Electric motor

A technology of electric motor and electric angle, applied in the field of electric motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

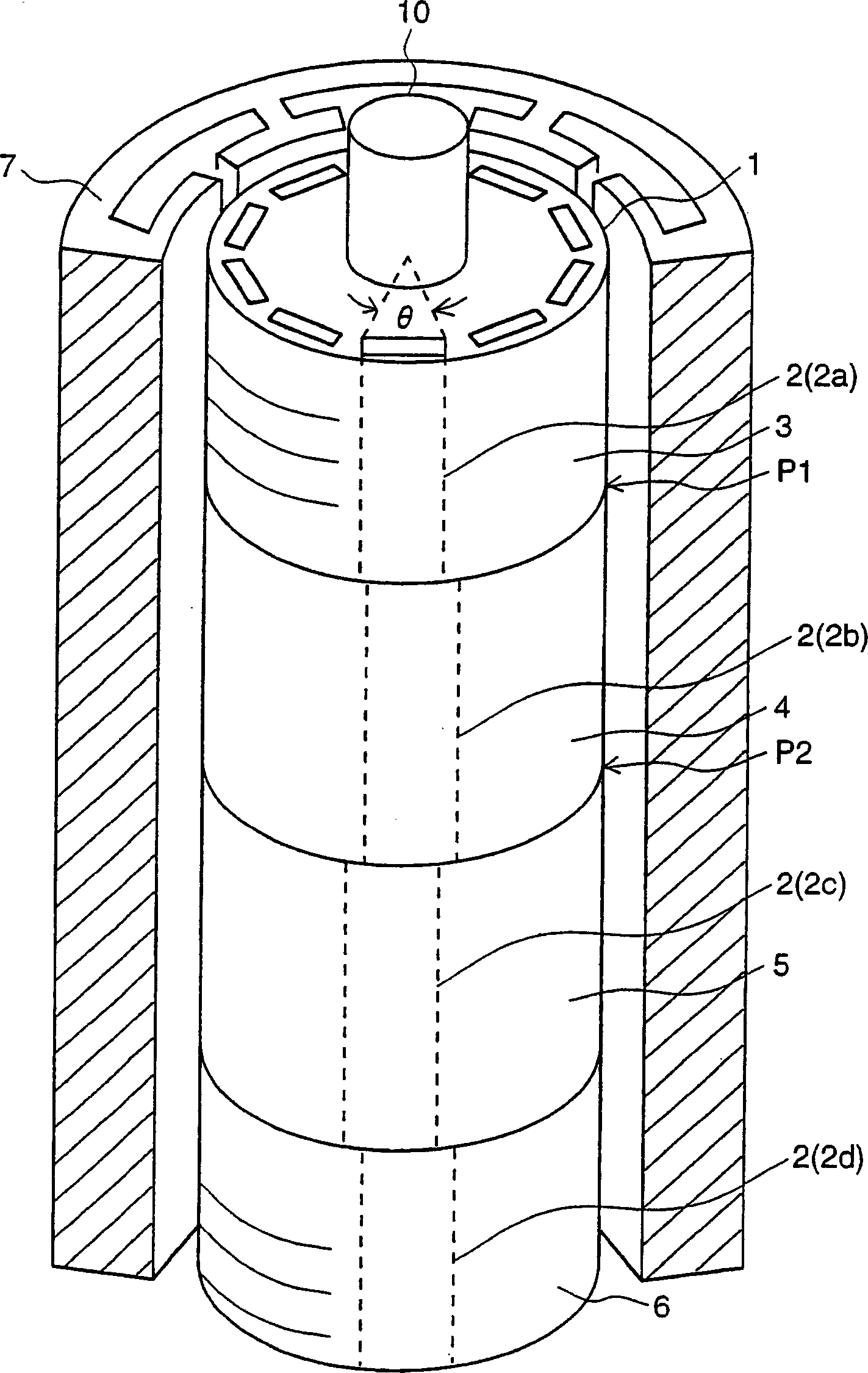

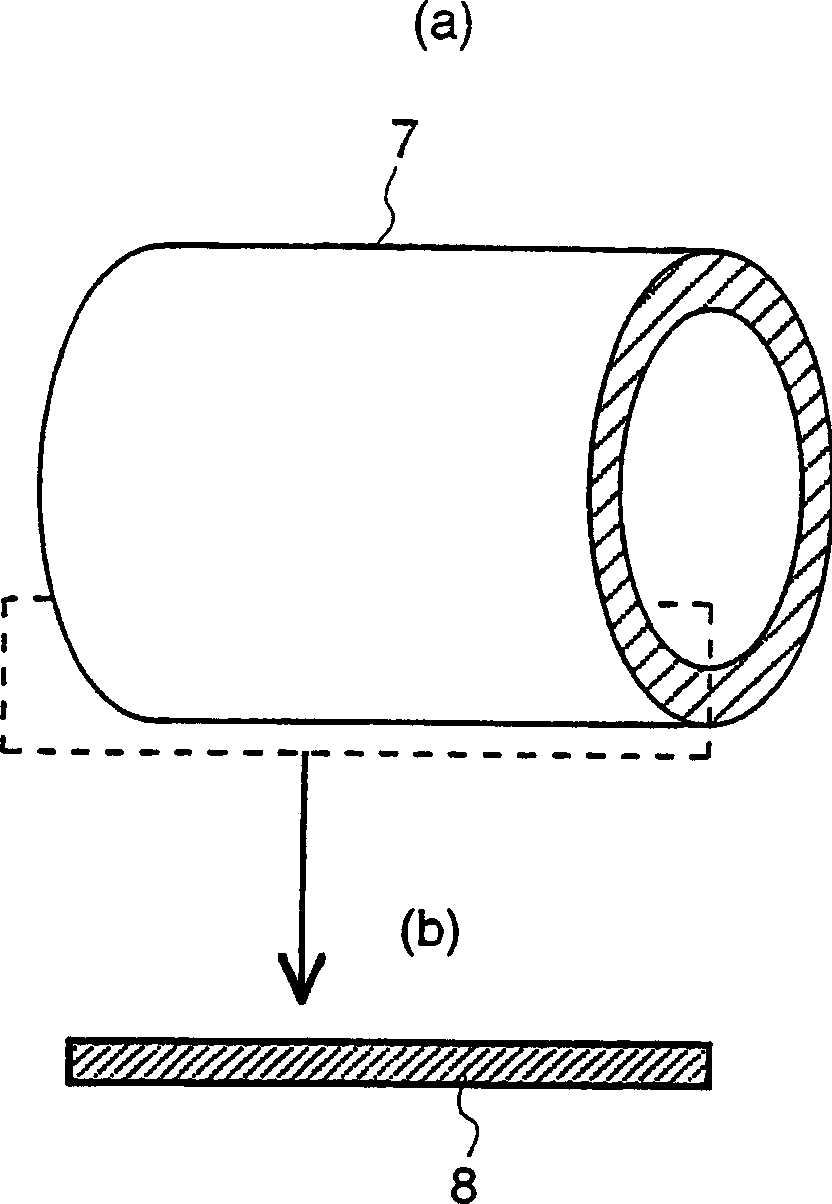

[0049] figure 1 It is a figure which shows an Example of the rotor 1 and the stator 7 when the permanent magnet motor of the electric motor 100 of this invention was taken as an example. image 3 A conceptual diagram showing a stator core (stator) 7, image 3 (a) represents a cylindrical graph, image 3(b) shows its section. In these figures, the magnetic core of the rotor 1 is formed by stacking laminated steel plates, and the stacked steel plates are divided into a plurality of blocks in the axial direction, that is, divided into rotor blocks. figure 1 The middle rotor 1 is composed of four rotor blocks 3, 4, 5, 6, a shaft 10 and permanent magnets 2 (2a, 2b, 2c, 2d) having the same length in the axial direction of the rotor blocks 3, 4, 5, 6 . Each permanent magnet 2 has an effective pole opening angle θ.

[0050] figure 1 In , the permanent magnet 2 constituti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com