Patents

Literature

74 results about "Quantum devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

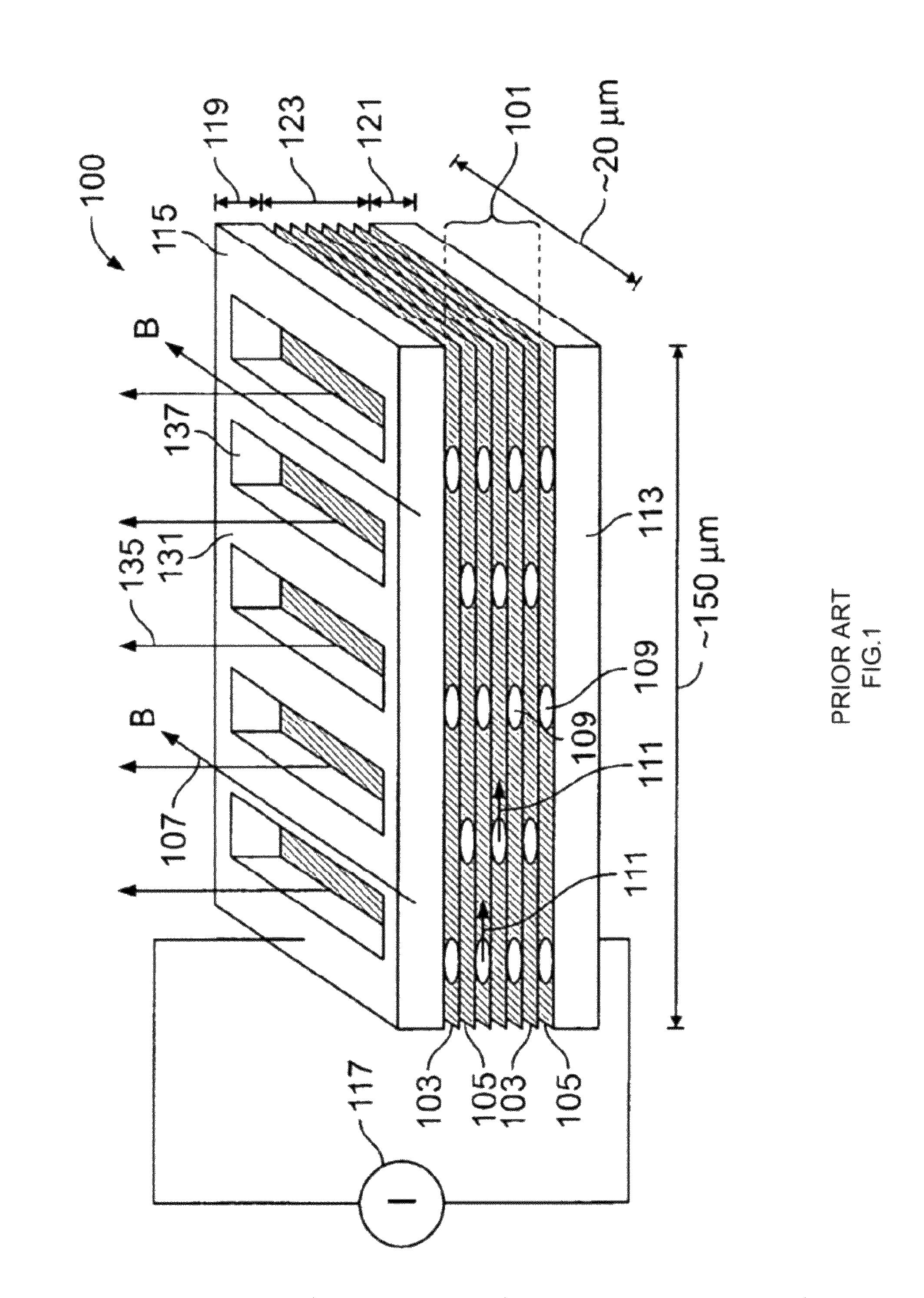

Analog processor comprising quantum devices

Owner:D WAVE SYSTEMS INC

Analog processor comprising quantum devices

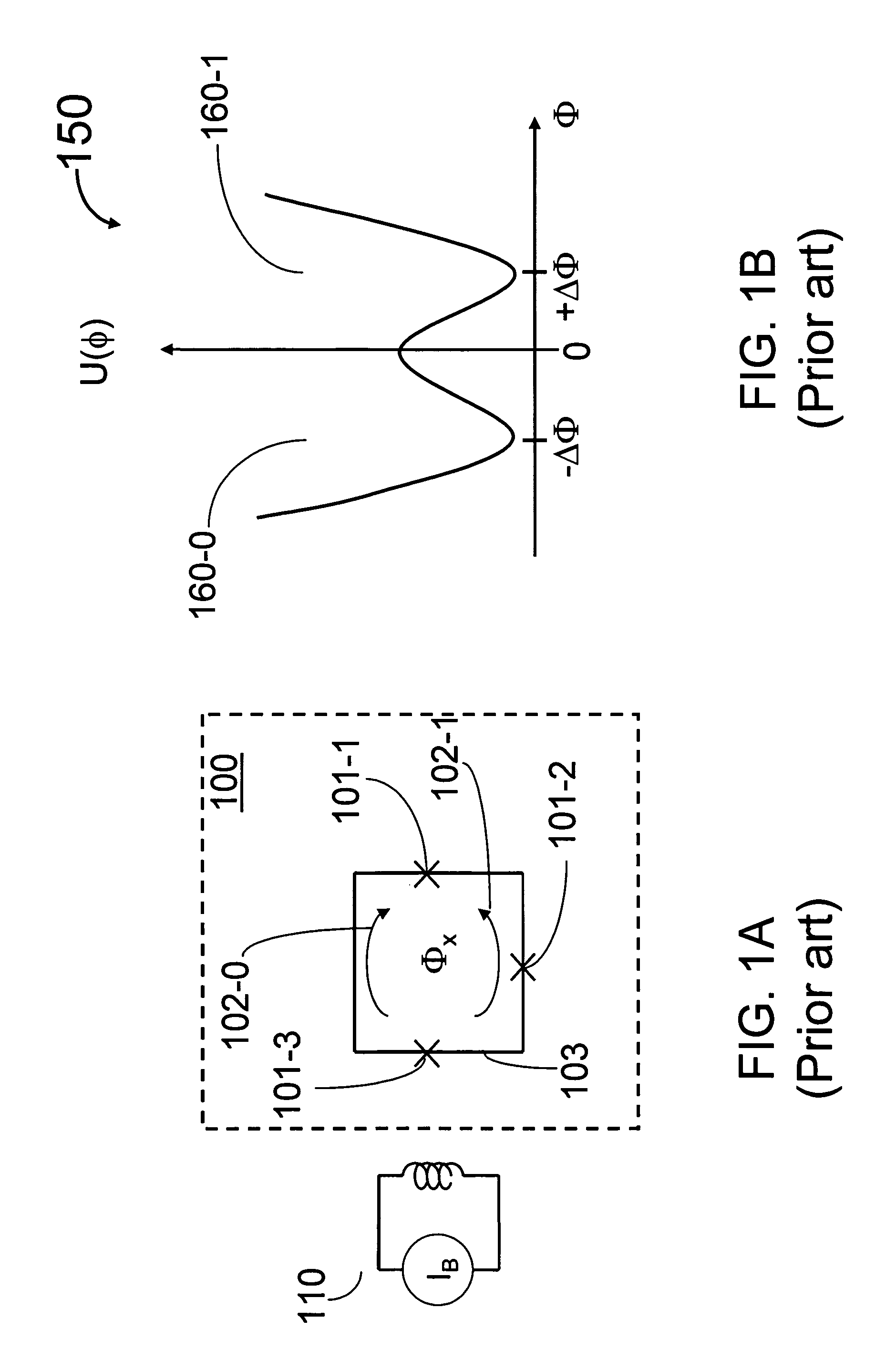

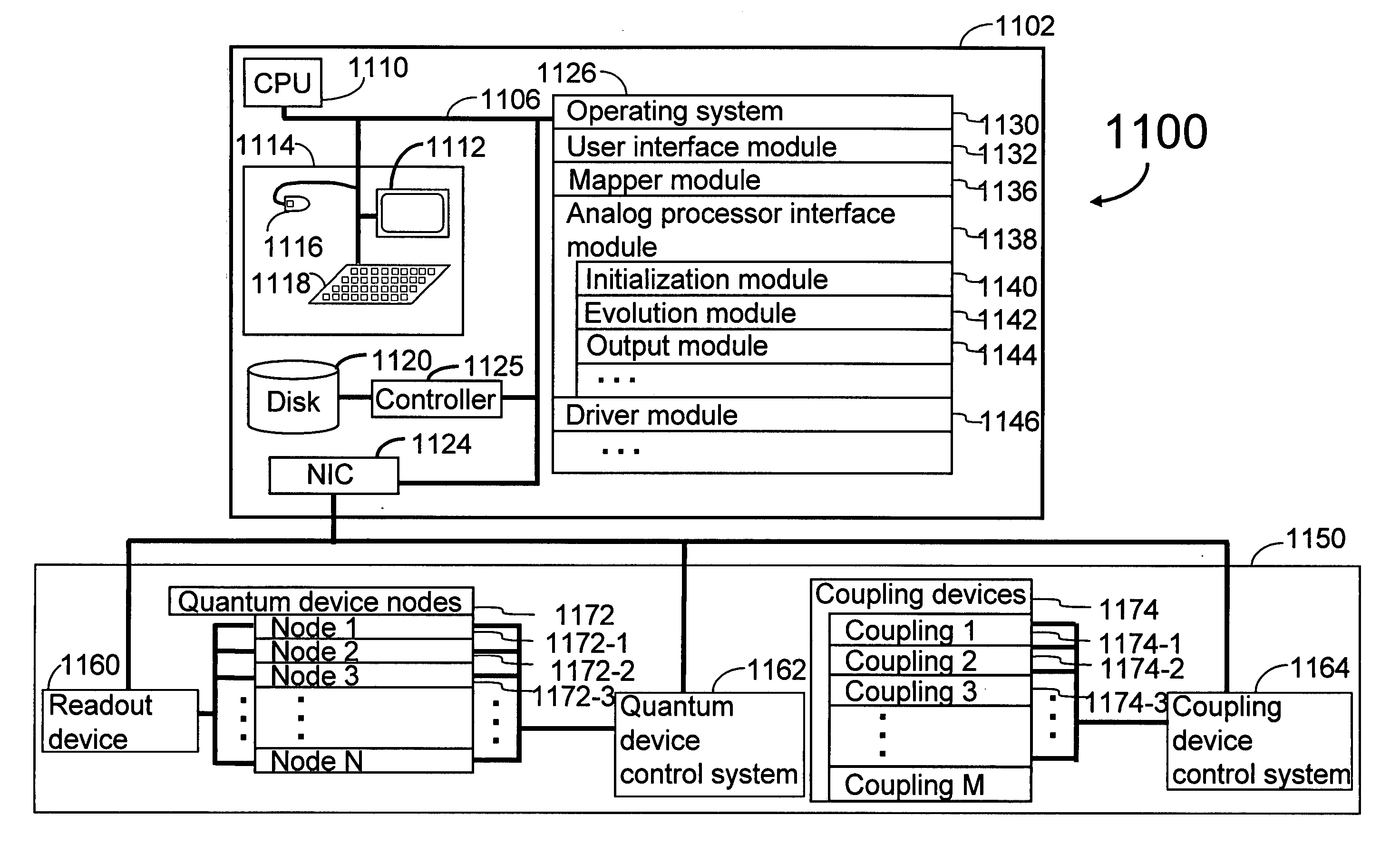

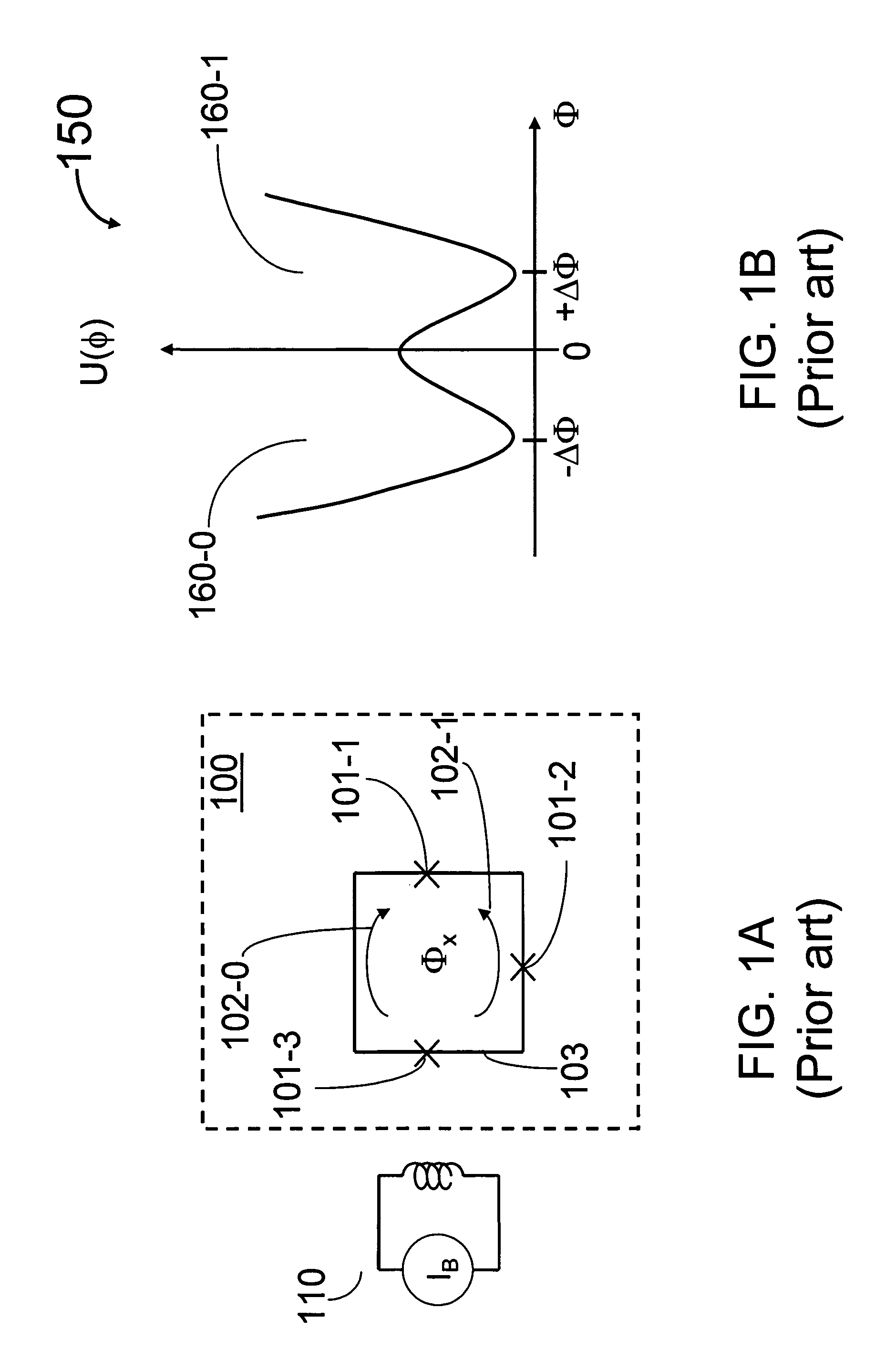

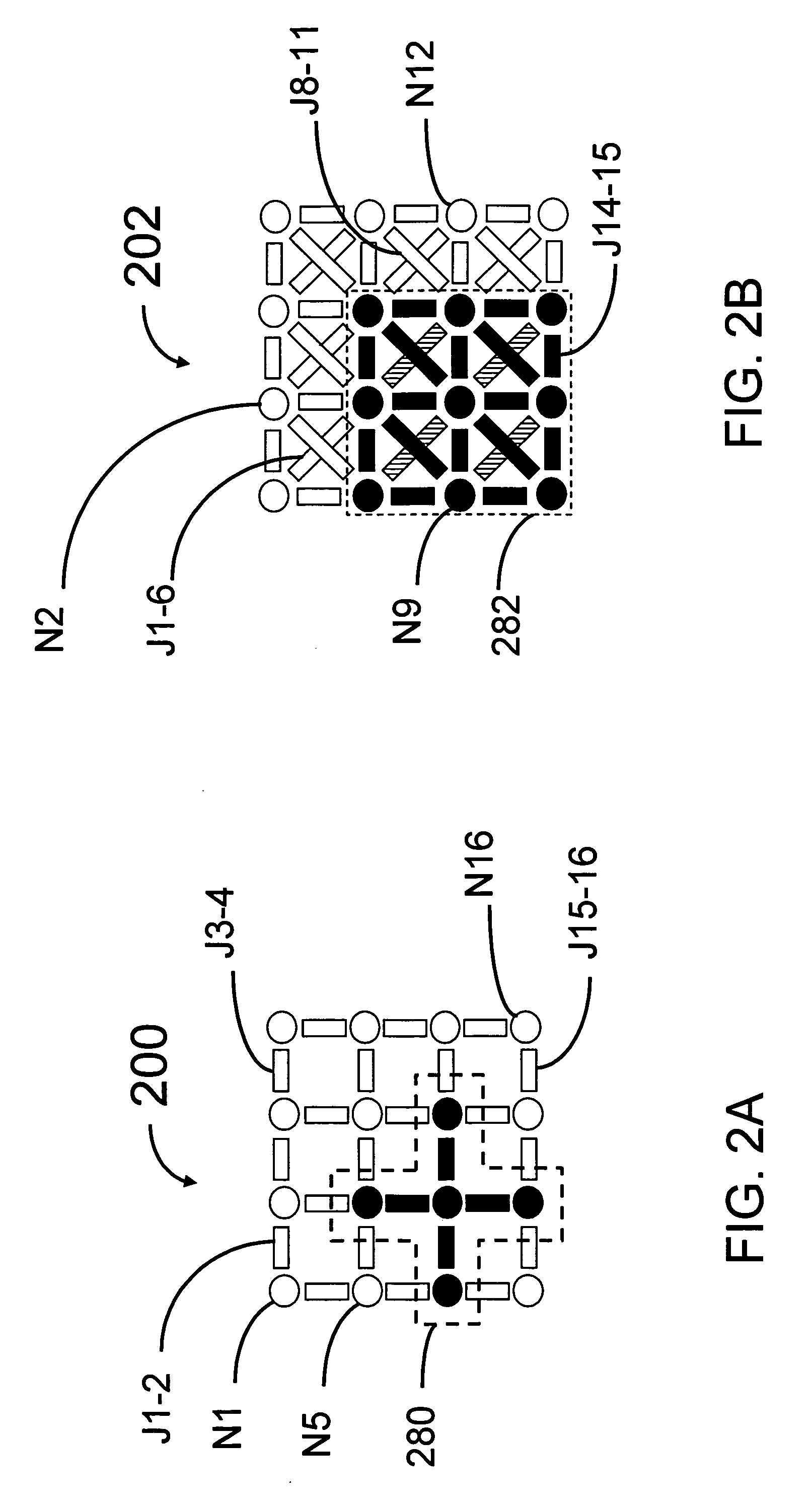

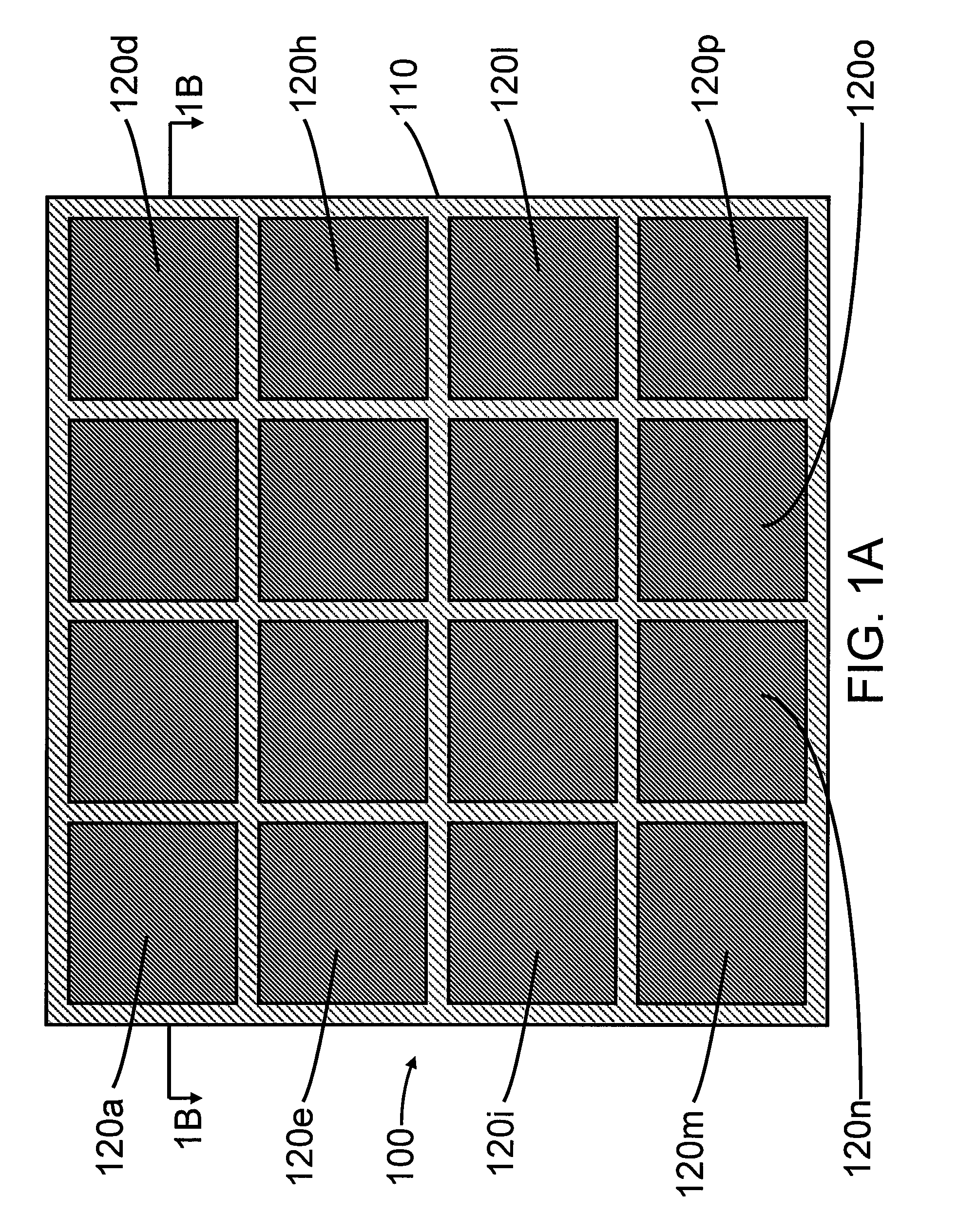

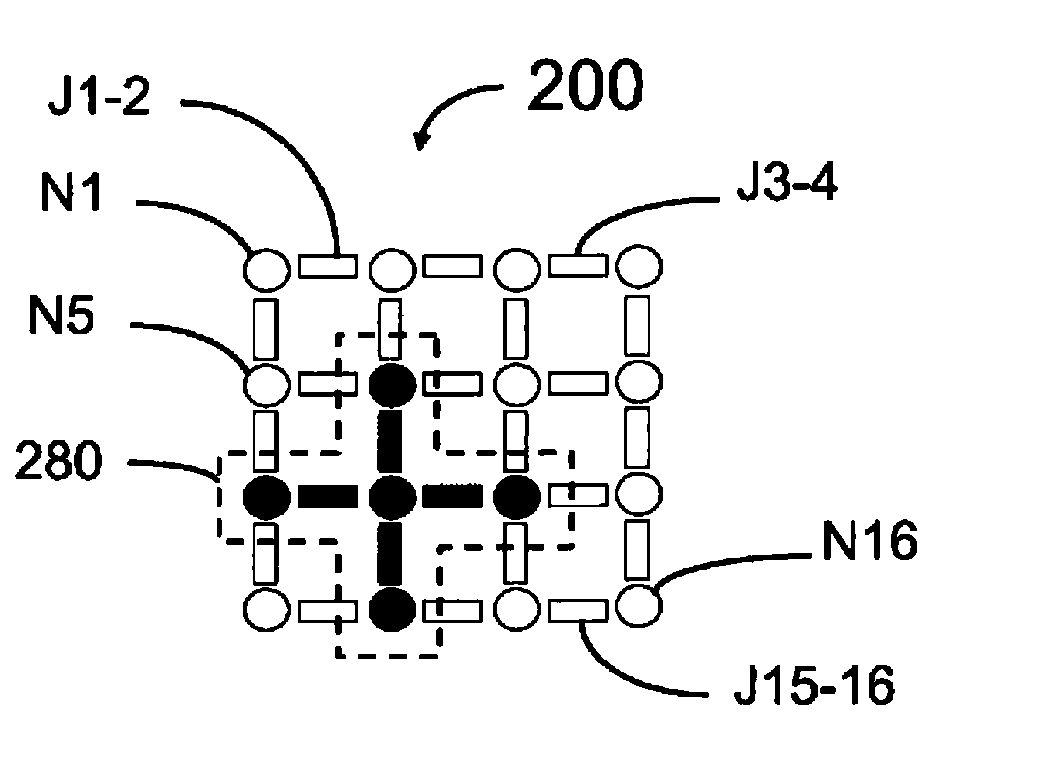

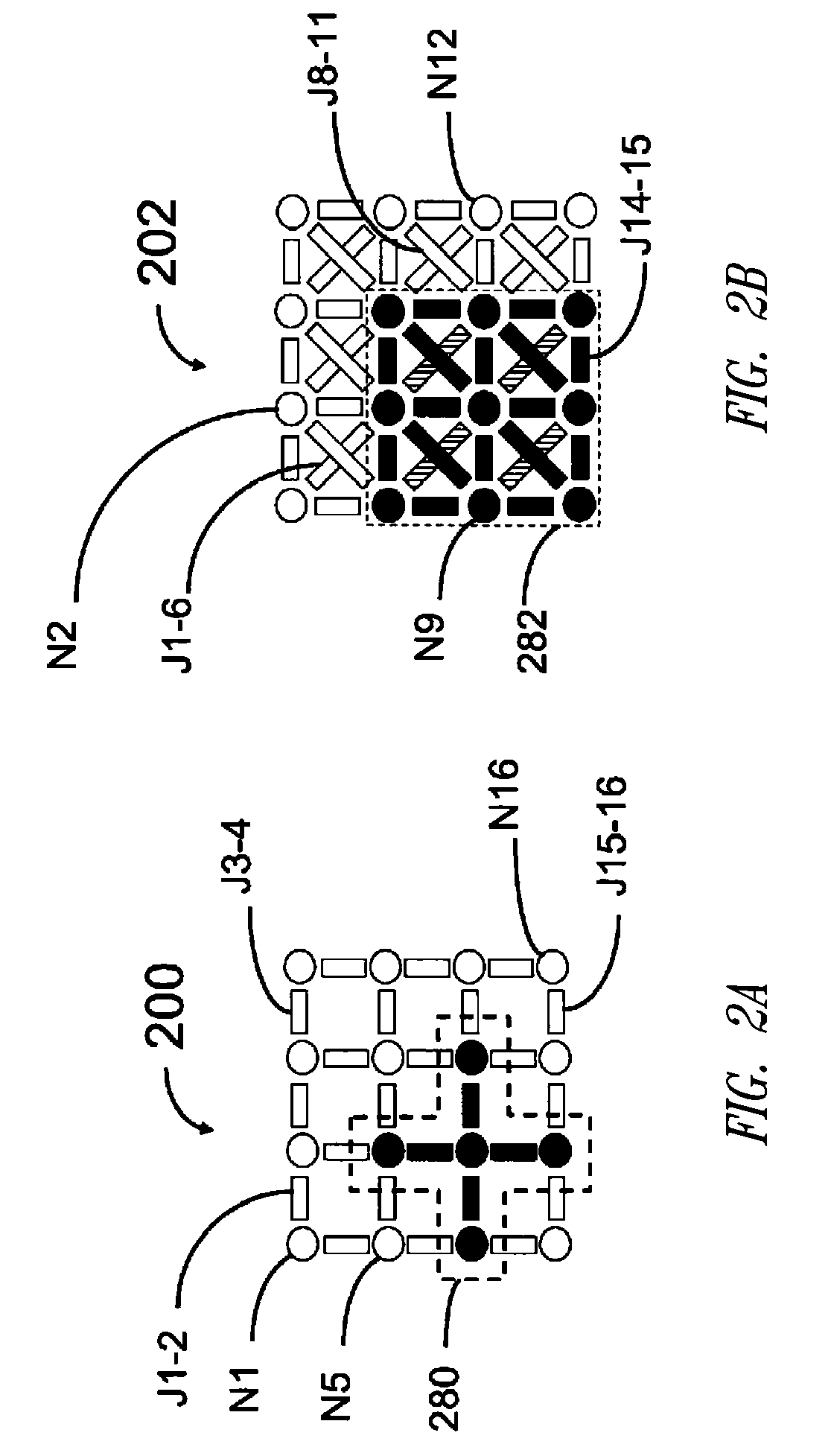

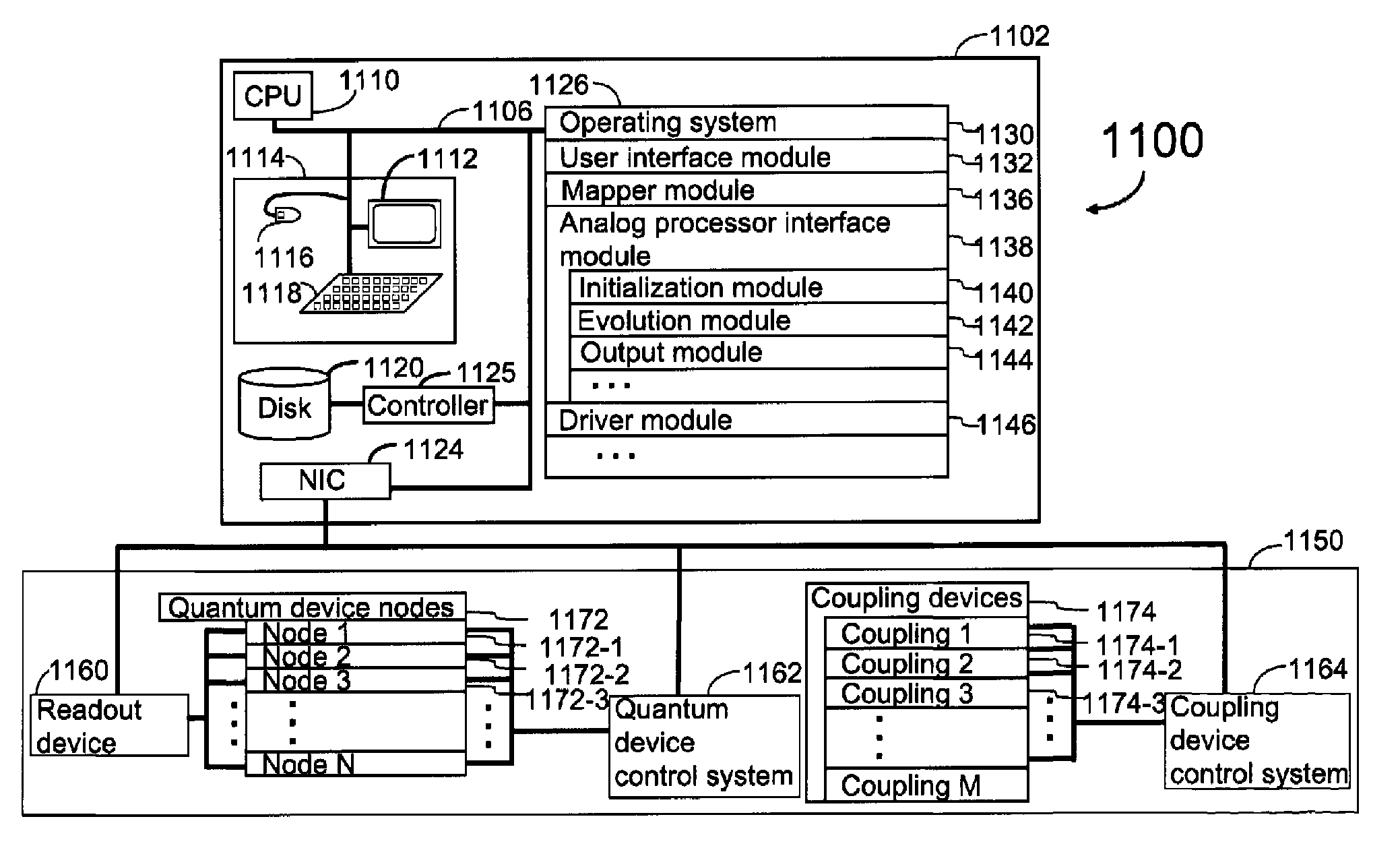

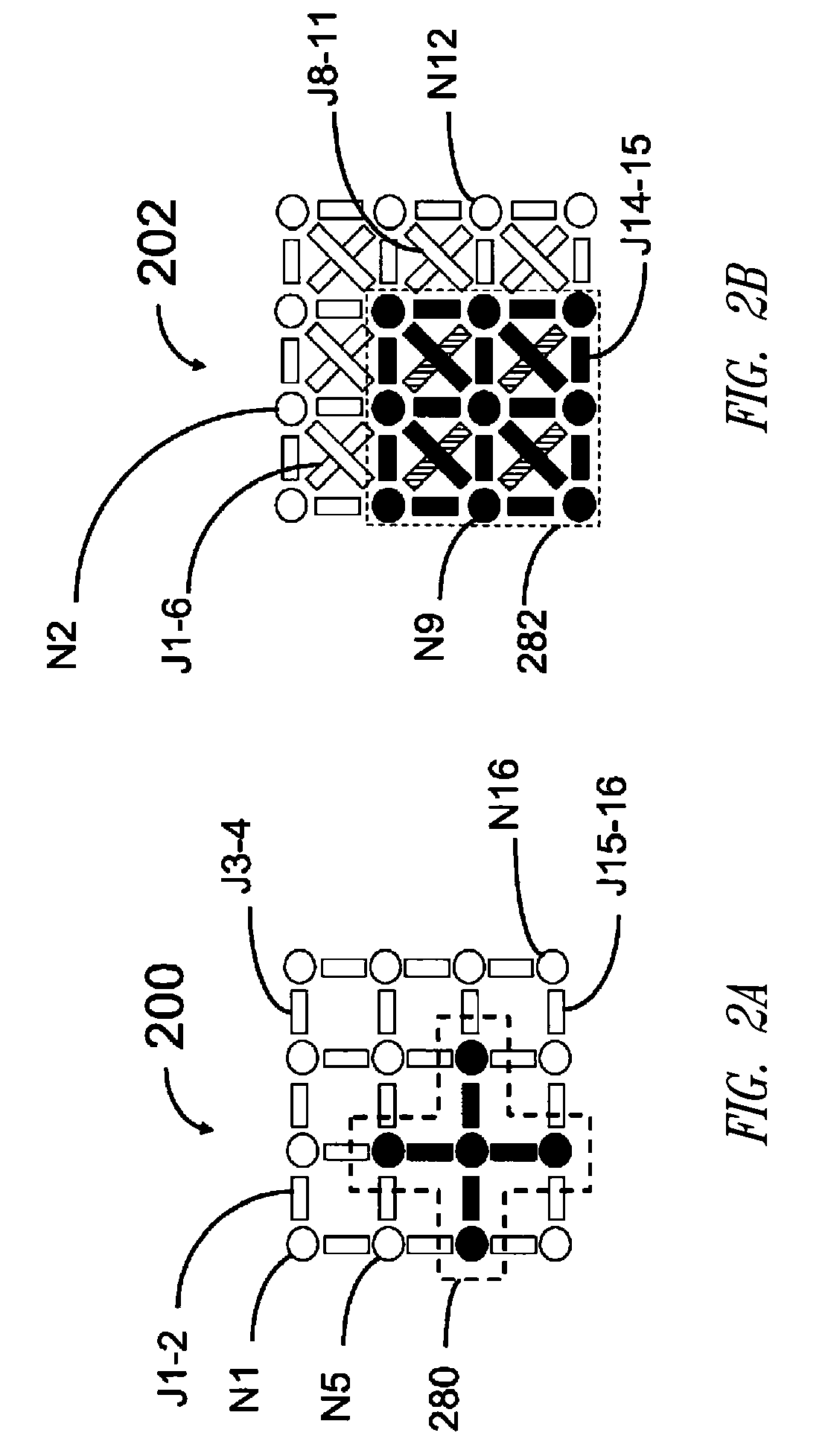

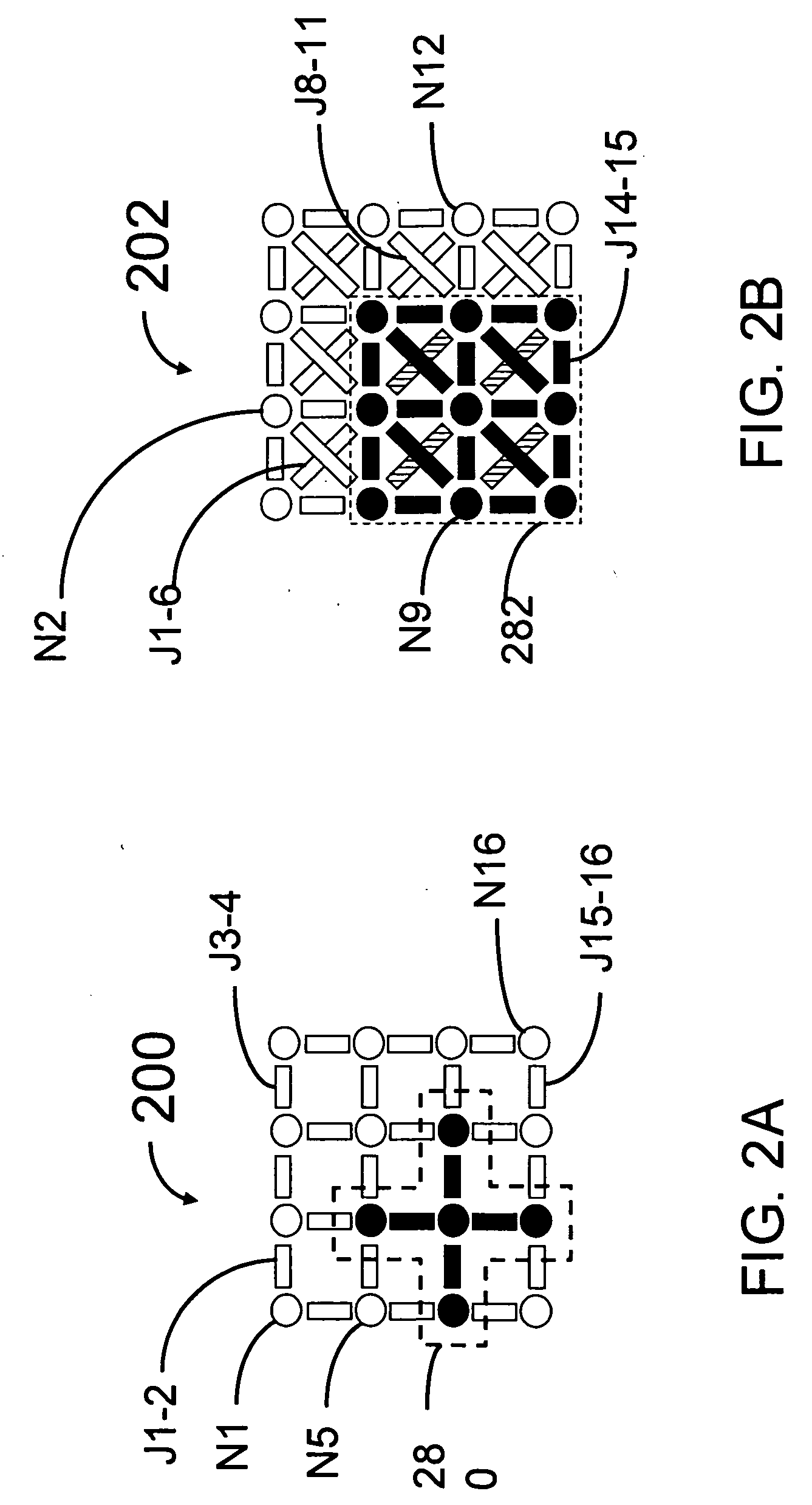

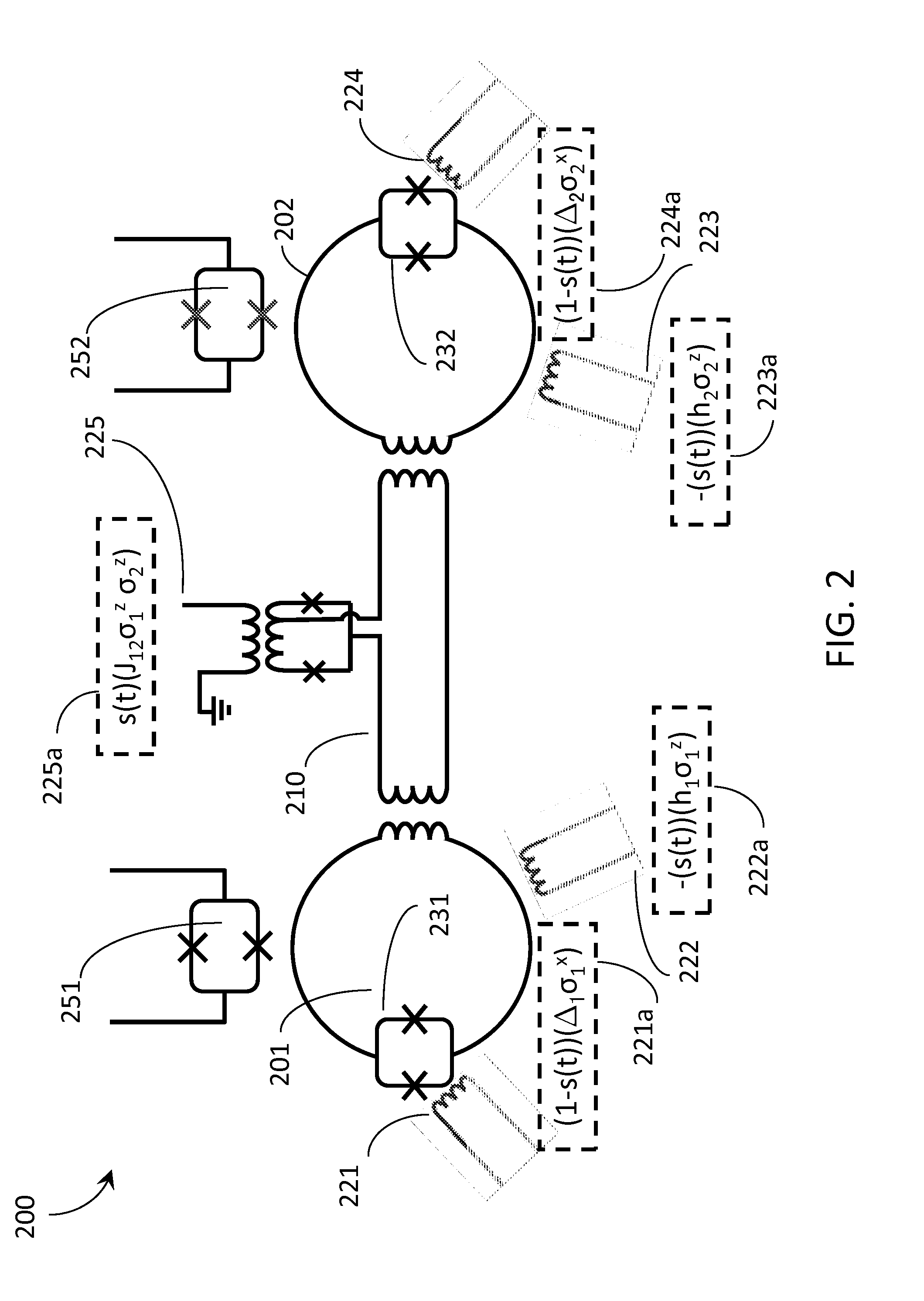

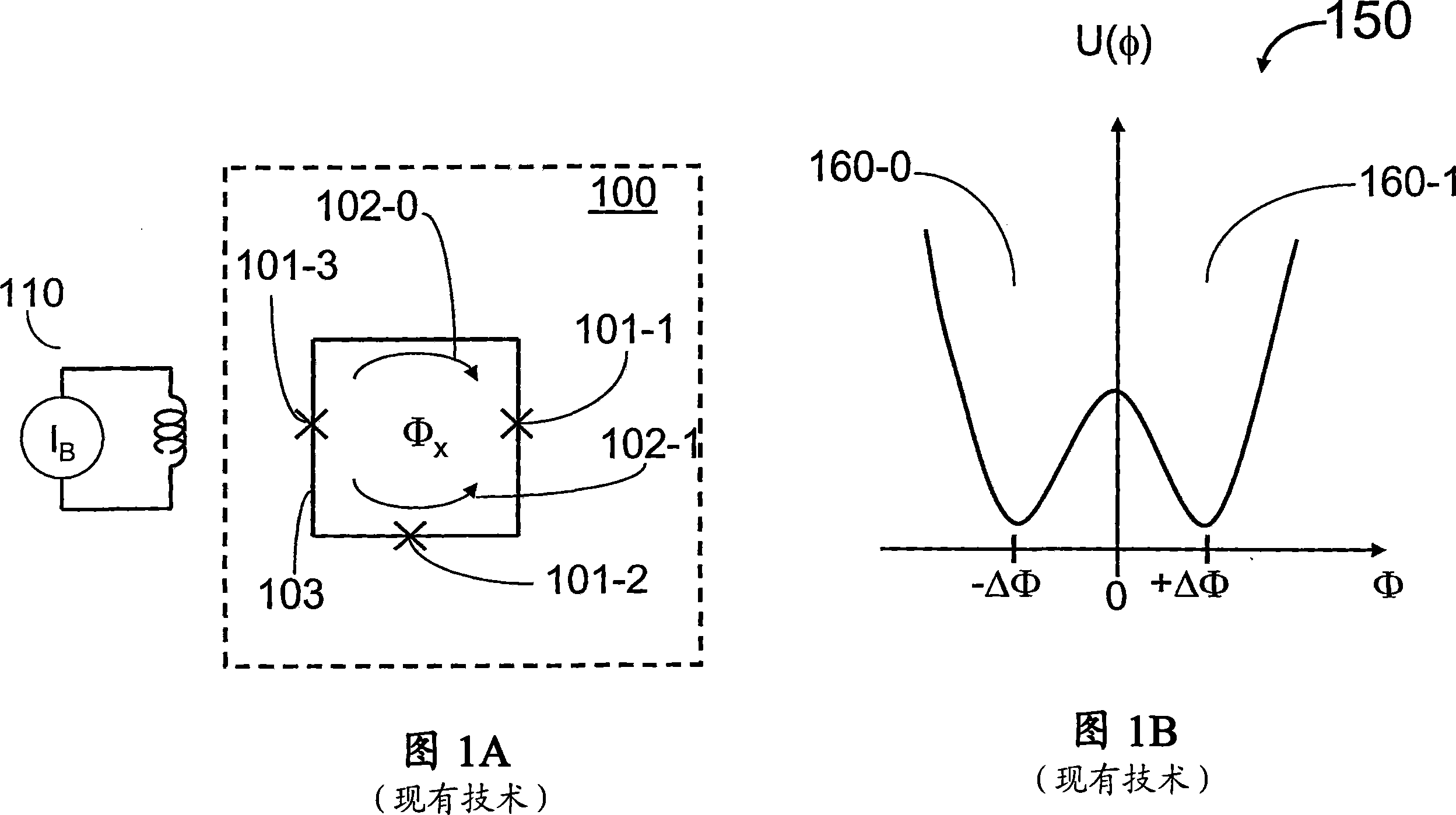

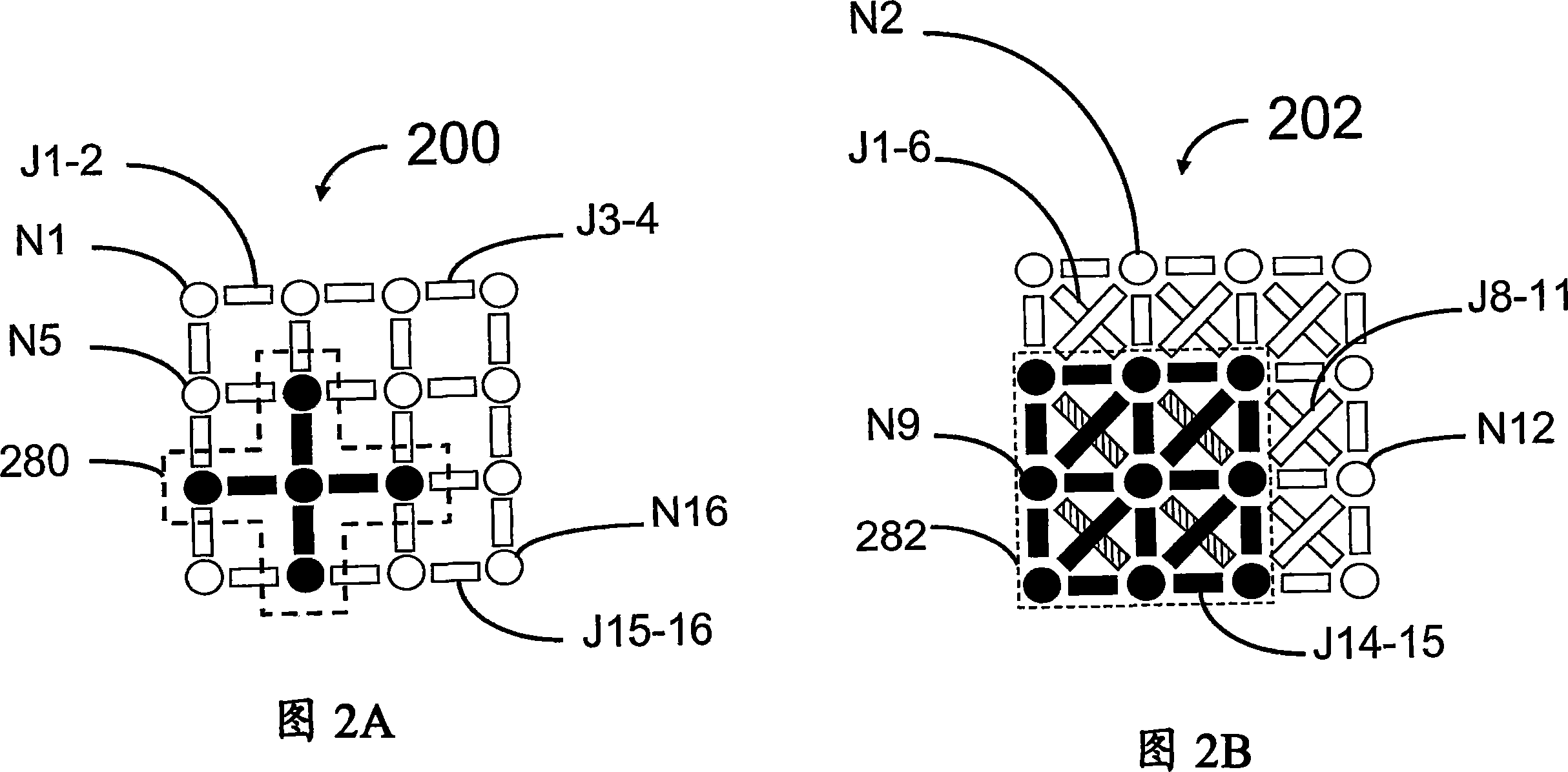

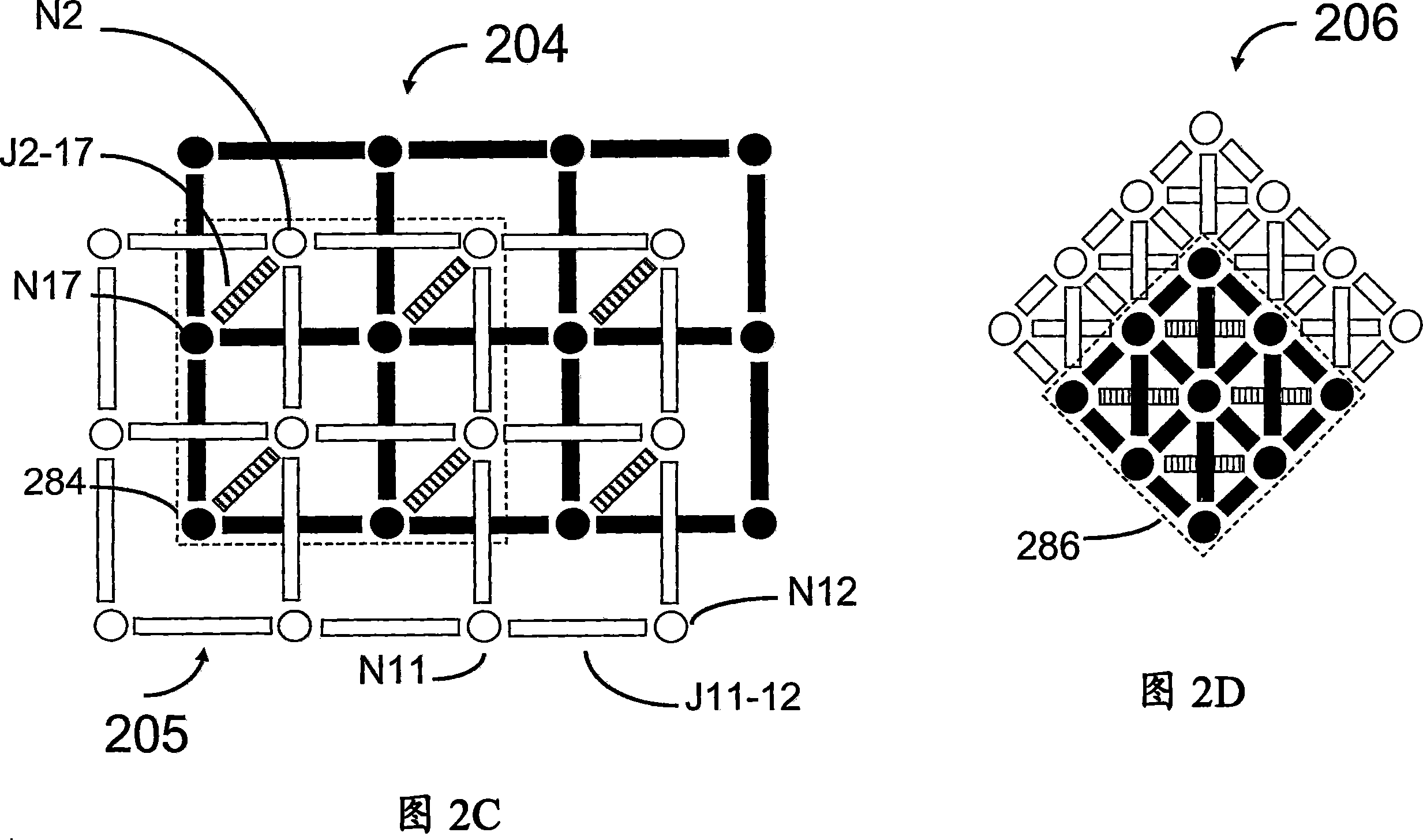

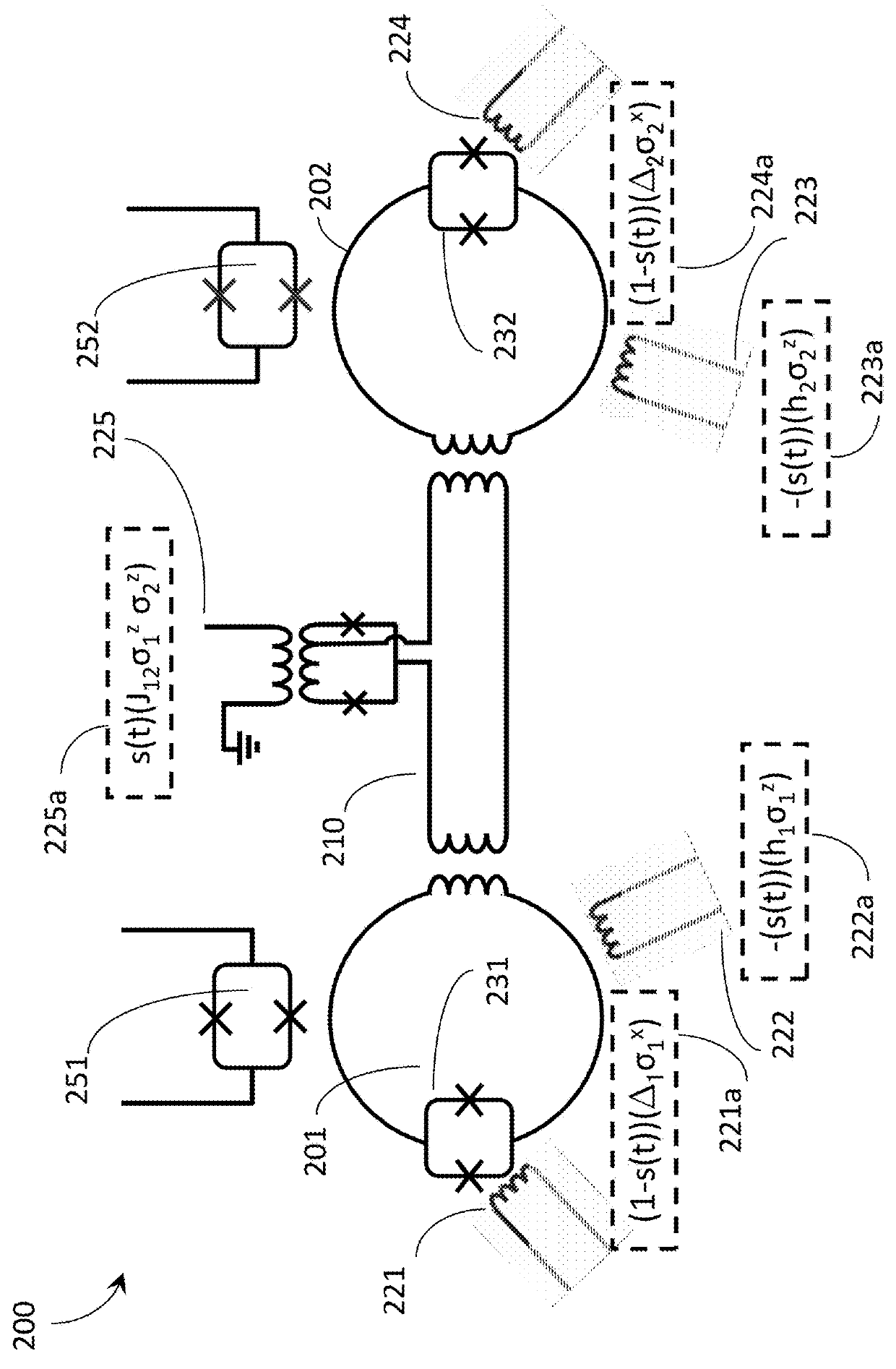

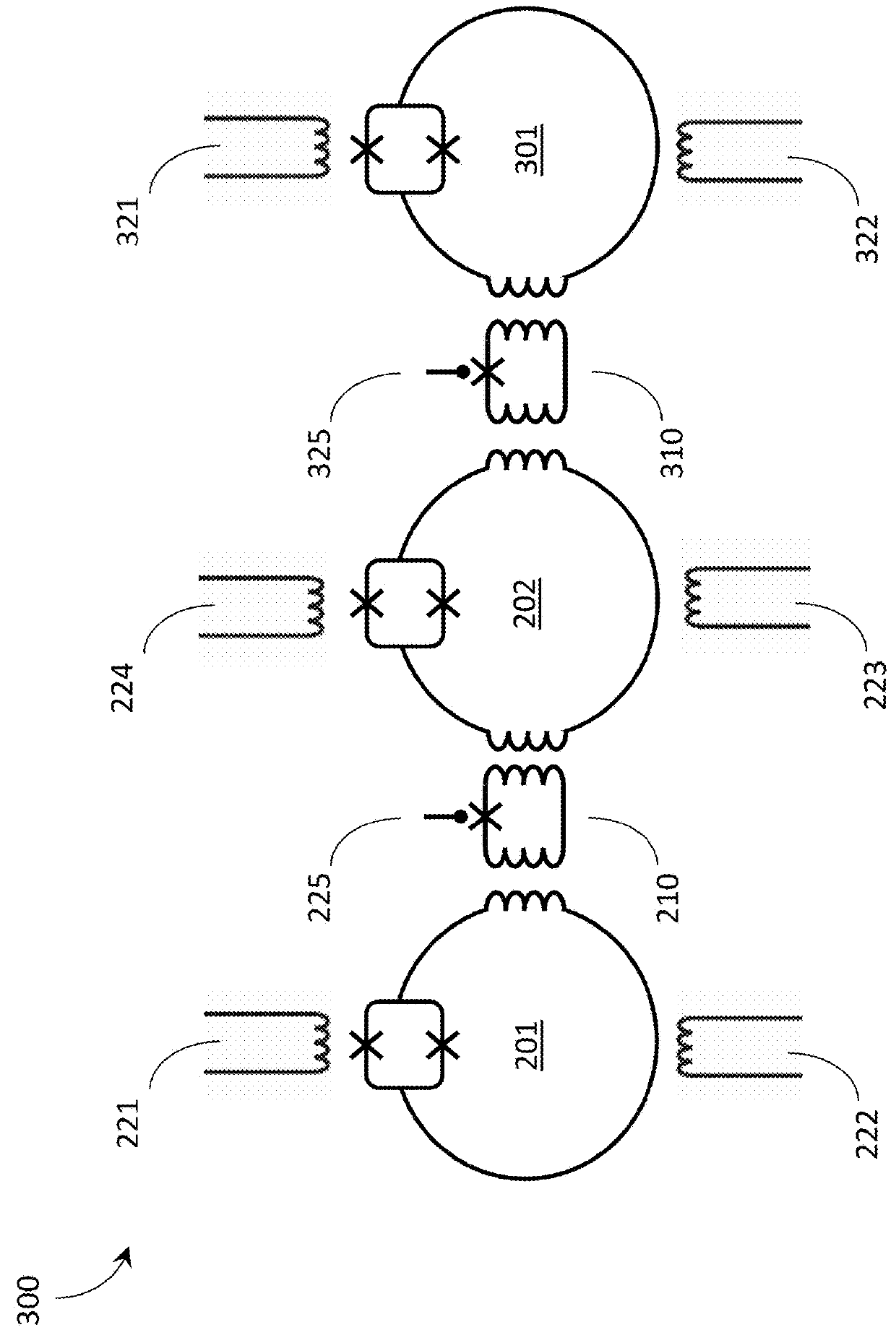

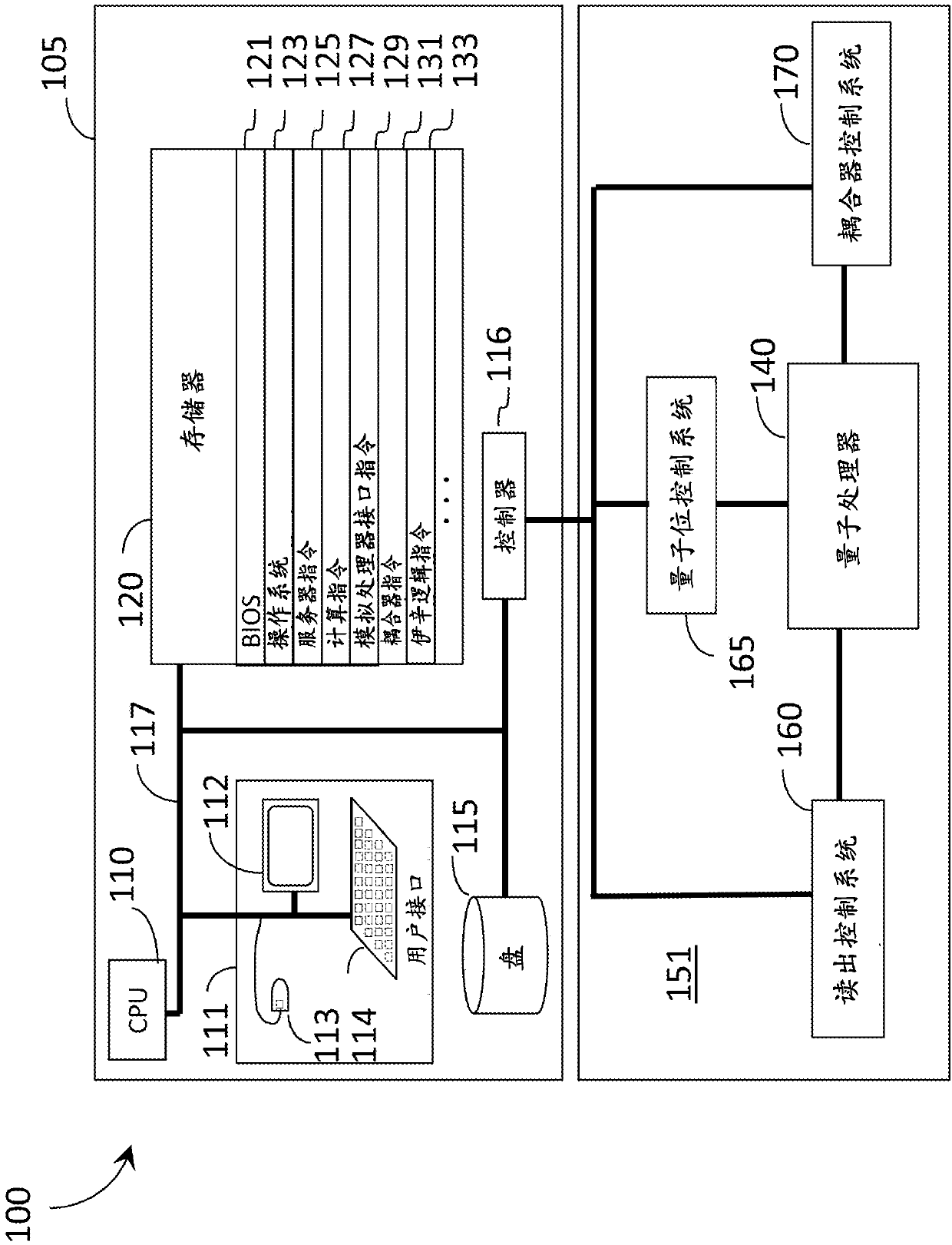

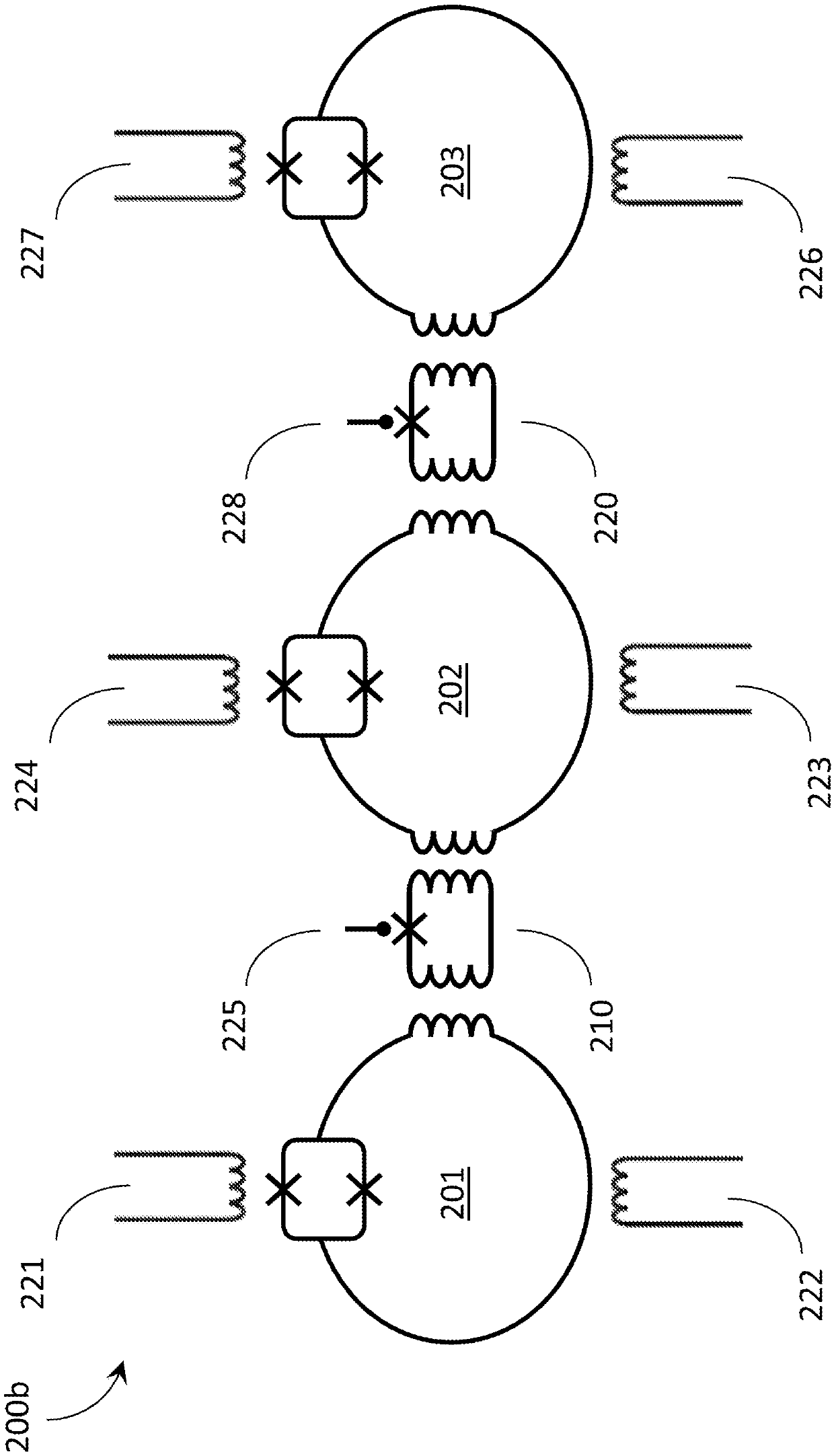

Analog processors for solving various computational problems are provided. Such analog processors comprise a plurality of quantum devices, arranged in a lattice, together with a plurality of coupling devices. The analog processors further comprise bias control systems each configured to apply a local effective bias on a corresponding quantum device. A set of coupling devices in the plurality of coupling devices is configured to couple nearest-neighbor quantum devices in the lattice. Another set of coupling devices is configured to couple next-nearest neighbor quantum devices. The analog processors further comprise a plurality of coupling control systems each configured to tune the coupling value of a corresponding coupling device in the plurality of coupling devices to a coupling. Such quantum processors further comprise a set of readout devices each configured to measure the information from a corresponding quantum device in the plurality of quantum devices.

Owner:D WAVE SYSTEMS INC

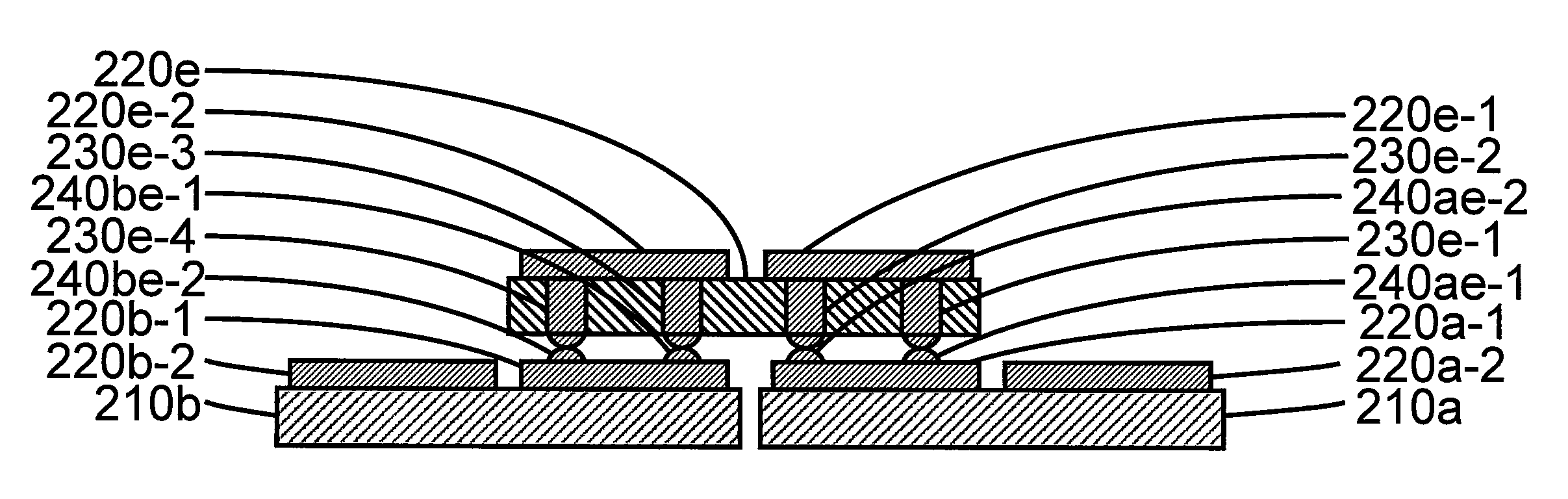

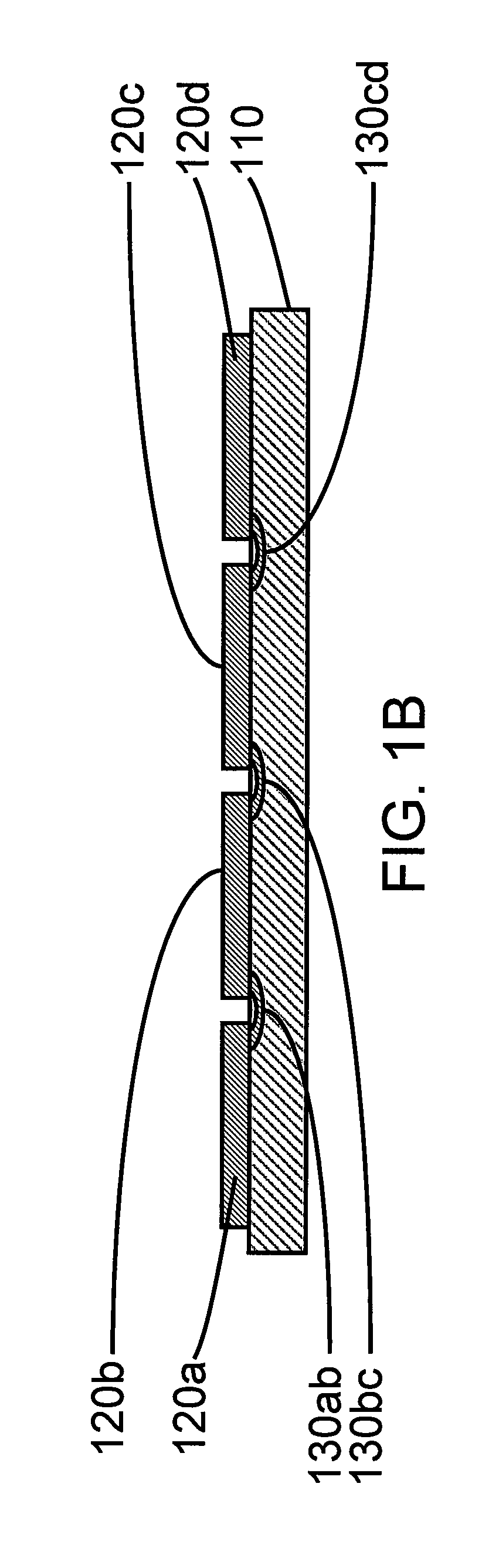

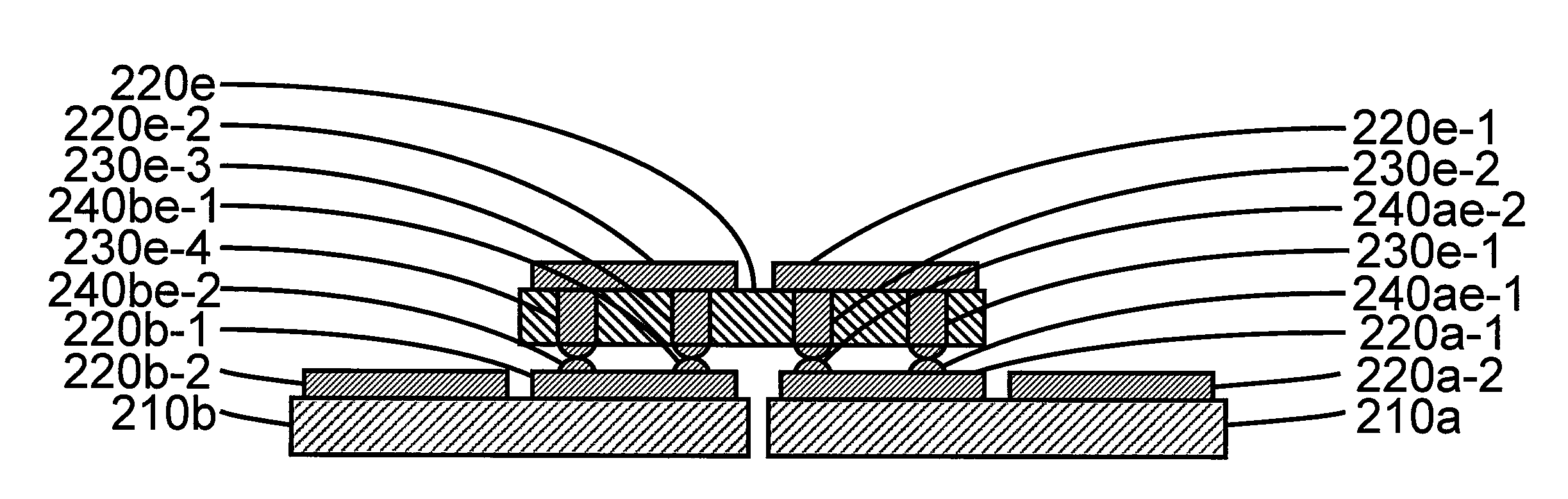

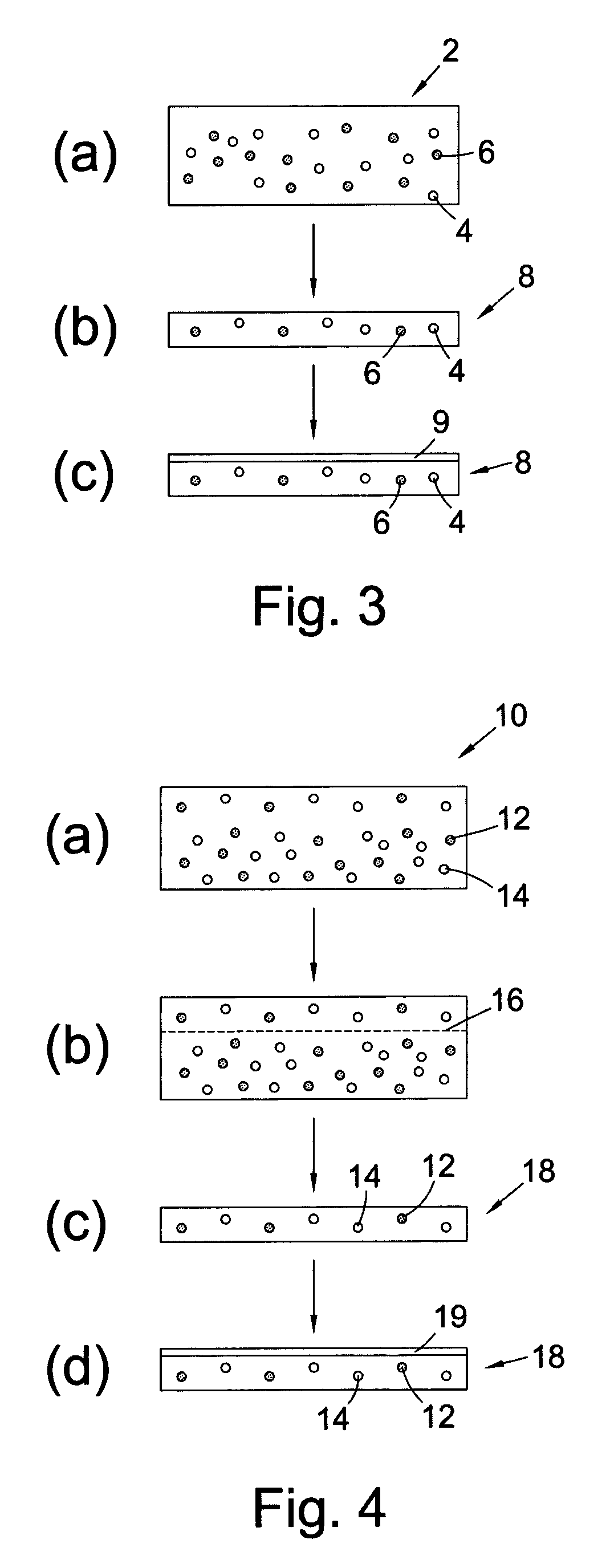

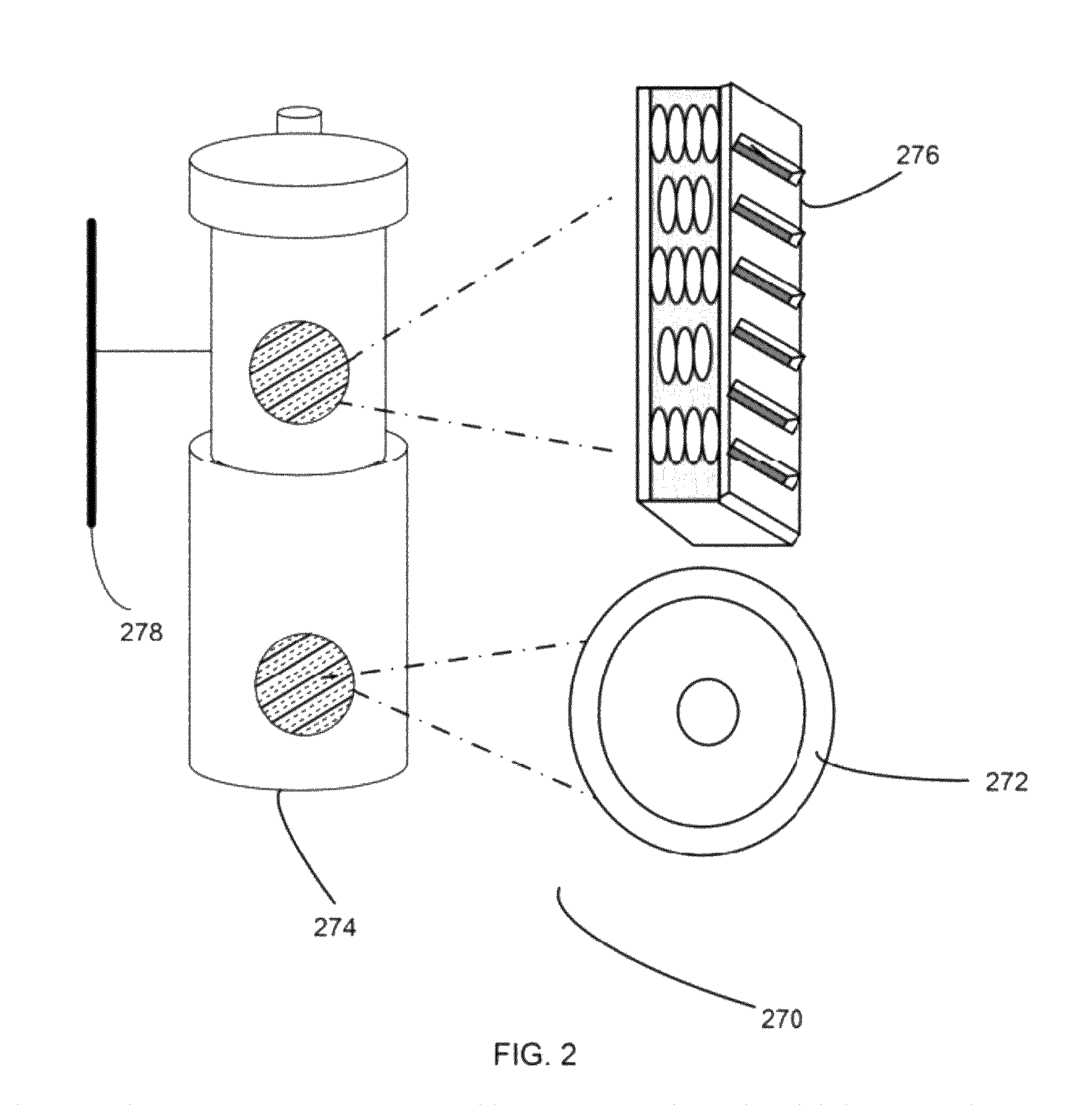

Quantum processor

Multiple substrates that carry quantum devices are coupled to provide quantum mechanical communicators therebetween, for example, using superconducting interconnects, vias, solder and / or magnetic flux. Such may advantageously reduce a footprint of a device such as a quantum processor.

Owner:D WAVE SYSTEMS INC

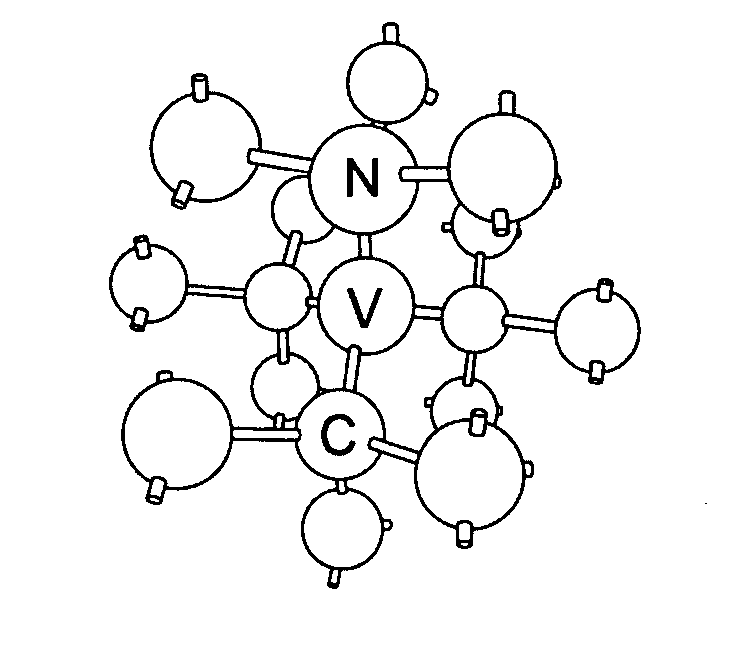

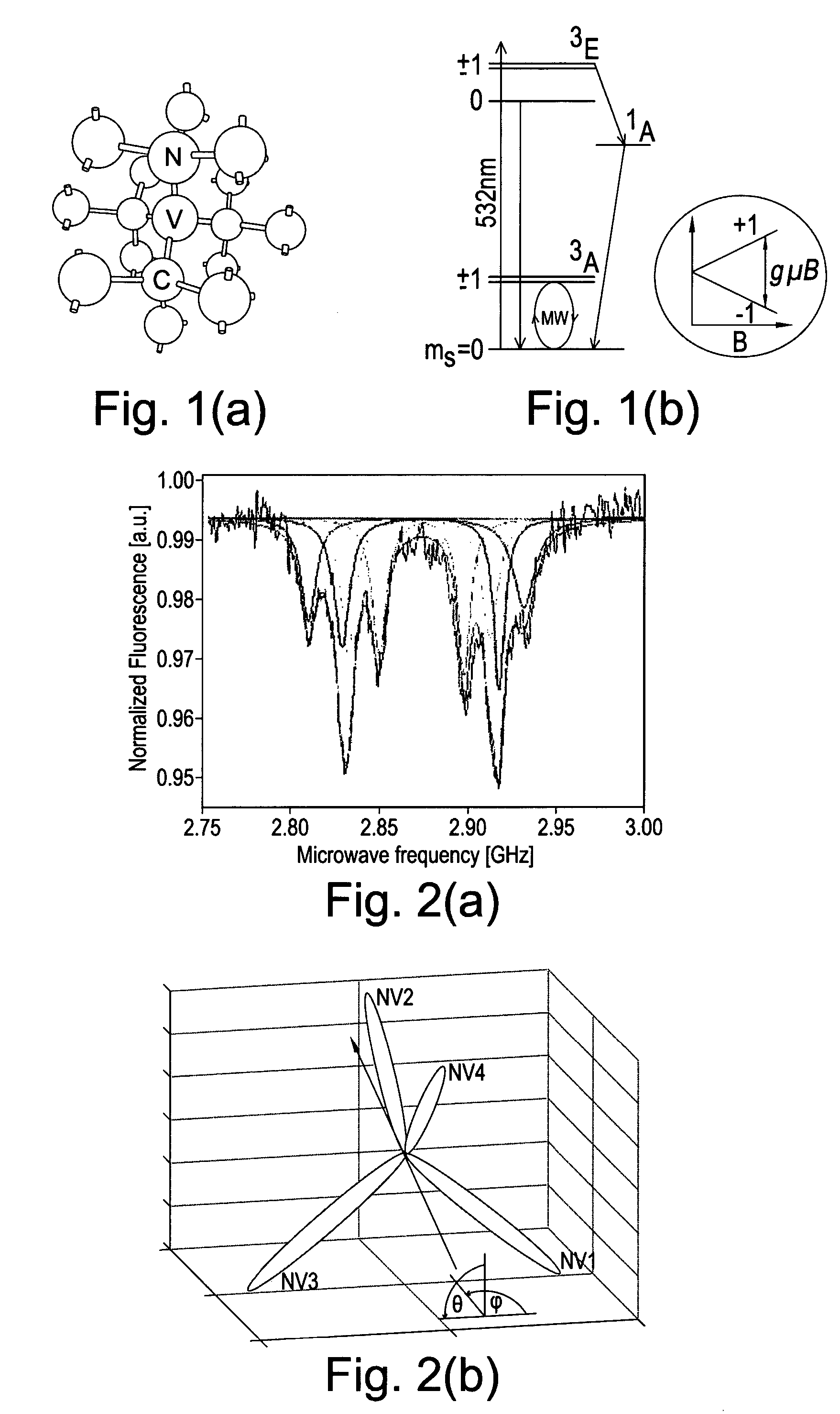

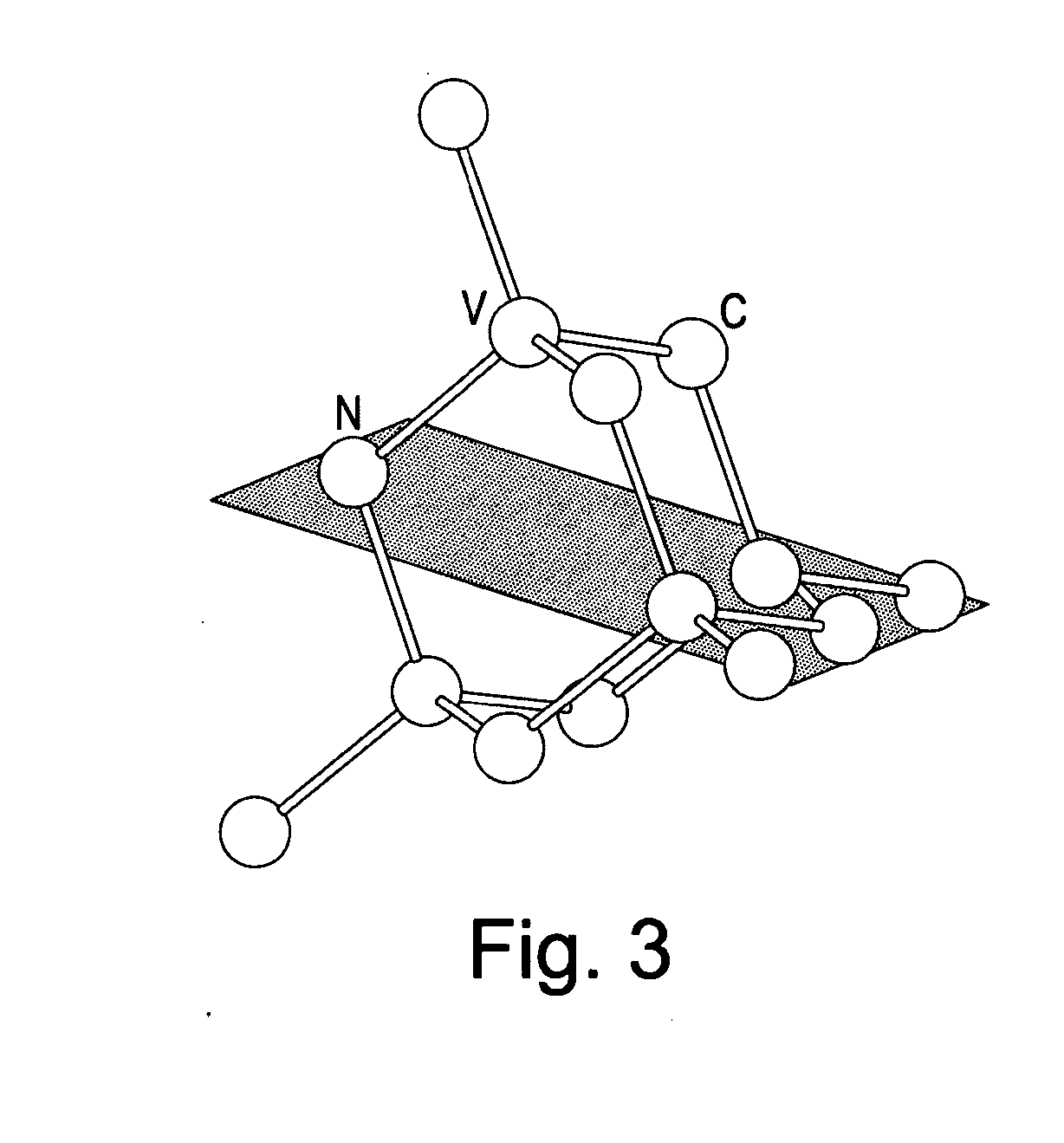

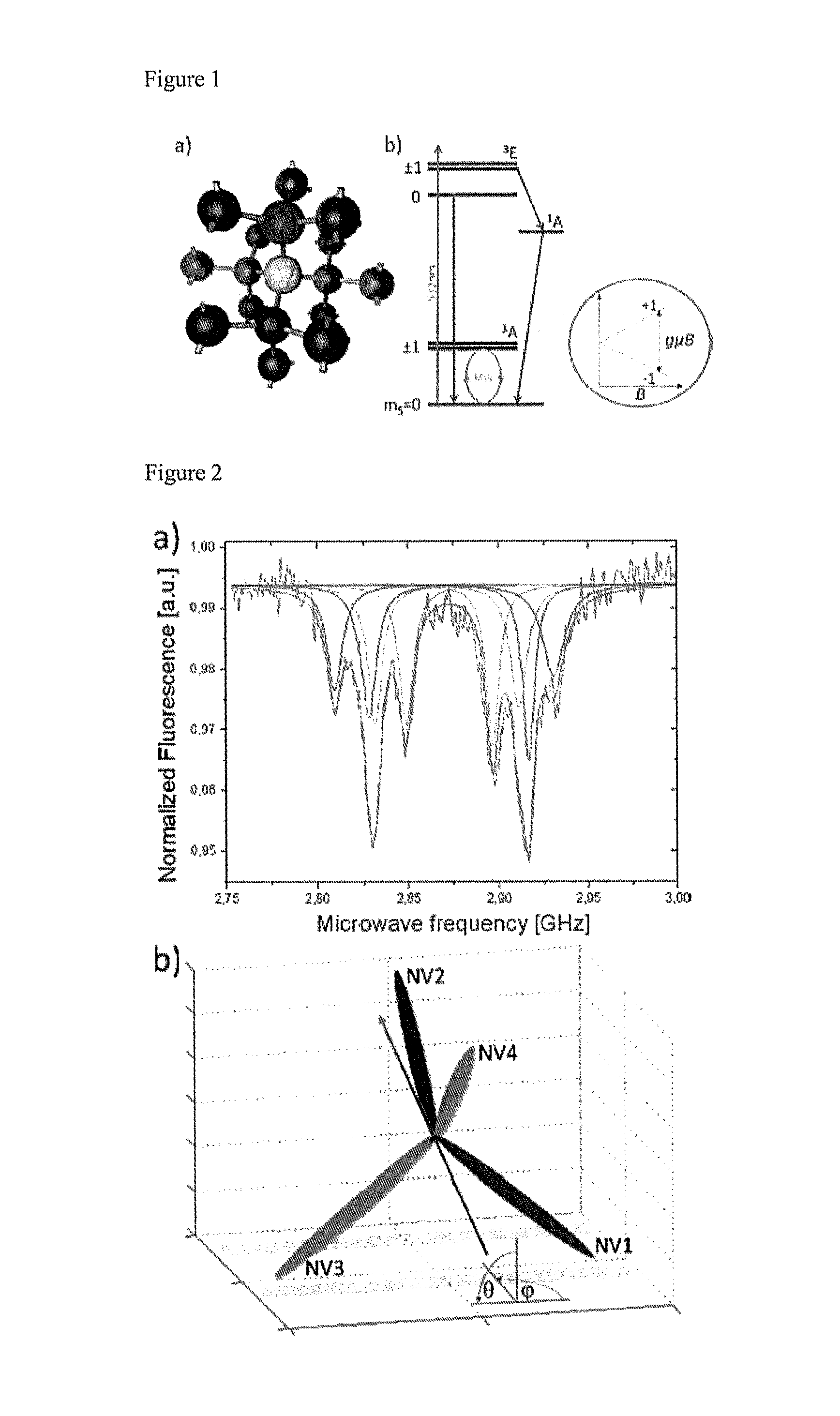

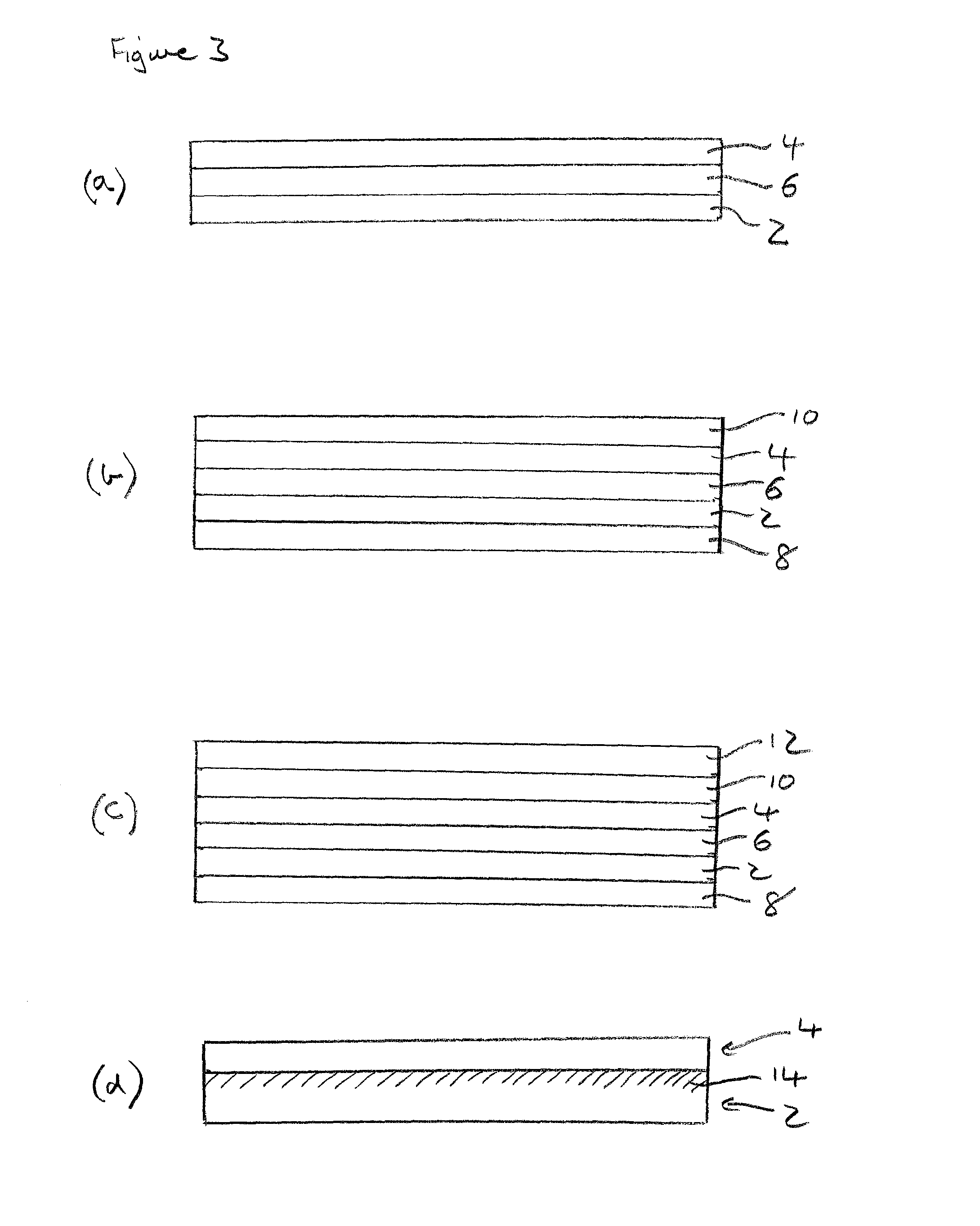

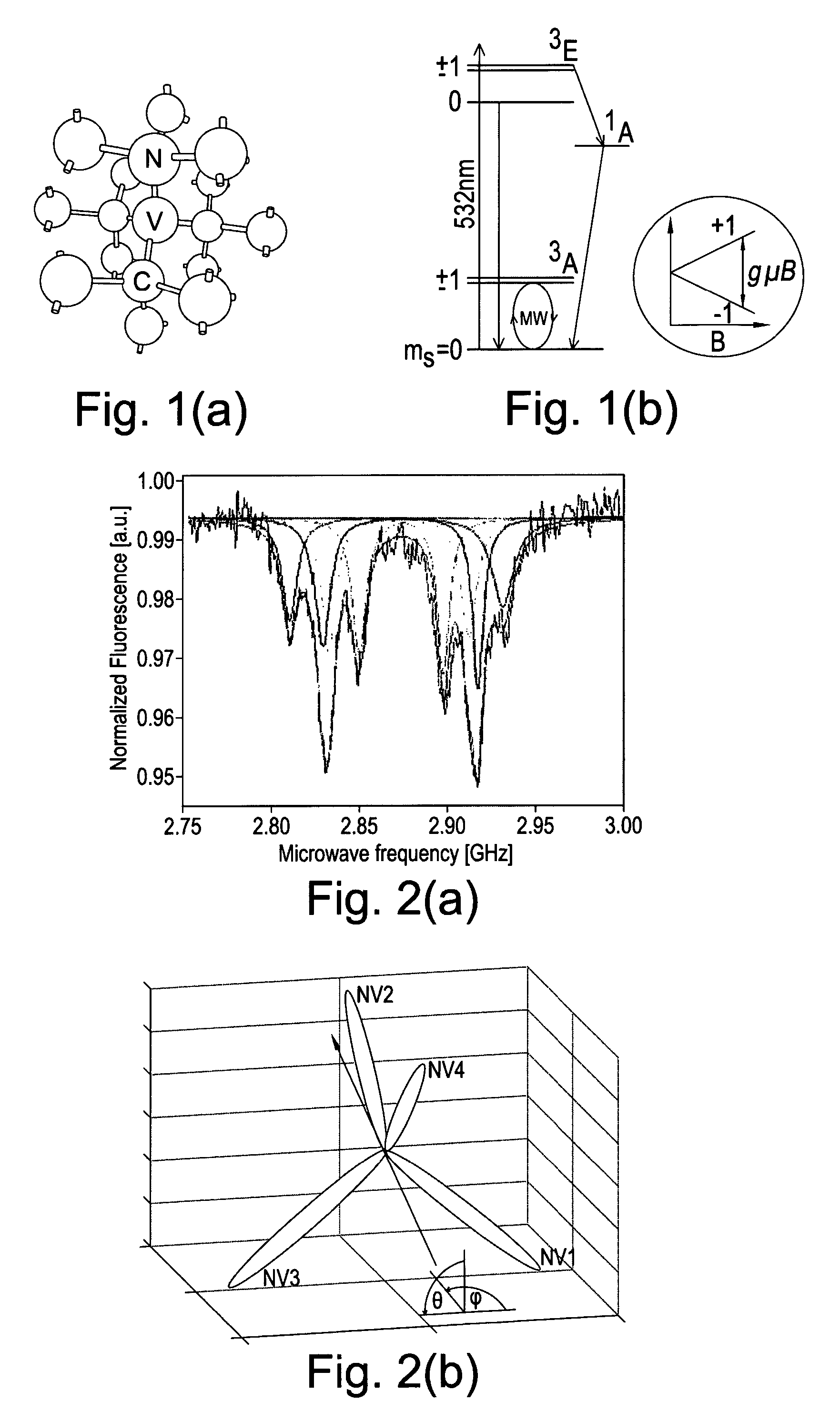

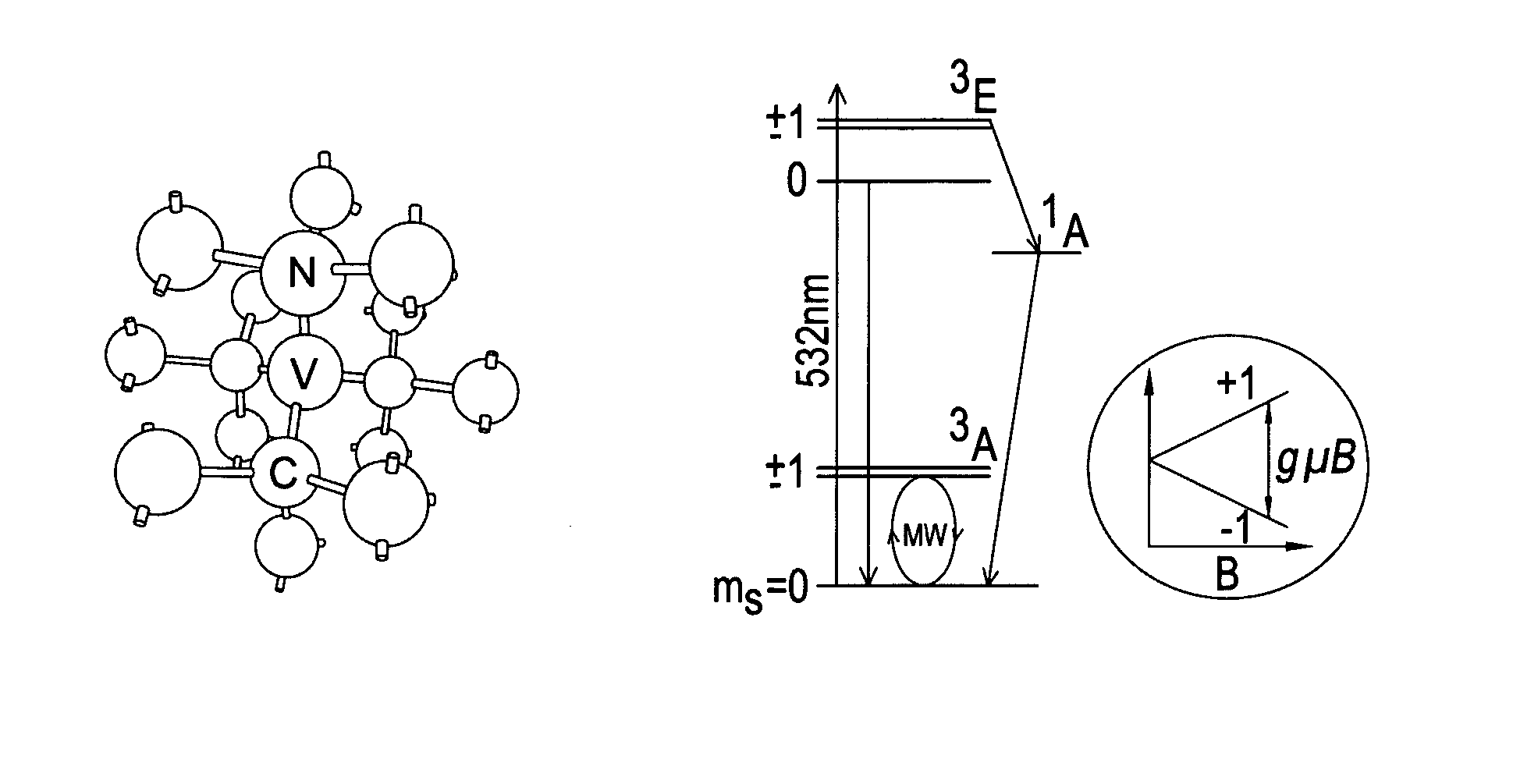

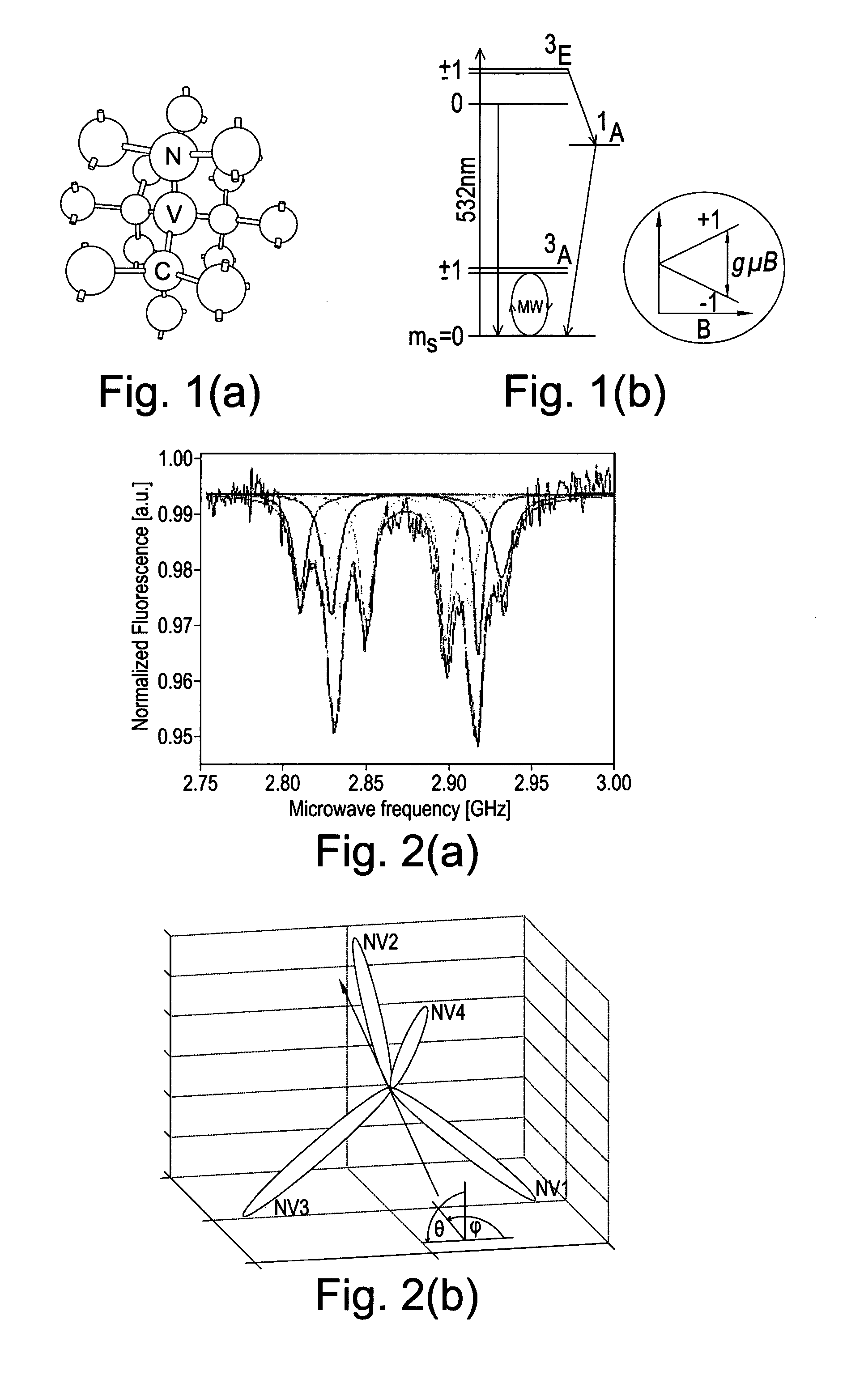

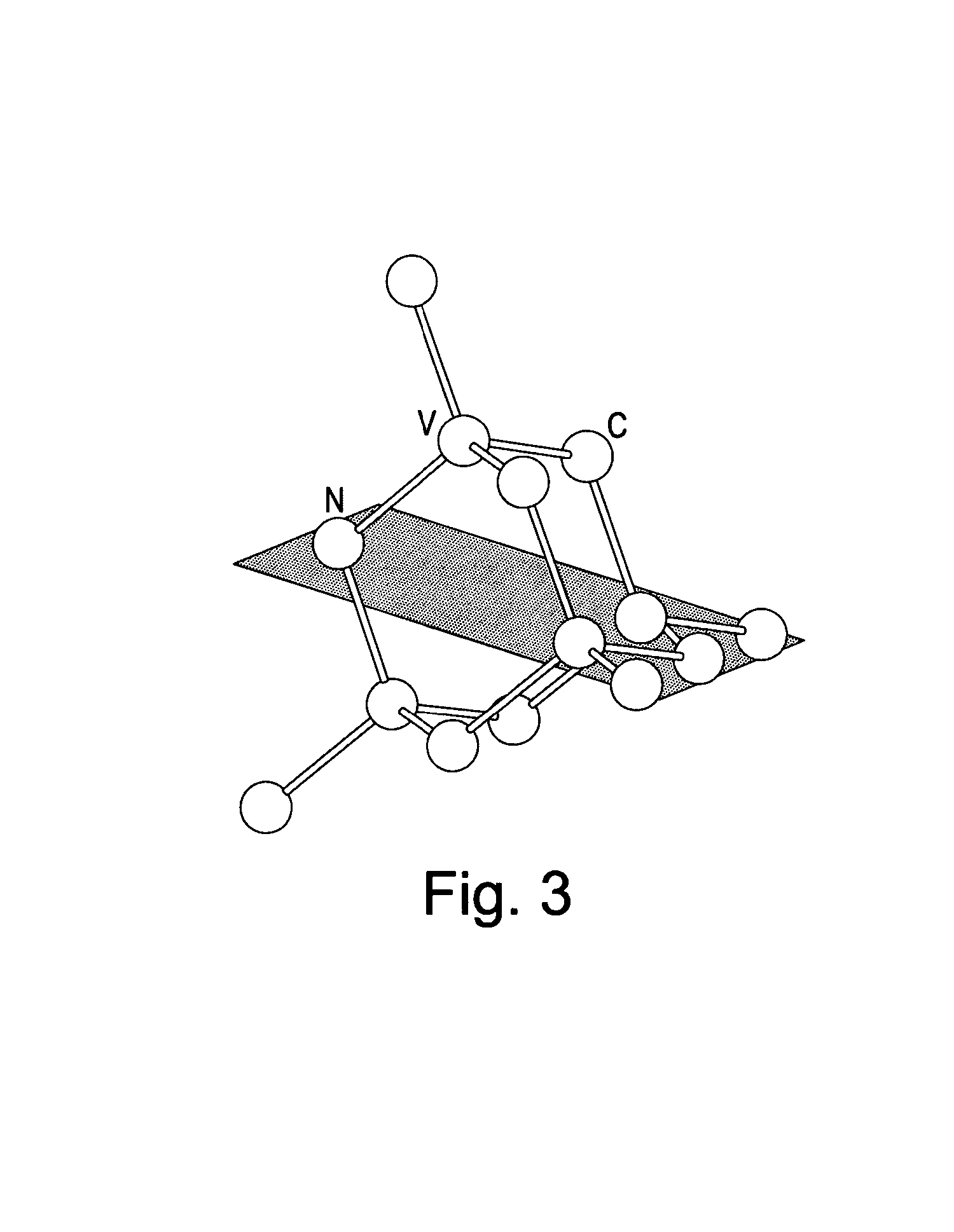

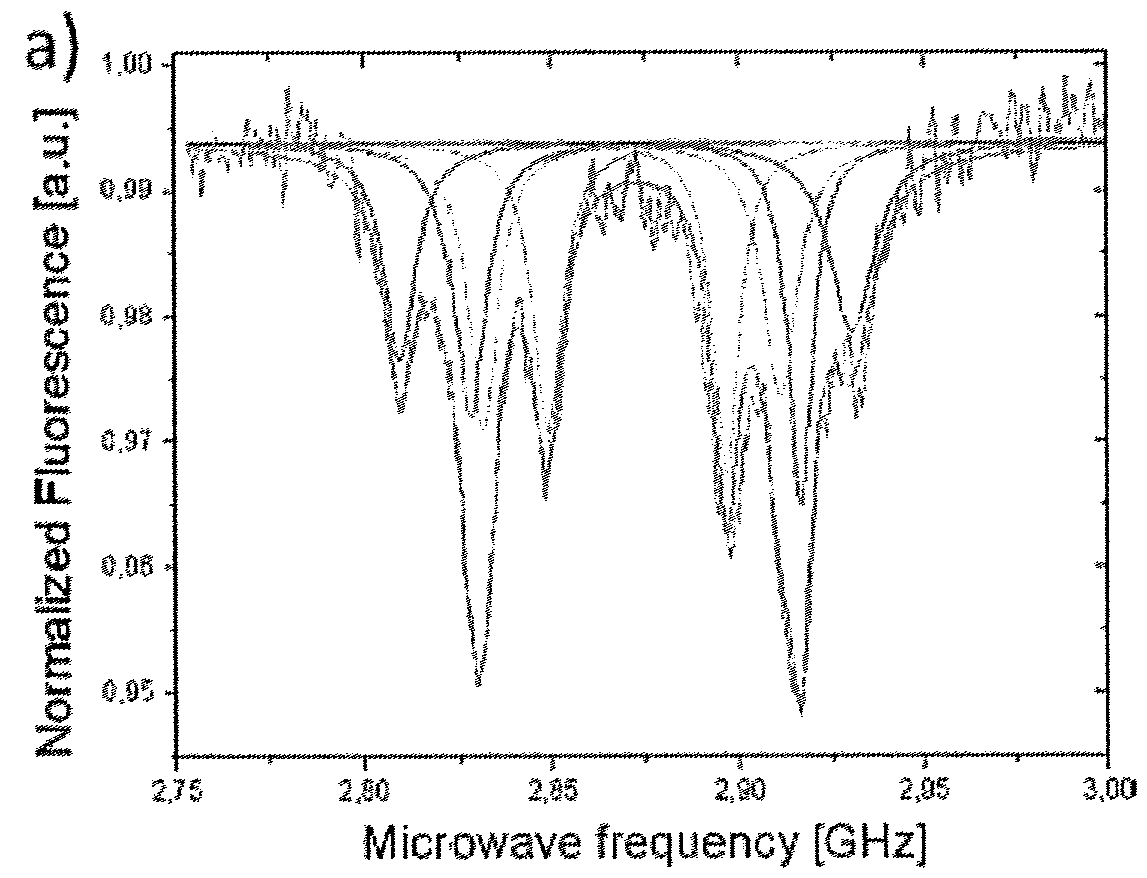

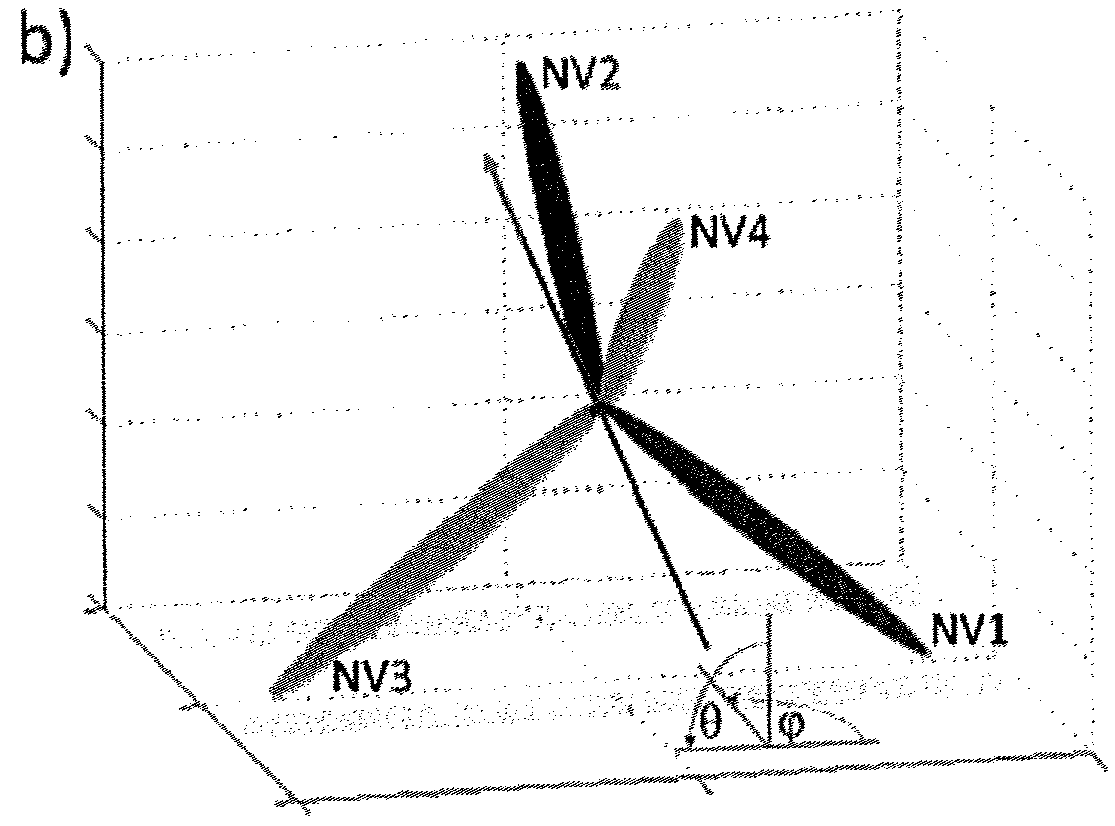

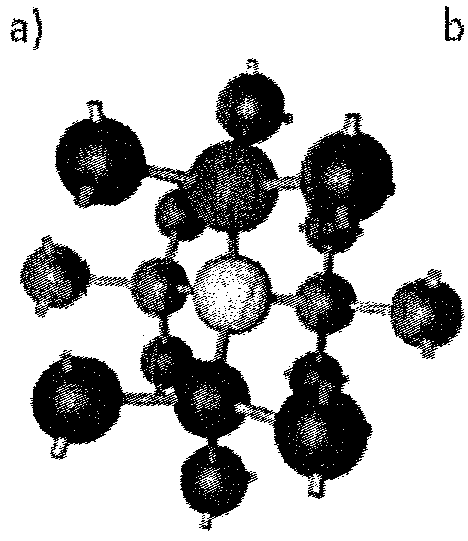

Diamond sensors, detectors, and quantum devices

ActiveUS20140061510A1Improve light outcoupling efficiencyEnhanced couplingPolycrystalline material growthUltra-high pressure processesVacancy defectPreferential alignment

A single crystal synthetic CVD diamond material comprising: a growth sector; and a plurality of point defects of one or more type within the growth sector, wherein at least one type of point defect is preferentially aligned within the growth sector, wherein at least 60% of said at least one type of point defect shows said preferential alignment, and wherein the at least one type of point defect is a negatively charged nitrogen-vacancy defect (NV−).

Owner:ELEMENT SIX LTD

Quantum processor

Multiple substrates that carry quantum devices are coupled to provide quantum mechanical communicators therebetween, for example, using superconducting interconnects, vias, solder and / or magnetic flux. Such may advantageously reduce a footprint of a device such as a quantum processor.

Owner:D WAVE SYSTEMS INC

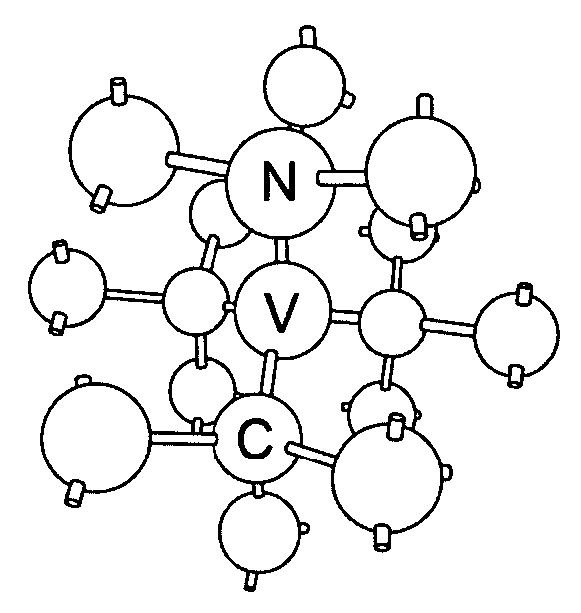

Diamond sensors, detectors, and quantum devices

ActiveUS20140037932A1High purityMinimizes strainQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region of synthetic single crystal diamond material comprising a plurality of electron donor defects; a second region of synthetic single crystal diamond material comprising a plurality of quantum spin defects; and a third region of synthetic single crystal diamond material disposed between the first and second regions such that the first and second regions are spaced apart by the third region, wherein the second and third regions of synthetic single crystal diamond material have a lower concentration of electron donor defects than the first region of synthetic single crystal diamond material, and wherein the first and second regions are spaced apart by a distance in a range 10 nm to 100 μm which is sufficiently close to allow electrons to be donated from the first region of synthetic single crystal diamond material to the second region of synthetic single crystal diamond material thus forming negatively charged quantum spin defects in the second region of synthetic single crystal diamond material and positively charged defects in the first region of synthetic single crystal diamond material while being sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region of synthetic single crystal diamond material.

Owner:ELEMENT SIX LTD

Diamond sensors, detectors, and quantum devices

ActiveUS8758509B2Improve excitation efficiencyIncrease the number ofUltra-high pressure processesNanoinformaticsBillionthSpins

A thin plate of synthetic single crystal diamond material, the thin plate of synthetic single crystal diamond material having: a thickness in a range 100 nm to 50 μιη; a concentration of quantum spin defects greater than 0.1 ppb (parts-per-billion); a concentration of point defects other than the quantum spin defects of below 200 ppm (parts-per-million); and wherein at least one major face of the thin plate of synthetic single crystal diamond material comprises surface termination species which have zero nuclear spin and / or zero electron spin.

Owner:ELEMENT SIX LTD

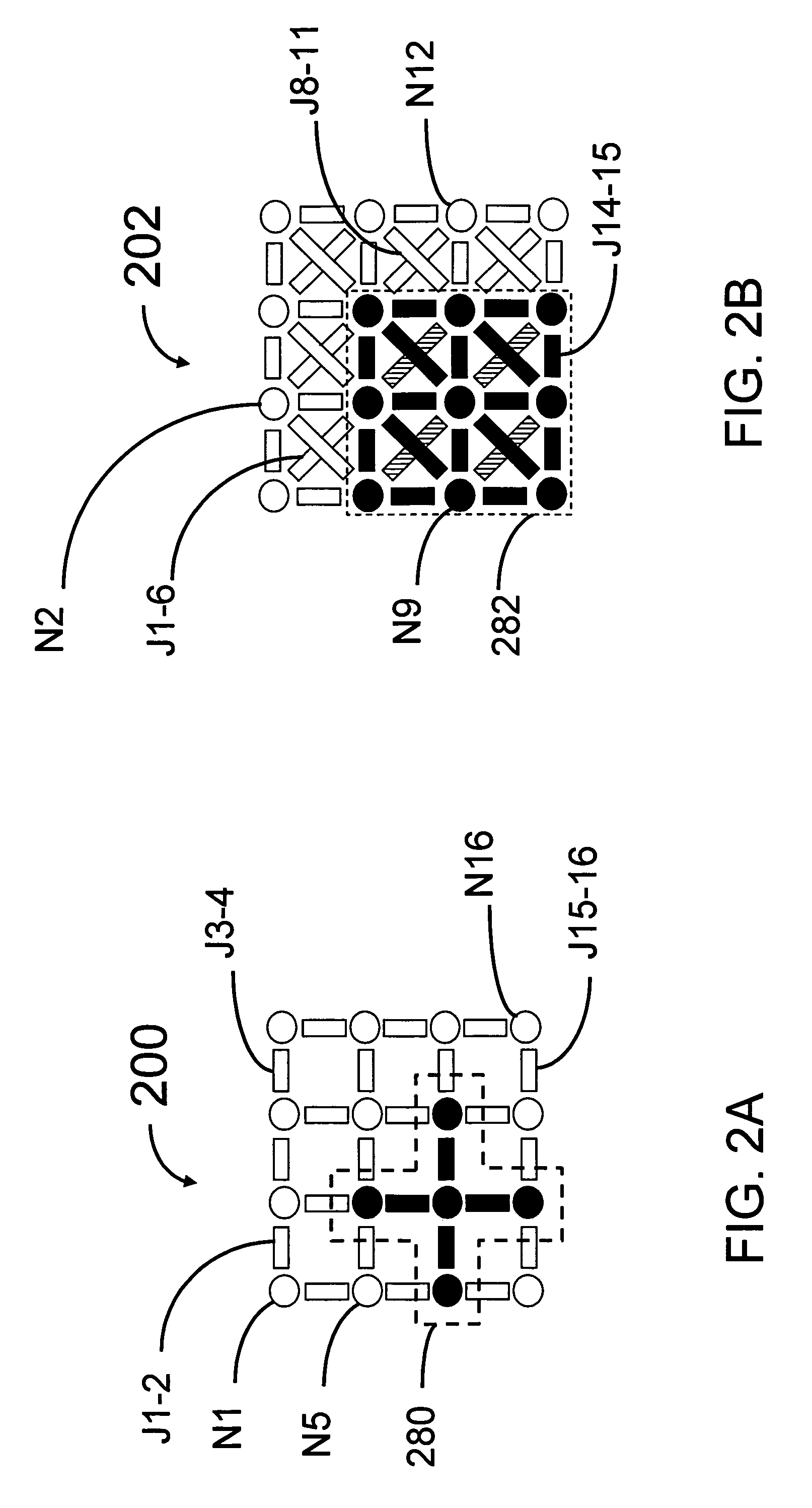

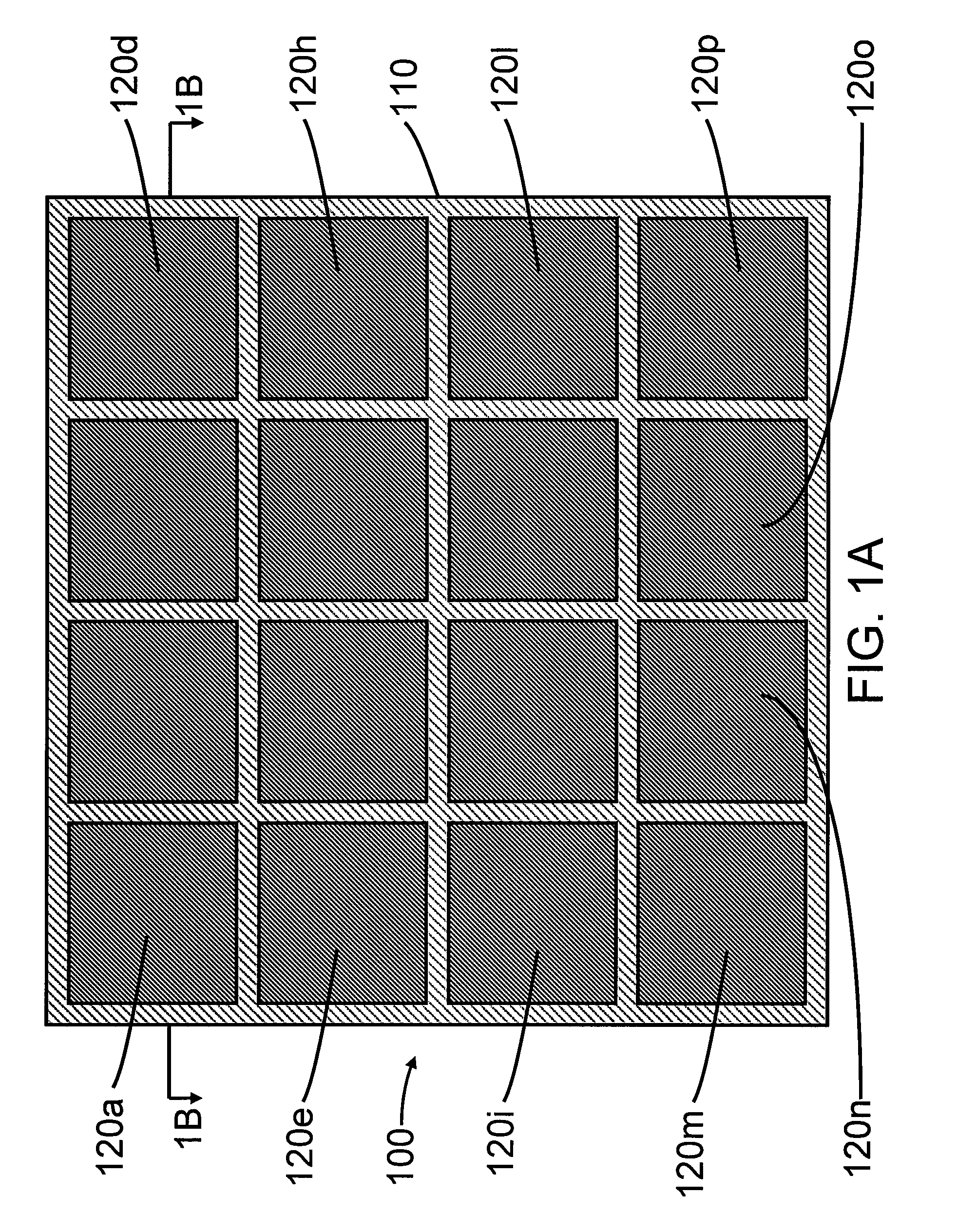

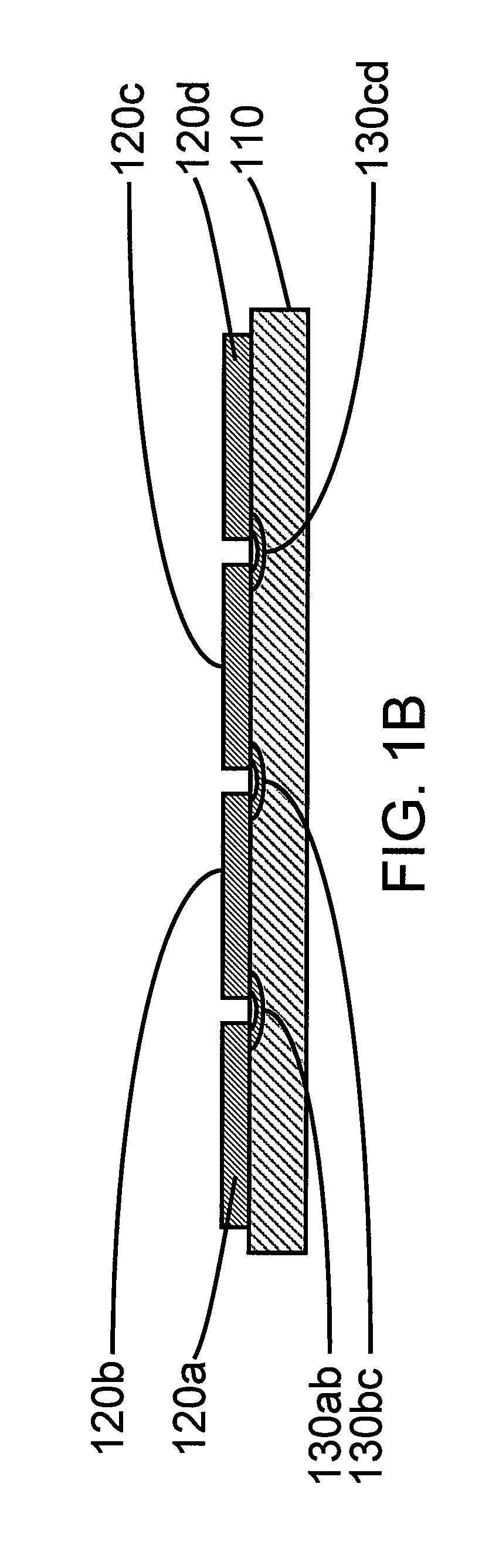

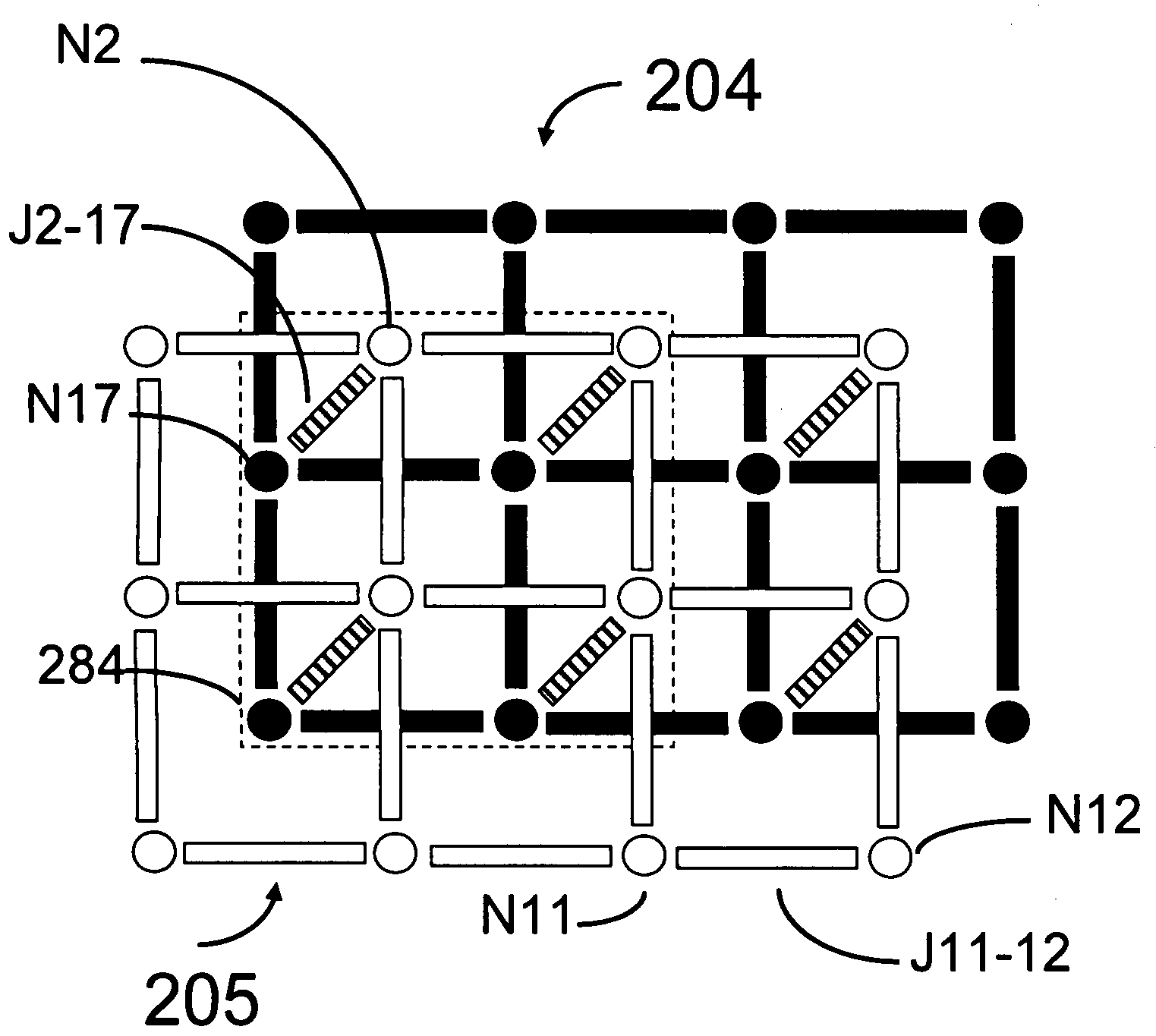

Analog processor comprising quantum devices

Analog processors for solving various computational problems are provided. Such analog processors comprise a plurality of quantum devices, for instance qubits, arranged in a lattice, together with a plurality of coupling devices. The analog processors further comprise bias control systems each configured to apply a local effective bias on a corresponding quantum device. A set of coupling devices in the plurality of coupling devices is configured to couple nearest-neighbor quantum devices in the lattice. Another set of coupling devices is configured to couple next-nearest neighbor quantum devices. The analog processors further comprise a plurality of coupling control systems each configured to tune the coupling value of a corresponding coupling device in the plurality of coupling devices to a coupling. Such quantum processors further comprise a set of readout devices each configured to measure the information from a corresponding quantum device in the plurality of quantum devices.

Owner:D-WAVE SYSTEMS

Diamond sensors, detectors, and quantum devices

ActiveUS8686377B2Convenient lightingHigh strengthDiamondNanoopticsVacancy defectPreferential alignment

Owner:ELEMENT SIX LTD

Diamond sensors, detectors, and quantum devices

ActiveUS9249526B2Minimizes strainShorten the timeQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region comprising electron donor defects; a second region comprising quantum spin defects; and a third region between the first and second regions. The second and third regions have a lower concentration of electron donor defects than the first region. The first and second regions are sufficiently close to allow electrons to be donated from the first region to the second region, thus forming negatively charged quantum spin defects in the second and positively charged defects in the first region, and sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region.

Owner:ELEMENT SIX LTD

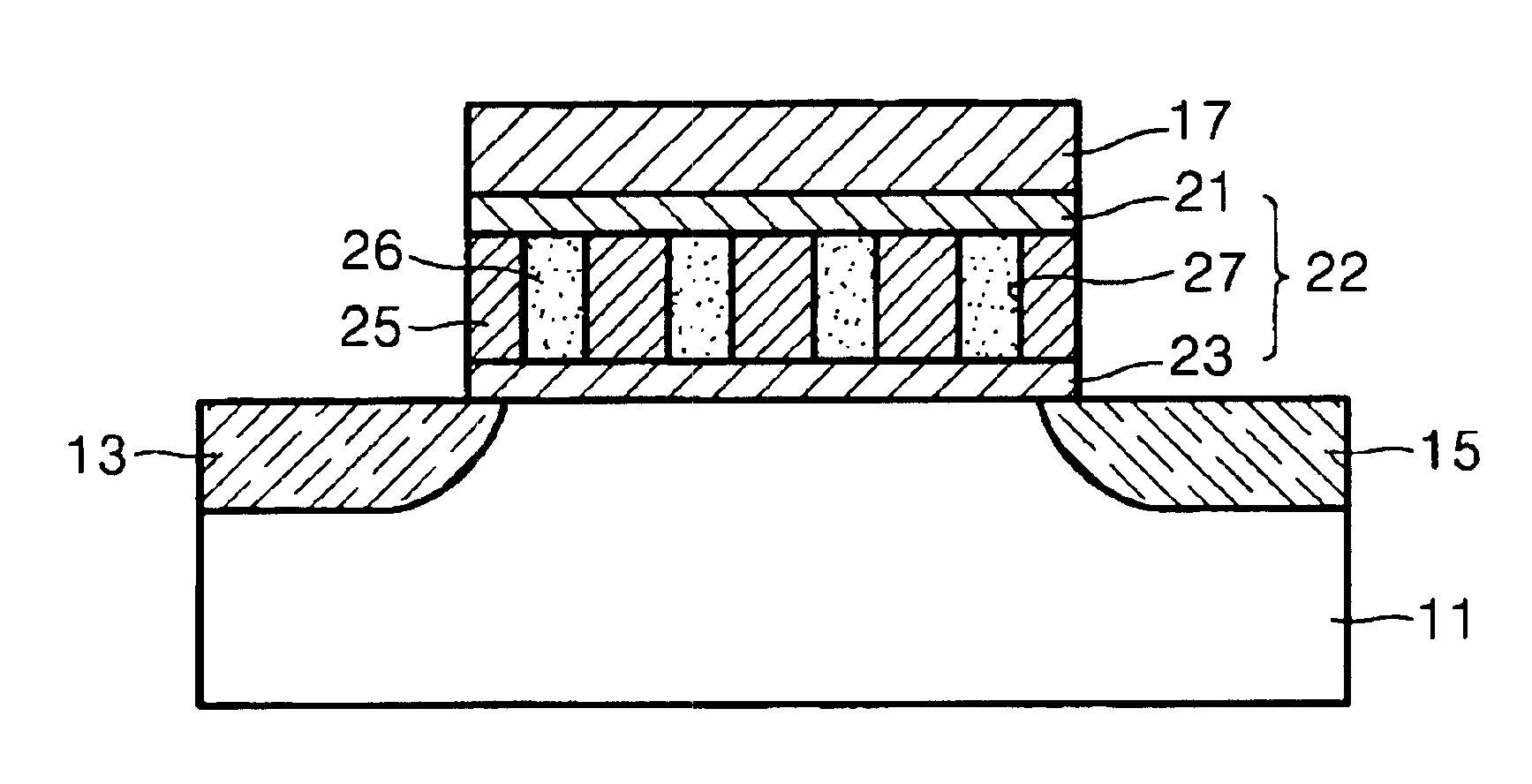

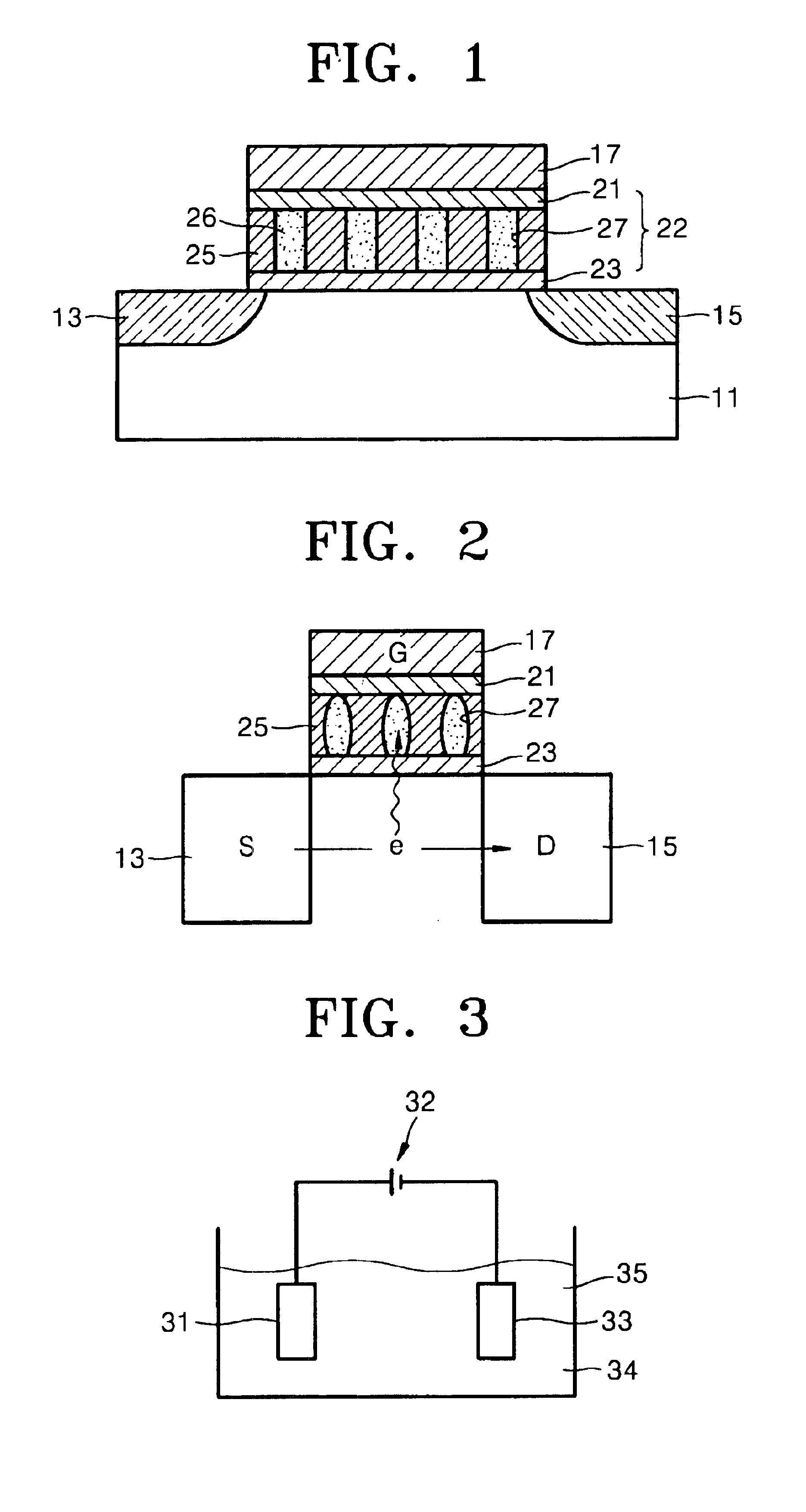

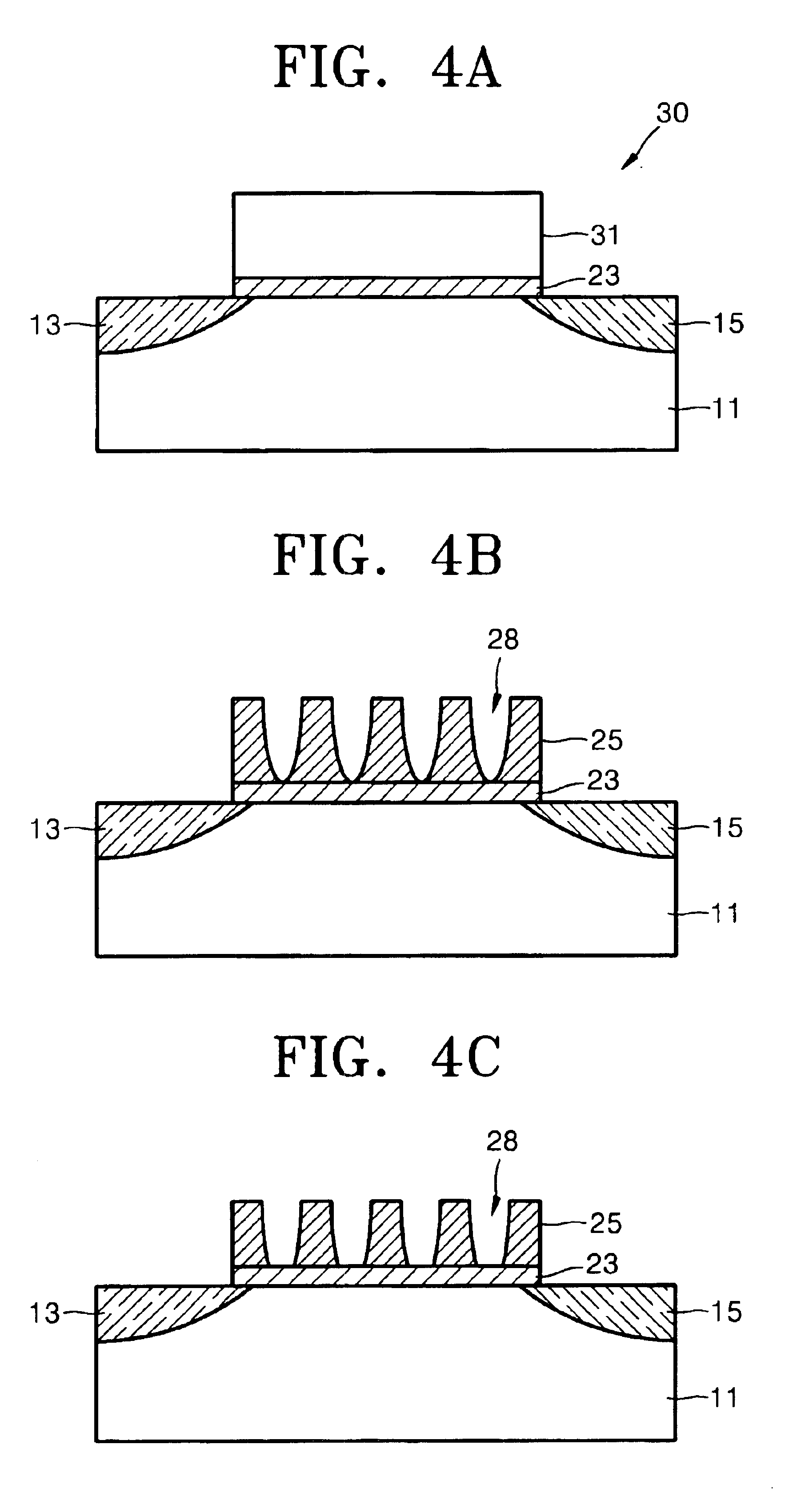

Memory device with quantum dot and method for manufacturing the same

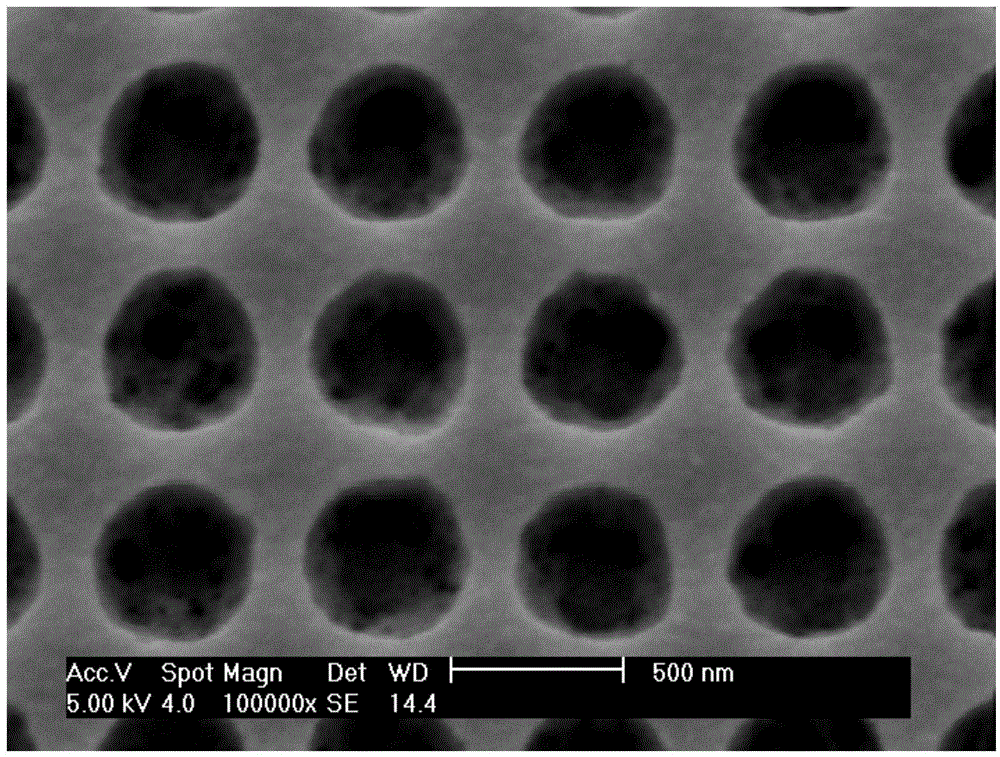

InactiveUS6949793B2Improve abilitiesHighly efficient and highly integratedTransistorNanoinformaticsDevice formQuantum dot

Provided is a memory device formed using quantum devices and a method for manufacturing the same. A memory device comprises a substrate; a source region and a drain region formed in the substrate so as to be separated from each other by a predetermined interval; a memory cell which is formed on the surface of the substrate to connect the source region and the drain region, and has a plurality of nano-sized quantum dots filled with material for storing electrons; and a control gate which is formed on the memory cell and controls the number of electrons stored in the memory cell. It is possible to embody a highly efficient and highly integrated memory device by providing a memory device having nano-sized quantum dots and a method for manufacturing the same.

Owner:SAMSUNG ELECTRONICS CO LTD

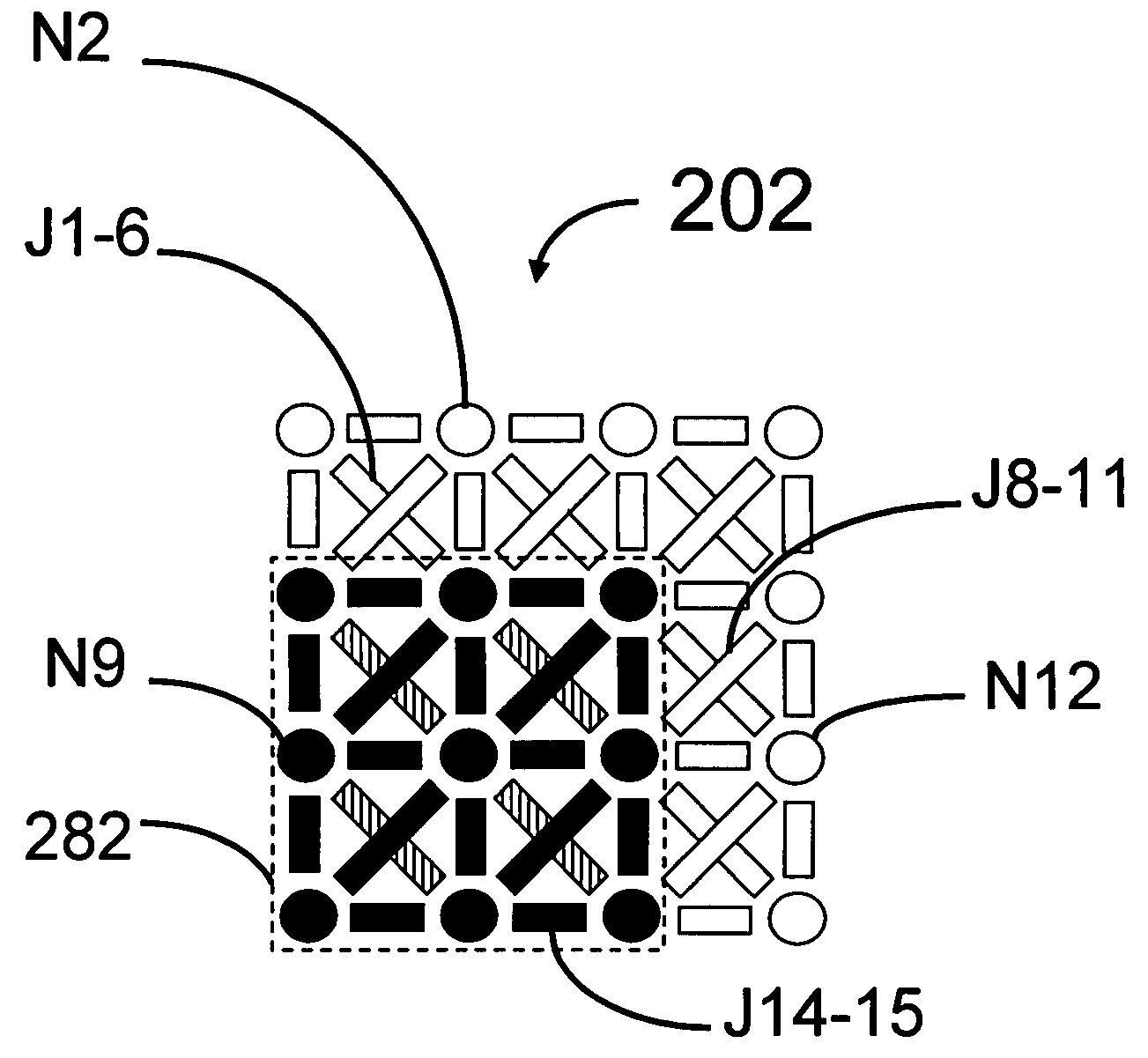

Analog processor comprising quantum devices

Analog processors for solving various computational problems are provided. Such analog processors comprise a plurality of quantum devices, for instance qubits, arranged in a lattice, together with a plurality of coupling devices. The analog processors further comprise bias control systems each configured to apply a local effective bias on a corresponding quantum device. A set of coupling devices in the plurality of coupling devices is configured to couple nearest-neighbor quantum devices in the lattice. Another set of coupling devices is configured to couple next-nearest neighbor quantum devices. The analog processors further comprise a plurality of coupling control systems each configured to tune the coupling value of a corresponding coupling device in the plurality of coupling devices to a coupling. Such quantum processors further comprise a set of readout devices each configured to measure the information from a corresponding quantum device in the plurality of quantum devices.

Owner:D WAVE SYSTEMS INC

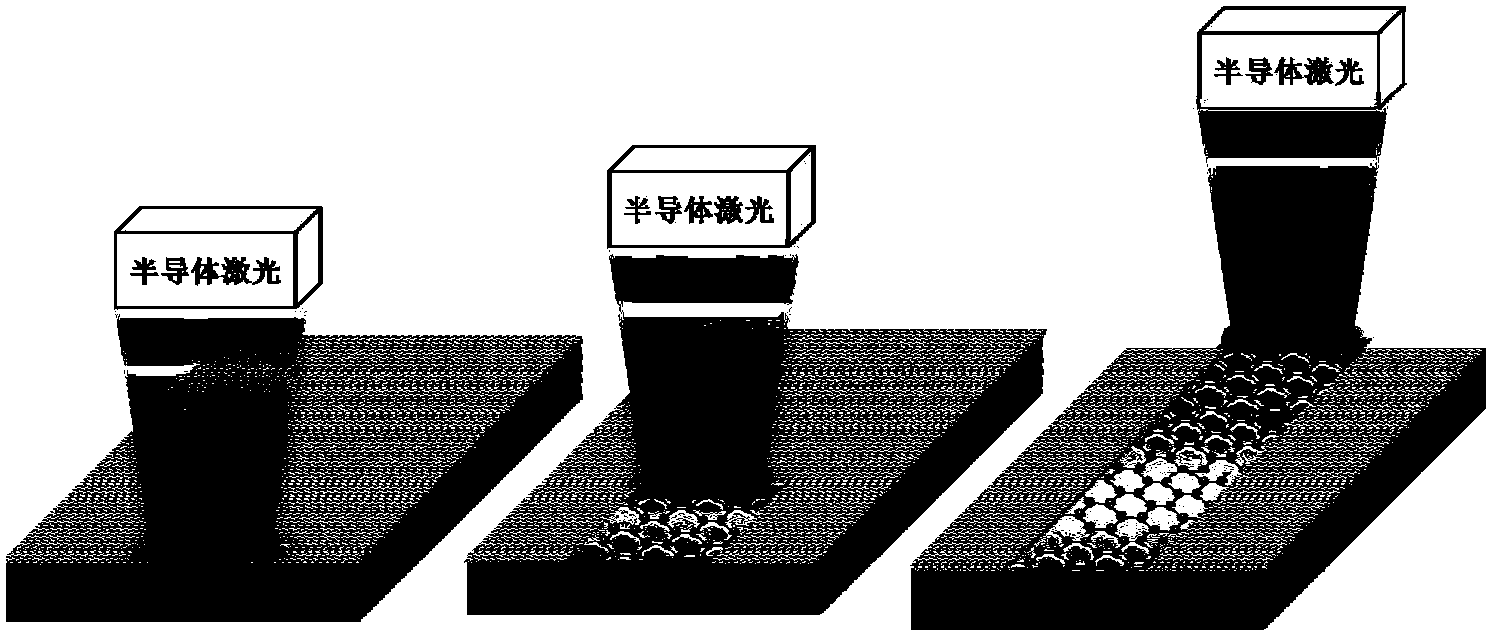

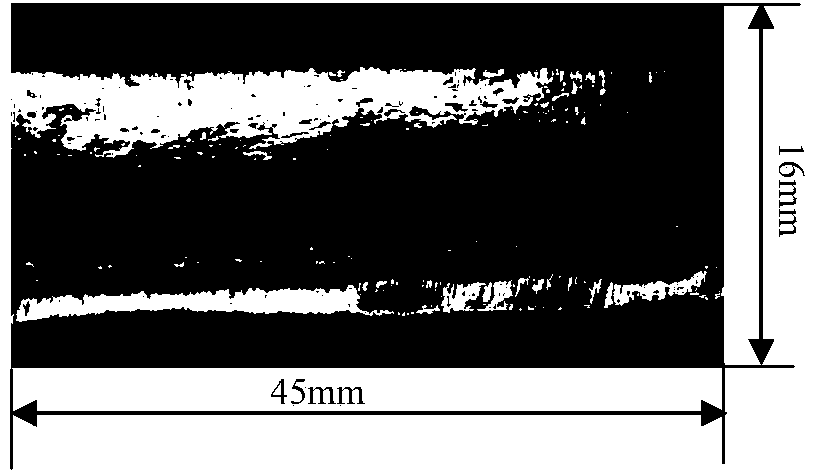

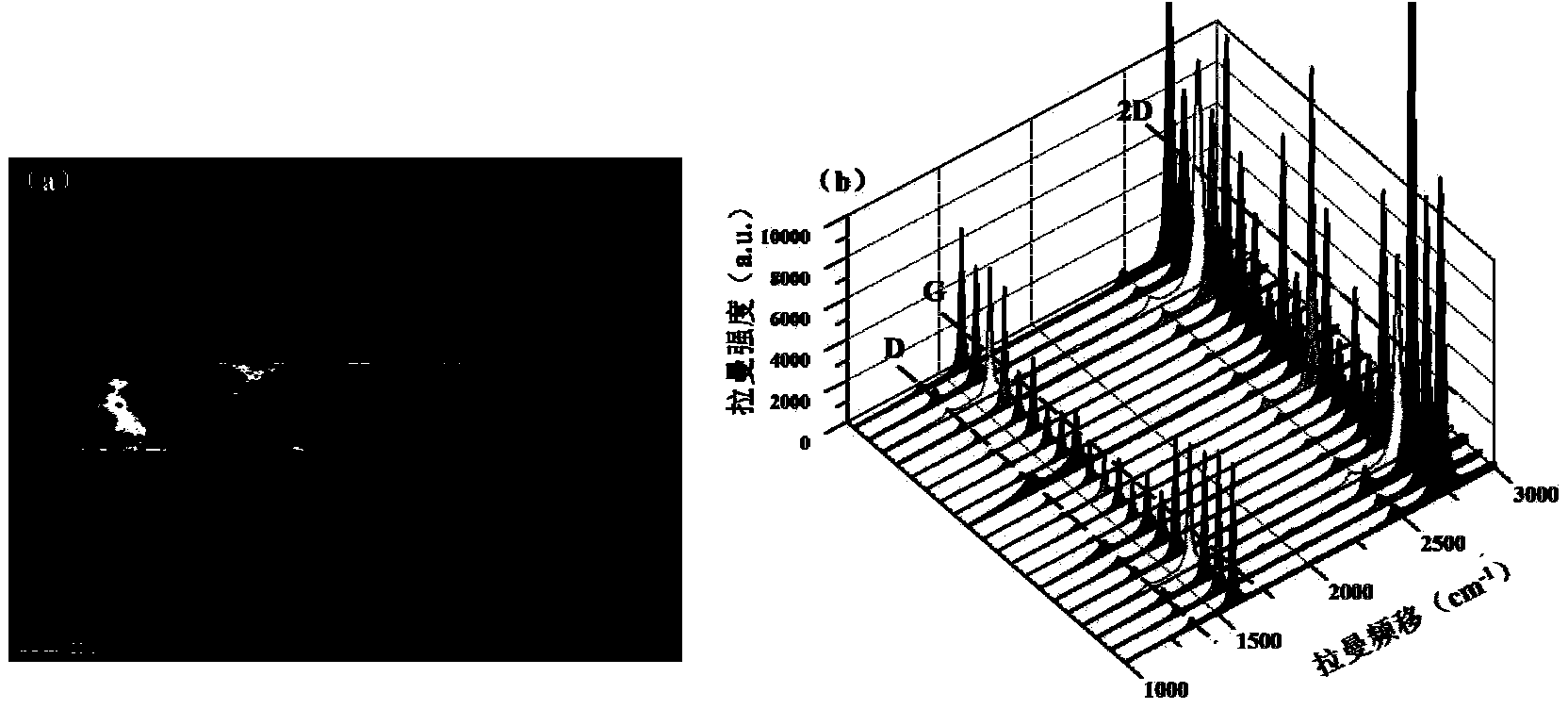

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

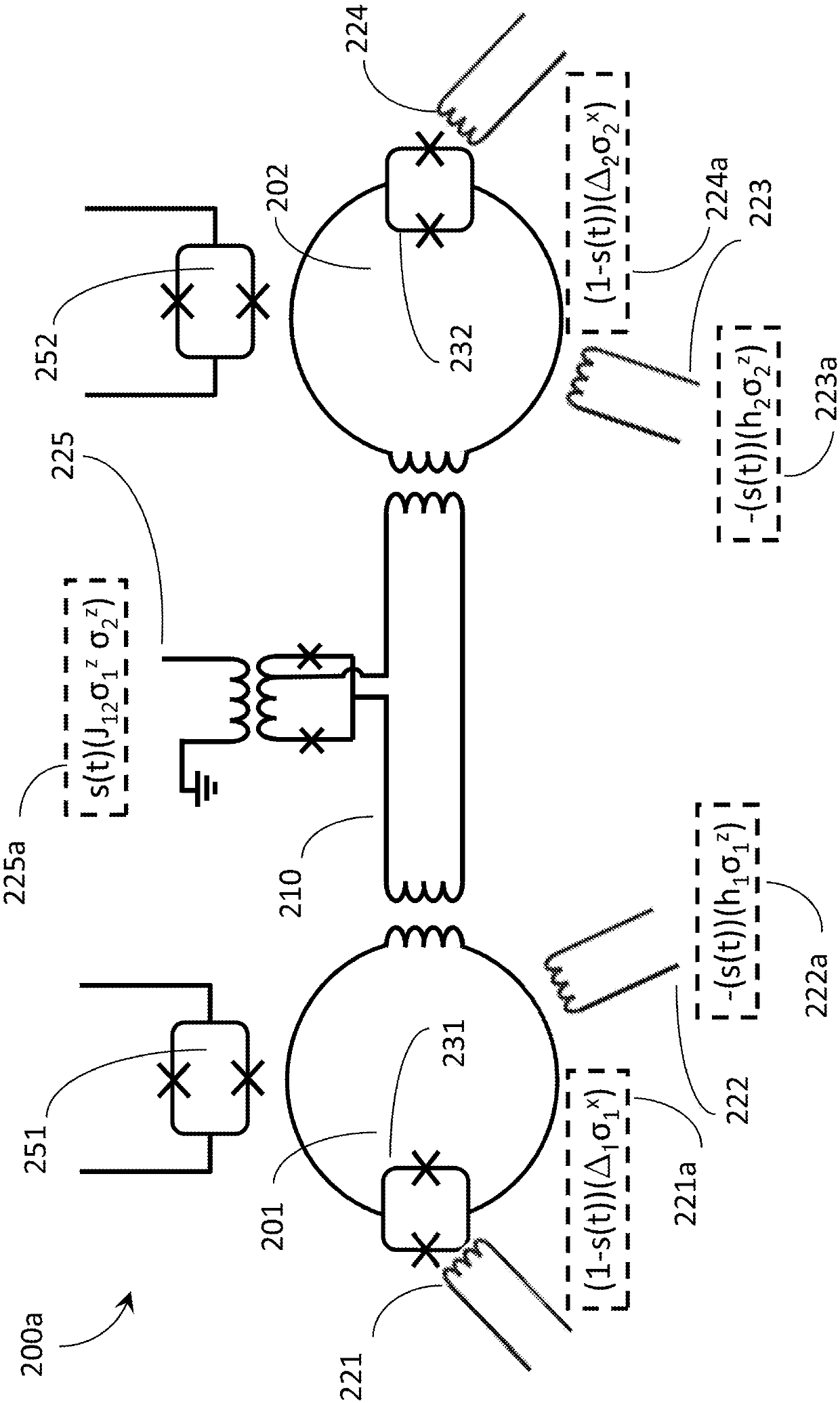

Analog processor comprising quantum devices

ActiveUS20090167342A1Quantum computersLogic circuits characterised by logic functionComputational problemAnalog processor

Analog processors for solving various computational problems are provided. Such analog processors comprise a plurality of quantum devices, arranged in a lattice, together with a plurality of coupling devices. The analog processors further comprise bias control systems each configured to apply a local effective bias on a corresponding quantum device. A set of coupling devices in the plurality of coupling devices is configured to couple nearest-neighbor quantum devices in the lattice. Another set of coupling devices is configured to couple next-nearest neighbor quantum devices. The analog processors further comprise a plurality of coupling control systems each configured to tune the coupling value of a corresponding coupling device in the plurality of coupling devices to a coupling. Such quantum processors further comprise a set of readout devices each configured to measure the information from a corresponding quantum device in the plurality of quantum devices.

Owner:D WAVE SYSTEMS INC

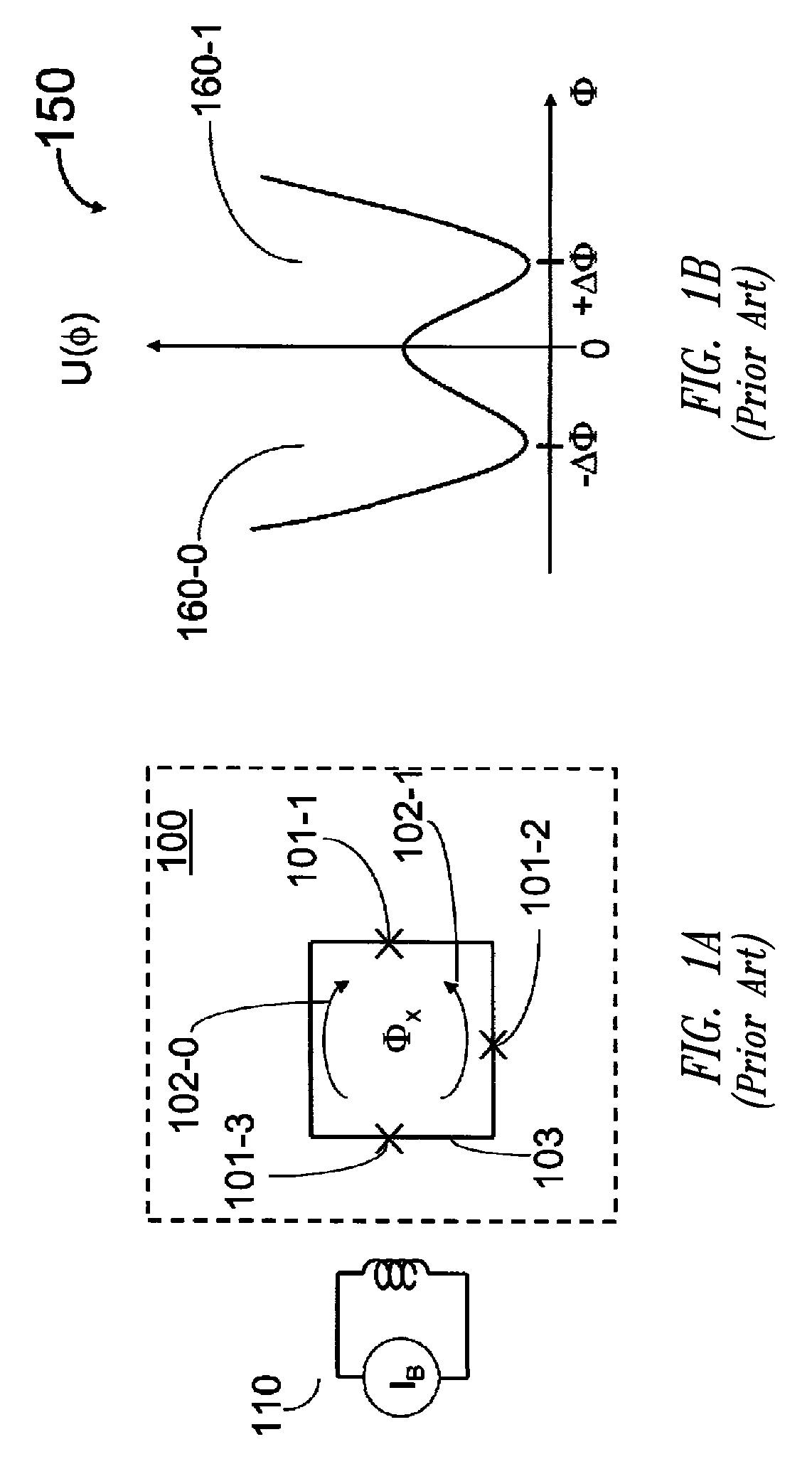

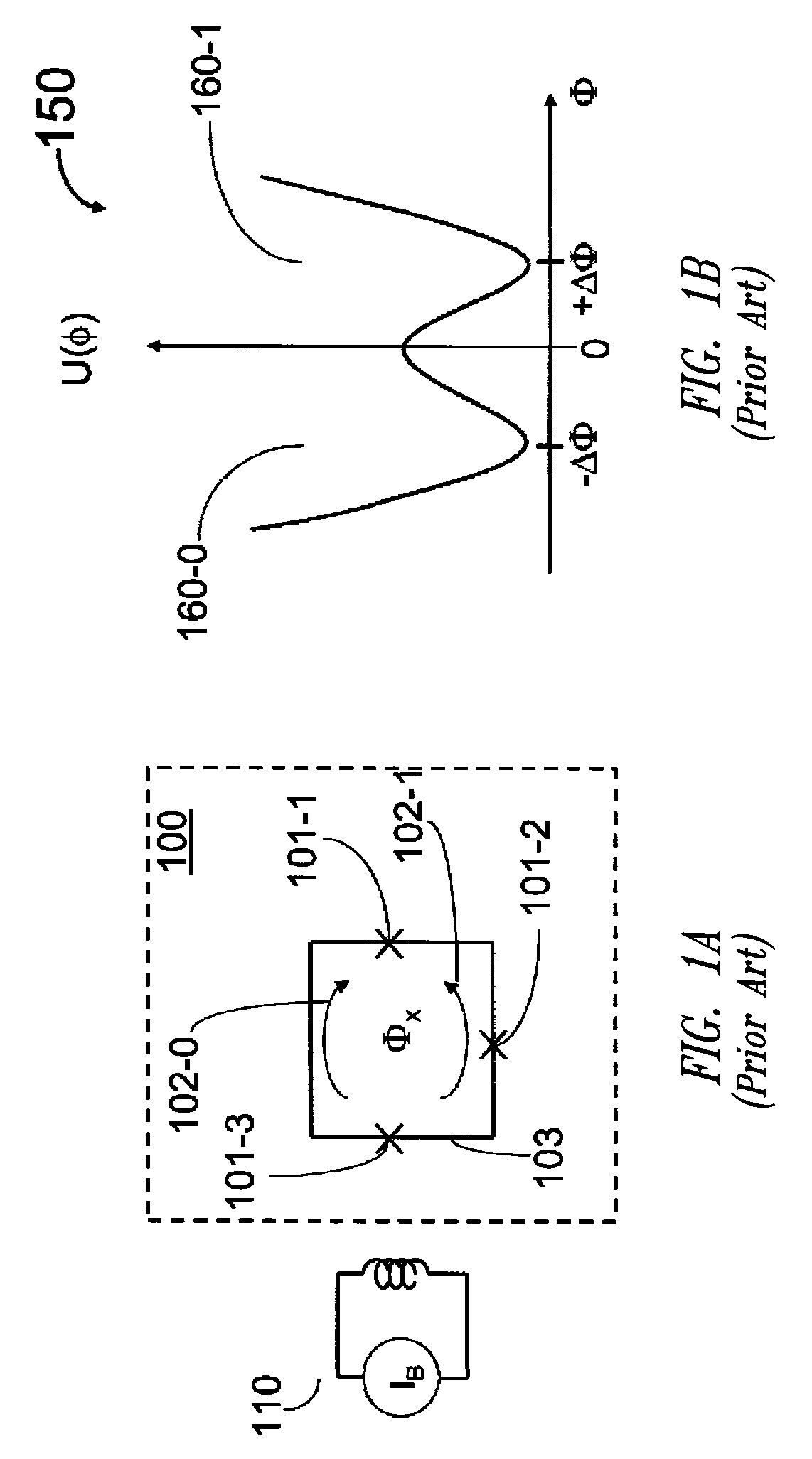

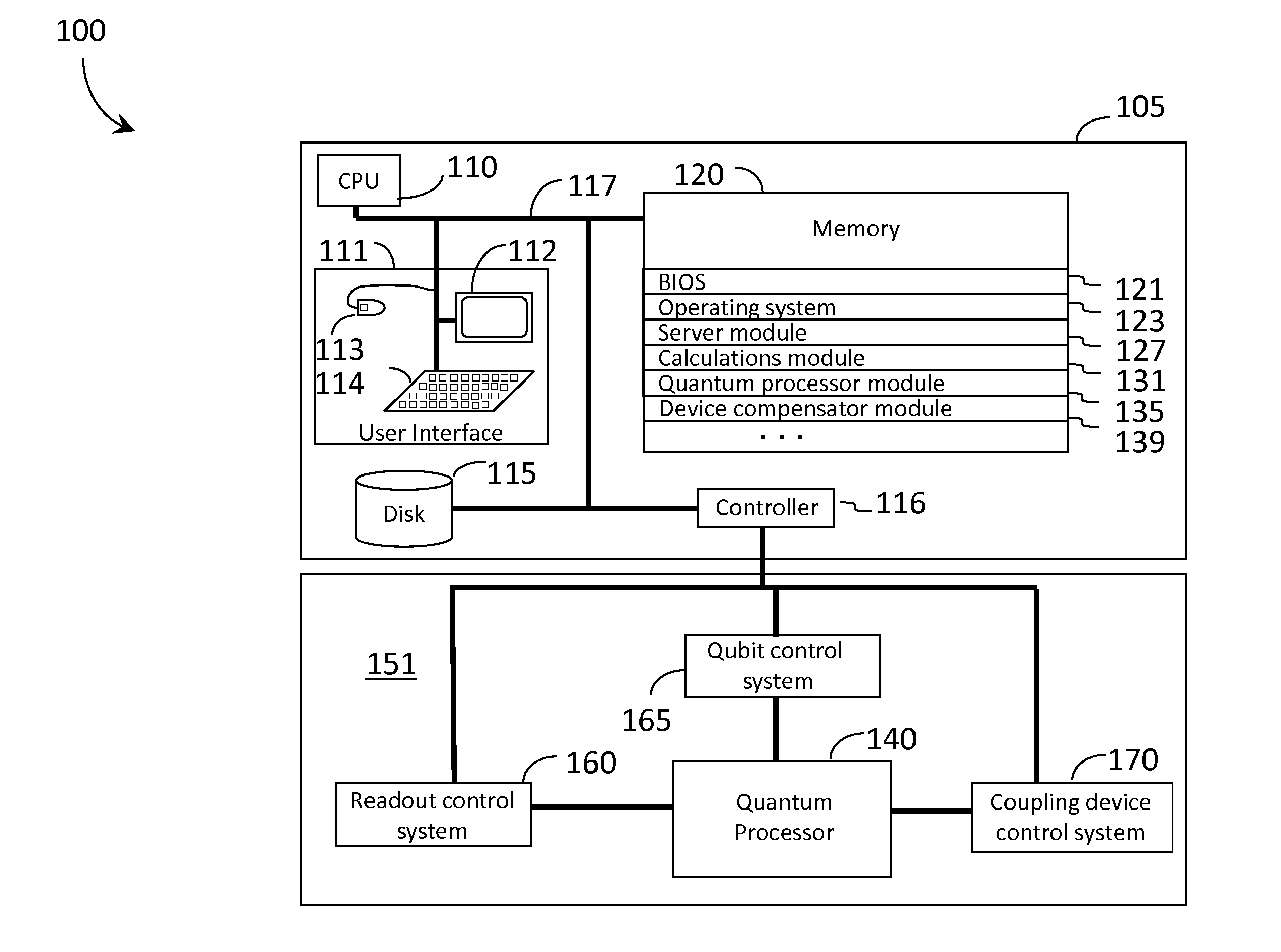

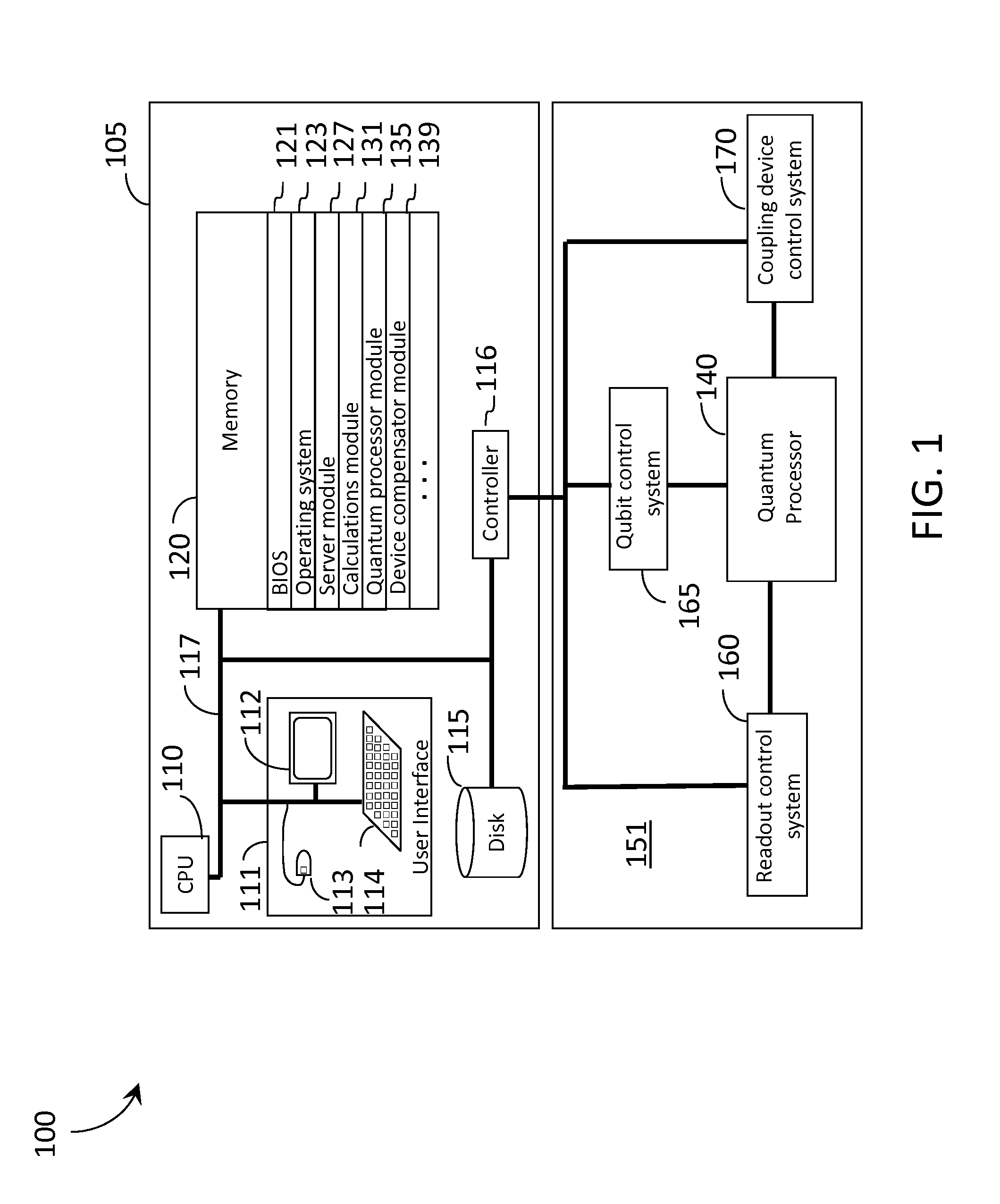

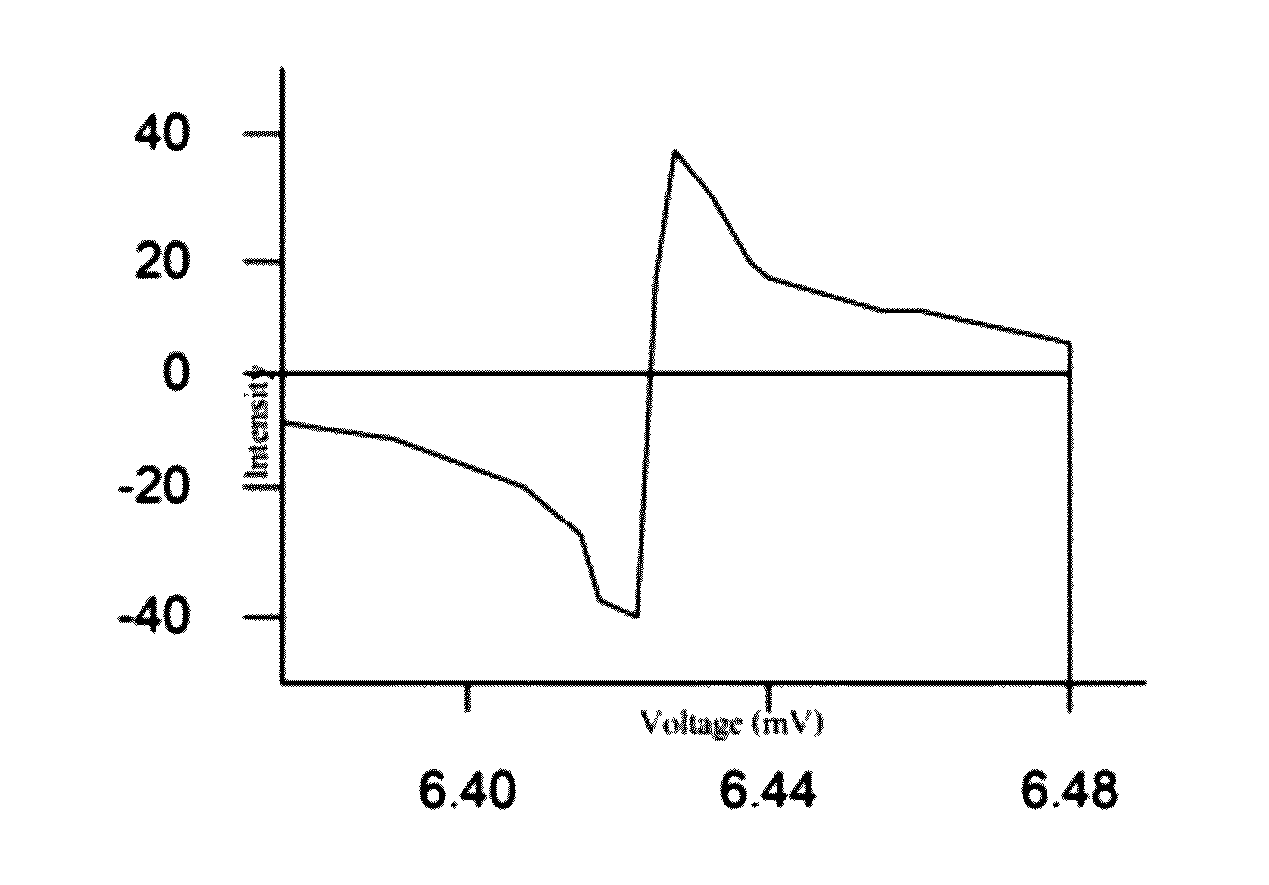

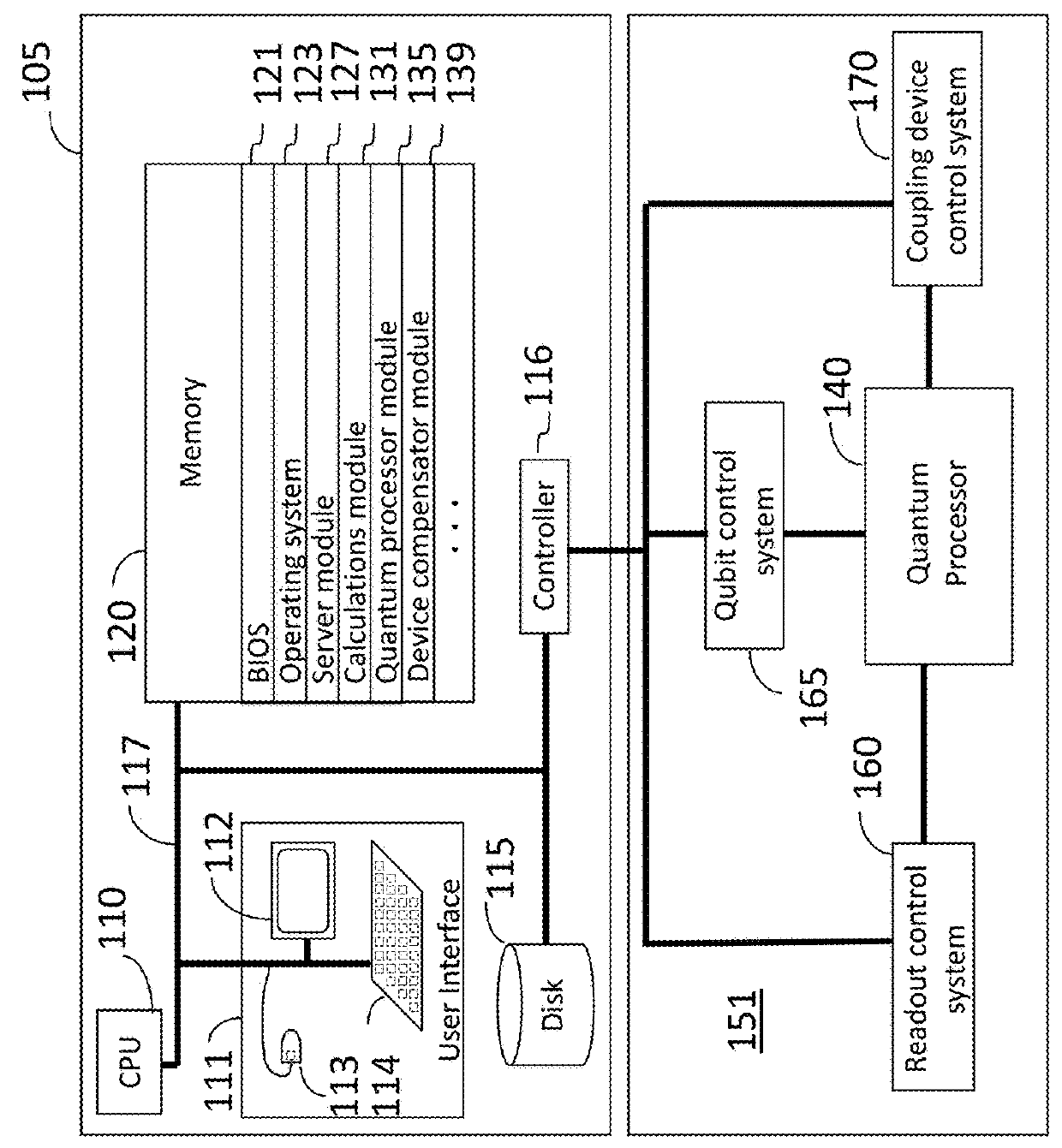

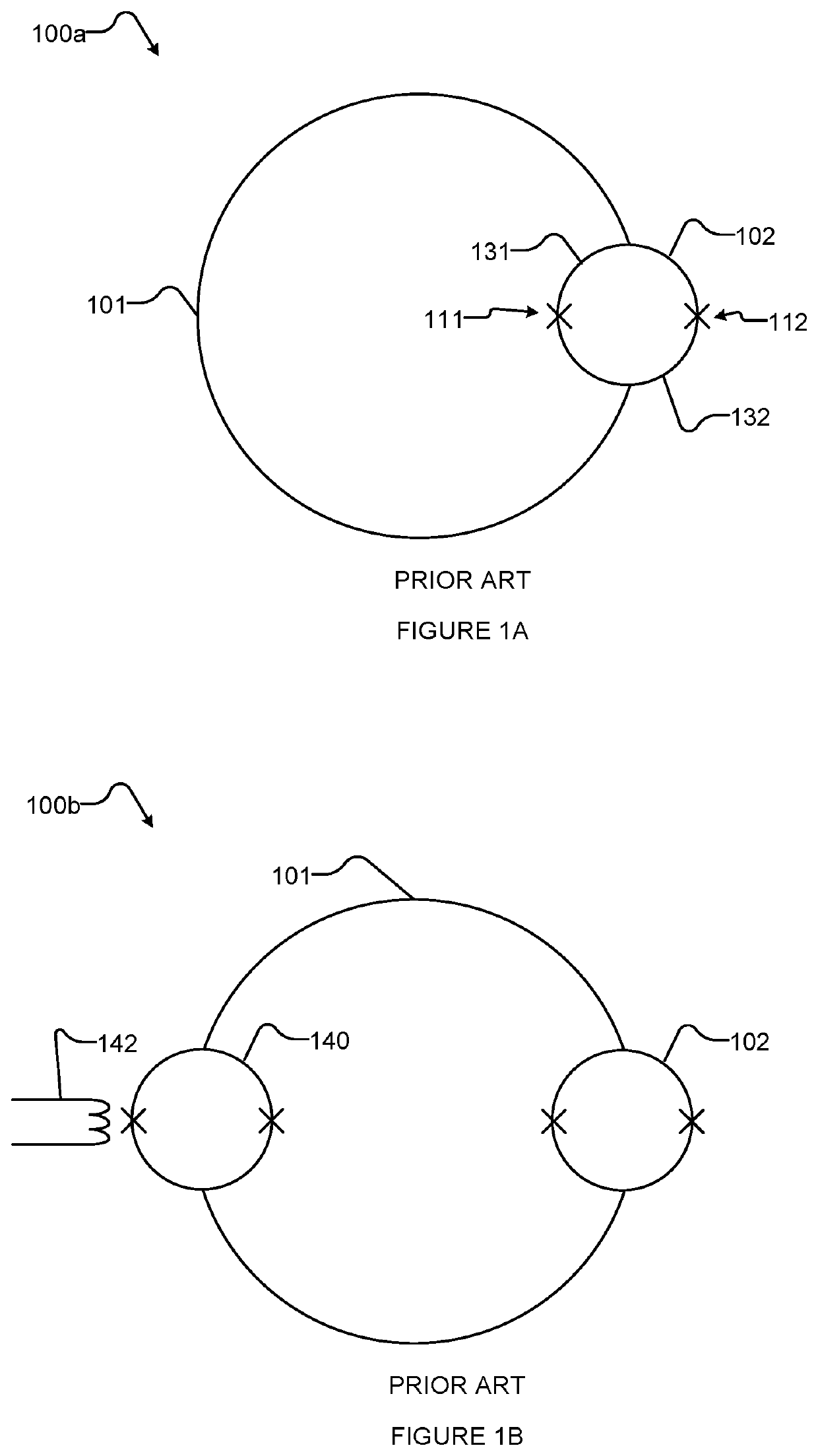

Systems and methods for removing unwanted interactions in quantum devices

ActiveUS20150262073A1Quantum computersGeneral purpose stored program computerMagnetic susceptibilityQuantum devices

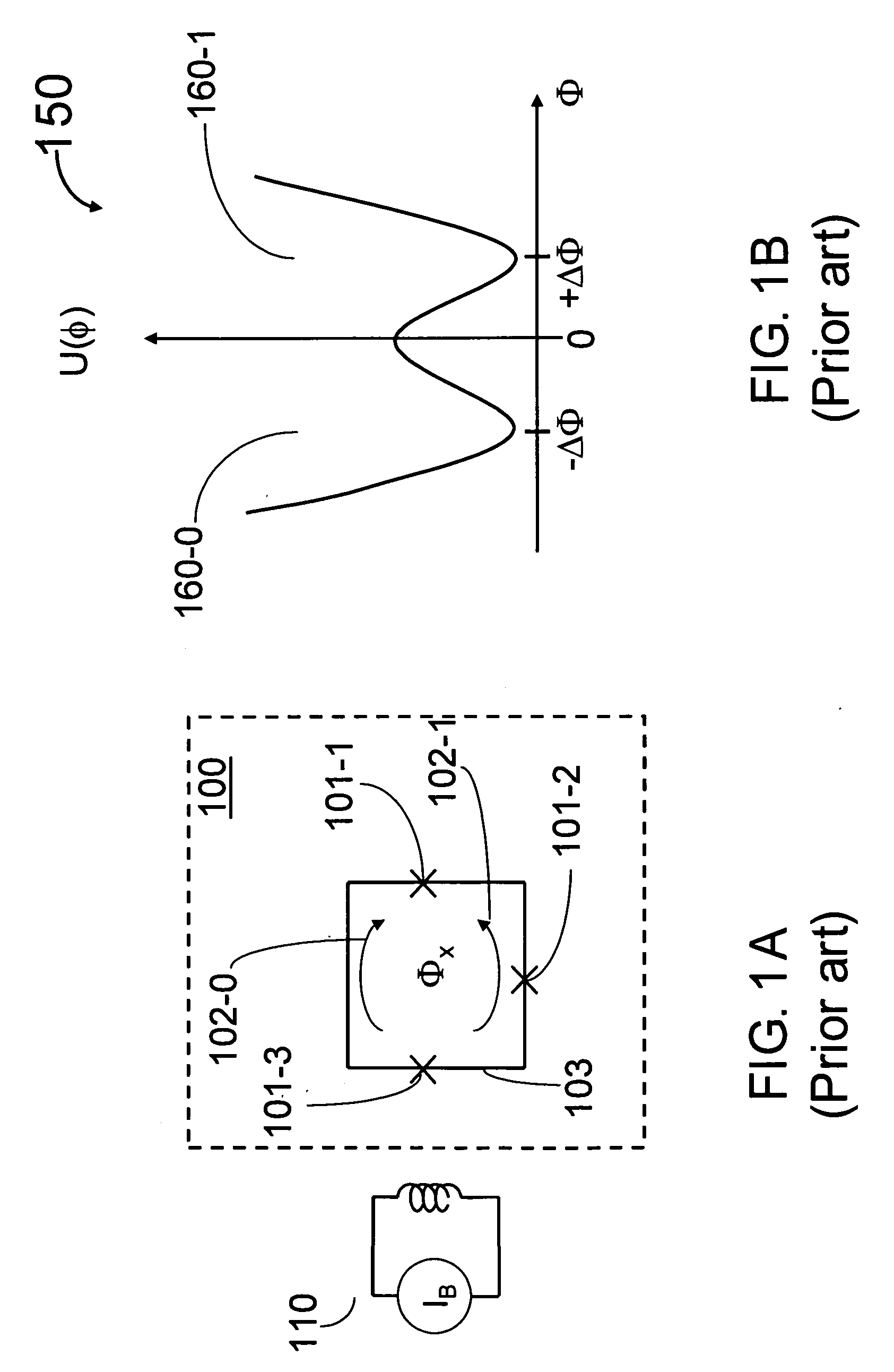

Systems, devices, articles, methods, and techniques for advancing quantum computing by removing unwanted interactions in one or more quantum processor. One approach includes creating an updated plurality of programmable parameters based at least in part on a received value for the characteristic magnetic susceptibility of the qubit in the at least one quantum processor, and returning the updated plurality of programmable parameters. Examples programmable parameters include local biases, and coupling values characterizing the problem Hamilton. Also, for example, a quantum processor may be summarized as including a first loop of superconducting material, a first compound Josephson junction interrupting the first loop of superconducting material, a first coupler inductively coupled to the first loop of superconducting material, a second coupler inductively coupled to the first loop of superconducting material, and a second loop of superconducting material proximally placed to the first loop of superconducting material inductively coupled to the first coupler and the second coupler.

Owner:D WAVE SYSTEMS INC

Analog processor comprising quantum devices

ActiveCN101088102AComputing modelsDissimilar materials junction devicesAnalog processorComputational problem

Analog processors for solving various computational problems are provided. Such analog processors comprise a plurality of quantum devices, arranged in a lattice, together with a plurality of coupling devices. The analog processors further comprise bias control systems each configured to apply a local effective bias on a corresponding quantum device. A set of coupling devices in the plurality of coupling devices is configured to couple nearest-neighbor quantum devices in the lattice. Another set of coupling devices is configured to couple next-nearest neighbor quantum devices. The analog processors further comprise a plurality of coupling control systems each configured to tune the coupling value of a corresponding coupling device in the plurality of coupling devices to a coupling. Such quantum processors further comprise a set of readout devices each configured to measure the information from a corresponding quantum device in the plurality of quantum devices.

Owner:D WAVE SYSTEMS INC

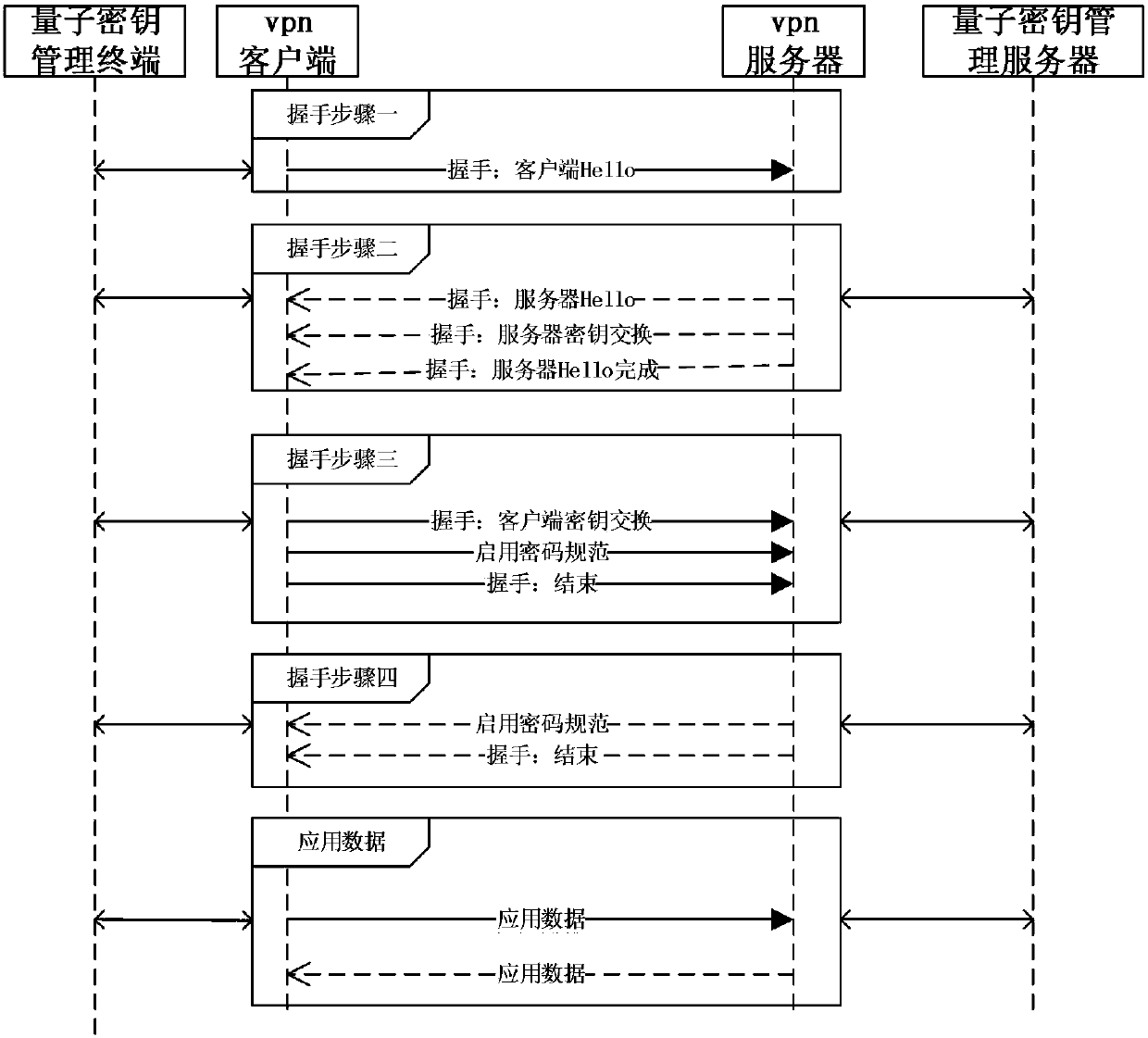

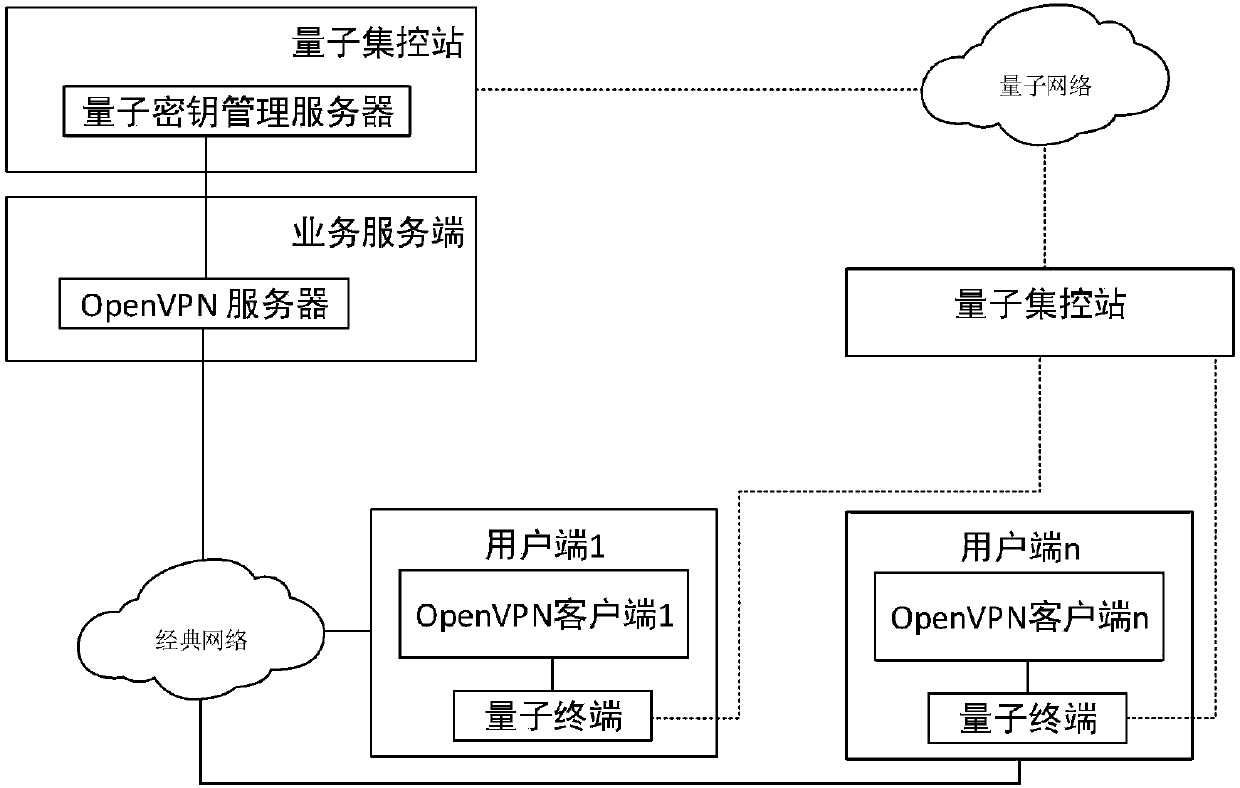

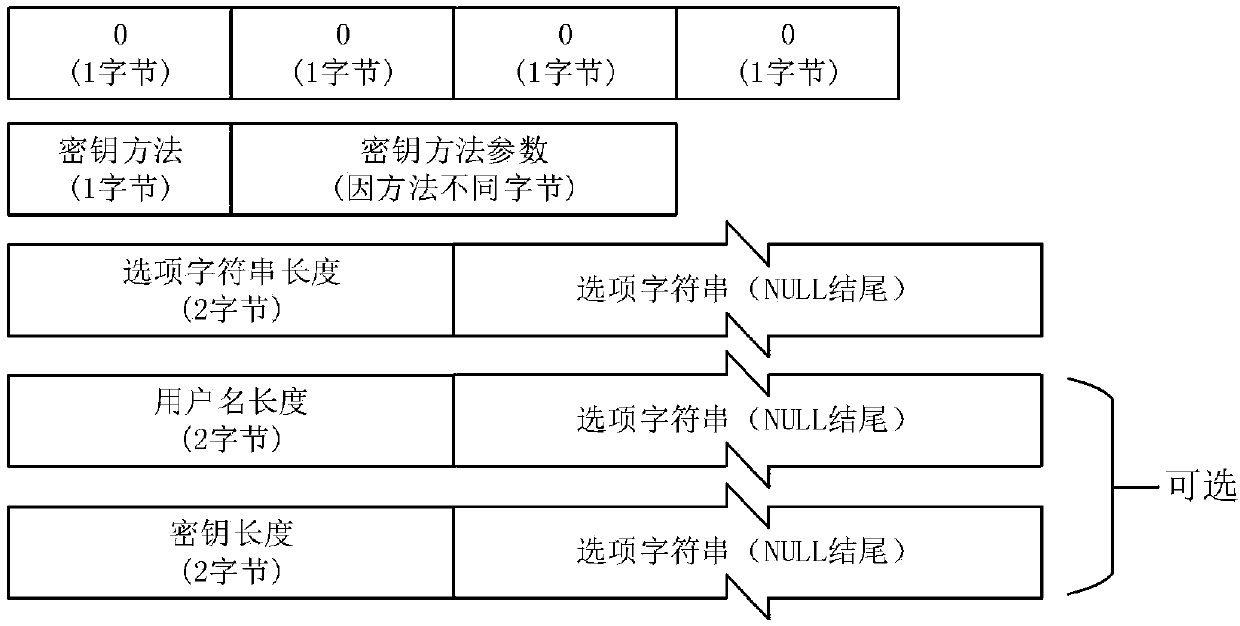

OpenVPN security communication method and communication system based on quantum keys

ActiveCN107612899AQuantum unconditional securityEnsure safetyKey distribution for secure communicationUser identity/authority verificationSecure communicationCommunications system

The invention discloses an OpenVPN security communication method and communication system based on quantum keys. The communication method is implemented between a server and at least one client whichserve as two parties of OpenVPN network communication. The communication system comprises the server and the at least one client which serve as the two parties of OpenVPN network communication, the two communication particles are each matched with a quantum device, and the corresponding quantum keys are stored in the quantum devices of the two communication parties to be used for achieving identity authentication and data encryption transmission between the two communication parties. According to the communication method and communication system, the advantages of the quantum keys and a quantum distribution network are fully utilized, the quantum keys are taken as the authentication keys and the session keys in OpenVPN system expanding, the session key updating frequency is high, and the security communication performance of an existing OpenVPN is greatly improved.

Owner:ZHEJIANG SHENZHOU QUANTUM NETWORK TECH CO LTD

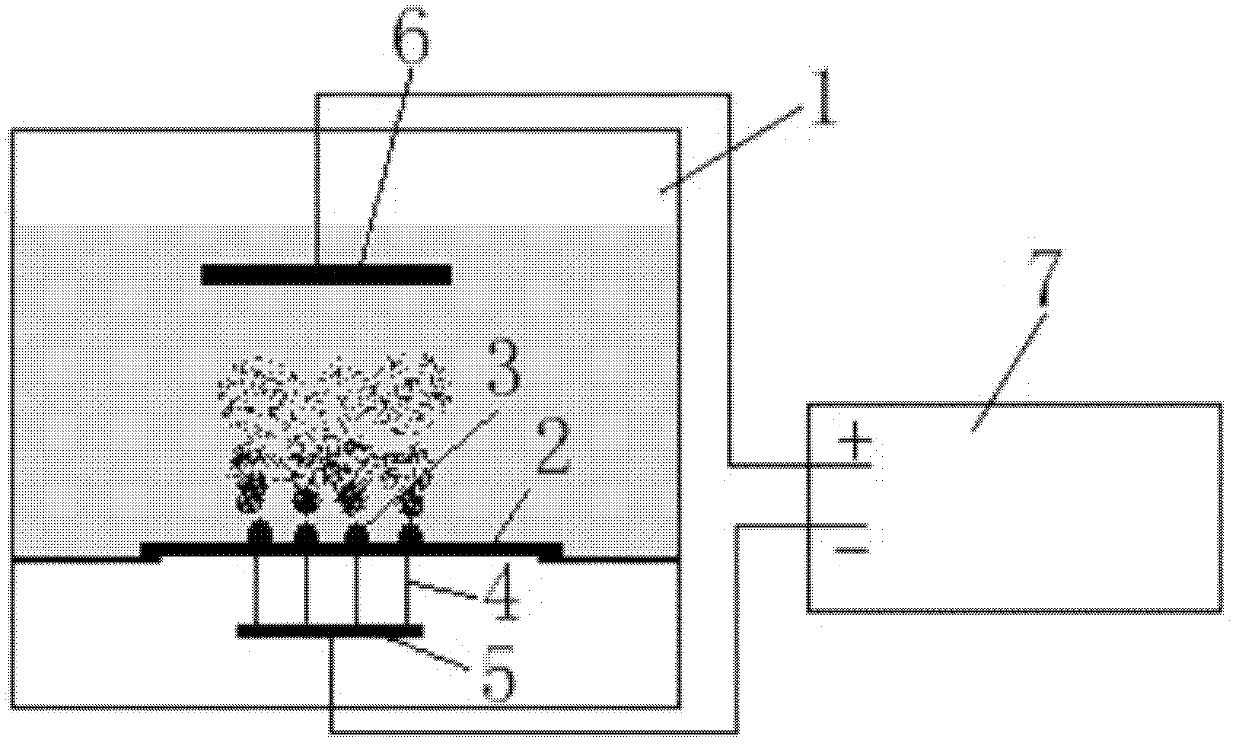

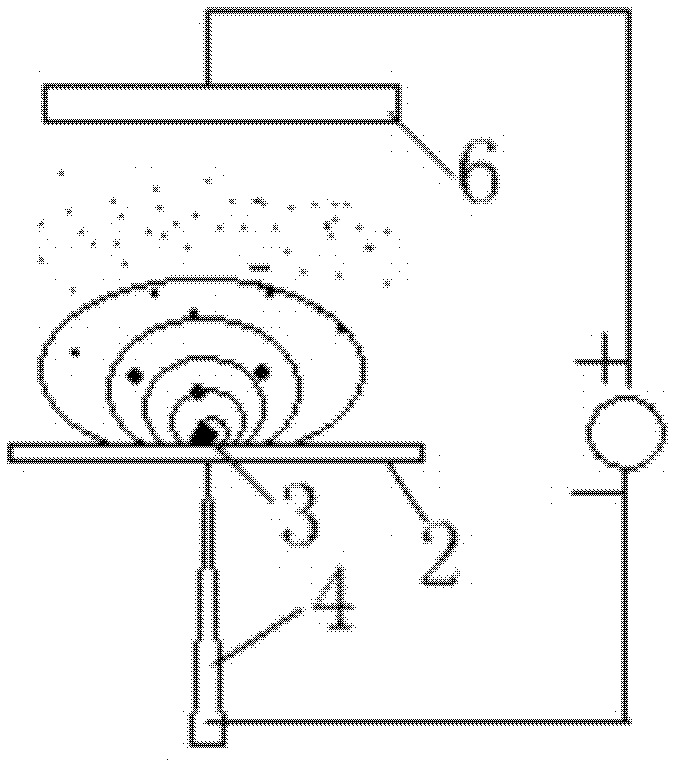

Method for controllable generation of quantum dots or quantum wires

InactiveCN102431964AAchieve controlled growthEasy to operateDecorative surface effectsNanotechnologyQuantum dotQuantum devices

The invention discloses a method for controllable generation of quantum dots or quantum wires, which belongs to the field of preparation of low-dimensional quantum materials. The method comprises the following steps: arranging a substrate for growing the quantum dots or the quantum wires in solution with dissolved the quantum dots or the quantum wires and arranging an electrode which is in contact with the lower surface of the substrate on the bottom surface of the substrate; applying voltage between the solution and the electrode for forming a steady electric field so as to enable quantum dot or quantum wire material in the solution to settle in the position where the electrode is located on the substrate under the action of electric field force of the steady electric field and grow the quantum dots or the quantum wires on the substrate in the position corresponding to the electrode; and adjusting the position of the electrode to control the growth positions of the quantum dots or the quantum wires on the substrate. The method is simple to operate and good in controllable effect; and according to the method disclosed by the invention, controllable growth in any quantum dot or quantum wire position can be realized, and a foundation is laid for processing and manufacturing of quantum devices.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

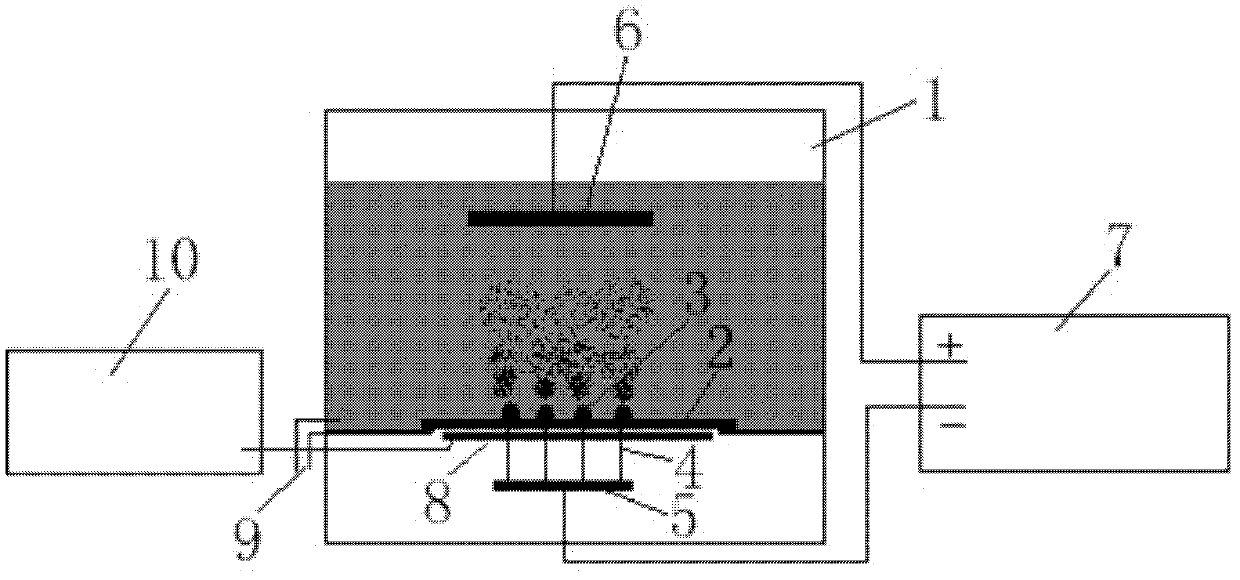

Stunnel communication method and Stunnel communication system based on quantum key

InactiveCN108429615AIncrease update frequencyImprove secure communication performanceKey distribution for secure communicationEncryption apparatus with shift registers/memoriesCommunications systemConfidentiality

The invention discloses a Stunnel communication method and a Stunnel communication system based on a quantum key. The Stunnel communication system includes a Stunnel server and a Stunnel client respectively as Stunnel network communication parties, the communication parties are respectively matched with a quantum device, and corresponding quantum keys are stored in the quantum devices of the communication parties for identity authentication and data encryption transmission between the communication parties. The Stunnel communication system provided by the invention uses a quantum random numbergenerator to generate a true random number to participate in generating a quantum key, and then replaces the key in SSL in the Stunnel with a quantum key, thereby greatly enhancing the encryption effect and improving the confidentiality. The server uses a quantum key management server to transmit the quantum key to the Stunnel server, and the client uses a quantum key card to transmit the quantumkey to the Stunnel client. The design of the quantum key card allows mobile clients to enjoy the security brought by encryption of the quantum key.

Owner:RUBAN QUANTUM TECH CO LTD

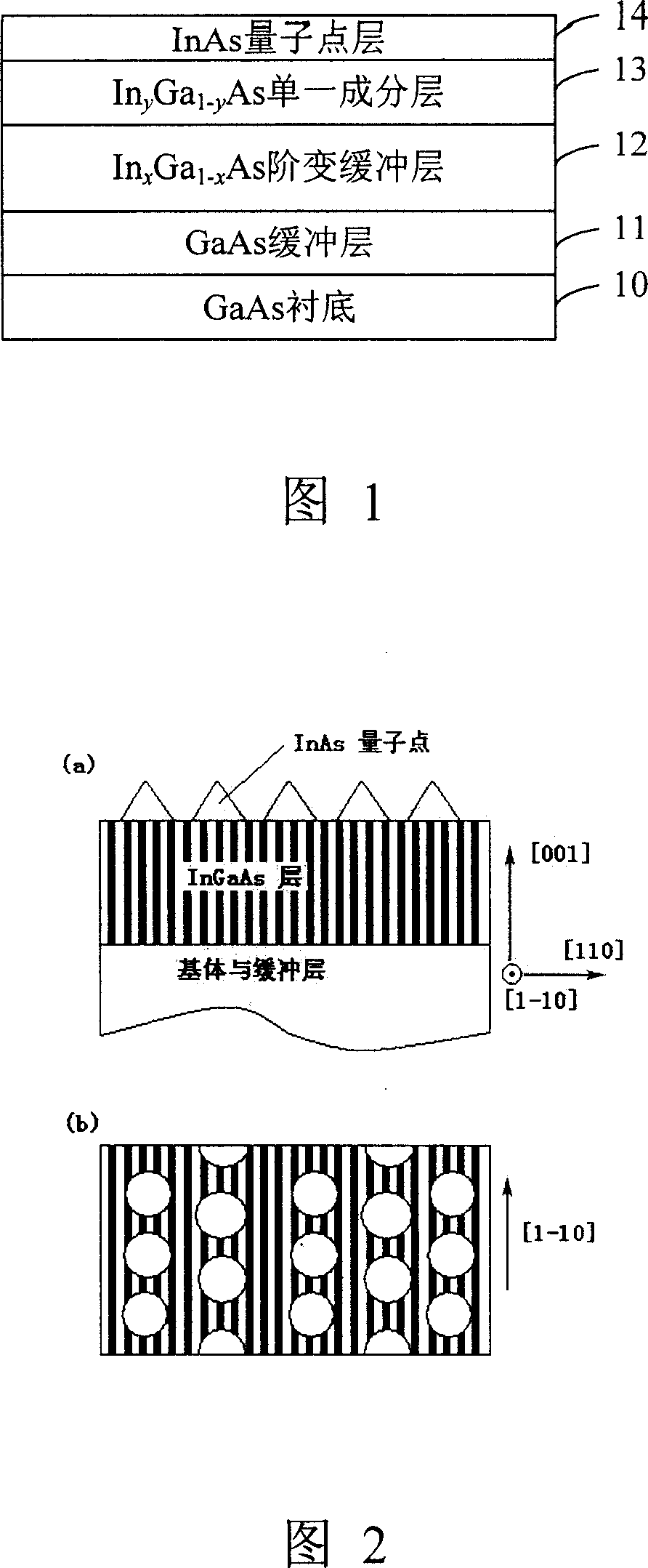

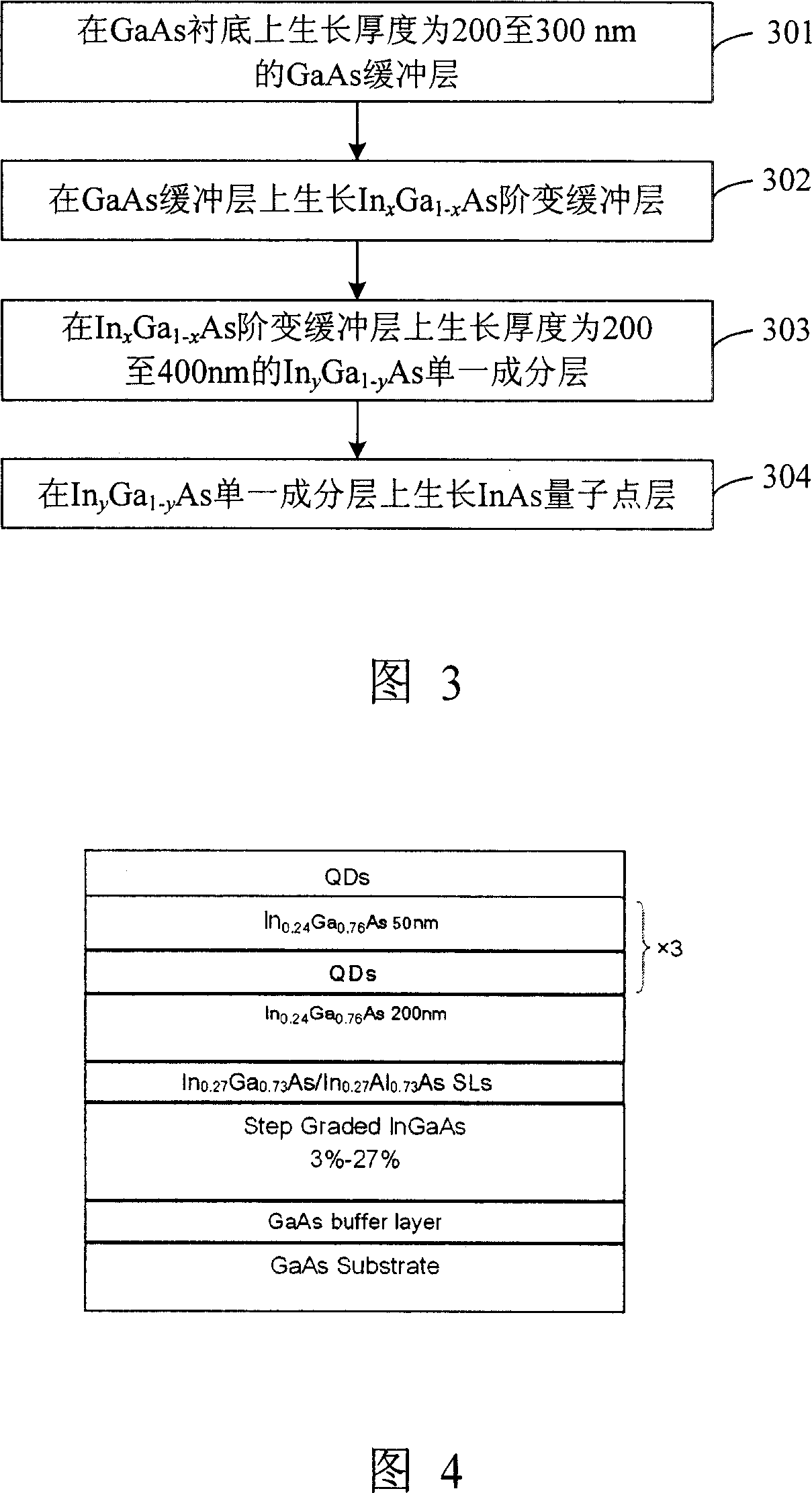

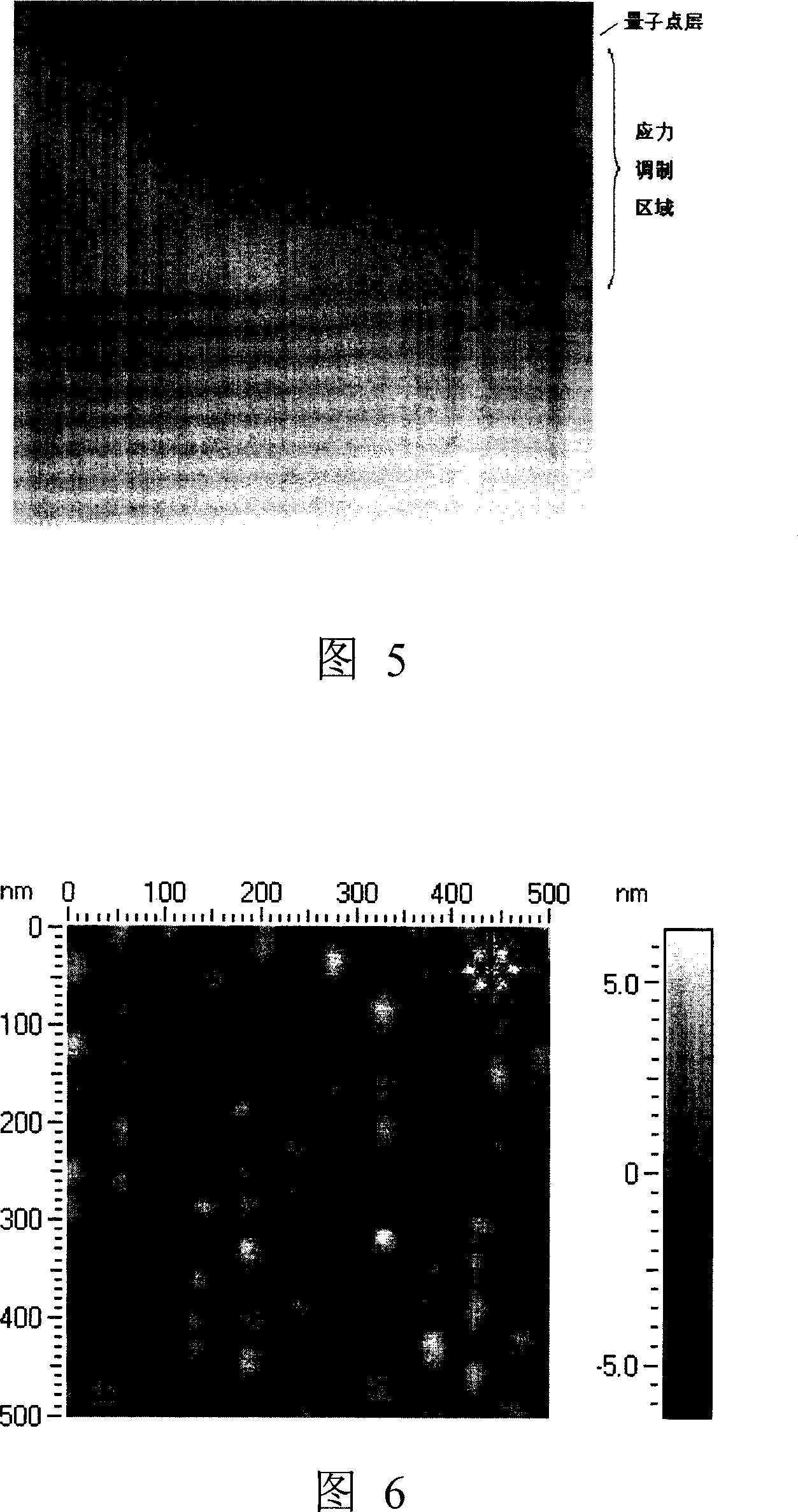

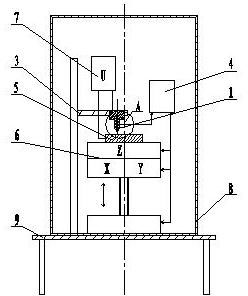

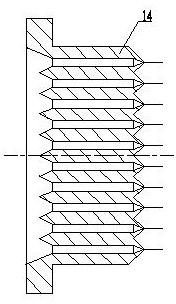

Quantum dot material structure and its growth method

InactiveCN101145590ARestrictiveSimple processLaser detailsFinal product manufactureQuantum devicesGallium arsenide

The invention discloses a quantum point material structure. The structure comprises a gallium arsenide GaAs substrate (10) for supporting the whole quantum point material structure, an epitaxial layer structure growing on the GaAs substrate (10) and comprising buffer layers (11,12,13) and an InAs quantum point layer (14), wherein the buffer layer comprises a GaAs buffer layer (11), an InxGa(1-x)As order variable buffer layer (12) and an InyGa(1-y)As single component layer (13) which grows in order on the substrate; and the InAs quantum point layer (14) grows on the InyGa(1-y)As single component layer (13). The invention further discloses a growth method of the quantum point material structure. With the inventive method, the large-area quantum points with ordered distribution are prepared by using the simple preparation process, the process is simple without special treatment of the substrate before growth and is completely compatible with the molecular beam epitaxy process. Additionally, the method is suitable for the bulk production of self-organization ordered-arrangement quantum point array material, which is significant for the quantum point material to be applied to the future quantum devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

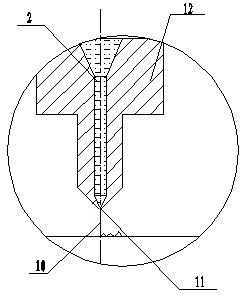

Device and method for manufacturing micro-nano structure

InactiveCN102205944AAchieve restorationAchieve depositionNanostructure manufactureElectricityMicro nano

The invention discloses a device and method for manufacturing a micro-nano structure, belonging to the field of micro-nano manufacture. The device mainly comprises a ballpoint pen, a plating solution, a ballpoint pen rack, an atomic force micro detection system, a cathode platform, a micro motion workbench and a trace electricity power supply, wherein the ballpoint pen containing the plating solution is fixed on the ballpoint pen rack, the ballpoint pen rack is integrally connected with the atomic force micro detection system and is used for roughly positioning and accurately positioning the atomic force micro detection system, the cathode platform and the micro motion workbench are fixedly connected and are spaced by using an insulation material, a ballpoint pen refill is connected with the anode of the trace electricity power supply, and the cathode platform is connected with the cathode of the trace electricity power supply. In the invention, by the application of the trace electricity power supply and a carbon nanotube, atomic assembly, atomic group sedimentation and three-dimensional micro-nano molding become easier, simpler and more precise. The device and the corresponding molding method have certain significances to precise manufacture of micro-nano devices, micro-nano electromechanical progress and development of quantum devices.

Owner:BEIJING UNIV OF CHEM TECH

Liquid metal quantum material and preparation method thereof

ActiveCN107573922AComplex physical and chemical behaviorPrevent oxidationMaterial nanotechnologyNanoopticsQuantum technologyLiquid state

The invention relates to a liquid metal quantum material and a preparation method thereof. The liquid metal quantum material comprises internal quantum dot particles or quantum devices and liquid metals coated outside the quantum dot particles or quantum devices; or the liquid metal quantum material comprises internal liquid metal nano liquid drops and liquid metal compound layers coated outside the liquid metal nano liquid drops. The invention also discloses the method for preparing the liquid metal quantum material. The liquid metal quantum material provided by the invention has the unique properties of liquid state, flexibility and deformability; and the preparation difficulty of the material is greatly reduced, so that the electronic interconnection difficulty of traditional quantum materials or devices is greatly lowered, thereby being more beneficial to application of quantum technology.

Owner:BEIJING DREAM INK TECH CO LTD

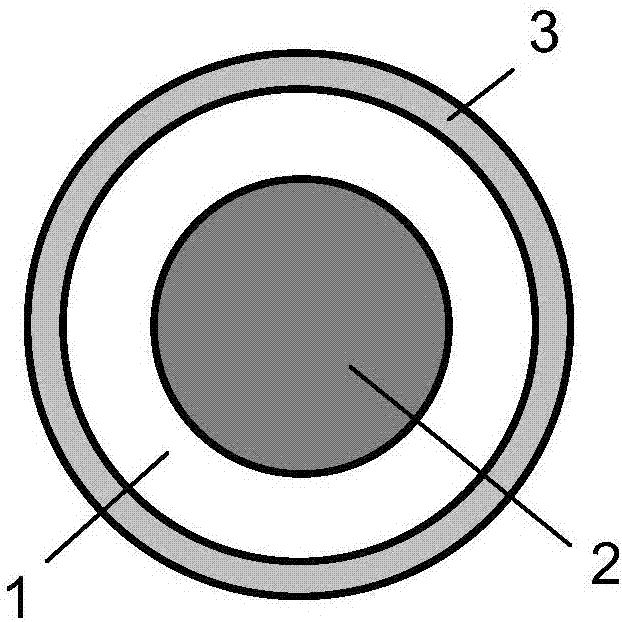

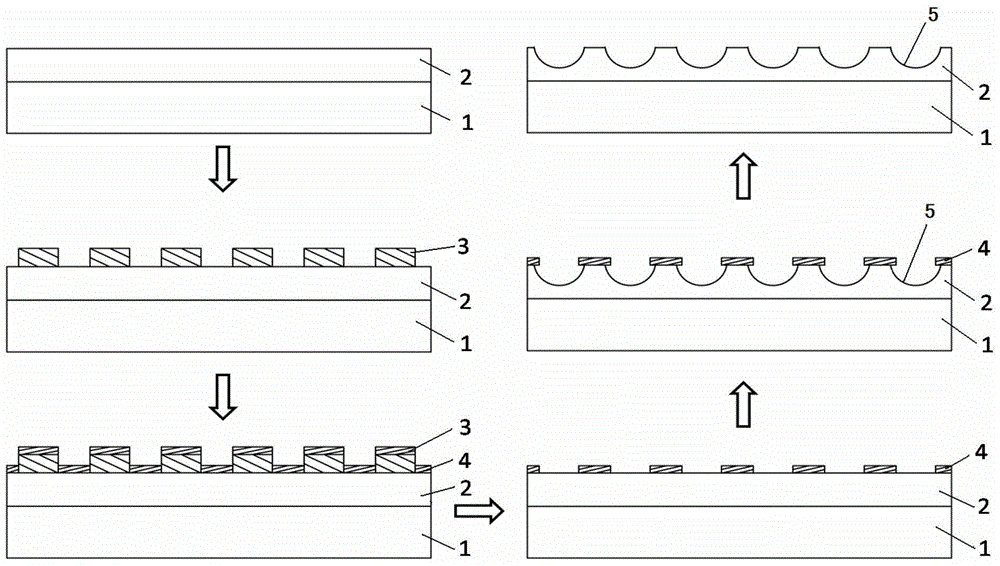

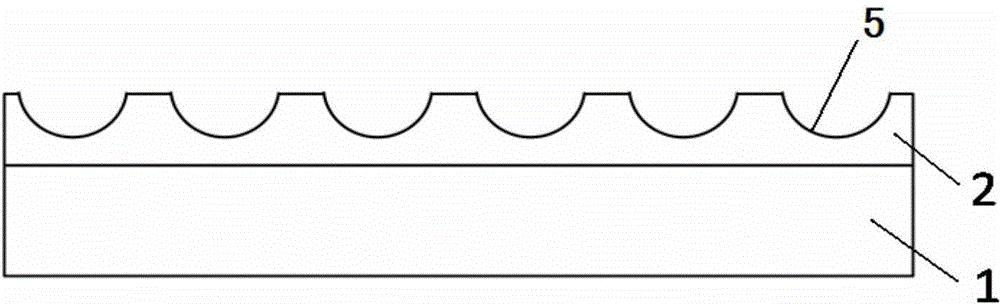

Periodic bowl-shaped structural template and preparation method thereof

InactiveCN104986725AUniform sizeThe size is easy to controlDecorative surface effectsCoupling light guidesNanolithographyNano structuring

The invention discloses a periodic bowl-shaped structural template and a preparation method thereof. The preparation method comprises the following steps: depositing a silicon dioxide mask layer on a substrate, spin-coating photoresist on the silicon dioxide mask layer, preparing a periodic micro / nano photoresist lattice pattern, depositing a thin metal film on the photoresist structure, peeling to obtain a metal hole array pattern, forming a bowl-shaped array structure of the silicon dioxide by adopting a wet etching technology by taking the metal hole array structure as a mask, and finally, removing the metal mask. The periodic bowl-shaped structural template prepared by the preparation method is large in area and uniform and complete in structure, has a very good application prospect in the aspects of preparation of patterned structures, photonic crystals, surface roughening, surface flocking and micro / nano devices and the like, can be widely applied to the aspects of LEDs (Light-Emitting Diodes), solar batteries, photonic crystals, quantum devices and the like, or serves as an etching mask layer of the substrate material, or is used for the manufacturing of other micro / nano structures.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Quantum devices based on crystallized electron pairs and methods for their manufacture and use

InactiveUS7014795B2Strong antimagneticImprove thermal stabilityNanoinformaticsSolid-state devicesNanowireDecomposition

This invention provides new, highly conductive materials comprising crystallized electron pairs within an insulating matrix. Crystallized electron pairs can combine with each other to form quasi-one-dimensional structures, quantum nanowires, that have nanoscale diameters and microscale lengths or longer. Quantum nanowires can also be formed as closed loops. Quantum nanowires comprising crystallized electron pairs exhibit very high electrical conductivity over a range of temperatures from 0 Kelvins up to the decomposition temperature of the materials. The quantum nanowires of this invention can be used in a variety of electronic, opto-electronic, electro-optical, motive, sensing and other ways to provide nanoscale structures for manufacturing small devices having low power requirements, low energy dissipation and very rapid responses.

Owner:QUANTUM POLYMER TECHNOLOGIES CORP

Method and apparatus for detecting explosives using differential inverse hilbert spectroscopy facilitated by a high temperature superconducting quantum system

InactiveUS8242447B1Without raising privacy concernRadiation pyrometryPhotometryJet aeroplaneSpectral response

An apparatus and method designed for generating and detecting reflected Terahertz waves using high-transition temperature (Tc) superconducting quantum devices (Josephson junctions) is described and the spectral response of reflected Terahertz radiation is mathematically analyzed to positively identify explosives strapped on a human or animal subject. This embodiment is well-suited for high traffic physical locations currently under surveillance such as security check points and also venues demanding significantly less obtrusive surveillance such as revolving entry doors, moving walkways, and entry gates of an airplane. The apparatus and method detects explosives through clothing without raising privacy concerns.

Owner:SYSTEM PLANNING CORPORATION

Systems and methods for removing unwanted interactions in quantum devices

ActiveUS20180267933A1Quantum computersDigital computer detailsMagnetic susceptibilityQuantum devices

Systems, devices, articles, methods, and techniques for advancing quantum computing by removing unwanted interactions in one or more quantum processor. One approach includes creating an updated plurality of programmable parameters based at least in part on a received value for the characteristic magnetic susceptibility of the qubit in the at least one quantum processor, and returning the updated plurality of programmable parameters. Examples programmable parameters include local biases, and coupling values characterizing the problem Hamilton. Also, for example, a quantum processor may be summarized as including a first loop of superconducting material, a first compound Josephson junction interrupting the first loop of superconducting material, a first coupler inductively coupled to the first loop of superconducting material, a second coupler inductively coupled to the first loop of superconducting material, and a second loop of superconducting material proximally placed to the first loop of superconducting material inductively coupled to the first coupler and the second coupler.

Owner:D WAVE SYSTEMS INC

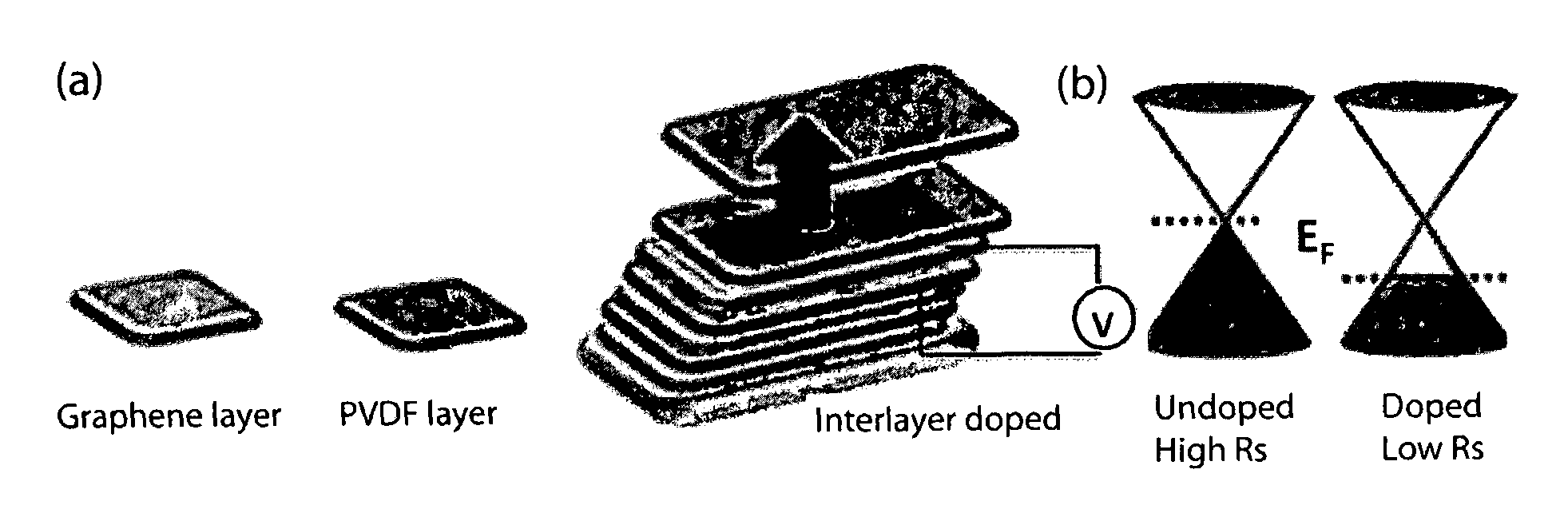

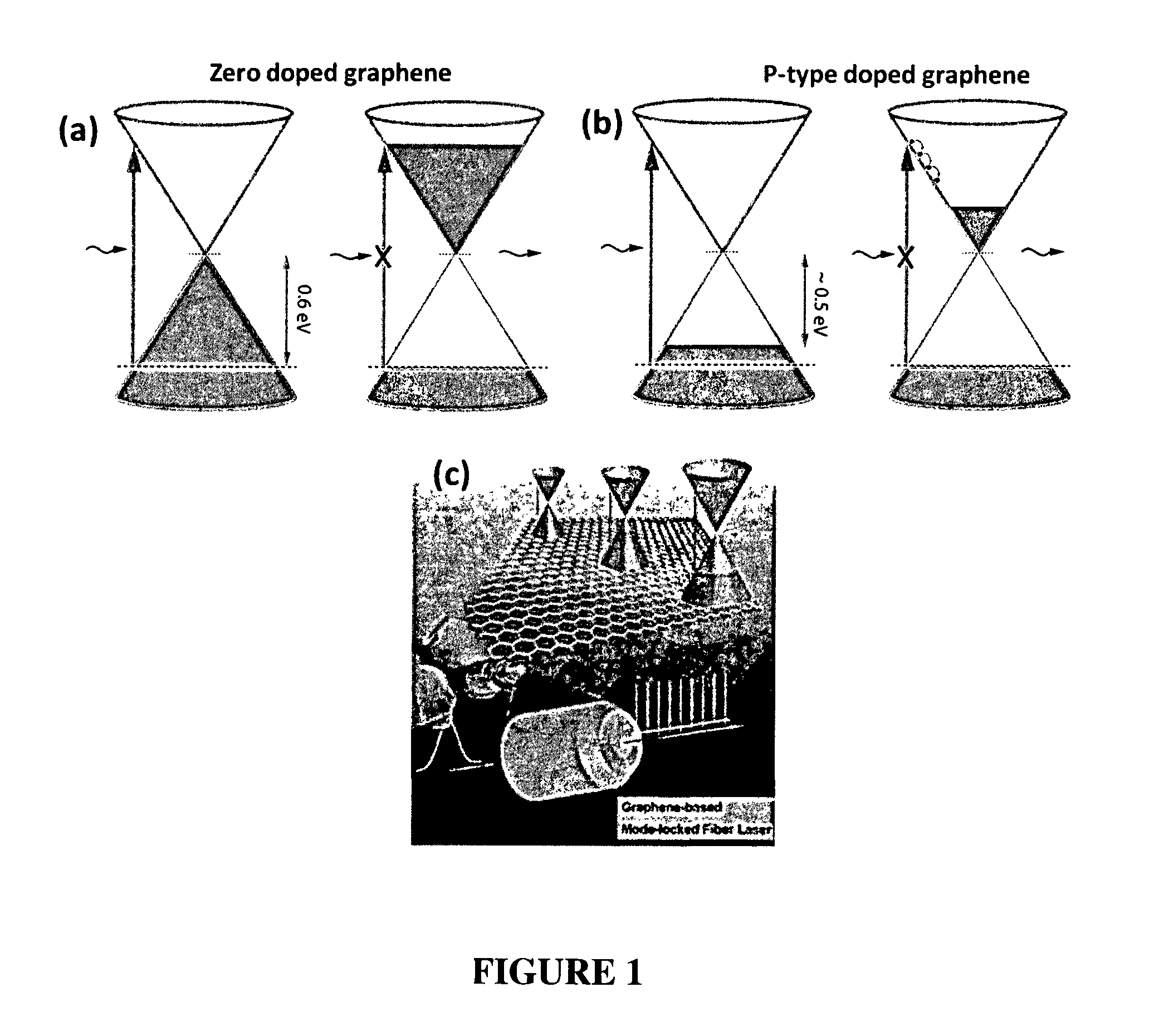

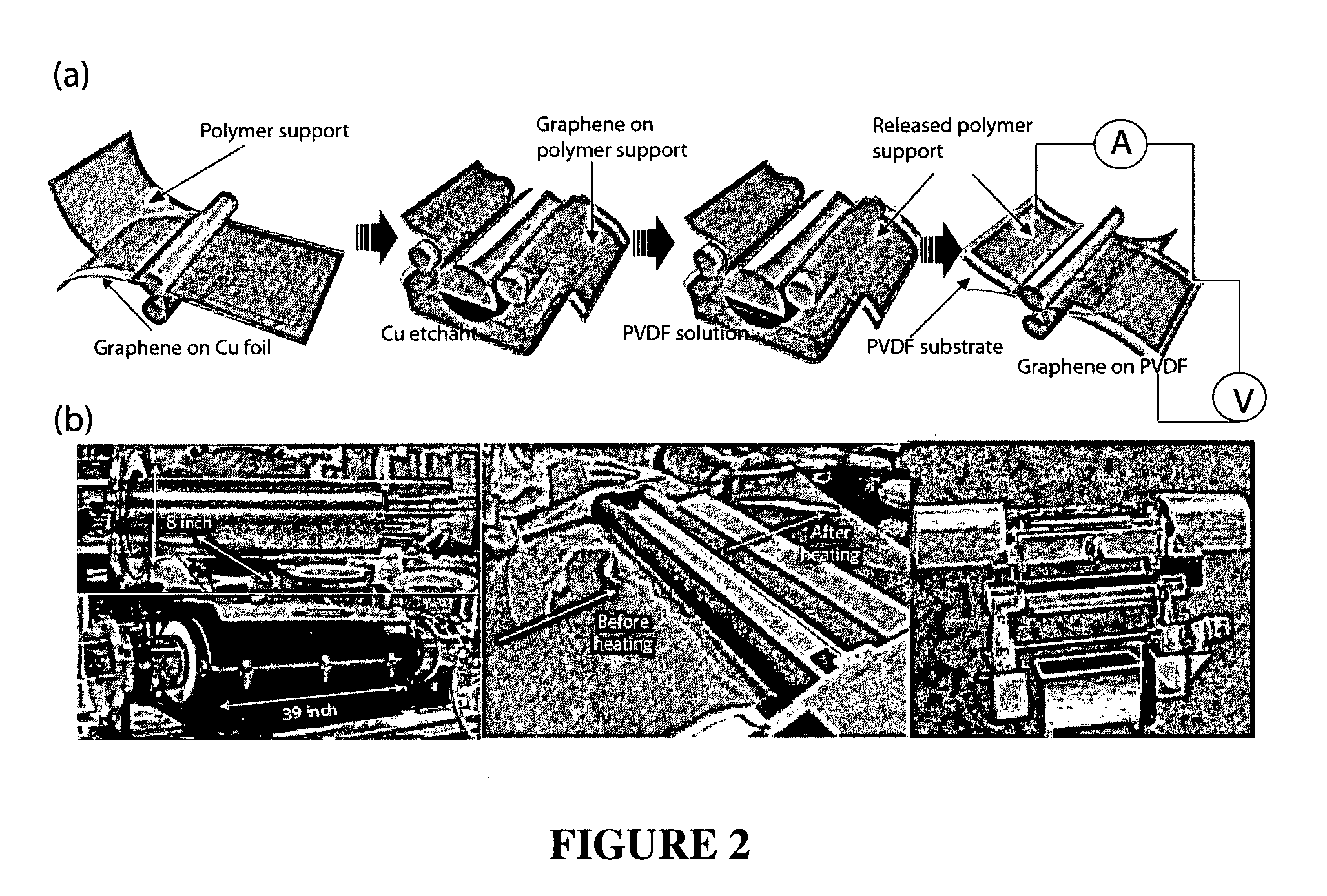

Gate-tunable graphene-ferroelectric hybrid structure for photonics and plasmonics

ActiveUS9184553B2Active medium shape and constructionChemical vapor deposition coatingElectricityPhotonics

Owner:NAT UNIV OF SINGAPORE

Systems and methods for creating and using higher degree interactions between quantum devices

A higher degree of interactions between qubits is realizable. This disclosure generally relates to devices, and architectures for quantum instruments comprising quantum devices and techniques for operating the same. Systems and processors for creating and using higher degree interactions between qubits may be found herein. Higher order interactions include interactions among three or more qubits.Methods for creating and using higher degree interactions among three or more qubits on a quantum processor may be found herein.

Owner:D WAVE SYSTEMS INC

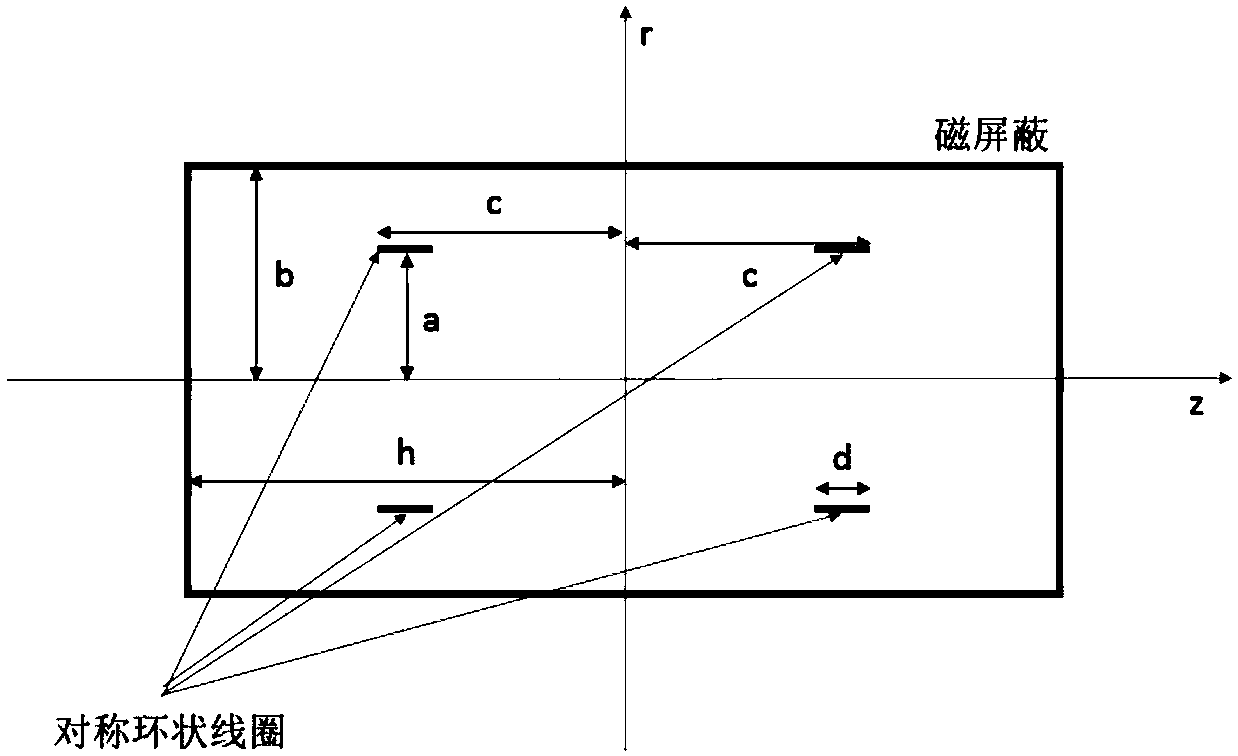

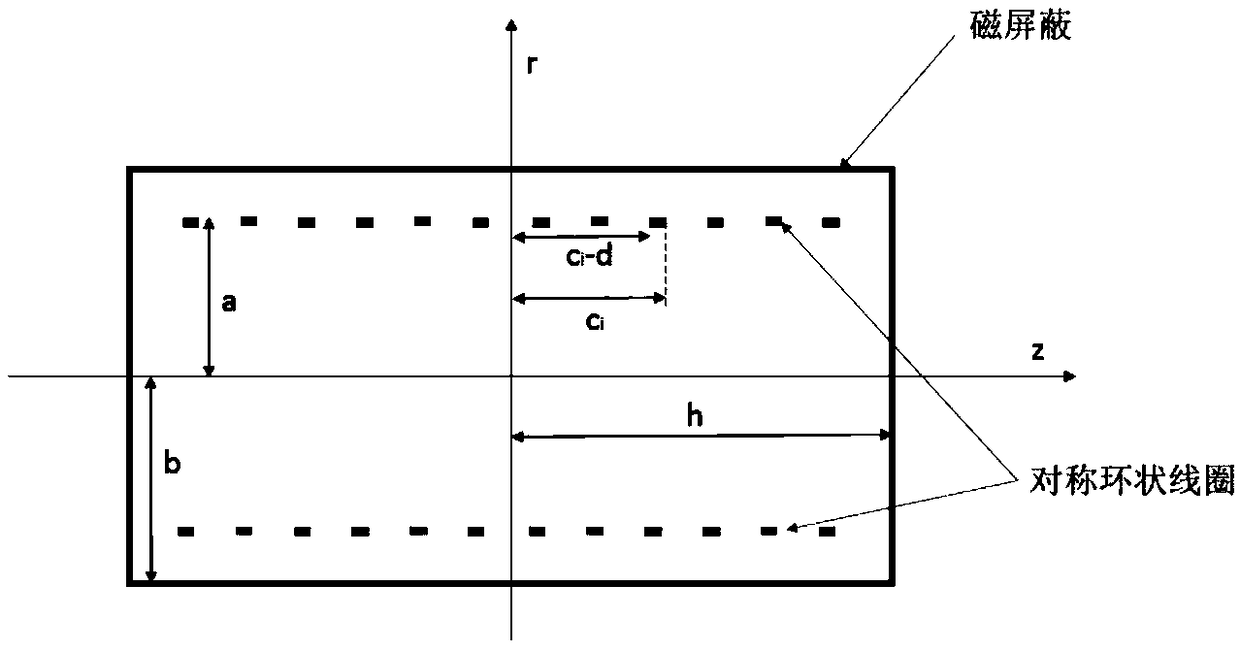

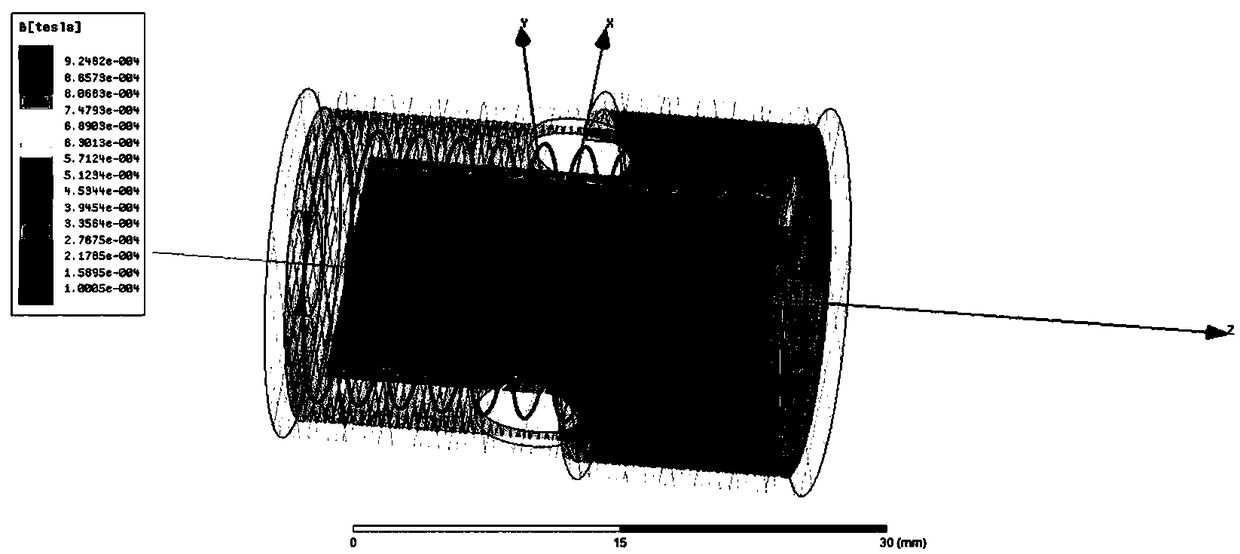

A global uniform magnetic field coil considering magnetic shielding coupling

ActiveCN109243751AMiniaturizationEasy to integrateDesign optimisation/simulationSpecial data processing applicationsCouplingMiniaturization

The invention relates to a global uniform magnetic field coil considering magnetic shielding coupling. According to the actual needs of the coil scheme, the appropriate coil pairs m are selected to obtain the required uniformity of the coil scheme. The invention obtains the analytic formula of coil design which can consider the influence of magnetic shielding, and is more convenient for coil design optimization. All the spatial magnetic fields in the coil are uniform, which is very convenient for the miniaturization and integration of new quantum devices. The number of coil loops can be adjusted reasonably according to the actual uniformity requirements, and the coil has considerable flexibility.

Owner:NAT UNIV OF DEFENSE TECH

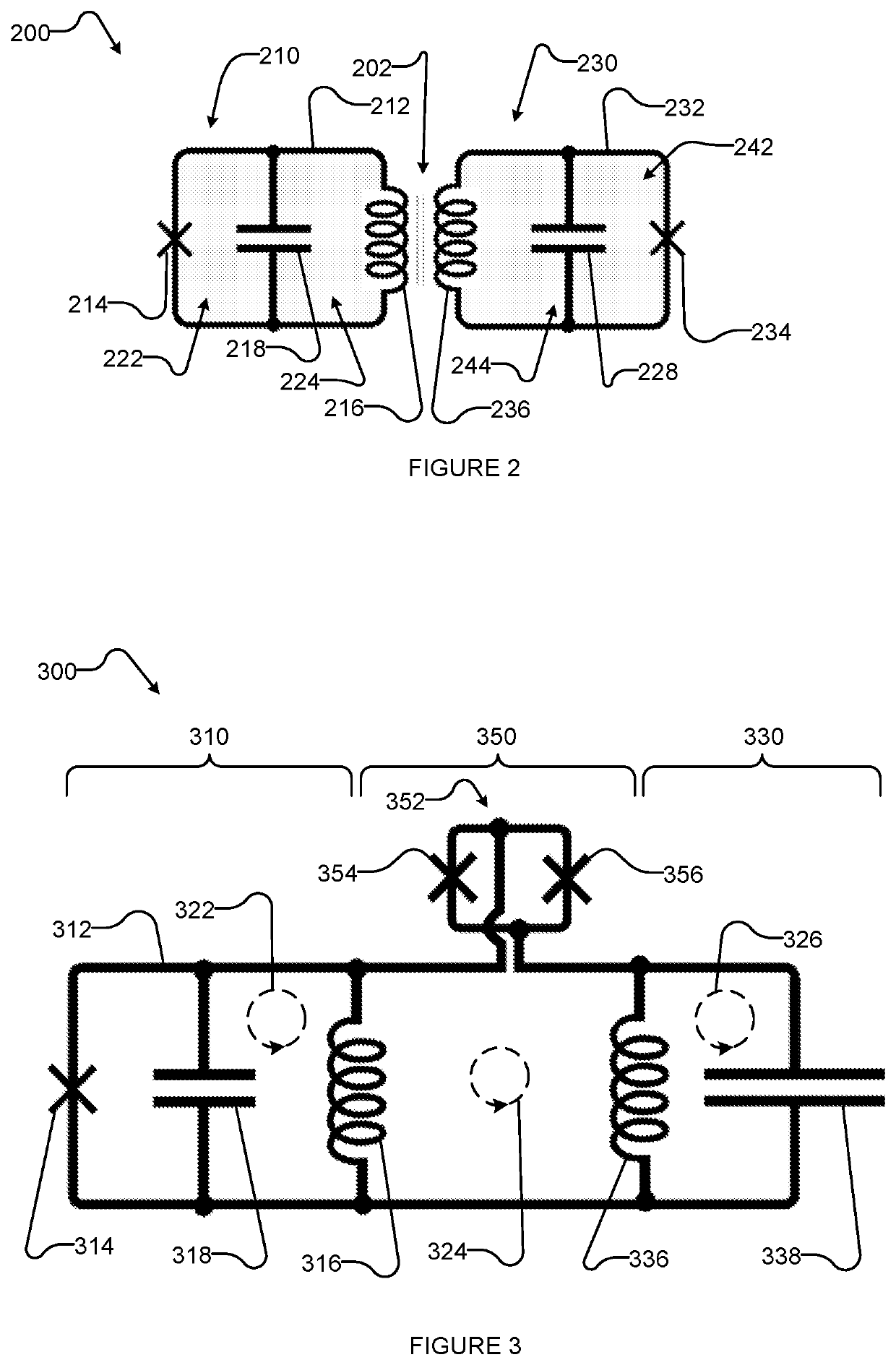

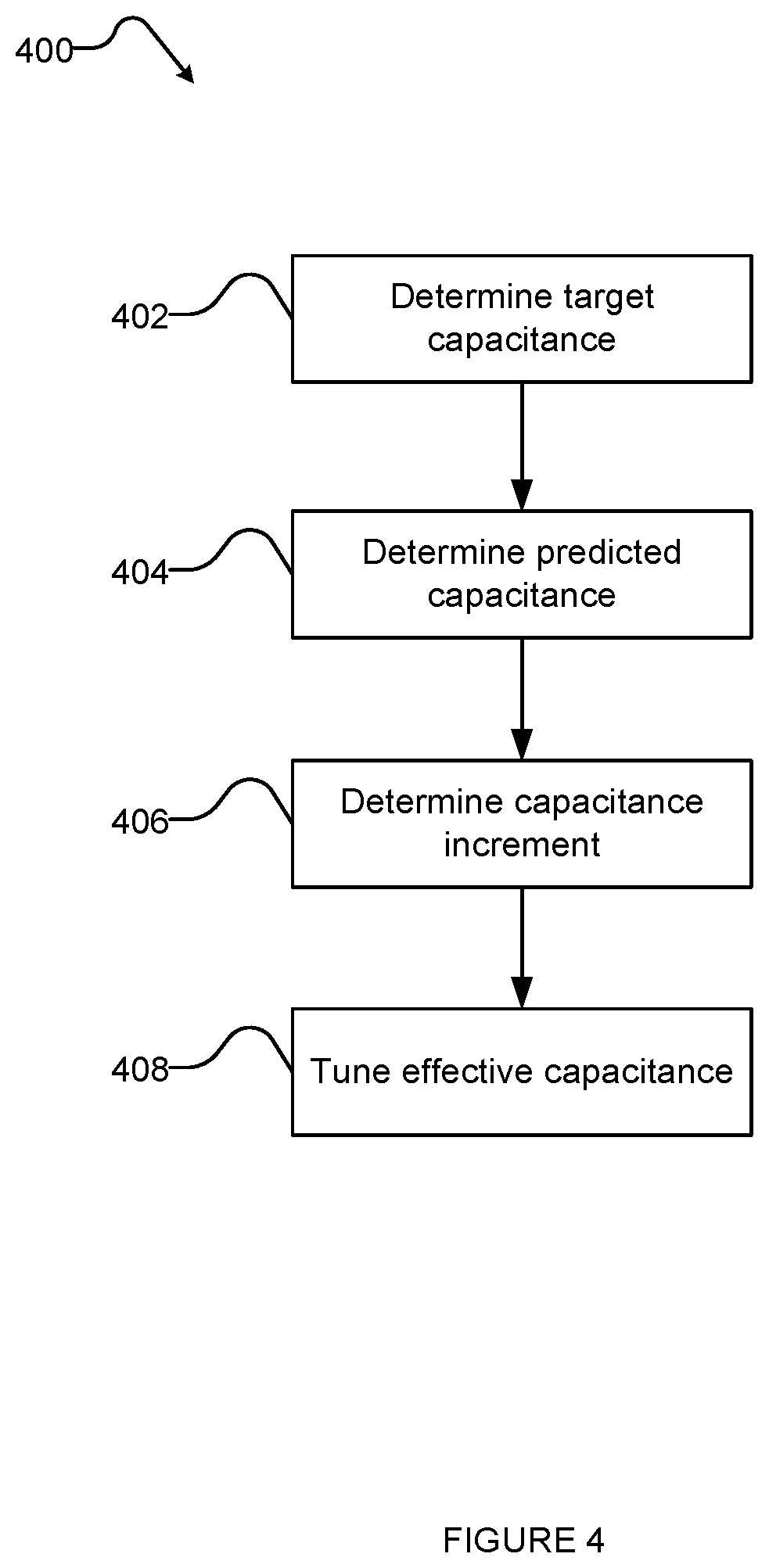

Systems and methods for tuning capacitance in quantum devices

ActiveUS20210073667A1Effective capacitanceDetermining a predicted capacitance for the qubitQuantum computersArchitecture with single central processing unitCapacitanceQuantum devices

Quantum processors having qubits with tunable capacitance are provided. The qubits include Josephson junctions shunted by capacitors and are tunably coupled to capacitance loops such that the resonant frequencies of the qubits and capacitance loops avoid entanglement with each other. Methods for tuning the capacitance of such qubits by varying the coupler's coupling strength are provided. These methods include methods for calibrating qubits' capacitance.

Owner:D WAVE SYSTEMS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com