Patents

Literature

632results about How to "Reduce heat radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

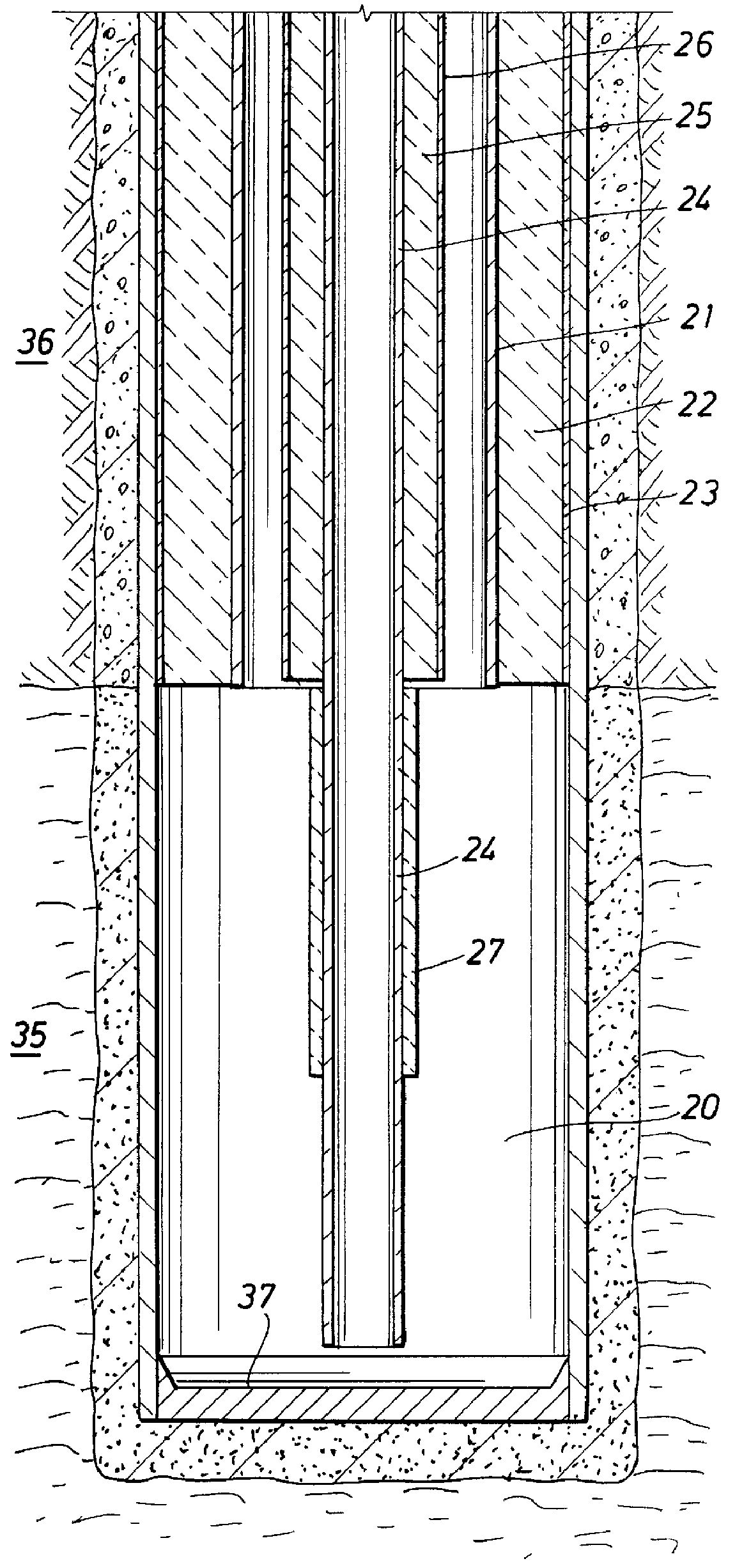

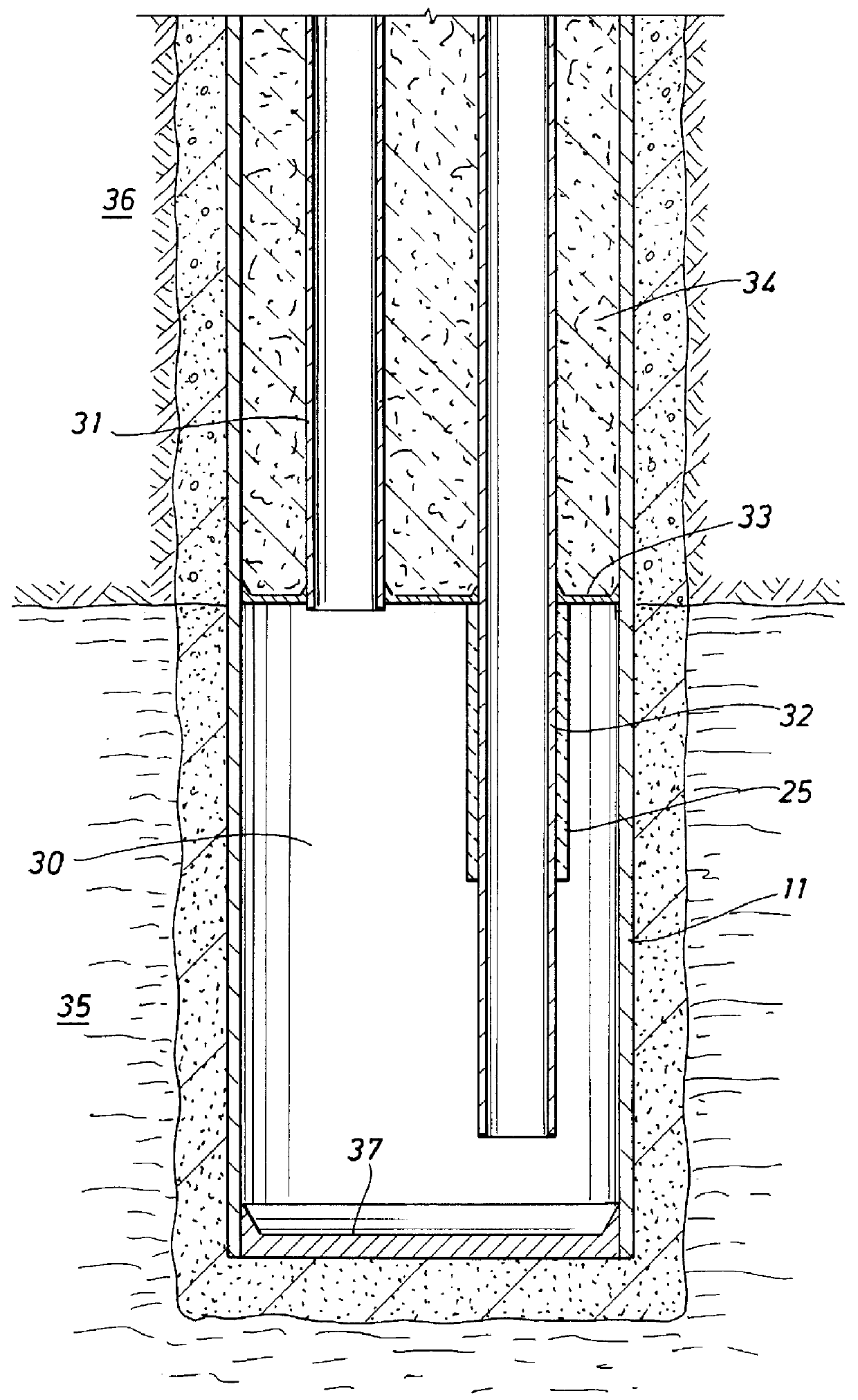

Heater well method and apparatus

InactiveUS6079499AImprove efficiencyImprove completenessInsulationFluid removalGeomorphologyWellbore

A method and apparatus is disclosed for heating of formations using fired heaters. The method includes the steps of: providing a wellbore within the formation to be heated, the wellbore comprising a casing within the formation to be heated, a tubular defining, in the inside of the tubular, a flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated, and a volume between the tubular and the casing providing a flowpath for hot gases from near the bottom of the formation to be heated to the top of the formation to be heated, wherein the flowpaths are in communication with each other near the bottom of the formation to be heated and the volume between the casing and the tubular at the top of the formation to be heated is in communication with a point above the surface, and insulation for a portion of the length of the wellbore within the formation to be heated between the flowpath for hot gases from the surface to the point in the wellbore near the bottom of the formation to be heated and the flowpath for hot gases from near the bottom of the formation to be heated to the surface; and supplying a flow of hot gases to the flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated.

Owner:SHELL OIL CO

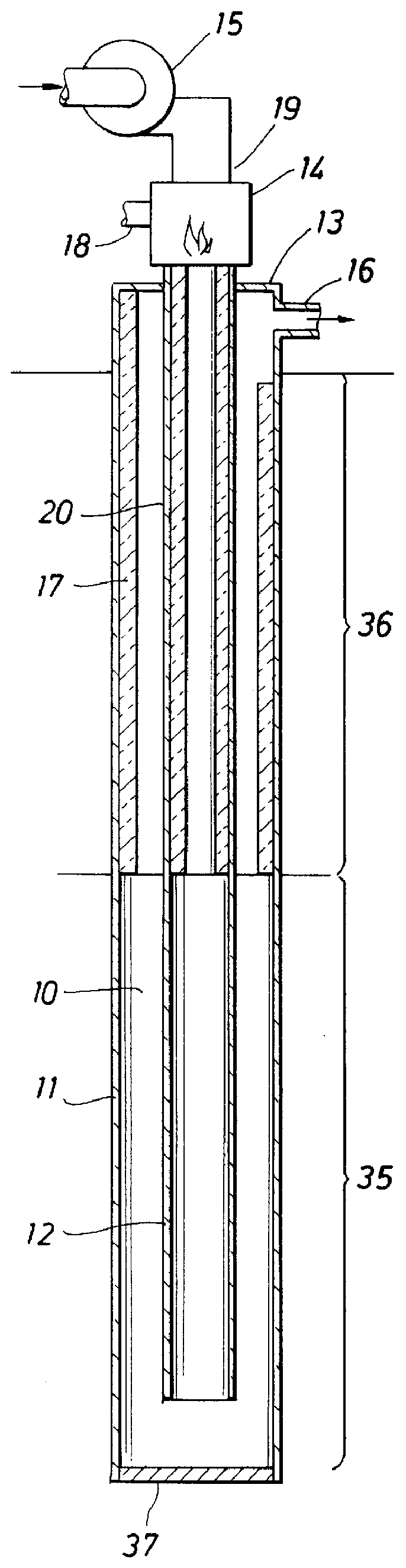

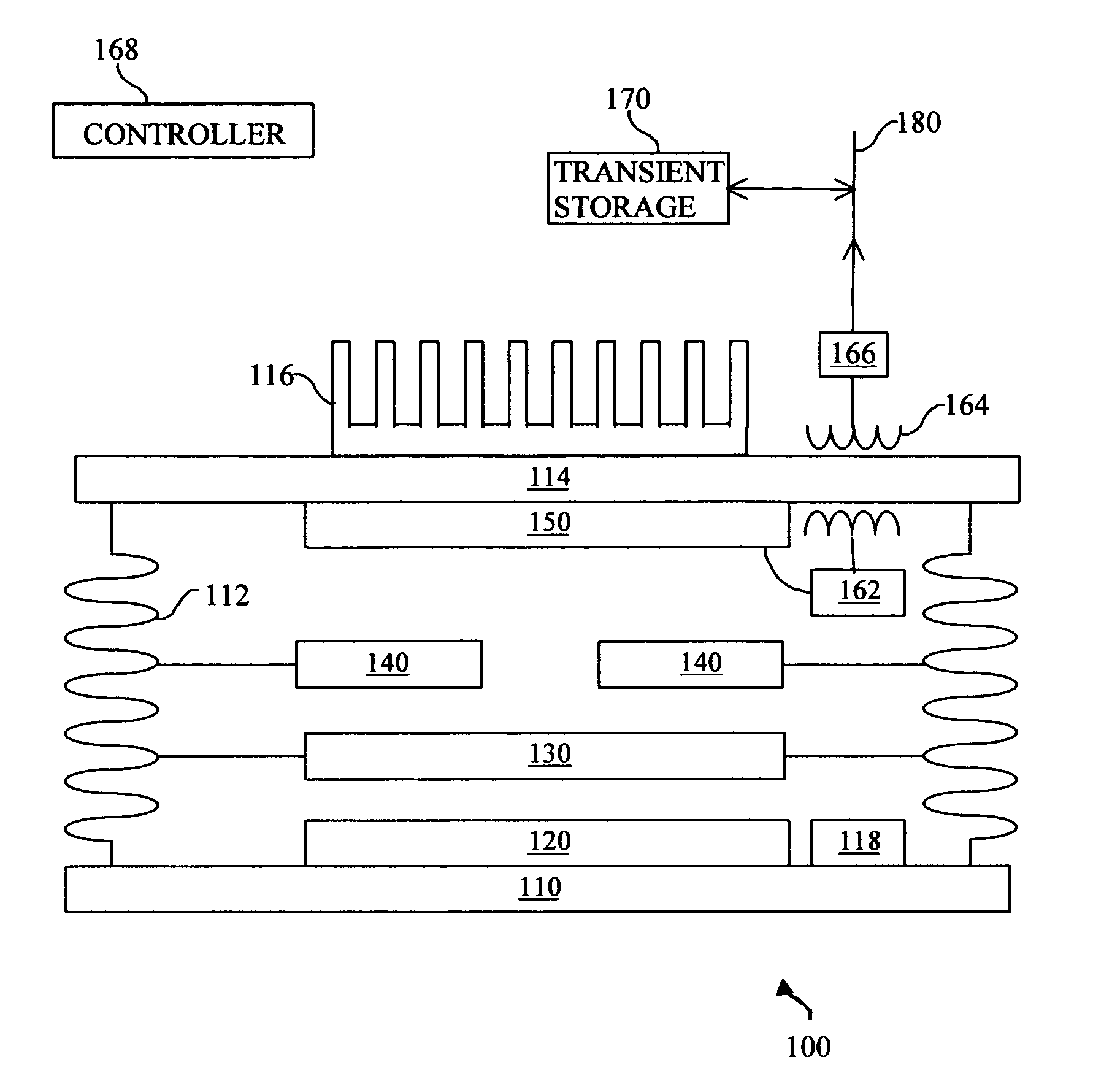

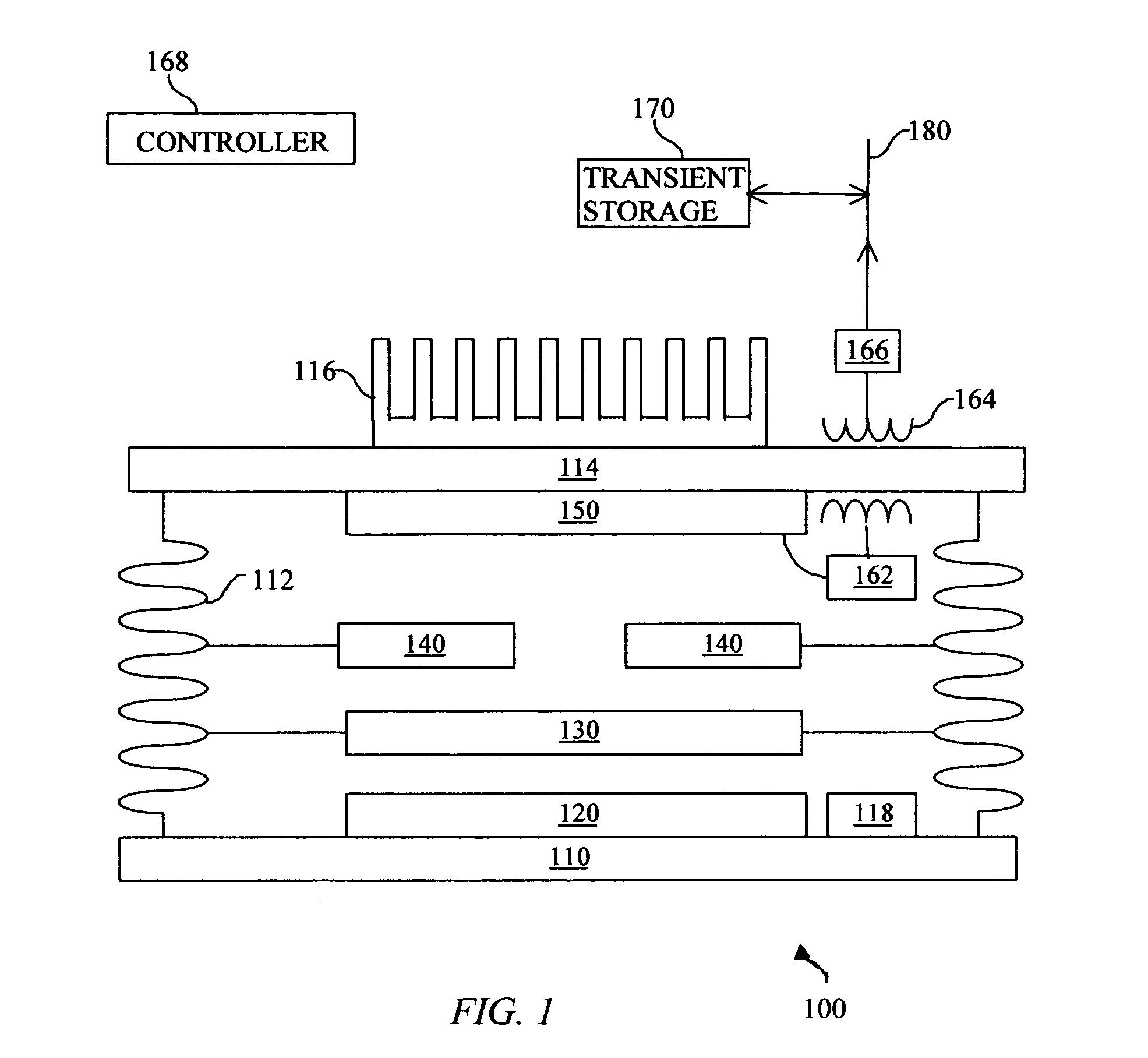

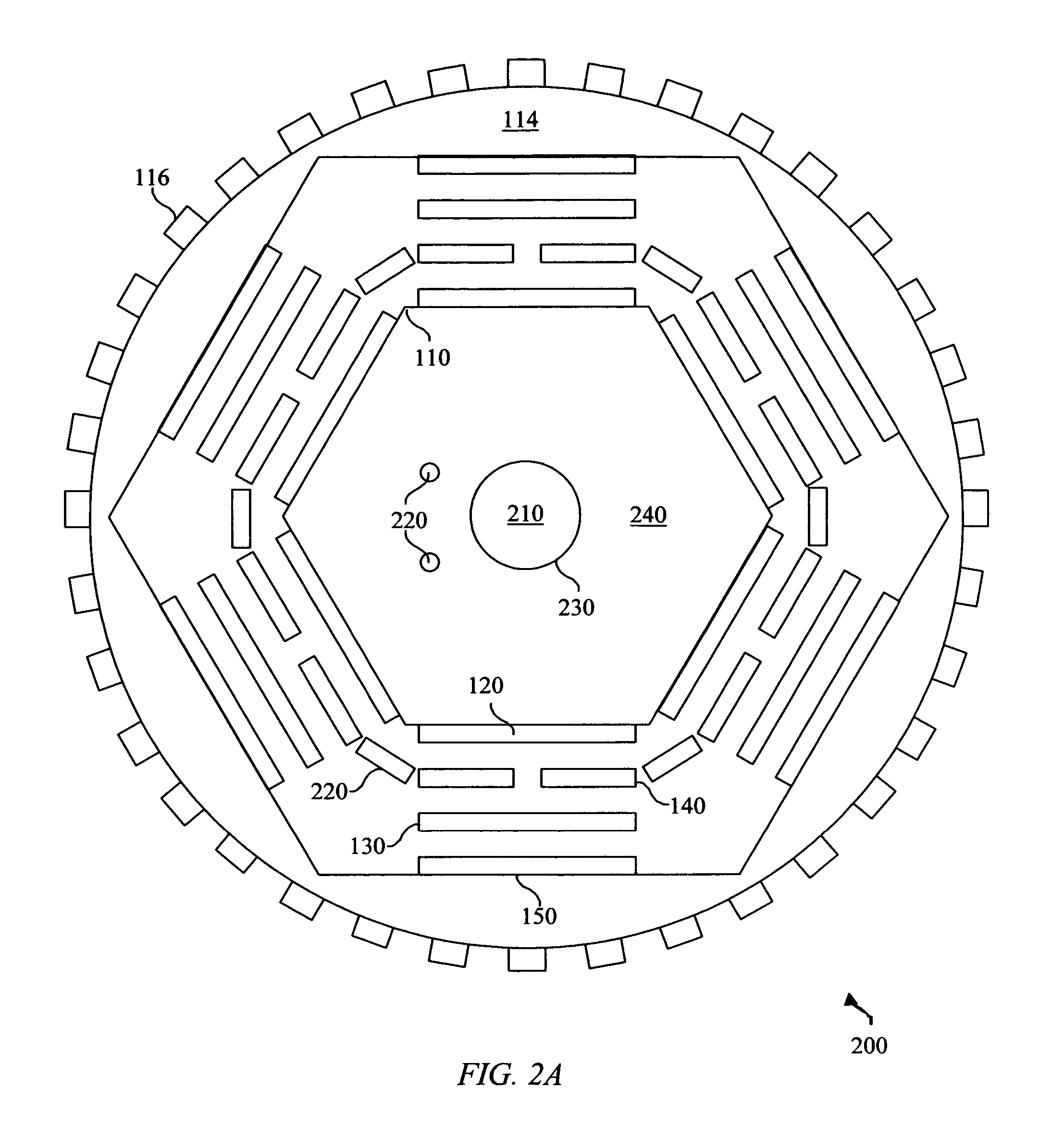

System and method for enhanced thermophotovoltaic generation

InactiveUS20050109386A1Reduce fossil fueled NOx emissionIncreasing burner efficiencyThermoelectric device with peltier/seeback effectPV power plantsThermophotovoltaicDistributed generation

A system and method for lower cost, high efficiency, thermophotovoltaic distributed generation includes: an emitter, a photovoltaic cell, and transient electrical energy storage.

Owner:PRACTICAL TECH

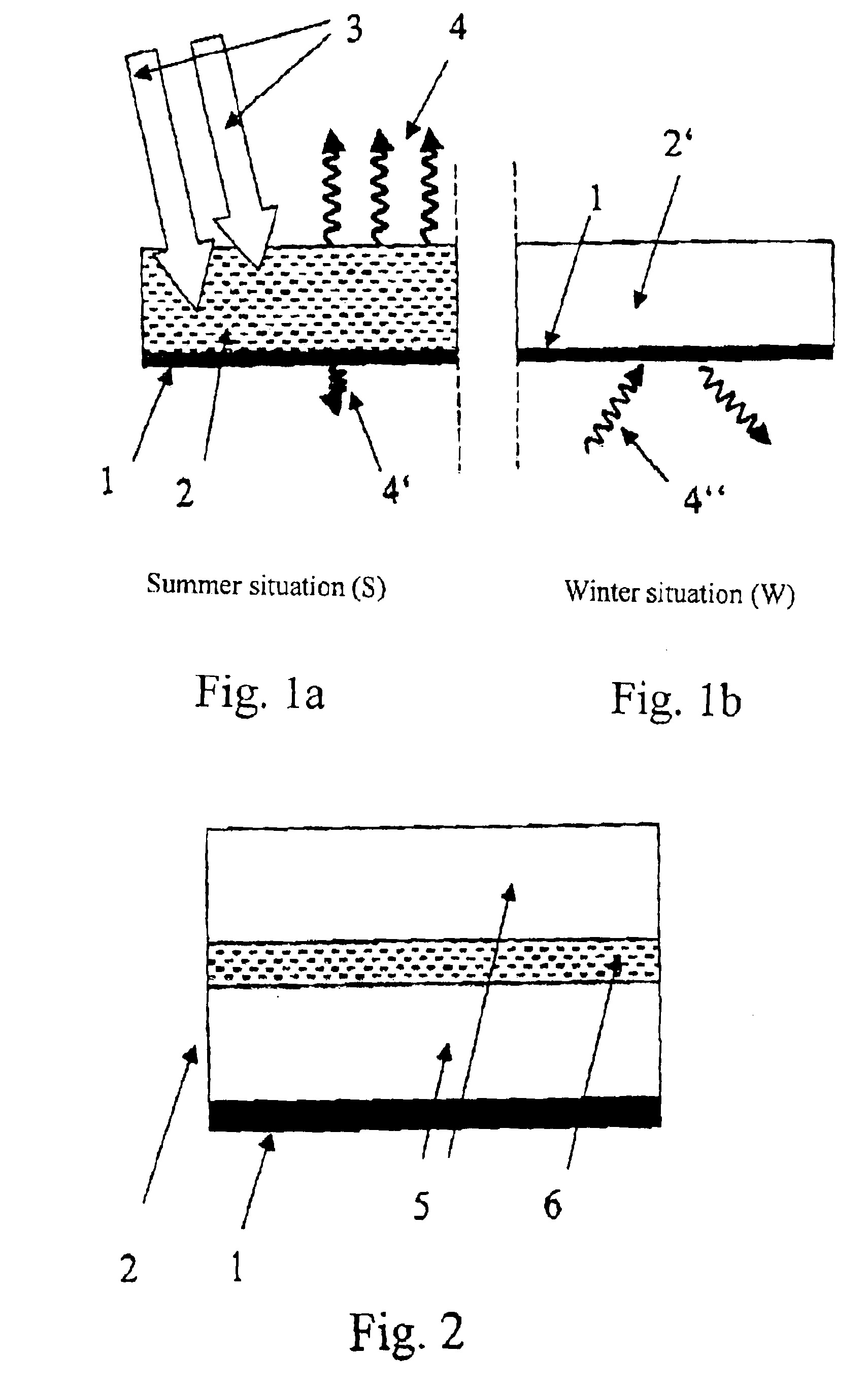

Thermally comfortable glass

InactiveUS6910729B2Improving thermal comfortImproves thermal comfortWindowsAntiglare equipmentThermal comfortGlass sheet

A vehicle window includes a pane of self-darkening or laminated glass and a function layer made of a low-emission material disposed on an inside surface of the pane. The function layer reflects a first infrared radiation into the vehicle and reduces an emission of a second infrared radiation from the glass pane into an interior of the vehicle. In addition, a method for regulating a thermal comfort of a passenger in an interior of a vehicle includes the steps of providing a self-darkening glazing as protection against glare and heat, disposing an IR-reflecting transparent layer on the glazing in form of a coating or film, reflecting an infrared radiation emitted from the vehicle interior back into the vehicle interior using the IR-reflecting transparent layer, and reducing a heat radiated by the glazing into the vehicle interior.

Owner:DAIMLER AG

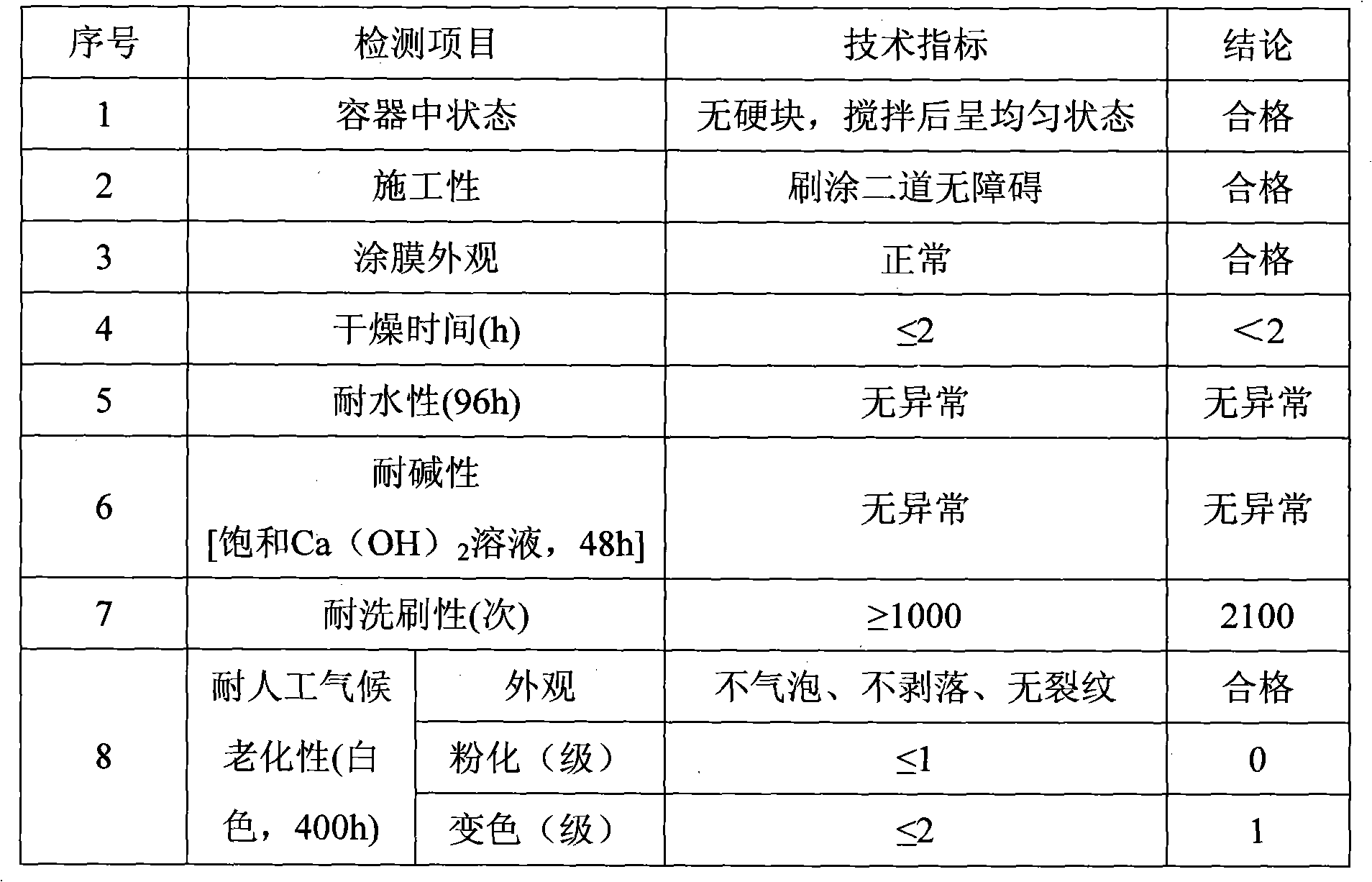

Aqueous flame-retardant and thermal-insulated coating and preparation method thereof

InactiveCN101671523AGood weather resistanceSimple preparation processCoatingsThermal insulationEmulsion

The invention discloses an aqueous flame-retardant and thermal-insulated coating and a preparation method thereof, relates to a building coating, and provides a building thermal-insulated coating integrating flame-retardant property, thermal-insulated property and decorative function. The coating consists of emulsion, a fire retardant, titanium, hollow glass beads, water and assistants, with the respective mass parts being 35-40, 20-30, 15-20, 5-10, 19-21 and 11-15. The coating uses fire retardants of inorganic type, phosphorus type and nitrogen type and utilizes synergistic action among different fire retardants to achieve the retardant effect with less amount and without influencing the physical properties of the coating layer; better thermal-insulated effect can be achieved when the thickness of the coating layer is about 1mm through obtaining thermal insulation property by reducing thermal conductivity, thermoconvection and thermal radiation through the glass beads; and the thermal-insulation and flame-retardant properties of the coating are reflected by that the heat conduction coefficient is not more than 0.090 w / (m.k), and the oxygen index is not less than 28.0 percent.

Owner:XIAMEN UNIV +1

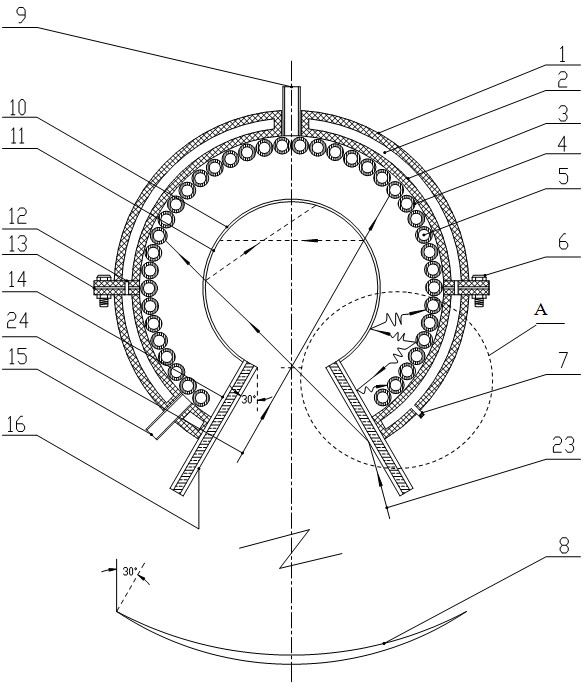

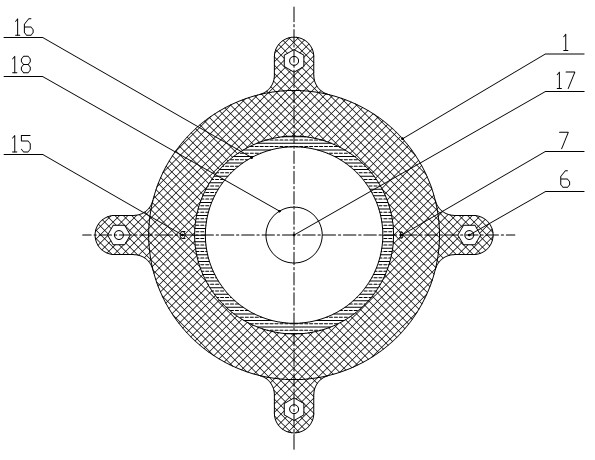

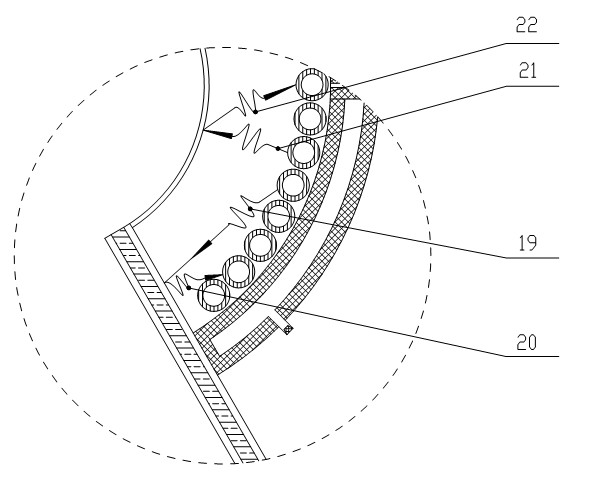

Spherical cavity type solar heat absorber with inwardly concave glass cover

InactiveCN102322694AImprove capture abilityNot easy to spillSolar heating energySolar heat devicesGlass coverEngineering

The invention discloses a spherical cavity type solar heat absorber with an inwardly concave glass cover. The heat absorber is mainly used for collecting sunlight and converting the sunlight into heat energy in a butterfly type solar high-temperature heat utilization system. The heat absorber mainly comprises a heat exchange coil pipe, the inwardly concave glass cover, an outer shell, an inner shell, a vacuum layer, a reflective wind shield and a heat conductive fluid. Different from the traditional opening type heat absorber and the cavity type heat absorber with the glass window at the cavity opening, the cavity type heat absorber disclosed by the invention is the opening type spherical heat absorber with the inwardly concave glass cover, therefore, the cavity type heat absorber not only has the light capturing capacity of the opening cavity type heat absorber but also has low heat loss of the cavity type heat absorber with the glass window at the cavity opening; meanwhile, the cavity type heat absorber is provided with the reflective wind shield, therefore, the capturing on deviated light can be strengthened, and the heat radiation on the inner wall and the convection heat transfer loss resulted from external natural wind can be reduced; and the cavity type heat absorber comprises the vacuum layer between the inner shell and the outer shell, therefore, the lost heat throughthe shells can be effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH

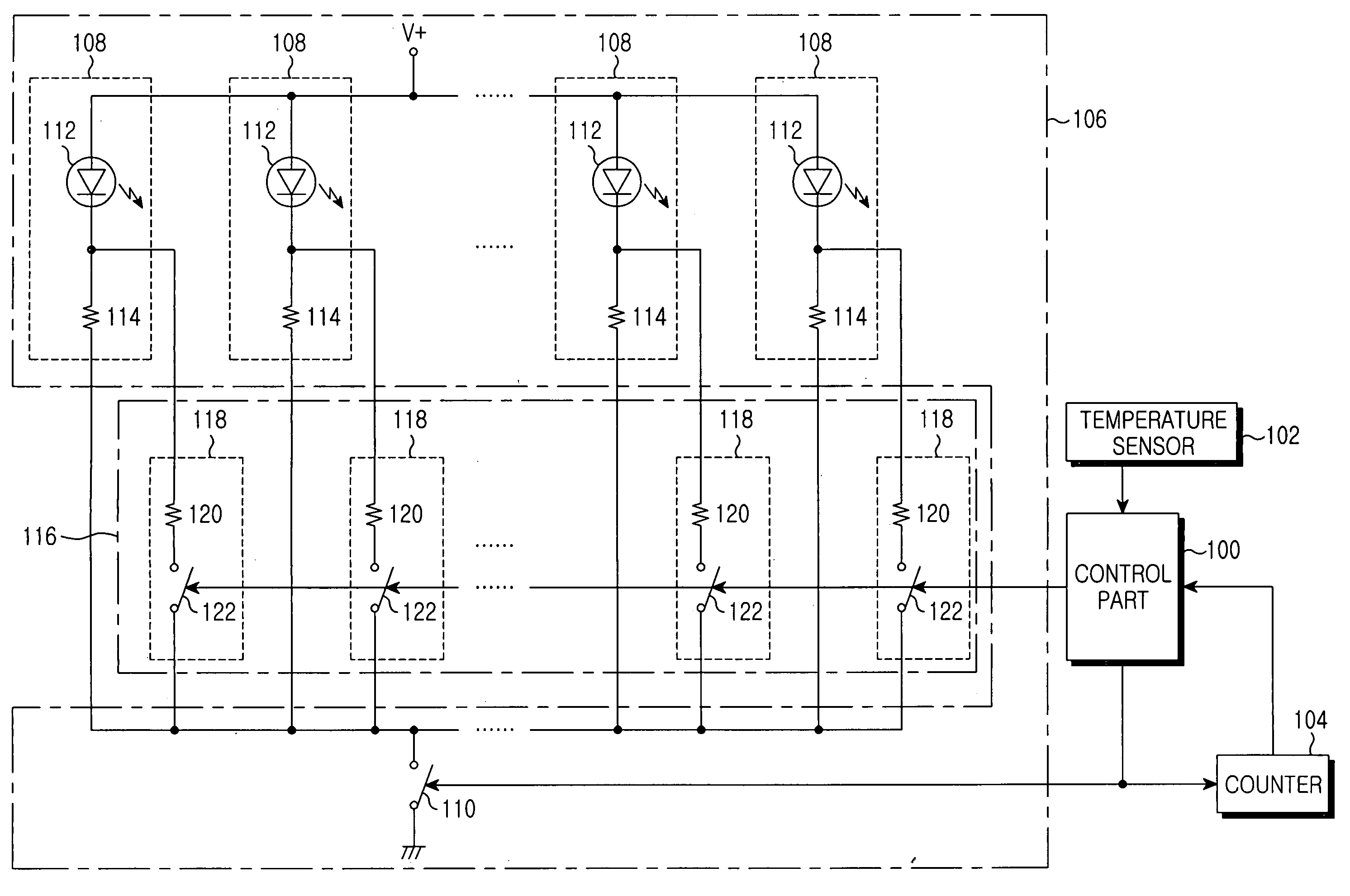

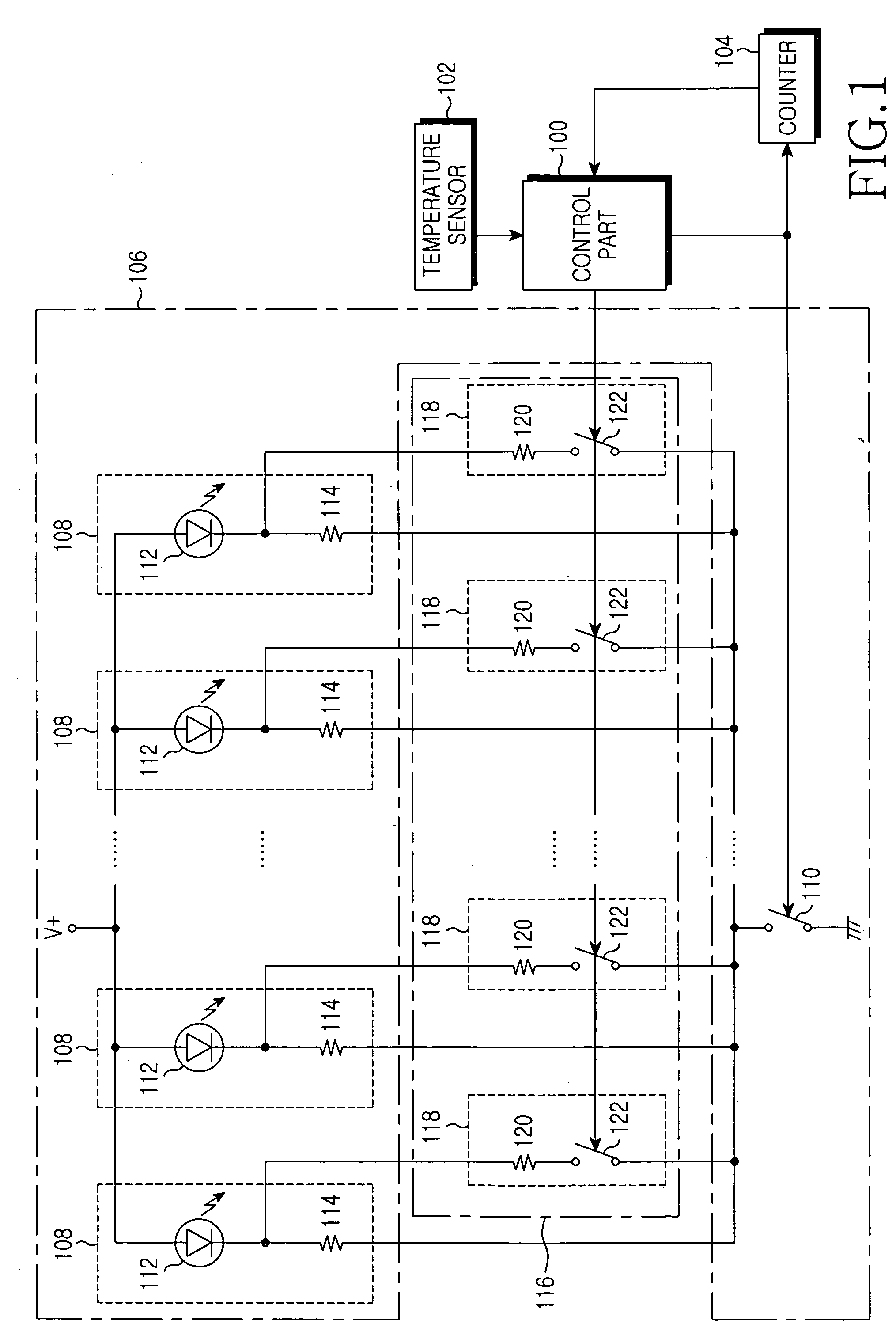

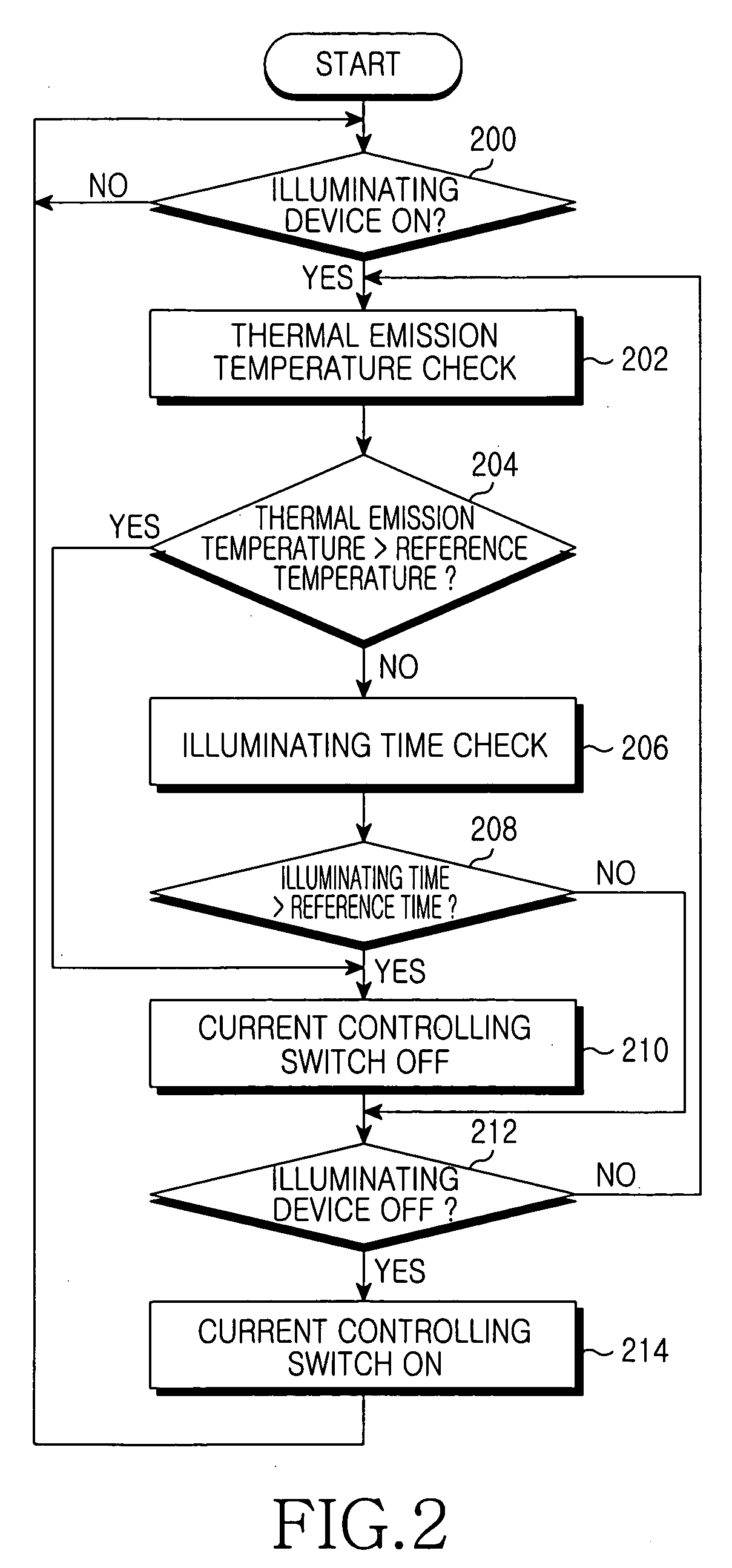

Backlight control circuit in portable device

InactiveUS20050151717A1Reduce current consumptionTotal current dropElectrical apparatusStatic indicating devicesEngineeringCurrent consumption

Disclosed is a backlight control circuit capable of decreasing current applied to an illuminating device or turning off a portion of illuminating devices if an illuminating time exceeds a predetermined reference time when the illuminating device is in a turned-on state, or a thermal emission temperature of the illuminating device is higher than a predetermined reference temperature. Accordingly, it is possible to reduce current consumption and thermal emission of the illuminating device resulting from continuous turn-on states of the illuminating device while using a backlight function.

Owner:SAMSUNG ELECTRONICS CO LTD

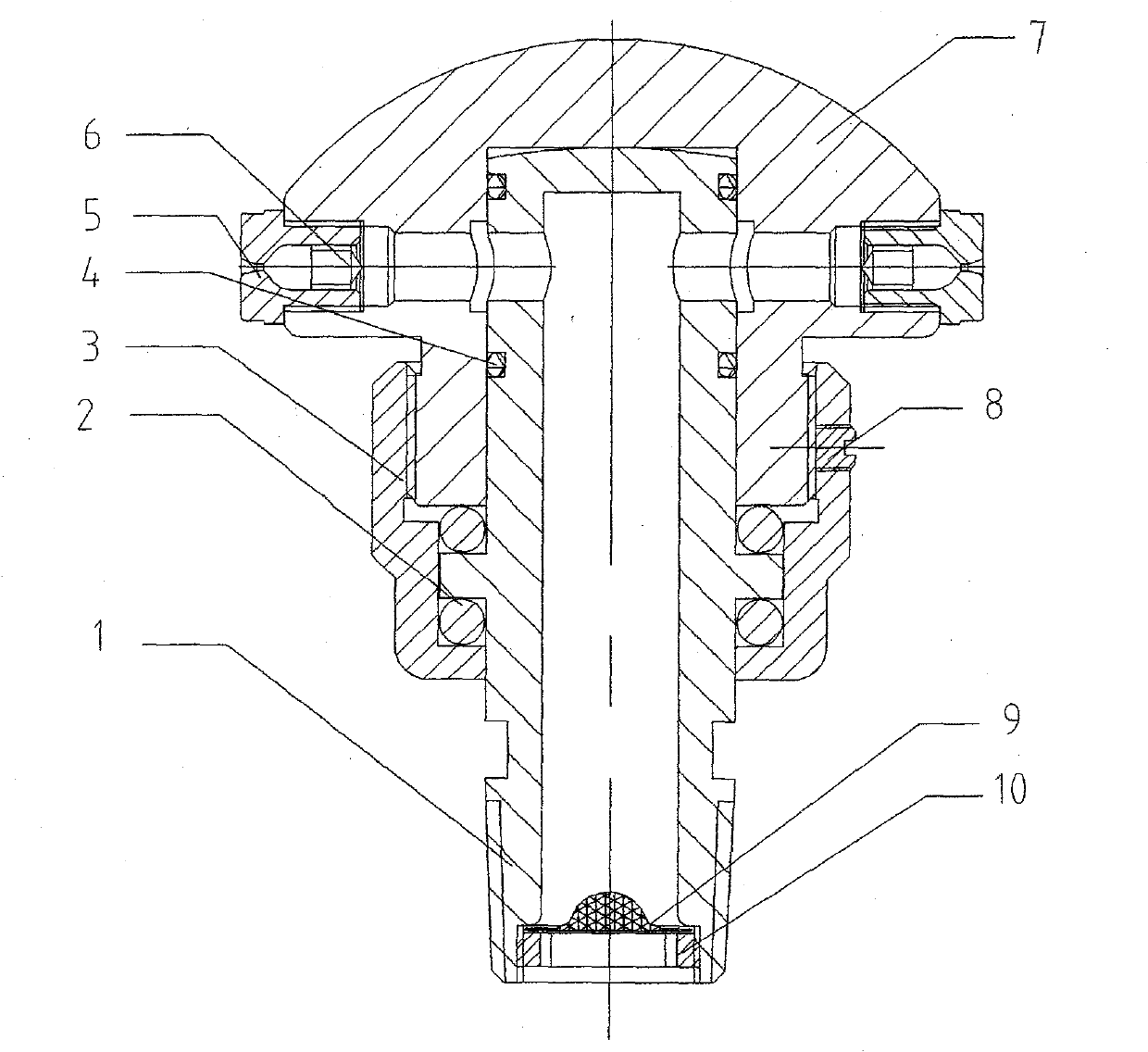

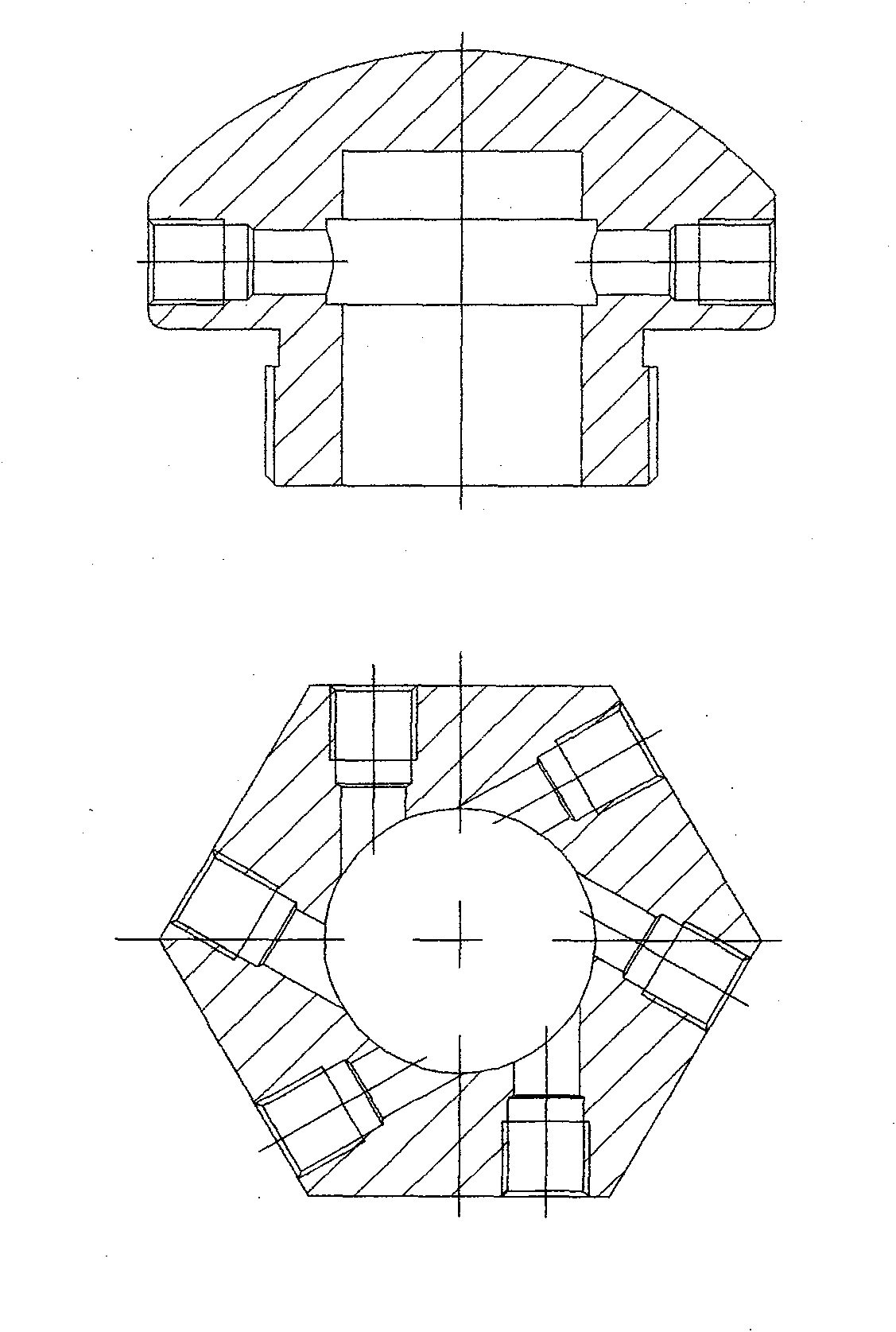

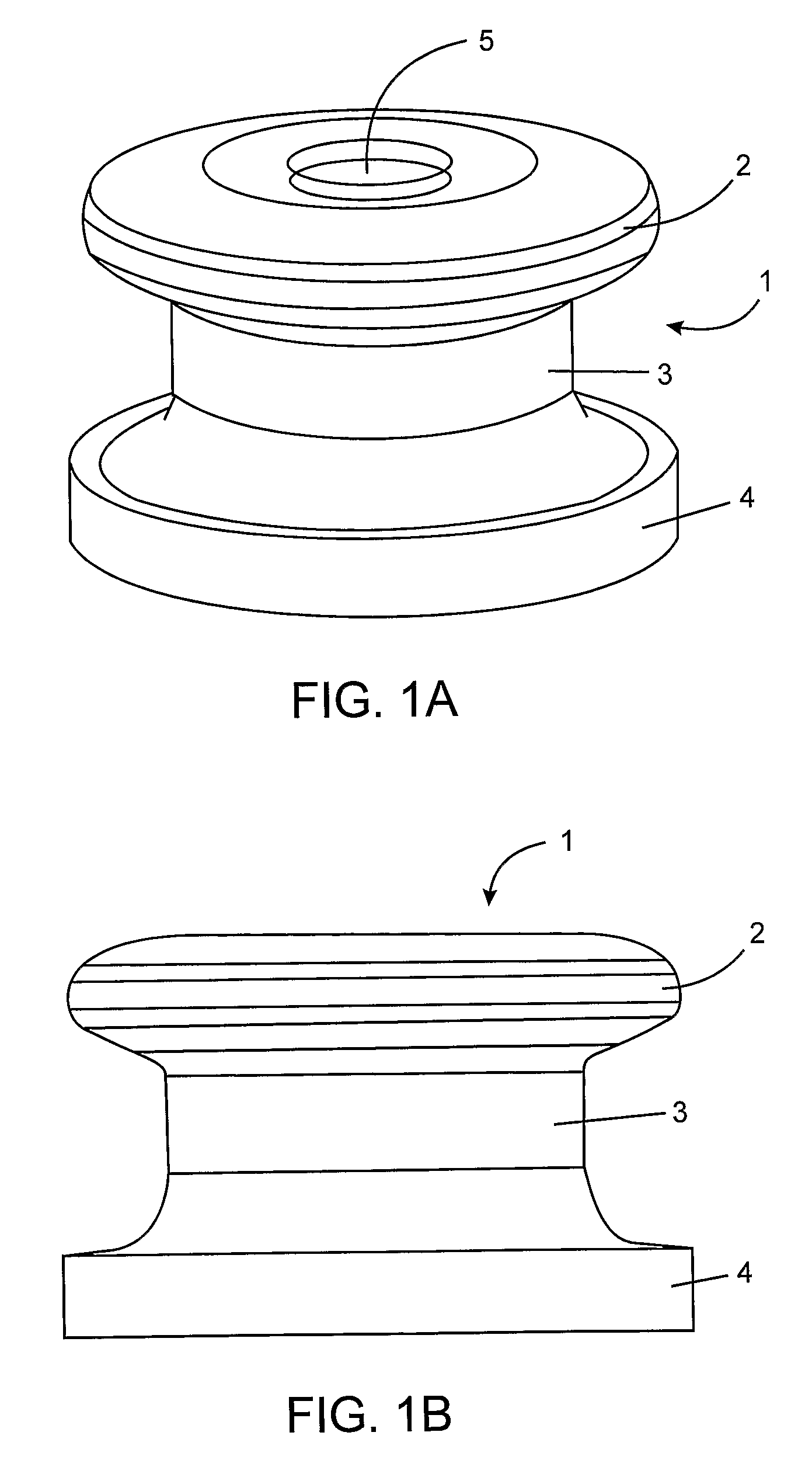

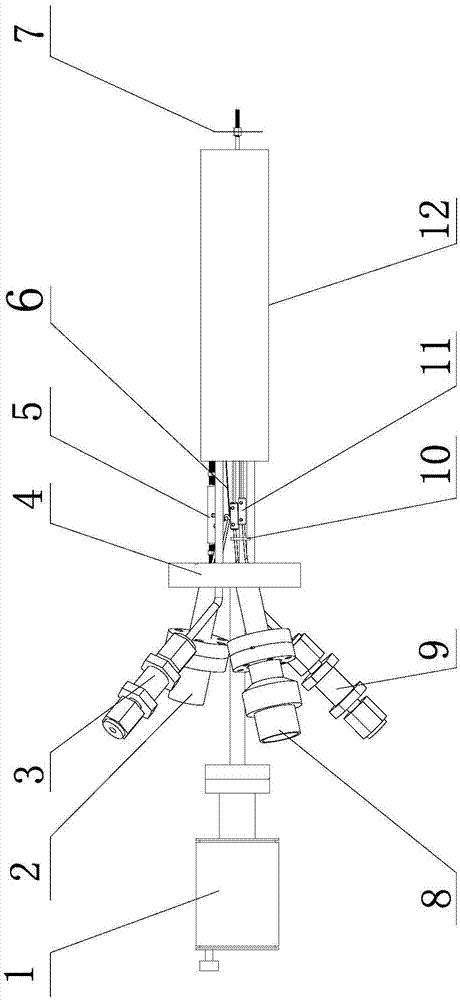

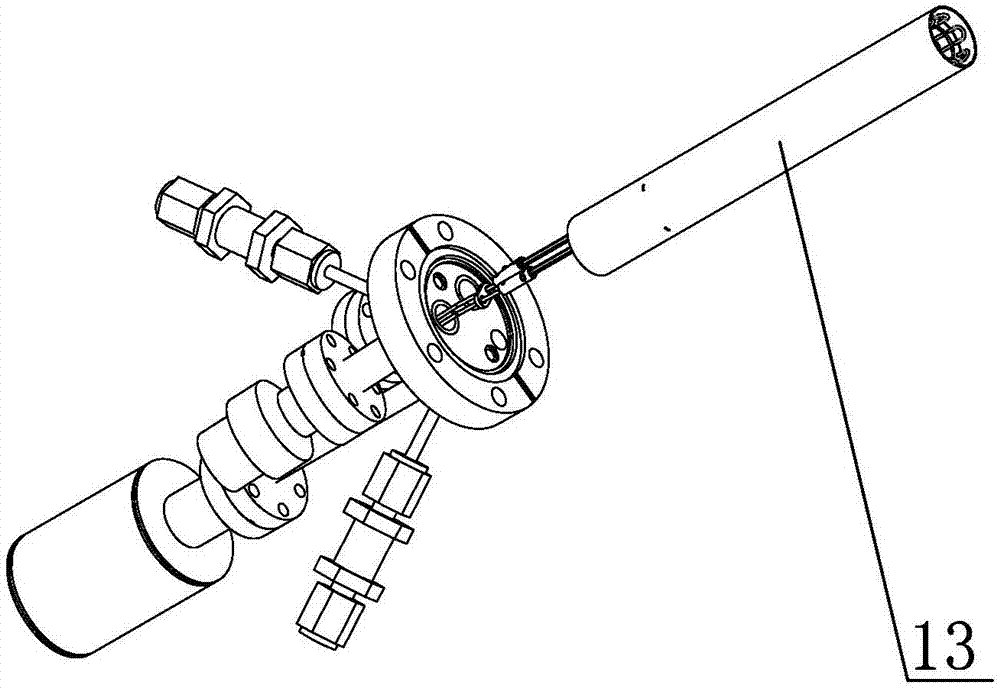

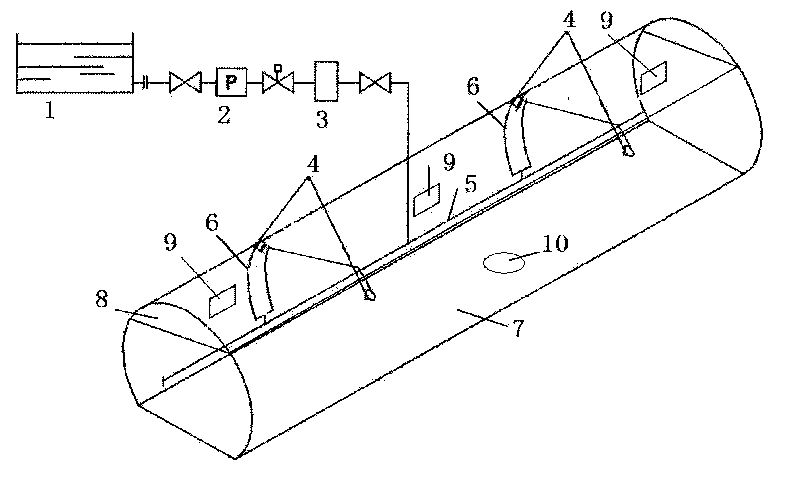

Rotary water mist sprayer

The invention relates to a rotary water mist sprayer which is usually installed outside protected facilities, at safety evacuation exits, air wells and the like. The rotary water mist sprayer adopts a structure of dual-way rolling balls and dual-way O-shaped rings and is shaped as a mushroom. When the rotary water mist sprayer works, a high-pressure water source enters a mandrel through a filter screen and arrives at each spray core and spray nozzle of the sprayer body, the water flow is atomized into fine water drops less than 120 mu m to be sprayed, and the eccentric reacting force generated by each spray nozzle enables the sprayer body to rotate around the mandrel, and the water mist is sprayed in complete 360 DEG C. The invention belongs to the fields of fire control isolation, protection cooling and elimination of infrared radiation and radar signature of protected facilities. The rotary water mist sprayer is provided with a lock plunger, a filter screen, the mandrel, the rolling balls, screws, the spray cores, the spray nozzles, the spray body and the O-shaped rings and is widely applied to military industry, electric power, chemical industry, aerospace, ships, metallurgy, undergrounds and tunnels.

Owner:上海南晓消防工程设备有限公司

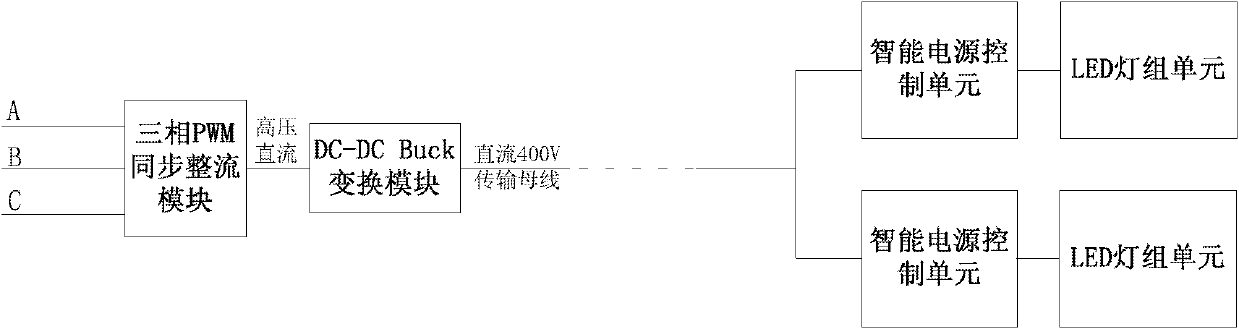

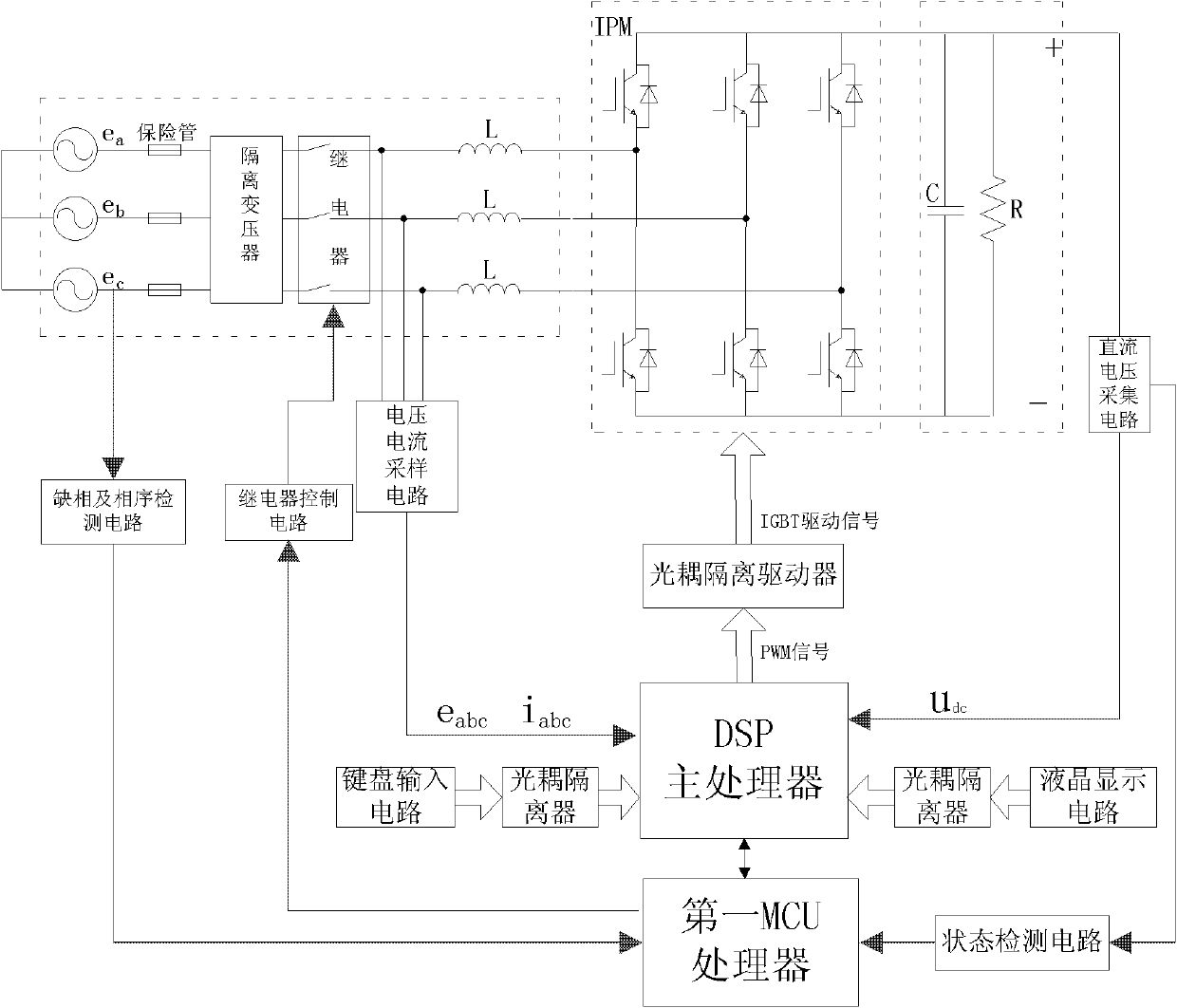

LED (Light Emitting Diode) illumination intelligent control system

InactiveCN102438378AImprove working environment temperatureReduce heat radiationAc-dc conversionElectric light circuit arrangementPower factorHigh-voltage direct current

The invention relates to an LED (Light Emitting Diode) illumination intelligent control system which comprises a synchronous rectification unit used for providing direct-current power for at least two intelligent power control units, wherein the output end of each intelligent power control unit is connected with a corresponding LED light group unit via an electric wire; and the synchronous rectification unit is connected with each intelligent power control unit by a high-voltage direct-current bus. In the intelligent control system, stable constant-voltage direct current is provided for an LED illumination system by the synchronous rectification unit, so that the whole illumination system can operate under high power factor with less harmonic wave. the corresponding LED light group units are dynamically and precisely dimmed by the intelligent power control units, and the LED operation situation is detected in real time and communication with an external control center is carried out. The intelligent control system has the characteristic of reasonable structure, and is convenient to control, the working environment temperature of an LED light group can be improved, and the reliability and the service life of an LED illumination light can be improved.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

Transient-state control method for a hybrid drive system for vehicles

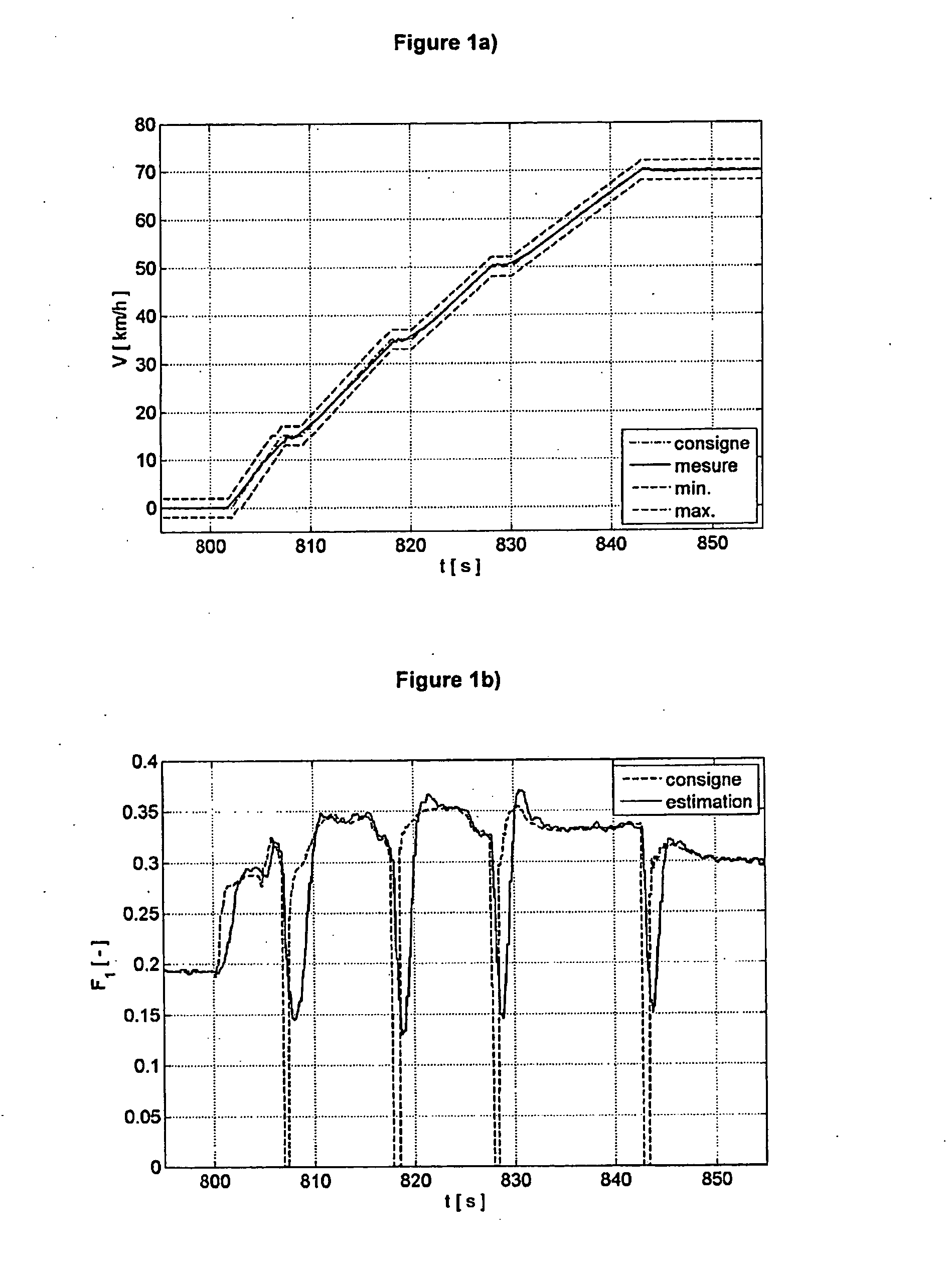

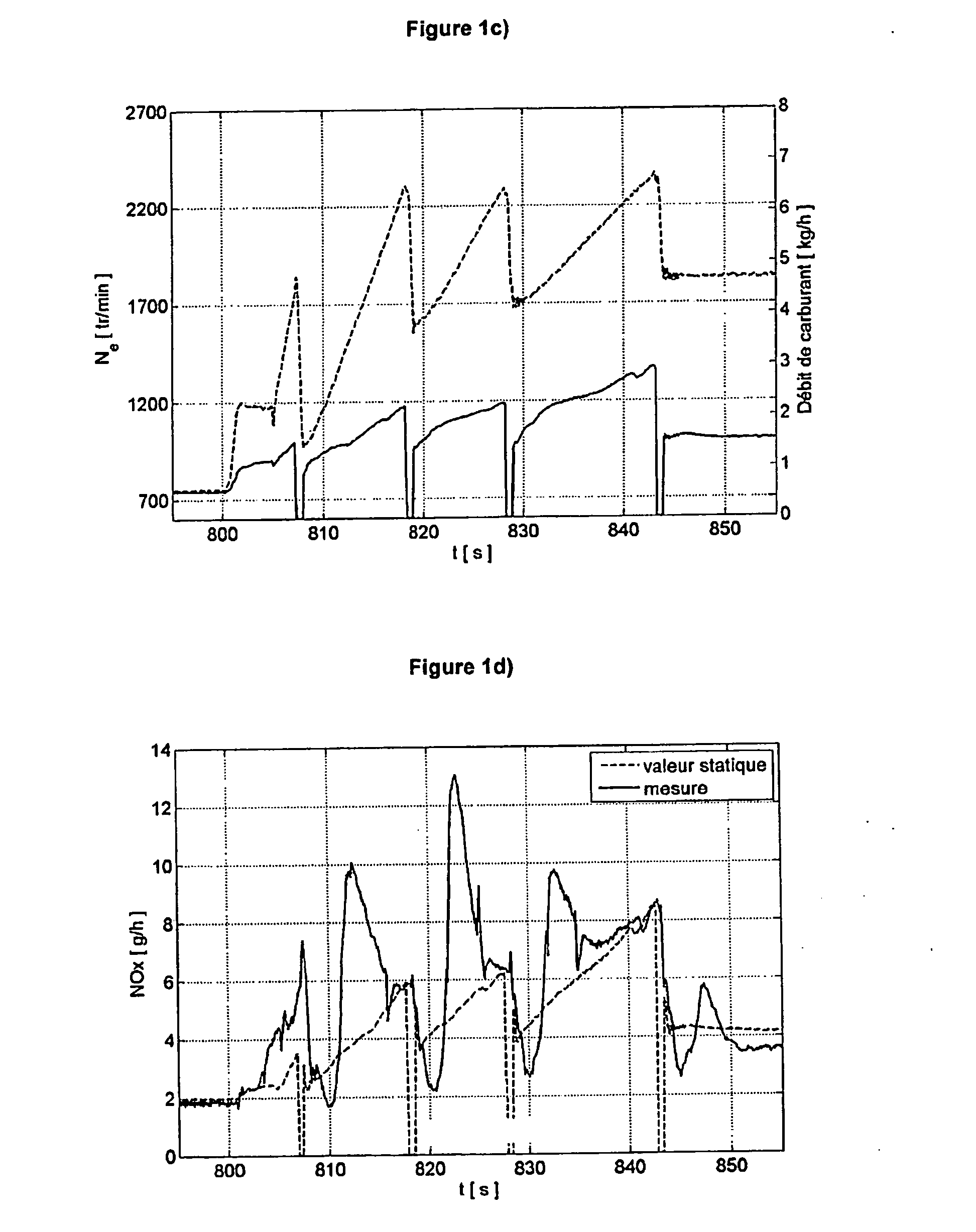

InactiveUS20130131956A1Reduce heat radiationReduction of transient partHybrid vehiclesAnalogue computers for vehiclesNitrogen oxidesHybrid drive

The invention relates to a method of controlling a hybrid drive system having at least one electric machine and at least one diesel engine. The invention corrects the static torque setpoint Teng,ssp of the diesel engine and is performed in transient state as follows: constructing a nitrogen oxides (NOx) emission model allowing estimation of the emissions of the diesel engine as a function of torque Teng of the diesel engine; calculating a dynamic NOx emission setpoint NOxsp from the NOx emission model and from the static torque setpoint Teng,ssp; determining a dynamic torque setpoint of the diesel engine Tengsp from NOx emission setpoint NOxsp; determining a dynamic torque setpoint of the electric machine Tmotsp as a function of the static torque setpoint Tpwtsp of the drive system and of the dynamic torque setpoint of the diesel engine TengspI and applying the dynamic torque setpoints to the drive system.

Owner:INST FR DU PETROLE

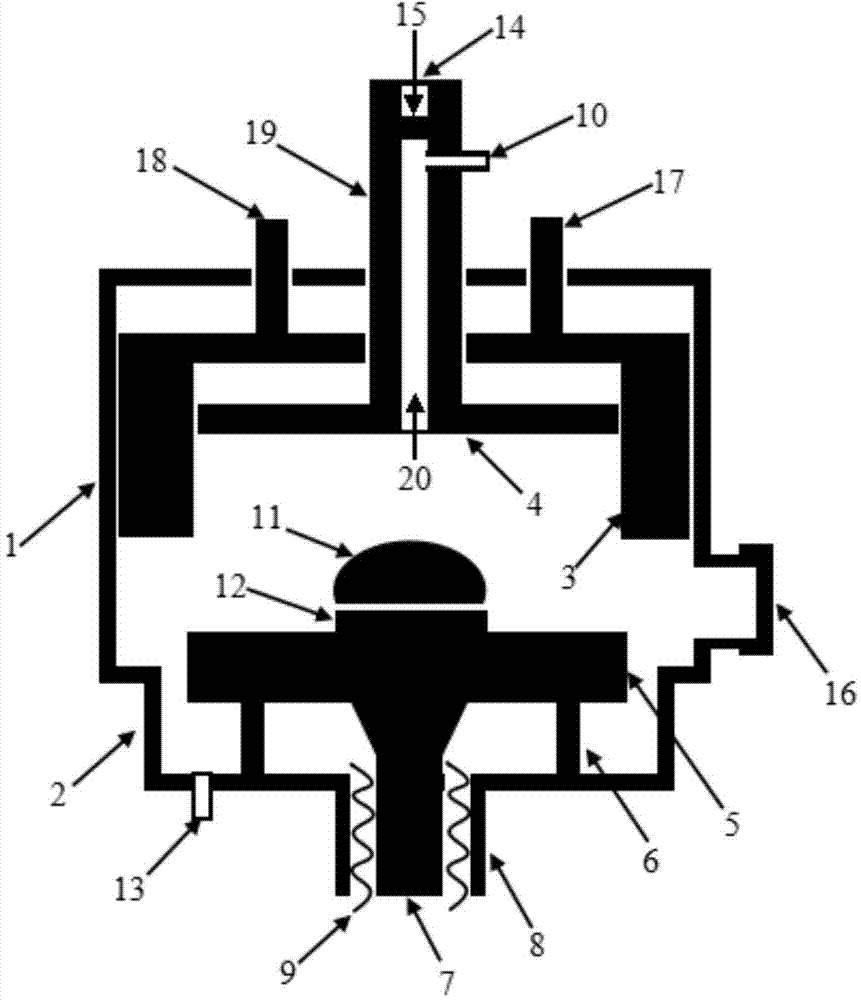

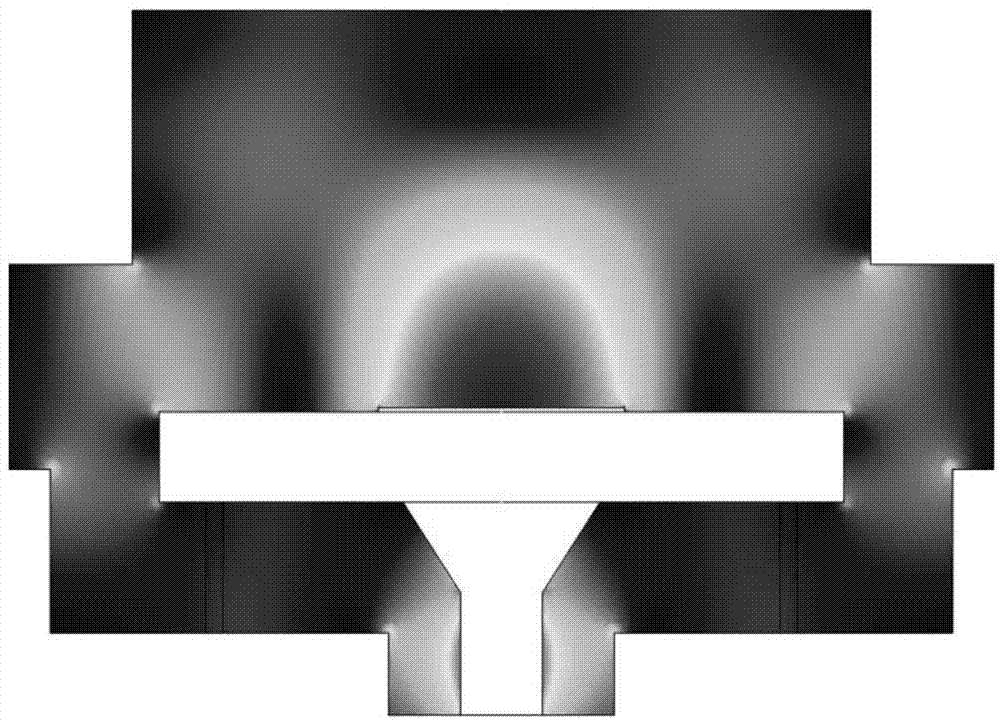

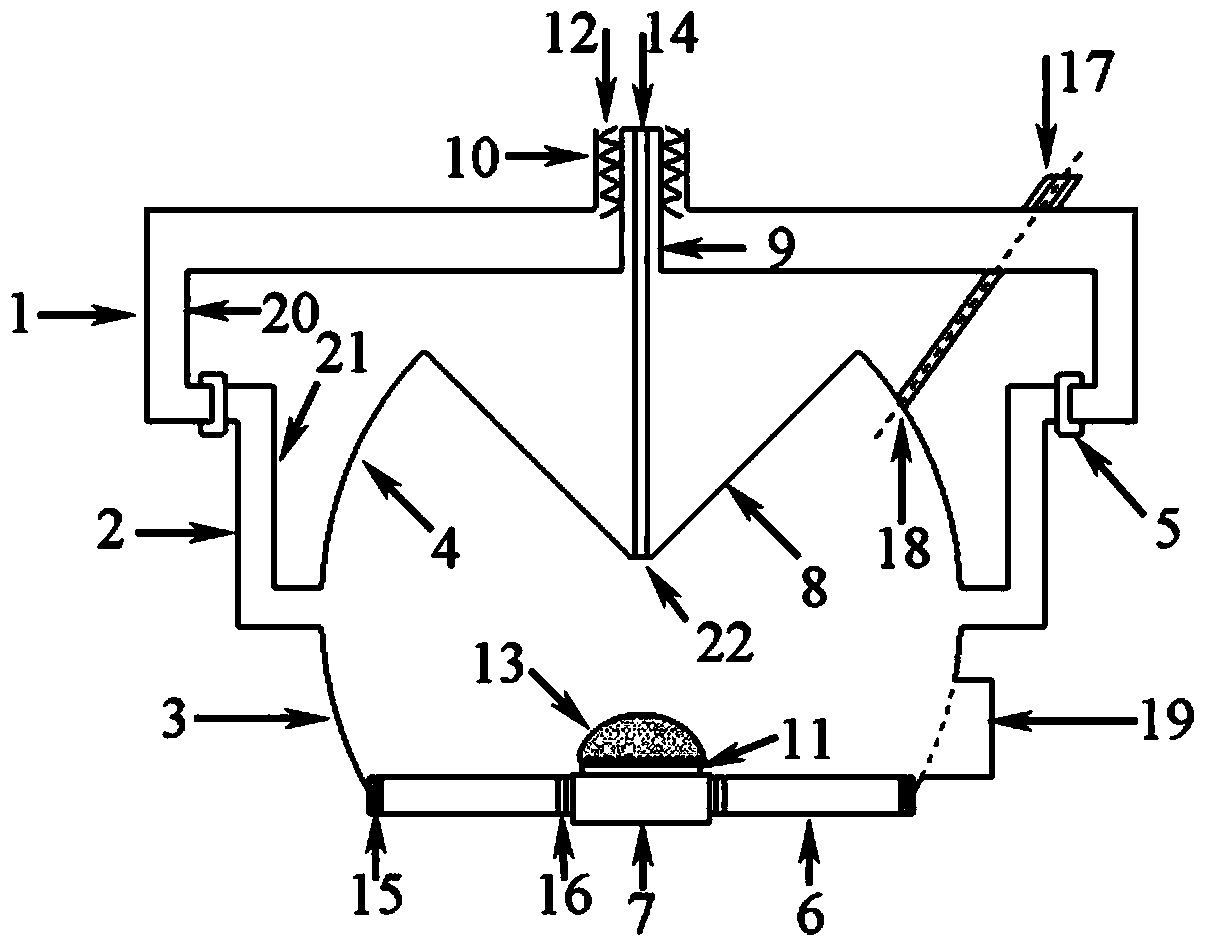

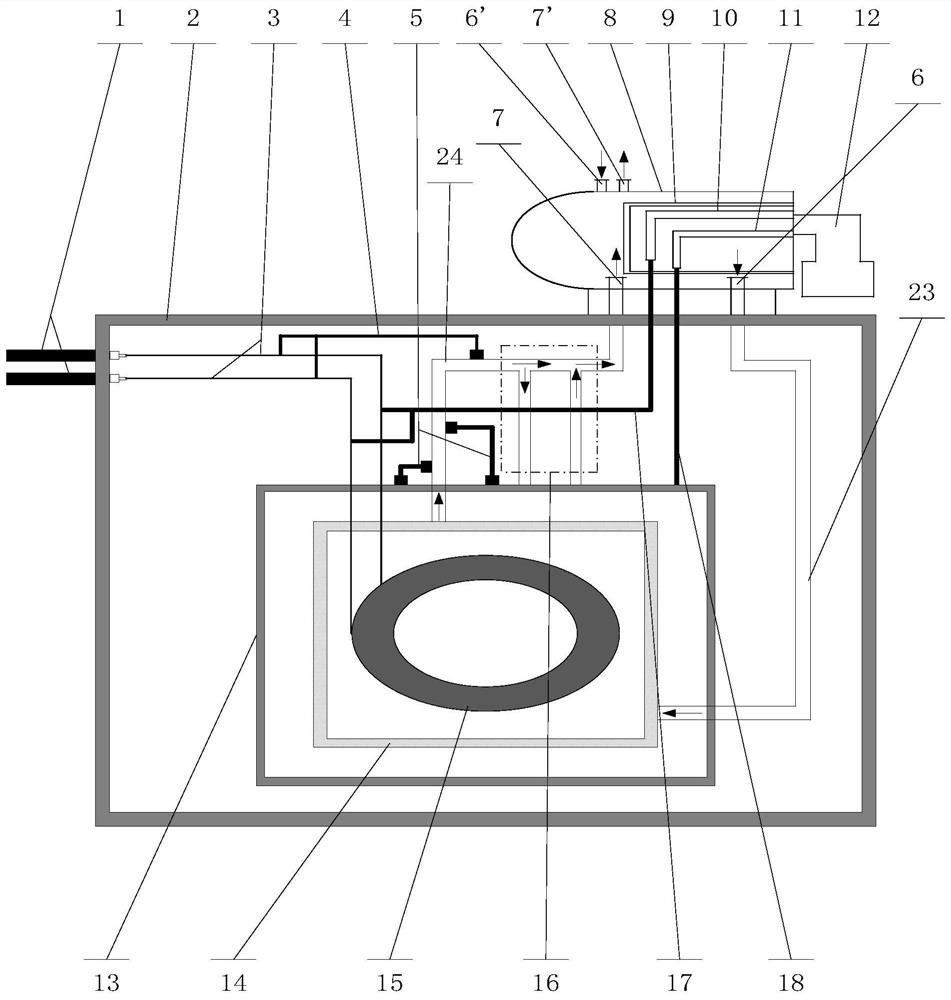

TM021 modal high-power microwave plasma diamond film deposition device

ActiveCN103695865ADeposition high speedStable positionElectric discharge tubesChemical vapor deposition coatingResonant cavityMaterials science

The invention provides a TM021 modal high-power microwave plasma diamond film deposition device. The TM021 modal high-power microwave plasma diamond film deposition device comprises an upper cylinder, a lower cylinder, an adjustable upper cavity, a microwave reflecting plate, a deposition table, a microwave coaxial excitation port, a microwave quartz port, a gas inlet, a gas outlet, a temperature measuring hole, an observing window and the like. The TM021 modal high-power microwave plasma diamond film deposition device has TM021 modal electric field distribution and the characteristics of centralized electric field distribution in a microwave resonator and stable excited plasma locations. The distribution of plasmas in the device can be optimized in real time through a regulating mechanism of the device. An annular microwave quartz window placed below the deposition table can be prevented from being excessively heated, polluted and etched by the plasmas. The inner wall of a resonant cavity is far away from a high-temperature plasma zone, so that the thermal radiation on the inner wall of the cavity is weakened, and foreign matter deposition is avoided. Each main part of the device can be directly water-cooled. Due to the advantages, the device can be applied to the input of relatively high-power microwaves, and the high-efficiency deposition of large-area high-quality diamond films is realized.

Owner:HEBEI PLASMA DIAMOND TECH

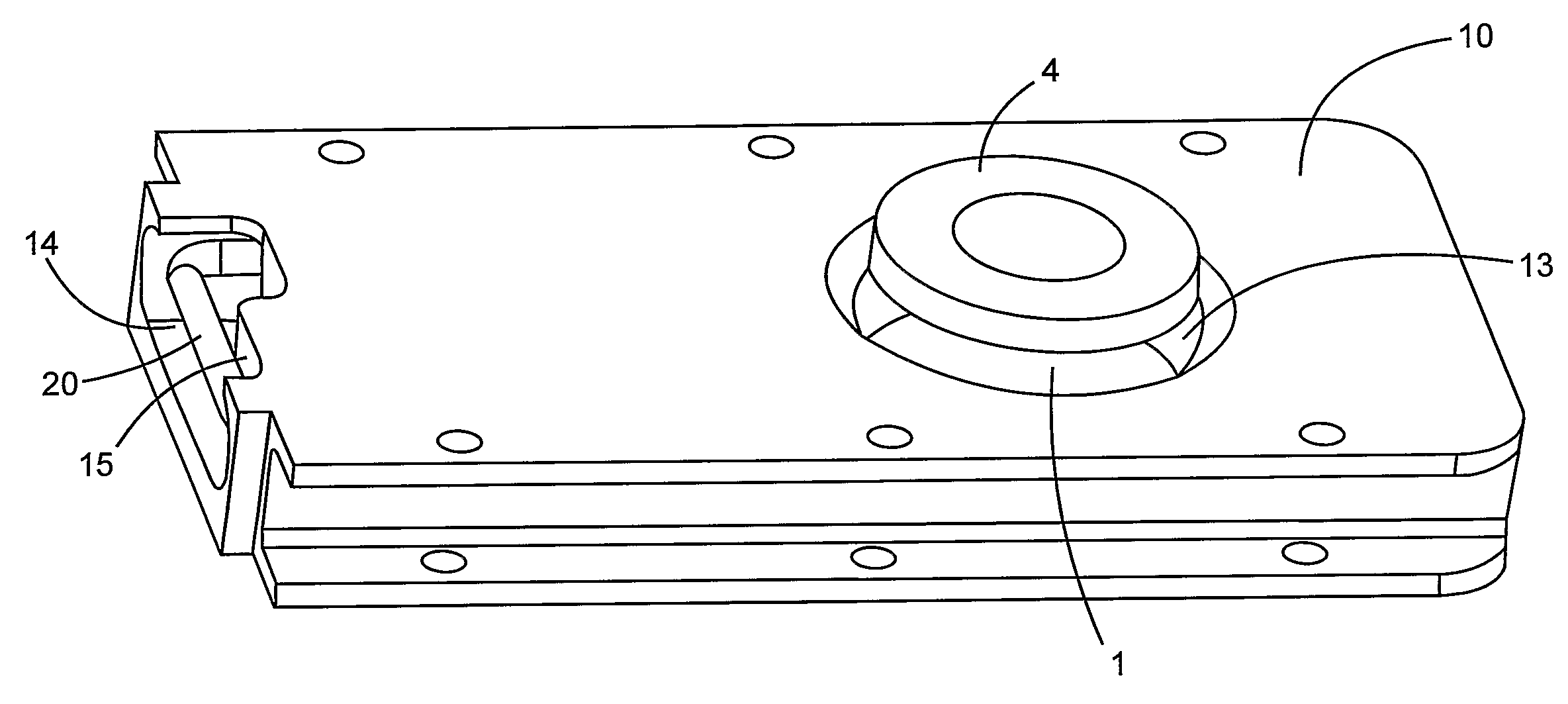

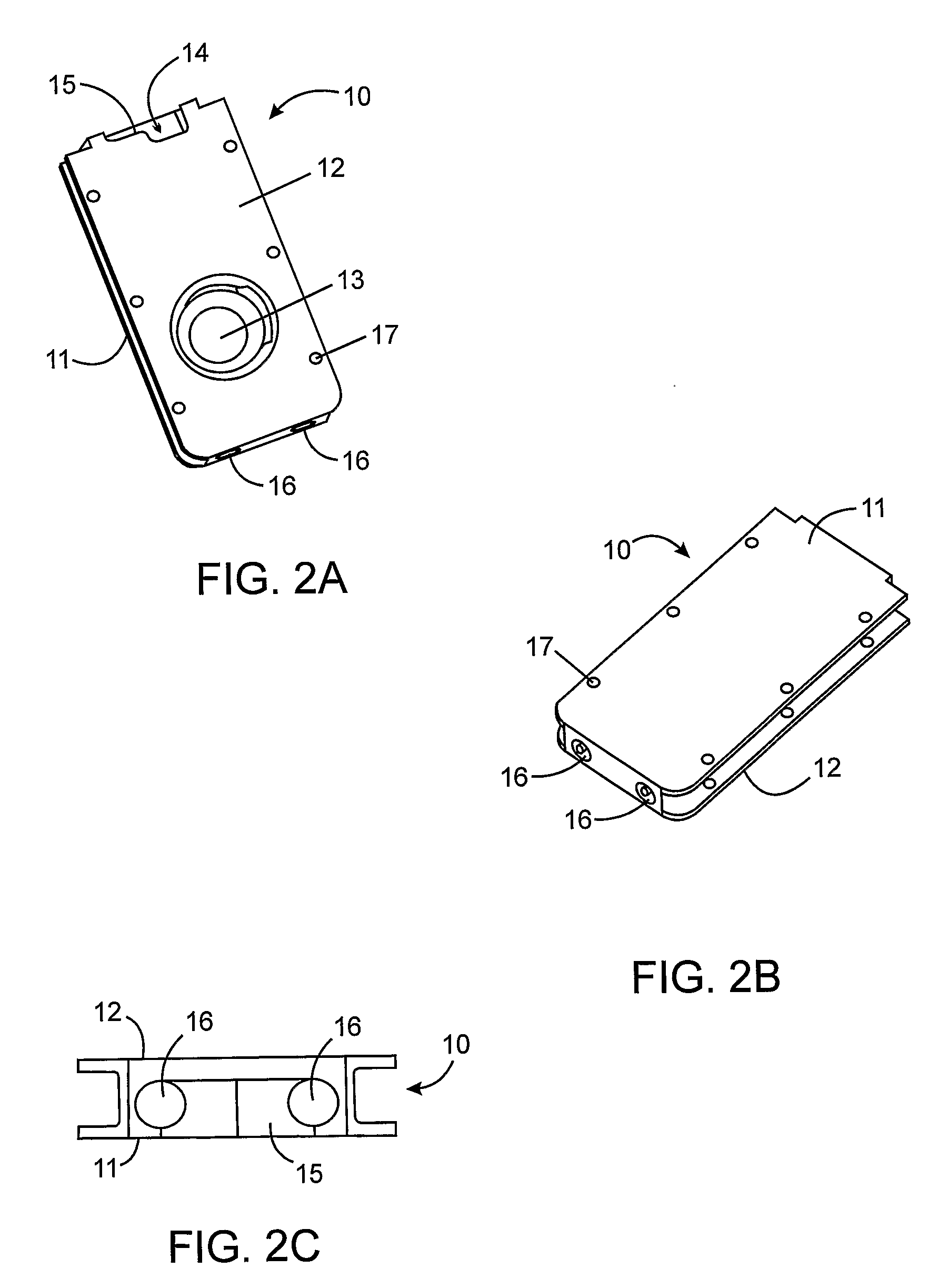

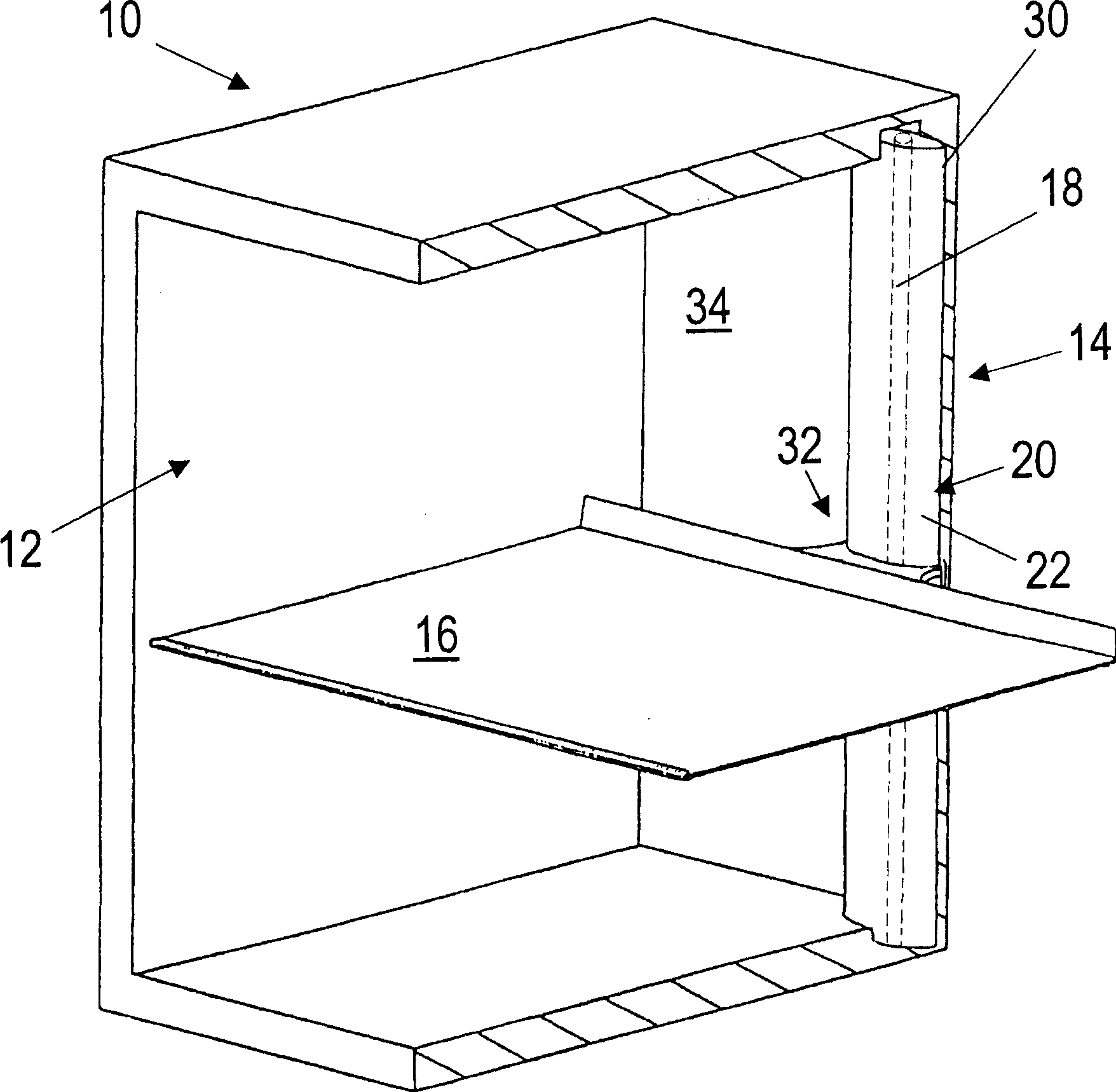

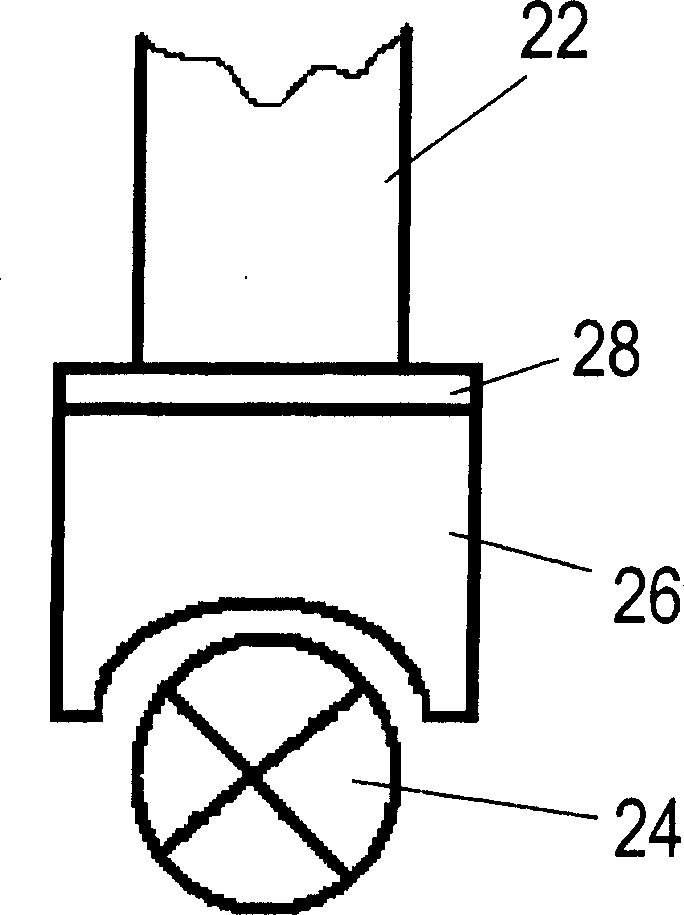

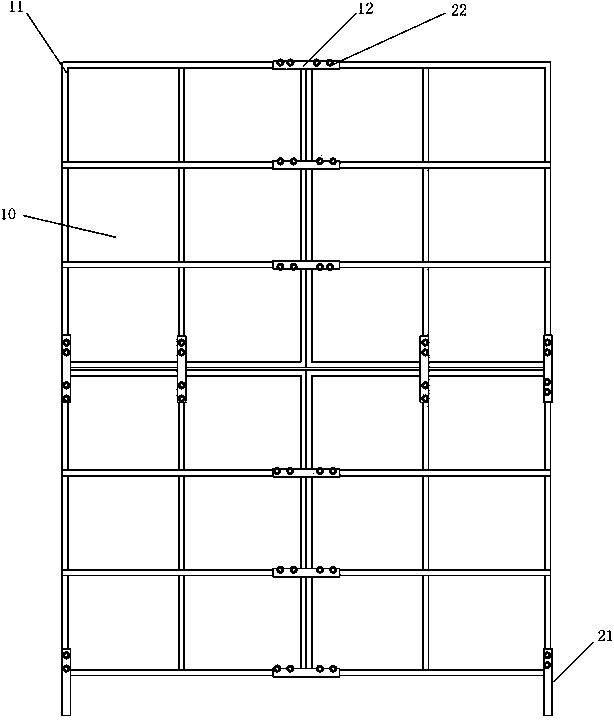

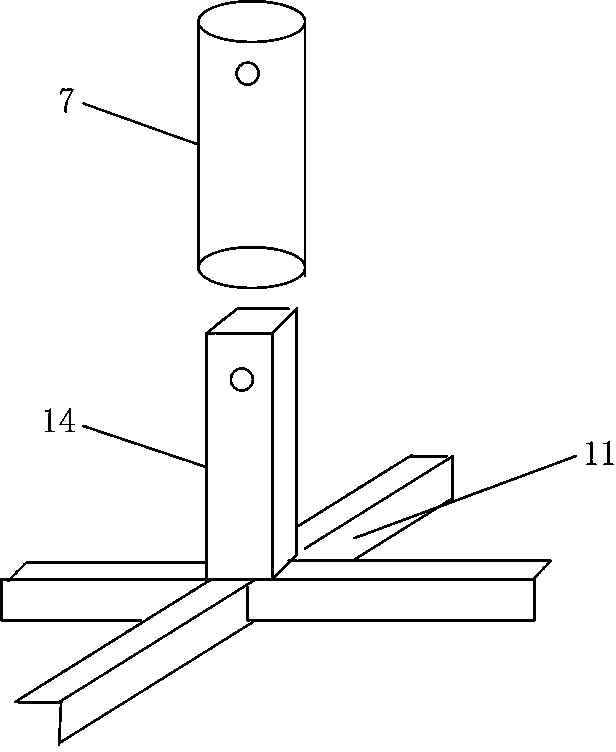

Armor mounting system

ActiveUS20090133571A1Reduce ballistic windowImprove versatilityArmoured vehiclesArmour platesRetrofittingFastener

A system for mounting armor to a structure such as a vehicle hull has a base for attachment to the structure, an adapter engaged with the base and with the armor for coupling the base to the armor, and a fastener, for example a pin or a bolt) for rigidly securing the adapter with the base. The system advantageously permits retrofitting of previously unarmored structures and / or permits replacement of damaged or obsolete armor. A kit for retrofitting a structure with armor has a base for attachment to the structure, an adapter for engagement with the base and with the armor for coupling the base to the armor, a fastener for rigidly engaging the adapter with the base, and instructions for mounting the armor on the structure using the base, the adapter and the fastener.

Owner:2040422 ONTARIO

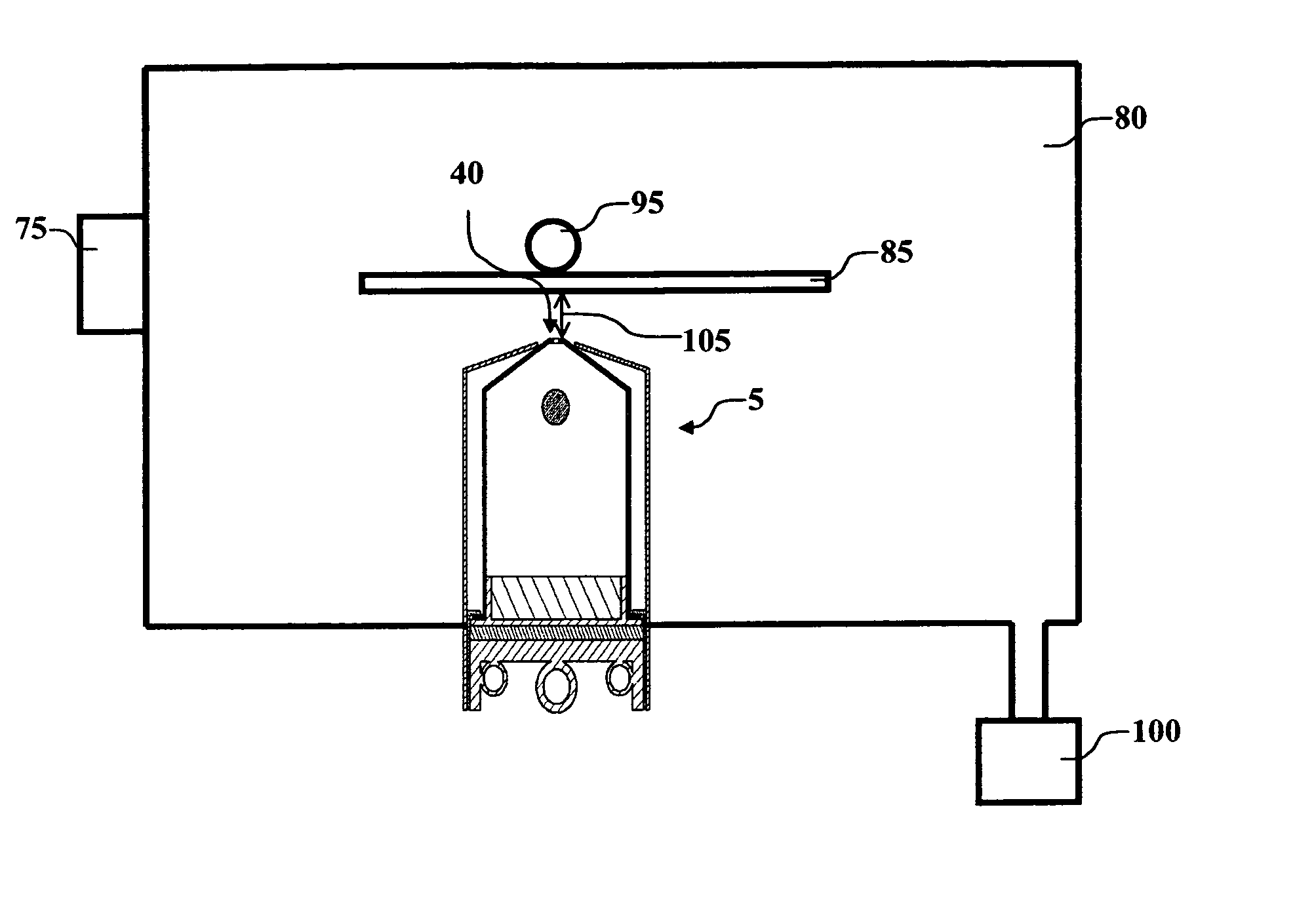

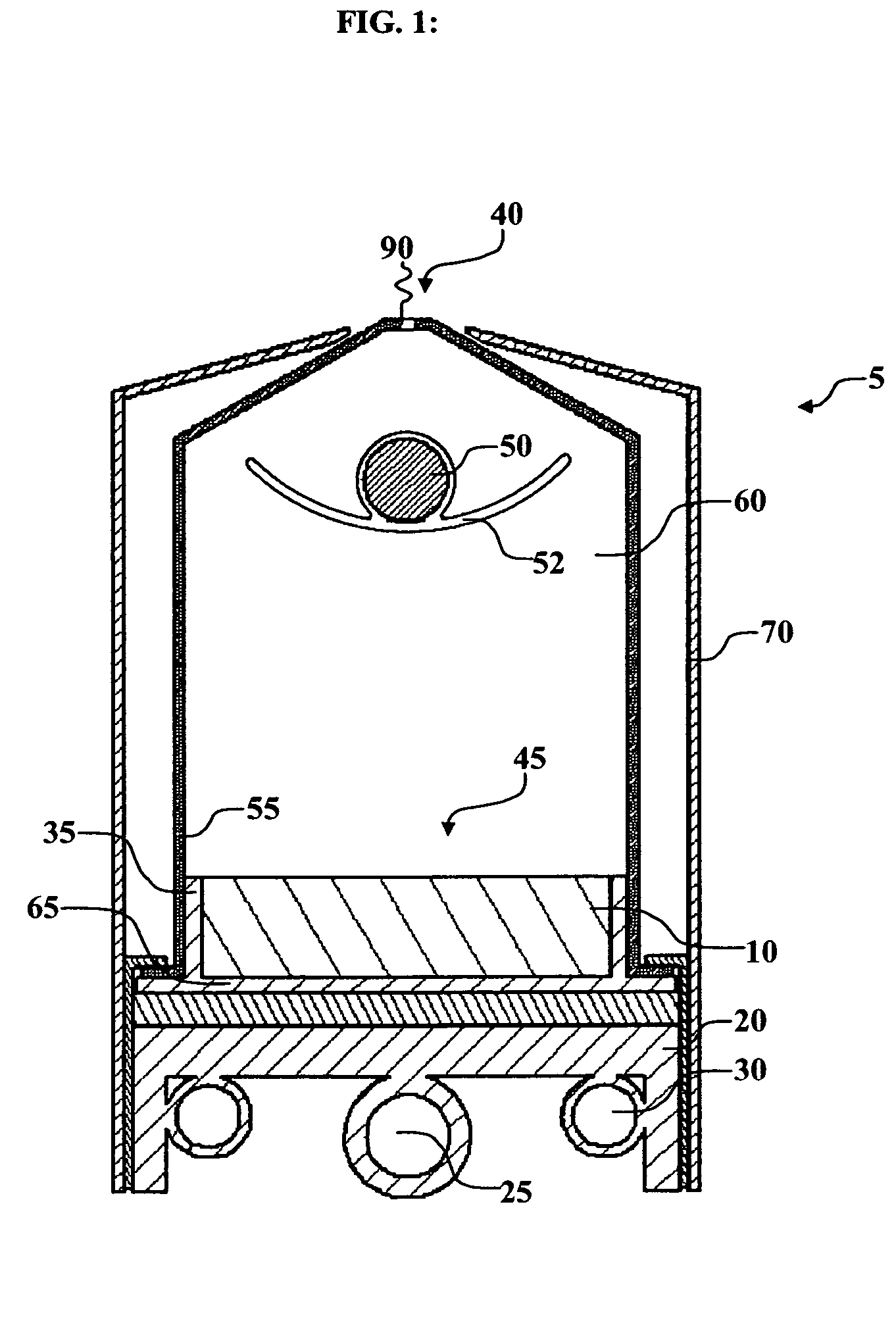

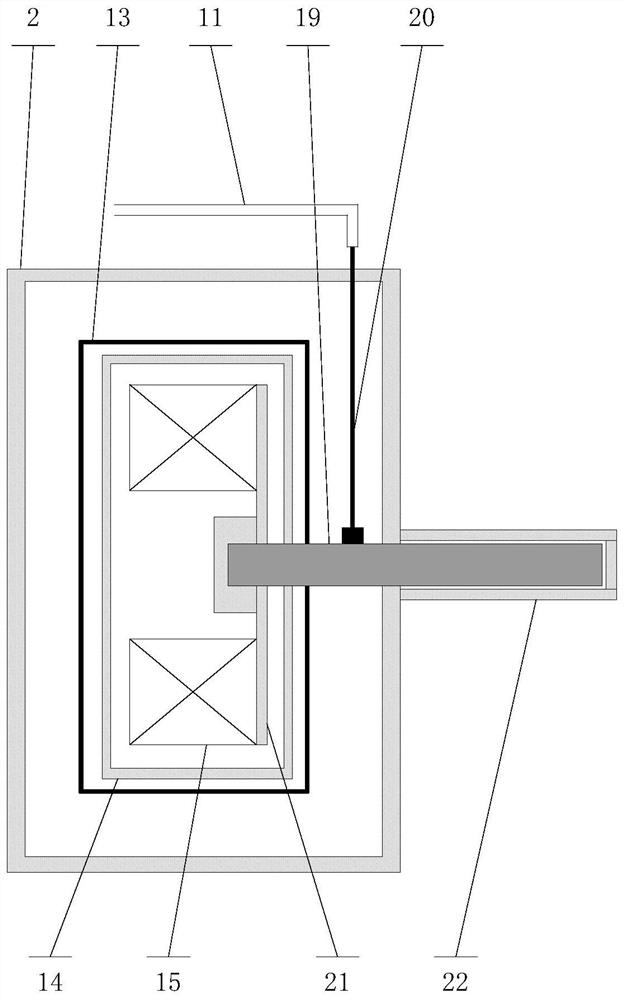

Ellipsoidal high-power microwave plasma diamond film deposition device

ActiveCN104164658AEfficient depositionStable positionElectric discharge tubesChemical vapor deposition coatingForeign matterEtching

The invention relates to an ellipsoidal high-power microwave plasma diamond film deposition device which is composed of a staisecase annular microwave coupled system, an annular quartz microwave window arranged at the staircase of an annular antenna, an ellipsoidal microwave resonant cavity, an adjustable deposition table, a conical upper reflecting body, an adjustable cylindrical lower reflecting body, an inlet and outlet, a temperature measurement hole, a view window and the like. By utilizing the design of the ellipsoidal upper and lower focal points, the conical upper microwave reflecting body is positioned on the upper focal point, the deposition table is positioned on the lower focal point, and the electric field is distributed centrally, so the excited plasma has high position stability and high density; the hidden microwave window can be protected from plasma heating, pollution and etching; the adjustable microwave lower reflecting body and the deposition table optimize the plasma distribution in real time; the inner wall of the ellipsoidal resonant cavity is far from the high-temperature plasma region, so that the heat radiation of the plasma to the inner wall of the cavity is reduced, thereby avoiding depositing foreign matters; and all the components of the device are cooled with water. The device can implement high-efficiency deposition of a large-area high-quality diamond film under the condition of high power.

Owner:HEBEI PLASMA DIAMOND TECH

High thickness uniformity vaporization source

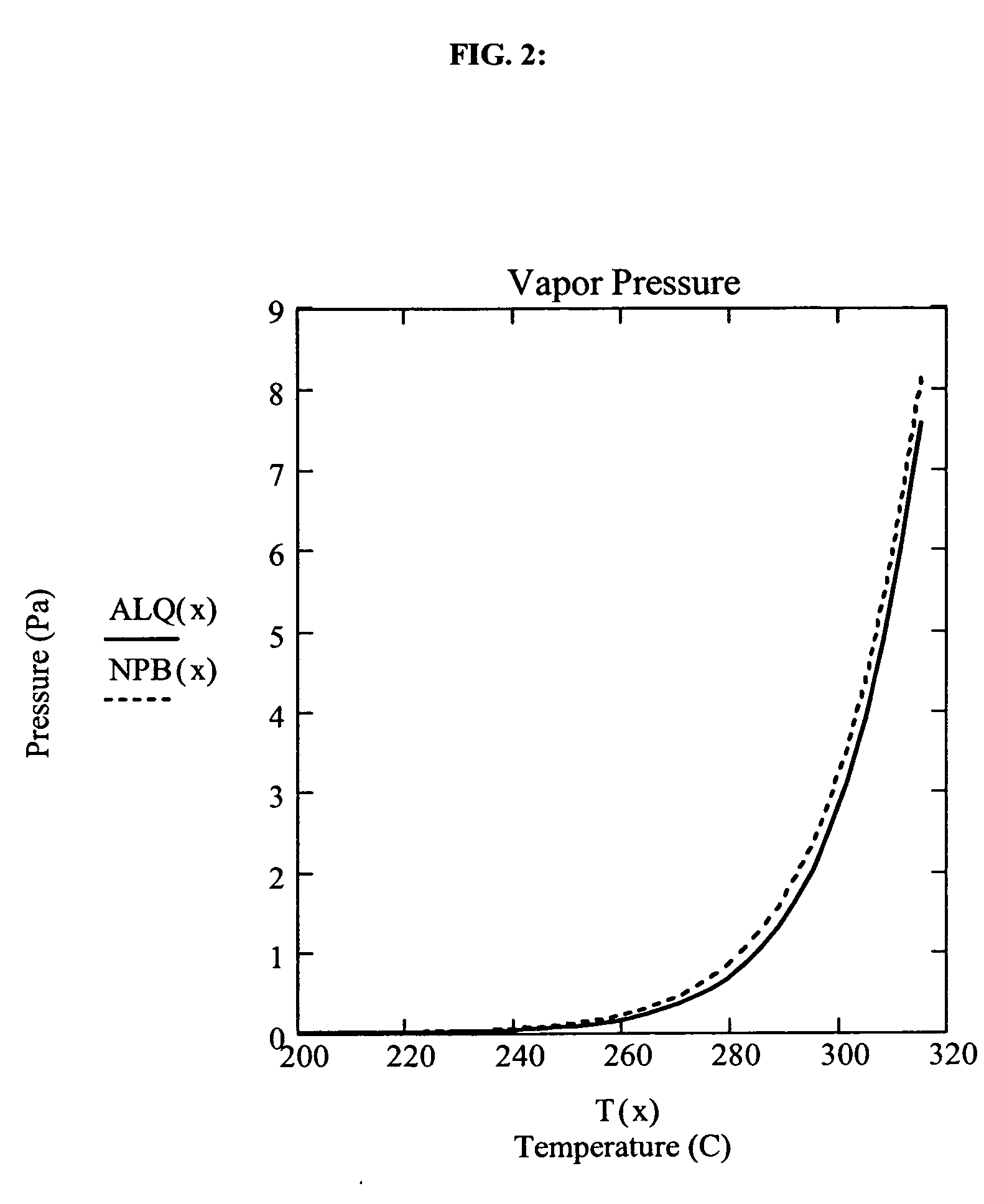

ActiveUS20050208216A1Improving deposit uniformityReduce heat radiationVacuum evaporation coatingSputtering coatingOrganic layerVaporization

A vapor deposition source for use in vacuum chamber for coating an organic layer on a substrate of an OLED device, includes a manifold including side and bottom walls defining a chamber for receiving organic material, and an aperture plate disposed between the side walls, the aperture plate having a plurality of spaced apart apertures for emitting vaporized organic material; the aperture plate including conductive material which in response to an electrical current produces heat; means for heating the organic material to a temperature which causes its vaporization, and heating the side walls of the manifold; and an electrical insulator coupling the aperture plate to the side walls for concentrating heat in the unsupported region of the aperture plate adjacent to the apertures, whereby the distance between the aperture plate and the substrate can be reduced to provide high coating thickness uniformity on the substrate.

Owner:GLOBAL OLED TECH

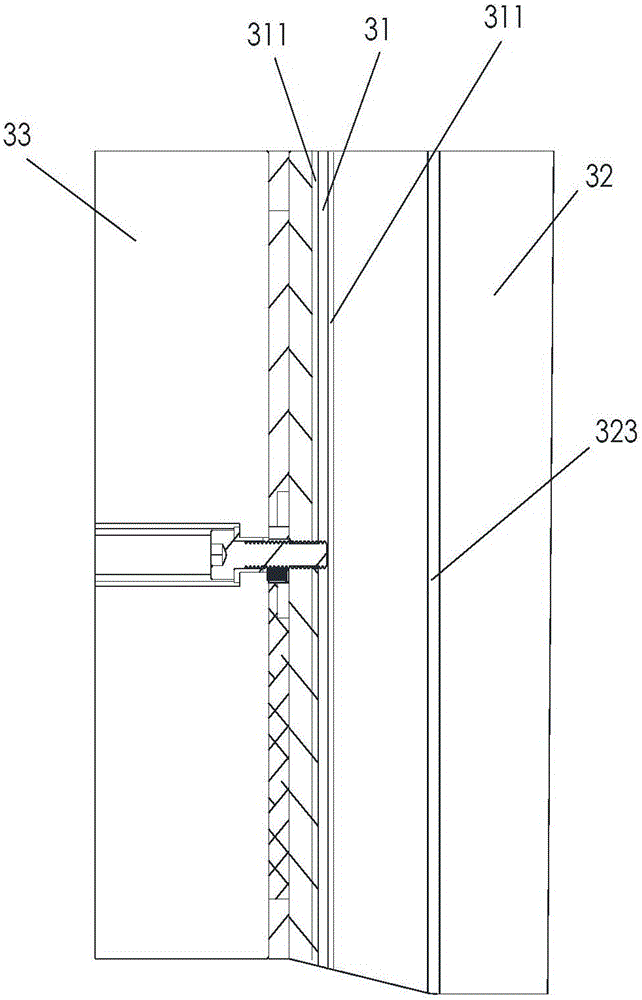

Integrated multi-function window

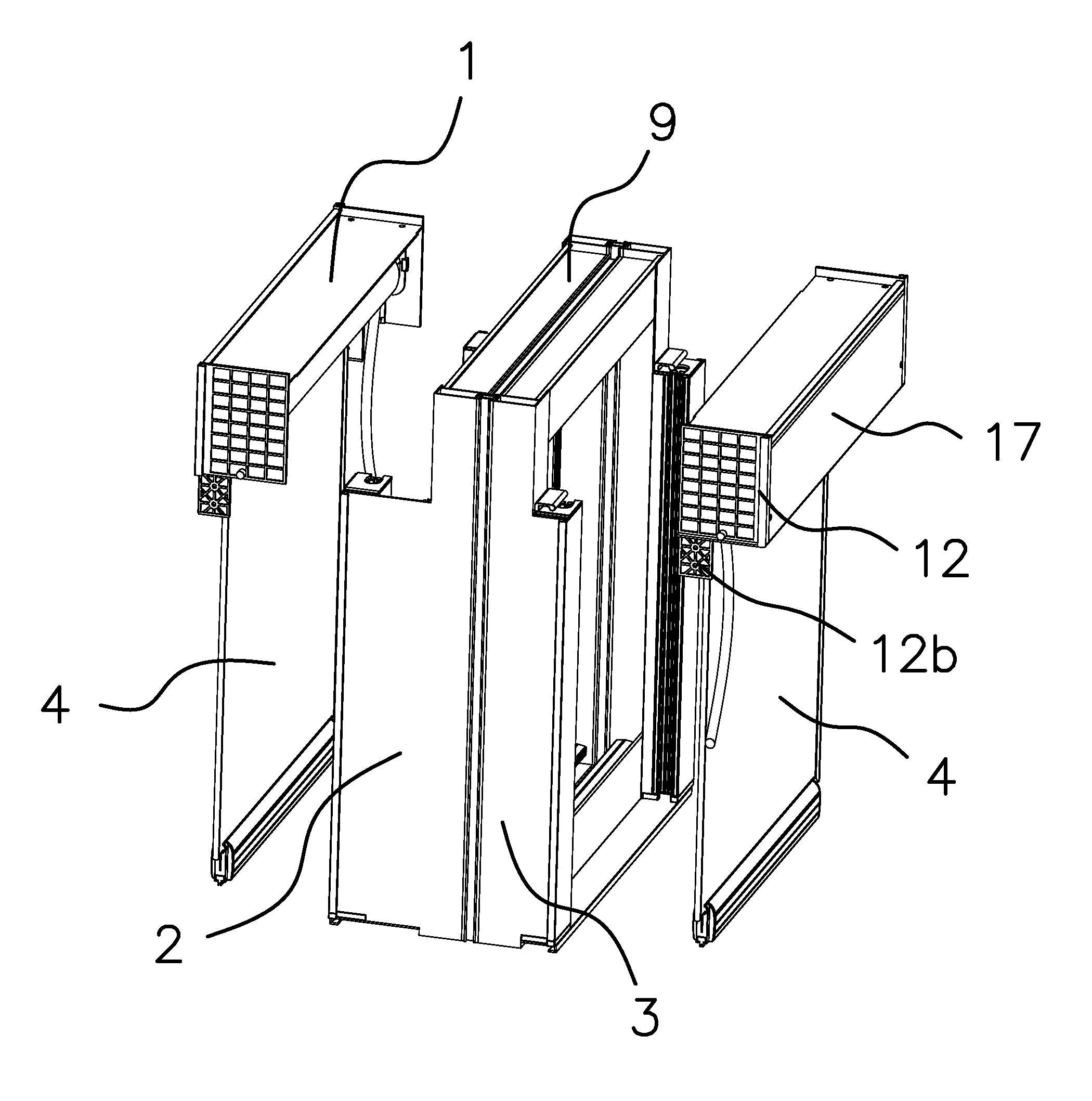

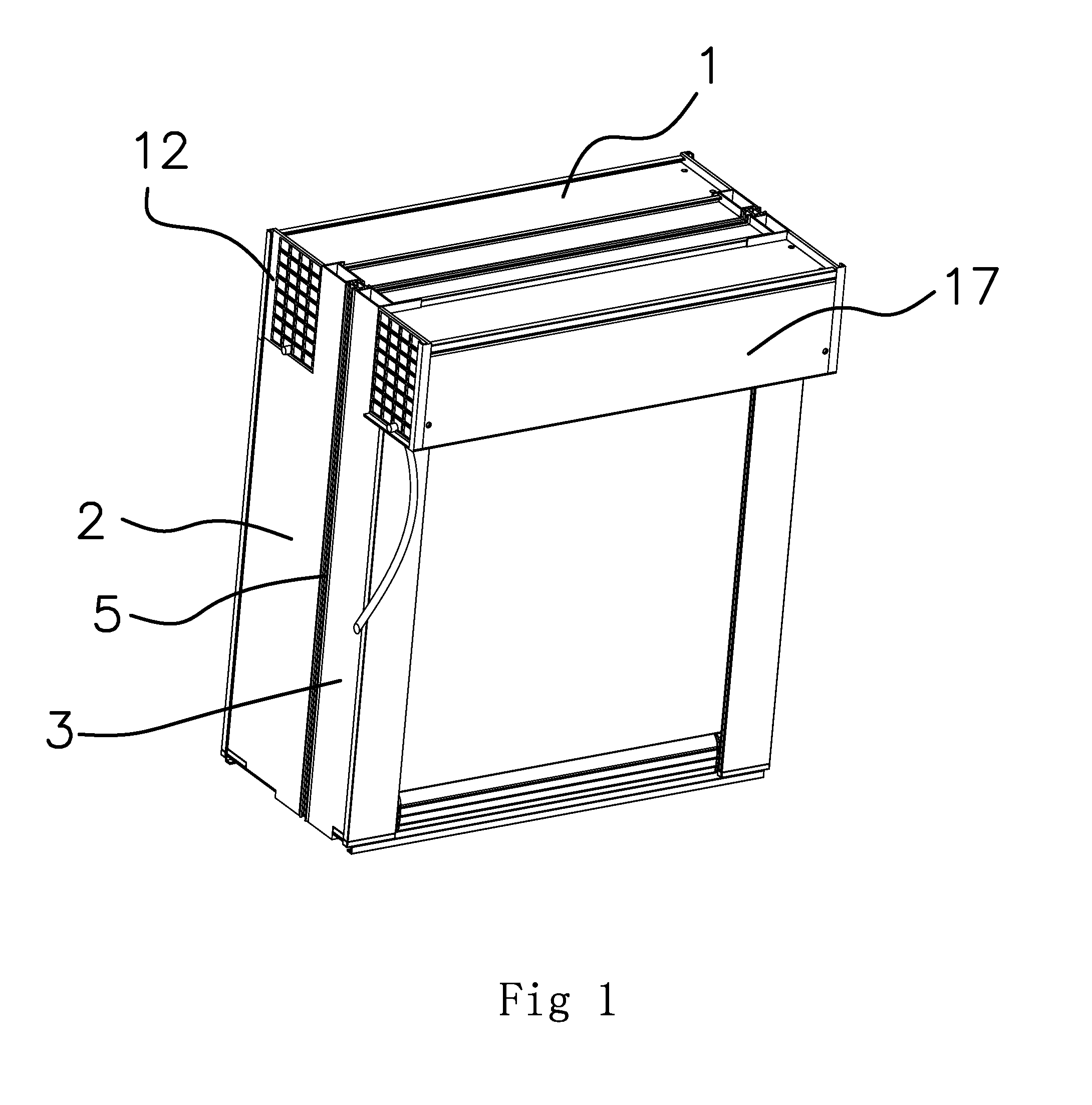

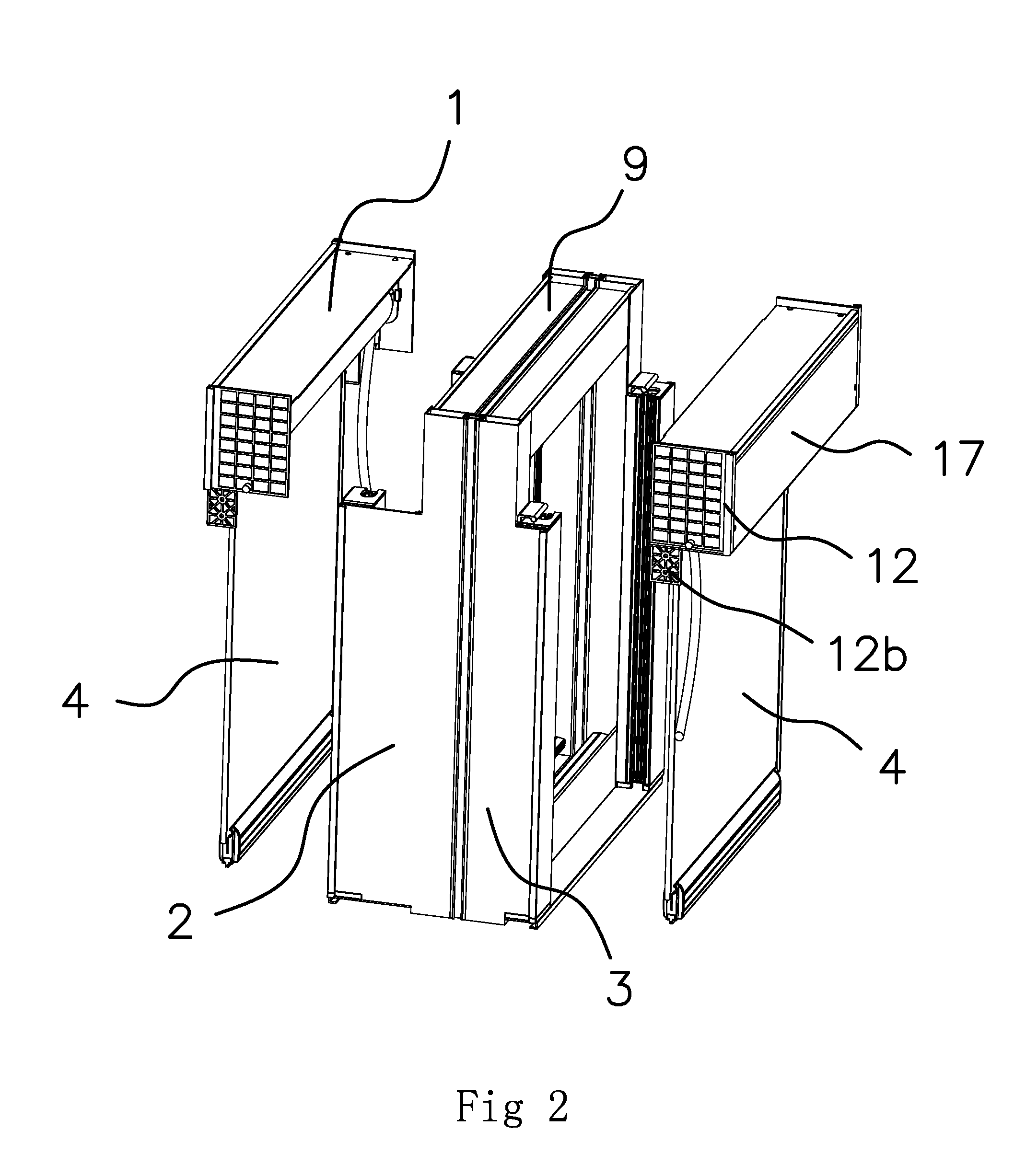

ActiveUS20150027059A1Reduce heat radiationImprove wind resistanceLight protection screensDoor/window applicationsEngineeringBuilding material

The present invention discloses an integrated multi-function window in the technical field of building material, which overcomes the disadvantages of the existing windows, including complicated structures and time, labor and cost consuming double constructions. The integrated multi-function window includes a first window frame having a first window. A first window cover is mounted at the upper part of the first window frame and first telescopic curtain cloth is located within the first window cover. One side of the first window frame is fixedly connected to the second window frame having a second window. The position of the second window is corresponding to that of the first window. The integrated multi-function window has a simple configuration and multiple functions and is of a low cost and improved reliability.

Owner:NINGBO XIANFENG NEW MATERIAL

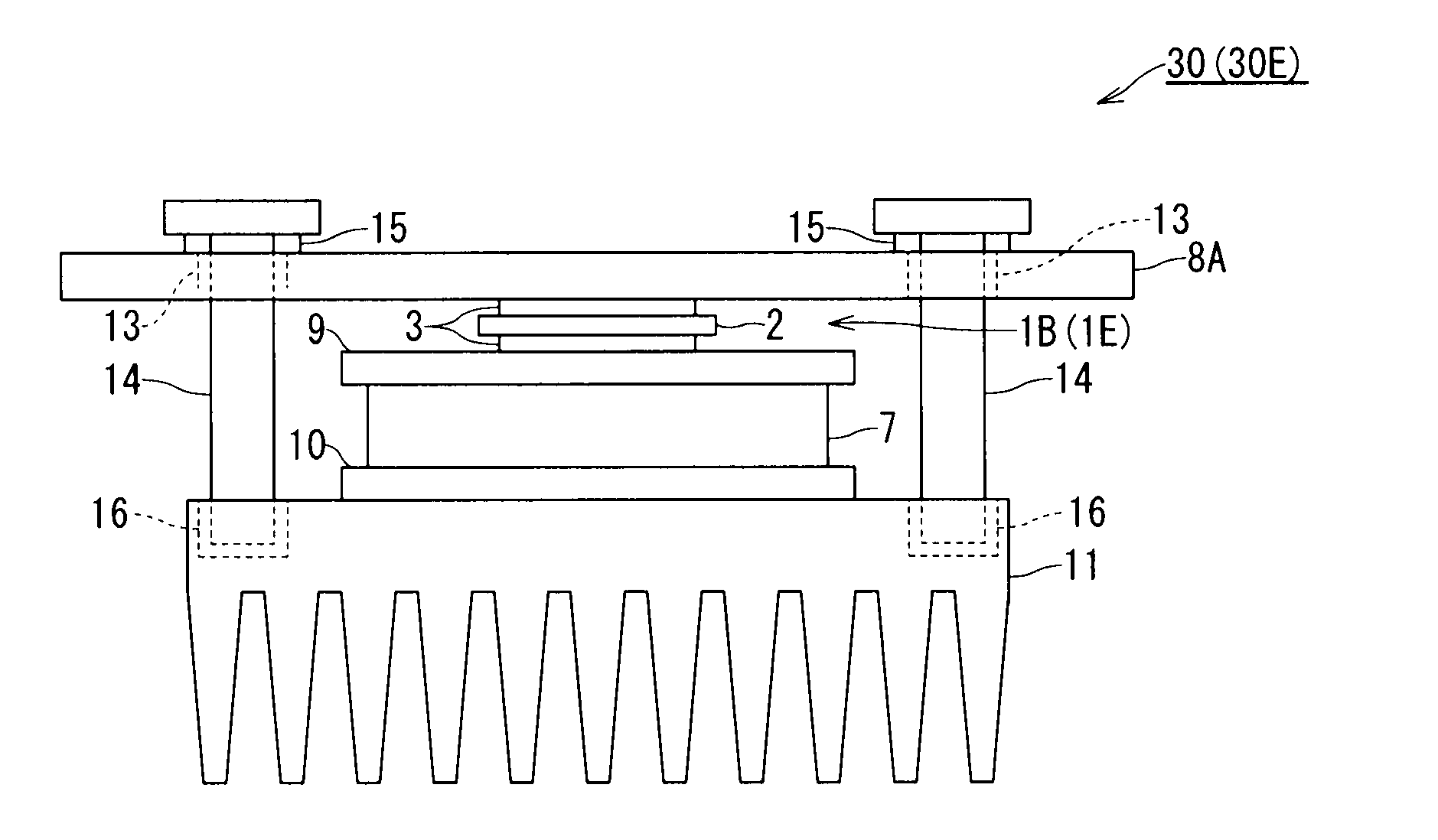

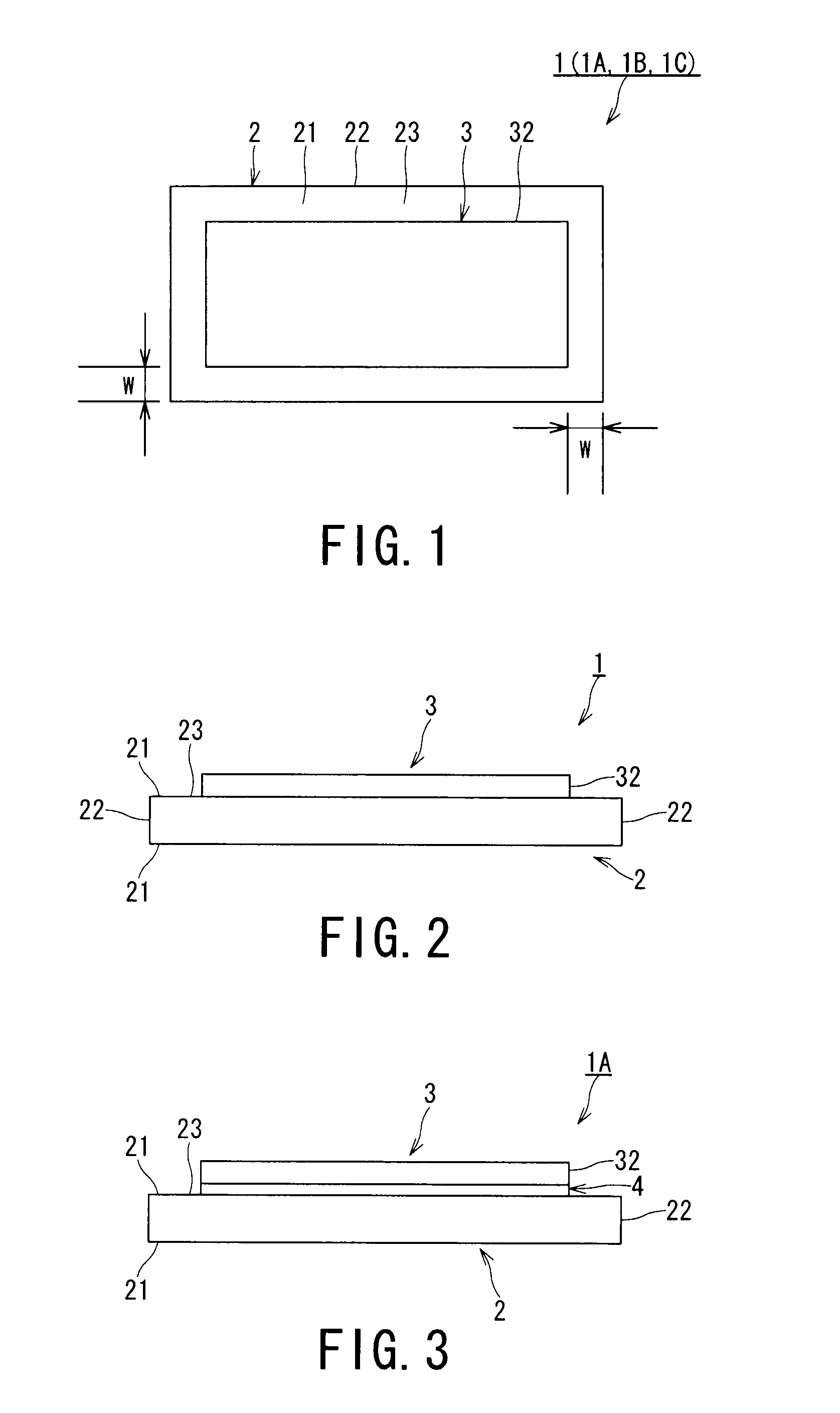

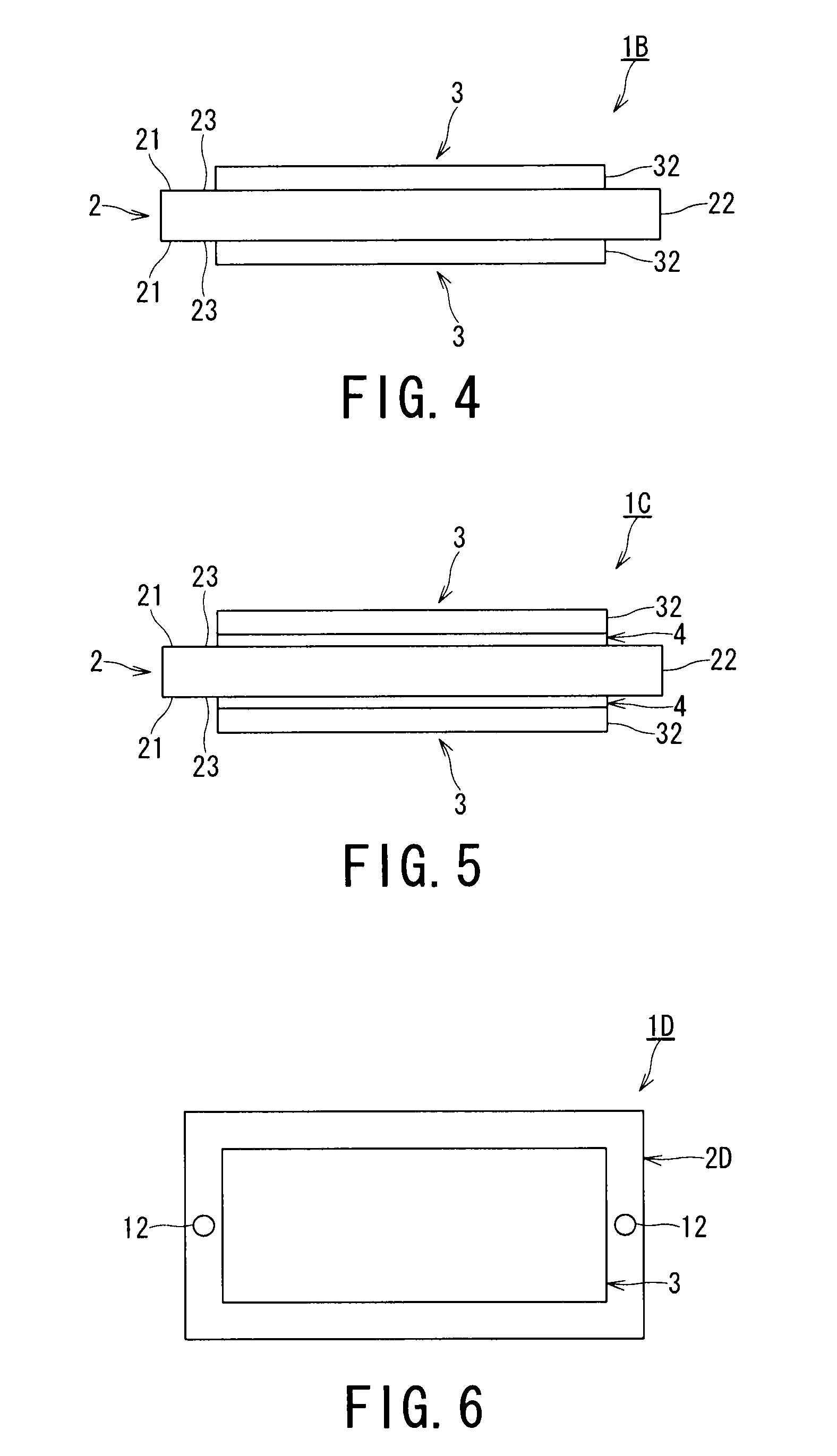

Insulation sheet made from silicon nitride, and semiconductor module structure using the same

ActiveUS20120119349A1Reduce heat radiationDecorative surface effectsSemiconductor/solid-state device detailsSurface layerMetallurgy

An insulation sheet made from silicon nitride comprising: a sheet-shaped silicon-nitride substrate which contains β-silicon-nitride crystal grains as a main phase; and a surface layer which is formed on one face or both front and back faces of surfaces of the silicon-nitride substrate and is formed from a resin or a metal which includes at least one element selected from among In, Sn, Al, Ag, Au, Cu, Ni, Pb, Pd, Sr, Ce, Fe, Nb, Ta, V and Ti. A semiconductor module structure using the insulation sheet made from silicon nitride.

Owner:KK TOSHIBA +1

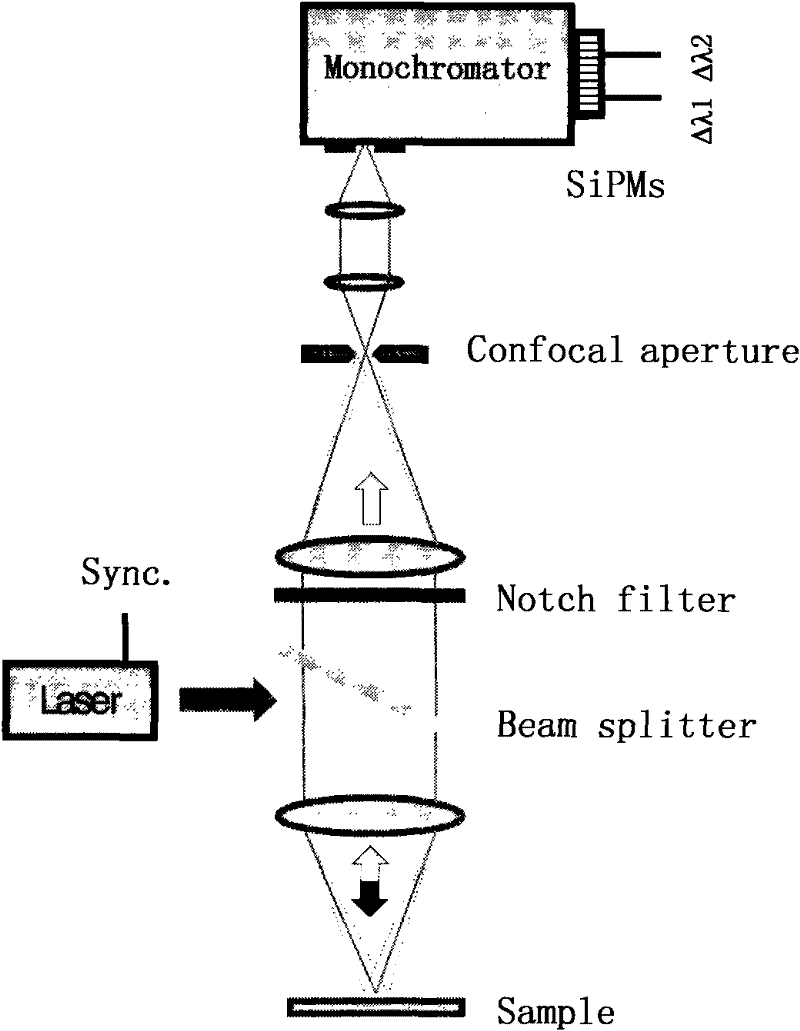

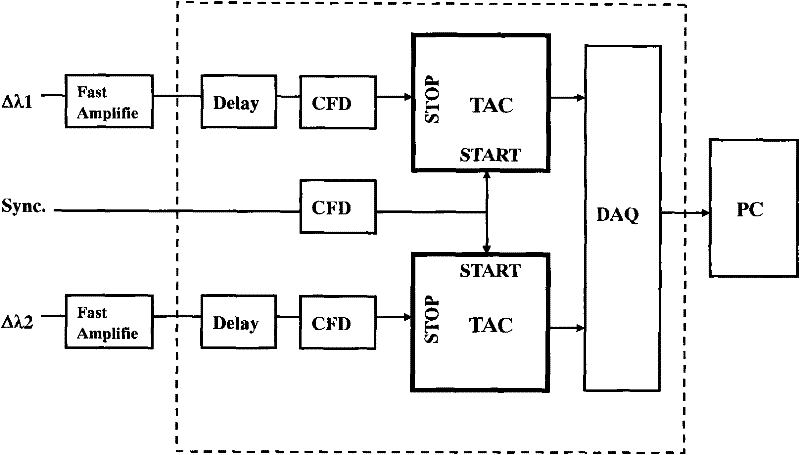

Time-resolved Raman scattering characteristic spectrum analyzer

InactiveCN102252976AImprove time resolutionImprove signal-to-noise ratioColor/spectral properties measurementsGratingPhotodetector

The invention provides a novel time-resolved Raman scattering method and device, namely a time-resolved Raman scattering characteristic spectrum analyzer, aiming at the problem that the common Raman spectrometer has the defects of fluorescence background interference, low time resolution and lower trace analysis detection speed. In the invention, a multielement strip silicon photo-multiplier detector (SiPM) with high gain and high response speed is used as a photodetector, and a Raman signal is measured by combining a time-correlated single photon counting (TCSPC) method with the photodetector, therefore, the time-resolved Raman scattering characteristic spectrum analyzer has time resolution of a picosecond order of magnitude and single photon counting detectivity. The time-resolved Raman scattering characteristic spectrum analyzer not only can be independently used as a Raman scattering characteristic spectrum analyzer for rapidly judging whether a sample contains a plurality of compositions synchronously by using the characteristic spectrum of the Raman scattering, or for accurately identifying the compositions through scanning the complete Raman spectrum of the detection sample by a grating monochromator, but also can be used as a function expansion module based on the traditional Raman spectrometer for enhancing the time resolution, reducing the fluorescence background interference, and increasing the signal to noise ratio and the detection speed.

Owner:BEIJING NORMAL UNIVERSITY

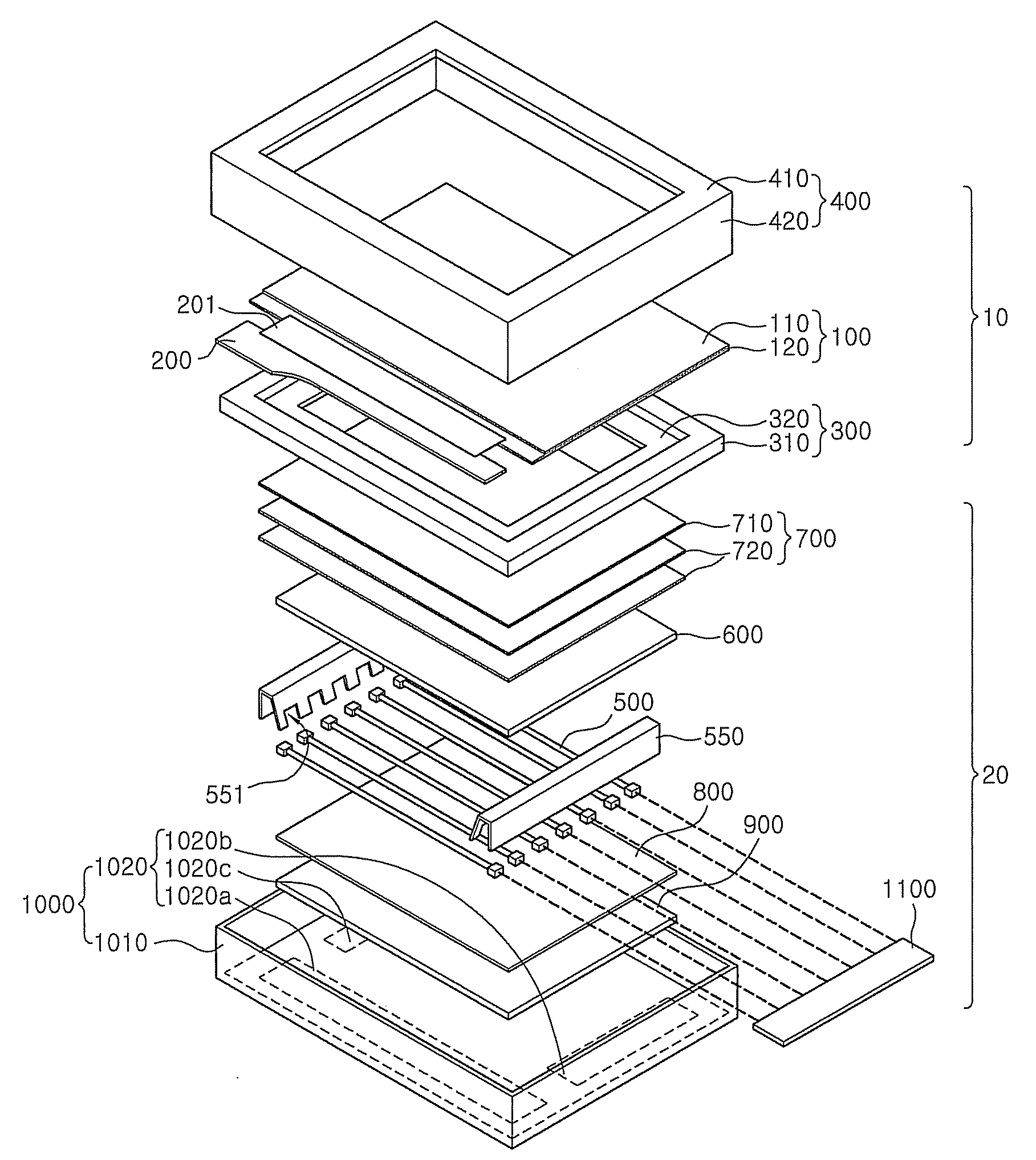

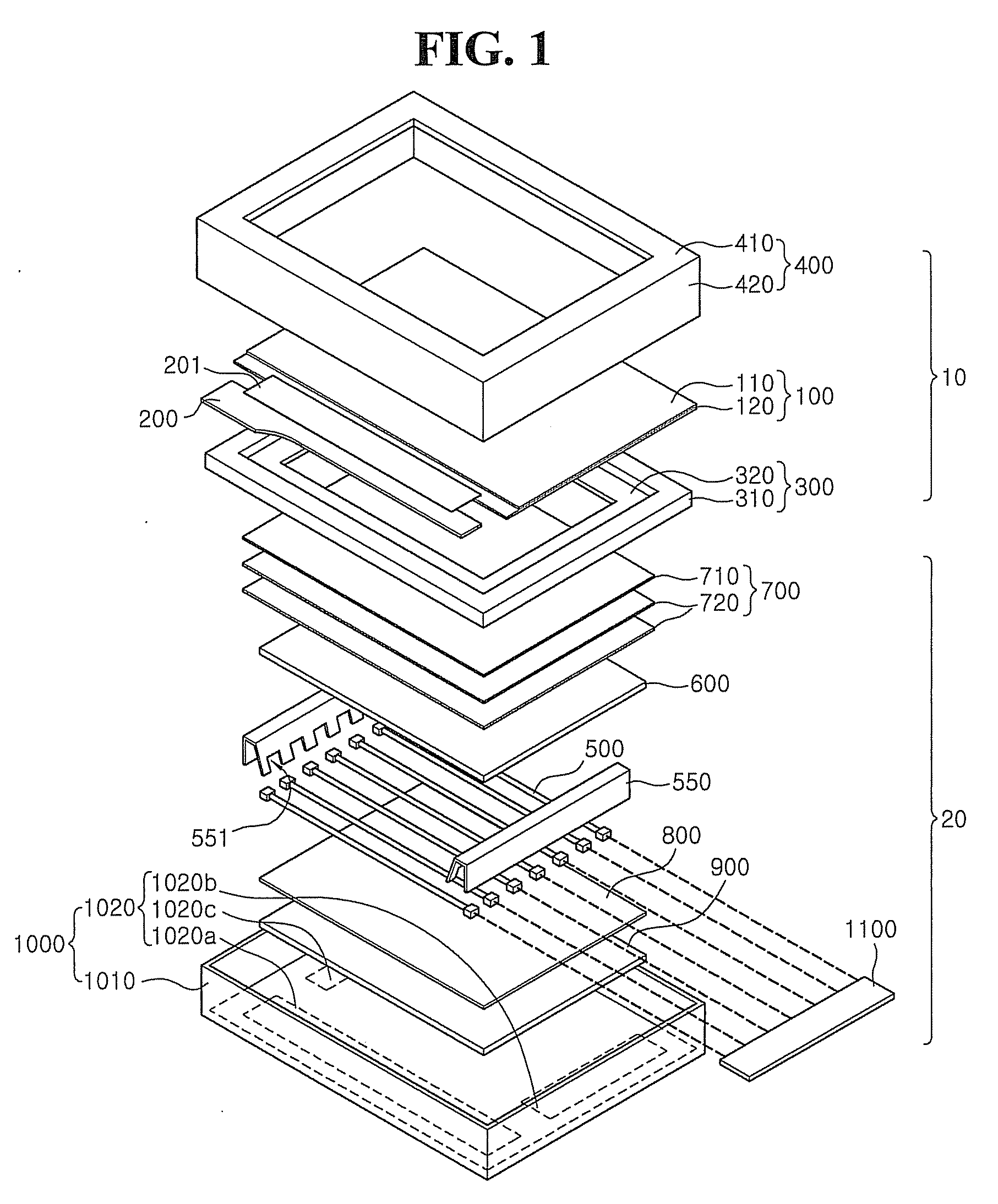

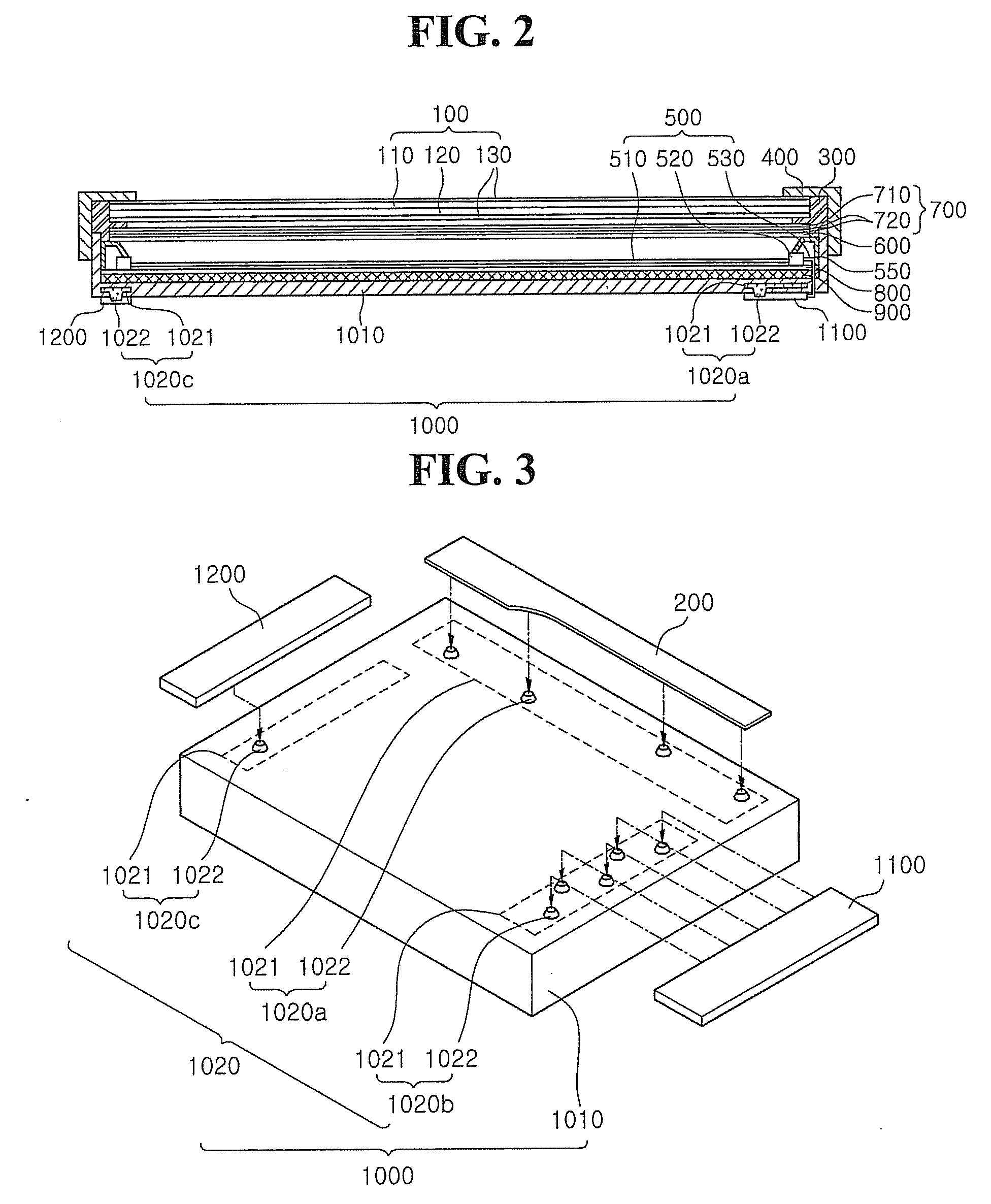

Receiving member, display having the same, and method thereof

InactiveUS20090180048A1Improve leakage currentCharacteristic (uniformityWave amplification devicesMagnetic/electric field screeningElectromagnetic interferenceDisplay device

The present invention relates to a receiving member which accommodates a display panel which displays an image. The receiving member includes an insulated body portion having a bottom plate and sidewalls to define a receiving space, and at least one ground metal portion provided at a region of the insulated body portion, the at least one ground metal portion formed integrally with the insulated body portion. Accordingly, the body portion of the receiving member is formed of an insulated material, thereby reducing the weight of the receiving member and improving heat radiation. Further, a local metal portion is provided in the receiving member, thereby improving electromagnetic interference (“EMI”) and electrostatic discharge performances of elements such as a control board.

Owner:SAMSUNG ELECTRONICS CO LTD

Lighting device for household appliances

InactiveCN1538106AReduce heat radiationReduce energy consumptionMechanical apparatusLighting support devicesElectrical conductorEffect light

Owner:舱壁玻璃公司

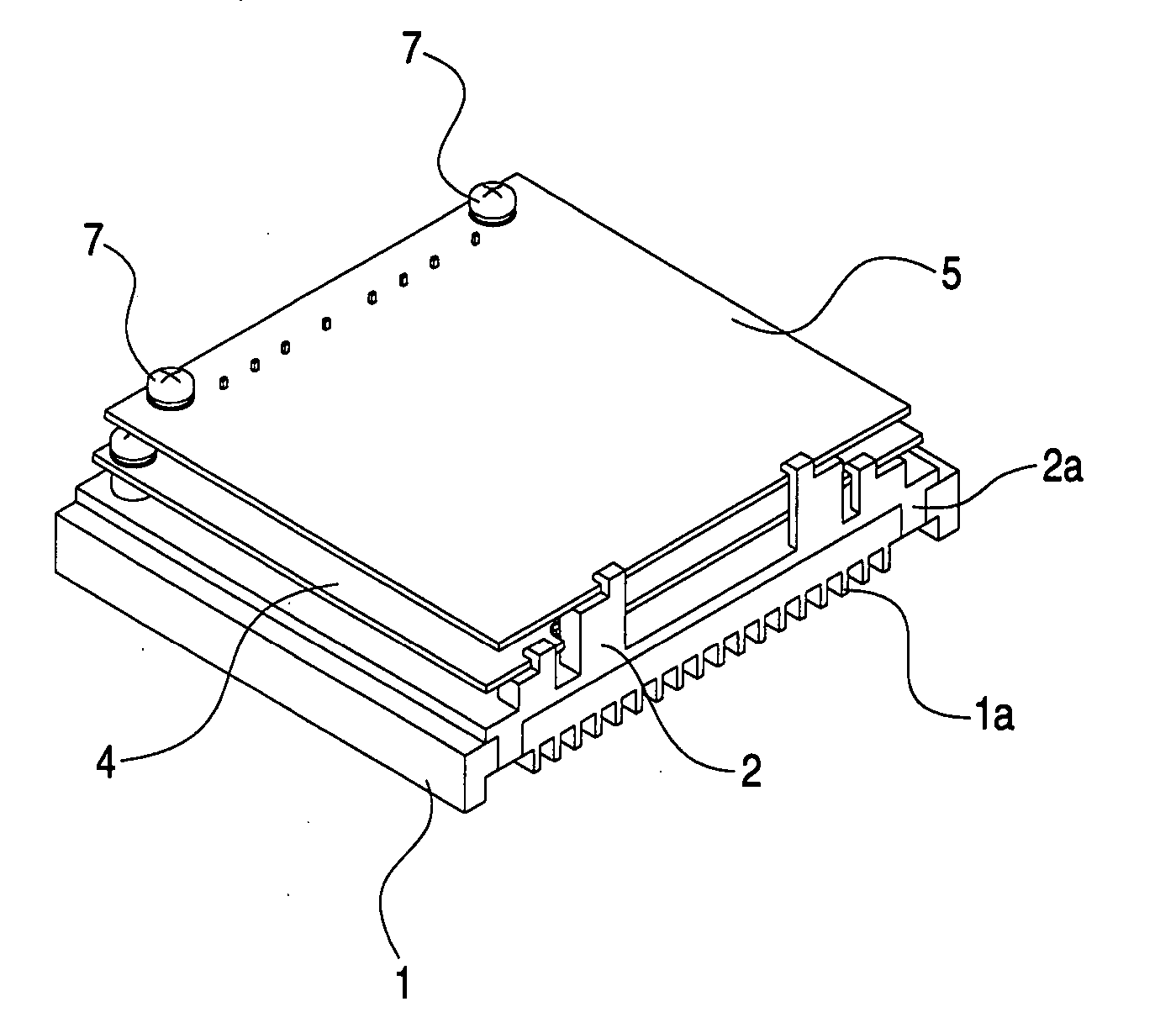

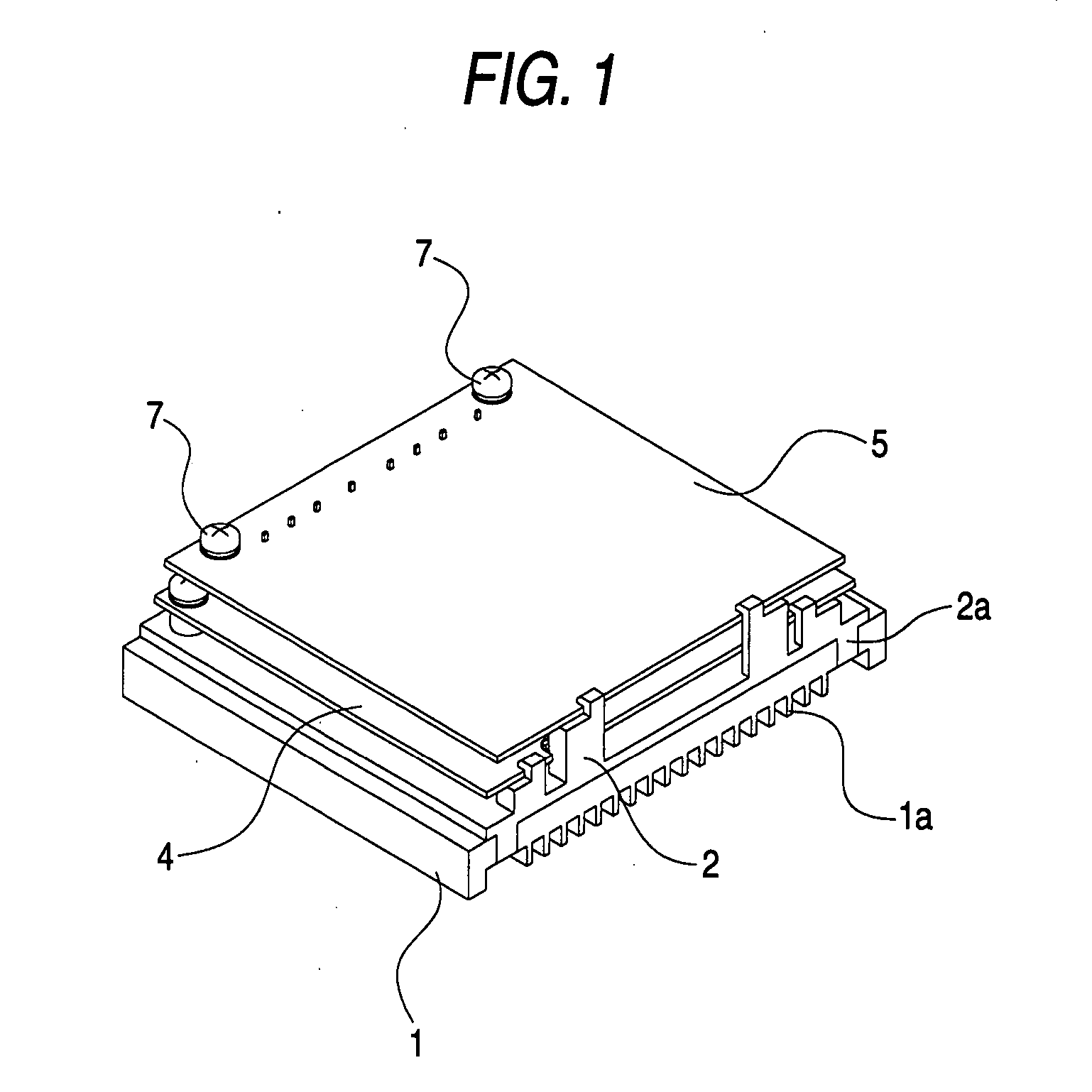

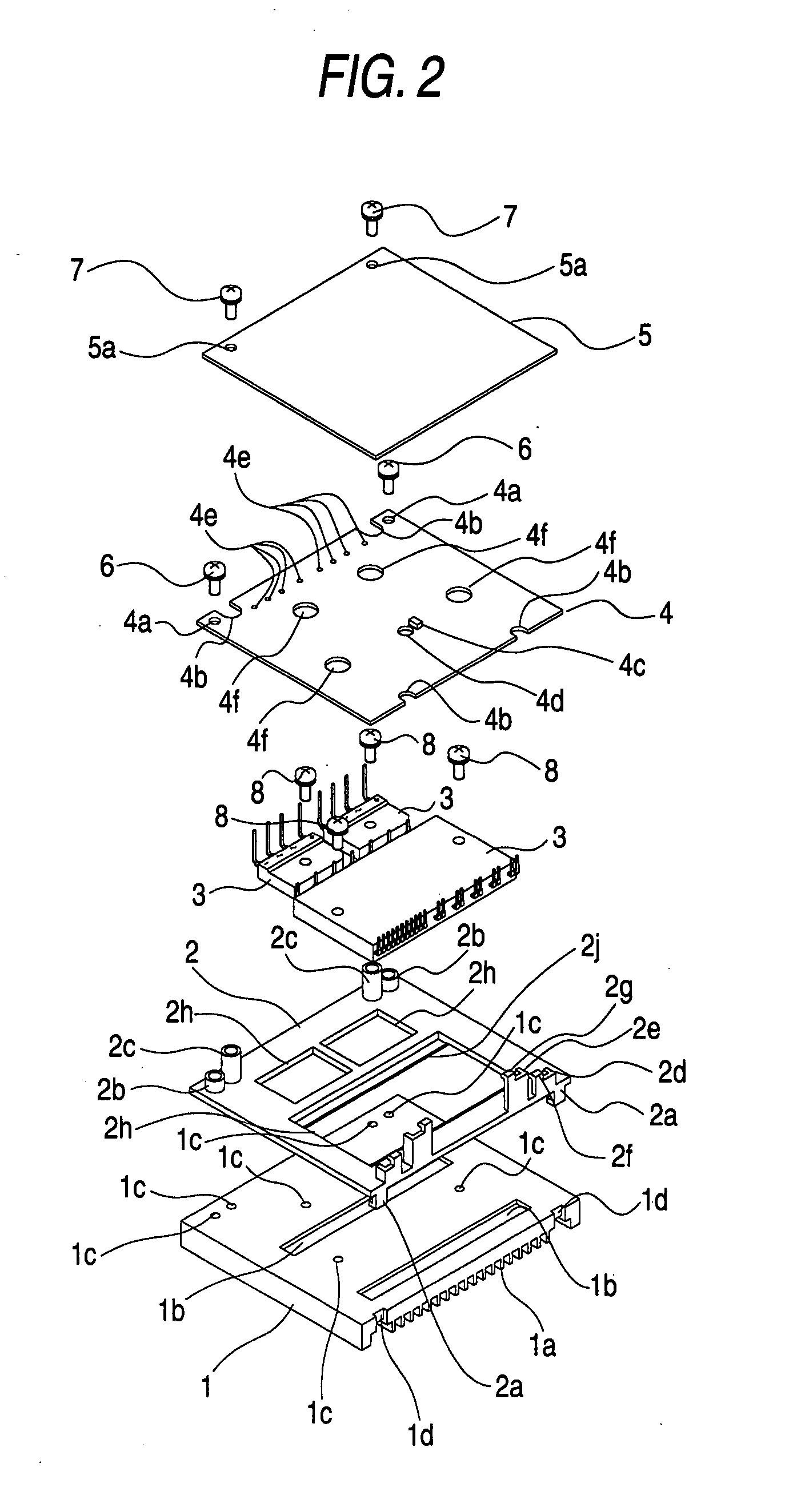

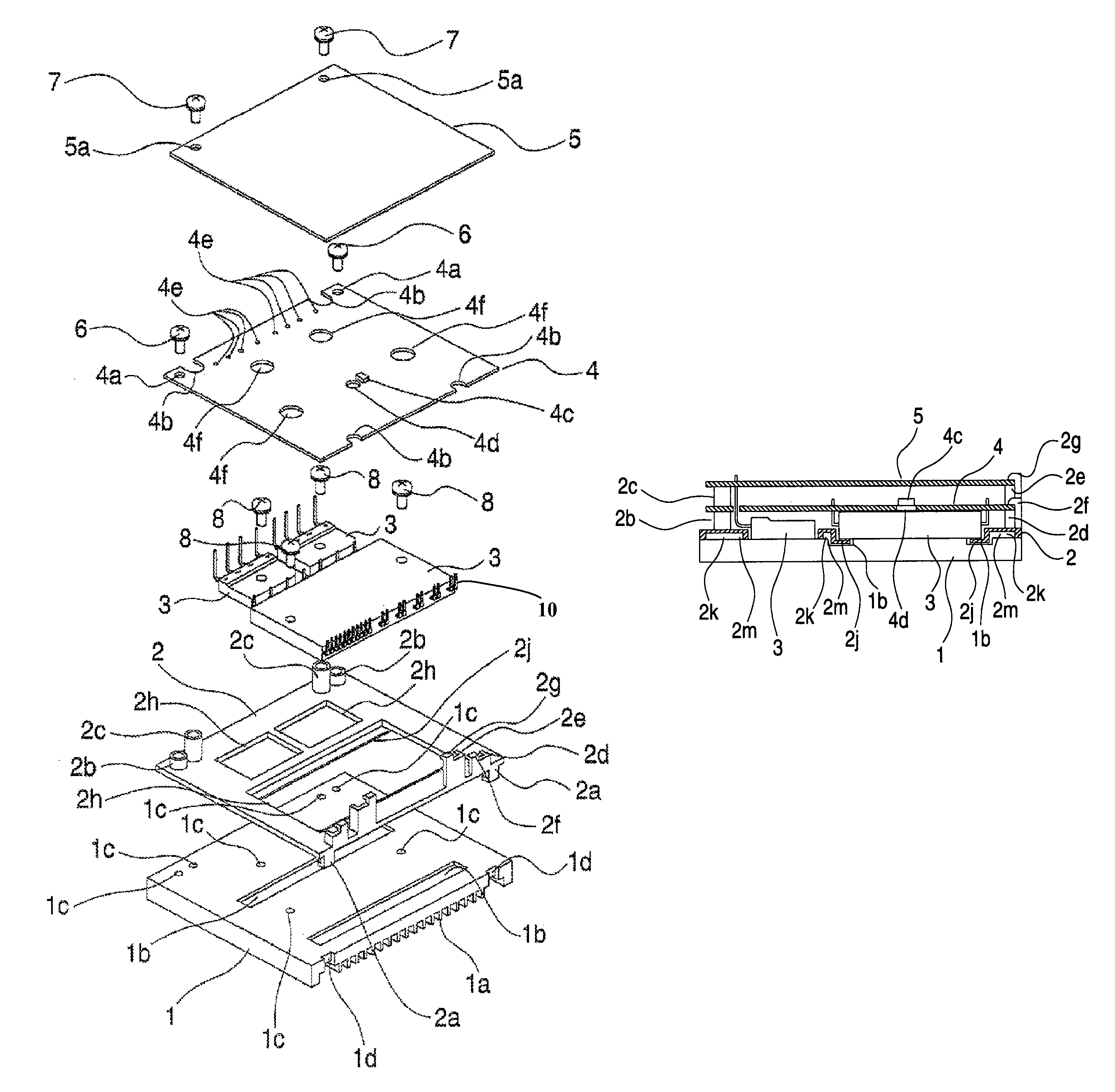

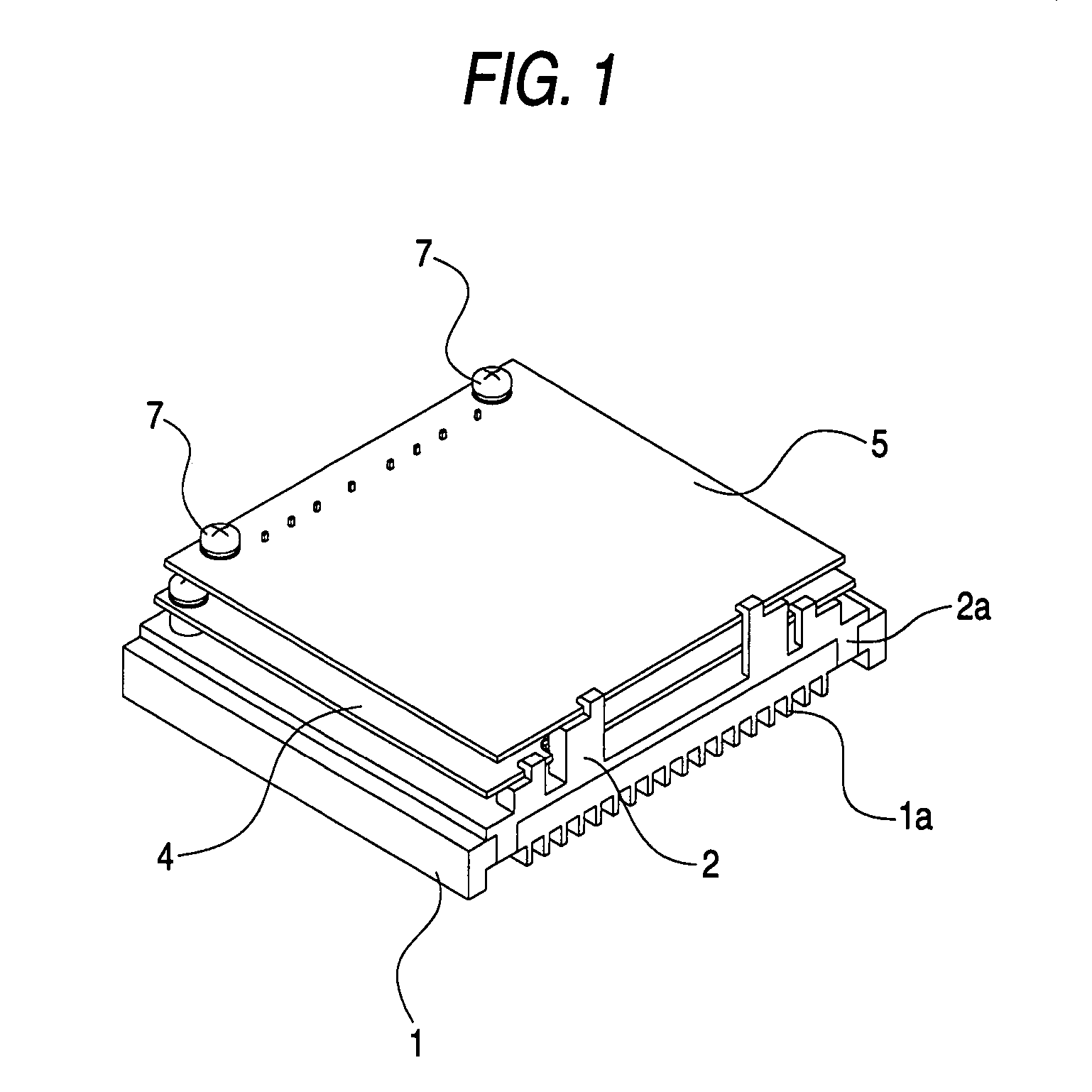

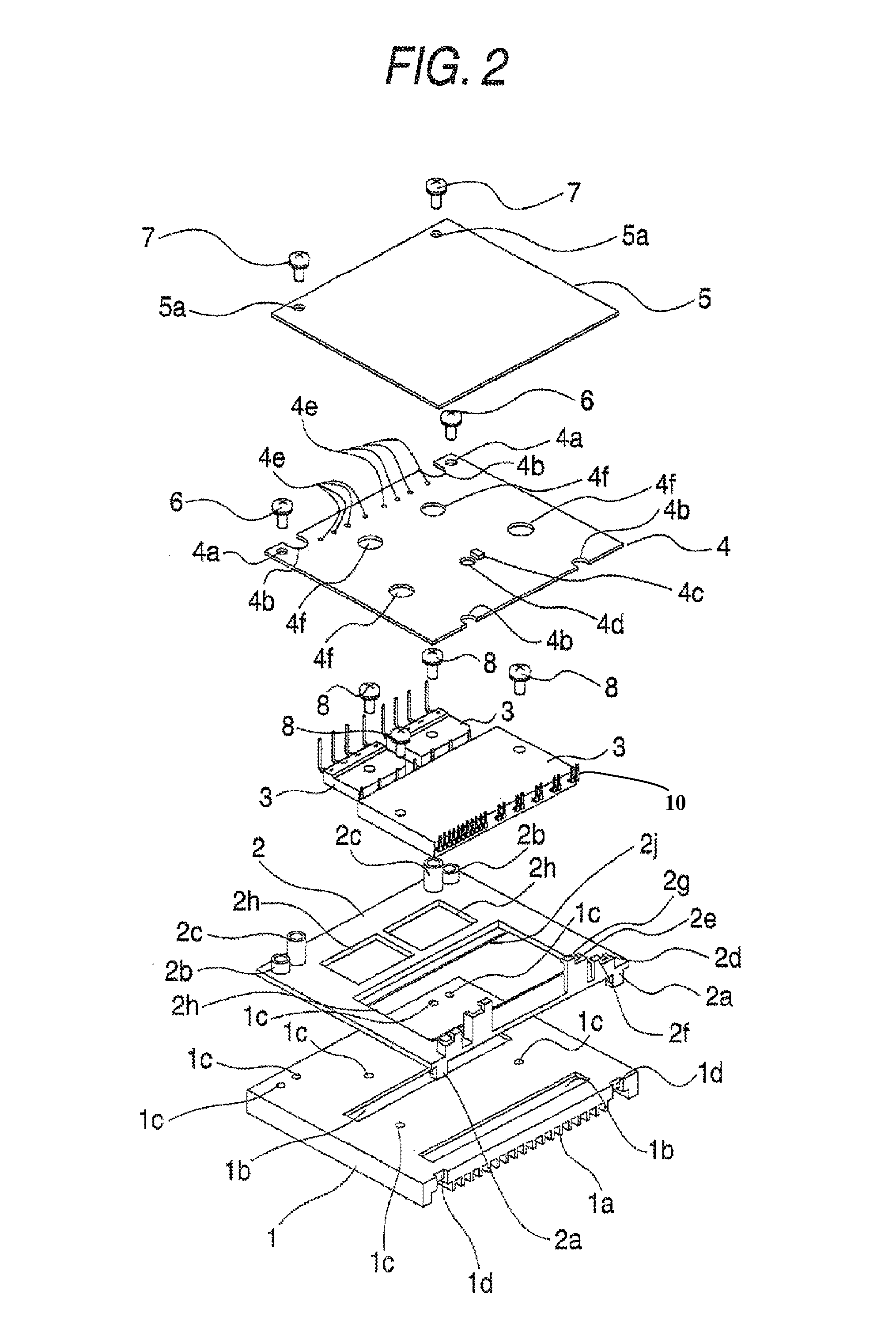

Motor Control Apparatus And method Of Assembling Motor Control Apparatus

InactiveUS20080007919A1Reduce numberReduce heat sinkingWave amplification devicesConversion constructional detailsEngineeringSemiconductor

There is provided a motor control apparatus in which a size of the apparatus can easily be reduced, a work for aligning a power semiconductor module with a substrate can be eliminated and an assembling property can be enhanced. In a motor control apparatus in which a power semiconductor module adhering to a heat sink is mounted on a first substrate, a spacer is provided between the heat sink and the substrate and the power semiconductor module is disposed in the spacer. Moreover, an edge part of a hole has such a structure as to block a space between a terminal protruded from a side portion of the power semiconductor module and the heat sink.

Owner:YASKAWA DENKI KK

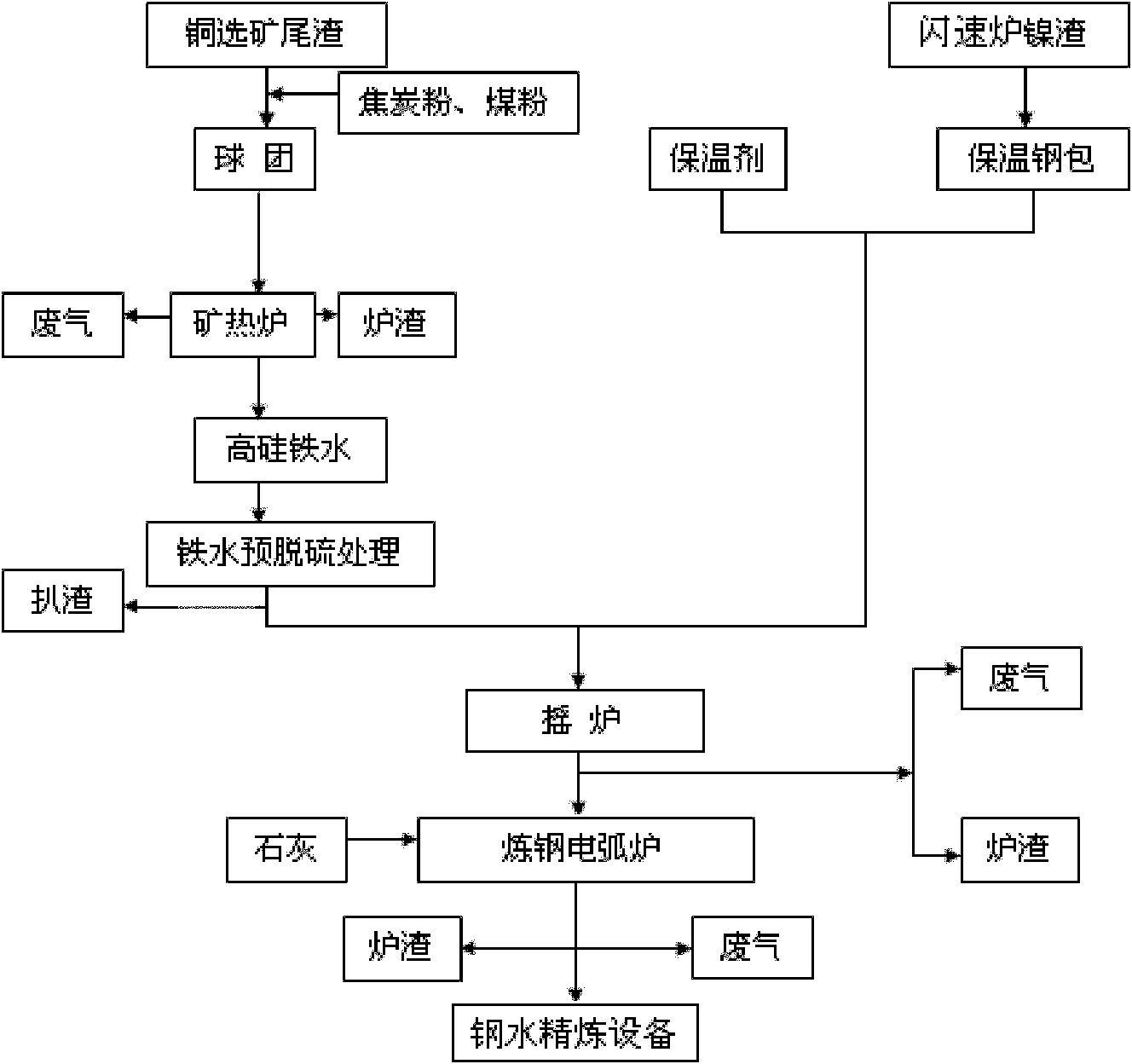

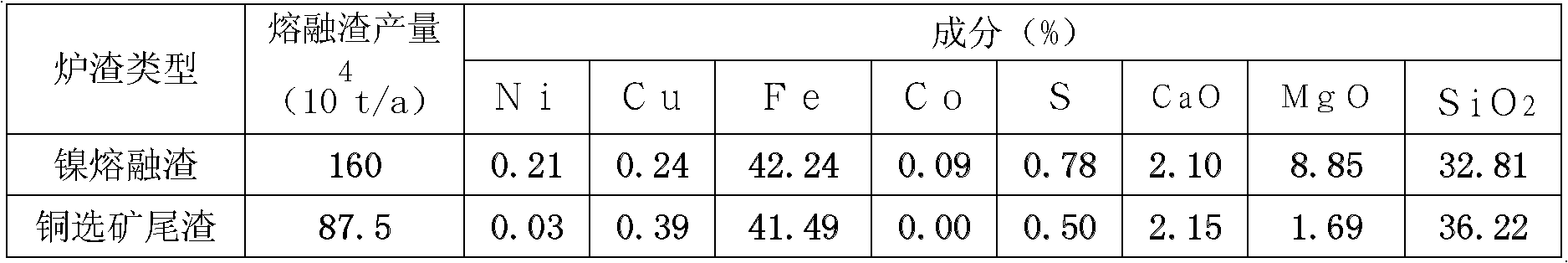

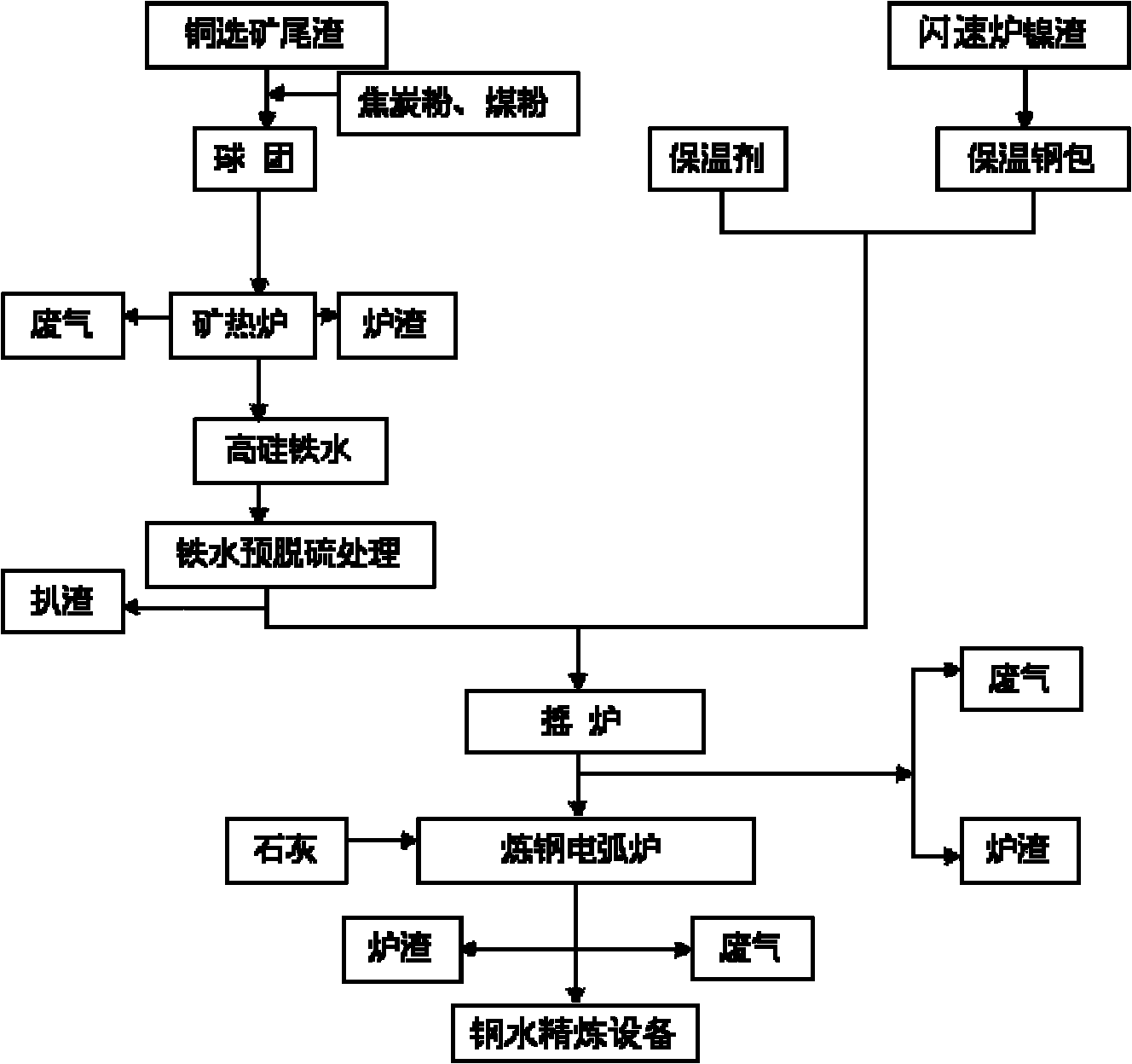

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

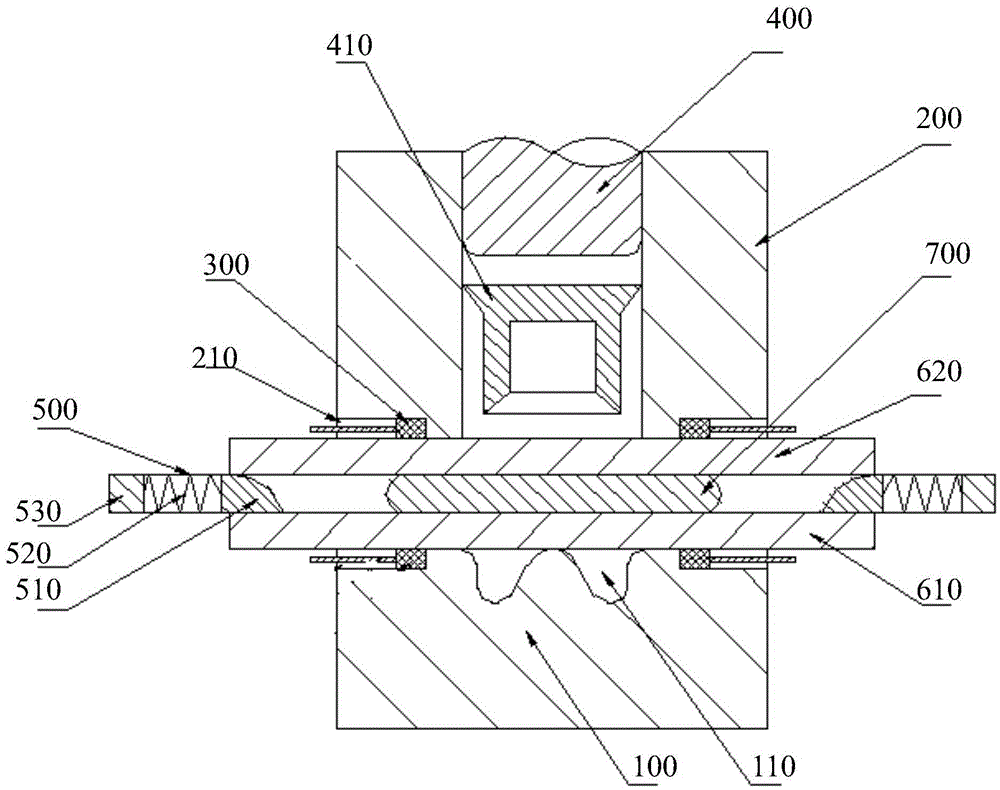

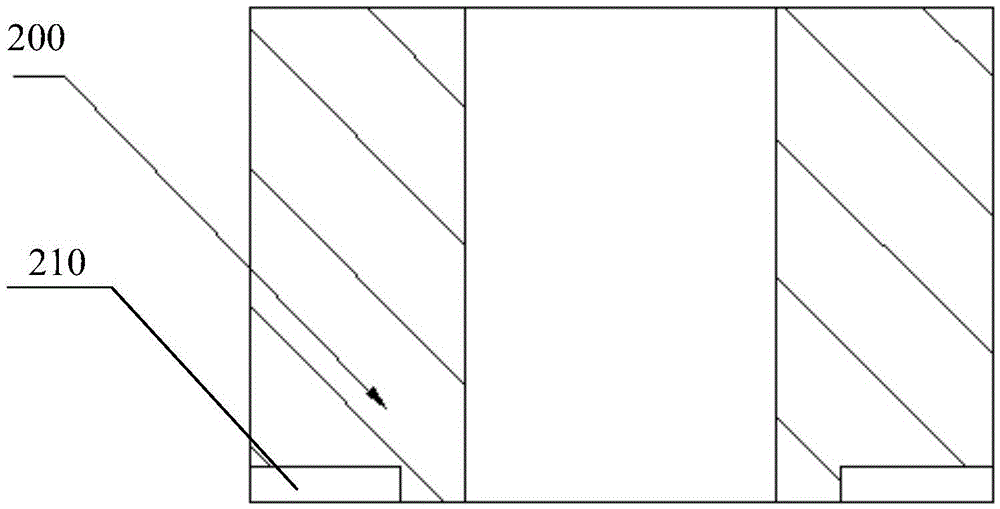

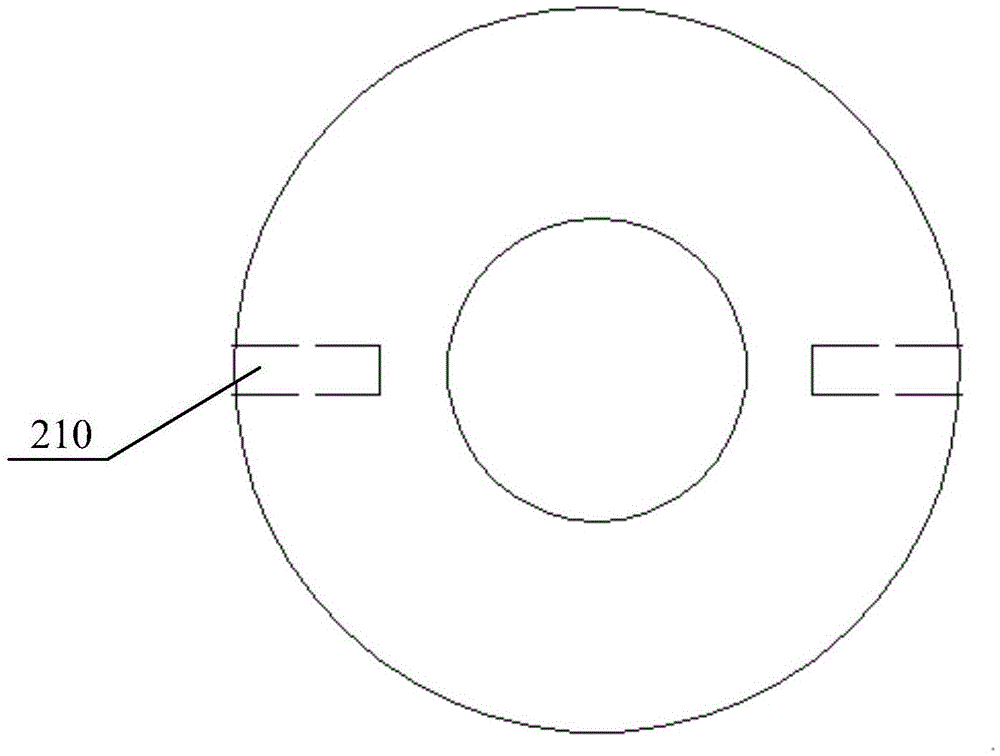

Self-punching bond-riveting connecting device and bond-riveting method

InactiveCN105458147ASelf-piercing riveting is possibleReduce intensityFurnace typesHeat treatment furnacesPunchingEngineering

A self-punching bond-riveting connecting device comprises a compound female die, a compound edge pressing ring, heat conduction electrodes and a punch, wherein an annular groove is formed in the compound female die, the compound edge pressing ring is opposite to the compound female die in the vertical direction, the compound edge pressing ring can move in the vertical direction and is used for pressing to-be-riveted pieces, the heat conduction electrodes are arranged at the bottom of the compound edge pressing ring and the upper portion of the compound female die and can heat the different to-be-riveted pieces independently, and the punch is a solid circular structural piece, is arranged in a central hole of the compound edge pressing ring and can slide up and down in the axial direction of the central hole. The expanding performance of super-strength steel nearby riveting points is greatly improved, and the problems that super-strength steel is difficult to deform and effective connectors can not be formed are solved. The invention further provides a self-punching bond-riveting connecting method. By precisely controlling the punching speed of the punch, the requirements for the strength of the rivet, the punch riveting capacity of the device and the rigidity of a C-shaped frame of a riveting gun are lowered, and production cost is reduced.

Owner:JILIN UNIV

Motor control apparatus and method of assembling motor control apparatus

InactiveUS7679915B2Reduce in quantityReduce assemblyWave amplification devicesConversion constructional detailsComputer moduleMotor control

There is provided a motor control apparatus in which a size of the apparatus can easily be reduced, a work for aligning a power semiconductor module with a substrate can be eliminated and an assembling property can be enhanced.In a motor control apparatus in which a power semiconductor module adhering to a heat sink is mounted on a first substrate, a spacer is provided between the heat sink and the substrate and the power semiconductor module is disposed in the spacer. Moreover, an edge part of a hole has such a structure as to block a space between a terminal protruded from a side portion of the power semiconductor module and the heat sink.

Owner:YASKAWA DENKI KK

High-temperature-resisting wet-process felt and preparation method thereof

ActiveCN104534223AHigh porosityLow thermal conductivityThermal insulationPipe protection by thermal insulationPorosityFiber

The invention discloses a high-temperature-resisting wet-process felt and a preparation method thereof. The porosity of the high-temperature-resisting wet-process felt is more than 93% and the thickness of the high-temperature-resisting wet-process felt is 6mm-22mm; a nano silicon dioxide coating is arranged on the outer surface of the high-temperature-resisting wet-process felt; the diameter of fiber monofilaments of the high-temperature-resisting wet-process felt is 0.1 micron-2 microns, and closed vacuum balls with the diameter being less than 20nm are uniformly arranged on the outer surfaces of the fiber monofilaments. By the aid of the high-temperature-resisting wet-process felt, the porosity of a fiber cotton felt is greatly improved and the heat conductivity coefficient of the fiber cotton felt is reduced; any binding agent is not added into the product so that the product has the advantages of no toxin, high temperature resistance, low moisture absorption rate, soft texture and small volume density, and can be repeatedly used at high and low temperatures, and the heat insulation performance is not obviously reduced when the product is used at the high temperature; the highest utilization temperature is up to 1000 DEG C; the high-temperature-resisting wet-process felt can be widely applied to fire prevention and heat insulation of high-temperature equipment and is particularly suitable for heat preservation and heat insulation of equipment which needs to be usually converted between high temperature and low temperature.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Low-temperature vacuum evaporation source

PendingCN107217236AEfficient exclusionTo achieve the purpose of coolingVacuum evaporation coatingSputtering coatingWater circulationOrganic compound

The invention discloses a low-temperature vacuum evaporation source. The low-temperature vacuum evaporation source comprises a heating system, a cooling system, a temperature measuring system, a control system and a connecting assembly. An electrode in the device is electrified to heat a lamp filament of the heating system, and when the temperature of the lamp filament reaches the sublimation temperature of substances in a crucible, a source substance starts to be evaporated, gas molecules obtained through evaporation are transmitted to a to-be-coated base body in a vacuum cavity, and evaporation of alkaline metal and an organic compound can be achieved. A real-time evaporation temperature of a thermocouple of the temperature measuring system is conducted and detected through an electric couple wire. Cooling water is led into a water inlet pipe of the cooling system, the crucible is cooled through water circulation in a cooling cover, and the low-temperature evaporation effect is achieved. A rotation baffle on a crucible opening can adjust and control whether the substances obtained through evaporation conduct coating on the base body or not through a manual rod.

Owner:DALIAN JIAOTONG UNIVERSITY

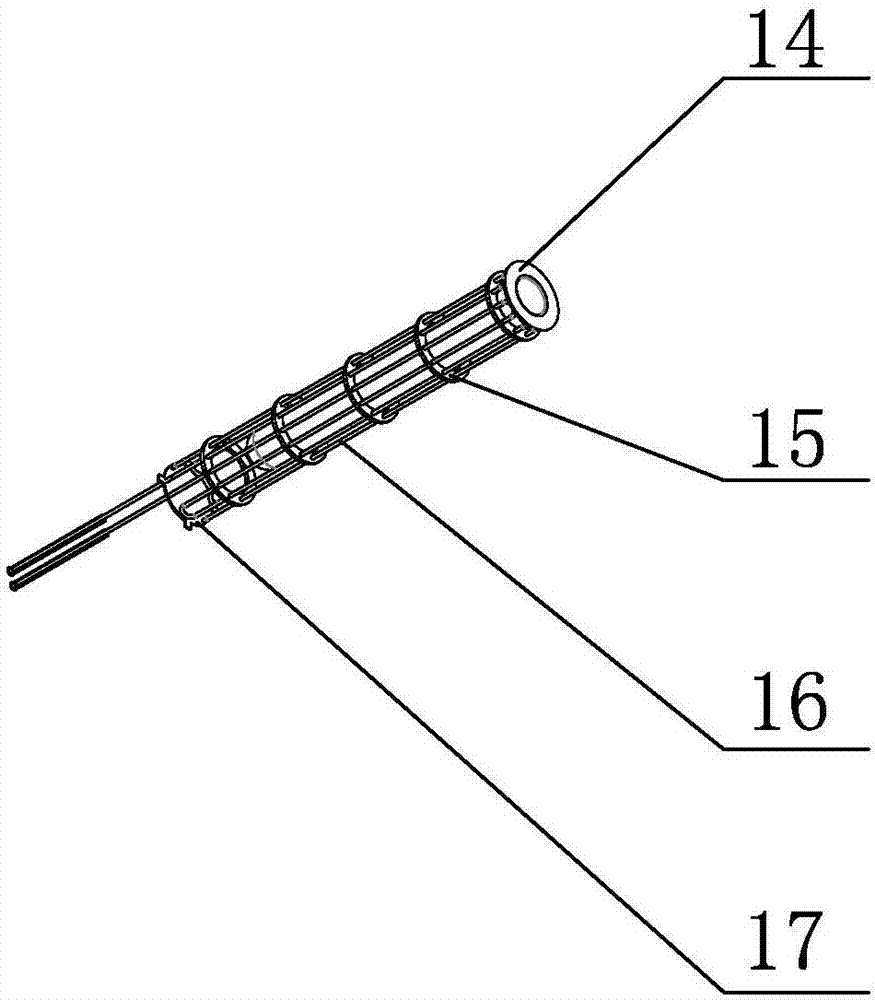

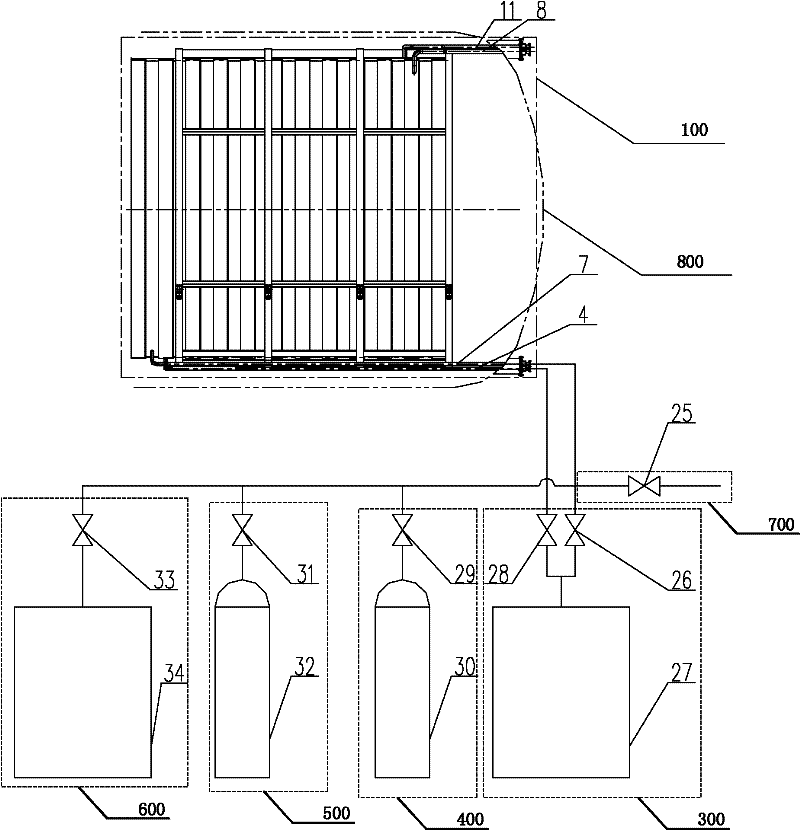

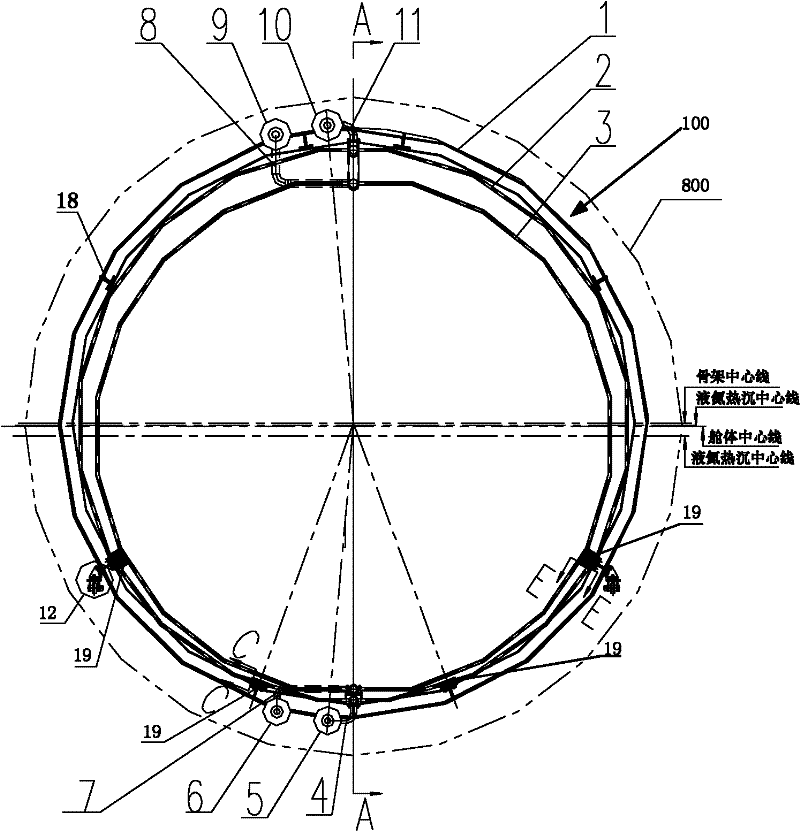

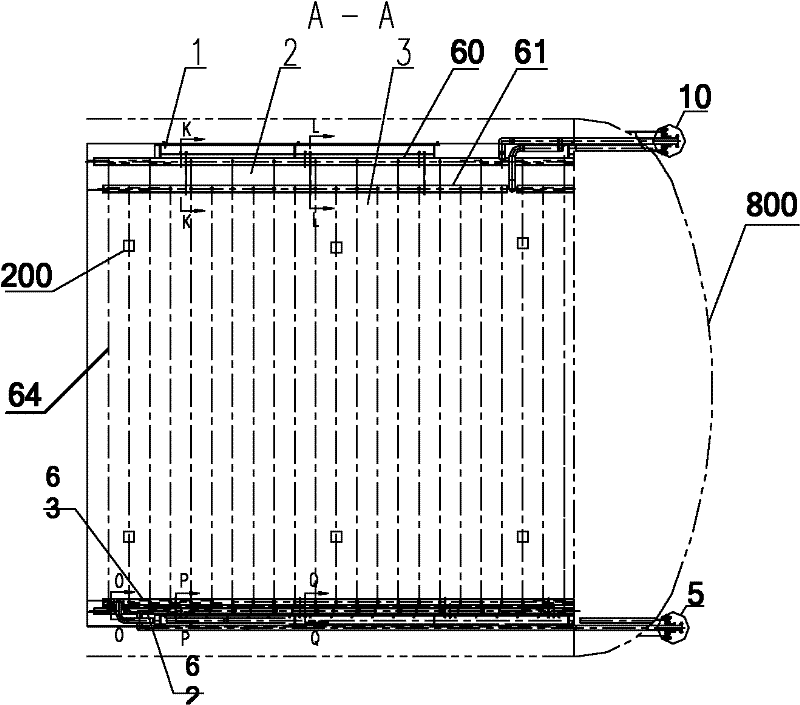

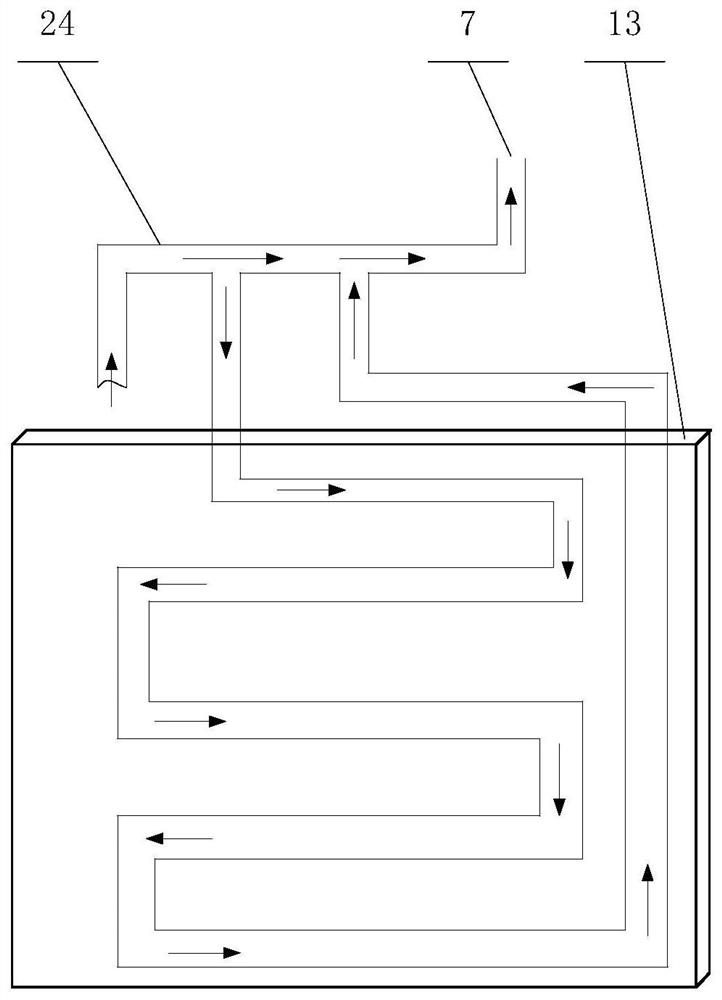

Straight cylindrical liquid-nitrogen liquid-helium double-medium compatible heat sink device and refrigeration method thereof

InactiveCN102175456AGuaranteed to workAvoid defectsGas-turbine engine testingDomestic cooling apparatusNitrogenEngineering

The invention relates to a straight cylindrical liquid-nitrogen liquid-helium double-medium compatible heat sink device and a refrigeration method thereof. The heat sink device comprises a heat sink main body, heat sink surface resistance temperature sensors, an auxiliary liquid drainage pipeline, a liquid-nitrogen supply system, a gas-nitrogen blow-off system, a gas-helium blow-off system and a liquid-helium supply system, wherein the heat sink main body is in a double fishbone type structure and is provided with a skeleton, a liquid-nitrogen heat sink and a liquid-helium heat sink; the liquid-helium heat sink is arranged inside the liquid-nitrogen heat sink; the heat sink surface resistance temperature sensors are uniformly distributed on the surfaces of the liquid-nitrogen and liquid-helium heat sinks; the liquid-nitrogen supply system, the gas-nitrogen blow-off system, the gas-helium blow-off system, the liquid-helium supply system and the auxiliary liquid drainage pipeline are all connected to an inlet of the liquid-helium heat sink; and the liquid-nitrogen supply system is further connected to the inlet of the liquid-nitrogen heat sink. The refrigeration method for the device comprises the following steps: in the working process, refrigerating the liquid-nitrogen heat sink by directly introducing the liquid nitrogen into the liquid-nitrogen heat sink, and then refrigerating the liquid-helium heat sink by introducing the liquid nitrogen and then introducing the liquid helium into the liquid-helium heat sink. By using the heat sink device and the refrigeration method provided by the invention, one heat sink channel is shared by the liquid nitrogen and the liquid helium, the requirement of plume test for engine is met, and the test cost is lowered.

Owner:BEIHANG UNIV

Sectional type tunnel smoke exhaust system and method by water curtain separation

InactiveCN101737076AImprove smoke exhaust effectSmall area of influenceDust removalFire preventionFire controlEngineering

The invention relates to a sectional type tunnel smoke exhaust system by water curtain separation, comprising a smoke exhaust duct, a smoke exhaust vent and an air valve. The smoke exhaust duct is positioned on the top or the side wall of a tunnel; the smoke exhaust vent is communicated with the smoke exhaust duct; the air valve is installed on the smoke exhaust vent; and the top or the side wall of the tunnel is provided with devices used for forming fire control water curtains. The invention also provides a smoke exhaust method which uses the sectional type tunnel smoke exhaust system. The smoke exhaust method comprises the following steps of: starting the devices which are used for forming the fire control water curtains and positioned on both sides of a fire source to form the water curtains and separating smoke gas generated by the fire source between the two water curtains; and starting the smoke exhaust vent which is positioned near the fire source to exhaust smoke. The invention has the advantages of optimizing the smoke exhaust effect of a highway tunnel, improving the smoke exhaust efficiency under the condition of the same smoke exhaust configuration, reducing the range of smoke gas influence, effectively controlling the diffusion of smoke gas within 200 meters, greatly reducing the heat radiation near the fire source and supplying better safety space for people escape and fire control.

Owner:WUHAN UNIV

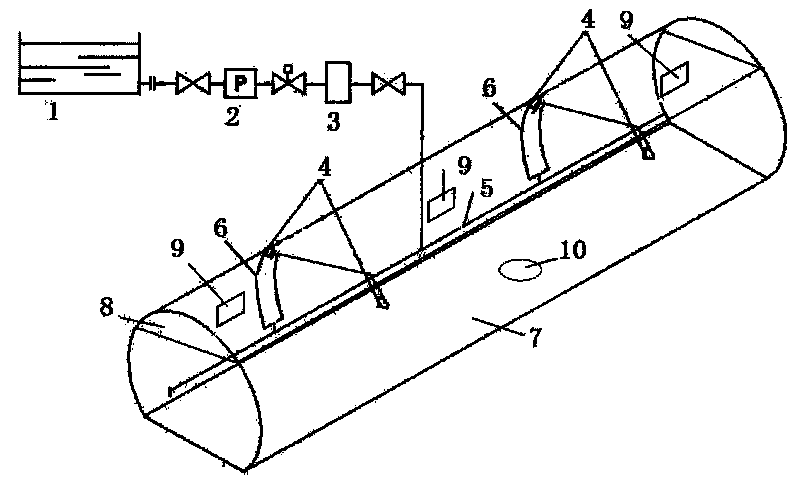

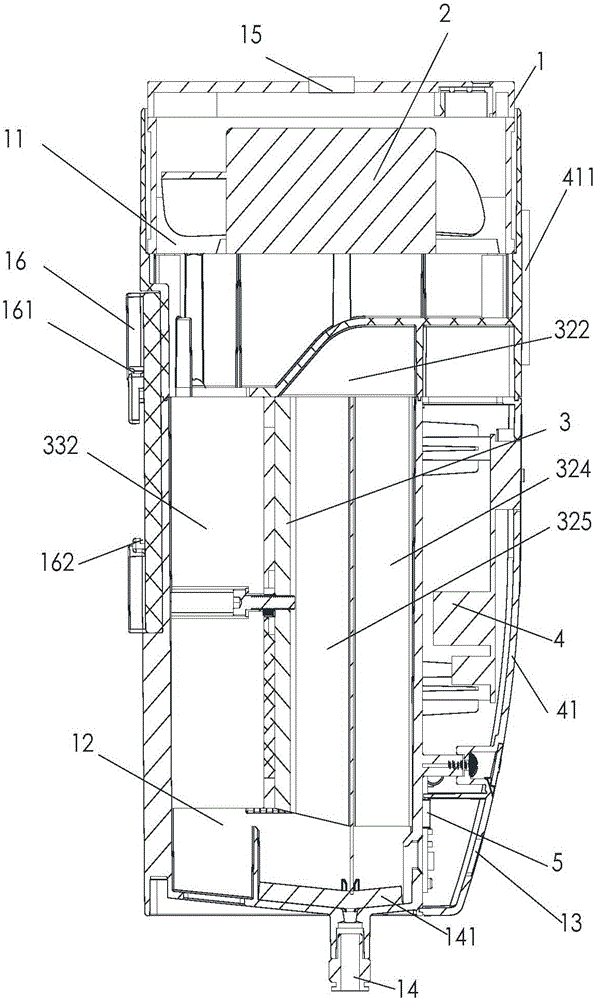

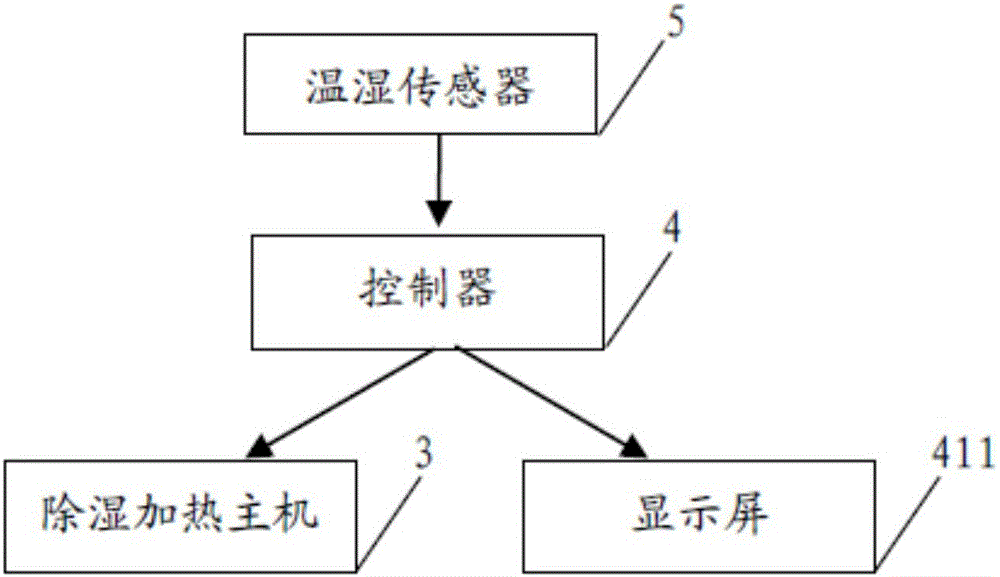

Semiconductor dehumidifier

ActiveCN105758059ANo change in power consumptionImprove dehumidification effectMechanical apparatusSpace heating and ventilation safety systemsRefrigerationSemiconductor

The invention discloses a semiconductor dehumidifier which comprises a machine case, an exhaust fan, a dehumidifying heating host and a controller.The machine case comprises a first chamber, a second chamber, a machine case air inlet, a machine case water drain outlet and a machine case air outlet.The exhaust fan is installed in the first chamber.The dehumidifying heating host is installed in the second chamber.The machine case air inlet is formed in the lower end of the side wall of the machine case and communicated with the second chamber.The machine case water drain outlet is formed in the bottom of the machine case.The machine case air outlet is installed in the upper end of the first chamber and communicated with the first chamber.The controller is installed on the side face of the machine case.According to the semiconductor dehumidifier, a hot end and a cold end are formed after a semiconductor refrigeration piece of the dehumidifying heating host is powered on; air is cooled through the cold end, and therefore the dehumidifying effect is achieved; air is heated through the hot end, and therefore it is avoided that the air temperature is too low during dehumidifying.

Owner:广州市雷子克电气机械有限公司

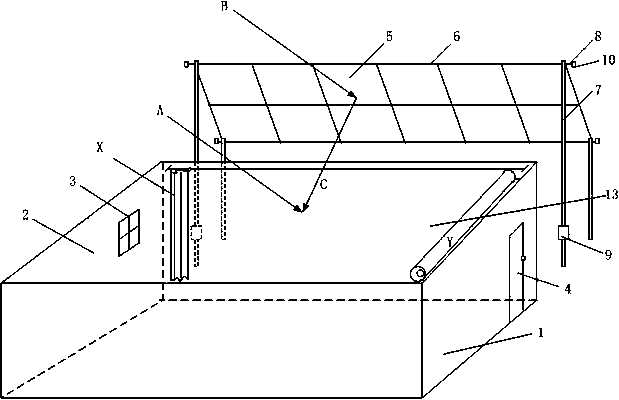

Efficient solar agricultural greenhouse

InactiveCN103749211AIncreased exposureWide range of partsClimate change adaptationSaving energy measuresAgricultural engineeringAgriculture

The invention discloses an efficient solar agricultural greenhouse which comprises surrounding walls (1), a light-pervious ceiling (2) arranged over the walls (1), and a roller blind (Y) arranged on the ceiling (2), wherein the walls (1) are provided with a ventilating window (3) and a door (4) capable of being opened and closed, the walls (1) include a light-pervious wall (13), a reflecting board (5) is further mounted near the northern side of the light-pervious wall (13), the reflecting side of the reflecting board (5) faces the ceiling (2) and the light-pervious wall (13), the reflecting board (5) is fixed on a reflecting board frame (6), the upper end of a reflecting board stand column (7) is connected with the reflecting board frame (6), and the lower end of the reflecting board stand column (7) is mounted on the ground. Under the condition of the same area, the same size and the same environment condition, compared with an agricultural greenhouse in the prior art, the efficient solar agricultural greenhouse has the advantages that the lighting rate is higher, the heat insulation effect is better, the temperature inside the greenhouse is higher, and the yield and quality of vegetables and fruits are improved. The efficient solar agricultural greenhouse can be used for the improvement of various agricultural greenhouses in the prior art.

Owner:赵杰

Refrigerating system of low-temperature superconducting magnet

ActiveCN113035486APrevent heat leakagePrevent heat radiationSuperconducting magnets/coilsSustainable buildingsPower applicationSuperconducting Coils

The invention belongs to the technical field of superconducting power application, and discloses a refrigerating system of a low-temperature superconducting magnet. The refrigerating system comprises a cold shield, a lead cooling channel, a cold shield cooling channel, a first liquid helium input opening, a first helium output opening, a helium tank, a liquid helium input pipe and a helium output pipe; the cold shield is arranged outside a low-temperature superconducting coil; the helium tank is arranged between the cold shield and the low-temperature superconducting coil and does not make contact with the cold shield and the low-temperature superconducting coil; the liquid helium input pipe and the helium output pipe are both connected with the helium tank; liquid helium is injected into the helium tank from the first liquid helium input opening through the liquid helium input pipe; helium volatilized from the helium tank is output from the first helium output opening through the helium output pipe; the lead cooling channel is connected between the helium output pipe and a superconducting current lead and is used for guiding cold to cool the superconducting current lead; the cold shield cooling channel is connected between the helium output pipe and the cold shield and is used for conducting cold to cool the cold shield. Therefore, volatilization of liquid helium can be effectively reduced, and the risk of quenching of the low-temperature superconducting magnet is reduced.

Owner:HIWING TECH ACAD OF CASIC

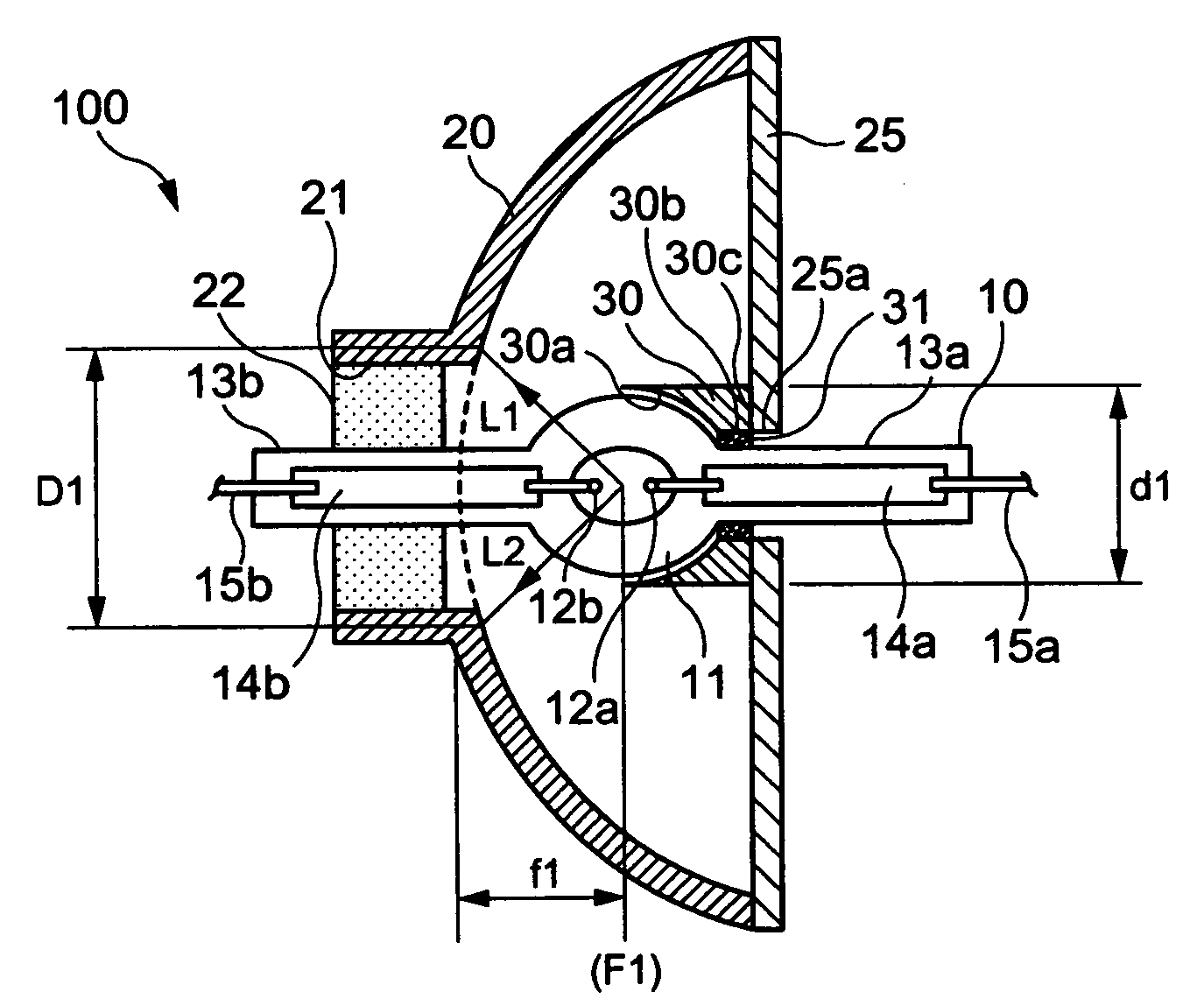

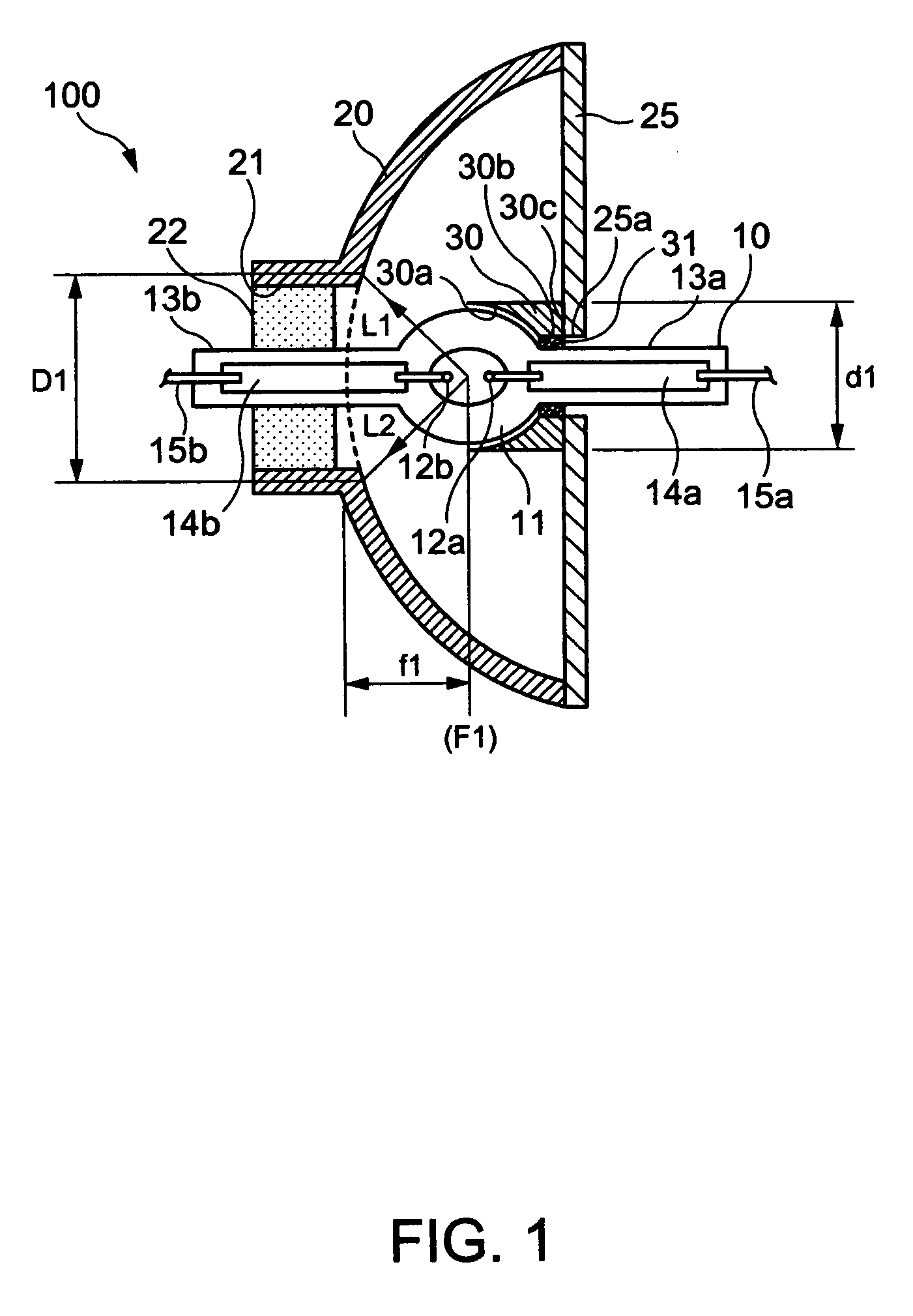

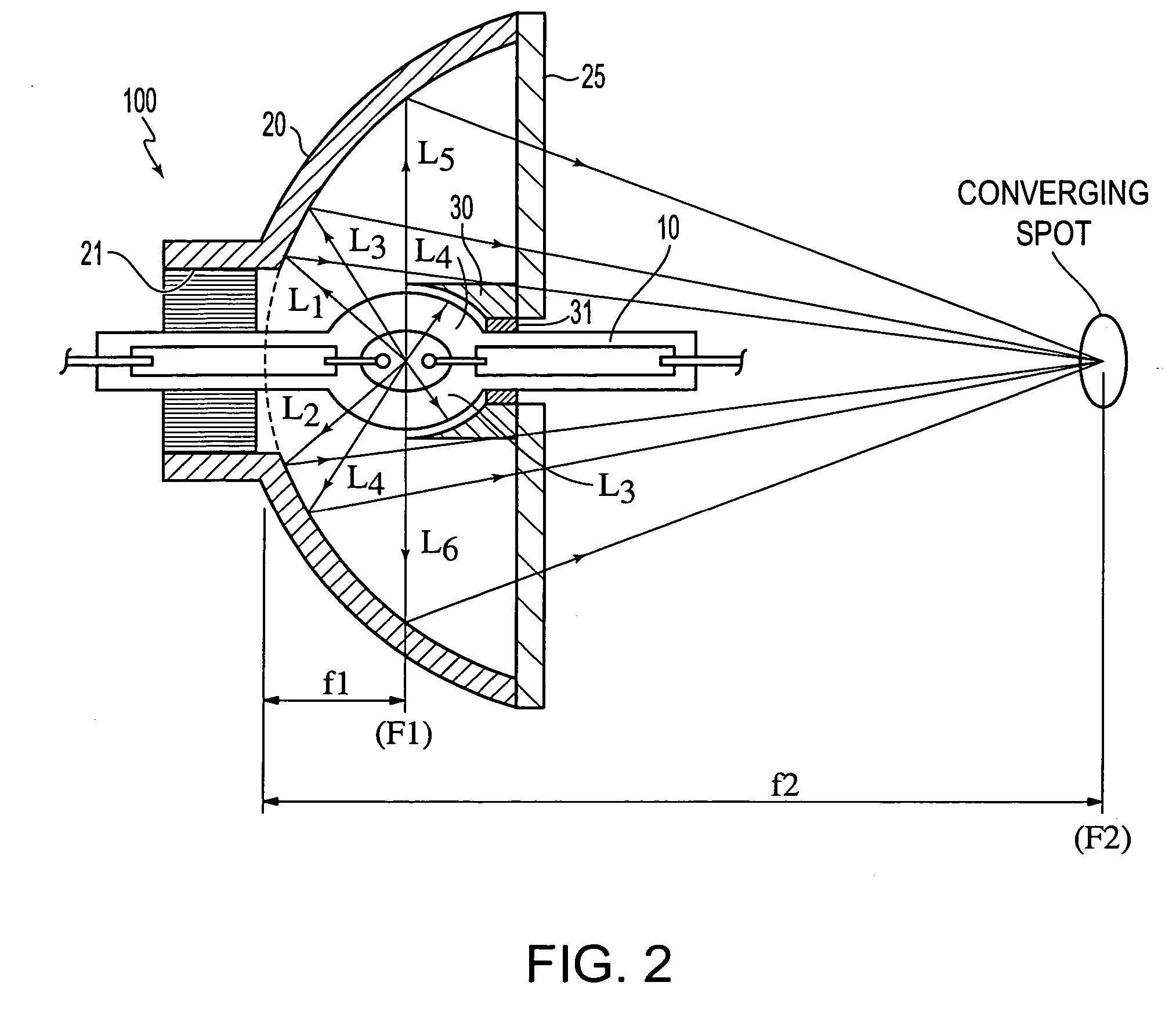

Illumination device and projector equipping the same

InactiveUS7059746B2Reduce heat radiationReduced service lifePoint-like light sourceLighting heating/cooling arrangementsLight emissionProjector

An illumination device including a light-emitting tube having a light-emitting member in which light emission is carried out between a pair of electrodes and sealing members located on both sides of the light-emitting member, a first reflecting mirror to hold the light-emitting tube, reflect the light emitted from the light-emitting tube, and direct the light forward, and a transparent plate disposed in a distal end portion of the first reflecting mirror, a second reflecting mirror that encloses a front portion of the light-emitting member and reflects the light from the light-emitting member toward the first reflecting mirror being fixed to at least one of the sealing member and the transparent plate, the transparent plate and the second reflecting mirror are brought into contact or fixedly attached to each other, and at least one of the transparent plate and the second reflecting mirror is brought into contact or fixedly attached to the sealing member.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com