Patents

Literature

59results about How to "Improve refrigeration cycle efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

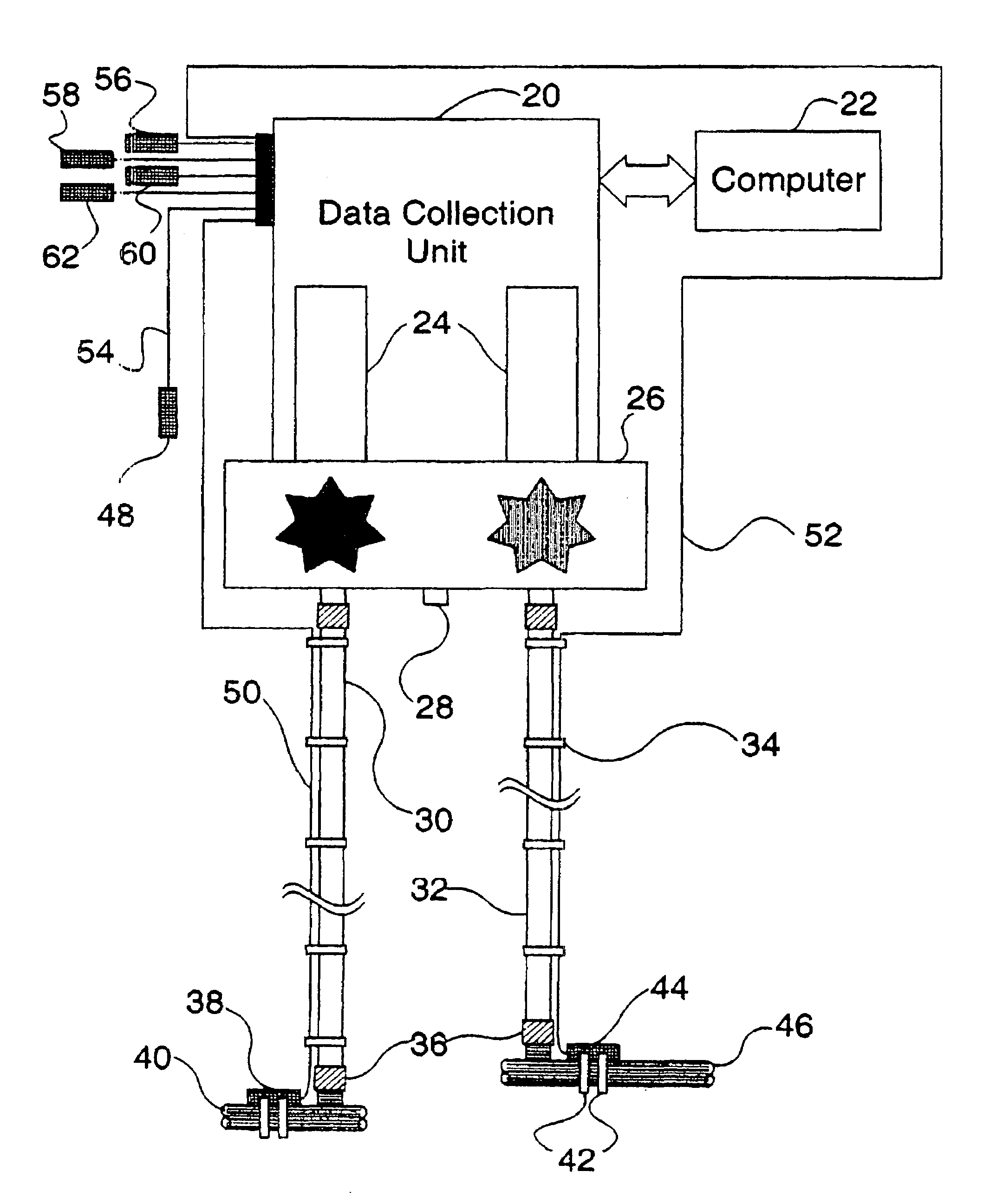

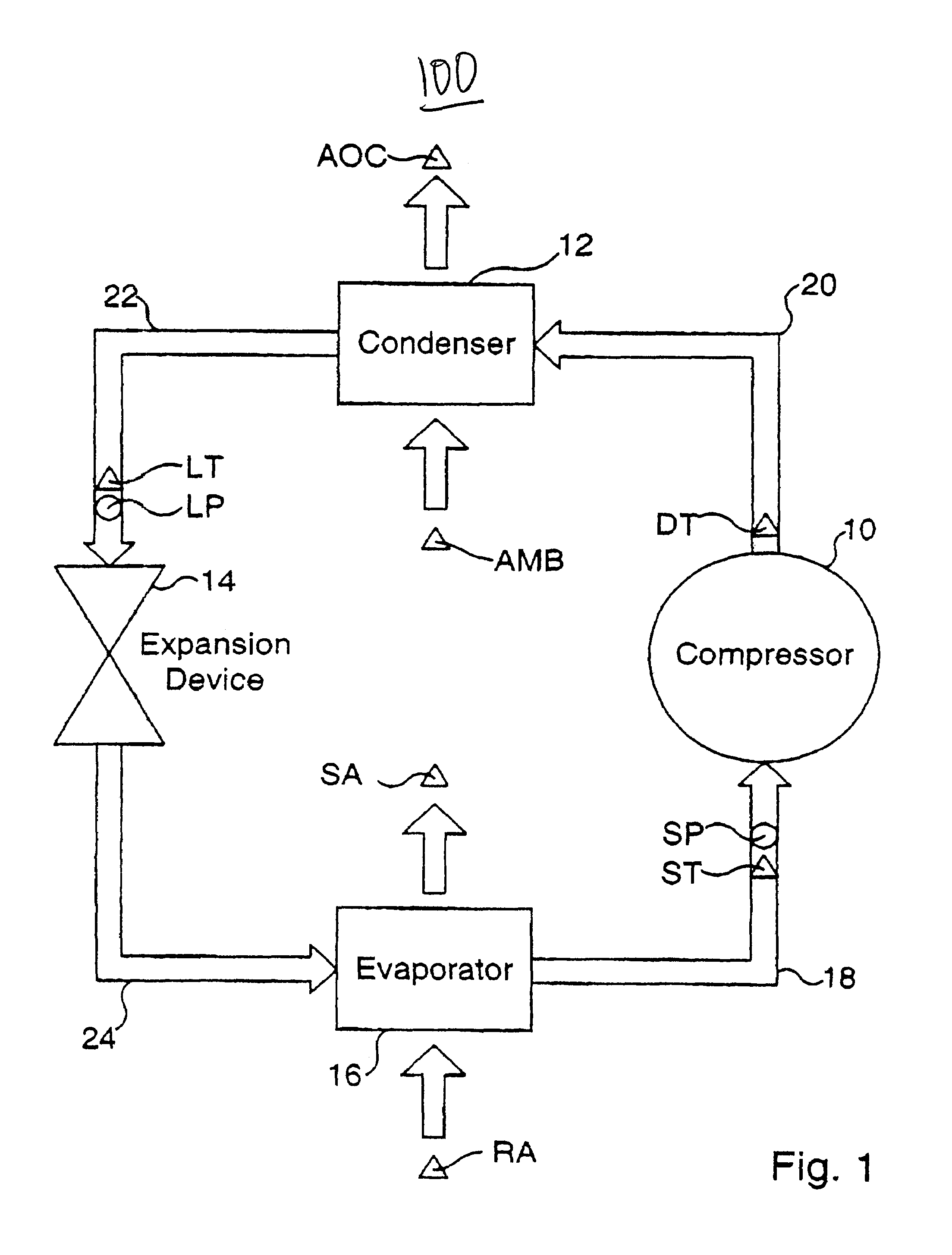

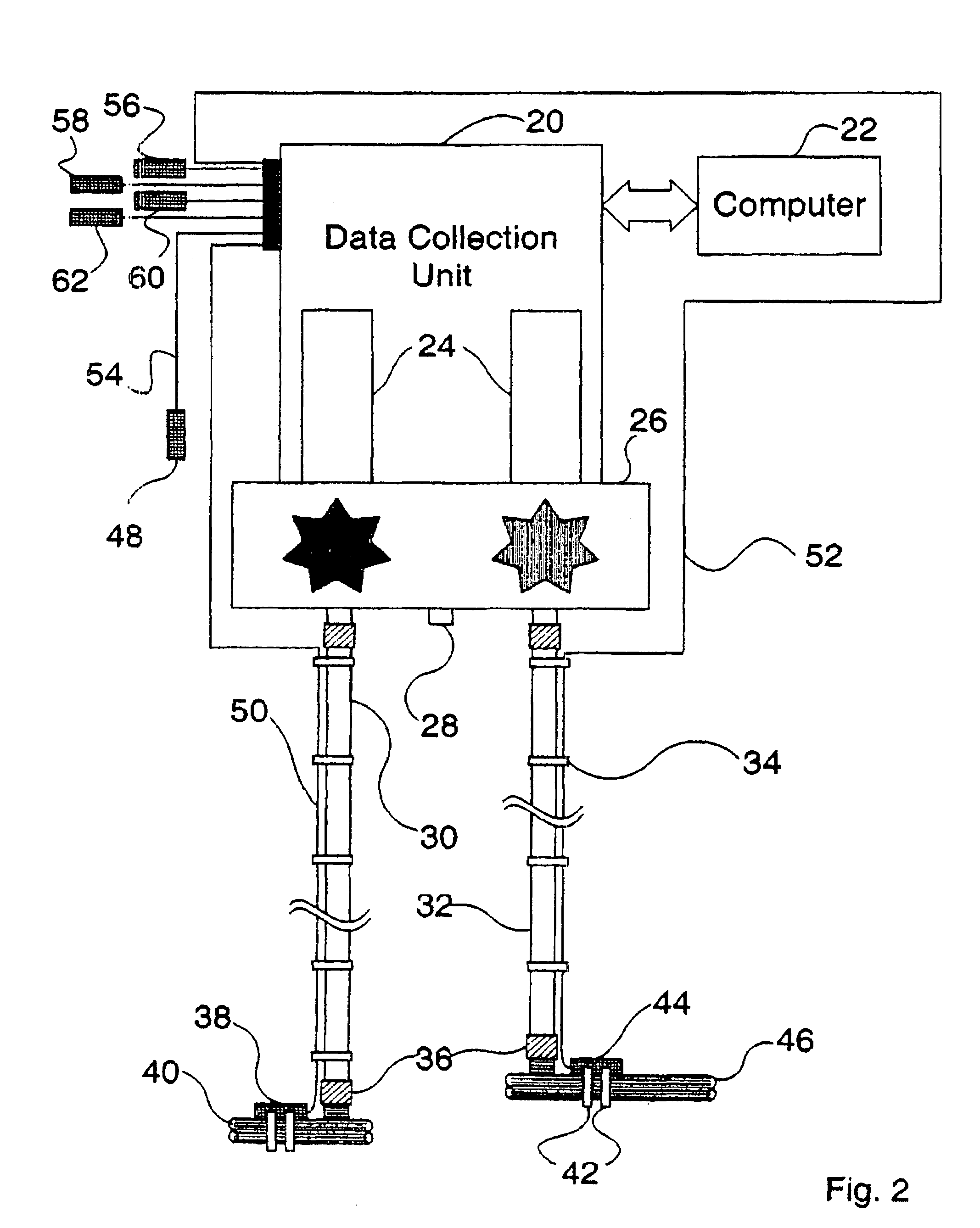

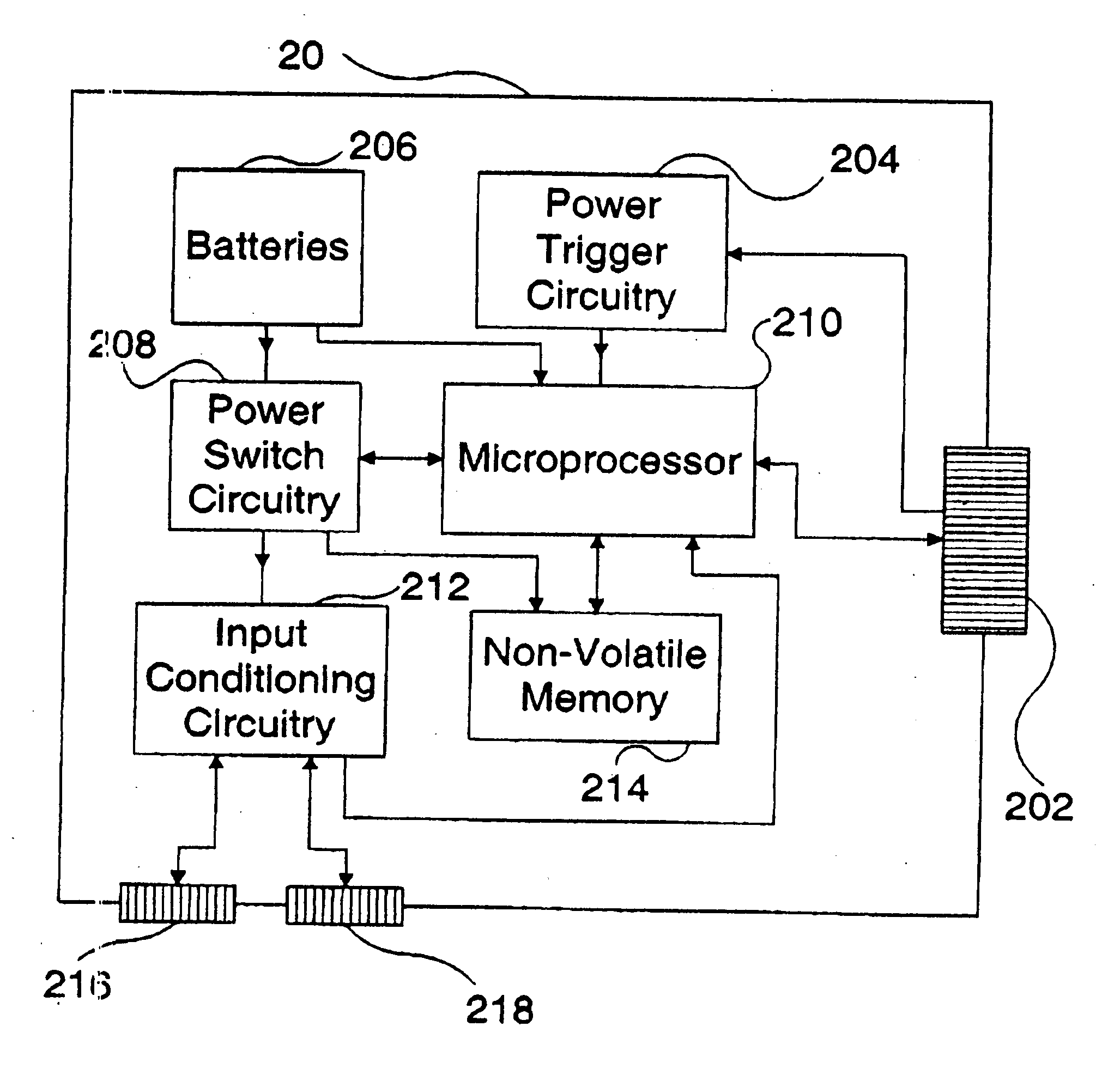

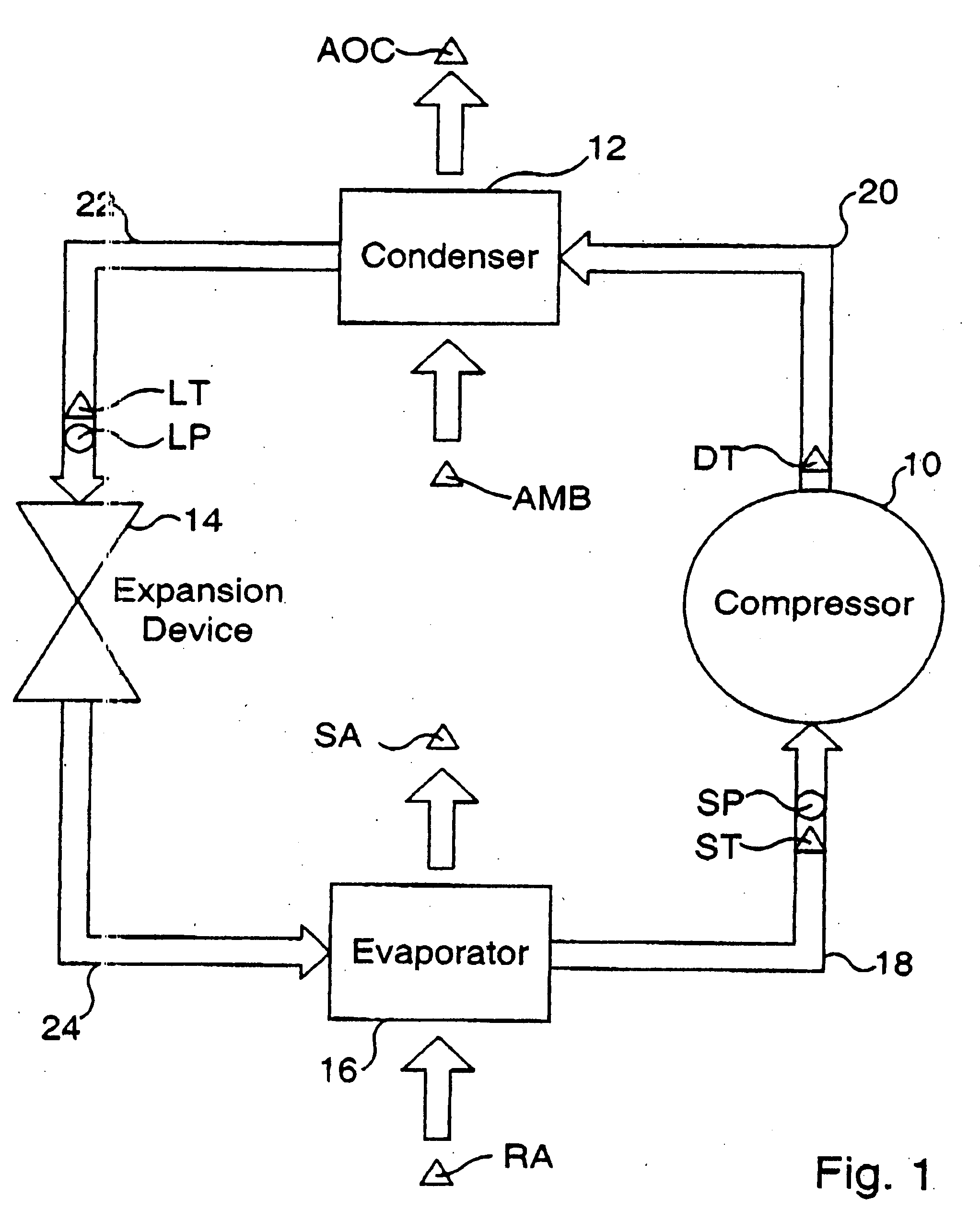

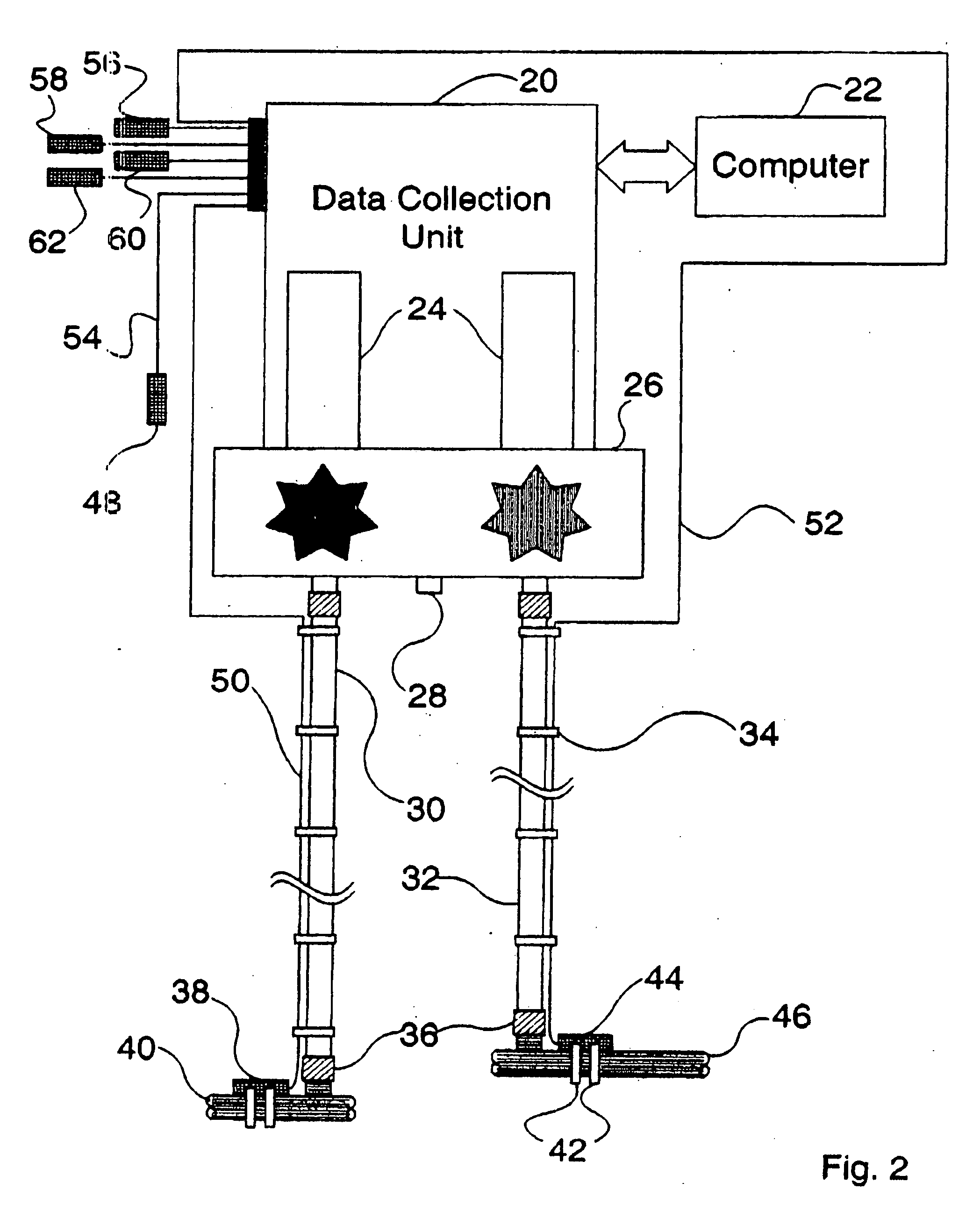

Apparatus and method for detecting faults and providing diagnostics in vapor compression cycle equipment

InactiveUS7079967B2Improve refrigeration cycle efficiencyInexpensive to implement in hardwareMechanical apparatusSpace heating and ventilation safety systemsDiagnostic informationEngineering

An apparatus and method for detecting faults and providing diagnostic information in a refrigeration system comprising a microprocessor, a means for inputting information to the microprocessor, a means for outputting information from the microprocessor, and five sensors.

Owner:MCLOUD TECH USA INC

Apparatus and method for detecting faults and providing diagnostics in vapor compression cycle equipment

InactiveUS20060259276A1Improve refrigeration cycle efficiencyInexpensive to implement in hardwareMechanical apparatusSpace heating and ventilation safety systemsSubject matterDiagnostic information

An apparatus and method for detecting faults and providing diagnostic information in a refrigeration system comprising a microprocessor, a means for inputting information to the microprocessor, a means for outputting information from the microprocessor, and five sensors. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that this abstract will not be used to interpret or limit the scope or meaning of the claims.

Owner:ROSSI TODD M +3

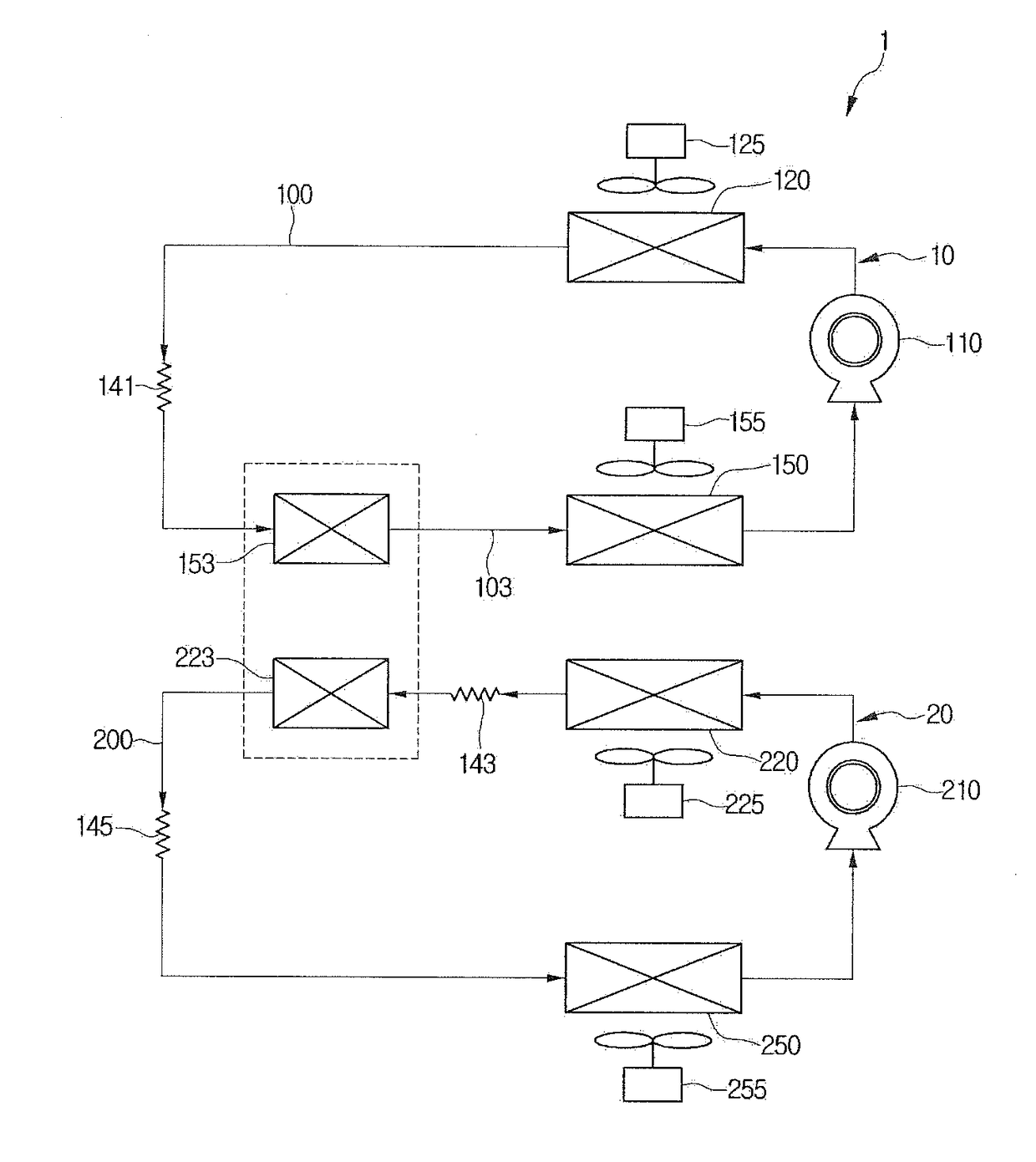

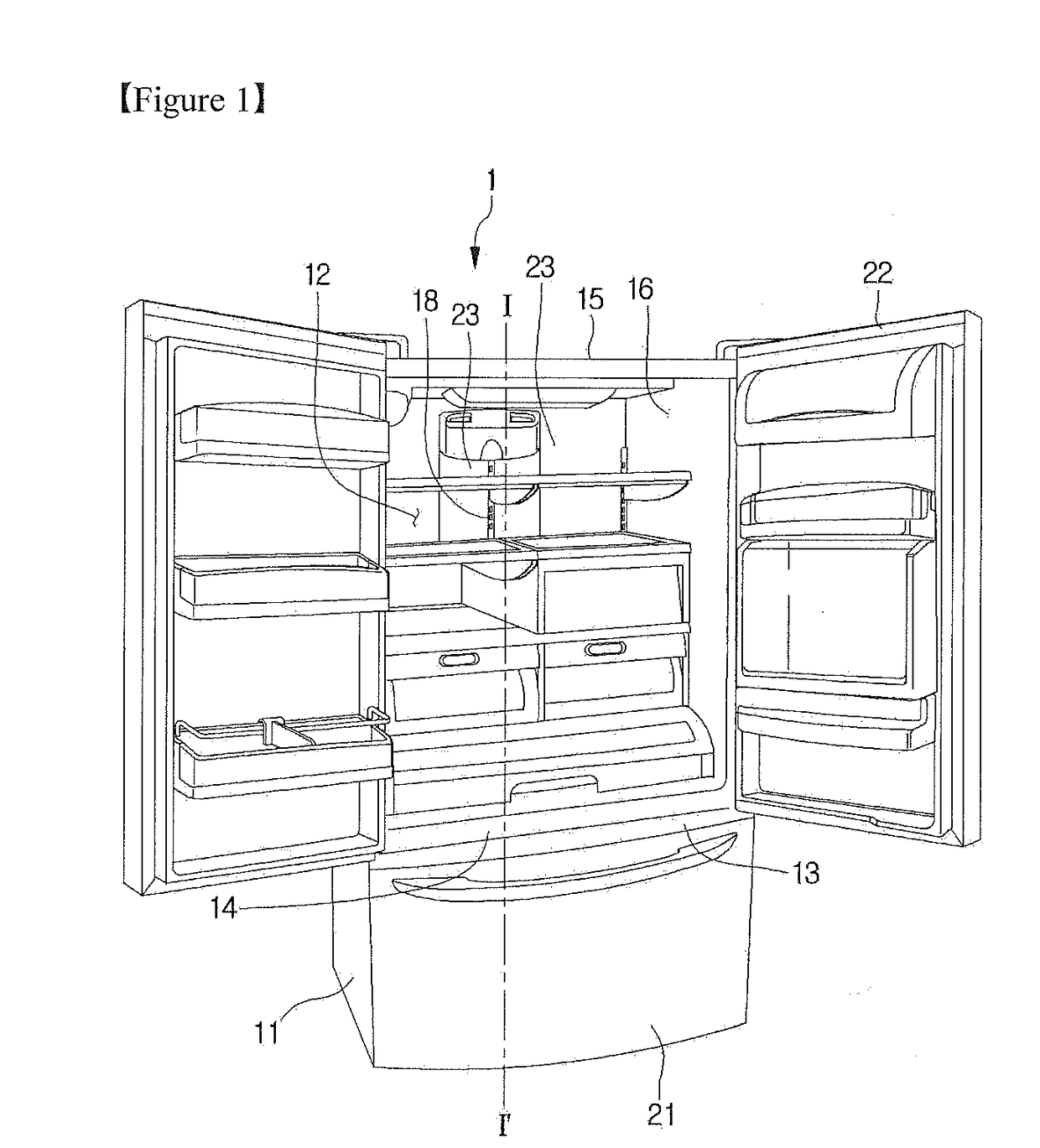

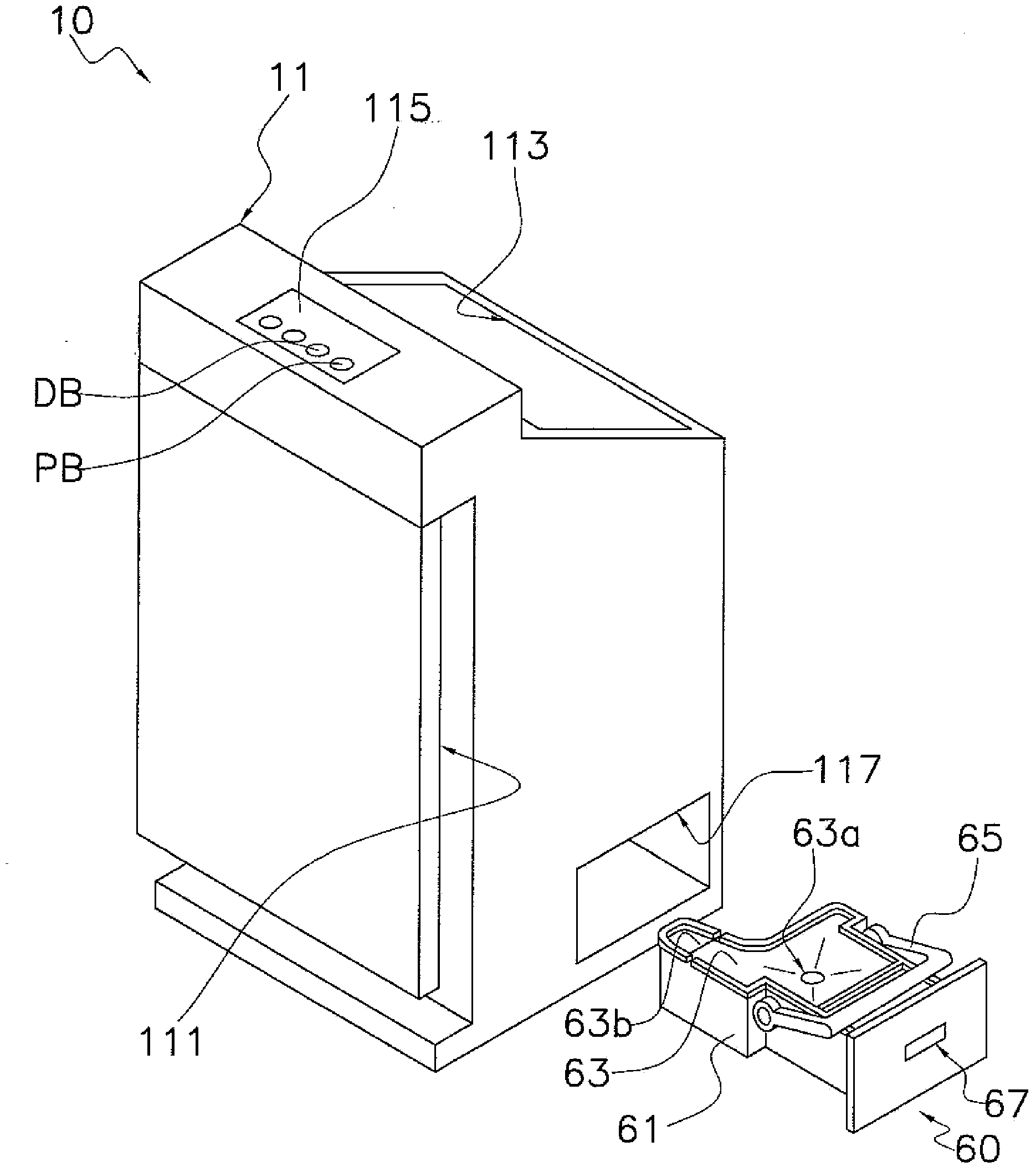

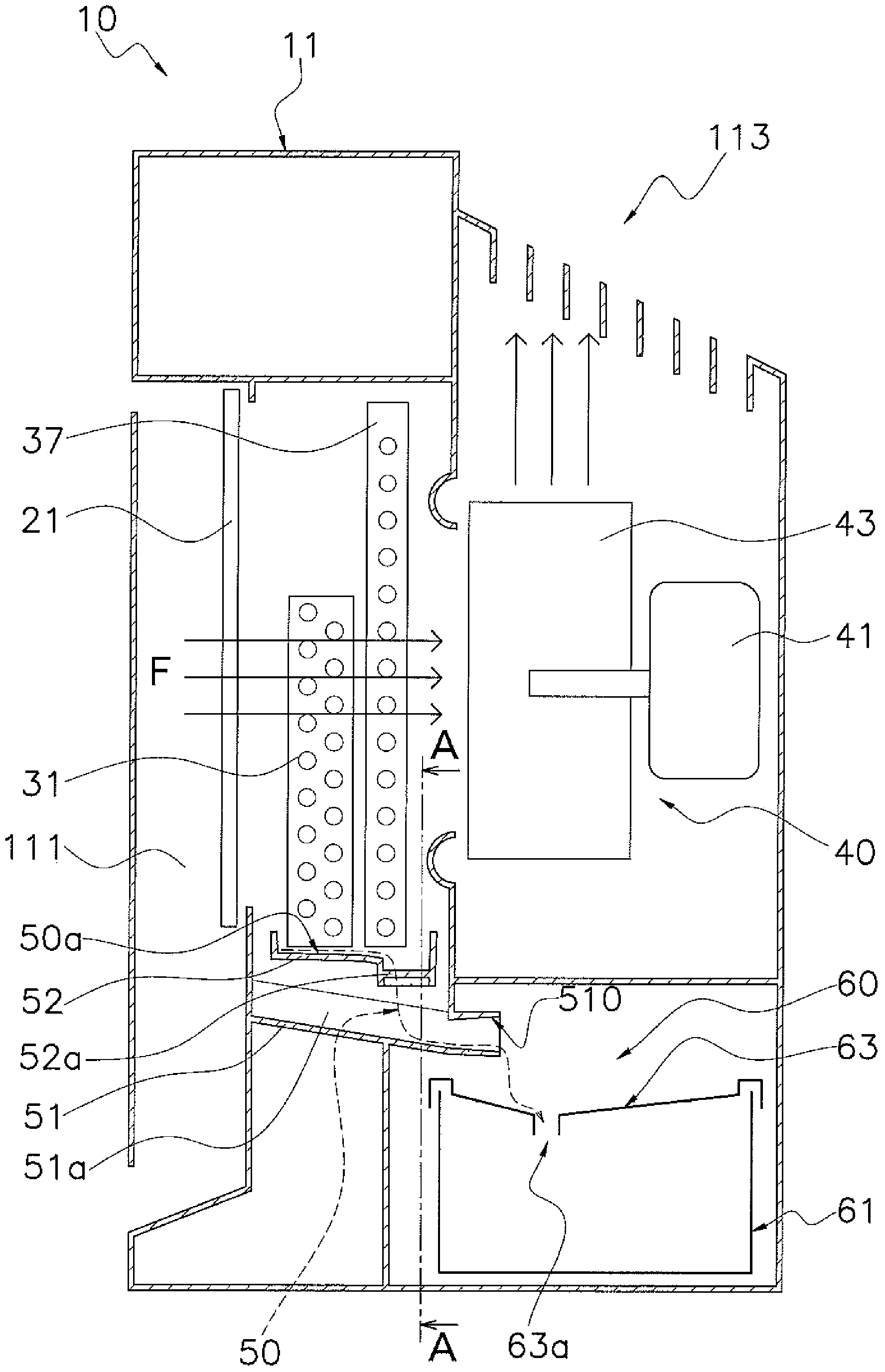

Refrigerator and control method thereof

ActiveUS20170176083A1Improve refrigeration cycle efficiencyImprove cooling efficiencyMechanical apparatusCompression machines with several condensersEvaporationEngineering

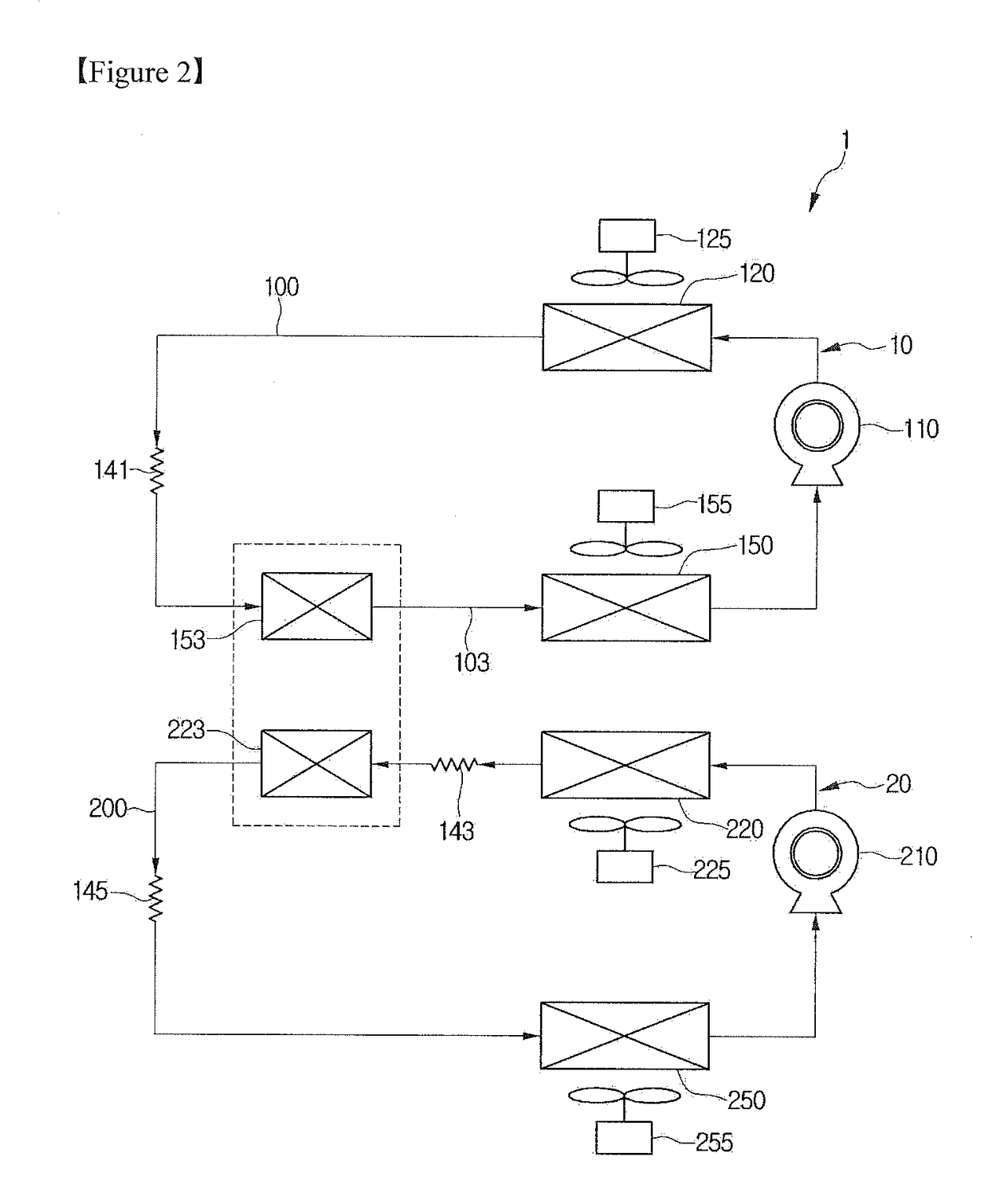

Disclosed are a refrigerator and a control method thereof. The refrigerator according to one aspect includes a main body having a storage chamber; a compressor configured to compress a refrigerant; a condenser configured to condense the refrigerant compressed by the compressor; an evaporation expander configured to depressurize the refrigerant condensed by the condenser; a first evaporator configured to evaporate the refrigerant depressurized by the evaporation expander and thus to cool the storage chamber; a condensing expander installed between the condenser and the evaporation expander and configured to depressurize the refrigerant condensed by the condenser; and a subsidiary condenser installed between the condensing expander and the evaporation expander and configured to condense the refrigerant depressurized by the condensing expander.

Owner:LG ELECTRONICS INC

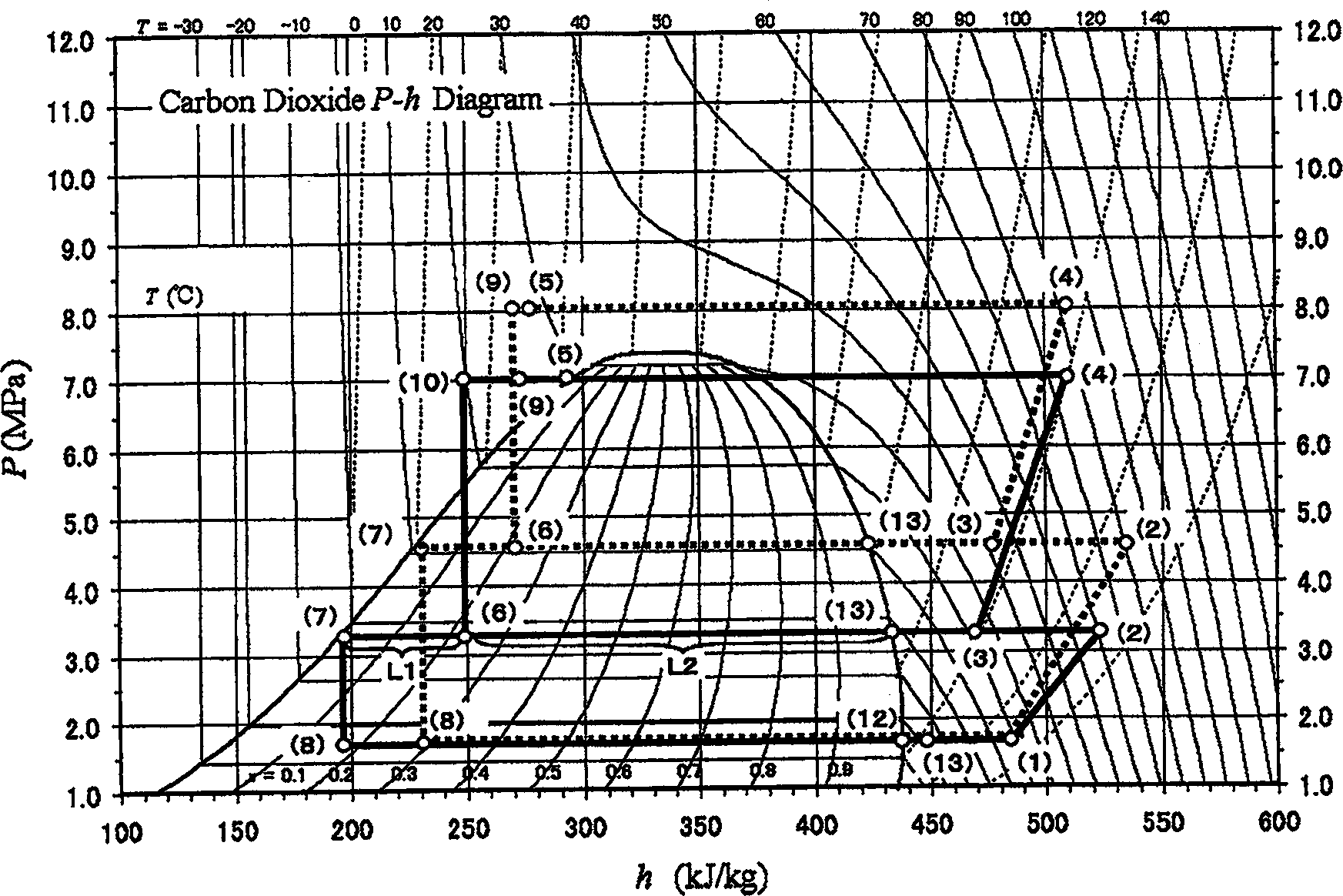

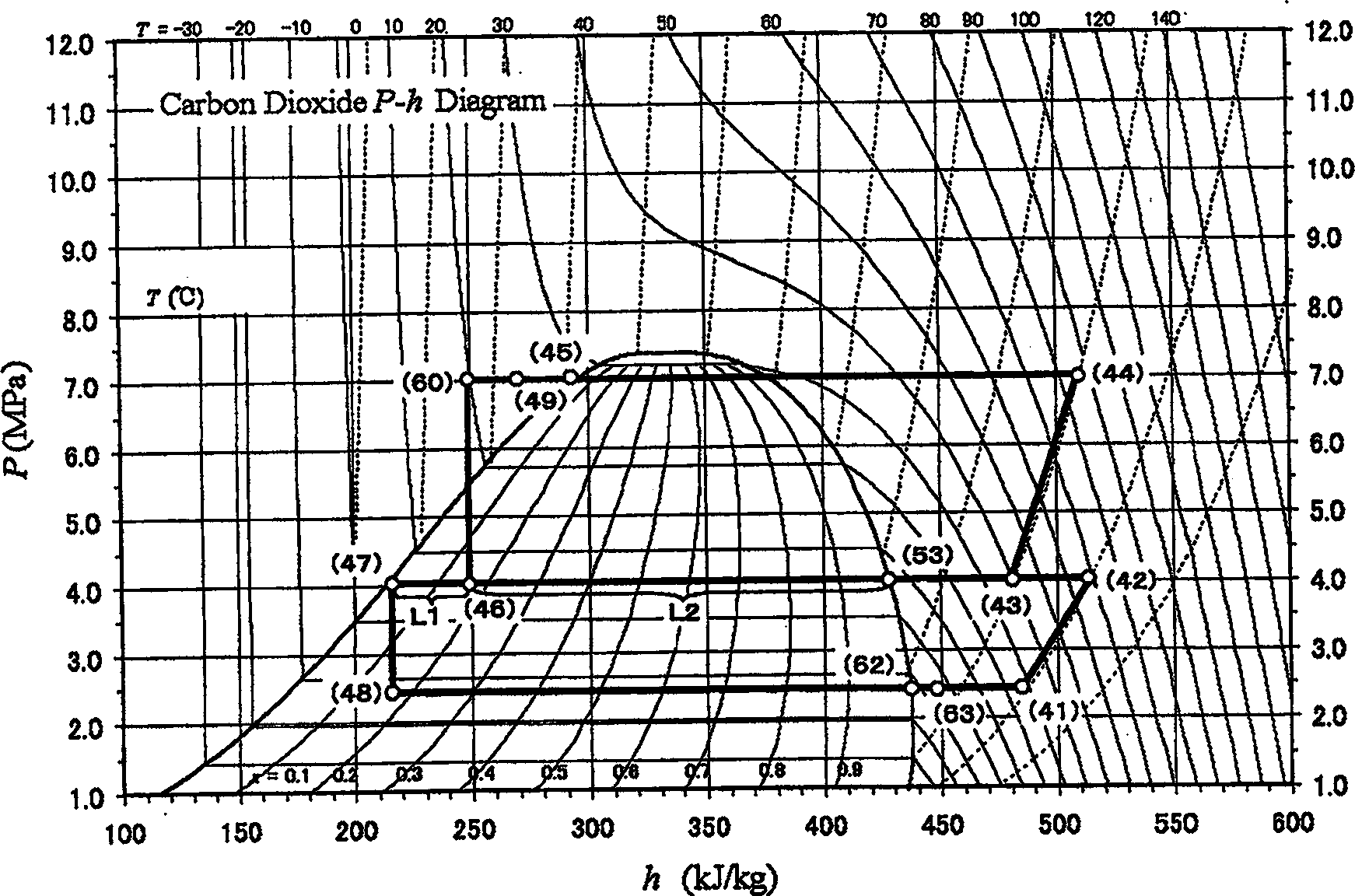

Refrigeration cycle apparatus

InactiveUS6923016B2Improve efficiencyIncrease amount of energy recoveredSolidificationMechanical apparatusProcess engineeringRefrigerant

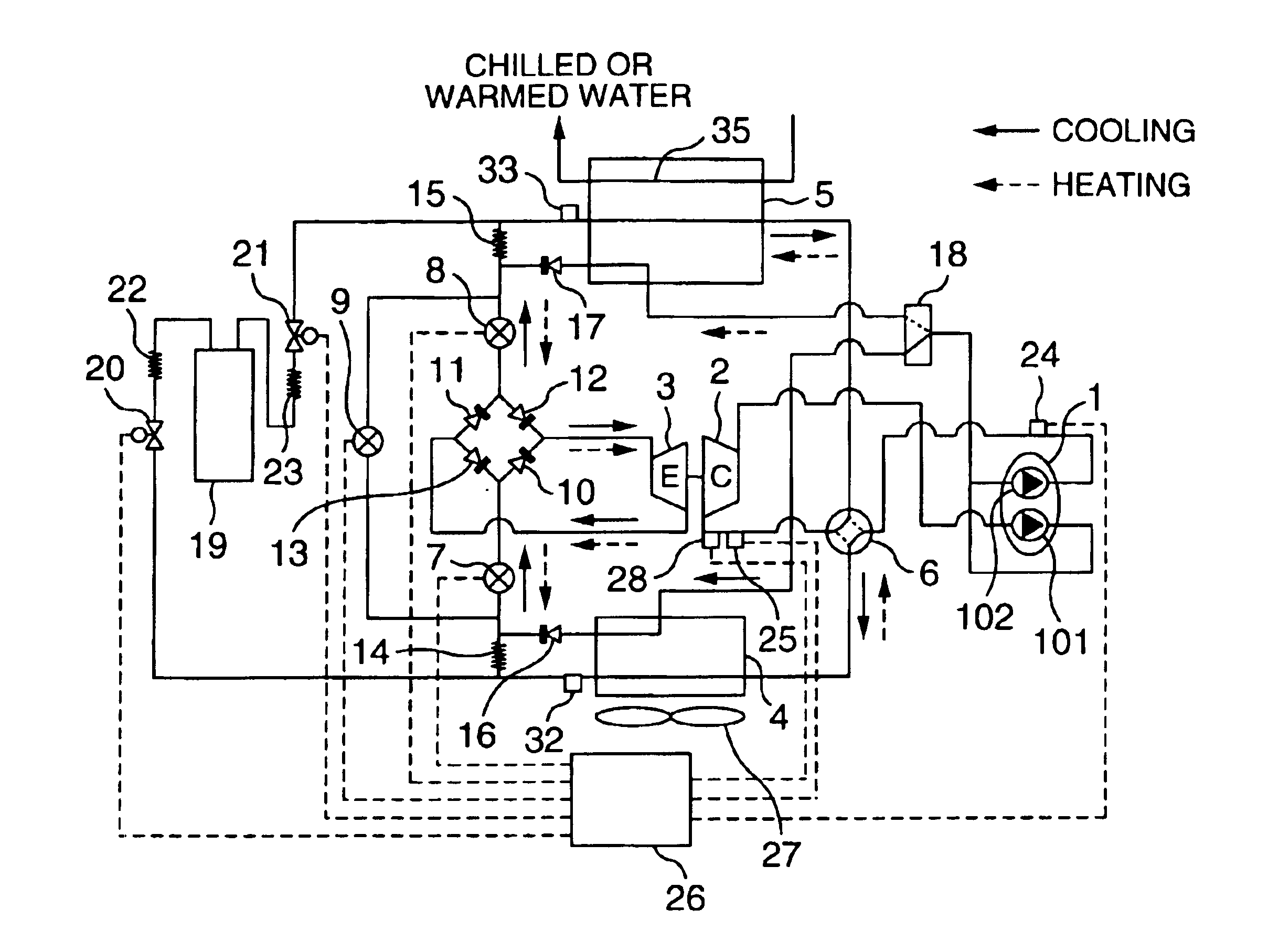

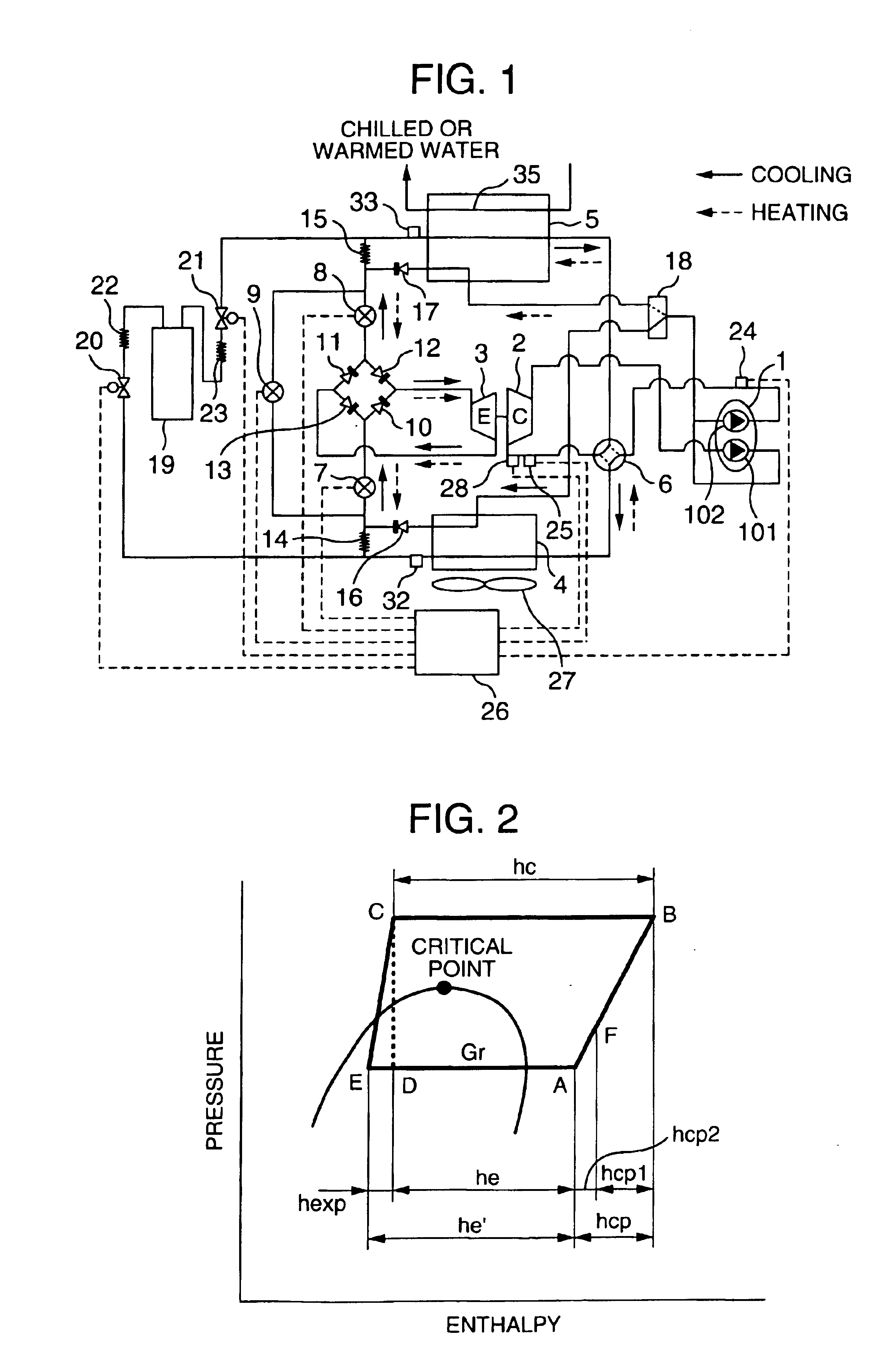

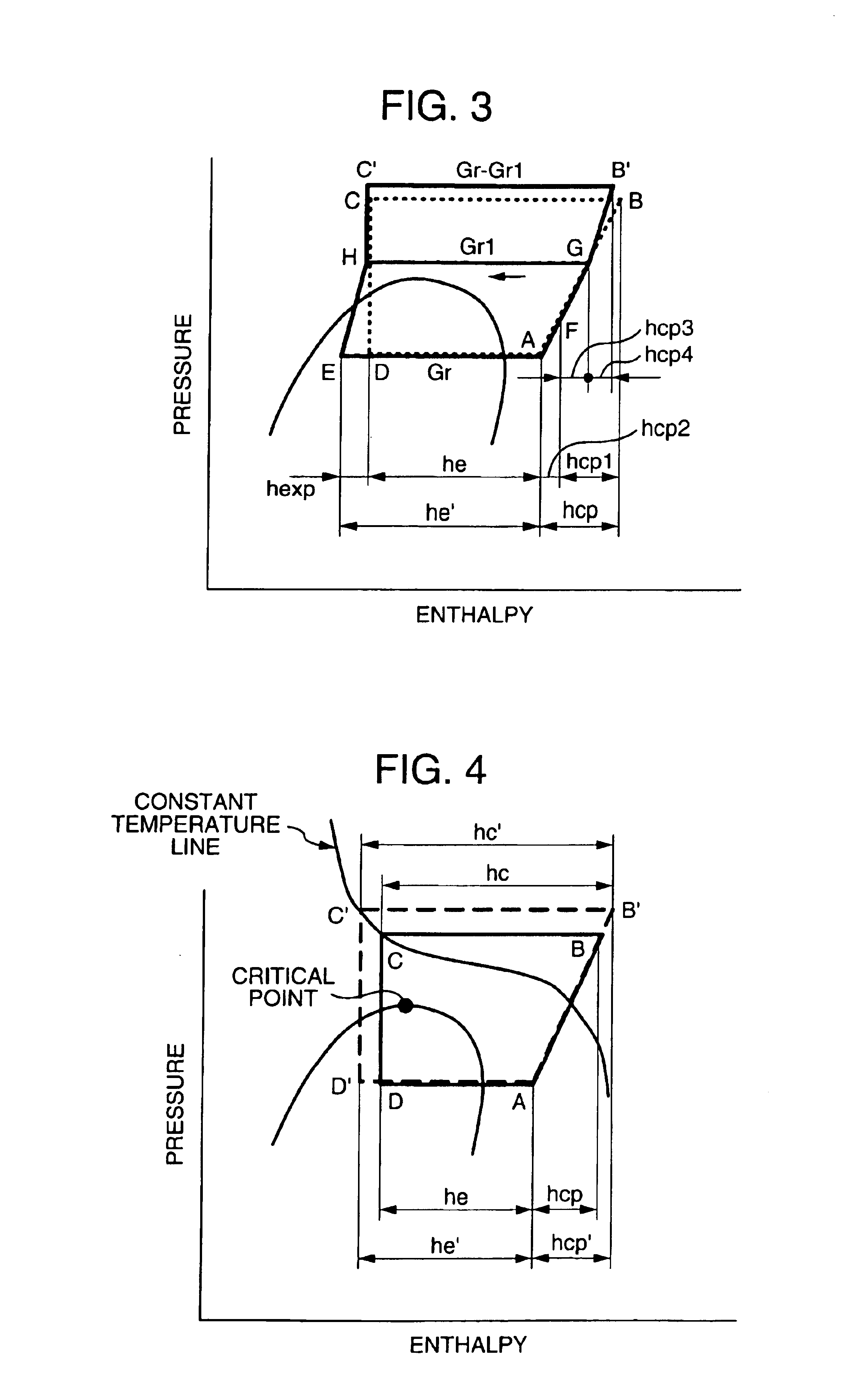

In a refrigerant cycle apparatus, an energy-saving operation is performed by using a refrigerant which is used in a supercritical state. A refrigeration cycle apparatus is constituted by a main compressor, an expander, a sub compressor independently placed in an upstream side of the main compressor, a use side heat exchanger, a heat source side heat exchanger and the like. A refrigerant such as a carbon dioxide or the like which is used in a supercritical state is employed as the refrigerant. The sub compressor is driven by utilizing a recovered energy by the expanding device. Further, a refrigerant tank is provided, and properly controls an amount of the refrigerant circulating in the refrigerant cycle.

Owner:HITACHI AIR CONDITIONING SYST

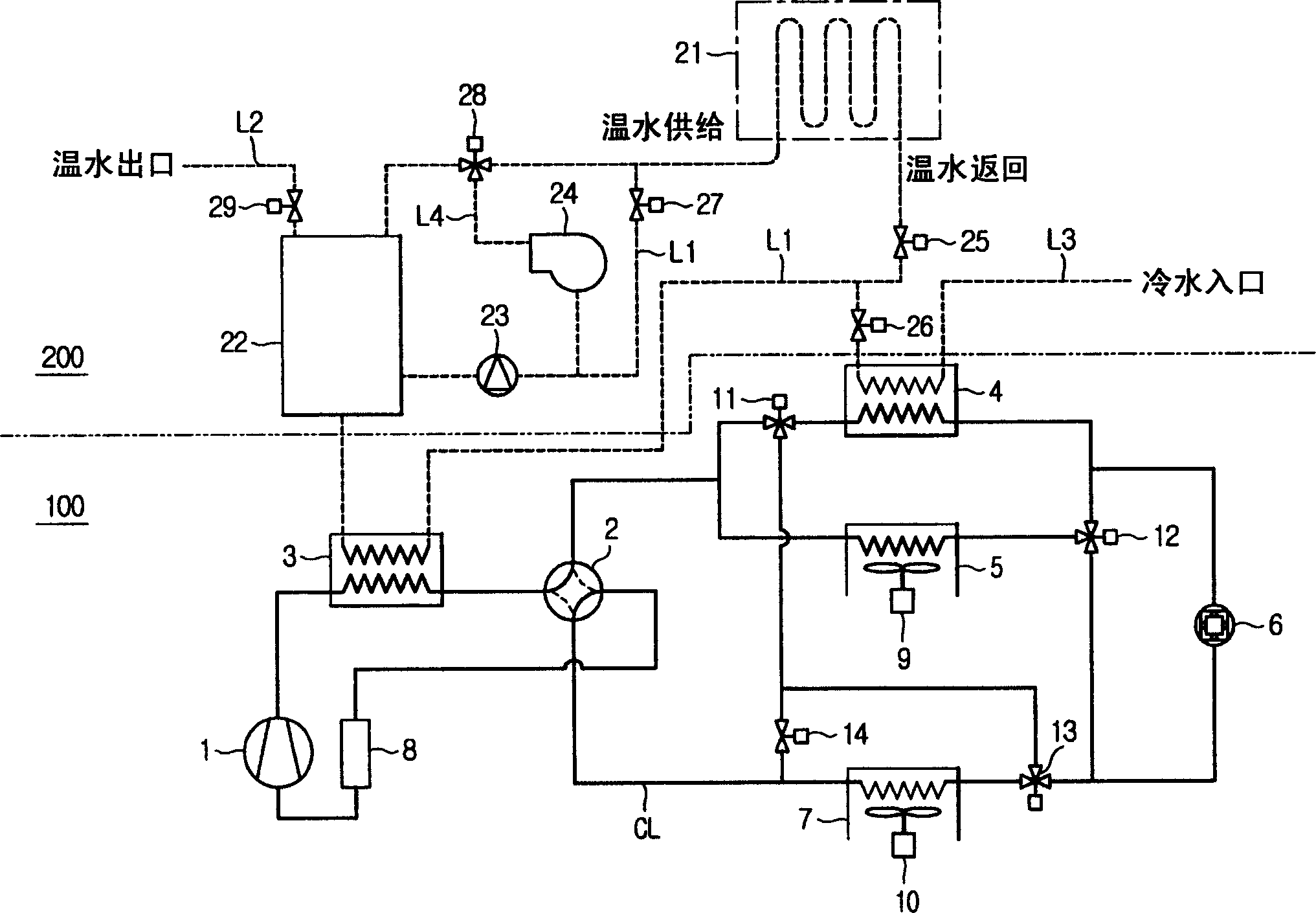

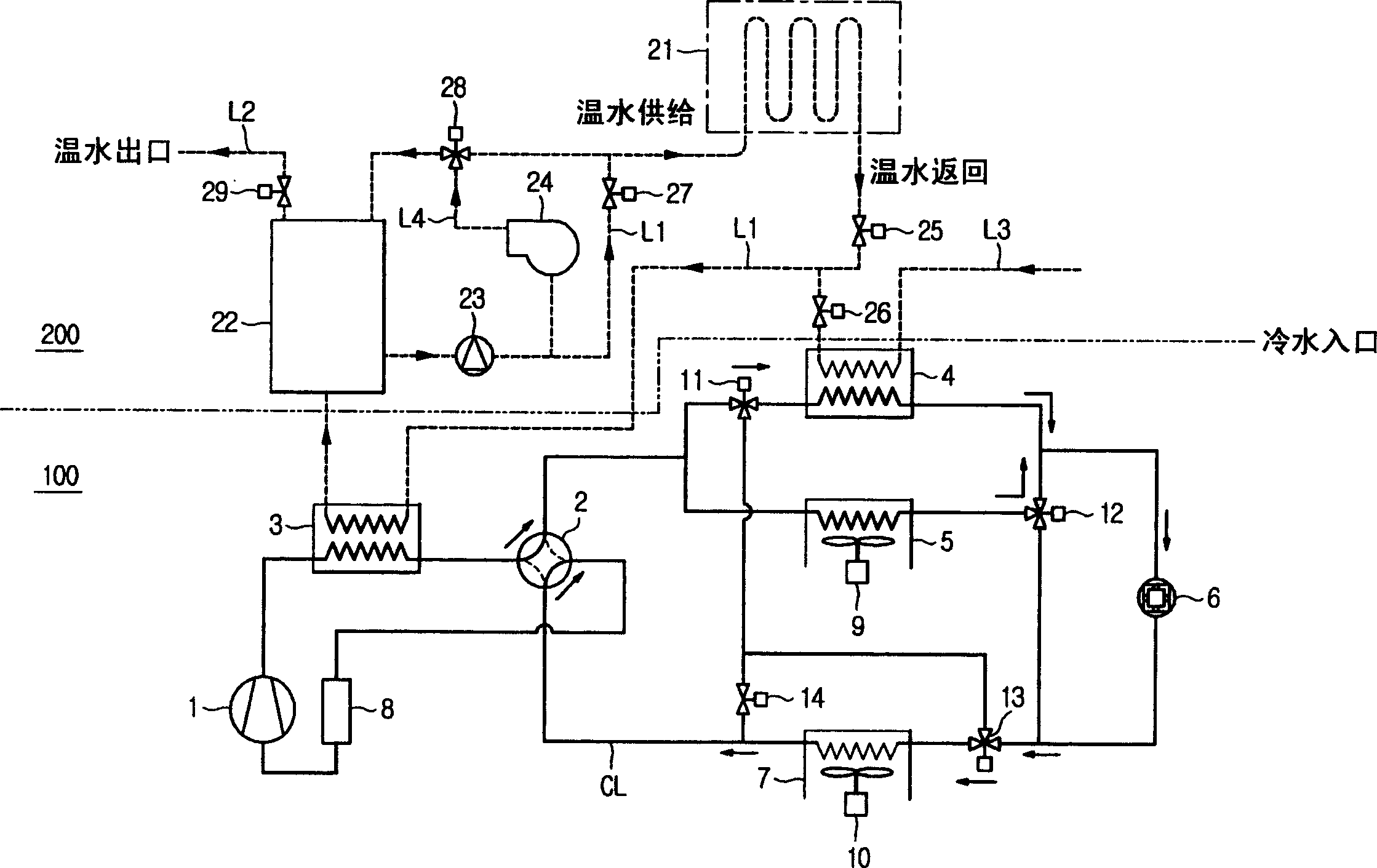

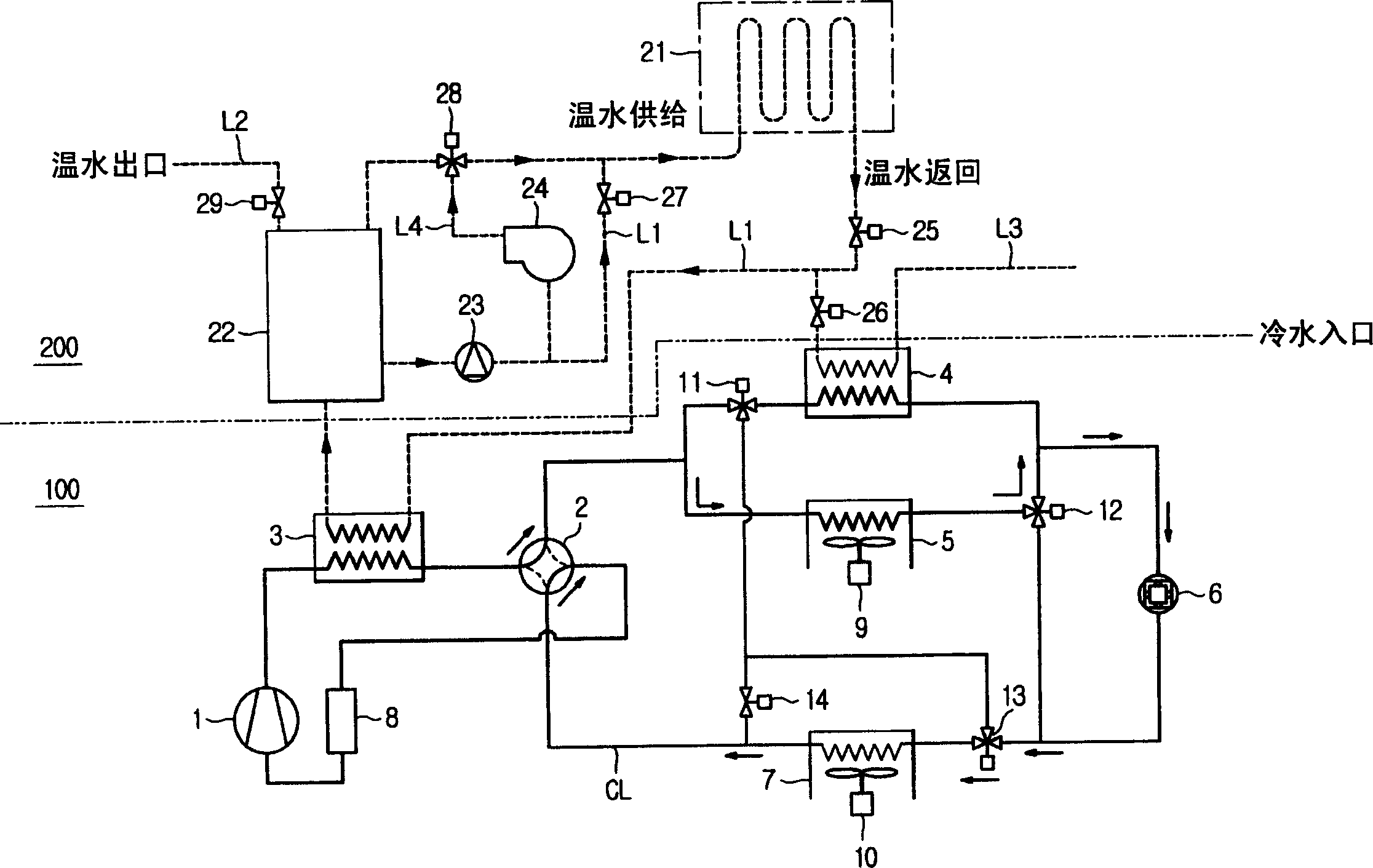

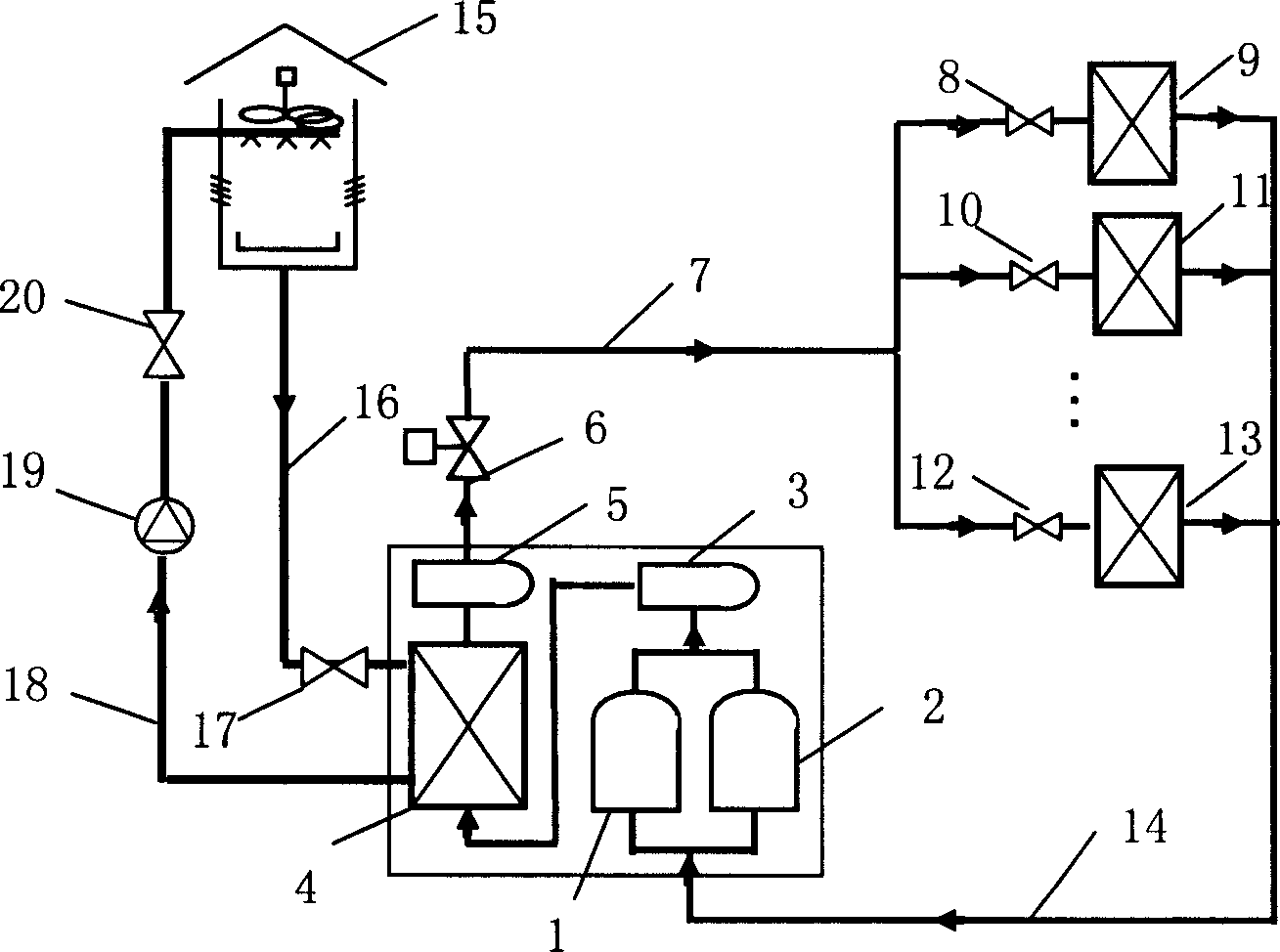

Complex refrigerating and heating system

InactiveCN1637352ASave cooling and heating costsReduce the temperatureEnergy efficient heating/coolingWater heatersFour-way valveUnderfloor heating

Provide a composite cooling and heating system with a heat pump system and a floor heating system. The heat pump system uses carbon dioxide as a natural refrigerant, and has a compressor connected by a refrigerant pipe, a four-way valve, an indoor heat exchanger, an expansion device, and an outdoor heat exchanger. and multiple heat exchangers for hot water supply. A floor heating system has a heating water supply pipe for circulating heating water and a heating water regulating valve for regulating the flow of heating water.

Owner:SAMSUNG ELECTRONICS CO LTD

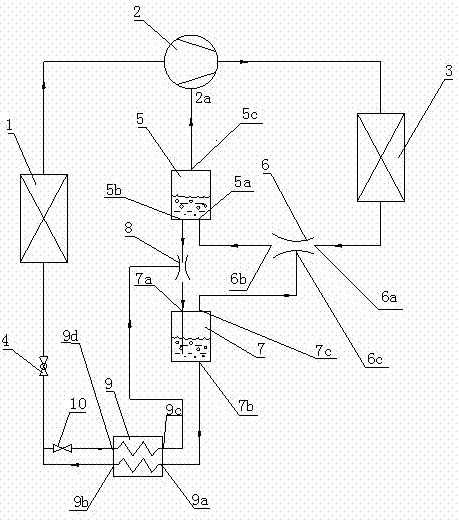

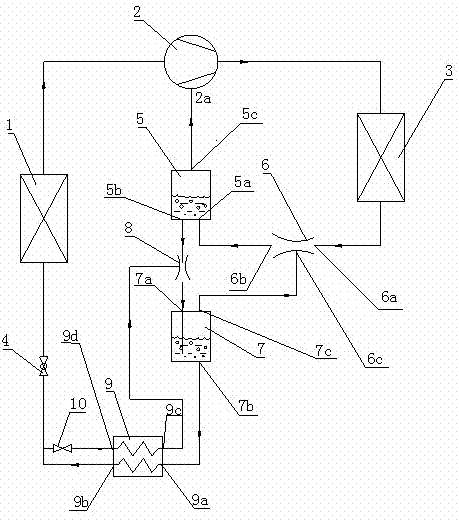

Energy-saving ultralow-temperature preservation box

ActiveCN102829572AImprove refrigeration cycle efficiencyFast coolingCompression machines with cascade operationAutomatic controlEngineering

The invention discloses an energy-saving ultralow-temperature preservation box which comprises a high-temperature refrigerating cycle unit and a low-temperature refrigerating cycle unit. The high-temperature refrigerating cycle unit and the low-temperature refrigerating cycle unit are coupled together by a heat exchanger; the high-temperature refrigerating cycle unit comprises a cycle compressor, a condenser, a first drying filter, a first capillary tube, a first automatic control valve component and a second capillary tube; and the low-temperature refrigerating cycle unit comprises a low-temperature compressor, an oil separator, a first heat regenerator, a second heat regenerator, a first drying filter,, a second drying filter, a third capillary tube, a second capillary tube, a first, automatic control valve component, a second automatic control valve component, a third automatic control valve component, a fourth automatic control valve component, a fifth automatic control valve component and an evaporator. The high-temperature refrigerating cycle and the low-temperature refrigerating cycle are coupled to realize low-temperature refrigeration, and the heat regenerating cycle form and the capillary tube energy-saving cycle form are used to improve the regenerating cycle efficiency. The energy-saving ultralow-temperature preservation box has the characteristics of high temperature decreasing speed, high regenerating efficiency, safety, reliability, energy saving and environment friendliness and can meet the regenerating requirement of the low-temperature environment of 50-90 DEG C below zero.

Owner:SUZHOU BEING MEDICAL DEVICES

Double-evaporation-temperature air conditioner with temperature and humidity controlled independently

InactiveCN102141316AAchieve independent controlImprove refrigeration cycle efficiencySpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorEngineering

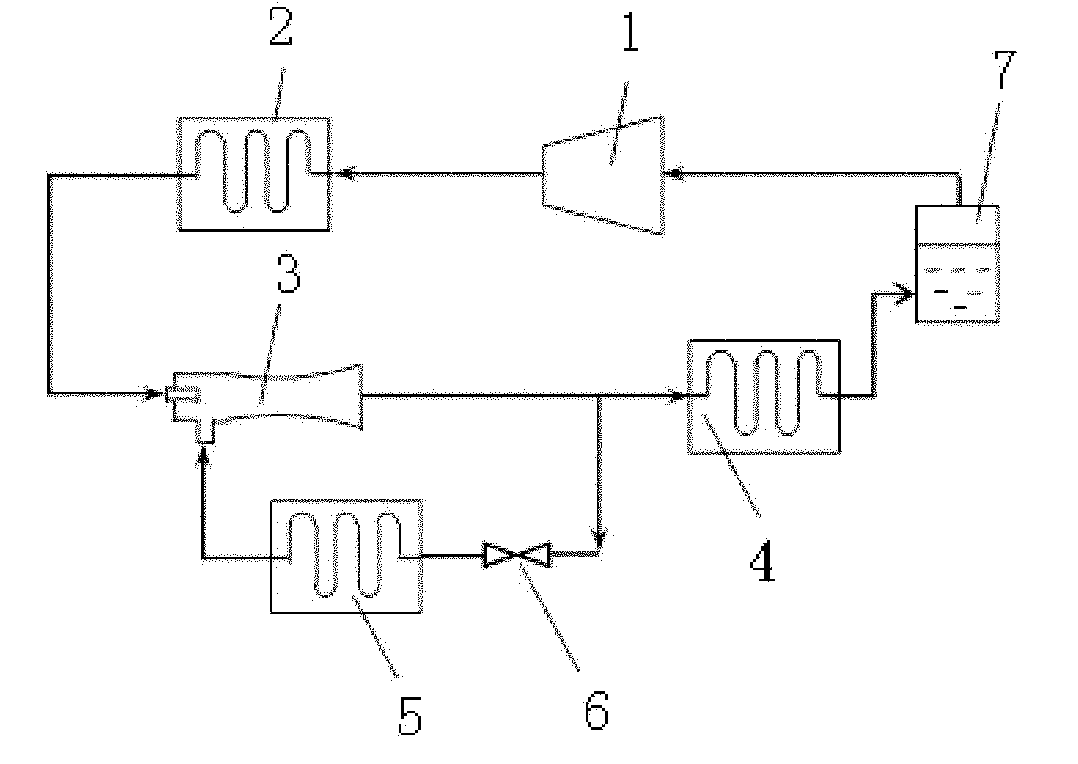

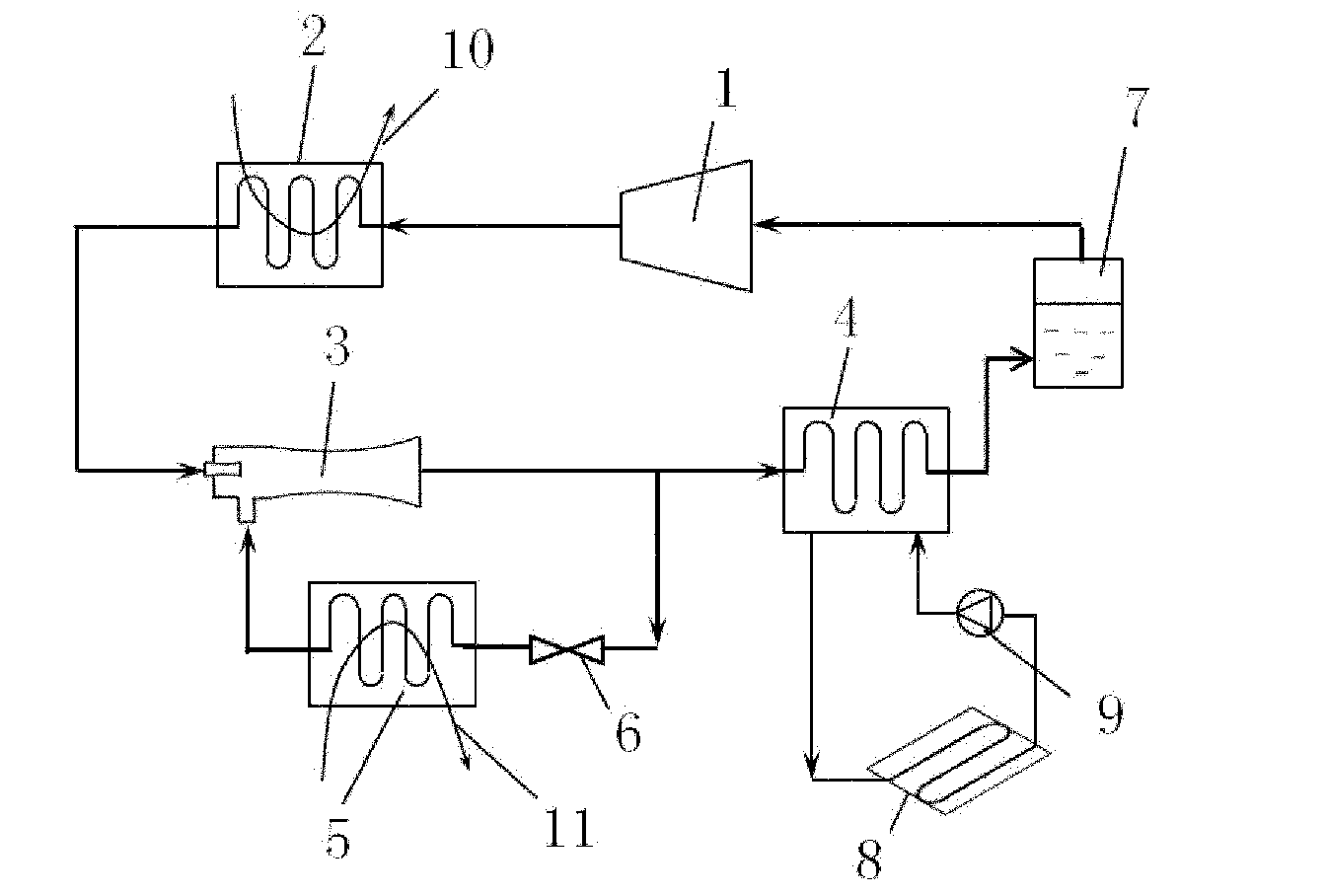

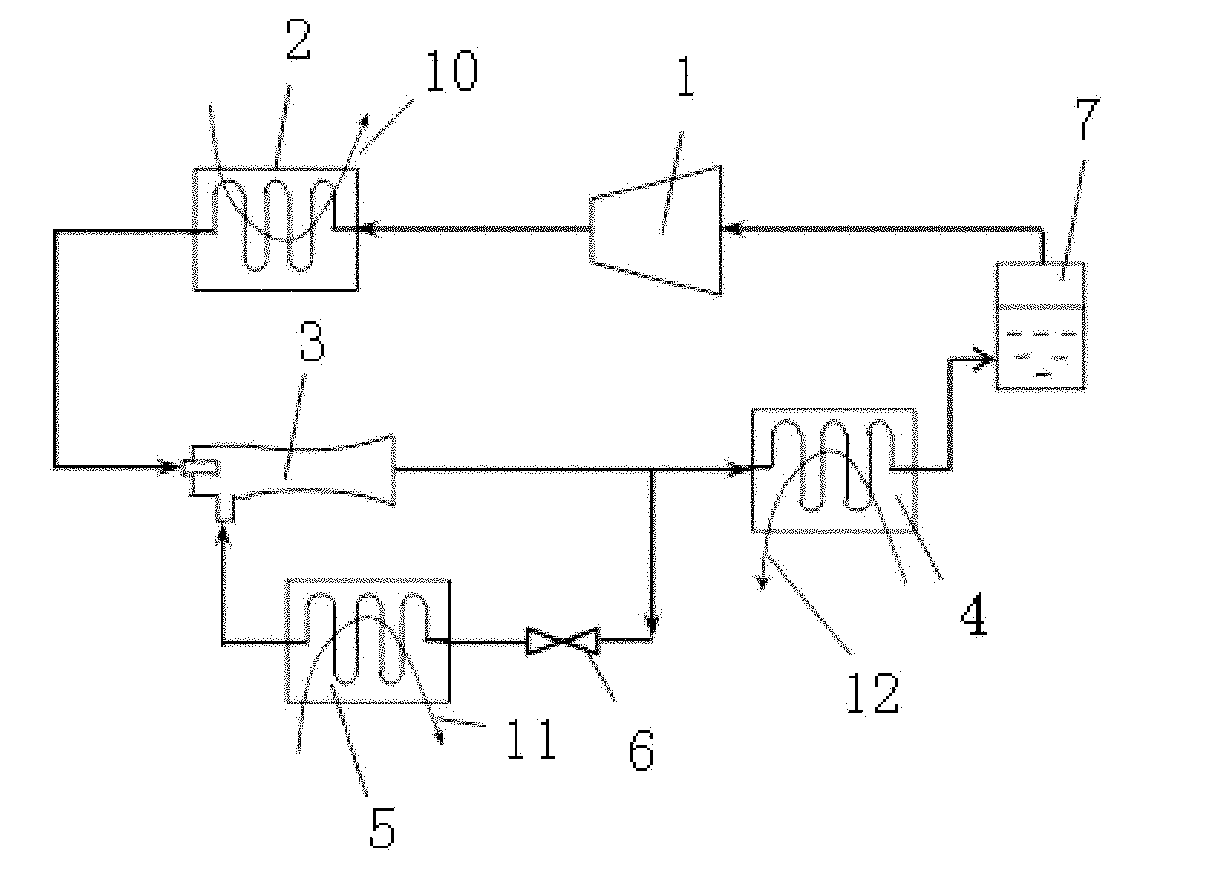

The invention relates to a double-evaporation-temperature air conditioner with temperature and humidity controlled independently, which is characterized by comprising a compressor, a condenser, an ejector, a high-temperature evaporator, a low-temperature evaporator, a throttling device and a gas-liquid separator, wherein an outlet of the compressor is connected with an inlet of the condenser; a first inlet of the ejector is connected with an outlet of the condenser and a second inlet is connected with an outlet of the low-temperature evaporator; an outlet of the ejector is divided into two paths, one path is connected with an inlet of the low-temperature evaporator through the throttling device and the other path is connected with an inlet of the high-temperature evaporator; and an outlet of the high-temperature evaporator is connected with an inlet of the compressor through the gas-liquid separator. The air conditioner provided by the invention is simple and is convenient in running and suitable for applications in the occasions such as small independent offices or families and the like with lower refrigerating output demand.

Owner:TSINGHUA UNIV

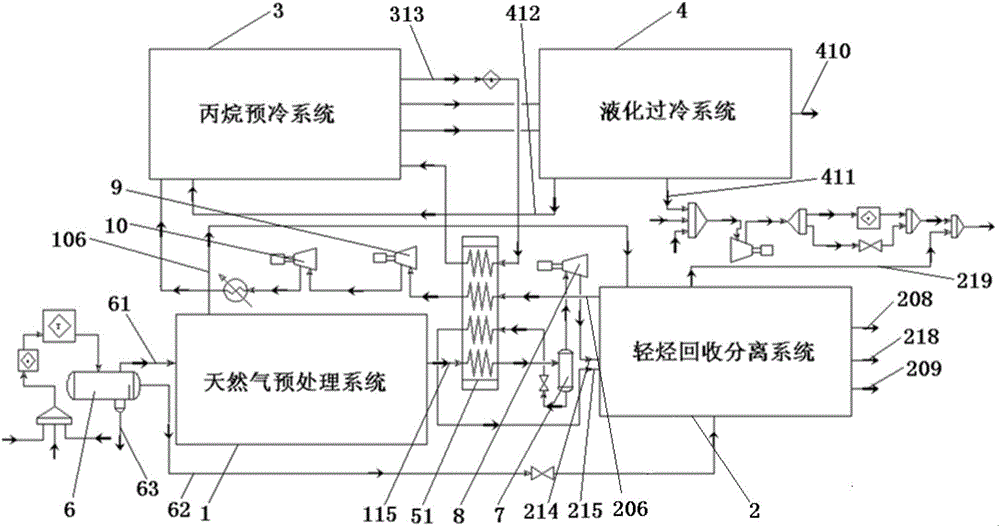

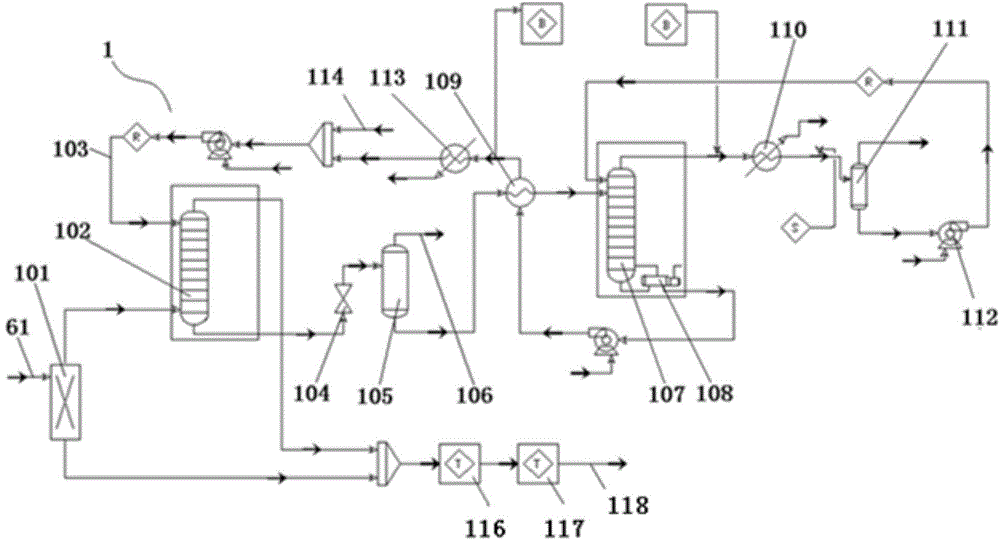

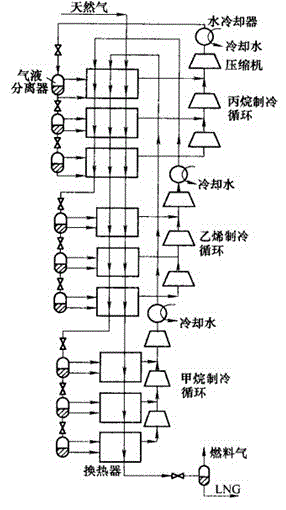

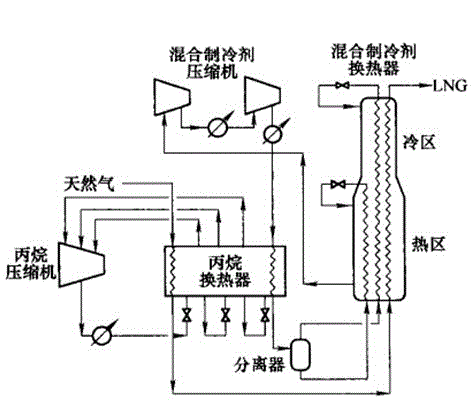

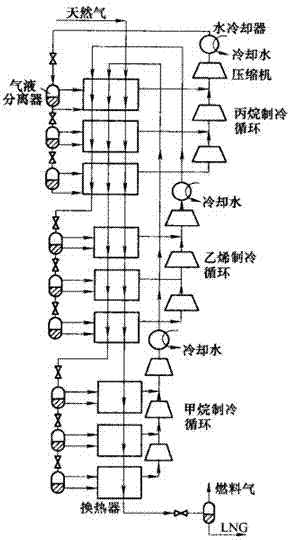

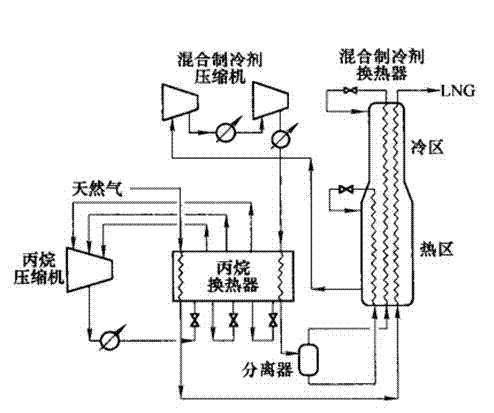

FLNG/FLPG oil gas pretreatment and liquefaction method

ActiveCN104833175AHigh yieldImprove refrigeration cycle efficiencySolidificationLiquefactionOcean bottomNitrogen

The invention relates to a FLNG / FLPG oil gas pretreatment and liquefaction method which comprises the following steps: 1) arranging an oil gas pretreatment and liquefaction system comprising a natural gas pretreatment system, a light hydrocarbon recovery and separation system, a propane precooling system, a liquefaction supercooling system and a plurality of cold boxes; 2) transmitting natural gas mixture transmitted via a submarine pipeline to a slug flow capturer, then, sending natural gases flowing out of a natural gas pipeline to the natural gas pretreatment system, and sending condensated oil flowing out of a condensated oil pipeline to the light hydrocarbon recovery and separation system; 3) carrying out deacidification, dehydration and demercuration pretreatment on the natural gases flowing out of the natural gas pipeline; 4) carrying out light hydrocarbon recovery and separation on the natural gases obtained after the pretreatment; 5) carrying out propane circulation precooling on the natural gases obtained after the light hydrocarbon recovery; and 6) carrying out liquidation and supercooling circulation processing on the natural gases obtained after the precooling. The method can well solve the problems that in an existing liquidation process, maritime applicability is poor, conventional nitrogen expansion process processing capacity is weak, and efficiency is low. The method can be widely applied to the FLNG / FLPG oil gas pretreatment and liquefaction process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

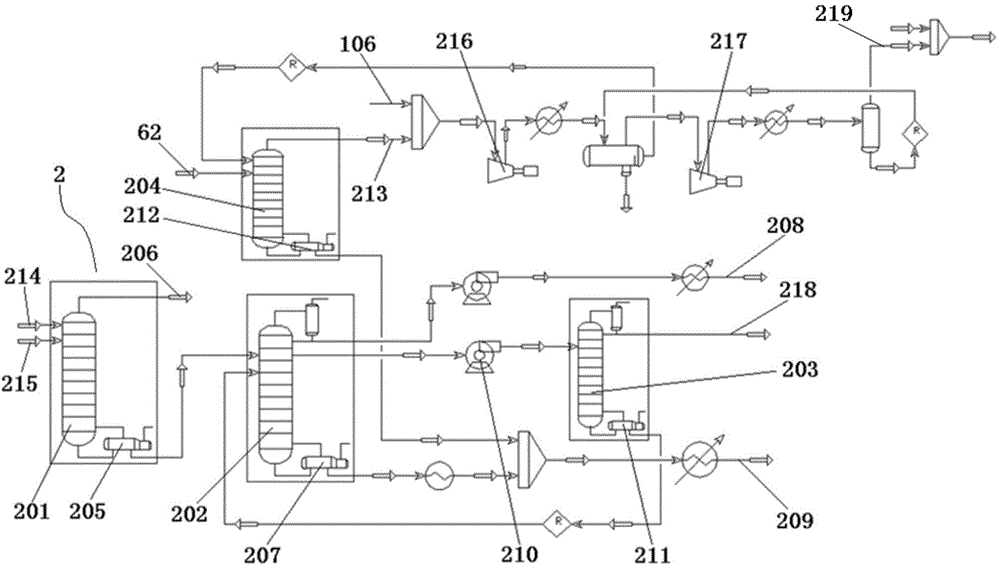

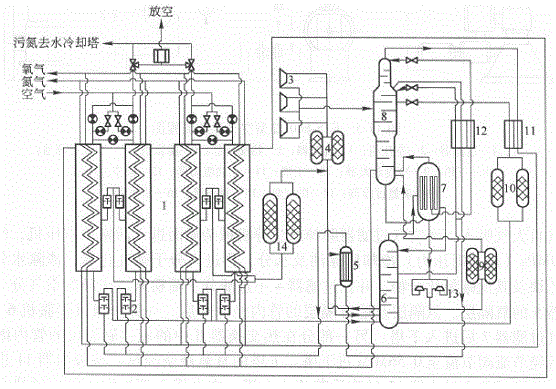

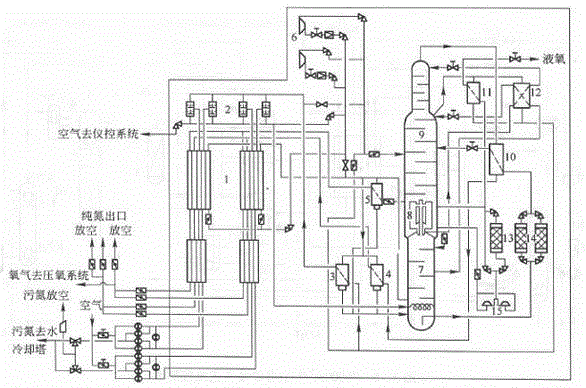

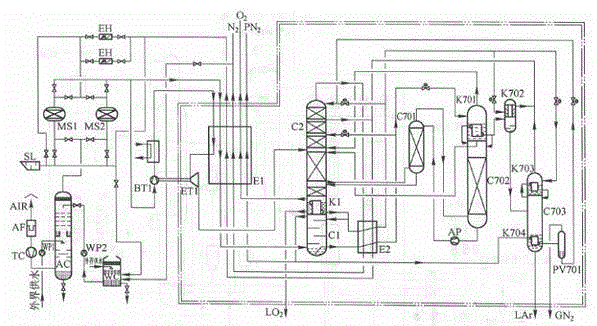

Air separation device for preparing oxygen and nitrogen through isobaric separation

ActiveCN103148676AAchieve isobaric separationImprove energy savingSolidificationLiquefactionThermal energyPower cycle

The invention relates to an air separation device for preparing oxygen and nitrogen through isobaric separation. In the air separation device, a Rankine cycle system with a similar thermal energy power cycle device at a low-temperature end is adopted, a liquid nitrogen washing process is adopted, and cold is replenished to the air separation device through a liquid nitrogen washing cold-replenishing system, so that nitrogen and oxygen can be prepared by performing isobaric separation on the air. Compared with the conventional advanced unit, the air separation device has the advantages that on the premise of the same refrigerating capacity, energy is saved by over 30 percent compared with the traditional advanced unit, equipment and materials are saved, and operation and adjustment are performed flexibly and conveniently; and meanwhile, multiple pressure grades and multi-gas supply can be realized conveniently through the air separation device, so that low-energy-consumption concentrated air supplying can be realized, the conventional air separation technology and theory are broken through, and remarkable economic, social and environmental protection benefits are achieved.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

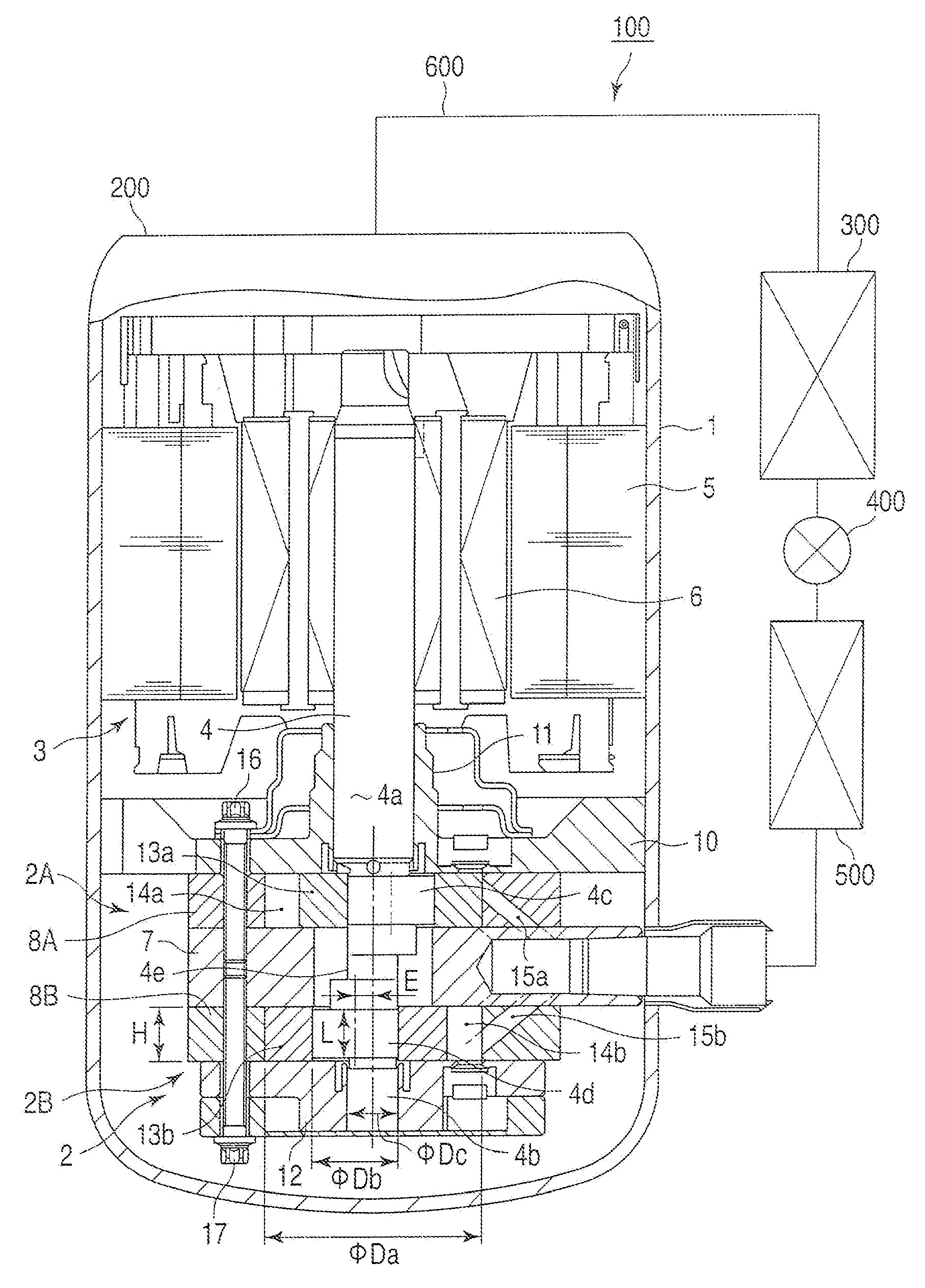

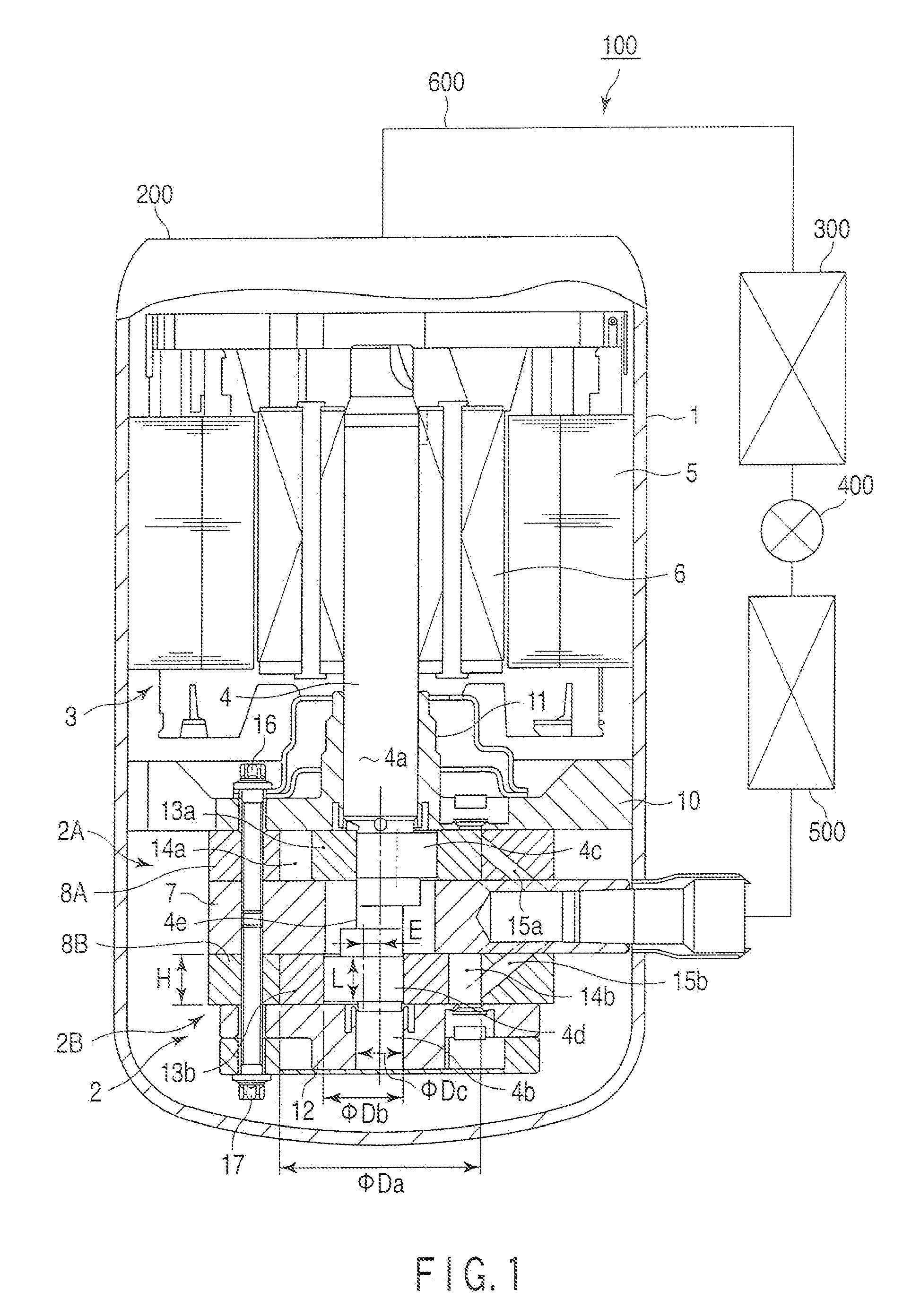

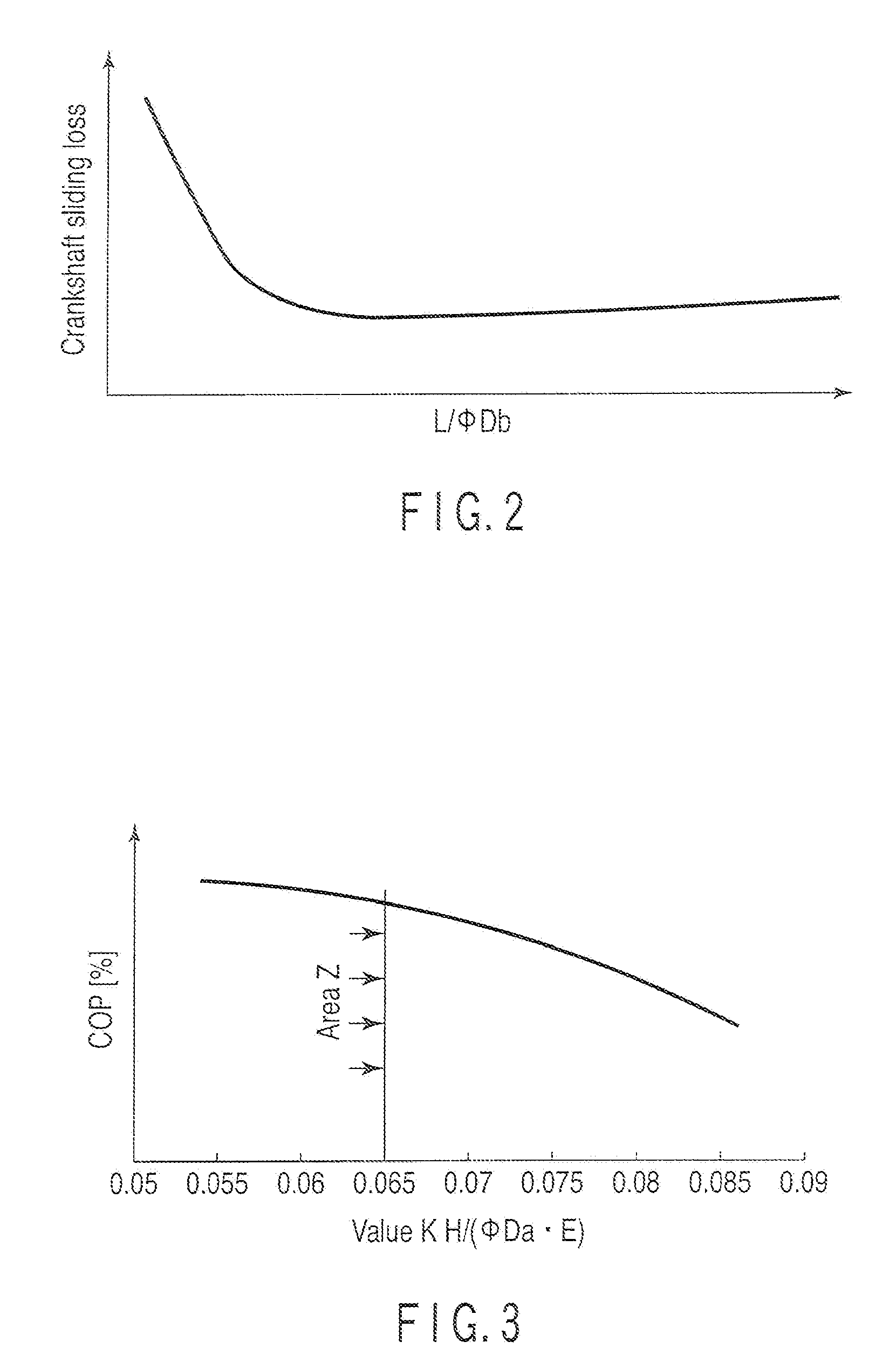

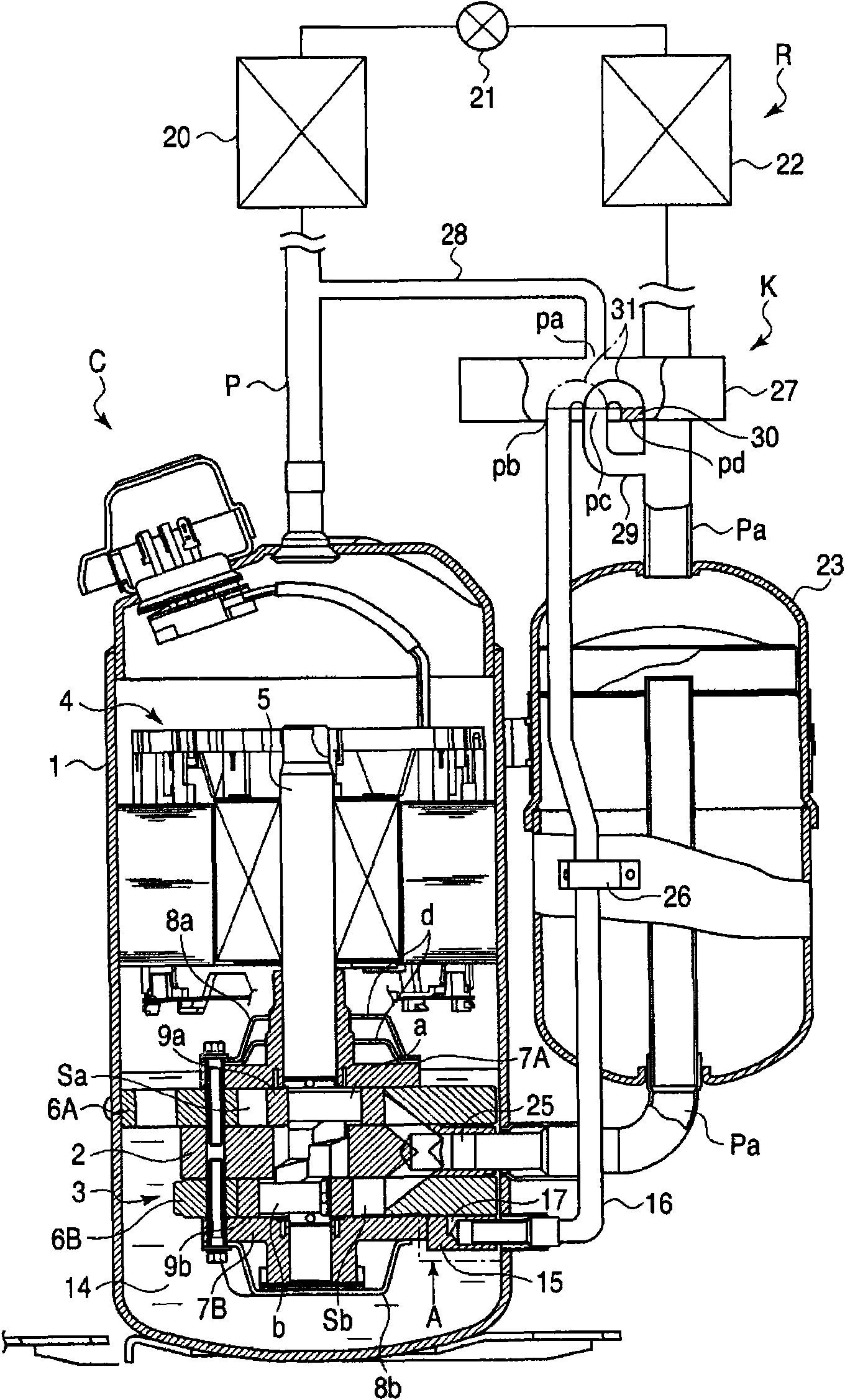

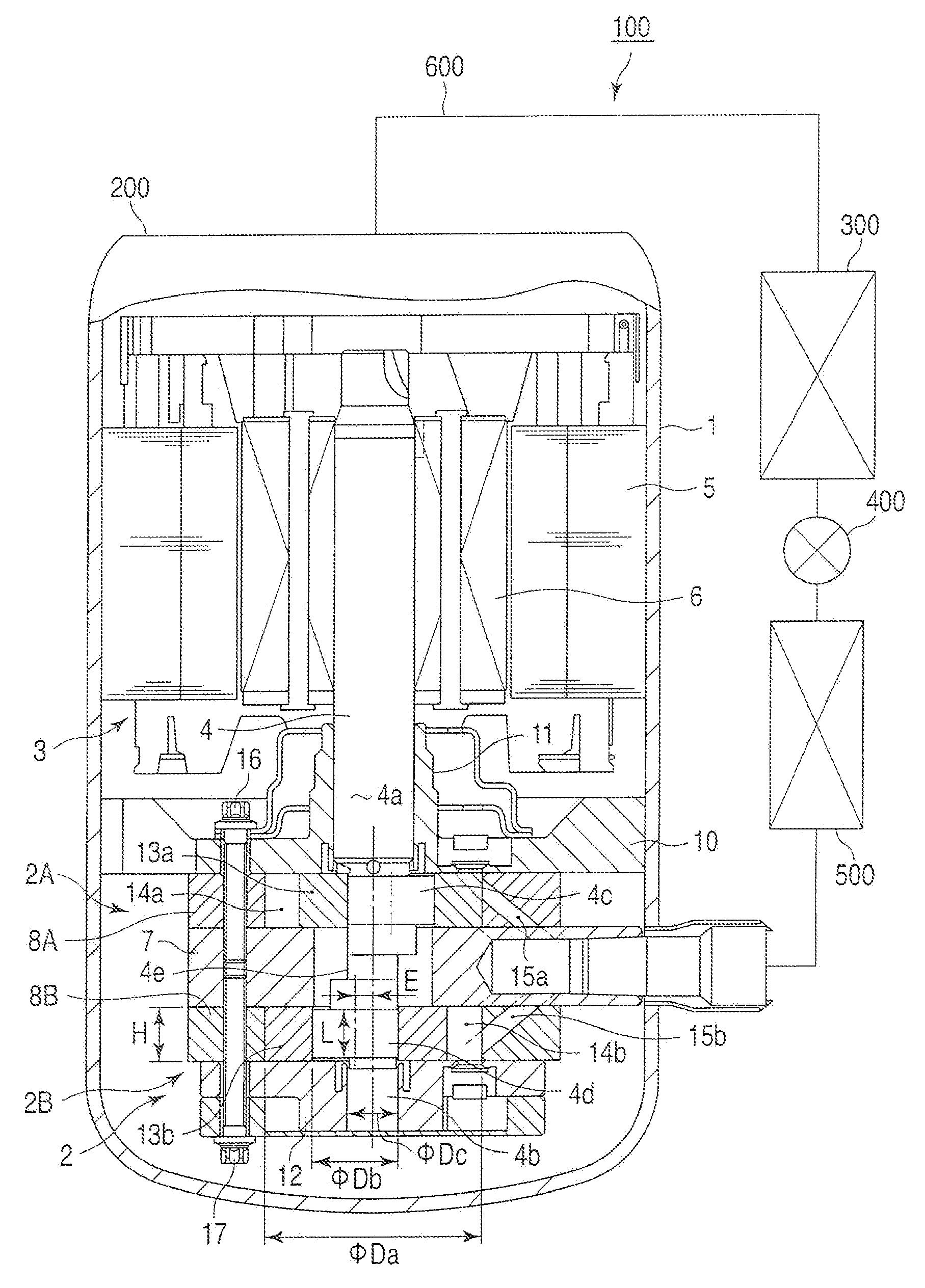

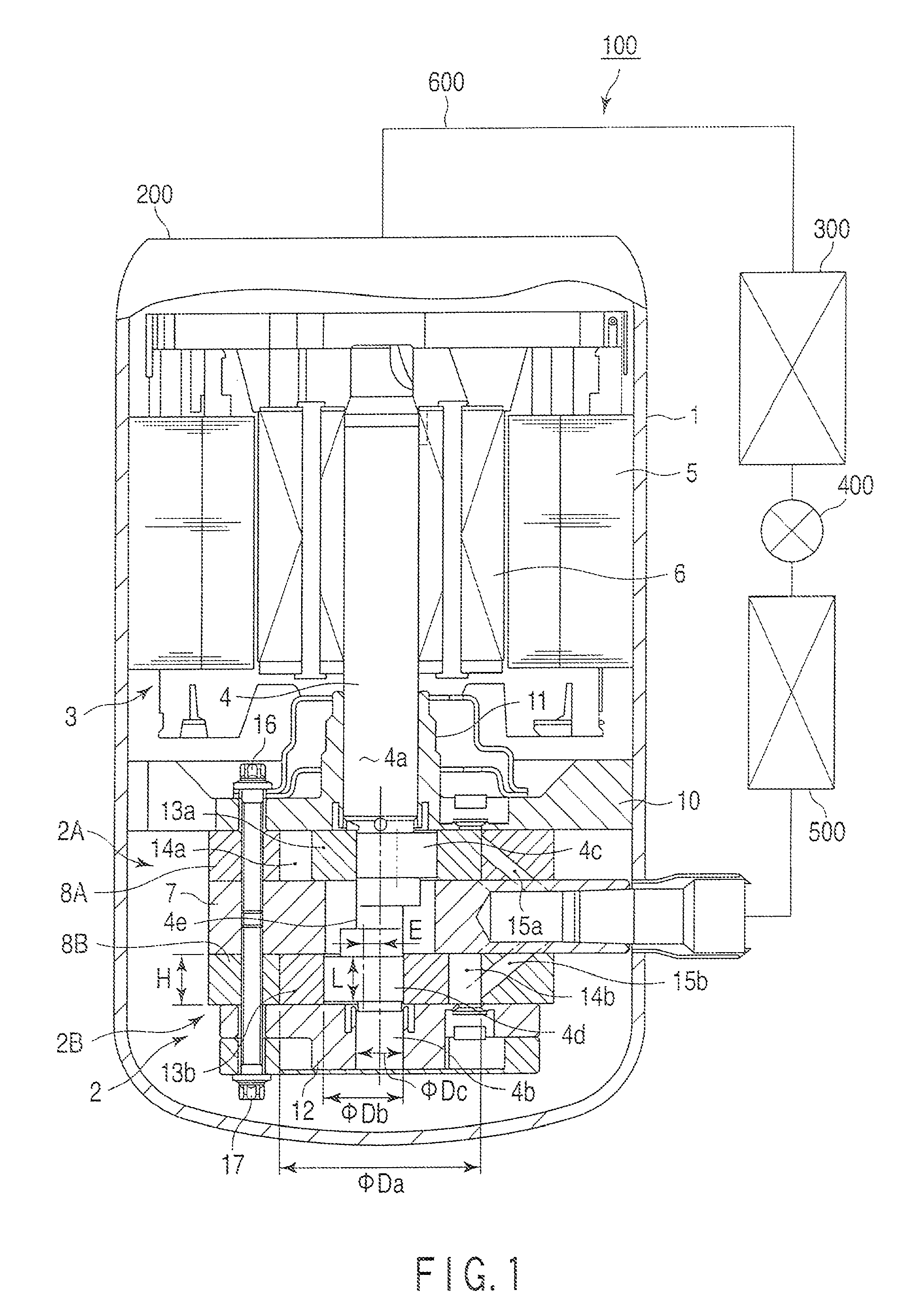

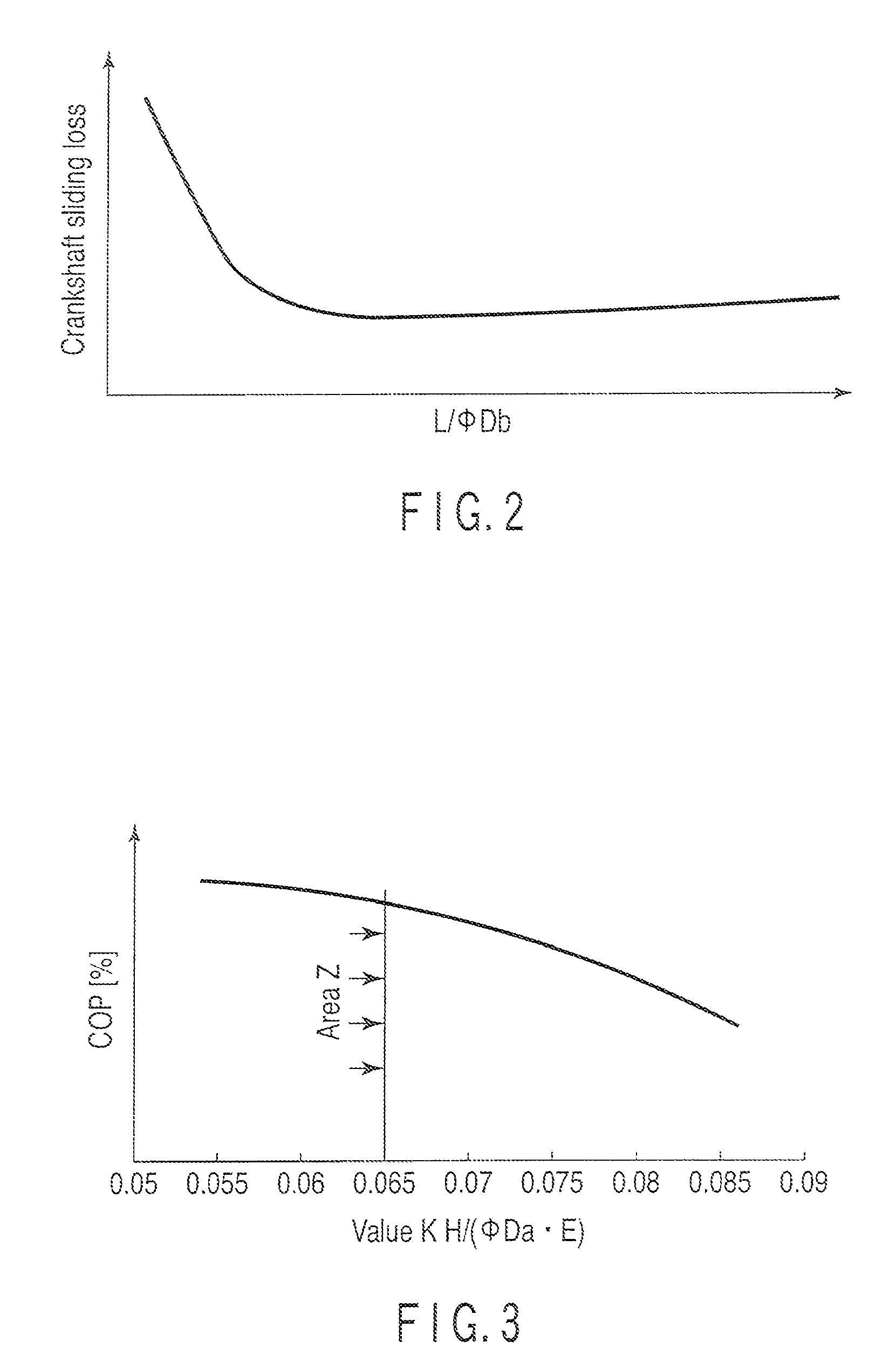

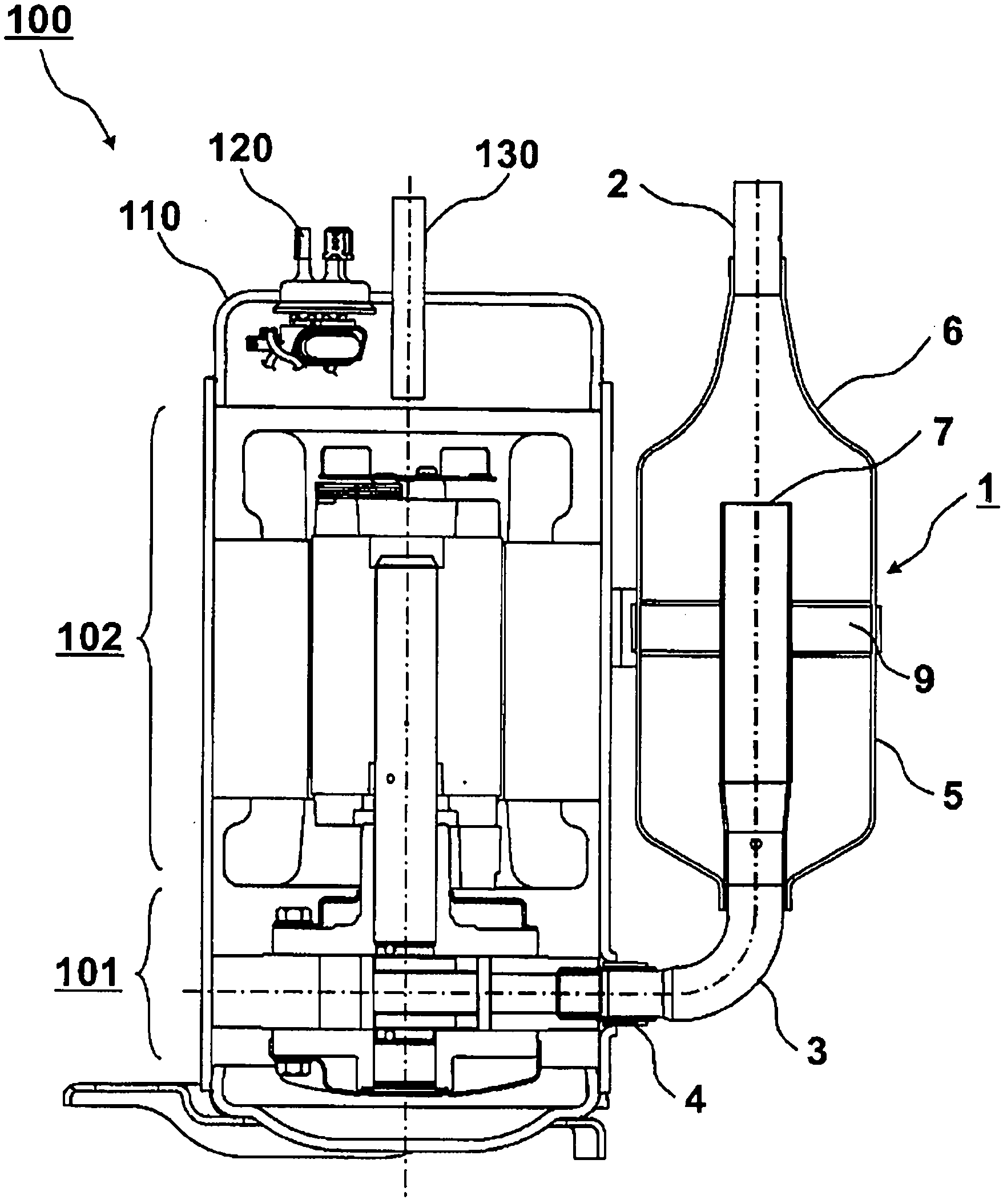

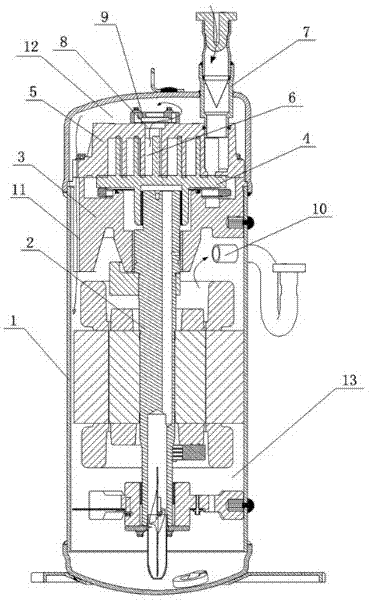

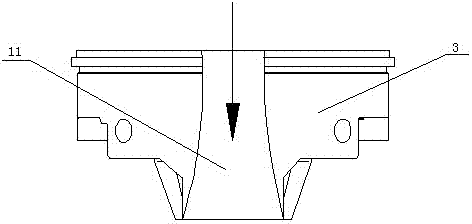

Rotary compressor and refrigeration cycle equipment

ActiveUS20100147020A1Reduce leakage lossImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A rotary compressor, which contains a motor unit and compression mechanism in a sealed case, transmits the rotational power of the motor to the compression mechanism through a rotary shaft and crankshafts eccentrically provided in the rotary shaft, and compresses a refrigerant in the compression mechanism, wherein the rotary compressor is configured to have H / (φa•E)=K, and K≦0.065, and the formula 0.35+0.07•K•H≦L / φDb≦0.45+0.07•K•H, assuming that the inside diameter of the cylinder forming the compression mechanism is φDa [mm], the cylinder height is H [mm], the crankshaft eccentricity is E [mm], the crankshaft diameter is φDb [mm], and the sliding lengths of the crankshaft and a roller fitted over the crank are set to L [mm].

Owner:TOSHIBA CARRIER CORP

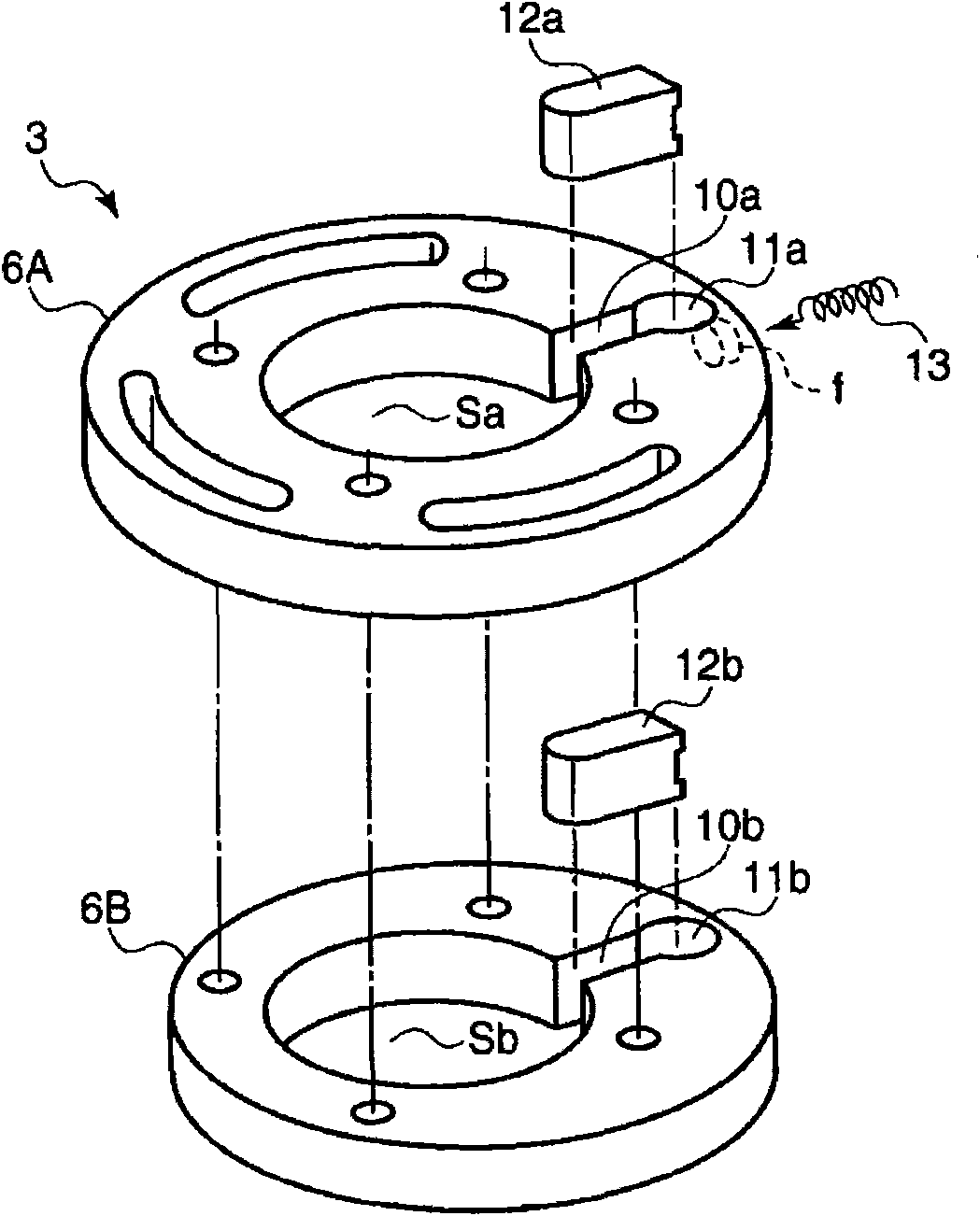

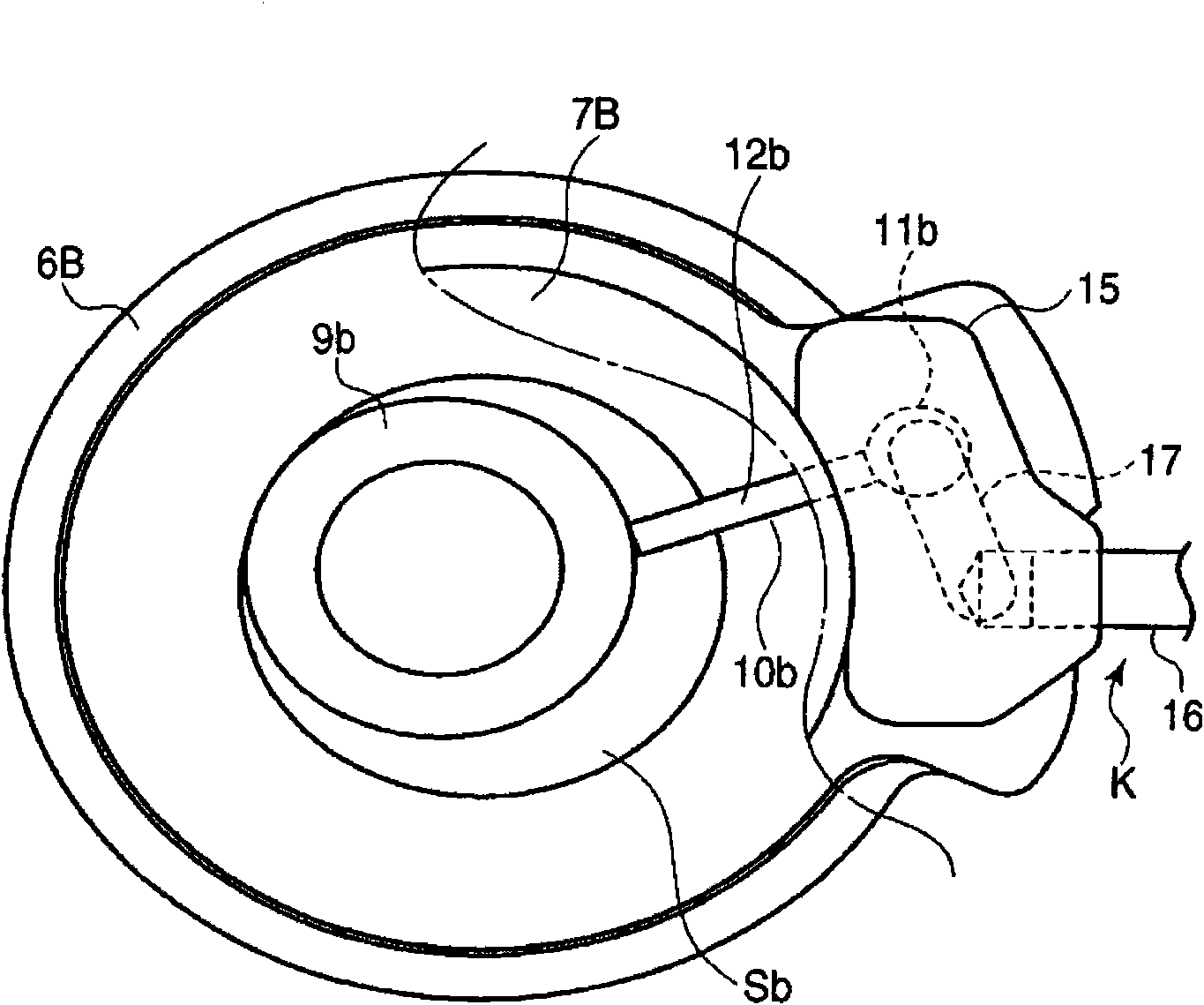

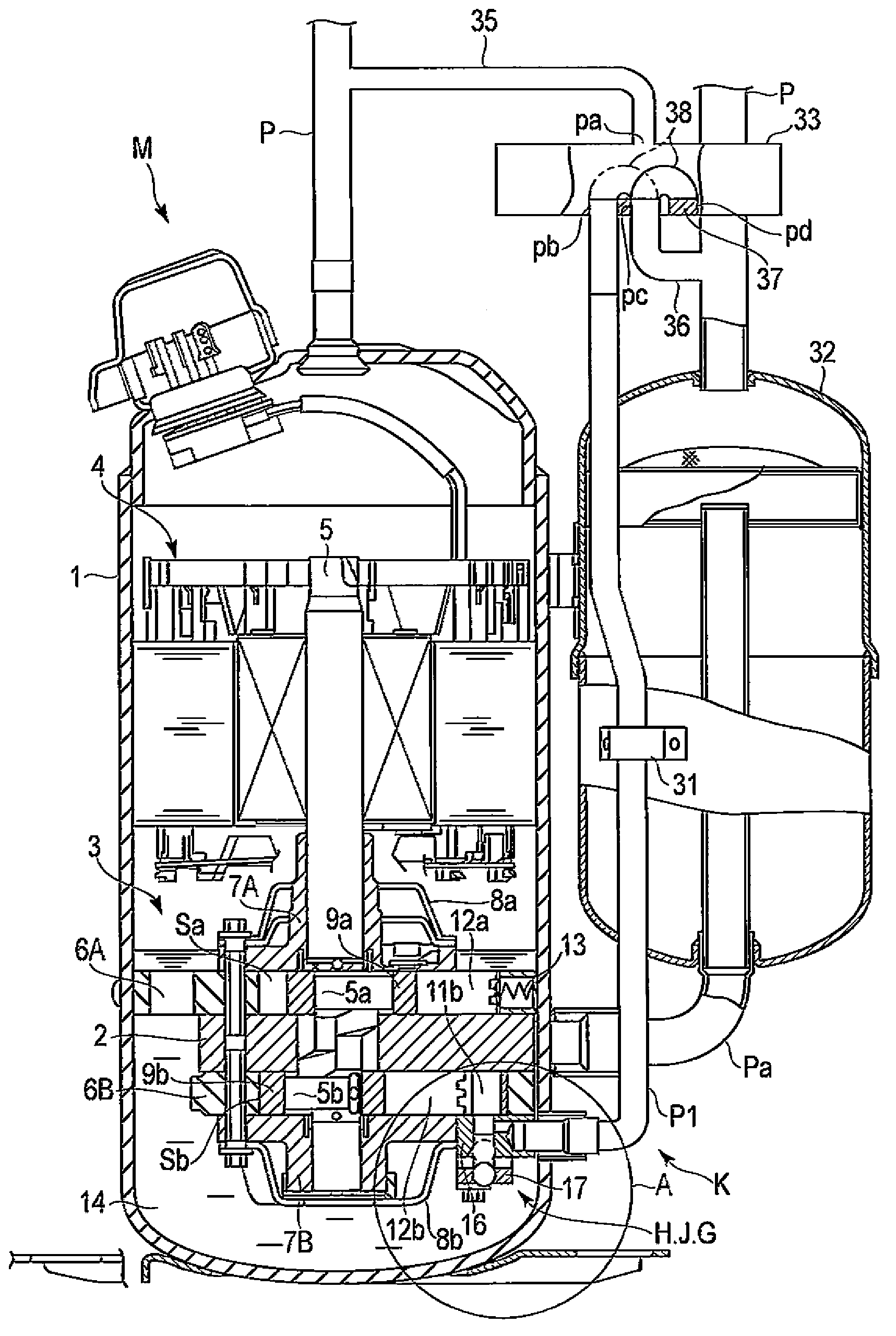

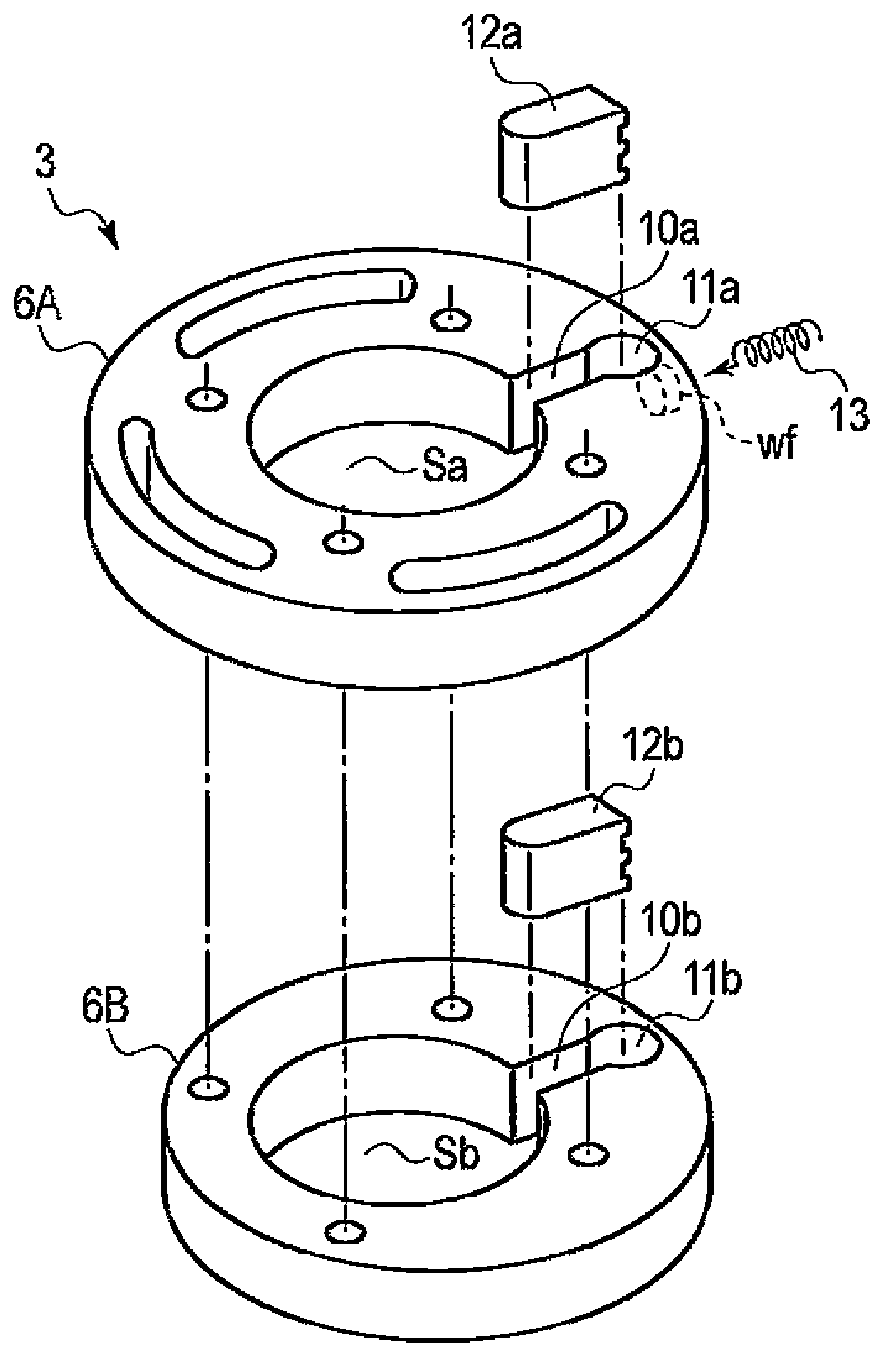

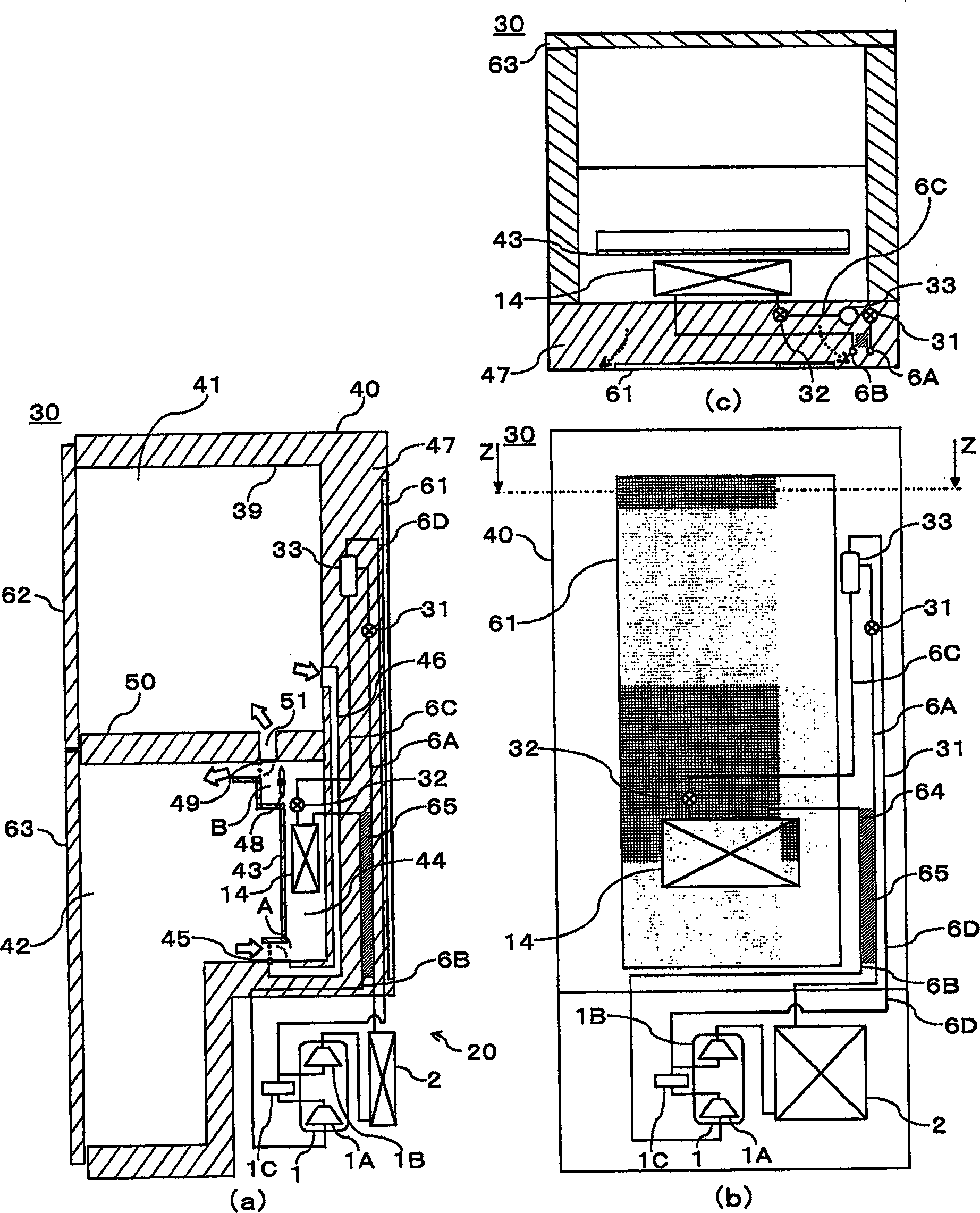

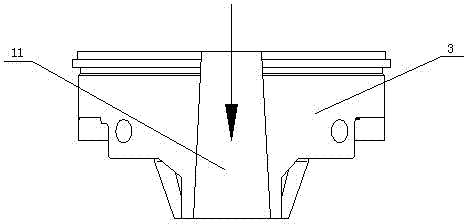

Multi-cylinder rotary compressor and refrigeration circulation device

ActiveCN102102669AParts cost reductionImproved manufacturability and machining accuracyRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringHigh pressure

The present invention relates to a multi-cylinder rotary compressor and a refrigeration circulation device, wherein the multi-cylinder rotary compressor can realize improvement of manufacturing performance and machining precision. The refrigeration circulation device comprises the multi-cylinder rotary compressor for realizing increase of the refrigeration circulation efficiency. In the multi-cylinder rotary compressor (C), a first cylinder (6A) and a second cylinder (6B) which are separated by a middle baffle (2) are provided as a compression mechanism part (3). Cylinder chambers (Sa,Sb) for introducing low-pressure gas are provided at the inner-diameter part. The blade back chambers (11a,11b) are provided on each cylinder chamber through blade grooves (10a,10b) which movably accommodate the blades (12a,12b). The first blade back chamber comprises a spring component (13) which exerts an elastic force to the back end of the blade and causes the front end of the blade to contact with a circumferential wall of a roller (9a). The second blade back chamber is closed by a closing component (15) and a middle baffle, wherein the closing component is formed separately from the auxiliary bearing. The closing component is connected with a pressure control pipe (16) for switching the high-pressure gas and the low-pressure gas for supplying, and is also provided with a guiding path (17) for communicating the closing component with the second blade back chamber.

Owner:TOSHIBA CARRIER CORP

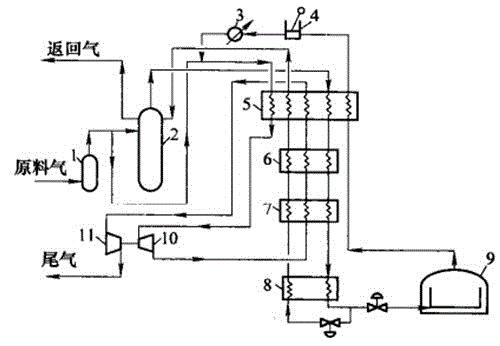

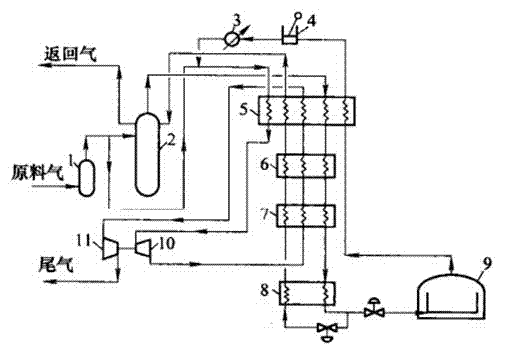

Natural gas isobaric liquefaction device

ActiveCN103148673ARealize isobaric liquefactionImprove energy savingSolidificationLiquefactionPower cycleMotive power

The invention relates to a natural gas isobaric liquefaction device. A Rankine cycle system of similar heat energy power cycle devices at a low temperature end is adopted, a cryogenic liquid pump is adopted to input power, and cold is compensated for the natural gas liquefaction device through refrigerant so as to realize the isobaric liquefaction of natural gas. On the premise of the same refrigerating capacity, compared with the conventional advanced unit, the natural gas liquefaction device disclosed by the invention can save energy by more than 30%, breaks through the conventional natural gas liquefaction technology, and has obvious economical, social and environment-friendly benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

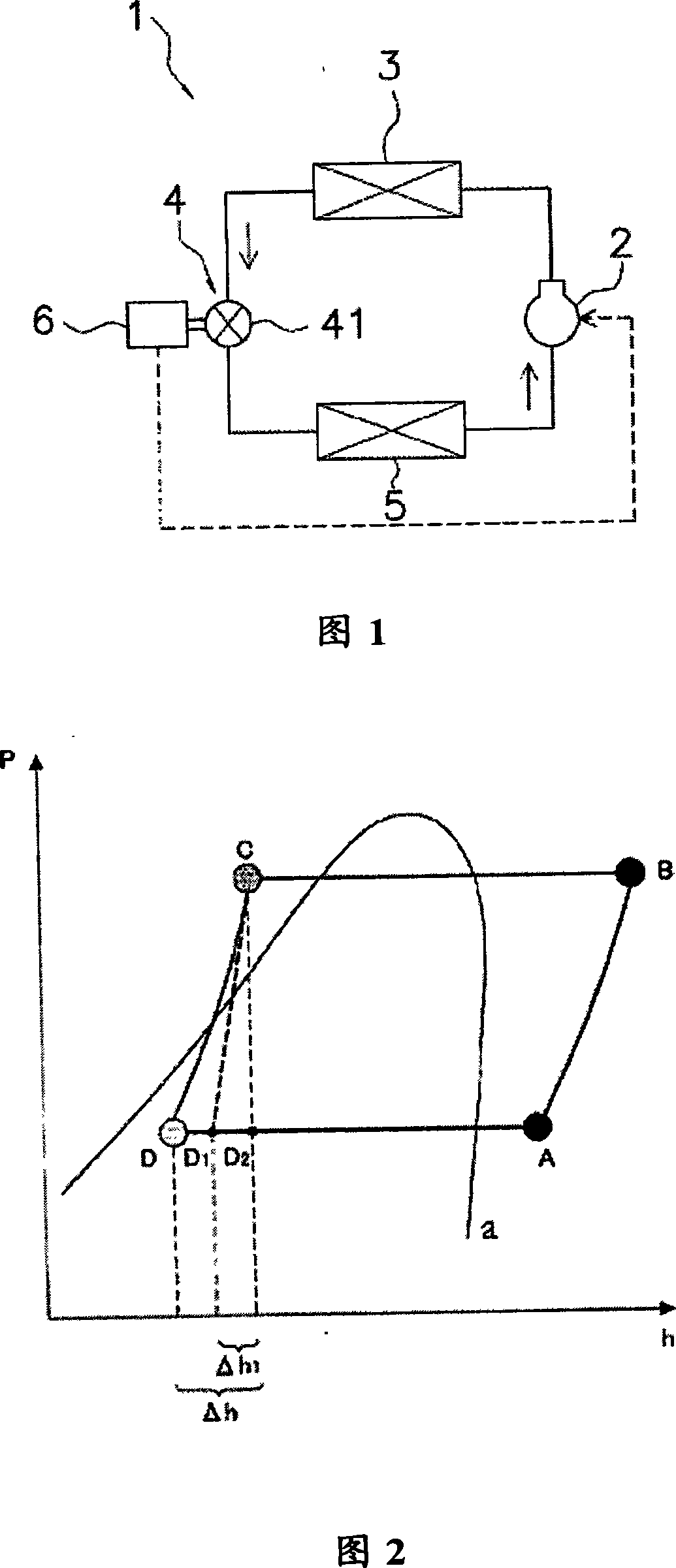

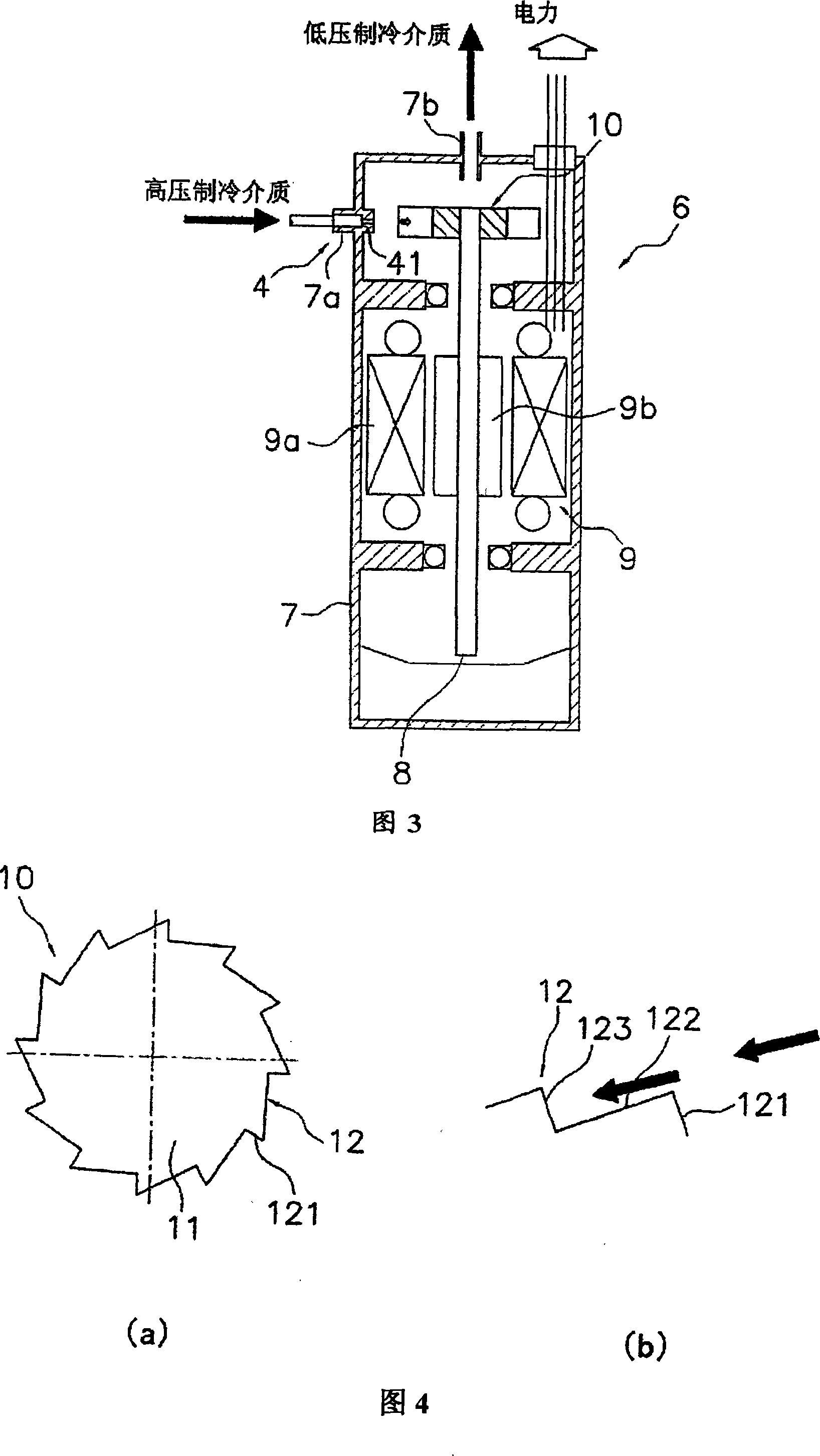

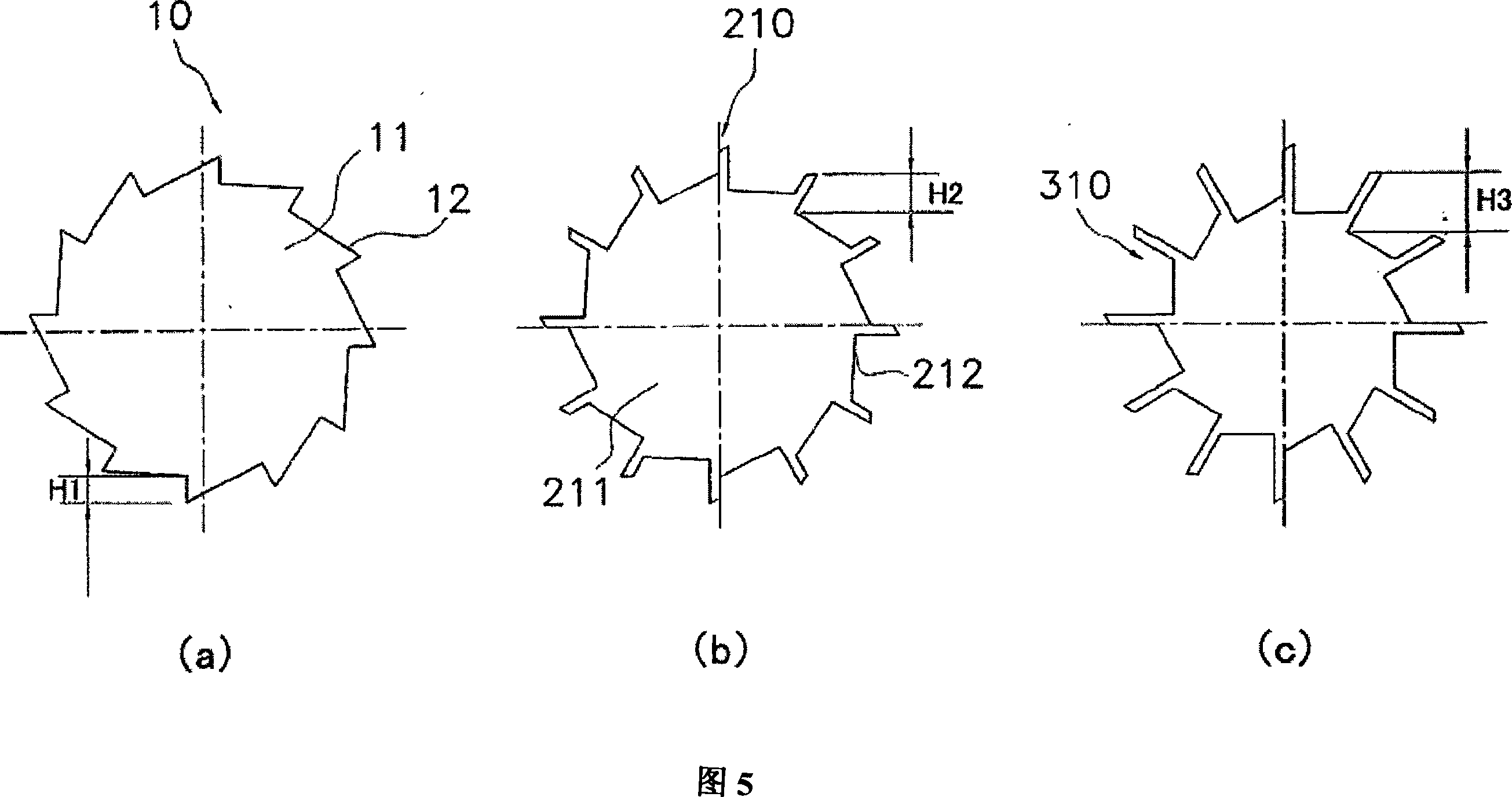

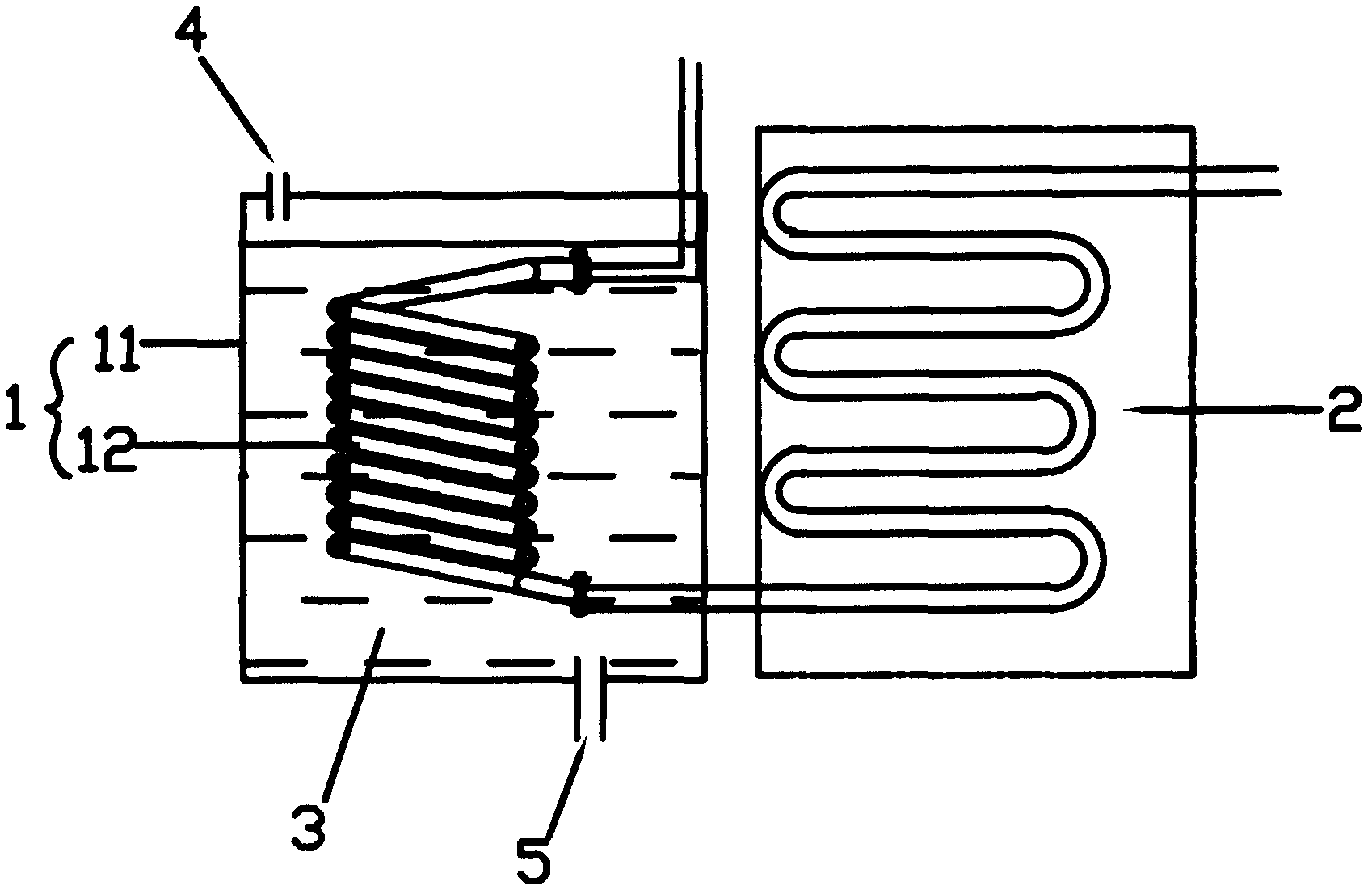

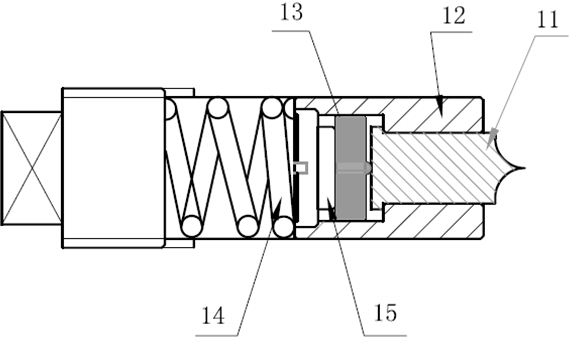

Expansion machine for refrigeration cycle

InactiveCN101251310AImprove energy conversion efficiencyImprove refrigeration cycle efficiencyCompression machinesHydro energy generationEnergy recoveryRefrigeration

The invention relates to an expansion machine for the refrigeration cycle, belonging to the refrigeration technical field. The expansion machine comprises an expansion turbine (10) and a nozzle (41) for injecting the refrigerating working substance to the expansion turbine (10), wherein, the expansion turbine (10) comprises a disc-shaped body part (11) and a plurality of periphery protrusions (12) which have injection-receiving surfaces (121) and periphery surfaces (122) and extend in radial along the body part (11); wherein, the injection-receiving surfaces (121) are parallel with the radial of the disc-shaped body part (11); the periphery surfaces (122) are perpendicular to the radial of the disc-shaped body part (11). The expansion machine for the refrigeration cycle has the characteristic that the energy recovery efficiency of the expansion turbine is raised by the simple structural design.

Owner:西安交通大学流体机械及圧缩机国家工程研究中心 +1

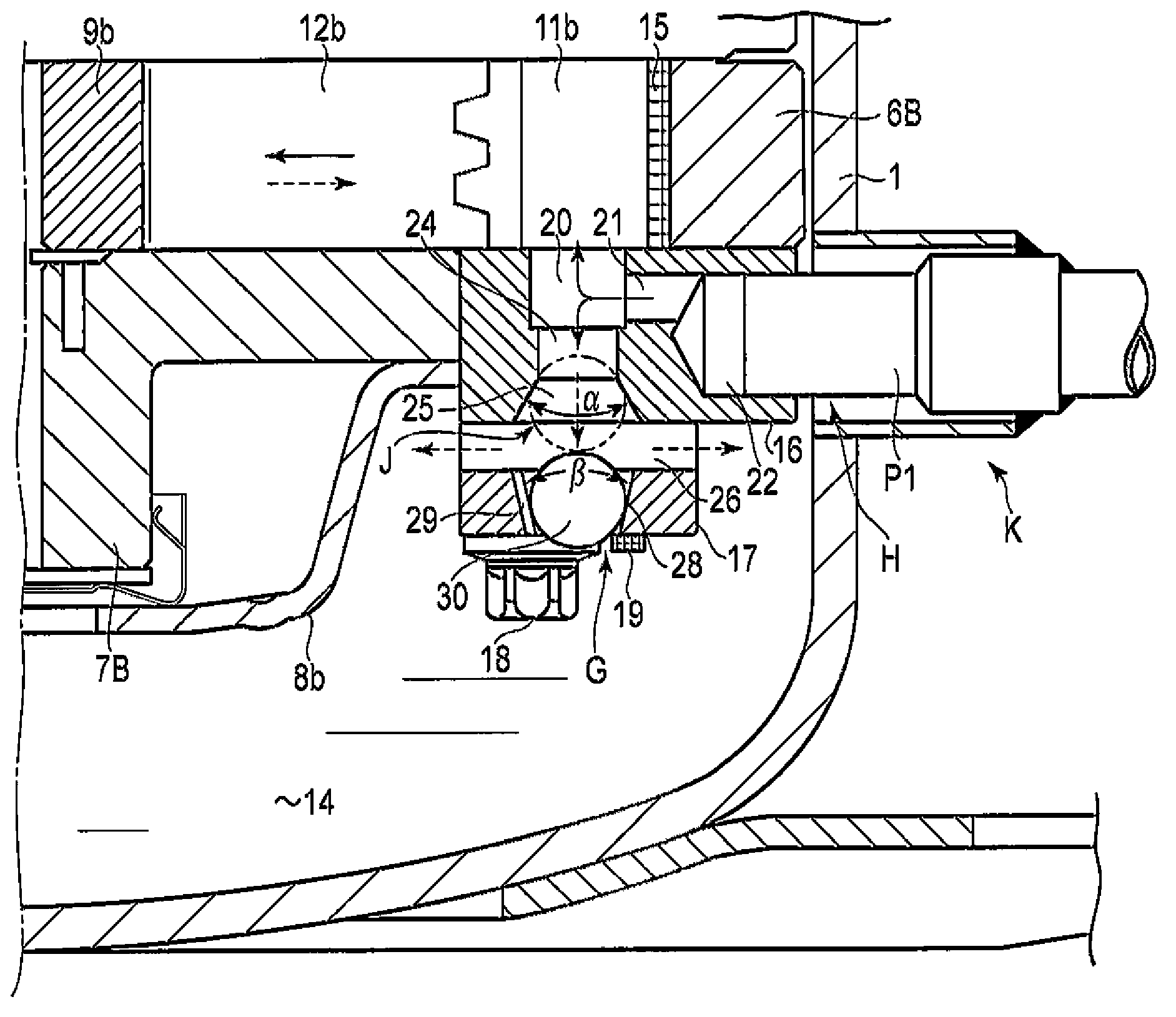

Multi-cylinder rotary compressor and refrigeration cycle device

ActiveCN103189653AImprove refrigeration cycle efficiencyImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringInterconnection

In a multi-cylinder rotary compressor (M), a compression mechanism (3) interconnects a back-pressure introduction pathway (H) to a blade back chamber (11b) that movably houses the back end of a second blade (12b). A check valve mechanism (G) is provided to a lubricating oil interconnection path (J) that interconnects the blade back chamber (11b) and an oil sump (14). When high pressure is introduced from the back-pressure introduction pathway (H) to the blade back chamber (11b), the lubricating oil interconnection path (J) opens, and when low pressure is introduced to the blade back chamber (11b), the lubricating oil interconnection path (J) closes. The back-pressure introduction pathway (H) and the lubricating oil interconnection path (J) are configured in a manner such that the amount of fluid flowing in from the back-pressure introduction pathway (H) to the blade back chamber (11b) when high pressure is introduced to the blade back chamber (11b) and the second blade (12b) moves in the direction that expands the volume of the blade back chamber (11b) is greater than the amount of fluid flowing out from the blade back chamber (11b) to the back-pressure introduction pathway (H) when the second blade (12b) moves in the direction that reduces the volume of the blade back chamber (11b).

Owner:TOSHIBA CARRIER CORP

Variable frequency water-ring heat pump air conditioner set

InactiveCN1851354AImprove energy savingReduce condensing pressureCompression machines with several evaporatorsCooling towerEngineering

The invention relates to frequency conversion type water cycle heat pump air conditioning unit in refrigeration technology field. It includes given frequency compressor, changed frequency compressor, oil separator, water-cooled condenser, liquid receiver, thermostatic expansion valve, refrigerant liquid supply tube, valve, evaporator, refrigerant liquid back tube, cooling tower, cooling water supply tube, supply valve, and back tube, water pump, and cooling water back valve. It adopts water cycle heat pump to improve refrigeration circular efficiency, and adopts two compressors according to demand.

Owner:SHANGHAI JIAO TONG UNIV

Refrigerator

InactiveCN1873354AImprove refrigeration cycle efficiencyCompression machines with non-reversible cycleDomestic refrigeratorsVapor–liquid separatorLiquid state

Owner:SANYO ELECTRIC CO LTD

Water cooling-assisted heat removal system

InactiveCN102997557AReduce consumptionTo achieve the effect of saving electricityLighting and heating apparatusCooling fluid circulationWater sourceEngineering

The invention discloses a water cooling-assisted heat removal system, which comprises a coiled pipe air radiator (2), and is characterized in that a set of water cooling-assisted radiator (1) which takes tap water (3) as a water source is connected in series to the front part of the coiled pipe air radiator (2); the water cooling-assisted radiator (1) comprises a water tank (11) and radiating pipes (12); the water tank (11) of the water cooling-assisted radiator (1) is connected in series with a water pipe; and the radiating pipes (12) are arranged inside the water tank (11), and are connected in series between a compressor and the coiled pipe air radiator (2). According to the water cooling-assisted heat removal system, air and the tap water (3) are combined for assisting in radiating, and the startup time of a compressor and the cycle period of a refrigerant are reduced in comparison to an air heat removal way, so that the effects of increasing the heat removal efficiency and saving electric energy are achieved; when the temperature of tap water is high, the heat removal capability is attenuated without influencing the air heat removal effect, and excessive influences on the conventional design are avoided; and the water cooling-assisted heat removal system is easy to arrange and popularize.

Owner:CHINA JILIANG UNIV

Natural gas constant-pressure liquefaction device

ActiveCN103162511ARealize isobaric liquefactionImprove energy savingSolidificationLiquefactionThermal energyPower cycle

The invention relates to a natural gas constant-pressure liquefaction device. A Rankine cycle system which is arranged at a low-temperature end and similar to a thermal power cycle device is used in the natural gas constant-pressure liquefaction device. A low-temperature pump is adopted to input power, and the natural gas constant-pressure liquefaction device is cooled through refrigerants in a compensating mode so as to achieve constant-pressure liquefaction of natural gas. On the premise of the same refrigerating capacity, compared with a traditional advanced set, the natural gas constant-pressure liquefaction device saves energy by more than 30%, and is a breakthrough of a traditional natural gas liquefaction technology, and is obvious in economic, social and environment protection benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

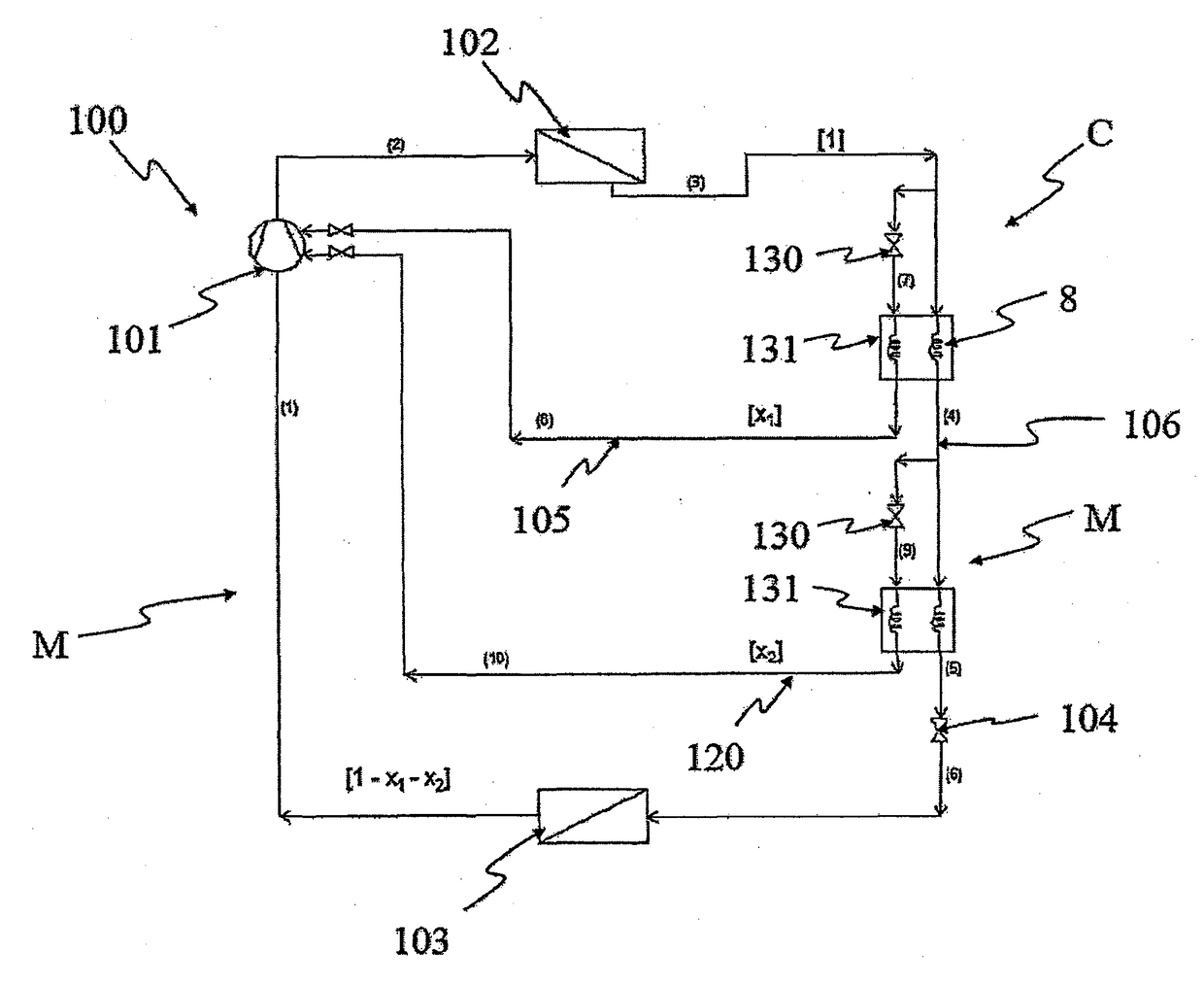

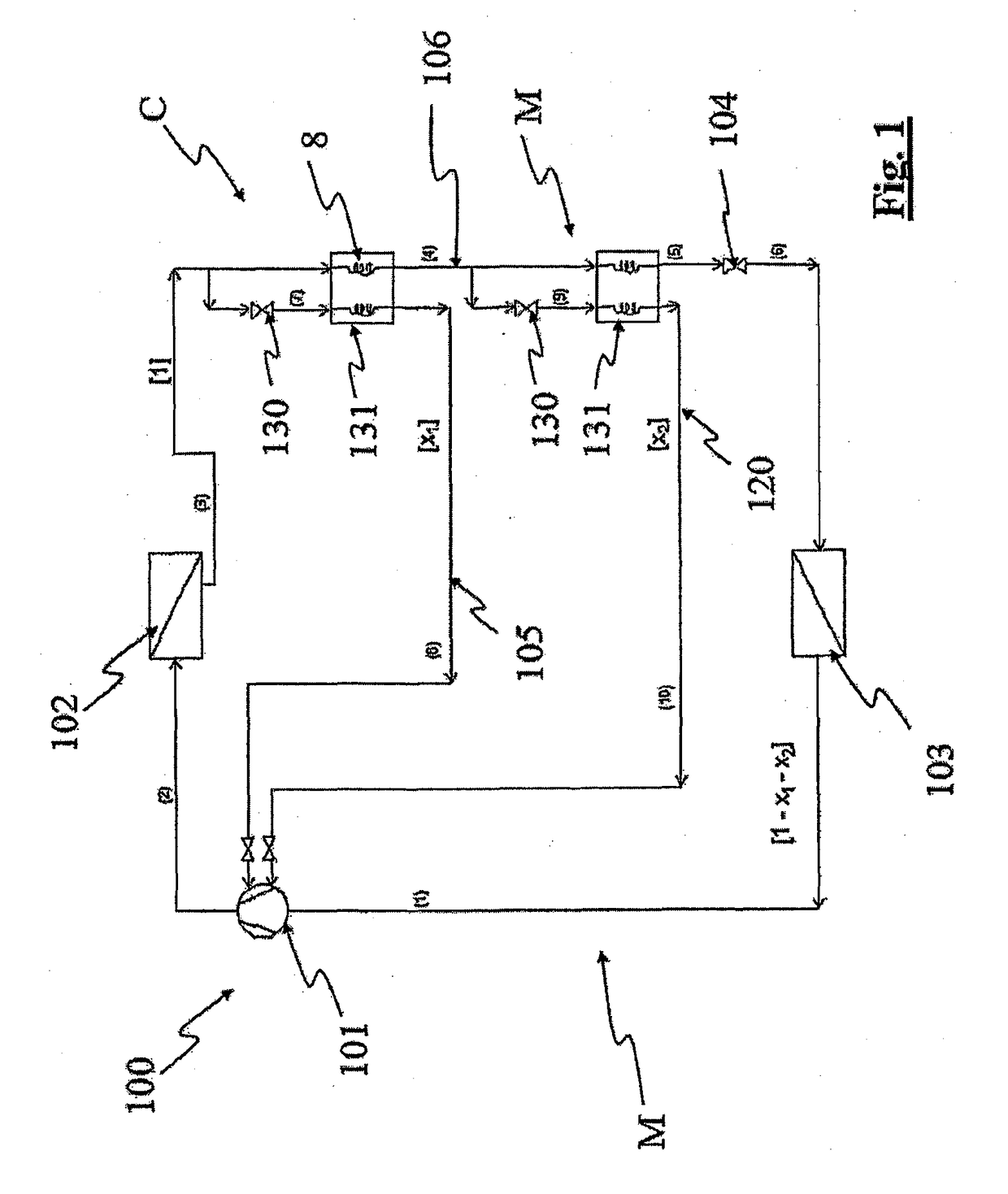

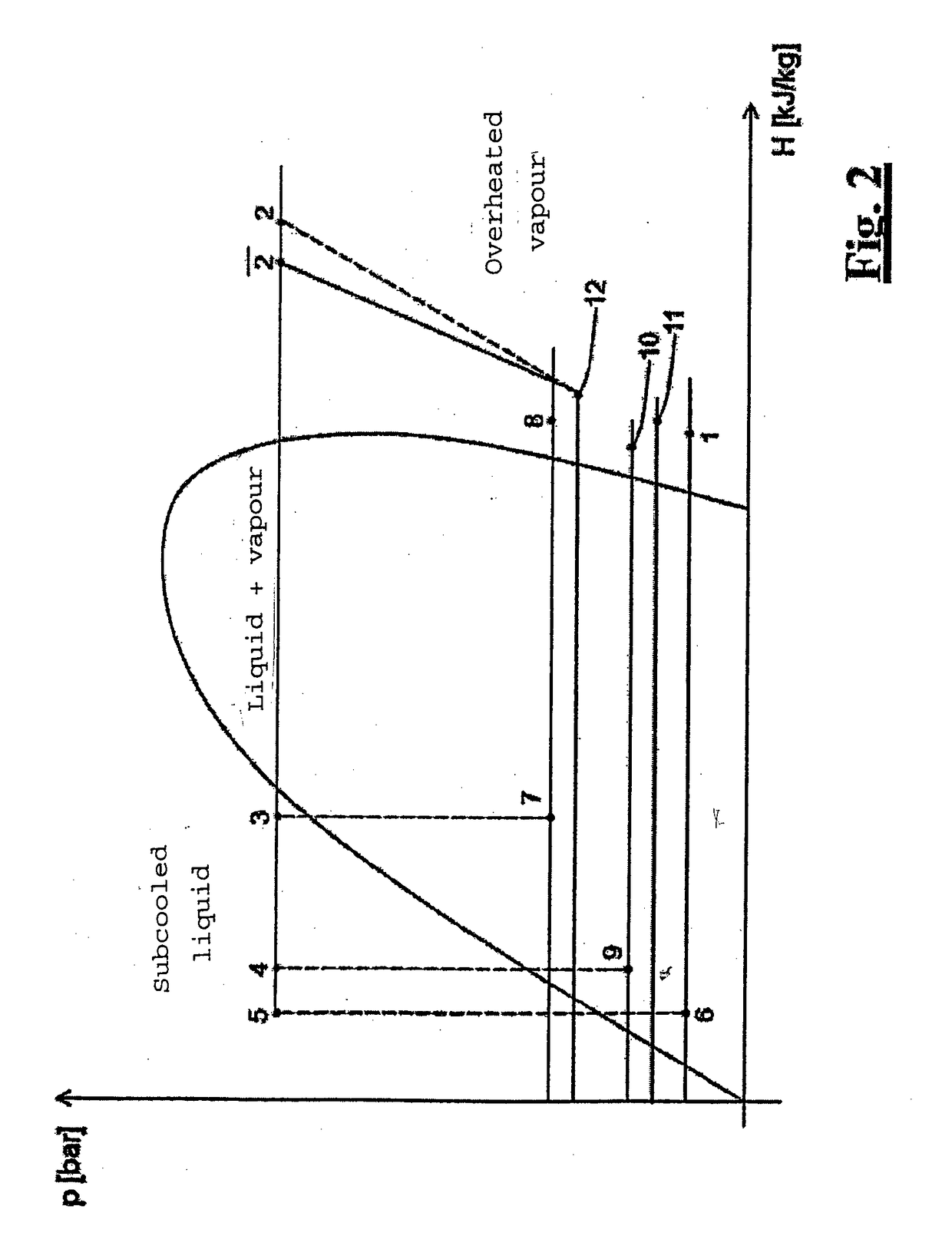

Refrigeration device

ActiveUS20170343244A1Improve efficiencyIncreased complexityMechanical apparatusCompression machines with non-reversible cycleMain branchEngineering

A refrigeration device having a closed circuit in which a flow rate of coolant is circulating is provided. The closed circuit has a condenser and a main branch provided with a reciprocating compressor inside which a defined flow rate of the coolant enters, from the main branch, at a defined suction pressure, of an evaporator and a first expansion valve that is arranged between the condenser and the evaporator. The closed circuit further has a first secondary economizer branch for a first fraction of flow rate of the coolant, the first secondary economizer branch fluidically connecting the compressor to a section of the closed circuit between the condenser and the first expansion valve, wherein the compressor has a first side inlet port for the entrance of the first fraction of coolant flow rate.

Owner:ANGELANTONI TEST TECH

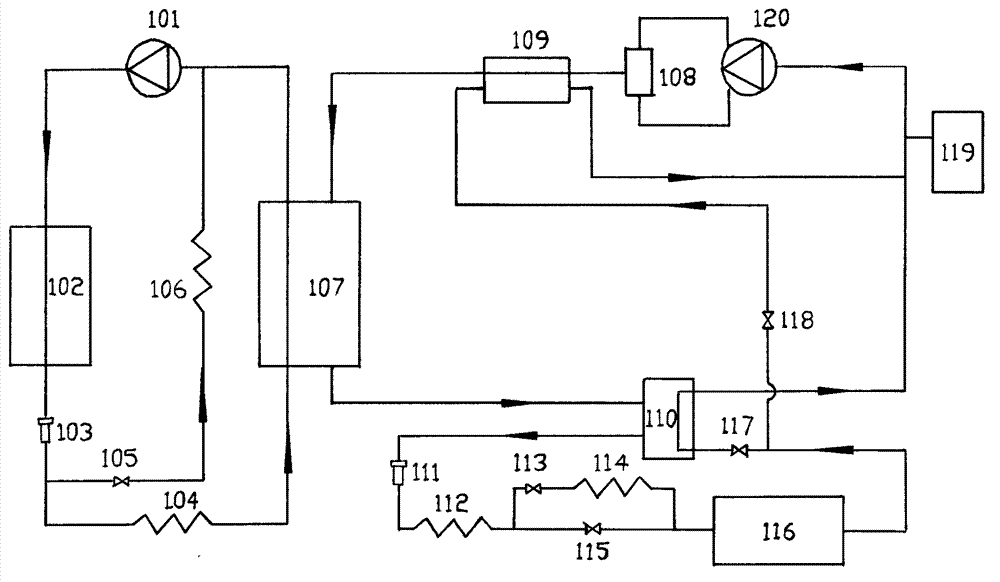

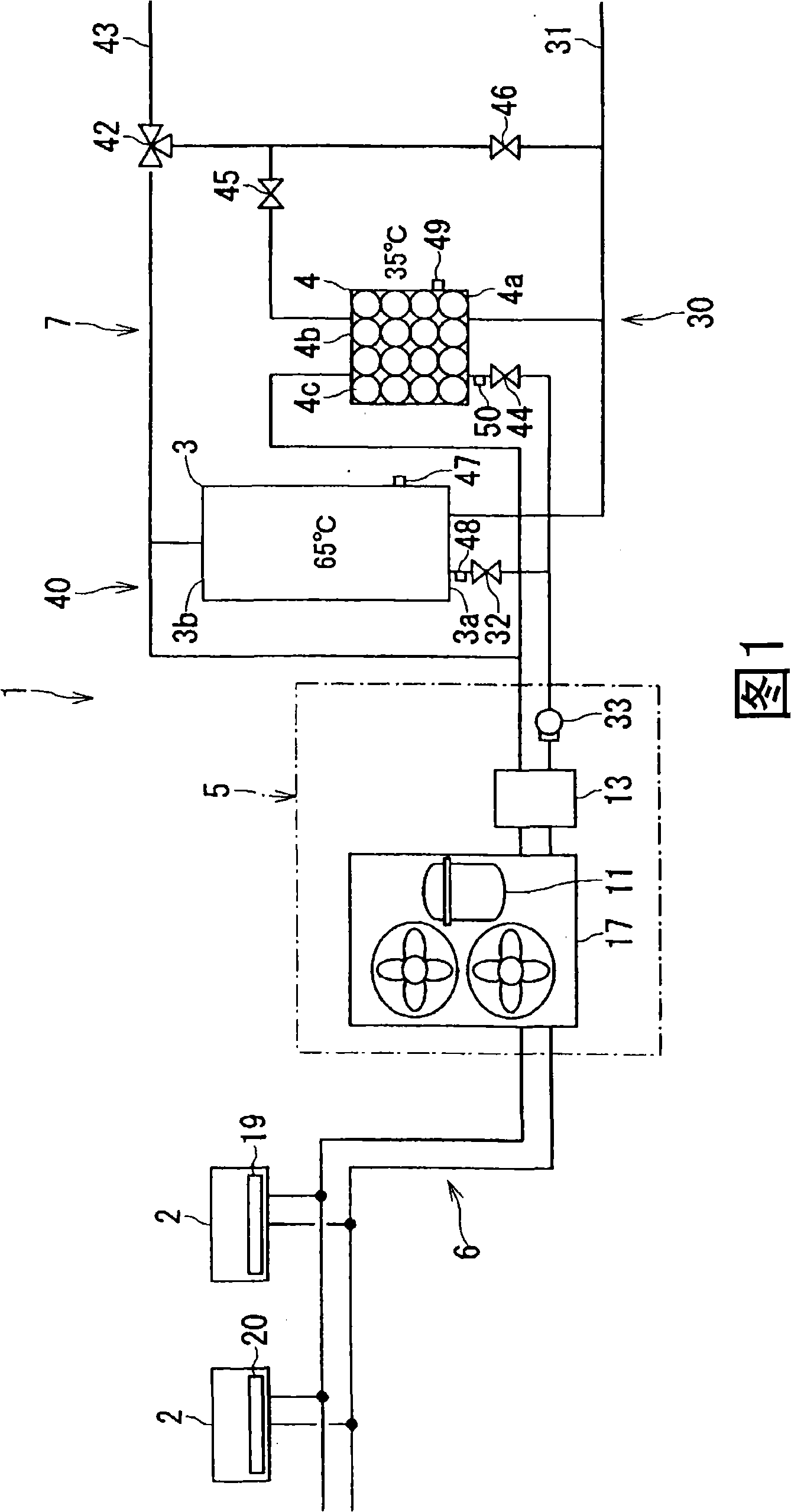

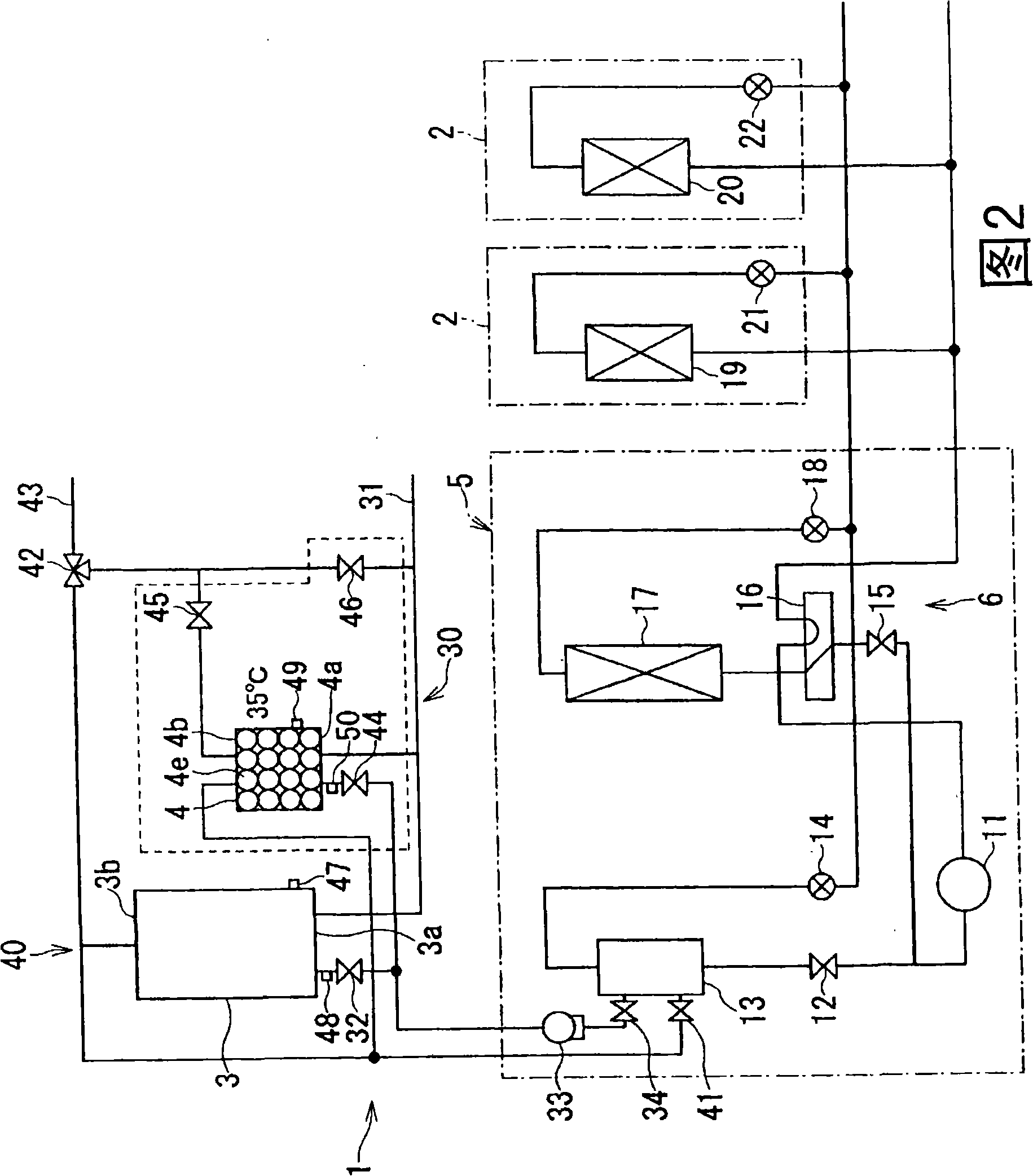

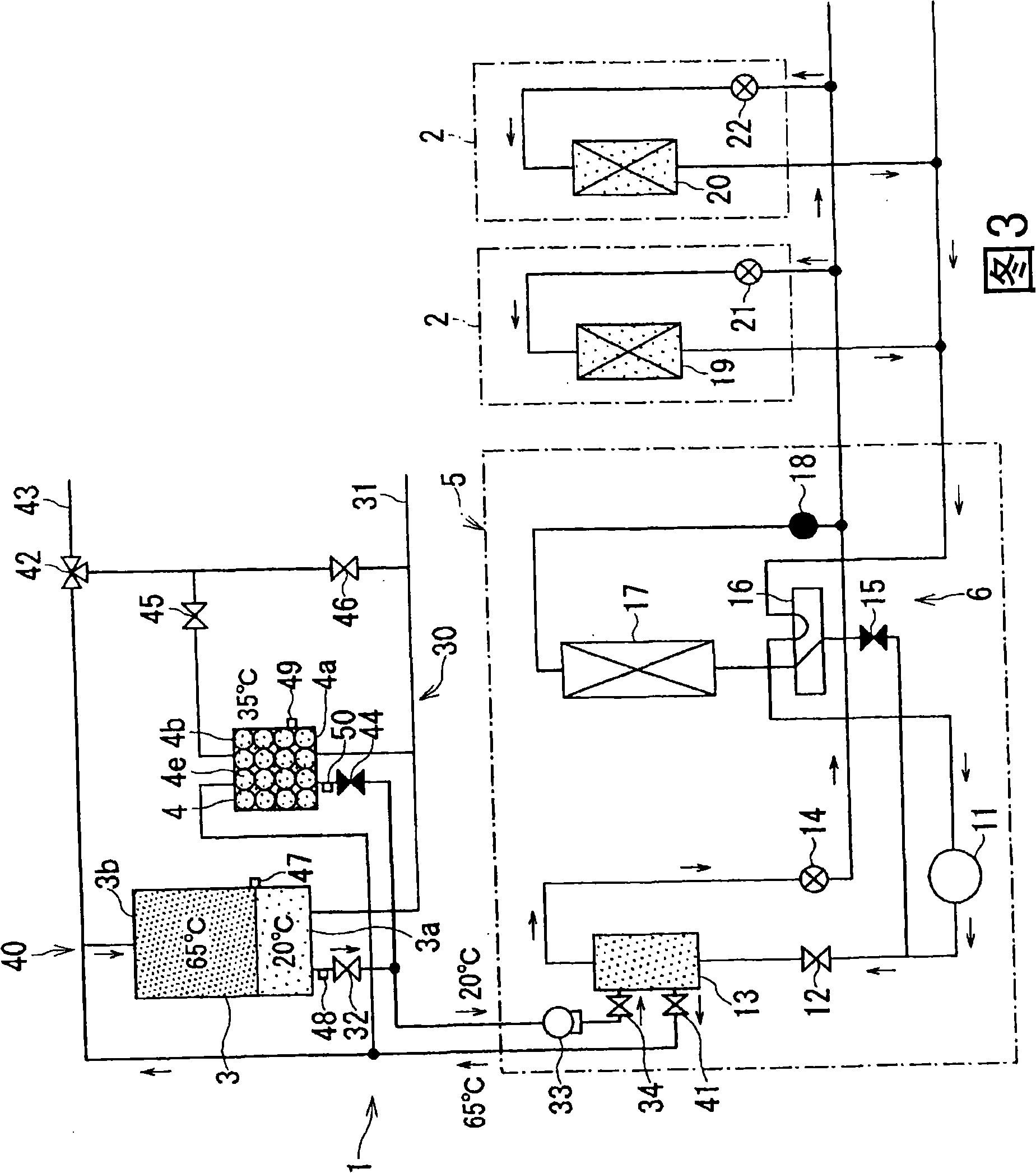

Heat pump air conditioning water supply machine

InactiveCN101275782AImprove refrigeration cycle efficiencyHeat pumpsStorage heatersEngineeringThrottle

The invention provides a heat pump type heat-supplying machine for an air conditioner implementing the improvement of the refrigerating circulative efficiency of the refrigerating heat-storing operation. The invention comprises the refrigerating circulation having a compressor, an outdoor heat exchanger, an indoor heat exchanger, a four-way valve, a throttle mechanism; a high temperature heat storing water tank for storing the hot water which is heated as the high temperature via the heat exchange by the outdoor heat exchanger; and a low temperature heat storing water tank for storing the hot water which is heated as the low temperature via the heat exchange by the outdoor heat exchanger; in the heat pump type heat-supplying machine for an air conditioner, the conditioner stores the high temperature hot water to the high temperature heat storing water tank in the night power operation under the situation of reducing charging at the deep nights; and the conditioner stores the low temperature hot water to the low temperature heat storing water tank in the night power operation under the situation of charging at the deep nights; the invention uses the high temperature hot water in the high temperature heat storing water tank and the low temperature hot water to the low temperature heat storing water tank in mixing way.

Owner:TOSHIBA CARRIER CORP

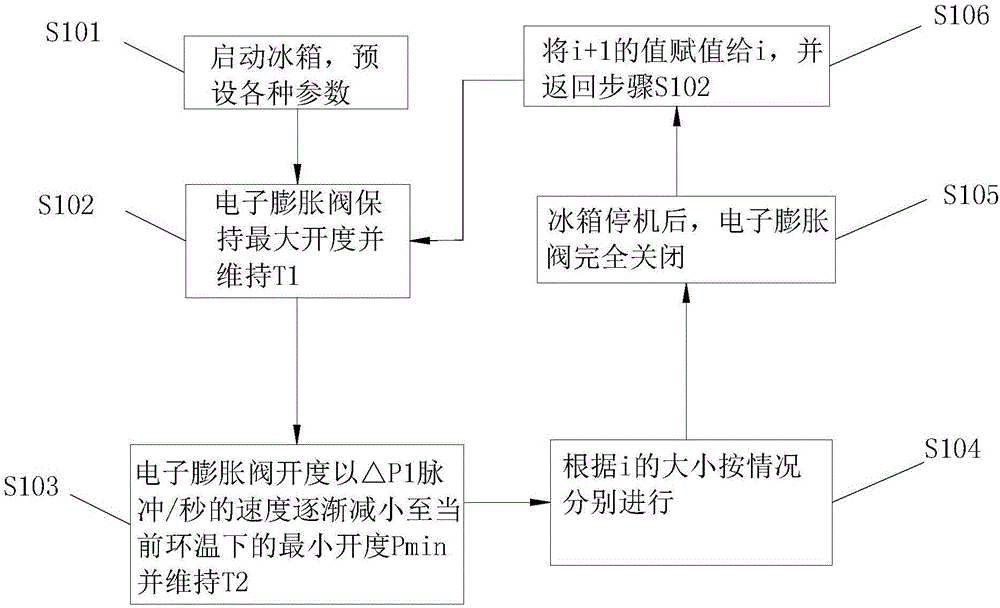

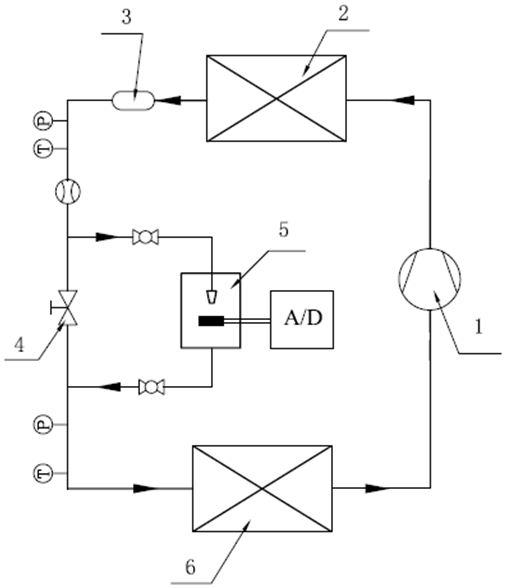

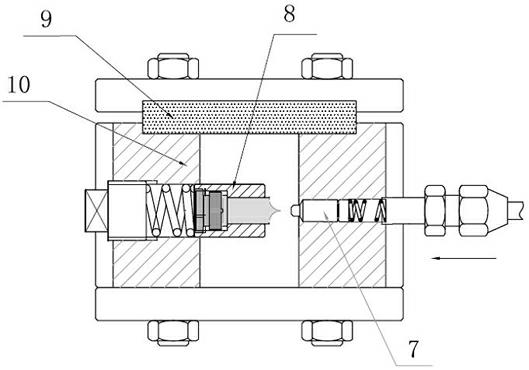

Control method for electronic expansion valve for refrigerator

ActiveCN106322912AImprove refrigeration cycle efficiencyReduce power consumptionLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

The invention discloses a control method for an electronic expansion valve for a refrigerator. The control method comprises the following steps of: starting the refrigerator and presetting parameters; keeping maximum opening of the electronic expansion valve for T1; gradually reducing opening of the electronic expansion valve until minimum opening at an existing environment temperature, and keeping the minimum opening for T2; separately performing operations according to the size of i; after stopping the refrigerator, completely closing the electronic expansion valve; and assigning a value of i+1 to i, and returning to step (2). Compared with the prior art, the control method disclosed by the invention has the advantages that: the control method is simple, degree of superheat of an evaporator or operation parameters of a compressor do not needed to be acquired, a self-regulating function of the electronic expansion valve is realized according to turn-on time, power consumption of the refrigerator is reduced, and service lives of system elements are favorably prolonged.

Owner:CHANGHONG MEILING CO LTD

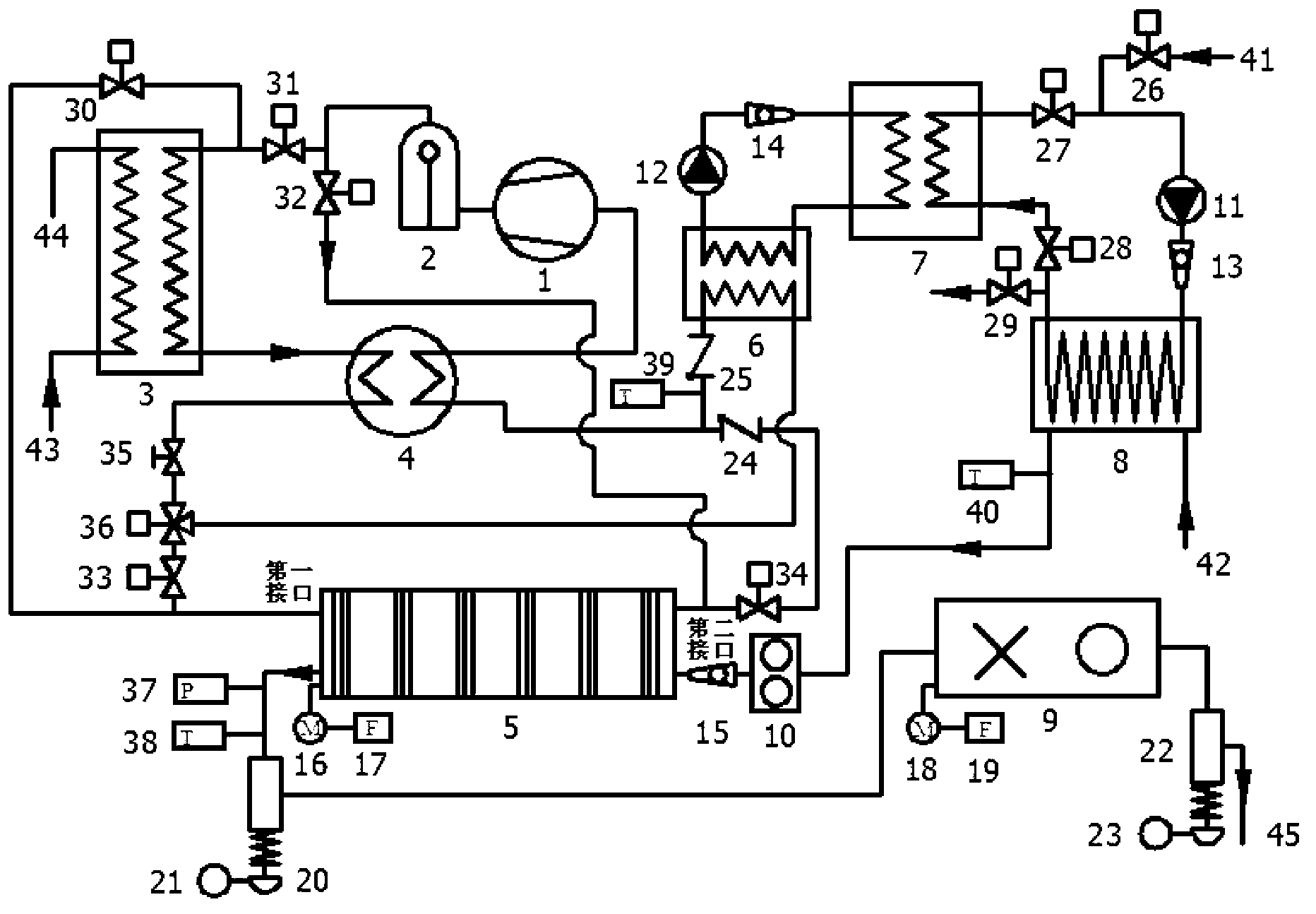

Margarine production system and process flow thereof

InactiveCN103156000AImprove refrigeration cycle efficiencyReduce energy consumptionEdible oils/fats production/working-upEngineeringRefrigerant

The invention relates to a margarine production system which is characterized by comprising a butter quenching circulation system, a cold accumulation circulation system, a butter pressure control system and a pre-cooling circulation system, wherein an electromagnetic three-way valve (36) is arranged behind an outlet of a heat regenerator (4) of the butter quenching circulation system; a first outlet of the electromagnetic three-way valve (36) is communicated with a refrigerant channel in a butter quenching machine (5), and the other outlet of the electromagnetic three-way valve (36) is communicated with a cold recovery heat exchanger (6); the two outlets are connected in parallel and then are communicated with an air suction port of a compressor (1) after passing through the heat regenerator (4); the butter pressure control system comprises a variable displacement piston pump (10), a pressed regulating valve (20) and a kneading machine pressed regulating valve (22); the variable displacement piston pump (10) is arranged in front of a feeding hole of the butter quenching machine (5); the pressed regulating valve (20) is arranged behind a discharge opening of the butter quenching machine (5); and the kneading machine pressed regulating valve (22) is connected with a kneading machine (9).

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

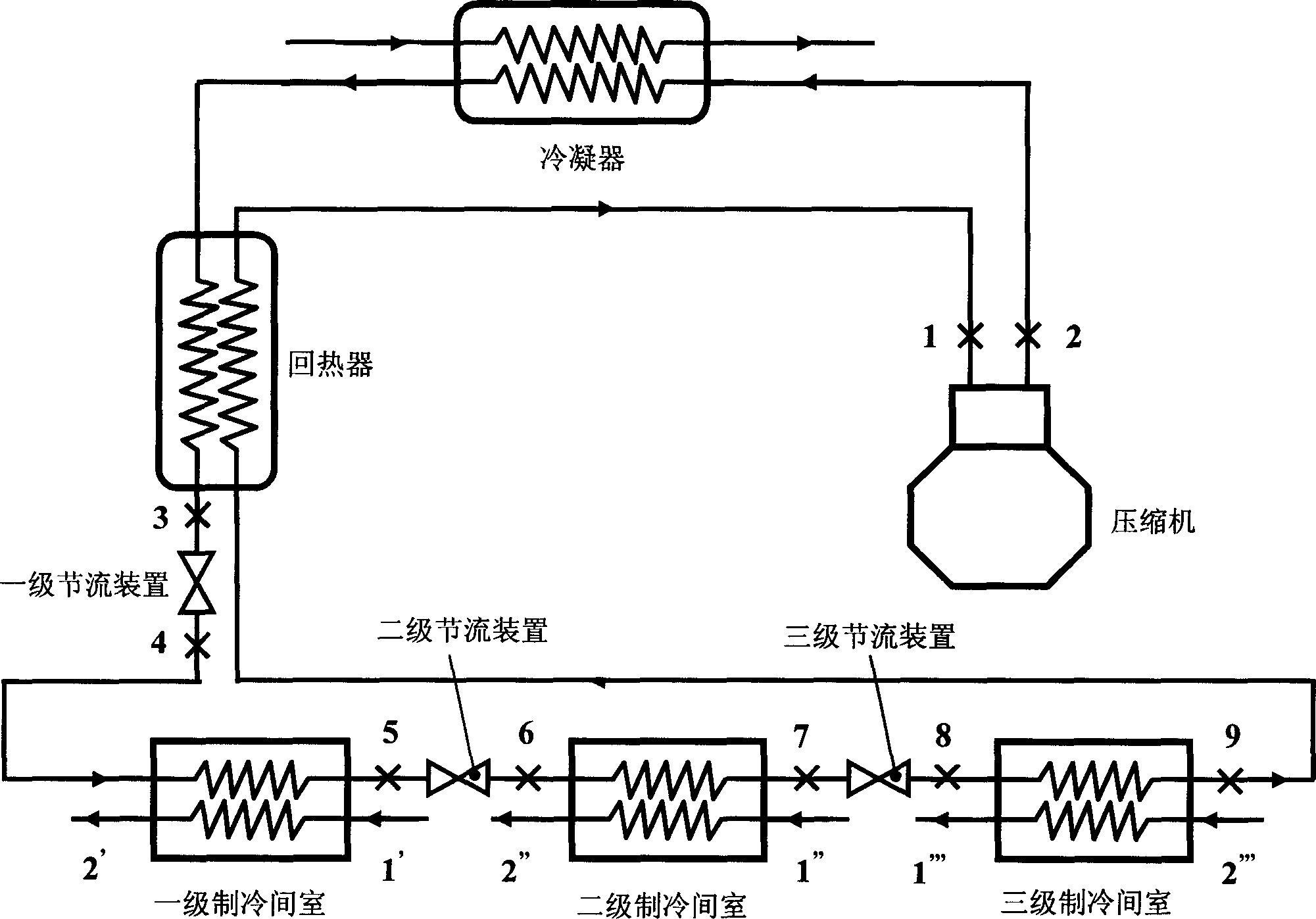

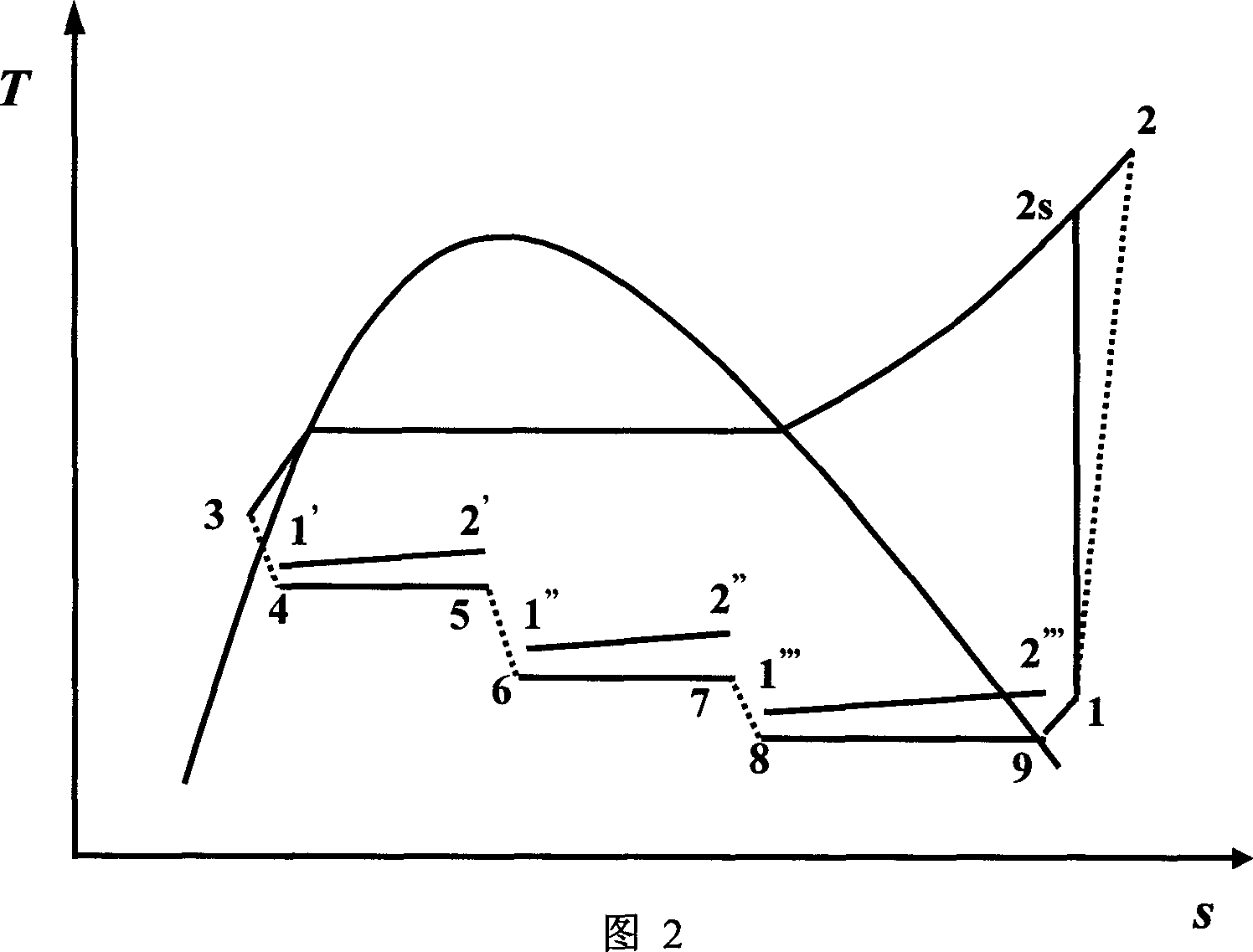

Refrigerating and circulating method with multi-stage throttles

InactiveCN1645011AAvoid the shortcomings of large heat transfer temperature difference and large irreversible lossControl evaporation temperatureCompression machines with several evaporatorsFluid circulation arrangementIceboxWorking temperature

The invention discloses a refrigerating and circulating method with multi-stage throttles, a same number of throttle devices are arranged according to the number of compartments in a refrigerating system, each throttle device is corresponding to a refrigerating compartment and arranged in front of the refrigerating compartment, all of the refrigerating compartments are arranged in series based on work temperatures thereof from higher to lower, in the whole refrigerating system, a refrigerating actuating medium grades and throttles based on a rule that an evaporation temperature of an evaporator in each refrigerating compartment is from higher to lower, so as to achieve and hold a set temperature of each refrigerating compartment. A refrigerating device designed according to the invention, has a simply designed structure, is capable of farthest reducing non-reversible loss of temperature difference heat diffusion when a heat exchanging temperature difference of each refrigerating compartment evaporator in a refrigerating device such as a refrigeratory, an icebox, or the like satisfies request of thermodynamics, heat transfer theory and hydrodynamics, effectively avoiding characteristics of big heat exchanging temperature difference and big non-reversible loss in the refrigerating compartments during conventional refrigerating and circulating, and increasing a refrigerating and circulating efficiency.

Owner:XI AN JIAOTONG UNIV

Method and device for measuring mixing velocity of gas-liquid two-phase flow of refrigerant

ActiveCN102680731AOptimize design parametersImprove refrigeration cycle efficiencyHydrodynamic testingFluid speed measurementMomentumSpray nozzle

The invention provides a method for measuring the mixing velocity of gas-liquid two-phase flow of a refrigerant, and a matched measuring device. The method comprises the following steps of: measuring the fluid mass flow m of the refrigerant in a refrigeration circuit and the jet impact force of a nozzle outlet, and calculating the average mixing velocity V1 of the gas-liquid two-phase flow which is sprayed by a nozzle and has phase change according to the law of momentum. The measuring method is simple and practical, the influence of a structural parameter of the nozzle on outlet velocity and the energy conversion efficiency of the nozzle can be further studied according to data obtained by studying the mixing velocity of the gas-liquid two-phase flow at the nozzle outlet, the design parameter of the gas-liquid two-phase flow nozzle is optimized, and the efficiency of the whole refrigeration cycle is improved.

Owner:HENAN UNIV OF SCI & TECH

Rotary compressor and refrigeration cycle equipment

ActiveUS8206139B2Reduce leakage lossImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigeration

A rotary compressor, which contains a motor unit and compression mechanism in a sealed case, transmits the rotational power of the motor to the compression mechanism through a rotary shaft and crankshafts eccentrically provided in the rotary shaft, and compresses a refrigerant in the compression mechanism, wherein the rotary compressor is configured to have H / (φDa•E)=K, and K≦0.065, and the formula 0.35+0.07•K•H≦L / φDb≦0.45+0.07•K•H, assuming that the inside diameter of the cylinder forming the compression mechanism is φDa [mm], the cylinder height is H [mm], the crankshaft eccentricity is E [mm], the crankshaft diameter is φDb [mm], and the sliding lengths of the crankshaft and a roller fitted over the crank are set to L [mm].

Owner:TOSHIBA CARRIER CORP

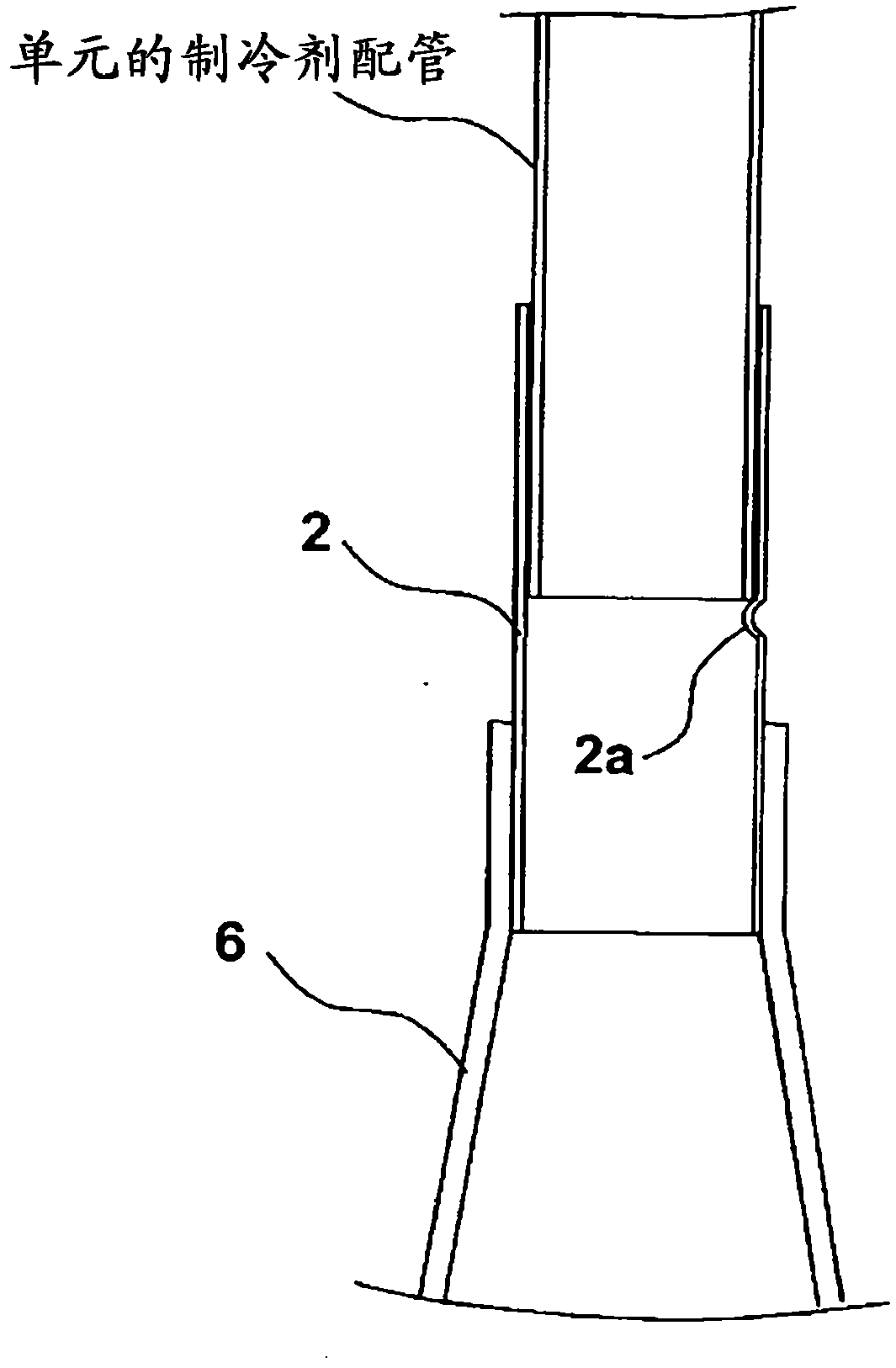

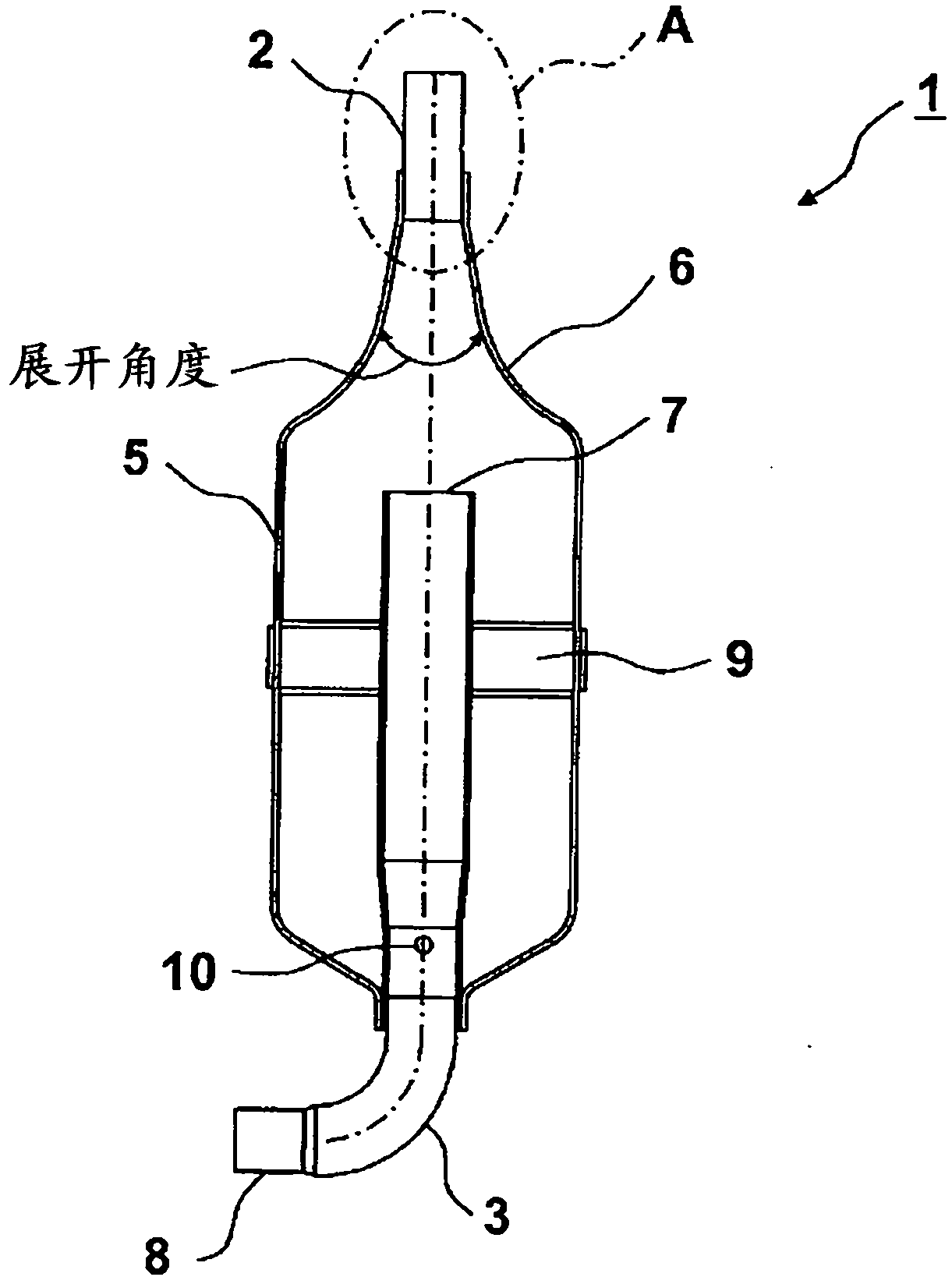

Hermetic type compressor

InactiveCN102588289AImprove suction efficiencyIncrease pressureRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsLiquid stateEngineering

The present invention provides a hermetic type compressor which can raise a suction efficiency of a refrigerant gas by minimizing pressure loss of the refrigerant gas when the refrigerant gas passes through a suction storing device. The hermetic type compressor is characterized in that: the suction storing device comprises the following elements: (1) an inflow pipe, which is a straight pipe with a fixed inner diameter, and is connected with a refrigerant piping of refrigeration cycle; (2) a main body part, which has a tubular integral body, wherein two ends of the main body part are in the shape of area contraction, and the main body part has a specified diameter of the following volume, the volume can realize the functions of performing gas-liquid separation for the suction refrigerant gas and storing the separated liquid-state refrigerant which contains refrigerating machine oil, the end of the main body part at the inflow pipe side is in the shape of diffuser with a specified opening angle, the diffuser shape part is smoothly formed by curves which are protruded inwards, and is connected with the inflow pipe; and (3) at least one outflow pipe, wherein a diameter of an inflow port of the outflow pipe is larger than a diameter of the inflow pipe, or the inflow port is in the shape of bell mouth.

Owner:MITSUBISHI ELECTRIC CORP

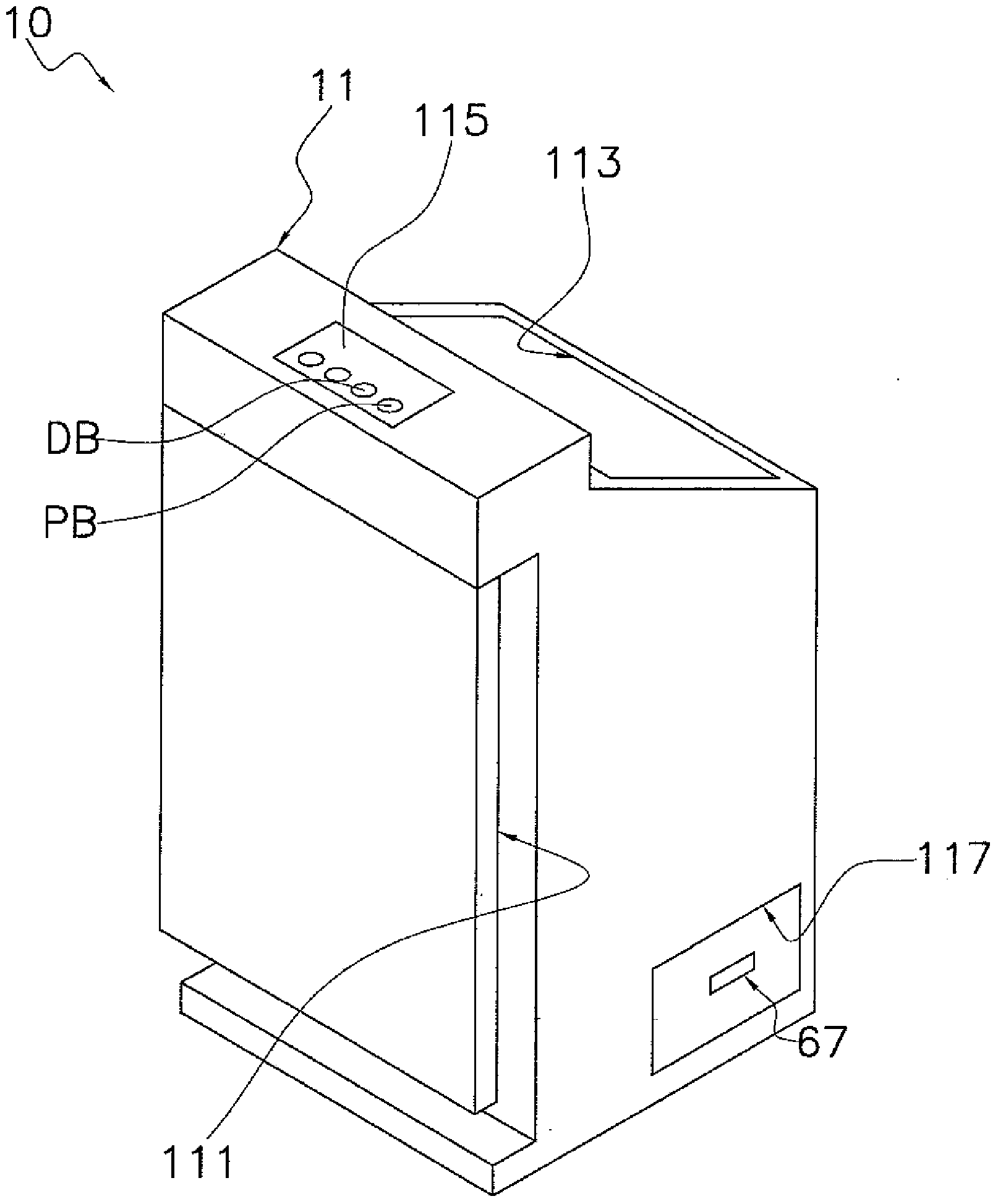

Dehumidifier

InactiveCN104165418AAvoid coolingPrevent condensationCondensate preventionLighting and heating apparatusMoisture condensationWater storage tank

The invention discloses a dehumidifer which can increase the temperature of the moisture condensation to inhibit the condenstation on the all surface of the water storage tank; in the dehumidifier (10), the second water discharging plate (52) has a water guiding surface (50a) which is close to the lower end of the evaporation device (31) and the lower end in the condenser close to the evaporation device (31). As a particular structure, the water guiding surface (50a) has a first water bearing surface (50aa) opposite to the lower end of the evaporation device (31), and a second water bearing surface (50ab) opposite to the lower end of the condenser. The condensation water which is dropped on the water bearing surface (50aa) contacts with part of the condenser (37) and increases the temperature.

Owner:DAIKIN IND LTD

Scroll compressor

InactiveCN102330680AReduce noiseImprove refrigeration cycle efficiencyRotary piston pumpsRotary piston liquid enginesRefrigerantGas separation

The invention discloses a scroll compressor, which comprises a shell, a crank shaft, a stander, a movable scroll disc, a fixed scroll disc, a gas suction pipe, an exhaust hole, an exhaust return stop mechanism and an exhaust pipe, wherein the crank shaft is arranged in the shell; the stander is arranged on the crank shaft; the movable scroll disc is arranged at the top end of the crank shaft and is positioned above the stander; the fixed scroll disc is arranged above the movable scroll disc and is mutually engaged with the movable scroll disc; the gas suction pipe is arranged on the fixed scroll disc and is communicated with a compression chamber which is formed by engaging the movable scroll disc with the fixed scroll disc; the exhaust hole is formed in the top of the fixed scroll disc and is communicated with the central compression chamber; the exhaust return stop mechanism is arranged above the fixed scroll disc and is communicated with the exhaust hole; the exhaust pipe is arranged below the stander; both the gas suction pipe and the exhaust pipe extend out of the shell; the outer wall of the stander is provided with an exhaust passage; and the exhaust passage has a divergent structure from top to bottom. The scroll compressor has a simple structure; only the groove shape of the exhaust passage is required to be changed; through the structure of the exhaust passage, the flow velocity for flowing a refrigerant into a low-pressure chamber is reduced, which contributes to oil-gas separation, and the noise level is reduced; and meanwhile, the degree of superheat of the refrigerant which enters the low-pressure chamber is reduced, so that the refrigeration cycle efficiency of the refrigerant is increased.

Owner:ANHUI MEIZHI COMPRESSOR

Refrigerating system of three-stage flash-evaporation ejection economizers

ActiveCN102230682AImprove refrigeration cycle efficiencySimple structureCompression machines with non-reversible cycleFluid circulation arrangementRefrigerantProcess engineering

The invention discloses a refrigerating system of three-stage flash-evaporation ejection economizers. The refrigerating system comprises an evaporator, a compressor, a condenser, a first-stage high-pressure flash-evaporation-tank economizer, a first-stage ejector, a second-stage flash-evaporation-tank economizer, a second-stage ejector and a third-stage economizer. The refrigerating system has a simple structure, high practicability and great using value, and is convenient to use; flash refrigerant steam produced by each stage of economizer is ejected and concentrated into a highest-pressure economizer and enters the compressor for compressing, and a liquid refrigerant produced by the economizers is ejected and concentrated into a lowest-pressure economizer and enters the evaporator for secondary evaporation, so that the refrigerating cycle efficiency of the economizers is remarkably increased.

Owner:合肥天鹅制冷科技有限公司

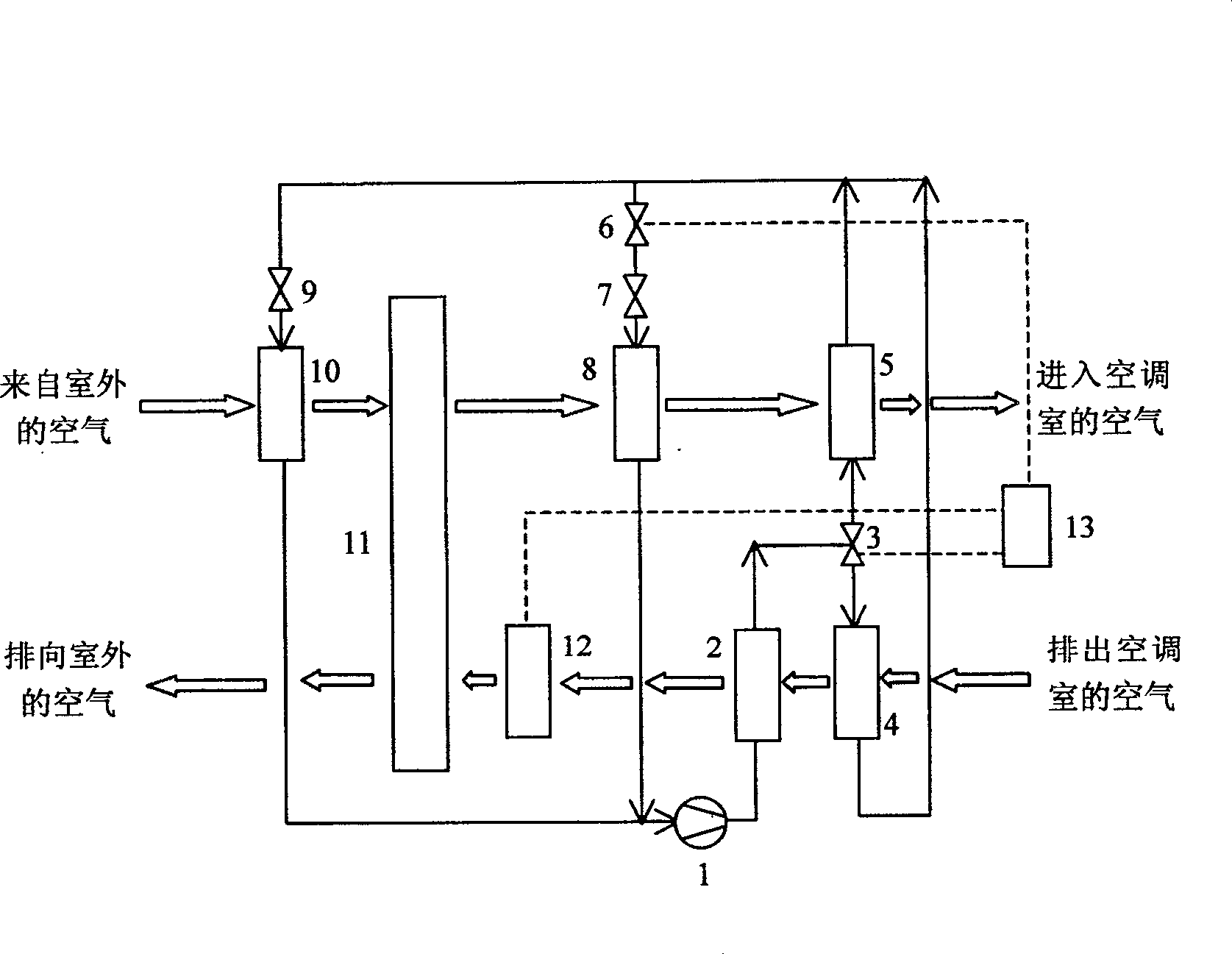

Over critical CO2 refrigeration and rotary wheel dehumidifying combined air conditioning system

InactiveCN100483041CReduce energy consumptionGood for dehumidification and regenerationAir treatment detailsCompression machines with non-reversible cycleGas coolerAir conditioning

Crossover criticality carbon dioxide refrigeration and ferriswheel desiccation combined type air conditioning system is of the refrigeration and air conditioning technique field, comprising major loop evaporator, ferriswheel dehumidifier, auxiliary loop evaporator and secondary accessory gas cooler, arranged in turn in the direction of air current flowing from the room outside to inside, first accessory gas cooler, major gas cooler, 8electric heater and ferriswheel dehumidifier arranged in turn in the direction of air current flowing from the room inside to outside, and compressor, flow control valve, first accessory gas cooler, stop valve, auxiliary loop evaporator, major loop throttle valve and major loop evaporator, with carbon dioxide as refrigeration working medium. The invention is benefit for increasing efficiency of refrigeration cycle, reducing energy cost of ferriswheel dehumidifier with environmental protection.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com