Multi-cylinder rotary compressor and refrigeration circulation device

A rotary compressor, multi-cylinder technology, used in rotary piston/oscillating piston pump components, rotary piston/oscillating piston pump combinations for elastic fluids, and components for elastic fluid pumping devices In other directions, it can solve the problems of production cost, difficult chuck fixing, high machining accuracy, etc., to achieve the effect of reducing parts cost, realizing refrigeration cycle efficiency, manufacturability and machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Embodiments of the present invention will be described below with reference to the drawings.

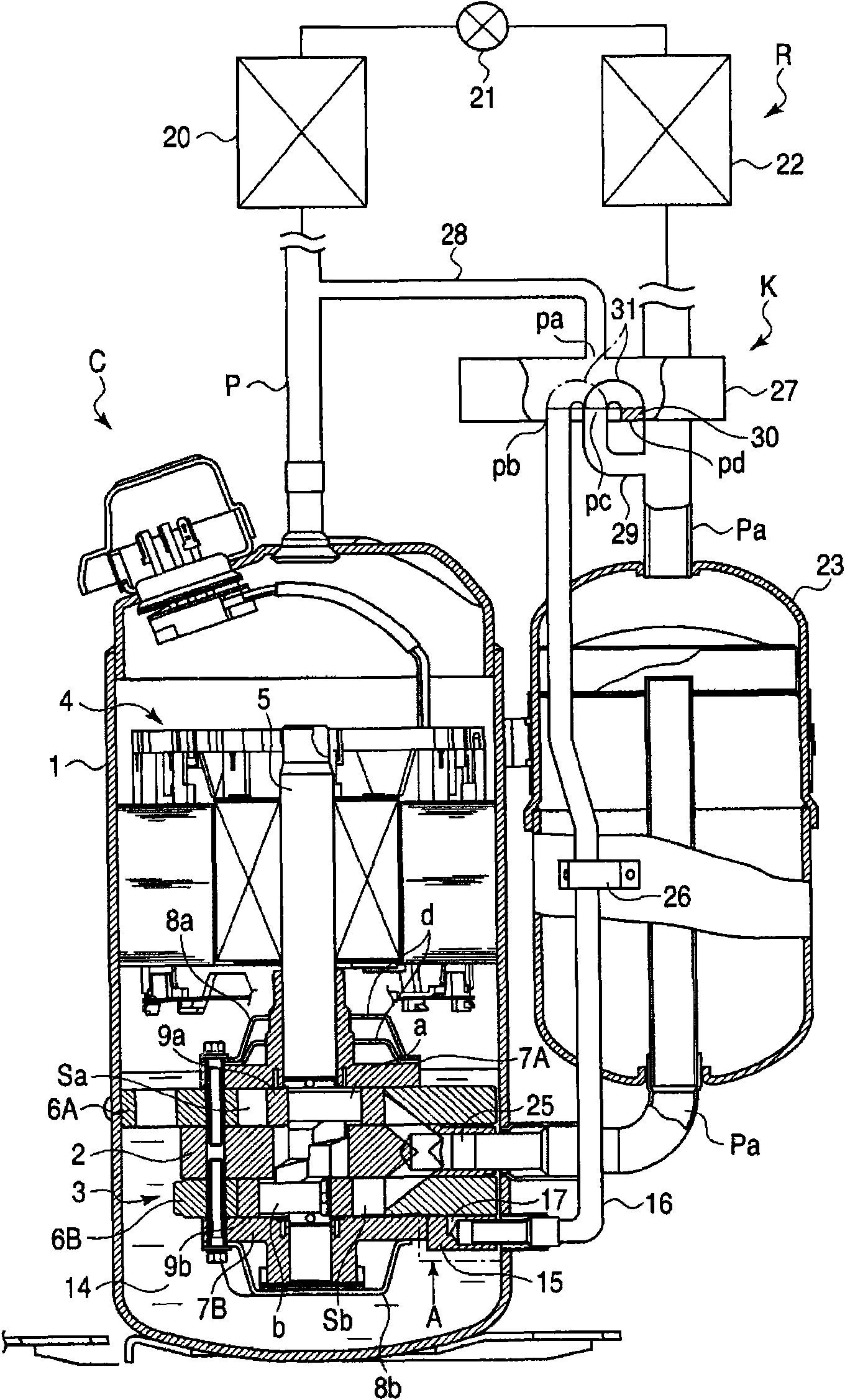

[0080] figure 1 It is a figure which shows the schematic cross-sectional structure of the multi-cylinder rotary compressor C of 1st Embodiment, and the refrigeration cycle structure of the refrigeration cycle apparatus R including this multi-cylinder rotary compressor C.

[0081] Firstly, the multi-cylinder rotary compressor C will be described. Reference numeral 1 is an airtight casing. A compression mechanism section 3 is provided in the lower part of the airtight container 1, and a motor section 4 is provided in the upper part. The motor unit 4 and the compression mechanism unit 3 are integrally connected by a rotating shaft 5 .

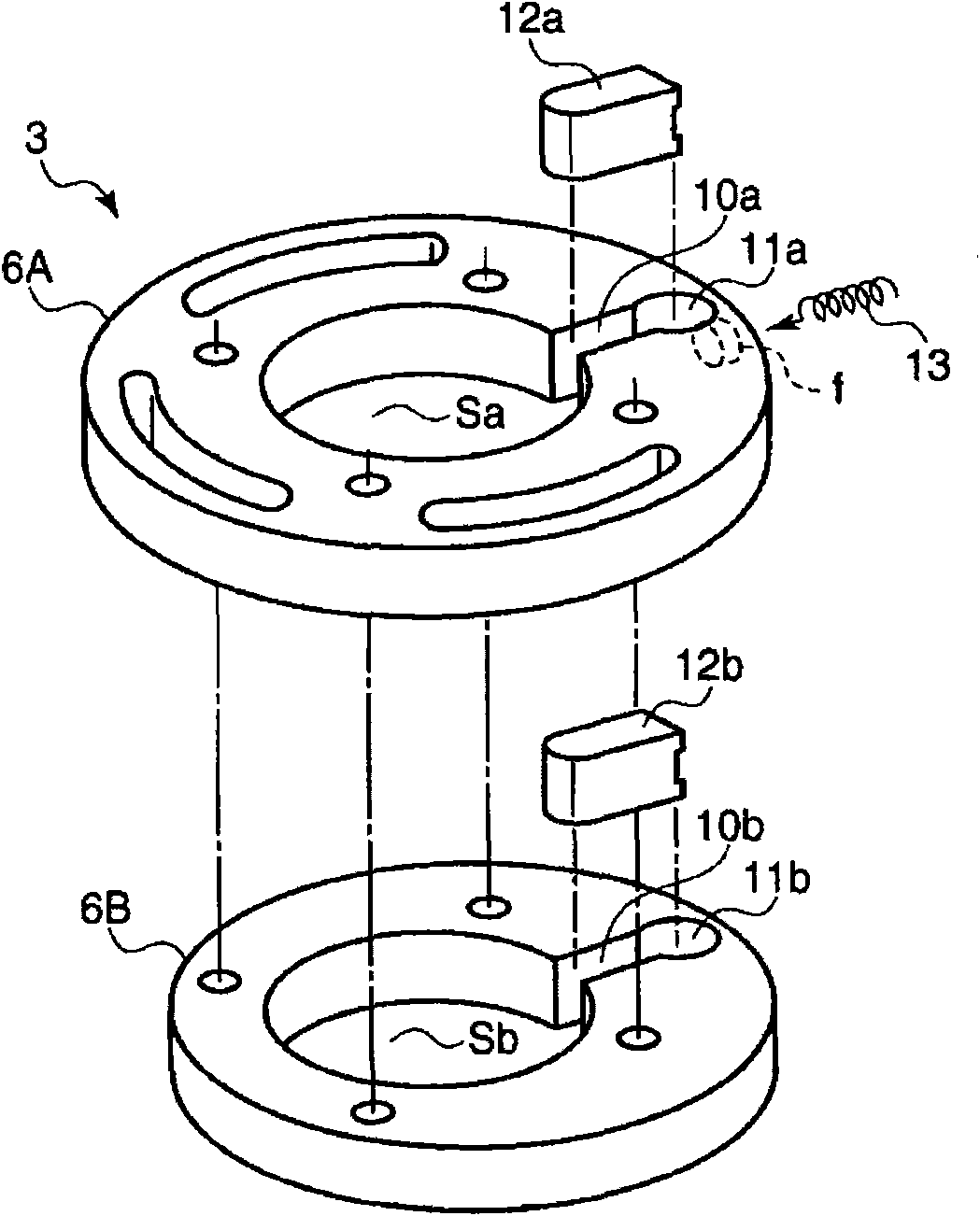

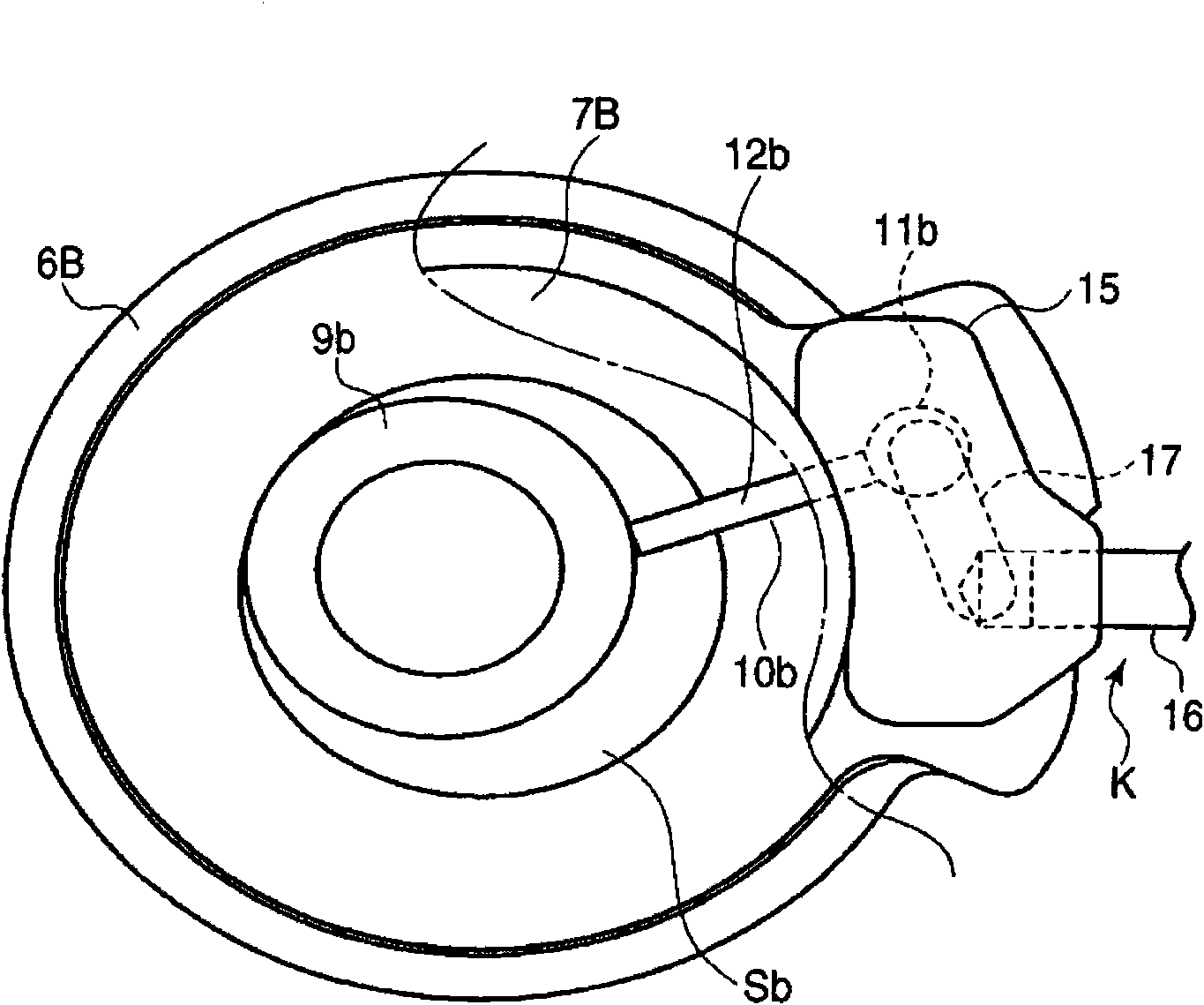

[0082] The compression mechanism unit 3 includes a first cylinder 6A on the upper side and a second cylinder 6B on the lower side. A main bearing 7A is fixed to the upper end surface of the first cylinder 6A, and a sub-bearing 7B is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com