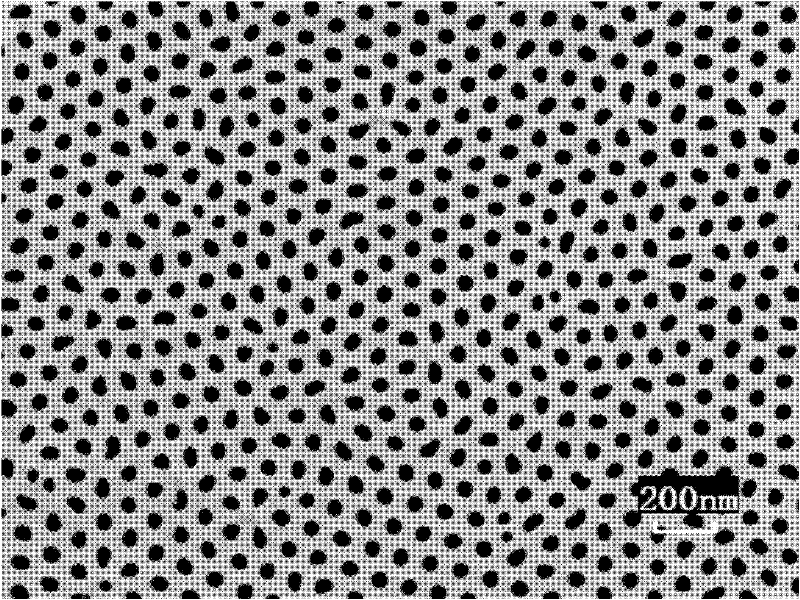

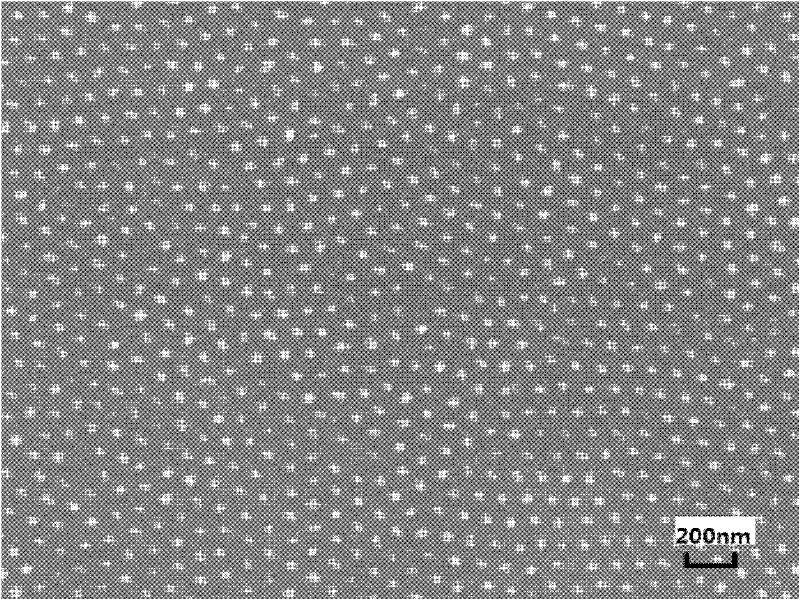

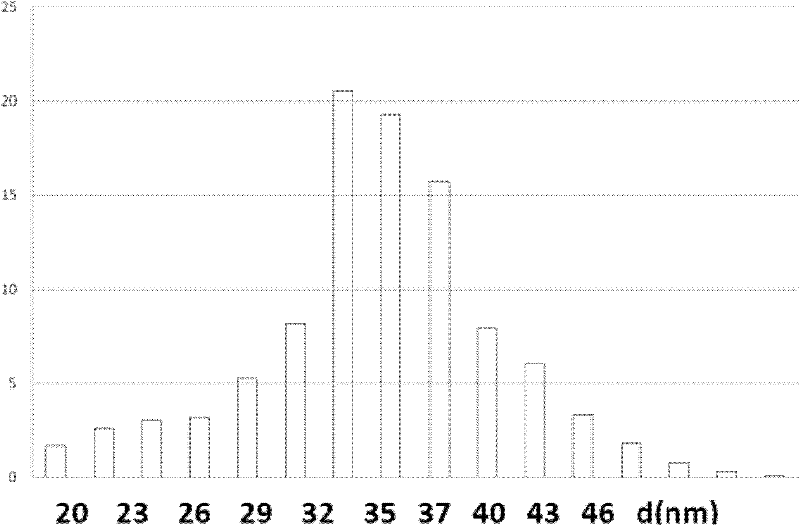

Method for growing ordered silicon-based germanium quantum dots

A quantum dot, silicon-based technology, applied in the field of growing ordered silicon-based germanium quantum dots, to achieve the effect of improving size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 18

[0029] (1) Two-inch single-polished p-type (111) silicon wafers are cleaned by RCA to obtain a clean surface, and are covered with a thin oxide layer; the oxide layer is dense SiO 2 ;

[0030] Wherein, the RCA cleaning step is: ultrasonic cleaning with acetone solution for 10 minutes, and then rinsing with deionized water; aqueous ammonia hydrogen peroxide solution (by volume ratio, NH 4 OH:H 2 o 2 :H 2 (0=1:1:5) boiled for 10 minutes, rinsed repeatedly with deionized water; soaked in HF (4% by mass) solution for 1 minute, rinsed with deionized water; hydrochloric acid hydrogen peroxide solution (in volume ratio, HCl:H 2 o 2 :H 2 (0=1:1:5) boiled for 10 minutes, rinsed repeatedly with deionized water; repeated two to three rounds of soaking in HF solution and boiling in hydrochloric acid hydrogen peroxide solution for two to three rounds, then sealed with deionized water and dried with nitrogen before use.

[0031] (2) stick the porous aluminum oxide film on the surface ...

Embodiment 28

[0039] (1) Two-inch single-polished p-type (111) silicon wafers are cleaned by RCA to obtain a clean surface, and are covered with a thin oxide layer; the oxide layer is dense SiO 2 ;

[0040] Wherein, the RCA cleaning step is: ultrasonic cleaning with acetone solution for 10 minutes, and then rinsing with deionized water; aqueous ammonia hydrogen peroxide solution (by volume ratio, NH 4 OH:H 2 o 2 :H 2 (0=1:1:5) boiled for 10 minutes, rinsed repeatedly with deionized water; soaked in HF (4% by mass) solution for 1 minute, rinsed with deionized water; hydrochloric acid hydrogen peroxide solution (in volume ratio, HCl:H 2 o 2 :H 2 (0=1:1:5) boiled for 10 minutes, rinsed repeatedly with deionized water; repeated two to three rounds of soaking in HF solution and boiling in hydrochloric acid hydrogen peroxide solution for two to three rounds, then sealed with deionized water and dried with nitrogen before use.

[0041] (2) The porous aluminum oxide film is pasted on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com