comprehensive nutrition and extrusion, the anti-nutrition factors are destroyed, and after the extruded hard pellet feed is used for feeding pregnant sows, the birth weights of piglets are above 1.6 kg in average.

Owner:安徽天邦饲料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com