Patents

Literature

228results about How to "Achieve deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

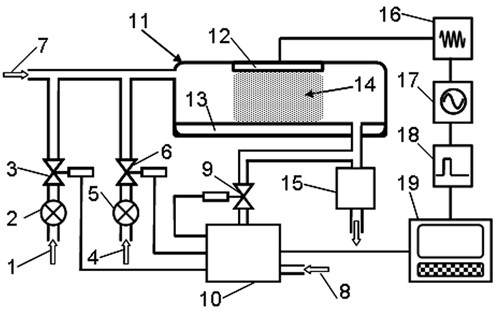

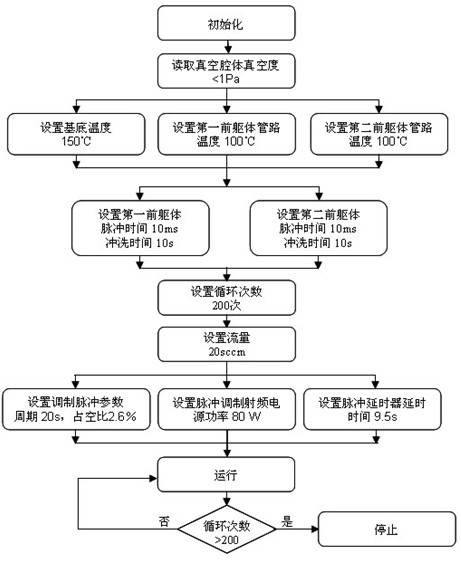

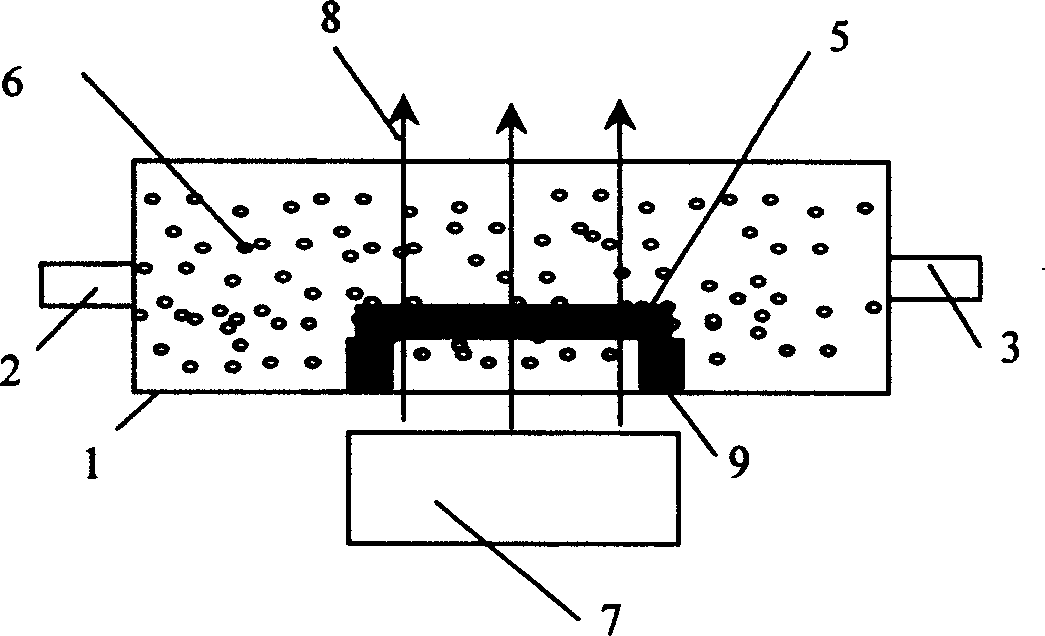

Device and method for enhancing atomic layer deposition by pulse-modulation radio frequency plasma

InactiveCN102127756AHigh activityIncrease the number of graftsChemical vapor deposition coatingIon bombardmentPhysical chemistry

The intention relates to a device and method for enhancing atomic layer deposition by pulse-modulation radio frequency plasma. The device comprises a vacuum reaction chamber, wherein a substrate is arranged at the inner bottom of the vacuum reaction chamber, and the vacuum reaction chamber is respectively connected with a vacuum mechanical pump and a precursor input pipeline. The device is characterized in that a plasma electrode is arranged at the inner top of the vacuum reaction chamber and is sequentially connected with a radio-frequency power matcher, a pulse modulation radio-frequency power supply and a pulse delay unit. In the method, plasma is generated by the pulse modulation radio-frequency power supply to assist deposition when at least one precursor is deposited. The device and method provided by the invention reduces the impact of ion bombardment on the deposited film during deposition process and prevents the temperature increase of the cavity during deposition process.

Owner:DONGHUA UNIV +1

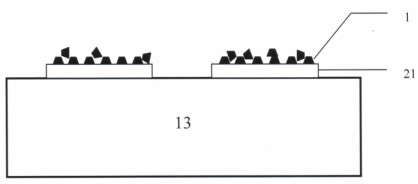

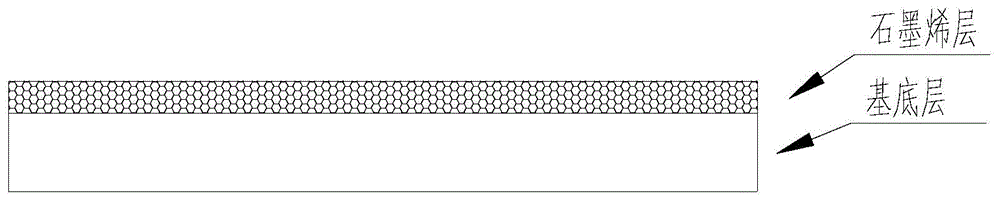

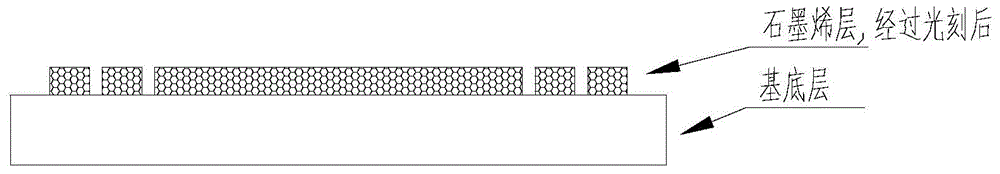

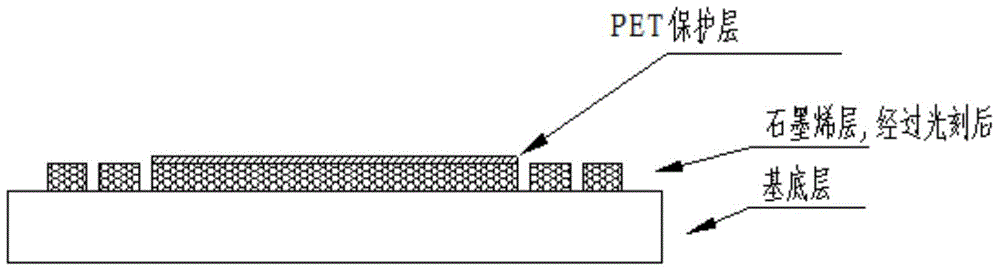

Method for preparing metal electrode on grapheme conductive film

InactiveCN103602964ASimple manufacturing processAvoid high temperature bakingLiquid/solution decomposition chemical coatingChemical vapor deposition coatingChemical platingCvd graphene

The invention provides a method for preparing metal electrode on grapheme conductive film, which comprises the following steps: 1) providing grapheme on a substrate; 2) depositing a metal layer on surface of grapheme film by electroplate or chemical plating; 3) patterning the grapheme before the step 2; or patterning the grapheme film and the metal layer after the step 2. The invention also provides a grapheme conductive film with metal electrode prepared by the method.

Owner:2D CARBON CHANGZHOU TECH INC

Thin film transistor on basis of metal oxide and preparation method and application thereof

InactiveCN102522429ALow costEasy for large area and mass productionTransistorSemiconductor/solid-state device manufacturingAnodic oxidationPhotoresist

The invention discloses a thin film transistor on the basis of metal oxide and a preparation method and application thereof. The preparation method comprises the following steps of: (1) making a buffer layer; (2) depositing a gate metal layer on the buffer layer; (3) preparing a gate insulation layer on the gate metal layer by using an anodic oxidation method, wherein the part in the gate metal layer, on which an oxide film does not need to be deposited, is protected by using a photoresist; (4) removing the photoresist; (5) removing an unrequired metal lead; (6) preparing an active layer on the gate insulation layer; and (7) according to the designed thin film transistor structure, depositing and patterning source and drain electrodes, a pixel electrode and a protection layer or an etched barrier layer. According to the invention, pure Al or Al alloy is used as gate metal and the gate insulation layer is prepared by using the anodic oxidation method. The performance of the gate insulation layer can be changed by regulating the components of the gate metal, so that the electrical properties of the thin film transistor are improved.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

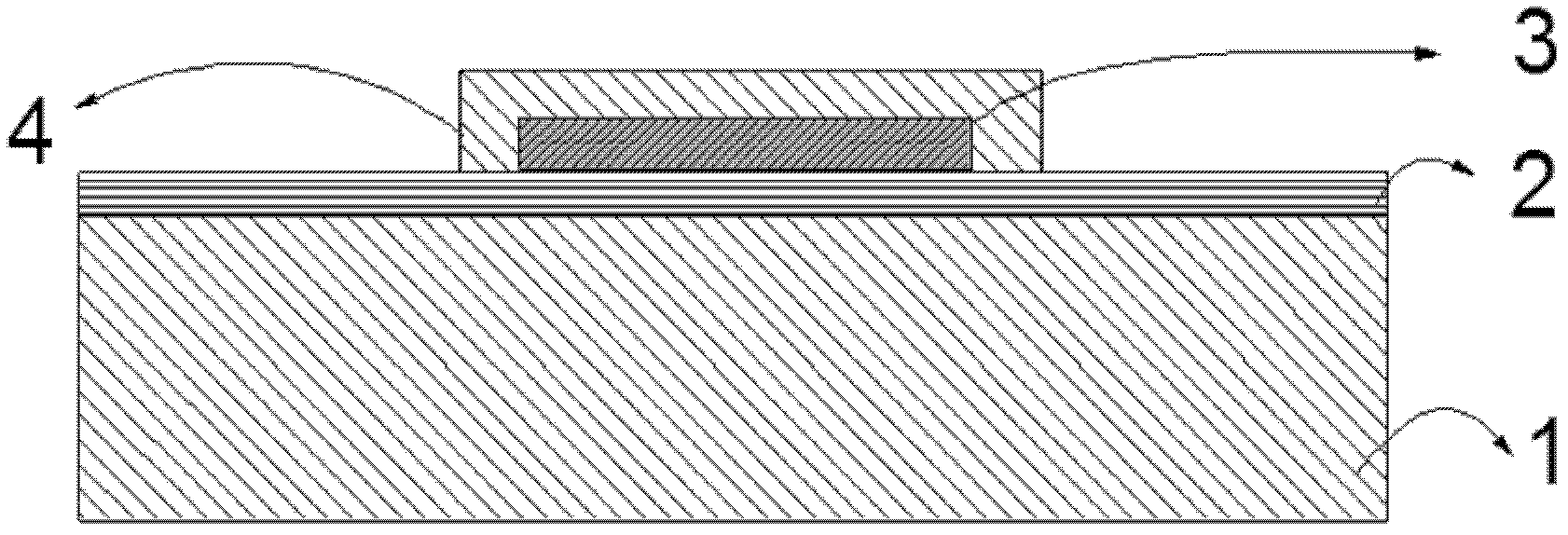

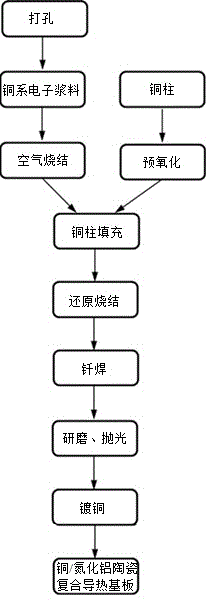

Preparation method for copper/aluminium nitride ceramic composite heat-conductive substrate

InactiveCN104064478AGuaranteed smoothGuaranteed flow capacitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingCeramic composite

The invention discloses a preparation method for a copper / aluminium nitride ceramic composite heat-conductive substrate. The method comprises the following steps: 1) providing through holes in the surface of an aluminium nitride substrate; 2) coating copper electronic paste layers on the double surfaces of the aluminium nitride substrate; 3) filling the through holes with pre-oxidation copper cylinders; 4) carrying out overall sintering for 30 min; 5) carrying out brazing after the double surfaces of the aluminium nitride substrate being coated with tin silver copper solder materials; 6) carrying out surface polishing; and 7) carrying out copper plating processing directly and forming uniform copper layers, and thus, the copper / aluminium nitride ceramic composite heat-conductive substrate is obtained. The through holes in the copper / aluminium nitride ceramic composite heat-conductive substrate produced with the preparation method are communicated up and down; the combination between the metalized layers in the holes and the ceramic substrate is strong; the middle copper cylinders can realize the communication of the copper layers on the upper and lower surfaces; and the copper / aluminium nitride ceramic composite heat-conductive substrate helps the transmission of electrical signals and has the advantages of ideal heat-conductive effect, low thermal expansion coefficients and good conductivity and the like.

Owner:NANJING MING KUANG ELECTRONICS TECH

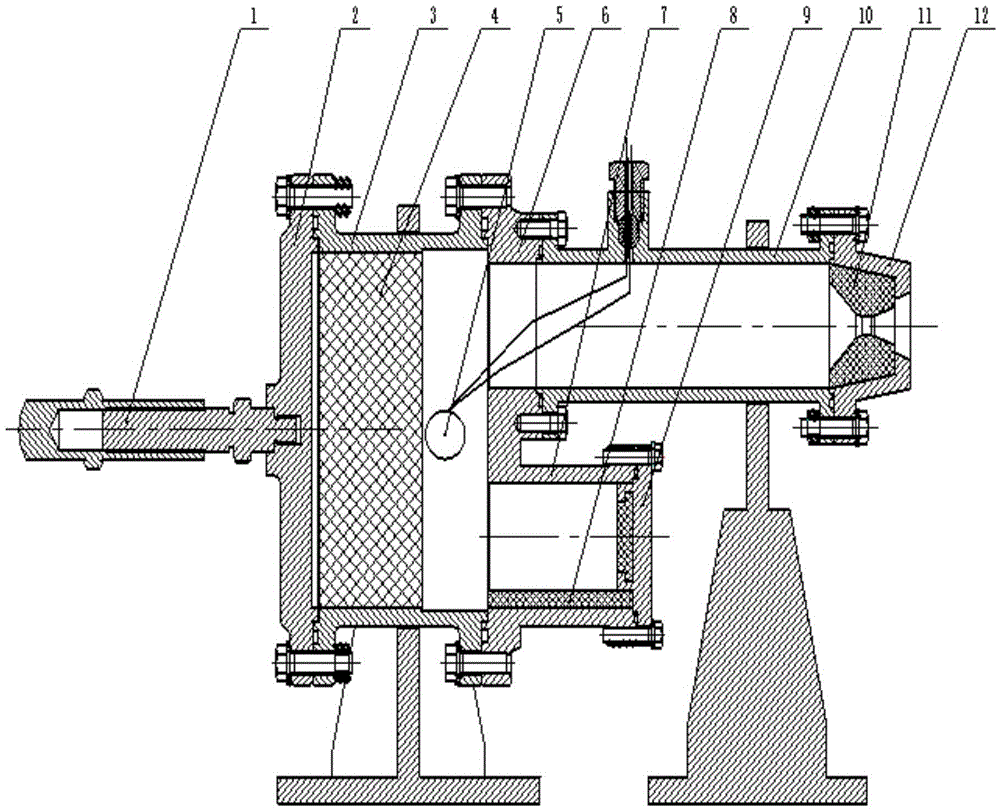

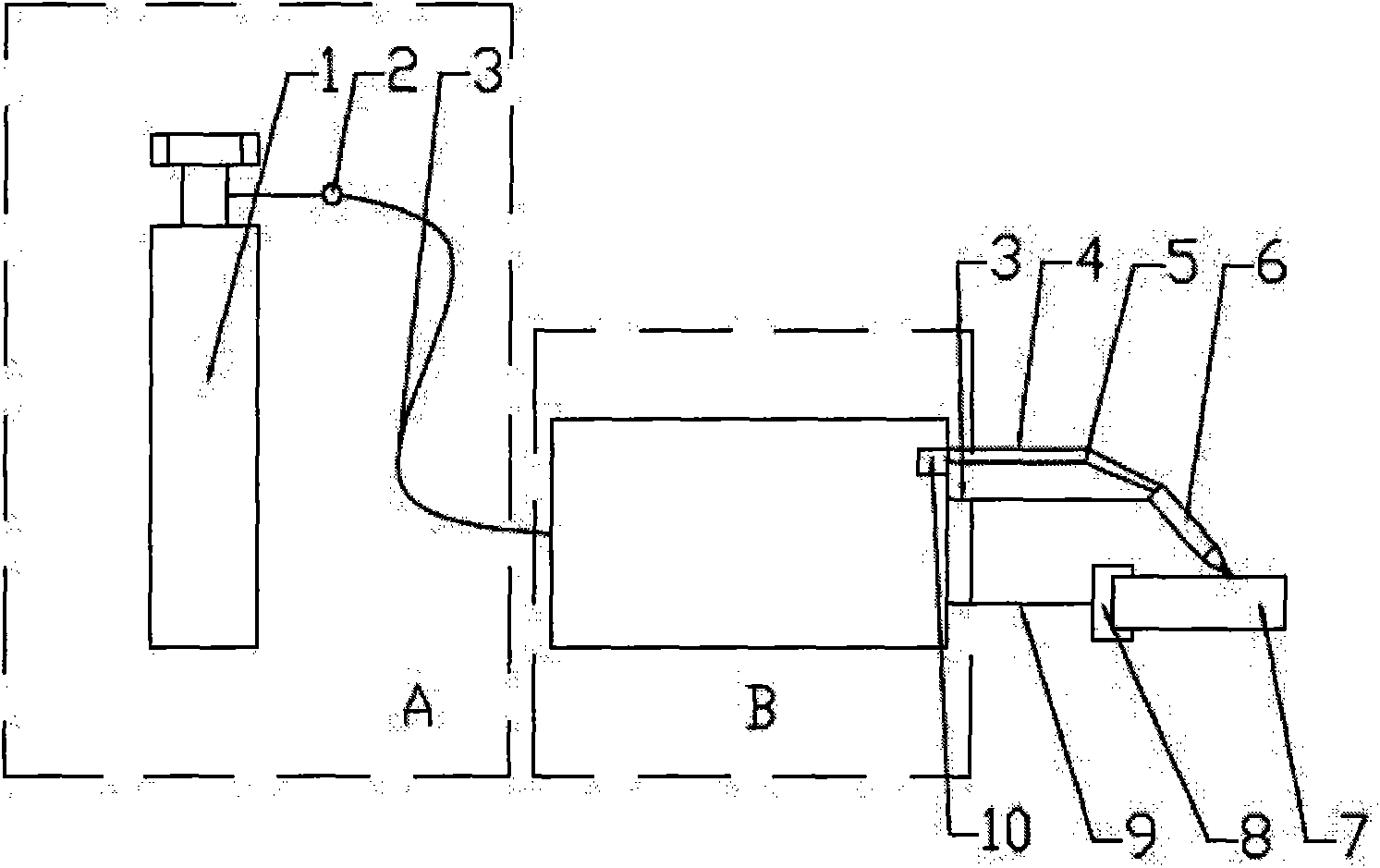

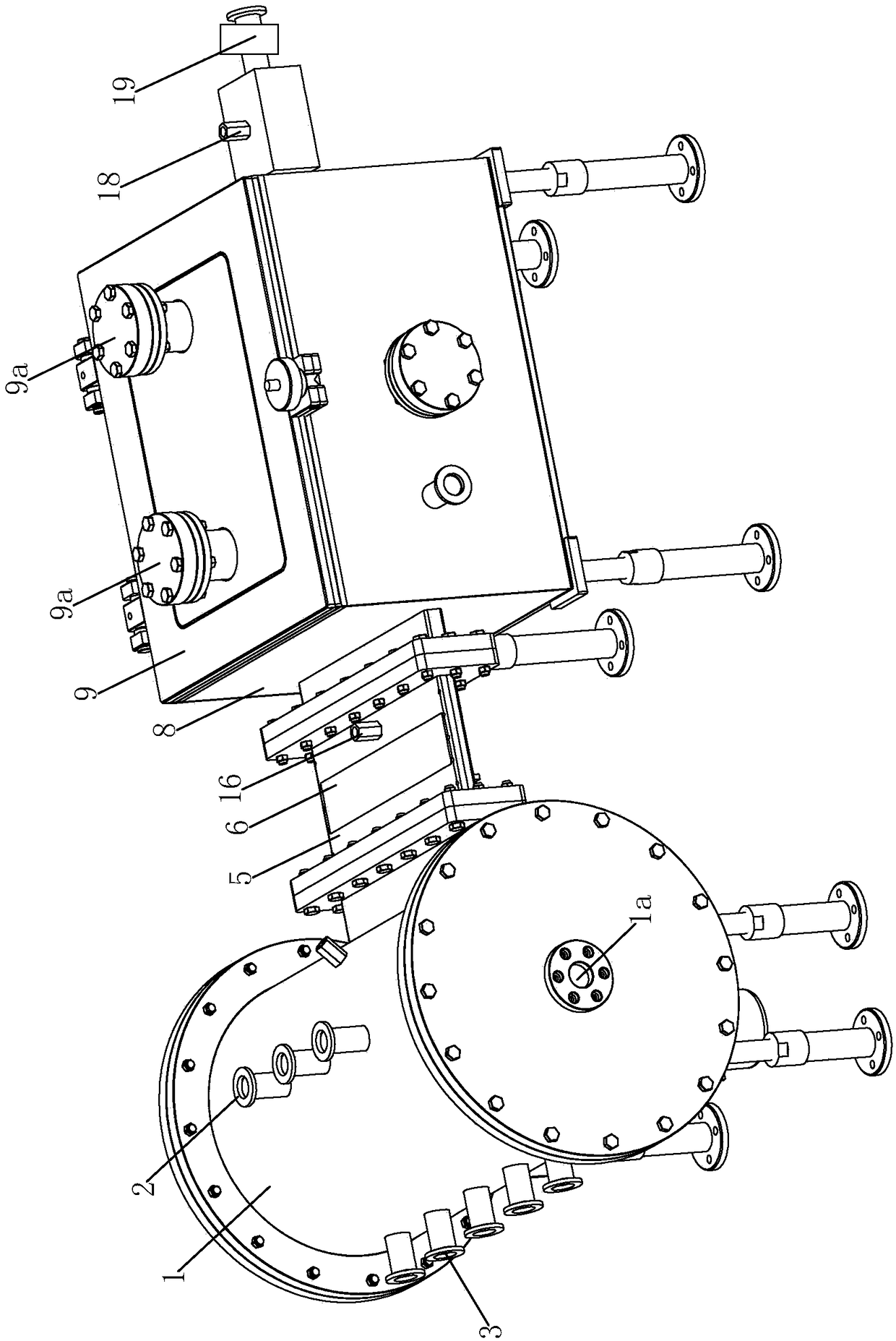

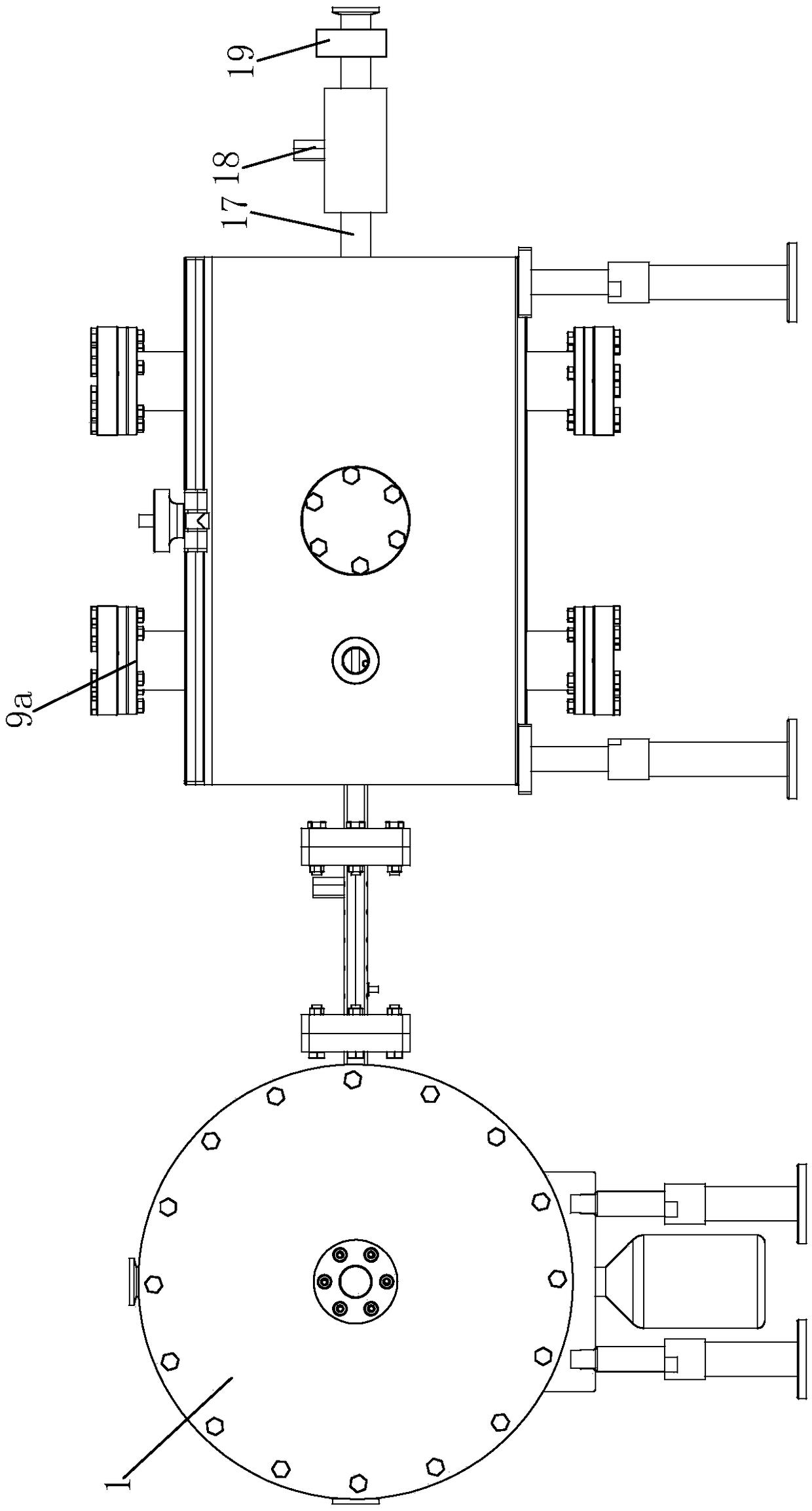

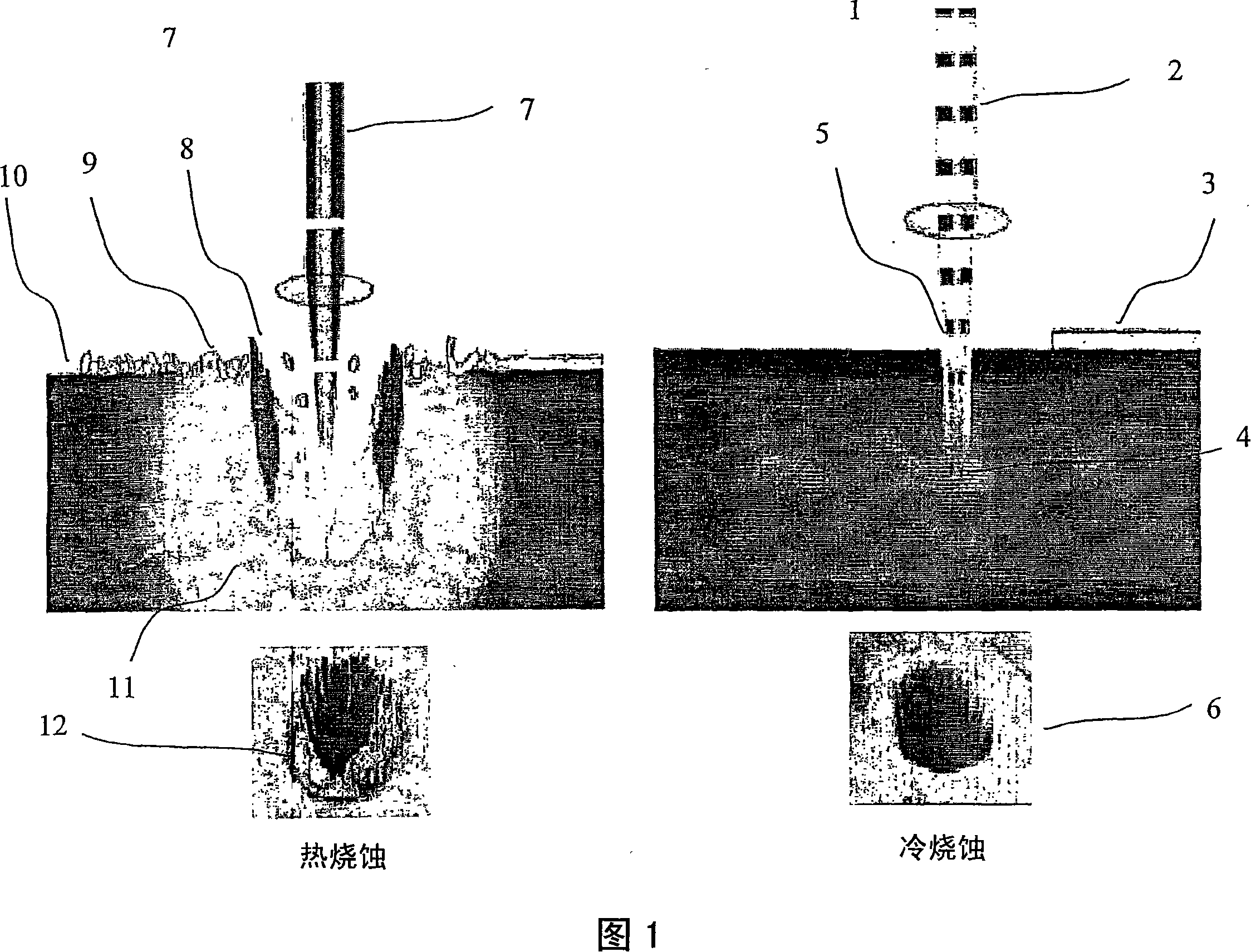

Apparatus for simulating insulation ablation under condition of particle deposition in cavity in back wall of submerged nozzle

ActiveCN105527370AConvenient researchAchieve depositionChemical analysis using combustionCombustion chamberParticle deposition

The invention discloses an apparatus for simulating insulation ablation under the condition of particle deposition in a cavity in a back wall of a submerged nozzle, which belongs to the technical field of rocket engines. The apparatus comprises a combustion chamber; one end of the combustion chamber is sealed, the other end of the combustion chamber is respectively in horizontal communication with a transition pipe and a deposition chamber from top to bottom, and the transition pipe is coaxially communicated with a channel pipe and a jet pipe in sequence; a propellant and an ignition cartridge bag used for igniting the propellant are arranged in the combustion chamber; and one end of the deposition chamber is communicated with the combustion chamber so as to form a through cavity, the other end of the deposition chamber is hermetically arranged, and the bottom inner wall and / or the inner wall of the sealed end of the deposition chamber is provided with an insulation test piece. The apparatus provided by the invention can directly simulate the flowing state of particles in the cavity in the back wall of the submerged nozzle of a large solid rocket engine and realizes research on the mechanism of insulation ablation under the condition of condensed-phase particle deposition.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

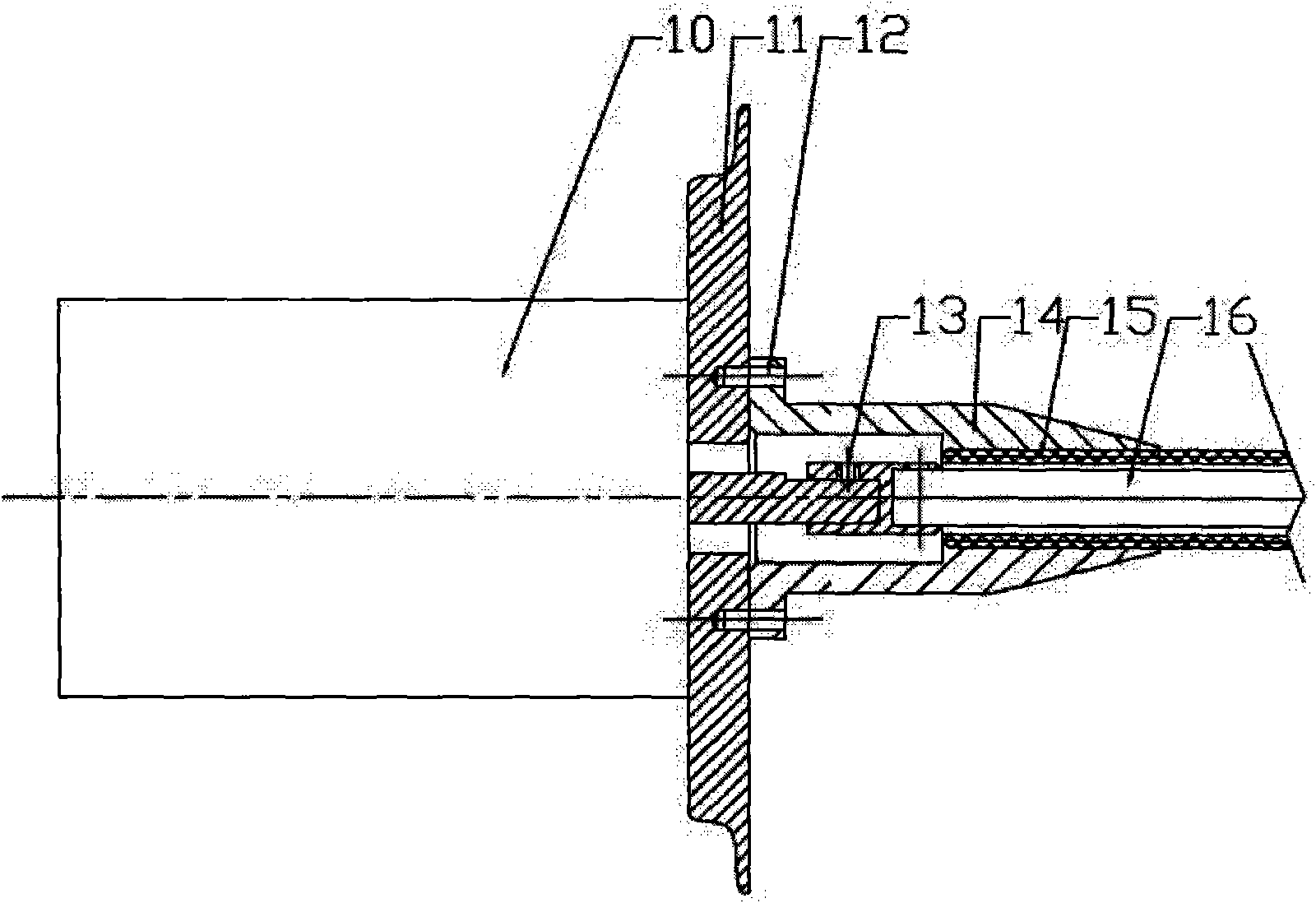

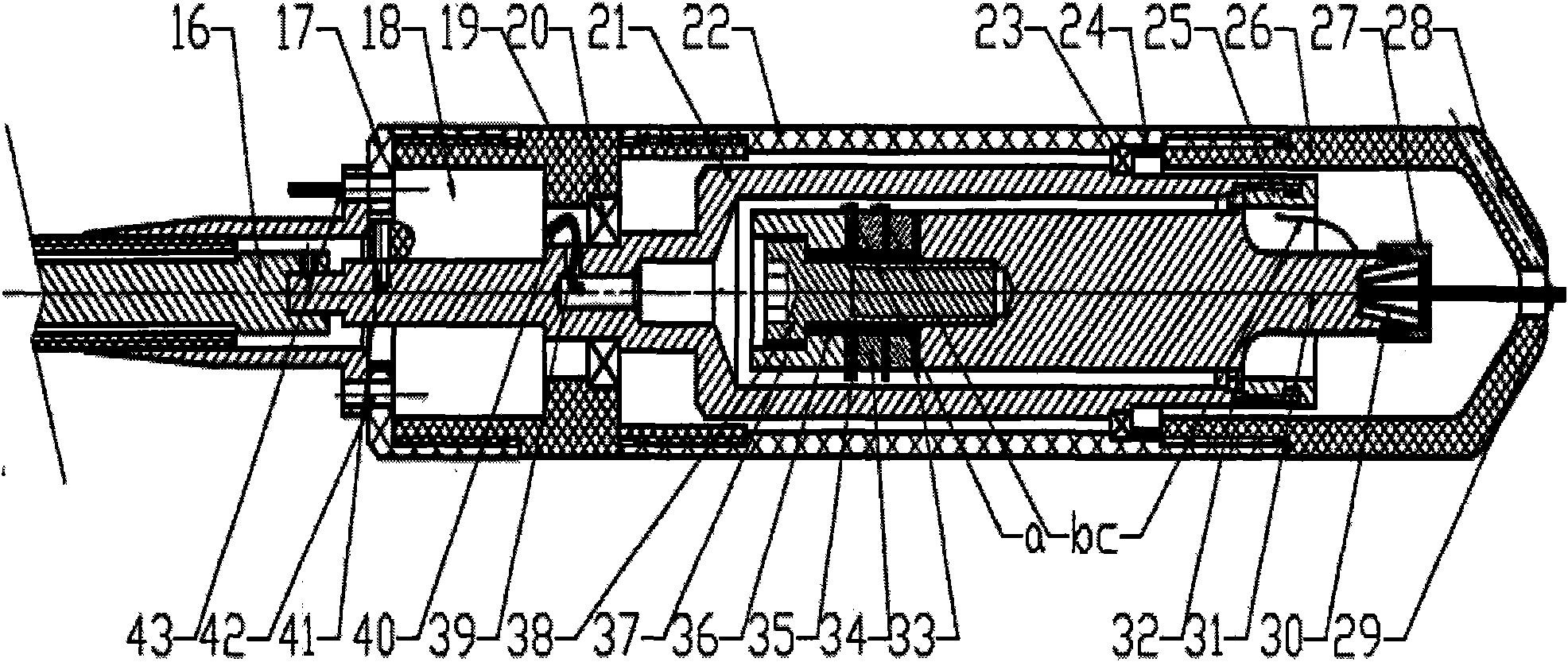

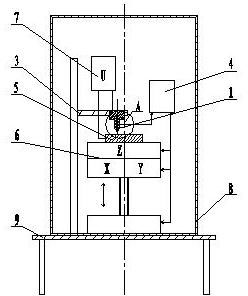

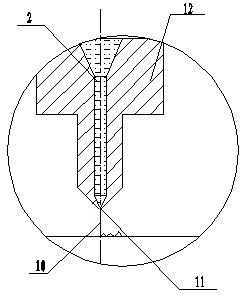

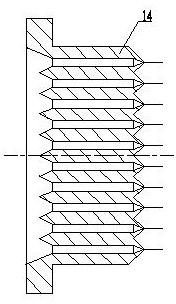

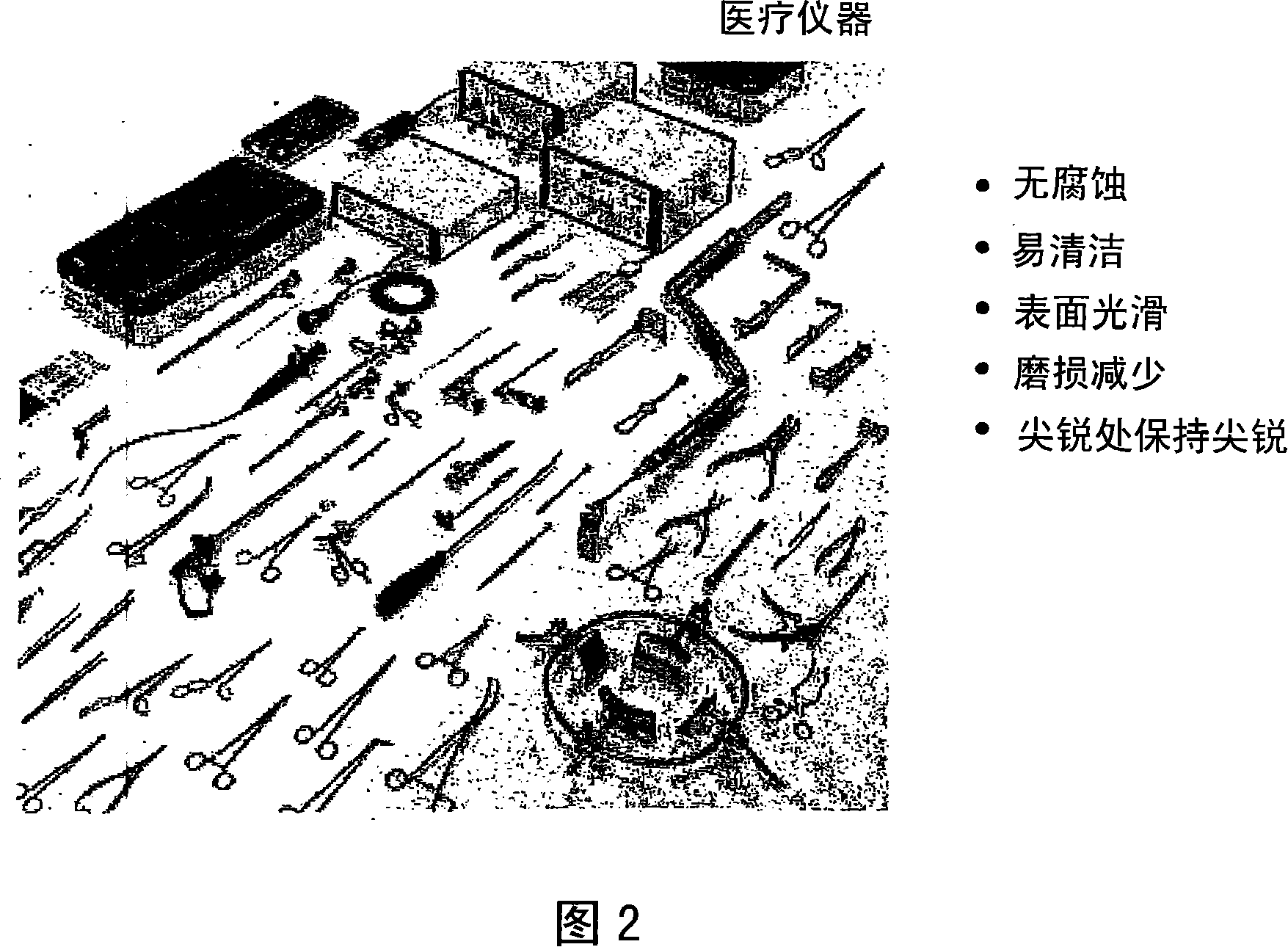

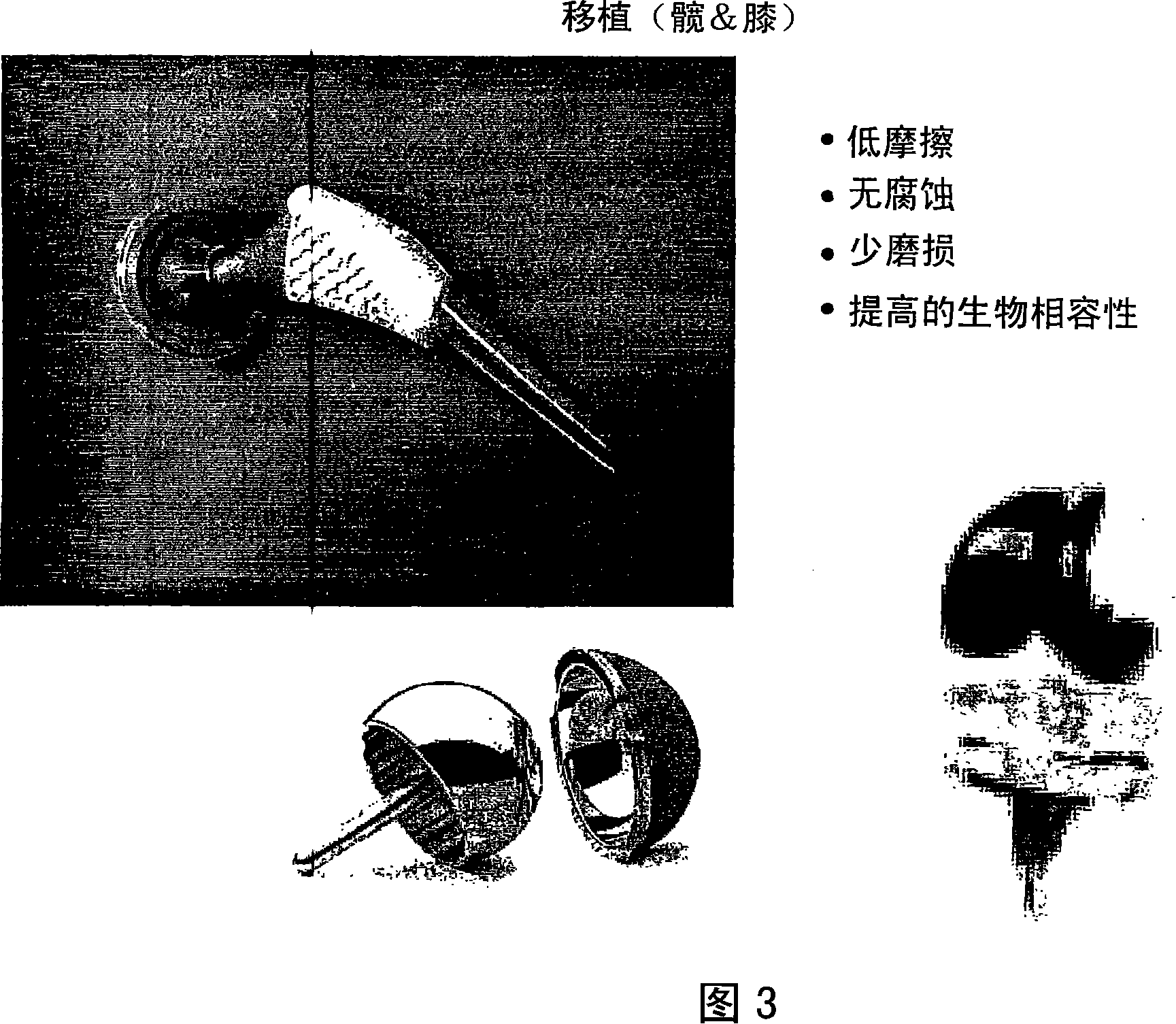

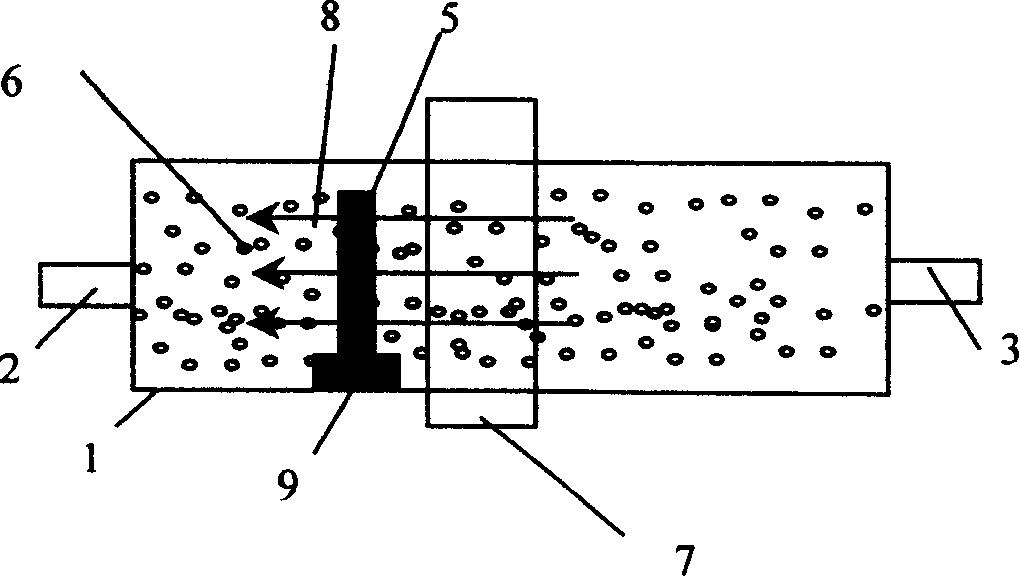

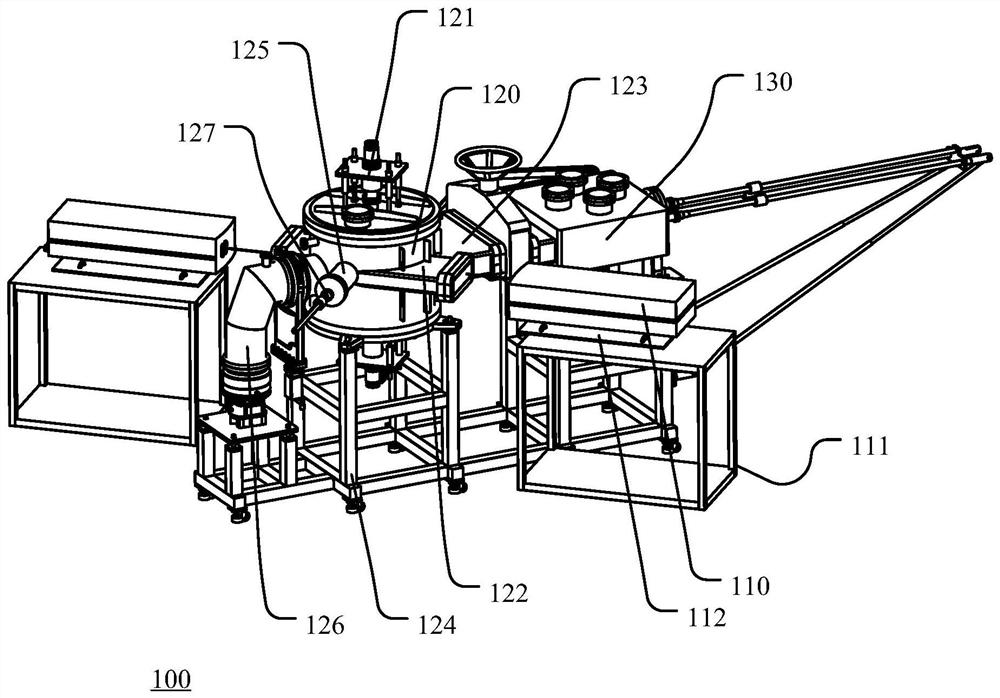

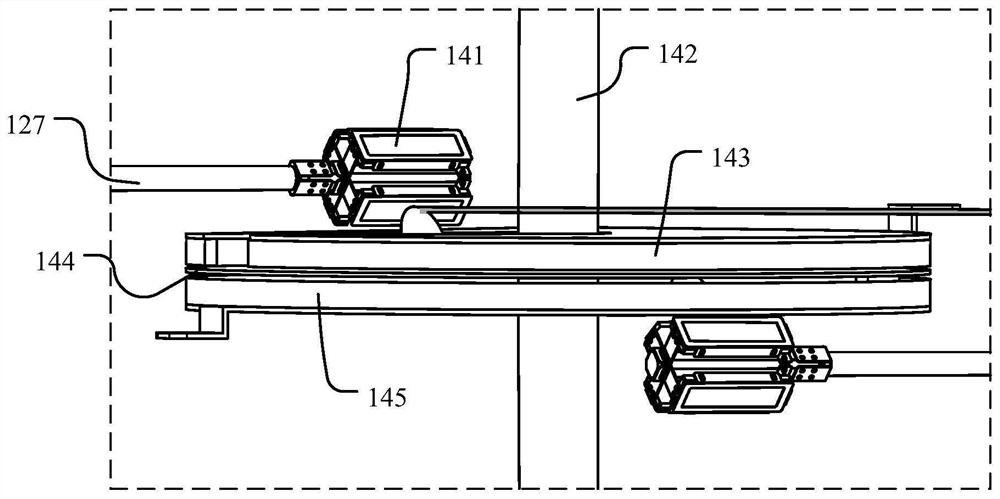

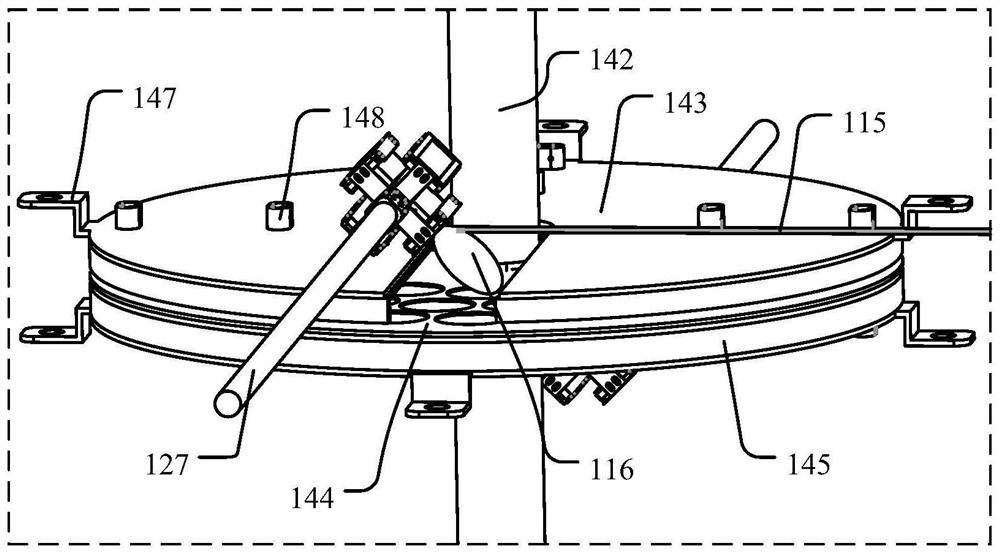

Portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated device and process thereof

ActiveCN102019531ALower acquisition costsPrevent electrode stickingArc welding apparatusCeramicPre stressing

The invention relates to a portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated device and a process thereof. The device comprises an air supply system for creating a protective atmosphere for sedimentation repairing, a power supply, a control box, an ultrasonic auxiliary spark sedimentation repairing and polishing integrated element, a workpiece chuck and a tool electrode, wherein the ultrasonic auxiliary spark sedimentation repairing and polishing integrated element comprises a shell, a spindle and an ultrasonic vibrator; the ultrasonic vibrator comprises a rear matching cover, two electrode plates of the ultrasonic vibrator, two piezoelectric ceramics, an insulation sleeve, an amplitude transformer, a pre-stress bolt and a electrode chuck. The device of the invention is portable and multifunctional, can repair the failure surfaces of module and parts through the ultrasonic spark sedimentation repairing, can improve the surface quality of the repaired sedimentation layer by ultrasonic polishing, can locally strengthen the surfaces of the module and parts through ultrasonic spark sedimentation and can remove surplus materials of the surfaces of the module and parts through reversed polarity spark processing. The portable ultrasonic auxiliary spark sedimentation repairing and polishing integrated processing method of the invention is simple in operation, is convenient and is practical.

Owner:广州市联合科技发展有限公司

Method for preparation of indium oxide transparent film with high electron mobility

InactiveCN101514440AStrong adhesionSmooth film surfaceVacuum evaporation coatingSputtering coatingIndiumRadio frequency magnetron sputtering

A method for the preparation of the indium oxide transparent film with high electron mobility adopts the double-chamber high- vacuum radio-frequency magnetron sputtering method, wherein the high-purity indium oxide with the purity of 99. 99 27634872s taken as the target material, the glass is taken as the substrate, one or two of the high-purity argon and oxygen with the purity of 99. 99 5869744s taken as the sputtering gas, the sputtering growth is performed in the magnetron sputtering device, thus the n-typed transparent In2O3semiconductor film material with different electron concentration and high electron mobility is obtained. The method has the advantages of easy control of the deposition parameter, reliable preparing process, good repetitiveness and lower cost of manufacture.

Owner:ZHEJIANG UNIV

Method for forming metal front medium layer and its structure

ActiveCN101197272AImprove reliabilityIncrease production capacitySemiconductor/solid-state device detailsSolid-state devicesMedia layerInternal stress

The invention relates to a forming method for metal front dielectric layer, which comprises the following steps of: forming a metal front dielectric layer depositing substrate on a semi-conductor substrate; depositing a first metal front dielectric layer on the depositing substrate by using a first CVD method; and depositing a second metal front dielectric layer on the first metal front dielectric layer by using a second CVD method. The metal front dielectric layer without depositing cave can be formed to improve the performance of device by changing the internal stress state of device. The first dielectric layer is deposited by HARP SACVD technics, thus reducing the depth width ratio in subsequent manufacture process. Then, the second dielectric layer is deposited by using HDPCVD, SACVD, PECVD or other traditional technics to complete the depositing of the dielectric layer, thereby ensuring that the subsequent work is identical with the prior technics, reducing the change to the prior technics to the lowest for the purpose of technics optimization, and reducing development cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

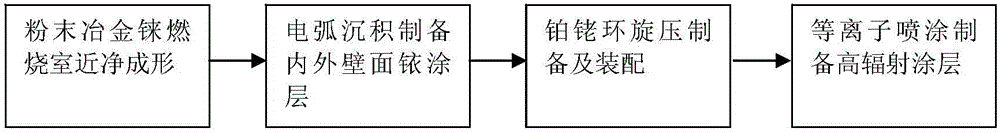

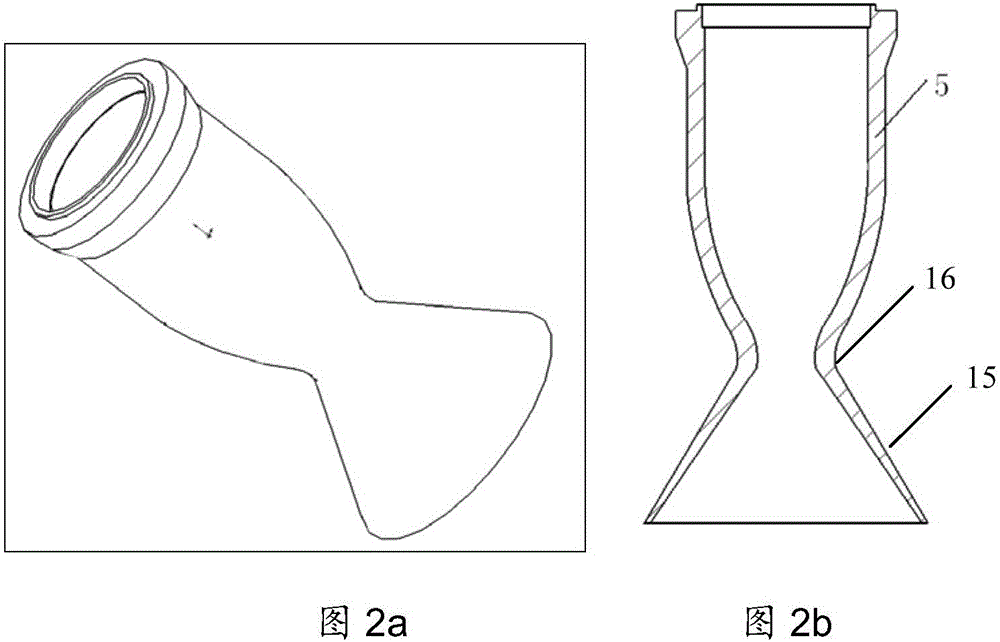

Preparation method for rhenium-iridium combustion chamber

ActiveCN106001554AIncrease the allowable operating temperatureImprove specific impulseShaping toolsMolten spray coatingRheniumIridium

The invention relates to a preparation method for a rhenium-iridium combustion chamber. The preparation method comprises the following steps: preparing a rhenium combustion chamber by adopting a powder metallurgy near-net shape forming technology; preparing iridium coatings at inner and outer surfaces of the rhenium combustion chamber by adopting an electric-arc deposition technology; preparing a platinum-rhodium ring by adopting a spinning technology and assembling the platinum-rhodium ring on the inner wall surface of the combustion chamber; and preparing a metal oxide high-radiation coating on the outer surface of the combustion chamber by adopting a plasma spraying technology. According to the preparation method, by virtue of an optimized design of process methods and process conditions at different stages of a preparation process, the prepared rhenium-iridium combustion chamber is applied to an engine, so that a use and working environment of the engine can be remarkably increased, specific impulse can be improved for the engine, and technical support is provided for prolonging flight life of an aircraft, increasing effective load of the aircraft or increasing range of the aircraft.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

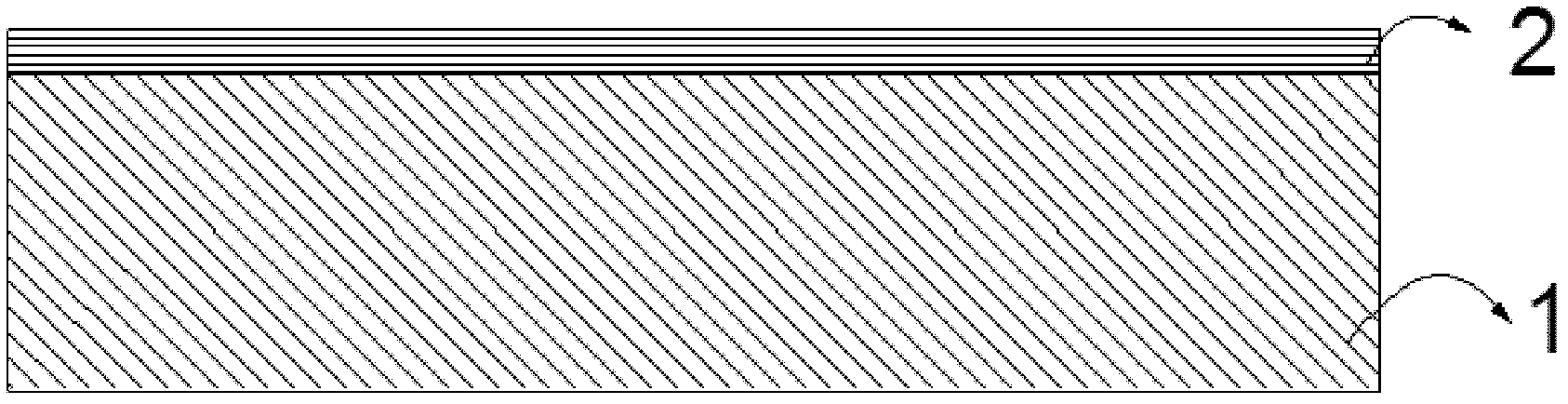

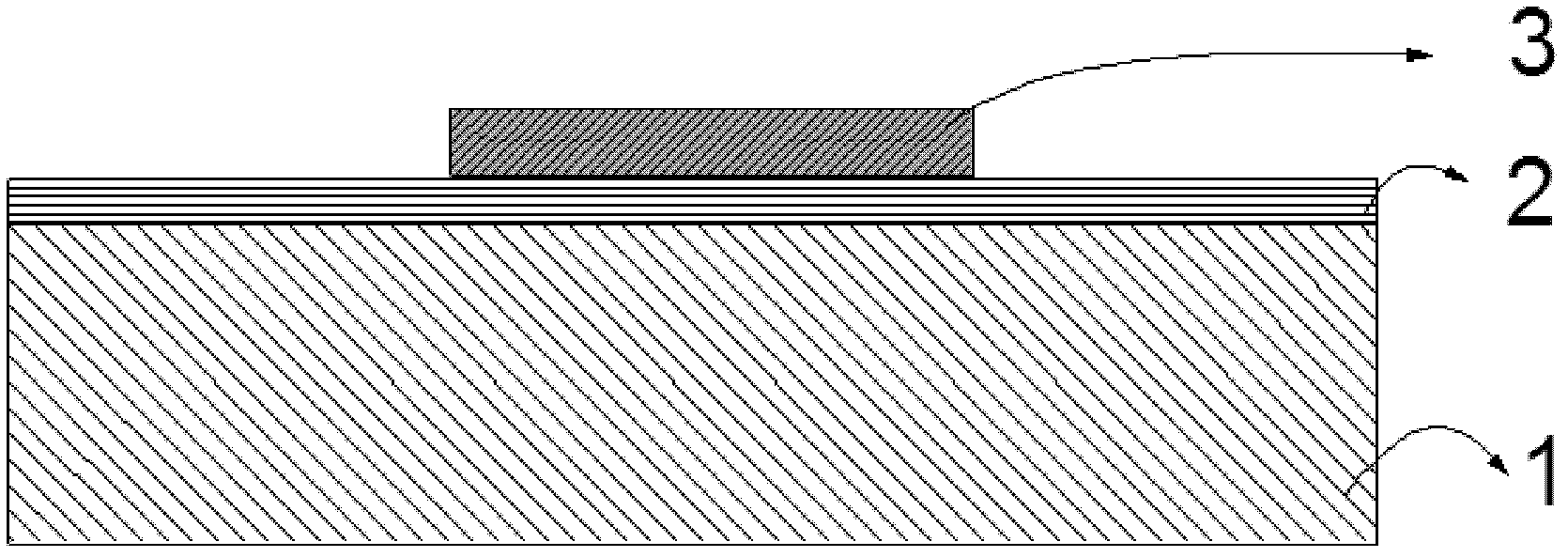

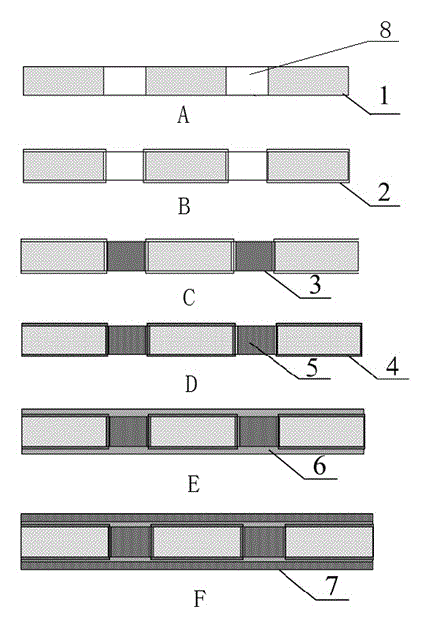

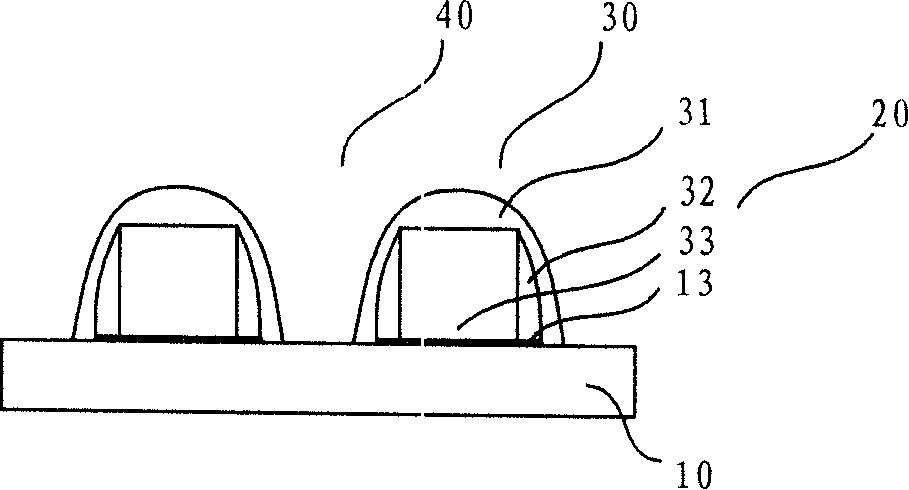

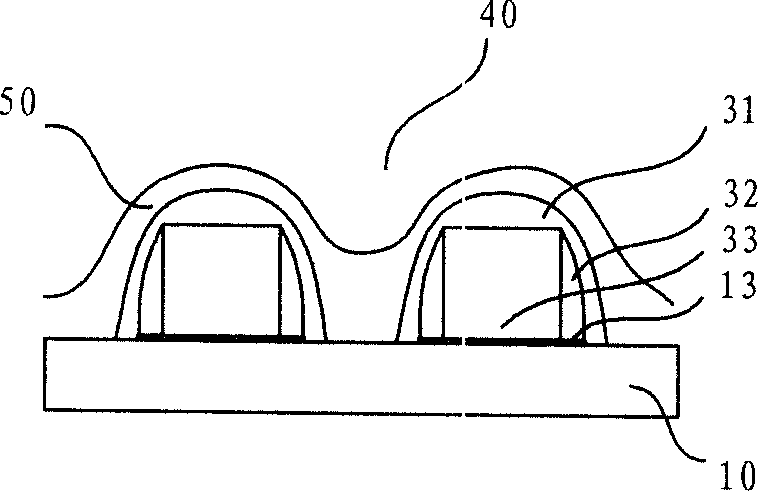

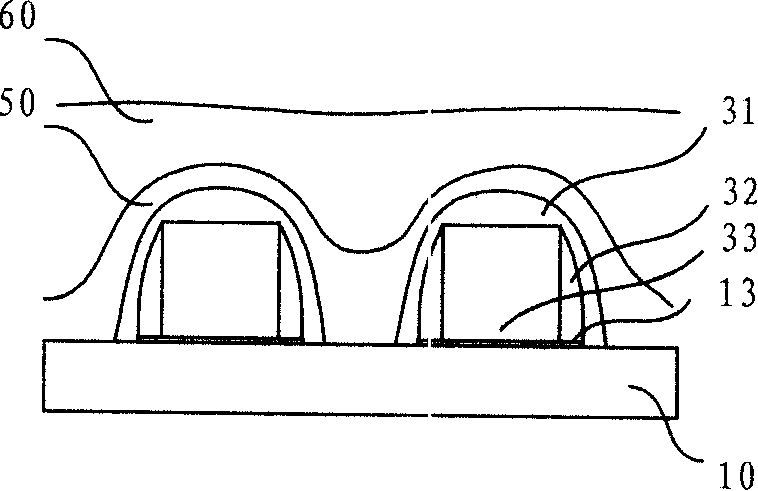

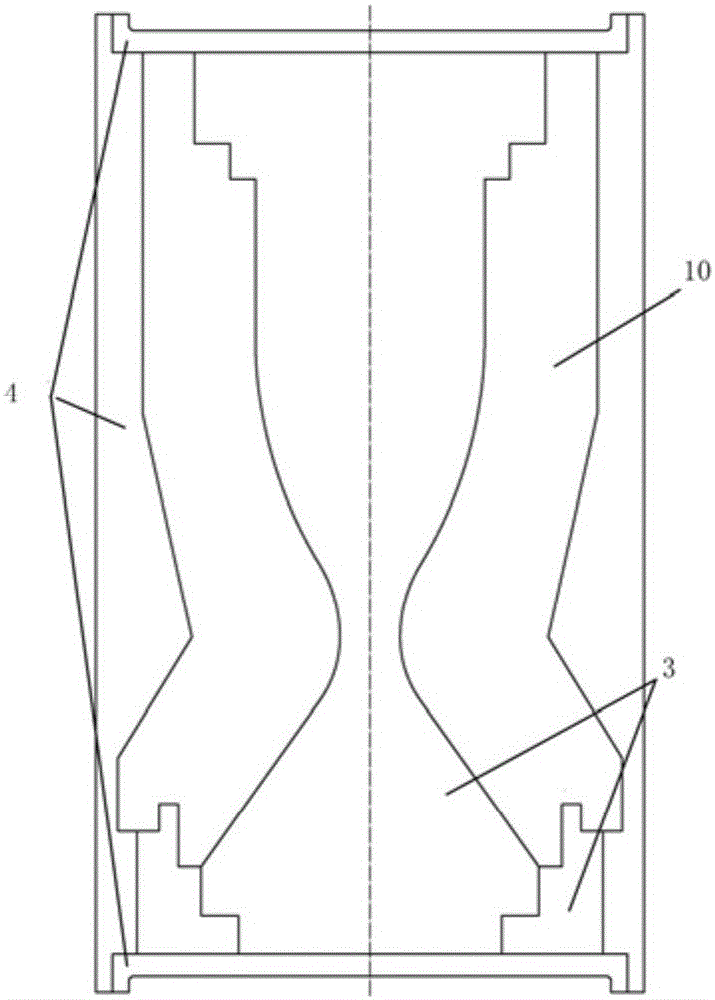

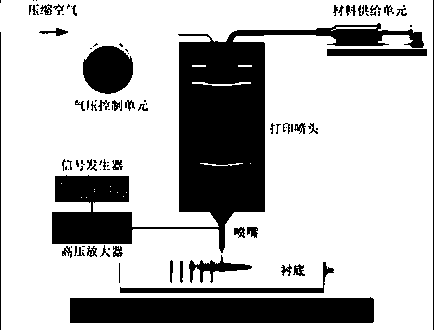

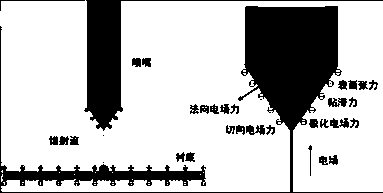

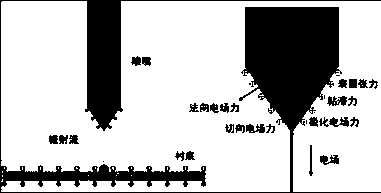

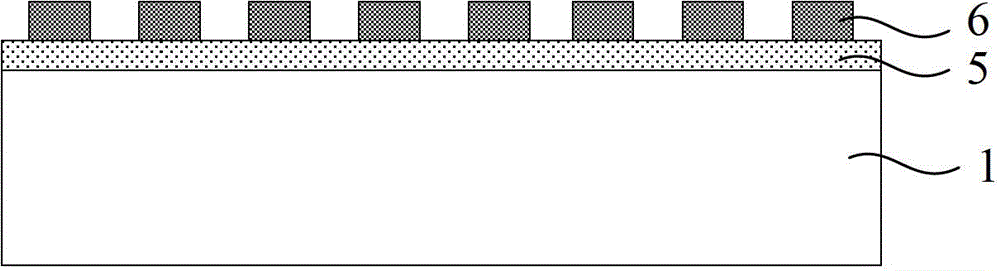

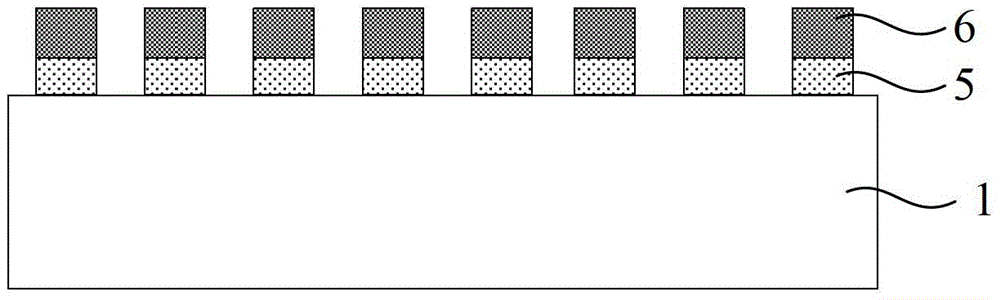

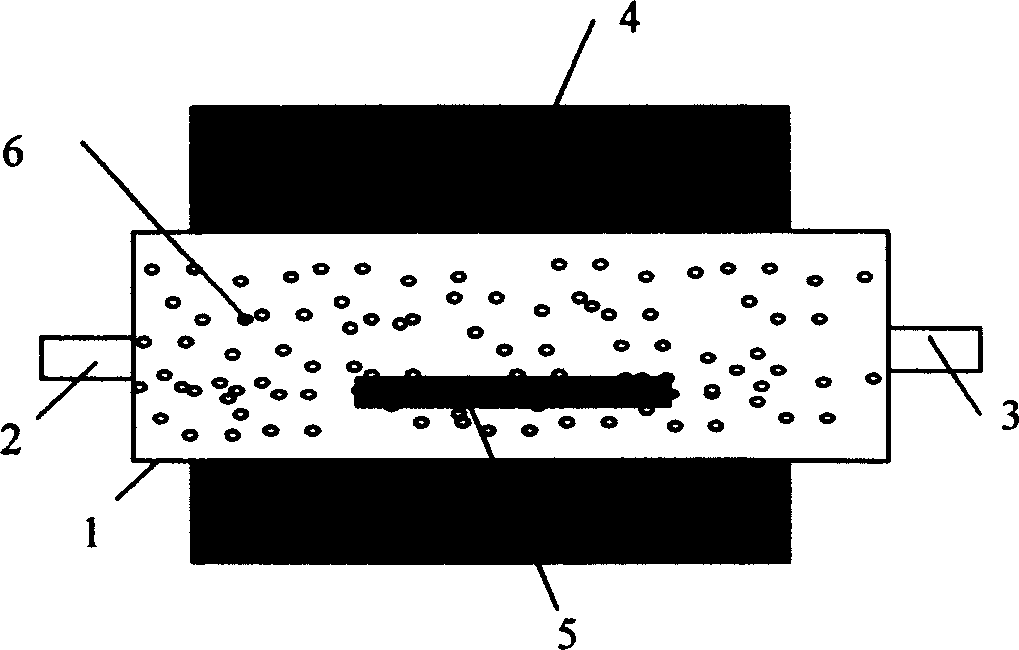

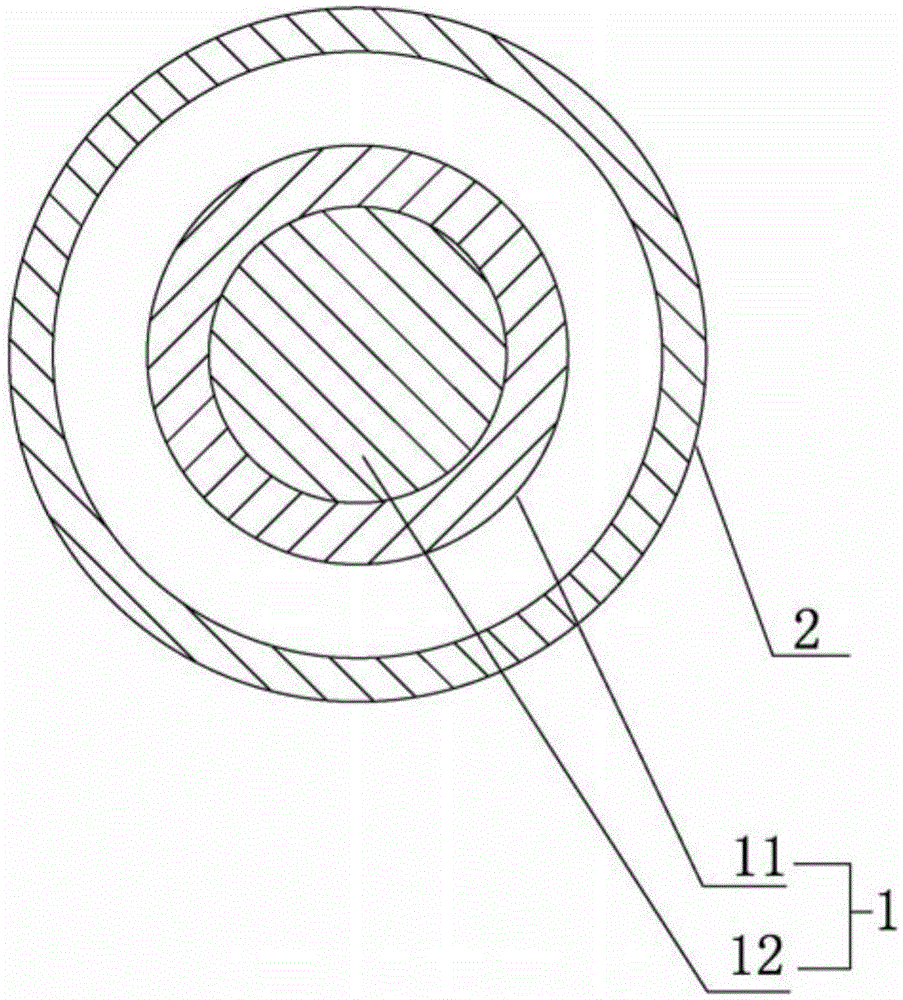

Preparation method of ultra-fine and large-height-width-ratio grid transparent electrode

ActiveCN108859098AAchieve depositionAchieve high-precision manufacturingAdditive manufacturing apparatusApparatus for manufacturing conducting/semi-conducting layersUltra fineAlternating current

The invention discloses a preparation method of an ultra-fine and large-height-width-ratio grid transparent electrode, and belongs to the technical field of additive manufacturing and electronic devices. According to the preparation method of the super-fine and large-height-width-ratio grid transparent electrode, an electric field is used for driving the jet 3D printing and the charge-induced self-aligning to be combined. In one pulse period of the alternating-current pulse power supply, positive-voltage induction generates printing material micro-droplets with positive charges, the negative voltage induction generates the printing material micro-droplets with negative charges, after being deposited on the substrate, the micro-droplets of the charged printing material are in contact with each other, the positive and negative charges are neutralized, and then the charge-induced self-aligning is utilized to realize the accumulation of the charged printing material micro-droplets on the formed layer, and printing of the grid with the set number of layers is completed. The preparation method of the ultra-fine, large and high-width-ratio grid transparent electrode is wide in applicationrange, can obtain the high-conductivity and high-light-transmittance transparent electrode, and high-light-transmittance transparent electrode, and has good popularization and application values.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

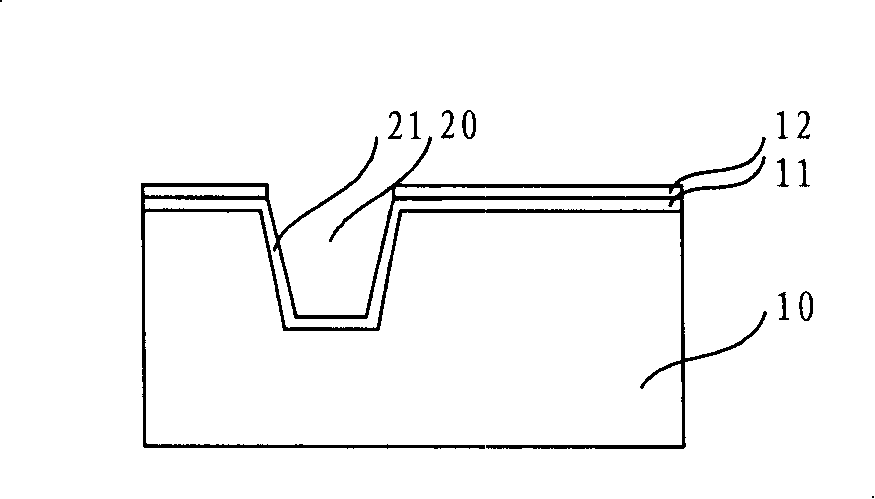

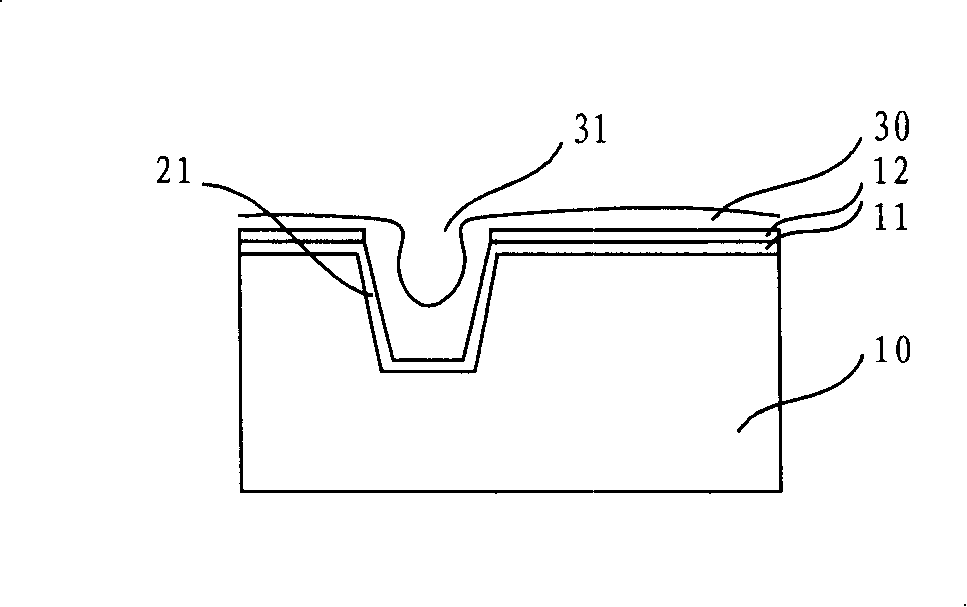

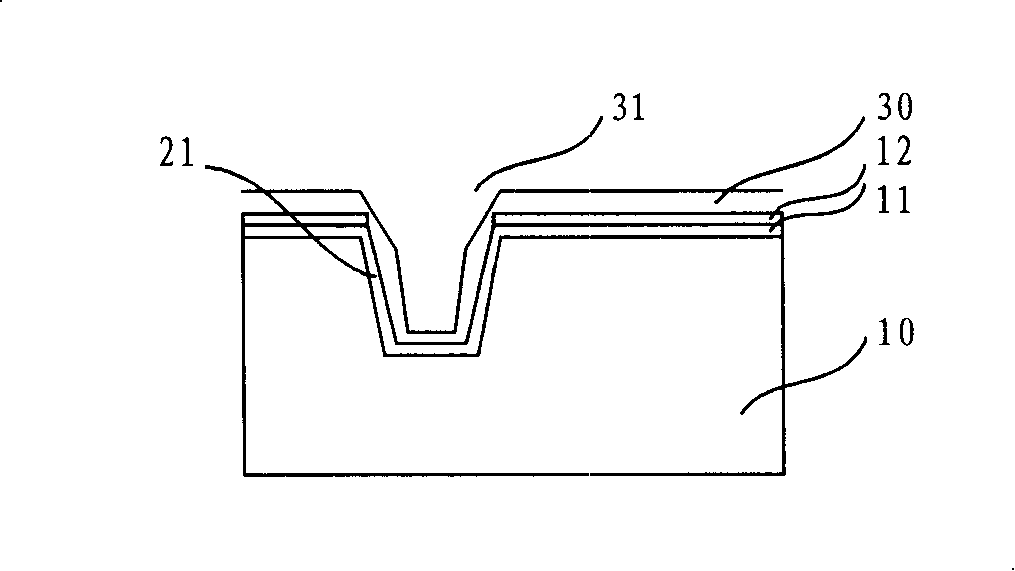

Oxide deposition method of shallow groove isolation region

ActiveCN101197307AReduce stressReduce stress valueSemiconductor/solid-state device manufacturingSemiconductorLow stress

An oxide deposition method of shallow groove isolation area comprises that: a groove is formed on a semiconductor substrate; a sidewall oxide layer is formed on the sidewall and the bottom of the groove; a first oxide layer is deposited on the sidewall oxide layer by low temperature process; the first oxide layer is etched to enlarge a second deposition opening; a second oxide layer is deposited on the first oxide layer. HDPCVD is applied to perform the deposition-etching-deposition technique and can achieve the oxide deposition in the shallow groove isolation area / film layer with no holes; through controlling the temperature of deposition reaction, the density of the deposited film layer can be reduced and further the shallow groove isolation area / film layer oxides with low stress can be achieved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

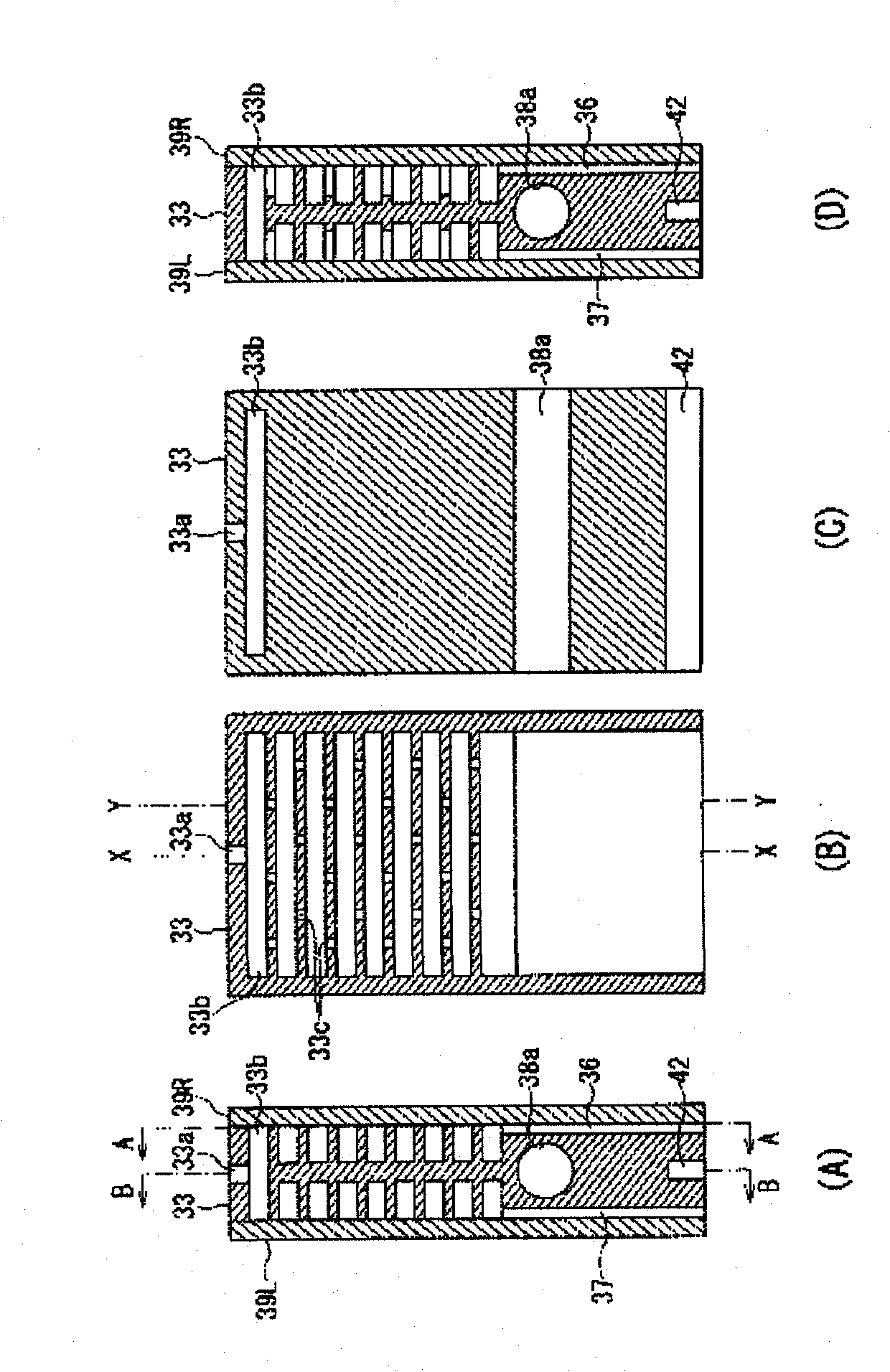

Device and method for manufacturing micro-nano structure

InactiveCN102205944AAchieve restorationAchieve depositionNanostructure manufactureElectricityMicro nano

The invention discloses a device and method for manufacturing a micro-nano structure, belonging to the field of micro-nano manufacture. The device mainly comprises a ballpoint pen, a plating solution, a ballpoint pen rack, an atomic force micro detection system, a cathode platform, a micro motion workbench and a trace electricity power supply, wherein the ballpoint pen containing the plating solution is fixed on the ballpoint pen rack, the ballpoint pen rack is integrally connected with the atomic force micro detection system and is used for roughly positioning and accurately positioning the atomic force micro detection system, the cathode platform and the micro motion workbench are fixedly connected and are spaced by using an insulation material, a ballpoint pen refill is connected with the anode of the trace electricity power supply, and the cathode platform is connected with the cathode of the trace electricity power supply. In the invention, by the application of the trace electricity power supply and a carbon nanotube, atomic assembly, atomic group sedimentation and three-dimensional micro-nano molding become easier, simpler and more precise. The device and the corresponding molding method have certain significances to precise manufacture of micro-nano devices, micro-nano electromechanical progress and development of quantum devices.

Owner:BEIJING UNIV OF CHEM TECH

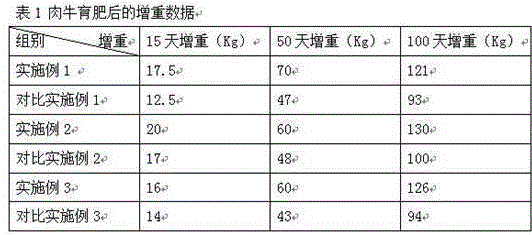

South high moisture and hot region beef cattle rapid fattening culture method

The invention discloses a south high moisture and hot region beef cattle rapid fattening culture method comprising four stages: beef cattle rapid fattening early stage preparation; beef cattle rapid fattening adaptation stage; beef cattle rapid fattening transition period; beef cattle rapid fattening later stage; the method also comprises a beef cattle cooling process, a beef cattle dermatopathy prevention process and a beef cattle enterogastritis prevention process. The method employs store cattle of 12-18 months, preferably uses castrated bulls, and the poise characteristics comprise the following: 300-400kg body weight, healthy growth, big physique, strong arms and legs, and anosis. The beef cattle cultured by the method can have fullness body muscles after fattening, the fur is bright, and average daily weight growth is obvious.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

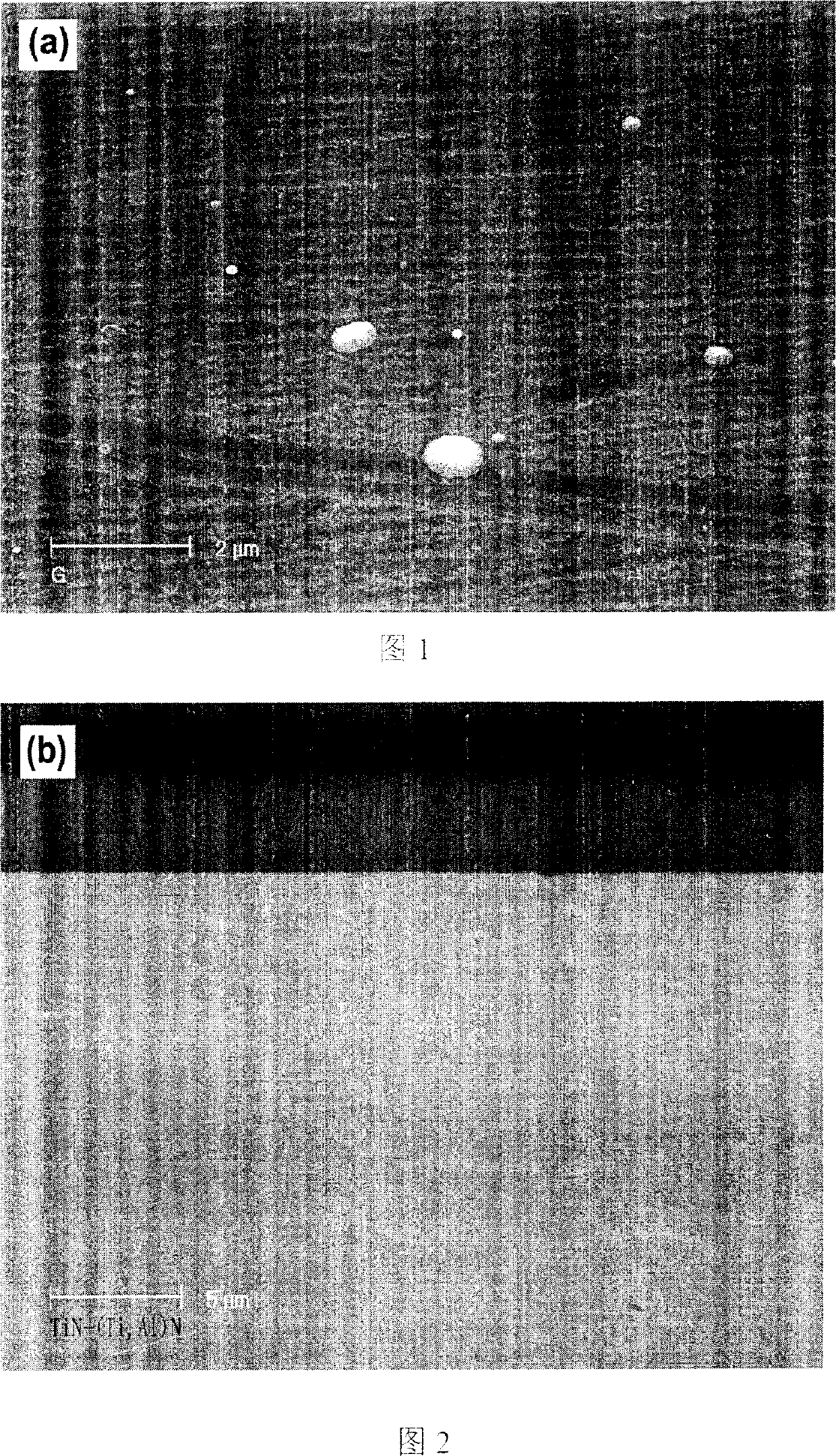

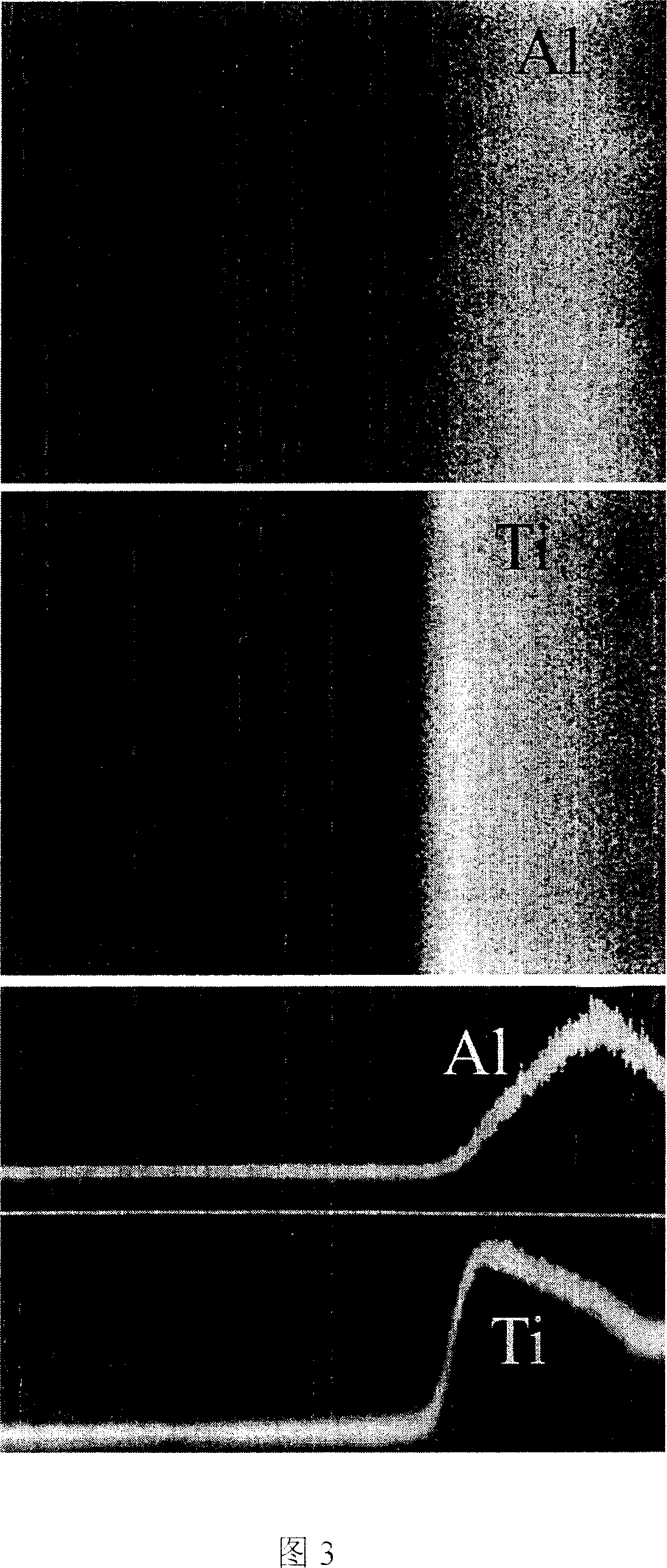

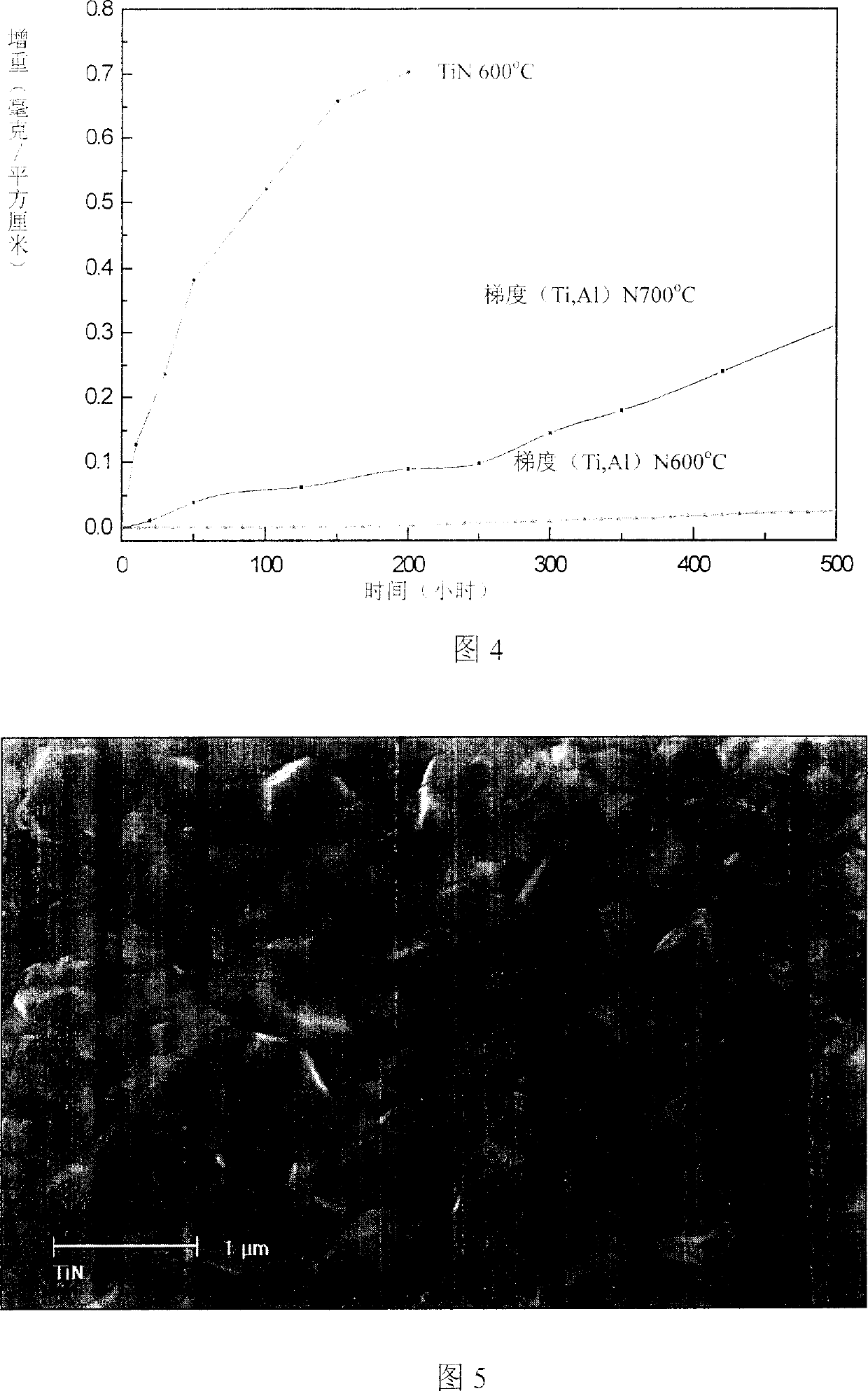

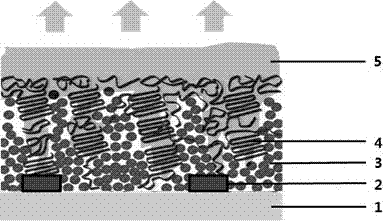

Metal materials protection method (1)

InactiveCN1962947AAchieve depositionSimple structureVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideOxidation resistant

The invention discloses a metal material protecting method, which is characterized by the following: coating hard film with multiple layers of titanium aluminium nitride coating on the surface of metal base; increasing aluminium content and reducing titanium content in the alloy; fitting for high-speed steel, stainless steel, titanium alloy and high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

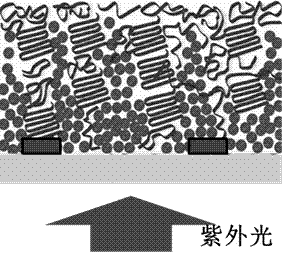

Metal oxide ultraviolet detector and production method thereof

InactiveCN104752546AWide variety of sourcesPromote low temperature conversionFinal product manufactureSemiconductor devicesHigh concentrationShellac

The invention discloses a metal oxide ultraviolet detector and a production method thereof, belongs to the field of optical detectors and solves the problems that due to structure and material reasons of a detection layer, the prior metal oxide ultraviolet detector has high requirement on the production environment, is low in sensitivity and is high in production cost. The metal oxide ultraviolet detector comprises a quartz glass substrate, interdigital electrodes, metal oxide nano-particles and a shellac mixed layer. The production method includes: mixing metal oxide precursor and shellac into mixed solution, coating the quartz glass substrate which the interdigital electrodes are sputtered to, through the mixed solution, after heating and pretreatment, subjecting thin film to solvent annealing with high-concentration ethanol vapor, allowing the shellac in the mixed thin film to rise to the top of the film, subjecting metal elements in the mixed thin film and hydroxyl in the shellac to coordination to convert the metal oxide precursor into metal oxide nano-particles at low temperature, and forming a pointed cone structure by natural stacking; finally, according to the unique thermal polymerization characteristic of the shellac, continuously heating the shellac to solidification, thereby packaging the detection layer of the detector in situ.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Micro nano structure solar battery and preparation method of back light trapping structure thereof

ActiveCN103943716AImprove current efficiencyImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationMicro nanoTrapping

The invention provides a micro nano structure solar battery and the preparation method of a back light trapping structure thereof. The method comprises the steps that a glass substrate is provided; an etching process is used to etch the glass substrate, so that the surface of the glass substrate is in a columnar array structure; and an ion beam etching technology is used and a predetermined angle is rotated, so that the glass substrate whose surface is in an angle-free periodic micro nano structure is acquired, and the angle-free periodic micro nano structure is the light trapping structure. According to the invention, the light trapping structure is located on the back of the solar battery; through reflection, refraction and scattering of the structure, the optical distance of a light in the solar battery is increased; and after the reactive ion etching technology and the ion beam etching technology are used to acquire the angle-free periodic micro nano light trapping structure on the surface, the problems of nonuniform deposition, conductive layer disconnection and the like are avoided when subsequent electrode and silica-based film deposition is carried out.

Owner:SHANGHAI JIAO TONG UNIV

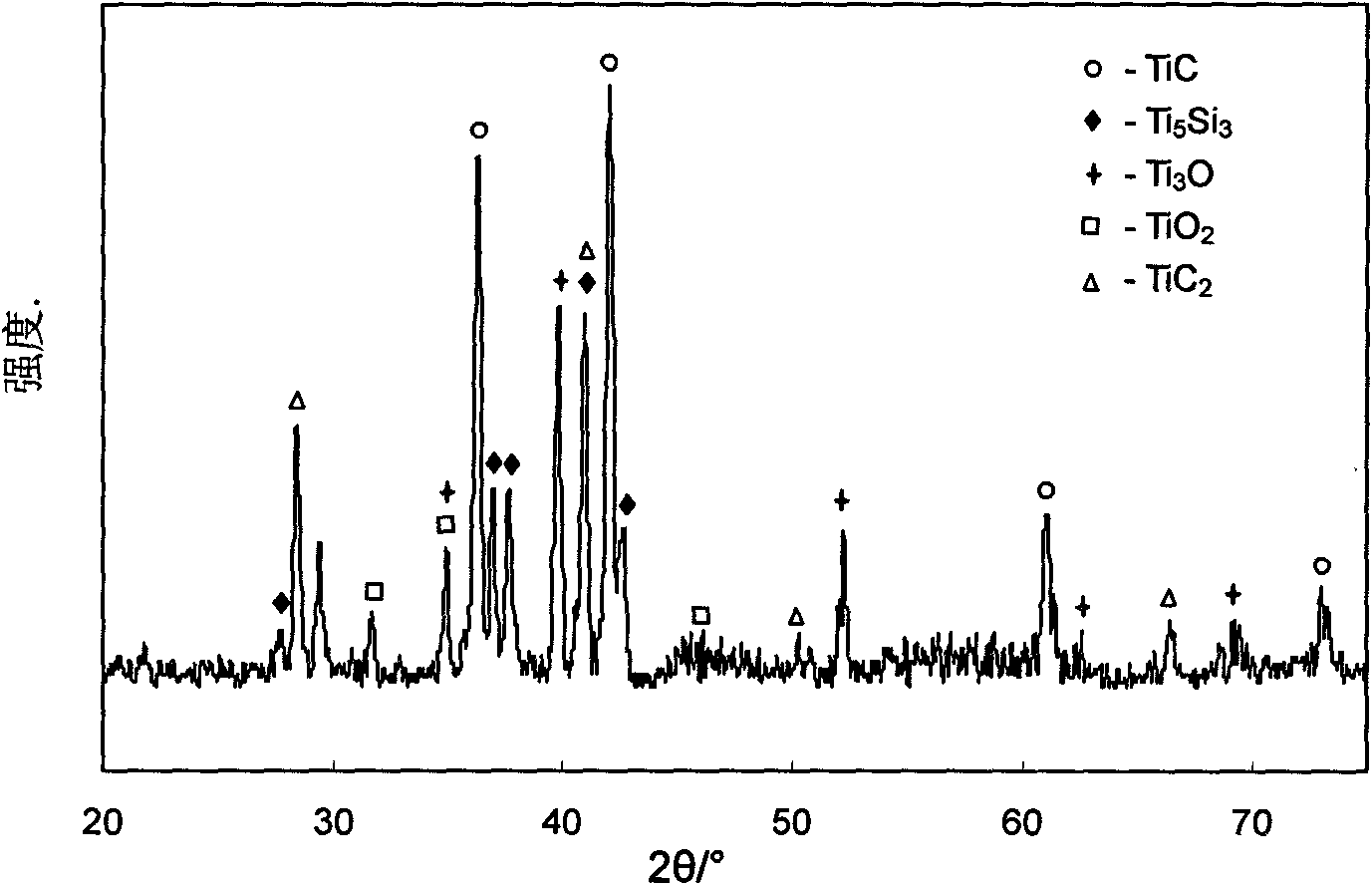

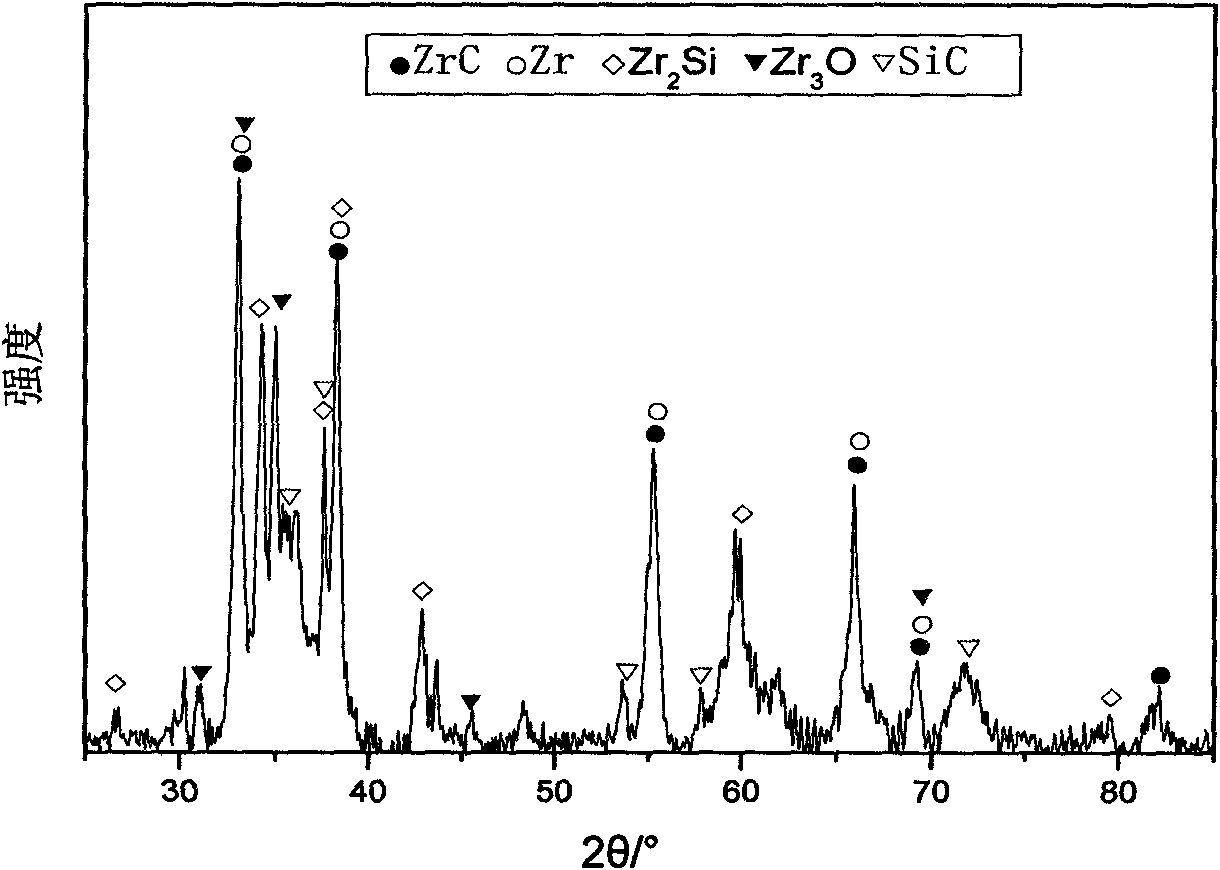

Process based on molten-salt growth method for metallizing surface of ceramic base composite material member

The invention discloses a process based on the molten-salt growth method for metallizing the surface of a ceramic base composite material member, including the following steps: firstly, a molten salt mixed raw material is arranged in a fixed container; secondly, the ceramic base composite material member of which the surface is cleaned is embedded in the molten salt mixed raw material, temperature is raised to 800 to 1200 DEG C under inert atmosphere, and after the temperature is preserved for 1 to 5 hours the ceramic base composite material member is cooled to room temperature along with the furnace; and finally, the ceramic base composite material member is taken out, and the surface thereof is repeatedly cleaned and dried, thereby obtaining the ceramic base composite material member with the metallized surface. The technological process of the invention has the advantages of high preparation speed and efficiency, simple and easily executed operation and high bonding strength between an obtained metallized layer and the ceramic base composite material, thereby meeting the requirement on metallizing the ceramic base composite material member.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of nano-Pd hydrogenation catalyst loaded with three-dimensional reduction graphene oxide

ActiveCN105964247AHigh catalytic activityImprove reusabilityMetal/metal-oxides/metal-hydroxide catalystsDispersityHydrogenation reaction

The invention relates to a preparation method of a nano-Pd hydrogenation catalyst loaded with three-dimensional reduction graphene oxide. The preparation method comprises the steps that a certain amount of PdCl2 and ascorbic acid are added into an aqueous solution of graphene oxide by taking the graphene oxide as a carrier precursor, Pd is uniformly deposited on the generated three-dimensional reduction graphene oxide through a one-step hydrothermal method, and then high-dispersity loaded nano-Pd particles are prepared. By applying the catalyst to a hydrogenation reaction of olefin, the very high catalytic activity and stability are achieved, and the high recycling rate is achieved; the catalyst is mild in preparation condition, simple in process and low in cost, and industrialized production is easy to achieve.

Owner:CHANGZHOU UNIV

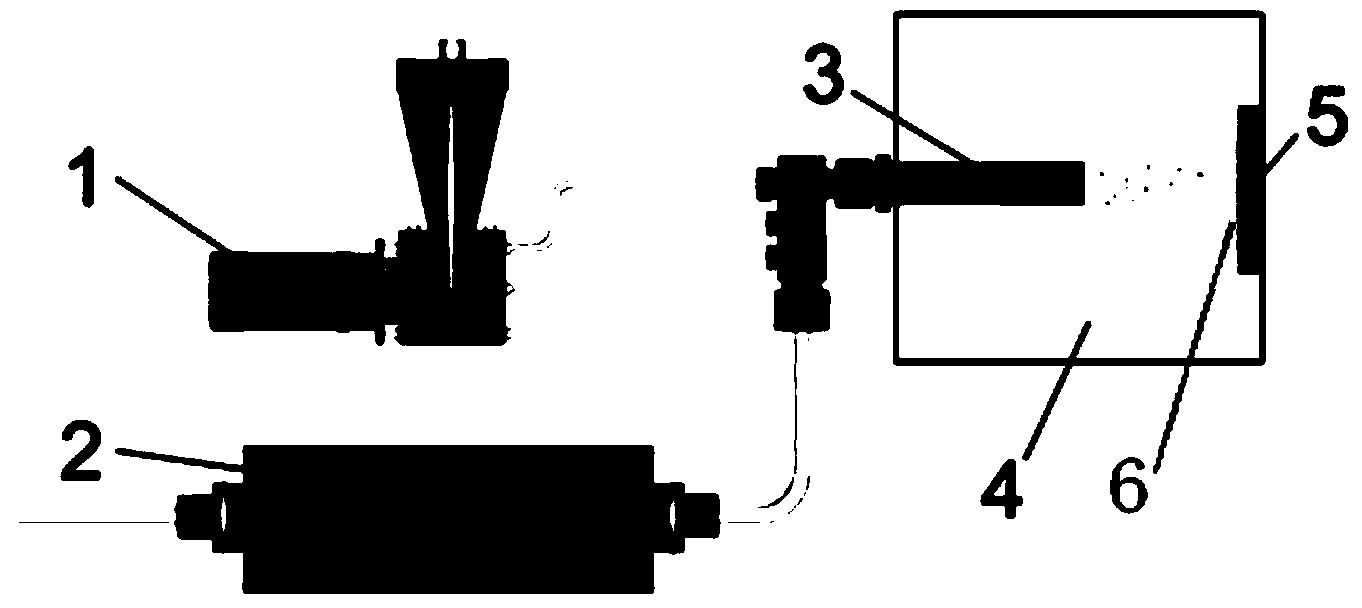

Atomization assisting CVD thin film deposition method

ActiveCN109440083AAdjust gas atmosphereAdjust the atmosphereLiquid/solution decomposition chemical coatingChemical vapor deposition coatingGas phaseRoom temperature

The invention discloses an atomization assisting CVD thin film deposition method. The atomization assisting CVD thin film deposition method is characterized by comprising the following steps that a, an atomization assisting CVD thin film deposition device is designed; b, a plane substrate being about to form a film is placed in an installing hole in a substrate template, then the substrate template is horizontally placed on the upper plate face of a lower lifting plate, and the position of the lower lifting plate is adjusted; d, after a temperature of a reaction area reaches a preset temperature, firstly an atomization source is opened, and is used for atomizing liquid precursors into aerosol precursors, the aerosol precursors are input into a buffering mixing chamber through carrier gas sent out of the atomization source; and e, after the temperature of the reaction area is close to a room temperature or is 45 DEG C or below, the operation that the precursors are input into the buffering mixing chamber through a gas phase matter inflow pipe and an aerosol inflow pipe firstly stops, then a gas sucking pump is closed, finally, a sealing cover is opened, the substrate template is taken out, and finally a substrate is taken down from the substrate template. The thin film deposition method is high in deposition efficiency, reasonable in process arrangement and high in thin film quality.

Owner:CHONGQING UNIV OF TECH +1

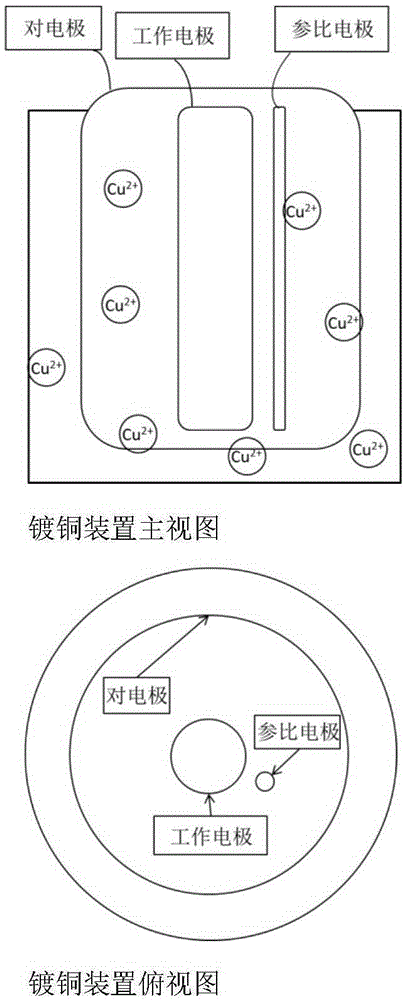

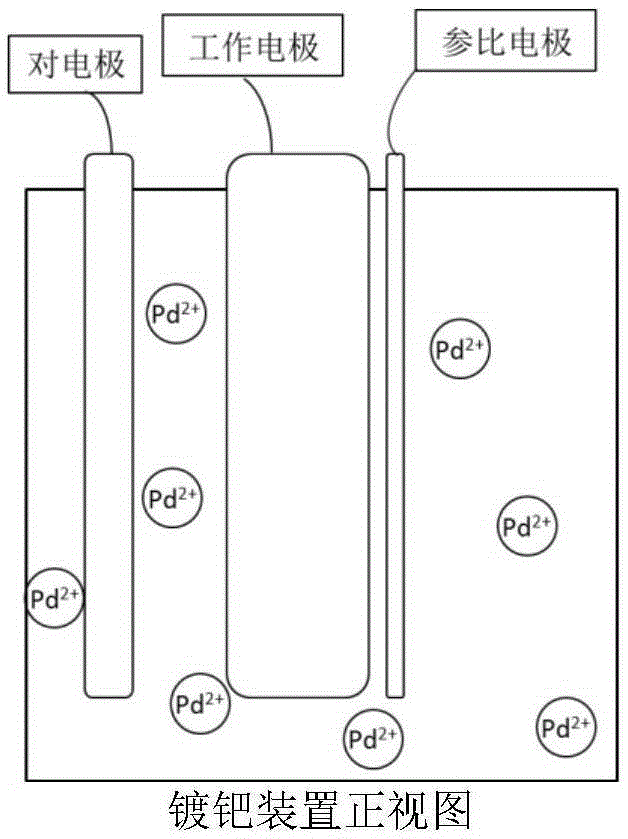

Preparation method of palladium-copper alloy film with controllable components and thickness, palladium-copper alloy film and application

InactiveCN106811778AGood low temperature stabilityGood sulfur resistanceChemical platingReduction potential

The invention relates to a preparation method of a palladium-copper alloy film with controllable components and thickness, the palladium-copper alloy film and application. The preparation method comprises the steps that a layered plating method is adopted, metal palladium and copper are alternately deposited on a carrier to be placed layer by layer, the metal thickness and substance amount on each layer are controlled separately, finally, high-temperature alloying is carried out, and the compact palladium-copper alloy film is formed. According to the method, by controlling the quantity of electric charge of a system, metal palladium and copper with the corresponding volume are accurately deposited, and then the purpose of controlling the components of the alloy film is achieved. In addition, by adjusting and controlling the current density and controlling the film quality, quantities of electric charge in different stages are adjusted and controlled, the composition of the palladium-copper alloy film is controlled, and then the alloy film thickness is adjusted and controlled. Traditional chemical plating is broken through, the limit of metal reduction potential is broken through due to the limit that each layer needs the alloying step, and deposition of palladium metal on the copper-based surface is achieved. The preparation period of the alloy film is greatly shortened, the application range of the film is expanded, and the preparation method has the advantages of being simple in process and good in repeatability and is suitable for large-scale alloy film preparation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Pulse laser sediment method

InactiveCN101128616AAchieve depositionMetallic material coating processesOptical elementsSedimentPulsed laser deposition

The invention relates to a method for coating a body of metal, glass, rock or plastic, in which the body is coated by laser ablation, with the body shifted in a material plasma fan ablated from a moving target in order to achieve a coating having as regular quality as possible. The invention also relates to the product produced by the method.

Owner:比克顿有限公司

Chemical vapor deposition equipment and deposition method

InactiveCN1696340AControl orientationTemperature controlChemical vapor deposition coatingFiberGas phase

A chemical vapor deposition apparatus for growing film or material (such as carbon nanofibres) on metal layer or catalyst is disclosed. A HF magnetic field acts on the metallic layer in the non-metal reaction chamber to generate eddy effect. The substrate containing metallic layer on a non-metal plate is heated to a controlled temp while the intensity, frequency and acting time of a magnetic field are controlled for growing film at defined position. The polarity of the magnetic field is controlled for directional growing.

Owner:SOUTHEAST UNIV

Preparation method of high-temperature creep resistant grounding substrate for semiconductor equipment

ActiveCN104294206AImprove conductivityUniform thicknessMolten spray coatingSemiconductor/solid-state device manufacturingCoated surfaceAlloy substrate

The invention relates to a method for preparing a pure aluminum coating on a metal or alloy substrate, and in particular relates to a preparation method of a high-temperature creep resistant grounding substrate for semiconductor equipment. The preparation method comprises the following steps: (1) pretreating a grounding substrate matrix; (2) putting the matrix on a special fixture; (3) spraying pure aluminum in a cold spraying mode; (4) performing heat treatment after spraying; and (5) performing subsequent treatment on the coating surface. The preparation method disclosed by the invention can be used for forming pure aluminum coatings on various metal or alloy substrates, and can ensure that a product keeps the performance such as high-temperature creep resistance of the substrate on the matrix and also has various properties of the pure aluminum coatings on the surface.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

Pulsed laser deposition device and method

PendingCN113445007AReduce energy lossImprove stabilityVacuum evaporation coatingSputtering coatingDeposition processPulsed laser deposition

The invention discloses a pulsed laser deposition device. The pulsed laser deposition device comprises a reaction cavity, a plurality of target machines, and a plurality of laser devices, wherein the reaction cavity is internally provided with a supporting column used for fixing a substrate table, a first heating element located above the substrate table and a second heating element located below the substrate table, target materials are fixed at the second ends of the target machines, the target materials are located above and / or below the substrate table in the reaction cavity, included angles are formed between the surfaces of the target materials and the surface of the substrate table, the plurality of laser devices respectively generate laser beams, the first heating element and the second heating element are both provided with notches, and the laser beams linearly reach the surfaces of the target materials in the direction parallel to the surface of the substrate table, and plasma formed by irradiating the surfaces of the target materials through the laser beams reaches the surface of the substrate table through the notches in the first heating element and the second heating element. According to the pulsed laser deposition device, a double-sided skew symmetry deposition process is adopted, so that film deposition can be carried out on both sides of the substrate table, and large-area, large-batch and high-quality film preparation is realized.

Owner:SONGSHAN LAKE MATERIALS LAB

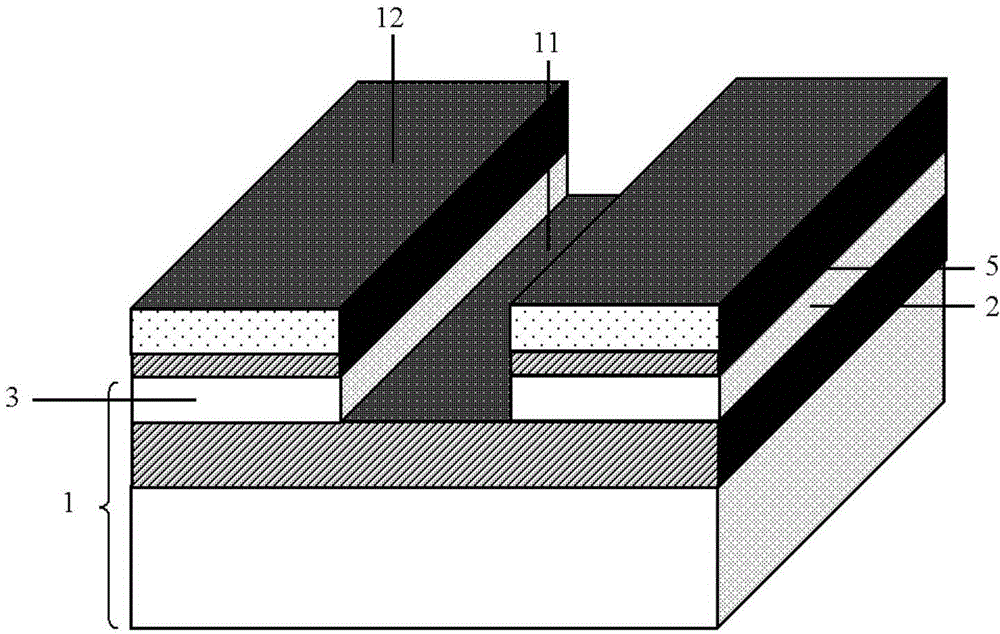

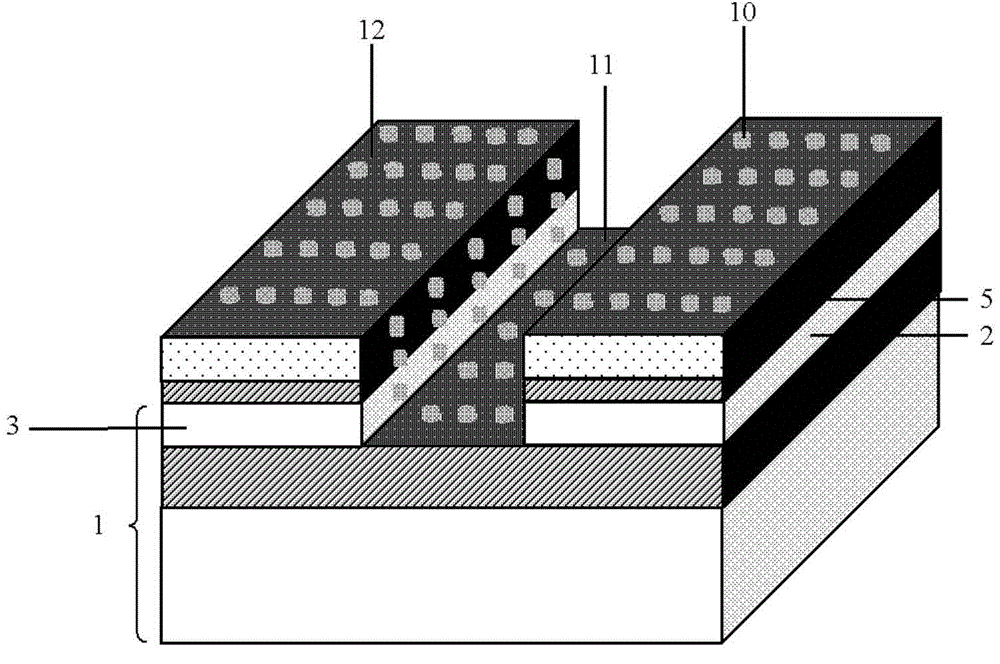

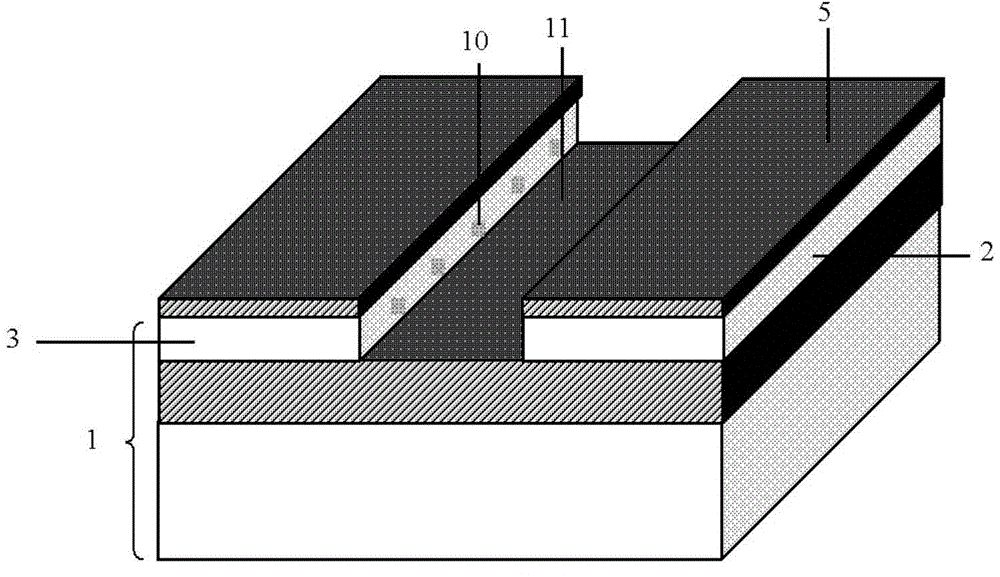

III-V clan nano wire planar transistor based on SOI substrate and preparation method thereof

InactiveCN104934479AAchieve depositionAchieve growthSemiconductor/solid-state device manufacturingNanotechnologyNanowireSoi substrate

An III-V clan nano wire planar transistor based on a SOI substrate and a preparation method thereof; the transistor comprises the following elements: the SOI substrate; a source zone and a drain zone formed on the SOI substrate; a plurality of III-V clan nano wires connected with the source zone and the drain zone; a SiO2 buffer layer formed on surfaces of the source zone and the drain zone; an insulation medium layer formed on surfaces of the III-V clan nano wires and the SiO2 buffer layer, and completely wrapping the III-V clan nano wires; a source electrode formed on the top of the soruce zone; a drain electrode formed on the top of the drain zone; a grid electrode formed on the plurality of III-V clan nano wires between the source zone and the drain zone, and wrapping the plurality of III-V clan nano wires. The preparation of plane nano wire transistors can be realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

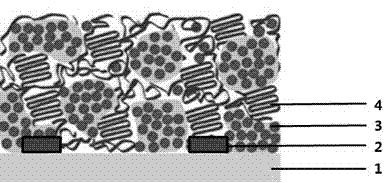

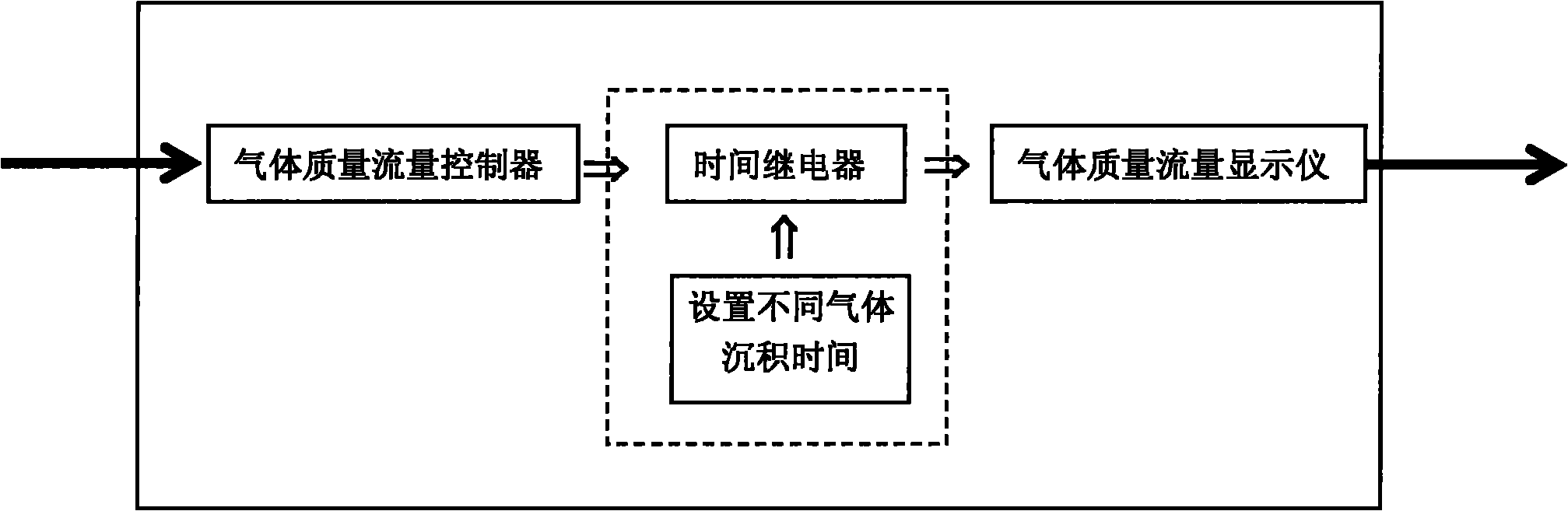

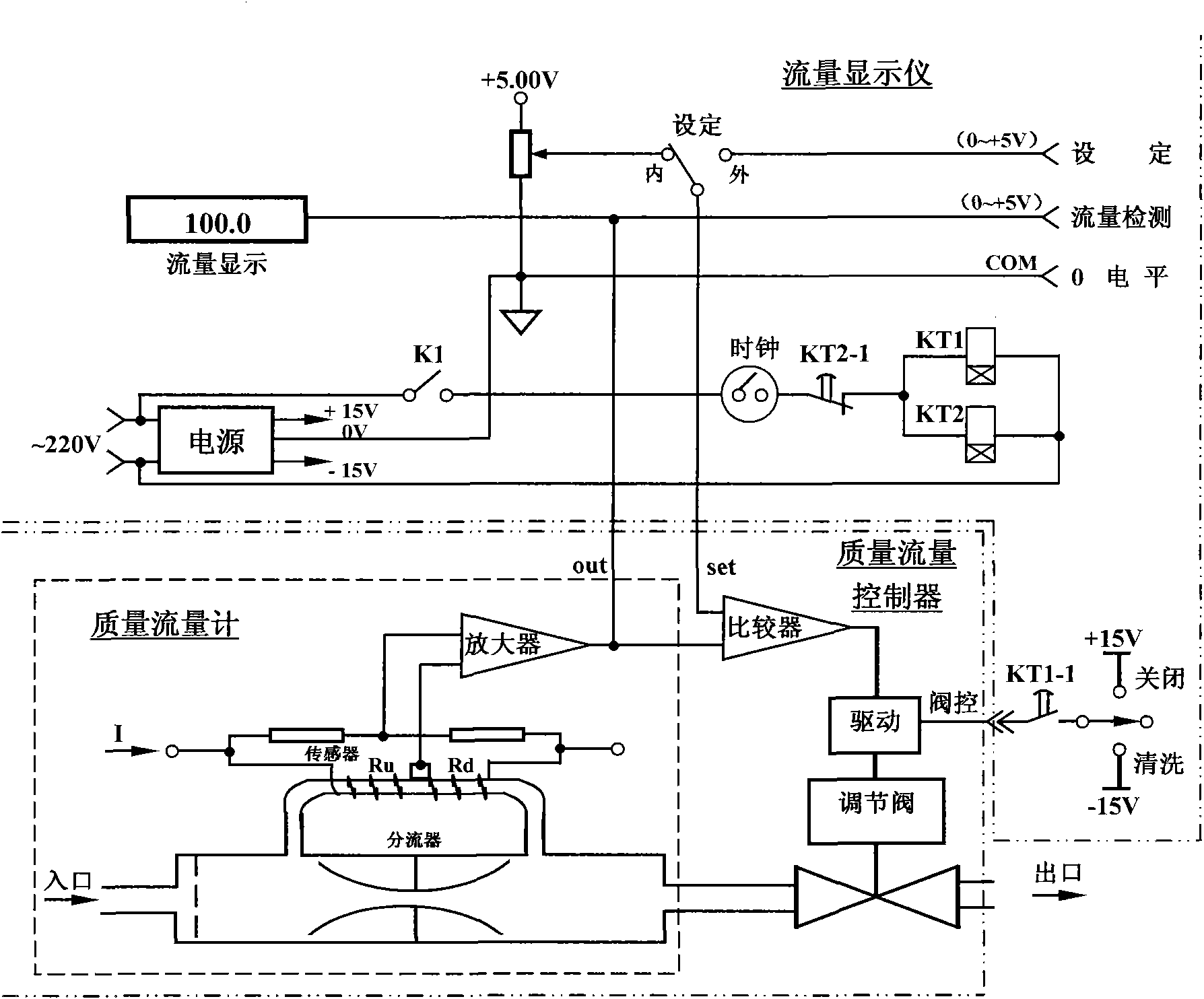

Multi-layer film deposition method

InactiveCN102094180AHigh control precisionAchieve depositionVacuum evaporation coatingSputtering coatingTitanium nitrideMetallic materials

The invention belongs to the technical field of the surface deposition of a superhard multi-layer coating on a metal material, and specifically relates to a titanium / titanium nitride multi-layer film deposition method which solves the problem of great thickness fluctuation of each unit layer in the multi-layer film deposition process based on common arc ion plating. The method comprises the following steps: (1) by alternately introducing gas, accurately controlling the flow and introducing time of the gas; and (2) depositing a metal / metal nitride multi-layer film on the surface of a workpieceby the arc ion plating technology. By using a gas mass and flow controller, multi-way gas of argon gas and nitrogen gas can be alternately introduced, the gas flow and the alternate gas introducing time can be accurately controlled, and the gas flow value and the corresponding deposition time can be set, so that a multi-layer film with 60 layers can be deposited. The alternate gas flow control technology can ensure that the thickness and mass of each unit layer of the multi-layer coating can be effectively controlled, thereby greatly enhancing the unit layer thickness control accuracy of the multi-layer film and effectively improving the performance of the multi-layer film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

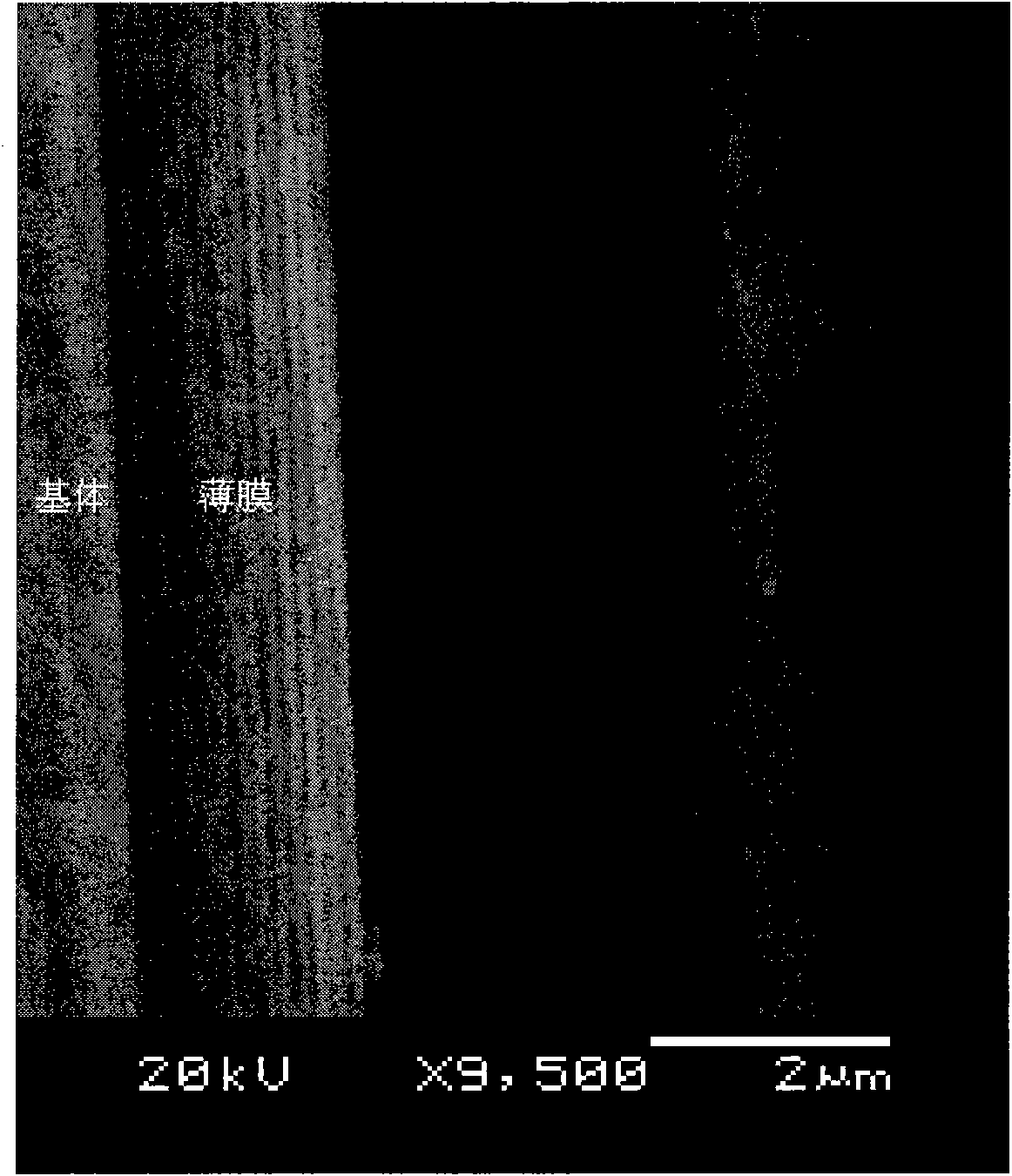

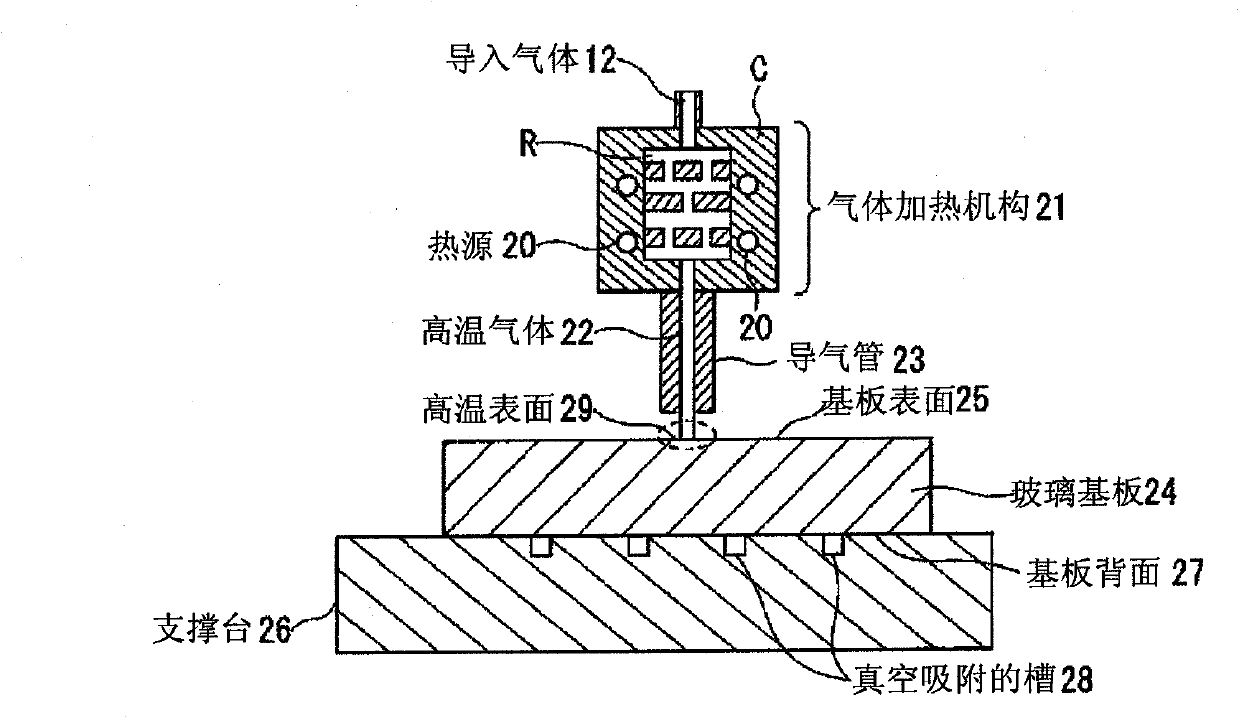

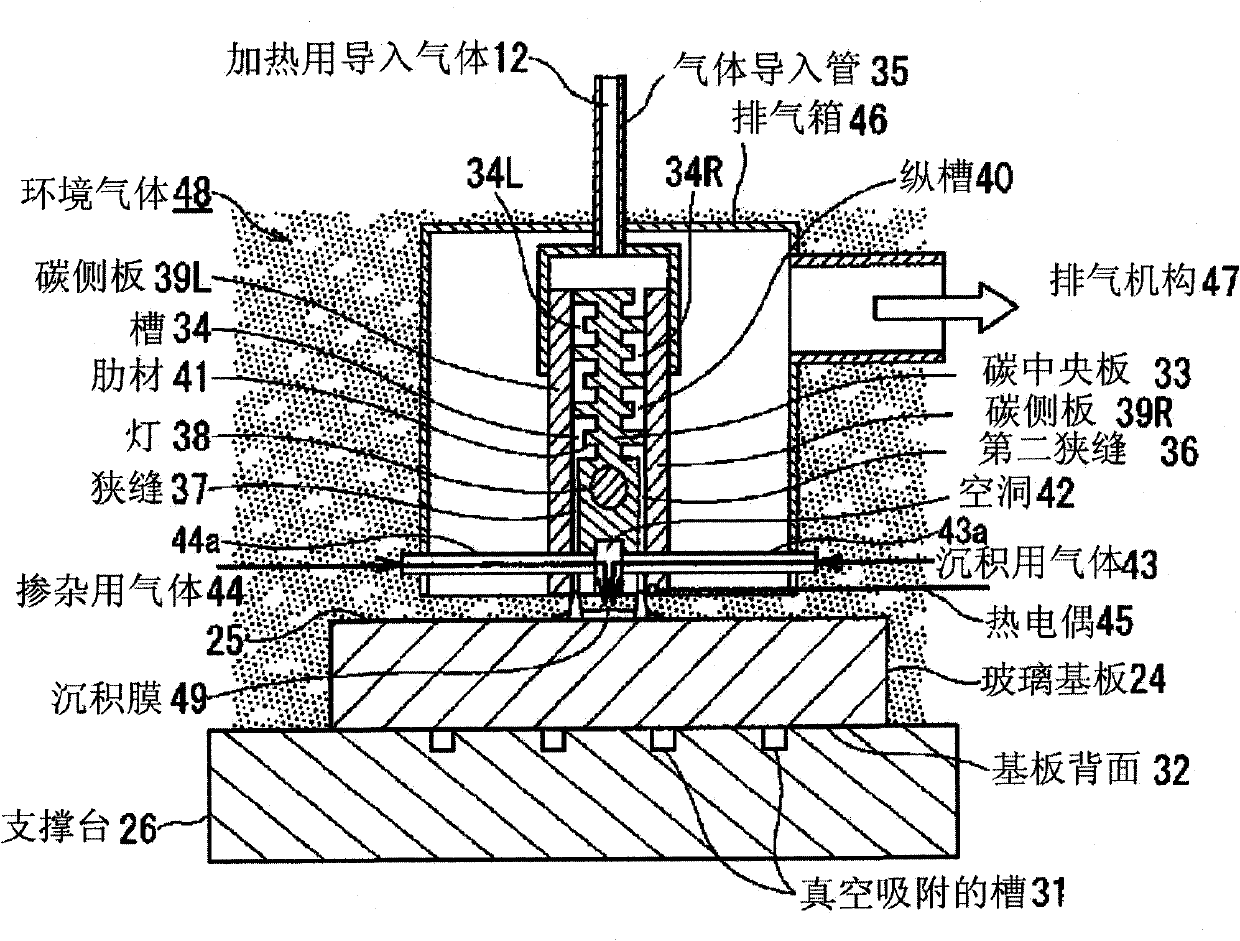

Heating device, film forming apparatus, film forming method, and device

InactiveCN102017084ALow costPrevent heat conductionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSoftening point

Provided is a heating device capable of forming a film efficiently on a glass substrate. Also provided is a film forming apparatus having the heating device. The film forming apparatus comprises the heating device for blowing such a high-temperature gas vertically to the surface (25) of a glass substrate (24) placed on a supporting bed (26), as has a temperature higher than the softening point temperature of the glass substrate. The film forming apparatus blows such a depositing gas (43) simultaneously with a high-temperature gas to the surface of the glass substrate, as is thermally decomposed to form a film deposit.

Owner:PHILTECH

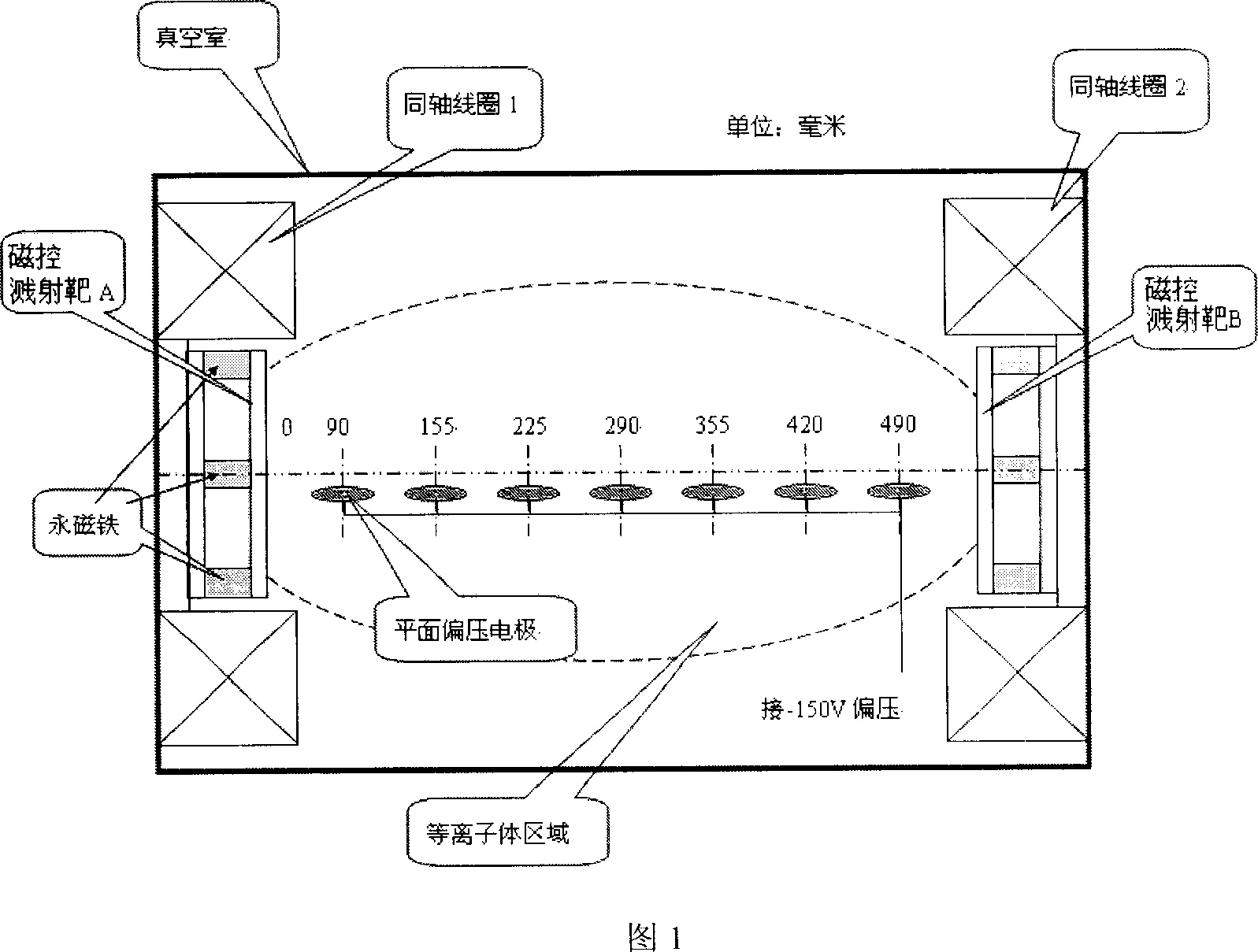

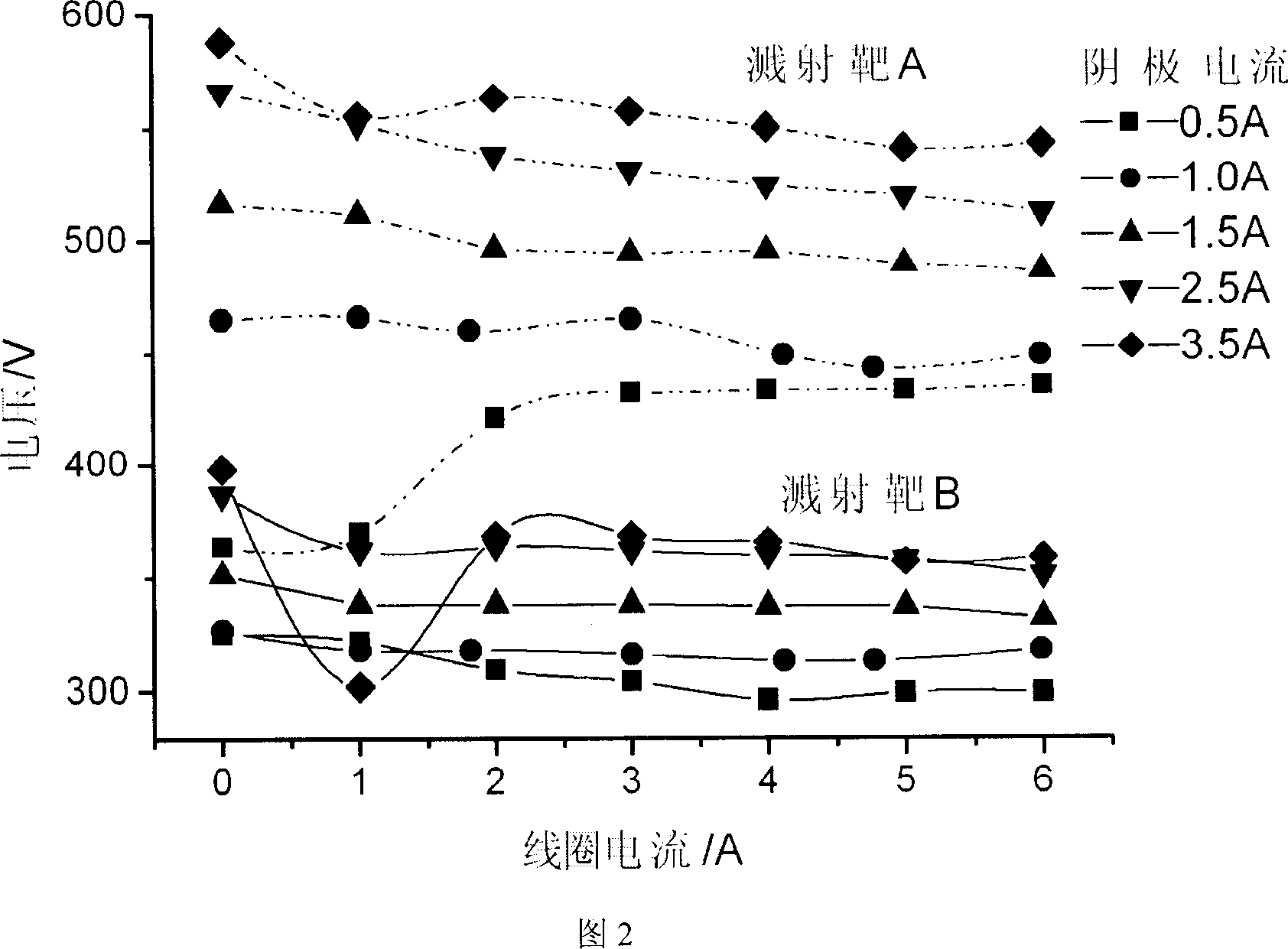

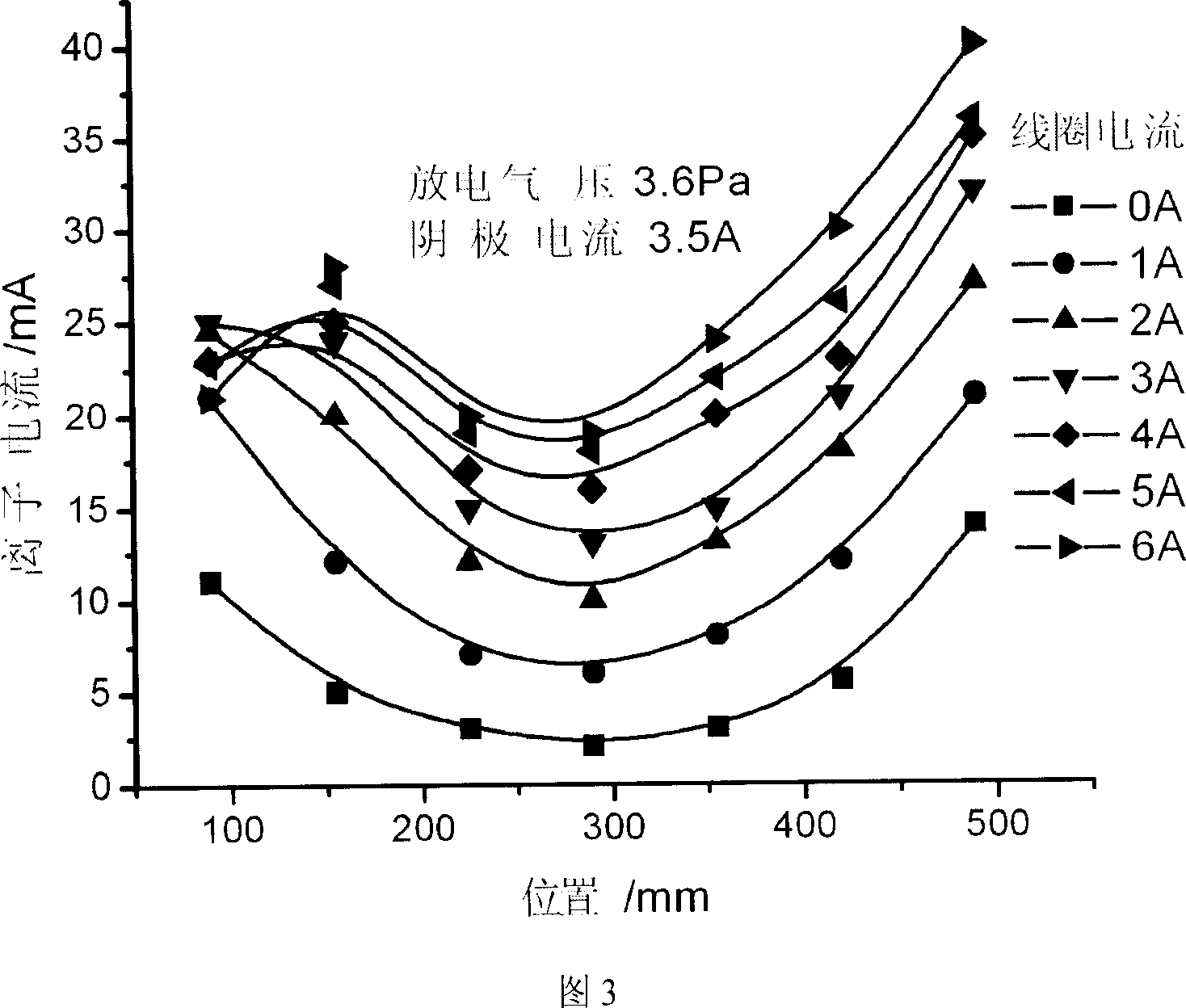

Magnetic mirror field constrained bitarget non balancing magnetron sputtering method

InactiveCN1948548AAchieve depositionRaise leadVacuum evaporation coatingSputtering coatingPower flowPlasma density

The invention discloses a opposite-target non-equilibrium magnetron spattering system with magnetic mirror field restriction, which is mainly used in technique field of surfacial project. It is characterized in that: Two electrified coaxial coils are set opposite two permanent-magnet magnetron targets. They can form a complete closed magnetic mirror field which is coaxial with magnetron targets. To control magnetic mirror field based on regulating current in coils, and adjust state, deposit parameter of discharging plasma subtly. Magnetic coils enhance cathode discharging, increase plasma derivation in cathode zone and advance plasma density in deposit zone. Applying coaxial magnetic mirror field to restrain plasma with adding coaxial coils can enlarge adjusting range of deposit parameter. Compared with routine magnetron spattering technique, non-equilibrium magnetron spattering technique has adjustable plasma state, high plasma leaving rate and high ion-atom arrival rate etc.

Owner:DALIAN UNIV OF TECH

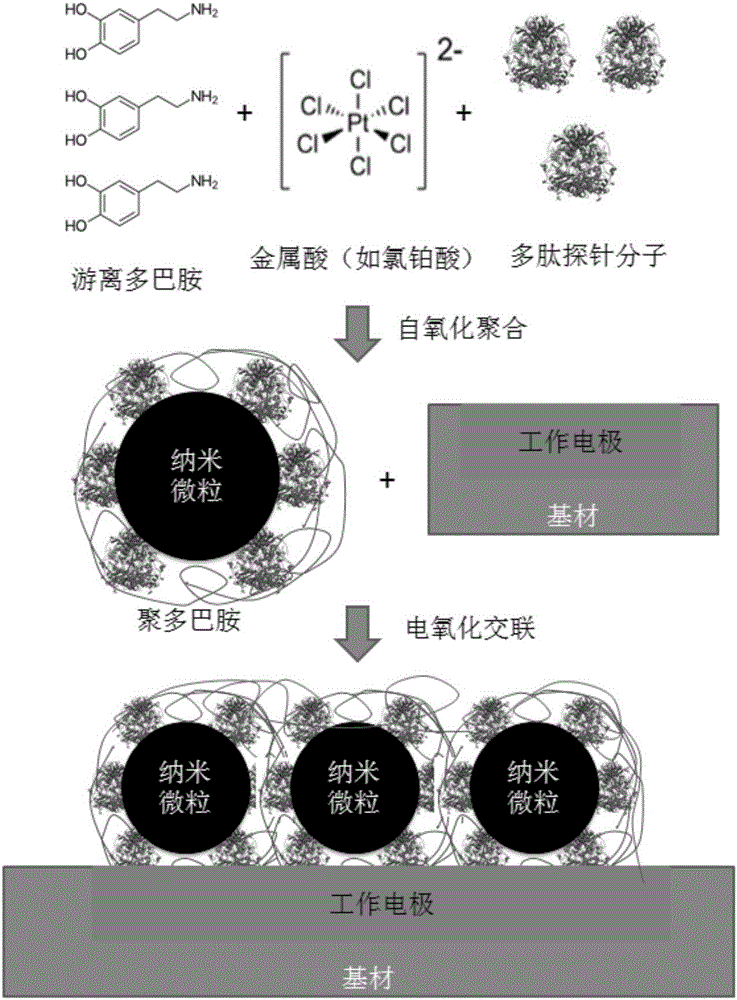

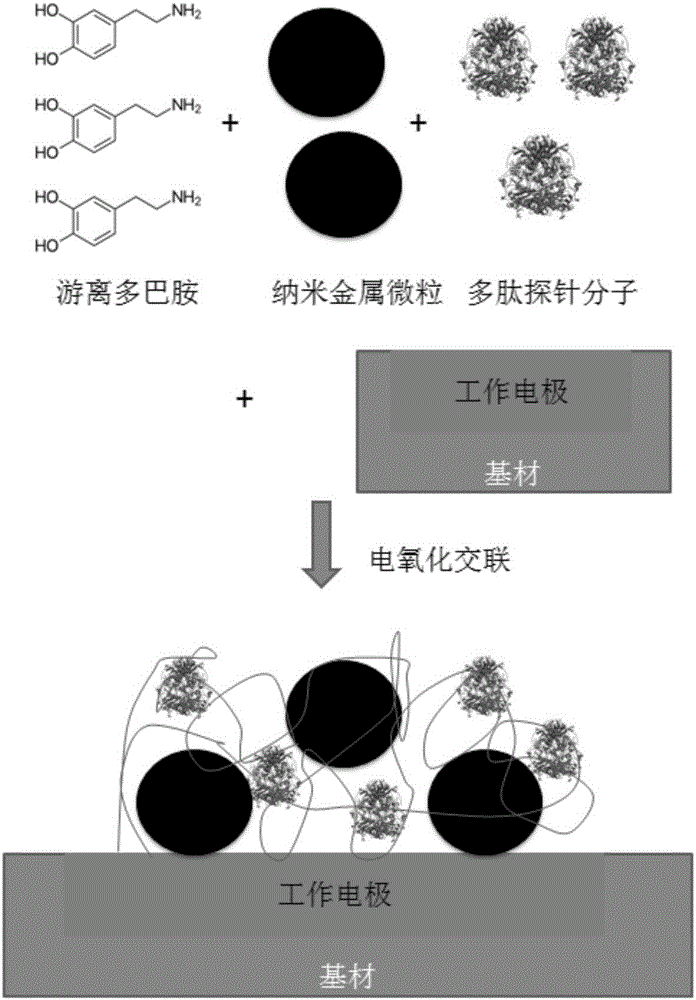

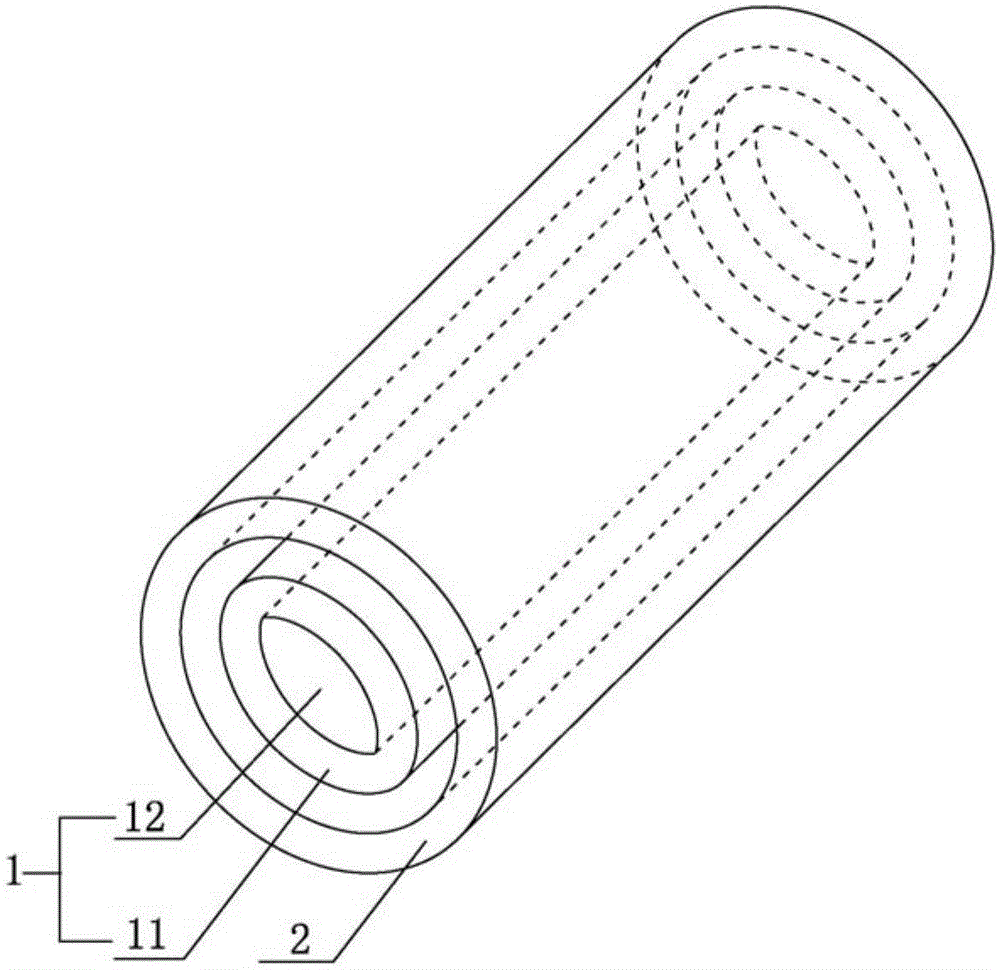

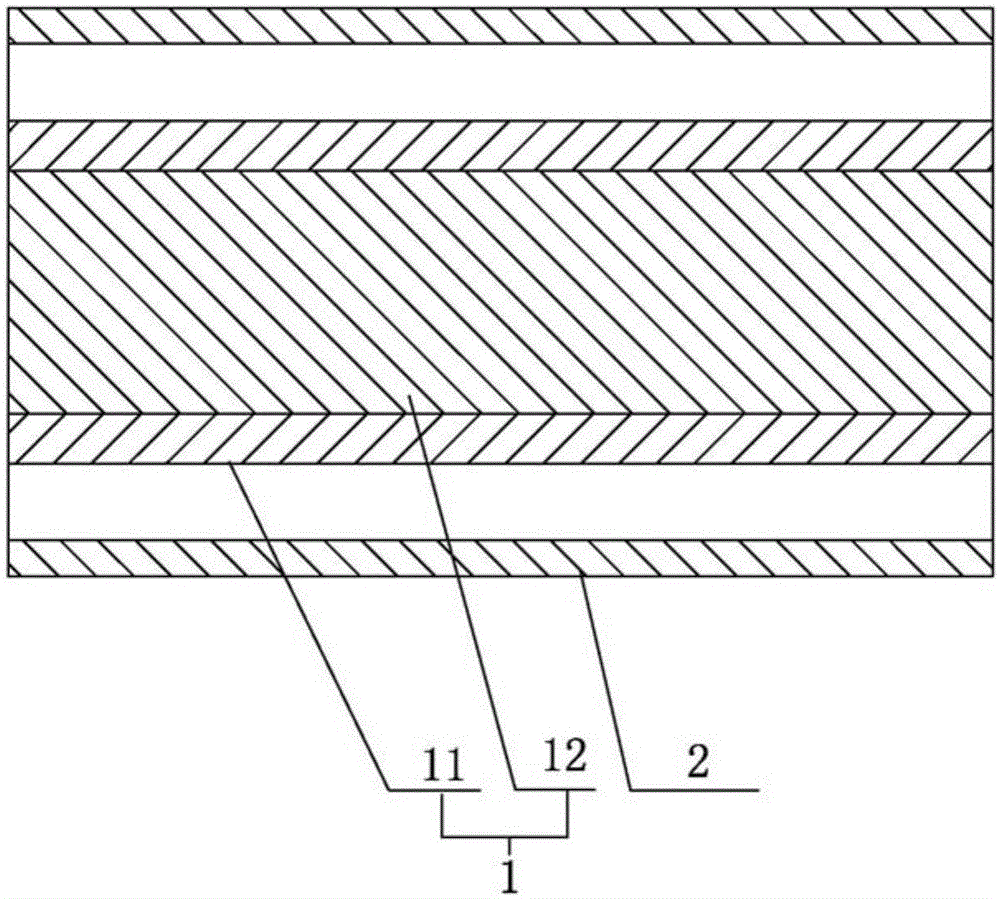

Preparation method of electrochemical sensor with surface curing polypeptide probe

ActiveCN106290520AActive preservationHigh activityMaterial analysis by electric/magnetic meansCross-linkAdhesive

The invention discloses a preparation method of an electrochemical sensor with a surface curing polypeptide probe. The method comprises the following steps that electrodes of the electrochemical sensor are prepared on a base material; oxidized dopamine is utilized for cross-linking metal nanometer particles and polypeptide probe molecules, and the cross-linked metal nanometer particles and polypeptide probe molecules are attached to a working electrode, that is to say, a polydopamine probe layer is formed on the working electrode; a permeable membrane solution is plated to the polydopamine probe layer and dried, and a permeable membrane solution is formed. According to the preparation method of the electrochemical sensor with the surface curing polypeptide probe, the multiple purposes such as electrode modification, polypeptide probe molecule curing and bonding layer adding are achieved in the same process simultaneously through a dopamine oxidation polymerization reaction, the manufacturing process is greatly simplified, and the manufacturing cost is reduced. Dopamine has good biocompatibility, achieves an excellent adhesive effect and can be closely boned to almost all types of surfaces. Therefore, for the manufacturing process, the step of adding biocompatibility adhesives or conducting bonding treatment after permeable membrane coating can be omitted, the production process is simplified, and the cost is reduced.

Owner:MICRO TECH MEDICAL HANGZHOU CO LTD

Device and method for coating inner wall of pipe

InactiveCN106282973AAchieve depositionUniform dischargeChemical vapor deposition coatingEngineeringConductive materials

The invention discloses a device for coating the inner wall of a pipe. The device comprises a power source and an inner electrode capable of being inserted into the pipe to be coated. The inner electrode is of a double-layer structure, the inner layer is an electric conductor and the outer layer is a dielectric layer. In use, the inner electrode is arranged in the pipe to be coated and connected to the power source, and the pipe to be coated is made of a conductive material and is connected to the power source. In the electrified state, dielectric barrier discharge is generated between the inner electrode and the pipe to be coated, gas raw materials are stimulated to generate plasma, and thin film deposition is achieved. The invention further discloses a method for coating the inner wall of the pipe through the device for coating the inner wall of the pipe. By the adoption of the device and method for coating the inner wall of the pipe, the inner electrode with the dielectric layer on the surface and the conductive pipe to be coated are adopted for forming a dielectric barrier discharge structure manner, the device can achieve uniform discharge under the high pressure even under the atmospheric pressure, accordingly the uniform plasma or relatively uniform plasma is generated through stimulation of the high-frequency high-voltage power source, and the thin film deposition of the inner wall of the metal pipe is achieved.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com