Patents

Literature

284results about "Inorganic chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

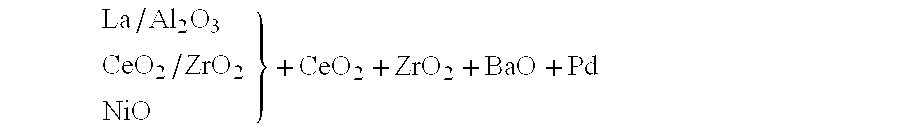

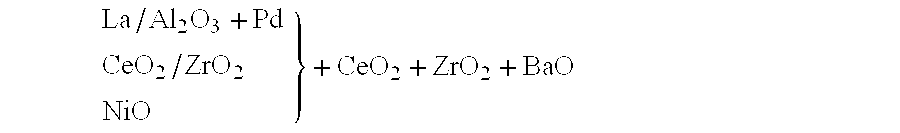

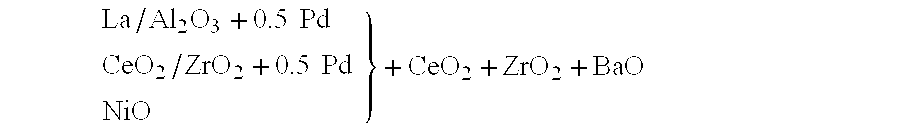

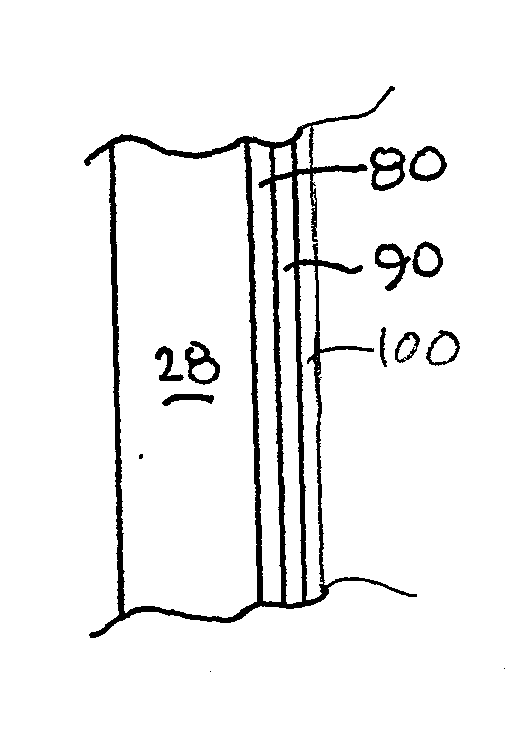

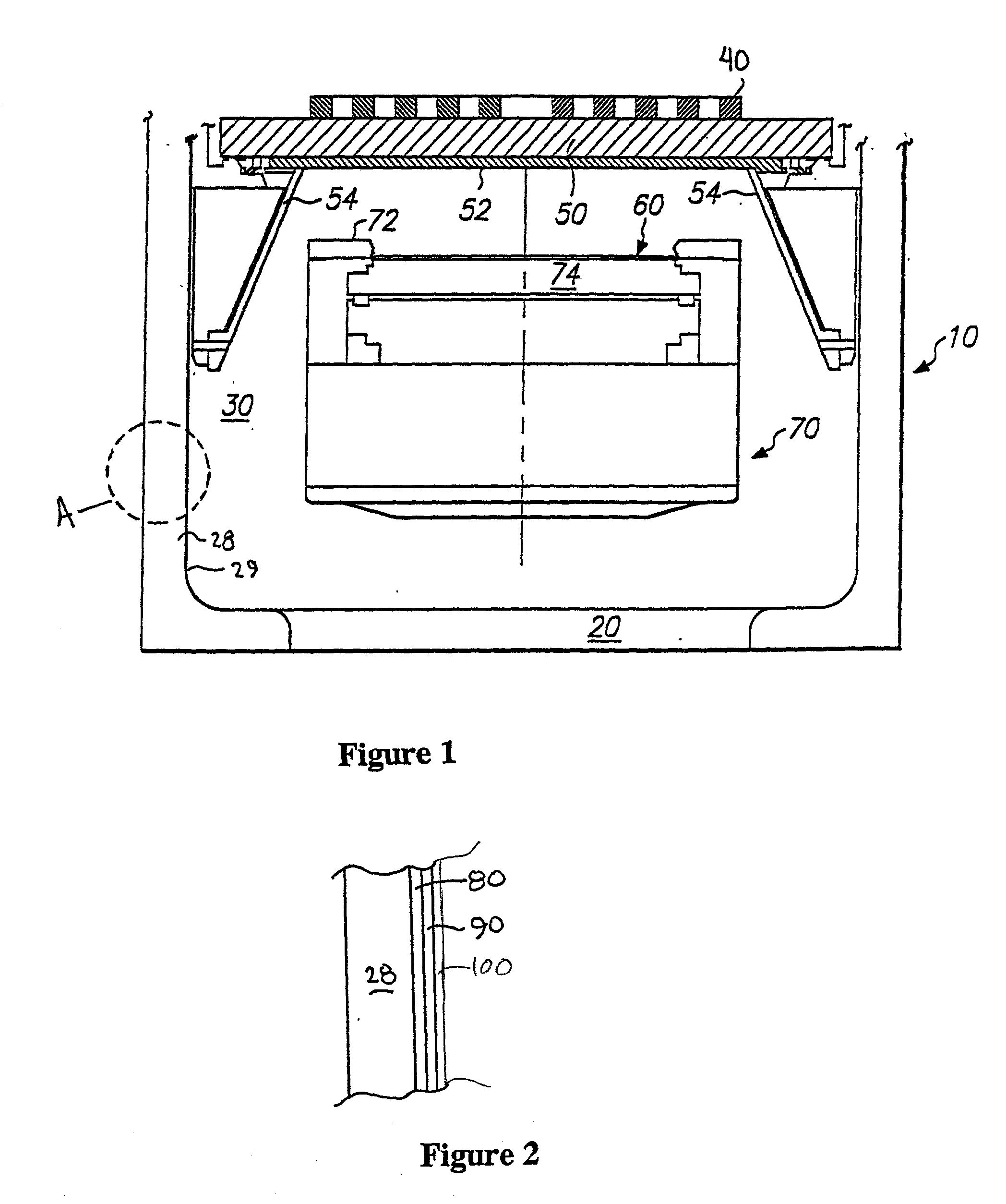

Exhaust gas treatment catalyst for internal combustion engines with two catalytically active layers on a carrier structure

InactiveUS6348430B1Improve heat resistanceHigh activityInorganic chemistryInternal combustion piston enginesParticulatesPartial oxidation

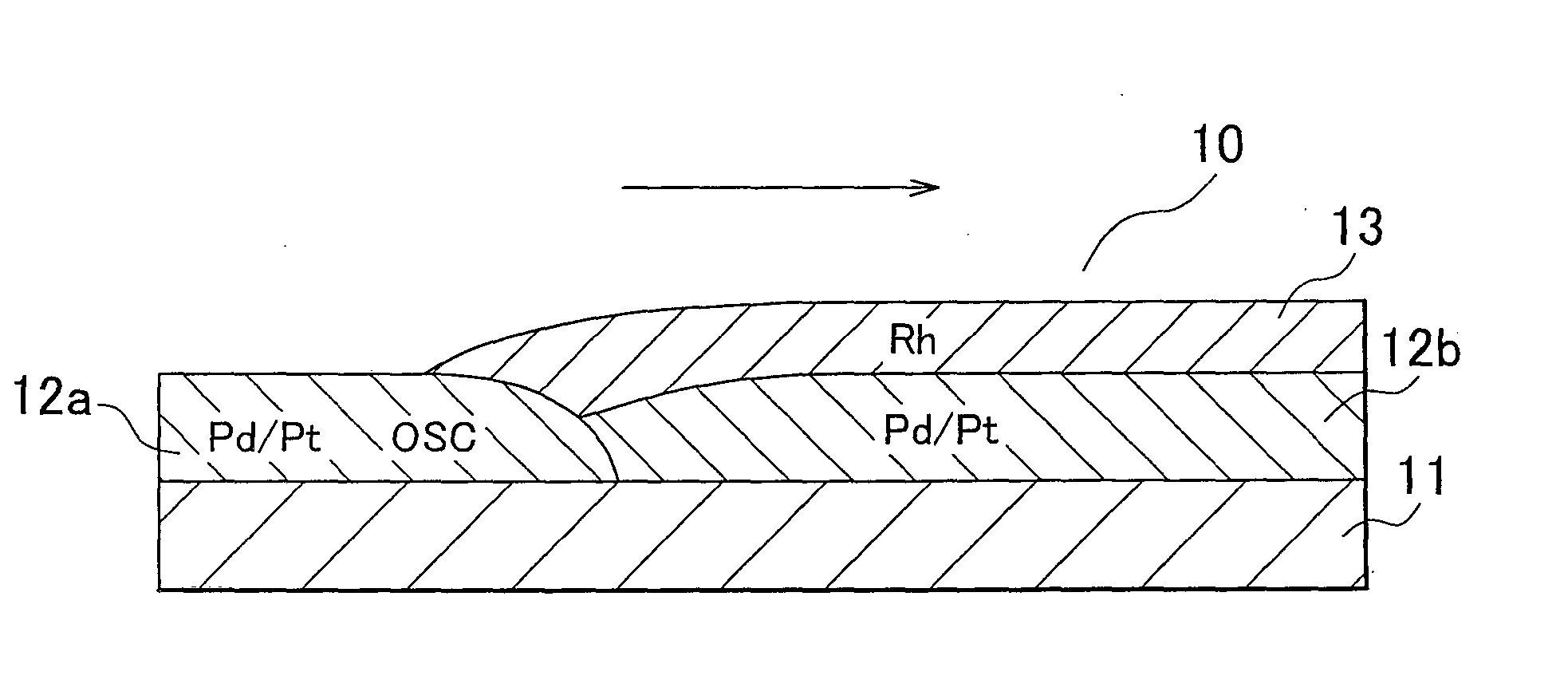

A catalyst for treating the exhaust gas from internal combustion engines is provided, wherein the catalyst contains two catalytically active layers supported on a support. The first catalytically active layer contains a platinum group metal in close contact with all of the constituents of the first catalytically active layer, wherein the constituents of the first catalytically active layer include particulate aluminum oxide; particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides, and alkaline earth metal oxides. The second catalytically active layer, which is in direct contact with the exhaust gas, contains particulate aluminum oxide and at least one particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides. Rhodium is supported on part of the aluminum oxides in the second catalytically active layer or on the particulate oxygen storage material in the second catalytically active layer. By providing the platinum group metal in close contact with all of the constituents of the first catalytically active layer, improved conversion efficiency of the impurities in the exhaust gas can be achieved.

Owner:UMICORE AG & CO KG +1

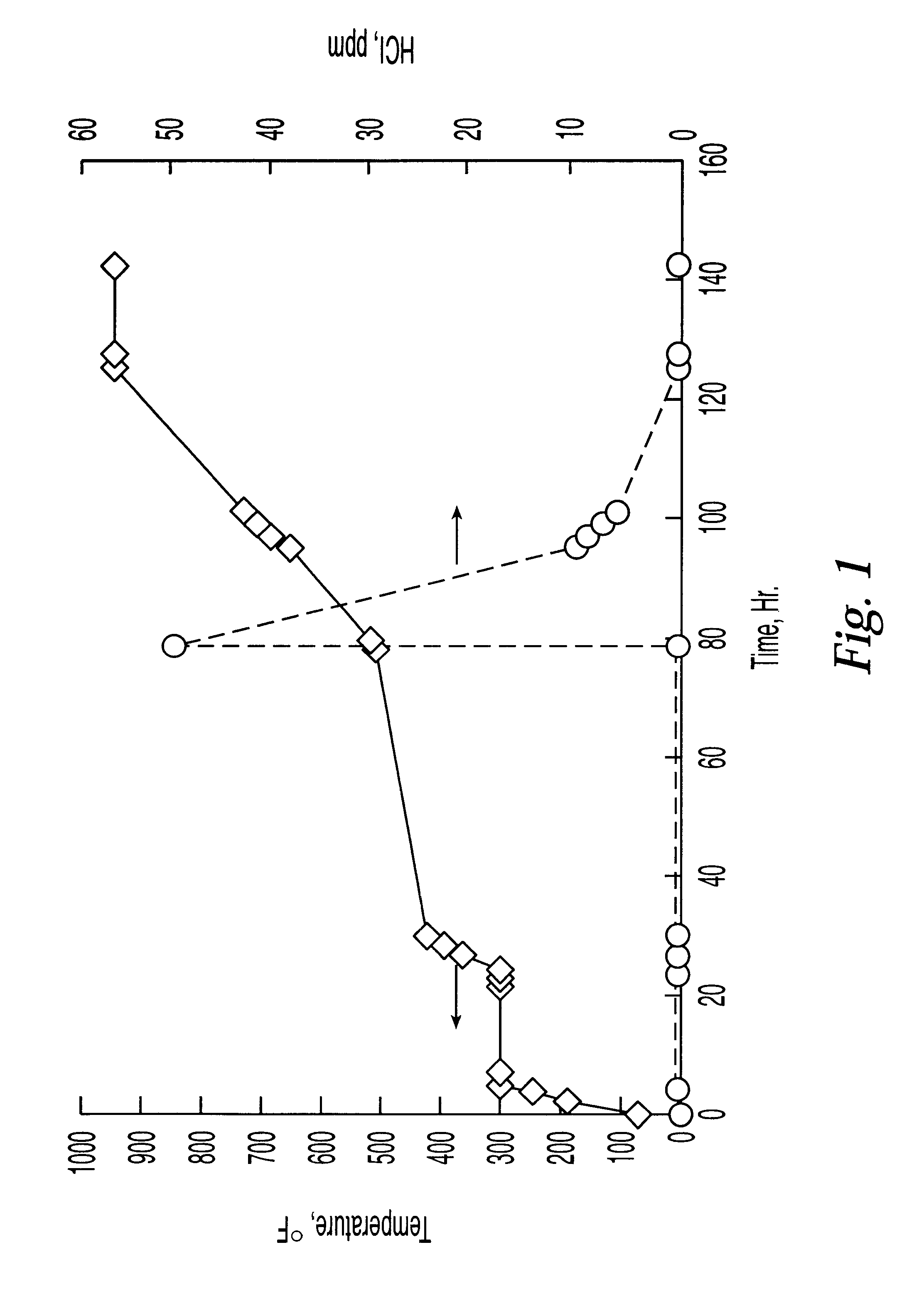

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

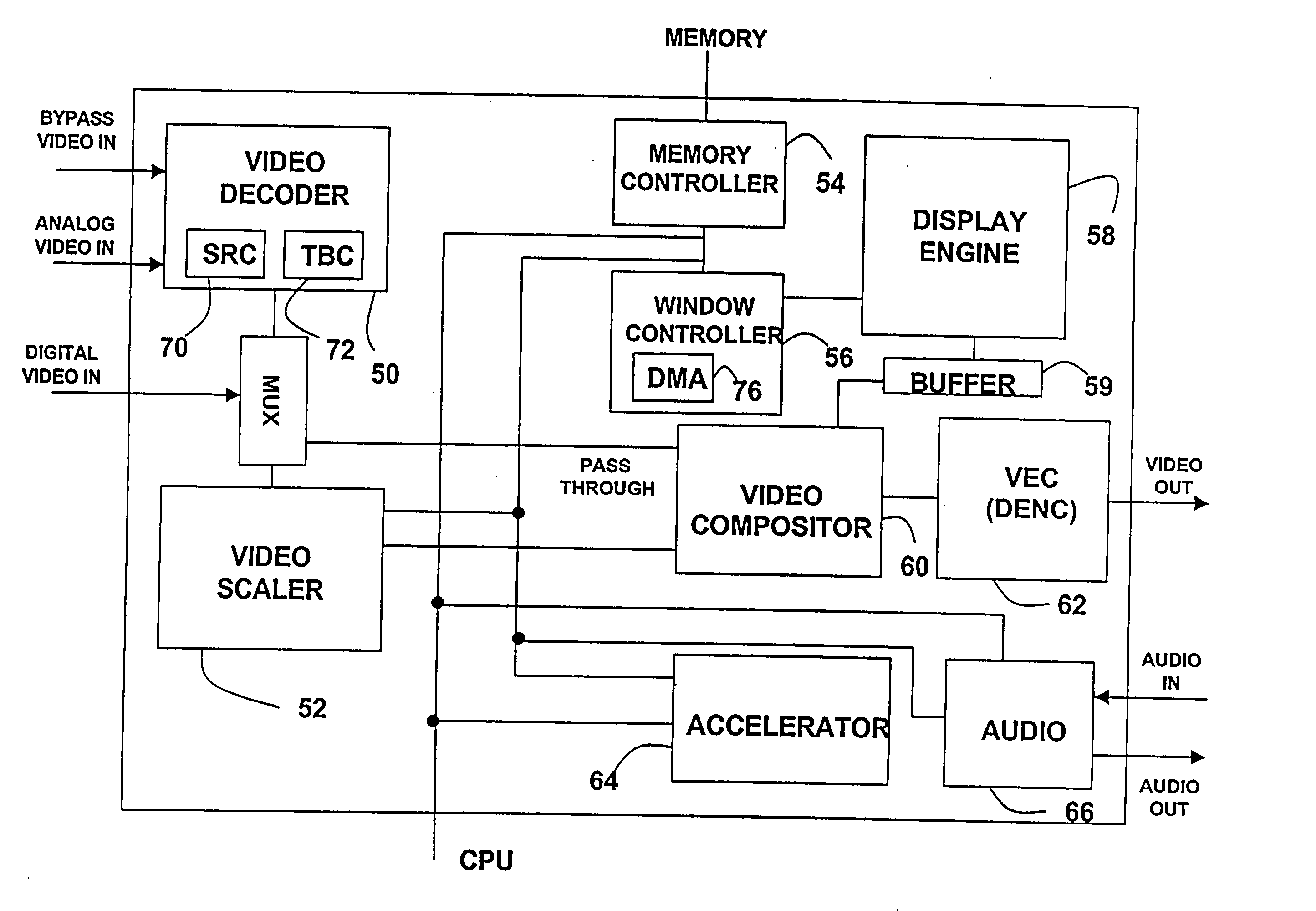

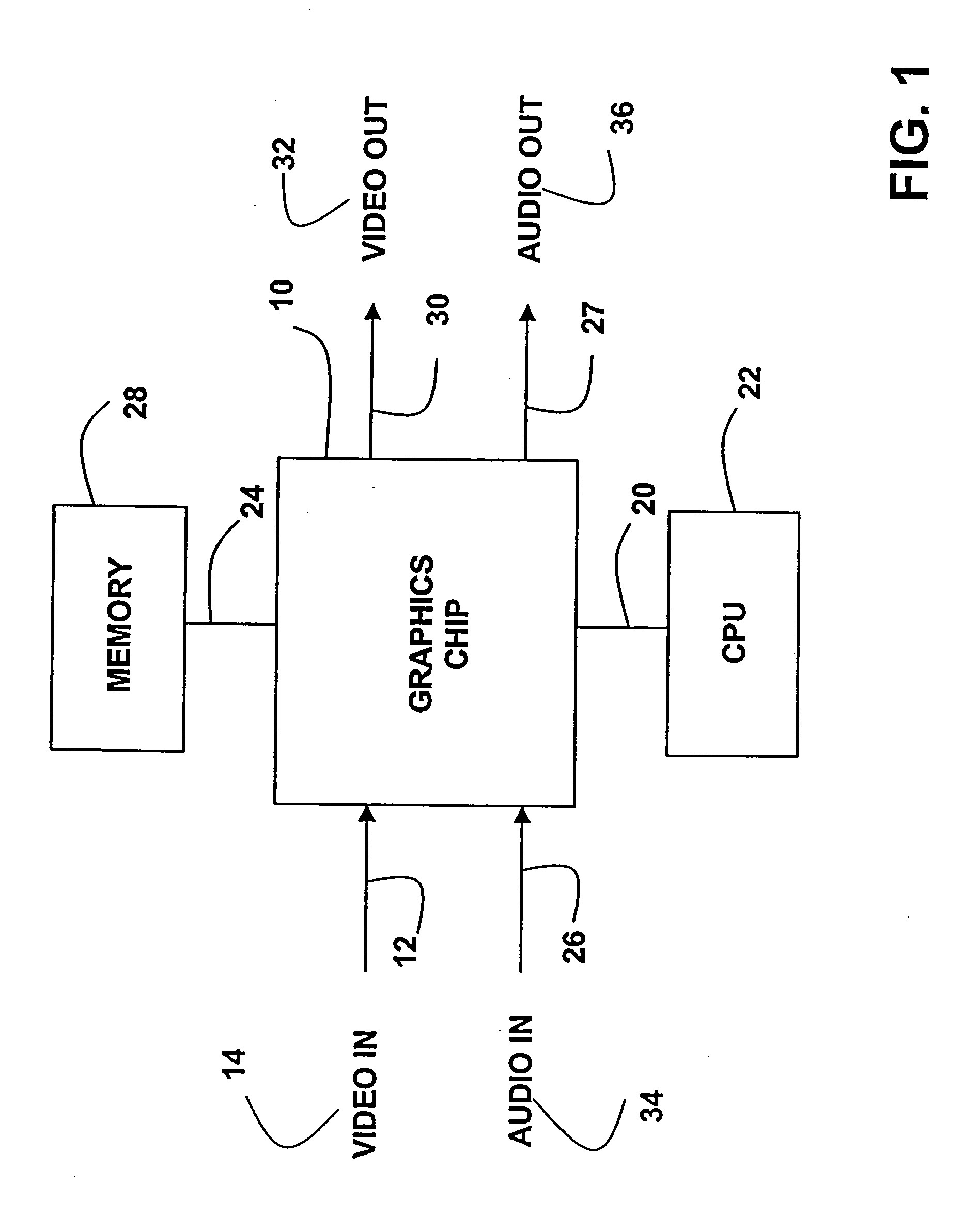

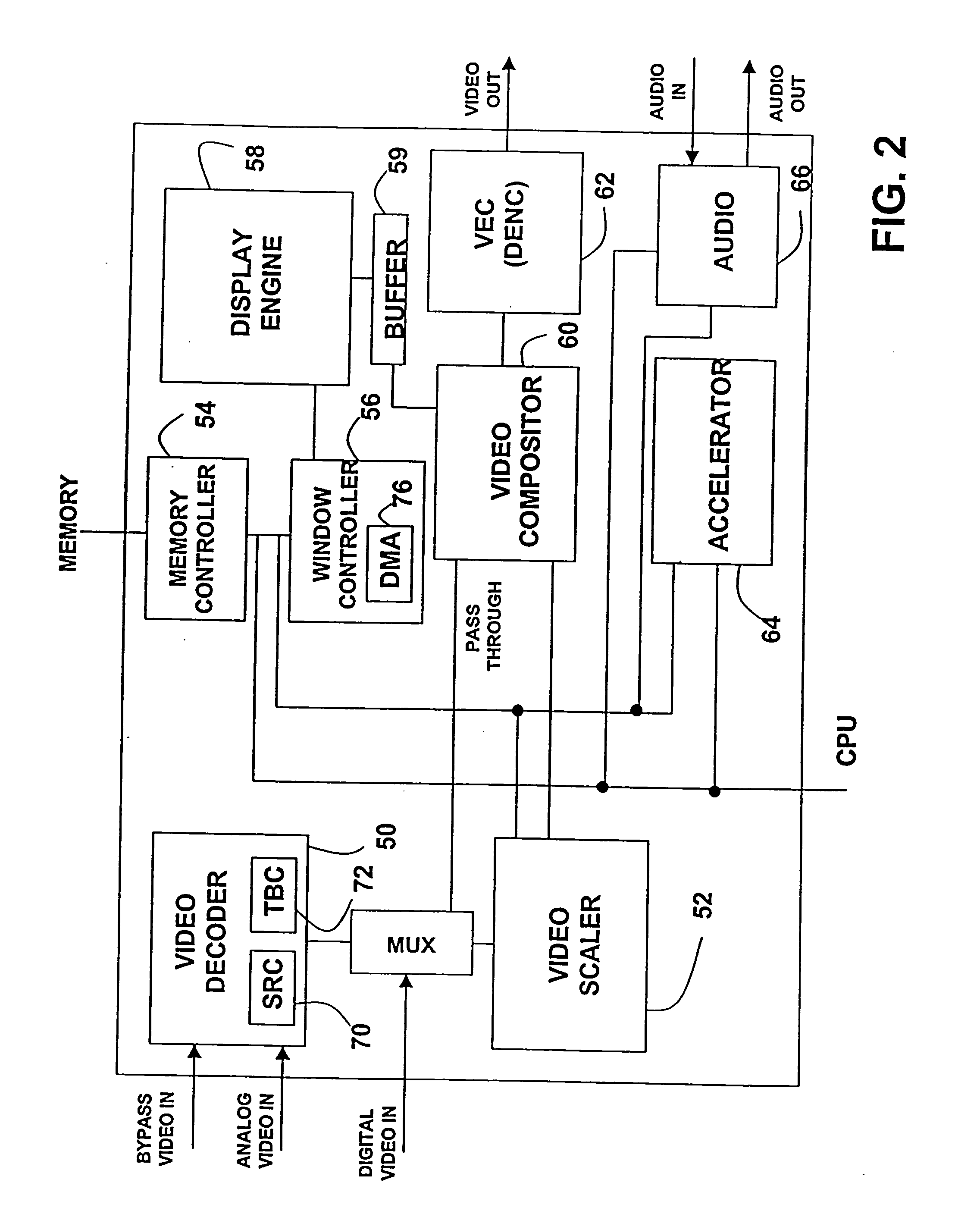

Video and graphics system with an MPEG video decoder for concurrent multi-row decoding

InactiveUS20050012759A1Television system detailsTelevision system scanning detailsDigital videoGraphics

A video and graphics system processes video data including both analog video, e.g., NTSC / PAL / SECAM / S-video, and digital video, e.g., MPEG-2 video in SDTV or HDTV format. The video and graphics system includes a video decoder, which is capable of concurrently decoding multiple SLICEs of MPEG-2 video data. The video decoder includes multiple row decoding engines for decoding the MPEG-2 video data. Each row decoding engine concurrently decodes two or more rows of the MPEG-2 video data. The row decoding engines have a pipelined architecture for concurrently decoding multiple rows of MPEG-2 video data. The video decoder may be integrated on an integrated circuit chip with other video and graphics system components such as transport processors for receiving one or more compressed data streams and for extracting video data, and a video compositor for blending processed video data with graphics.

Owner:AVAGO TECH INT SALES PTE LTD

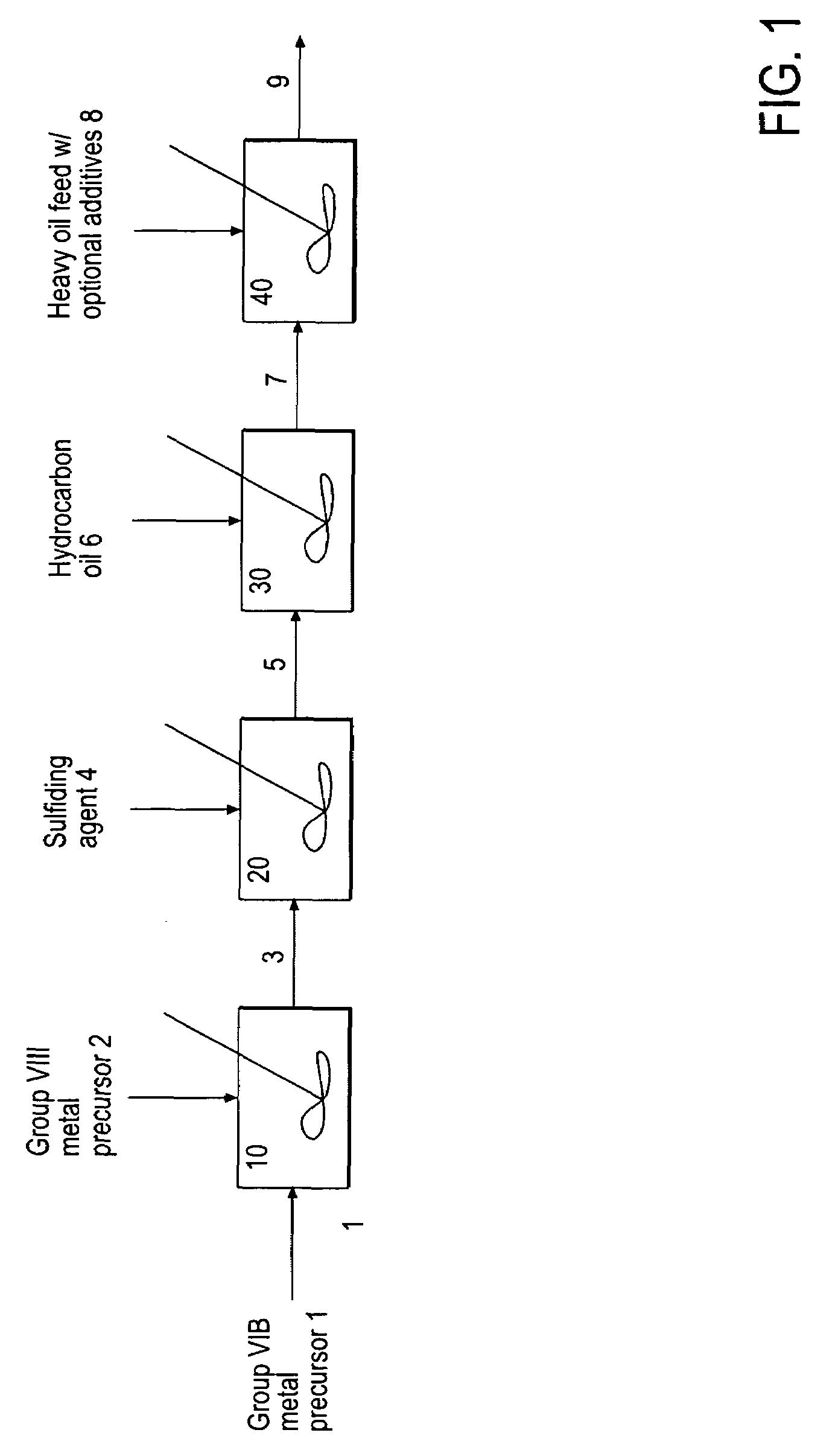

Process for sulfiding a hydrotreating catalyst comprising an organic compound comprising n and carbonyl

InactiveUS6540908B1Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenSulfidation

The invention pertains to a process for preparing a sulfided hydrotreating catalyst in which a hydrotreating catalyst is subjected to a sulfidation step, wherein the hydrotreating catalyst comprises a carrier comprising at least 50 wt % of alumina, the catalyst comprising at least one hydrogenation metal component and an organic compound comprising at least one covalently bonded nitrogen atom and at least one carbonyl moiety, the molar ratio between the organic compound and the total hydrogenation metal content being at least 0.01:1. The invention further pertains to the use of said hydrotreating catalyst in hydrotreating a hydrocarbon feed, in particular to achieve hydrodenitrogenation, (deep) hydrodesulfurization, or hydrodearomatization.

Owner:ALBEMARLE NETHERLANDS BV

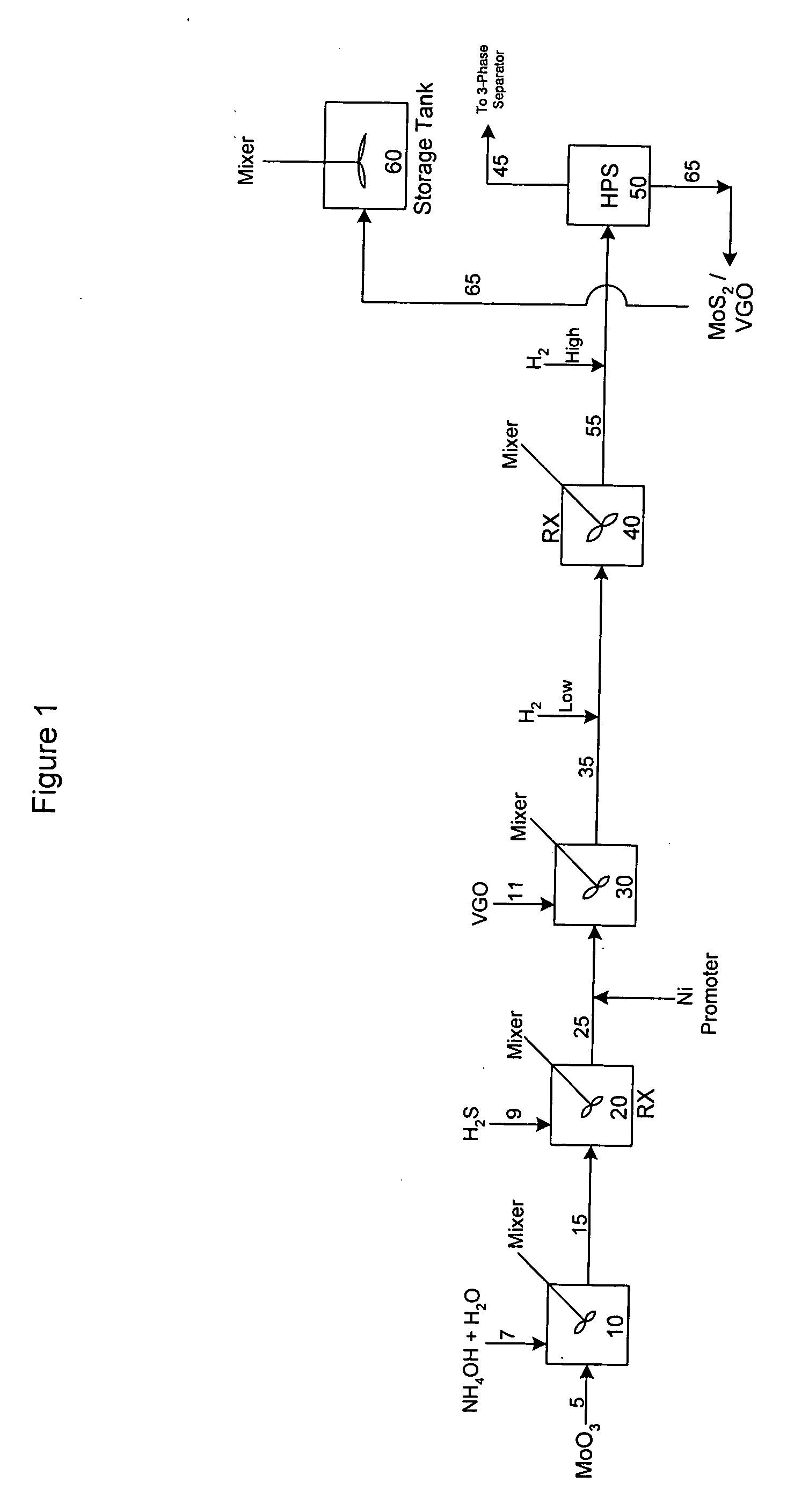

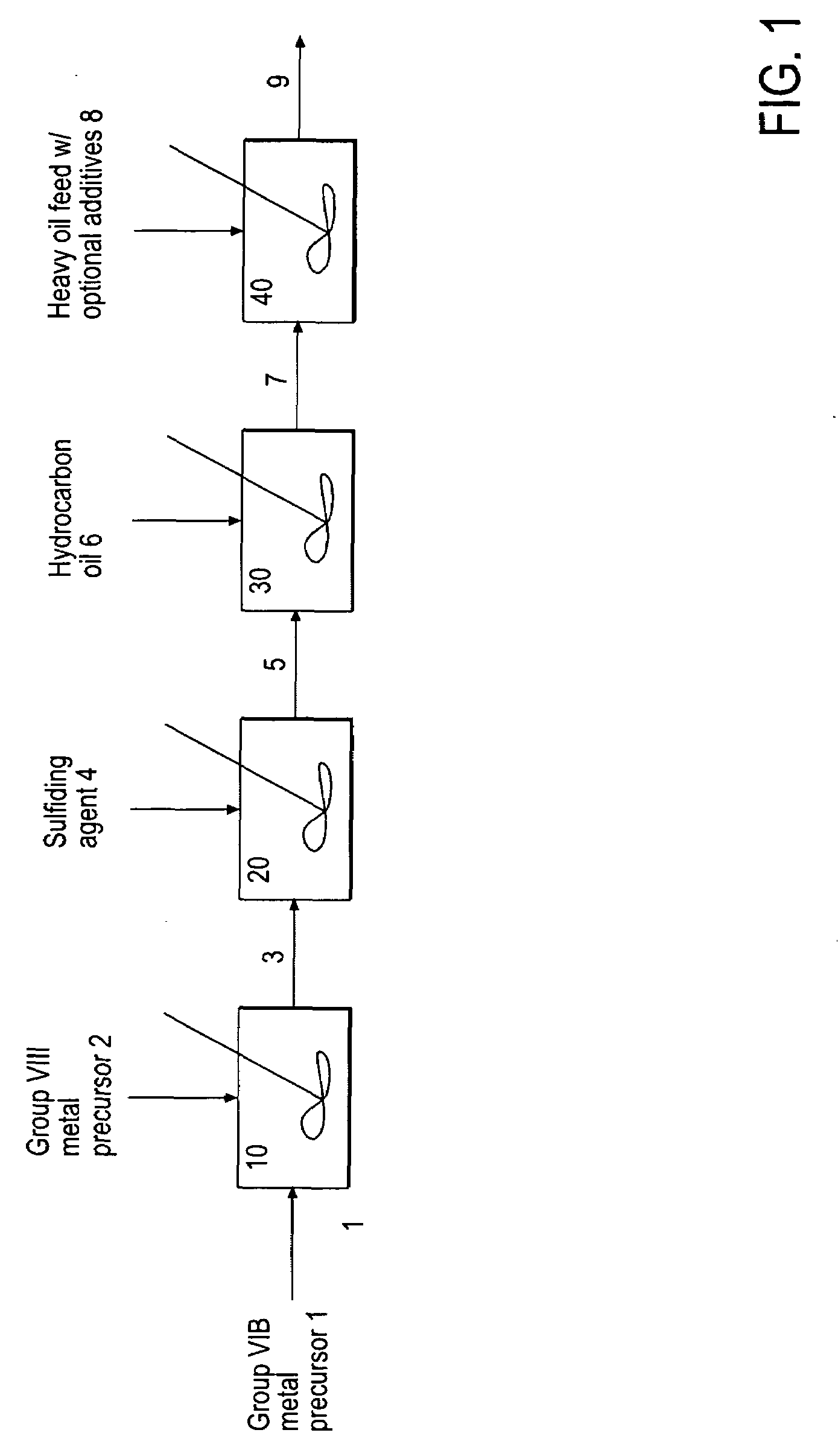

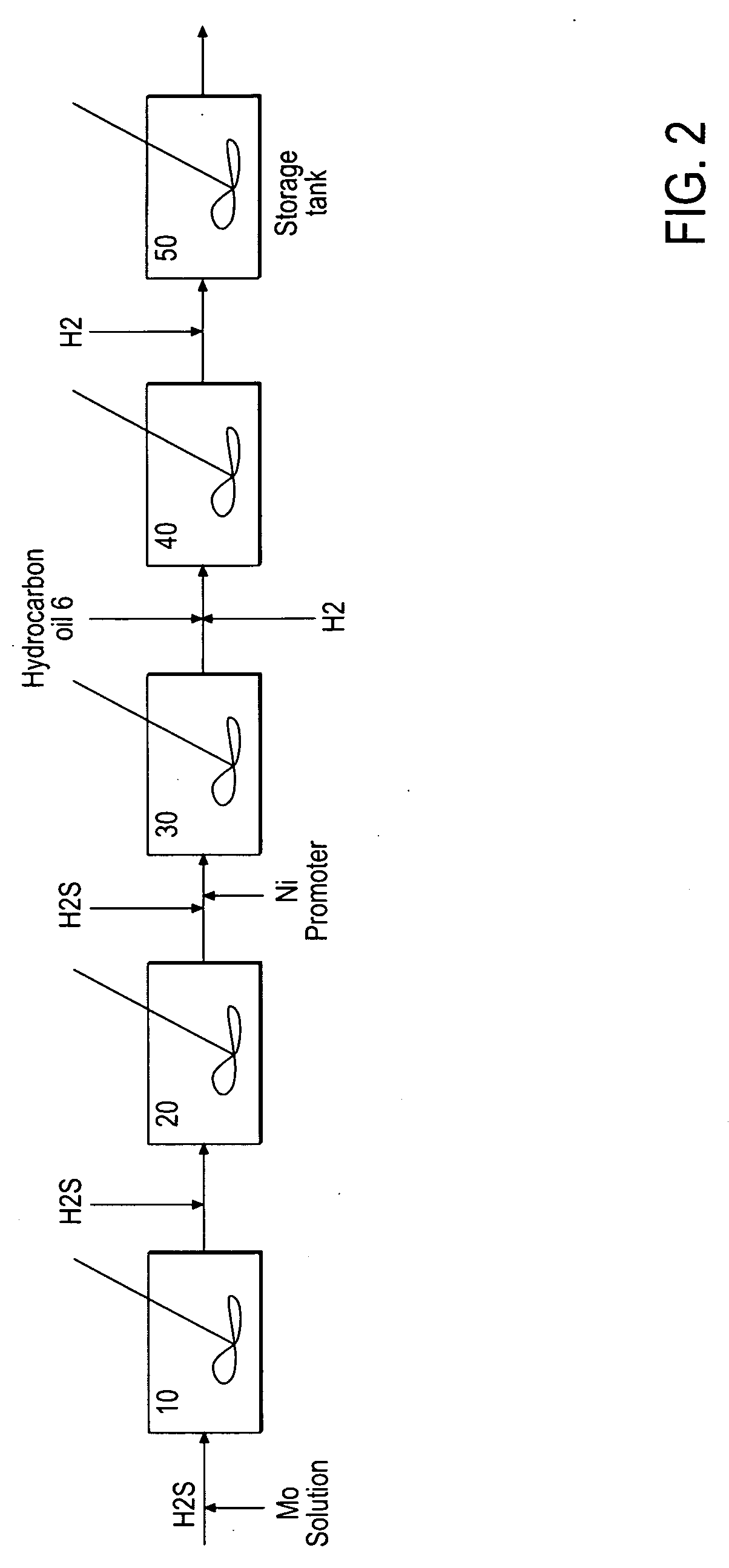

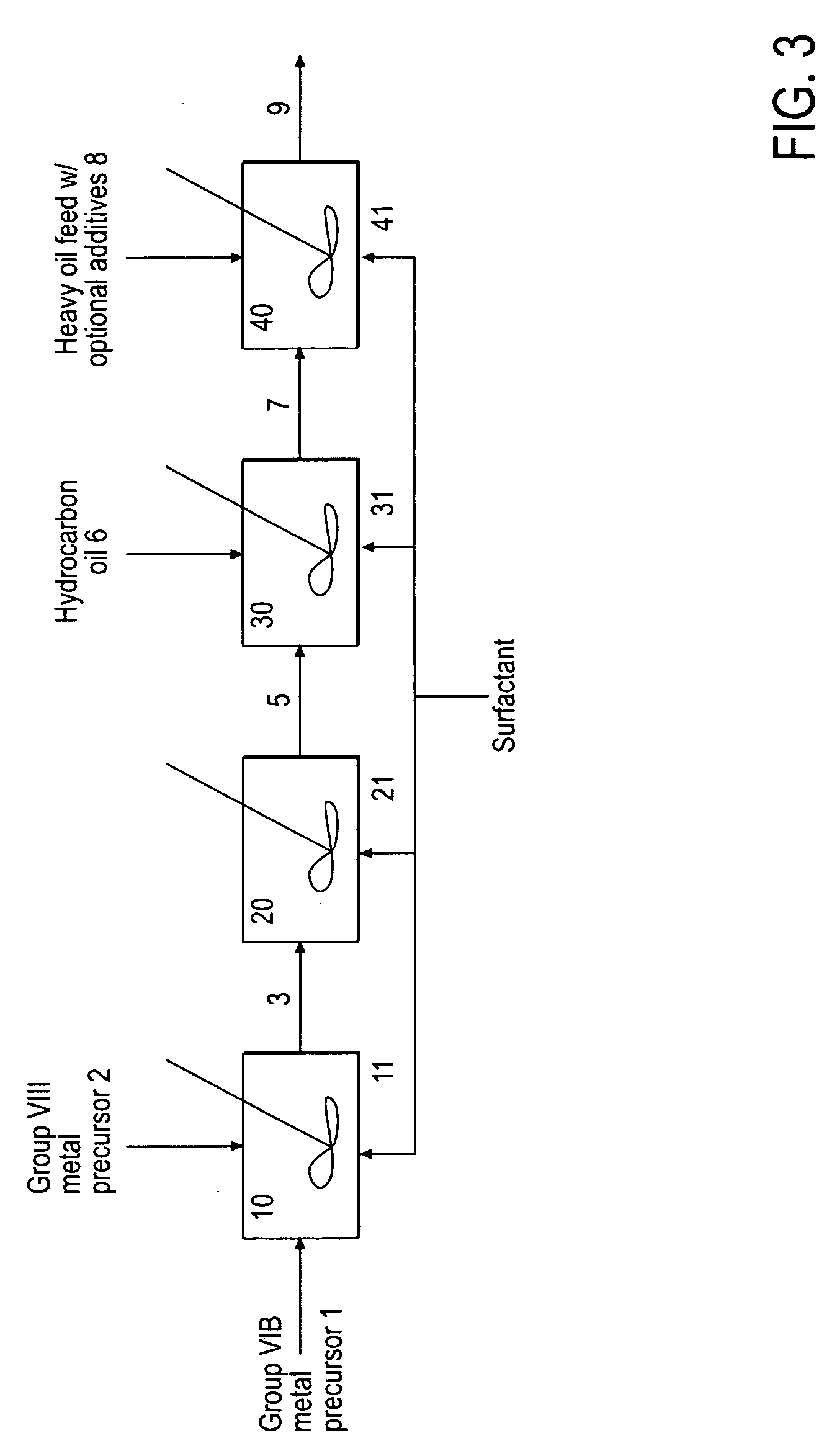

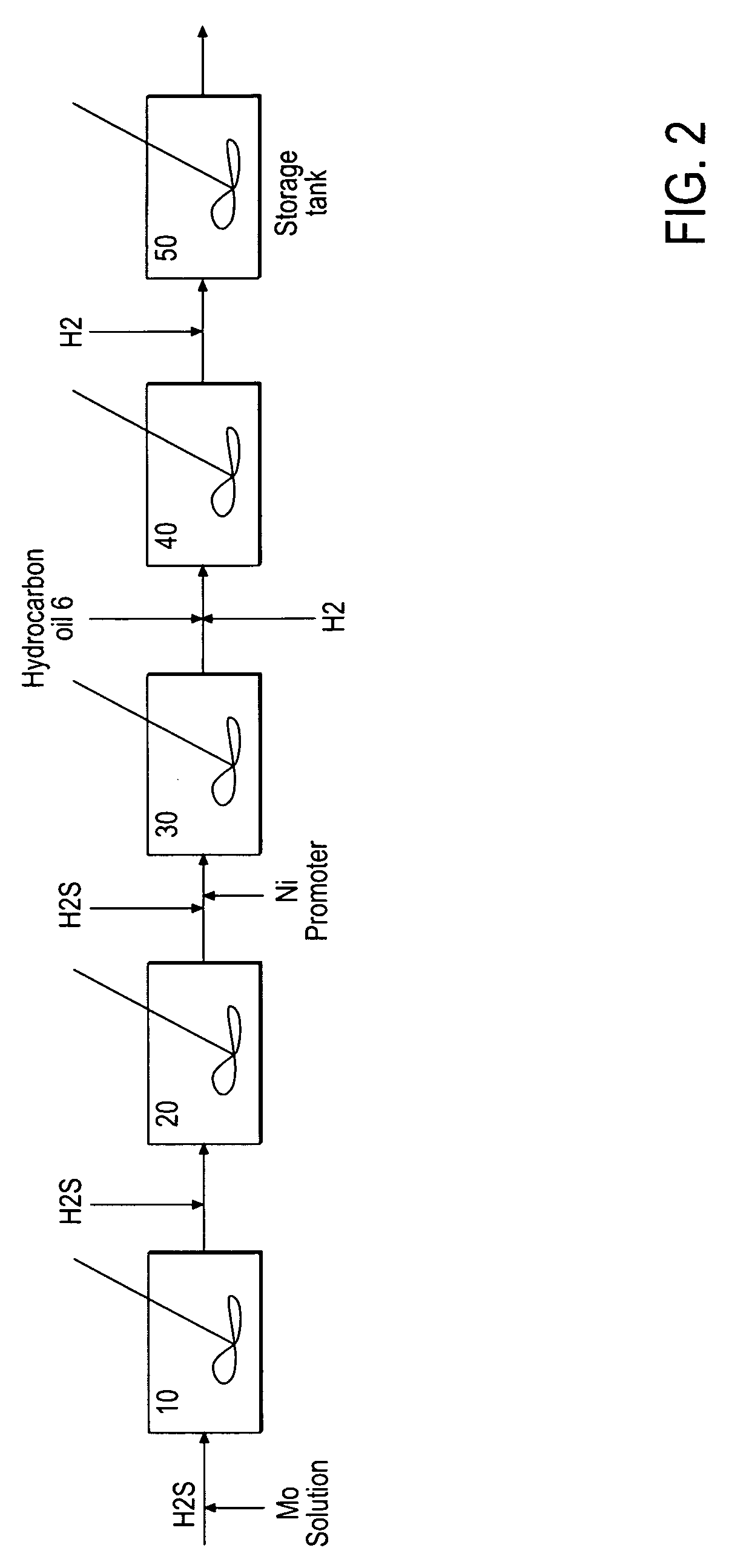

Highly active slurry catalyst composition

InactiveUS20060058174A1High viscosity carbonaceousHigh viscosityInorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenSlurry

The instant invention is directed to the preparation of a slurry catalyst composition. The slurry catalyst composition is prepared in a series of steps, involving mixing a Group VIB metal oxide and aqueous ammonia to form an aqueous mixture and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal. Subsequent steps involve mixing the slurry with a hydrocarbon oil, and combining the resulting mixture with hydrogen gas (under conditions which maintain the water in a liquid phase) to produce the active slurry catalyst.

Owner:CHEVROU USA INC

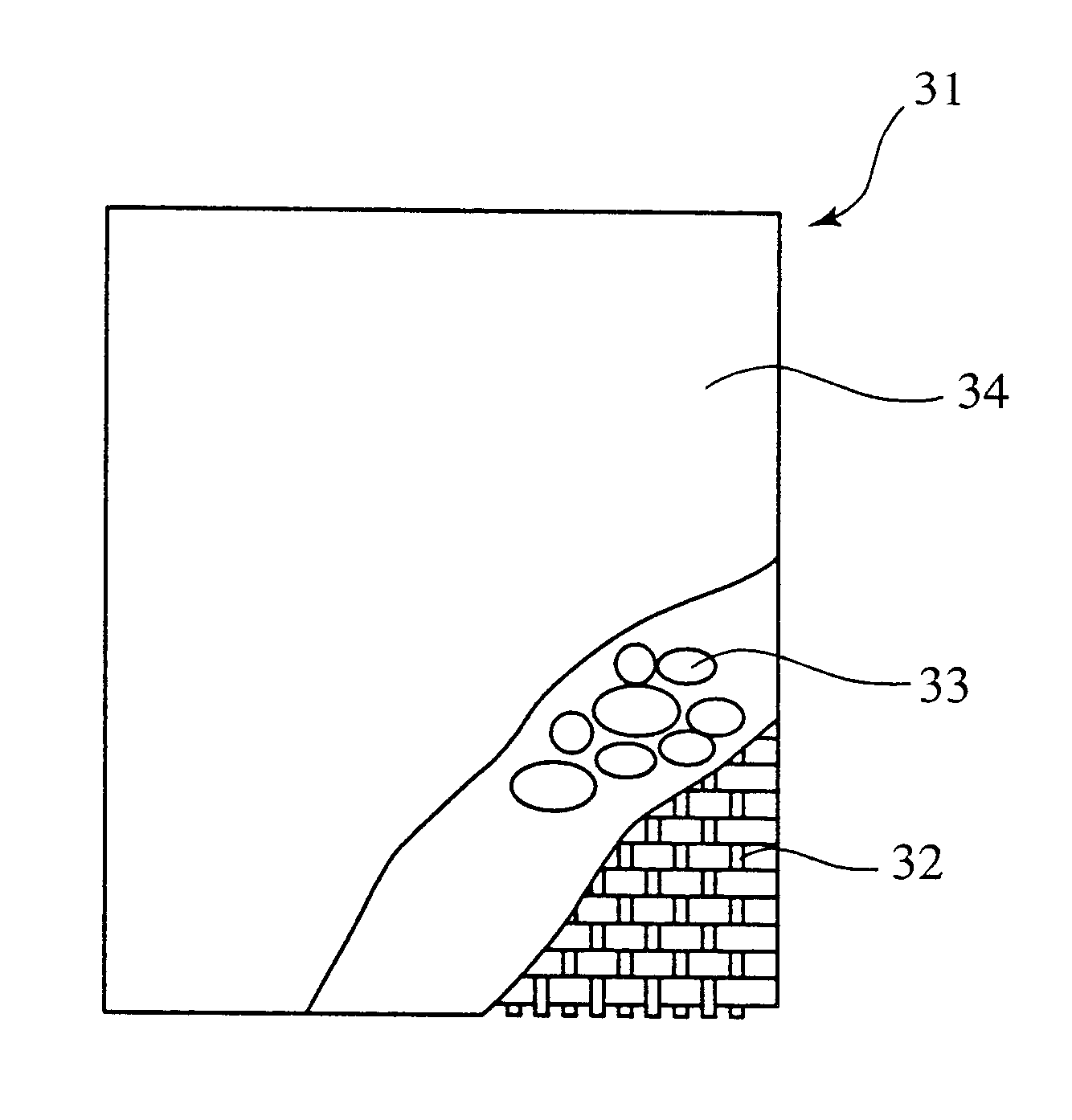

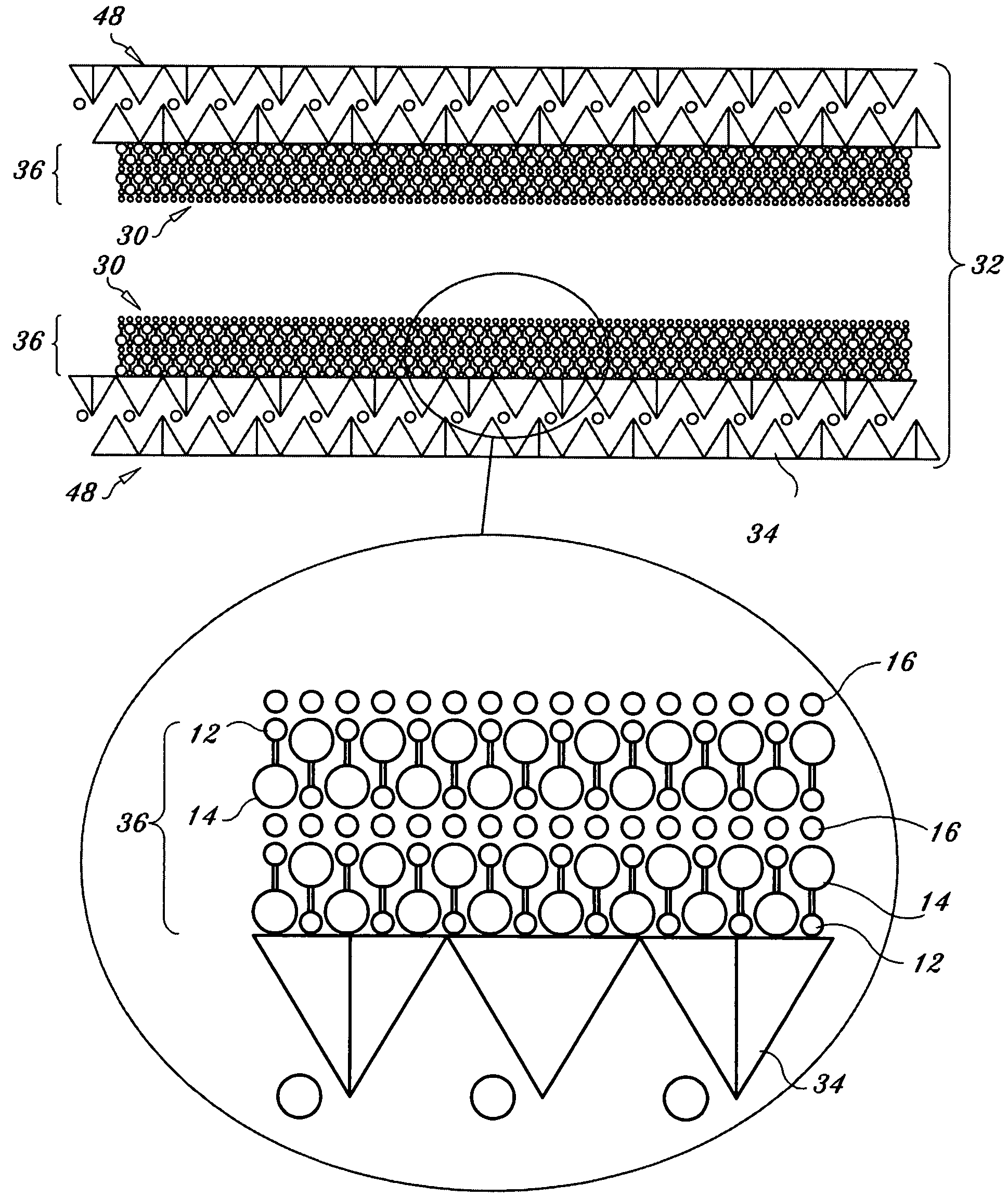

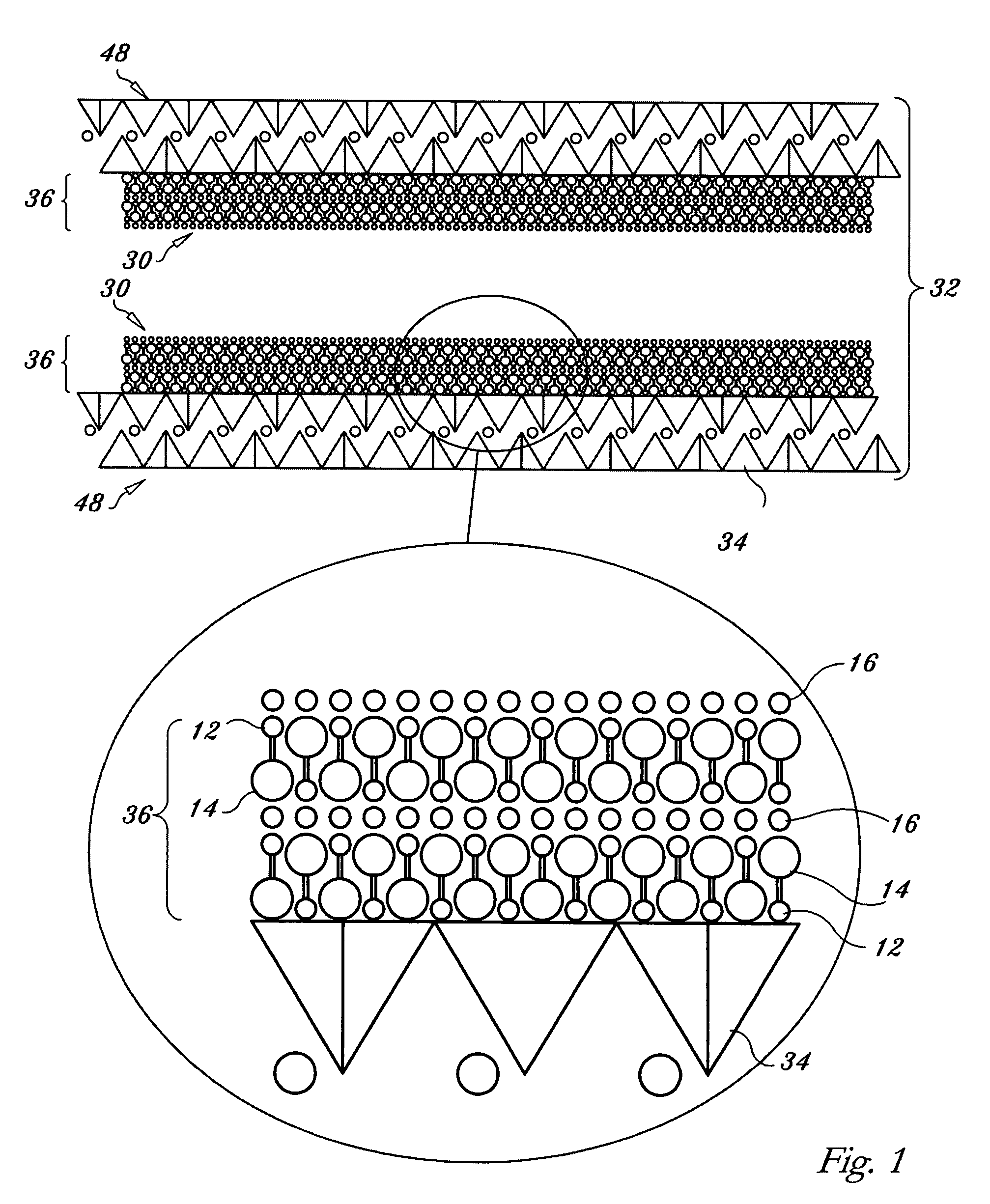

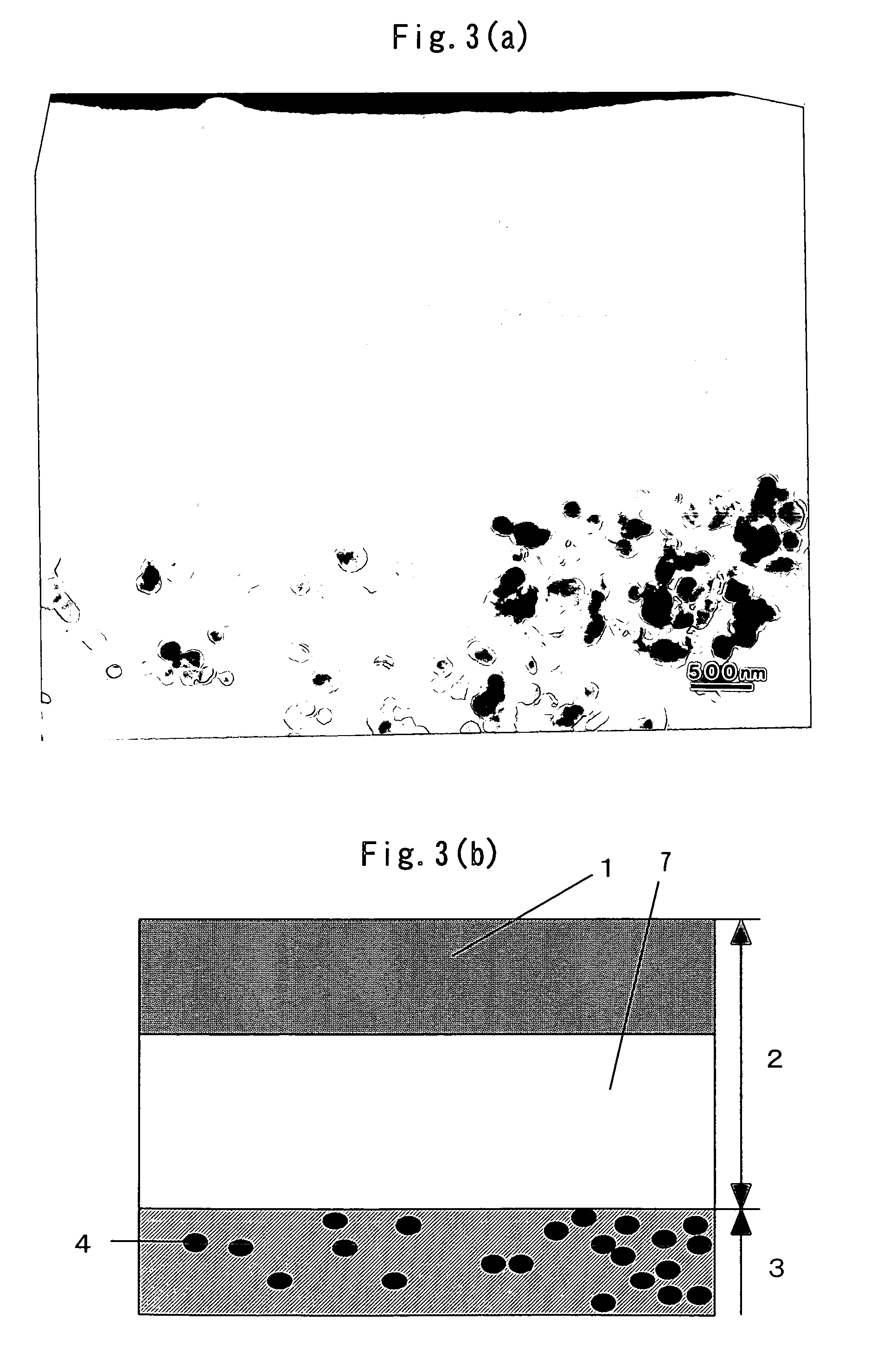

Photocatalyst-supporting body and photocatalytic apparatus

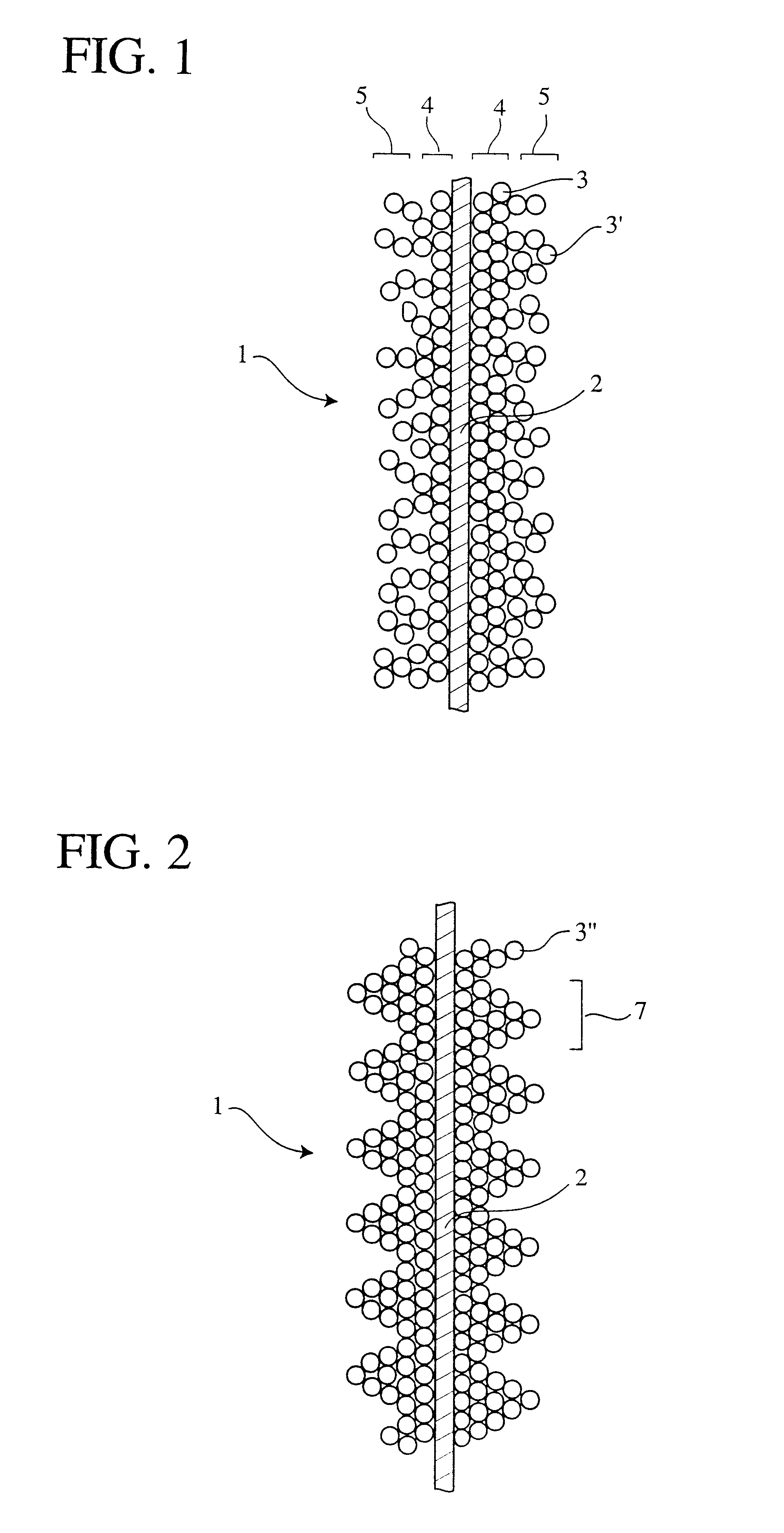

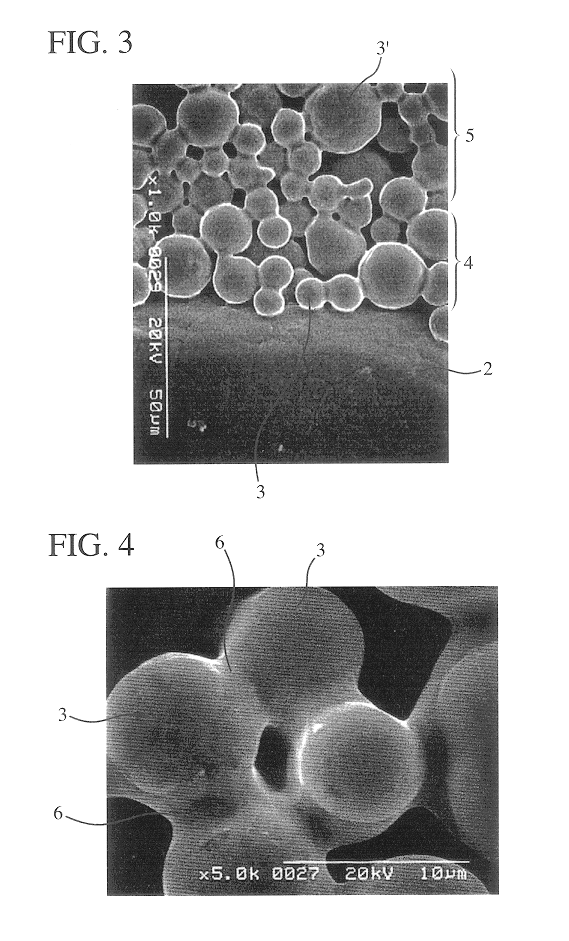

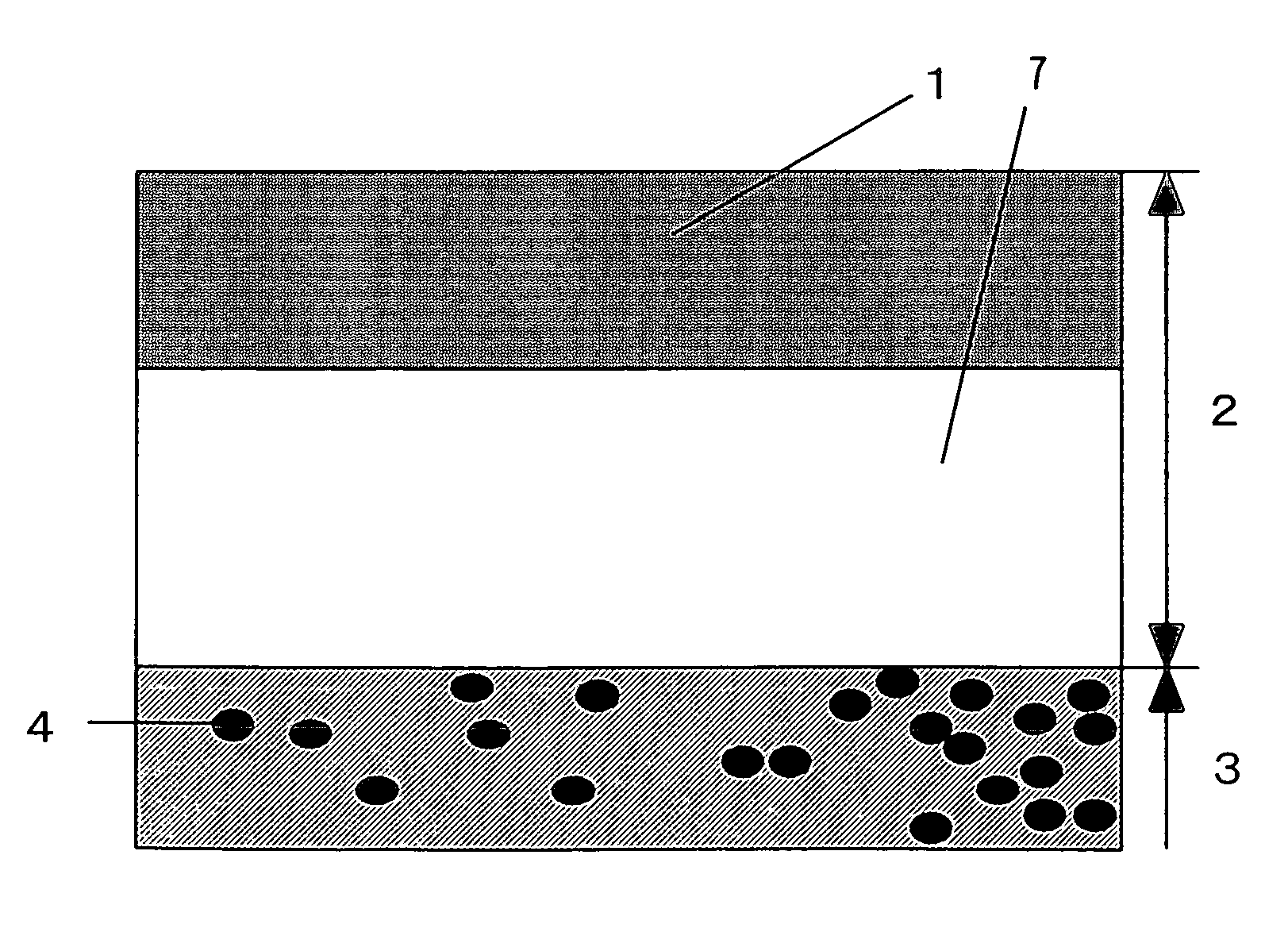

InactiveUS6531100B1Fine surfaceIncrease the areaCombination devicesInorganic chemistryPollutantPorous layer

A photocatalyst-supporting body comprises a substrate, a porous layer fixedly disposed on at least one surface of the substrate, and a semiconductor photocatalyst layer deposited on the surface of the porous layer. The porous layer is made of fine particles or porous nonwoven metal fabric. Since the semiconductor photocatalyst is bound to the substrate through the porous layer, the area of the photocatalytic surface is increased and the contaminants in a fluid flow being treated adequately contact the photocatalytic surface thereby to enhance the photocatalytic efficiency. The photocatalytic efficiency is further improved by making the porous layer dense (rough) in the vicinity of the surface of the substrate and rough (dense) with increasing distance from the surface of the substrate.

Owner:TECH OF ART & ORIGINAL COLORS INC +1

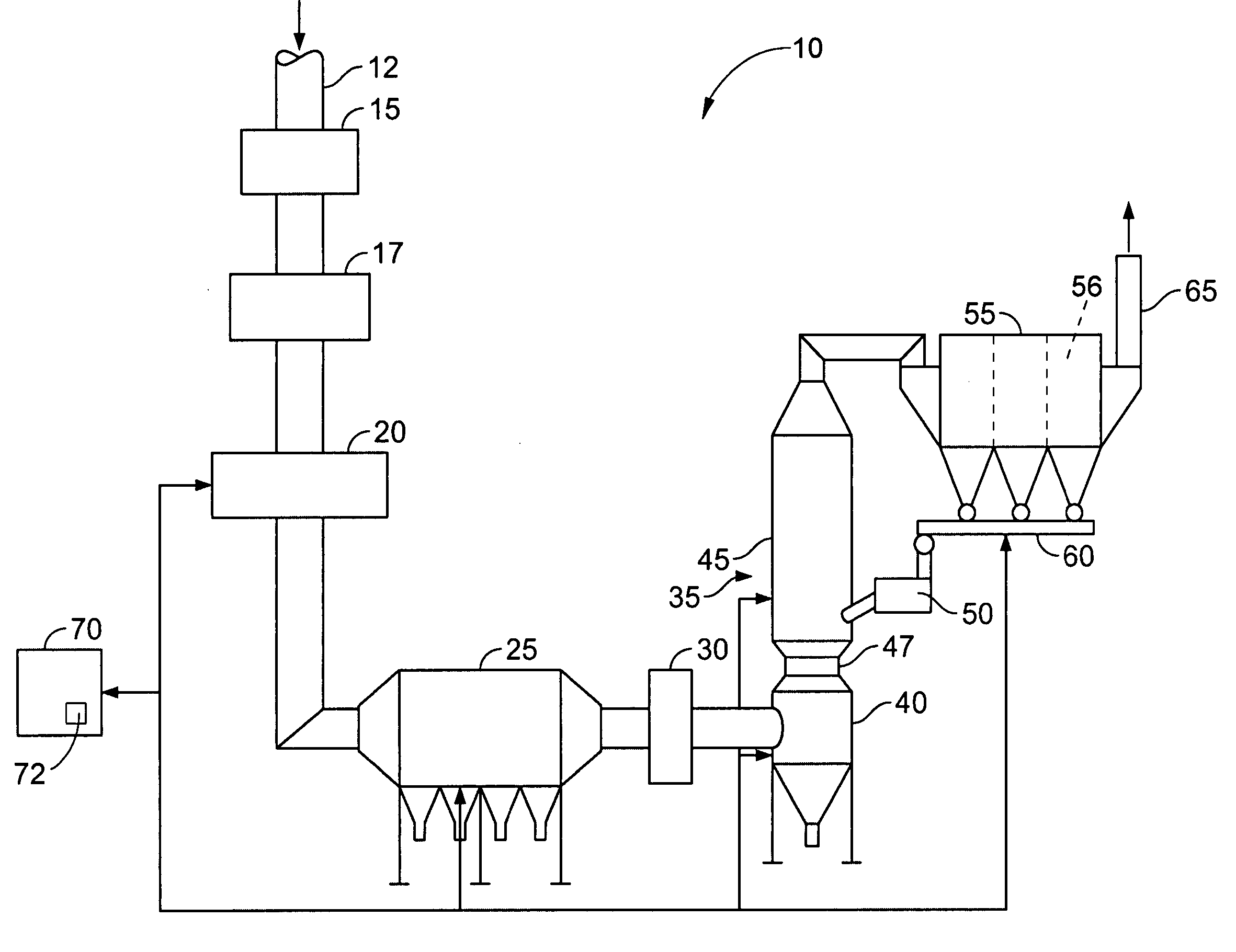

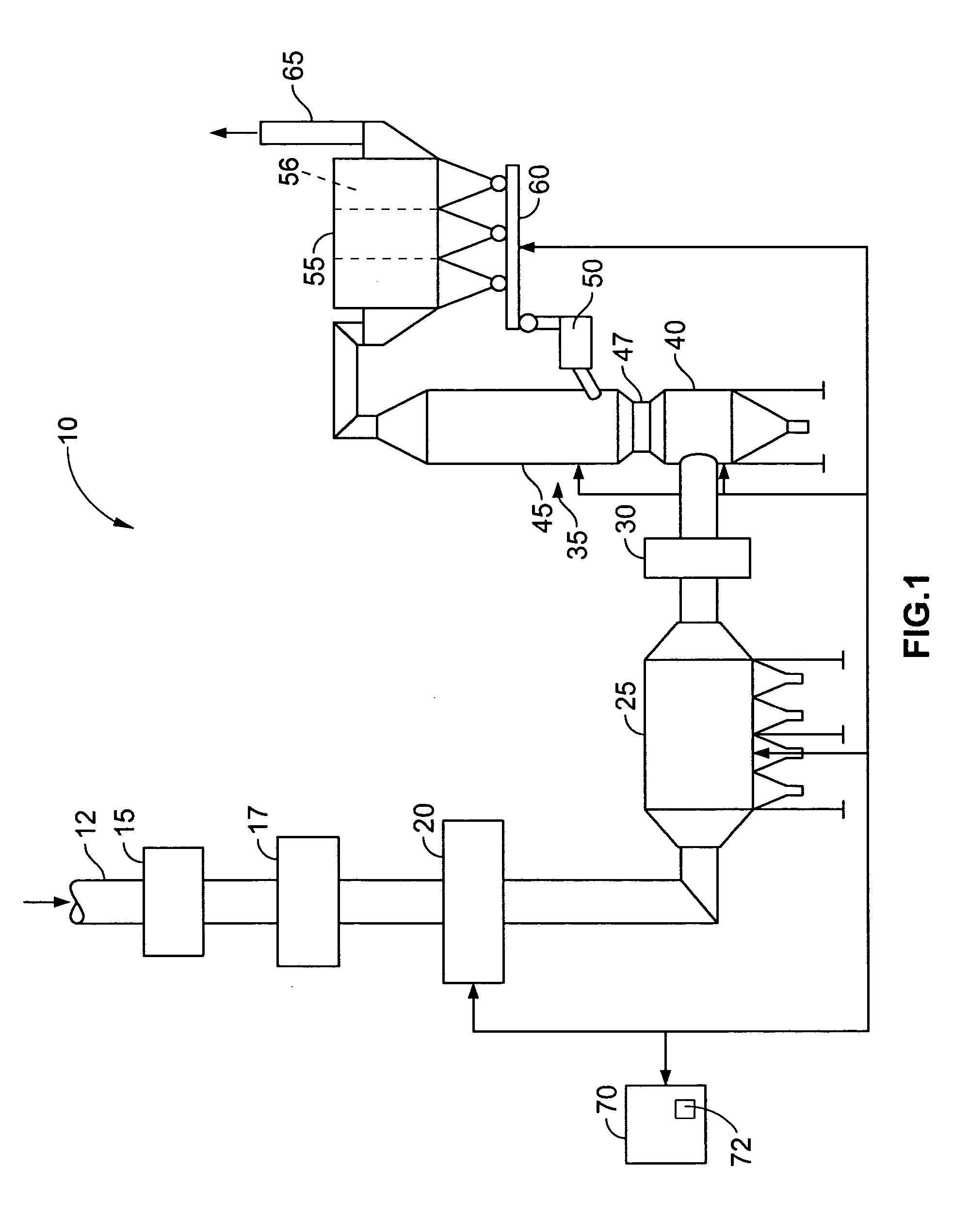

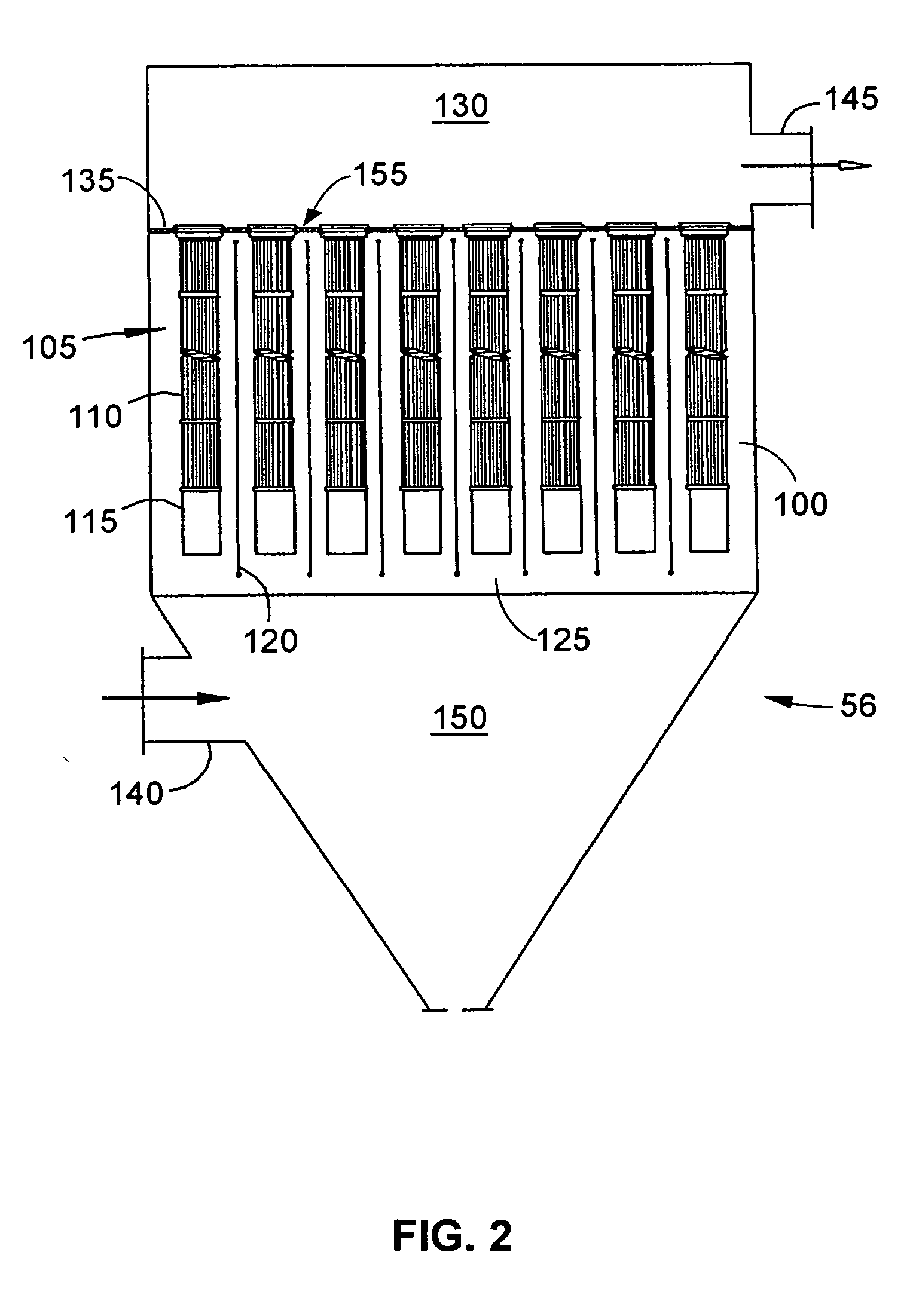

Method and system for removing mercury from combustion gas

A method for continuously removing mercury from a supply of combustion gas is provided. The method includes adjusting a power input to an electrostatic precipitator to control a quantity of fly ash emitted from the electrostatic precipitator. A turbulent flow of combustion gas is produced to suspend particulate matter including the quantity of fly ash contained in the supply of combustion gas. A substantial portion of the mercury is absorbed within the particulate matter including the quantity of fly ash. The supply of combustion gas is filtered to remove the particulate matter from the mercury. A quantity of absorption sites available for absorbing mercury is controlled by monitoring an emission of fly ash from the electrostatic precipitator.

Owner:GENERAL ELECTRIC CO

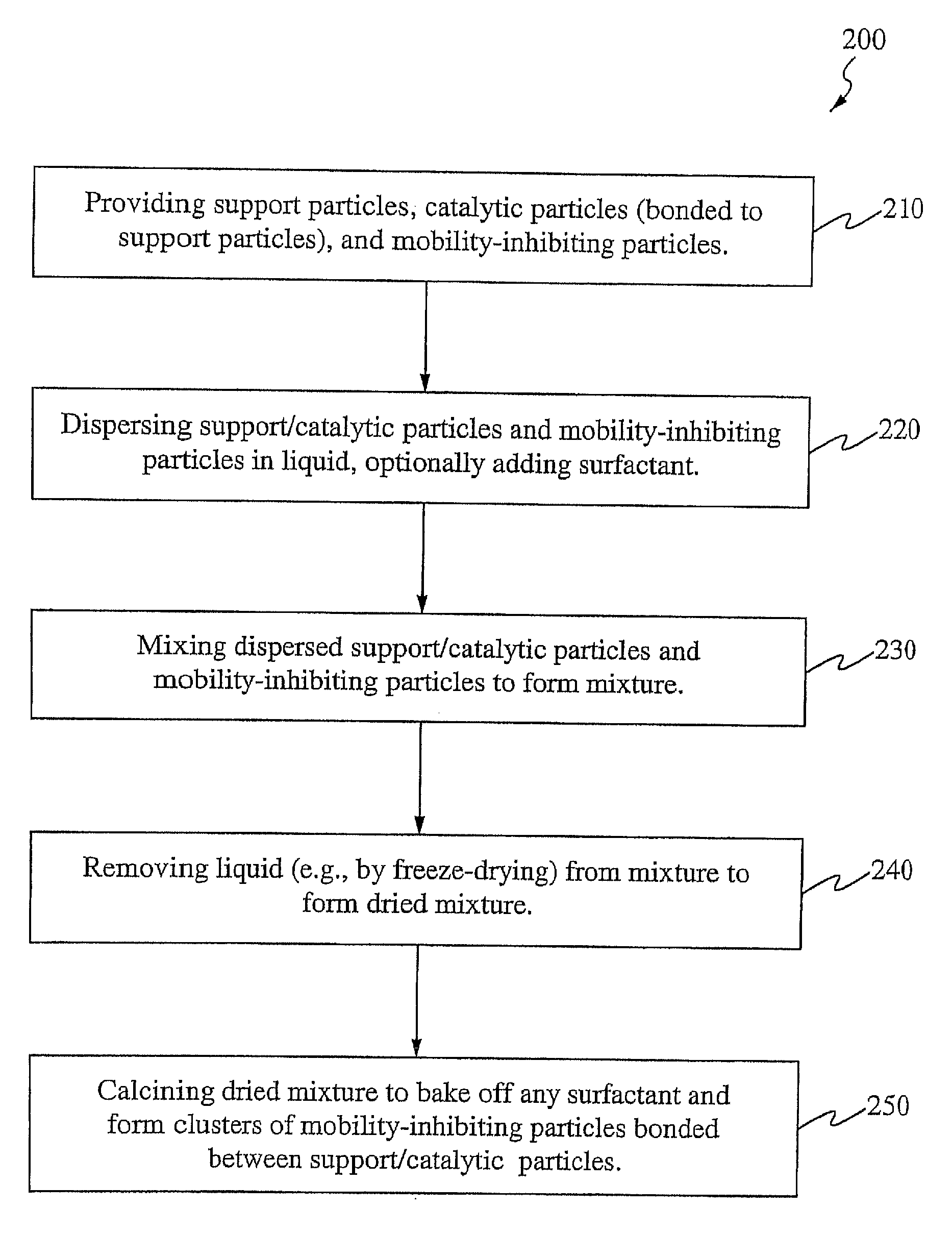

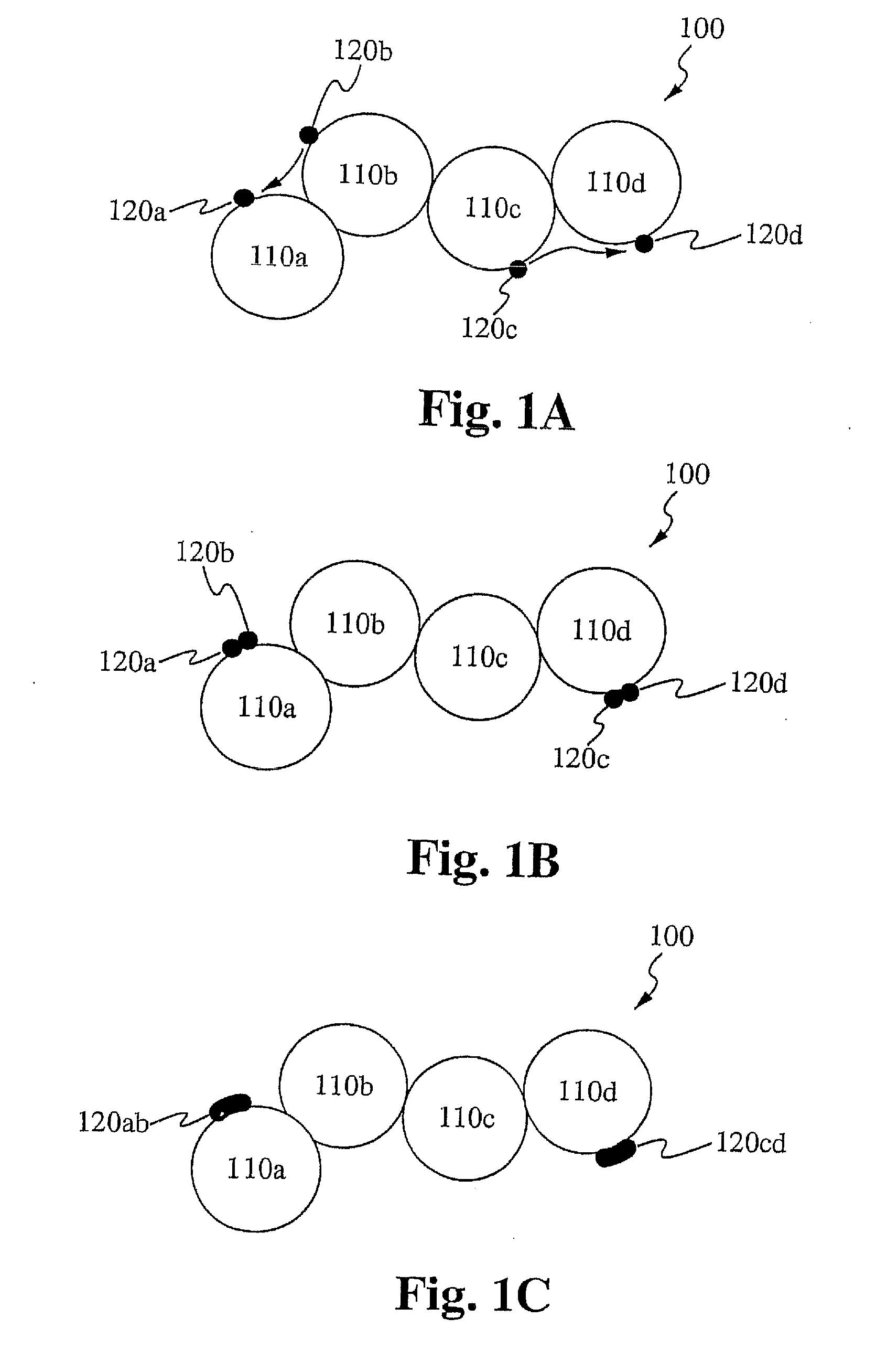

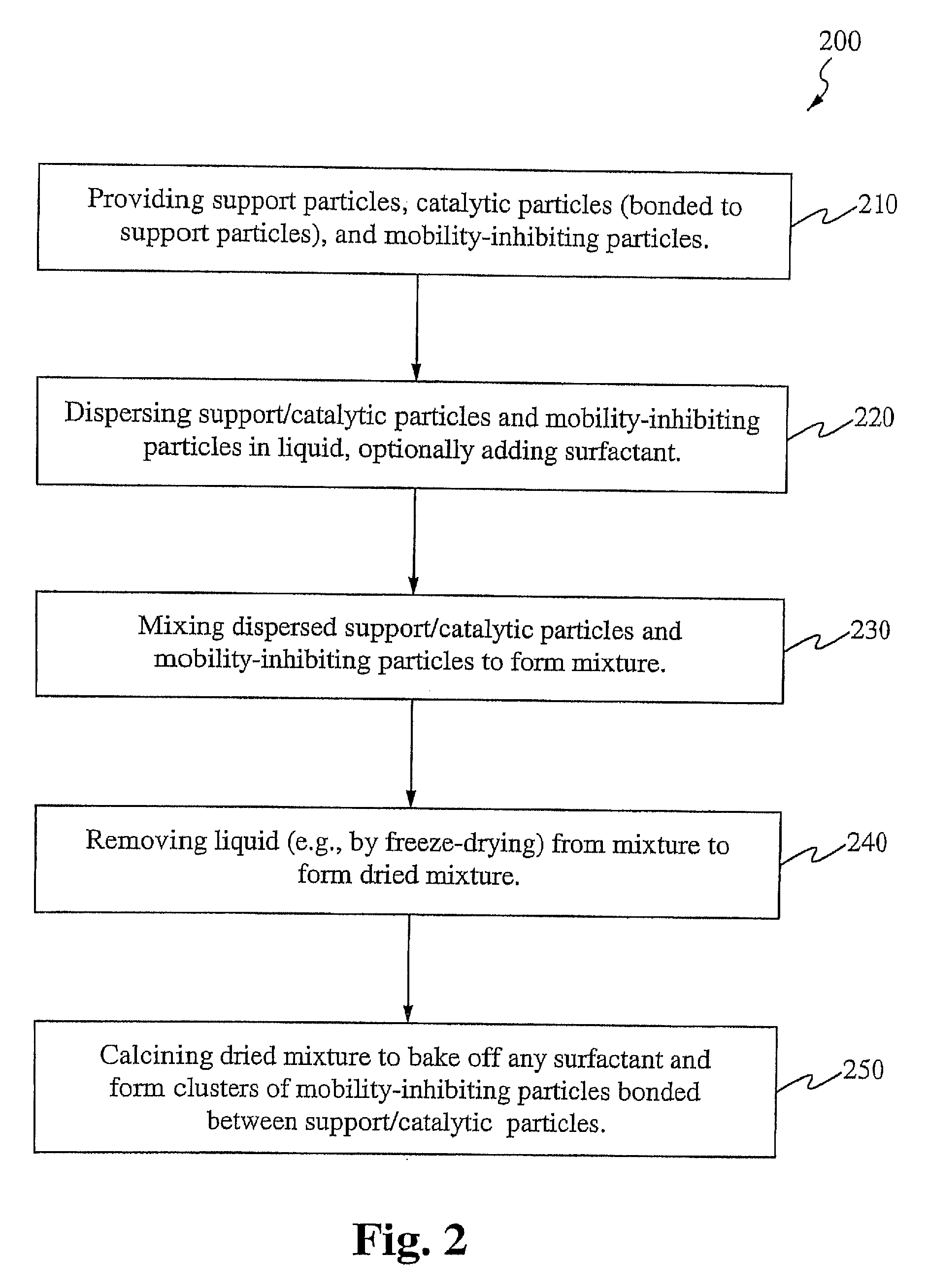

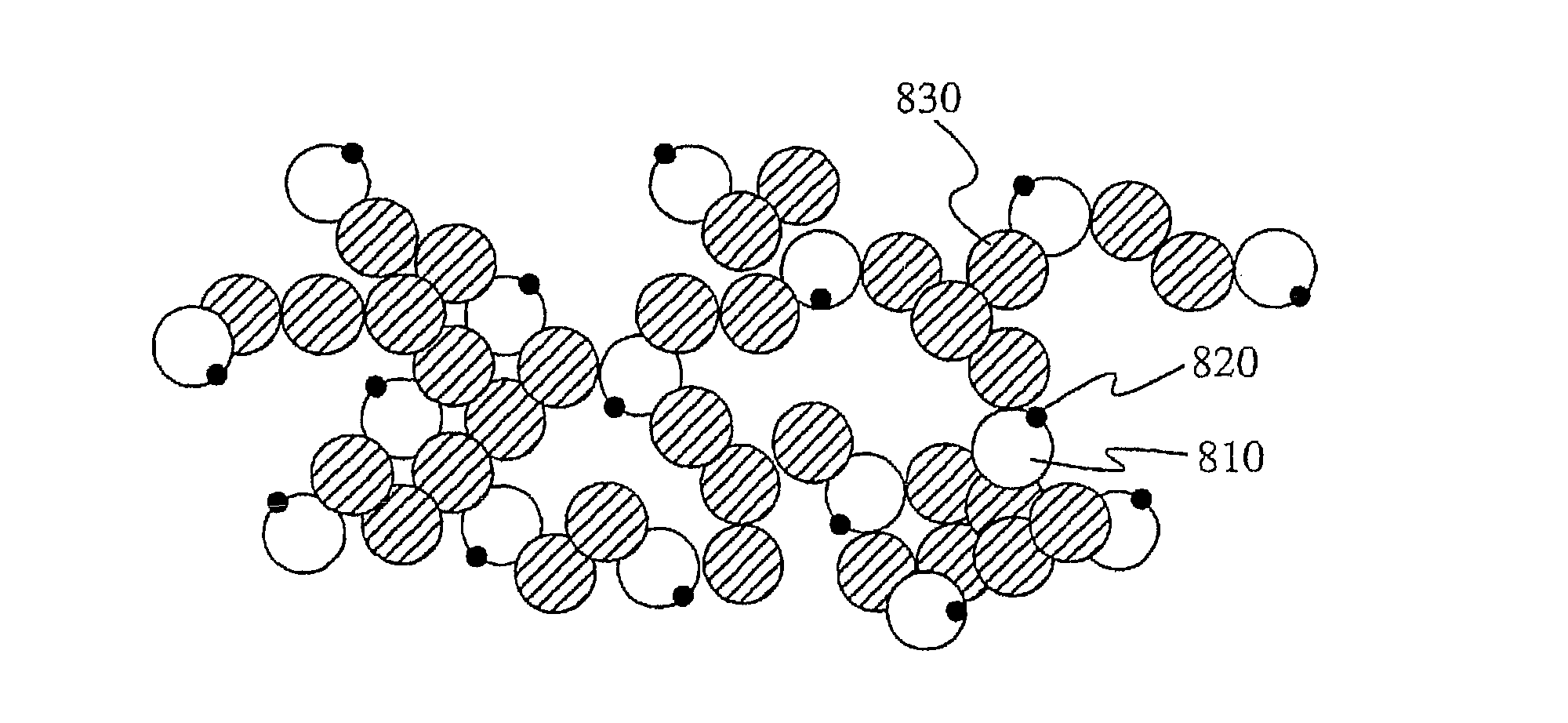

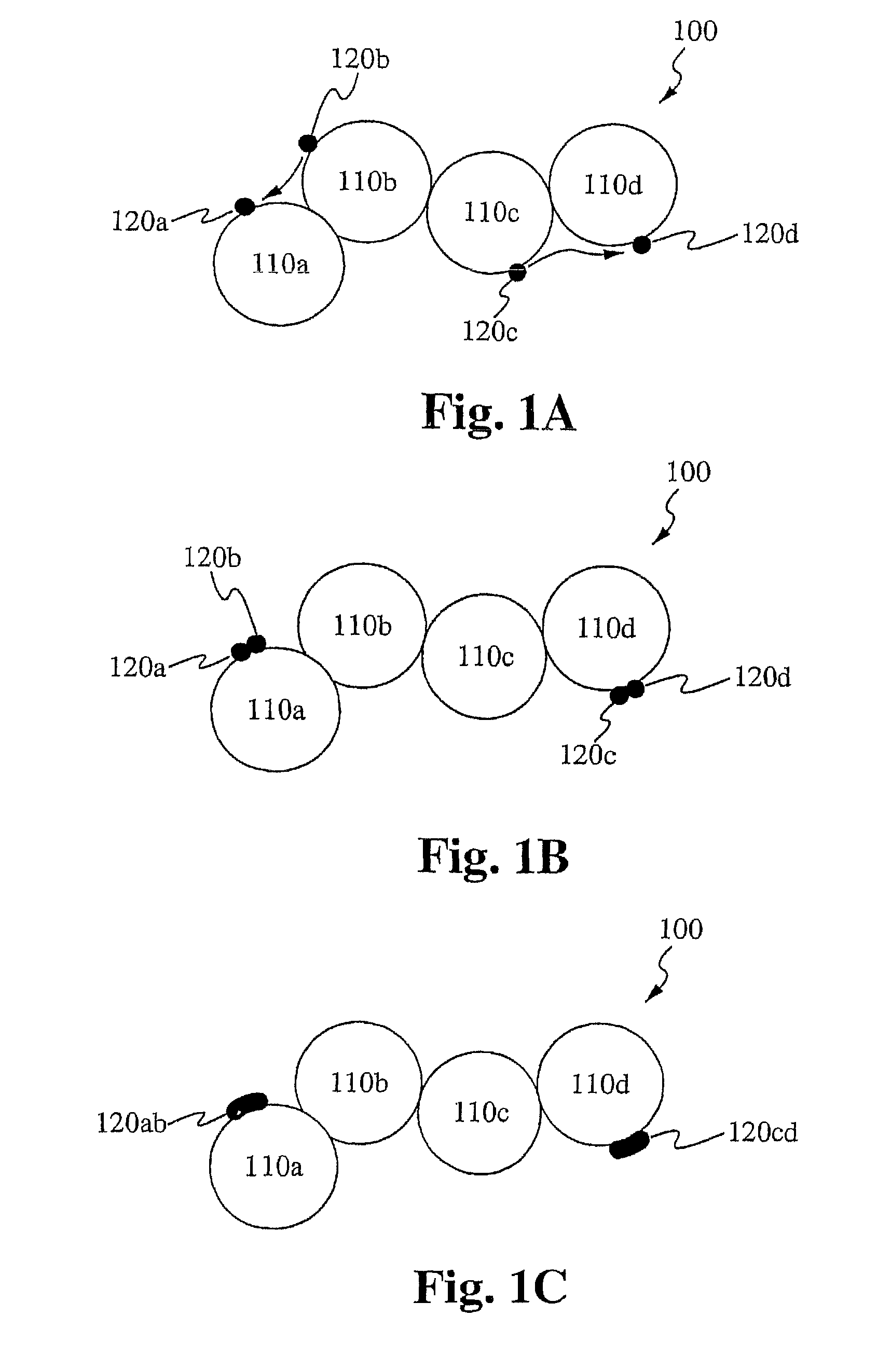

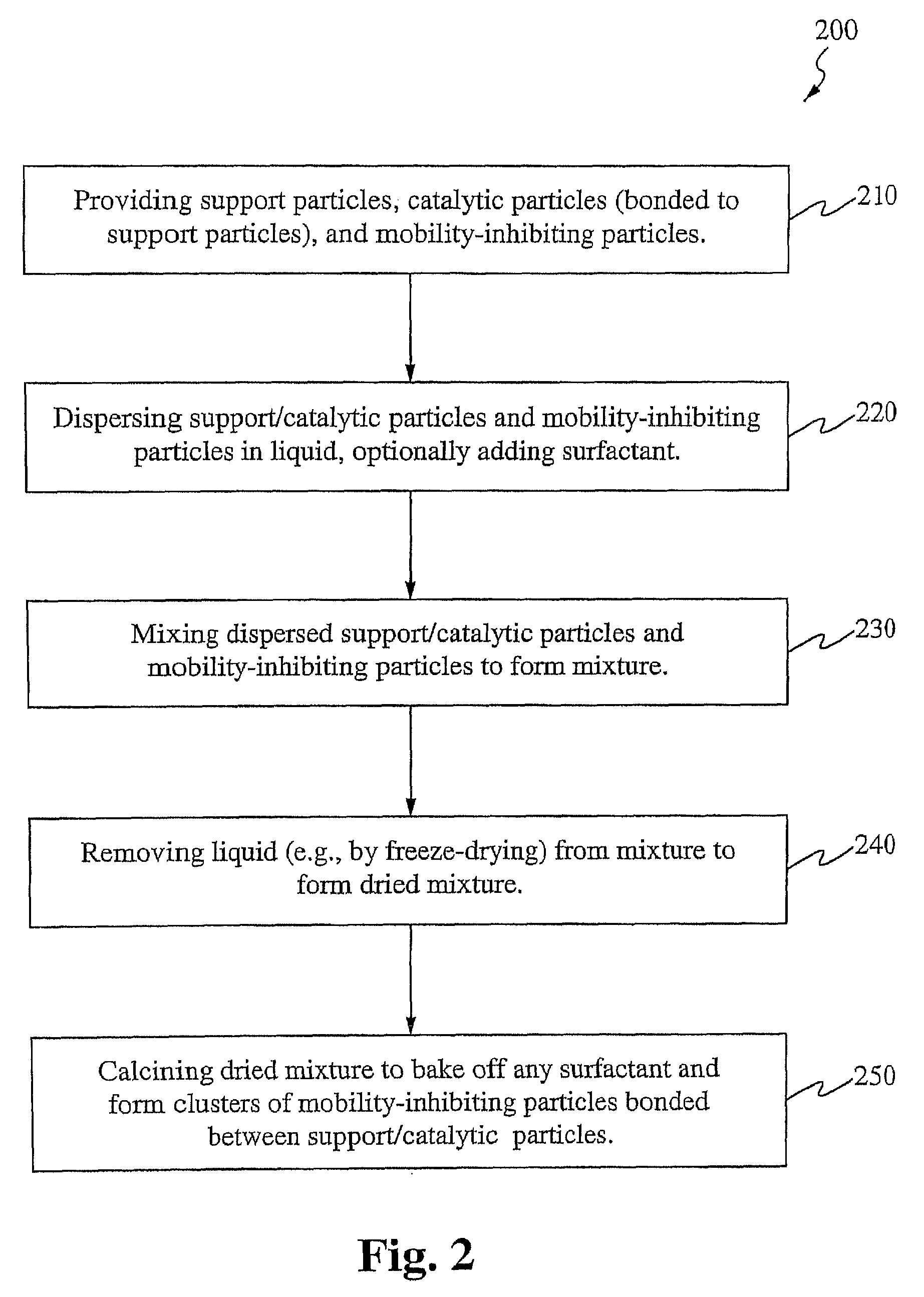

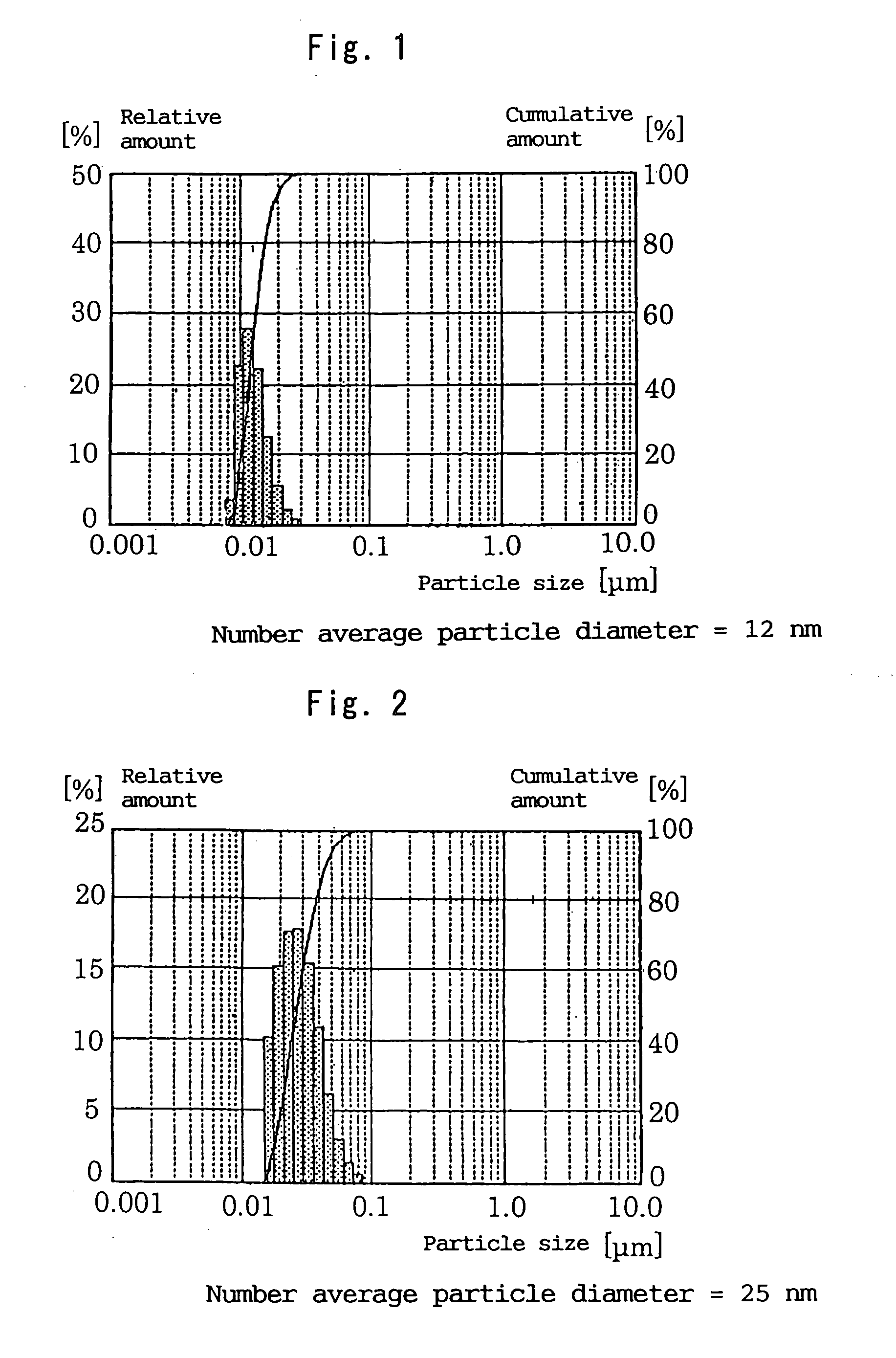

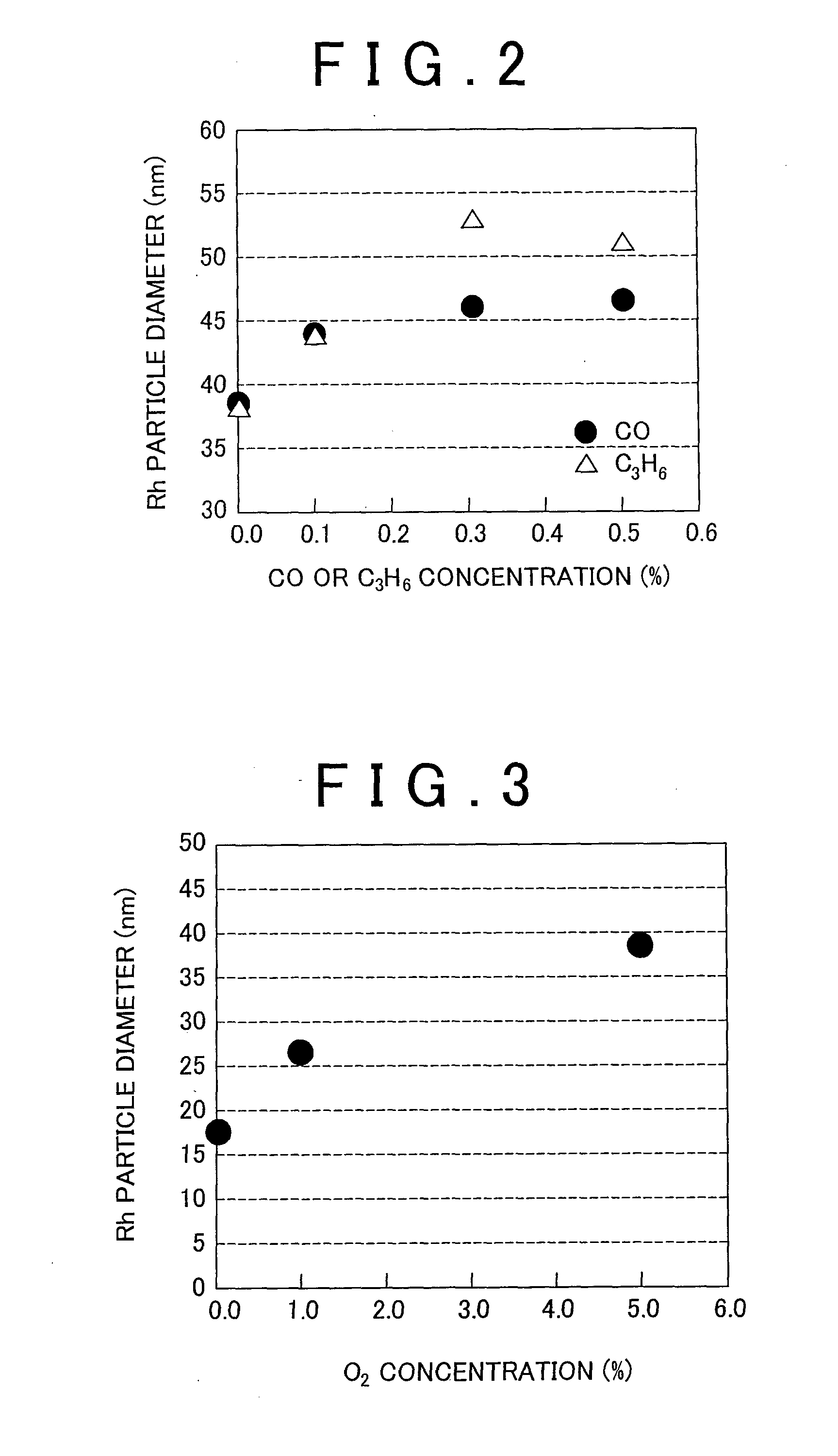

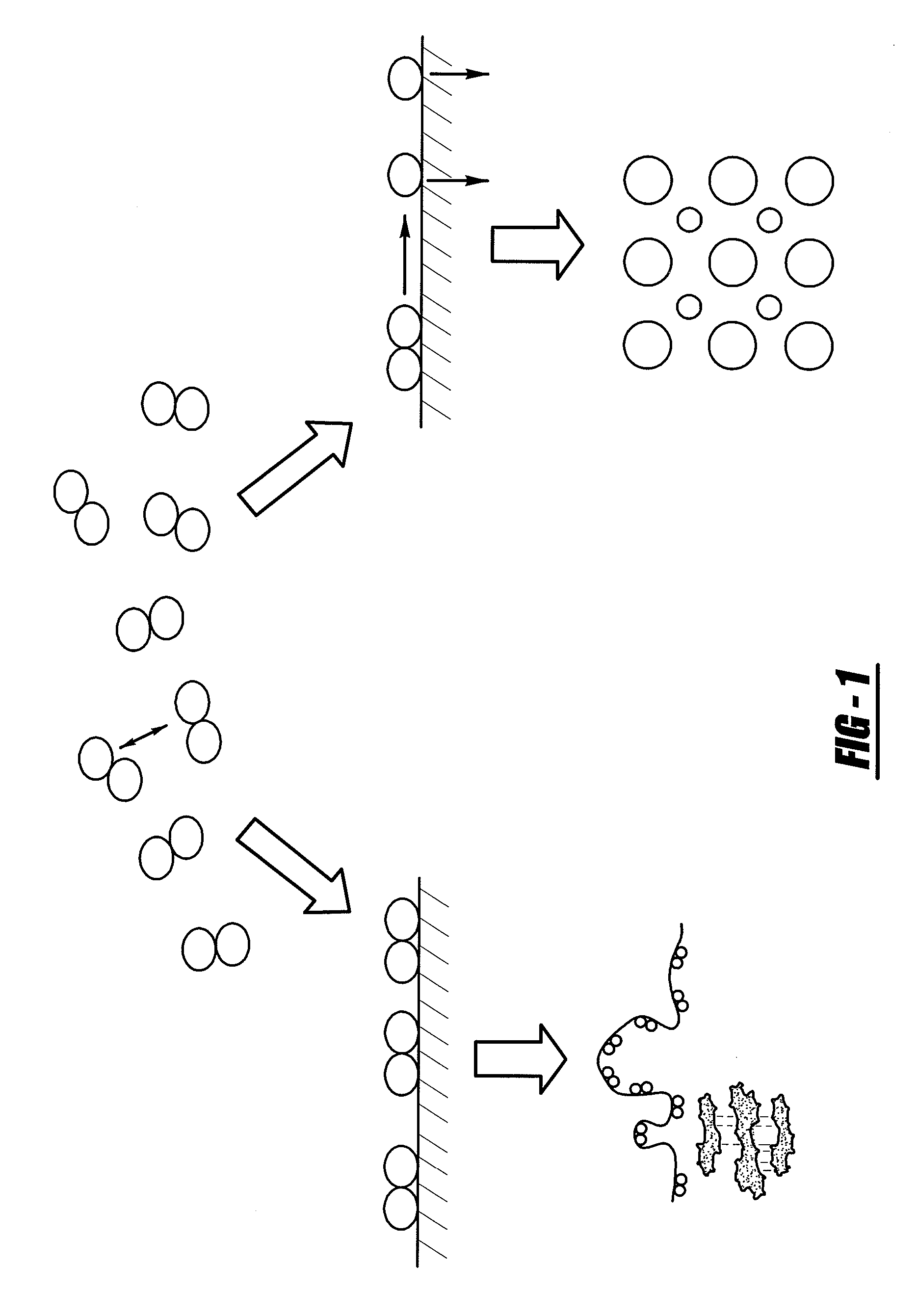

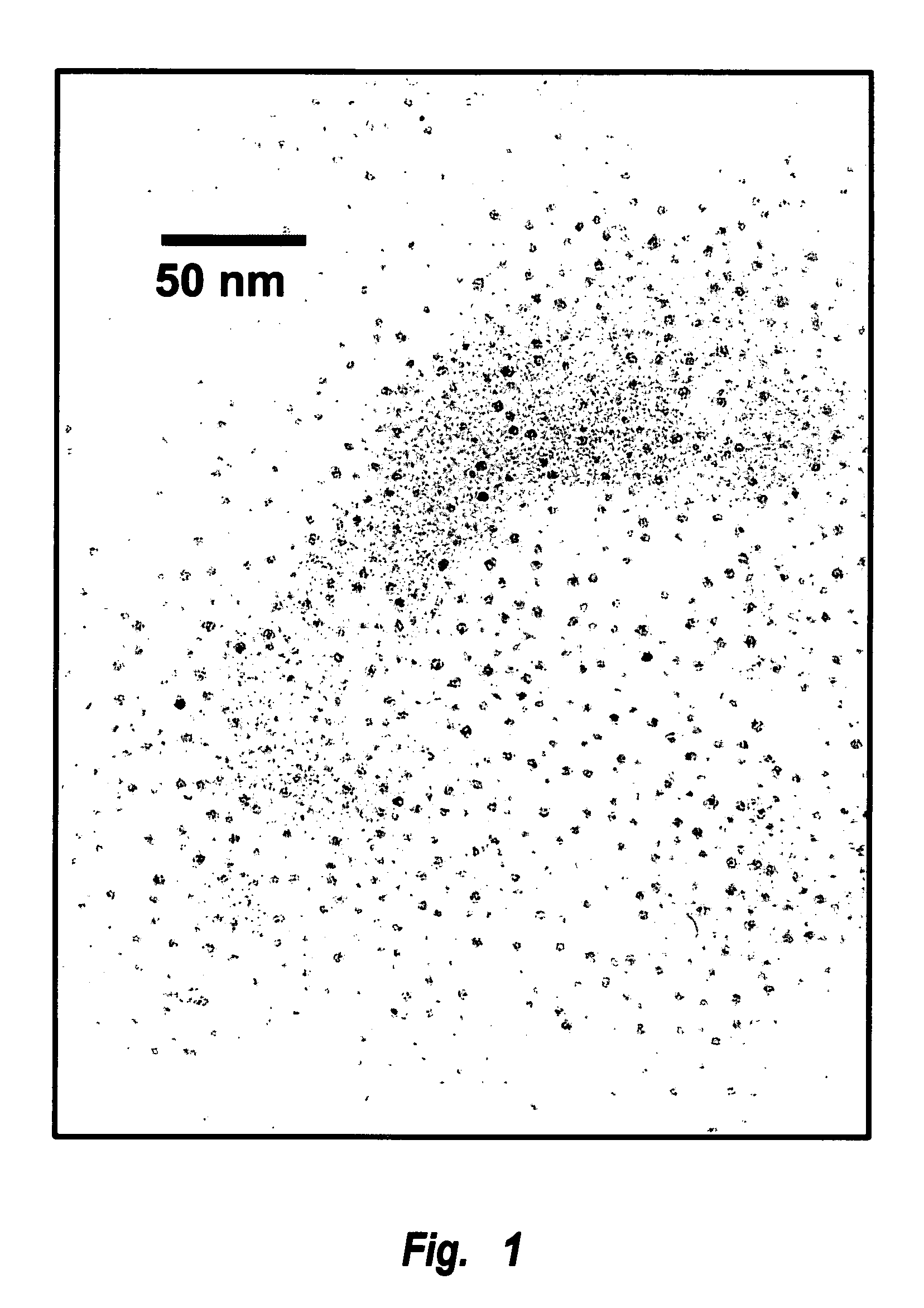

Method of forming a catalyst with inhibited mobility of nano-active material

InactiveUS20110143926A1Reduce coalescenceMinimized in sizeMaterial nanotechnologyInorganic chemistryEngineeringNanometre

A method of forming a catalyst, comprising: providing a plurality of support particles and a plurality of mobility-inhibiting particles, wherein each support particle in the plurality of support particles is bonded with its own catalytic particle; and bonding the plurality of mobility-inhibiting particles to the plurality of support particles, wherein each support particle is separated from every other support particle in the plurality of support particles by at least one of the mobility-inhibiting particles, and wherein the mobility-inhibiting particles are configured to prevent the catalytic particles from moving from one support particle to another support particle.

Owner:SDC MATERIALS +1

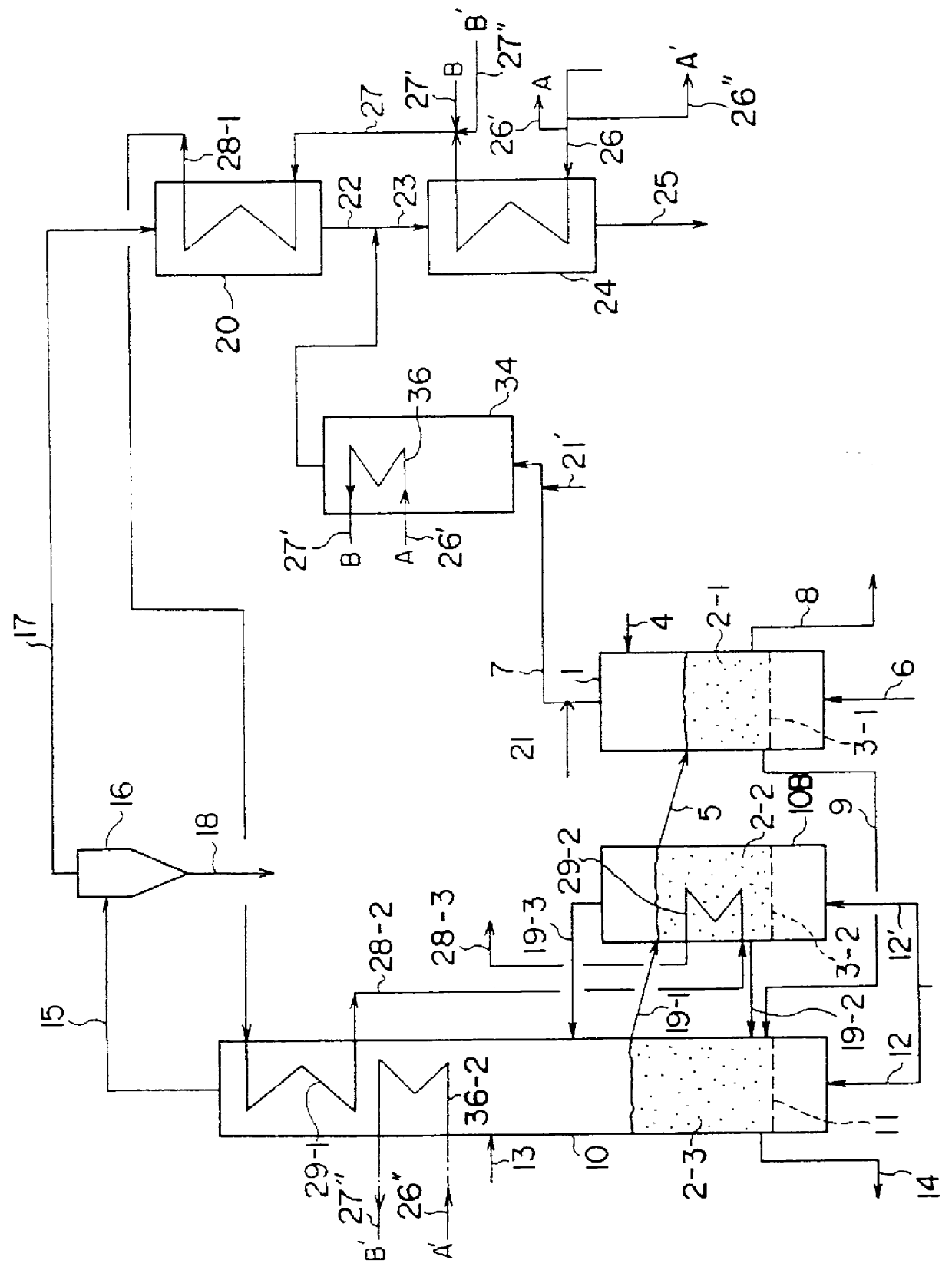

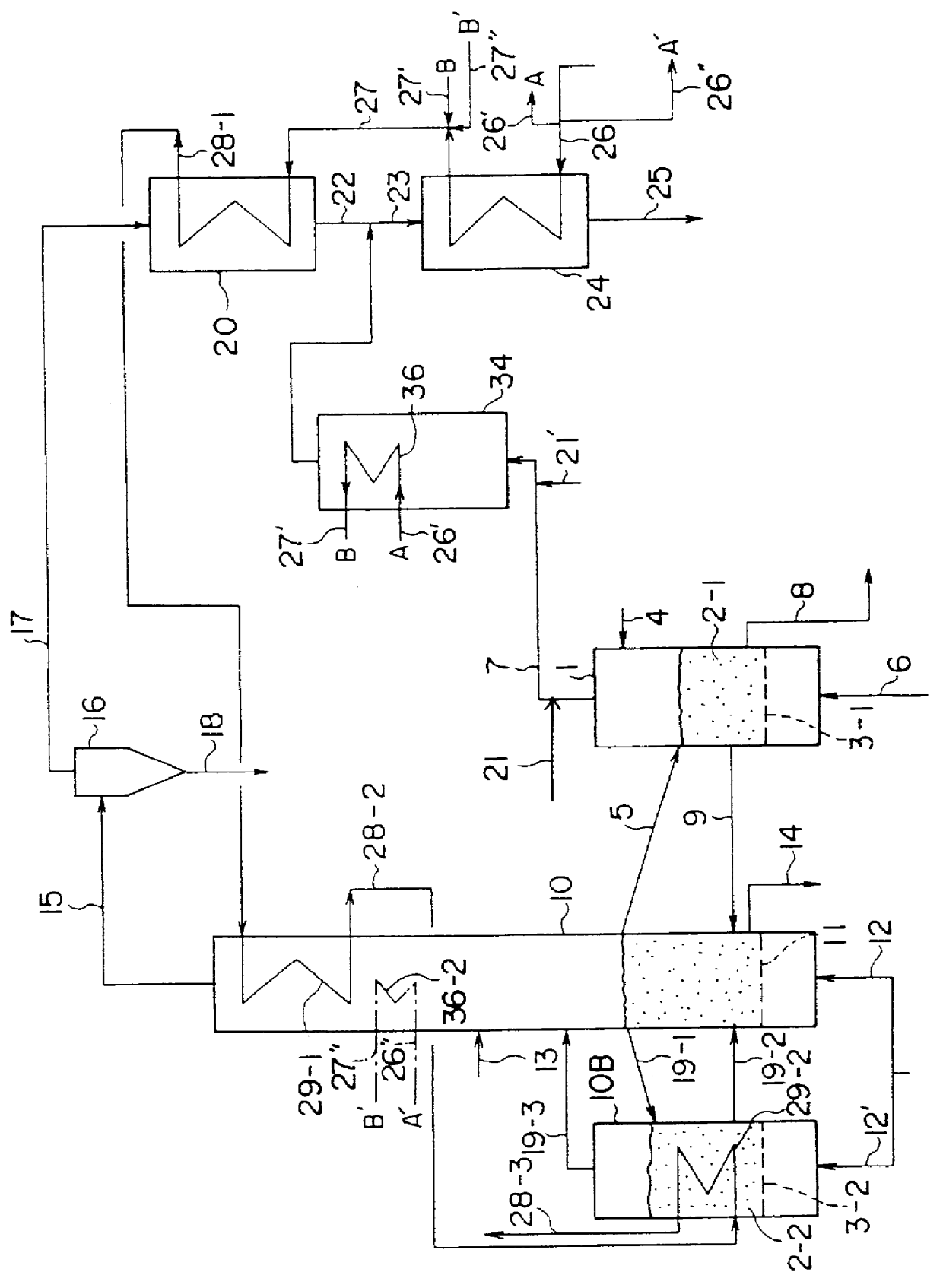

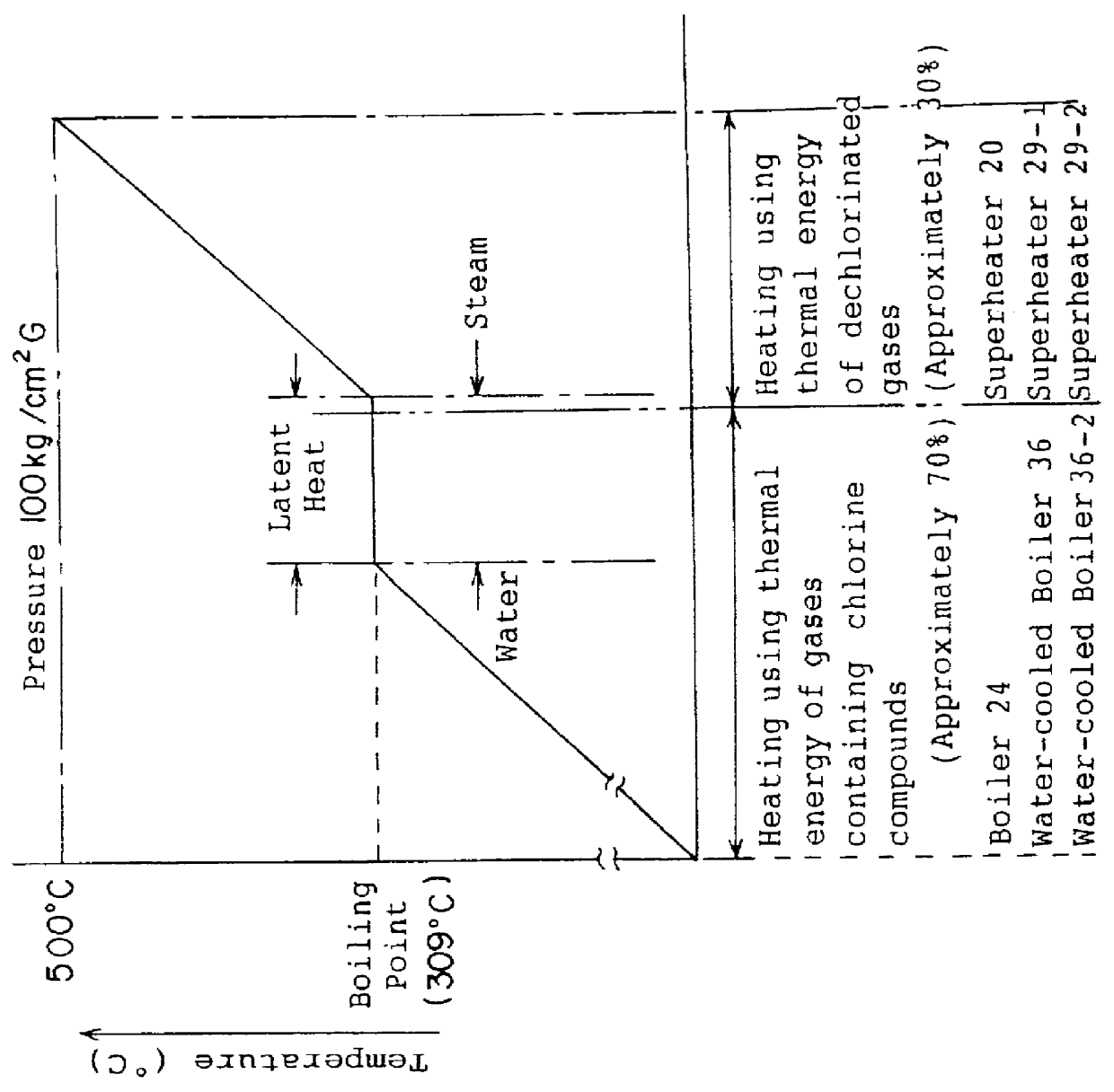

Method and apparatus for producing superheated steam using heat from the incineration of waste material

PCT No. PCT / JP97 / 00573 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32161 PCT Pub. Date Sep. 4, 1997According to the present invention, boiler water is pressurized so that its boiling point is set at approximately 200 DEG C. to 320 DEG C. The boiler water is heated in at least two stages. Thermal energy of gases containing chlorine compounds is used to heat the water to its boiling point. Thermal energy of gases which do not contain chlorine compounds is used to heat the water from its boiling point until superheated steam of a given temperature is generated. The heating which uses the thermal energy of gases containing chlorine compounds is accomplished using the thermal energy from the combustion of pyrolysis gases obtained from a pyrolysis means in which waste material is supplied into a chamber containing a fluidized bed medium which has been heated to at least 300 DEG C., and a pyrolytic reaction is induced. The heating which uses the thermal energy of gases which do not contain chlorine compounds is accomplished using the thermal energy obtained from a char combustion means to combust char in which a char mixture consisting of unpyrolyzed residue and fluidized bed medium removed from the pyrolysis means is fluidized by a stream of air, and the unpyrolyzed residue is combusted.

Owner:MITSUBISHI HEAVY IND LTD

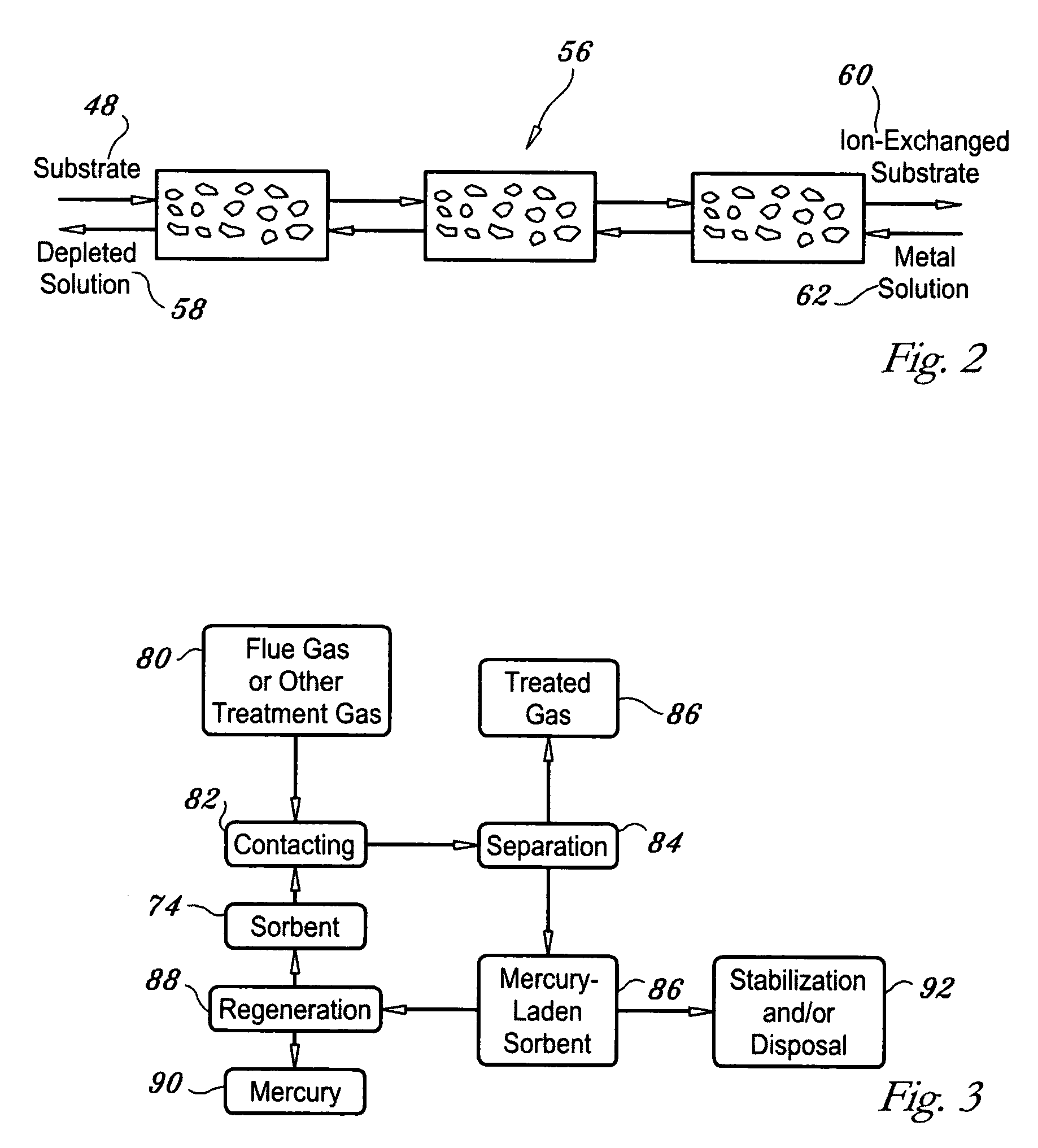

Regenerable high capacity sorbent for removal of mercury from flue gas

InactiveUS7288499B1Low costLower performance requirementsInorganic chemistryGas treatmentSorbentManganese

A regenerable, high-capacity sorbent for removal of mercury from flue gas and processes and systems for making and using the sorbent. A phyllosilicate substrate, for example vermiculite or montmorillinite, acts as an inexpensive support to a thin layer for a polyvalent metal sulfide, ensuring that more of the metal sulfide is engaged in the sorption process. The sorbent is prepared by ion exchange between the silicate substrate material and a solution containing one or more of a group of polyvalent metals including tin (both Sn(II) and Sn(IV)), iron (both Fe(II) and Fe(III)), titanium, manganese, zirconium and molybdenum, dissolved as salts, to produce an exchanged substrate. Controlled reaction of a sulfide ion source with the one or more polyvalent metals that are exchanged on the silicate substrate produces the sorbent. The sorbent is used to absorb elemental mercury or oxidized mercury species such as mercuric chloride from flue gas containing acid gases (e.g., SO2, NO and NO2, and HCl) and other gases over a wide range of temperatures.

Owner:ENVIRONMENTAL ENERGY SERVICES

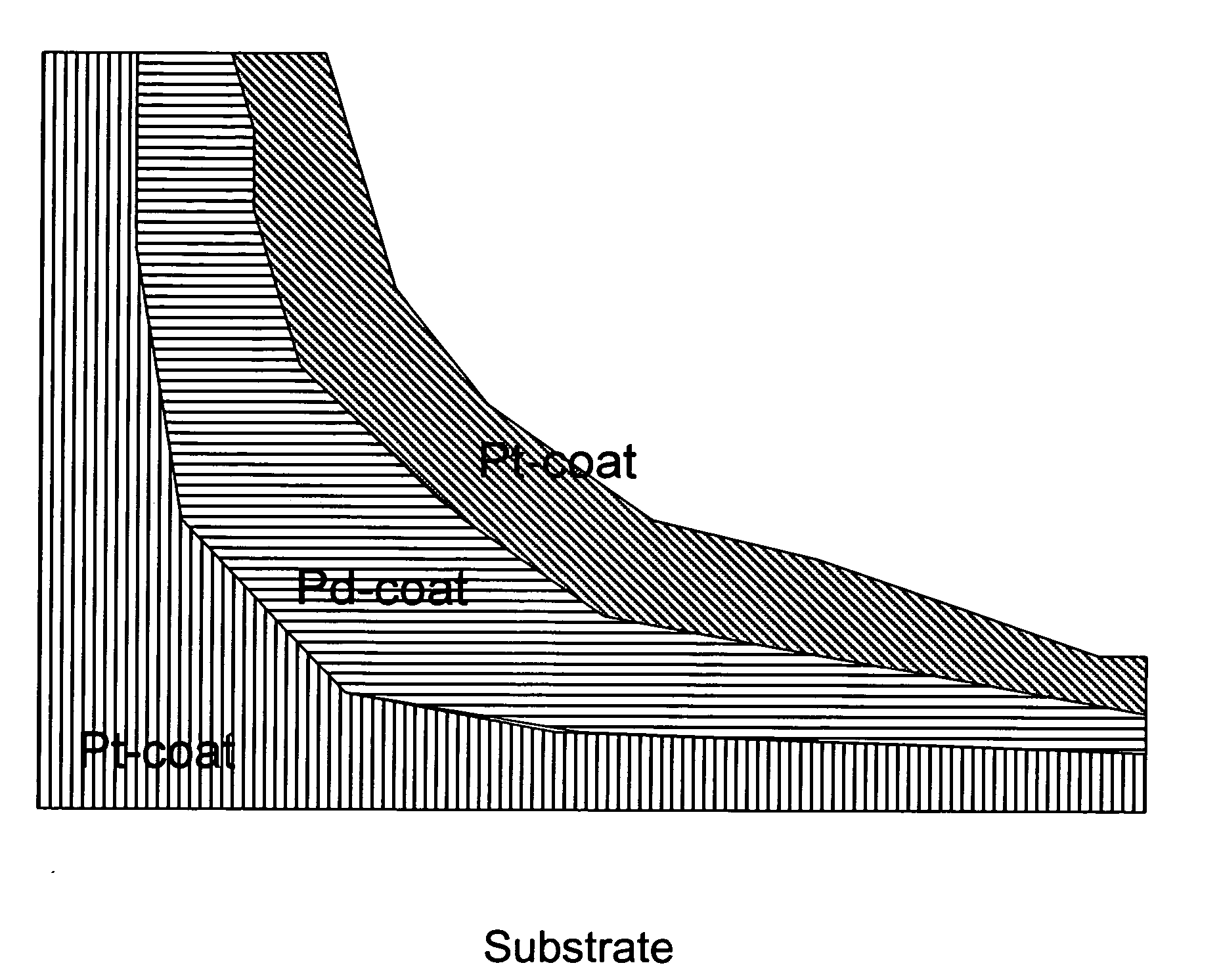

Three-layered catalyst system for purifying exhaust gases of internal engines

Disclosed herein is a three-layered catalyst system in which layers including predetermined precious metal components are sequentially layered on a substrate, and thus the conversion ratio of HC and CO is increased, thereby improving purification efficiency. The three-layered catalyst system includes a substrate, a lower layer containing a precious metal component of only platinum, an intermediate layer containing a precious metal component of only palladium, and an upper layer containing a precious metal component of only platinum, all of which are sequentially layered.

Owner:HEESUNG CATALYSTS CORP

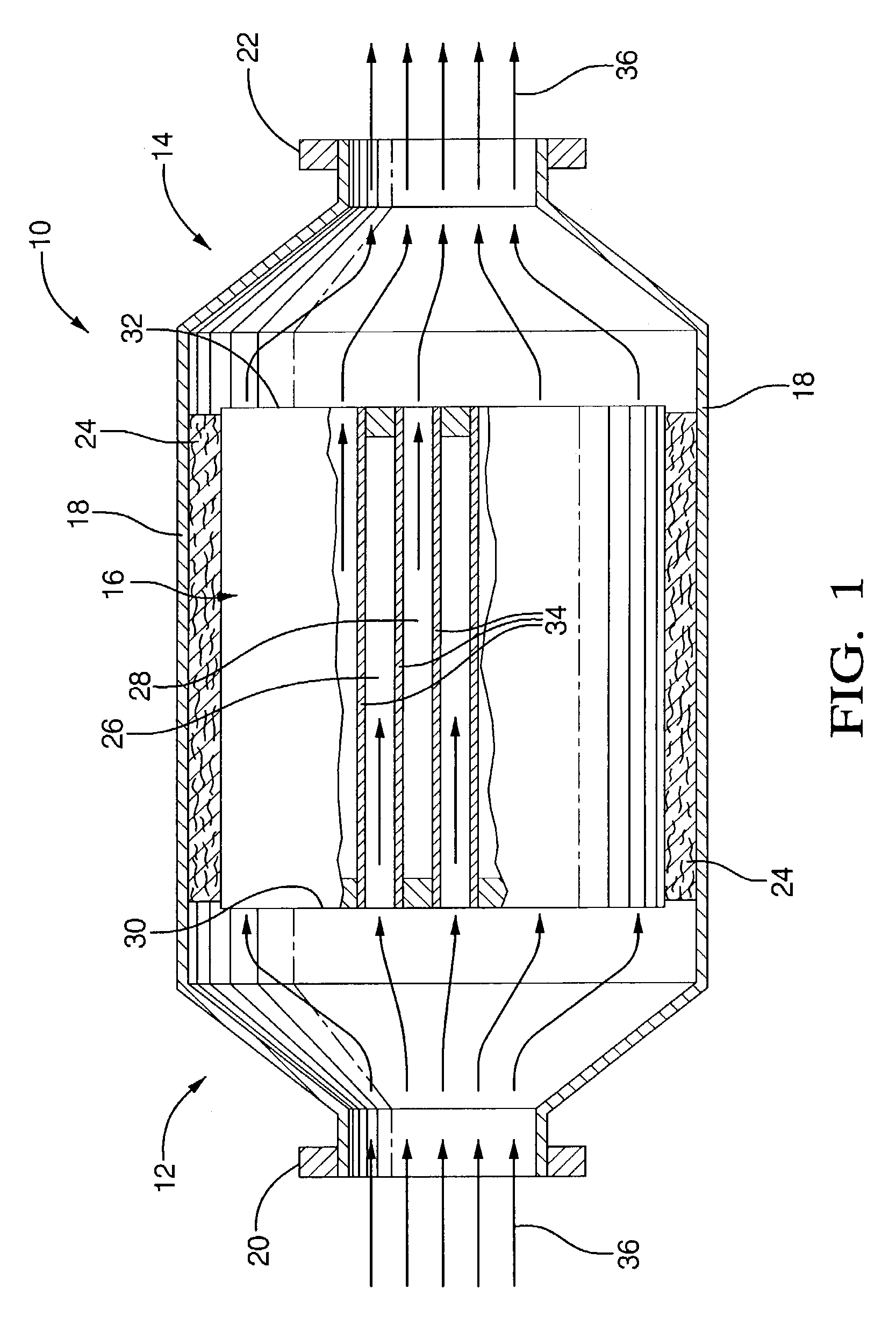

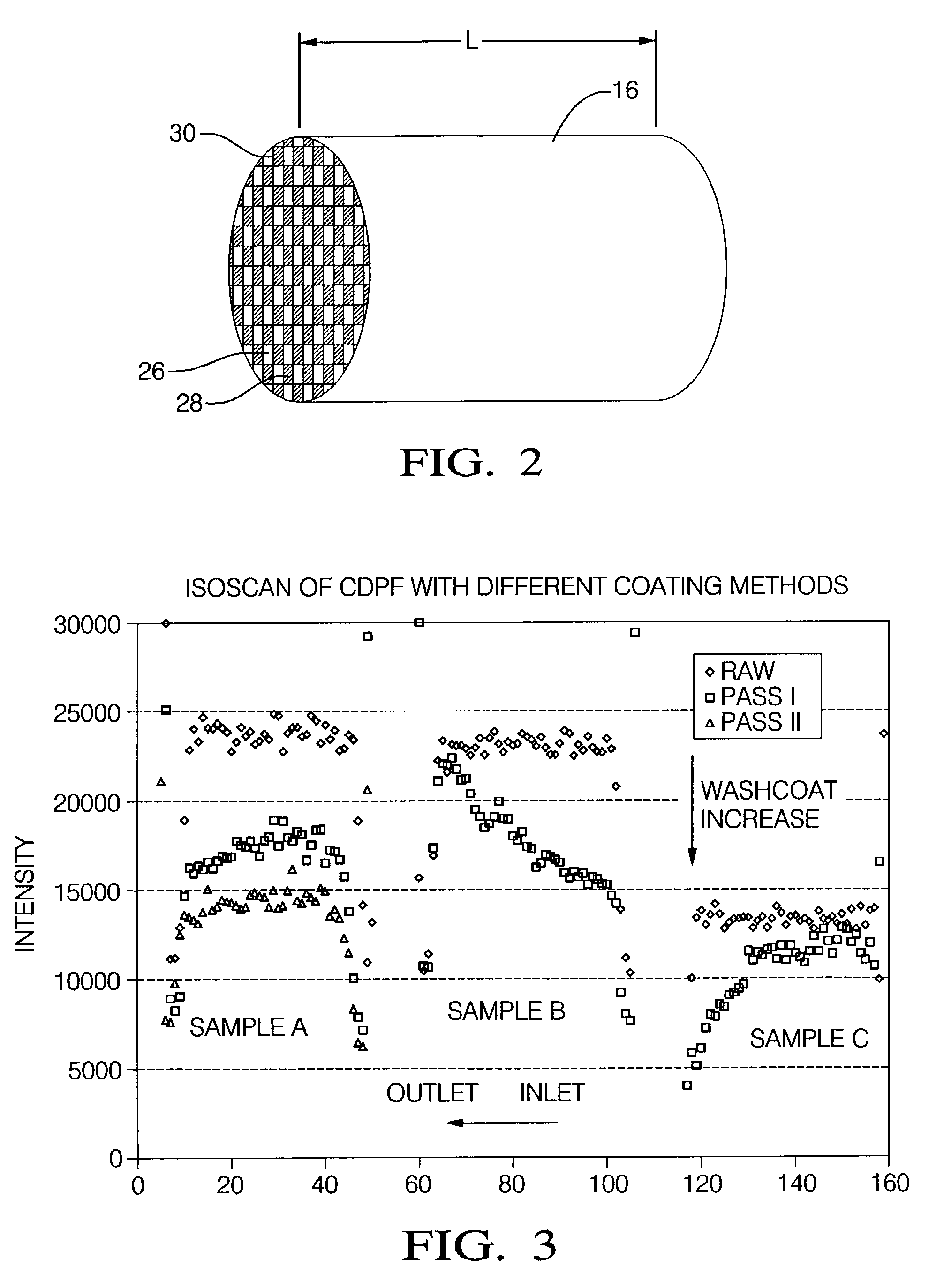

Method for control of washcoat distribution along channels of a particulate filter substrate

Disclosed herein is a method of distributing a washcoat along channels of a particulate filter substrate, the method including: forcing a washcoat slurry a predetermined distance into the channels, the predetermined distance being less than or equal to the full length of the channels; clearing an excess amount of washcoat slurry from the channels; and arranging a remainder of the washcoat slurry within the channels, the arranging including applying a first vacuum to a first end of the particulate filter substrate after the clearing. In one embodiment the clearing includes applying a second vacuum to a second end of the particulate filter substrate. In another embodiment, the clearing includes pulling the excess washcoat slurry from the channels. The predetermined distance may be less than or equal to the full length of the channels. The arranging may provide a layer of a washcoat composition comprising a catalytically active material arranged anisotropically along a length of the channels of the particulate filter substrate.

Owner:UMICORE AG & CO KG

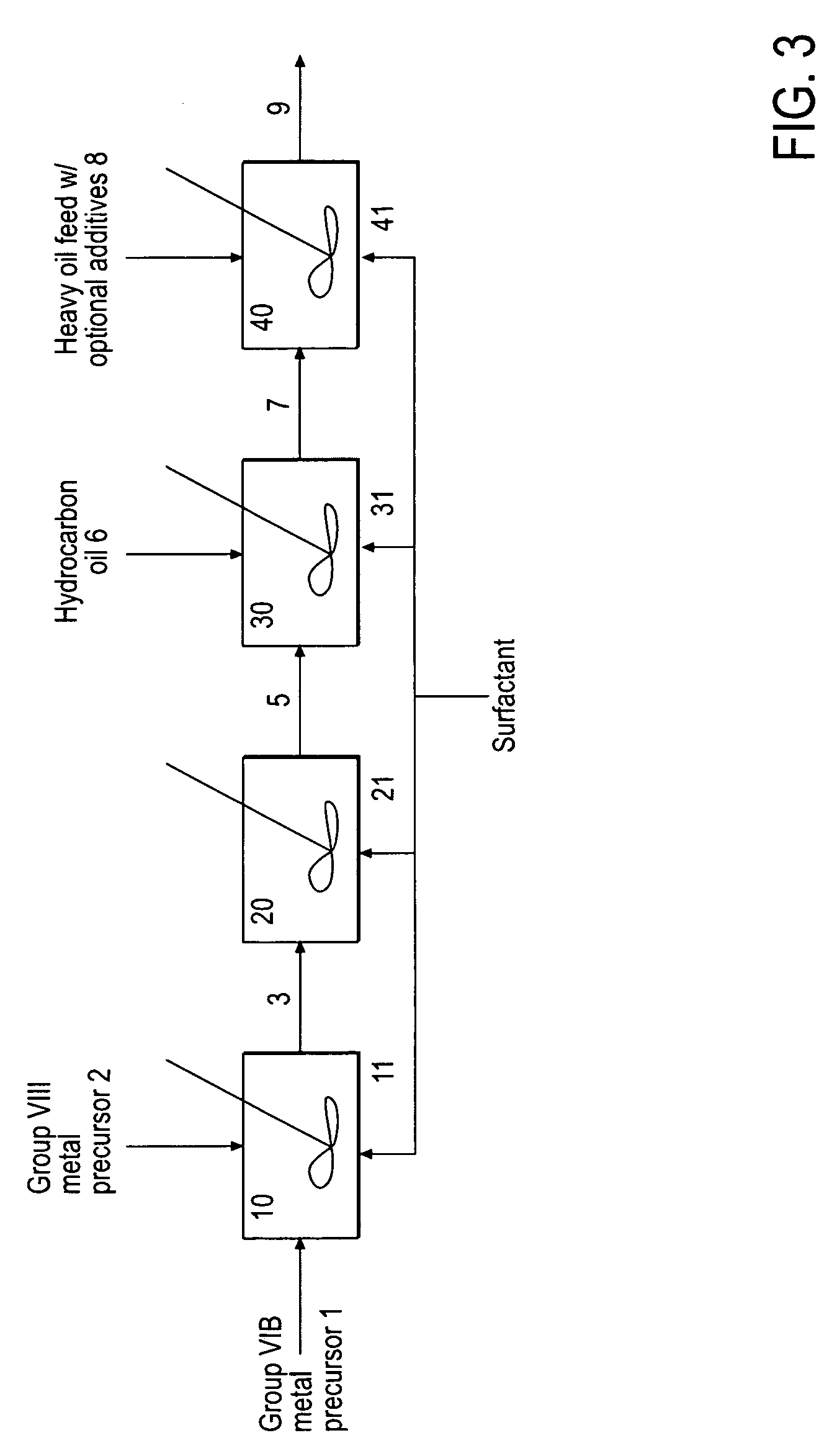

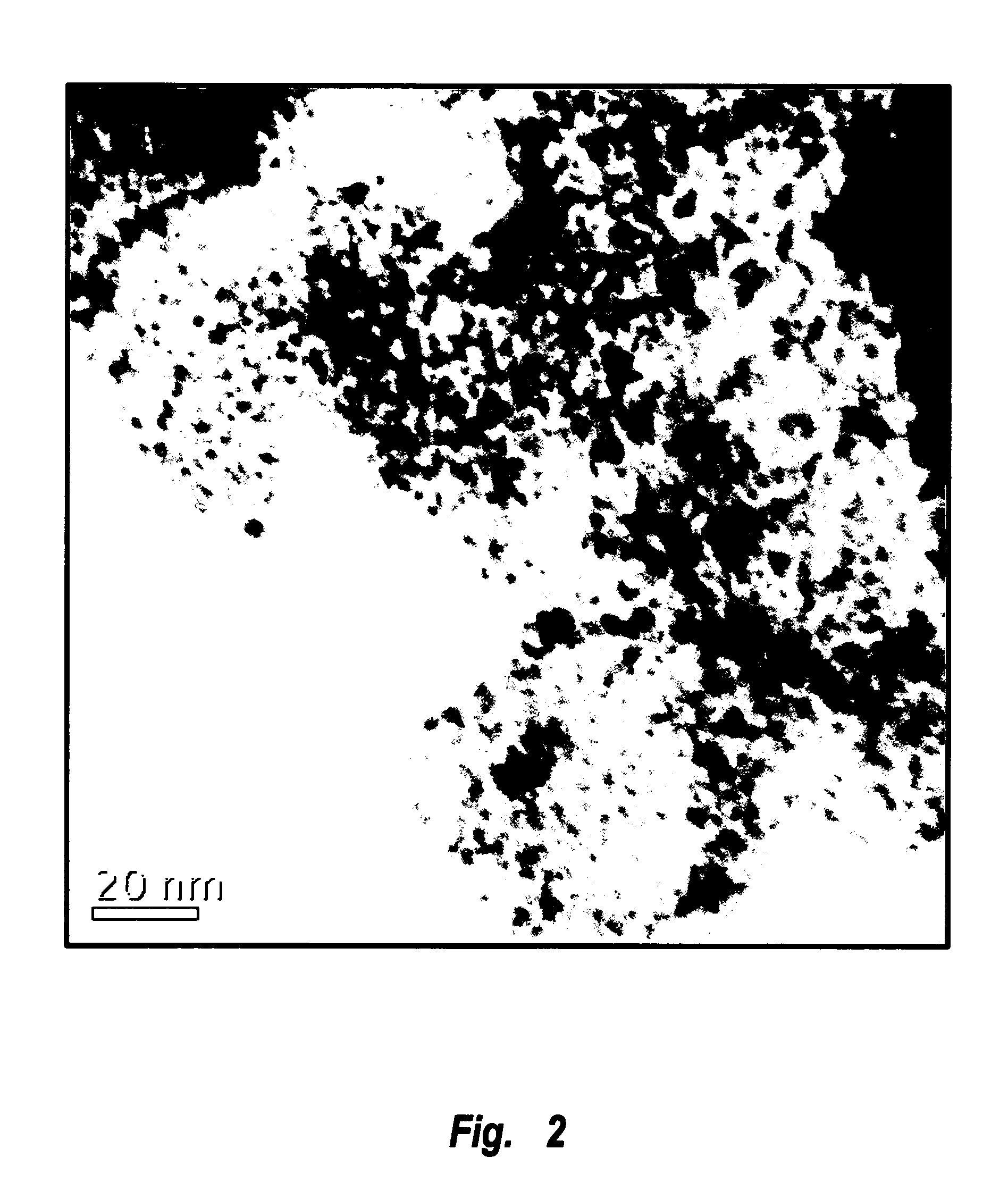

Hydroprocessing bulk catalyst and uses thereof

ActiveUS20090057201A1Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNon noble metalPowder diffraction

A hydroprocessing bulk catalyst is provided. A process to prepare hydroprocessing bulk catalysts is also provided. The hydroprocessing catalyst has the formula (Mt)d(Lu)b(Sv)d(Cw)e(Hx)f(Oy)g(Nz)h, wherein M is at least one group VIB metal; promoter metal L is optional and if present, L is at least one Group VIII non-noble metal; t, u, v, w, x, y, z representing the total charge for each of the components (M, L, S, C, H, O and N, respectively); ta+ub+vd+we+xf+yg+zh=0; 0 =<b; and 0=<b / a=<5, (a+0.5b)<=d<=(5a+2b), 0<=e<=11(a+b), 0<=f<=7(a+b), 0<=g<=5(a+b), 0<=h<=0.5(a+b). The catalyst has an X-ray powder diffraction pattern with at least one broad diffraction peak at any of Bragg angles: 8 to 18°, 32 to 40°, and 55 to 65° (from 0 to 70° 2-θ scale). In one embodiment, the catalyst is prepared by sulfiding at least one Group VIB metal compound and optionally at least one group VIII metal compound with a sulfiding agent forming a catalyst precursor; and mixing the catalyst precursor with a hydrocarbon compound to form the hydroprocessing catalyst composition.

Owner:CHEVROU USA INC

Method of preparing a catalyst for use in the hydrotreating of high boiling hydrocarbon feedstocks

InactiveUS6387248B2Reduce contentPermit treatmentInorganic chemistryCatalyst activation/preparationSulfurBoiling point

A catalyst characterized by its ability to hydrotreat a charge hydrocarbon feed containing components boiling above 1000° F., and sediment-formers, sulfur, metals, asphaltenes, carbon residue, and nitrogen is prepared by mulling a porous alumina support with a salt of a Group VIII metal oxide and with a salt of a Group VI-B metal oxide in the presence of an acid to provide a mixture, by extruding the mixture to form an extrudate, by drying the extrudate and by subjecting the dried extrudate to hydrothermal calcination to provide the catalyst.

Owner:TEXACO INC

Method for recovering metal value from concentrates of sulfide minerals

InactiveUS6146444APromote recoveryIncrease heightInorganic chemistryContaminated soil reclamationMaceralPrecious metal

A method of recovering precious metal values from refractory sulfide ores is provided. The method includes the steps of separating clays and fines from a crushed refractory sulfide ore, forming a heap from the refractory sulfide ore, producing a concentrate of refractory sulfide minerals from the separated fines and adding the concentrate to the heap, bioleaching the heap to thereby oxidize iron sulfides contained therein, and hydrometallurgically treating the bioleached ore to recover precious metal values contained therein.

Owner:GEOSYNFUELS LLC (US)

NOx reduction composition for use in FCC processes

A composition for controlling NOx emissions during FCC processes comprises (i) an acidic oxide support, (ii) cerium oxide, (iii) a lanthanide oxide other than ceria such as praseodymium oxide, and (iv), optionally, an oxide of a metal from Groups Ib and IIb such as copper, silver and zinc.

Owner:ENGELHARD CORP

Method of forming a catalyst with inhibited mobility of nano-active material

InactiveUS8557727B2Reduce coalescenceMinimized in sizeMaterial nanotechnologyInorganic chemistryEngineeringNanometre

A method of forming a catalyst, comprising: providing a plurality of support particles and a plurality of mobility-inhibiting particles, wherein each support particle in the plurality of support particles is bonded with its own catalytic particle; and bonding the plurality of mobility-inhibiting particles to the plurality of support particles, wherein each support particle is separated from every other support particle in the plurality of support particles by at least one of the mobility-inhibiting particles, and wherein the mobility-inhibiting particles are configured to prevent the catalytic particles from moving from one support particle to another support particle.

Owner:SDC MATERIALS +1

Fullerene coated component of semiconductor processing equipment and method of manufacturing thereof

InactiveUS20020086553A1High purityIncrease resistanceMaterial nanotechnologyLiquid surface applicatorsMetallurgyFullerene

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a fullerene containing surface and process for manufacturing thereof.

Owner:LAM RES CORP

Process for regenerating a catalyst

InactiveUS20080214384A1Reduced activityIncreased space-time yieldInorganic chemistryMolecular sieve catalystsAcroleinGlycerol

Owner:EVONIK DEGUSSA GMBH

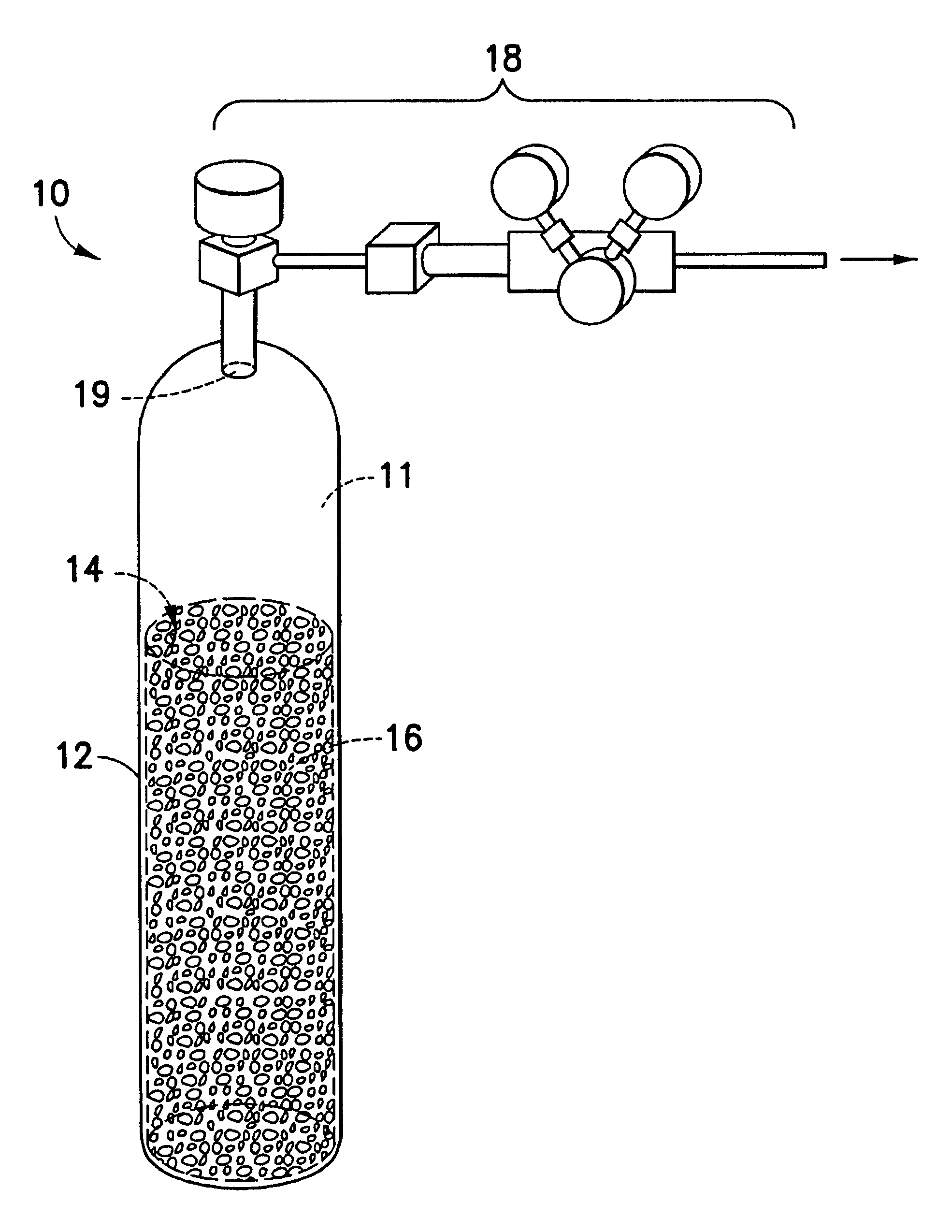

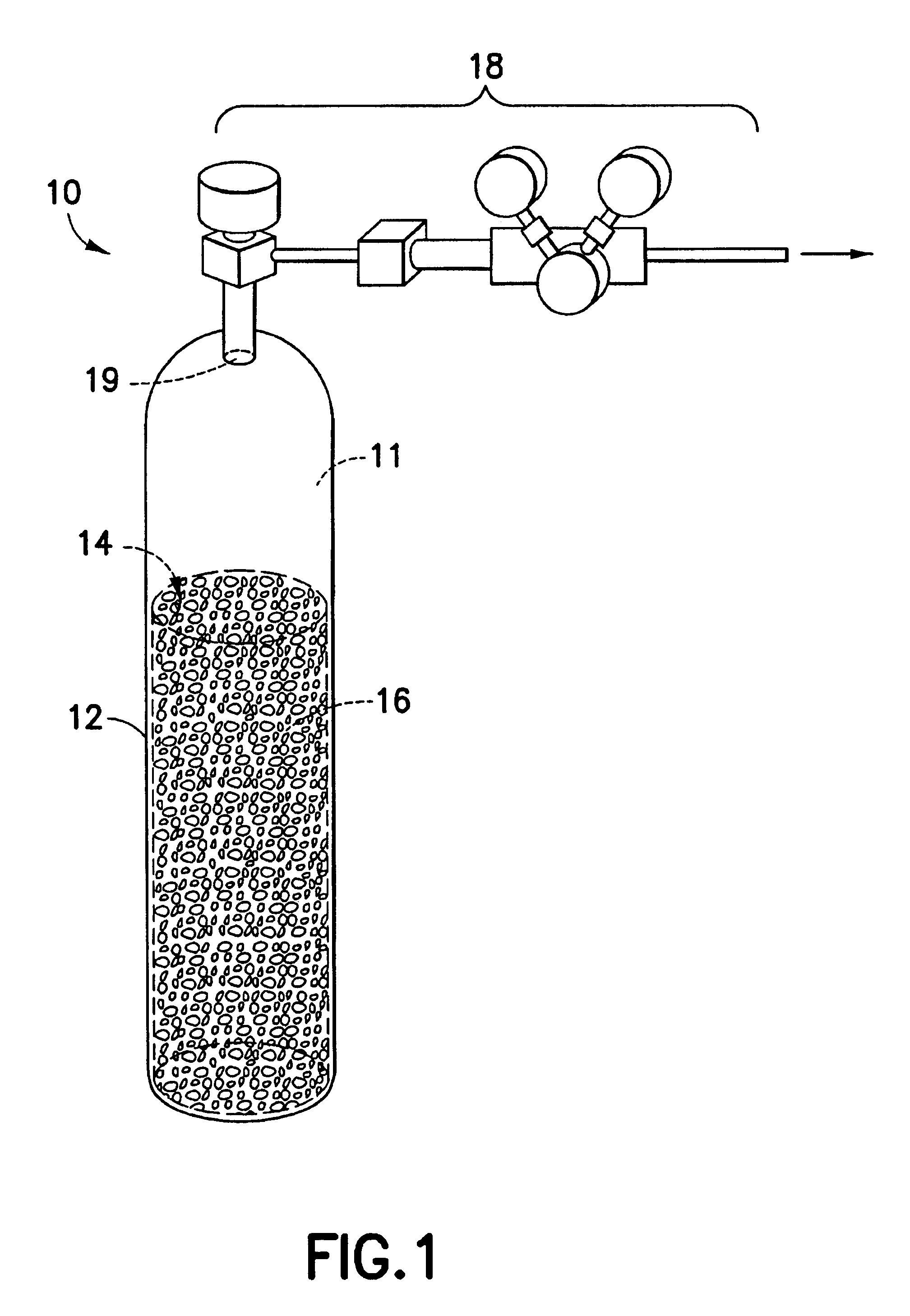

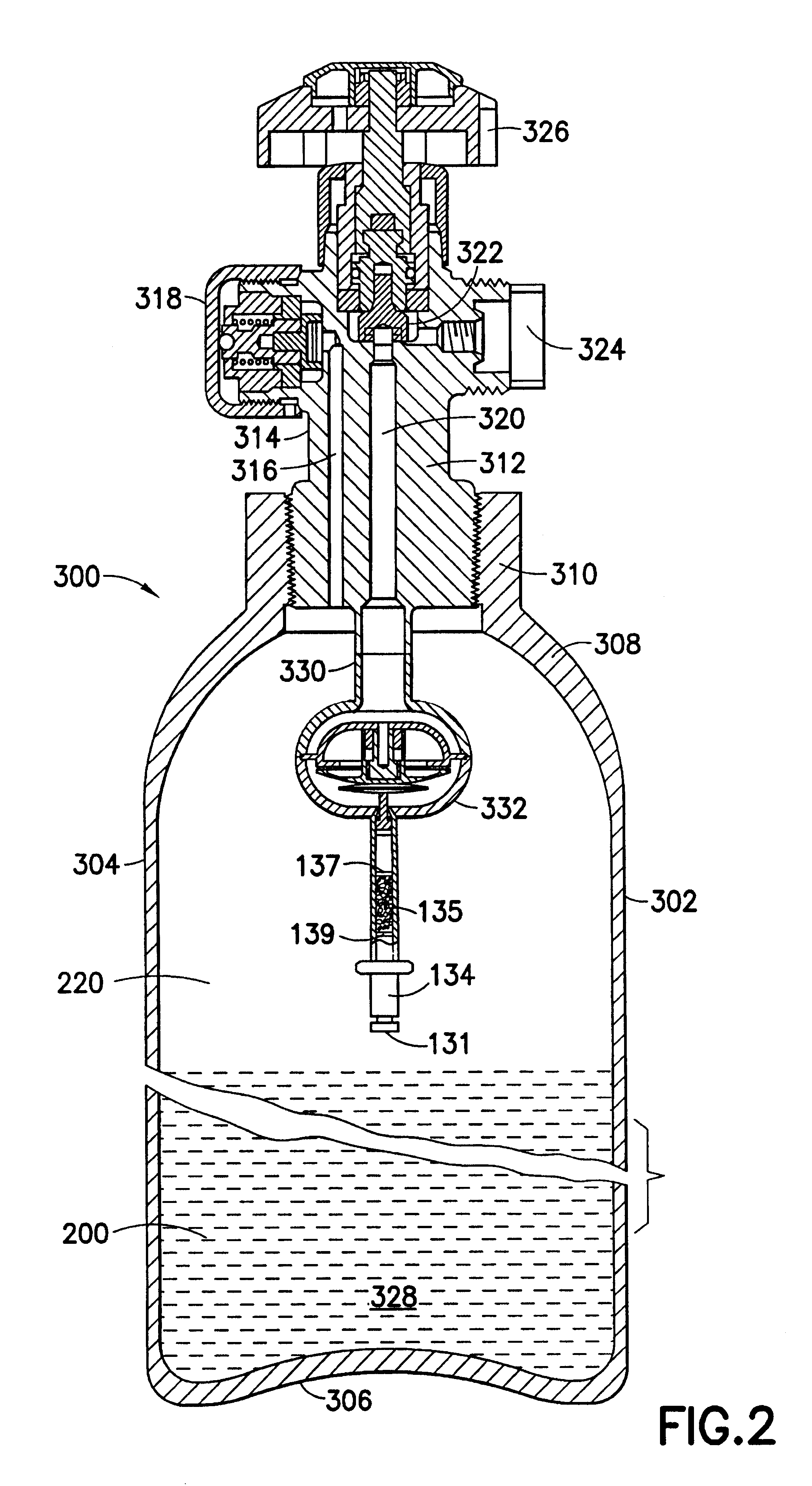

Adsorbents for low vapor pressure fluid storage and delivery

The invention relates to a fluid storage and delivery system utilizing a porous metal matrix that comprises at least one Group VIII metal or Group IB metal therein. In one aspect of the invention, such porous metal matrix forms a solid-phase metal adsorbent medium, characterized by an average pore diameter of from about 0.5 nm to about 2.0 nm and a porosity of from about 10% to about 30%. Such solid-phase metal adsorbent medium is particularly useful for sorptively storing and desoprotively dispensing a low vapor pressure fluid, e.g., ClF3, HF, GeF4, Br2, etc. In another aspect of the invention, such porous metal matrix forms a solid-phase metal sorbent, characterized by an average pore diameter of from about 0.25 mum to about 500 mum and a porosity of from about 15% to about 95%, which can effectively immobilize low vapor pressure liquefied gas.

Owner:ENTEGRIS INC

Use of shaped bodies having catalytic properties as reactor internals

InactiveUS8119554B2Easy to useLower overall pressure dropAdditive manufacturing apparatusInorganic chemistryChemical reactionActive component

Shaped bodies having catalytic properties which can be obtained by a process comprising the steps:a) production of a shaped body by means of a powder-based rapid prototyping process,b) if appropriate, a heat treatment of the shaped body,c) if appropriate, application of at least one catalytically active component to the shaped body,d) if appropriate, a further heat treatment,where steps b), c) and / or d) can be carried out a number of times,are used as reactor internals in heterogeneously catalyzed chemical reactions.

Owner:BASF SE

Photocatalyst composition

InactiveUS7211543B2Improve balanceIncrease flexibilityInorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical compoundOxygen

A photocatalyst composition which comprises (A) modified photocatalyst particles, the modified photocatalyst particles (A) being prepared by subjecting particles of a photocatalyst to a modification treatment with at least one modifier compound selected from the group consisting of different compounds each of which independently comprises at least one structural unit selected from the group consisting of a triorganosilane unit, a monooxydiorganosilane unit and a dioxyorganosilane unit; and (B) a binder component comprising a phenyl group-containing silicone optionally containing an alkyl group. A film formed using the above-mentioned photocatalyst composition, a functional composite comprising a substrate and the above-mentioned film formed on the substrate, and a shaped article produced by shaping the above-mentioned photocatalyst composition.

Owner:ASAHI KASEI KK

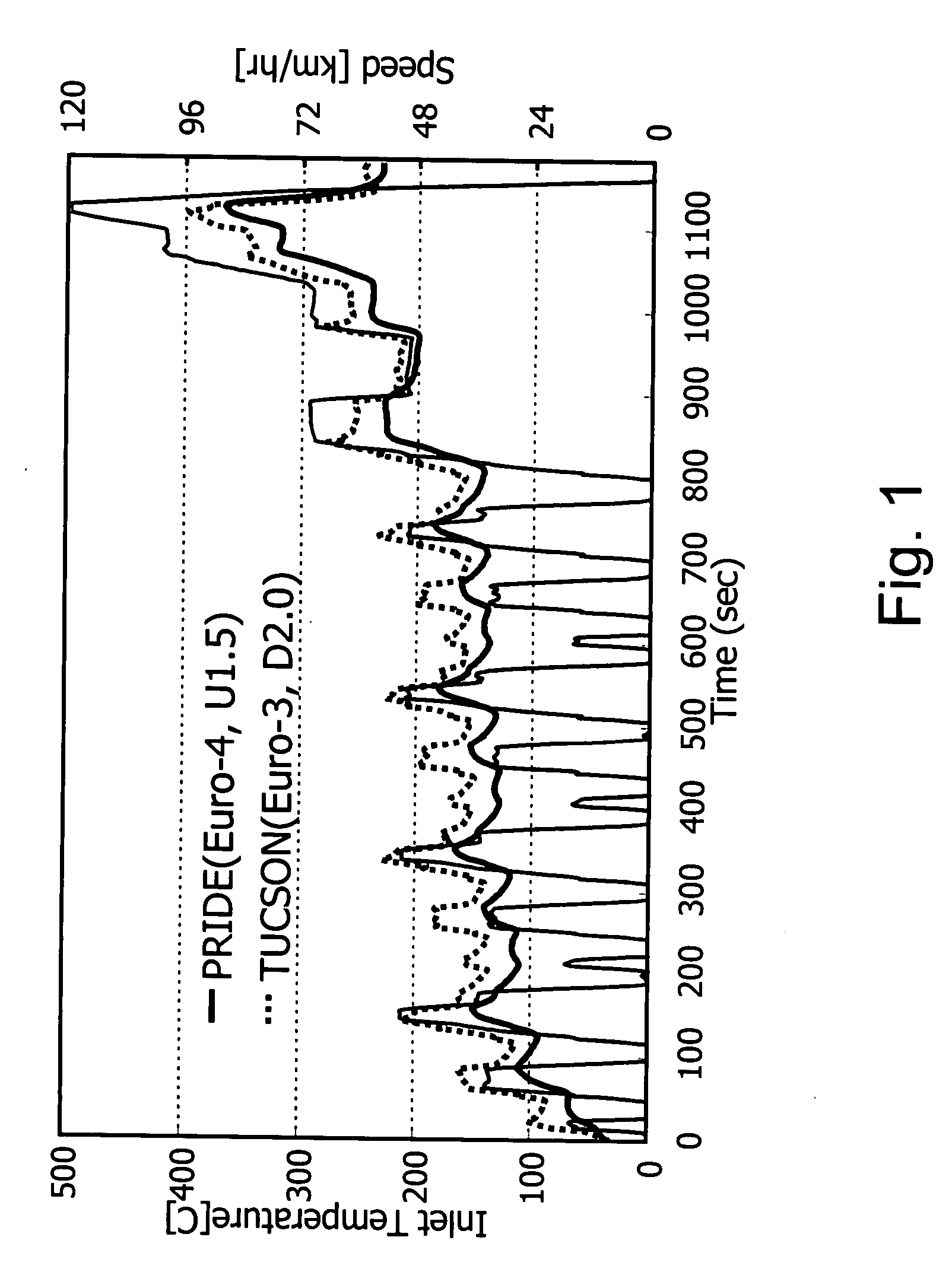

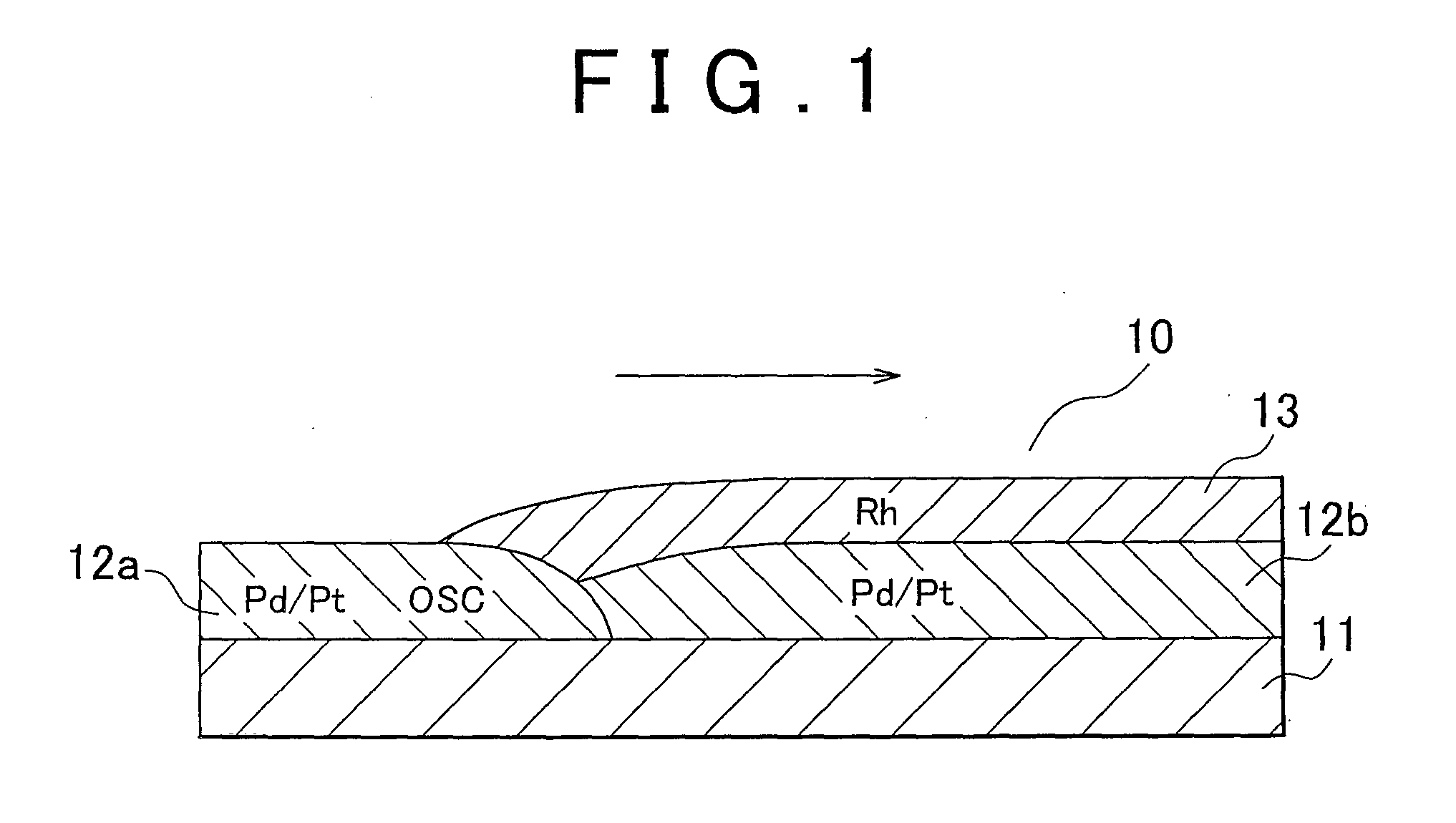

Double layered exhaust gas purification catalyst

ActiveUS20130310248A1Satisfactory catalyst warm-up performanceImprove exhaust gas purification performanceInorganic chemistryInternal combustion piston enginesOxygen storageChemistry

Owner:TOYOTA JIDOSHA KK

Hydroprocessing bulk catalyst and uses thereof

ActiveUS7737073B2Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTO-18X-ray

A hydroprocessing bulk catalyst is provided. A process to prepare hydroprocessing bulk catalysts is also provided. The hydroprocessing catalyst has the formula (Mt)a(Lu)b(Sv)d(Cw)e(Hx)f(Oy)g(Nz)h, wherein M is at least one group VIB metal; promoter metal L is optional and if present, L is at least one Group VIII non-noble metal; t, u, v, w, x, y, z representing the total charge for each of the components (M, L, S, C, H, O and N, respectively); ta+ub+vd+we+xf+yg+zh=0; 0=<b; and 0=<b / a=<5, (a+0.5b)<=d<=(5a+2b), 0<=e<=11(a+b), 0<=f<=7(a+b), 0<=g<=5(a+b), 0<=h<=0.5(a+b). The catalyst has an X-ray powder diffraction pattern with at least one broad diffraction peak at any of Bragg angles: 8 to 18°, 32 to 40°, and 55 to 65° (from 0 to 70° 2-θ scale). In one embodiment, the catalyst is prepared by sulfiding at least one Group VIB metal compound and optionally at least one group VIII metal compound with a sulfiding agent forming a catalyst precursor; and mixing the catalyst precursor with a hydrocarbon compound to form the hydroprocessing catalyst composition.

Owner:CHEVROU USA INC

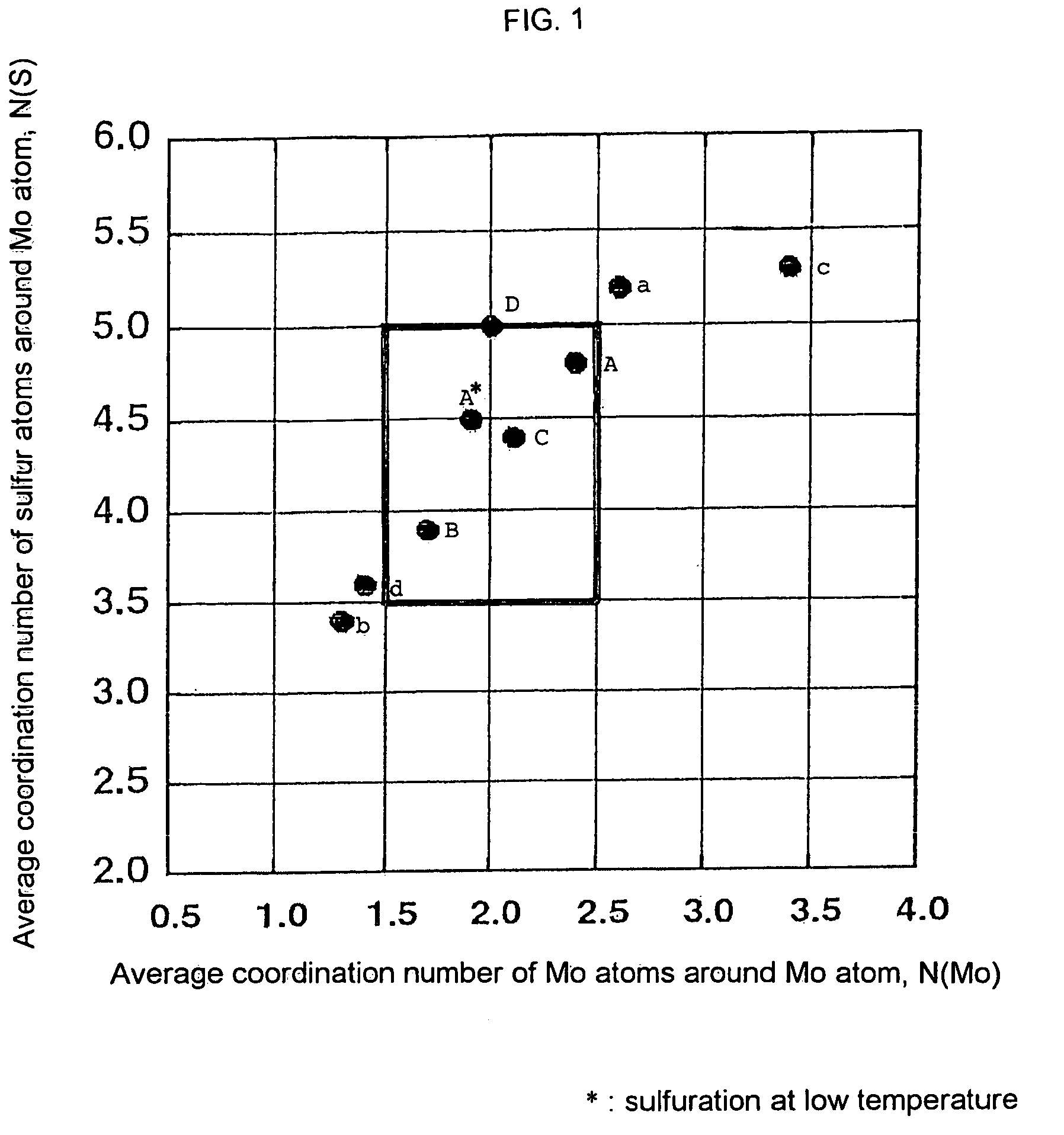

Hydrotreating catalyst of catalytic cracking gasoline

InactiveUS20050261124A1High degreeHigh desulfurization activityInorganic chemistryCatalyst activation/preparationXANES SpectroscopyStructure analysis

A hydrotreating catalyst comprising a Group 8 metal of the periodic table, molybdenum (Mo), phosphorus and sulfur, wherein the average coordination number [N(Mo)] of the molybdenum atoms around the molybdenum atom is from 1.5 to 2.5 and the average coordination number [N(S)] of the sulfur atoms around the molybdenum atom is from 3.5 to 5.0 when MoS2 structure in the catalyst is measured in accordance with extended X-ray absorption fine structure (EXAFS) analysis.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Process for manufacture and use of improved attrition resistant catalyst

A method for manufacturing of an improved attrition resistant catalyst having an oxide-rich surface layer involving forming a slurry comprising; catalyst, catalyst precursor or catalyst support particles (e.g., transition metal oxides), a colloidal oxide sol (e.g., colloidal silica), and a solution of a solvent and solute wherein the solute consist essentially of a precursor of said oxide-rich surface with particle size no greater than 5 nm (e.g., aqueous silicic acid or polysilicic acid) and then spray drying the slurry to form porous microspheres of attrition resistant catalyst; and, calcining the spray dried microspheres. Such a catalyst is particularly useful in oxidation processes wherein the oxidation is performed by an oxidized form of the catalyst and the resulting reduced form of the catalyst is separately regenerated (e.g., two-step vapor phase processes carried out in recirculating solids reactors, transport bed reactors or circulating fluidized bed reactors and the like).

Owner:EI DU PONT DE NEMOURS & CO

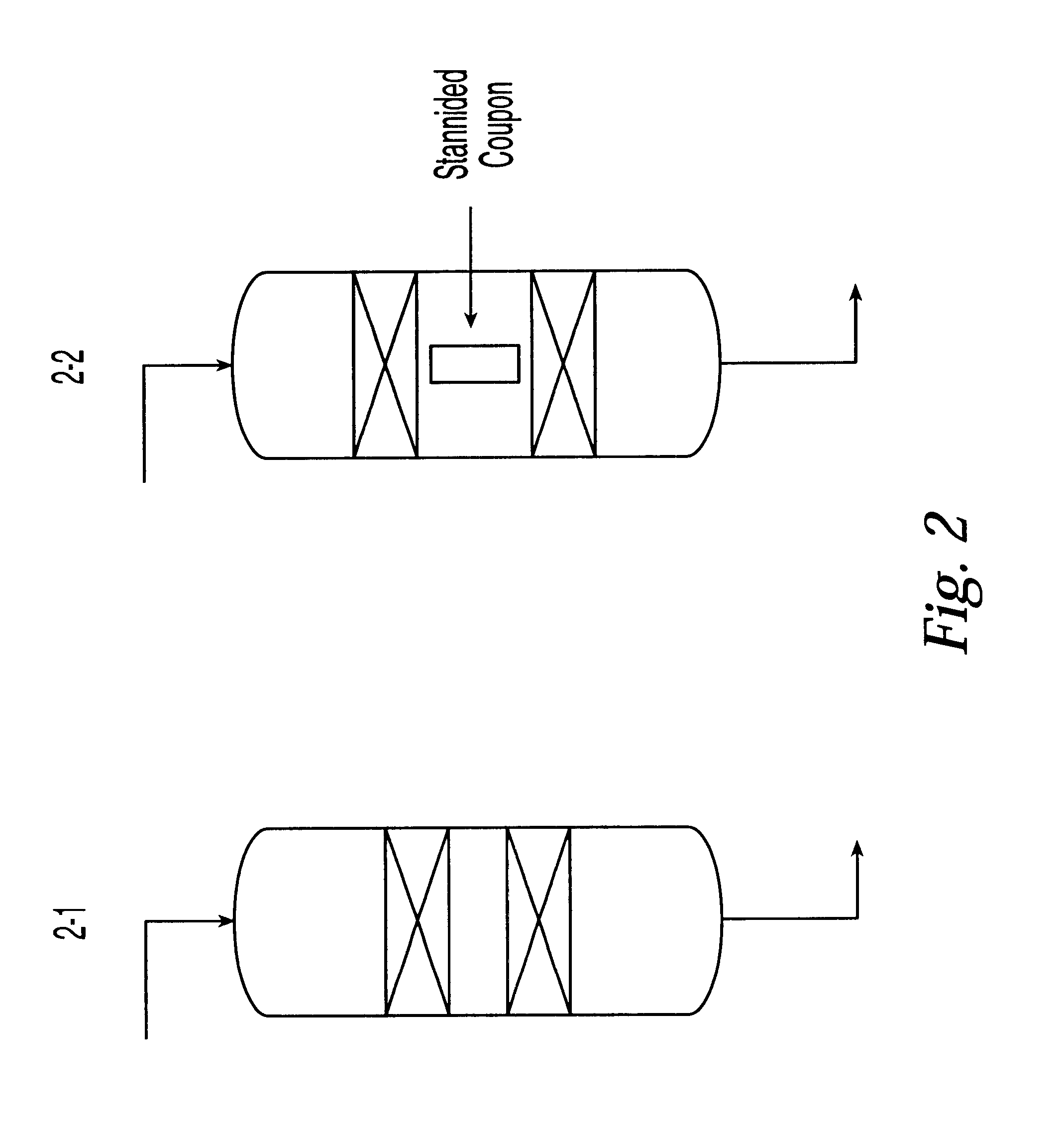

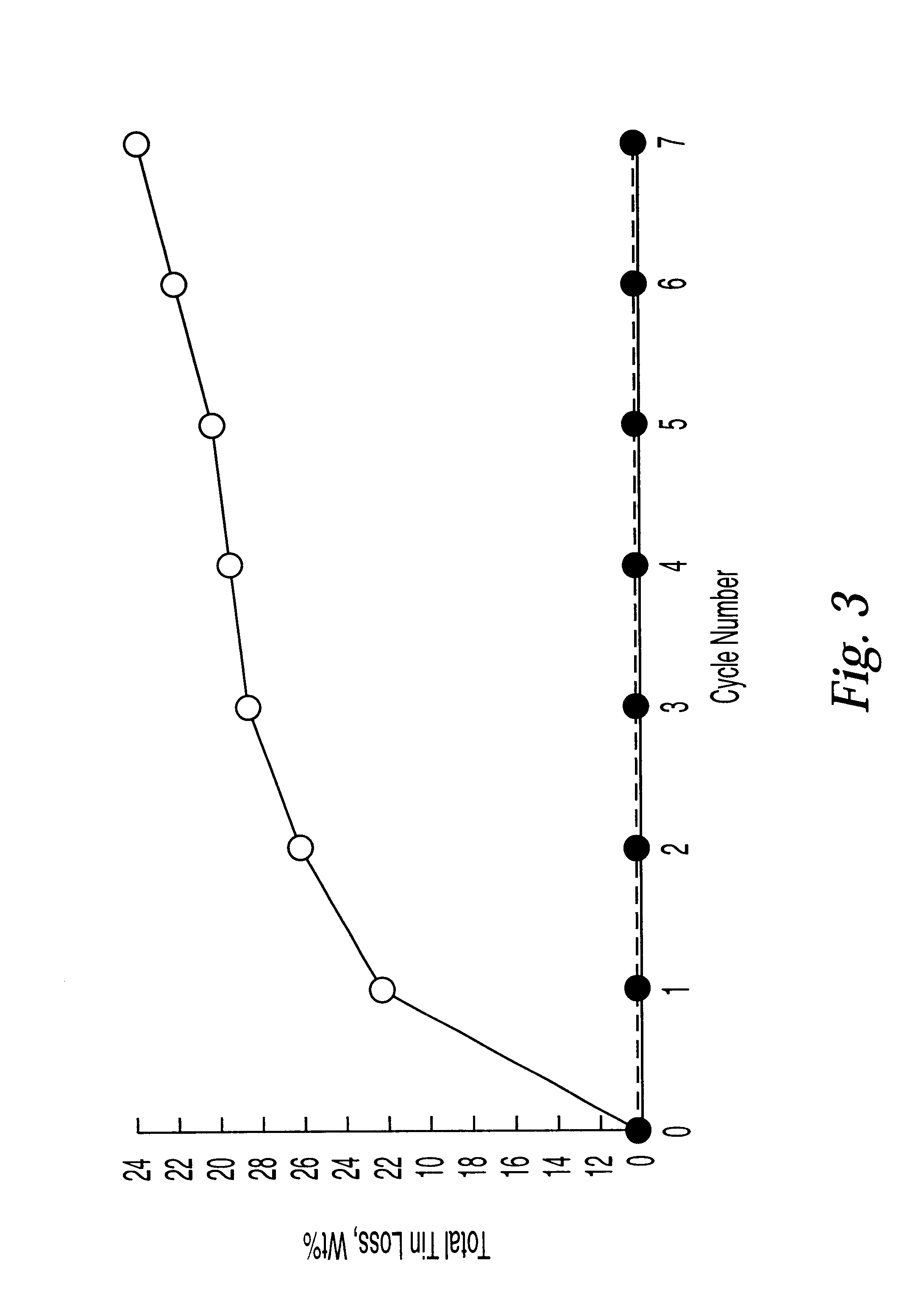

Method for removing reactive metal from a reactor system

InactiveUS6419986B1Reduce catalyst contaminationGood reproducibilityDistillation corrosion inhibitionCatalytic naphtha reformingReactor systemHalogen

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

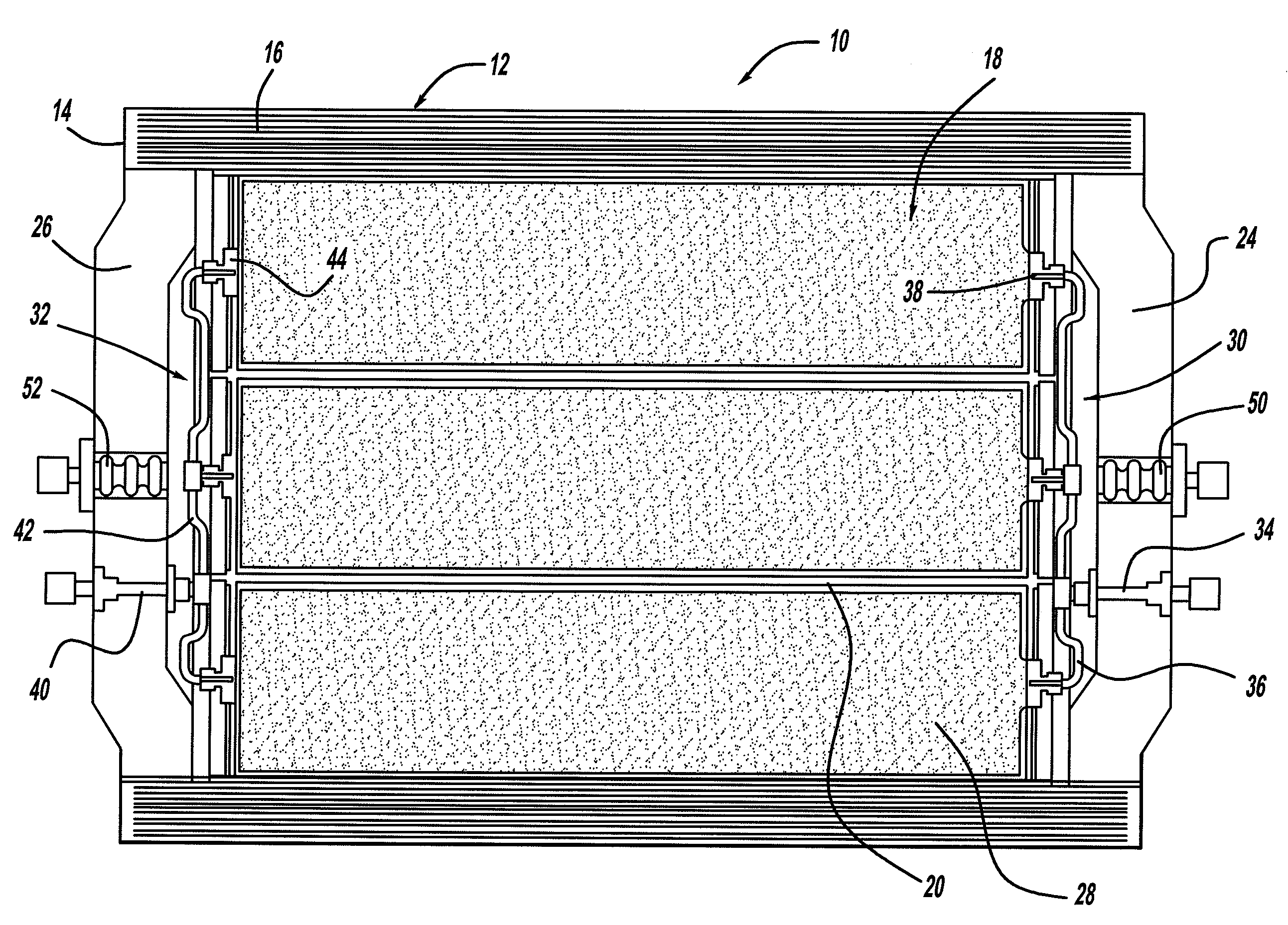

Hydrogen Storage Tank System Based on Gas Adsorption on High-Surface Materials Comprising an Integrated Heat Exchanger

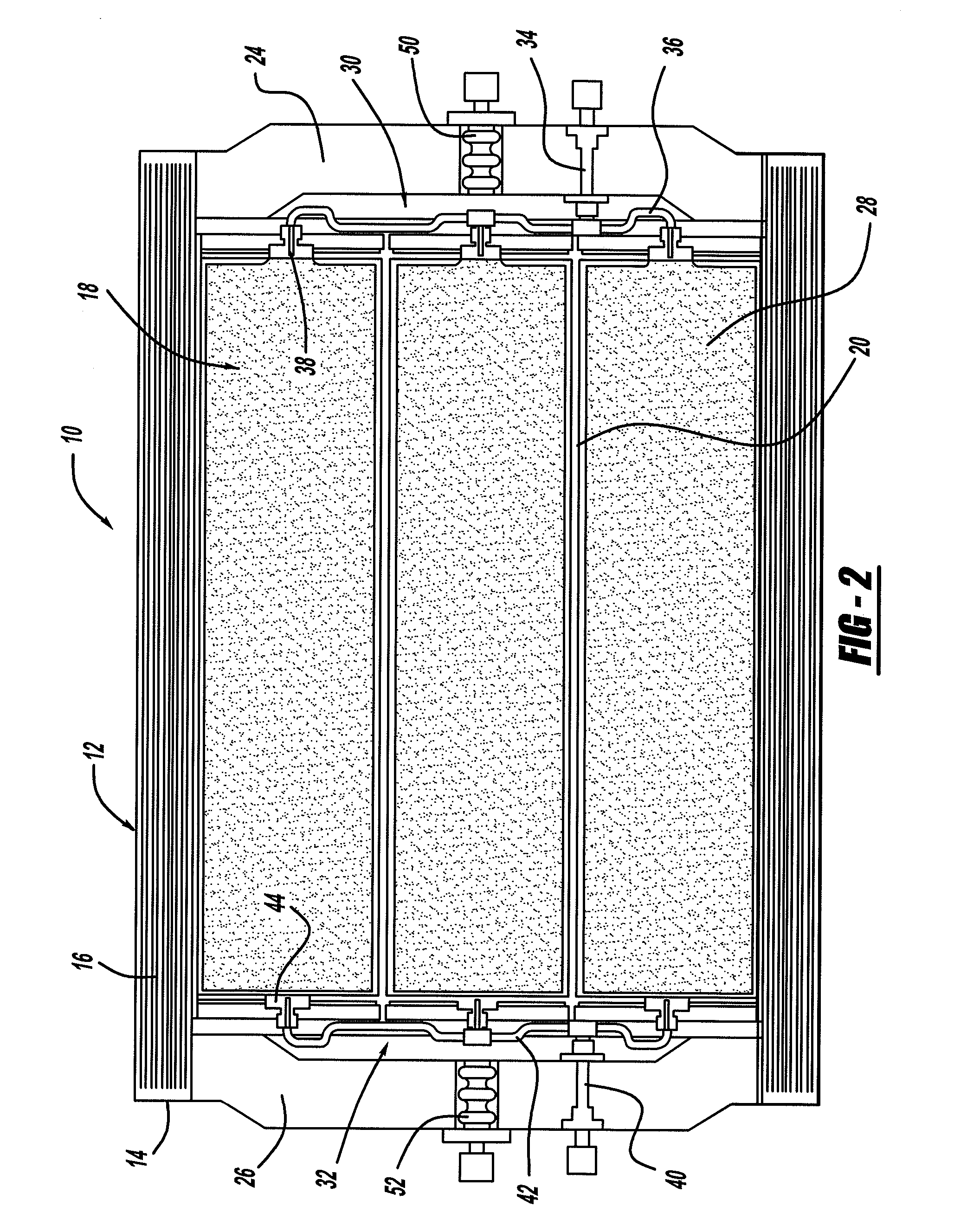

A gas storage system that stores a gas by cryo-adsorption on high surface materials. The gas storage system includes an outer container having insulated walls and a plurality of pressure vessels disposed therein. Each of the pressure vessels includes a high surface material. A manifold assembly distributes the gas under pressure to the pressure vessels where the gas is adsorbed by cryo-adsorption using the high surface materials. A cooling fluid is provided within voids between the pressure vessels to remove heat as the pressure vessels are being filled with the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method For Producing A Catalyst And The Catalyst Made Therefrom

InactiveUS20080038161A1Combination devicesInternal combustion piston enginesDecompositionElectromagnetic radiation

Disclosed herein are methods for manufacturing a catalyst composition. In one embodiment, a method for manufacturing a catalyst can comprise: forming a catalyst composition from a catalyst precursor and a volatile compound, disposing the catalyst composition on a substrate to form a supported composition, treating the supported composition with electromagnetic radiation, and removing at least a portion of the volatile compound to form the catalyst. In another embodiment, the method for manufacturing a catalyst can comprise: forming a catalyst composition comprising a volatile compound and a catalyst precursor, disposing the catalyst composition onto a substrate, and drying the catalyst composition at a temperature greater than or equal to a dew point of the volatile compound and less than or equal to a decomposition temperature of the catalyst precursor.

Owner:UMICORE AG & CO KG

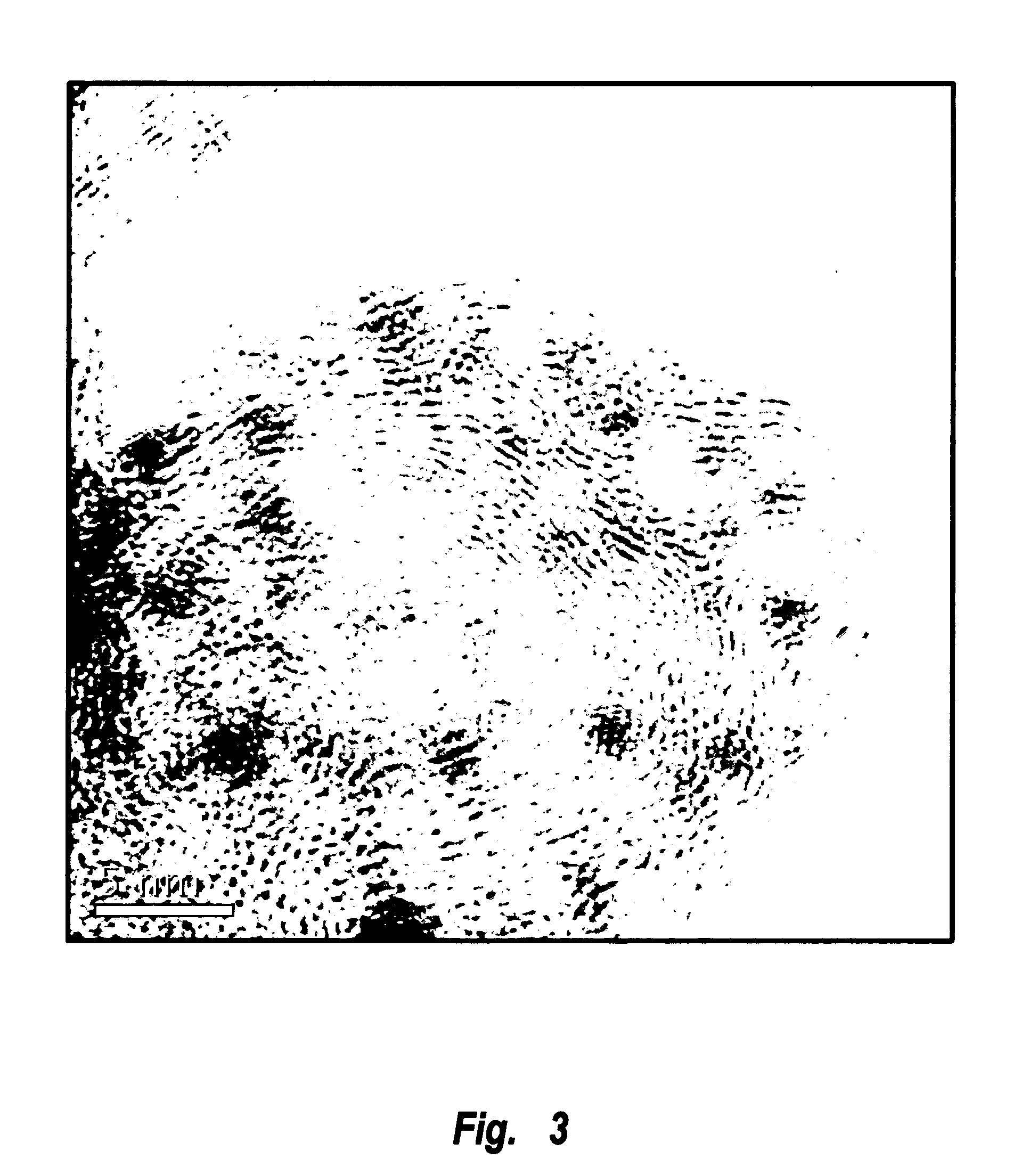

Supported nanoparticle catalysts manufactured using caged catalyst atoms

InactiveUS20080045401A1Increased durabilityImprove performanceInorganic chemistryMolecular sieve catalystsNanoparticleSolvent

Nanoparticle catalysts are manufactured by first preparing a solution of a solvent and a plurality of complexed and caged catalyst atoms. Each of the complexed and caged catalyst atoms has at least three organic ligands forming a cage around the catalyst atom. The complexed and caged catalyst atoms are reduced to form a plurality of nanoparticles. During formation of the nanoparticles, the organic ligands provide spacing between the catalyst atoms via steric hindrances and / or provide interactions with a support material. The spacing and interactions with the support material allow formation of small, stable, and uniform nanoparticles.

Owner:HEADWATERS TECH INNOVATION GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com