Detachable type thermal insulation device for high-temperature or low-temperature pipelines

A pipeline thermal insulation and dismantling technology, applied in pipeline protection, thermal insulation, pipeline protection through thermal insulation, etc., can solve the problems of affecting the clean room environment, easy slag loss of thermal insulation cotton, cumbersome production and processing, etc., achieving simple and convenient operation, thermal insulation Compact thermal insulation structure and clean disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

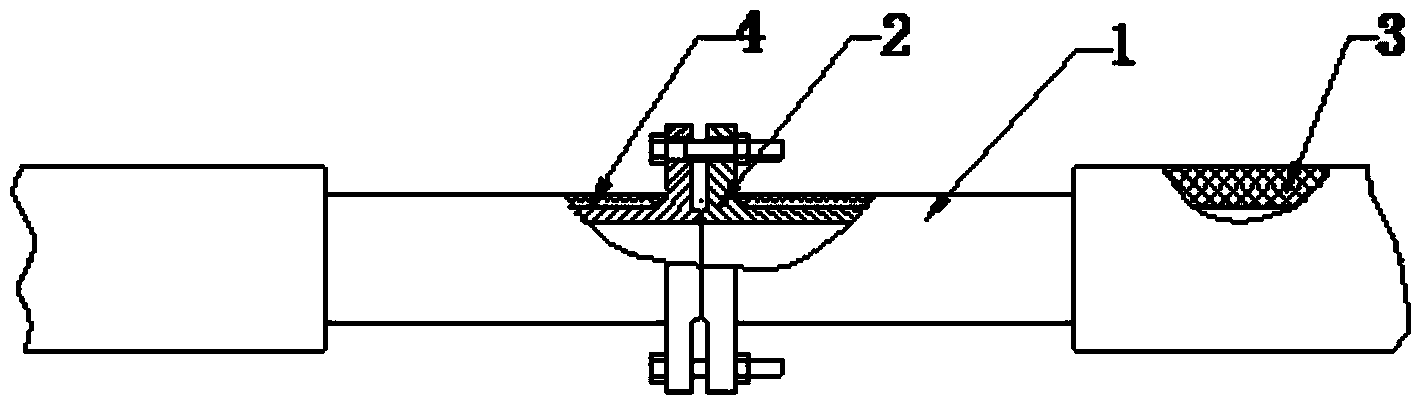

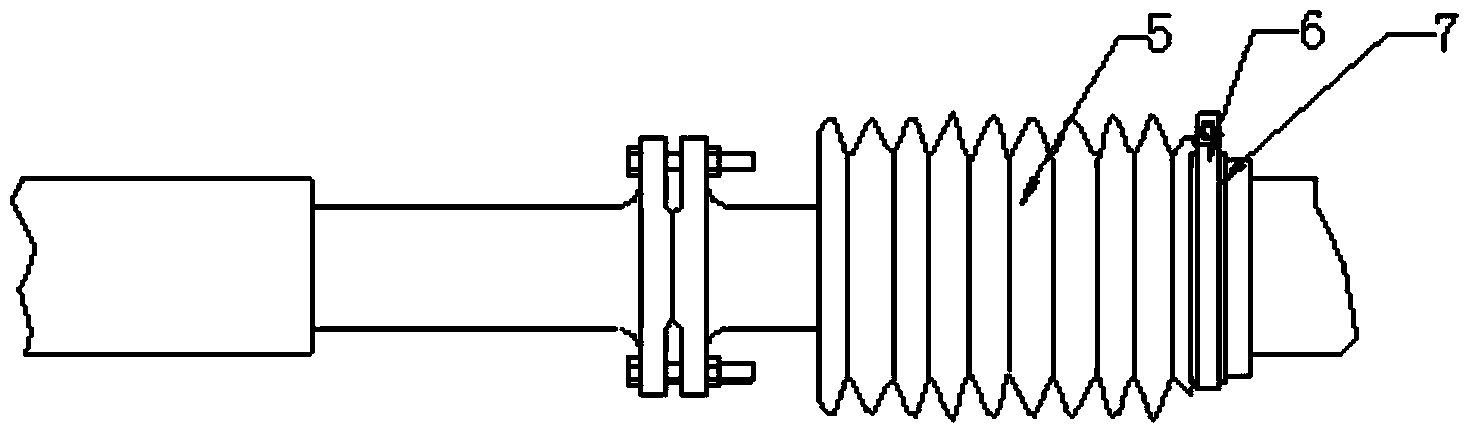

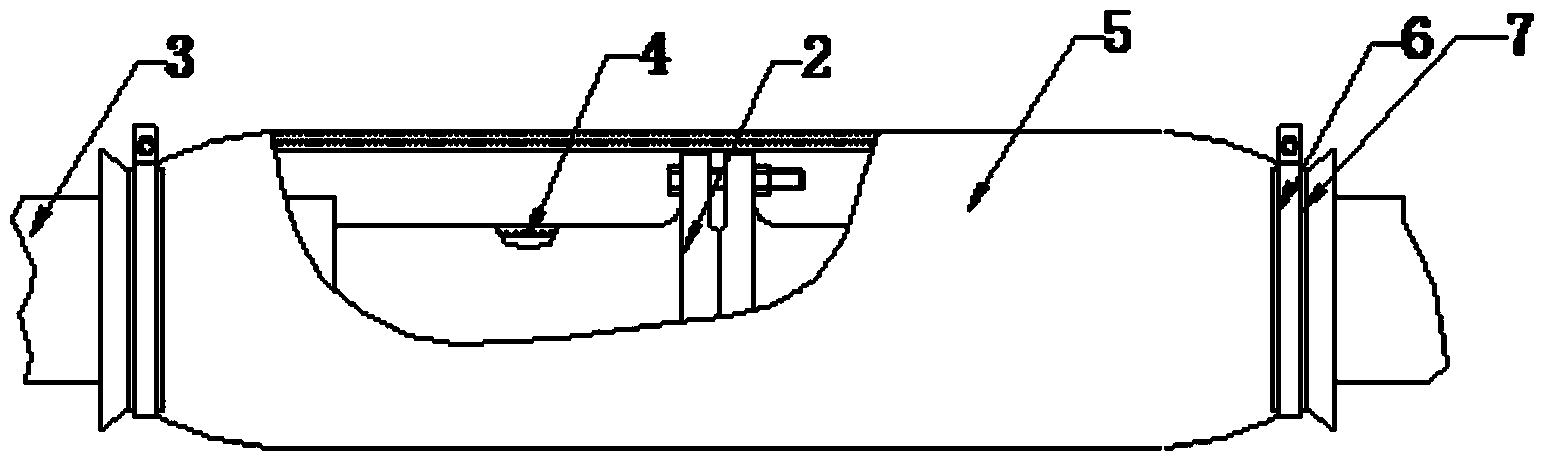

[0025] Such as figure 1 As shown, the main frame structure of this embodiment includes: a conventional heat-insulated high-temperature or low-temperature pipeline 1, a flange 2, a main body heat-insulating component 3, and an airgel felt 4; figure 2 , image 3 It is a schematic diagram of the installation of the protective cover. In addition to the above components, it also includes: a protective cover 5 made of flexible multi-layer materials, a stainless steel throat clamp 6 and an airgel pressure ring 7 for quick installation.

[0026] The high-temperature or low-temperature pipeline 1 in this embodiment is a DN200 stainless steel pipeline, and the pipelines are connected by welding through flanges 2 . The main body insulation part 3 of the high-temperature or low-temperature pipeline is implemented according to actual needs. In a preferred embodiment, glass wool or airgel felt is used for conventional insulation, and the outer side is covered with aluminum skin; Airgel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com