Patents

Literature

228 results about "Artificial lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial lift refers to the use of artificial means to increase the flow of liquids, such as crude oil or water, from a production well. Generally this is achieved by the use of a mechanical device inside the well (known as pump or velocity string) or by decreasing the weight of the hydrostatic column by injecting gas into the liquid some distance down the well. A newer method called Continuous Belt Transportation (CBT) uses an oil absorbing belt to extract from marginal and idle wells. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but often used in naturally flowing wells (which do not technically need it) to increase the flow rate above what would flow naturally. The produced fluid can be oil, water or a mix of oil and water, typically mixed with some amount of gas.

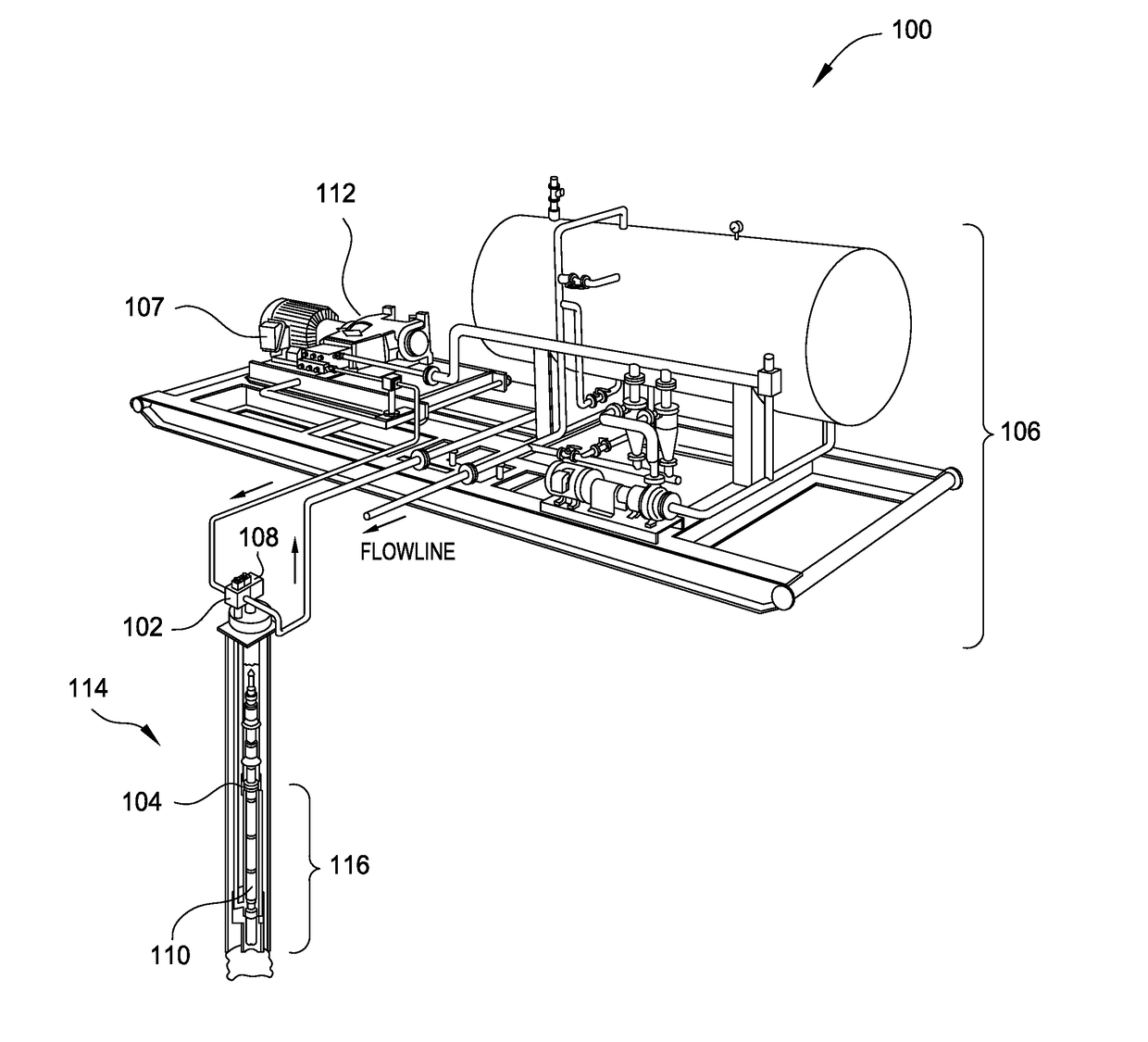

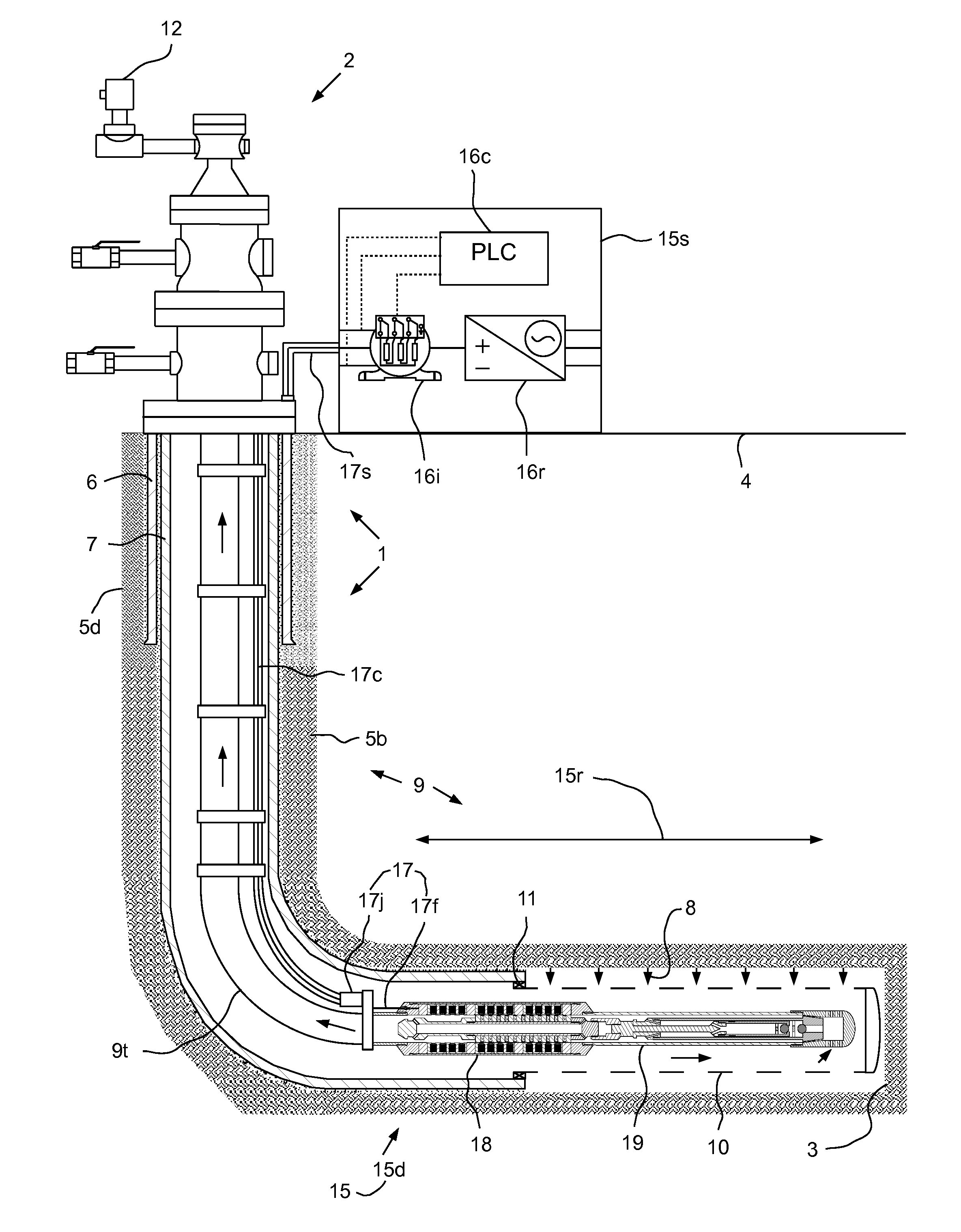

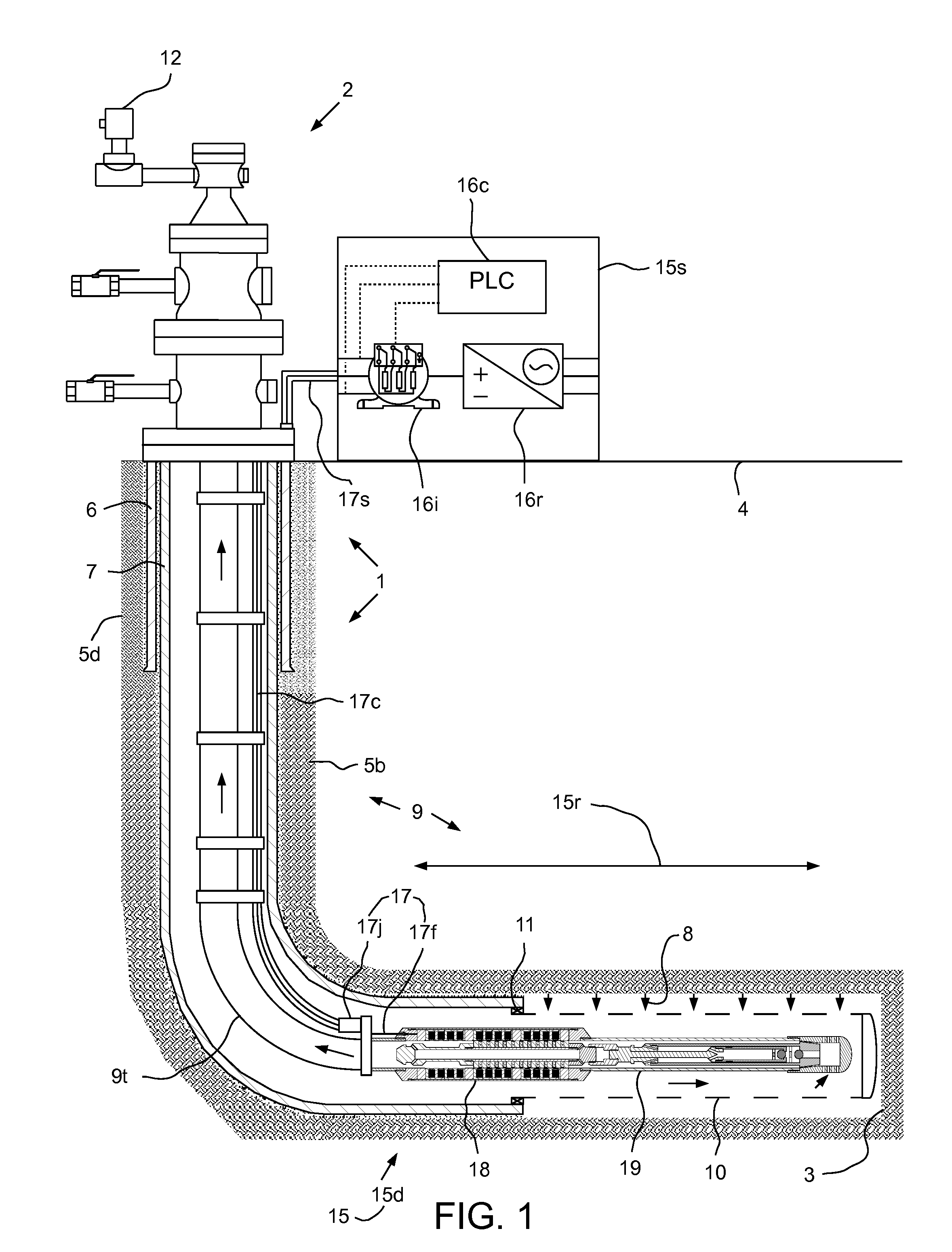

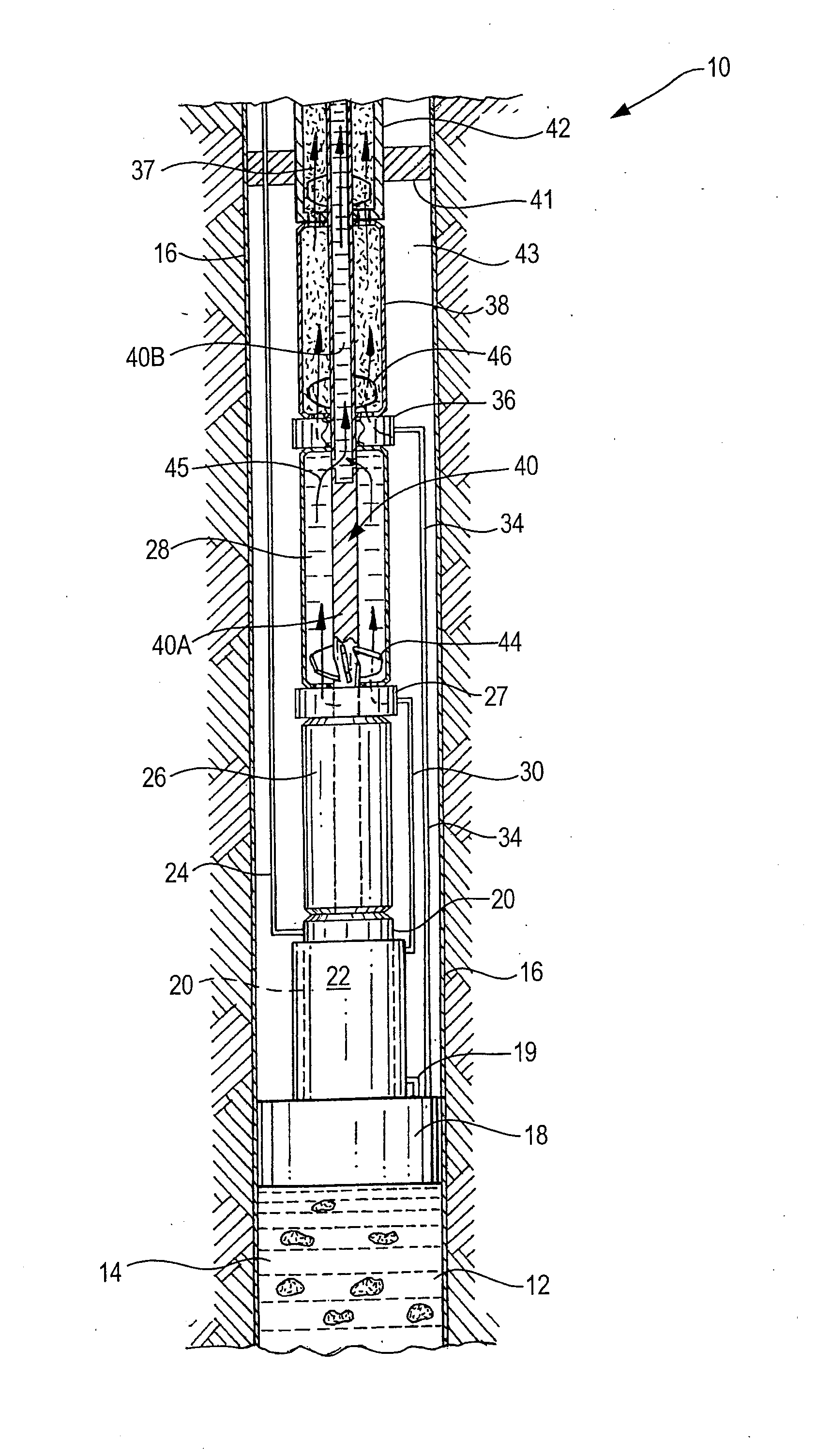

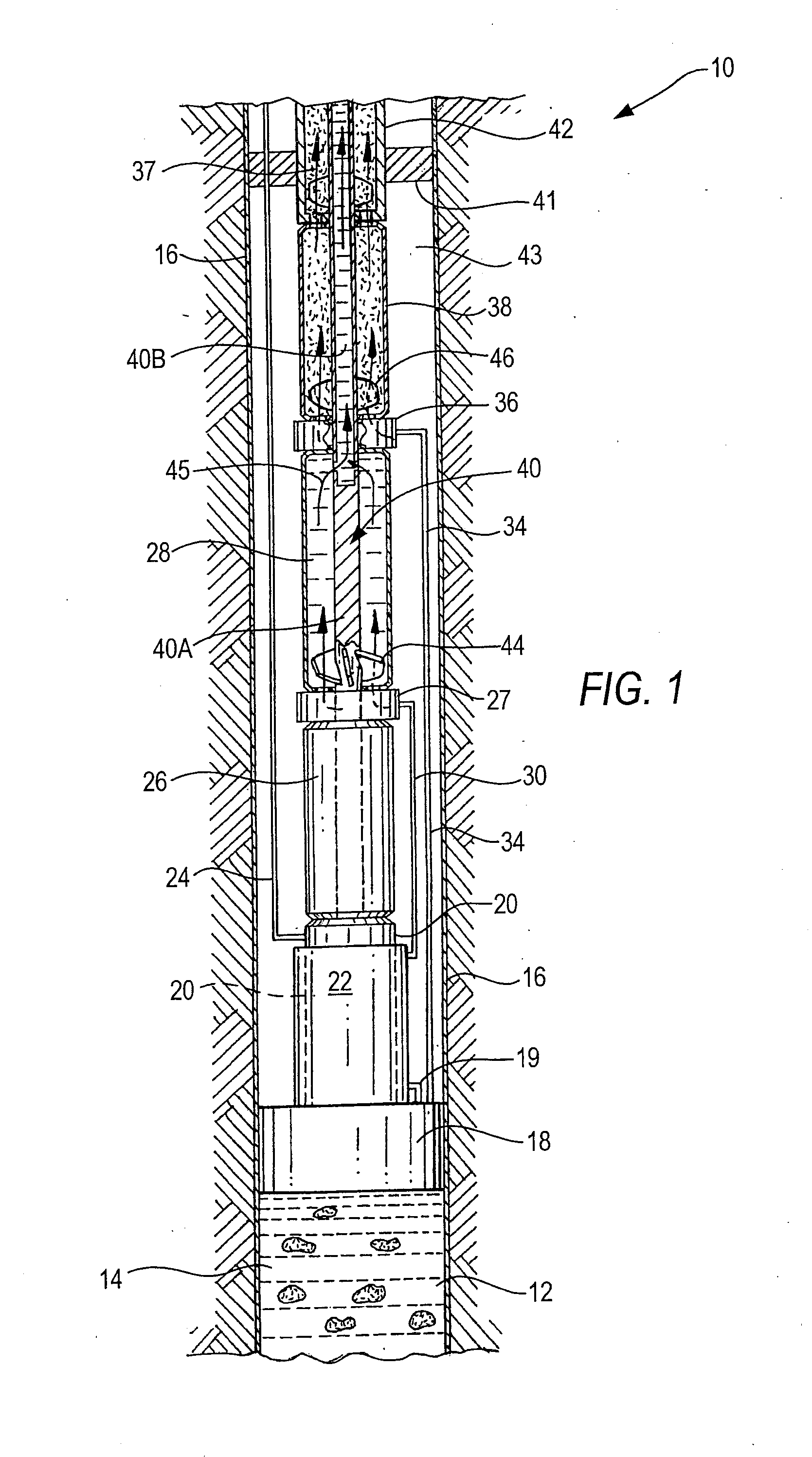

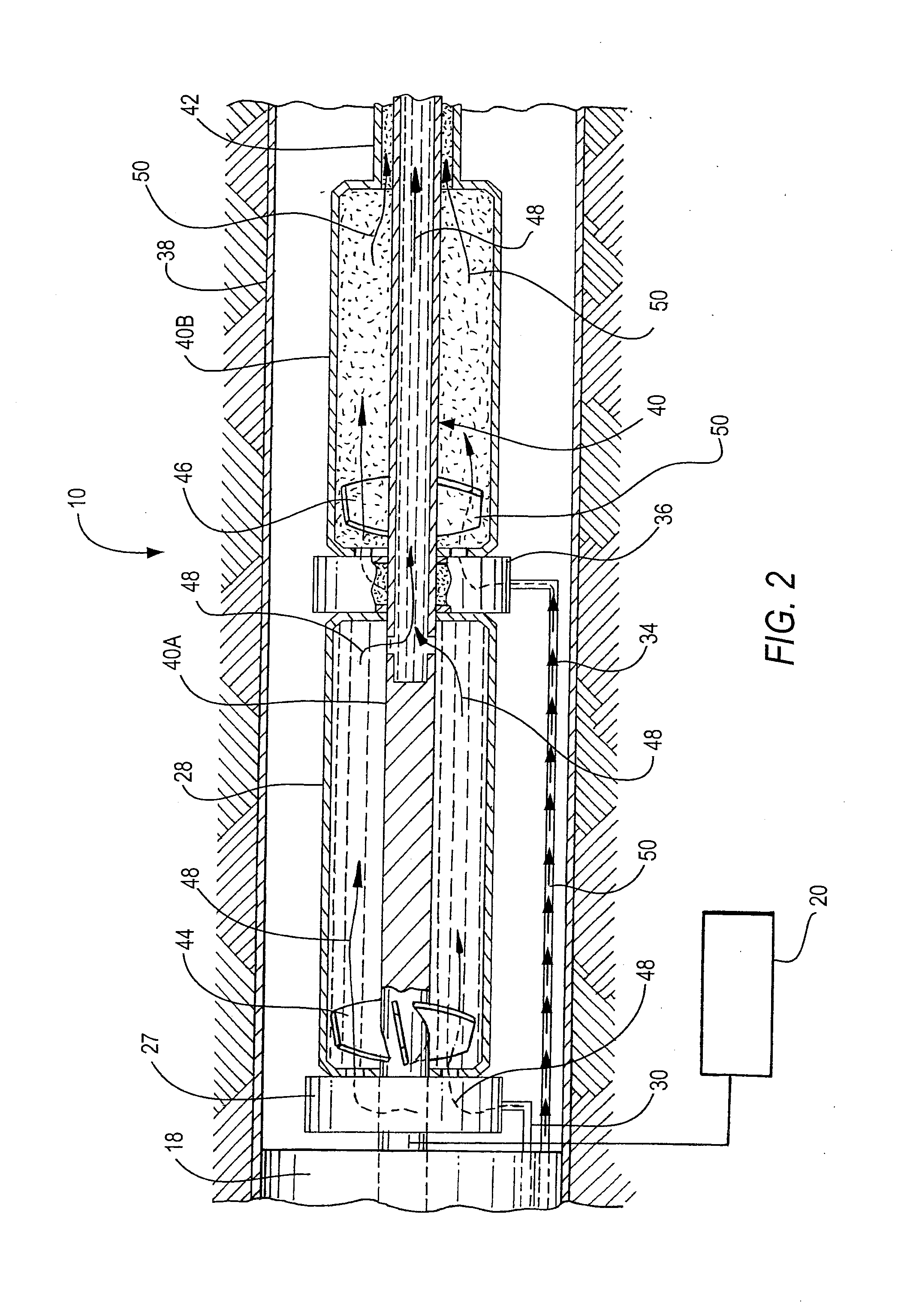

Sensing cavitation-related events in artificial lift systems

Methods and apparatus are provided for sensing a cavitation-related event in an artificial lift system for hydrocarbon production and operating the system based on the sensed event. One example method of operating an artificial lift system for a wellbore generally includes monitoring the wellbore for an indication (e.g., an acoustic or vibrational indication) of an event associated with cavitation in the artificial lift system and adjusting at least one parameter of the artificial lift system if the event is detected. One example system for hydrocarbon production generally includes an artificial lift system for a wellbore and at least one sensor configured to detect an indication of an event associated with cavitation in the artificial lift system.

Owner:WEATHERFORD TECH HLDG LLC

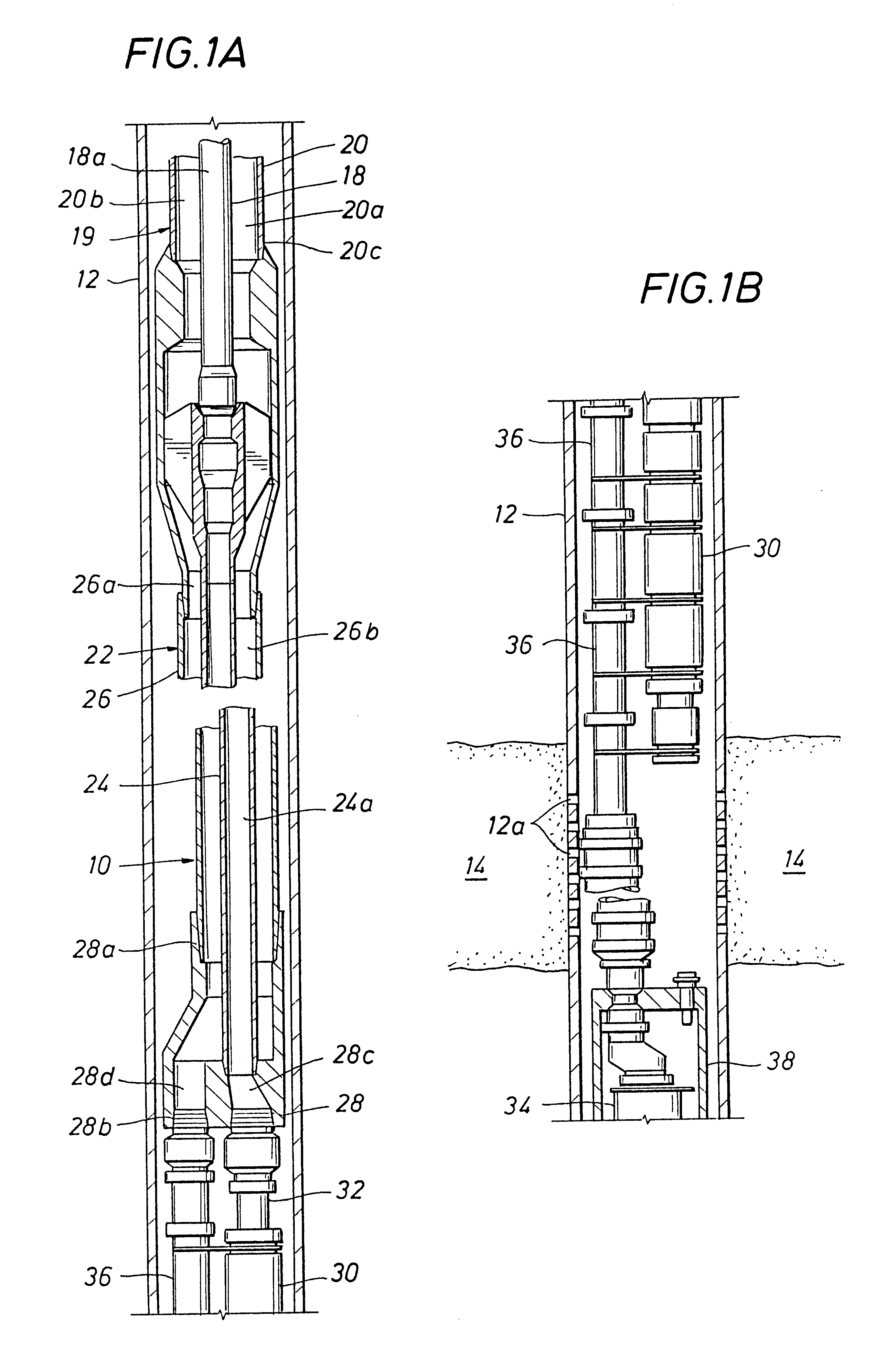

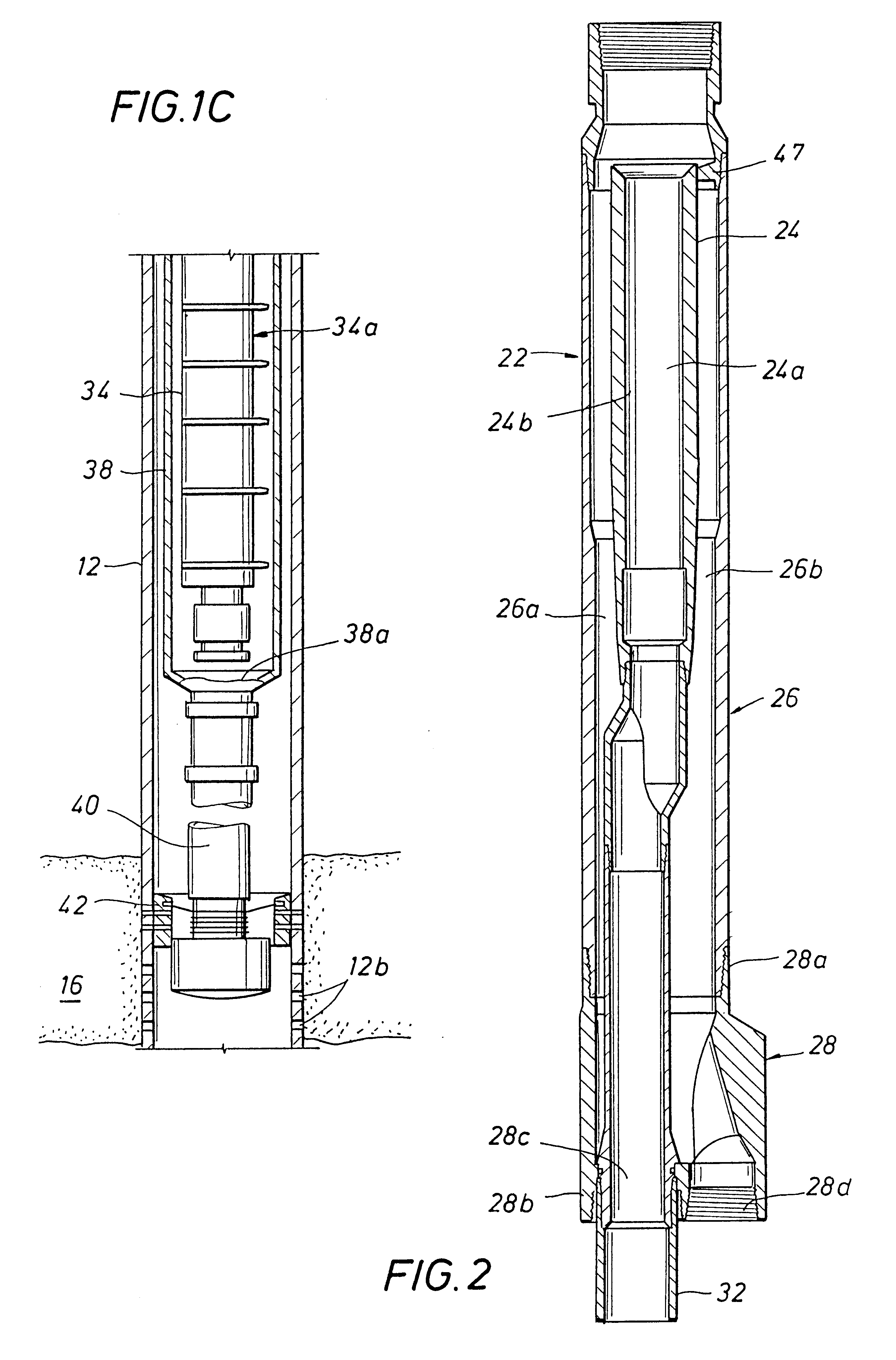

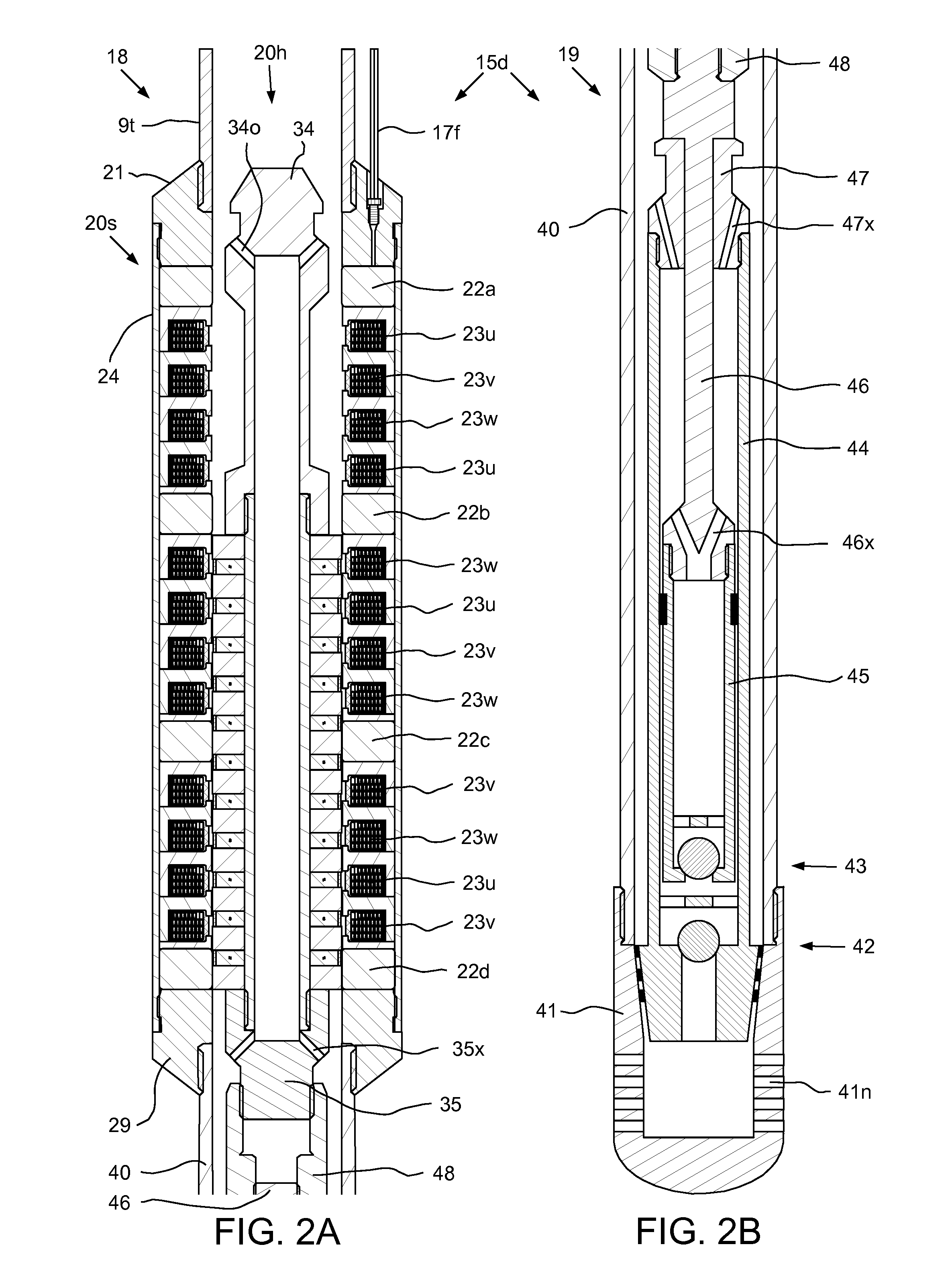

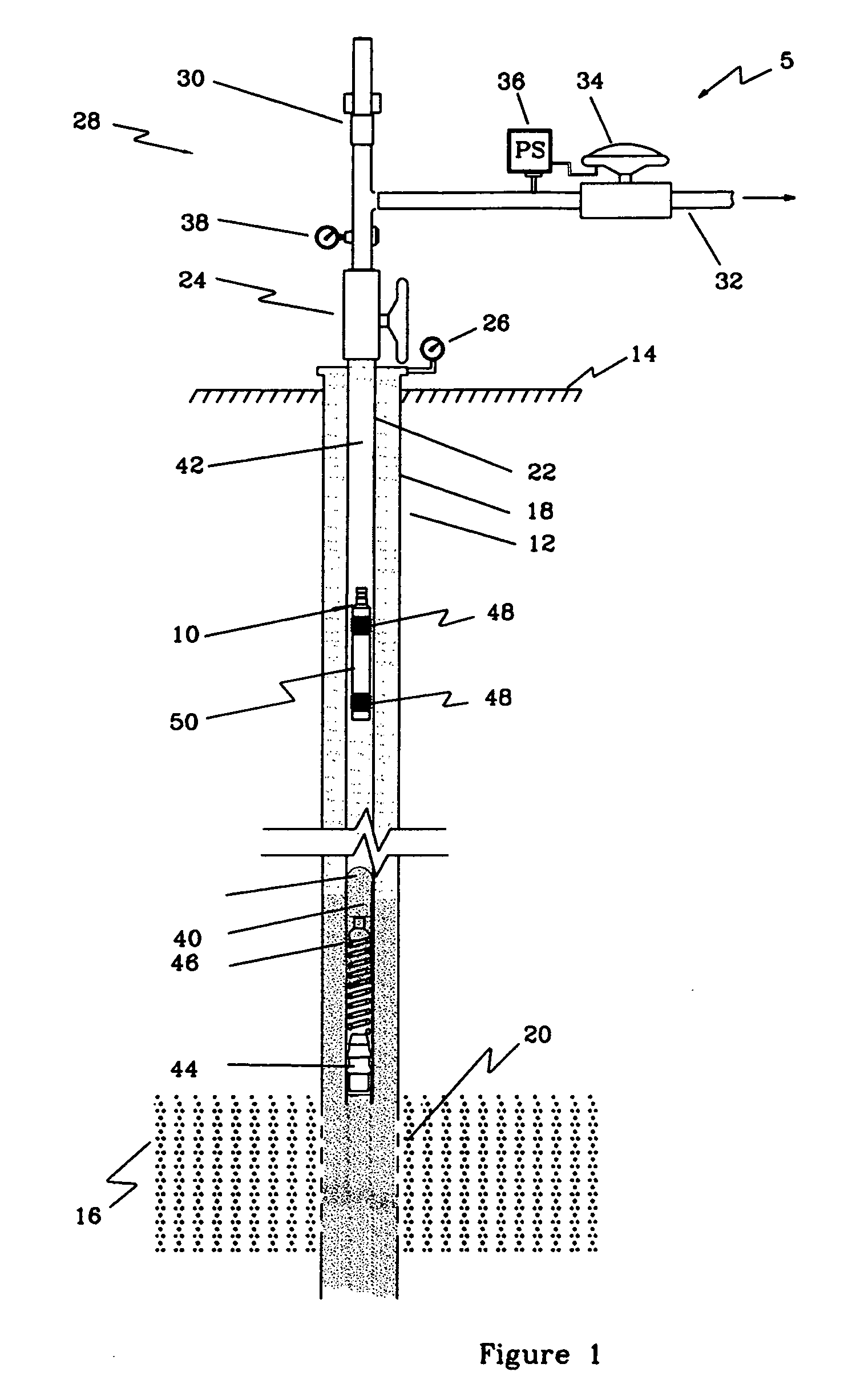

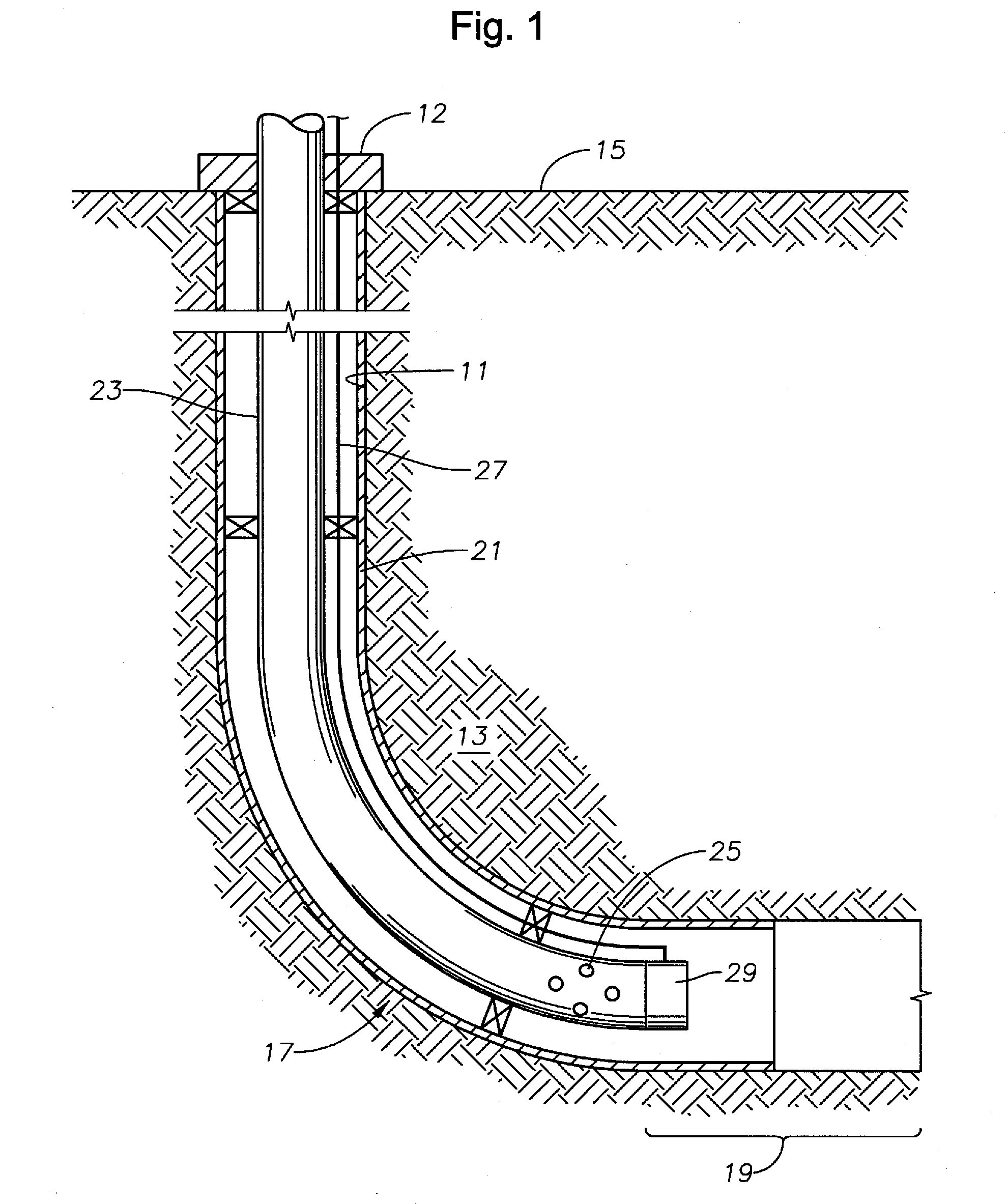

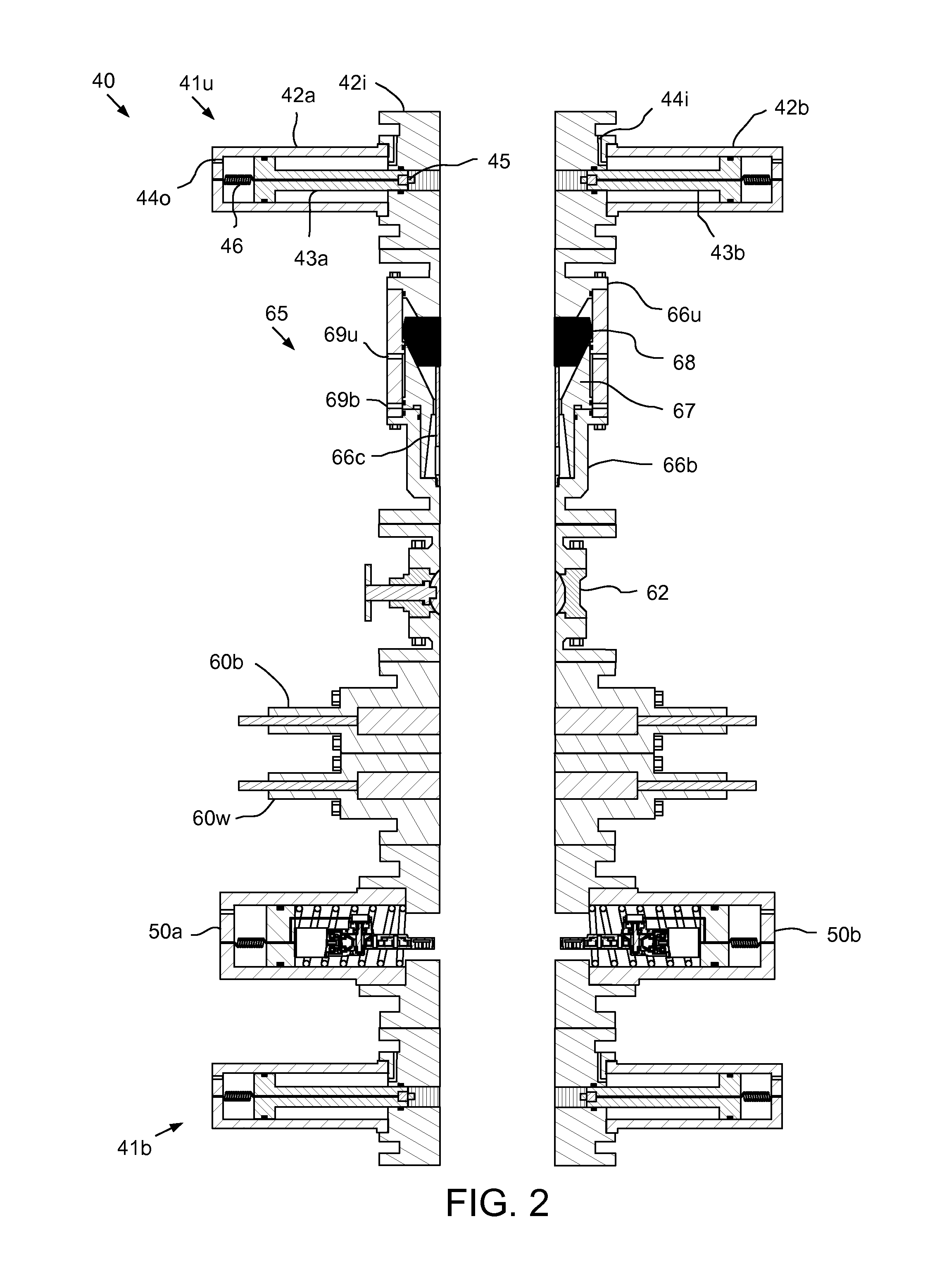

Artificial lift, concentric tubing production system for wells and method of using same

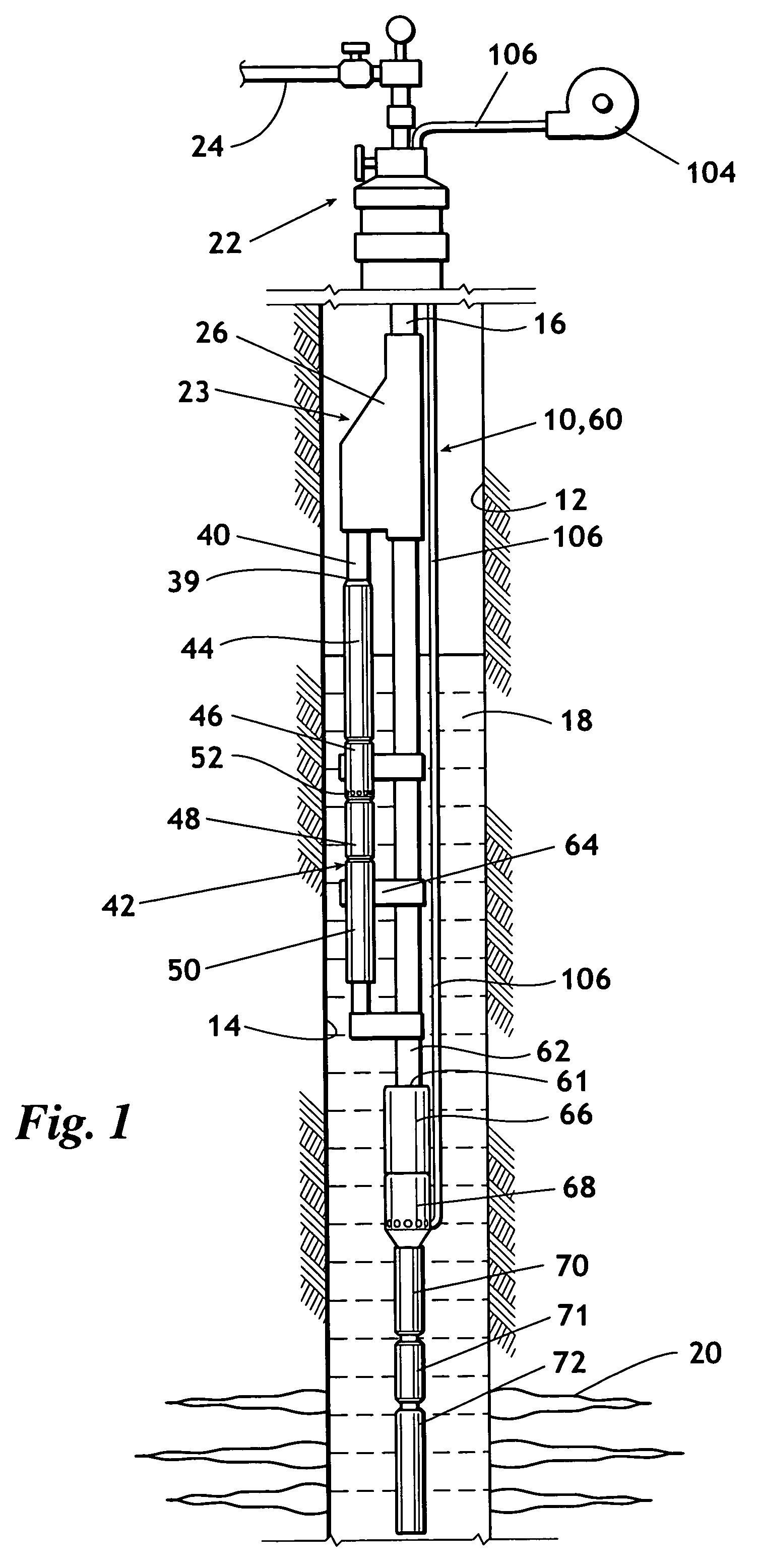

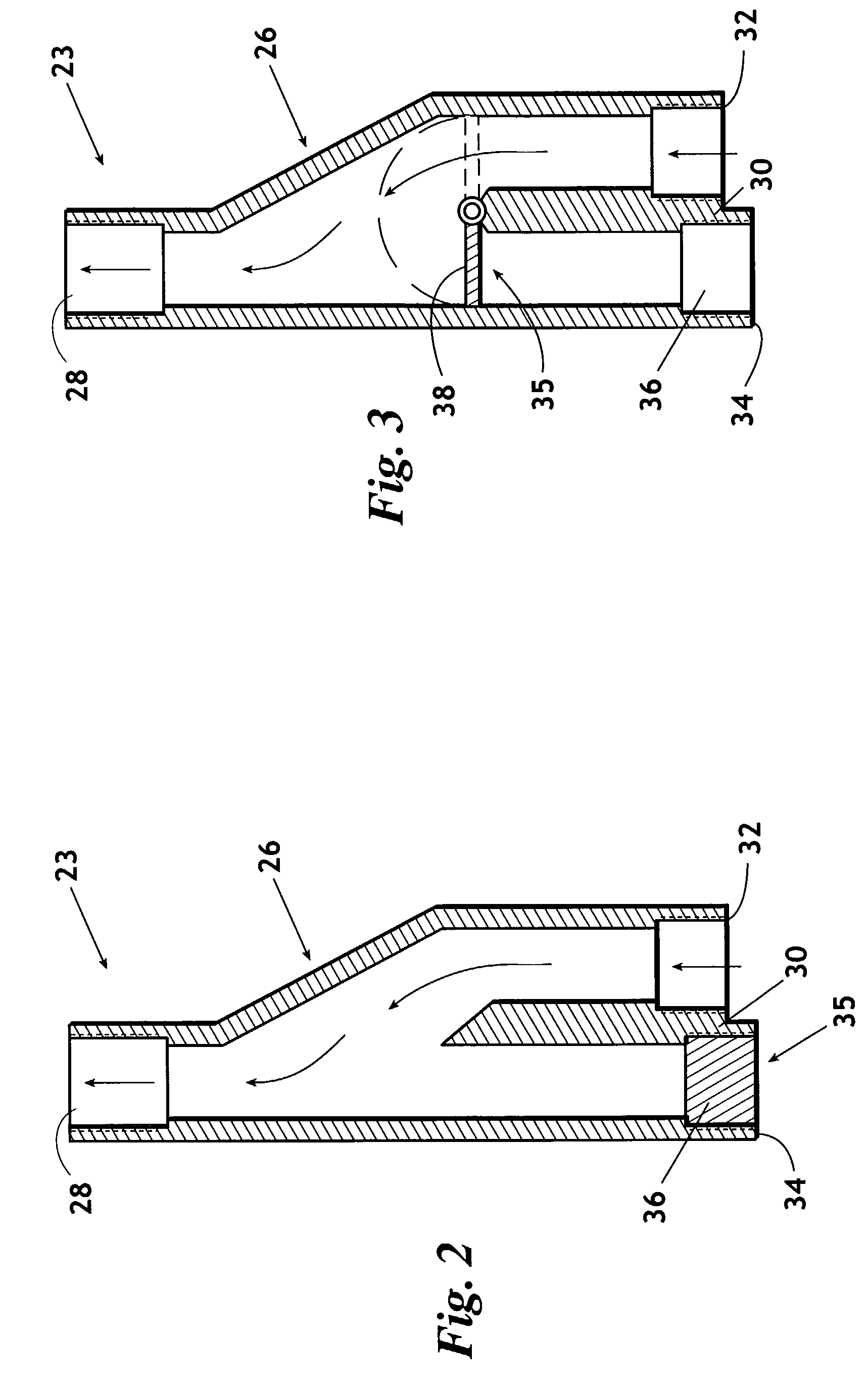

An artificial lift, concentric tubing production system for a well and method of using same. The system including an upper concentric tubing string portion comprising an inner production tubing string positioned within an outer production tubing string. A flow crossover assembly is connected to the upper concentric tubing string portion. The flow crossover assembly has first and second passageways. The inner production tubing string is in fluid communication with the first passageway and the outer production tubing string in fluid communication with the second passageway. An upper transducer is in fluid communication with one of the passageways of the flow crossover assembly and a lower apparatus is in fluid communication with the other of the passageways of the flow crossover assembly. The upper transducer may be a pump such as an electric submersible pump or a progressive cavity pump. The lower apparatus may be a pump, including an electric submersible pump, or a liquid / gas separator.

Owner:YPF INT

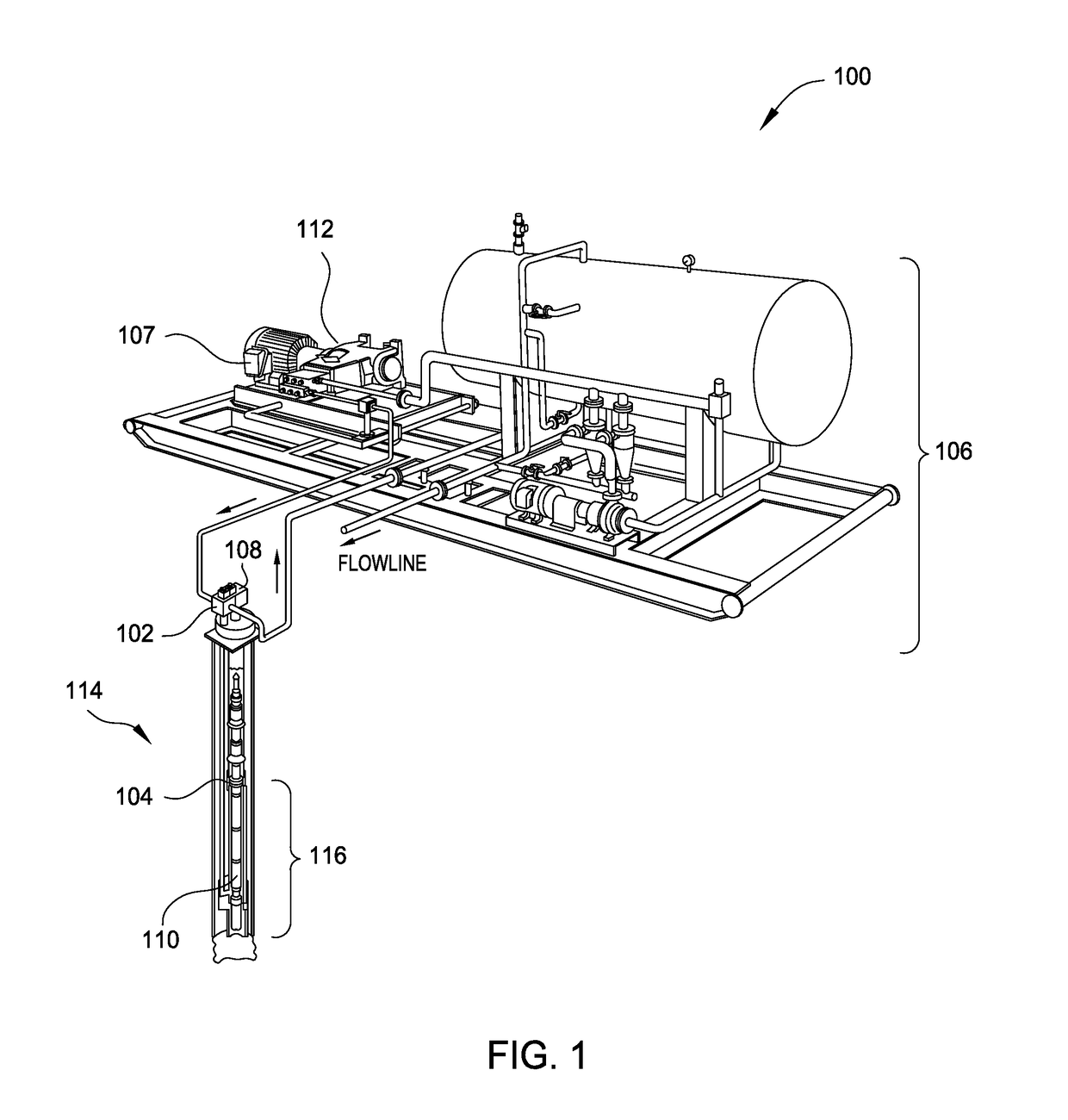

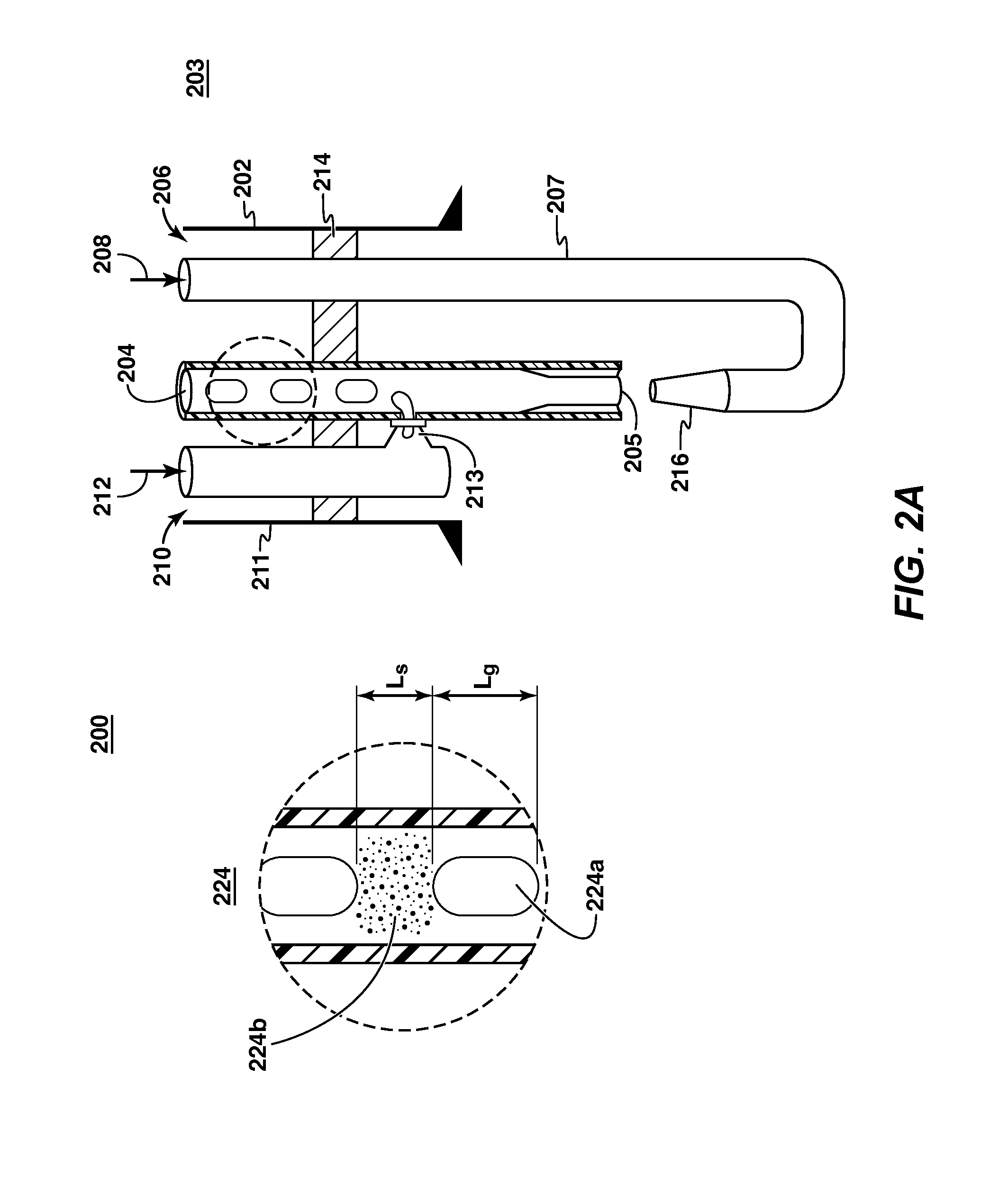

Method and apparatus for downhole artificial lift system protection

A fluid conditioning system designed to be installed between the well perforation and the intake of a pump used to effect artificial lift is used to filter and chemically treat production fluids. The fluid conditioning system is an apparatus that provides scale inhibitors and / or other chemical treatments into the production stream. In some embodiments, the fluid conditioning system may be a part of the production stream filter wherein the filtering material is comprised of a porous medium that contains and supports the treatment chemical. In other embodiments, the chemical treatment may be accomplished by the gradual dissolution of a solid phase chemical. The treating chemical may be recharged or replenished by various downhole reservoirs or feeding means. In yet other embodiments, the treating chemical may be replenished from the surface by means of a capillary tube. In certain other embodiments, the apparatus may be retrievable from the surface thereby permitting recharge or replenishment of the chemical in the apparatus on an as-needed basis. The filtration apparatus may incorporate a by-pass valve that allows fluid to by-pass the filter as sand or other particulate matter fills up or blocks the filter.

Owner:OILFIELD EQUIP DEVMENT CENT

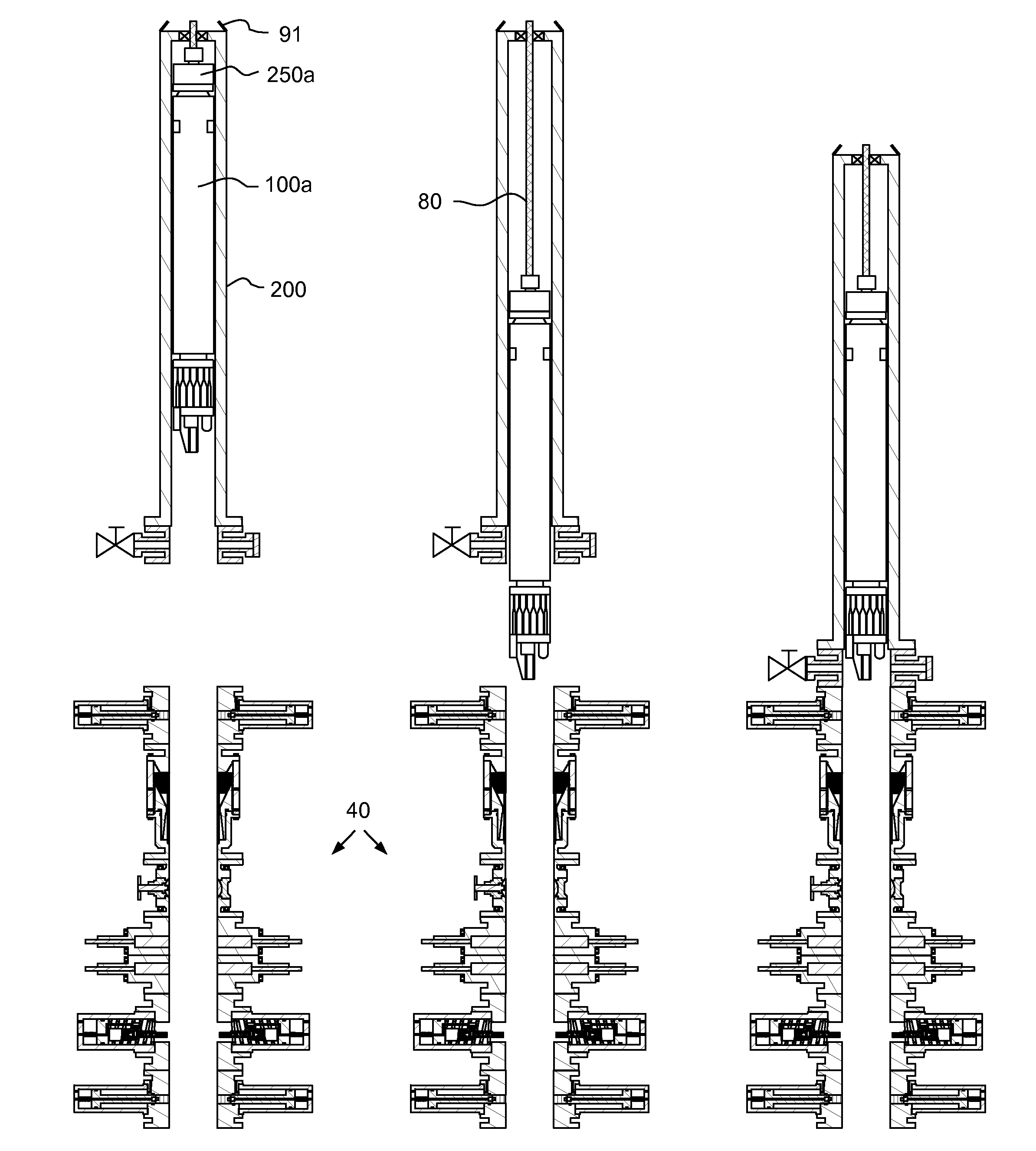

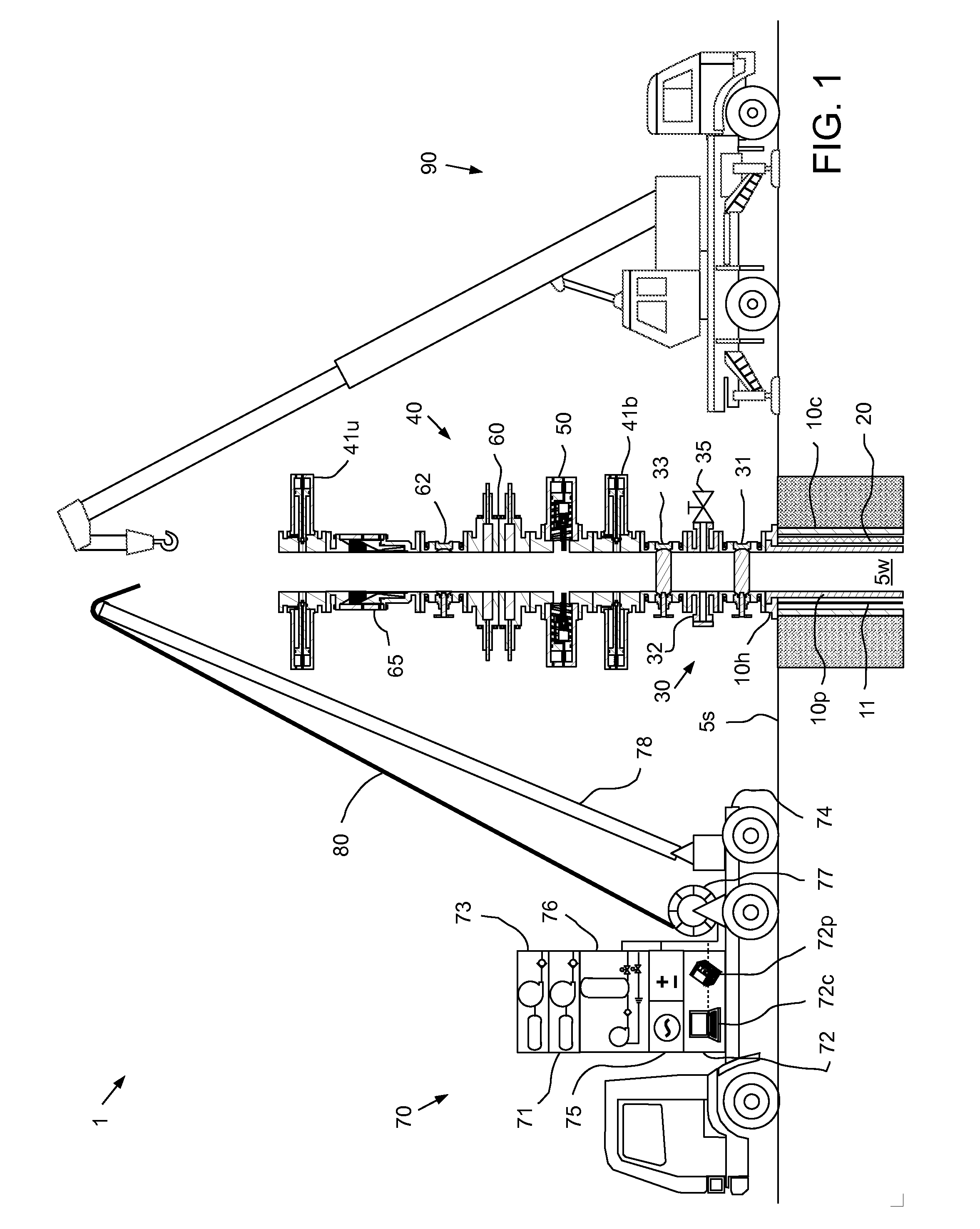

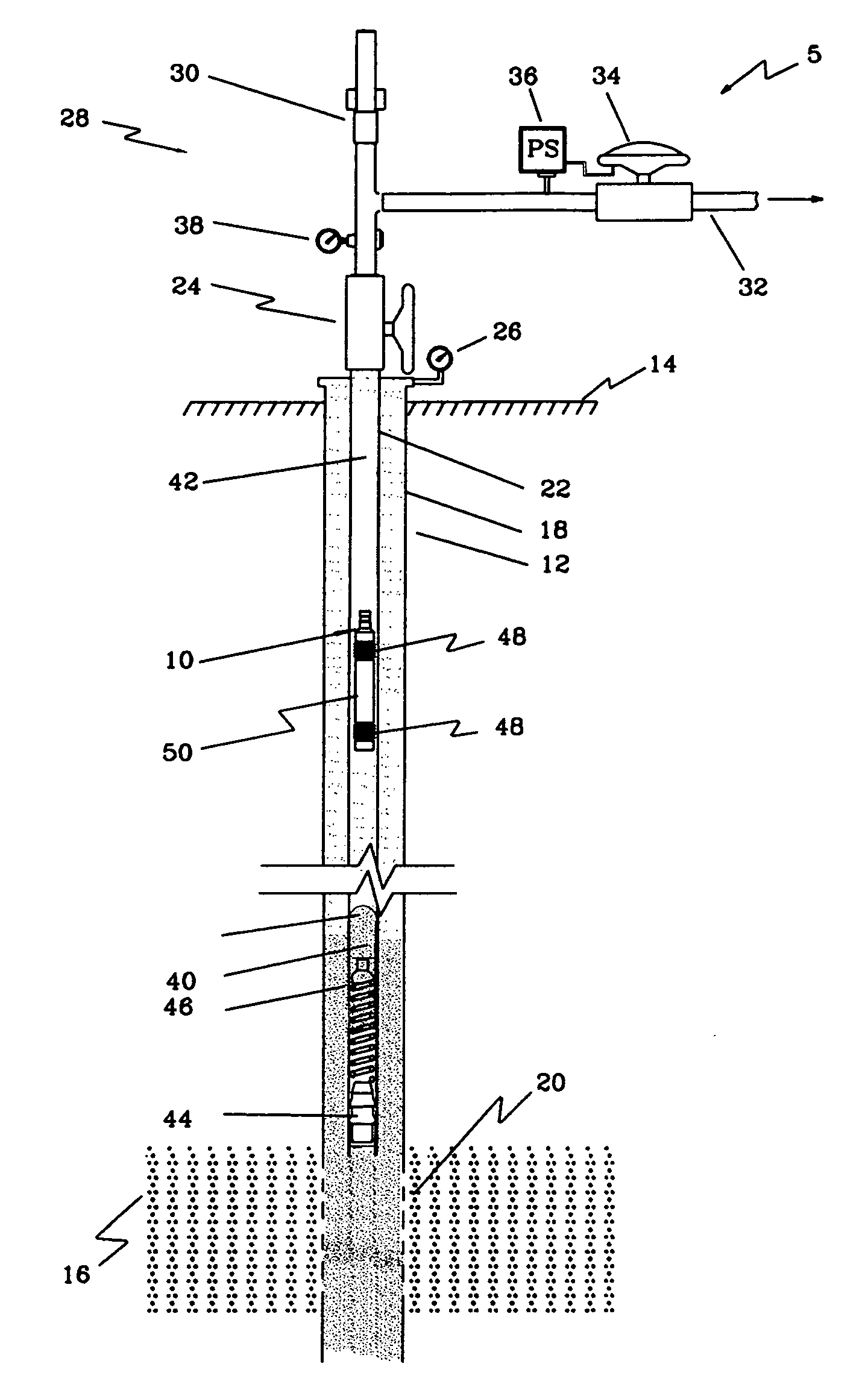

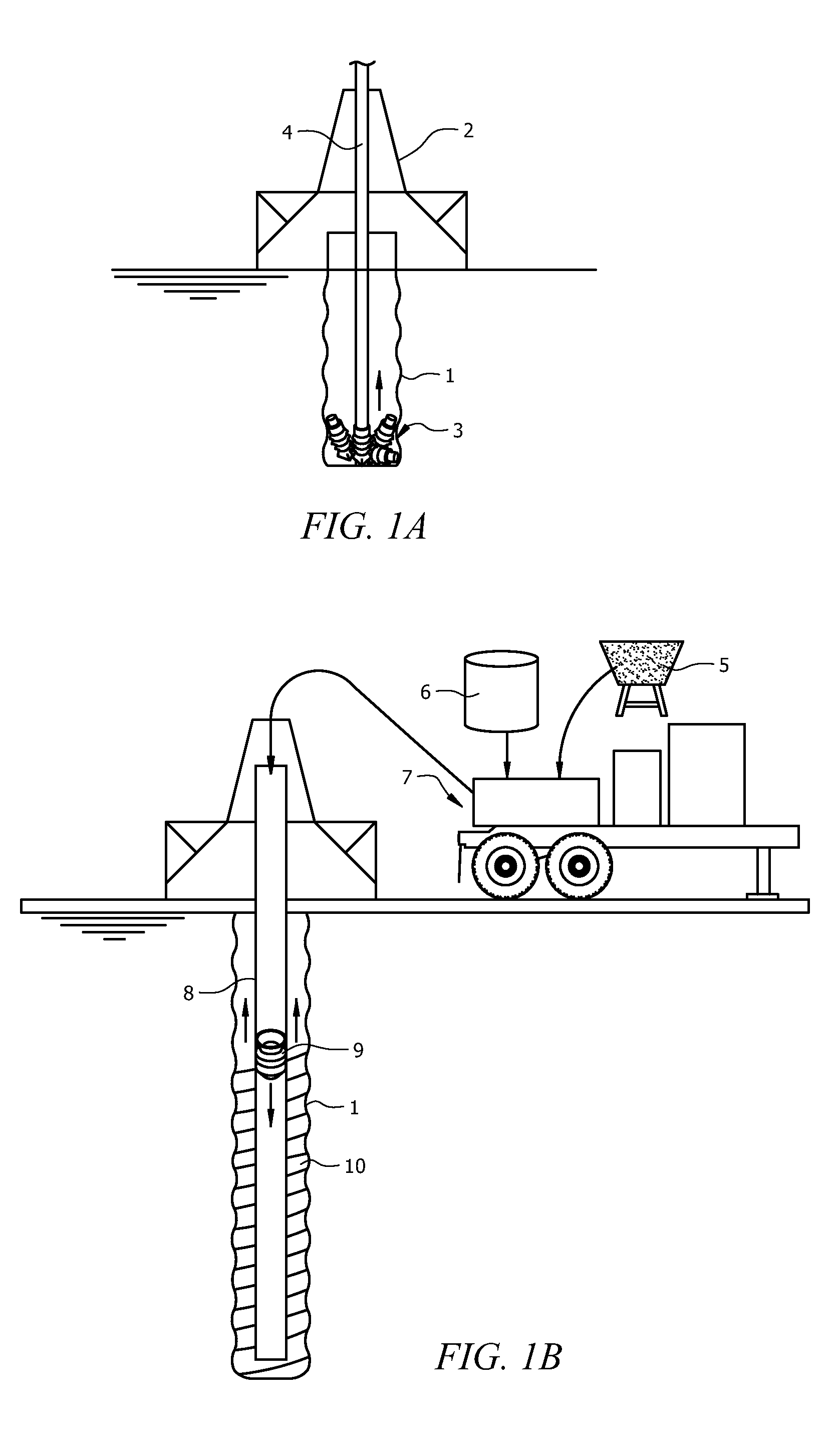

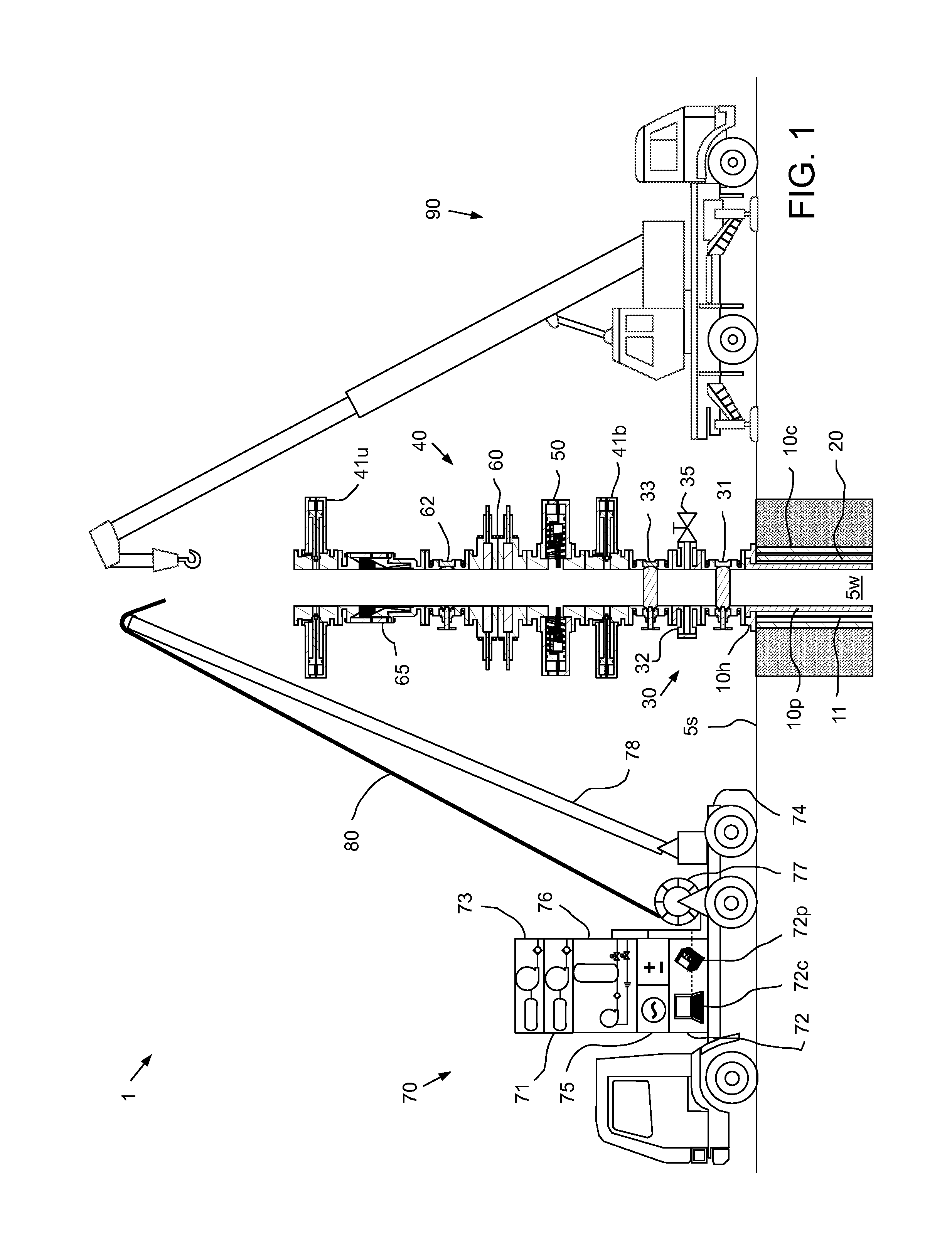

Gradational insertion of an artificial lift system into a live wellbore

A method of inserting a downhole assembly into a live wellbore, includes: assembling a pressure control assembly (PCA) onto a production tree of the live wellbore; inserting a first deployment section of the downhole assembly into a lubricator; landing the lubricator onto the PCA; connecting the lubricator to the PCA; lowering the first deployment section into the PCA; engaging a clamp of the PCA with the first deployment section; after engaging the clamp, isolating an upper portion of the PCA from a lower portion of the PCA; and after isolating the PCA, removing the lubricator from the PCA.

Owner:SCHLUMBERGER TECH BV

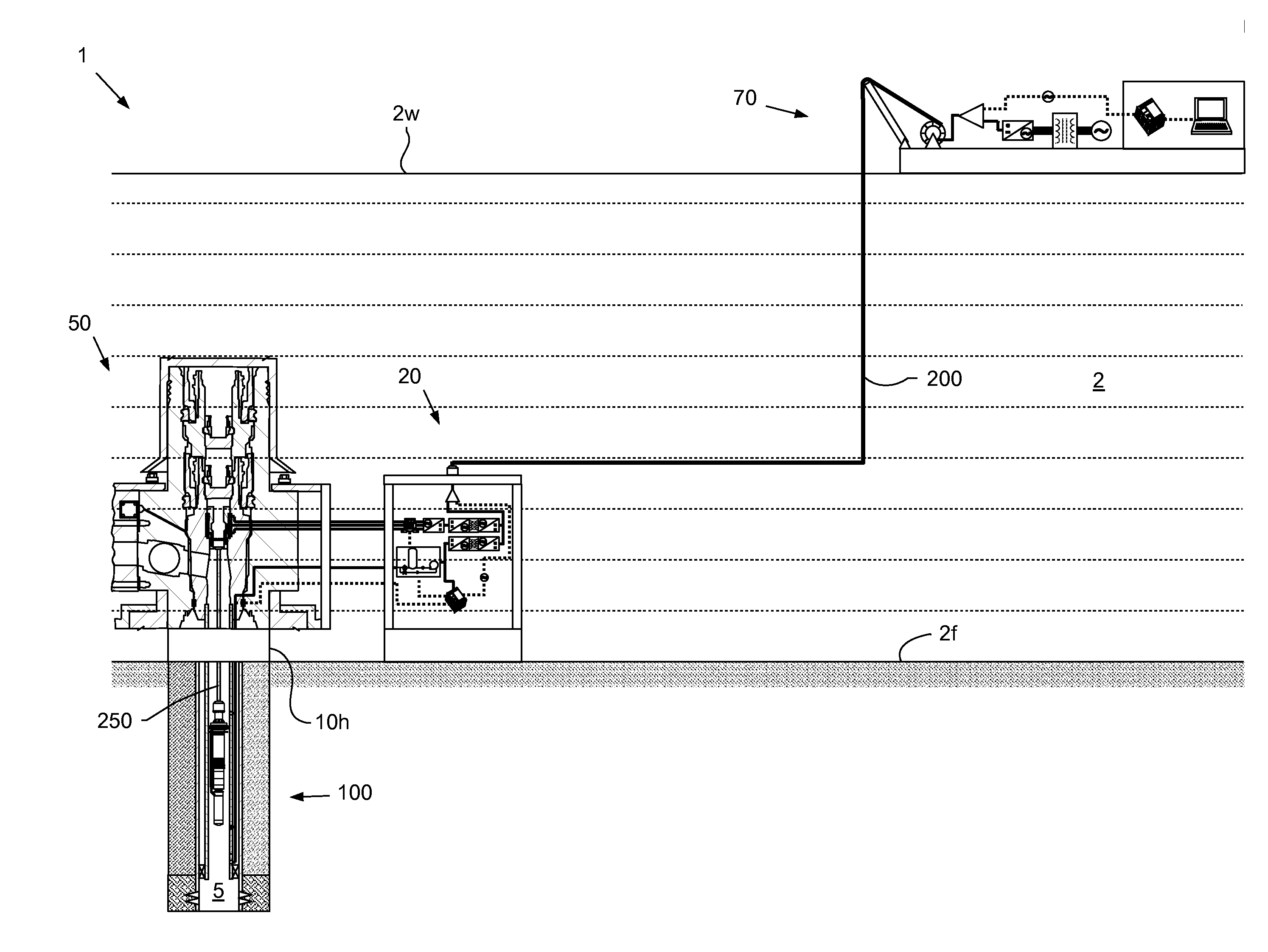

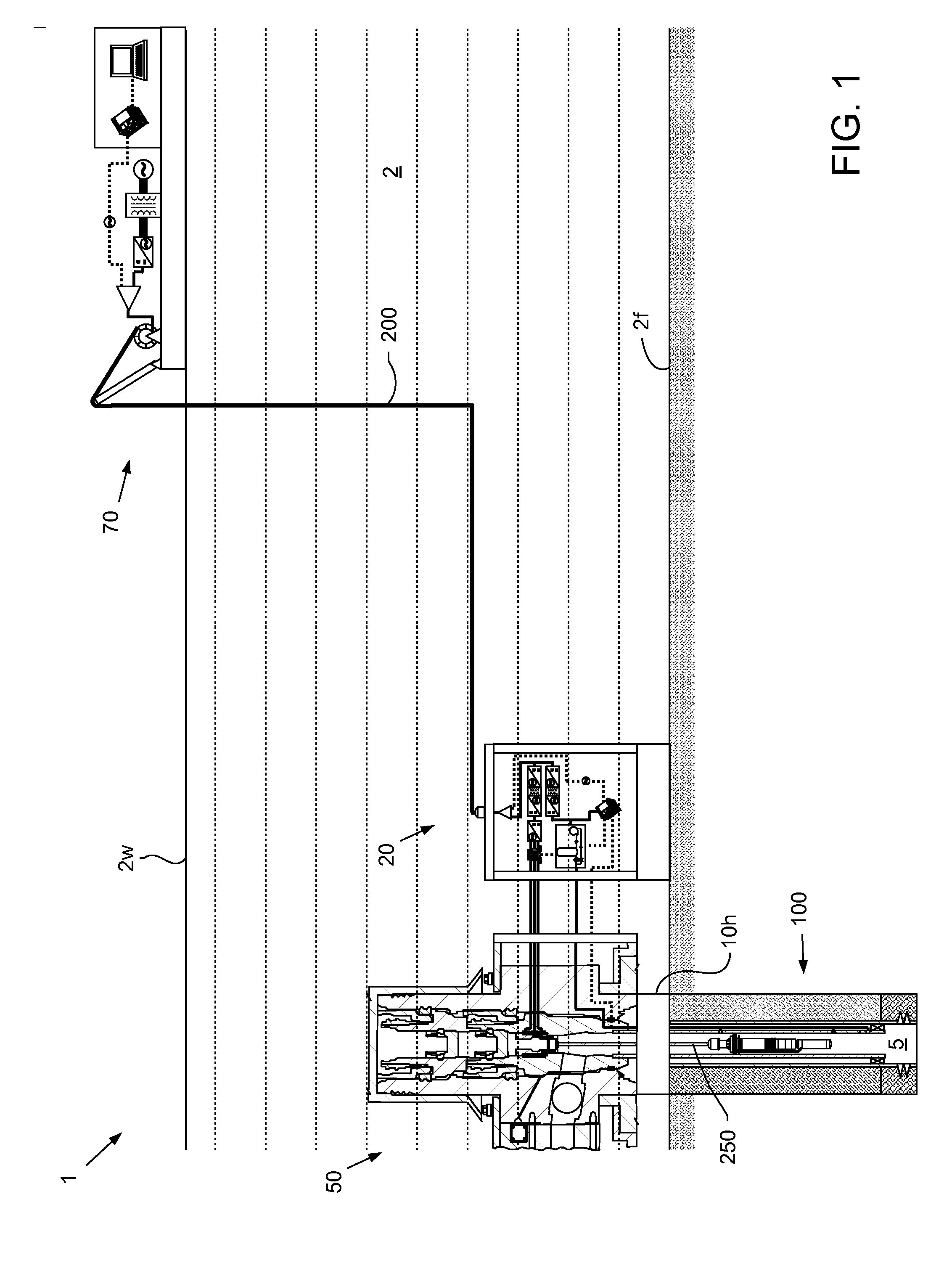

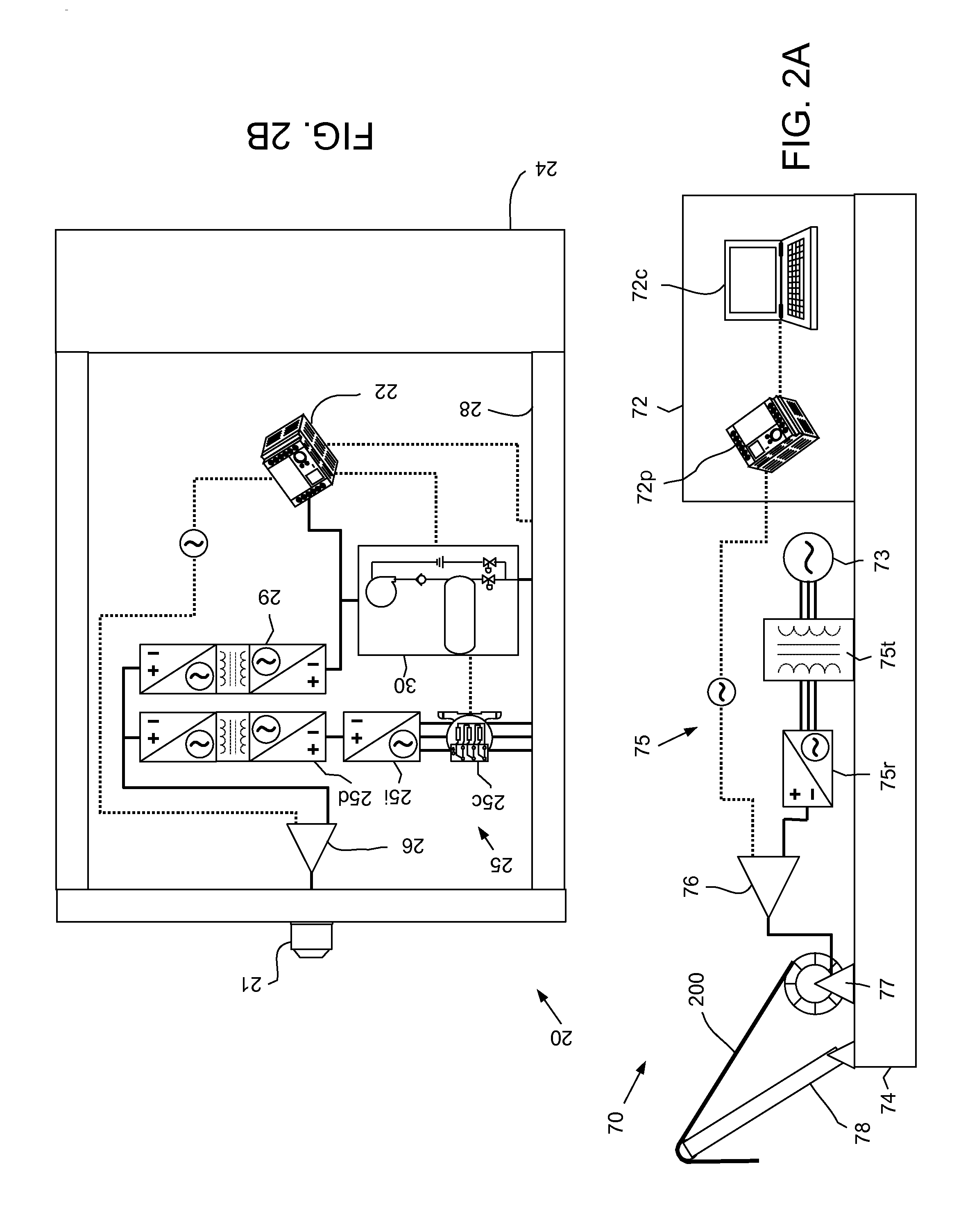

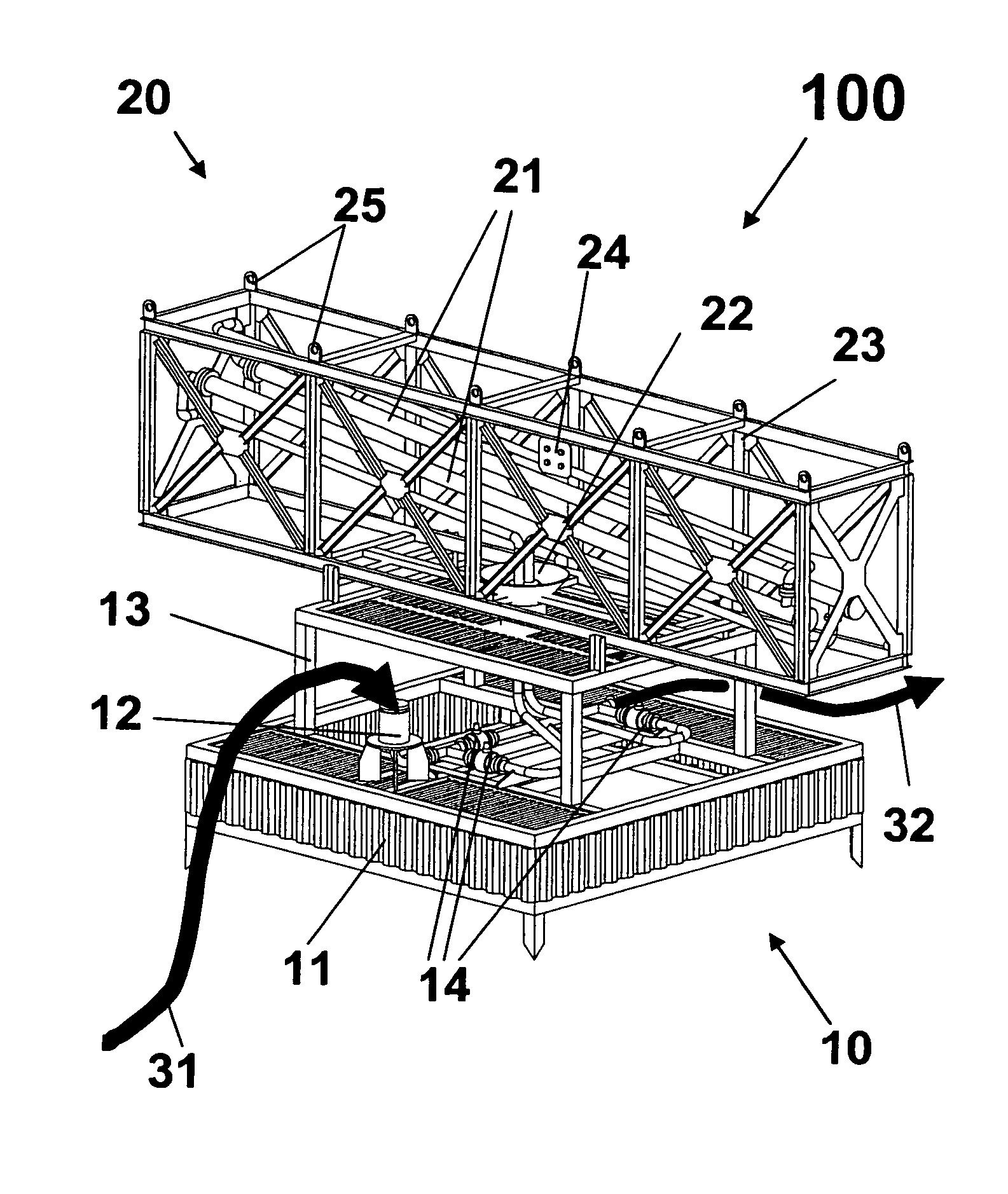

Power and control pod for a subsea artificial lift system

Embodiments of the present invention generally relate to a power and control pod for subsea artificial lift system. In one embodiment, a method of operating a downhole tool in a subsea wellbore includes: supplying a direct current (DC) power signal from a dry location to a subsea control pod; converting the DC power signal to an alternating current (AC) power signal by the control pod; and supplying the AC power signal from the control pod, into the subsea wellbore, and to the downhole tool.

Owner:SCHLUMBERGER TECH BV

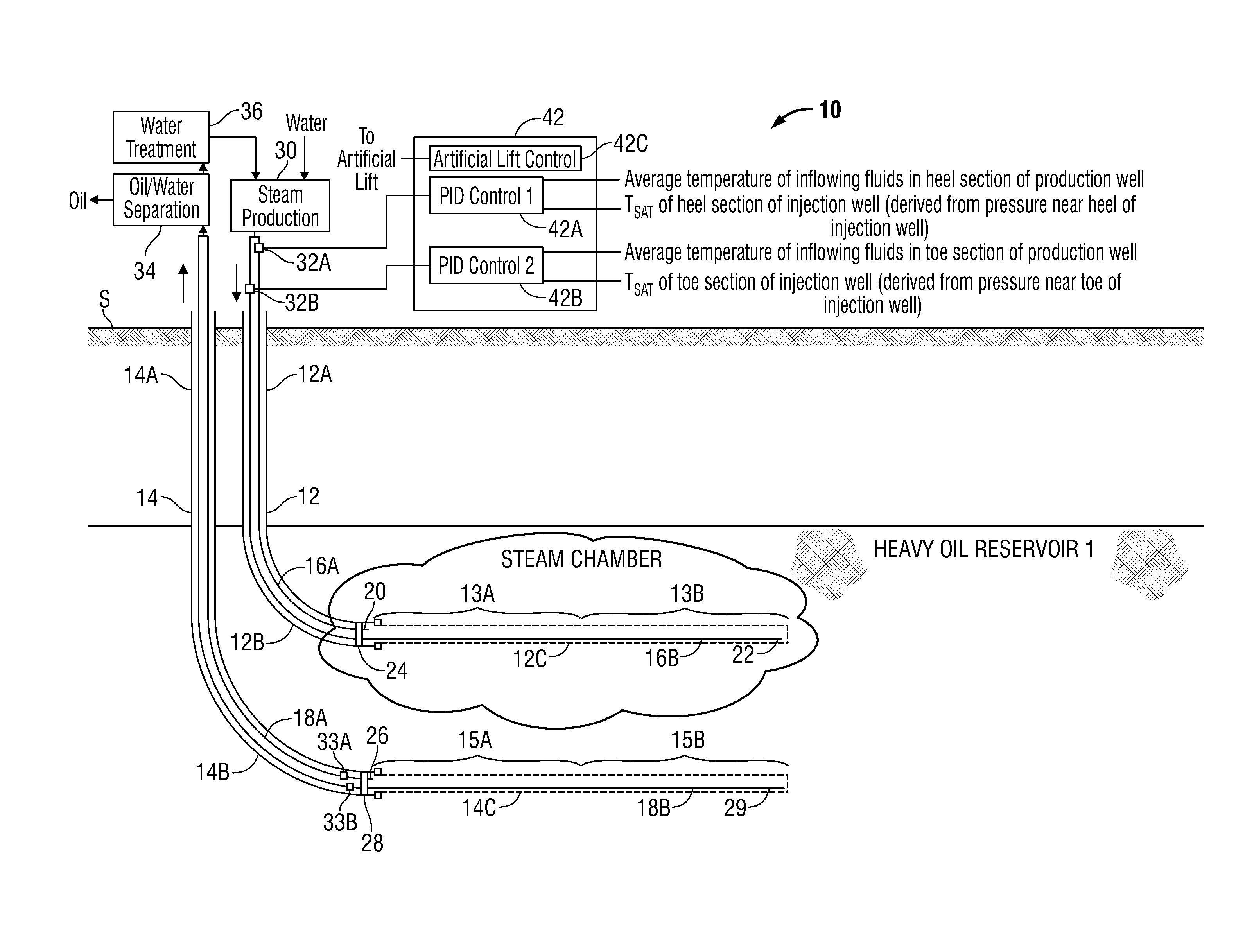

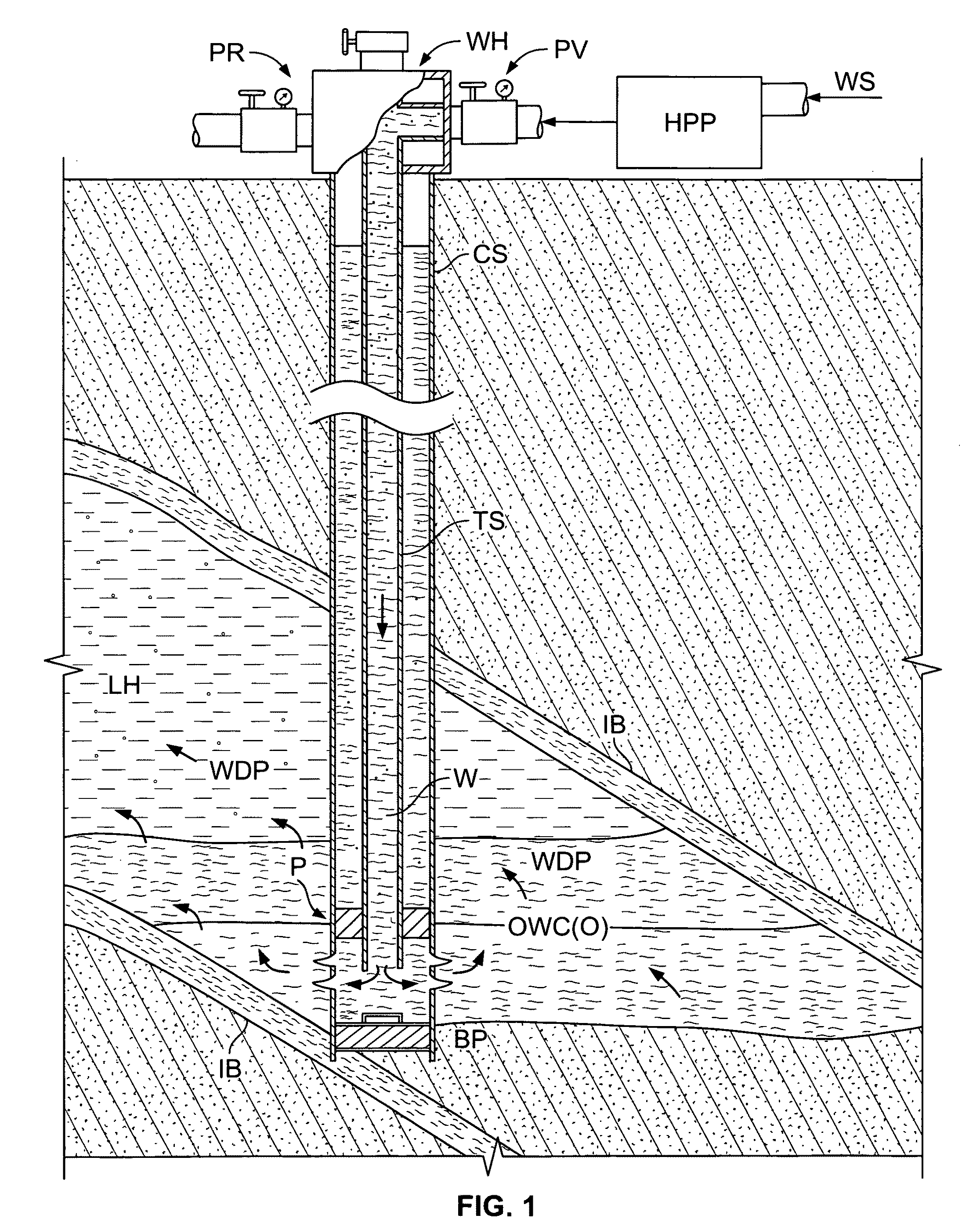

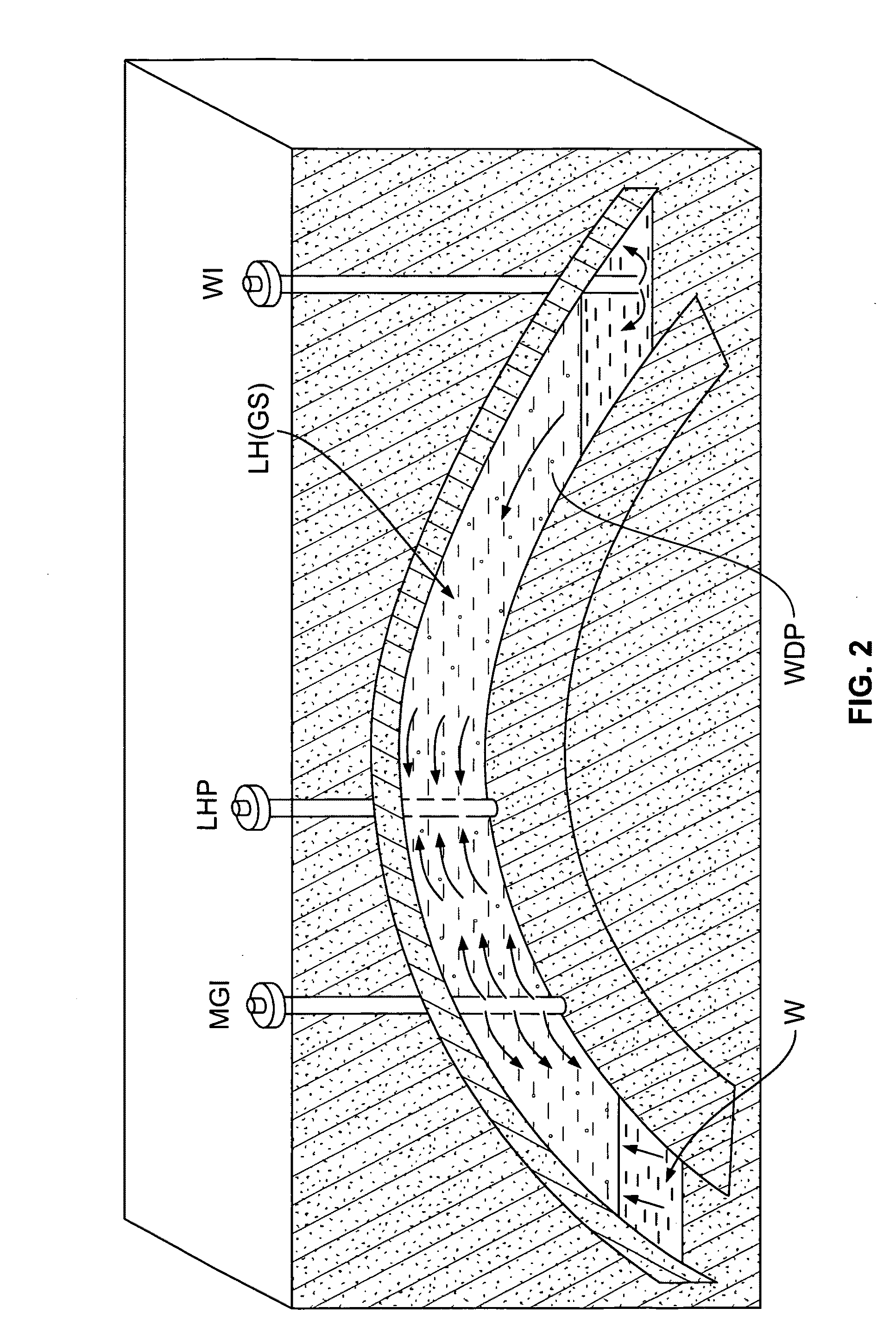

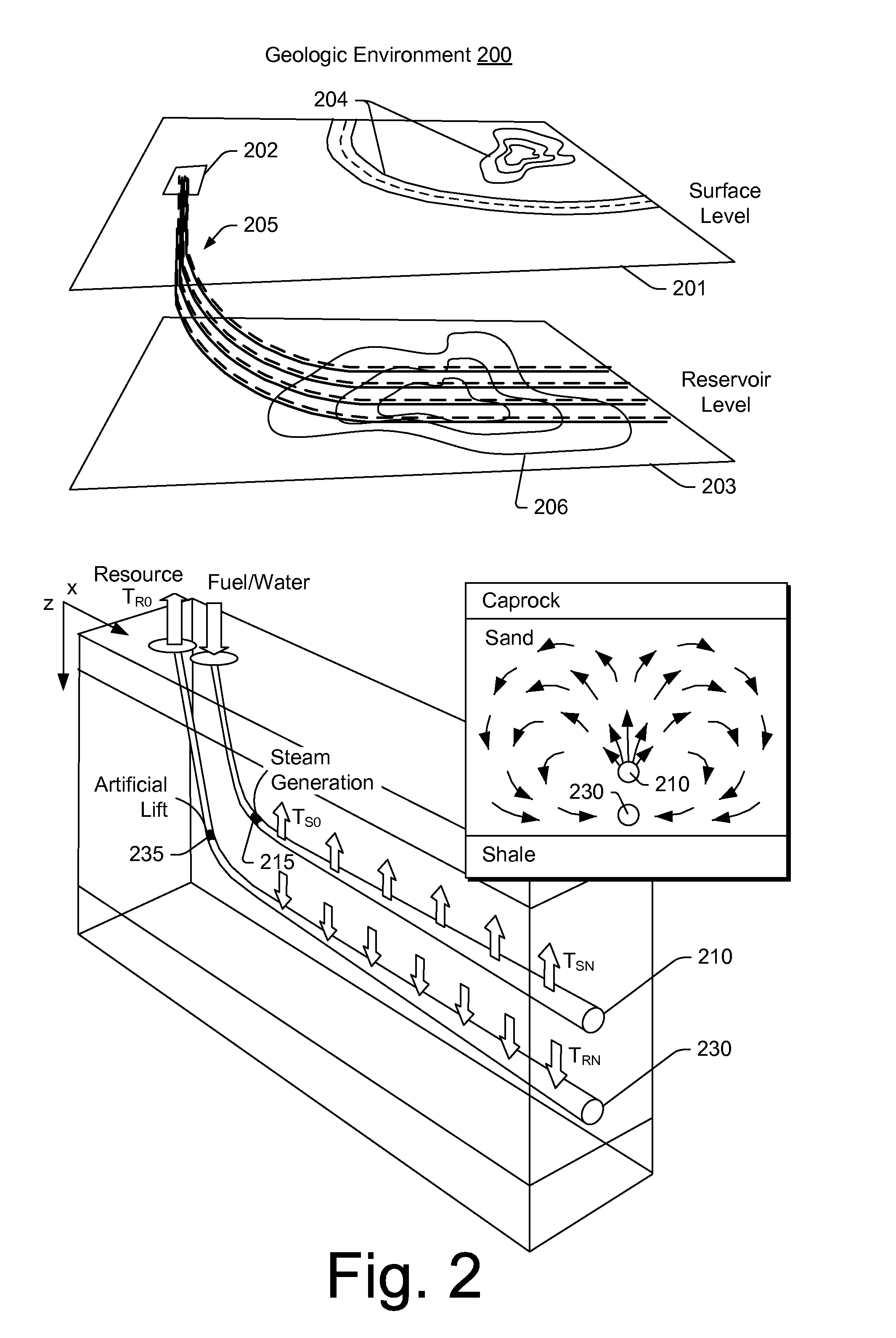

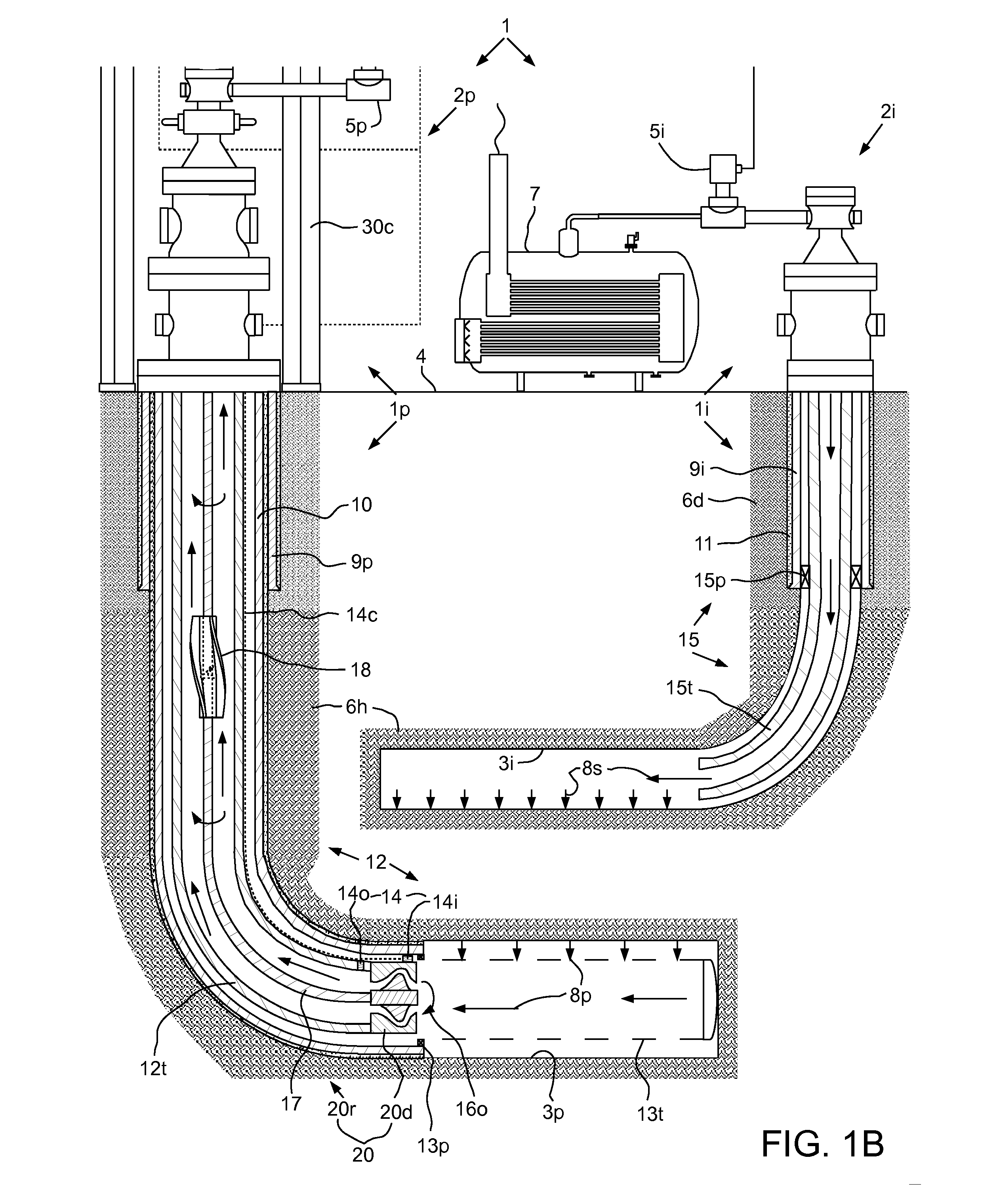

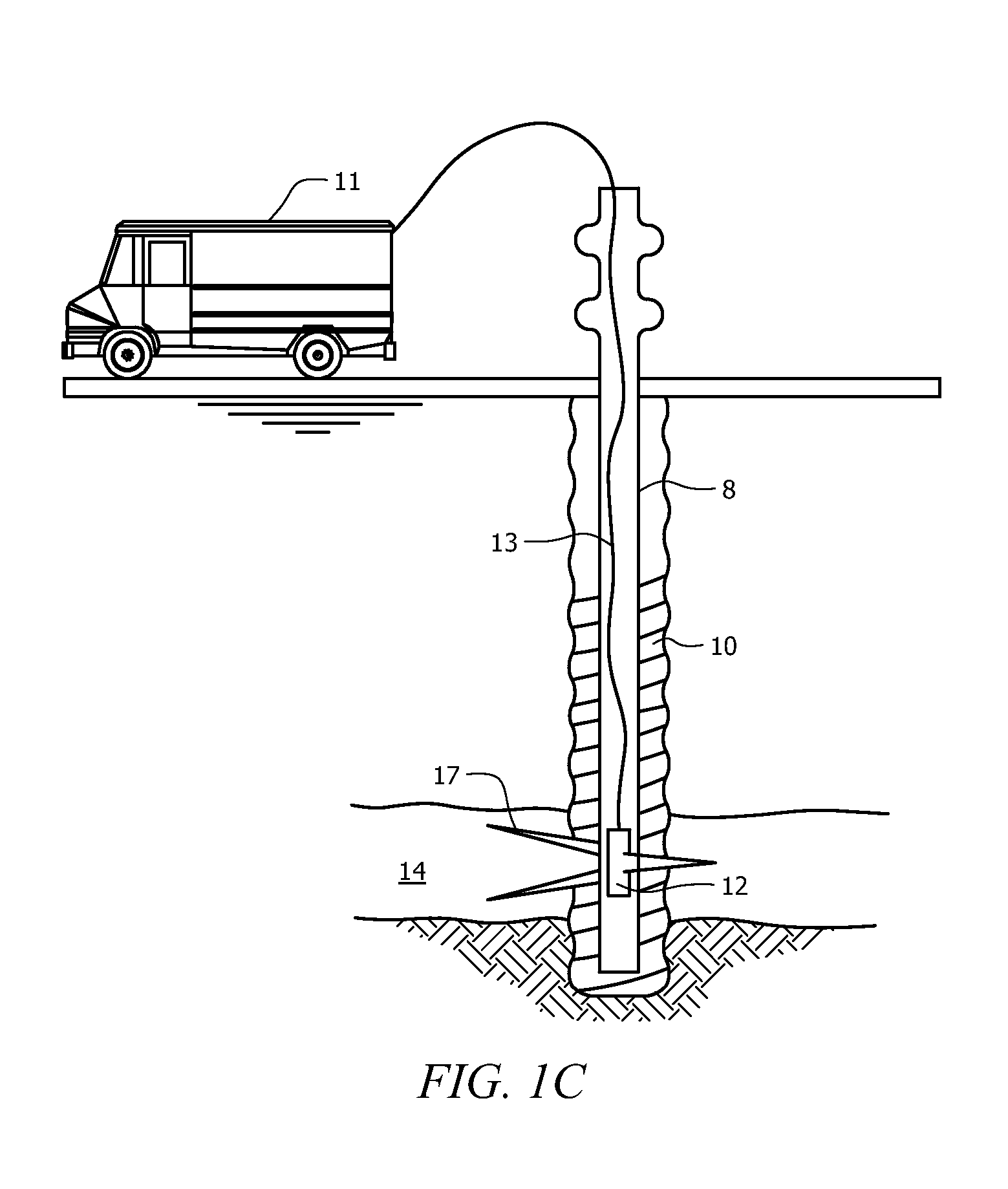

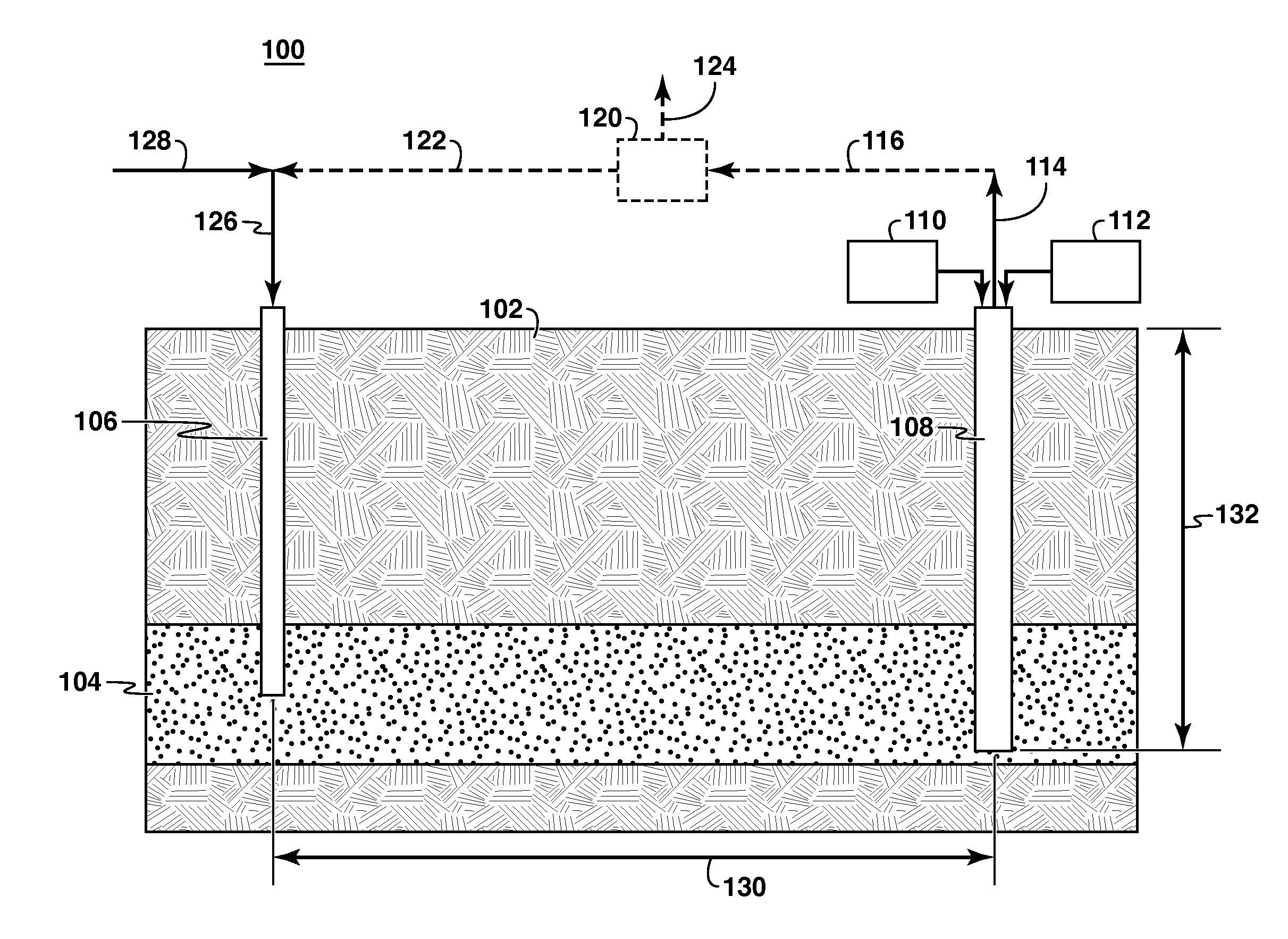

Hydrocarbon recovery employing an injection well and a production well having multiple tubing strings with active feedback control

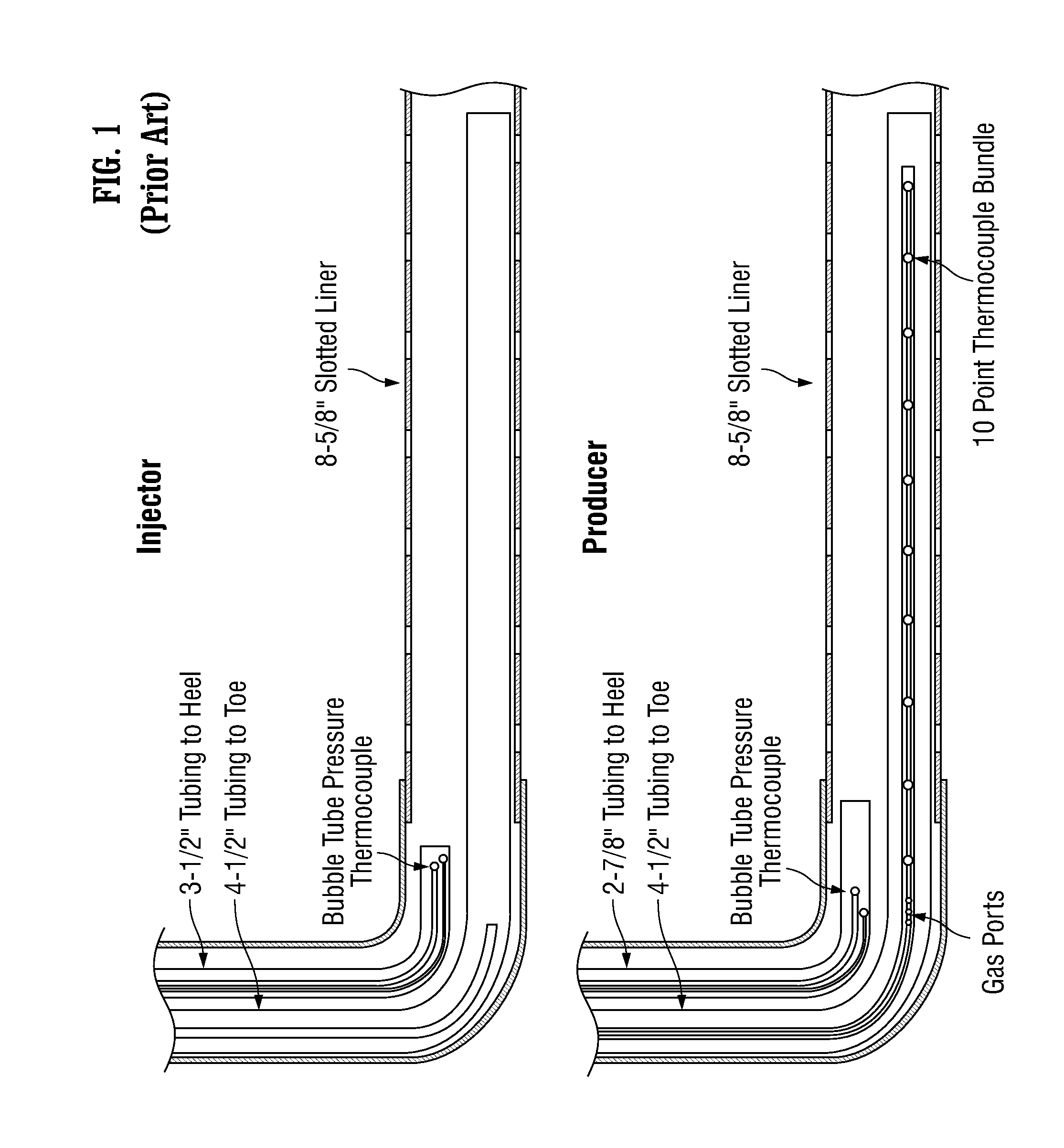

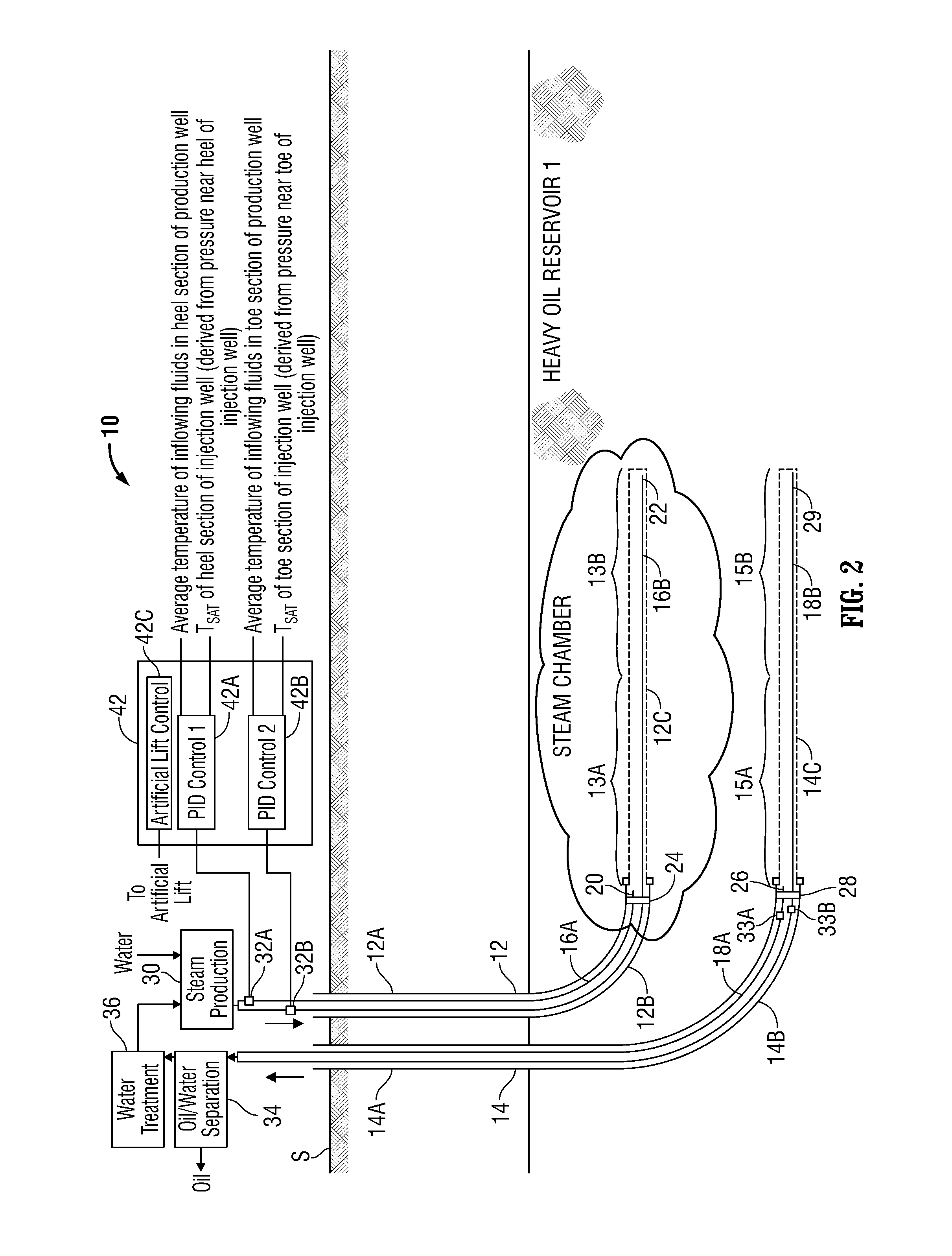

System and method for producing fluids from a hydrocarbon reservoir where an injector well segment and parallel underlying producer well segment are both completed with slotted liners. The injector and producer segments are logically partitioned into corresponding sections to define a plurality of injector-producer section pairs. Injection tubing strings supply stimulating fluid (e.g., saturated steam) to associated sections of the injector segment for injection into the hydrocarbon reservoir. Surface-located control devices control the pressure of the stimulating fluid flowing through the respective injection tubing strings. Production tubing strings (with the aid of artificial lift) carry fluids produced from associated sections of the producer segment. A plurality of controllers is provided for the injector-producer section pairs to control at least one process variable (e.g., interwell subcool temperature) associated with respective injector-producer section pairs over time by adjusting control variables that dictate operation of the control devices for the injection tubing strings.

Owner:SCHLUMBERGER TECH CORP

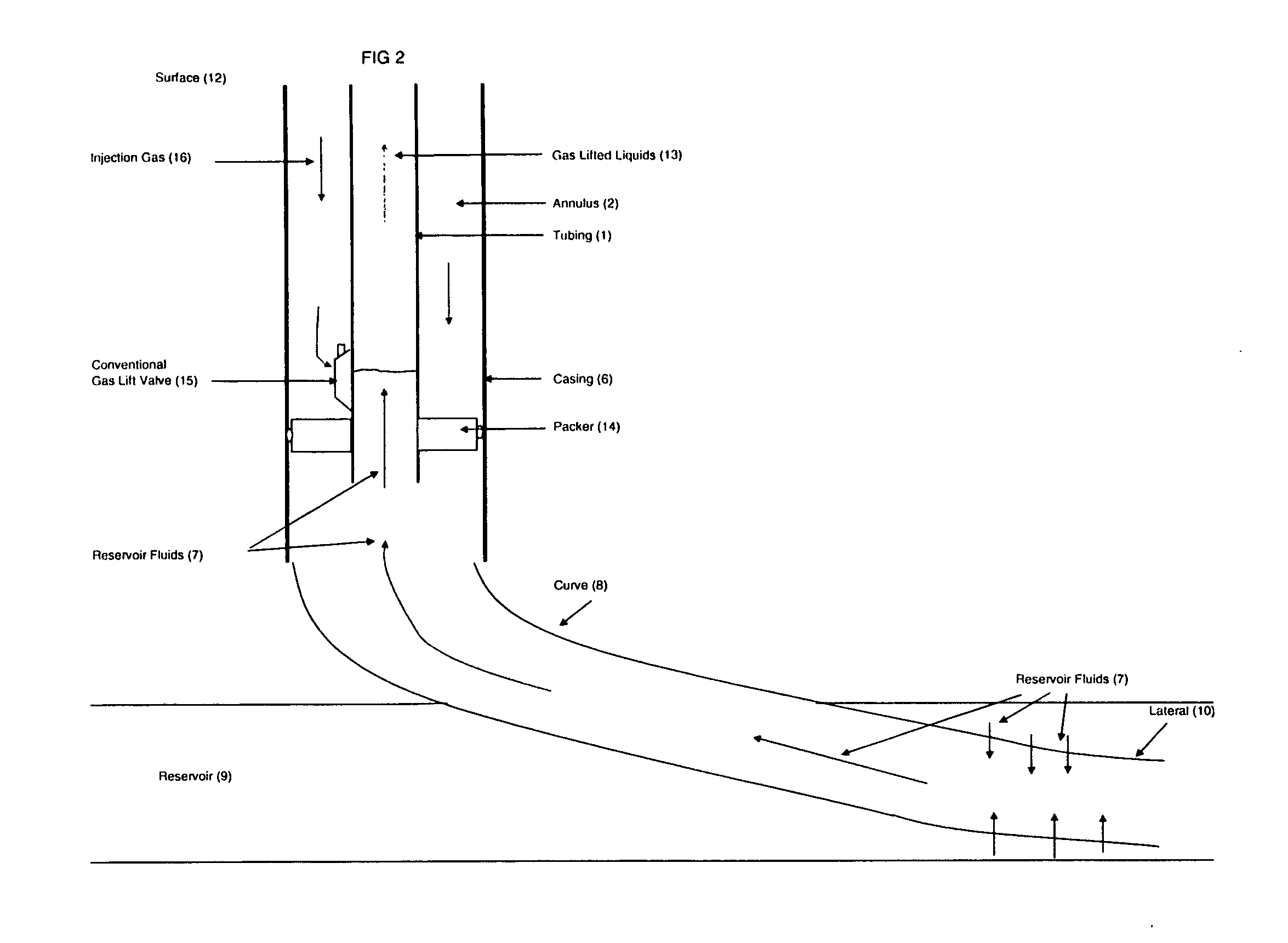

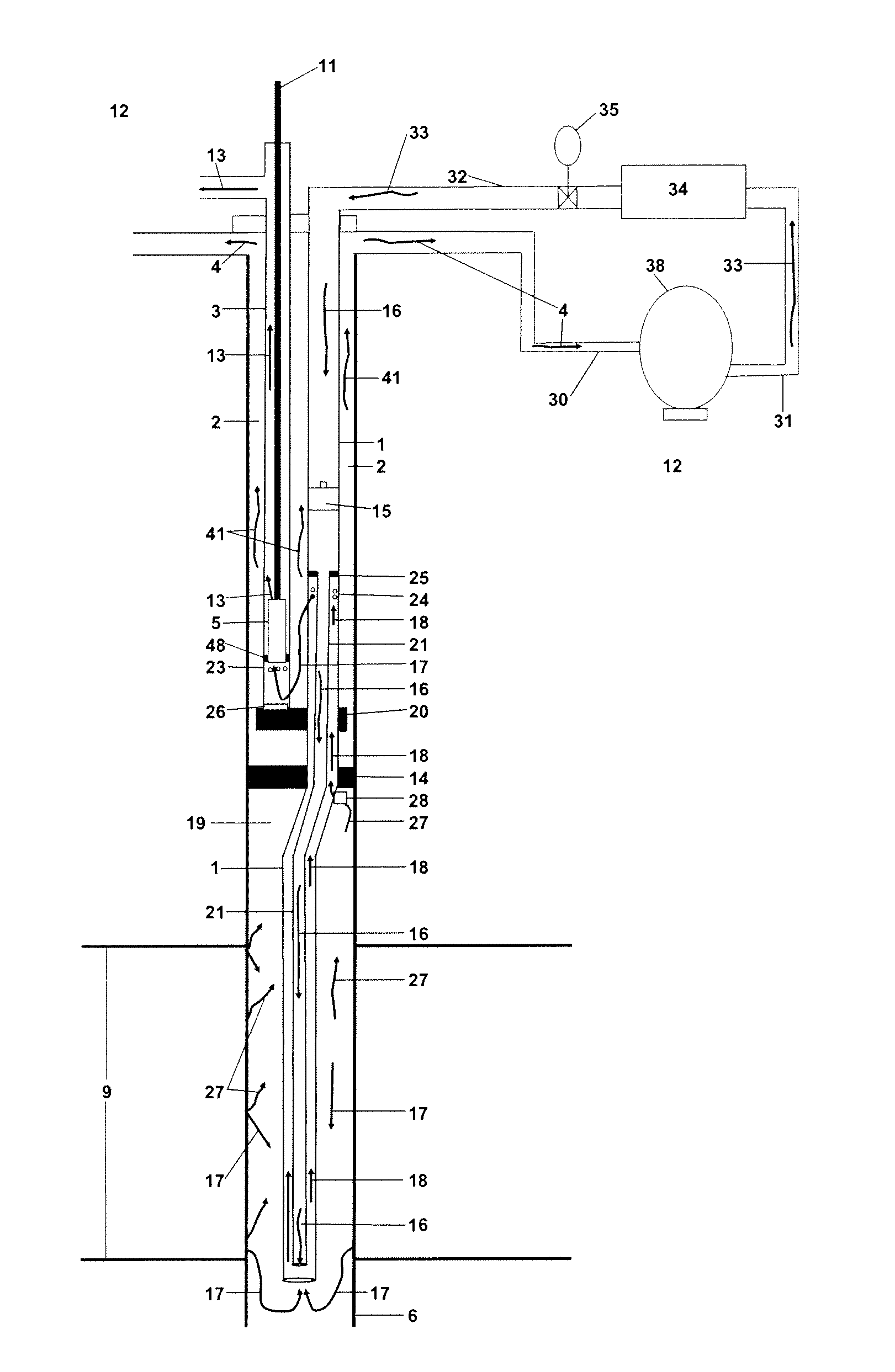

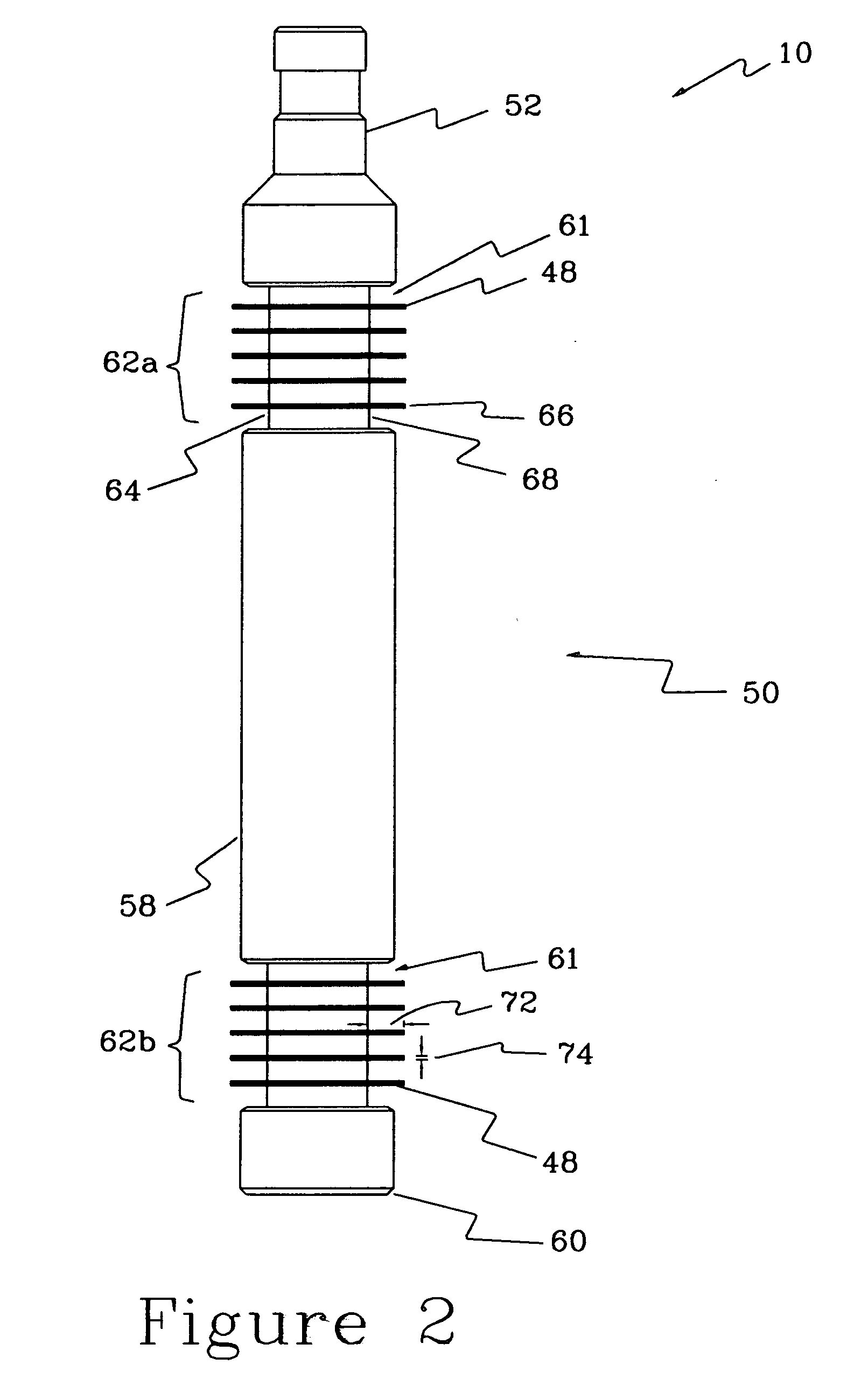

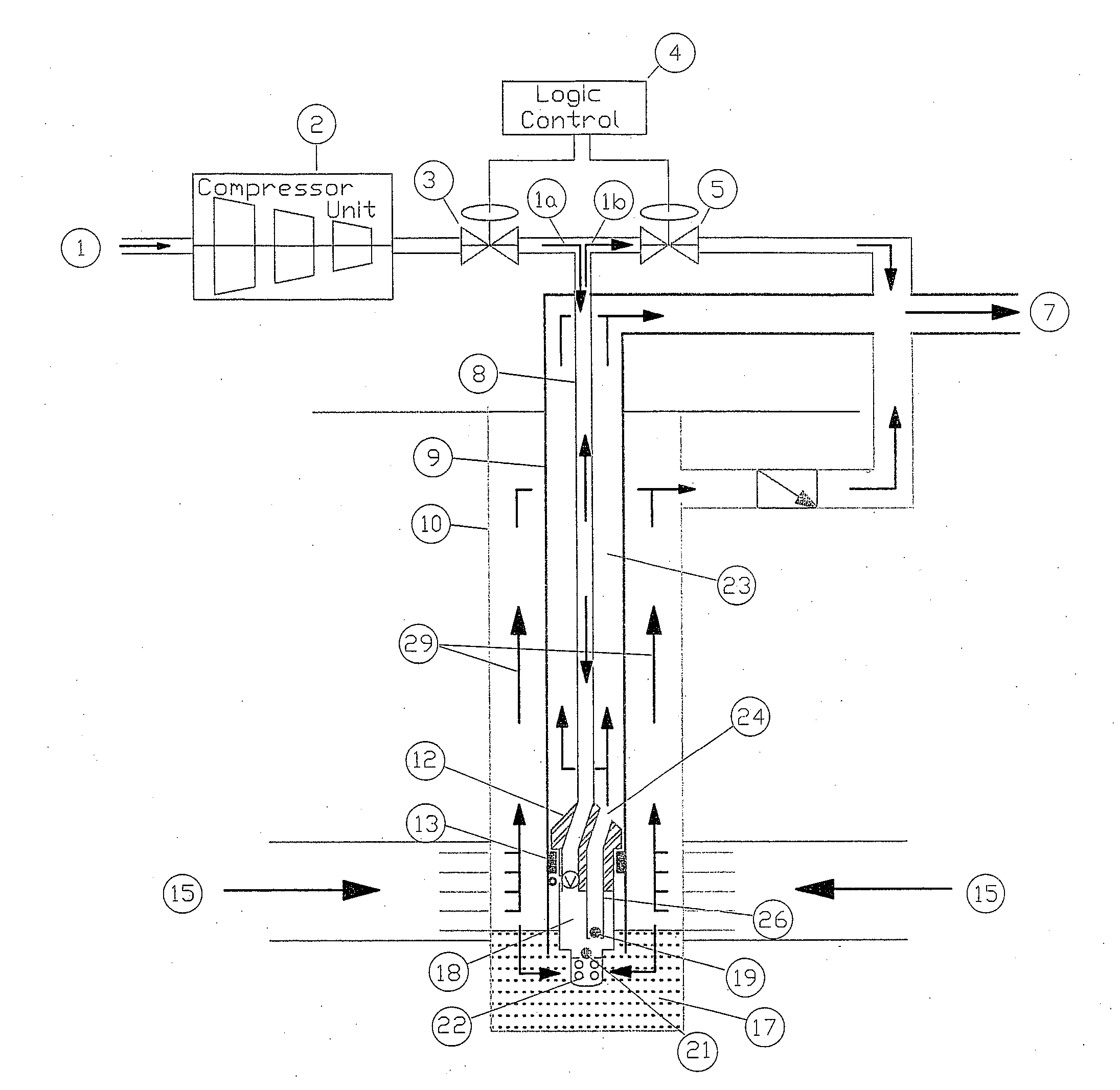

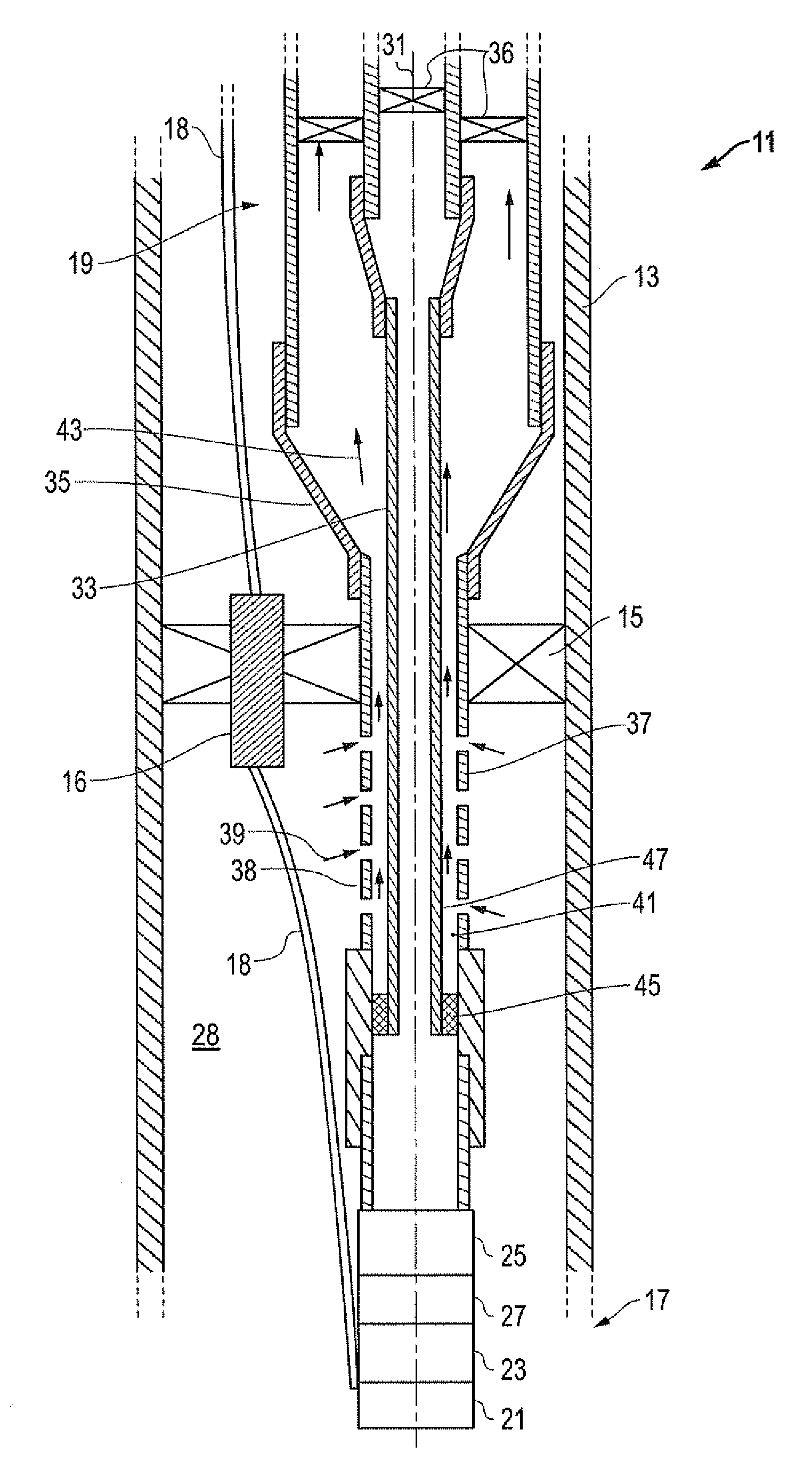

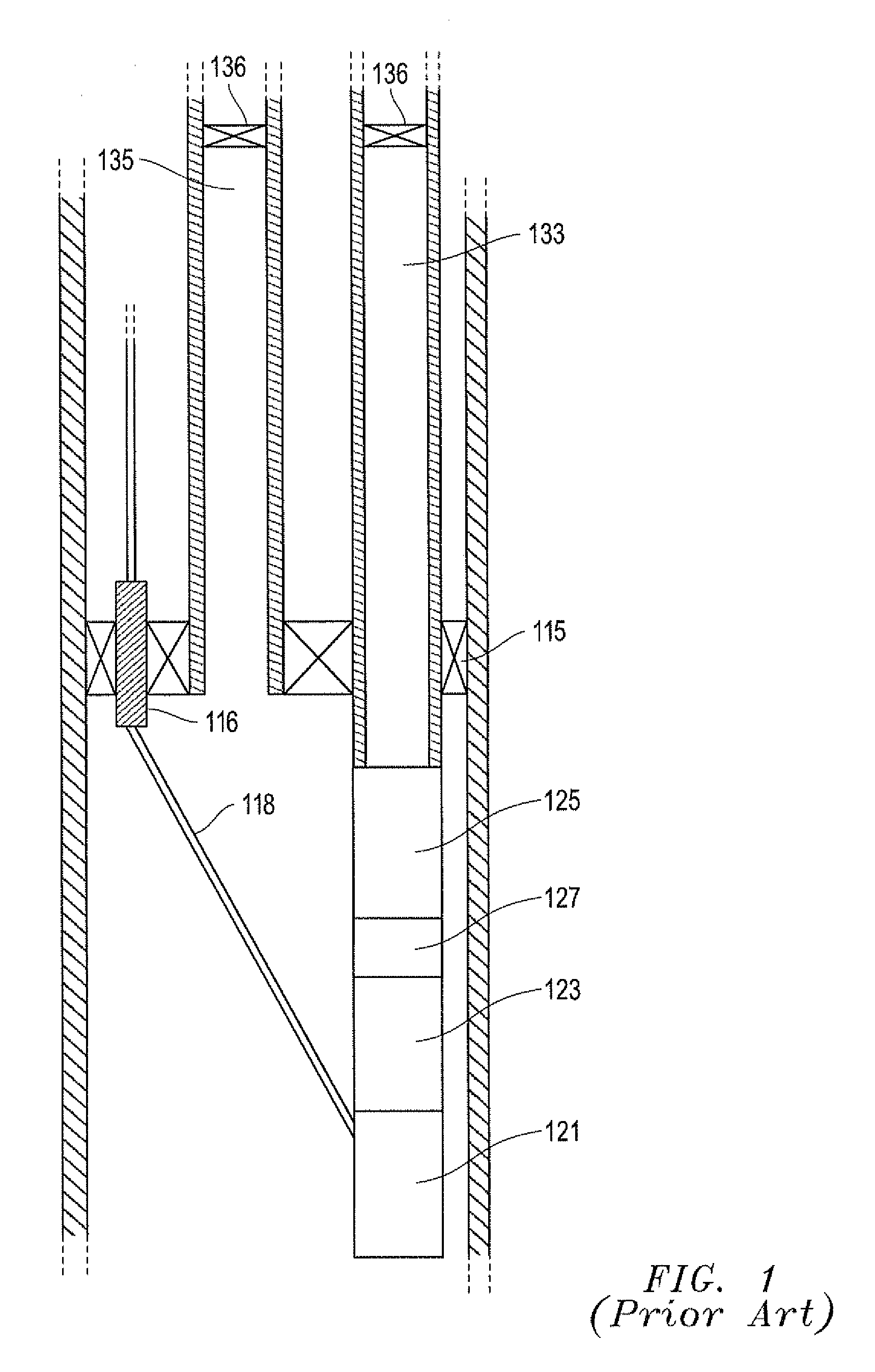

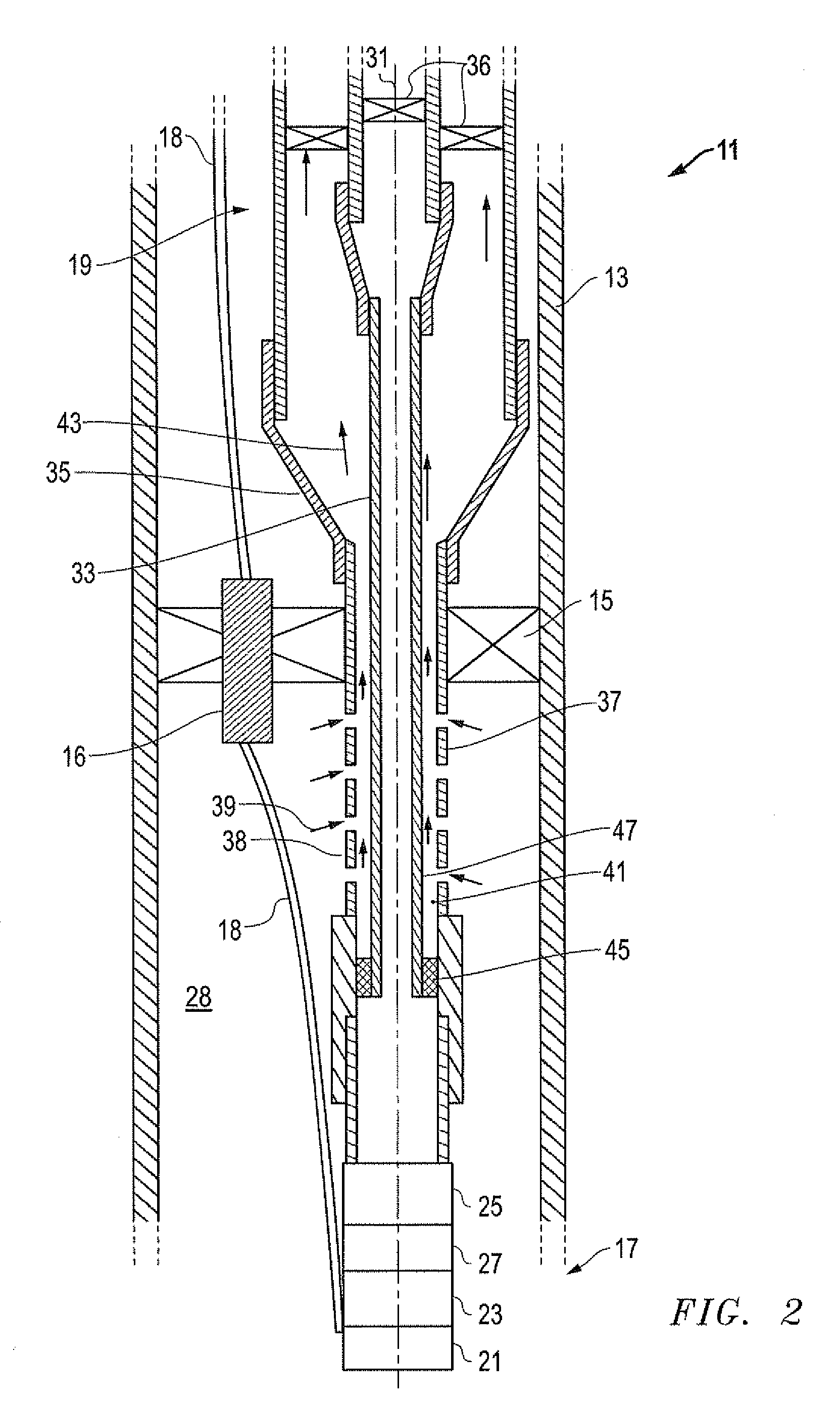

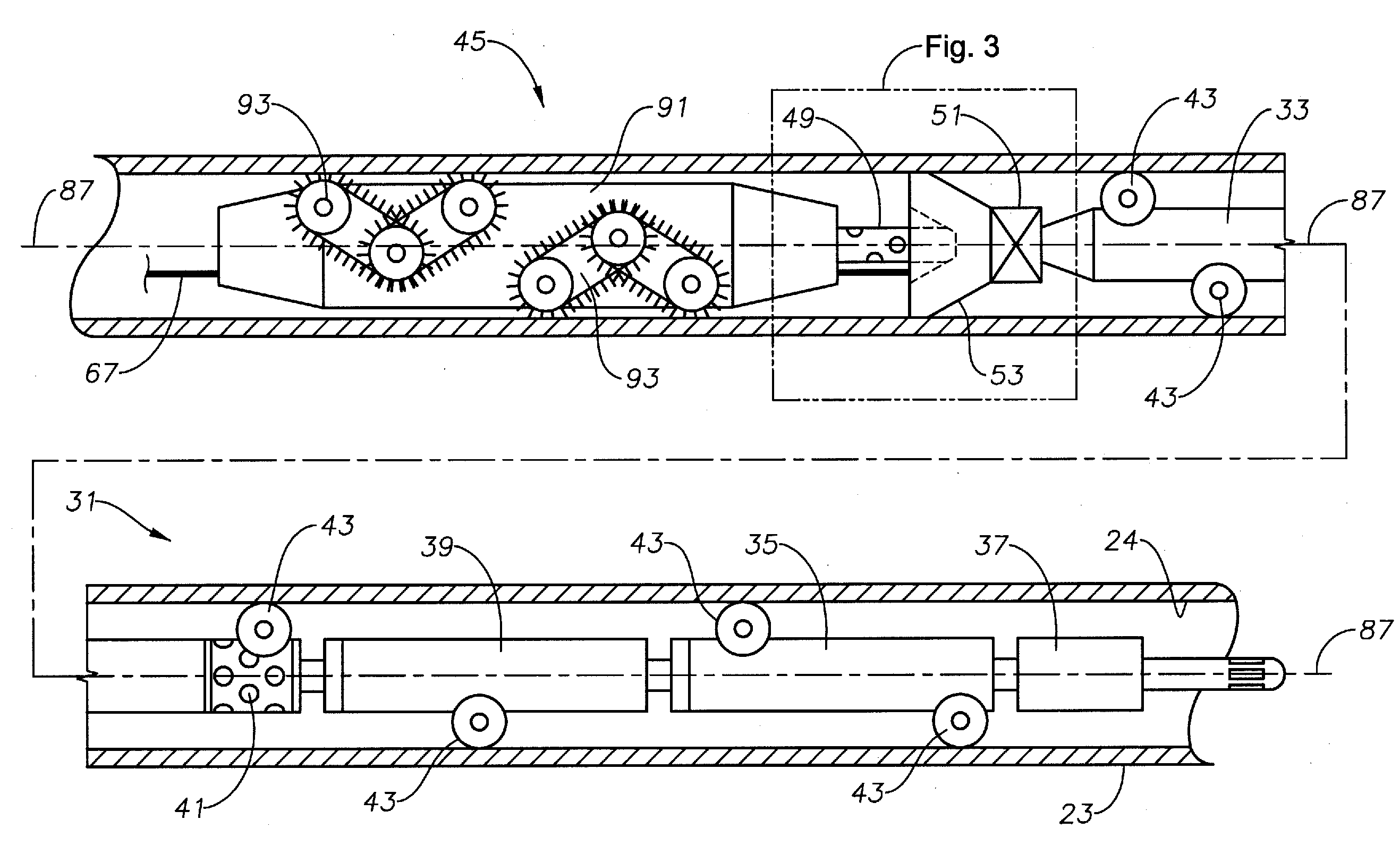

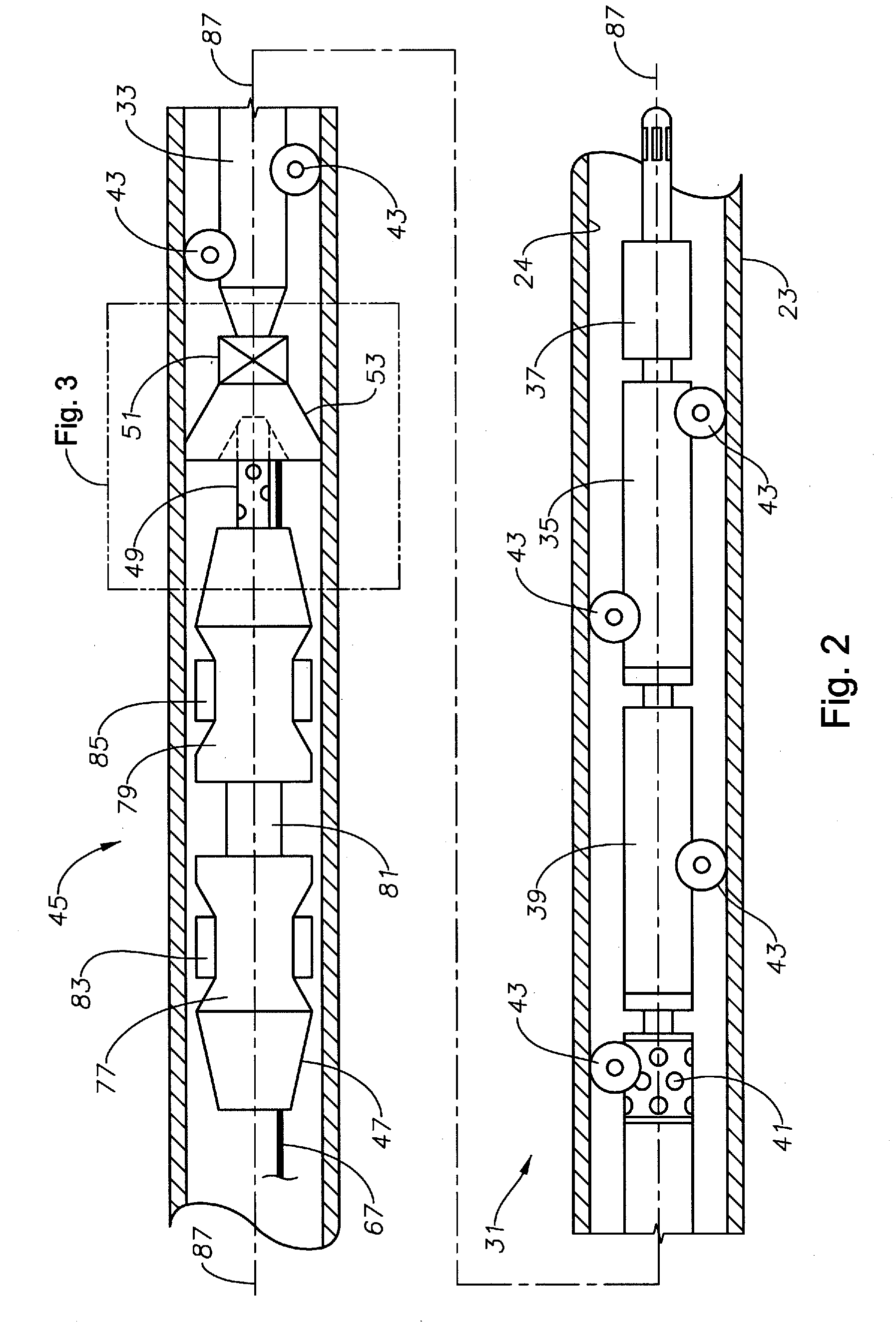

Gas assisted downhole pump

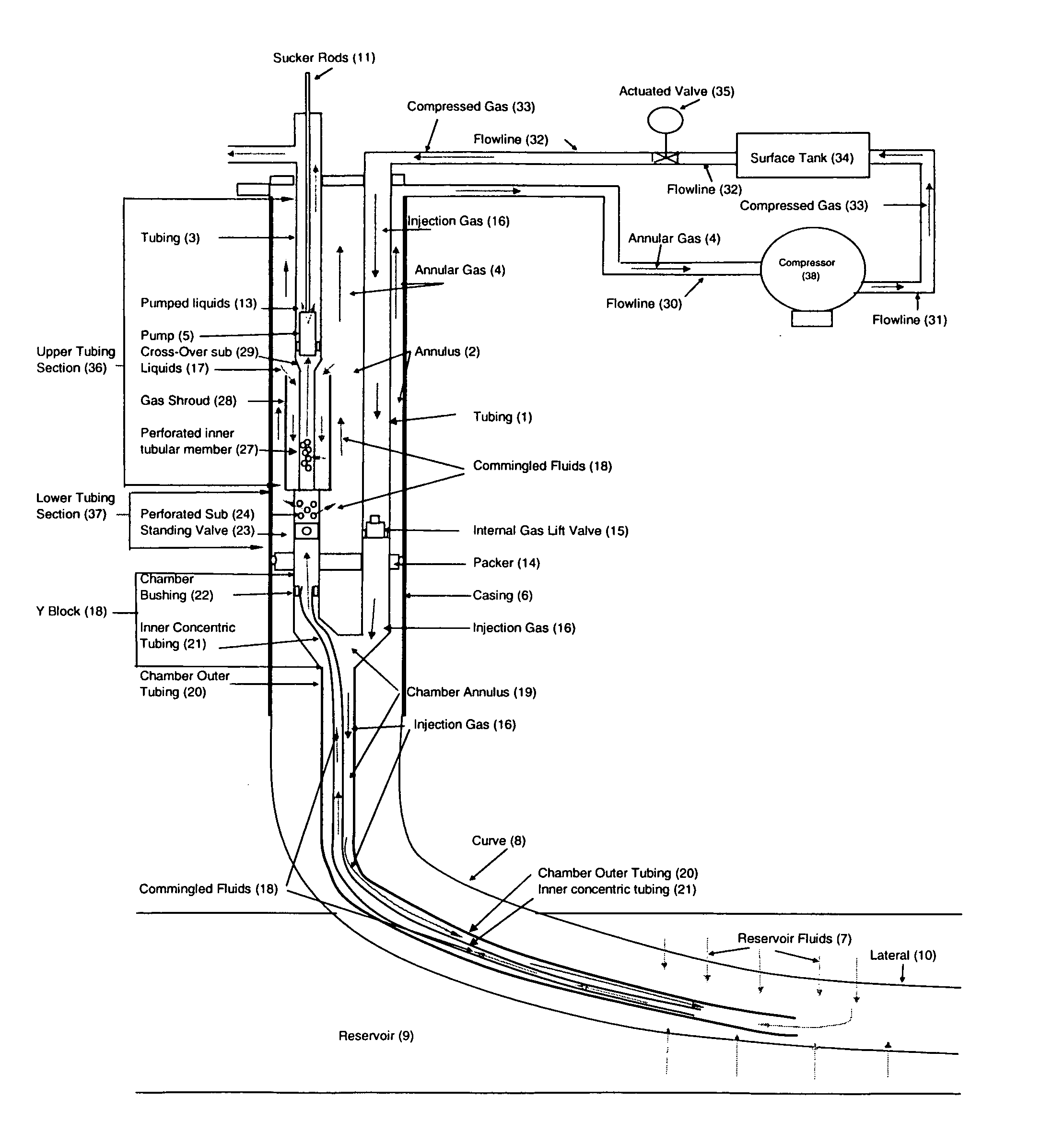

An artificial lift system is disclosed for removing wellbore fluids from directional or horizontal wellbores. The artificial lift system incorporates a dual tubing arrangement in which each string contains (respectively) a downhole pumping system or a gas lift system. In one string, a gas lift system, preferably intermittent, is utilized to lift reservoir fluids from below a packer assembly to above a packer assembly. This same tubing string is sealingly engaged to the packer and also contains a concentric inner tubing string which extends through and below the packer into the deviated well bore section. This concentric tubing arrangement provides a conduit for the injection gas and also a conduit for the return of commingled reservoir fluids and injection gas where the commingled fluids exit into the annular void between the dual tubing arrangement and the casing, located above the packer. The second tubing string, which is not sealingly engaged to the packer, contains a downhole pump placed above the exit point of the commingled fluids into the annulus. Because these liquids are trapped above the packer, each time the gas lift system cycles, they accumulate over time and rise above the downhole pump, which pumps the liquids to the surface. In an alternate embodiment of the invention, a plurality of tubing string arrangements are utilized A plurality of tubing string arrangements are sealingly engaged to a packer and operatively connected to a concentric tubing string that extends into the deviated section of the wellbore. A gas lift system, preferably intermittent, is utilized to lift reservoir fluids from below the packer to above the packer. This concentric tubing arrangement provides a conduit for the injection gas and also a conduit for the return of commingled reservoir fluids and injection gas. The commingled fluids exit through a perforated sub in one of the tubing strings above the packer and enter into the annular void between the dual tubing arrangement and the casing. A standing valve is located in the second tubing string below the perforated sub, which effectively trap the liquids in the annulus above the packer. Each time the gas lift system cycles, these liquids accumulate over time and rise above the downhole pump, which pumps the liquids to the surface.

Owner:NGSIP

System and method for production of reservoir fluids

InactiveUS20110278015A1Reduce back pressureIncrease productionDrilling rodsFluid removalArtificial liftEngineering

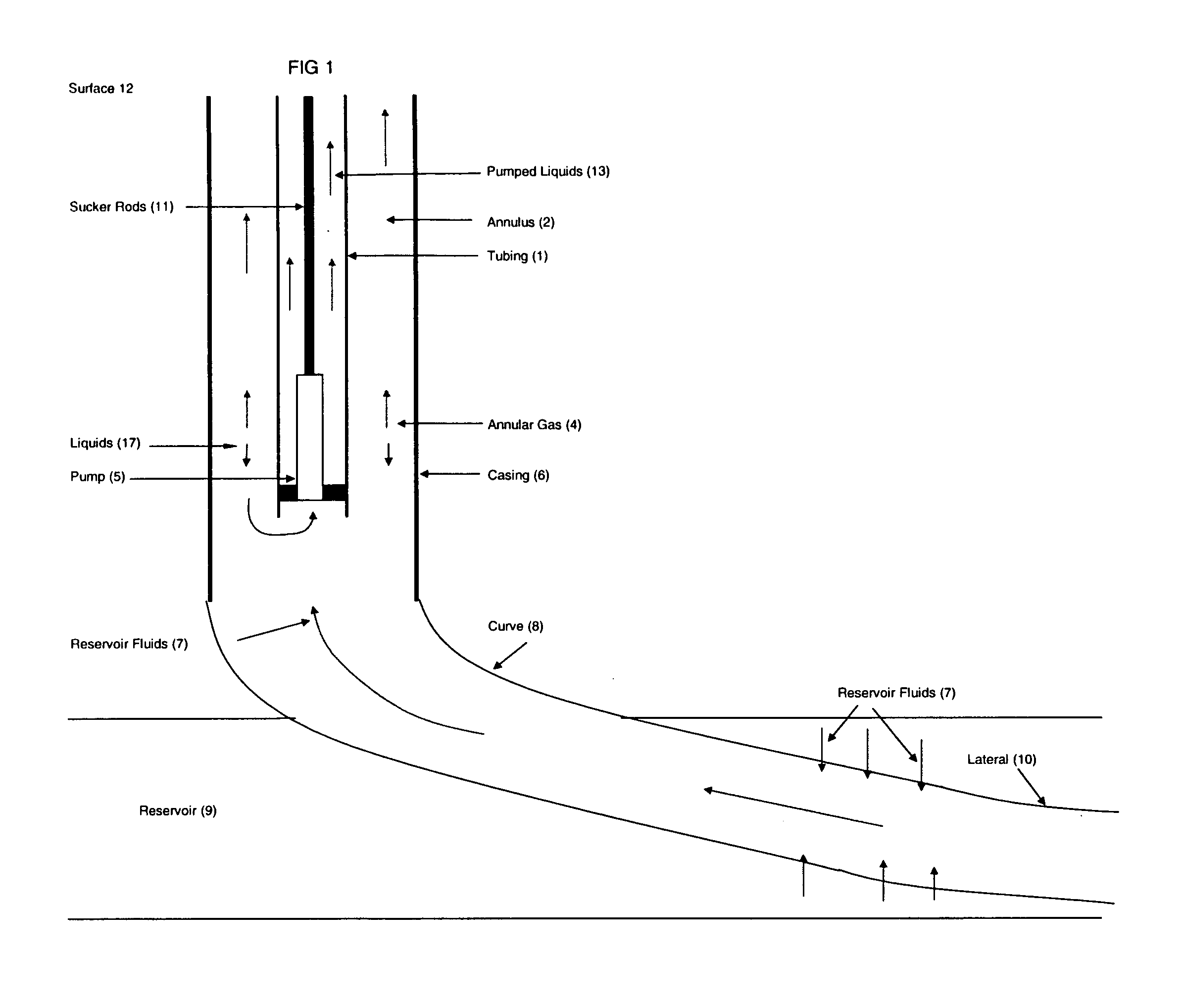

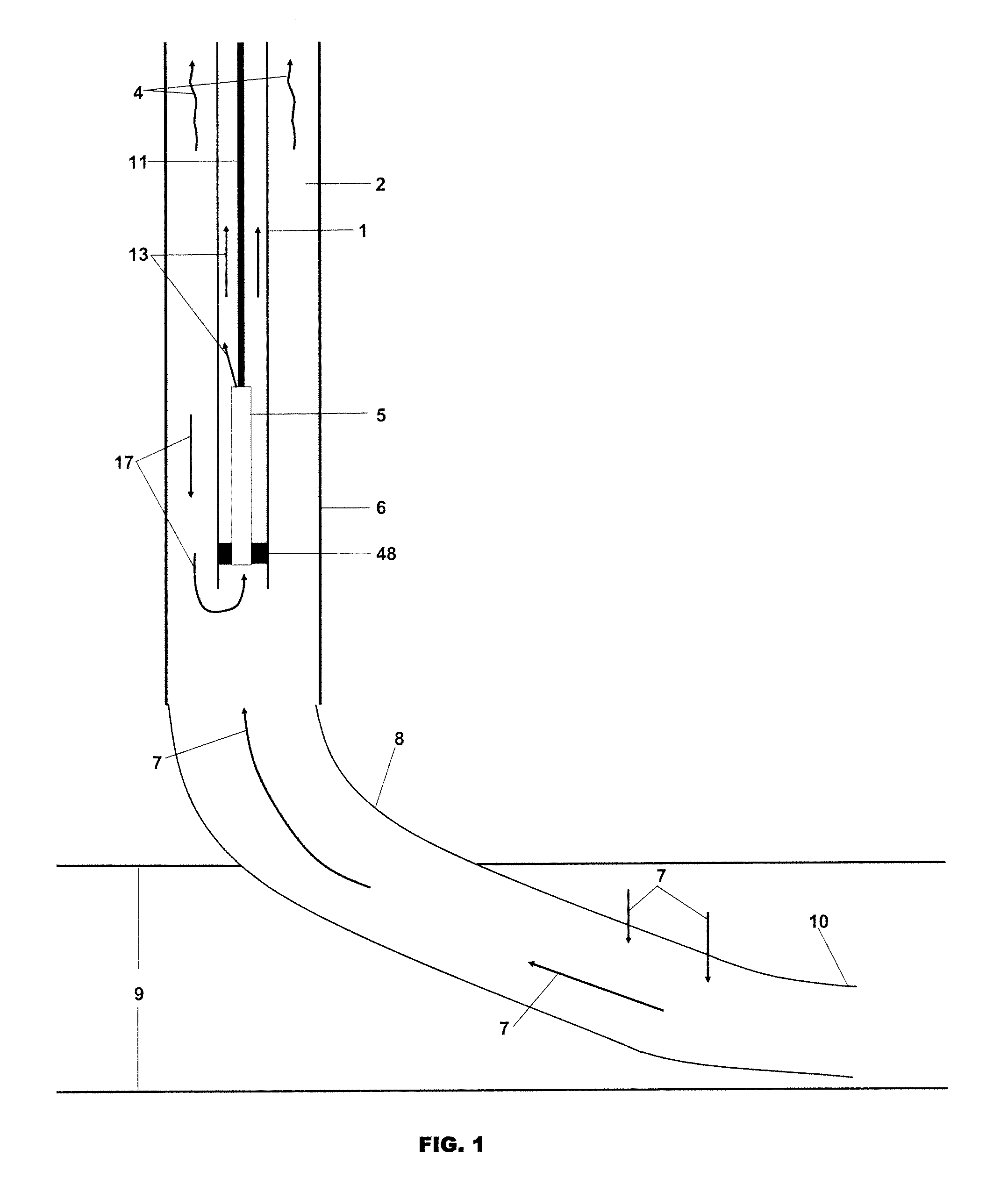

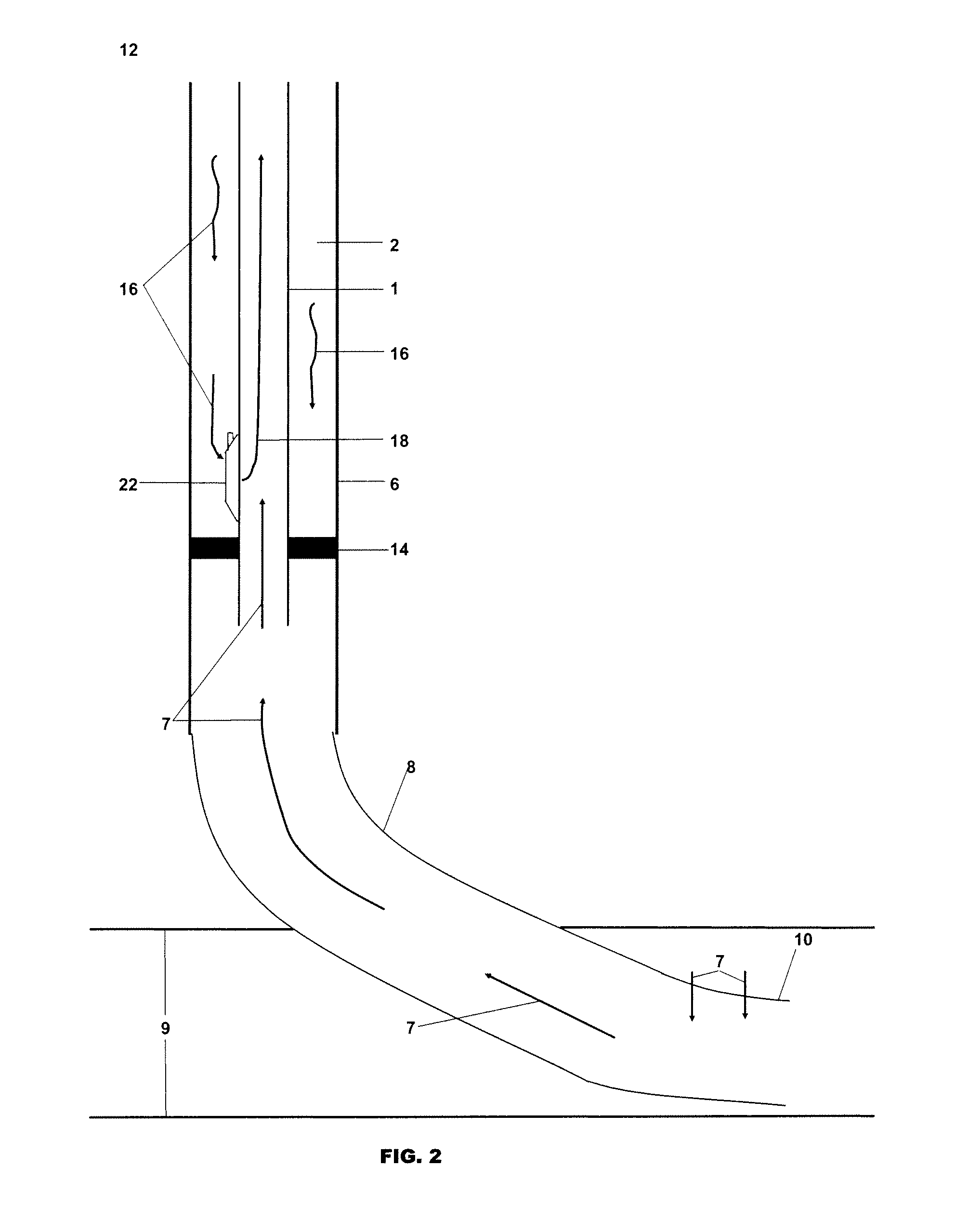

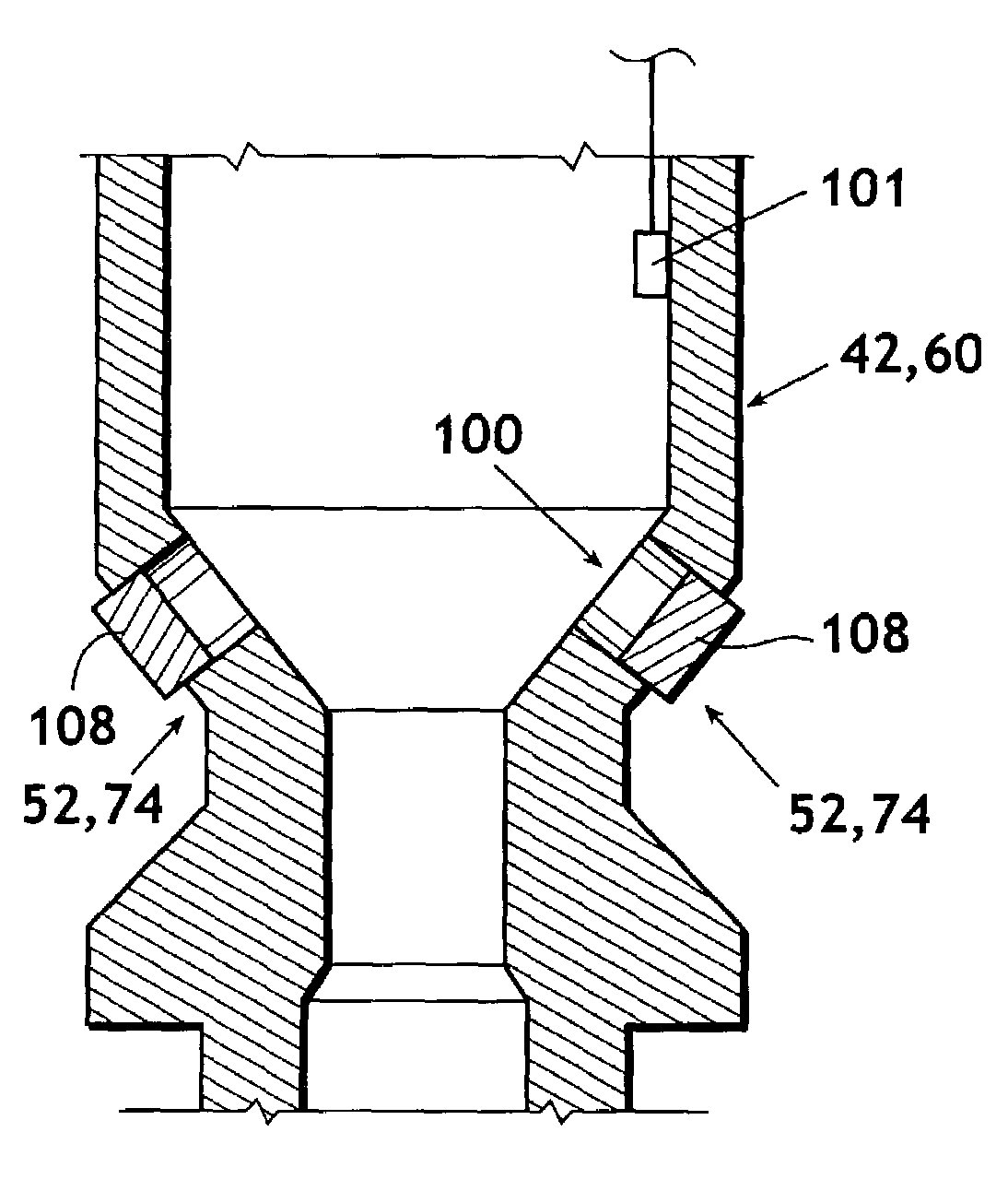

An artificial lift system removes reservoir fluids from a wellbore. A gas lift system is disposed in a first tubing string anchored by a packer, and a downhole pump, or alternative plunger lift, may be positioned with a second tubing string. A dual string anchor may be disposed with the first tubing string to limit the movement of the second tubing string. The second tubing string may be removably attached with the dual string anchor with an on-off tool without disturbing the first tubing string. A one-way valve may also be used to allow reservoir fluids to flow into the first tubing string in one direction only. The second tubing string may be positioned within the first tubing string and the injected gas may travel down the annulus between the first and second tubing strings. A bi-flow connector may anchor the second string to the first string and allow reservoir liquids in the casing tubing annulus to pass through the connector to the downhole pump. Injected gas may be allowed to pass vertically through the bi-flow connector to lift liquids from below the downhole pump to above the downhole pump. The bi-flow connector prevents the downwardly injected gas from interfering with the reservoir fluids flowing through the bi-flow connector. In another embodiment, gas from the reservoir lifts reservoir liquids from below the downhole pump to above the downhole pump. A first tubing string may contain a downhole pumping system or alternative plunger lift above a packer assembly. A concentric tubing system below the packer may lift liquids using the gas from the reservoir.

Owner:NGSIP

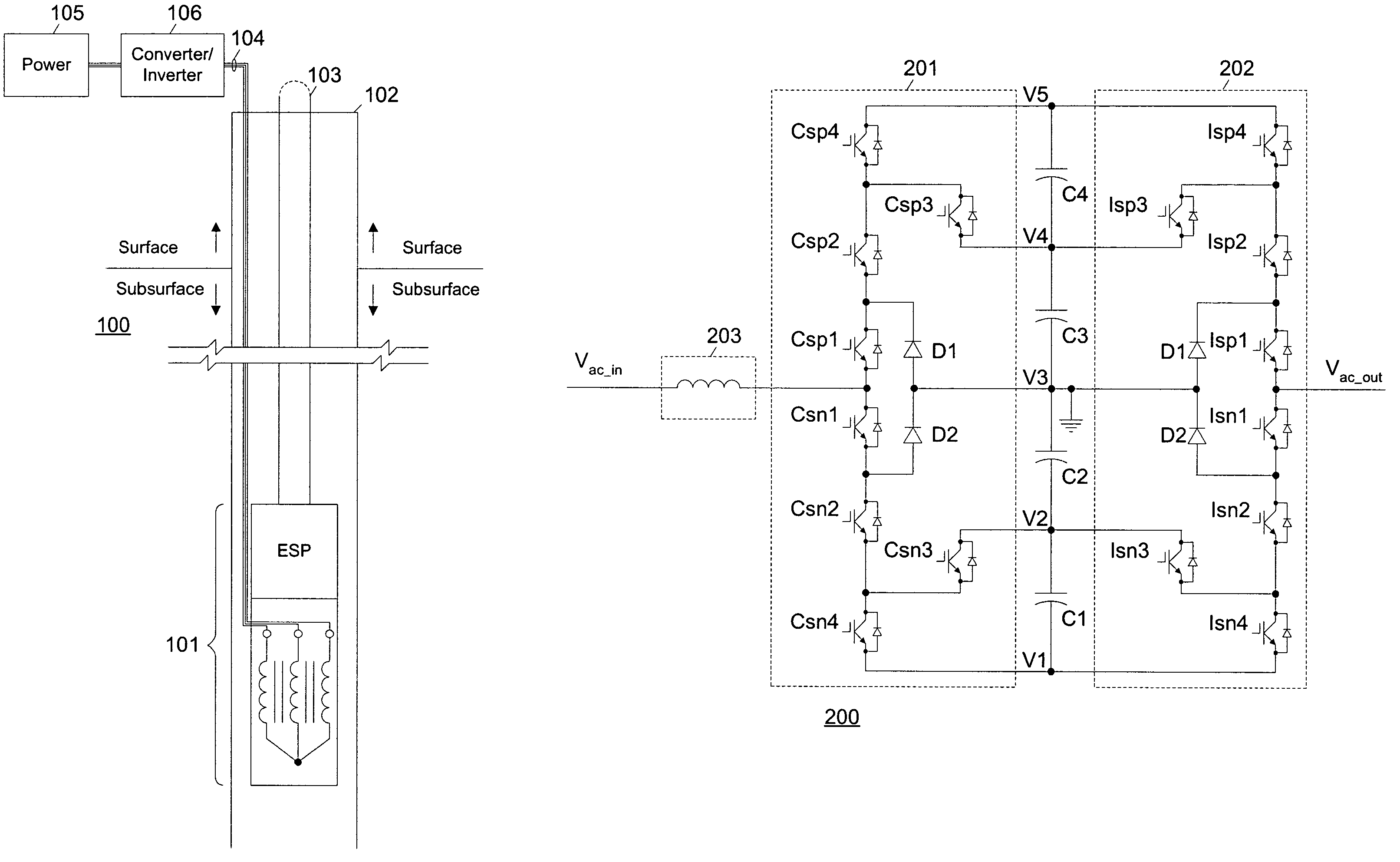

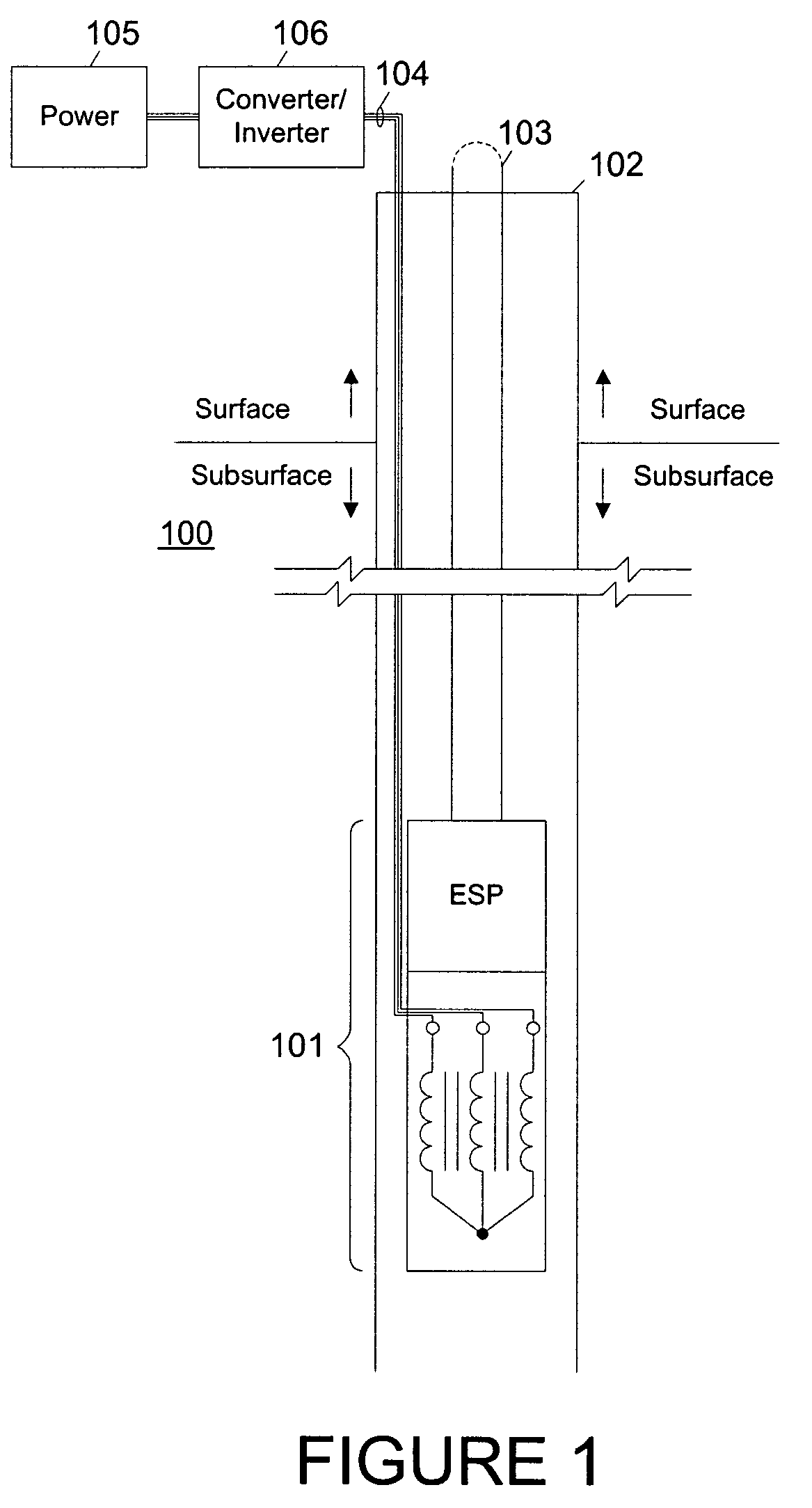

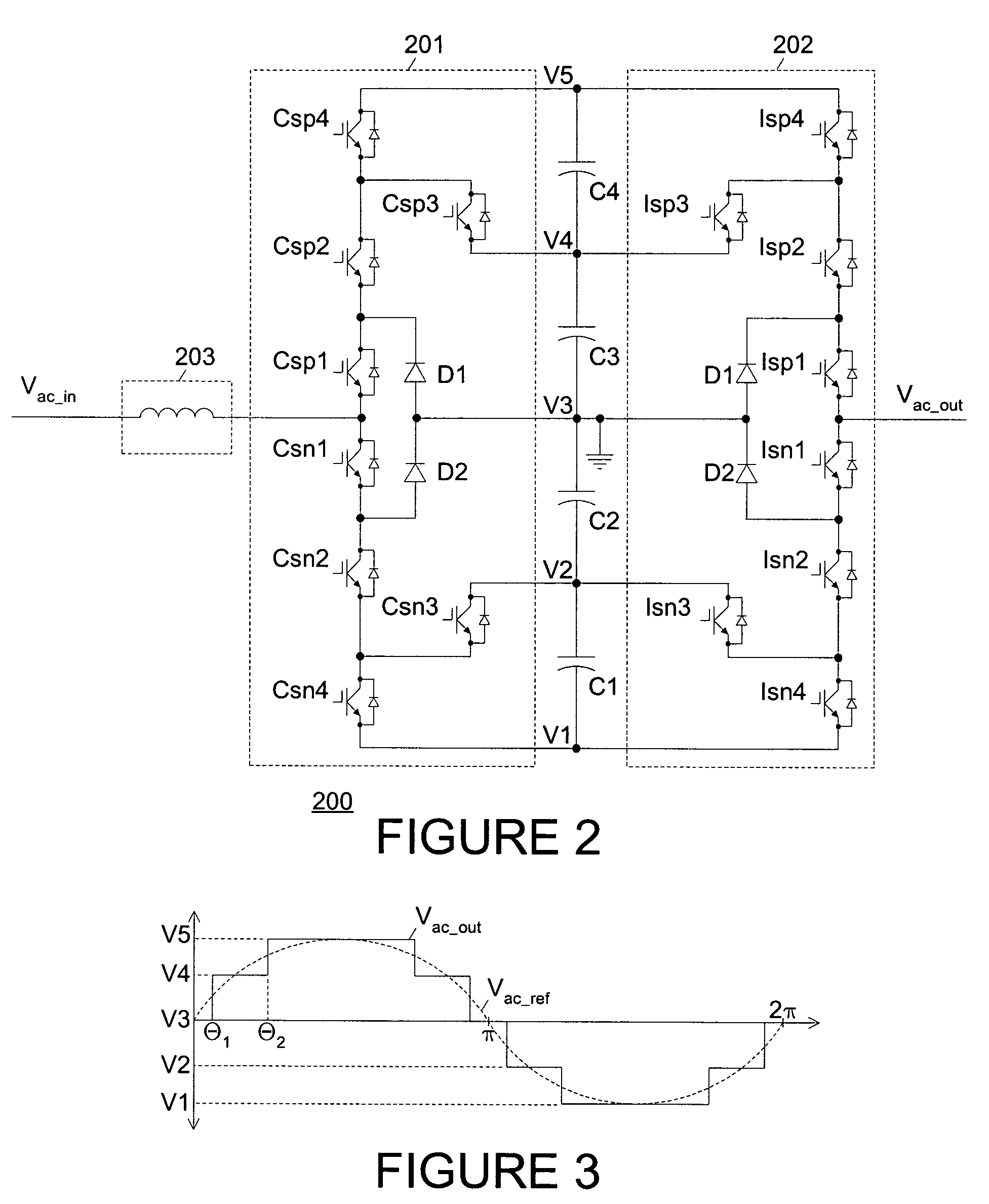

Low harmonic diode clamped converter/inverter

ActiveUS7040391B2Optimized switching angleShorten the counting processAC motor controlCurrent/voltage measurementPower inverterHarmonic

First and second networks of switching devices, each of which are an insulated gate bipolar transistor with an intrinsic reverse-biased clamping diode, are controlled to selectively connect a sinusoidal input voltage and an output to different nodes within a series of capacitors during different portions of input and output voltage cycles to produce a stepped sinusoidal output voltage. The topology requires a low part count, produces relatively low harmonics without filtering when powering artificial lift equipment within a borehole, and scales up to medium voltages without a step-up transformer. During variable speed operation of the lift equipment, optimized switching angles for controlling the switching devices during the voltage cycles may be selected based on modulation producing the desired speed and phase measurements.

Owner:BAKER HUGHES INC

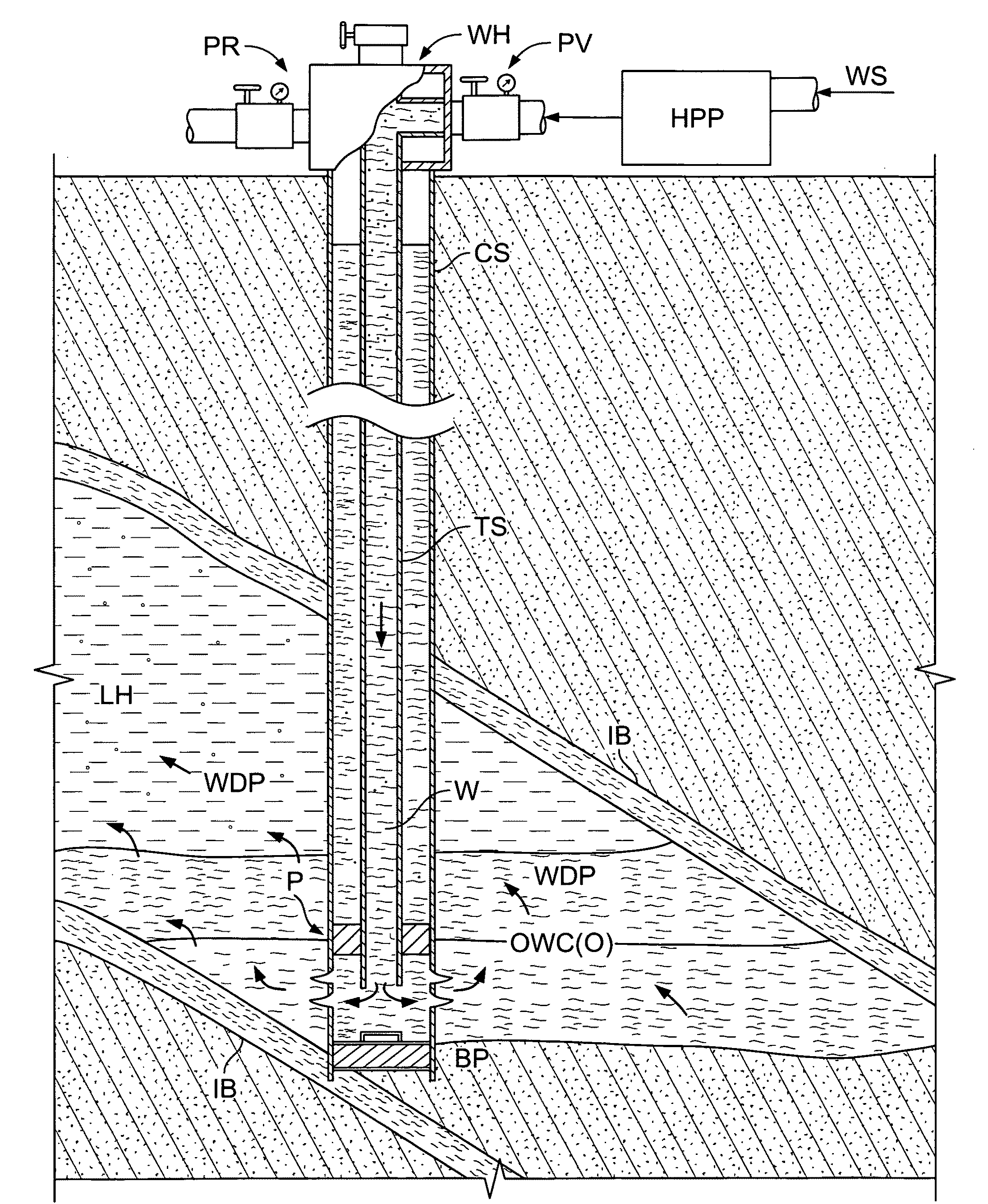

Total in place hydrocarbon recovery by isolated liquid & gas production through expanded volumetric wellbore exposure +

Higher volumetric hydrocarbon exposed original or restored by miscible gas injection, solution gas saturated oil is recovered through enlarged expandable liner, sand screened wellbores by controlled wellbore to formation pressure maintained above recovering oils critical bubble point. Exclusively hydrocarbon formation liquids are differential pressure forced through invention's centralizer held larger O.D. Liquid Displacer into the production tubing, while maintaining gas volume, pressure, and solution gas saturation in the formation, for higher volume flow for total in place oil recovery. Injected downstructure waterdrive pressure WDP into oil or gas formations augments oil and / or gas production and recovery.Complete gas well De-liquefying is attained by flowing gas recovery through enlarged expandable liner and sand screened wellbores and up the wellbore annulus dry, while producing all liquids separately through the centralized larger O.D. Liquid Displacer into the production tubing, to be artificial lifted to surface, while waterdrive pressure WDP augments natural gas recovery.

Owner:KELLEY TERRY EARL

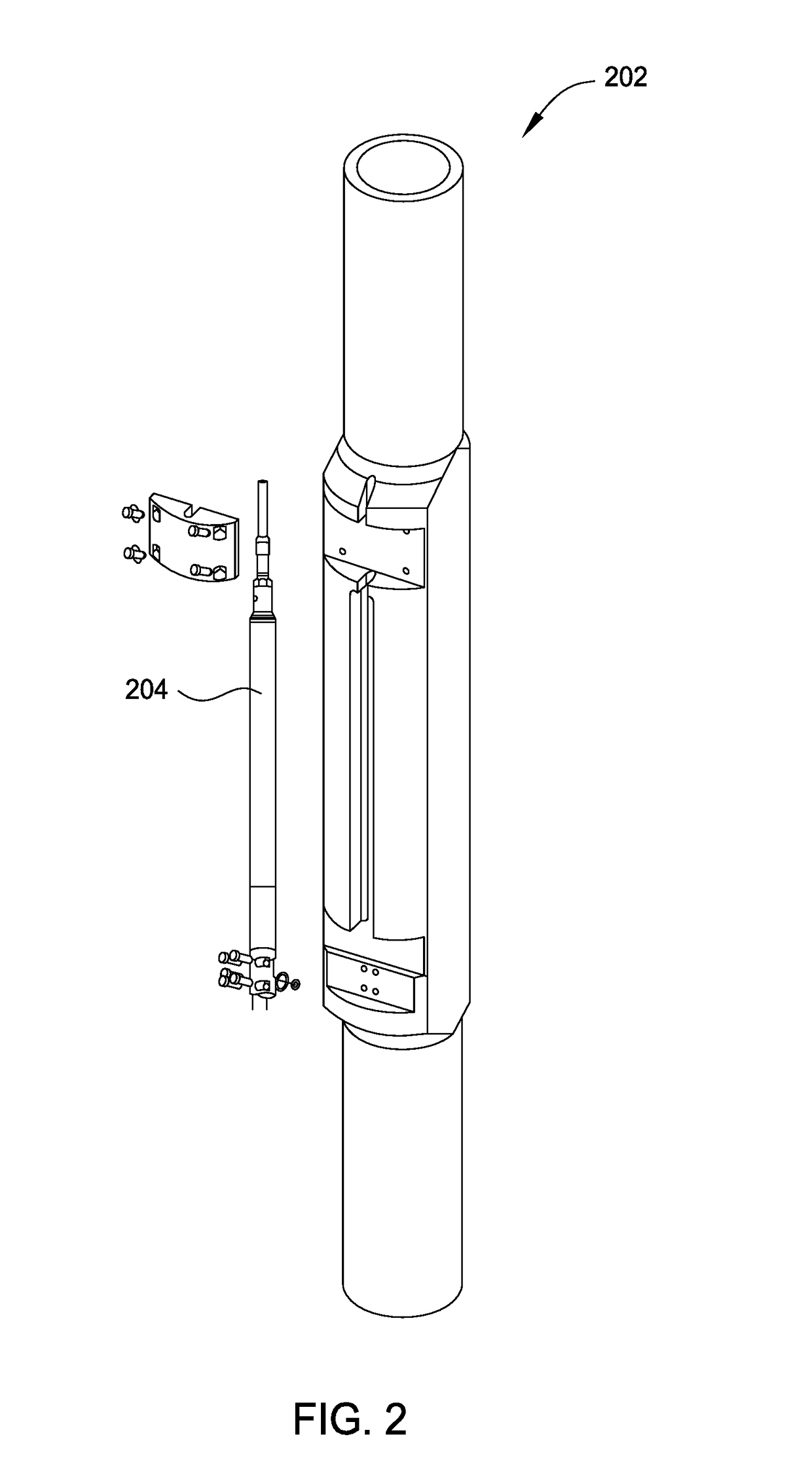

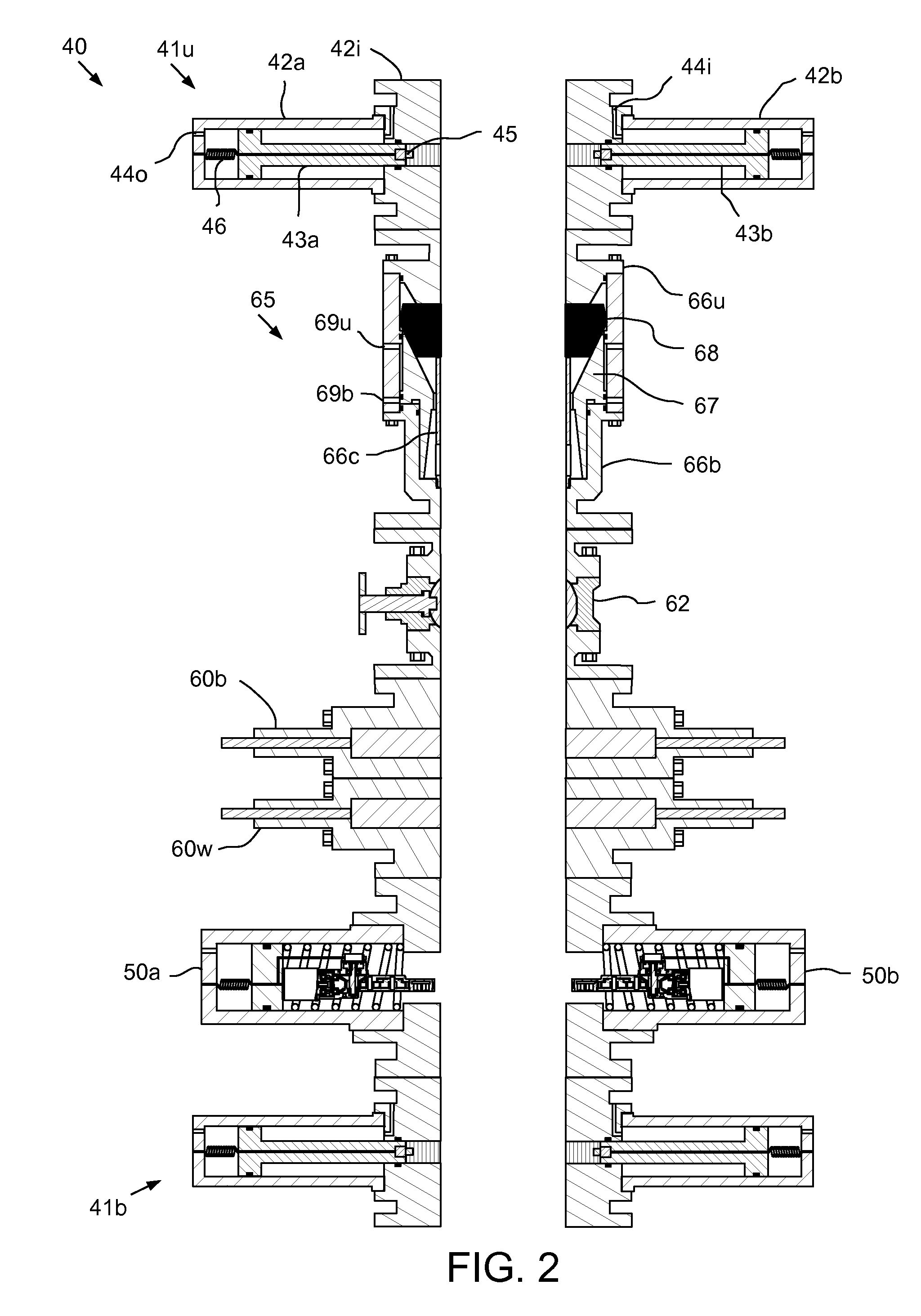

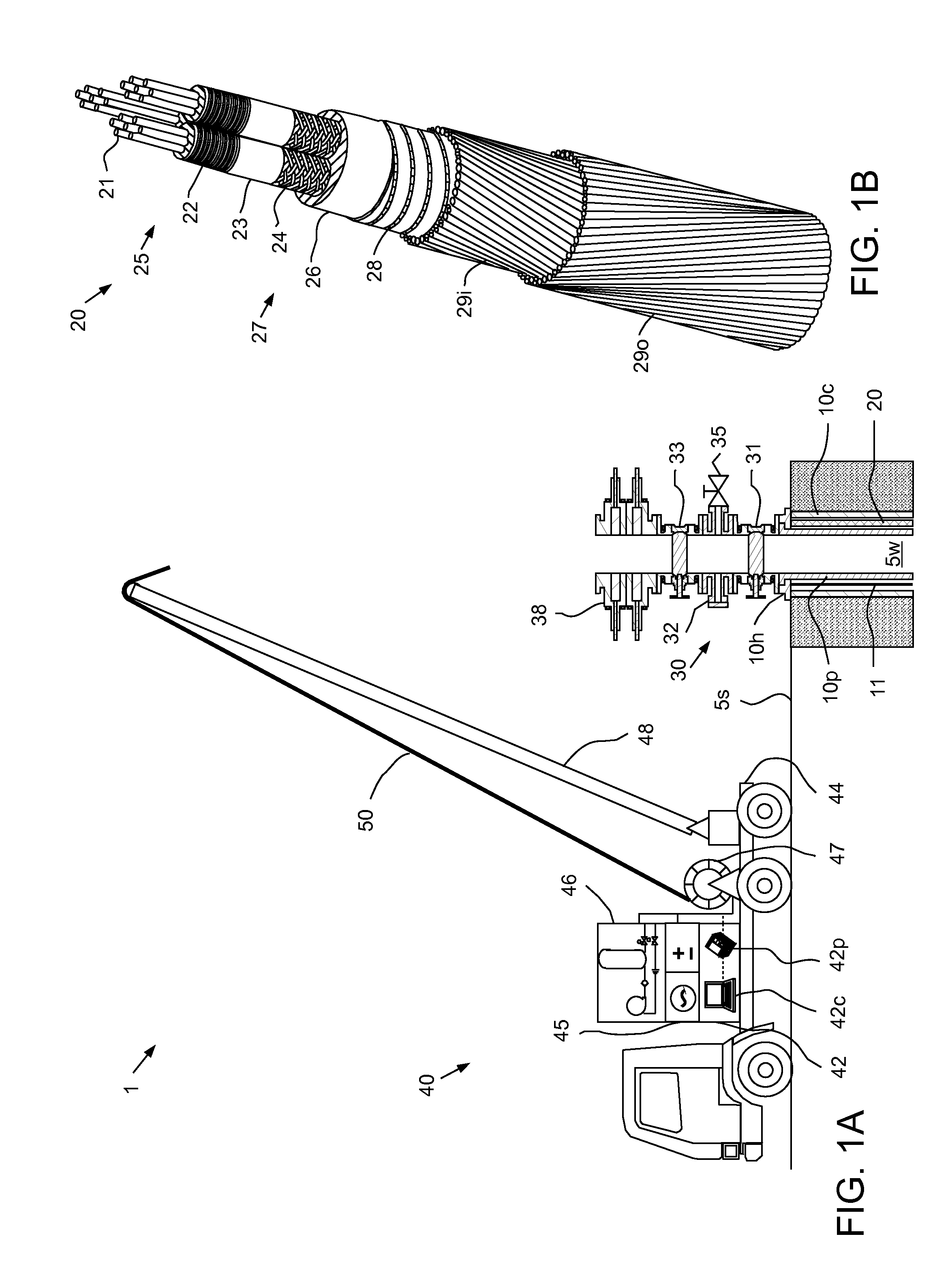

Cable injector for deploying artificial lift system

Owner:ZEITECS

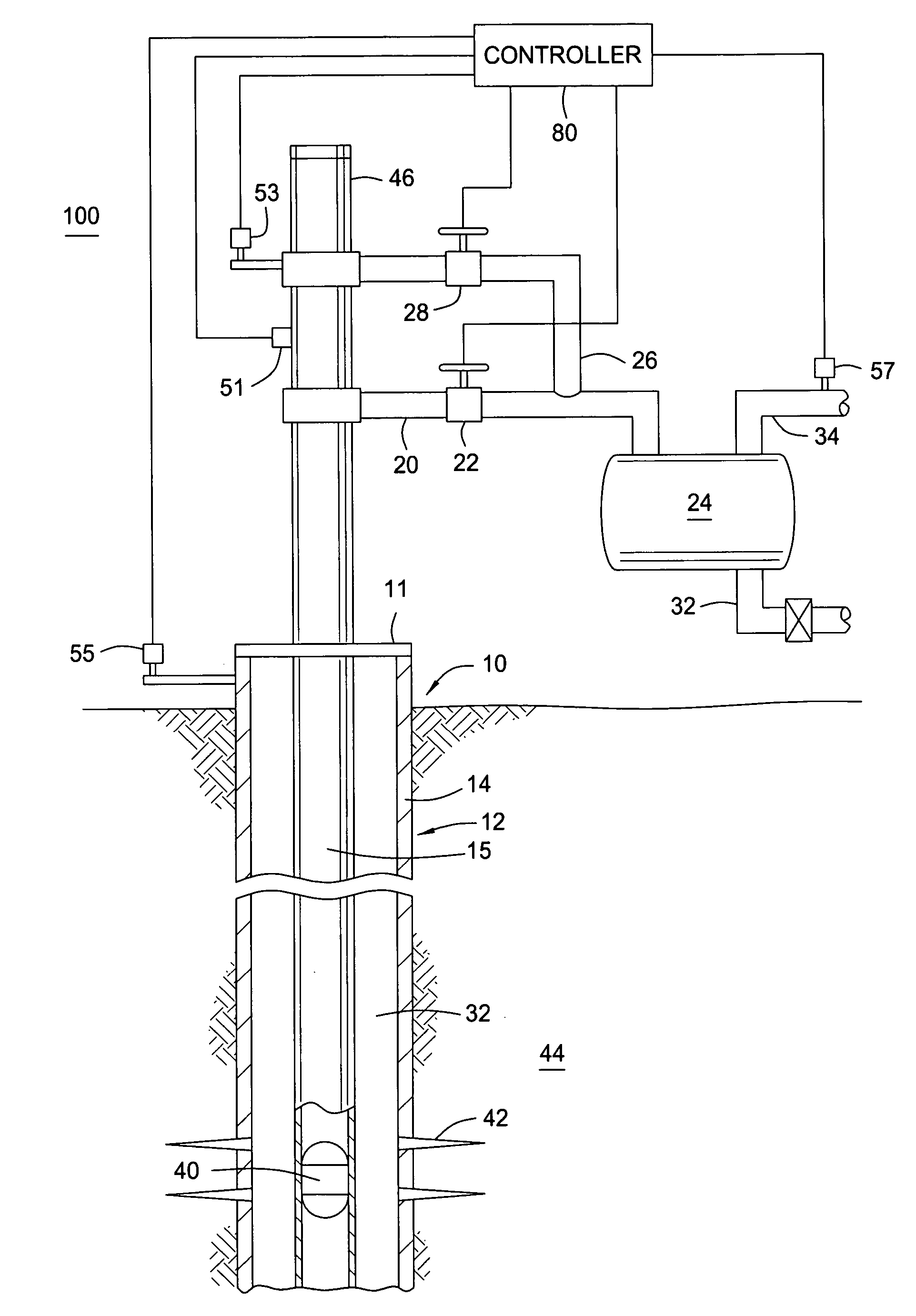

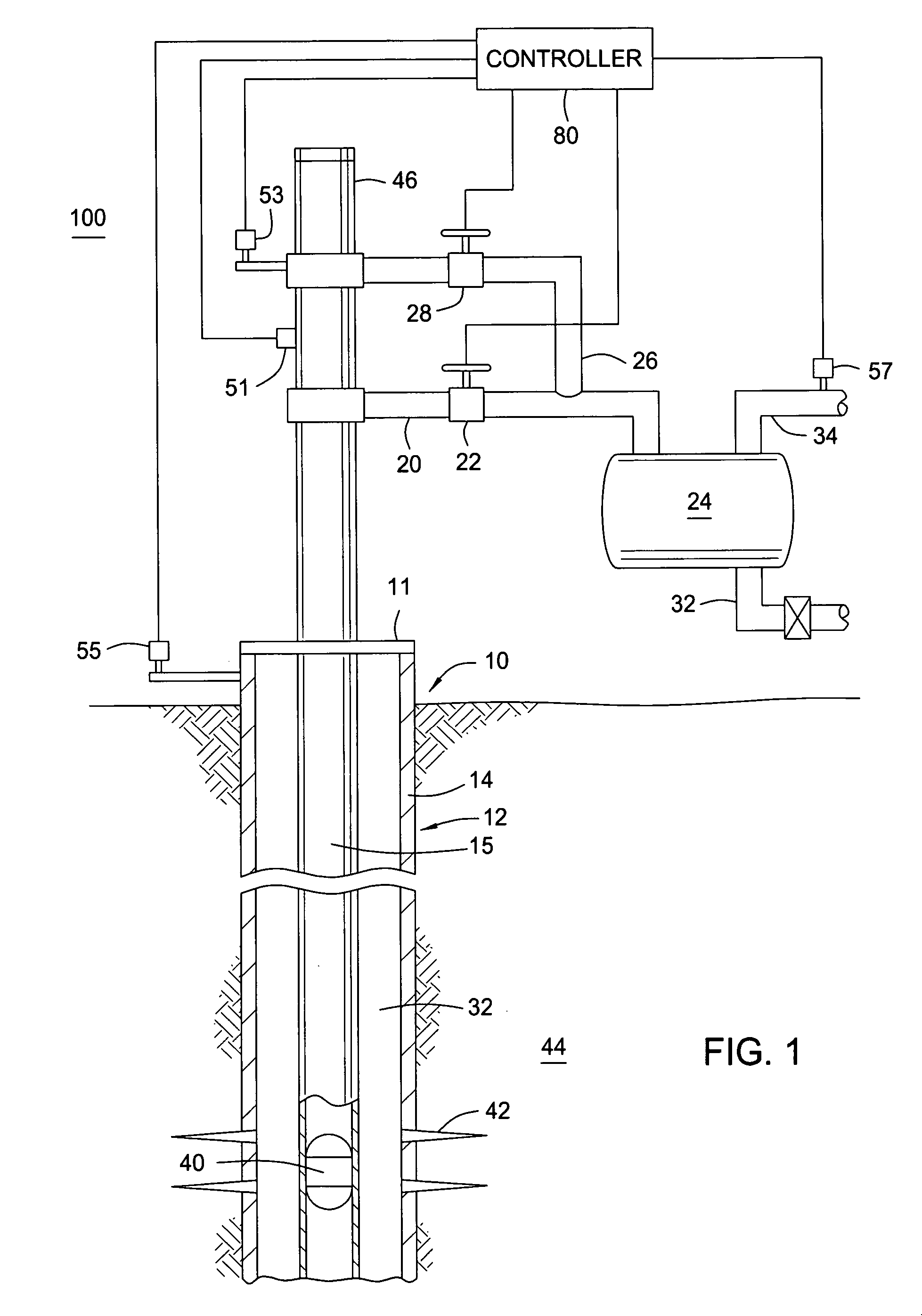

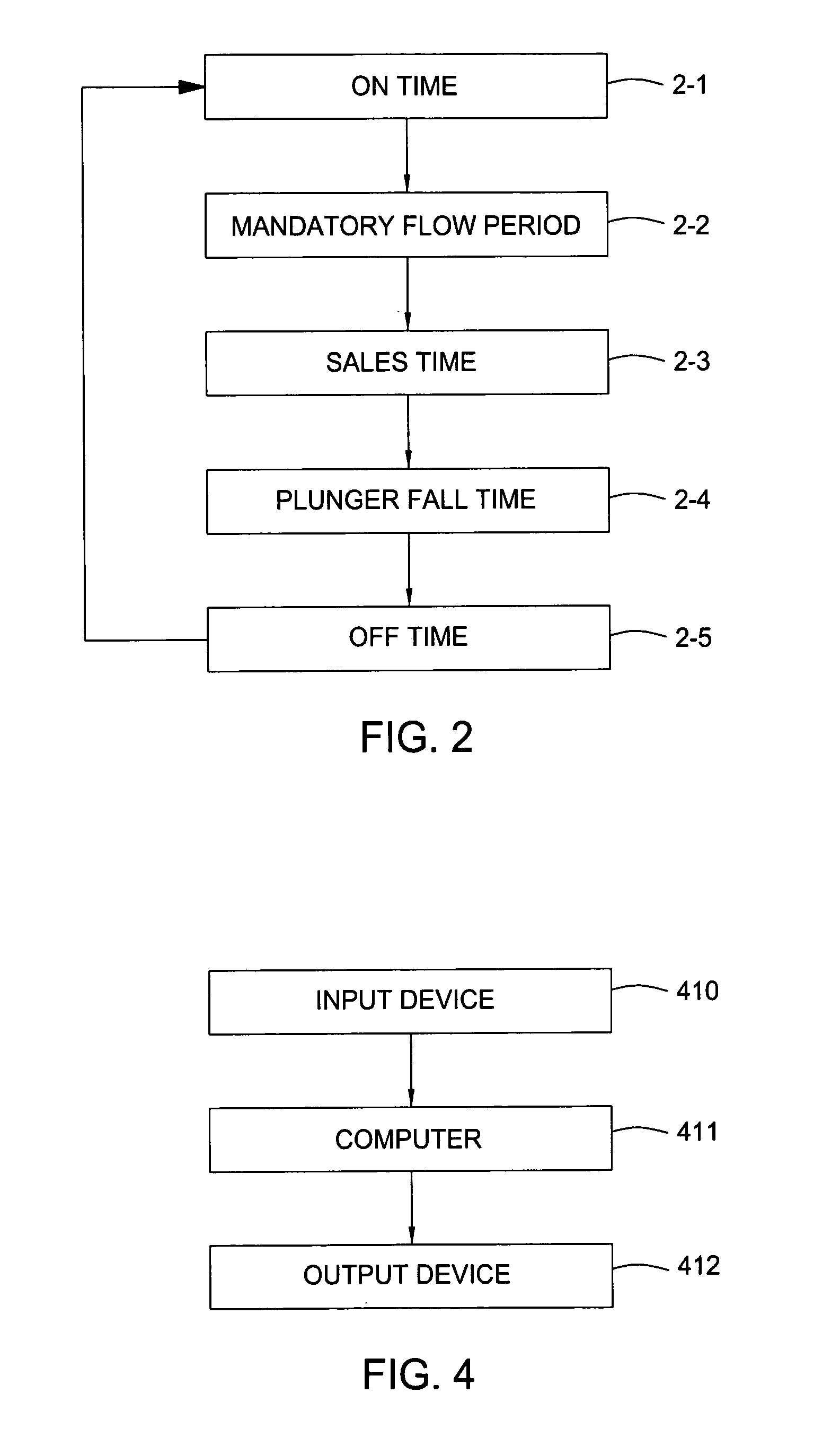

Methods and apparatus for optimizing well production

ActiveUS20070012442A1Optimize well 's productionSurveyFluid removalProcess engineeringPressure difference

Embodiments of the present invention generally relates to methods and apparatus for operating an artificial lift well. In one embodiment, the well is operated between an on cycle and an off cycle. Preferably, the off cycle is determined by detecting an increase in the pressure differential between the casing pressure and the tubing pressure. In another embodiment, the well is optimized by measuring the production of the well in one cycle of operation. The measured production is compared to the production of a previous cycle. A controller then optimizes the well based on the increase or decrease of the production from the previous cycle.

Owner:WEATHERFORD TECH HLDG LLC

Protection scheme and method for deployment of artificial lift devices in a wellbore

InactiveUS7048057B2Reduce damage rateAvoid communicationFluid removalWell/borehole valve arrangementsPositive pressureProtection system

A protection system for an artificial lift device including but not limited to electrical submersible pump (ESP) and an electrical submersible progressing cavity pup (ESPCP). The artificial lift device is suspended on a tubing string into a wellbore where the artificial lift device contacts well fluids. The artificial lift device is provided with a barrier such as an intake barrier or output barrier that deters an ingress of well fluids into the artificial lift device. As a result, the artificial lift device may remain idle and submerged within well fluids for an extended period of time without experiencing degradation of the artificial lift device internals. The intake barrier may include a plug, burst disk, dissolvable material, a selectively openable barrier such as a sleeve or a spring biased member or other member that is capable of providing a suitable barrier. The barrier may be removed once the artificial lift device is ready for operation. The artificial lift device may be filled with a protective fluid. An optional pressure sensor may be provided that is in communication with the interior of the backup unit for communicating with a compressor that may be activated to maintain a positive pressure within the artificial lift device to prevent well fluids from entering the unit. The protection system of the invention is desirable for protecting an idle artificial lift device, including when the artificial lift device is a backup unit in a multi-artificial lift device deployment.

Owner:BAKER HUGHES INC

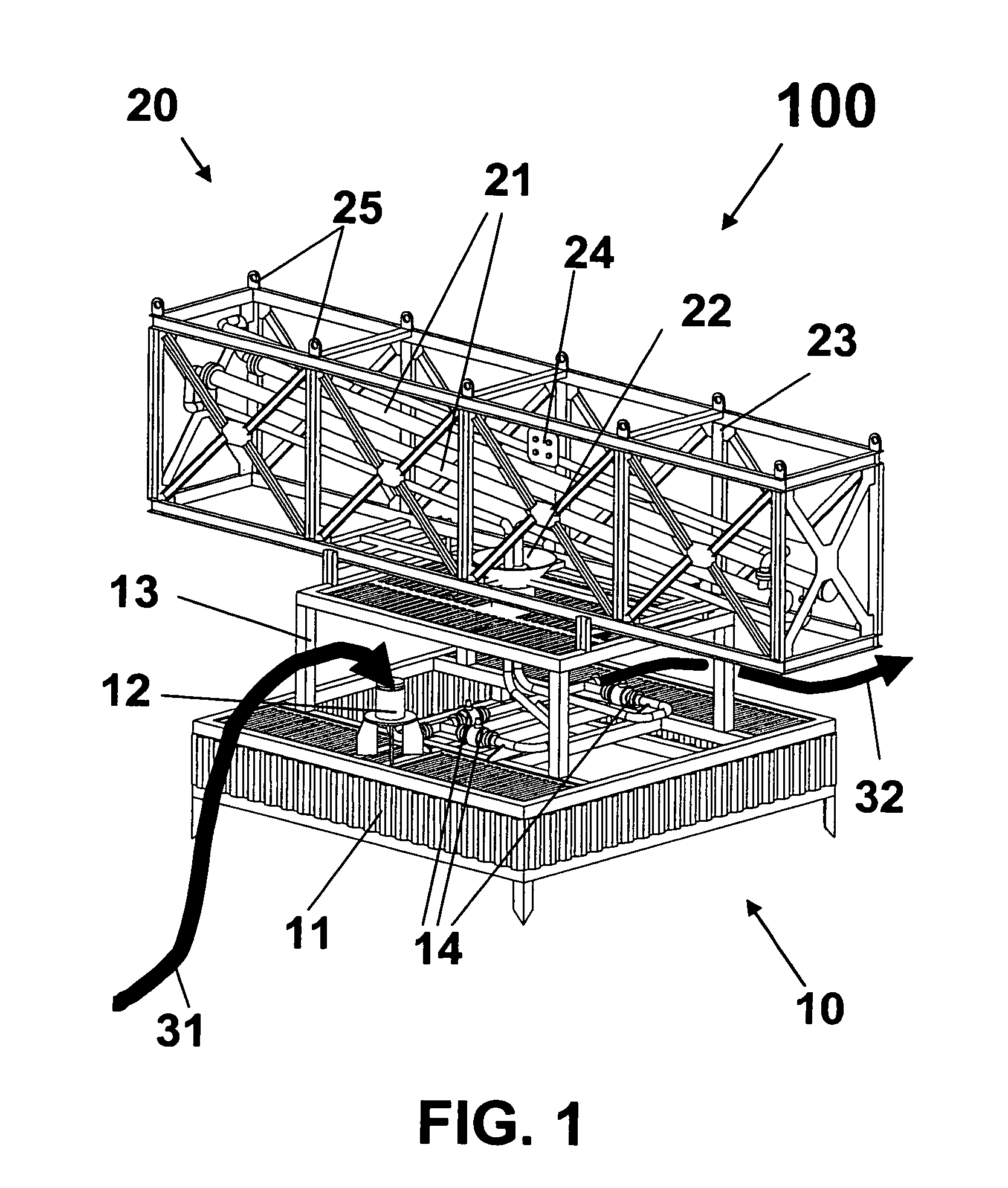

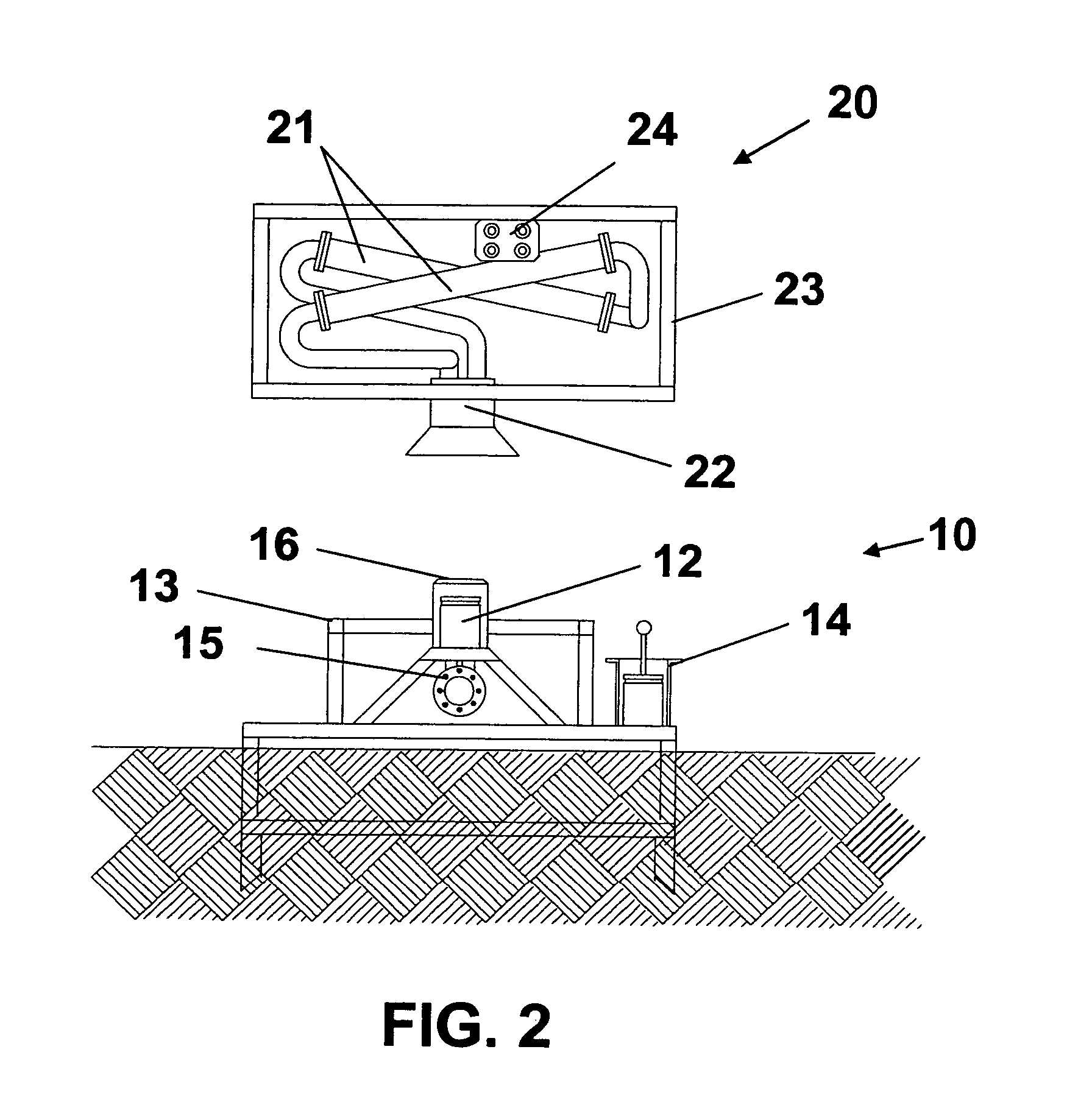

Subsea petroleum production system method of installation and use of the same

ActiveUS7516795B2Low costFast replacementFluid removalUnderwater drillingOcean bottomArtificial lift

A subsea petroleum production system for artificial lift, including a pumping module coupled to a flow base, the system being installed downstream of a Wet Christmas Tree (WCT) on the seabed. The pumping module includes at least one submersible centrifugal pump (SCP) inclined with respect to the vertical direction at an inclination of up to 85 degrees from the vertical direction, wherein a flow in said at least one pump is ascending.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Linear electric motor for artificial lift system

ActiveUS20130186638A1Fluid removalManufacturing dynamo-electric machinesReciprocating motionLinear motor

A method for pumping production fluid from a wellbore includes deploying a downhole assembly of an artificial lift system (ALS) into the wellbore. The downhole assembly includes a linear electric motor (LEM) and a pump. The method further includes operating the LEM, thereby reciprocating the pump and lifting production fluid from the wellbore to surface. The LEM includes a stator and a reciprocating head having permanent magnets. The production fluid leaks through an interface formed between the head and the stator.

Owner:OILFIELD EQUIP DEVMENT CENT

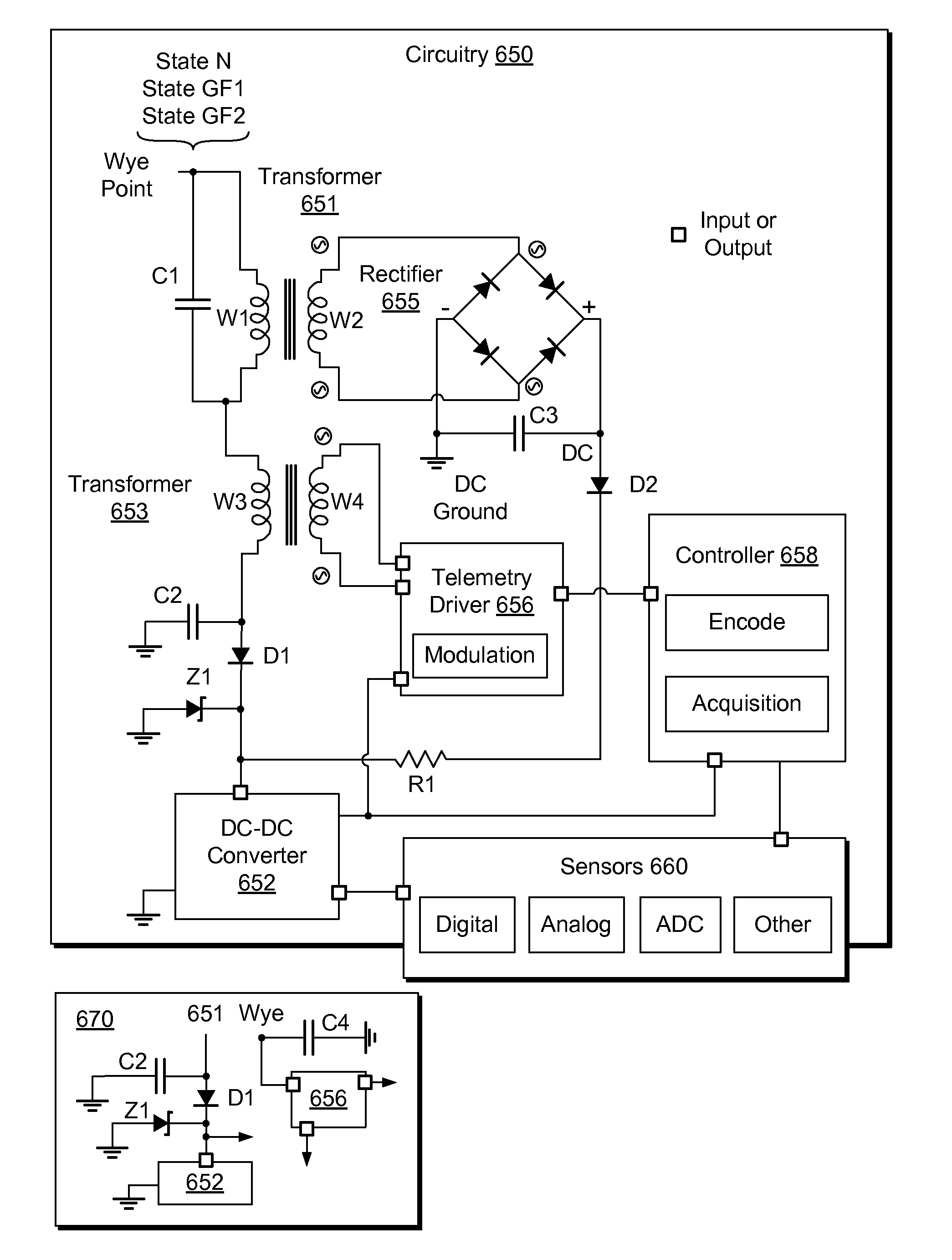

Artificial Lift Equipment Power Line Communication

A system can include a transformer and a rectifier to derive DC power from AC power at a wye point of an electric motor; a sensor that includes a sensor signal output to output a sensor signal; a telemetry driver that includes a DC power input to receive the derived DC power and that includes an input to receive the sensor signal and an output to output a data signal representing the sensor signal; and circuitry to deliver the data signal representing the sensor signal to the wye point of the electric motor. Various other apparatuses, systems, methods, etc., are also disclosed.

Owner:SCHLUMBERGER TECH CORP

Interference-seal plunger for an artificial lift system

InactiveUS20070158061A1Increase physical activityFluid removalSealing/packingInterference fitEngineering

A plunger for an artificial lift system and embodiment of the plunger includes a solid body adapted to travel within a production string positioned in a wellbore. At least one sealing ring connected about the body. The at least one sealing ring having an inner surface, an outer surface, a width and a thickness. The width is sufficient such that when the body is disposed in the production string the outer surface contacts and substantially forms a seal between the body and an inner wall of the production string. The at least one sealing ring having an outside diameter greater than the inner diameter of the production tubing within which the body is adapted to travel such that when the body is disposed within the production string an interference fit causes the sealing rings to roll-form into a constricted shape and diameter that exerts the sealing contact with the production string.

Owner:CASEY DANNY M

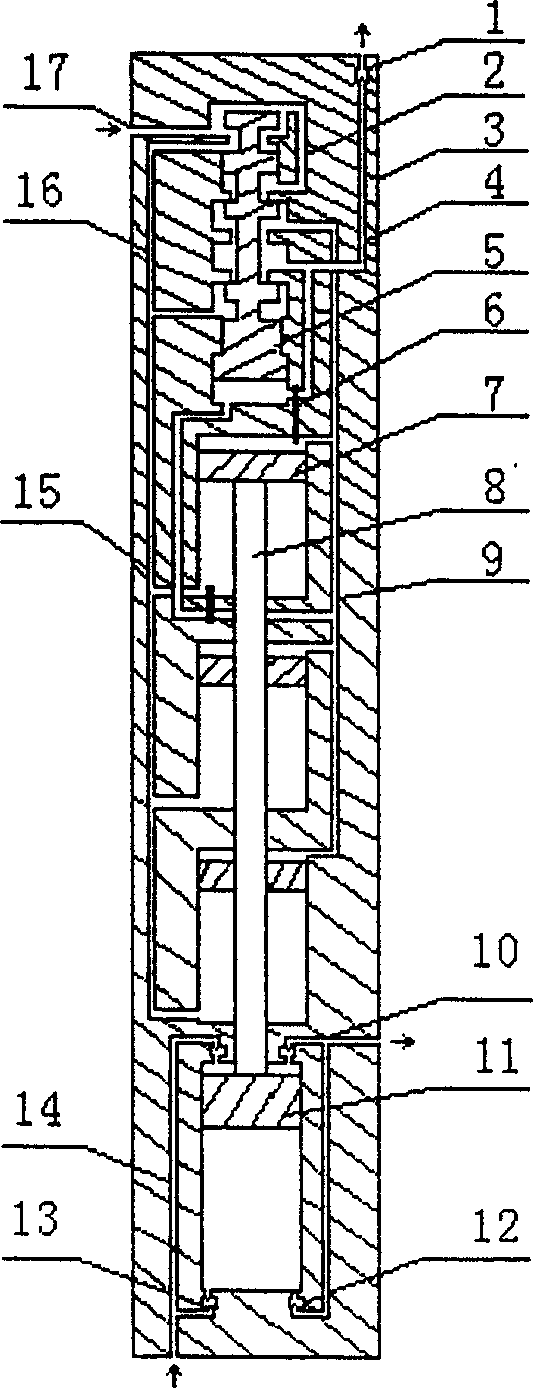

Ground injecting gas boosting oil production and liquid discharging gas producing device and method

InactiveCN1648406AImprove applicabilityEasy to operate and manageFluid removalSealing/packingDrive motorBottom pressure

The present invention relates to oil and gas extracting apparatus and method suitable for deep well and super deep well, and aims at raising the hydrocarbon reservoir yield via lowering the pressure in bottom of gas lift well and solving the artificial lift problem of various kinds of well. The technological scheme of the present invention includes: injecting high pressure air via ground pipe and oil jacket to pneumatic motors in well gas booster pump to drive motor pistons and pump pistons; pumping out well liquid via the opened sucking valve, pump barrel and opened draining valve; and exhausting the mixture of exhaust air and pumped well liquid via oil pipe to well head output pipe. The present invention has the advantages of both gas lift and staff pump, can lower the bottom pressure to level lower than gas lift, and is especially suitable for the artificial lift of low pressure low potential oil / gas well, deep well and super deep well.

Owner:SOUTHWEST PETROLEUM UNIV

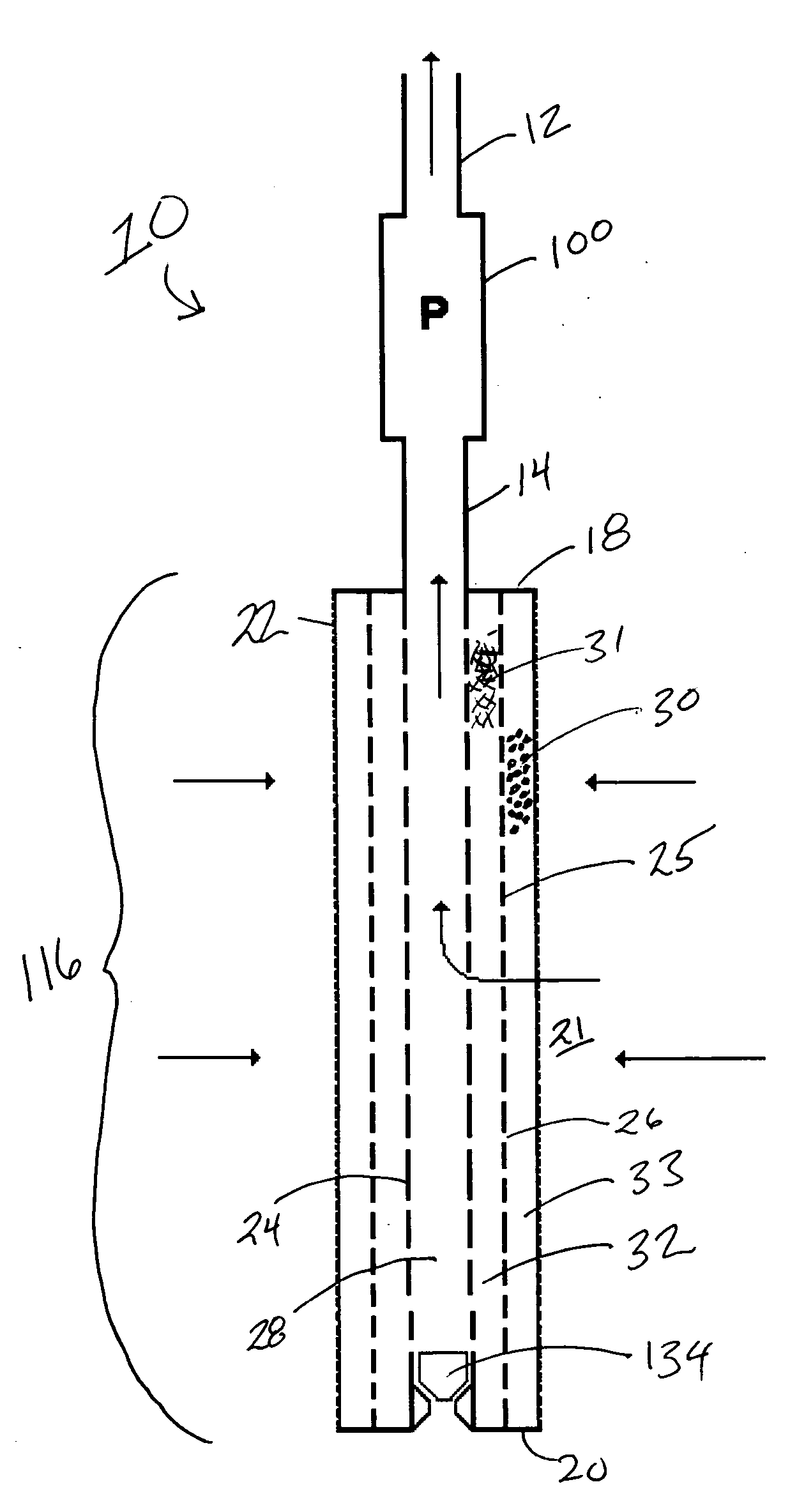

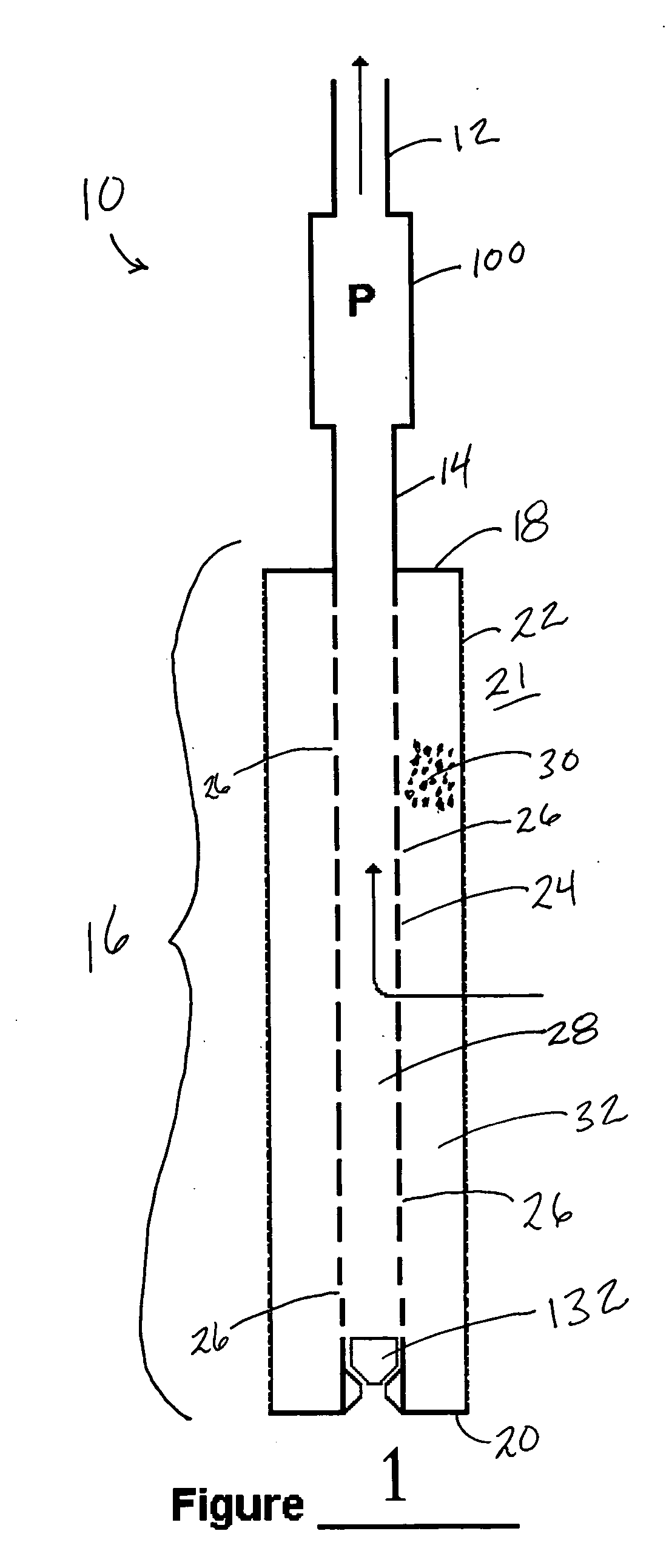

Artificial Lift System

An artificial lift system provides an artificial lift design specifically for the pumping of liquids from natural gas wells, but not limited to this application. In doing so, production rates and reserves recovered can be significantly increased. The artificial lift system uses small diameter continuous tubing to run the pump in the hole and deliver small volumes of high pressure dry gas as a power fluid to the pump. This power fluid forces liquid that has been drawn into the pump from the bottom of the wellbore to surface. By removing the liquids from the wellbore the natural gas can flow unrestricted to surface. The design and equipment allow for a cost effective artificial lift alternative.

Owner:BULLEN TERRY

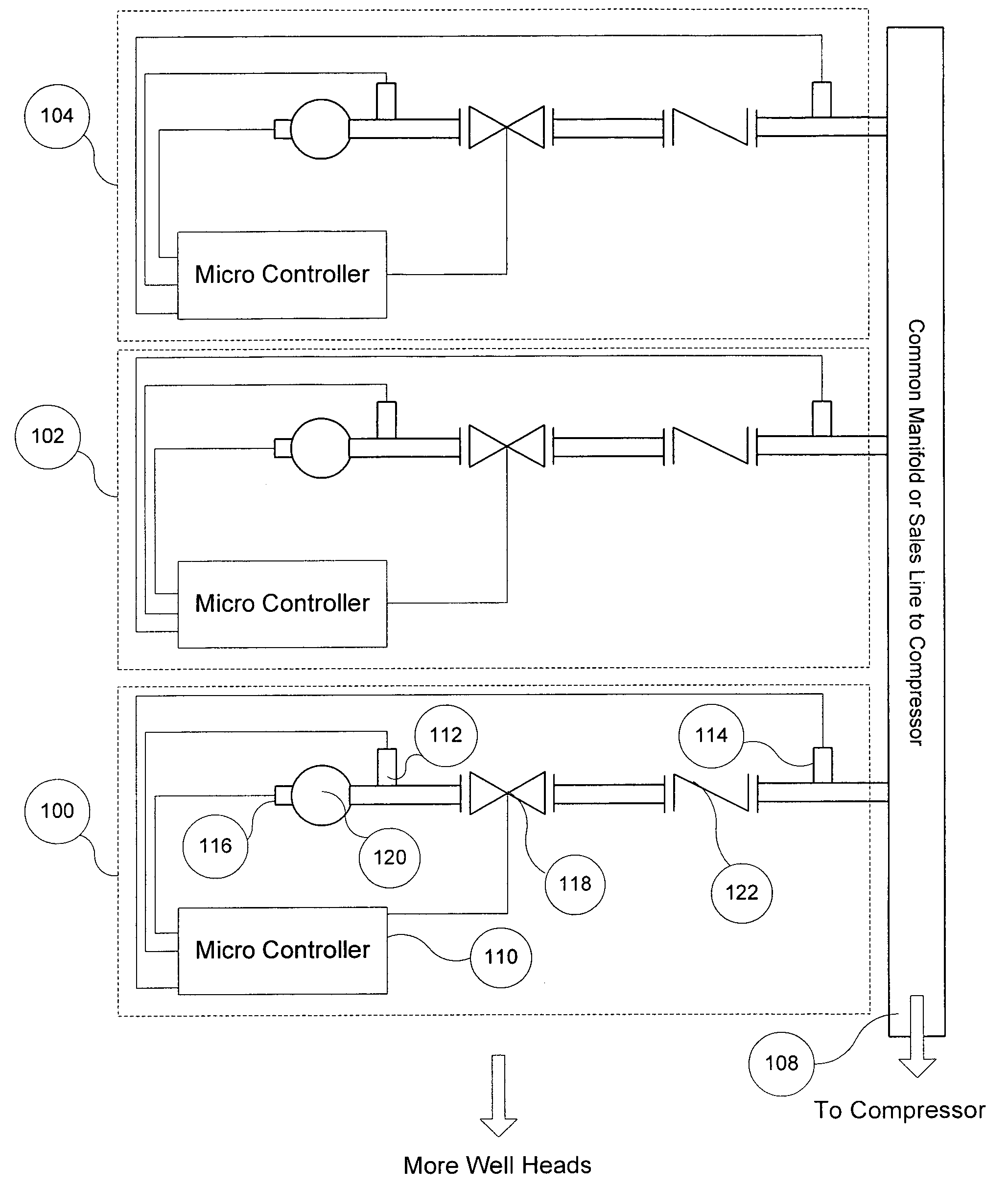

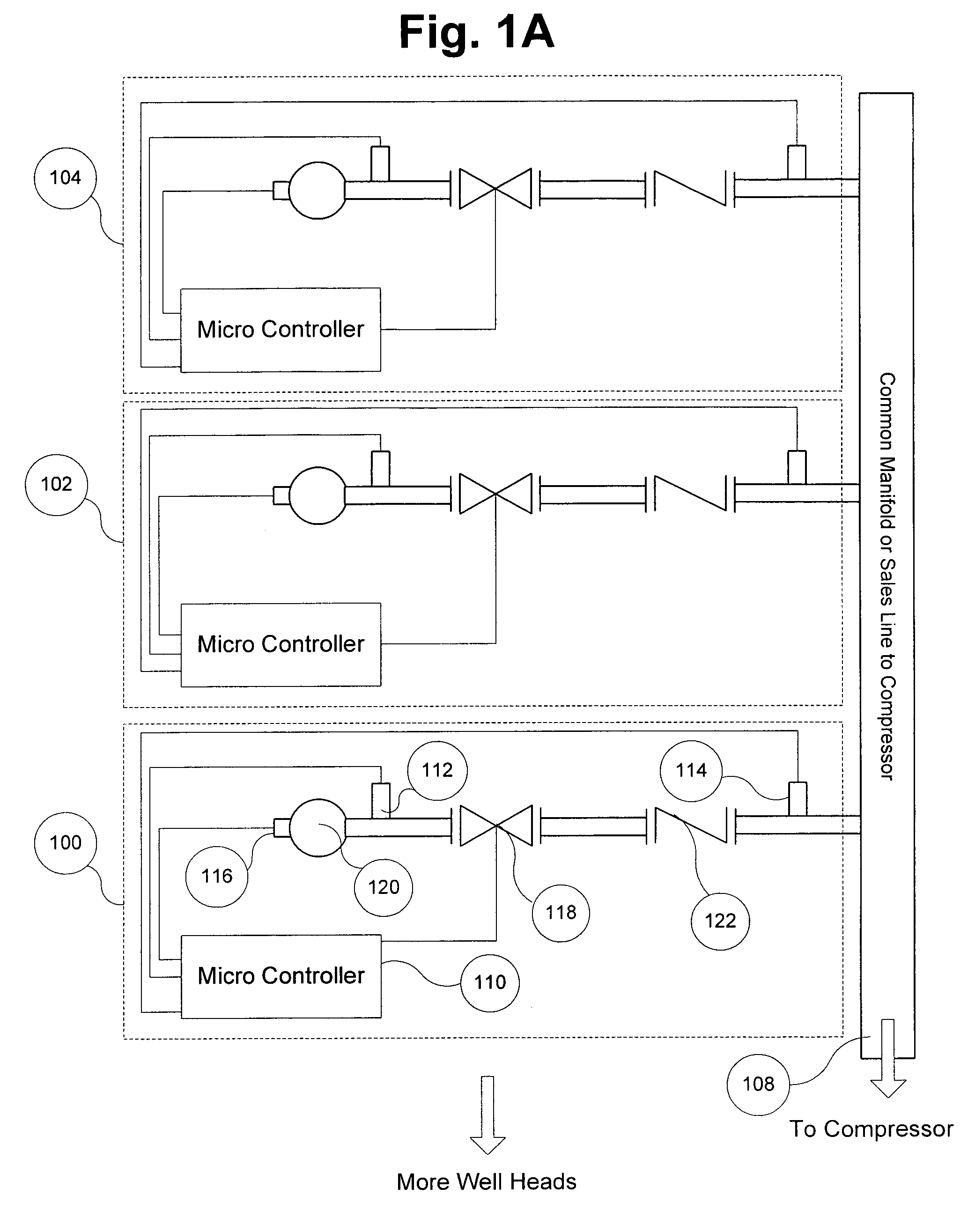

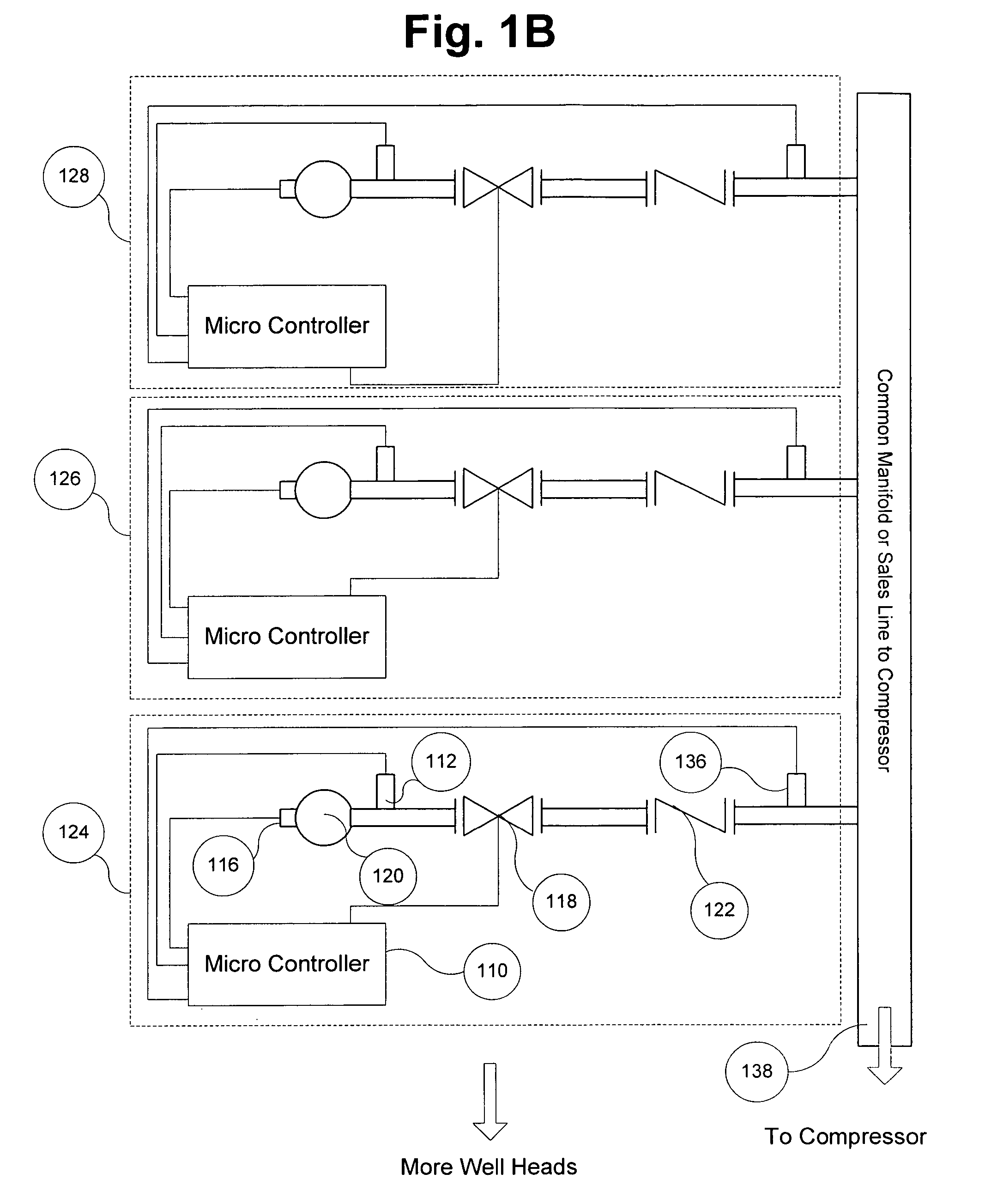

Method for controlling oil and gas well production from multiple wells

A method for producing oil or gas from multiple wells, the wells including at least a first well and a second well, with each well using an artificial lift system that includes a plunger associated with a motor valve off time, and first and second identical connecting subsystems that connect their respective wells to a common sales line. The first connecting subsystem includes: a) a plunger arrival sensor connected to a micro controller; b) a wellhead connected to the first well; c) a motor valve connected to the wellhead; d) first and second pressure transducers on either side of the motor valve, conductively coupled to the micro controller; and e) a micro controller for keeping the motor valve closed during the motor valve off time, and extending the motor valve off time following a determination of the existence of a pressure spike in the common sales line.

Owner:SUPERIOR ENERGY SERVICES LLC

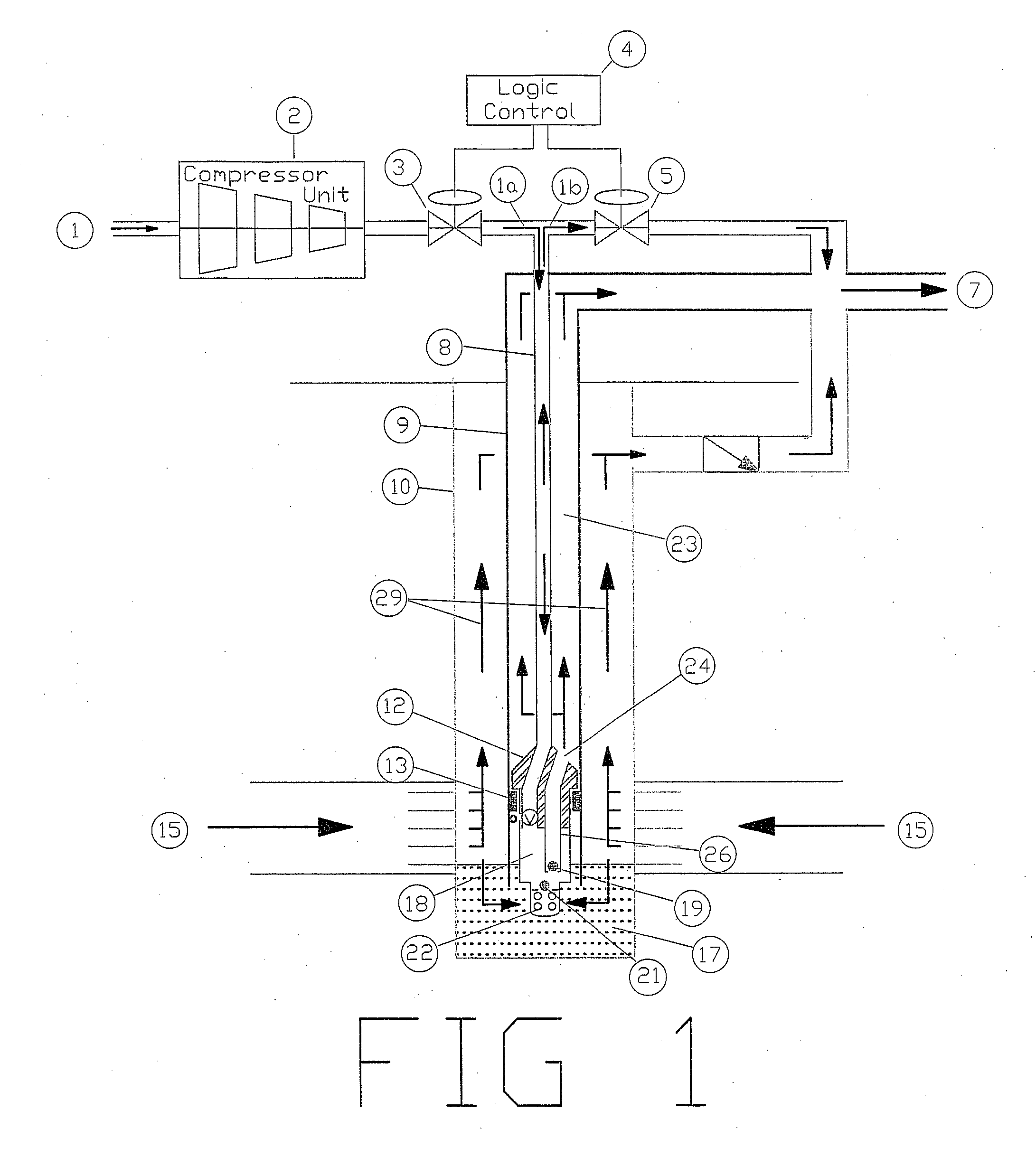

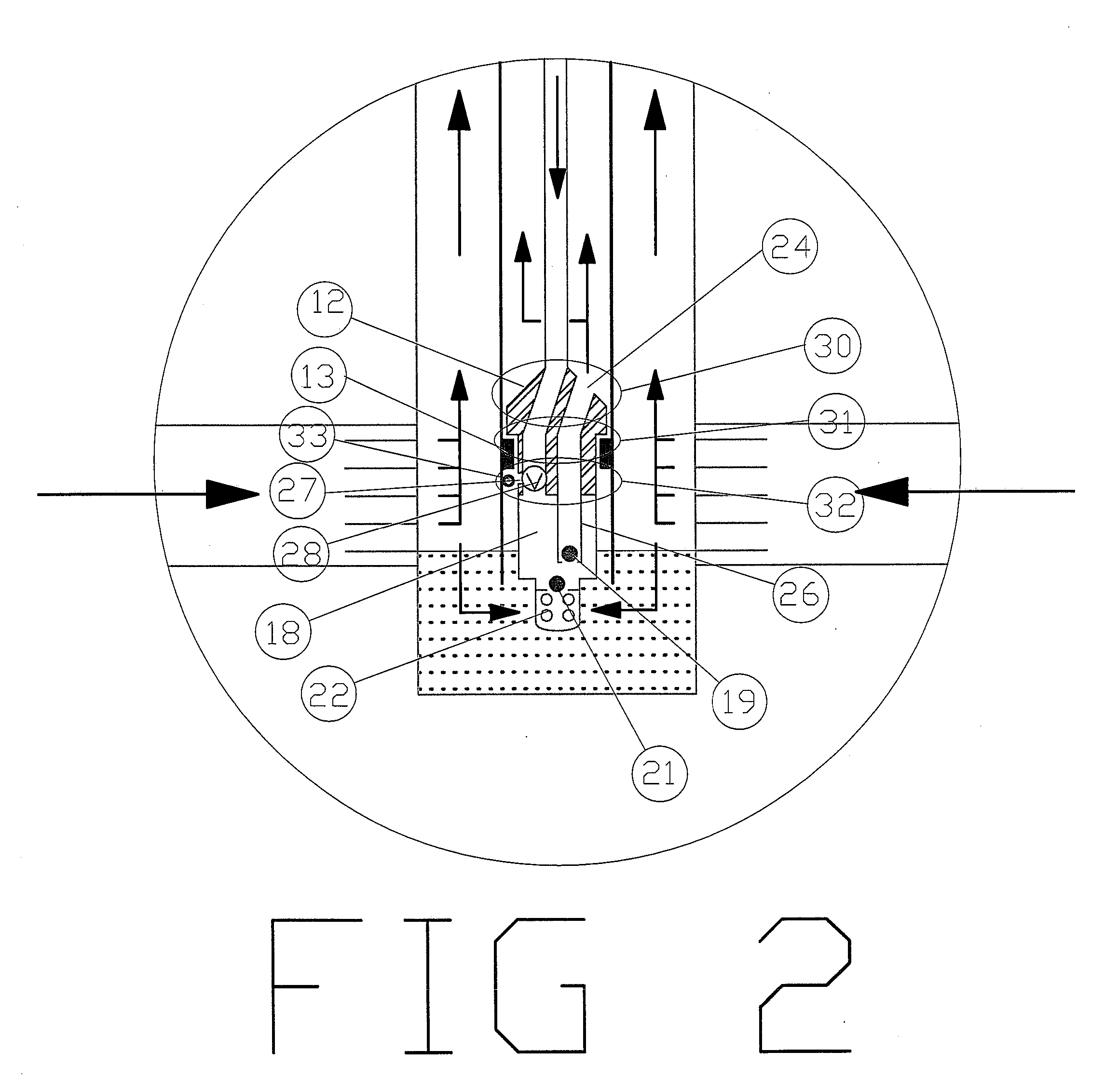

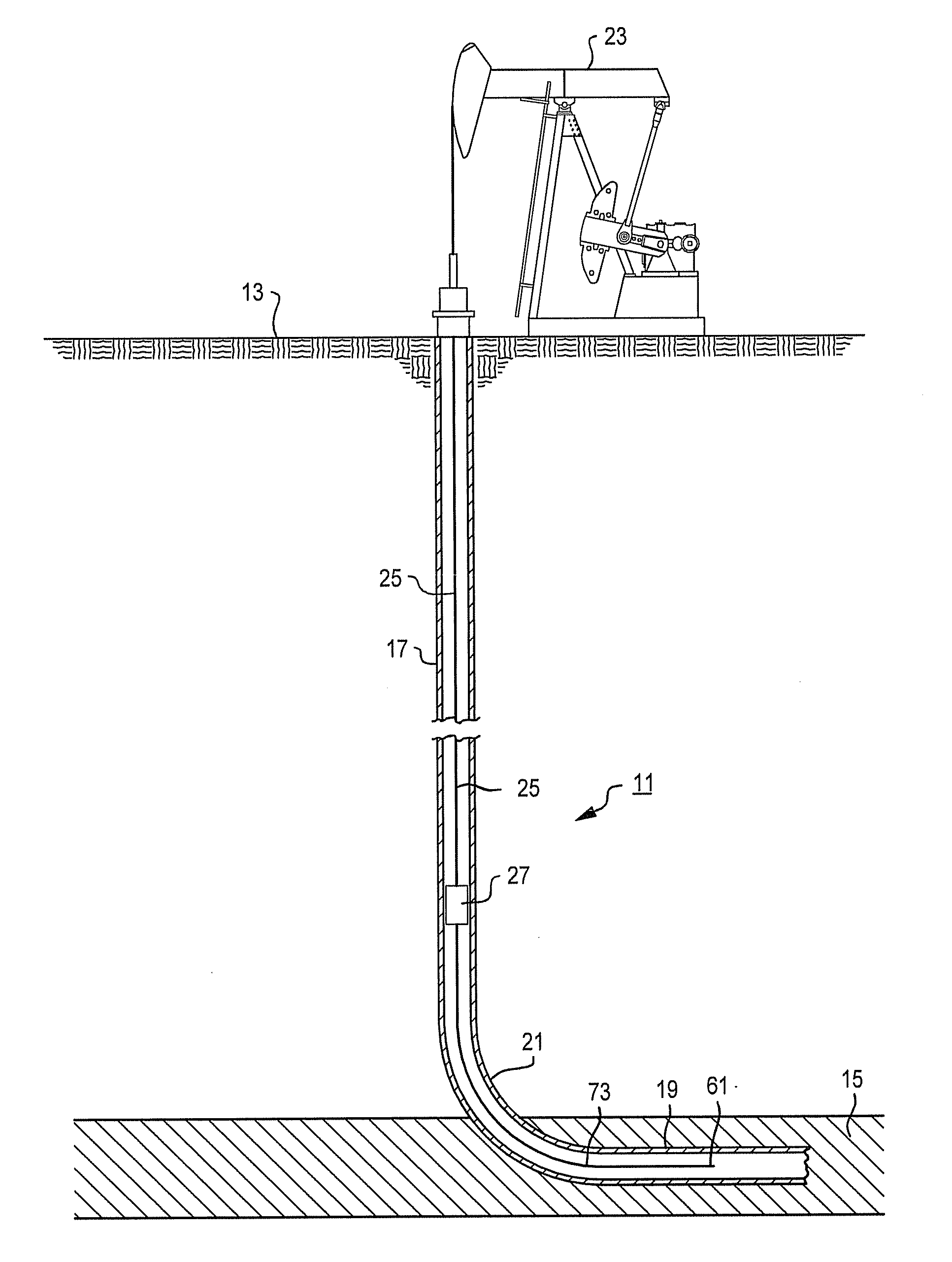

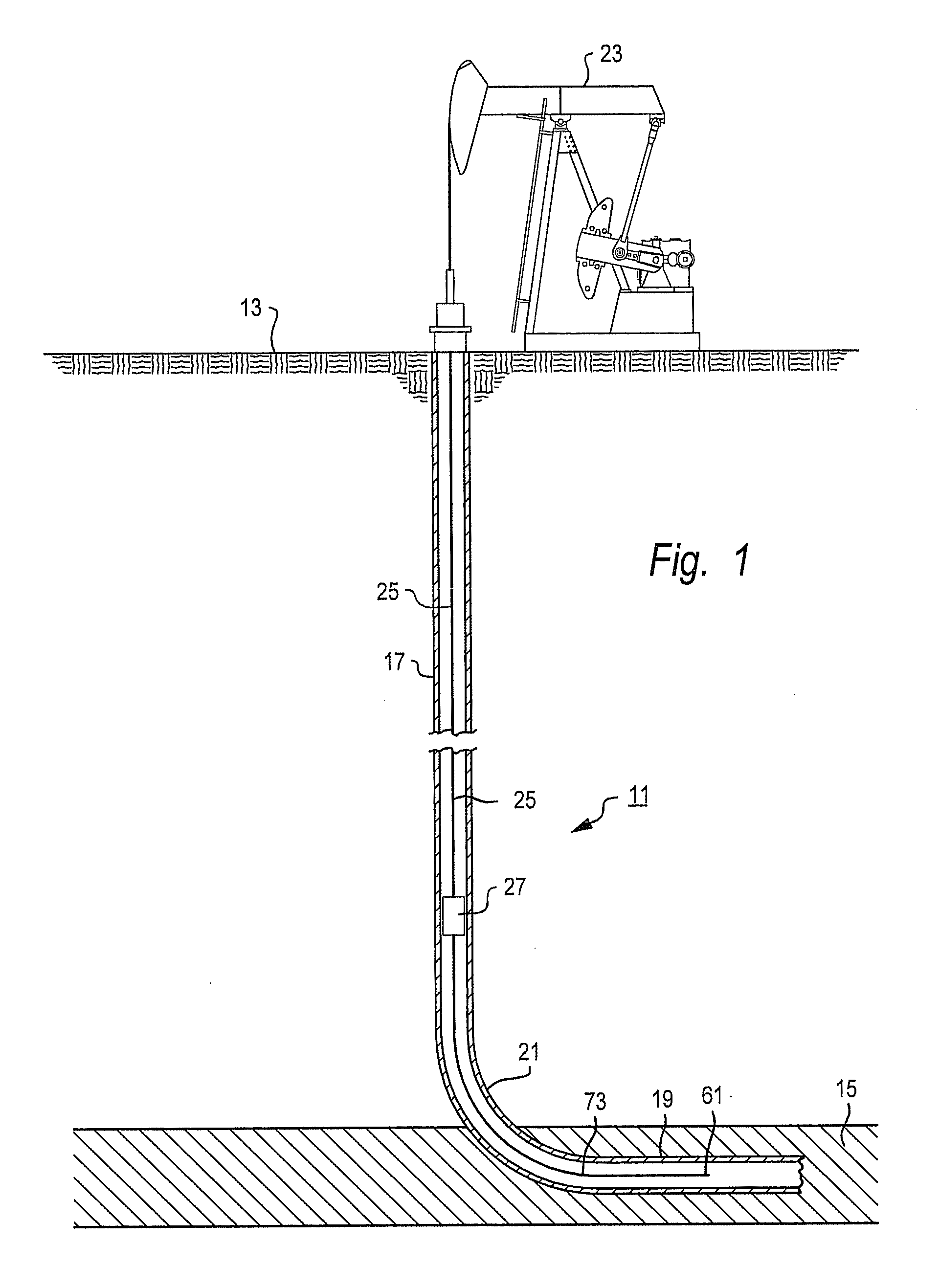

Artificial lift system

An artificial lift system provides an artificial lift design specifically for the pumping of liquids from natural gas wells, but not limited to this application. In doing so, production rates and reserves recovered can be significantly increased. The artificial lift system uses small diameter continuous tubing to run the pump in the hole and deliver small volumes of high pressure dry gas as a power fluid to the pump. This power fluid forces liquid that has been drawn into the pump from the bottom of the wellbore to surface. By removing the liquids from the wellbore the natural gas can flow unrestricted to surface. A control system for the artificial lift system delivers a pre-determined volume of power fluid to the pump on a periodic basis. Feedback mechanisms may adjust the volume and / or the period to improve the efficiency of the pump.

Owner:BULLEN TERRY

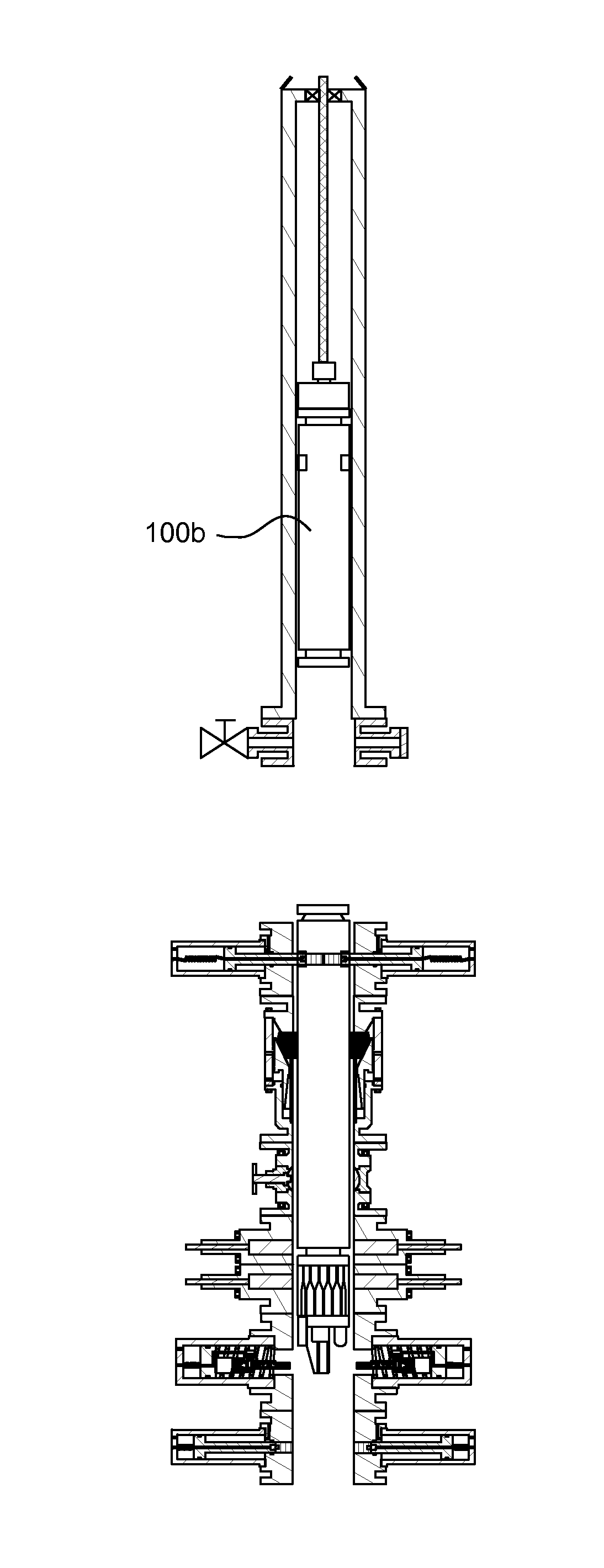

Rod driven centrifugal pumping system for adverse well production

A downhole assembly of an artificial lift system includes: an adapter for connection to production tubing; a receptacle shaft; an up-thrust bearing; a centrifugal pump; and a down-thrust bearing. The receptacle shaft has a latch profile for receiving a latch fastener of a drive coupling and a torsional profile for mating with the coupling to longitudinally and torsionally connect thereto. The up-thrust bearing includes: a thrust driver longitudinally and torsionally connected to the receptacle shaft; and a thrust carrier connected to the adapter. The centrifugal pump includes: a diffuser connected to the adapter; a pump shaft torsionally connected to the receptacle shaft; and an impeller connected to the pump shaft. The down-thrust bearing includes: a thrust driver longitudinally and torsionally connected to the pump shaft; and a thrust carrier connected to the adapter.

Owner:OILFIELD EQUIP DEVMENT CENT +1

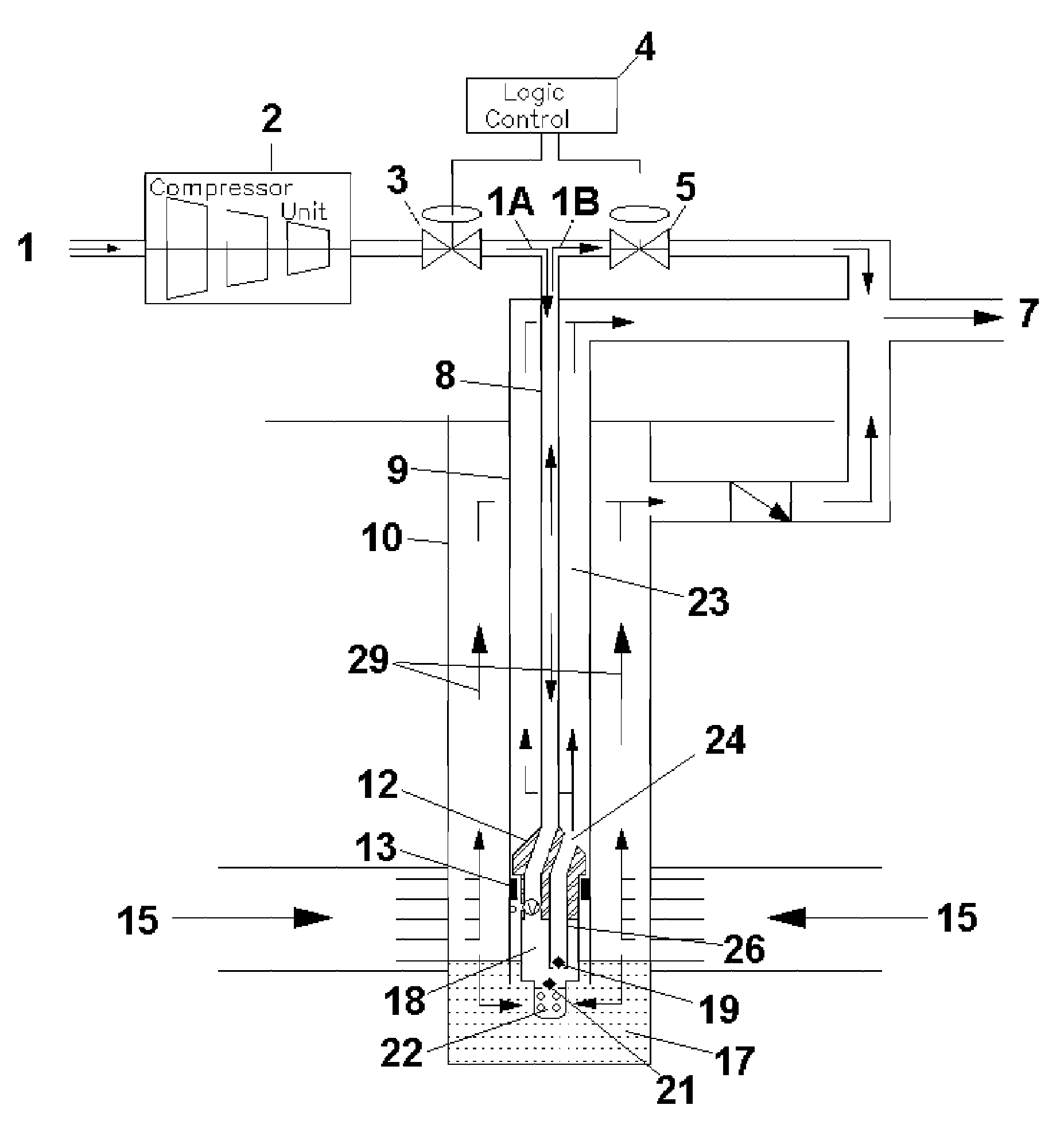

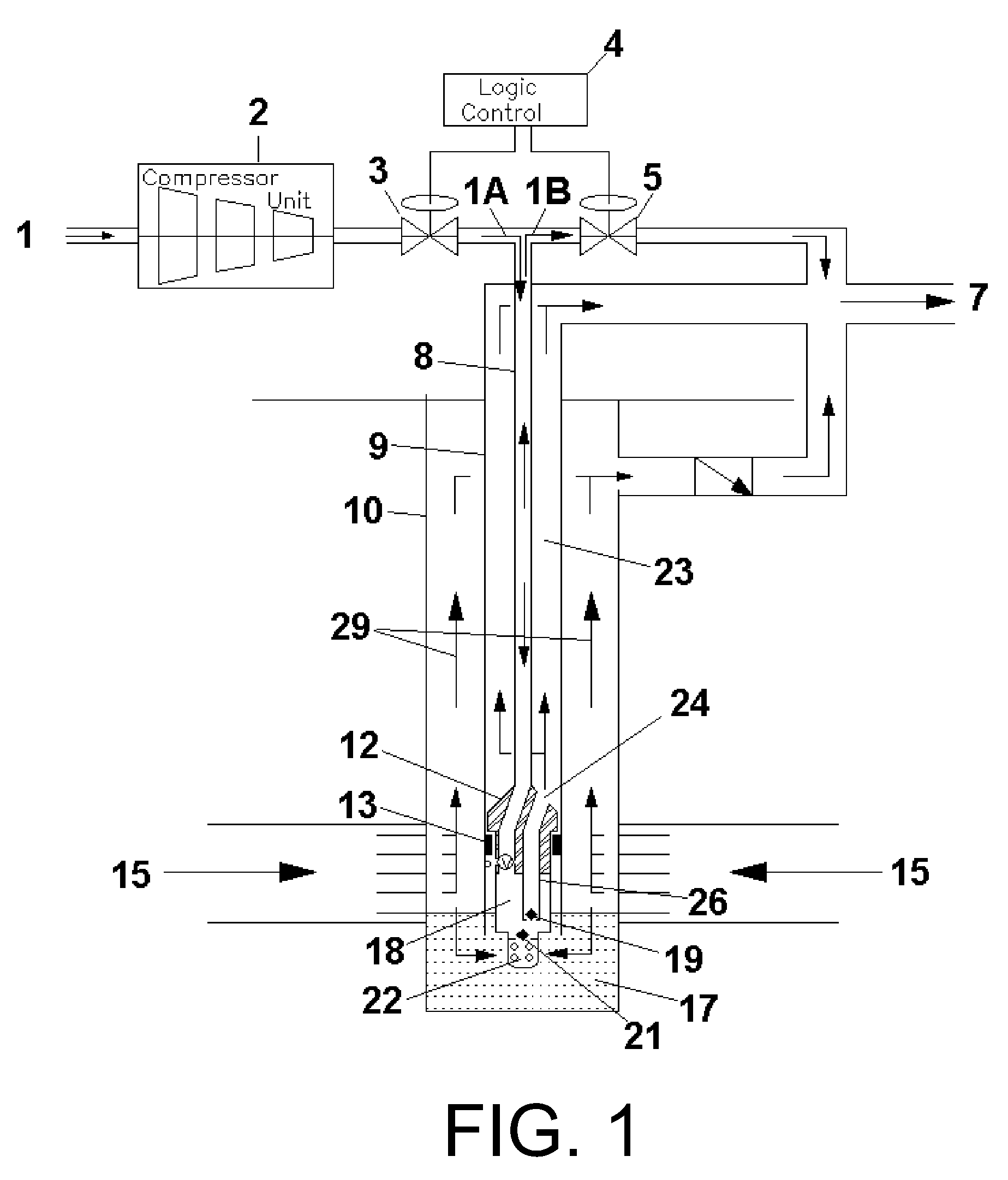

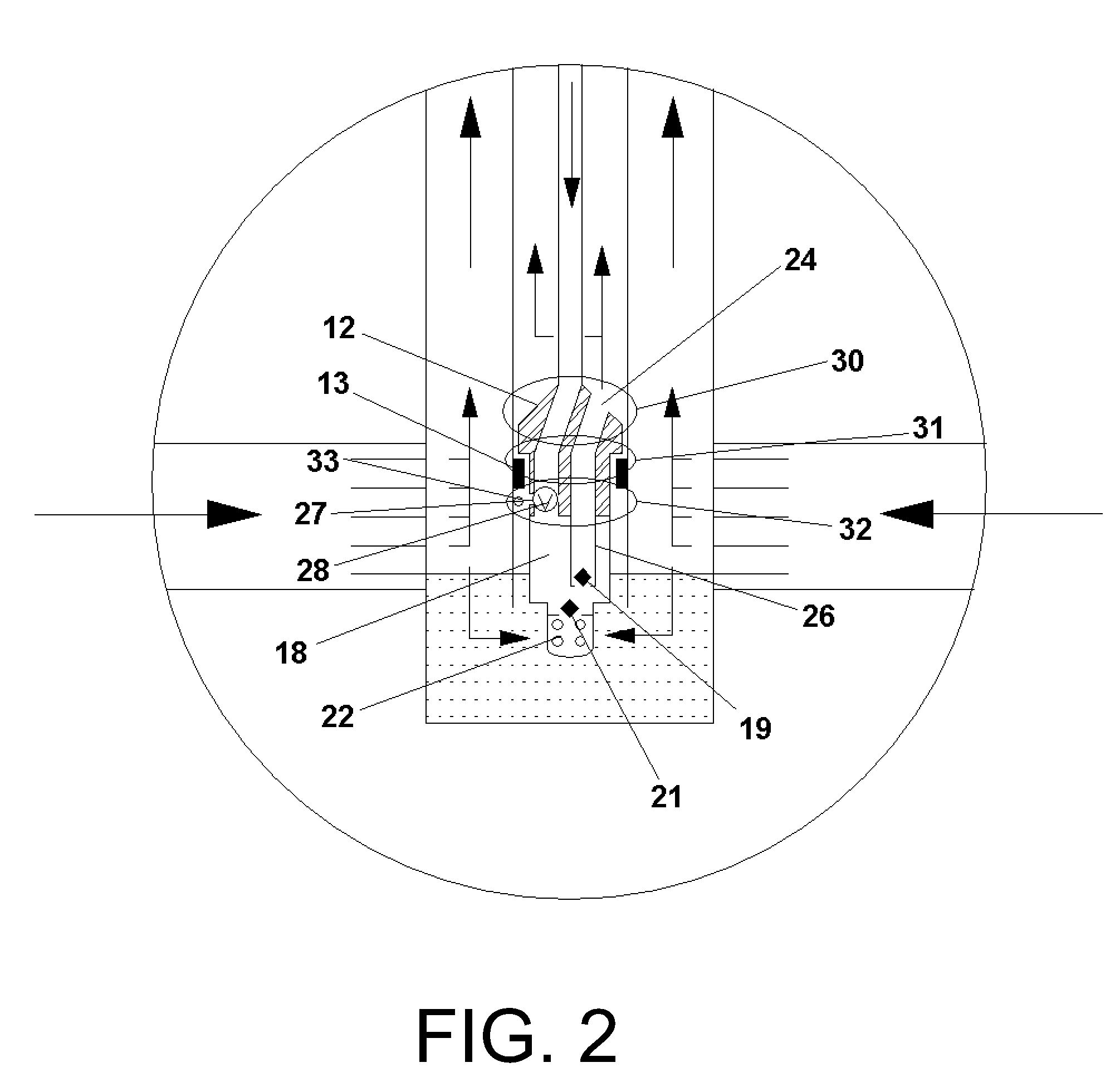

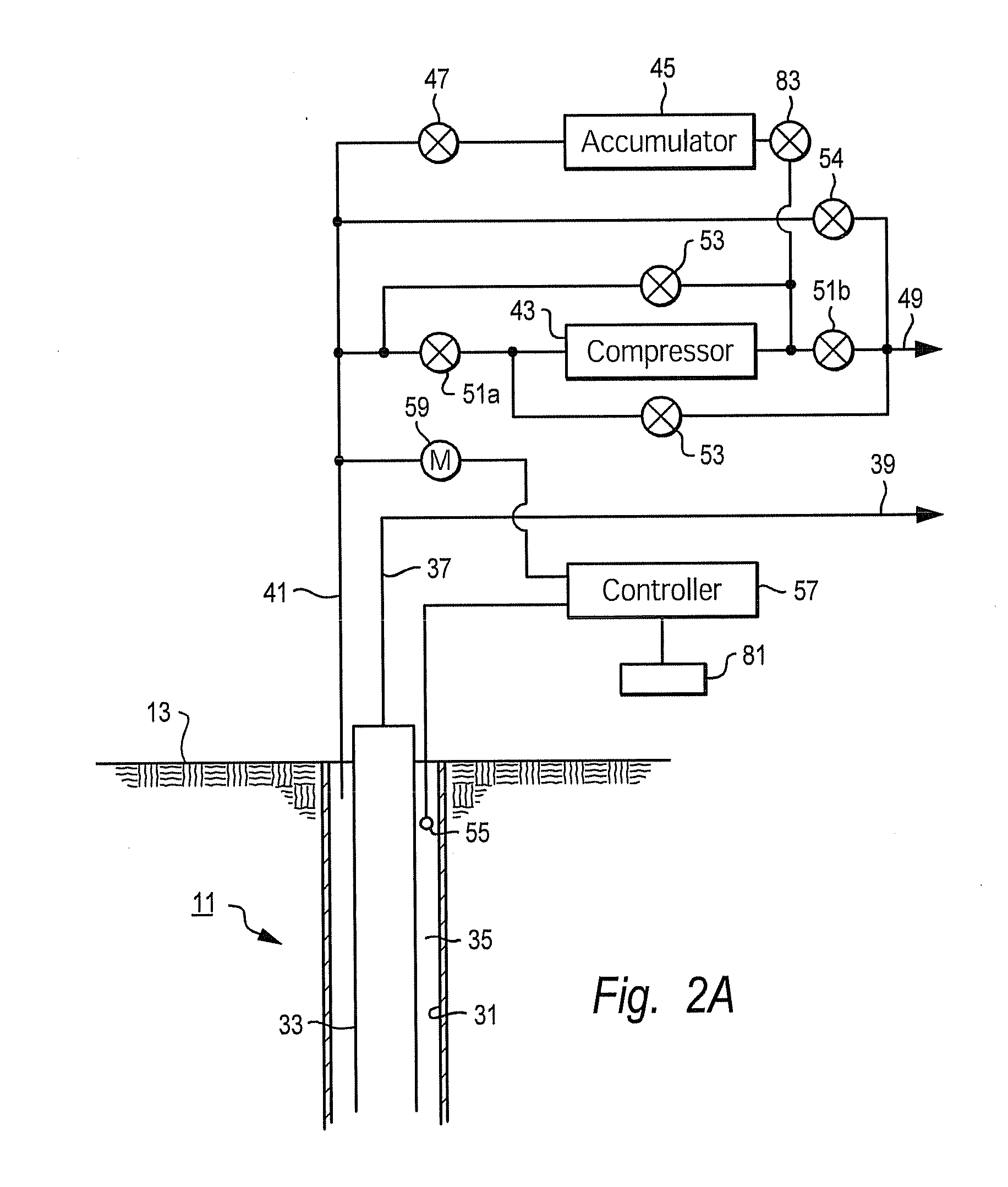

Artificial lift system and method for well

ActiveUS20110214880A1Adequate movementFluid removalSealing/packingProcess engineeringArtificial lift

An artificial lift system provides a lifting mechanism located in a well. The lifting mechanism communicates with a remote intake that is located below in the well. A compressed gas source provides compressed gas to the well annulus at a pressure that is sufficient to move the well fluid from the remote intake up to the lifting mechanism. The well has an annulus and tubing. The well has isolation elements that isolate the producing formation from compressed gas in the annulus. Various sources of compressed gas can be used such as a compressor, an accumulator or a gas sales line. A controller is provided to control the intermittent application and removal of compressed gas in the annulus and also to control the operation of the lifting mechanism. The well could be a horizontal well or a vertical well. The well could be a cased hole or an open hole well.

Owner:HARBISON FISCHER

Integrated pump and compressor and method of producing multiphase well fluid downhole and at surface

ActiveUS20140377080A1Improve efficiencyImprove cooling effectPositive displacement pump componentsFlexible member pumpsGas compressorProduct gas

An integrated system is disclosed to handle production of multiphase fluid consisting of oil, gas and water. The production stream is first separated into two streams: a liquid dominated stream (GVF<5% for example) and a gas dominated stream (GVF>95% for example). The separation can be done through shrouds, cylindrical cyclonic, gravity, in-line or the like separation techniques. The two streams are then routed separately to pumps which pump dissimilar fluids, such as a liquid pump and a gas compressor, and subsequently recombined. Both pumps are driven by a single motor shaft which includes an internal passageway associated with one of the pumps for reception of the fluid from the other pump, thereby providing better cooling and greater overall efficiency of all systems associated therewith. A method for providing artificial lift or pressure boosting of multiphase fluid is also disclosed.

Owner:SAUDI ARABIAN OIL CO

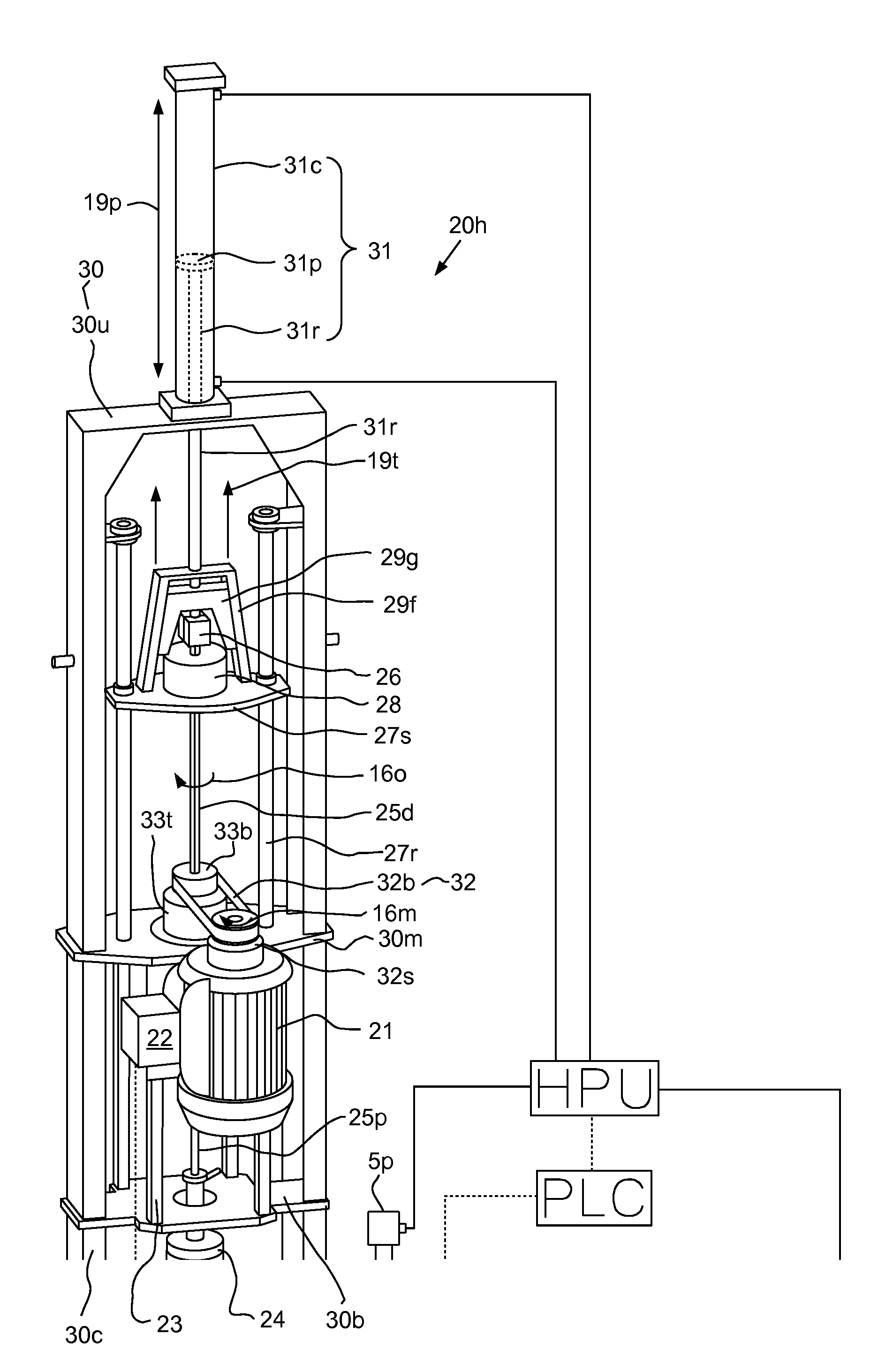

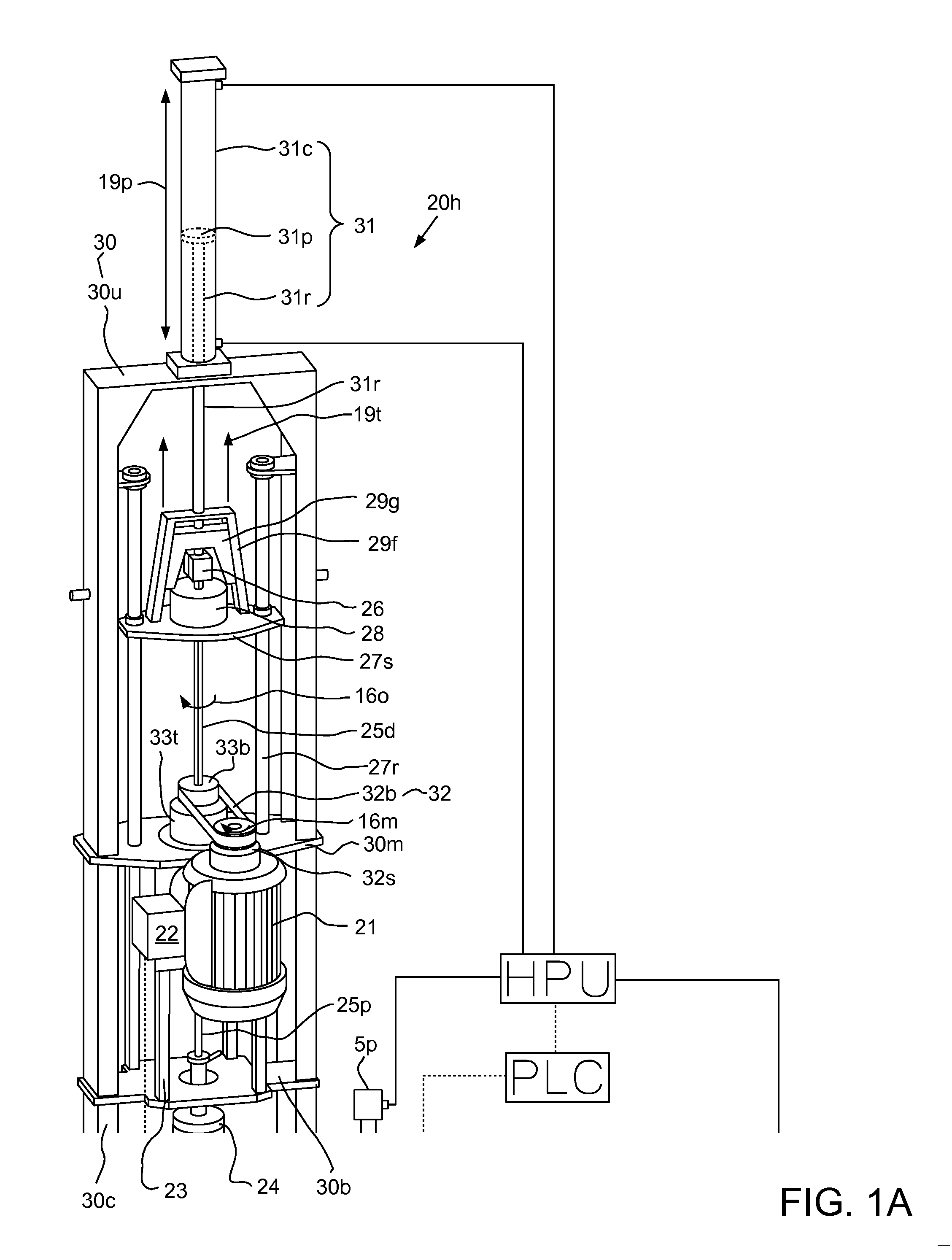

Submersible hydraulic artificial lift systems and methods of operating same

The present invention is directed to methods for extracting fluids from oil and gas wells. More specifically, it is directed toward methods and apparatuses to power and control down hole hydraulic devices using subterranean centrifugal pumps. This invention represents a vast improvement over current hydraulic artificial lift systems. This invention provides for safe, efficient, and increased fluid recovery of oil and gas reserves from subterranean reservoirs in all types of wells, including deviated and horizontal wells.

Owner:SMITH DAVID RANDOLPH +1

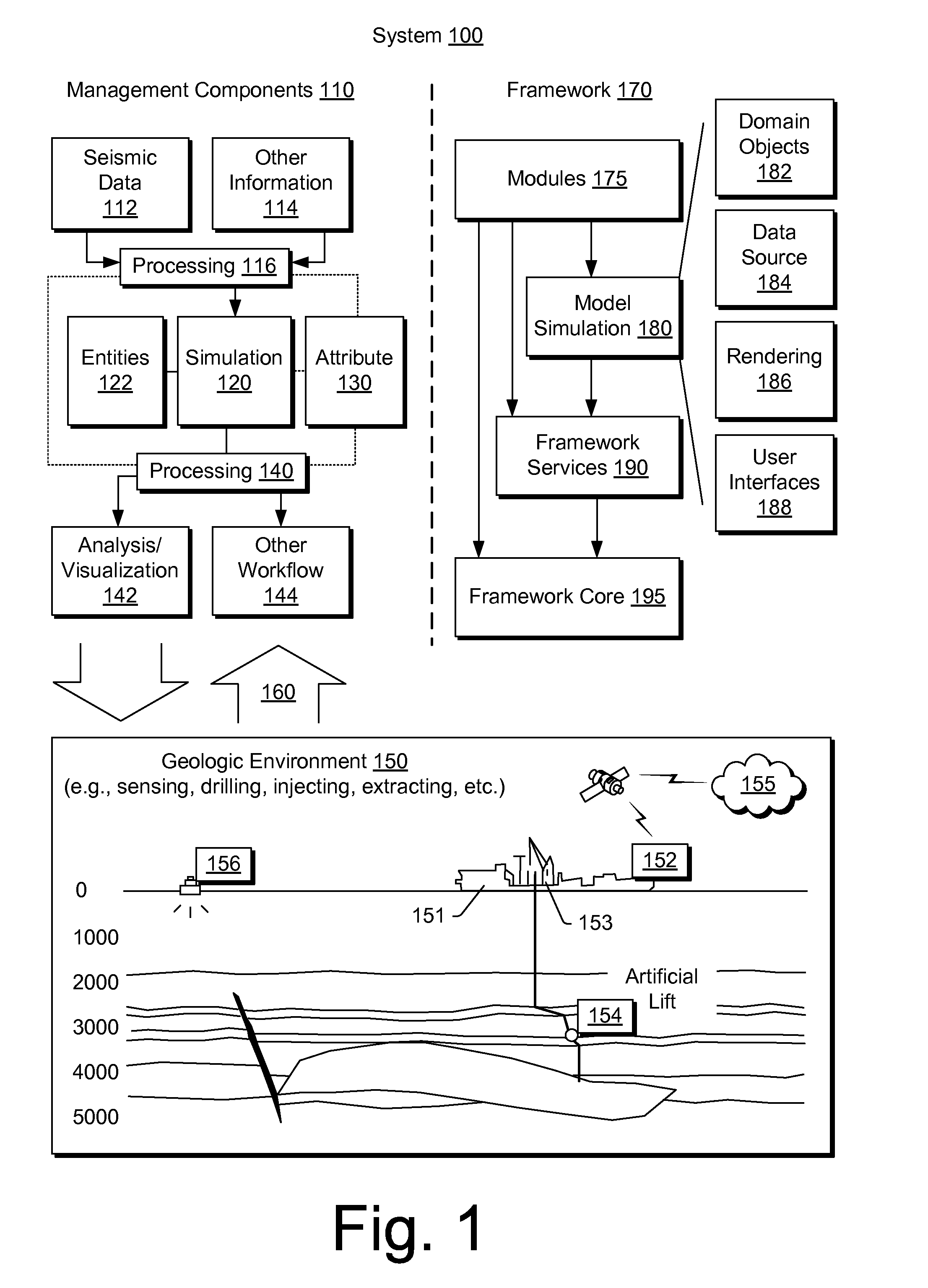

Artificial Lift Modeling Methods and Systems

InactiveUS20120211228A1Fluid removalComputation using non-denominational number representationComputational modelSlurry

Methods for modeling, configuring, and controlling artificial lift processes are provided as well as systems for controlling artificial lift and hydrocarbon production systems. In particular, the methods and systems include the use of computation solid-liquid slurry models and reservoir inputs configured to provide inputs to configure parameters of an artificial lift system. The methods and systems may also incorporate fluid lift computational models and volume of fluid (VOF) models for verifying the numerical results. The disclosed methods and systems may beneficially be used in combination with hydrocarbon production processes such as fluidized in-situ reservoir extraction (FIRE) process; a SRBR process; an enhanced CHOPS process; and any combination thereof.

Owner:TROSHKO ANDREY A +1

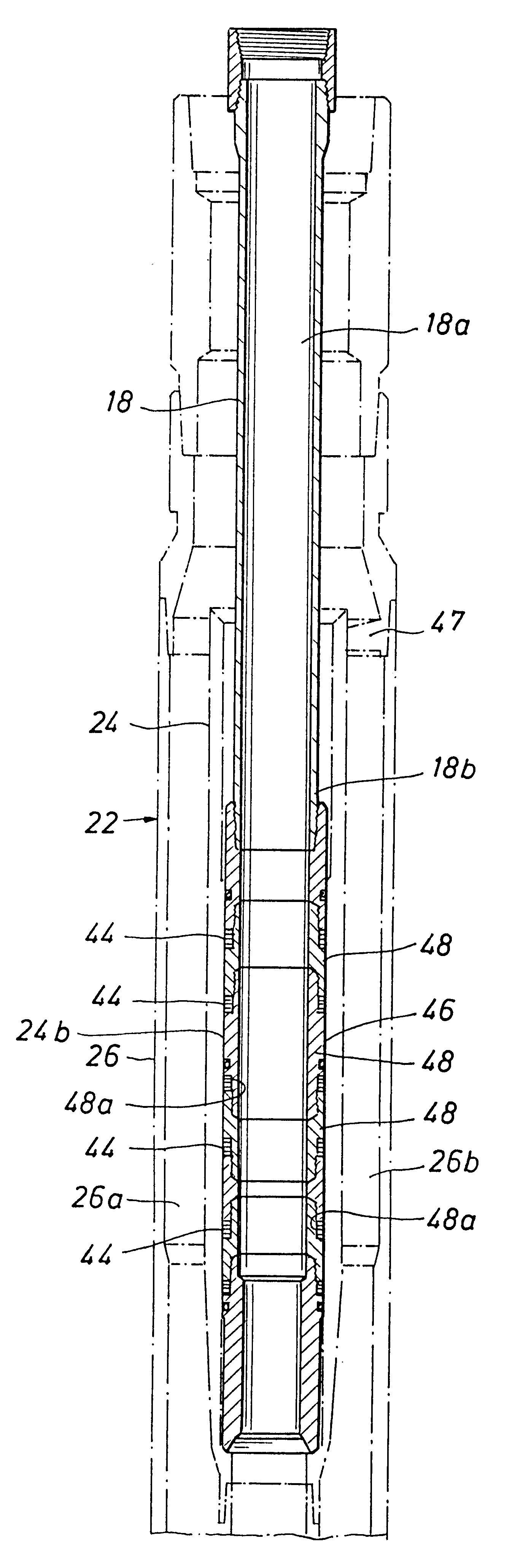

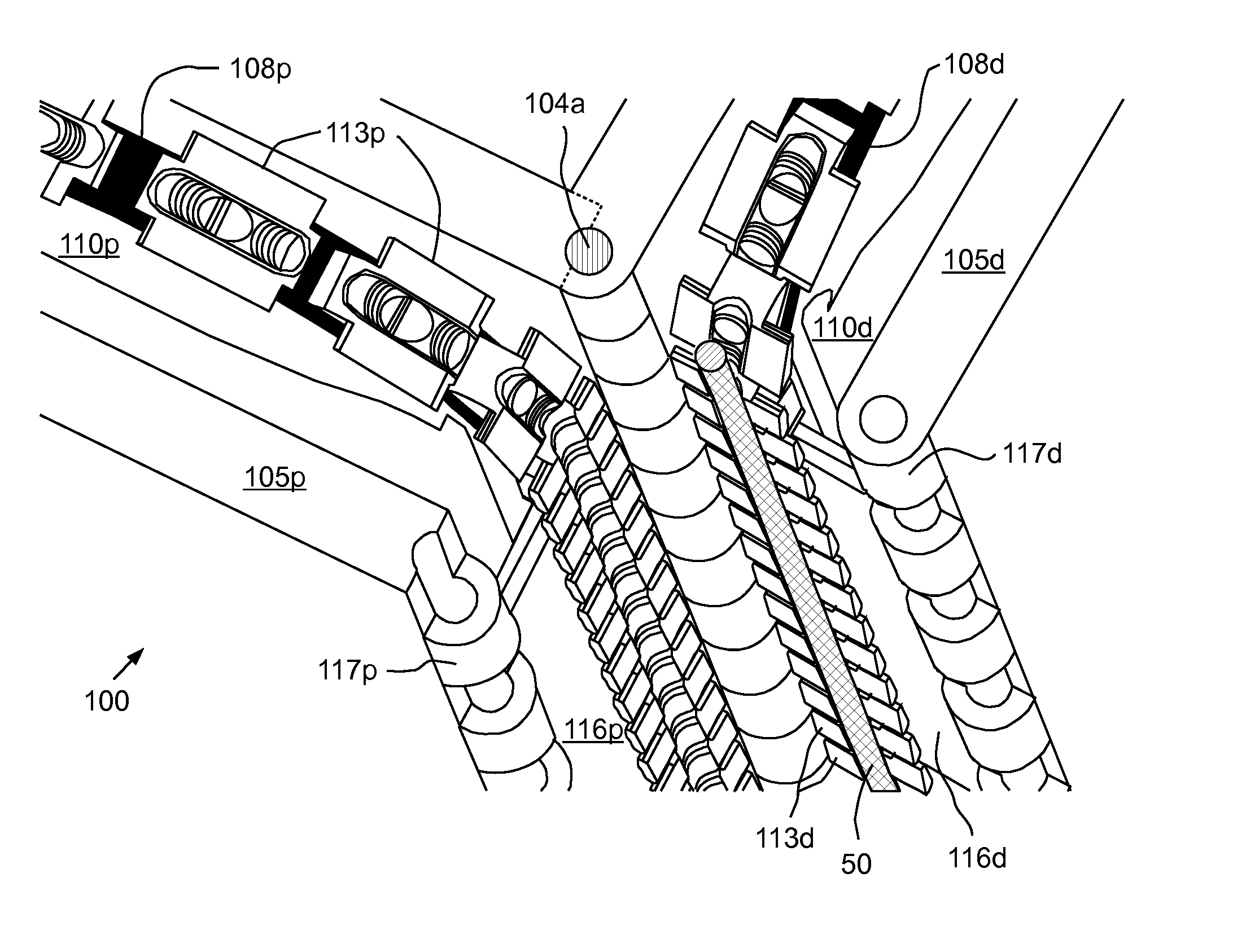

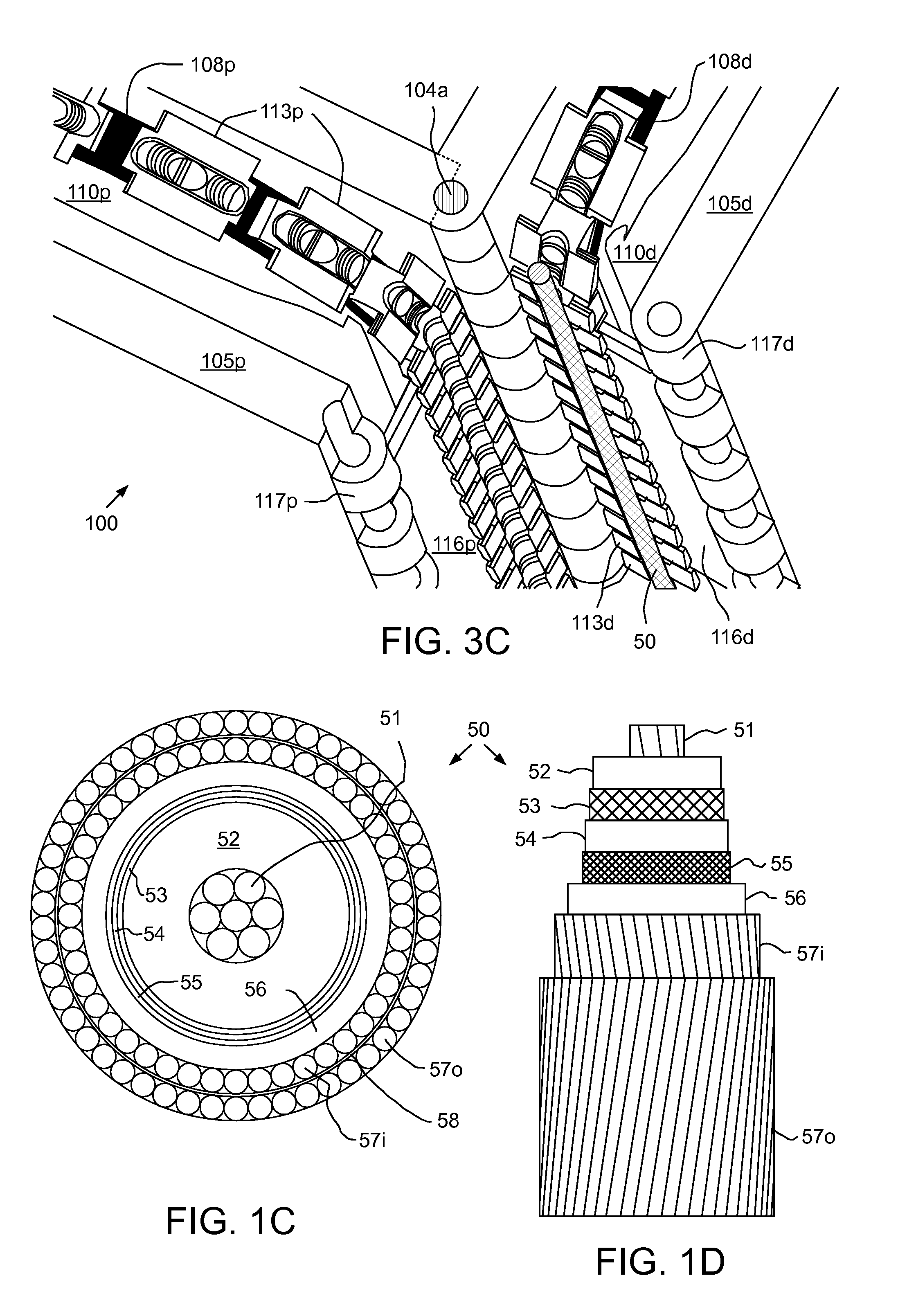

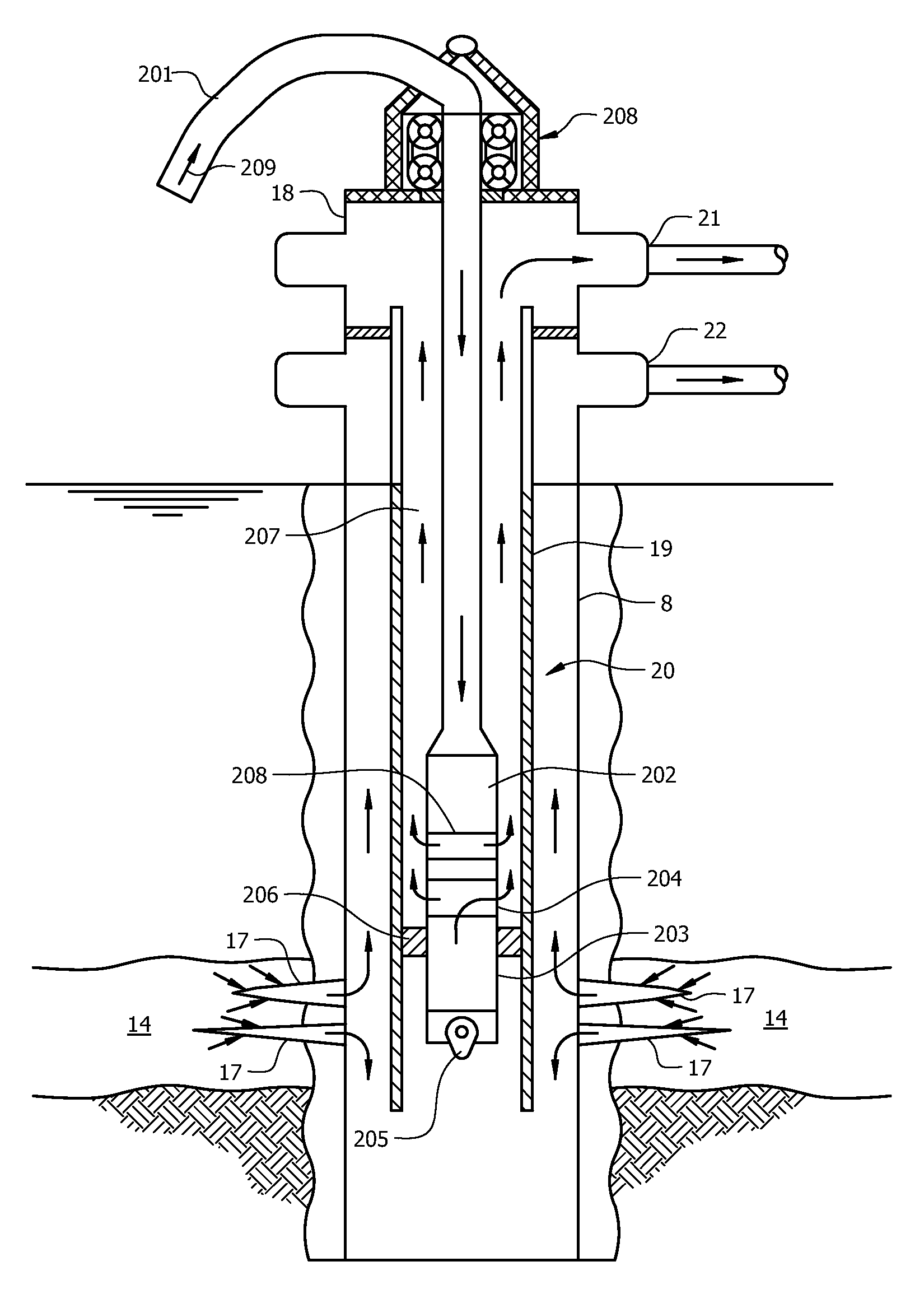

System, method and apparatus for concentric tubing deployed, artificial lift allowing gas venting from below packers

An artificial lift deployed on concentric tubing allows gas to be vented from below packers in a well. A central flow path is used for the fluid production from the artificial lift system, while an outer concentric tubing allows for the venting and production of gas from below a packer. The gas enters the outer concentric flow path through a perforated sub set that is located below the packer. Sealing of the inner concentric string flow from the outer concentric flow path is achieved with a polished bore receptacle and stinger assembly.

Owner:BAKER HUGHES INC

Hydraulic assist deployment system for artificial lift systems and methods for using the same

A well conveyance system couples to an uphole end of an artificial lift system and operates to push the artificial lift system through a tubing string for deployment in a wellbore. The well conveyance system includes a wellbore tractor adapted to push the artificial lift system through the tubing string and a swab cup assembly having a swab cup and a perforated nipple extending therethrough. The perforated nipple includes a nipple passage allowing for fluid flow from an area downhole from the swab cup to an area uphole from the swab cup when the wellbore tractor operates. A valve selectively blocks the perforated nipple to permit a hydraulic pressure to be applied to the tubing string uphole of the swab cup, exerting a downhole force on the swab cup to aid in deployment of the artificial lift system.

Owner:BAKER HUGHES INC

Gradational insertion of an artificial lift system into a live wellbore

A method of inserting a downhole assembly into a live wellbore, includes: assembling a pressure control assembly (PCA) onto a production tree of the live wellbore; inserting a first deployment section of the downhole assembly into a lubricator; landing the lubricator onto the PCA; connecting the lubricator to the PCA; lowering the first deployment section into the PCA; engaging a clamp of the PCA with the first deployment section; after engaging the clamp, isolating an upper portion of the PCA from a lower portion of the PCA; and after isolating the PCA, removing the lubricator from the PCA.

Owner:SCHLUMBERGER TECH BV

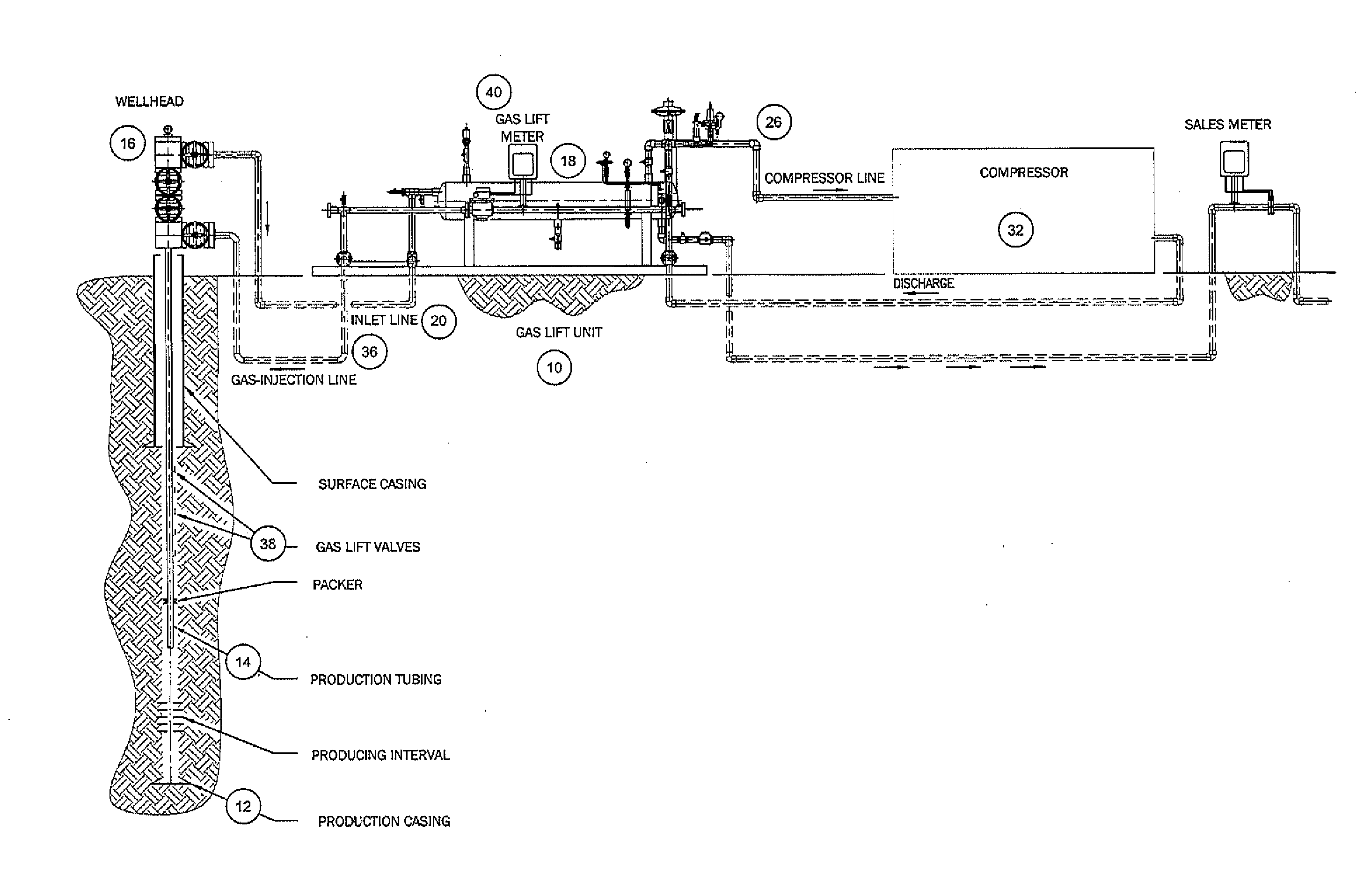

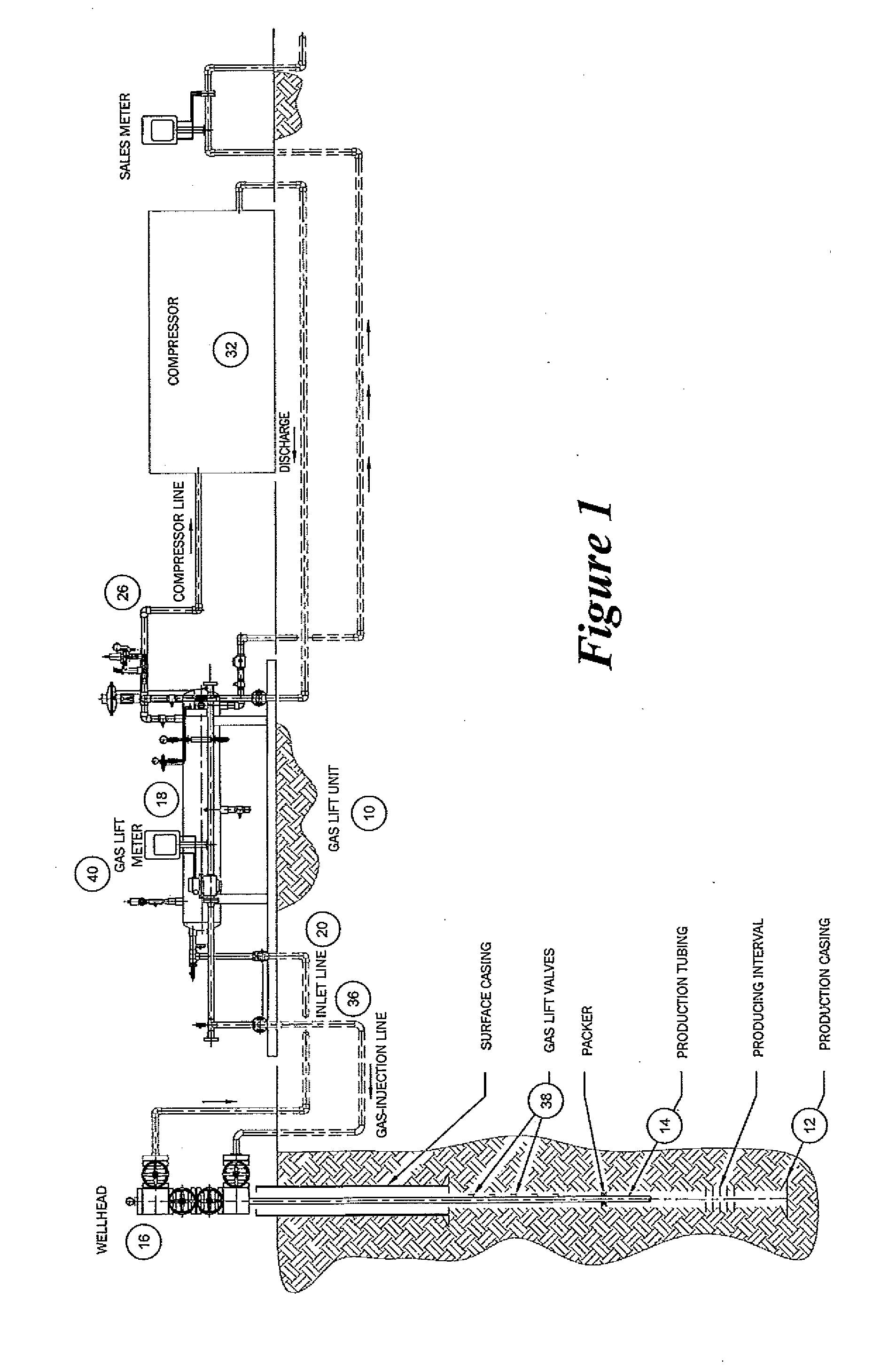

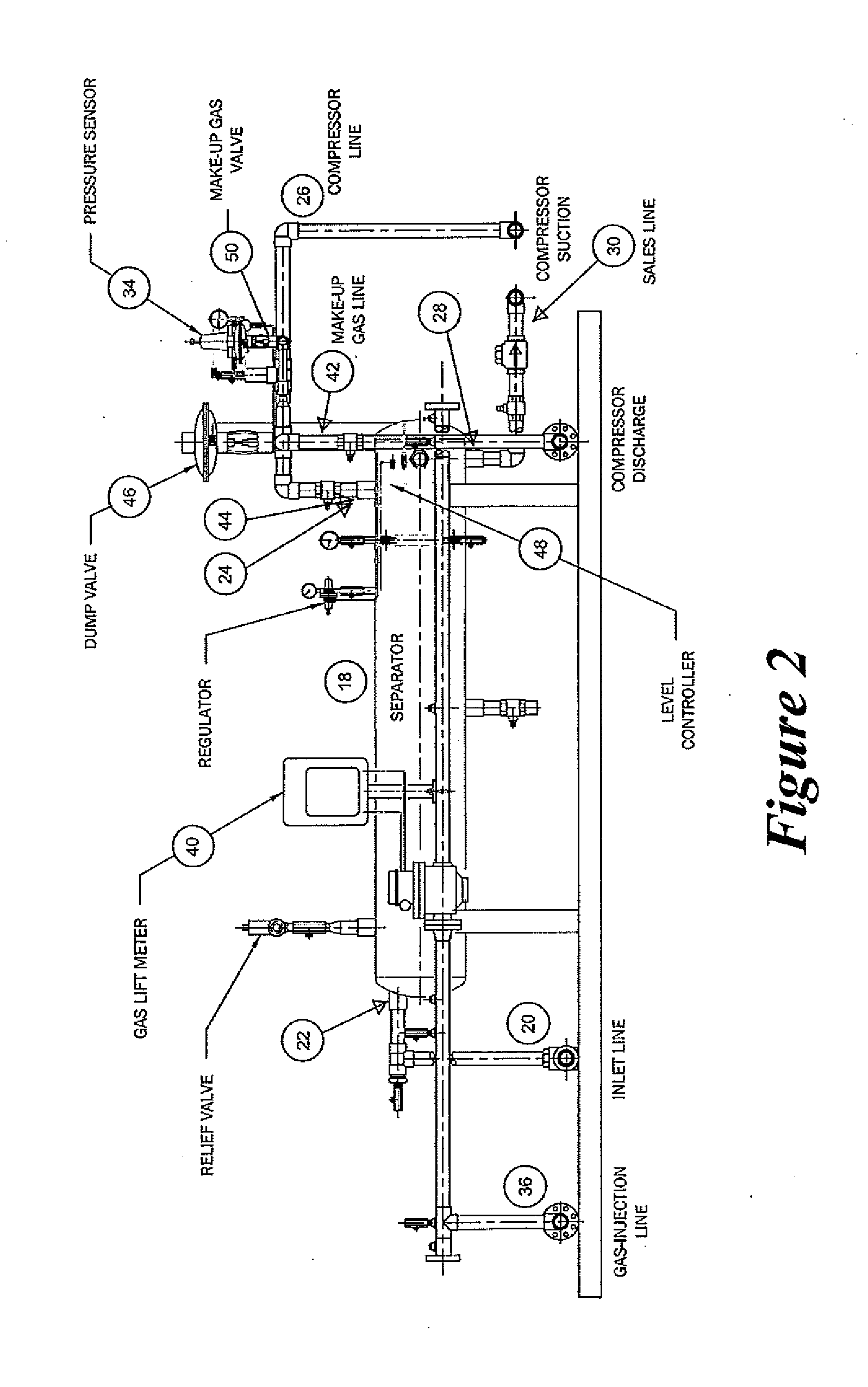

System and Method for Optimizing Production in Gas-Lift Wells

The system and method are utilized to control the flow of crude oil, natural gas, and field produced salt water to optimize production from an oil or gas well. The invention is suitable for use with a well that utilizes gas-lift as artificial lift. The equipment is designed to regulate the flow of injection gas into the production tubing to optimize production of the well.

Owner:BACHTELL DAVID +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com