Cable injector for deploying artificial lift system

a technology of artificial lift system and injector, which is applied in the direction of sealing/packing, drilling pipes, and well accessories, etc., can solve the problems of limited cable deployment in coil tubing, cost, reliability and availability of coiled tubing units, and the inability to use a broader base of cable insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

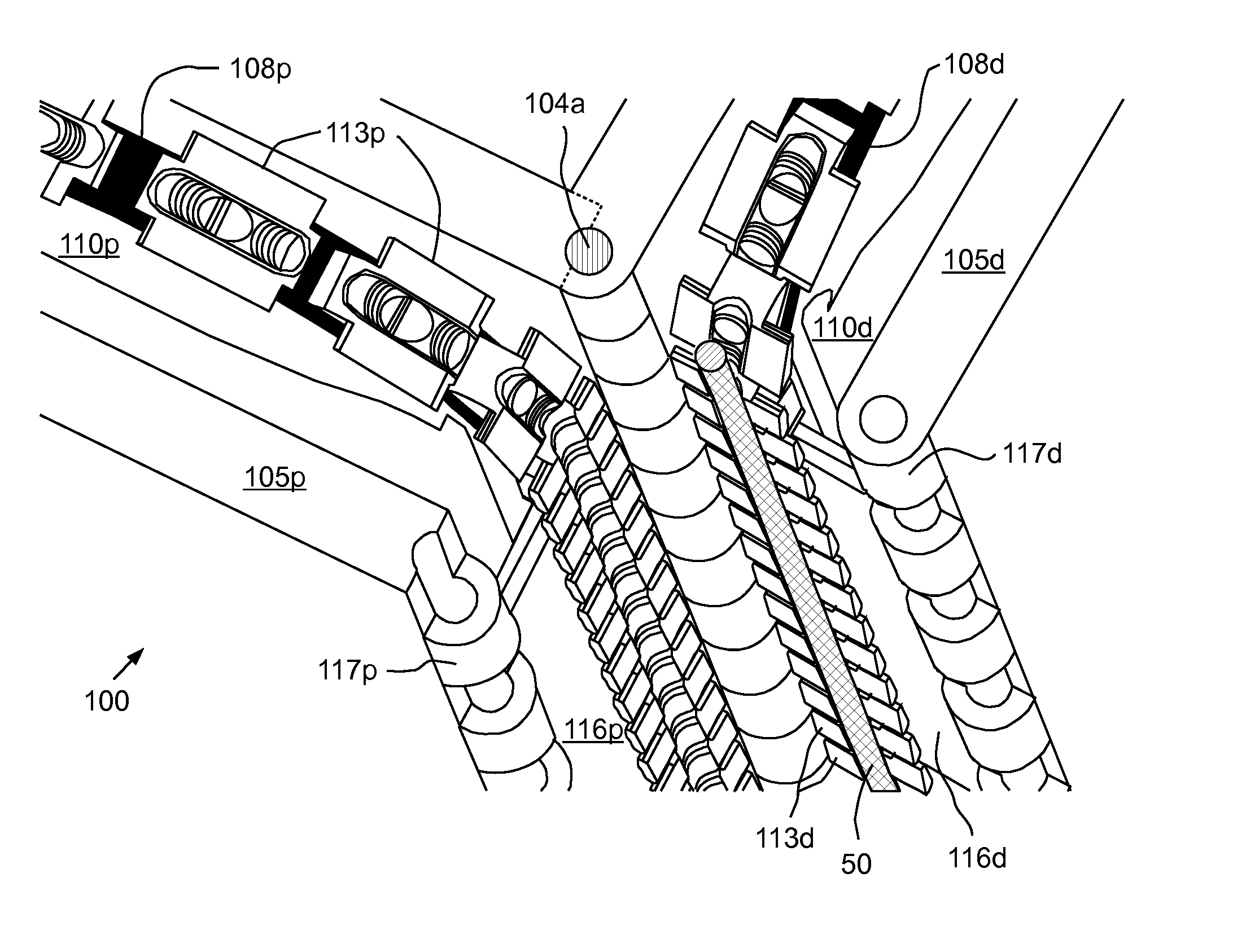

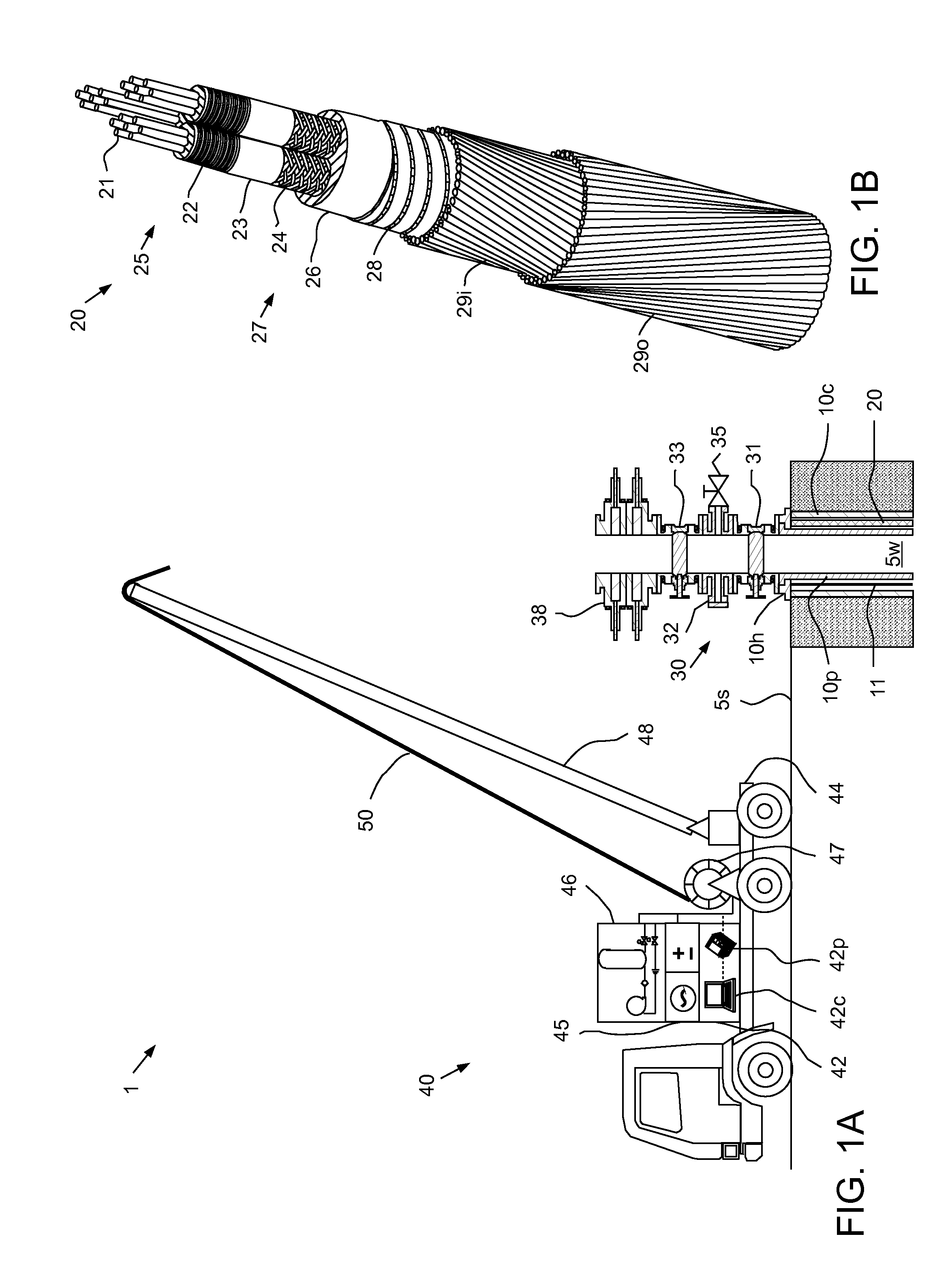

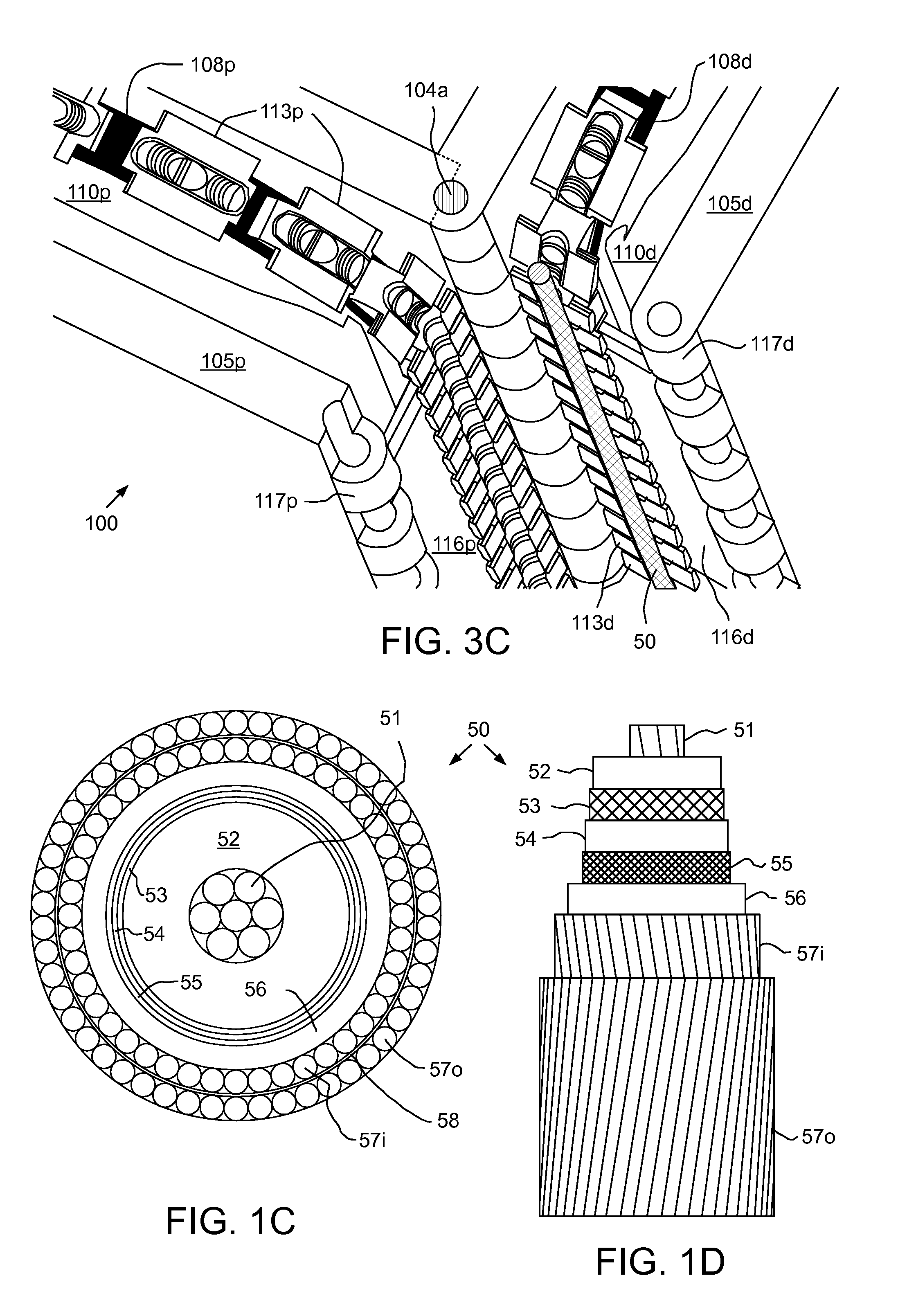

[0016]FIG. 1A illustrates a launch and recovery system (LARS) 1 at a wellsite for deploying an artificial lift system (ALS), according to one embodiment of the present disclosure. The LARS 1 may include a wireleine truck 40, a pressure control assembly (PCA), such as one or more (two shown) blowout preventers (BOPs) 38, one or more running tools 59 (FIG. 4A), and a cable injector 100 (FIG. 3A).

[0017]A wellbore 5w has been drilled from a surface 5s of the earth into a hydrocarbon-bearing (i.e., crude oil and / or natural gas) reservoir 6 (FIG. 4A). A string of casing 10c has been run into the wellbore 5w and set therein with cement (not shown). The casing 10c has been perforated 9 (FIG. 4B) to provide to provide fluid communication between the reservoir 6 and a bore of the casing 10c. A wellhead 10h has been mounted on an end of the casing string 10c. A string of production tubing 10p extends from the wellhead 10h to the reservoir 6 to transport production fluid 7 (FIG. 4C) from the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com