Patents

Literature

330results about How to "Warm up fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery low-temperature preheating and charging method

ActiveCN103825060AWarm up fastAvoid it happening againSecondary cells charging/dischargingLithiumProduction rate

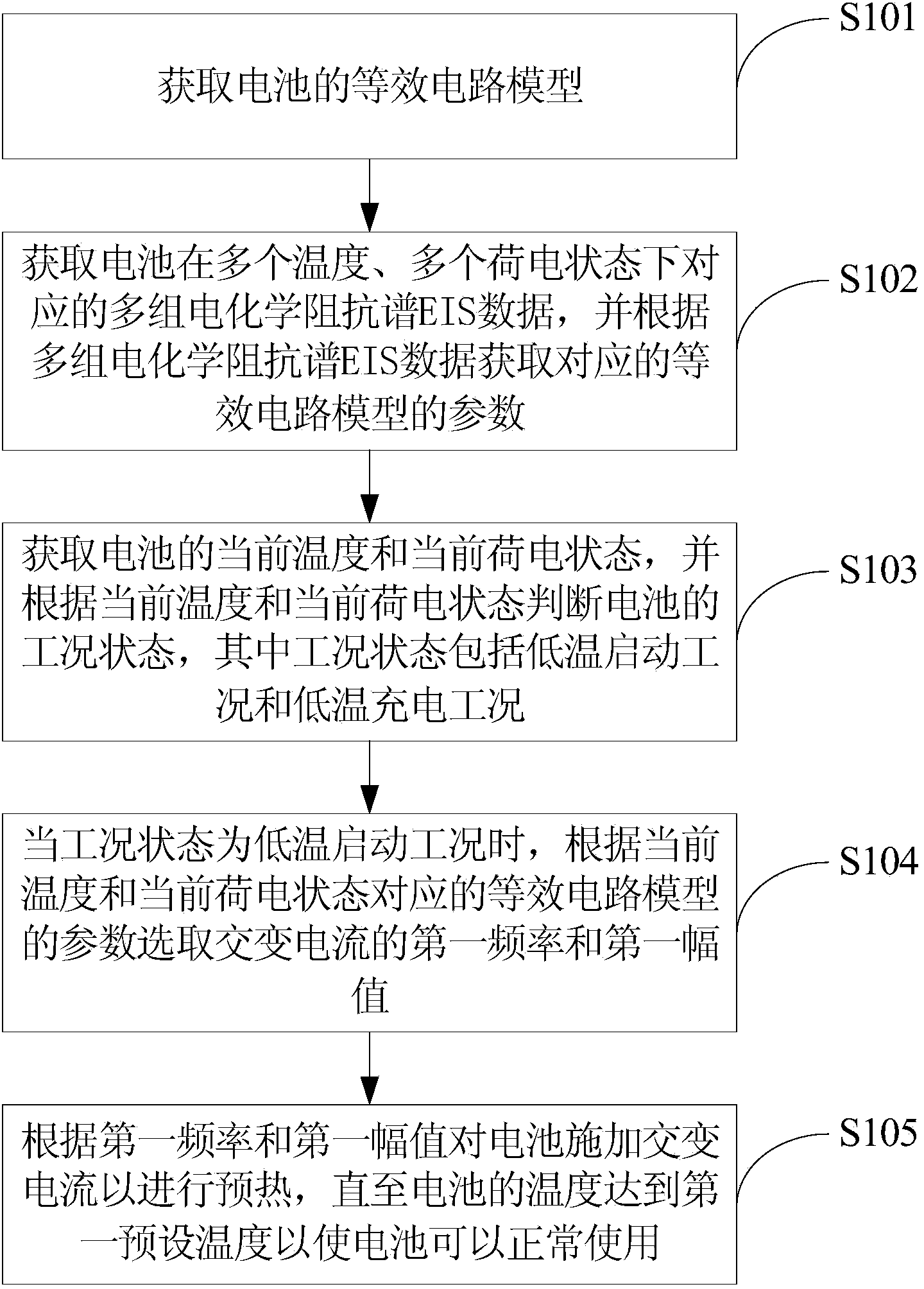

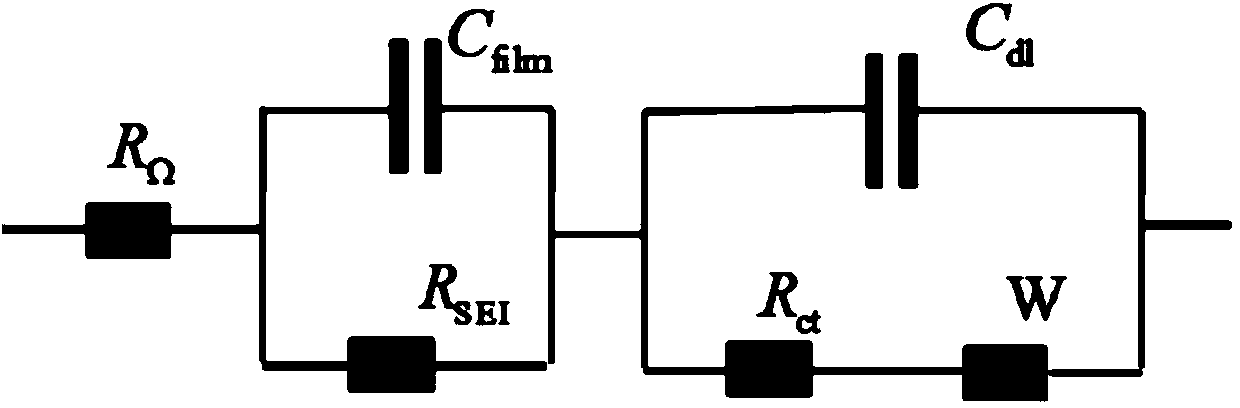

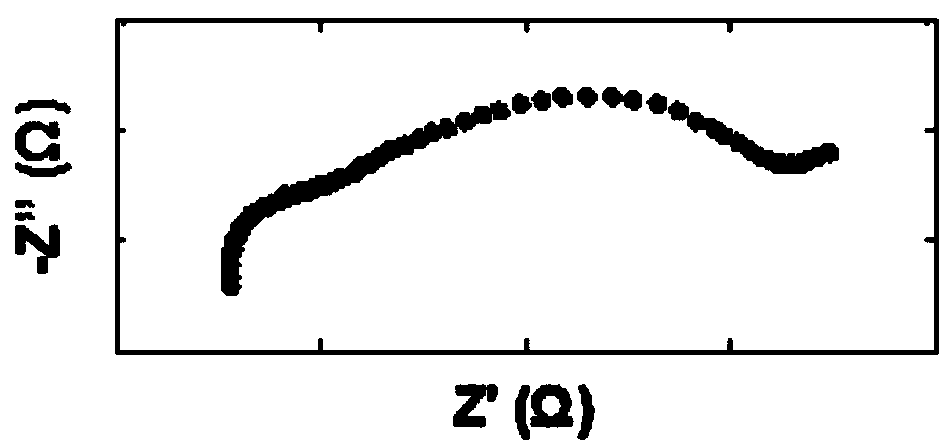

The invention brings forward a battery low-temperature preheating and charging method which comprises the following steps: an equivalent circuit model of a battery is obtained; multiple electrochemical impedance spectroscopy EIS data corresponding to multiple temperatures and multiple charged states are obtained, and corresponding parameters of the equivalent circuit model are obtained according to the multiple electrochemical impedance spectroscopy EIS data; current temperature and current charged state of the battery are obtained, and the working condition state of the battery, including low-temperature starting condition and low-temperature charging condition, is judged according to the current temperature and the current charged state; when the working condition state is the low-temperature starting condition, first frequency and a first amplitude of alternating current are selected according to parameter values of the equivalent circuit model corresponding to the current temperature and the current charged state; alternating current is applied on the battery according to the first frequency and the first amplitude for preheating until the temperature of the battery reaches a first preset temperature so as to make the battery to be normally used. By the method of the embodiment, lithium precipitation is avoided, and heat production rate inside the battery is raised.

Owner:TSINGHUA UNIV

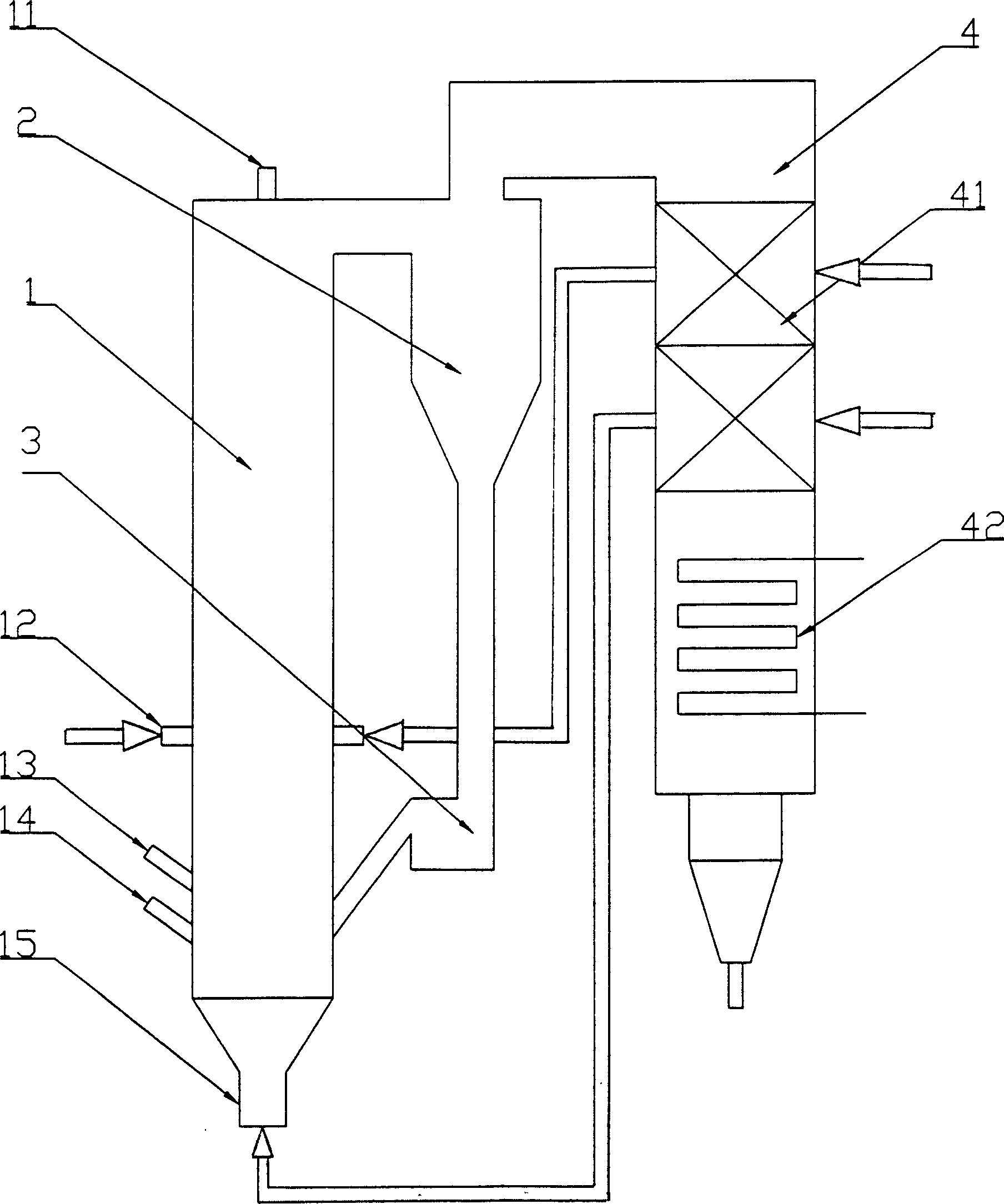

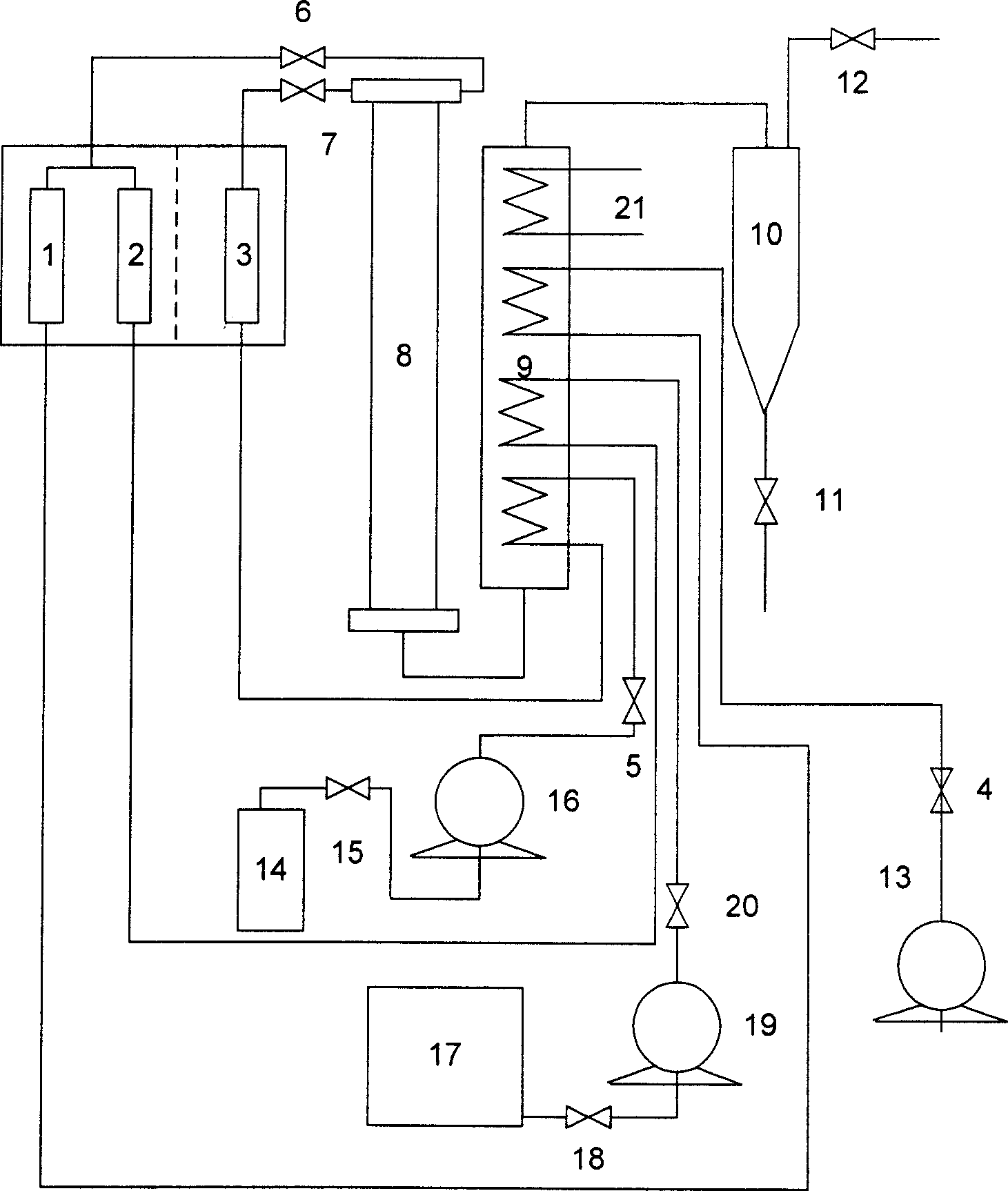

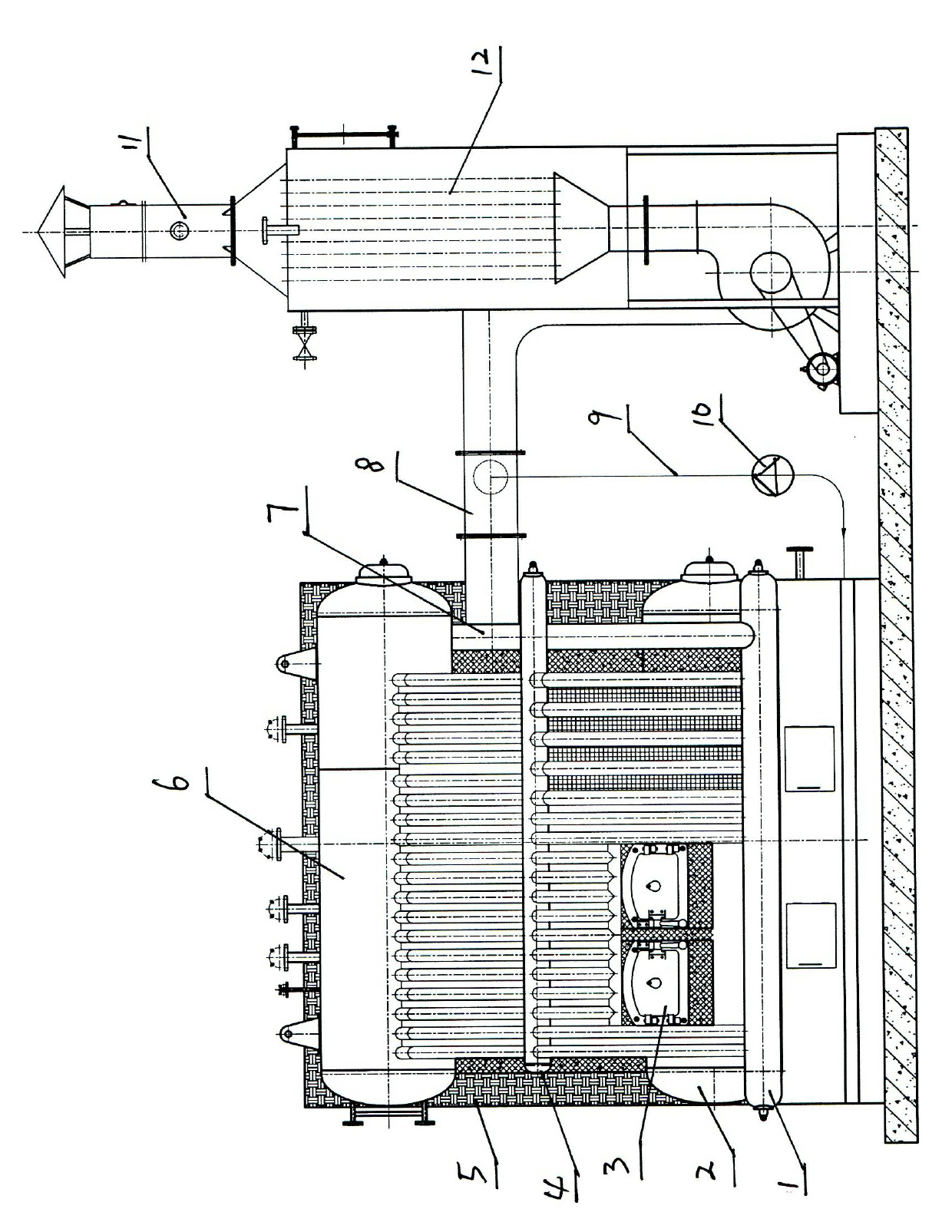

Incineration processing method and device for wet sludge

ActiveCN1763431ASimplify the incineration processAchieving Low Level EmissionsIncinerator apparatusAir preheaterSludge

The invention discloses wet sludge burning disposal method and device, which comprises the following steps: burning the wet sludge in the furnace directly or adding auxiliary fuel; supplying air to the hearth step by step; adding limestone in the furnace to reduce the SO2 drainage. The device comprises the following parts: hearth, cyclone separator, refeed unit and rear flue, wherein the sludge filling inlet and auxiliary fuel filling inlet are set on the top and bottom of hearth separately; the high-temperature air preheater ranged from 300 to 600 deg.c is set in the rear flue. The invention simplifies the disposal technology due to drying, burning and smoke innocent treatment in one device, which discharges at low level.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Super critical water treatment system of waste organic liquid pollution less discharge and resources utilization

InactiveCN1868915AWarm up fastAvoid cloggingWater/sewage treatment by heatingWater/sewage treatment by oxidationWater treatment systemResource utilization

A supercritical water treating system for reclaiming the rejected organic sewage and recovering its energy without draining of pollutants features that it has three preheaters (gas preheater, liquid preheater and material preheater) for respectively preheating the gas oxidant, liquid oxidant (or reaction medium) and material to suppress the generation of tar and coke and simplifying the design of reactor, and the oxidizing reaction and gasifying reaction are simultaneously preformed in this system.

Owner:XI AN JIAOTONG UNIV

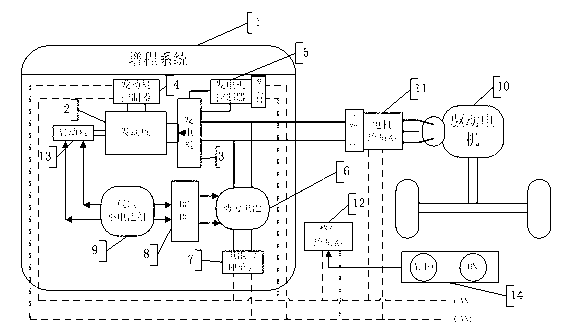

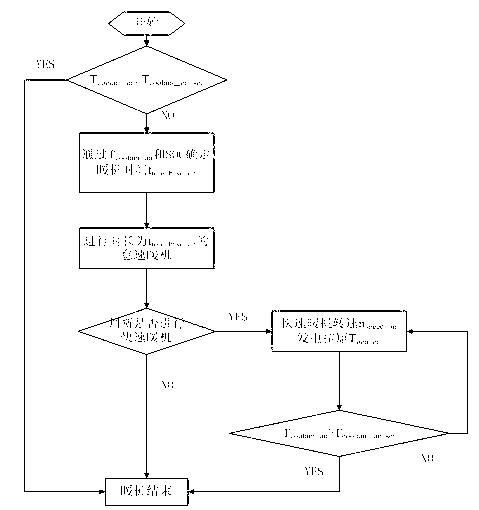

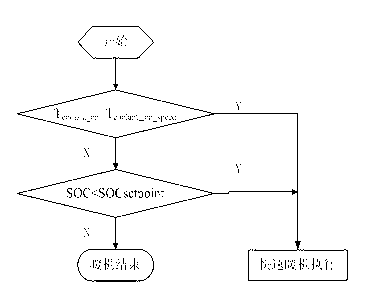

Extended-range electric vehicle engine heating control method

The invention provides an extended-range electric vehicle engine heating control method. The purpose of high-efficiency and low-emission driving range lengthening is achieved. A whole vehicle controller controls an engine heating process according to the water temperature of an engine and the SOC value of a power battery. After the whole vehicle controller receives a starting command of an extended-range unit, the water temperature of the engine is detected first, if the water temperature of the engine is lower than preset idling engine heating temperature, the whole vehicle controller sets the time of idling engine heating of the engine according to the water temperature of the engine and the SOC value of the power battery and controls the engine to carry out idling engine heating, otherwise, engine heating is finished, after idling engine heating of the engine is finished, the whole vehicle controller judges whether quick engine heating is needed according to the water temperature of the engine or the SOC value of the power battery, if the water temperature of the engine is lower than the preset quick engine heating temperature or the SOC value of the power battery is smaller than a preset value, the whole vehicle controller sets engine rotating speed and generator load torque and controls the engine to carry out quick engine heating, and otherwise, engine heating is finished.

Owner:奇瑞新能源汽车股份有限公司

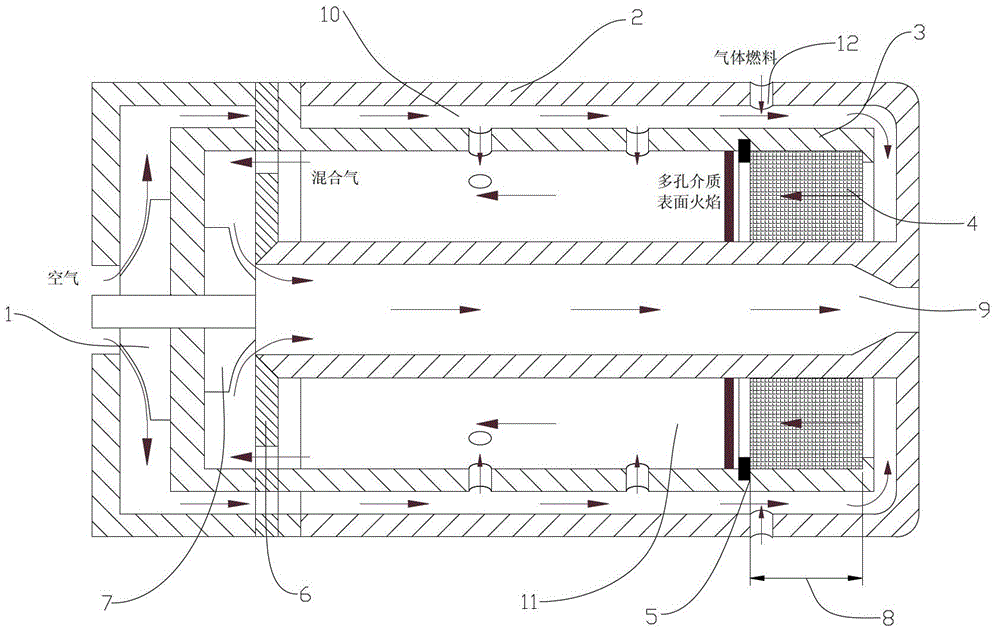

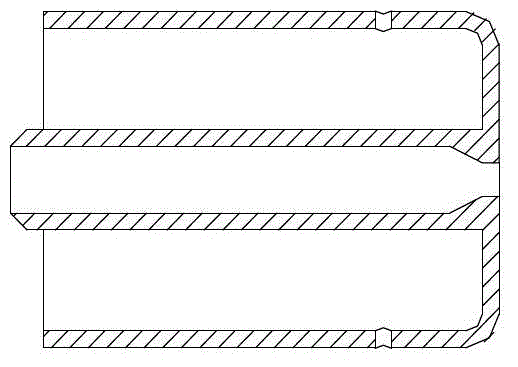

Rear-placed combustor with annular porous medium head for ultramicro turbojet engine

ActiveCN102878579AOvercoming short stay timeReduce foggingContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

Disclosed is a rear-placed combustor with an annular porous medium head for an ultramicro turbojet engine. An annular reflux structure is adopted for the combustor which is formed by a combustor box, a flame tube wall, a combustor outlet and the annular porous medium head. Air flow passes through a centrifugal compressor of the engine for compression, enters an annular cavity channel of the combustor, and then is mixed with gas fuel which is jetted in horizontally; premixed gas is pre-heated through the flame tube wall and then flows back to enter a flame tube through the annular porous medium head, and stable ignition is achieved; the whole mixed gas combustion process is finished in the flame tube, and high-temperature gas is discharged from the outlet of the rear-placed combustor; and then the high-temperature gas is discharged into air through a tail pipe after turbine blades of an impact engine does work. The combustor box, the flame tube wall and the combustor outlet are connected through bolts with high temperature glue sprayed on annular edges to guarantee the sealing. According to the combustor, features and advantages of stable flame of the annular porous medium head can be adapted to and played to the greatest extent, proneness to flameout of ultramicro combustors can be improved, so that the combustor can work for the ultramicro turbojet engine reliably and stably.

Owner:BEIHANG UNIV

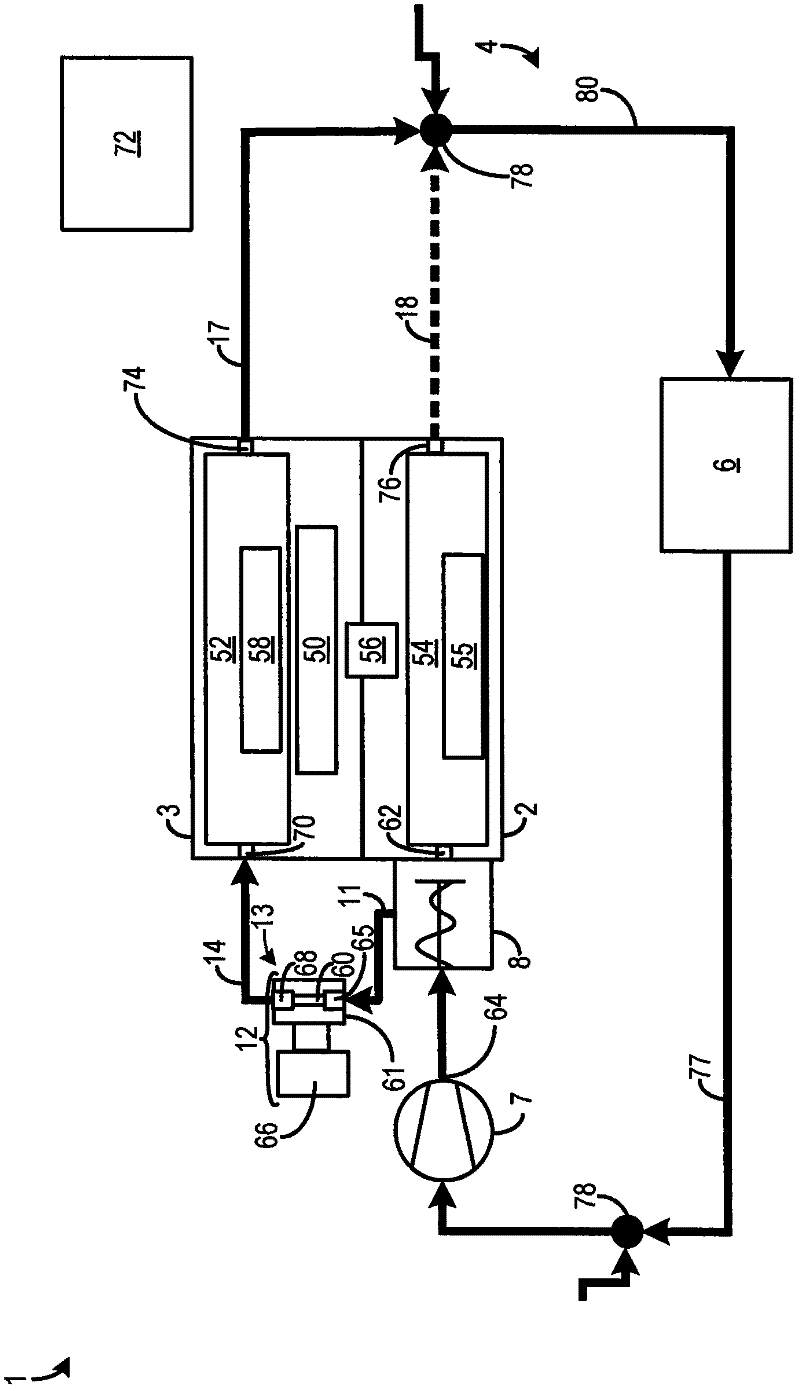

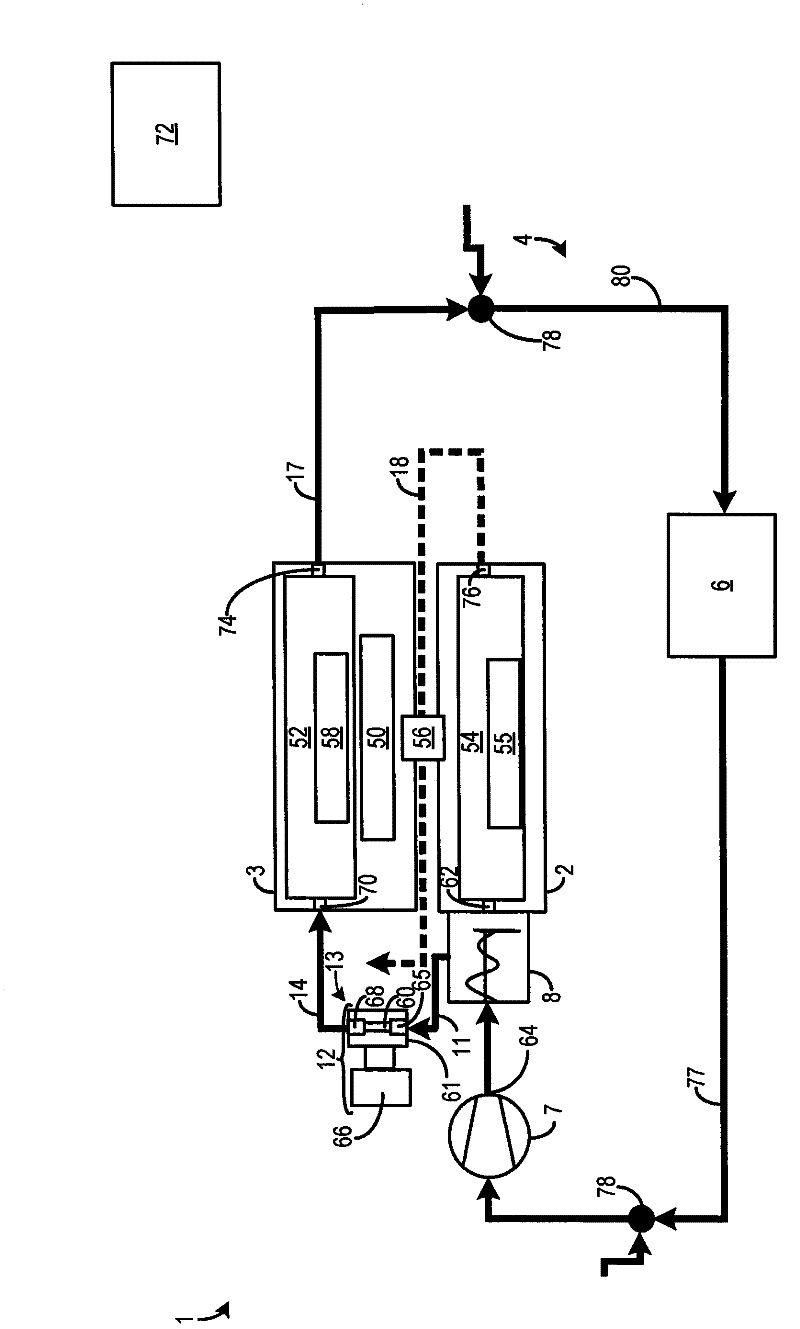

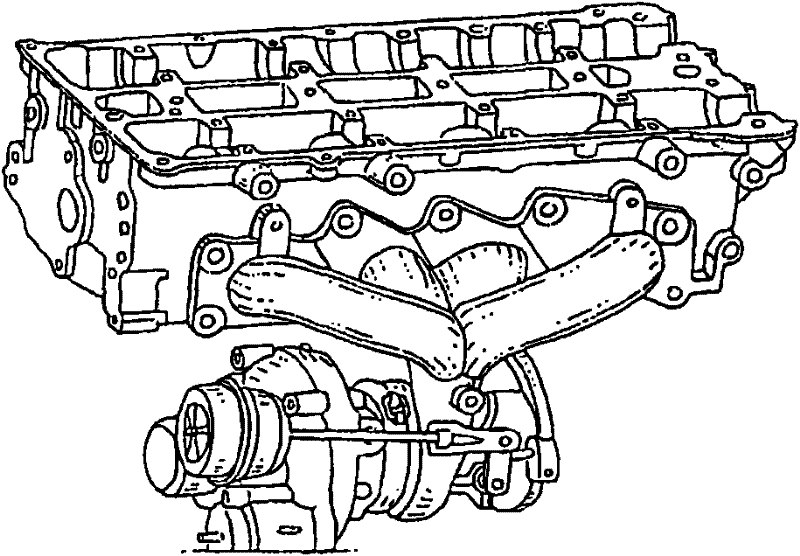

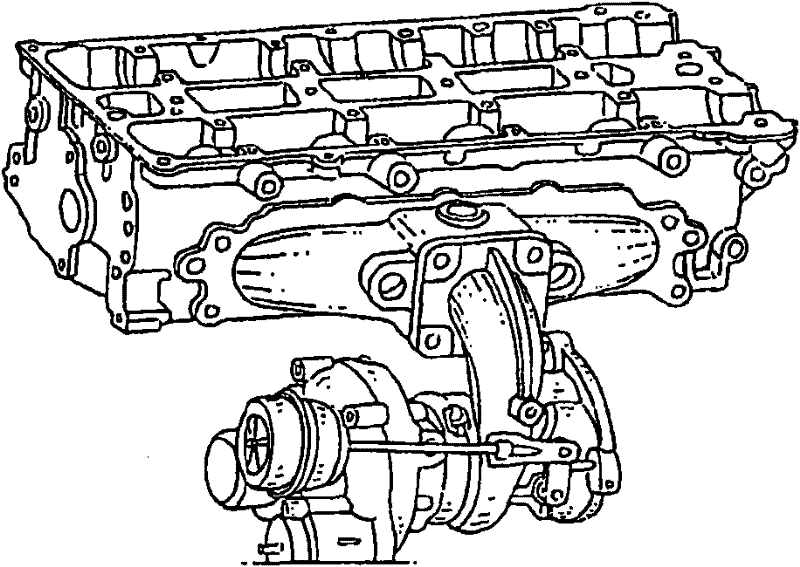

Individually cooled turbocharger for no flow strategy in engine block coolant jacket

ActiveCN102269037AWarm up fastReduce consumption rateLiquid coolingCoolant flow controlNitrogen oxidesTurbocharger

The engine (1) has a cylinder block coolant jacket operated in a turbine housing (13) in a turbocharger (12) during a subphase of a heating phase of the engine according to nitrogen oxide flow strategy. A cooling circuit (4) is separated from the cylinder block coolant jacket and connected with a common pump (7) that is joined to the cylinder block coolant jacket. A bypass (11) is provided downstream to the pump and upstream to a cylinder block coolant inlet (9). The housing is made of light material i.e. aluminum, where the housing or the turbocharger is provided with the cooling circuit. An independent claim is also included for a method for controlling coolant during a heating phase of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

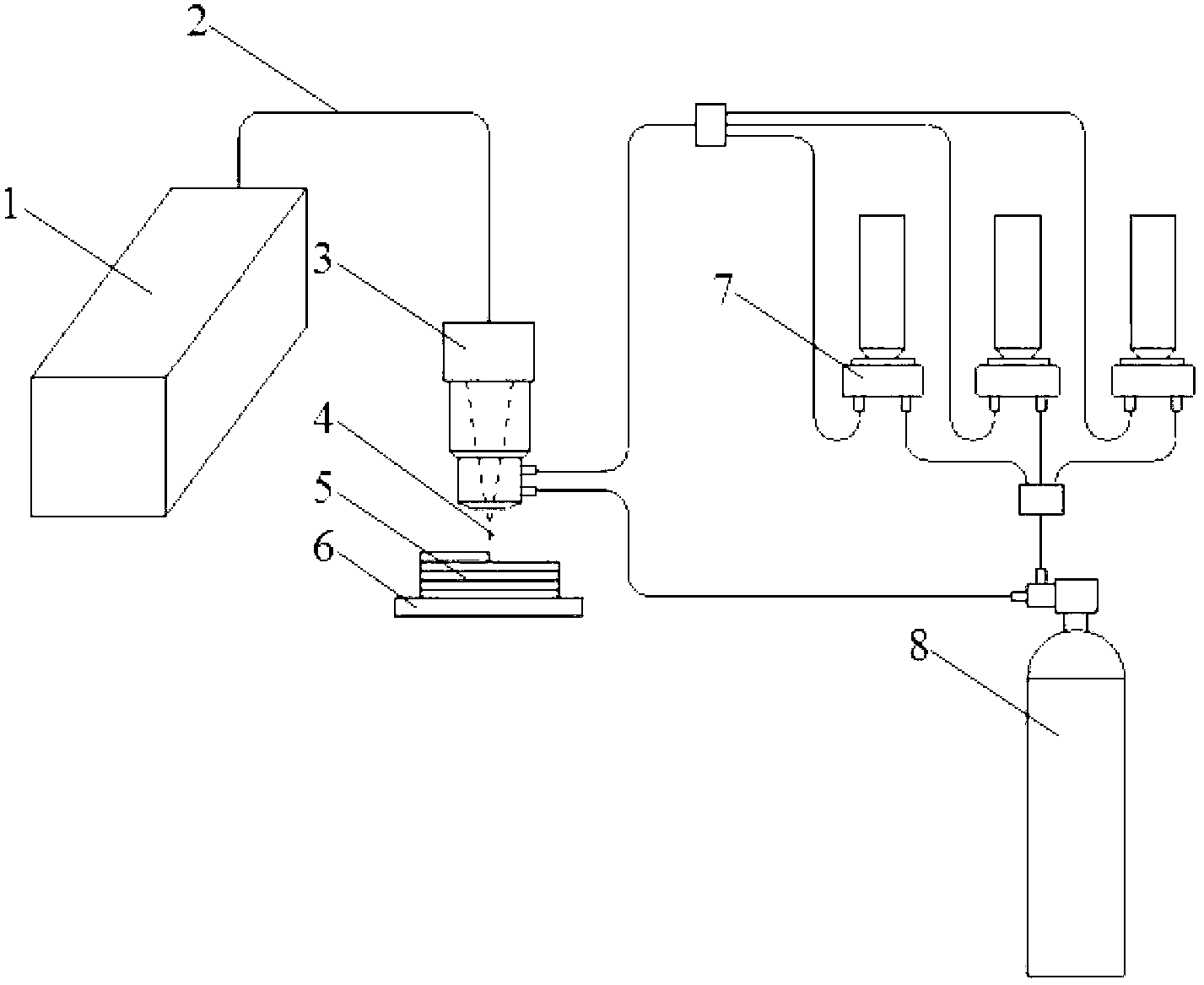

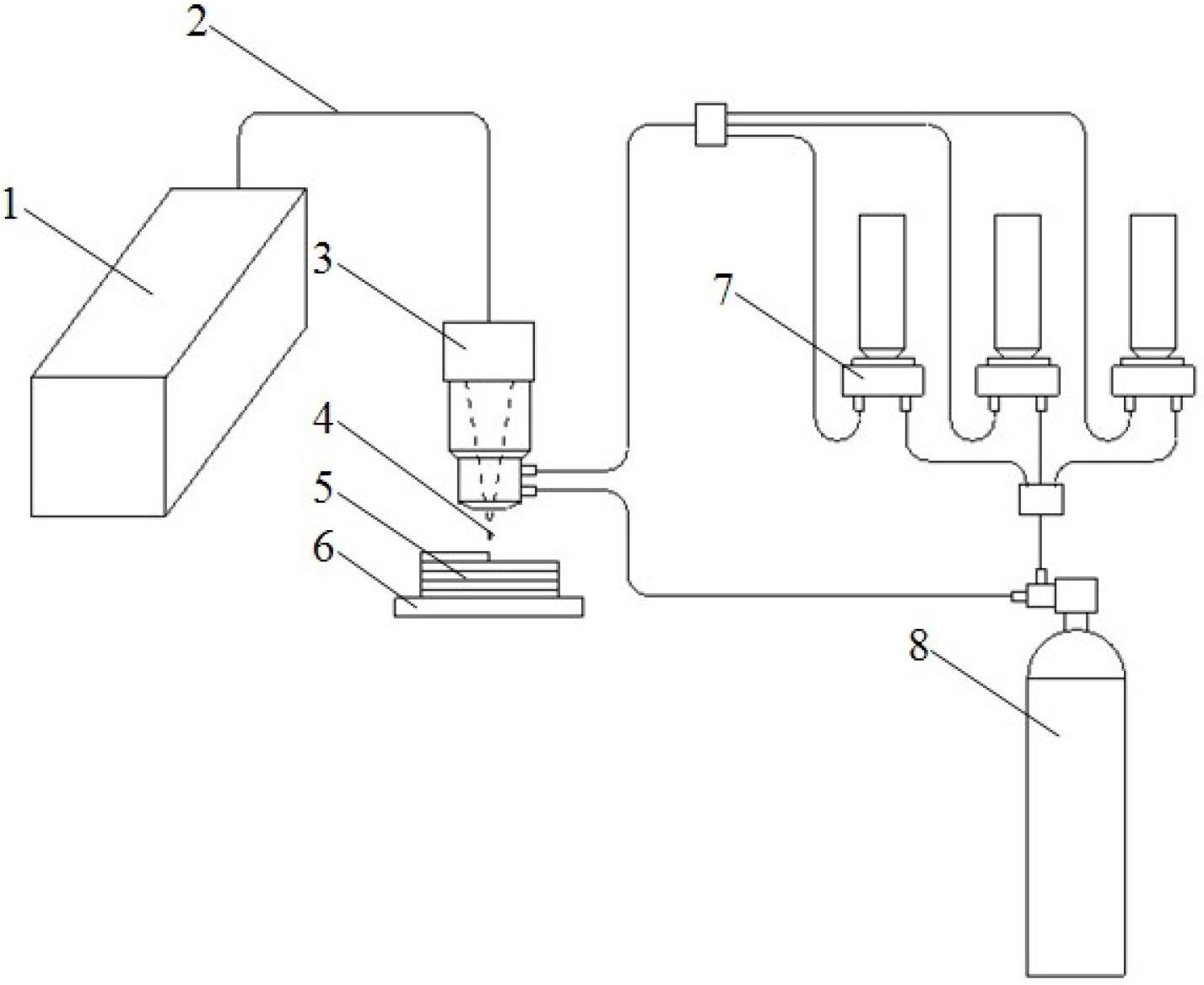

Preparation method of self-preheating laser engineered net shaped ZrO2-Al2O3 composite ceramic thin-walled part

The invention relates to a preparation method of a self-preheating laser engineered net shaped ZrO2-Al2O3 composite ceramic thin-walled part. The preparation method comprises the following steps: ZrO2 powder and Al2O3 powder are respectively fed in a powder feeder after being dried, and argon is taken as powder feeding gas, and is conveyed in powder nozzles; Nd:YAG continuous laser is transmittedin the powder nozzle through optical fibers to form coaxial laser beams to be irradiated to powder focal points, and the distance between a shower nozzle and a base material is adjusted so as to enable laser to heat melted powder and the base material synchronously; the moving tracks of the powder nozzles are controlled, the moving track of the powder nozzle on the first layer is repeated for 8 to 20 times, the rapid cyclic scanning is carried out by the laser beams, a metal substrate is heated quickly, and after the metal substrate is preheated, ceramic powder and the metal substrate are stably bonded together; and fed powder is formed, and the laser engineered net shaping manufacturing of the ceramic structural part is achieved through laminated accumulation. The invention achieves the crack-free rapid manufacturing from powder to the structural part of the ceramic structural part, needs no auxiliary heating device and binding element addition as well as green ceramic body preparation, and improves the production efficiency.

Owner:DALIAN UNIV OF TECH

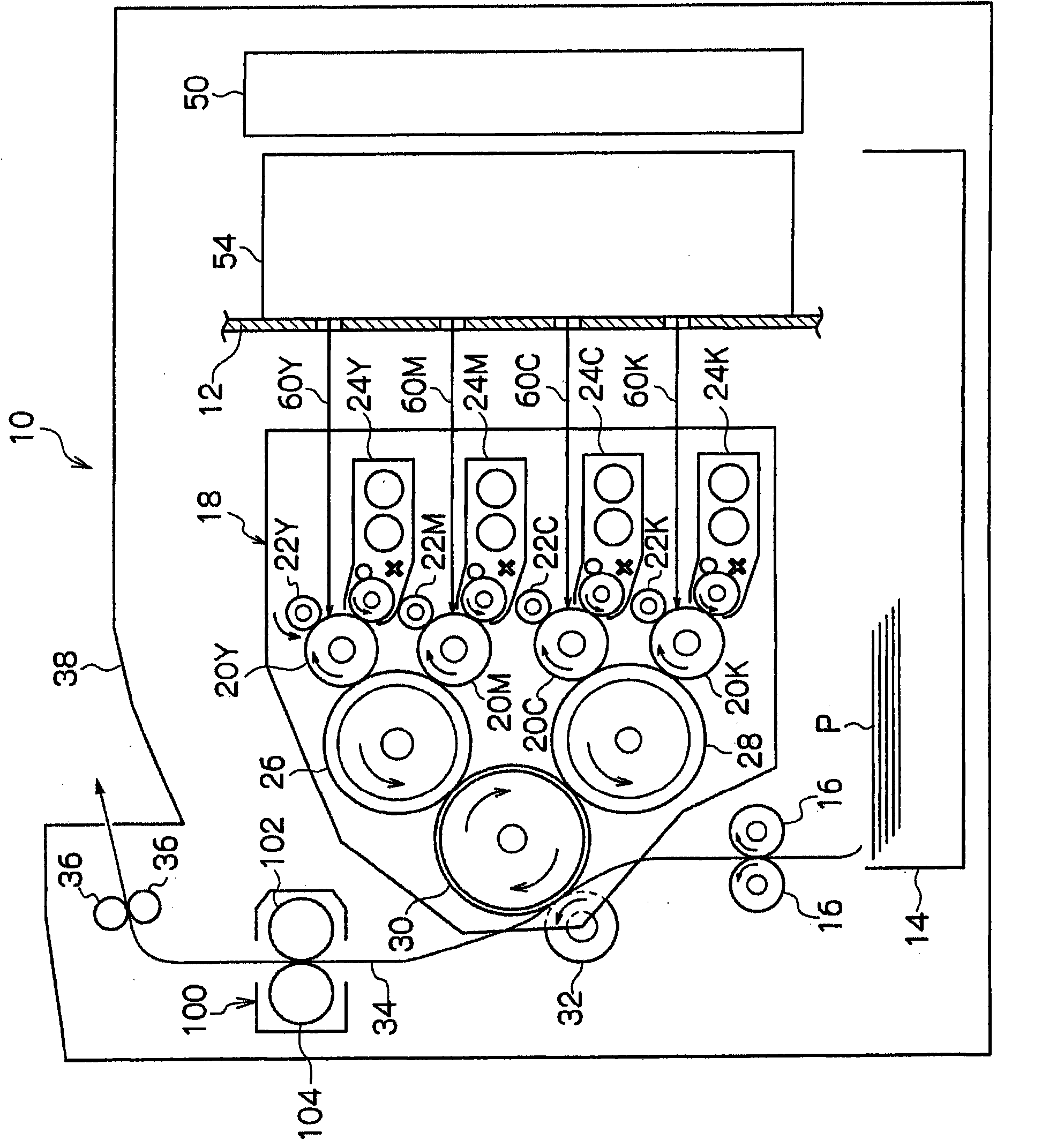

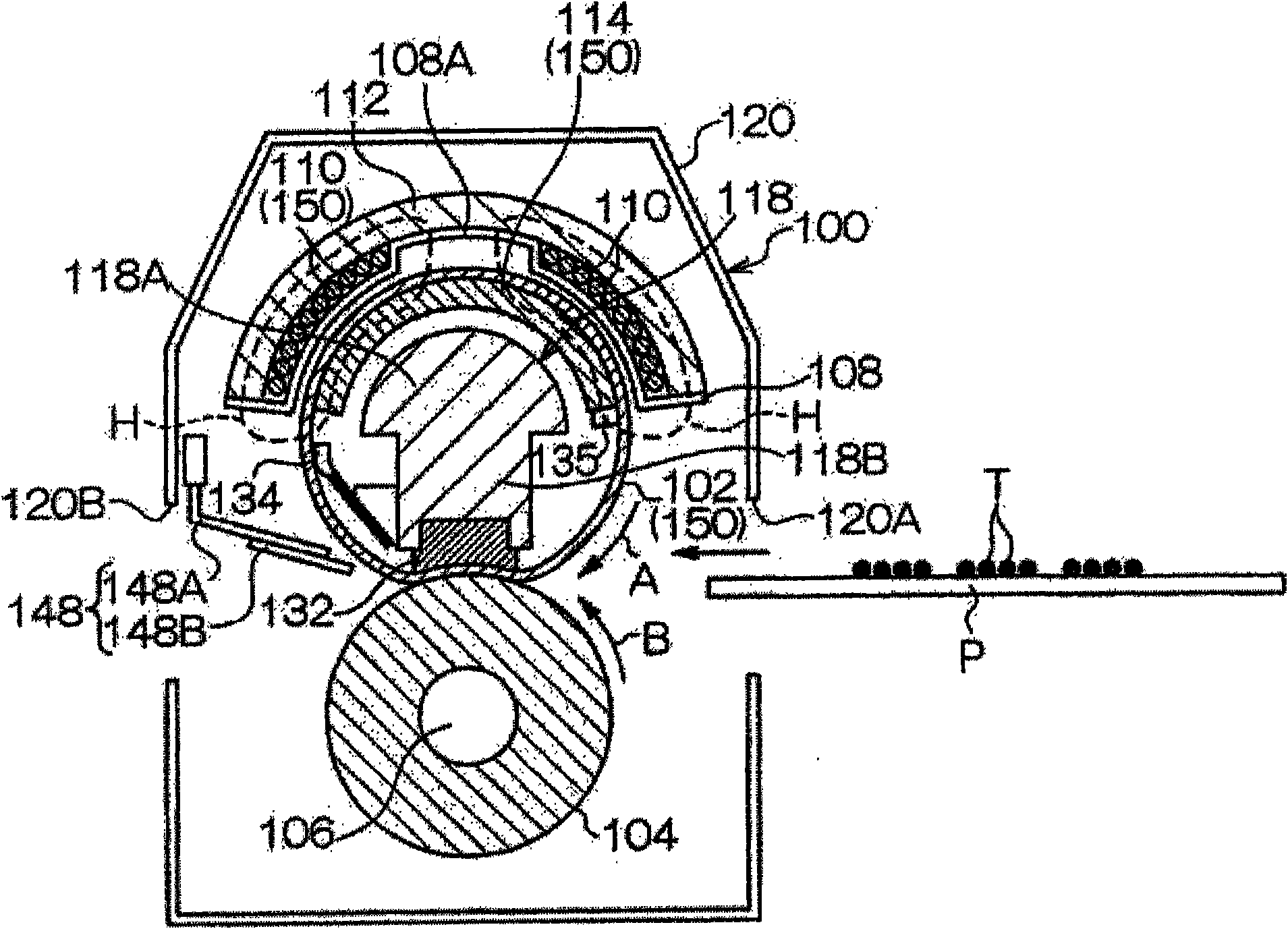

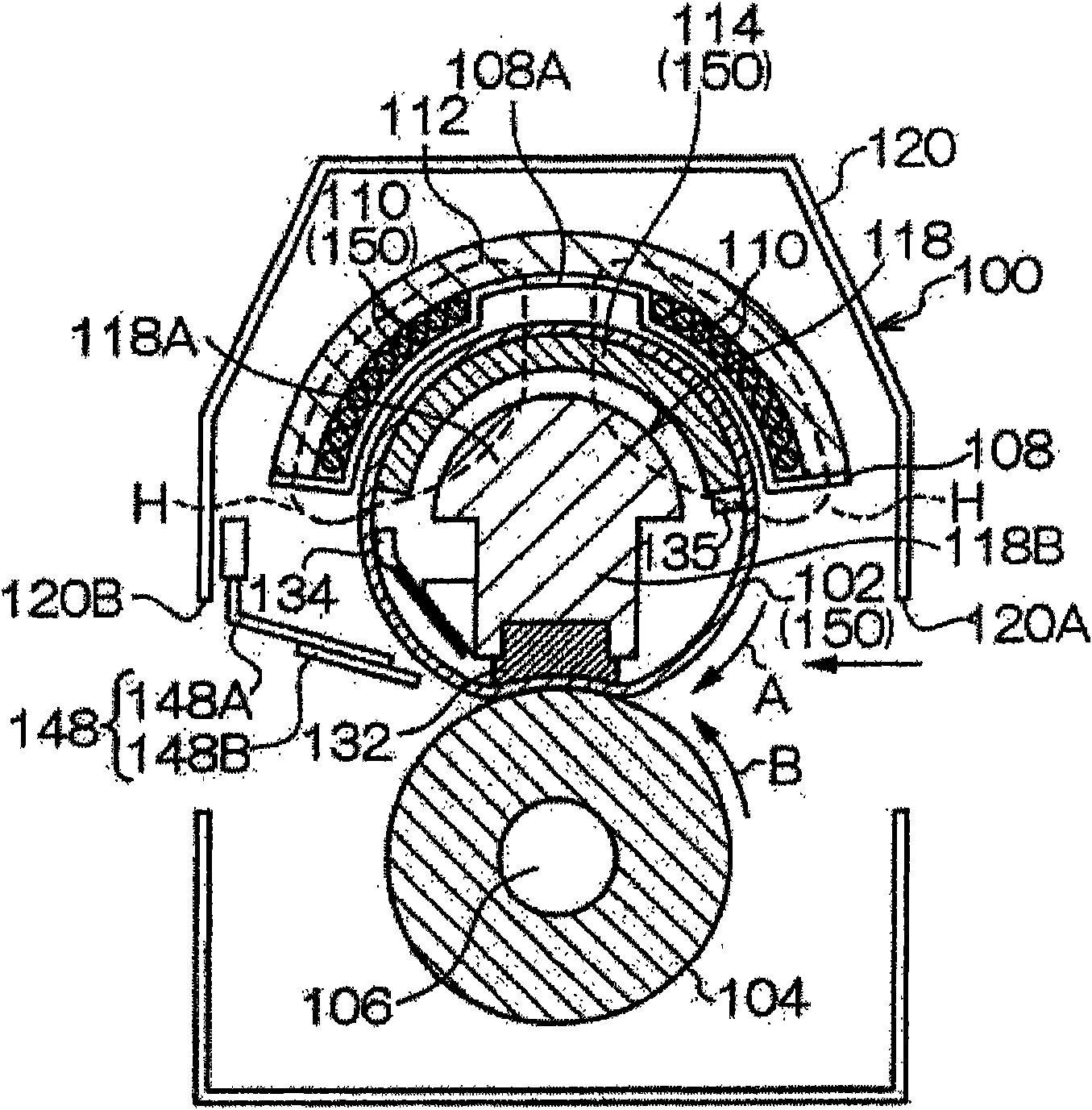

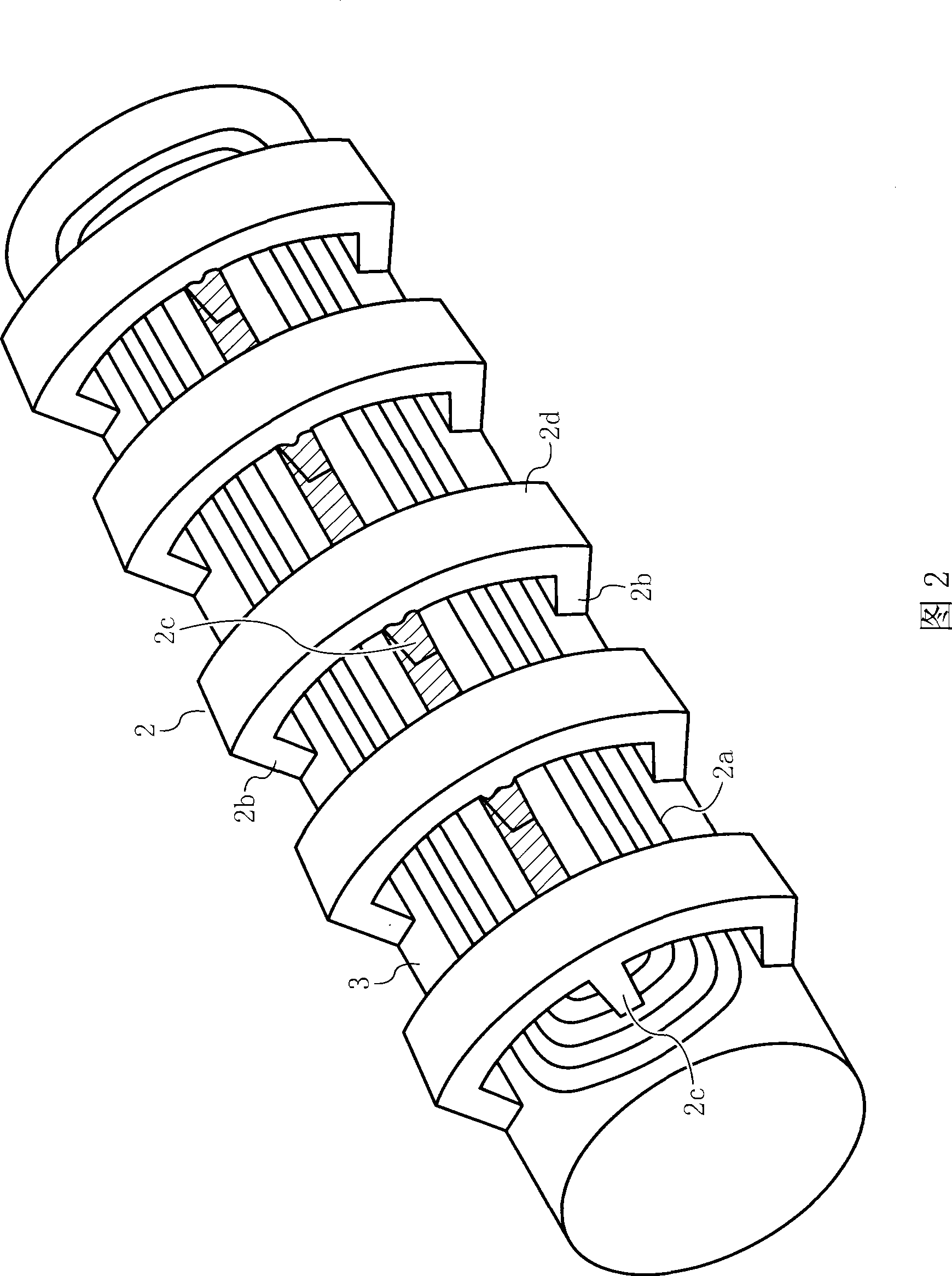

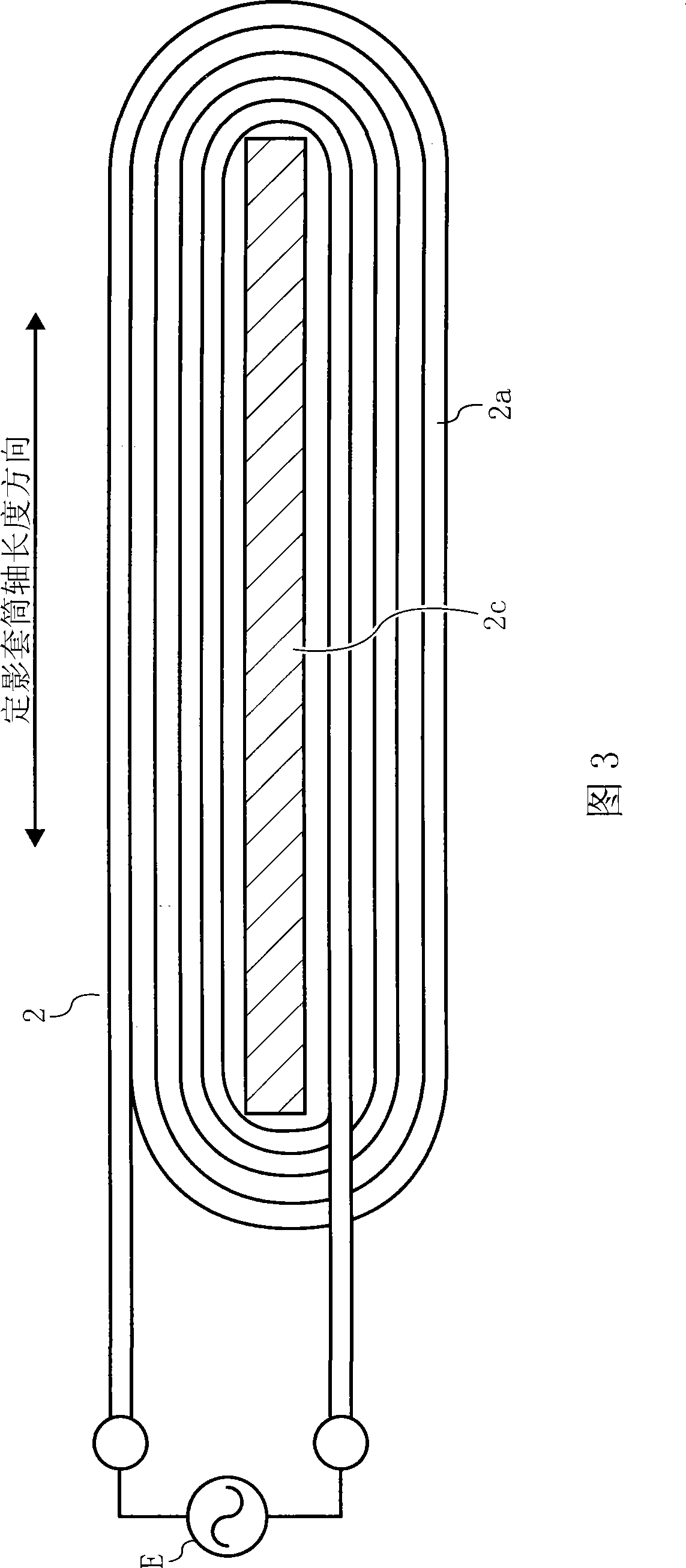

Heating rotating body, heating device, fixing device and image forming device

ActiveCN101587320AReduce the temperatureIncrease temperatureElectrographic process apparatusInduction heating apparatusElectromagnetic inductionTemperature sensitive

A heating device includes: a magnetic field generating unit generating a magnetic field; a heat-generating member generating heat due to electromagnetic induction of the magnetic field, and having a heat-generating layer of a thickness that is thinner than a skin depth; a temperature-sensitive member including a temperature-sensitive magnetic member whose magnetic permeability starts to decrease continuously from a magnetic permeability change start temperature that is in a temperature region that is greater than or equal to a set temperature and less than or equal to a heat-resistant temperature; and an approaching / separating mechanism maintaining the temperature-sensitive member in a state of being separated from the heat-generating member until before a temperature of the temperature-sensitive member reaches the set temperature, and causing the temperature-sensitive member to contact the heat-generating member at and after the time when the temperature-sensitive member reaches the set temperature.

Owner:FUJIFILM BUSINESS INNOVATION CORP

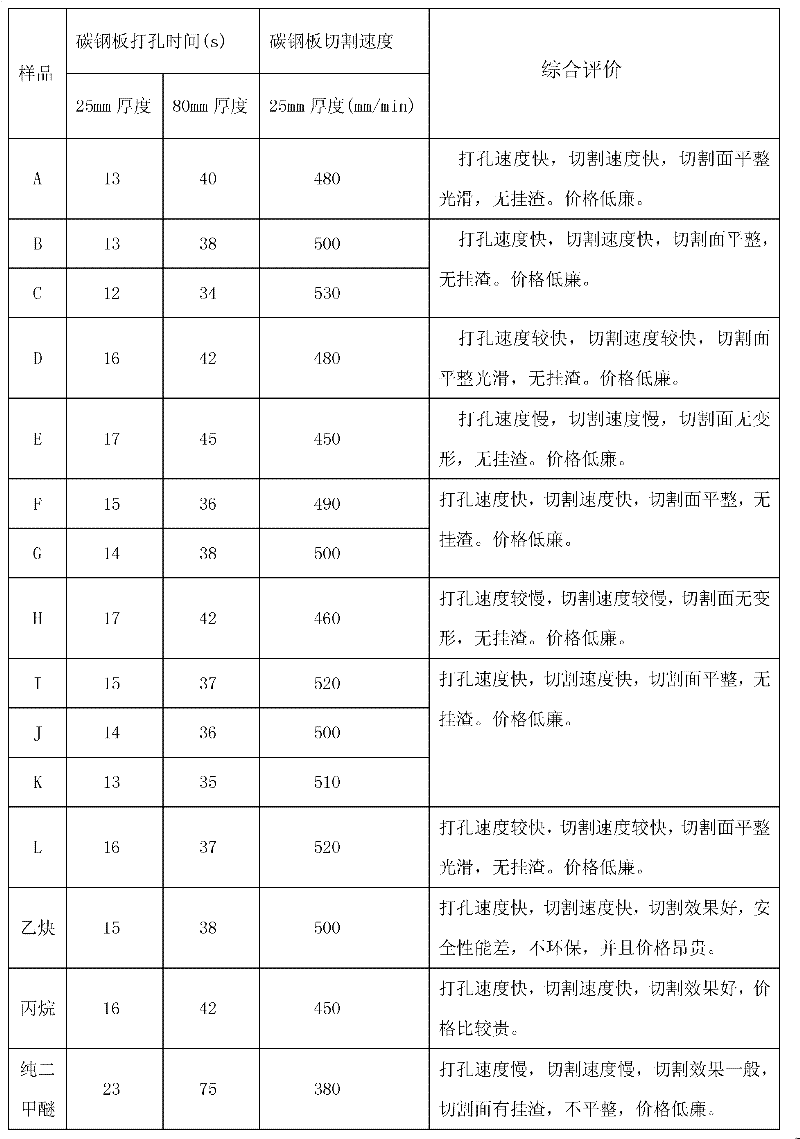

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

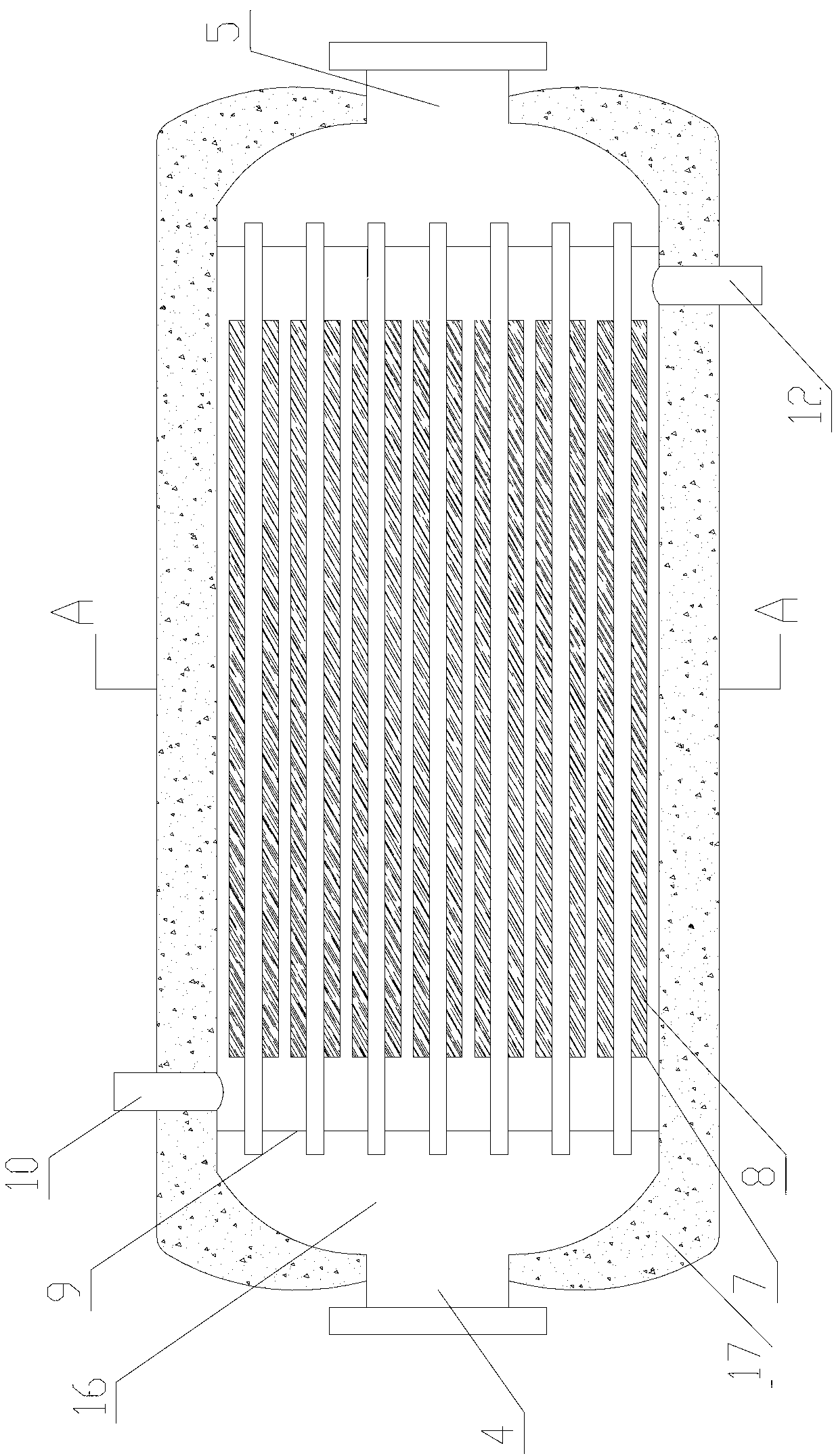

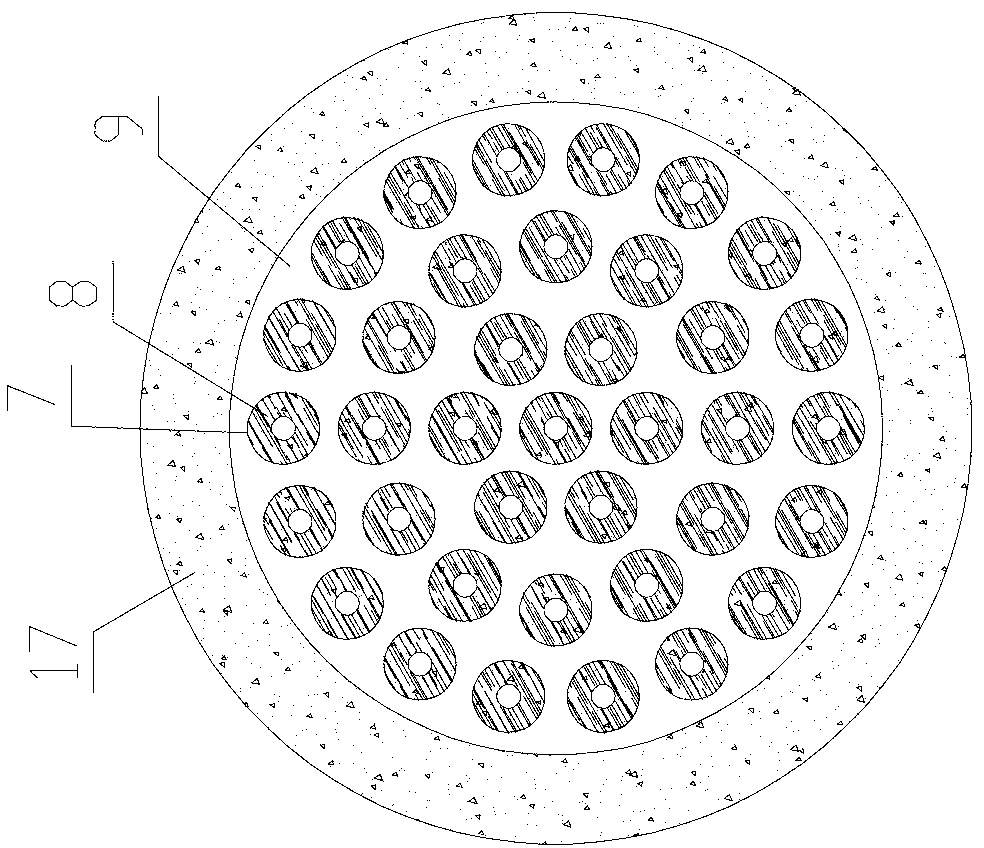

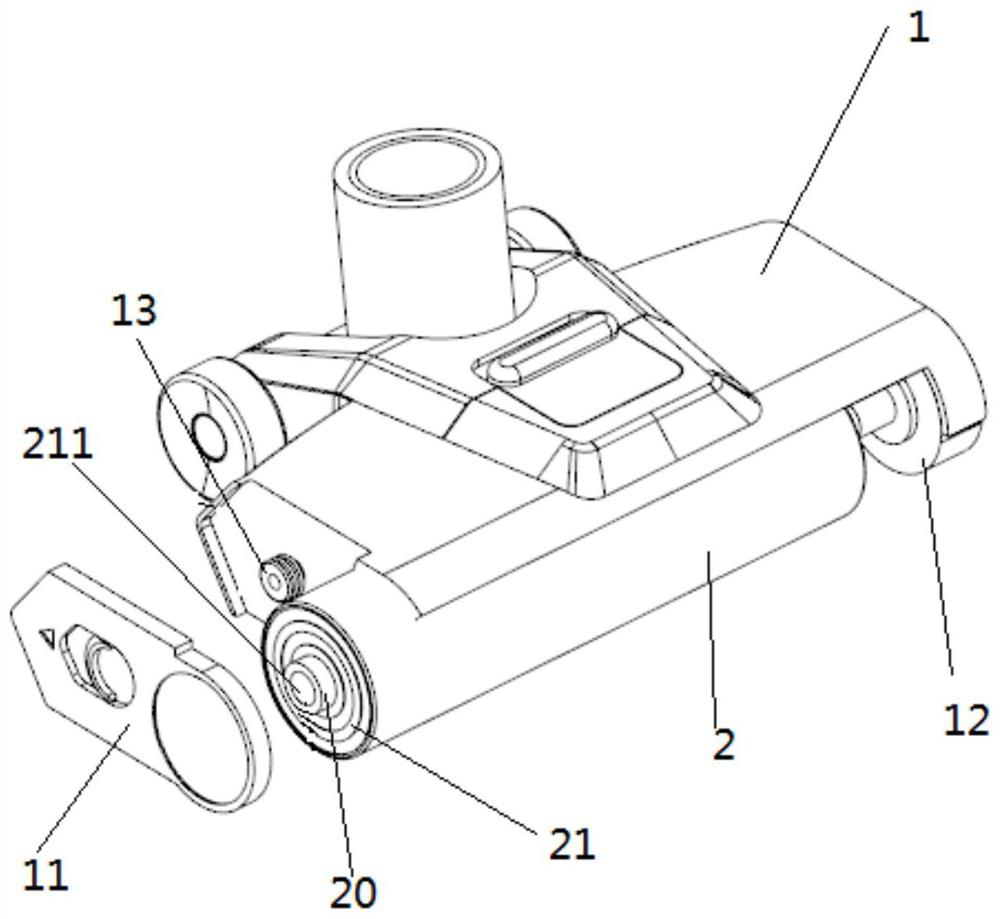

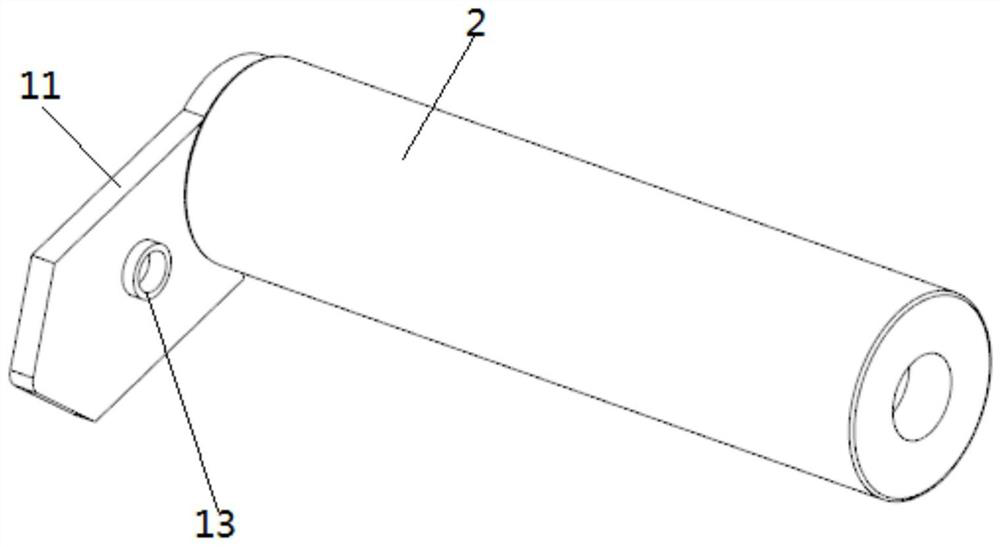

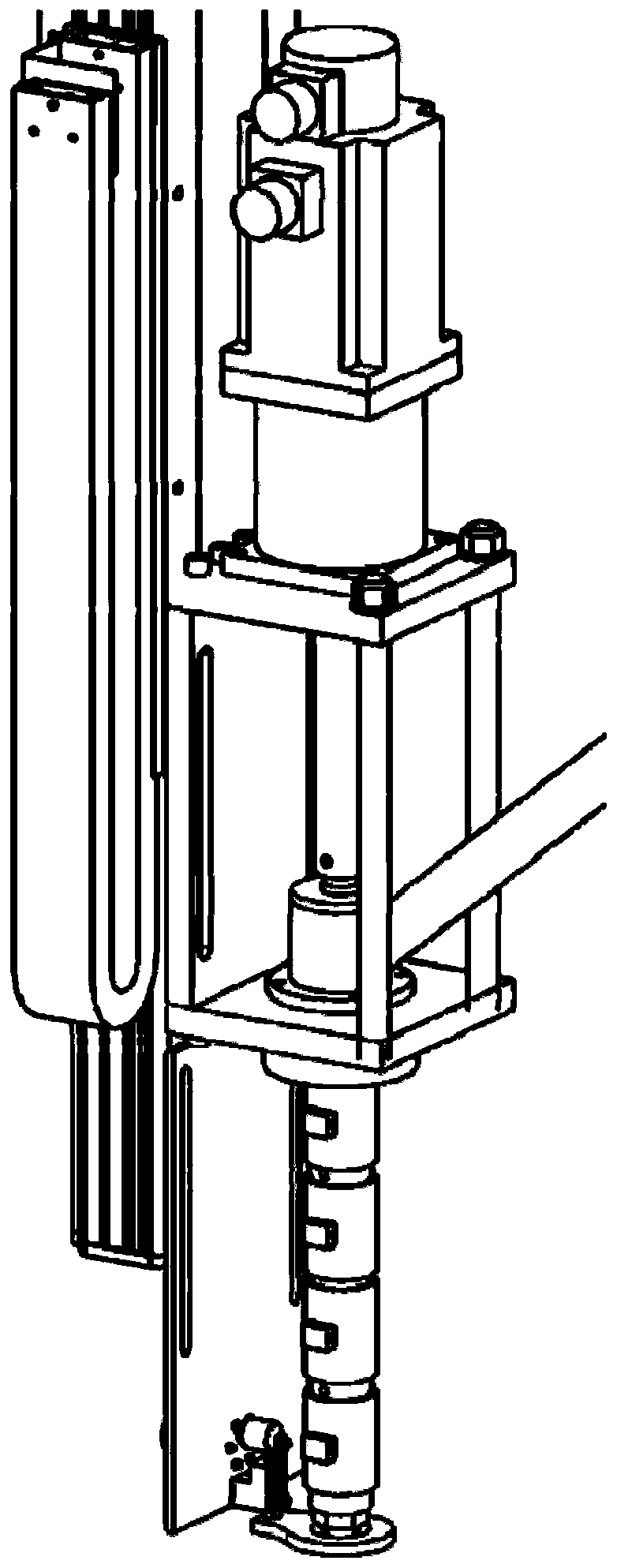

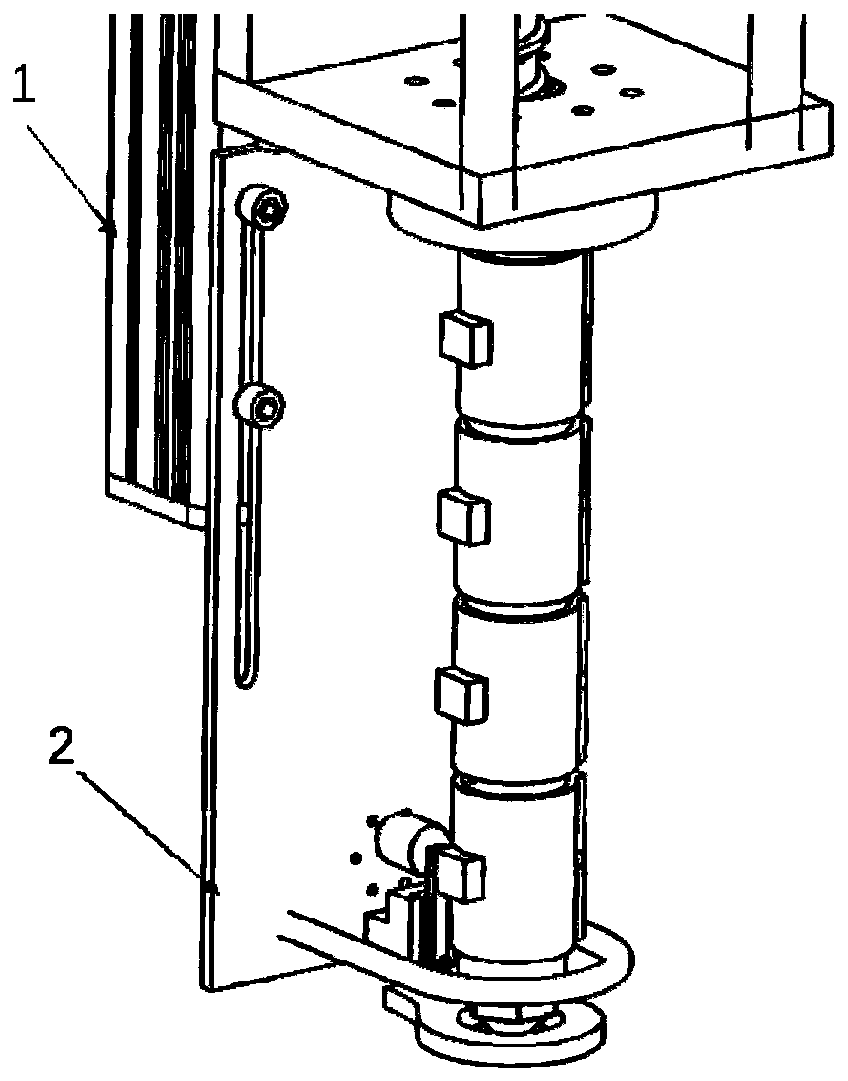

Engine cold-start preheating device

InactiveCN103061947AHigh exhaust gas temperatureStable warm-up performanceInternal combustion piston enginesExhaust apparatusEngineeringPhase change

The invention discloses an engine cold-start preheating device. A heat storing heat exchanger (3) is in a parallel connection with an exhaust pipe (2) of an engine (1), the heat storing heat exchanger (3) is used for storing exhaust air waste heat of the engine (1), the heat storing heat exchanger (3) is in a columnar structure, a plurality of heat storing units are distributed in the heat storing heat exchanger (3), each heat storing unit is a concentric casing pipe (7) which comprises an inner pipe and an outer pipe, a phase change thermal storage material (8) is encapsulated in annular space between the inner pipe and the outer pipe, two ends of the inner pipe are welded on two flow guide plates (9) respectively, a hollow cavity for enabling cooling water of the engine (1) to flow through is formed by the two flow guide plates (9) and inner walls of the heat storing heat exchanger (3), and the inner walls of the heat storing heat exchanger (3) are located between the two flow guide plates (9). The engine cold-start preheating device has the advantages of being low in costs, small in size, efficient, energy-saving and convenient to popularize and use in a wide range.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

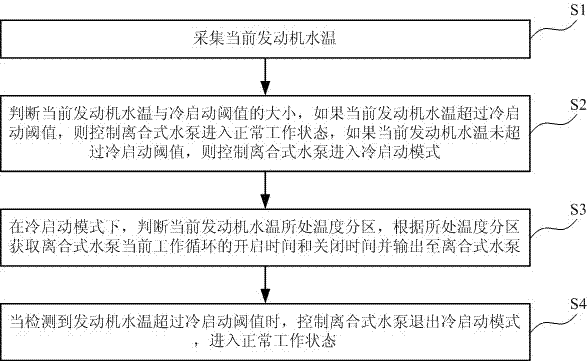

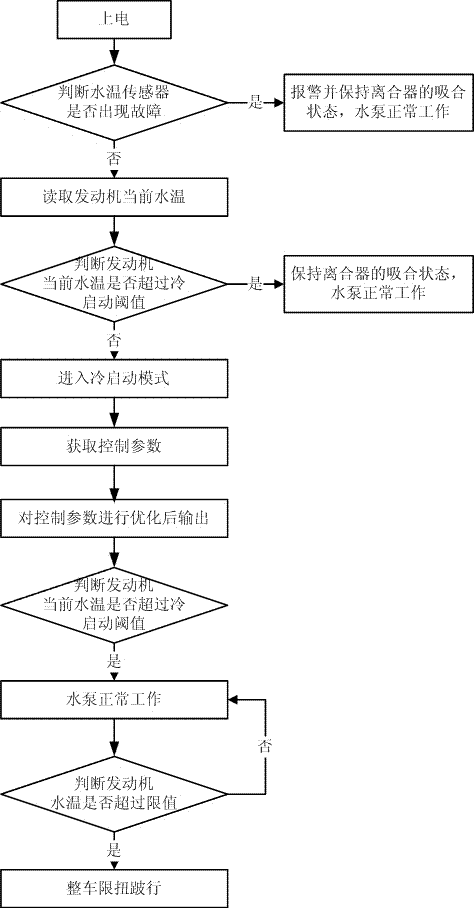

Control method and device of separation and reunion type water pump for engine

ActiveCN106870100ANo risk of overheatingEasy to controlCoolant flow controlMachines/enginesEngineeringWater temperature

The invention provides a control method and device of a separation and reunion type water pump for an engine. The control method comprises the steps that S1, the current engine water temperature is collected; S2, the magnitude of the current engine water temperature and a cold start threshold value is judged, if the current engine water temperature exceeds the cold start threshold value, the separation and reunion type water pump is controlled to enter a normal working state, and if the current engine water temperature does not exceed the cold start threshold value, the separation and reunion type water pump is controlled to enter a cold start mode; S3, in the cold start mode, a temperature partition where the current engine water temperature is located is judged, and according to the temperature partition, the opening time and closing time of current working circulation of the separation and reunion type water pump are obtained and output to the separation and reunion type water pump; and S4, when the situation that the engine water temperature exceeds the cold start threshold value is detected, the separation and reunion type water pump is controlled to exit the cold start mode and enter the normal working state. Precise control over the separation and reunion type water pump can be realized, and the effect of fast machine warming is guaranteed to the maximum limit.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

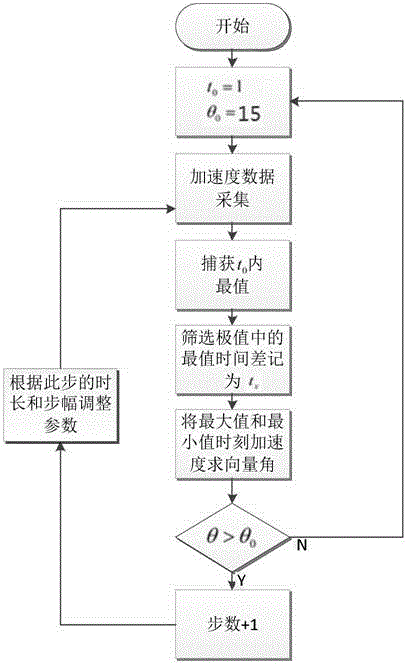

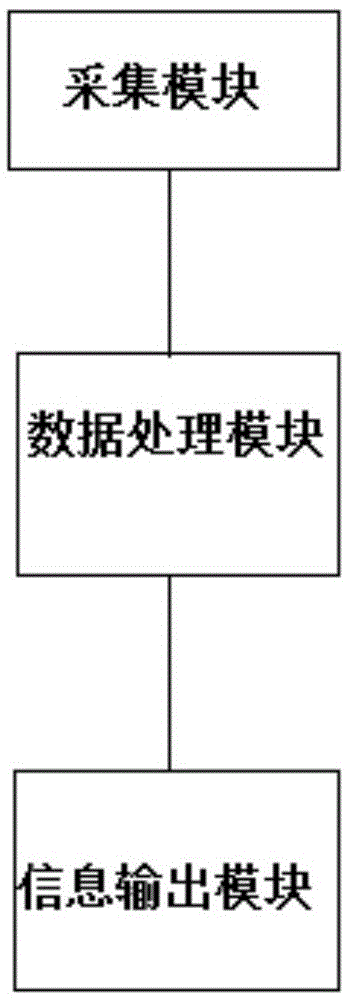

Pace counting system and pace counting method based on three-axis acceleration sensor

InactiveCN105651303AAvoid obvious missed stepsAvoid missed stepsNavigation instrumentsDistance measurementAcquisition timeClassical mechanics

The invention discloses a pace counting system and a pace counting method based on a three-axis acceleration sensor and belongs to the technical field of electronic application. The pace counting method includes acquiring three-axis accelerated speeds through the three-axis acceleration sensor, smoothing and denoising to obtain a resultant acceleration speed, obtaining a maximum value and a minimum value of the resultant acceleration speed as well as corresponding three-axis acceleration data within every time length, taking the three-axis acceleration data as three-dimensional vector coordinates to obtain a vectorial angle of two points, comparing the vectorial angle with common people walking single pace time length and stride, and changing pace-counting walking single pace acquisition time length and stride to judge an angle according to deviations. The pace counting system and the pace counting method based on the three-axis acceleration sensor have the advantages that according to dual judgments of resultant acceleration speed peak detection and resultant acceleration speed vectorial angle detection within single-pace time length, every single discontinuous pace can be recorded, and the system and the method can conform to characteristic adjustment parameters of different walkers in a continuous walking process, so that accuracy in pace counting is achieved.

Owner:JIANGSU UNIV +2

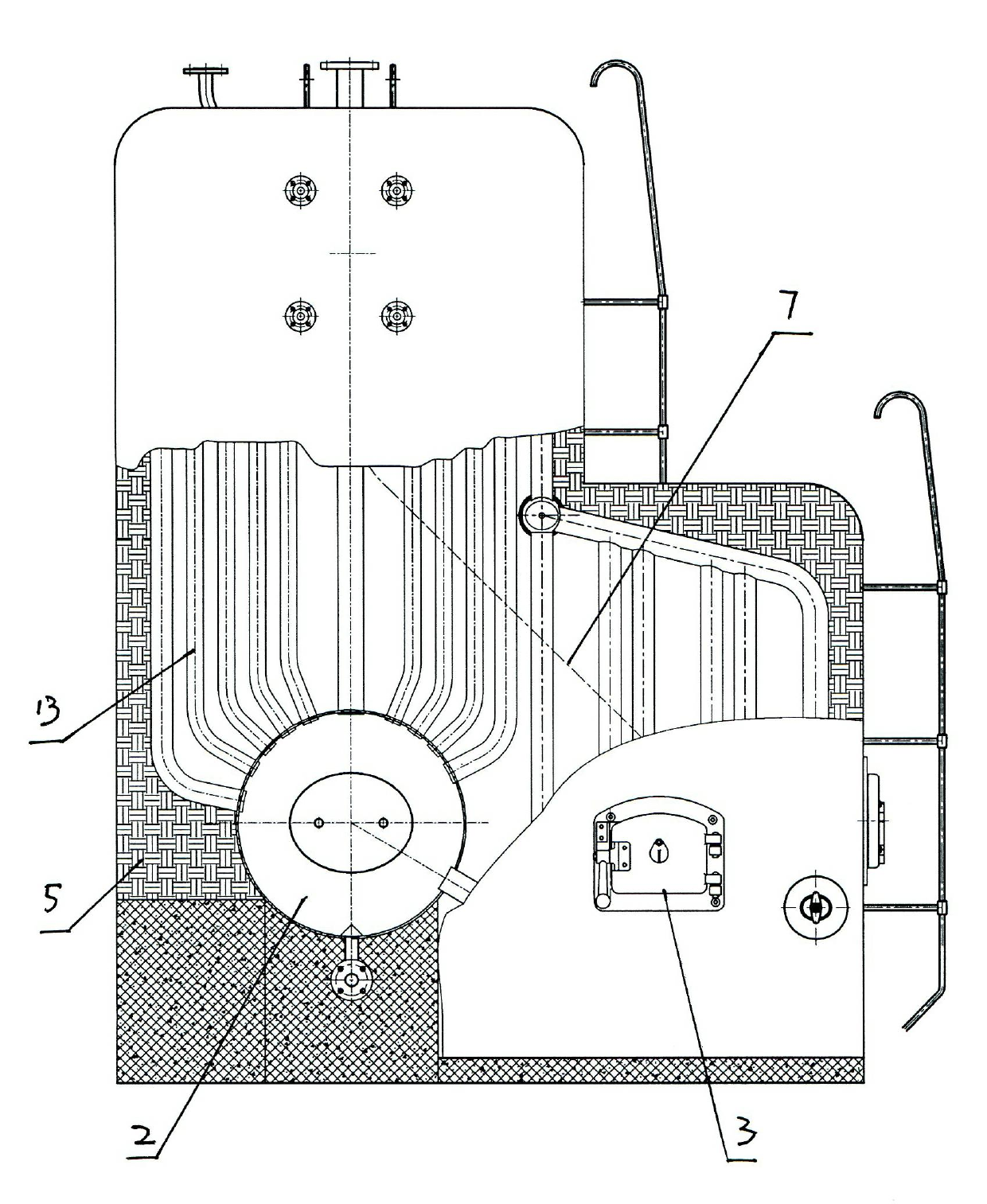

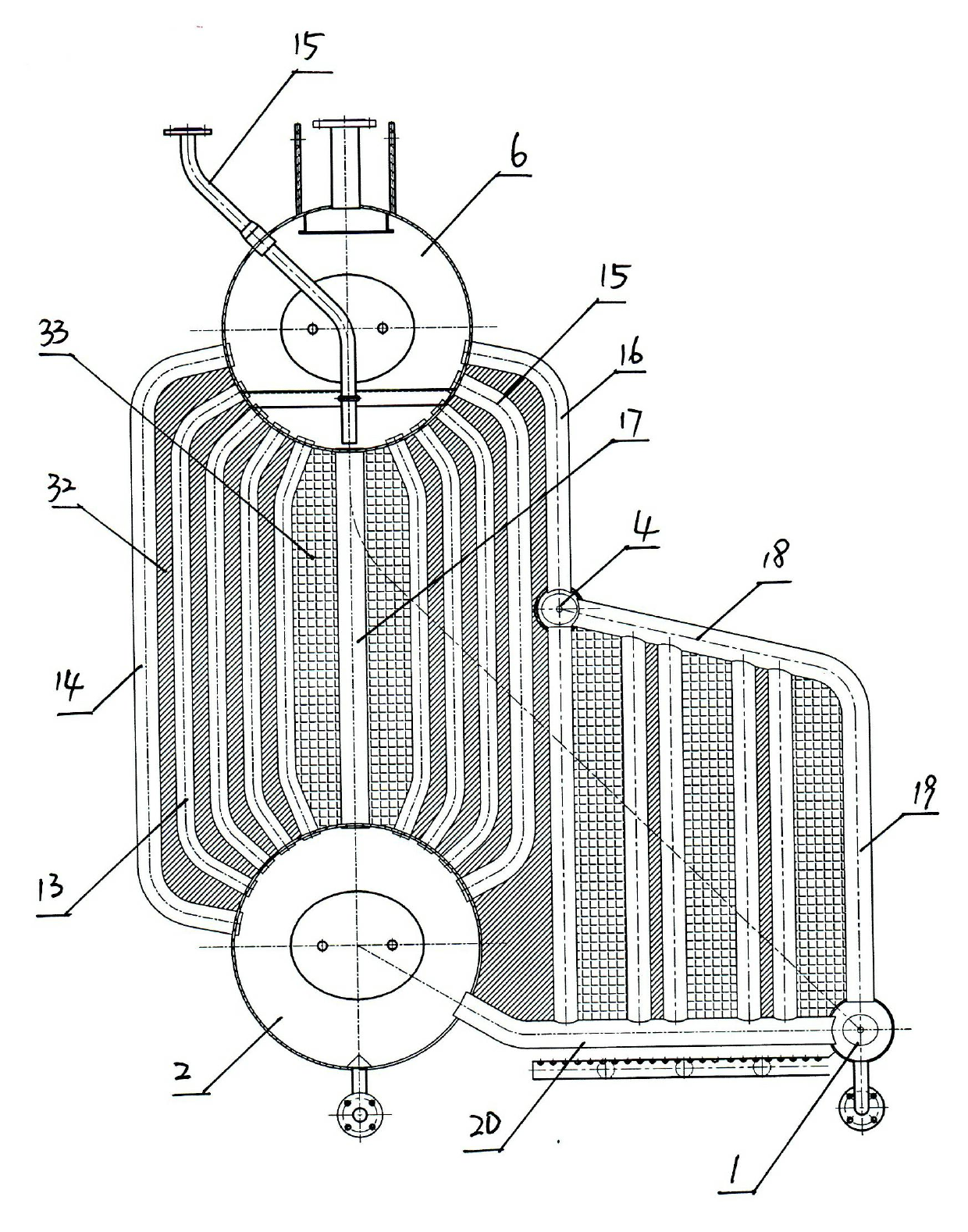

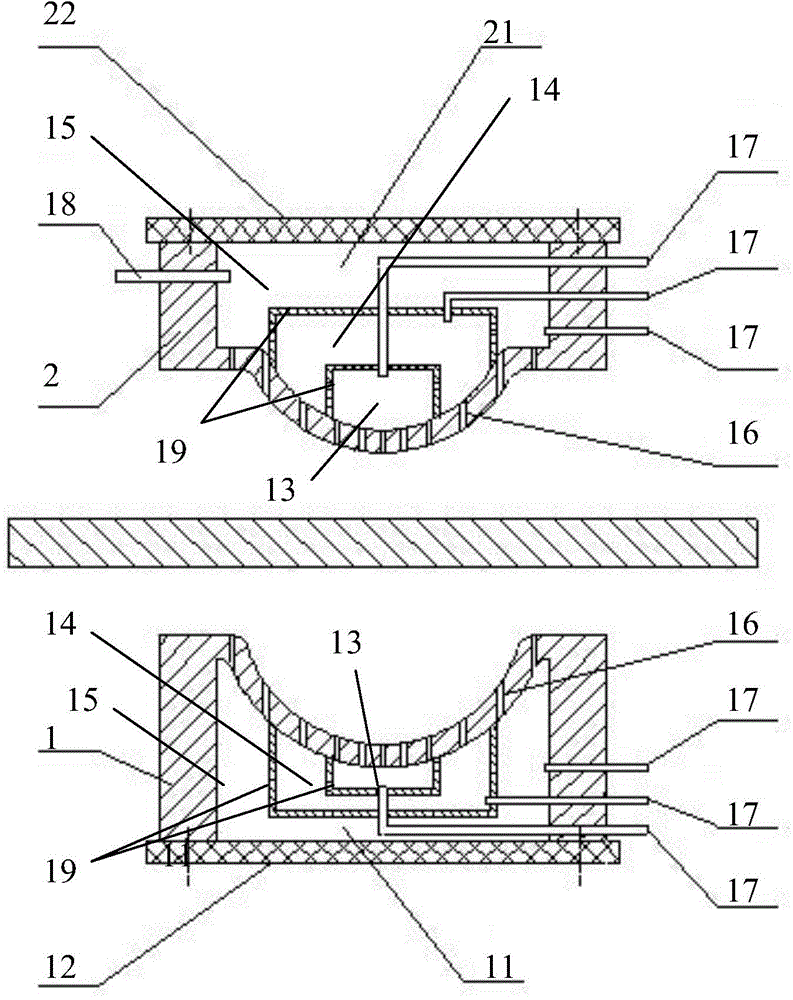

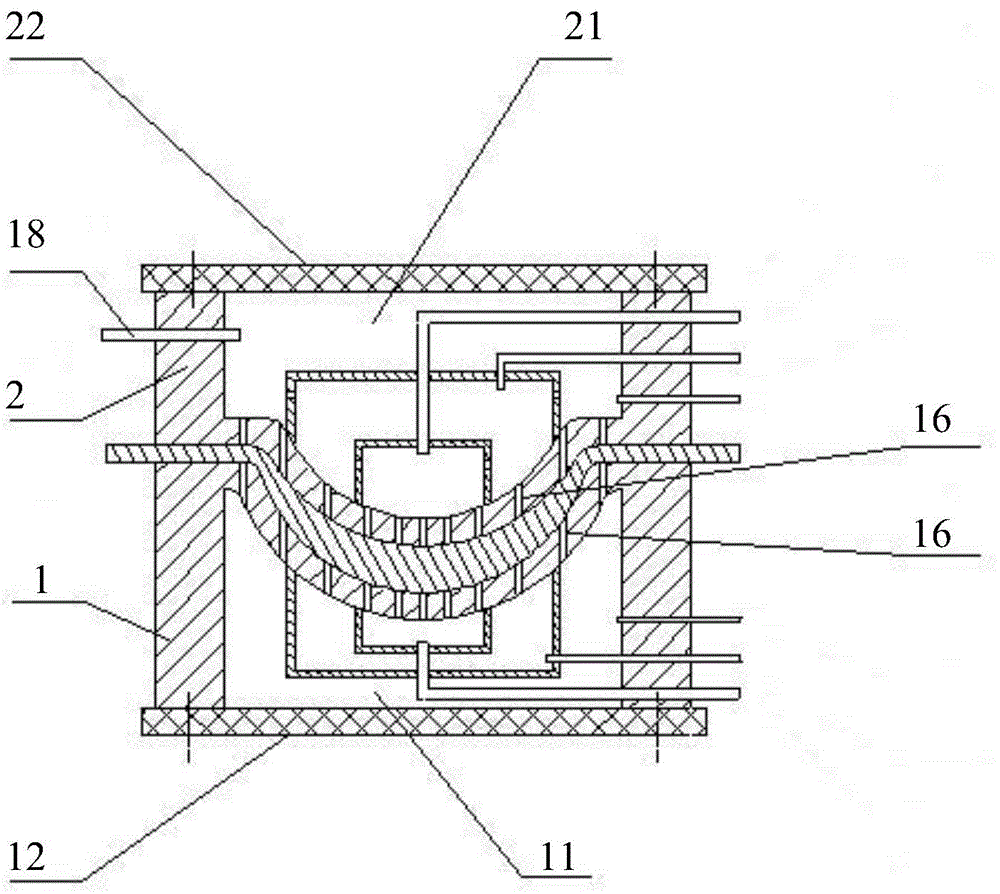

Horizontal dual-drum energy-efficient boiler without fireproofing-material furnace-building process

ActiveCN102679303AHigh outputHigh thermal efficiencyCombustion processWater-tube boilersCast ironWater pipe

The invention discloses a horizontal dual-drum energy-efficient boiler without a fireproofing-material furnace-building process. The horizontal dual-drum energy-efficient boiler comprises an upper drum, a lower drum and a hearth, wherein the upper drum is connected the lower drum through a plurality of rows of convection pipe bundles, all an outer partition wall, a middle partition wall and an inner partition wall are in water pipe type structures, and fins and / or cast iron hangers are assembled; the hearth is arranged on outside the inner partition wall, and is composed of an upper header, a lower header and a fire grate as well as an outer water pipe wall; a combustion chamber is arranged at the front part of the hearth, a high-temperature smoke chamber is arranged on the rear part of the hearth, a plurality of high-temperature water-passing pipes are vertically arranged in the high-temperature smoke chamber, and the high-temperature smoke chamber has a three-return stroke combustion structure; and a smoke outlet is sequentially connected with a hot air chamber and a chimney of a smoke residual heat recycling device, and a smoke purifying pond can be additionally arranged. Hot air of the hot air chamber is supplied to the hearth, high-temperature water of the smoke residual heat recycling device is replenished for the boiler, thus heat energy utilization rate can be greatly increased, steam yield is high and heat efficiency is high. The energy-efficient boiler has the advantages of light integral weight, convenience and time conservation in hoisting, transporting and installing, and cost conservation.

Owner:仲伟军

Underwear cup molding die and underwear molding method thereof

The invention discloses an underwear cup molding die. Cavities are formed in upper and lower dies, and superheated airflow is introduced into the cavities for heating, so that the die is rapidly preheated in a short time. The cavities are separated into multiple areas for respectively performing heating treatment at different temperatures, the condition that the temperature on the surface of the die is consistent with the temperature needed at each part of a mold pressing material is ensured, the heating effect of the cup material is improved, the problem caused by extremely high or low temperature is solved, the quality of the mold cup is improved, and the mold cup molding process is effectively perfected and improved. The molding die is suitable for molding modern three-dimensional cups of which the lower sides are thick and the upper sides are thin, so that the mold pressing temperature distribution on the die surface is reasonable, only the hot airflow is introduced into the first area of the lower die during mold pressing, so that the heating can be performed, the power consumption is reduced, the time is saved, the working efficiency is improved, the mold cup quality is improved, and the mold cup molding process is effectively perfected and improved.

Owner:SUZHOU UNIV

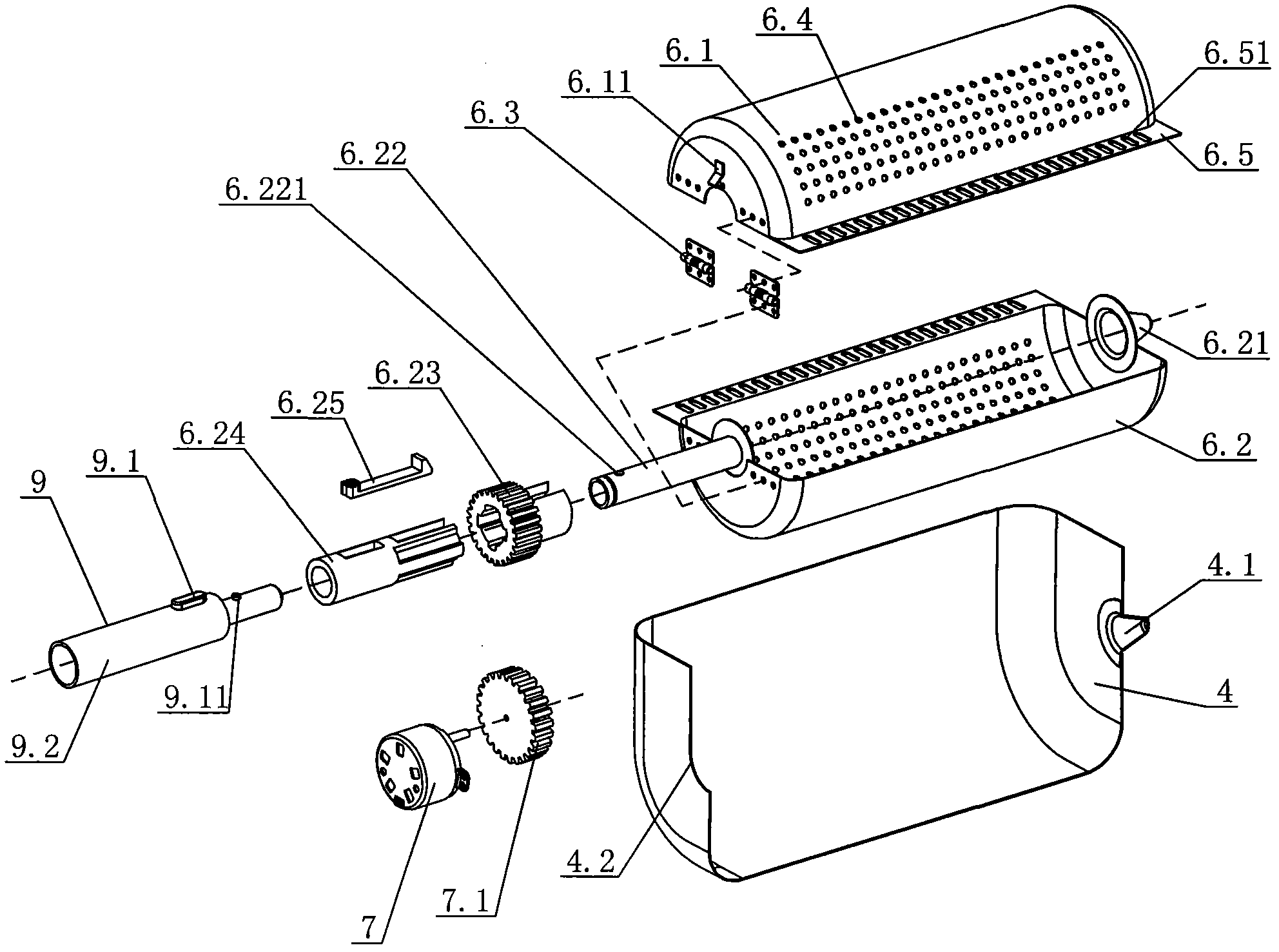

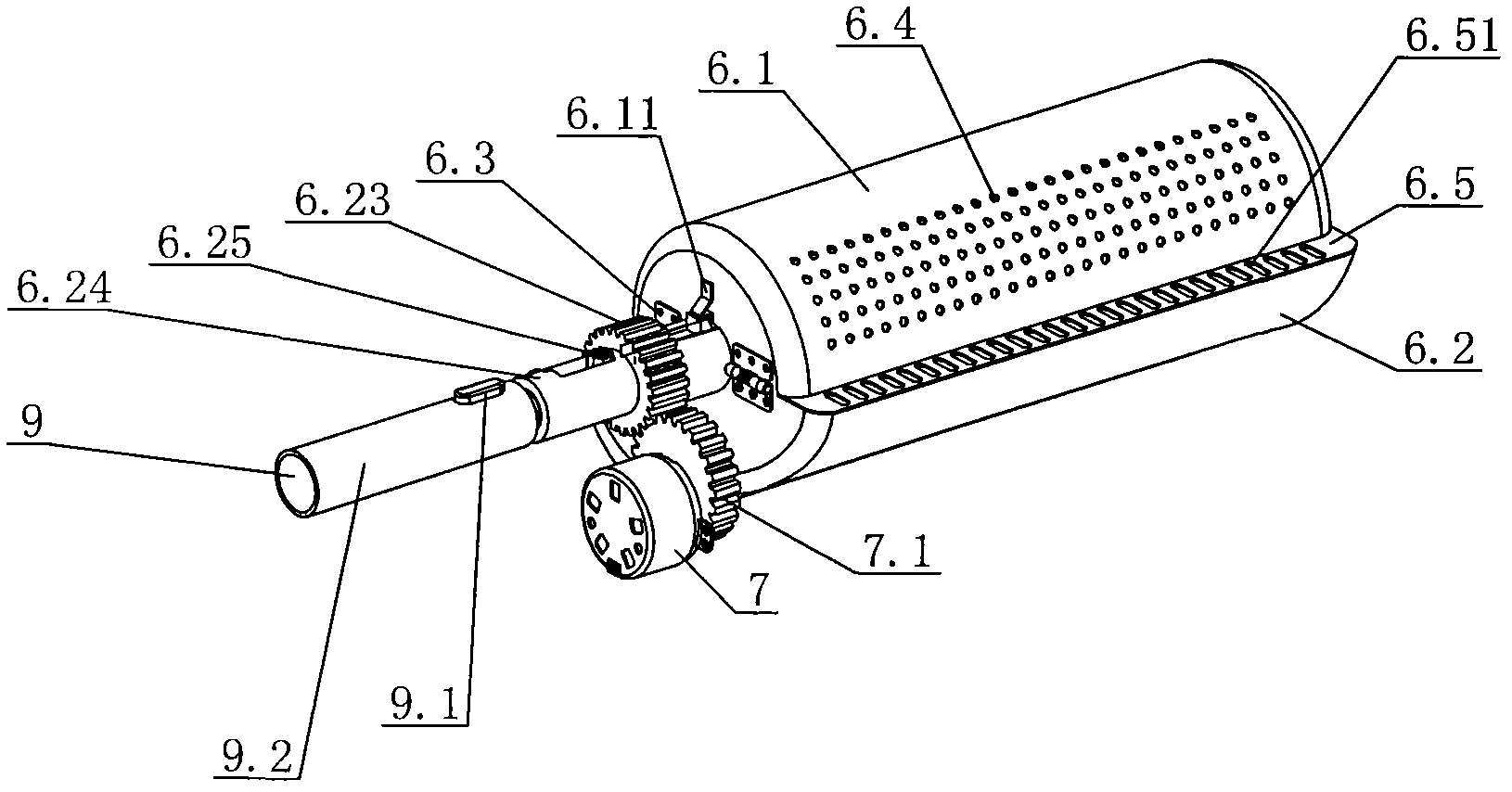

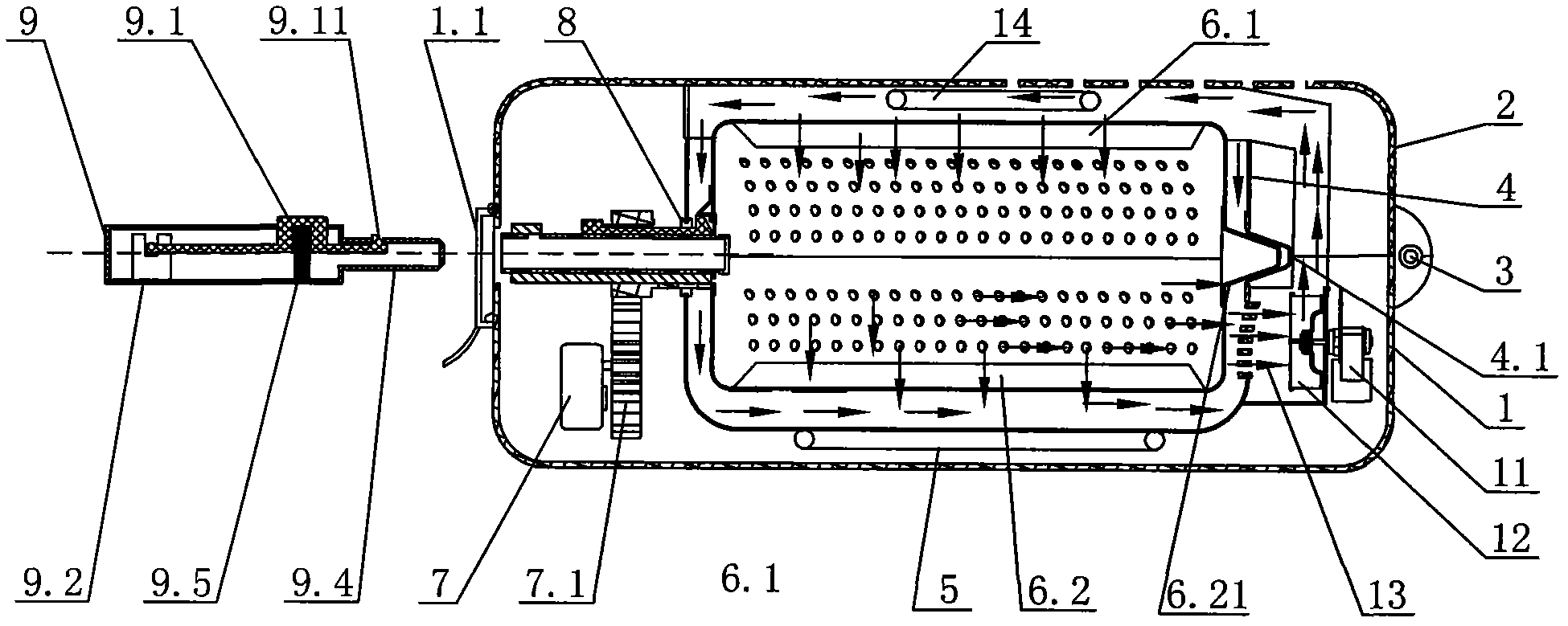

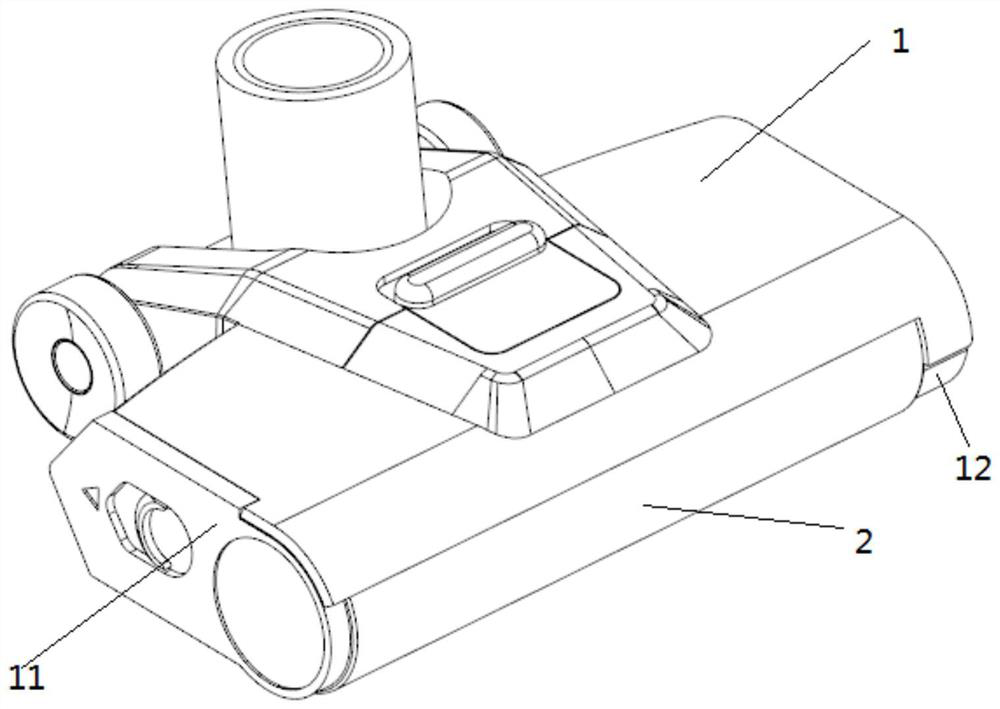

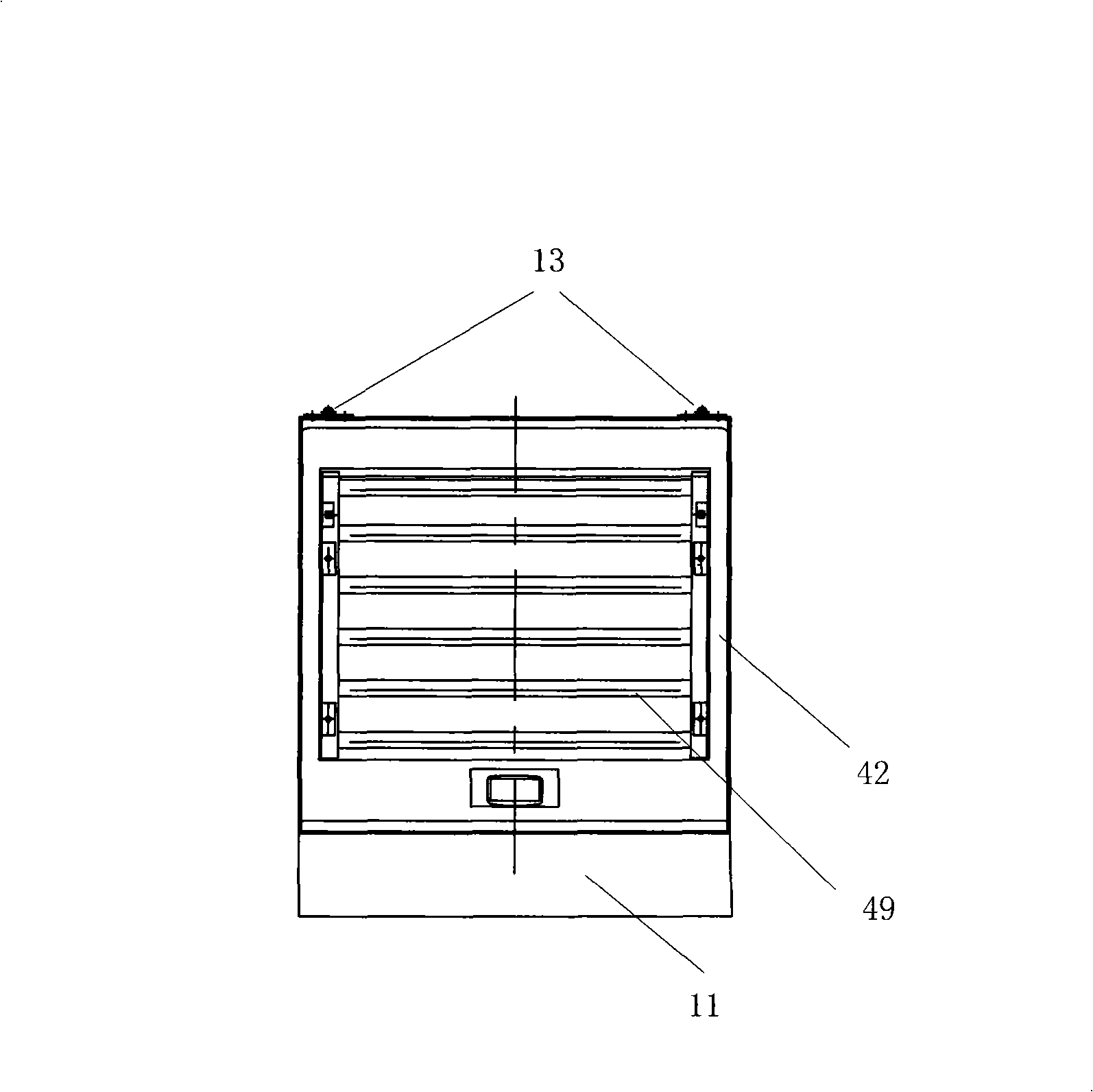

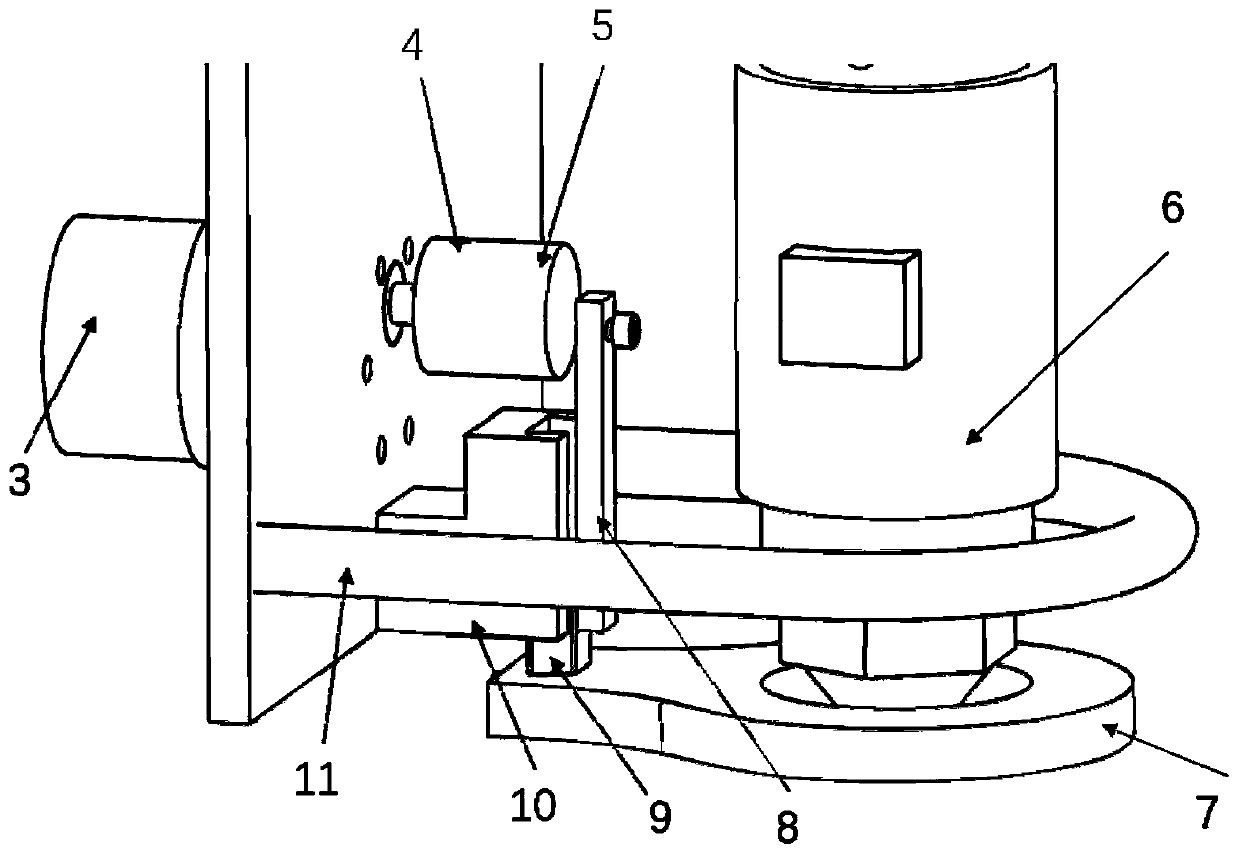

Oven

InactiveCN102319028AWarm up fastReduce energy consumptionBaking ovenRoasters/grillsDrive motorEnergy consumption

The invention relates to an oven, which comprises a main body having a liner, wherein a roller-type grill basket module which can be driven by a driving motor to rotate is installed inside the liner, the roller-type grill basket module comprises an upper grill basket and a lower grill basket, which are connected with each other in the vertical direction in an open-close way, the roller-type grillbasket module is provided with a rotating shaft to be coupled and connected with the driving motor, the roller-type grill basket module is detachably connected with a handle module, and the liner is provided with an internal circulating airflow module. The inner bottom parts of the upper grill basket and the lower grill basket are respectively provided with a stop block. The edges of openings at one sides of the upper and the lower grill baskets respectively extend out to form a wind breaking plate to be symmetric to each other, and the edges of openings at the other sides of the upper and the lower grill baskets are respectively connected with the wind breaking plates in a buckling way. The roller-type grill basket module is rotated along the rotation of the motor, annular airflow is produced by the internal circulating airflow module inside the liner, and through holes and the wind breaking plates are arranged on the roller-type grill basket module to be more convenience for the annular airflow to pass through, so the roller-type grill basket module can be quickly preheated, the energy consumption is low, the cooking efficiency is high, the use cost can be saved, and the environmental protection concept of modern people can be satisfied.

Owner:广德睿纳鲜果酒业有限公司

Floor brush with rolling brush heating function, cleaning equipment and control method thereof

PendingCN113951784AExcellent Dielectric StrengthGood heat transfer efficiencyCarpet cleanersFloor cleanersElectric heatingEngineering

Owner:深圳市银舍智能科技有限公司

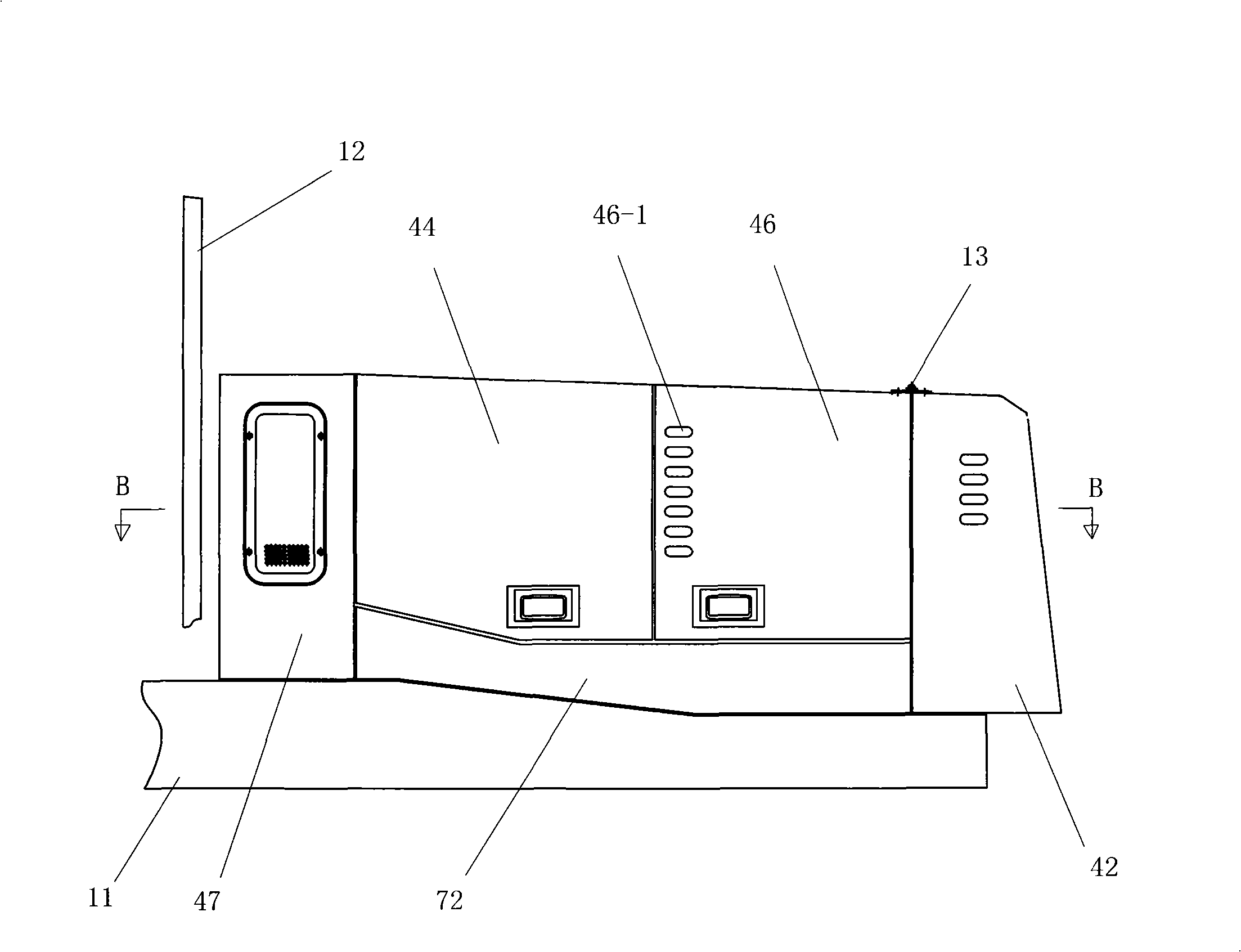

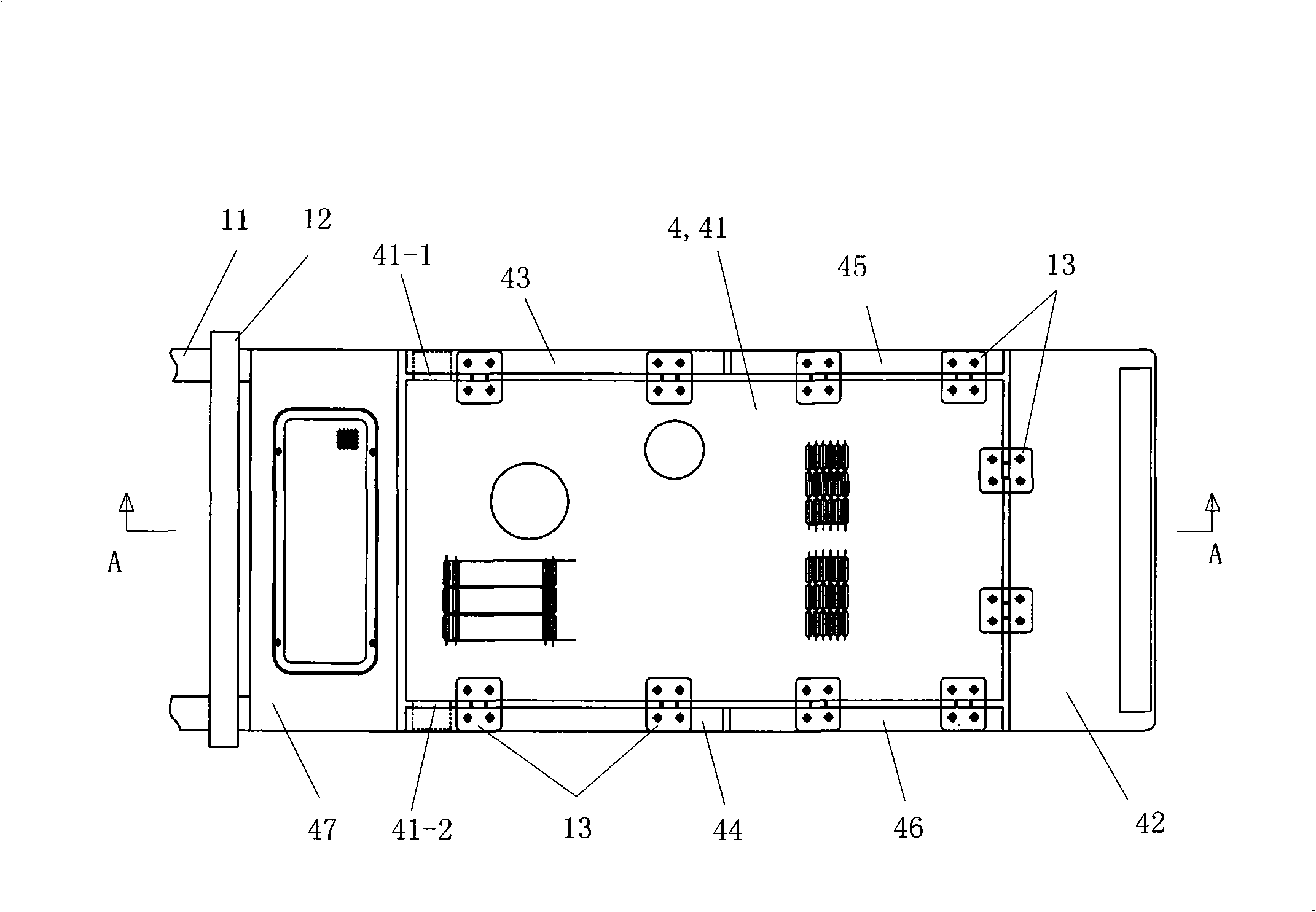

Cooling apparatus of scrapers

InactiveCN101298784AGuaranteed reliabilityReduce work stressSoil-shifting machines/dredgersAerodynamic dragVehicle frame

The invention relates to a cooling device of scooptram mechanism, comprising a vehicle frame, an outer cover, a cooling fan and a heat dissipating device. A mounting deck is fixed on the vehicle frame; the heat dissipating device is fixed on the mounting deck; each component of the heat dissipating device is arranged in three rows in fore-and-after direction; the cooling fan is positioned at the back row and installed at the tail part of the vehicle frame; a water radiator is positioned at the middle row; a charge air cooler and an oil radiator are positioned at the front row; thermal baffles are positioned in front of the charge air cooler and the oil heat radiator; the outer cover is installed on the mounting deck so that the outer cover and the thermal baffles as well as the space surrounded by both form a cooling chamber positioned at the back side of an engine and that the cooling fan, the water radiator, the charge air cooler and the oil radiator are positioned inside the cooling chamber. The cooling device of the invention is separated from an engine body via the cooling chamber, and the air draught is basically in the state of stable flowing when a suction cooling fan works; therefore, the structure reduces the air friction, reduces the working pressure of the fan and has better wind cooling effect.

Owner:SINOMACH CHANGLIN CO LTD

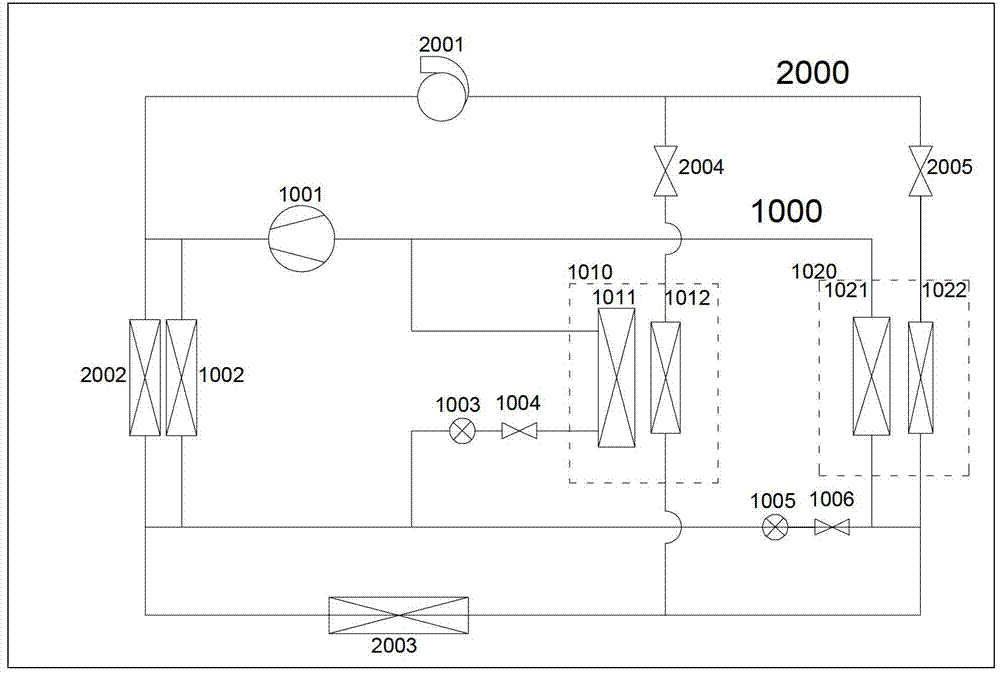

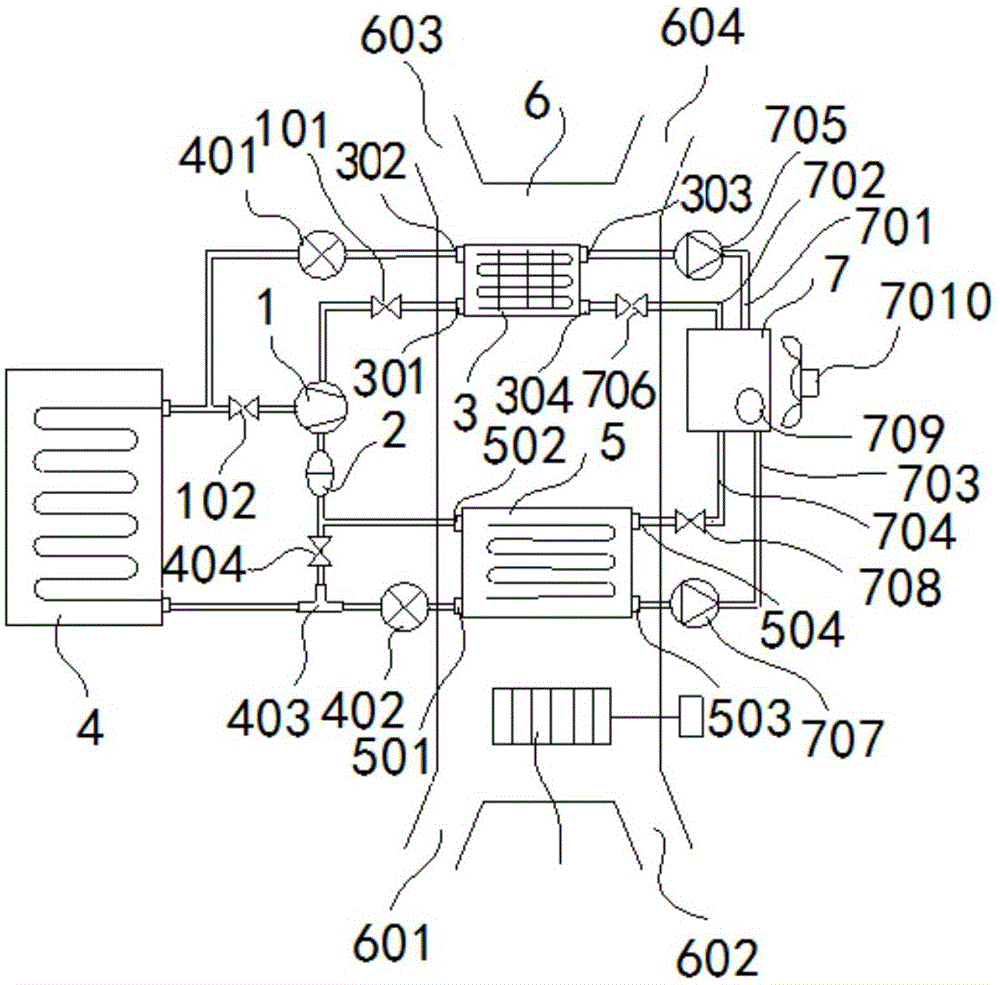

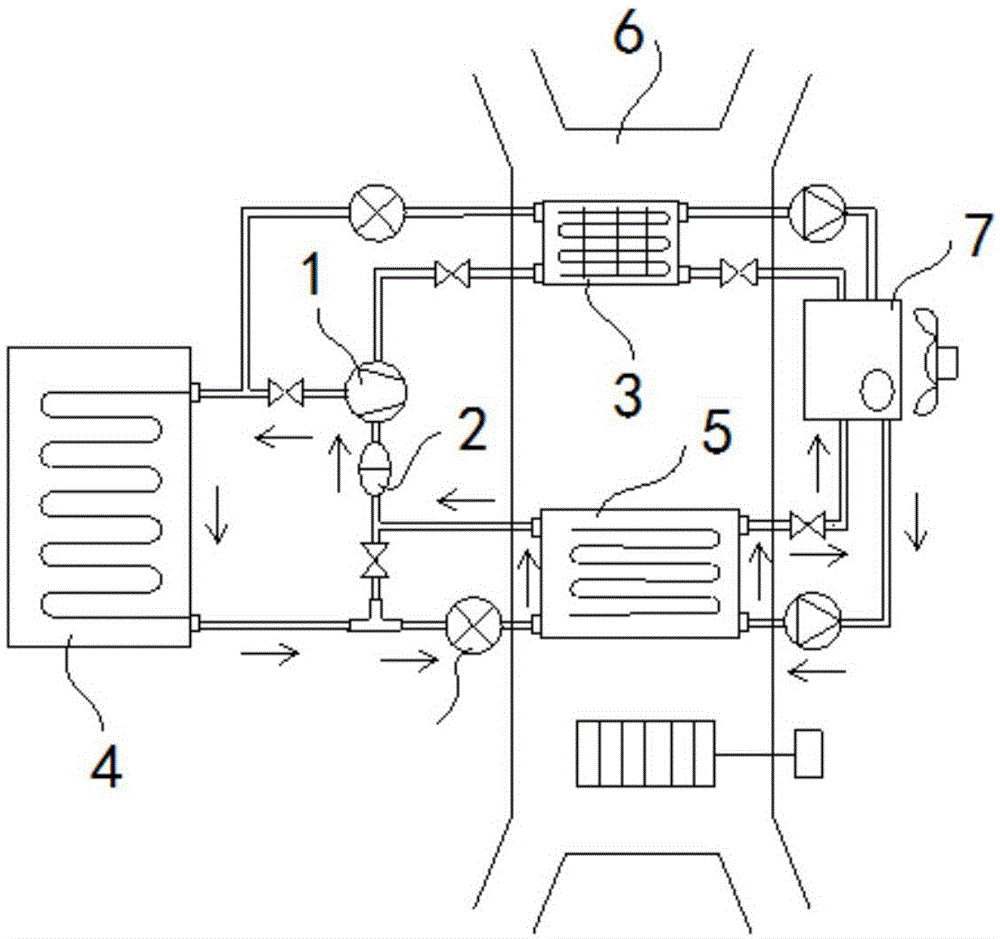

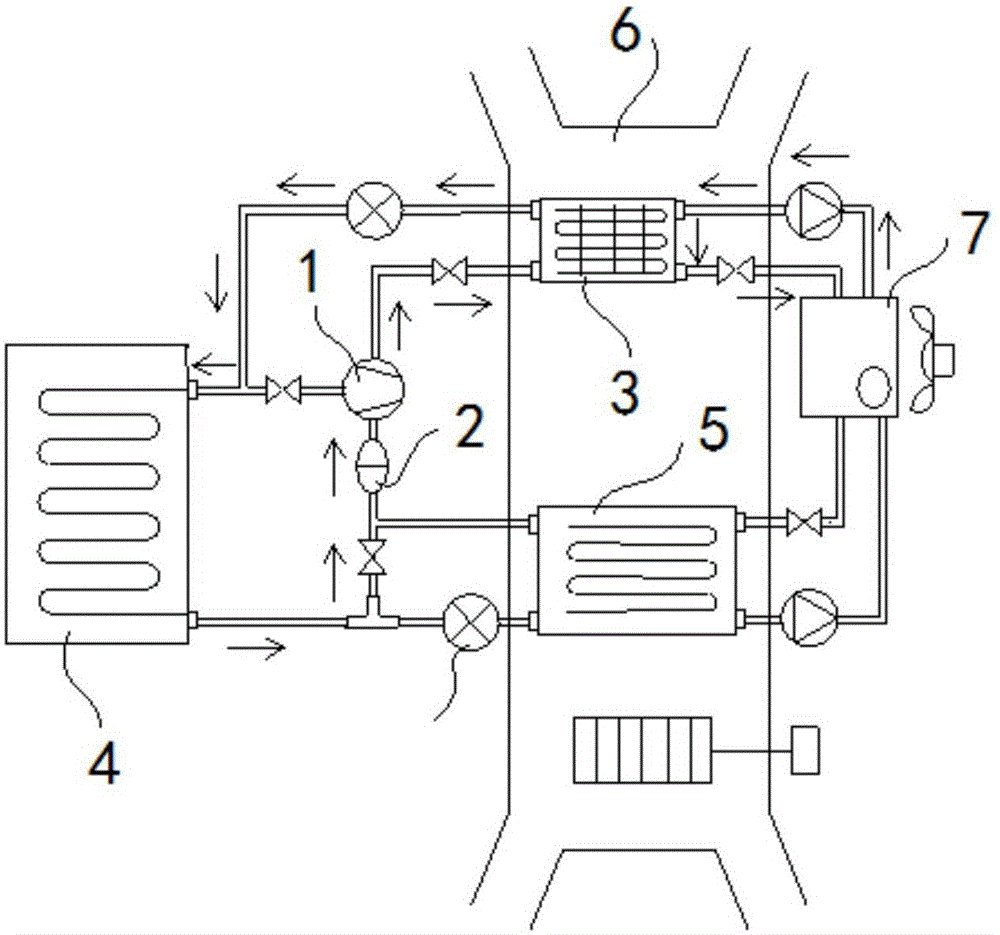

Automobile air-conditioning system

ActiveCN103712277AImprove efficiencyLower pressure ratioMechanical apparatusCompression machinesIntermediate heat exchangerAutomobile air conditioning

The invention discloses an automobile air-conditioning system. The automobile air-conditioning system further comprises an ejector (12) and an intermediate heat exchanger (6). In a heating mode, a working medium flowing from an outlet of a second heat exchange (102) is divided into a first channel and a second channel; the first channel of the working medium flows into the ejector (12) through a drive inlet after flowing out of a high-temperature side (62), and then is divided into a first branch and a second branch after being ejected from an outlet of the ejector (12), the first branch of the working medium flows back into a compressor (1) through a low-temperature side (61), and the second branch of the working medium flows into the ejector (12) through a bypass guide hole via a third heat exchanger (3). The automobile air-conditioning system has the advantages that efficiency of the compressor and the air-conditioning system can be improved effectively, requirements for heat in high and cold environment can be guaranteed, and comfortableness of passengers and stable and efficient performance of heating components are guaranteed.

Owner:HANGZHOU SANHUA RES INST CO LTD

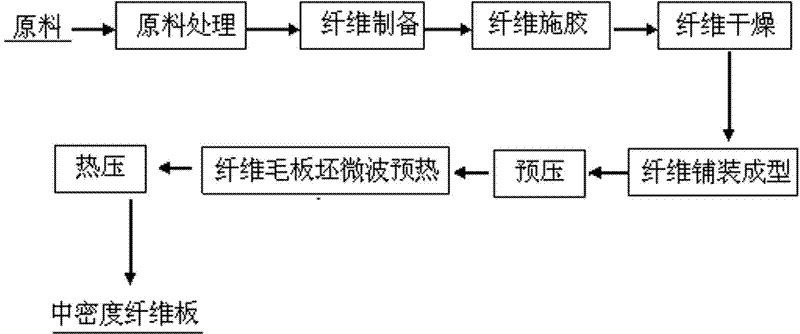

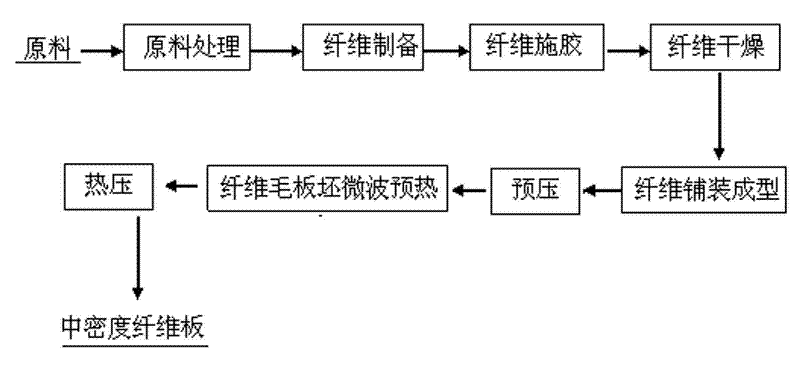

Method for preparing medium density fiberboard by using microwave to pre-heat

InactiveCN102335947AReduce heating time of heat pressShort manufacturing timeWood working apparatusDomestic articlesFiberTemperature control

The invention discloses a method for preparing a medium density fiberboard by using microwave to pre-heat. The method comprises the procedures of treating raw materials, preparing fibers, gluing the fibers, drying the fibers, paving and molding the fibers, pre-pressing and hotly pressing. The method also comprises a procedure for pre-heating a fiber plate blank by using the microwave between the procedure for pre-pressing and the procedure for hotly pressing. The procedure for pre-heating the fiber plate blank by using the microwave to pre-heat is used for rapidly pre-heating the pre-pressed fiber plate blank by using the microwave through arranging a continuous tunnel type microwave heating device and the temperature of the fiber plate blank which is pre-heated by the microwave is controlled in a range of 50-60 DEG C. With the adoption of the method provided by the invention, the time for hotly pressing and raising the temperature of the fiber plate blank can be reduced so that the whole preparation time of the medium density fiberboard is shortened, the production efficiency of the medium density fiberboard is improved and the energy is saved, and the quality of the medium density fiberboard product also can be improved and enhanced.

Owner:FUJIAN YONGAN FORESTRY GRP CO LTD

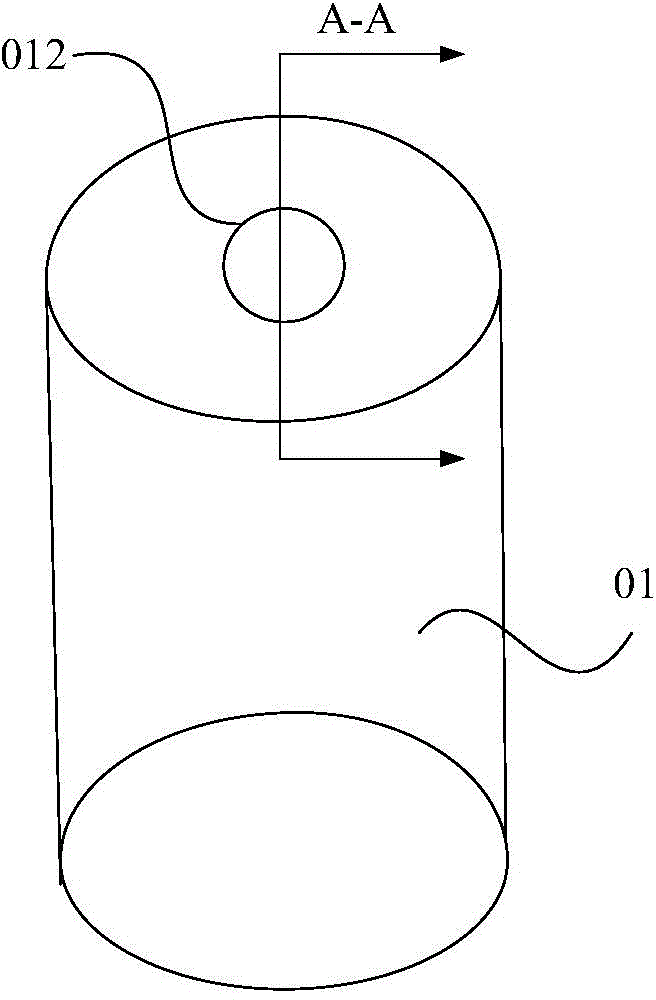

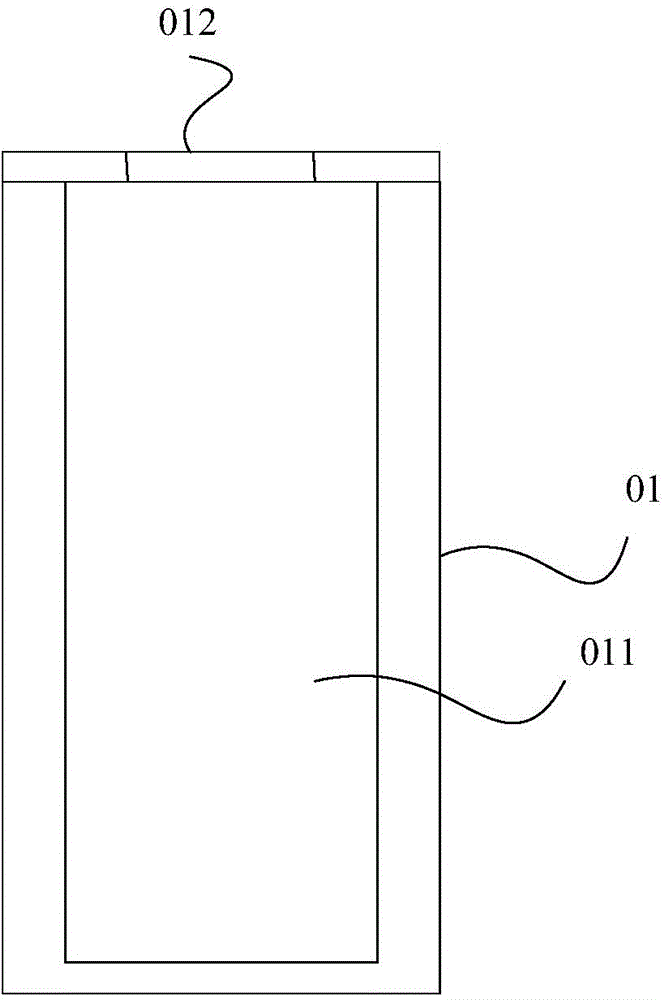

Crucible

InactiveCN104694883AWarm up fastEvenly distributedVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention relates to the technical field of evaporation and discloses a crucible. The crucible comprises a crucible body, the crucible body is provided with a cavity, the first end of the crucible body is sealed, and an opening communicated with the cavity is formed in the second end of the crucible body. The crucible further comprises at least one heat conduction part, each heat conduction part is located in the cavity, and the heat conduction parts divide the cavity into multiple containing areas. According to the crucible, the cavity of the crucible body is divided into the containing areas through the heat conduction parts, so that when organic materials are placed in the crucible, the organic materials are located in the containing areas, when the crucible is heated, heat will be transferred to the heat conduction parts through the inner wall of the crucible, the crucible heats the organic materials in the containing areas respectively, the organic materials can be quickly preheated, and heat is uniformly distributed. Thus, heating uniformity of the organic materials in the crucible can be improved, and the display effect of a display device is enhanced.

Owner:BOE TECH GRP CO LTD

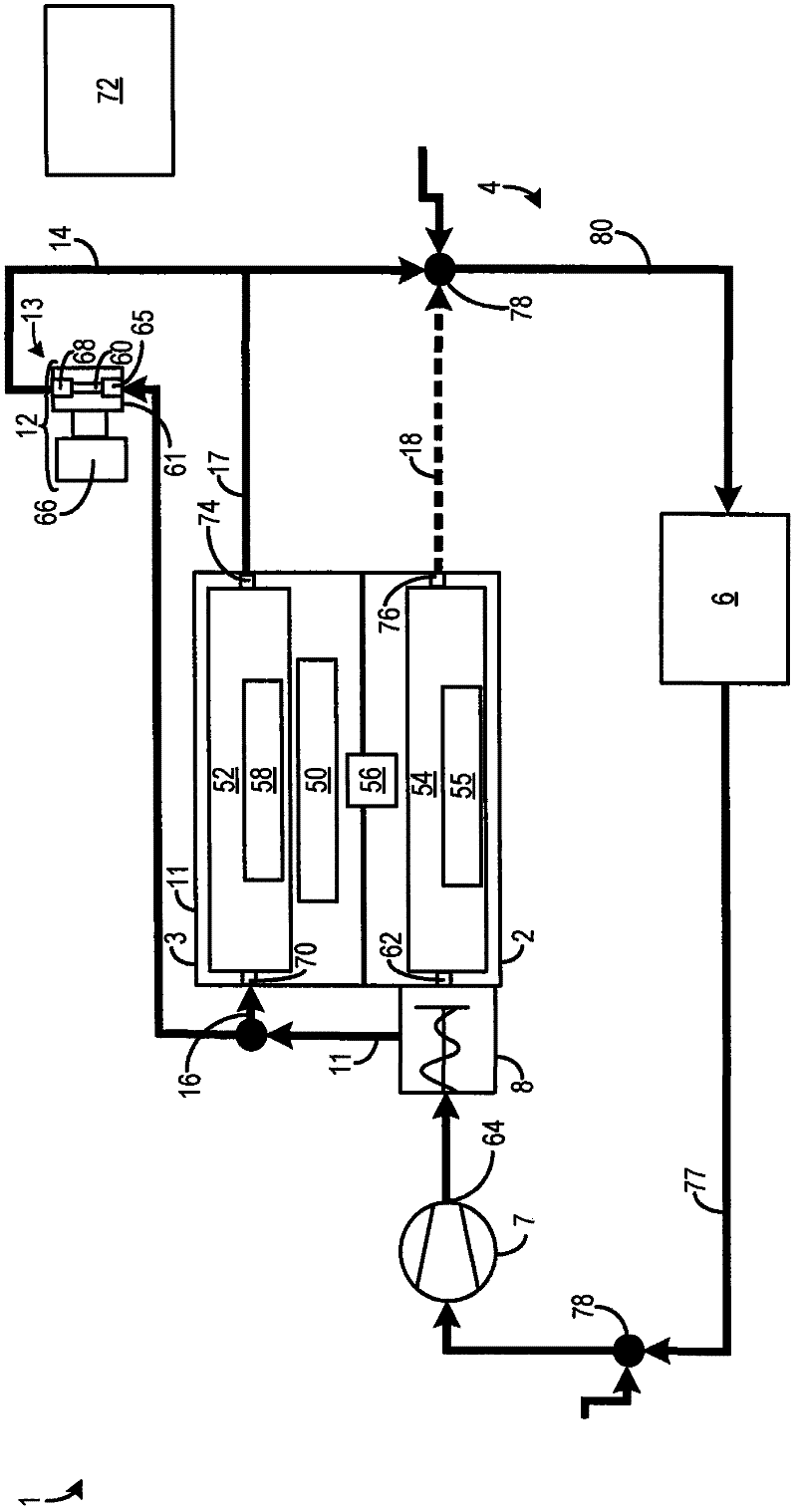

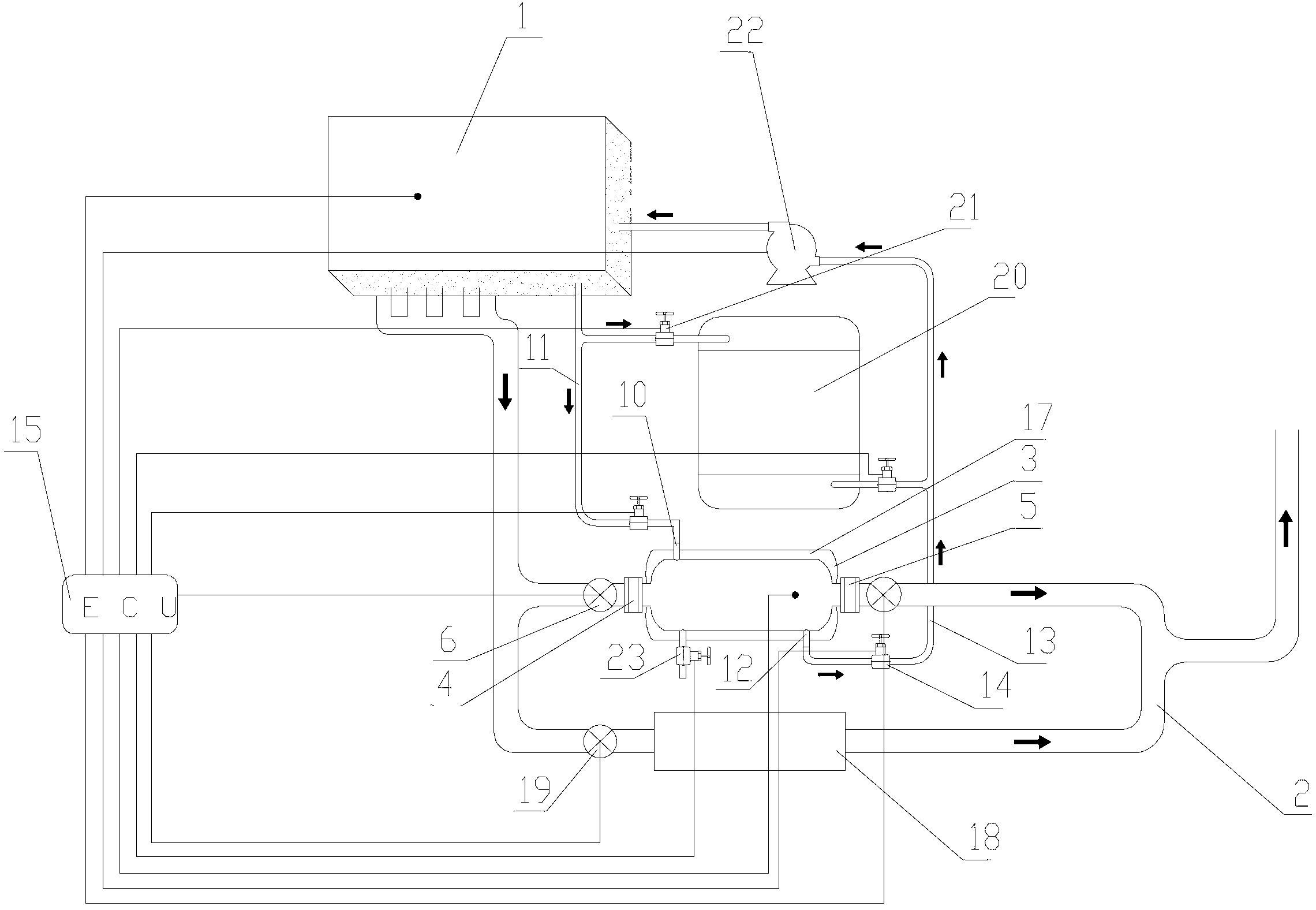

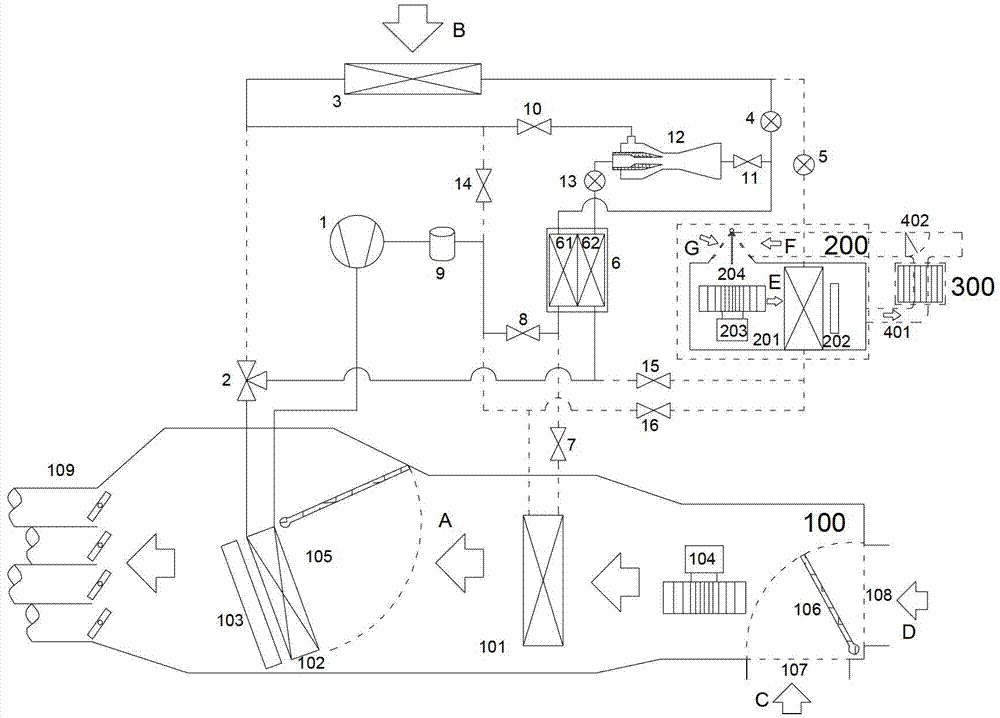

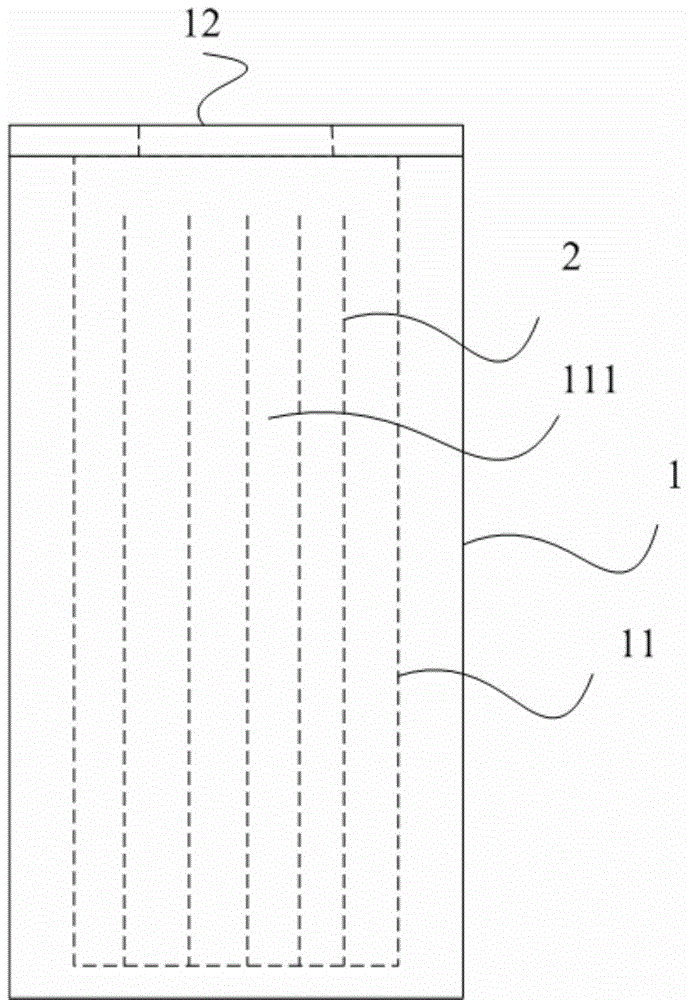

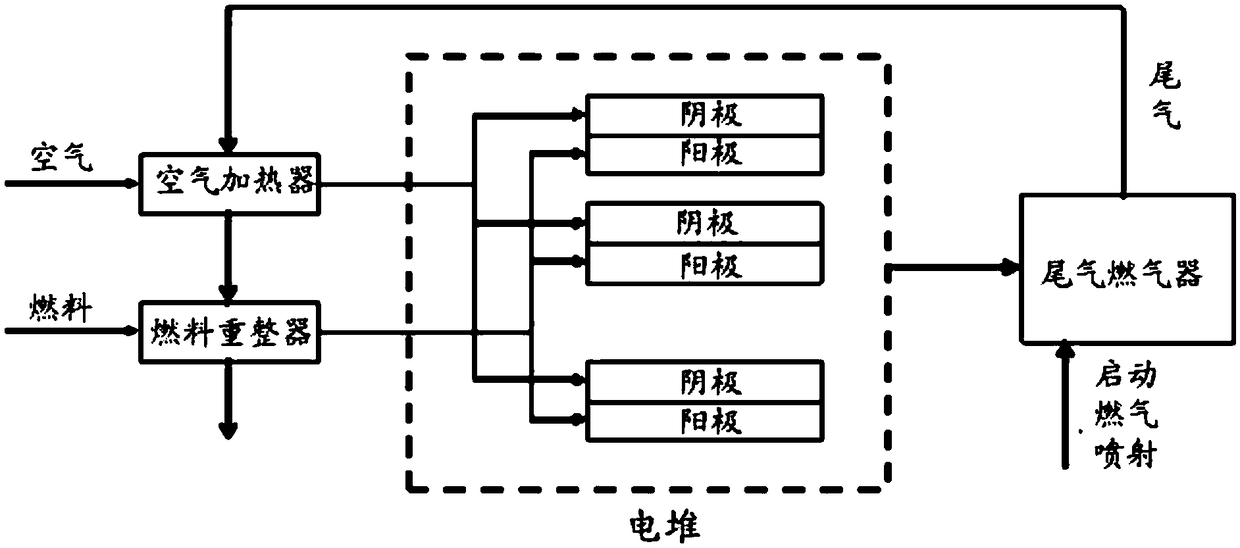

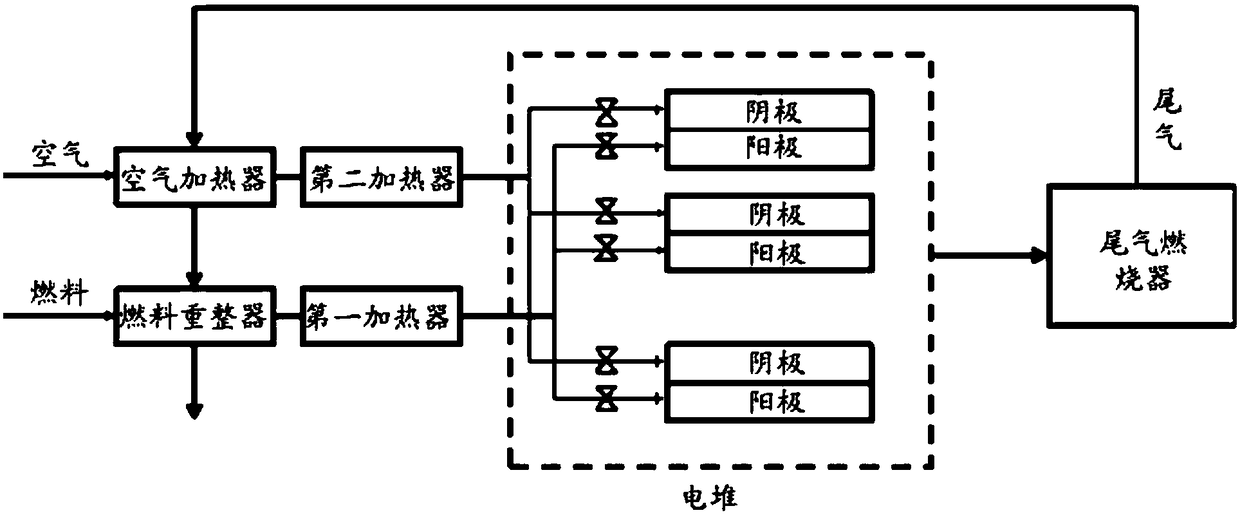

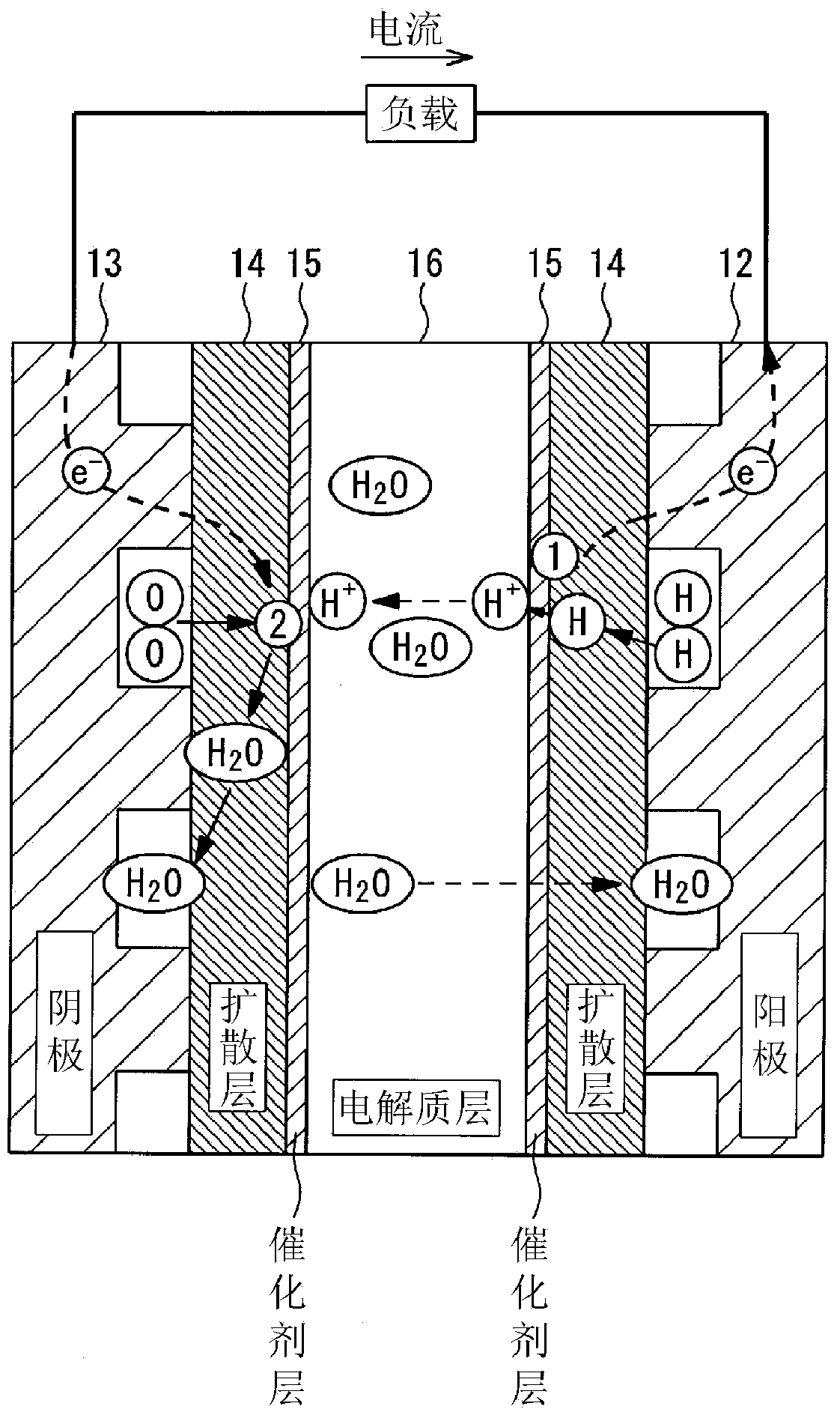

Solid oxide fuel cell system and starting method thereof

ActiveCN108711631AReduce startup timeFast heatingFuel cell heat exchangeReactant parameters controlFuel cellsStart time

The invention discloses a solid oxide fuel cell system and a starting method thereof. The starting method of the solid oxide fuel cell system comprises the following steps: heating air; heating fuel;and making heated air and fuel enter a fuel cell stack to complete preheating, wherein the step of heating fuel comprises the following specific step: heating fuel with a first heater, and the first heater is connected in series with a fuel reformer; and / or the step of heating air comprises the following specific step: heating air with a second heater, and the second heater is connected in serieswith an air heater. Through adoption of the starting method of the solid oxide fuel cell system disclosed by the invention, the heating speed of the fuel and / or air can be increased, thereby increasing the preheating speed of the fuel cell stack, and shortening the starting time of the solid oxide fuel cell system.

Owner:WEICHAI POWER CO LTD

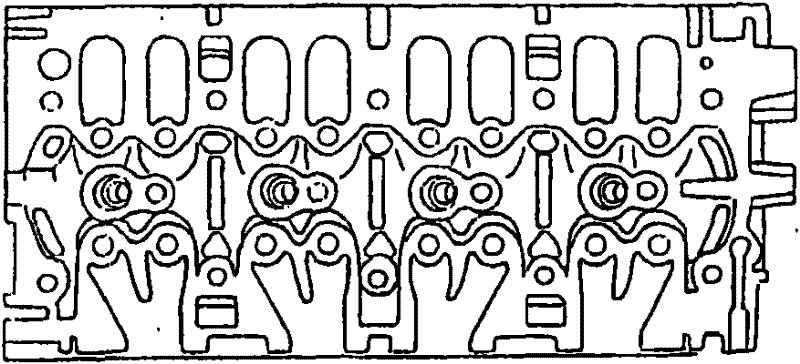

Motor arrangement with integrated exhaust gas manifold

InactiveCN102099558AWarm up fastEffective heatingExhaust apparatusCylinder headsCylinder headGasoline

It is proposed that the exhaust gas manifold be integrated into the cylinder head (100), a first for turbo applications, and that an associated cooling concept be provided. In the process, significant attribute improvements can be accomplished while at the same time achieving much lower system costs. For example, the advantages of this application are illustrated using a four cylinder gasoline engine with direct injection and turbocharging. What are particularly notable are the reduced fuel usage in full load and near full load ranges, lower CO2 emissions in European driving cycles, faster catalytic converter start, improved engine warm-up and heating of the vehicle cab, and significant reduction of complexity by eliminating the classical exhaust gas manifold and the significant weight and cost reduction associated therewith.

Owner:FORD GLOBAL TECH LLC

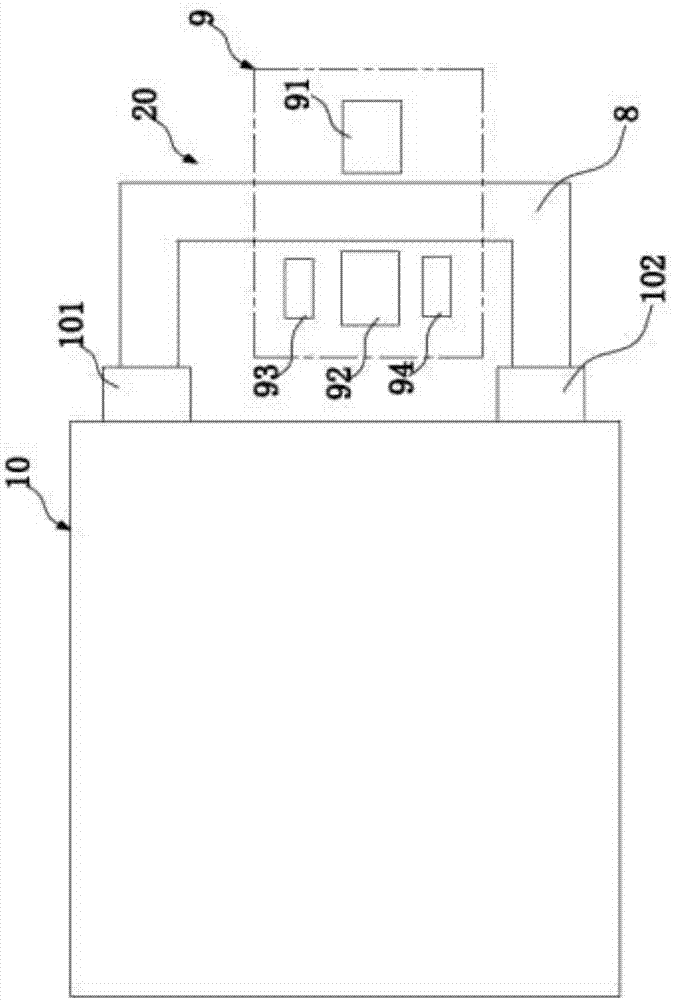

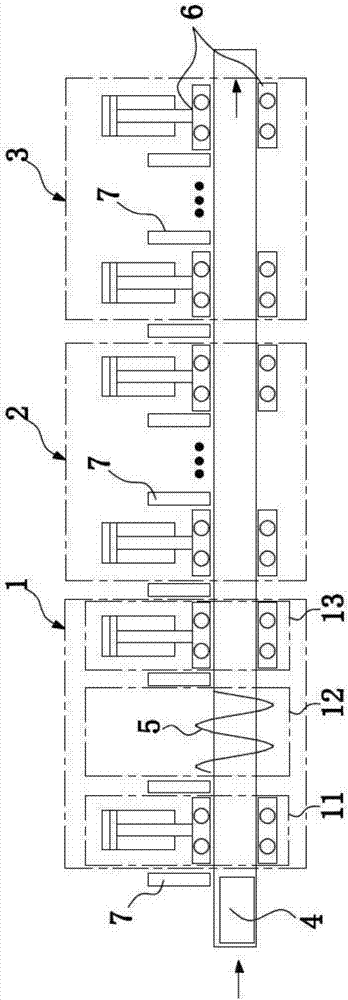

Automatic transferring, loading and unloading device for high-temperature molds, high-efficiency machining system for 3D cover glass and machining method of system

PendingCN107879606AExquisite designSimple structureGlass reforming apparatusGlass productionEngineeringCover glass

The invention discloses an automatic transferring, loading and unloading device for high-temperature molds, a high-efficiency machining system for 3D cover glass and a machining method of the system.The automatic transferring, loading and unloading device for the high-temperature molds comprises a mold conveying mechanism which is used for conveying molds at the temperature not lower than 100 DEGC to an unloading and loading position from a discharge end of machining equipment and conveying the molds to a feed end of the machining equipment from the unloading and loading position; the unloading and loading position comprises an upper mold moving device and a part taking and arranging device, the upper mold moving device is used for lifting and dropping upper molds of the molds to controlmold opening and assembling; the part taking and arranging device is used for taking molded parts out of lower molds of the molds, taking parts from a to-be-machined part storage area and placing theparts to the lower molds. According to the scheme, manual operation is not needed, the overall machining efficiency and product yield can be increased, the output molds have no temperature limit andcan be output at higher temperature, cooling time can be reduced, time consumed for preheating is reduced, and increase of overall machining rate and decrease of energy consumption are facilitated.

Owner:苏州赛万玉山智能科技有限公司

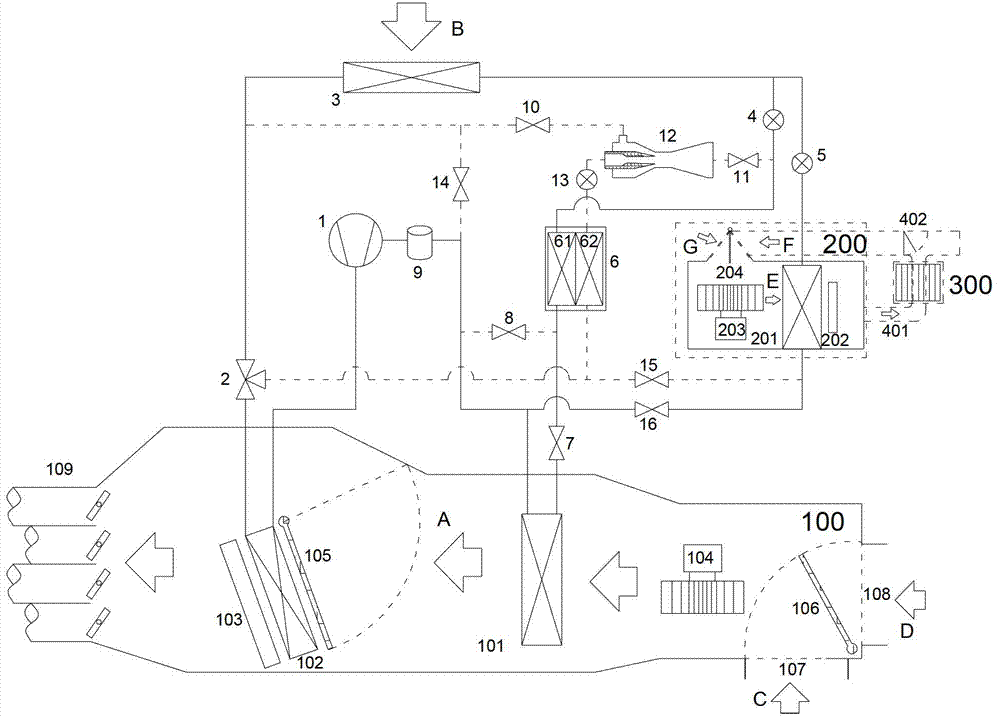

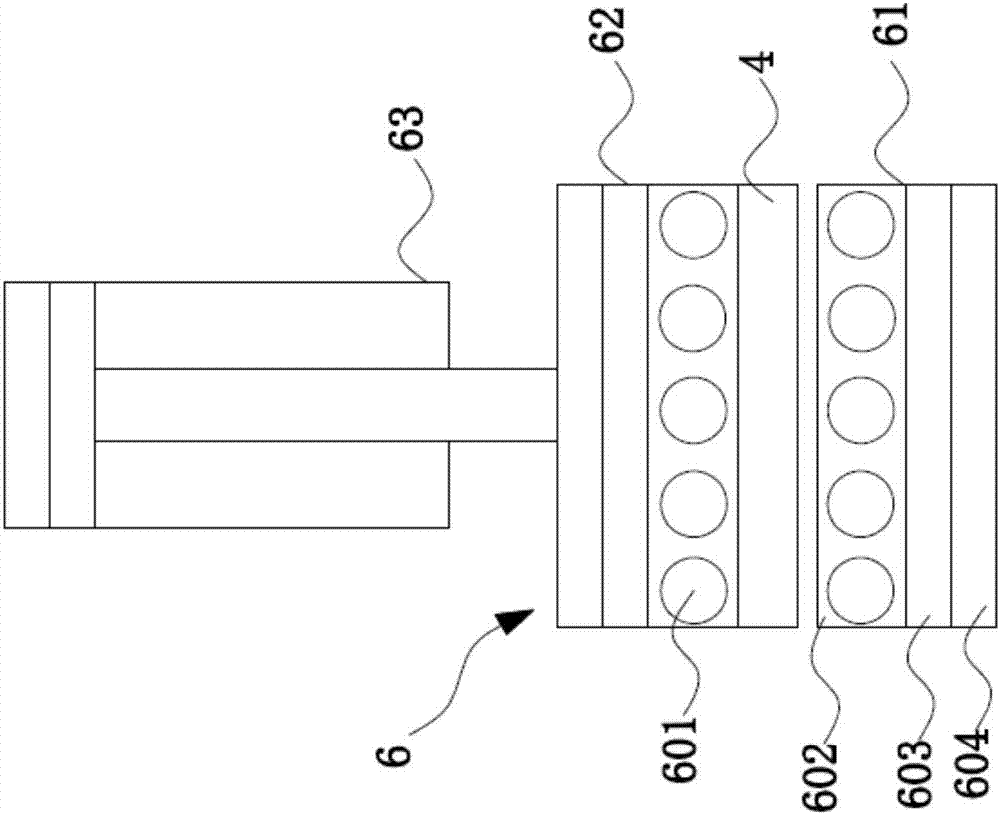

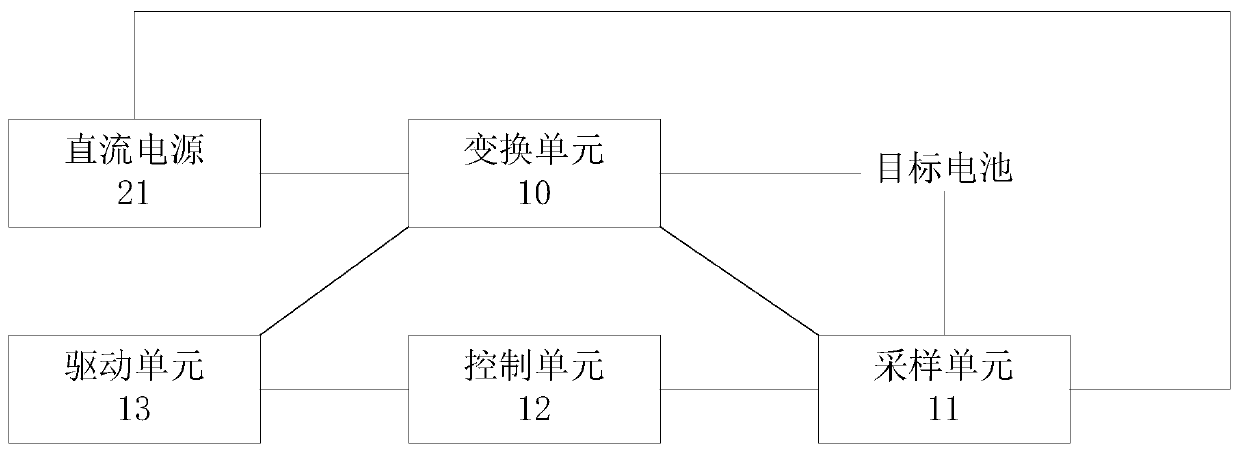

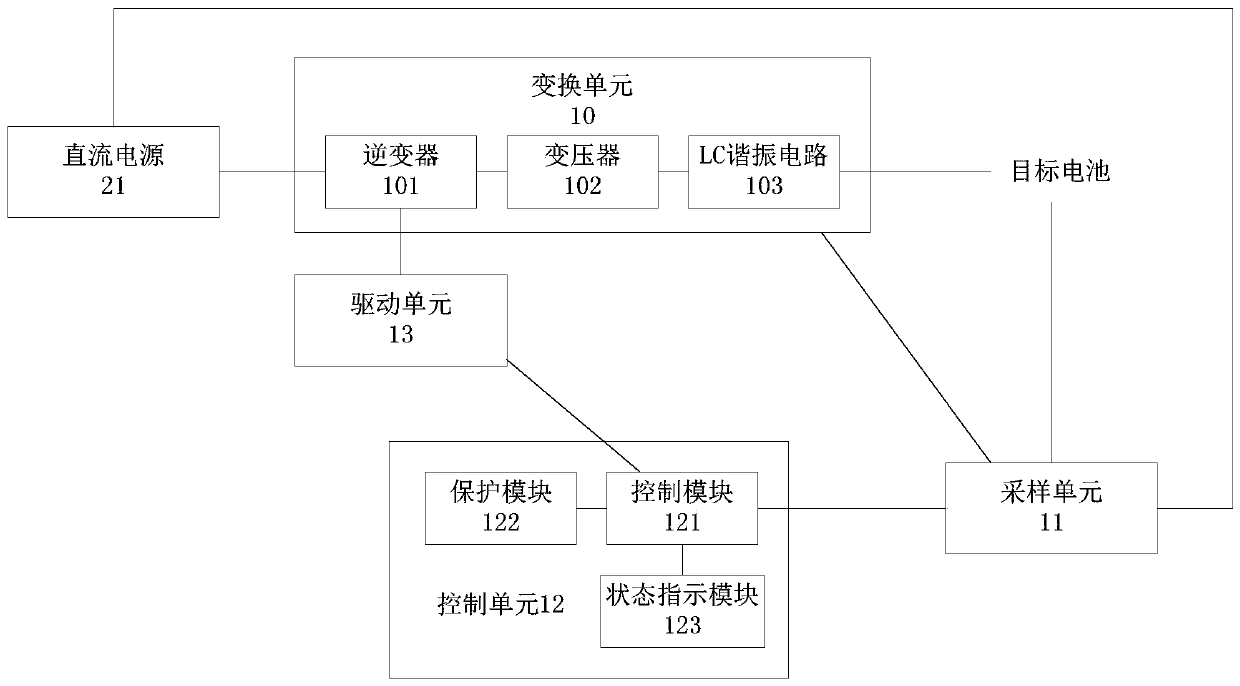

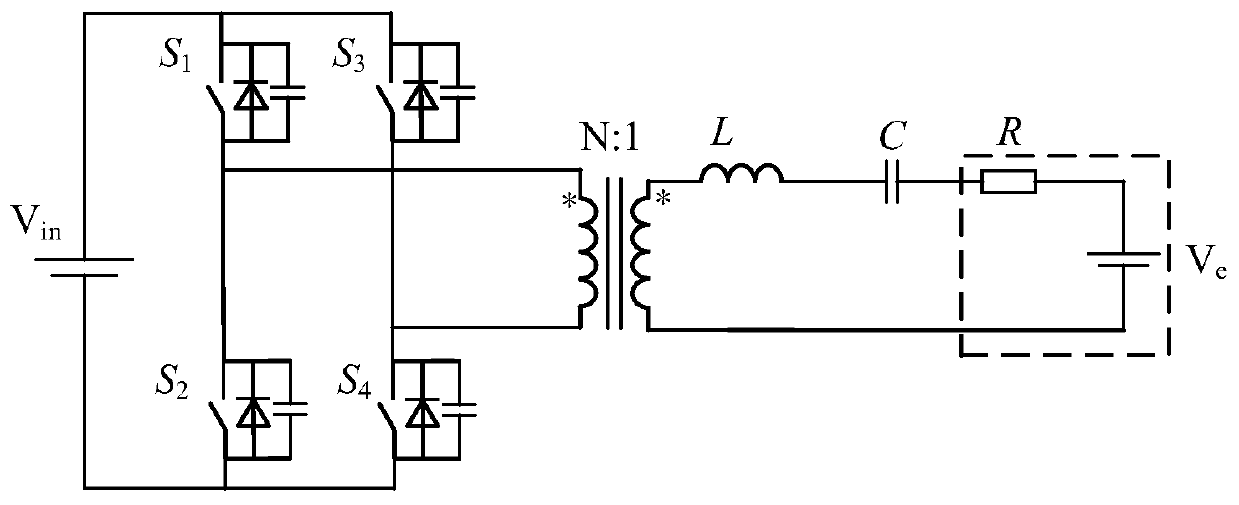

Battery charging preheating device and system

The invention provides a battery charging preheating device and system. The device comprises a conversion unit, a sampling unit, a control unit and a driving unit; the sampling unit collects a currentvalue and a temperature value of a target battery, and transmits the current value and temperature value of the target battery to the control unit; the control unit determines a current control signal according to the current value and temperature value of the target battery, and transmits the current control signal to the driving unit, so that the driving unit generates a driving signal according to the current control signal and transmits the driving signal to a transformation unit; and the transformation unit receives DC provided by the DC power supply, and converts the DC into target AC according to the driving signal, and transmits the target AC to a target battery so as to preheat the target battery. The preheating current of the target battery is controlled accurately and stably, and the preheating speed of the target battery is improved.

Owner:BEIJING JIAOTONG UNIV

Battery pack cooling device of electric car

ActiveCN105119025AAvoid excessive heatEnsure efficient and safe operationSecondary cellsOutdoor temperatureElectric cars

The invention discloses a battery pack cooling device of an electric car. The battery pack cooling device comprises a compressor, a gas-liquid separator, a car inside condenser, a car outside heat exchanger, a car inside heat exchanger, an air channel and a battery pack cooling device body. A first connecting pipeline and a second connecting pipeline are arranged between the battery pack cooling device body and the car inside condenser, a third connecting pipeline and a fourth connecting pipeline are arranged between the battery pack cooling device body and the car inside heat exchanger, so that when outdoor temperature is too high, cooling fluid in the third connecting pipeline carries out heat exchange with refrigerating fluid in the car inside heat exchanger and then flows to the battery pack cooling device body from the fourth connecting pipeline, therefore, a battery pack is cooled, the temperature of the battery pack is prevented from being too high, and efficient and safe operating of batteries is guaranteed. When the outdoor temperature is too low, cooling fluid in the first connecting pipeline carries out heat exchange with refrigerating fluid in the car inside condenser and then flows to the battery pack cooling device body from the second connecting pipeline, and therefore the battery pack is fast preheated. The battery pack cooling device is good in heat dispersion performance and long in runtime.

Owner:WM MOTOR TECH GRP CO LTD

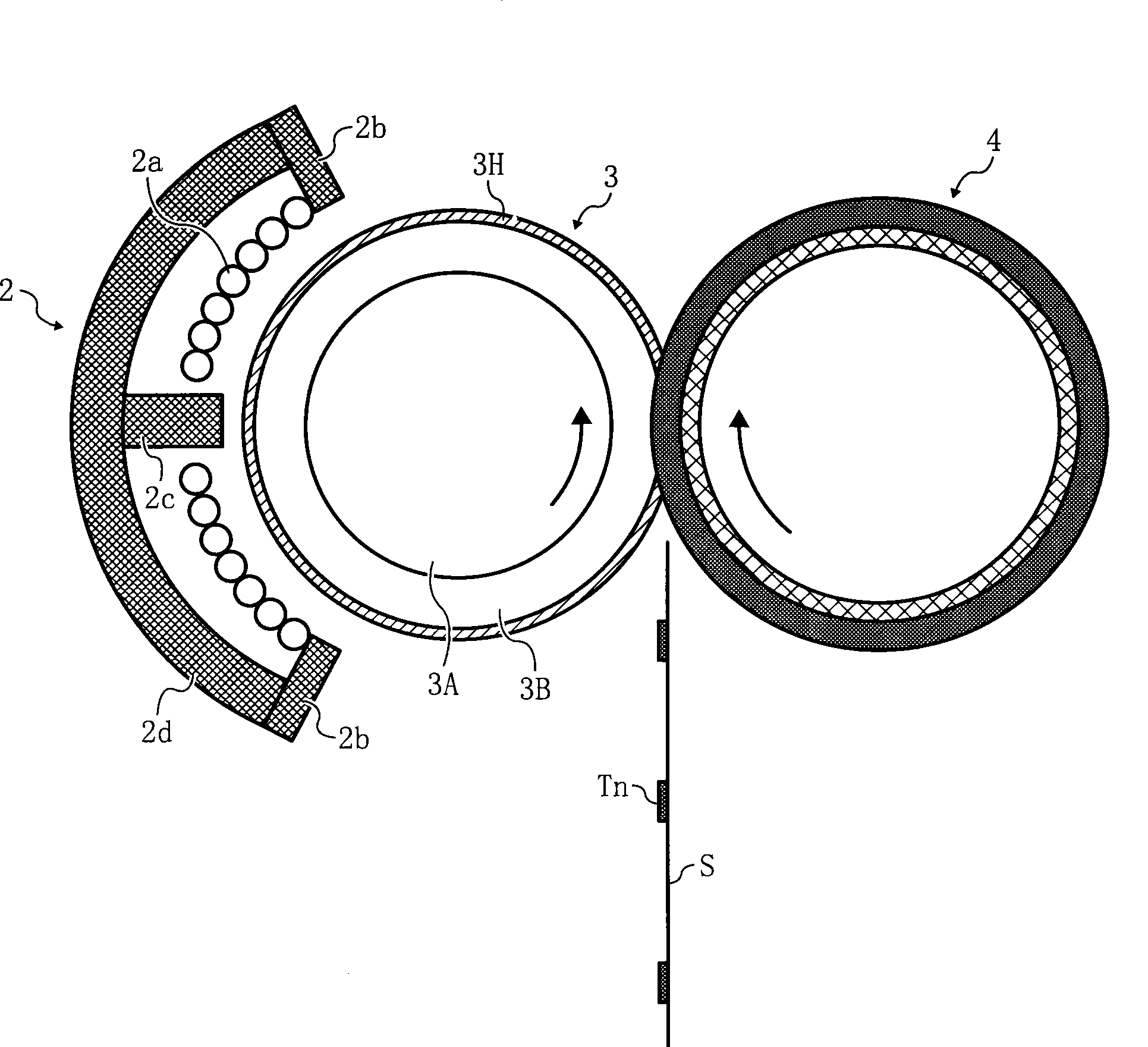

Fixing device, image forming apparatus, heat-generating rotary member and temperature control method

InactiveCN101382766AQuality improvementWarm up fastCoil arrangementsElectrographic process apparatusTemperature controlImage formation

The present invention relates to a fixing device using electromagnetic induction heating mode in an image forming apparatus, a heat-generating rotary member for the fixing device, and a temperature control method of the fixing device. The invention aims to provide a developing method, component and device, which can exert the characteristic of high-speed temperature rise by electromagnetic induction heating of the heat-generating rotary member, the risen temperature exceeding the Curie temperature of a magnetic shunt alloy. Specifically, the fixing device comprises a heat-generating rotary member including an exciting coil 2a, a metal sleeve 3H (including a heat-generating layer and a magnetic shunt alloy) and a degaussing member 3A-1. The magnetic shunt alloy layer is disposed between the exciting coil and the degaussing member. The heat-generating rotary member performs self-temperature control using a repulsive magnetic flux of the degaussing member caused by the magnetic flux of the exciting coil. The magnetic flux adjuster (magnet core 3Q and degaussing member 3A-1) adjusts an amount of the repulsive magnetic flux by adjusting the rotation position relative to the exciting coil 2a.

Owner:RICOH KK

Novel industrial cutting gas with dimethyl ether as main component

The invention discloses novel industrial cutting gas with dimethyl ether as a main component. The novel industrial cutting gas comprises (but not limited to) the following components in percentage by mass: 60-99.99% of the dimethyl ether, 0.01-40% of additives and the like, wherein the additive is prepared from tert-butylferrocene, diethyl ether, aromatic hydrocarbon, solvent oil No.6, tert-butyl alcohol and potassium permanganate according to a certain proportion. Auxiliary gas can also be added into the cutting gas and is one or some of acetylene, propane, propylene, butane and butylene. The novel industrial cutting gas disclosed by the invention presents strong advantages in the aspects of economy, safety, environment friendliness and cutting performance.

Owner:ENN XINNENG BEIJING TECH

3D printing head with follow-up pressurization and heating

PendingCN109719935AHigh bonding strengthPromote mutual integrationManufacturing heating elements3D object support structuresReciprocating motionUltimate tensile strength

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

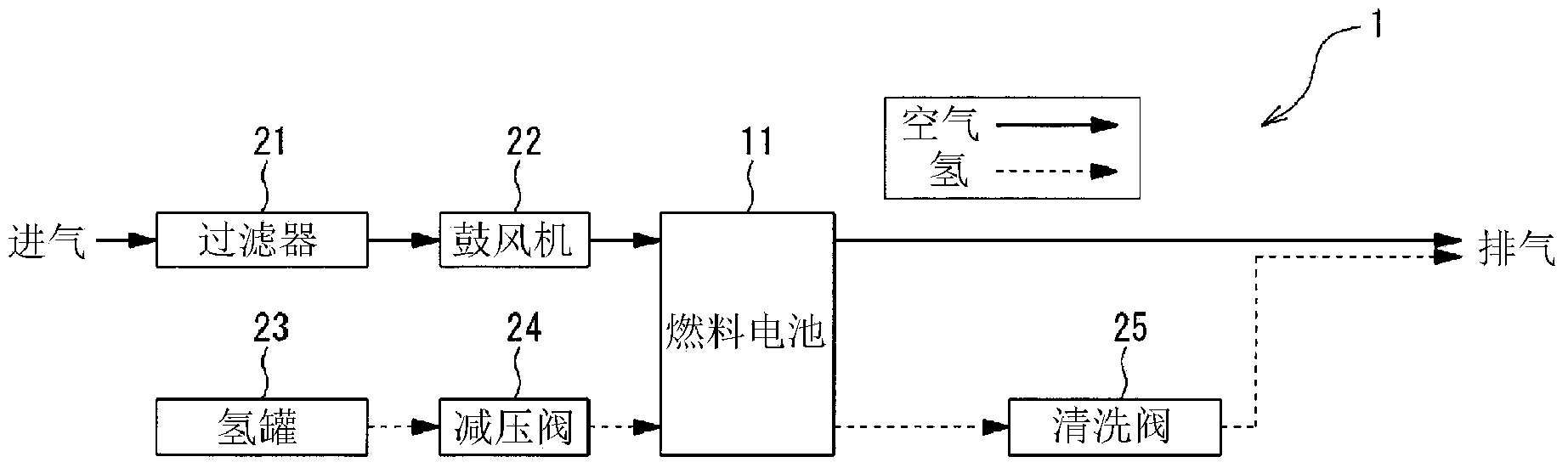

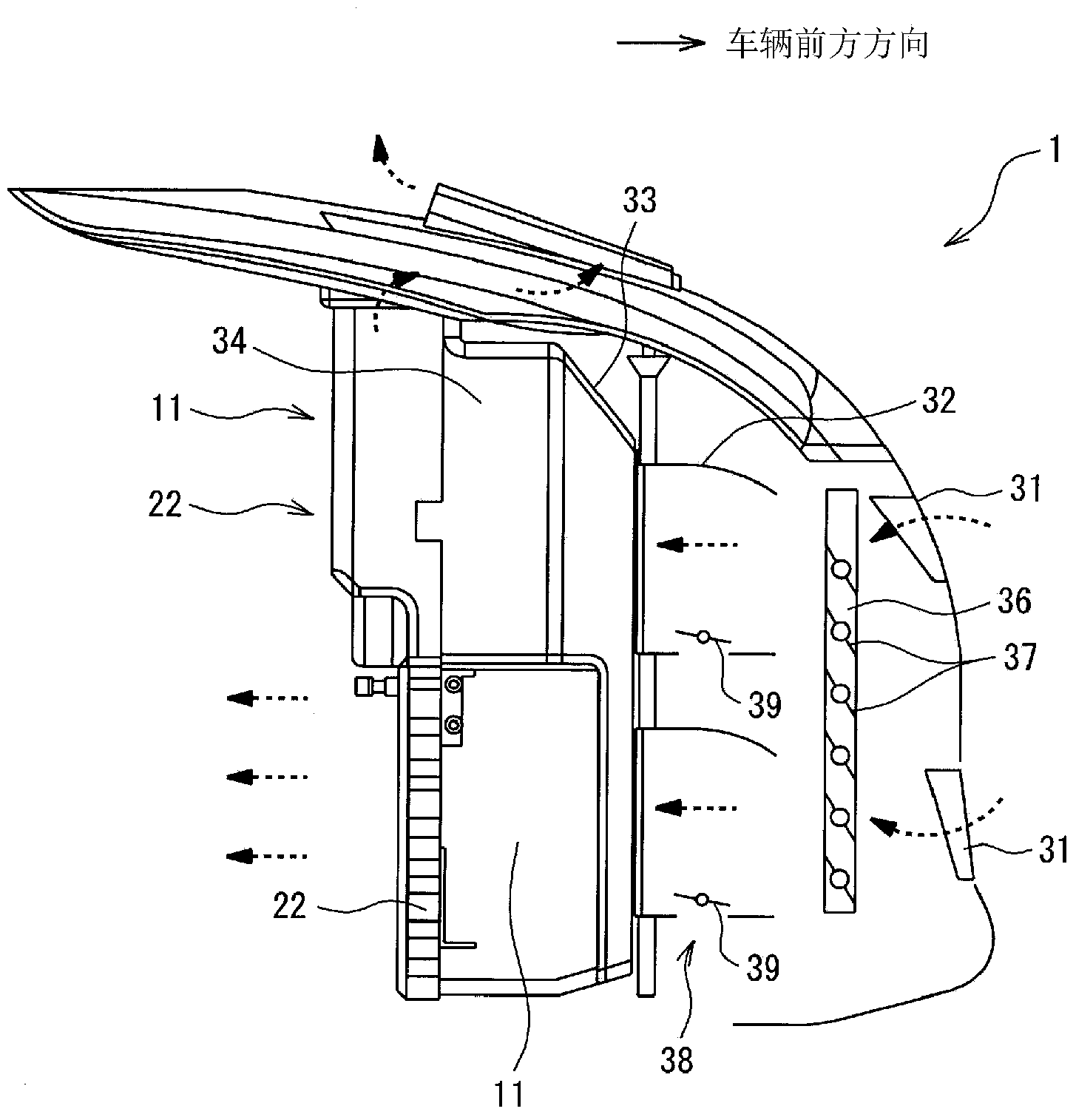

Vehicle fuel cell cooling device and fuel cell vehicle

ActiveCN103702854ASuppress power consumptionPrevent intrusionFuel cell heat exchangeElectric propulsion mountingHydrogen fuel cellEngineering

In the invention, a grill shutter (36) is disposed between a front grill (31) and an air intake duct (32). This grill shutter (36) can open and close a shutter member (37), and when opening the shutter member (37) the grill shutter (36) can adjust the opening degree of the shutter member (37). When the maximum air flow rate supplied by running wind is greater than the air flow rate required by a hydrogen fuel cell (11), the air flow rate required by the hydrogen fuel cell (11) is accounted for solely by means of opening-and-closing control of the shutter member (37) through the issuing of grill shutter opening degree instructions. Otherwise, the grill shutter member (37) is fully opened through the issuing of grill shutter opening degree instructions, maximizing the running wind taken in from the front grill (31), and the lacking air flow rate required by the hydrogen fuel cell (11) is accounted for by activating a blower (22) through the issuing of blower speed instructions.

Owner:SUZUKI MOTOR CORP

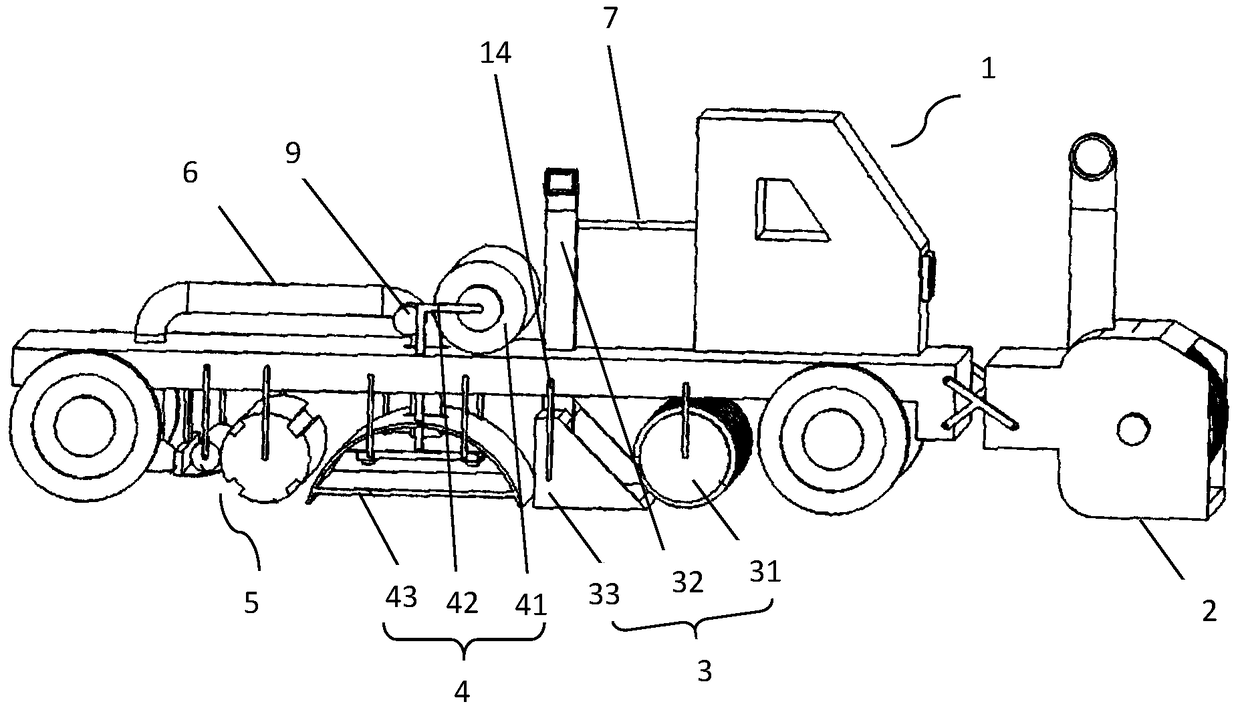

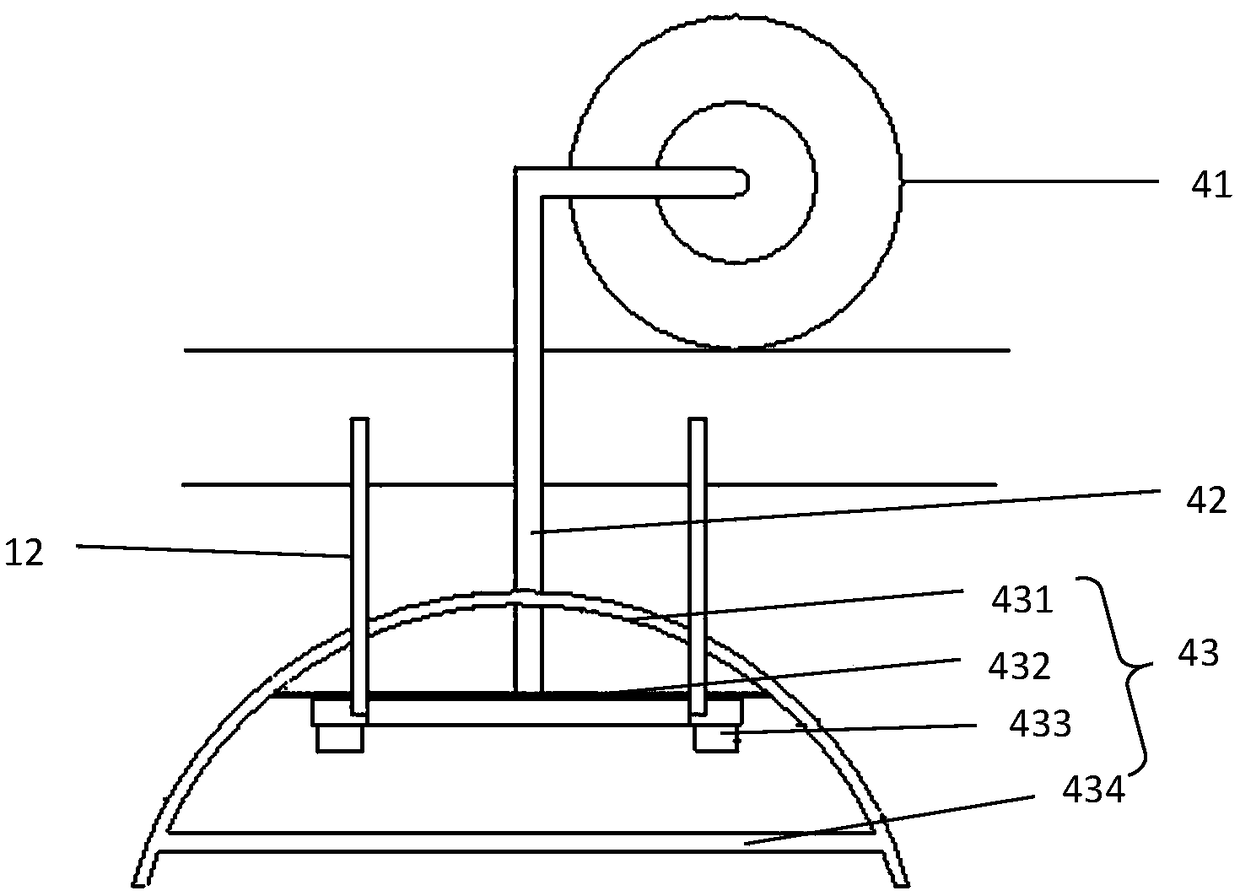

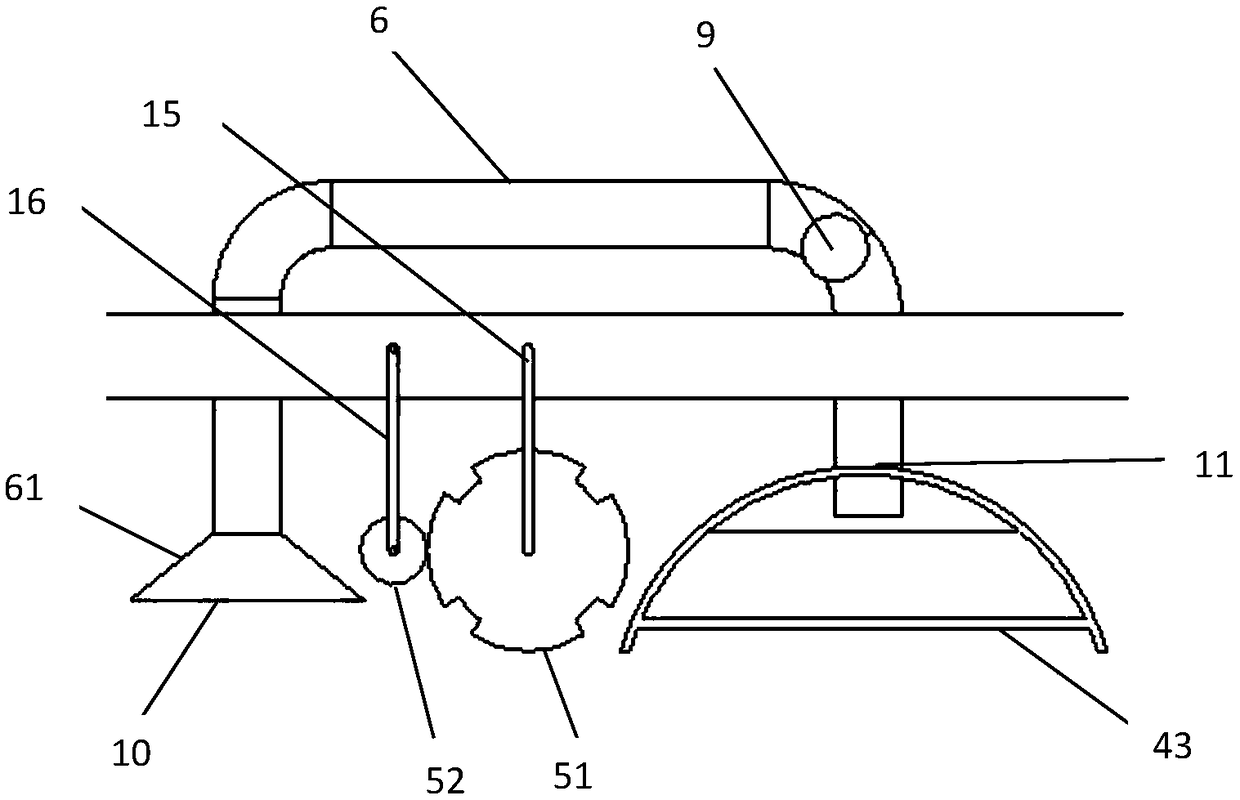

Snow and ice removal vehicle

The invention discloses a snow and ice removal vehicle which comprises a vehicle body, a snow throwing machine, an ice-breaking device, an ice-melting device and a heat transferring pipeline. The snowthrowing machine is connected to the front portion of the vehicle body, and the ice-breaking device is connected to the front portion of a vehicle body chassis. The ice-melting device is connected tothe middle of the vehicle body chassis. One end of the heat transferring pipeline communicates with a heat output opening of the ice-melting device, and the other end of the heat transferring pipeline is connected with a horn opening structure. The snow and ice removal vehicle provided by the invention is easy to operate and control, ice and snow layers can be efficiently and thoroughly removed,damage to tracks is not prone to being caused, energy conservation and environmental friendliness are achieved, and secondary environmental pollution is avoided.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com