Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

A comprehensive treatment and melting slag technology, which is applied in the field of iron extraction and steelmaking, can solve problems such as patents that have not yet been seen, and achieve the effects of improving smelting efficiency, good reduction reaction kinetics conditions, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

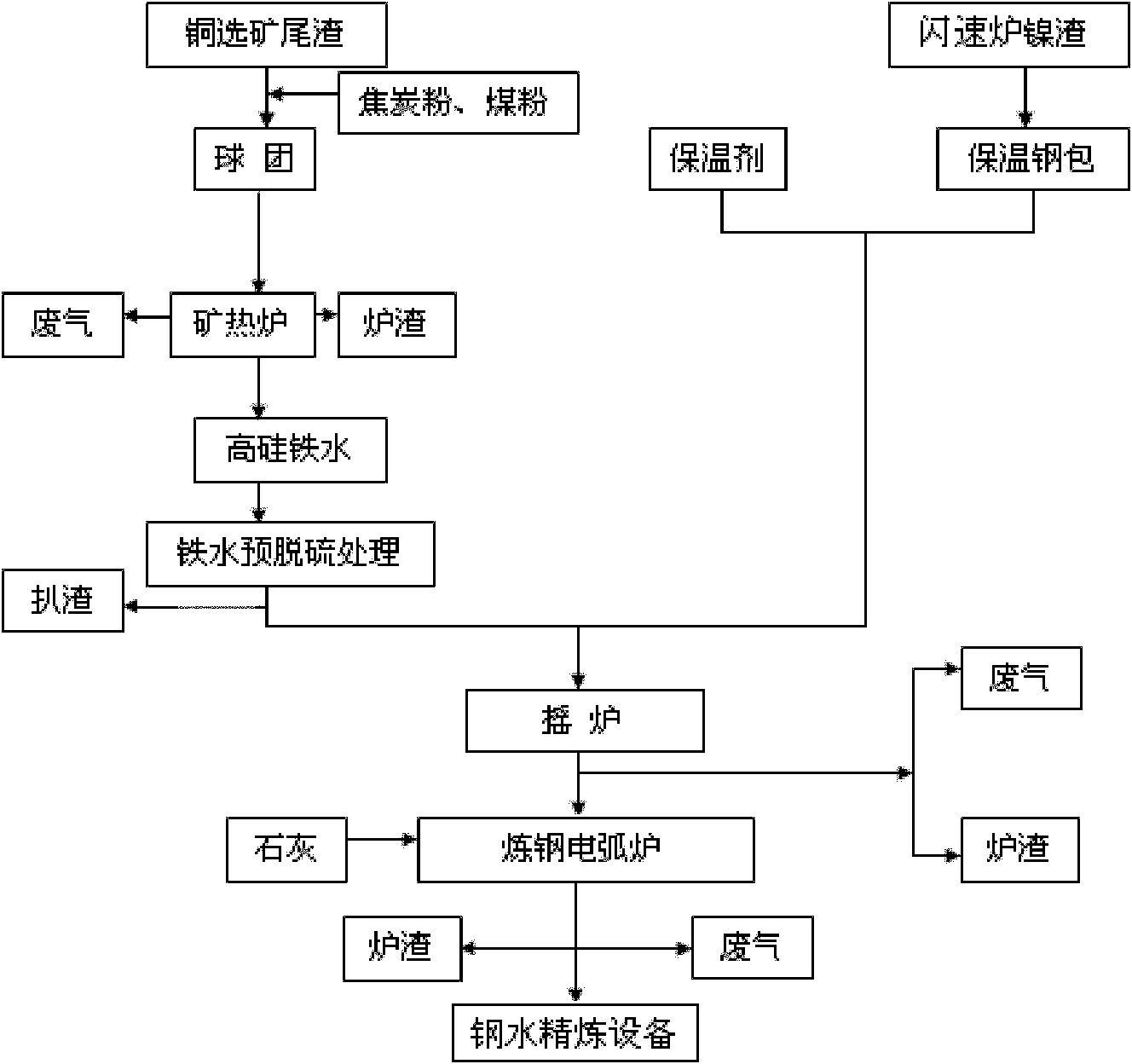

[0037] see figure 1 , the present invention uses submerged arc furnace-shaking furnace-steelmaking furnace to comprehensively process the iron extraction and steelmaking process of copper beneficiation tailings and nickel molten slag, and the specific operation process is as follows:

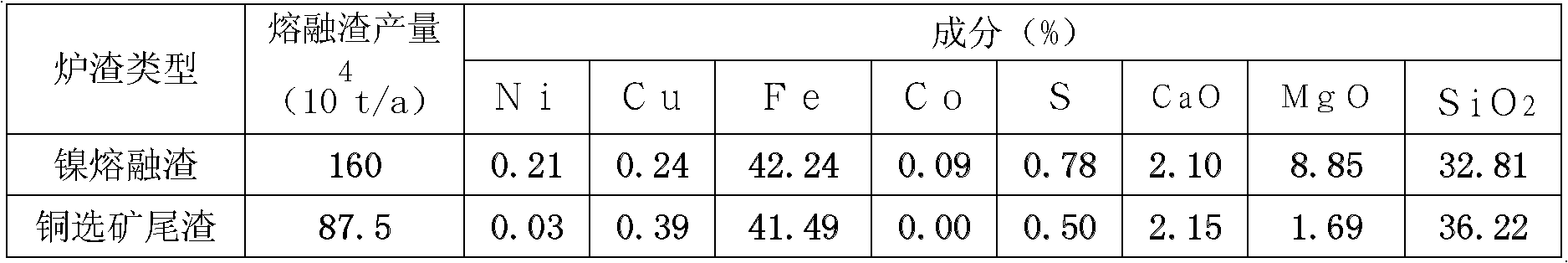

[0038] 1) Select the copper beneficiation tailings or diluted electric furnace slag from the factory. The composition of the copper beneficiation tailings contains Fe≥40%, and the content of alkaline oxides (CaO+MgO)2)≥90%, use this slag as raw material for smelting low-grade ferrosilicon.

[0039] Submerged arc furnace smelting requires raw materials to have a certain particle size. The reducing agent (metallurgical coke particles, anthracite coal powder or semi-coke particles) is crushed, the particle size is 150-200 mesh, and the weight ratio of copper beneficiation tailings and carbonaceous reducing agent is 1:0.28-0.34, and the weight ratio is fully mixed evenly. The embodiment provides th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com