Patents

Literature

166 results about "Natural gas field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil and natural gas are produced by the same geological process according fossil fuel suggestion: anaerobic decay of organic matter deep under the Earth's surface. As a consequence, oil and natural gas are often found together. In common usage, deposits rich in oil are known as oil fields, and deposits rich in natural gas are called natural gas fields. In general, organic sediments buried in depths of 1,000 m to 6,000 m generate oil, while sediments buried deeper and at higher temperatures generate natural gas. The deeper the source, the "drier" the gas. Because both oil and natural gas are lighter than water, they tend to rise from their sources until they either seep to the surface or are trapped by a non-permeable layer of rock. They can be extracted from the trap by drilling. The largest natural gas field is South Pars/Asalouyeh gas field, which is shared between Iran and Qatar. The second largest natural gas field is the Urengoy gas field in Russia. The gas field Haynesville Shale Louisiana-Texas has been projected bigger than South Pars, since this a new well it has not been officially recorded its overall power.

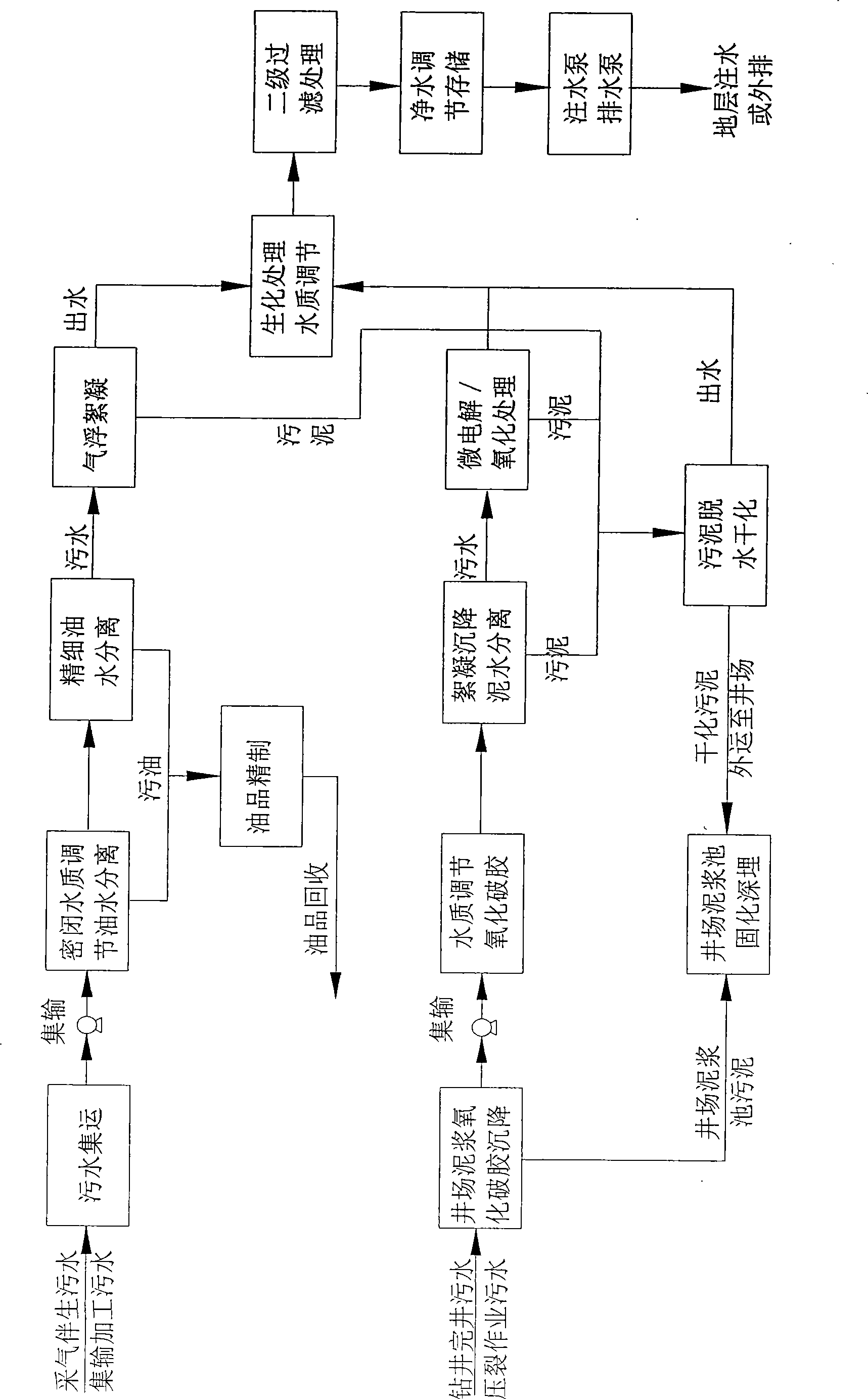

Gas field sewerage and solid pollutant comprehensive processing technological process

InactiveCN101475285AEasy to handleReduce pollutionSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSocial benefitsSludge

The invention relates to a comprehensive treatment process method for sewage and solid pollutants in a natural gas field. The process method comprises five process units, namely, purification treatment for gas production accompanying sewage, purification treatment for drilling mud sewage, biochemical treatment for yielding water and water quality adjustment, fine filtering discharge of the yielding water, mud purification and solidification treatment for the solid pollutants. From the reality of development and production of the natural gas field, the comprehensive treatment process method for the sewage and the solid pollutants in the natural gas field combines environmental protection requirement, has strong comprehensiveness and practicality, is easy to execute, can effectively treat the sewage and the solid pollutants in the natural gas field, changes waste into valuable, effectively reduces environment pollution, and acquires good economic and social benefits.

Owner:LIAONING TIANYI IND CO LTD

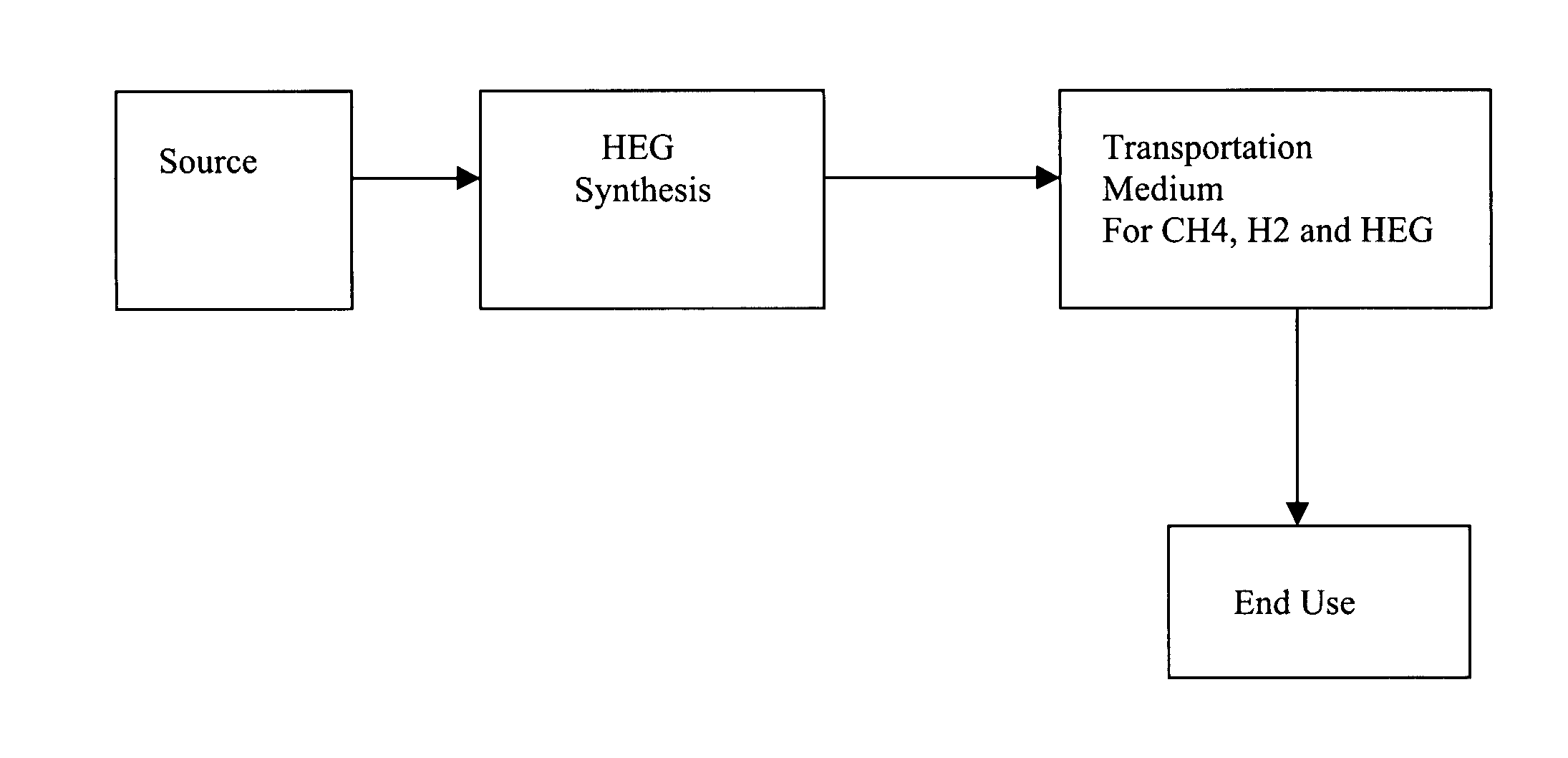

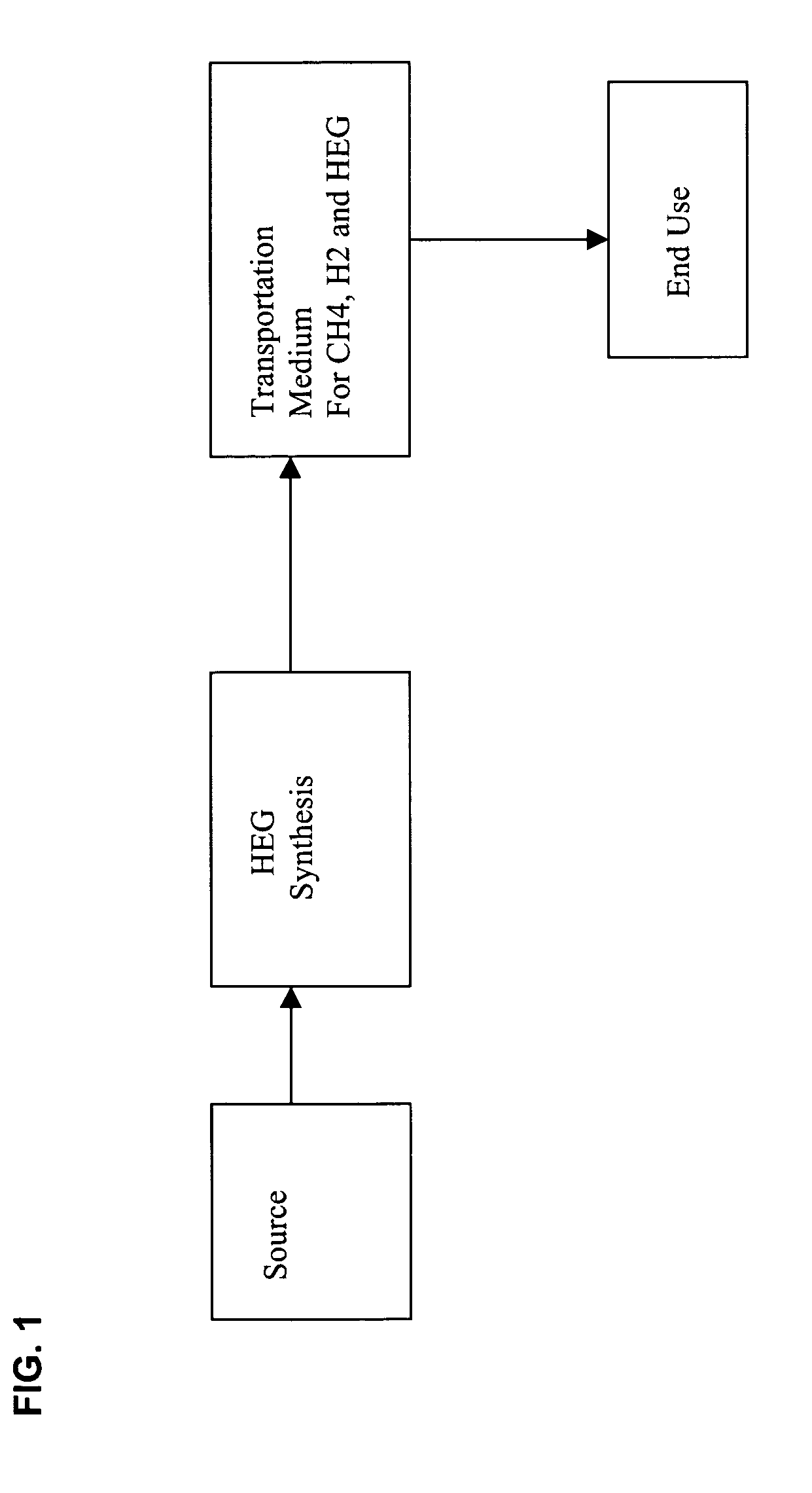

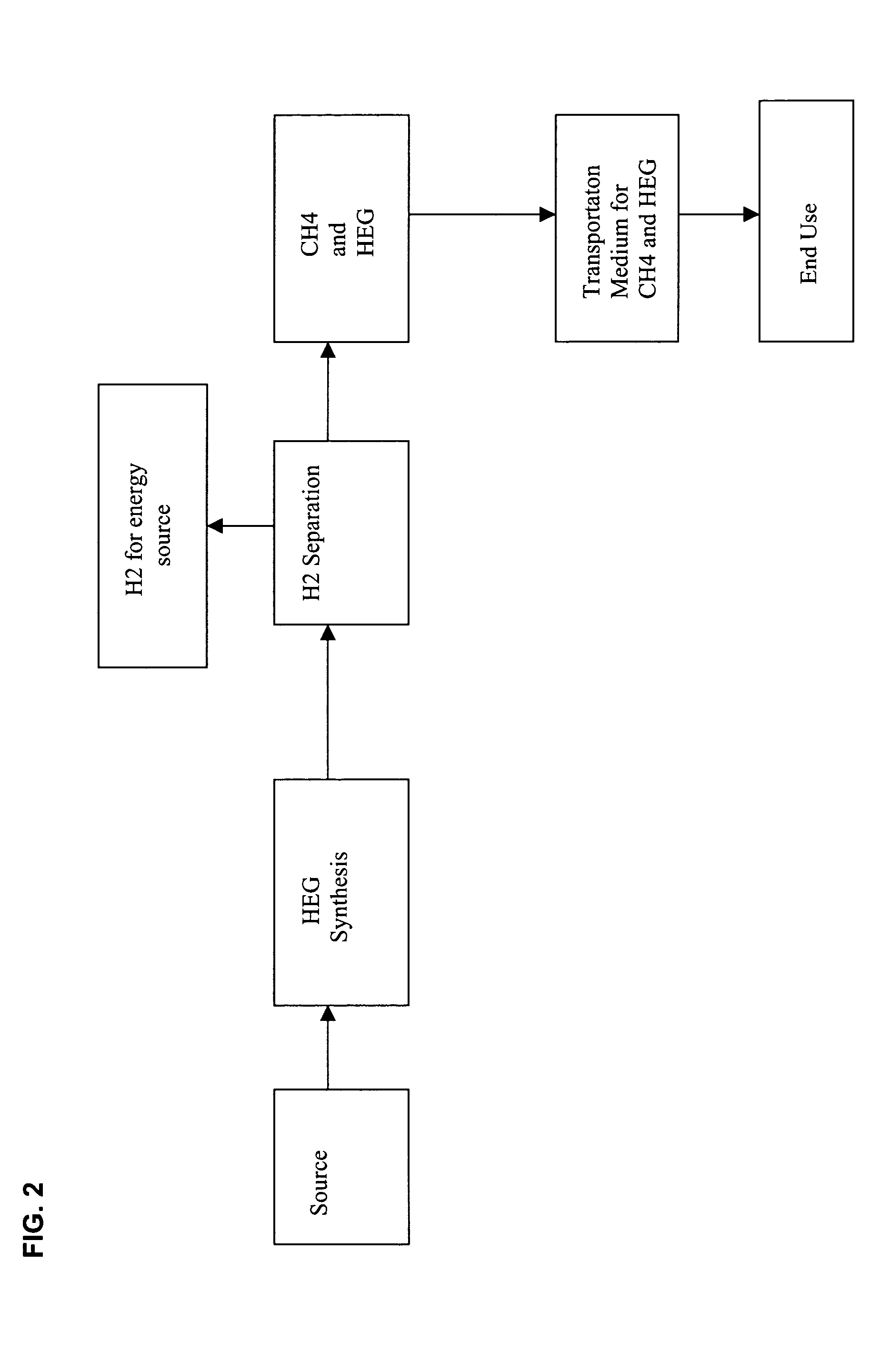

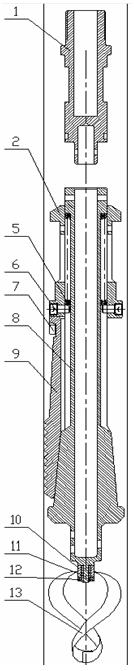

High energy transport gas and method to transport same

InactiveUS8277525B2Increase volumeHigh boiling pointGas modification by gas mixingIndirect heat exchangersThermodynamicsFuel cells

Owner:DALTON ROBERT C

High energy transport gas and method to transport same

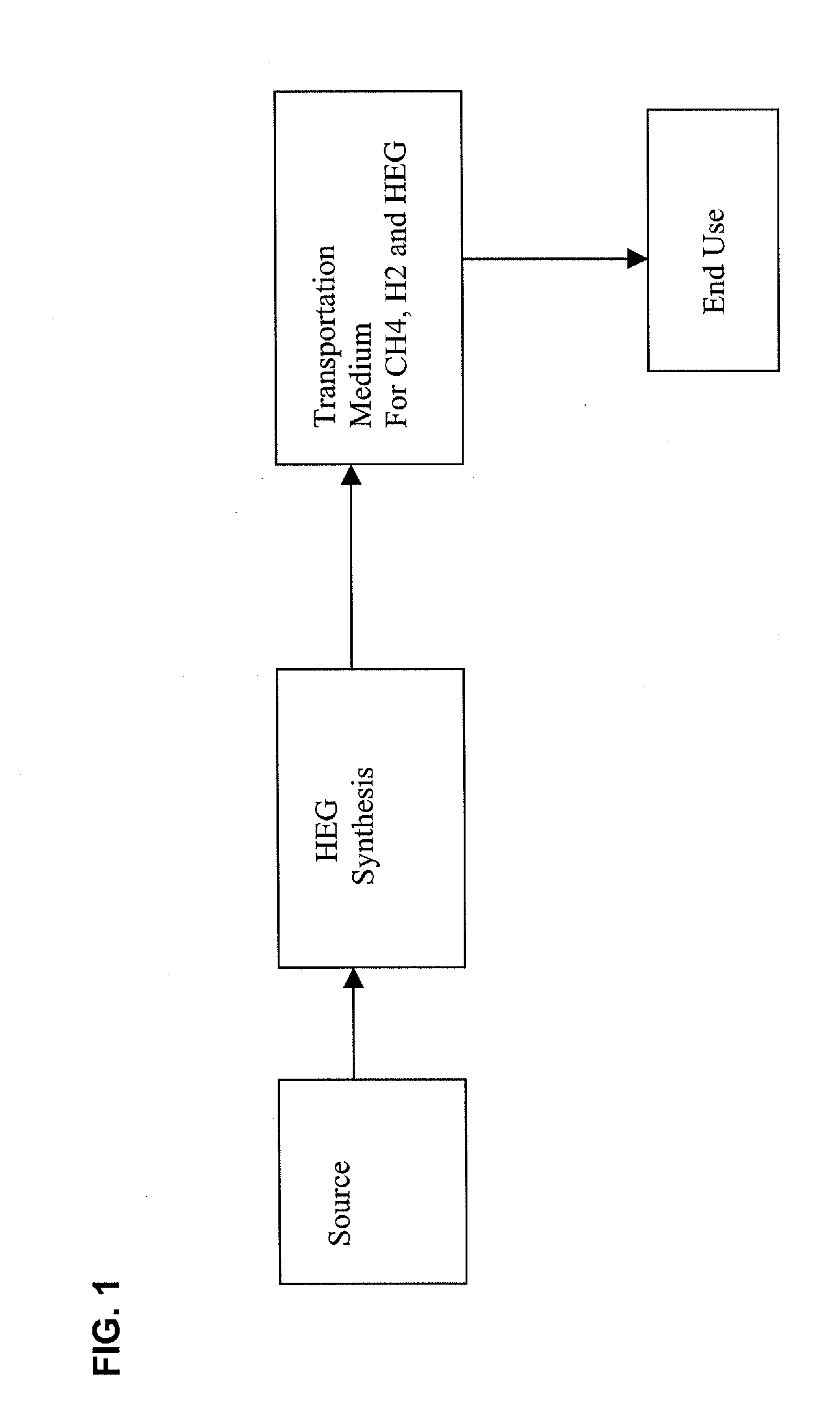

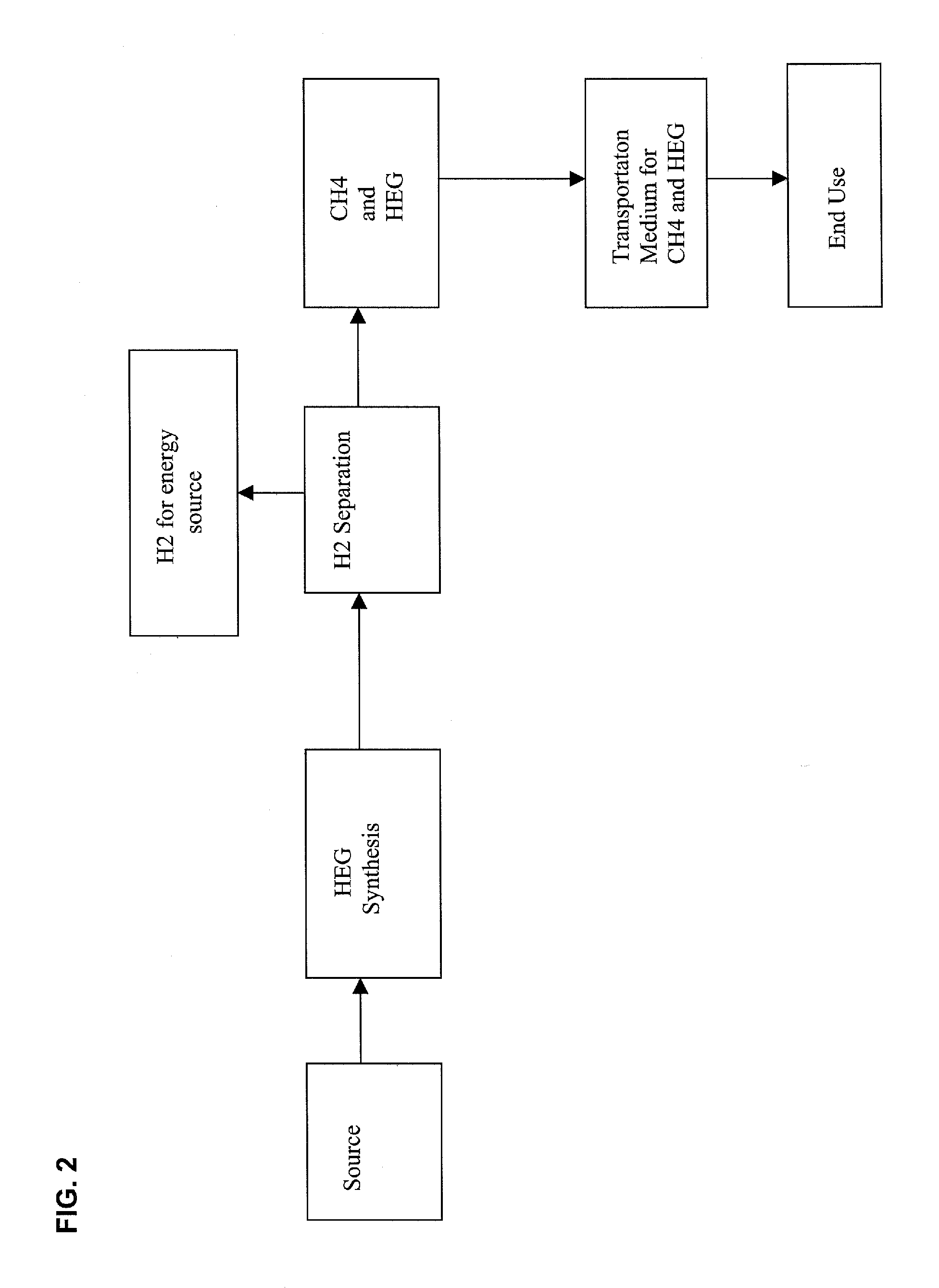

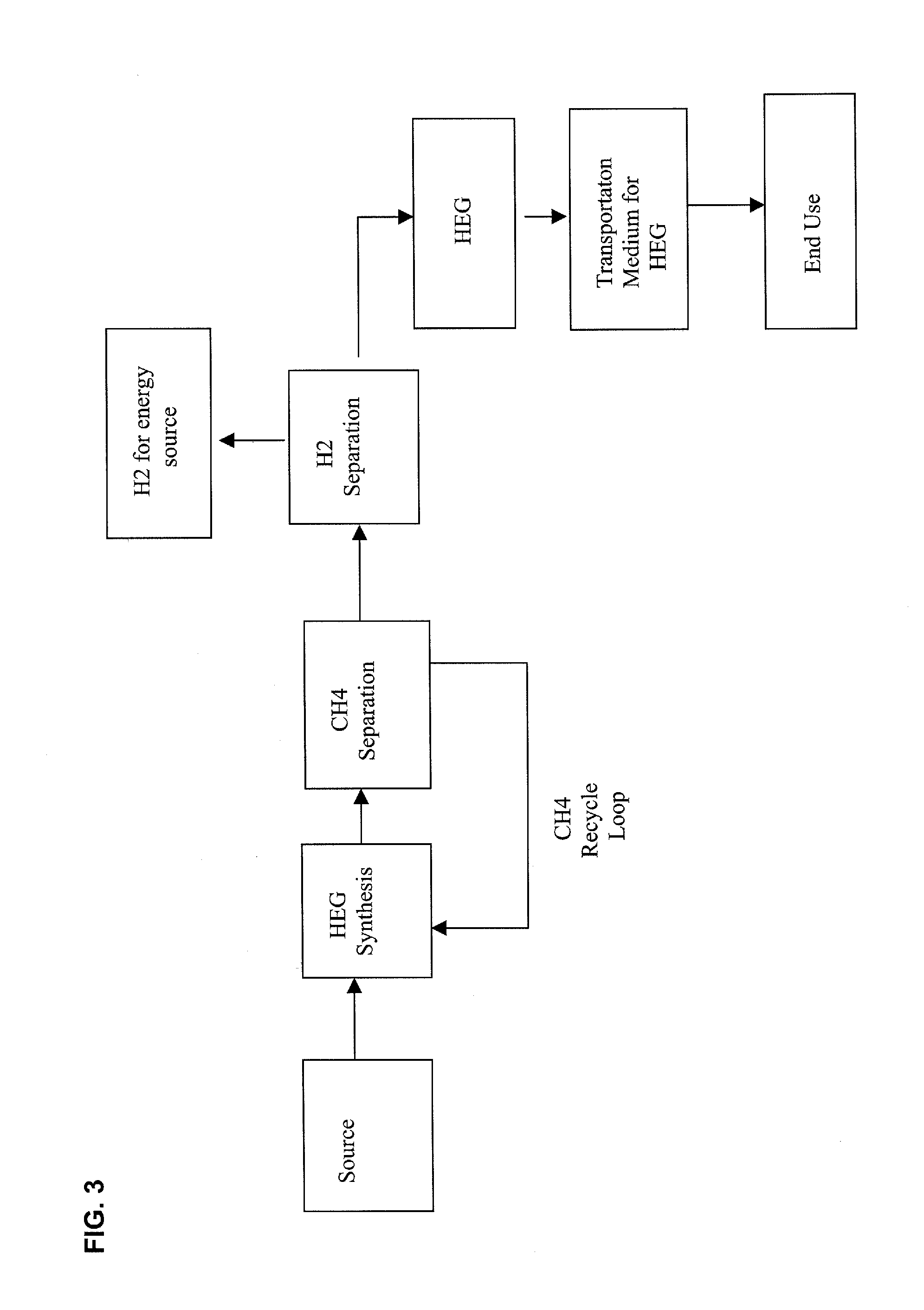

A high energy transport gas and a method to transport the high energy transport gas are used to increase the energy content of a pipeline and other vessels that are designed to carry natural gas under ambient conditions, in a compressed state or in a liquefied state. Methane and other gases are used as the feedstock, with methane from natural gas fields, coal beds or derived from hydrogen reacting with coal being primary energy sources. Also, this gas and method can provide an abundant source for hydrogen production, and the energy from hydrogen can be used for fuel cell applications that generate electricity and power motor vehicles. This gas and method are capable of increasing the energy capacity of current natural gas pipelines and other storage and transport vessels.

Owner:DALTON ROBERT C

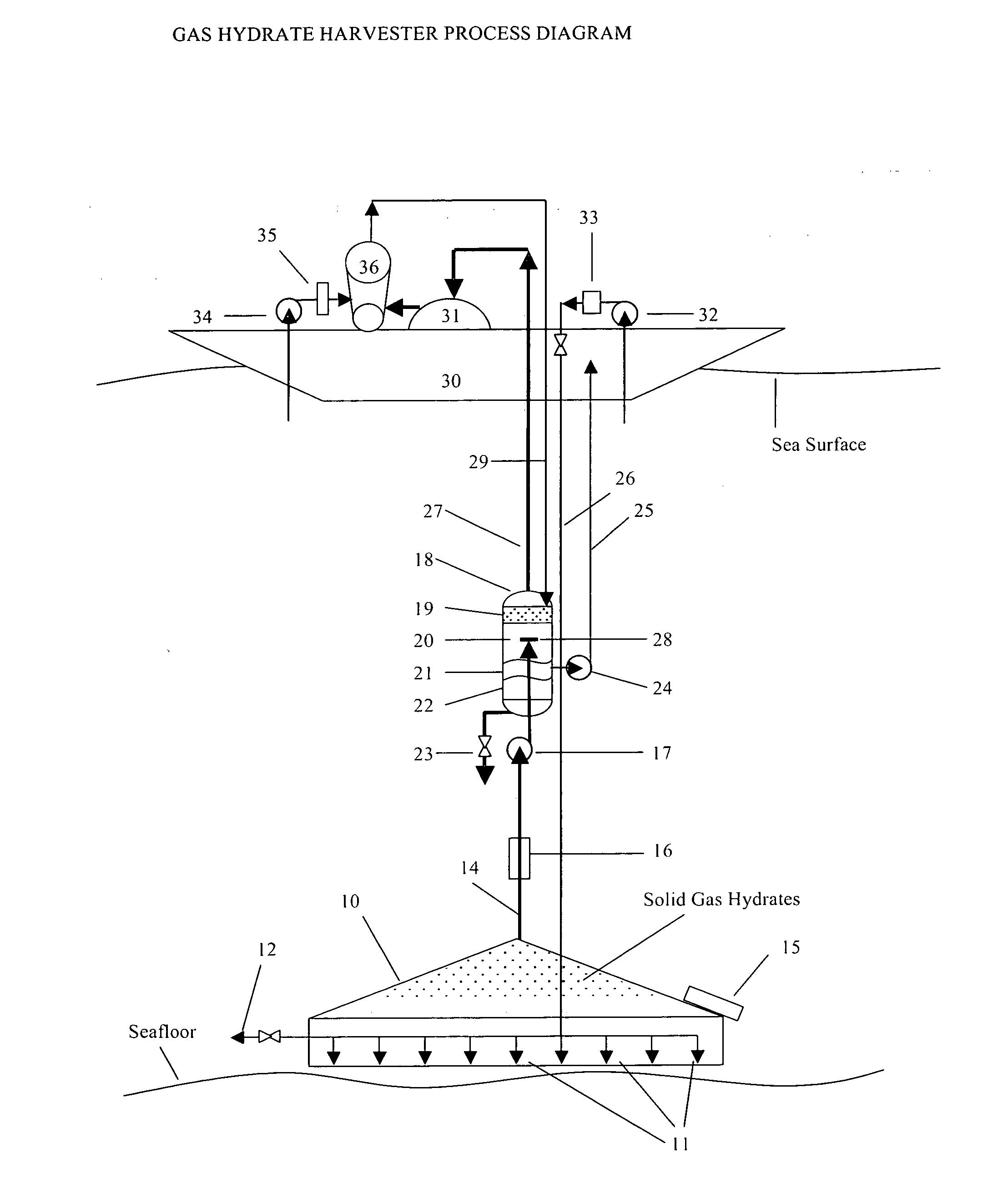

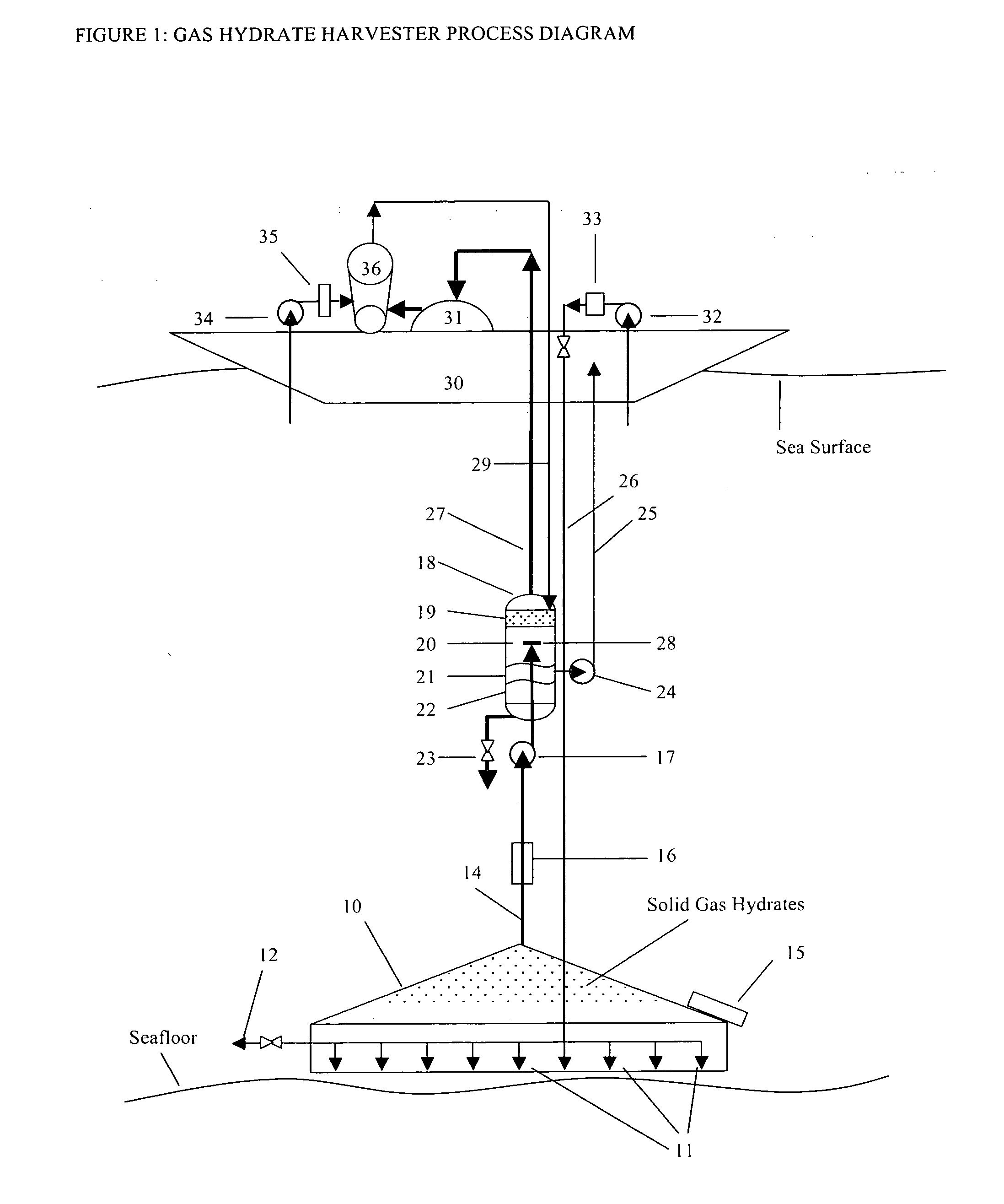

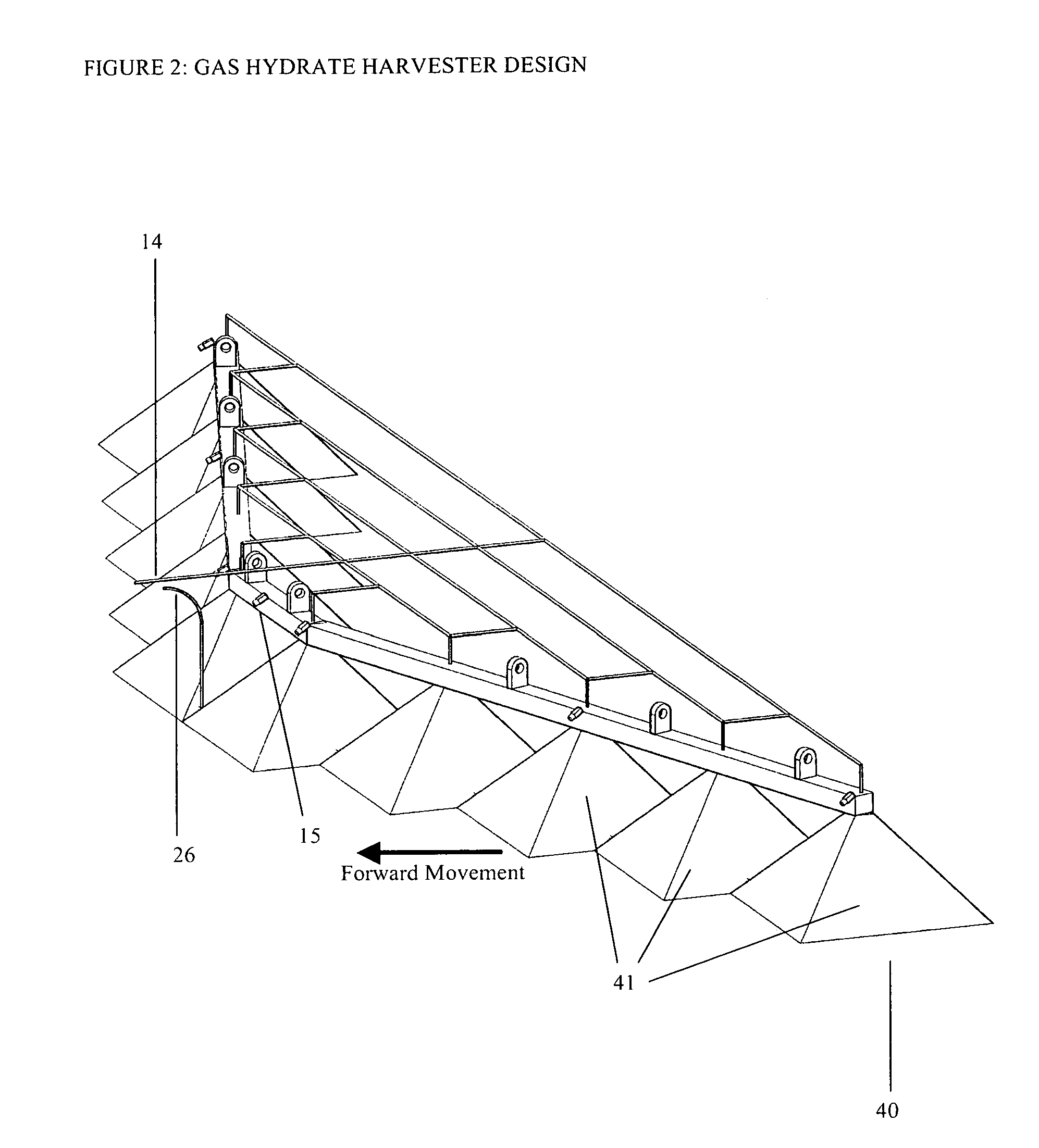

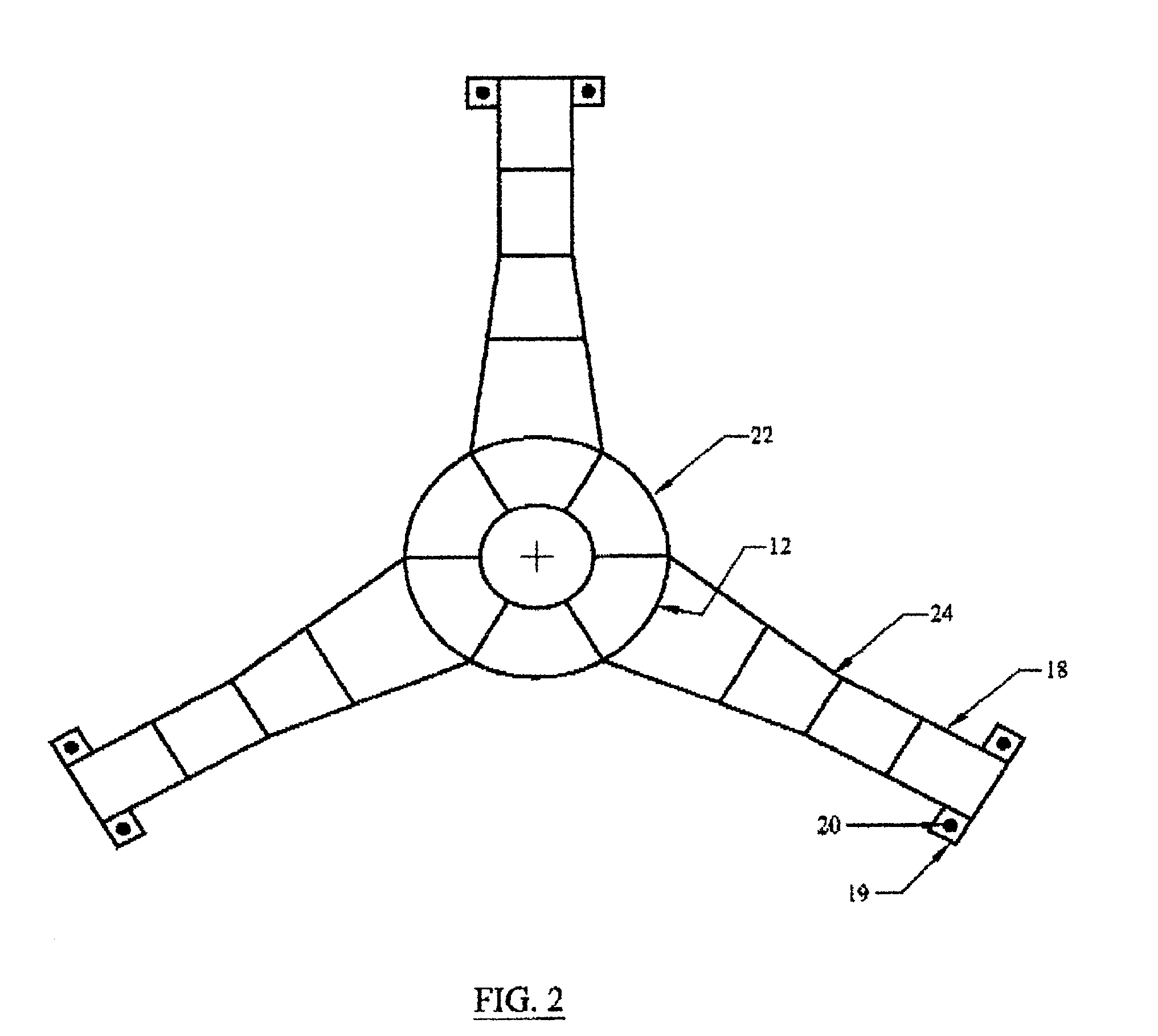

Gas Hydrate Harvesting

A harvester (10) with warm water spray jets (11) that fluidizes and releases gas hydrates from seafloor sand and soil. The released gas hydrates float into the harvester (10) and are then transferred through a hydrate slurry pipe (14) to a separation vessel (18). Dissociation of the gas hydrates into methane gas occurs in the separation vessel (18) from its lower pressure than the seafloor and the optional use of heat. The liberated methane gas flows upward in a gas vent pipe (27) to a topside vessel (30) for storage from the pressure of the submerged separation vessel (18). Alternatively, the vent pipe can be fed directly into an available natural gas pipeline. Crude oil collected in the separation vessel (18) can be separated and pumped to a topside vessel (30) for storage and use in a refinery. No other processing is required to produce commercial quality natural gas harvested directly from gas hydrates on or near the seafloor.

Owner:WILLMAN TODD JENNINGS

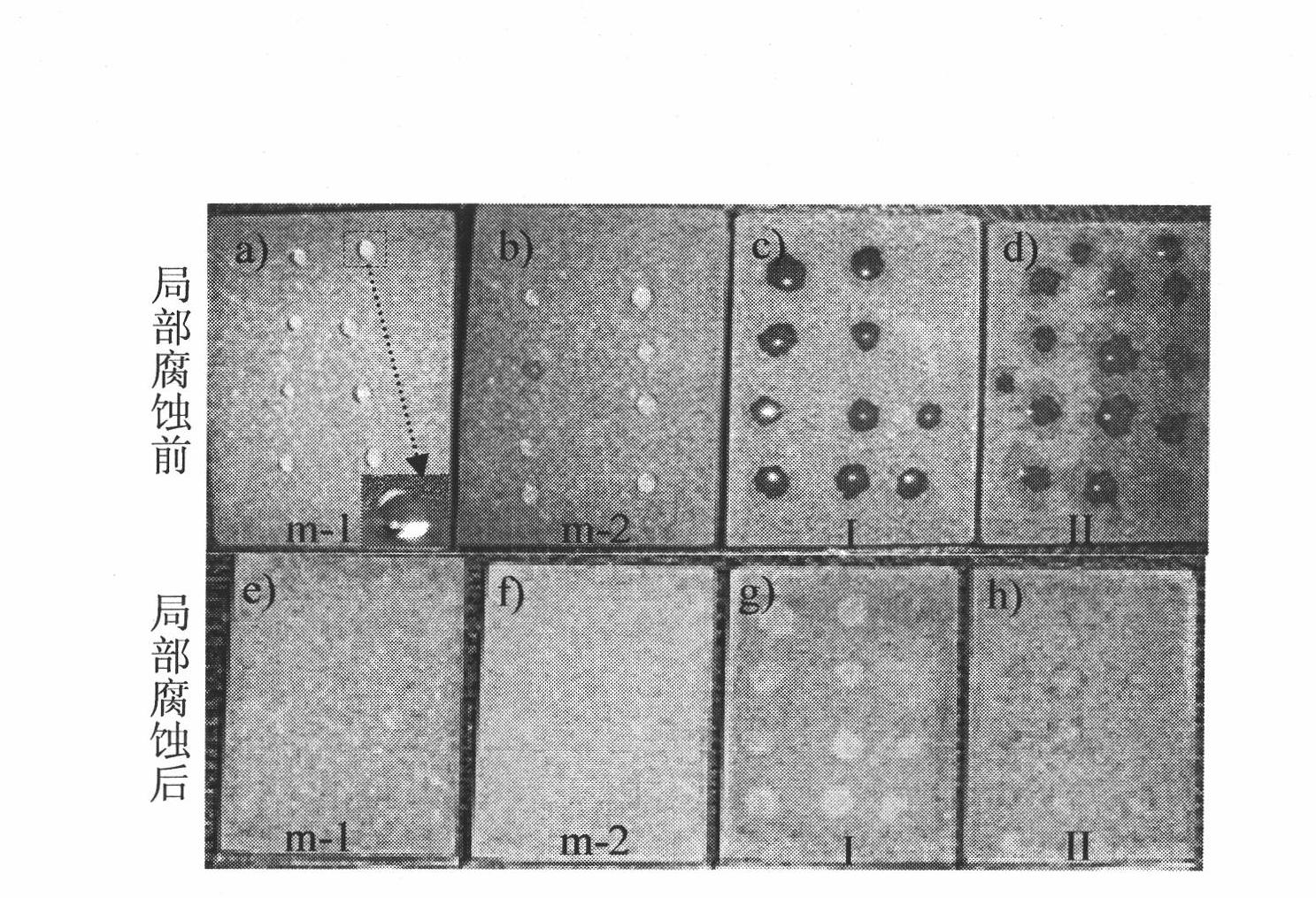

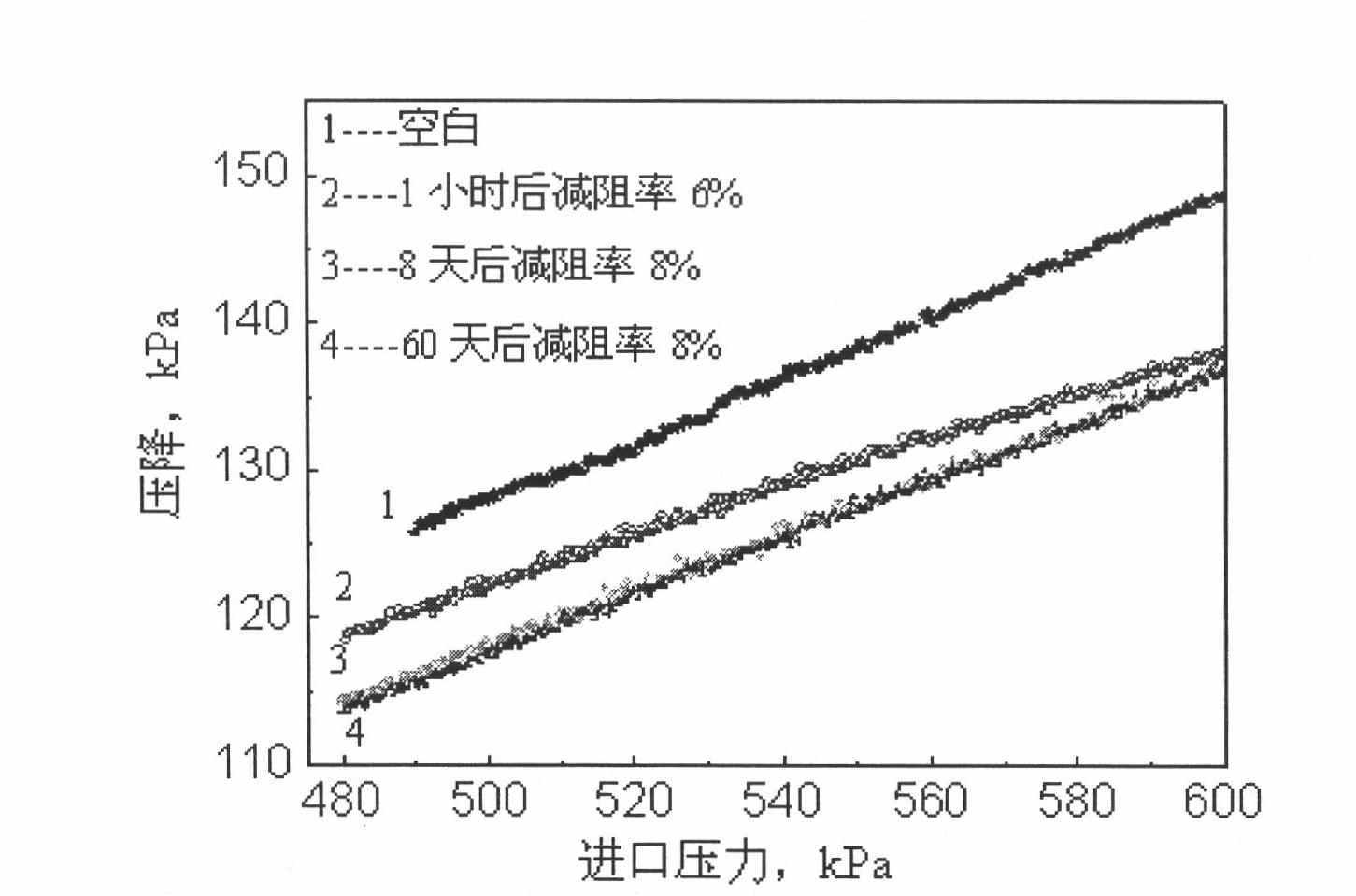

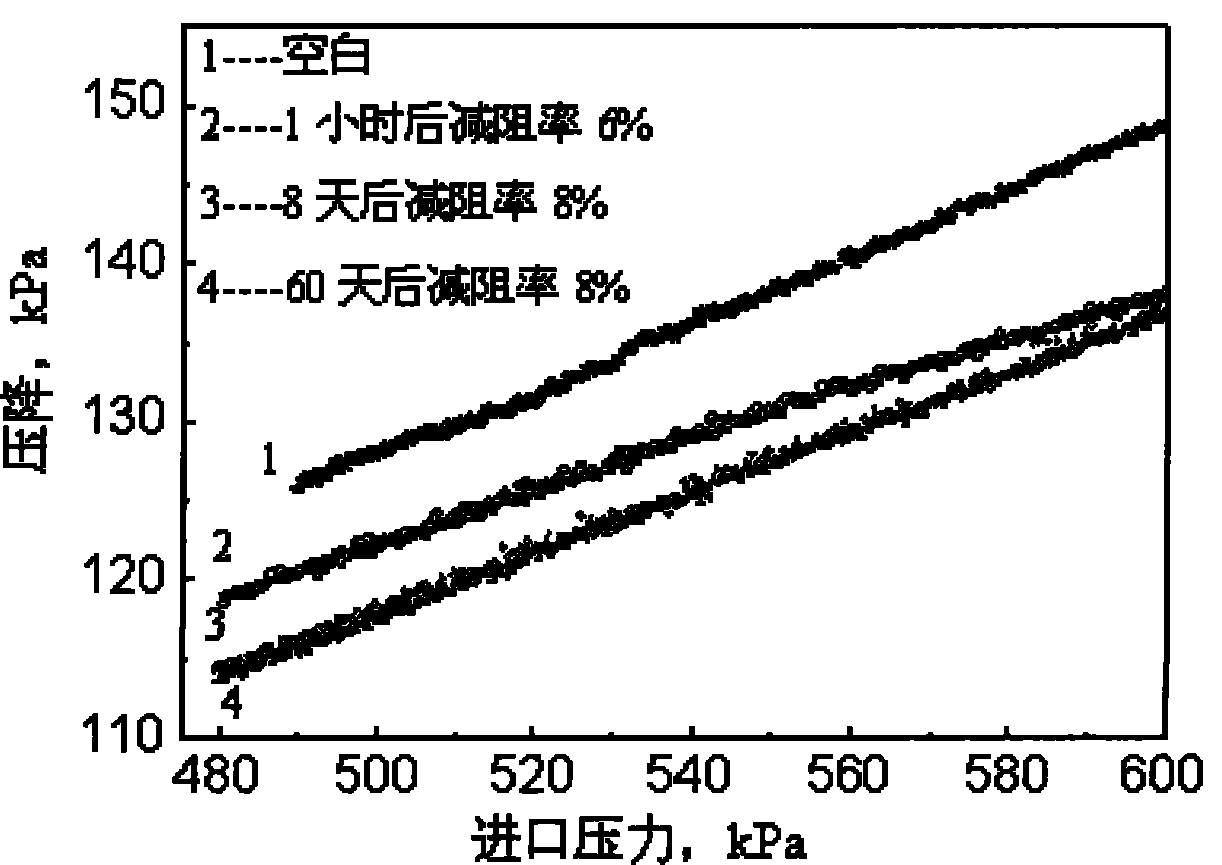

Antisepsis and antidrag chemical additive of natural gas pipeline and preparation method thereof

ActiveCN102040908AEase of application for pipingGood anti-corrosion functionCorrosion preventionAnti-corrosive paintsSilanesChemical compound

The invention discloses an antisepsis and antidrag chemical additive of natural gas pipeline and a preparation method thereof, and relates to the technical field of anticorrosion of common metal material, composition of macromolecular compound and pipeline system. Dodecyl trimethoxy silane is prepared by trimethoxy silane and Alpha-laurylene of which the mole ratio is 1:1-1.3:1 and a platinum catalyst under catalyzing, wherein the mole ratio of the platinum catalyst to Alpha-laurylene is 10*10-6:1-12*10-6:1; and the methyltrimethoxy silane and the synthetic dodecyl trimethoxy silane are successively added to a solvent normal hexane with the mole ratio as 0:1-0.1:1 and mixed and configured into a solution of 40-60wt%. In the invention, the pipe wall has strong adsorption force, functions are multiple, the process is simple, and the effect is preferable.

Owner:PIPECHINA SOUTH CHINA CO

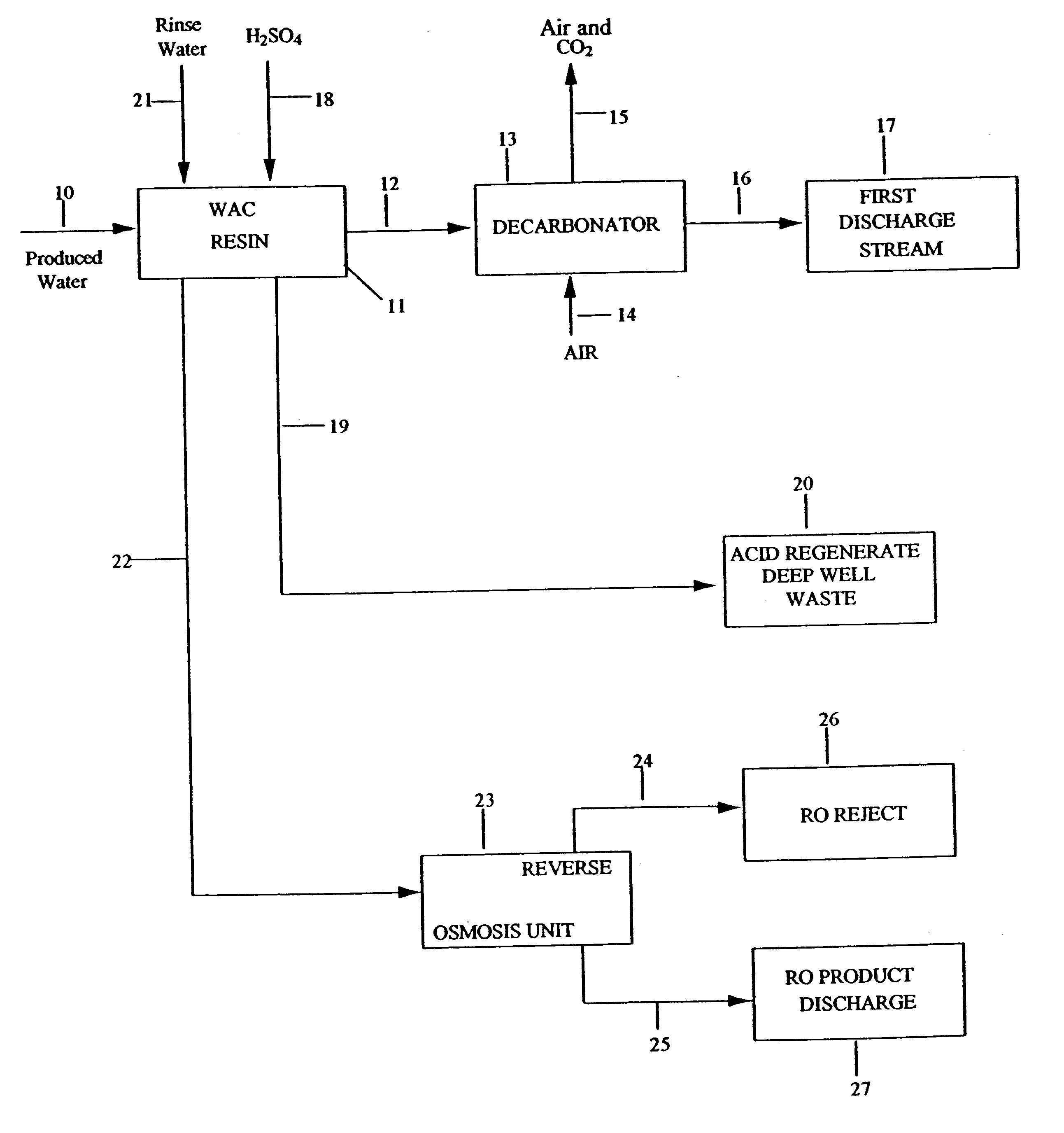

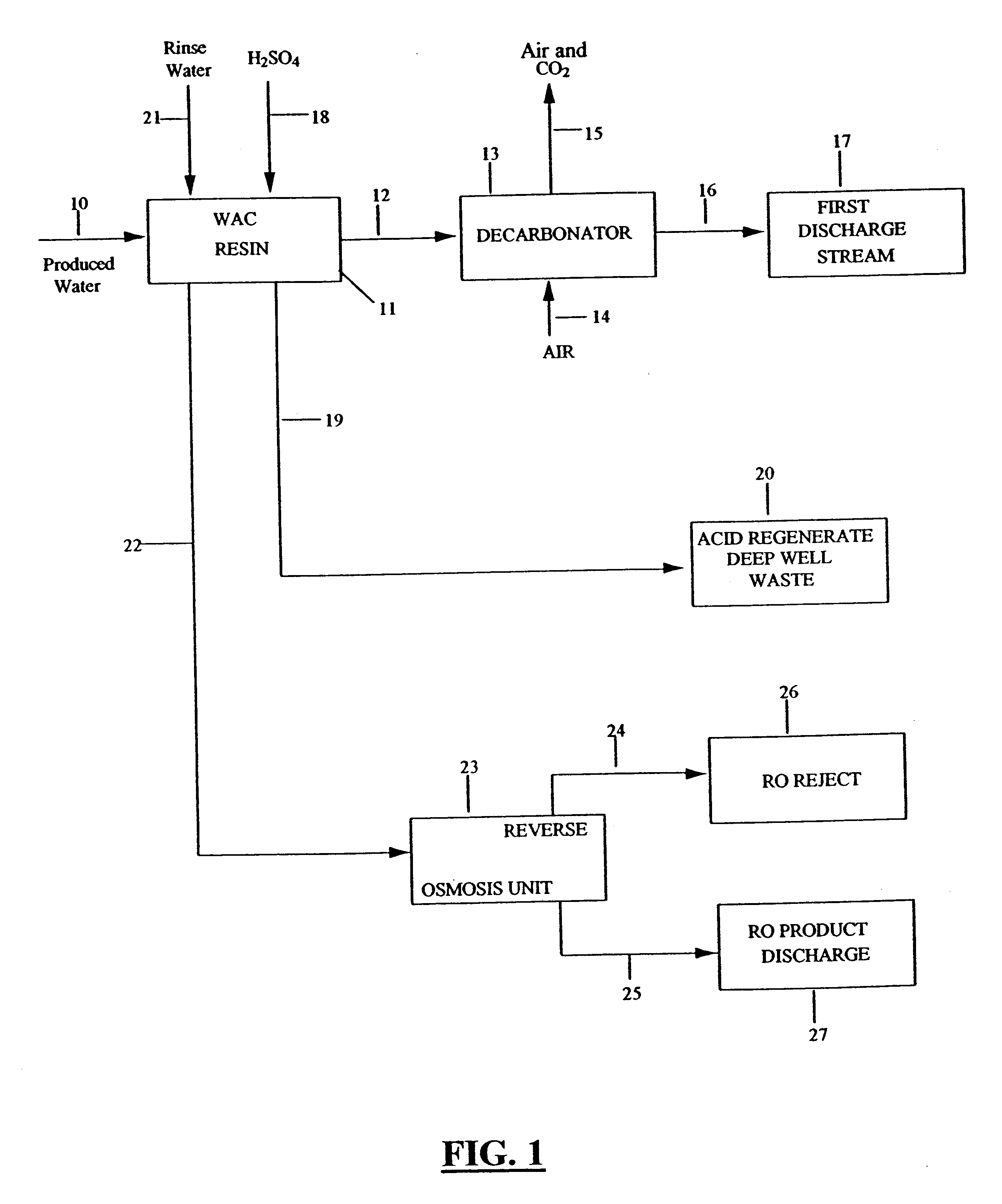

Purification of produced water from coal seam natural gas wells using ion exchange and reverse osmosis

A method and apparatus are provided for treating produced water to lower the total dissolved solids of the water for safe discharge to the environment. The produced water is passed through a weak acid cation resin in H+ form to remove cations in the produced water and then preferably through a decarbonator to remove formed CO2 and to provide a first discharge stream. The cation loaded resin is then regenerated using a dilute acid, preferably diluted with produced water, to regenerate the resin to the H+ form. The resultant acid regenerated waste stream is discharged to a reject deep well. The acid regenerated resin is then rinsed, preferably with produced water, to remove residual salts to form a residual salt containing rinse stream. This salt stream is passed into a reverse osmosis unit to form a high salt containing reject stream which is discharged to a waste deep well and a low salt containing product discharge stream which may be safely discharged to the environment.

Owner:ASARCO LLC

Artificial Lift System

An artificial lift system provides an artificial lift design specifically for the pumping of liquids from natural gas wells, but not limited to this application. In doing so, production rates and reserves recovered can be significantly increased. The artificial lift system uses small diameter continuous tubing to run the pump in the hole and deliver small volumes of high pressure dry gas as a power fluid to the pump. This power fluid forces liquid that has been drawn into the pump from the bottom of the wellbore to surface. By removing the liquids from the wellbore the natural gas can flow unrestricted to surface. The design and equipment allow for a cost effective artificial lift alternative.

Owner:BULLEN TERRY

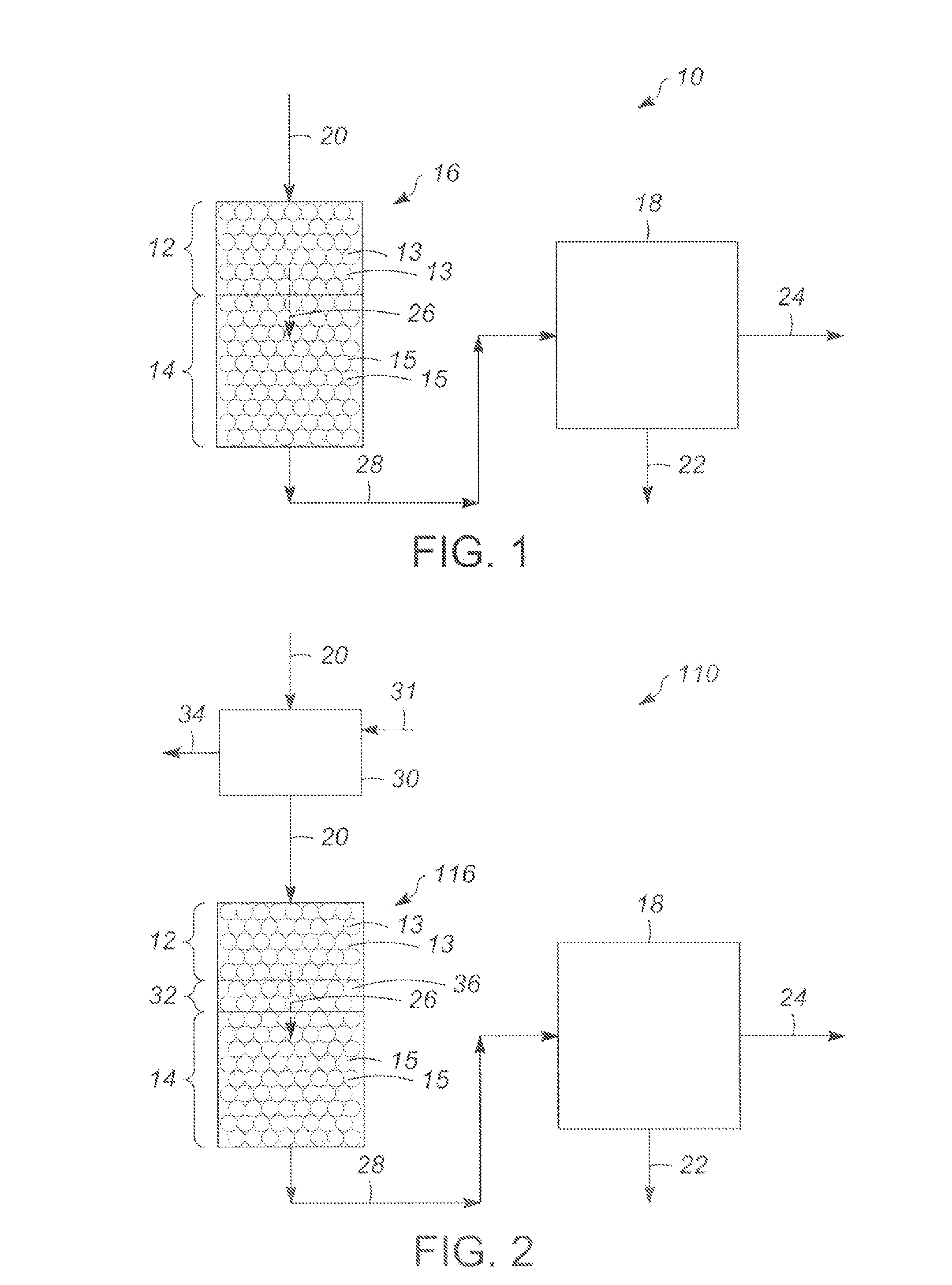

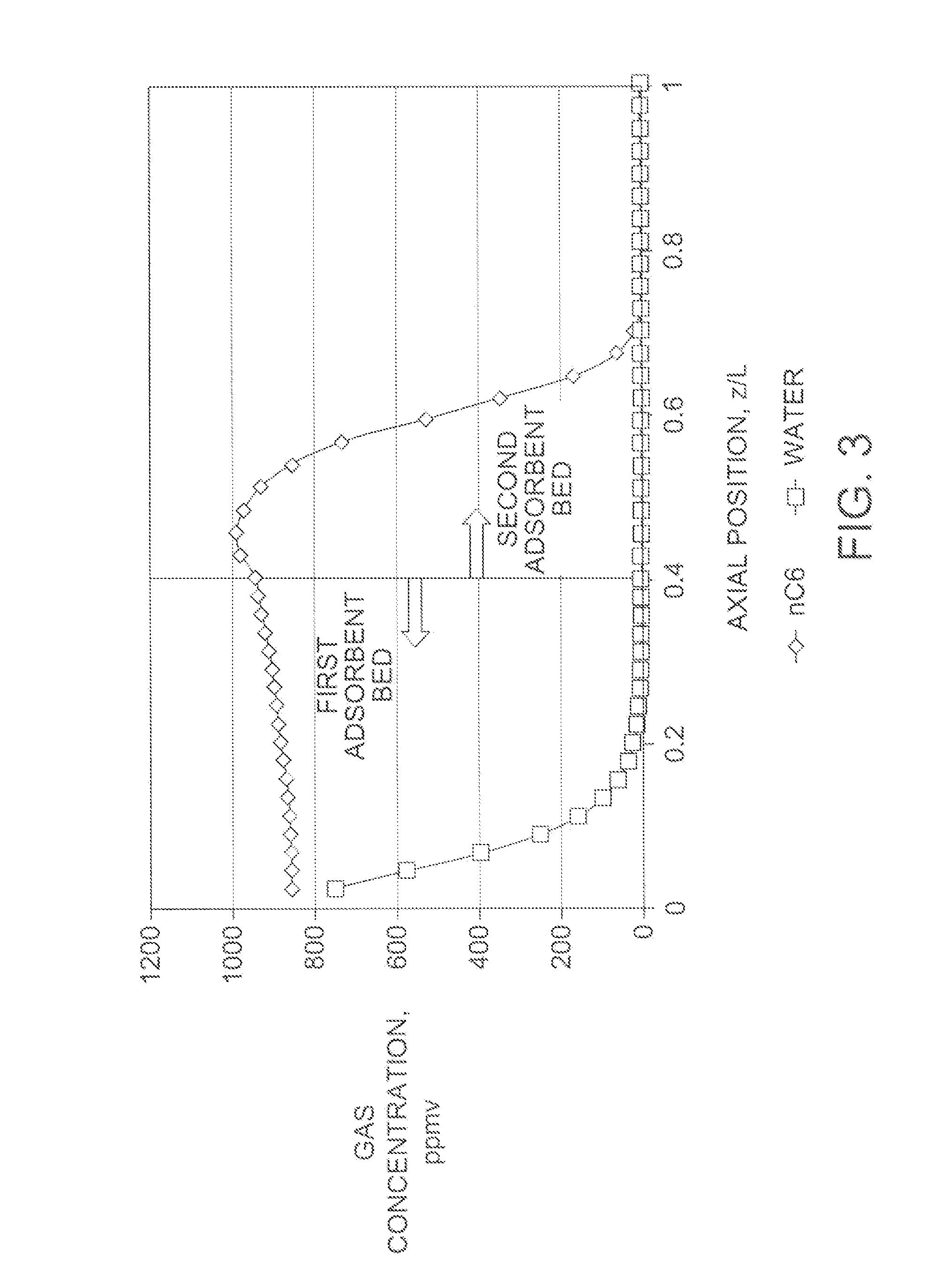

Processes and apparatuses for preparing liquified natural gas

ActiveUS20130291723A1High selectivityIncrease capacitySolidificationLiquefactionPreferential adsorptionHigh selectivity

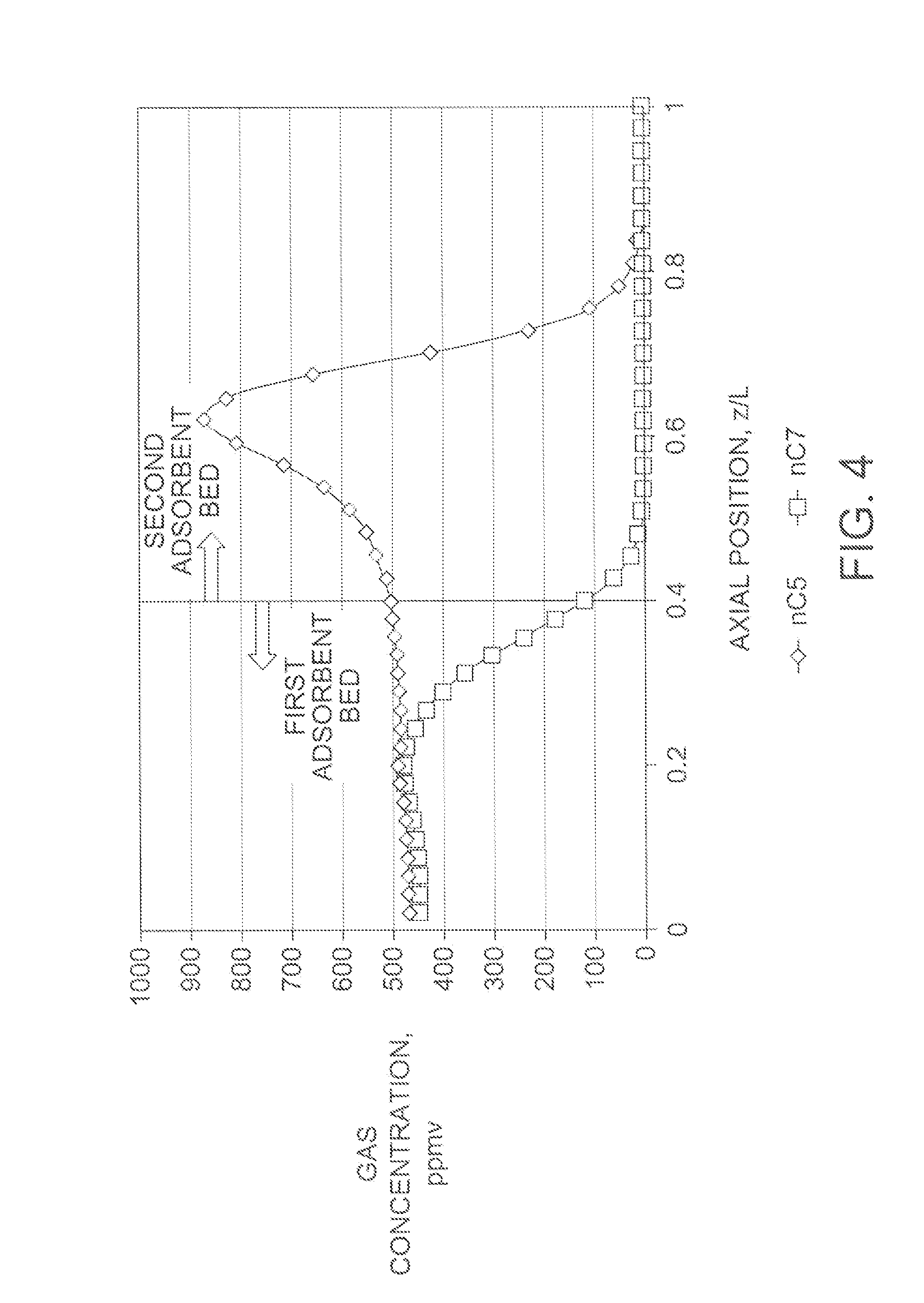

Processes and apparatuses are provided for preparing liquified natural gas from a natural gas feed that comprises C5 to C7 hydrocarbons and C8 or greater hydrocarbons. An exemplary process includes effecting the preferential adsorption of the C8 or greater hydrocarbons from the natural gas feed over adsorption of hydrocarbons having less than 8 carbon atoms to provide a C8-depleted natural gas stream. The process continues with effecting the preferential adsorption of the C5 to C7 hydrocarbons from the C8-depleted natural gas stream over adsorption of hydrocarbons having less than 5 carbon atoms to form a C5 to C8-depleted natural gas stream. The C5 to C7 hydrocarbons are preferentially adsorbed with higher selectivity and capacity than adsorption of the C5 to C7 hydrocarbons during preferentially adsorbing the C8 or greater hydrocarbons. The C5 to C8-depleted natural gas stream is then liquified.

Owner:UOP LLC

Integrated process for floating liquefied natural gas pretreatment

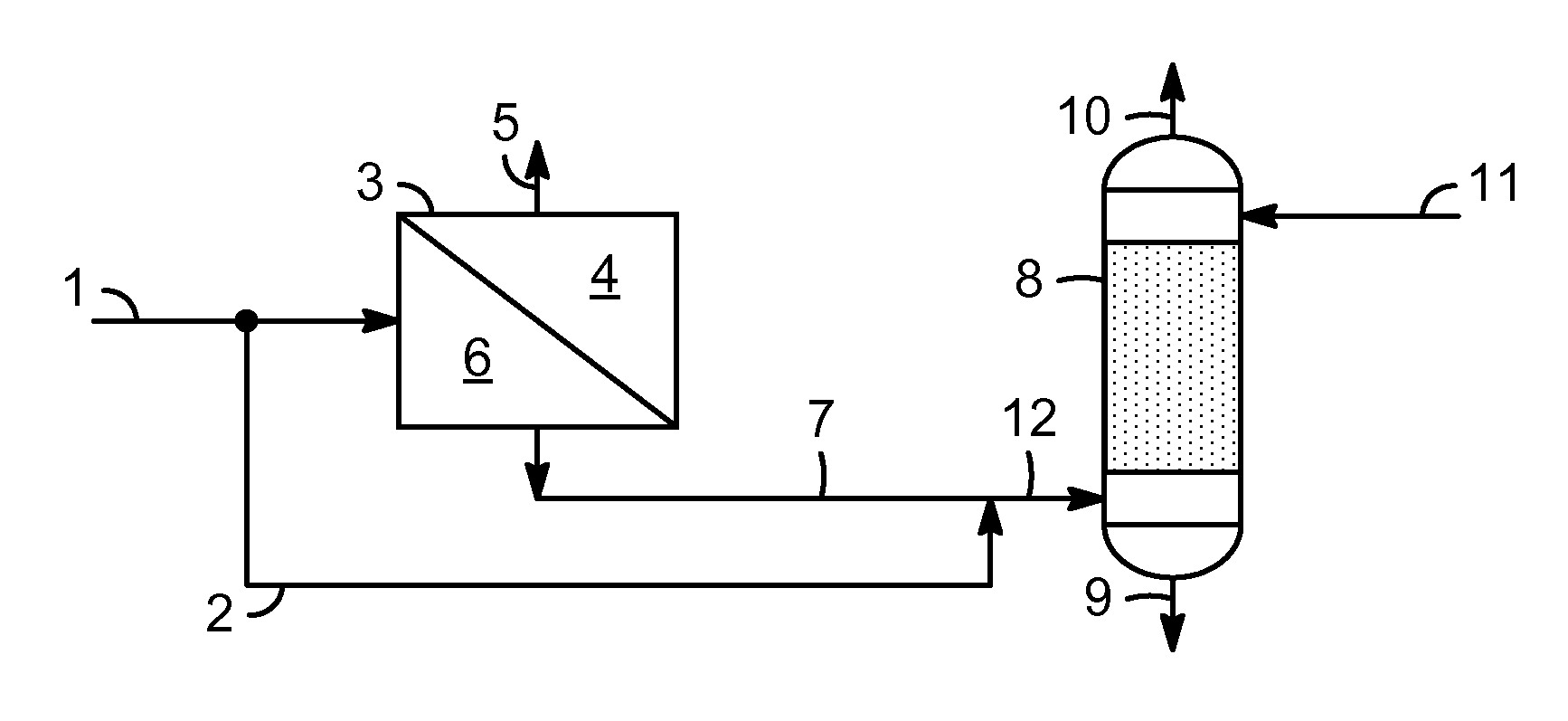

InactiveUS20110290110A1Reduce the impactReduce gas contentMembranesGas treatmentProcess configurationPre treatment

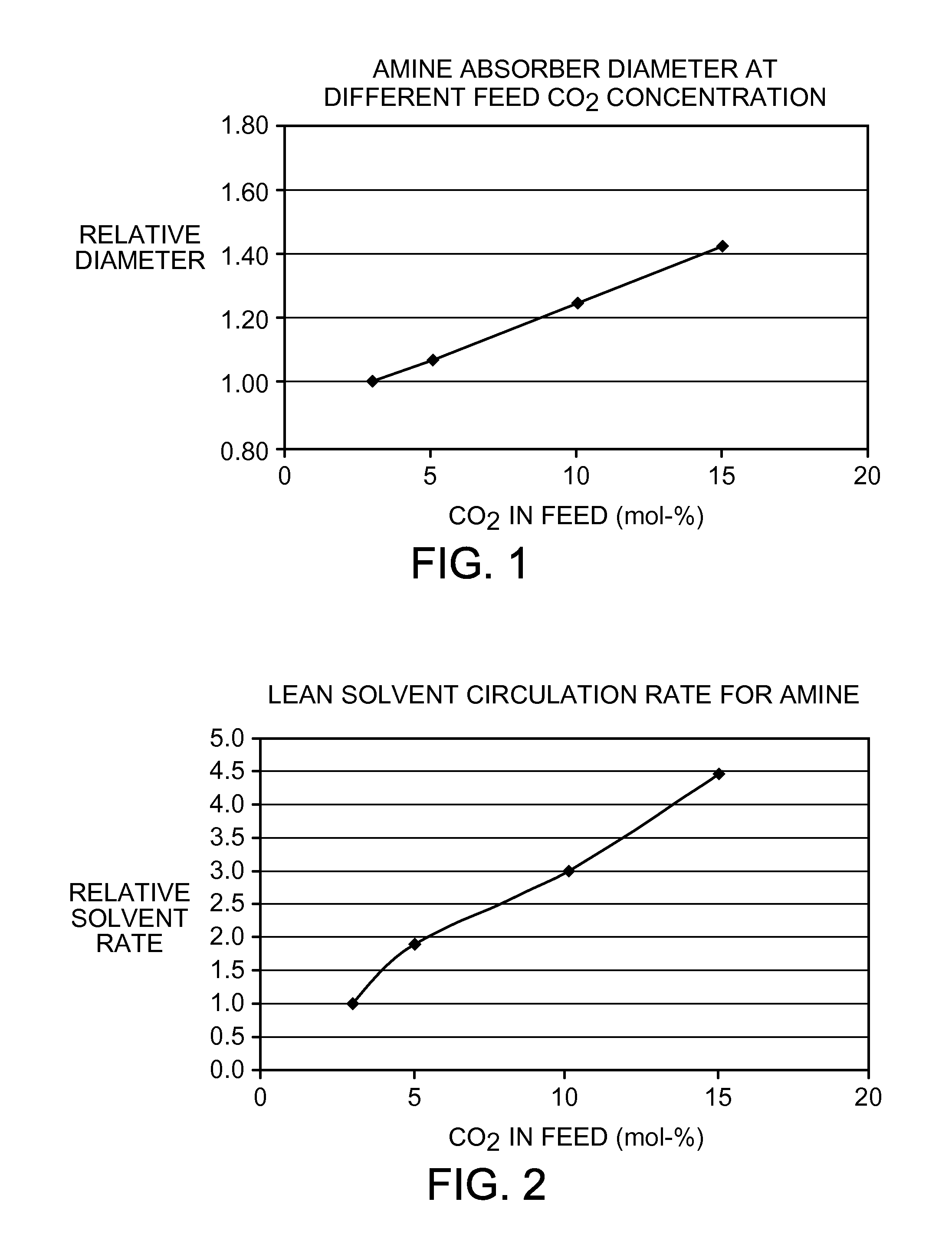

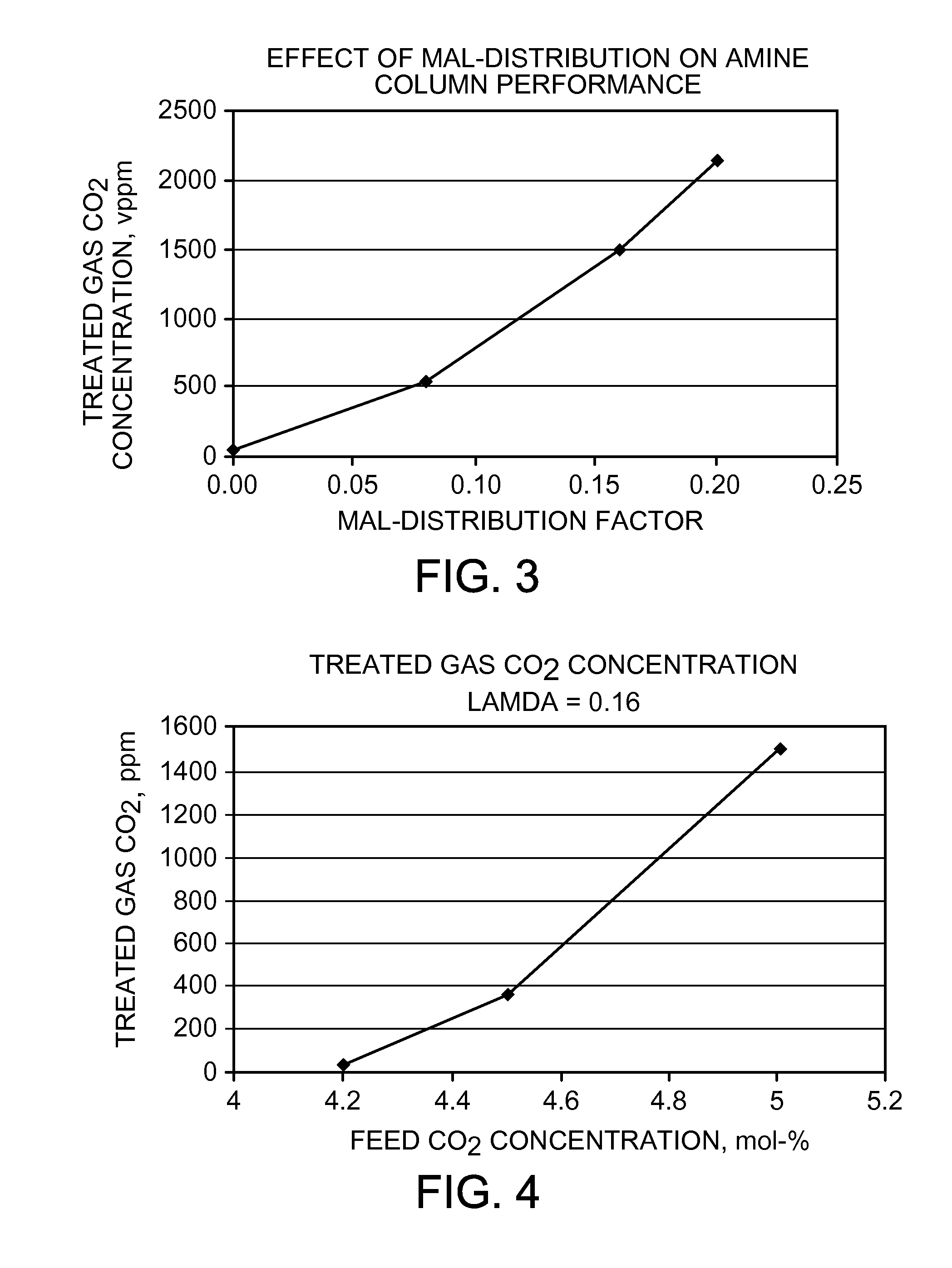

The present invention provides a membrane / amine column system and process for removing acid gases from natural gas on a floating liquefied natural gas vessel. Several process configurations are provided to deal with a reduction in the effectiveness of the amine column by increasing the amount of acid gases being removed by the membrane system prior to the natural gas being sent to the amine column.

Owner:UOP LLC

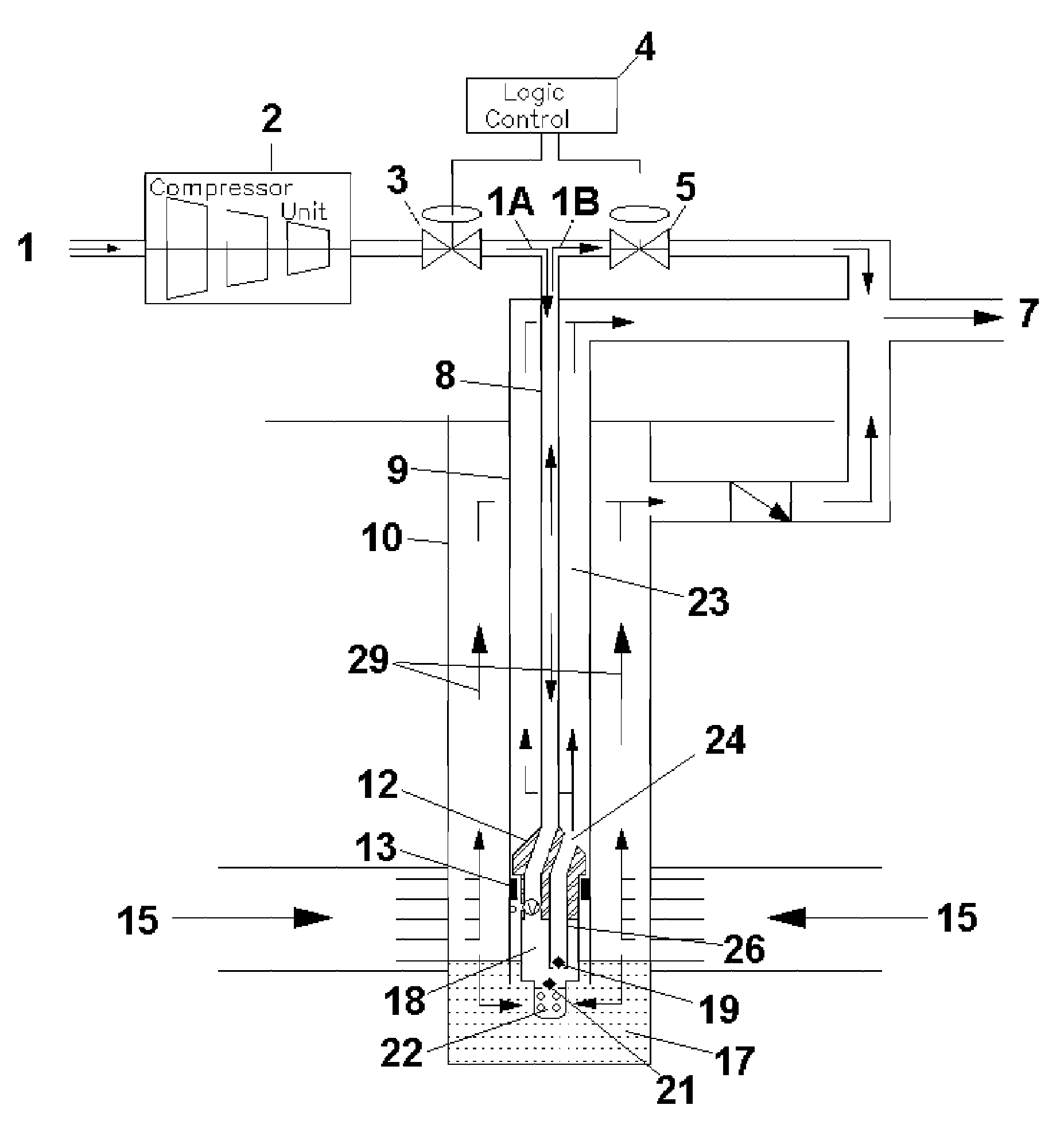

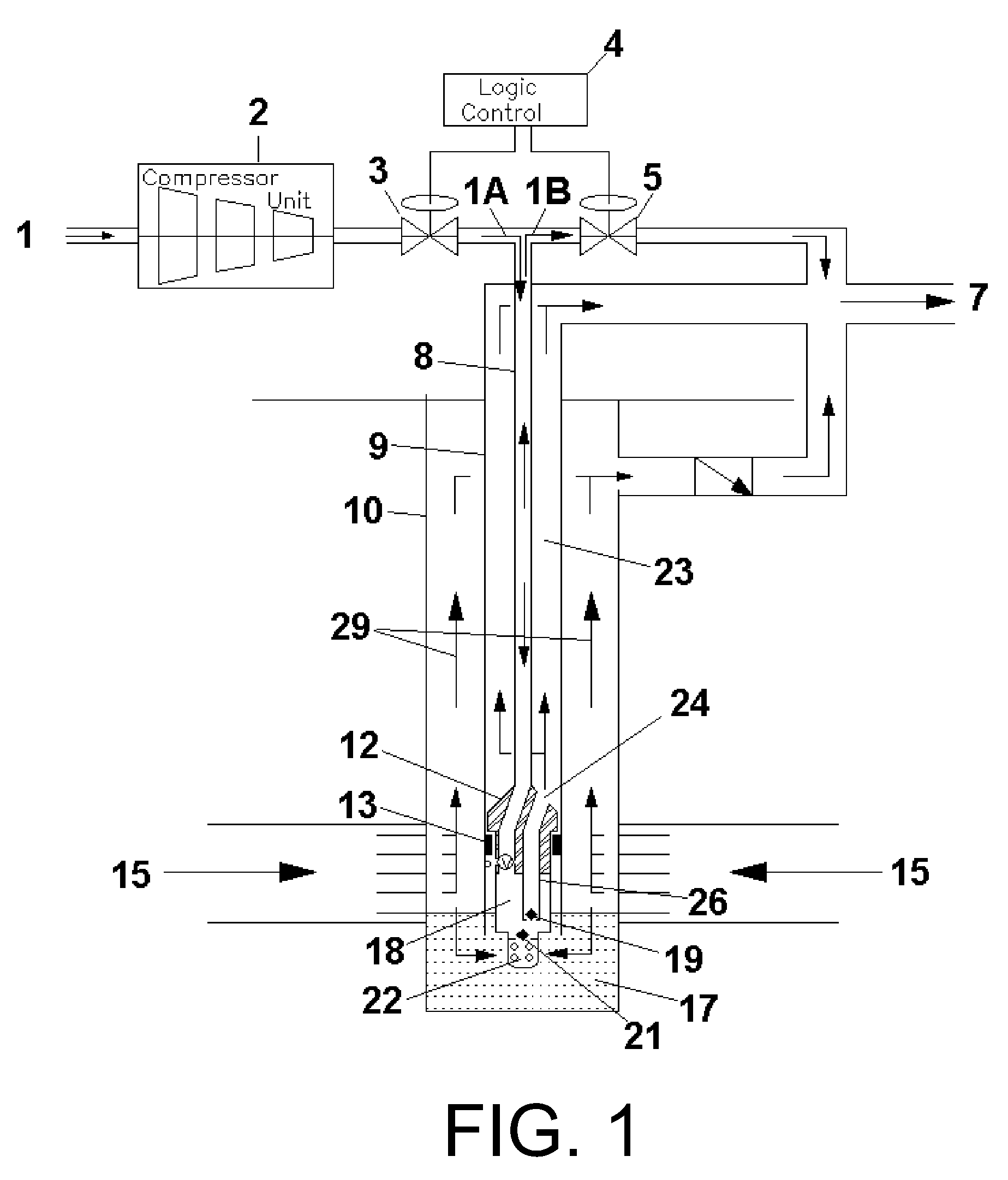

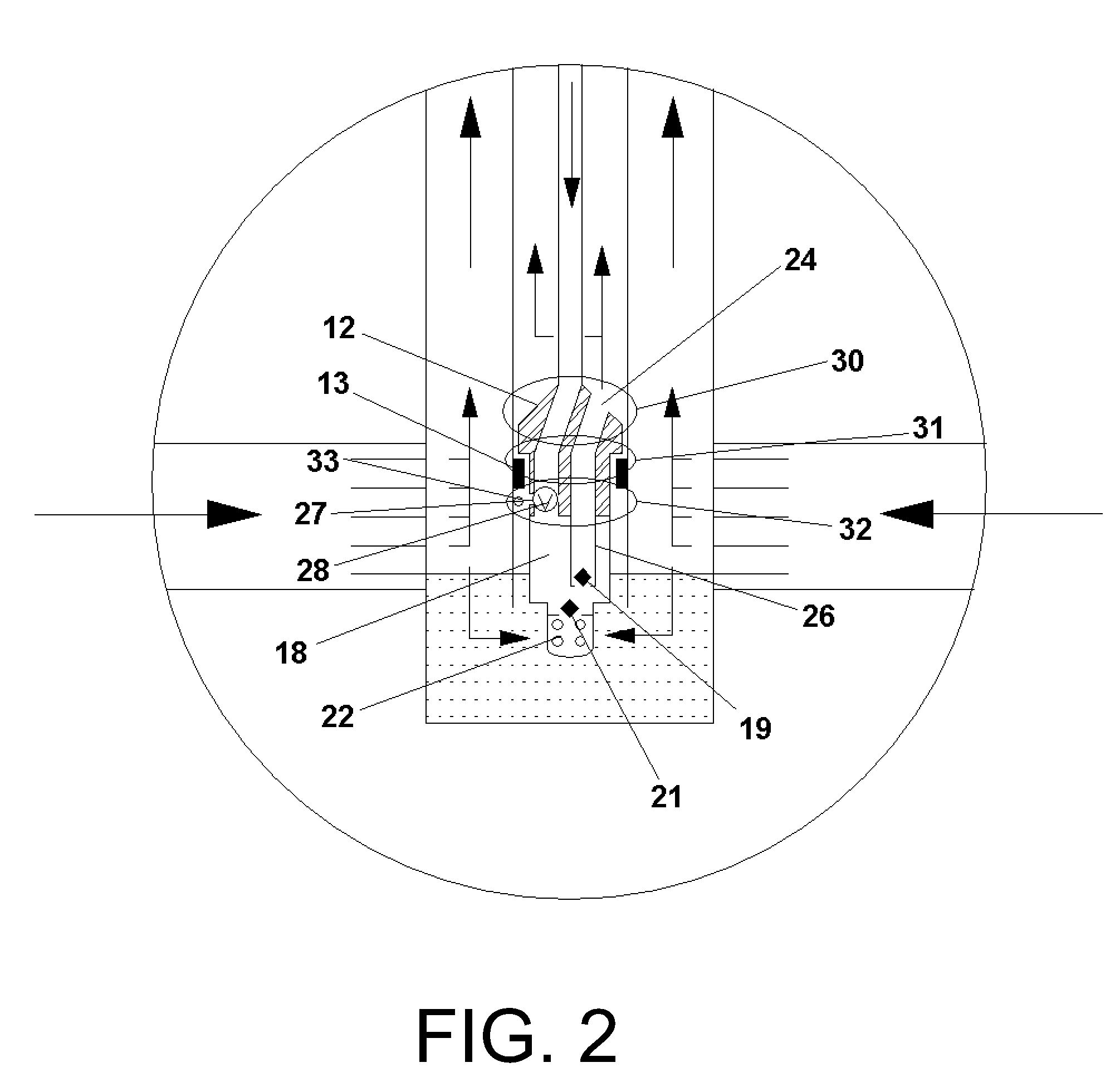

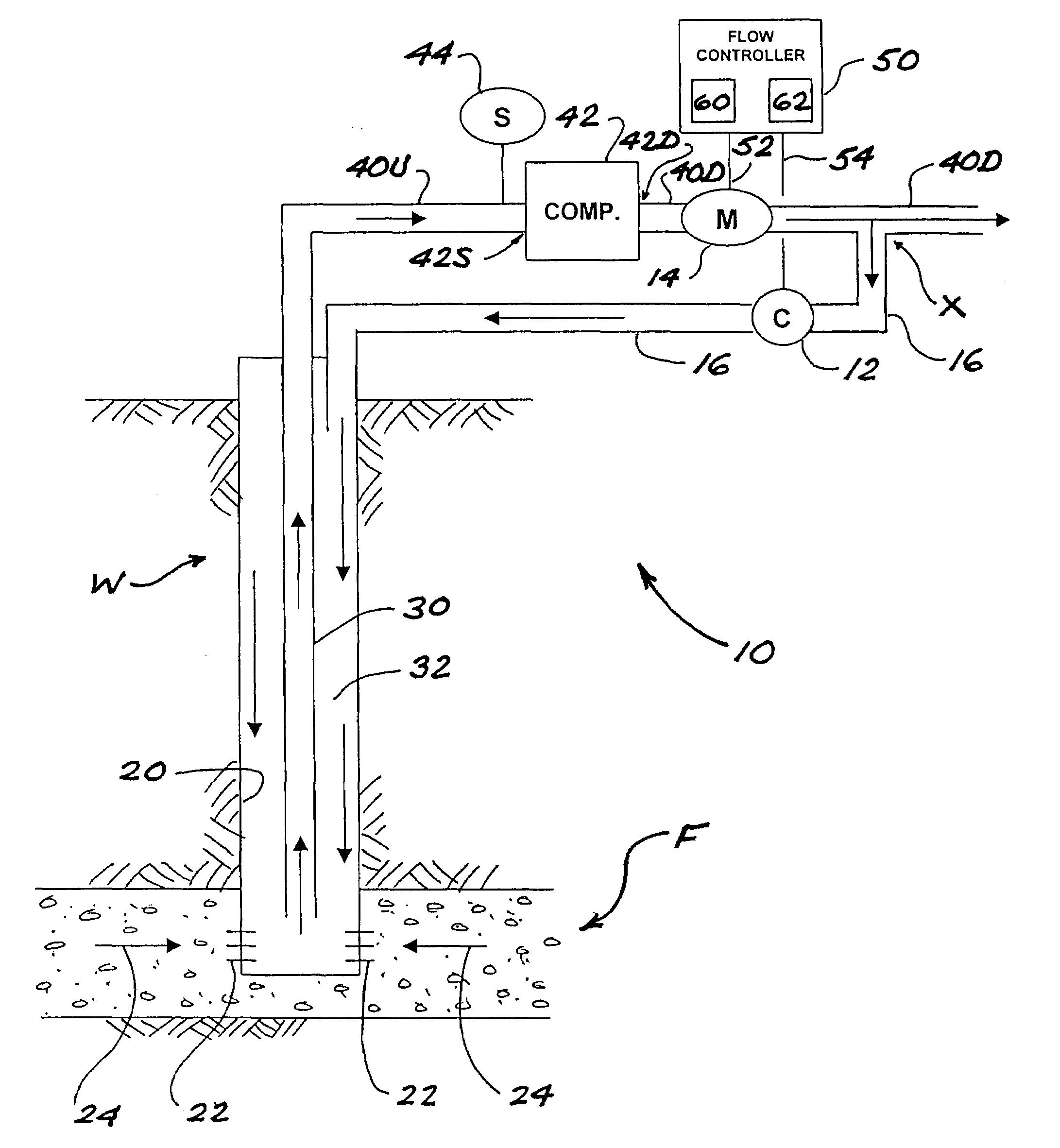

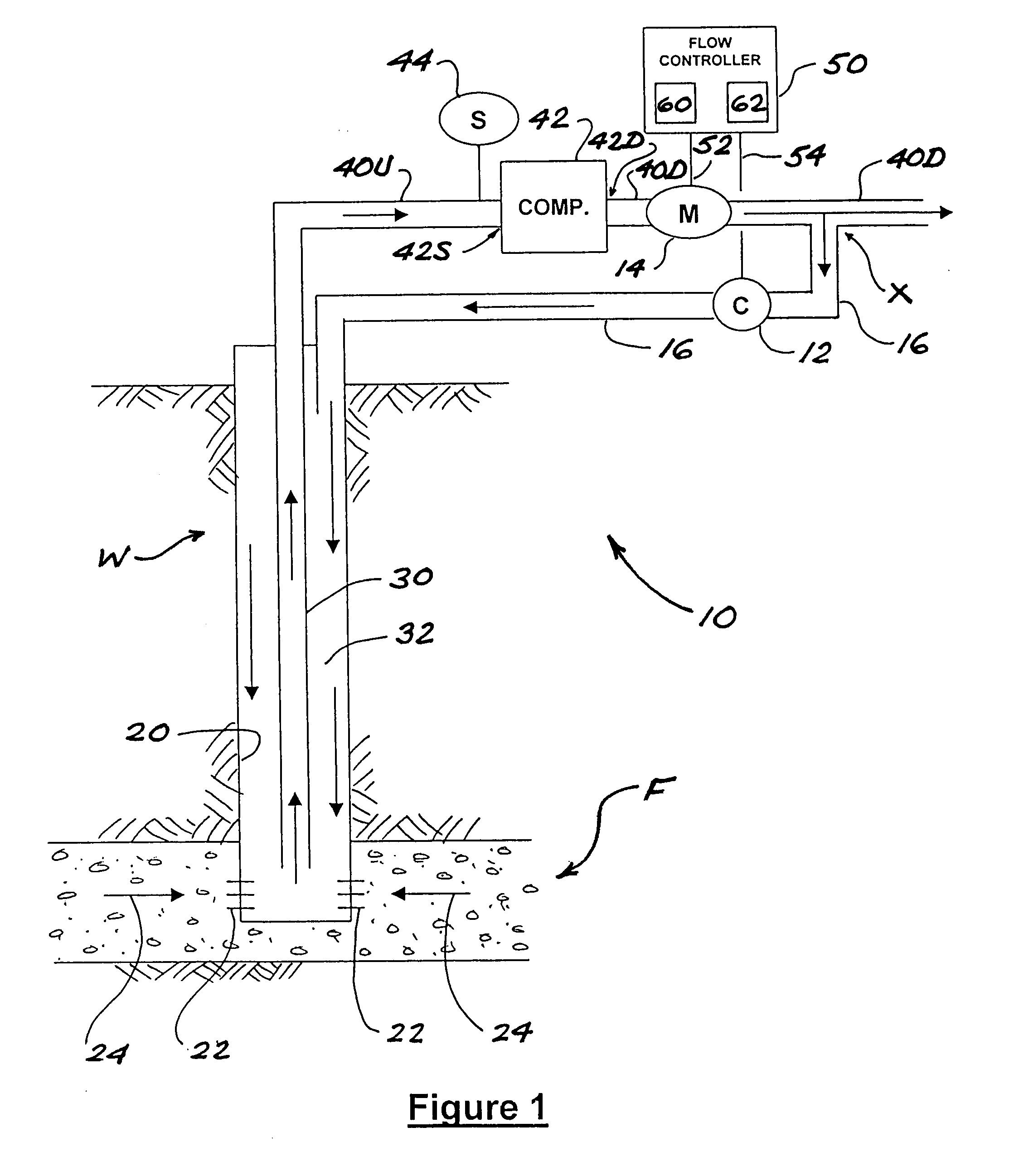

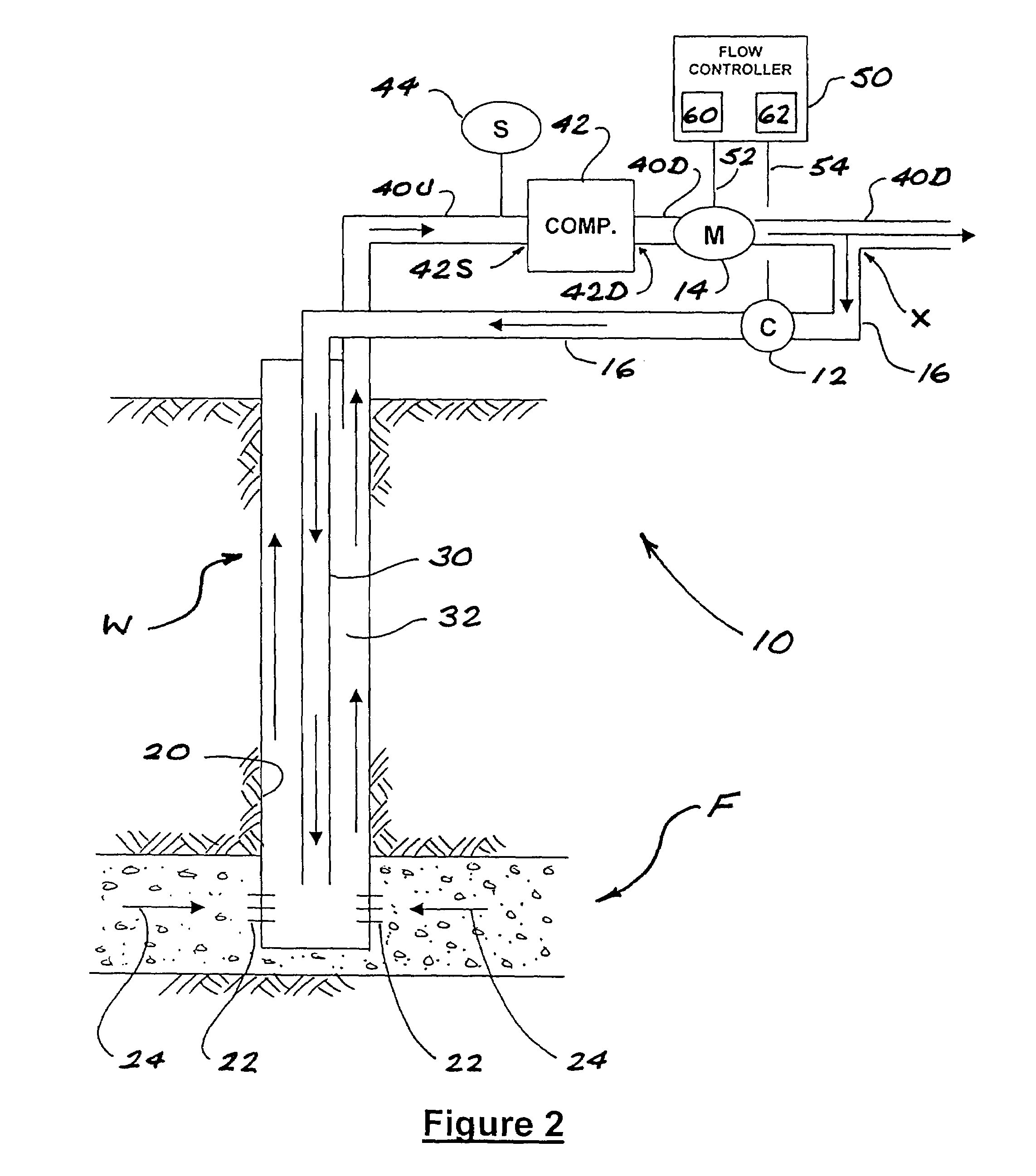

Apparatus and method for enhancing productivity of natural gas wells

ActiveUS6991034B2Extend product lifeReducing bottomhole pressureSurveyDrilling rodsProduct gasProcess engineering

A natural gas production system prevents liquid accumulation in the wellbore and minimizes friction loading in the wellbore by maintaining production gas velocity above a critical minimum velocity. A pressurized gas is injected into the well to supplement the flow of production gas such that the velocity of the total gas flow up the well exceeds the critical velocity. A choke is fitted to the gas injection line, and total gas flows are measured by a flow meter. A flow controller compares the measured total gas flow rate against the critical flow rate, and determines a minimum gas injection rate required to maintain the total gas flow rate at or above the critical flow rate. The flow controller then adjusts the choke to achieve the desired gas injection rate. The injection gas may be recirculated production gas from the well, or a gas from a separate source.

Owner:OPTIMUM PROD TECH INC

Methods of and Formulations for Reducing and Inhibiting the Growth of the Concentration of Microbes in Water-Based Fluids and Systems Used with Them

ActiveUS20100298275A1Maximize synergyEffective controlBiocidePhosphorous compound active ingredientsWater basedPhosphonium

The present invention provides methods and formulations for reducing or inhibiting increase in the concentration of microbes in a water-based fluid. The methods and formulations of the present invention use glutaraldehyde and a hydroxymethyl-substituted phosphorus compound selected from the group consisting of tetrakis(hydroxymethyl)phosphonium salts, C1-C3 alkyl- and alkenyltris(hydroxymethyl)phosphonium salts and tris(hydroxymethyl)phosphine, in a ratio of hydroxymethyl-substituted phosphorus compound to glutaraldehyde in the range of about 2:1 to about 7:1, or about 3.5:1 to about 7.5:1. The methods and formulations of the present invention can be useful in treating water contaminated with aerobic or anaerobic bacteria in oilfield, natural gas field and other industrial applications.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC

Methods of and Formulations for Reducing and Inhibiting the Growth of the Concentration of Microbes in Water-Based Fluids and Systems Used with Them

ActiveUS20100286096A1Maximize synergyLow biocide loadingBiocideSpecific water treatment objectivesWater basedPhosphonium

The present invention provides methods and formulations for reducing or inhibiting increase in the concentration of microbes in a water-based fluid. The methods and formulations of the present invention use an oxazolidine compound and a hydroxymethyl-substituted phosphorus compound selected from the group consisting of tetrakis(hydroxymethyl)phosphonium salts, C1-C3 alkyl- and alkenyltris(hydroxymethyl)phosphonium salts and tris(hydroxymethyl)phosphine. The methods and formulations of the present invention can be useful in treating water contaminated with aerobic or anaerobic bacteria in oilfield, natural gas field, and other industrial applications.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC

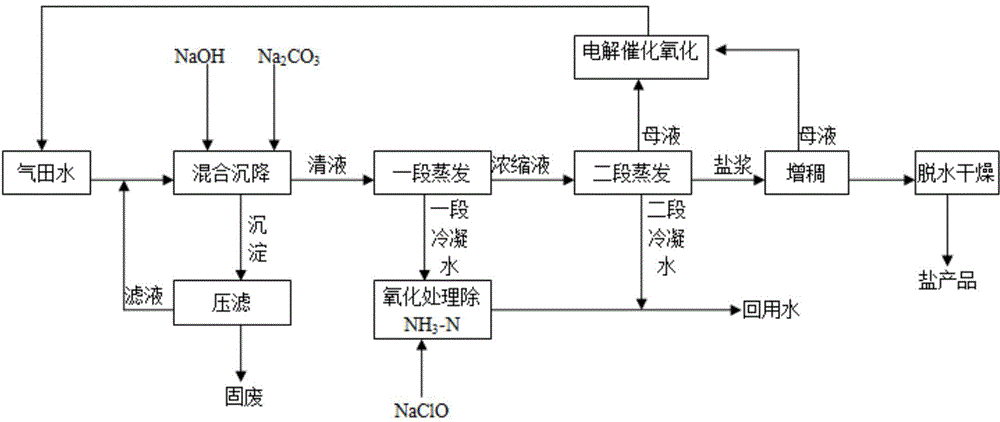

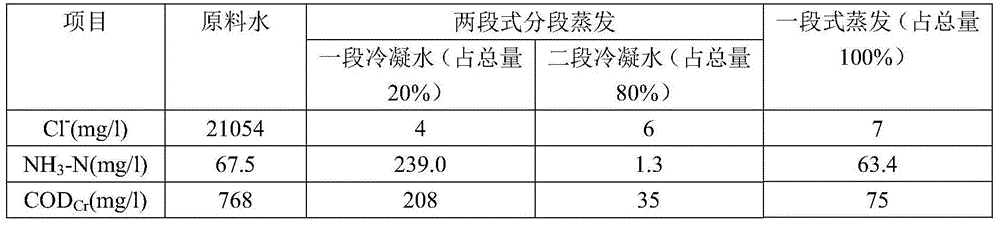

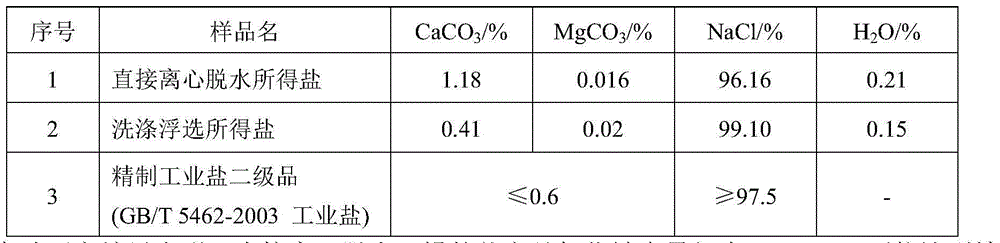

Treatment method of high-salt content, high-ammonia nitrogen content and high-COD (Chemical Oxygen Demand) gas field water

ActiveCN104891723AWaste water treatment from quariesMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention discloses a treatment method of high-salt content, high-ammonia nitrogen content and high-COD (Chemical Oxygen Demand) gas field water and belongs to the field of wastewater treatment processes. The treatment method comprises the following steps of: firstly removing calcium, magnesium and suspended matters in the gas field water, and regulating the pH value to be above 10; then performing staged evaporation, namely adopting primary feeding batch operation for the first stage of evaporation; performing the second stage of evaporation on concentrated liquid, namely adopting vacuum evaporation for the second stage of evaporation; thickening salt slurry discharged in the second stage of evaporation, and then washing, dewatering and drying to obtain a salt product; performing electrolytic and catalytic oxidation on mother liquor discharged in the second stage of evaporation for removing COD, and returning the treated mother liquor as well as mother liquor obtained by thickening with the salt slurry to the gas field water for reuse, wherein the second stage of condensate water obtained in the second stage of evaporation is water reaching the standards, and after the first stage of condensate water obtained in the first stage of evaporation is treated, subjected to ammonia nitrogen removal and mixed with the second stage of condensate water, water reaching the standards is obtained. According to the treatment method disclosed by the invention, the problems of low possibility of removing salt, ammonia nitrogen and COD in the high-salt content, high-ammonia nitrogen content and high-COD sulfur-containing natural gas field produced water in the prior art can be solved.

Owner:自贡市轻工业设计研究院有限责任公司

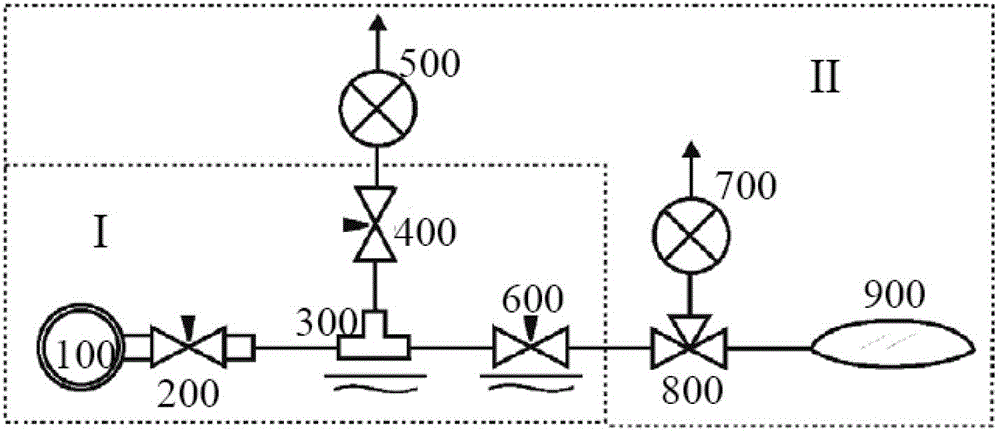

Natural gas sample collecting method for detecting content of mercury in natural gas

ActiveCN103149057AMercury content reflects the trueAvoid condensationWithdrawing sample devicesPipe fittingEngineering

The invention provides a natural gas sample collecting method for detecting content of mercury in natural gas. The method comprises the steps of: mounting a sampling device on a to-be-tested natural gas pipeline, wherein the sampling device comprises a three-way pipe fitting for dividing gas flow from the natural gas pipeline into a main path and a bypath, the main path is orderly connected with a first needle valve and a three-way valve in series, two outlets of the tree-way valve are respectively connected with a gas bag for collecting a gas sample and a first flow meter, and the bypath is orderly connected with a second needle valve and a second flow meter in series. During sampling, the second needle valve is regulated so that flow speed in the bypath is 25-35L / min, the three-way valve of the main path is placed to be communicated with the first flow meter for regulating the flow speed in the main path to be 55-65L / min, and then the three-way valve is placed to be communicated with the gas bag so that the natural gas flows into the gas bag so that the sample is collected. By adopting the method provided by the invention, mercury loss in the natural gas sampling process is eliminated to the greatest extent, the collected sample can truly reflect the mercury content in the natural gas inside the pipeline, and the method is simple and convenient for operation, strong in applicability, high in safety and convenient for popularization.

Owner:PETROCHINA CO LTD

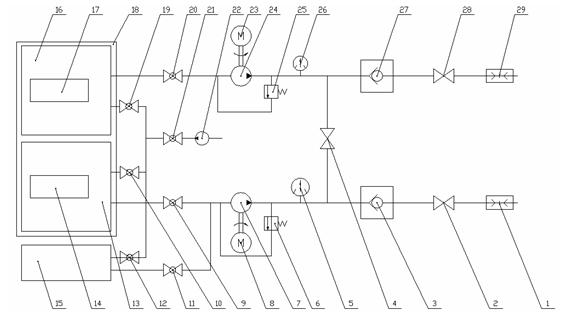

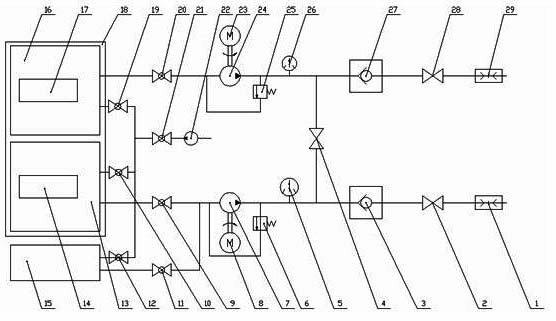

Injection device capable of adapting to low-temperature environment in foam drainage gas recovery

InactiveCN102162347AMeet the requirements of foam drainage and gas recovery operationsAchieve reuseFluid removalEngineeringElectric control

The invention discloses an injection device capable of adapting to a low-temperature environment in foam drainage gas recovery, which is applied to a water-bearing natural gas field and can overcome the difficulties of removing liquid accumulations of the well shaft in the gas well with accumulated liquids and removing foams in the produced fluids under the conditions of no commercial power supply and low ambient temperature. The technical scheme adopted in the invention is as follows: a liquid feeding pump is connected with ball valves through a pipe and then connected in parallel with a chemical tank I, a chemical tank II and an anti-freezing agent tank through the ball valves; heaters are arranged inside the chemical tanks; tail gas jackets are arranged at the periphery of the chemical tanks; a first quick-acting coupling is connected with a first cut-off valve and a first one-way valve through a pipe and then connected with a first electric contact pressure gauge, a first plunger pump and a first motor; the outlet end of the first plunger pump is connected with the ball valves respectively and then connected with the chemical tanks and the anti-freezing agent tank; a second quick-acting coupling is connected with a second cut-off valve and a second one-way valve through a pipe and then connected with a second electric contact pressure gauge, a second plunger pump and a second motor; the outlet end of the second plunger pump is connected with the chemical tanks; and an oil-fired generator and an electric control system form a circuit system. The injection device has compact structure, is convenient in transportation, is suitable for the actual environments in natural gas field production, and improves the drainage gas recovery effect.

Owner:SOUTHWEST PETROLEUM UNIV

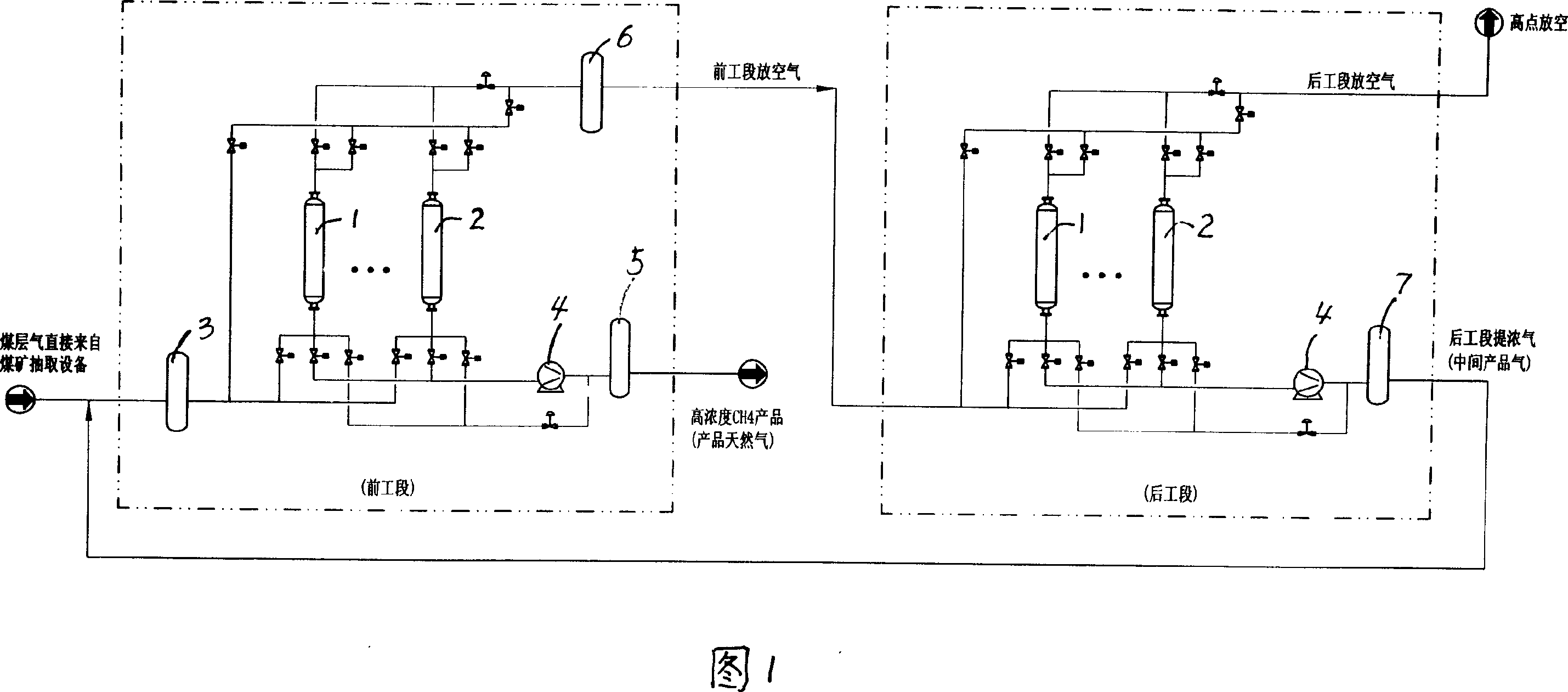

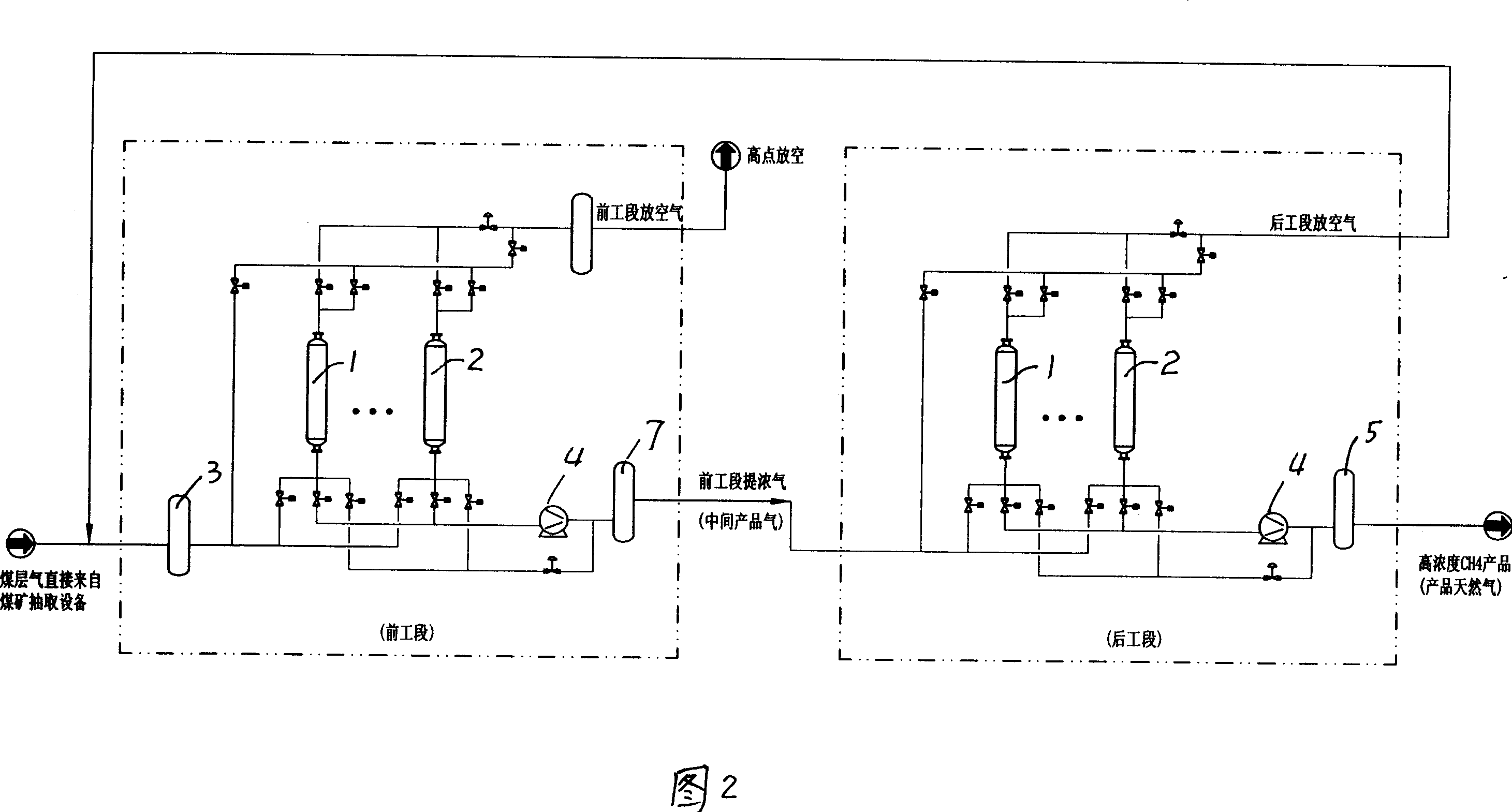

Two stage low pressure method coal bed gas producing natural gas method

The invention discloses a preparing method of natural gas from coal bed gas with two stage low pressure method, which is characterized by the following: adopting two stage low pressure CH4 gas absorption series cycle of operation; loading 2-3 species high effective CH4 gas sorbent in each department absorption tower; proceeding CH4 gas dense lift with pressure not more than 0.05MPa. G; adopting vacuum regeneration mode; getting CH4 gas with high density; comprising two department structure; getting CH4 gas with high density; setting the drained air as the raw gas of the back department; purifying in the back department; getting CH4 gas with high density; backing to the front department; using as raw gas of the front department; purifying as the front department; using middle product as raw material of the back department; backing the drained air to the front department; purifying continuously as the back department.

Owner:上海汉兴化工科技有限公司

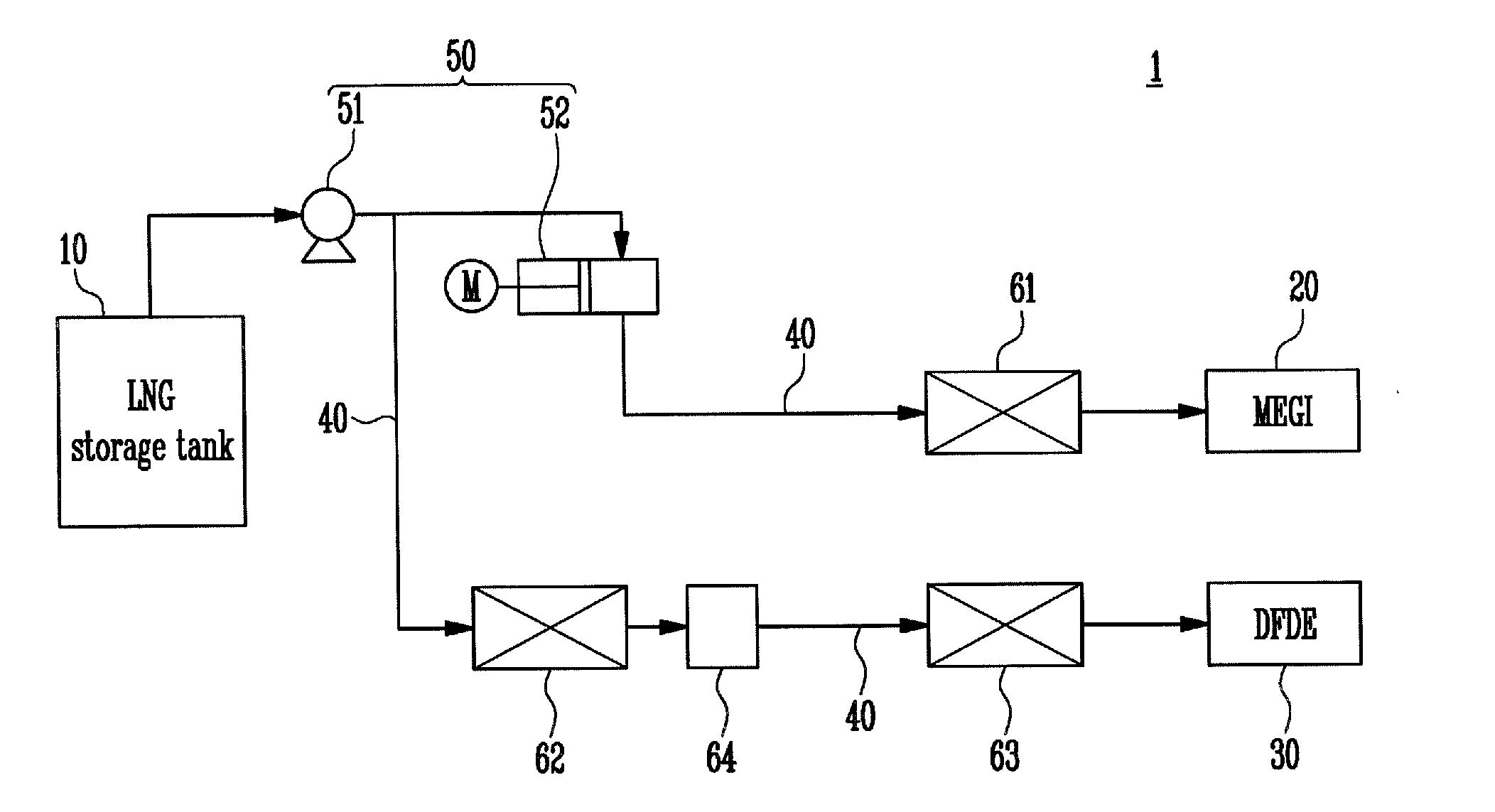

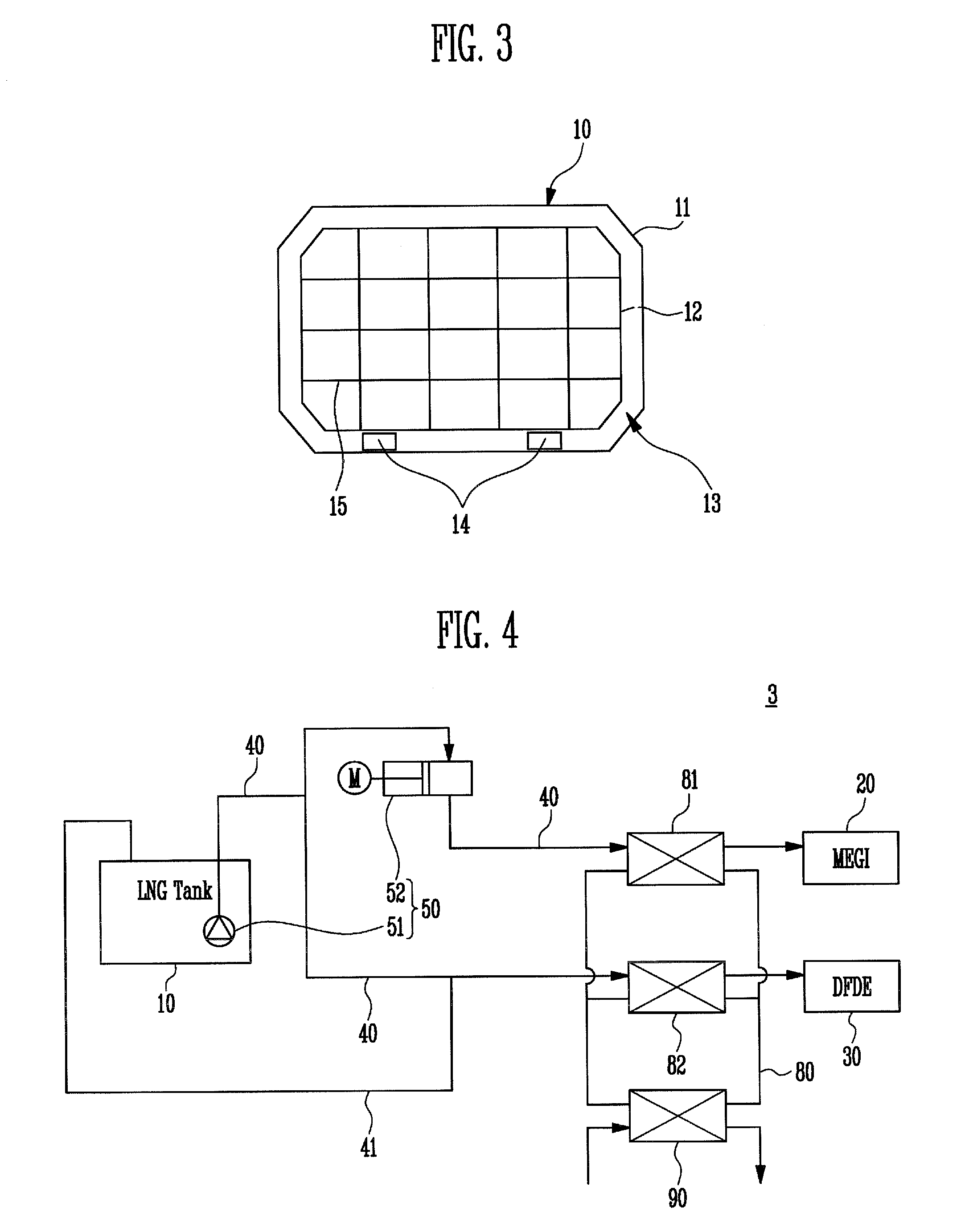

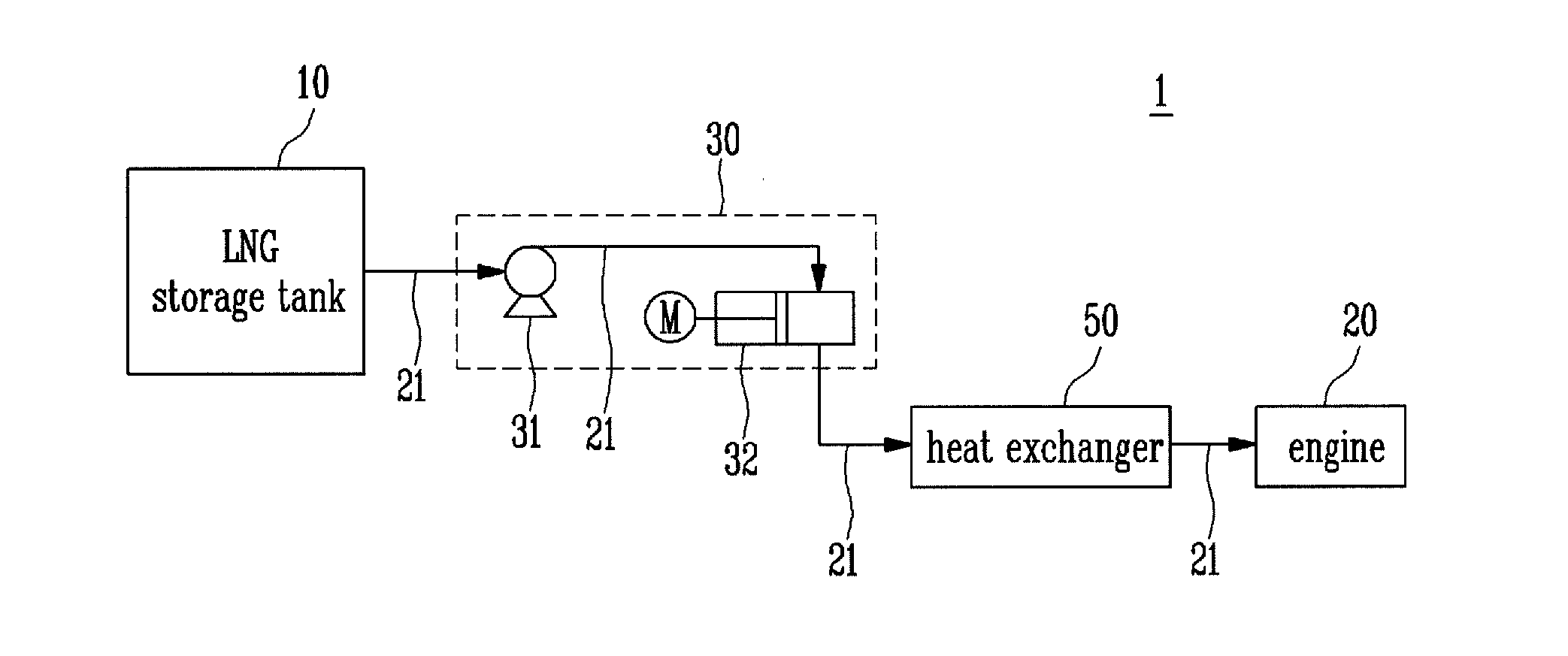

System for supplying liquefied natural gas fuel

InactiveUS20140250922A1Simple system configurationEnsure economic viabilityInternal combustion piston enginesGas handling/storage effectsLiquid stateProcess engineering

A system for supplying LNG fuel is disclosed. The system includes a fuel supplying line connected from an LNG storage tank to a high pressure engine and a low pressure engine, respectively, a pump formed on the fuel supplying line, and configured to pressurize LNG outputted from the LNG storage tank to high pressure, a first heat exchanger formed on the fuel supplying line between the high pressure engine and the pump, and configured to heat the LNG supplied from the pump, a second heat exchanger formed on the fuel supplying line between the low pressure engine and the LNG storage tank, and configured to evaporate the LNG in a liquid state supplied from the LNG storage tank and a heat source supplying line configured to supply heat to the LNG by supplying glycol water to the first heat exchanger and the second heat exchanger.

Owner:HYUNDAI HEAVY IND CO LTD

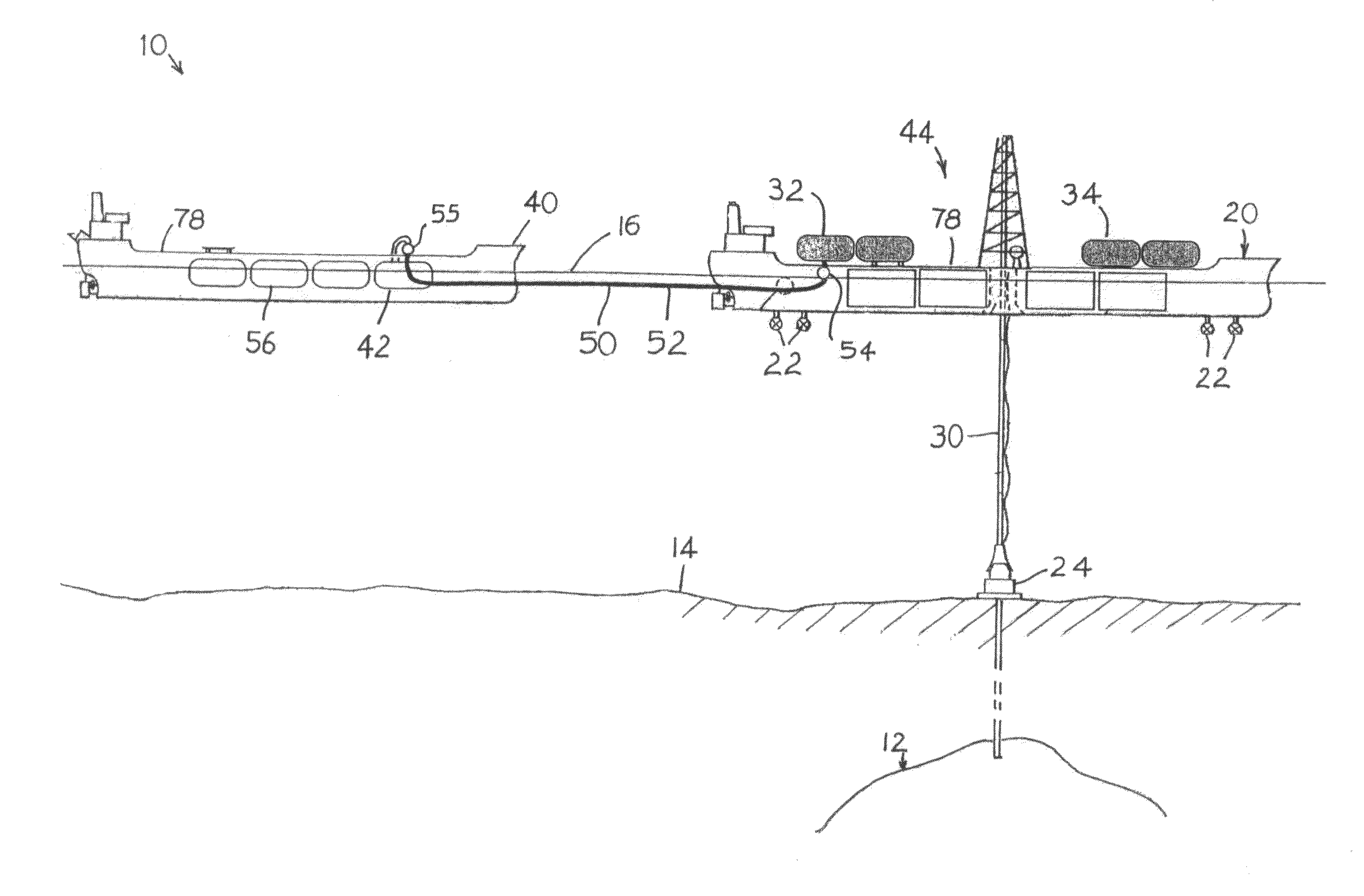

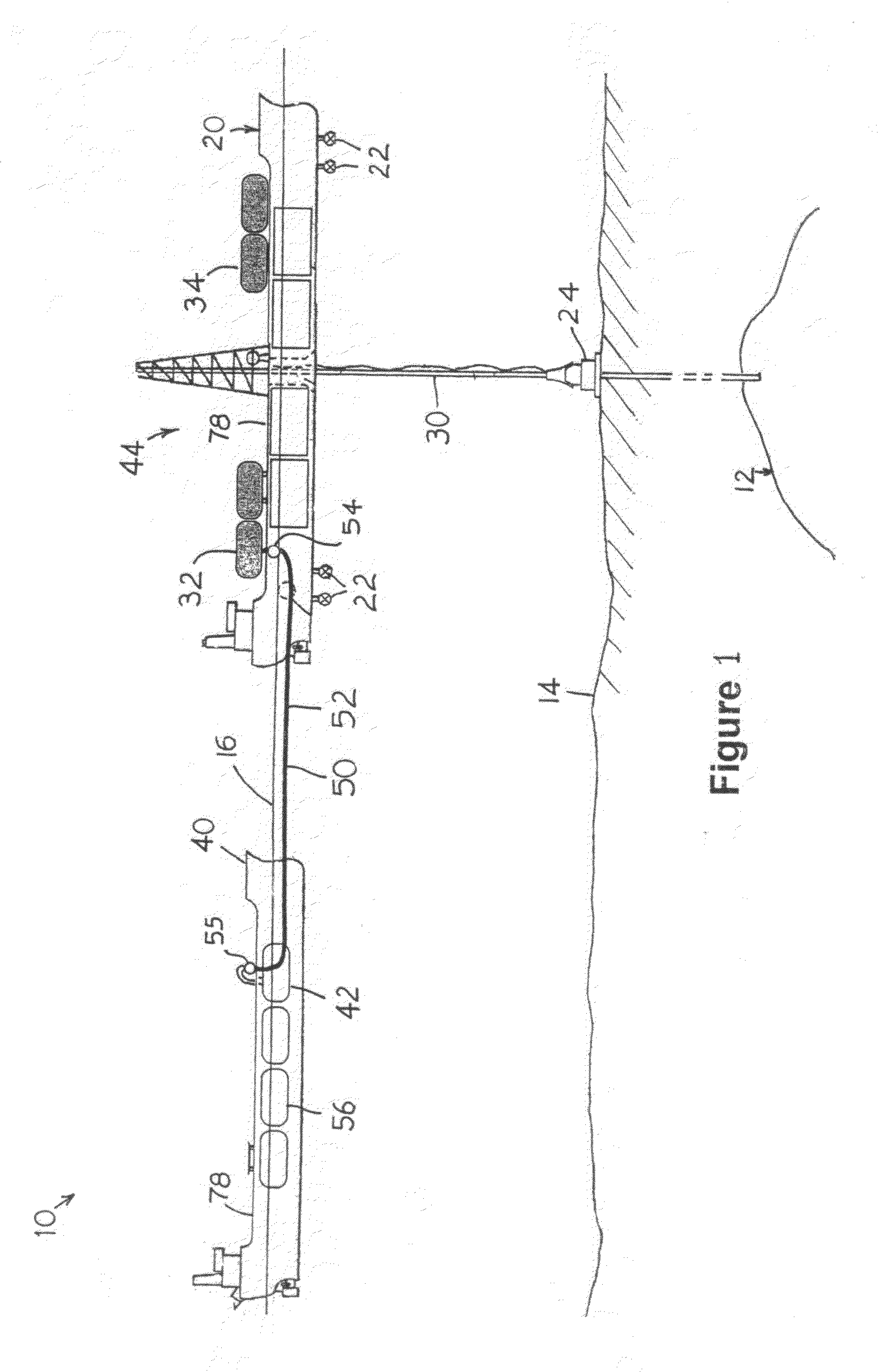

Offshore gas recovery

During an Extended Well Test or Early Floating Production at an offshore hydrocarbon production site, where oil and gas hydrocarbons are produced by a production vessel, applicant stores the natural gas as pressured gas in a storage tank and occasionally transfers the pressured gas to a shuttle vessel which carries the gas to a site where it is used, as by pumping it into a natural gas pipeline. The transfer of natural gas to the shuttle can be accomplished by pumping it through a conduit extending between the vessels to a second tank on the shuttle, or can be accomplished by moving a gas-filled tank on the production vessel to the shuttle.

Owner:SINGLE BUOY MOORINGS INC

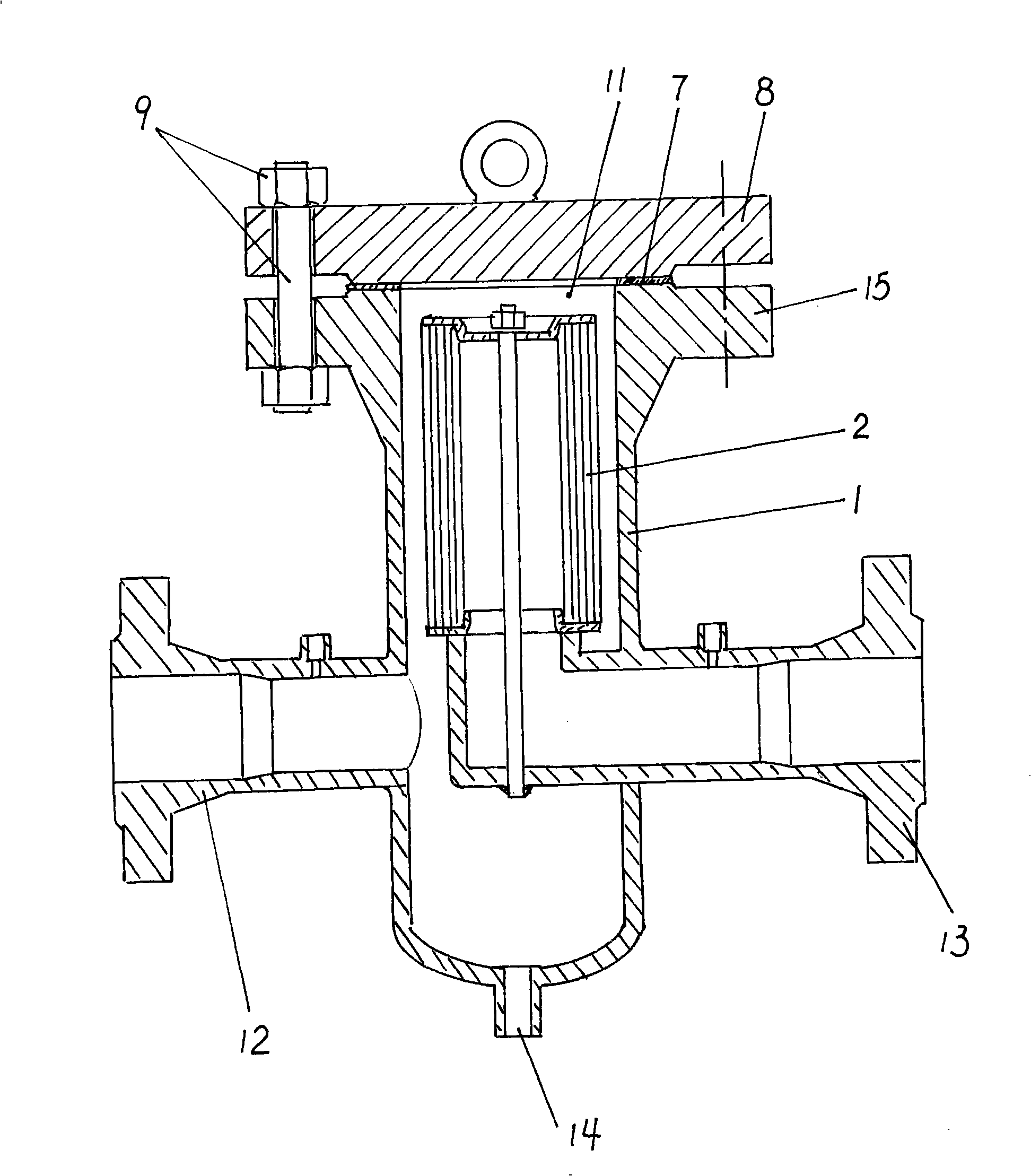

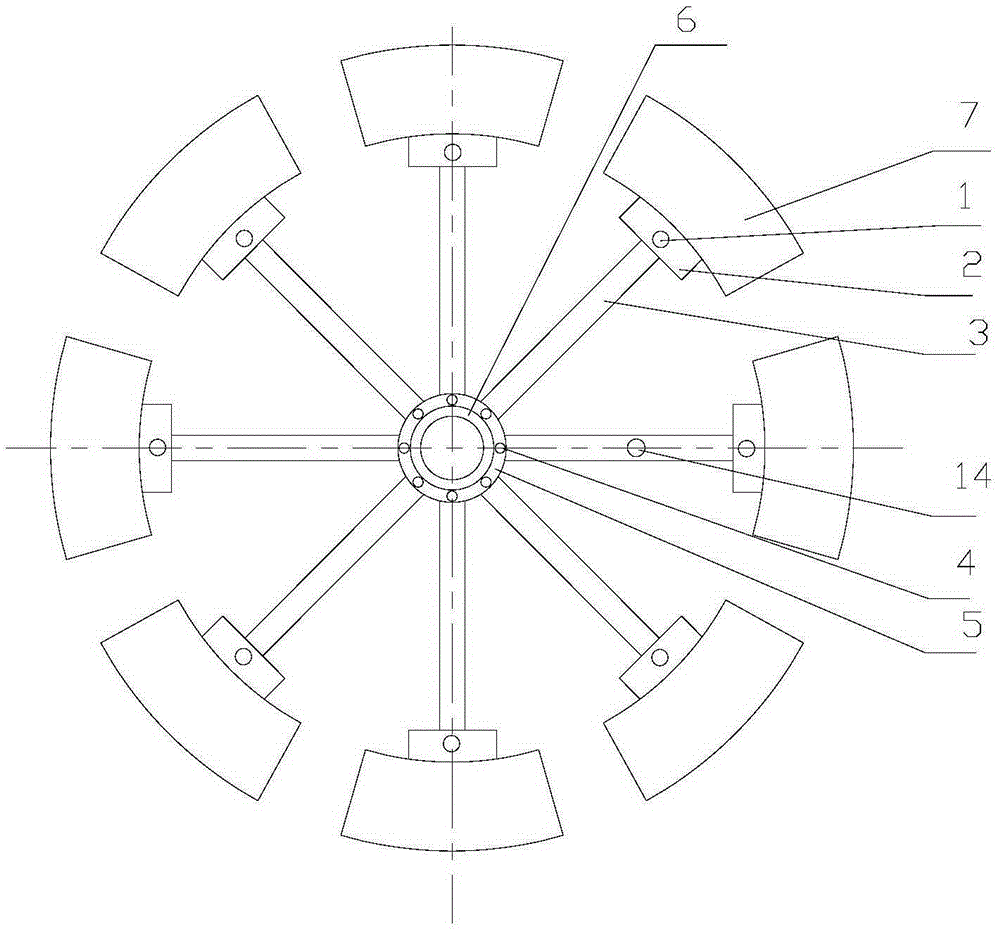

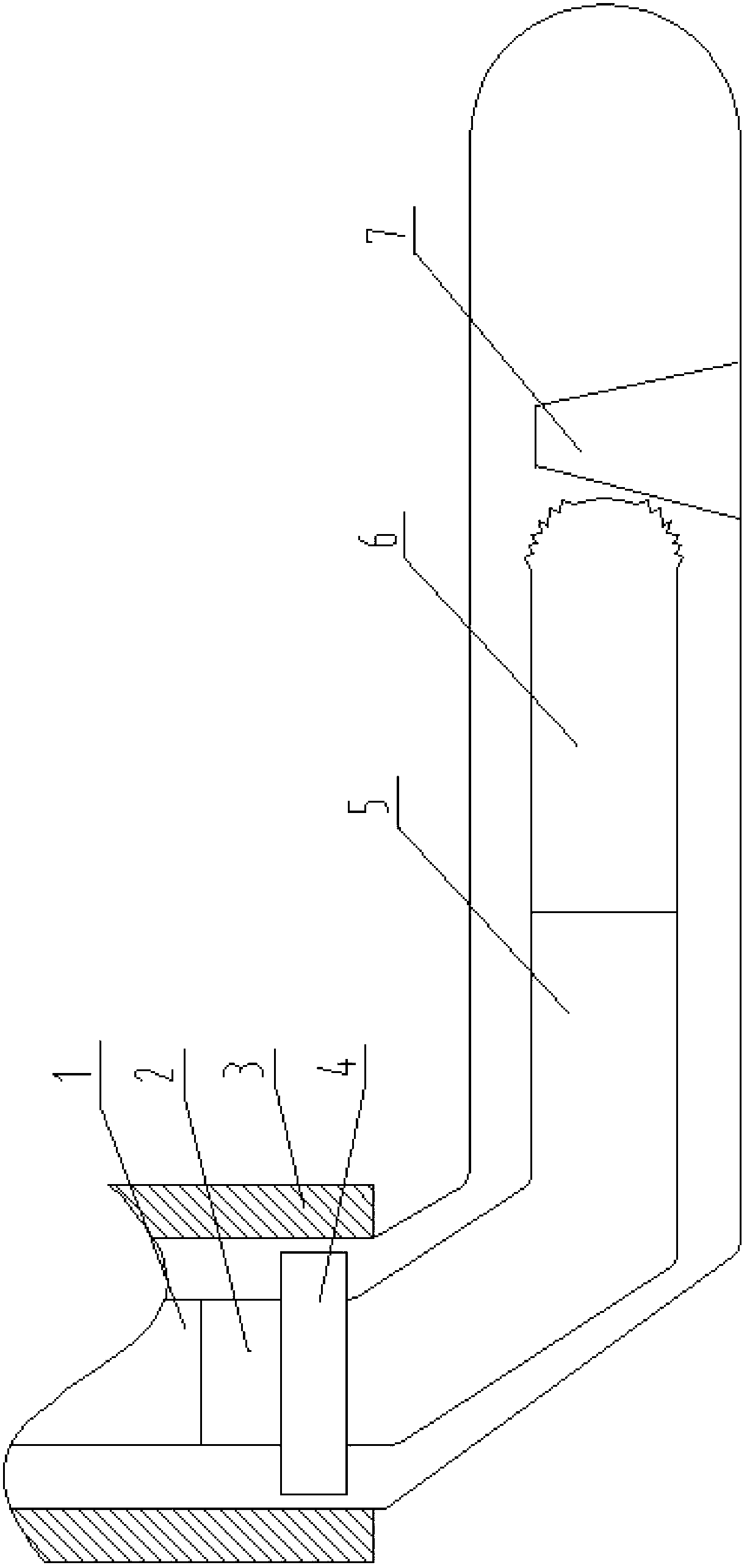

Natural gas filter

InactiveCN101260960APrevent air leakageReduce incidenceDispersed particle filtrationPipe elementsProcess engineeringSelf locking

The invention discloses a natural gas filter belonging to a natural gas pipe filtering device used in a petroleum collection and transmission engineering such as a natural gas field, a fuel gas transmission and distribution and pressure-regulating system and city gate stations and so on. The natural gas filter comprises a cylinder with an opening on the upper part, a filtering core arranged in the cylinder and a closed mechanism used for sealing an opening. The cylinder is provided with a feed gas inlet, a purified gas outlet and a drain, the upper end of the filtering core is close to the opening, the lower end of the filtering core is communicated with the detergent gas outlet. The natural gas filter is characterized in that the closed mechanism comprises a hub which is extendedly arranged on the top of the cylinder, a sealing cover, a quartered ring, a protecting cover and a fixing screw. The natural gas filter has the advantages that an opening vessel is rapid and convenient, time and labor-saving and cost-saving; the closed mechanism is provided with a self-locking structure, which uses the self-pressure of natural gas to prop up the sealed cover which is sealed with the hub through an O-shaped ring, the quartered ring props up the protection cover so as to meet the requirement of sealing; moreover, the sealing performance is excellent, the leakage of the vessel is prevented and the occurrence of accidents is reduced.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

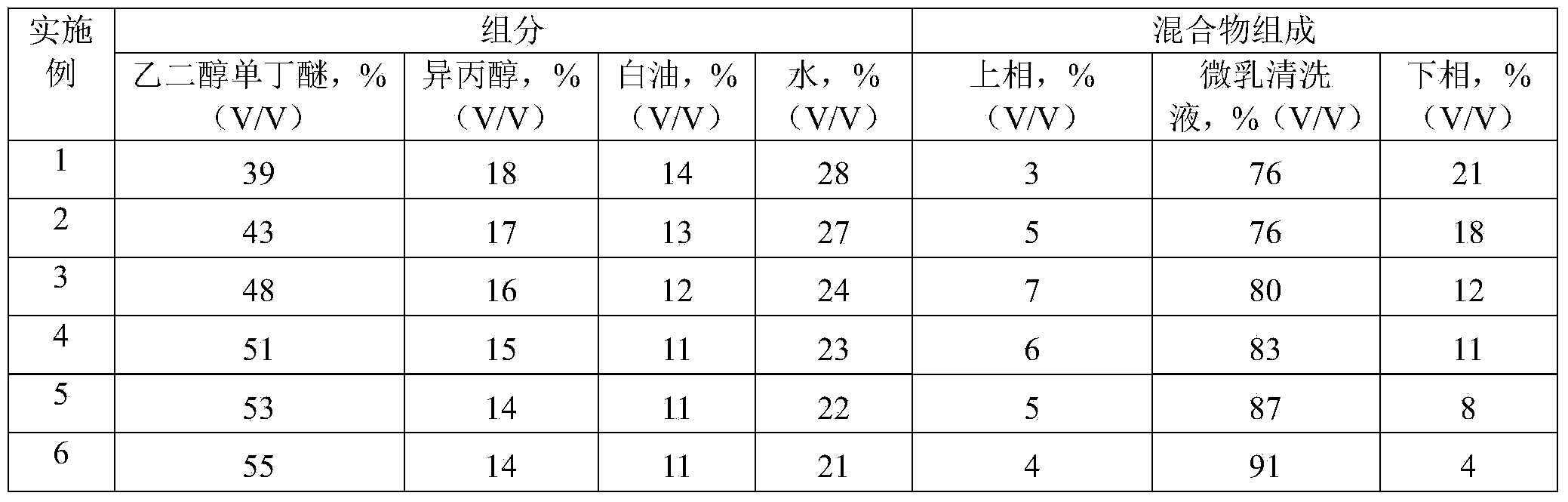

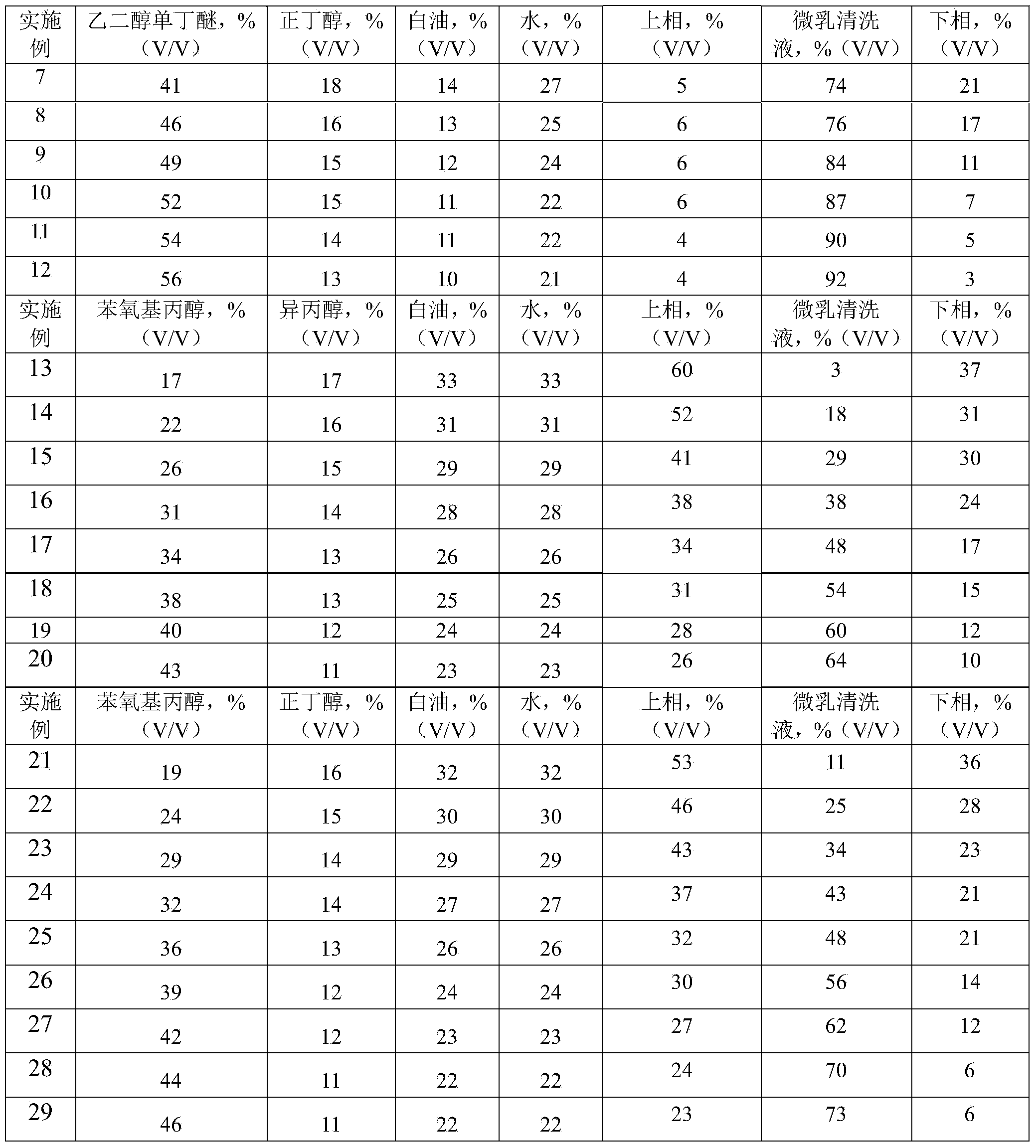

Oil based drilling cutting microemulsion cleaning solution and cleaning method thereof

InactiveCN104140799AReduce surface tensionReduce processing costsDrilling compositionEnvironmental resistanceOil phase

Belonging to the technical field of environment-friendly application of drilling engineering oilfield chemistry in the petroleum and natural gas field, the invention relates to an oil based drilling cutting microemulsion cleaning solution and a cleaning method thereof. For the oil based drilling cutting microemulsion cleaning solution, a surfactant, a cosurfactant, an oil phase and water are mixed in a volume percentage of (17-56):(11-18):(10-33):(21-33) to form three phases, and the middle phase is the microemulsion cleaning solution. The surfactant is ether alcohol, preferably ethylene glycol monobutyl ether or phenoxy propanol, and the cosurfactant is short chain alcohol, preferably n-butyl alcohol or isopropyl alcohol. The cleaning solution and drilling cuttings are mixed uniformly according to a mass ratio of (0.5:1)-(3:1), then solid-liquid separation is carried out, and the base oil, cleaning solution and drilling cuttings cleaned out from the oil based drilling cuttings are separated into different phases. Compared with other oil based drilling cutting treatment technologies, the process is simple, the base oil recovery rate is greater than 80%, and the residual oil content of the drilling cuttings is less than 2%, thus meeting relevant environmental protection technical standards. Also, the microemulsion cleaning solution can be used repeatedly, and the treatment cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +3

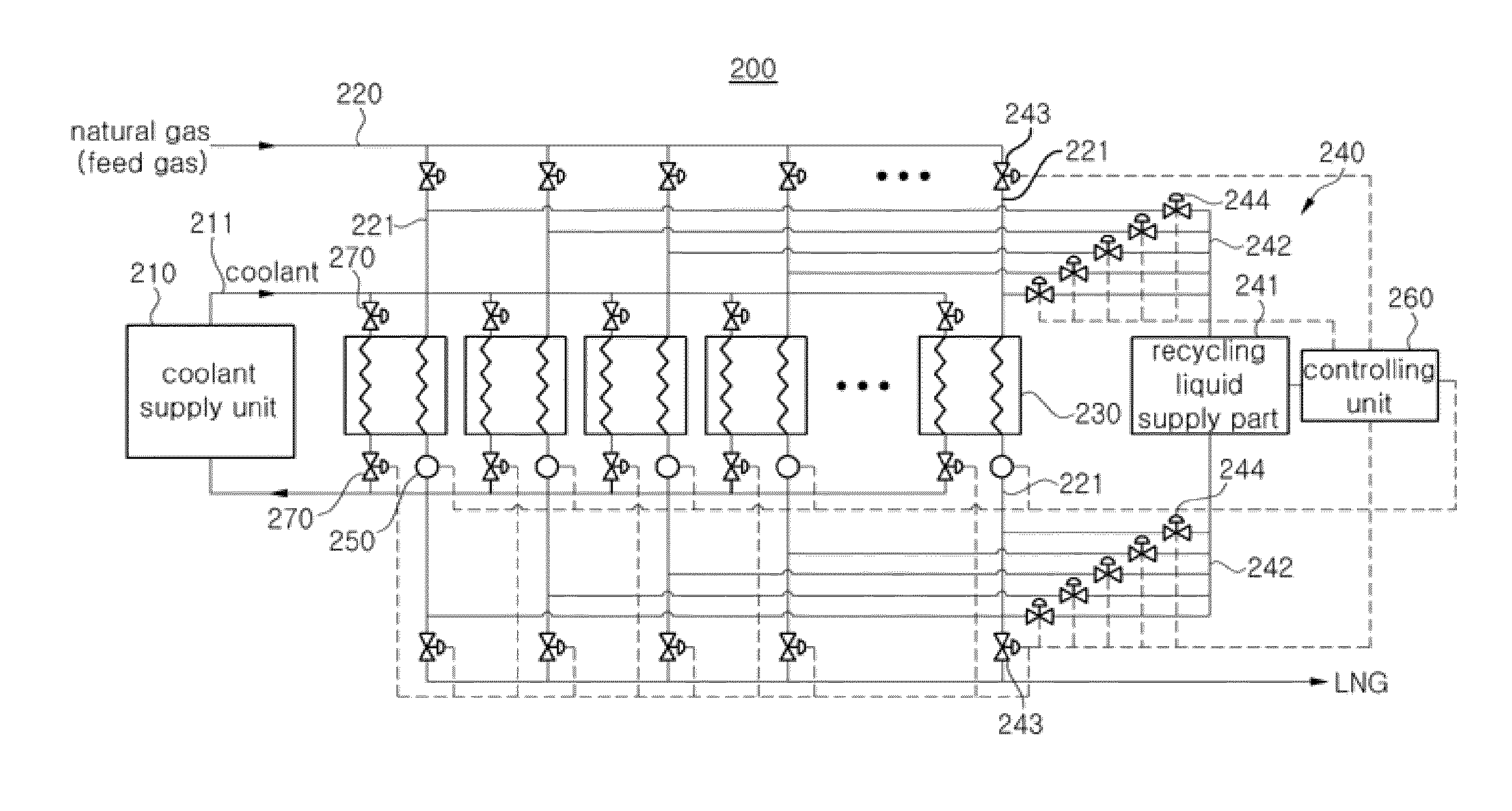

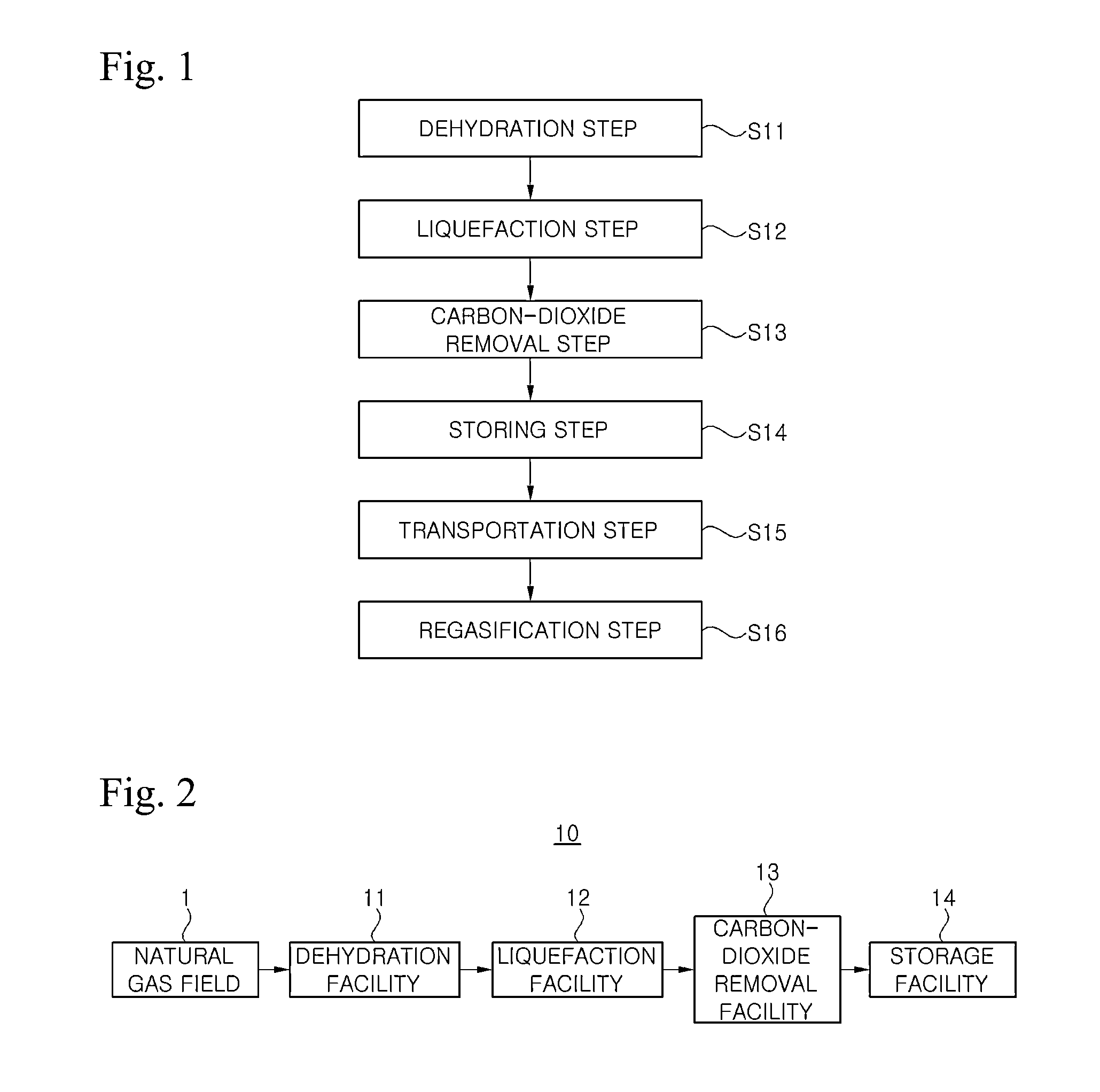

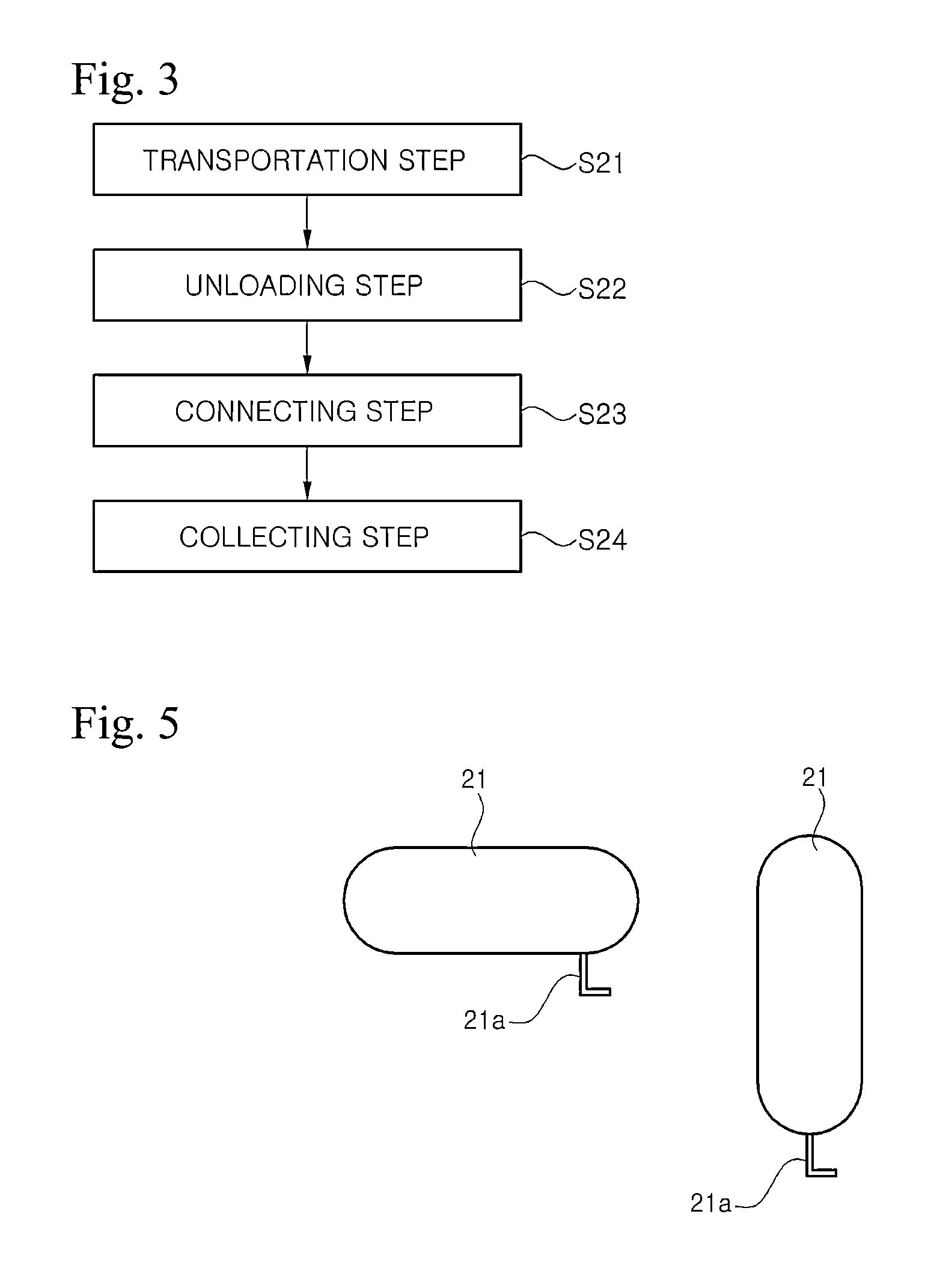

Method for producing pressurized liquefied natural gas, and production system used in same

InactiveUS20130219955A1Reduce expensesReduce plant construction costsSolidificationLiquefactionProcess engineeringNatural gas fuel

A method for producing pressurized liquefied natural gas and a production system therefor are provided. The method for producing pressurized liquefied natural gas includes: performing a dehydration process to remove water from natural gas supplied from a natural gas field, without a process of removing acid gas from the natural gas; and performing a liquefaction process to produce pressurized liquefied natural gas by liquefying the natural gas, which has undergone the dehydration process, at a pressure of 13 to 25 bar and a temperature of −120 to −95° C., without a process of fractionating natural gas liquid (NGL). Accordingly, it is possible to reduce plant construction costs and maintenance expenses and reduce LNG production costs. In addition, it is possible to guarantee high economic profit and reduce payback period in small and medium-sized gas fields, from which economic feasibility could not be ensured by the use of a conventional method.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

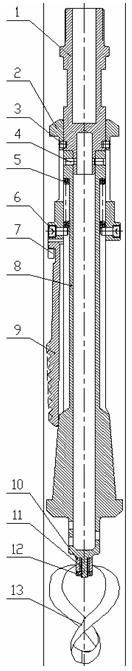

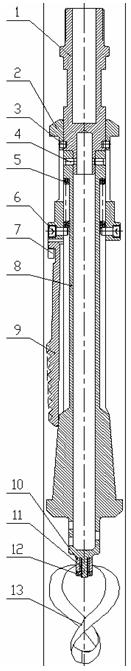

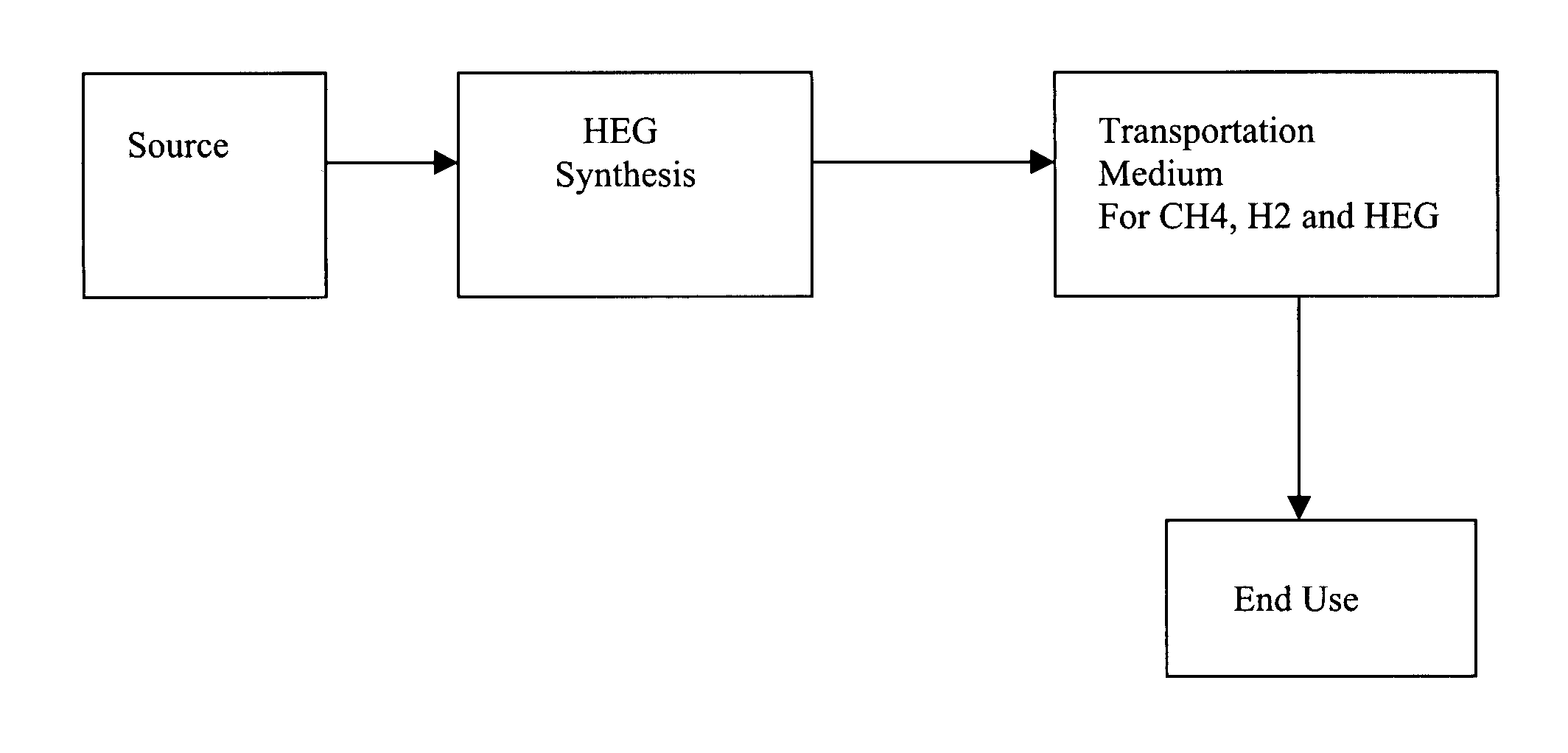

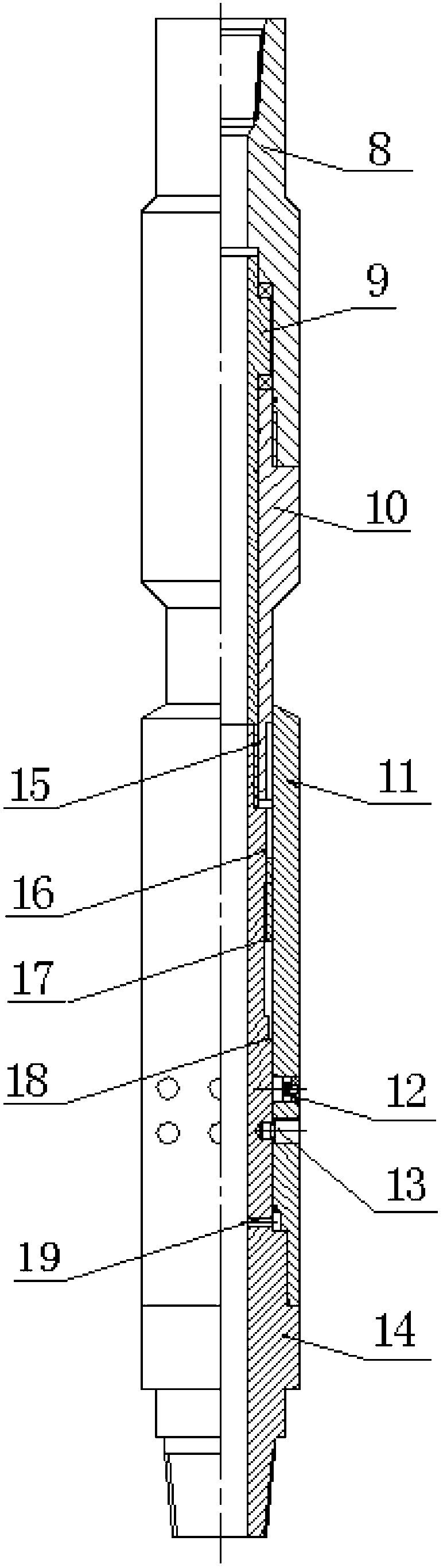

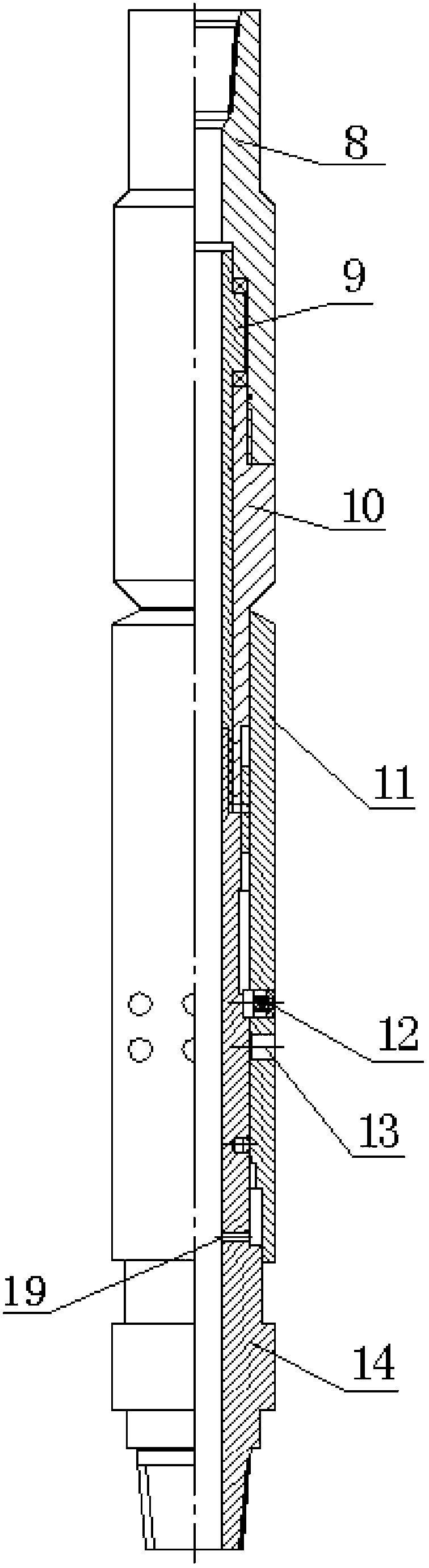

Retrievable underground foaming agent mixing device

The invention relates to a retrievable underground foaming agent mixing device which is used for implementing the action effect of foam draining and gas production in a gas field, solving the difficulty that the action effect of the foam draining and gas production technology is influenced by insufficient mixing of a foaming agent and shattering of foam fluid. The following technical scheme is adopted: the upper end of a releasing joint is provided with a threaded button to be connected with a conventional releasing joint, and the lower end of the releasing joint is provided with a stepped platform and a pin hole; the lower end of an outer tube is provided with a screw hole, and the tail end of the outer tube is connected with a slips carrying ring; the upper end of a core tube is provided with a pin hole, a spring slot is arranged at the middle of the core tube, the tail end of the core tube is circumferentially provided with an orifice, a stepped shaft and a ball groove, a core tubesleeve is connected on the releasing joint by a pin; a spring is arranged in the spring slot; the outer tube is sheathed on the core tube and is connected by a pin in the pin hole in a releasing joint platform; the upper end of a slips is connected with the slips carrying ring, and the tail end of the slips is contacted with the core tube; the ball is arranged in the ball groove, and a hub is arranged on the ball; a locking nut is connected with the stepped shaft at the tail end of the core tube; and a rotating blade is connected with the hub. The retrievable underground foaming agent mixing device has a simple structure, is wide in application scope, can give full play to the action effect of the foam draining and gas production technology, and can be used in a water outlet gas well adopting the foam draining and gas production technology.

Owner:SOUTHWEST PETROLEUM UNIV

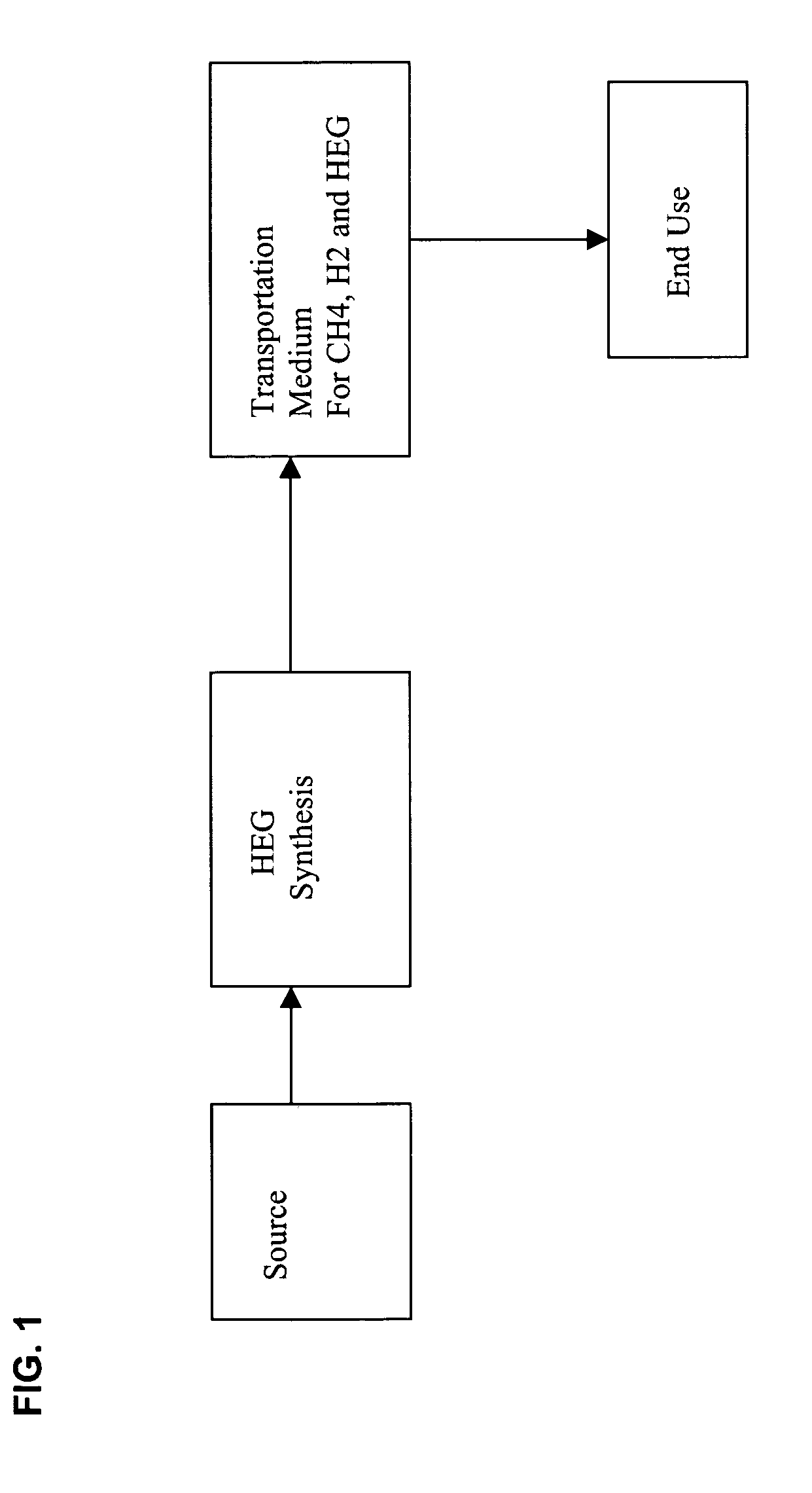

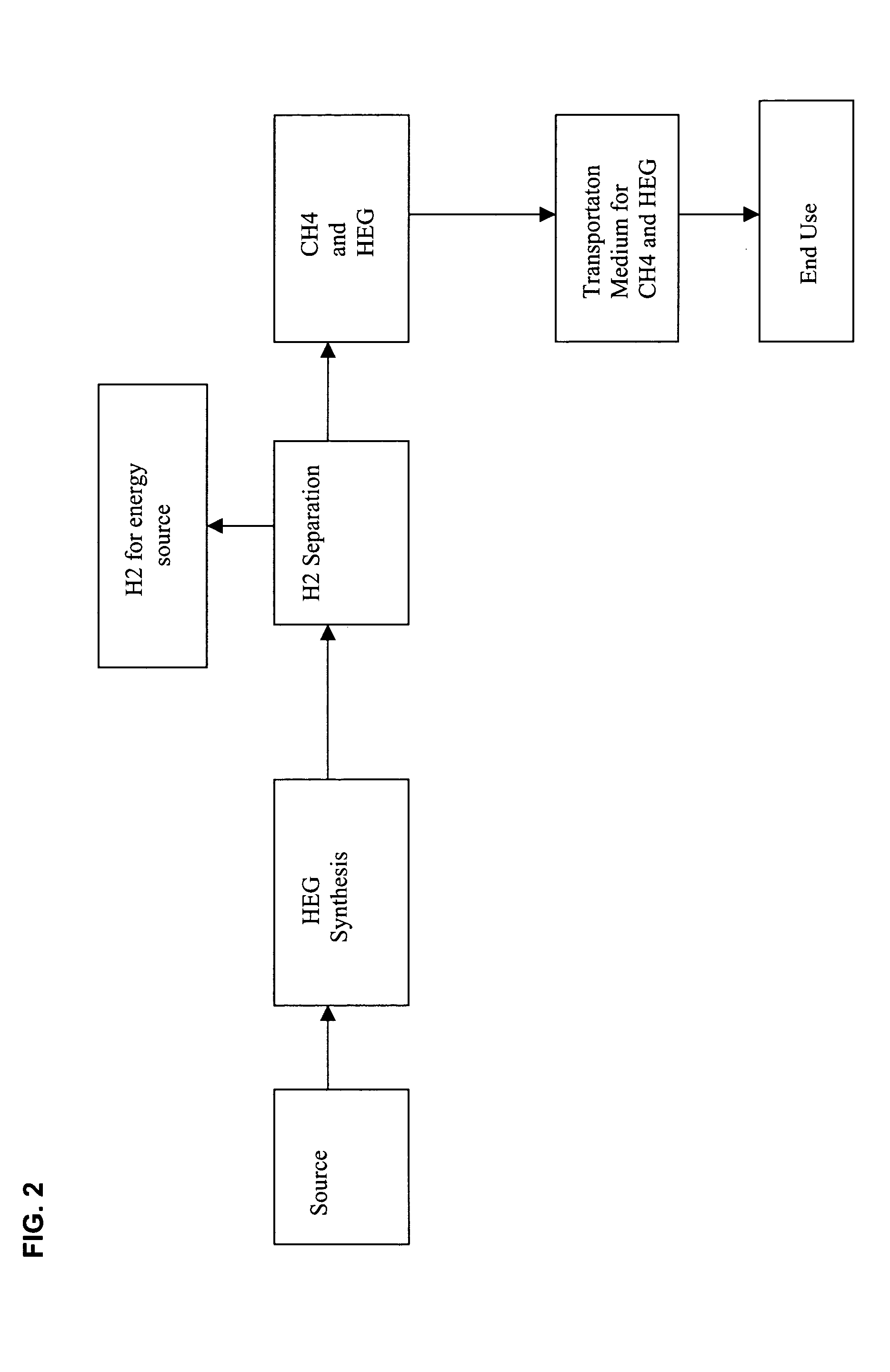

High energy transport gas and method to transport same

InactiveUS20050000163A1Increase volumeHigh boiling pointGas modification by gas mixingMachines/enginesElectricityFuel cells

A high energy transport gas and a method to transport the high energy transport gas are used to increase the energy content of a pipeline and other vessels that are designed to carry natural gas under ambient conditions, in a compressed state or in a liquefied state. Methane and other gases are used as the feedstock, with methane from natural gas fields, coal beds or derived from hydrogen reacting with coal being primary energy sources. Also, this gas and method can provide an abundant source for hydrogen production, and the energy from hydrogen can be used for fuel cell applications that generate electricity and power motor vehicles. This gas and method are capable of increasing the energy capacity of current natural gas pipelines and other storage and transport vessels.

Owner:DALTON ROBERT C

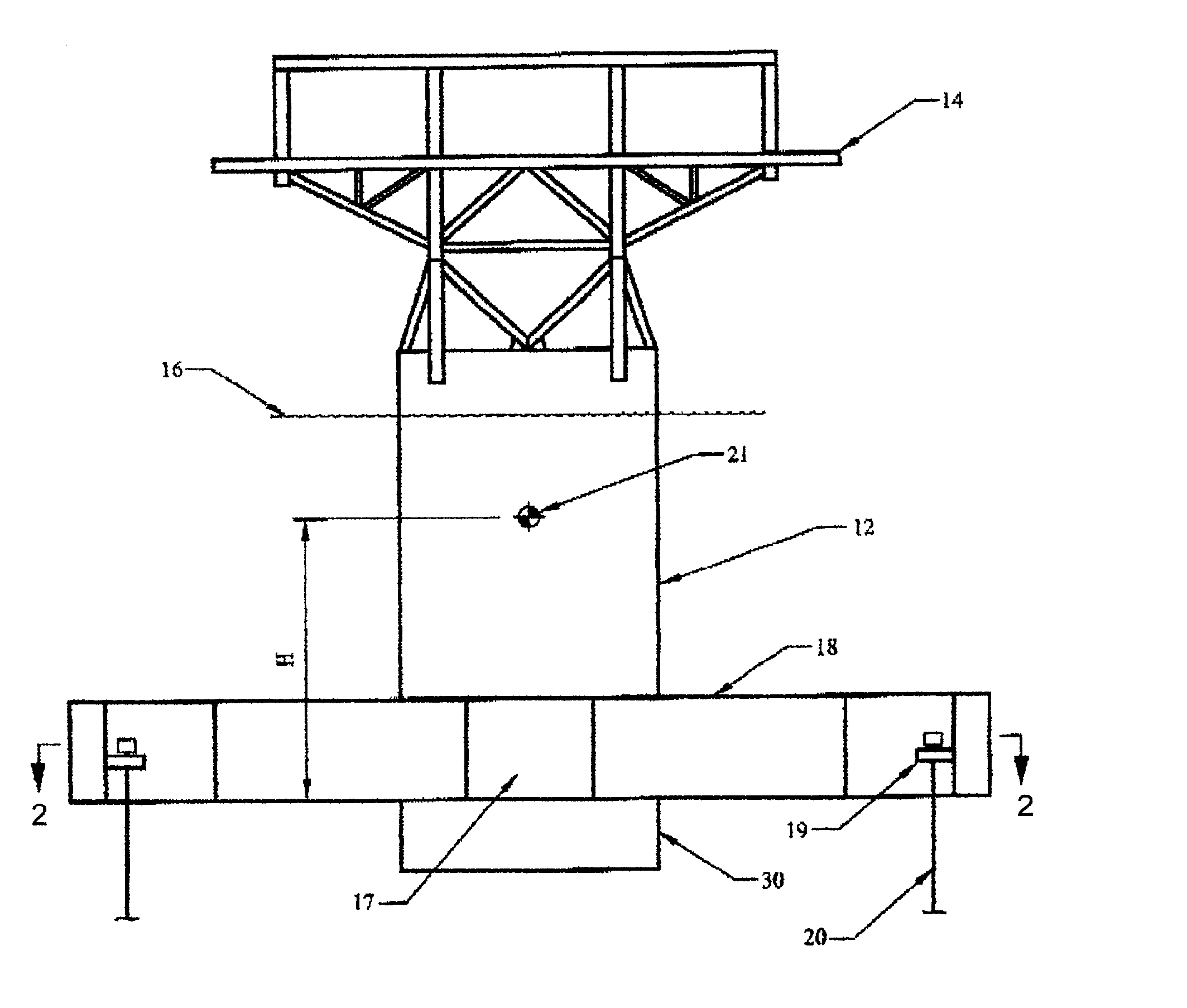

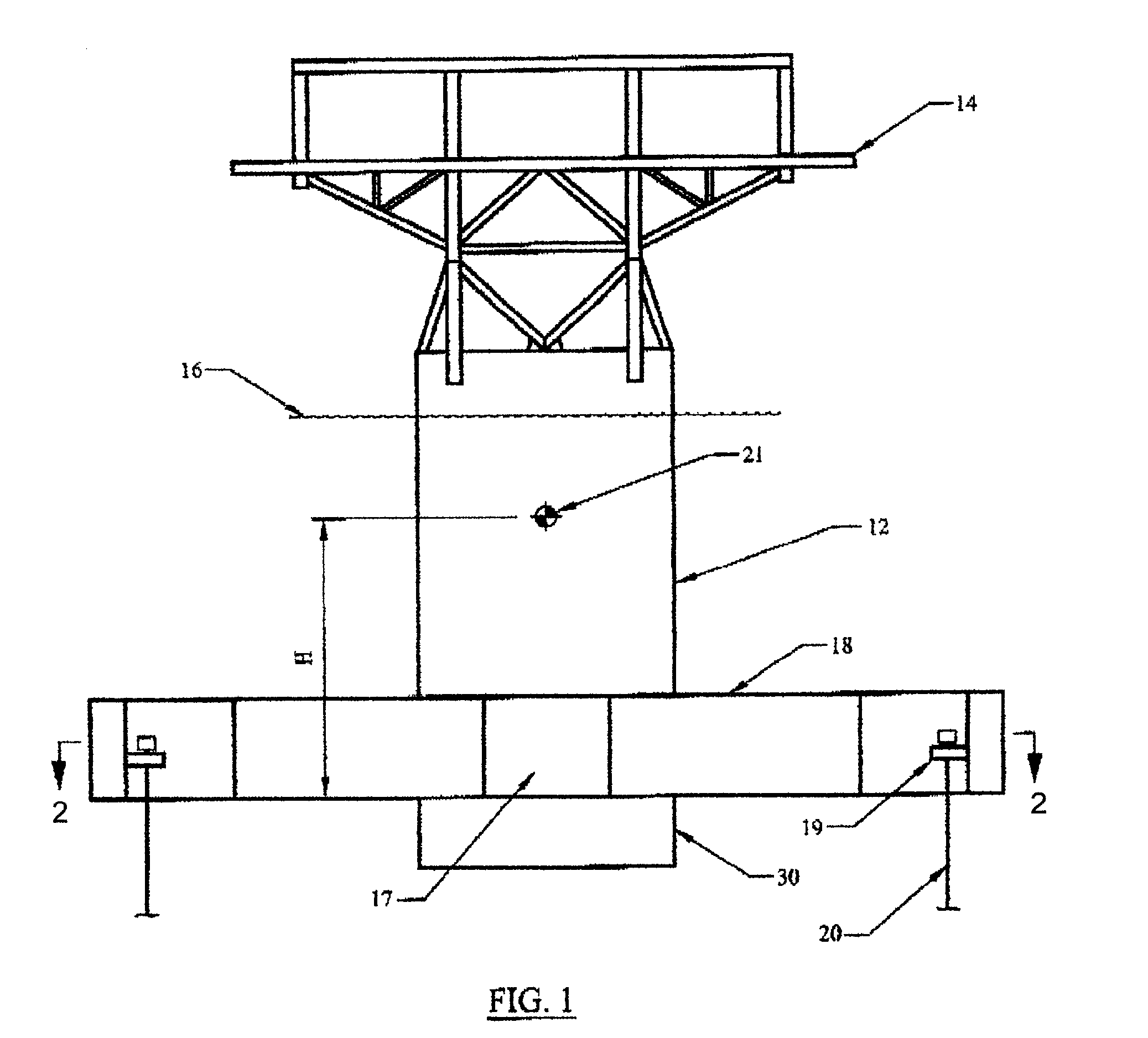

Method and apparatus for reducing tension variations in mono-column TLP systems

A floating platform for recovery of oil and gas from offshore oil and gas fields supports one or more decks above the water surface to accommodate equipment for drilling and processing oil, gas and water recovered from the oil and gas field. The platform includes a central column having a portion substantially below the water surface, and including a portion which extends above the water surface. The central column includes a base node and a plurality of pontoons extending outwardly therefrom and is anchored to the seabed by one or more tendons secured to the pontoons and to the seabed. Ballast modules fixedly or removably secured to the base node and / or the pontoons accept solid or liquid ballast for lowering the vertical center of gravity of the platform.

Owner:SINGLE BUOY MOORINGS INC

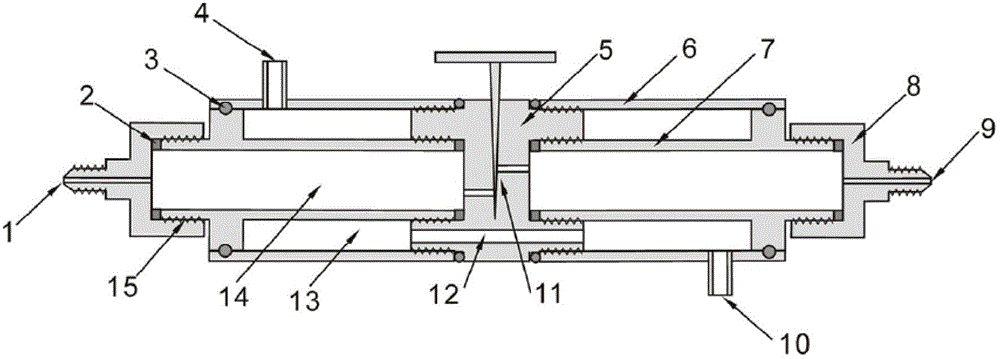

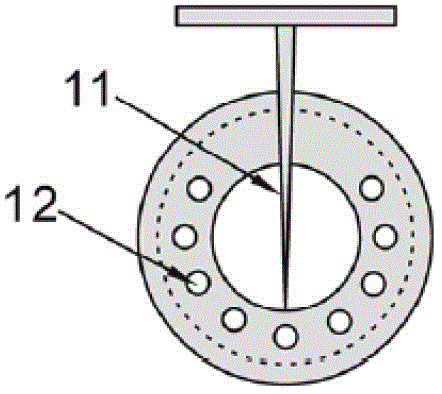

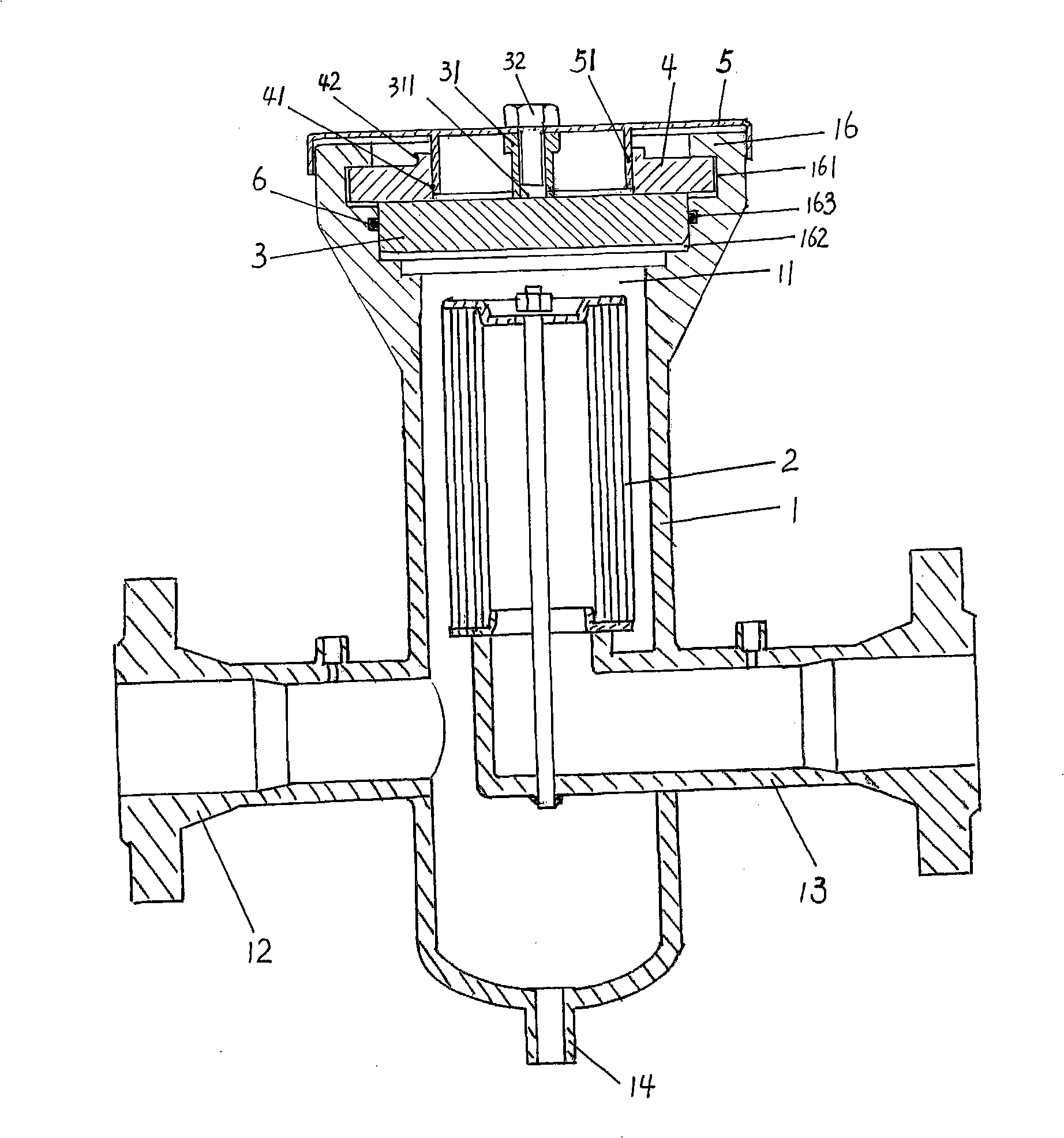

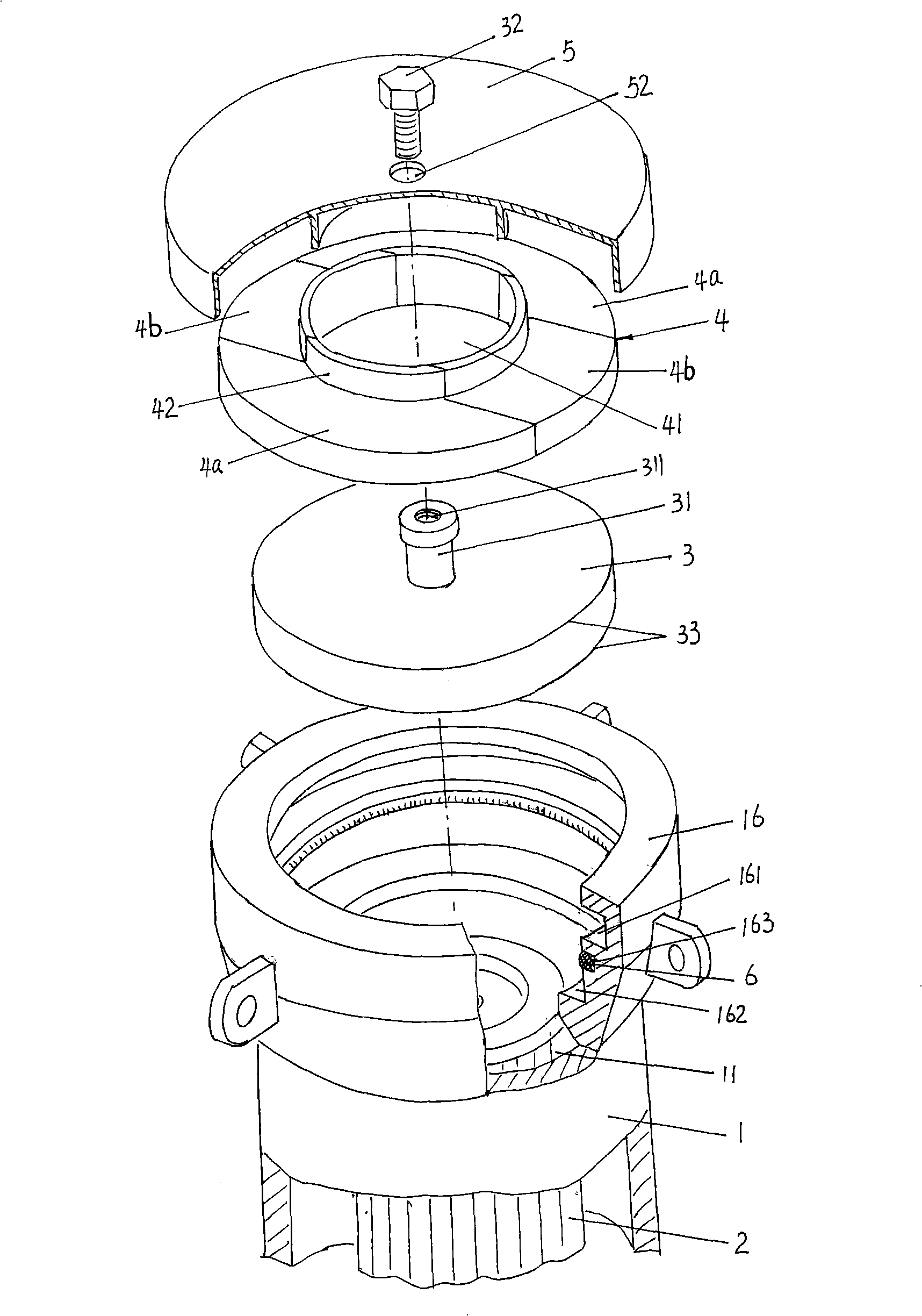

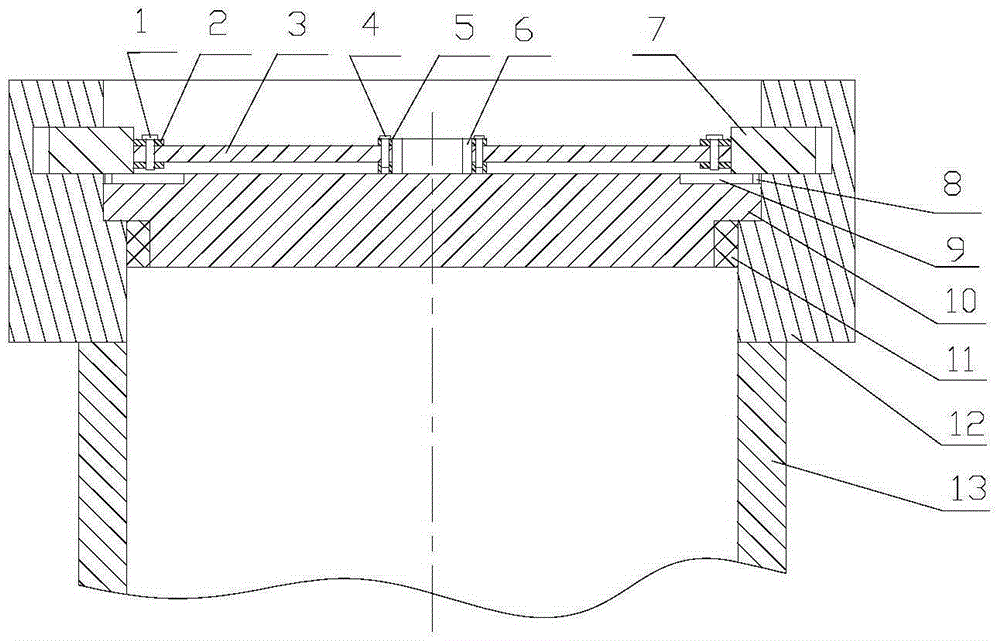

Subdivision ring type fast opening device for container sealing end cover and natural gas filter

The invention discloses a subdivision ring type fast opening device for a container sealing end cover. The subdivision ring type fast opening device is arranged on an operating hole (13) of a container and comprises a barrel body flange (12), a sealing ring (11), a flat cover (10), a plurality of guiding mechanisms and a plurality of subdivision claw mechanisms. The barrel body flange (12) is fixed to the operating hole (13) of the container and comprises an inner hole with a step. The flat cover (10) is arranged on the step of the inner hole. A sealing ring (11) is arranged between the flange (12) and the flat cover (10). The flat cover (10) is controlled by the subdivision claw mechanisms so that the flat cover (10) and the flange (12) can be pressed, sealed, opened and separated. The subdivision ring type fast opening device is simple and compact in structure, reasonable in stress, reliable in operation, not prone to being stuck and good in sealing performance.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

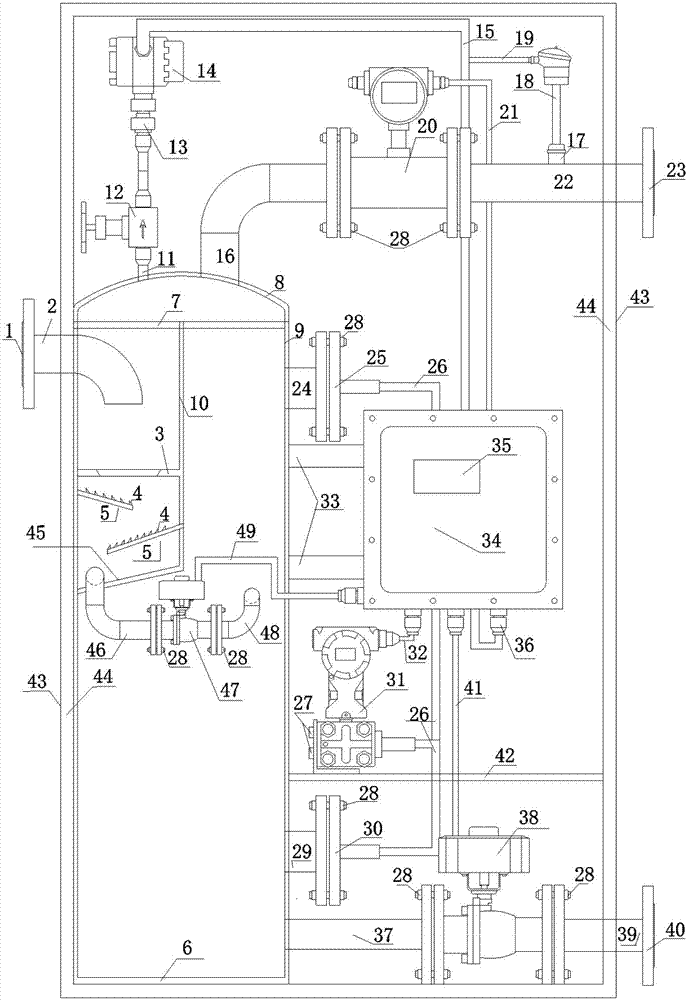

Natural gas single well multiphase flow metering equipment

The invention discloses natural gas single well multiphase flow metering equipment comprising a gas-liquid separation container system, a gas metering system, a liquid metering control system, a pressure measuring element, a temperature measuring element and a signal treatment system. The natural gas single well multiphase flow metering equipment is suitable for effectively metering a large number of existing intermittent liquid outlet gas well with foam scrubbing, plunger gas lift and the like; metering precision can be improved; and the natural gas single well multiphase flow metering equipment is suitable for being used in a severe field environment, light, low in using cost, more powerful in function, high in measuring using safety, high in automation degree and capable of saving manpower and equipment resources, meets the natural gas single well metering requirement and is wide in applicable occasion and considerable in application and market prospect.

Owner:JIANGSU HUAERWEI TECH GRP

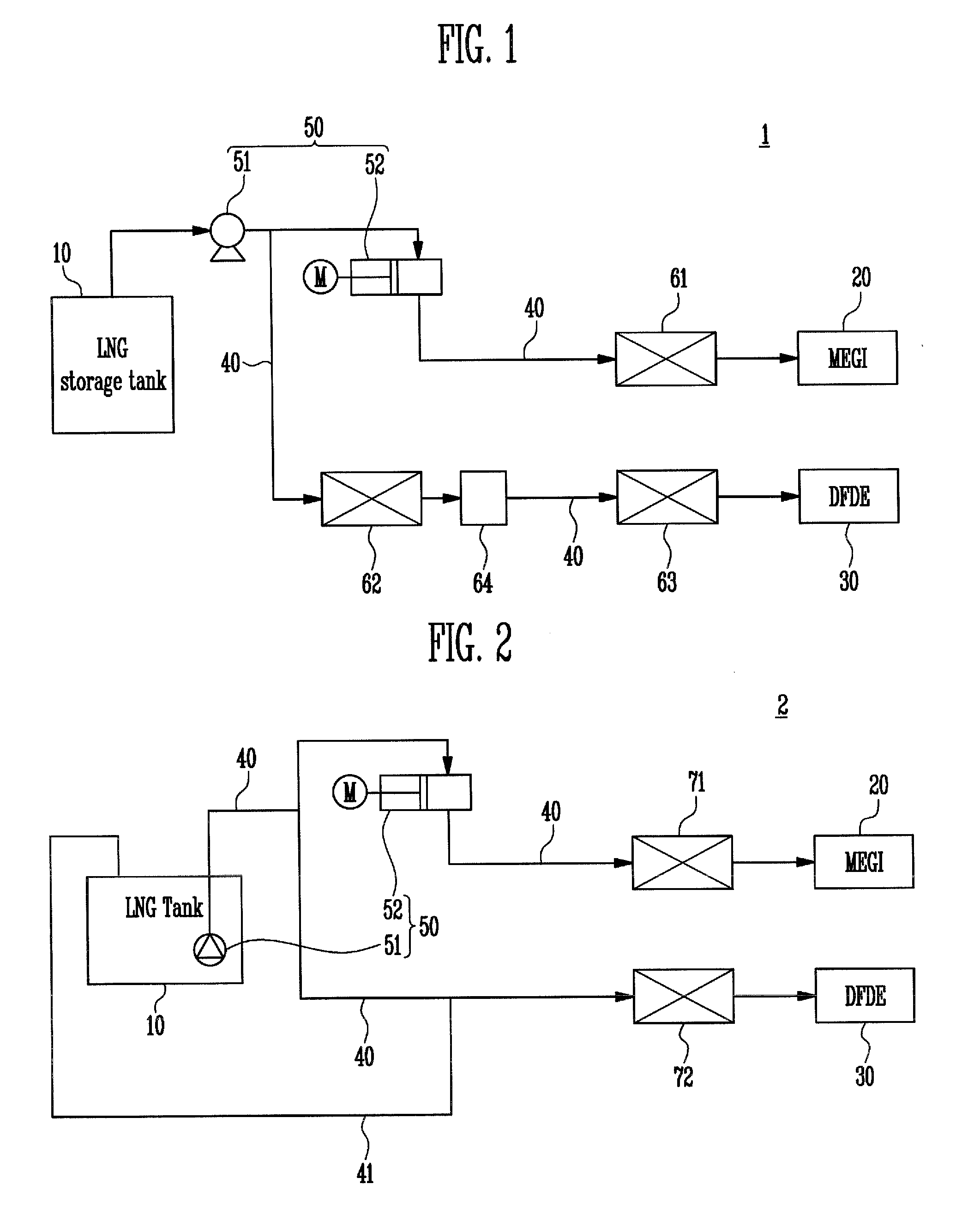

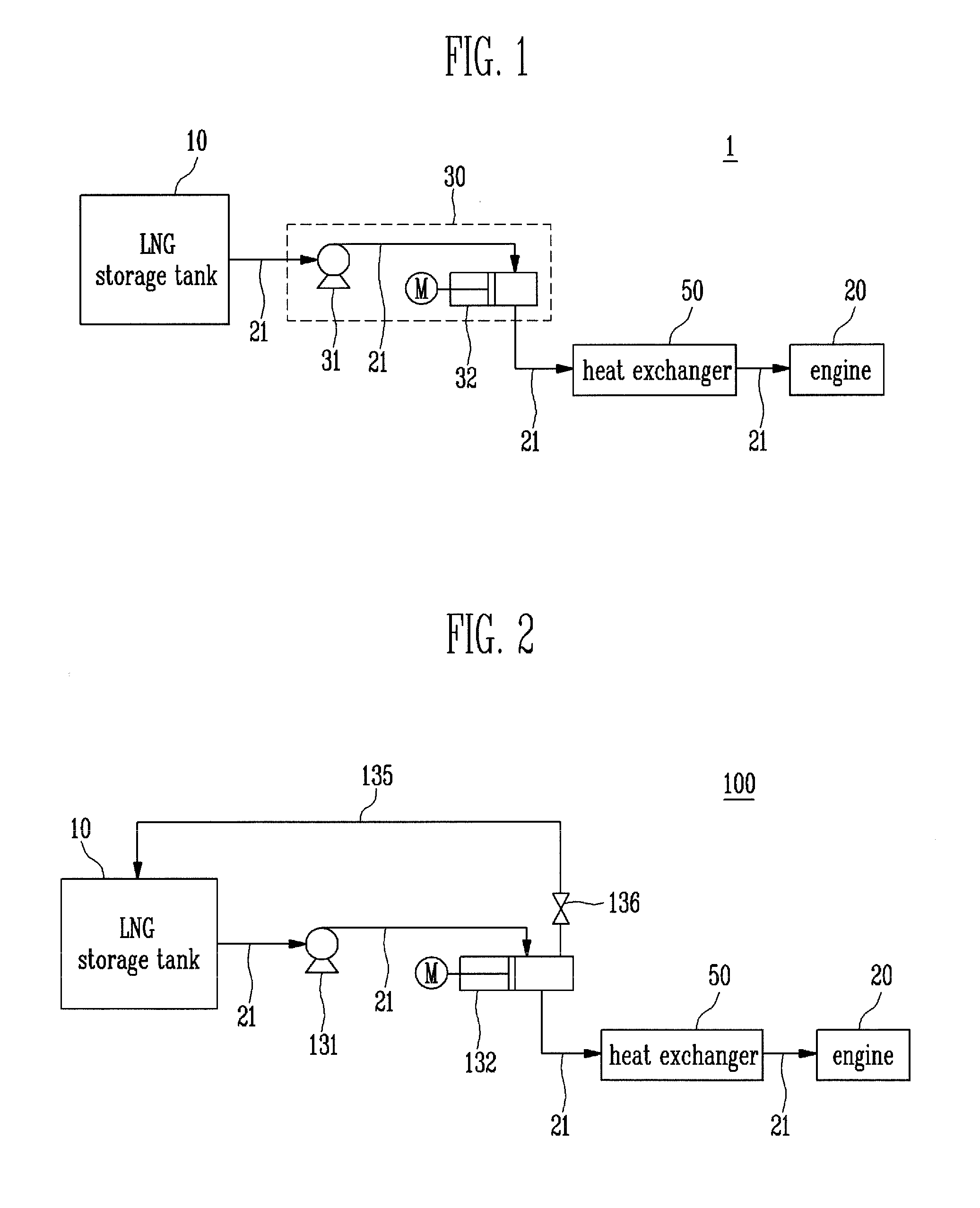

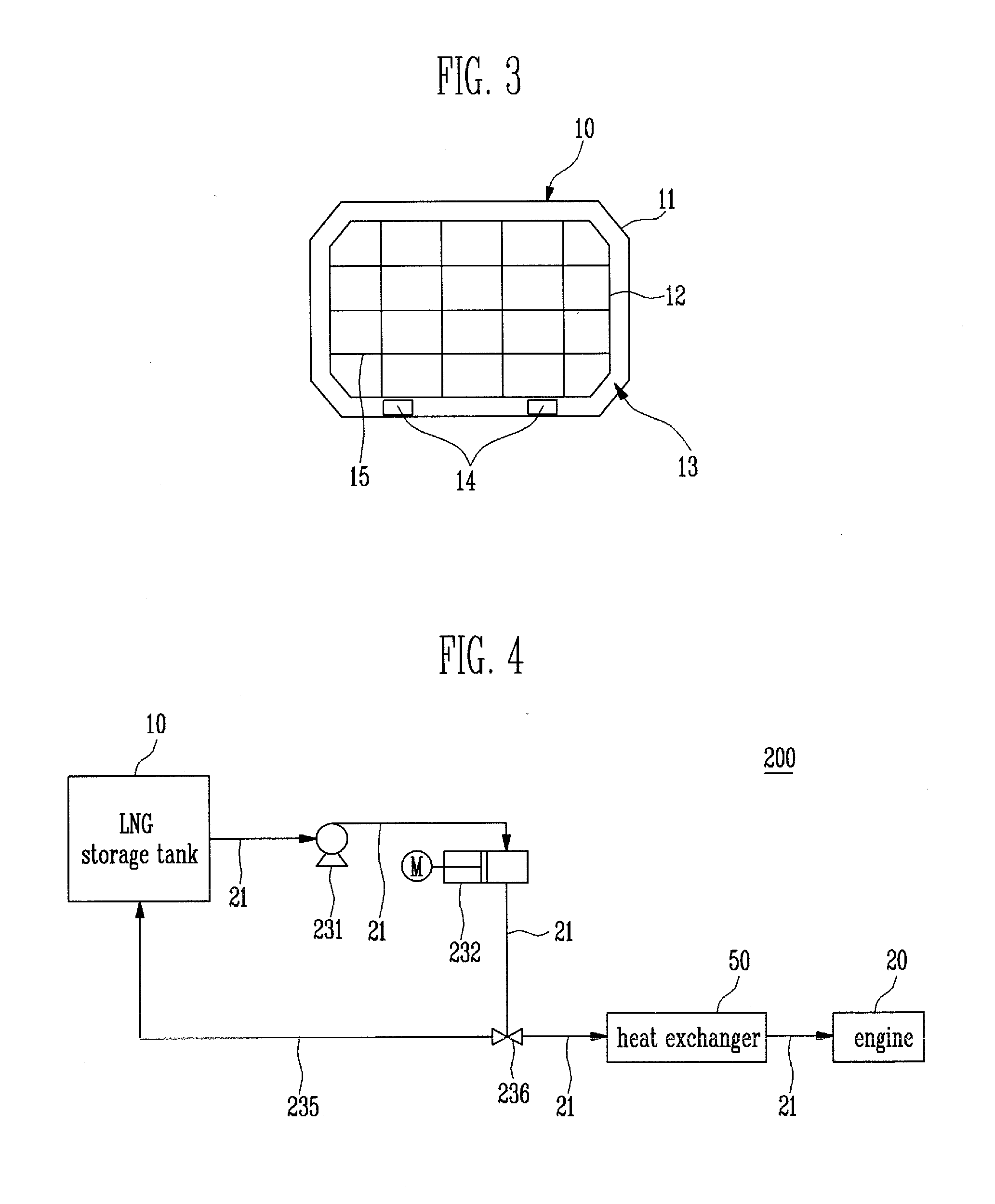

System for supplying liquefied natural gas fuel and method of operating the same

A system for supplying LNG fuel includes a fuel supplying line connected from an LNG storage tank to an engine, a boosting pump provided on the fuel supplying line and configured to pressurize LNG outputted from the LNG storage tank and cool down in a standby mode, a high pressure pump configured to pressurize the LNG outputted from the boosting pump to high pressure, and a return line connected between the LNG storage tank and the high pressure pump, in which the LNG is returned through the return line.

Owner:HYUNDAI HEAVY IND CO LTD

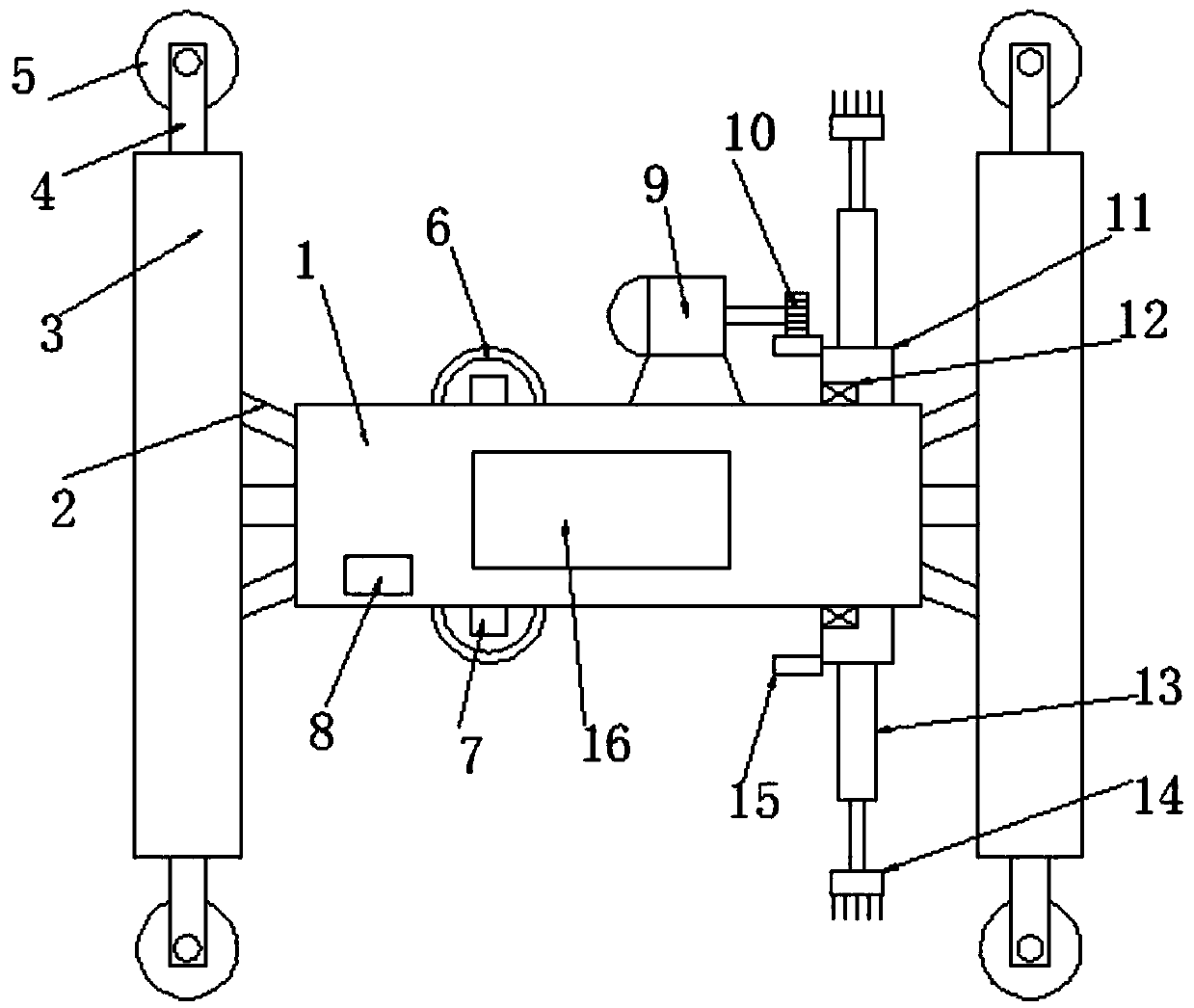

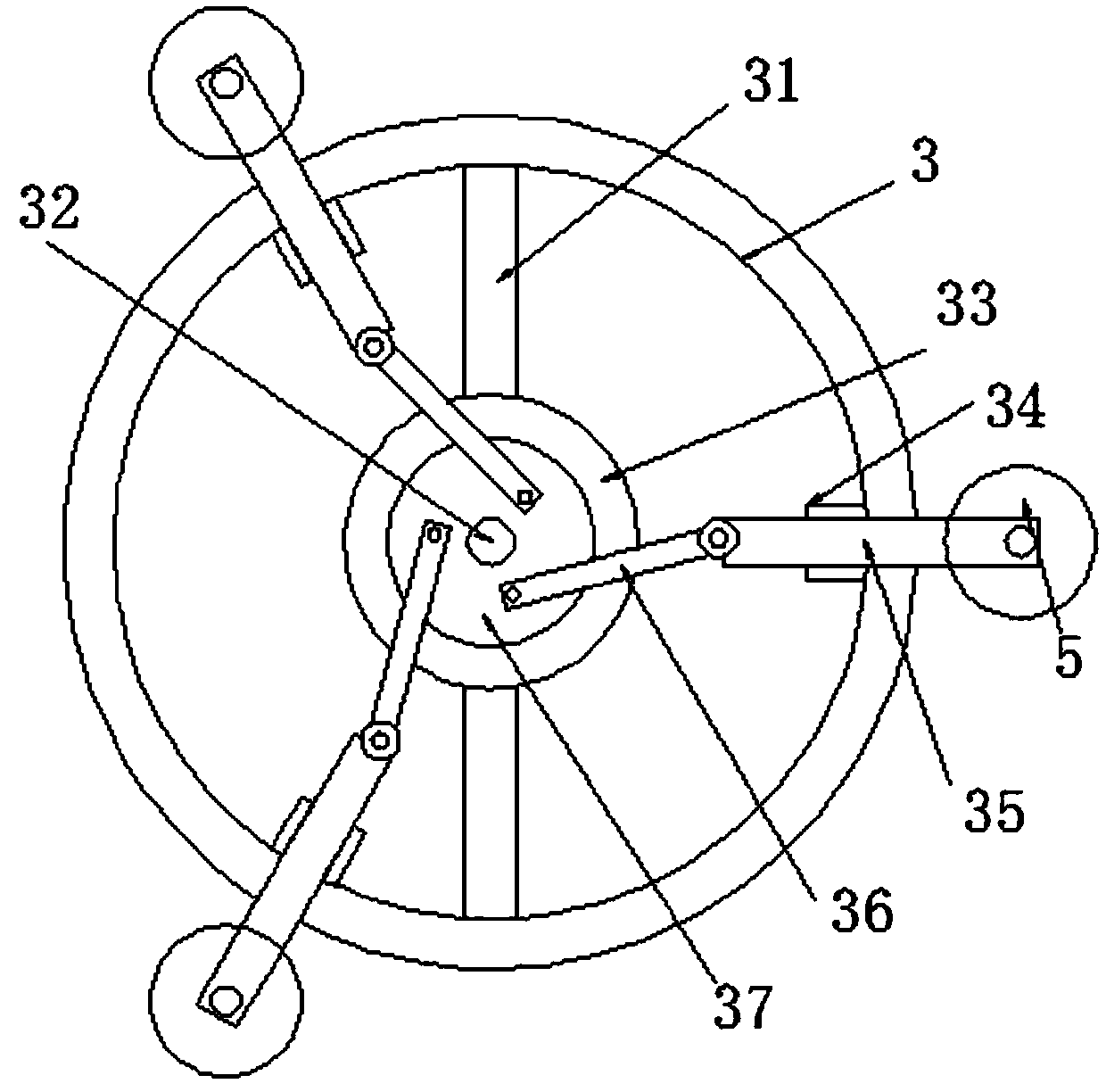

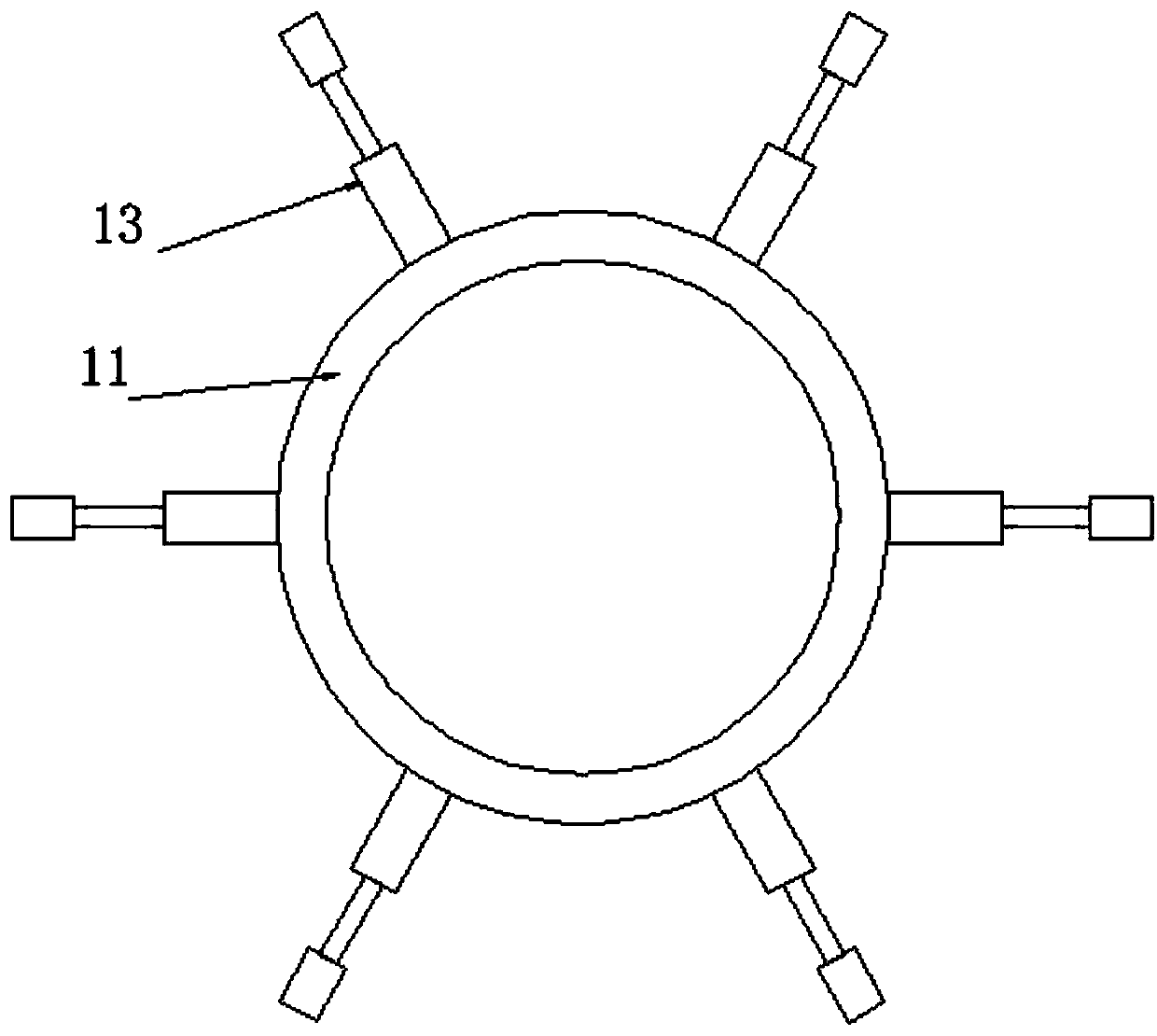

Natural gas pipeline cleaning device

The invention discloses a natural gas pipeline cleaning device which comprises a mounting plate. Driving mechanisms are symmetrically arranged at the left end and the right end of the mounting plate,the driving mechanisms are electrically connected to a control panel located on the mounting plate, and each driving mechanism comprises a fixing ring, wherein the fixing ring is fixedly connected with a connecting rod and the mounting plate, the middle position of the of fixing ring is connected with a fixing seat through a positioning rod, and an adjusting motor is mounted in the middle of the fixing seat. The natural gas pipeline cleaning device overcomes the defects of existing devices, when the natural gas pipeline cleaning device is used, the adjusting motors drive driving discs to rotate, the driving discs pull transmission connecting rods to rotate when rotating, the transmission connecting rods drive piston rods to slide along guiding sleeves, and therefore the diameter of the positions where rollers are located is adjusted, and the cleaning device can be conveniently mounted in natural gas pipelines with different diameters; driving motors drive the rollers to rotate, and thus the whole cleaning device moves on the inner wall of a pipeline and is matched with a cleaning module to clean the inner wall of the pipeline, and practicability is high.

Owner:芜湖中燃城市燃气发展有限公司

Method and tool for putting well completion pipe down by utilizing drill rod

ActiveCN102704876AReduces the effect of drop forceDrilling rodsDrilling casingsFree rotationWell drilling

The invention relates to a method for putting a well completion pipe down by utilizing a drill rod. The method is suitable for a petroleum natural gas field, in which the well completion pipe is put into a drill well via the drill rod. The method comprises the steps as follows: a whole well completion pipe string is connected and put into a drill well, wherein during the process of putting the well completion pipe string into the drill well, when a sleeve suspender, a well completion sleeve and a well completion pipe putting-down tool at the lower part of a rotary pup joint begin to rotate, the rotary pup joint is in an original state, and the drill rod can rotate relative to the well completion pipe. When the lower parts of the well completion sleeve and the well completion pipe putting-down tool are blocked by obstacles, the obstacles can be cut by repeatedly lifting the drill rod up and putting the drill rod down. Next, the sleeve suspender is hung on the inner wall of the upper layer of the sleeve. The operation of the sleeve suspender without hands can be realized by rotating the drill rod, and the construction that the well completion pipe is put down via the drill rod can be realized by lifting the drill rod up and rotating the pup joint. The method has the effects as follows: during the process of putting the well completion pipe string into the drill well, the drill rod can rotate freely relative to the well completion pipe, and the well completion pipe which only bears the pressing-down force can not rotate, so that the influence on the putting-down force of the well completion pipe caused by the frictional resistance of a well bore is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

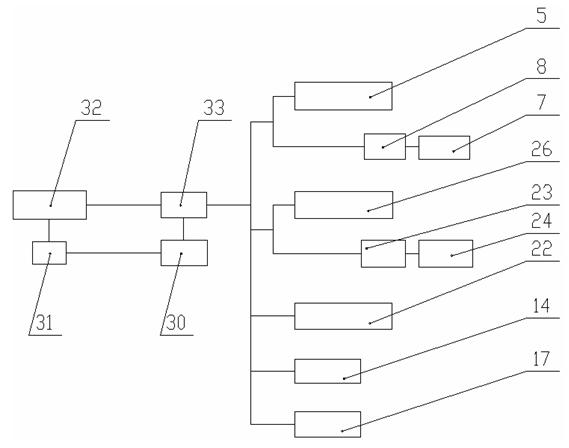

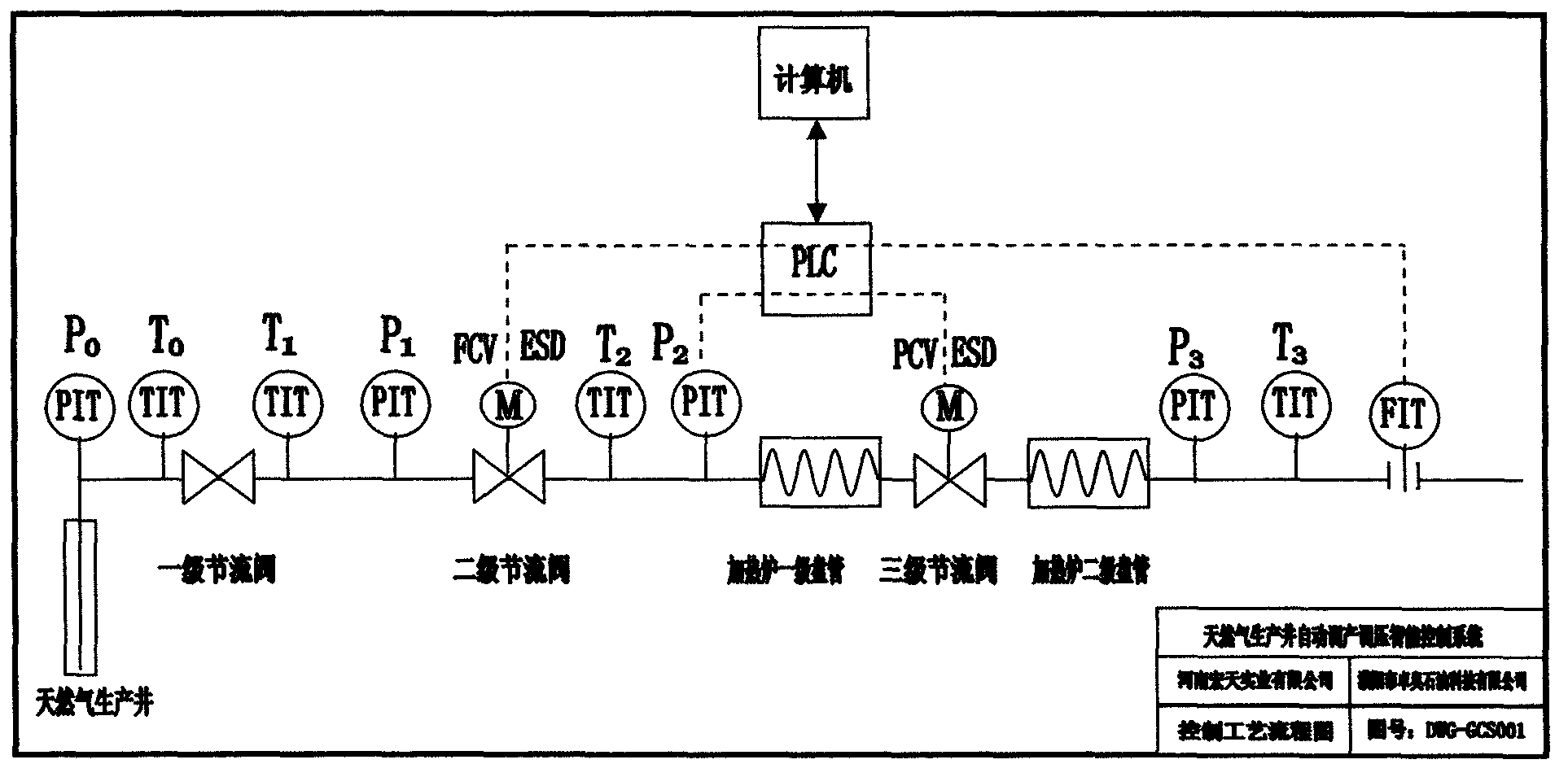

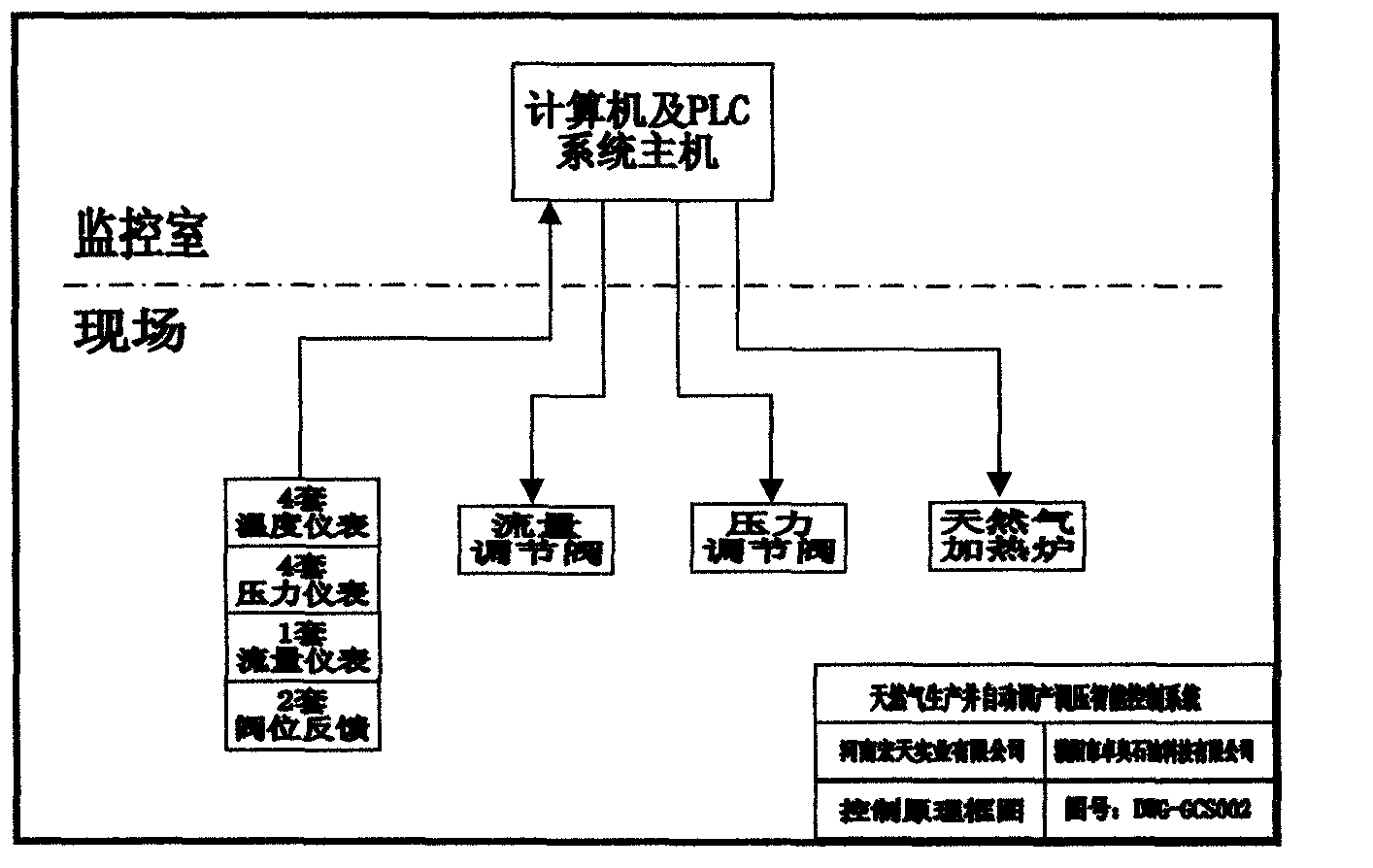

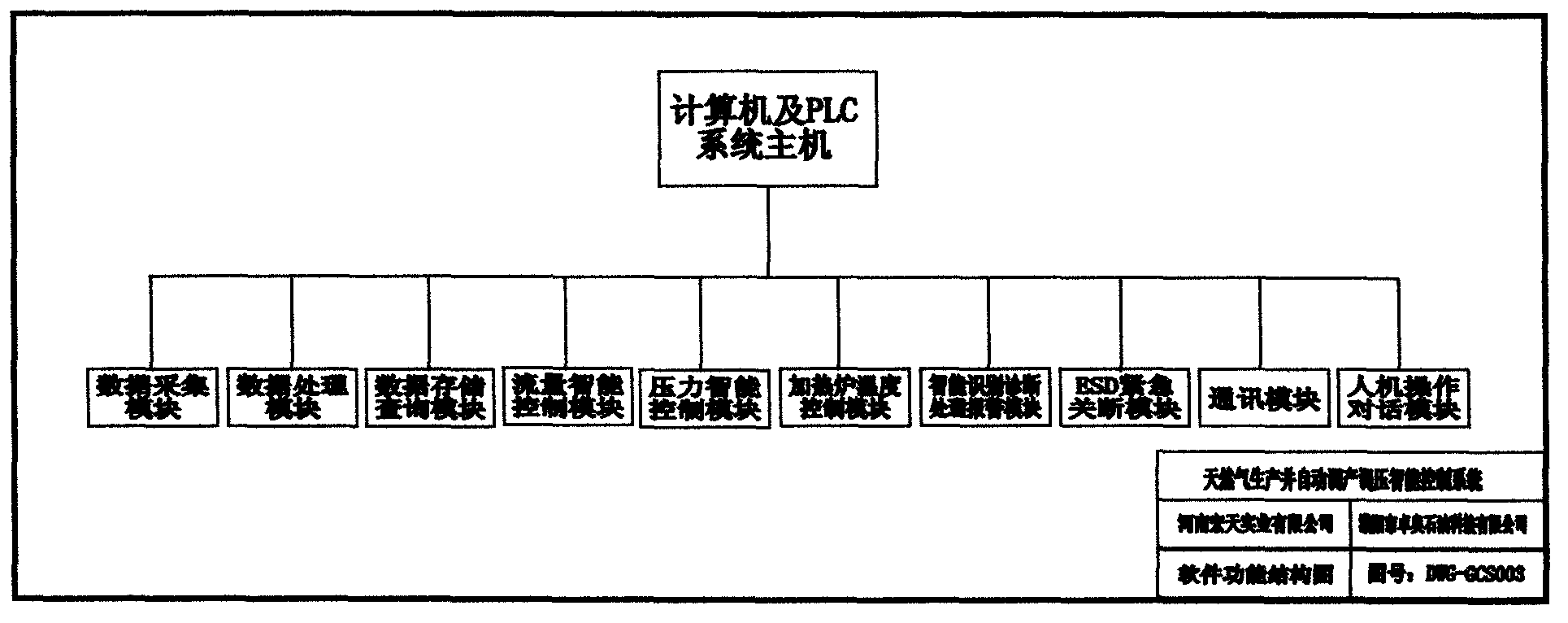

Natural gas producing well production and pressure automatically adjusting intelligent control system

InactiveCN103809528ATotal factory controlProgramme total factory controlProcess equipmentAutomatic control

The invention provides a natural gas producing well production and pressure automatically adjusting intelligent control system, belonging to the field of natural gas development and production technology and automatic control technology. The system is an intelligent control system formed by a computer, a PLC, related process equipment and a measuring meter in the natural gas field development and production process. According to the system, through the method of the combination of the automation technology and the natural gas development and production technology, the intelligent control technology is applied in the production process of a natural gas well, the gas well production and wellhead pressure are automatically controlled, the natural gas production and wellhead pressure can be automatically adjusted and controlled according to a production need, and technical method and guarantee are provided for the optimization of the natural gas field development speed and the realization of a best working effect. The technology can be widely applied to the production control of different types of natural gas field producing wells at home and abroad, and the system has a targeted intelligent monitoring alarm function for a gas field production well containing high sulfate gas at the same time.

Owner:HENAN HONGTIAN IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com