Patents

Literature

716 results about "Gas lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas lift or bubble pumps use the artificial lift technique of raising a fluid such as water or oil by introducing bubbles of compressed air, water vapor or other vaporous bubbles into the outlet tube. This has the effect of reducing the hydrostatic pressure in the outlet tube vs. the hydrostatic pressure at the inlet side of the tube.

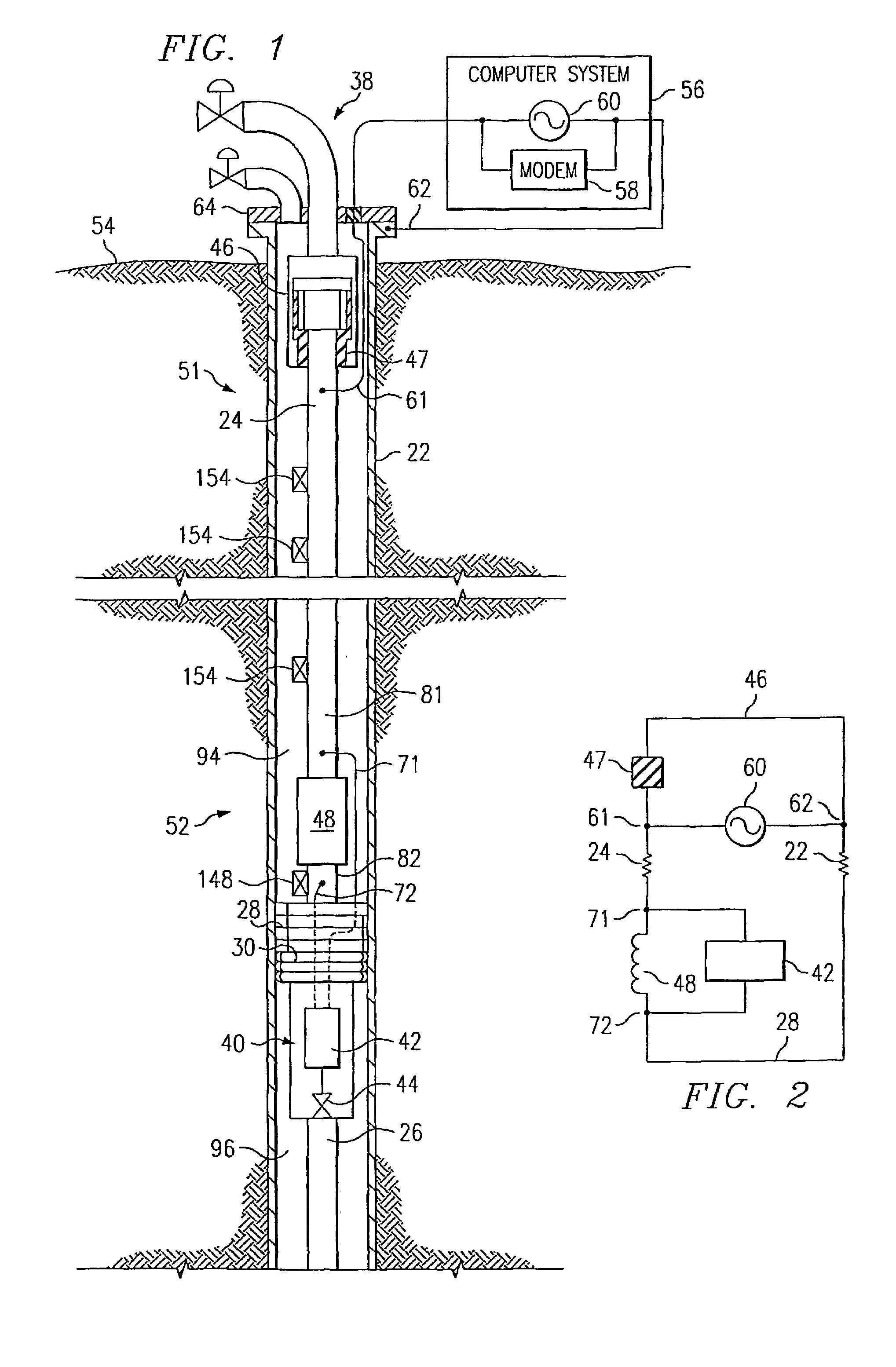

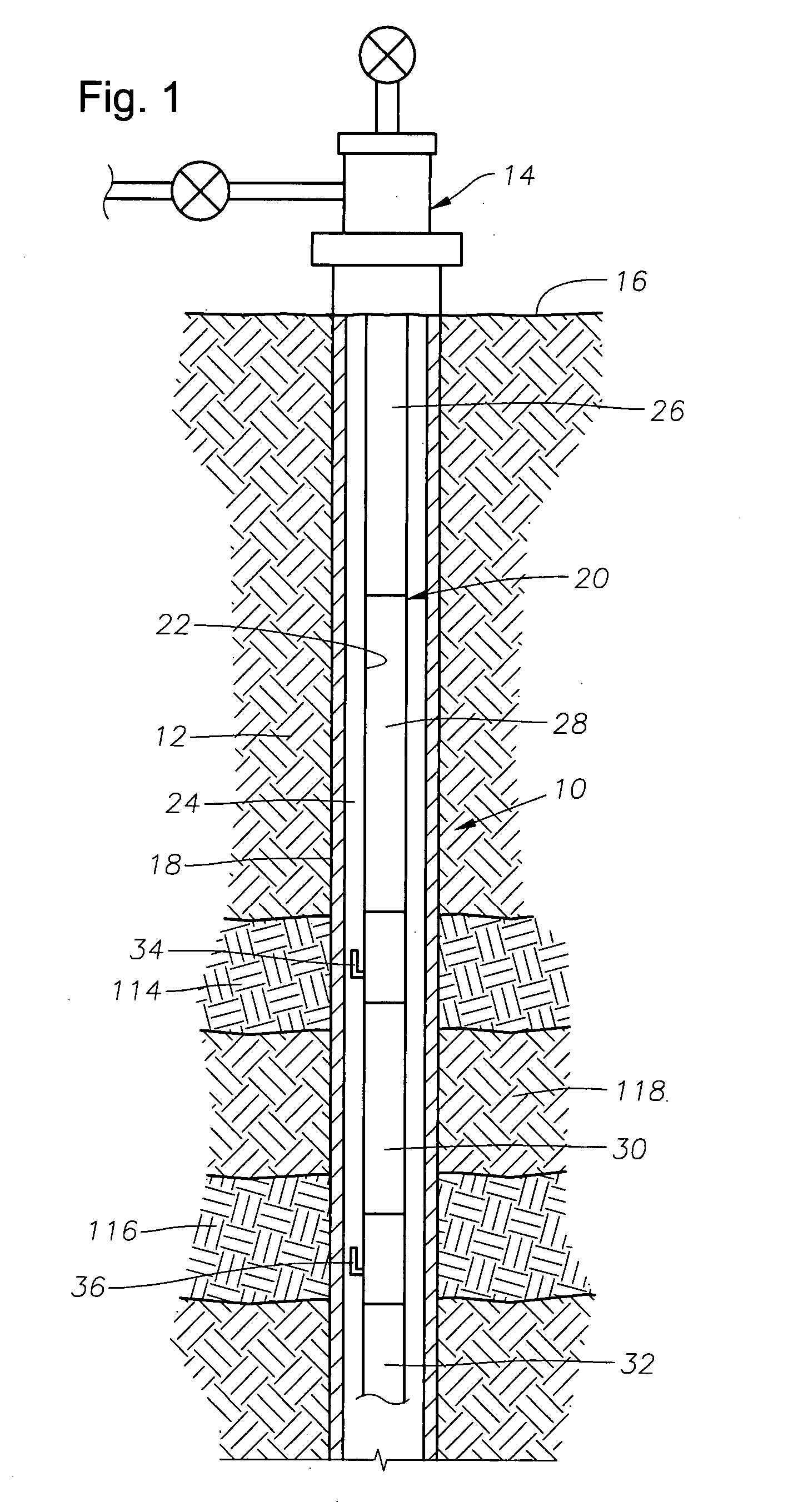

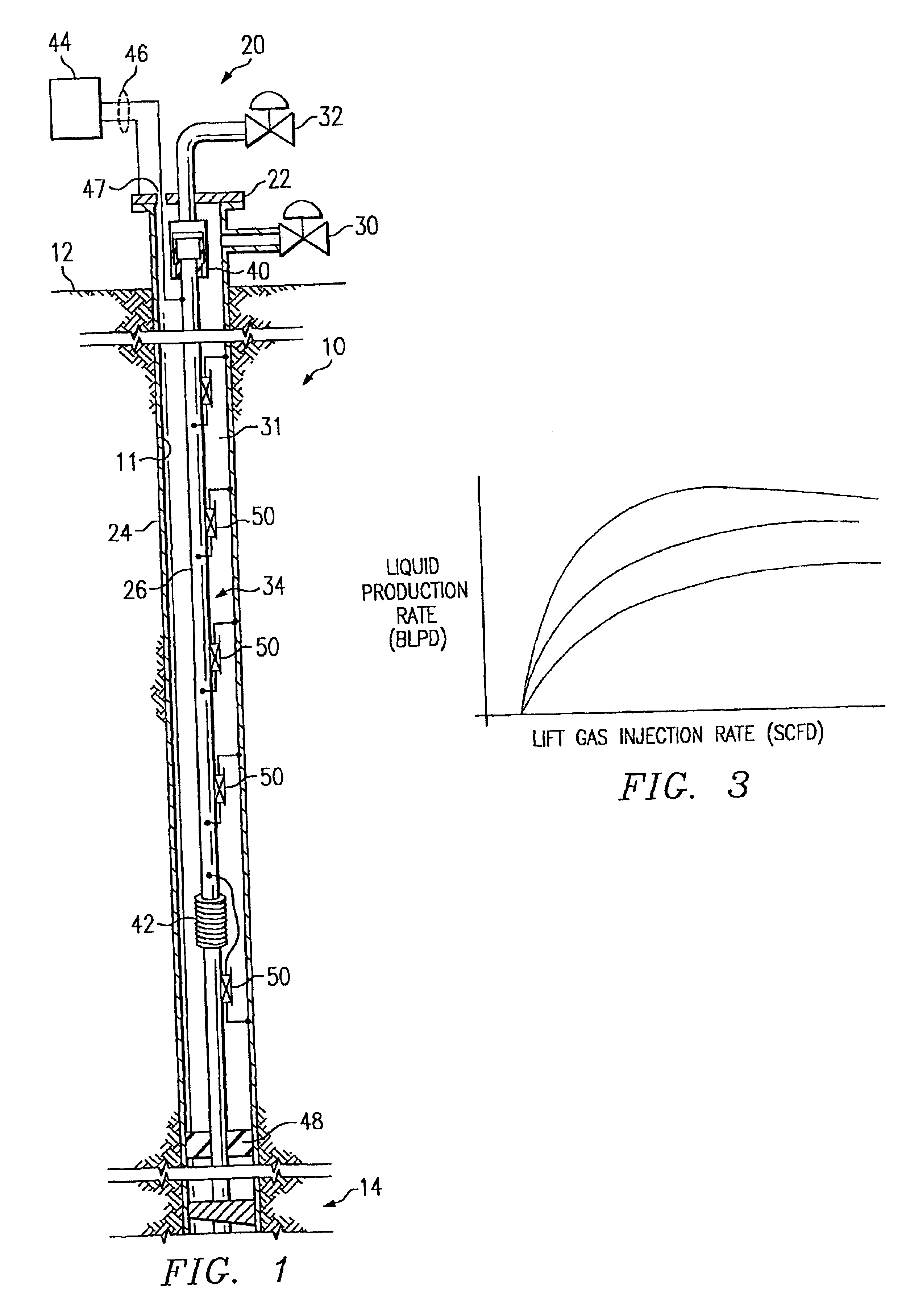

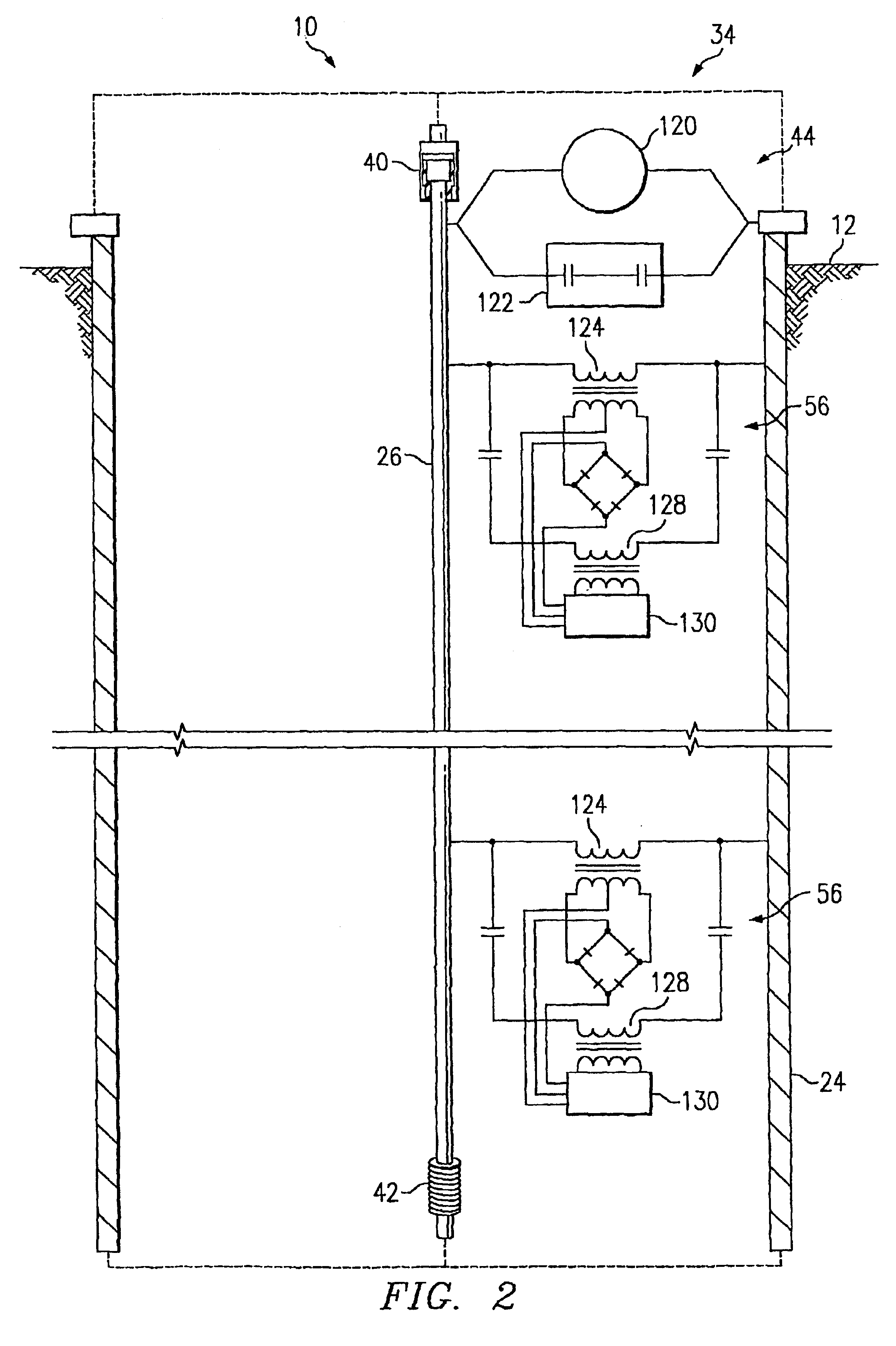

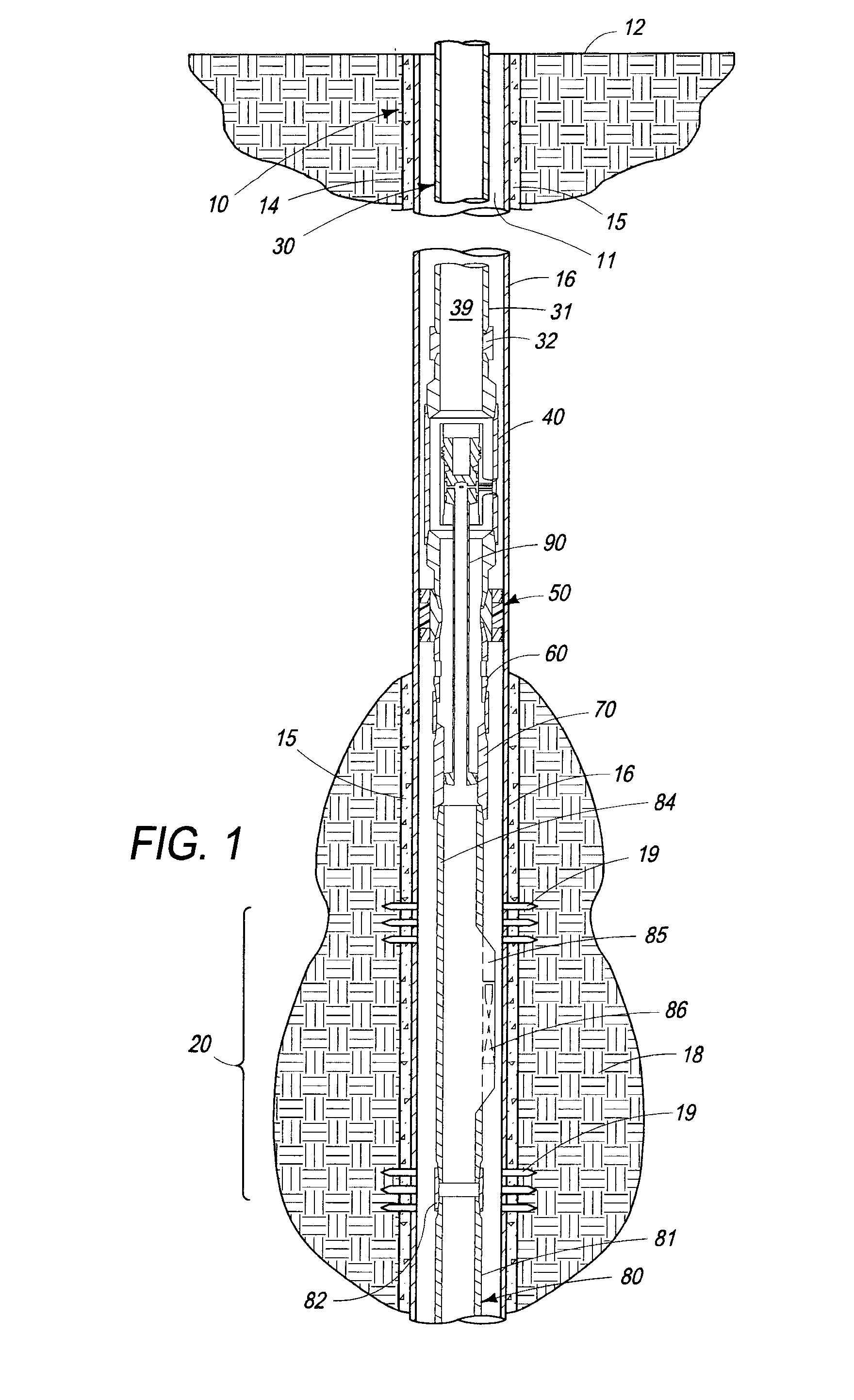

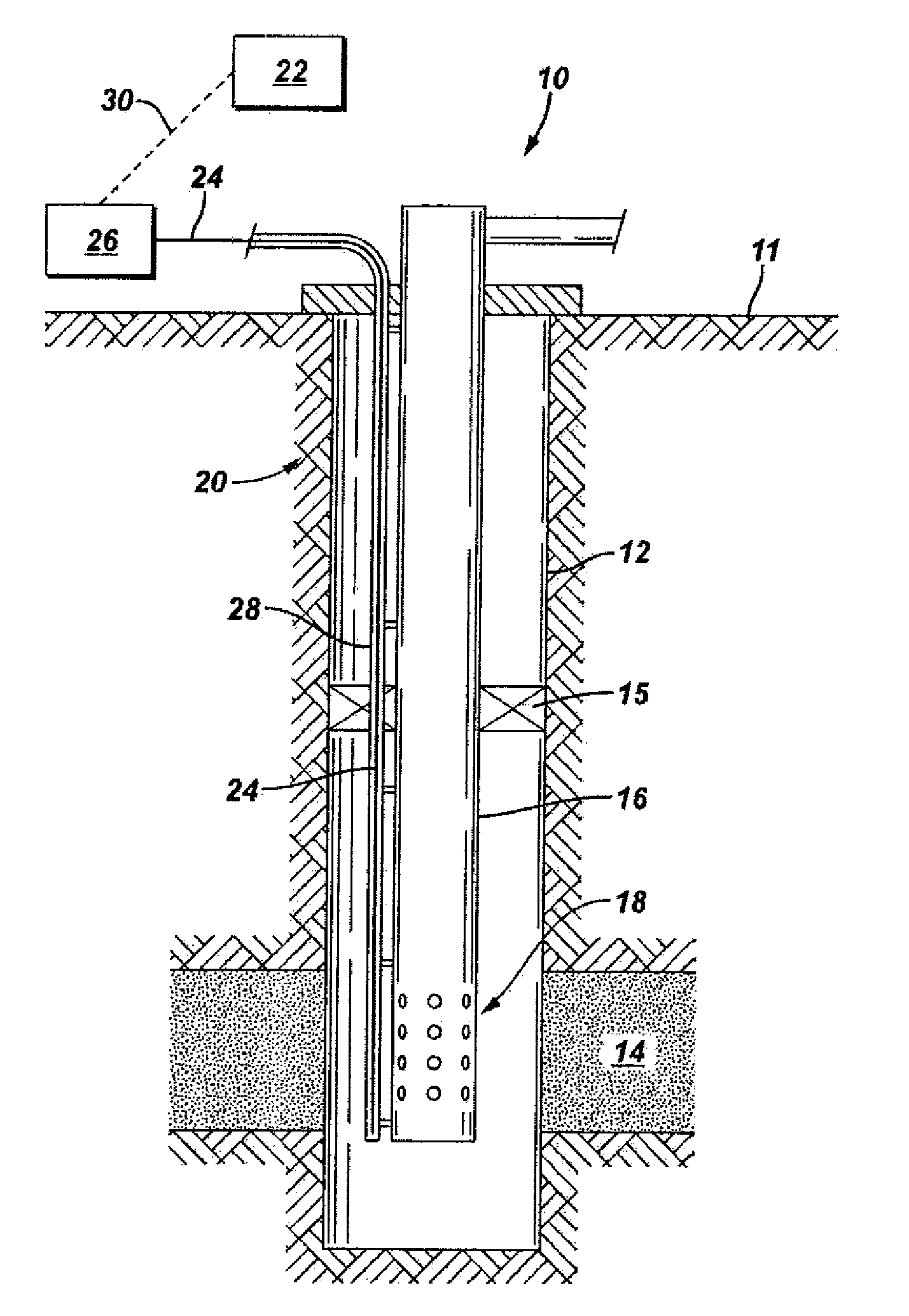

Use of downhole high pressure gas in a gas-lift well and associated methods

InactiveUS7147059B2Simplified installation procedureLow costNear-field transmissionSurveyElectrical conductorPetroleum product

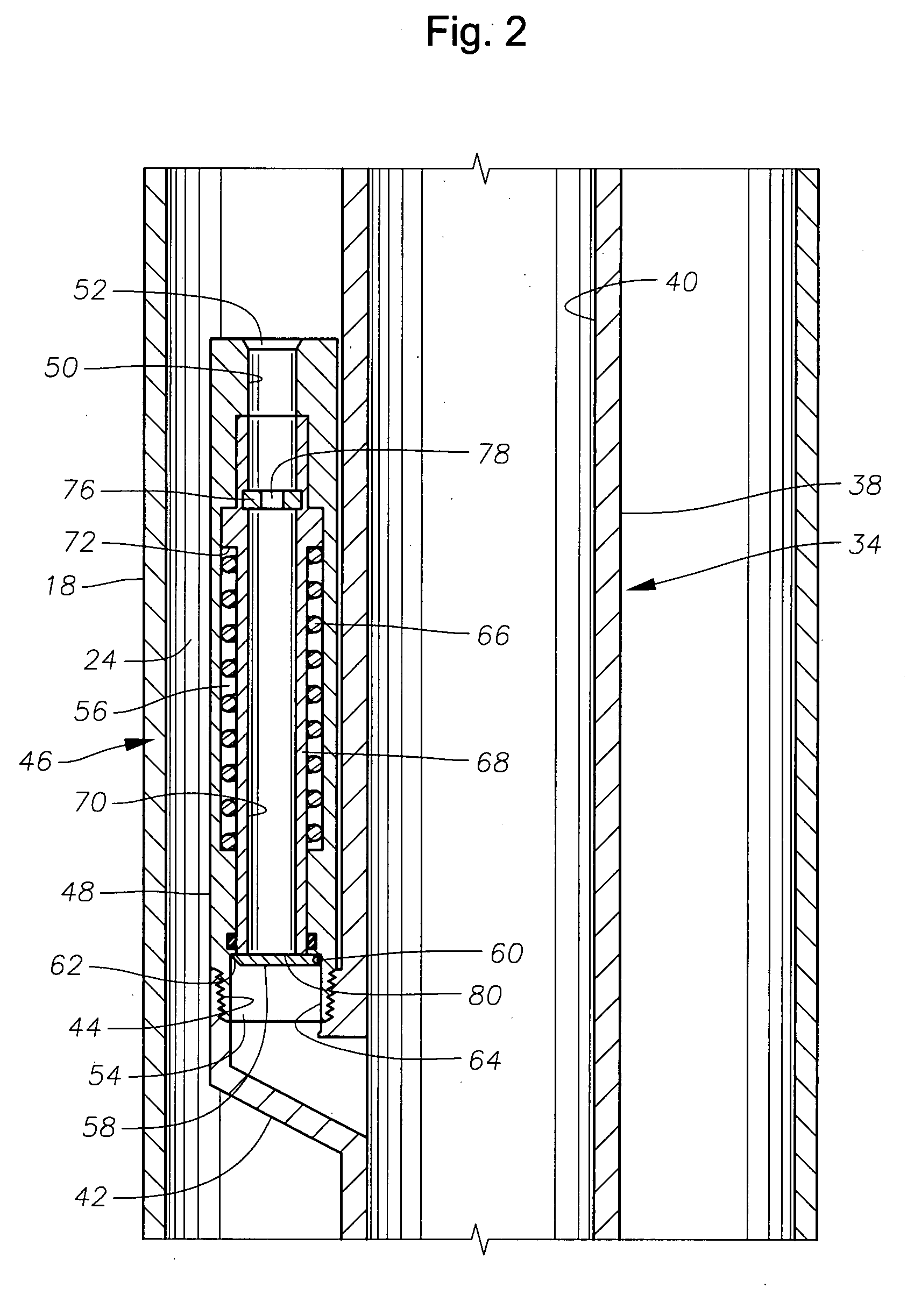

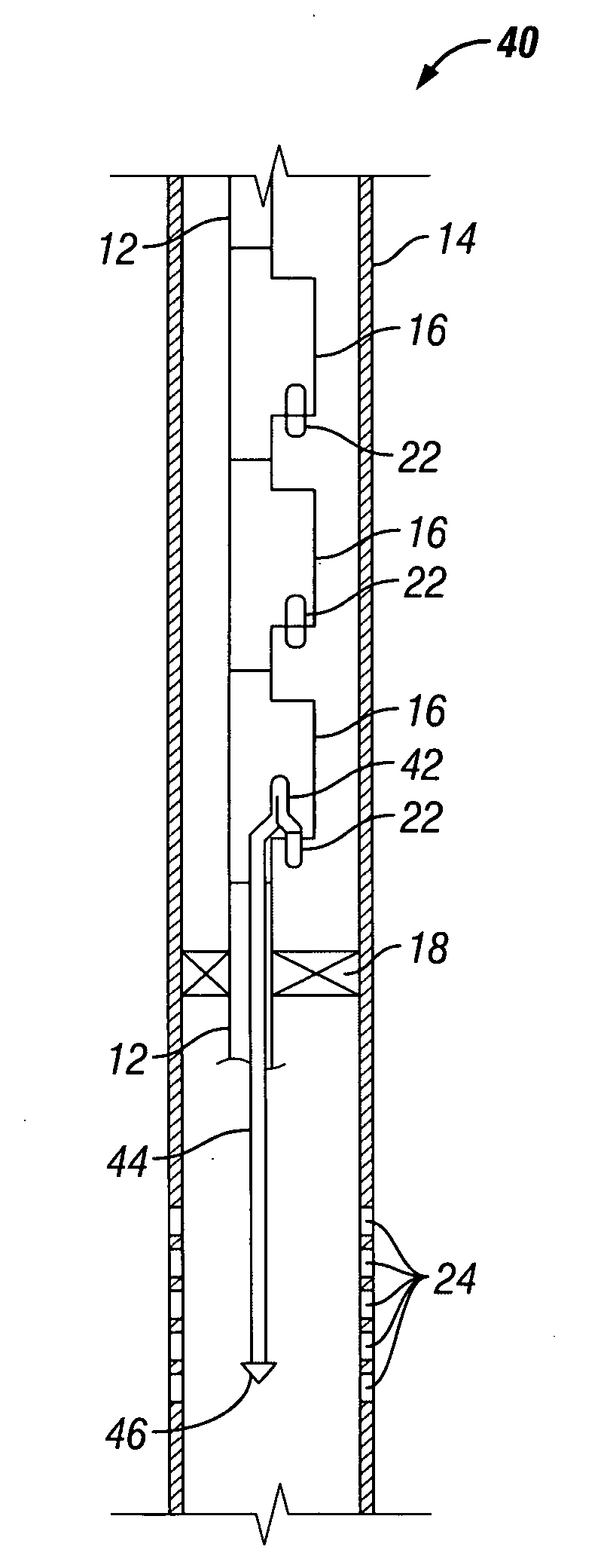

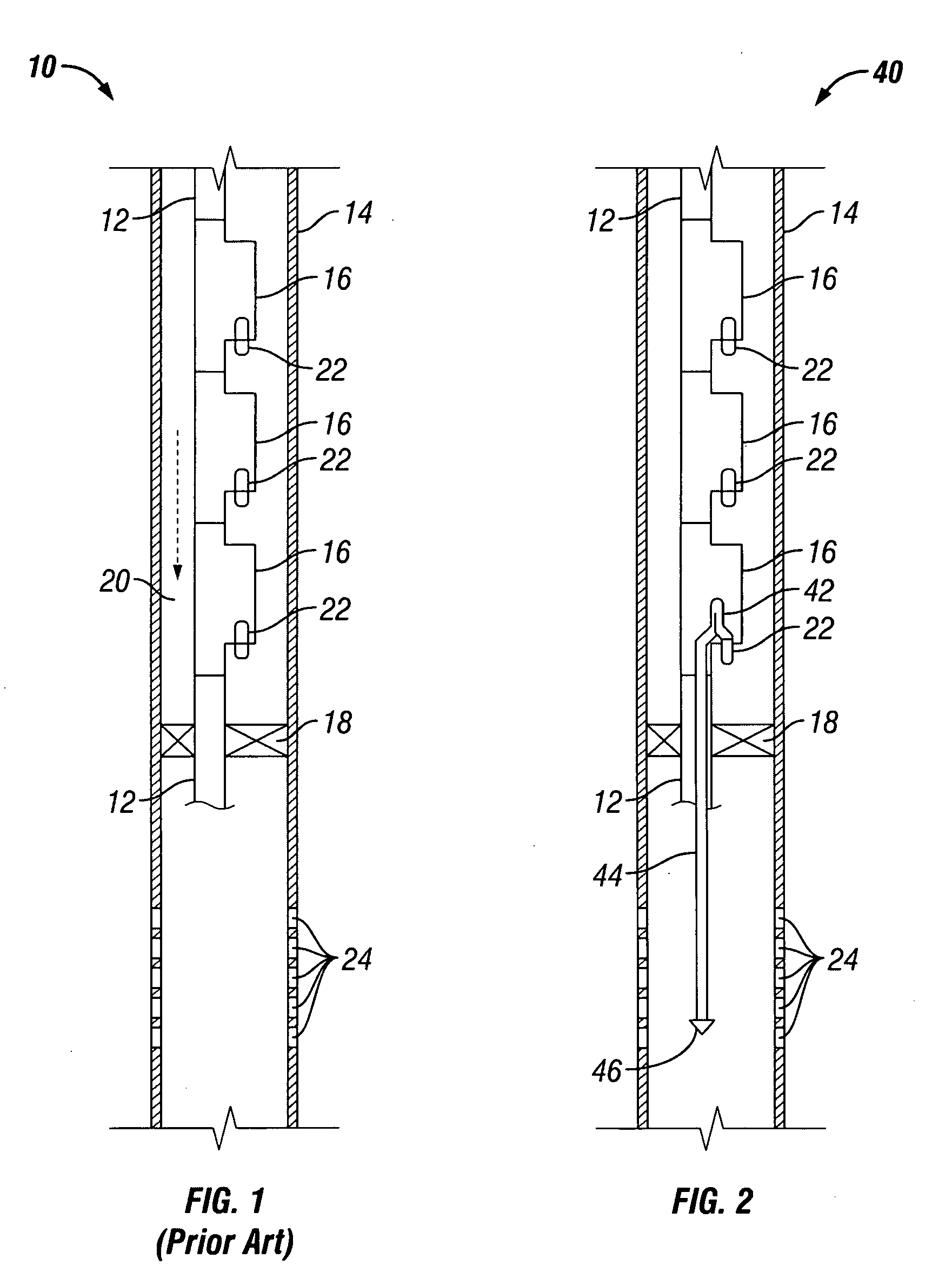

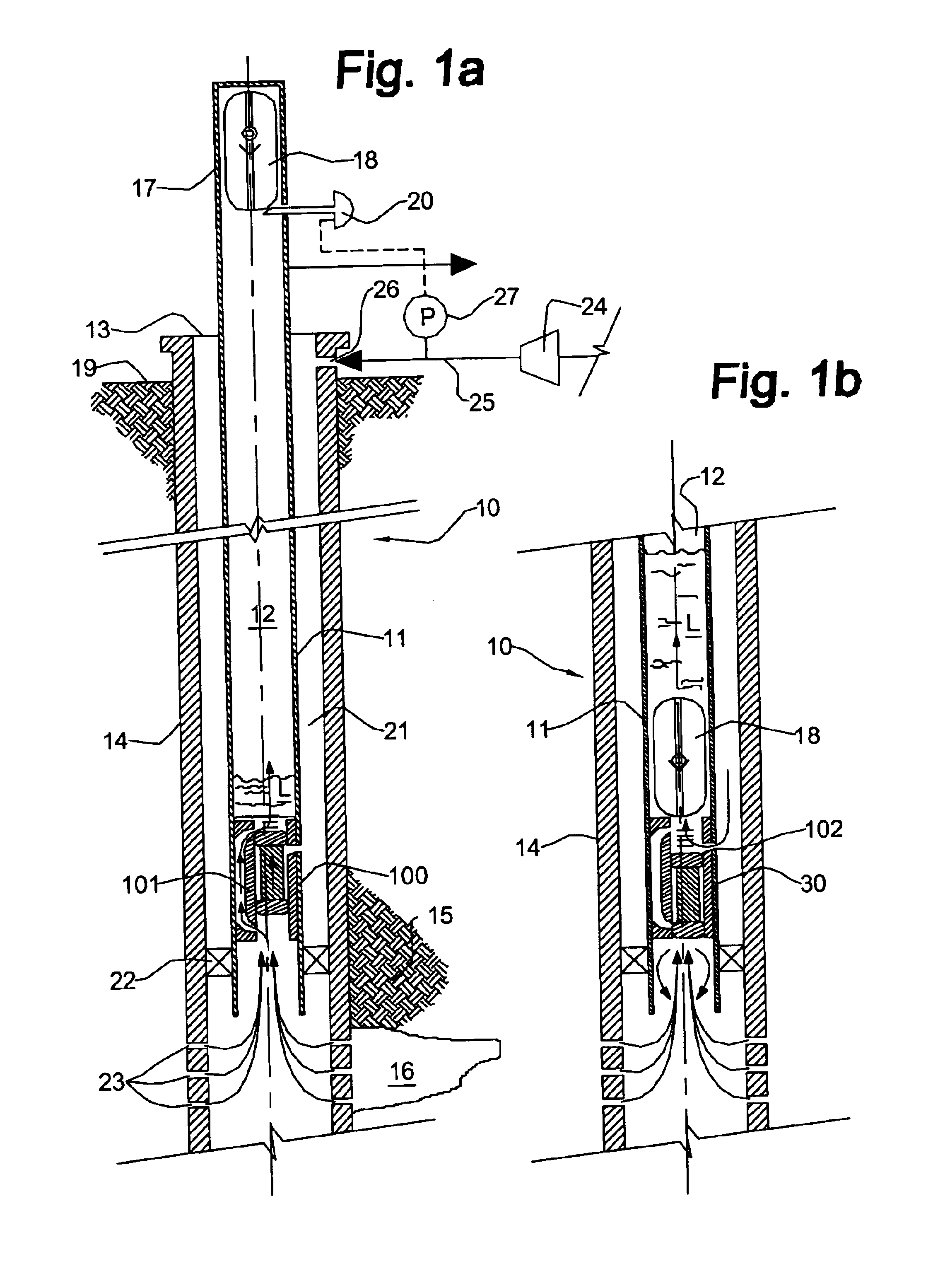

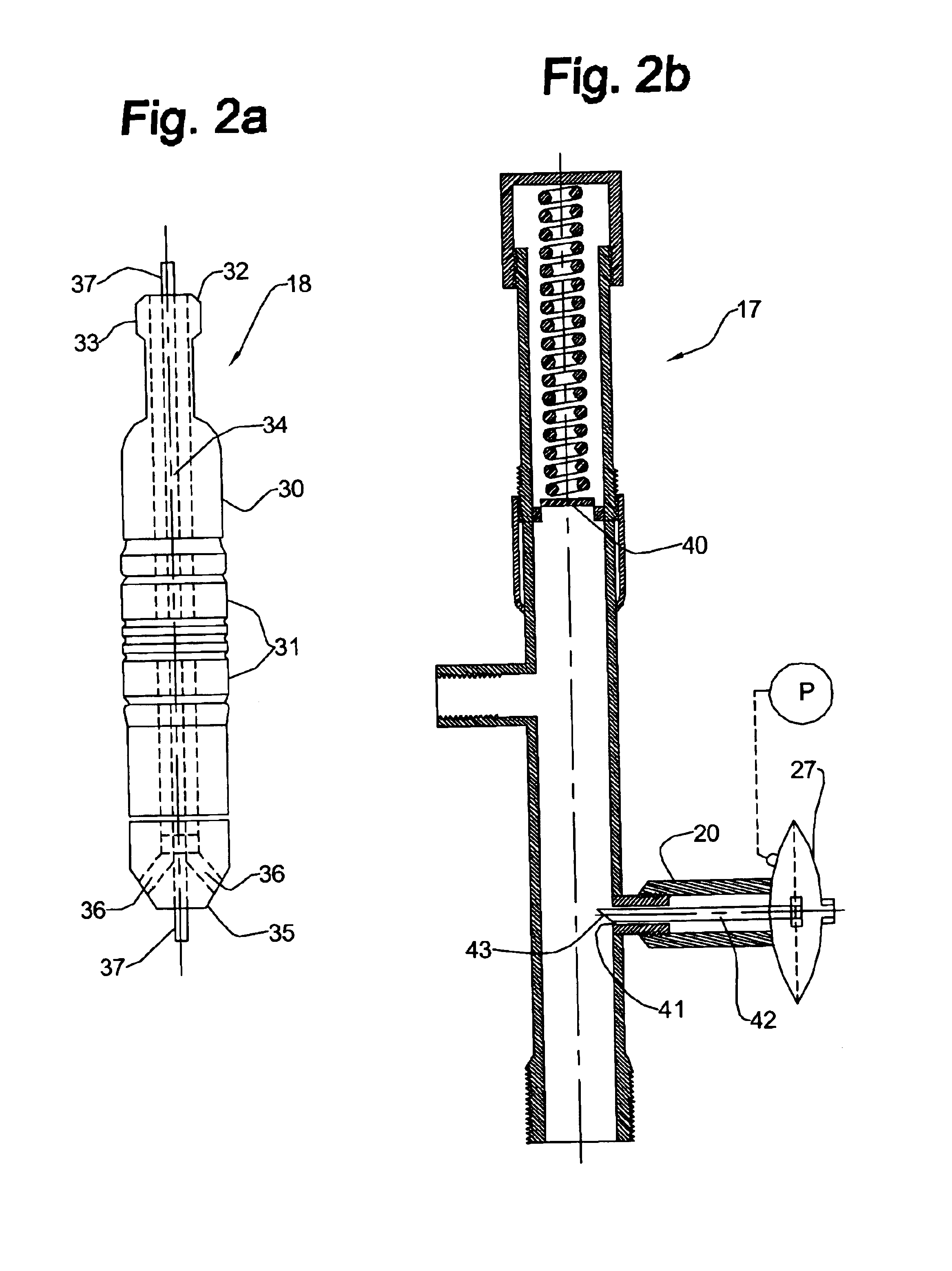

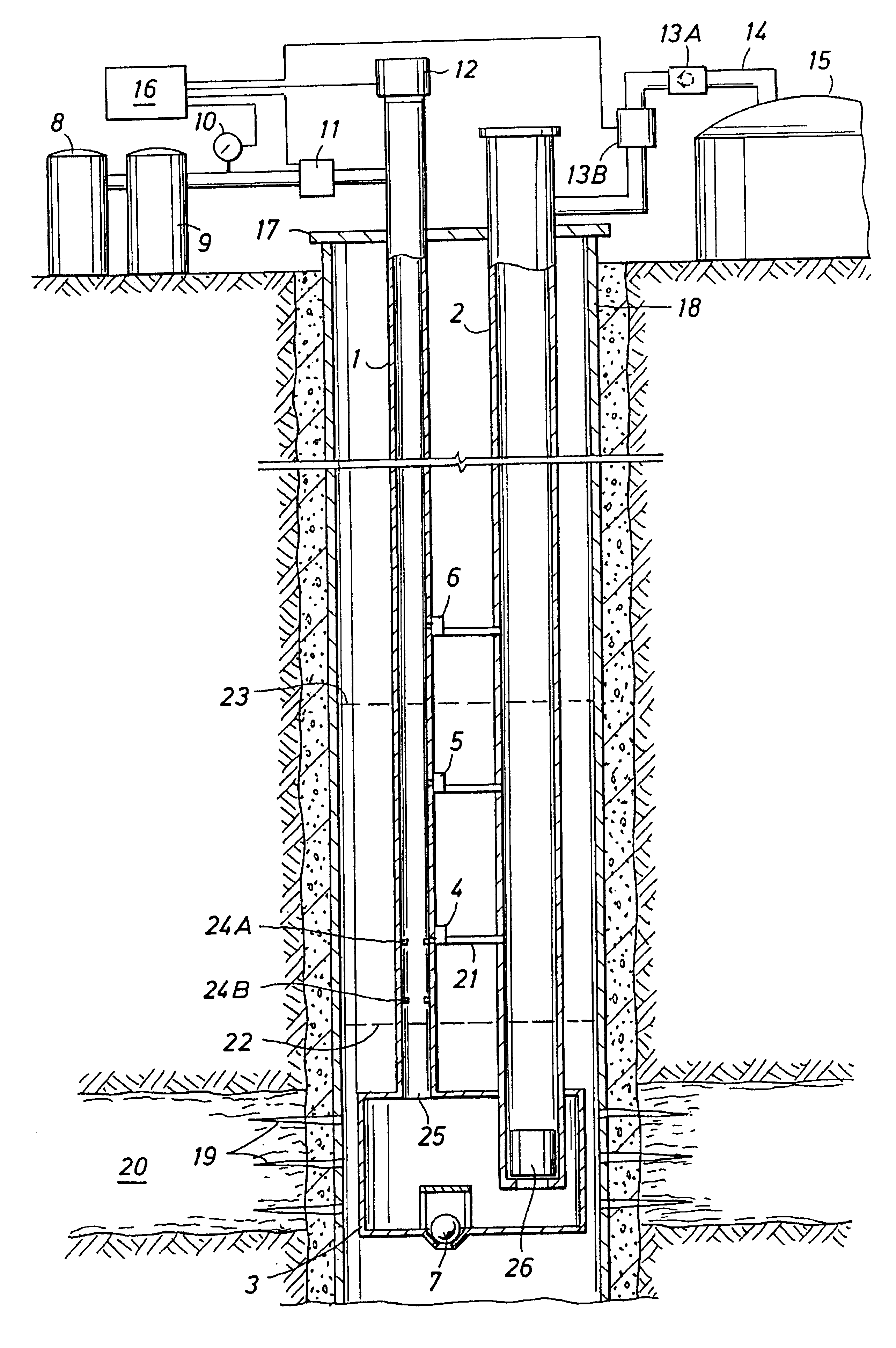

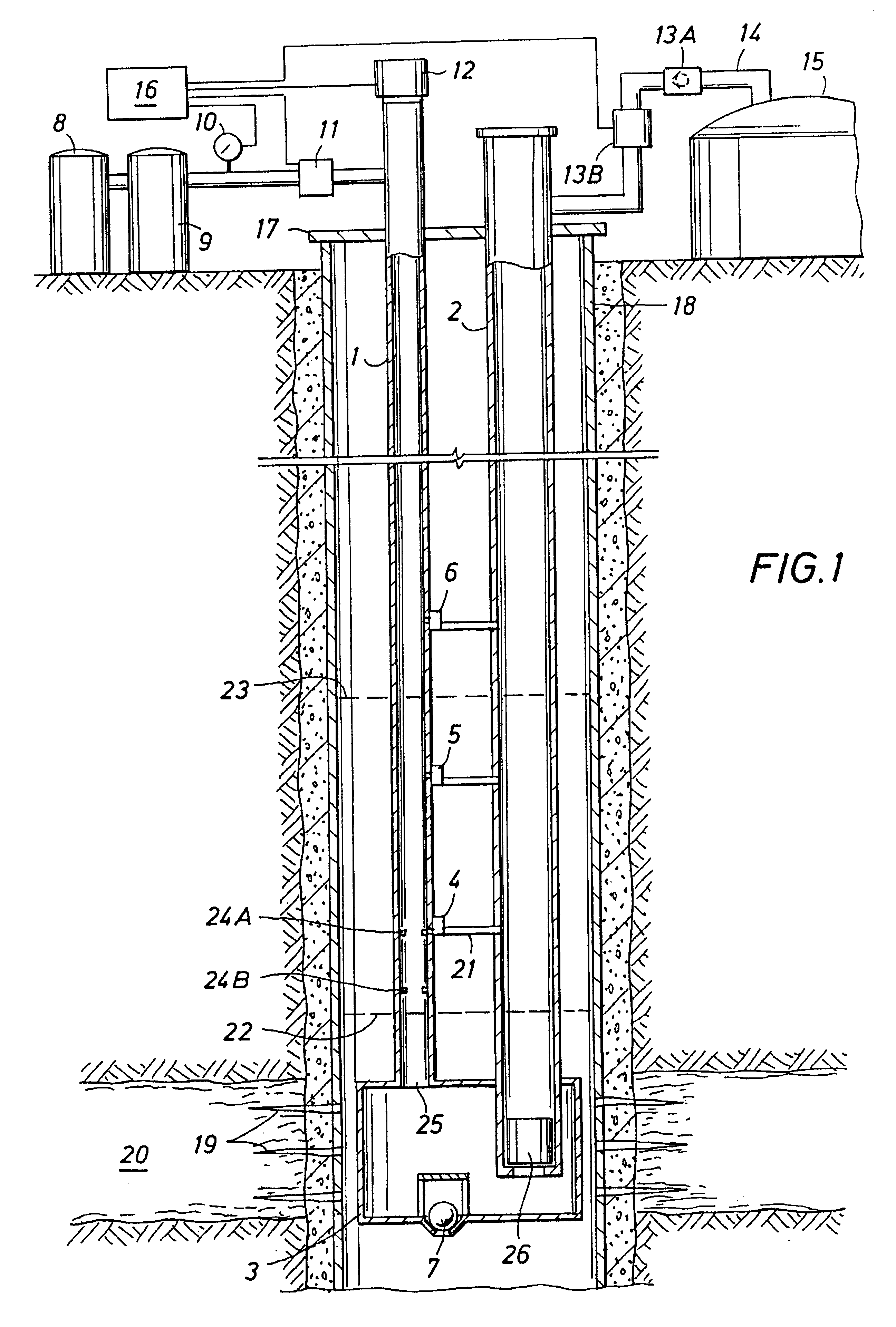

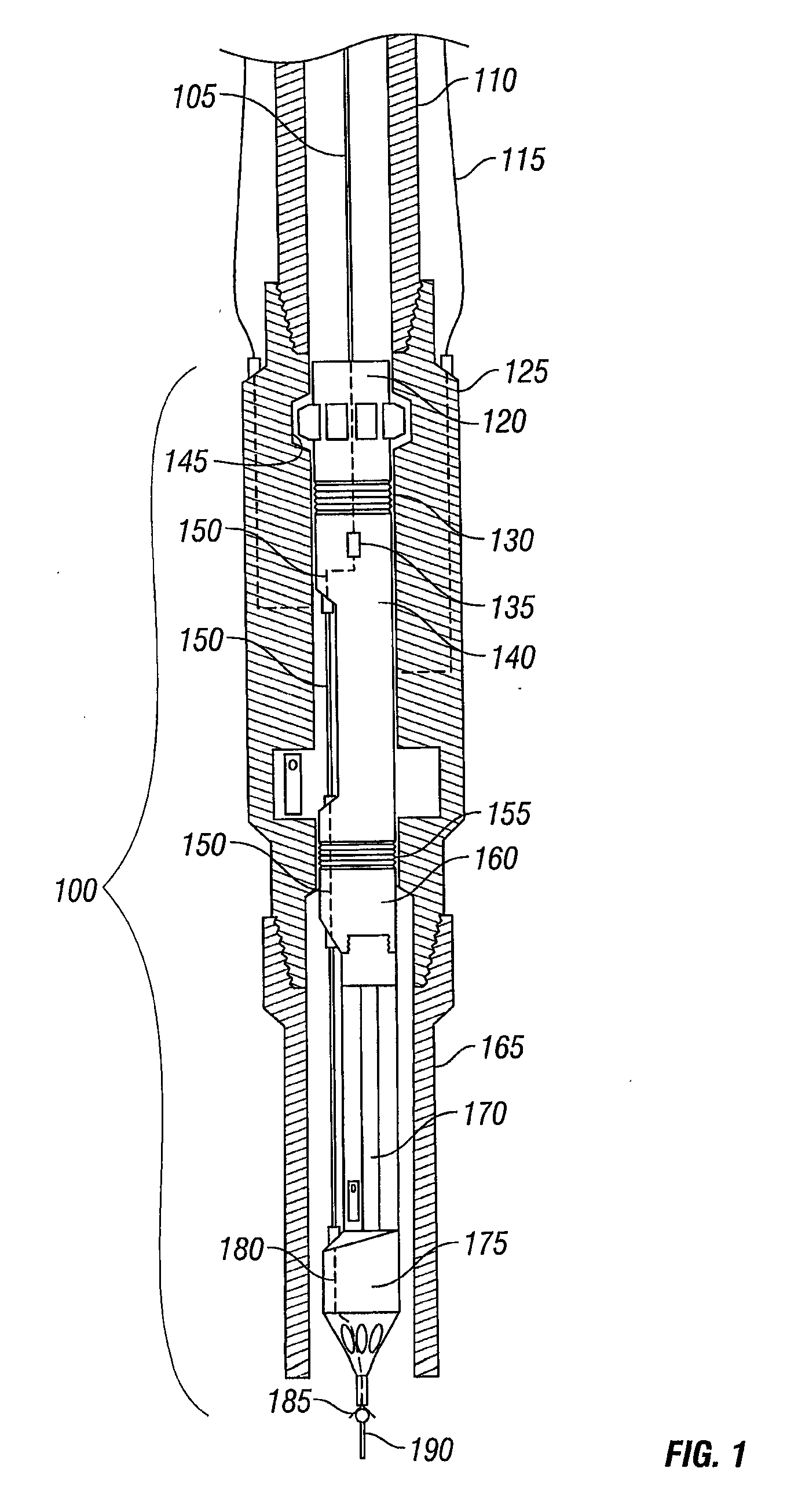

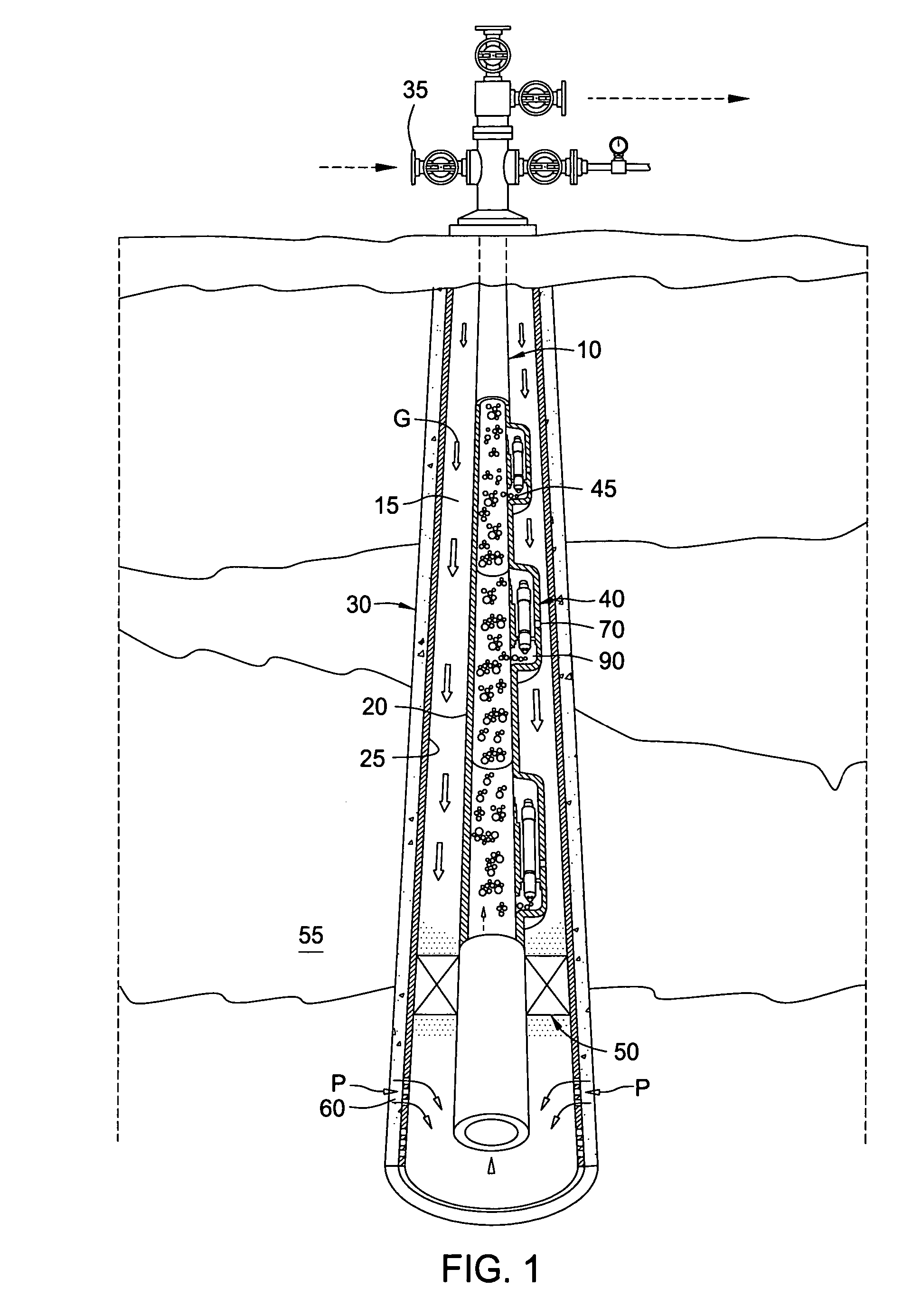

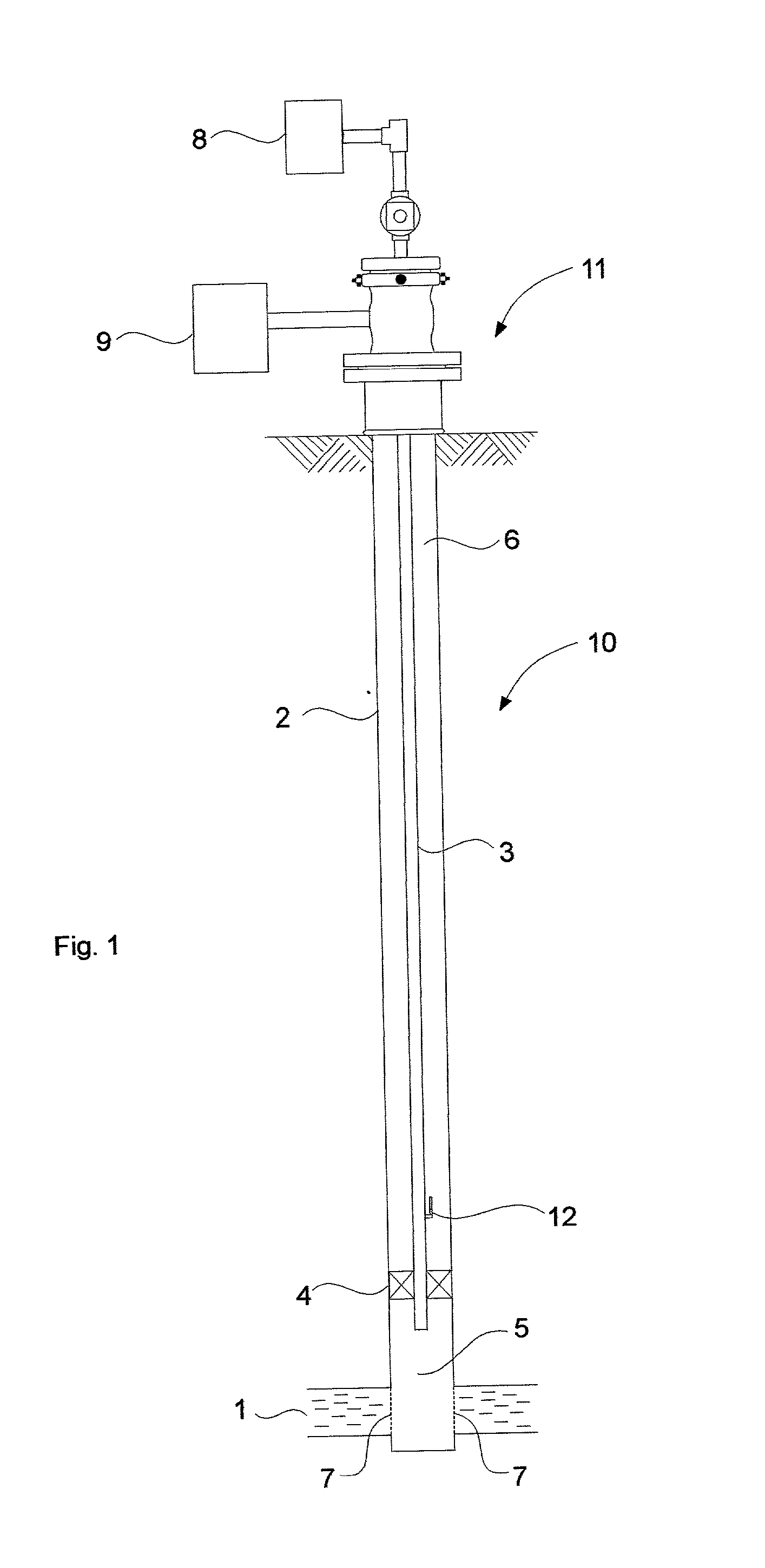

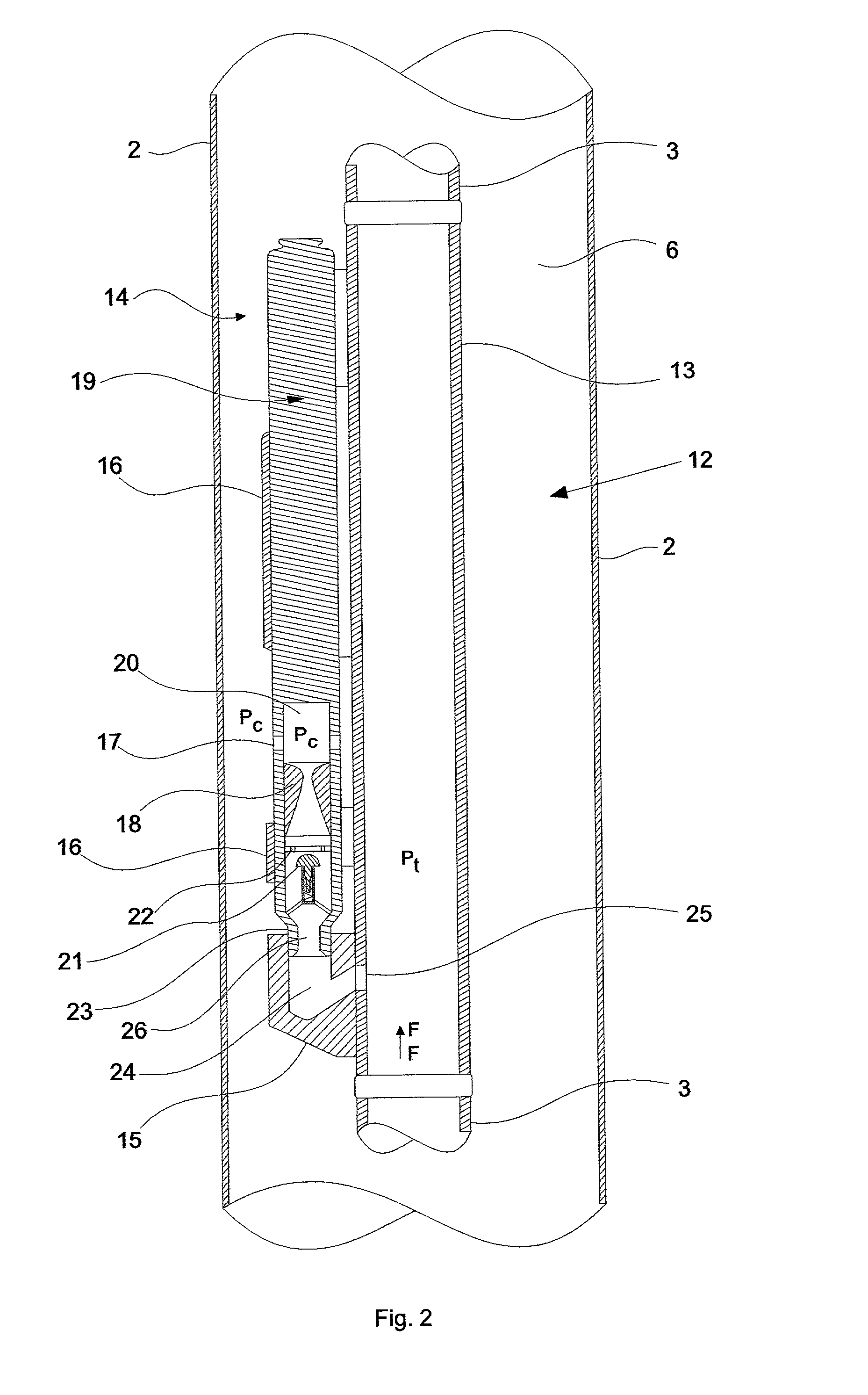

A gas-lift petroleum well and method for producing petroleum products using downhole pressurized gas to provide lift. The gas-lift well having a well casing, a production tubing, a packer, and a gas-lift valve. The well casing extends within a wellbore of the well, and the wellbore extends through oil and gas zones. The production tubing extends within the casing. The tubing having an opening formed therein, which is in fluid communication with an oil zone. The packer is located downhole in the casing and coupled to the tubing. The packer can have an electrically controllable packer valve, which is adapted to control a flow of downhole pressurized gas from one side of the packer to another. The downhole pressurized gas is provided by a gas zone that the wellbore passes through. The downhole gas-lift valve is coupled to the tubing and is adapted to control a flow of downhole pressurized gas into oil in the tubing for lifting the oil. The gas-lift valve can be an electrically controllable valve. The tubing and casing are used as electrical conductors for supplying power and / or communications downhole. The current in the tubing is routed using a ferromagnetic induction choke to create a voltage potential, which provides electrical power to downhole electrical devices. Also, there may be a bypass passageway to route downhole gas to gas-lift valves. There may also be downhole sensors to measure physical quantities (e.g., pressure). Such measurements can be used for feedback control of downhole electrically controllable valves.

Owner:SHELL OIL CO

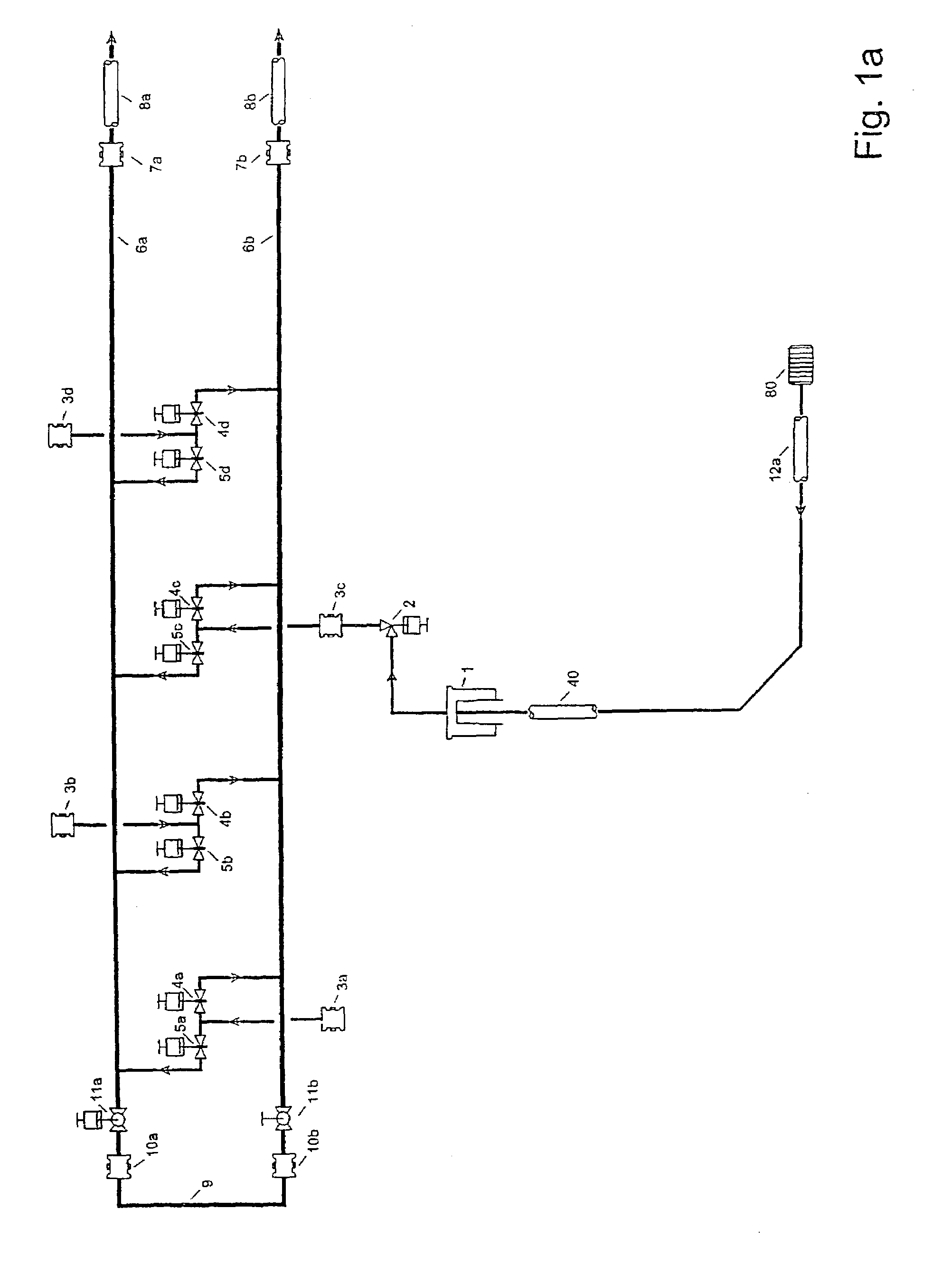

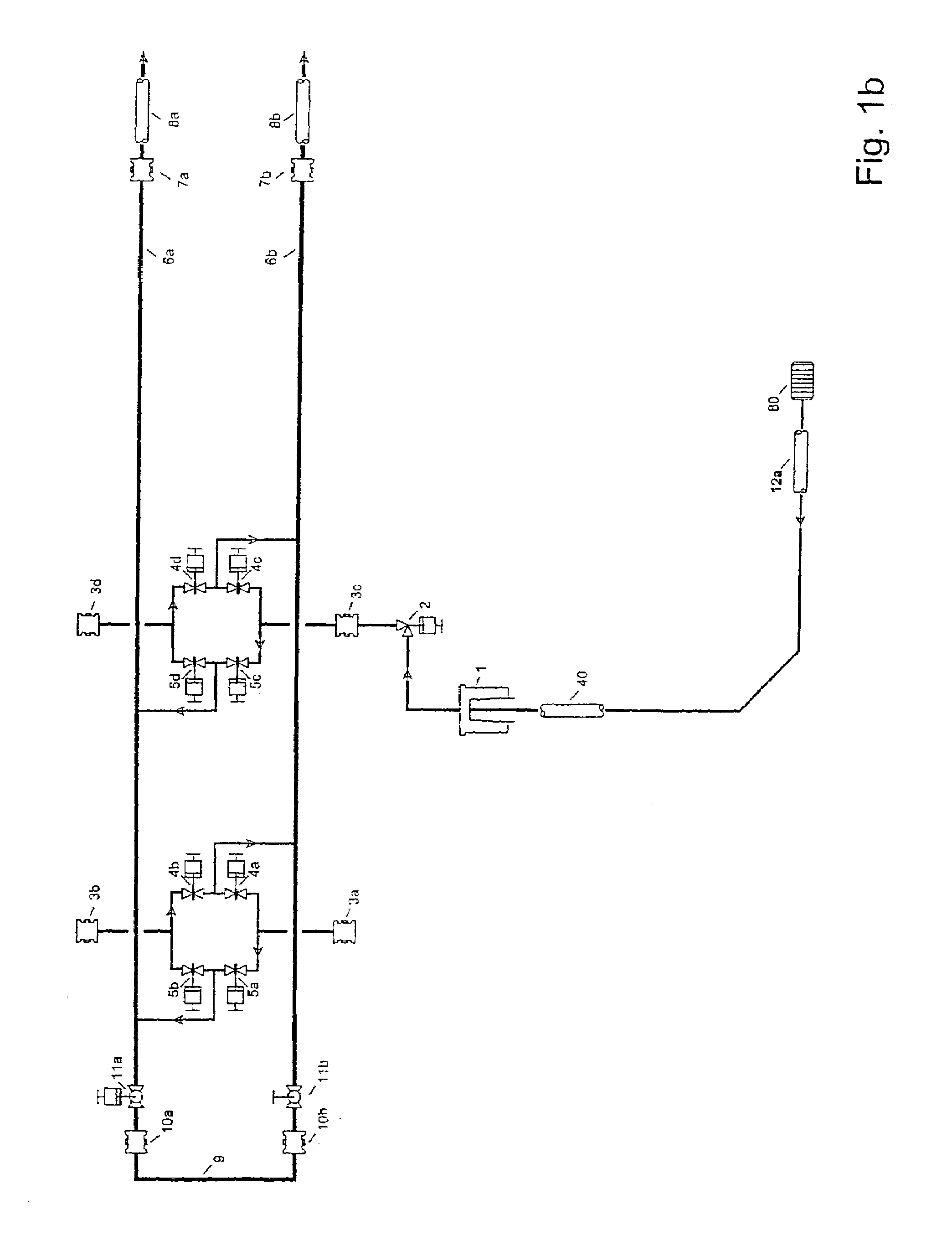

Subsea production system

InactiveUS7093661B2Increase supplyEasy to controlCleaning apparatusSettling tanks feed/dischargePetroleum productPigging

Methods and arrangements for production of petroleum products from a subsea well. The methods comprise control of a downhole separator, supplying power fluid to a downhole turbine / pump hydraulic converter, performing pigging of a subsea manifold, providing gas lift and performing three phase downhole separation. Arrangement for performing the methods are also described.

Owner:AKER SUBSEA LTD

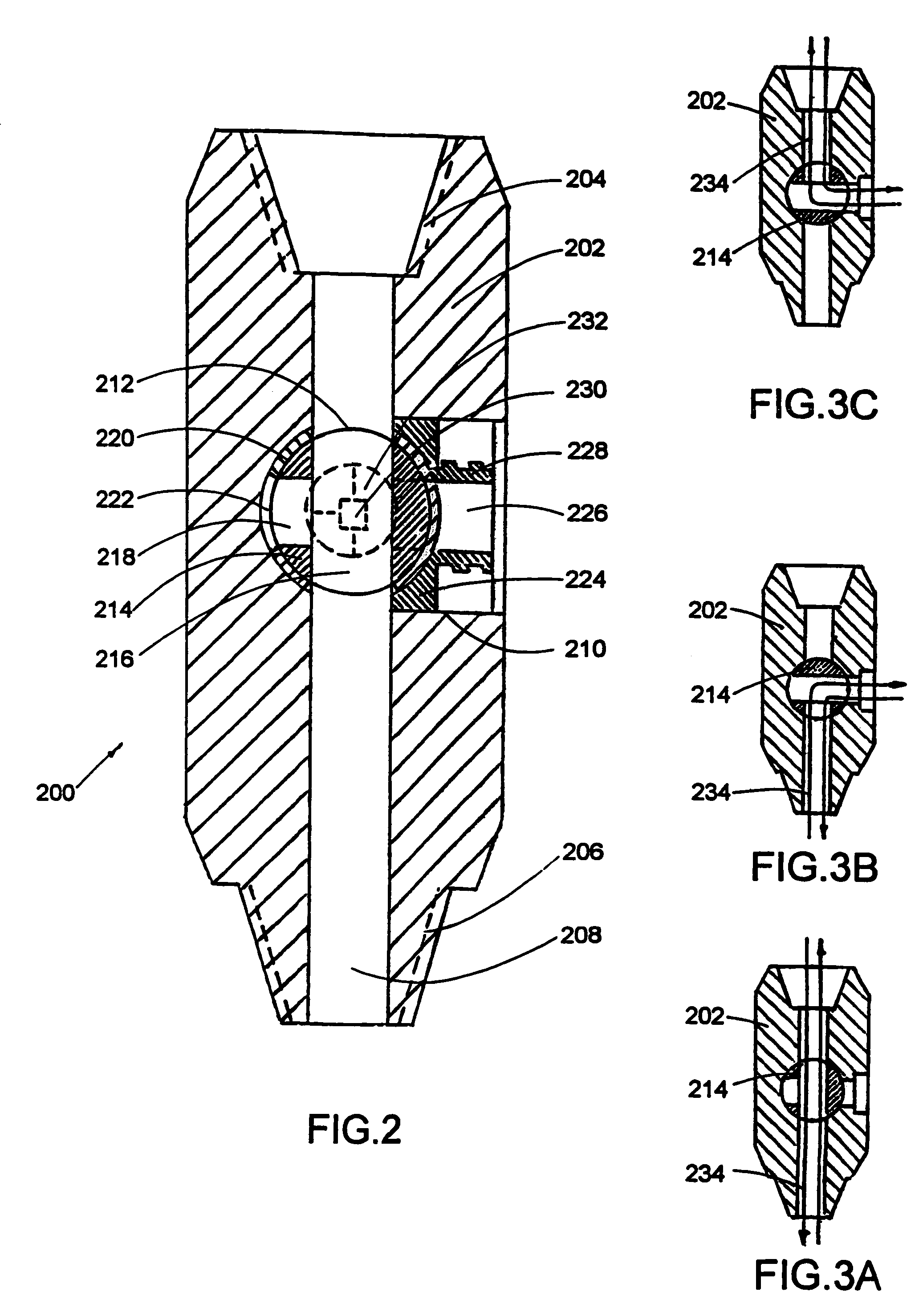

Barrier orifice valve for gas lift

ActiveUS20070181312A1Increase flow ratePrevent backflowPressure pumpsFluid removalEngineeringGas lift

Gas lift valve designs and gas lift systems are described that feature a positive closure mechanism that is highly resistant to significant wear or damage that would result in fluid leakage. A pivotable flapper member is incorporated into a gas lift valve and used as a flow control mechanism. The flapper member provides a positive barrier to fluid flow from the production tubing to the annulus, even after substantial wear or damage.

Owner:BAKER HUGHES INC

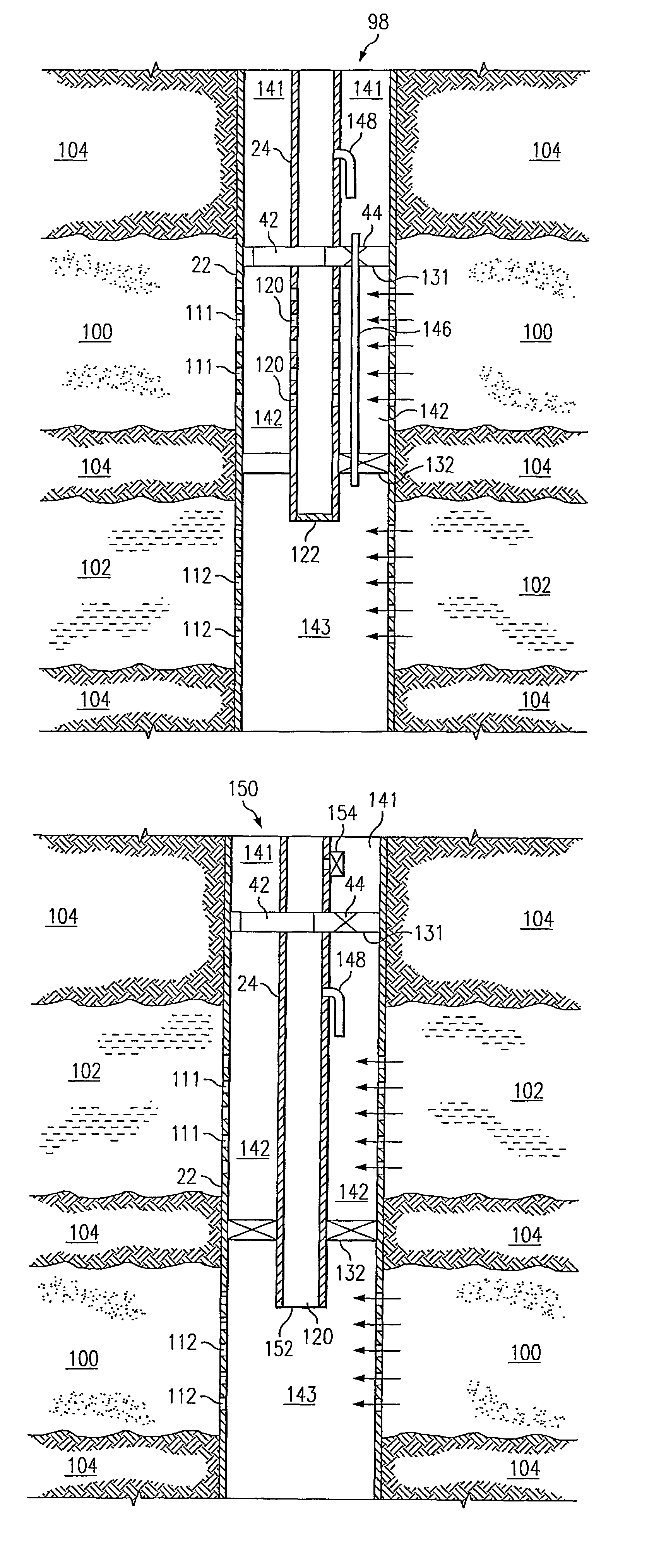

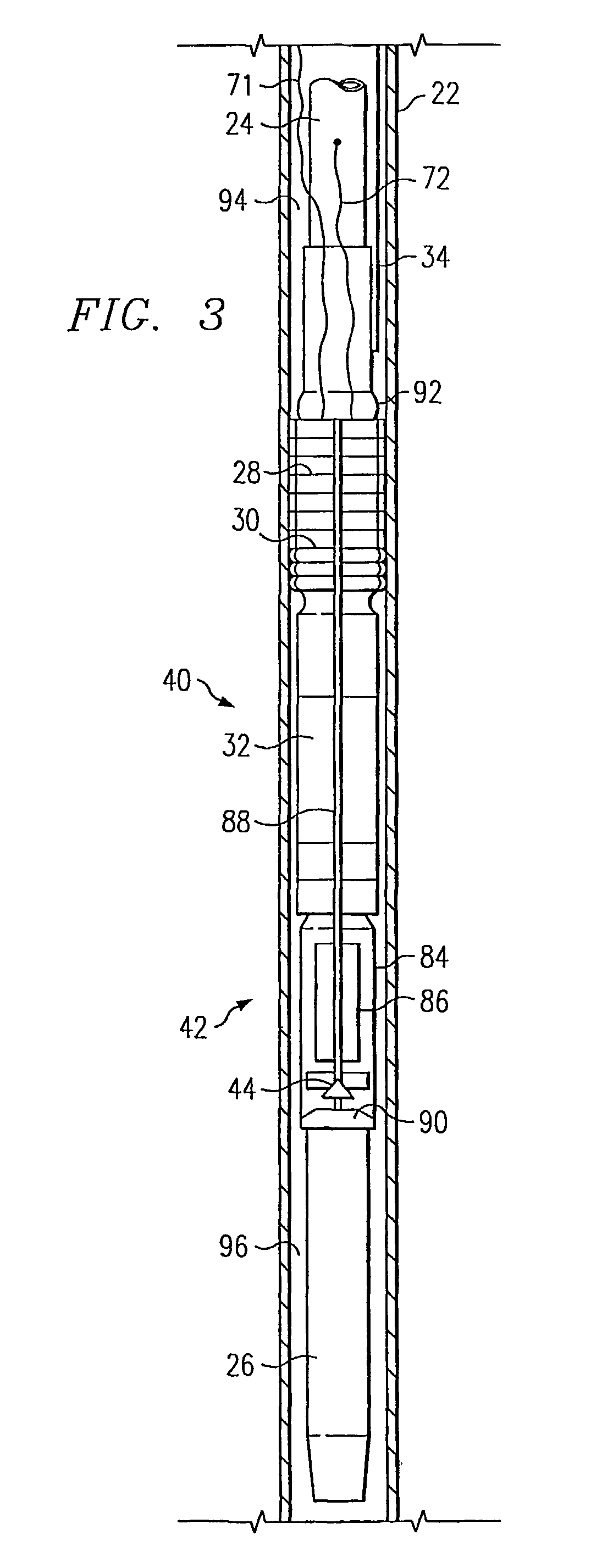

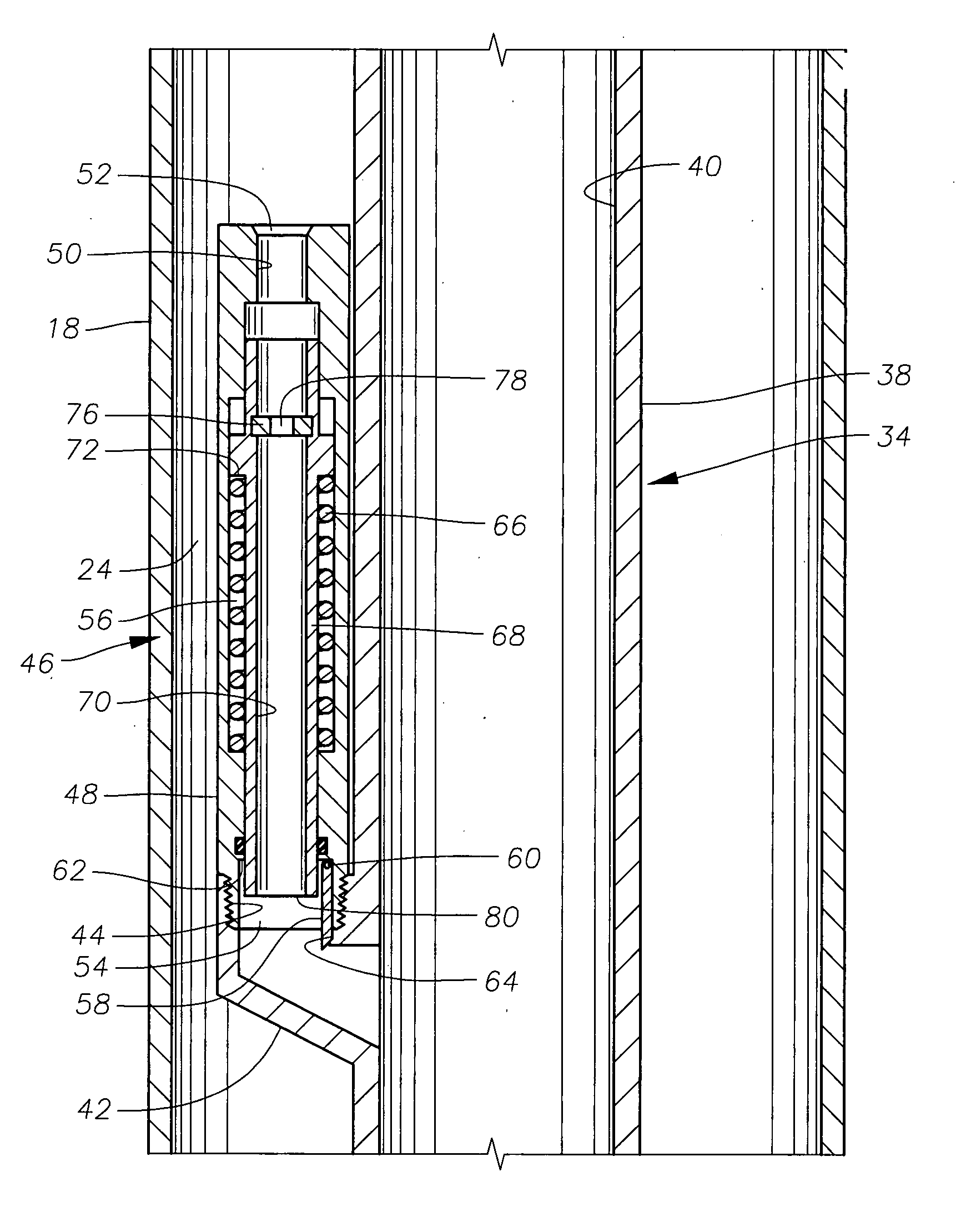

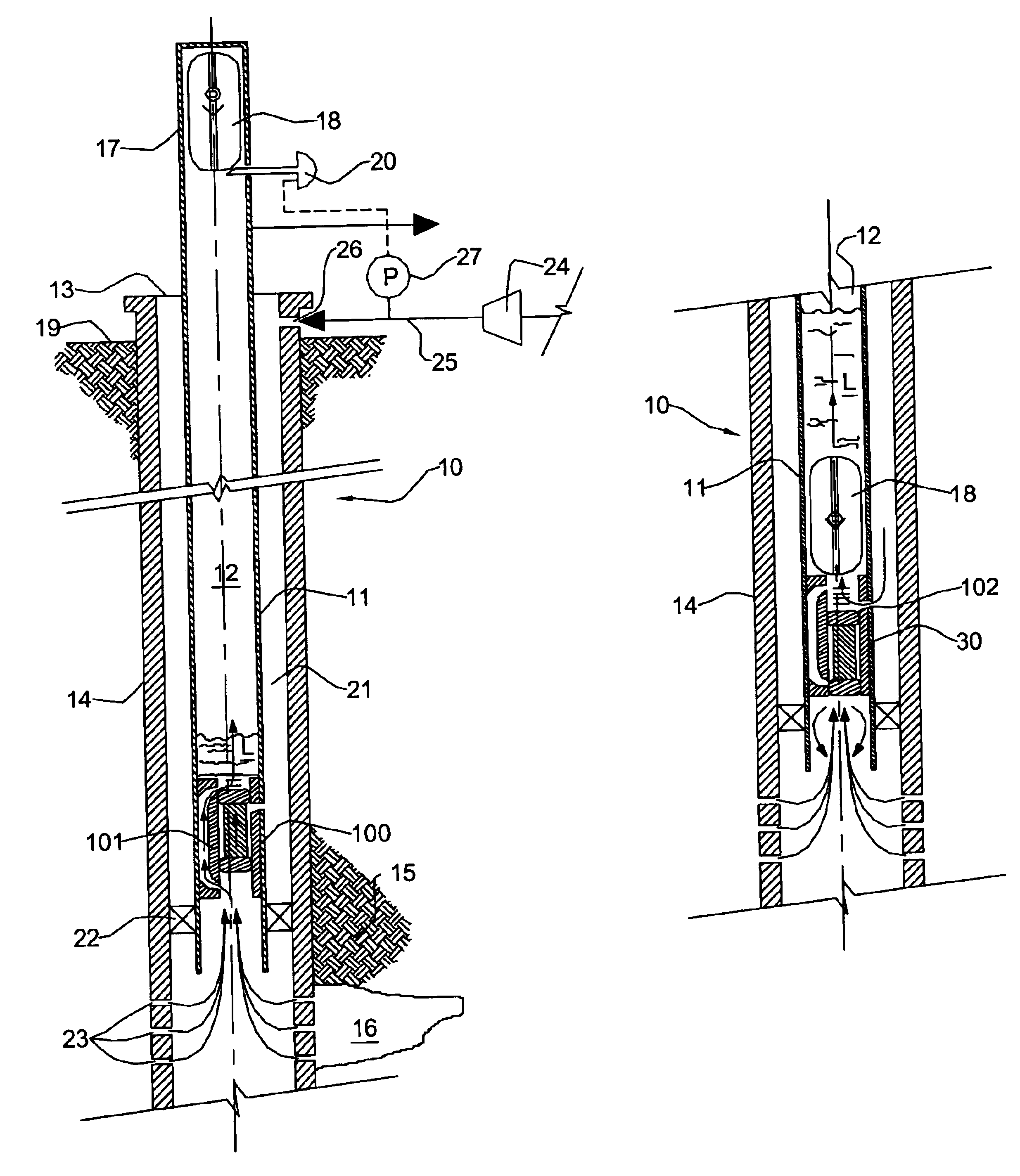

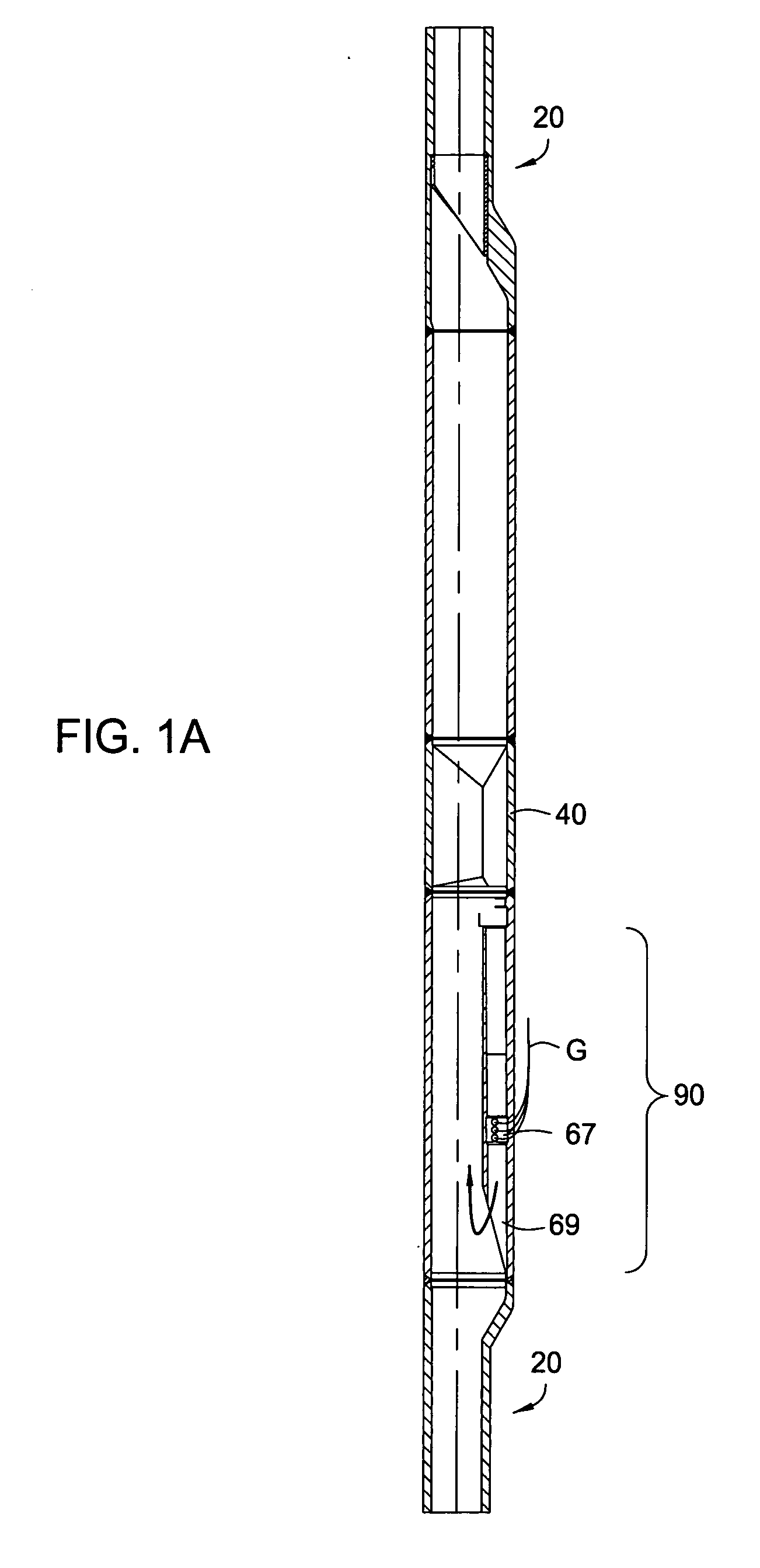

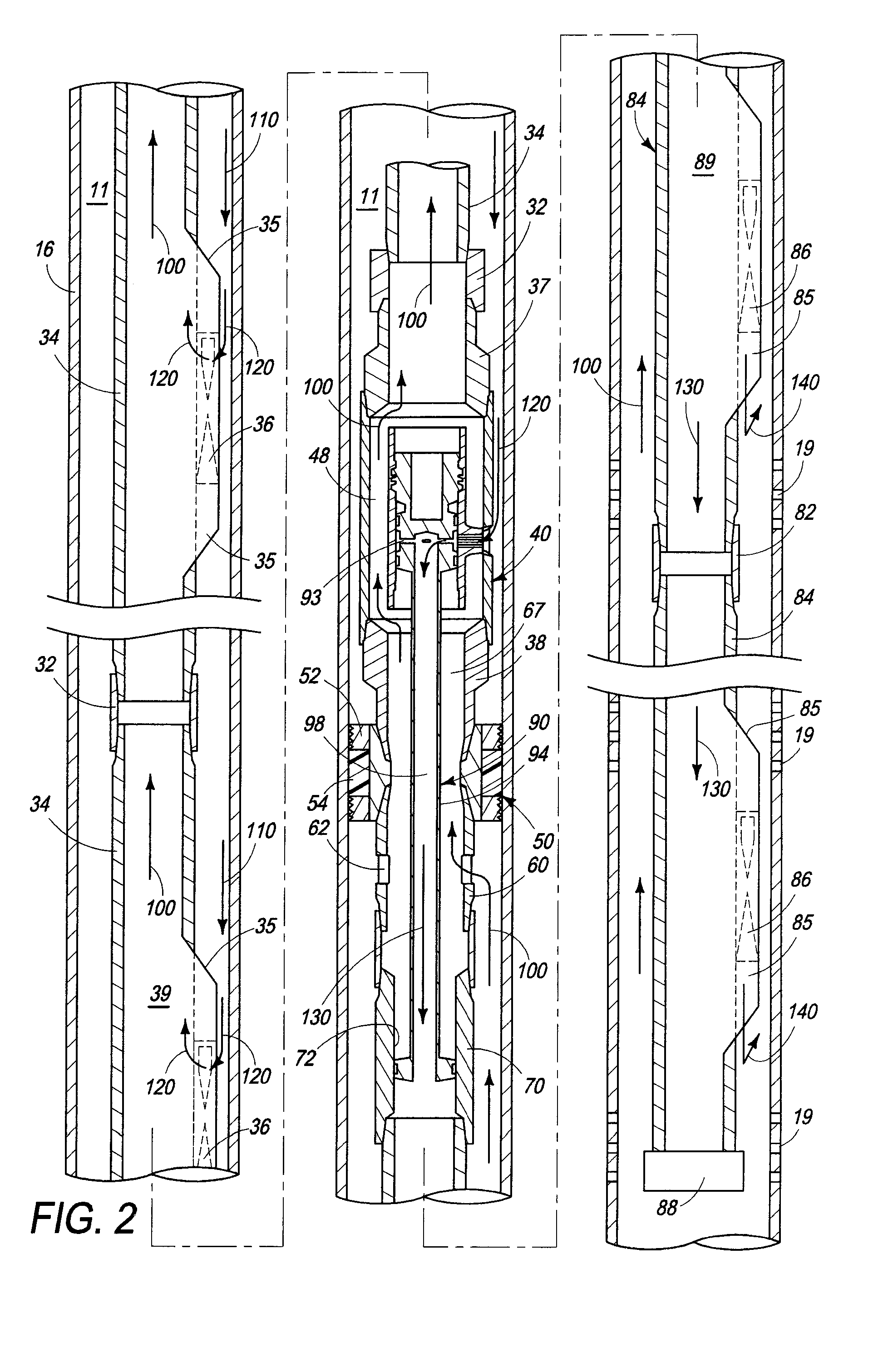

System and method for thru tubing deepening of gas lift

ActiveUS20090255684A1Blowout preventionFluid removalWell/borehole valve arrangementsProduction packerInjection point

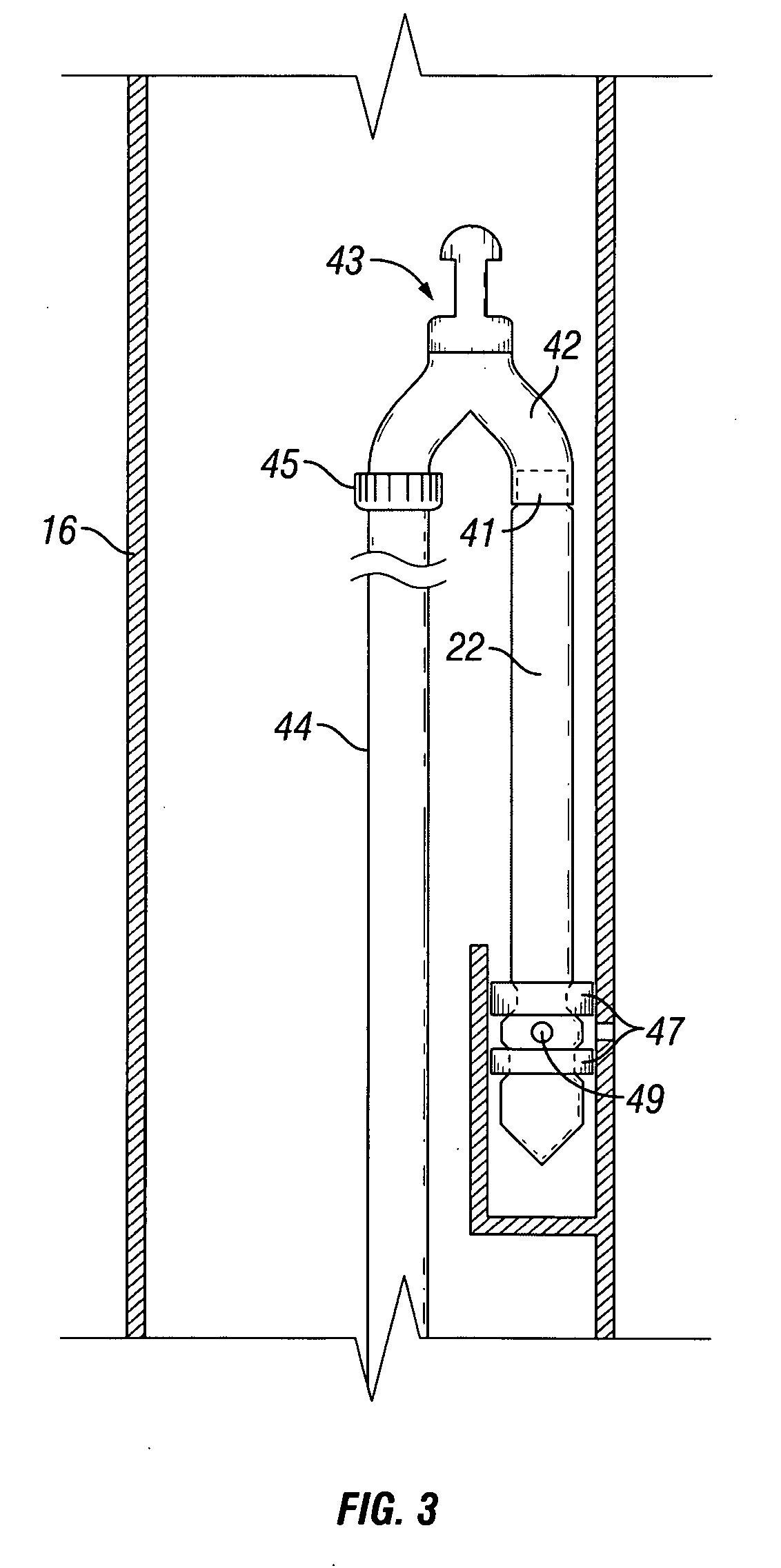

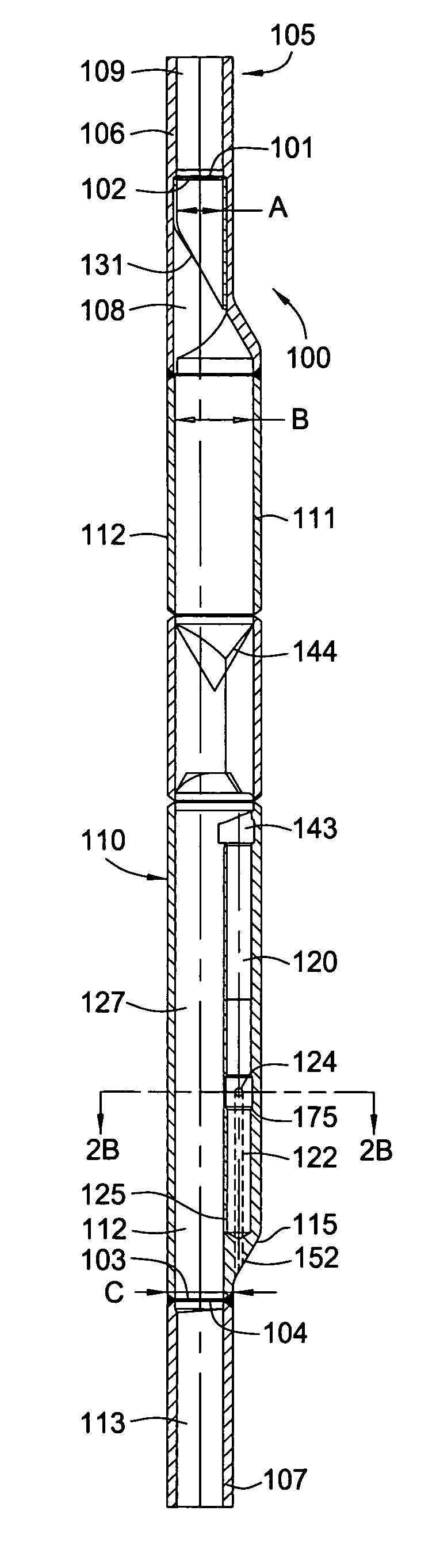

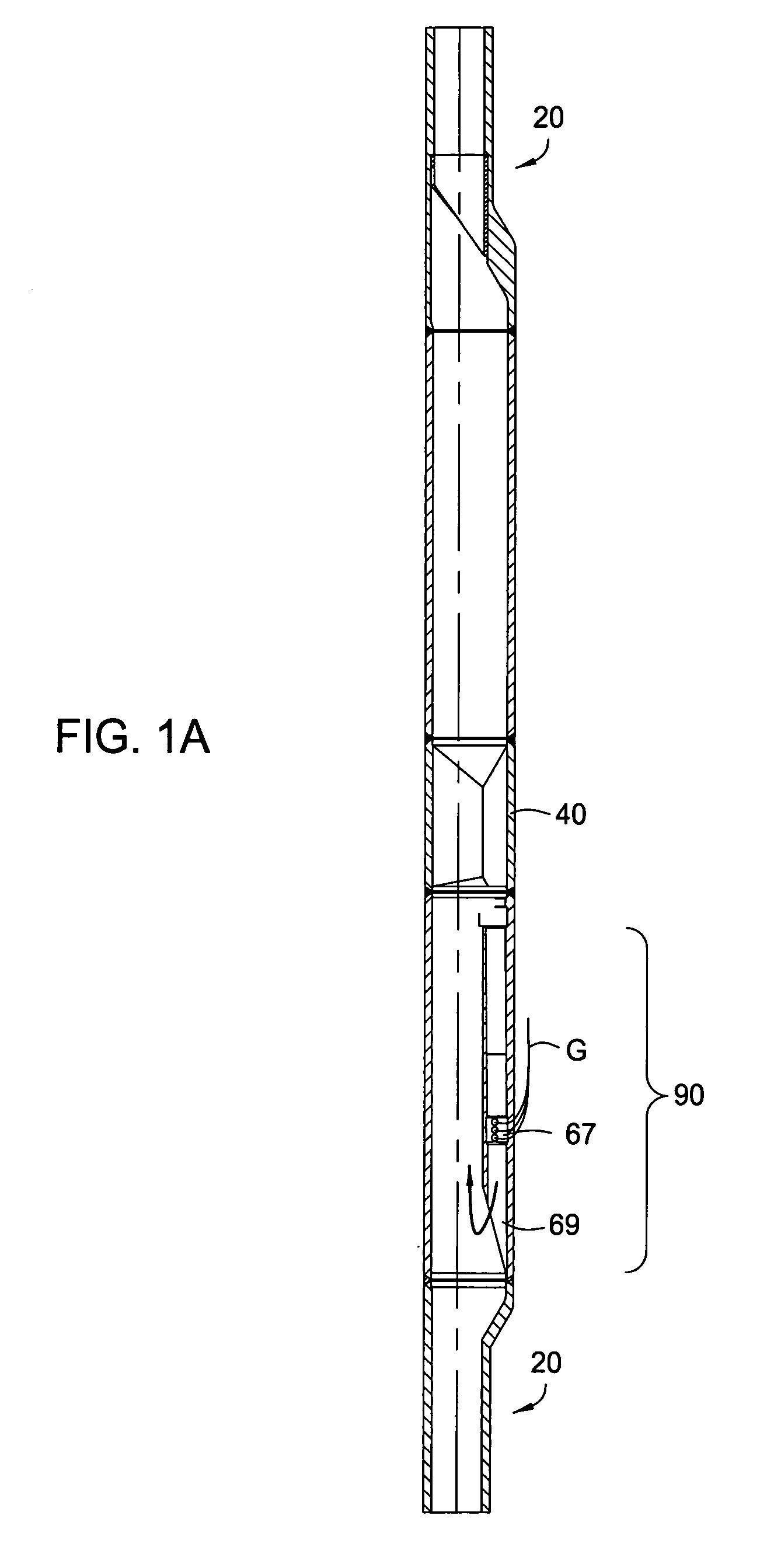

The present disclosure is directed to a gas lift system adapted to provide a gas injection point to a deeper location in a wellbore. A turn-over suspension mandrel can be landed inside a side pocket mandrel and connected to a gas lift valve on one end and a coil on the other end. A length of production tubing can extend from the side pocket mandrel. The production tubing can include a production packer to seal the annulus between the tubing and the well casing. The turn-over suspension mandrel can be constructed such that gas entering the gas lift valve is directed down through the coil and into the wellbore beneath the production packer. A plug can be placed at the bottom of the coil in order to prevent blowouts during installation of the gas lift system. An alternative embodiment of the present disclosure provides a coil and plug hung from a gas lift valve of a pack-off assembly.

Owner:BAKER HUGHES INC

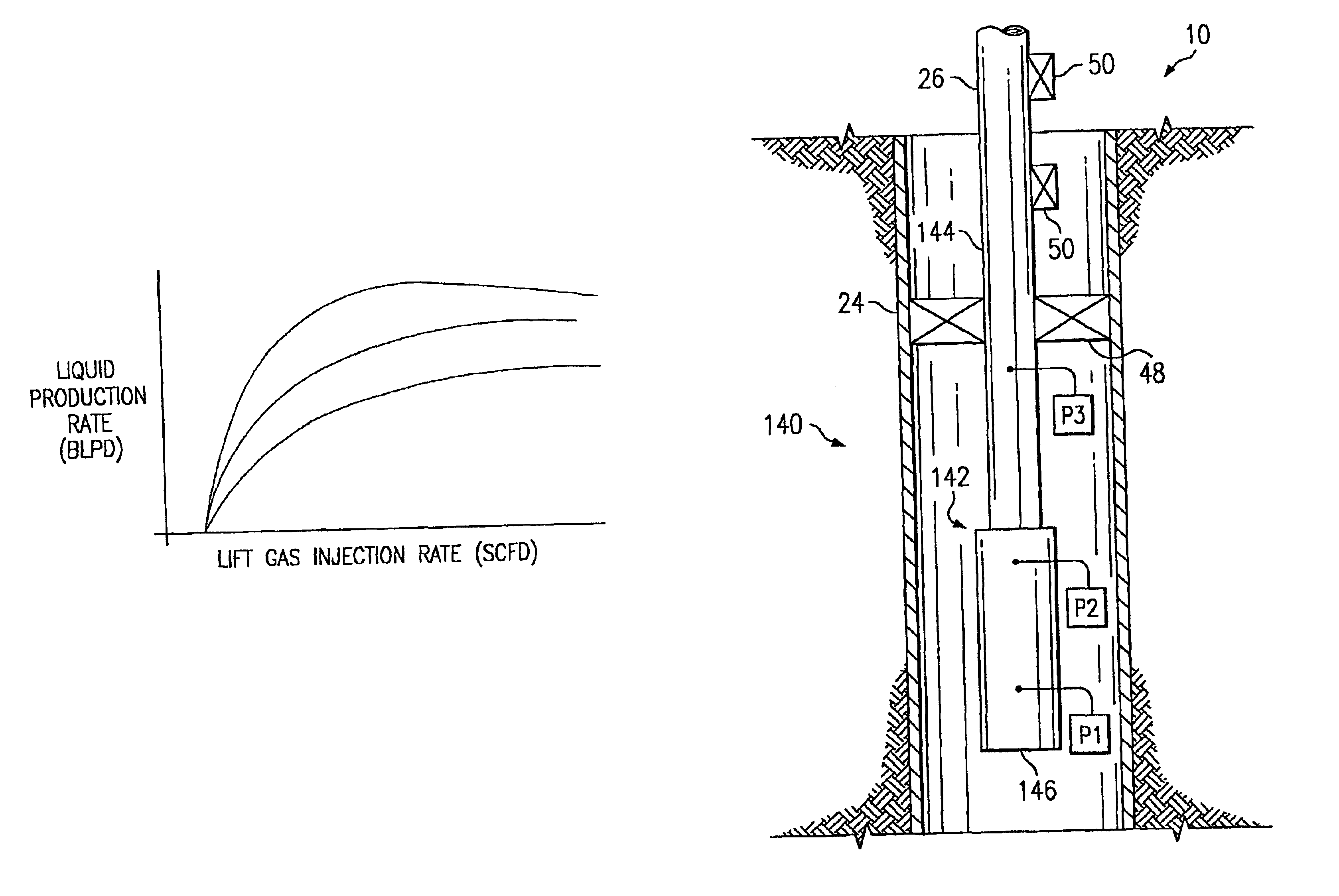

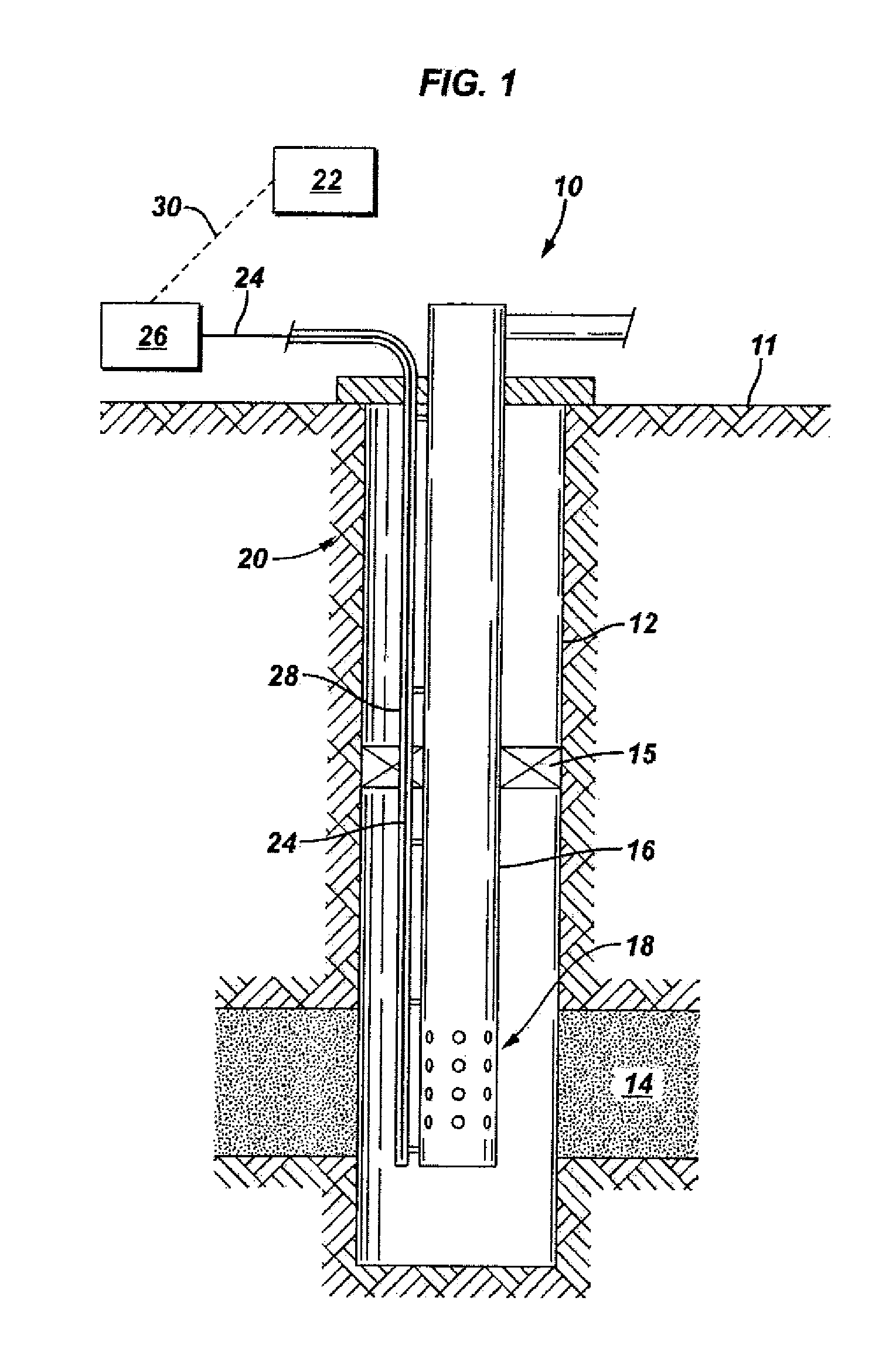

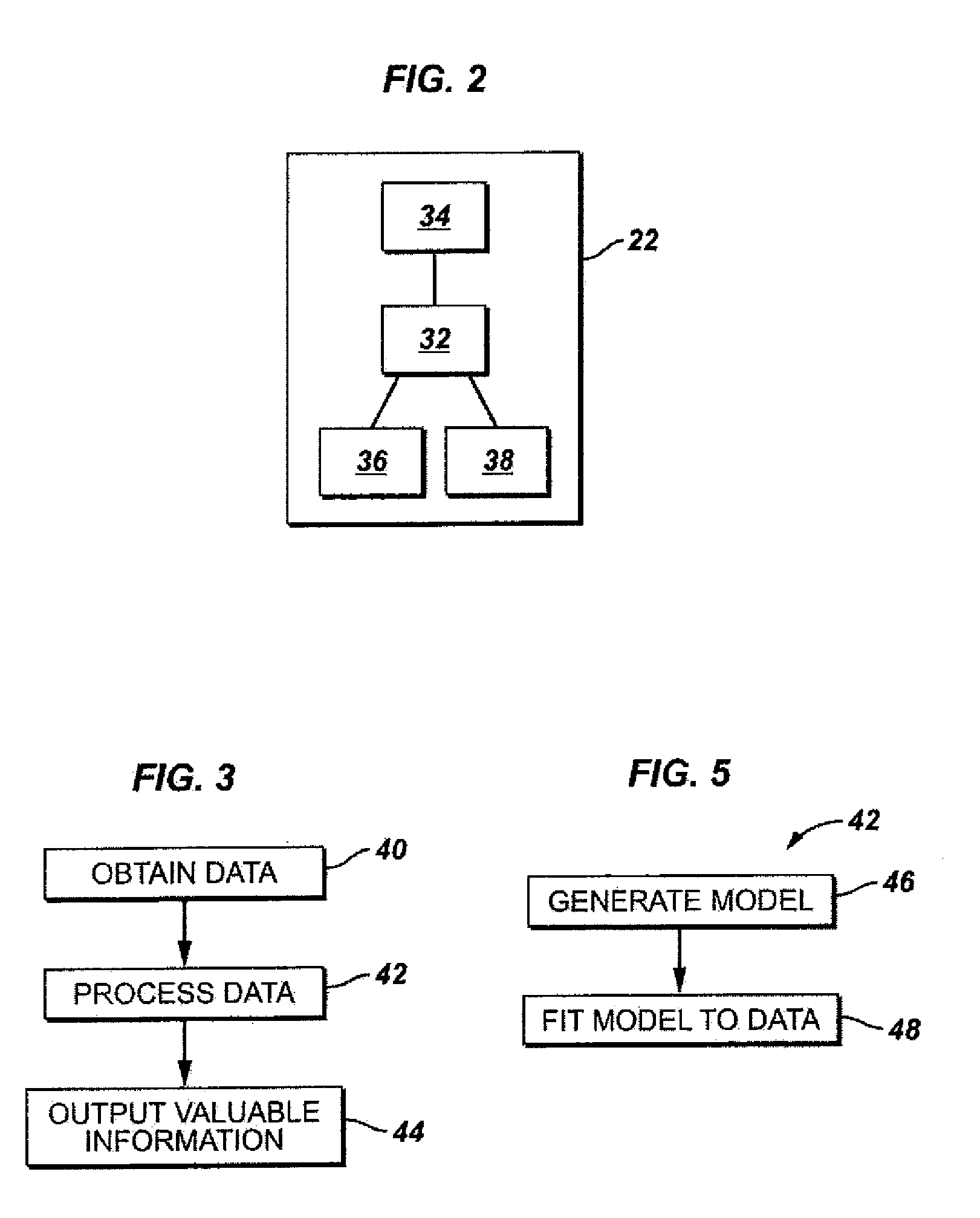

Wireless downwhole measurement and control for optimizing gas lift well and field performance

A method for optimizing the production of a petroleum well is provided. The petroleum well includes a borehole, a piping structure positioned within the borehole, and a tubing string positioned within the borehole for conveying a production fluid. Production of the well is optimized by determining a flow rate of the production fluid within the tubing string and determining a lift-gas injection rate for the gas being injected into the tubing string. The flow rate and injection rate data is communicated along the piping structure of the well to a selected location, where the data is collected and analyzed. After analysis of the data, an optimum operating point for the well can be determined.

Owner:SHELL OIL CO

Open well plunger-actuated gas lift valve and method of use

InactiveUS6907926B2Increase gas productionReduce hydrostatic pressureFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

A system is provided for unloading accumulated liquids and enhancing the recovery of gas from a reservoir having diminished pressure. An annulus between a tubing string and casing is isolated by a packer and continually pressurized with a slipstream of compressed gas while the well continues to produce. A unique valve positioned in the tubing string is shuttled between a production position in which production fluids are permitted to bypass the valve to the surface and a lift position in which the bypass is blocked and an unloading port is opened to vent high pressure annulus gas to the tubing string above the valve, lifting accumulated liquids with it. Preferably, the valve is actuated to the lift position by the impact of a plunger dropped from a lubricator at the wellhead, when the pressure in the annulus has reached a predetermined threshold. When the gas has been vented and the pressure in the annulus drops, the valve is actuated to the uphole production position as a result of the higher reservoir pressure.

Owner:G BOSLEY OILFIELD SERVICES

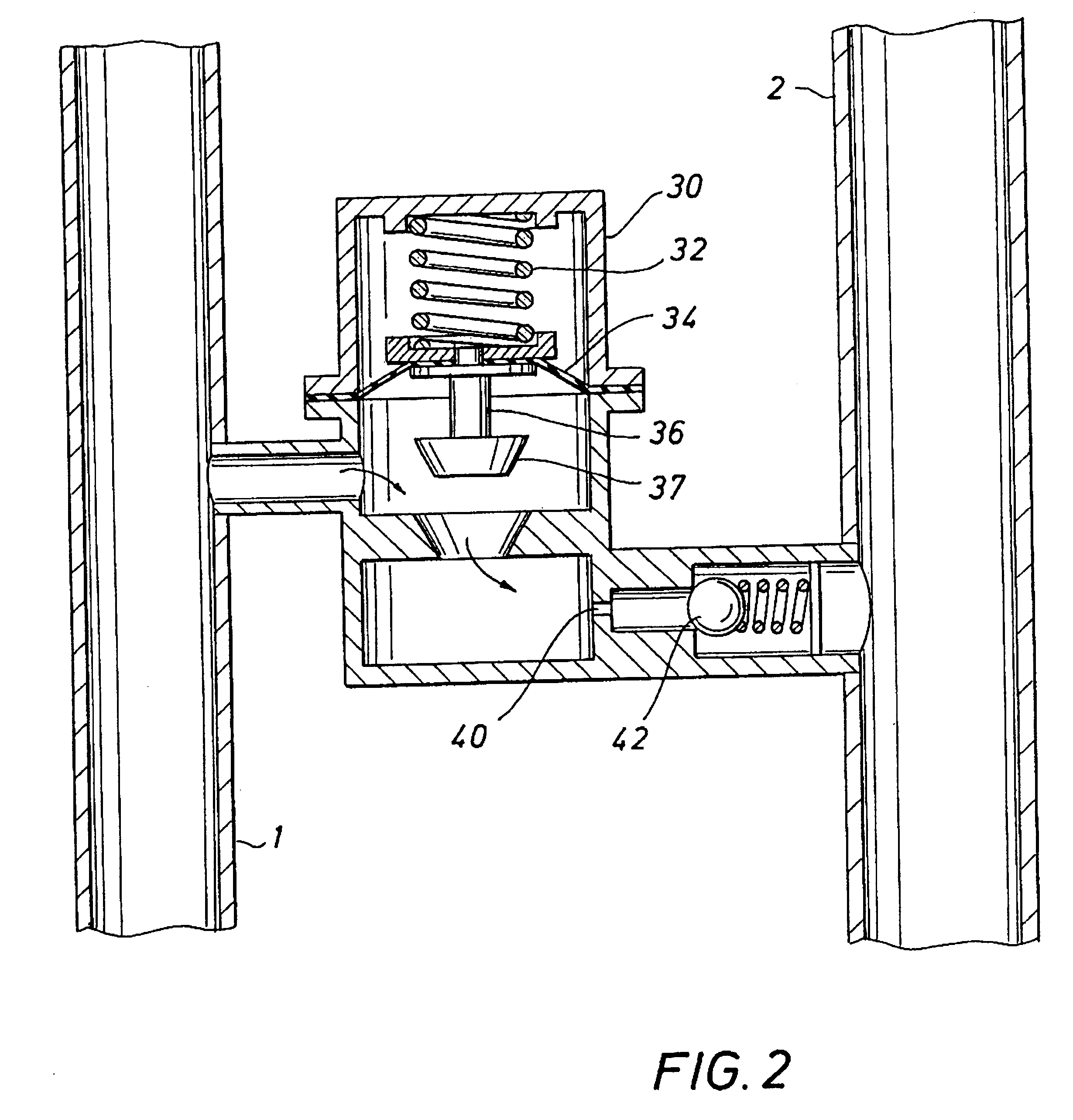

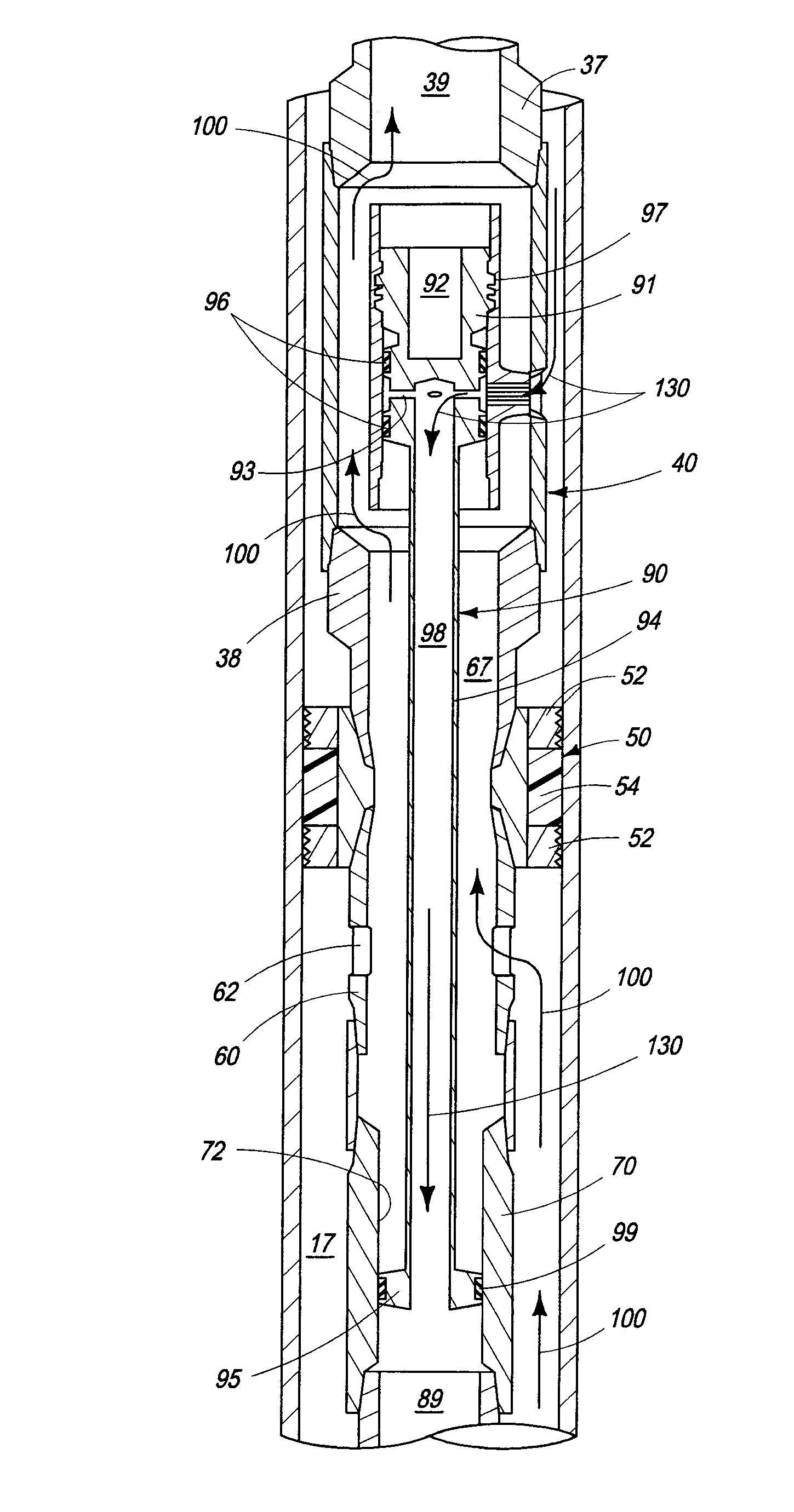

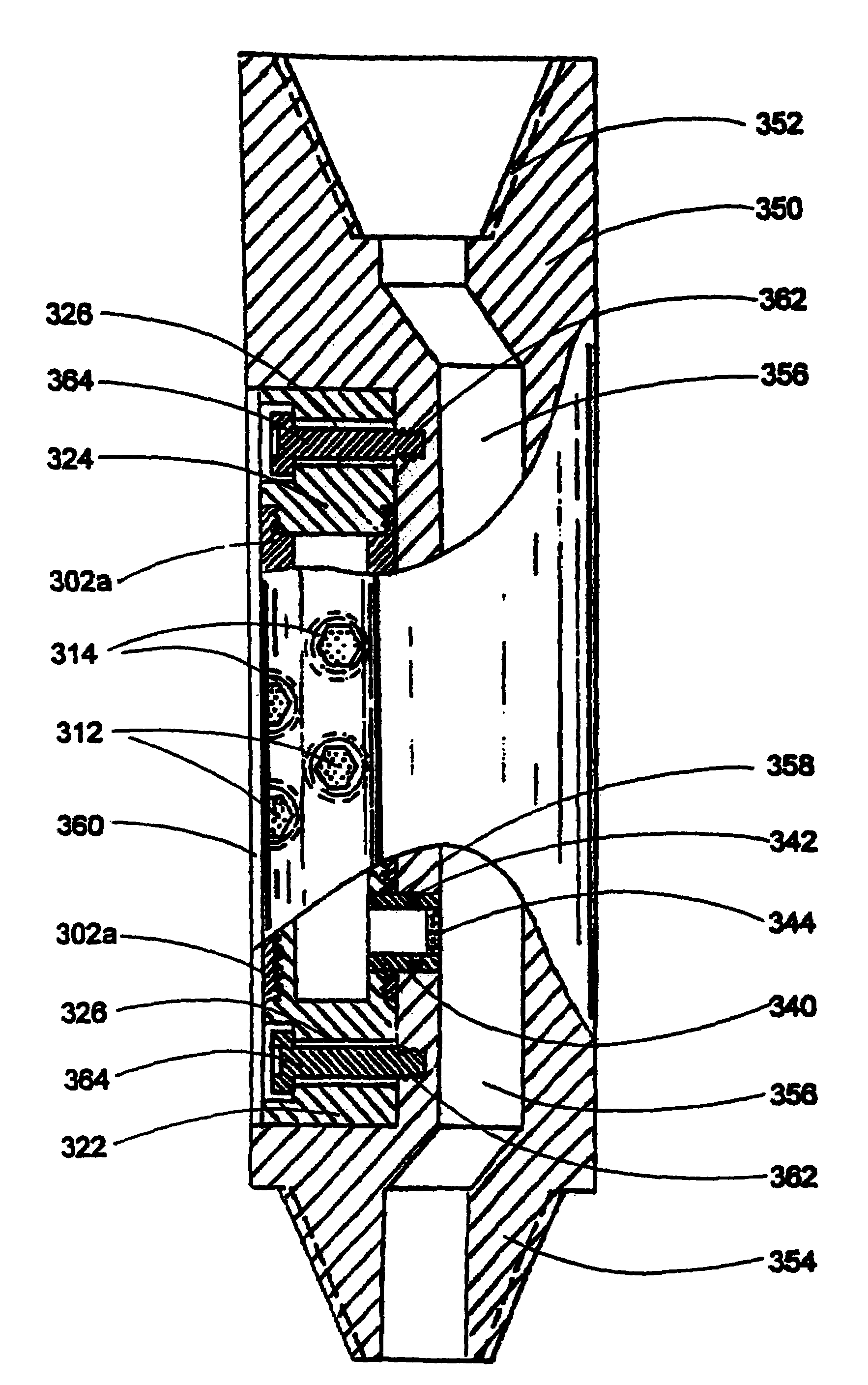

One-way valve for a side pocket mandrel of a gas lift system

Embodiments include providing a gas lift system comprising production tubing disposed within a wellbore, the production tubing capable of allowing fluid flow in a first direction from outside the production tubing through a wall of the production tubing to inside the production tubing to introduce a gas into the bore of the production tubing, while preventing fluid flow in a second direction from inside the production tubing through the wall of the production tubing to outside the production tubing. In one aspect, fluid flow in the second direction is prevented by operation of at least two valve members disposed within a side pocket of a side pocket mandrel in the production tubing. At least one of the valve members is capable of preventing fluid flow in the second direction even when the other valve member is removed from the wellbore or is at least partially inoperative.

Owner:WEATHERFORD TECH HLDG LLC

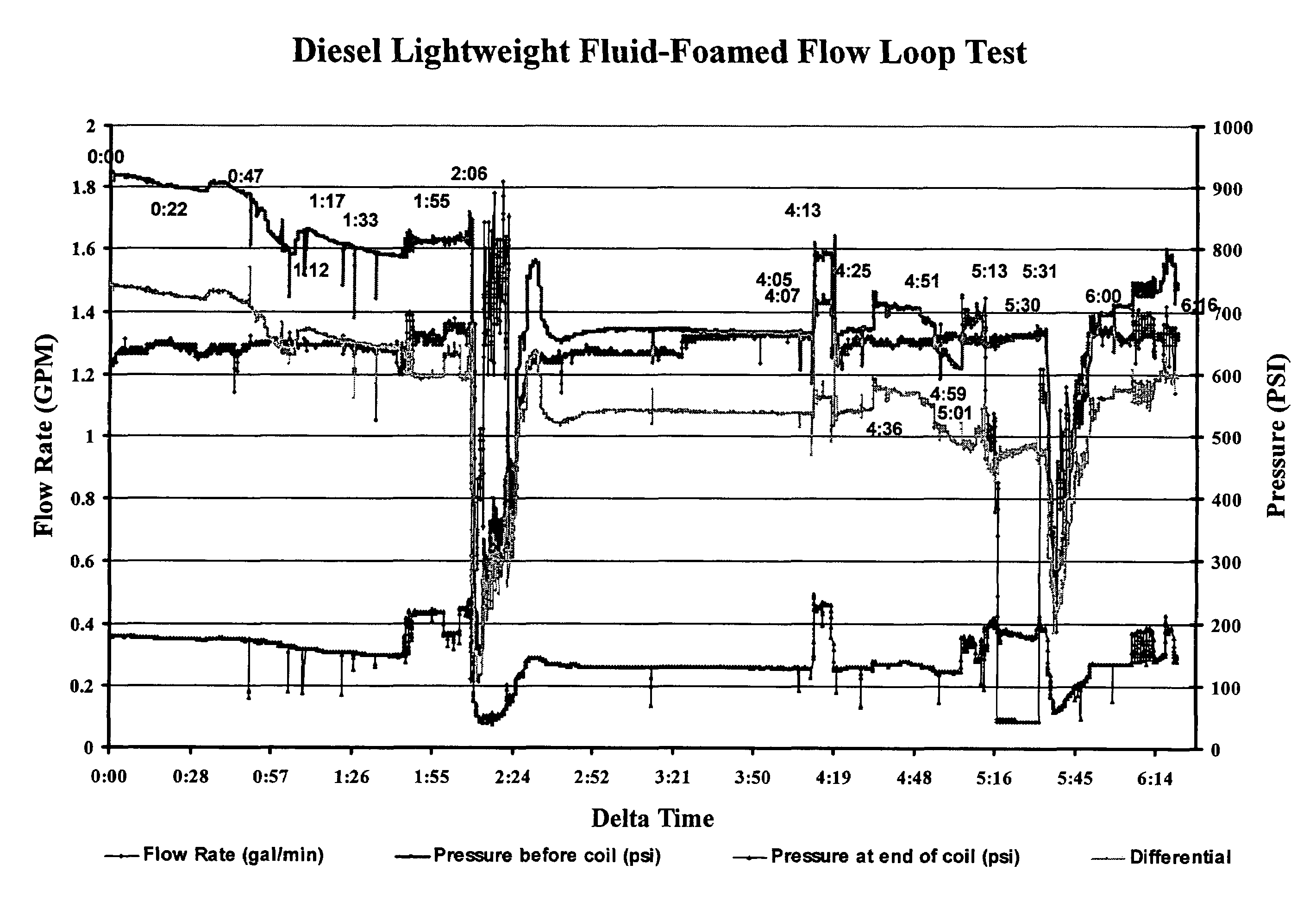

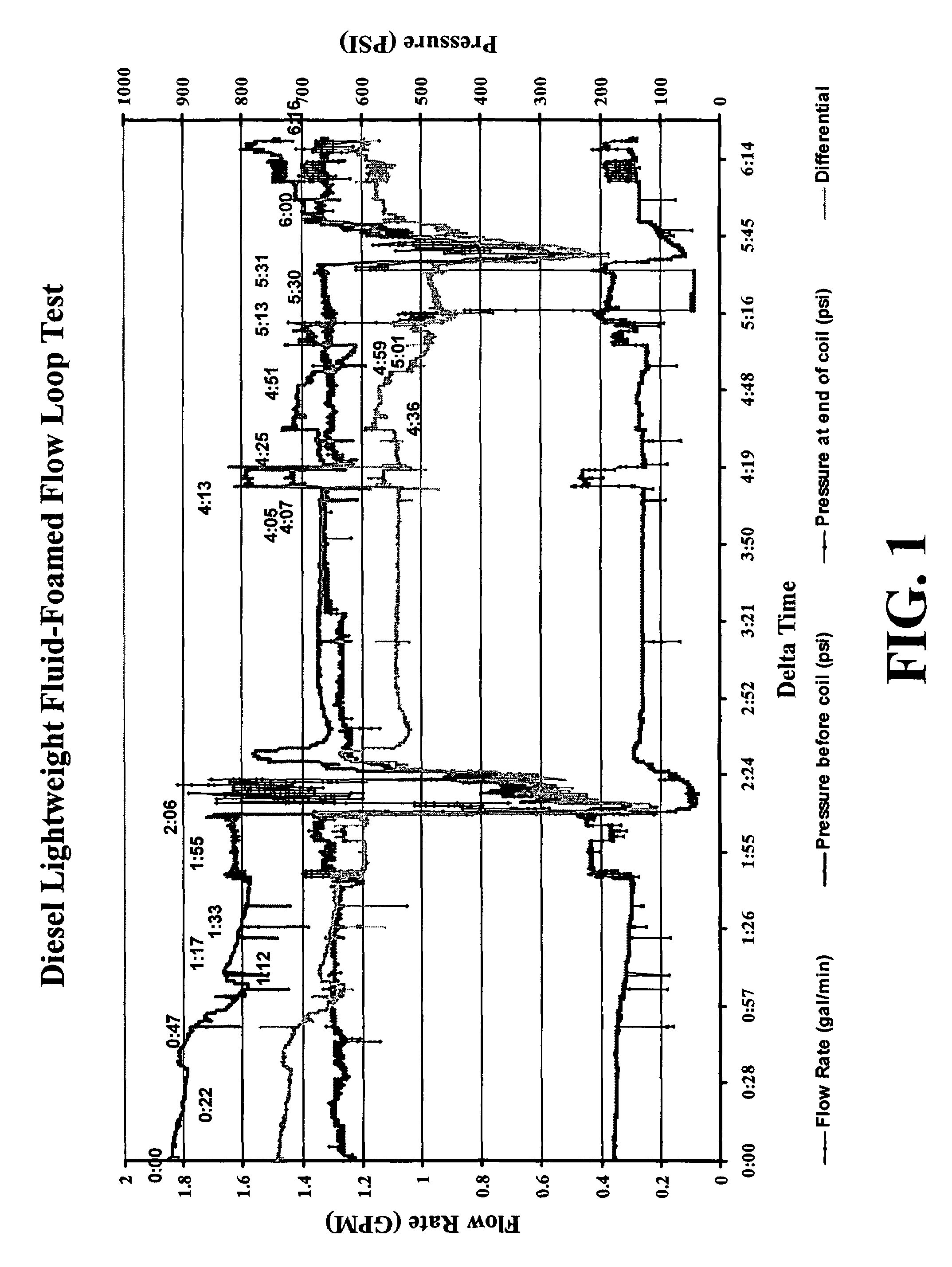

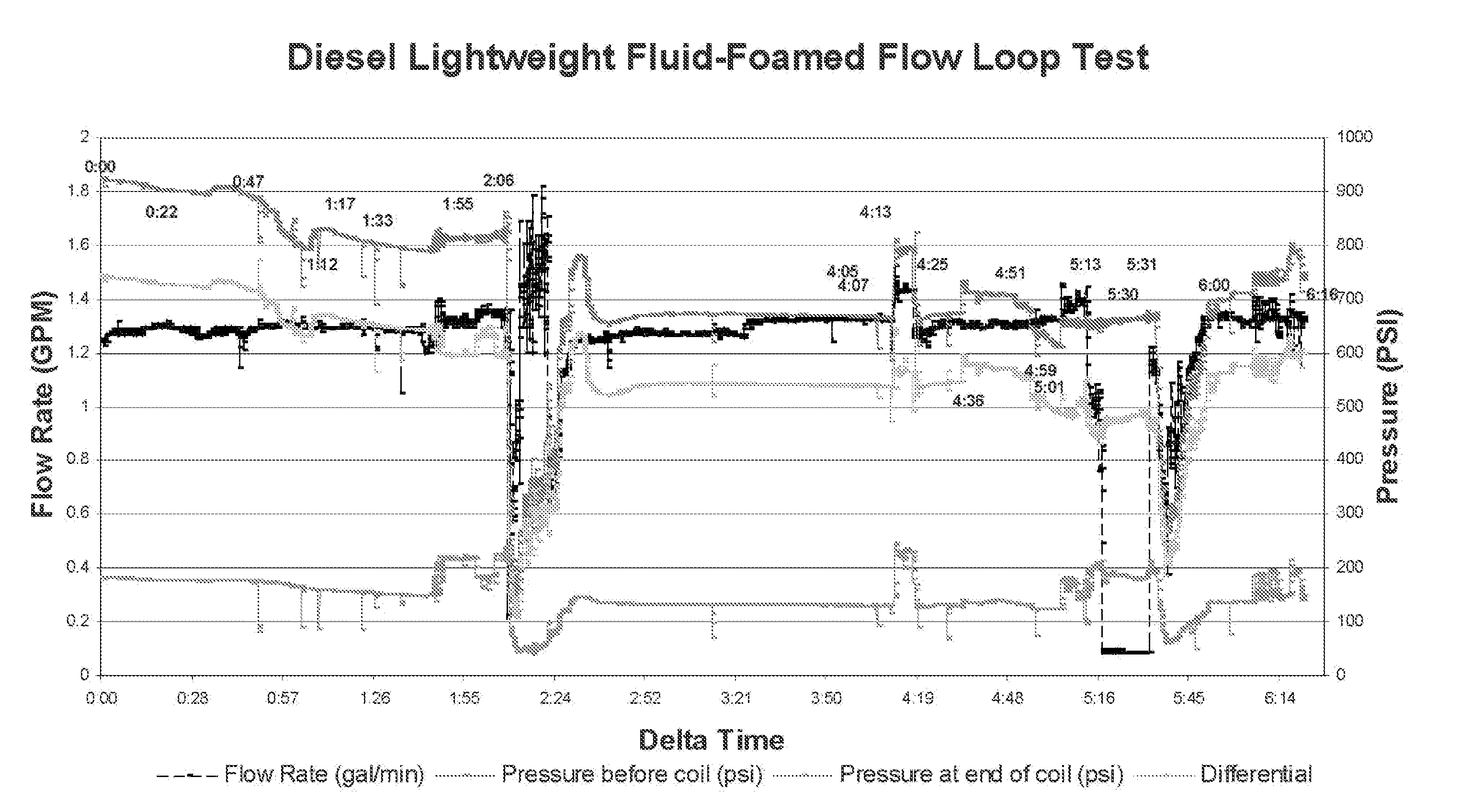

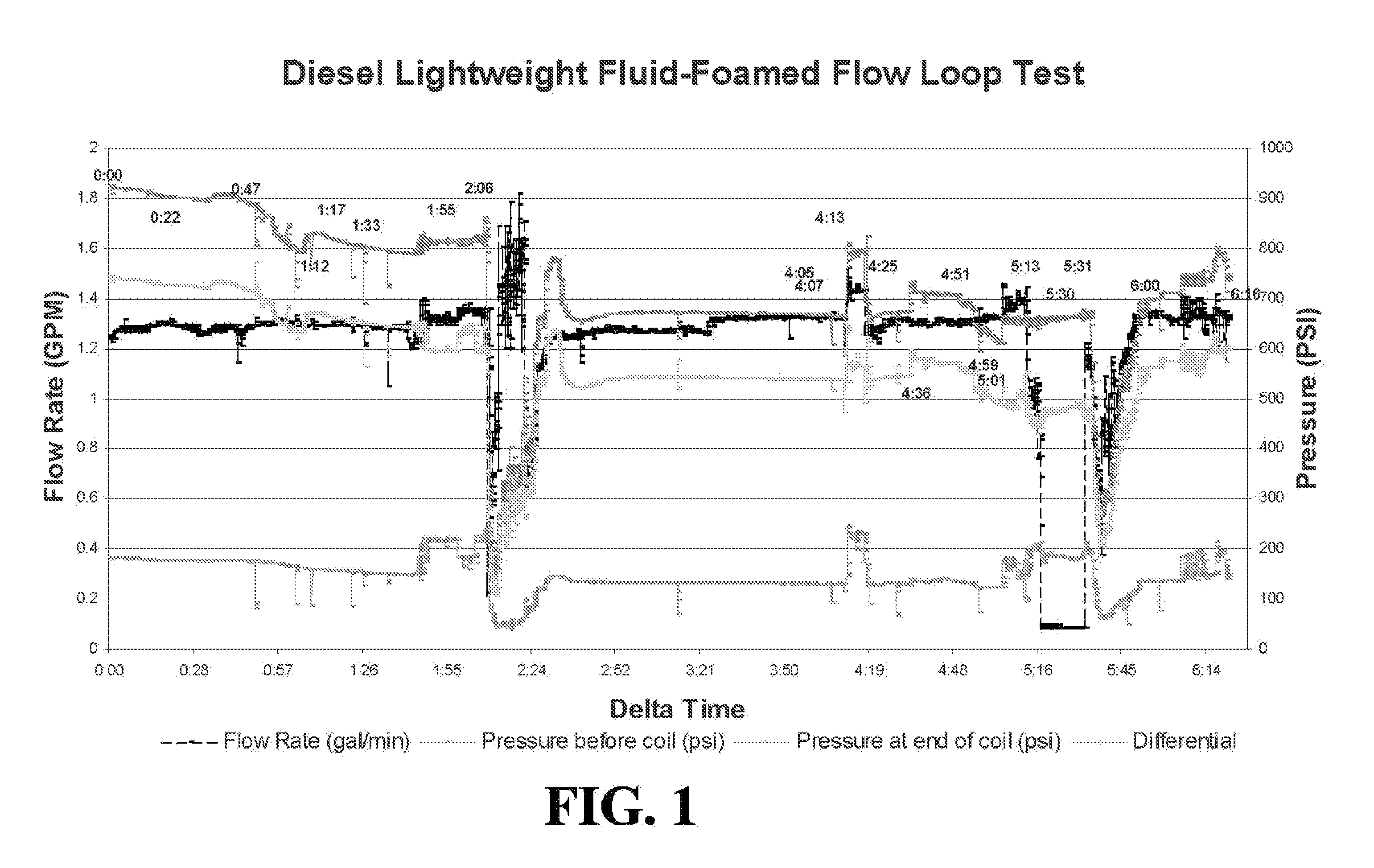

Non-aqueous foam composition for gas lift injection and methods for making and using same

InactiveUS7565933B2Reduce hydrostatic pressureHigh trafficFluid removalDrilling compositionFoaming agentGas lift

A hydrocarbon drilling fluid system is disclosed including a hydrocarbon fluid and a foaming composition, where the foaming composition includes a polymer, a gelling agent and its cross-linking agent, an optional foaming agent, or mixtures or combinations thereof. Uses of this drilling fluid system in a variety of downhole application are also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

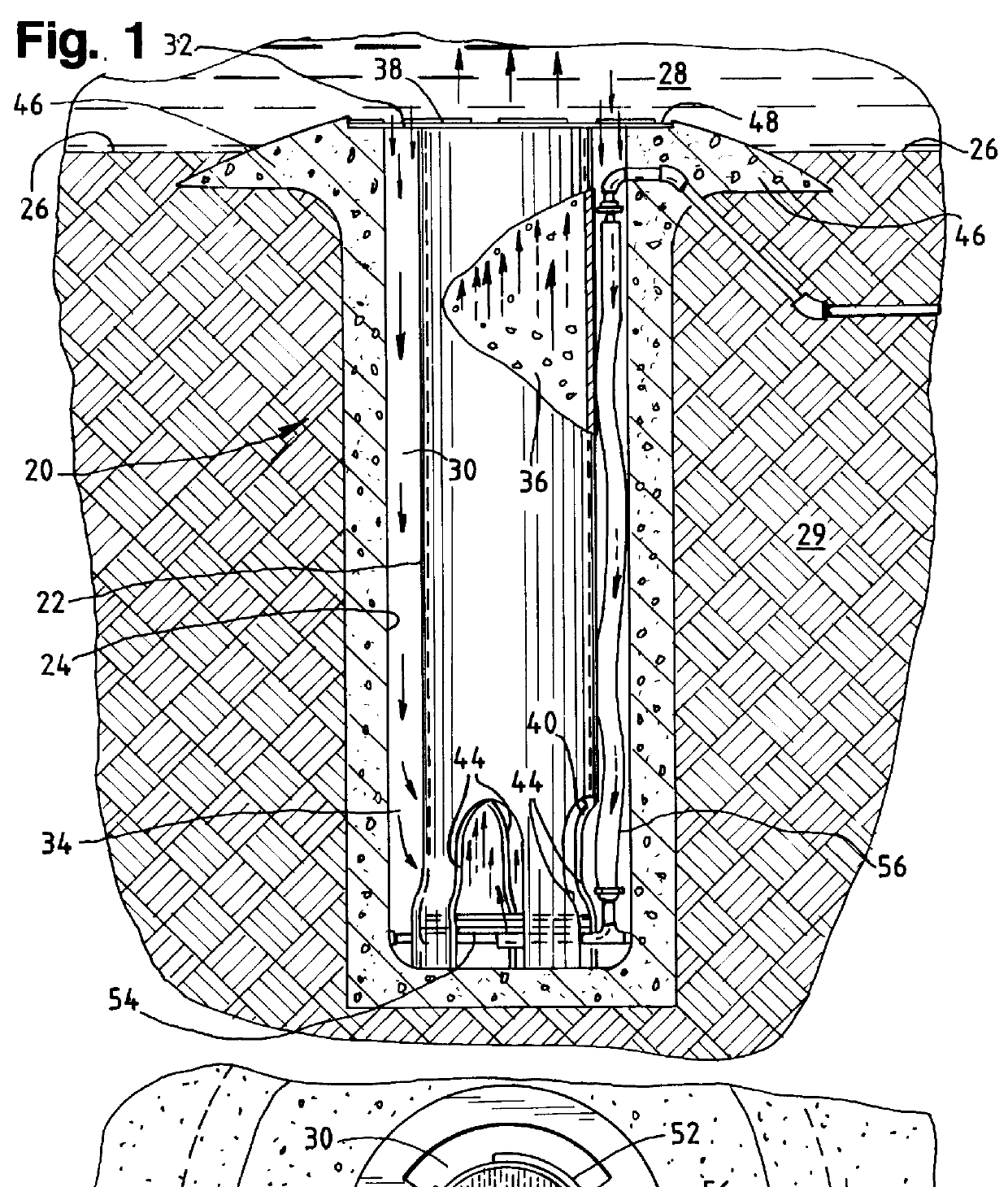

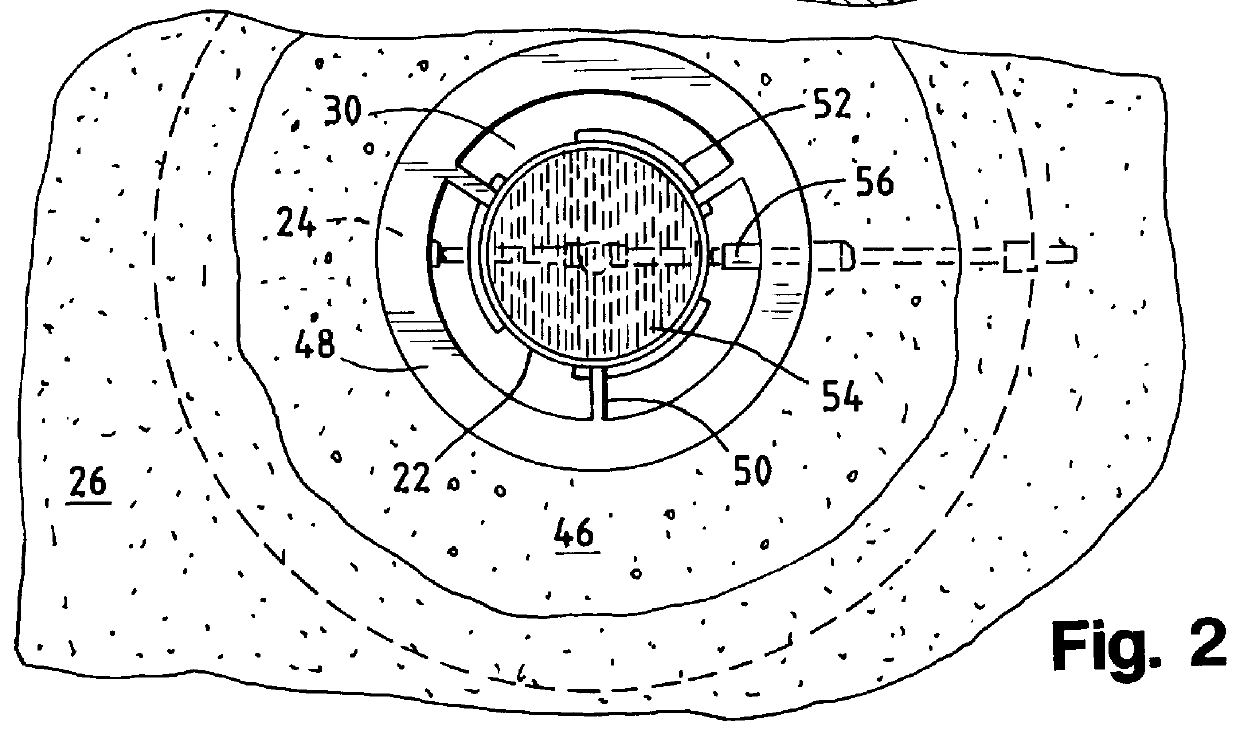

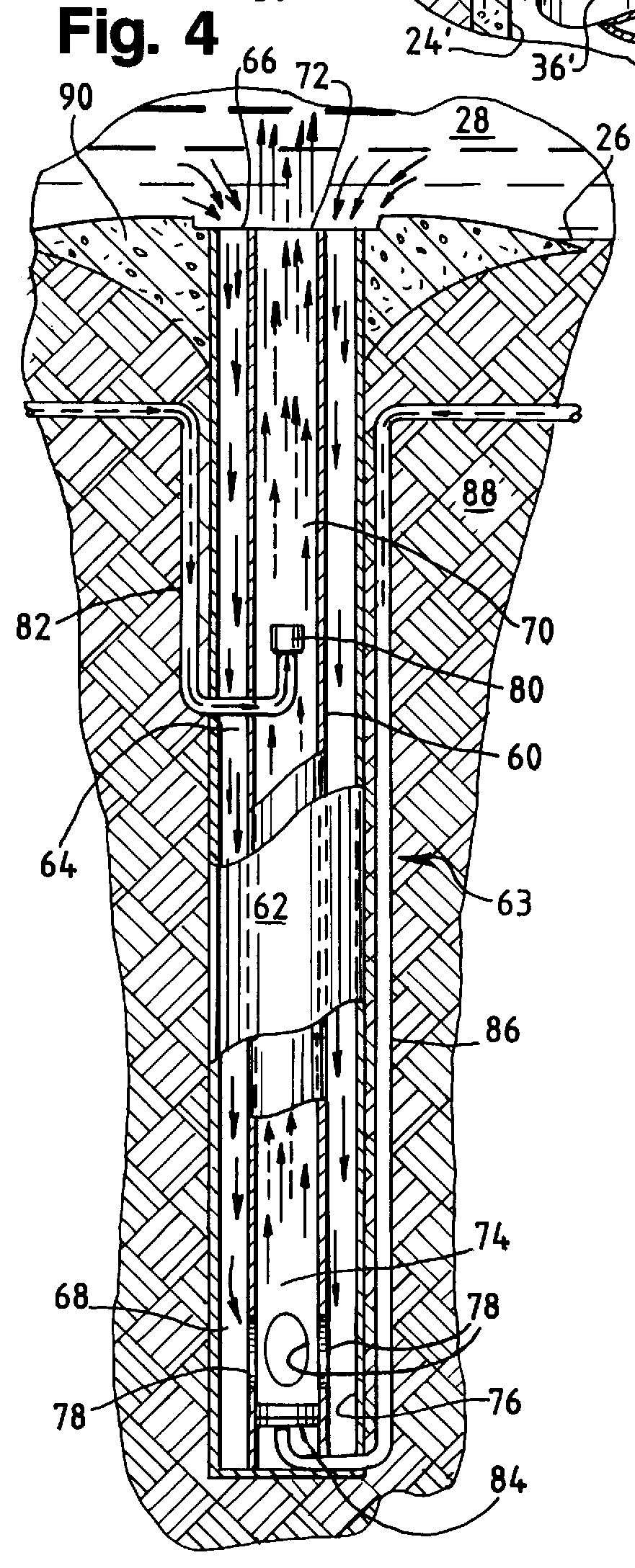

System and method for diffusing gas bubbles into a body of water

InactiveUS6017020ATreatment using aerobic processesTransportation and packagingAbove groundWhole body

System and method for diffusing gas bubbles into a pond, lagoon or basin that is used for fish farming or other form of aquaculture. A small amount of water is continuously removed from the bottom of the body of water by one or more counterflow gas lift diffusers. This small amount of water is flowed down underground, has gas bubbles introduced into it, and is then returned to the body of water. The quantity of water removed and treated in this way is a small fraction of the total body of water in the pond, lagoon or basin. The ratio of (1) the total volume of the channels below ground through which the water flows downward, and then back up into the body of water, to (2) the volume of the body of water above ground is at all times less than about 1:100. In the broadest form of the invention, a gas diffuser introduces gas bubbles into the water in the return channel at a level at least about 2 feet below the bottom of the body of water, and no more then about 50 feet below the surface of the body of water being treated. The downflow and return channels and the space joining them at their bottom ends extend no more than about 50 feet below the surface of the water being treated.

Owner:BAUGHMAN MICHAEL L +1

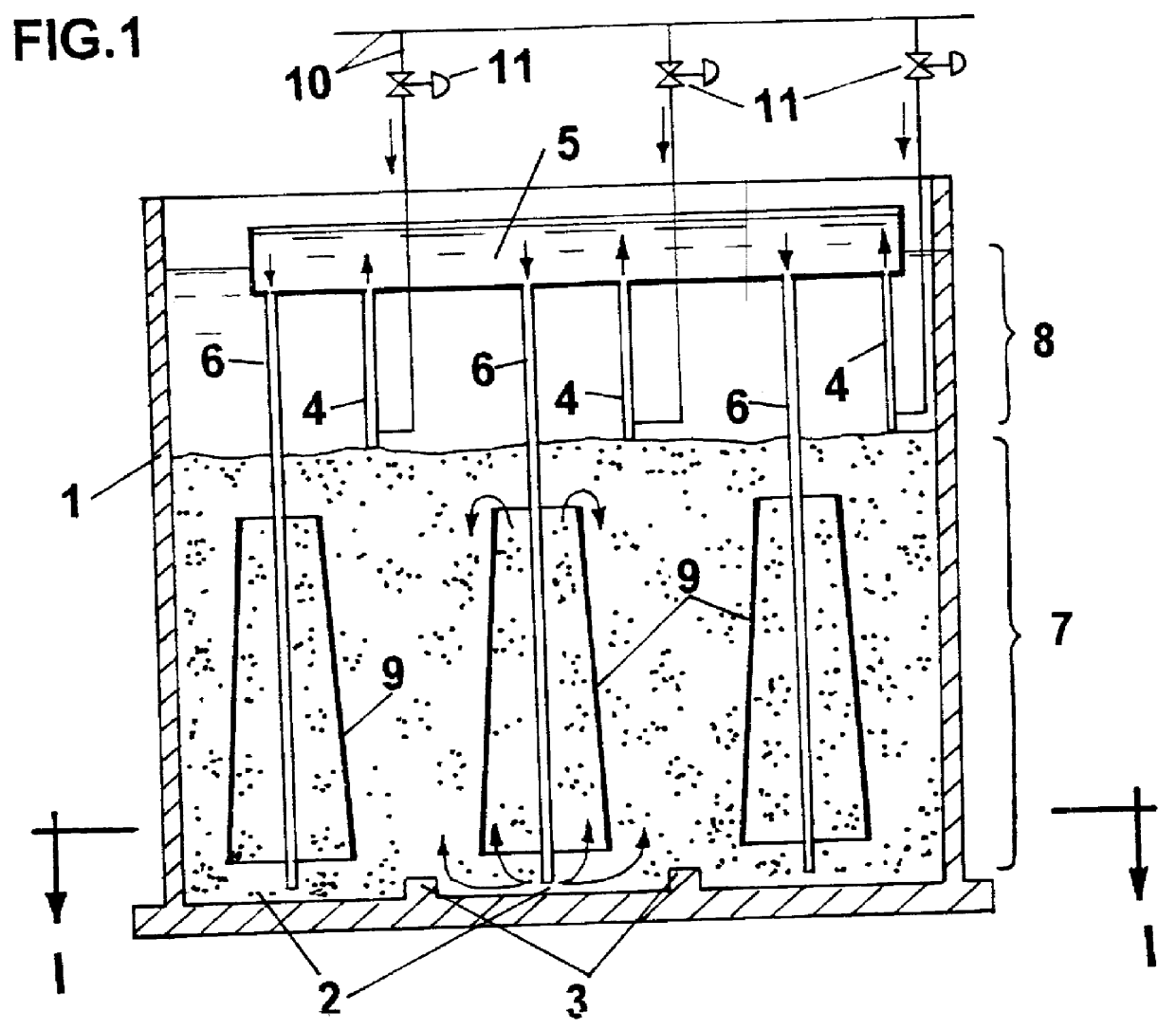

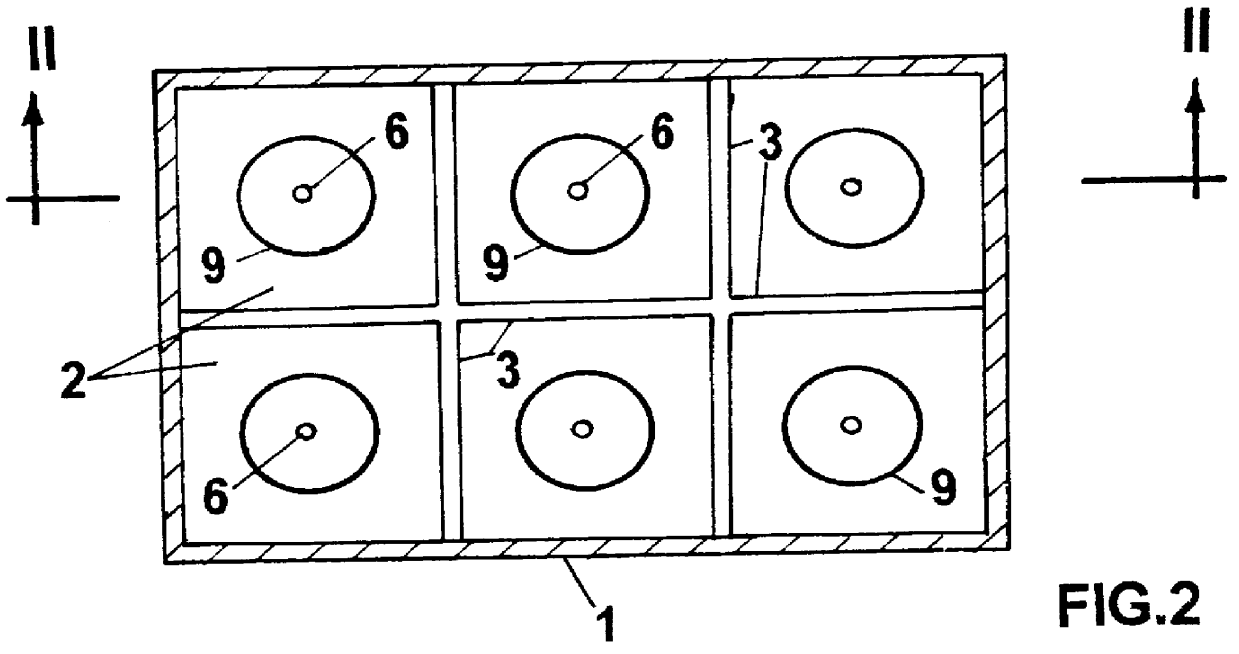

Method and apparatus for fluidization of particulate bed materials

InactiveUS6048459ATreatment using aerobic processesSolid sorbent liquid separationParticulatesOrganismal Process

A method for fluidization of a particulate bed material in a fluidized bed reactor with an upflow of fliud being treated, wherein a step of recycling said treated fluid is provided and further comprising the steps of (a) uniformly collecting at least a portion of the fluid above the fluidized bed and lifting this fluid by at least one gaslift having an intake above the bed, and (b) recycling the lifted fluid under the bed via at least one downcomer positioned within the bed. An generic apparatus for conducting the method steps in a variety of applications is also provided. The fluidized bed reactor can be used for chemical, physical chemical, biological processes, and combinations thereof in the chemical processing, food, environmental and other industries.

Owner:MOCKBA CORP

Method and apparatus for gas lift system for oil and gas wells

An intermittent gas lift well pumping system containing an accumulator, a gas line, a liquid discharge line, and a battery operated controller. By using one or more constrictions in the gas line and acoustical techniques, accurate liquid level is determined in the pumping system for optimum production. Bypasses are connected between the gas line and the liquid discharge line. Each contains a valve that opens at a preset absolute pressure in the gas line, an orifice, and a one-way valve. The bypasses are strategically placed to prevent overloading of the system. A liquid slug sensor on the upper end of the liquid discharge line and a rabbit in this line enables optimum production and gas conservation.

Owner:BUCKMAN SR WILLIAM G

Method and system for production of gas and water from a gas bearing strata during drilling and after drilling completion

A method for producing gas and water during and after drilling from a subterranean coal seam, including the steps of: (a) drilling a main bore intersecting the coal seam, the main bore having an upper substantially vertical portion, a lower substantially horizontal portion or portions, and a curved portion connecting the vertical and horizontal portions; (b) drilling one sumphole drainage bore exiting the curve or horizontal portion of the main bore and extending in the direction at least partially vertically and downwardly with respect to the horizontal portion of the main bore; (c) collecting gas produced from the coal seam through the main bore and branched bores; (d) removing water and effluent from the main bore both during drilling operations and afterwards through the use of parallel casing, whereby a first casing introduces compressed air or gas to the main bore and the annular space between the first and second casing is used for return of the mixture of water, effluent and air or gas to the surface; and (e) enhancing gas production by simultaneously removing effluent and water from the main bore by utilizing gas lifting or dewatering pumps in the drainage bore after drilling completion. The system includes a directional drilling system having a drill mechanism for cutting an object area of the coal seam, and a drill string connected to the drill mechanism to power and control. The system also includes using two casings or one casing and a compressed air tubing to air lift waste material during drilling and a dewatering device(s) installed in the sumphole drainage bore used to dewater the main bore after drilling completion.

Owner:TARGET DRILLING LLC

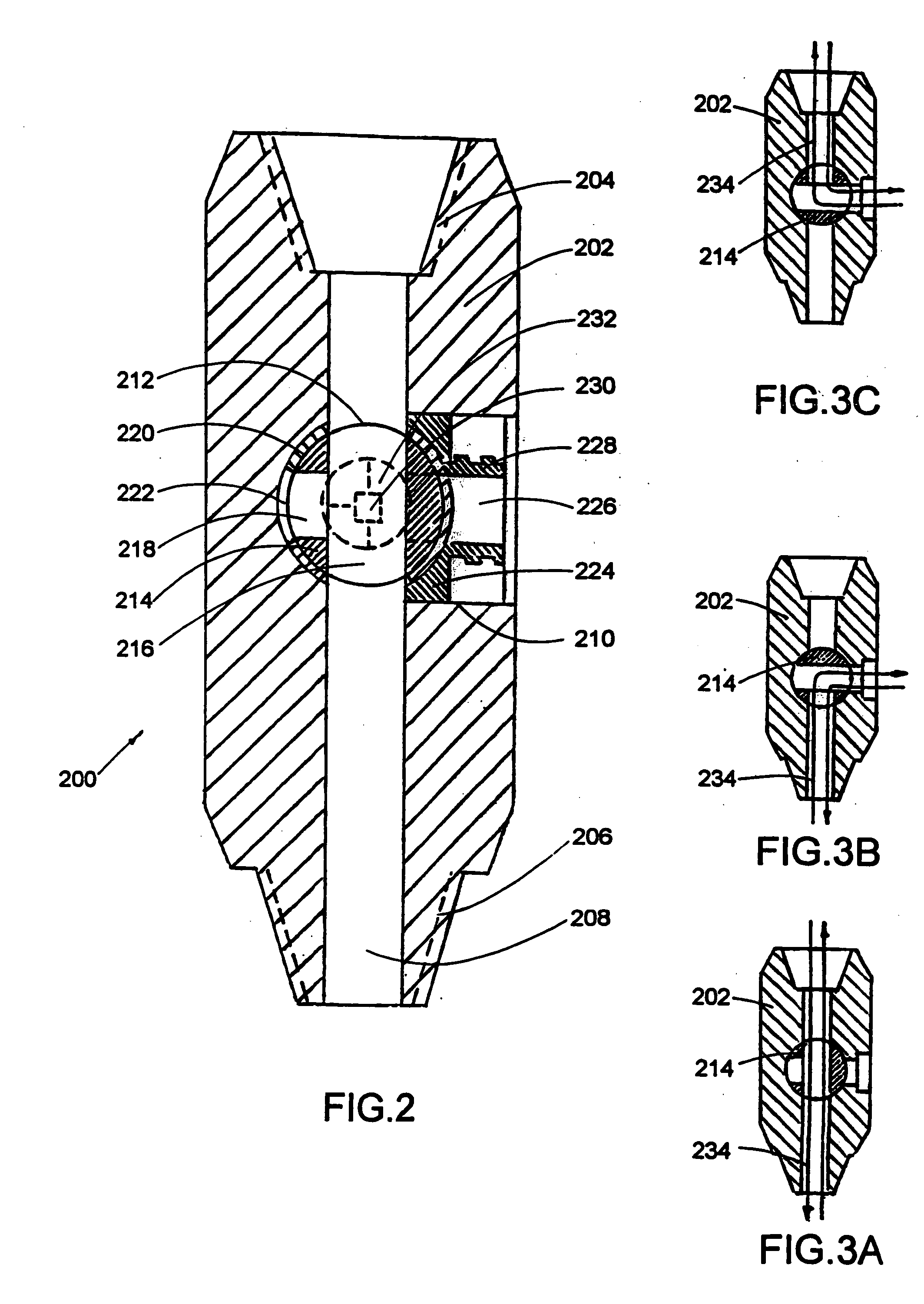

Apparatus, assembly and process for injecting fluid into a subterranean well

Apparatus, assembly and process for allowing gas lift operations to be conducted along a relatively long perforated interval below a packer in a subterranean well. An elongated segregation member is lowered into locking engagement with a bypass mandrel secured to a tubing string above the packer. This segregation member is configured and dimensioned to define two fluid flow paths. A first flow path extends from the surface of the earth through the annulus formed between the tubing string above the packer and casing secured in the well, the bypass mandrel, a bore through a portion of the segregation member and the interior of the tubing string below the packer. A second flow path extends from the subterranean region penetrated by the well through the annulus formed between the tubing string below the packer and casing secured in the well, the annulus between the segregation member and the packer, and the interior of the tubing string above the packer. Fluid produced into the well from the subterranean region is conveyed to the surface via the second flow path and can be assisted by gas injected into the first flow path via retrievable gas lift valves in the tubing string above and below the packer. Pressurized gas is conveyed via the first flow path to these retrievable gas lift valves.

Owner:PCS FERGUSON

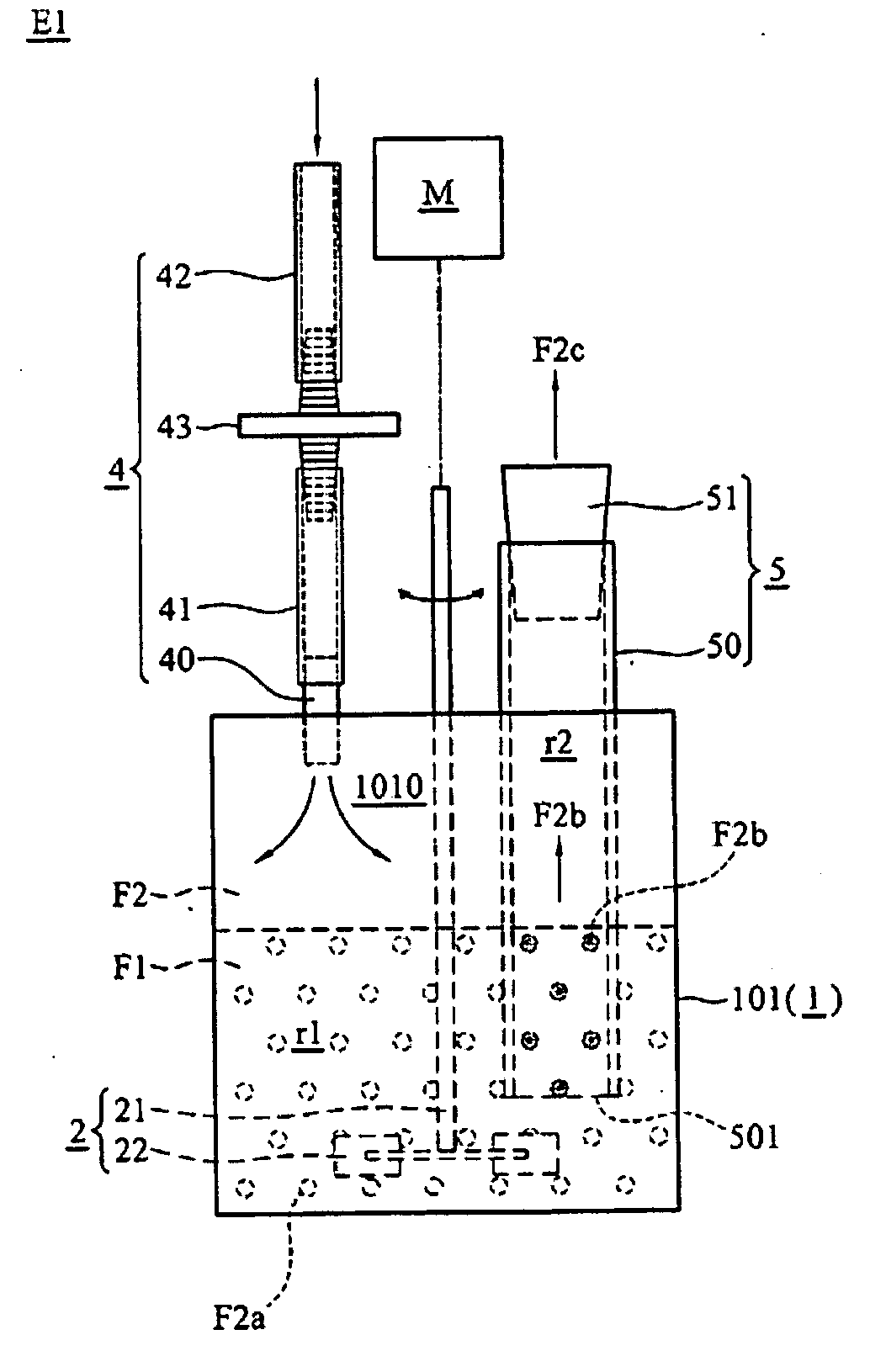

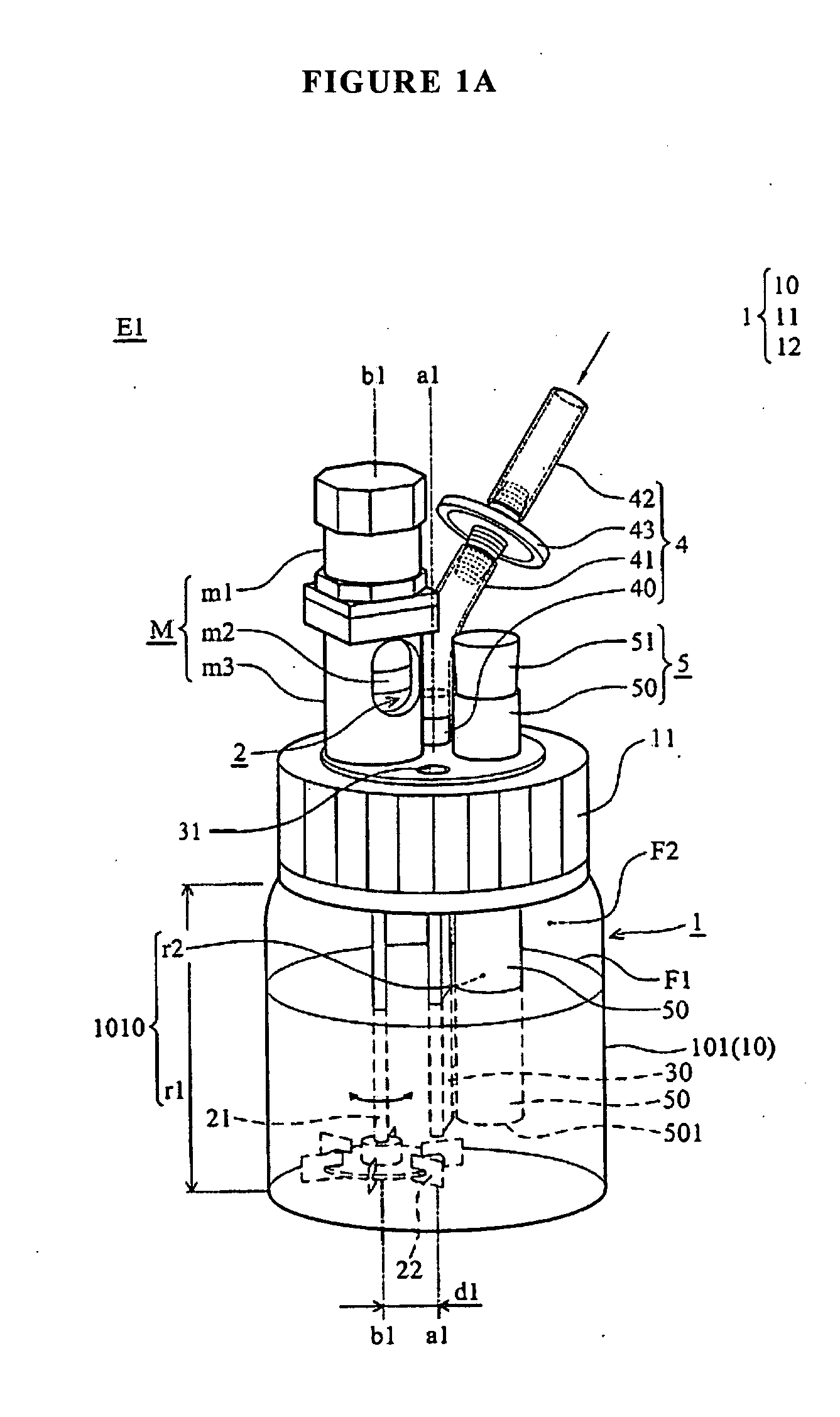

Reaction vessel assembly with gas exchange means

ActiveUS20090152744A1Enhanced convective gassing flowEnhanced mixing power drawnCarburetting airLighting and heating apparatusLine tubingProcess engineering

A reaction vessel assembly achieves enhanced aeration or gas exchange in its gas-in-liquid multiphase mixing reaction through the use of its mixing energy and gas-lift venting, and without the traditionally practiced external line gas sparging. It combines the best of both shake flask and stirred tank reactor vessel and possesses some of the key generic features like cost and parallel experiment advantages of the traditional flasks and shaker hybrid but without their shortcomings like limited gas exchange and uncharacteristic mixing.

Owner:MOU DUEN GANG

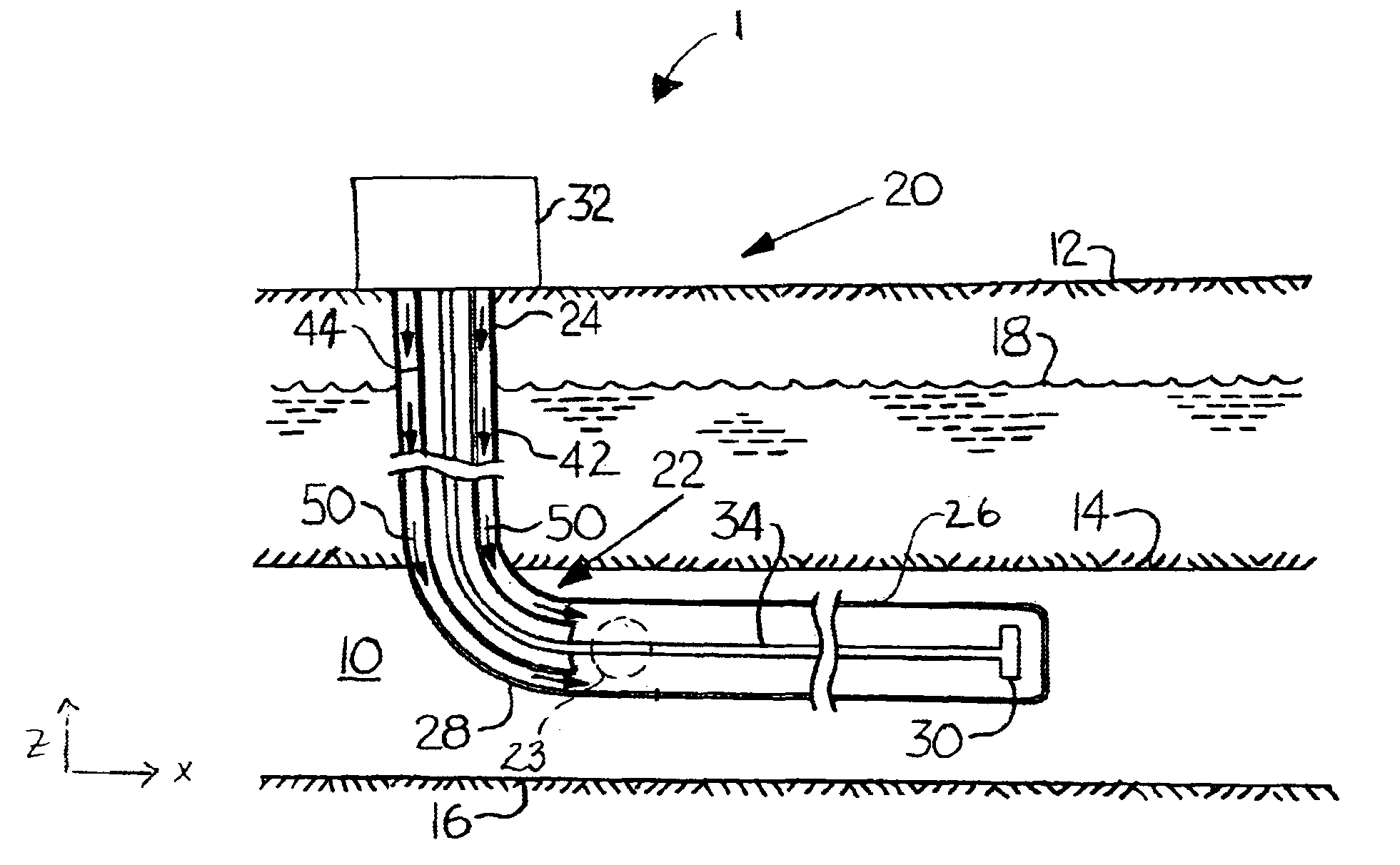

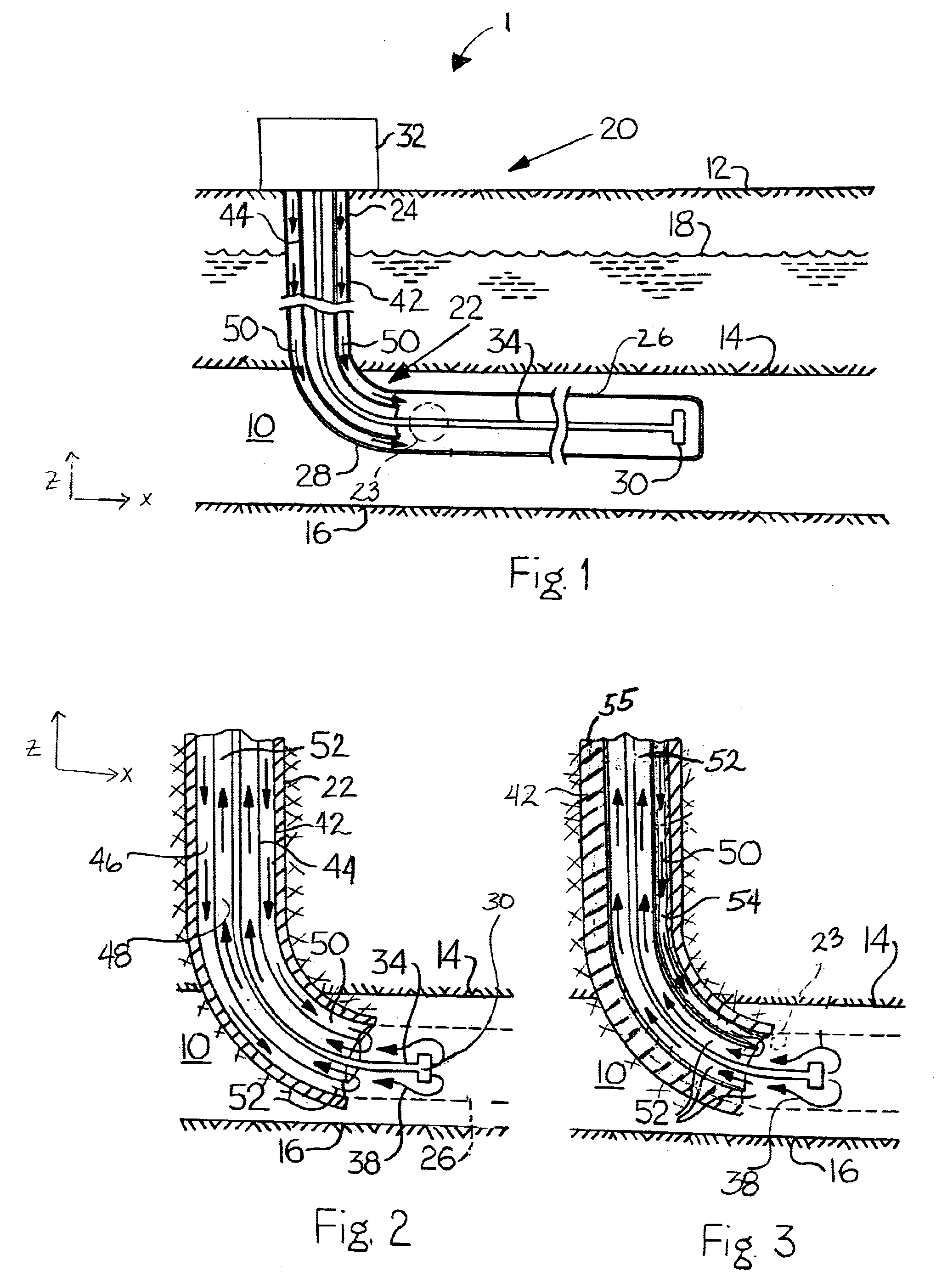

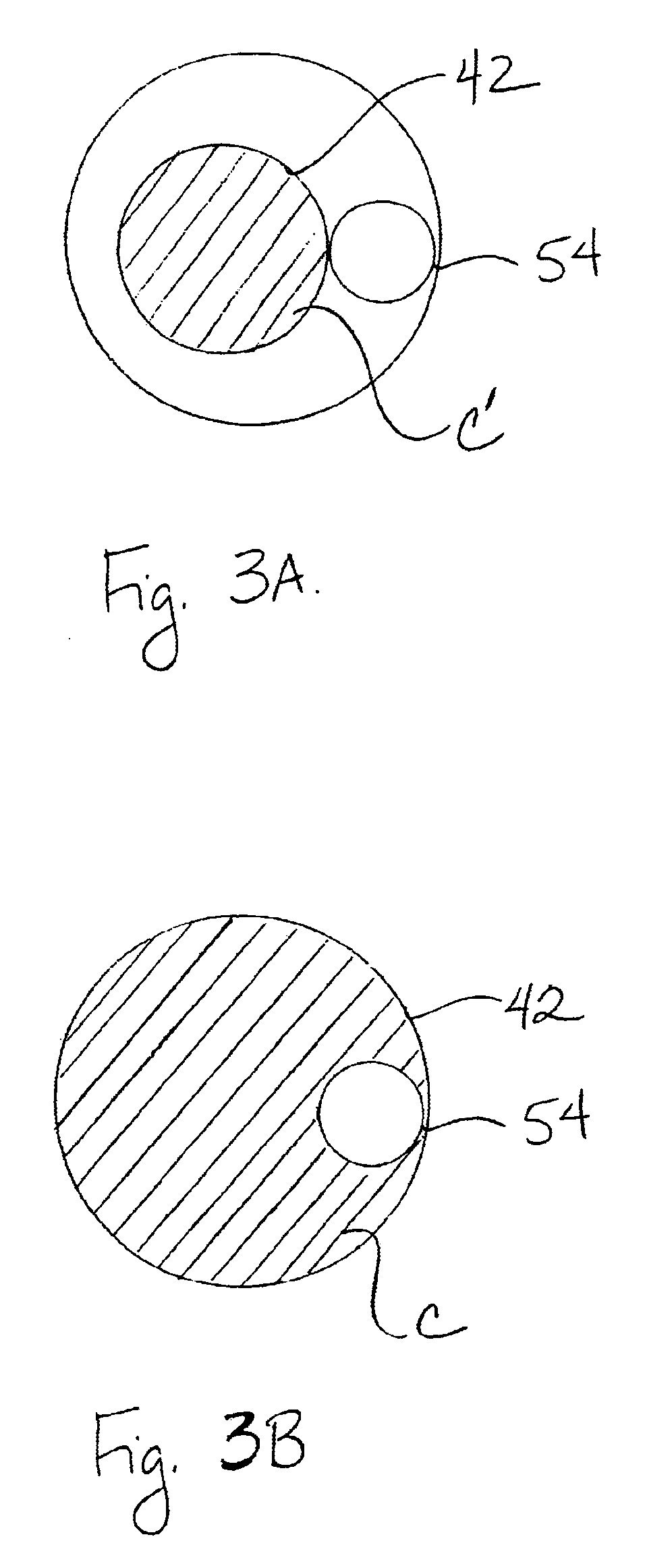

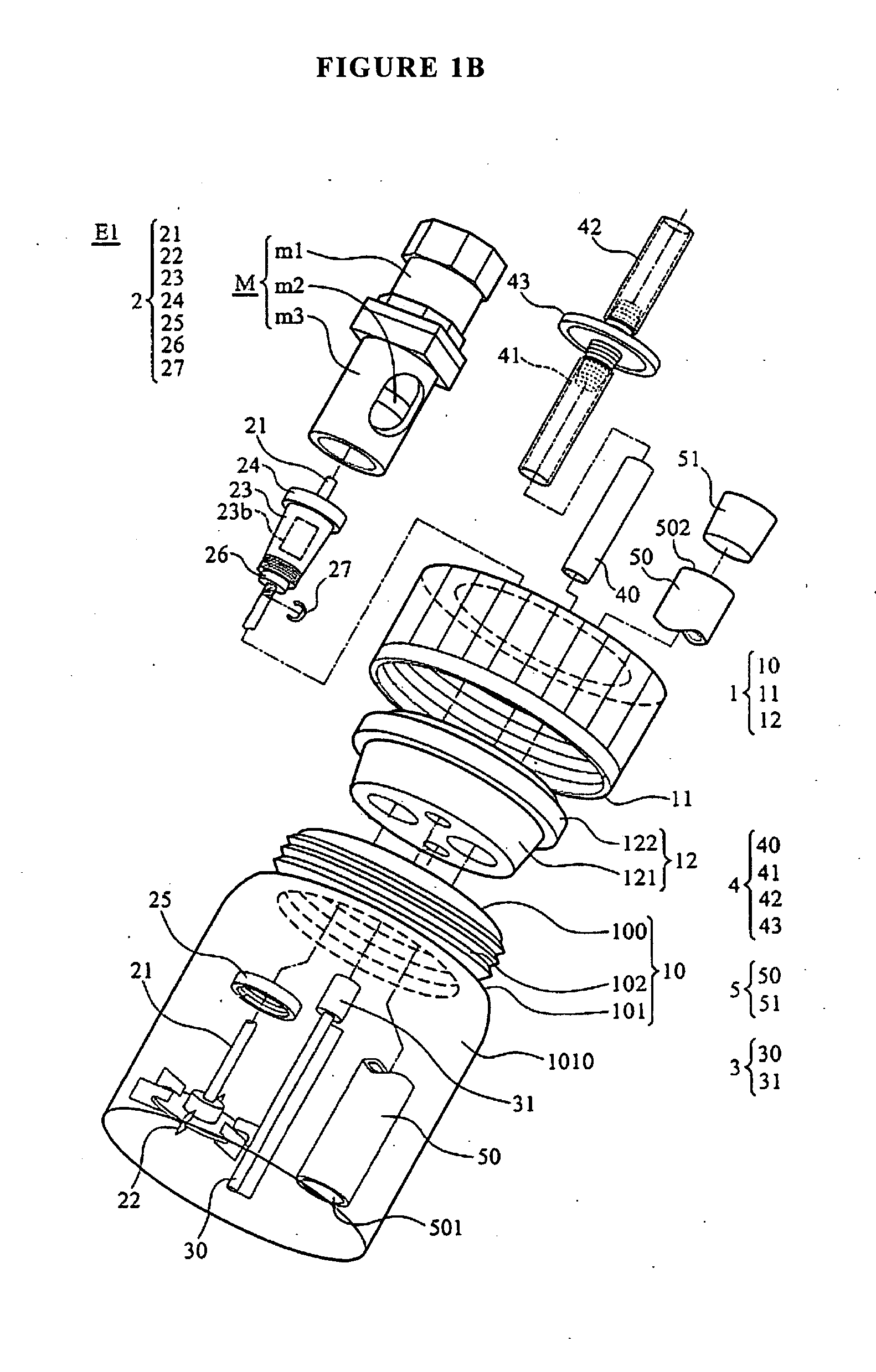

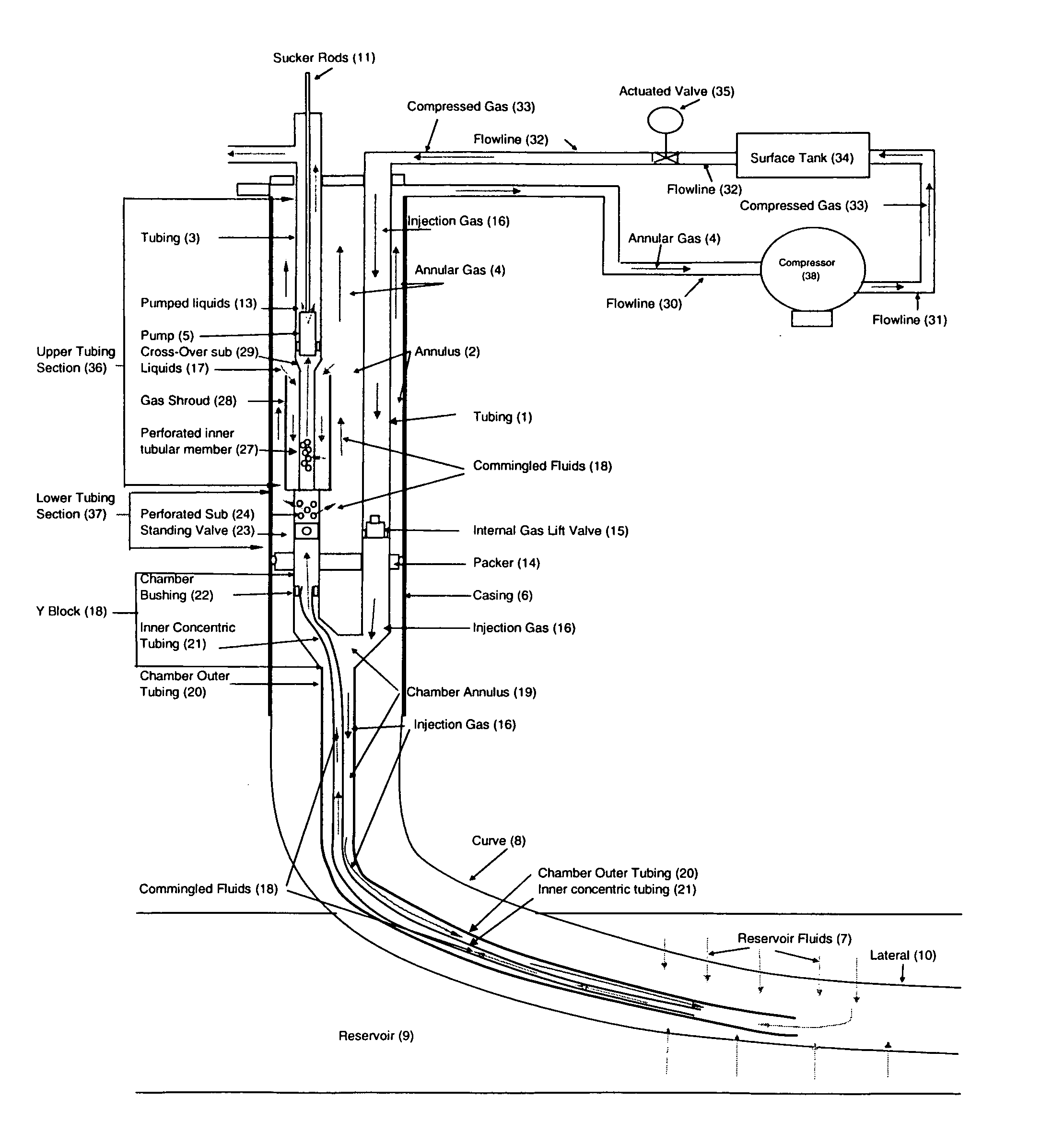

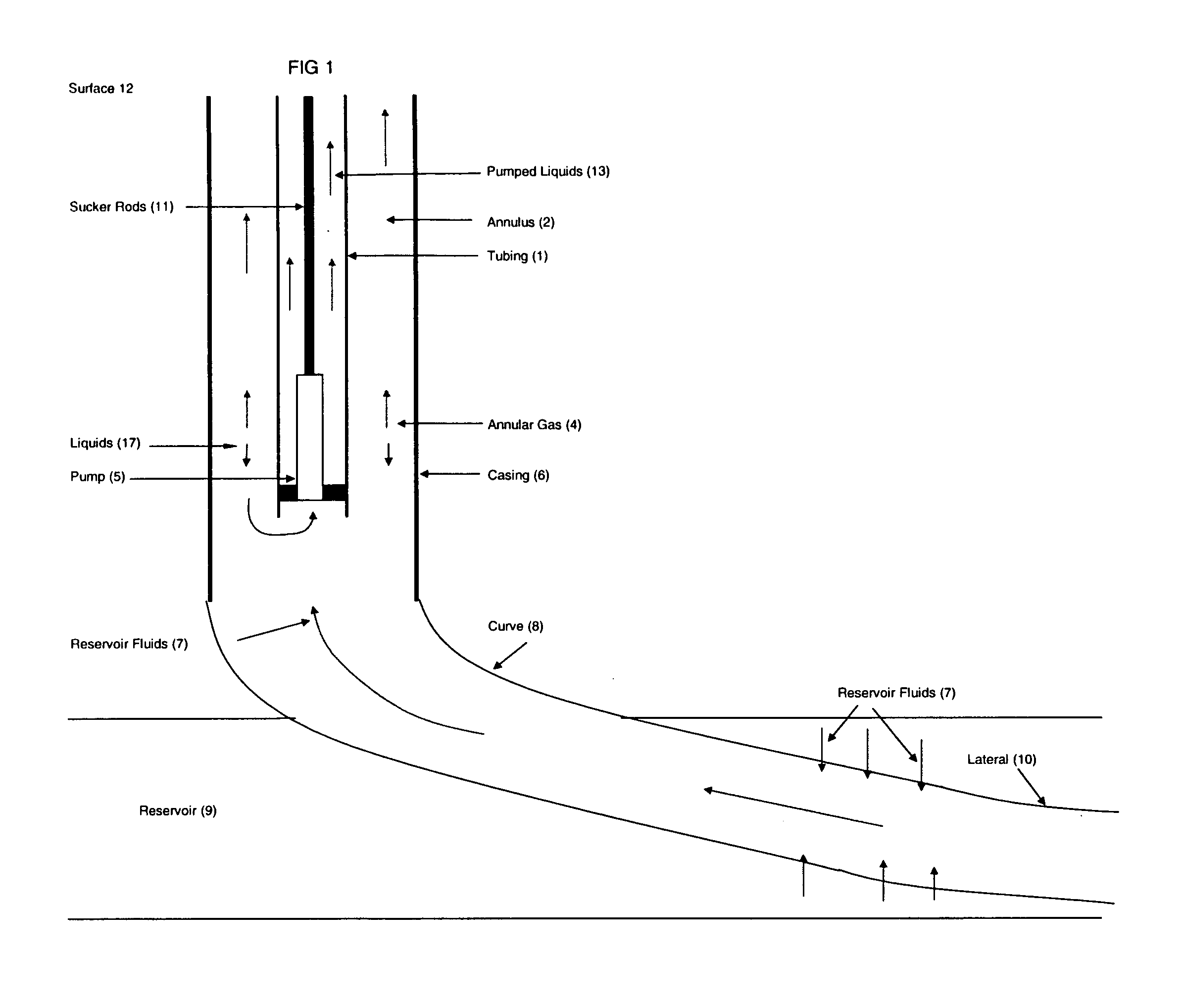

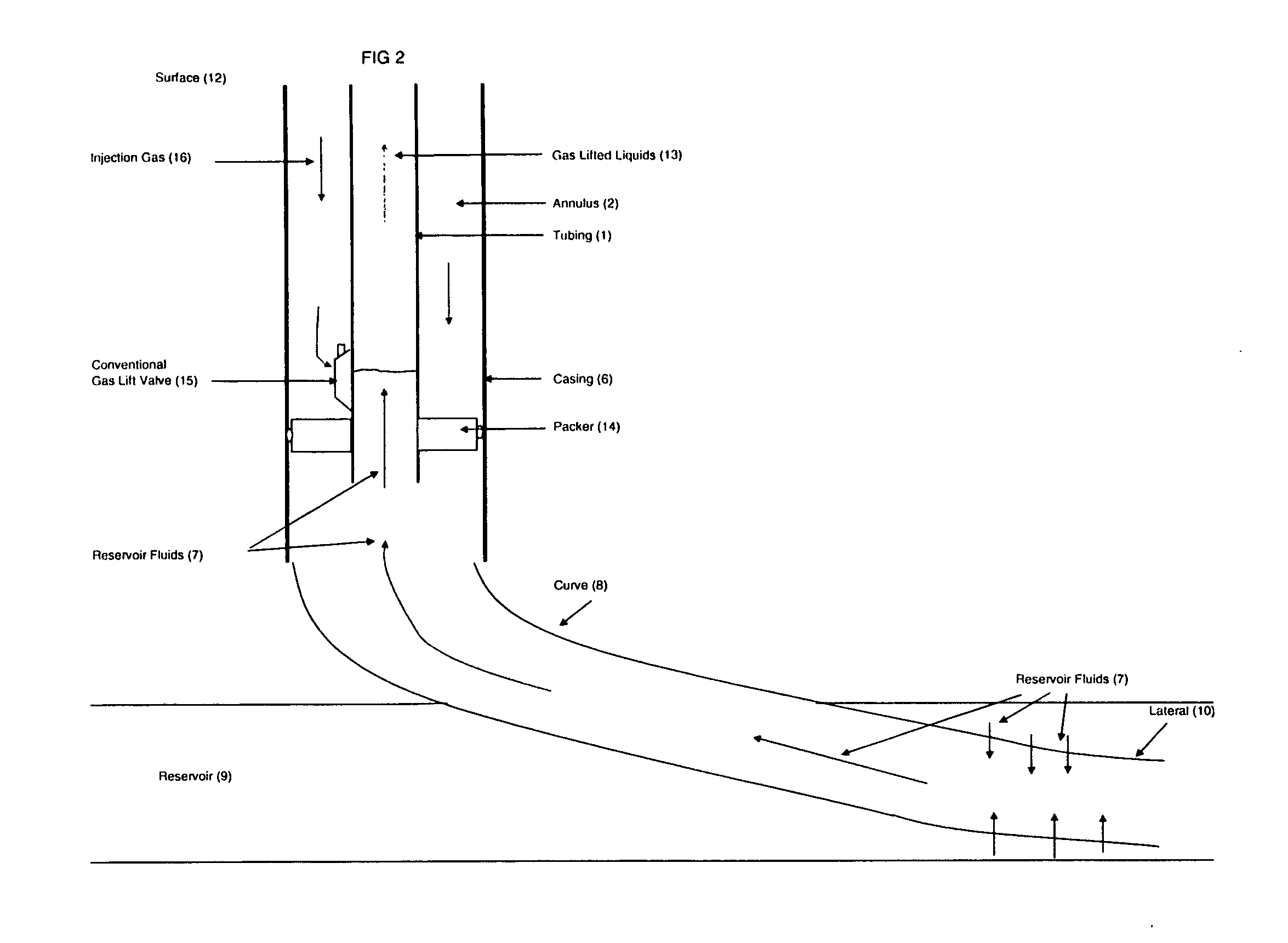

Gas assisted downhole pump

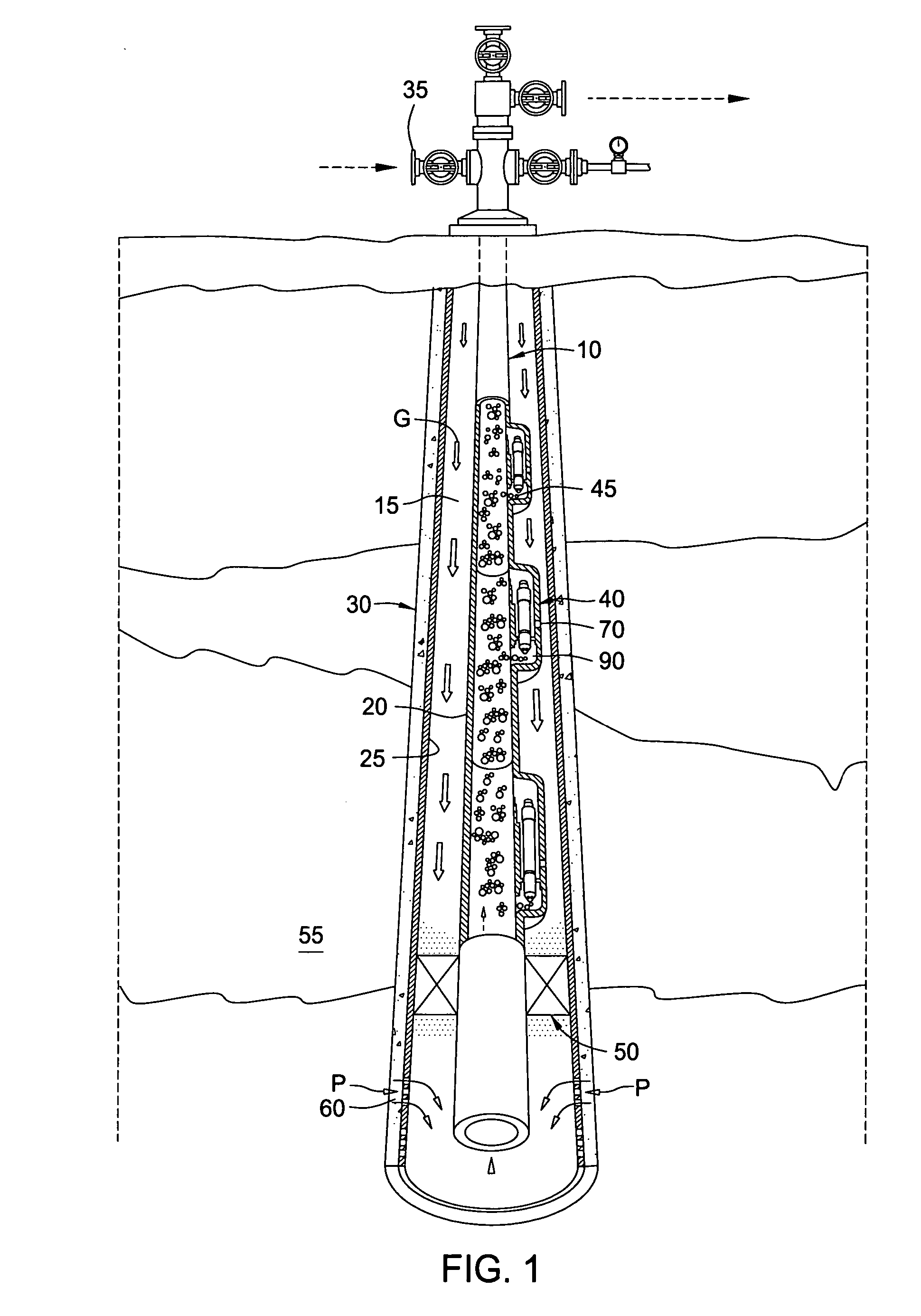

An artificial lift system is disclosed for removing wellbore fluids from directional or horizontal wellbores. The artificial lift system incorporates a dual tubing arrangement in which each string contains (respectively) a downhole pumping system or a gas lift system. In one string, a gas lift system, preferably intermittent, is utilized to lift reservoir fluids from below a packer assembly to above a packer assembly. This same tubing string is sealingly engaged to the packer and also contains a concentric inner tubing string which extends through and below the packer into the deviated well bore section. This concentric tubing arrangement provides a conduit for the injection gas and also a conduit for the return of commingled reservoir fluids and injection gas where the commingled fluids exit into the annular void between the dual tubing arrangement and the casing, located above the packer. The second tubing string, which is not sealingly engaged to the packer, contains a downhole pump placed above the exit point of the commingled fluids into the annulus. Because these liquids are trapped above the packer, each time the gas lift system cycles, they accumulate over time and rise above the downhole pump, which pumps the liquids to the surface. In an alternate embodiment of the invention, a plurality of tubing string arrangements are utilized A plurality of tubing string arrangements are sealingly engaged to a packer and operatively connected to a concentric tubing string that extends into the deviated section of the wellbore. A gas lift system, preferably intermittent, is utilized to lift reservoir fluids from below the packer to above the packer. This concentric tubing arrangement provides a conduit for the injection gas and also a conduit for the return of commingled reservoir fluids and injection gas. The commingled fluids exit through a perforated sub in one of the tubing strings above the packer and enter into the annular void between the dual tubing arrangement and the casing. A standing valve is located in the second tubing string below the perforated sub, which effectively trap the liquids in the annulus above the packer. Each time the gas lift system cycles, these liquids accumulate over time and rise above the downhole pump, which pumps the liquids to the surface.

Owner:NGSIP

System and method to interpret distributed temperature sensor data and to determine a flow rate in a well

InactiveUS20090173494A1Electric/magnetic detection for well-loggingSurveyGas liftEnvironmental geology

Owner:SCHLUMBERGER TECH CORP

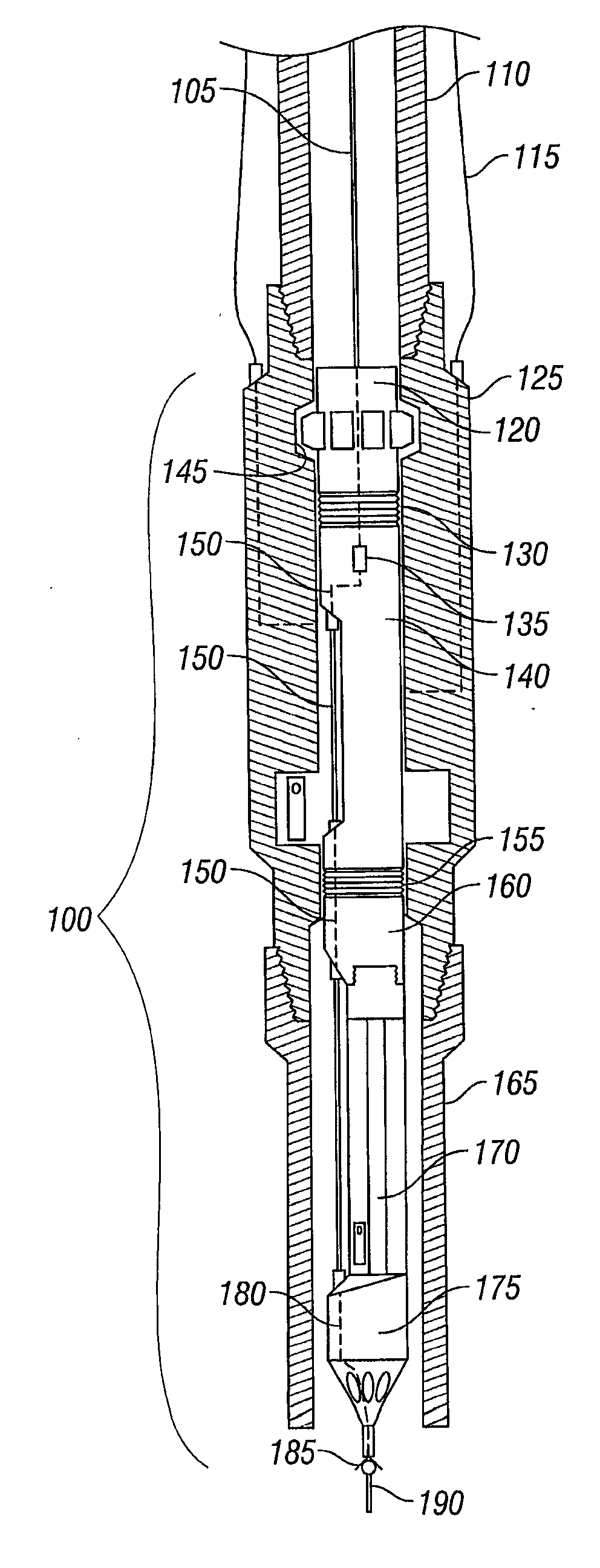

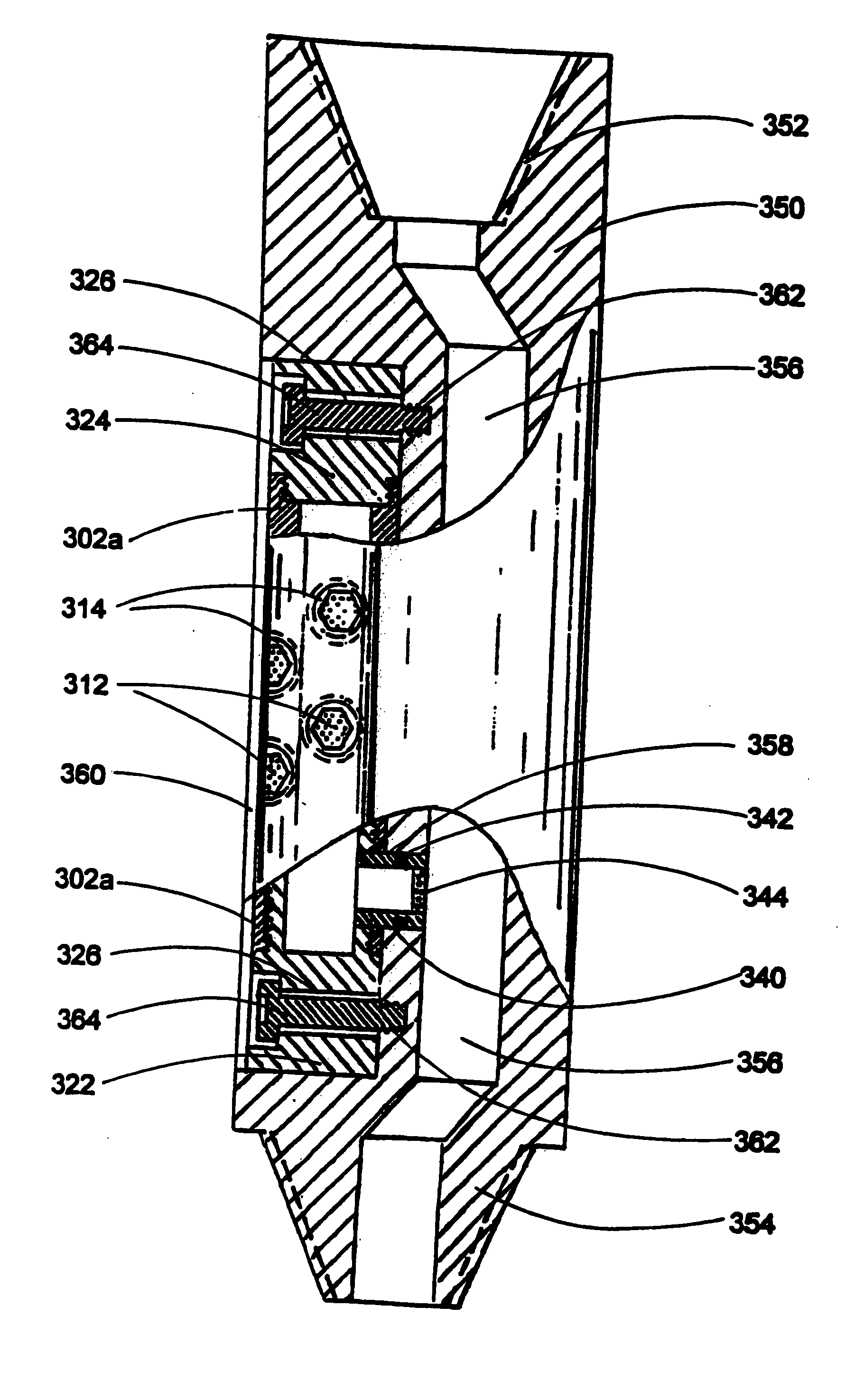

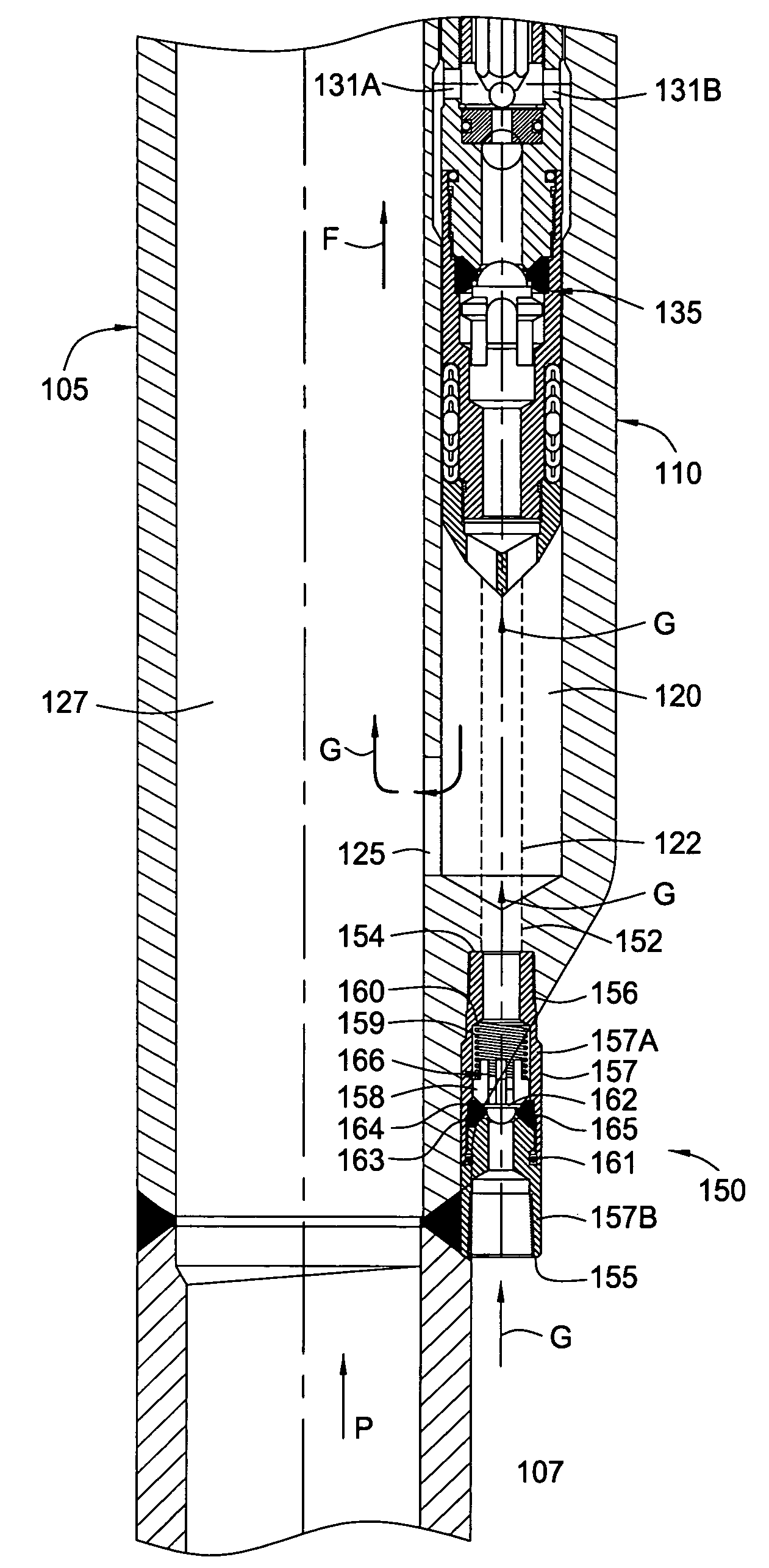

Method and Apparatus for Continuously Injecting Fluid in a Wellbore While Maintaining Safety Valve Operation

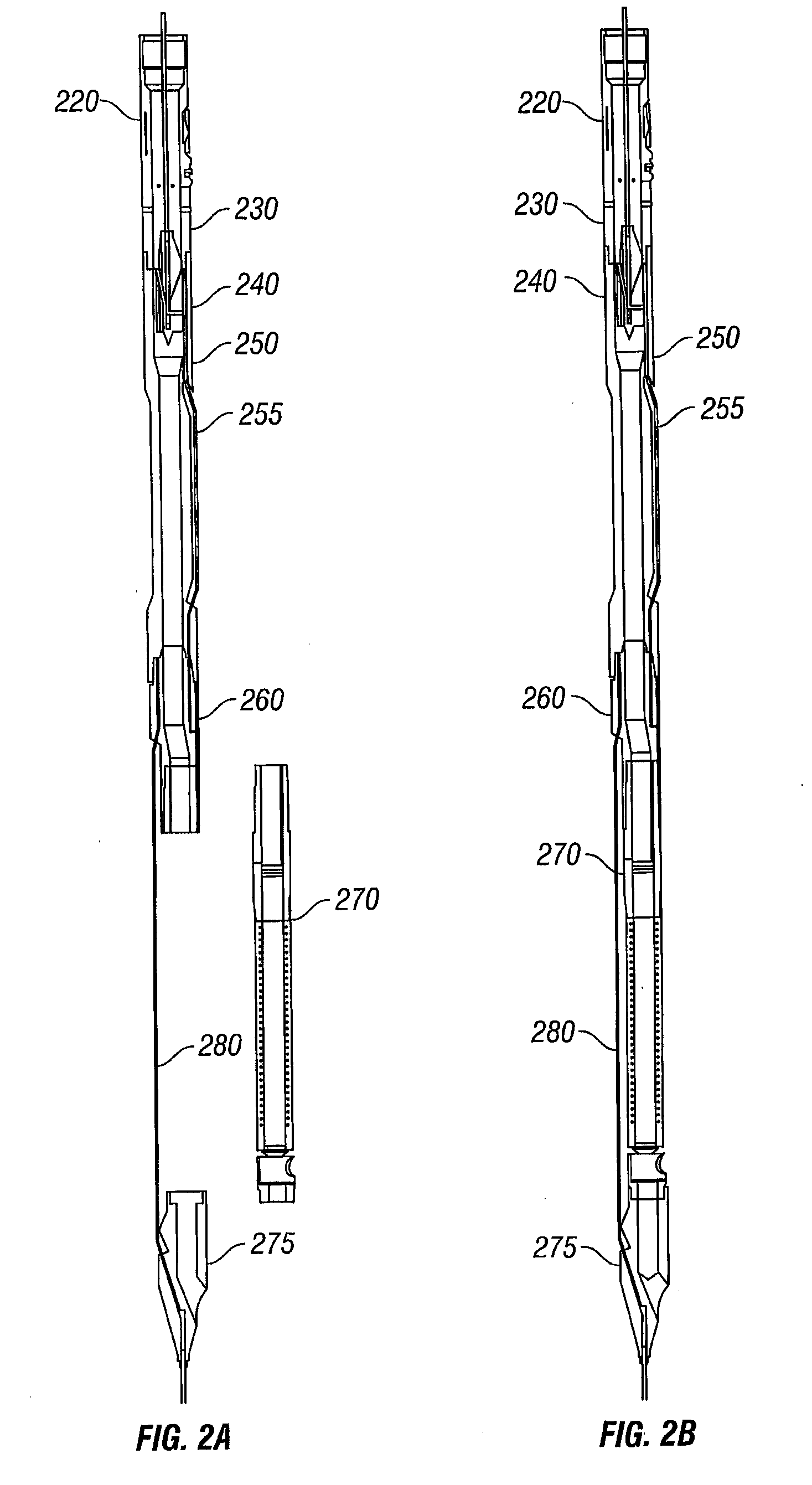

A kit for converting an existing wireline retrievable surface controlled subsurface safety valve (170, 270, 370) into a bypass passageway apparatus (100) allowing the injection of production-enhancing fluid into a wellbore while maintaining the operation of the closure member (374). Bypass passageway (280) can extend between upper (260) and lower (275) adapters external to the existing wireline retrievable surface controlled subsurface safety valve (270) to allow fluid injection bypass thereof. Conversion kit can include a tubing string hanger to suspend a velocity tubing string (407, 507), a gas lift valve (475) for gas lift operations, a locking mandrel (220), and / or a spacer tube (240).

Owner:BAKER HUGHES INC

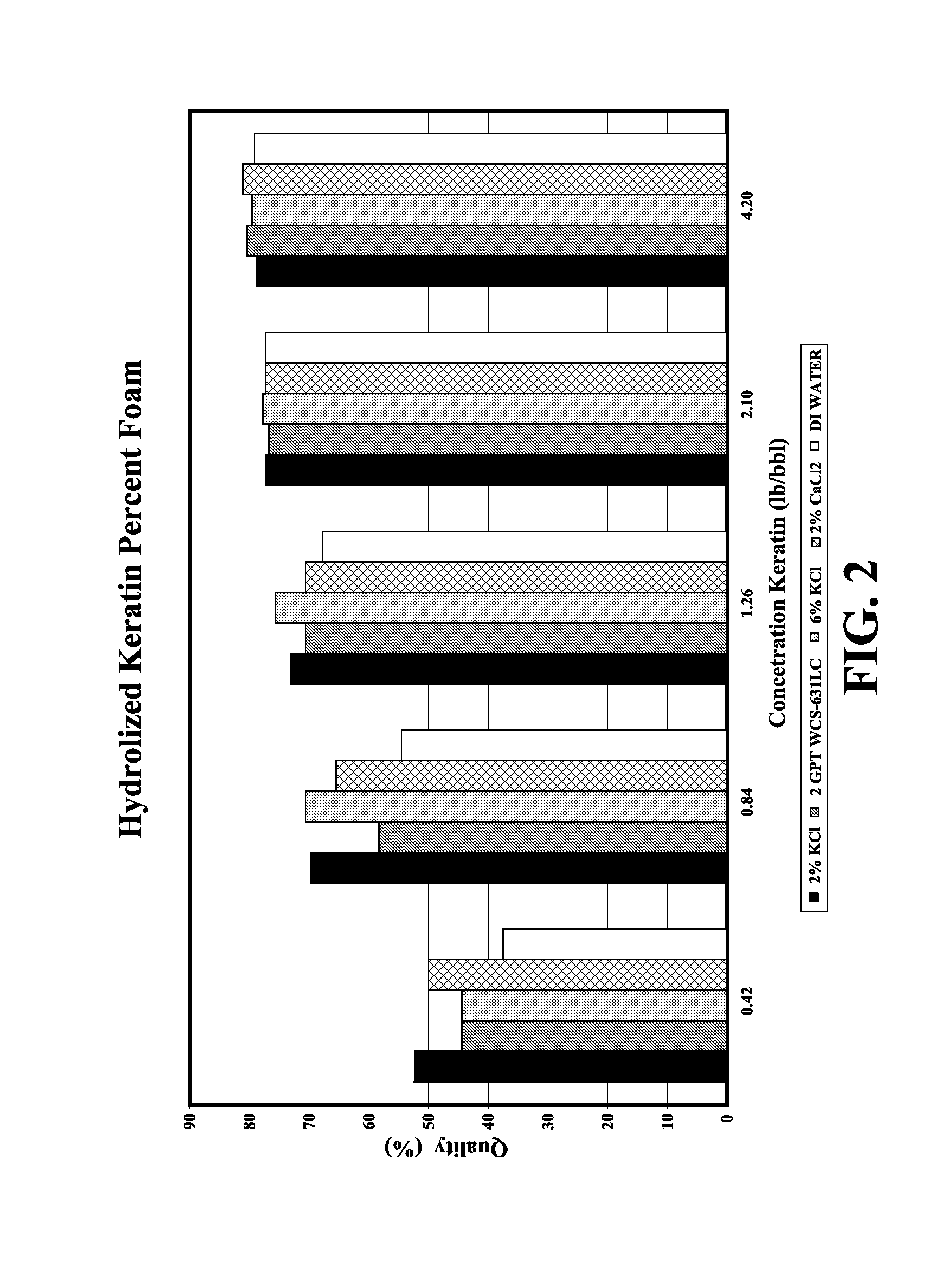

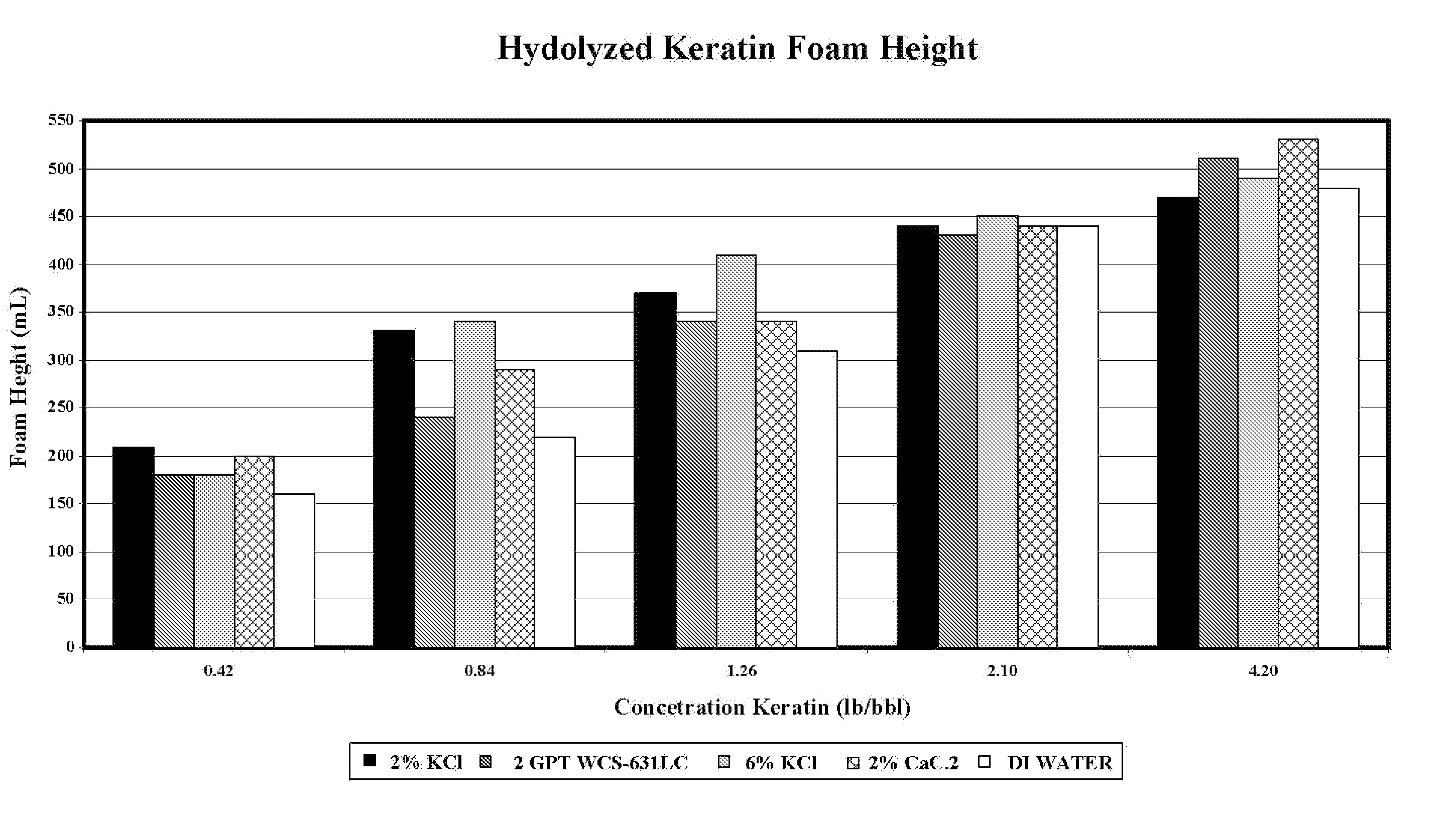

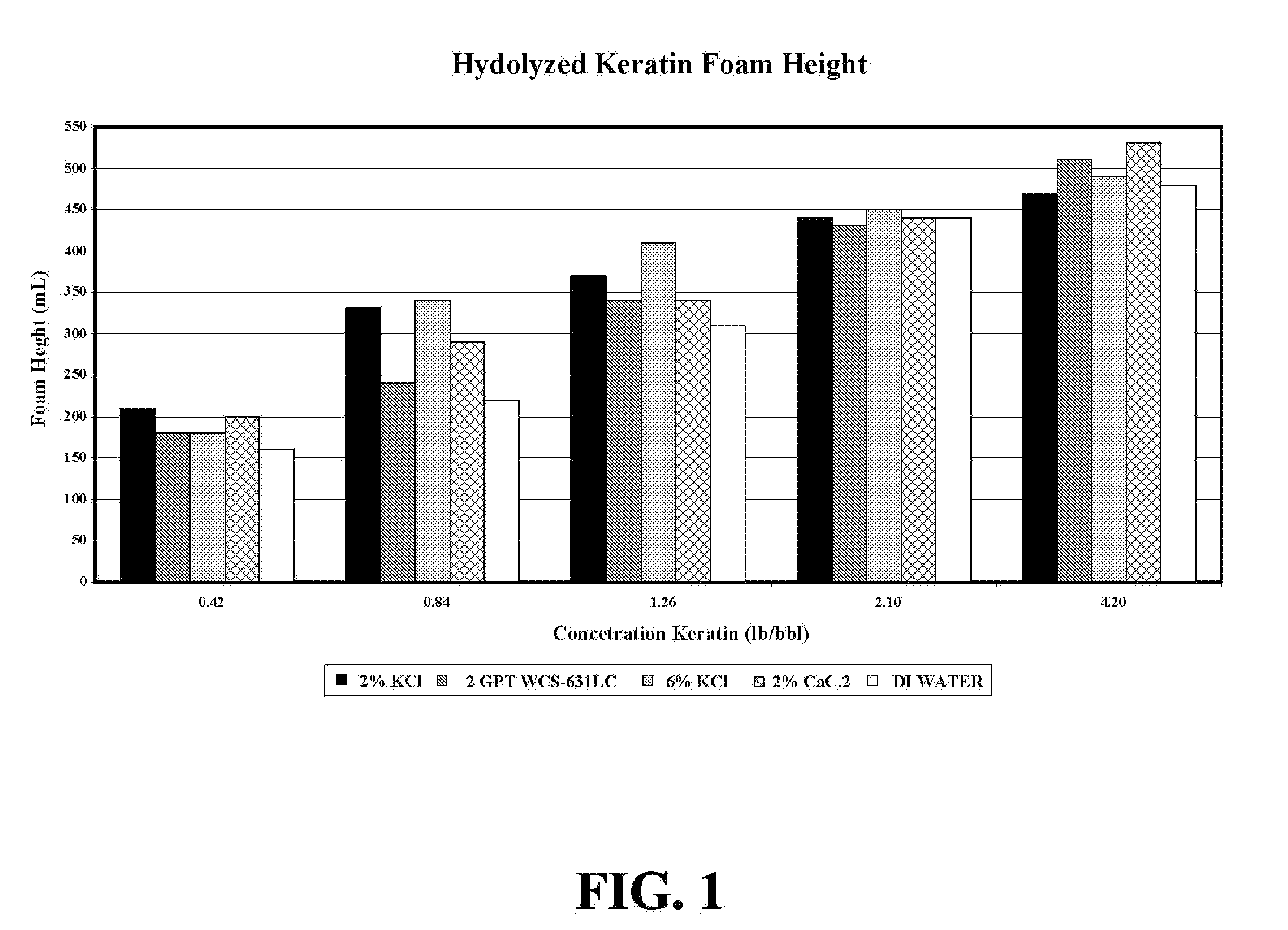

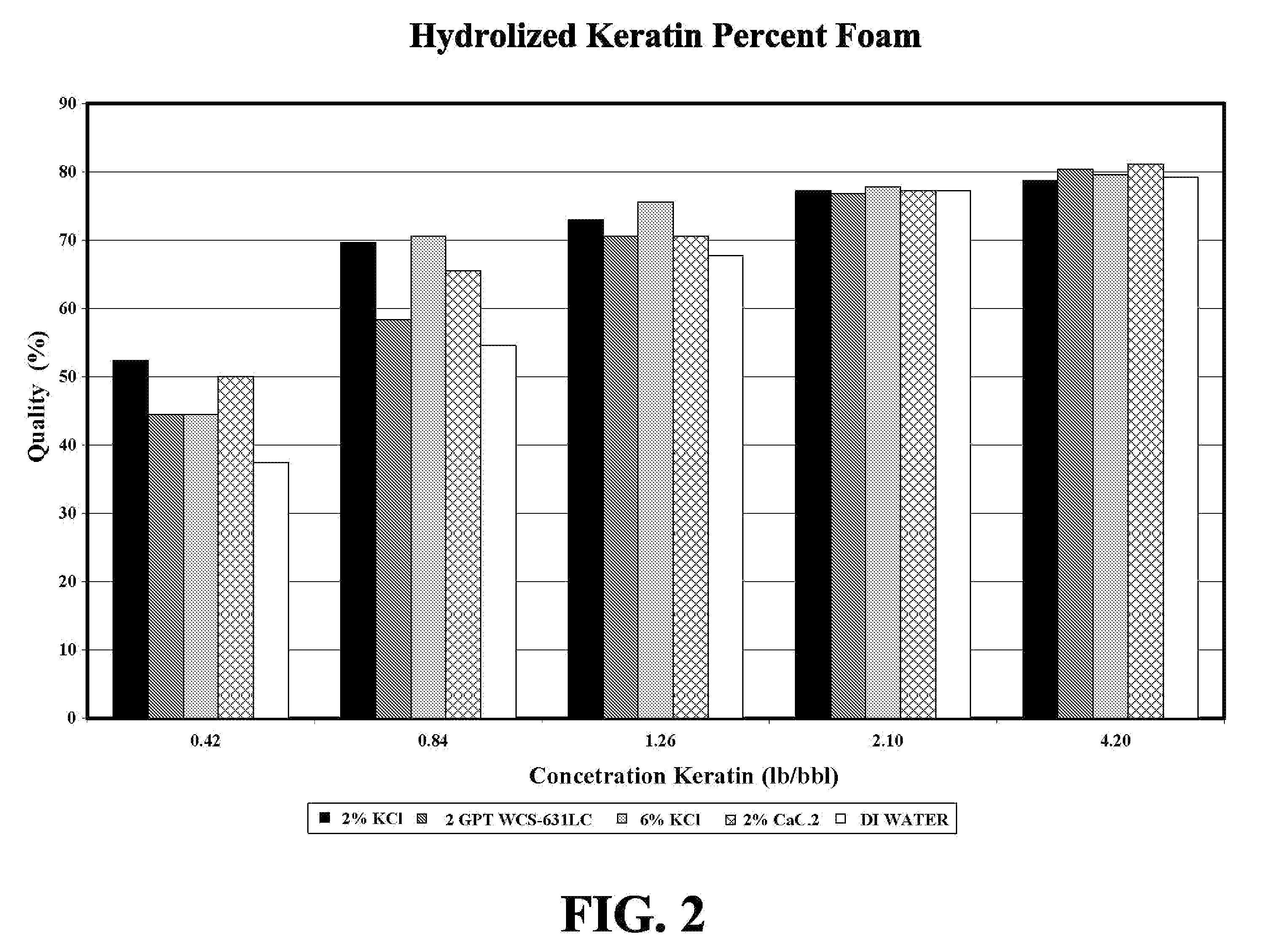

Foamed fluid additive for underbalance drilling

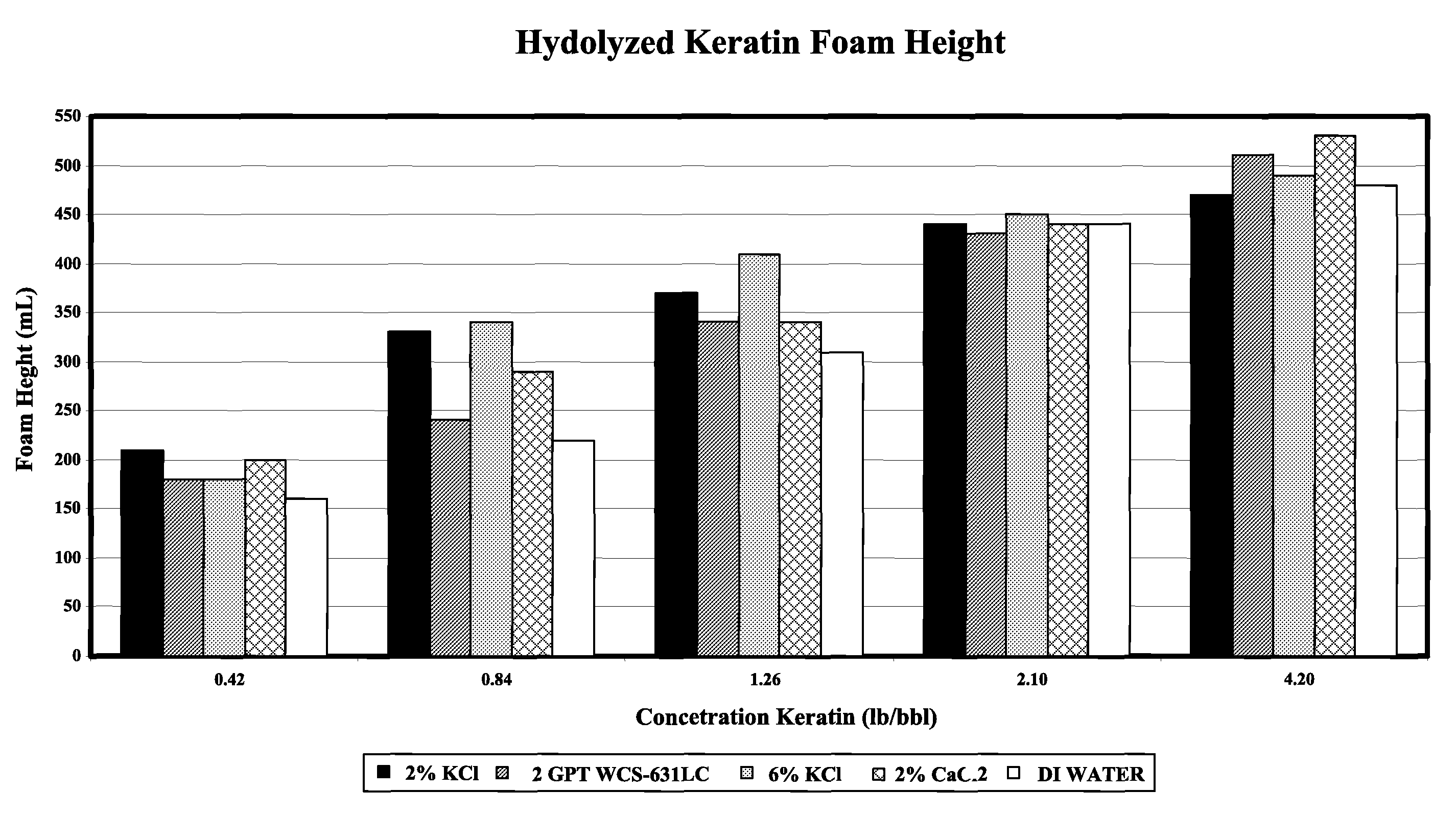

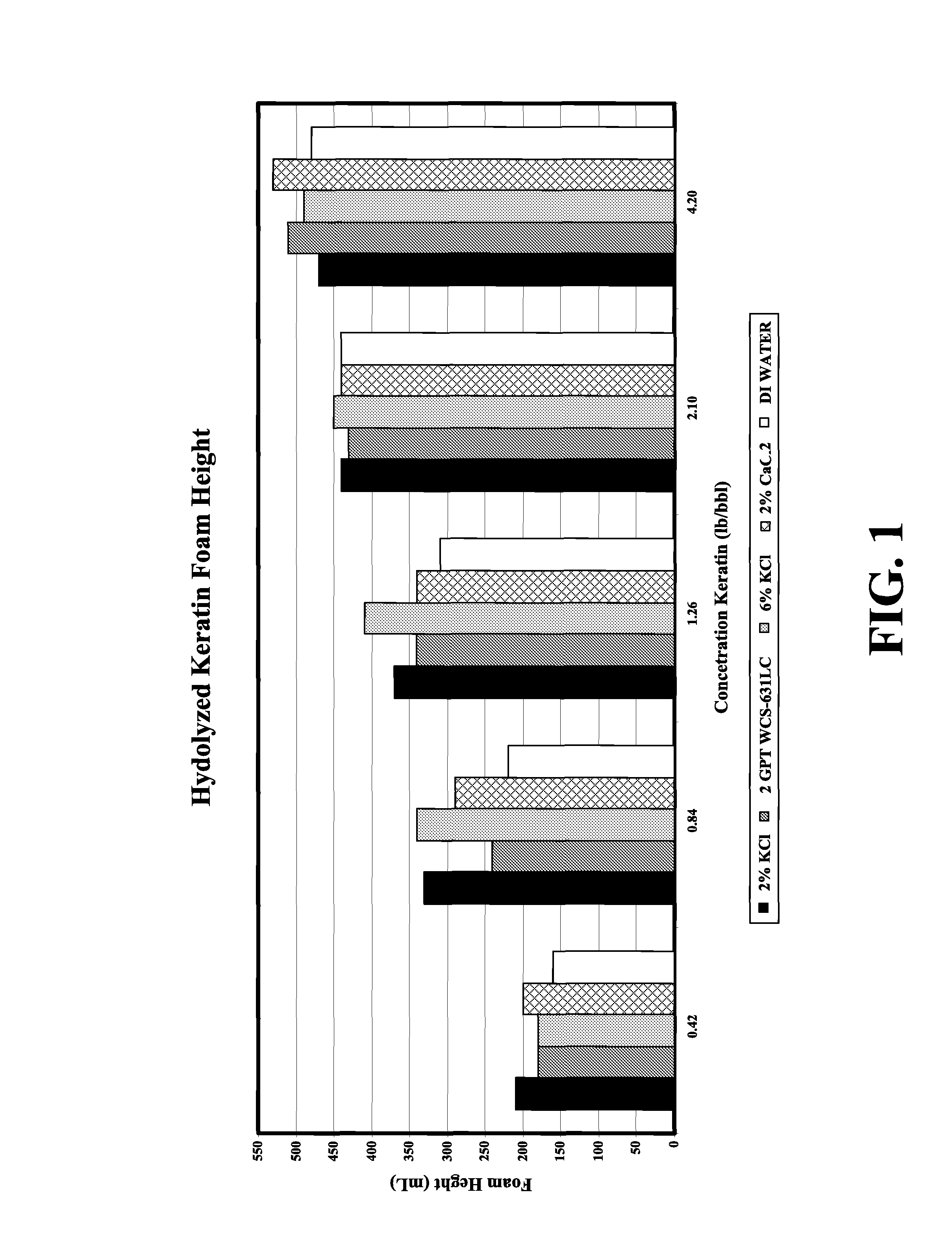

A method of drilling or gas-lifting is disclosed where the methods including the use of a foaming agent and a gas, where the foaming agent is a keratin and the hydrostatic pressure of the fluid in the well is for a portion of the drilling or gas-lift operation less than an hydrostatic pressure of the formation being drilled or under production.

Owner:WEATHERFORD TECH HLDG LLC

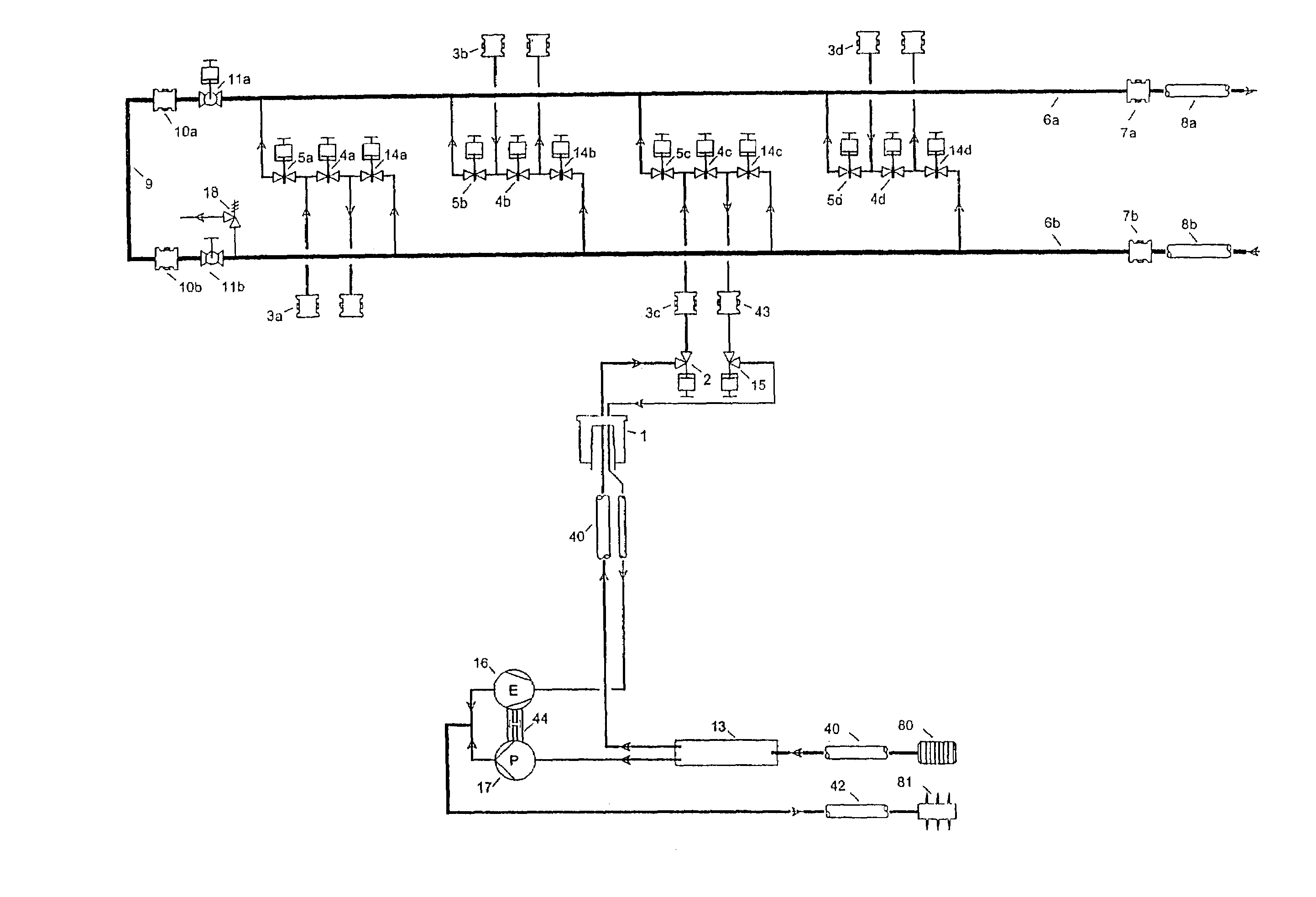

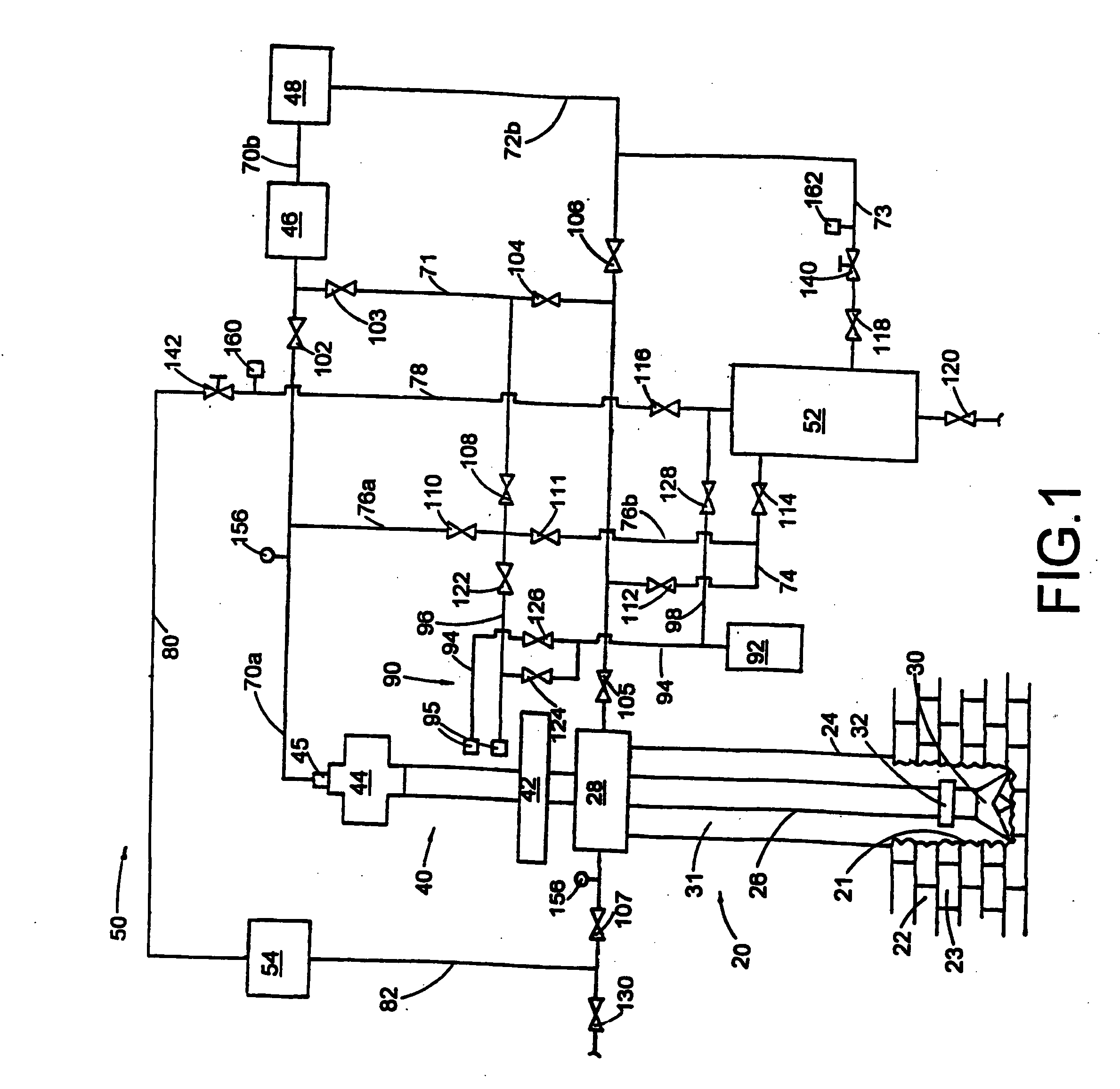

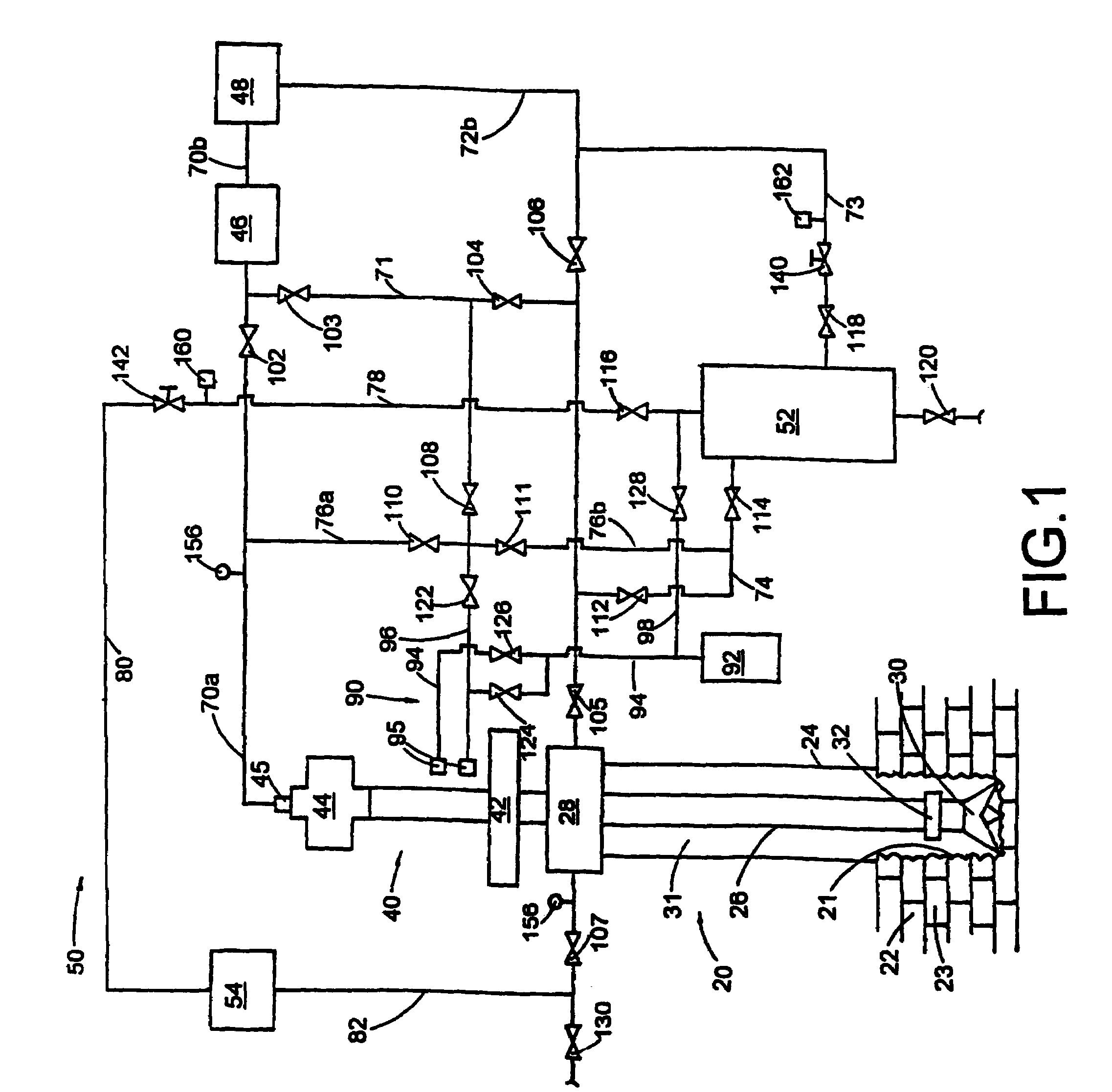

Underbalanced drilling method and apparatus

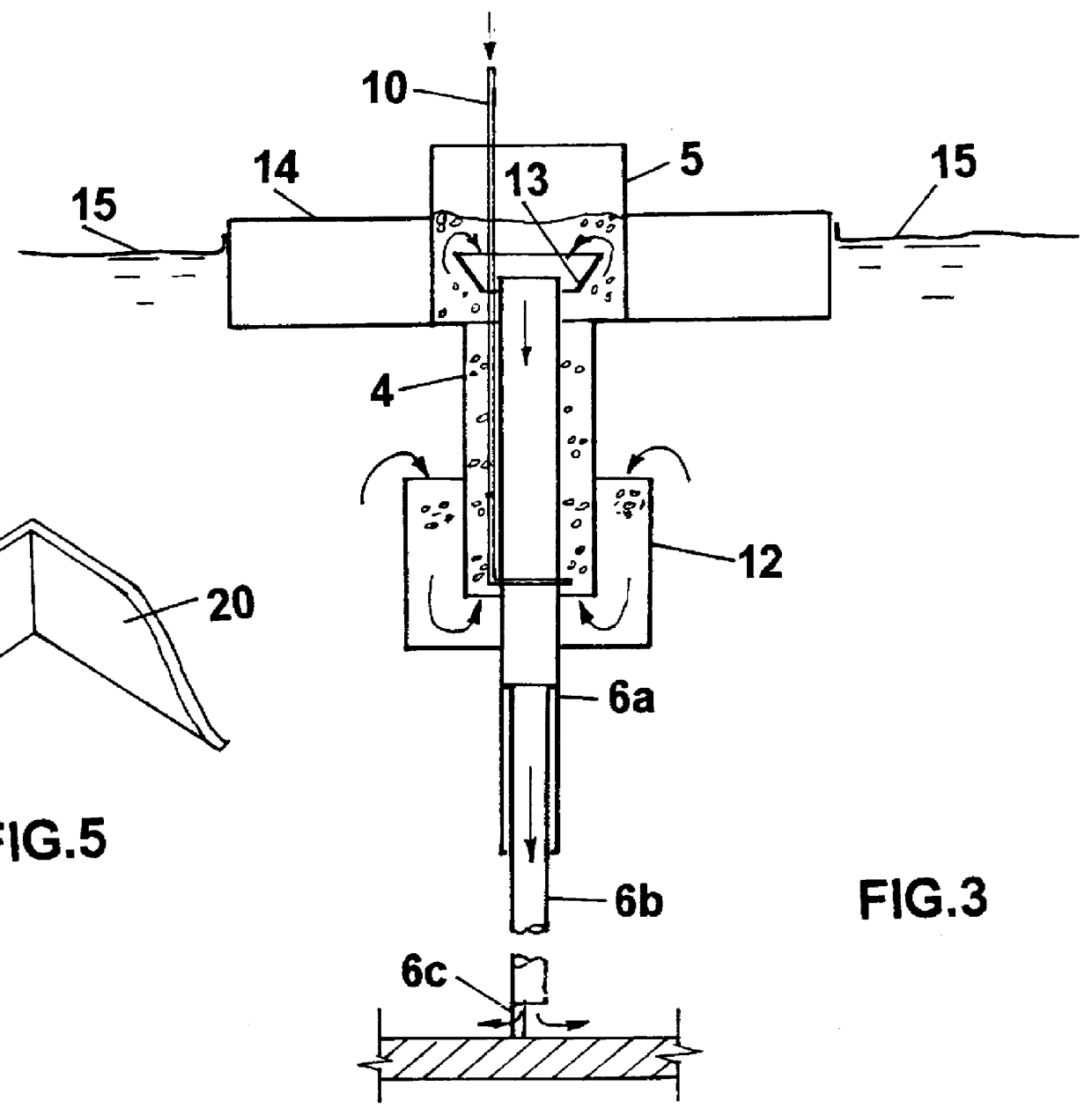

InactiveUS20050269134A1Loss is particularly problematicCost-effectiveDrilling rodsConstructionsGas liftMechanics

A method of drilling well bore (20) through and below permeable formation (22) bearing such fluids as gas, oil, water wherein drill cuttings may be evacuated by formation fluid (23) being produced through the drill string (26) either by decreasing well head back pressure or by gas lift. Production rate is kept substantially stable by operating choke valves (140) and (142) placed after separator (52). Formation fluid being produced while drilling may be pumped into well bore (20) through annulus (31) or utilized. The unique injector included in the drill string provides for possibility to pump simultaneously into annulus (31) lifting gas and produced liquid and may be operated from the surface. A method and system (90) comprising a plurality of special 3-way valves included in drill string (26), are provided for making connections without interrupting flushing the well bore.

Owner:STRAZHGORODSKIY SEMEN IOSIPHOVICH

Underbalanced drilling method and apparatus

InactiveUS7308952B2Eliminate the problemAvoid excessive volumeConstructionsFluid removalGas liftMechanics

A method of drilling well bore (20) through and below permeable formation (22) bearing such fluids as gas, oil, water wherein drill cuttings may be evacuated by formation fluid (23) being produced through the drill string (26) either by decreasing well head back pressure or by gas lift. Production rate is kept substantially stable by operating choke valves (140) and (142) placed after separator (52). Formation fluid being produced while drilling may be pumped into well bore (20) through annulus (31) or utilized. The unique injector included in the drill string provides for possibility to pump simultaneously into annulus (31) lifting gas and produced liquid and may be operated from the surface. A method and system (90) comprising a plurality of special 3-way valves included in drill string (26), are provided for making connections without interrupting flushing the well bore.

Owner:STRAZHGORODSKIY SEMEN IOSIPHOVICH

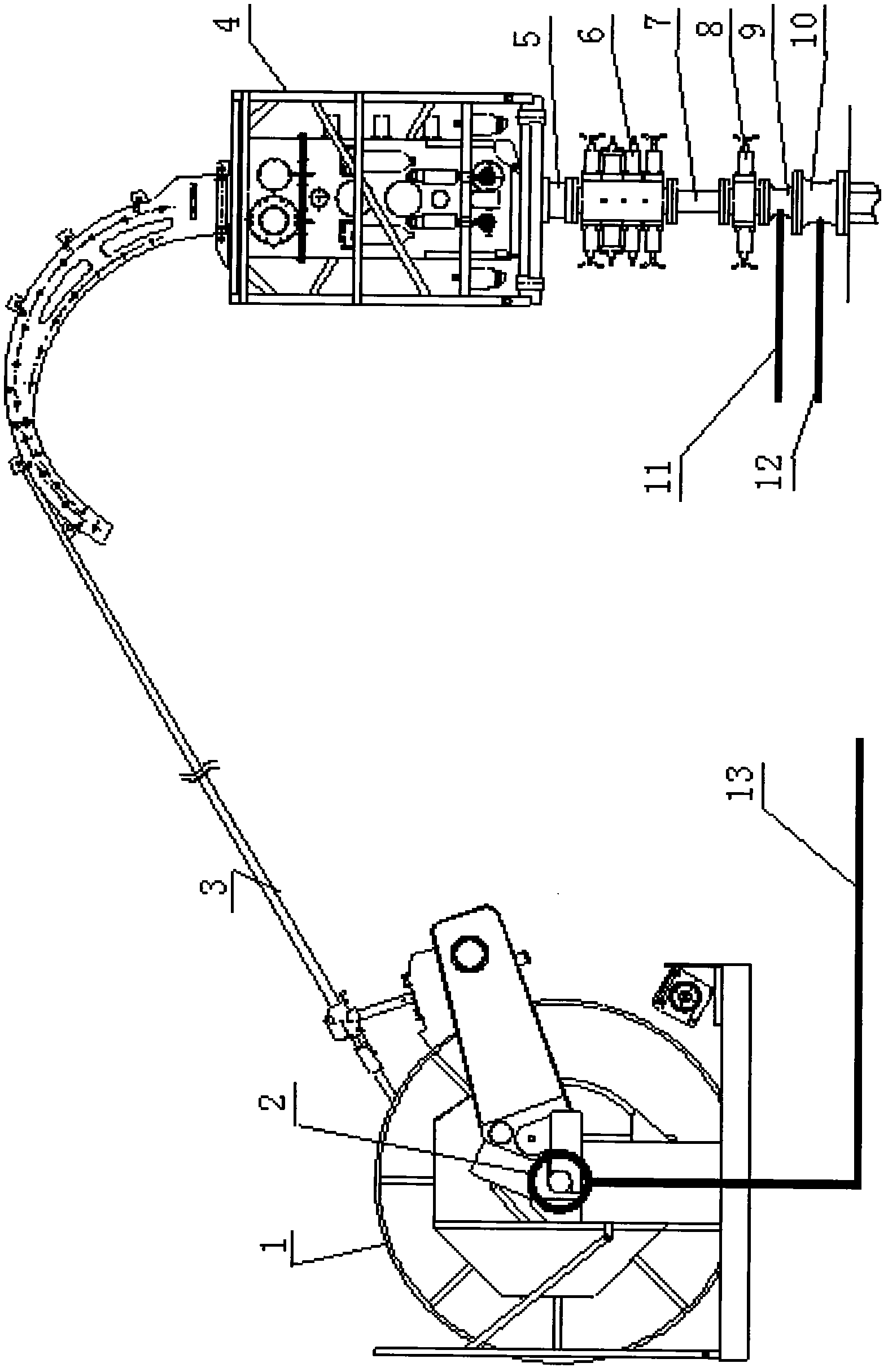

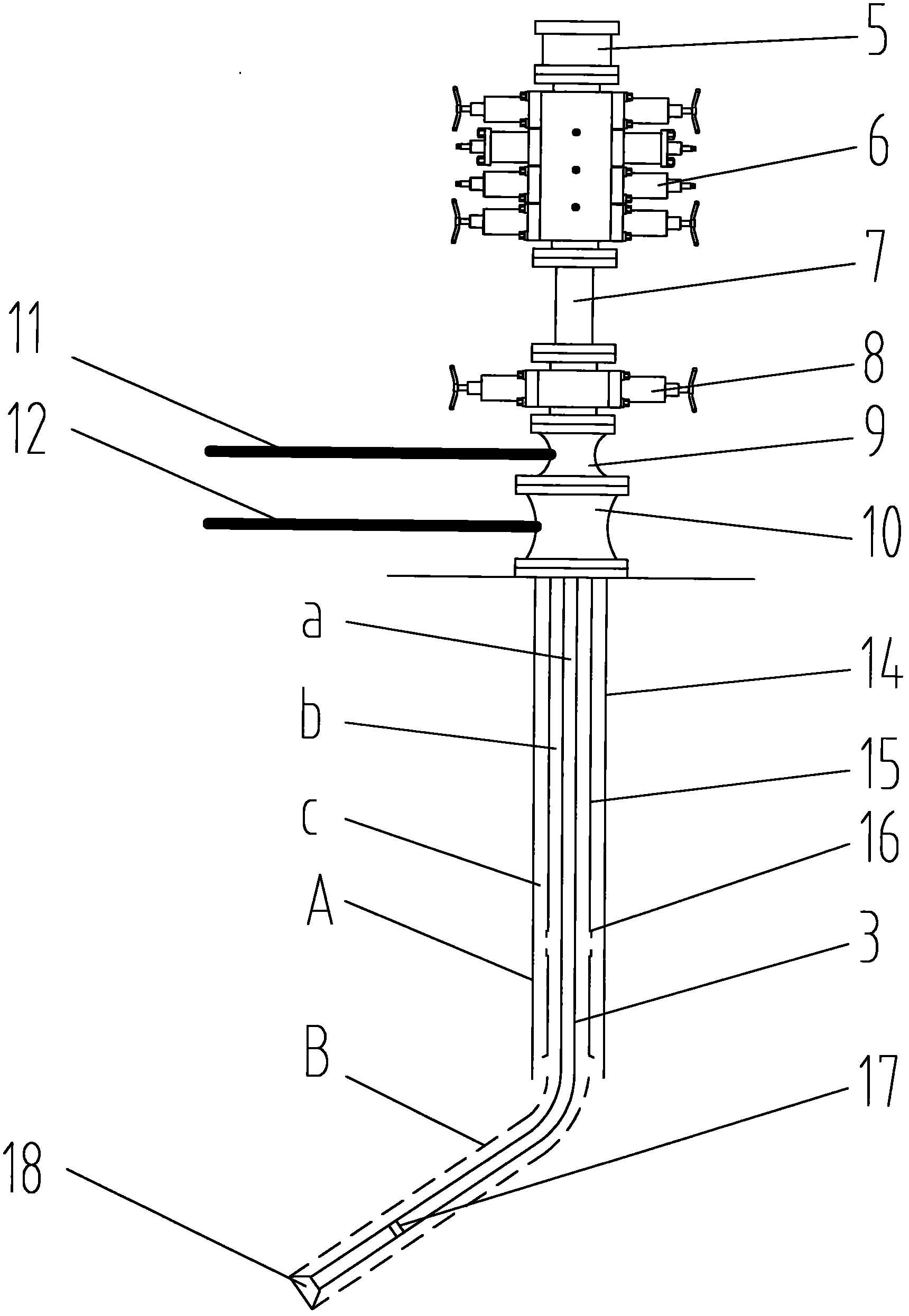

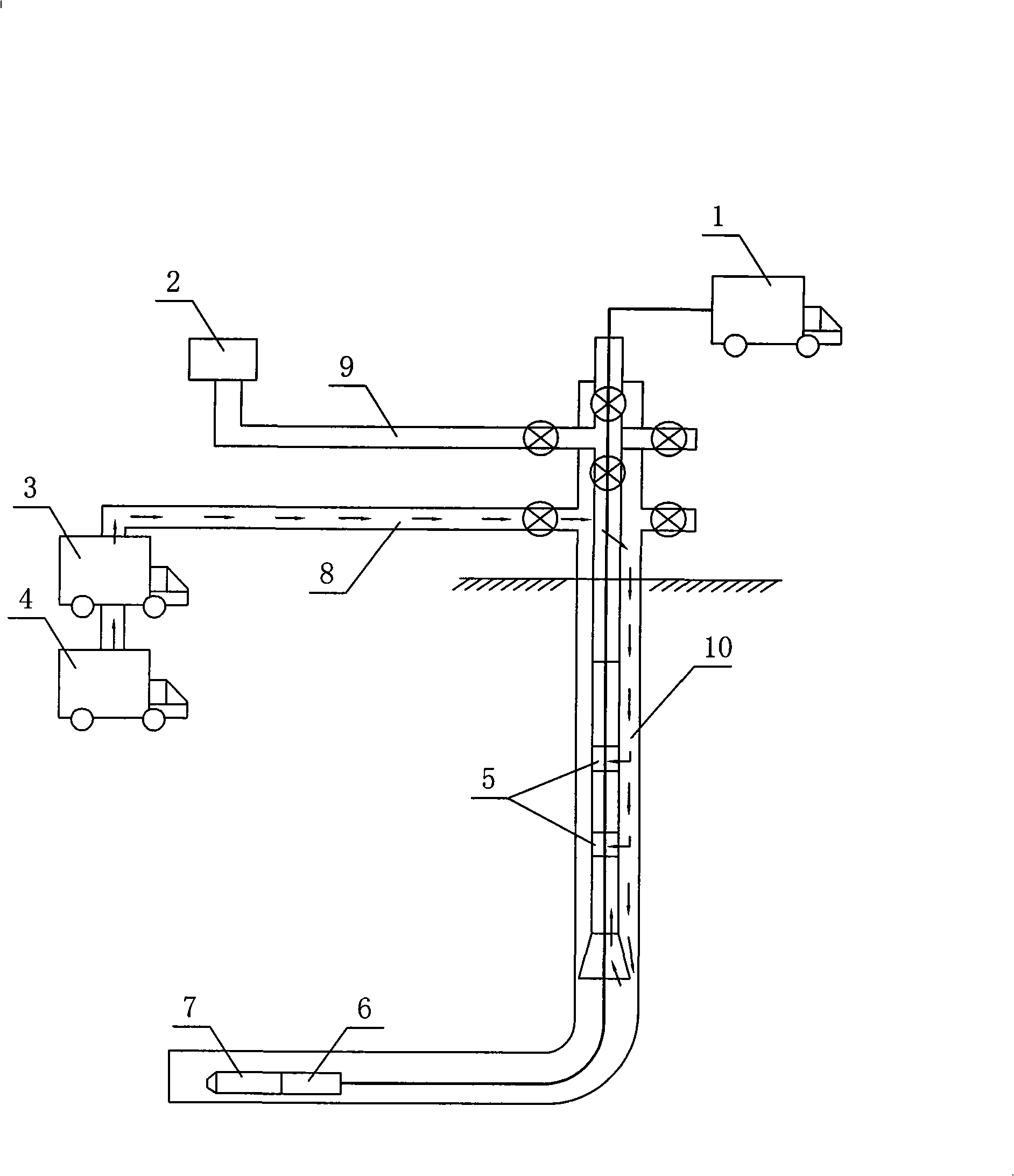

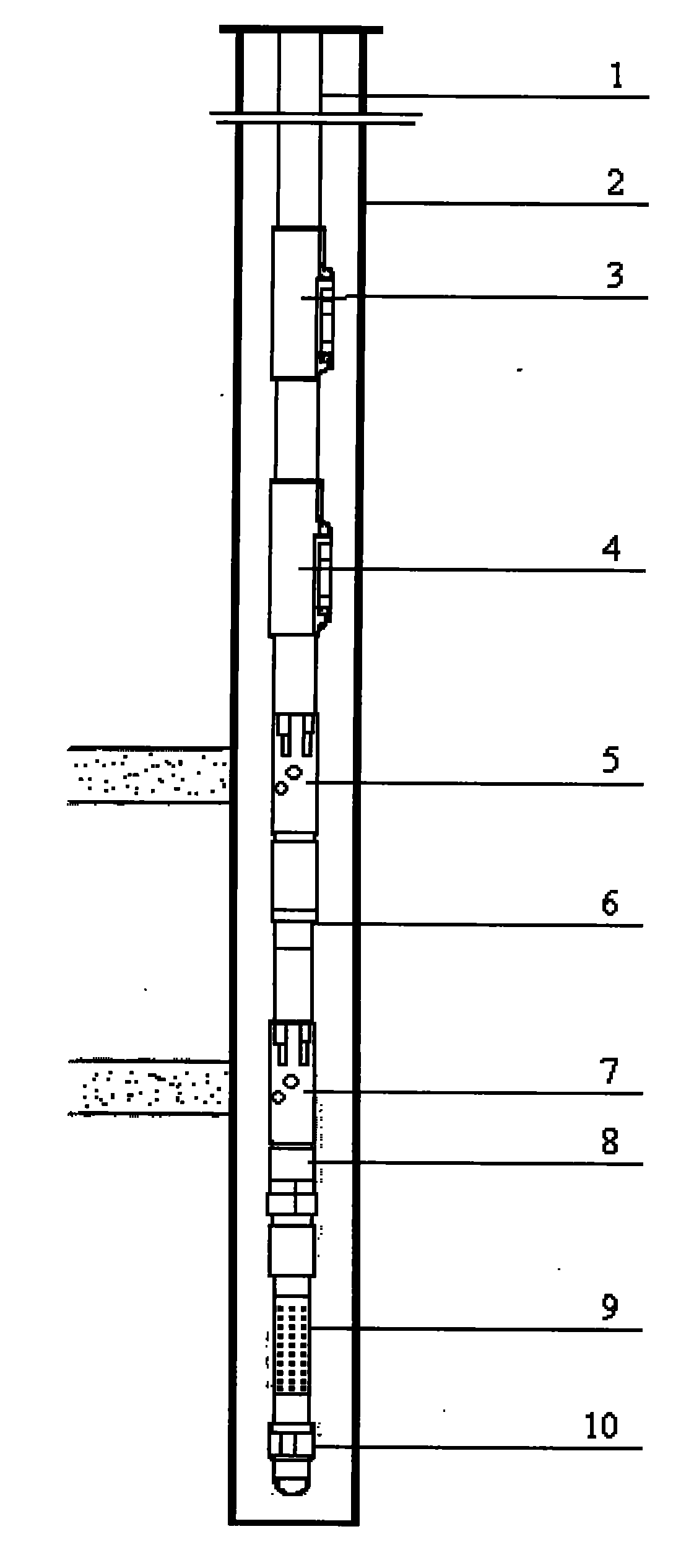

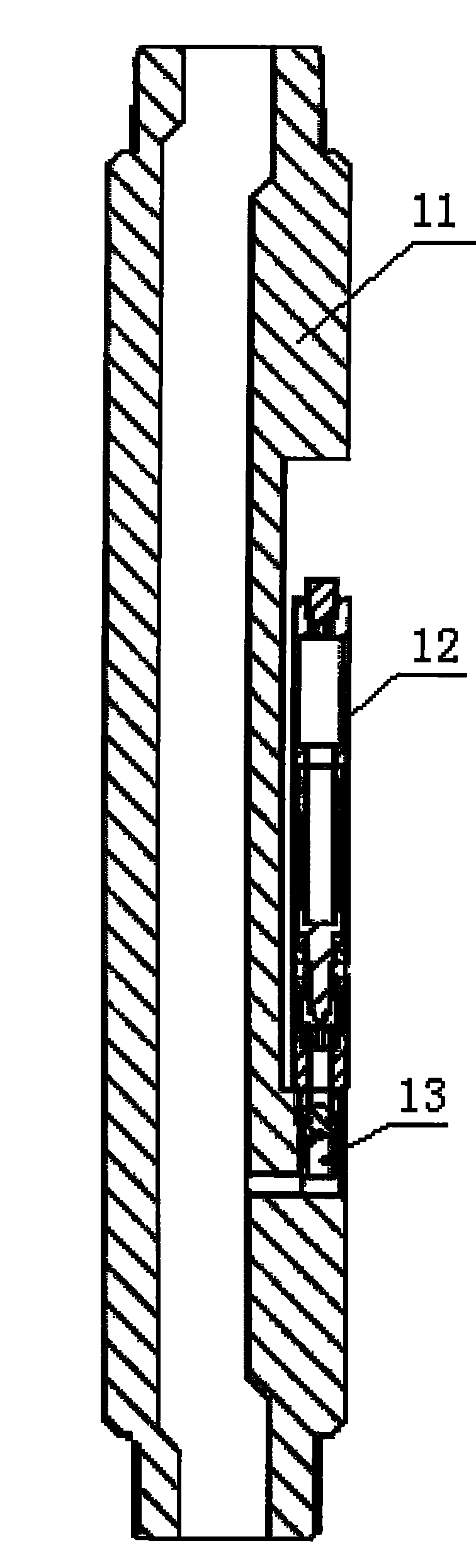

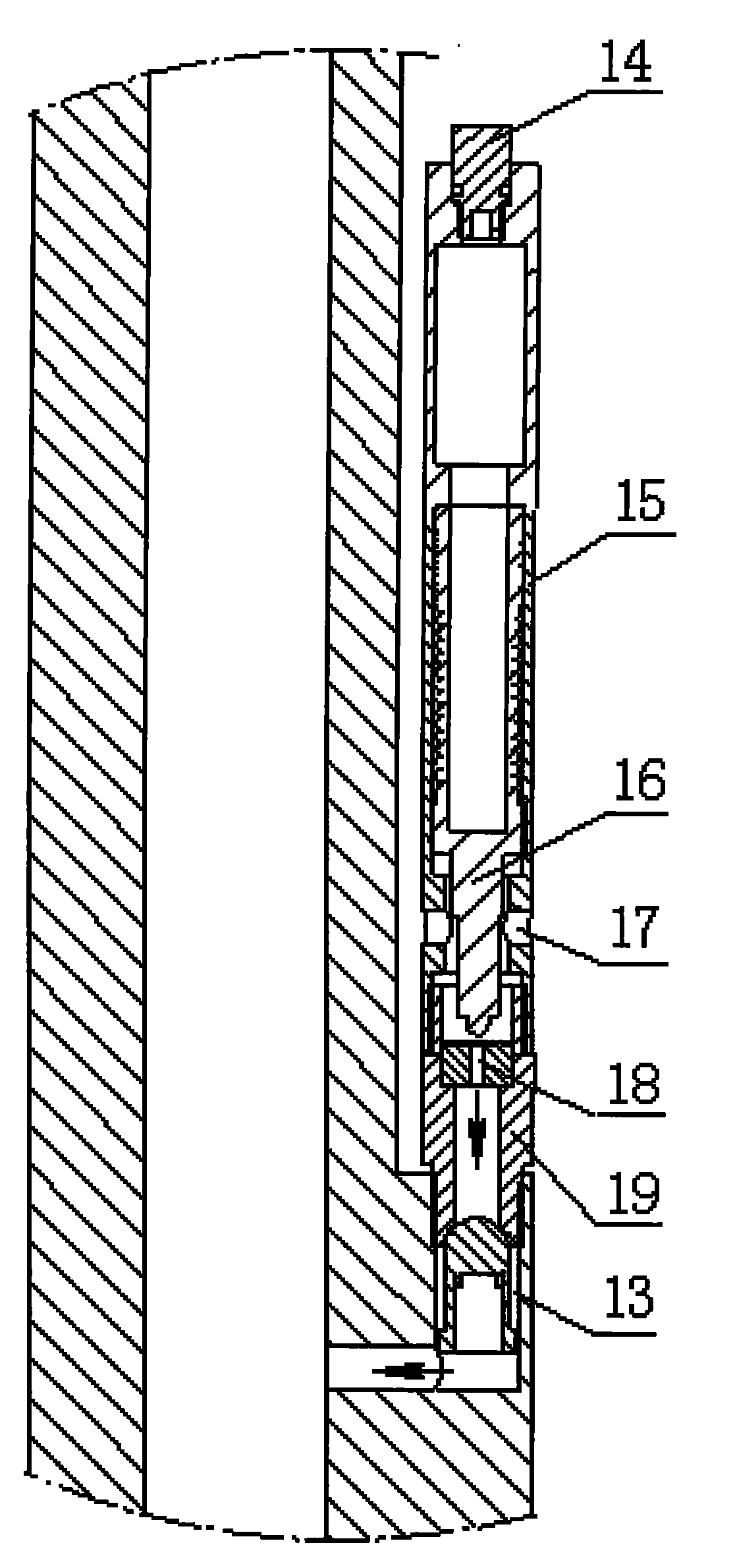

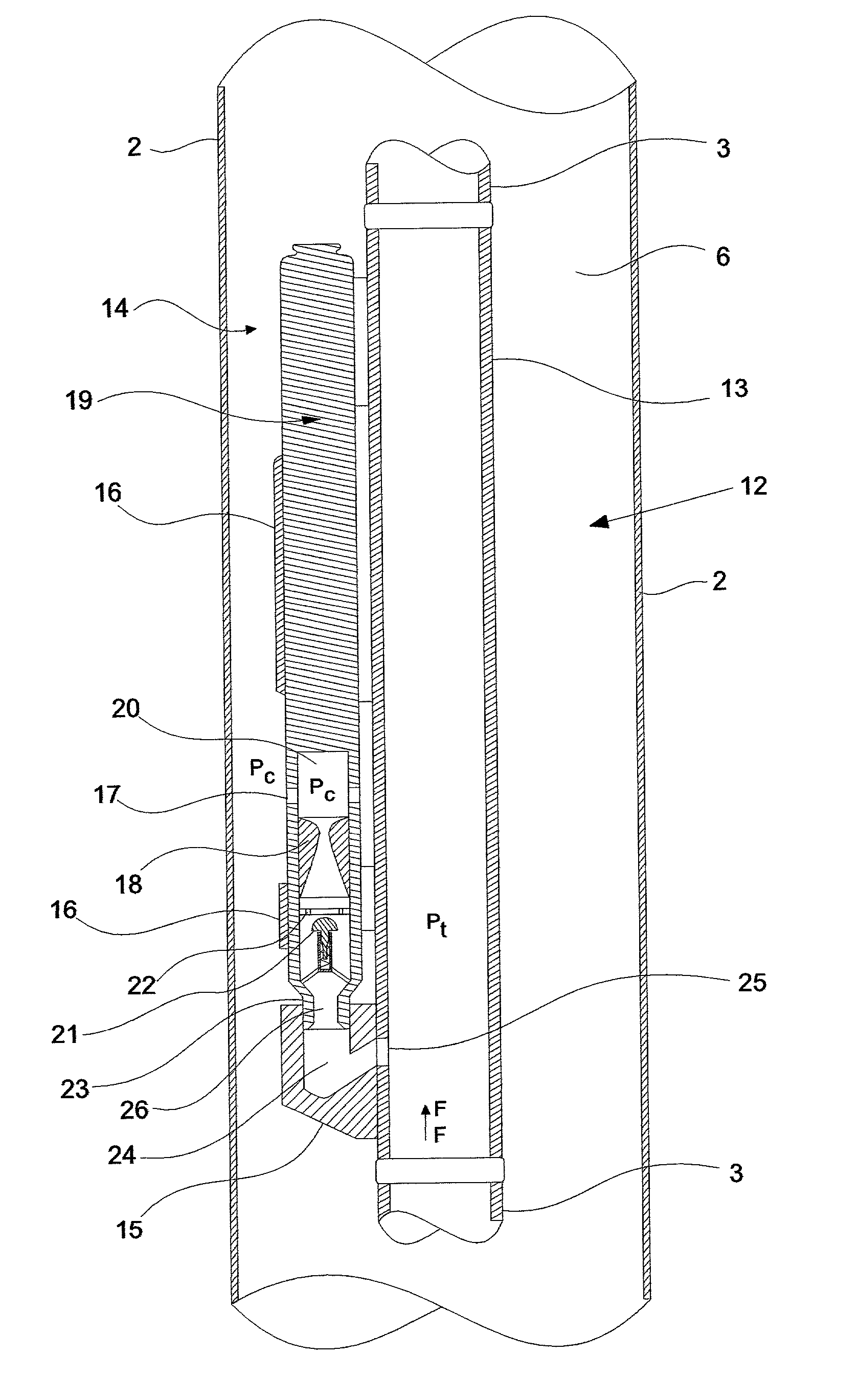

Well drilling method of through tubing of gas lift under-balanced coiled tubing

ActiveCN101942962AOvercoming the effect of jacking forcePromote maturityDirectional drillingFlushingDirectional wellSlurry

The invention relates to a well drilling method of a through tubing of a gas lift under-balanced coiled tubing, which is applied in the technical field of petroleum well drilling. The through tubing operation way of the coiled tubing is adopted for carrying out under-balanced well drilling or low-pressure well drilling on target well sections at the lower part in a shaft with a drilled upper borehole, wherein the target well sections are a vertical well, a directional well or a horizontal well. The method has the following effects: the adoption of the through tubing operation of the coiled tubing can form three circulation channels by utilizing the coiled tubing, an oil tube and a sleeve, and a matching pipe column has good universality, does not need a special drilling column or an inner tube and does not need to use a rotary blowout preventer and other special equipment; a gas injection channel and a slurry injection channel are independent mutually, thereby being capable of more conveniently controlling the well bottom pressure and the under-pressure value and using an underground power drilling tool and a slurry pulse measurement system which are applicable to slurry well drilling to carry out well drilling operation and trajectory control; and the method does not need to be connected with a single and can keep the continuous circulation during the tripping process and the drilling process, and realize the full-process controllable under-balanced well drilling operation and the full-process controllable low-pressure well drilling operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Foamed fluid additive for underbalance drilling

A method of drilling or gas-lifting is disclosed where the methods including the use of a foaming agent and a gas, where the foaming agent is a keratin and the hydrostatic pressure of the fluid in the well is for a portion of the drilling or gas-lift operation less than an hyrdrostatic pressure of the formation being drilled or under production.

Owner:WEATHERFORD TECH HLDG LLC

Gas lifting reverse circulation porus cleaning construction method for slurry bulkhead cast-in-situ bored pile

InactiveCN101109179AReduce usageEmission reductionCleaning apparatusBulkheads/pilesSlurryEngineering

The invention discloses a construction method using gas-lift back-circulation hole cleaning for cast piles by drilling in slurry dado, which comprises the following procedures: (1) setting steel guide tube in the rebar cage depending upon the diameter of the pile; (2) installing special guide-pipe epimerite with an inserting port for hi-pressure rubber tube at top of the steel tube; (3) measuring the specific weight of the slurry in the hole, determining the length of the hi-pressure rubber tube to be inserted into the steel guide tube depending upon the specific weight of the slurry; (4) inserting into the steel guide tube the hi-pressure rubber tube having capillary holes at its bottom; (5) connecting the hi-pressure rubber tube with an air compressor; (6) turning on the air compressor to clear out dregs by gas-lift back circulation. The invention is furnished with rapid dreg-clearing speed, clean and through dreg clearing; comparing with prior process, the invention can improve 3-5 times dreg-clearing speed; the invention guarantees the quality of pipe foundation, is free from slurry pollution and good for environmental protection; and can save water and land. The hole-clearing device and equipment used are easy to install and operate, are practical, the materials are readily available, the price is low and the process is convenient.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

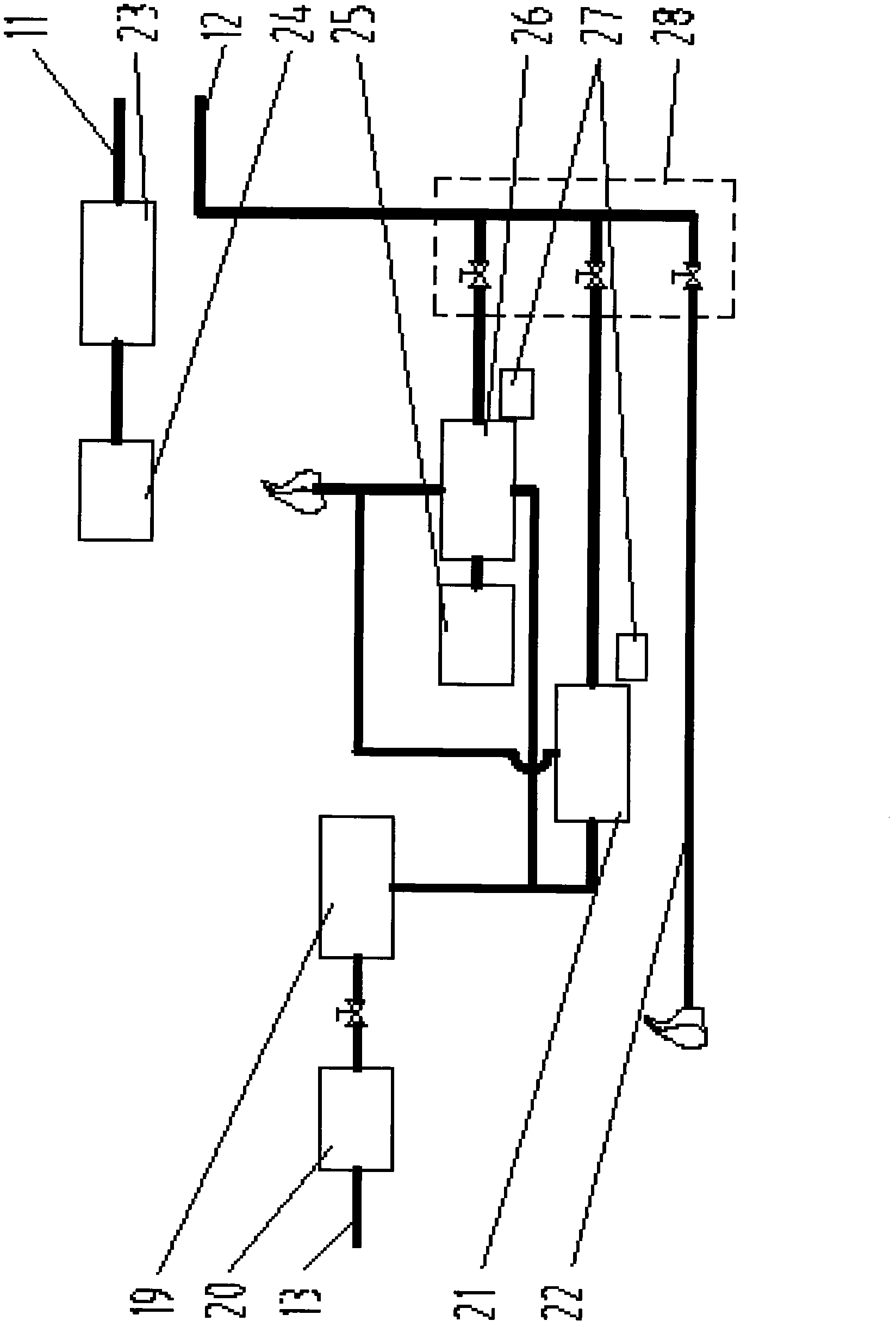

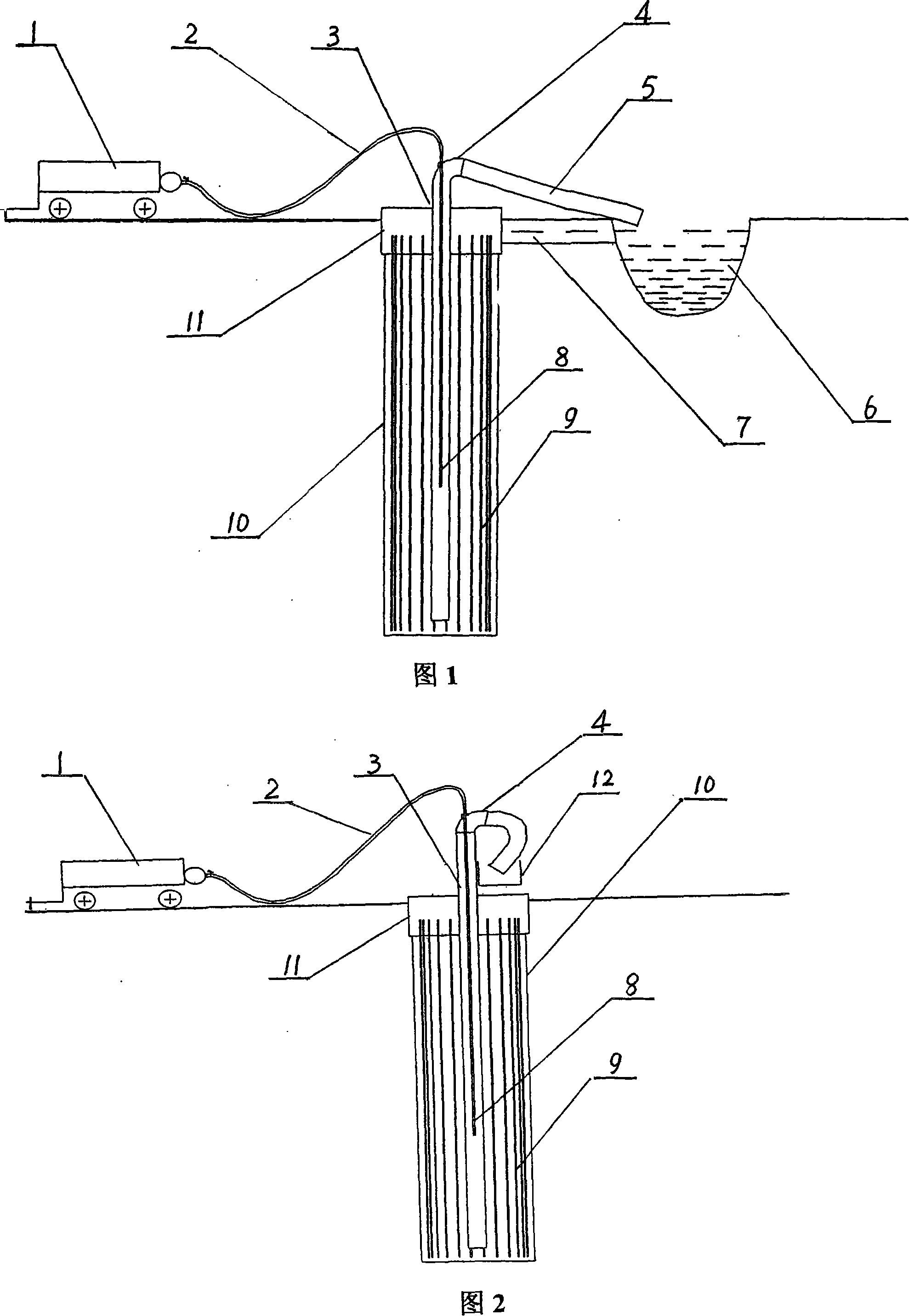

Gas lift method production fluid section plane test technique of mechanical mining horizontal well

InactiveCN101403292ASmall footprintImplement output profile testingSurveyFluid removalLine tubingSection plane

The invention relates to a produced fluid profile logging technique method of a mechanical recovery horizontal well by a pneumatic lifting method, aiming at solving the problem that the existing horizontal well can not carry out profile testing in normal production state. The method is characterized in that: a. a pneumatic lifting production string (10) is put into the well, and a gas transmission line (8) and a pipe laying (9) are connected; b. a tester (7) and a traction apparatus (6) are put into the well by the pneumatic lifting production string (10); and c. a nitrogen gas generation locomotive (4) and a compressing locomotive (3) are started for carrying out oil extraction, and a cable is lifted up to carry out testing when the oil extraction production is stable. The produced fluid profile logging technique method of the mechanical recovery horizontal well by the pneumatic lifting method can leave enough testing channel for the tester, thereby finally realizing the produced fluid profile testing of the horizontal well in normal production state.

Owner:DAQING OILFIELD CO LTD

One-way valve for a side pocket mandrel of a gas lift system

Owner:WEATHERFORD TECH HLDG LLC

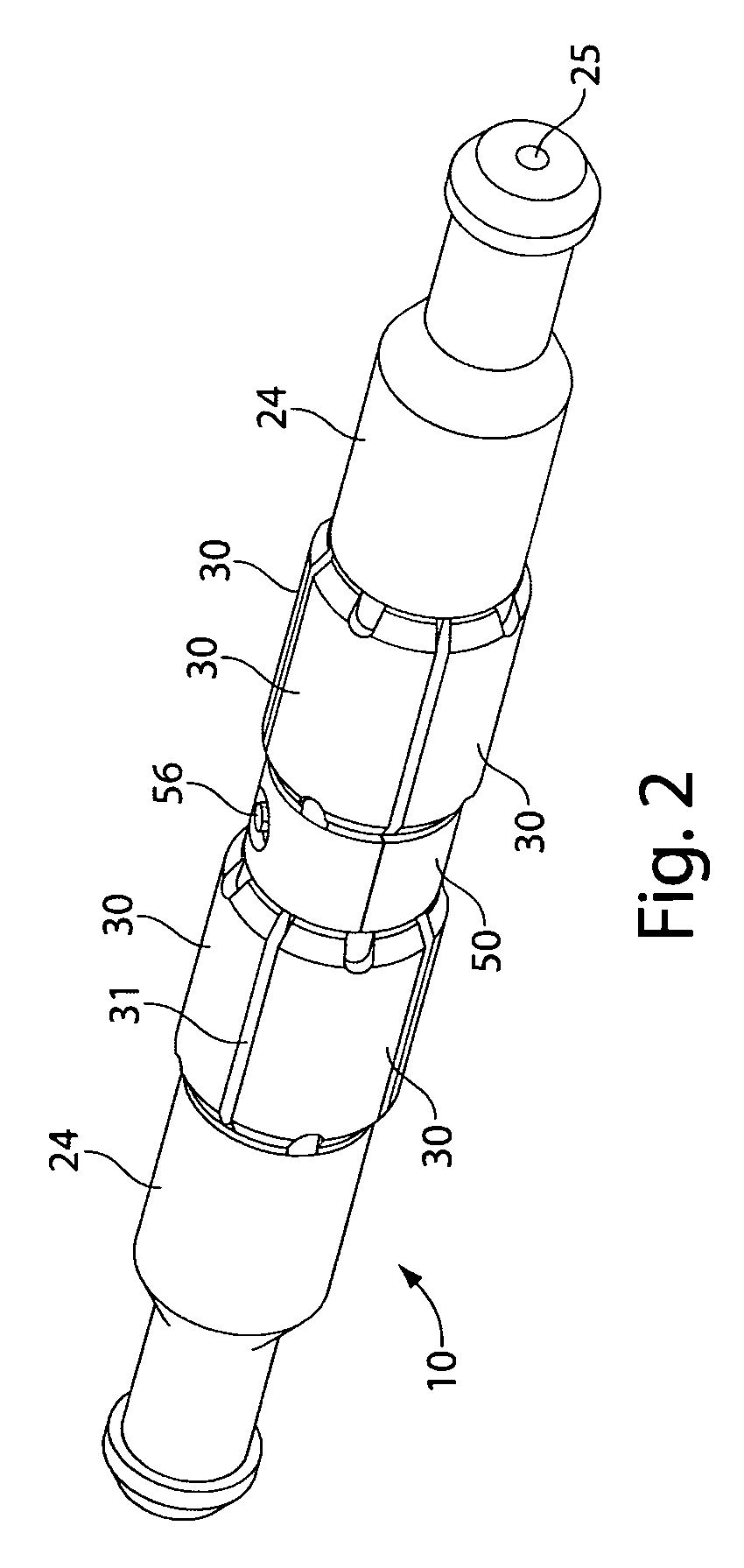

Gas lift plunger assembly arrangement

ActiveUS20090272519A1Wear is promotedReduce lossesDrilling rodsCleaning apparatusGas liftBiomedical engineering

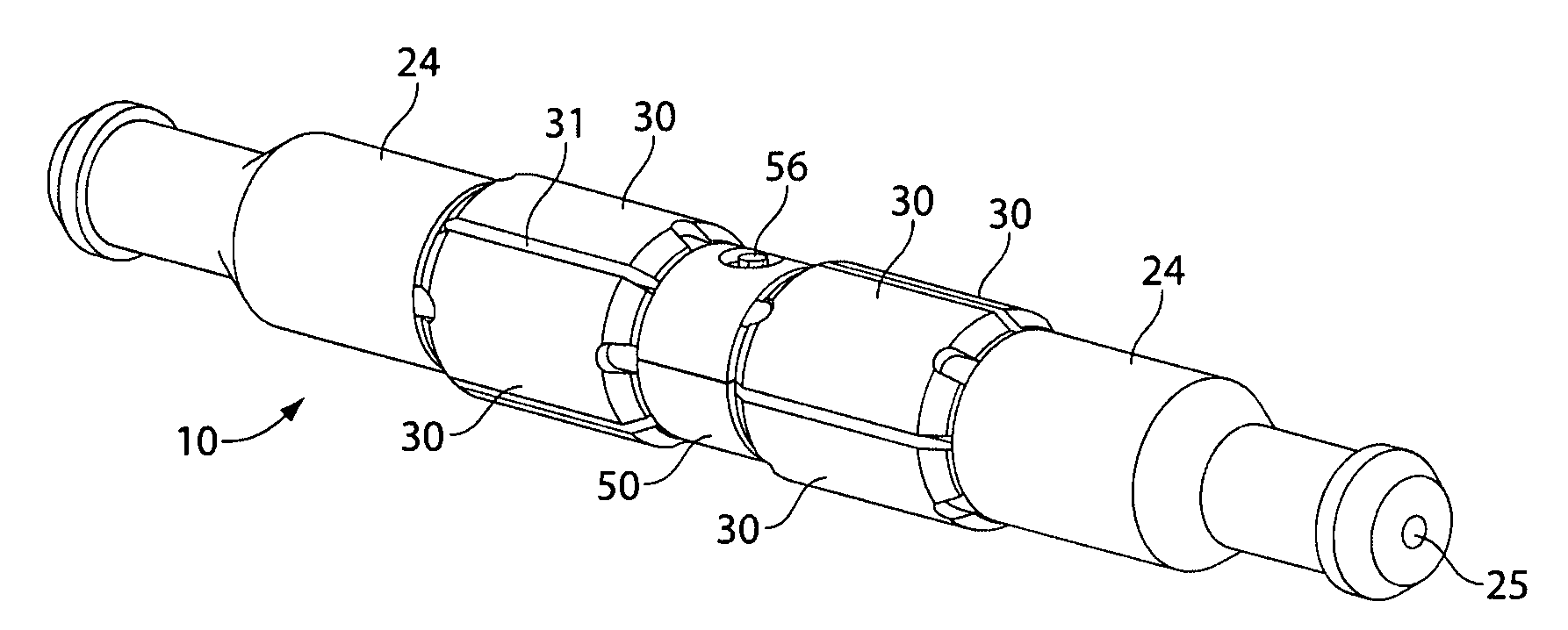

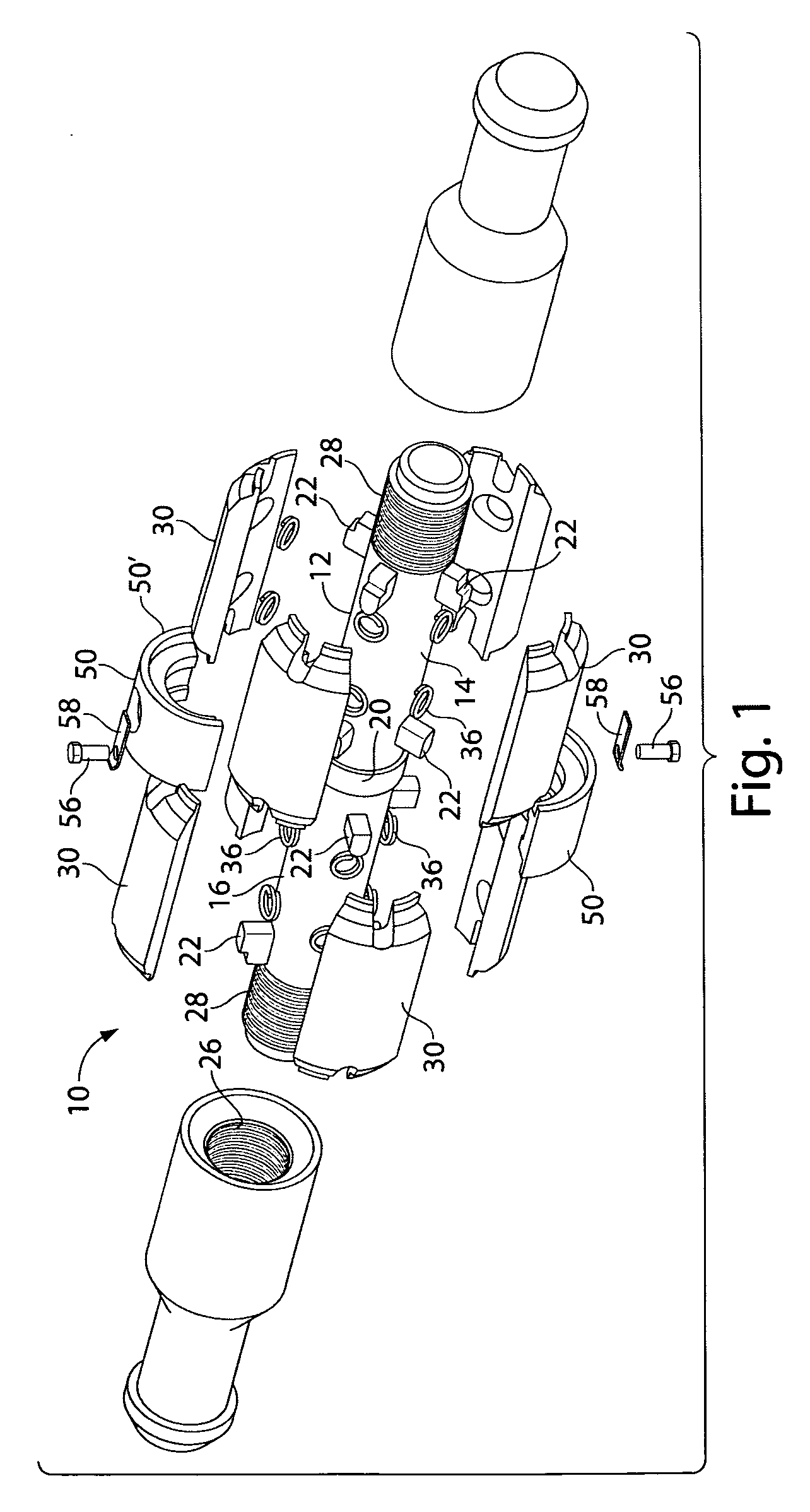

A elongated plunger assembly for pressurized, conduit-enclosed travel utilized in recovery of hydrocarbon deposits in a ground penetrating oil or gas well. The plunger comprises an elongated mandrel, a plurality of radially movable curvilinear wear pads circumferentially disposed adjacent each end of the elongated mandrel, a pad-edge retaining housing extending on at least one end of the elongated mandrel to enclosably retain the longitudinally distal end of a circumferential array of wear pads onto the mandrel, and a centrally disposed wear pad securement ring arrangement to permit release of a worn wear pad, replacement of the worn wear pad at an inner longitudinal edge thereof, thus to permit simple field-accessable removal and replacement of any particular “conduit-worn”“wear” pad from the mandrel of the plunger.

Owner:WELL MASTER CORP

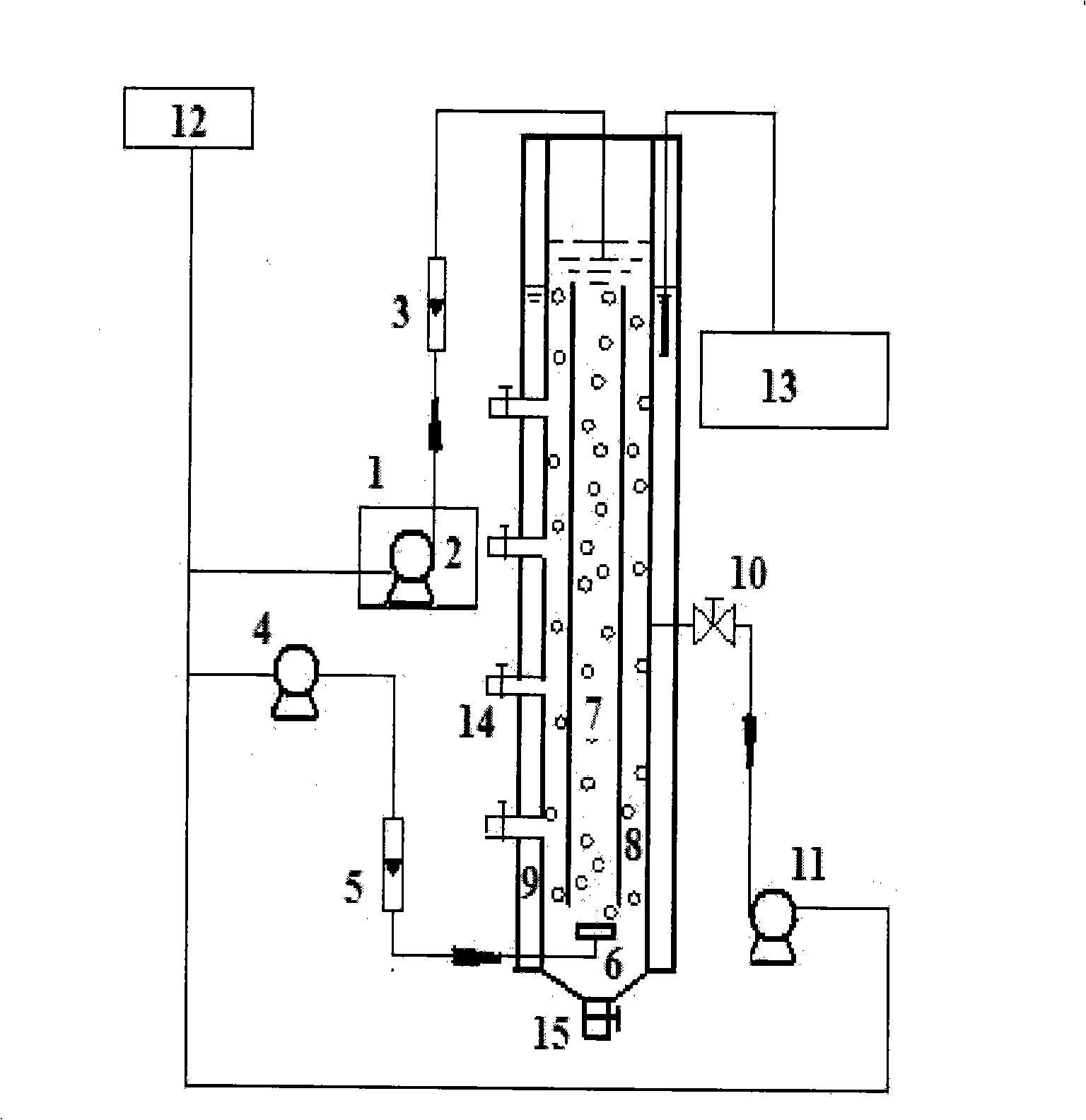

Gas-lifting internal circulation intermission aerobic granule sludge reactor and water treatment process thereof

InactiveCN101333037AEnhanced mass transferImprove the mixing effectSustainable biological treatmentBiological water/sewage treatmentWater bathsMicroecosystem

The invention discloses an airlift type internal circulation intermittent aerobic granular sludge reactor, which comprises an organic glass column, a temperature controller, a water inlet tank, an aeration pump, a water feed pump, a draining pump, a flow meter, a programmable logical controller, etc. The main body of the reactor is the organic glass column and can be divided into an inner sleeve and an outer sleeve, and the inner one is an upspout, while the outer one is a downcast pipe; the ratio of height to diameter is 15. The exterior of the downcast pipe is provided with a water bath heating casing for controlling reaction temperature. Mixed liquor in the reactor flows between the upspout and the downcast pipe in internal circulation to endow granular sludge with a self-balanced micro-ecosystem, the property of the micro-ecosystem is suitable for an up-flow type wastewater treatment system. The reactor adopts the sequence batch operation mode and can realize automatic control by the programmable logical controller. The reactor of the invention has the advantages of flexible operation, compact structure, little sludge remained, good treatment effect, and the like, and can bear high volume load and impact load; furthermore, the reactor has small occupying space and can reduce pork barrel due to relatively large H / D.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-aqueous foam composition for gas lift injection and methods for making and using same

InactiveUS20080257556A1Reduce hydrostatic pressureHigh trafficFluid removalDrilling compositionFoaming agentGas lift

A hydrocarbon drilling fluid system is disclosed including a hydrocarbon fluid and a foaming composition, where the foaming composition includes a polymer, a gelling agent and its cross-linking agent, an optional foaming agent, or mixtures or combinations thereof. Uses of this drilling fluid system in a variety of downhole application are also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

Hydraulic jet perforation, fracturing and gas lift liquid drainage integrated technical pipe column

The invention discloses a hydraulic jet perforation, fracture and gas lift liquid drainage integrated technical pipe column, which is applied to the oilfield gas well vertical shaft hydraulic jet perforation and fracture and the liquid drainage after the fracture, and a row of pipe columns can complete the oilfield gas well vertical shaft hydraulic jet perforation and fracture and the liquid drainage after the fracture. 2 to 5 gas lifting valves are connected in a casing sequentially from top to bottom by an oil pipe; the lower part of the gas lifting valve is connected with 1 to 4 first-stage hydraulic injectors by the oil pipe; the lower part of each first-stage hydraulic injector is connected with a sliding sleeve base; the lower end of the lower sliding sleeve base is connected with a second-stage hydraulic injector by the oil pipe; the lower end of the second-stage hydraulic injector is connected with a check valve; the lower end of the check valve is connected with a sieve tube and a pipe plug; the first-stage hydraulic injectors are arranged opposite to the top of an upper gas pay; and the second-stage hydraulic injector is arranged opposite to the top of a low gas pay. The invention has the advantages of realizing the jet perforation, fracturing of separated layers and gas lift liquid drainage without moving the pipe columns.

Owner:PETROCHINA CO LTD

Gas lift valve with central body venturi for controlling the flow of injection gas in oil wells producing by continuous gas lift

The present invention relates to a gas lift valve for use in an oil well producing by means of gas lift, said gas lift valve making use of a central body venturi for both controlling the flow of the injection gas from the annulus between the tubing and the casing of the oil well, and precluding a reverse flow of fluids from said oil well towards said annulus to occur.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com