Chromite oxide pellet and preparation method thereof

A technology for oxidizing pellets and chromite, which is applied in the field of chromite oxidizing pellets and its preparation, can solve the problems of poor high-temperature smelting performance and low strength, and achieves the effect of good spheroidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

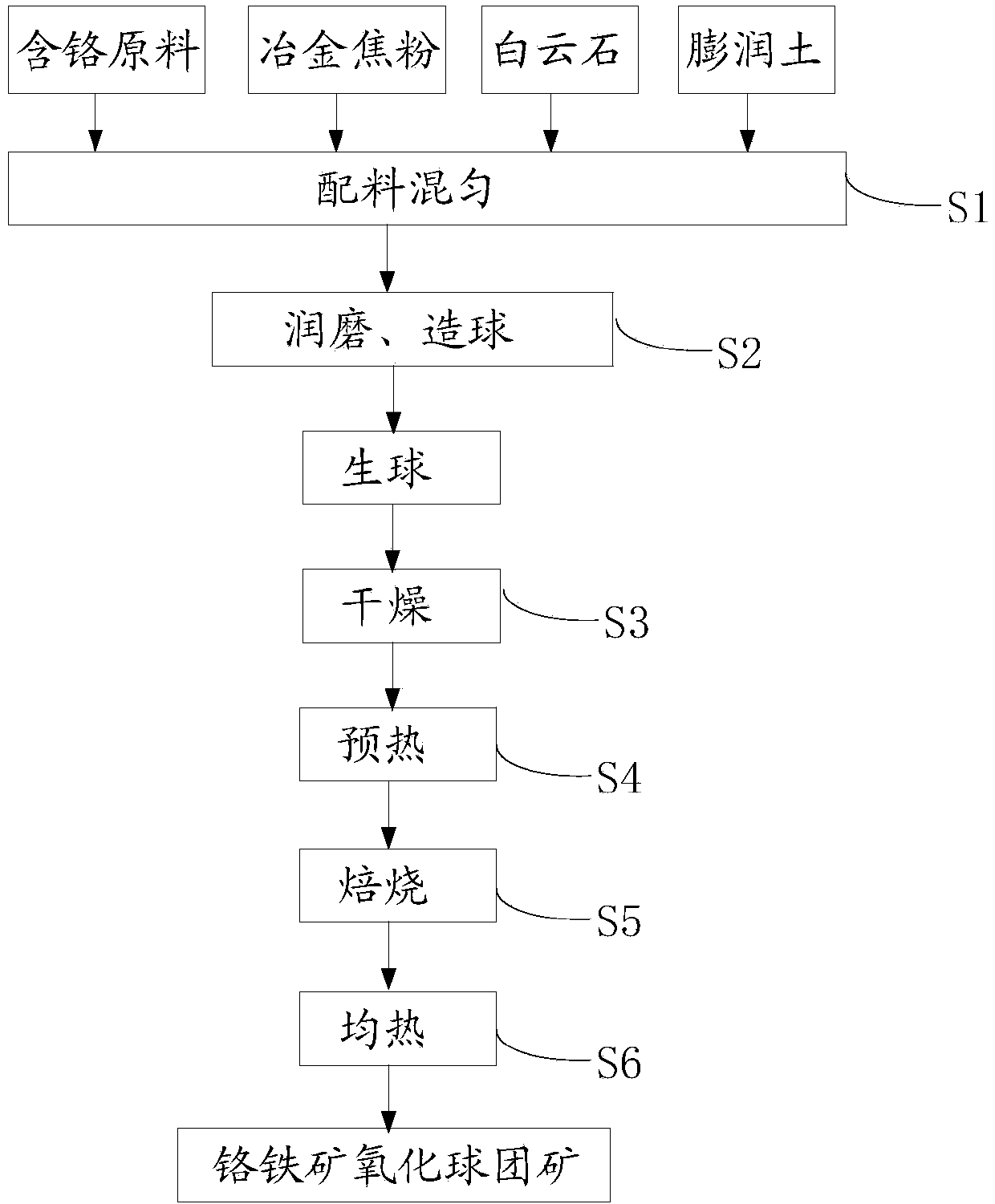

[0028] Such as figure 1 Shown, the preparation method of chromite oxide pellets is as follows:

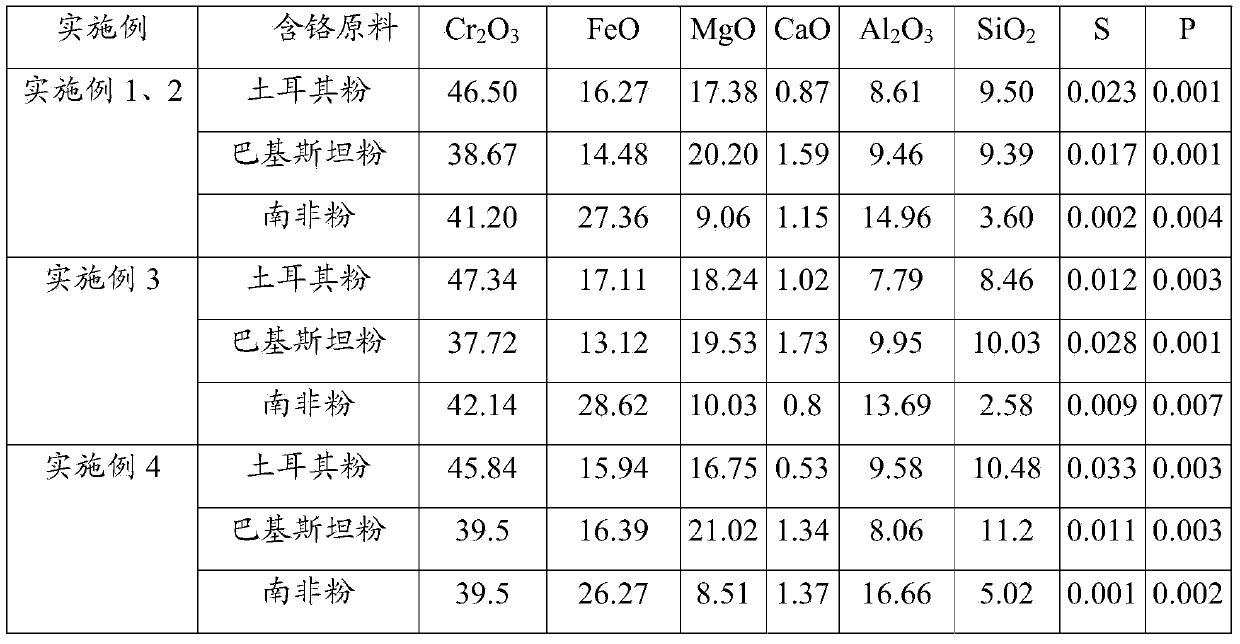

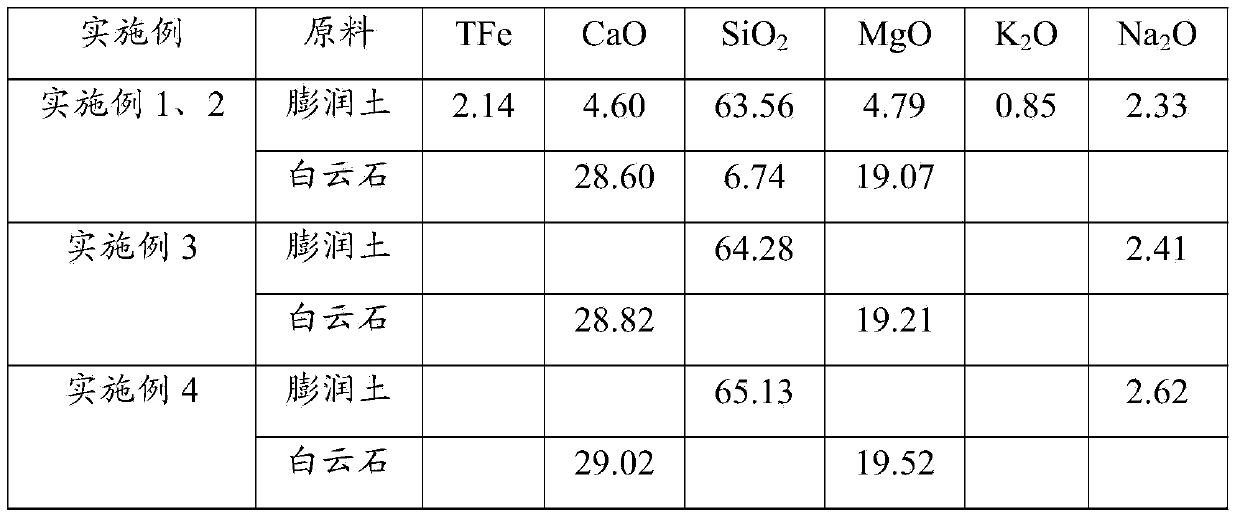

[0029] S1: Add 1% to 2% of bentonite, 1% to 2% of metallurgical coke powder and 0.5% to 2% of dolomite to the chromium-containing raw material and mix thoroughly to obtain a mixture. Preferably, the bentonite is sodium bentonite.

[0030] S2: Grind the mixture into fine powder, wherein the powder with a particle size of 200 mesh accounts for 80%±2% of the total fine powder volume, and pelletize to obtain green pellets.

[0031] S3: The raw balls are dried at a temperature of 450-600° C. for 5-10 minutes to obtain dry balls.

[0032] S4: Preheating the dry bulbs at a temperature of 1150-1250° C. for 5-10 minutes to obtain preheated bulbs.

[0033] S5: The preheated balls are roasted at a temperature of 1300-1350° C. for 5-10 minutes to obtain roasted balls.

[0034] S6: So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com