'Funnel'-shaped three-dimensional cell aggregation and culture chip and preparation method thereof

A three-dimensional cell and funnel technology, used in tissue cell/virus culture devices, biochemical equipment and methods, and methods for supporting/immobilizing microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

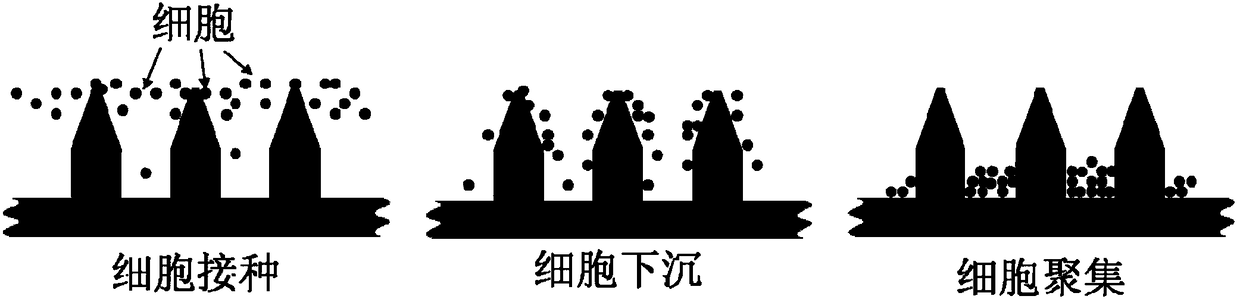

Method used

Image

Examples

Embodiment 1

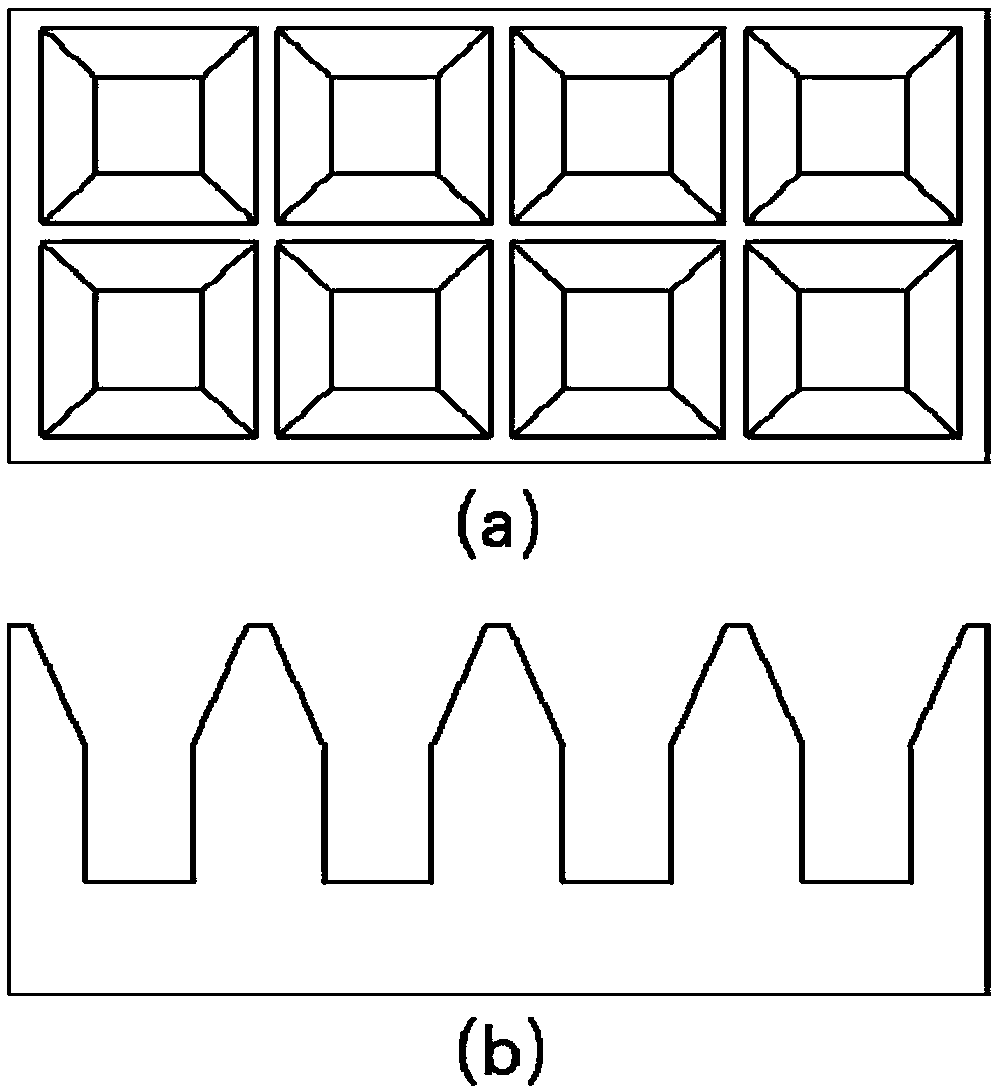

[0027] A method for preparing a "funnel"-like three-dimensional cell aggregation culture chip, characterized in that it is carried out in accordance with the following steps:

[0028] (1) Spin-coat SU-8 photoresist with a thickness of 400 microns on the surface of the glass substrate, and bake it at 95°C for 4 hours,

[0029] (2) Tilt angle exposure: fix a square array mask with a side length of 350 microns on the surface of the substrate containing photoresist, and place it on a platform that can adjust the tilt angle and rotate freely.

[0030] (3) During UV exposure, expose 4 times along the apex with an inclination angle of 60 degrees, and expose 4 times along the edge with an inclination angle of 40 degrees and rotate 45 degrees each time.

[0031] (4) Post-bake at 95°C for 10-30 minutes, add 400 micron thick SU-8 photoresist, and bake for 4 hours at 95°C for the second time.

[0032] (5) Vertical exposure: Use the same square mask with a side length of 350 microns to ex...

Embodiment 2

[0036] A method for preparing a "funnel"-like three-dimensional cell aggregation culture chip, characterized in that it is carried out in accordance with the following steps:

[0037] (1) Spin-coat SU-8 photoresist with a thickness of 300 microns on the surface of the glass substrate, and bake it at 95°C for 4 hours,

[0038] (2) Tilt angle exposure: fix a square array mask with a side length of 350 microns on the surface of the substrate containing photoresist, and place it on a platform that can adjust the tilt angle and rotate freely.

[0039] (3) During ultraviolet exposure, expose 4 times along the apex with a tilt angle of 50 degrees, and expose 4 times along the edge with a tilt angle of 35 degrees and rotate 45 degrees each time.

[0040] (4) Post-bake at 95°C for 10-30 minutes, add 500 micron thick SU-8 photoresist, and bake for 4 hours at 95°C for the second time.

[0041] (5) Vertical exposure: After the circular array mask of a square with a side length of 350 mic...

Embodiment 3

[0045] A method for preparing a "funnel"-like three-dimensional cell aggregation culture chip, characterized in that it is carried out in accordance with the following steps:

[0046] (1) Spin-coat SU-8 photoresist with a thickness of 300 microns on the surface of glass or silicon substrate, and bake it at 95°C for 4 hours,

[0047] (2) Tilt angle exposure: Fix a square array mask with a side length of 400 microns on the surface of the substrate containing photoresist, and place it on a platform that can adjust the tilt angle and rotate freely.

[0048] (3) During ultraviolet exposure, expose 4 times along the apex with a tilt angle of 50 degrees, and expose 4 times along the edge with a tilt angle of 35 degrees and rotate 45 degrees each time.

[0049] (4) Post-bake at 95°C for 10 minutes, add a 450-micron thick SU-8 photoresist, and bake for 8 hours at 95°C for the second time.

[0050](5) Vertical exposure: After the circular array mask of a square with a side length of 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com