Patents

Literature

69results about How to "Prevent heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

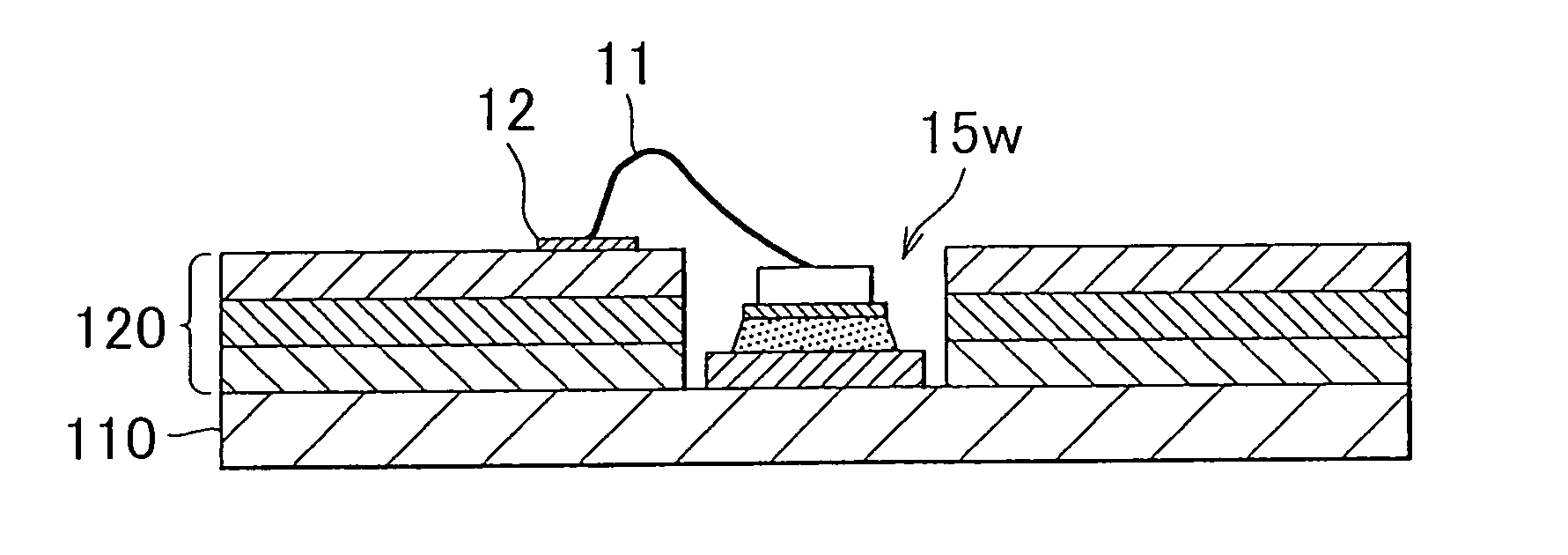

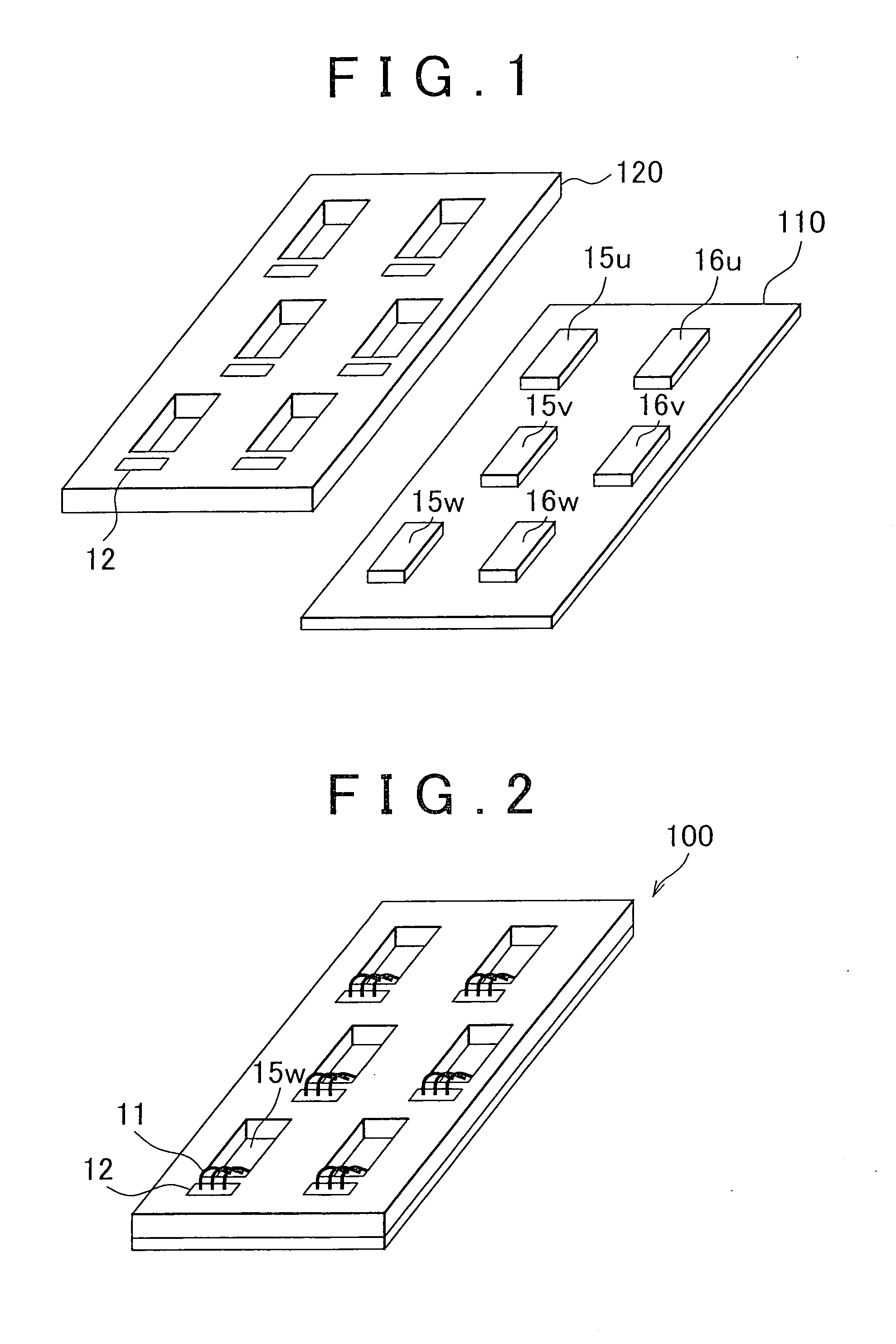

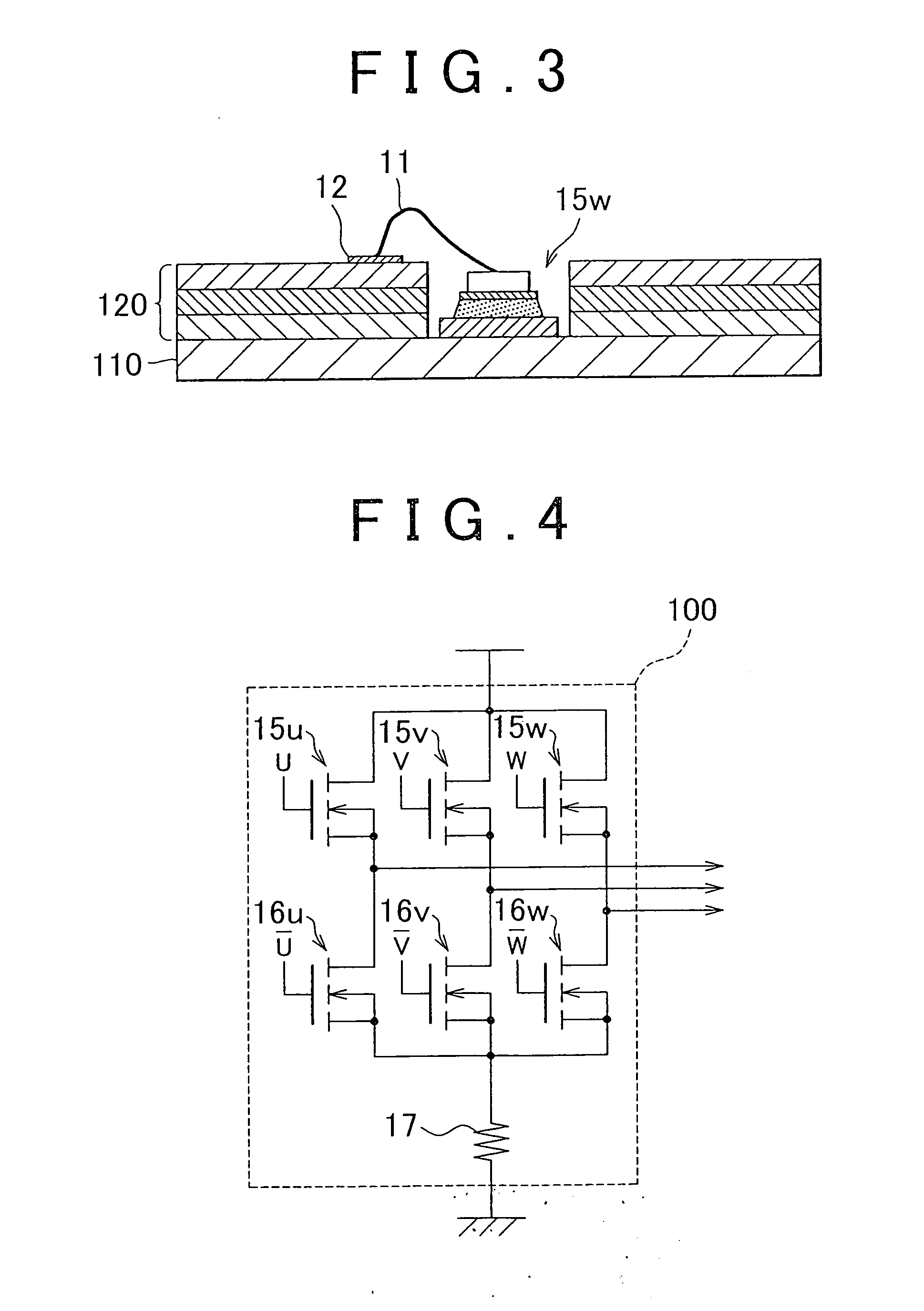

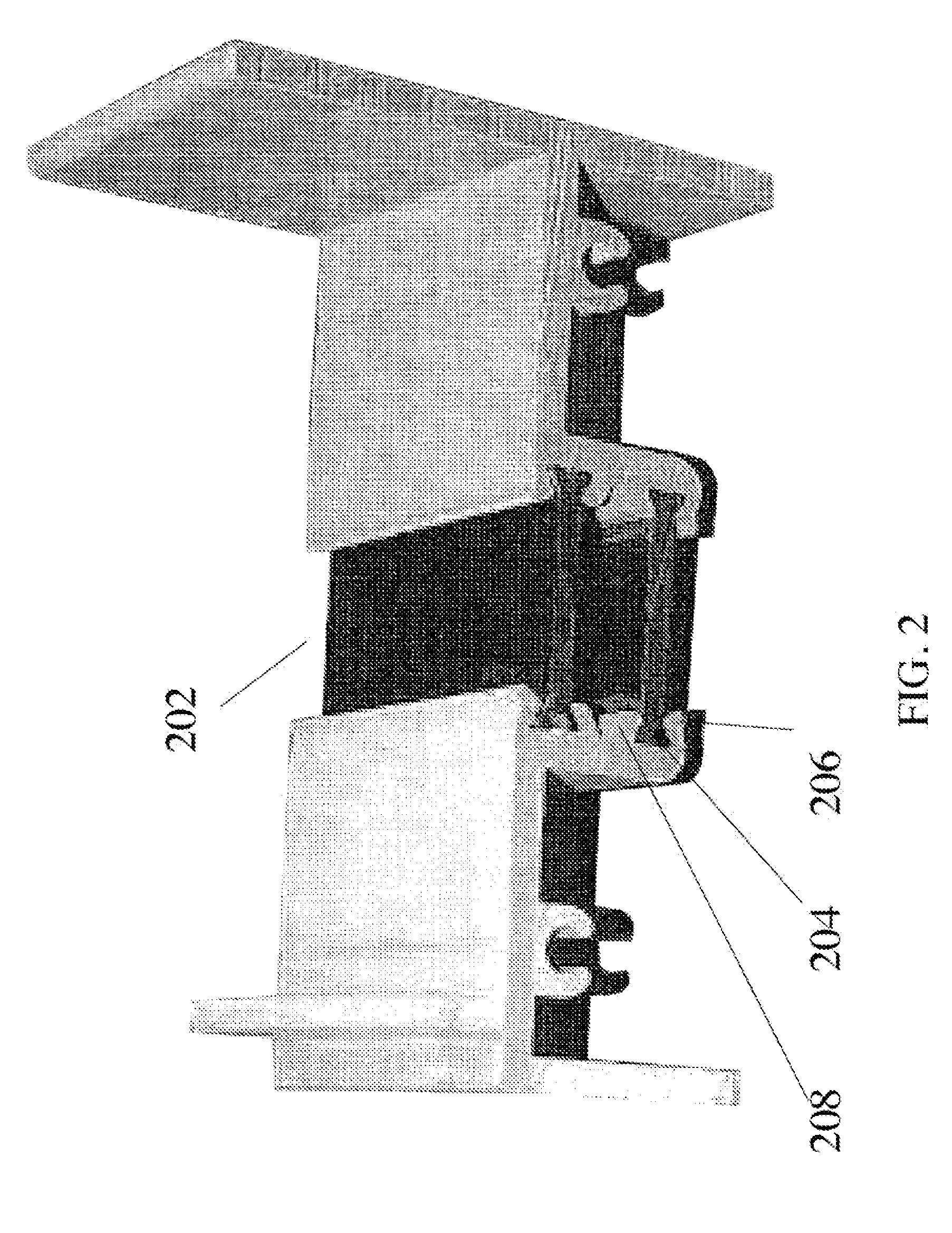

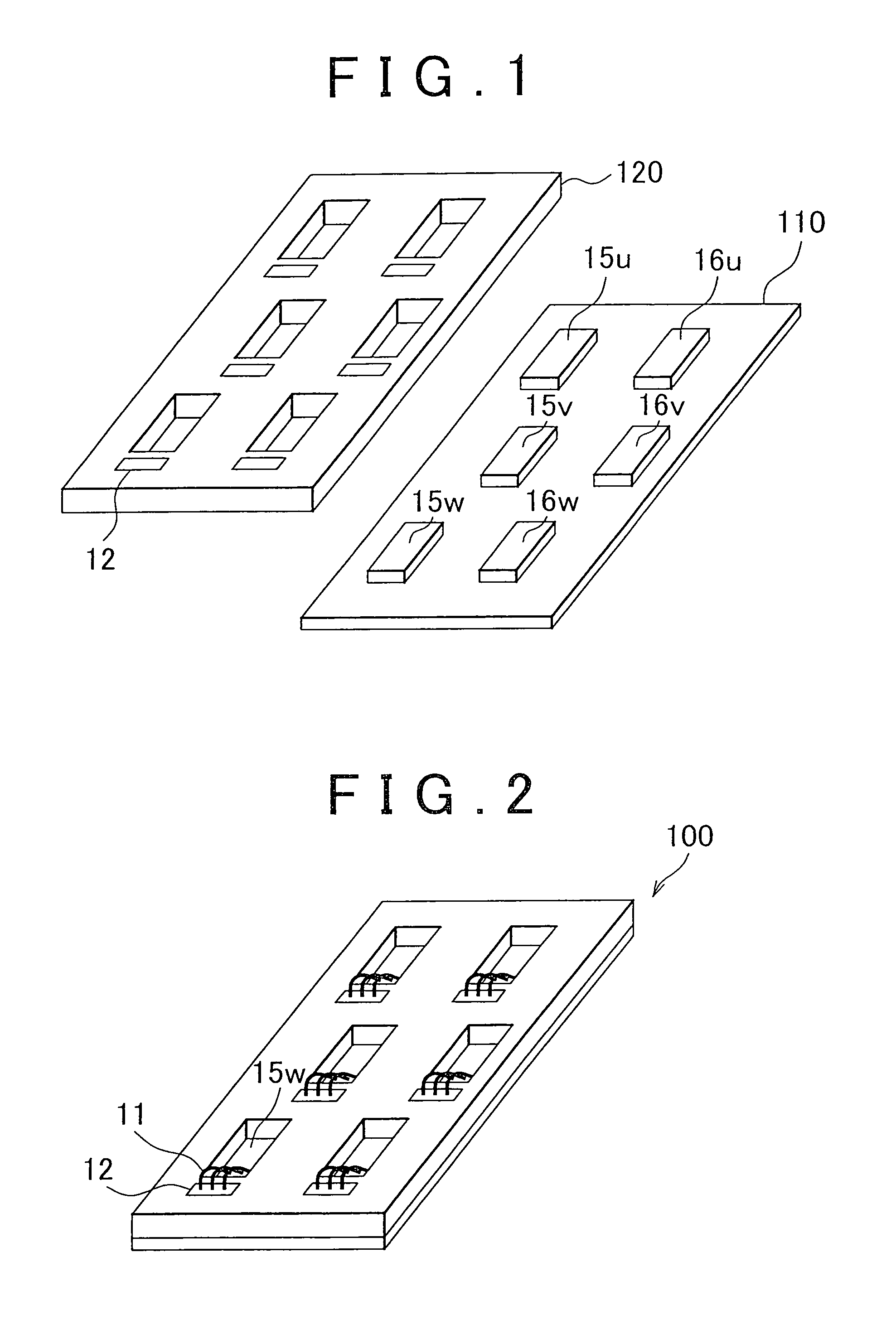

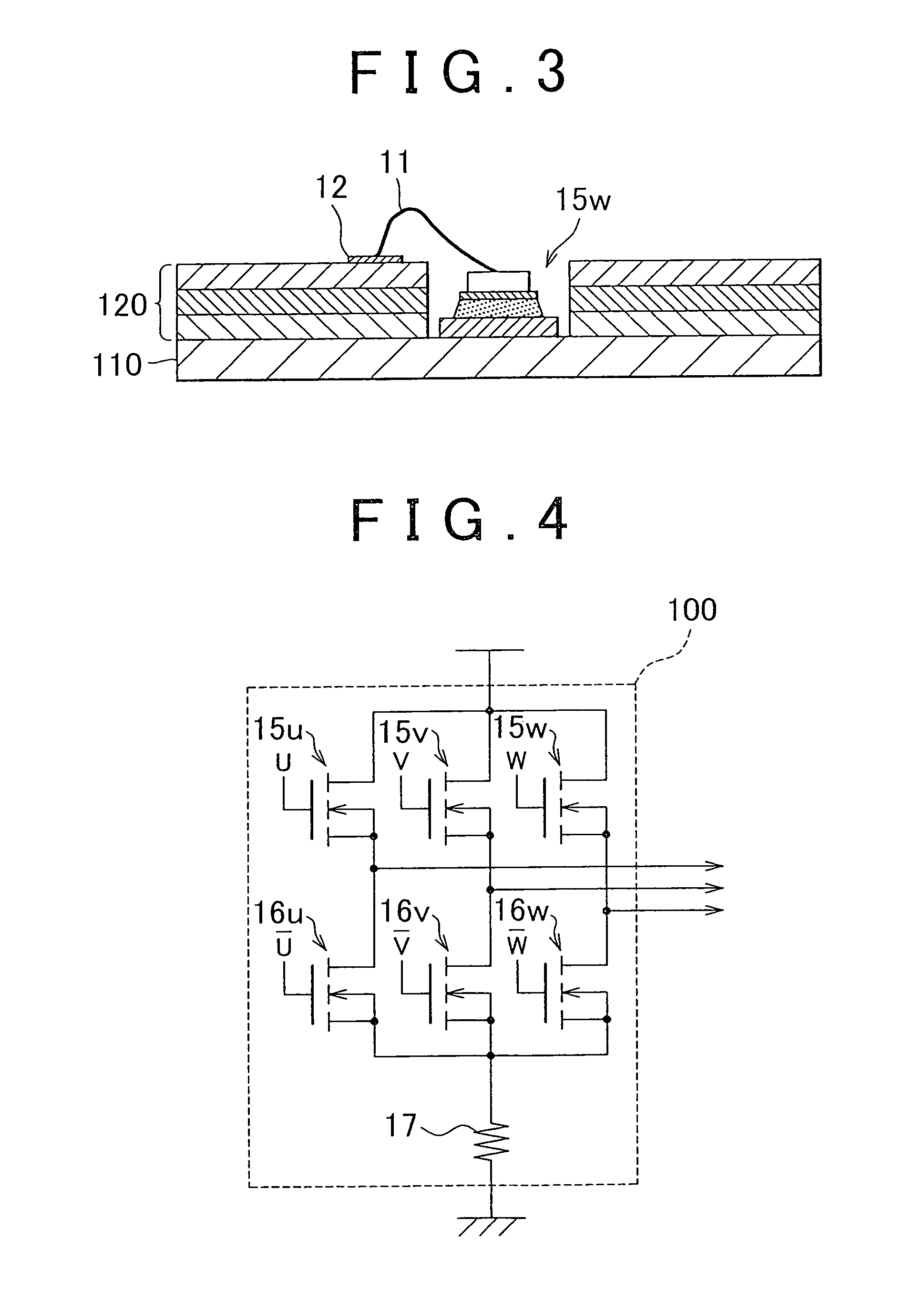

Multilayer circuit substrate

ActiveUS20100065307A1Improve cooling efficiencyImprove thermal conductivityPrinted electric component incorporationPrinted circuit aspectsElectronic componentMetal substrate

A multilayer circuit substrate includes: a laminated circuit portion in which conductive layers and resin insulating layers are alternately laminated; and a metal substrate portion, wherein the laminated circuit portion is fixed to the metal substrate portion so that at least part of a lower surface of the laminated circuit portion is in contact with at least part of an upper surface of the metal substrate portion. An electronic component is mounted on the metal substrate portion.

Owner:JTEKT CORP

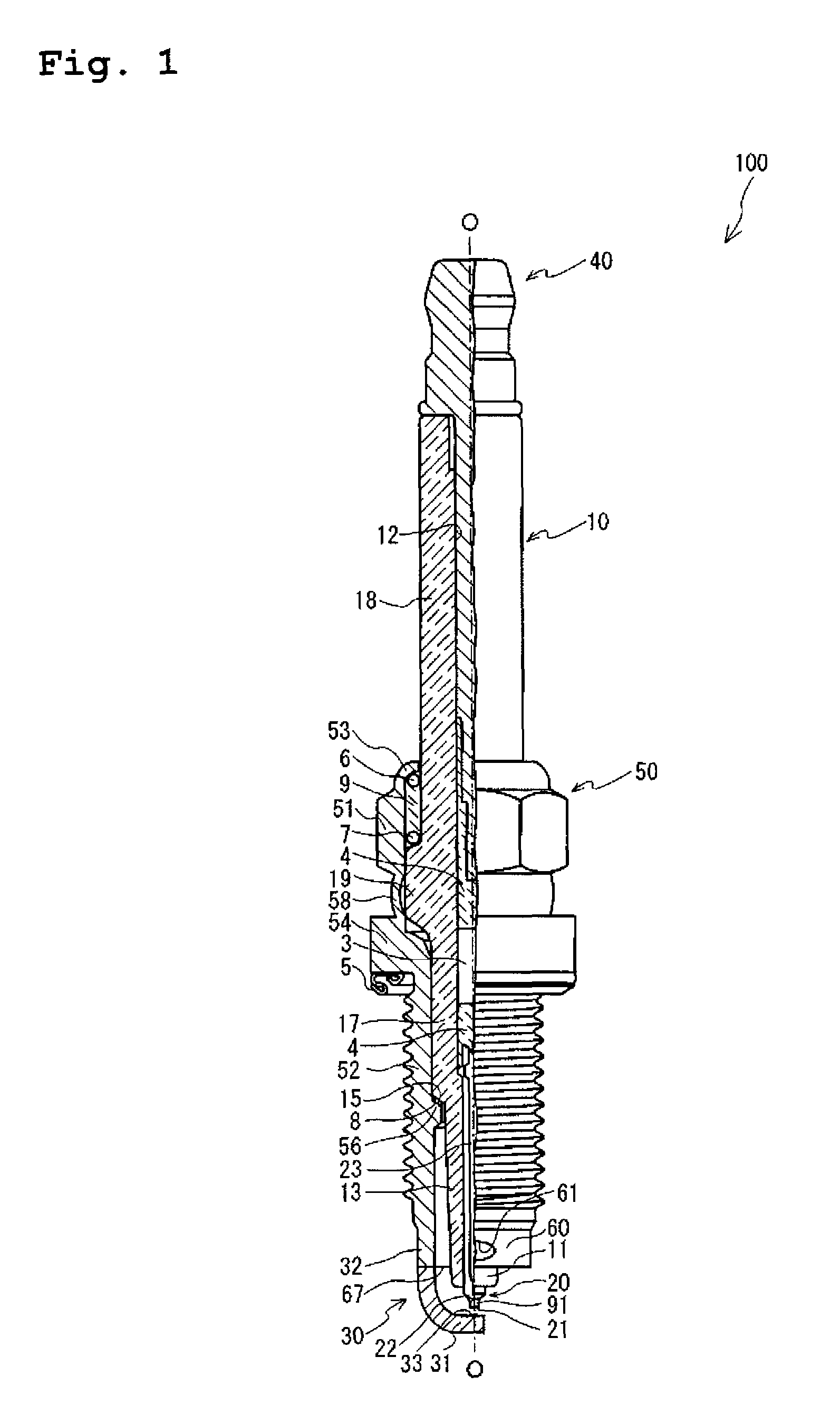

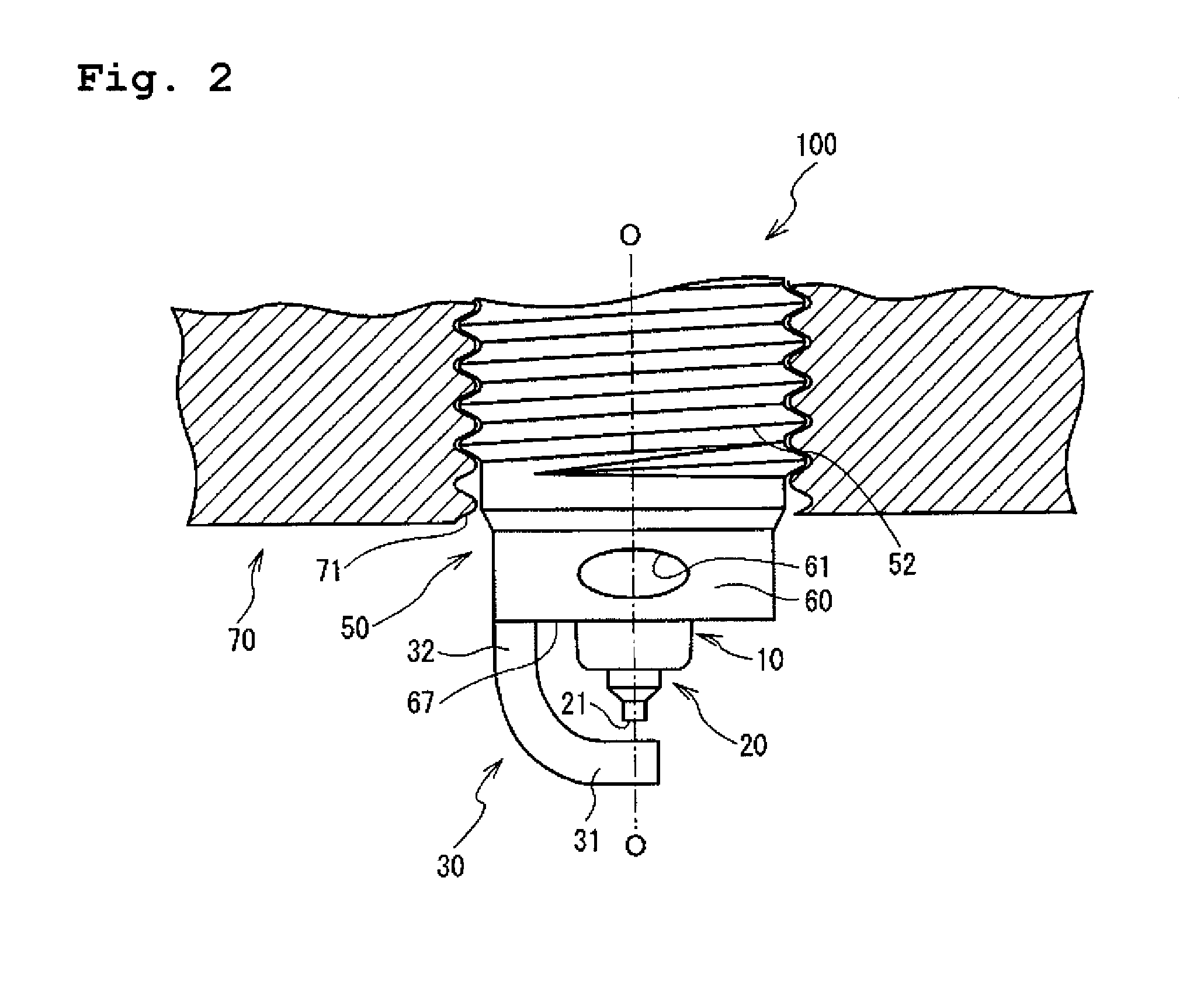

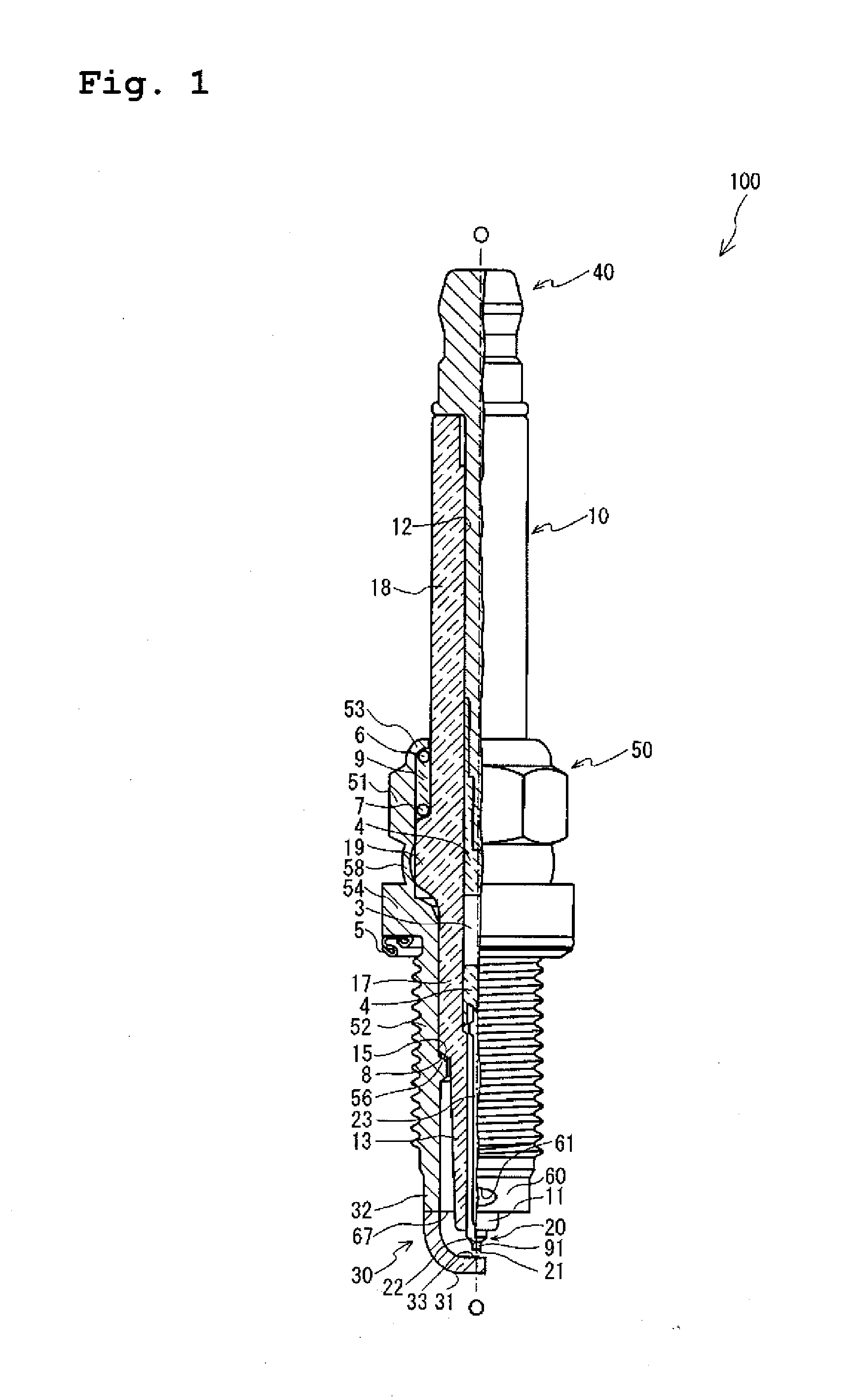

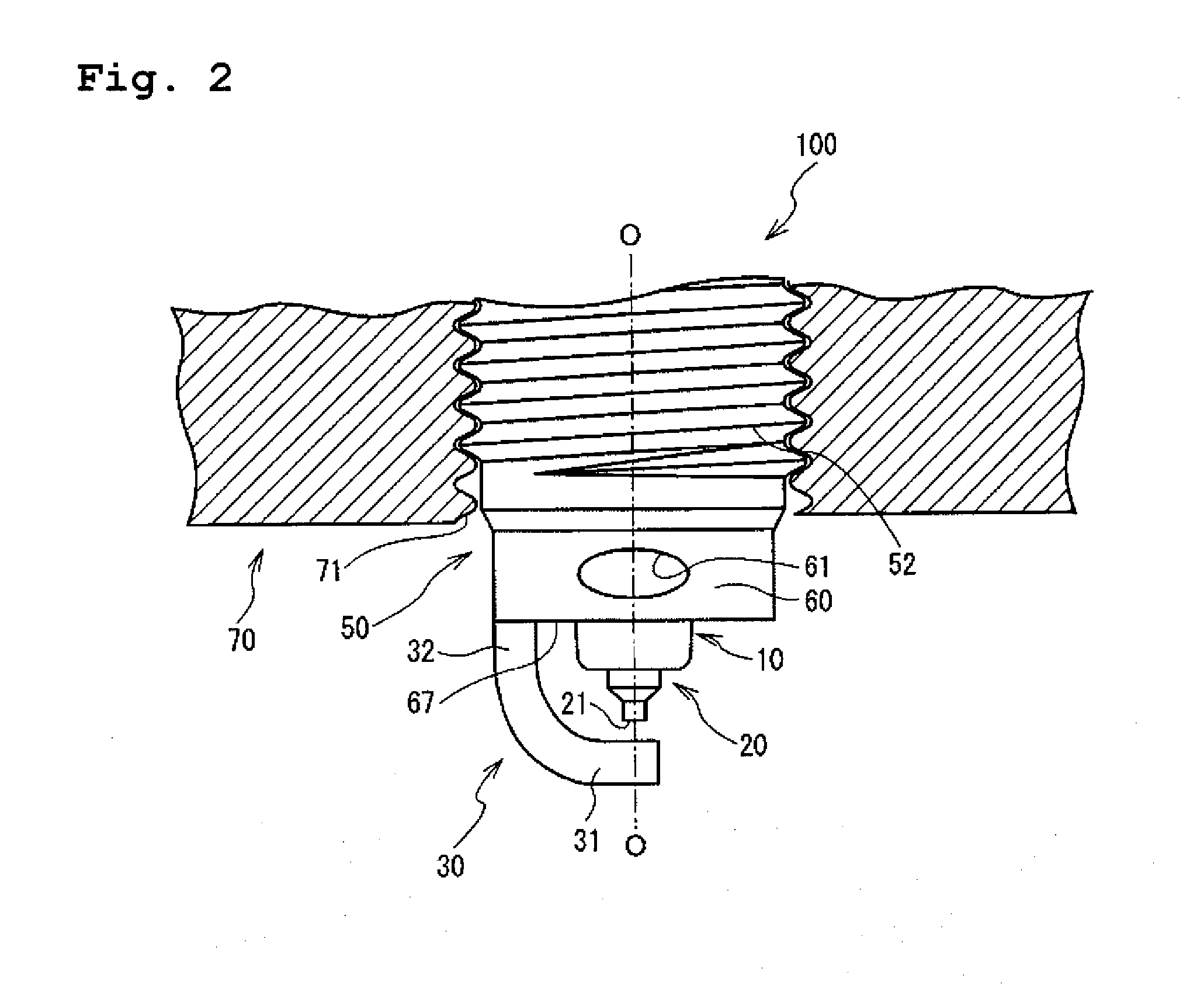

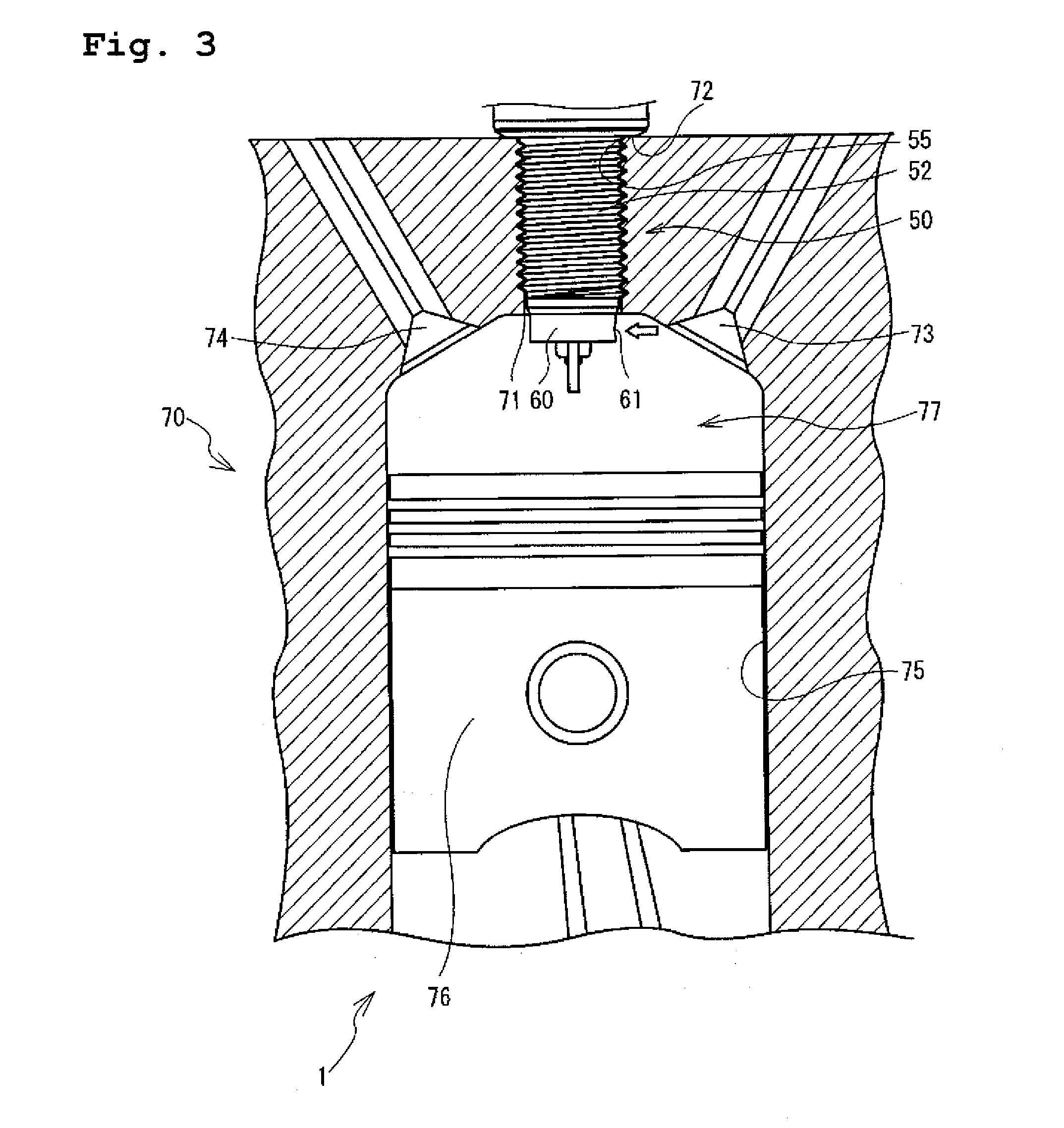

Spark plug and internal combustion engine provided with the same

InactiveUS7975665B2Prevent heat conductionImprove staminaSparking plugsFuel injection apparatusExternal combustion engineEngineering

A spark plug comprising a cylindrical portion which projects into a combustion chamber from an inner wall face of an engine head when the spark plug is fixed to the engine head, wherein the cylindrical portion has one or more ventilating portion comprised of a through hole or a notch in an outer circumferential face thereof. An igniting portion projecting into the combustion chamber improves ignitability. Further, because an air-fuel mixture fed from an inlet of the internal combustion engine flows to inside of the cylindrical portion through the ventilating portion, heat of an insulator is taken away and cooled down, whereby an occurrence of pre-ignition is prevented.

Owner:NGK SPARK PLUG CO LTD

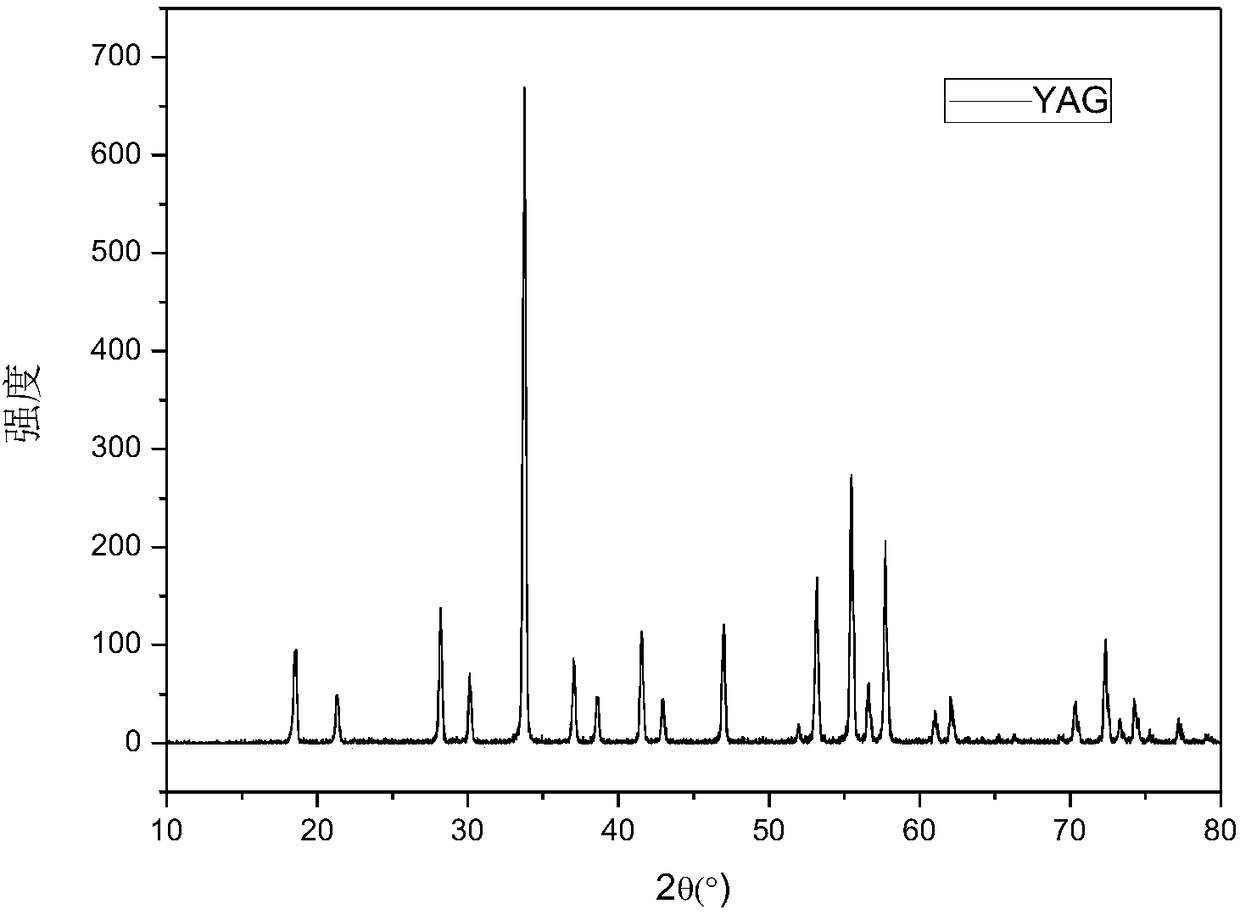

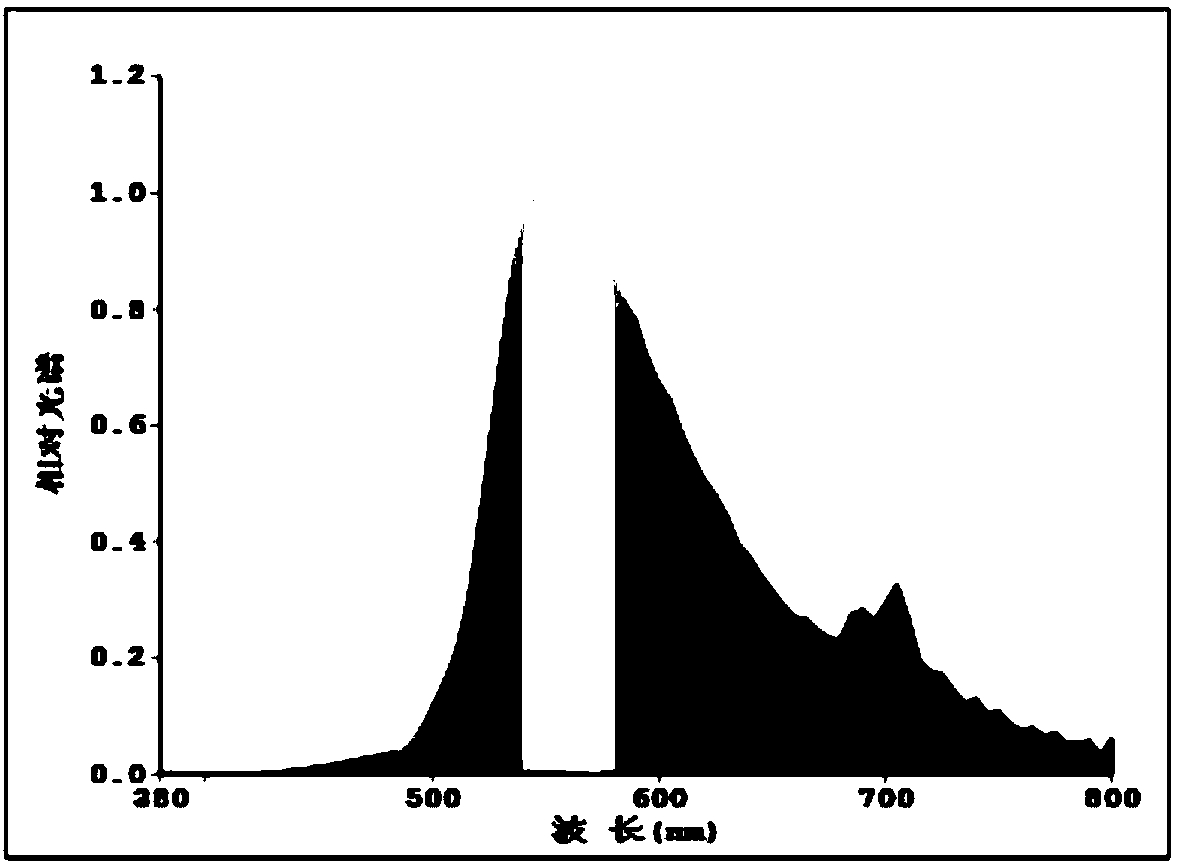

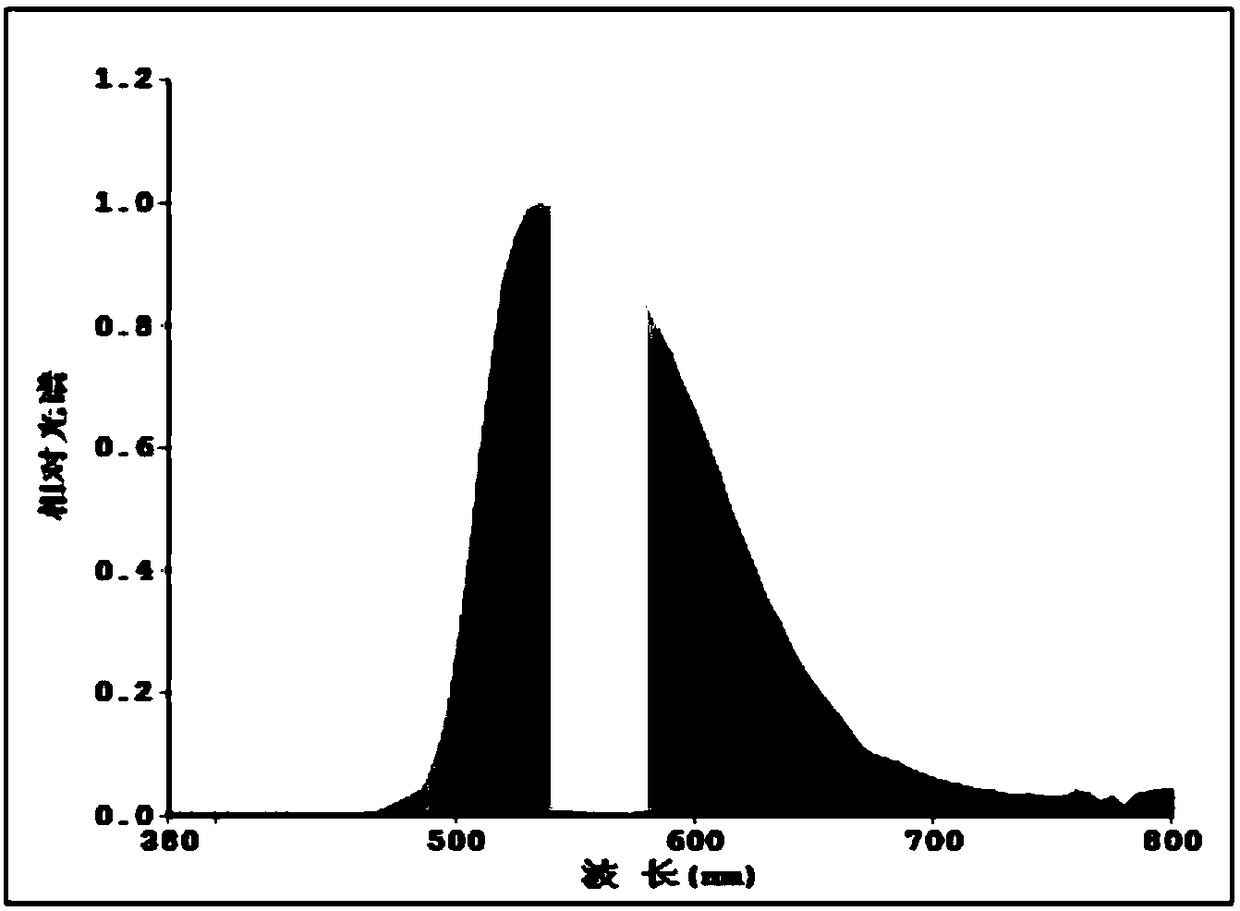

YAG fluorescent ceramic as well as preparation method and application thereof

InactiveCN108530071AImprove efficiencyImprove low color rendering indexLuminescent compositionsSemiconductor devicesFluorescenceRare earth

The invention discloses a YAG fluorescent ceramic as well as a preparation method and application thereof. Light-emitting center ions of the YAG fluorescent ceramic comprise Ce<3+> and M capable of emitting red light / green light; the molecular formula is (Y1-xCex)3(Al1-yMy)5O12, wherein x is greater than or equal to 0.004 and is less than or equal to 0.5, and y is greater than 0 and is less than or equal to 0.5. The preparation method of the YAG fluorescent ceramic comprises the following steps: uniformly mixing powder of raw materials, molding to prepare biscuits and carrying out high-temperature solid-phase synthesis reaction sintering to prepare the YAG transparent ceramic. After rare earth-doped YAG transparent ceramic is encapsulated with a commercial blue light LED chip, high-qualityemitted light capable of simulating sunlight can be obtained; compared with the rare earth-doped YAG transparent ceramic prepared by a two-step method, the step of synthesizing YAG:Ce<3+>, M fluorescent powder is avoided in the reaction sintering method; the preparation method has the characteristics of simple process and low production cost.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

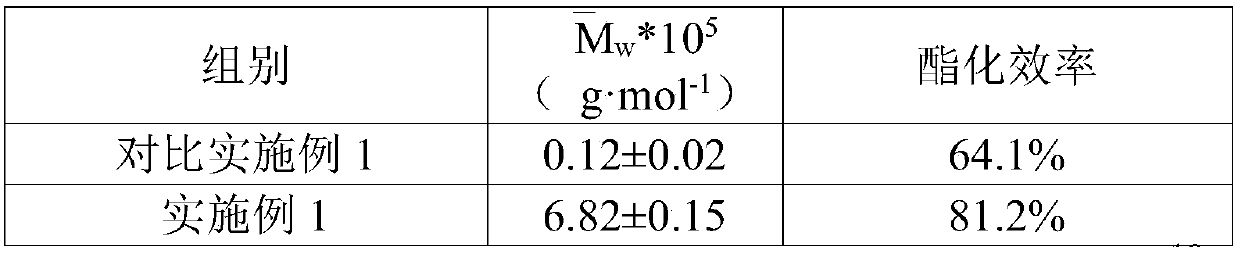

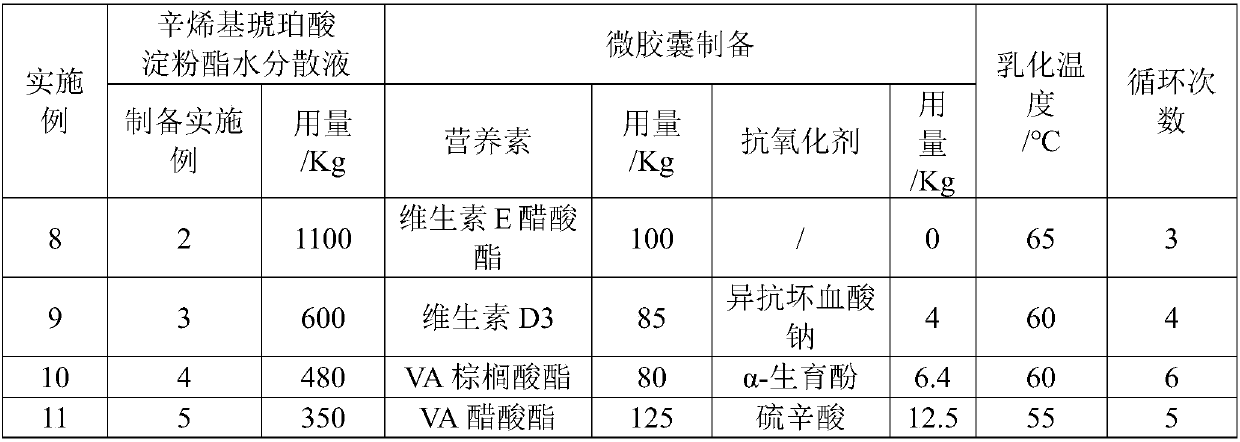

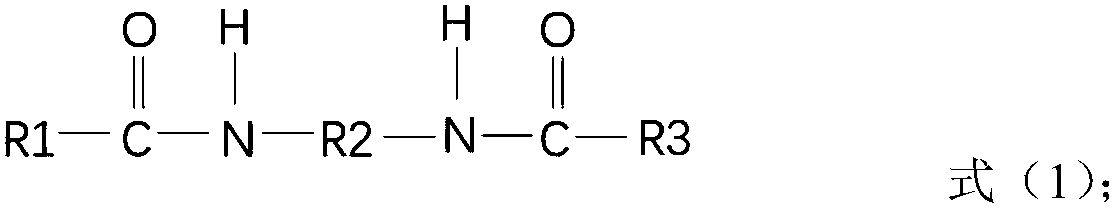

Octenyl succinic acid starch ester, lipid-soluble nutrient microcapsule as well as preparation method application of lipid-soluble nutrient microcapsule

ActiveCN109517080AHigh esterification rateGood emulsifying effectAccessory food factorsFood ingredientsChain lengthSuccinic acid

The invention relates to octenyl succinic acid starch ester, a lipid-soluble nutrient microcapsule as well as a preparation method application of the lipid-soluble nutrient microcapsule. A preparationmethod of octenyl succinic acid starch ester comprises the step of carrying out esterification reaction on gelatinized starch and octenyl succinic anhydride in a cavitation emulsification process, soas to obtain octenyl succinic acid starch ester. According to the preparation method, the esterification reaction is promoted and intensified by virtue of the cavitation emulsification process, remarkably substitution occurs in a crystallization region and an amorphous region of the starch through the molecular collision of the collision between gelatinized starch and octenyl succinic anhydride,so that the esterification rate of prepared octenyl succinic acid starch ester is increased, and the emulsifying property is greatly improved. The method is rapid and efficient, and a hydrolysis stepis omitted after the esterification, so that the problems that molecular chains are damaged in different degrees due to the hydrolysis, the chain length and content of amylose are remarkably decreased, the compactness of a film formed by octenyl succinic acid starch ester is decreased, and the film easily absorbs moisture and conducts heat and is crispy are avoided, and the application performanceof octenyl succinic acid starch ester is improved.

Owner:ZHEJIANG UNIV +2

Polyimide film and preparation method thereof

The invention provides polyimide film. The polyimide film is prepared by subjecting a polyamide acid solution compound to casting and imidization stretching, and the polyamide acid solution compound is mainly prepared by mixing the following components in parts by weight: 100-150 parts of polyamide acid resin, 5-20 parts of a plasticizer, 0.5-10 parts of a slipping agent and 50-125 parts of heat-conducting slurry. The prepared polyimide film is high in heat-conducting performance, excellent in mechanical performance, and easy in machine shaping and industrial production, and has wide application prospects in the aspect of interface heat-conducting insulating materials. The invention further provides a preparation method of the polyimide film; the preparation method has the advantages of short technology process, simple operation, low cost, environment friendliness, and suitability for large-scale production.

Owner:株洲时代华鑫新材料技术有限公司

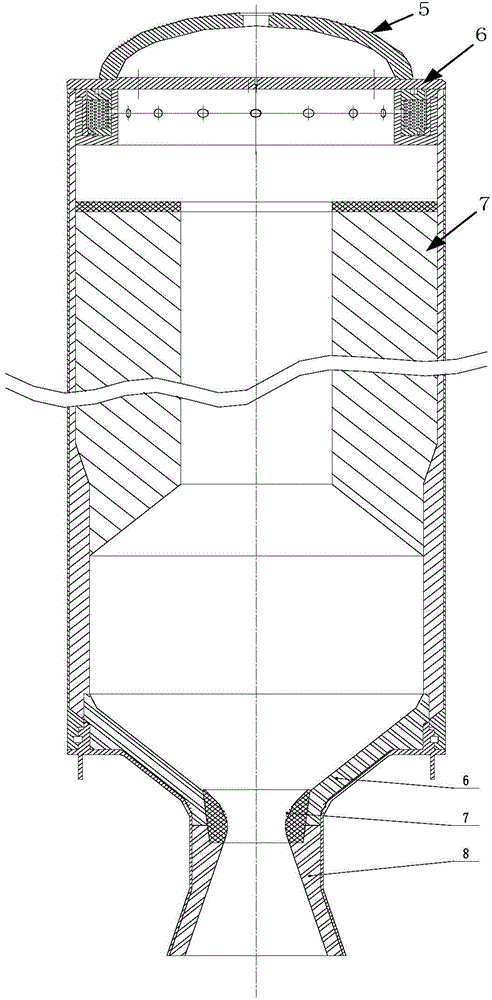

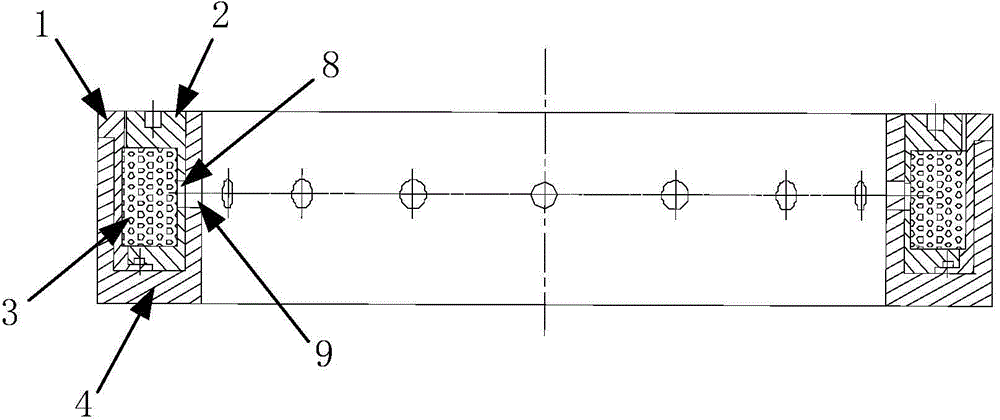

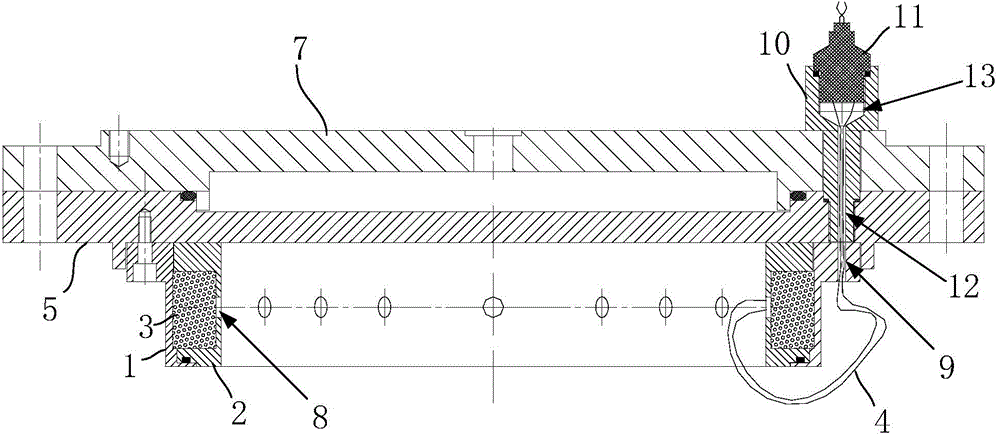

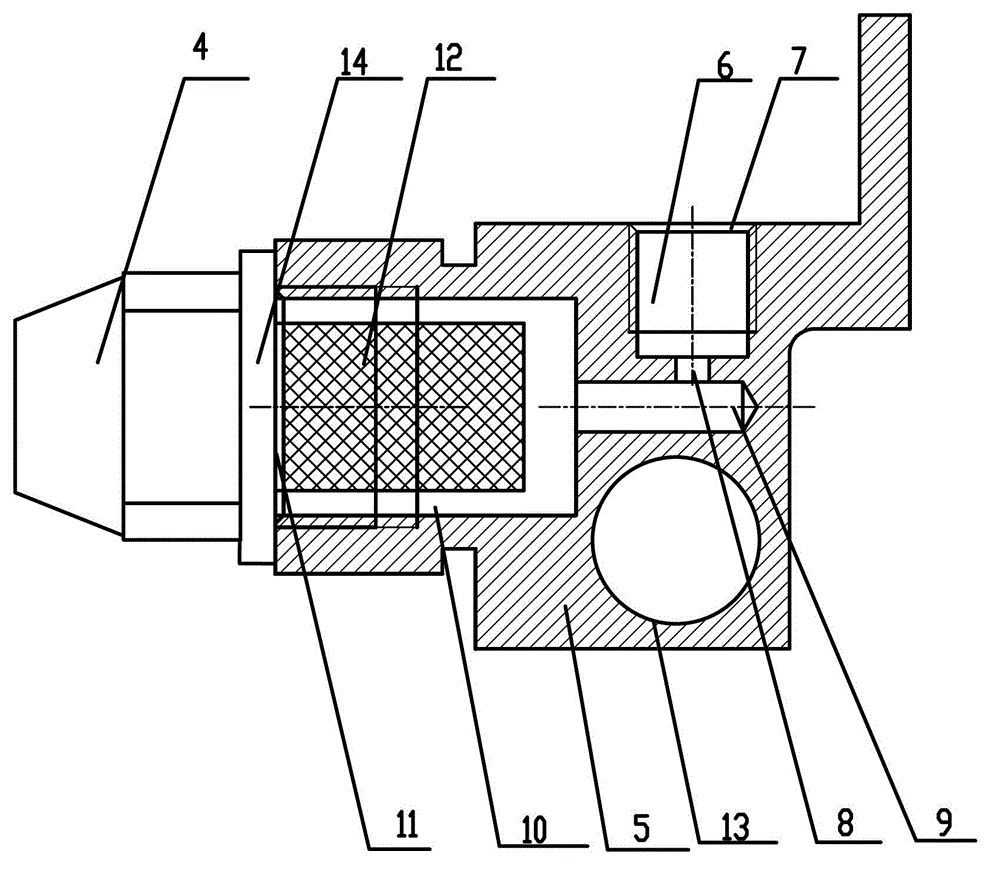

Hybrid rocket engine igniter

ActiveCN104791135AStart fastRapid heating oxidationRocket engine plantsInsulation layerIgnition delay

The invention discloses a hybrid rocket engine igniter which comprises an igniter thread ring, an igniter box body, an igniter heat insulation layer and ignition powder. The igniter thread ring is connected with the igniter box body through a large thread, and therefore a cavity structure with inner and outer annular side walls is formed. The containing cavity is filled with the ignition powder which is composed of ignition materials and fuel. The igniter thread ring, the igniter box body and the igniter heat insulation layer are adhesively connected. The inner wall face of the igniter box body and the inner wall face of the igniter heat insulation layer are provided with fire outlet holes. A sealing belt is laid on the inner annular side wall of the igniter box body. It is ensured that the ignition powder is reliably sealed before the igniter works. One end of an igniter lead is provided with an ignition head which produces electric sparks after being powered on, and the other end of the igniter lead is provided with an electric wire. The igniter starts to work after the igniter lead is powered on. The hybrid rocket engine igniter has the advantages that the start energy is high, the energy is released rapidly, the engine ignition delay is short, and the ignition delay time of the improved igniter is shorter than 1s when a large-flow hybrid rocket engine starts.

Owner:BEIHANG UNIV

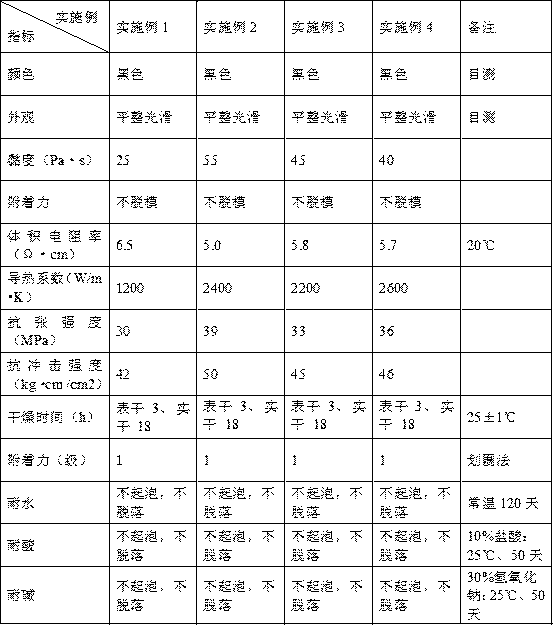

Graphene electricity and heat conductive coating and preparation method thereof

ActiveCN109206961AHigh glossAvoid reunionFireproof paintsAntifouling/underwater paintsSemiconductor materialsHeat conducting

The invention discloses a graphene electricity and heat conductive coating and a preparation method thereof. The graphene electricity and heat conductive coating is composed of the following components in parts by weight: 1-10 parts of graphene, 2-5 parts of carbon nano tubes, 2-5 parts of sodium silicate, 1-3 parts of paint oil, 1-3 parts of tung oil, 0.3-1.5 parts of maleic anhydride, 3-5 partsof a dispersing agent, 1-3 parts of acrylic resin, 0.05-0.5 part of a composite drier, 1-3 parts of a coupling agent, 0.2-1 part of silicon dioxide, 0.2-1 part of a composite additive, 0.5-2 parts ofmodified cellulose, 1.5-2 parts of zeolite powder, 1-8 parts of heat-conducting metal powder and 40-60 parts of ethanol. The graphene electricity and heat conductive coating prepared by spraying and printing can be applied to the fields of semiconductor materials, conductive and heat-conducting composite materials and the like, and has relatively strong application value.

Owner:中山励诺包装制品有限公司

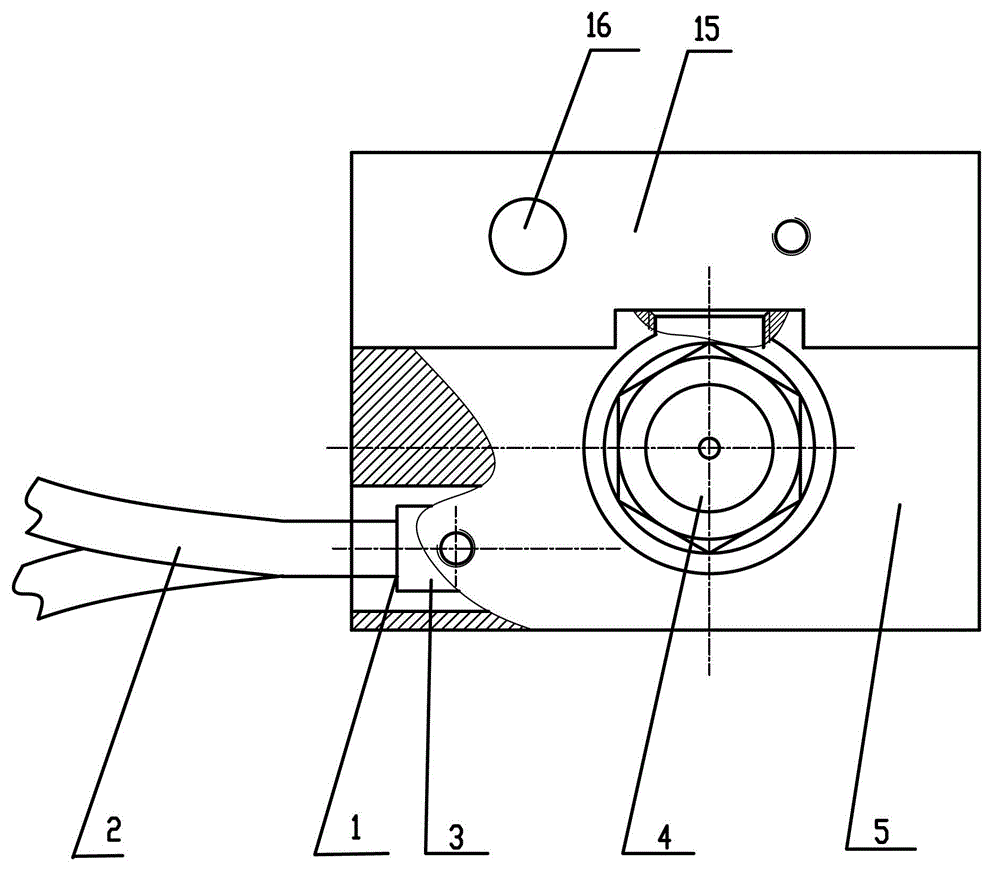

Solid-liquid rocket engine igniter and head wire-outgoing method thereof

The invention discloses a solid-liquid rocket engine igniter and a head wire-outgoing method thereof, wherein the igniter comprises an igniter box body, an igniter thread ring, and an ignition powder. The igniter box body is threaded to the igniter thread ring, is sealed by a sealing ring, with an annular cavity for filling the ignition powder being formed therein. The head wire-outgoing method of the solid-liquid rocket engine igniter comprises the following steps: employing an igniter sealing head for being threaded to an igniter adaptation sleeve; and threading the igniter adaptation sleeve to an injection panel; inserting one end of an igniter lead wire into an ignition material of the ignition powder; leading out the lead wire from an ignition hole of the igniter box body; and leading the lead wire outside the engine through a wire hole of the igniter box body, an inner hole of the igniter adaptation sleeve, and the igniter sealing head. The solid-liquid rocket engine igniter has the advantage of reasonable in structure; and the head wire-outgoing method thereof has the advantages of greatly reducing the length of the igniter lead wire, avoiding the breakage of the igniter lead wire after the igniter is working, reducing the wiring difficulty of the igniter, and increasing the reliability of the igniter.

Owner:BEIHANG UNIV

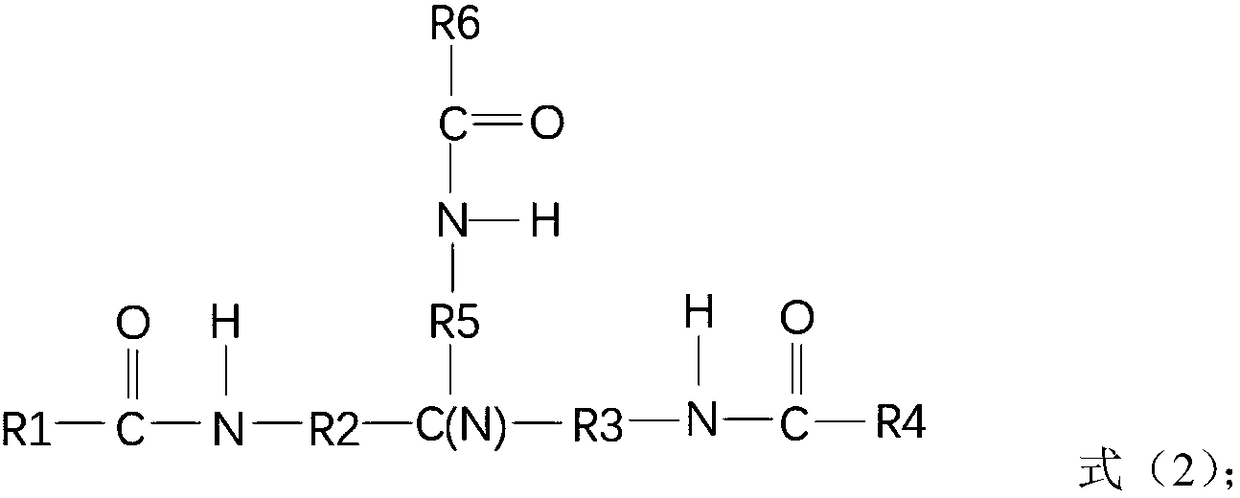

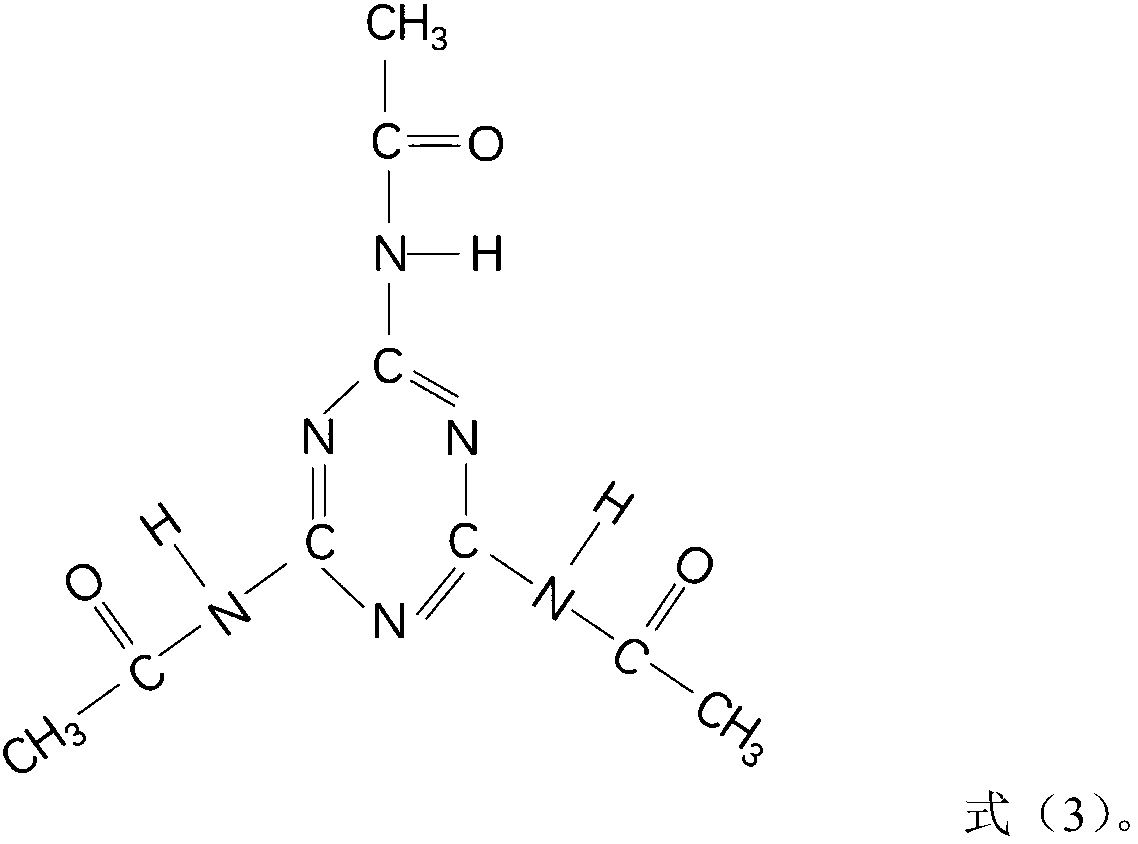

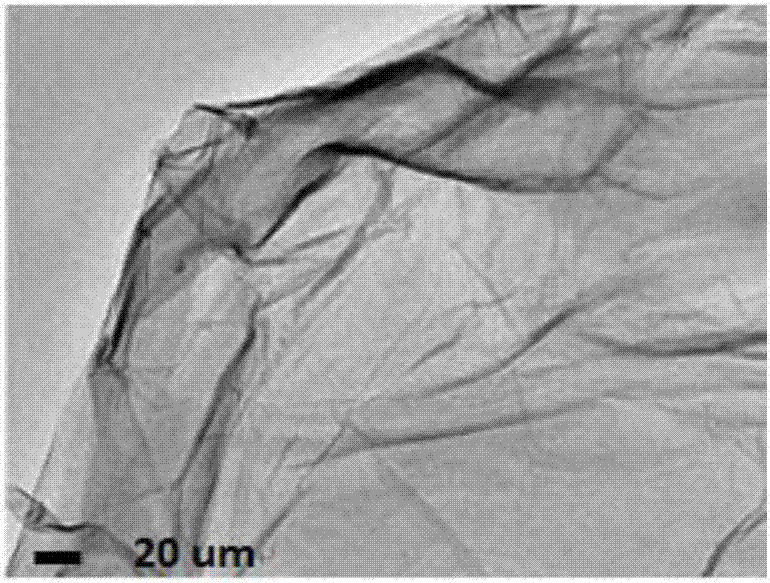

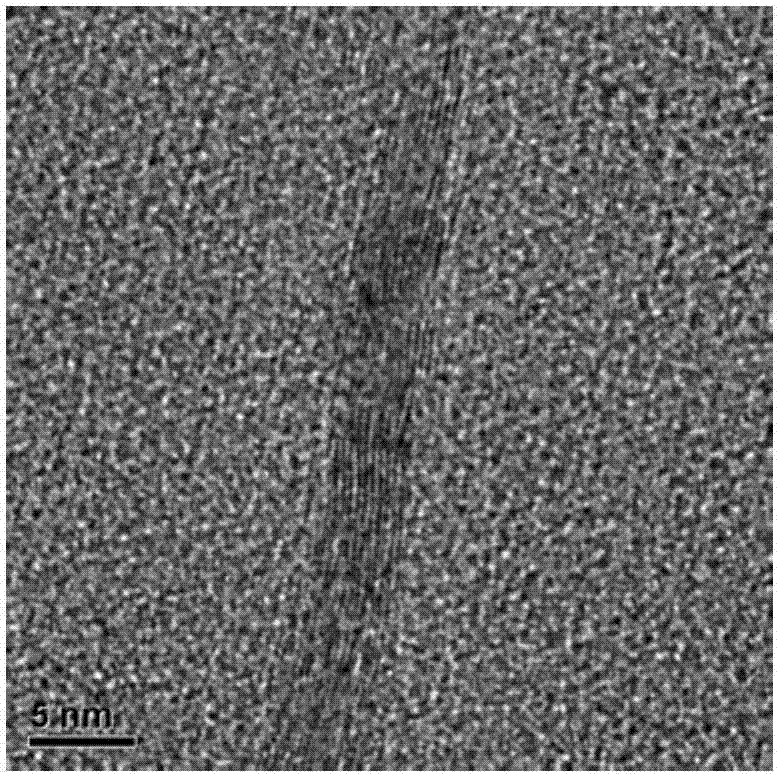

Graphene/cyanate composite material and preparation method and application thereof

ActiveCN106893322AAvoid conductive propertiesPrevent heat conductionThermal expansionCyanate compound

The invention relates to a graphene / cyanate composite material and a preparation method and application thereof. The preparation method includes: mixing the graphene, graphene nanoplatelets and pi-pi small conjugate molecules with deionized water prior to performing primary dispersion; pouring a water solution to an ice bath cooled ultrasonic cell disruptor, pouring obtained dispersion liquid in liquid nitrogen for quick cooling, placing the mixture in a freeze dryer after complete freezing, and dewatering to obtain the foamed and pre-dispersed graphene / graphene nanoplatelets; finally, mixing the foamed graphene-graphene nanoplatelets with cyanate ester resin to obtain the graphene / cyanate composite material through stirring, grinding and stripping. The graphene / graphene nanoplatelets are well dispersed in the cyanate ester resin, conductivity, thermal conductivity and mechanical property are improved under low content and low viscosity, thermal expansion coefficient is lowered, and the graphene / cyanate composite material can be applied to composite components of electricity conductivity, thermal conductivity and low thermal expansion coefficient structure of space vehicles.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

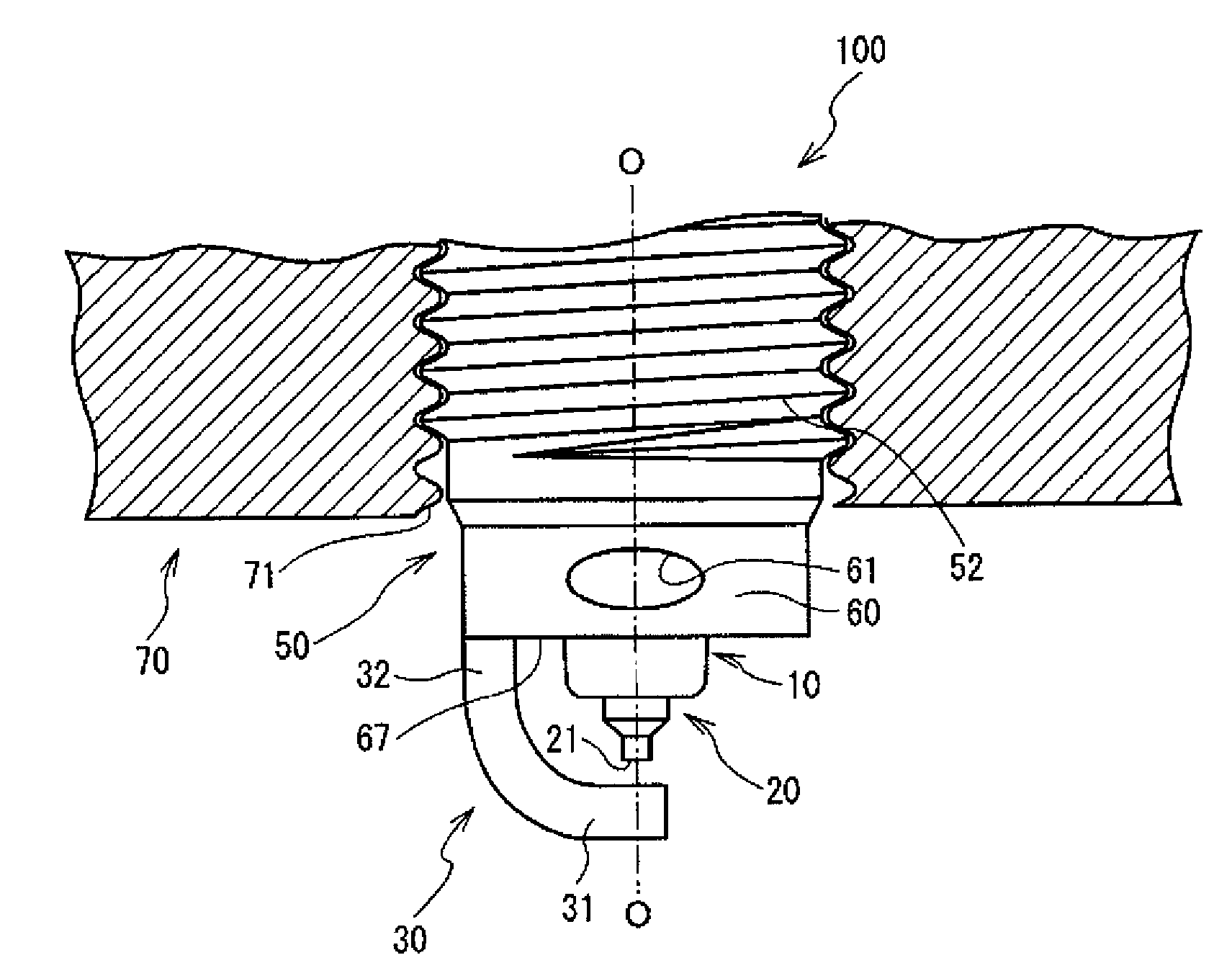

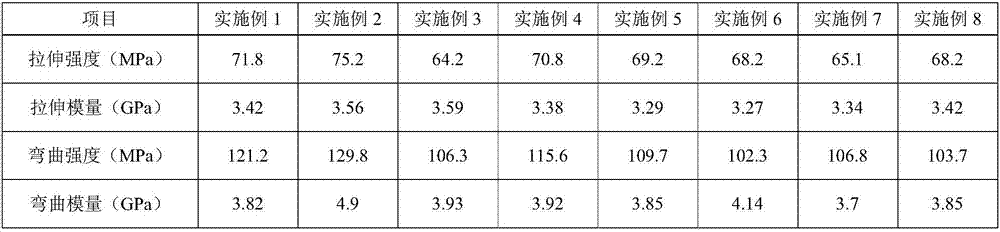

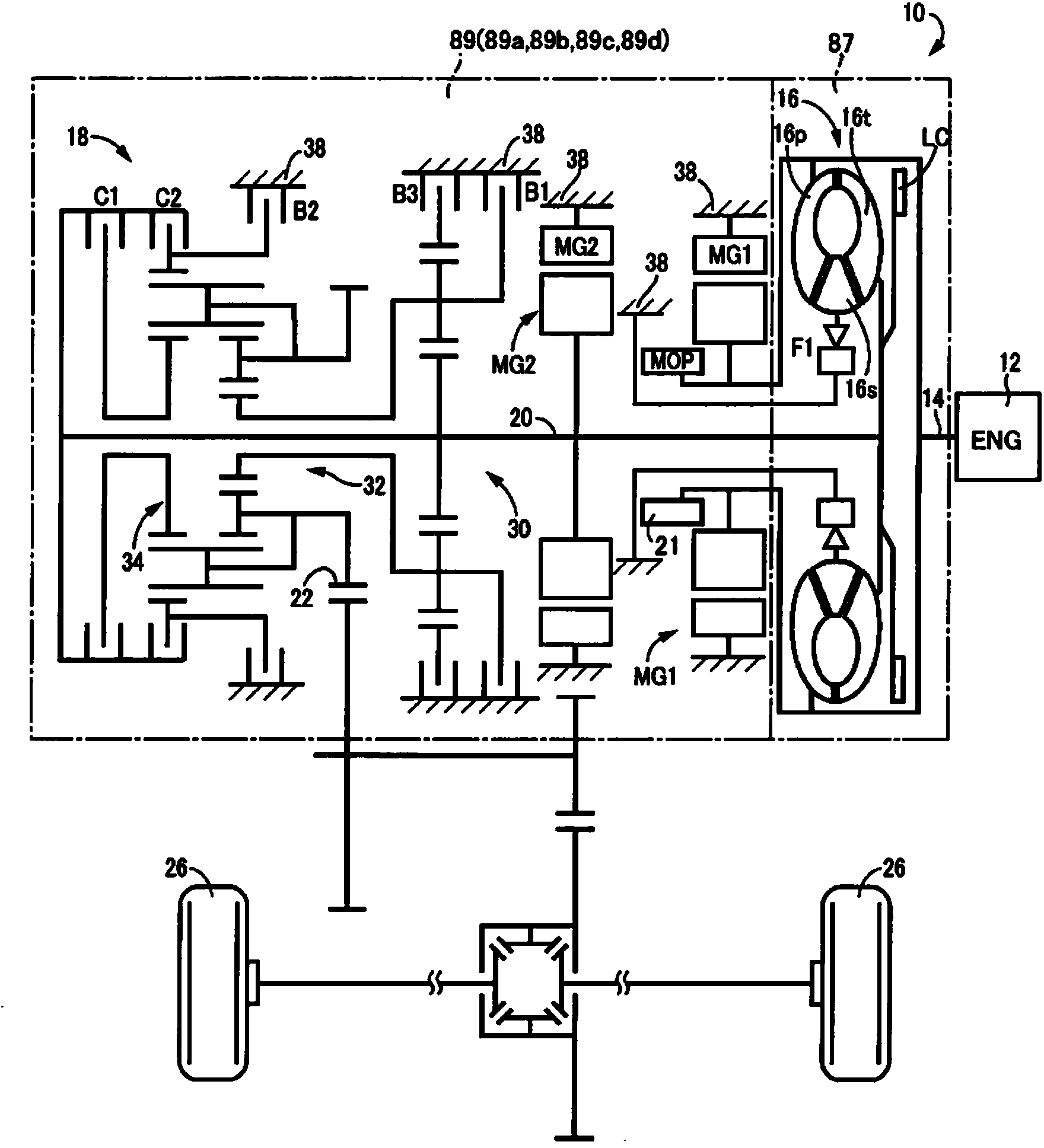

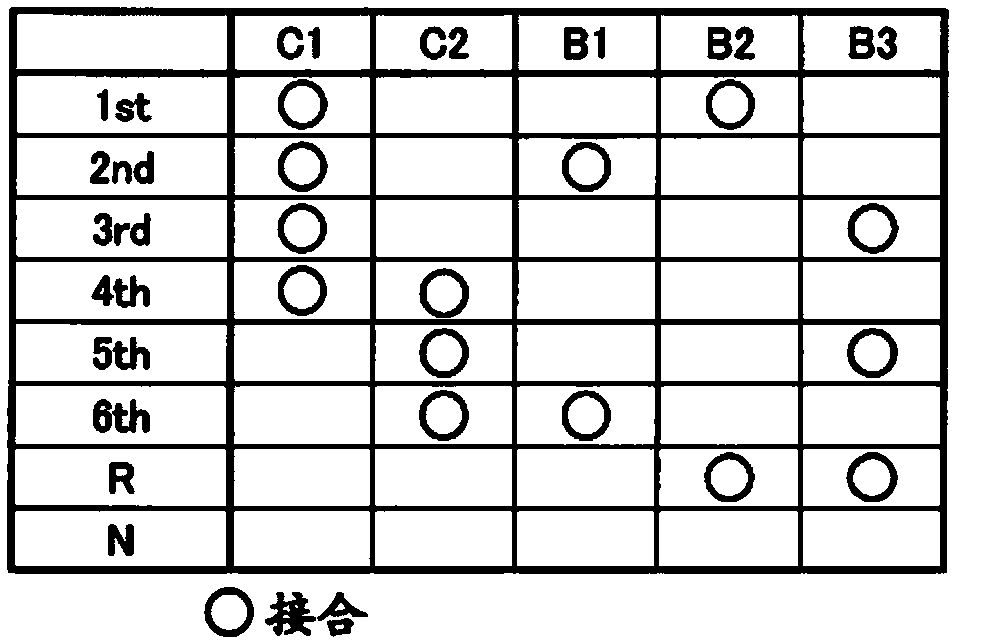

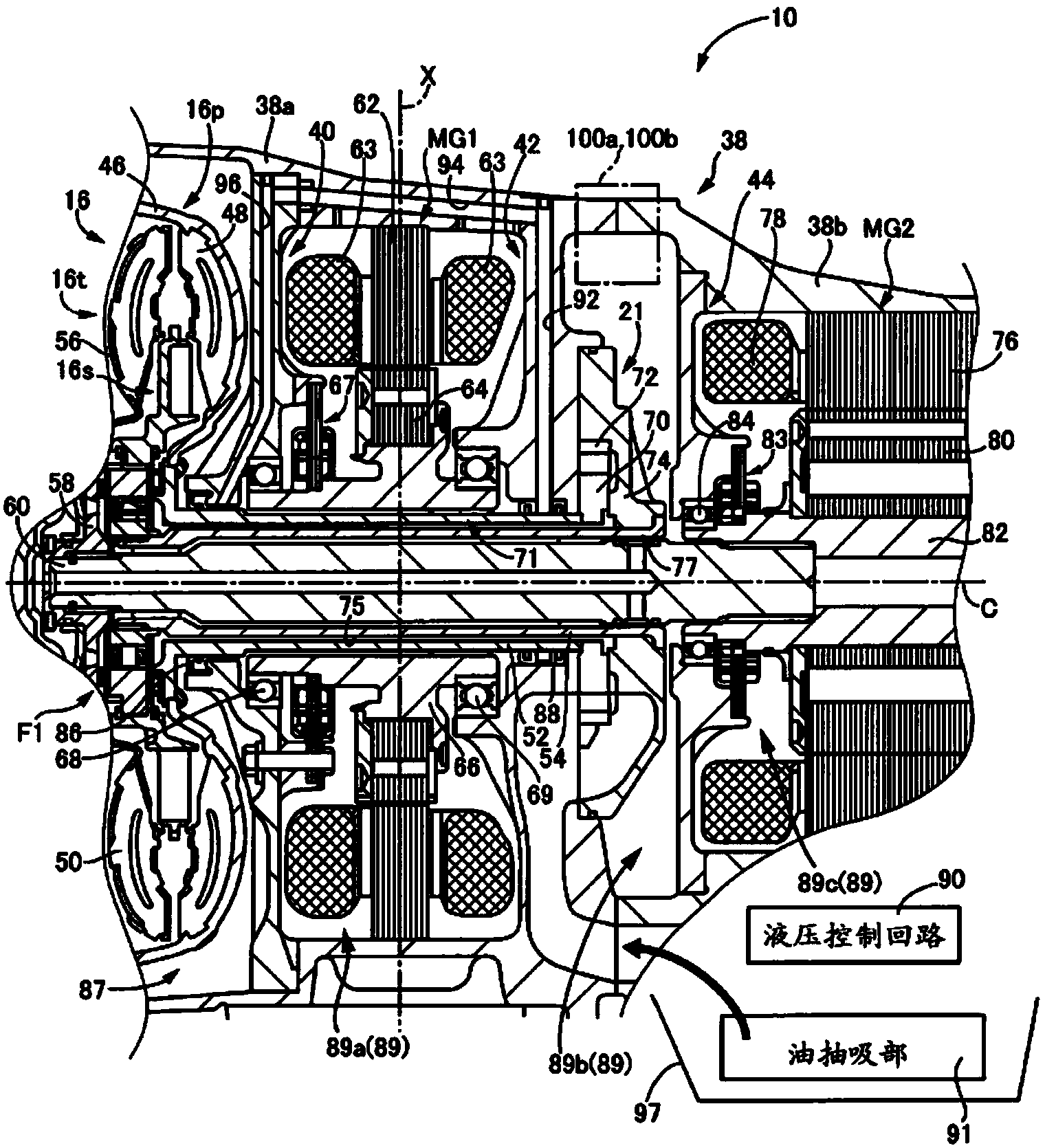

Vehicle drive device

ActiveCN104066608AImprove cooling effectAchieve oil coolingElectric propulsion mountingGas pressure propulsion mountingImpellerAutomatic transmission

Provided is the structure of a vehicle drive device provided with a fluid transmission device, an electric motor and a transmission, said vehicle drive device being capable of improving the cooling performance of the electric motor. Even in a configuration in which an engine (12) and a first electric motor (MG1) are linked to a pump impeller (16p) of a torque converter (16), the engine (12) and the first electric motor (MG1) are positioned in a location where the torque converter (16) is sandwiched in the axial direction, thus enabling the first electric motor (MG1) to be positioned in a space (89) (inside an oil chamber) in which an automatic transmission (18) is housed. Moreover, housing the first electric motor (MG1) inside said space (89) allows the first electric motor (MG1) to be cooled by oil, thus enabling the cooling performance of the first electric motor (MG1) to be improved.

Owner:TOYOTA JIDOSHA KK

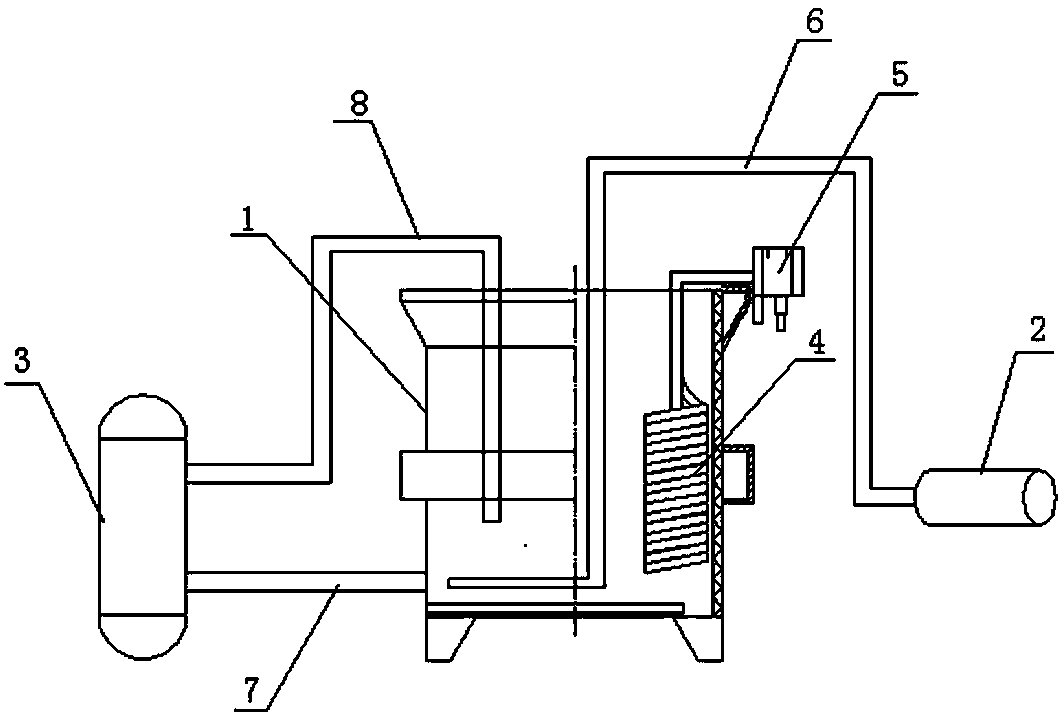

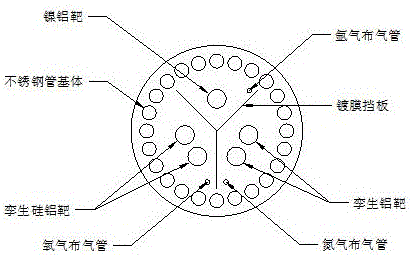

Chemical nickel plating device and chemical nickel plating method

InactiveCN104294241APrevent heat conductionAvoid intensityLiquid/solution decomposition chemical coatingFiltrationAir compressor

The invention provides a chemical nickel plating device and a chemical nickel plating method. The chemical nickel plating device comprises a groove body, an air compressor and a circulating filter, wherein the groove body is internally provided with an electrical heating pipe, and the electrical heating pipe is connected with a temperature controller arranged outside the groove body; the air compressor is connected with an air pipe, and the tail end of the air pipe extends into the bottom of the groove body; and two ends of the circulating filter are connected with a liquid inlet pipe and a liquid outlet pipe, the liquid inlet pipe is communicated with the bottom of the groove body, and the liquid outlet pipe extends into the groove body. According to the chemical nickel plating device, the groove body is made from high-purity polypropylene, so that the defects of poor heat conductivity and poor groove body strength of the groove body are prevented; no metal substance contacts with a chemical nickel plating solution in an integral nickel plating process, so that nickel and phosphorus are prevented from being deposited in the groove body and on other parts of the chemical nickel plating device; and an obtained plating layer is bright, smooth and exquisite without pocking marks due to the effect of air stirring and circulating filtration.

Owner:JINCHUAN GROUP LIMITED

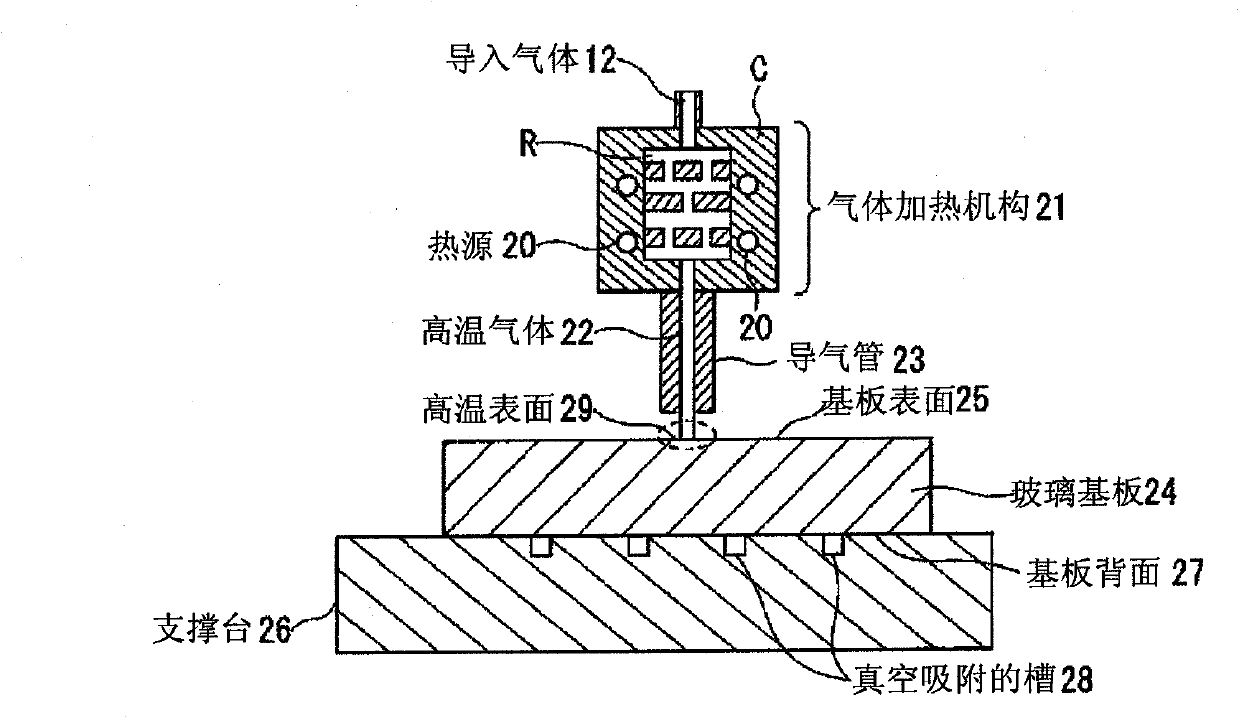

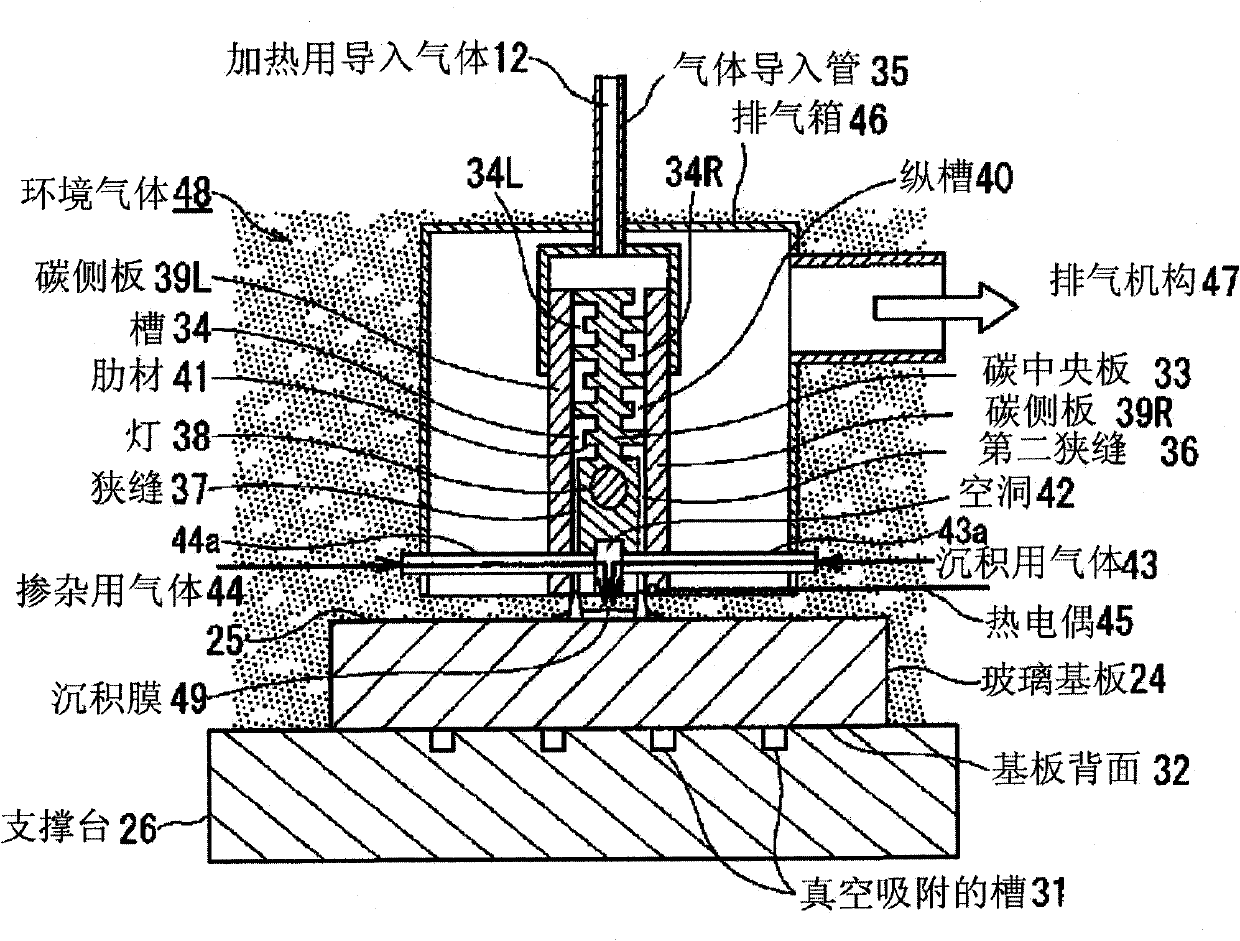

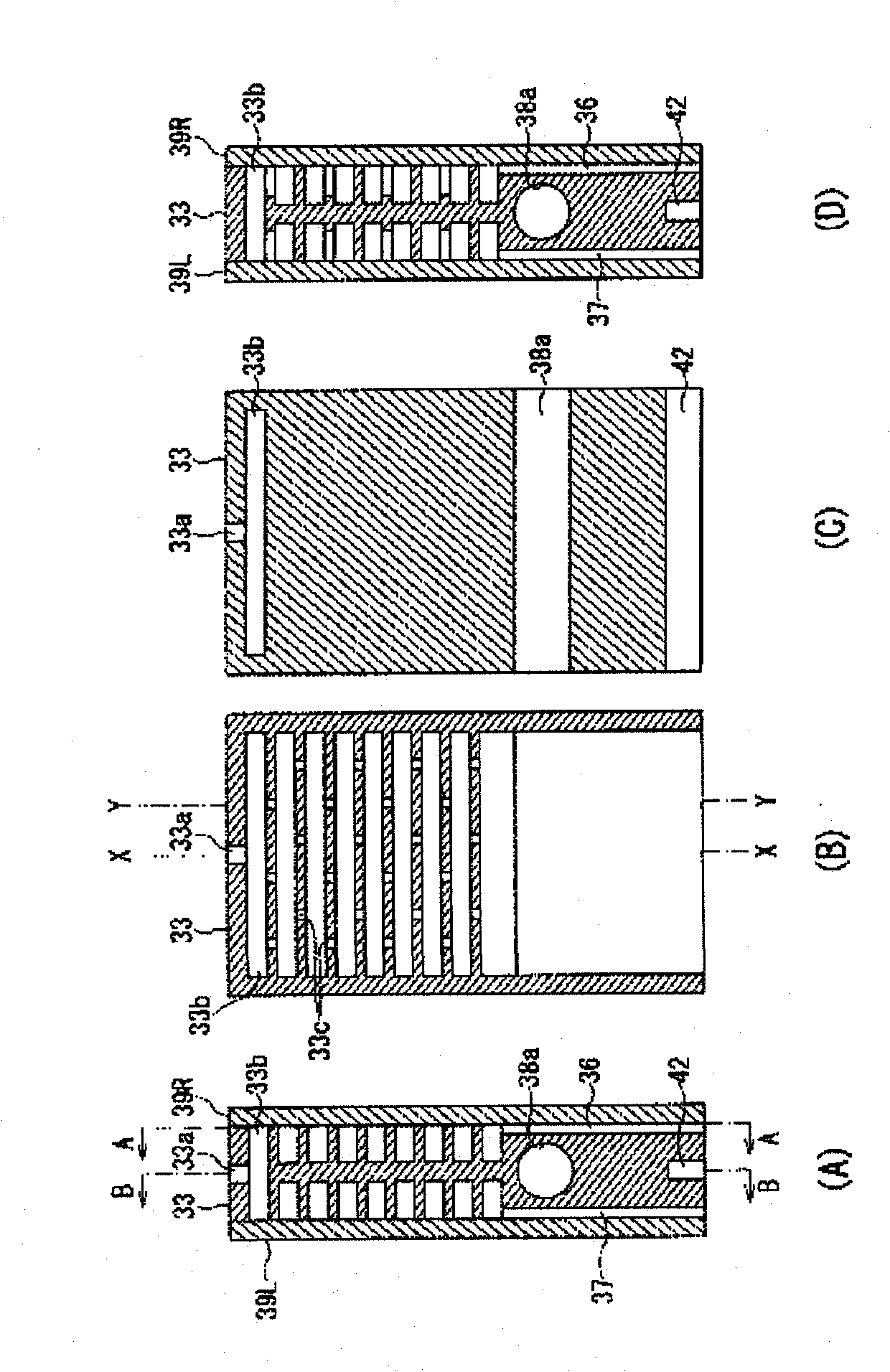

Heating device, film forming apparatus, film forming method, and device

InactiveCN102017084ALow costPrevent heat conductionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSoftening point

Provided is a heating device capable of forming a film efficiently on a glass substrate. Also provided is a film forming apparatus having the heating device. The film forming apparatus comprises the heating device for blowing such a high-temperature gas vertically to the surface (25) of a glass substrate (24) placed on a supporting bed (26), as has a temperature higher than the softening point temperature of the glass substrate. The film forming apparatus blows such a depositing gas (43) simultaneously with a high-temperature gas to the surface of the glass substrate, as is thermally decomposed to form a film deposit.

Owner:PHILTECH

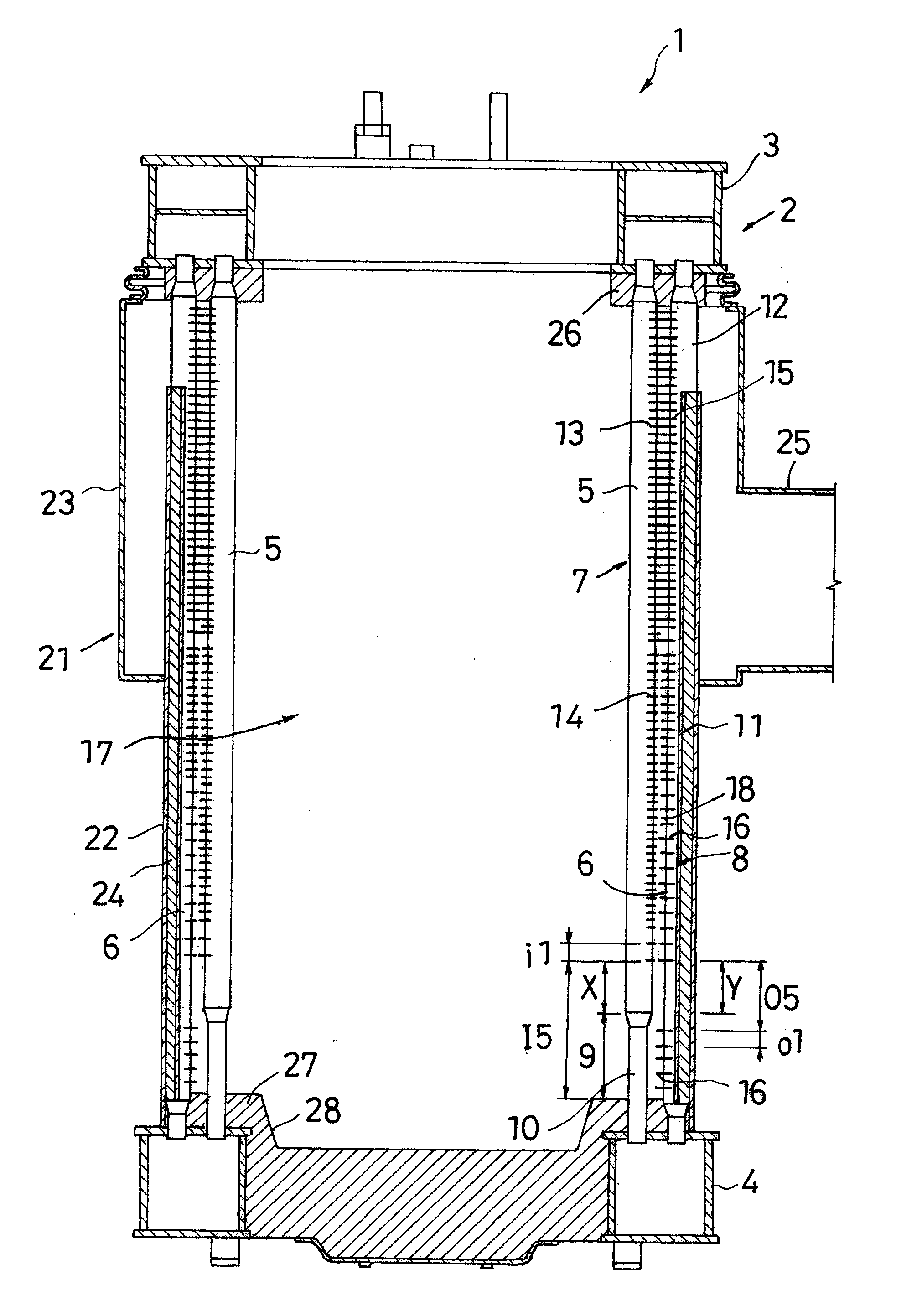

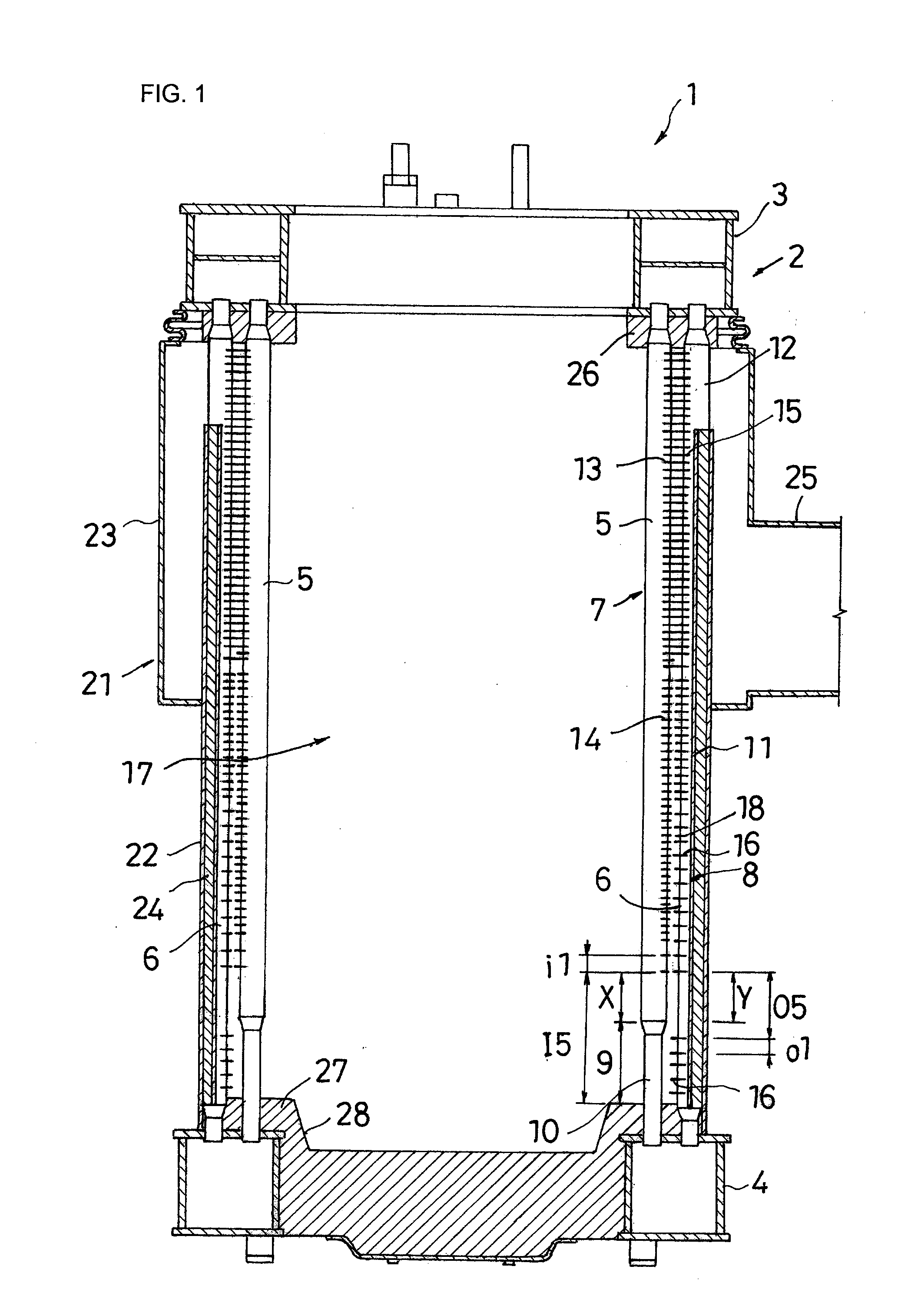

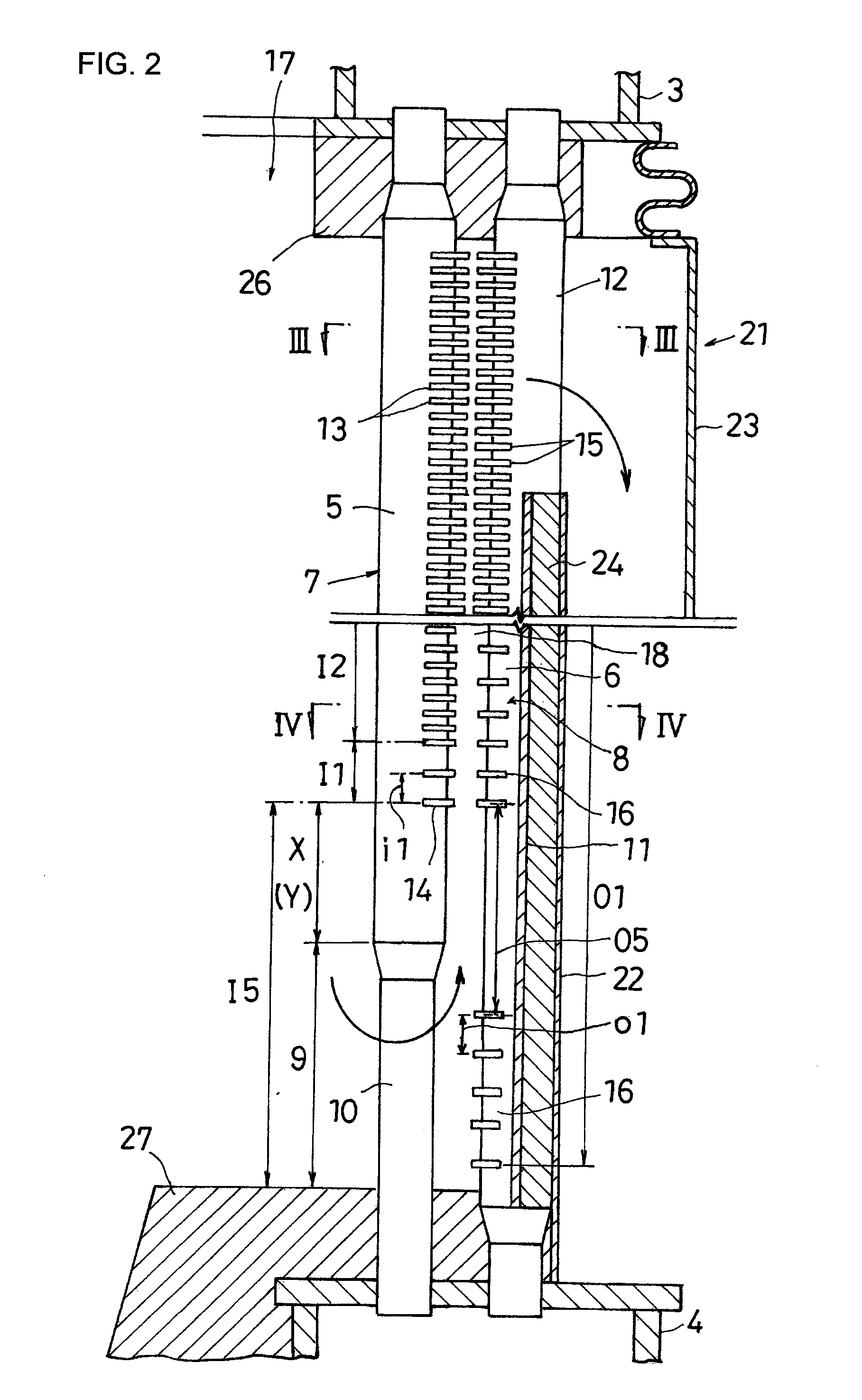

Boiler

ActiveUS20120240868A1Prevent heat conductivityPrevent pressure lossBoiler water tubesSpeed sensing governorsHeat transfer tubeEngineering

Owner:MIURA COMPANY LIMITED

Preparation method for polyimide film used for graphite sintering

The invention relates to the field of preparation of polyimide films, specifically to a preparation method for a polyimide film used for graphite sintering. With the preparation method for the polyimide film used for graphite sintering provided by the invention, aromatic diamine is dissolved in a polar solvent and then polymerized with aromatic dianhydride to prepare polyimide acid resin; a heat-conductive material is introduced in the synthesis process of resin; when the resin is guided to solidify and imidize, a molecular chain is in two-dimensional and uniform-tendency arrangement; thus, growth of a hexagonal two-dimensional carbon plane during high-temperature sintering is easily realized; problems like uneven wrinkles and low heat conductivity of a graphite film due to heat shrinkage and structural problems of the polyimide film are avoided; the problems of large heat shrinkage, a plurality of wrinkles and low heat conductivity of sintered graphite are solved; and the polyimide film obtained by using the preparation method provided by the invention has smooth and fine surface and achieves heat conductivity of 1500 W / MK or above after high-temperature sintering.

Owner:富优特(山东)新材料科技有限公司

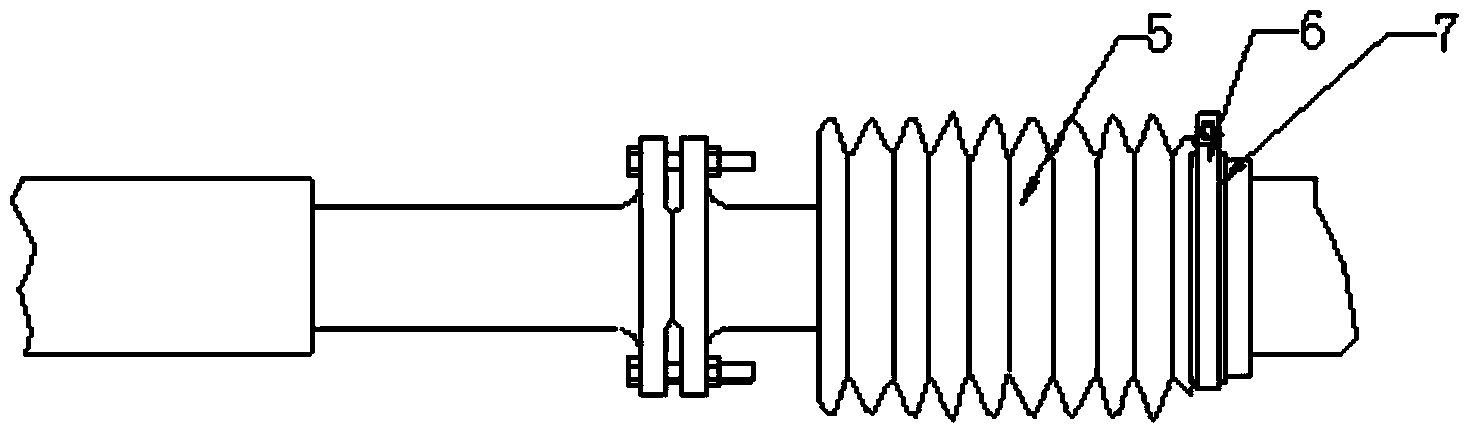

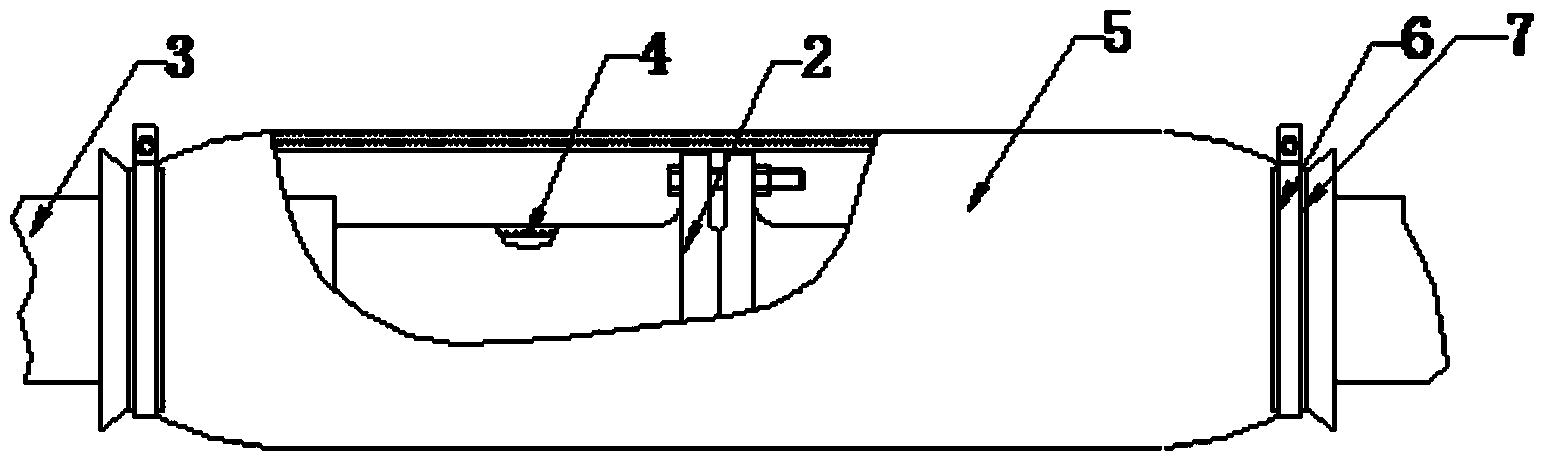

Detachable type thermal insulation device for high-temperature or low-temperature pipelines

ActiveCN104033699APrevent heat conductionAvoid convectionThermal insulationPipe protection by thermal insulationHoopingThermal insulation

The invention discloses a detachable type thermal insulation device for high-temperature or low-temperature pipelines. The detachable type thermal insulation device comprises a pair of flanges, a protective sleeve and a hooping component. The protective sleeve which is made of multi-layer flexible thermal insulation materials is coaxial with thermal insulation pipelines, circumferentially covered with a thermal insulation section and sleeved with the flanges and capable of freely retracting in an axial direction of the pipelines to do thermal insulation of a pipeline connecting position. Two ends of the protective sleeve are connected with common thermal insulation sections of the thermal insulation pipelines in an airtight sleeving manner through the rapid detachable banding component. The detachable type thermal insulation device is adaptable to connecting the pipelines with working temperature ranging from -100degrees to 135degrees, compact in structure, reusable, simple and convenient to detach and free of dropping residues or generating dust, and is particularly adaptable to applications with cleanliness requirement.

Owner:SHANGHAI JIAO TONG UNIV

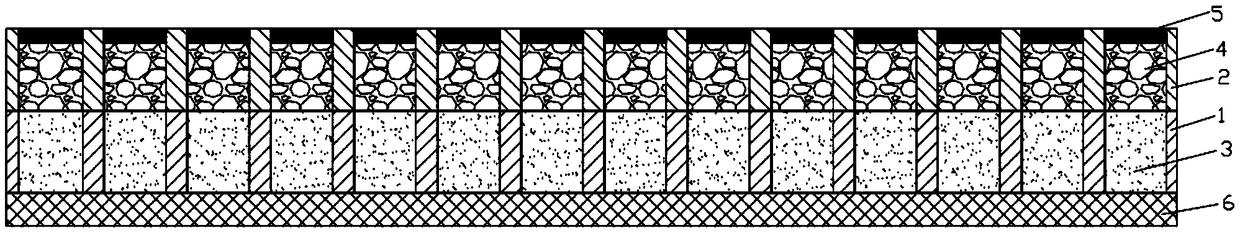

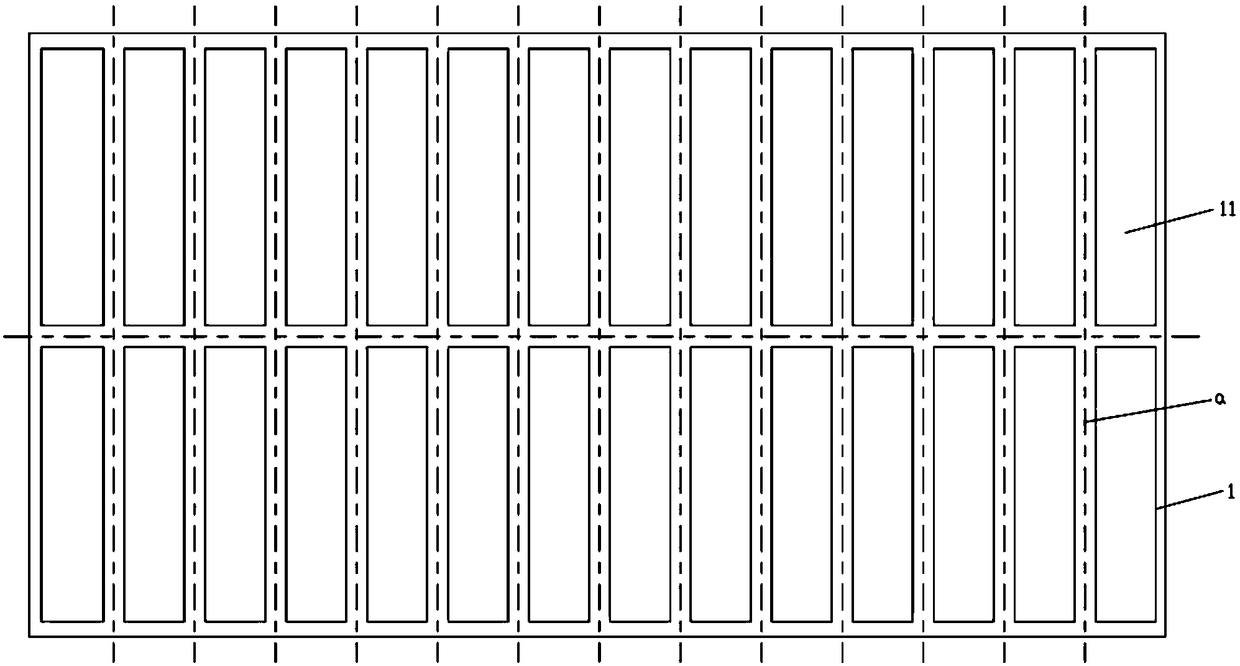

Conductive heat-conducting foam adhesive tape and production method thereof

ActiveCN108650872AAvoid reduction in thermal conductivityGuaranteed strength and stabilityMagnetic/electric field screeningElectrically conductiveEngineering

The invention provides a conductive heat-conducting foam adhesive tape and a production method thereof. The conductive heat-conducting foam adhesive tape comprises a frame structure, wherein the framestructure possesses a plurality of uniformly distributed square through holes, a conductive adhesive layer containing conductive heat-conducting particles as well as foam are sequentially arranged from bottom to top in each square through hole, release paper bonded with the conductive adhesive layer is arranged on the bottom surface of each square through hole, a conductive heat-conducting ink layer is attached on the foam, and the top surface of the conductive heat-conducting ink layer is flushed with the top surface of the corresponding square through hole. The conductive heat-conducting foam adhesive tape has the advantages that periphery protection can be carried out on the conductive adhesive layers and the foam by virtue of the frame structure, the conductive heat-conducting foam adhesive tape can be cut into a plurality of conductive heat-conducting foam adhesive tape small pieces along the edges of the square through holes while cutting, and the cutting is mainly specific to the frame structure in the process, so that the problem that stripping or heat conduction efficacy between structural layers is reduced due to the cutting is avoided.

Owner:苏州盛达飞智能科技股份有限公司

Preparation method of high-performance composite carbon felt

InactiveCN110607687AGuaranteed service lifeSolve the impurity situationCarbon fibresFibre chemical featuresCarbon fibersCarbonization

The invention discloses a preparation method of a high-performance composite carbon felt, and particularly relates to the technical field of fiber products. The preparation method comprises the specific steps of material cleaning, PAN (polyacrylonitrile) precursor preparation, pre-oxidation, carbonization, graphitization, surface treatment and coating treatment. According to the invention, a material cleaning step is added to the composite carbon felt process, impurities in the finished carbon felt can be effectively eliminated from the source, and the influence of the impurities upon the quality of the finished carbon felt is prevented; polyacrylonitrile is dissolved using n-butyl alcohol, the characteristics of the carbon fiber and the carbon felt of the subsequent branch are ensured accordingly, the parts of the carbon felt are stressed uniformly so that the fracture caused by uneven stress at impurity positions in the traditional process is avoided, the stretching effect of the finished carbon felt in the using process is effectively improved, and the service life of the carbon felt is ensured; volatilized n-butyl alcohol vapor can be liquefied again after being cooled for secondary use, and therefore, the production cost of a manufacturer is guaranteed.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

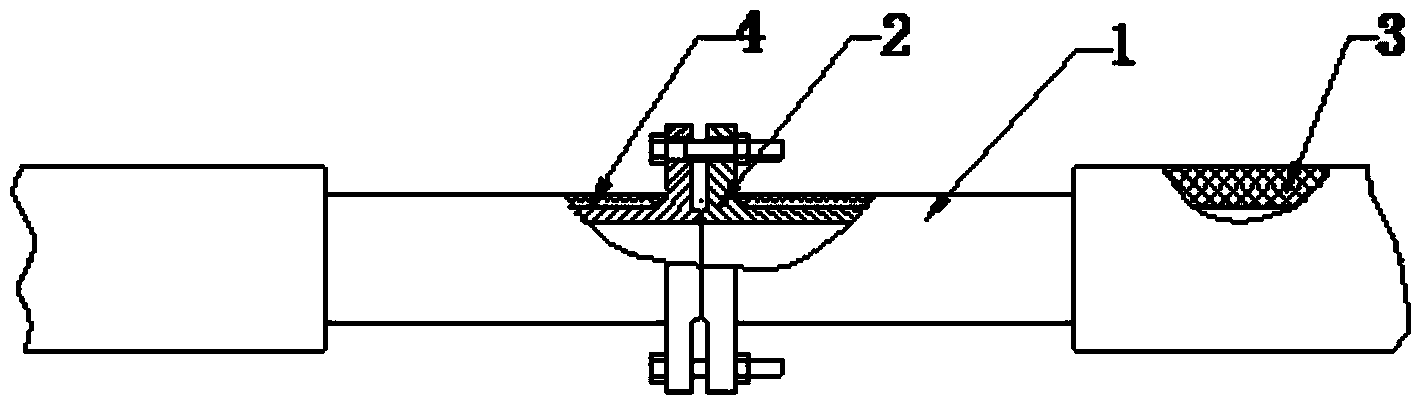

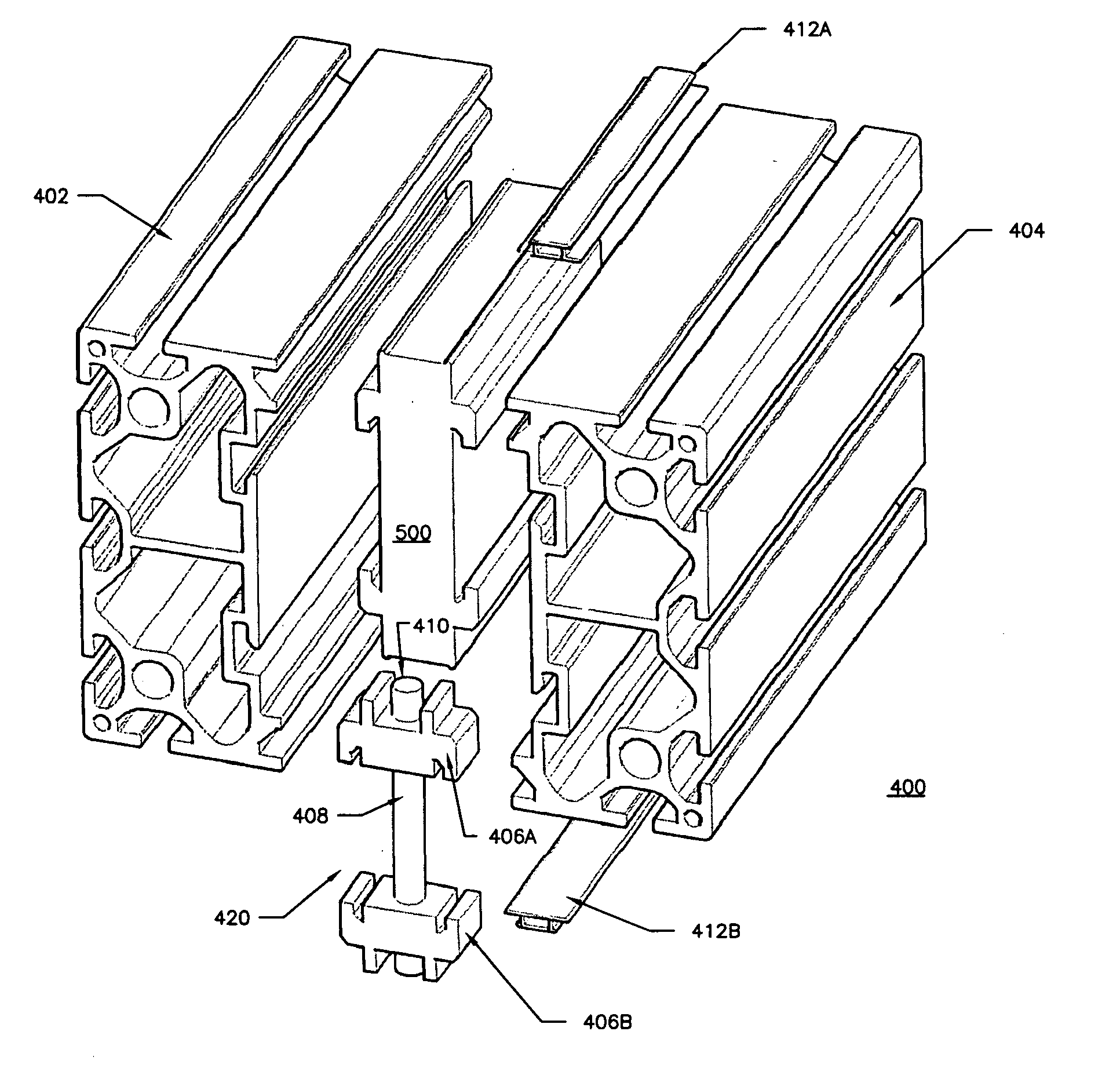

Thermal Break for Aluminum Structures

InactiveUS20090197025A1Prevent heat conductionEnvelopes/bags making machineryWallsThermal breakEngineering

A thermal insulating structural assembly and a method for forming a thermal insulating structural assembly includes longitudinally separating an elongated metallic support beam into a first portion and a second portion, mechanically coupling the first beam portion to the second beam portion with a plurality of clamp assemblies so that the first beam portion is spaced a predetermined non-zero distance from the second beam portion and is mechanically coupled to the second beam portion only by the clamp assemblies, and introducing between the beam portions, a low thermal-conductive material at least partially thermally insulating the first beam portion from the second beam portion.

Owner:BURST SHAWN MICHAEL +1

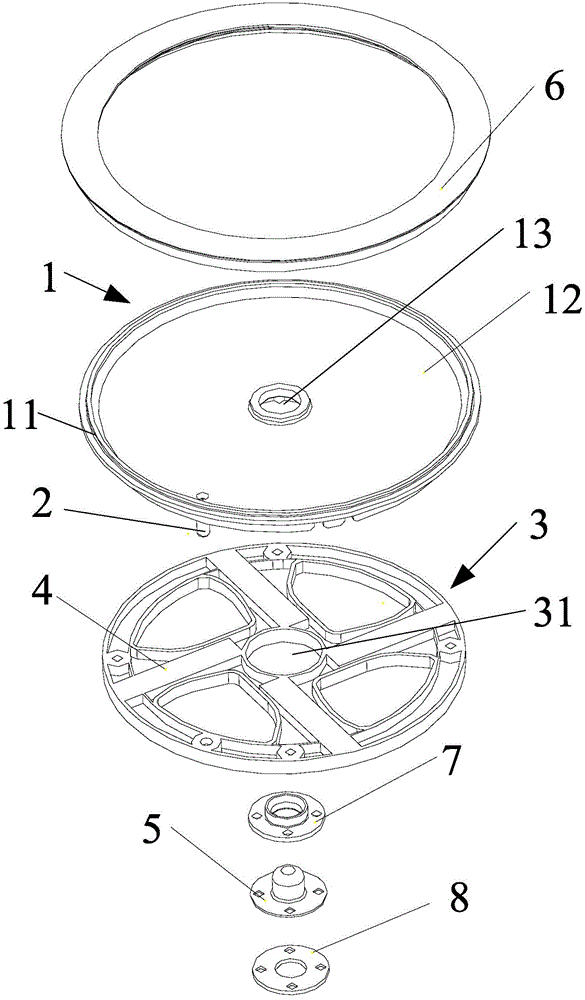

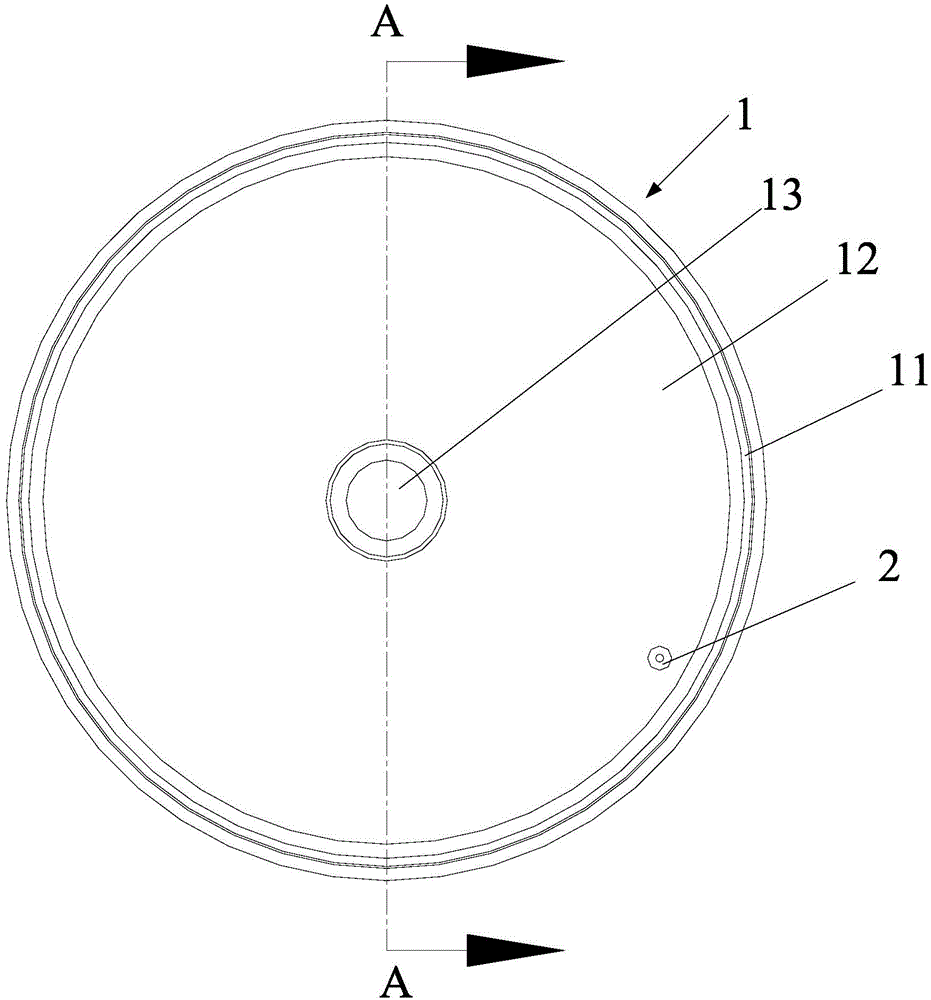

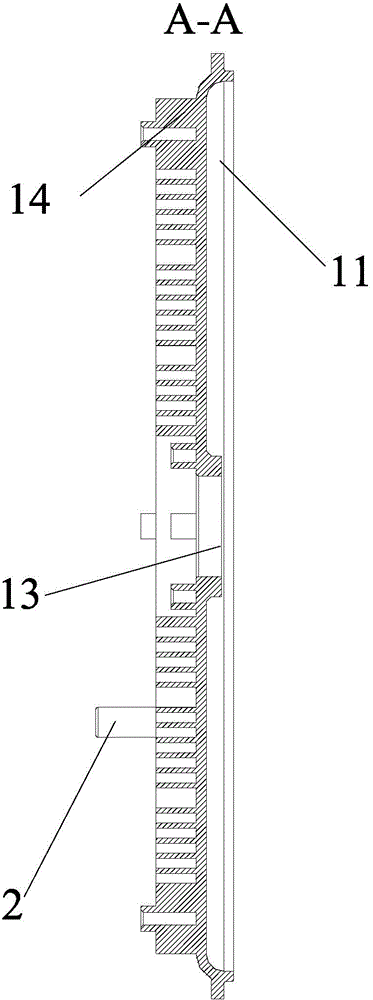

Coil disc and induction cooker

ActiveCN106162976AExtended service lifeHigh thermal efficiencyDomestic stoves or rangesCoil arrangementsThermal insulationInduction motor

The invention provides a coil disc and an induction cooker. The coil disc comprises a coil disc support, wherein the coil disc support comprises a disc body, an edge portion of an upper surface of the disc body is provided with an annular convex rib, an upper end face of the convex rib is in matching with a lower surface of a heating panel of the induction cooker to form a heat insulation chamber between the disc body and the heating panel, a reflection layer is composited on the upper surface of the disc body, and the reflection layer is used for reflecting heat radiation generated by the induction cooker. The coil disc has multiple types of heat insulation functions, not only can heat insulation be realized through the vacuum chamber formed by the coil disc and the heating panel, but also heat radiation generated by the induction cooker can be reflected through the reflection layer arranged on the coil disc, so the induction cooker is prevented from emitting heat downwards to damage a heating assembly, service life of the induction cooker is effectively prolonged, and heat efficiency of the induction cooker is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

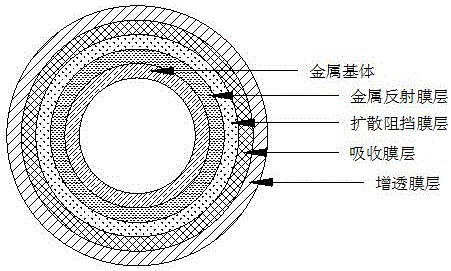

High-temperature solar selective absorbing coating and preparation method thereof

InactiveCN106403329AImprove high temperature resistanceStrong absorption capacitySolar heat devicesVacuum evaporation coatingMetallic substrateHot Temperature

The invention provides a high-temperature solar selective absorbing coating and a preparation method thereof. According to the high-temperature solar selective absorbing coating, a metal material serves as a base material, and a metal reflection film layer, a diffusion stop film layer, an absorbing film layer and an antireflection film layer are arranged on the surface of the metal base material sequentially from inside to outside, wherein the absorbing film layer comprises four absorbing sublayers with metal contents decreasing in a gradient mode from inside to outside. The absorbing film layer comprises the four absorbing sublayers with the gradually varied metal contents, and the metal contents change in the gradient mode, so that diffusion of the coating is slight during the high-temperature work process, and the high temperature stability of the film layers is improved.

Owner:SHANDONG BEACONERGY ASSOC EQUIP CORP

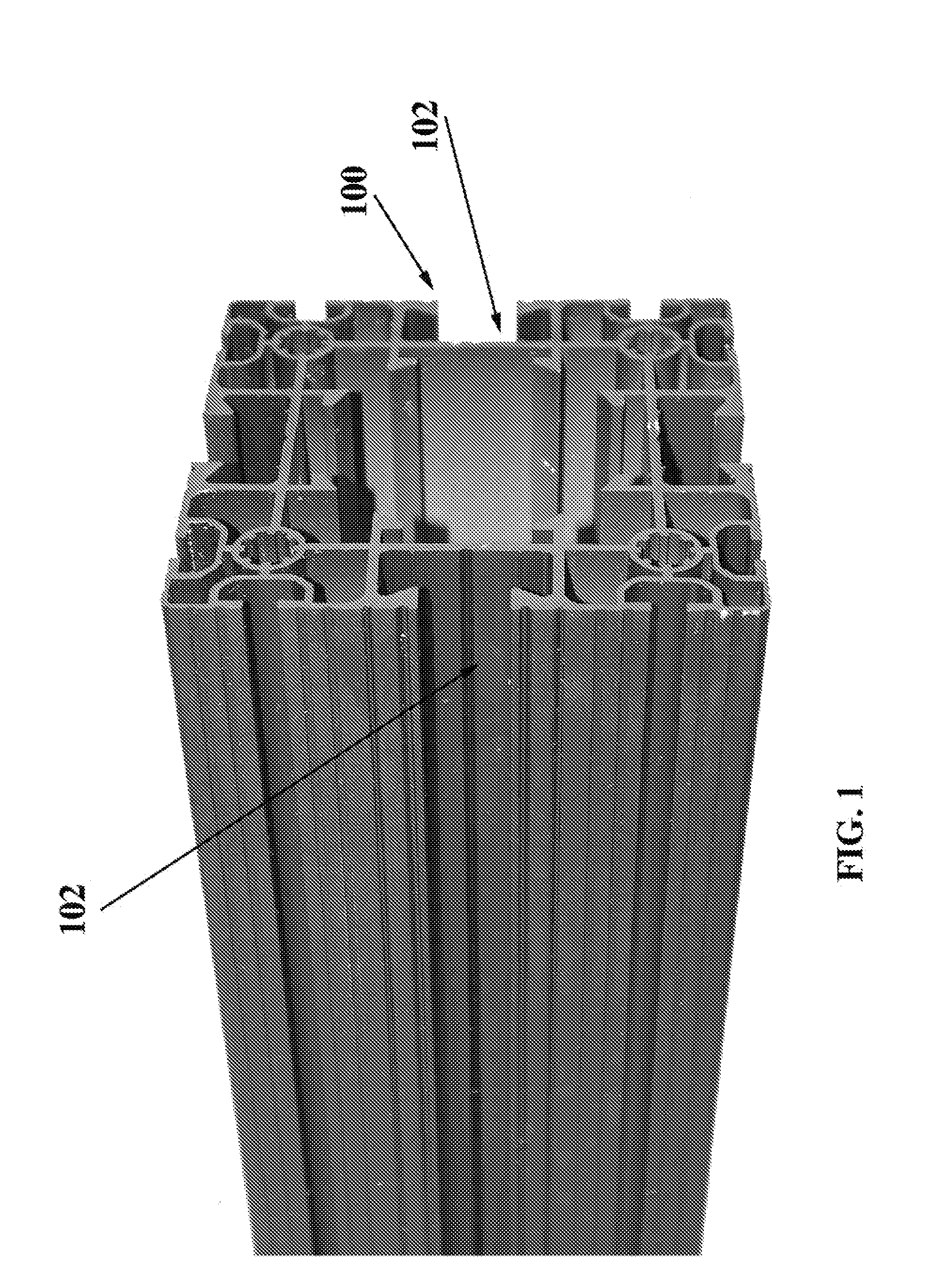

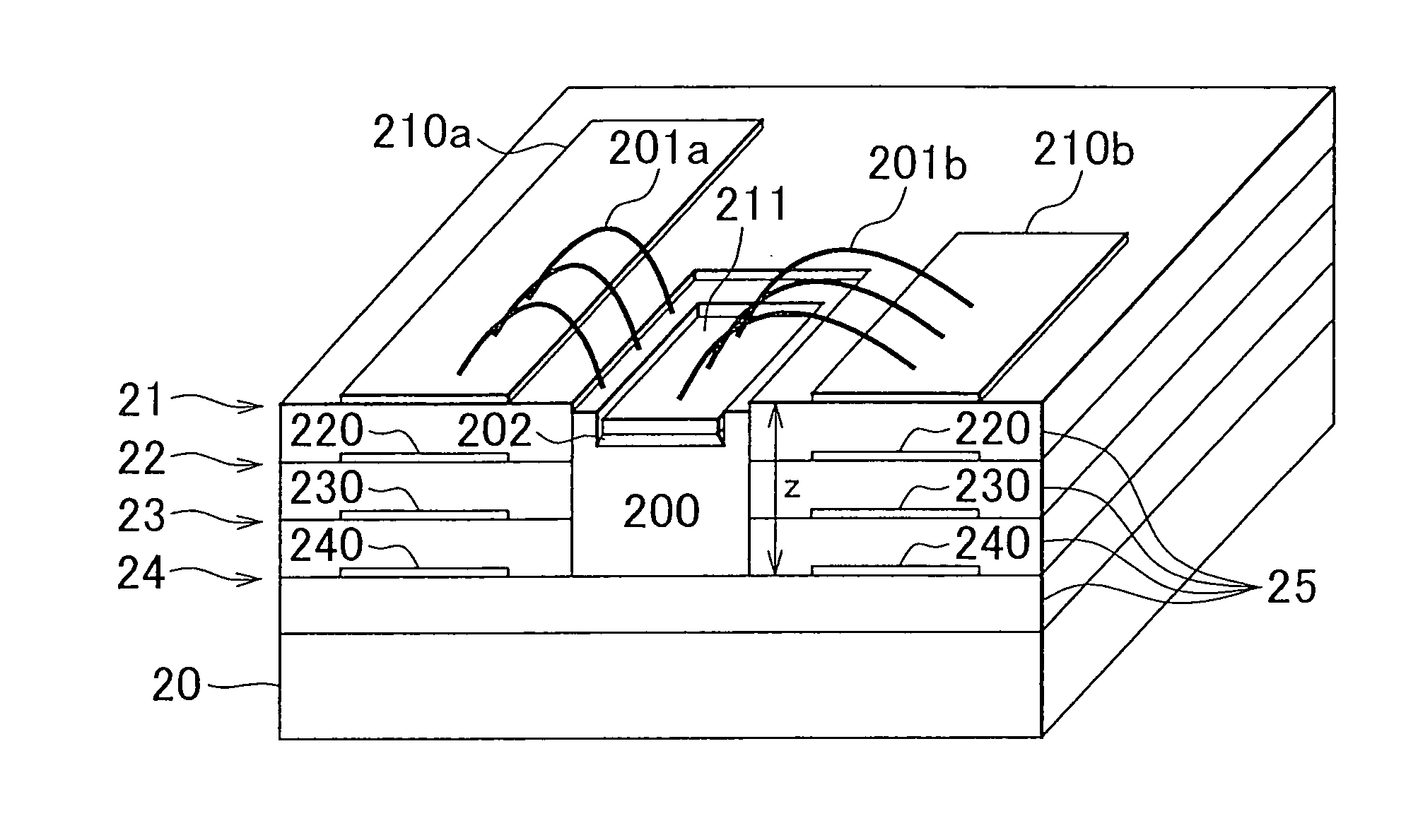

Multilayer circuit substrate

ActiveUS8415565B2Improve cooling efficiencyImprove thermal conductivityPrinted electric component incorporationPrinted circuit aspectsEngineeringElectronic component

A multilayer circuit substrate includes: a laminated circuit portion in which conductive layers and resin insulating layers are alternately laminated; and a metal substrate portion, wherein the laminated circuit portion is fixed to the metal substrate portion so that at least part of a lower surface of the laminated circuit portion is in contact with at least part of an upper surface of the metal substrate portion. An electronic component is mounted on the metal substrate portion.

Owner:JTEKT CORP

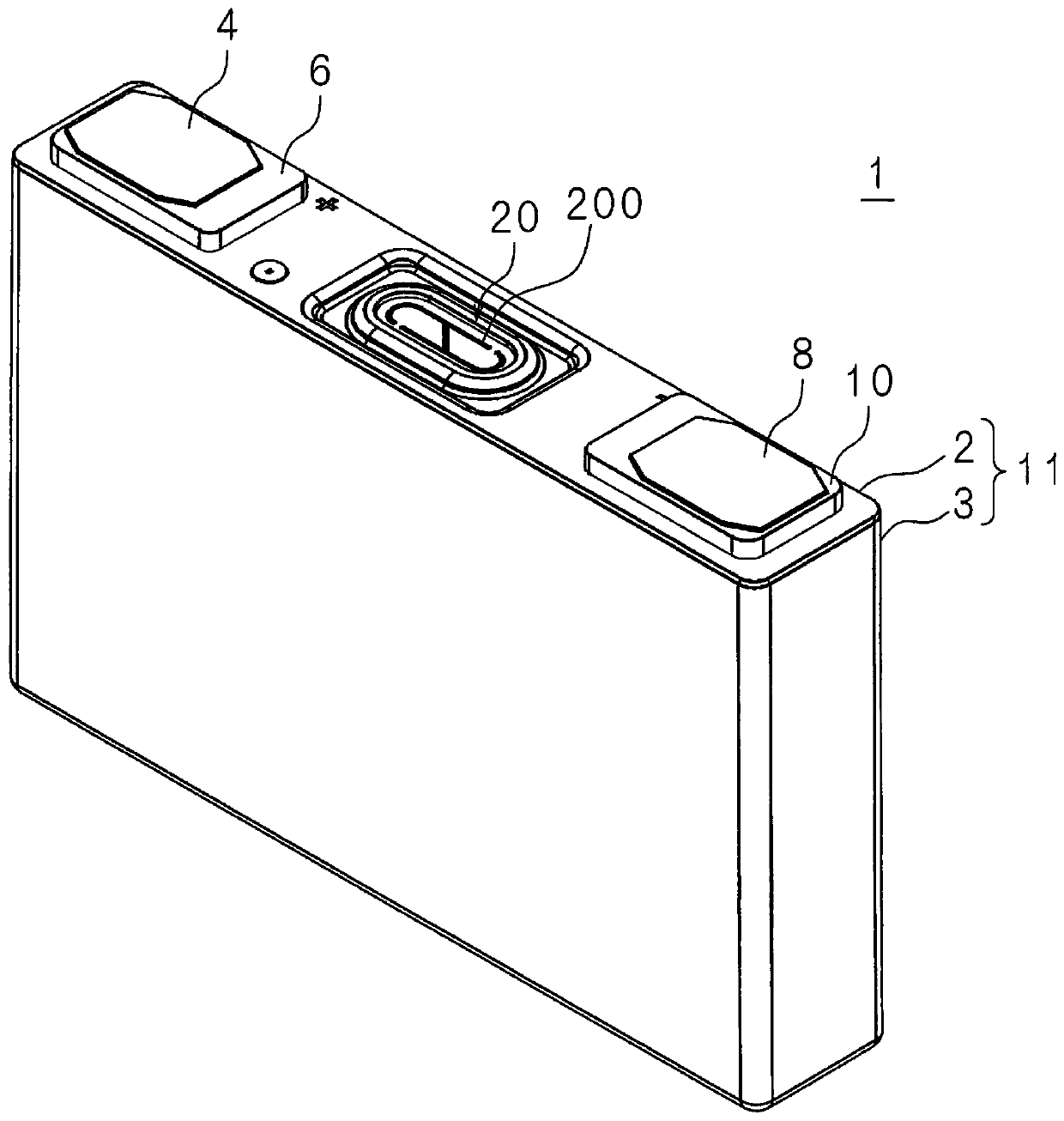

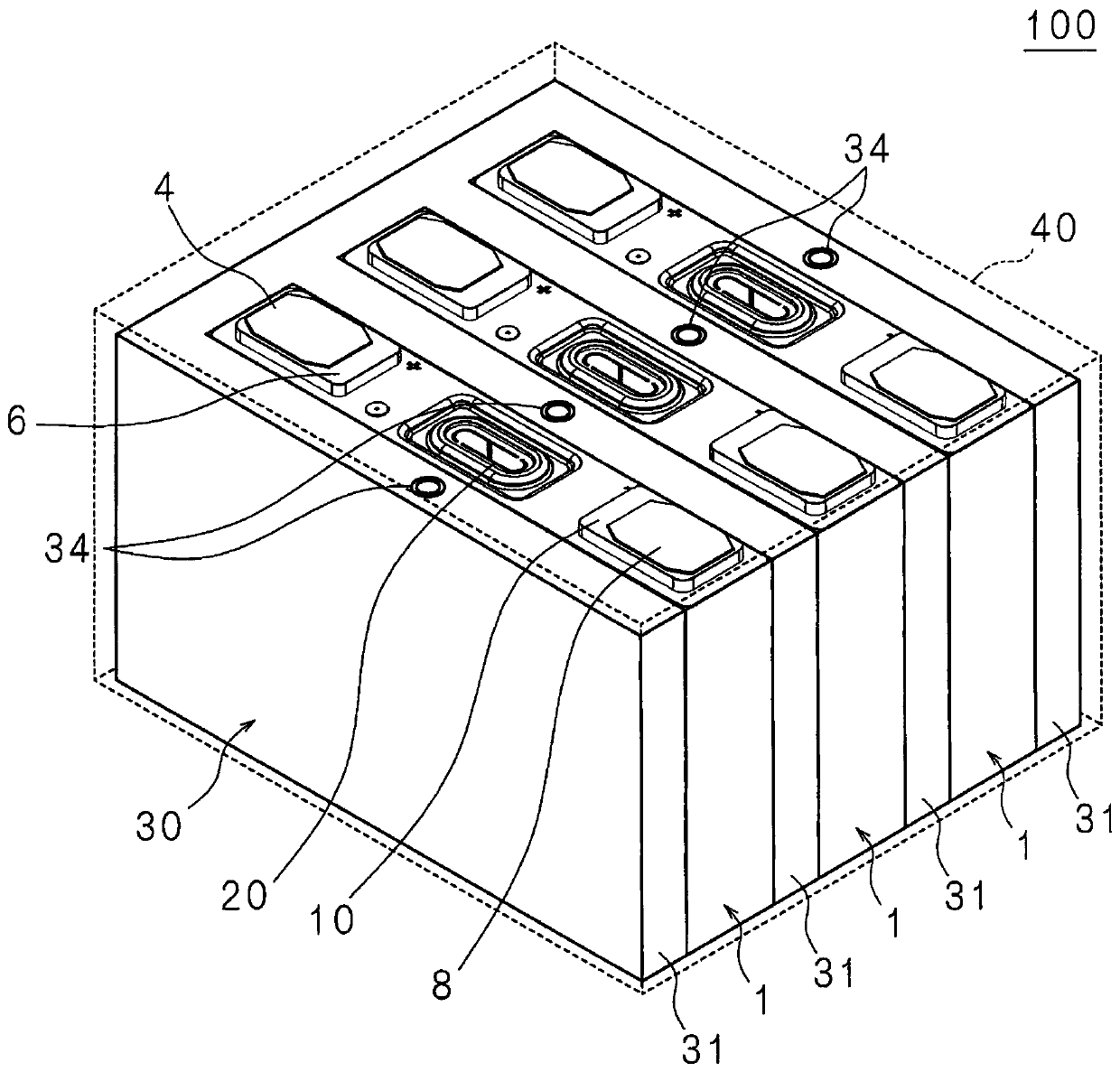

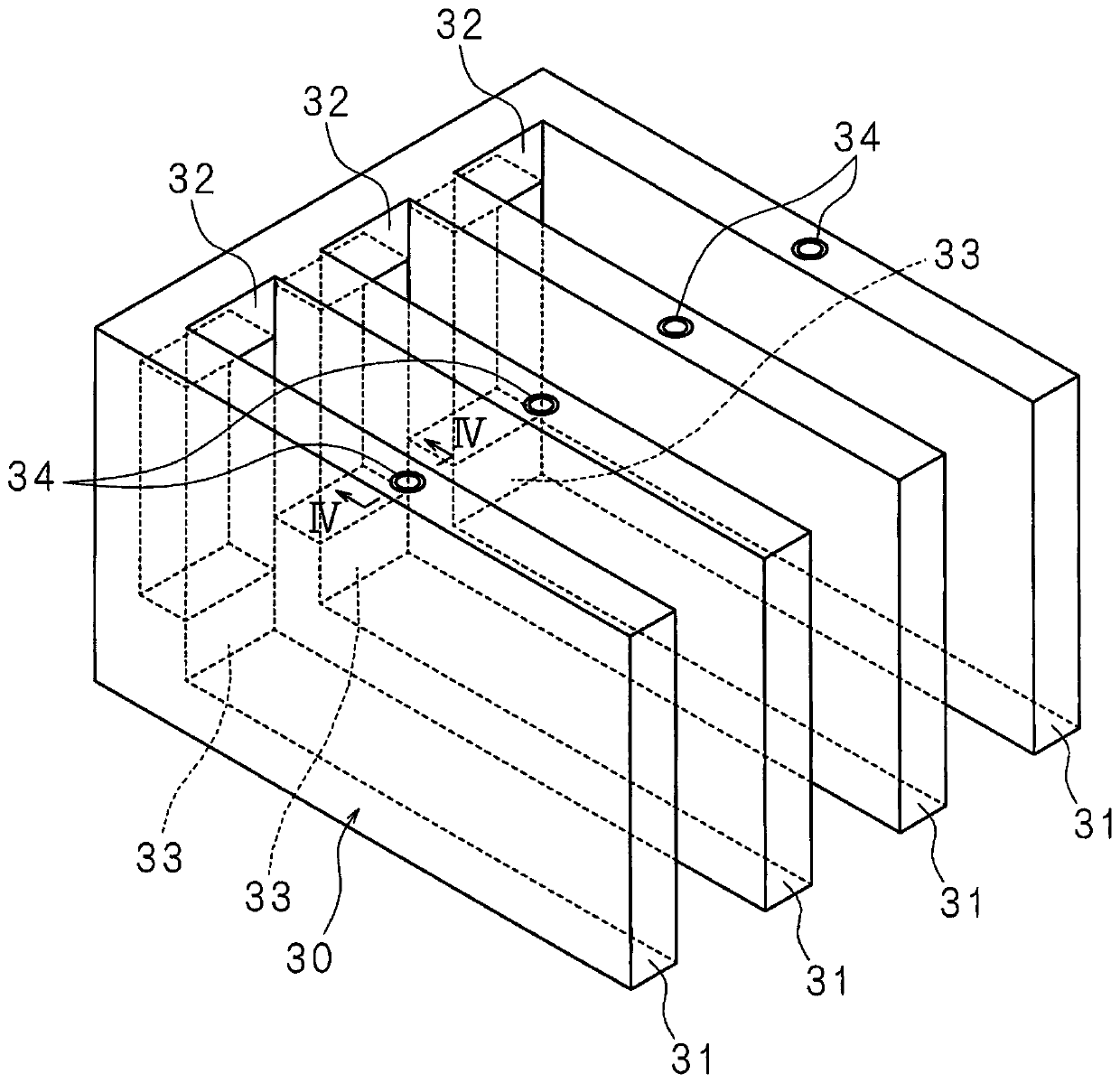

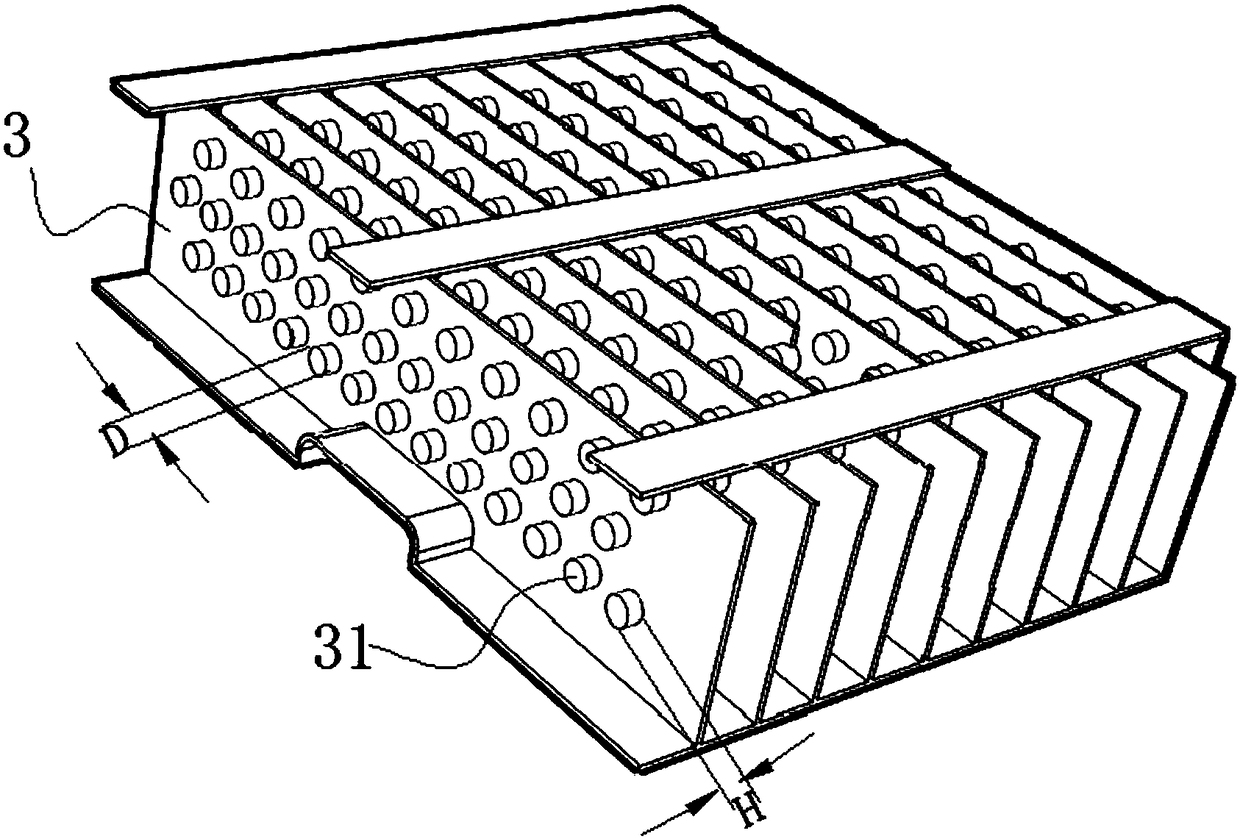

Electricity storage device

PendingCN111247686AImprove cooling effectInhibit conduction heatSecondary cellsFire rescueProcess engineeringFire retardant

The invention provides an electricity storage device. The electricity storage device (100) is provided with a plurality of electricity storage elements (1) and a cooling module (30) which cools the electricity storage elements (1). The cooling module (30) comprises at least a cooling unit (31) which is arranged between the electricity storage elements (1) and internally contains a flameproofing agent, thereby cooling the electricity storage elements (1) by means of heat absorption during vaporization of the flameproofing agent. Consequently, the electricity storage elements (1), in which heathas been generated, are successfully cooled by the cooling unit (31) that is in contact with the electricity storage elements (1) by means of the vaporization heat at the time when the flameproofing agent contained within the cooling unit is vaporized, thereby preventing a chain of overheated states among the electricity storage elements (1).

Owner:GS YUASA INT LTD

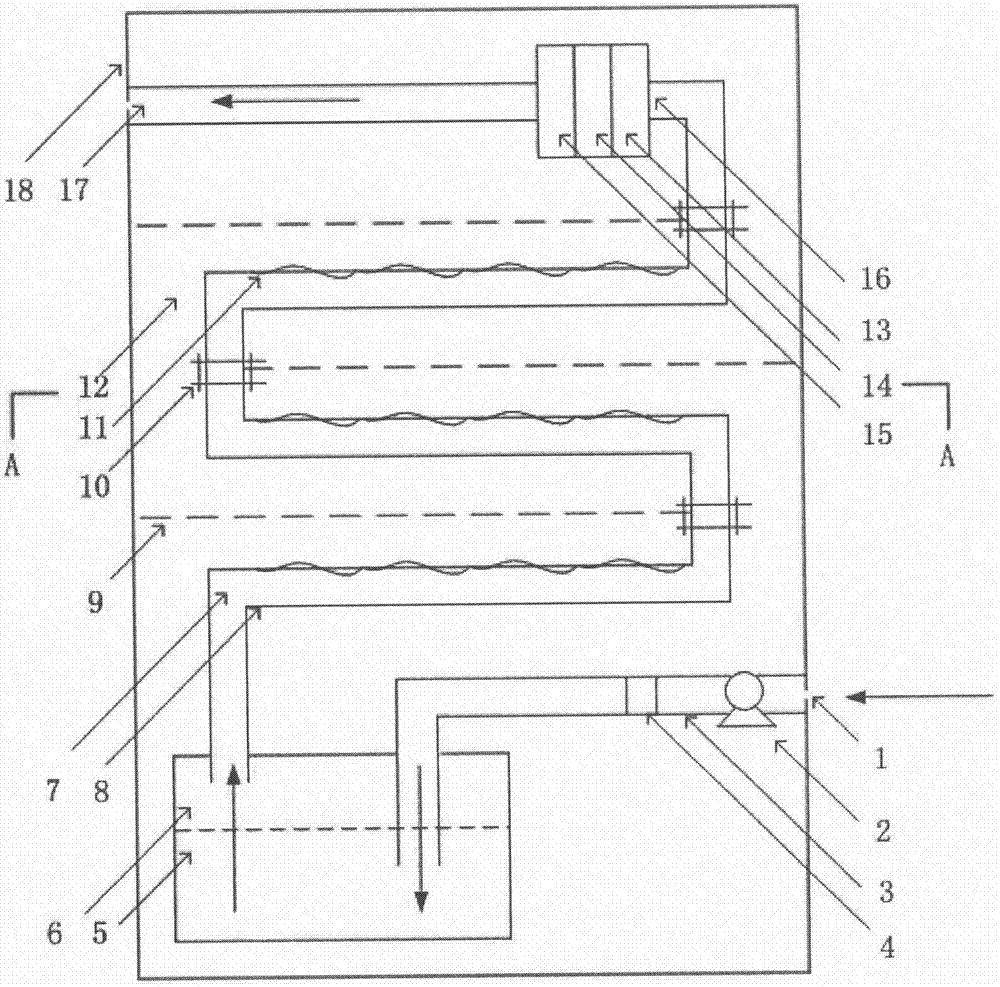

Thermophoresis air filtering device

InactiveCN106964230AImprove comfortIncrease or decrease indoor temperatureCombination devicesTemperature controlAir filter

The invention discloses a thermophoresis air filtering device which comprises three parts, namely an air washing device, a thermophoresis treatment device, a temperature control device. Air to be treated is fed into the air washing device with a liquid for primary filtration through an air pump; the air is fed into the thermophoresis treatment device later; thermophoresis pipelines are S-shaped and are connected through thermal insulating flanges; a low reflection thermal insulating plate is inserted between adjacent parallel pipelines; finally filtered air enters a temperature control device to be heated or cooled to a required temperature, and the heated or cooled air is discharged out from an air discharge hole. The thermophoresis air filtering device is environment-friendly, efficient, good in comfort, and convenient to disassemble, wash and maintain.

Owner:NANJING UNIV OF TECH

White cement clinker bleaching process high in waste heat utilization rate

The invention discloses a white cement clinker bleaching process high in waste heat utilization rate. High-temperature clinker discharged from a rotary kiln is guided into a water-cooling bleaching machine and a grate cooler through a distribution device; the clinker entering the water-cooling bleaching machine is subjected to water cooling to 500-600 DEG C, sent to the middle rear section of thegrate cooler from a discharging end and subjected to air cooling to 80-100 DEG C, and the cooled clinker is conveyed to a clinker silo by a chain bucket conveyor (5). The problem that heat generated in cooling of the clinker from 600 DEG C to 80 DEG C does not play a role in bleaching and is not used in water-cooling bleaching in the prior art is effectively solved. The clinker cooled to 600 DEG Cin water-cooling bleaching is further subjected to air cooling in the grate cooler to make use of high-temperature air generated in air cooling, and accordingly waste heat utilization rate is increased.

Owner:江西银杉白水泥股份有限公司

Spark plug and internal combustion engine provided with the same

InactiveUS20100101521A1Improve flammabilityPrevent scalingSparking plugsFuel injection apparatusExternal combustion engineEngineering

A spark plug comprising a cylindrical portion which projects into a combustion chamber from an inner wall face of an engine head when the spark plug is fixed to the engine head, wherein the cylindrical portion has one or more ventilating portion comprised of a through hole or a notch in an outer circumferential face thereof. An igniting portion projecting into the combustion chamber improves ignitability. Further, because an air-fuel mixture fed from an inlet of the internal combustion engine flows to inside of the cylindrical portion through the ventilating portion, heat of an insulator is taken away and cooled down, whereby an occurrence of pre-ignition is prevented.

Owner:NGK SPARK PLUG CO LTD

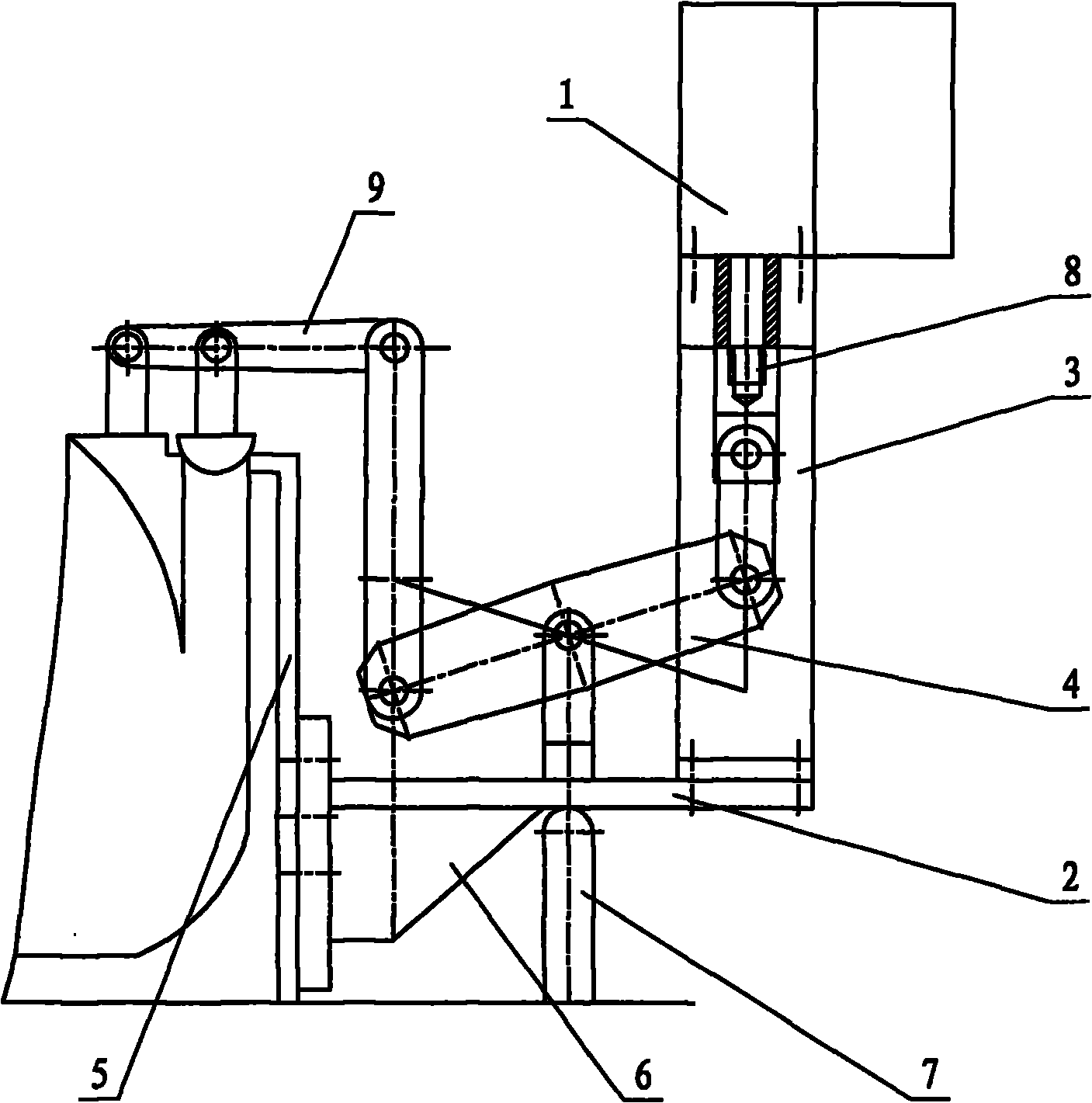

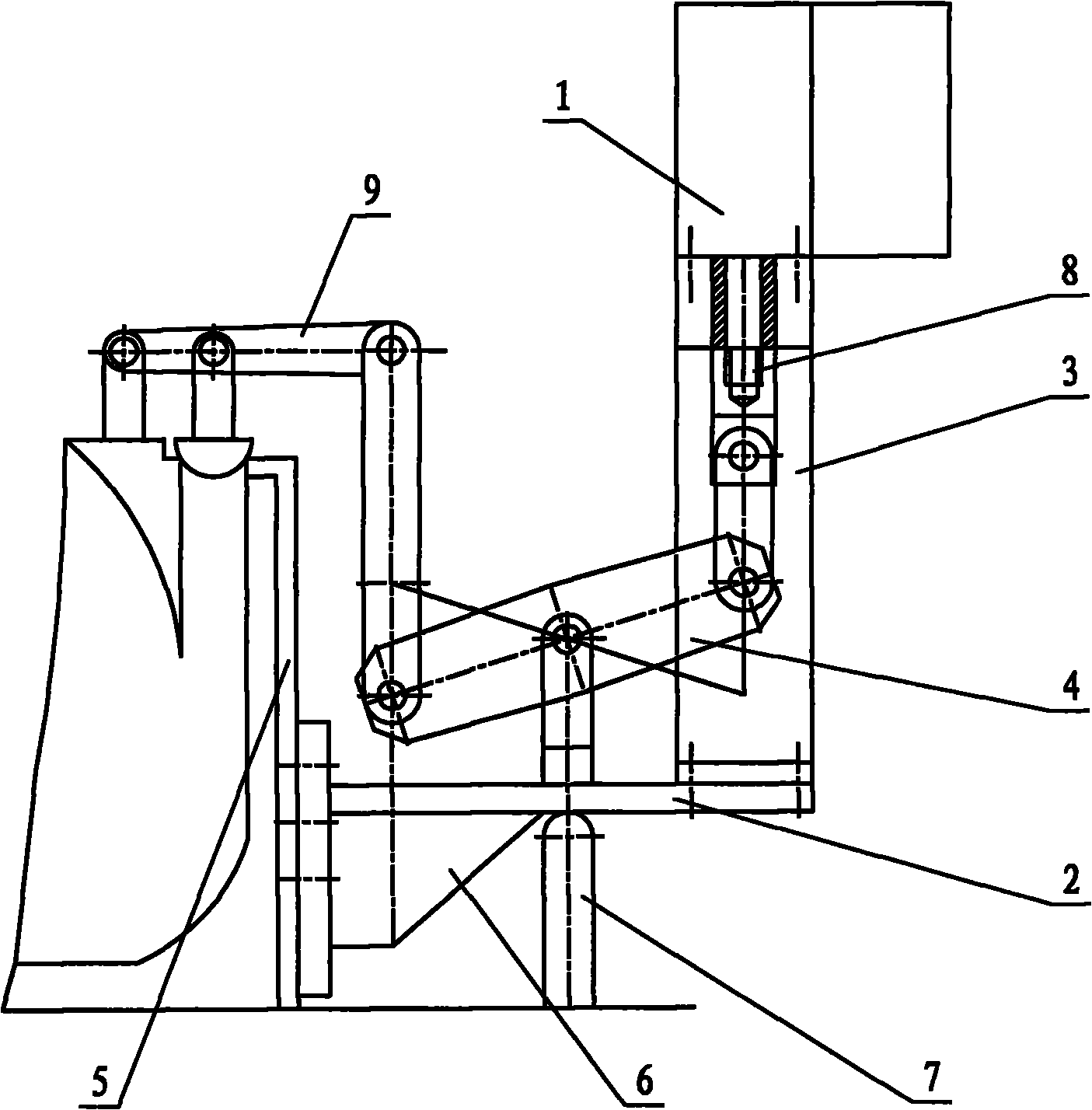

Fixed form of hydraulic servomotor in electro-hydraulic control system

InactiveCN101988396AAvoid radiant heatPrevent heat conductionMachines/enginesEngine componentsControl systemControl engineering

The invention provides a fixed form of a hydraulic servomotor in an electro-hydraulic control system. The fixed form solves the problems of quick ageing and invalidation of a guide sleeve and a pipe joint sealing element of the hydraulic servomotor because the hydraulic servomotor close to an oil cylinder works under a high-temperature environment for a long term. The fixed form is characterized in that: a hydraulic servomotor bracket is fixed on a table top at one end of an inverse T-shaped transition plate, the hydraulic servomotor is fixed on the hydraulic servomotor bracket in an inverse mode, and one end of the transition plate is fixed on a bent plate; and a lever is provided by using an upright post of the T-shaped transition plate as a pivot (C), one end of the lever is hinged (A) with a hydraulic servomotor piston rod, the other end of the lever is hinged (B) with a driving high-pressure adjusting valve lever mechanism, and two sides of the pivot (C) are provided with equal arms. The fixed form has the advantage that the hydraulic servomotor is integrally moved outside to keep away from the oil cylinder serving as a heat source.

Owner:LIAONING ELECTRIC POWER CONTROL TECH

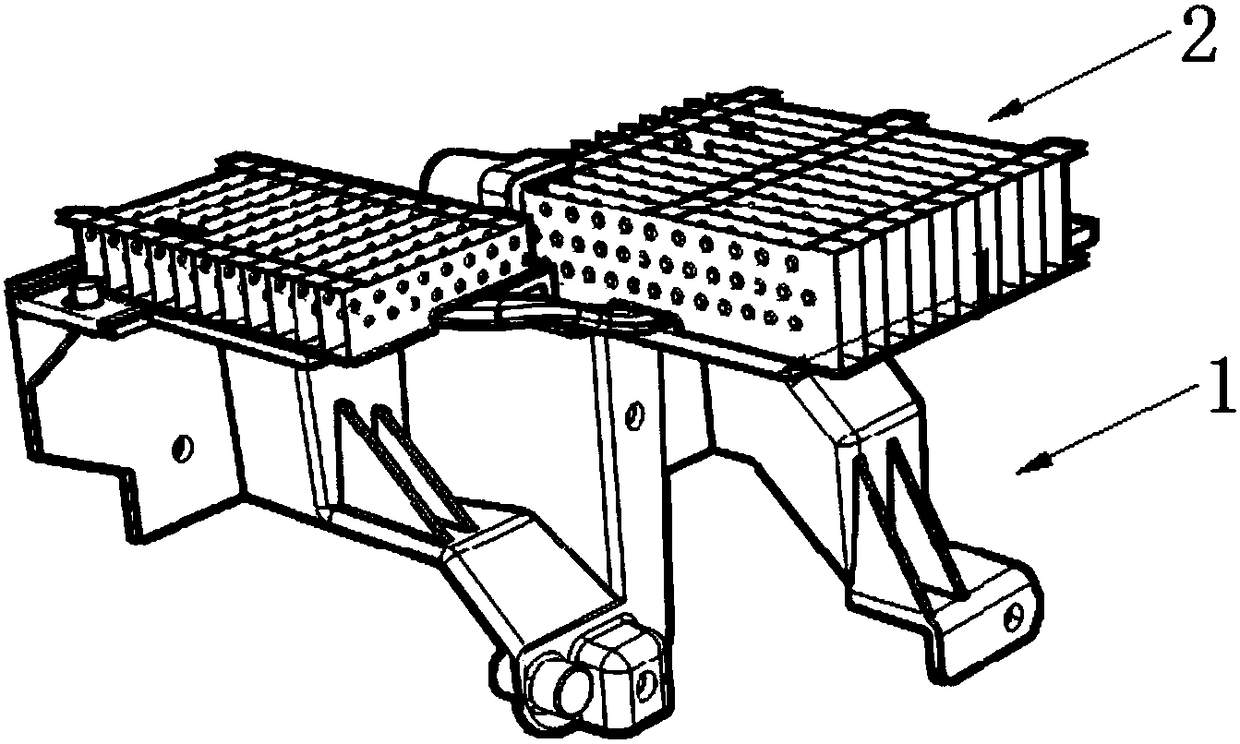

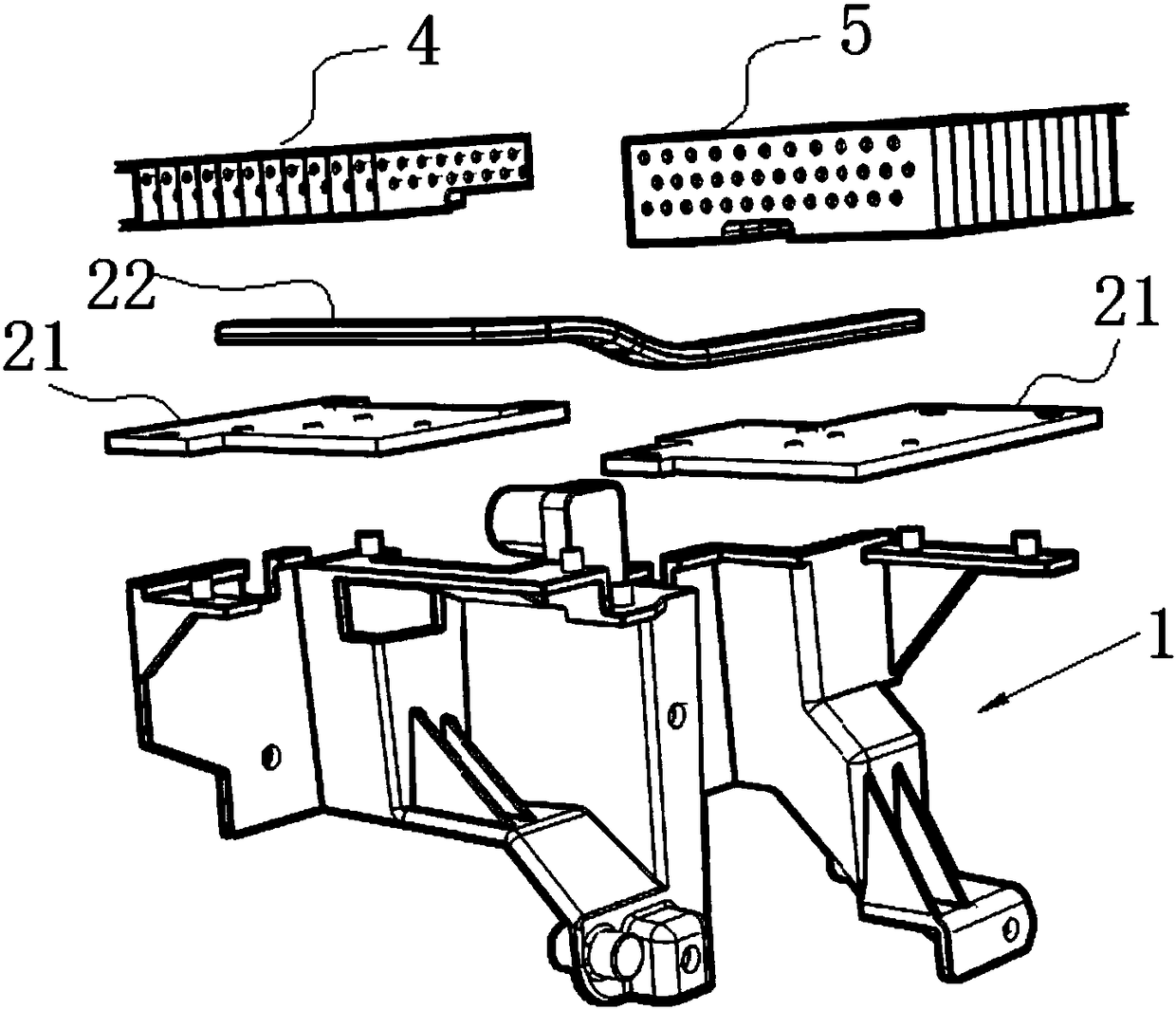

LED vehicle lamp efficient cooling module

PendingCN108591964AImprove cooling efficiencyPrevent heat conductionLighting heating/cooling arrangementsSignalling/lighting devicesEngineeringLead vehicle

The invention discloses an LED vehicle lamp efficient cooling module which comprises a supporting frame, a vehicle lamp substrate and a cooling structure. The cooling structure comprises a cooling substrate, a heat pipe and a fin structure. The heat pipe is fixed between the cooling substrate and the fin structure, the cooling substrate is fixed above the supporting frame, the vehicle lamp substrate is fixed below the cooling substrate, the upper surface of the heat pipe communicates with the fin structure, the lower surface of the heat pipe communicates with the cooling substrate, the fin structure comprises a plurality of fins distributed at equal intervals and perpendicular to the cooling substrate, one side of each fin is evenly provided with a plurality of rows of convex hulls, everytwo adjacent rows of convex hulls are distributed in a crossed mode, and the side, opposite to the vehicle lamp substrate, of the cooling substrate is coated with a heat conduction layer. The coolingstructure can be simplified, the overall weight can be reduced, and the cooling effect can be enhanced.

Owner:太仓市华盈电子材料有限公司

A diesel preheating device

ActiveCN103089494BFully warmed upWarm up fastFuel injection apparatusMachines/enginesViscosityEnergy consumption

The invention provides a diesel preheating device. The diesel preheating device comprises a preheater, a diesel storage device and an atomizing nozzle. The diesel storage device is a heat conduction entity, and a diesel flow path is arranged in the diesel storage device. The diesel flow path comprises a diesel inlet and a diesel outlet, the diesel outlet is connected with the atomizing nozzle in a sealing mode, a preheater containing cavity is formed in the diesel storage device, and the preheater is arranged in the preheater containing cavity. According to the diesel preheating device, the preheater is fixed inside the diesel storage device, fixed point preheating technology is adopted, liquid heat exchange principle is applied, and therefore heat exchange efficiency is improved, energy consumption is reduced, diesel can be preheated most efficiently, viscosity of the diesel can be reduced, and flowability of the diesel can be improved.

Owner:北京北机机电工业有限责任公司

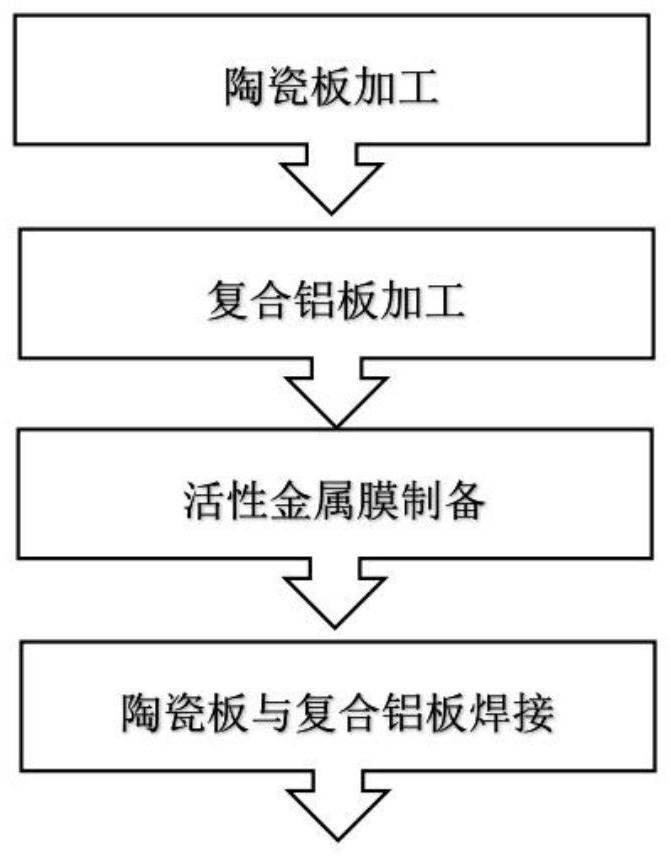

Ceramic aluminum-coated plate for IGBT (Insulated Gate Bipolar Translator) packaging and preparation method thereof

ActiveCN114349471AHigh densityHigh compressive strengthClaywaresCarbide siliconCompressive resistance

The invention discloses a ceramic aluminum-coated plate for IGBT packaging and a preparation method thereof, and relates to the technical field of ceramic metallization, the ceramic aluminum-coated plate comprises a ceramic bottom plate, an active metal liquid film and a composite aluminum plate, the outer surface of the ceramic bottom plate is uniformly covered with the active metal liquid film, and the ceramic bottom plate is connected with the composite aluminum plate through the active metal liquid film. According to the invention, a certain proportion of silicon carbide is added into the production raw materials of clay, quartz and feldspar of the ceramic bottom plate, so that the density, compressive strength, thermal conductivity and other properties of the composite ceramic containing silicon carbide are obviously improved, and the single component of a single ceramic bottom plate is avoided; and when the outer side of the ceramic bottom plate is covered with an aluminum plate, a composite aluminum plate composed of aluminum-magnesium alloy, industrial pure aluminum and aluminum-copper alloy is adopted, so that the corrosion resistance and the pressure resistance of the workpiece are enhanced, and meanwhile, the heat-conducting property of the workpiece is also enhanced.

Owner:深圳思睿辰新材料有限公司

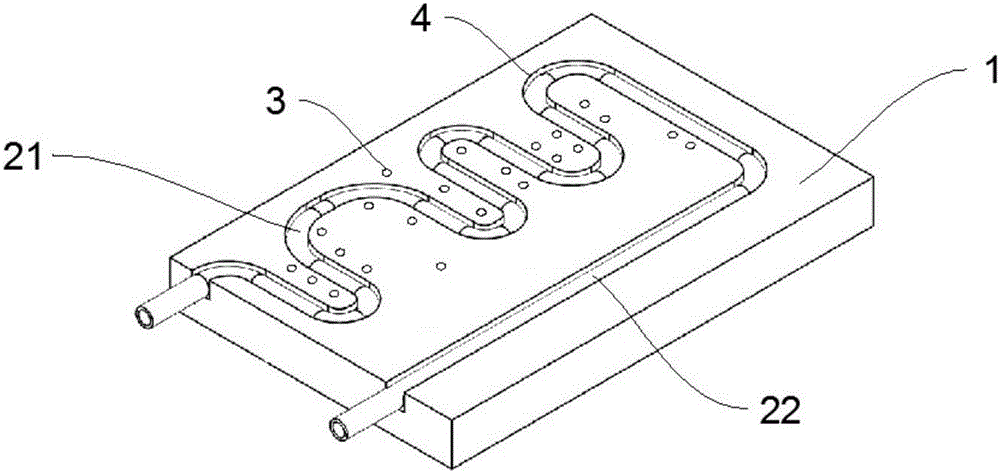

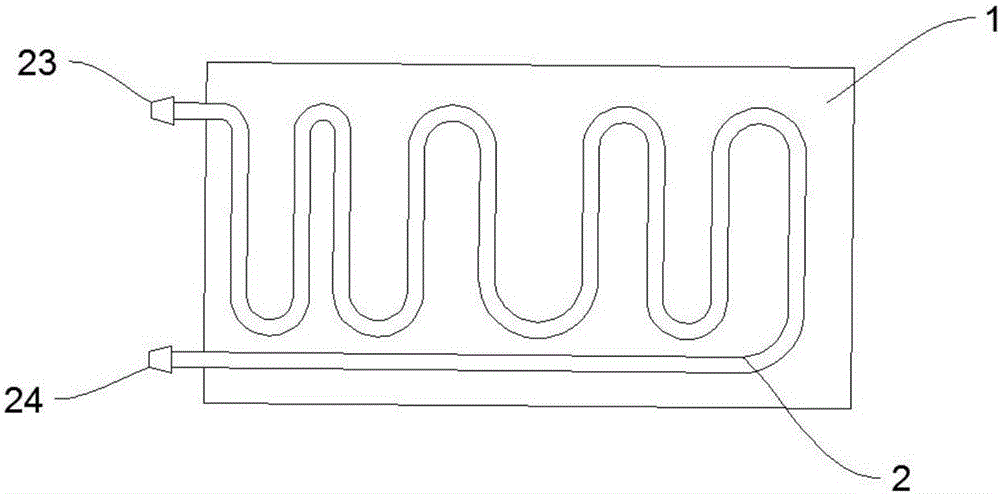

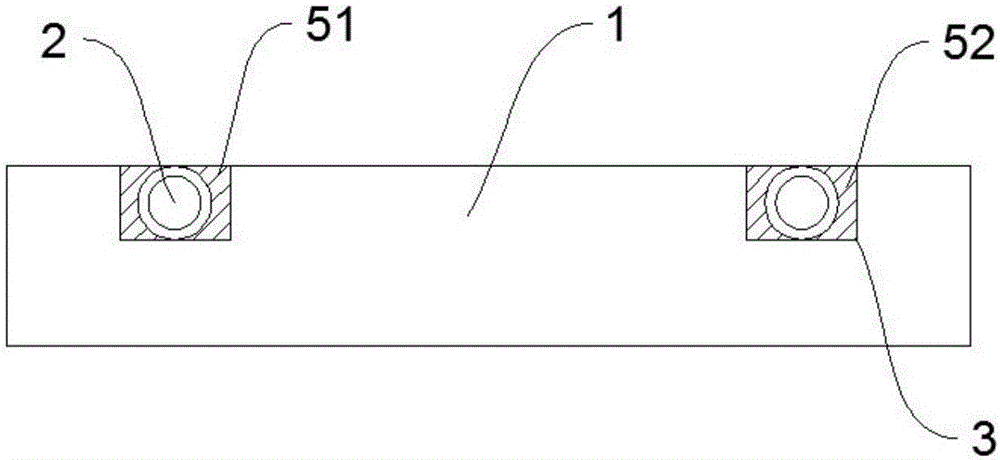

Water-cooled radiator

PendingCN106352722ALarge thermal resistancePrevent heat conductionStationary conduit assembliesCooling/ventilation/heating modificationsAdhesiveMetallurgy

A water-cooled radiator belongs to the field of radiators. In order to improve the cooling efficiency of the existing copper tube-embedded water-cooled radiator, the existing water-cooled radiator is improved as follows: a water-cooled radiator, including an aluminum plate for installing electronic components , there is a groove on the aluminum plate, and a copper pipe is arranged in the groove. The copper pipe is divided into two sections, one is a serpentine water inlet section, and the other is a linear water outlet section; It is bonded with thermally conductive adhesive, and the water outlet section and the groove are bonded with a weak thermally conductive adhesive; the cooling efficiency is improved by reducing the conduction of heat from the high-temperature cooling water in the water outlet section of the copper pipe to the aluminum block.

Owner:池州脉纬散热器有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com