Method for preparing monodisperse nanosphere medicine carrier

A nano-microsphere, monodisperse technology, applied in non-active ingredient medical preparations, pharmaceutical formulations, powder delivery, etc., can solve the problems of affecting the overall uniformity of the drug carrier, cumbersome washing procedures, and difficult to precisely control, etc., and achieve good results. The effect of biocompatibility, good size uniformity and high emulsification efficiency

Active Publication Date: 2011-06-15

广州智焜生物科技有限公司

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although polyvinyl alcohol has a good ball-forming effect, it has certain toxicity; and if it is necessary to prepare microsphere carriers with a diameter of less than 500nm, it is necessary to use high-concentration polyvinyl alcohol, which has a high viscosity and is difficult to prepare. The middle washing process is cumbersome and easy to remain; in addition, the distribution of nano-microspheres prepared by high-viscosity polyvinyl alcohol as an emulsifier is wide, and it is easy to form larger-sized microspheres, which affects the overall uniformity of the drug carrier, resulting in the slow-control of the drug. Difficult to precisely control during the release phase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Login to View More

Abstract

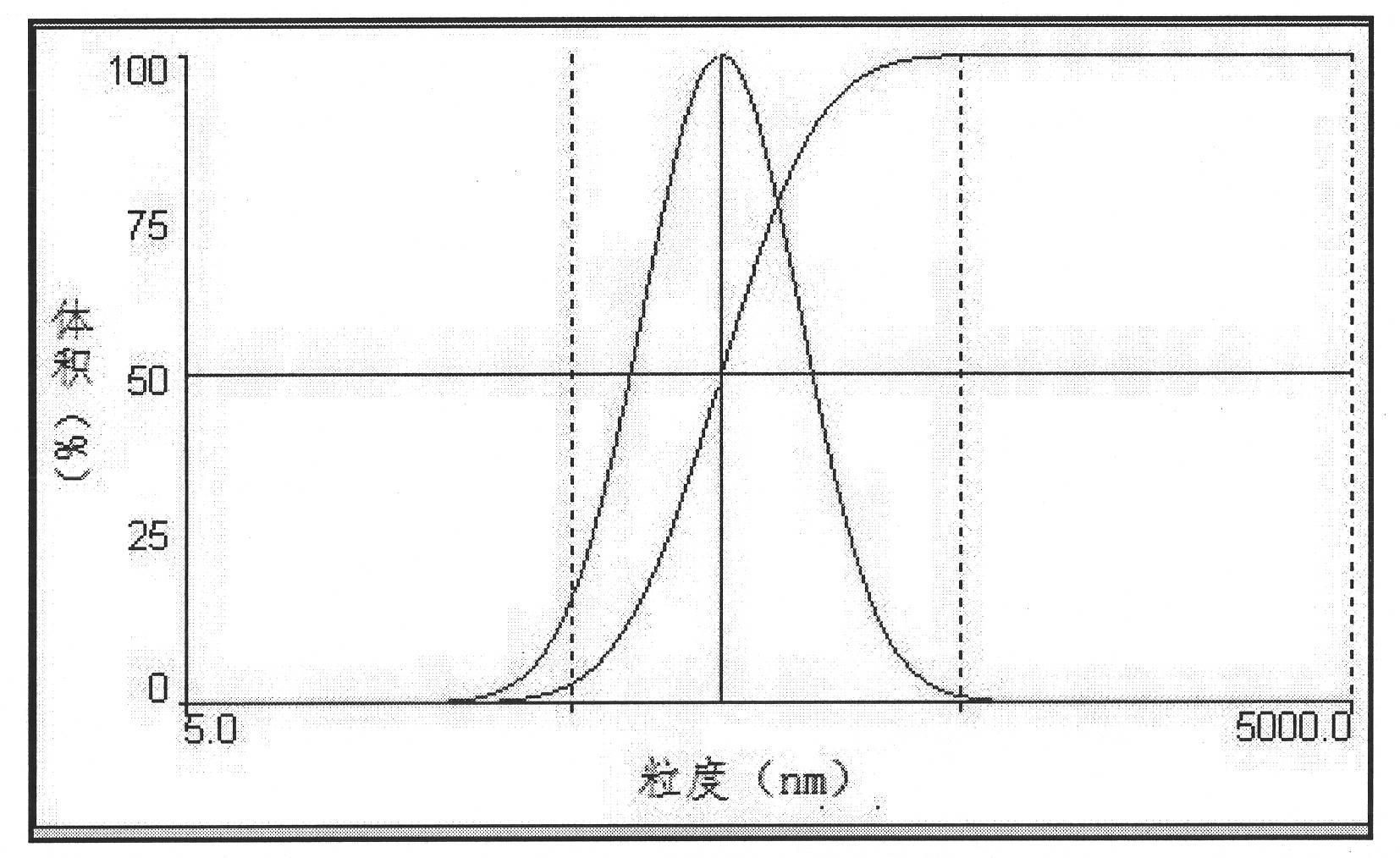

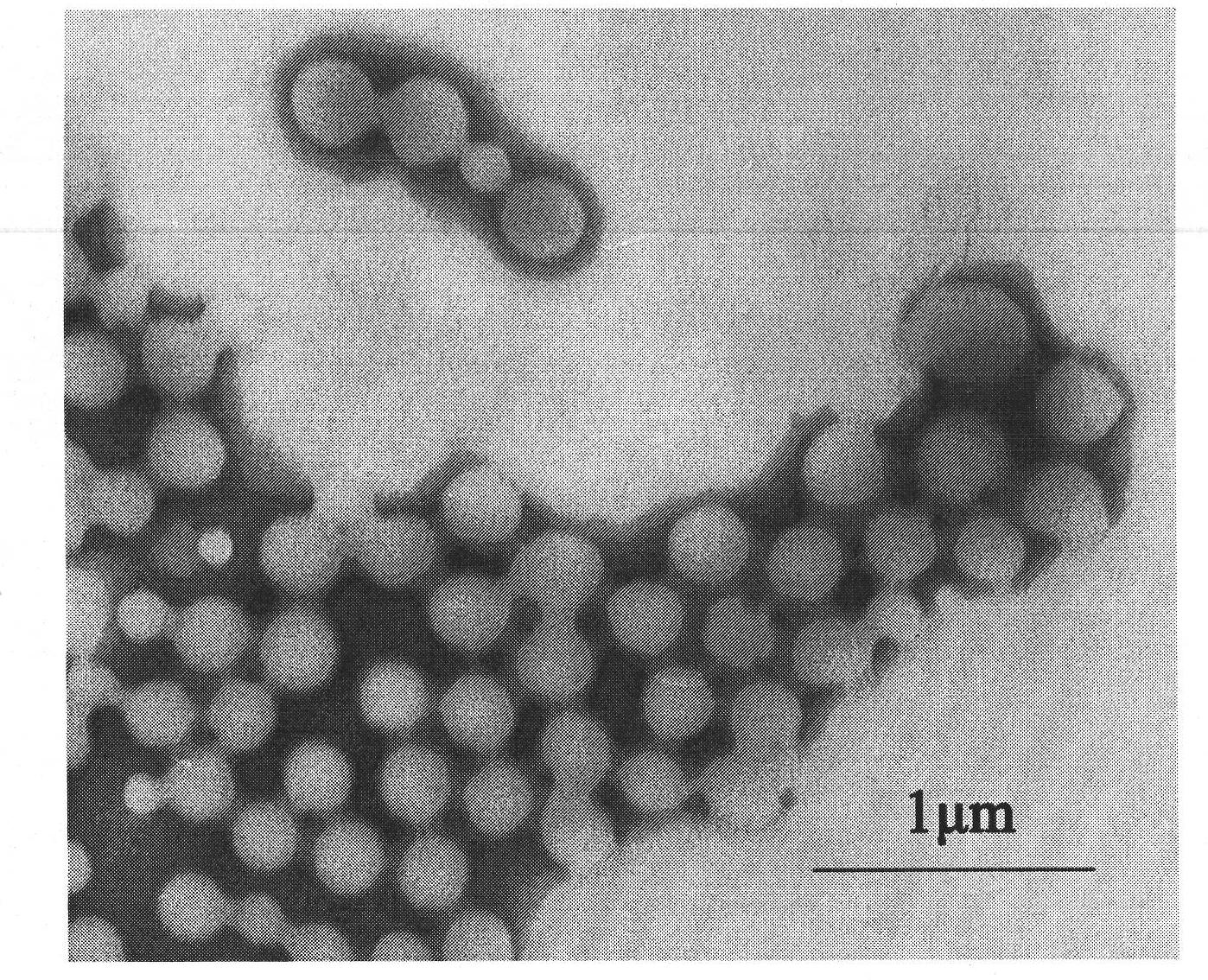

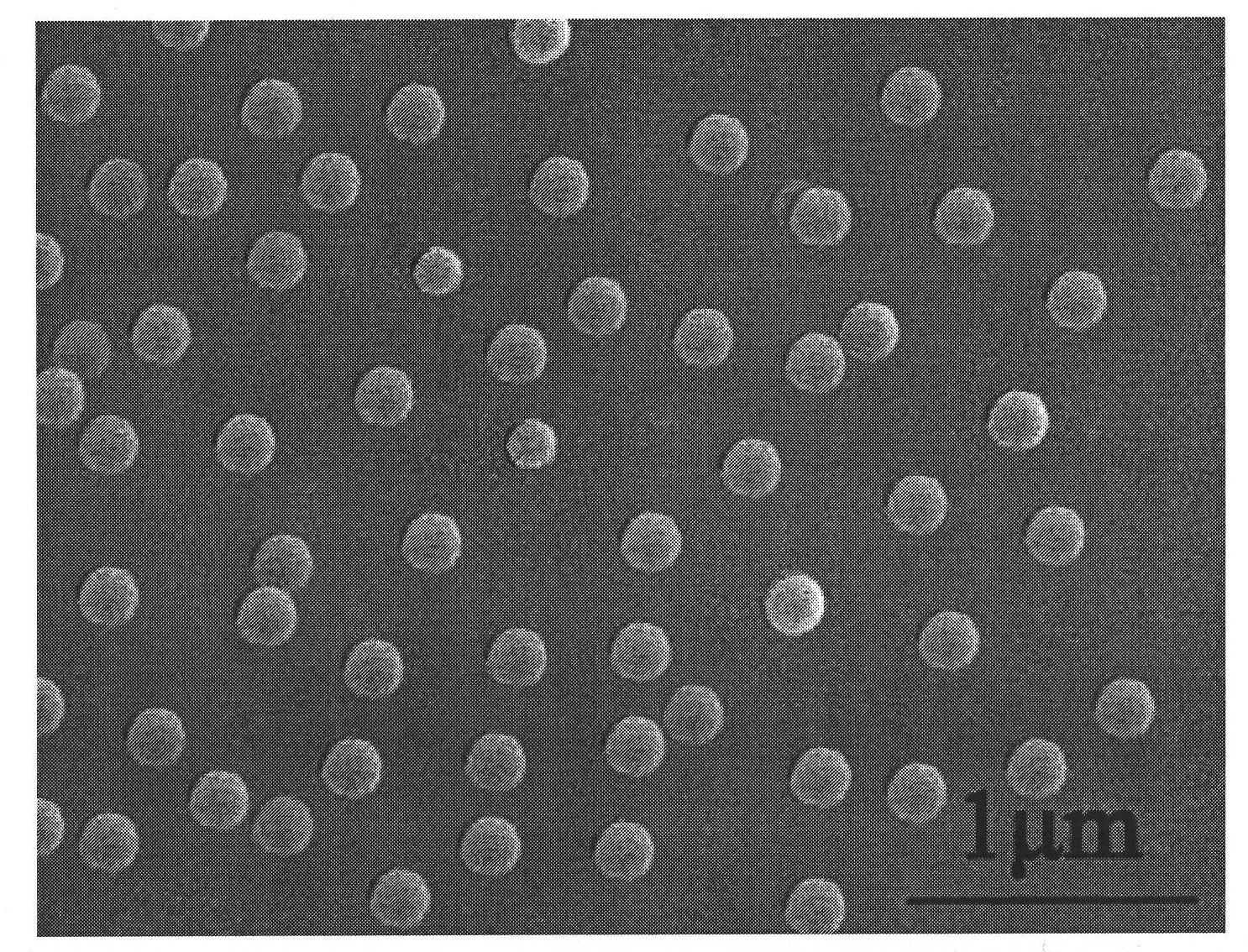

The invention discloses a method for preparing a monodisperse nanosphere medicine carrier, which comprises the following steps: dissolving poly(lactic-co-glycolic acid) in organic solvent to form an organic phase; dissolving emulsifier in distilled water to form a water phase; under the synergistic effect of ultrasound and stirring and in an ice water bath, adding an organic phase into a water phase according to a volume ratio to obtain oil-in-water emulsion; continuously stirring the emulsion at normal temperature for 4 to 20 hours, and removing organic solvent; and performing low-speed centrifugation to remove aggregate, subjecting supernate to ultrafiltration, refrigeration, centrifugation and washing to obtain the monodisperse nanosphere medicine carrier. In the monodisperse nanospheres, the spherical shape is regular, the particle size is between 100 and 500 nanometers, the size is controllable and the specifications are uniform. The monodisperse nanospheres are suitable for coating and carrying various water soluble or liposoluble medicines and have the advantages of biodegradability, controlled medicine release and the like.

Description

A kind of preparation method of monodisperse nano microsphere drug carrier technical field The invention belongs to the field of preparation of medicinal nano-microsphere materials, and in particular relates to a preparation method of a monodisperse nano-microsphere drug carrier. Background technique Nanospheres refer to polymer materials or polymer composite materials with diameters ranging from nanometers to micrometers, spherical or other geometric shapes, and their shapes can include solid, hollow, porous, etc. Due to their unique shape and morphology, monodisperse nano-scale and micron-scale polymer particles have special functions that other materials do not have, and have been widely used in nanotechnology, particle adsorption, biochemistry, polymer fillers, catalysts, Electronic information, drug controlled release and other fields. Poly(lactic-co-glycolic acid) copolymer (PolyLactic-co-GlycolicAcid, referred to as: PLGA) is randomly polymerized from two monomers...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61K9/14A61K47/34A61K47/22

Inventor 魏坤凌友

Owner 广州智焜生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com