Rotary compressor and freezing cycle device using the same

A technology of rotary compressors and compression mechanisms, applied in the direction of rotary piston machines, compressors, rotary piston pumps, etc., can solve problems such as compression performance degradation, achieve the effects of suppressing sliding loss and eliminating insufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

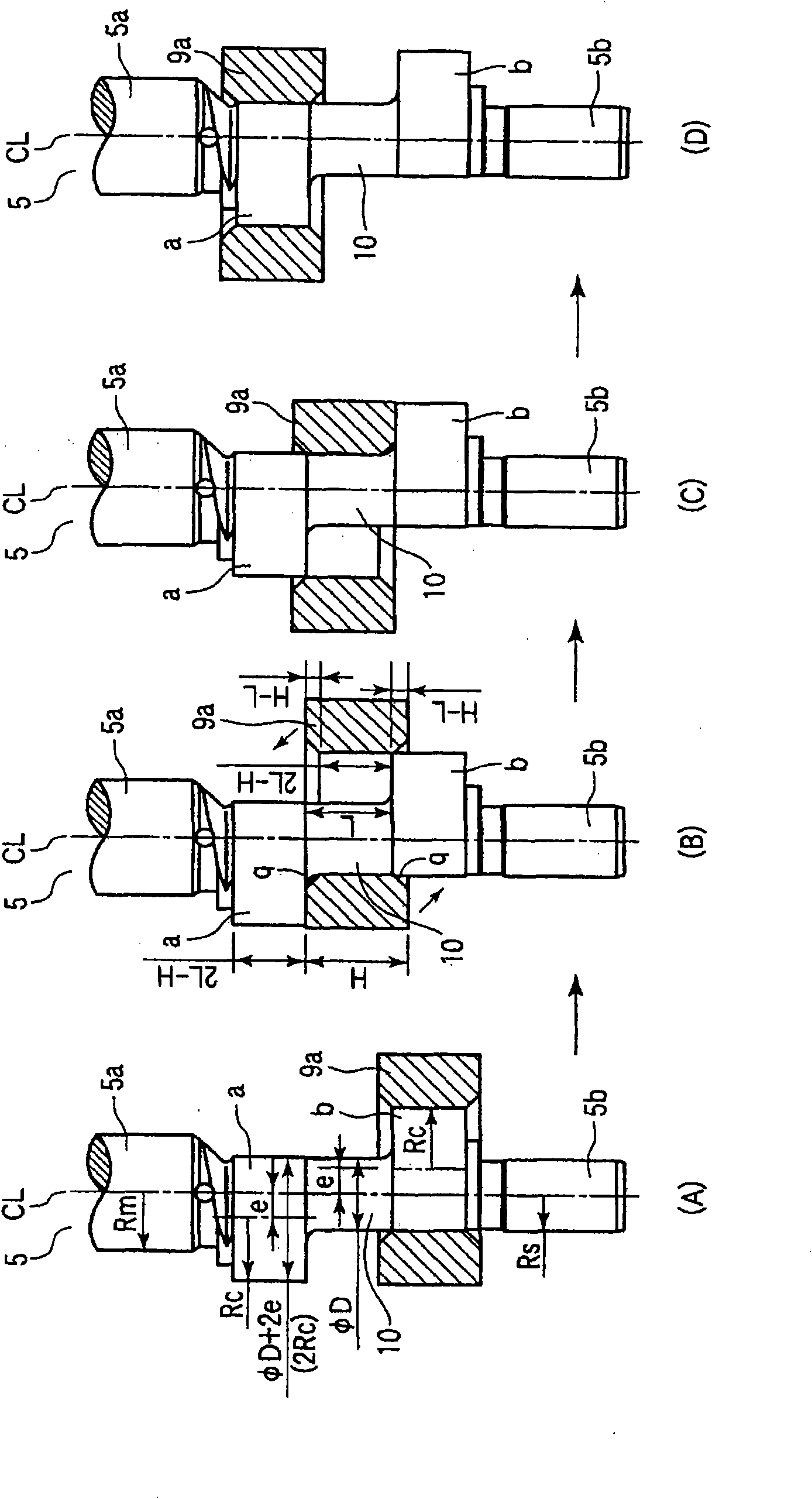

[0025] Embodiments of the present invention will be described below with reference to the drawings.

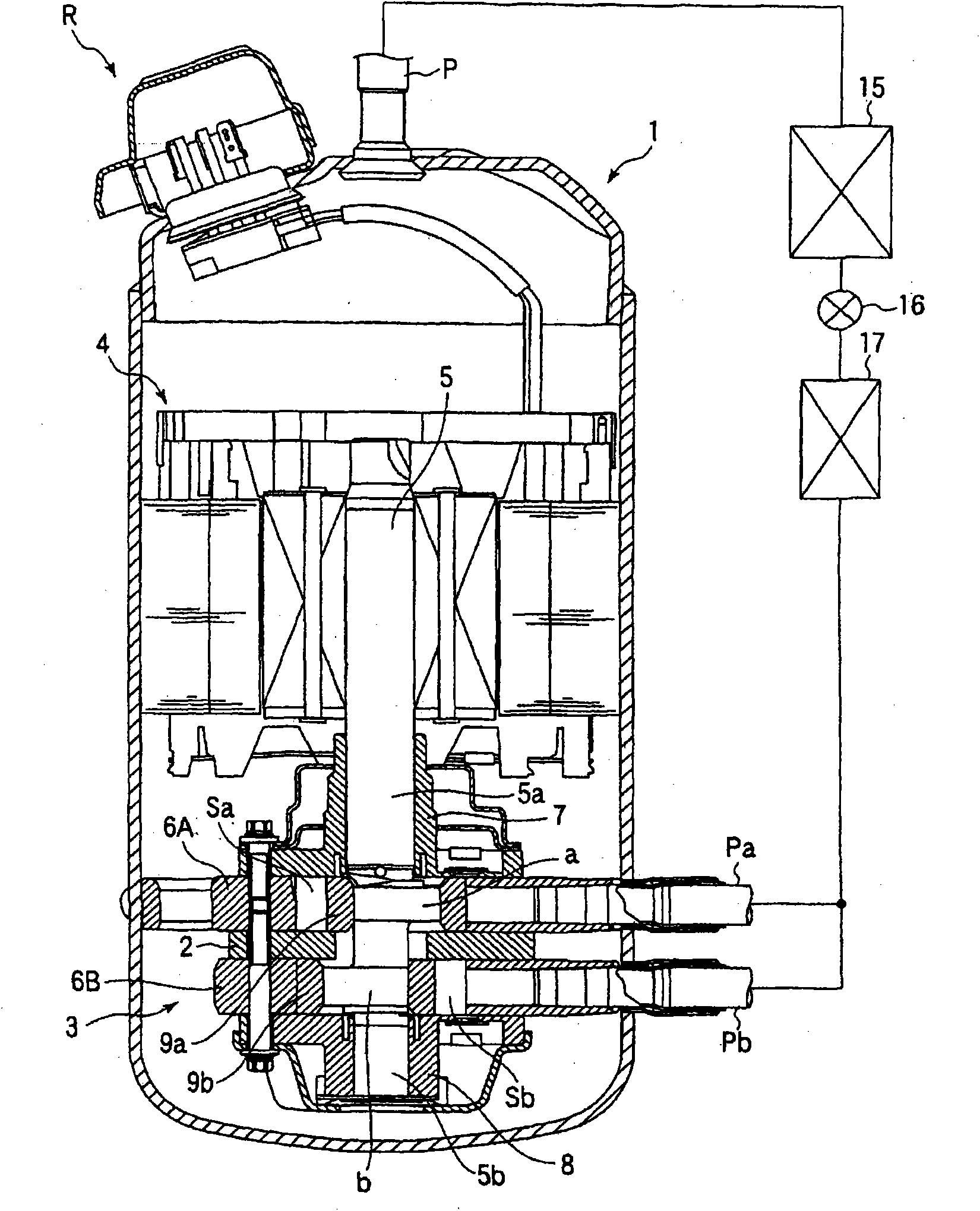

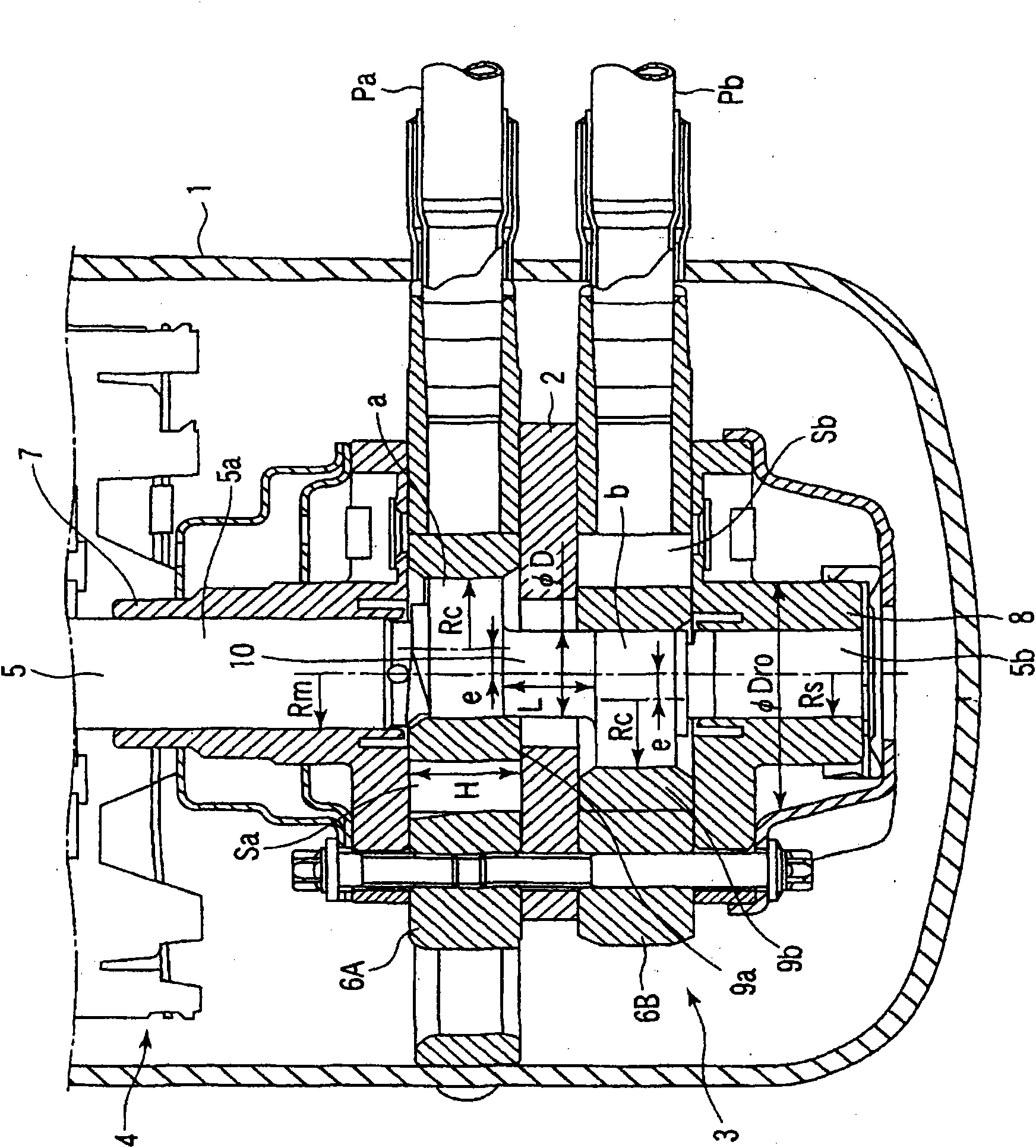

[0026] figure 1 It is a vertical cross-sectional view and a refrigeration cycle configuration diagram of the refrigeration cycle apparatus with a part of the rotary compressor R omitted. figure 2 It is an enlarged longitudinal sectional view of the main part of the rotary compressor (In order to avoid complicating the drawings, there are parts that are described but not marked, and there are also parts that are shown but not described. The same applies to the following) .

[0027] First, the rotary compressor R will be described, and reference numeral 1 is an airtight container, and the compression mechanism part 3 is provided in the lower part of the airtight container 1, and the motor part 4 is provided in the upper part. The compression mechanism unit 3 and the motor unit 4 are connected by a shaft 5 .

[0028] The compression mechanism unit 3 has a first cylinder 6A on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com