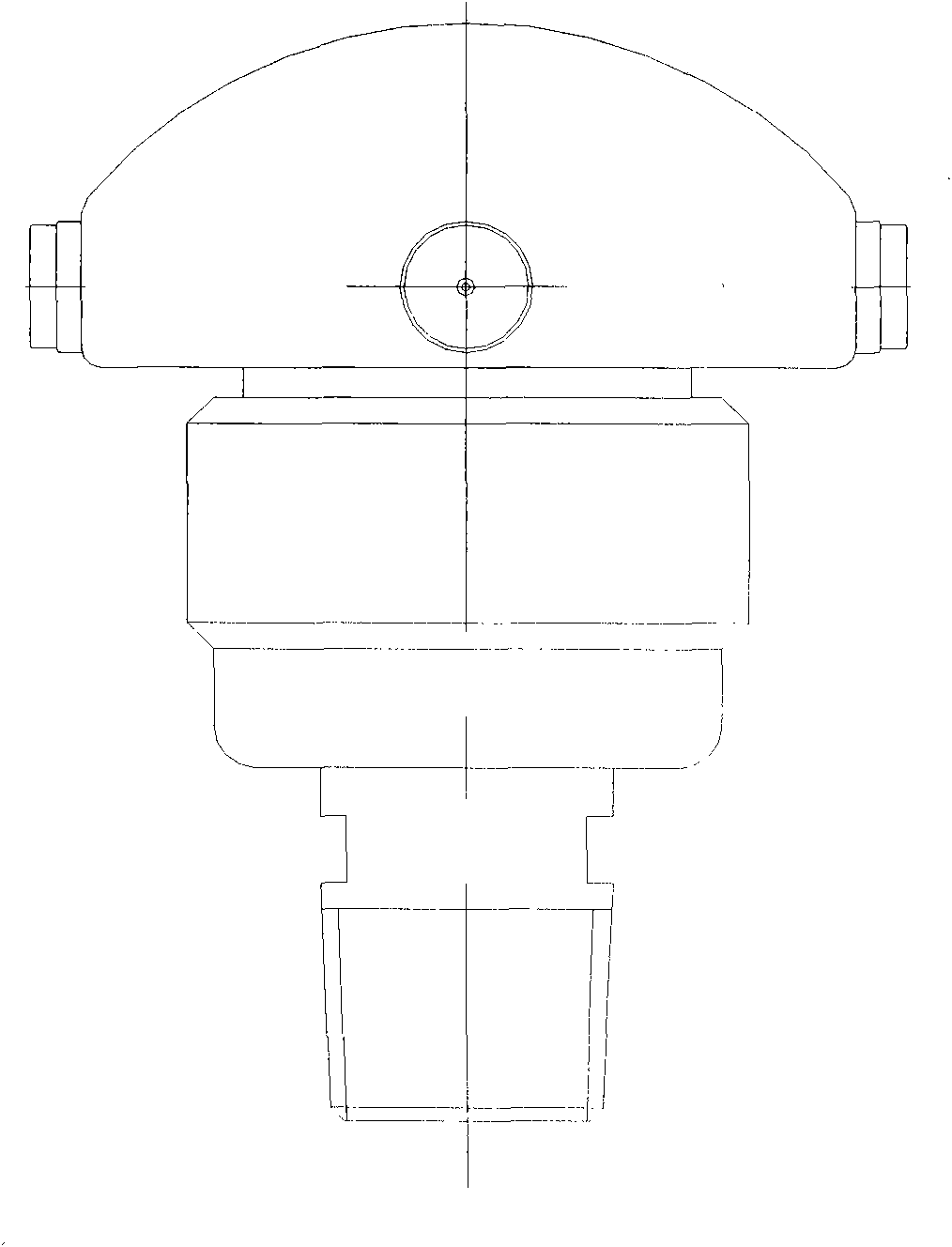

Rotary water mist sprayer

A fine water mist nozzle and fine water mist technology, applied in fire rescue and other directions, can solve the problems of thick spray droplets, large water consumption, uneven spraying, etc., and achieve rapid heat absorption and vaporization, attenuation of heat radiation, and uniform spraying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

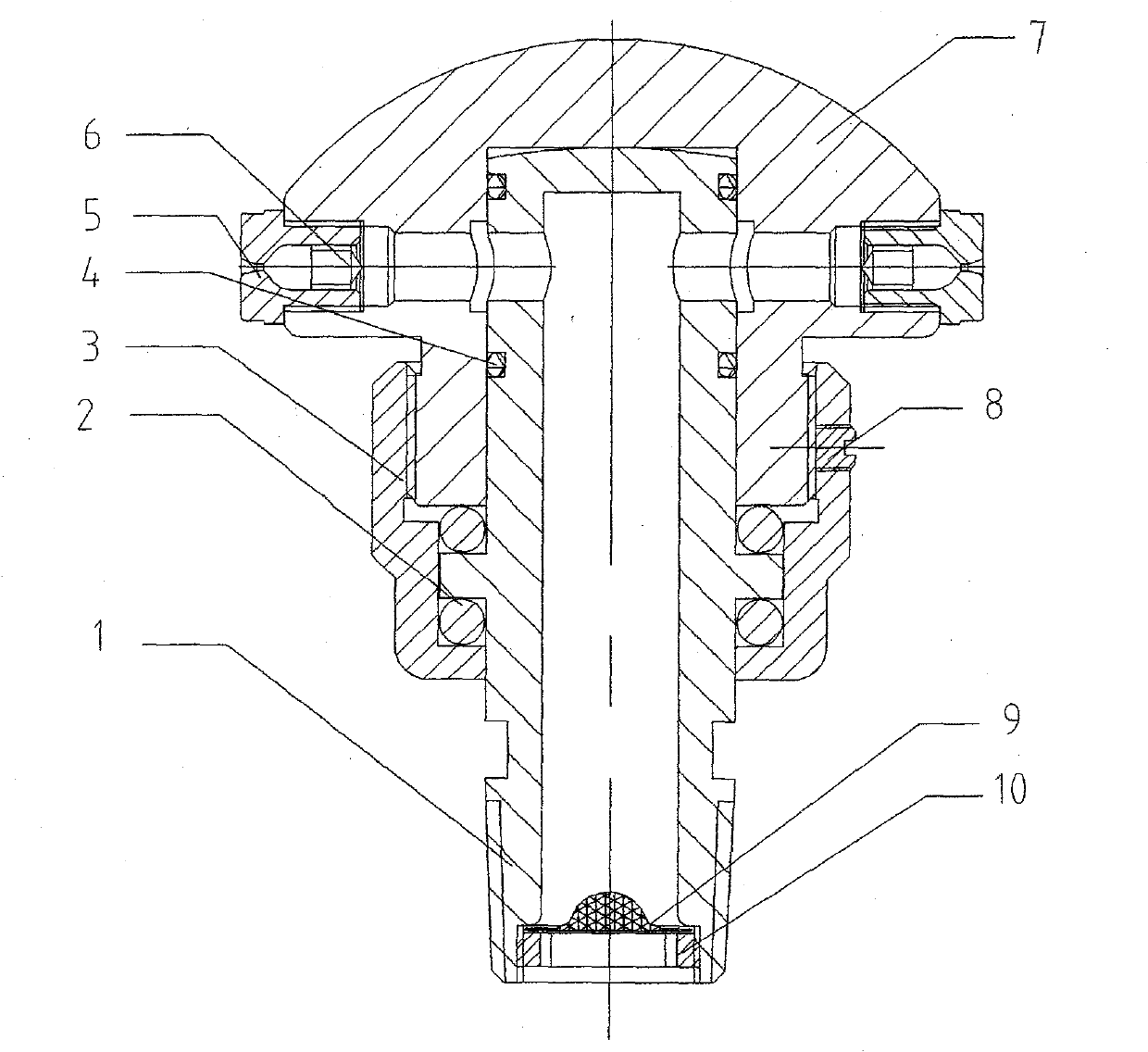

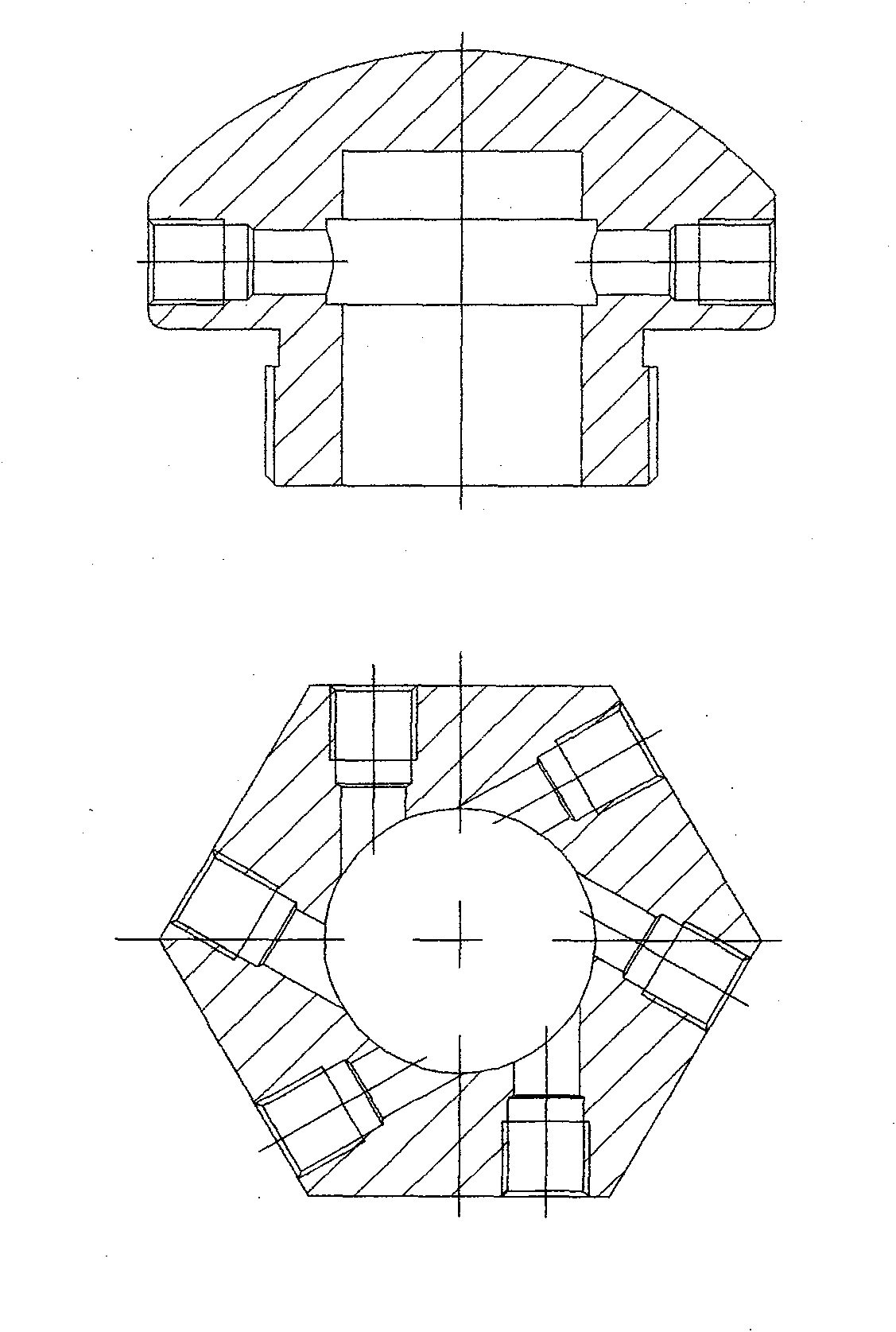

[0018] The spray core is embedded in the spray nozzle, the spray nozzle is screwed into the screw hole of the nozzle body, the mandrel is inserted into the nozzle body, and locked with a screw cover, and a filter screen is set at the water inlet of the mandrel. When spraying, high-pressure water flows through the filter screen and mandrel into each spray nozzle of the nozzle body for atomization and spraying; the tangential reaction force generated by each spray nozzle makes the nozzle body rotate to achieve 360° full coverage and uniform spraying. Effectively eliminate thermal radiation, infrared radiation and radar features of protected facilities; function of blocking hot air flow and harmful smoke.

[0019] 1) Material: 316L stainless steel is used for the atomizing core, screw cover, filter screen and ball; the locking bolt is made of copper alloy, and the surface is chrome-plated for anti-corrosion treatment; the mandrel, nozzle body and spray nozzle are made of titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com