Patents

Literature

300 results about "Metallurgical coke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

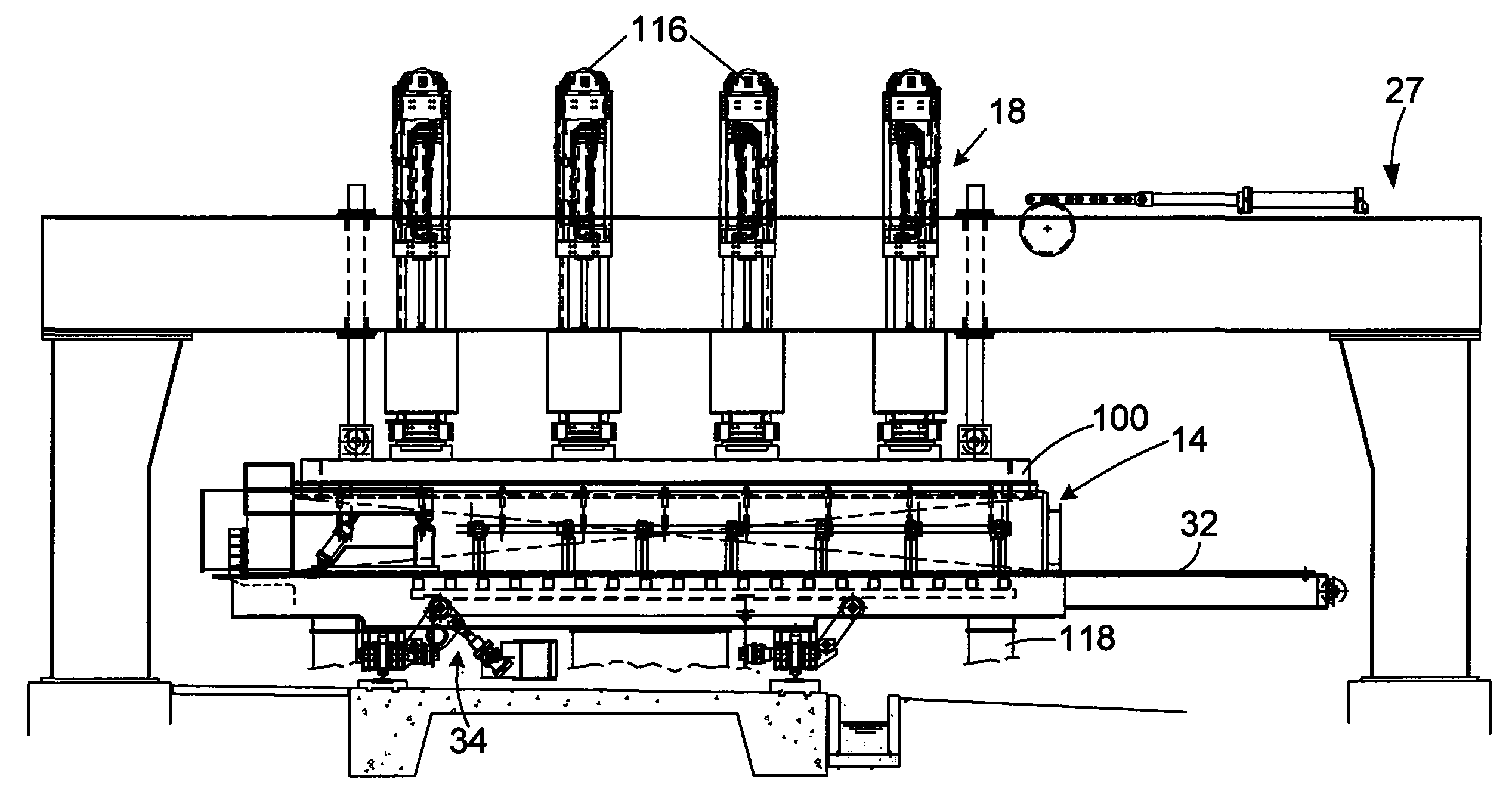

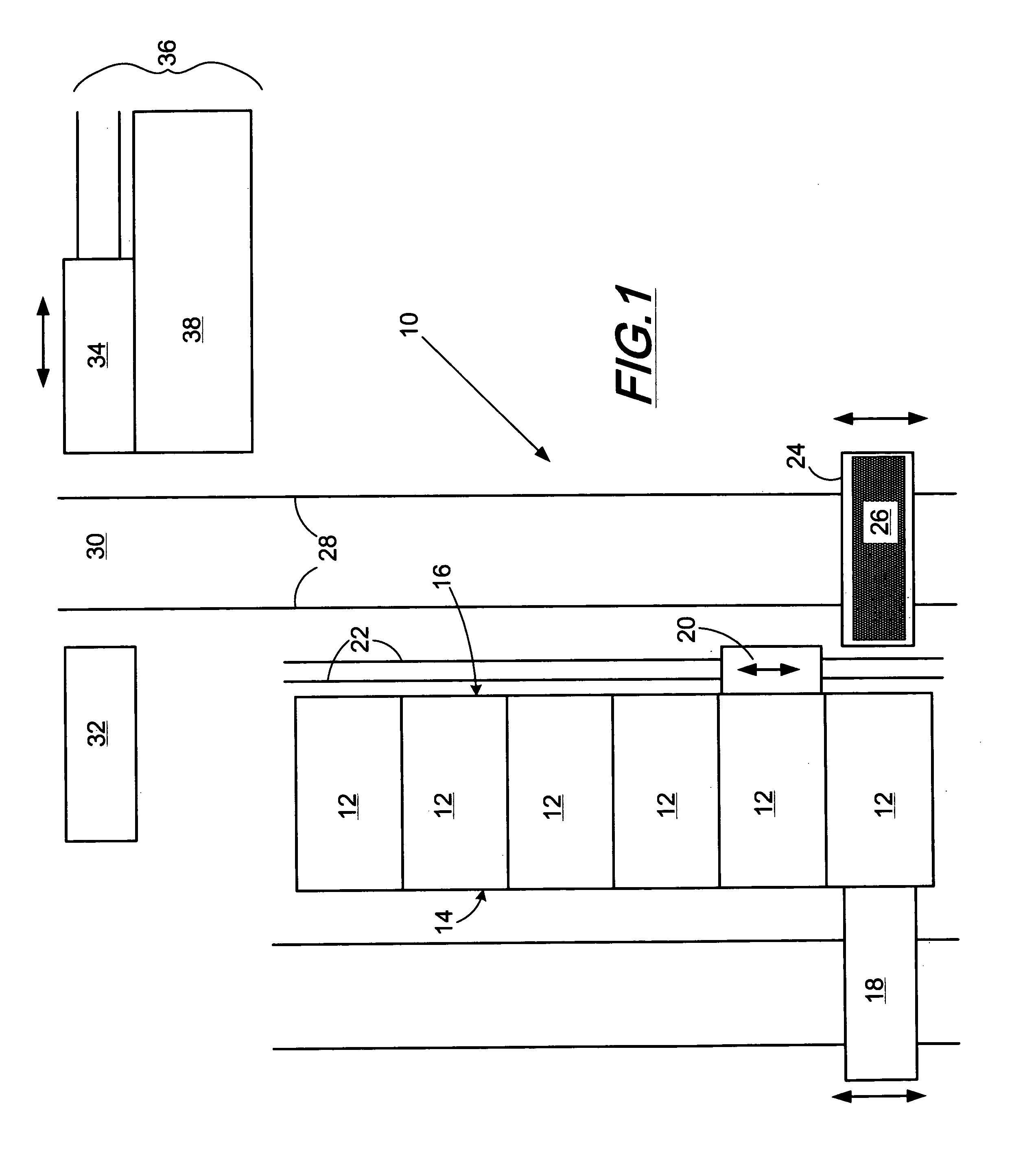

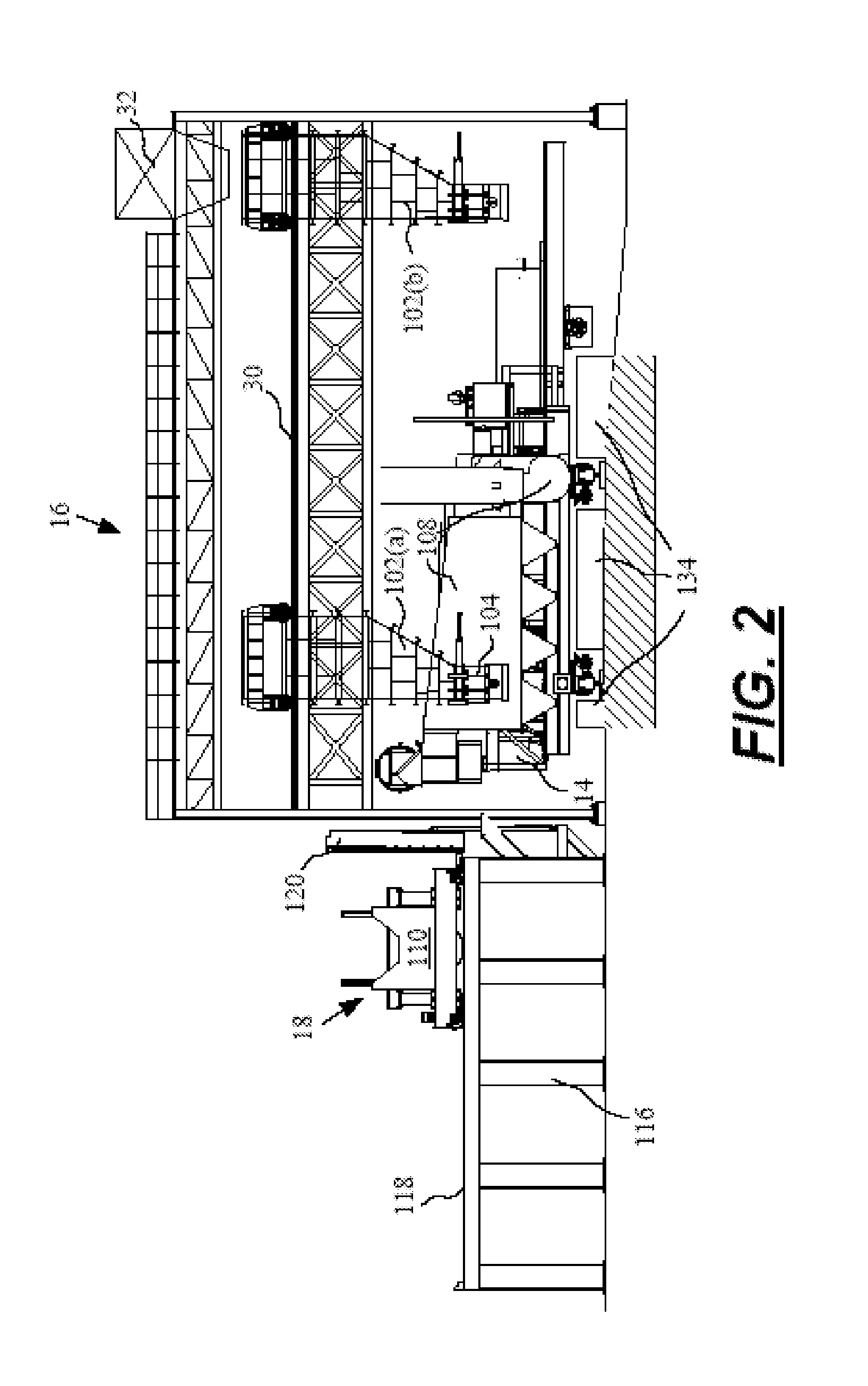

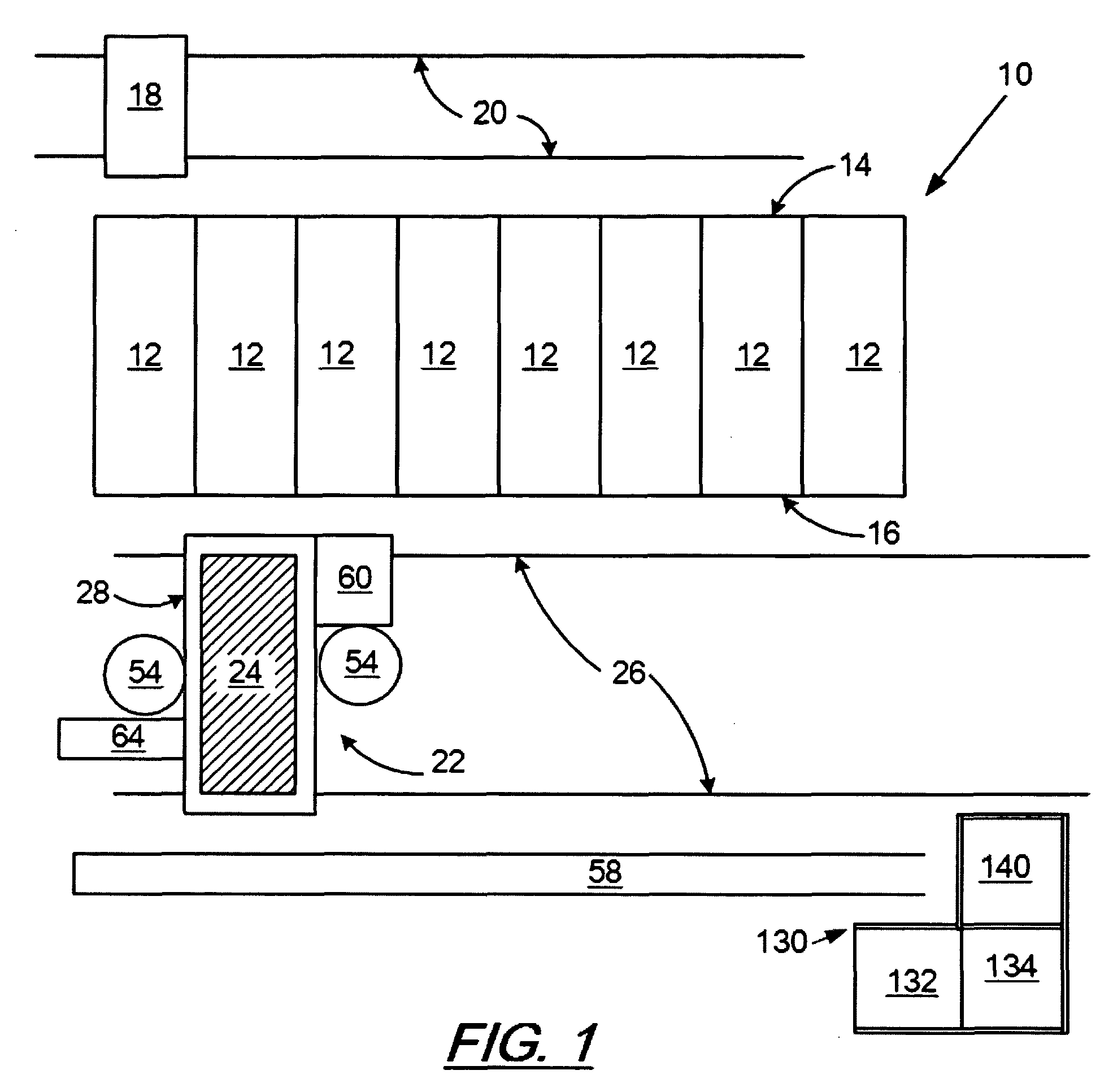

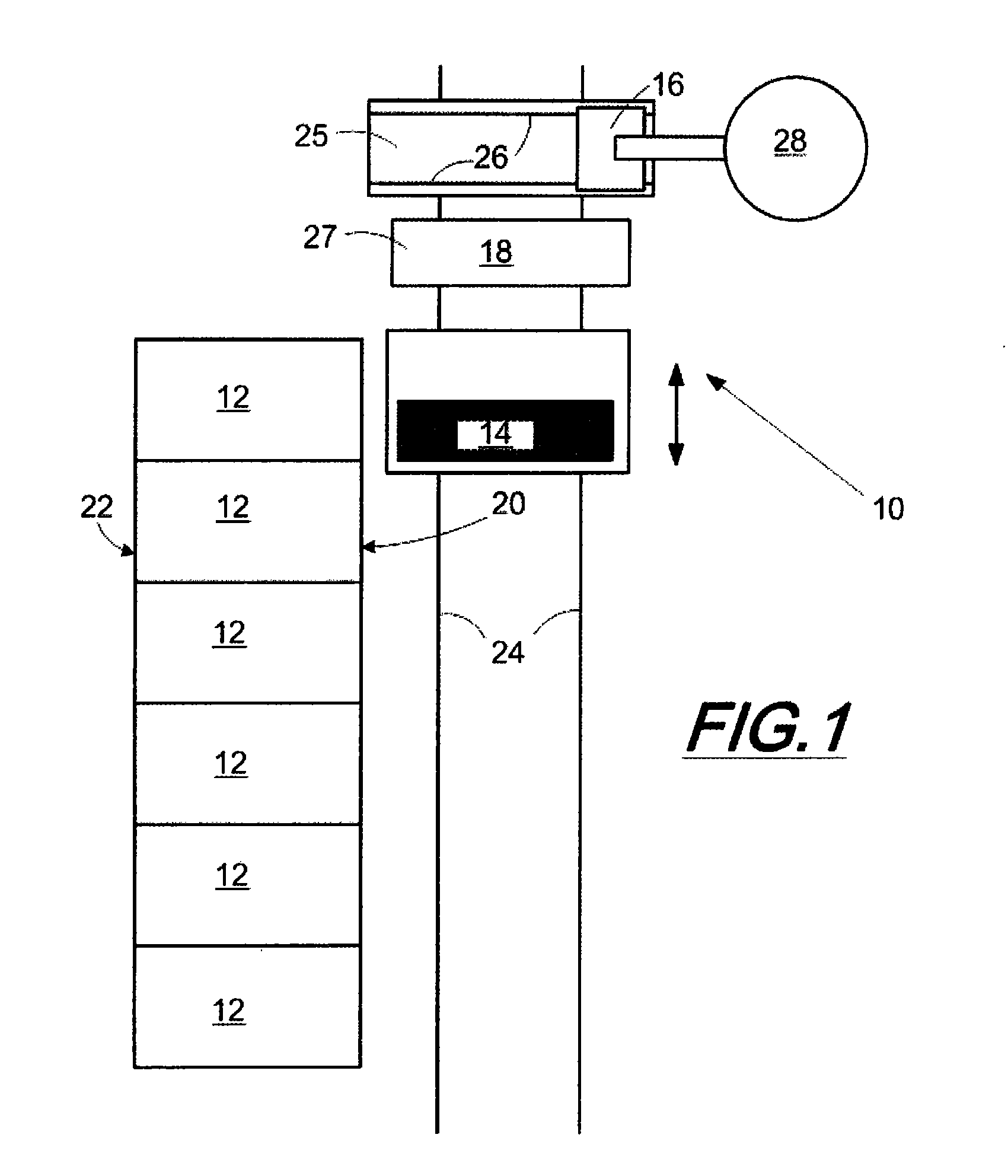

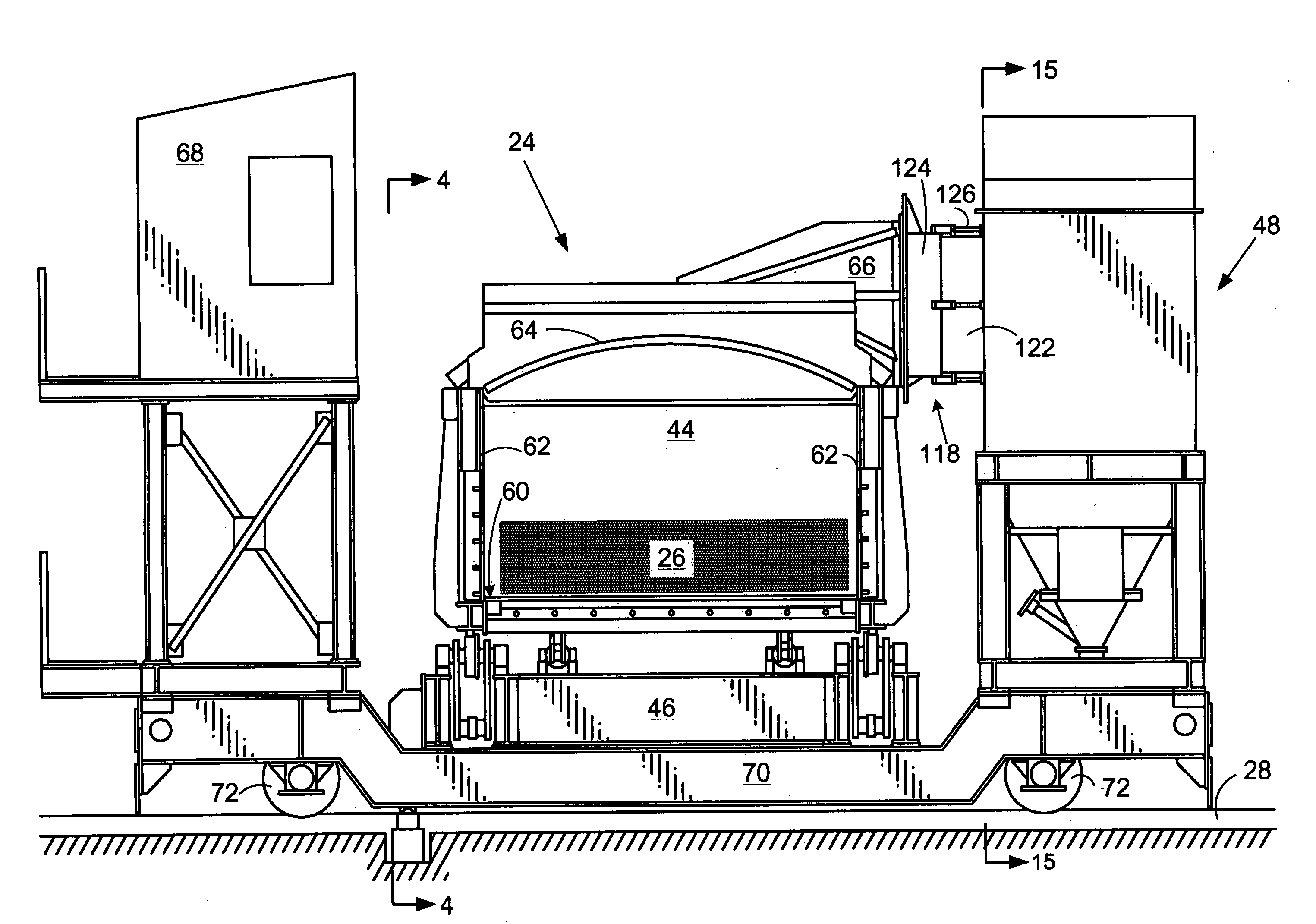

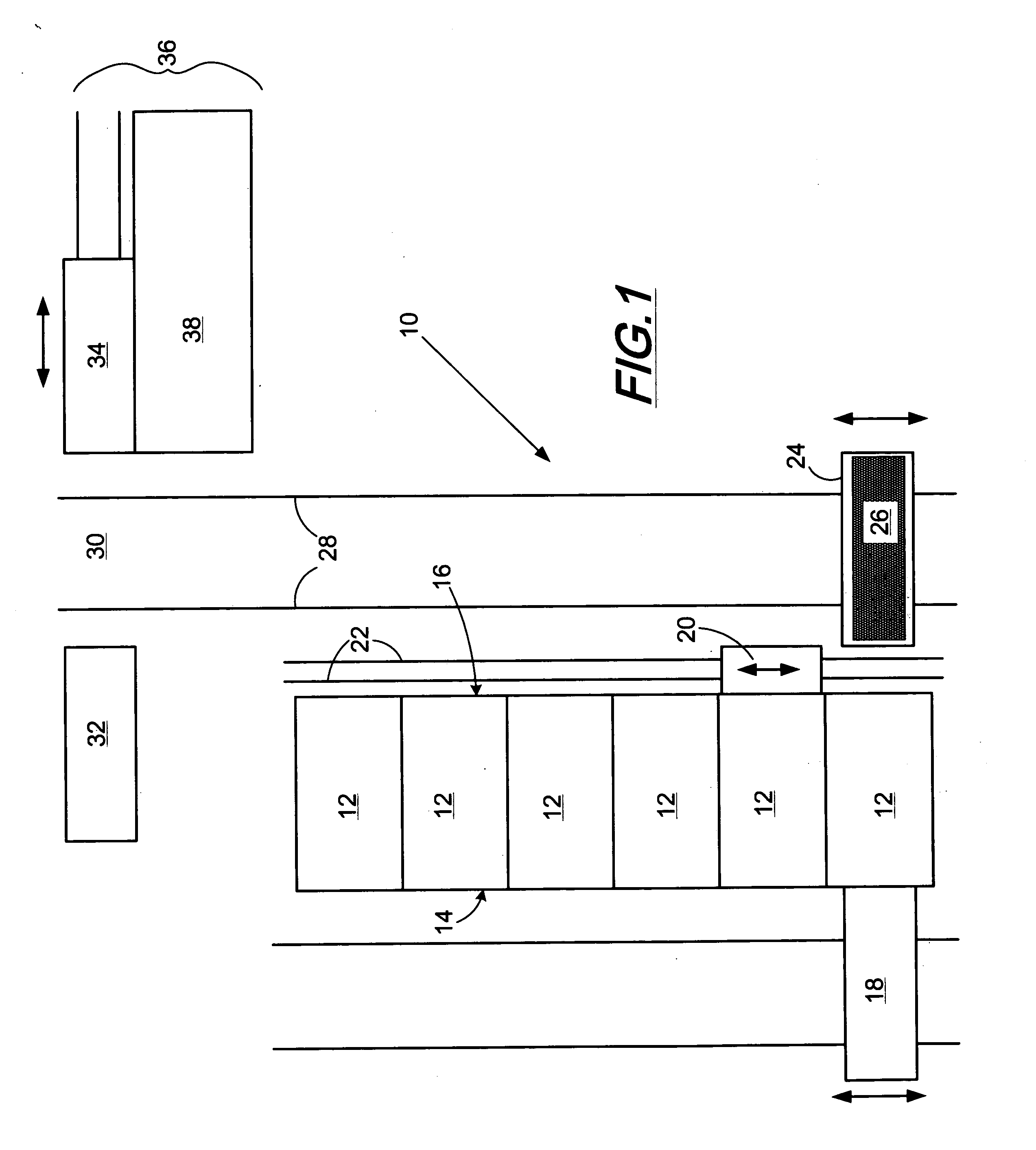

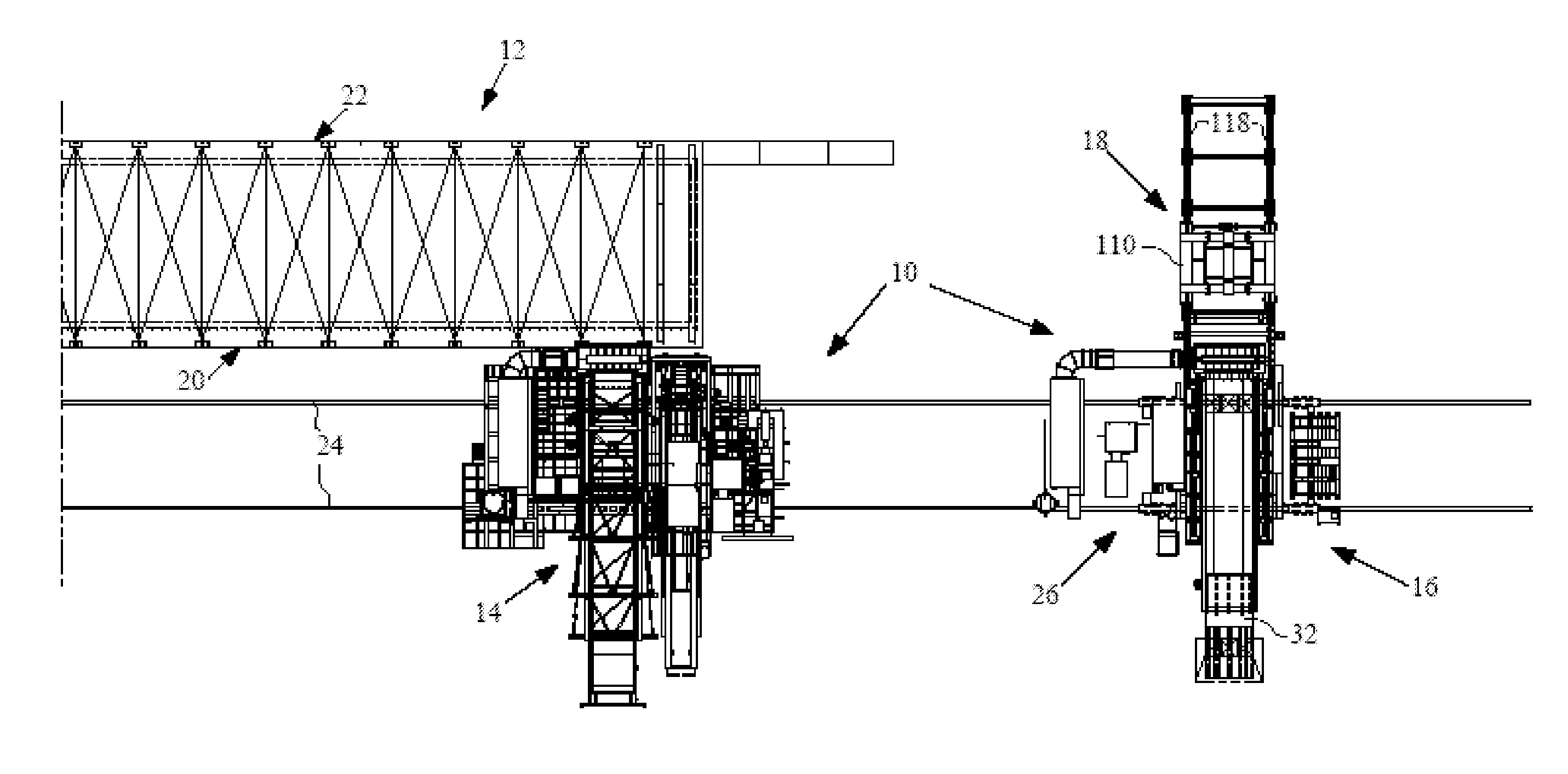

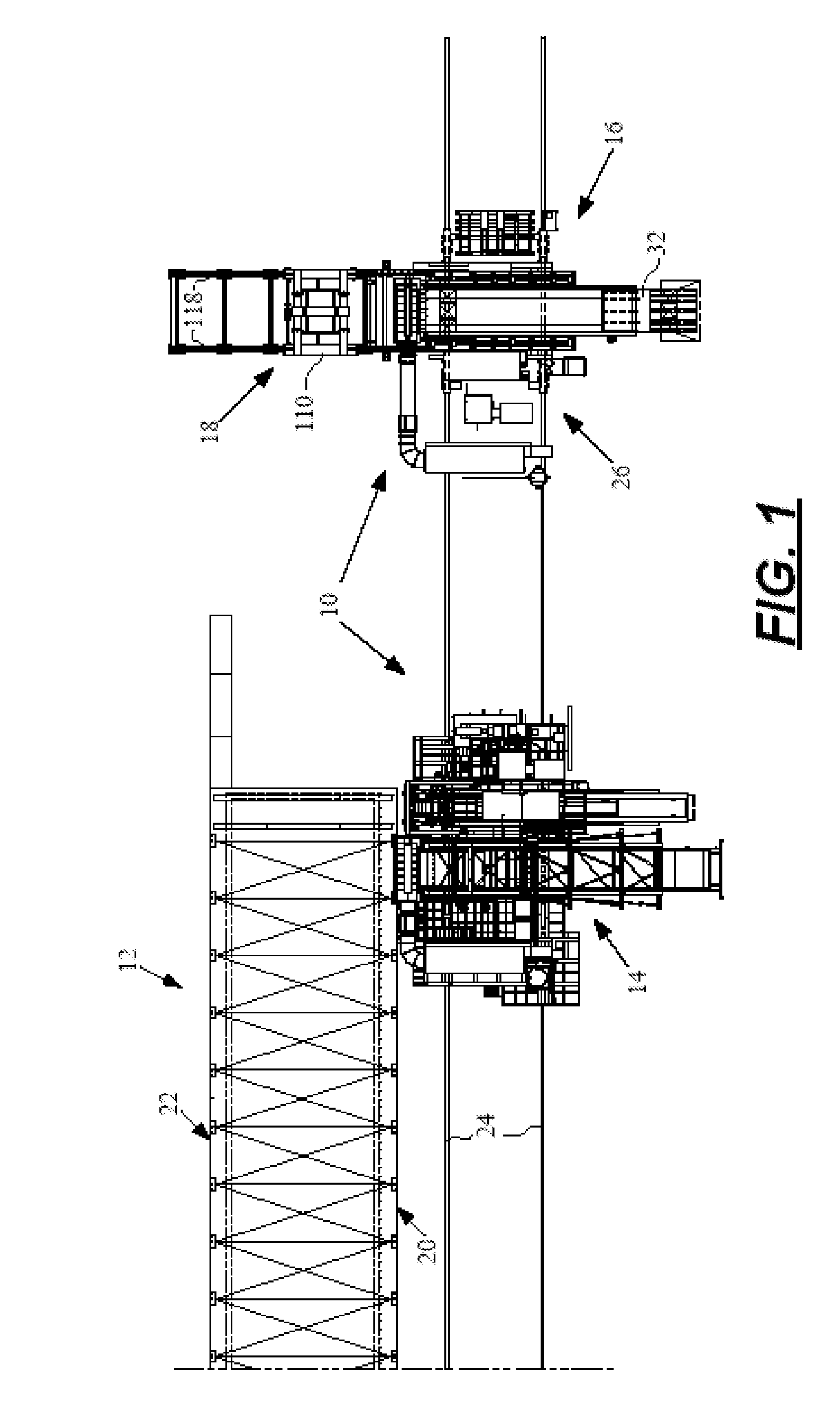

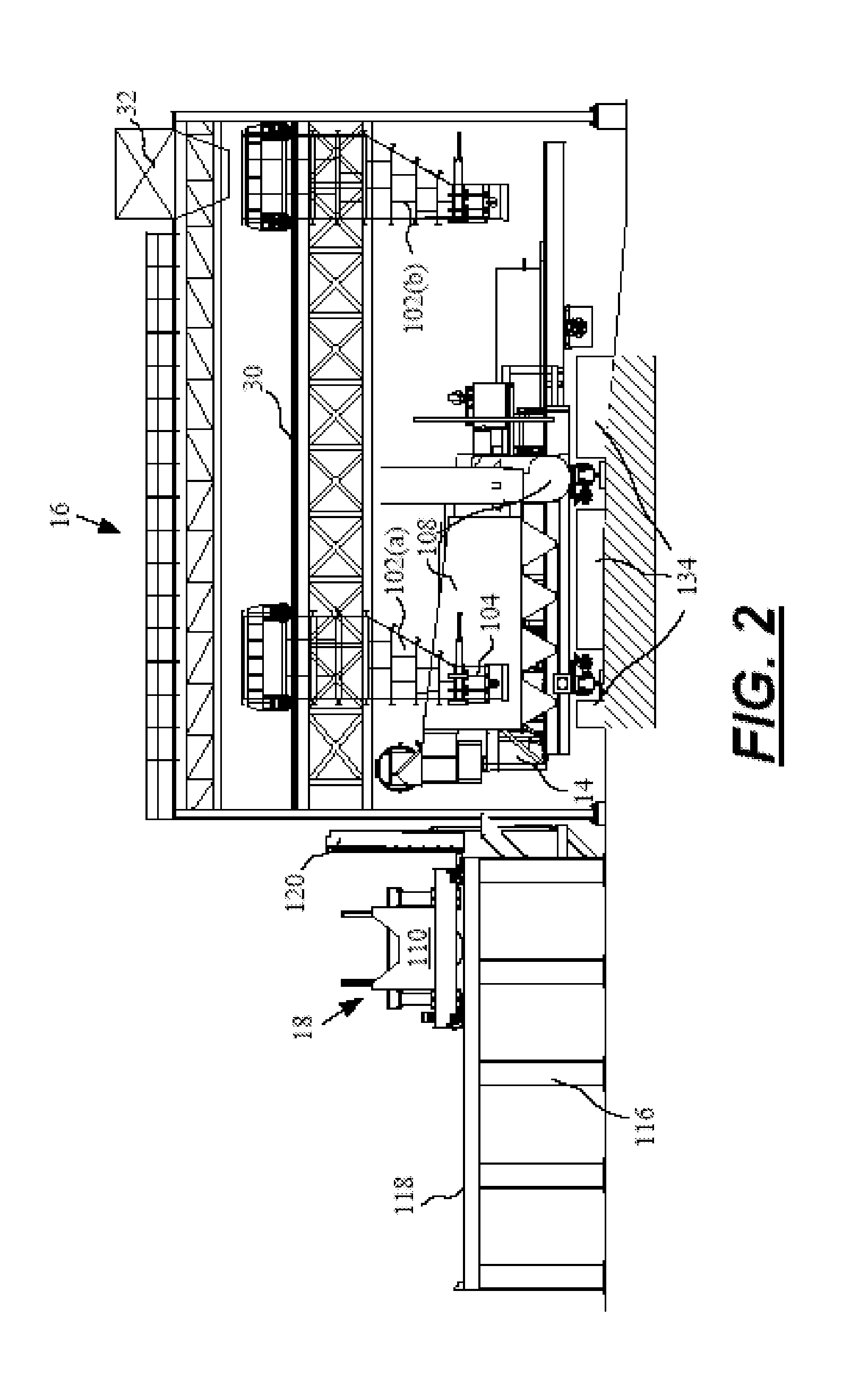

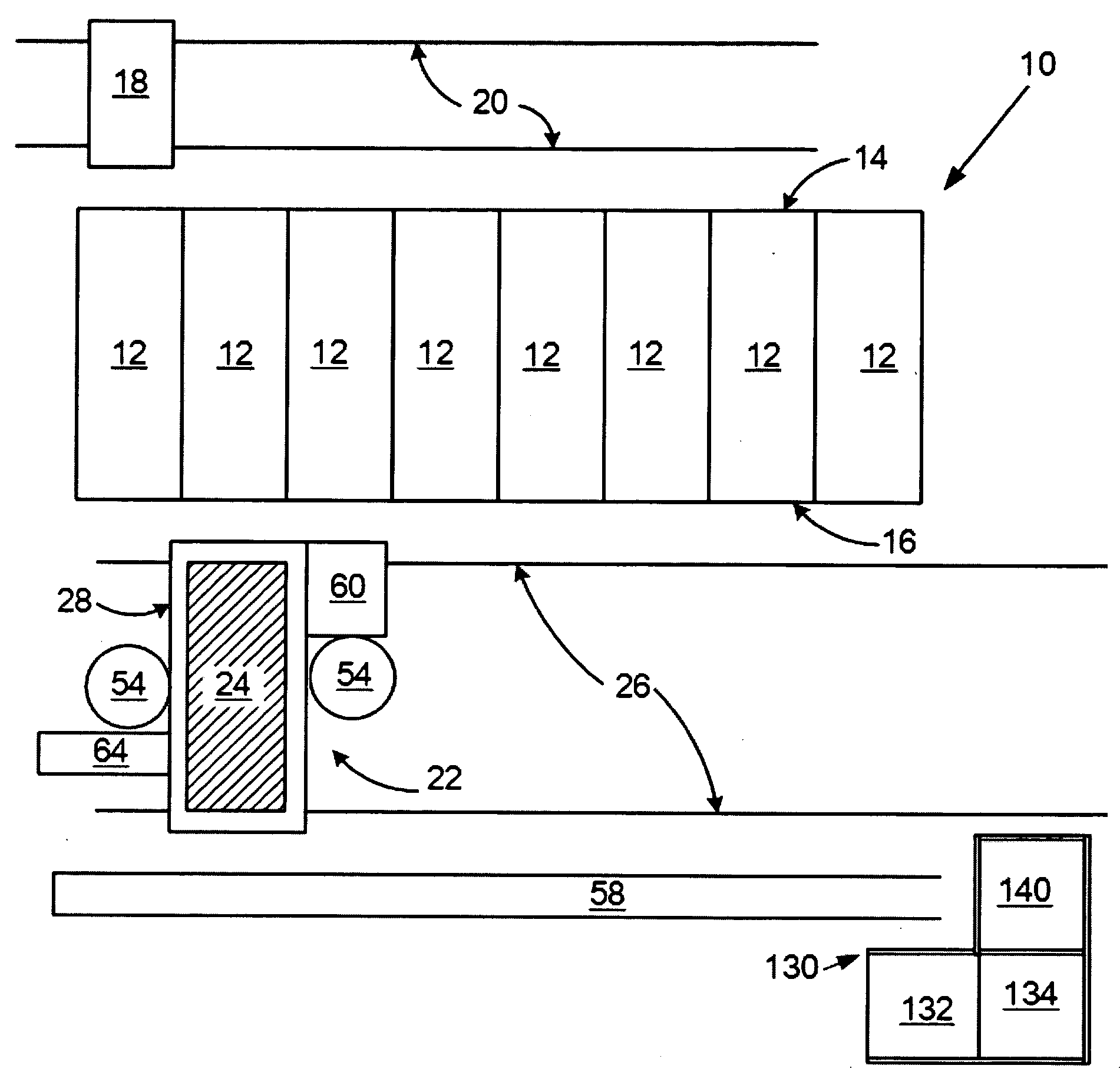

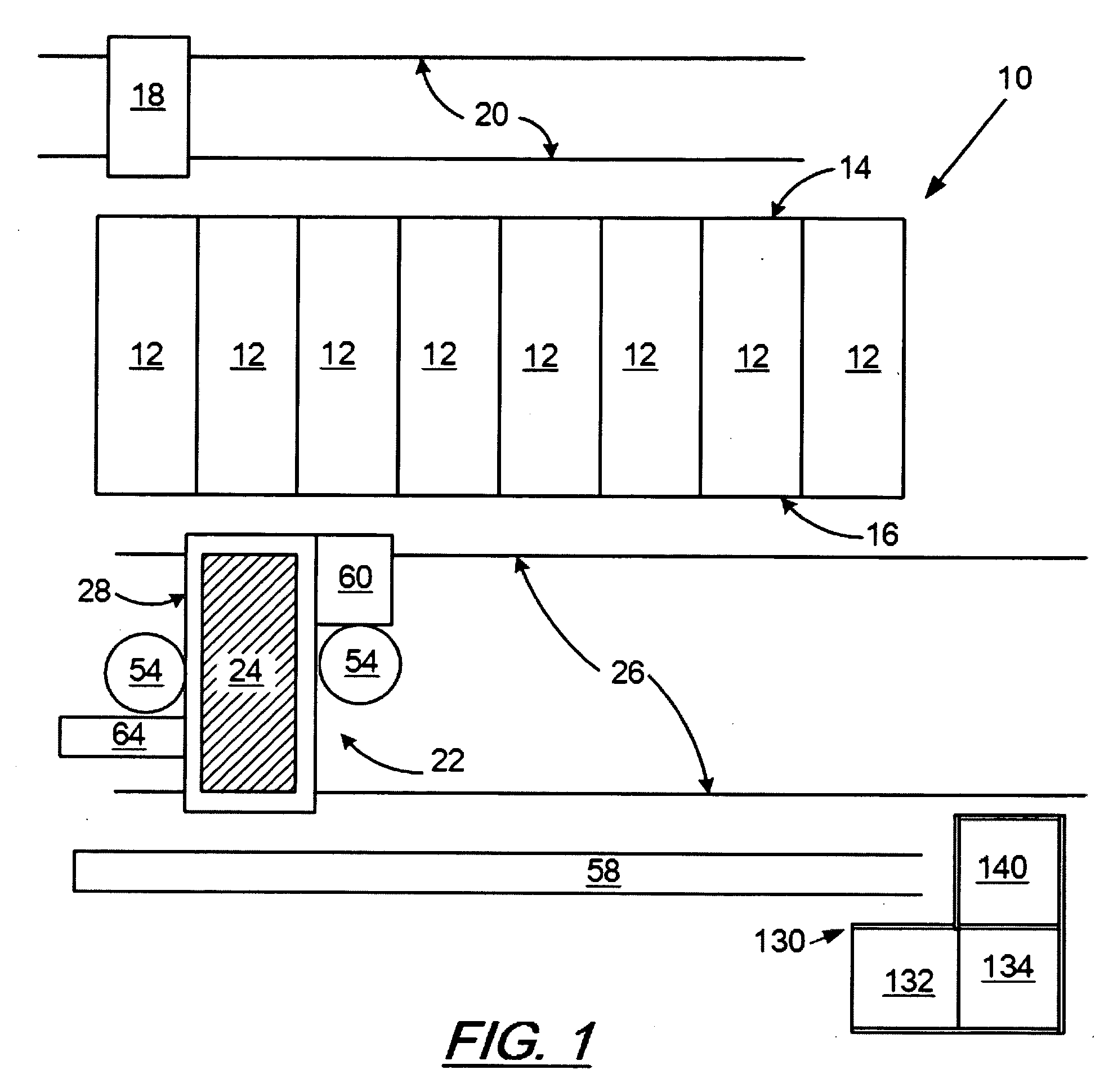

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

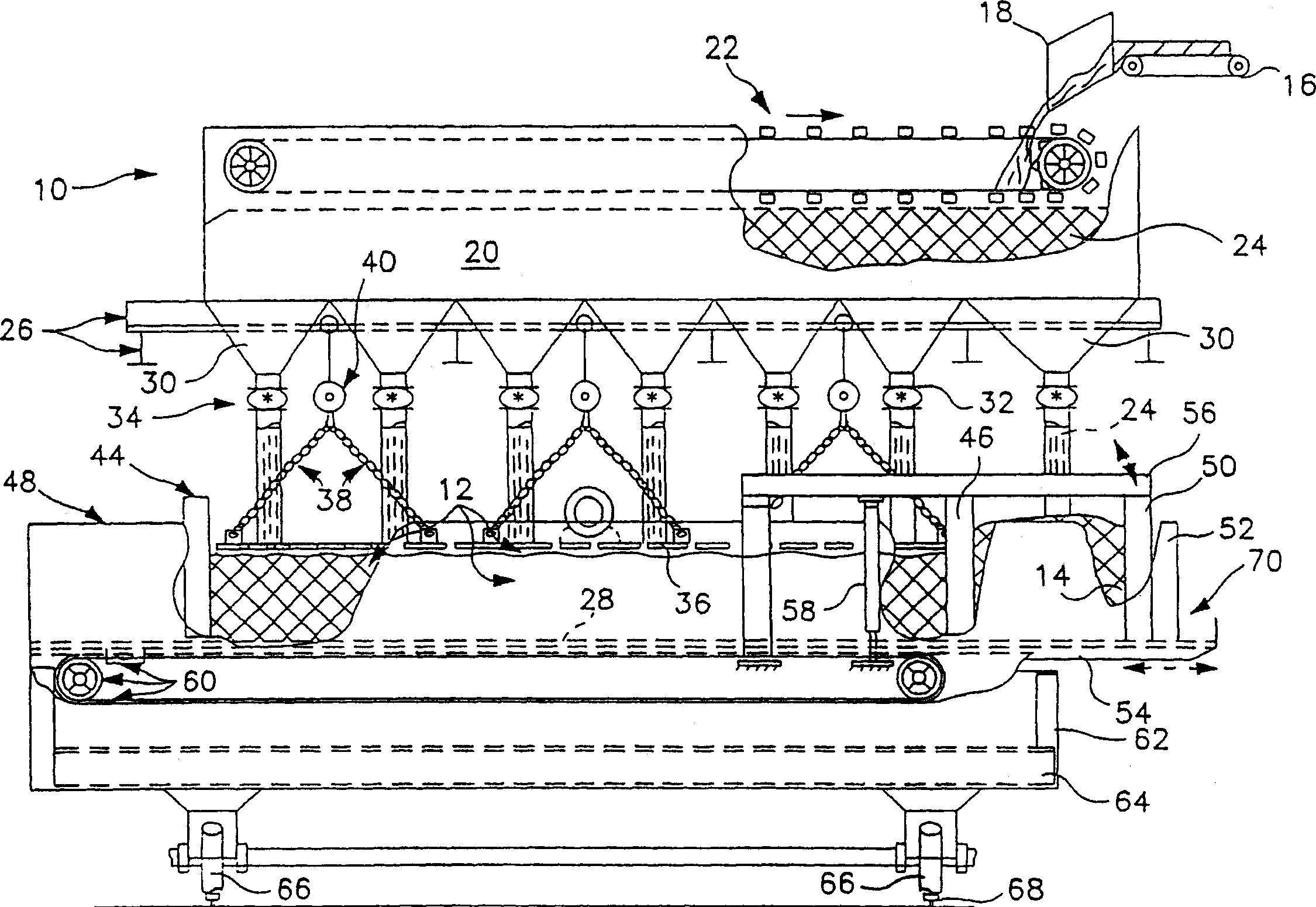

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

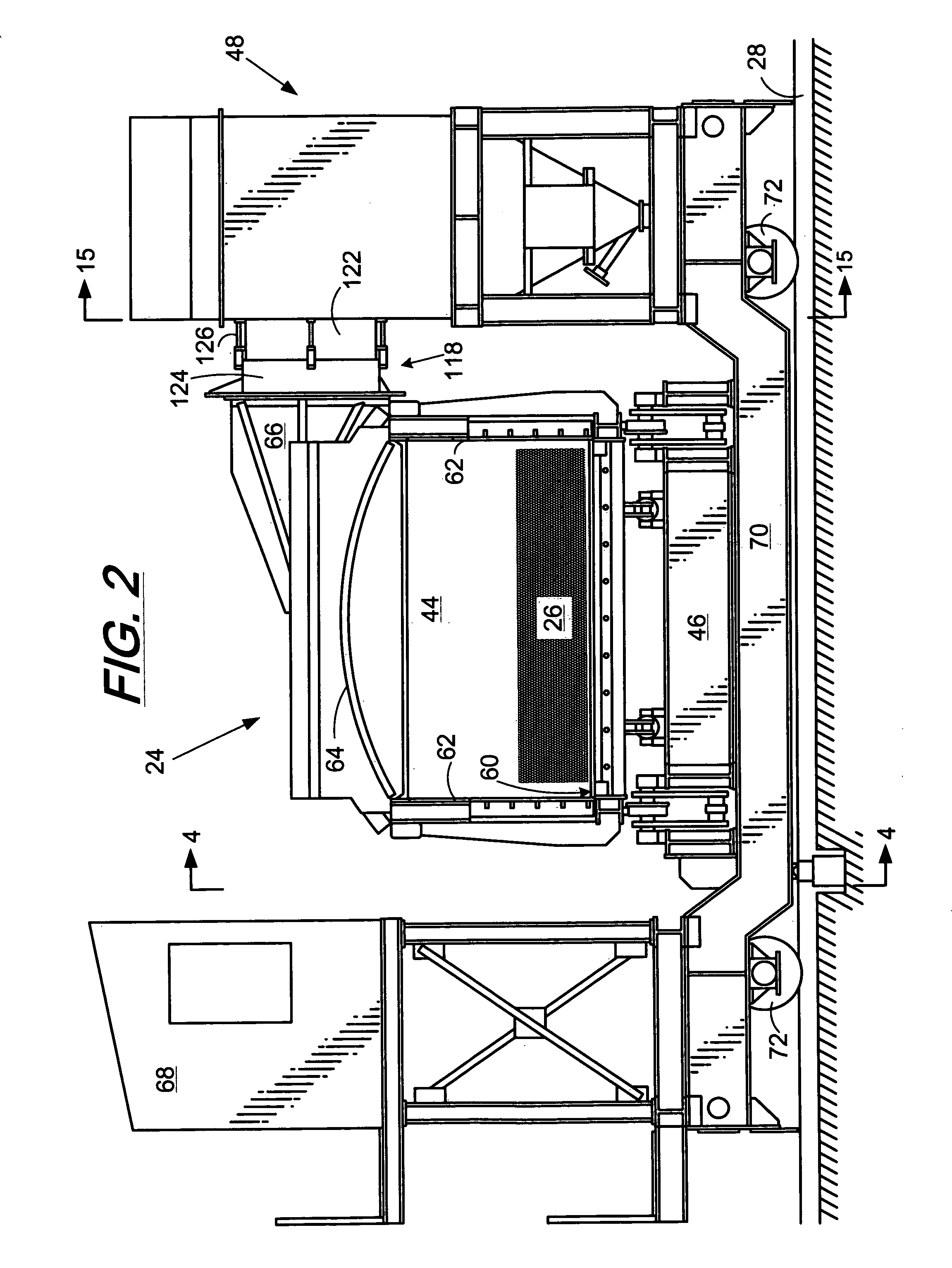

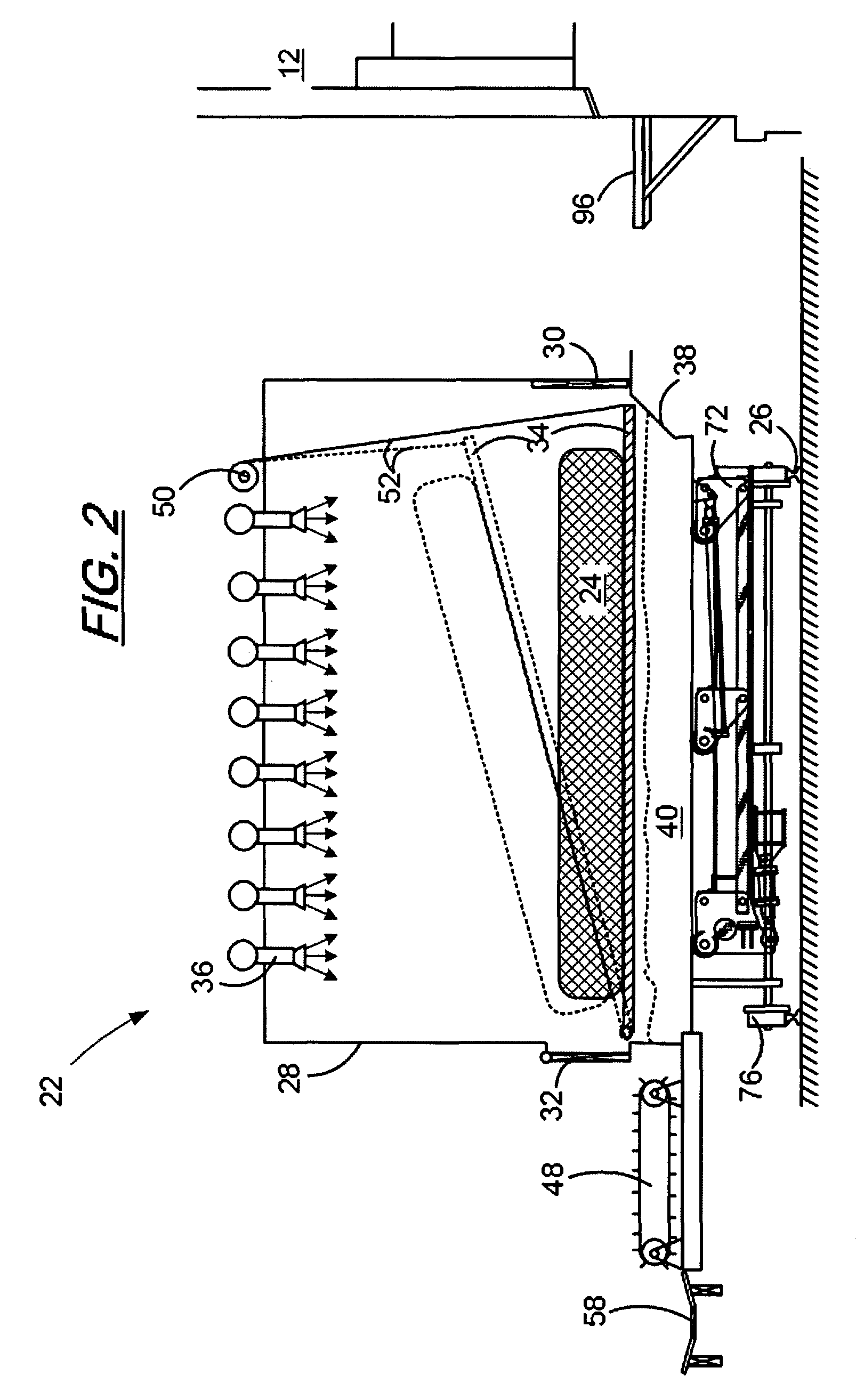

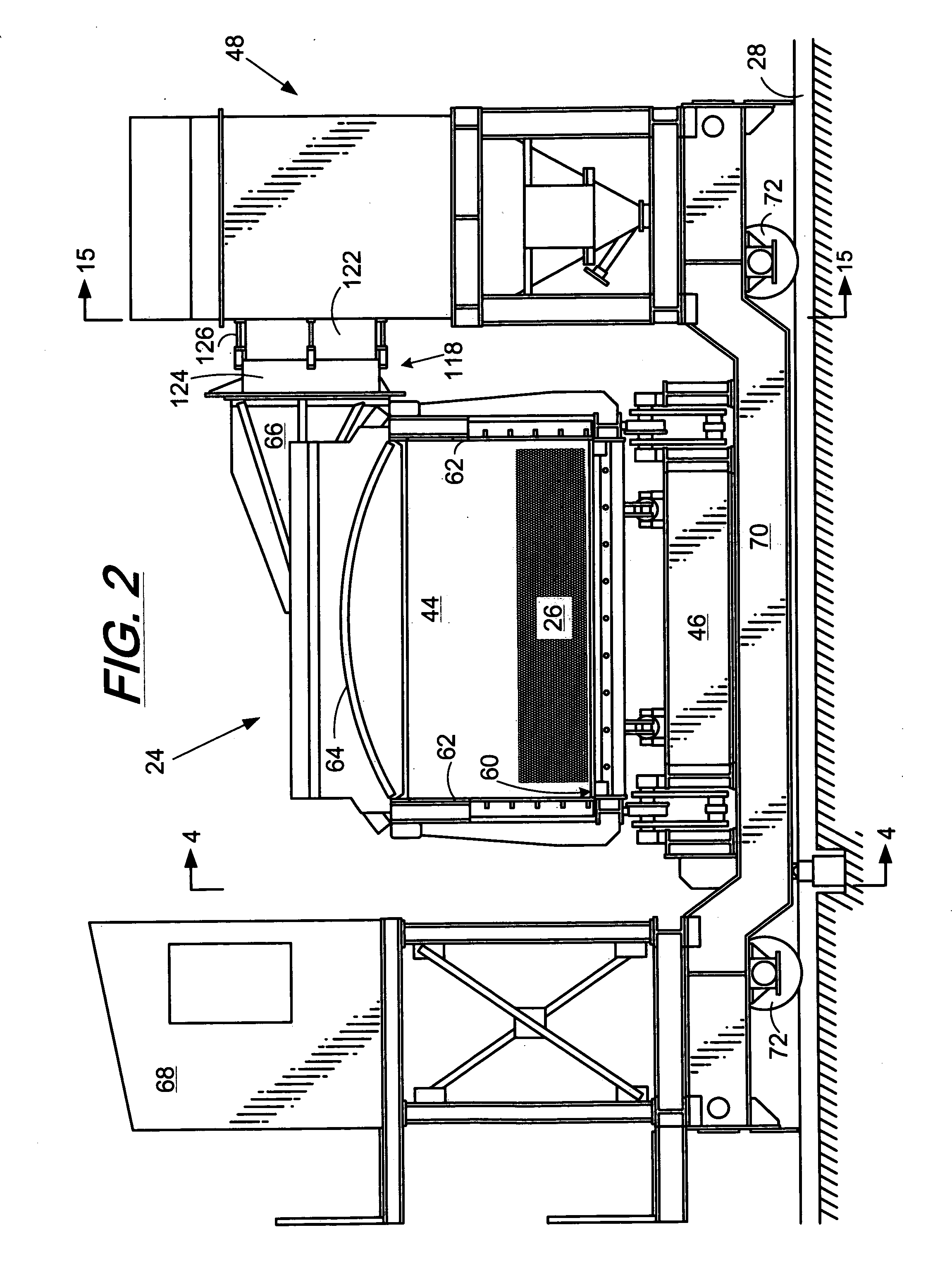

Method and apparatus for producing coke

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

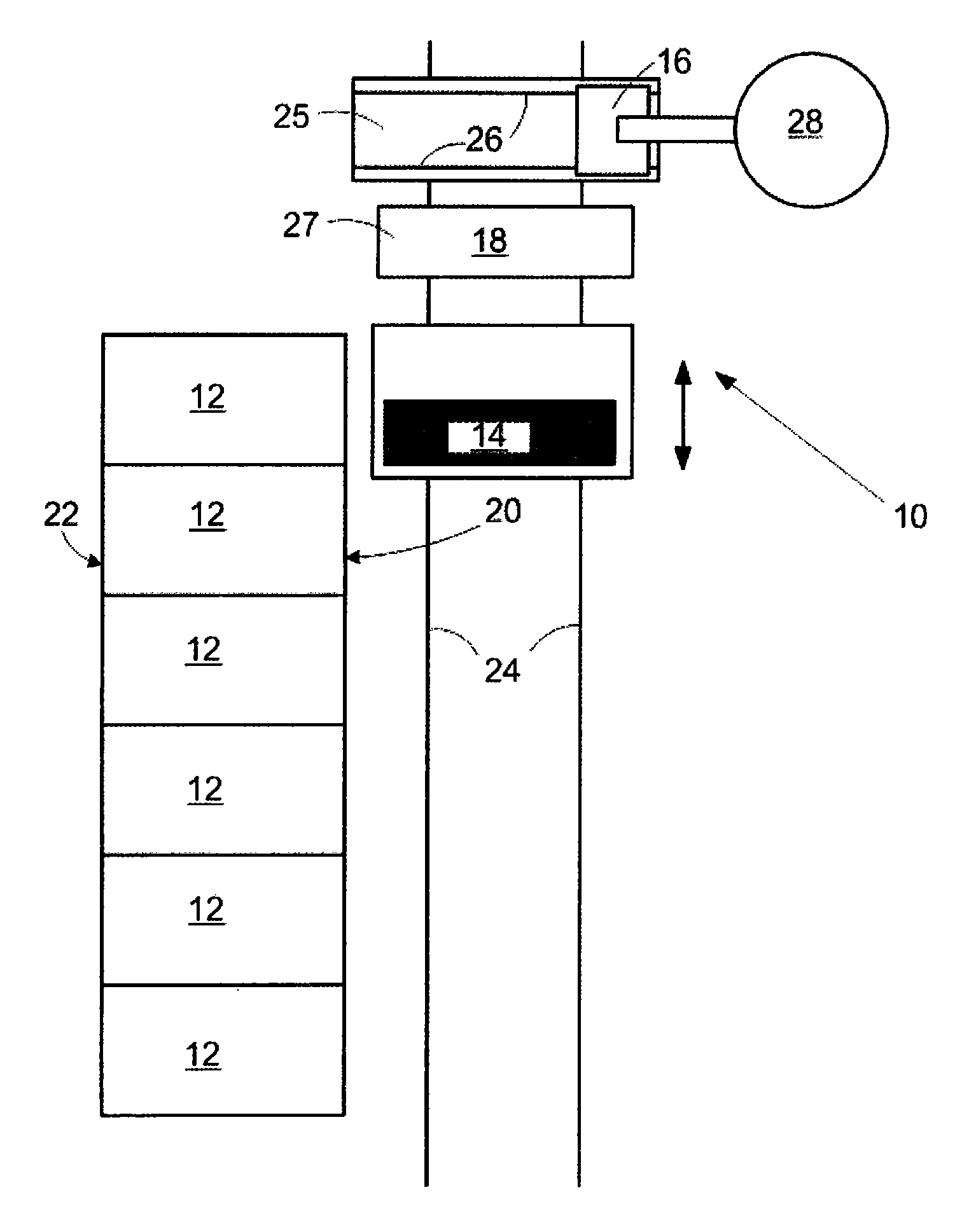

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

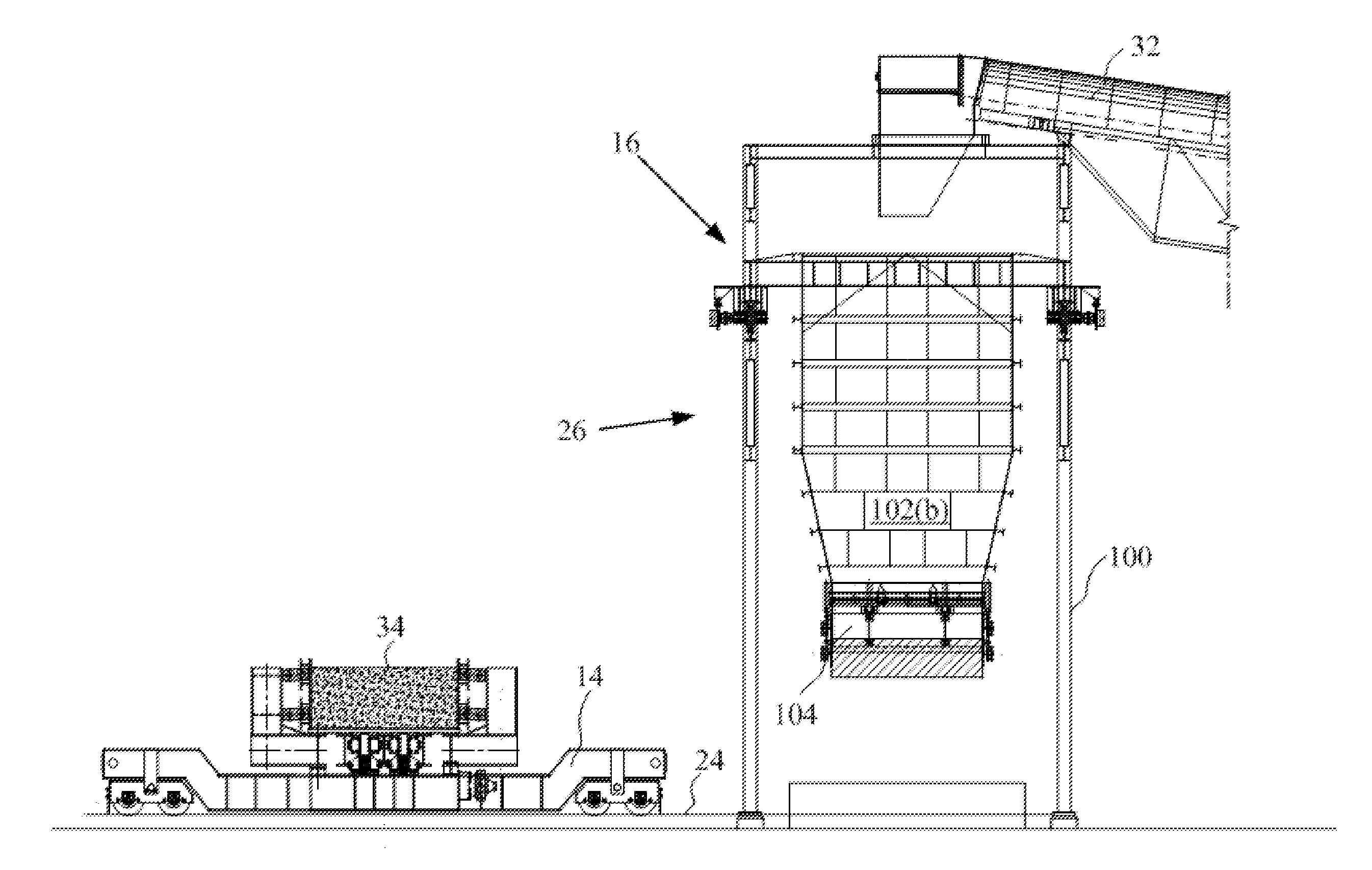

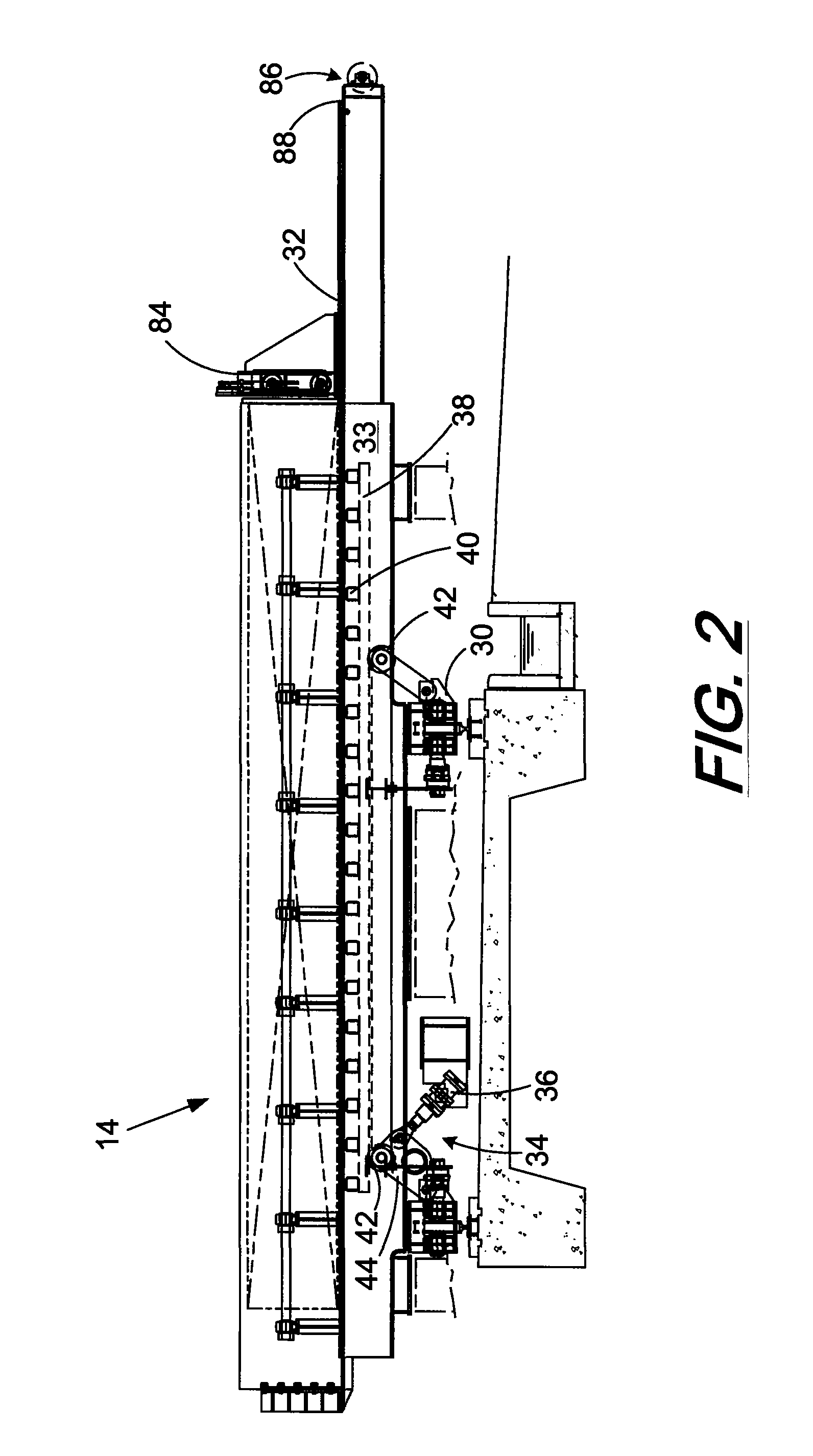

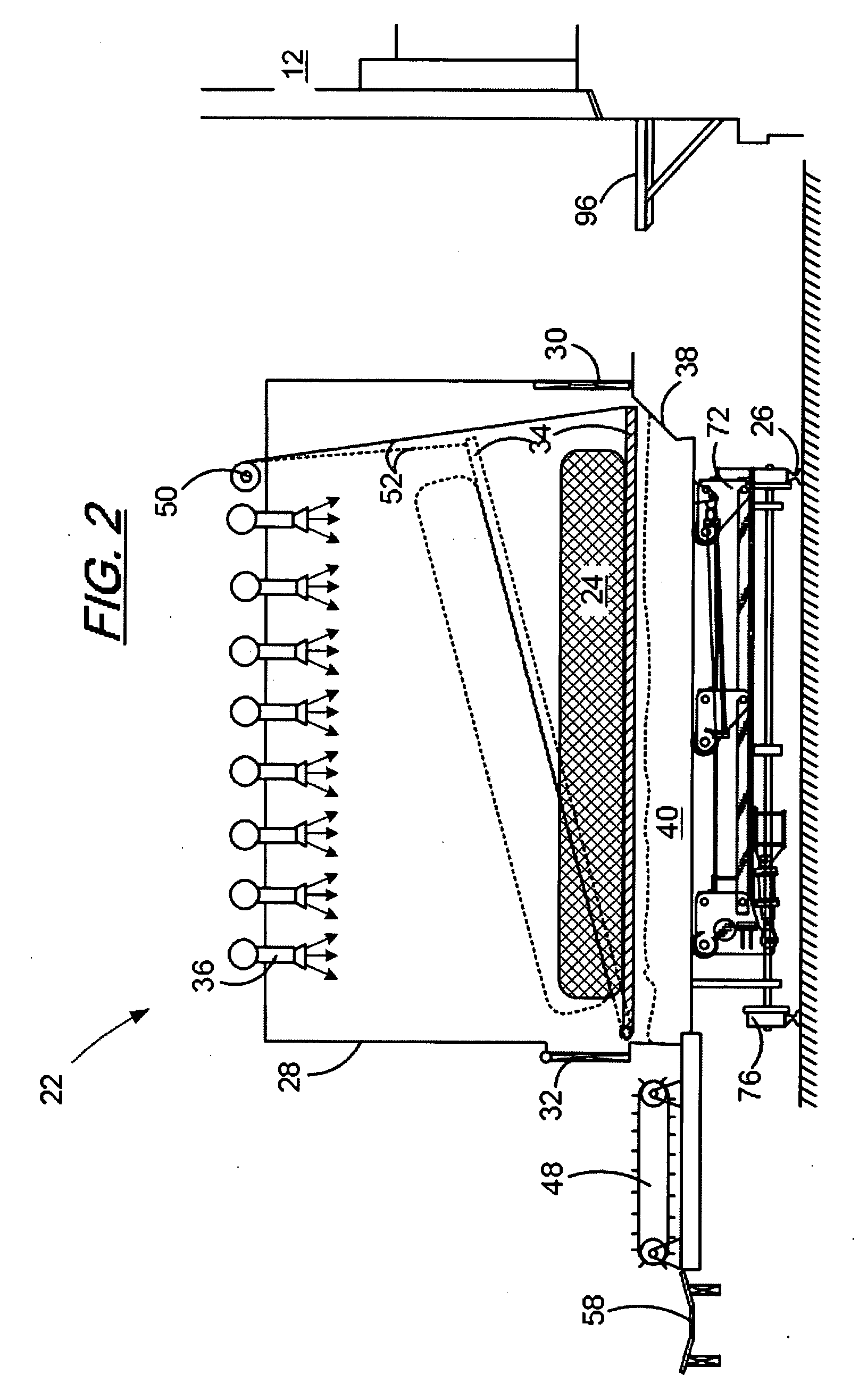

Method and apparatus for compacting coal for a coal coking process

ActiveUS20120030998A1High bulk densityShort timeCharging-discharging device combinationsSolid fuelsDiameter ratioEngineering

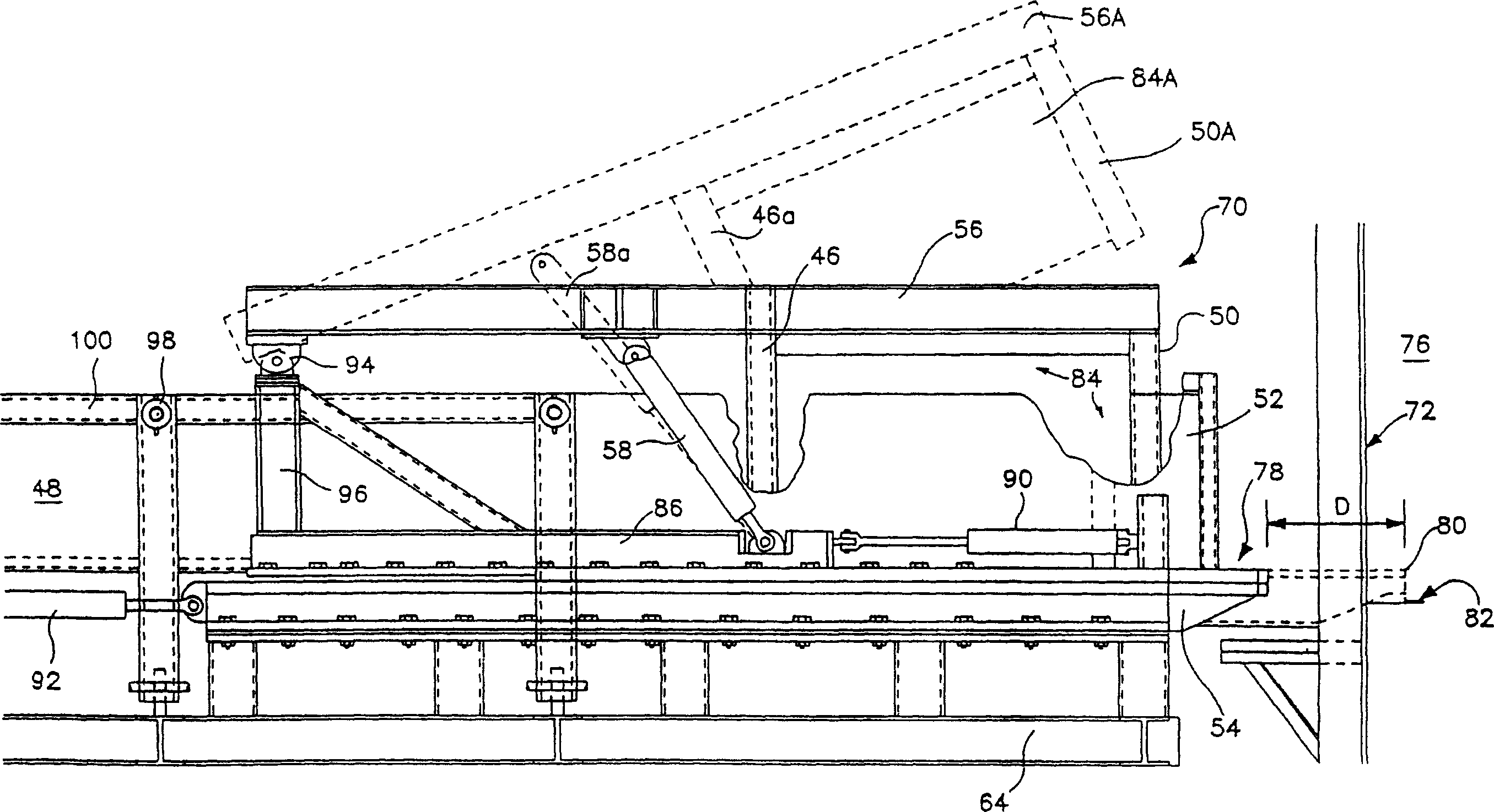

Relatively high speed methods for increasing the bulk density of coal particles without impacting the coal particles and an apparatus for compacting coal for making metallurgical coke. The method includes depositing coal particles onto a charging plate external to a coking oven. The charging plate has side walls, and at least one movable end wall to provide an elongate bed of dry, uncompacted coal having an upper surface on the charging plate. The uncompacted coal is compacted by passing a vibratory cylindrical compactor along a length of the uncompacted coal for a number of passes sufficient to decrease a thickness of the bed of coal to less than about 80 percent of an original thickness of the uncompacted coal. The vibratory cylindrical compactor has a length to diameter ratio ranging from about 1.4:1 to about 2:1.

Owner:SUNCOKE TECH & DEV LLC

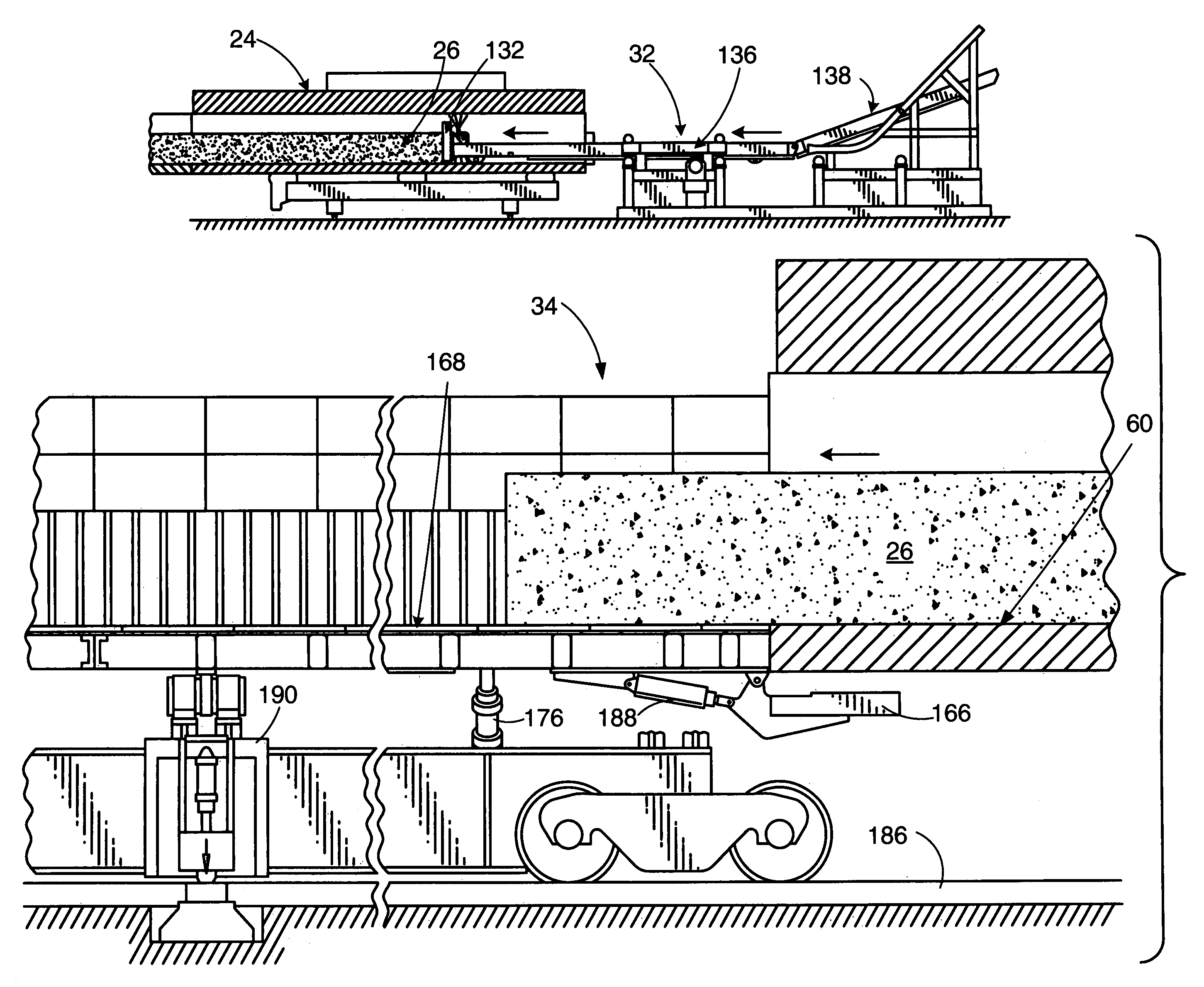

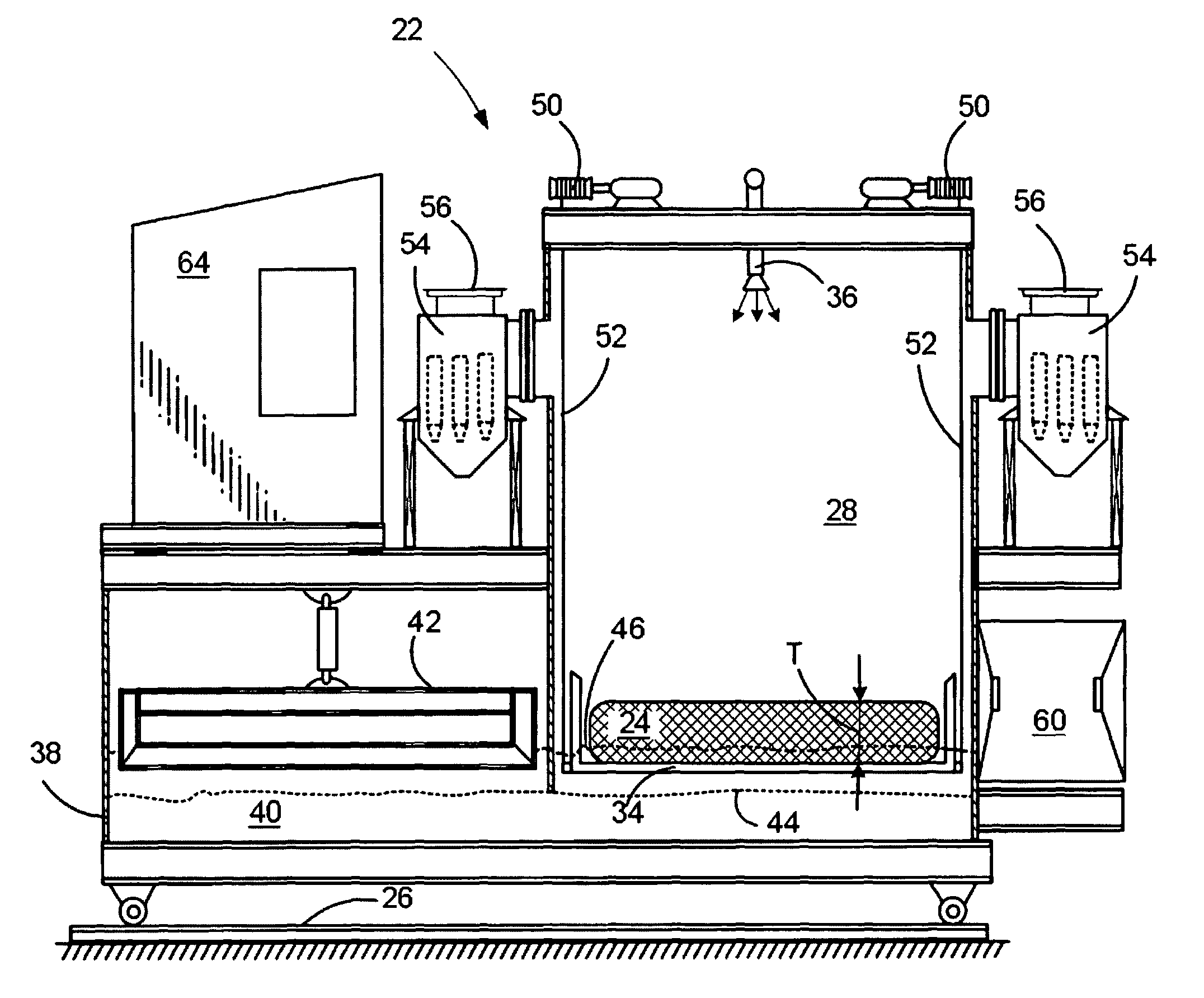

Flat push coke wet quenching apparatus and process

InactiveUS7998316B2Reduce the amount requiredImprove efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

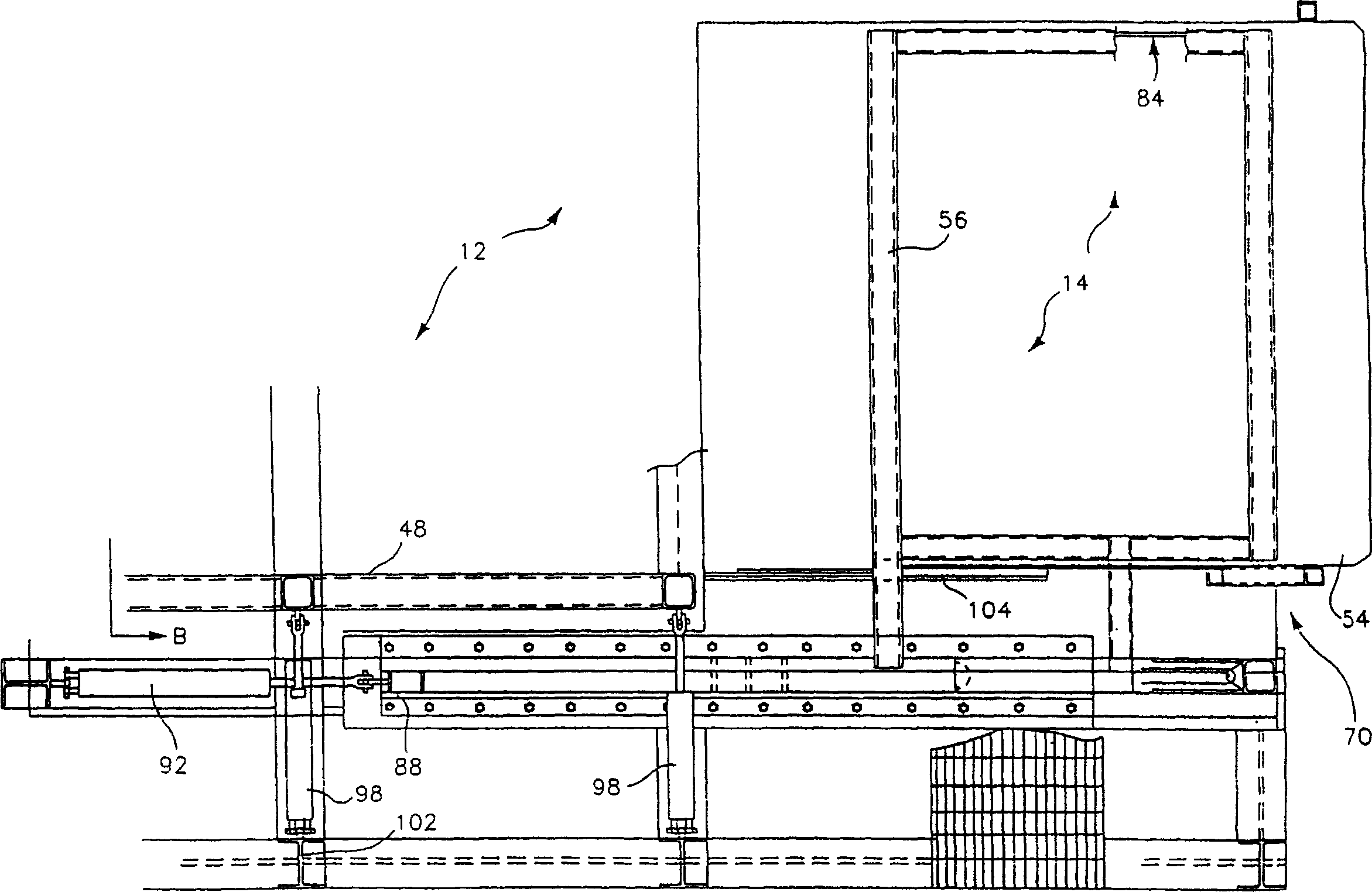

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

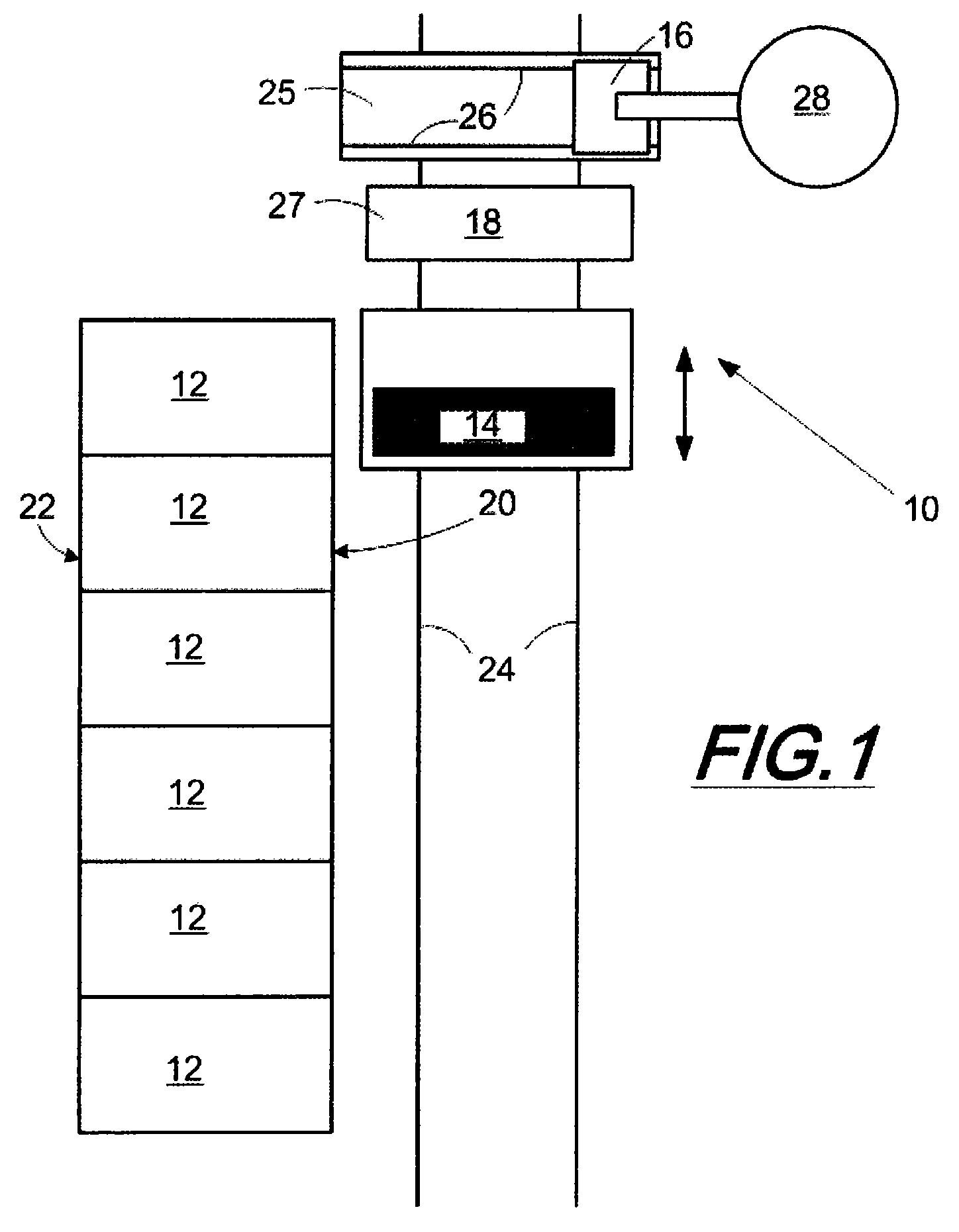

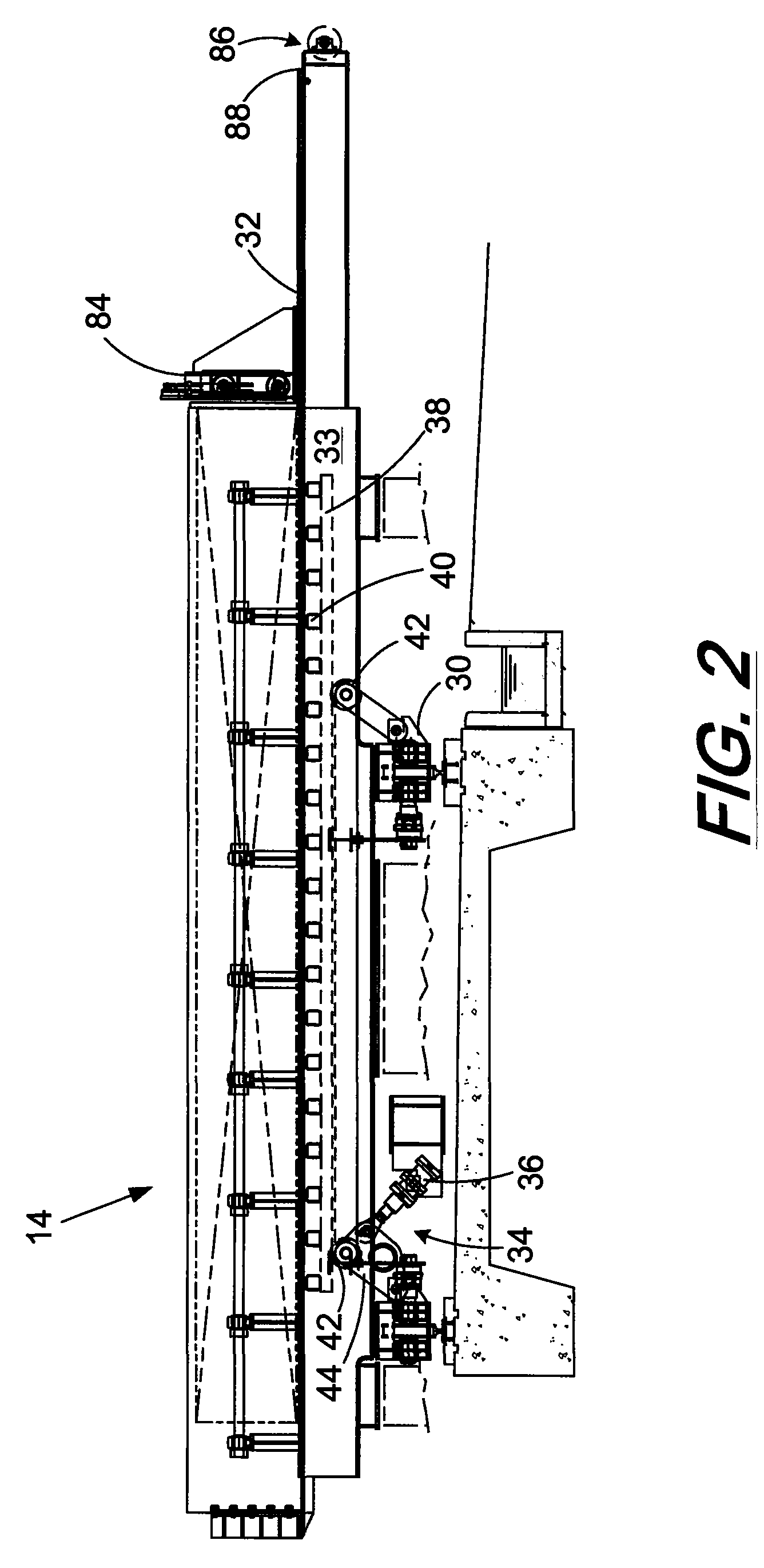

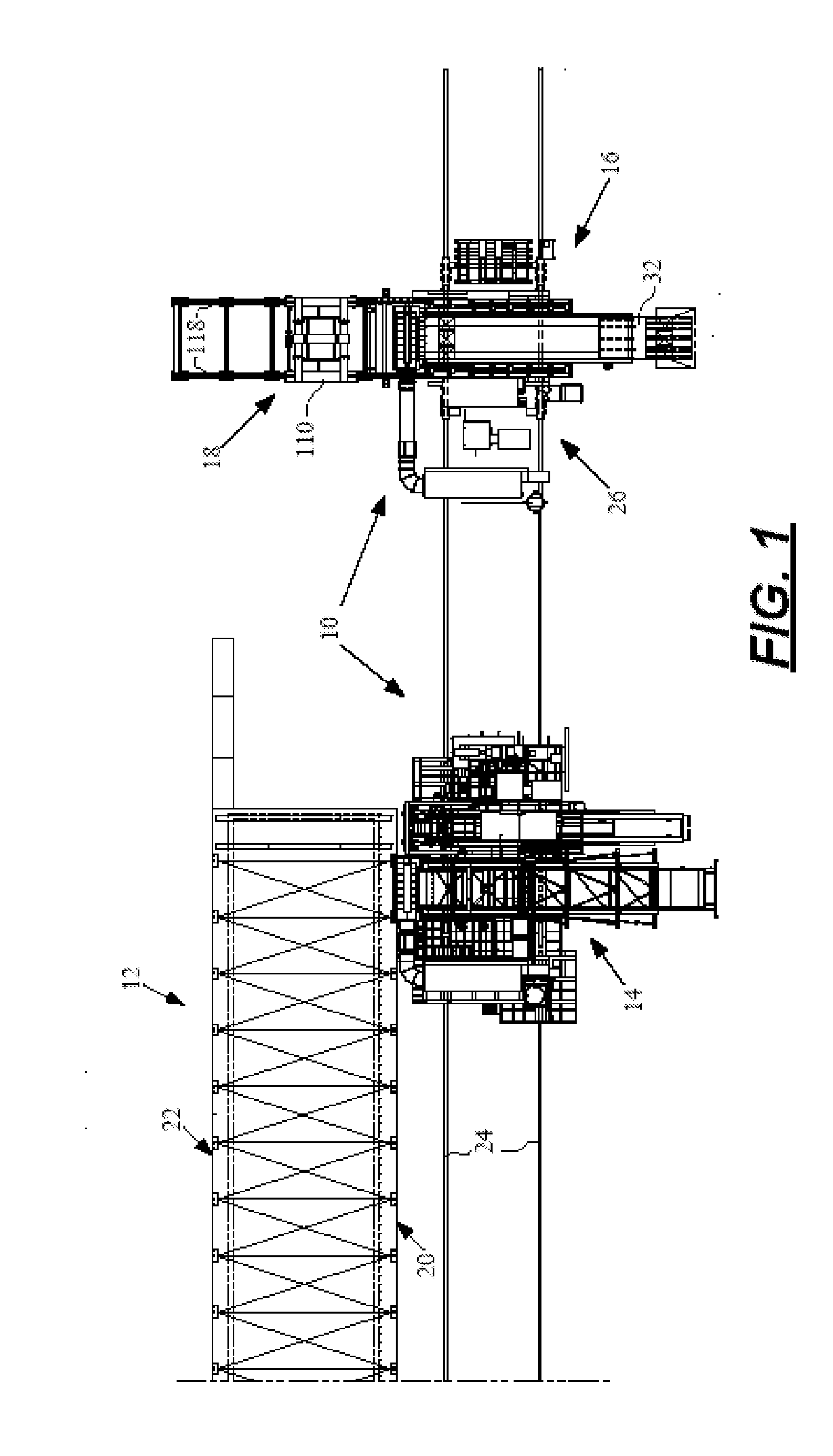

Method and apparatus for coal coking

InactiveCN1468364AReduce warpageReduce sliding frictionCharge manipulationCharging devicesEngineeringCoke oven

The invention provides a coke oven charging machine including a mobile frame and a coke oven feed device on the mobile frame. The coke oven feed device includes a movable, elongate charging plate having a first end and a second end, retractable side-walls adjacent the charging plate, first and second end walls adjacent the first and second ends of the charging plate and a shuttle section adjacent the first end of the charging plate for spanning an area between the first end of the charging plate and an entrance to the oven. The shuttle section has opposed shuttle side walls and a shuttle end wall. A charging plate moving device is provided for moving the charging plate into and out of the oven. The charging machine apparatus provides a means for quickly charging coking ovens with a compacted coal charge so that lower quality coals may be used to make metallurgical coke.

Owner:桑科克技术和发展有限责任公司

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

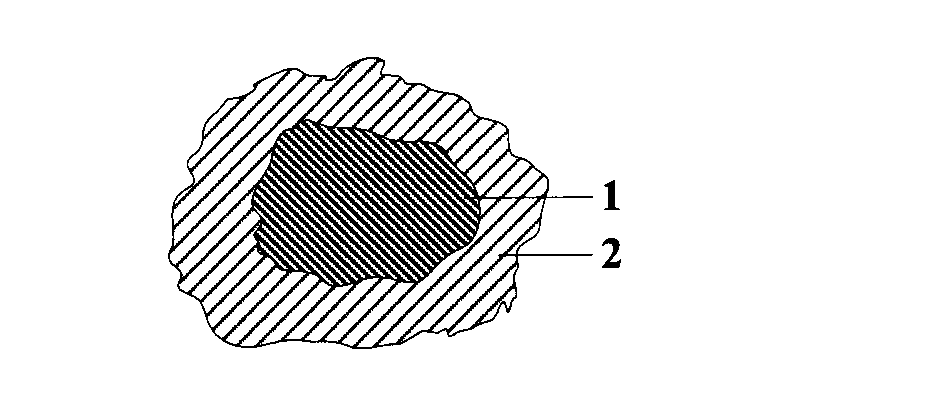

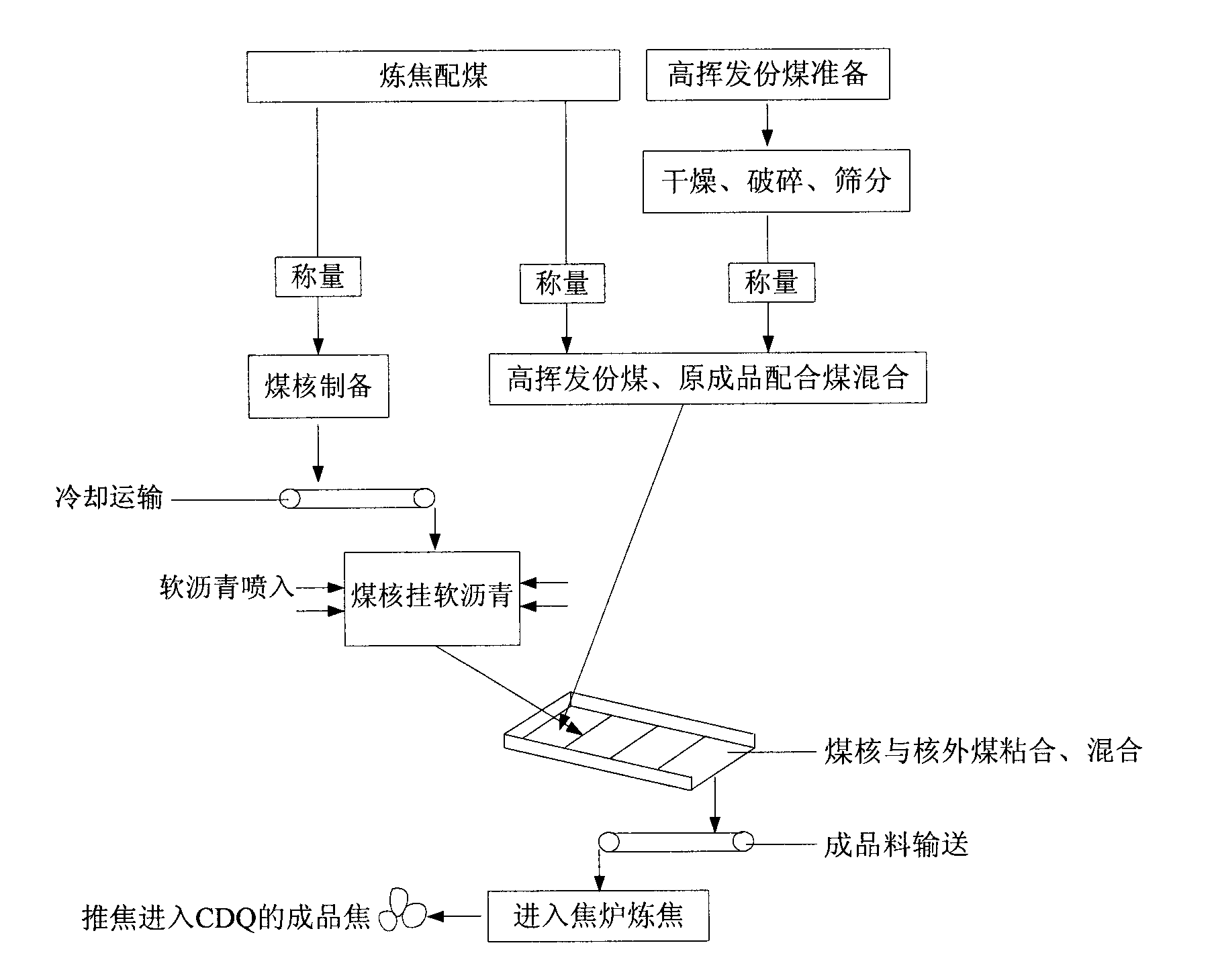

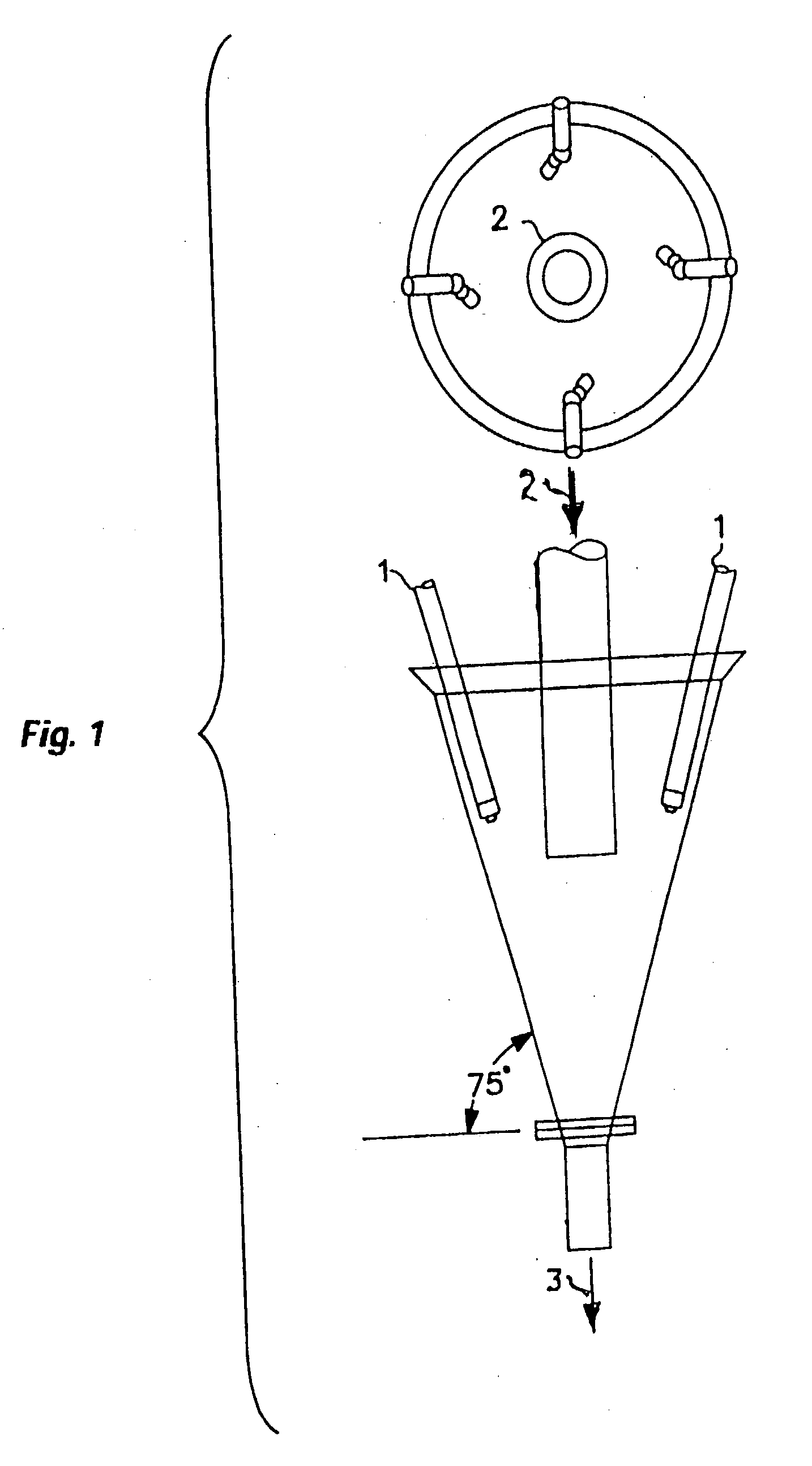

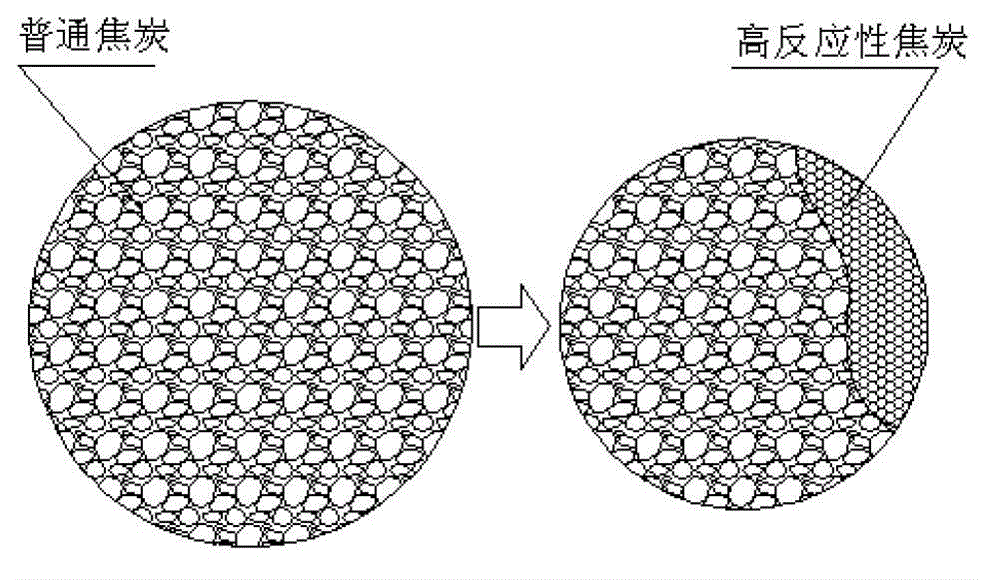

High-reactivity coke and manufacture method thereof

ActiveCN102719264AImprove responseHigh heat intensitySpecial form destructive distillationMethods of productionUltimate tensile strength

The invention provides high-reactivity coke and a manufacture method thereof, and the coke has an internal and external structure, wherein a core is prepared from blended coking coals and an external layer is prepared from high-volatile coals and blended coking coals through mixing. The method comprises: 1, blending coals; 2, preparing coal cores, comprising weighing 45% - 50% of coking coals, preparing the coal cores through crushing, binder addition, and ball-pressing, and sending into a soft asphalt spray room to spray asphalt to get the coal core; 3, processing external coking coals, comprising weighing 20% -25% of high-volatile coals, drying, crushing, screening and then sending particles with a grain size of less than 3 millimeters into a pre-mixer to evenly mix with 30% - 35% of coking coals; 4, preparing raw materials of finished products, comprising sending the external coking coals into a micro-swing mixing tank, and then putting in the coal cores to bond the external coking coals by mixing; 5, coking to get the finished coke. The high-reactivity cokes and manufacture method thereof are not only suitable for the present coke process to produce a high-reactivity and high-strength metallurgical coke with a low cost, but also can improve the operation of blast furnace production, thereby further reducing the ironmaking cost.

Owner:ANGANG STEEL CO LTD

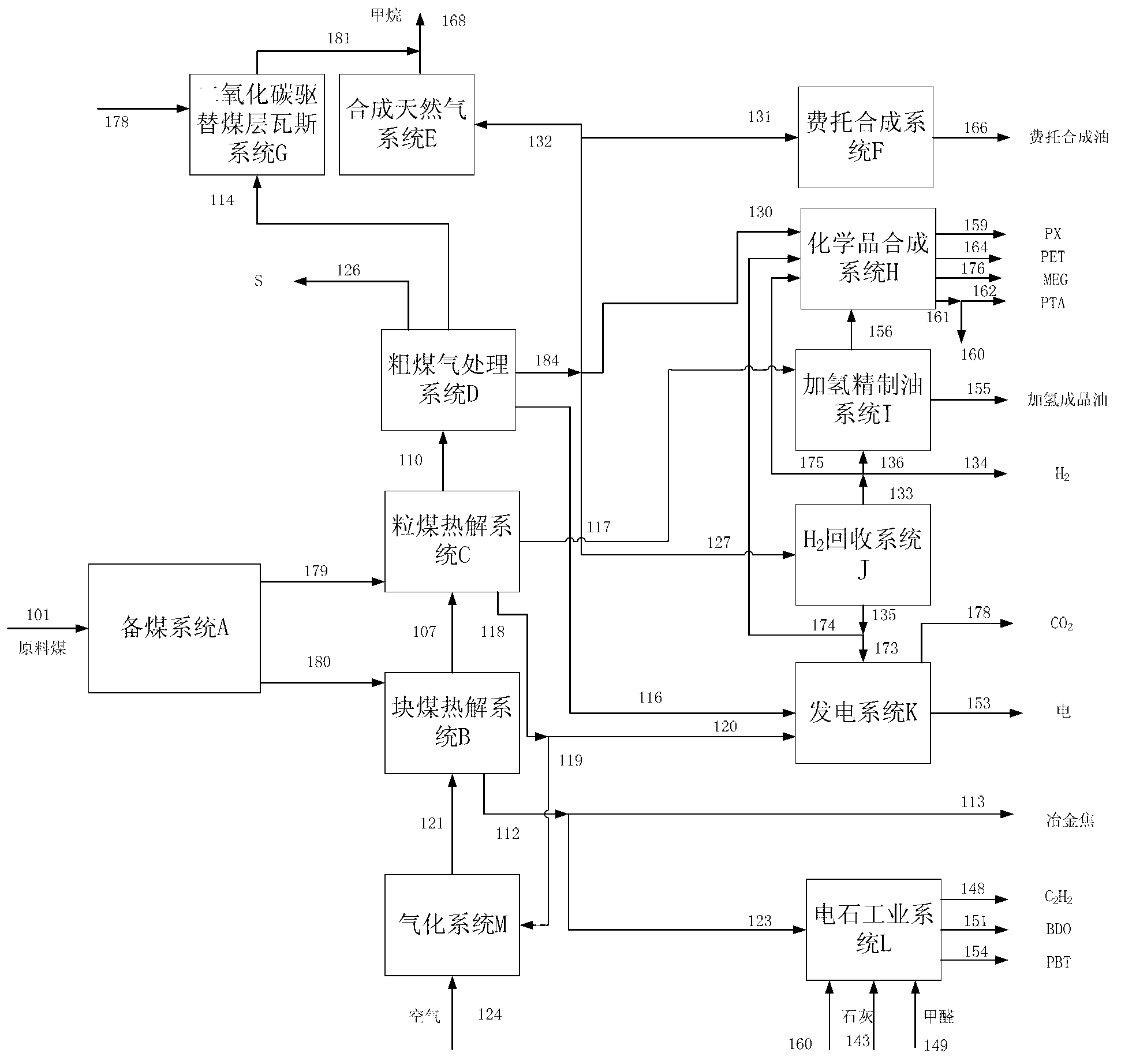

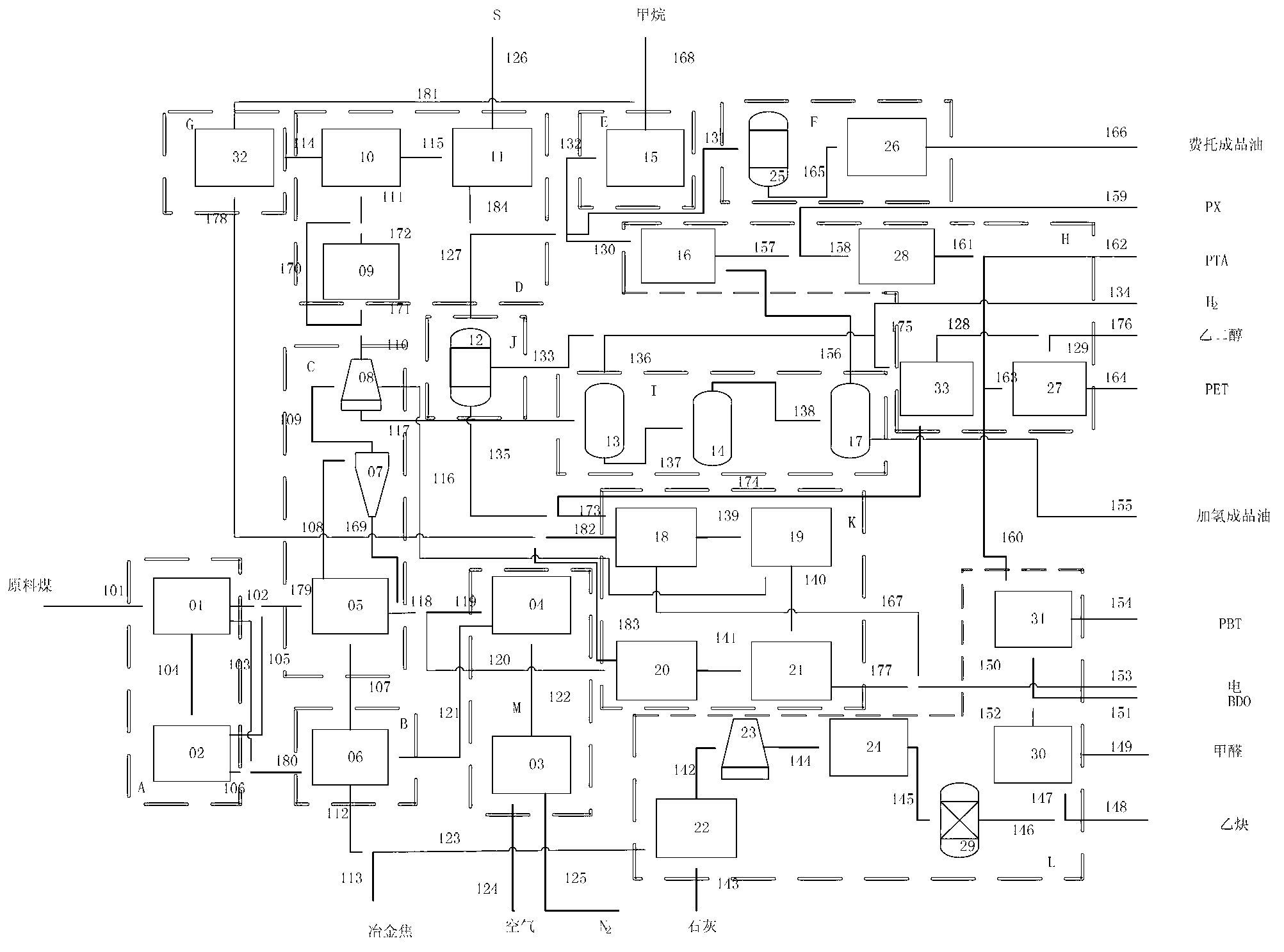

Omnibearing coproduction system and method by utilizing coal grading

ActiveCN103160294AImprove applicabilityAchieve self-balancingDirect heating destructive distillationEnergy inputHeat carrierCarbide

The invention provides an omnibearing coproduction system and method by utilizing coal grading. A standby coal system is respectively connected with a lump coal pyrolysis system and a pea coal pyrolysis system; a gasification system uses air as an input, semicoke generated by the pea coal pyrolysis system as a raw material, and generated gasified coal gas as a heat carrier of the lump coal pyrolysis system; lump coal pyrolysis oil gas generated by the lump coal pyrolysis system is used as a heat carrier of the pea coal pyrolysis system, part of generated lump coke is output as metallurgical coke, and the rest lump coke is used as a raw material for preparing carbide; pyrolysis coal gas generated by the pea coal pyrolysis system enters a crude gas treatment system, generated pyrolysis tar is used for hydrogenation grading, and generated semicoke is respectively used as semicoke for power generation and semicoke for gasification; and the crude gas treatment system uses pyrolysis coal gas generated by the pea coal pyrolysis system as a raw material, generated recovery waste heat is applied to a waste heat boiler of a power generation system, and generated carbon dioxide enters a carbon dioxide displaced coal gas system.

Owner:SHAANXI COAL & CHEM TECH INST

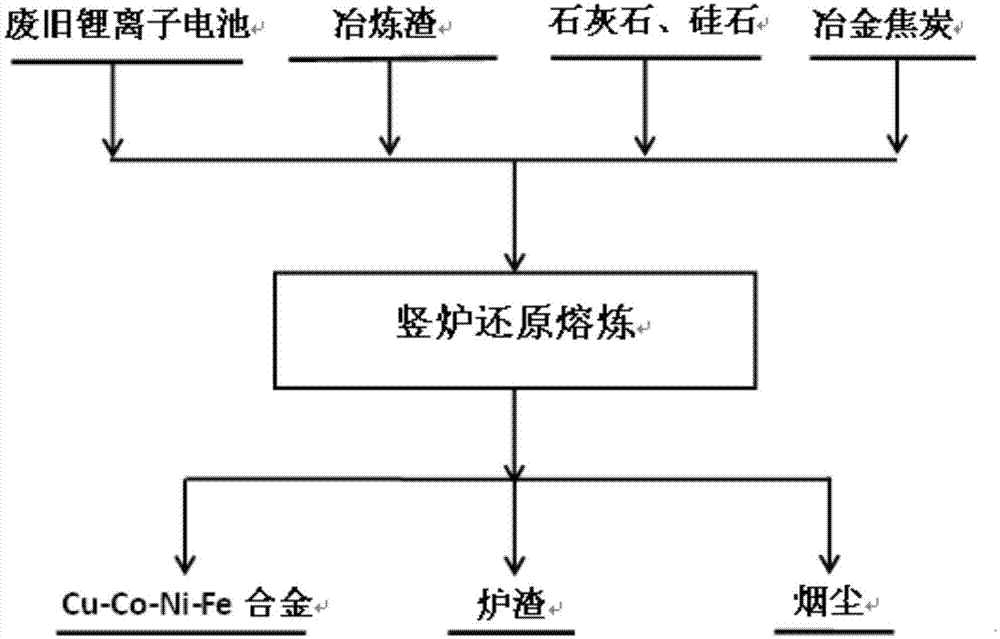

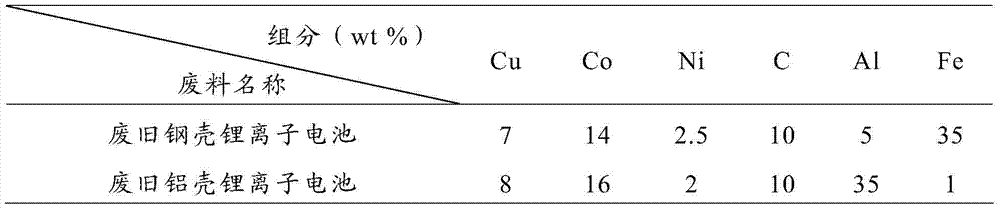

Method for recycling valuable metals from waste lithium ion batteries and/or other materials

The invention provides a method for recycling valuable metals from waste lithium ion batteries and / or other materials. The method comprises the following steps that the waste lithium ion batteries and / or the other materials, metallurgical coke and fluxing agents and / or waste containing one or more of Cu, Co and Ni are mixed to obtain mixed materials; the metallurgical coke accounts for 0-20wt % of the mixed materials, and CaO / SiO2 is equal to or higher than 1, or (CaO +MgO) / SiO2 is equal to or higher than 1 in the mixed materials; the mixed materials are subjected to reduction smelting under the temperature of 1400-1600 DEG C, and alloy containing valuable metals and slags are obtained. According to the method, alkaline slags are adopted for smelting, efficient recycling of valuable metals can be achieved, and the amount of valuable metals in slags is reduced.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing binder-free graphite product

The invention provides a method for preparing a binder-free graphite product, which is characterized in that the graphite product is composed of crude petroleum coke and coal pitch mesophase pellet powder, and is characterized by comprising the following steps: drying, dewatering and smashing the crude petroleum coke; grinding the smashed crude petroleum coke to obtain crude petroleum coke powder by using a ball mill and an airflow pulverizer in sequence; heating the coal pitch mesophase pellet powder to carry out pre-oxidation treatment; cooling to room temperature; fully mixing by a blender; charging under vibration and preforming; placing blended power into a hydraulic cylinder, and obtaining isostatic pressing graphite green bodies through the steps of boosting pressure, maintaining pressure, reducing pressure and demoulding in an isostatic pressing forming process; placing the isostatic pressing graphite green bodies into an iron crucible; taking river sand and metallurgical coke powder as fillers in the roasting process, wherein the fillers are used for preventing the products from oxidization and deformation and fixing green body shapes; putting the iron crucible filled with the isostatic pressing graphite green bodies into a roasting furnace for roasting treatment to obtain isostatic pressing graphite roasting products after roasting; carrying out graphitization treatment on the isostatic pressing graphite roasting products by using a graphitized furnace to obtain the binder-free graphite products.

Owner:JILIN CARBON

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

Preparation of asphalt for producing coal-based needle coke

InactiveCN101302431AHigh yieldImprove product qualityTar working-up by distillationCoking carbonaceous materialsDistillationCoal dust

The invention discloses a method for preparing pitch used for producing coal-based needle coke. The method comprises the following steps that: coal tar and coal pitch are taken as raw materials; coal tar light compositions are taken as solvent; coal dust, metallurgical coke powder, or mixture of the metallurgical coke powder and diatomite, or mixture of the metallurgical coke powder and expanded perlite are taken as filter aid; uniform filter aid filter cakes are formed in a centrifuge by filter aid mixture at first, and then mixture of the coal pitch or the coal tar, wash oil and the filter aid is added into the centrifuge in which the uniform filter aid filter cakes are formed for centrifugal filtration; and obtained centrifugate is driven to pass through atmospheric distillation recovery solvent, so as toe obtain the refining pitch raw materials which are suitable for producing the coal-based needle coke. The yield of the pitch raw materials used for producing the coal-based needle coke prepared by the technology is improved by 10 to 15 percent compared with other methods; the manufacturing technique is simple and the preparation cost is low; and the mass production is easy to realize.

Owner:邯郸市鑫宝煤化工有限公司

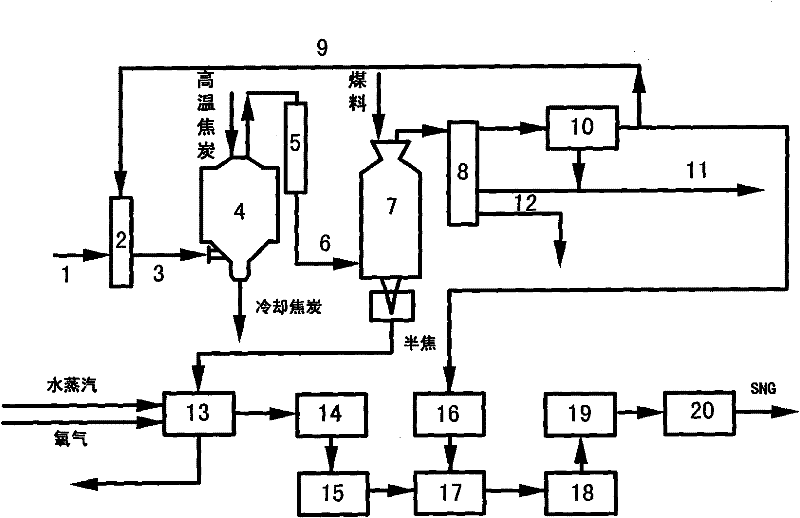

Method for preparing natural gas by dry quenching co-production coal

InactiveCN101747918AAvoid pollutionAchieve emissionsCoke quenchingDirect heating destructive distillationMethanationQuenching

The invention provides a method for preparing natural gas by dry quenching co-production coal. In the method, reducing gas is taken as heat-carrying gas, refrigerant and a pyrolytic process thereof are adopted to recover a great quantity of sensible heat of high-temperature coke so as to couple the dry-method coke quenching process and the coal pyrolytic process of high-temperature metallurgical coke, thus cancelling a gas and air supply system, a combustion control system and a waste gas discharging system in the original pyrolytic process, avoiding pyrolytic combustion process, saving a great quantity of energy, and realizing smoke-free, NOX-free, SOX-free and CO2-free discharging. Meanwhile, gasification gas produced by pyrolytic gas and semi-coke gasification is used for producing andsynthetizing natural gas in a methanation manner so as to realize clean conversion of coal. In addition, the method cancels N2 preparation equipment and waste heat boiler systems in dry quenching, thus simplifying the operation and maintenance process and greatly lowering investment and operation cost.

Owner:山西中元煤洁净技术有限公司

Method and system for improving metallurgical coke strength by utilizing waste plastics

The present invention relates to a method for raising strength of metallurgical coke and its system. Said invention adopts traditional coking process and equipment, and adds waste plastics in the course of coking process, and is characterized by that after the waste plastics and additive are processed, they are added into coking furnace to implement co-coking with coking coal, at the same time of that the waste plastics are charred at high temp., and converted into coke, tar and gas the coke quality can be improved, crushing strength of coke M40 can be raised, abrasive resistance index of coke M10 is reduced, coke reactivity CPI is reduced and coke postreaction strength can be raised. Said system includes waste plastics processing system, additive and waste plastics mixing system, waste plastics and additive mixture and coking coal mixing system and traditional coking system.

Owner:SHOUGANG CORPORATION

Method for recovering noble metals from spent auto-catalyst

ActiveCN104073641AHigh enrichment factorReduce energy consumptionProcess efficiency improvementPlatinumPtru catalyst

The invention discloses a method for recovering noble metals from a spent auto-catalyst. The method comprises the following steps: (1) early treatment of materials; (2) burdening, and mixing, namely mixing the materials processed in the step (1) according to the ratio, wherein the materials comprise 75-85 parts of spent auto-catalyst taking cordierite as a carrier, 2-4 parts of magnetite, 1-3 parts of metallurgical coke, 10-13 parts of lime and 1-3 parts of fluorite mine; (3) processing the obtained materials by adopting a plasma furnace: a, introducing argon of which the purity is 99.99% into the plasma furnace, so as to keep micro negative pressure inside the furnace; b, beginning to feed the materials obtained in the step (2) to the plasma furnace when the temperature inside the plasma furnace is within the range of 1500-1600 DEG C; c, beginning to discharge slag from a slag phase discharge hole after smelting for 3-6 hours, d, carrying out heat preservation at 1600-1650 DEG C for 30 minutes after charging the materials obtained in the step (2), and then opening the metal phase discharge hole, so as to obtain alloy containing noble metals. By adopting the method, the total yield of platinum, palladium and rhodium is greater than 98%, the recovery rate of platinum is greater than 98%, the recovery rate of palladium is greater than 98%, and the recovery rate of rhodium is greater than 97%.

Owner:GUIYAN RESOURCE YIMEN

Method and apparatus for producing coke

ActiveUS20070205091A1Reduce the amount requiredImprove dust collection efficiencySpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

Process for upgrading raw phosphate ore

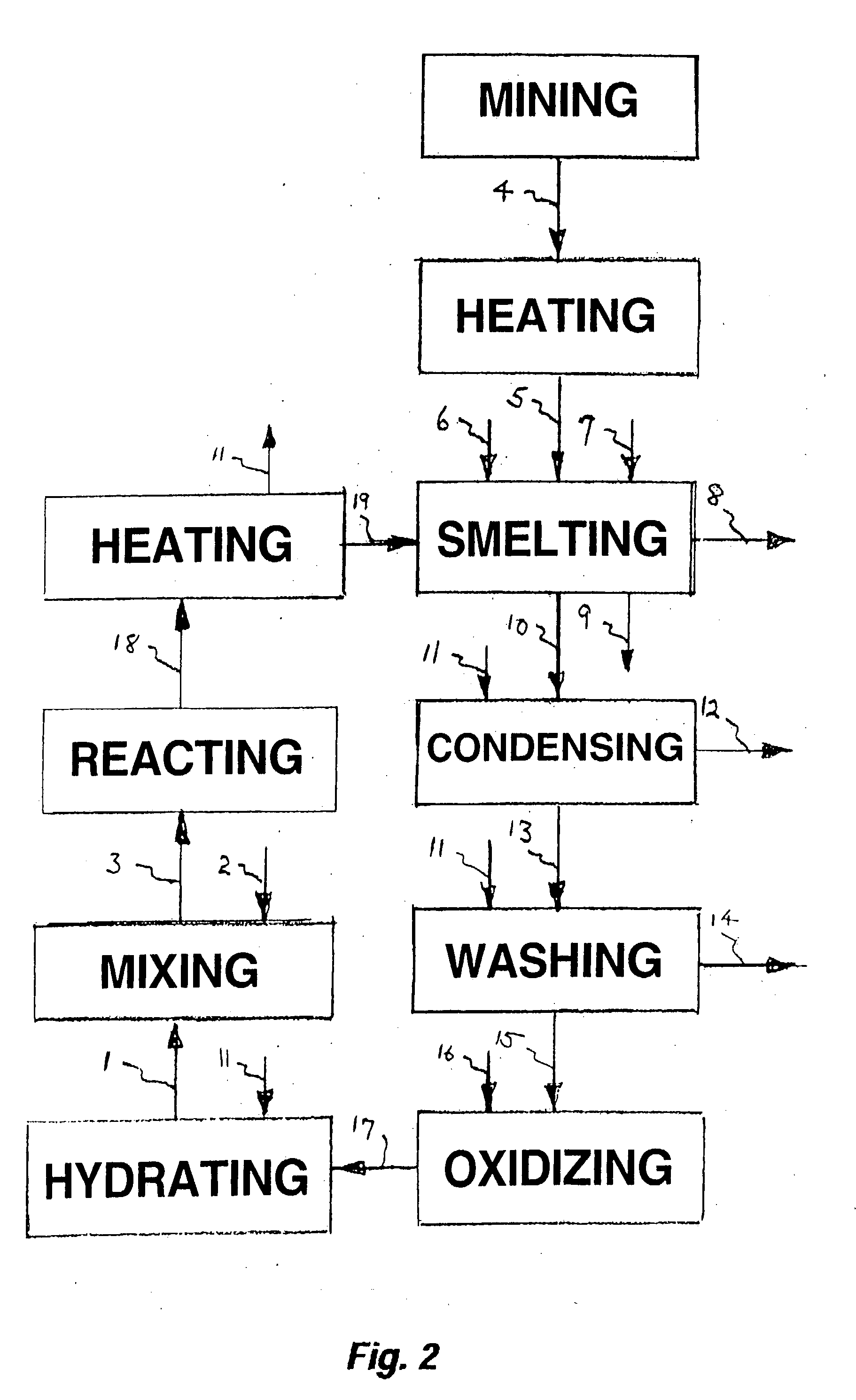

InactiveUS20040067187A1High-purity phosphorusIncrease productionPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesO-Phosphoric AcidSludge

Fluorapatite mineral deposits in middle Tennessee were formerly beneficiated by washing out most of the clay, but some of the clay remained in the beneficiated ore. The ore was agglomerated by heating to temperatures high enough to melt clay remaining in the ore thereby obtaining a fluid phase for agglomeration in rotary kilns. The agglomerated phosphatic material was mixed with silica rock and metallurgical coke and the mixture was smelted in electric furnaces to produce elemental phosphorus. The feedstock had a percent P O in the phosphate-plus-silica of about 25.7. Phosphate ore deposits amenable tp beneficiation by washing were used up. Furthermore, mud ponds containing the washed-out clay polluted ground water and water courses. An endeavor was made to smelt feedstock prepared from raw phosphate ore but the percent P O in the feedstock was too low for smelting. The present invention is a process for upgrading feedstock prepared from raw phosphate ore. Phosphorus sludge is burned to produce impure phosphoric acid and the acid is combined with beneficiated phosphate ore to prepare anhydrous monocalcium phosphate. Feedstock prepared from raw phosphate ore is blended with anhydrous monocalcium phosphate to upgrade the feedstock.

Owner:JAMES C BARBER & ASSOCS

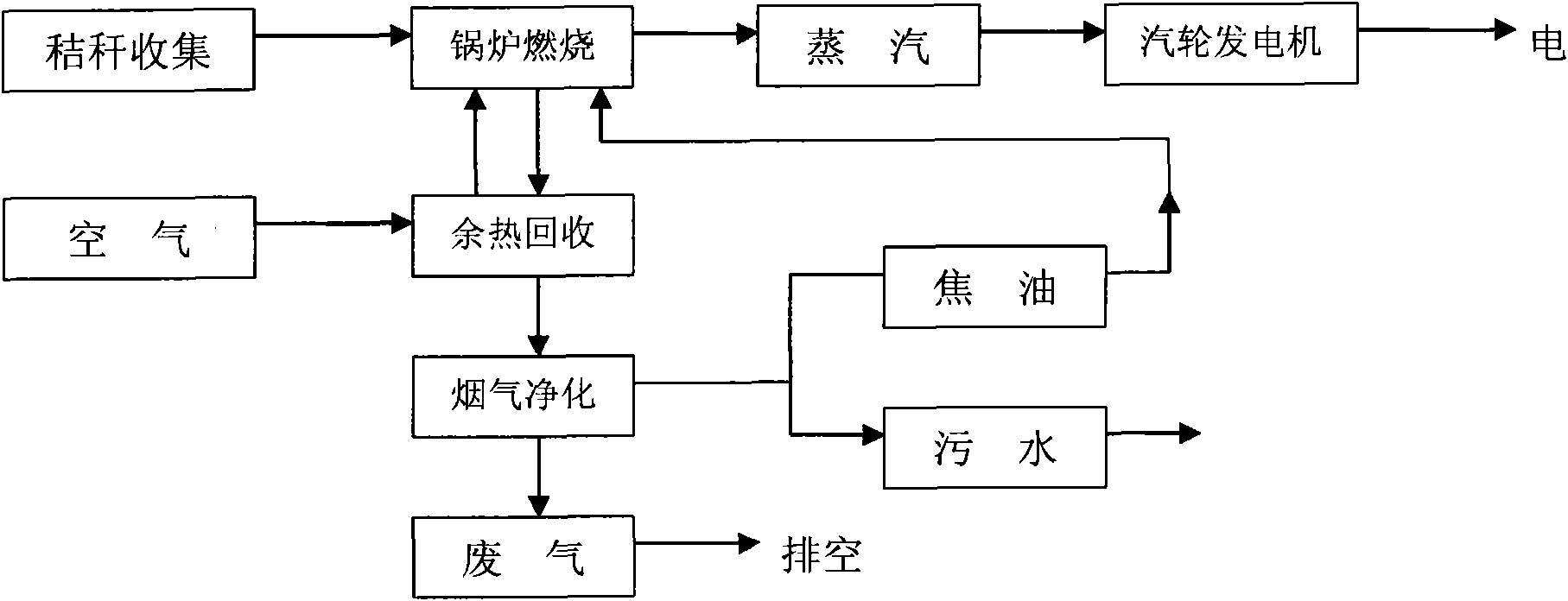

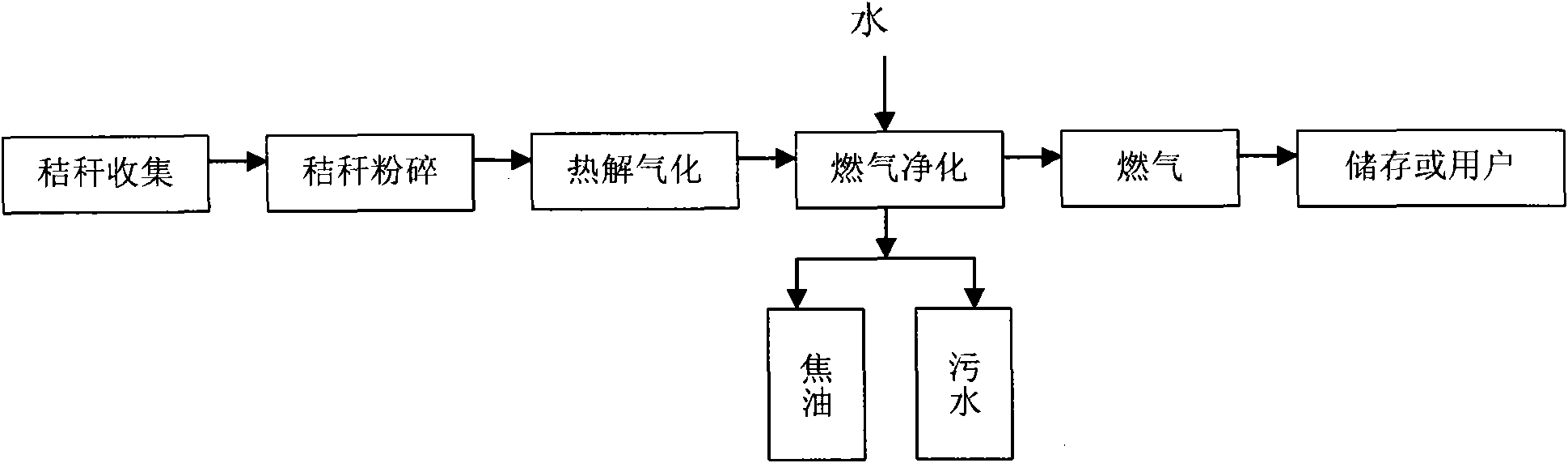

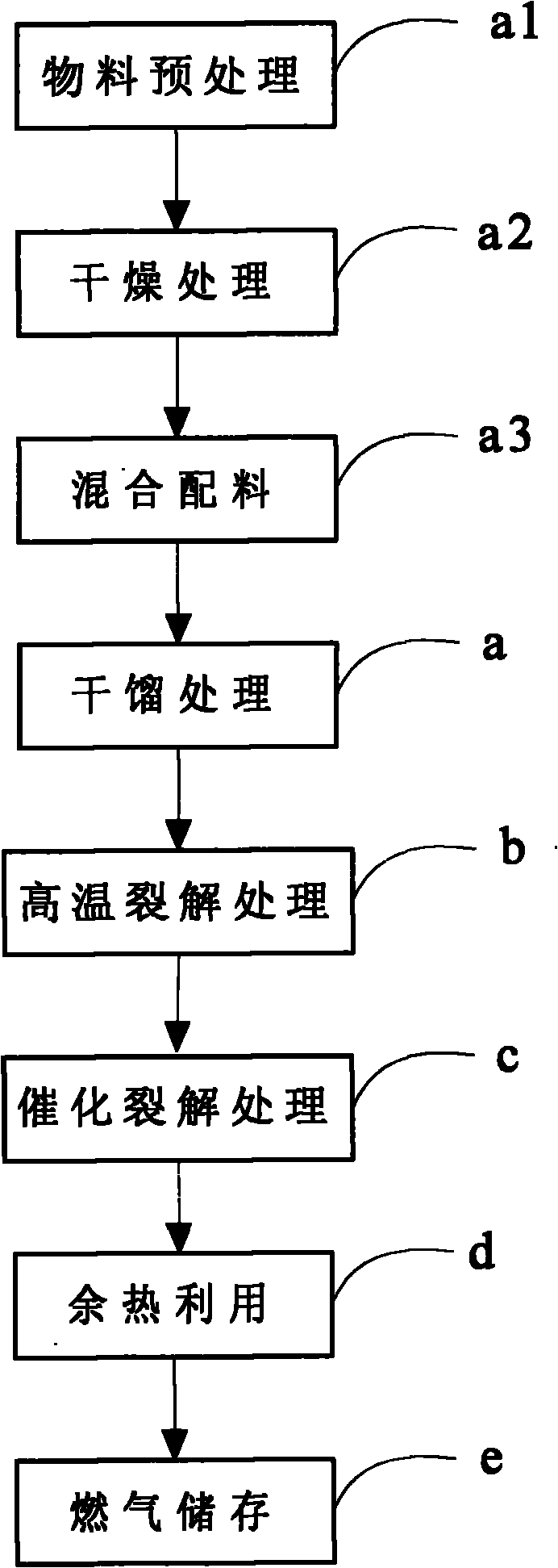

Solid biomass gasification system and process thereof

The invention discloses a solid biomass gasification cracking process which comprises the following steps: a) dry distillation treatment: carrying out the dry distillation treatment on solid biomass for forming biological coke and dry distillation gas; b) high-temperature cracking treatment: inputting the biological coke and the dry distillation gas into a thermal cracking gasification furnace for carrying out the high-temperature cracking treatment; and c) catalytic cracking treatment: using a fixed bed layer constituted by a metallurgical coke block catalyst to carry out the catalytic cracking treatment on the dry distillation gas which flows by the fixed bed layer and residual coke tar in pyrolysis gas. The solid biomass gasification cracking process can solve the technical difficult problem that the complete cracking of the coke tar can not be realized by dry distillation gasification or pyrolysis gasification through the combination of the dry distillation gasification, the high-temperature thermal cracking gasification and the catalytic cracking technology, and further prevent and treat coke tar sewage, environmental pollution caused by heavy metal salts and the like. The invention further discloses a solid biomass gasification cracking system, which comprises a dry distillation furnace, a thermal cracking gasification furnace connected with a gas outlet and a slag outlet of the dry distillation furnace and a gas purification device connected with the gas outlet of the thermal cracking gasification furnace.

Owner:合肥天焱绿色能源开发有限公司

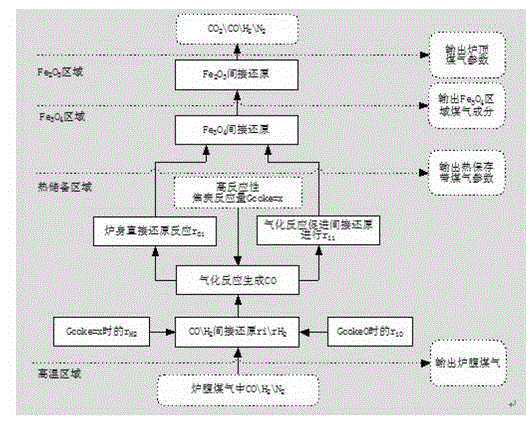

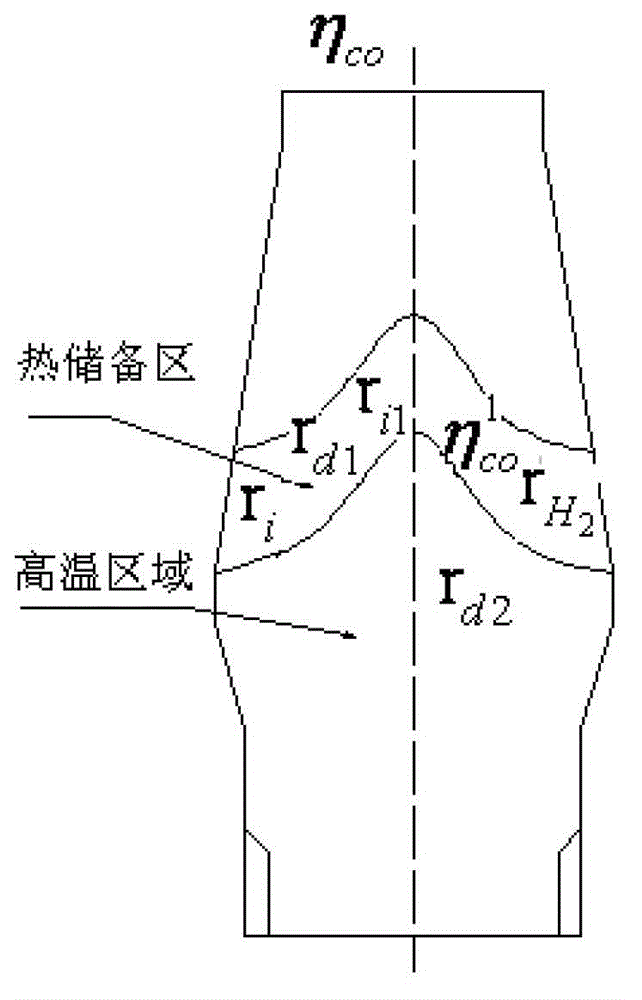

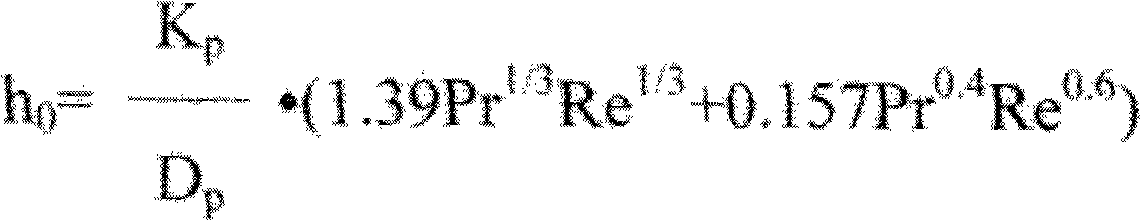

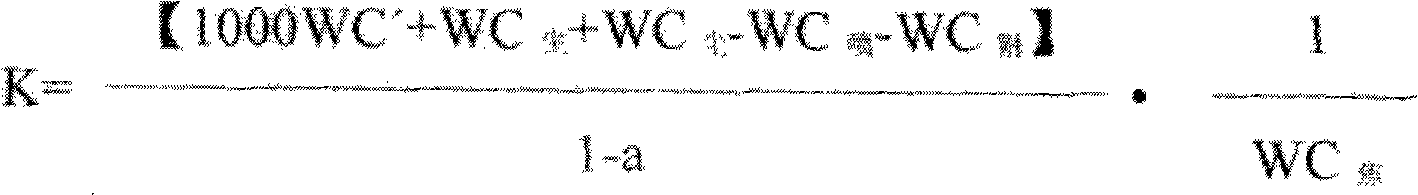

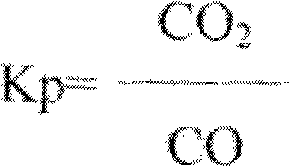

Method for computing degree of direct reduction and gas utilization rate of blast furnace under condition of high-reactivity coke

InactiveCN102876823ABlast furnace detailsSpecial data processing applicationsMetallurgical cokeCalculation methods

The invention belongs to the field of blast furnace iron making, and relates to a method for computing the gas utilization efficiency of a blast furnace under the condition that high-reactivity coke is added into the blast furnace. The method further can be used for respectively computing degrees of direct reduction and degrees of indirect reaction of a high-temperature region and a heat storage region of the blast furnace under the condition that the high-reactivity coke is added into the blast furnace. The total degree of direct reduction of the blast furnace is r<d>, and the gas utilization rate of the blast furnace is eta<co>. By the method, the degree of direct reduction of the blast furnace for smelting and the gas utilization of the blast furnace can be accurately computed under raw material conditions, production of the blast furnace can be guided, and the method is also applicable to the traditional blast furnace under the condition of using metallurgical coke.

Owner:UNIV OF SCI & TECH BEIJING

Carbon material cold ramming paste

The invention discloses a carbon material cold ramming paste which is obtained by mixing and ramming following raw materials of, by gross weight, 45%-70% of calcined anthracite, 8%-20% of metallurgical coke, 0%-60% of artificial graphite, 13%-15% of coal tar, 3%-5% of anthracene oil or wash oil, 0.5%-5% of sulphur, 0.5%-5% of 2,4-dinitrotoluene and 0.5%-5% of 1,3-dinitrotoluene. According to the carbon material cold ramming paste, asphalt is not required for being used as an adhesion agent, heating is not required during production and construction processes, the cold ramming paste can be directly used on required portions for ramming, intermittent construction can be performed, and the ramming quality of the cold ramming paste is obviously superior to that of cold ramming paste and hot ramming paste in the market.

Owner:朱岳屏

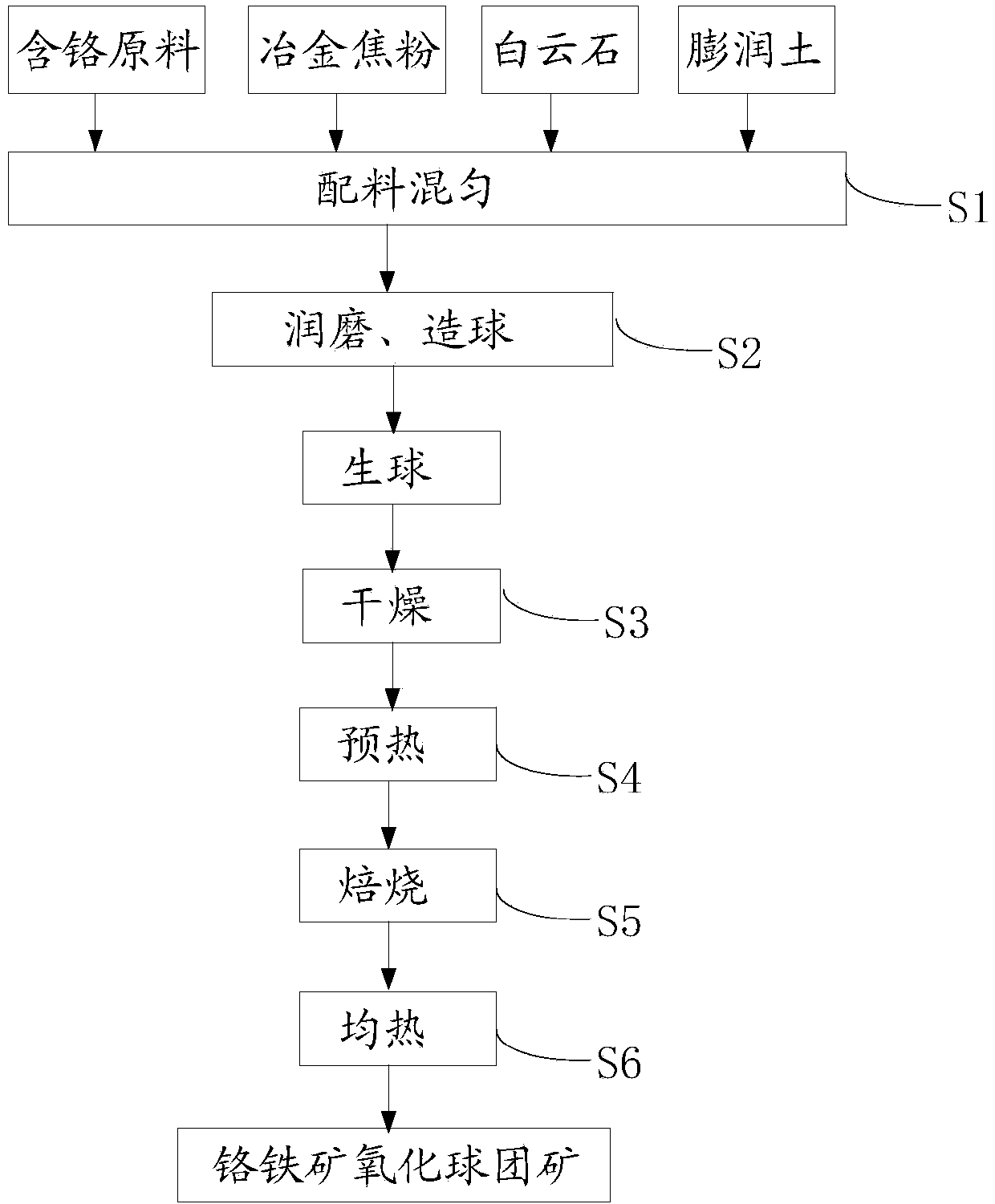

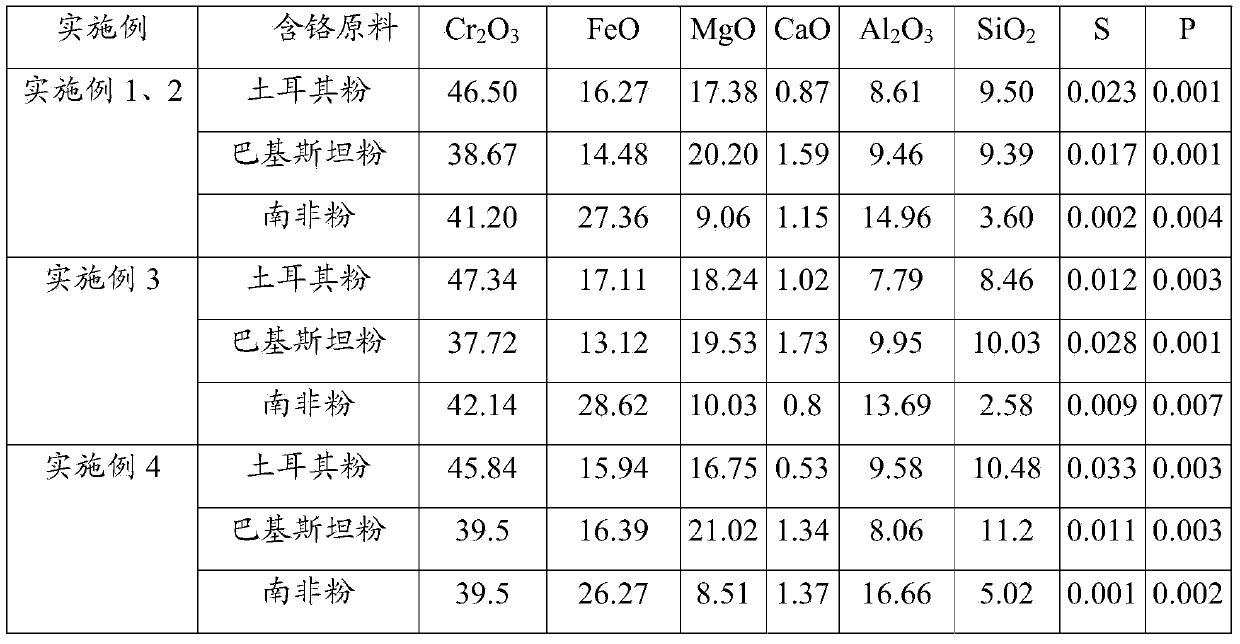

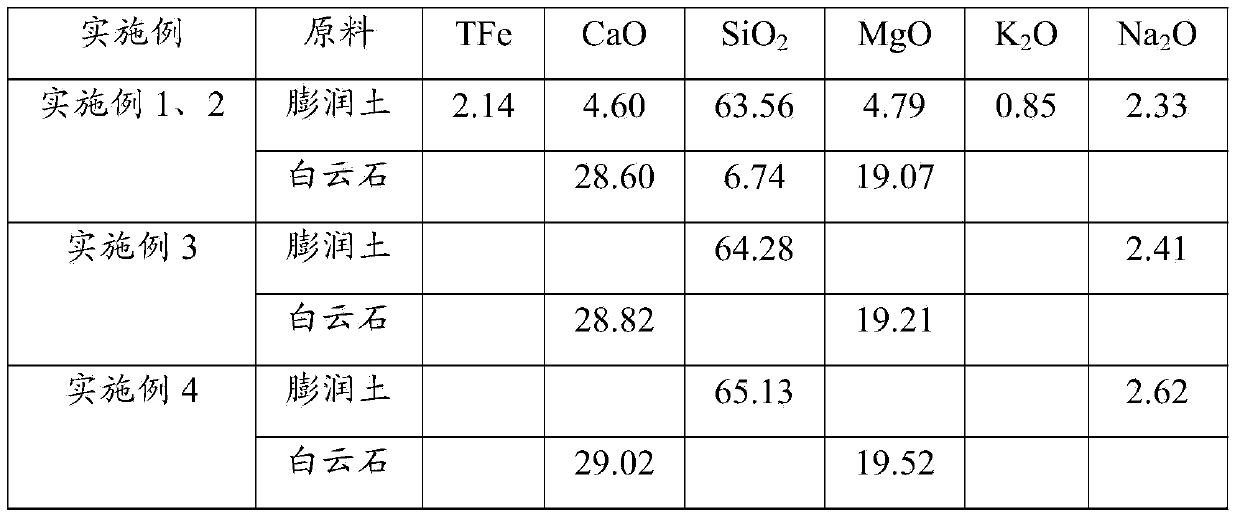

Chromite oxide pellet and preparation method thereof

The invention discloses a chromite oxide pellet. Raw materials of the chromite oxide pellet comprise 40-60wt% of first chromite, 10-15wt% of second chromite, 25-50wt% of third chromite, 1-2wt% of bentonite, 1-2wt% of metallurgical coke powder and 0.5-2wt% of dolomite. The invention also discloses a preparation method of the chromite oxide pellet. The prepared chromite oxide pellet has a good ballability, a high strength and an excellent smelting performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method and apparatus for compacting coal for a coal coking process

ActiveUS9200225B2Minimize amount of timeHigh speedCharging-discharging device combinationsSolid fuelsDiameter ratioEngineering

Relatively high speed methods for increasing the bulk density of coal particles without impacting the coal particles and an apparatus for compacting coal for making metallurgical coke. The method includes depositing coal particles onto a charging plate external to a coking oven. The charging plate has side walls, and at least one movable end wall to provide an elongate bed of dry, uncompacted coal having an upper surface on the charging plate. The uncompacted coal is compacted by passing a vibratory cylindrical compactor along a length of the uncompacted coal for a number of passes sufficient to decrease a thickness of the bed of coal to less than about 80 percent of an original thickness of the uncompacted coal. The vibratory cylindrical compactor has a length to diameter ratio ranging from about 1.4:1 to about 2:1.

Owner:SUNCOKE TECH & DEV LLC

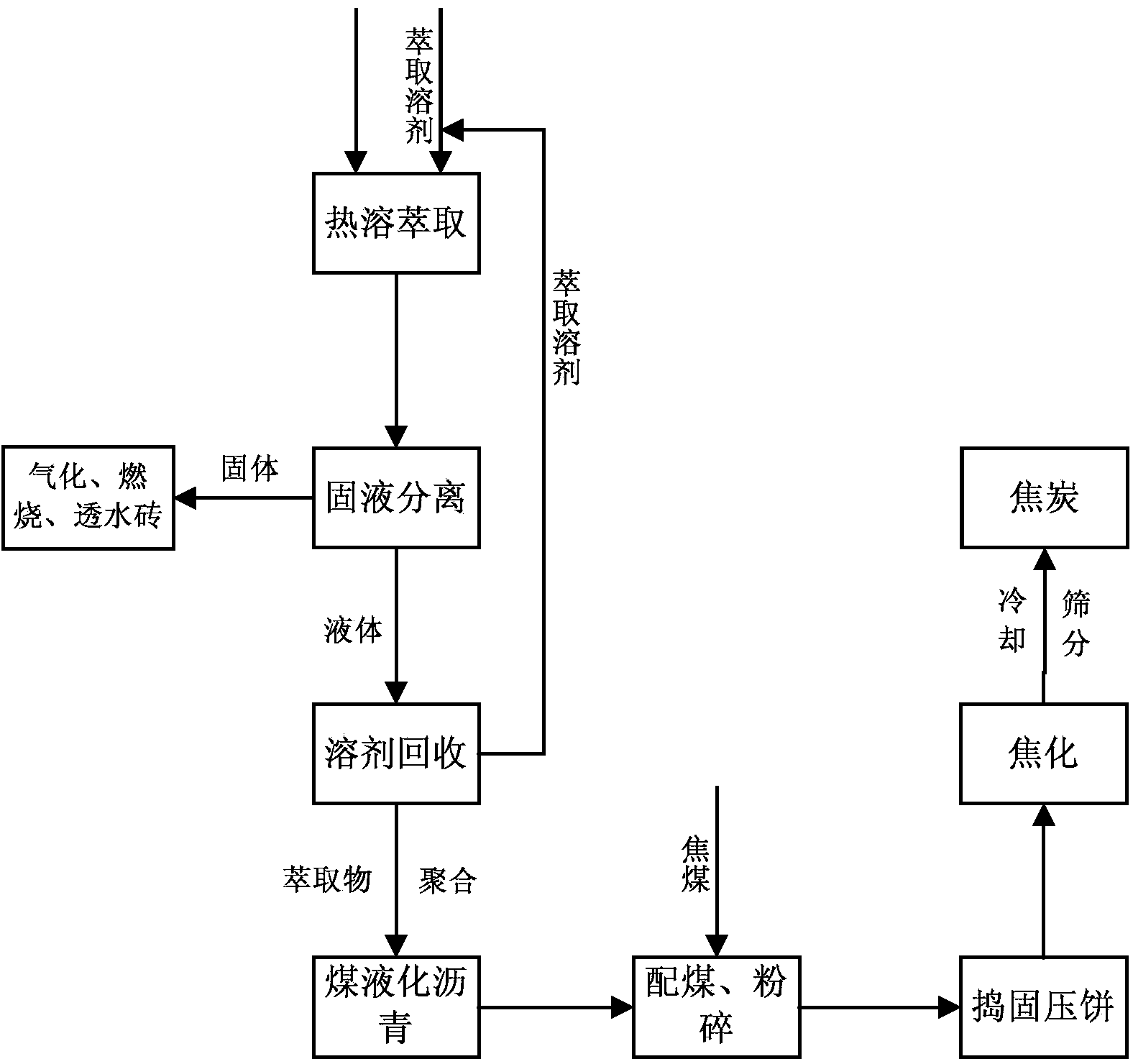

Method for preparing coke by using direct coal-liquefied residue

ActiveCN103436280AHigh beta-resin contentHigh softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCoal briquetteCoke burner

The invention discloses a method for preparing coke by using direct coal-liquefied residue. The method comprises the following steps: S1, orderly carrying out primary hot melt-extraction, primary solid-liquid separation and polymeric modification on the direct coal-liquefied residue, so as to obtain coal-liquefied modified asphalt; S2, mixing the coal-liquefied modified asphalt with cleaned coal for coking, crushing, tamping and pressing into a cake, so as to obtain a coal briquette; and S3, conveying the coal cake to a coke burner to heat and insulate heat in isolated air, and then cooling and screening to obtain the coke. The coal-liquefied modified asphalt which is obtained from the direct coal-liquefied residue in manners of hot melt-extraction, solid-liquid separation and polymeric modification is applied to a tamping coking process, so that the coke of which all indexes achieve the first national metallurgical coke standard is obtained; the yield of qualified products can be up to over 82%.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

Compact silica refractory material and preparation method thereof

InactiveCN101597174AImprove thermal conductivityImprove thermal shock resistanceSilica particleRefractory

The invention relates to a compact silica refractory material and a preparation method thereof, and belongs to the field of refractory materials. The refractory material comprises the following raw materials in percentage by weight: 62.5 to 58.3 percent of crystal silica particles with the grain diameter of 1.40 to 2.26 mm, 37.5 to 41.7 percent of crystal silica particles with the grain diameter of 0.59 to 0.088 mm, 34 to 46 percent of mixed fine powder with the grain diameter less than or equal to 0.088 mm, 3 to 4 percent of mineralizing agent, and 3 to 10 percent of additive. The preparation method comprises the following steps: performing dry mixing on the raw materials for one minute, adding concentrated pulp waste liquor into the mixture to be mixed for 8 minutes, and ageing the mixture for 4 hours, wherein the molding pressure of a blank is more than or equal to 100 MPa; and drying the blank for 10 hours at the temperature of 60 to 100 DEG C, performing hard fire on the blank at the temperature of 1,400 to 1,430 DEG C, and keeping the temperature for 6 to 8 hours. The compactness and the tridymite content of the silica refractory material are higher than those of a control sample, and the invention can provide a novel silica refractory material for metallurgical coke and the coal chemical industry.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

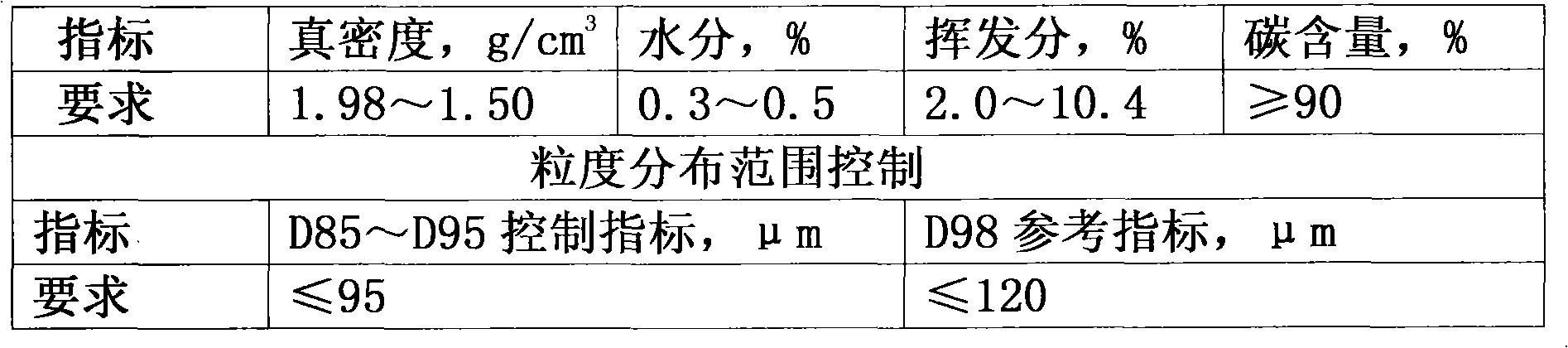

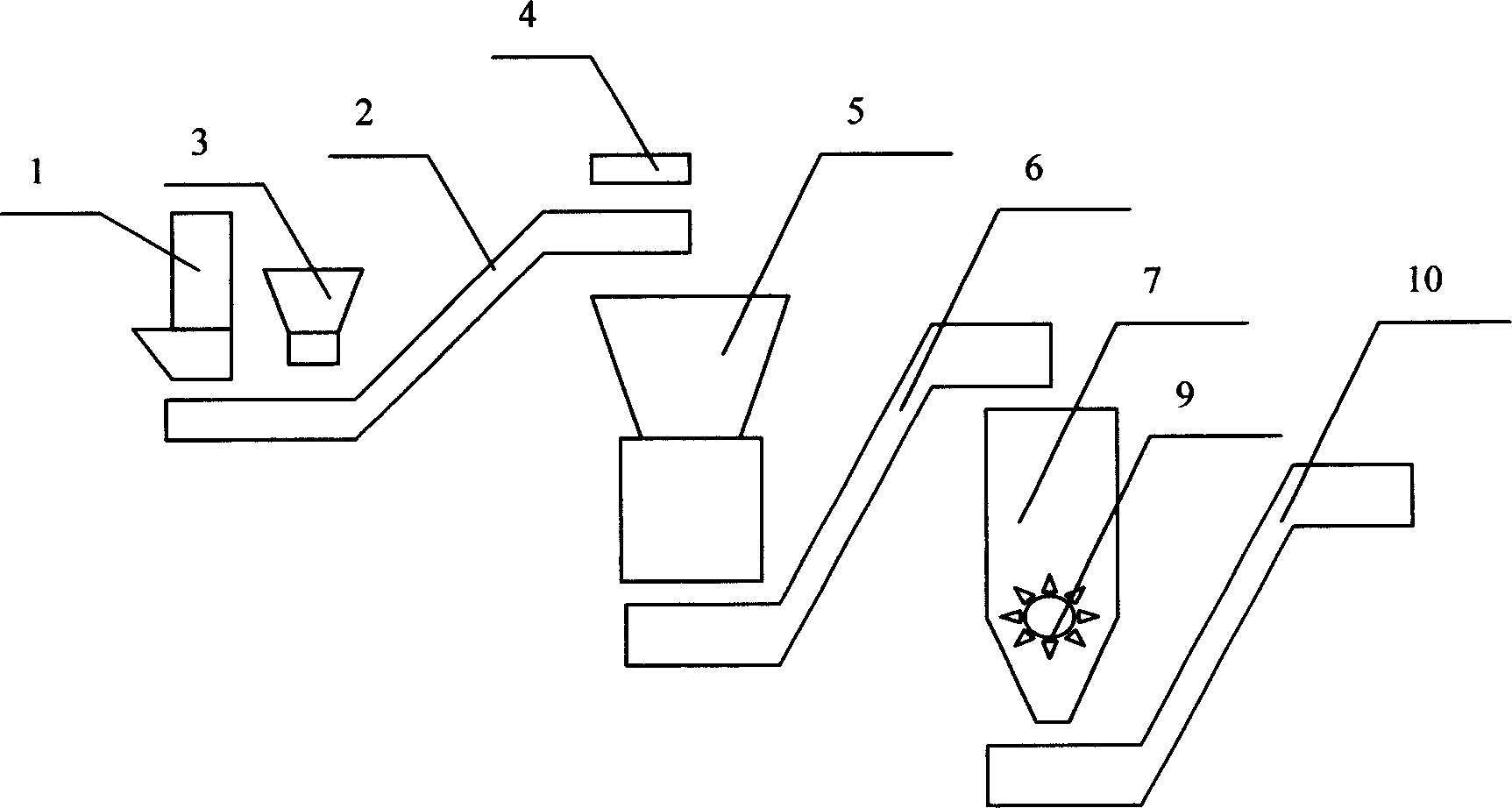

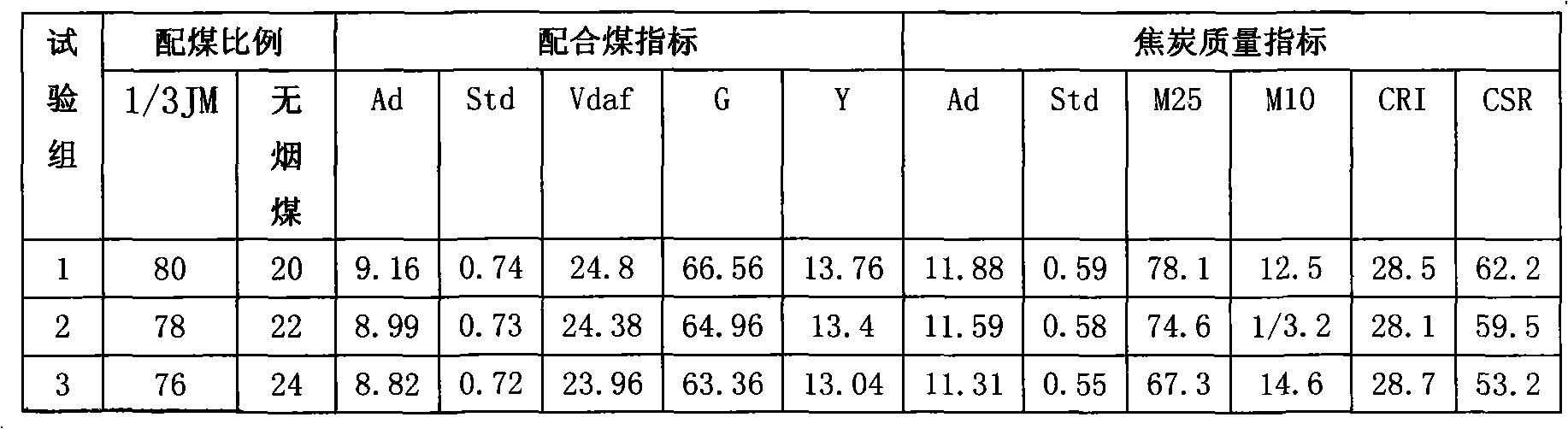

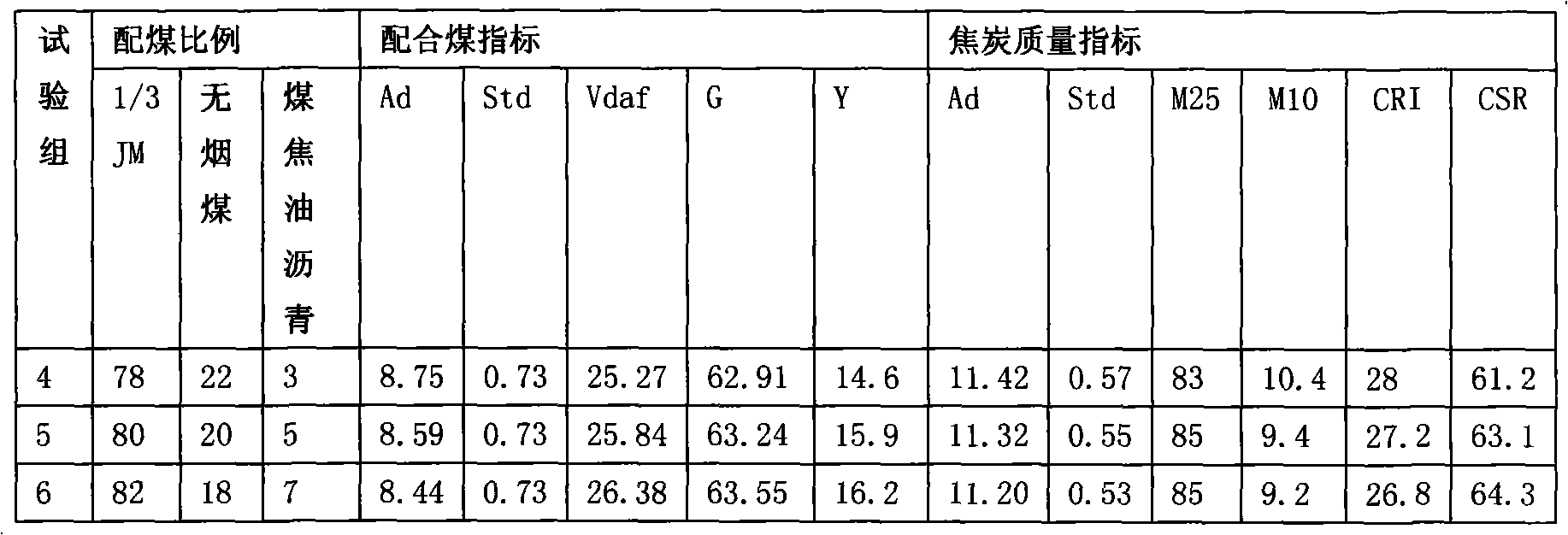

Process for producing first-class metallurgical coke by coking coal with high sulphur and high ash

ActiveCN101284997ASolve the problem of inconvenient operation of coal blendingIncrease valueCoke ovensAnthraciteBriquette

The invention discloses a method for utilizing high-sulfur high-ash coking coal to produce first-level metallurgical coke. The method uses high-sulfur high-ash 1 / 3JM as main material blended with anthracite, adds in pitch as binder, and adopts a tamping-coking process to produce first-level metallurgical coke. The method matches anthracite in proper amount with a coal blending proposal to ensure that the ash content and sulfur content of coke meet the index requirements of first-level metallurgical coke, and adds in the binder to solve the problem that the blended anthracite causes mechanical strength to drop. The method controls the indexes of matched coal fineness, moisture content, coal matching precision and tamping briquette density, and realizes the objective of using the high-sulfur high-ash 1 / 3JM as main material to produce first-level metallurgical coke through the tamping-coking method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

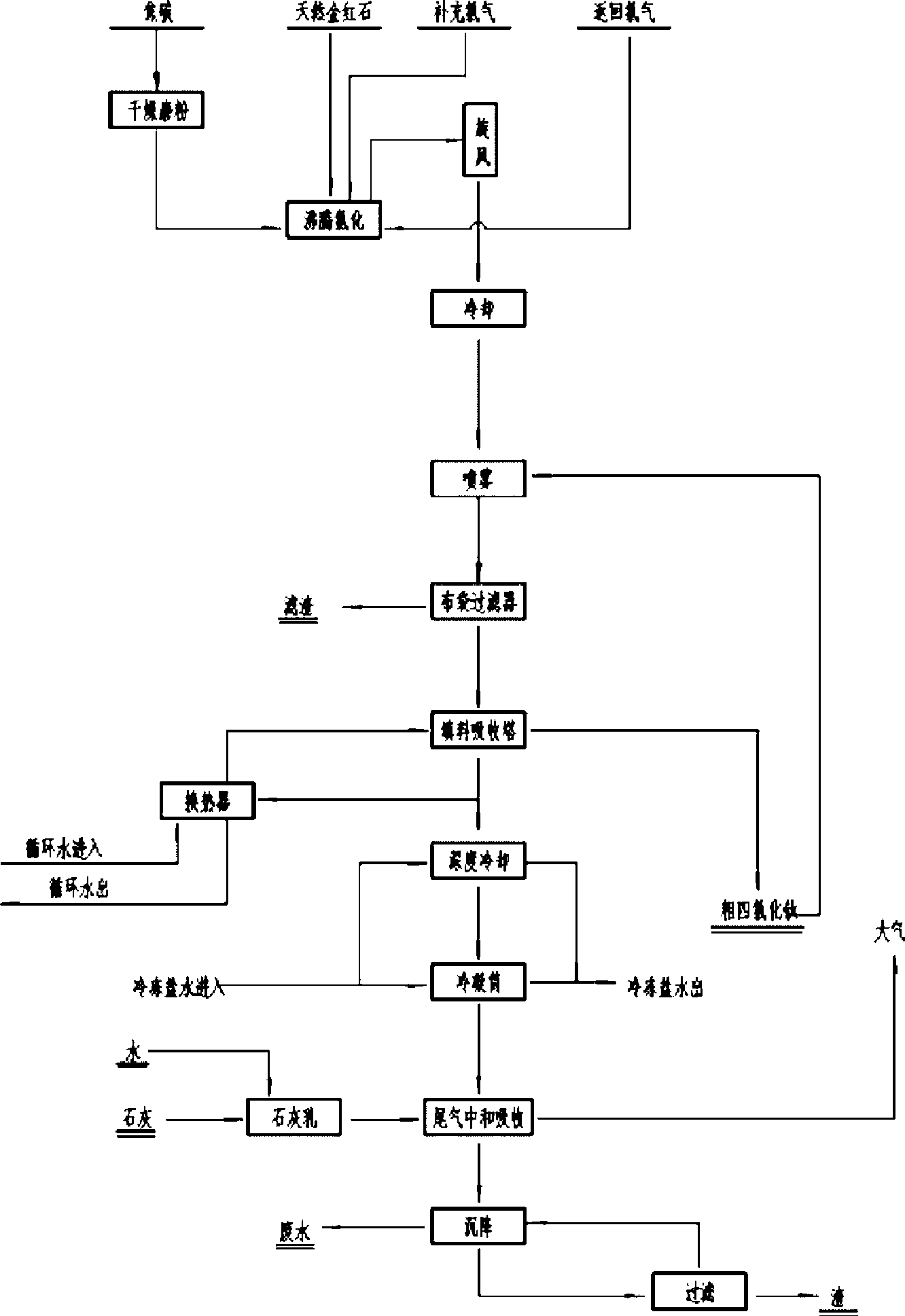

Preparation of crude titanic chloride

InactiveCN101462767ABroaden sources of raw materialsHighly Valuable ElementsTitanium halidesLeucoxeneFiltration

The invention provides a method for preparing coarse titanium tetrachloride. The method uses natural leucoxene as a raw material and metallurgical coke as a reducing agent to obtain the coarse titanium tetrachloride through the addition of chlorine for boiling chloridization, the cooling of a cyclone exhaust fan, atomization, the filtration of a cloth envelop collector and the absorption of a packed absorption tower. The invention has the advantages of expanding the sources used for producing the coarse titanium tetrachloride by using the natural leucoxene as a raw material, and removing slag and collecting titanium tetrachloride in a mixed furnace gas discharged from the top of a chlorination furnace. In the prior art, furnace slag produced during the production of titanium tetrachloride by using high titanium slag as a raw material is discharged from the bottom of the furnace, and the operation environment is severe and requires a gas mask for operation.

Owner:GUIYANG AL-MG DESIGN & RES INST

Flat push coke wet quenching apparatus and process

ActiveUS20100236914A1Reduce the amount requiredImprove dust collection efficiencyCoke quenchingDirect heating destructive distillationCoke ovenWater level

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of incandescent coke onto a substantially planar receiving surface of an enclosed quenching car so that substantially all of the coke from the coking oven is pushed as a unitary slab onto the receiving surface of the quenching car. The slab of incandescent coke is quenched in an enclosed environment within the quenching car with a plurality of water quench nozzles while submerging at least a portion of the slab of incandescent coke by raising a water level in the quenching car. Subsequent to quenching the coke, the planar receiving surface is tilted to an angle sufficient to slide the quenched coke off of the planar receiving surface and onto a product collection conveyer and sufficient to drain water from the quenched coke.

Owner:SUNCOKE TECH & DEV LLC

Production process of modem blast furnace nickel smelting for nickel concentrate

InactiveCN101285129AHighlight substantiveSignificantly progressiveSodium BentoniteMetallurgical coke

The invention provides a process of producing modern blast furnace nickel smelting with nickel ore concentrate, The process comprises the following steps of: selecting nickel ore concentrate which comprises sulfuration nickel ore, nickel limonite ore and secondary paragenetic ore, and nickel-containing byproduct tailings of main metal mineral processing such as copper, molybdenum, zinc, arsenic and so on; mixing the nickel ore concentrate to obtain mixed ore, the weight percentages of each component of the mixed ore are: Ni=8.5 percent +- 0.5 percent, Fe=30 percent +-0.5 percent, and SiO2=8.5 percent +-0.5 percent; adding the following ingredients into the mixed ore, the ingredients comprise calcareousness CaO, washing head coal, bentonite, manganese slag and hot water; mixing the materials to granulate to obtain sintered materials; sintering, crushing and screening the sintered materials to obtain sintered ore; packing respectively the sintered ore and metallurgical coke with 3.6:1 of the weight proportion into the blast furnace to smelt into nickel pig iron; and carrying out de-C, de-Si, de-P, de-S treatment to the nickel pig iron through a revolving furnace to obtain ferronickel products. The process has the characteristics of less slag quantity, high nickel content, energy economization and emission reduction as well as various minerals.

Owner:马和平 +2

Method for evaluating metallurgical coke

The invention discloses a method for evaluating metallurgical coke, which comprises several steps of determining and characterizing the relevant basic technical parameters coking single coal and matched coal in different areas to establish a data information base, analyzing the influence weight of the main technical parameters of the metallurgical coke on the behavior of the blast furnace, determining the core parameters for evaluating the quality performance of the metallurgical coke to establish a mathematical equation of the thermal state of the tuyere coke, obtaining the coke thermal reaction property and the post reaction strength of the coke property of the tuyere through putting the core parameter data of the furnace coke into the thermal state performance mathematical equation of the tuyere coke and characterizing the quality of the metallurgical coke in the blast furnace smelting process. The method for evaluating metallurgical coke provides a new scientific basis for reasonably utilizing the low-deterioration degree coking coal with abundant reserves and low cost, and has great economic and social benefits.

Owner:BAOTOU IRON & STEEL GRP

Blast furnace injection material

InactiveCN101899343AAlleviate needsReduce demandSolid fuelsBlast furnace detailsMetallurgical cokeCast iron

The invention relates to a blast furnace injection material which is prepared in steps of preparing candle coal or noncaking coal into a lumpiness of 10-100 mm, carrying out carbonization in a carbonization furnace at 600-700 DEG C for 24 hours, classifying and processing the coal after the carbonization, and selecting powder of which the particle size is less than 5 mm as the blast furnace injection material. The invention lowers the blast furnace ironmaking coke ratio and the cast iron cost; can regulate the thermal system of the furnace, improve the operating state of the blast furnace hearth and ensure the stable and smooth operation of the blast furnace; and reduces the theoretical combustion temperature and creates conditions for realizing high-wind temperature and oxygen-enriched blast of the blast furnace. Compared with the gasification of coke, the gasification of injection coal powder discharges more hydrogen, thereby enhancing the reducibility and the penetration diffusivity of the gas and being beneficial to the improvement on ore reduction and blast furnace operation indexes. Metallurgical coke is replaced by the injection coal powder partially, thereby moderating requirements for the coke, decreasing coking facilities and saving the investment of capital construction. Besides, the invention decreases coke furnaces and produced coke and reduces the environmental pollution caused by coking production, and simultaneously, and powder generated in the semicoke production can be fully utilized.

Owner:杨兴平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com