FLNG/FLPG oil gas pretreatment and liquefaction method

A pretreatment, oil and gas technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of low efficiency, poor applicability, and small processing capacity of nitrogen expansion process, and achieve the effect of small footprint, less equipment, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] like figure 1 As shown, the oil and gas pretreatment and liquefaction method of a kind of FLNG / FLPG device provided by the present invention comprise the following steps:

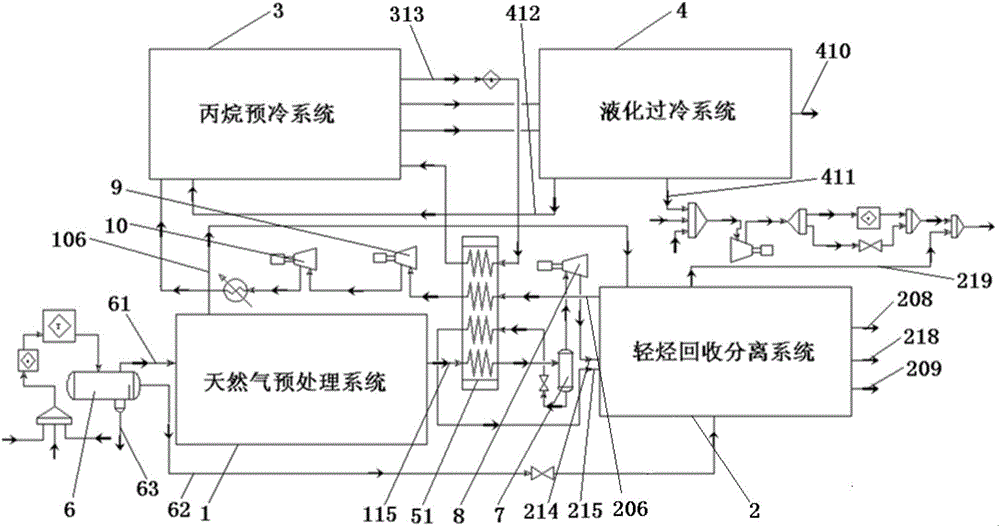

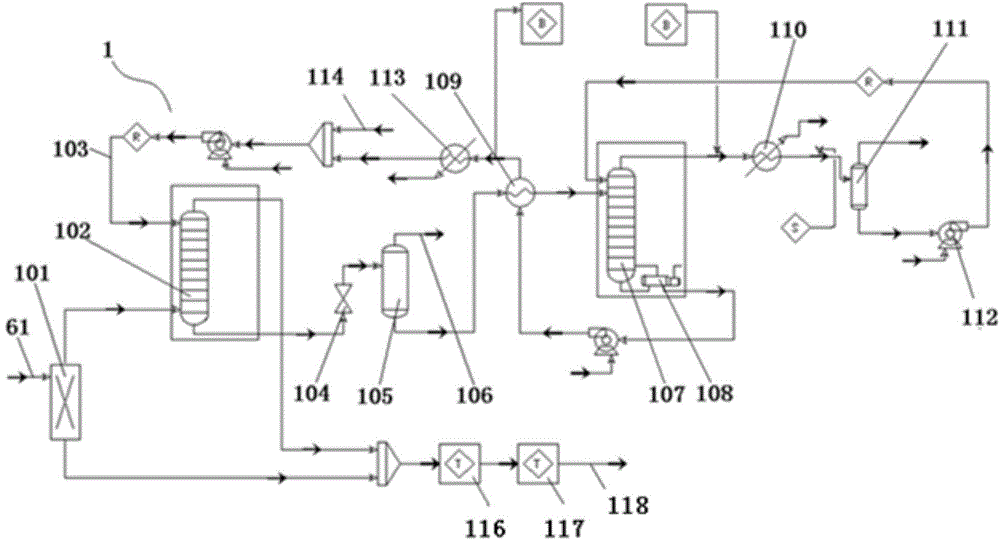

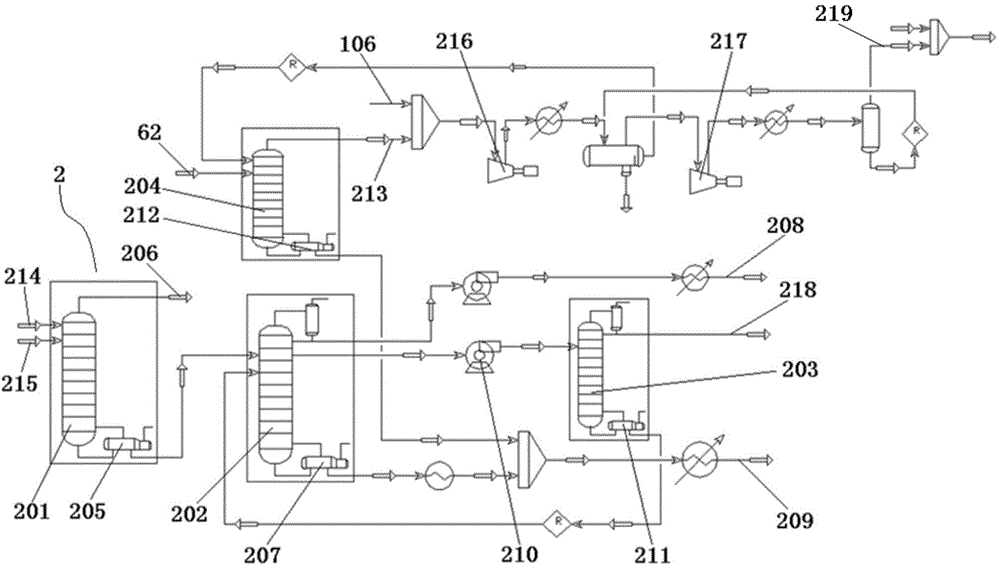

[0046] 1) Set up a natural gas pretreatment system 1, light hydrocarbon recovery and separation system 2, propane precooling system 3, liquefaction subcooling system 4 and several cold boxes 5 (including figure 1 51 of Figure 4 52 in and Figure 5 53, 54) oil and gas pretreatment and liquefaction system.

[0047] 2) First, the natural gas mixture transported from the submarine pipeline is transported into the slug flow catcher 6 of the FLNG device, and the natural gas mixture is divided into three pipelines for delivery through the slug flow catcher 6, namely the natural gas pipeline 61, the condensate oil pipeline Road 62 and sewage pipeline 63; then the natural gas flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com