Gas-lifting internal circulation intermission aerobic granule sludge reactor and water treatment process thereof

An aerobic granular sludge and reactor technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of easy disintegration, unstable sludge, and affecting treatment effects, etc. problems, to achieve the effect of less residual sludge, easy separation of sludge and water, and good mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

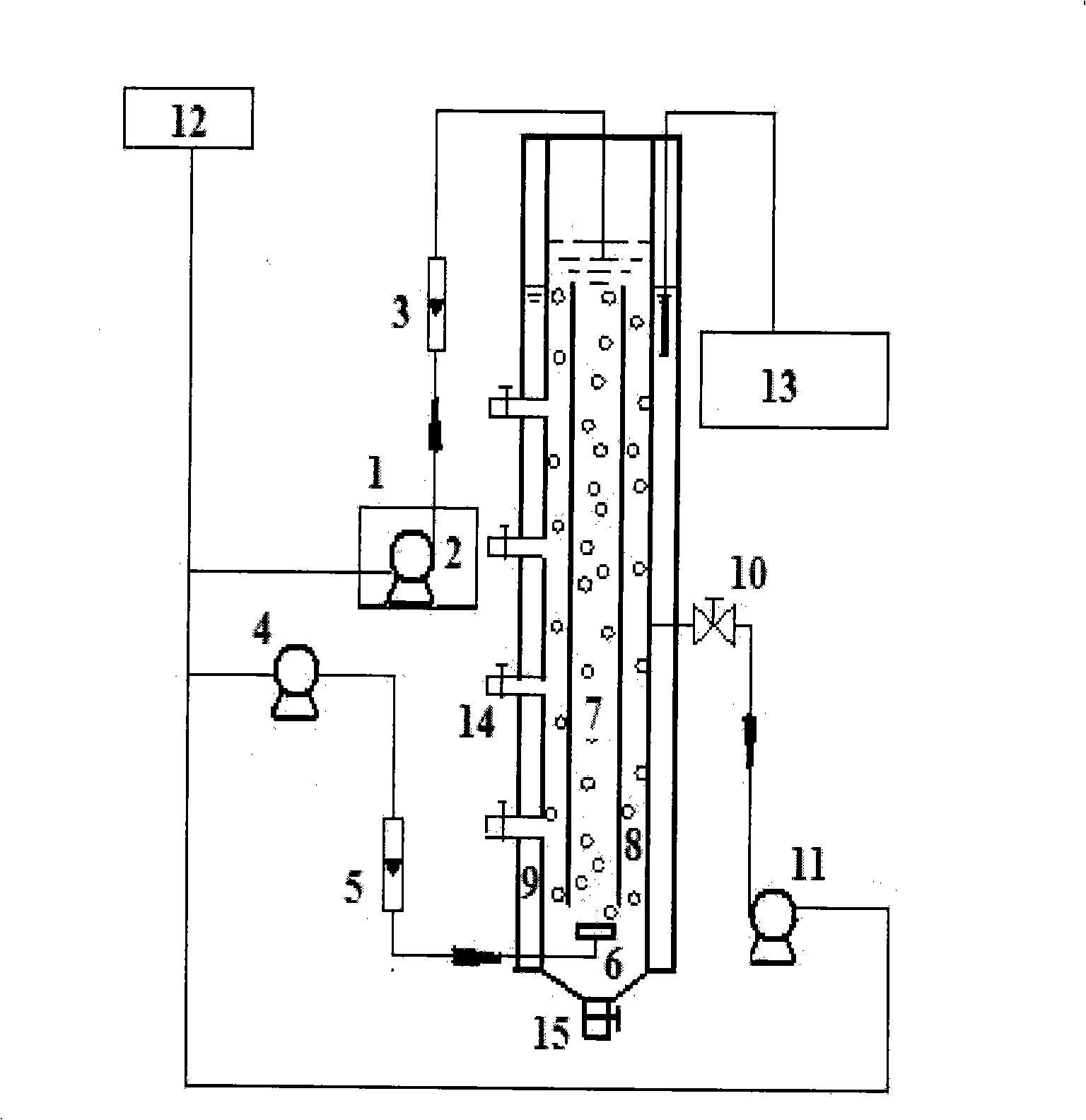

[0045] Embodiment 1: airlift type internal circulation batch reactor, the main body is a plexiglass cylinder, divided into inner and outer sleeves, wherein the outer tube 8 (downflow tube) has an inner diameter of 8 cm and a height of 120 cm, and the inner tube 7 (up flow tube) The inner diameter is 6cm, the height is 90cm, the total volume is 5.0L, and the ratio of height to diameter is about 15. The water is fed from the upper part of the reactor by the water inlet pump 2, and the air is fed from the bottom of the riser tube of the reactor by the air pump 4. The air flow is given by Controlled by the gas flow meter 5, the surface air velocity is not less than 2.4cm / s to ensure the smooth circulation of the mixed liquid. The specific air flow can be determined according to the properties and water quality of the inoculated sludge. Driven by the updraft, the mixed liquid in the reactor is in a state of circulating flow between the riser tube 7 and the downcomer tube 8, moves up...

Embodiment 2

[0050] Embodiment 2: using the reactor described in Example 1, the influent adopts the simulated water sample configured by glucose, the influent COD load is 1200-1600mg / L, and the inoculum sludge used for reactor start-up is ordinary activated sludge, taken from In the secondary settling tank of the domestic sewage treatment plant, granular sludge is formed in the reactor after about 30 days, and the sludge concentration is 6000-7000mg / L. The reaction temperature is 30°C, and the reaction period is 6 hours (water intake: 10 minutes, aeration: first week: 320 minutes, second week: 325 minutes, after the third week: 330 minutes, precipitation: first week 15 minutes, second week 10 minutes , 5min after the third week; drainage: 15min), the removal rate of COD reached over 95% after the reaction system was running stably, and the removal rate of NH 3 -N removal rate is above 90%, TP removal rate is 70%, basically no residual sludge is produced.

Embodiment 3

[0051] Embodiment 3: The reactor described in Example 1 is adopted, the influent adopts actual domestic sewage, the influent COD load is 400-800mg / L, and the inoculated sludge used for reactor start-up is ordinary activated sludge, taken from domestic sewage treatment In the secondary settling tank of the plant, granular sludge is formed in the reactor after about 30 days, and the sludge concentration is 2500-3000mg / L. Operating at room temperature (25°C), the reaction cycle is 8 hours (10 minutes of water inflow, 445 minutes of aeration, 15 minutes of sedimentation, and 10 minutes of drainage), the surface air velocity is 2.4cm / s, and the COD removal rate of the reaction system is over 94% after the reaction system runs stably NH 3 -N removal rate is above 88%, TP removal rate is 80%, basically no residual sludge is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com