Magnetic mirror field constrained bitarget non balancing magnetron sputtering method

A magnetron sputtering and unbalanced technology, applied in the field of surface engineering, can solve the problems of low plasma density, small adjustment range, and reduced plasma density, so as to improve sputtering efficiency, improve film quality, and strengthen ionization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

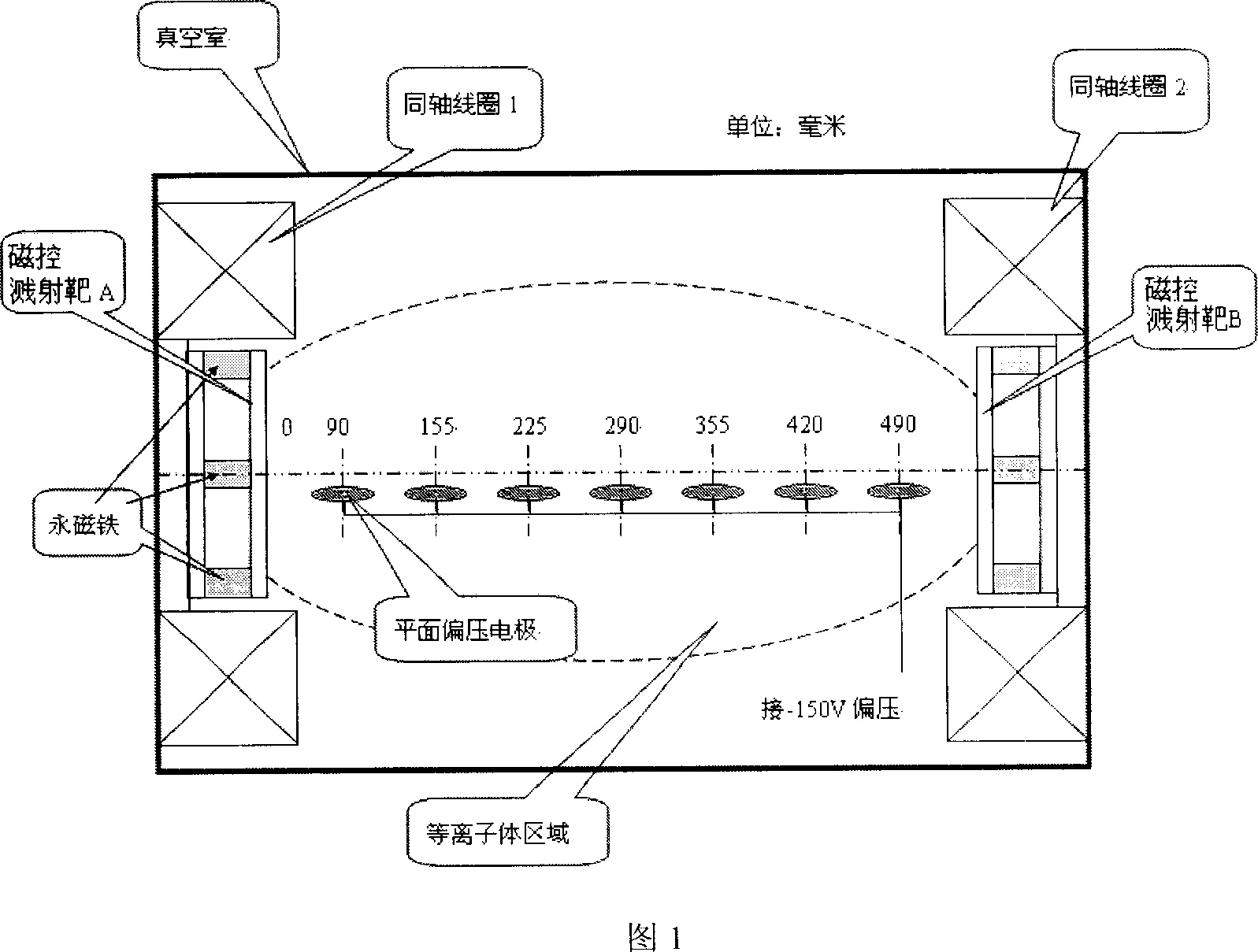

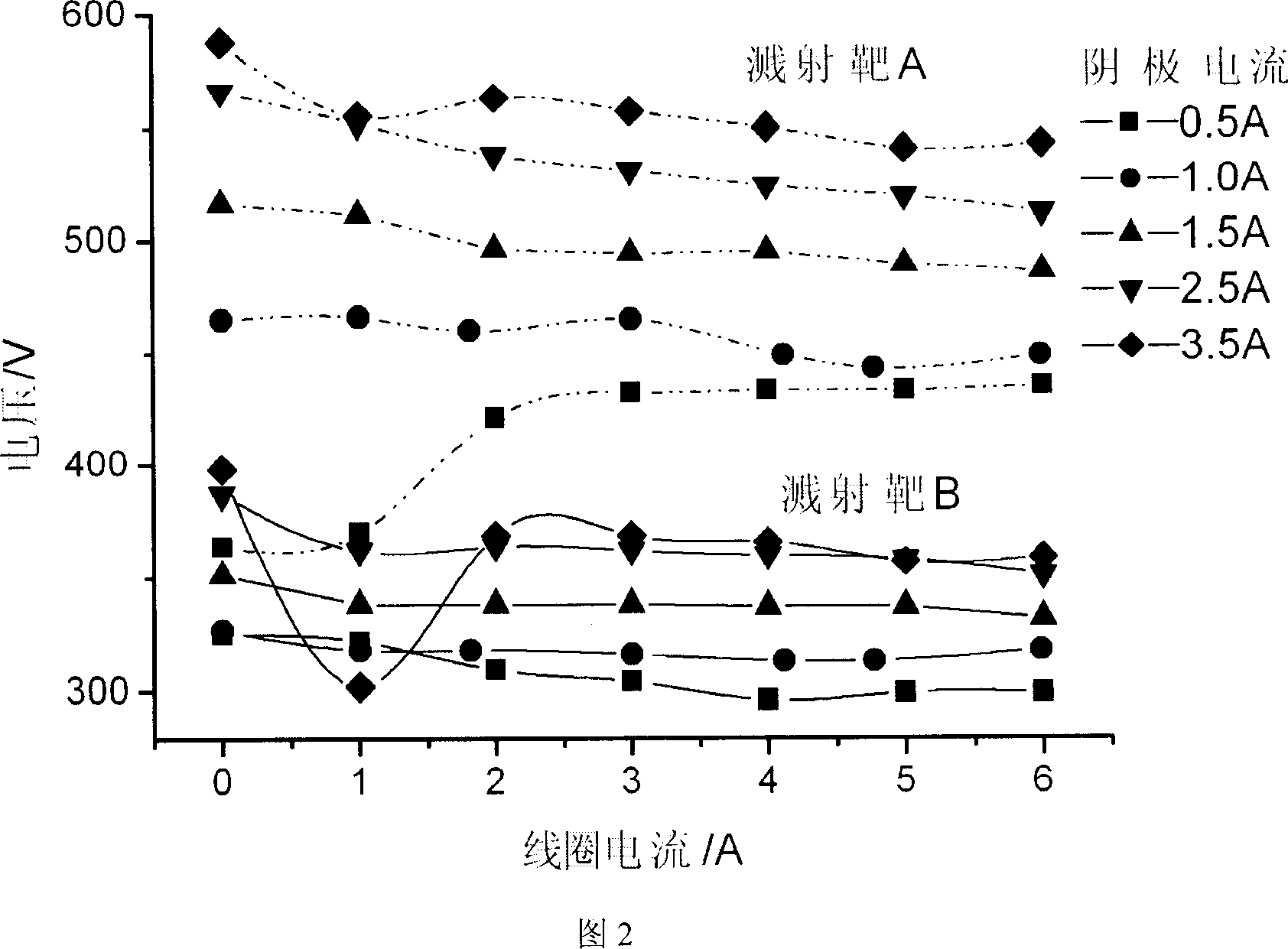

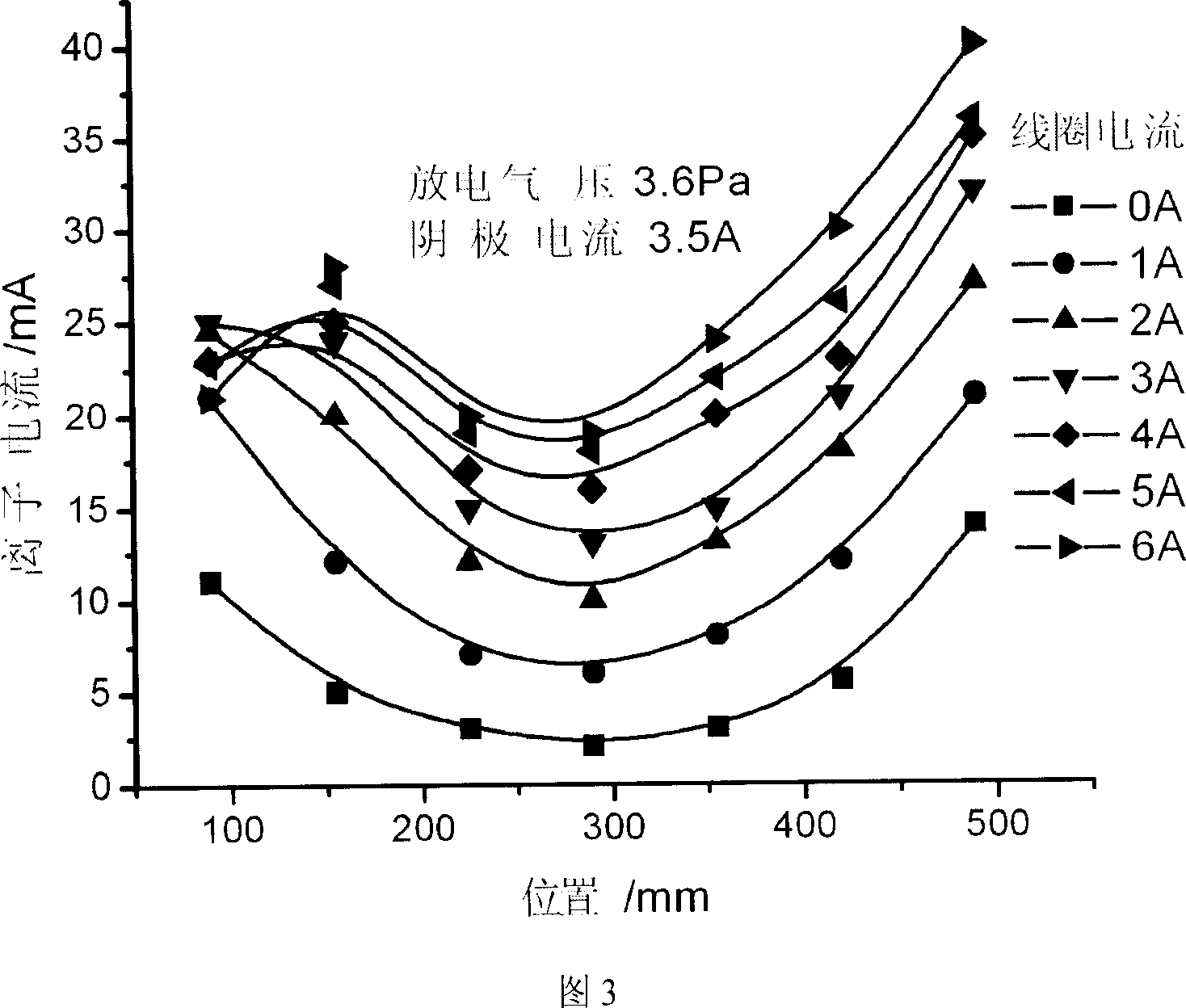

[0015] A magnetic mirror field-constrained double-target unbalanced magnetron sputtering method uses two permanent magnet magnetron sputtering targets A and magnetron sputtering targets B to be placed oppositely, and two coaxial coils 1 and 2 It is two Helmholtz coils, coaxially placed on the periphery of magnetron sputtering target A and magnetron sputtering target B, two oppositely placed permanent magnet magnetron sputtering targets A and magnetron sputtering targets B The two Helmholtz coaxial coils 1 and 2 coaxially placed around form a magnetic mirror field after the current is applied. During the application process, the permanent magnet magnetron sputtering target A and the magnetron sputtering target B The internal permanent magnet forms a closed magnetic field on the surface of the magnetron sputtering tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com