Fixing device, image forming apparatus, heat-generating rotary member and temperature control method

A technology of temperature control and rotating body, which is applied in the direction of coil device, electric recording process using charge pattern, and equipment for electric recording process using charge pattern, which can solve problems such as poor gloss and increased upper limit of temperature rise, and achieve rapid prediction Heat, the effect of improving the quality of the fixed image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

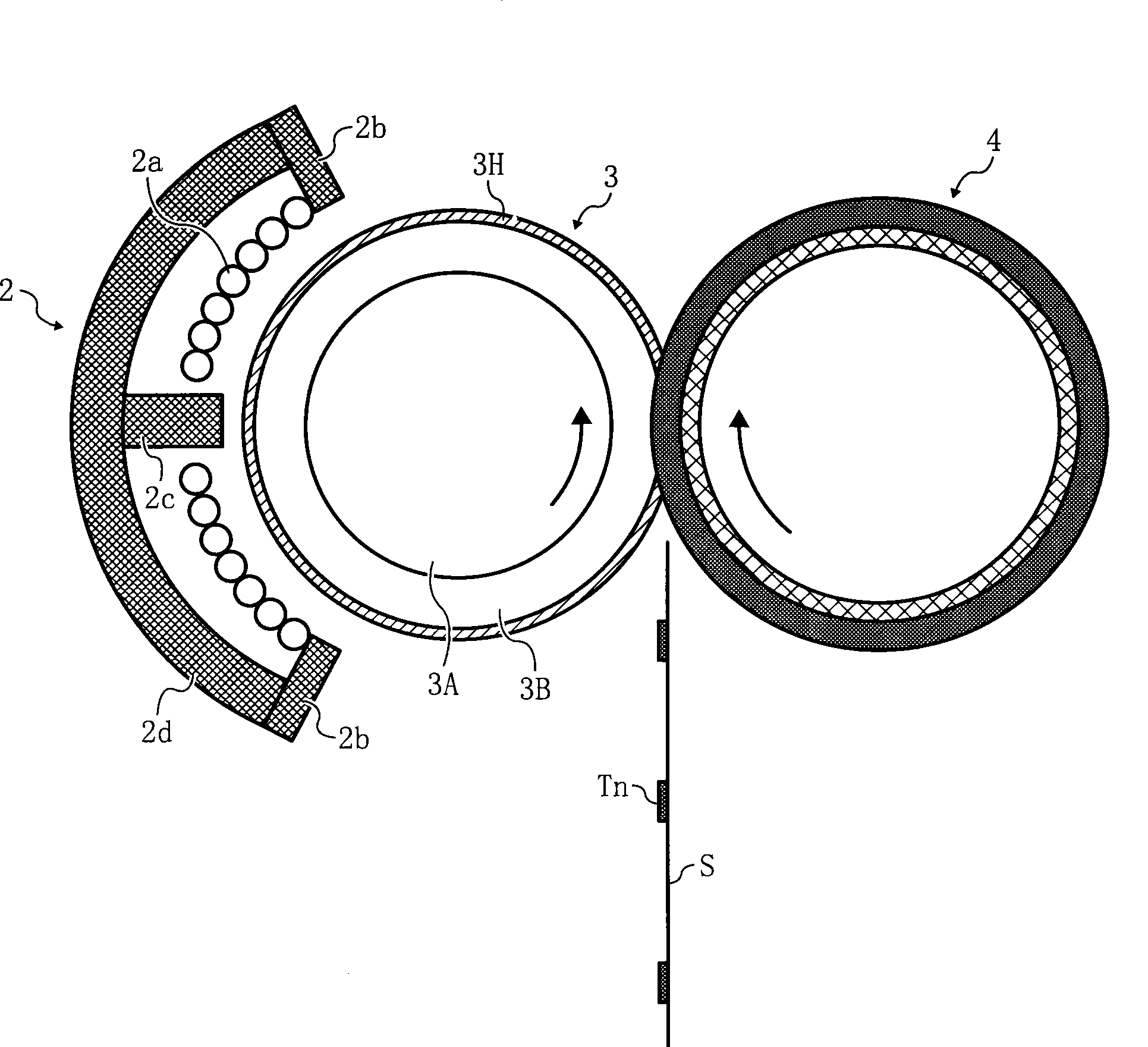

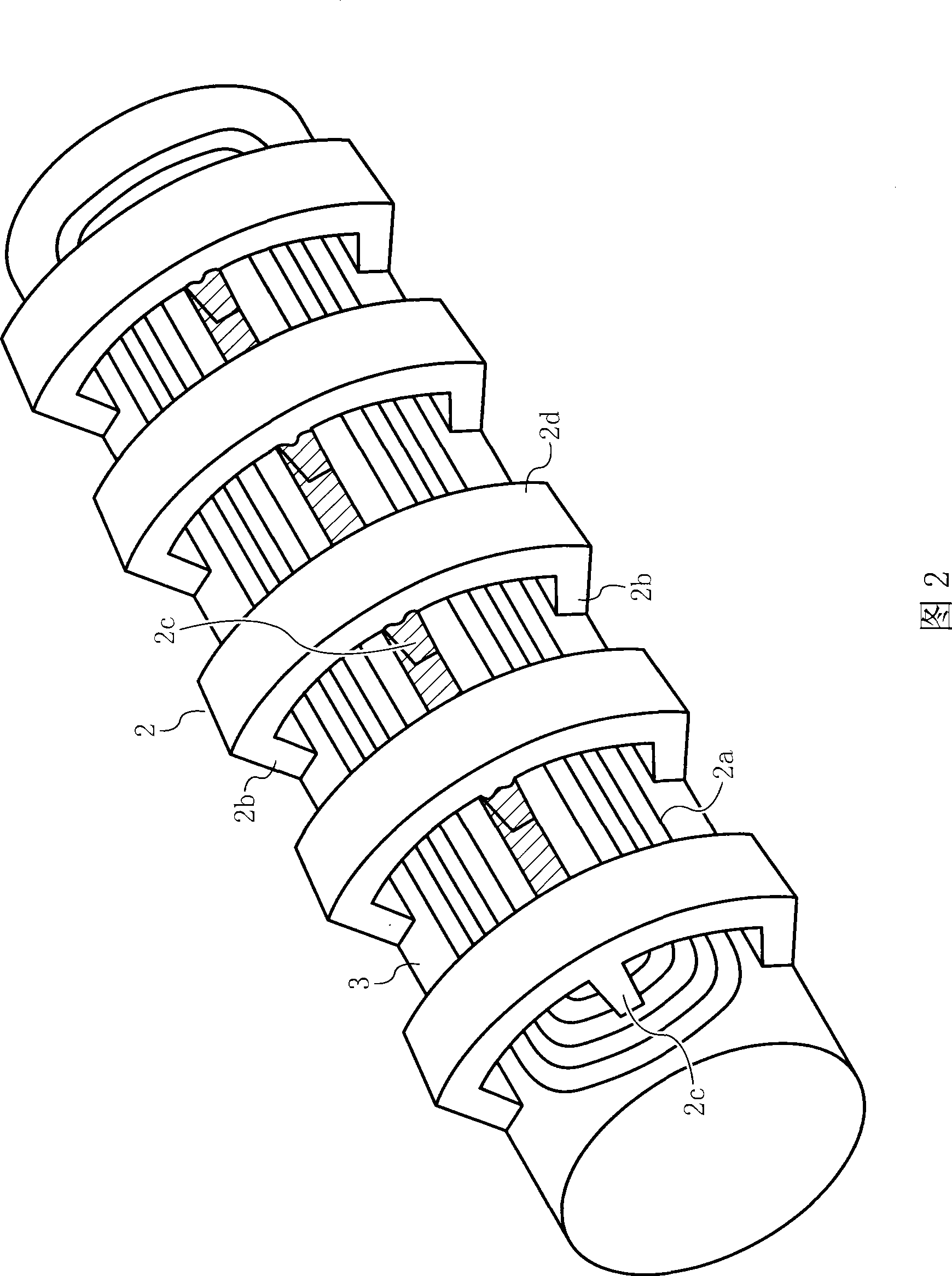

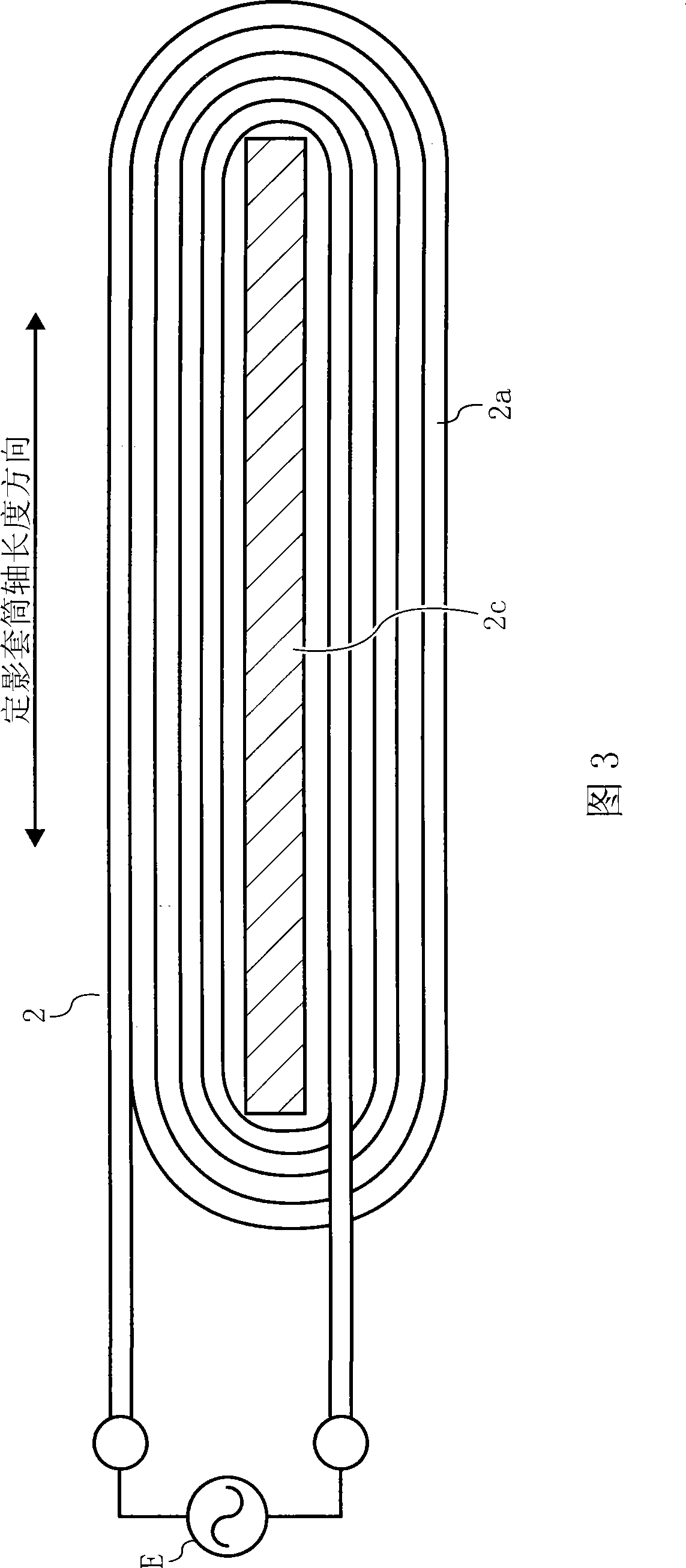

[0085] FIG. 8 shows the configuration and operation state of the magnetic flux generating unit 2 and the fixing roller 30 as a heat-generating rotating body. The configuration of the magnetic flux generating unit 2 is the same as that referred to in the above-mentioned reference example. figure 1 , Fig. 2, Fig. 3, Fig. 5 etc. described same. Regarding the fixing roller 30, the metal sleeve 3H is referred to as a reference example figure 1 , Figure 4 etc. described in the basic structure is the same.

[0086] In this example, in order to fix under the condition of high heating efficiency and use the amount of diamagnetic flux as a variable variable to increase the range of temperature settings for self-temperature control, the magnetic modulation alloy 3C adopts a Curie temperature higher than that of the existing fixing device. The material at the fusing temperature set in. Here, the existing fixing device is as the above-mentioned reference example in which the position ...

Embodiment 2

[0122] FIG. 15 shows the structure and operation of the magnetic flux generator 2 and the fixing roller 300 of the heat-generating rotor. The structure of the magnetic flux generating unit 2 is the same as the example shown in FIG. 8 . The metal sleeve 3H constituting the fixing roller 300 is also the same as that shown in FIG. 8 . The difference in structure between the metal sleeve 300 of this example and the metal sleeve 30 shown in FIG. The left shaft 6L is fixed to the left side plate 8L instead of the degaussing member 3A-1 and the magnetic core 3Q shown in FIG. 8 . In this way, even if the metal sleeve 3H is turned, the relative positions between the degaussing coils 3L, 3L and the exciting coil 2a are not changed.

[0123] The degaussing coils 3L, 3L are switched on or off by the switching element 16 to control the induced magnetic flux generated by the exciting coil 2a. Compared with embodiment 1, embodiment 2 does not need a device for moving the degaussing compon...

Embodiment 3

[0149] Figure 20 is a schematic diagram of a color image forming apparatus using the fixing device exemplified in the above embodiments. Of course, the present invention is neither limited to Figure 20 The image forming apparatus of the type shown is not limited to an apparatus for forming a color image, and an apparatus for forming a single image is also one of objects of the present invention.

[0150] This image forming apparatus includes a reading unit C, a discharged paper storage unit D, an image forming unit A, and a paper feeding unit B from above.

[0151] The reading part C is a device for reading the original placed on the original glass table C2. The original image is scanned by the reading walking body C1, and the image information is imaged on the CCD (Charge Coupled Devices) C4 through the lens C3. The image is captured It is converted into an electrical signal and sent to the exposure device A10 to provide image information data for exposure.

[0152] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com