Patents

Literature

245 results about "Shaft length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Standard shaft lengths are 15, 20 and 25″ (38, 50 and 63 cm). Those shaft lengths are an industry standard but there are exceptions. For mid range engines, the most common shaft length is 20″ (508 mm).

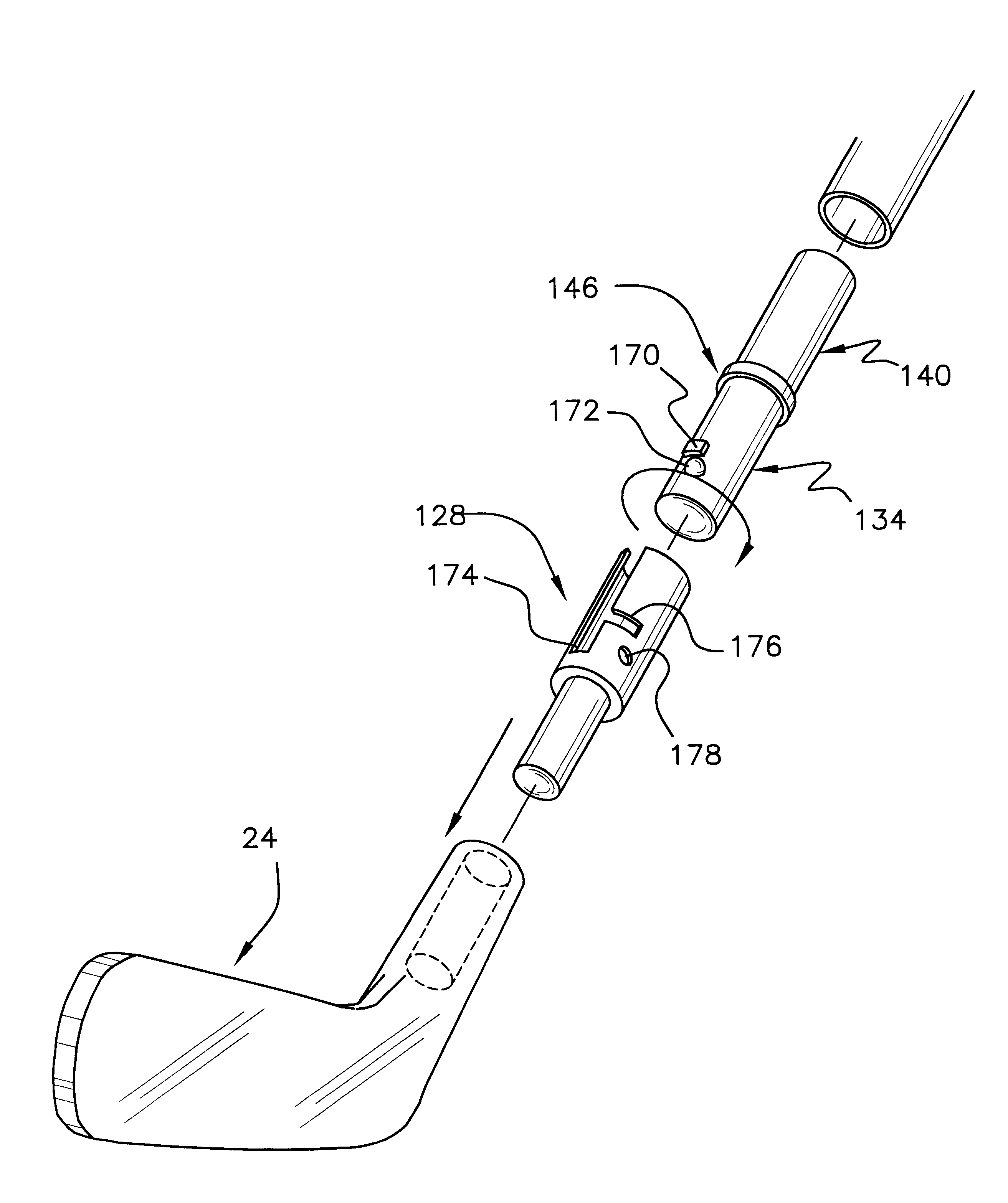

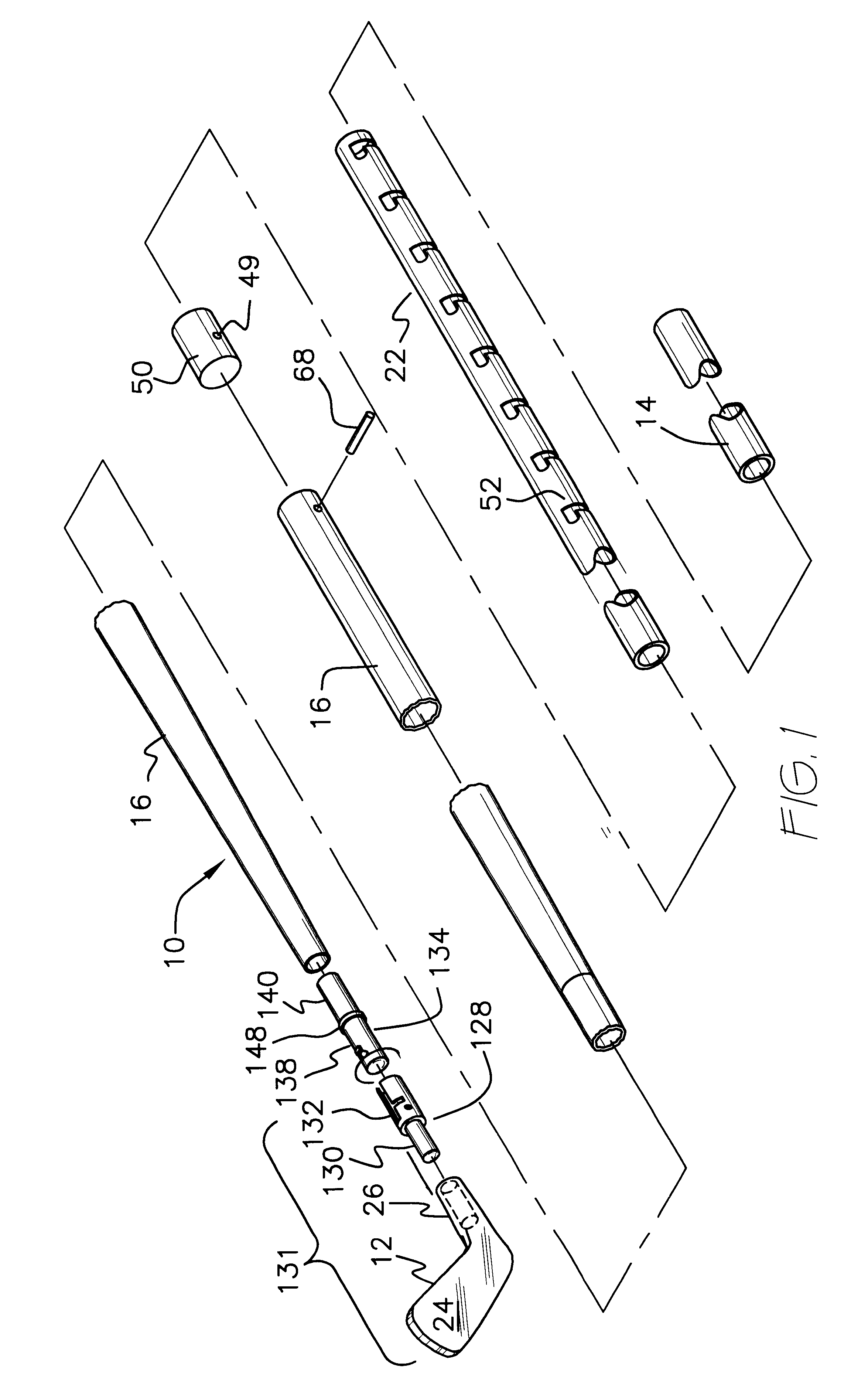

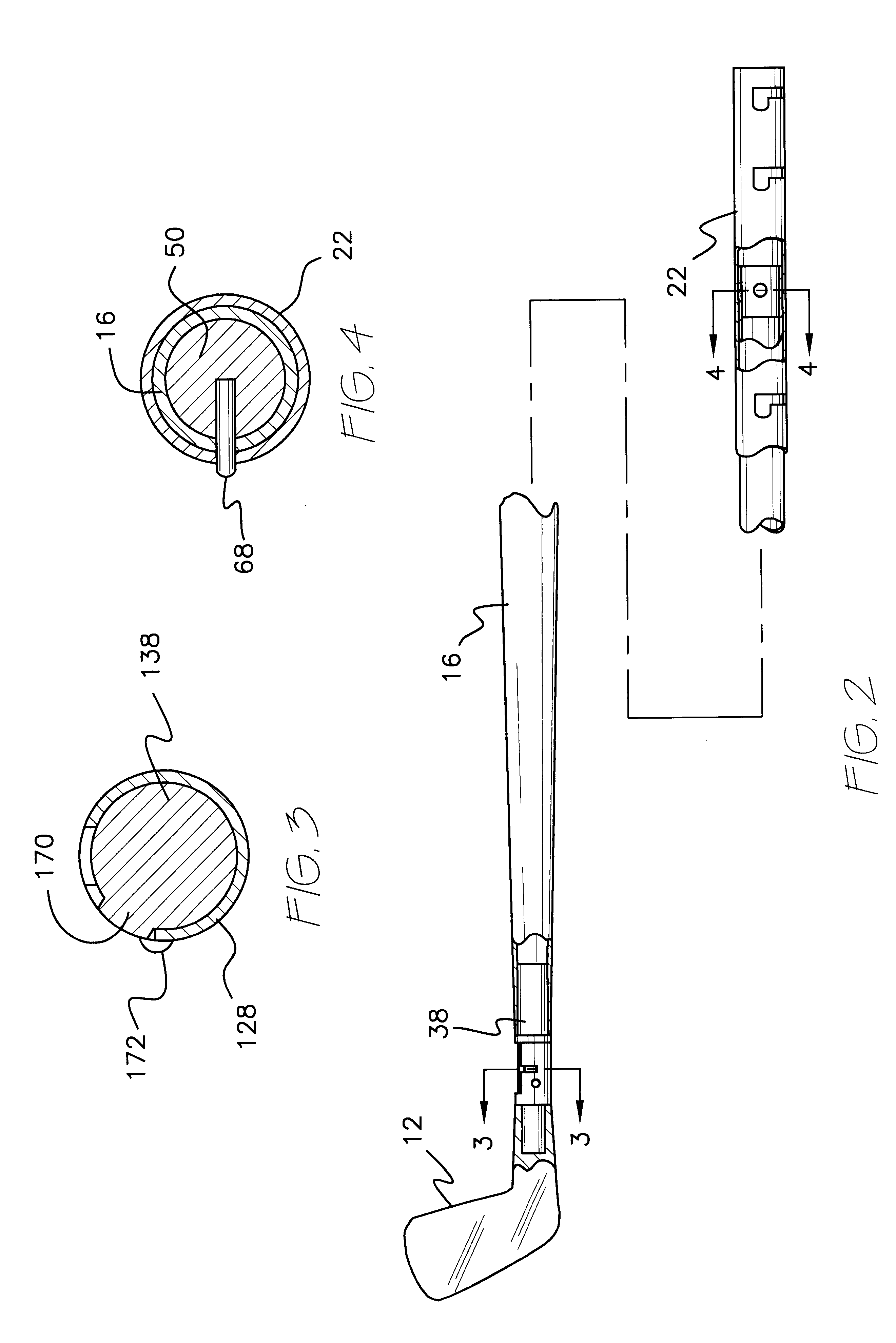

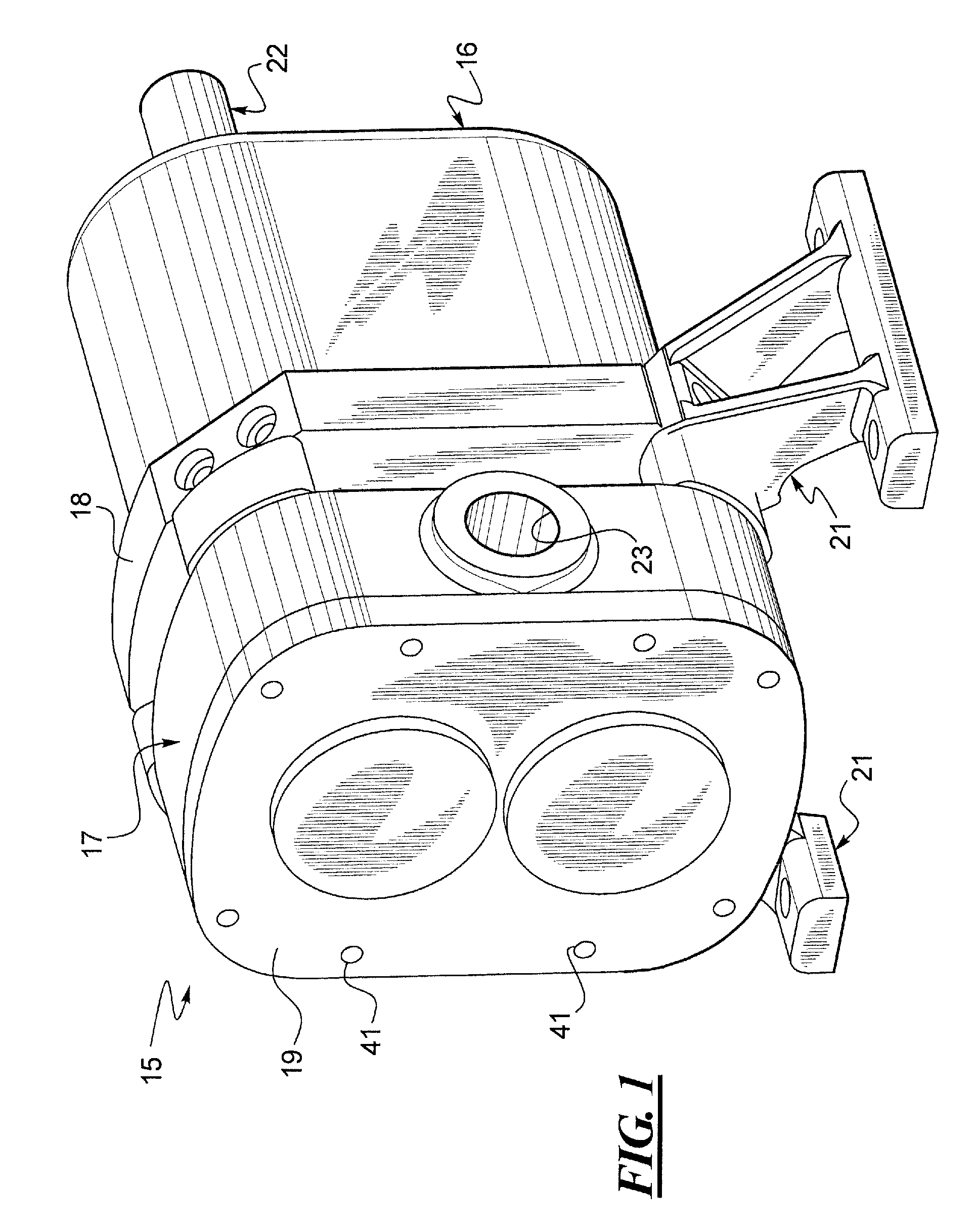

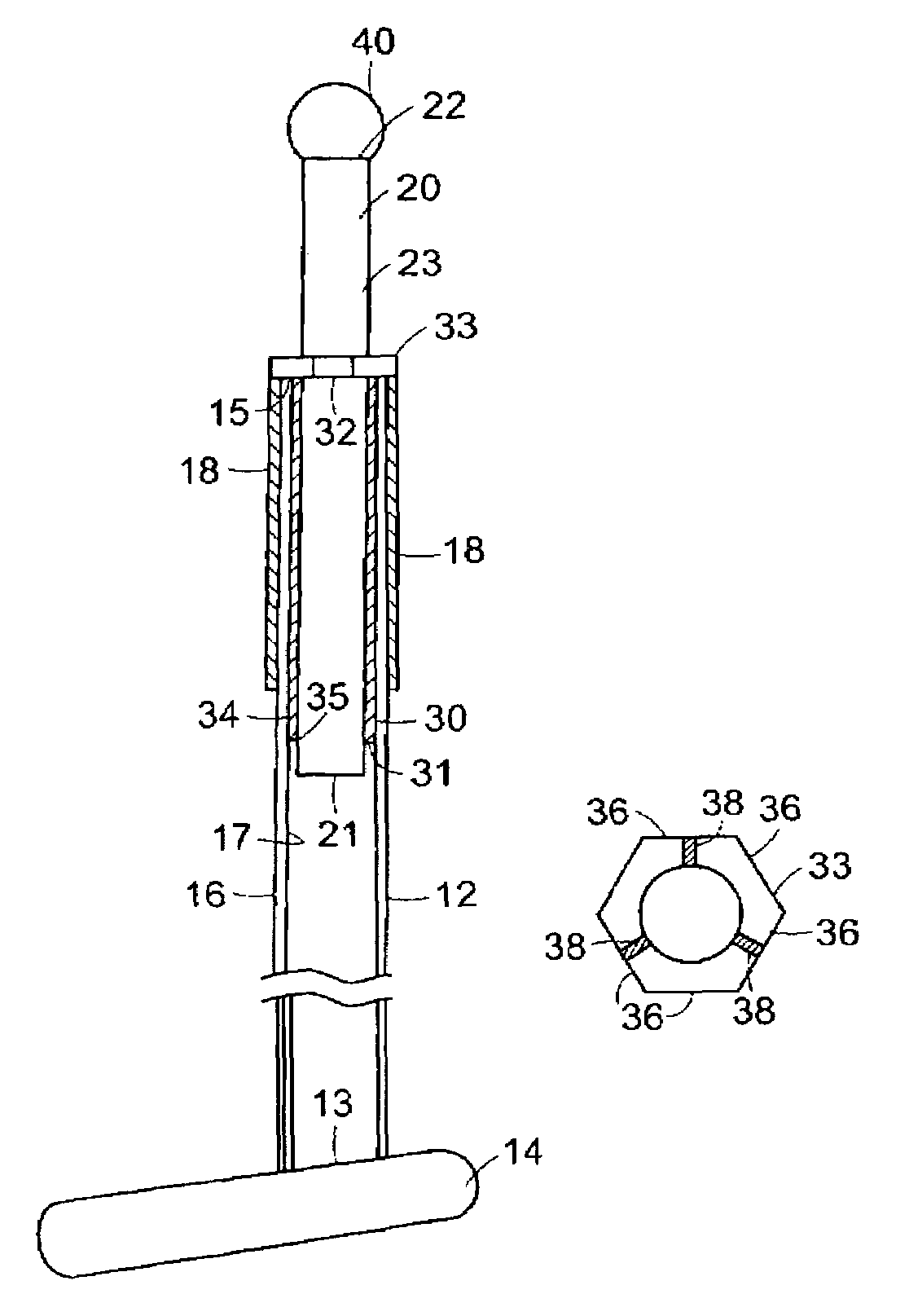

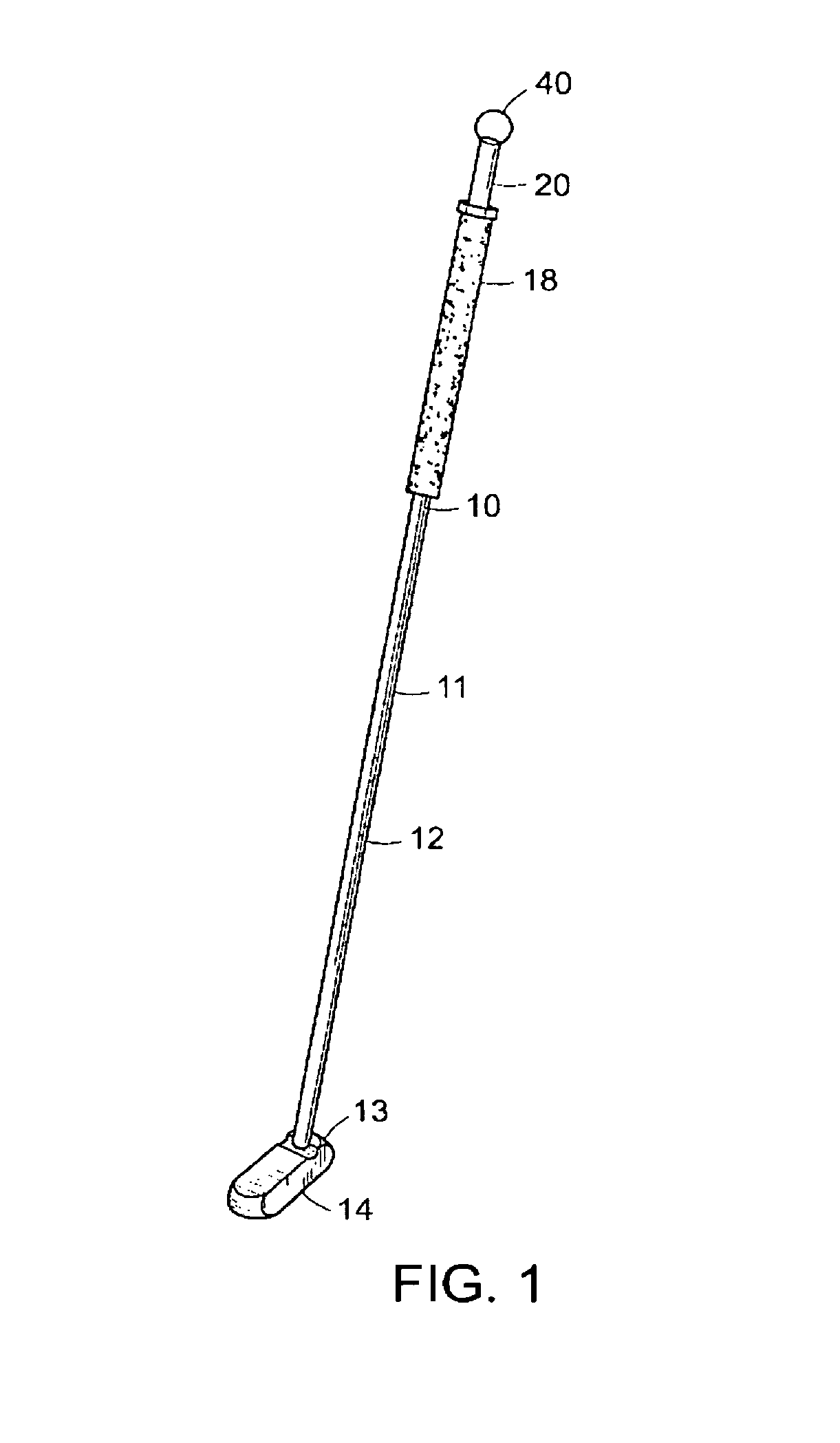

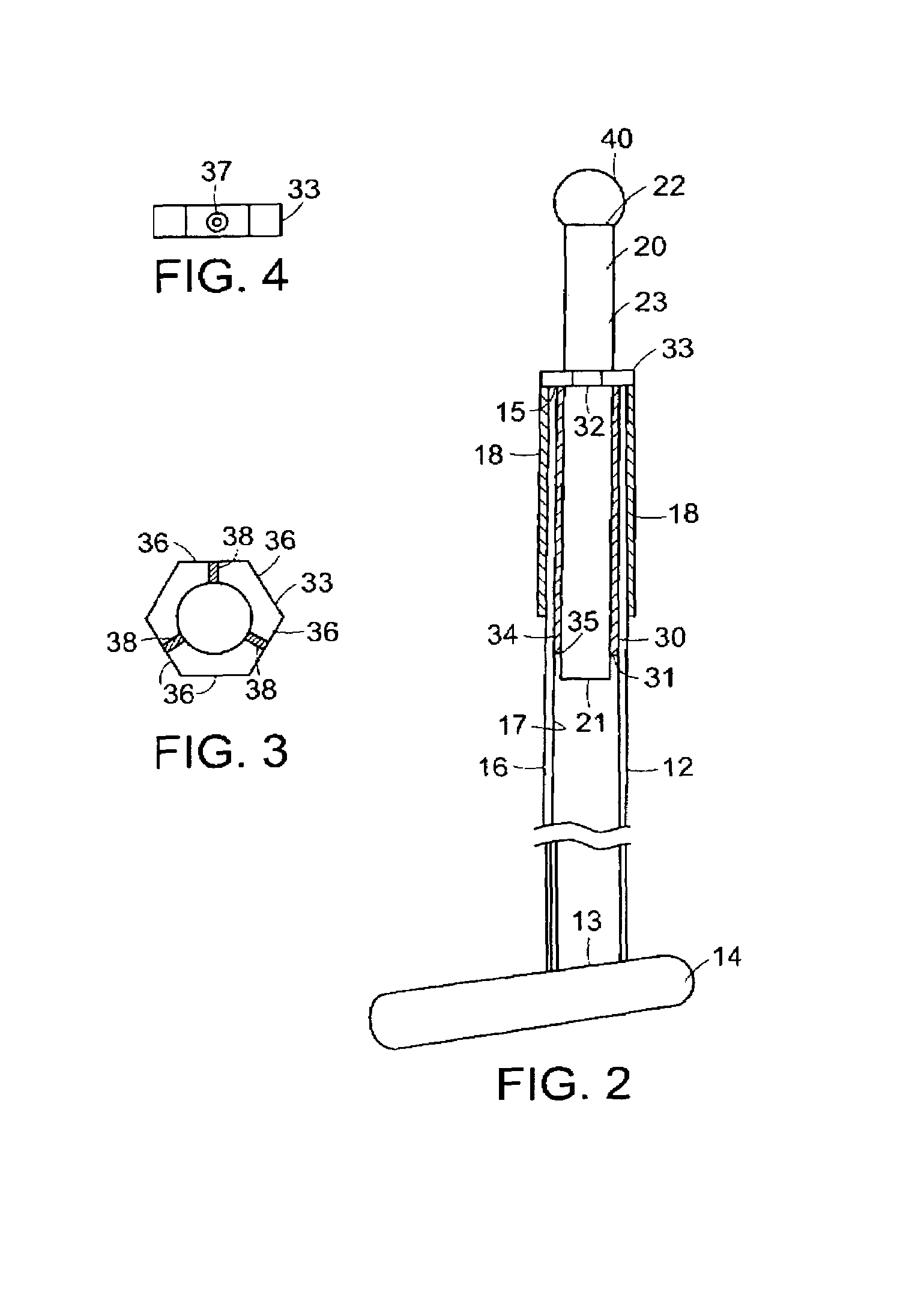

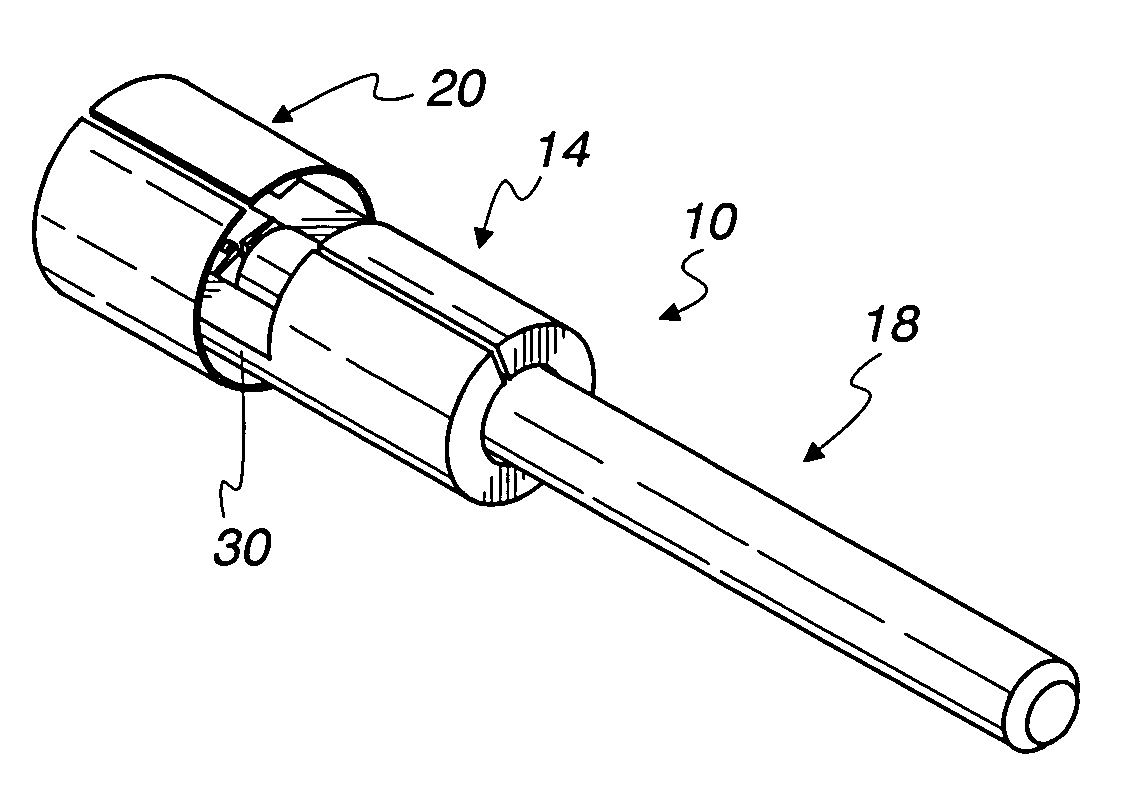

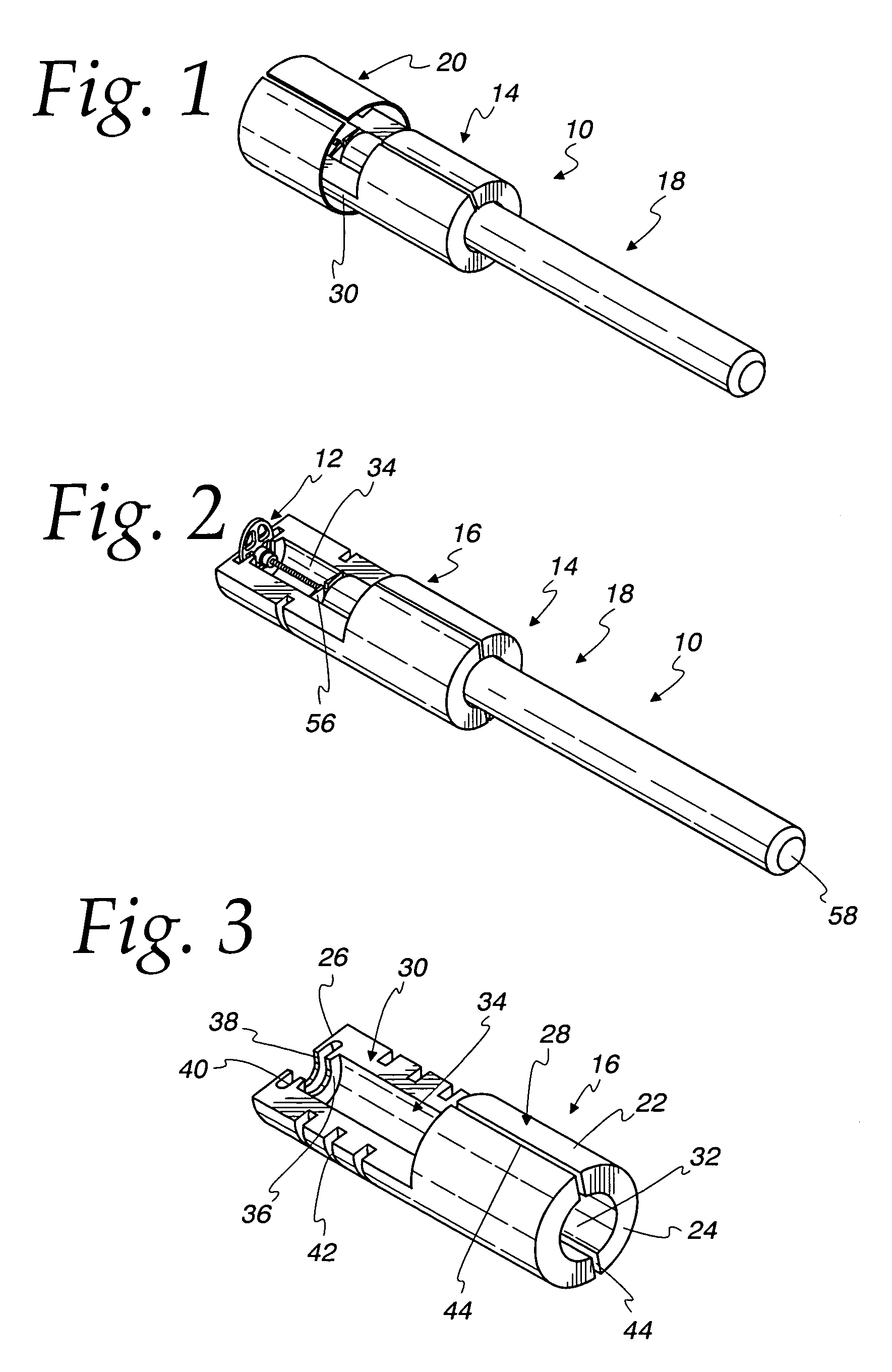

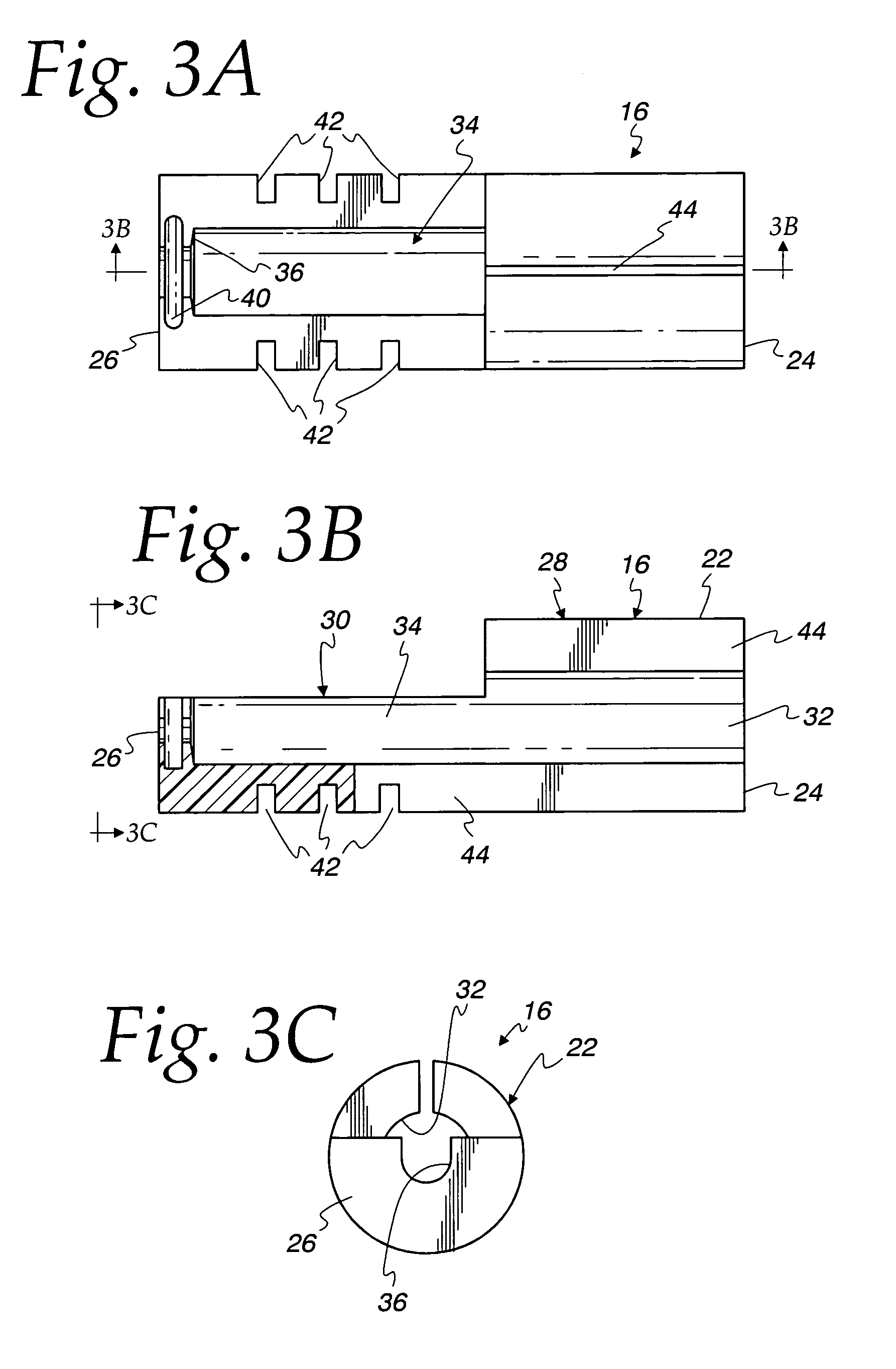

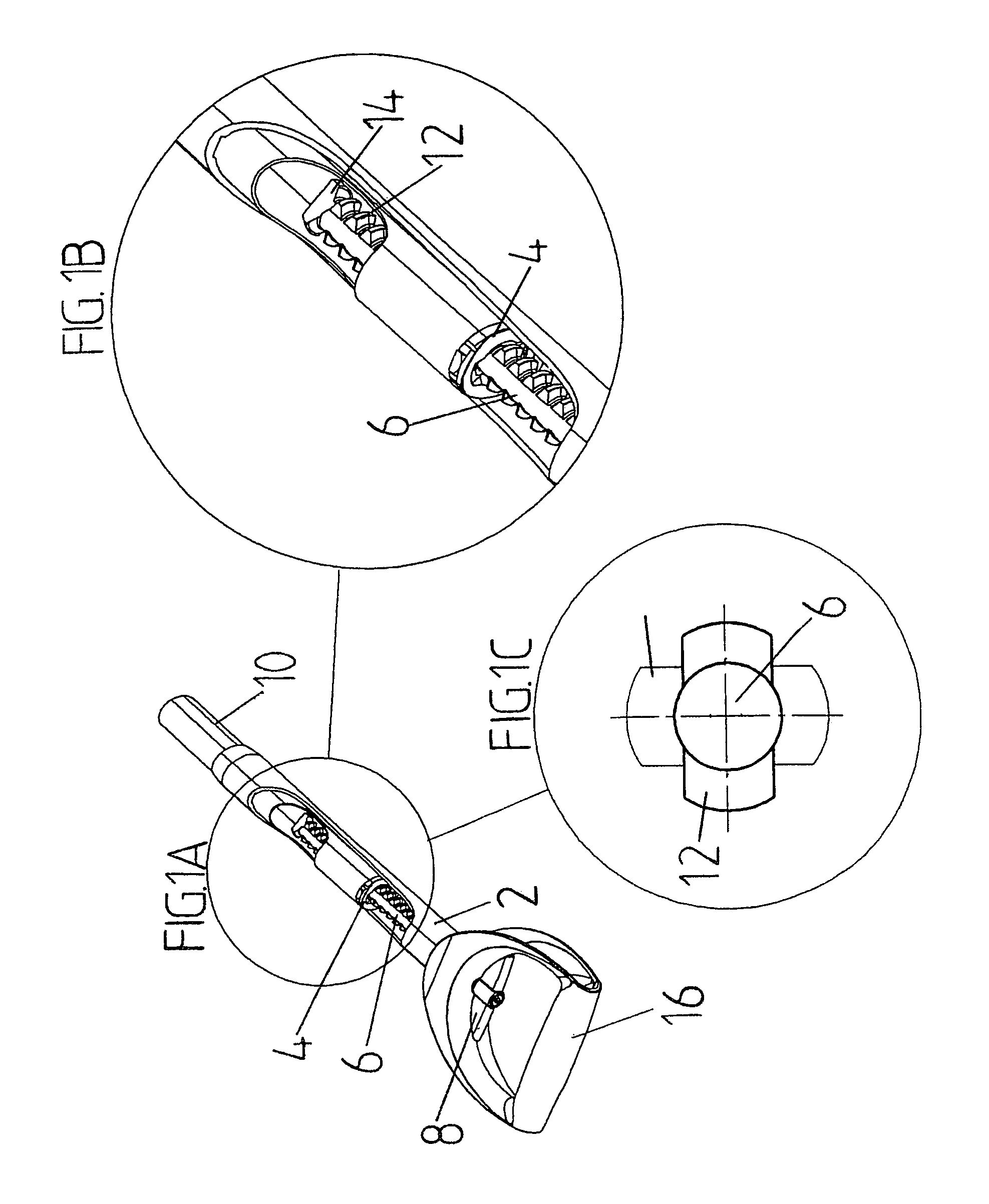

Interchangeable golf club head and adjustable handle system

InactiveUS6547673B2Easy to disassembleEasy to transportSpace saving gamesGolf clubsOff the shelfHandling system

A system for converting readily available standard off the shelf golf club parts into a interchangeable golf club system. A conversion system consists of a head insert which can be glued into the hosel of a standard golf club head. A shaft insert having a central flange is insertable and glueable into place on a standard shaft of a golf club. The shaft insert and the head insert forming a quick connect to attach the shaft to the golf club head. Through the use of different club heads representing the full range of woods, irons, and putter, each having a head insert pre-installed, the club may have emulating any club by attaching the desired club head. A shaft length adjustment is made by a cooperating pin installed in the top of the shaft and slidable within a number of slots provided in a telescoping sleeve slidable over the shaft.

Owner:ROARK GARY

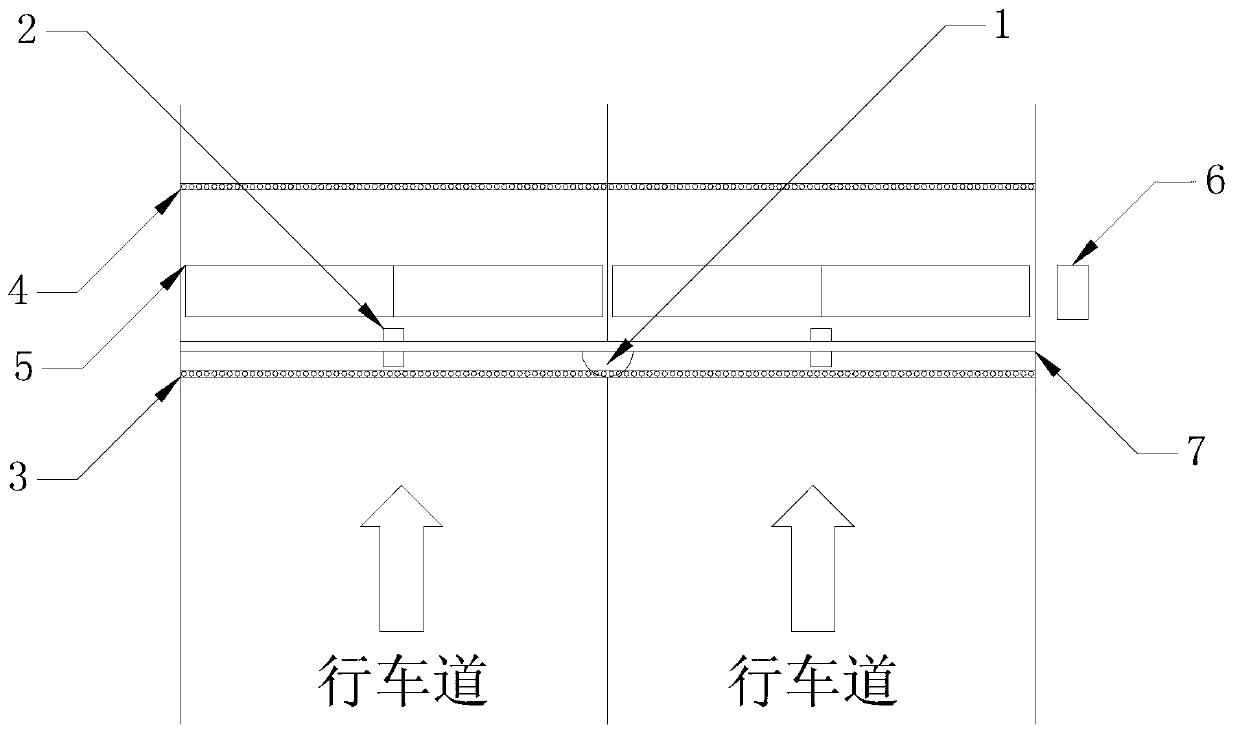

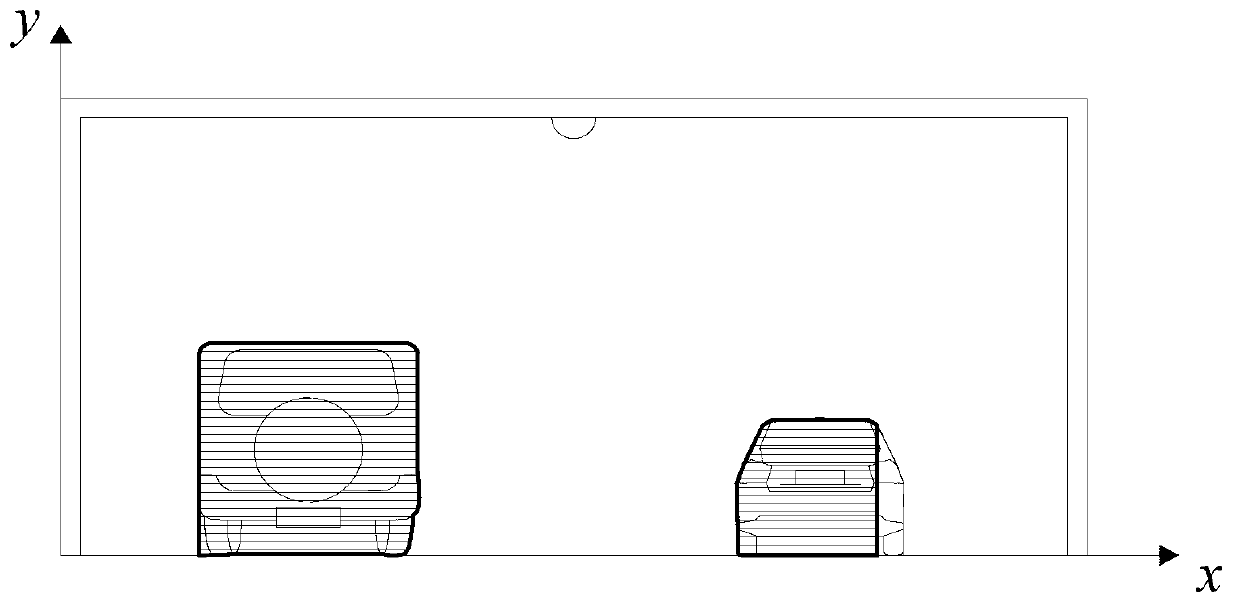

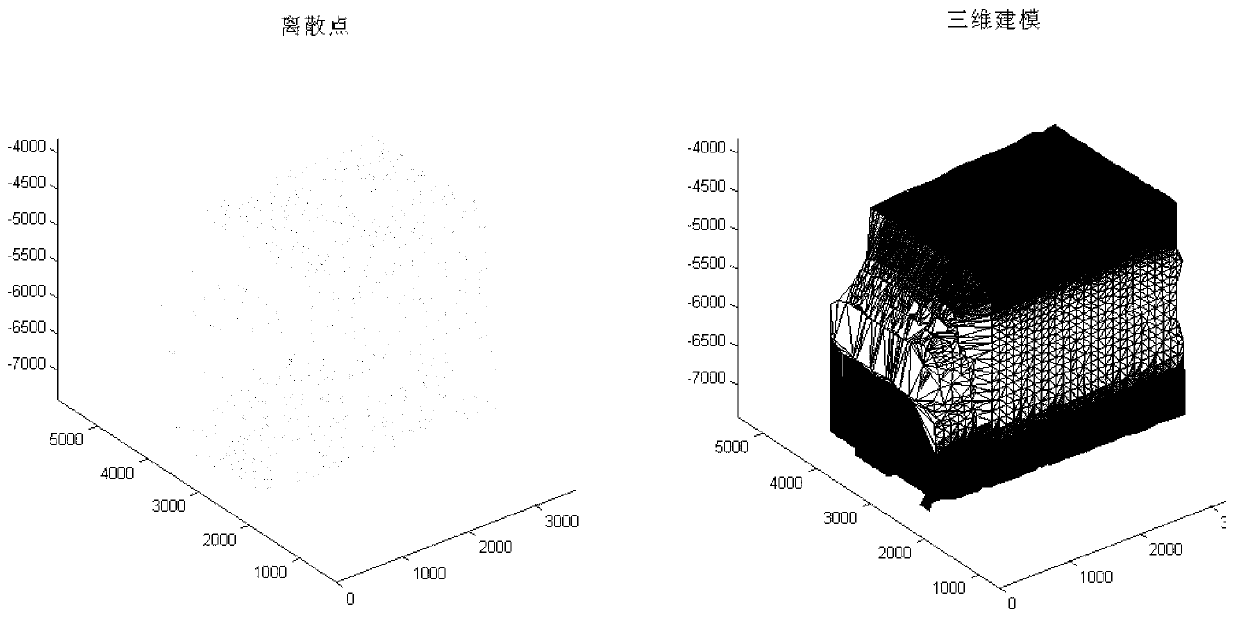

Vehicle information detecting and recognizing system under multilane condition

ActiveCN103279996AImprove detection accuracyEasy to identifyTicket-issuing apparatusRoad vehicles traffic controlDot matrixLaser scanning

The invention discloses a vehicle information detecting and recognizing system under the multilane condition. The vehicle information detecting and recognizing system comprises a computer system and a portal frame stretching over lanes, wherein a laser scanner and a high-definition license plate recognition device are arranged on the portal frame, a first dot matrix type wheel shaft sensor, a shaft weight sensor and a second dot matrix type wheel shaft sensor are sequentially arranged on the lane under the portal frame, and the laser scanner, the high-definition license plate recognition device, the first dot matrix type wheel shaft sensor, the shaft weight sensor and the second dot matrix type wheel shaft sensor are respectively connected with the computer system. The vehicle information detecting and recognizing system has the advantages that the two-dimension cross section size and the running position of a vehicle are detected through the laser scanner, and the vehicle three-dimension reconstitution and the vehicle separation are realized; the license plate information and the human face information are precisely collected through the license plate recognition device; the vehicle information such as the shaft distance, the shaft length, the shaft number, the shaft type, the wheel distance, the wheel width and the wheel number are measured according to signals output after a vehicle tyre presses the wheel shaft sensor; and the shaft weight and the total weight are measured through the shaft weight sensor.

Owner:广州顺如电子科技有限公司

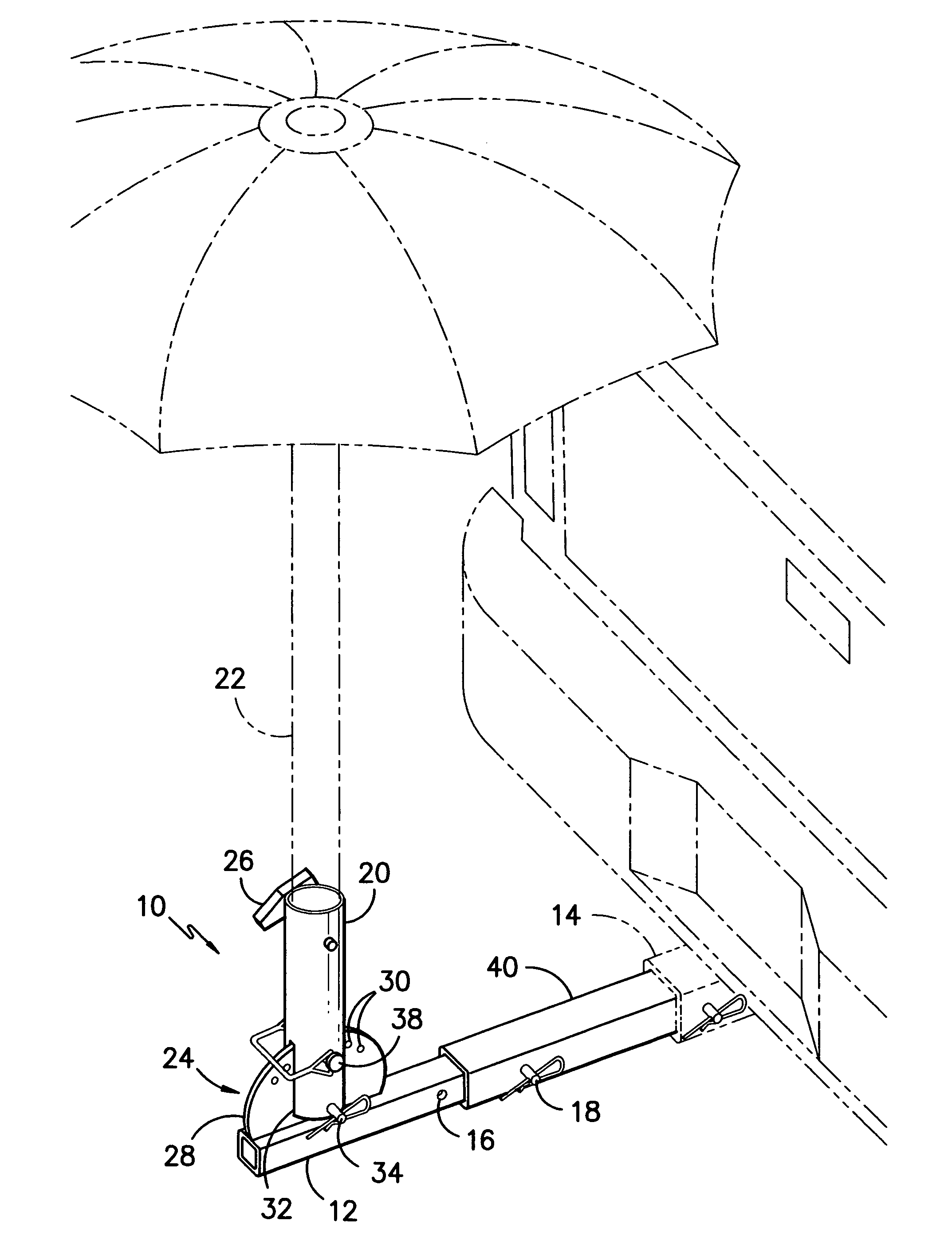

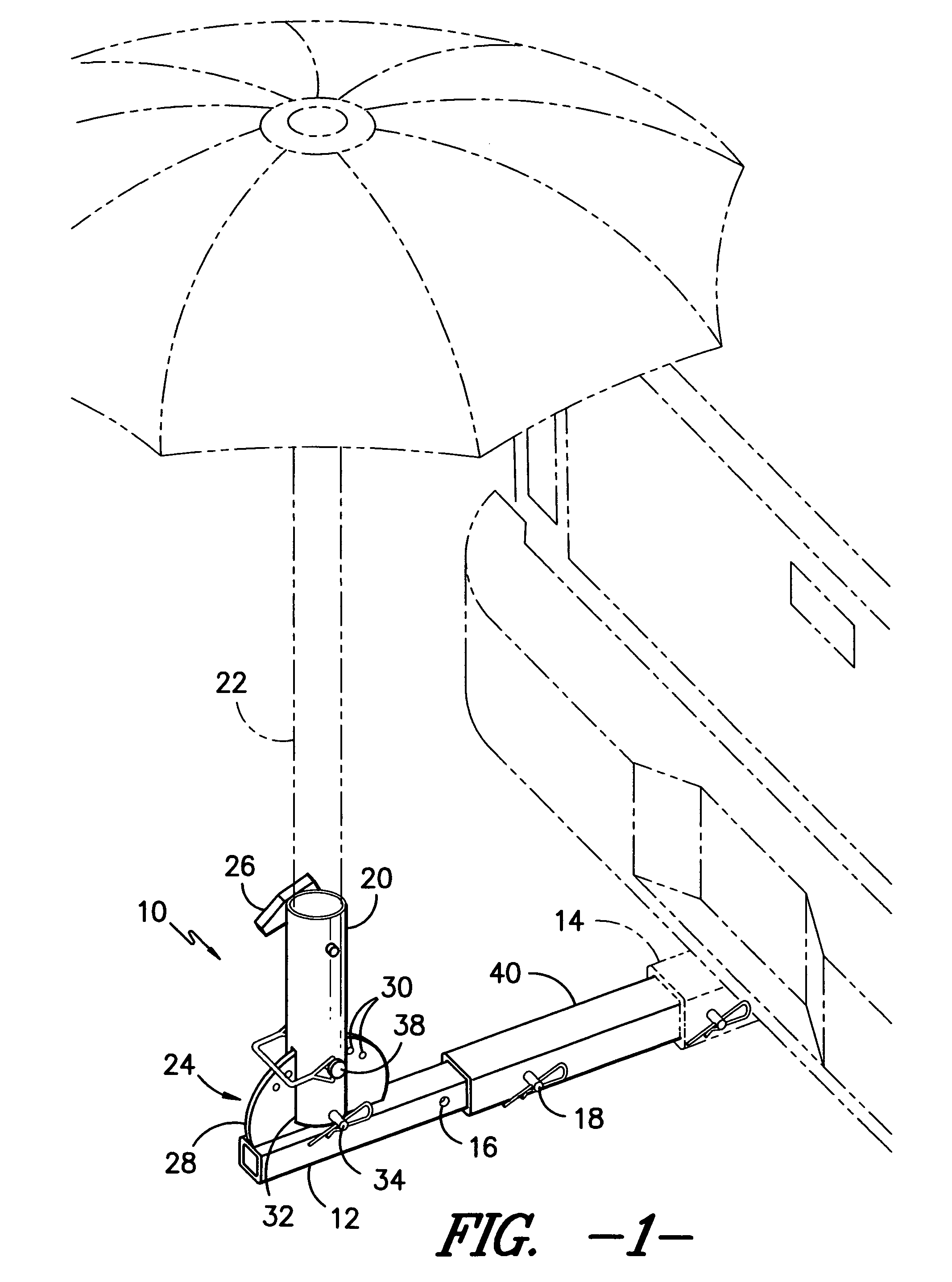

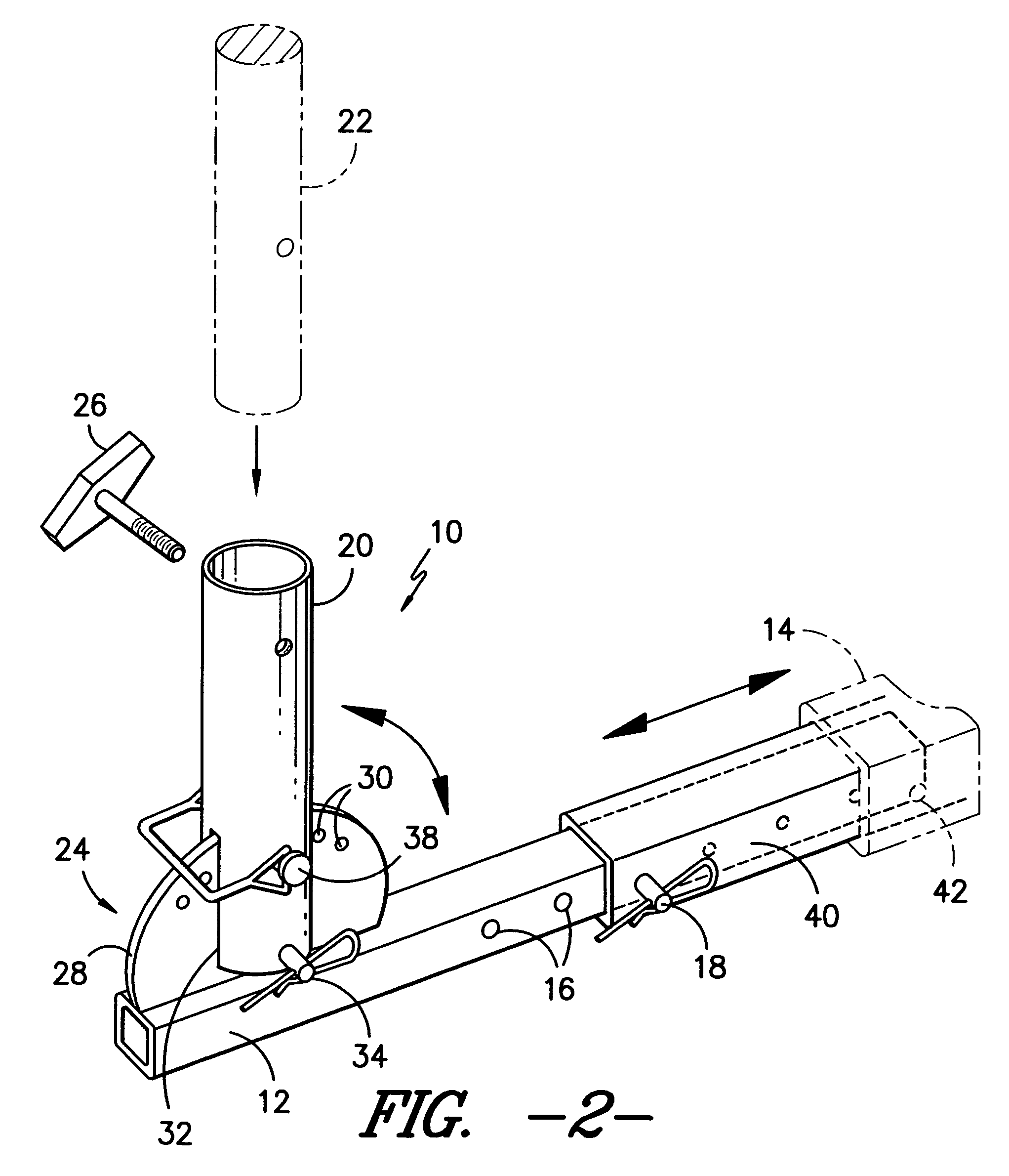

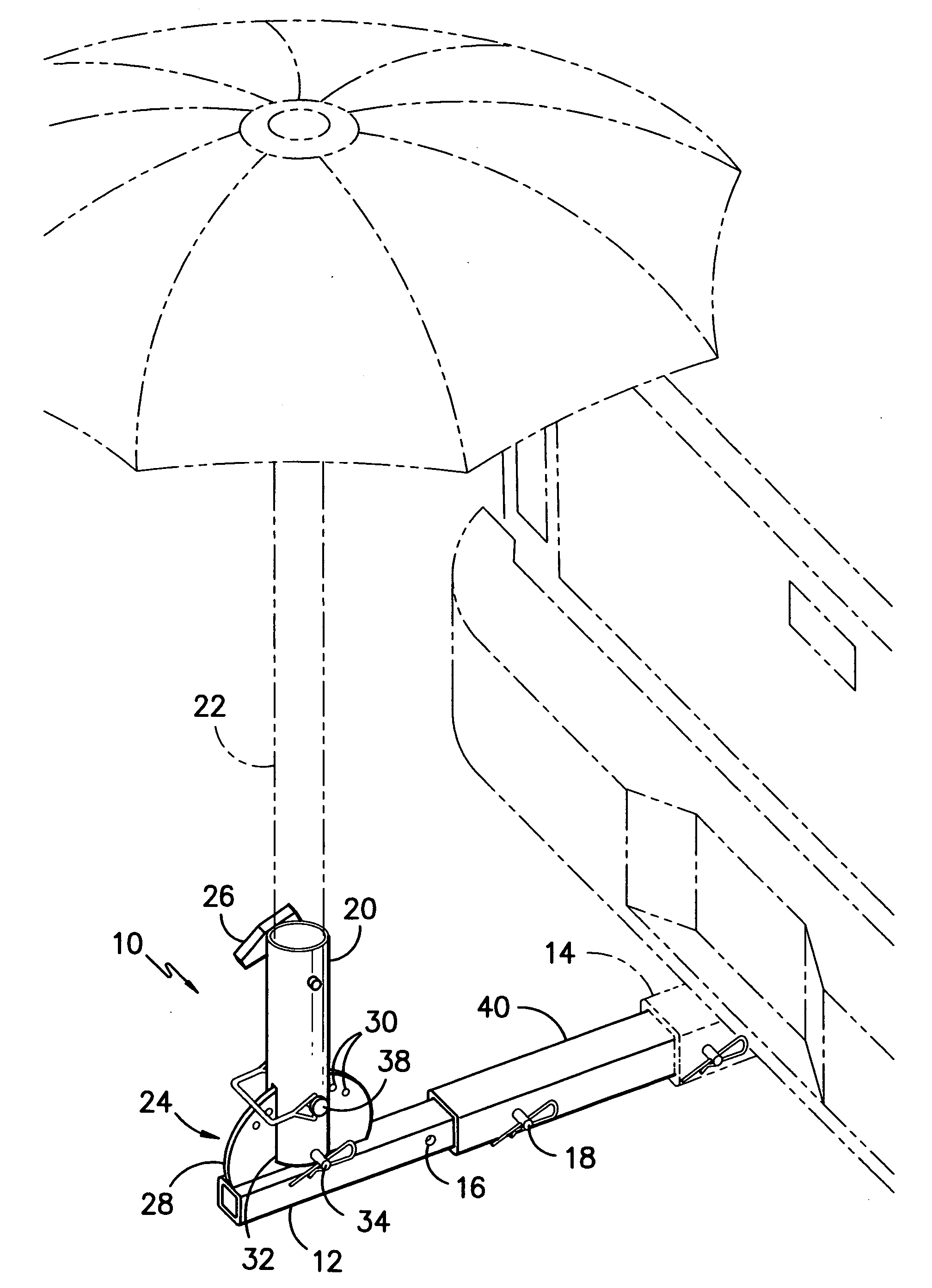

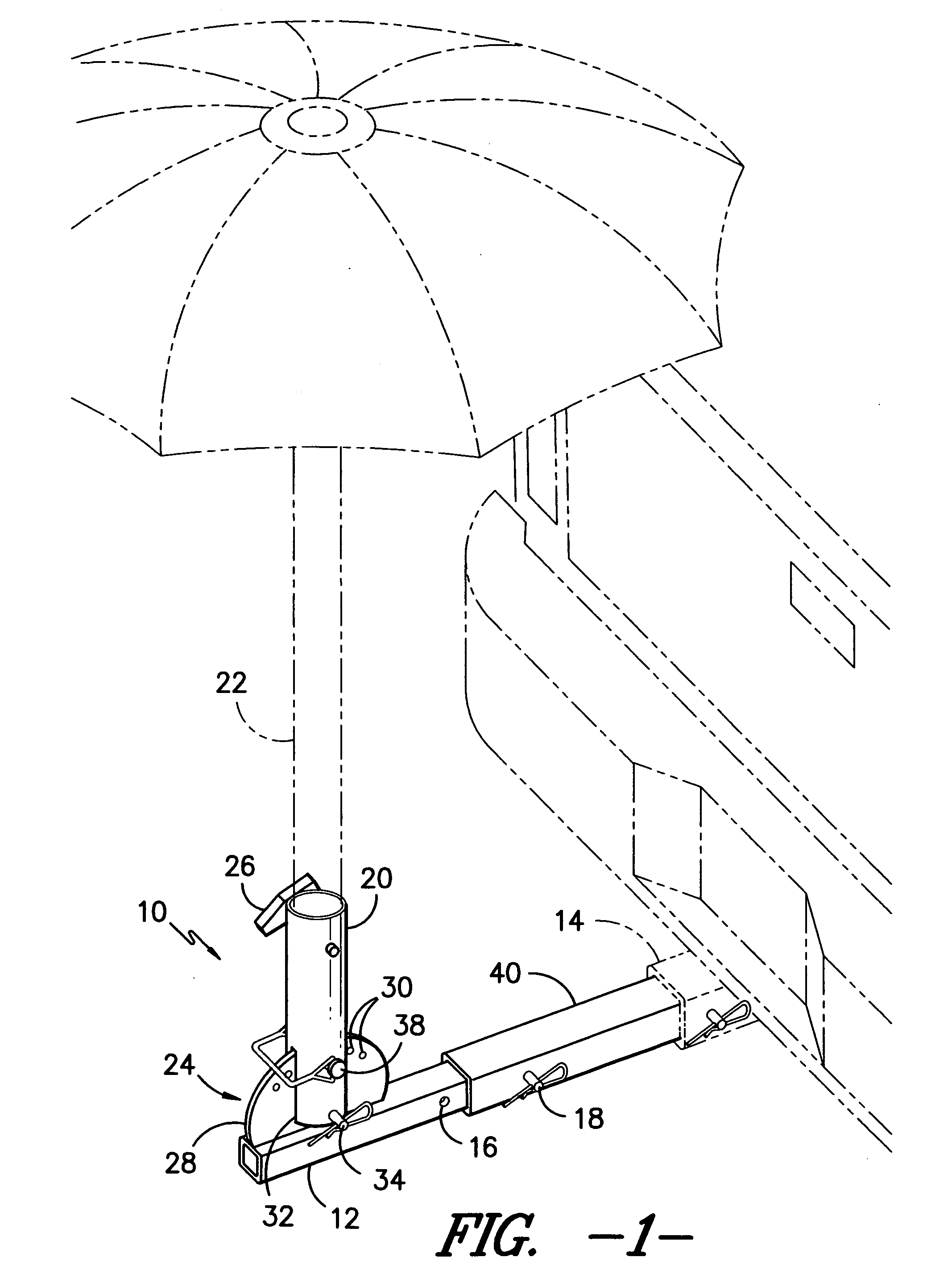

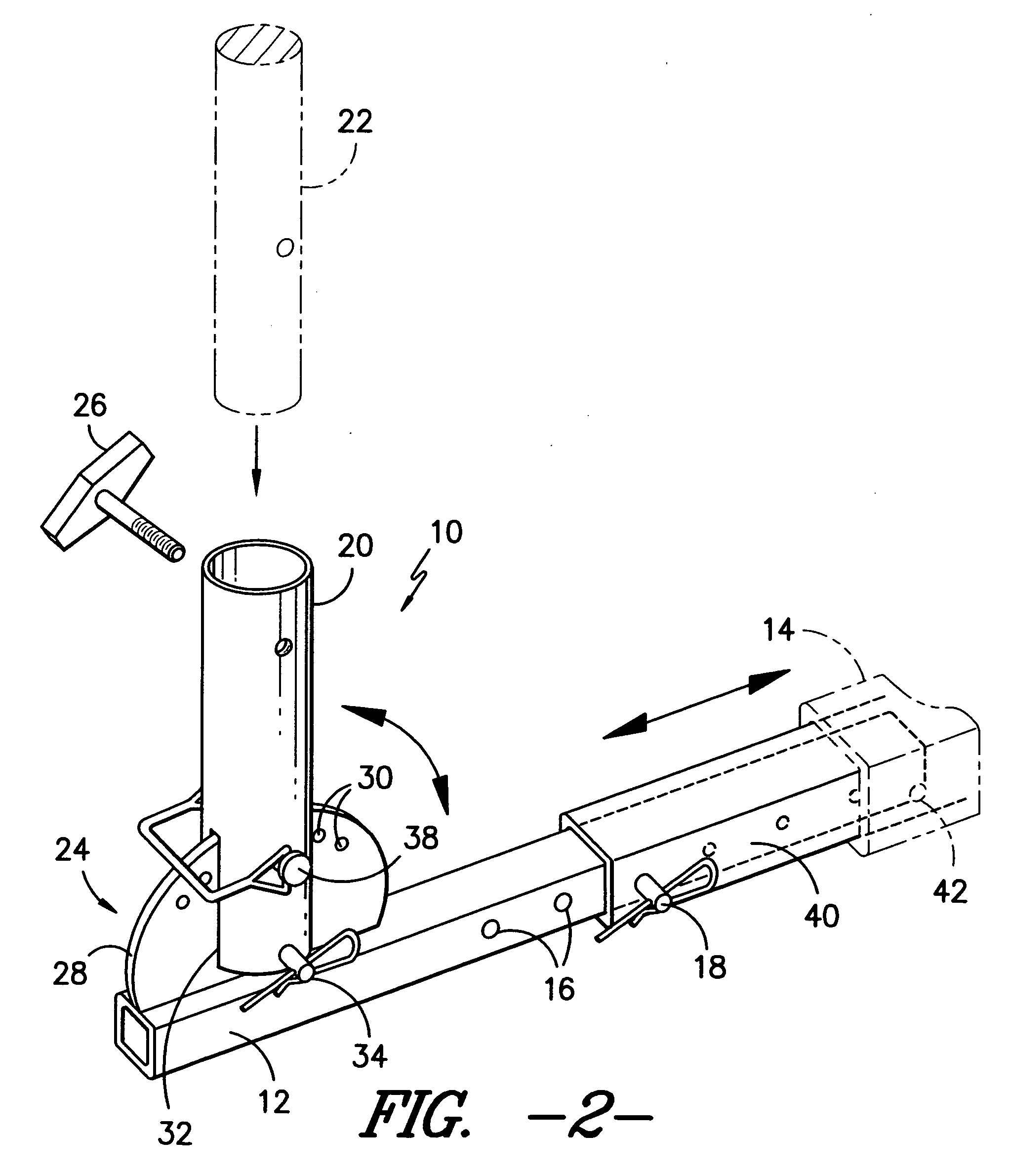

Adjustable trailer hitch mount for an umbrella

InactiveUS7819128B2Increase distanceDesired lengthWalking sticksUmbrellasSquare cross sectionScrew position

The trailer hitch mount for an umbrella includes a square cross-section shaft that is adapted to slide into a standard sleeve-style trailer hitch receiver that is currently available on many vehicles. The shaft includes a series of holes along the sides thereof to receive a pin in order to secure the shaft to the trailer hitch receiver in a telescopic relationship. The series of holes allows the shaft length to be adjusted, so that the distance between the trailer hitch receiver and the opposed end of the shaft may be shortened or lengthened, as desired. The shaft includes two ends, one of which slides into the trailer hitch receiver, and the other end includes a hollow pivoting cylindrical tube that is used to receive the bottom end of an umbrella pole. The pivoting tube includes adjustment means, so that the pivoting tube may be tilted to a desired angle and secured in that position. For travel or storage purposes, the pivoting tube may be folded down and secured into a compact position parallel with the shaft. At an upper end of the pivoting tube is receiving and securing means for the umbrella pole. The umbrella pole, in a preferred embodiment, slides into the hollow pivoting tube and a hand screw positioned on the side of the pivoting tube at its upper end may be tightened against the umbrella pole and secured thereby.

Owner:CLARK SCOTTY OBRIAN +1

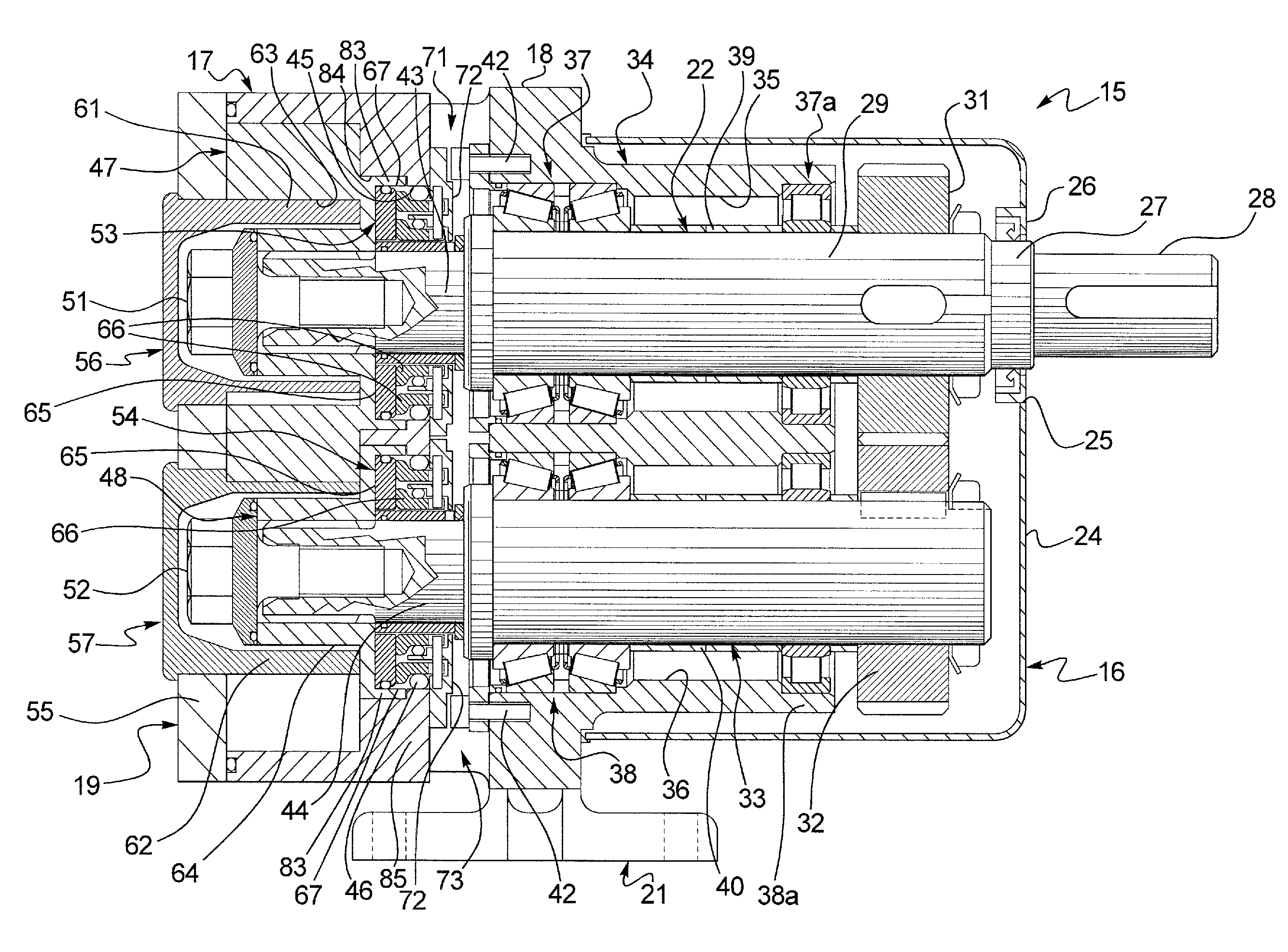

Spindle motor and disk drive utilizing the spindle motor

InactiveUS6888278B2Simplify and slim down structureMaintain relatively stableApparatus for flat record carriersShaftsThrust bearingEngineering

Low-profile spindle motor whose entire shaft length is utilized to configure, along an encompassing sleeve, a radial dynamic-pressure bearing section. One end of the shaft is unitary with the rotor, and a cover member closes the other end. Between the sleeve upper-end face and the rotor undersurface a thrust bearing section is configured. Micro-gaps are formed continuing between the sleeve upper-end face and the rotor undersurface; the sleeve inner-circumferential surface and the shaft outer-circumferential surface; and the cover member inner face and the shaft end face, where an axial support section is established. Oil continuously fills the micro-gaps, configuring a full-fill hydrodynamic bearing structure. Hydrodynamic pressure-generating grooves in the radial bearing section are configured either so that no axial flow, or so that a unidirectional flow that recirculates from one to the other axial end of the radial bearing section through a communicating pathway is induced in the oil.

Owner:NIDEC CORP

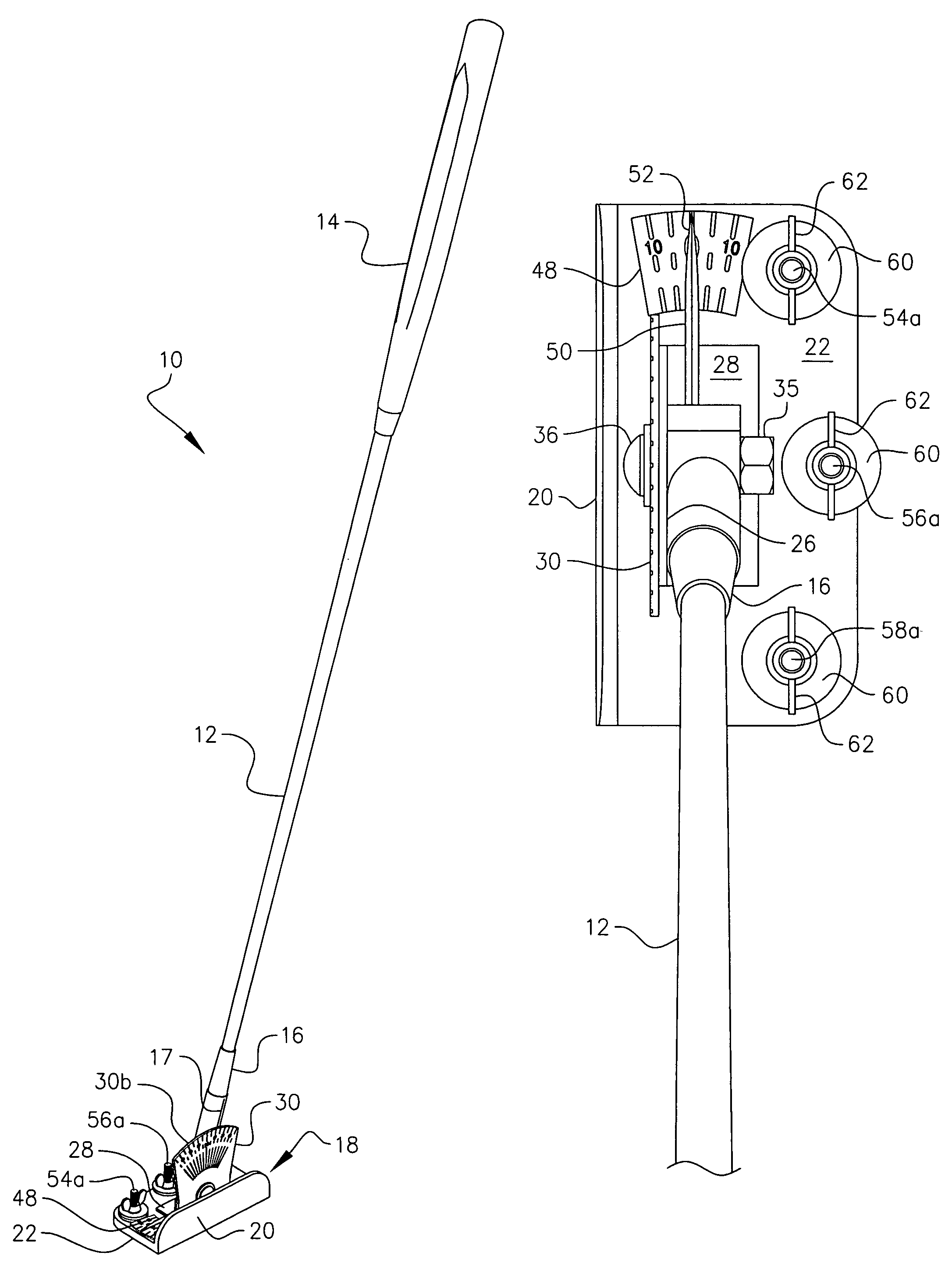

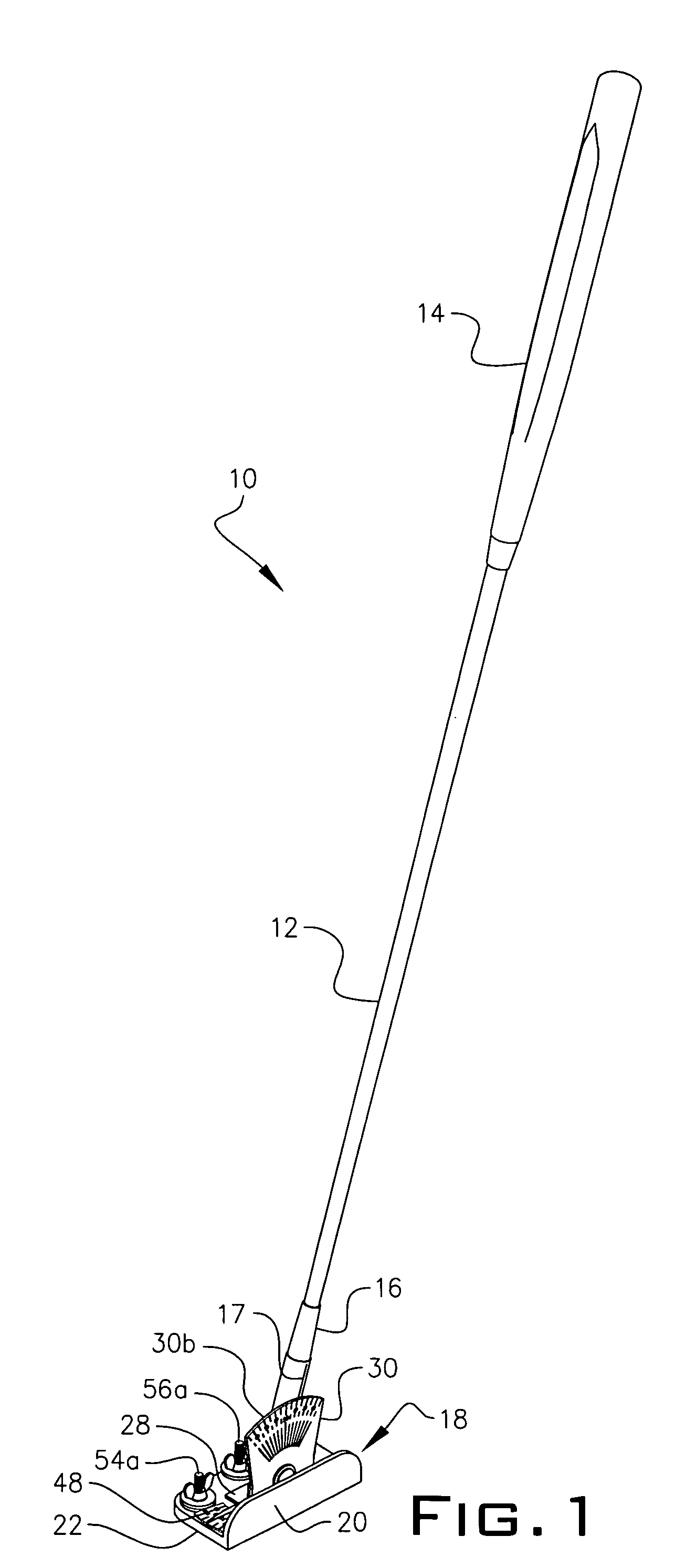

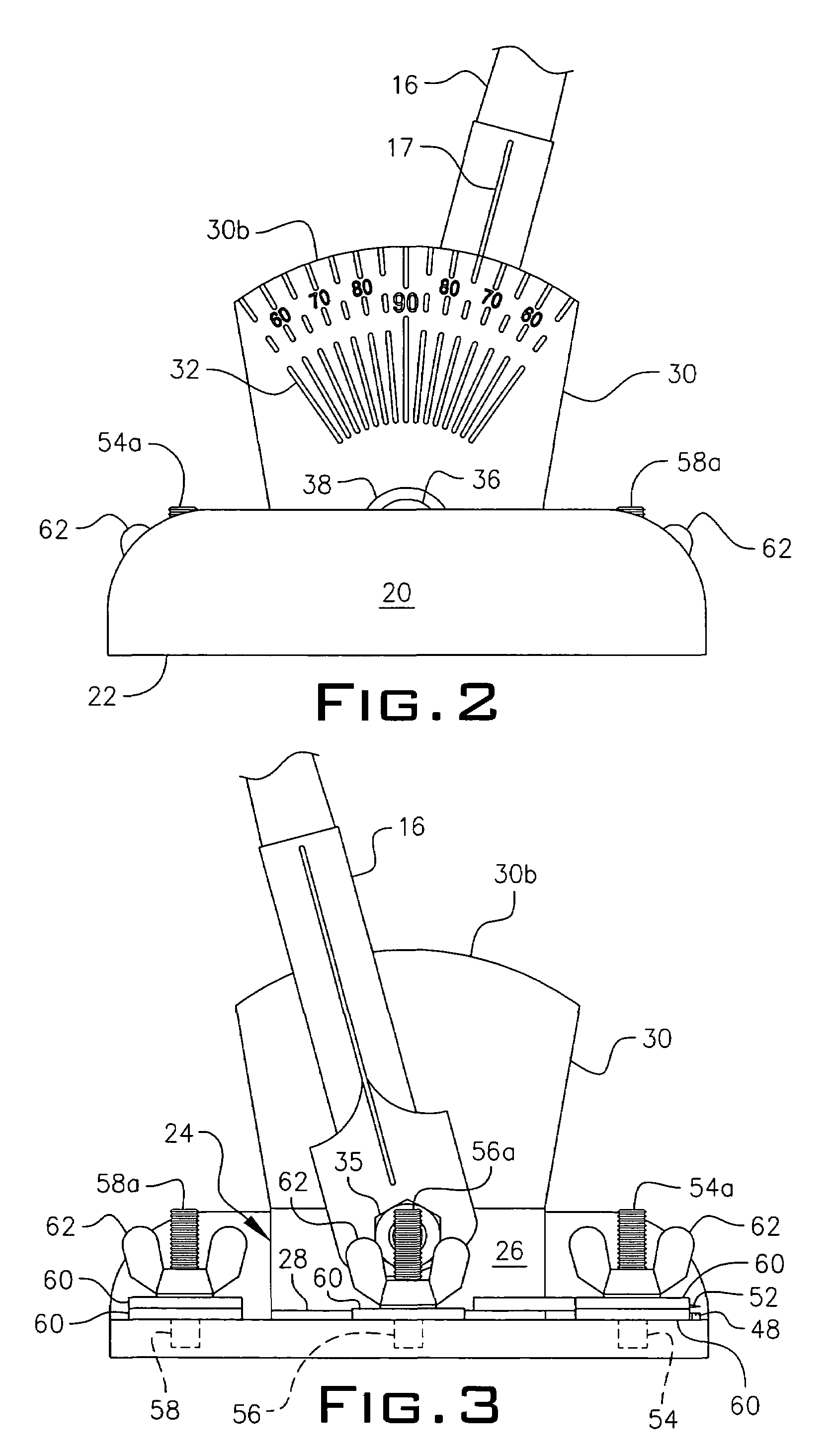

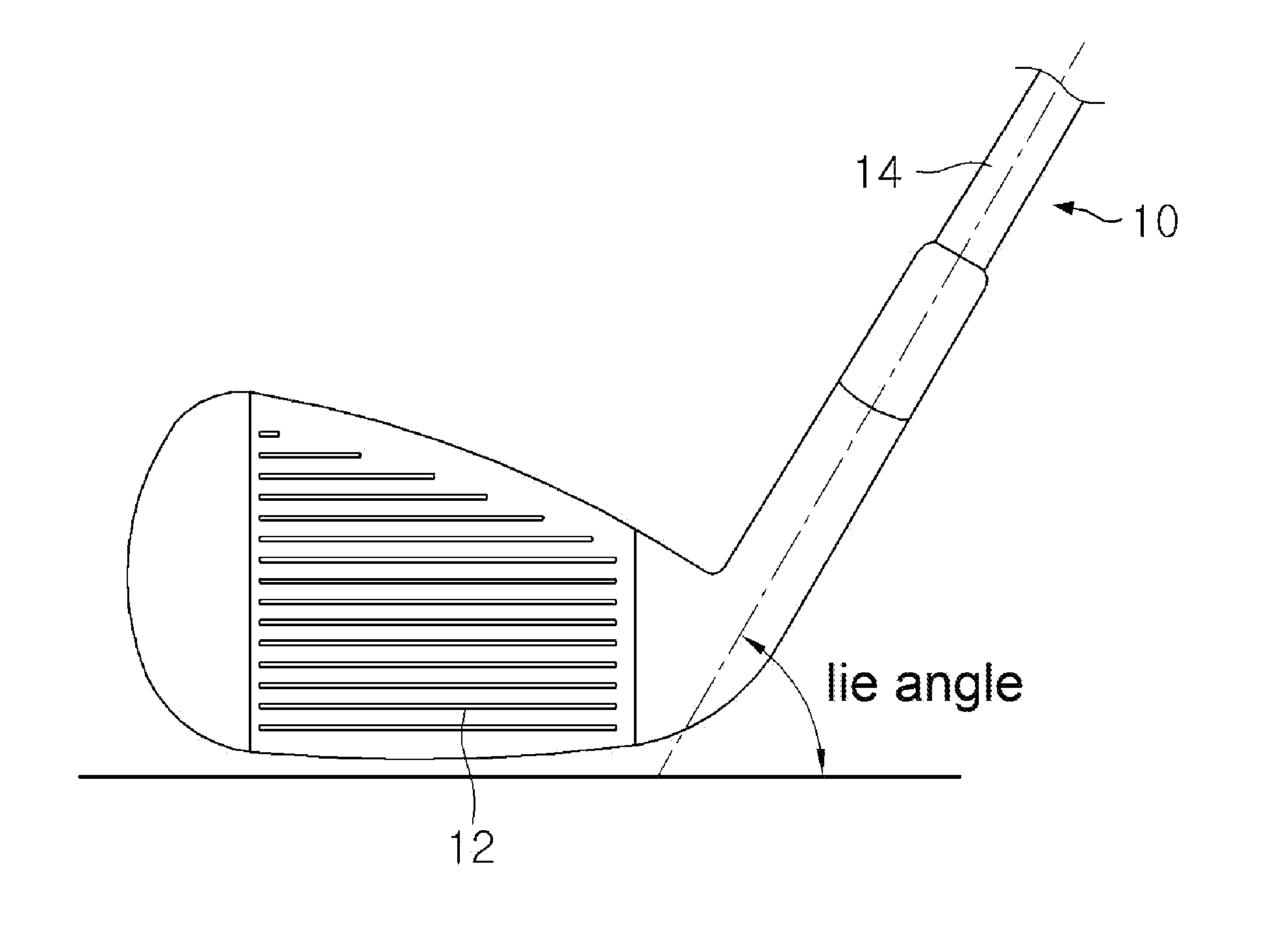

Tool for determining optimal putter characteristics

A tool has an adjustable lie angle, face angle, weight, and shaft length and is used by a golfer to adjust a putter to the optimal lie angle, face angle, weight and shaft length for that golfer. The tool head has a face plate and a sole disposed normal to one another. An angle member has a vertical wall disposed parallel to the face plate and a horizontal wall that overlies the sole. A hosel is pivotally mounted to the vertical wall and a first protractor is fixedly secured to the vertical wall. A marker on the hosel indicates the lie angle on the first protractor. A second protractor secured to the sole indicates a face angle when the shaft of the club is rotated about its axis. Weights are selectively added to the toe, heel, or mid-point of the putter head to determine an optimal weight and weight distribution.

Owner:RINKER JAMES

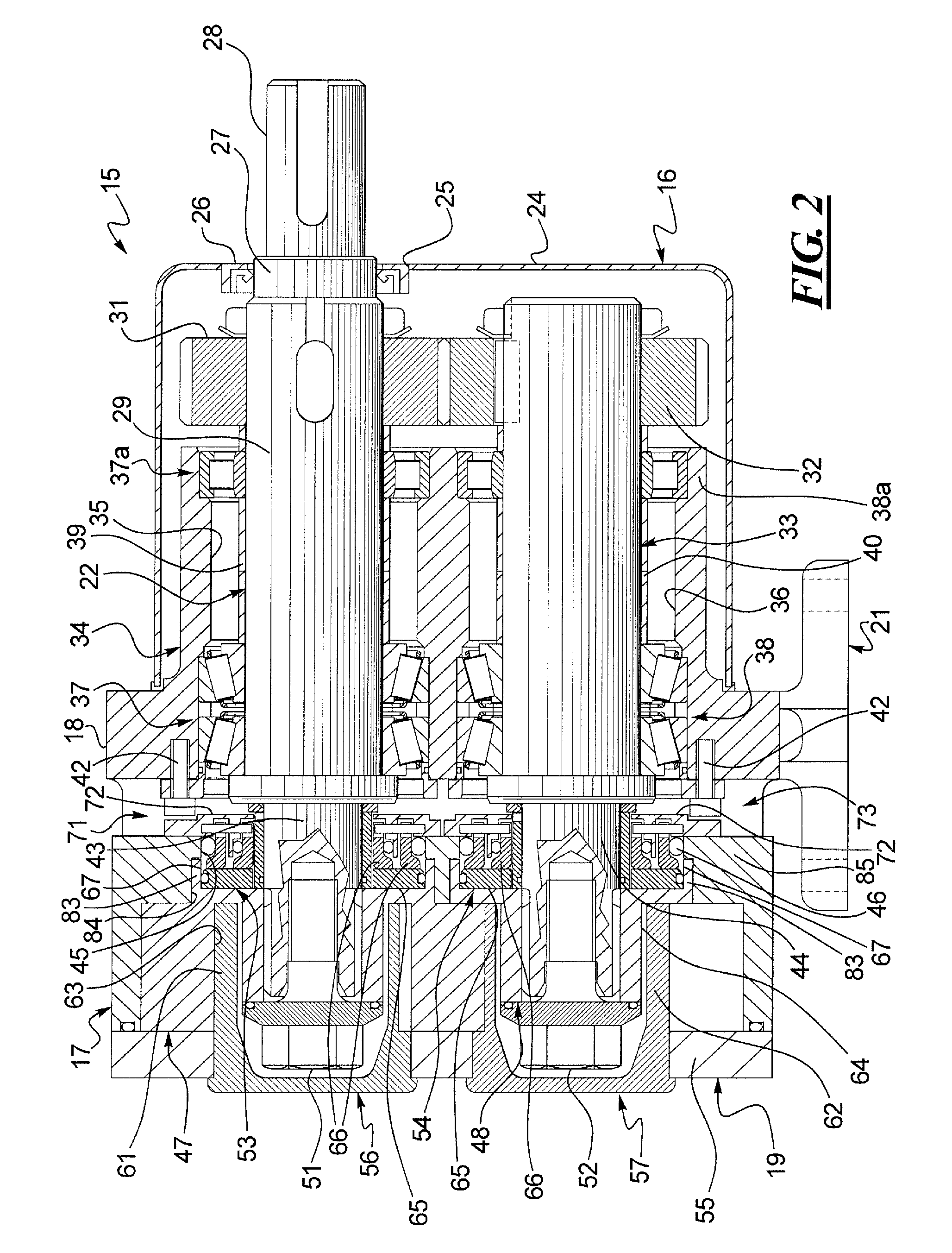

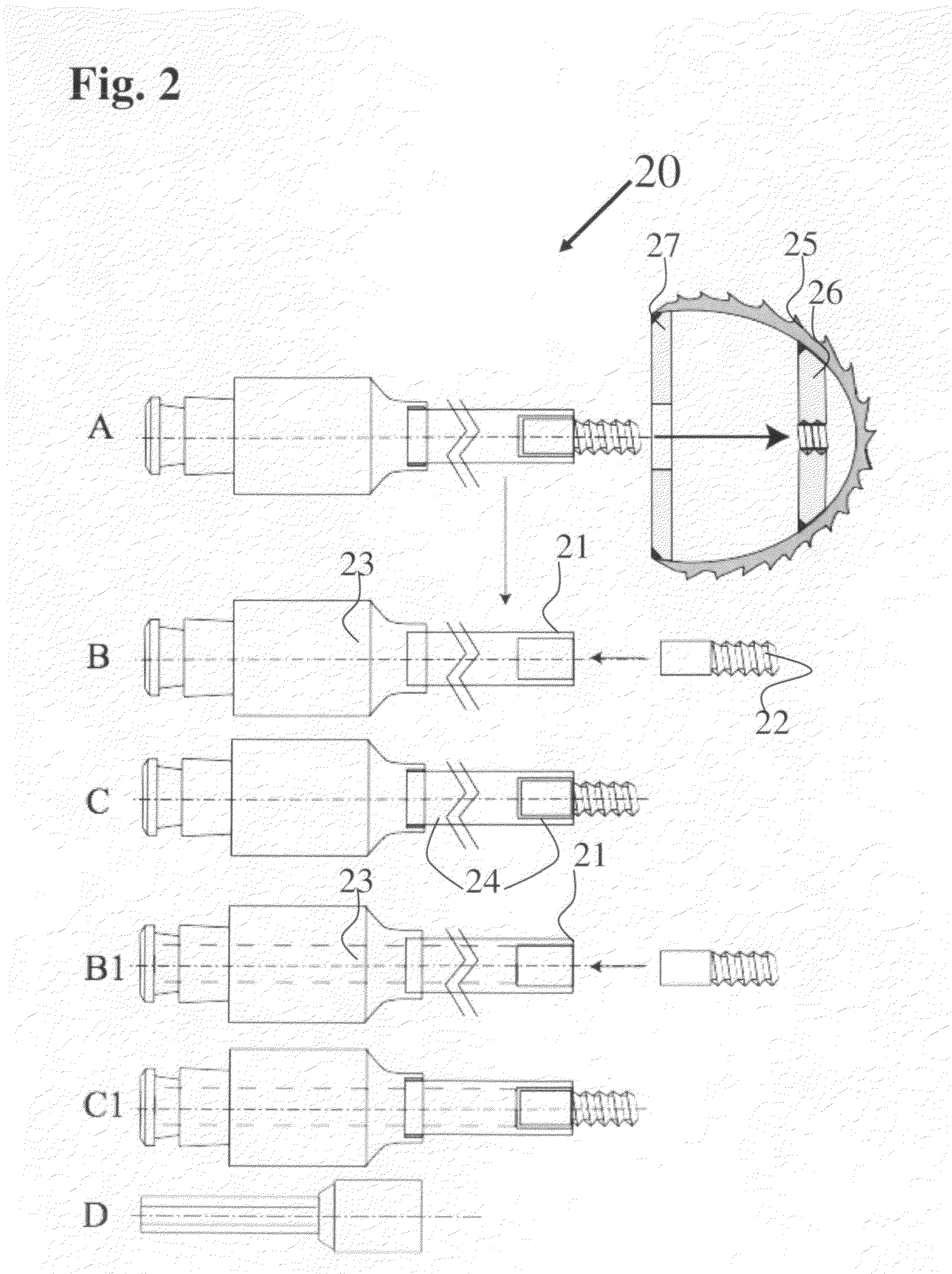

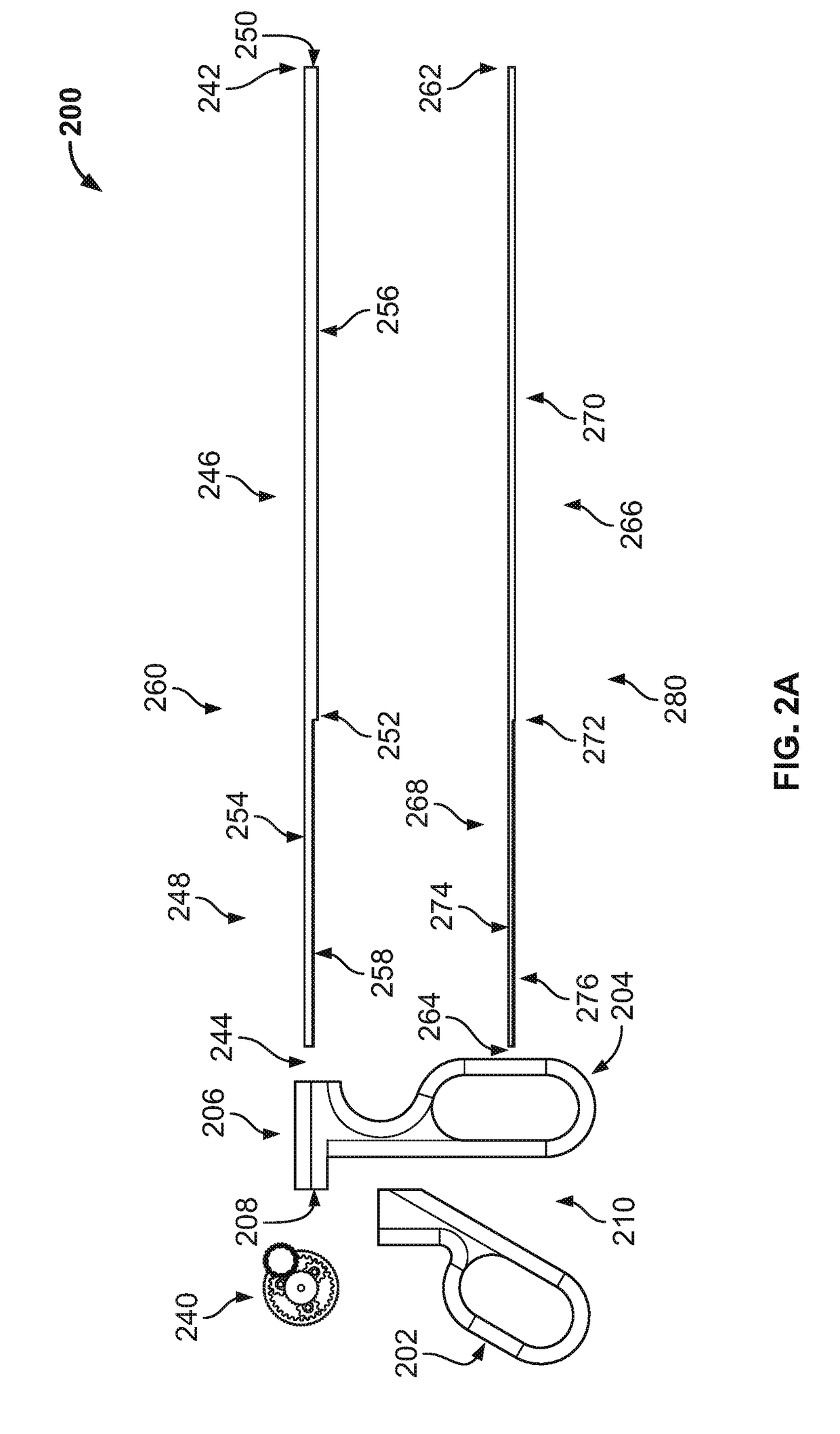

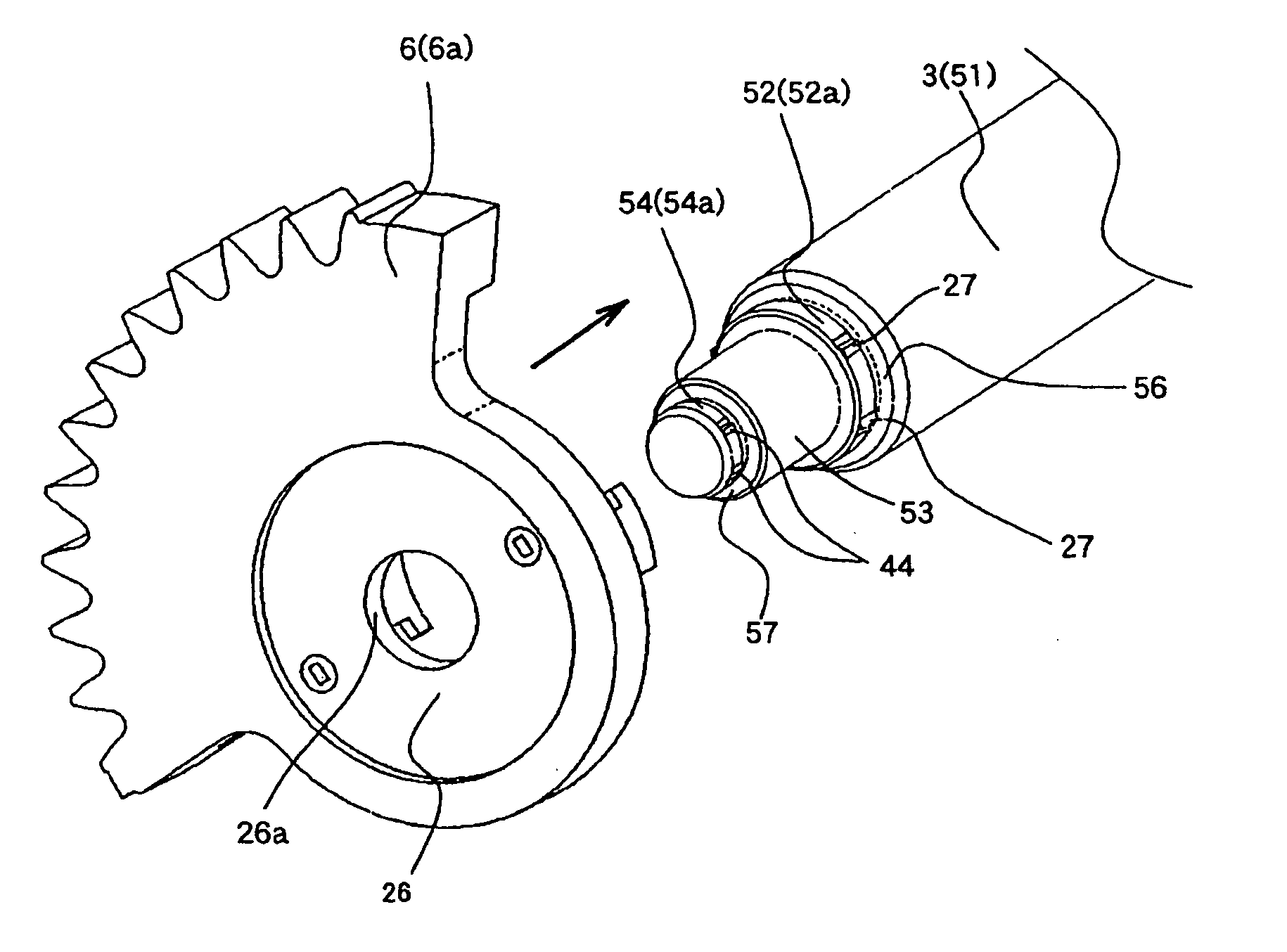

PD Pumps with a Common Gearbox Module and Varying Capacities and Easy Access to Mechanical Seals

ActiveUS20090304540A1Ease in which the seals can be serviced or replacedOscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

Rotary lobe pump and circumferential piston pump designs are disclosed where the drive and driven shafts are detachably connected to their respective rotors. The rotors are disposed in a pump or rotor casing, which is sandwiched between a head cover and a gearbox. The drive and driven shafts pass through mechanical seal assemblies, which are sandwiched between the first and second rotors and the gear box respectively. The seal assemblies can be serviced or replaced by simply removing the head cover and removing the rotors from the drive and driven shafts. The pump casing does not need to be removed to replace or service the seal assemblies. Further, the capacities of the disclosed rotary lobe and circumferential piston pumps can be modified without changing the gearboxes or shaft length. To modify a pump capacity, all that needs to be changed are the rotors, the pump or rotor casing and, in some designs, the head cover or cover plate. In some designs, the cover plate is universal to the gearbox so that only the rotors and pump casing need to be changed to modify the pump capacity.

Owner:VIKING PUMP HYGIENIC LTD

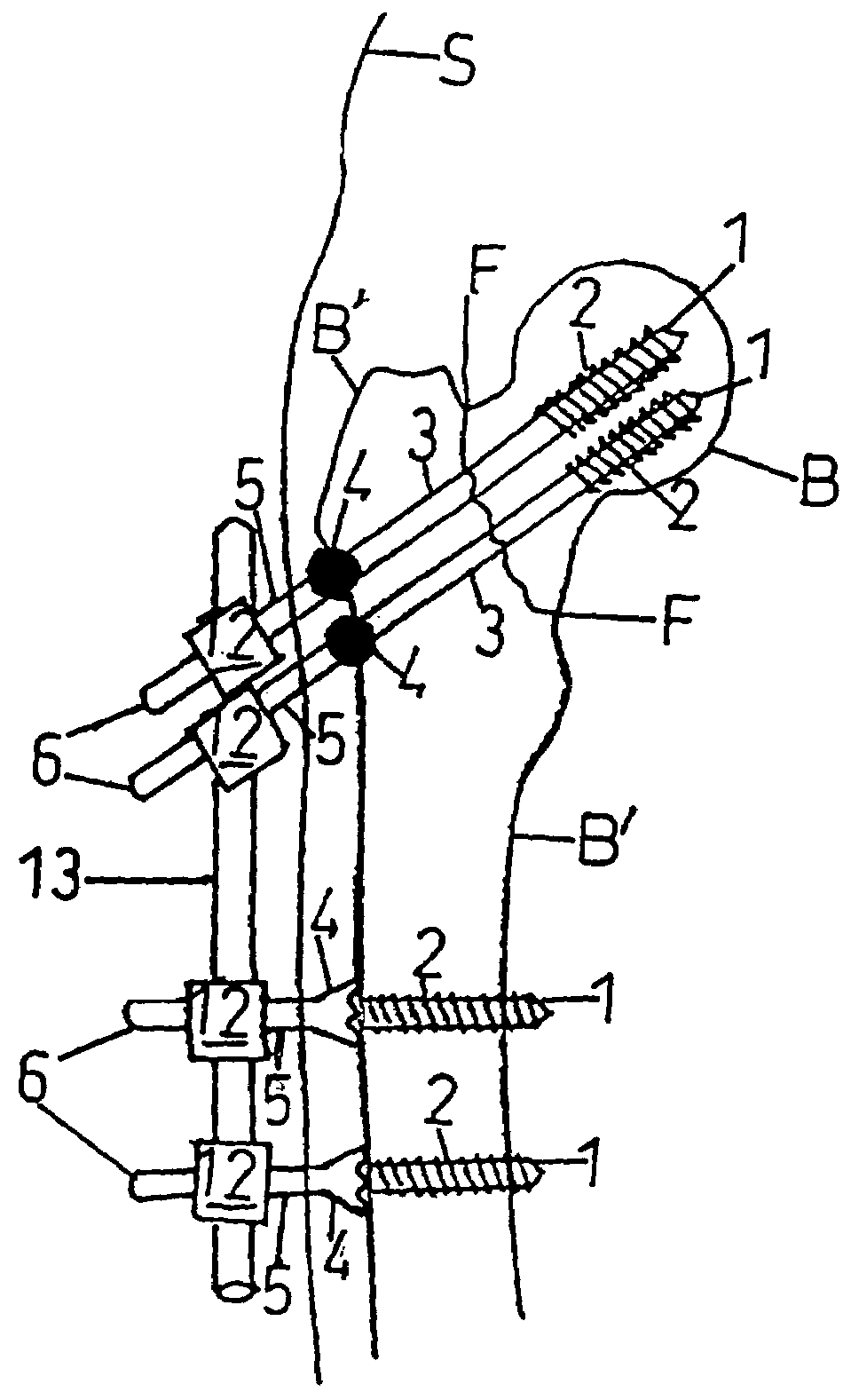

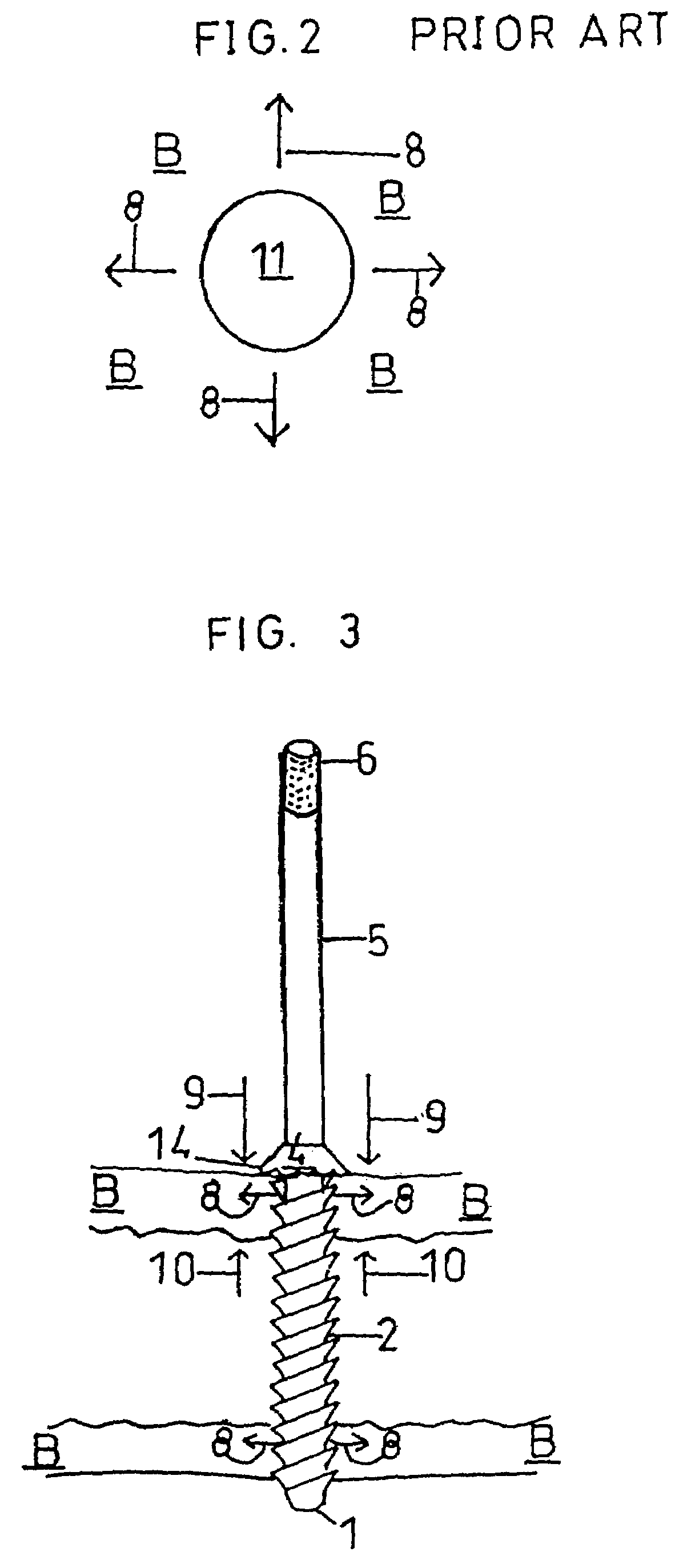

Renew compression screw

InactiveUS7666212B2Preserving and augmenting functionEffect durabilitySuture equipmentsLigamentsShaft lengthGuide wires

An external fixator implant screw with an intercalated head, of which one embodiment for lag screw mode has a spherical head, and a partial thread. The spherical head in countersunk bone exerts concentric wide contact on insertion at various angles to surface. Optional canalization of central rod allows guide wire technique and optional mobility of head allows variable shaft length between head and thread. Another embodiment for use in basic implant mode, in a single bone fragment, at right angles to bone surface, has a conical head with limited basal contact on bone, the head being integrated to a solid rod and is fully threaded from head to leading tip. In both embodiments, the load transmission is renewable from outside in case of loosening, without reopening any wound. The implant is made of biocompatible material.

Owner:DROR PALEY

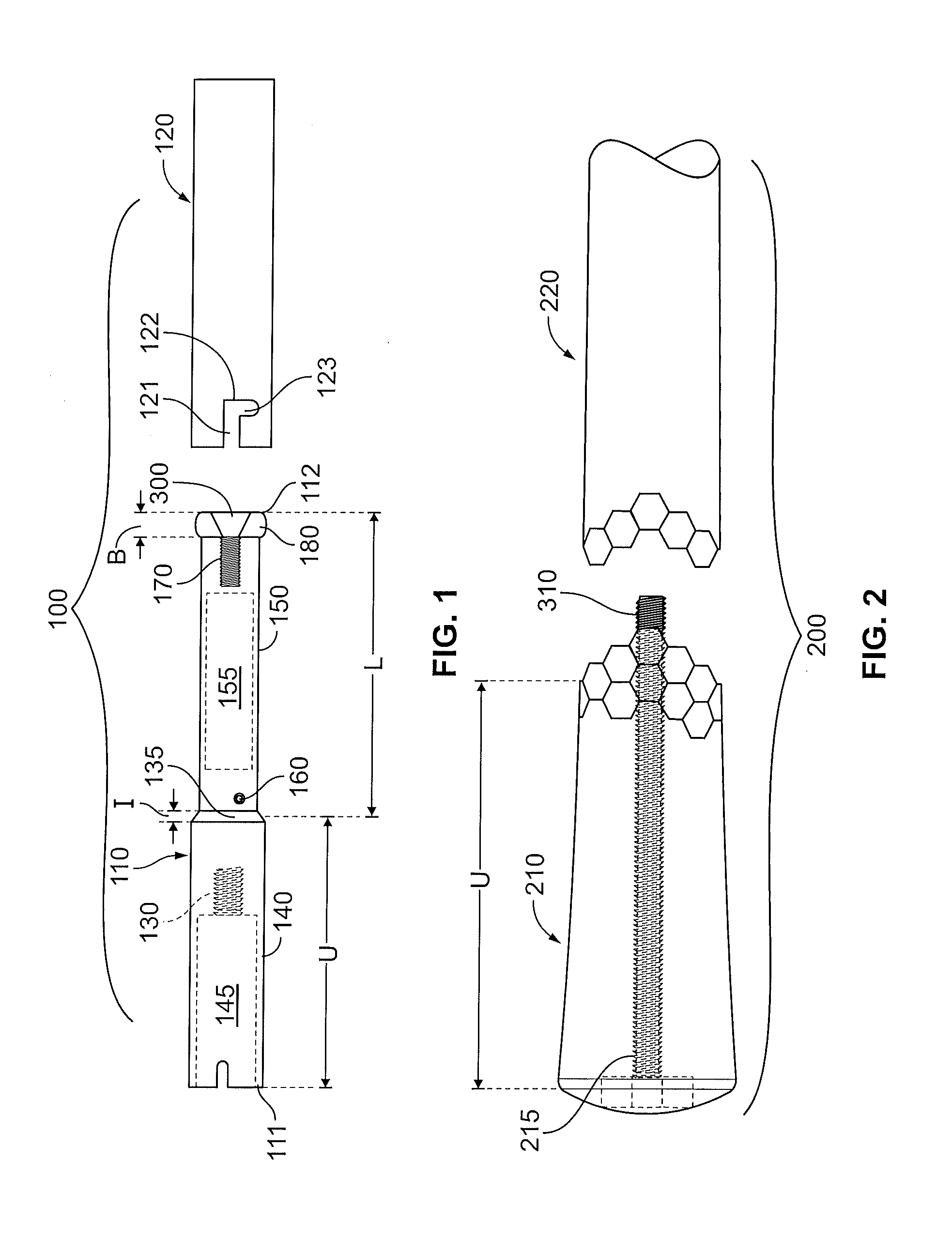

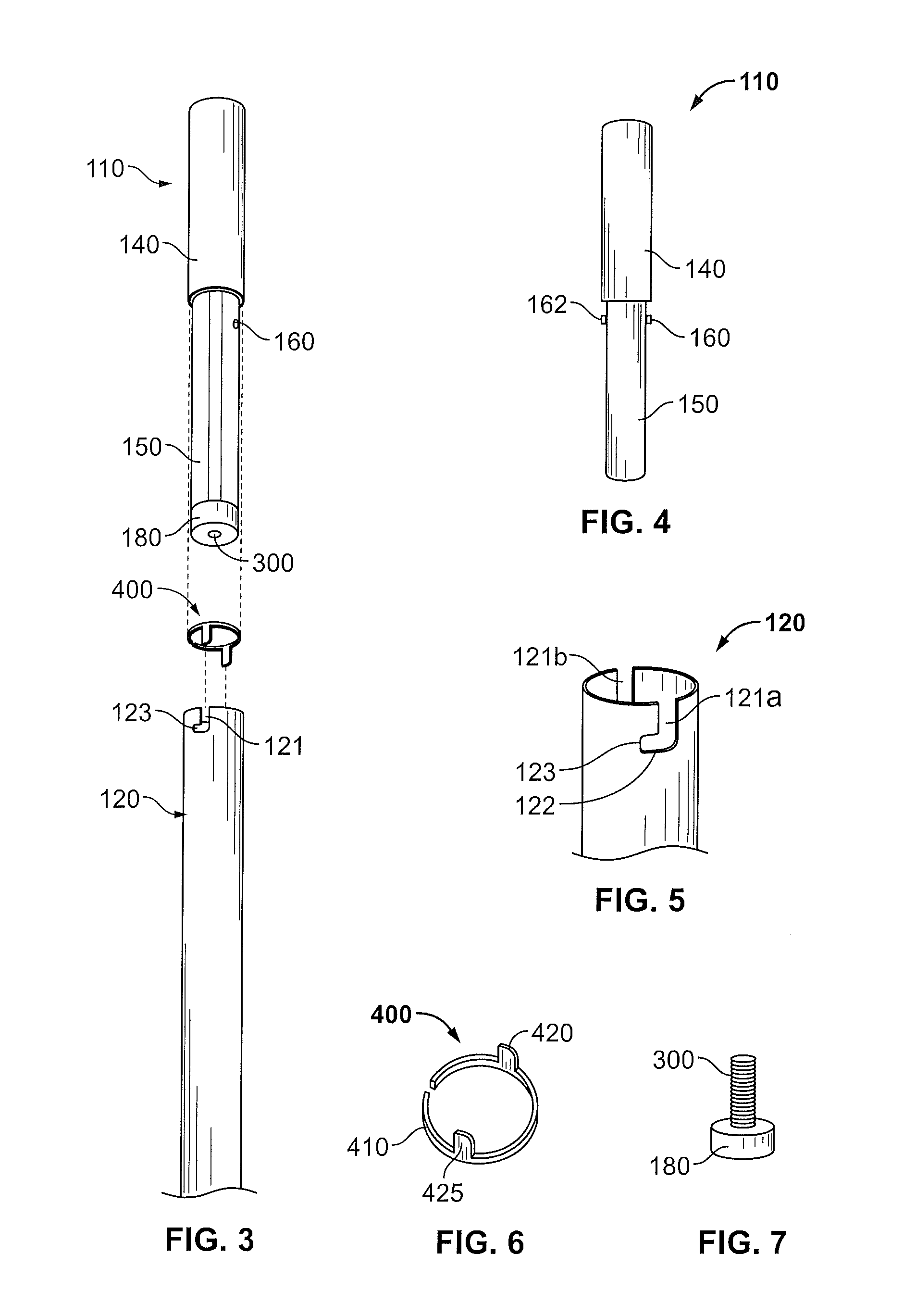

Variable length shaft

A variable length golf club shaft is disclosed herein. The variable length shaft includes a hollow lower shaft with a plurality of holes, a hollow upper shaft with at least one protrusion extending from an inner surface that is sized to fit within the plurality of holes, and an unlocking bar. The shaft length can be adjusted by sliding the upper shaft over the lower shaft and using the unlocking bar to release the protrusion from the holes to allow overall shaft length adjustments. In another embodiment, the variable length shaft includes a hollow lower shaft, a hollow upper shaft, an engaging insert, and a locking bar.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Adjustable length belly putter

A belly putter incorporating an adjustable shaft length feature. The adjustable length shaft feature may be added to an existing standard putter or may be incorporated into a specifically built belly putter. A rounded top to the belly putter shaft with completely curved and rounded sides is also provided.

Owner:BUTLER WILLIAM B

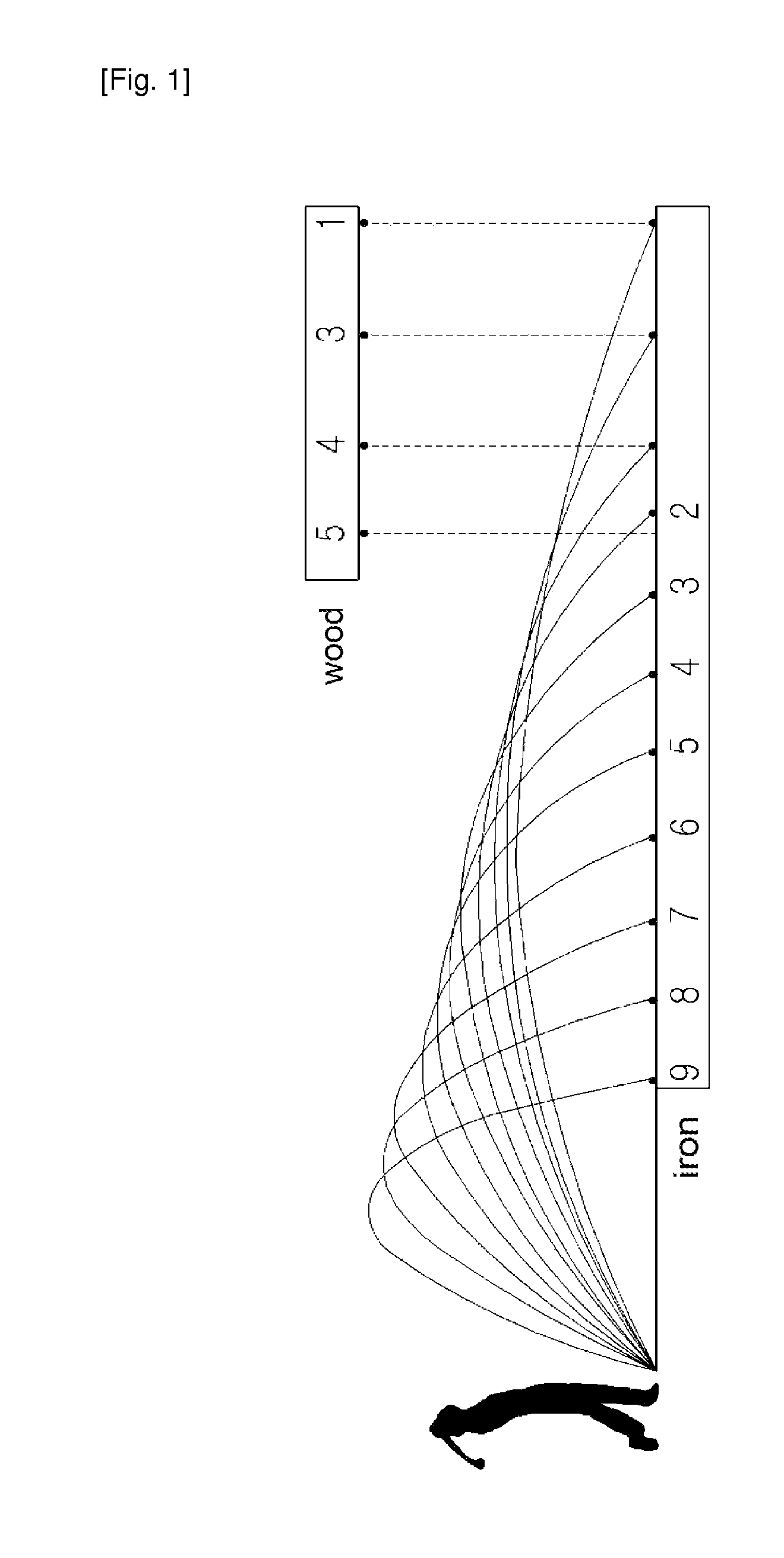

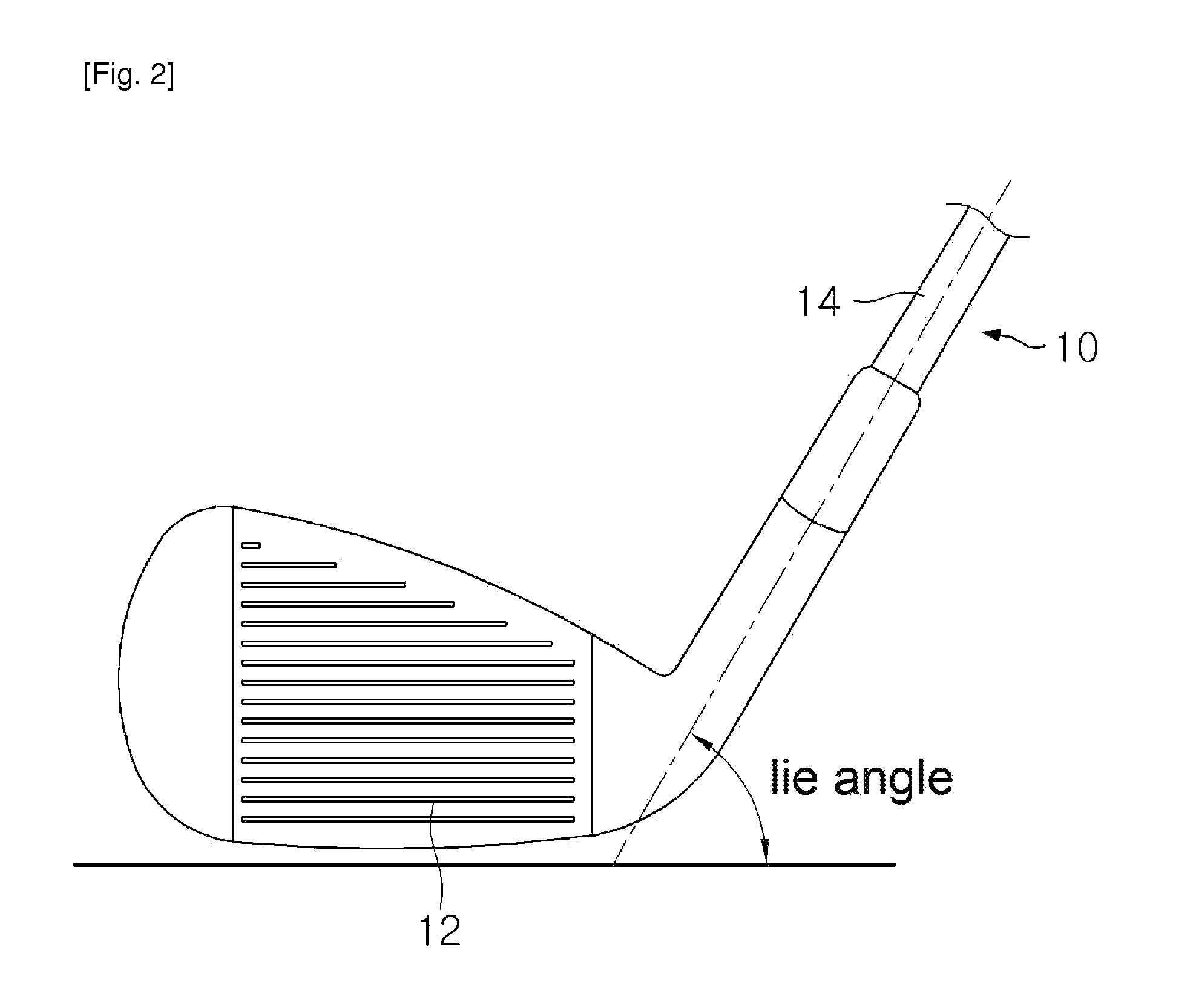

Utility iron

InactiveUS20150057097A1Extended driving distanceLess attentionGolf clubsRacket sportsEngineeringGolf Ball

The present invention relates to a utility iron which is characterized in that it has a lie angle of 58 to 64°, a loft angle of 20 to 28°, a head weight of 270 to 300g, and a shaft length of 35 to 38 inches. Thus, the loft angle is relatively reduced so as to prevent a golf ball from being hit high and increasing flight distance. Also, because the lie angle is relatively increased, the possibility of a hook or a slice occurring is reduced. Because the weight of the head is increased, repulsive force is augmented by the striking of the golf ball, which relatively increases the flight distance of the golf ball. Because the length of the shaft is relatively shortened, swing trajectory is reduced, and accurate striking is made easier so as to also increase flight distance.

Owner:CHO HEE JIN

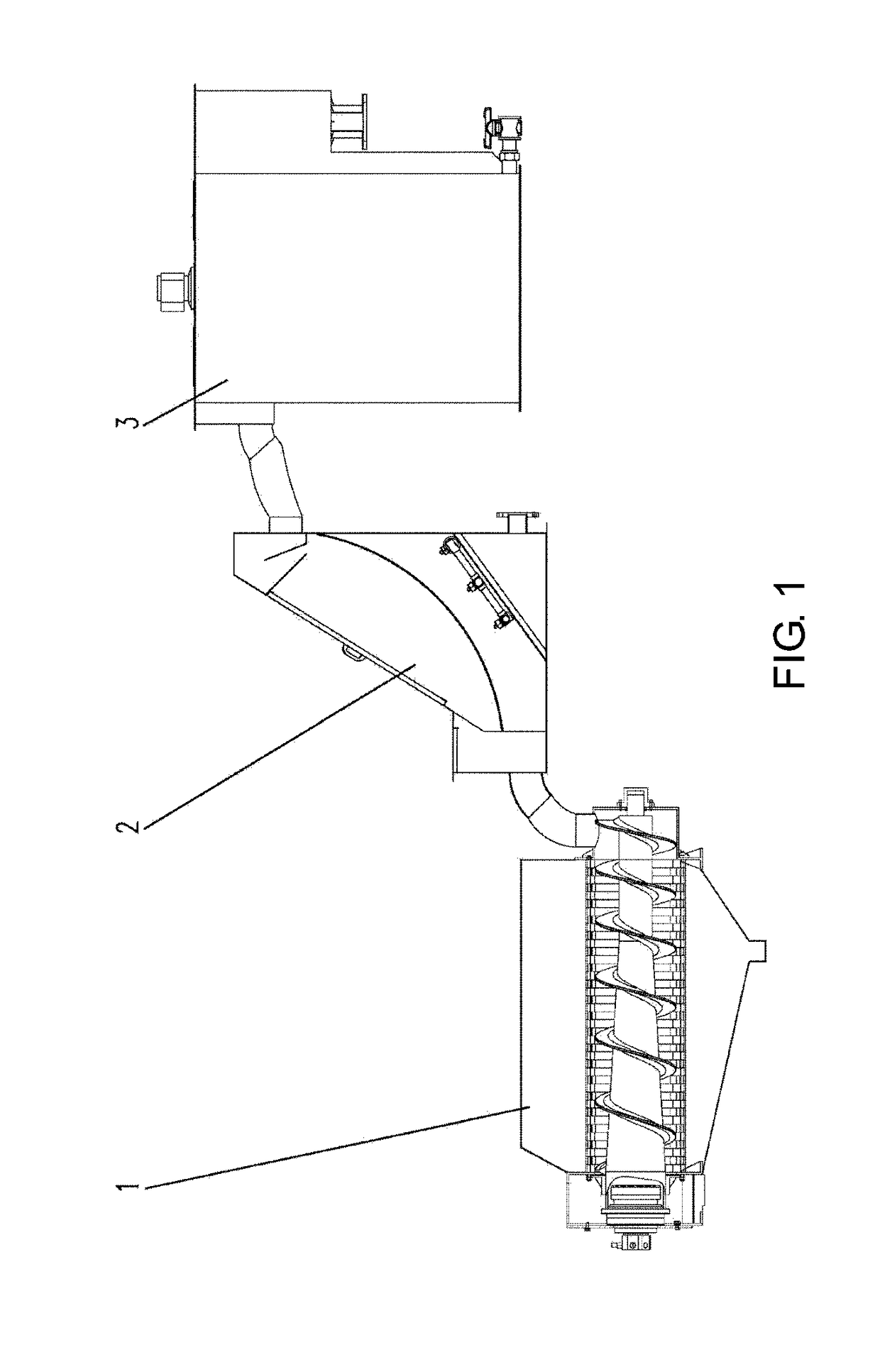

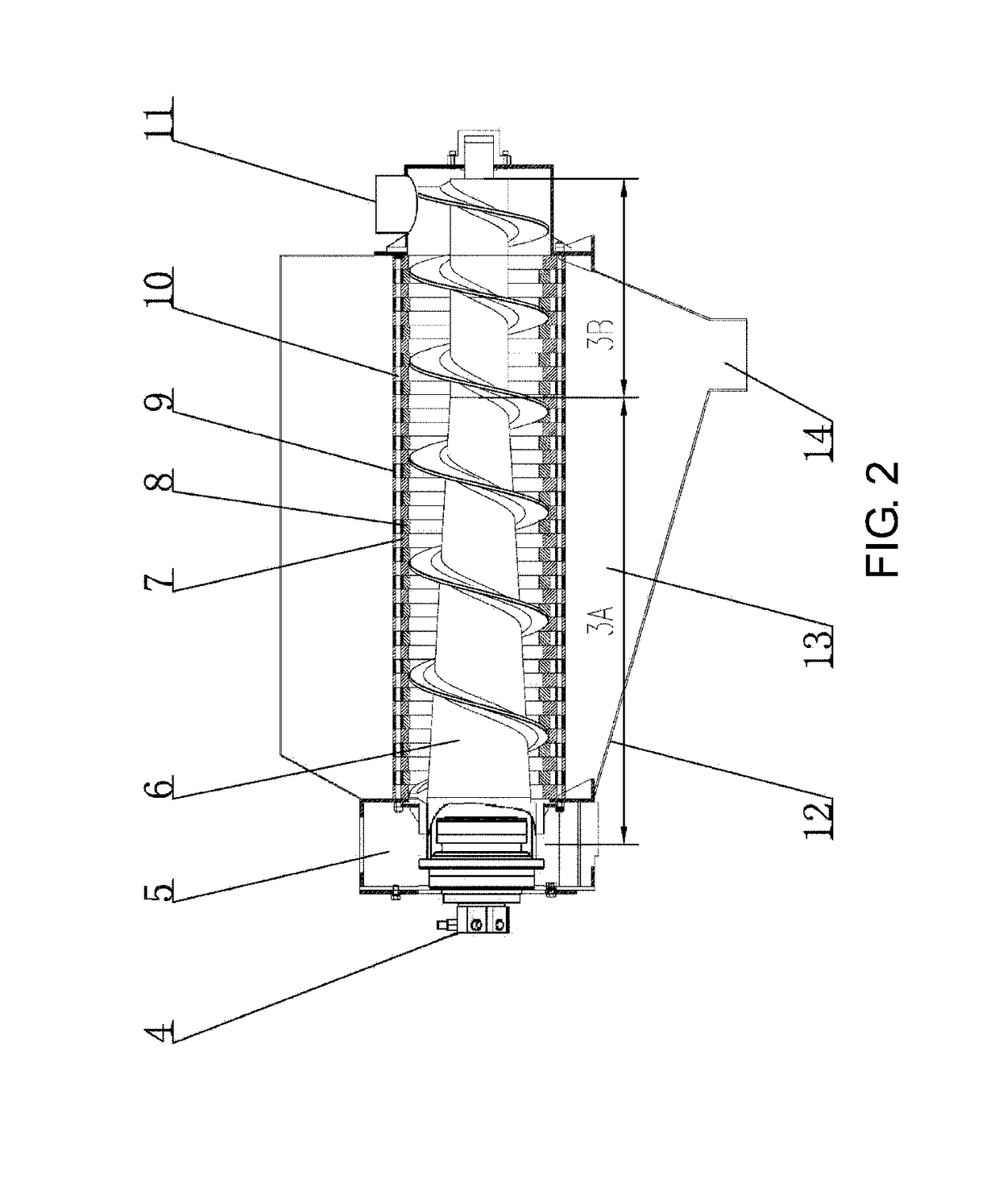

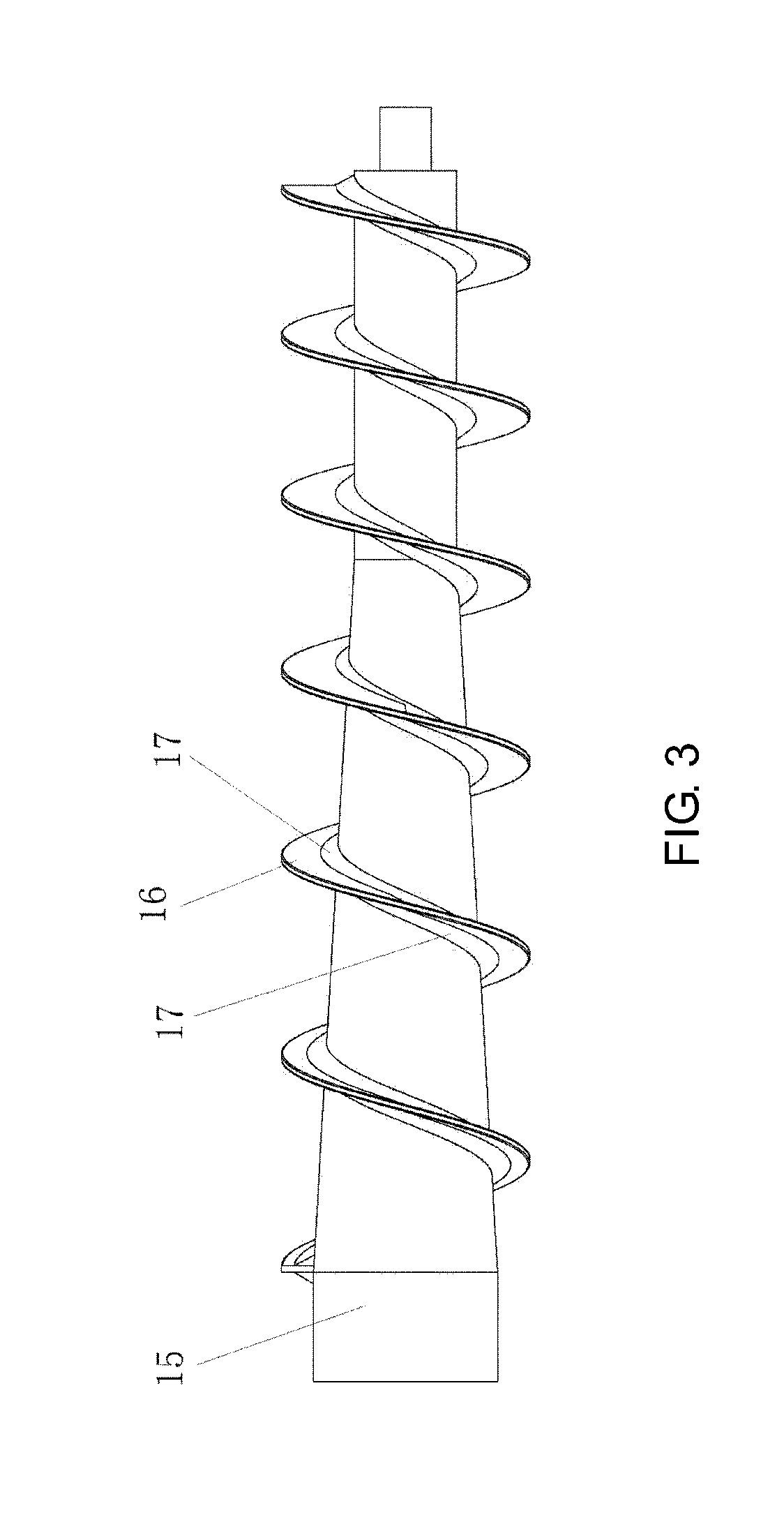

Multi plate screw press sludge dewatering machine

ActiveUS20180346362A1Convenience to workReduced footprintSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHelical scanHelical blade

The present invention provides a multi plate screw press sludge dewatering machine and a helical shaft thereof. The multi plate screw press sludge dewatering machine includes fixed rings, movable rings, the helical shaft, a sludge inlet tank and a sludge discharging tank; the helical shaft adopts a variable diameter variable pitch helical shaft, a lead angle arrangement sequence of a helical blade of the whole helical shaft is gradual reduction from the sludge discharging tank to the sludge inlet tank, and the lead angle arrangement sequence is gradually reduced from 16°-22° to 6°-14°; a pitch of the helical shaft is gradually increased along a direction from the sludge inlet tank to the sludge discharging tank; a diameter of a shaft body of the helical shaft is gradually increased along with a direction of the sludge discharging tank from a ⅓ position of a shaft length; and blockage prevention plates are arranged on two sides of the bottom of the helical blade. The helical shaft in the present invention is specially designed, so that the pitch is more reasonable, a helical angle is gentler, frictional resistance when sludge passes through the helical shaft may be effectively reduced, and phenomena of shaft blockage and shaft sticking of the sludge may be reduced.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

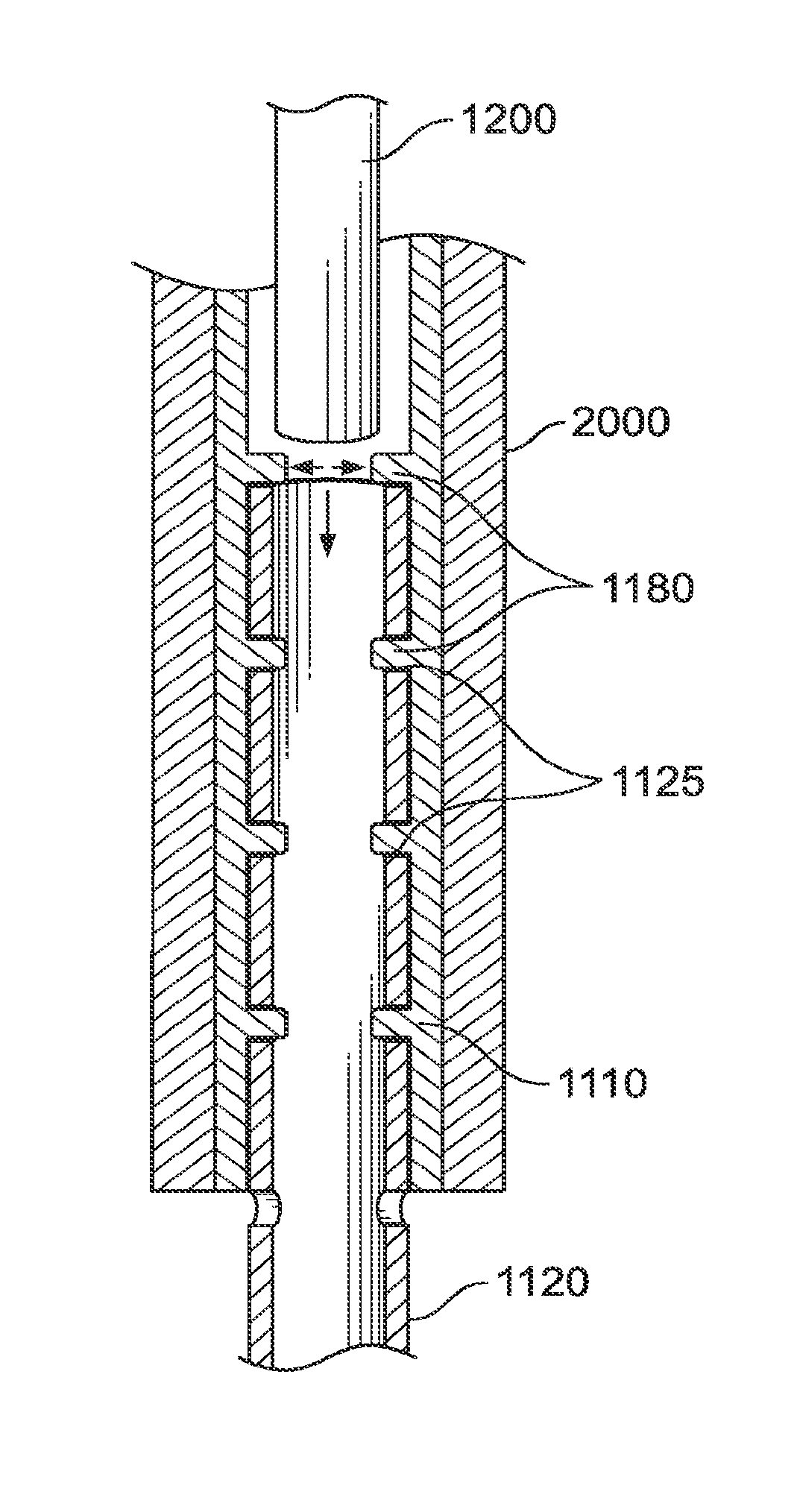

Ossicular prosthesis adjusting device

An ossicular prosthesis delivery system having an ossicular prosthesis including an enlarged head and a shaft axially, moveably mounted to the head to adjust shaft length. An elongate main body having an operating portion, including a cylindrical through bore, connected to an adjusting portion, including a generally semi-cylindrical upwardly opening channel coaxial with the bore. An end wall at a distal end of the adjusting portion includes a through passage coaxial with the channel and an upwardly opening cavity. An elongate cylindrical plunger has a claw at one end. The plunger is received in the bore with the claw in the channel and an opposite end extending outwardly of the operating portion. The ossicular prosthesis' shaft is positioned in the channel with the head received in the cavity and the plunger is rotatable in the bore to capture the shaft and is reciprocally moveable in the bore to adjust shaft length of the ossicular prosthesis.

Owner:CLARITY

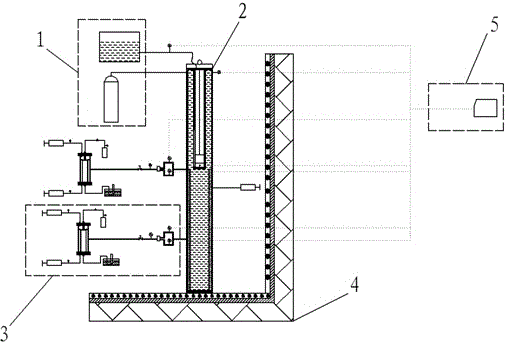

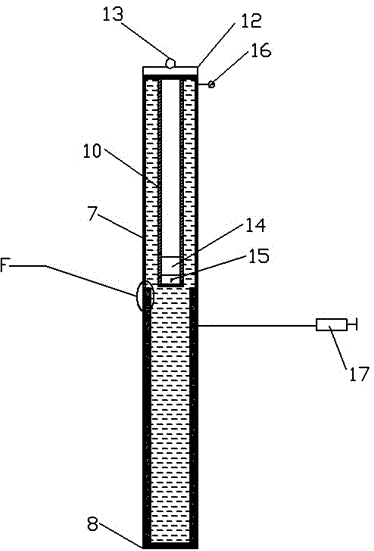

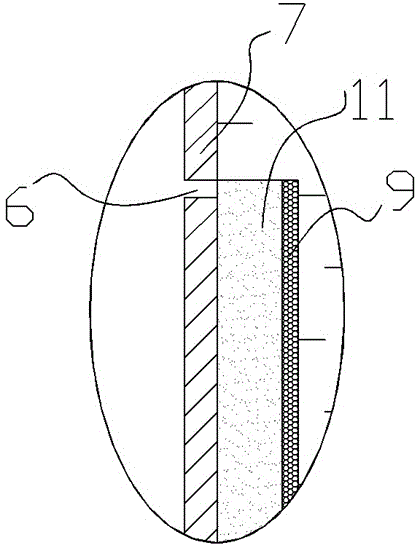

Multi-seam joint exploitation coal seam gas shaft gas-liquid two-phase flow simulation device

InactiveCN104453802AInterference Avoidance or MitigationSurveyFluid removalDrift angleData acquisition

The invention discloses a multi-seam joint exploitation coal seam gas shaft gas-liquid two-phase flow simulation device. The simulation device comprises a recovery system connected to the top of a shaft simulation device. A reservoir simulation system is connected with a guide hole in the shaft simulation device, an adjusting system is connected to the outer side and the bottom of the shaft simulation device and used for controlling inclination of the shaft simulation device, and a data acquisition system is connected to joints between the recovery system, the shaft simulation device and the reservoir simulation system. The simulation device can simulate the physical process that under the conditions of a certain shaft length, a hole drift angle and the like, multiple seams are sequentially desorbed under the original reservoir condition after water is drained and pressure is reduced and output is generated through an annulus of a coal seam gas shaft and an oil pipe., the displacement and the casing pressure are adjusted, flow pressure and gas output data are recorded and analyzed, the characteristics of multi-seam joint exploitation coal seam gas shaft gas-liquid two-phase flow are qualitatively recognized, an optimized discharge and recovery working system is acquired, and a guidance suggestion is provided for formulation of the on-site coal seam gas well discharge and recovery working system.

Owner:贵州省煤层气页岩气工程技术研究中心

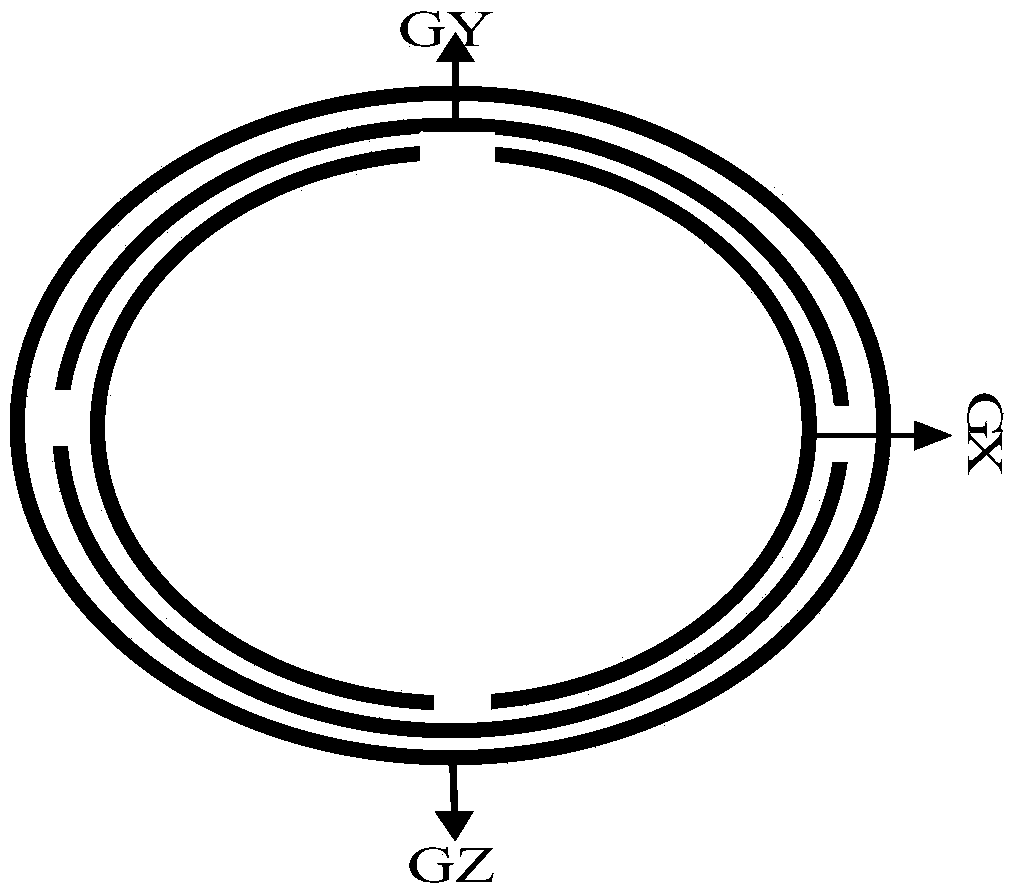

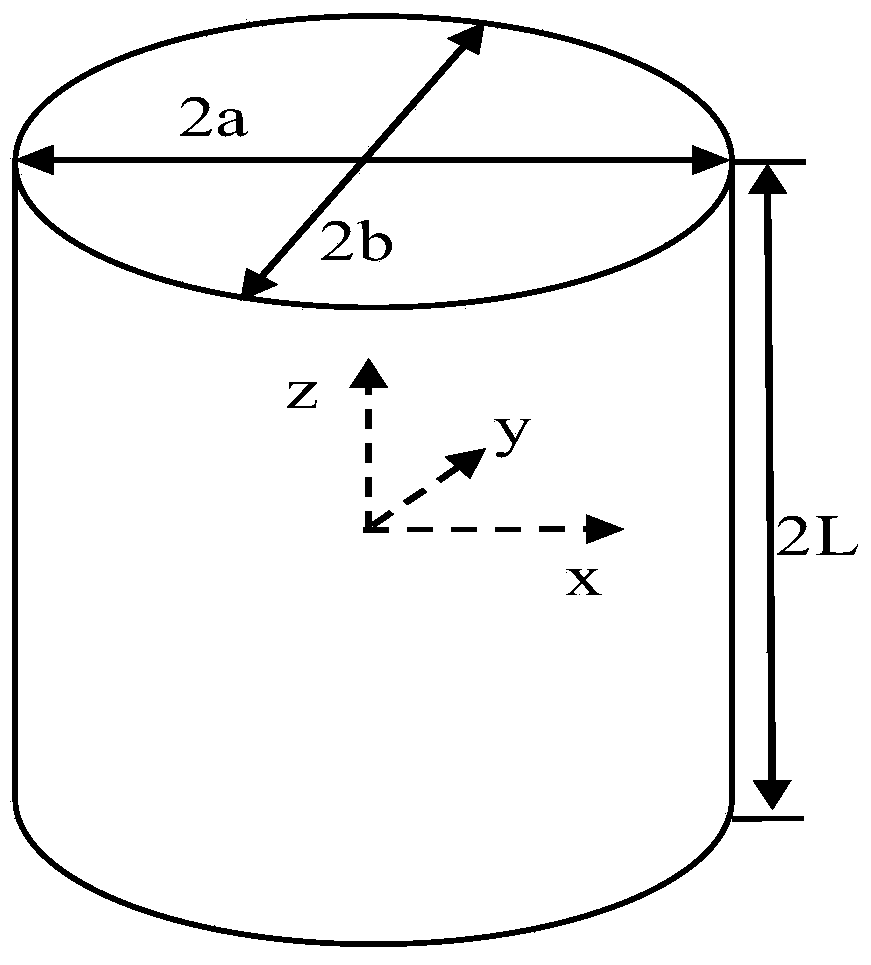

Method for designing elliptic cylindrical surface transverse gradient coil based on spatial alternation

InactiveCN104007406AAvoid cumbersome calculationsImprove efficiencyMagnetic measurementsCoils manufactureEngineeringSpatial transformation

The invention discloses a method for designing an elliptic cylindrical surface transverse gradient coil based on spatial alternation. The method is characterized by comprising the steps that firstly, two shafts of the elliptic cylindrical surface where the gradient coil is located are defined to be in the direction x and the direction y, the shaft length of the elliptic cylindrical surface where the gradient coil is located in the direction x is 2a, the shaft length in the direction y is 2b, the wiring length in the axial direction is 2L, the strength of the gradient field is G, and the linearity is E; secondly, spatial alternation is utilized for converting the elliptic cylindrical surface into a cylindrical face, and the current density basis function and the expression are constructed under the cylindrical face; thirdly, a functional construction related to the current density is built, and the coefficient of the current density expression is obtained by solving the functional extreme value; fourthly, the solved coefficient of the current density expression is utilized for solving distribution of current density in the space, and the wiring shape of the gradient coil is obtained. The complex calculation of gradient coil designed through the network discrete method is avoided, and the high efficiency and precision are obtained.

Owner:HOHAI UNIV

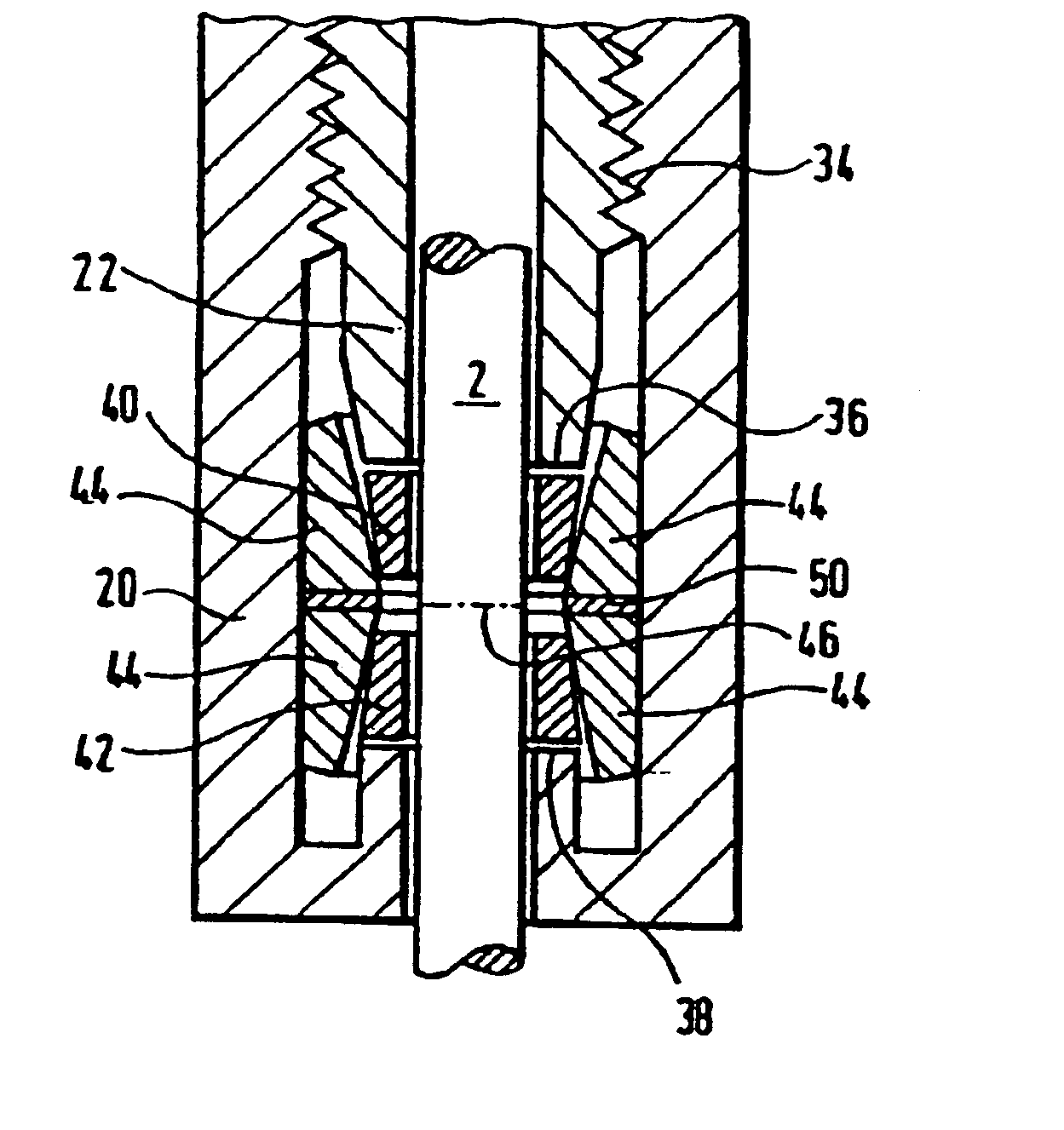

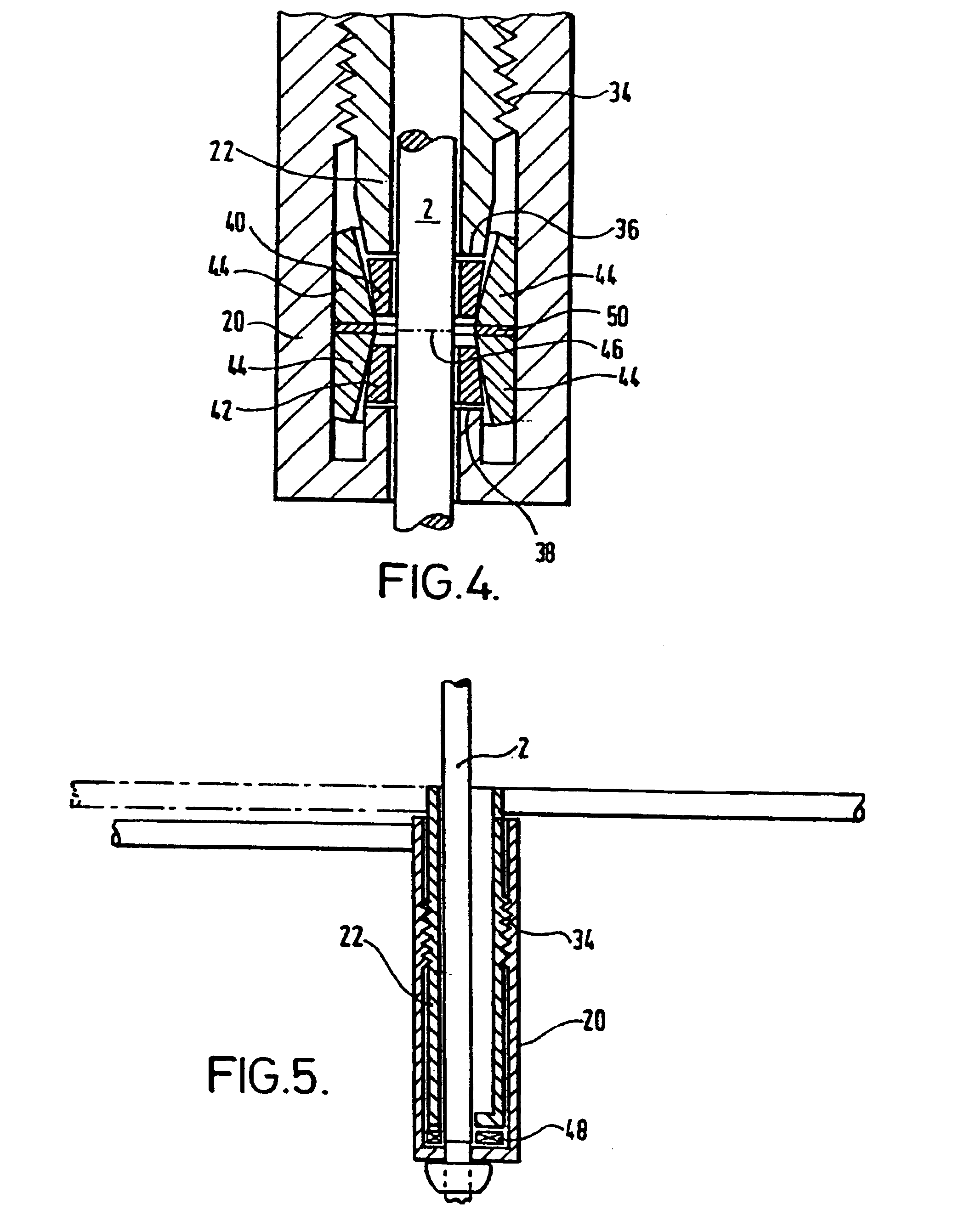

Tool for shearing bolts

InactiveUS6928900B2Improve stabilityEffective lockingInternal osteosythesisLoad modified fastenersEngineeringScrew thread

A tool for breaking a shaft includes two aligned tubular elements (20, 22), each having an end portion for receiving a contiguous length of the same shaft (2). Means are provided for locking each end portion against rotation relative to the shaft length received therein, and the elements are adapted for rotation relative to one another with the end portions so locked, to relatively twist the shaft lengths and shear the lengths at the interface between them. The element end portions will normally have juxtaposed faces, and it is preferred that the faces are moved towards each other during the relative rotation and as the shaft lengths are twisted relative to each other. This assists in achieving a substantially planar face at the fracture plane. A compressible washer may be disposed between the juxtaposed faces. This can stabilize the moving parts as the shaft is broken, although normally screw threads on the tubular elements will effect the movement of the element. towards each other, and this in itself may provide sufficient stability.

Owner:V O DESIGN & INNOVATION

Adjustable trailer hitch mount for an umbrella

InactiveUS20100059093A1Increase distanceDesired lengthWalking sticksUmbrellasSquare cross sectionScrew position

The trailer hitch mount for an umbrella includes a square cross-section shaft that is adapted to slide into a standard sleeve-style trailer hitch receiver that is currently available on many vehicles. The shaft includes a series of holes along the sides thereof to receive a pin in order to secure the shaft to the trailer hitch receiver in a telescopic relationship. The series of holes allows the shaft length to be adjusted, so that the distance between the trailer hitch receiver and the opposed end of the shaft may be shortened or lengthened, as desired. The shaft includes two ends, one of which slides into the trailer hitch receiver, and the other end includes a hollow pivoting cylindrical tube that is used to receive the bottom end of an umbrella pole. The pivoting tube includes adjustment means, so that the pivoting tube may be tilted to a desired angle and secured in that position. For travel or storage purposes, the pivoting tube may be folded down and secured into a compact position parallel with the shaft. At an upper end of the pivoting tube is receiving and securing means for the umbrella pole. The umbrella pole, in a preferred embodiment, slides into the hollow pivoting tube and a hand screw positioned on the side of the pivoting tube at its upper end may be tightened against the umbrella pole and secured thereby.

Owner:CLARK SCOTTY OBRIAN +1

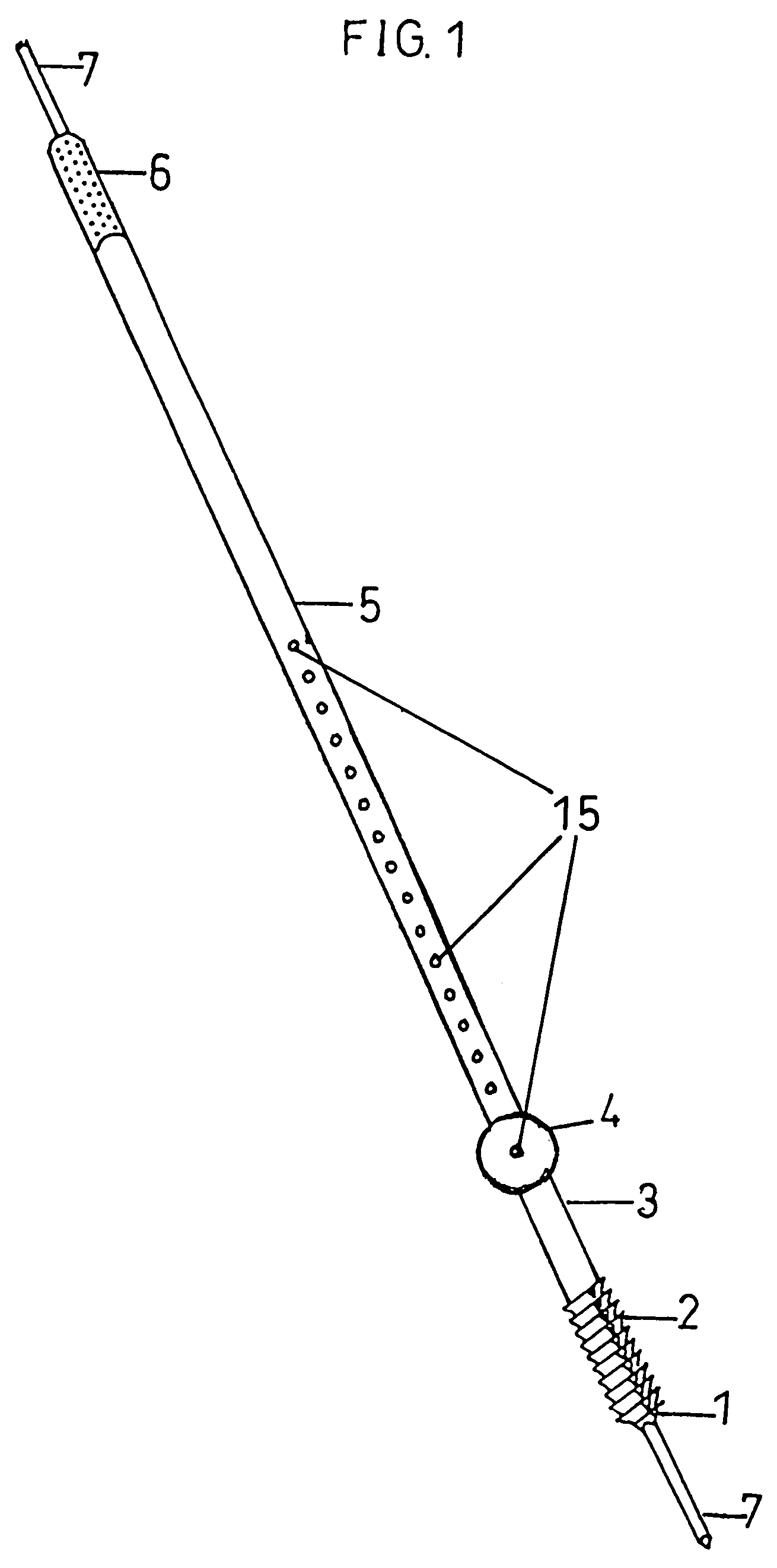

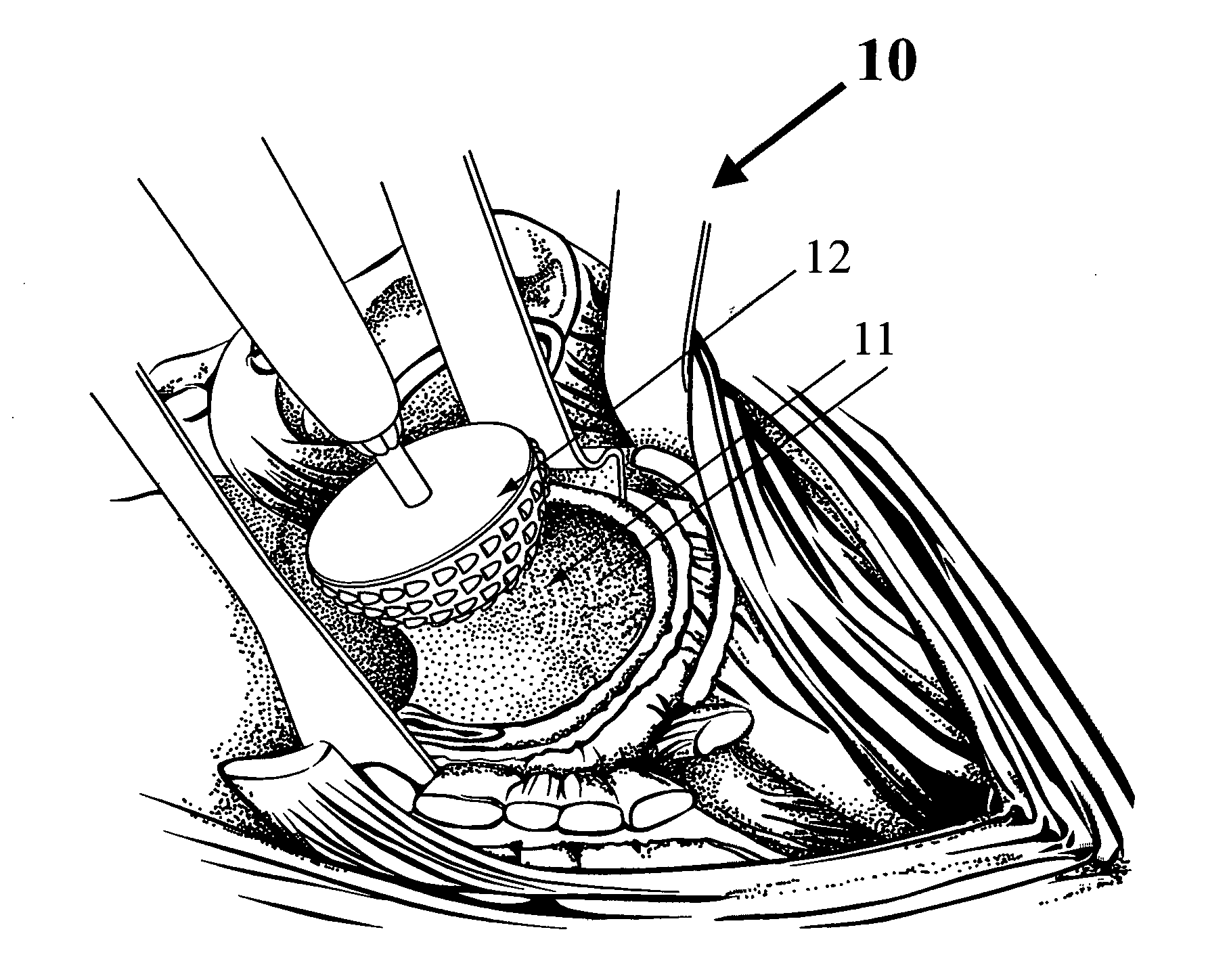

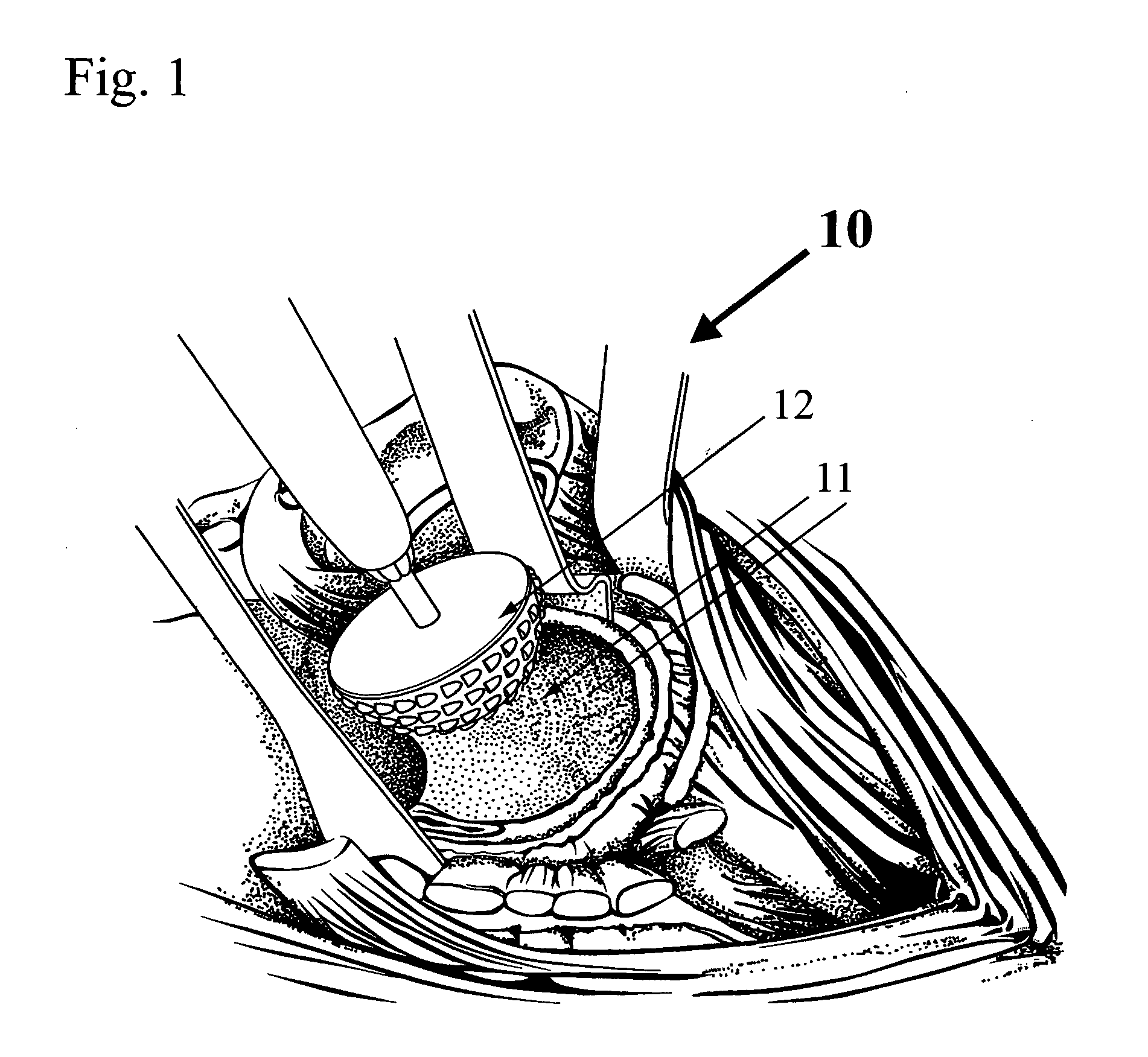

Disposable reamer shaft or modular spherical or tapered hollow reamer assembly for medical applications

ActiveUS20100168749A1Reduce manufacturing costPrecise processingMetal-working drilling toolsSurgeryFiberEpoxy

A low cost disposable reamer shaft is made from a rod or tube stock of stainless steel, Nitinol or fiber reinforced polymer having a precise outer diameter in the range of 4 to 14 millimeter and is cut to a shaft length of 250 to 400 millimeters. An attachment piece with male or female thread matching a spherical hollow or tapered hollow reamer is machined and glued with epoxy on one end of the rod of tube stock using a precision centerline aligning jig. An attachment piece for connecting to a drive power unit is machined and glued with epoxy to the other end of the rod or tube stock thus forming a low cost disposable reamer shaft that aligns the centerline of the shaft with that of the reamer. The shaft contacts the reamer at two attachment locations that are displaced from each other, providing precise centerline alignment.

Owner:LRS SCI & TECH LLC

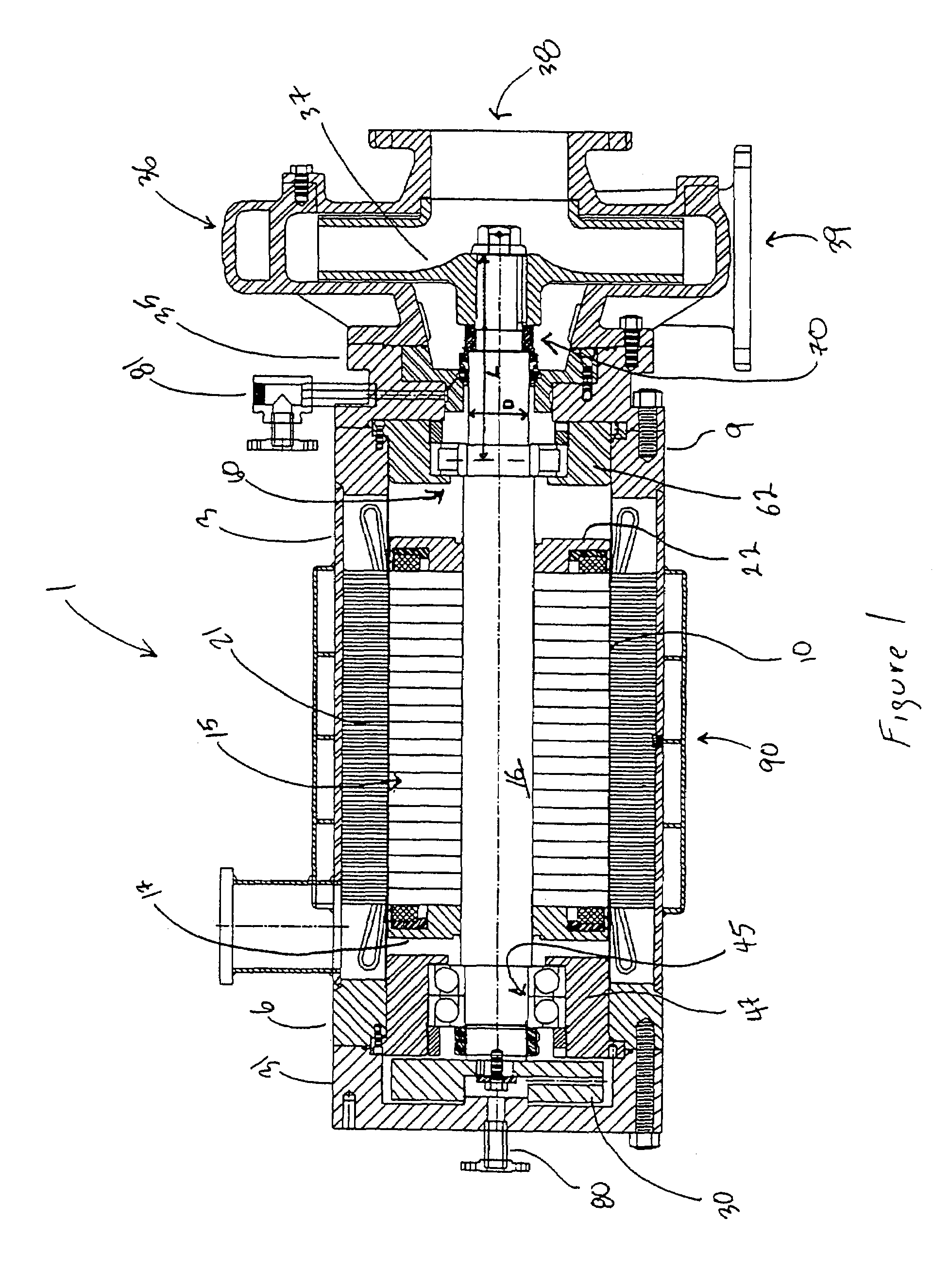

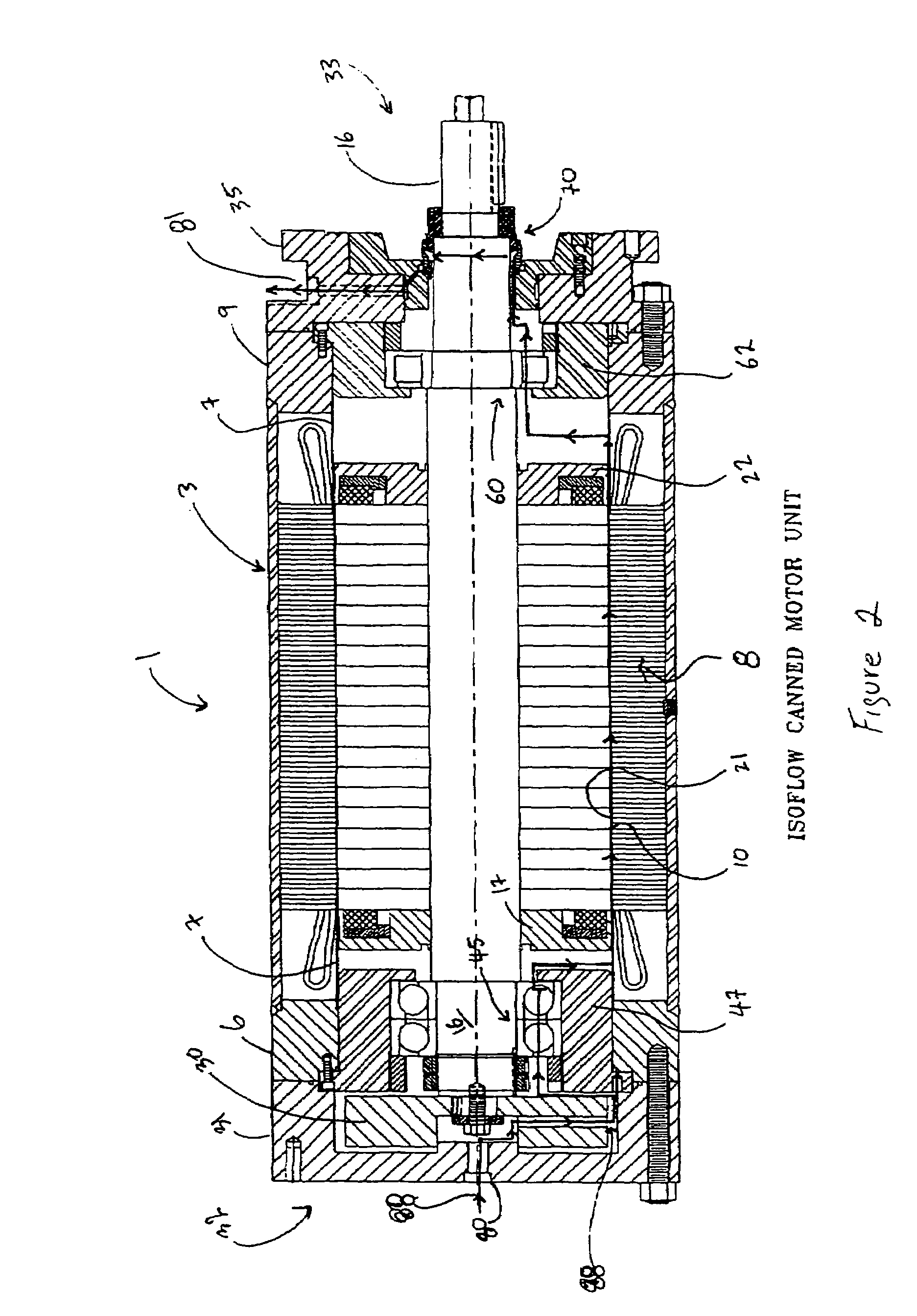

Low speed canned motor

A canned motor has an L3 / D4 ratio of less than 50, with one bearing on one end of the rotor assembly configured to resist longitudinal displacement of the rotor as by an axial shaft load, and another bearing on the other end of the rotor assembly configured to allow limited longitudinal displacement of the rotor assembly within the bearing as from thermal expansion, lengthwise adjustment or pressure from an axial shaft load. The rotor assembly may include a center shaft coaxially extended through a hollow shaft, with rotor windings mounted on the hollow shaft, with the first bearing positioned on one end of the hollow shaft and the second bearing mounted on the second hollow shaft end. A cap and nut assembly on the second hollow shaft end, into which the rotor shaft end is threaded, provides for adjusting the effective rotor shaft length protruding from the motor, and for replacement of the rotor shaft within the hollow shaft without removing the rotor assembly from motor.

Owner:FLOWSERVE MANAGEMENT CO

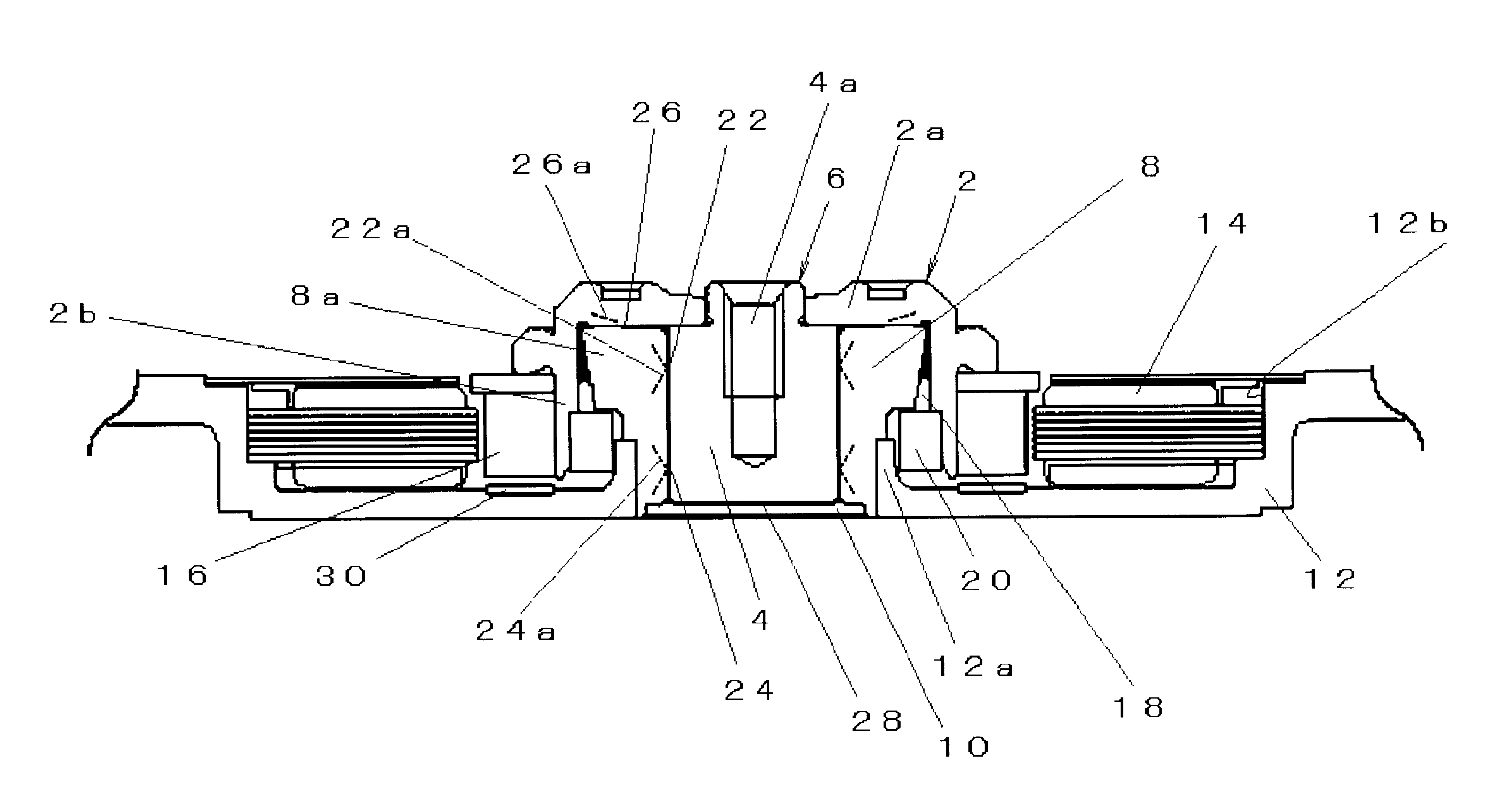

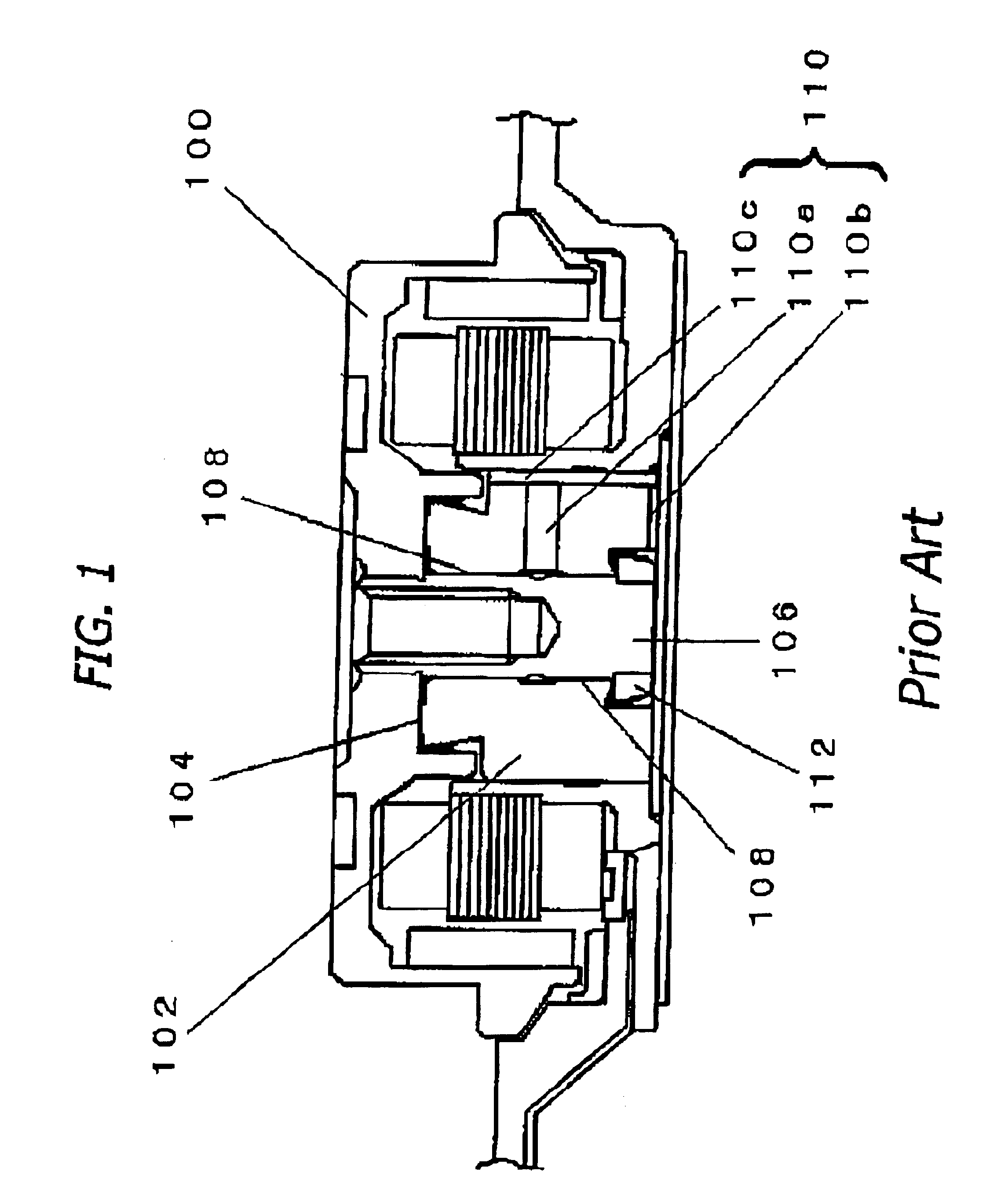

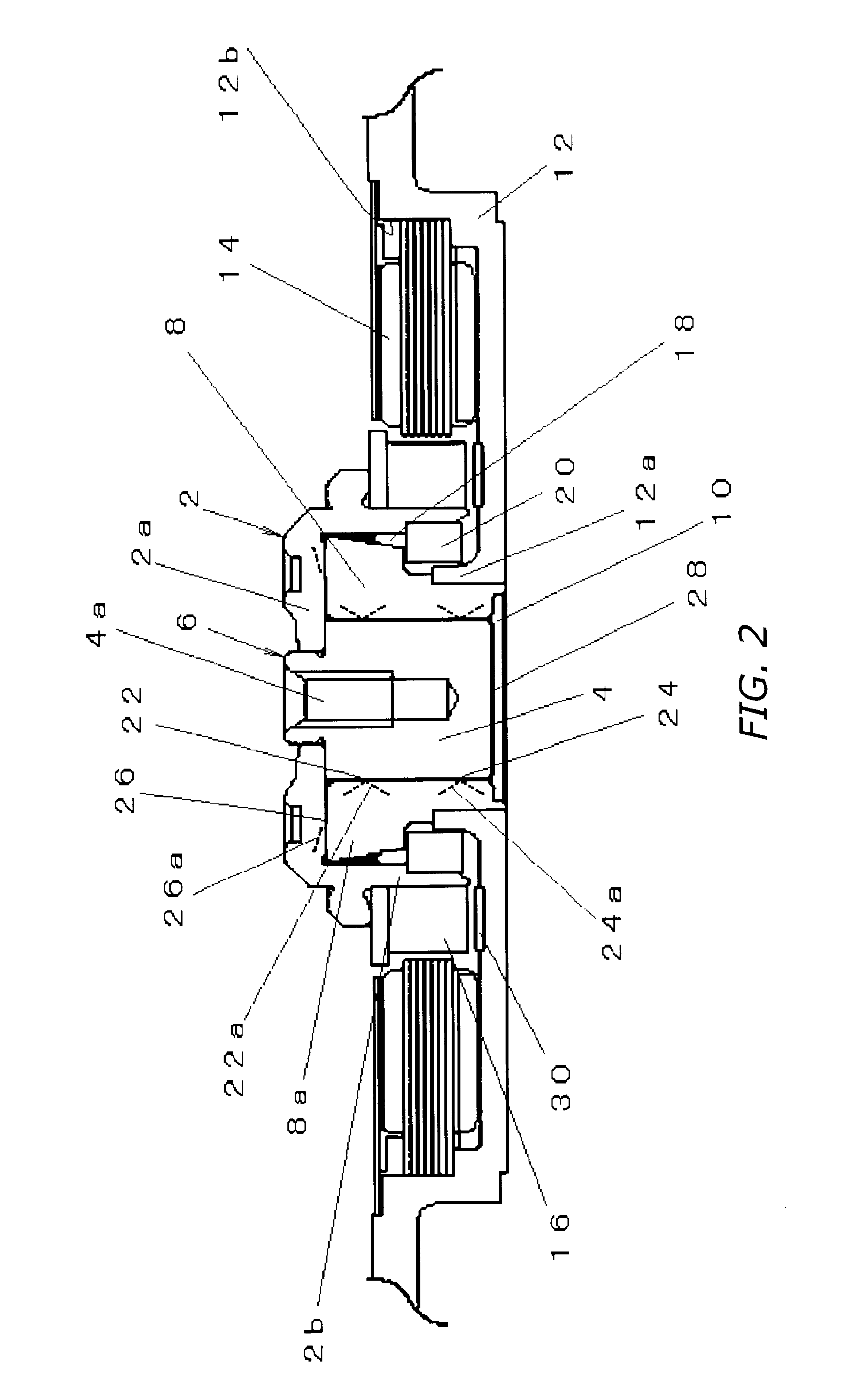

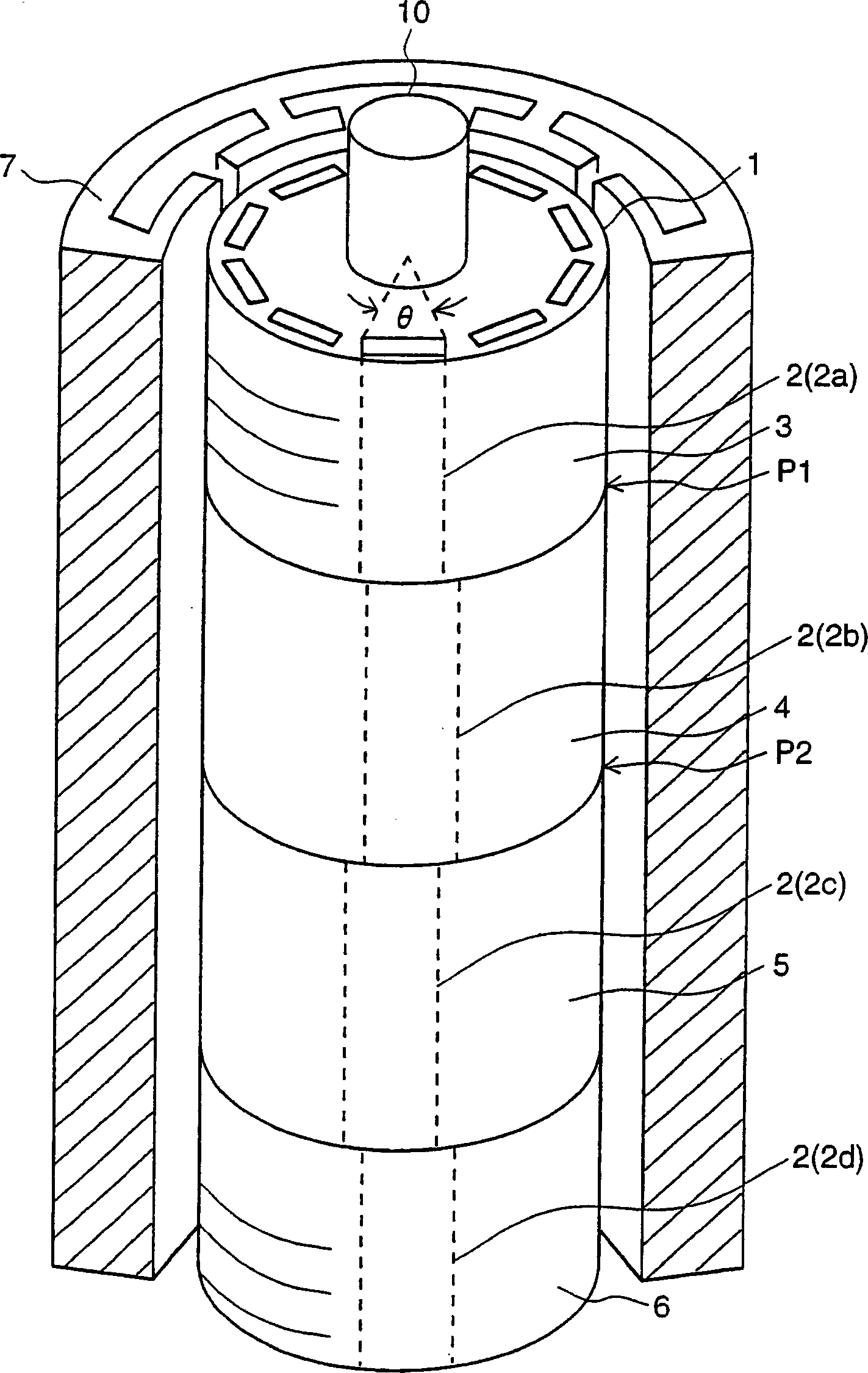

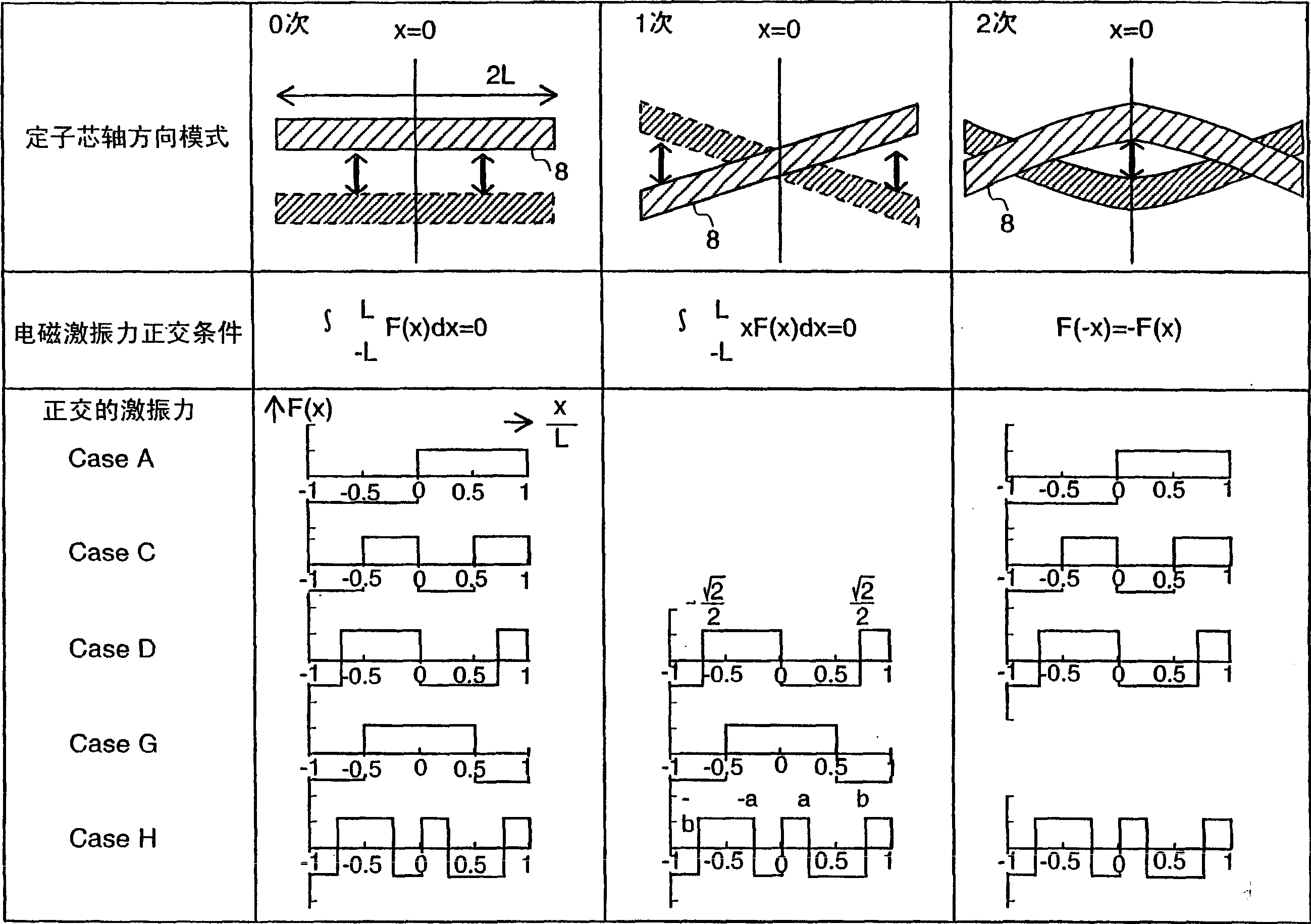

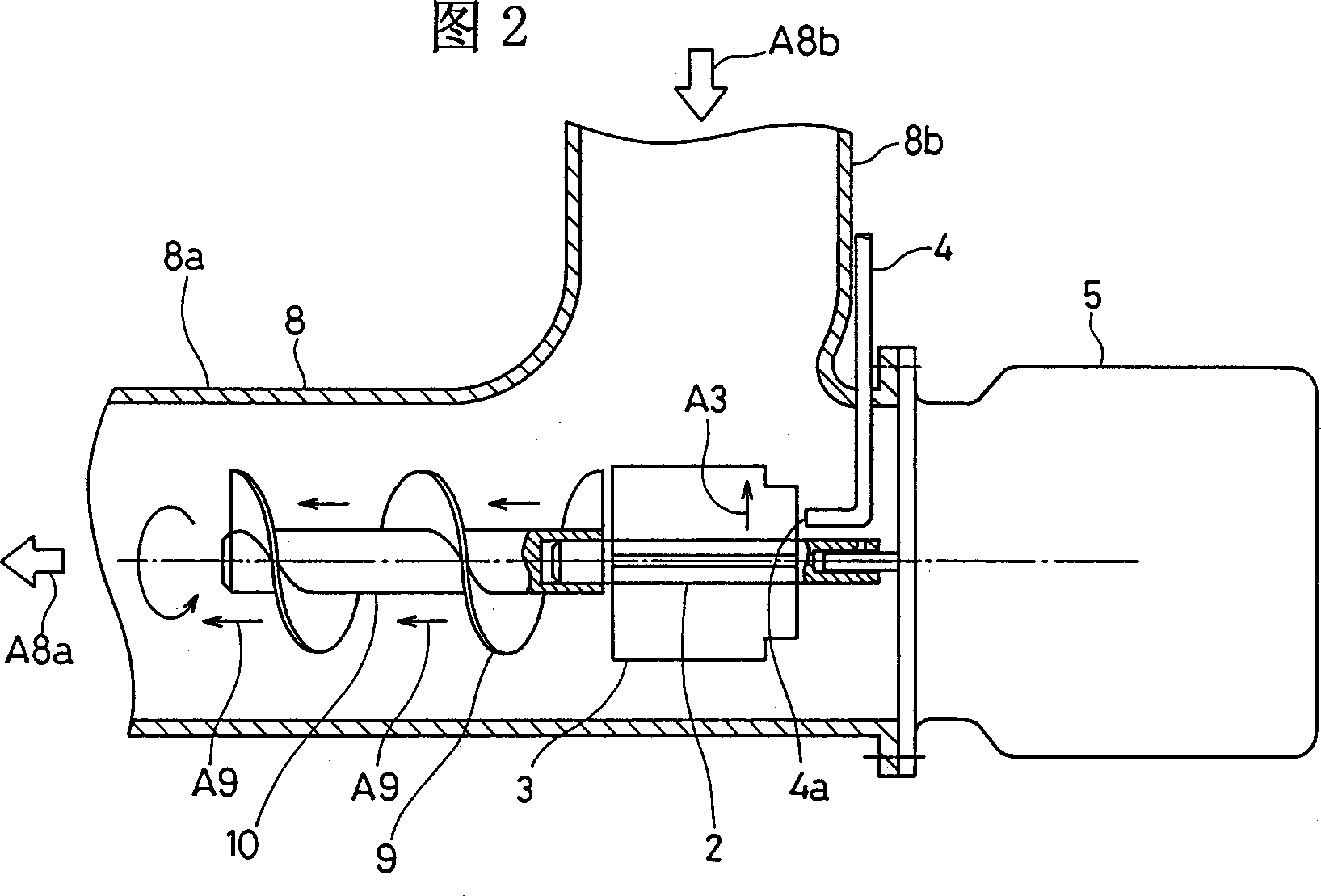

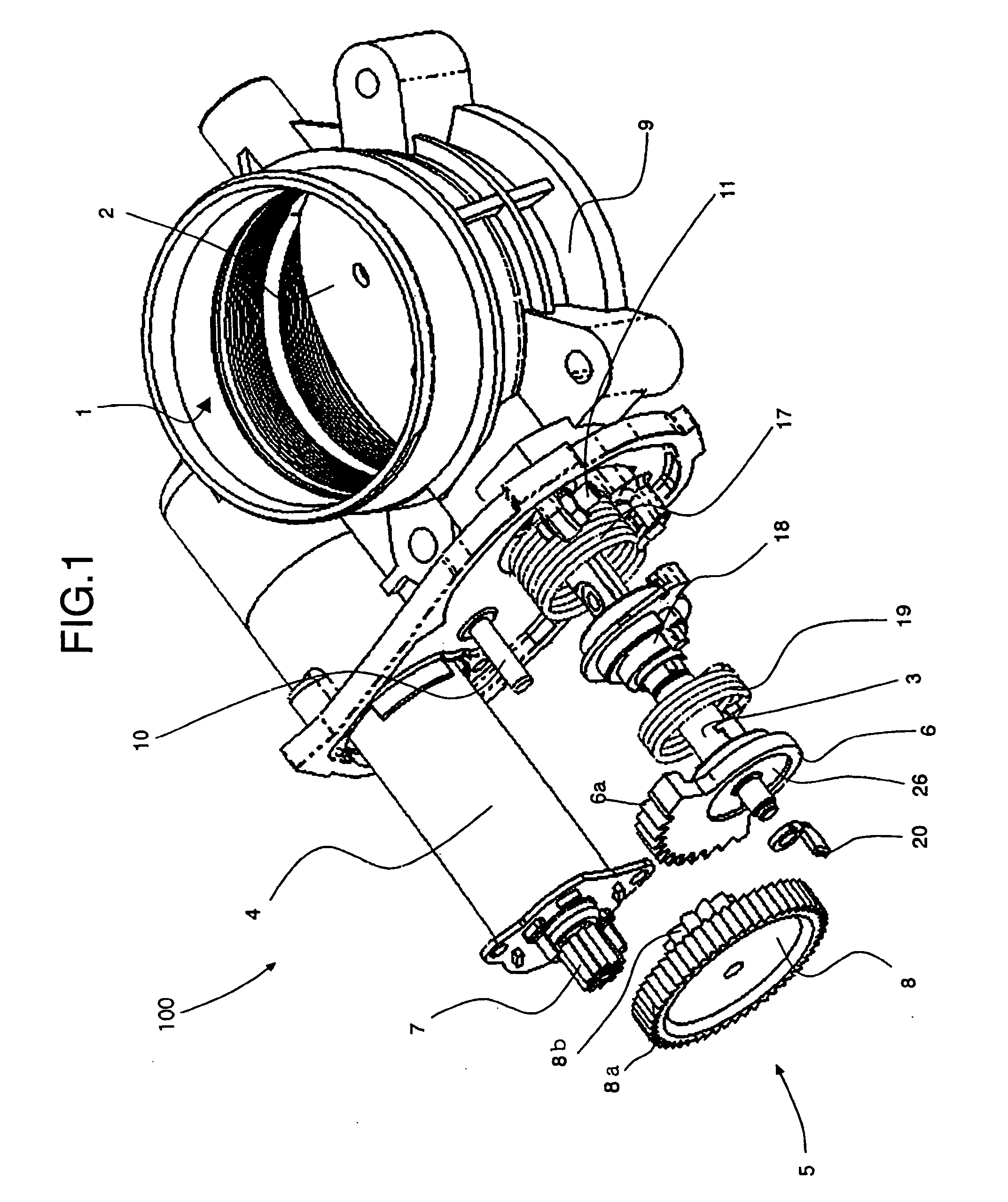

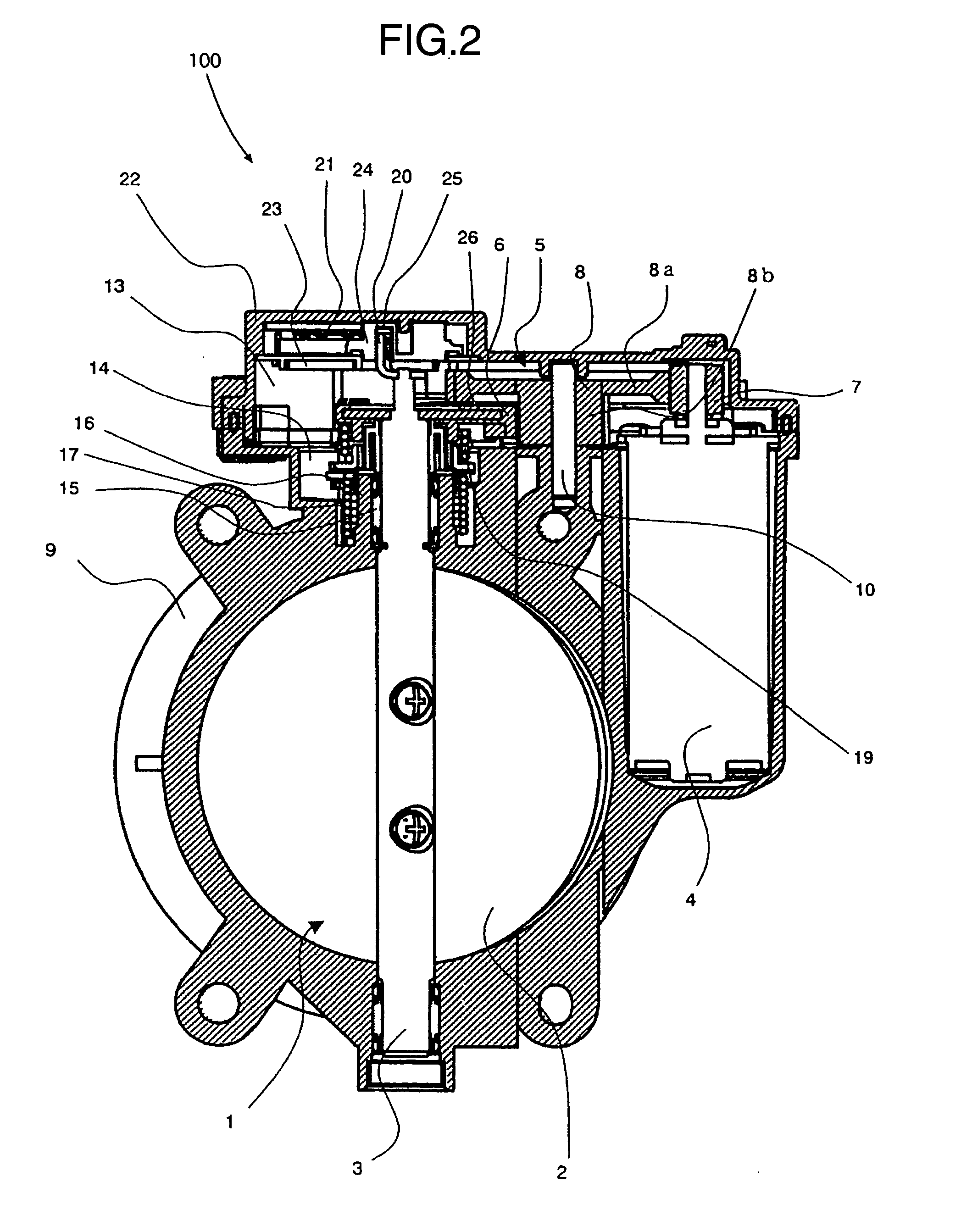

Electric motor

InactiveCN1799176AReduce noiseMagnetic circuit rotating partsMagnetic circuit stationary partsPhase differenceShaft length

It is possible to suppress vibration and noise caused by radial-direction electromagnetic excitation force of an electric motor. In an electric motor (100), a rotor (1) is divided into four rotator pieces (3, 4, 5, 6) with respect to a shaft length 2L of a group of rotor cores. For example, it is ideal that the four rotor pieces (3, 4, 5, 6) respectively have a shaft-direction length: 0.29L, 0.71L, 0.71L, and 0.29L. Permanent magnets (2) of the respective rotor pieces (3, 4, 5, 6) are arranged in such a manner that the phase difference of the electrical angle in the circumferential direction of the rotor (1) is 0, pi, 0, pi. Moreover, when effect can be obtained even when the theoretical shaft length is changed, the tolerance with respect to the aforementioned shaft length is +-0.1L.

Owner:HITACHI LTD +1

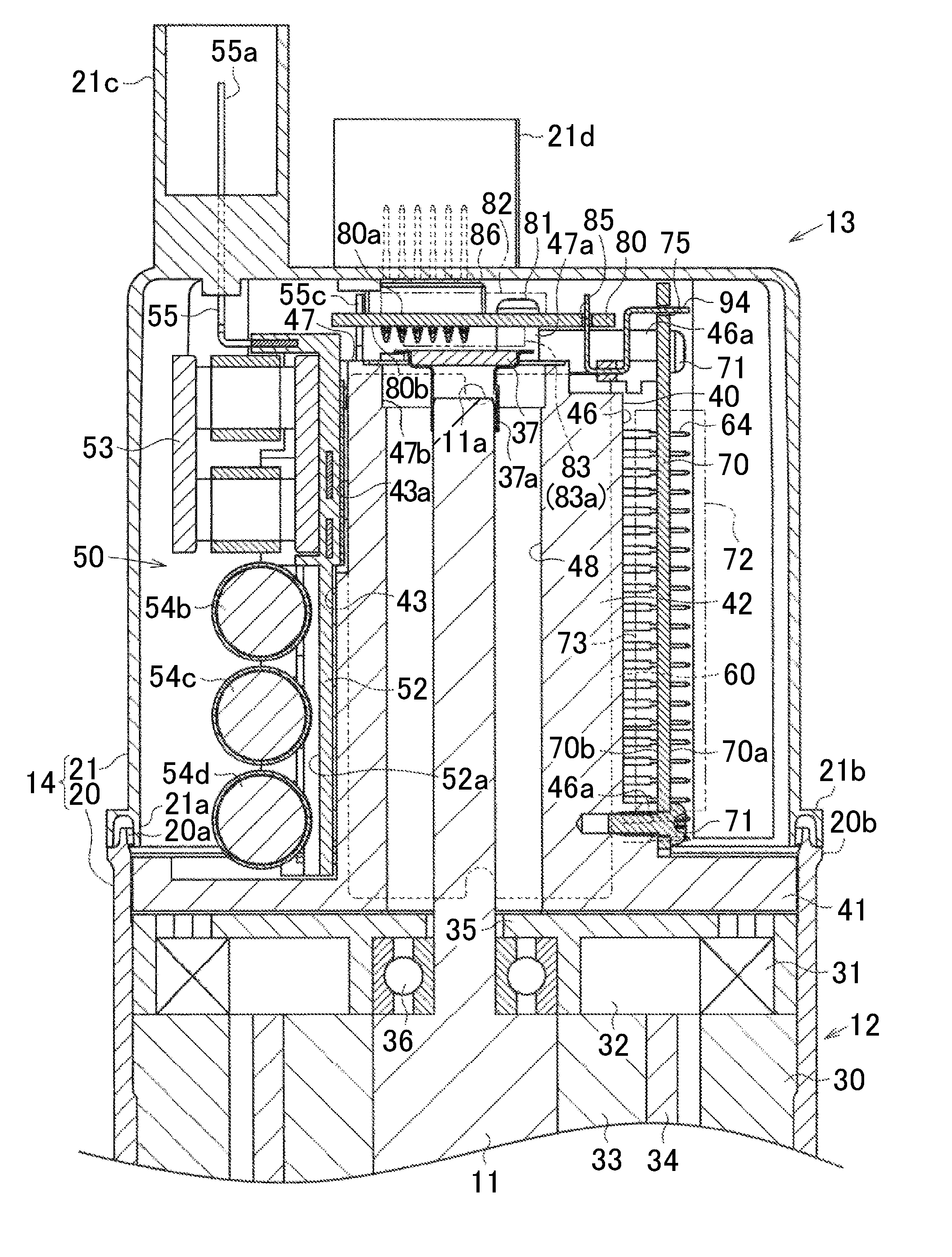

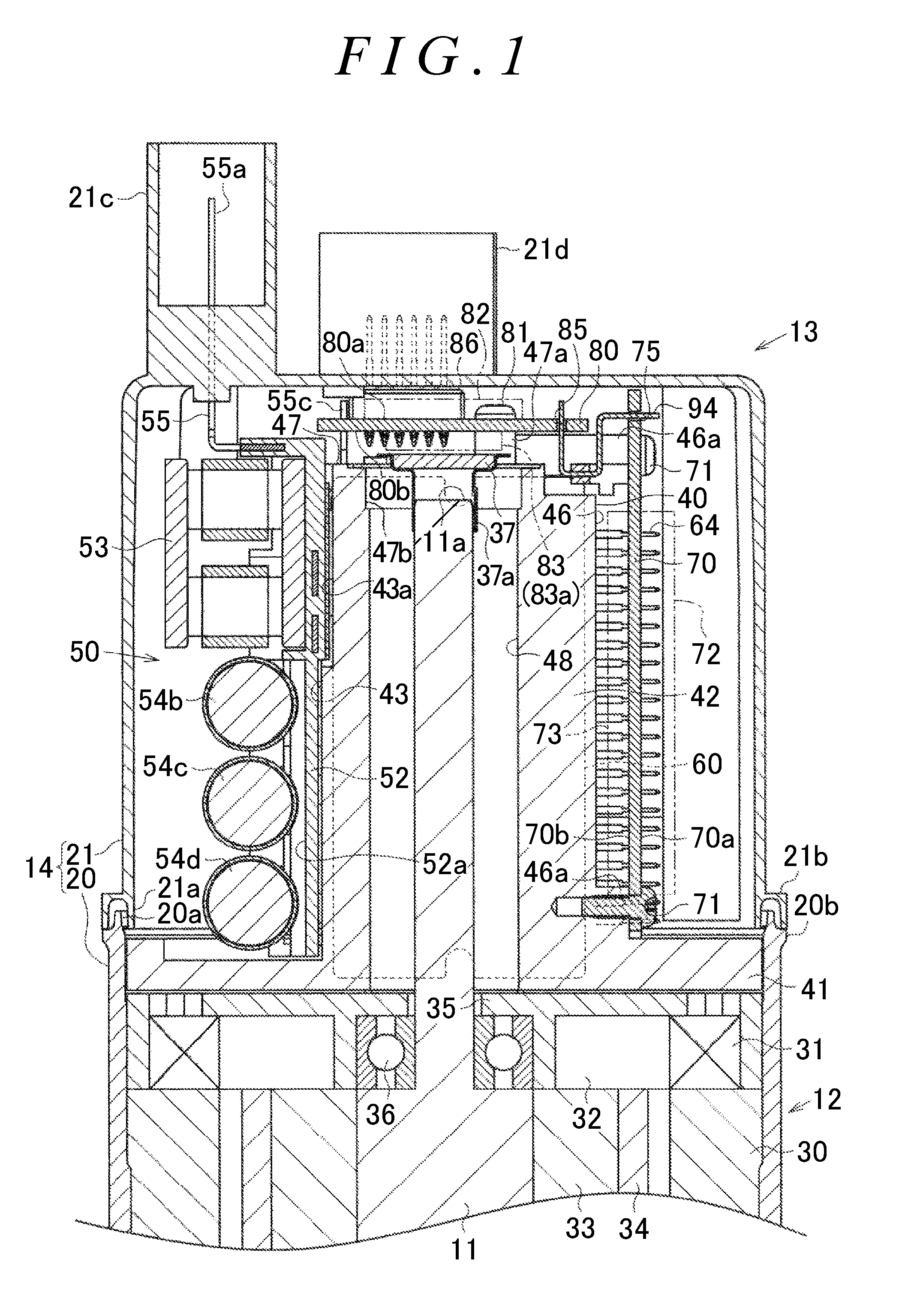

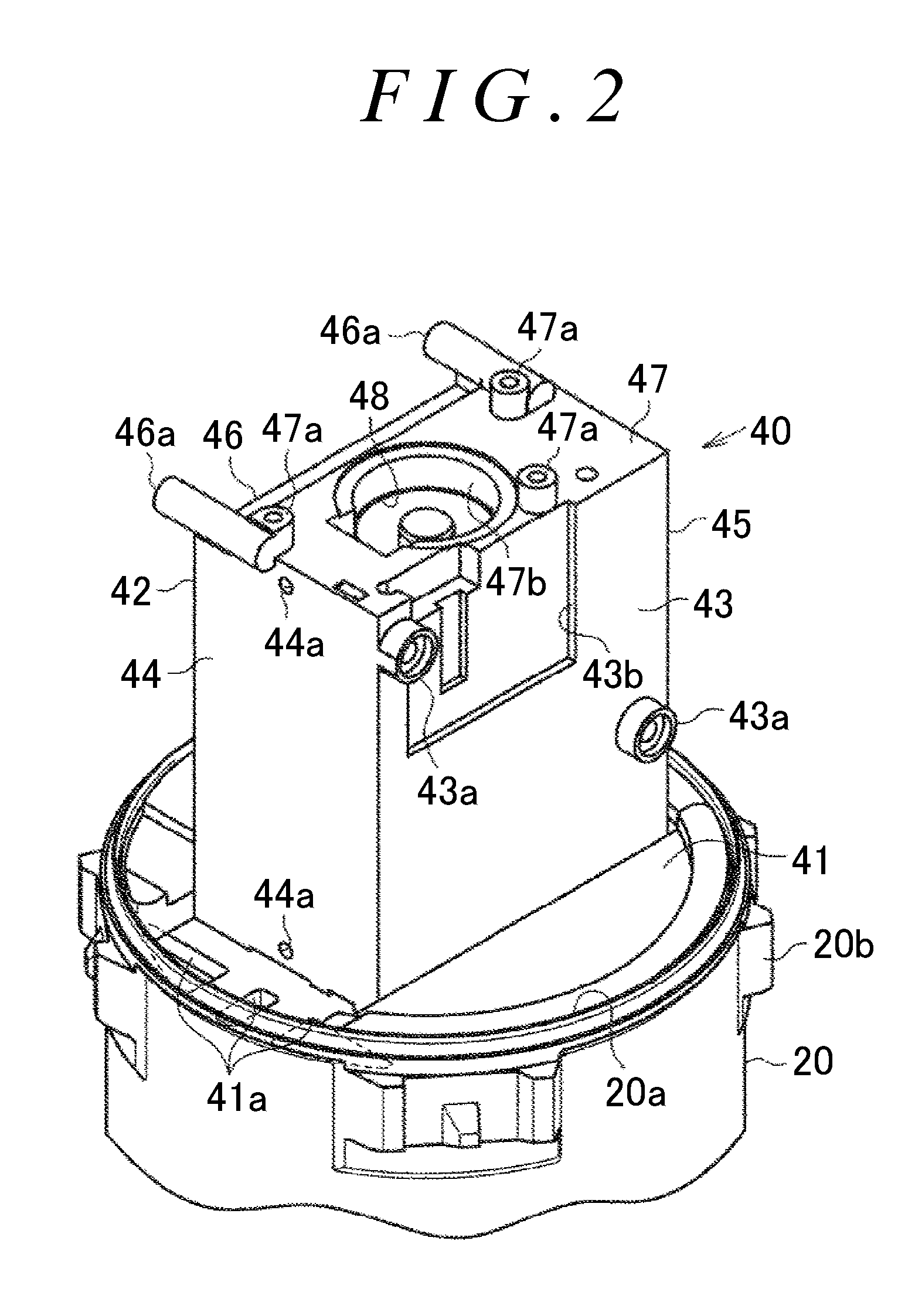

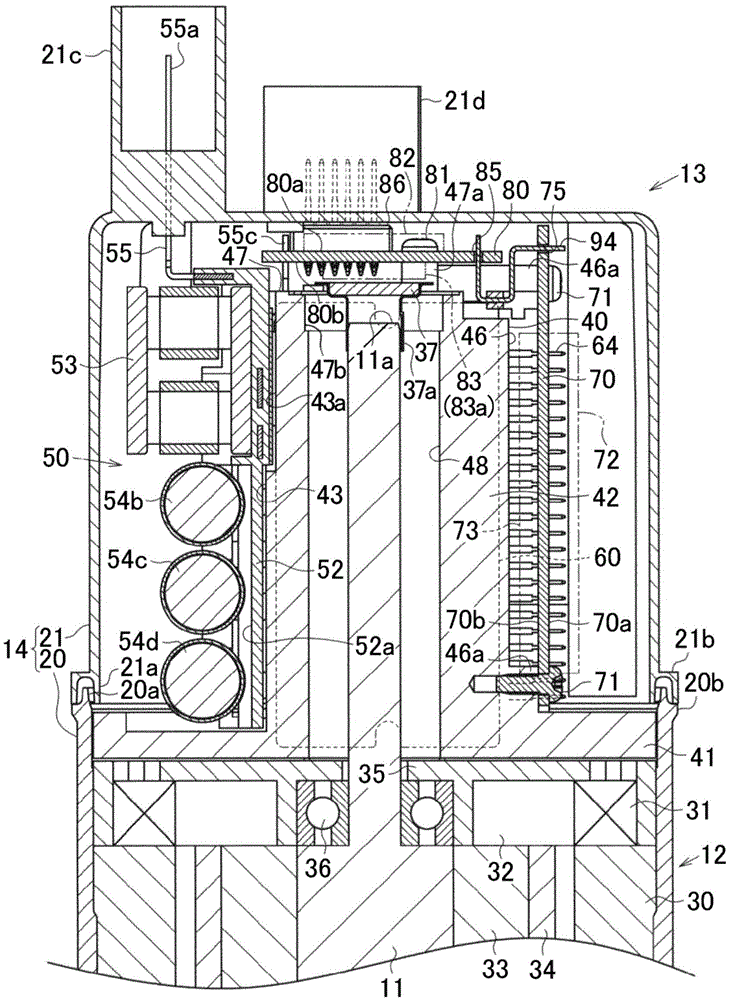

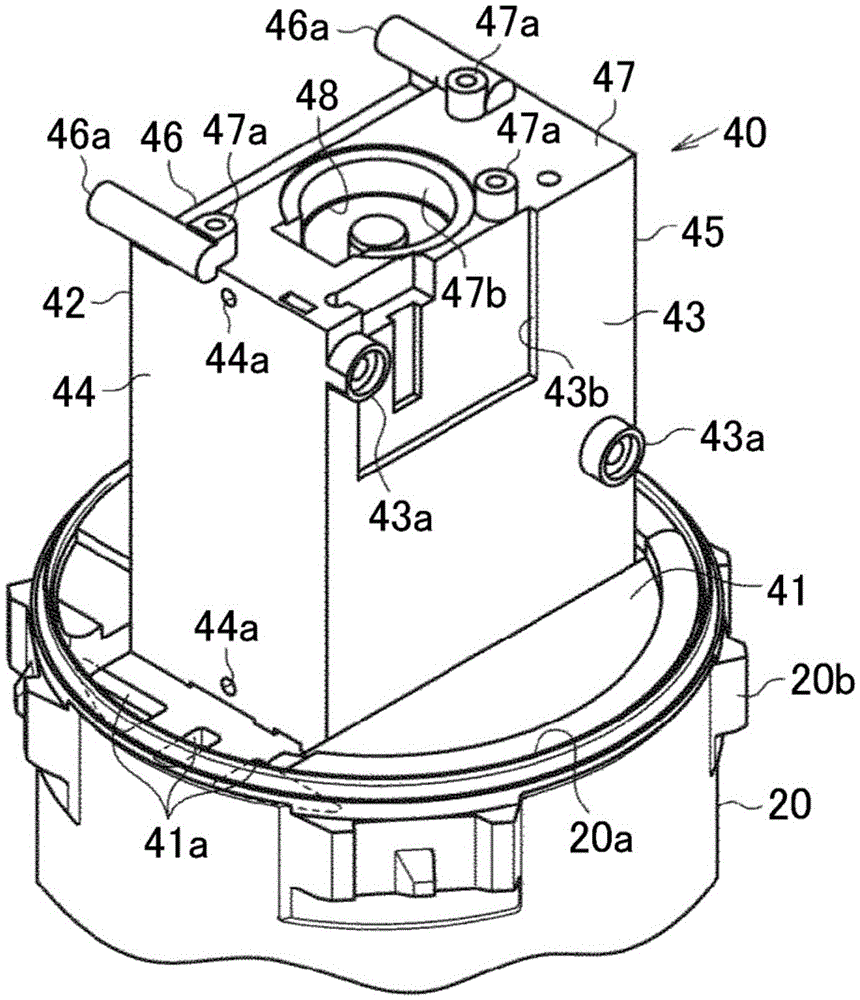

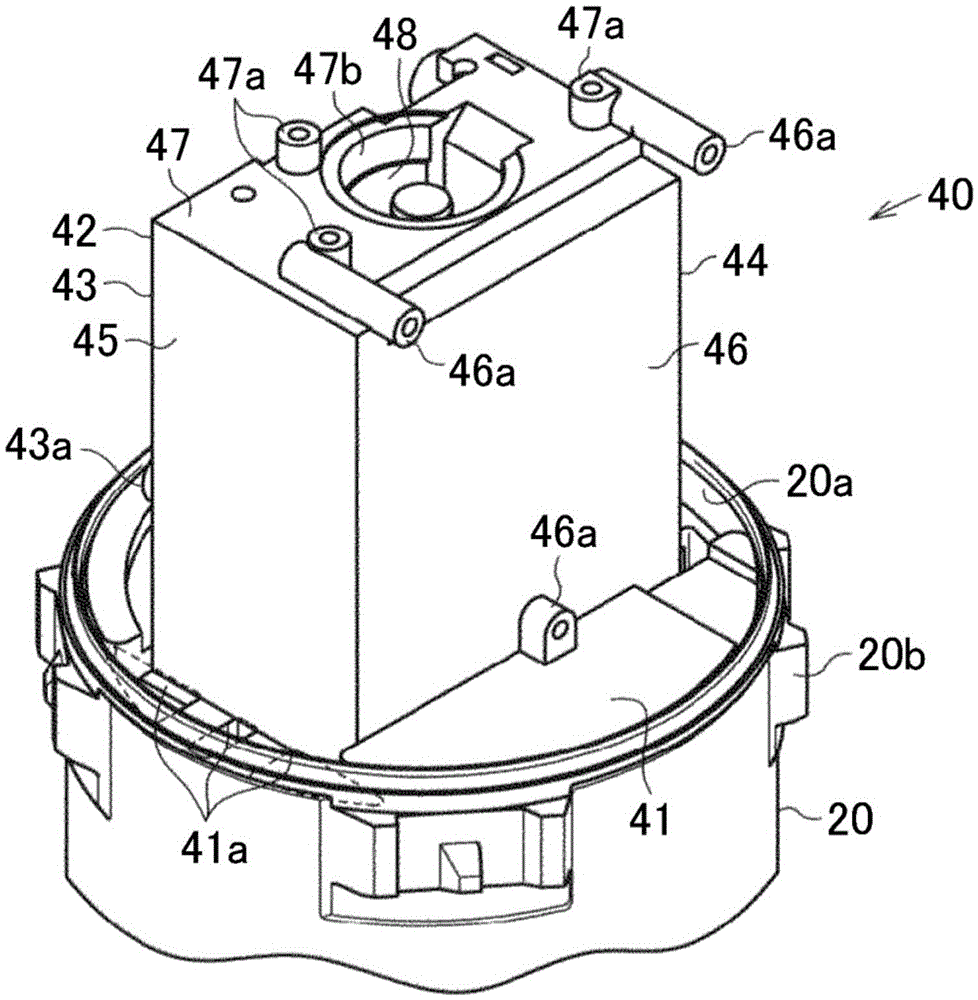

Motor unit

InactiveUS20160254732A1Increase in sizeIncrease the number ofAssociation with control/drive circuitsPower driven steeringEngineeringElectronic component

A motor unit includes a motor; and a control board configured to execute a control to drive the motor. The control board includes a first control board and a second control board. The first control board is provided such that a mounting space for at least one electronic component perpendicularly intersects with an extension line extending from a shaft end part of a motor shaft and extends along a shaft radial direction so as to allow the at least one electronic component to be disposed along the shaft radial direction. The second control board is provided such that a mounting space for at least one electronic component extends along a shaft length direction so as to allow the at least one electronic component to be disposed along the shaft length direction. The motor and the control board are unitized.

Owner:JTEKT CORP

Motor Unit

InactiveCN105932830AInhibit heat generationAssociation with control/drive circuitsPower driven steeringDrive motorEngineering

Owner:JTEKT CORP

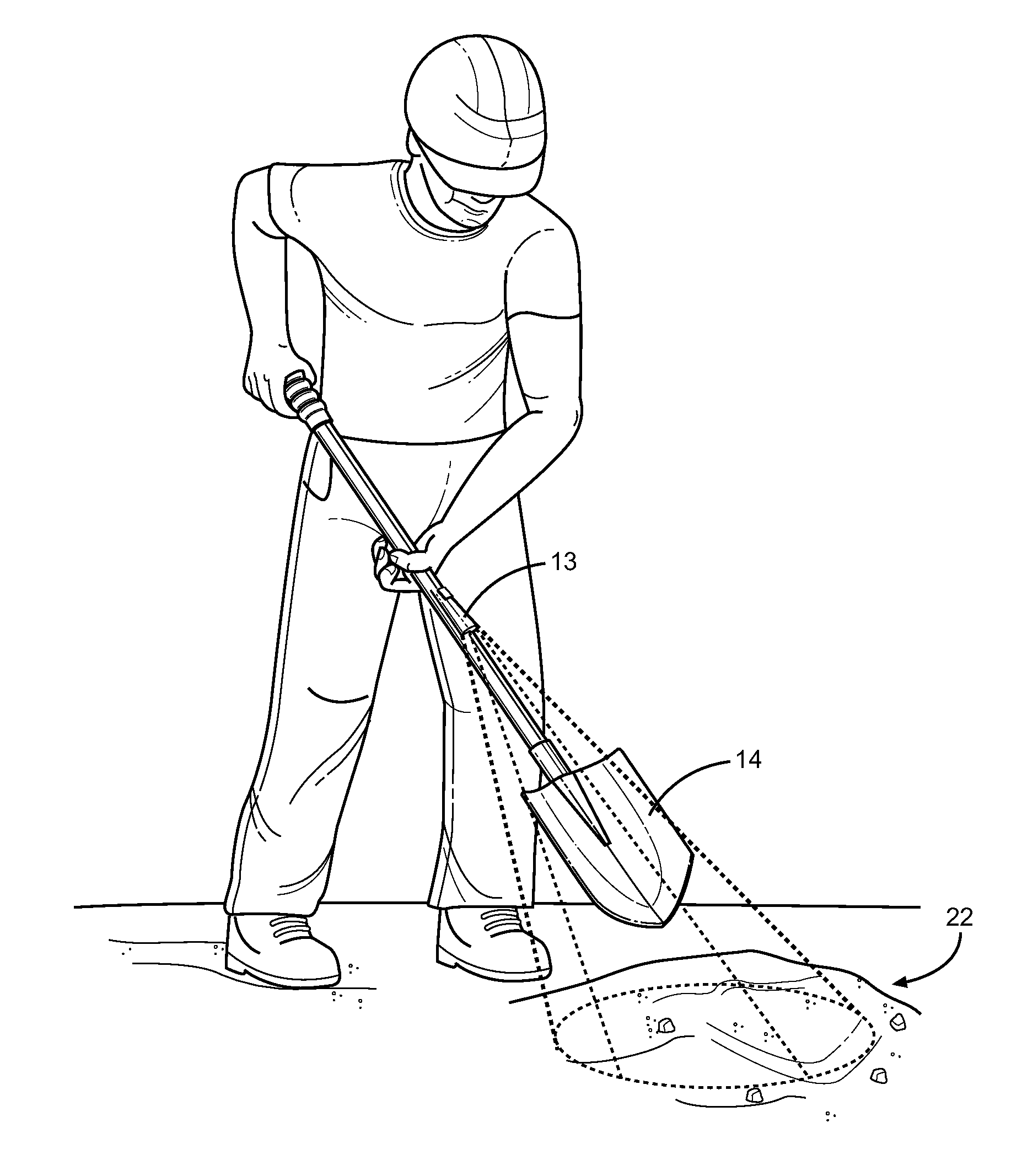

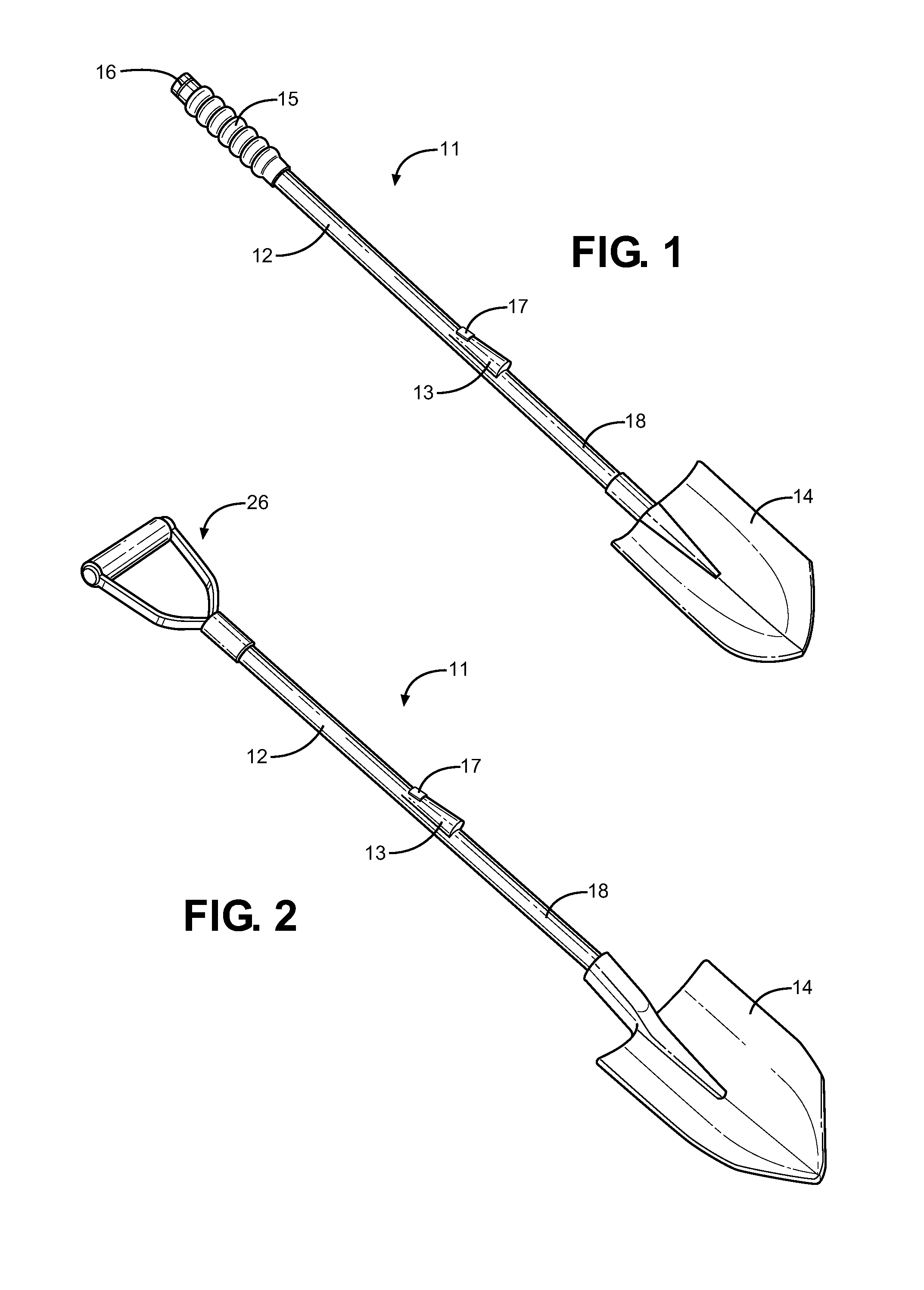

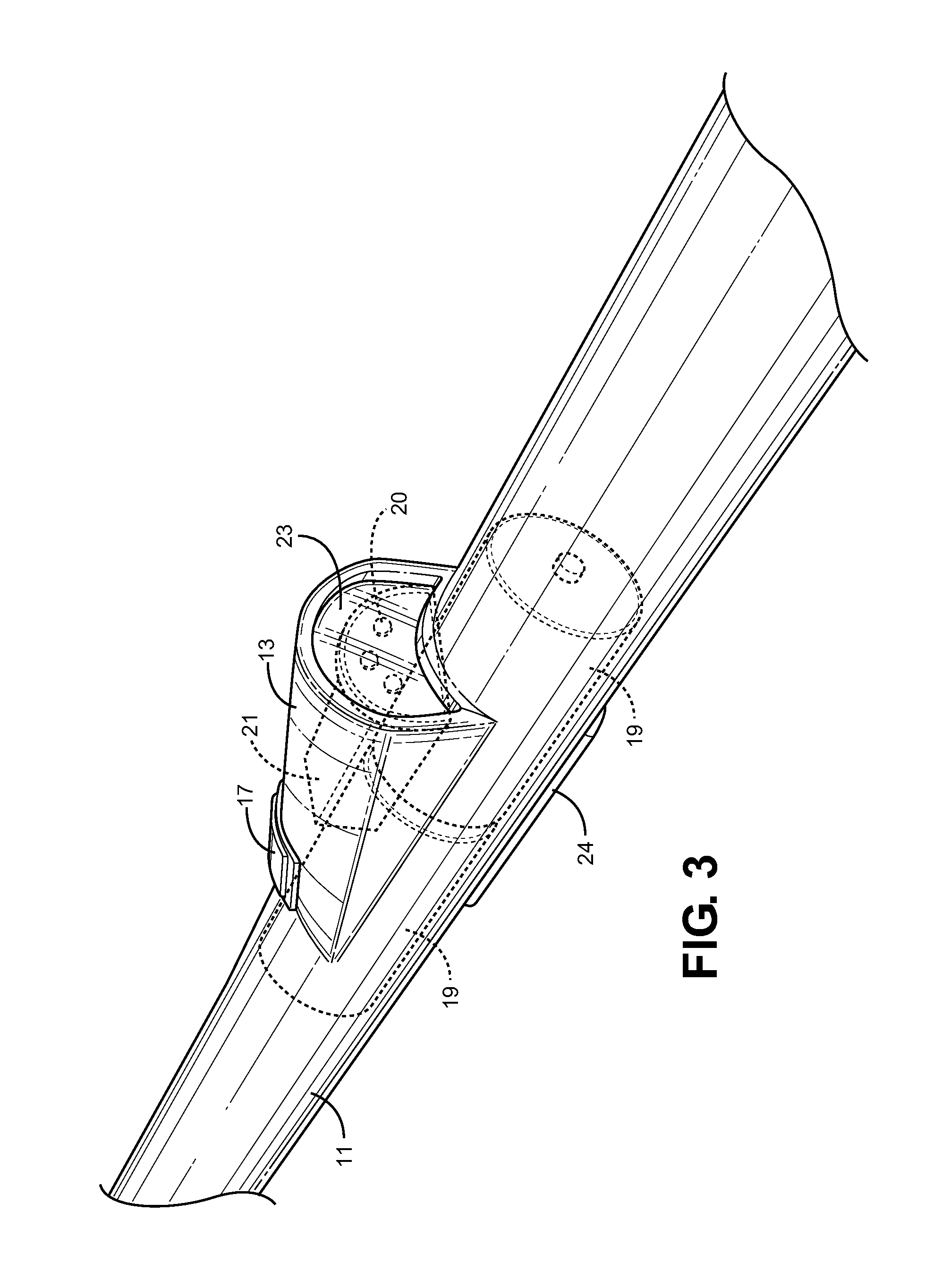

Illuminated Shovel Tool

Disclosed is a shovel tool implement having an imbedded illumination means and a means for storing an auxiliary light source in its handle. The tool comprises an elongated shaft having a proximal handle end and distal working end, the distal end preferably connecting to a shovel implement, the proximal handle end preferably having a slot in which to store a removable flashlight. At a location along the shaft length is provided an outward projection for housing a light source, power supply and on / off switch. The projection extends outward from the shaft and directs light towards the shovel working end, while the backside of the projection includes a removable cover for replacement of batteries and light source elements. The projection is situated such that normal handling of the shovel is not impeded, while the directed light allows a user to visualize a given work area in a low light environment.

Owner:BEST JASON

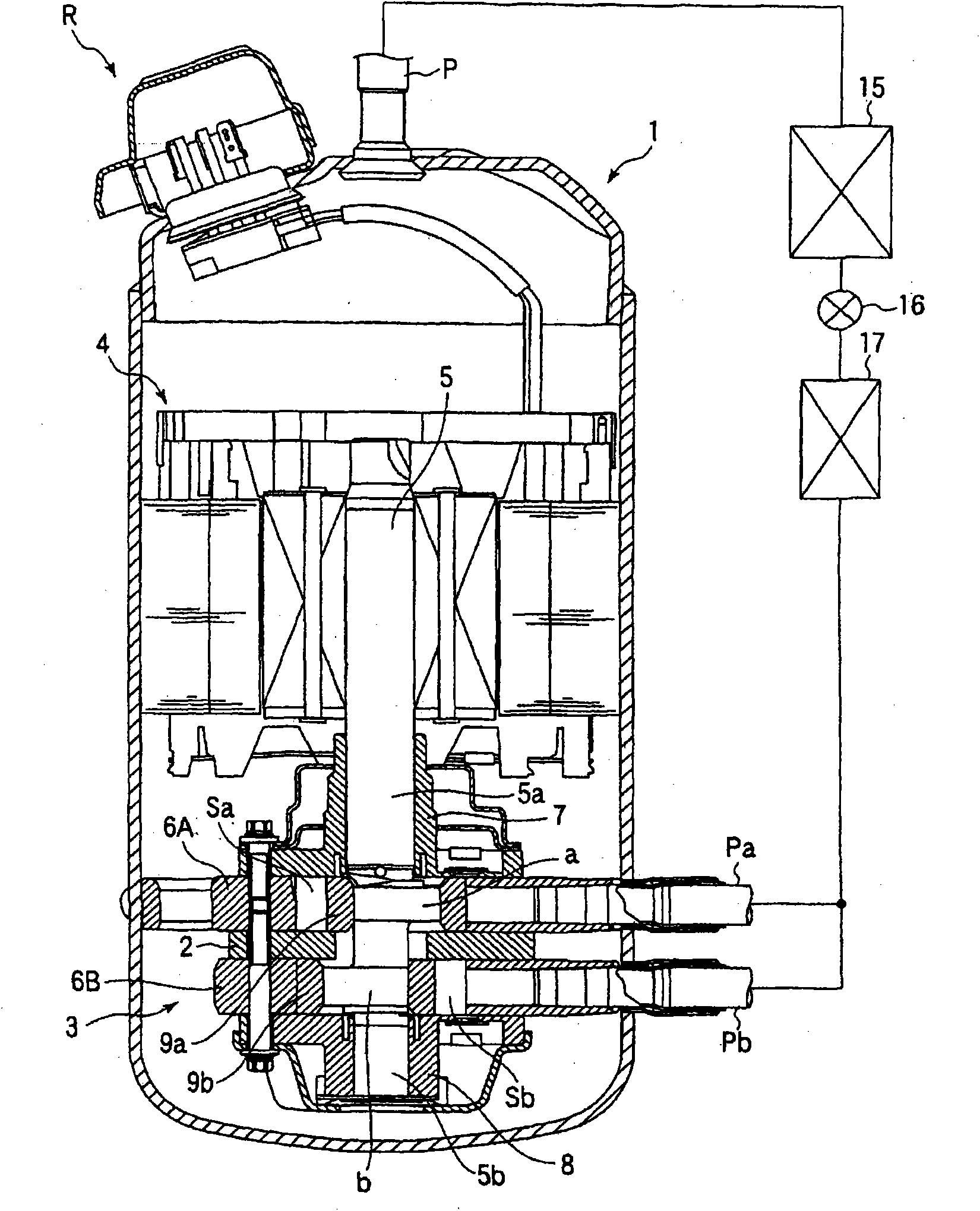

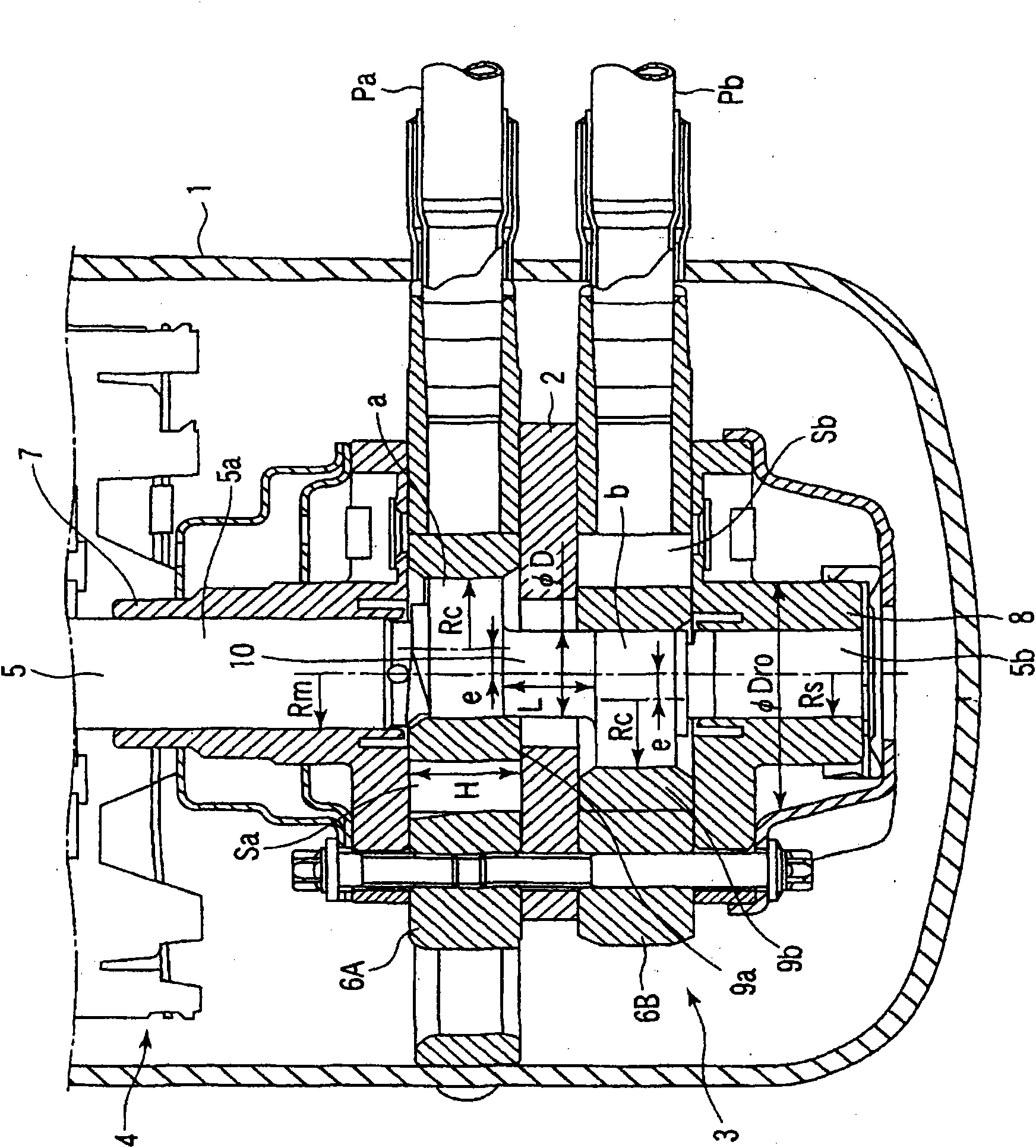

Rotary compressor and freezing cycle device using the same

ActiveCN101684792ASuppression of sliding lossEliminate lack of rigidityCompression machines with non-reversible cycleRotary piston pumpsDifferential pressureYoung's modulus

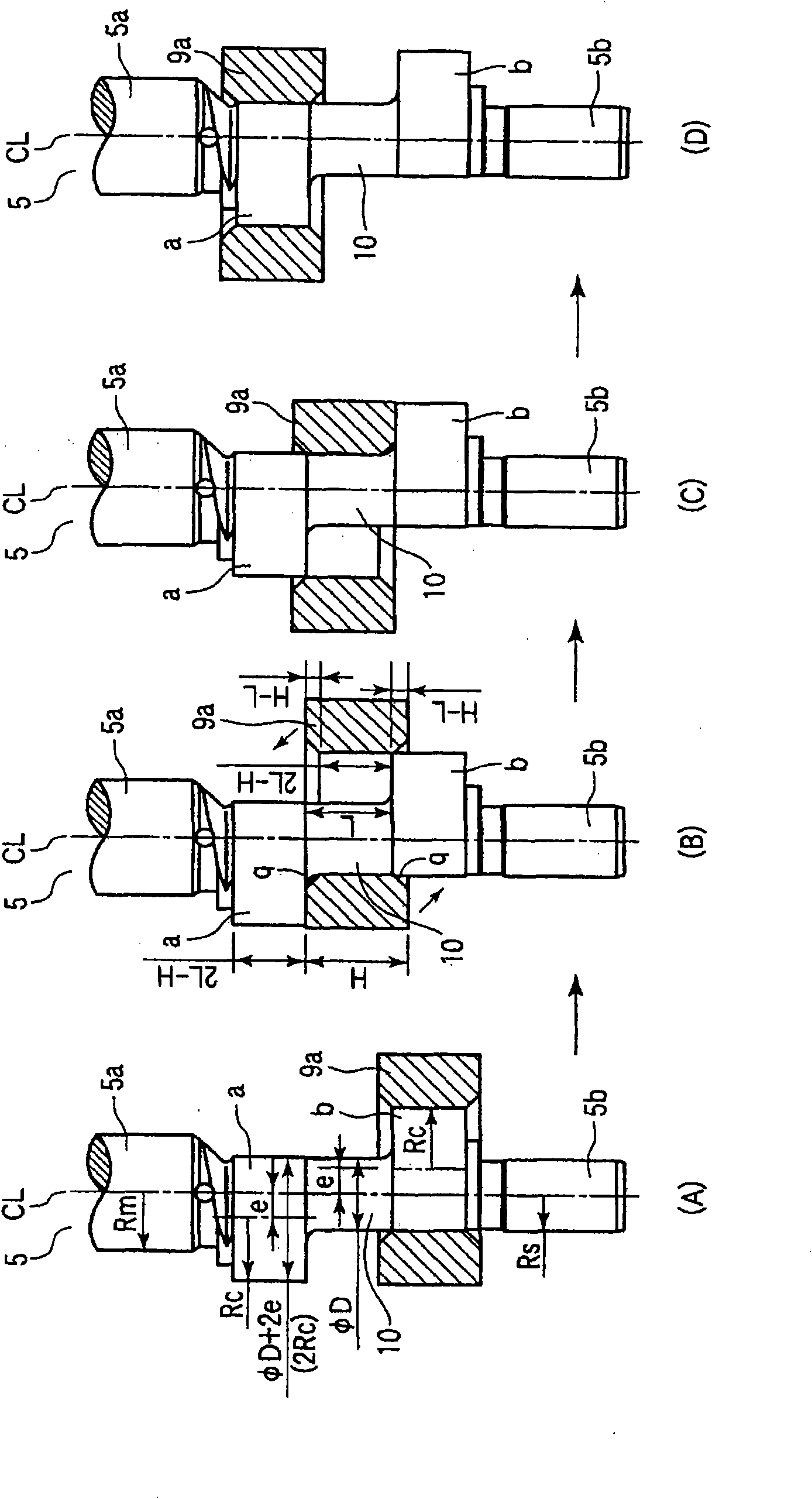

The invention provides a rotary compressor and a freezing cycle device which can inhibit slippage loss of an eccentric part of a rotating shaft and an eccentric roller, prevent flexible deformation and improve compression performance. The structure of the rotary compressor comprises that: the radius of the eccentric part of the rotating shaft is set to be Rc, the radius of a main shaft part is Rm,the radius of an auxiliary shaft part is Rs, the eccentricity of the eccentric part is e, a formula 1 which is Rc<Rm+e is satisfied, and a formula 2 which is Rc>=Rs+e is satisfied; the shaft length of a connecting part is L, the diameter of a shaft of the connecting part is phiD, and the shaft length (thickness) of the eccentric roller is H, a formula 3 which is (2L-H) / (D+2e)>=0.5 is satisfied; the differential pressure of a discharge pressure and a suction pressure is deltaP, the outer diameter of the eccentric roller is phiDro, the Young modulus of the rotating shaft is E, section moment ofinertia of the connecting part is M, the cylinder inner diameter of the connecting part is Di, and a formula 4 which is (deltaP*Dro*H*L<3>) / (E*M)<=0.02mm, wherein M=pi*(D<4>-Di<4>) / 64.

Owner:TOSHIBA CARRIER CORP

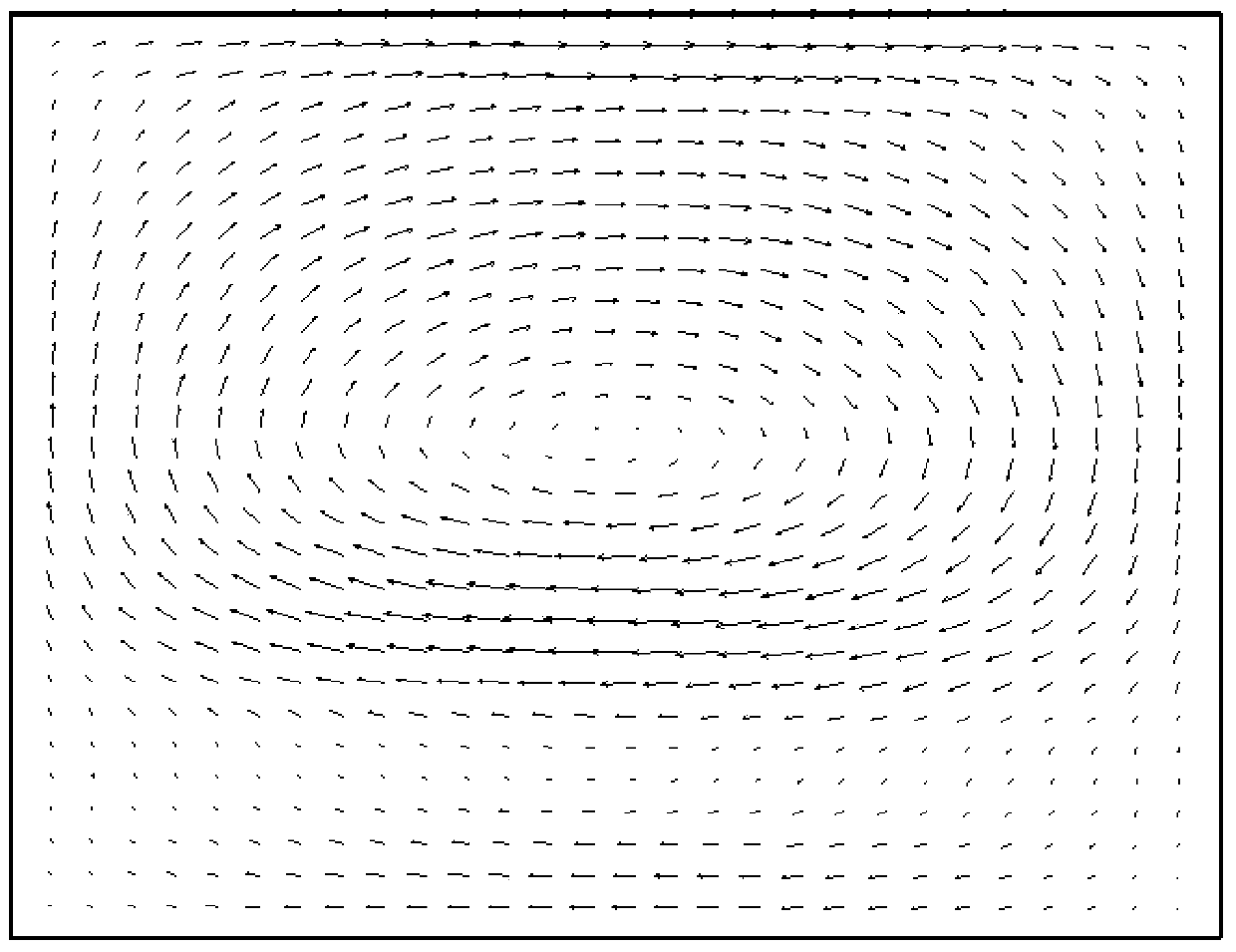

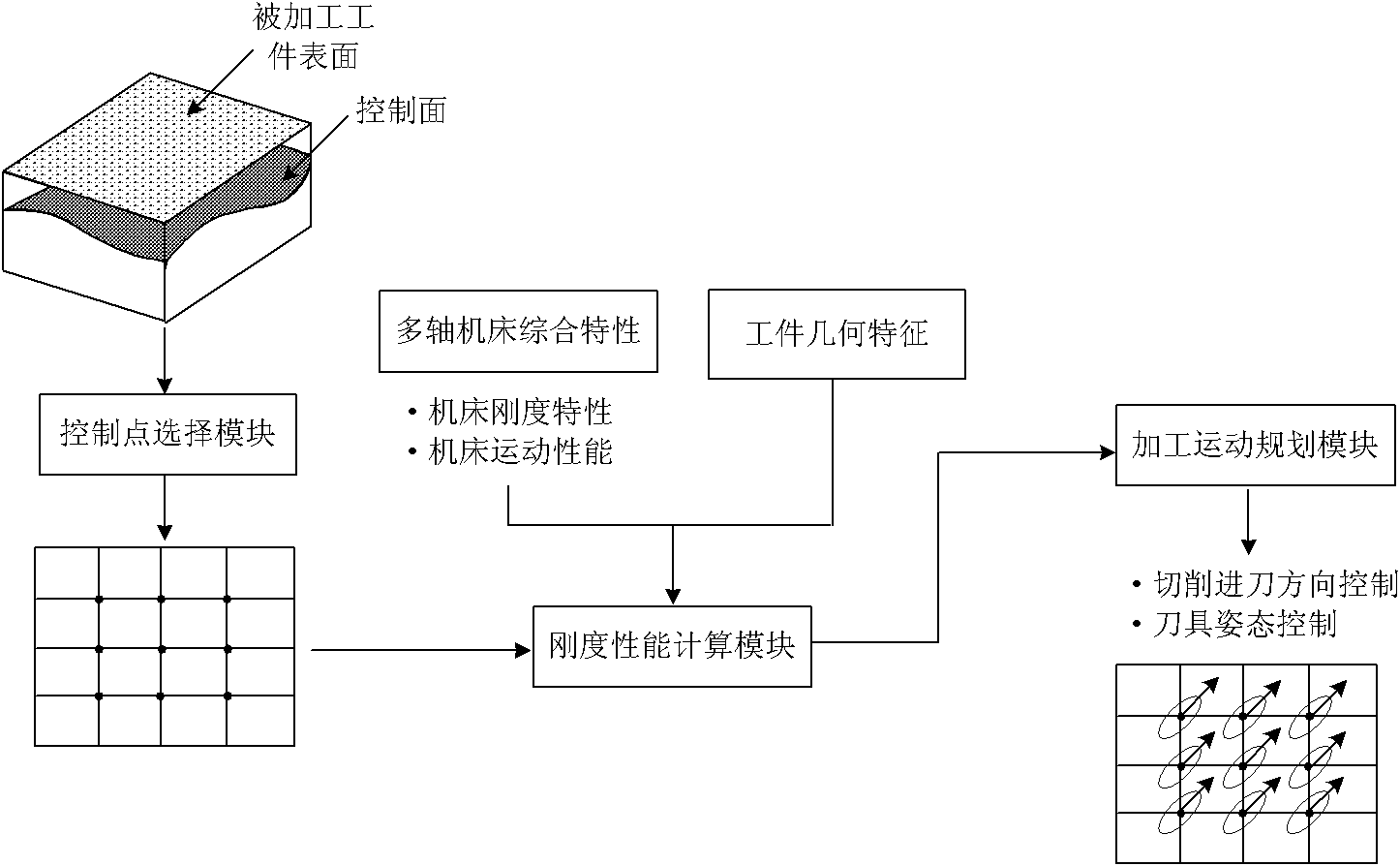

Multi-axis numerical control machining tool motion planning method based on process system rigidity characteristic

ActiveCN101870073AAnalyzing the distribution of stiffness propertiesImprove the level of application technologyAutomatic control devicesFeeding apparatusProcess systemsNumerical control

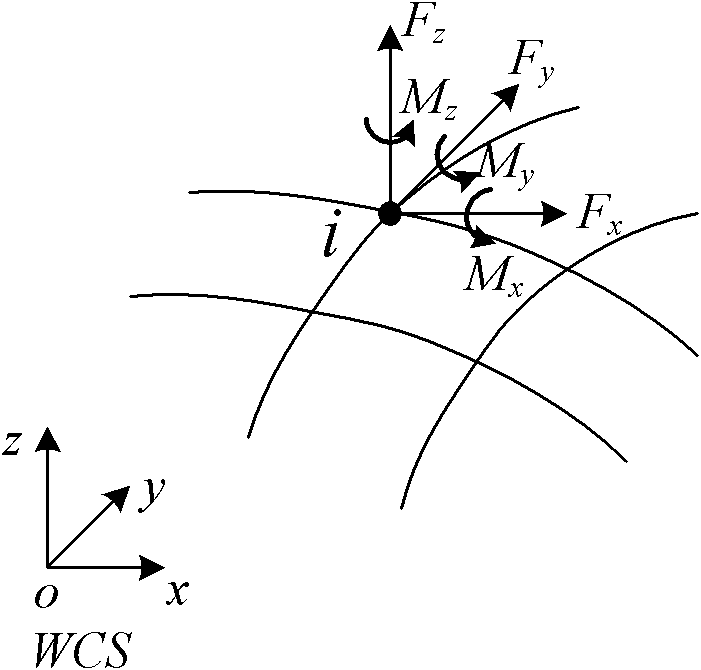

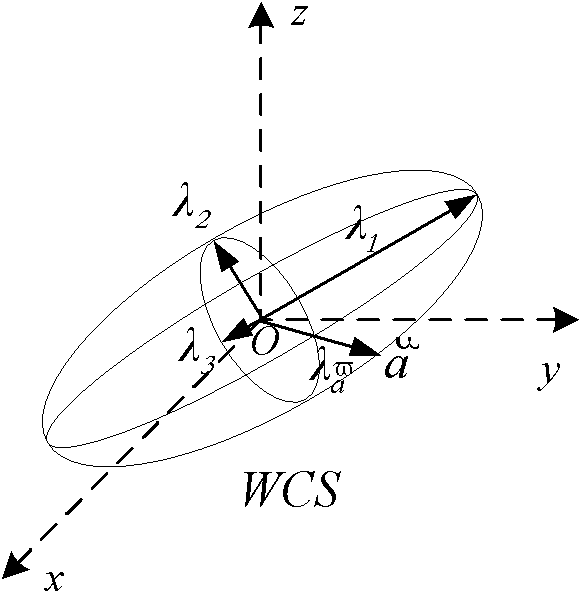

The invention relates to a multi-axis numerical control machining tool motion planning method based on a process system rigidity characteristic. The method comprises the following steps of: establishing a multi-axis numerical control equipment process system comprehensive rigidity model through a Jacques matrix method and a finite element method; establishing a three-dimensional space force ellipsoid according to the rigidity field model; optimizing the cutting feed direction according to the rigidity performance index of all control points by taking the force ellipsoid axial length corresponding to the cutting feed direction at any control point in a complex curved surface as the rigidity performance index; and optimizing the cutter orientationtool gesture according to the rigidity performance index of all control points by taking the shortest force ellipsoid axial length corresponding to the cutter orientationtool gesture at any control point. The invention makes up the defect that only the geometrical condition is considered in the traditional multi-axis machining motion planning, can realize the multi-axis machining tool motion planning based on the comprehensive rigidity characteristics of a multi-axis numerical control equipment process system and the geometric constraint condition, and adds a new method for the large-scale complex curved surface multi-axis numerical control machining motion planning.

Owner:HUAZHONG UNIV OF SCI & TECH

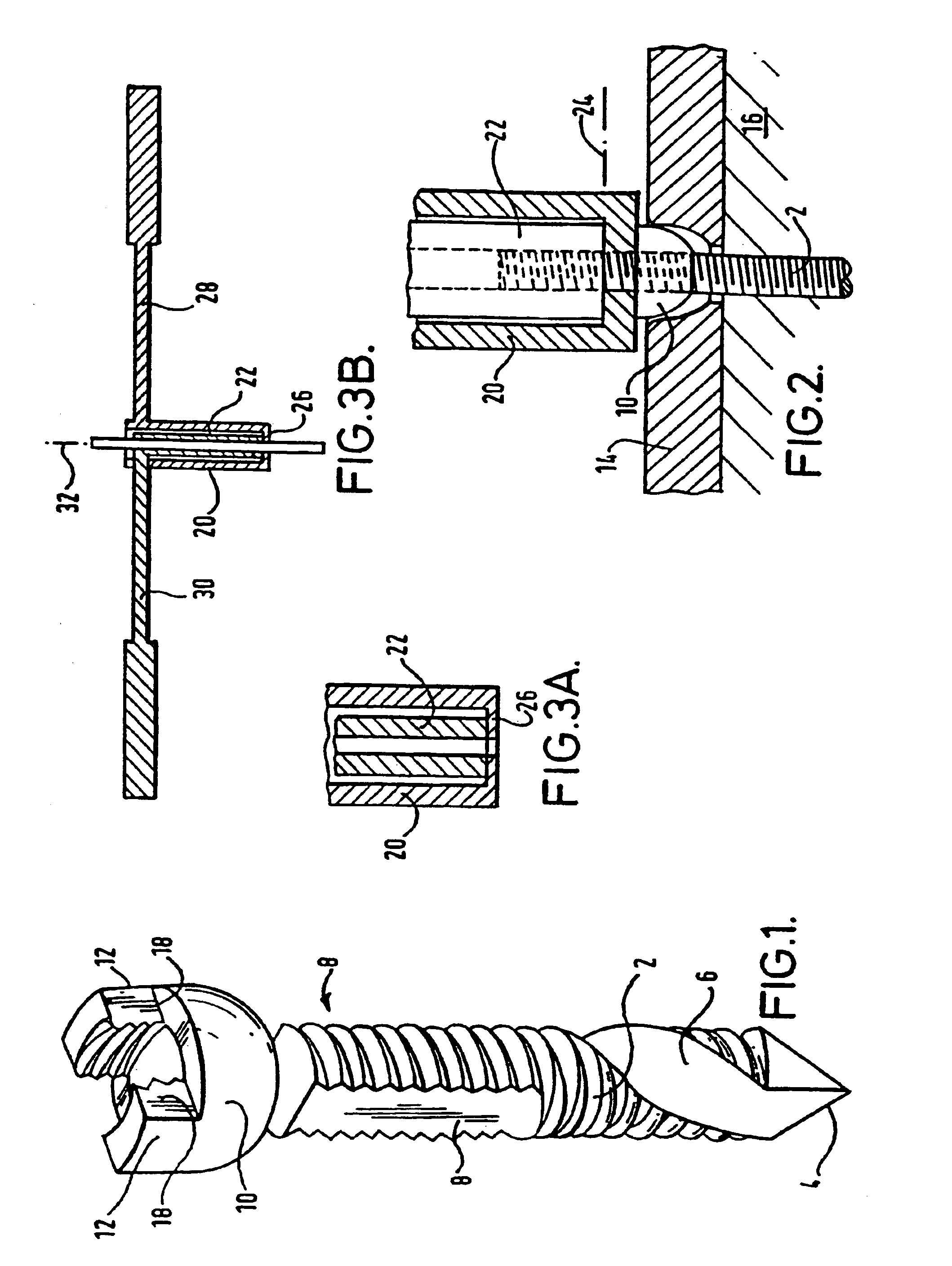

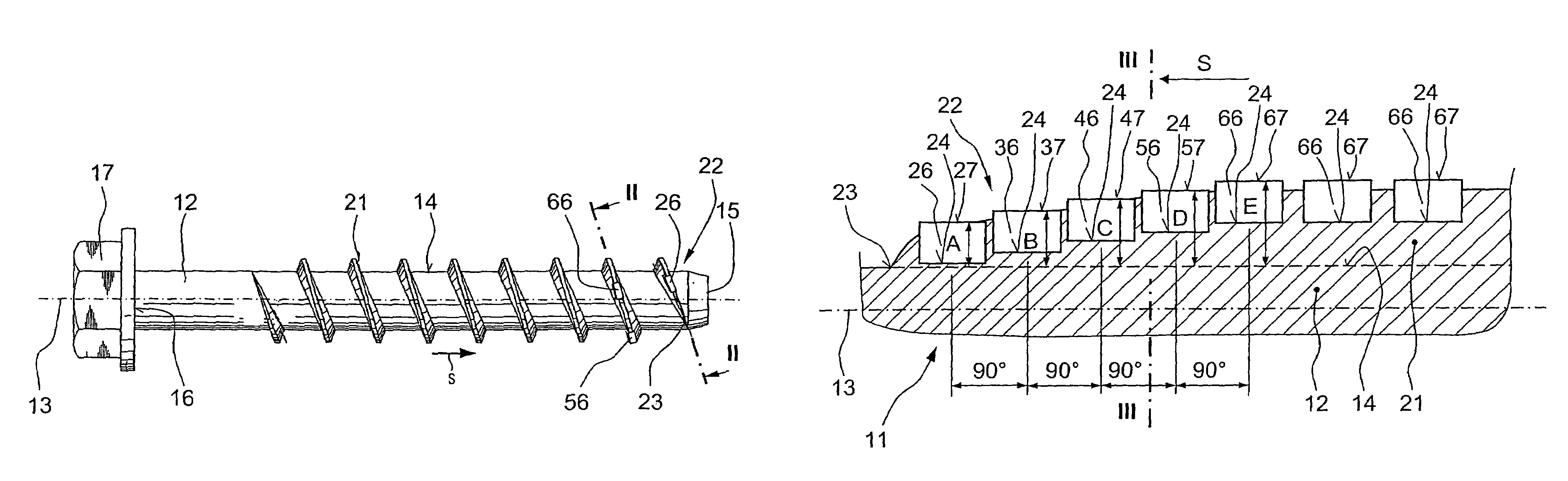

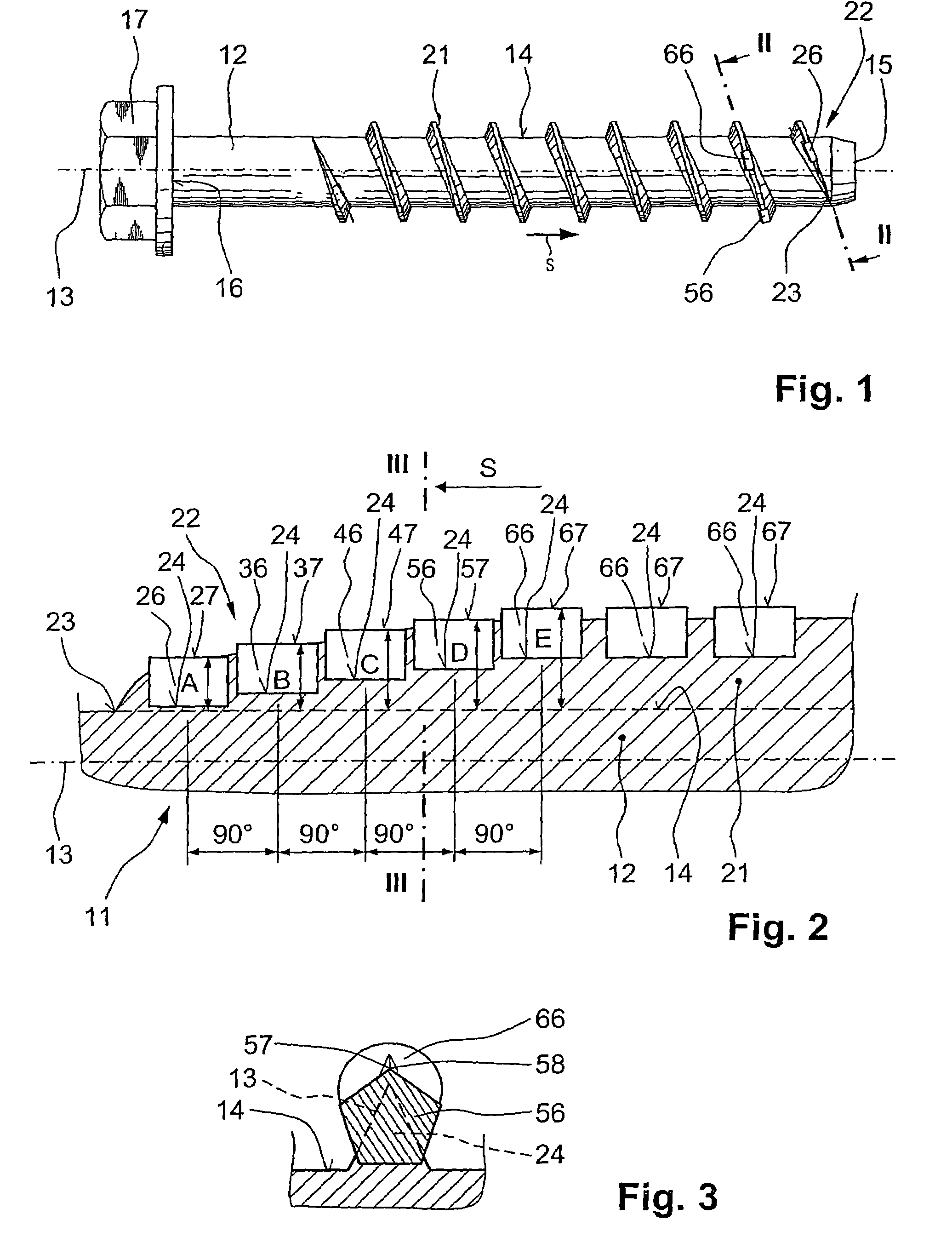

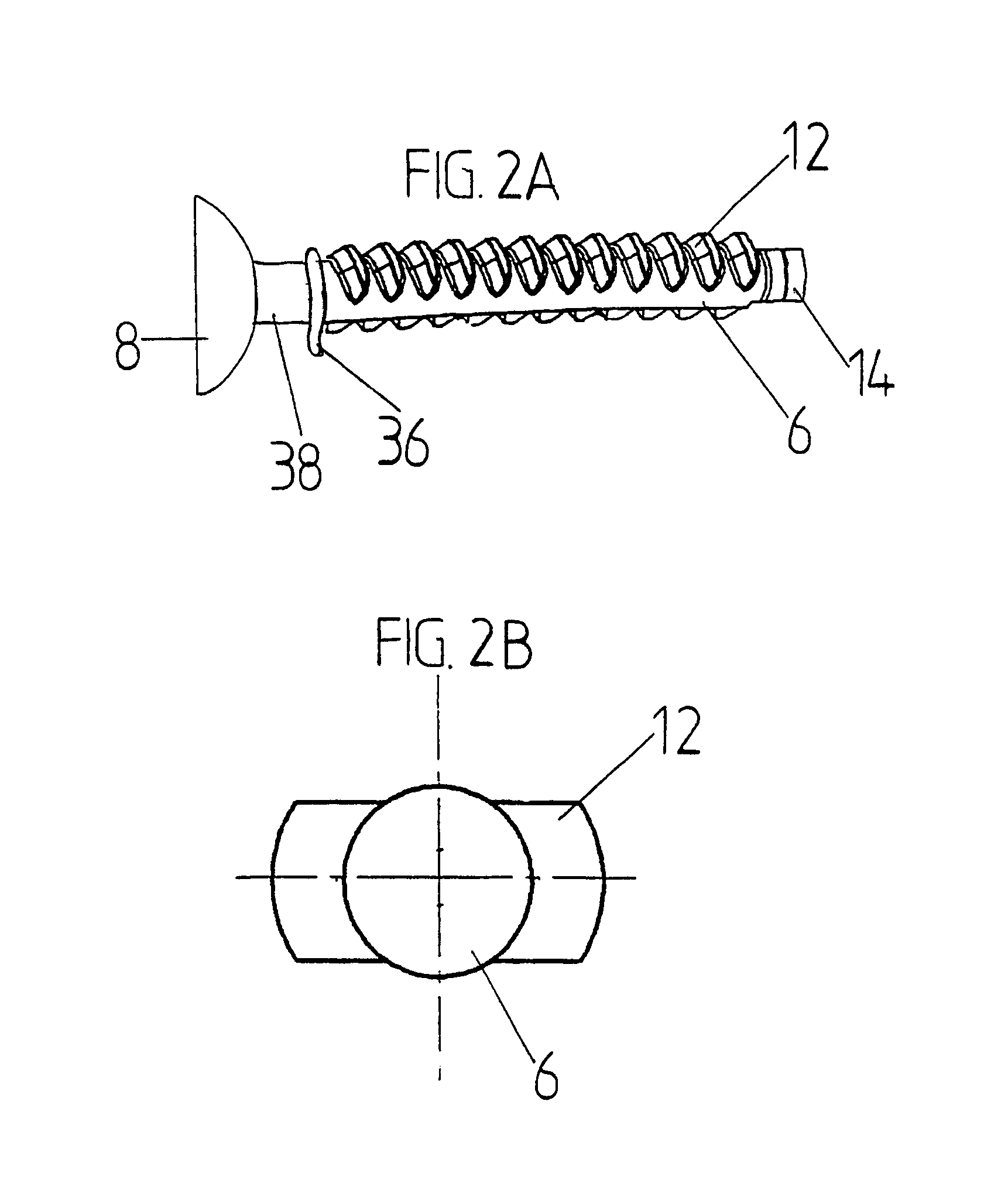

Thread-tapping screw

A thread-tapping screw (11) has a thread (21) extending, starting from the screw shaft free end (15), at least along a portion of the shaft length and a height of which constantly decreasing toward the free end (15) of the shaft (12), and a plurality of cutting bodies (26, 36, 46, 56, 66) formed of a material having a greater hardness than hardness of the thread (21), located in recesses (24) formed in the thread (21) and opening radially outwardly and having, respectively, a radial outer profile (27, 37, 47, 57, 67) projecting, at least partially, beyond the thread and a height (A, B, C, D, E) of which decreases toward the free end (15) of the shaft (12) stepwise.

Owner:HILTI AG

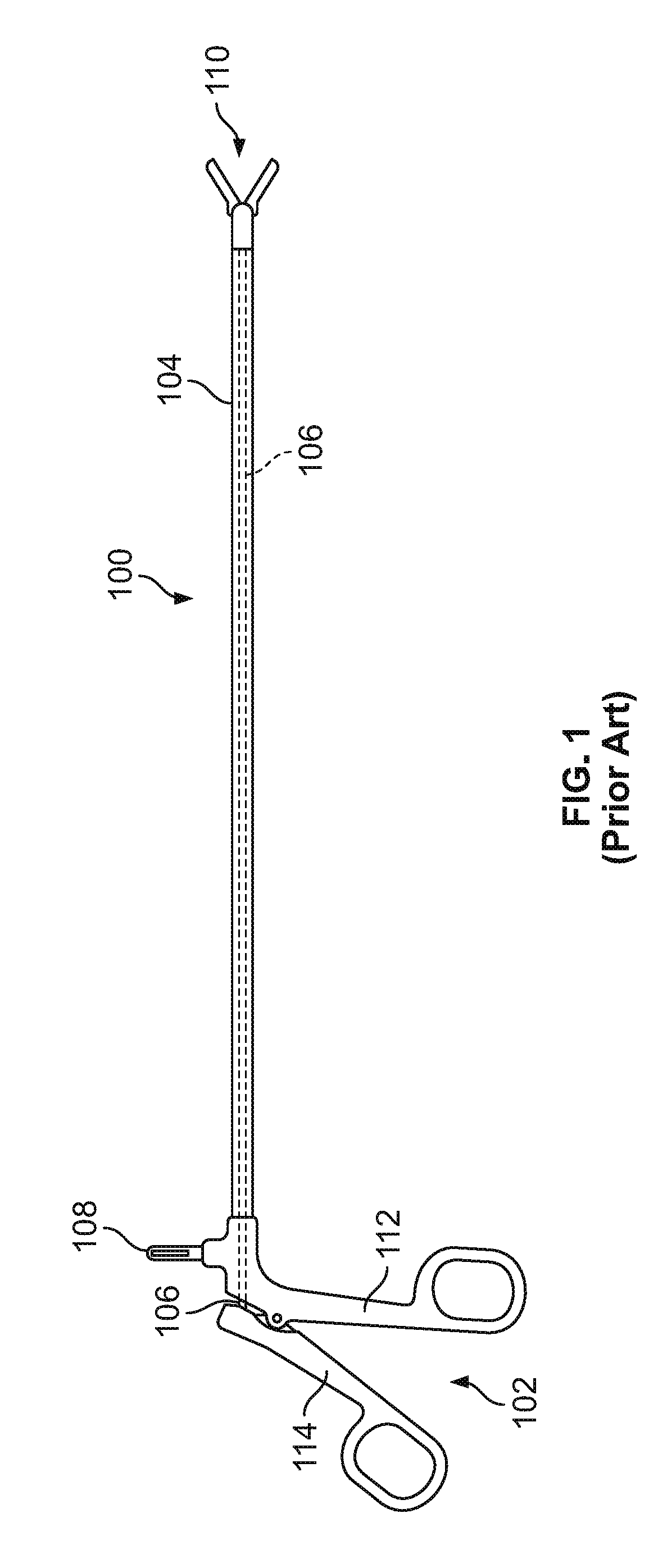

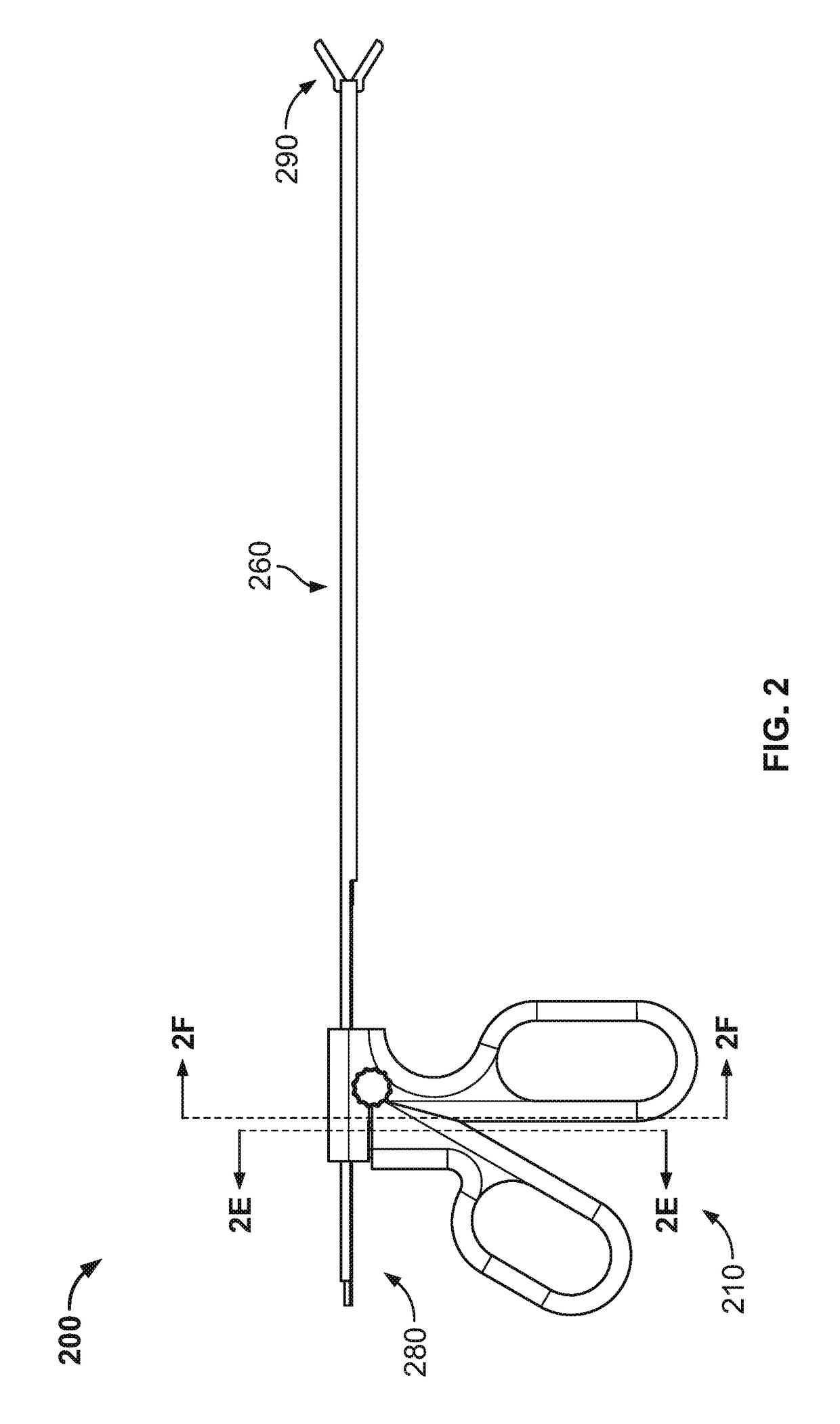

Adjustable length laparoscopic instrument

ActiveUS20190059923A1Increase costIncrease management costsSurgical needlesSurgical scissorsEngineeringActuator

An adjustable length laparoscopic instrument is provided. The instrument includes a shaft with a shaft distal end and a shaft proximal end. The instrument further includes an actuation rod with an actuation rode distal end and an actuation rod proximal end. The actuation rod is receivable by the shaft such that the actuation rod can translate longitudinally relative to the shaft to actuate an end effector. The instrument further includes a handle configured to hold the shaft and the actuation rod. The handle is configured to cause the actuation rod to translate longitudinally relative to the shaft to actuate the end effector. The instrument further includes a length adjustment mechanism configured to adjust a shaft length. The shaft length is defined between the handle and the shaft distal end.

Owner:CAREFUSION 2200 INC

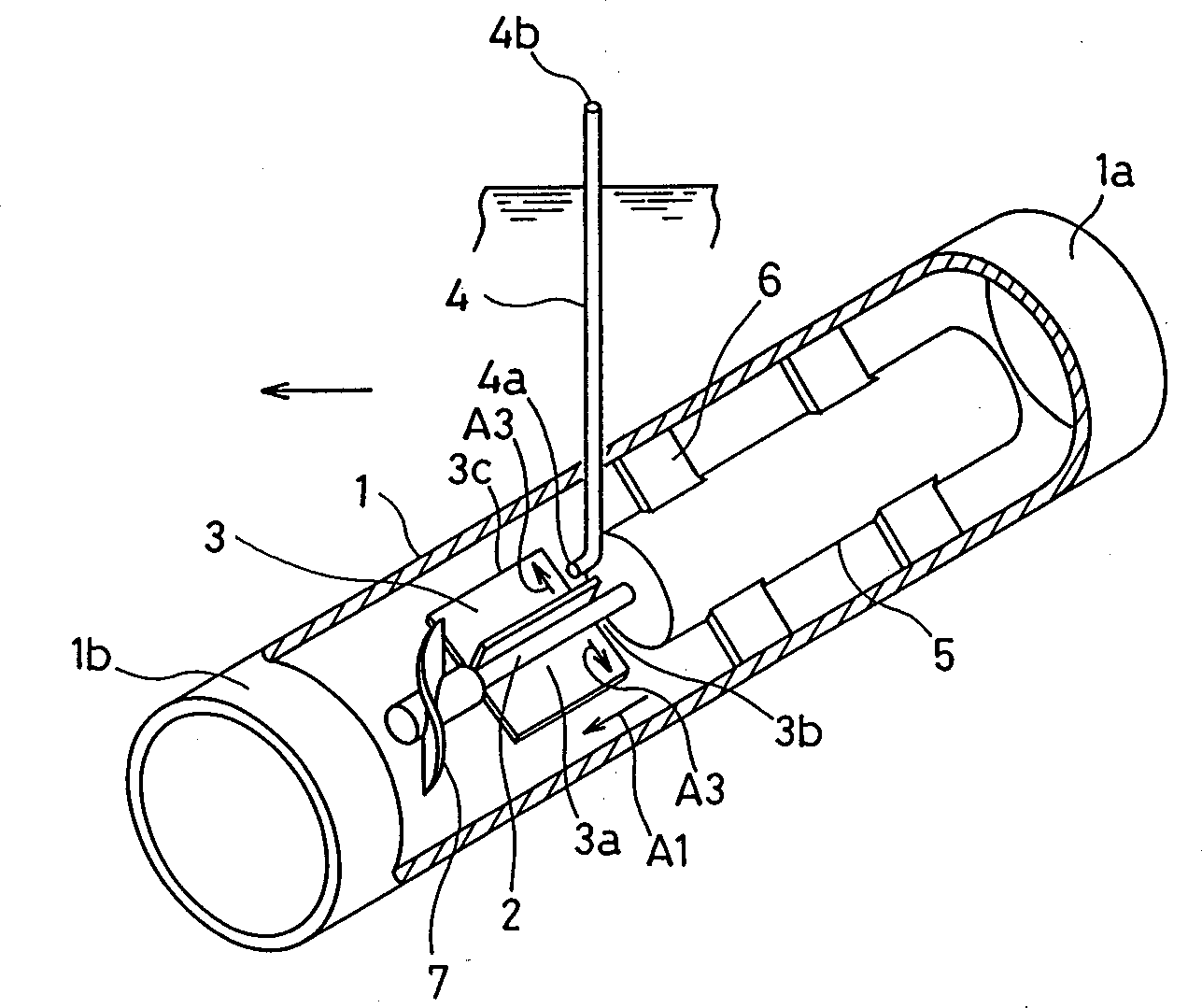

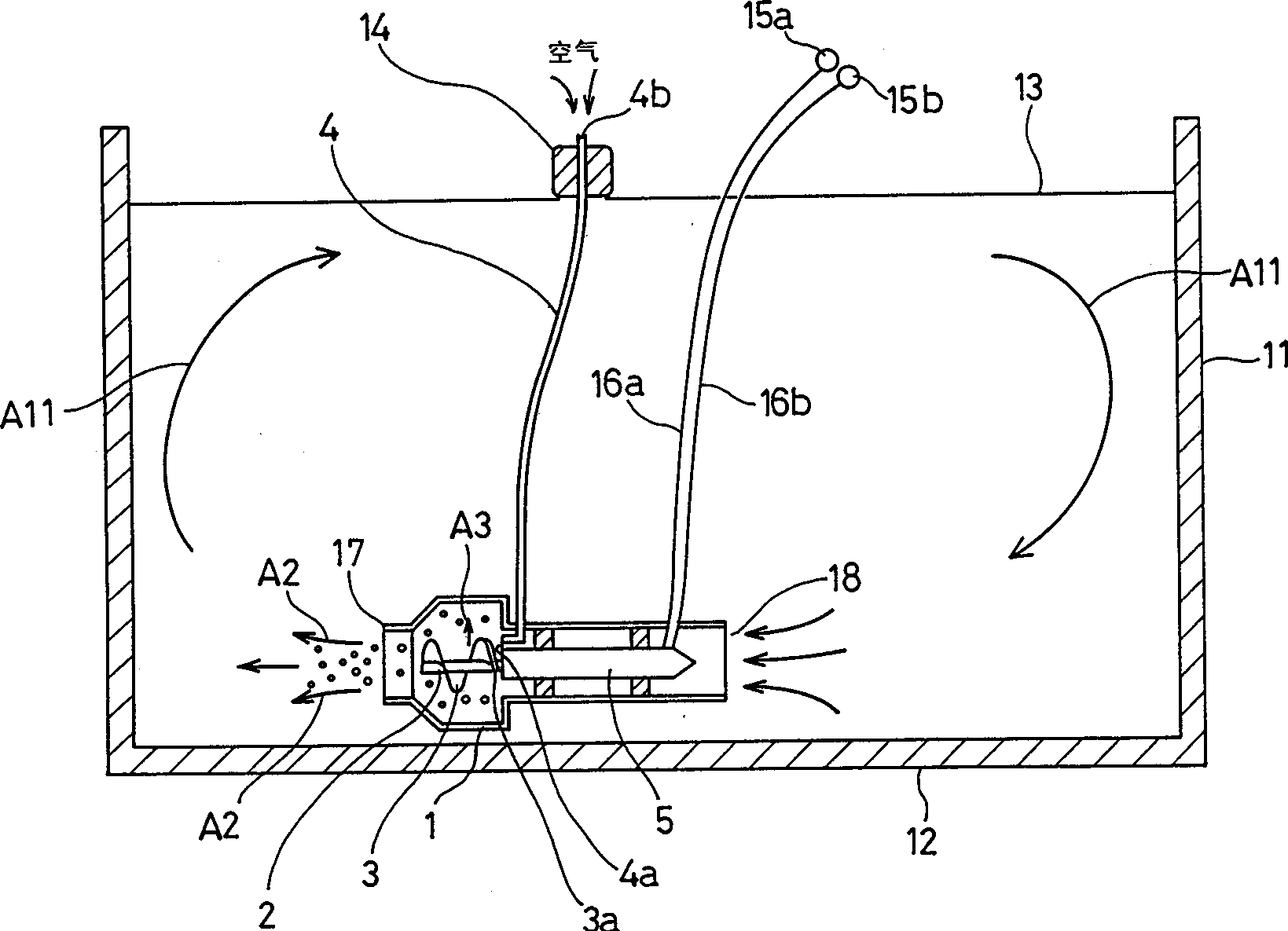

Gas-liquid mixing device

Gas-liquid mixing device, wherein a rotating shaft is installed in a water tank horizontally along the flow direction of a water tube, a base end part of a rotating vane is fixed to the periphery of the rotating shaft, one end opening part of an air pipe is allowed to face near the base end part of the rotating vane on the upstream side, and the other end opening of it is disposed in the air outside the water tube, whereby such defects that, when the rotating vane disposed at the bottom part of a sewage water tank is rotated by a motor installed on a frame located over the surface of the liquid contained in the sewage water tank, a transmission shaft length is increased to cause vibration, and each part of the device is damaged and its life is shortened are eliminated, and air bubbles caused by the rotating vane are finer so as to increase the solubility of oxygen.

Owner:今子贤一

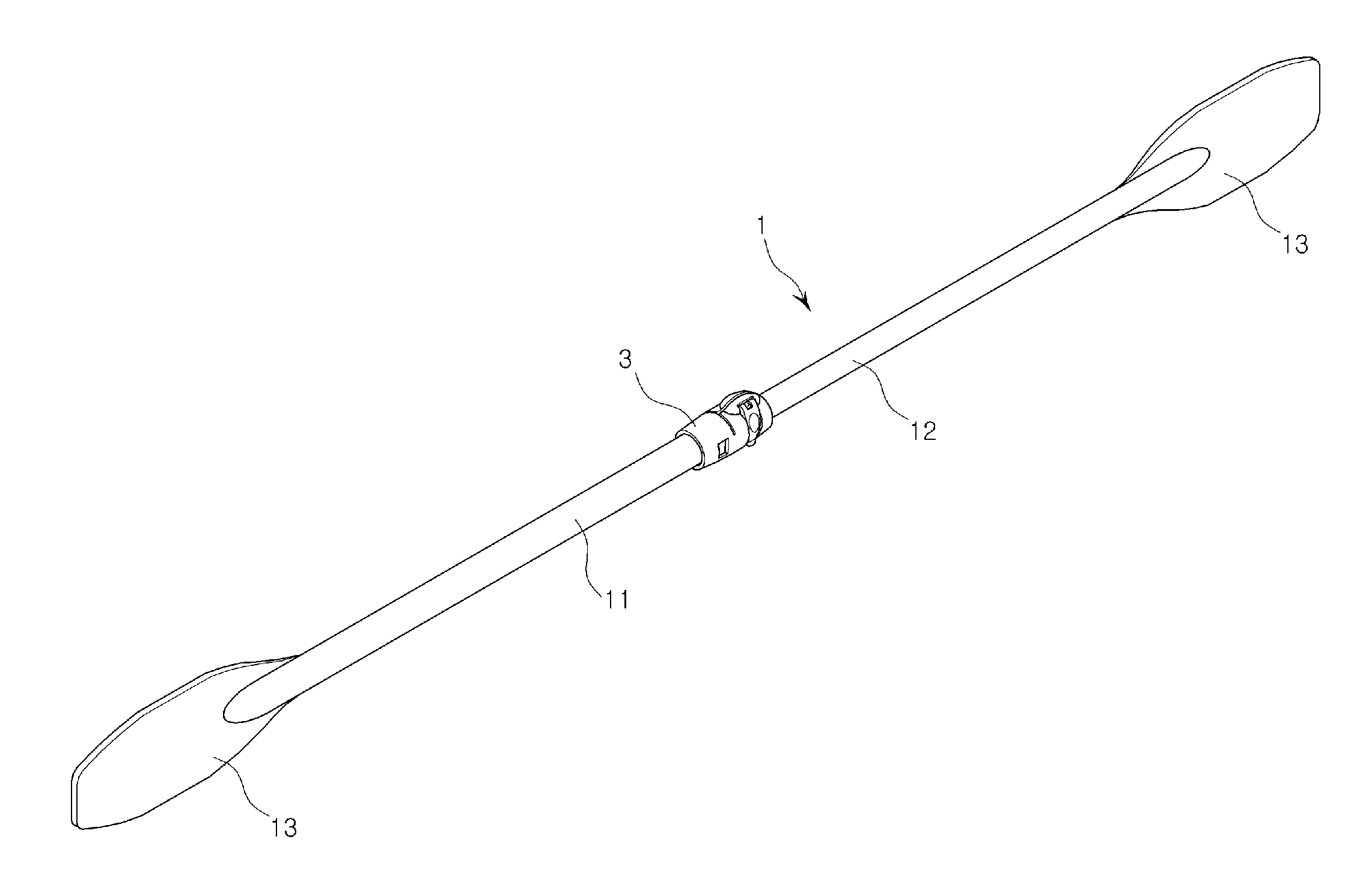

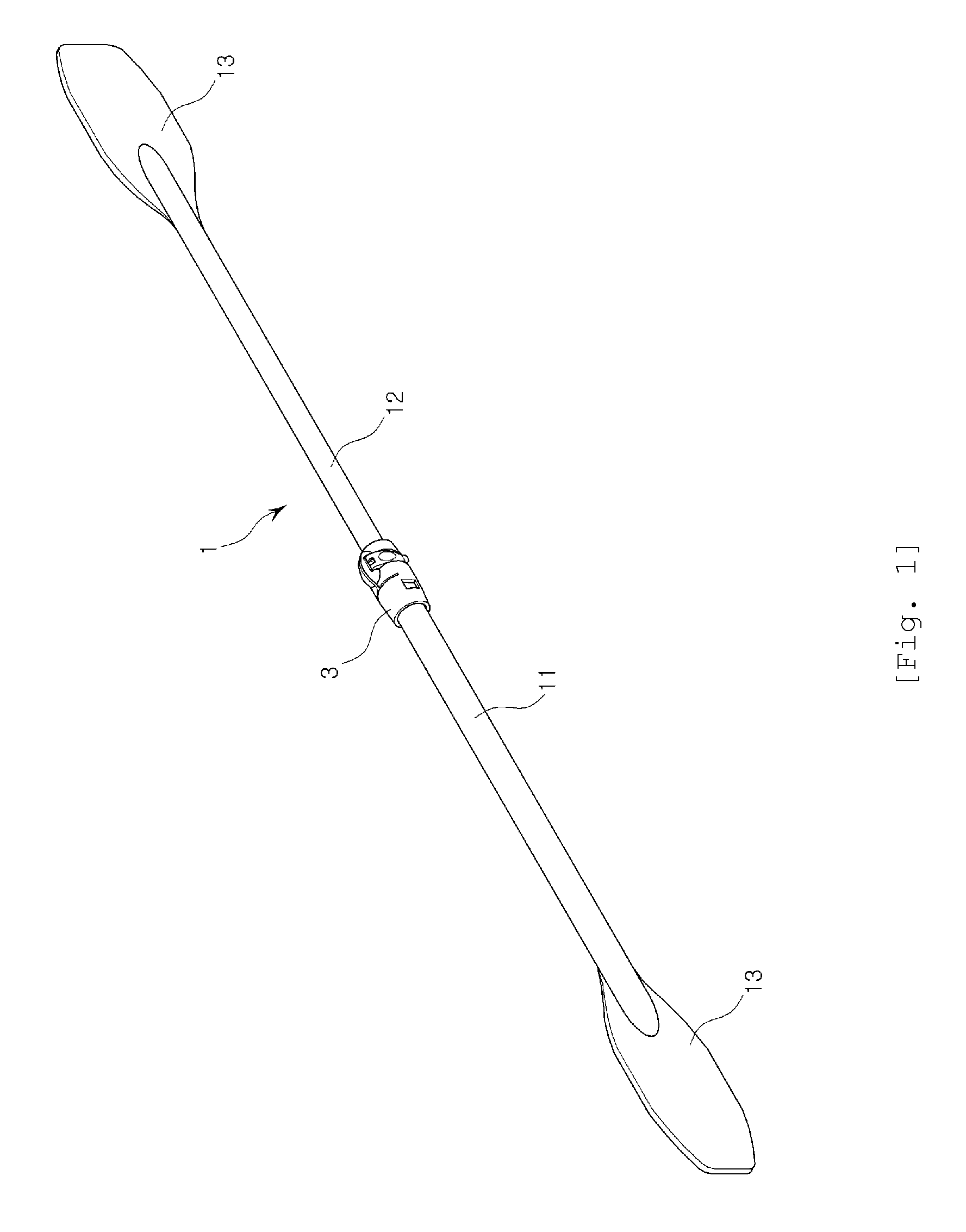

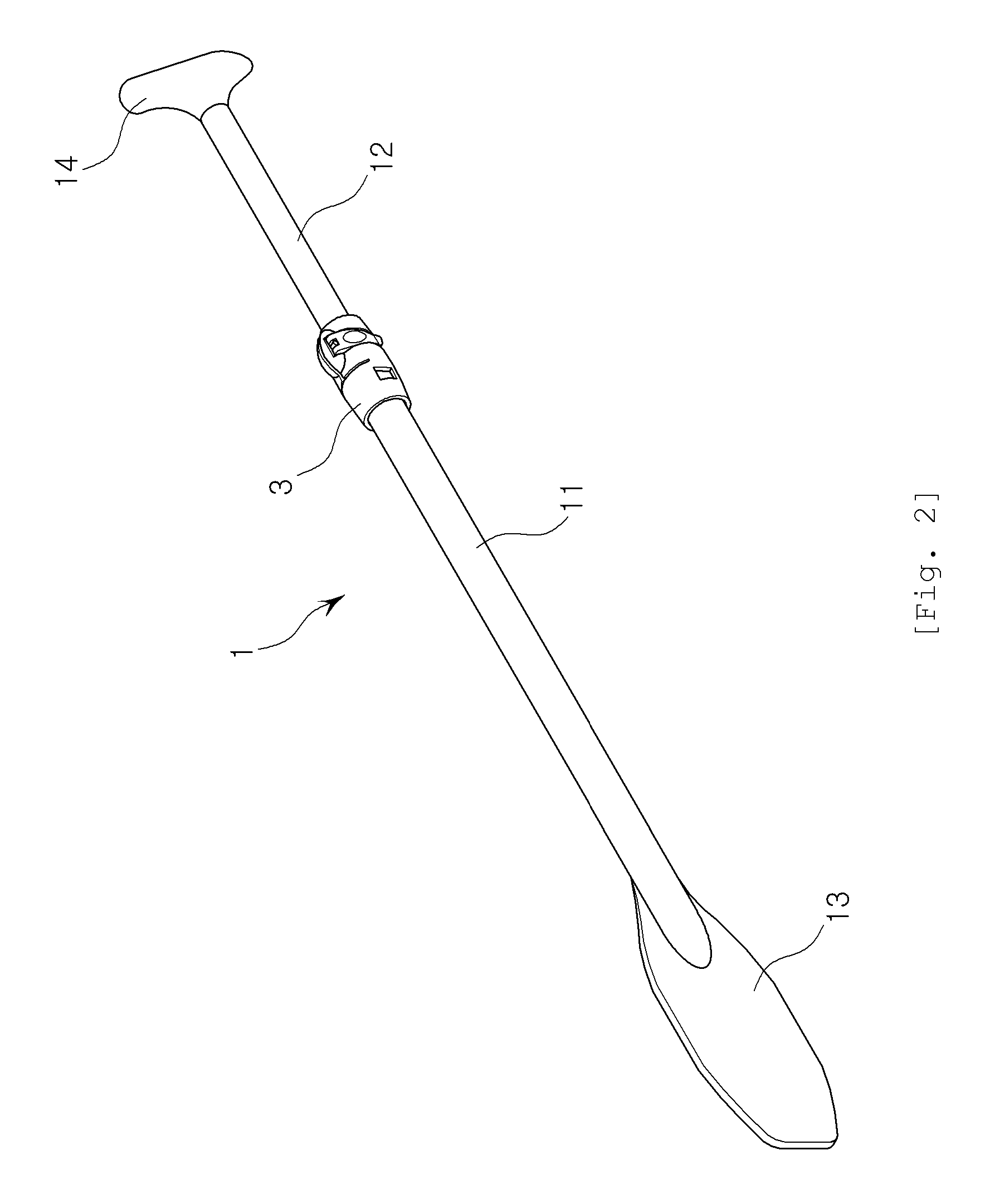

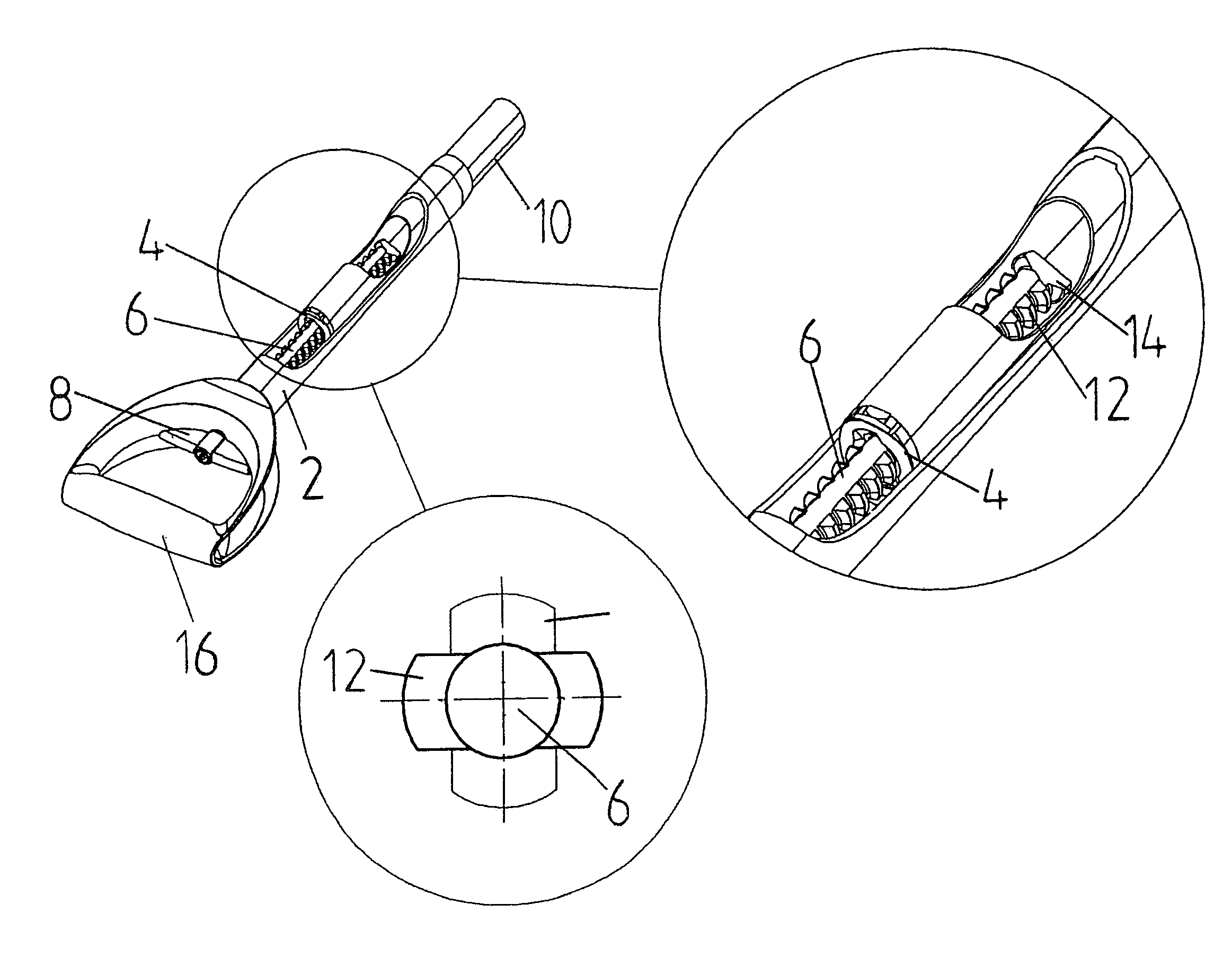

Paddle shaft length adjustment device

InactiveUS20140248075A1Easy to assembleReduce the overall diameterRod connectionsMuscle power acting propulsive elementsEngineeringShaft length

Disclosed is a paddle shaft length adjustment device in which a connection end portion of a large-diameter first shaft is connected and secured to a connector pipe via simplified insertion to ensure easy assembly between the first shaft and the connector pipe, and a second shaft is secured by reducing the diameter of a contractible pipe portion of the resilient connector pipe, thereby allowing the length adjustment device to be repeatedly used with a paddle shaft formed of a non-elastic material, such as aluminum. The paddle shaft length adjustment device includes snap insertion holes perforated in the front and rear sides of a connection end portion of a tubular first shaft, a second shaft shaped to be inserted into the first shaft, a connector pipe consisting of, on the basis of a boundary wall formed at a middle position of an inner bore thereof, an expandable pipe portion at one side of the boundary, into which the connection end portion of the first shaft is inserted, and a contractible pipe portion at the other side of the boundary, into which the second shaft to be inserted into the first shaft is inserted such that an outer circumferential surface of the second shaft comes into close contact with an inner circumferential surface of the contractible pipe portion, the connector pipe having a longitudinal elongated slot perforated in the top of the contractible pipe portion, front and rear snap type retainers provided at the front and rear sides of the expandable pipe portion and configured to be snap fitted into the snap insertion holes perforated in the front and rear sides of the first shaft, and a clamping member provided at the contractible pipe portion of the connector pipe, the clamping member securing the second shaft to the contractible pipe portion by reducing the width of the elongated slot, and consequently reducing the diameter of the contractible pipe portion.

Owner:WOOSUNG I B

Shaft of a tool or the like

InactiveUS7089625B2Avoid adjustmentEasy to manageTravelling carriersWing handlesShaft lengthEngineering

The invention relates to a shaft of a tool or the like with an adjustable length, the shaft comprising a first shaft section (2) and a second shaft section (10) which are attached to each other by adjusting means and move telescopically with respect to each other when the shaft length is adjusted. In that case, the adjusting means for adjusting the shaft length comprise a sleeve (4) provided in the second shaft section (10) and an at least partly toothed spindle (6) provided in the first shaft section (2), the first end of the spindle being taken through the sleeve (4). The sleeve (4) and the spindle (6) attach the first (2) and the second (10) shaft section adjustably to each other so that the sleeve (4) and the spindle (6) can be turned with respect to each other into a position preventing the adjustment of the shaft length and into a position allowing the adjustment of the shaft length where the spindle (6) can move in the sleeve (4) in the longitudinal direction.

Owner:FISKARS CONSUMER

Connecting structure between rotary shaft and metal plate and method of connecting therebetween

ActiveUS20050120998A1Reduce manufacturing costLow costFuel-injection pumpsCouplings for rigid shaftsEngineeringHigh intensity

In a connecting structure between a rotary shaft and a metal plate and a method of connecting them together, in which the metal plate can be joined to the rotary shaft with a high degree of accuracy with high strength at a low manufacturing cost without causing eccentricity, inclination, or the like as far as possible, a large-diameter shaft portion and a small-diameter shaft portion are connected to each other with a predetermined difference in diameter so as to form therebetween a shoulder surface perpendicular to an axis of rotation, plural stripes of coining indents extending in a direction of shaft length are formed on the outer peripheral surface of the small-diameter shaft portion, a circular-shaped mount hole adapted to be fitted onto the small-diameter shaft portion is formed in the metal plate, the mount hole of the metal plate is press-fitted onto the small-diameter shaft portion so as to be subjected to plastic deformation by the coining indents, a portion surrounding the mount hole on one side surface of the metal plate is pushed against the shoulder surface, and the outer peripheral surface of the small-diameter shaft portion and the mount hole of the metal plate are joined together by laser welding or the like.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com